Patents

Literature

807results about "Lithium oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame made metal oxides

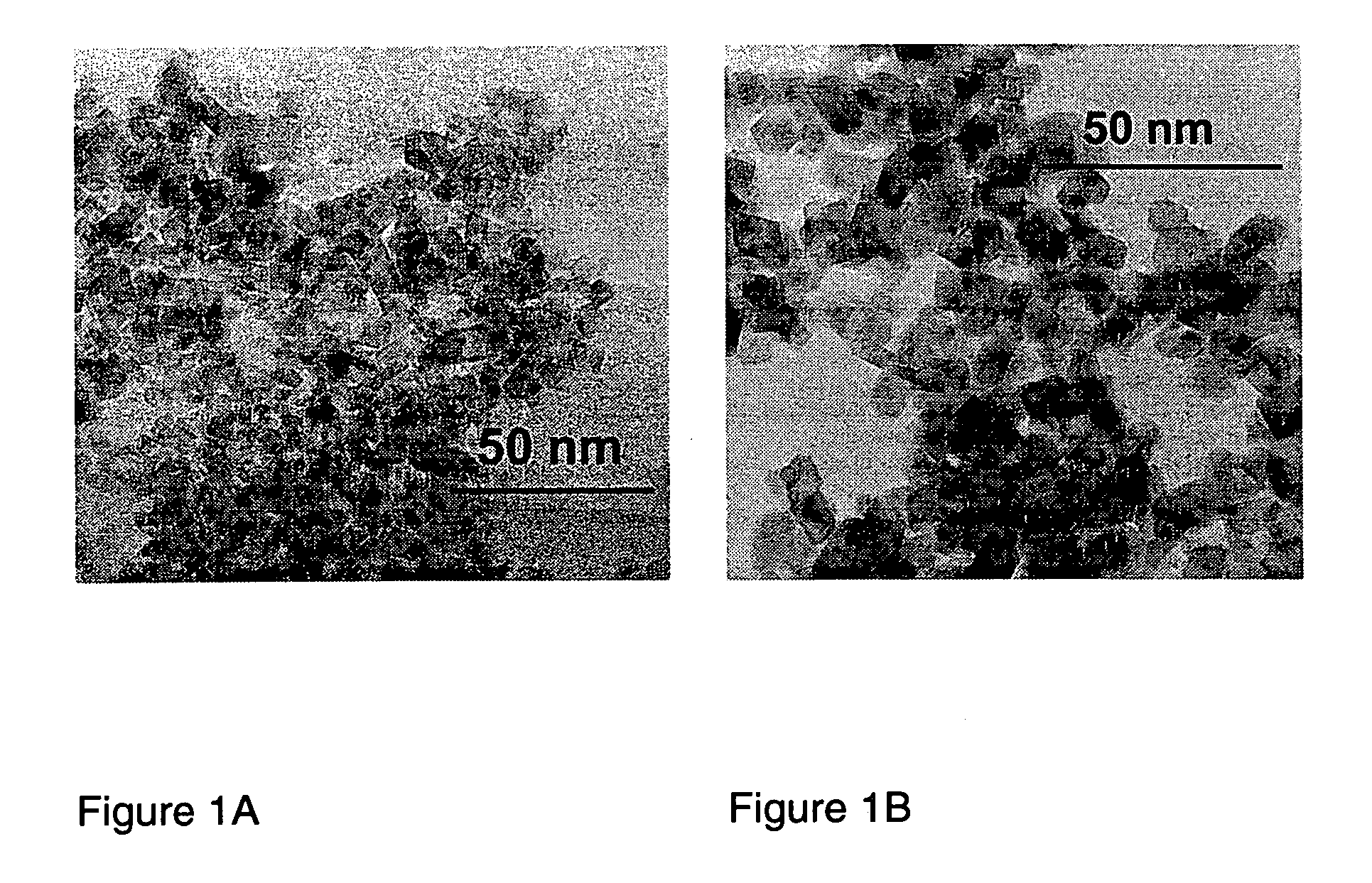

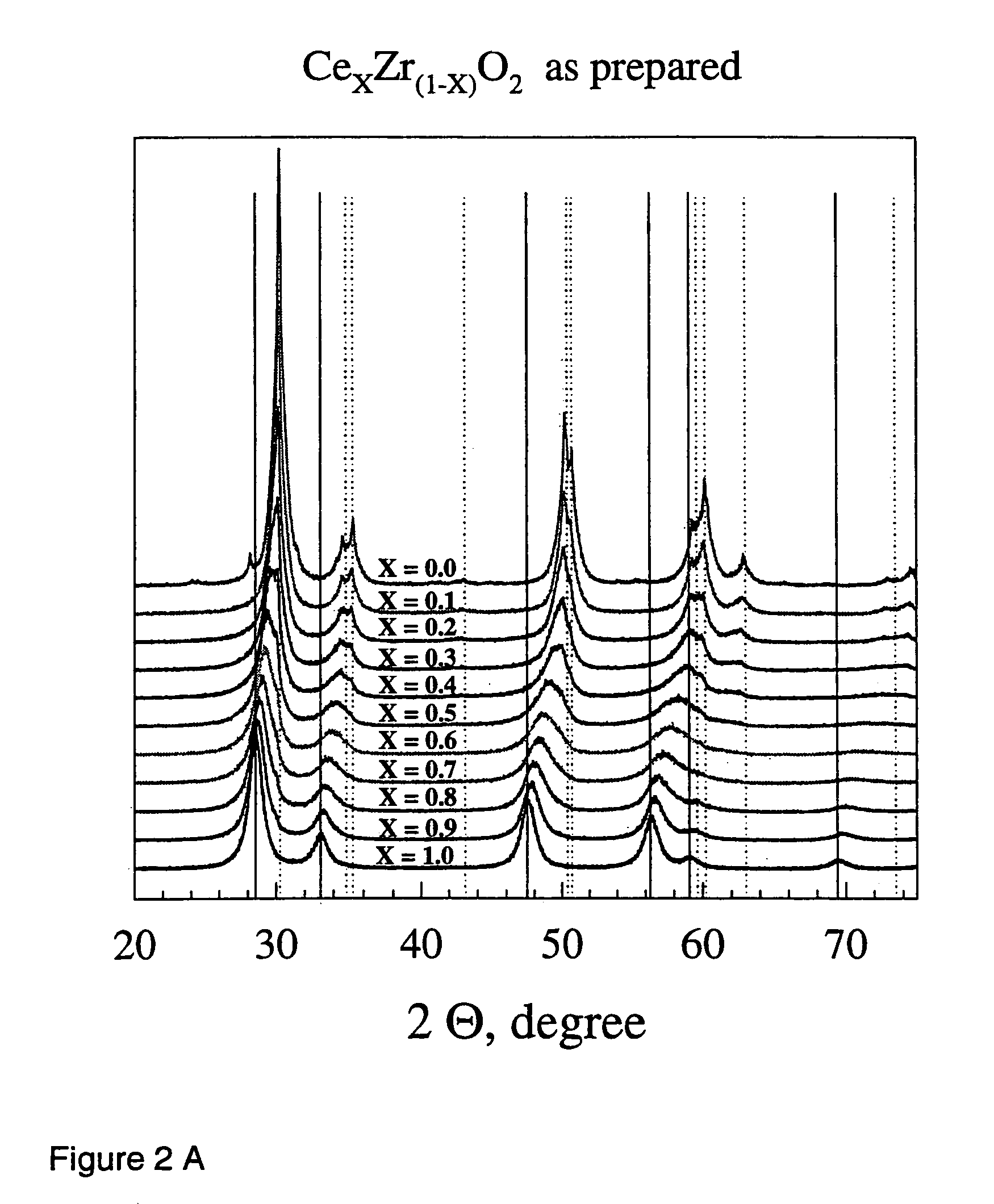

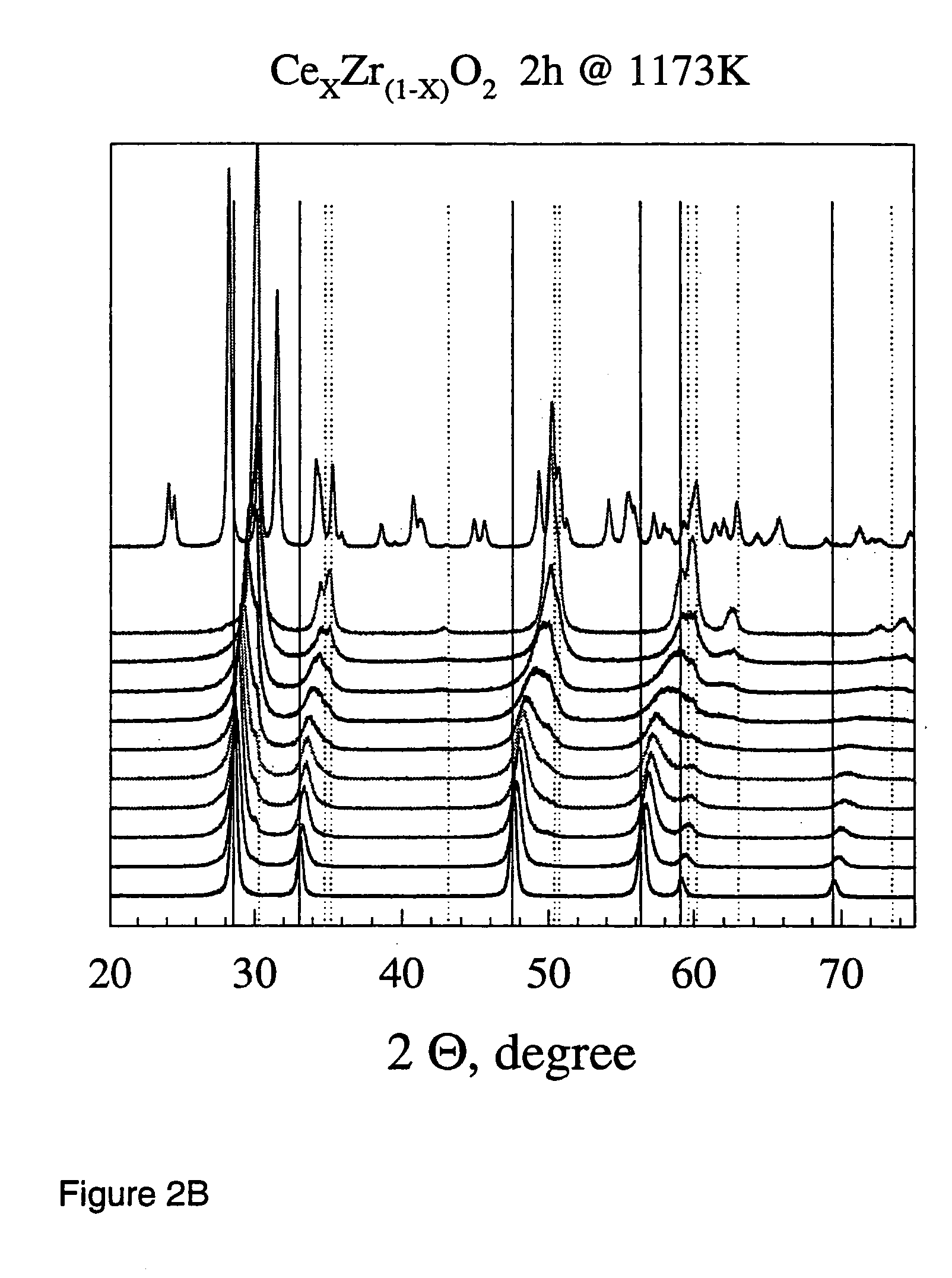

ActiveUS7211236B2Add featureWell mixedMaterial nanotechnologyZirconium oxidesSpray pyrolysisCarboxylic acid

Described is a method for the production of metal oxides by flame spray pyrolysis, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

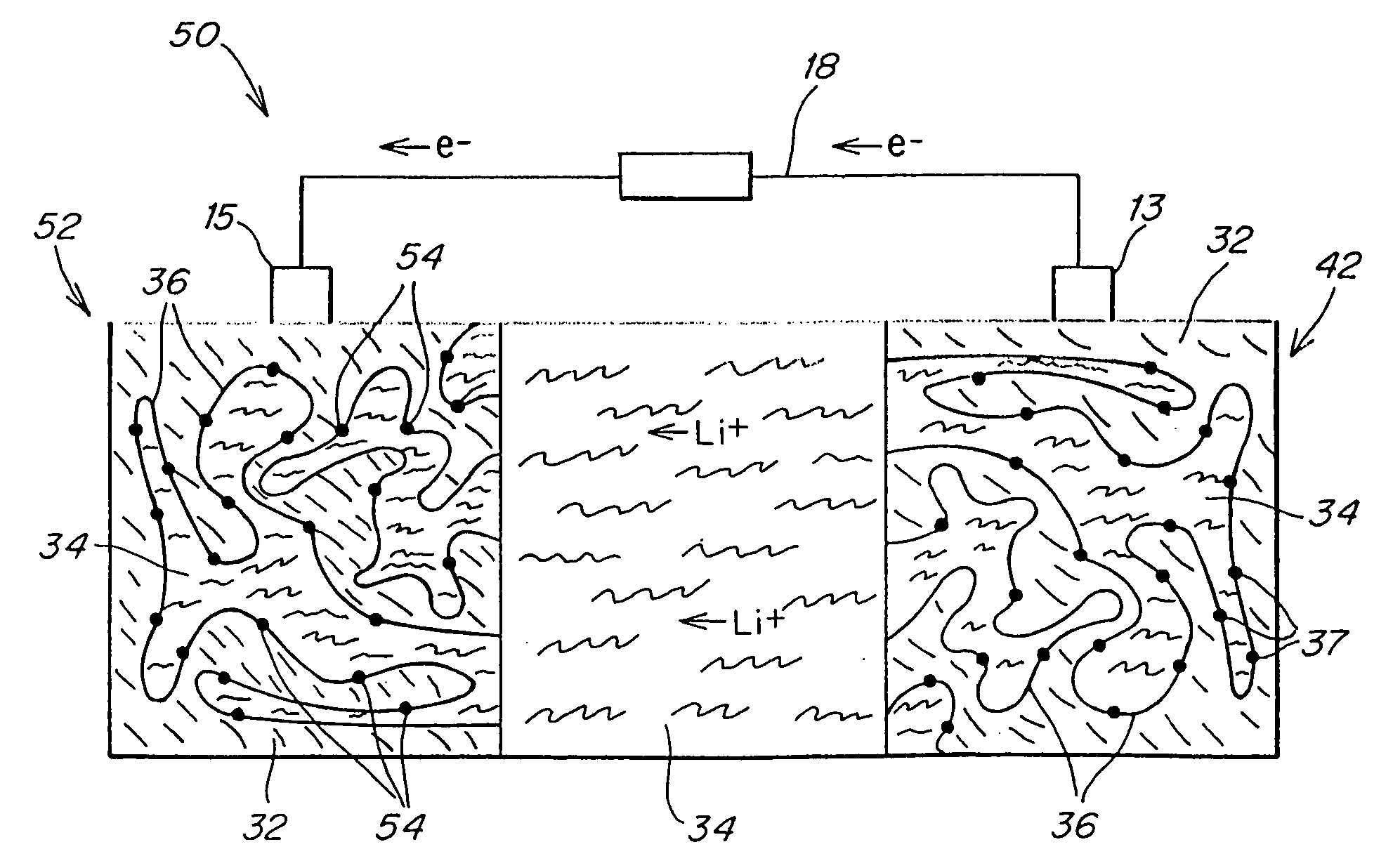

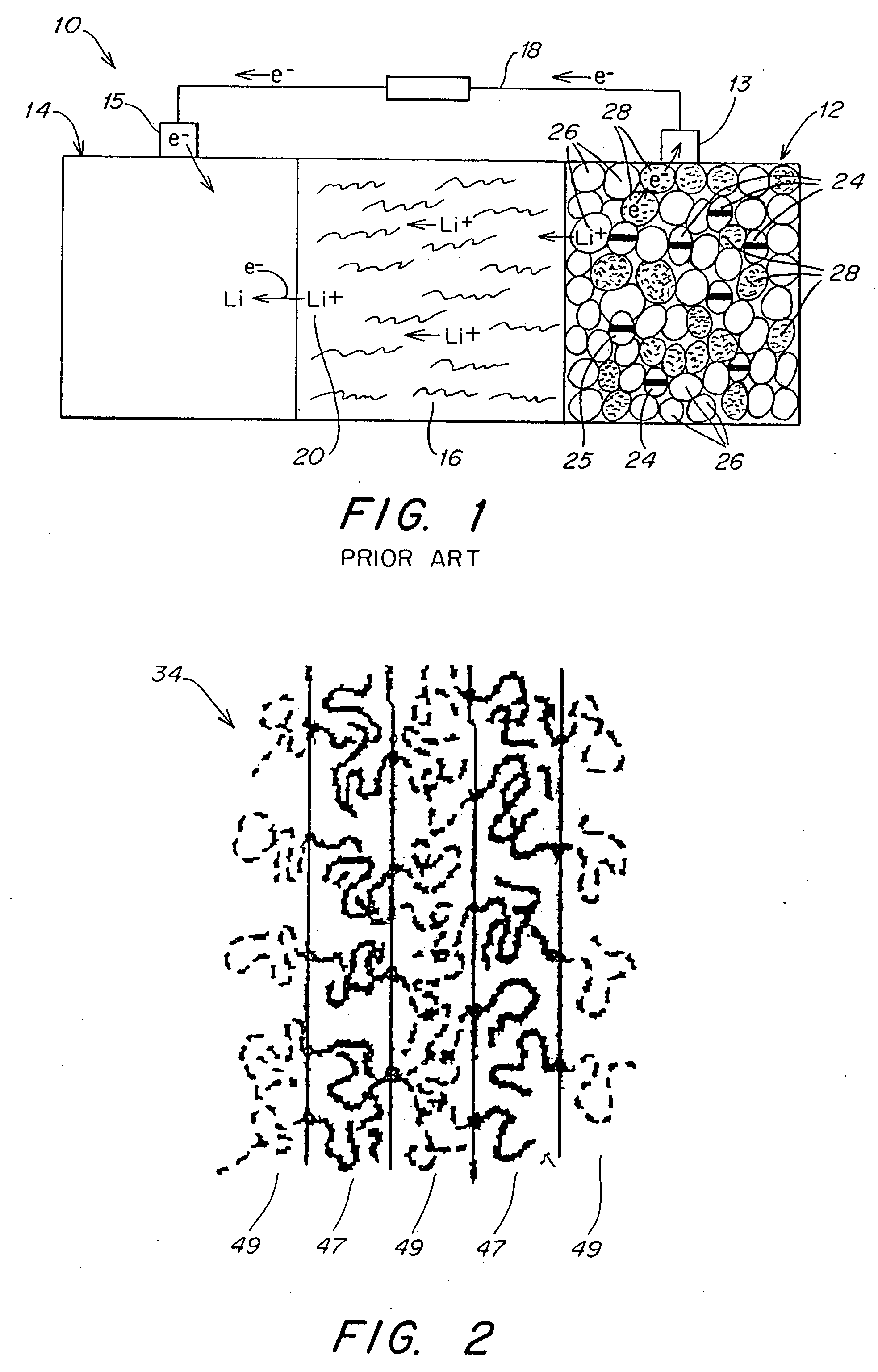

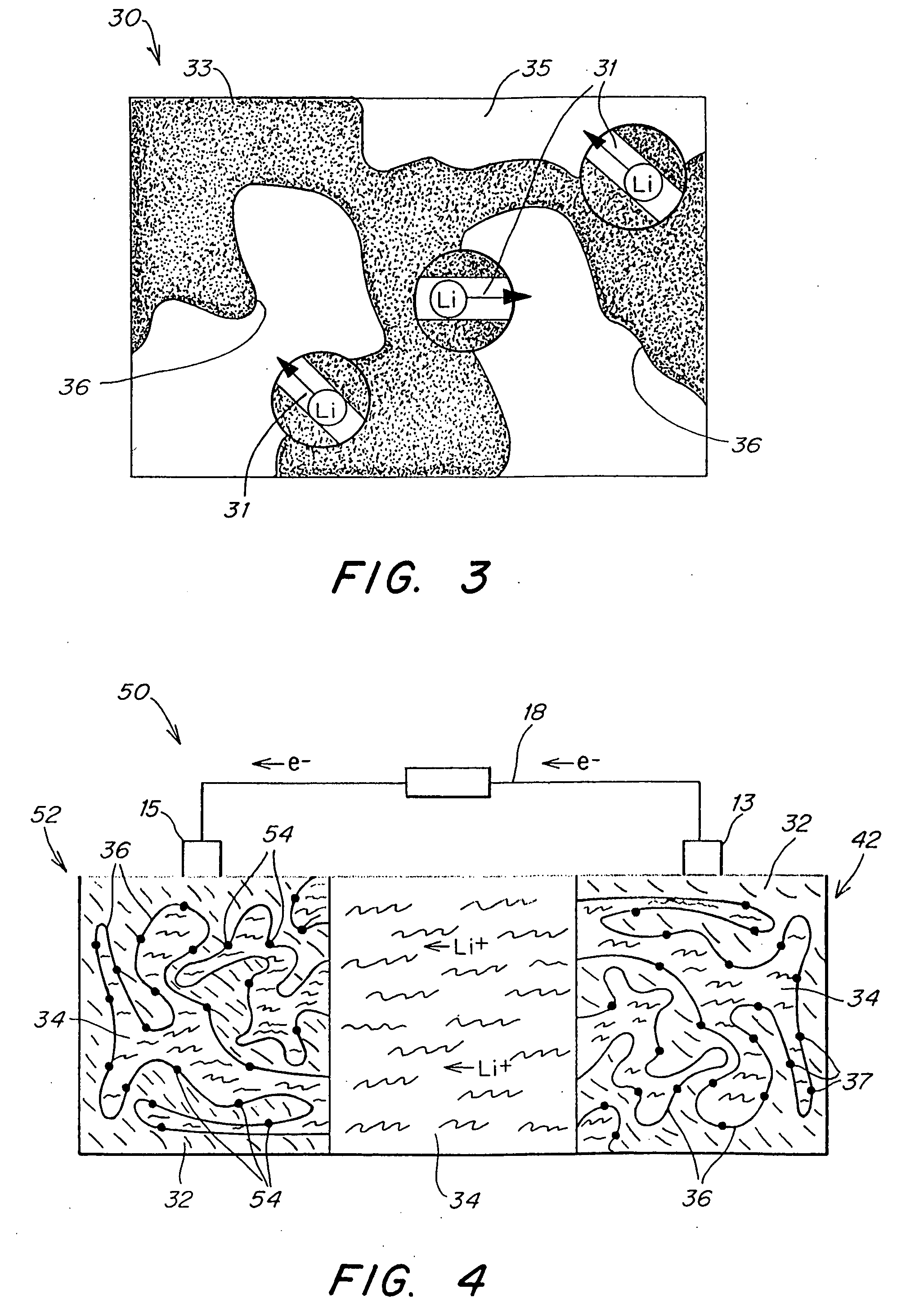

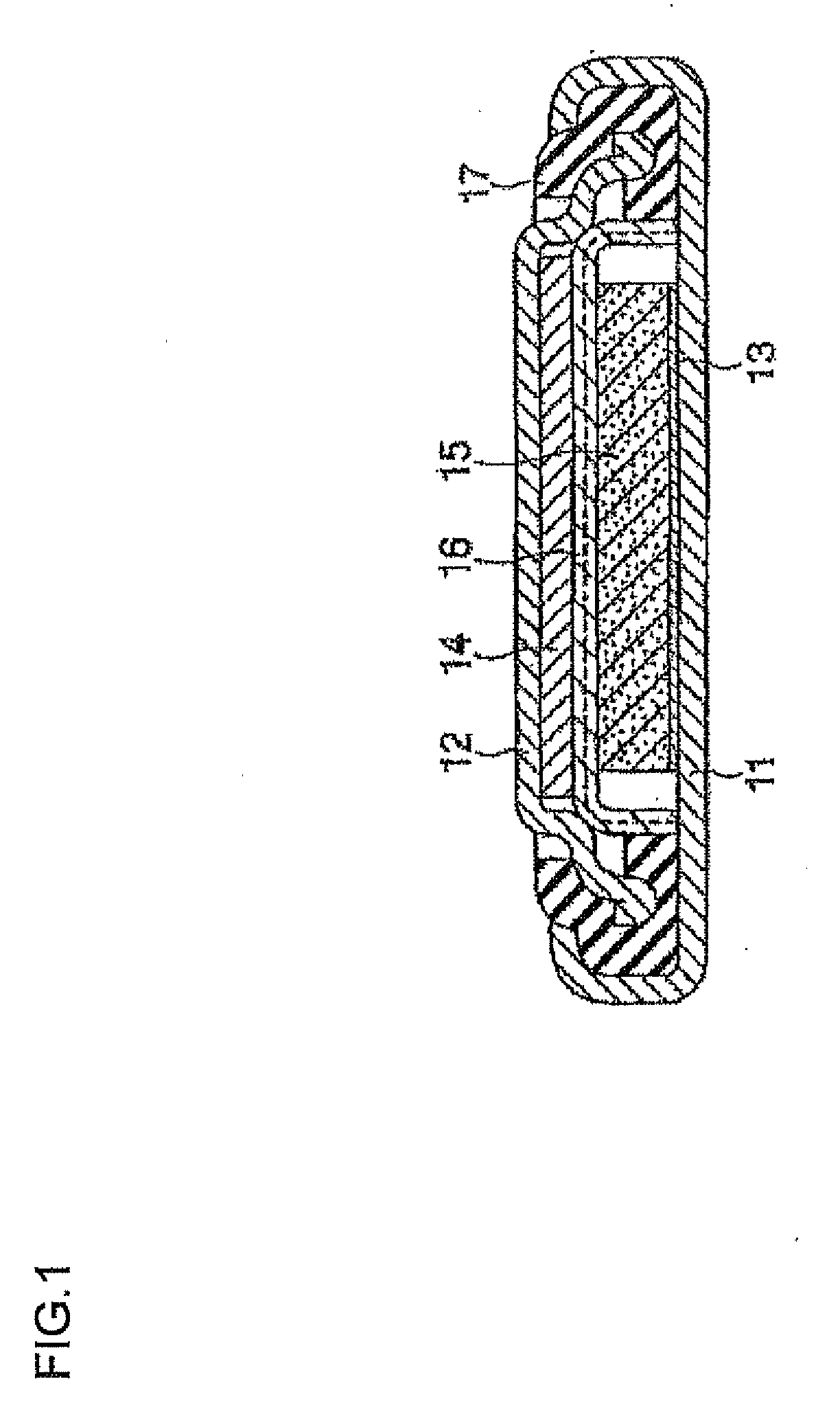

Polymer electrolyte, intercalation compounds and electrodes for batteries

Solid battery components are provided. A block copolymeric electrolyte is non-crosslinked and non-glassy through the entire range of typical battery service temperatures, that is, through the entire range of at least from about 0° C. to about 70° C. The chains of which the copolymer is made each include at least one ionically-conductive block and at least one second block immiscible with the ionically-conductive block. The chains form an amorphous association and are arranged in an ordered nanostructure including a continuous matrix of amorphous ionically-conductive domains and amorphous second domains that are immiscible with the ionically-conductive domains. A compound is provided that has a formula of LixMyNzO2. M and N are each metal atoms or a main group elements, and x, y and z are each numbers from about 0 to about 1. y and z are chosen such that a formal charge on the MyNz portion of the compound is (4-x). In certain embodiments, these compounds are used in the cathodes of rechargeable batteries. The present invention also includes methods of predicting the potential utility of metal dichalgogenide compounds for use in lithium intercalation compounds. It also provides methods for processing lithium intercalation oxides with the structure and compositional homogeneity necessary to realize the increased formation energies of said compounds. An article is made of a dimensionally-stable, interpenetrating microstructure of a first phase including a first component and a second phase, immiscible with the first phase, including a second component. The first and second phases define interphase boundaries between them, and at least one particle is positioned between a first phase and a second phase at an interphase boundary. When the first and second phases are electronically-conductive and ionically-conductive polymers, respectively, and the particles are ion host particles, the arrangement is an electrode of a battery.

Owner:MASSACHUSETTS INST OF TECH

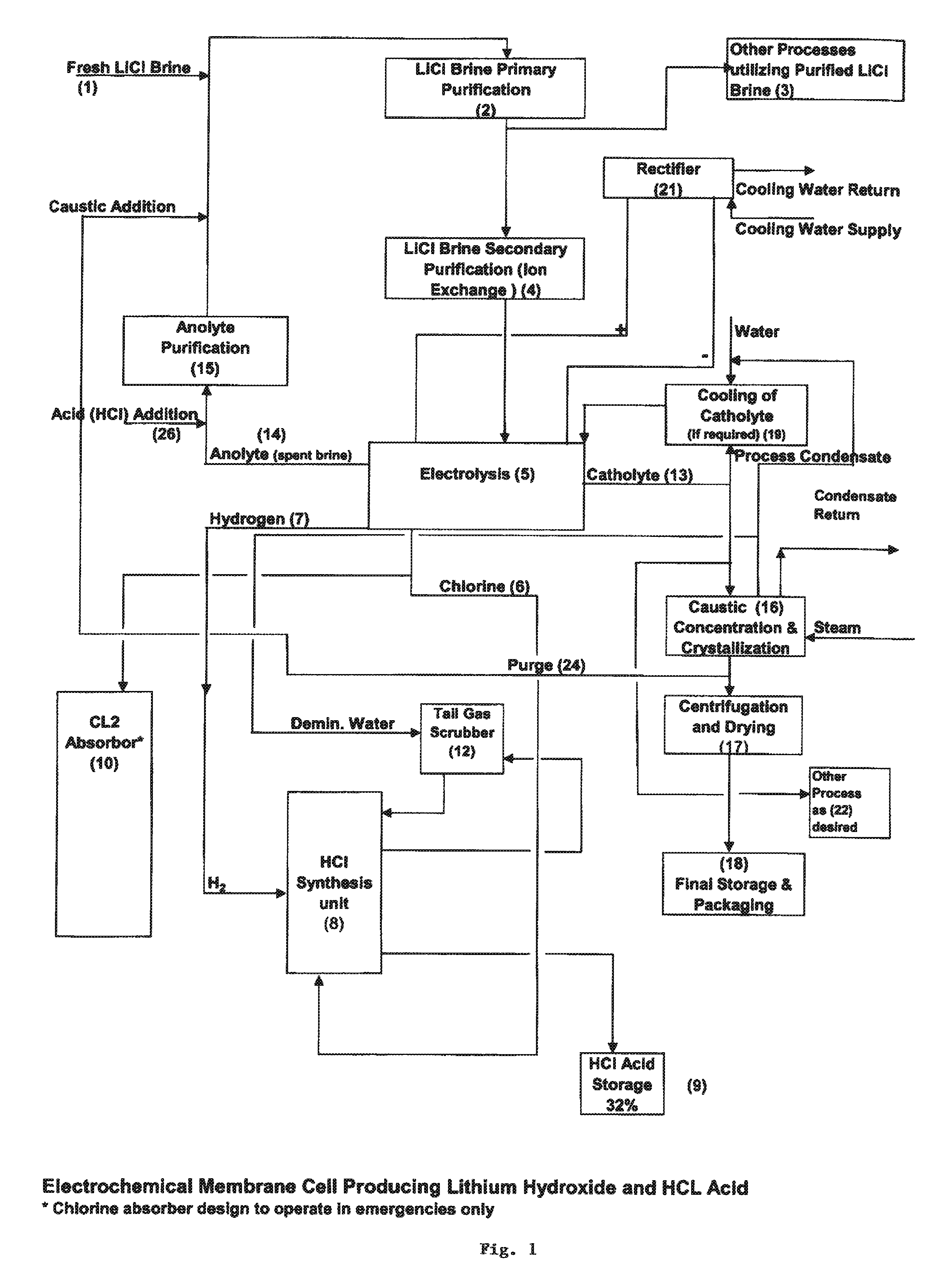

Method of making high purity lithium hydroxide and hydrochloric acid

InactiveUS20110044882A1Simple and economical processEasy to convertElectrolysis componentsEnergy inputElectrolysisIon exchange

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

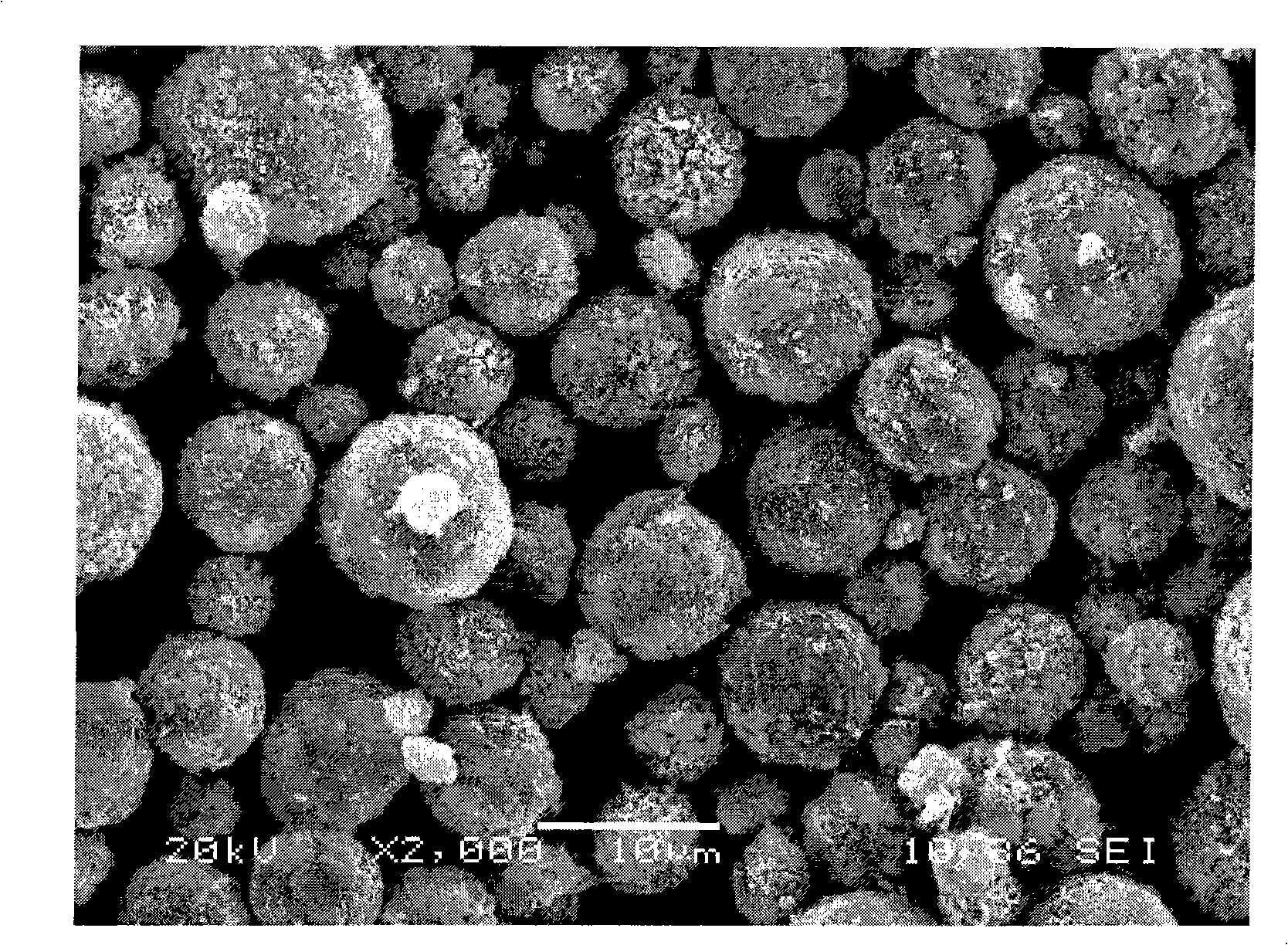

Method of synthesizing electrochemically active materials from a slurry of precursors

InactiveUS6913855B2Quality improvementHigh-quality materialPhosphatesElectrode thermal treatmentCompound (substance)Slurry

A method for making an active material comprises the steps of forming a slurry, spray drying the slurry to form a powdered precursor composition, and heating the powdered precursor composition at a temperature and for a time sufficient to form a reaction product. The slurry has a liquid phase and a solid phase, and contains at least an alkali metal compound and a transition metal compound. Preferably the liquid phase contains dissolved alkali metal compound, and the solid phase contains an insoluble transition metal compound, an insoluble carbonaceous material compound, or both. Electrodes and batteries are provided that contain the active materials.

Owner:RIL USA INC +1

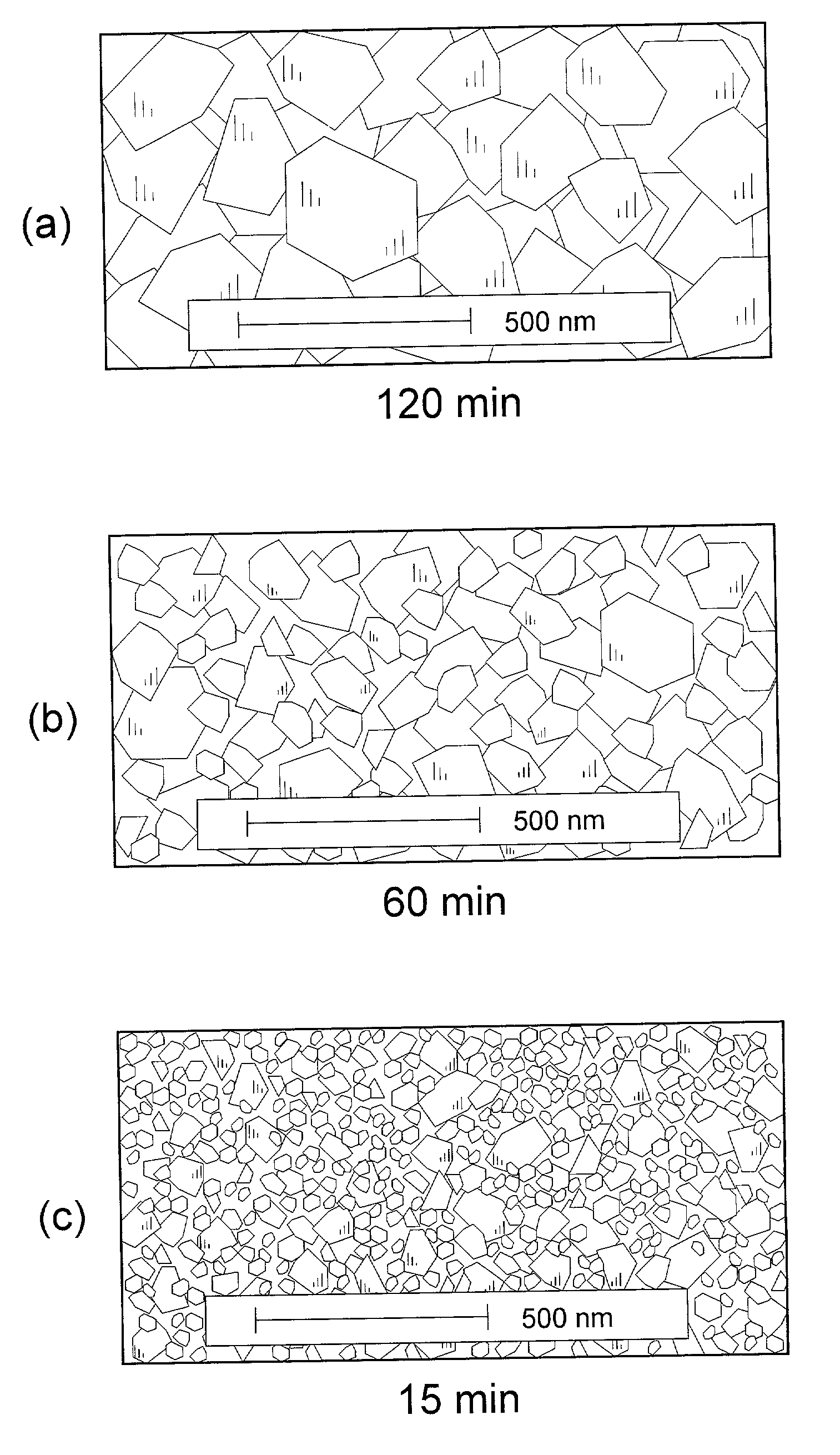

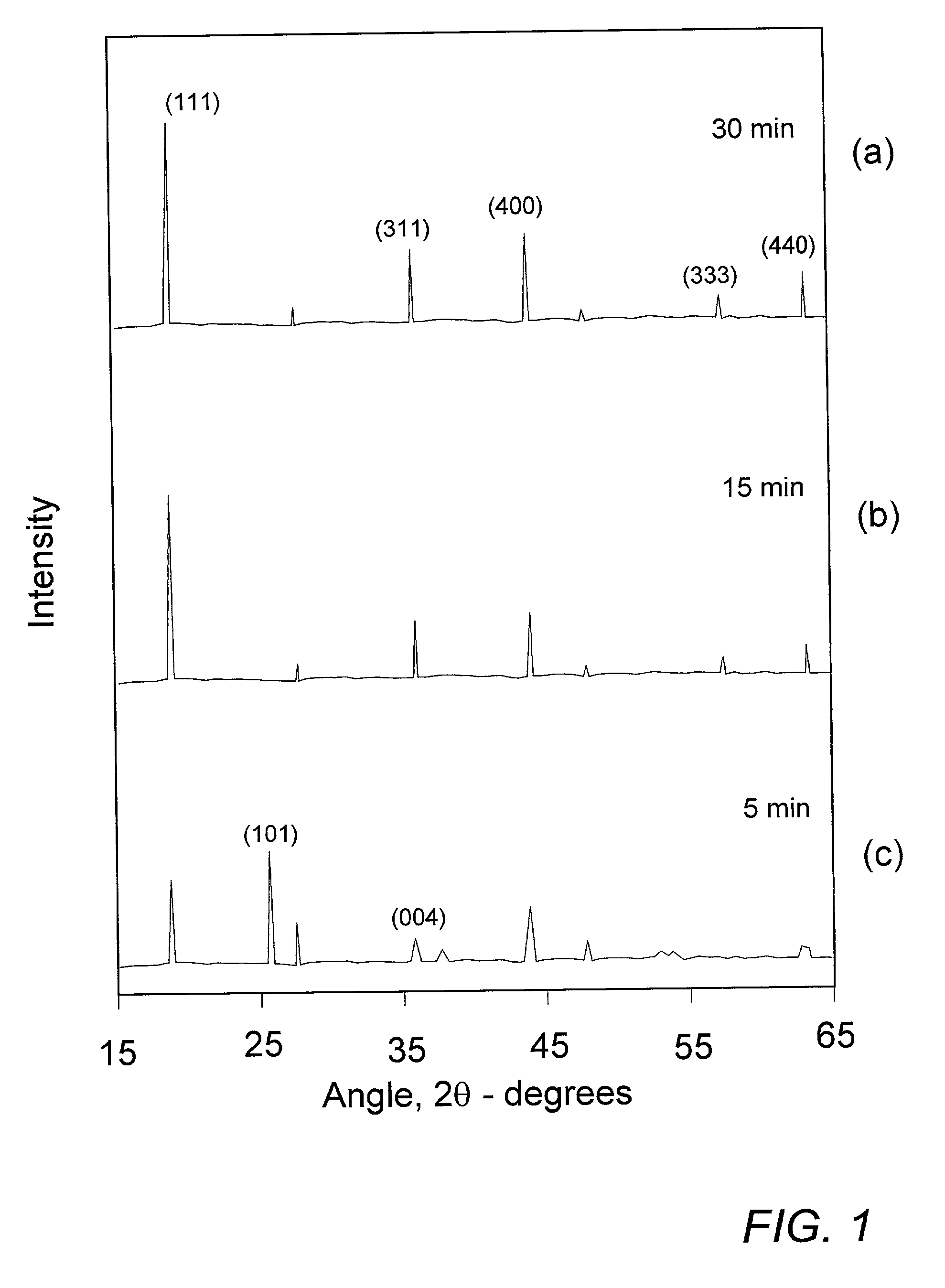

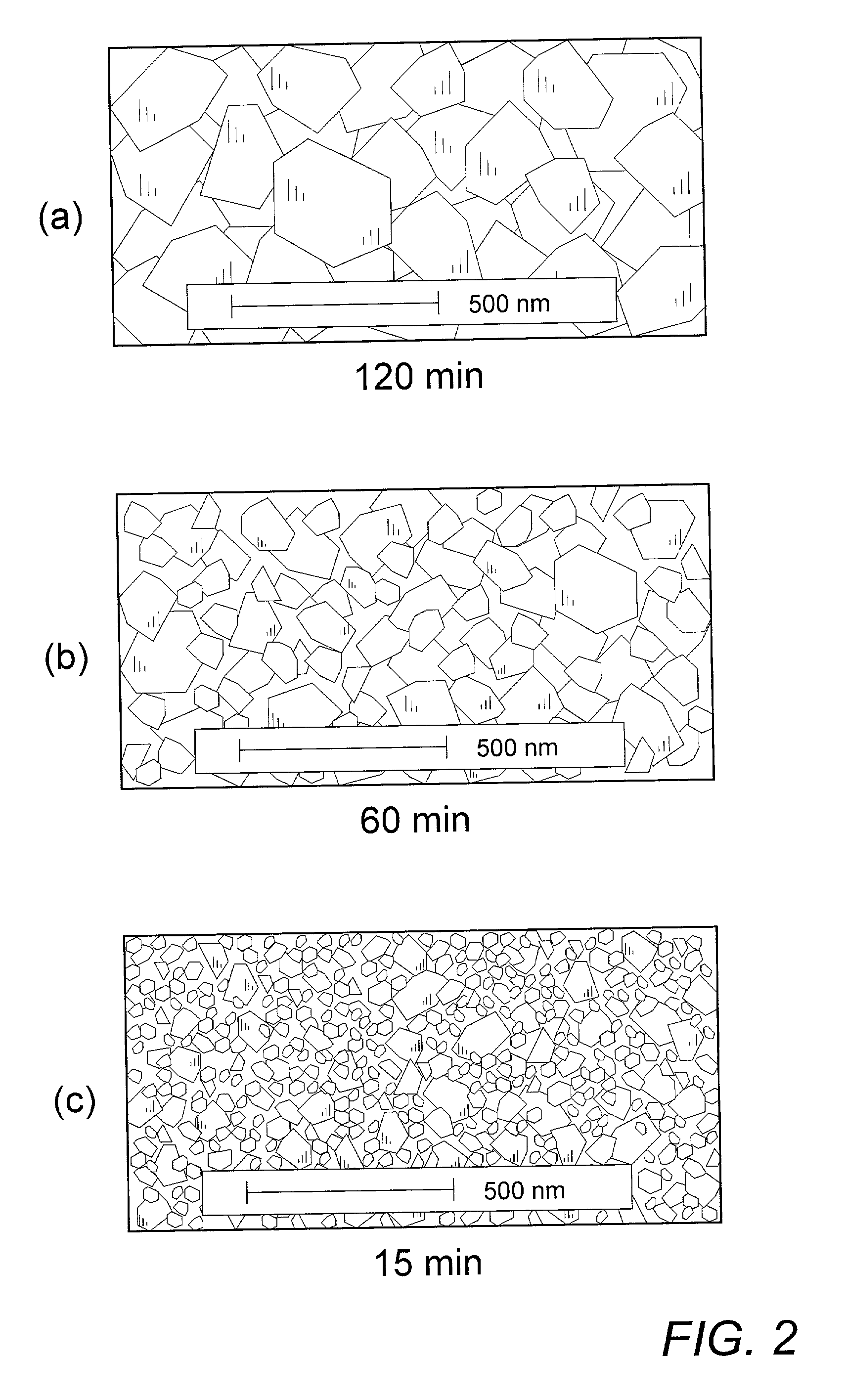

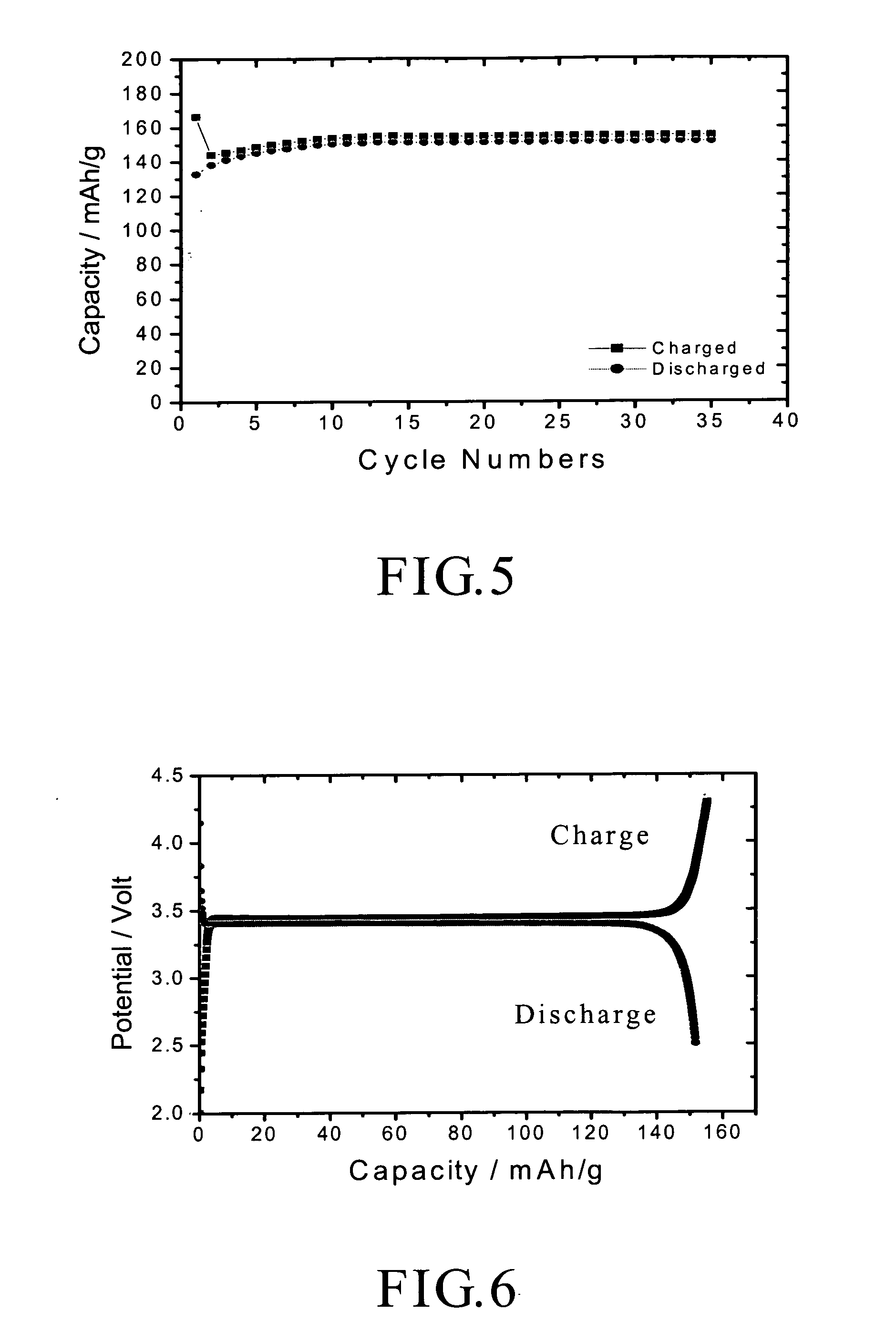

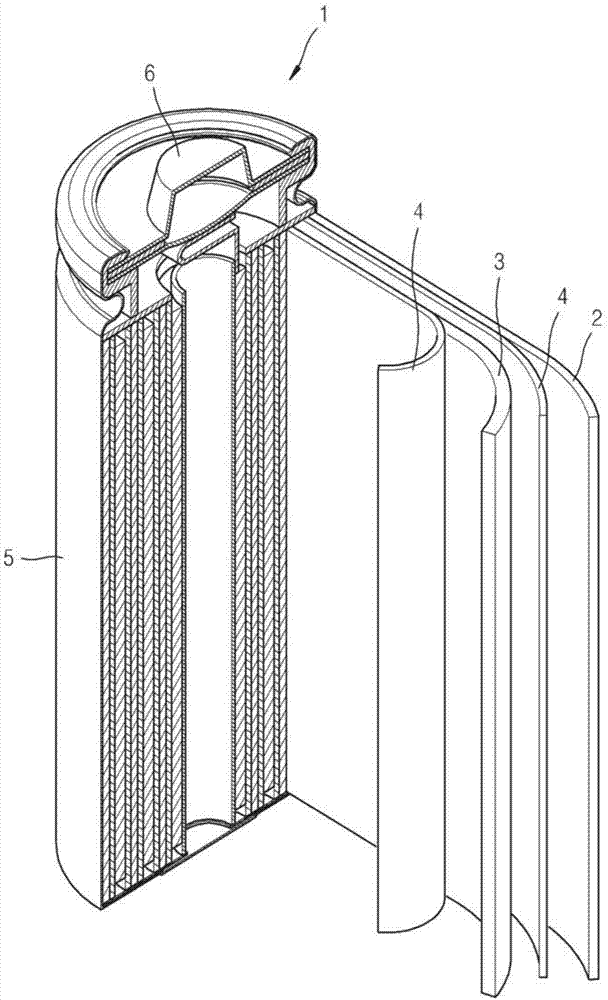

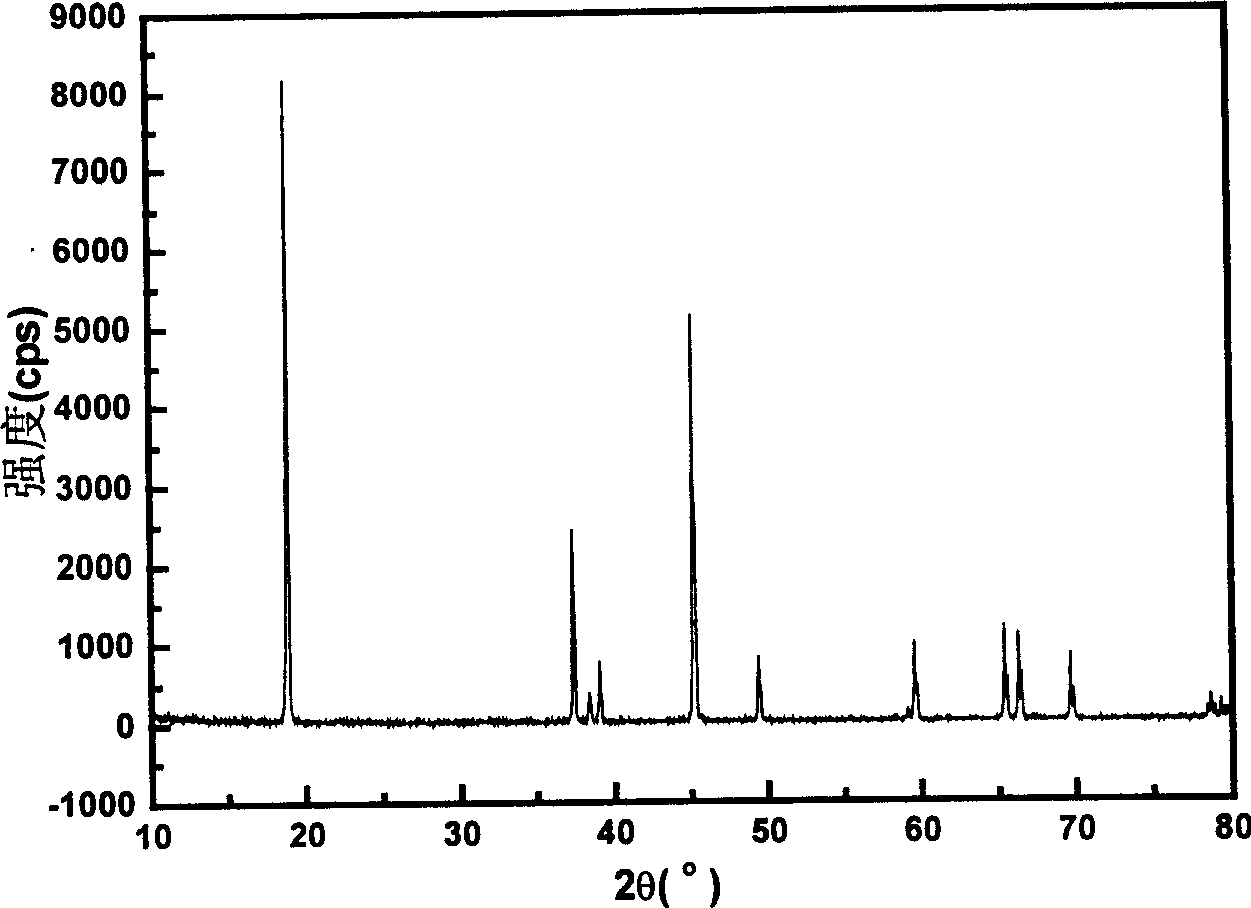

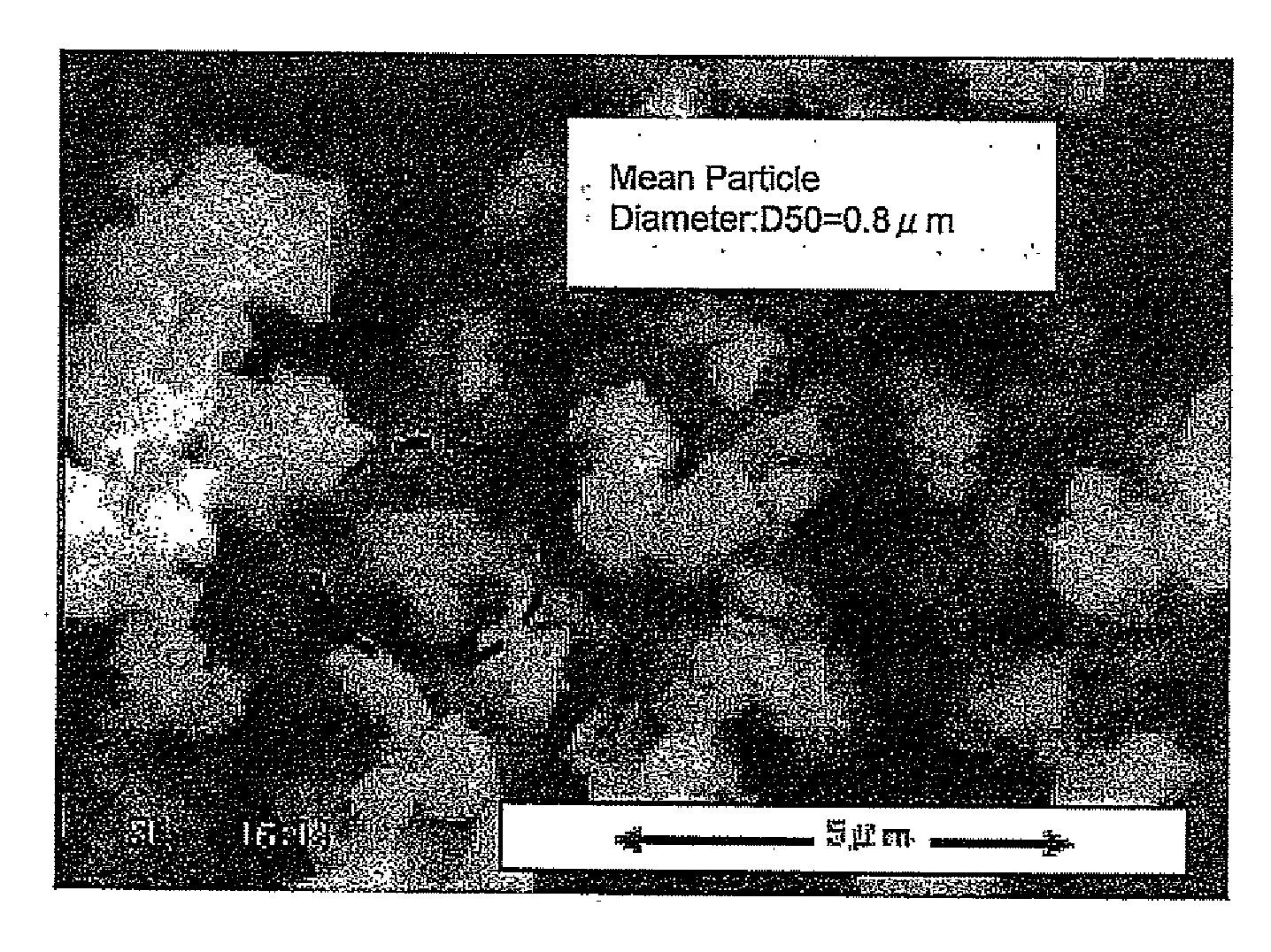

Nanostructure lithium titanate electrode for high cycle rate rechargeable electrochemical cell

Rechargeable electrochemical cells, such as lithium batteries and asymmetric hybrid battery / supercapacitor systems, exhibiting exceptional specific capacity levels and stability over extended high-rate recharge cycling comprise nanostructure zero strain Li4Ti5O12 intercalation electrode material synthesized in a short duration process of annealing mixed TiO2 and Li-source precursor compounds at about 800° C. for a time of about 15–30 min which is not substantially longer than that required to effect maximum available reaction between the precursors, thereby substantially eliminating the growth of synthesized Li4Ti5O12 particles beyond nanostructure size. The process reduces by order of magnitude the time and energy required for synthesis of the active electrode material and fabrication of utilizing cell devices, and provides such nanostructure material which enables repeated, high-rate recharge cycling without loss of cell capacity or efficiency.

Owner:RUTGERS THE STATE UNIV

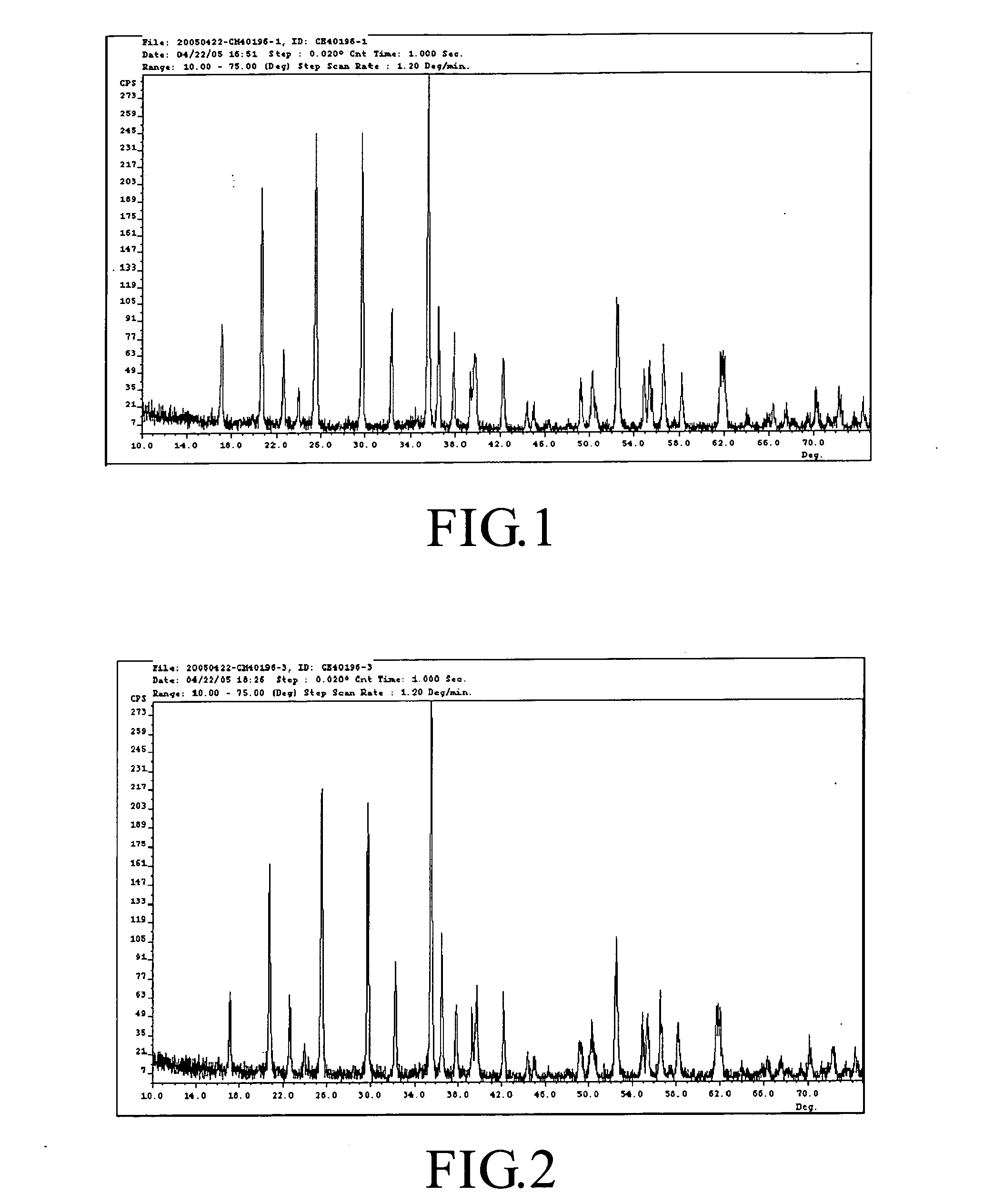

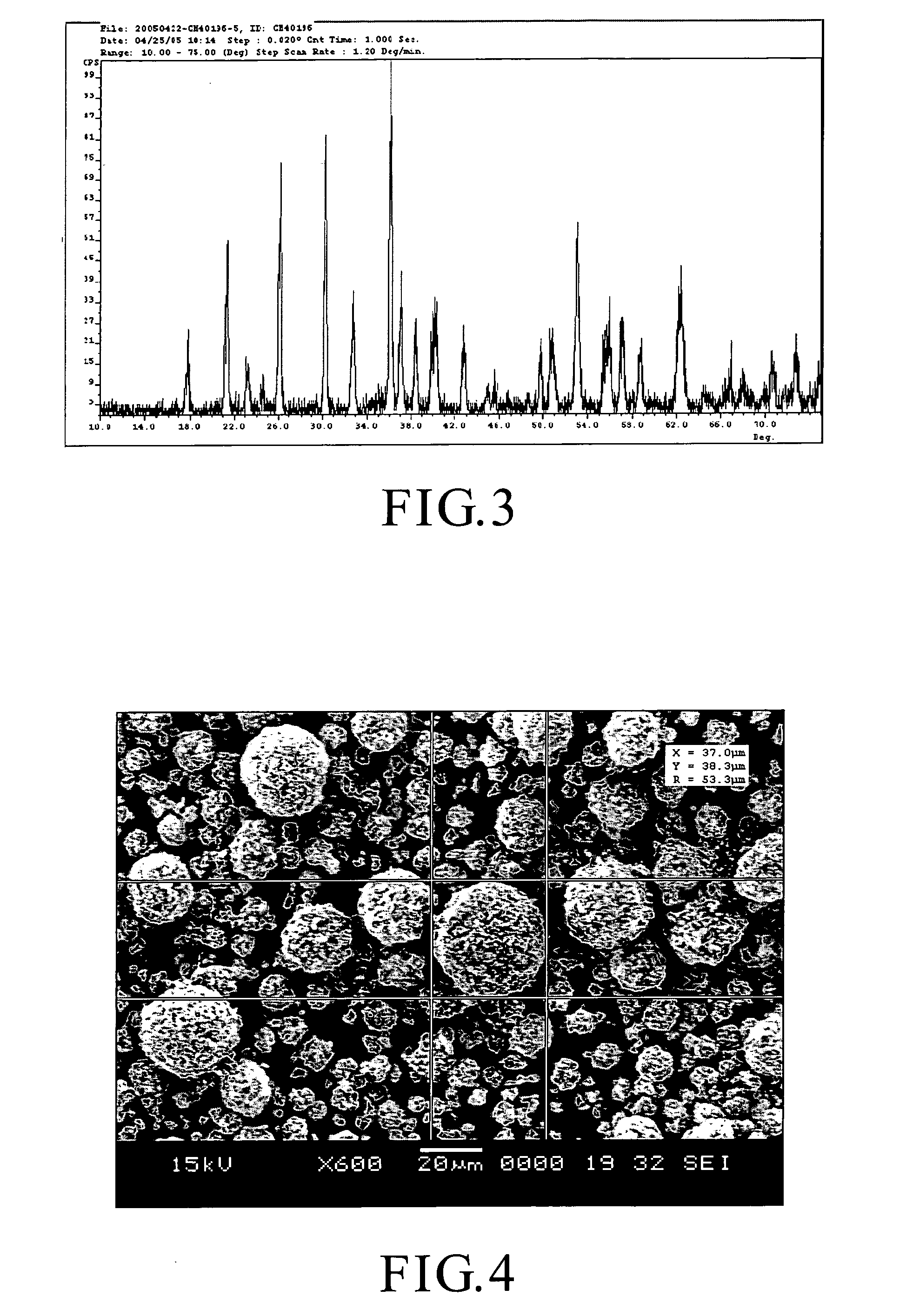

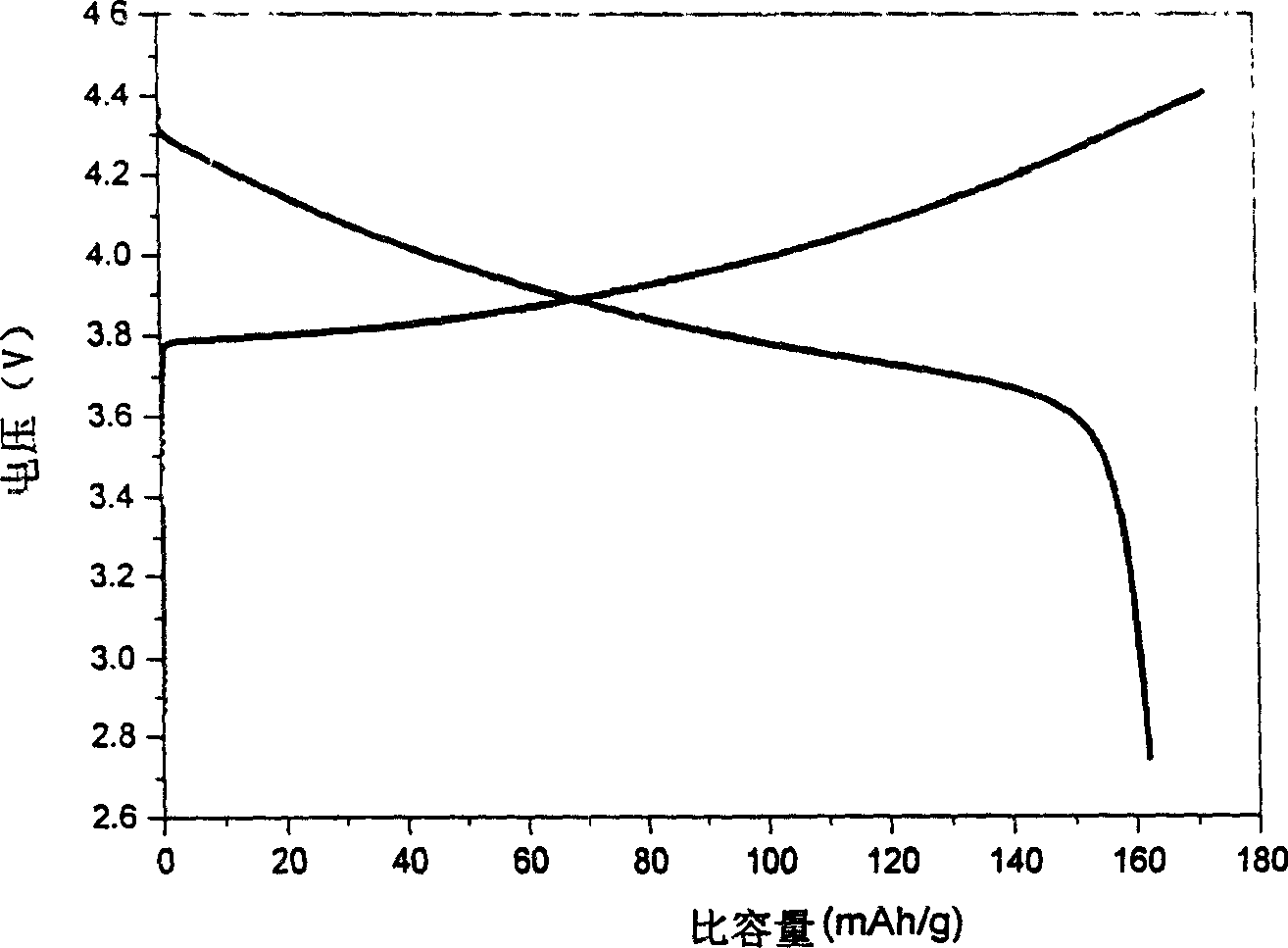

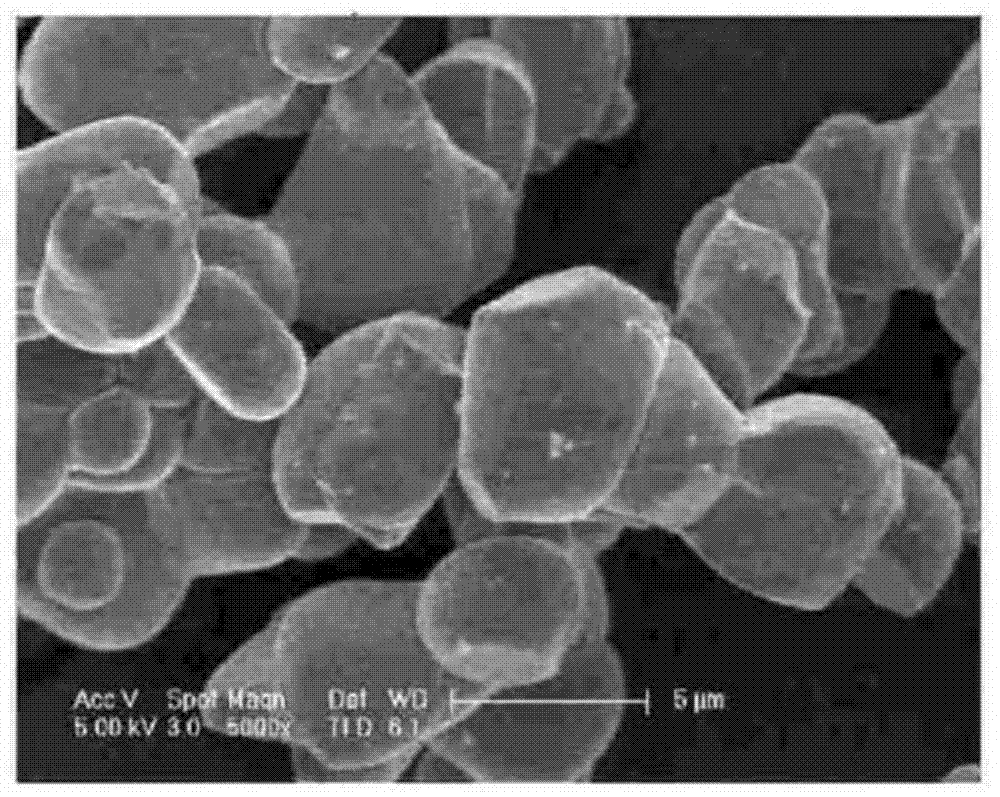

Lithium-nickel-cobalt-maganese containing composite oxide, material for positive electrode active material for lithium secondary battery, and methods for producing these

ActiveUS20060083989A1Large capacityExcels in charge-discharge cycle durabilityElectrode rolling/calenderingFluoride preparationManganeseOxygen

Coagulated particles of nickel-cobalt-manganese hydroxide wherein primary particles are coagulated to form secondary particles are synthesized by allowing an aqueous solution of a nickel-cobalt-manganese salt, an aqueous solution of an alkali-metal hydroxide, and an ammonium-ion donor to react under specific conditions; and a lithium-nickel-cobalt-manganese-containing composite oxide represented by a general formula, LipNixMn1-x-yCoyO2-qFq (where 0.98≦p≦1.07, 0.3≦x≦0.5, 0.1≦y≦0.38, and 0≦q≦0.05), which is a positive electrode active material for a lithium secondary cell having a wide usable voltage range, a charge-discharge cycle durability, a high capacity and high safety, is obtained by dry-blending coagulated particles of nickel-cobalt-manganese composite oxyhydroxide formed by making an oxidant to act on the coagulated particles with a lithium salt, and firing the mixture in an oxygen-containing atmosphere.

Owner:SUMITOMO CHEM CO LTD

Lithium cell positive electrode materials and preparing method thereof

InactiveCN1457111AImprove conductivityHigh conductivity at room temperatureElectrode thermal treatmentPositive electrodesNano structuringElectrical battery

The chemical general formula of the material is expressed as follows: LixM1-xFePO4, where M is selected from Mg2+, Ca2+...P5+ etc. With conduction adulterant added, reaction at 500-900 deg.C for 10 hr. by using metal oxide, phoshpate, fluoride etc. and non saturated crystal of Li-Fe phoshpate through nonstoichiometric method obtains the crystal of Li-Fe phosphate with high conductivity, which can be expressed as LiFePO4-y. The formula of material prepared by using method of pressurized type substitution ion is LixM1-xFezM'1-z. The formula of material of solid power prepared by using method of solid phase reaction is as LixM1-xFezMn1-zPO4. The formula of anode material in nano structure prepared by using method of vacuum sputter deposition is LixFePO4-y, whose conductivity and discharge capacity can reach 10 to the power -2 S / cm and 240 Ah / g.

Owner:徐瑞松

Method for making a lithium mixed metal compound

A method for making a lithium mixed metal compound includes: preparing a reactant mixture that contains a metal compound, a lithium compound, and optionally, a phosphate-containing compound; and exposing the reactant mixture to an atmosphere in the presence of suspended carbon particles, and conducting a reduction to reduce oxidation state of at least one metal ion of the reactant mixture at a temperature sufficient to form a reaction product containing lithium and the reduced metal ion.

Owner:AQUIRE ENERGY CO LTD

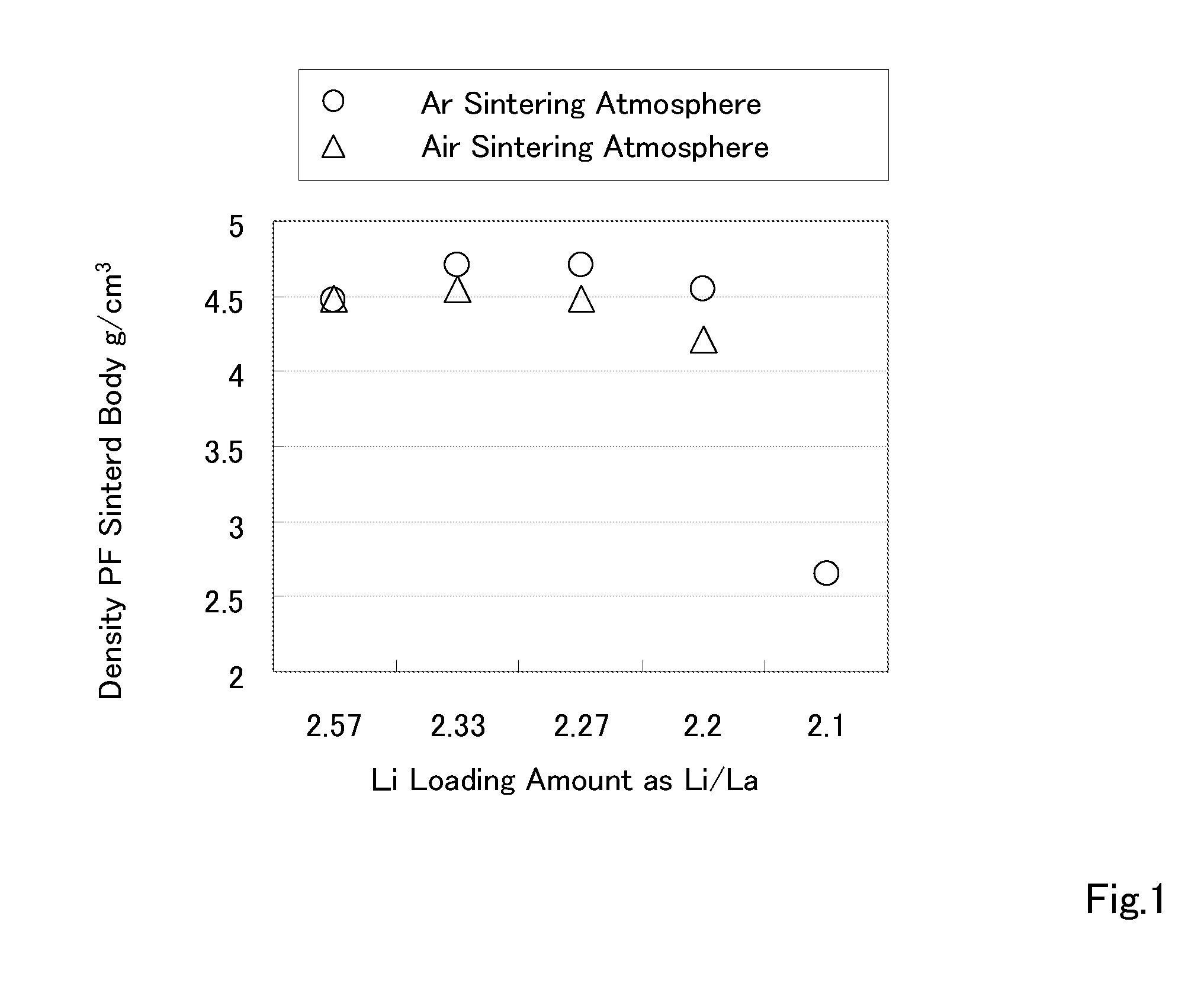

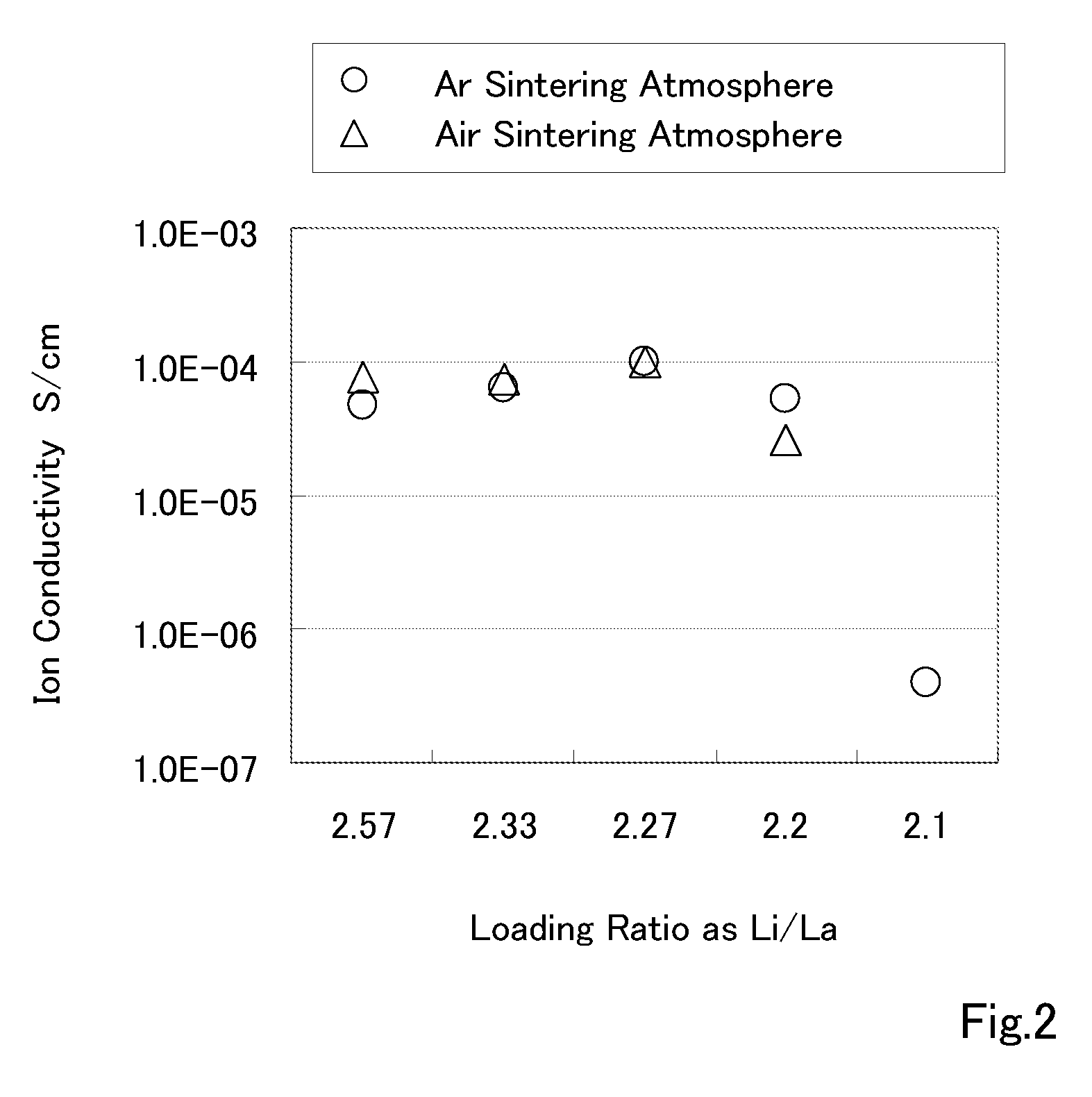

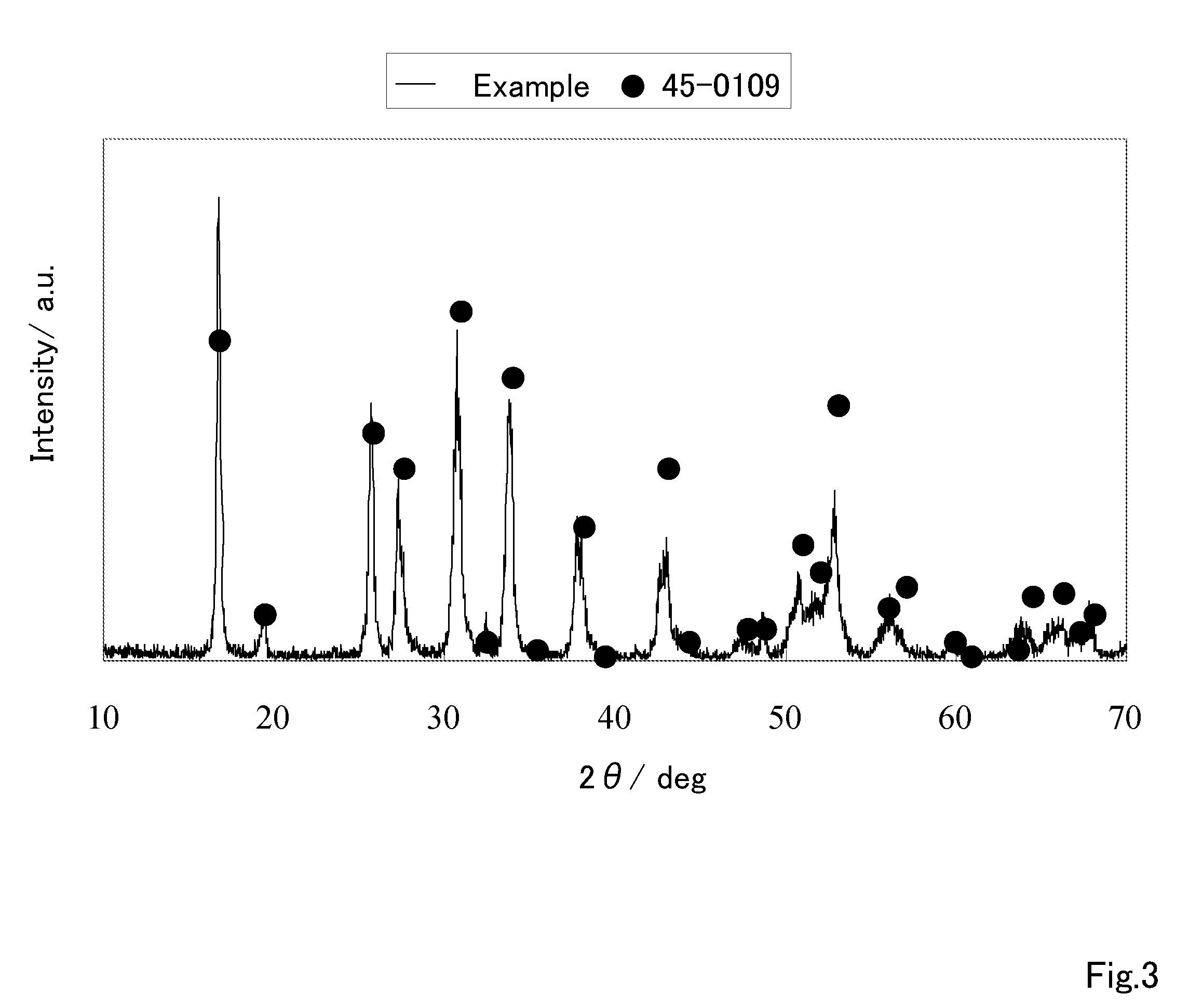

Ceramic material and use thereof

ActiveUS20110053000A1High densitySatisfactory Li ion conductionZirconium compoundsSecondary cellsHigh densityMetallurgy

The present invention provides a ceramic material allowing a pellet having higher density and satisfactory Li ion conduction to be obtained. The ceramic material contains Li, La, Zr, Al and O and has a garnet-type or garnet-like crystal structure, the ratio of the number of moles of Li with respect to La being 2.0 or greater to 2.5 or lower.

Owner:TOKYO METROPOLITAN PUBLIC UNIV CORP +1

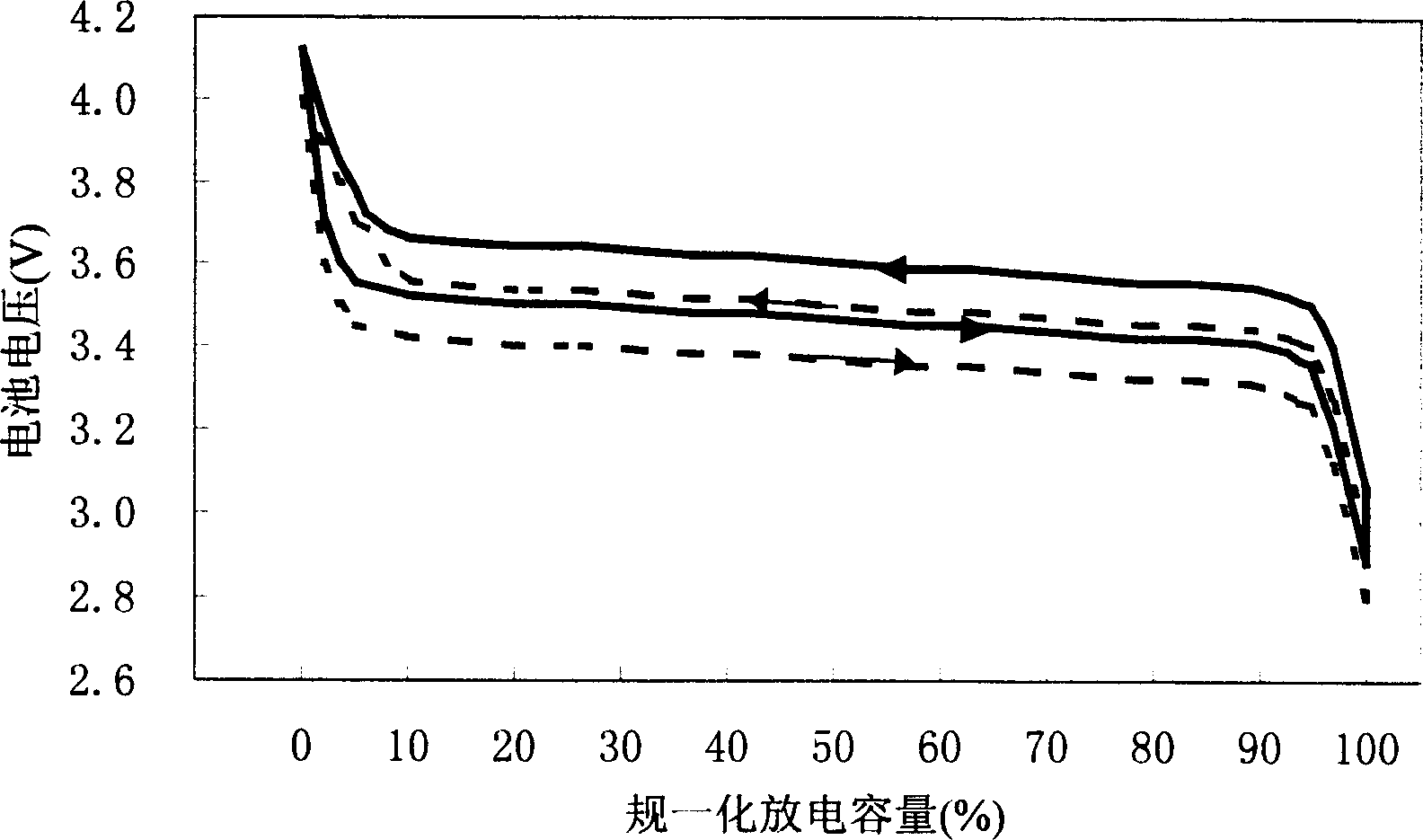

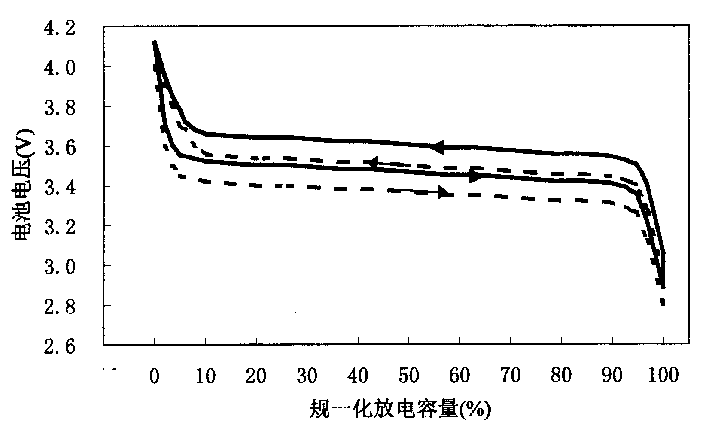

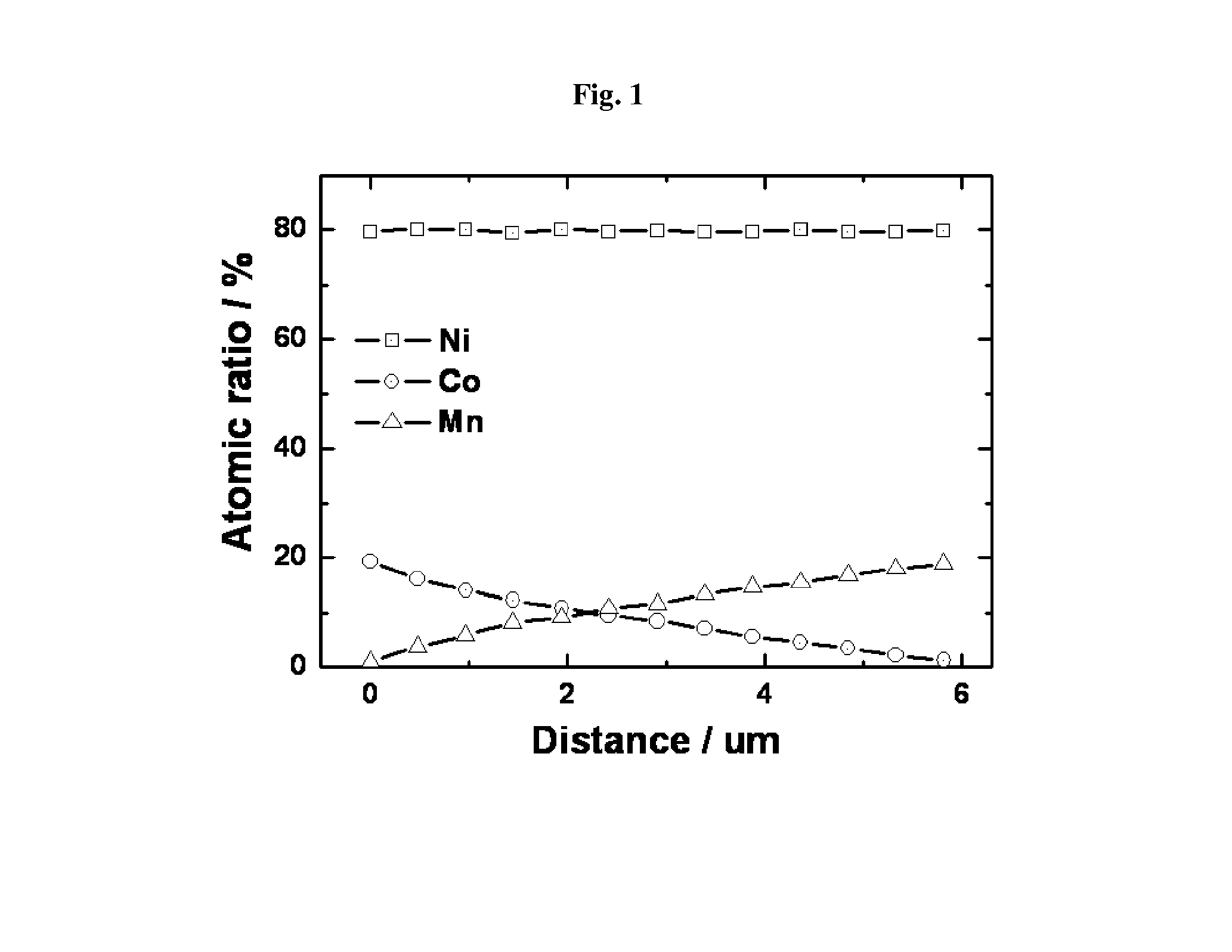

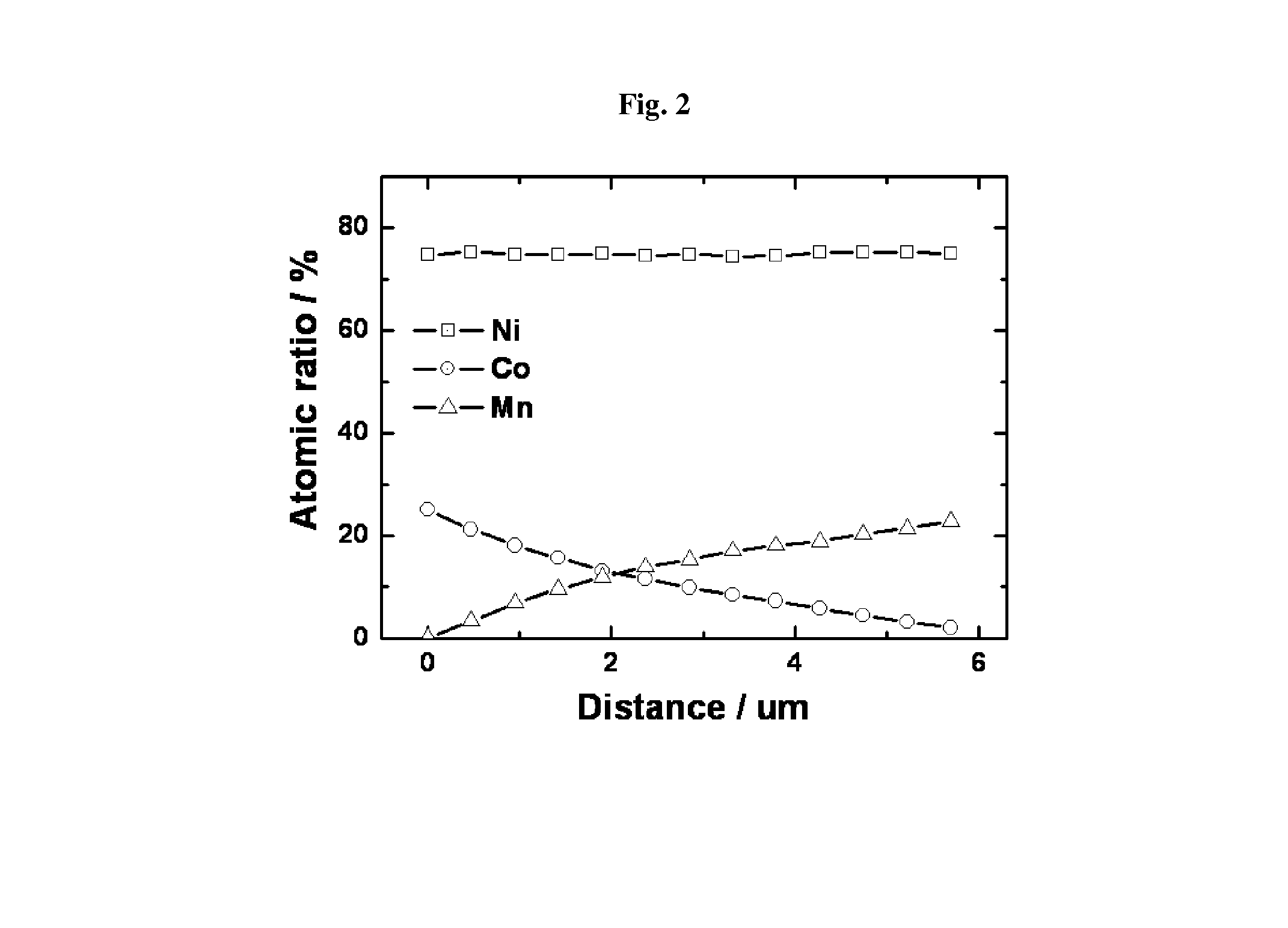

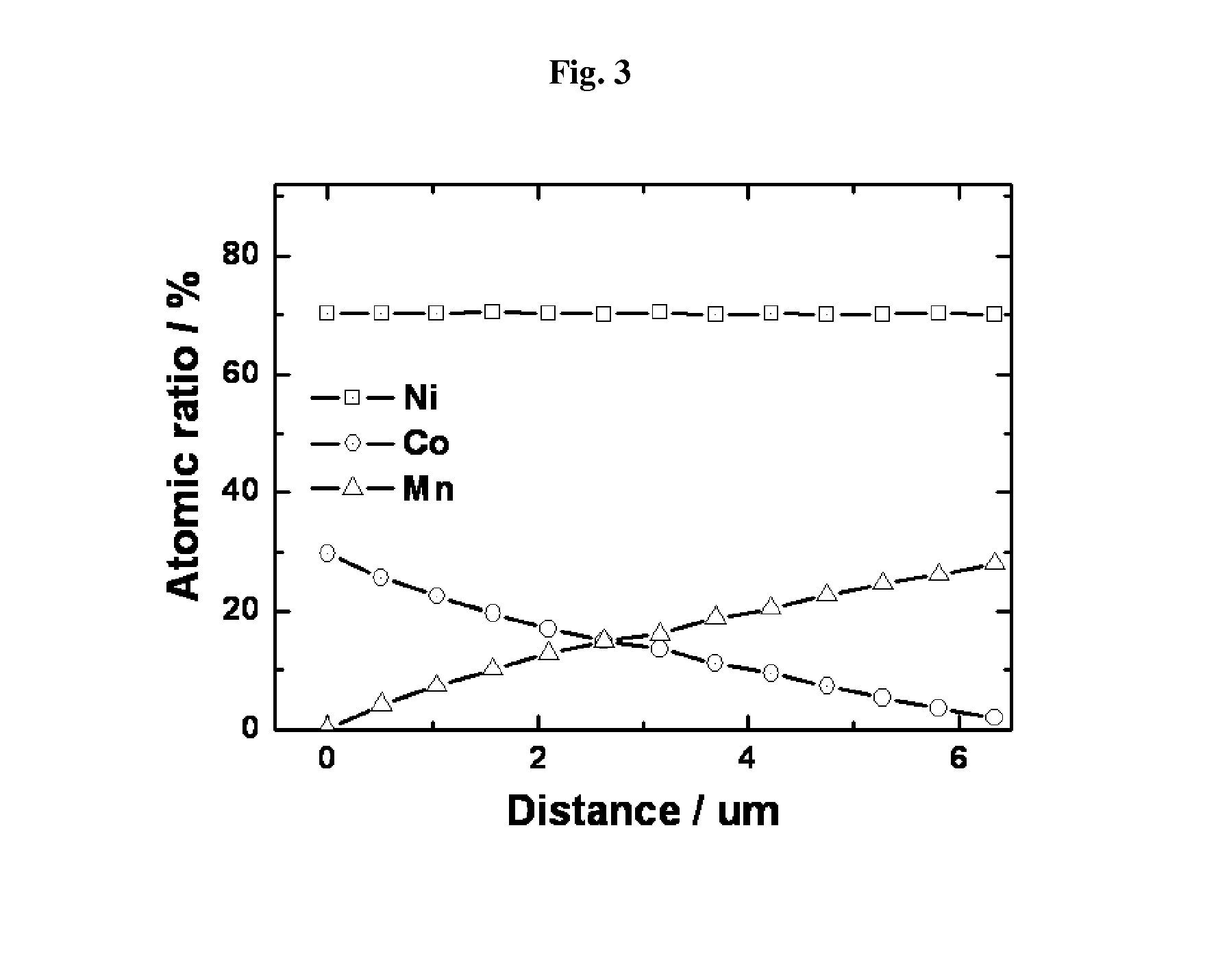

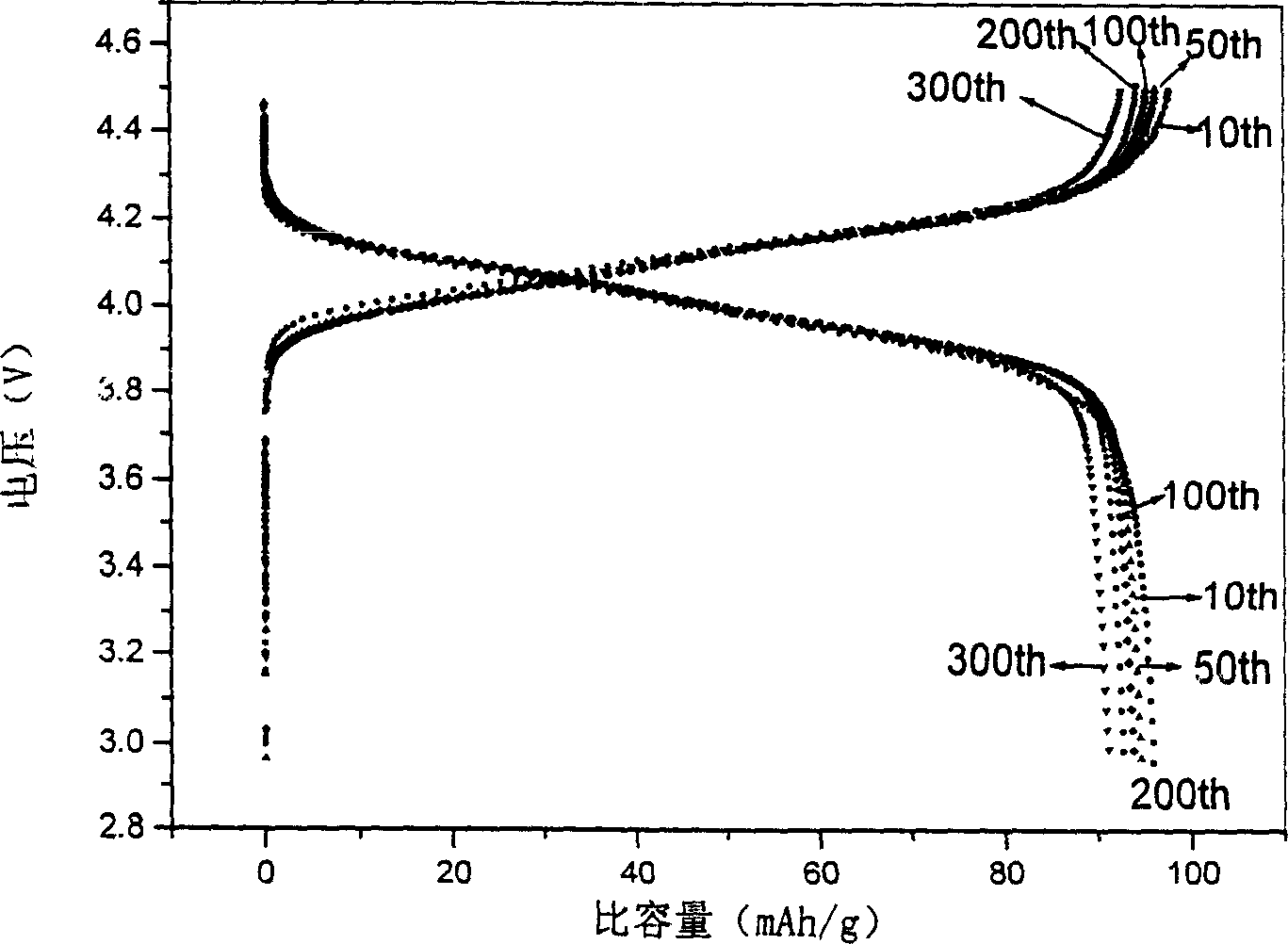

Anode active material with whole particle concentration gradient for lithium secondary battery, method for preparing same, and lithium secondary battery having same

ActiveUS20140027670A1Improve thermal stabilityExcellent capacity characteristicsFinal product manufacturePositive electrodesComposite cathodeCrystal structure

The present invention relates to a cathode active material with whole particle concentration gradient for a lithium secondary battery, a method for preparing same, and a lithium secondary battery having same, and more specifically, to a composite cathode active material, a method for manufacturing same, and a lithium secondary battery having same, the composite cathode active material having excellent lifetime characteristics and charge / discharge characteristics through the stabilization of crystal structure as the concentration of a metal comprising the cathode active material shows concentration gradient in the whole particle, and having thermostability even in high temperatures.

Owner:LG CHEM LTD

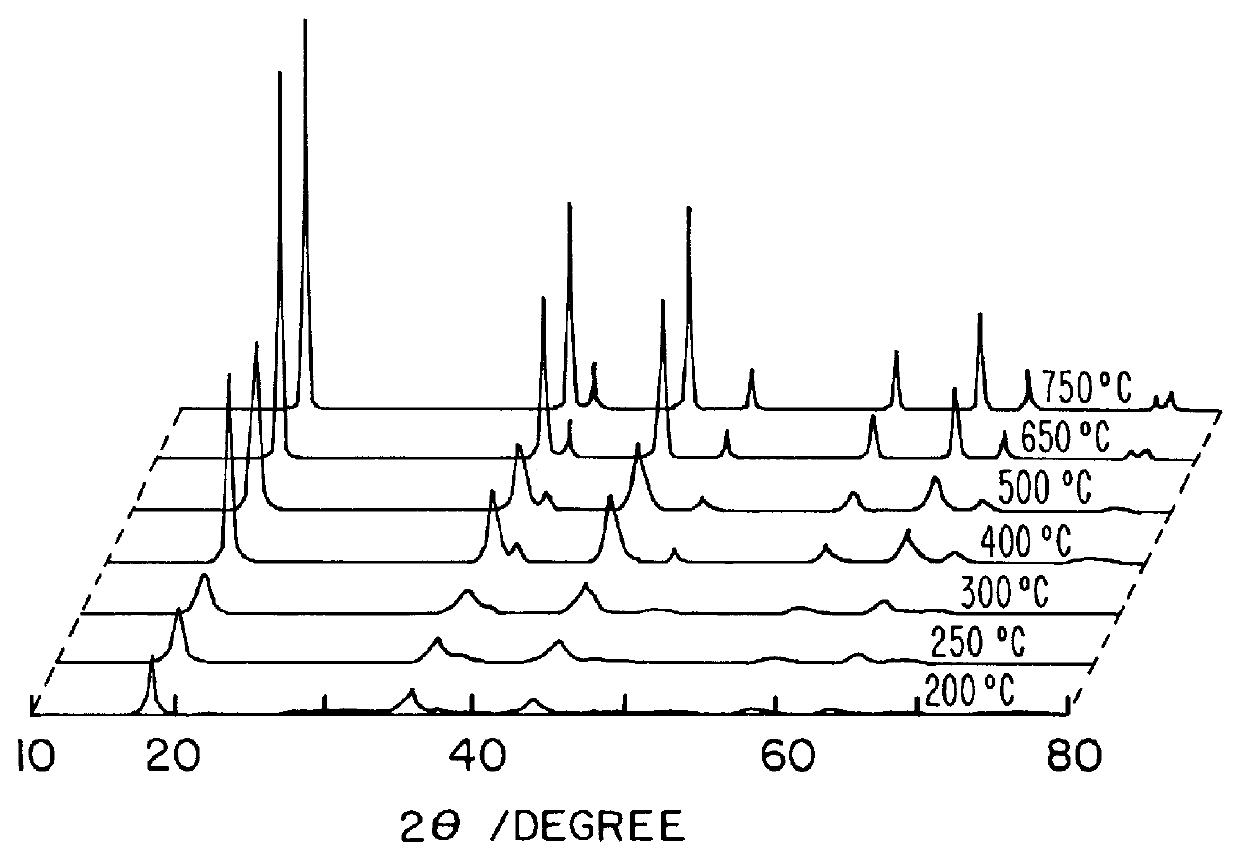

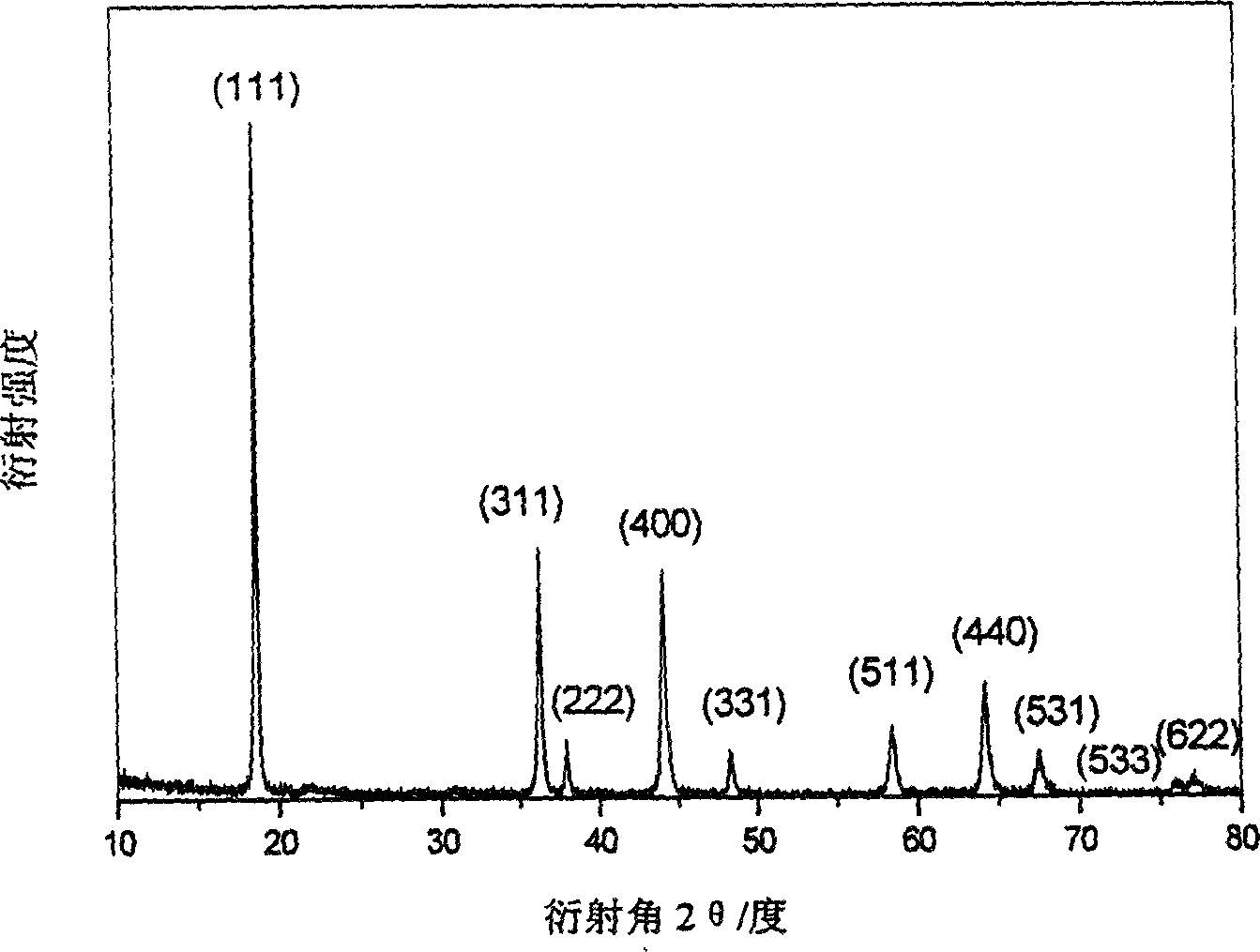

Methods of preparing cathode active materials for lithium secondary battery

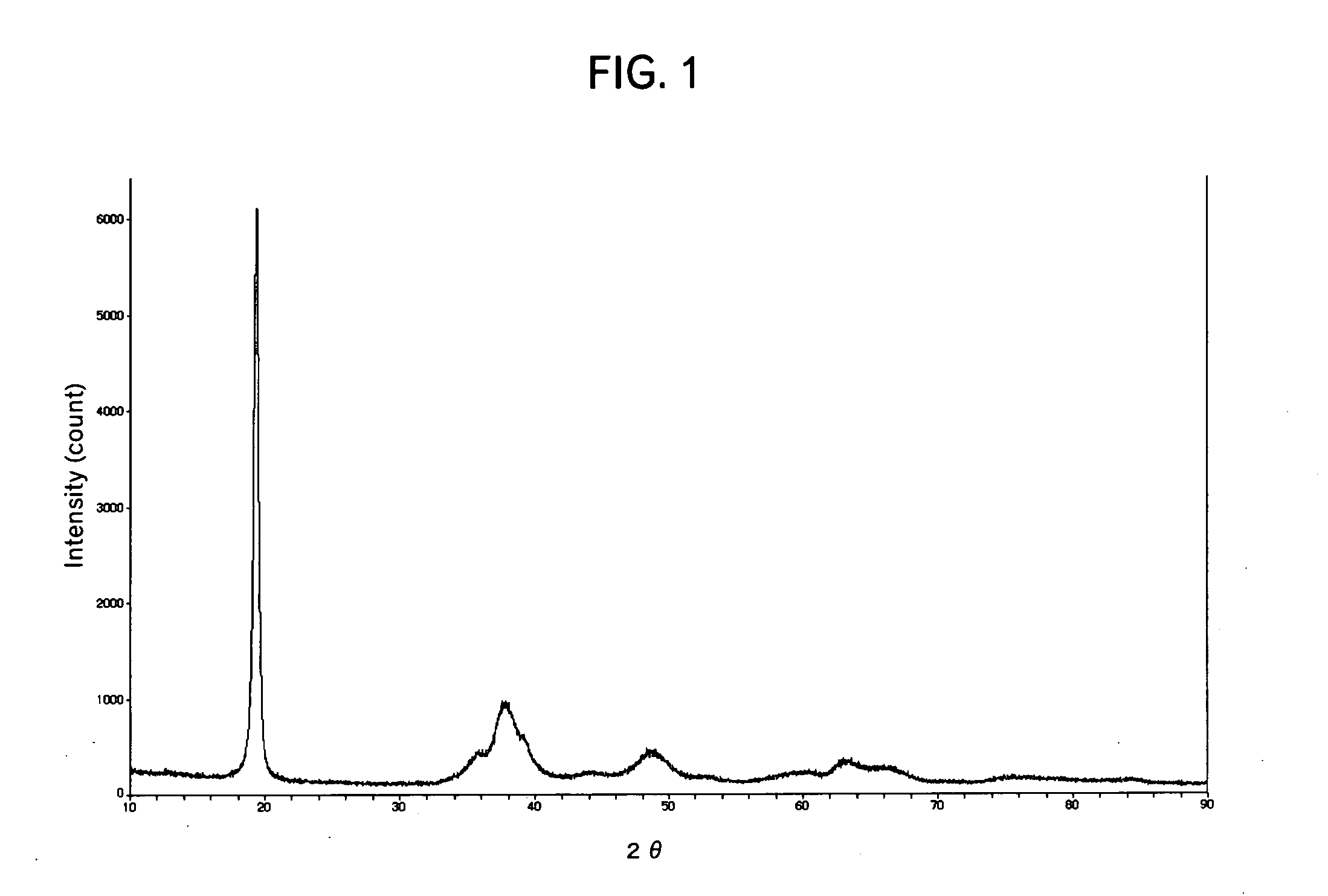

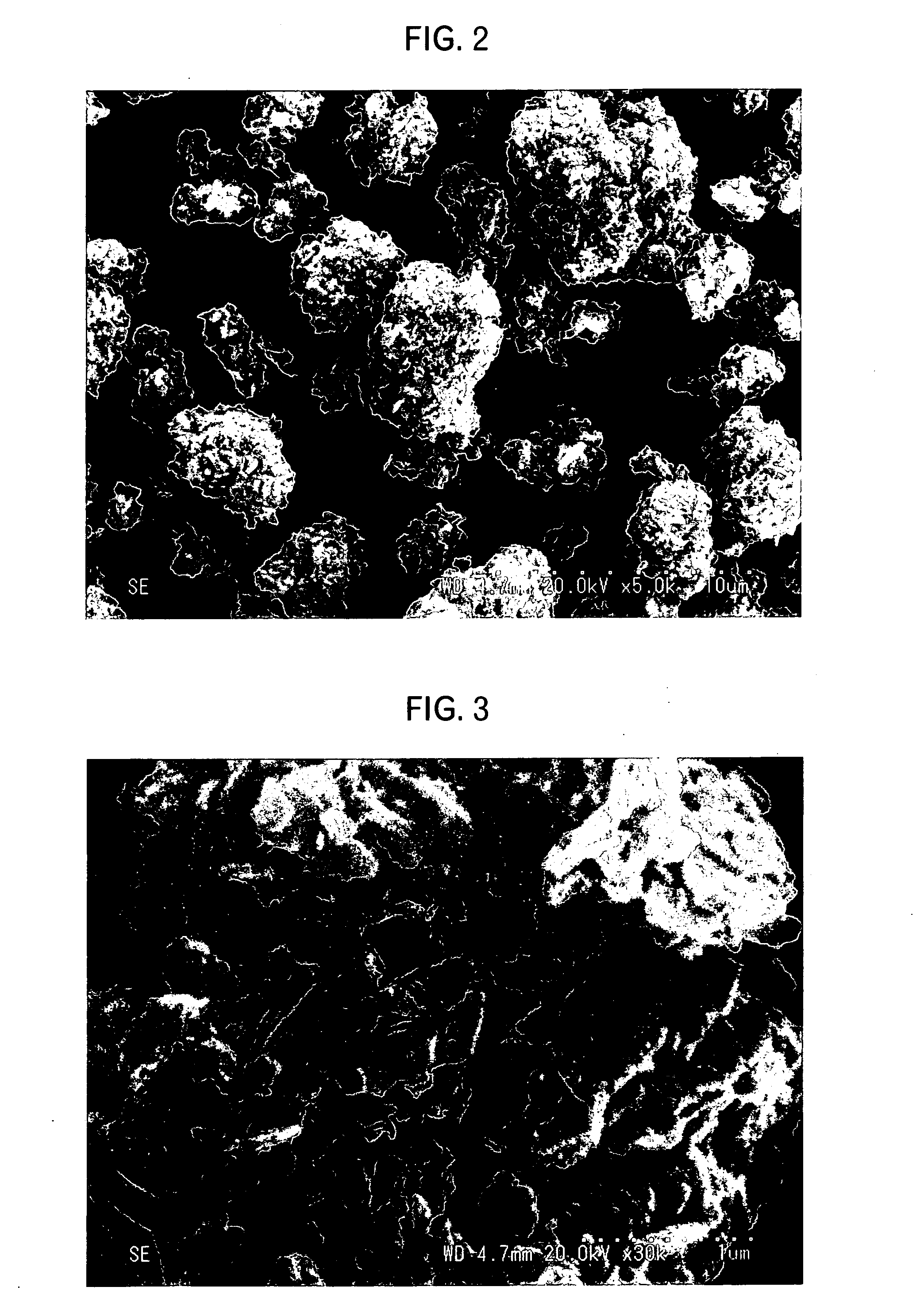

InactiveUS6071489AEasy to optimizeHigh crystallinityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsManganeseEthyl acetate

The LixMn2O4 powder for cathode active material of a lithium secondary battery of the present invention is prepared by a method of comprising the steps of mixing an acetate aqueous solution using Li acetate and Mn acetate as metal precursors, and a chelating agent aqueous solution using PVB, GA, PAA or GC as a chelating agent; heating the mixed solution at 70 DIFFERENCE 90 DEG C. to form a sol; further heating the sol at 70 DIFFERENCE 90 DEG C. to form a gel precursor; calcining the produced gel precursor at 200 DIFFERENCE 900 DEG C. for 5 DIFFERENCE 30 hours under atmosphere. The cathode active material, LixMn2O4 powder for a lithium secondary battery in accordance with the present invention has a uniform particle size distribution, a high crystallinity and a pure spinel-phase, and a particle size, a specific surface area, a lattice of a cubic structure and the like can be controlled upon the preparing conditions. The present invention also provides a method of preparing LiNi1-xCoxO2 powder, which comprises the steps of providing a gel precursor using PAA as a chelating agent and hydroxide, nitrate or acetate of Li, Co and Ni as metal precursors; heating the gel precursor at 200 DIFFERENCE 900 DEG C. for 5 DIFFERENCE 30 hours to form a powder. The LixMn2O4 and LiNi1-xCoxO2 powder of the present invention can be used for a cathode active material of a lithium secondary battery such as a lithium ion battery or lithium polymer battery.

Owner:SAMSUNG DISPLAY DEVICES CO LTD

Method of preparation of positive electrode material

InactiveUS20050069484A1Prolong lifeReduce moisture contentElectrode thermal treatmentOrganic electrolyte cellsElectrical batteryPhysical chemistry

A method for preparing a positive electrode material for a lithium-ion or lithium-ion polymer battery to reduce the moisture content of the positive electrode material. A lithiated transition metal oxide positive electrode material having at least one water-containing compound therein is treated to convert the water-containing compound to a water-free compound. One treatment in the method of the present invention involves exposing the positive electrode material at a temperature of 0-650° C. to a CO2-containing gas. The other treatment in the method of the present invention involves heating the positive electrode material to a temperature greater than 250° C. in the presence of an oxygen-containing gas, such as air and / or O2. The treatments may be, performed sequentially or concurrently.

Owner:ENERDEL

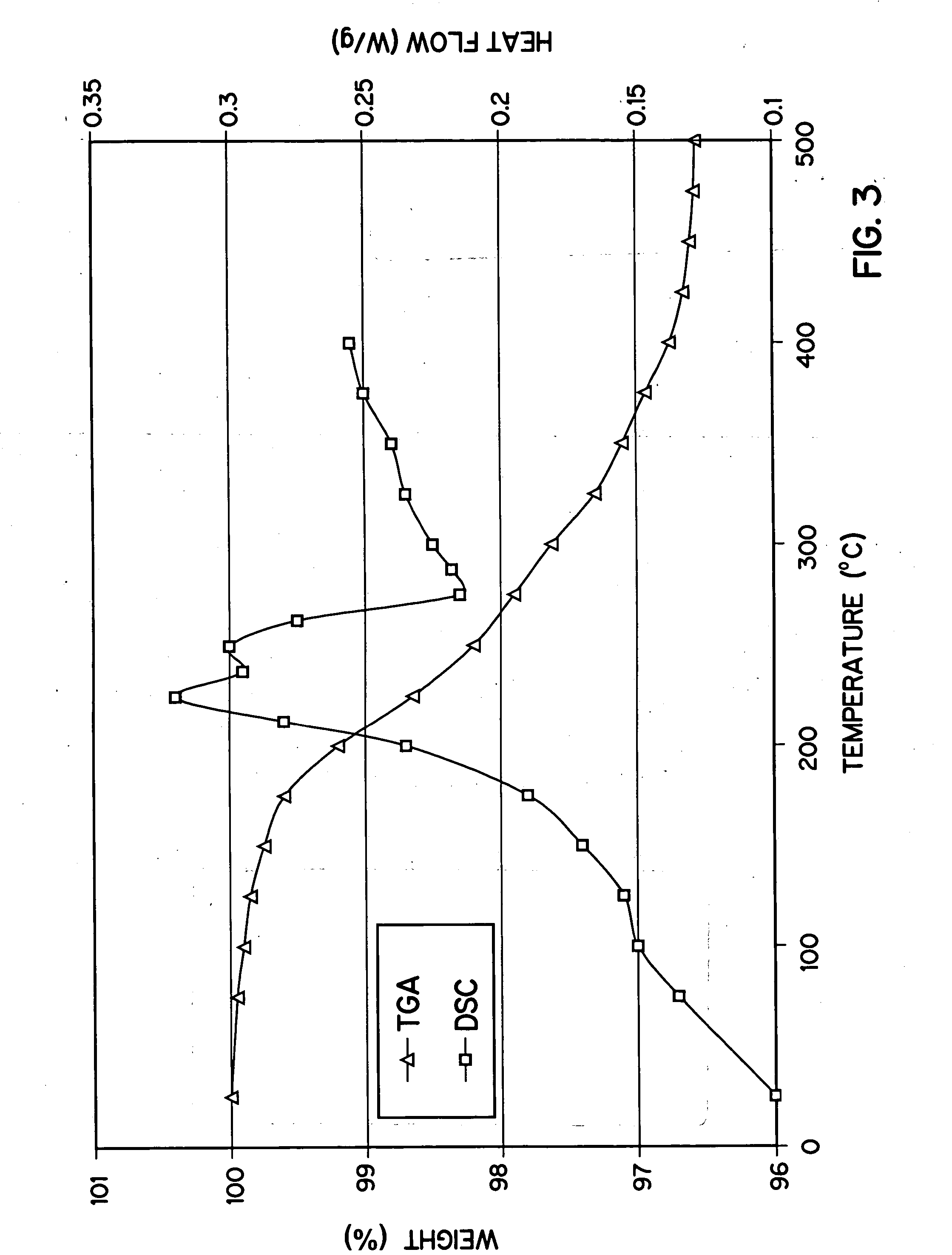

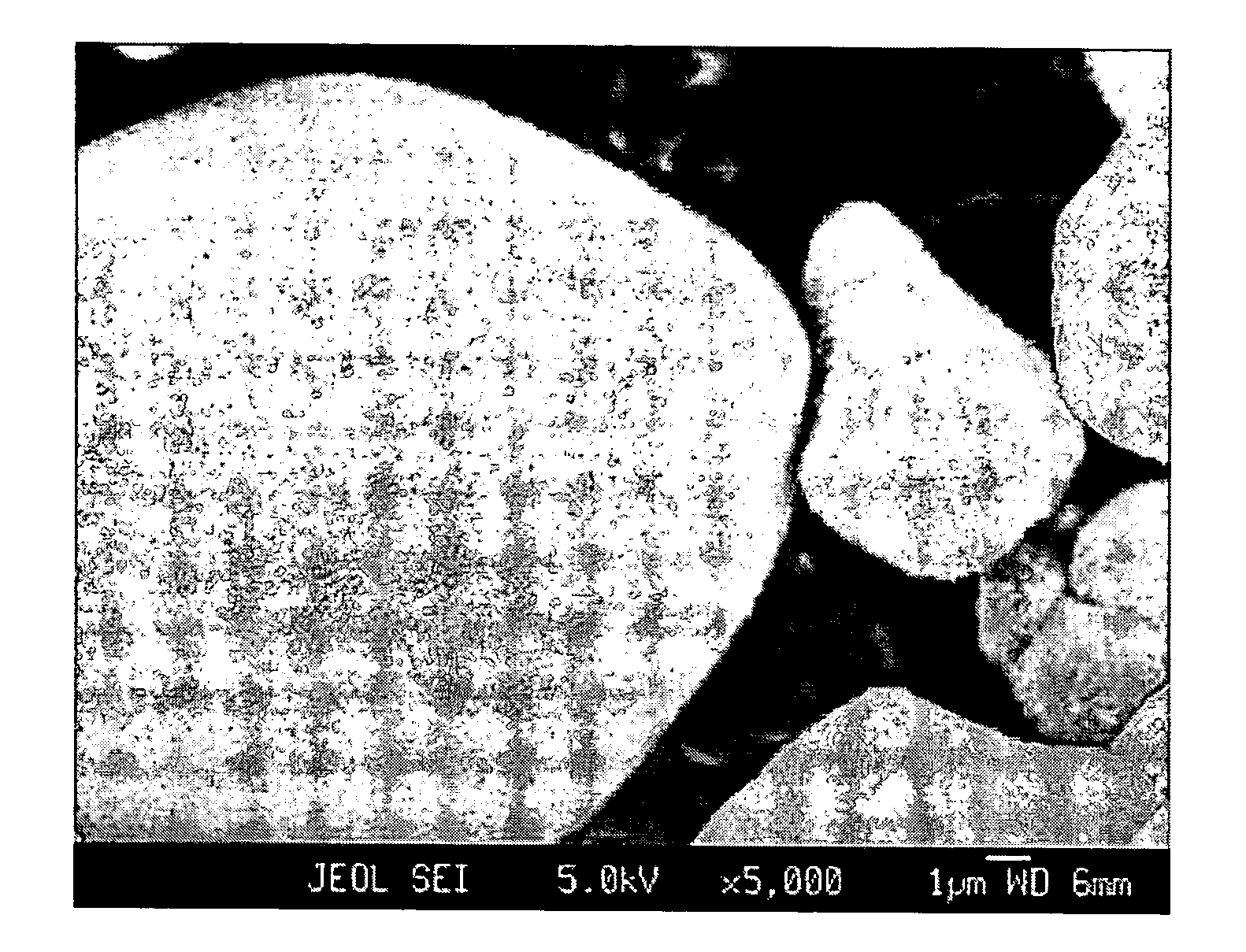

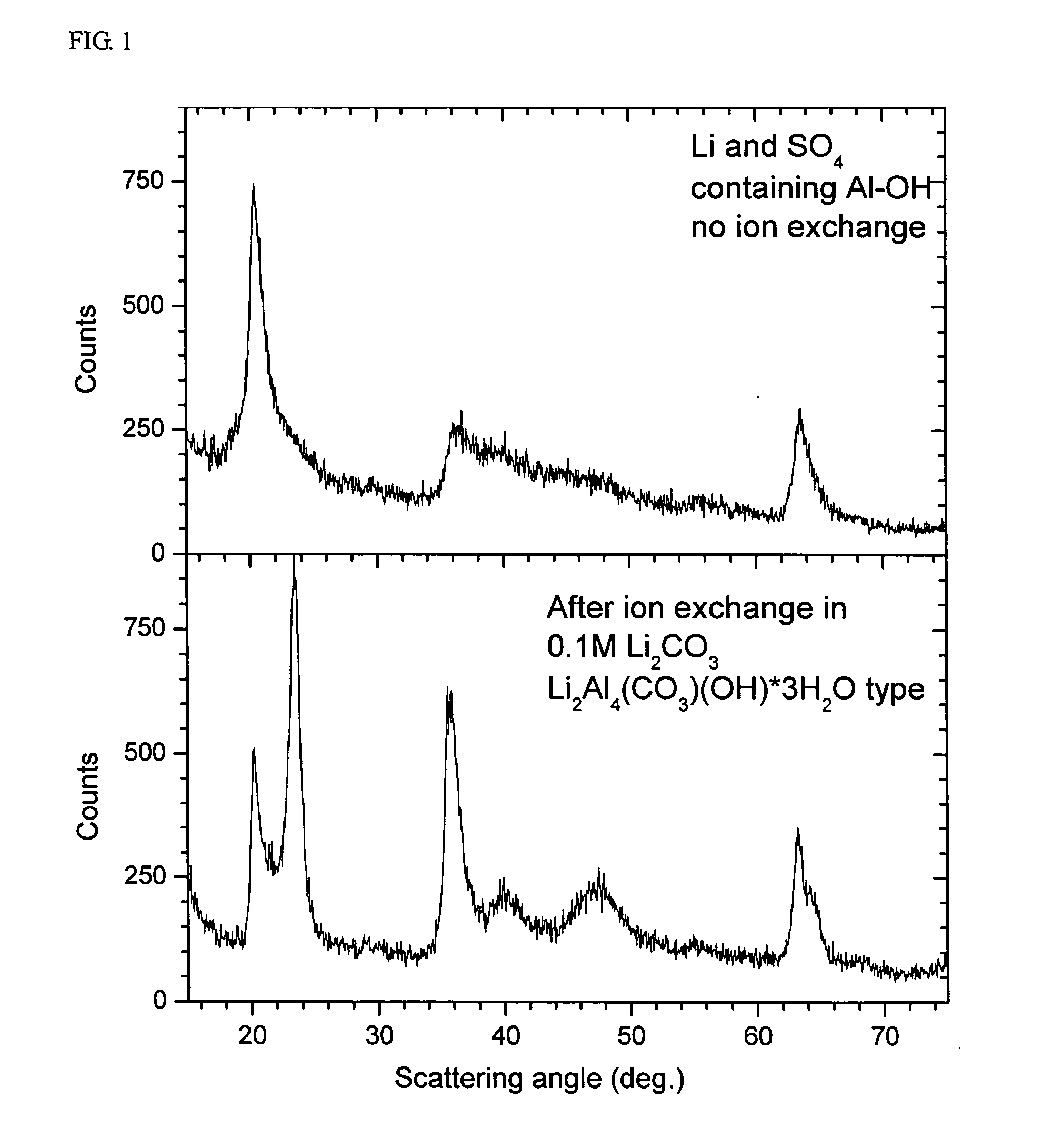

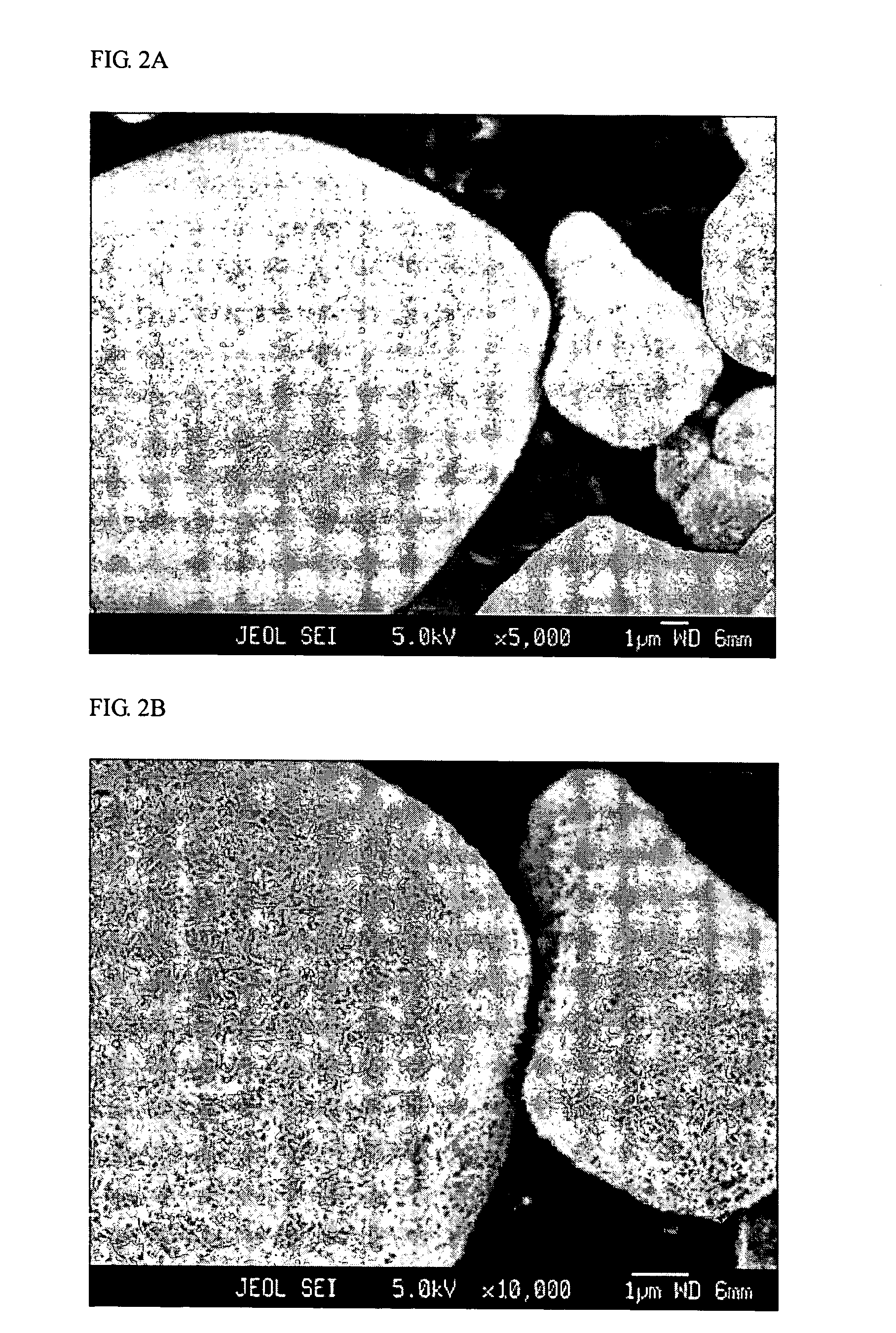

Composite precursor for aluminum-containing lithium transition metal oxide and process for preparation of the same

ActiveUS20060068289A1Coating stabilityEasy to replaceElectrode manufacturing processesConductive materialWater basedAluminium hydroxide

The present invention provides a powdery composite precursor, which comprises a core of a lithium transition metal oxide, and an aluminum hydroxide-based precipitate layer coated on the surface of the core, and a process to prepare the composite precursor. The preparation process comprises the formation of a water based slurry by dispersing lithium transition metal oxide powder in water, and a precipitation reaction of an aluminum salt solution with a base solution where the lithium transition metal particles act as seed particles, whereby a mechanically stable precipitate layer of homogeneous thickness can be achieved. The composite precursor can be converted into aluminum-containing, e.g., aluminum-doped, lithium transition metal oxide suitable for a cathode active material of lithium rechargeable battery by heat treatment.

Owner:LG ENERGY SOLUTION LTD

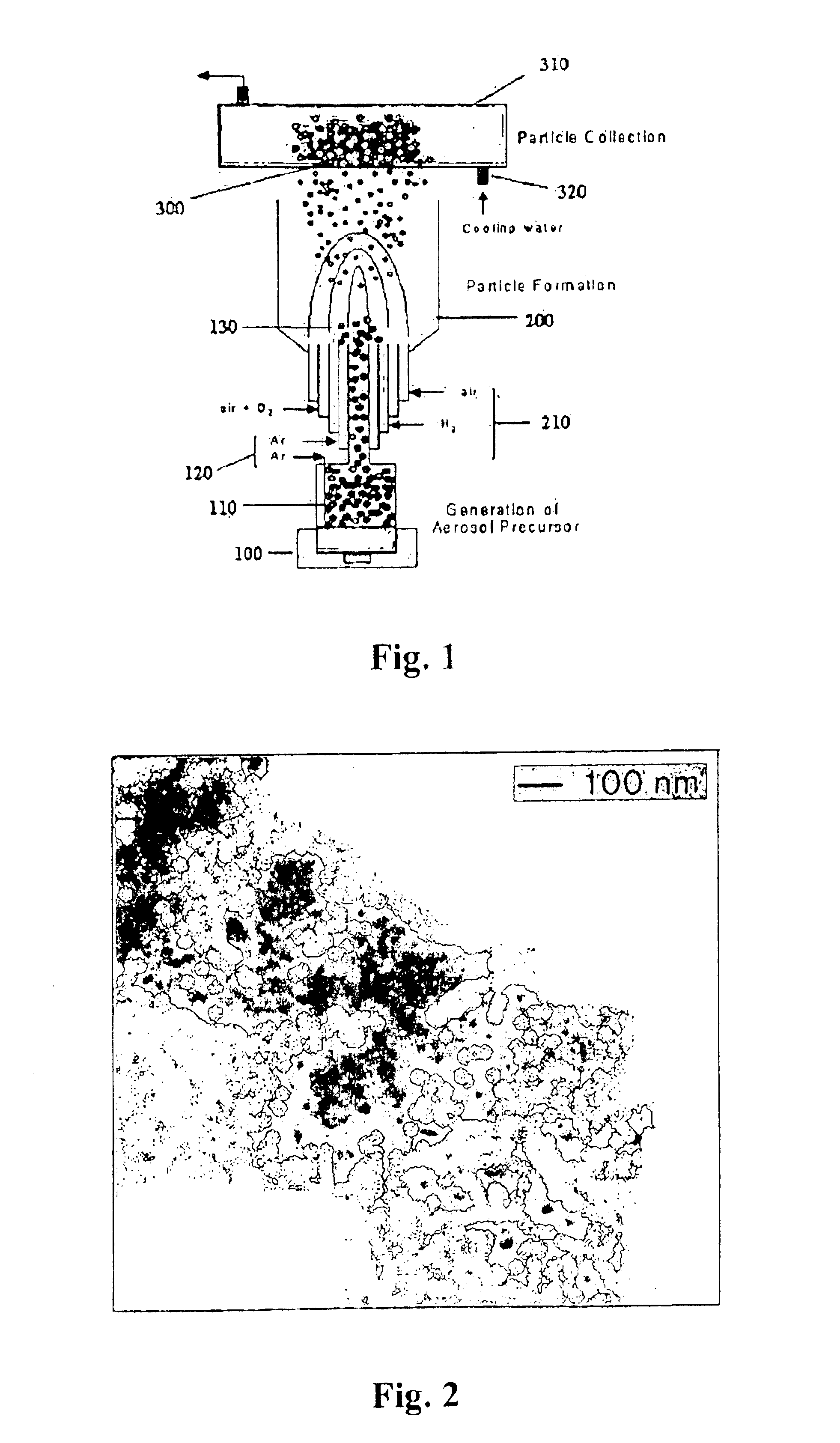

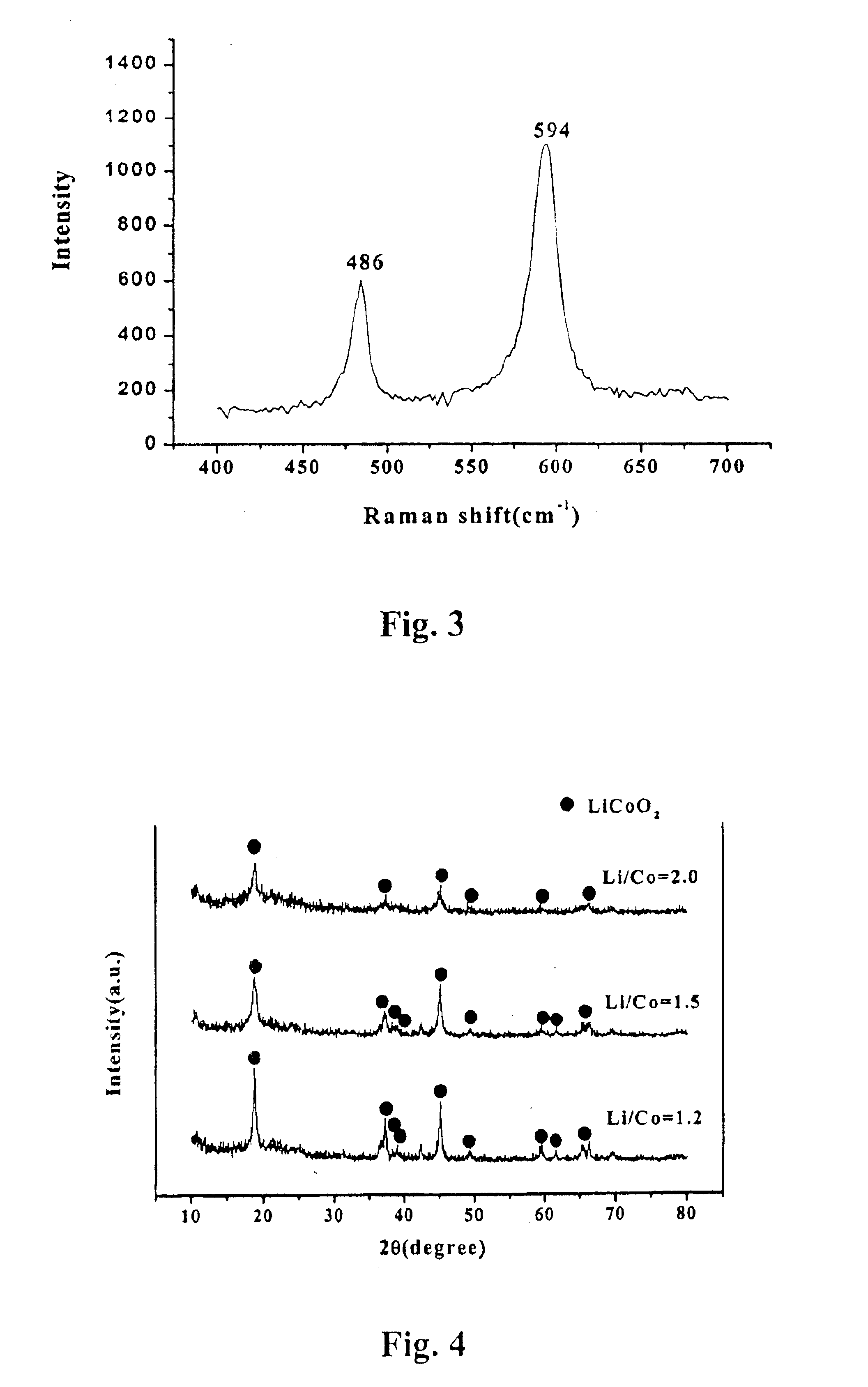

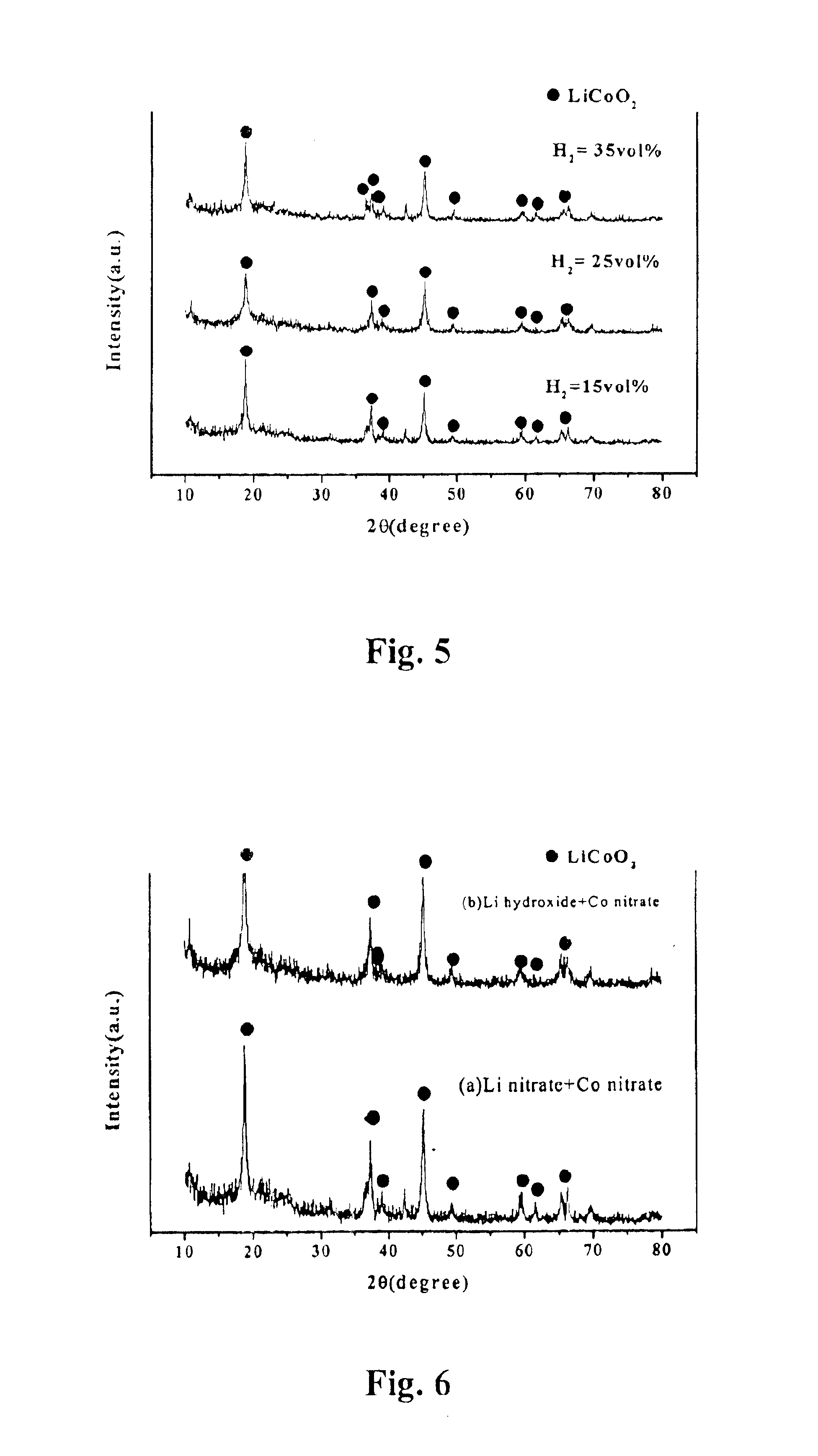

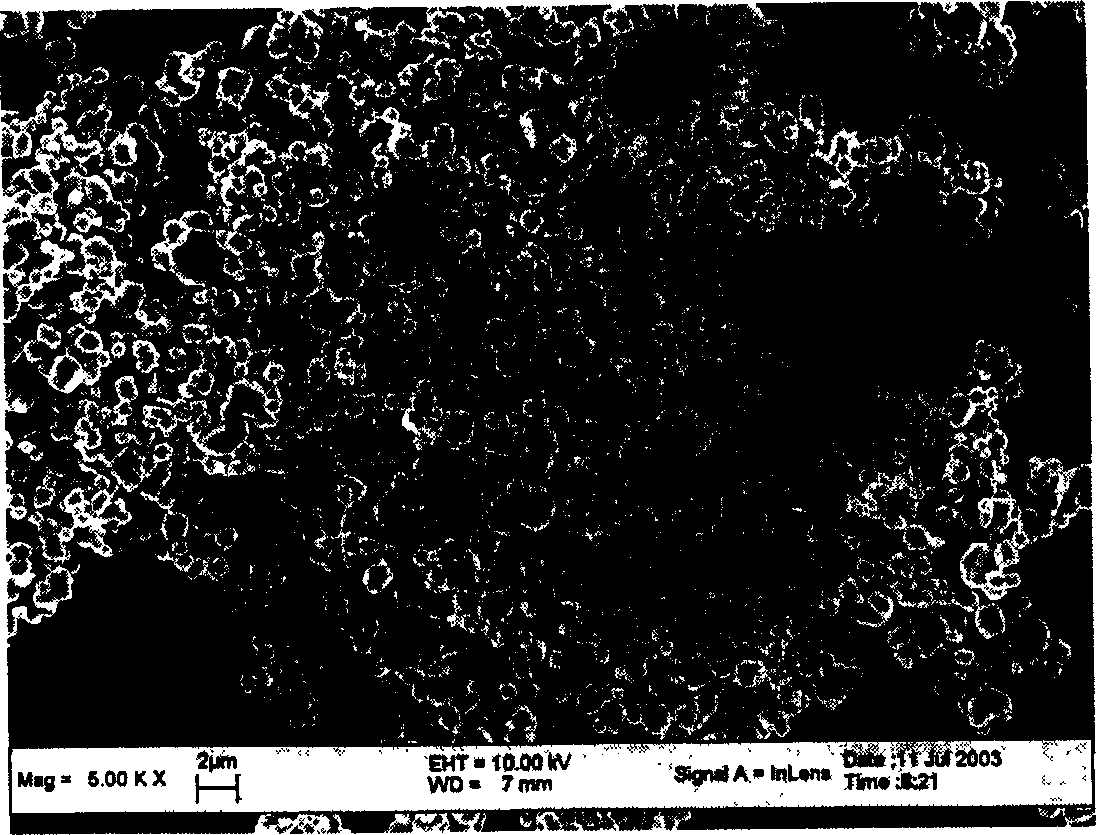

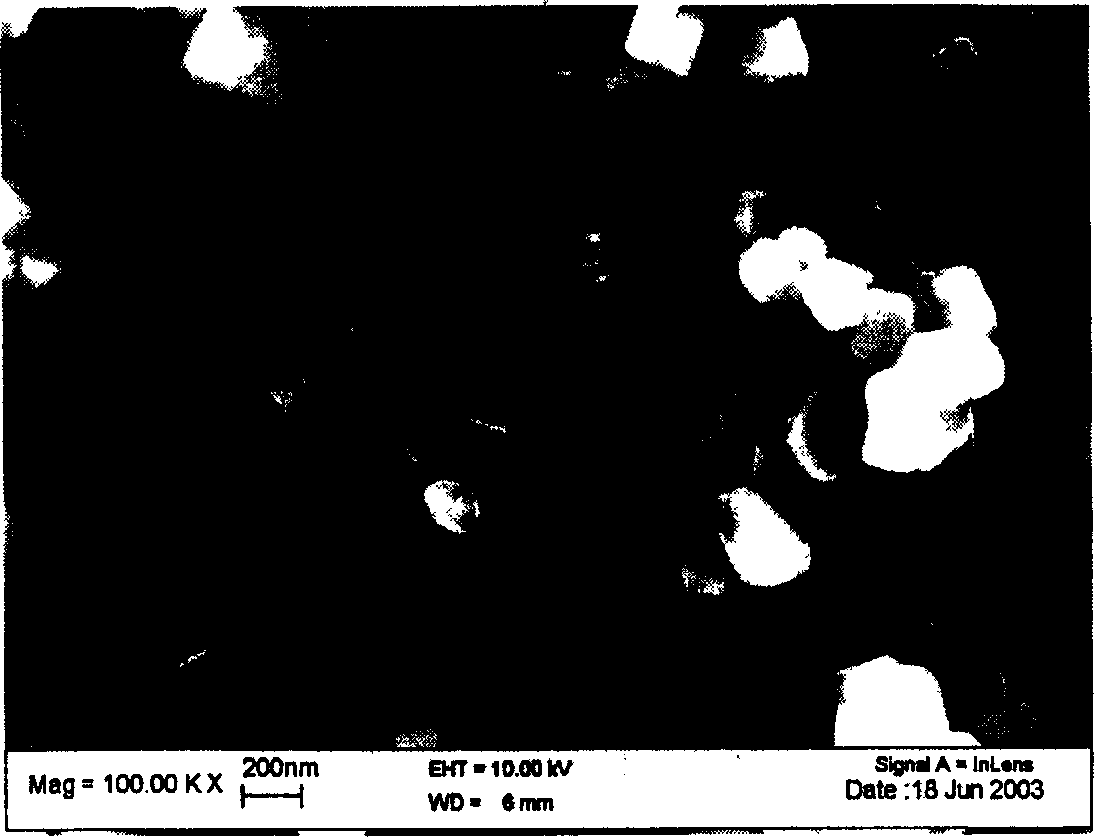

Method of manufacturing nano-sized lithium-cobalt oxides by flame spraying pyrolysis

InactiveUS6902745B2Extend your lifeImprove efficiencyHeavy metal active ingredientsMaterial nanotechnologyGas phaseOxygen

A method for producing nano-sized lithium-cobalt oxide is provided by using flame-spray pyrolysis. The method comprises the steps of: spraying minute droplets, which is a solution dissolved lithium salt with cobalt salt at room temperature; atomizing the minute droplets through rapid expansion into a high temperature environment generated by combusting oxygen and hydrogen; decomposing and oxidizing the atomized minute droplets thermally at high temperature to produce nano-sized oxides in gaseous phase: and collecting the produced nano-sized composite oxides particles. The produced nano-sized lithium-cobalt oxide can be applied to a highly efficient lithium battery as the electrode materials and a thin film type of battery as well as to a miniaturized battery.

Owner:KWAK YOUNG HOON

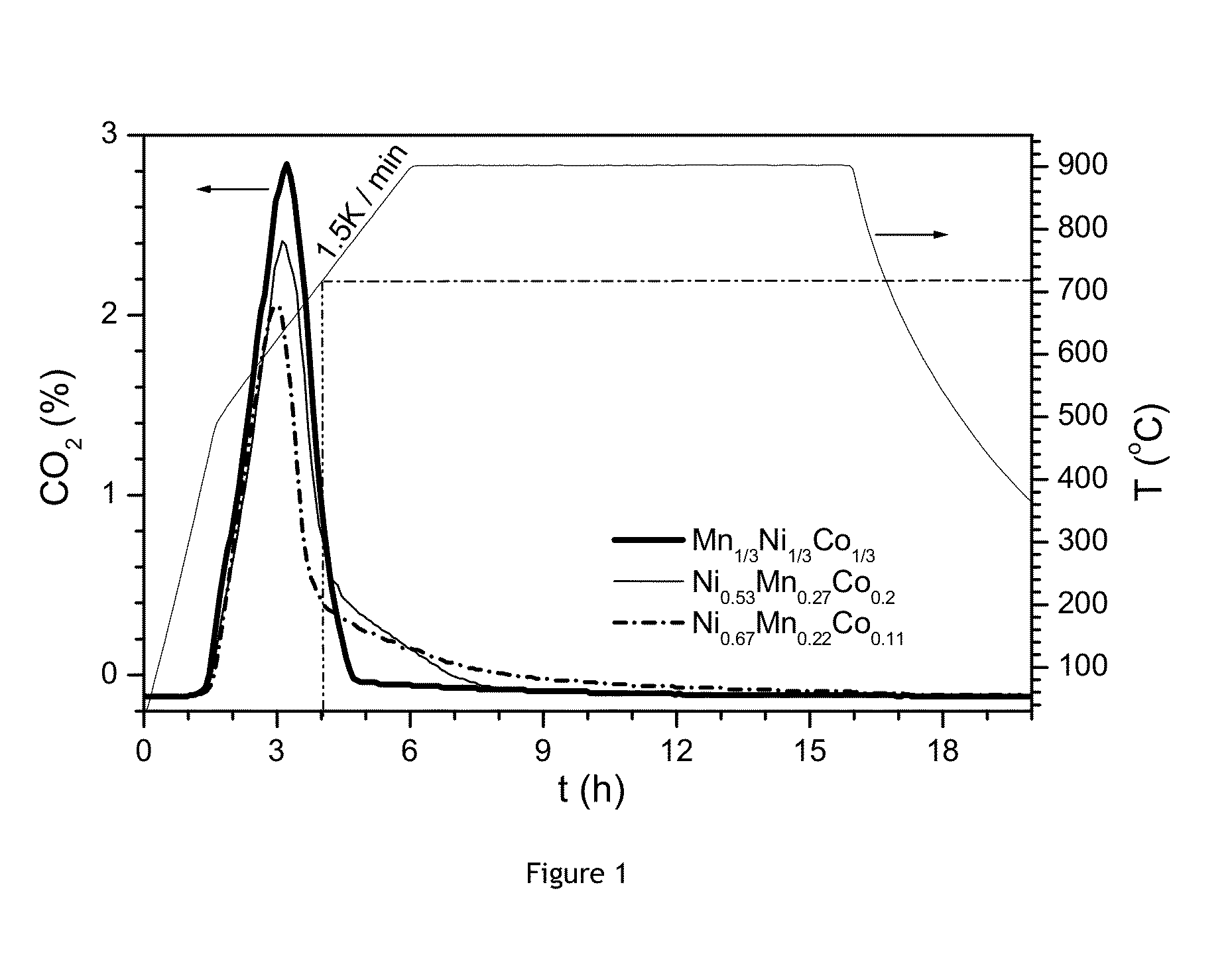

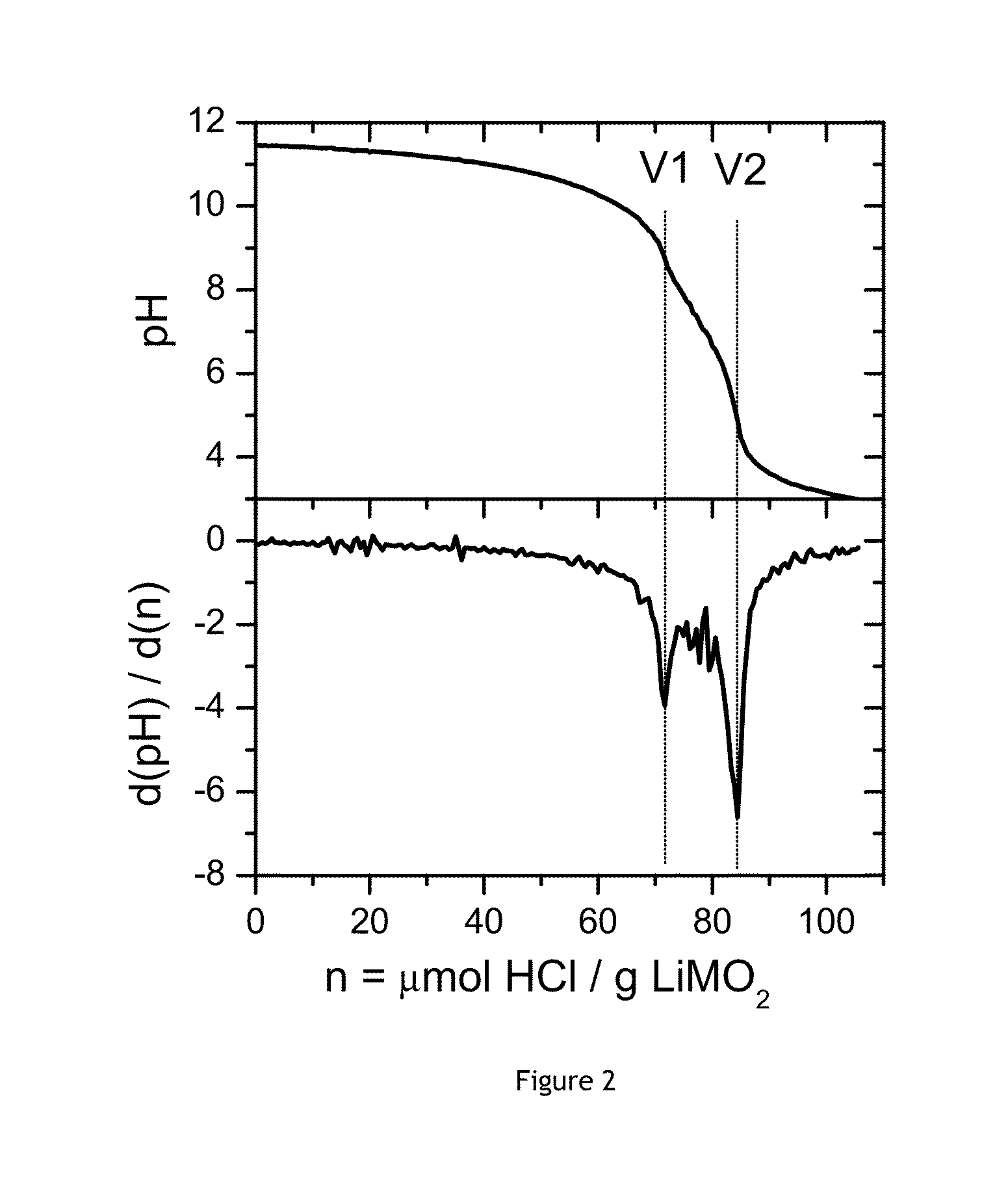

High nickel cathode material having low soluble base content

ActiveUS20140054495A1Improve performanceSecondary cell gas removalLi-accumulatorsDopantCathode material

The invention relates to cathode materials for Li-ion batteries in the quaternary phase diagram Li[Li1 / 3Mn2 / 3]O2—LiMn1 / 2Ni1 / 2O2—LiNiO2—LiCoO2, and having a high nickel content. Also a method to manufacture these materials is disclosed. The cathode material has a general formula Lia((Niz(Ni1 / 2Mn1 / 2)yCox)1-kAk)2-aO2, wherein x+y+z=1, 0.1≦x≦0.4, 0.36≦z≦0.50, A is a dopant, 0≦k≦0.1, and 0.95≦a≦1.05, and having a soluble base content (SBC) within 10% of the equilibrium soluble base content.

Owner:UMICORE AG & CO KG

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

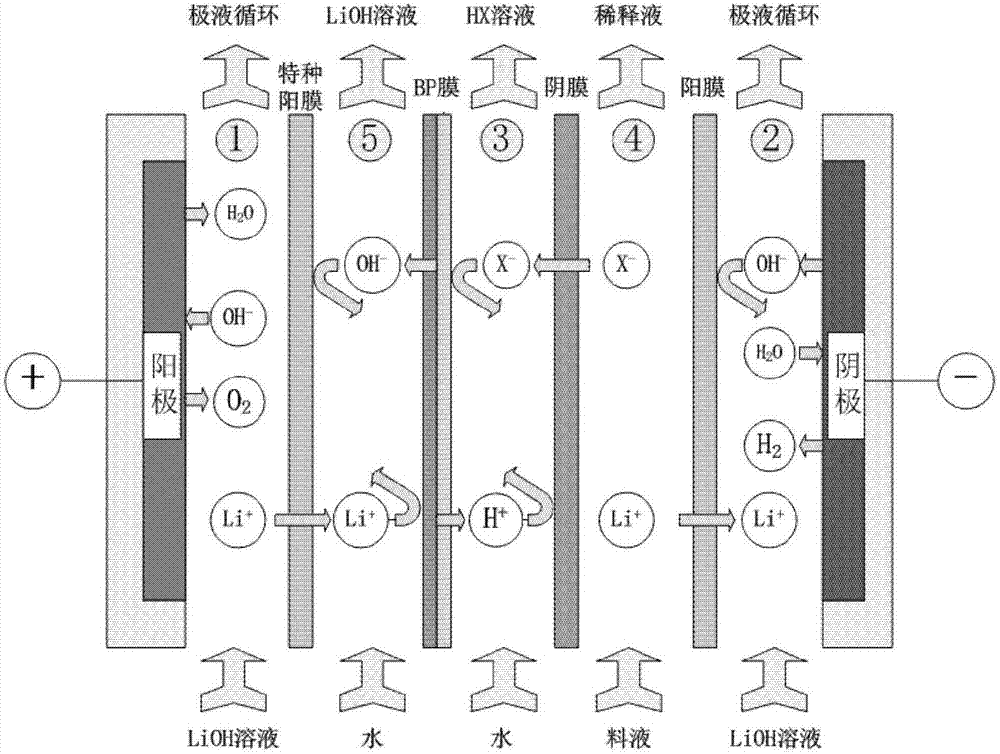

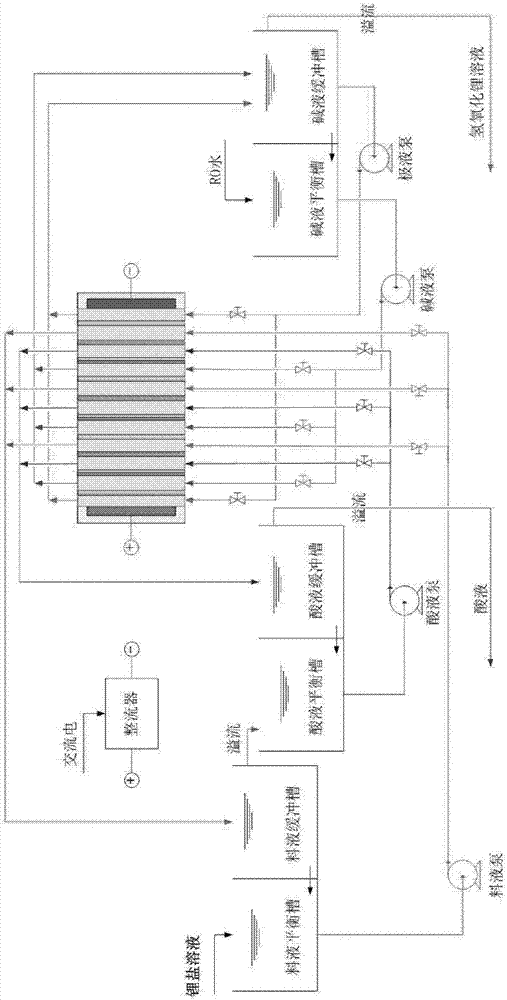

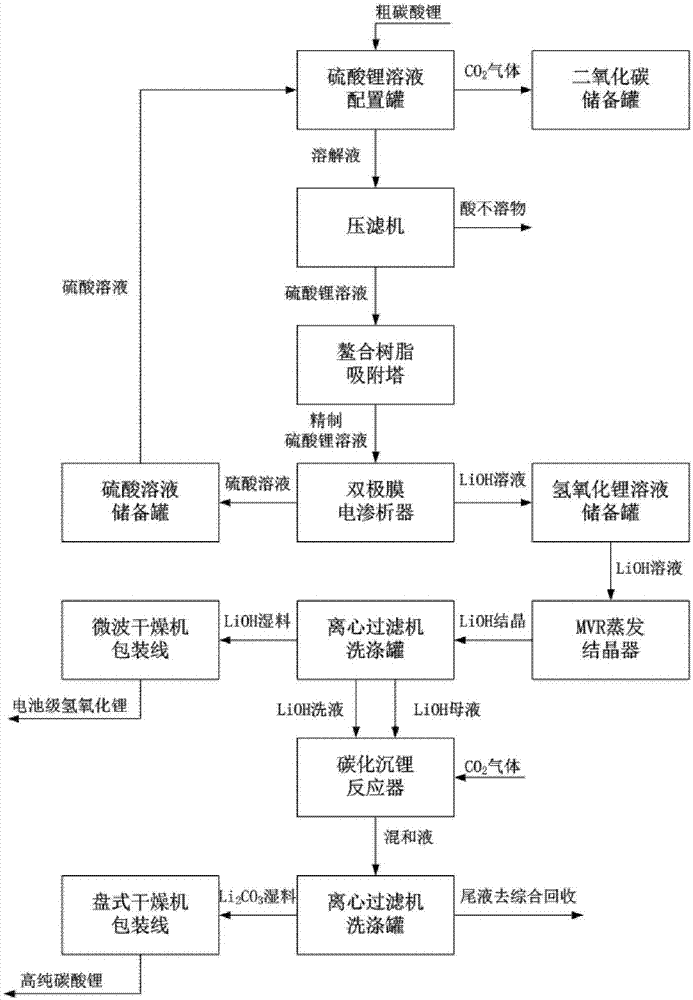

Method for preparing lithium hydroxide and lithium carbonate by utilizing soluble lithium-salt solution

ActiveCN107298450AAvoid cumbersomeAvoid pollutionLithium oxides/hydroxidesLithium carbonates/bicarbonatesCalcium hydroxideHigh concentration

The invention discloses a method for preparing lithium hydroxide and lithium carbonate by utilizing a soluble lithium-salt solution. The method comprises the following steps: the soluble lithium-salt solution is used as a raw material to produce the battery-level lithium hydroxide, and a lithium hydroxide solution is utilized to produce the high-purity lithium carbonate. The method is characterized in that various soluble lithium-salt solutions (the lithium solutions are expressed as LiX in the description) can be utilized, and a bipolar membrane electrodialyzer is applied to treat the soluble lithium-salt solutions, so that a higher-concentration LiOH solution and a corresponding HX acidic solution are obtained; the HX acidic solution returns to a previous-stage process for preparing the lithium salt solution; and the LiOH solution is subjected to evaporation concentration and crystallization to obtain the battery-level lithium hydroxide solid, and the produced lithium hydroxide solution can be further reacted with a carbon dioxide gas through a gas-liquid reactor, so that the high-purity lithium carbonate is obtained. The method can realize continuous stable production with low energy consumption, free pollution and large scale, and realize low-cost and high-efficiency manufacture of the battery-level lithium hydroxide and the high-purity lithium carbonate.

Owner:JIANGSU LITHITECH CO LTD

Method for preparing positive electrode material of lithium ion accumulator

InactiveCN1595680AReduce manufacturing costImprove securityElectrode manufacturing processesSecondary cellsLithium hydroxideLithium carbonate

The invention relates to a manufacture method for positive material of lithium ion accumulator , whose component concentration is: at least one element between LiNi0.5-xM0.5-XM2xO2 (M=Co,Ti,Al) (0<=X<0.5). The manufacture method includes the following steps: dry or wet mix of sentiment hydroxide or carbonate compounds of at least one element between Ni,Mn,Co,Ti and Al or its oxide and lithium hydroxide or carbonate lithium (dry for the material of wet mixture); accumulate the mixture whose width is 2mm~60mm; make particle under the pressure of 4MPa~40MPa; high temperature solid state reaction happens under the temperature of 700~1050deg.C; shatter it after cooling, the diameter of particle is 0.5~25mu m. The manufacture method can make the density of products reach 2.0g / cm3~2.8g / cm3, increase positive filler level of lithium ion and lithium polymer accumulator and its capacity.

Owner:吴孟涛

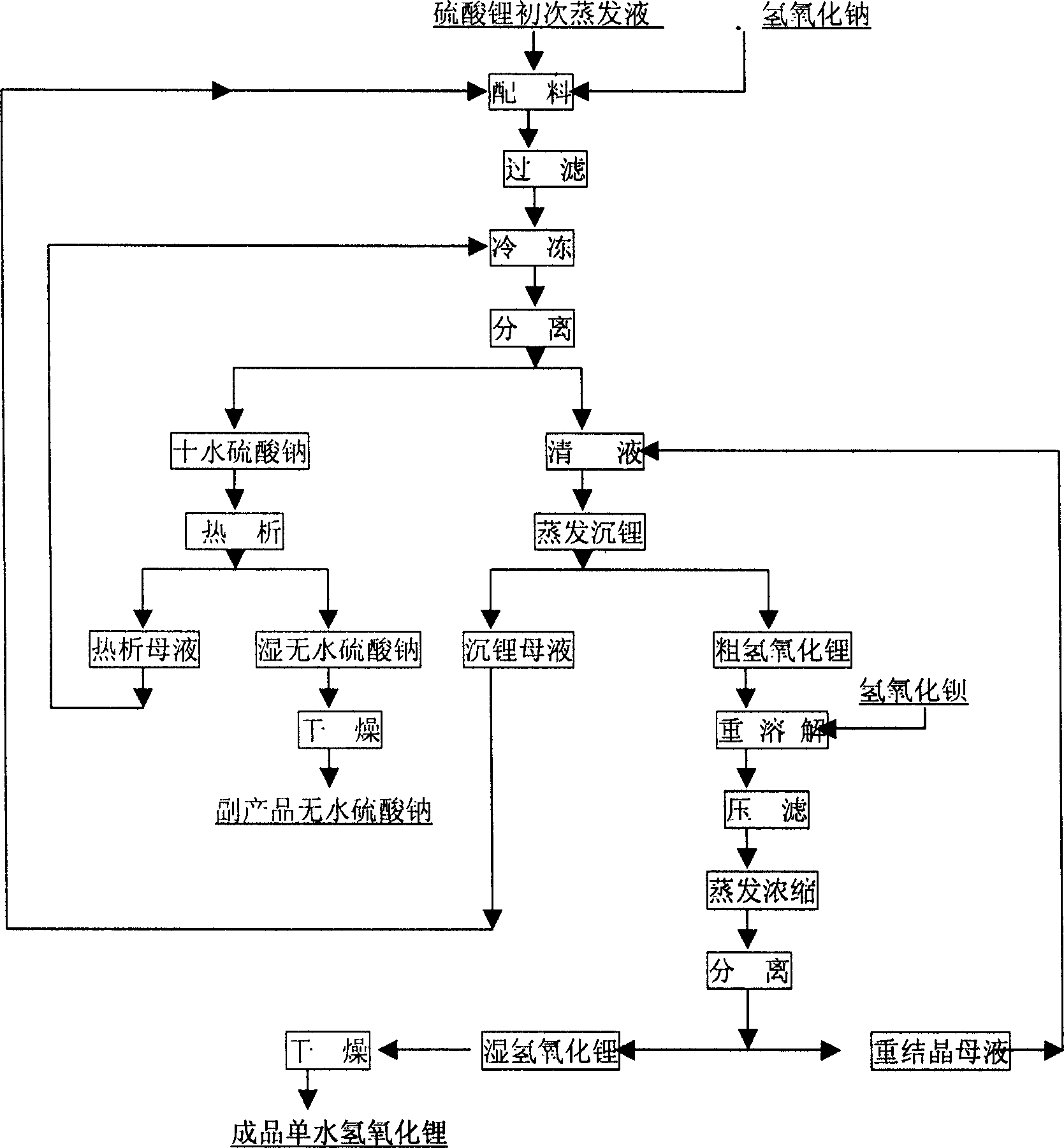

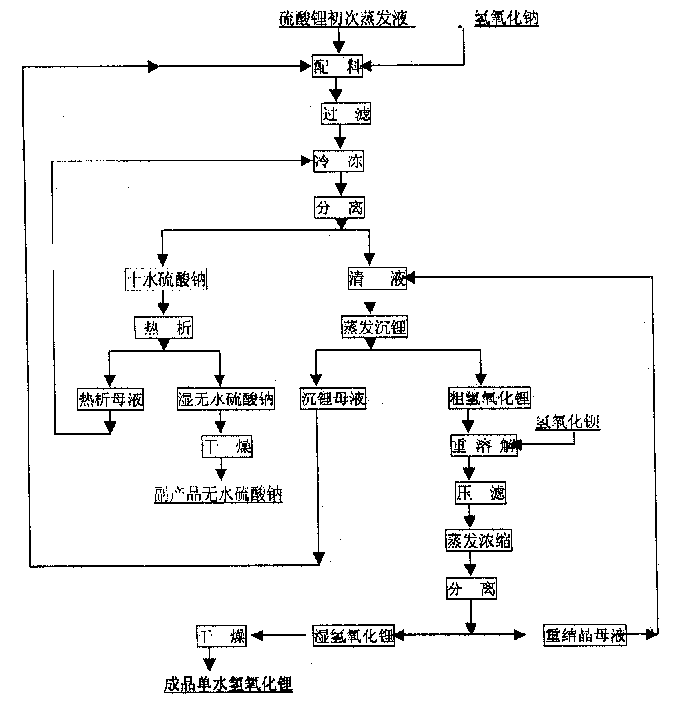

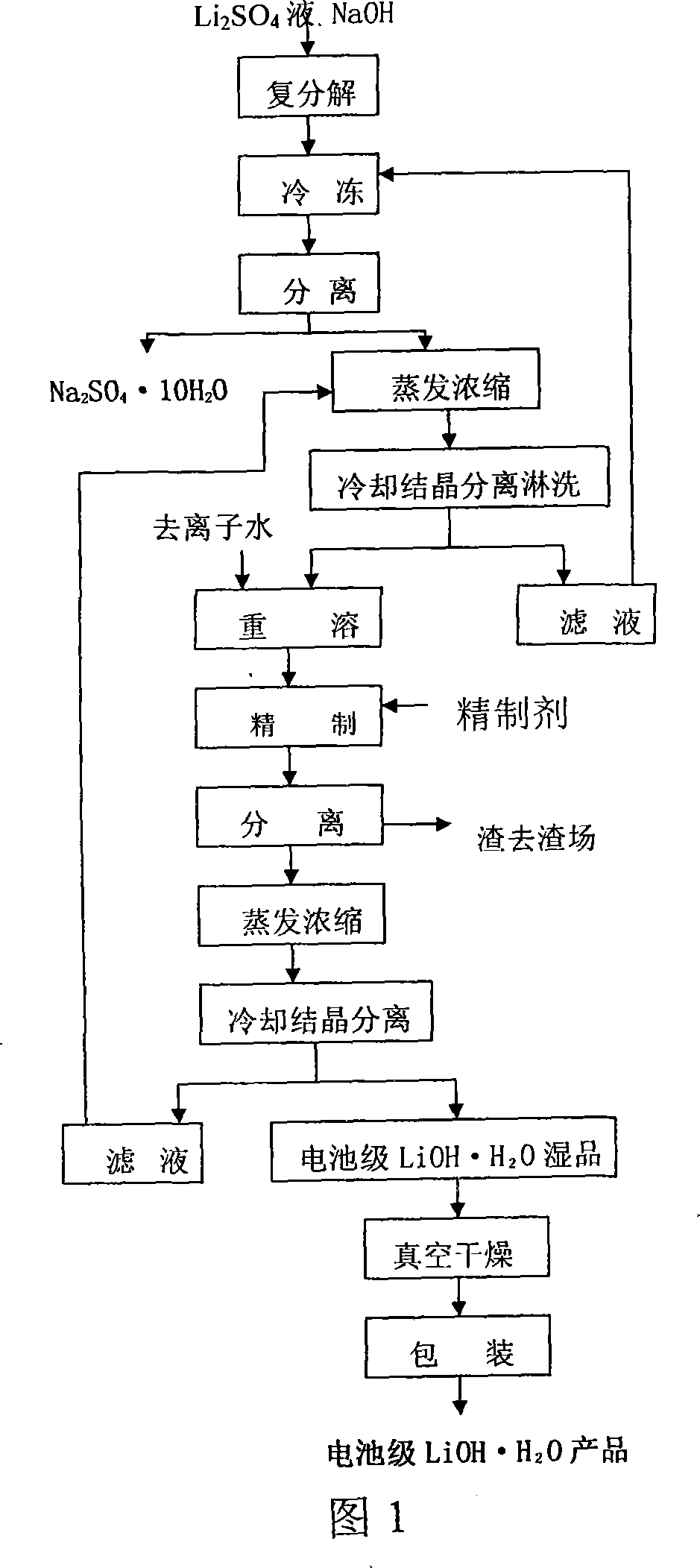

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

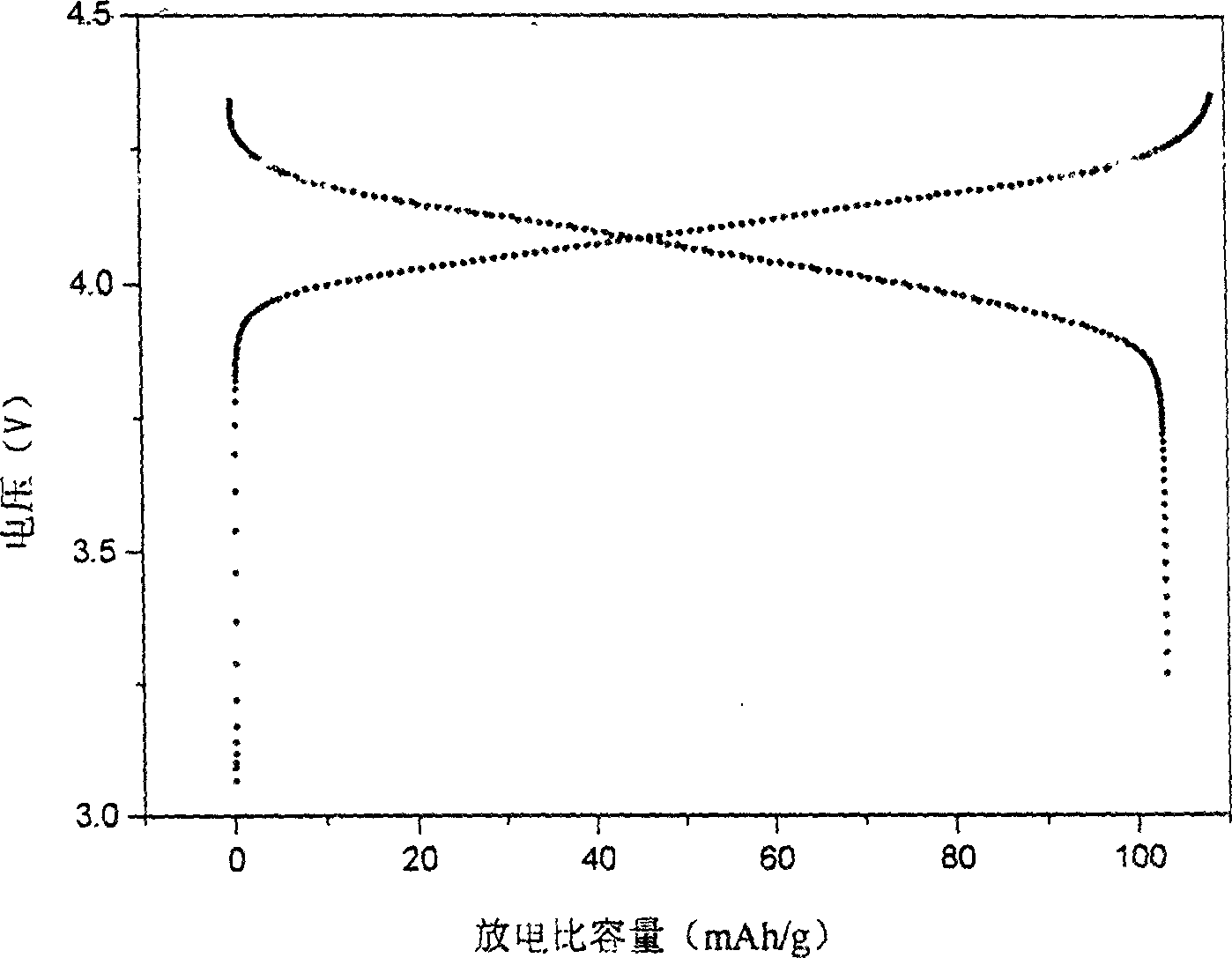

Positive electrode material of manganese series, and preparation and usage thereof

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

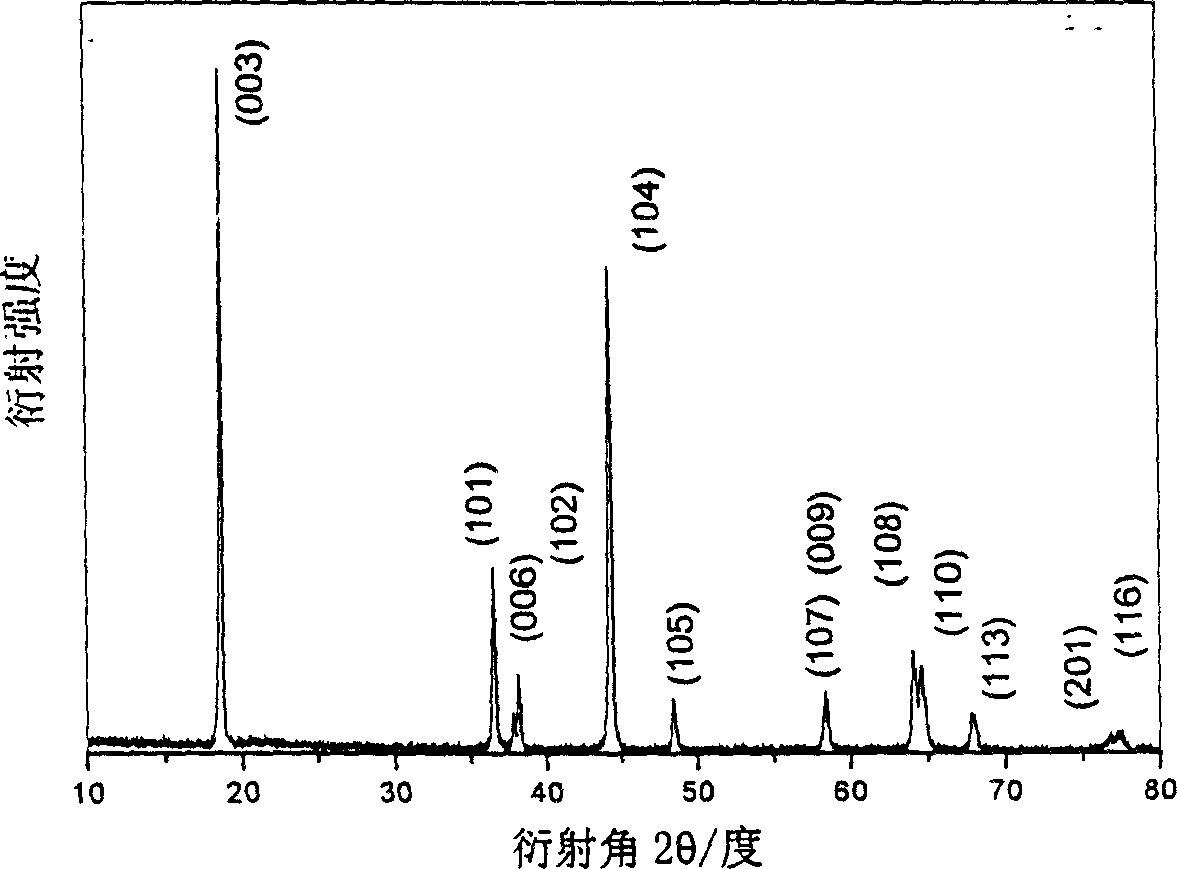

Cathode active material, method of preparing the cathode material, cathode, and lithium secondary battery including the same

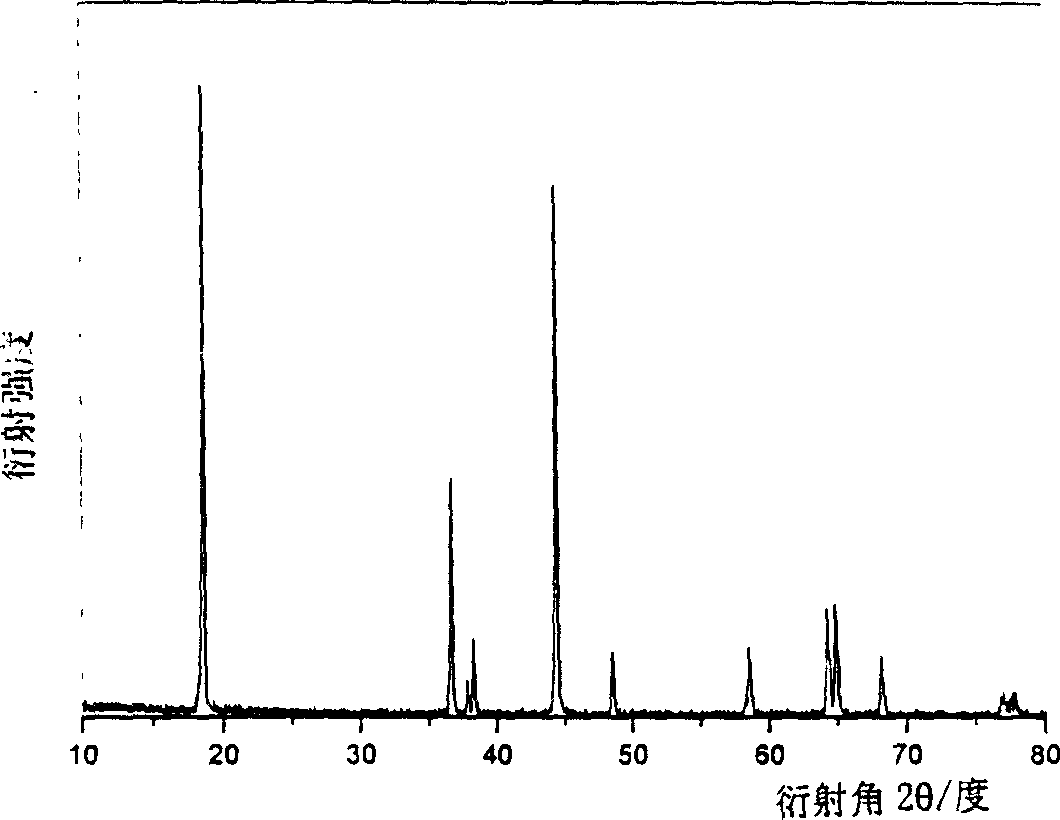

A cathode active material including at least two agglomerates of primary particles and a cathode and a lithium secondary battery containing the same are disclosed. In the cathode active material, a secondary particle includes a nickel-based lithium transition metal oxide, an average particle diameter of each primary particle is in a range from about 3 to about 5 µ m, and the at least one secondary particle comprises at least one selected from the group consisting of a first particle having an average particle diameter in the range from about 5 µm to about 8µm and a second particle having an average particle diameter in the range from about 10 µm to about 20 µm, and wherein a full width at half maximum of a (003) peak is in the range from about 0.120° to about 0.125° in an X-ray diffraction (XRD) spectrum analysis.

Owner:SAMSUNG SDI CO LTD

Method for preparing battery-stage monohydrate lithium hydroxide

ActiveCN101214978AHigh recovery rateSuit one's needsCell electrodesLithium oxides/hydroxidesLithium sulphateSodium hydroxide

The invention provides a process for preparing battery grade lithium hydroxide monohydrate, comprising: (1) adding sodium hydroxide in lithium sulfate purification fluid and obtaining solid of Na2SO4, 10H2O and liquid of LiOH after completely dissolving and cooling, (2) obtaining liquid of LiOH after filtering and separating, (3) evaporating and concentrating the liquid of LiOH and filtering, separating and leaching the liquid of LiOH after cooling and crystallizing to obtain one-time crude product of LiOH, H2O, (4) adding deionized water in the one-time crude product of LiOH, H2O and obtaining re-dissolving solution of the one-time crude product of LiOH, H2O, (5) adding refining agent in the re-dissolving solution of the one-time crude product of LiOH, H2O and obtaining filtrate of LiOH refined liquor after filtering and separating, (6) filtering and separating the LiOH refined liquor after evaporating, concentrating, cooling and crystallizing to obtain solid of battery grade wet product of LiOH, H2O and (7) taking out the battery grade wet product of LiOH, H2O after drying to obtain battery product of LiOH, H2O. The invention is simple in production process, easy operation and perfect product quality.

Owner:TIANQI LITHIUM CORP

Novel method for producing lithium carbonate and lithium hydroxide

InactiveCN102115101ASimple production processLow costLithium oxides/hydroxidesLithium carbonates/bicarbonatesLithium sulphateCalcium hydroxide

The invention relates to a novel method for producing lithium carbonate and lithium hydroxide, which belongs to the technical field of production of lithium salts. The method comprises the following steps of: baking spodumene concentrate; preparing a lithium sulfate solution; preparing lithium carbonate mother liquor; and preparing lithium hydroxide, wherein the lithium hydroxide can also be obtained by adding barium hydroxide into the lithium carbonate mother liquor. The method has the advantages that: lime is added into a lithium carbonate sinker mother liquor to produce the lithium hydroxide by causticizing and transforming, and the production of lithium carbonate is combined with the production of the lithium hydroxide, so that a process flow is simplified, investment and production costs are lowered, a production process is more flexible to regulate and control, and the quality of a lithium carbonate product is more stable. By adopting the method, the mother liquor of lithium carbonate is easier to treat, impurities in the lithium hydroxide mother liquor are easy to treat, and the product quality is not influenced.

Owner:屈俊鸿

Preparation method of lithium transition metal oxide

InactiveCN1493522ASimple preparation processFacilitated DiffusionOxide/hydroxide preparationCell electrodesReaction speedComposite oxide

A process for preparing the composite oxide of Li and transition metals in order to use is as positive electrode of rechargeable Li or Li-ion battery features that the oxides, hydroxides or salts of Li and transition metal (Co, Ni and Mn) are used as raw materials, and the oxide, hydroxide or salt of Co, Ni, Mn, Cr, Al, or Mg is used as doping element, and includes mixing them with fusable salt, heating, constant-temp calcining, cooling, watshing to remove residual salt and baking. Its advantages are high reaction speed, and high specific capacity of product.

Owner:TSINGHUA UNIV

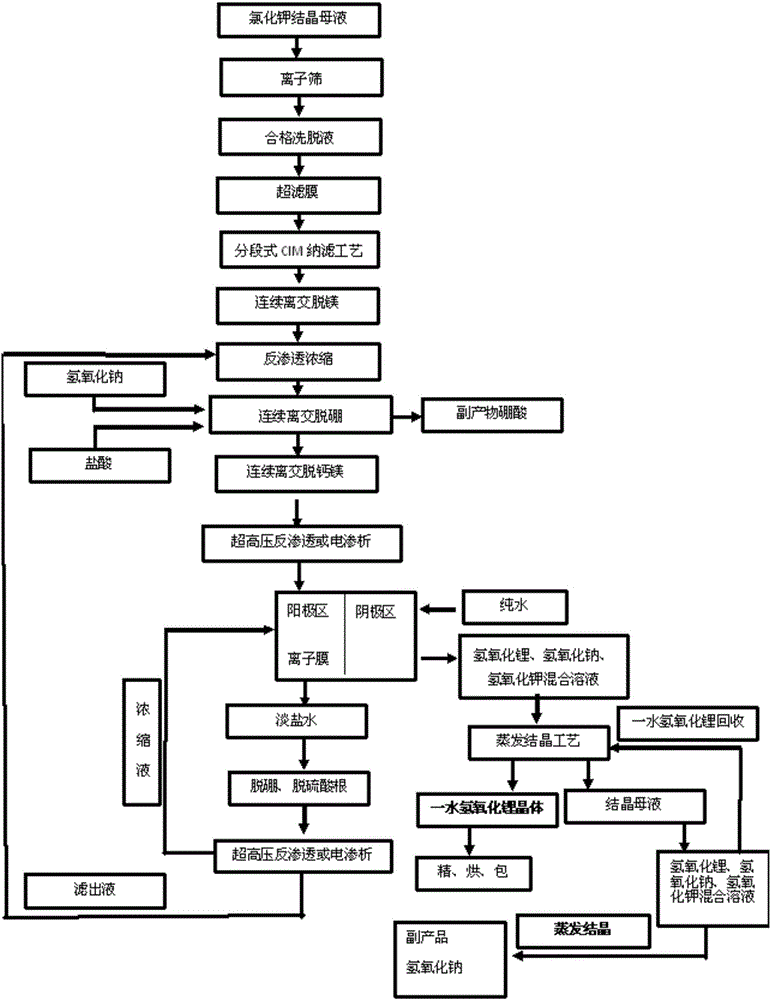

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

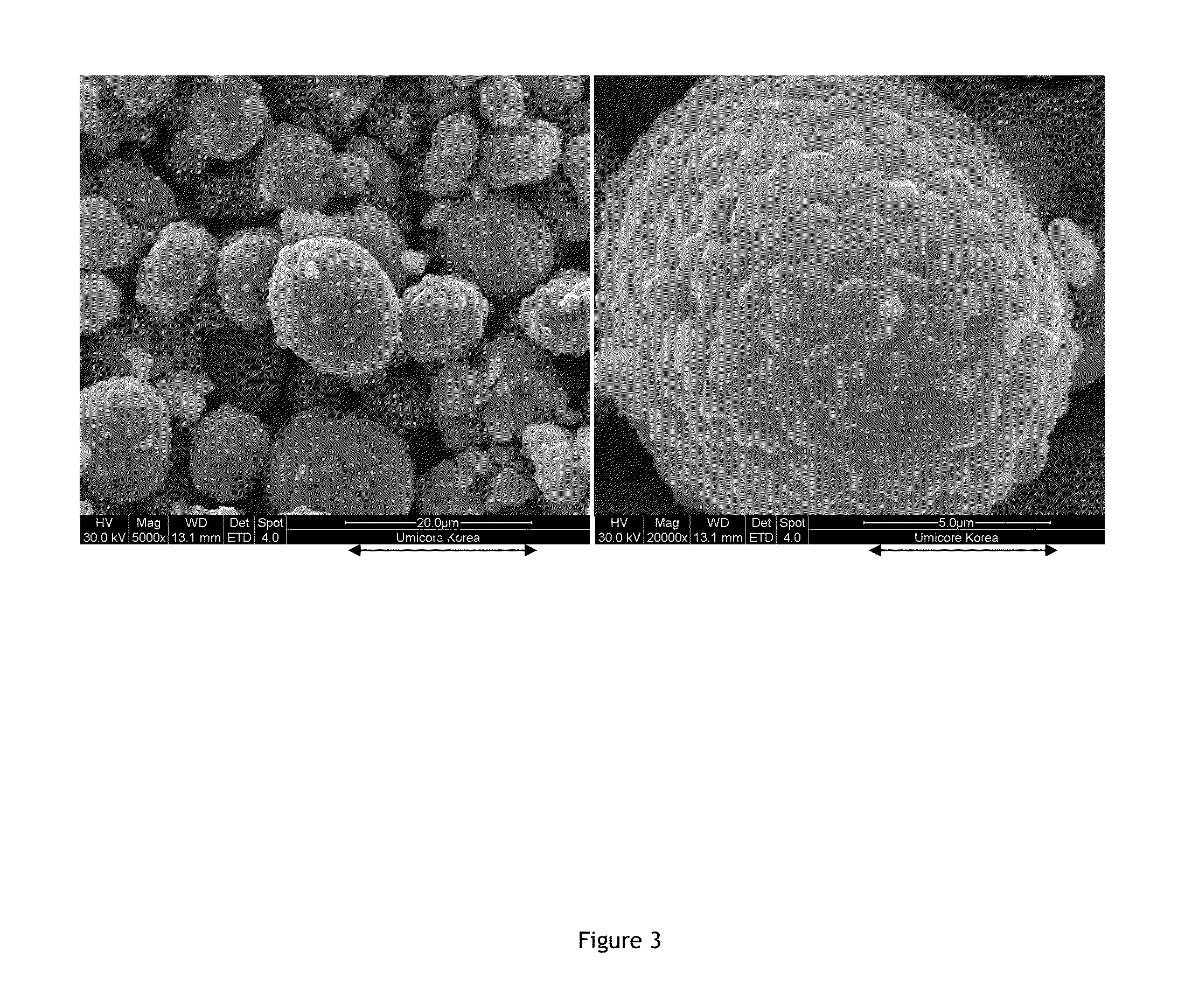

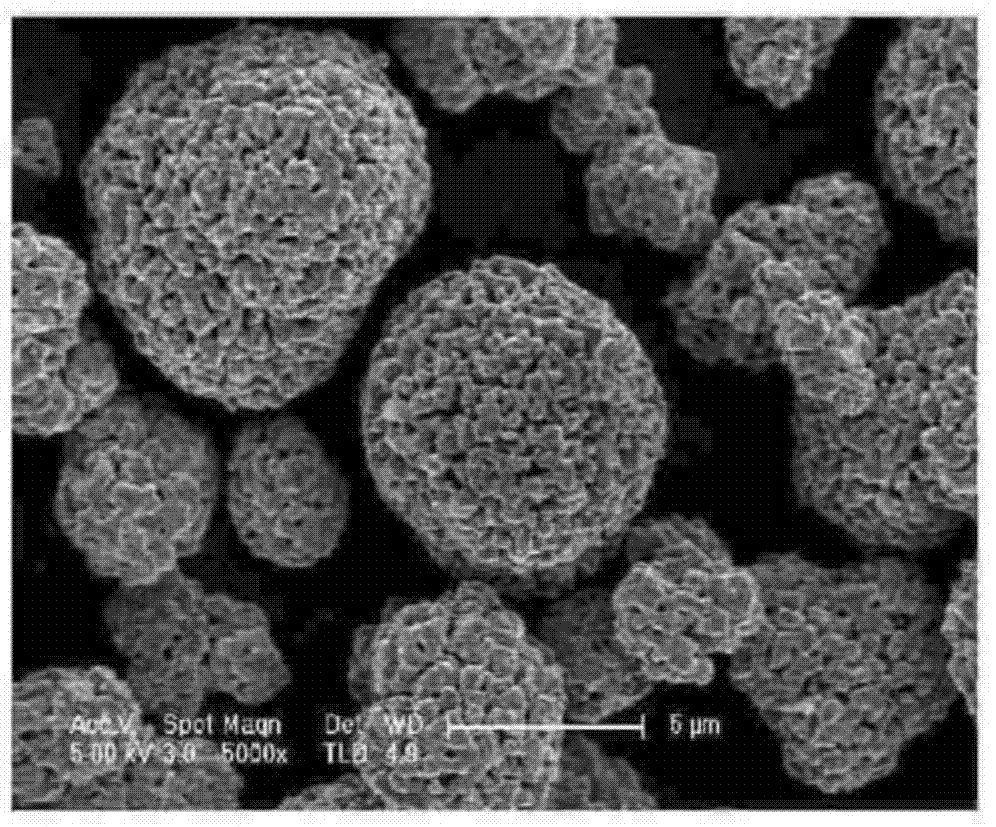

High-density spherical lithium nickel cobalt manganese oxygen and method for preparing the same

InactiveCN101269849AHigh densityComplete crystal structureCell electrodesManganese oxides/hydroxidesChemical industryManganese

The invention relates to a high density spherical shape LiNixCoyMn(1-x-y)O2 and a preparation method thereof, and belongs to the products of chemical industry, in particular to the preparation of the high density spherical shape LiNixCoyMn(1-x-y)O2 which is mainly used for manufacturing a lithium ion battery. Firstly, a high density spherical shape nickel cobalt and manganese predecessor body is synthesized by controlling the synthetic technology, secondly, the high density spherical shape nickel cobalt and manganese predecessor body is mixed with a lithium source and then is calcined under the specified conditions, so the high density spherical shape LiNixCoyMn(1-x-y)O2 can be obtained. The LiNixCoyMn(1-x-y)O2 is a spherical shape crystal, the mean grain size is 3-20 micrometers, the loose packed density is more than or equal to 1.0g / cm<3>, and the tap density is more than or equal to 2.0g / cm<3>. The synthesized LiNixCoyMn(1-x-y)O2 is of a single spherical shape, has better tap density, and can improve the volume ration capacity of the battery. The LiNixCoyMn(1-x-y)O2 is formed by calcining the predecessor body which has a spherical shape particle, high density, and complete crystalline form structure, compared with the synthetic technology of the predecessor body, the preparation method is simple, the cost is low, and the particle size can be controlled, and the industrialization is easy.

Owner:GUANGZHOU RONGJIE MATERIAL TECH

Lithium Transition Metal Oxide Having Layered Structure

ActiveUS20100117025A1Improve life characteristicsMaintain good propertiesAlkali metal oxidesPositive electrodesOn boardHybrid vehicle

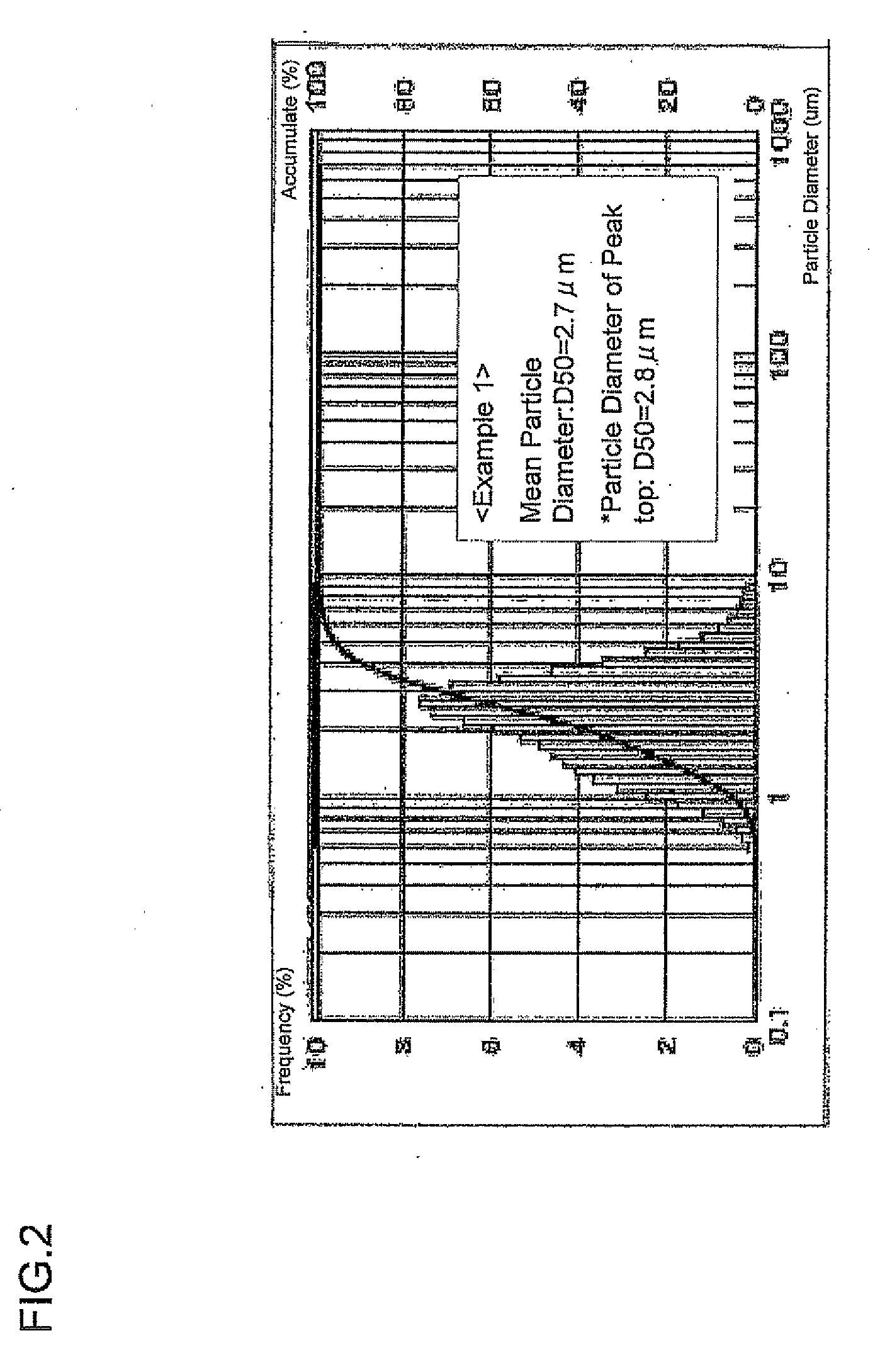

In a lithium transition metal oxide having a layered structure, one is provided, which is particularly excellent as a positive electrode active material of a battery on board of an electric vehicle or a hybrid vehicle in particular. A lithium transition metal oxide having a layered structure is proposed, wherein the ratio of the crystallite diameter determined by Measurement Method 1 according to the Rietveld method with respect to the mean powder particle diameter (D50) determined by the laser diffraction / scattering-type particle size distribution measurement method is 0.05 to 0.20.

Owner:MITSUI MINING & SMELTING CO LTD

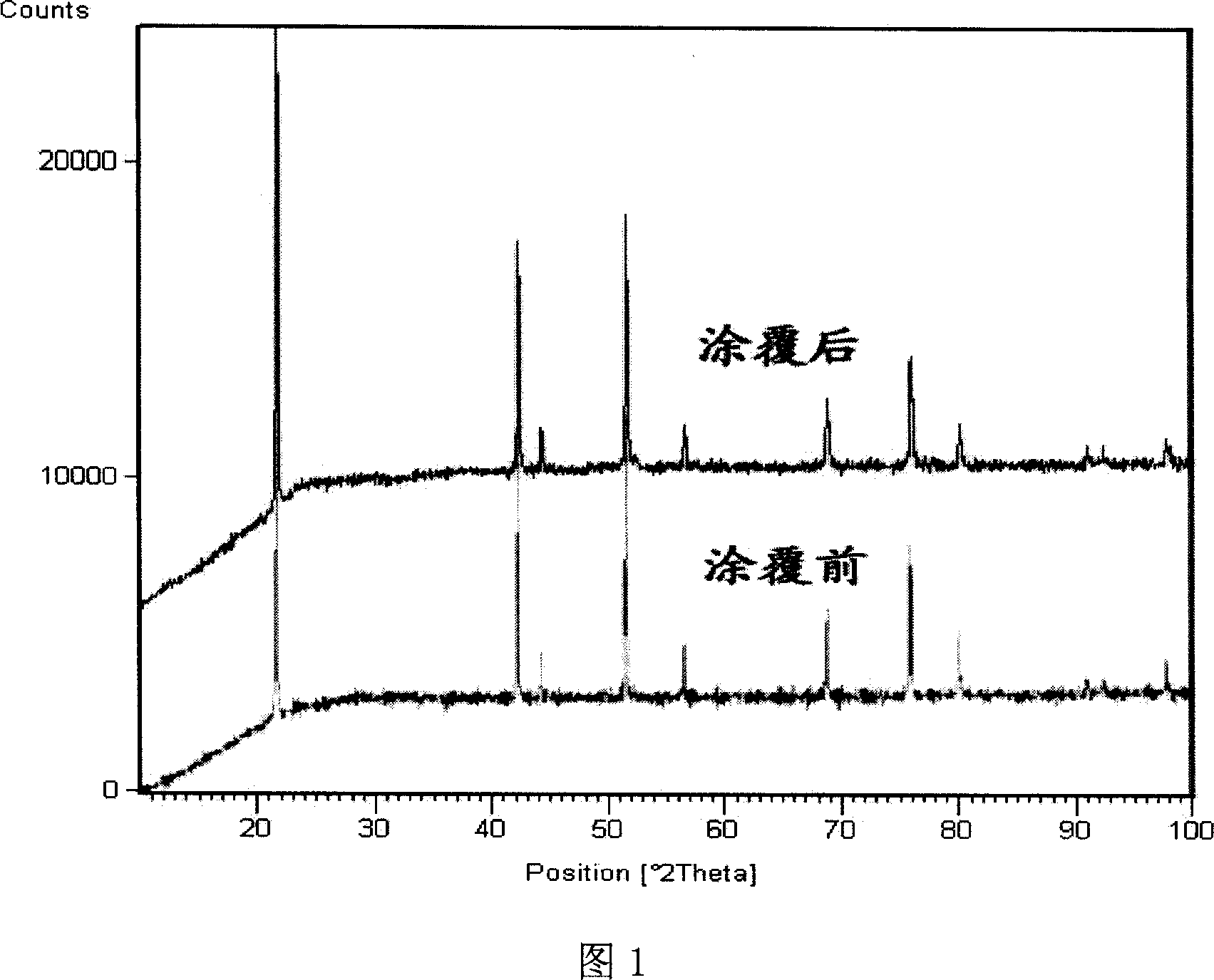

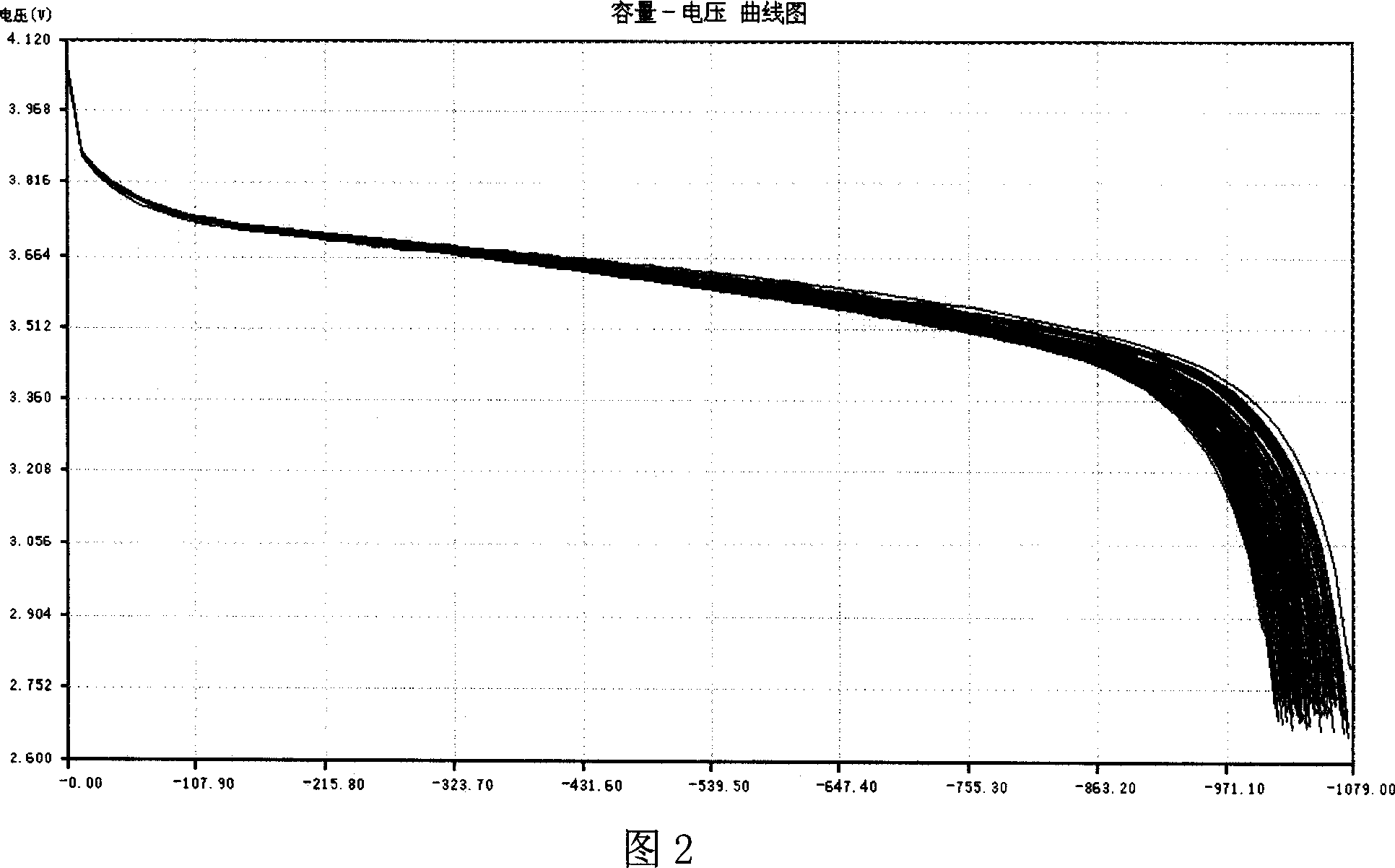

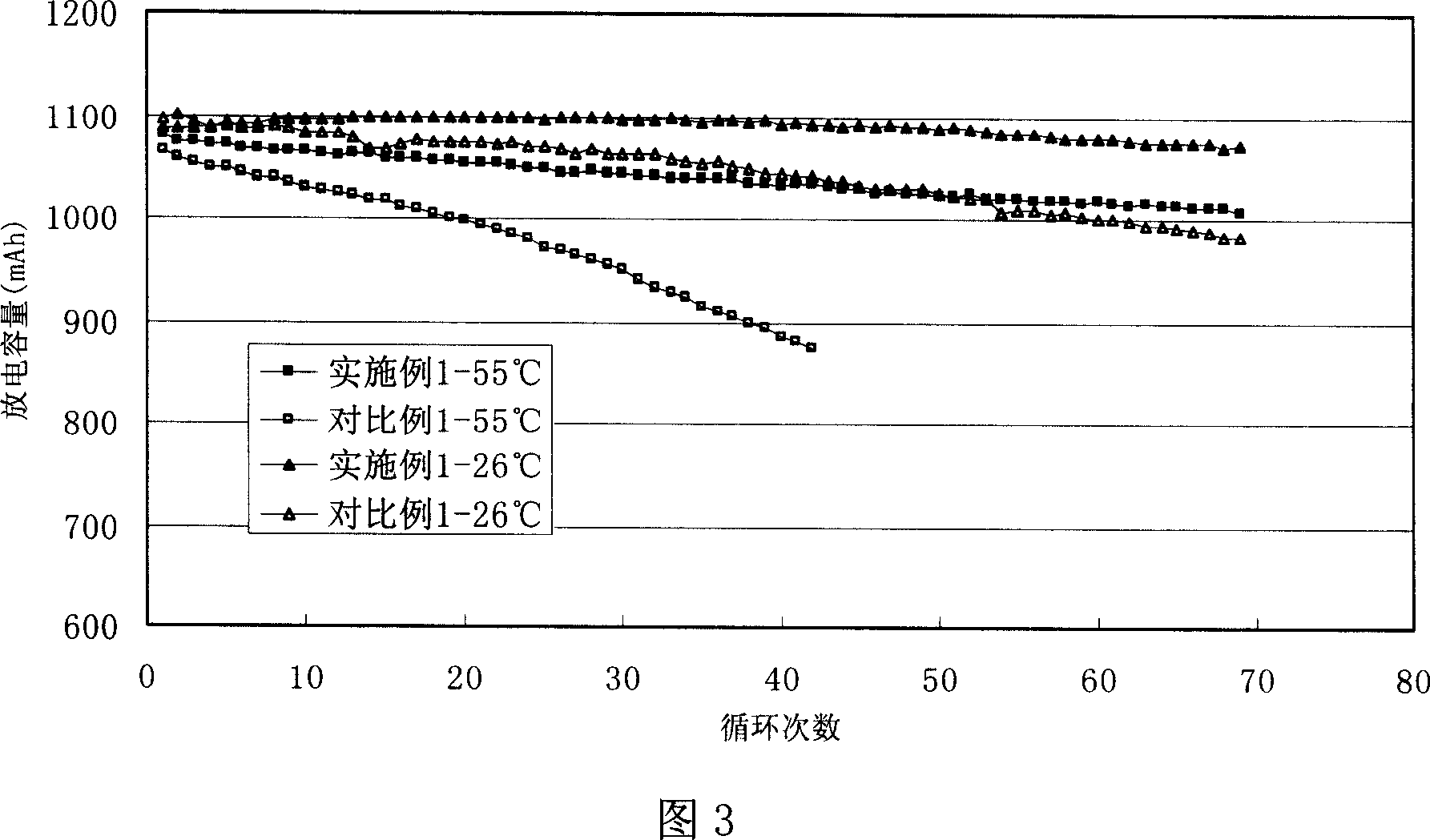

Complex Li-Mn-oxide, manufacture method and battery made of this material

ActiveCN101060173AImprove rate charge and discharge performanceEasy to prepareElectrode manufacturing processesSecondary cellsPhosphateComposite oxide

The disclosed Li-Mn composite oxide for positive of secondary Li cell comprises the core LiaMn2-bXbO4 and a coating layer, wherein 0. 97<=a<=1. 06, 0 <=b<=0. 5, X for other metal (except Li and Mn) or Si; the coating layer comprises one of more of Li-B composite oxide, Li-Co oxide, Li-V oxide, Al oxide, Al phosphate, Ti oxide, Cr. Oxide, Mg oxide, and Ca oxide This invention improves material performance, special the circulation performance at high temperature.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Lithium Metal Oxide Particles Coated with a Mixture of the Elements of the Core Material and One or More Metal Oxides

A lithium metal oxide powder for use as a cathode material in a rechargeable battery, consisting of a core material and a surface layer, the core having a layered crystal structure consisting of the elements Li, a metal M and oxygen, wherein the Li content is stoichiometrically controlled, wherein the metal M has the formula M=Co1-aM′a, with 0≦a≦0.05, wherein M′ is either one or more metals of the group consisting of Al, Ga and B; and the surface layer consisting of a mixture of the elements of the core material and inorganic N-based oxides, wherein N is either one or more metals of the group consisting of Mg, Ti, Fe, Cu, Ca, Ba, Y, Sn, Sb, Na, Zn, Zr and Si.

Owner:UMICORE AG & CO KG

Lithium secondary battery and positive electrode material thereof

InactiveUS20090011334A1Low costImprove the immunityAlkali metal oxidesAlkaline accumulator electrodesCrystal structureCobalt

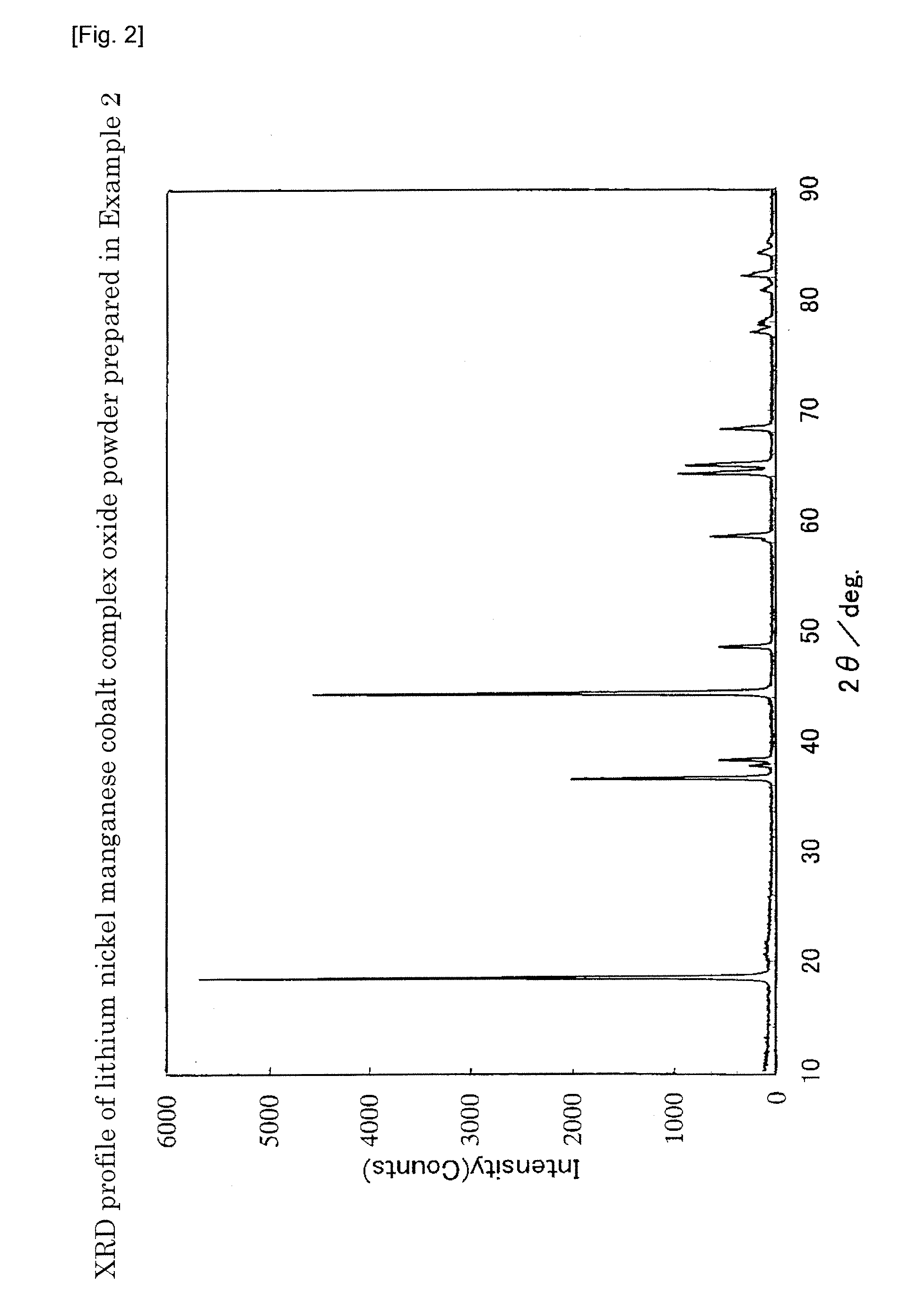

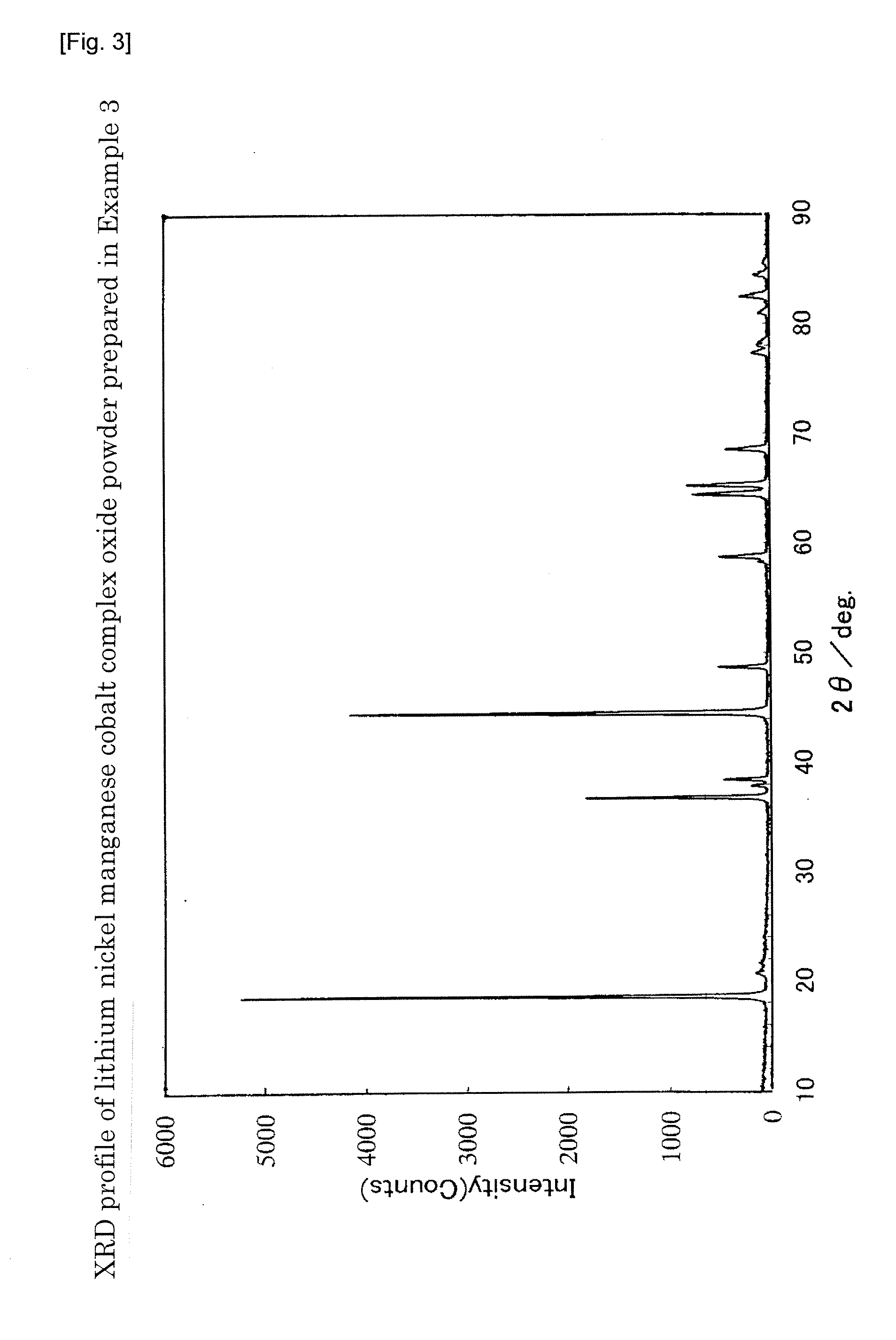

A lithium nickel manganese cobalt complex oxide powder for a lithium secondary battery positive electrode material, which is composed of a crystal structure having a layered structure, and the composition thereof is expressed by the following formula:Li[Liz / (2+z){(LixNi(1−3x) / 2Mn(1+x) / 2)(1−y)Coy}2 / (2+z)]O2 wherein 0.01≦x≦0.15, 0≦y≦0.35, and 0.02(1−y)(1−3x)≦z≦0.15(1−y)(1−3x).

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com