Nickel composite hydroxide and method for producing the same, positive electrode active material and method for producing the same as well as nonaqueous electrolytic secondary cell

一种复合氢氧化物、正极活性物质的技术,应用在非水电解质蓄电池、二次电池、氧化镍/氢氧化镍等方向,能够解决输出功率特性不良影响、电池容量没有进行记载、难以得到电极膜输出功率正极活性物质等问题,达到实施容易、高输出能量特性和电池容量、生产率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0247] In Example 1 and Comparative Example 1, unless otherwise specified, special-grade samples manufactured by Wako Pure Chemical Industries, Ltd. were used in the production of the composite hydroxide, the positive electrode active material, and the production of the secondary battery.

[0248] [Evaluation of composite hydroxide]

[0249] First, composite hydroxides were produced, and particle shape, volume average particle diameter, and aspect ratio were evaluated.

[0250]

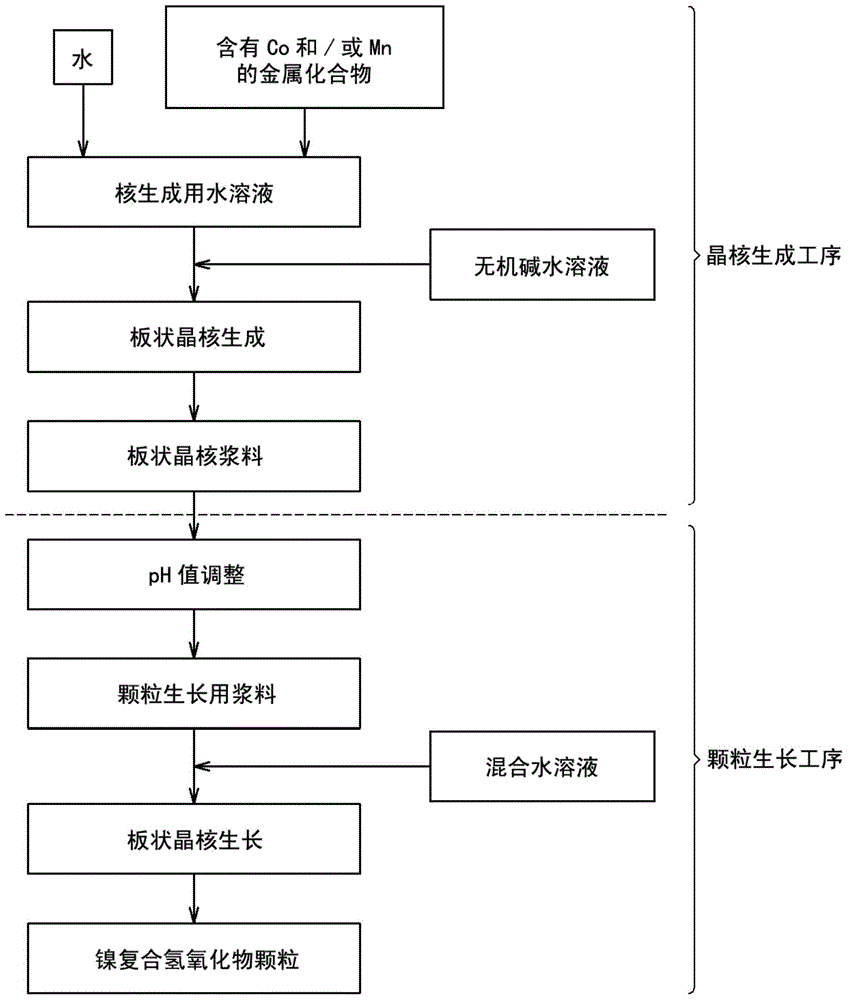

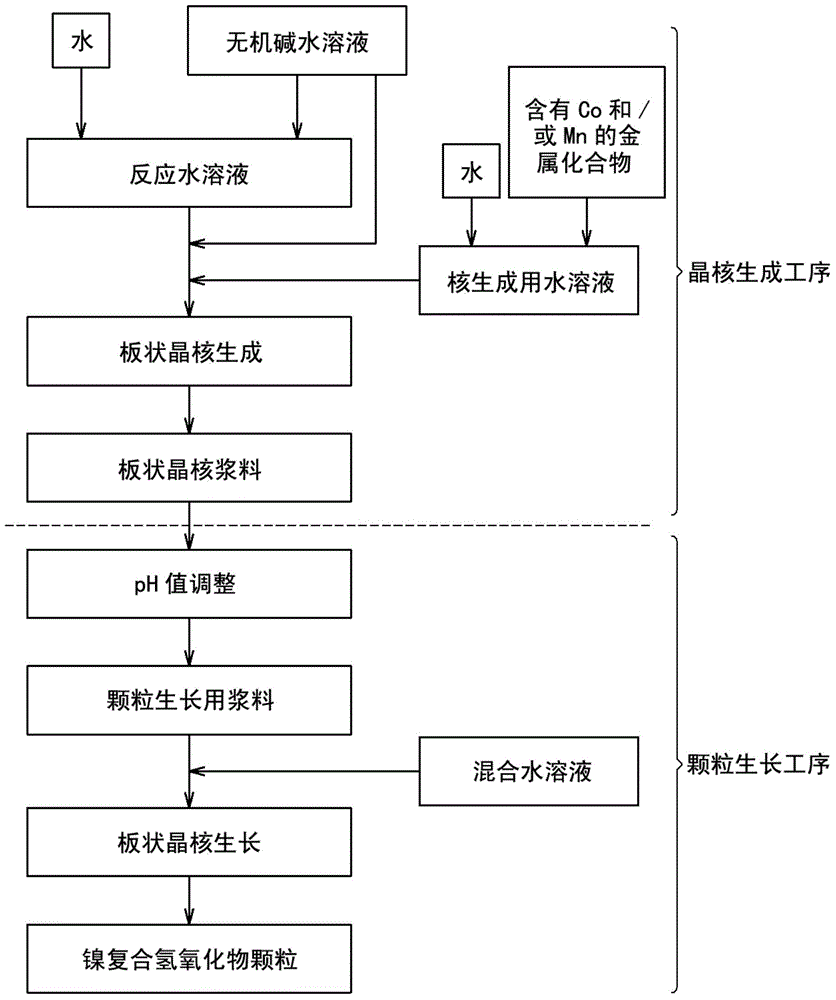

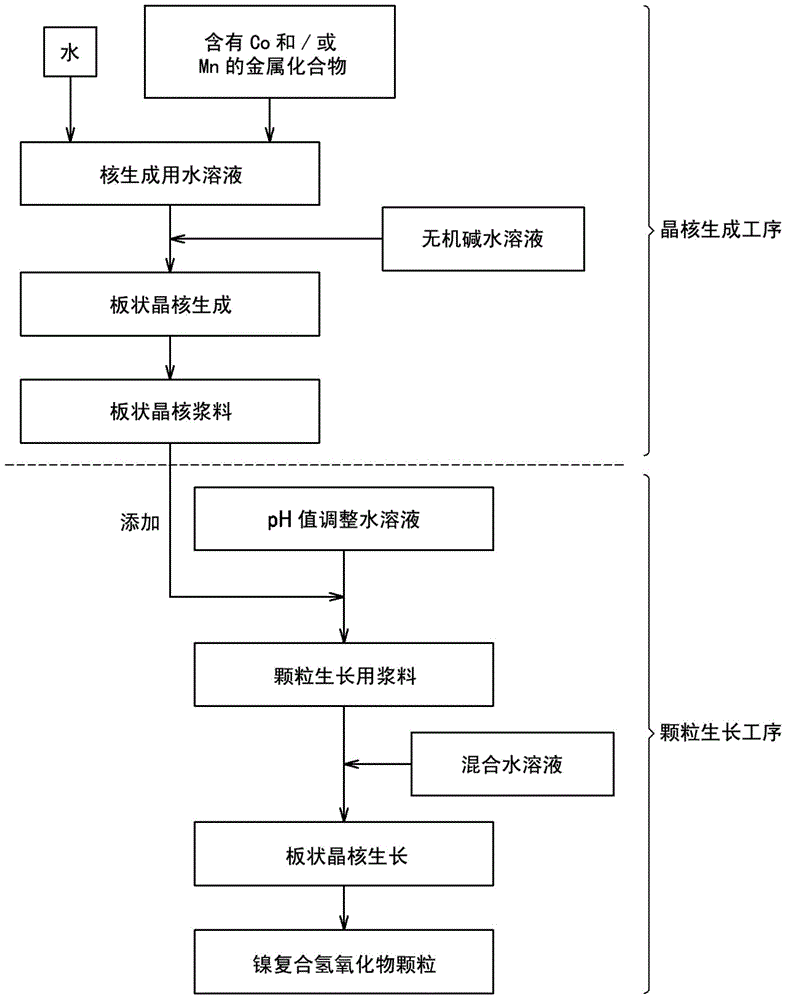

[0251] (Crystal nucleation process)

[0252] In Example 1, 900 ml of cobalt sulfate heptahydrate and pure water were dropped into a crystallization reaction vessel with a volume of 5 L equipped with four baffle plates, and stirred at a speed of 1000 rpm with 6 blades inclined paddles while using a constant temperature bath and heating jacket to 60°C to obtain an aqueous solution for nucleation. Nitrogen gas was flowed into the reaction vessel to form a nitrogen atmosphere, and the oxygen concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com