Patents

Literature

127results about How to "High conductivity at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium cell positive electrode materials and preparing method thereof

InactiveCN1457111AImprove conductivityHigh conductivity at room temperatureElectrode thermal treatmentPositive electrodesNano structuringElectrical battery

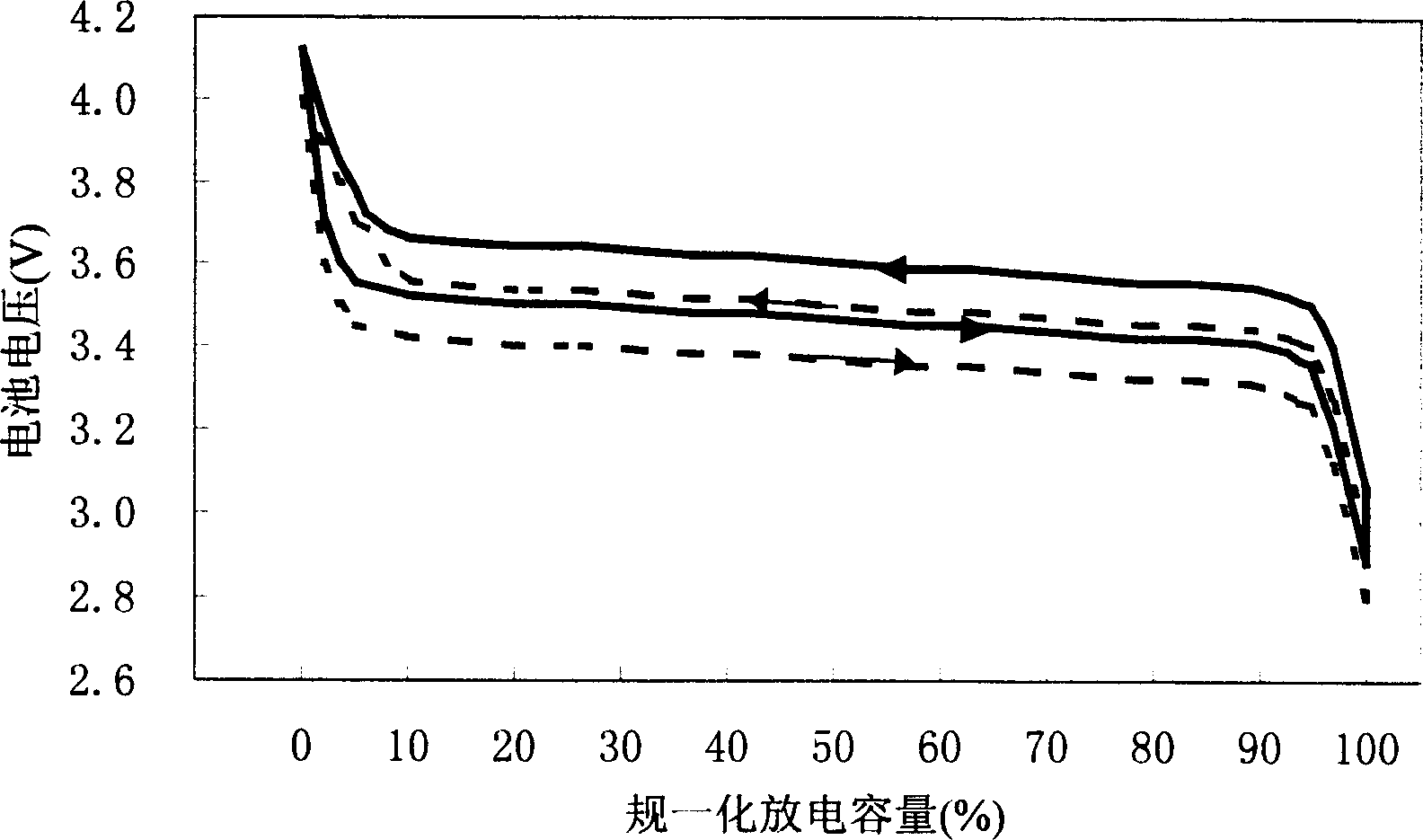

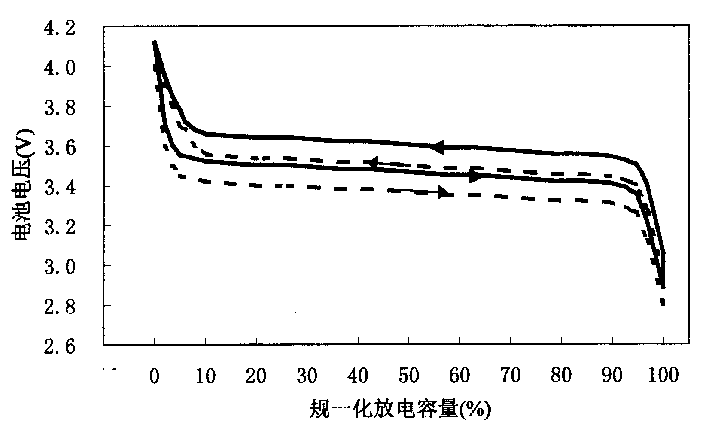

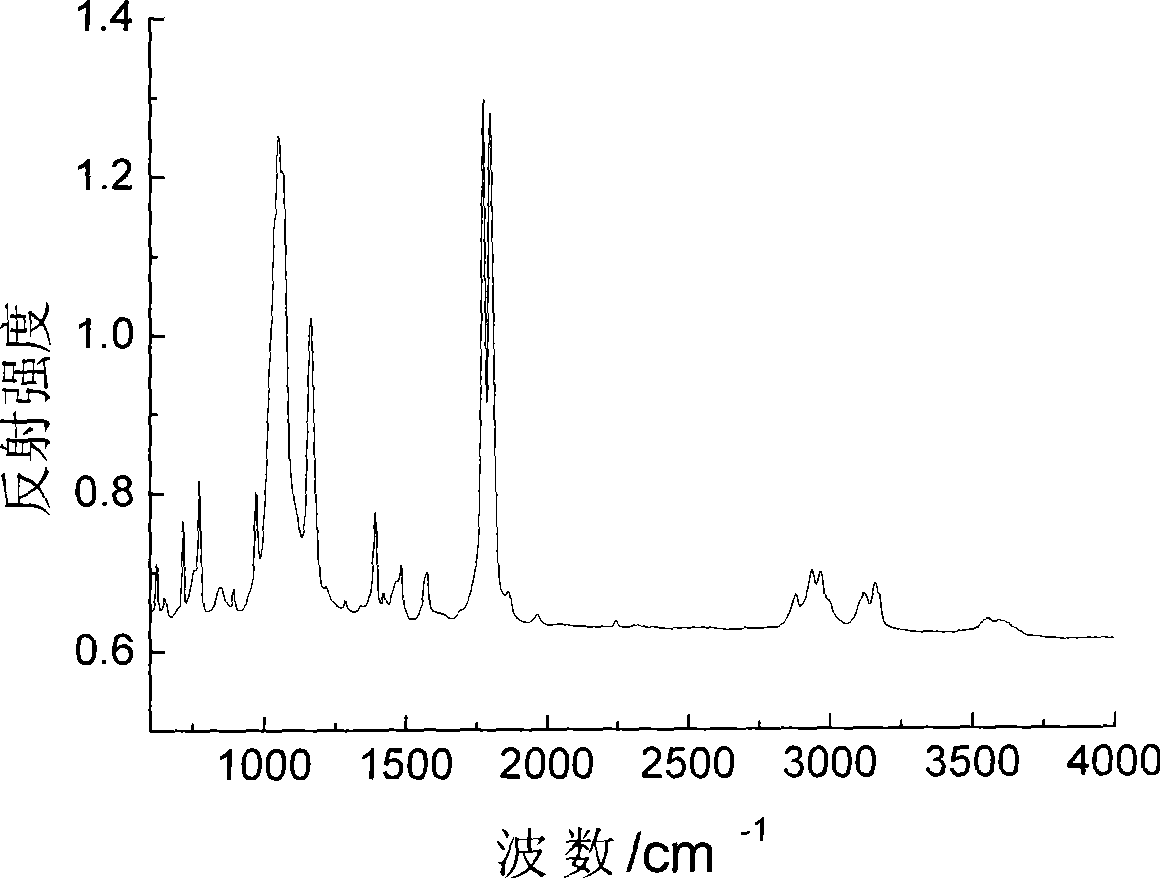

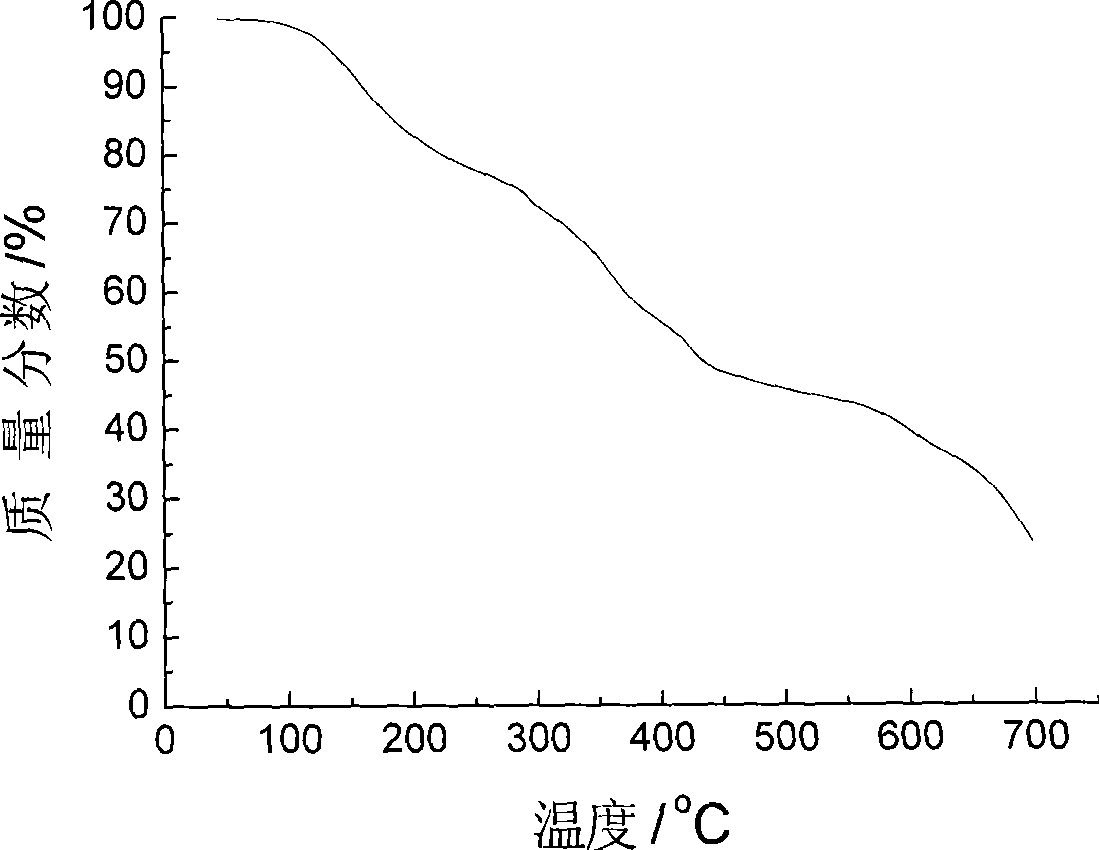

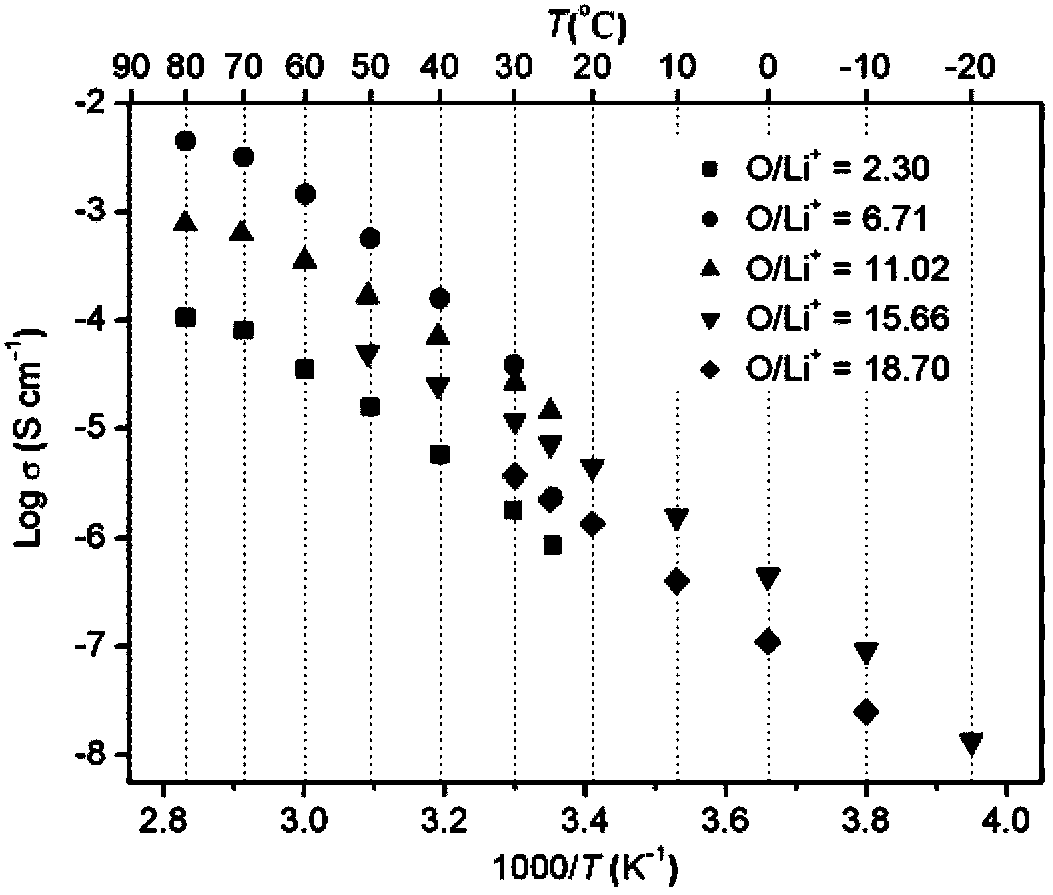

The chemical general formula of the material is expressed as follows: LixM1-xFePO4, where M is selected from Mg2+, Ca2+...P5+ etc. With conduction adulterant added, reaction at 500-900 deg.C for 10 hr. by using metal oxide, phoshpate, fluoride etc. and non saturated crystal of Li-Fe phoshpate through nonstoichiometric method obtains the crystal of Li-Fe phosphate with high conductivity, which can be expressed as LiFePO4-y. The formula of material prepared by using method of pressurized type substitution ion is LixM1-xFezM'1-z. The formula of material of solid power prepared by using method of solid phase reaction is as LixM1-xFezMn1-zPO4. The formula of anode material in nano structure prepared by using method of vacuum sputter deposition is LixFePO4-y, whose conductivity and discharge capacity can reach 10 to the power -2 S / cm and 240 Ah / g.

Owner:徐瑞松

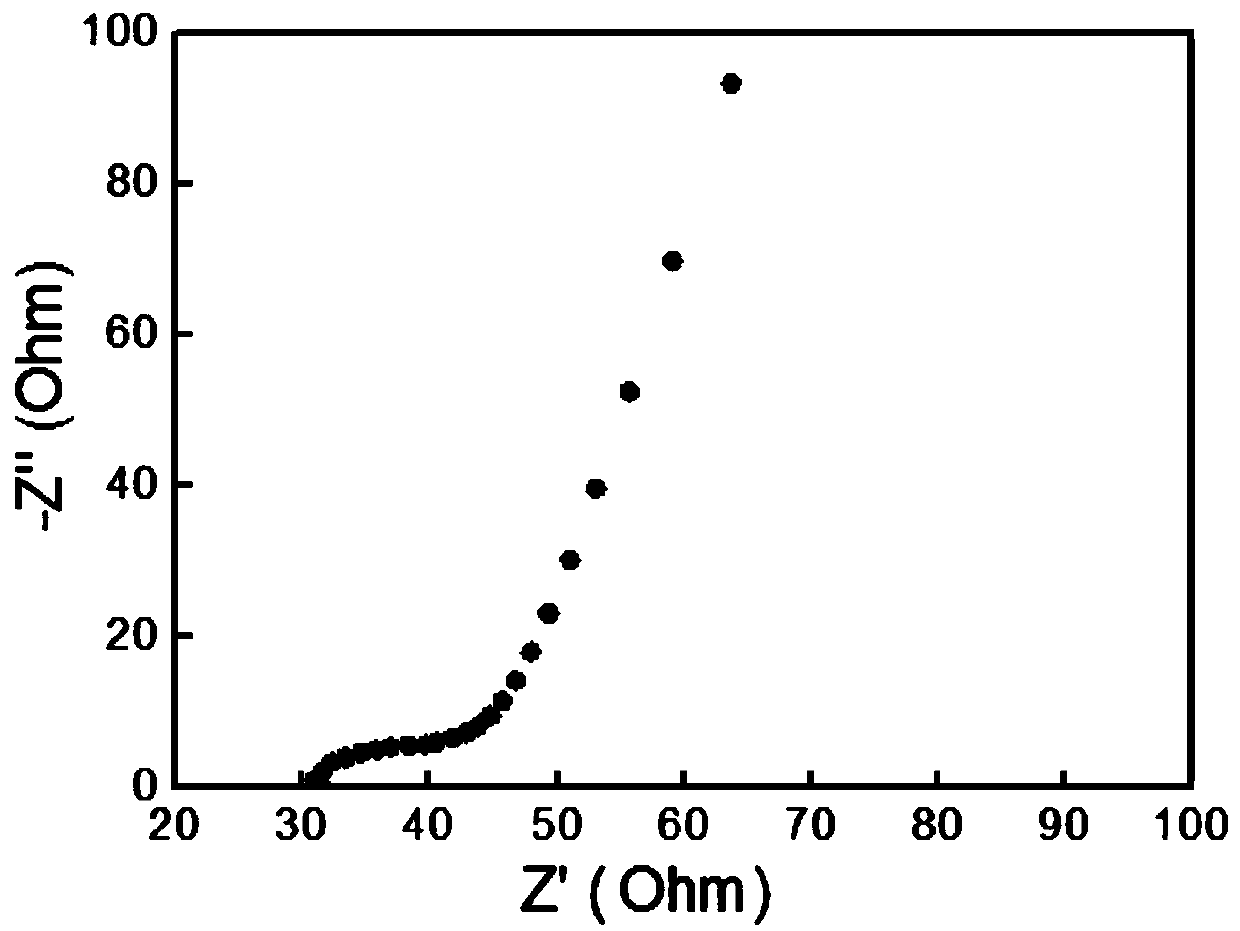

Method for preparing ion liquid type gel polymer electrolyte and battery by in situ polymerization

ActiveCN101475663ASimple preparation processSimple manufacturing processFinal product manufactureSecondary cellsPolymer scienceTetrafluoroborate

The invention relates to a method for preparing ionic liquid type gel polymer electrolyte through home position polymerization. The method comprises the following steps: taking acrylonitrile and polyethylene glycol dimethyl acrylic acid ester as monomers, taking ethylene carbonate as an organic plasticizer, taking azo diisobutyl cyanogen as an initiator, taking lithium perchlorate as a lithium salt, adding ionic liquid 1-butyl-3-methylimidazole tetrafluoborate as the component of the electrolyte, and adopting a free radical initiation and home polymerization mode to prepare the stable ionic liquid type gel polymer electrolyte. The home polymerization mode has a simple and feasible process, and is capable of directly assembling a lithium cell while simultaneously preparing the electrolyte. The prepared ionic liquid type gel polymer electrolyte has higher room temperature conductivity, good dimensional stability and mechanic properties, and can also be applied to dye sensitization solar cells. The prepared ionic liquid type gel polymer electrolyte cell can avoid the leakage and volatilization of the electrolyte and improve the safety of the cell.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

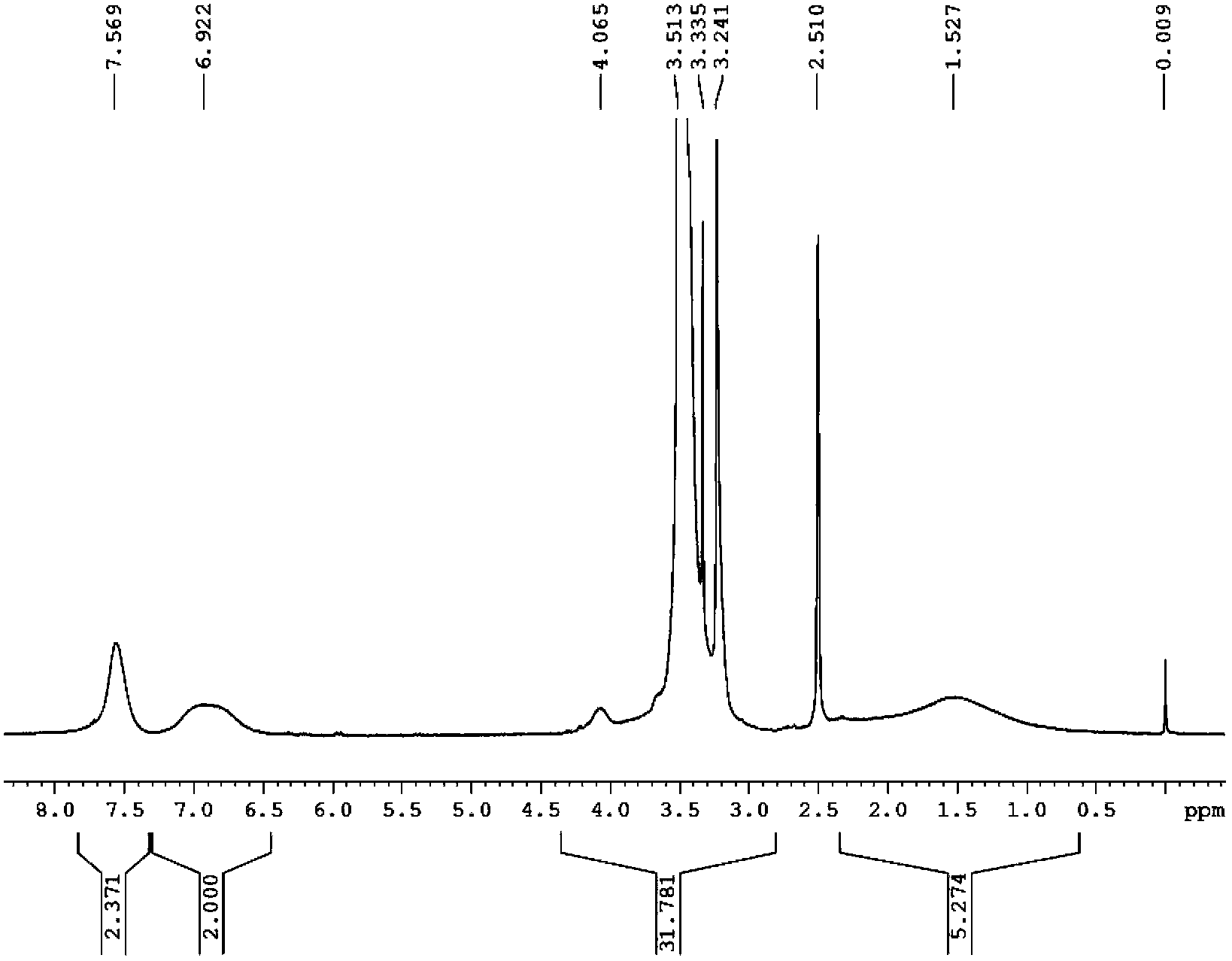

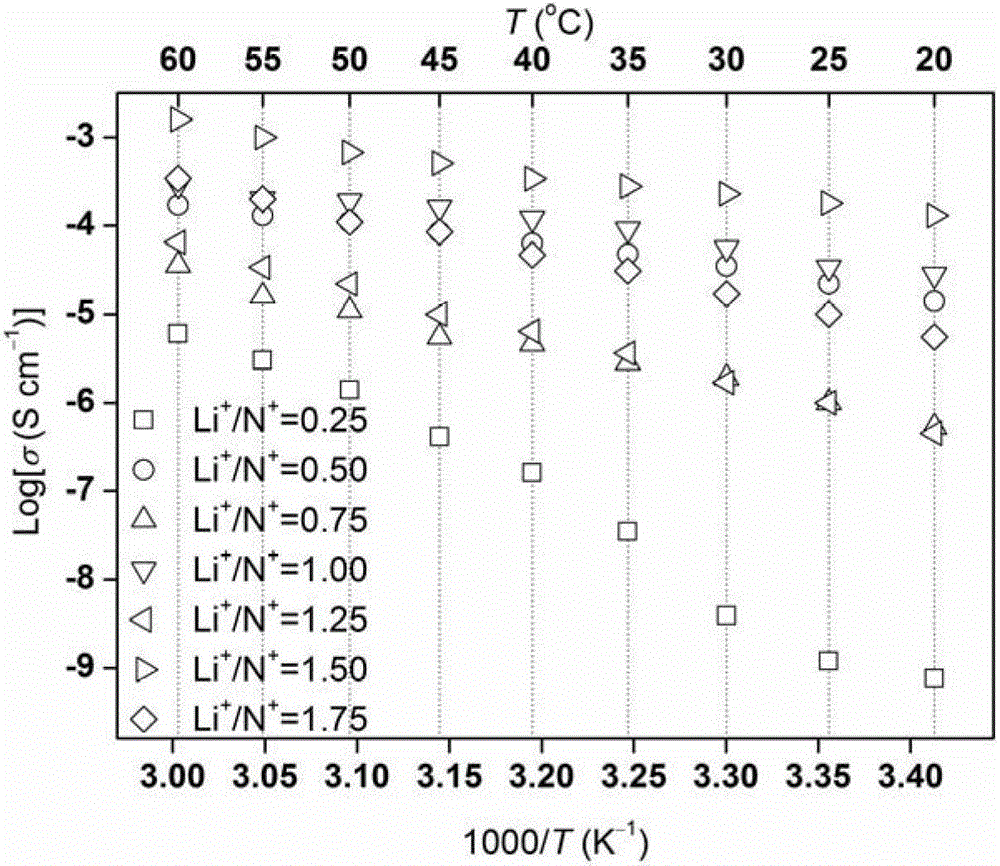

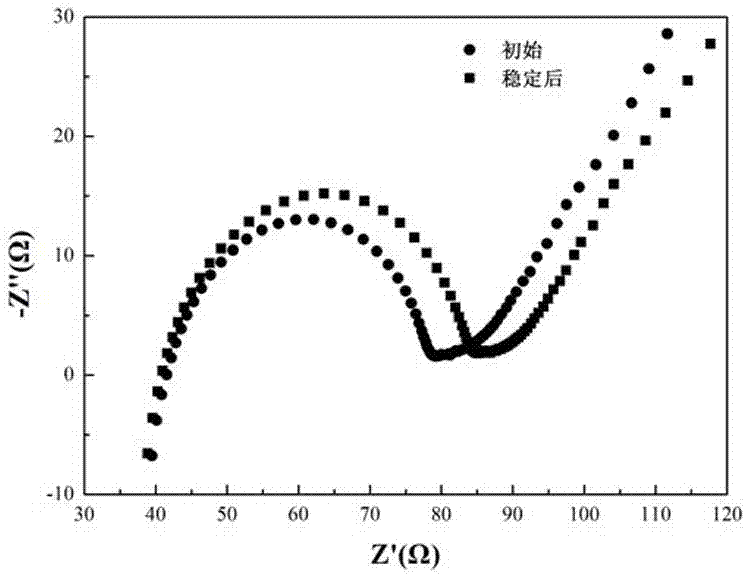

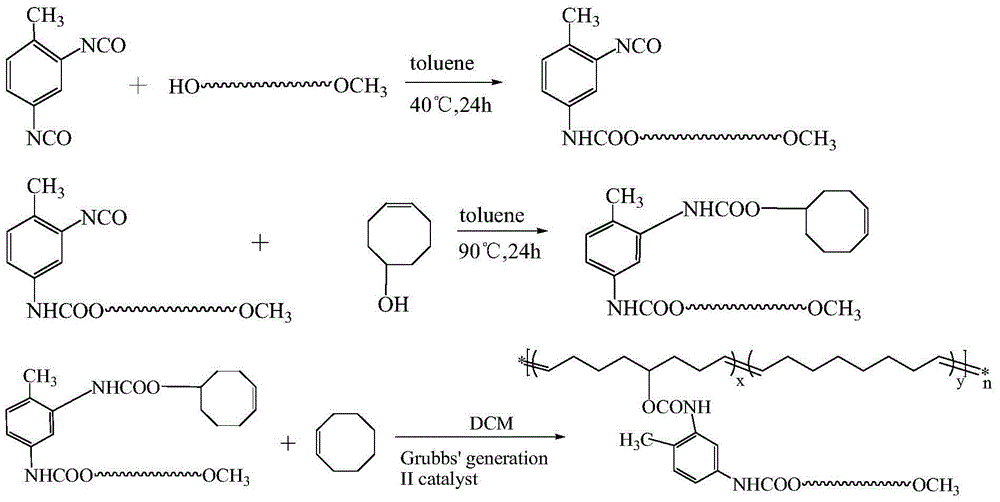

Polymer single-ion electrolyte and preparation method thereof

ActiveCN103509153AHigh conductivity at room temperatureReduce crystallinitySecondary cellsLithium imideCrystallinity

The invention discloses random copolymerization single-ion polymer electrolyte or block copolymerization single-ion polymer electrolyte which is obtained through copolymerization between a (p-vinyl phenylsulfonyl) (perfluoroalkyl sulfonyl) lithium imide monomer and a methoxyl polyethylene glycol acrylate monomer, and a preparation method of the electrolyte. The polymer single-ion electrolyte prepared by the method disclosed by the invention has the advantages of high room-temperature conductivity, high lithium ion transference number, low glass state temperature and degree of crystallinity, good mechanical strength and film-forming properties, wide electrochemical window, good thermal stability and the like, and has potential application values in the aspects of lithium (ion) batteries, carbon-based super-capacitors, solar batteries and the like.

Owner:武汉市瑞华新能源科技有限公司

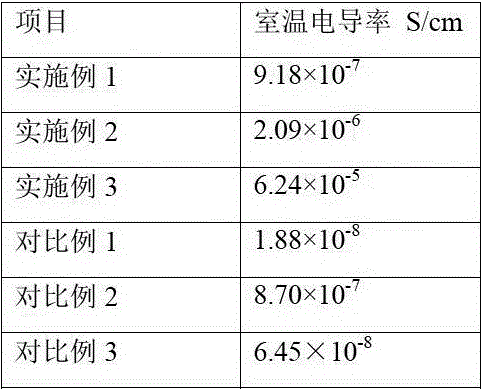

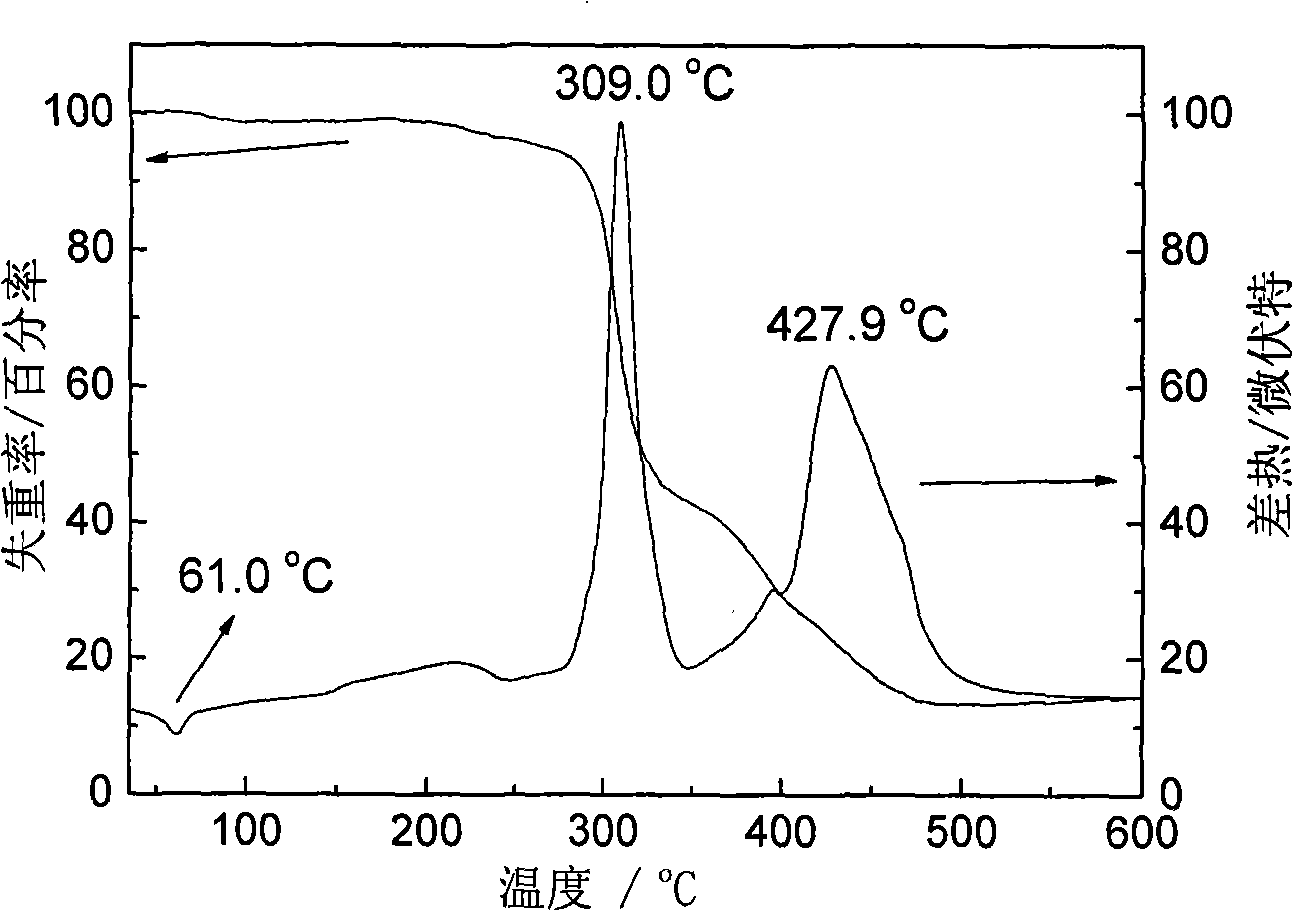

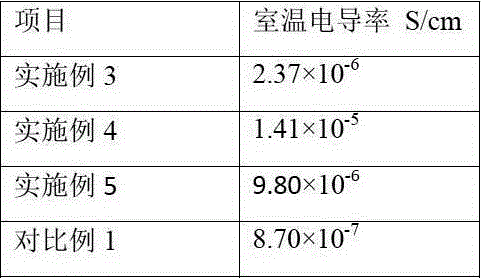

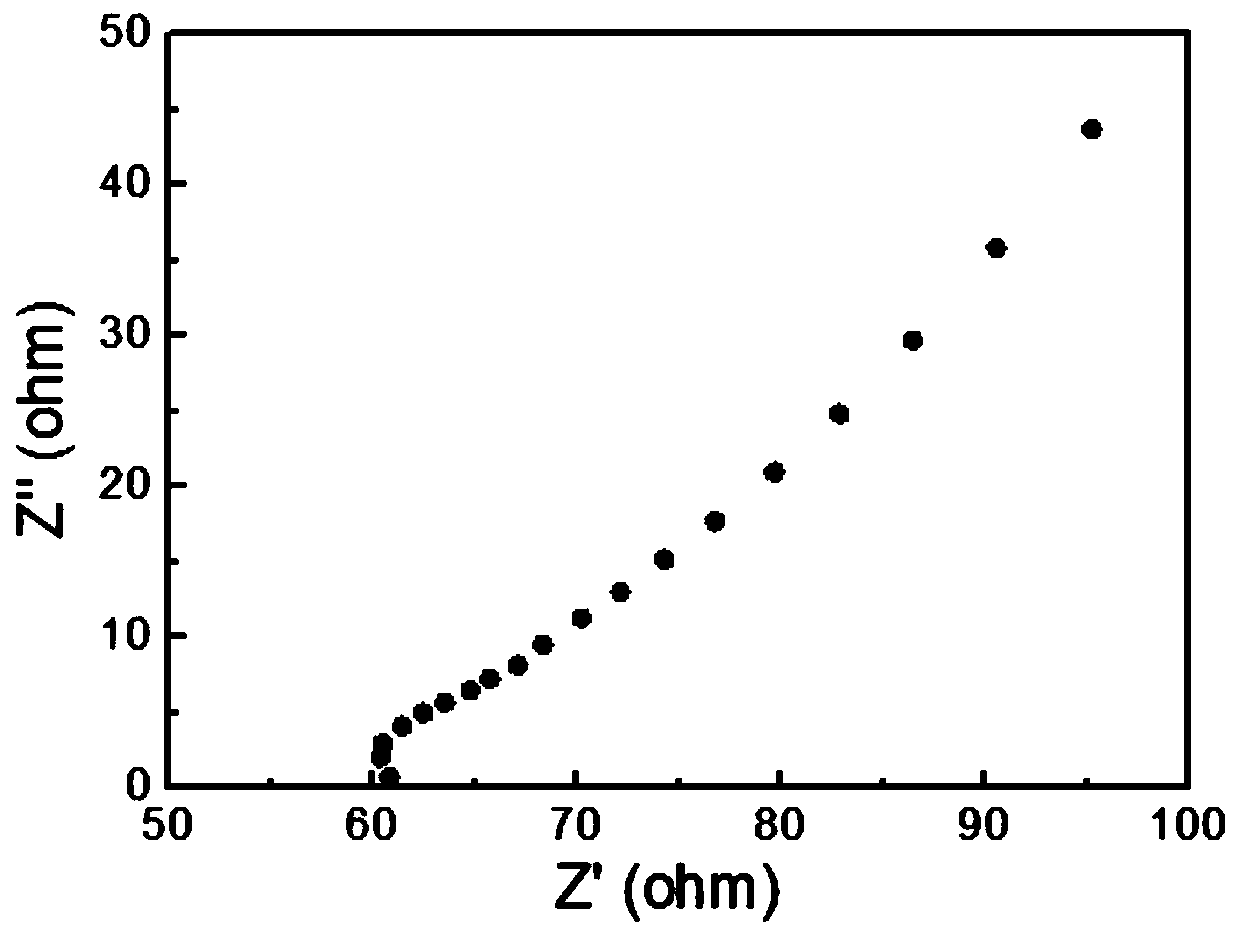

Solid polymer electrolyte added with high-concentration lithium salt and preparation method thereof

InactiveCN106602138AEasy to makeHigh conductivity at room temperatureSecondary cellsBatteriesLithiumHigh concentration

The invention discloses a solid polymer electrolyte added with a high-concentration lithium salt. The solid polymer electrolyte comprises a lithium salt and solid polycarbonate, wherein the lithium salt is dispersed in a substrate of the solid polycarbonate; and the solid polymer electrolyte comprises 40-90 percent by weight of lithium salt. The solid polymer electrolyte is easy to prepare, and has high room-temperature conductivity, high electrochemical performance and high interface stability.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte and preparation method thereof

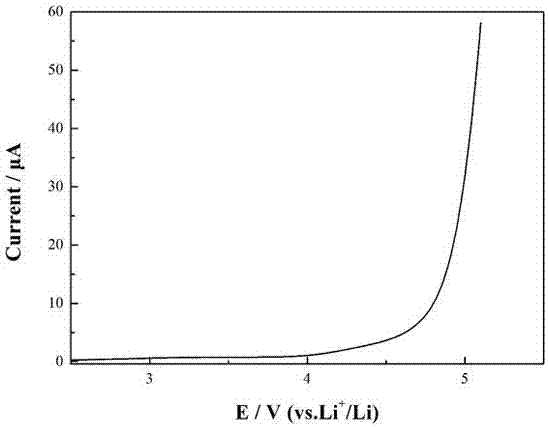

ActiveCN107768717AEasy to prepareHigh conductivity at room temperatureSolid electrolytesFinal product manufactureCross-linkPolymer science

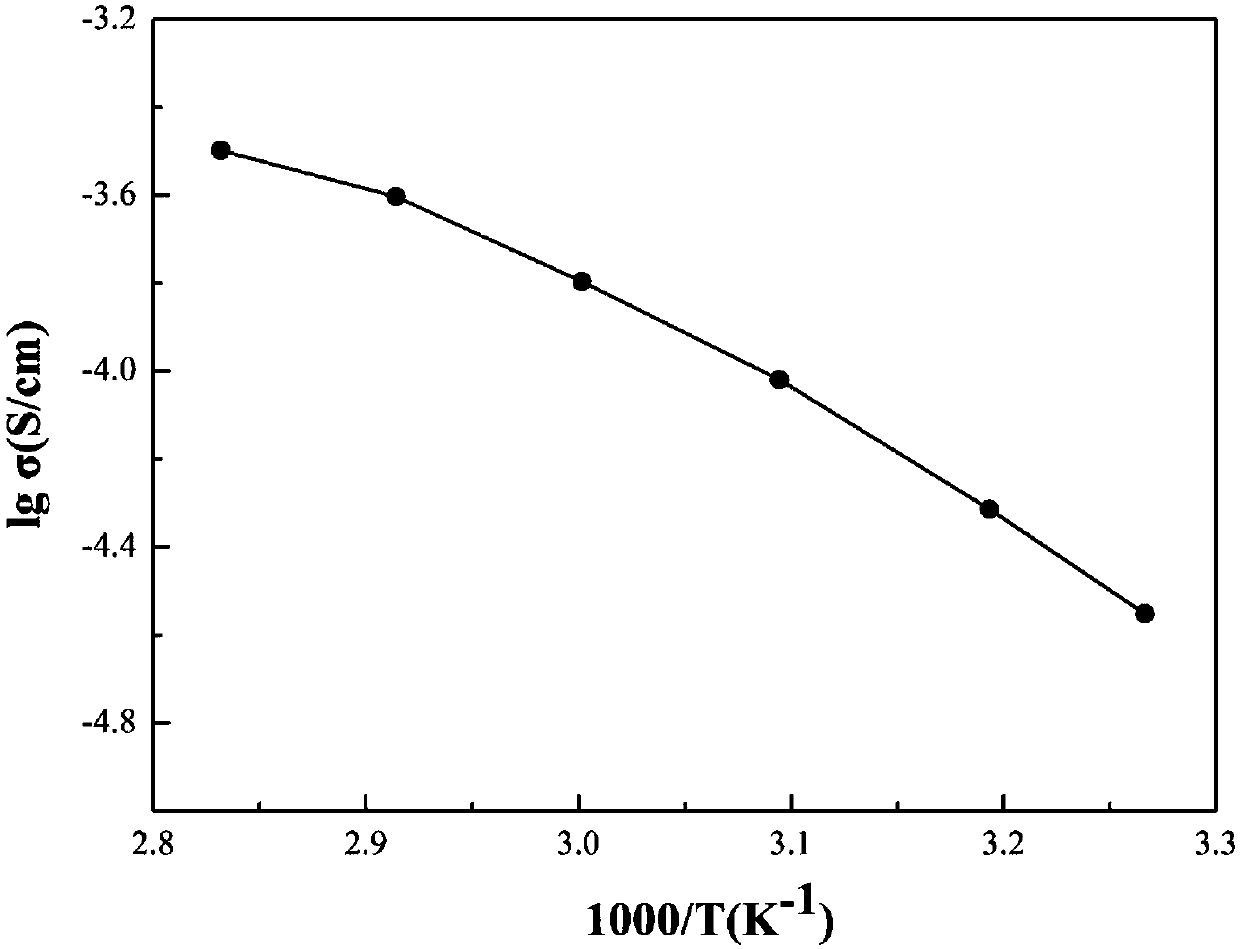

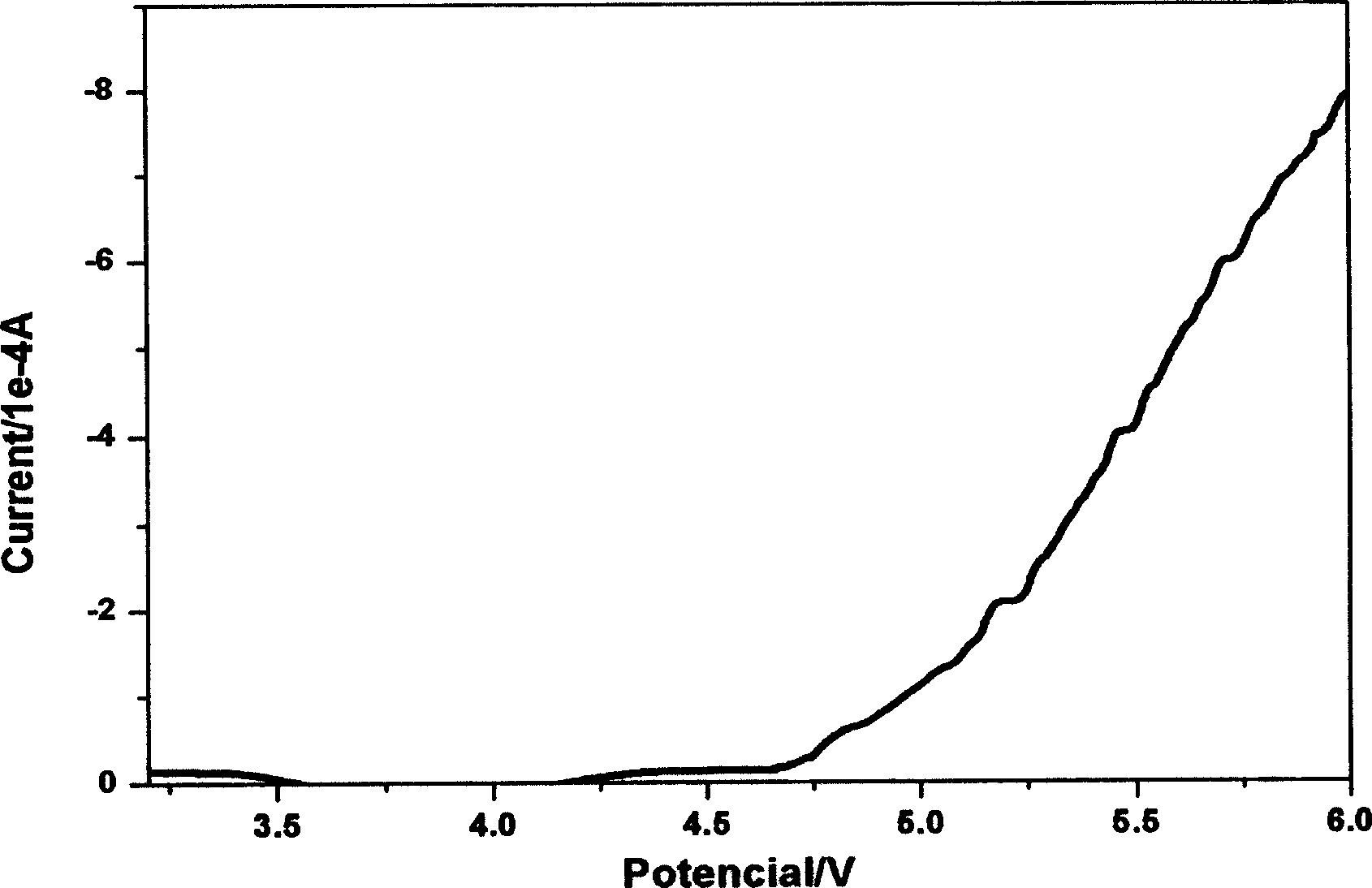

The invention discloses an ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte and a preparation method thereof. The ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte is characterized in that a crosslinking agent is automatically cross-linked to form a framework, polycarbonate is taken as a solid-state polymer substrate uniformly filled in the framework, a lithium salt is dispersed in the solid-state polymer substrate, the weight ratio of the lithium salt and the polycarbonate is (4:6)-(9:1), and the crosslinking agent accounts for 5-50% of total weight of the solid-state polymer electrolyte. The solid-state polymer electrolyte is simple in preparation method, high in room-temperature electrical conductivity and good in electrochemical and interface stability, can be self-supported and can be used as an electrolyte of a lithium ion battery, and the oxygenolysis potential is larger than 4.5V.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Lithium metal cathode coated with solid polymer electrolyte and preparation method thereof

InactiveCN108511687AEasy to prepareHigh conductivity at room temperatureSolid electrolytesCell electrodesChemistryVinylene carbonate

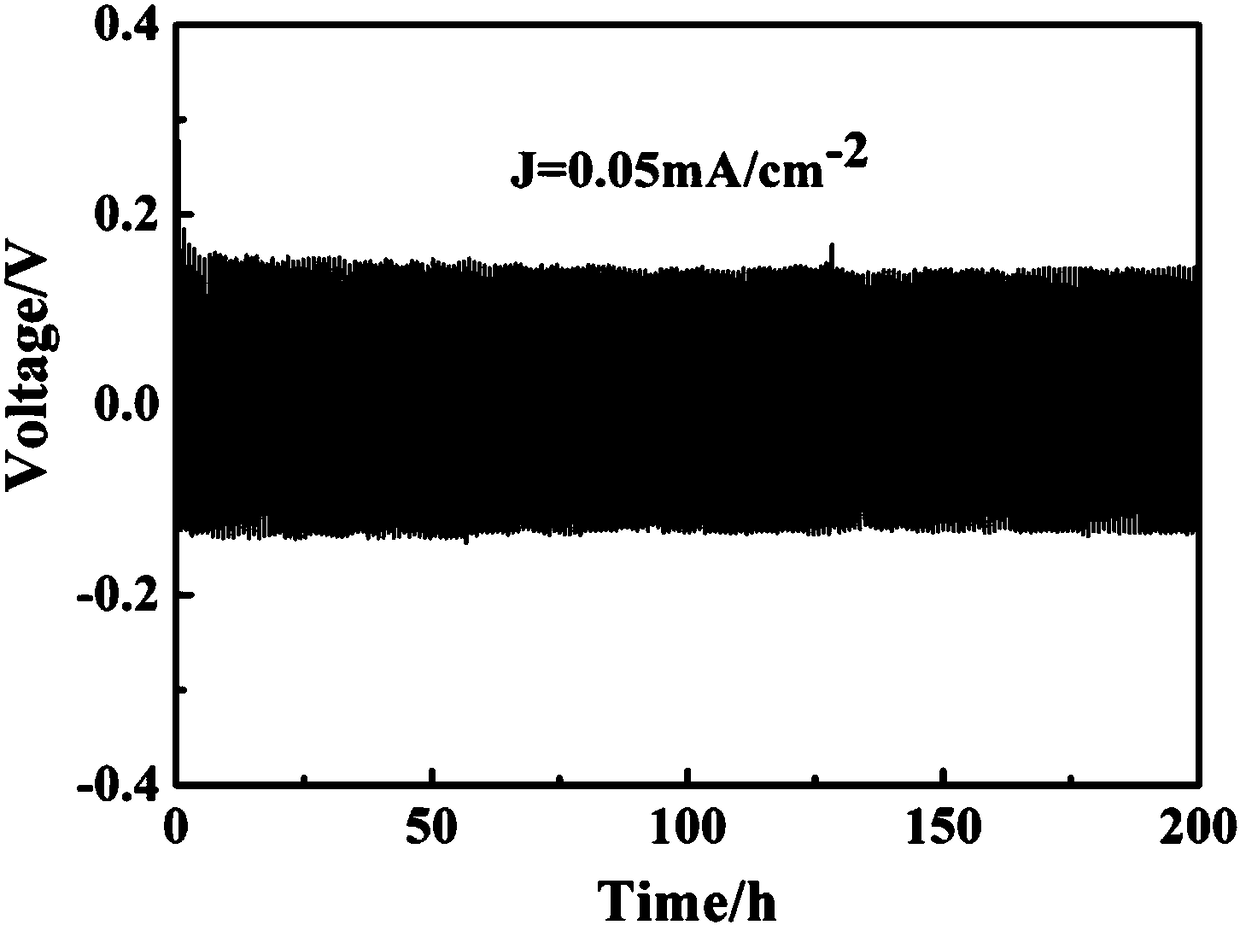

The invention discloses a lithium metal cathode coated with a solid polymer electrolyte and a preparation method thereof. The lithium metal cathode coated with the solid polymer electrolyte is characterized in that metal lithium is used as a cathode, and the surface of the metal lithium is coated with the solid polymer electrolyte in an in-situ polymerizing way; the solid polymer electrolyte is apolymer of vinylene carbonate and polyethylene glycol (methyl) acrylate, or a polymer of vinylene carbonate, polyethylene glycol (methyl) acrylate and a framework monomer. The lithium metal cathode has the advantages that the preparation is simple, the room-temperature conductivity is high, the oxidizing decomposing potential is greater than 4.8V, the stability in interface with the metal lithiumis good, and the cycle property of the metal lithium battery using the metal lithium cathode coated with the electrolyte is obviously improved.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Production for gel polymer electrolyte

ActiveCN1645662AHigh mechanical strengthImprove electrochemical stabilityOrganic electrolyte cellsSecondary cellsPolymer electrolytesPolymer science

The method includes following step: two monomers are mixed according to the ratio of 1.0 to 1.0-9.0; then it mixes with thermal booster and liquid lithium ion battery solution to form the fore body of gel polymer dielectric; the fore body is injected into half finished battery. the half finished battery is vacuumized and sealed; the half finished battery is made thermal polymerization reaction, and the gel polymer dielectric is obtained.

Owner:SHENZHEN CAPCHEM TECH

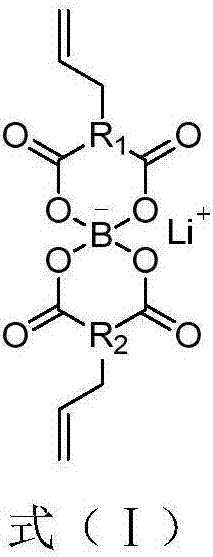

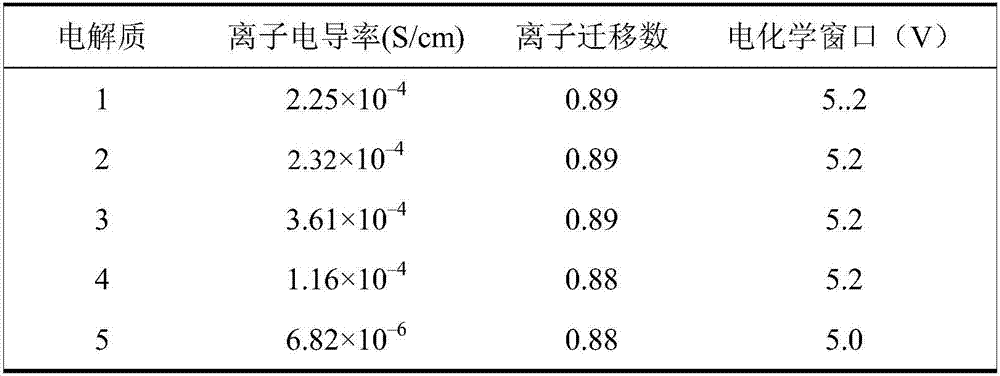

Lithium single ion conduction polymer electrolyte based on functionalized lithium borate

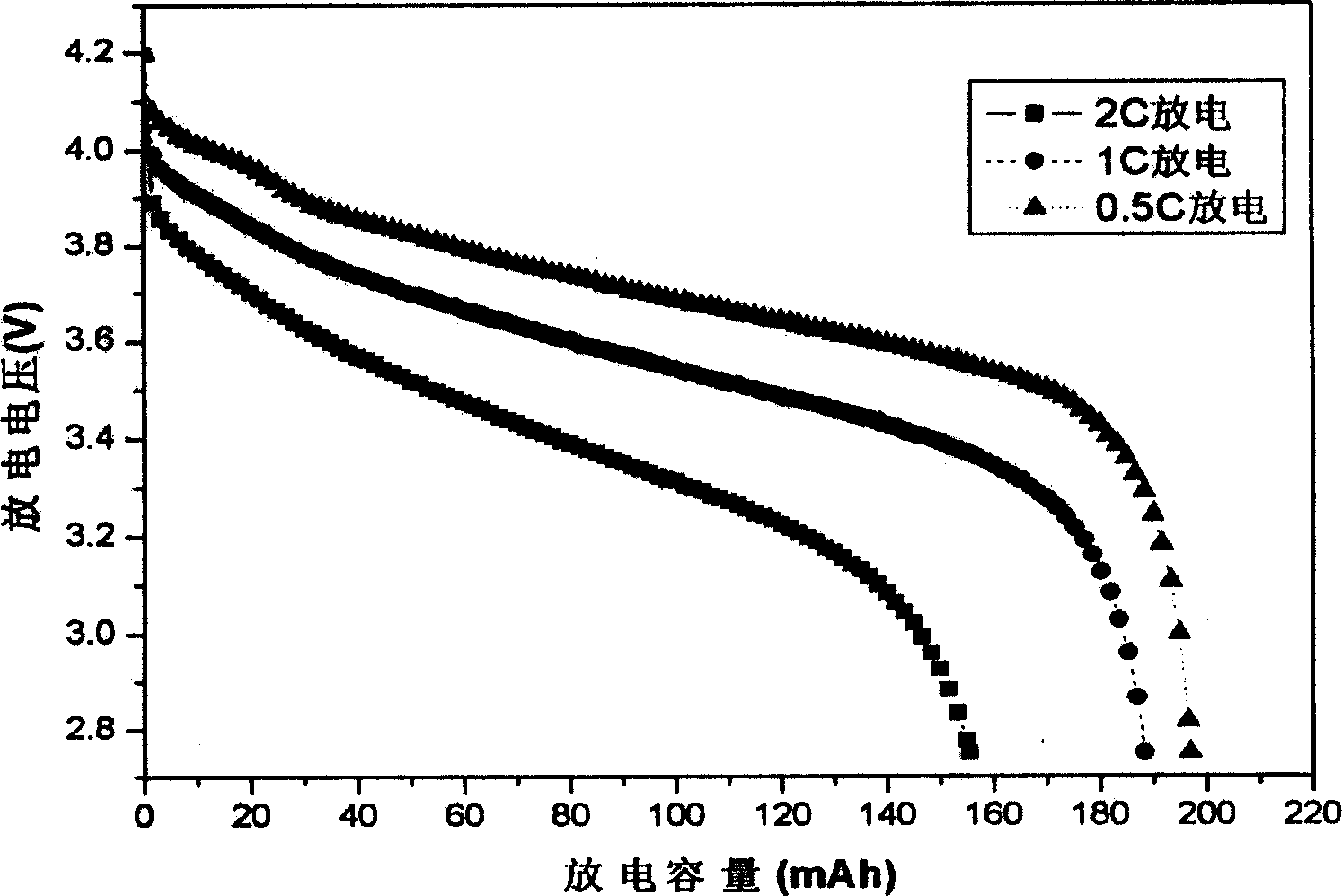

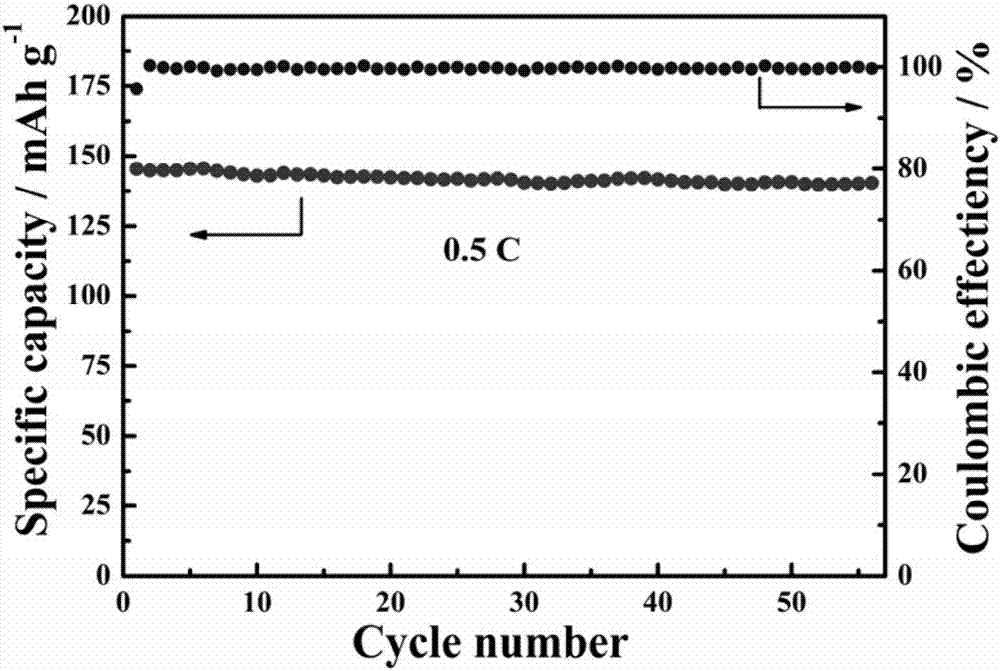

ActiveCN106935904AEasy to synthesizeRaw materials are cheap and easy to getSolid electrolytesCell electrodesHigh rateElectrochemical window

The invention discloses a lithium single ion conduction polymer electrolyte based on functionalized lithium borate. A double-bond-containing functionalized lithium borate and a sulfydryl-containing compound are subjected to an alkene-sulfydryl click reaction, or the double-bond-containing functionalized lithium borate and the sulfydryl-containing compound and a double-bond-containing polyether are subjected to a poly-alkene-sulfydryl click reaction to prepare a linear or network-shaped all-solid-state or gel catalyst. The lithium single ion conduction polymer electrolyte prepared by the invention has the advantages of simple and easily implemented synthesis, low-cost and easily available raw materials, high room-temperature conductivity, high lithium ion mobility, wide electrochemical window, and the like; and a lithium battery assembled by the electrolyte provided by the invention has high safety, high rate capability, long cycle life and stability.

Owner:SUN YAT SEN UNIV +1

Polymer lithium ion cell and its preparing method

InactiveCN1426126AHigh conductivity at room temperatureImprove Interface StabilityFinal product manufactureElectrolyte accumulators manufactureMethacrylateHexafluoropropylene

The polymer lithium ion cell includes anode plate, cathode plate and electrolyte. At least one of the anode plate and the cathode plate has polymer substrate material film comprising polymer A and polymer B, the polymer A is poly(methyl methacrylate-acrylonitrile-lithium methacrylate) and the polymer B is poly(vinylidene difluoride) or poly(vinylidene difluoride-hexafluoropropylene). During the preparation of the cell, the polymer substrate material is painted directly onto anode plate and / or the cathode plate to form cell diaphragm, and electrolyte liquid is filled to form polymer electrolyte. The polymer lithium ion cell has simple preparation process and no need of addition diaphragm.

Owner:TIANJIN UNIV

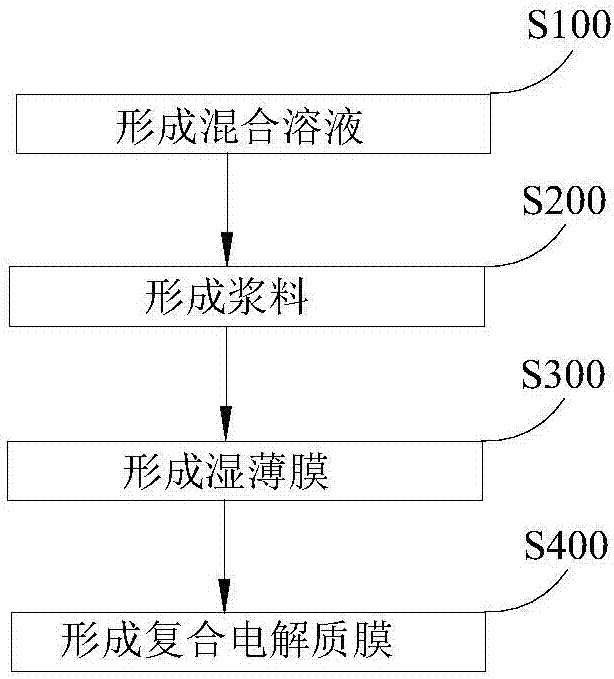

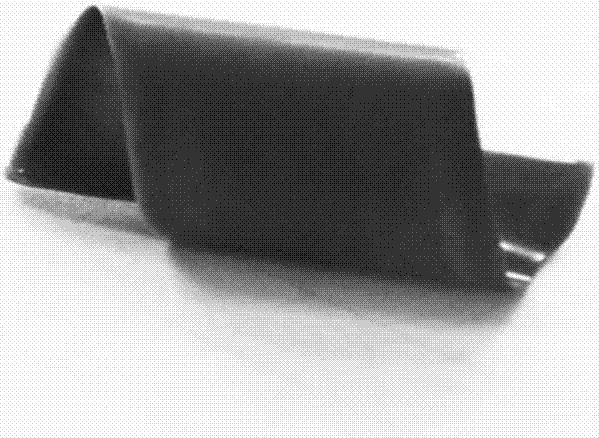

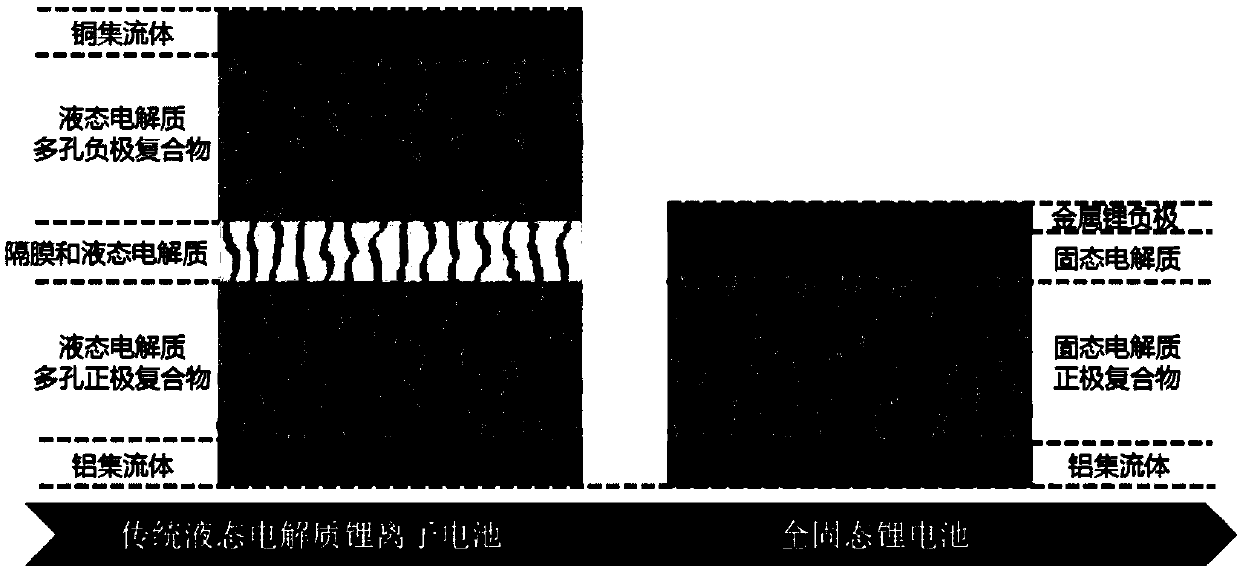

Composite electrolyte membrane, preparation method thereof and all solid-state lithium battery having same

InactiveCN107394255AHigh conductivity at room temperatureImprove electrochemical performanceLi-accumulatorsComposite electrolyteOxygen

The invention discloses a composite electrolyte membrane, a preparation method thereof and an all solid-state lithium battery having the same. The composite electrolyte membrane comprises a base body which comprises at least one of PVDF and PAN; lithium salts; and a lithium-lanthanum-zirconium oxygen base oxide. Therefore, the composite electrolyte membrane is high in room-temperature conductivity, steady in electrochemical performance, good in thermal stability, good in mechanical property, easy to process and simple to prepare; the cost is reduced; and the composite electrolyte membrane is beneficial to industrial production.

Owner:TSINGHUA UNIV

Polymer ion liquid electrolyte and preparation method thereof

InactiveCN104031193AImprove conductivityImprove solubilitySecondary cellsComposite electrolyteElectrical battery

The invention discloses an ether group-containing polymer ion liquid composite-electrolyte and a preparation method thereof. The polymer ion liquid composite-electrolyte has the advantages of high room-temperature conductivity, high lithium ion transport number, low vitrification point, good mechanical strength, good film forming performances, wide electrochemical window and good heat stability, and has wide application values in fields of lithium (ion) cells, carbon-based supercapacitors and solar cells.

Owner:HUAZHONG UNIV OF SCI & TECH

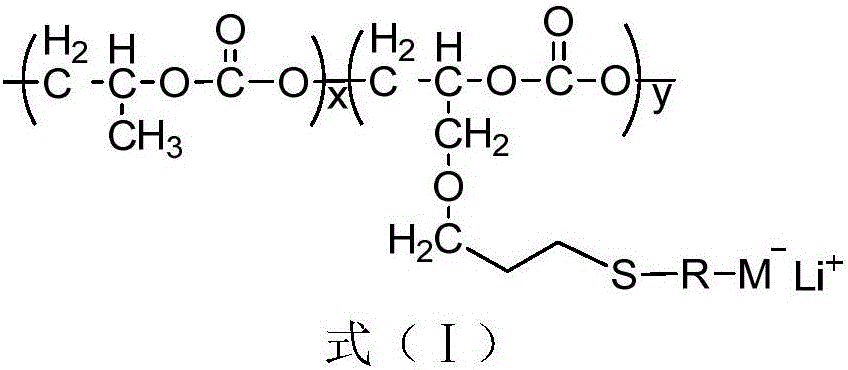

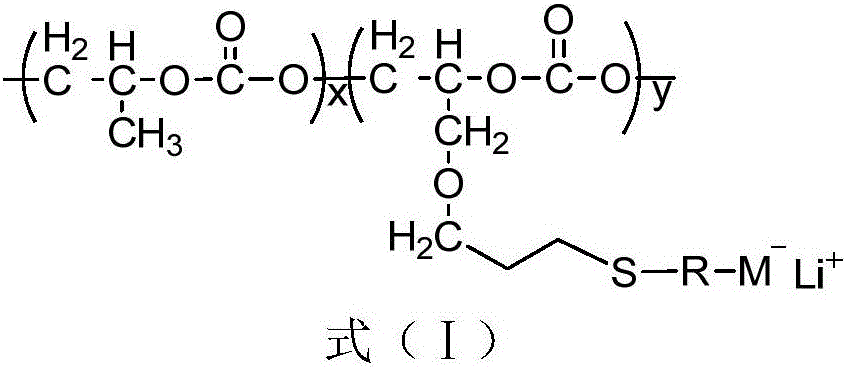

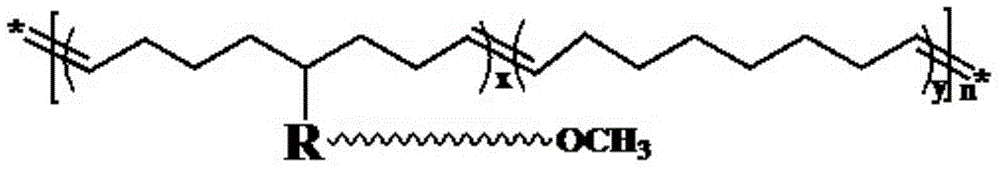

Single-lithium-ion-conducting solid polymer electrolyte adopting carbon dioxide based polycarbonate as main chain and preparation method of single-lithium-ion-conducting solid polymer electrolyte

ActiveCN106410270AEasy to synthesizeRaw materials are cheap and easy to getHybrid capacitor electrolytesSecondary cellsPolymer scienceElectrochemical window

The invention discloses a single-lithium-ion-conducting solid polymer electrolyte adopting carbon dioxide based polycarbonate as a main chain and a preparation method of the single-lithium-ion-conducting solid polymer electrolyte. The structure of the electrolyte is as shown in formula (I), M-Li<+> in the formula (I) is COOLi or SO3Li or the like; the number-average molecular weight of the polymer in the formula (I) is 2,000-15,0000 Da, R is (CH2)n, and n is an integer ranging from 0 to 20; the molar percentage of an ion functional group chain segment is included in the formula (I), that is, y / (x+y), is 10%-80%. The prepared polymer single-ion electrolyte has the advantages of being simple and easy to synthesize, environment-friendly, high in room temperature conductivity, high in lithium ion transference number, low in glass transition temperature, good in mechanical strength and film-forming property, wide in electrochemical window, good in thermostability and the like; the electrolyte adopts cheap and available raw materials and has potential application value in lithium batteries, carbon-based supercapacitors, solar cells and the like.

Owner:SUN YAT SEN UNIV +1

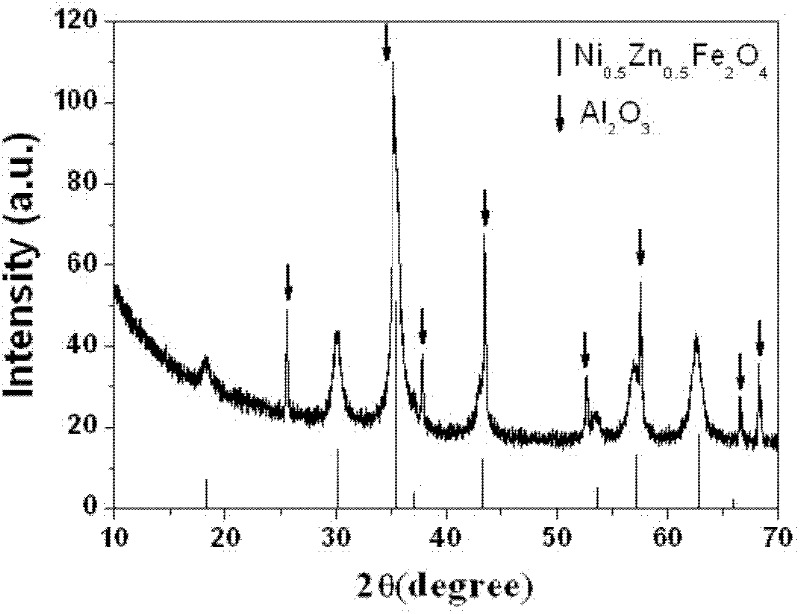

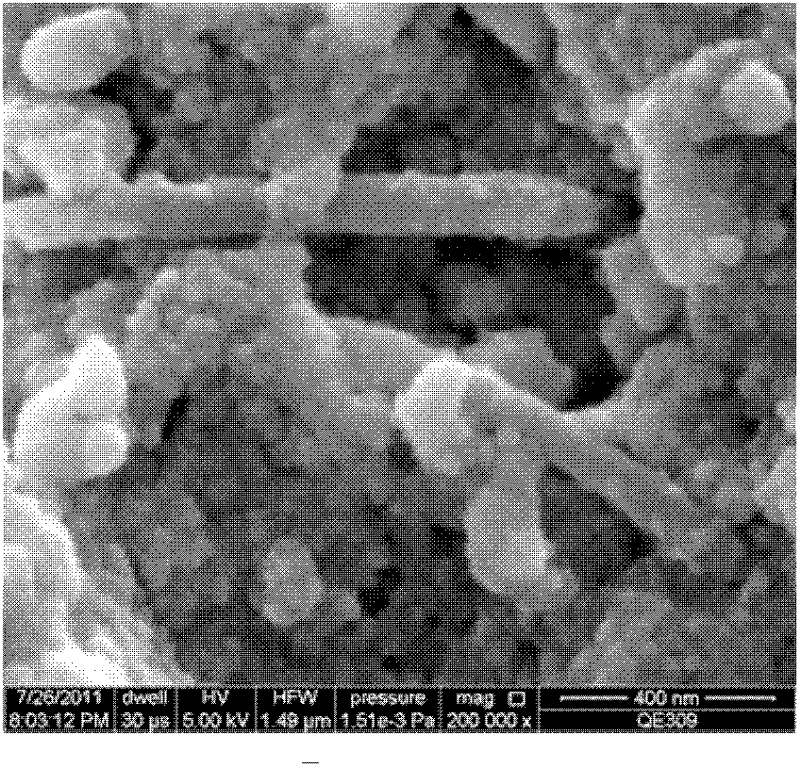

Ferrite-based ceramic composite material as well as preparation method and application thereof

ActiveCN102390989AMeet low temperature requirementsRealize the structureCeramic compositeStructure and function

The invention discloses a ferrite-based ceramic composite material as well as a preparation method and application thereof. The composite material is composed of ferrite, a carbon nanotube and a ceramic material, wherein the ferrite and the ceramic material are cladded on the tube wall of the carbon nanotube, and the ceramic material is one or several kinds of aluminum oxide, aluminum nitride, and silicon nitride. The three phases of materials, namely, the ferrite, the carbon nanotube and the ceramic, are compounded to make the advantages and disadvantages of all phases of materials complementary, so that the electrical conductance of the composite material is increased, the impedance matching performance of the composite material is improved, the wave absorption performance of the composite material is made adjustable, the structure and function integration of the ferrite-based ceramic material is realized, and thus, the application range of the composite material in the high-tech field is expanded. In addition, the powder of the composite material is prepared by adopting a coprecipitation hydrothermal method and is further prepared into a block material by adopting a microwave sintering method, and the ferrite-based ceramic composite material has the advantages that all phases are dispersed uniformly, the densification degree of the sintered material is high, the production cost is low, and the large-scale industrialization is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

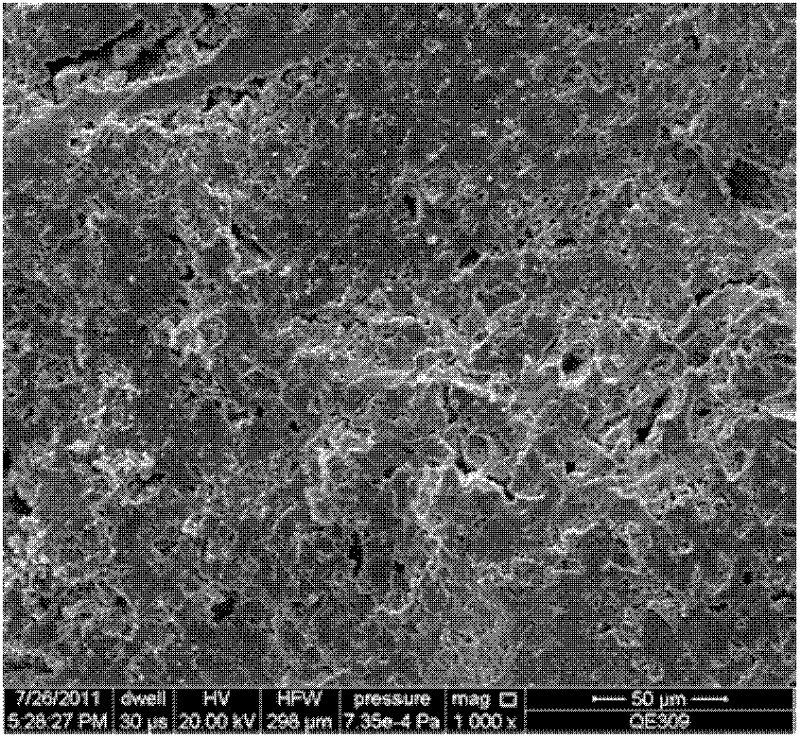

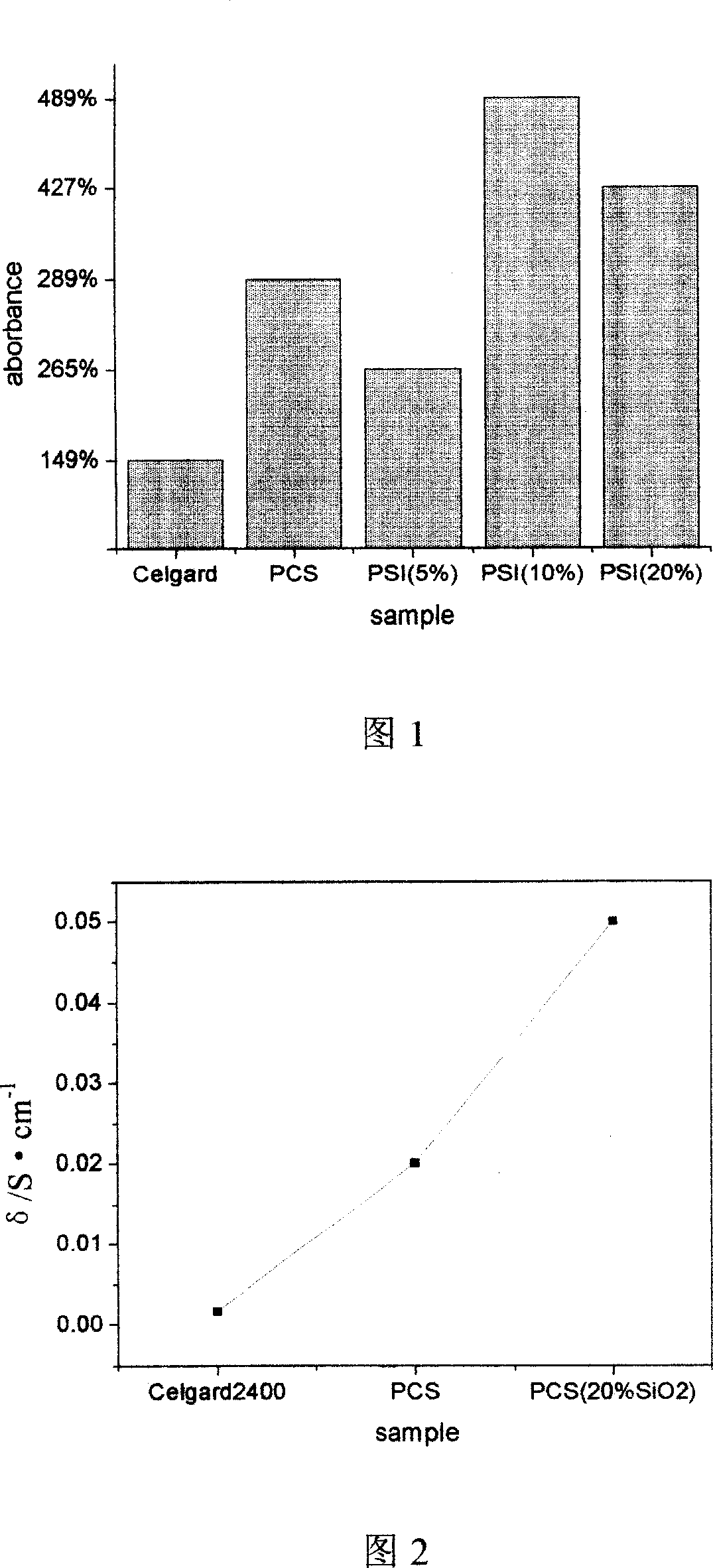

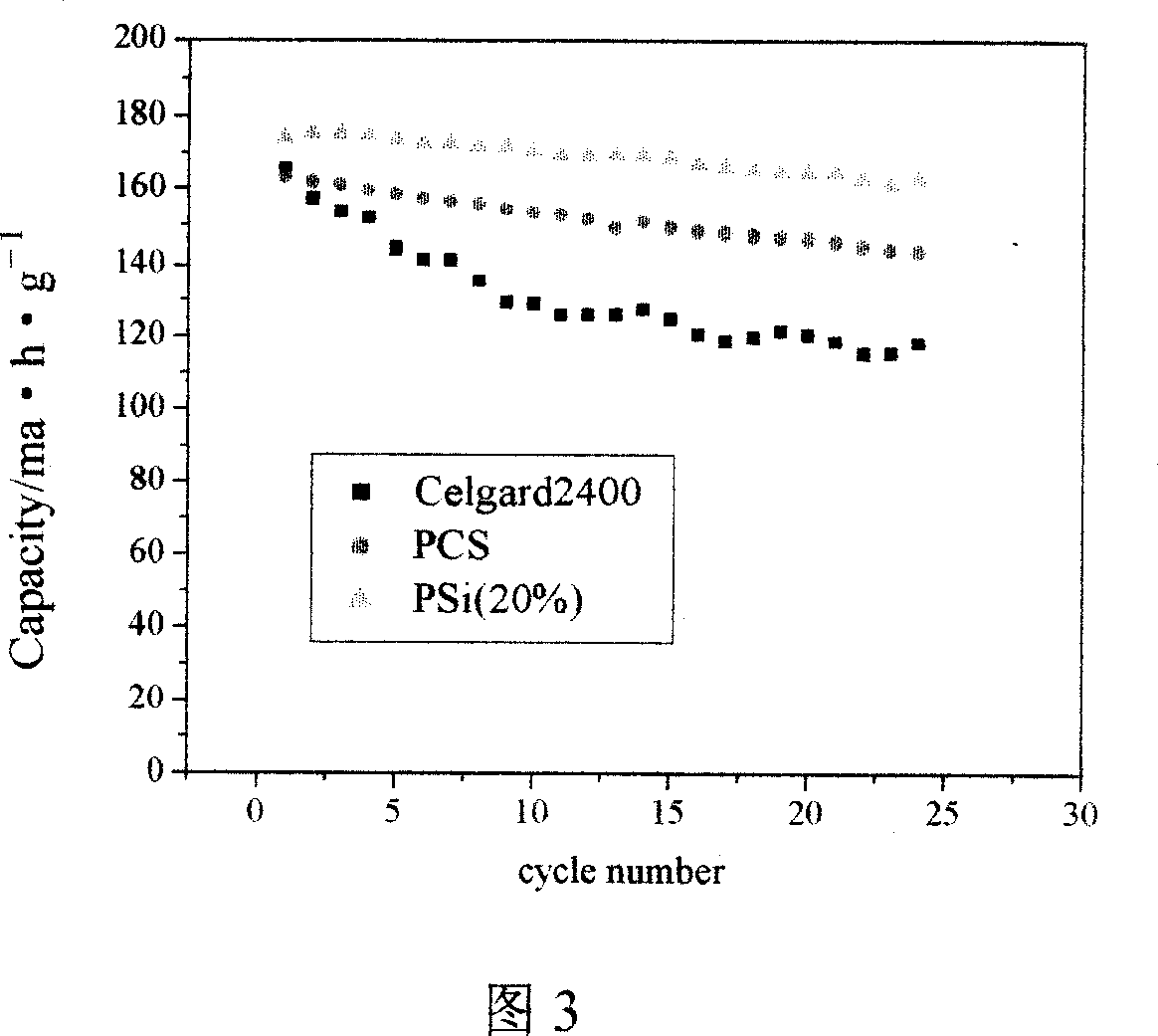

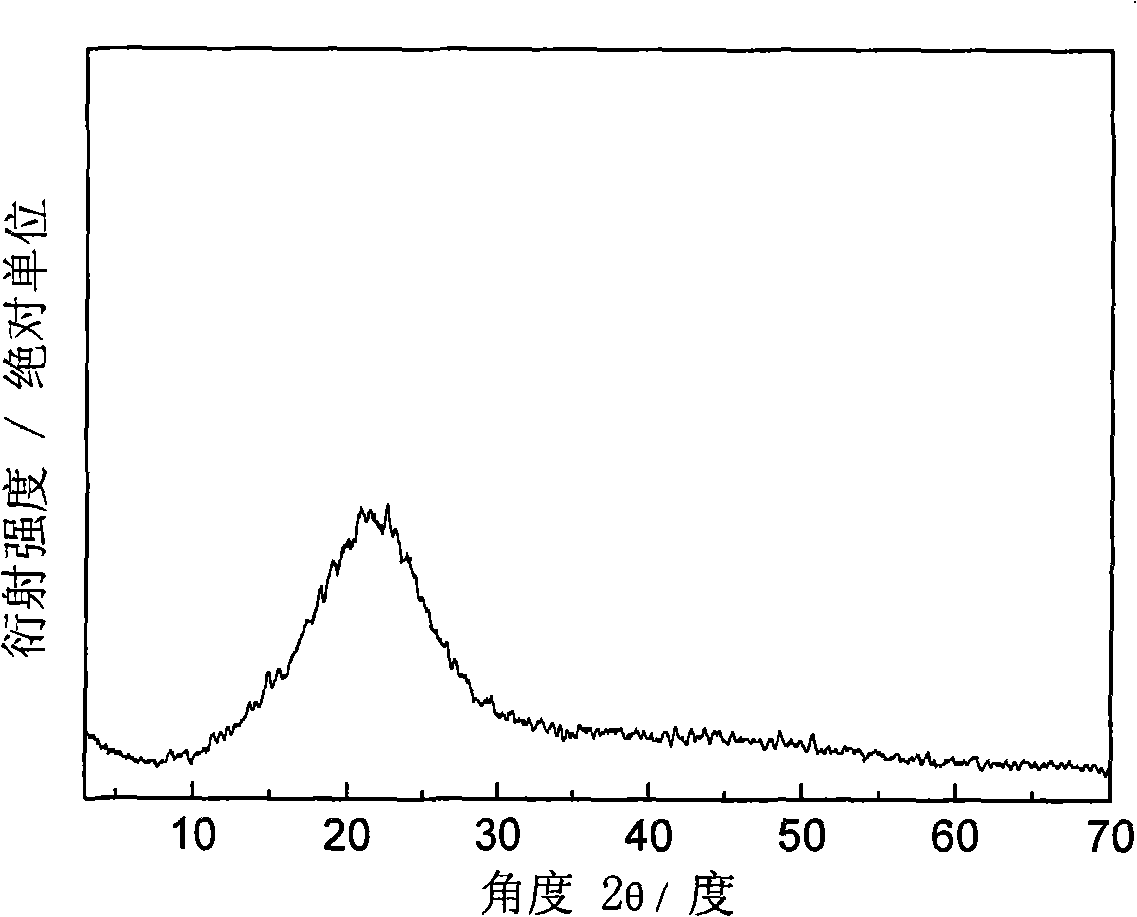

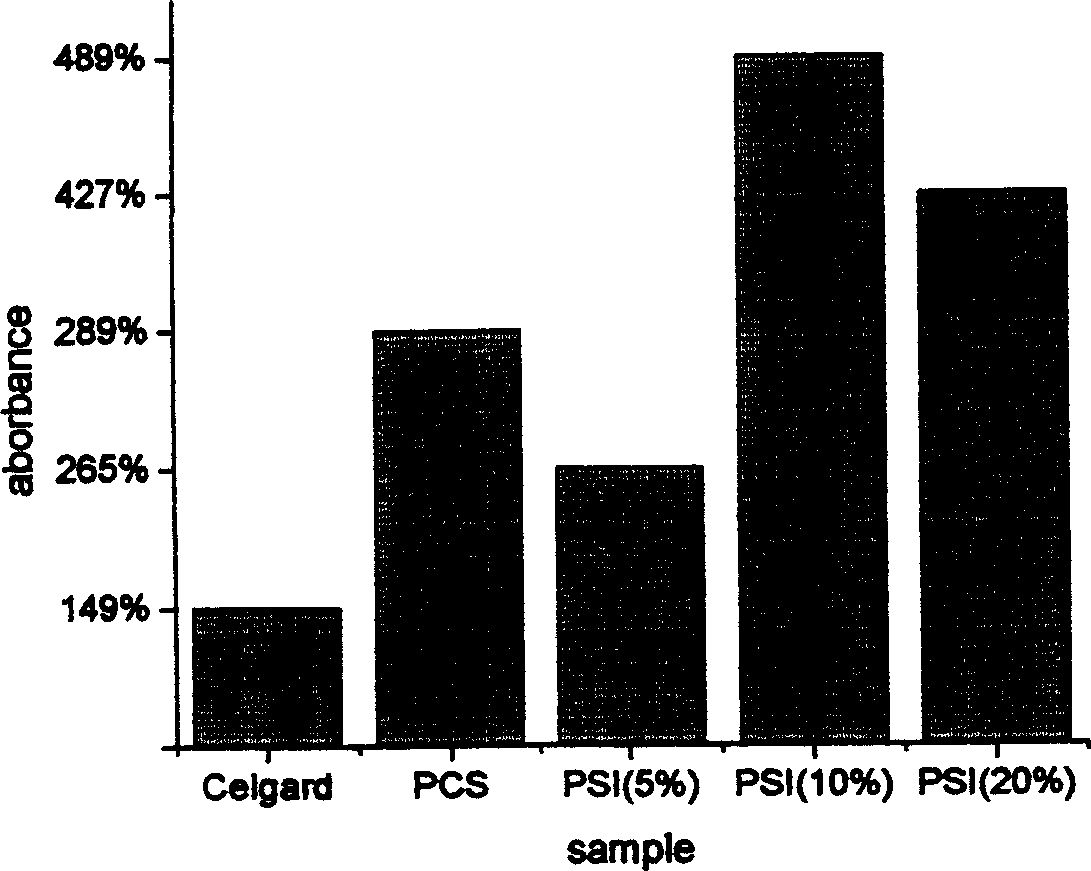

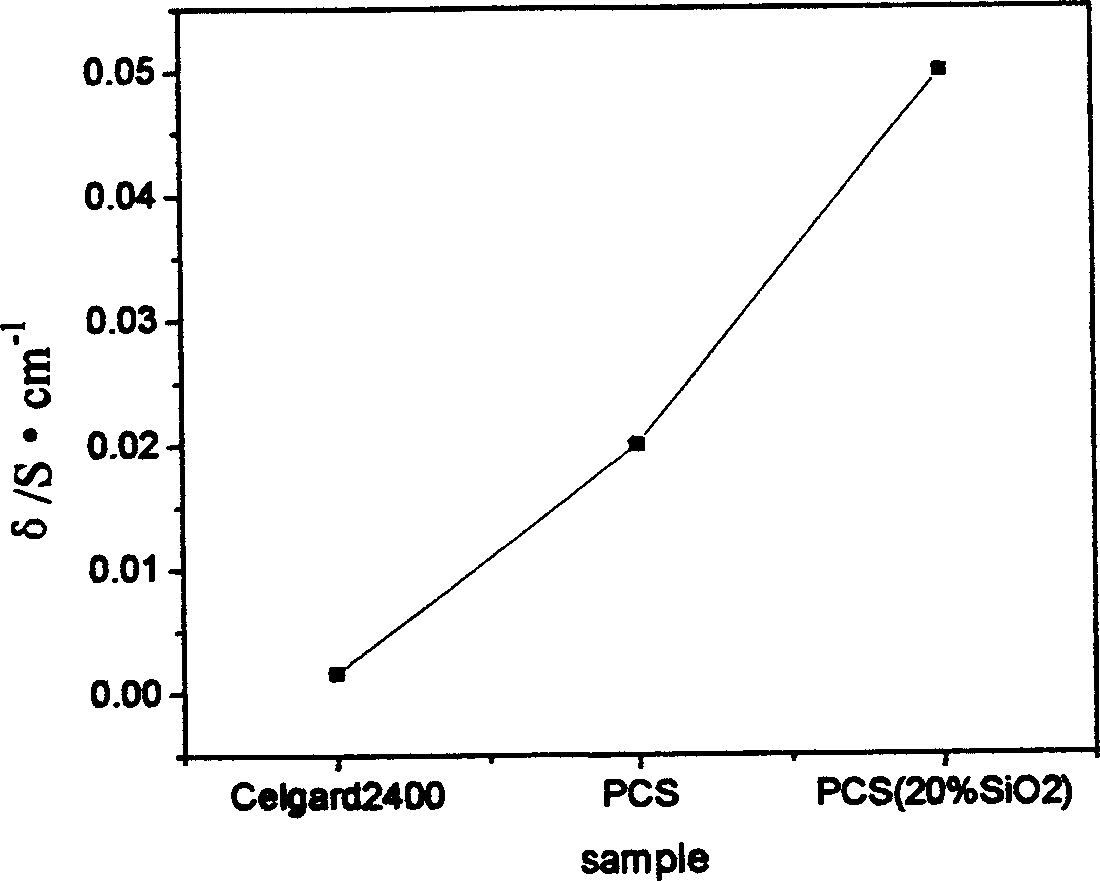

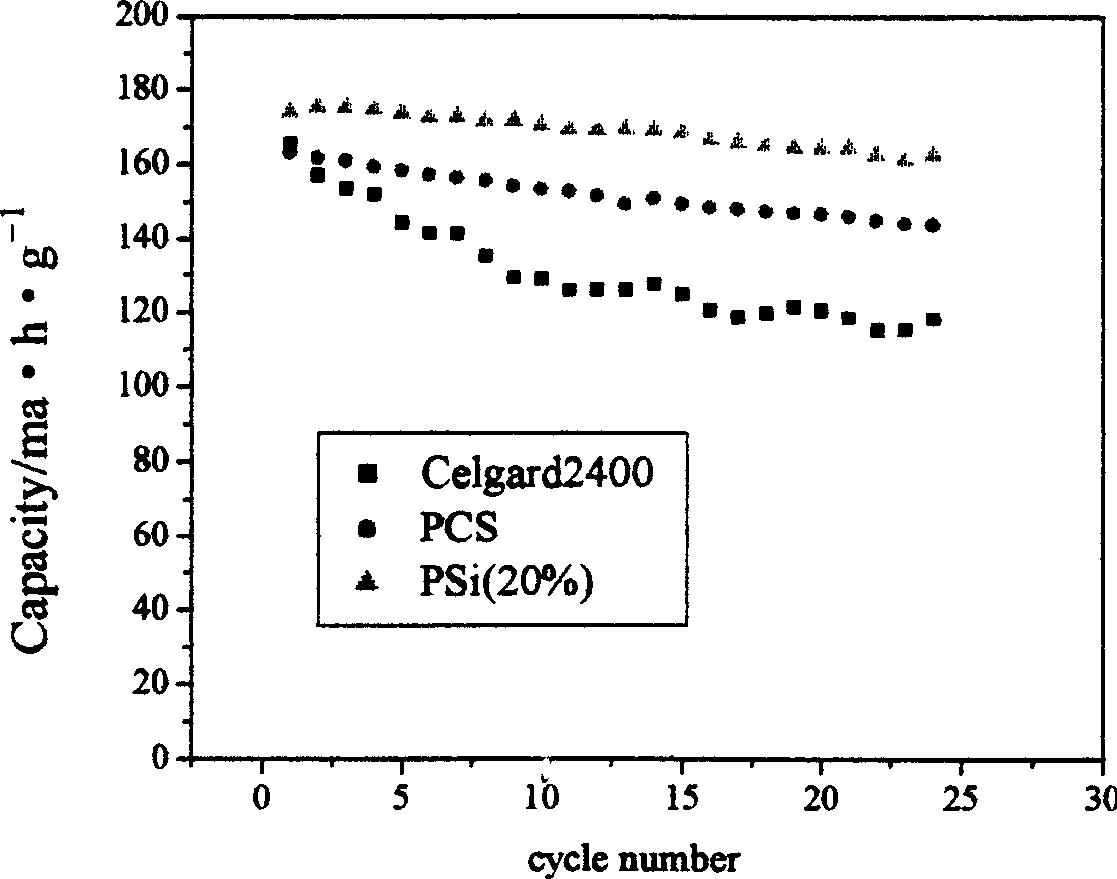

Composite lithium battery membrane and method for making same

InactiveCN1312789CImprove interface propertiesHigh conductivity at room temperatureCell component detailsElectrical batteryNano sio2

The invention refers to a manufacturing method for a kind of compound polypropylene lithium membrane. The materials are base membrane, polymer and nano SiO2 fillers; the step is: the materials are solved in the solvent, the sol compound can be acquired, and then they are transferred to the culture dish, the membrane is immersed in them; the membrane is taken out and transferred to the template, the solvent is absorbed by the molecular sift, then they are transferred into the vacuum drying box to be dried. The invention emphasizes the humidity to membrane by the polymer and the improvement to the interface performance, the organic group component of the SiO2 surface is important to the performance of the compound membrane. The compound membrane upgrades the room temperature conductivity, and improves the interface performance of the positive material / membrane, lithium / membrane. The assembled battery has an excellent circular performance.

Owner:XIAMEN UNIV

Inorganic/organic nano composite solid electrolyte and method of preparing the same

InactiveCN101276658AHigh conductivity at room temperatureHigh lithium ion transfer numberSolid electrolytesIndividual molecule manipulationPolyethylene oxideHeat stability

The invention discloses an inorganic / organic nanometer composite solid electrolyte and a preparation method thereof, belonging to the inorganic / organic nanometer composite material and the preparation process field. The solid electrolyte is composed by polyethylene oxides PEO, lithium perchlorates LiClO4 and hydrotalcite nanometer sheets LDHNS, has a chemical formula of PEO / LiClO4 / LDHNS, the mass parts of each component are 54-91%, 8-16% and 1-30% respectively. The preparation method of the composite solid electrolyte comprises: mixing PEO, LiClO4 and LDHNS in water equably and sufficiently, and then vaporizing the solvent to obtain the composite solid electrolyte of the invention. The inorganic / organic nanometer composite solid electrolyte according to the invention has high conductivity, high lithium ion transference number and heat stability, the electrolyte can be used as the electrolyte of a solid lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Solid polymer electrolyte added with graphene quantum dots and preparation method of solid polymer electrolyte

ActiveCN106848394AEasy to prepareHigh conductivity at room temperatureSecondary cellsGraphene quantum dotElectrolyte

The invention discloses solid polymer electrolyte added with graphene quantum dots. The solid polymer electrolyte contains the following components: lithium salt, modified graphene quantum dots and solid polyoxyethylene, wherein the lithium salt and the modified graphene quantum dots are dispersed into a matrix of solid polyoxyethylene, the use amount of the lithium salt is 8%-40% of the mass of solid polyoxyethylene, and the use amount of the graphene quantum dots is 1%-80% of the mass of solid polyoxyethylene. The solid polymer electrolyte is easy to prepare, high in room-temperature conductivity and good in electrochemical and interface stability.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

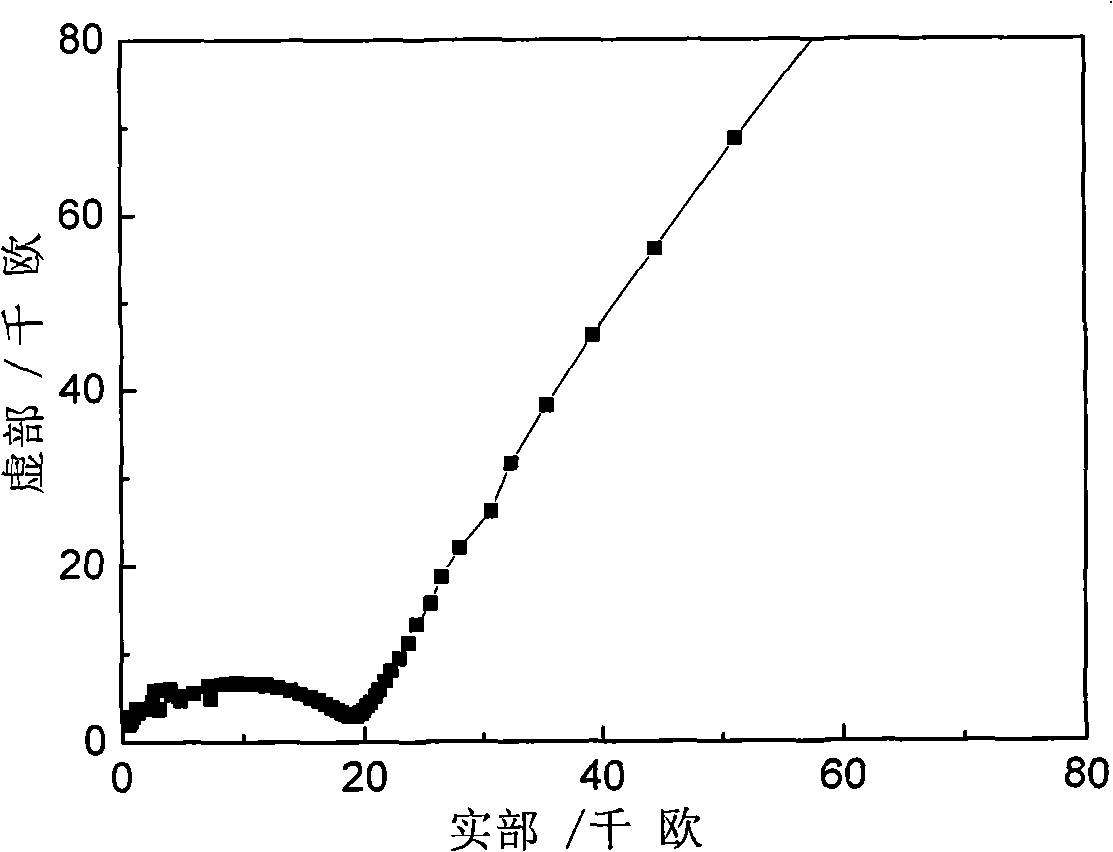

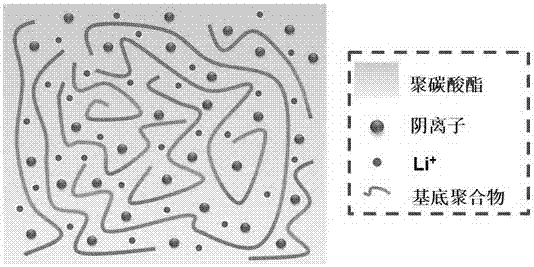

High-conductivity polymer electrolyte and preparation method thereof

InactiveCN107195963AEasy to prepareHigh conductivity at room temperatureSolid electrolytesSecondary cellsLithiumPolymer science

The invention discloses a high-conductivity polymer electrolyte and a preparation method thereof. The polymer electrolyte is formed by mixing polycarbonate dissolved with a lithium salt and a substrate polymer, wherein the polycarbonate dissolved with a lithium salt is used as a substrate, the substrate is a conductive constituent, and the substrate polymer is a support body. The polymer electrolyte is simple to prepare and is high in conductivity under a room temperature.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Self-crosslinkingcomb-shaped polymer and lithium-ionsolid polymerelectrolyte

ActiveCN104479112AHigh mechanical strengthThere will be no problems such as unevennessSecondary cellsLithiumPolyolefin

The invention relates to a solidelectrolyte which has the self-crosslinking property and adopts a controllable structure. Acomb-shaped polymer with a main chain adopting a self-crosslinkingpolyolefinstructure and a side chain of PEG (polyethylene glycol) is used as the solidelectrolyte for ion transport, the excellent electrochemical performance is acquired, and meanwhile, a material is ensured to have good molding machinability and high mechanical strength.

Owner:BEIJING DANGDAIJINGDIAN TECH CO LTD

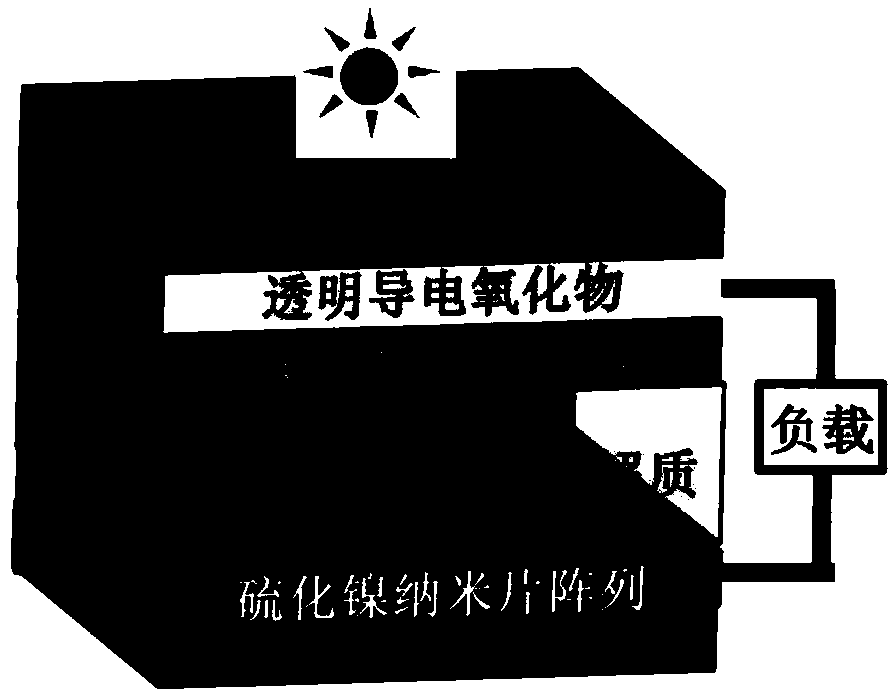

Preparation method for dye-sensitized solar cell counter electrode based on nickel sulfide nanosheets

ActiveCN103474243AHigh conductivity at room temperatureEfficient collectionLight-sensitive devicesCapacitor electrodesAlcoholNickel sulfide

The invention discloses a preparation method for a dye-sensitized solar cell counter electrode based on nickel sulfide nanosheets. The method includes the steps that (1) nickel xanthate precursor is synthesized; (2) the nickel sulfide nanosheet counter electrode is prepared, firstly, a substrate is cleaned by the adoption of ethyl alcohol and acetone and dried for use, then, the substrate is placed to the position, nearby the nickel xanthate precursor, in a heating device and heated to 160-360 DEG C, the temperature is kept for 10-300mins, and the substrate is cooled to normal temperature and taken out to obtain the nickel sulfide nanosheet counter electrode; (3) a dye-sensitized titanium dioxide photo anode and the prepared counter electrode are assembled together, an electrolytic solution is injected to obtain a dye-sensitized solar cell, and the dye-sensitized solar cell counter electrode is compared with a traditional platinized conducting glass counter electrode to test photovoltaic conversion performance of the dye-sensitized solar cell counter electrode. The preparation method is simple in technical process, good in repeatability and excellent in material and device performance and can be produced on a large scale in an industrialized mode, and the preparation parameters are easy to control. Through the processes, common multi-step complex processes, long process periods and expensive high-vacuum devices can be avoided.

Owner:山东百帝气动科技股份有限公司

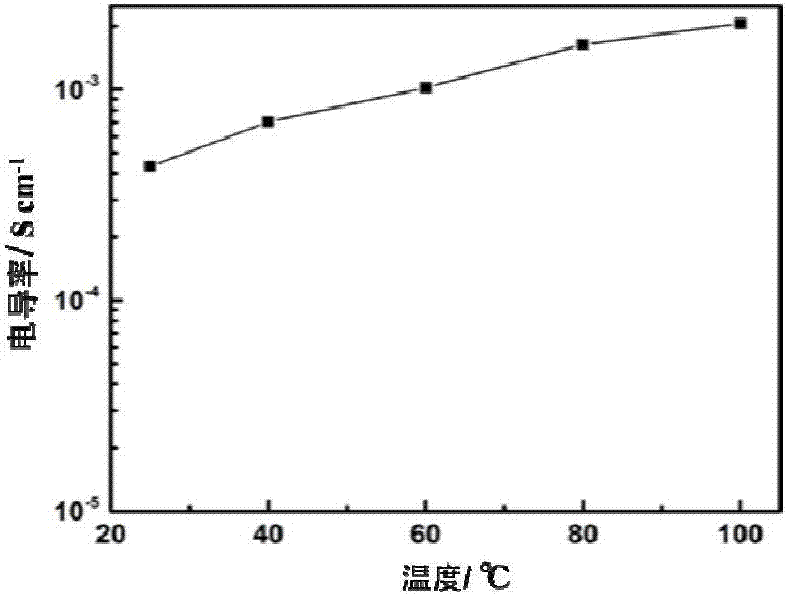

Solid electrolyte and preparation method and application thereof

ActiveCN110165291AEasy to makeLow costNon-metal conductorsSolid electrolytesSolid state electrolyteInorganic particle

The invention discloses a solid electrolyte and a preparation method and application thereof, and the solid electrolyte contains a membrane material and electrolyte salt, wherein an organic phase comprises a three-dimensional communicated interface, the specific area of the organic phase is greater than or equal to 1 * 10<4> cm2 / cm3, and the electrolyte salt is dissolved in the organic phase. Thepreparation method of the solid electrolyte comprises the following steps: spraying the solution of a high polymer material to a selected receiving surface by adopting an electrostatic spinning technology to form a continuous three-dimensional structure, selectively and simultaneously spraying dispersion liquid of inorganic particles to the selected receiving surface by adopting the electrostaticspraying technology, and then carrying out pressurizing treatment to obtain a membrane material; and dropwise adding or spraying the solution of the electrolyte salt into the membrane material or impregnating the membrane material into the solution of the electrolyte salt. The room-temperature conductivity of the solid electrolyte reaches up to 10<-3> S / cm, and the method does not depend on the addition of a special polymer or filler. The solid electrolyte has the advantages of simple preparation, low cost, wide raw material source and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Composite lithium battery membrane and method for making same

InactiveCN1547270AImprove interface propertiesHigh conductivity at room temperatureCell component detailsElectrical batteryNano sio2

The invention refers to a manufacturing method for a kind of compound polypropylene lithium membrane. The materials are base membrane, polymer and nano SiO2 fillers; the step is: the materials are solved in the solvent, the sol compound can be acquired, and then they are transferred to the culture dish, the membrane is immersed in them; the membrane is taken out and transferred to the template, the solvent is absorbed by the molecular sift, then they are transferred into the vacuum drying box to be dried. The invention emphasizes the humidity to membrane by the polymer and the improvement to the interface performance, the organic group component of the SiO2 surface is important to the performance of the compound membrane. The compound membrane upgrades the room temperature conductivity, and improves the interface performance of the positive material / membrane, lithium / membrane. The assembled battery has an excellent circular performance.

Owner:XIAMEN UNIV

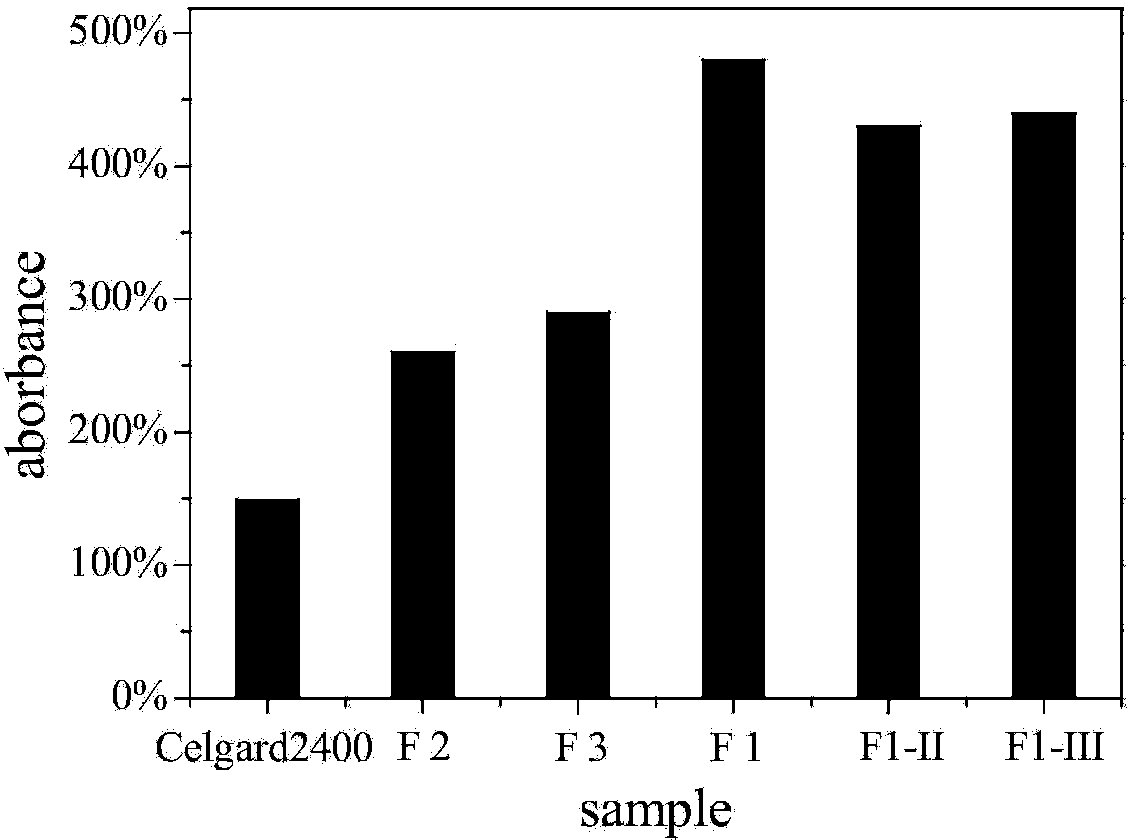

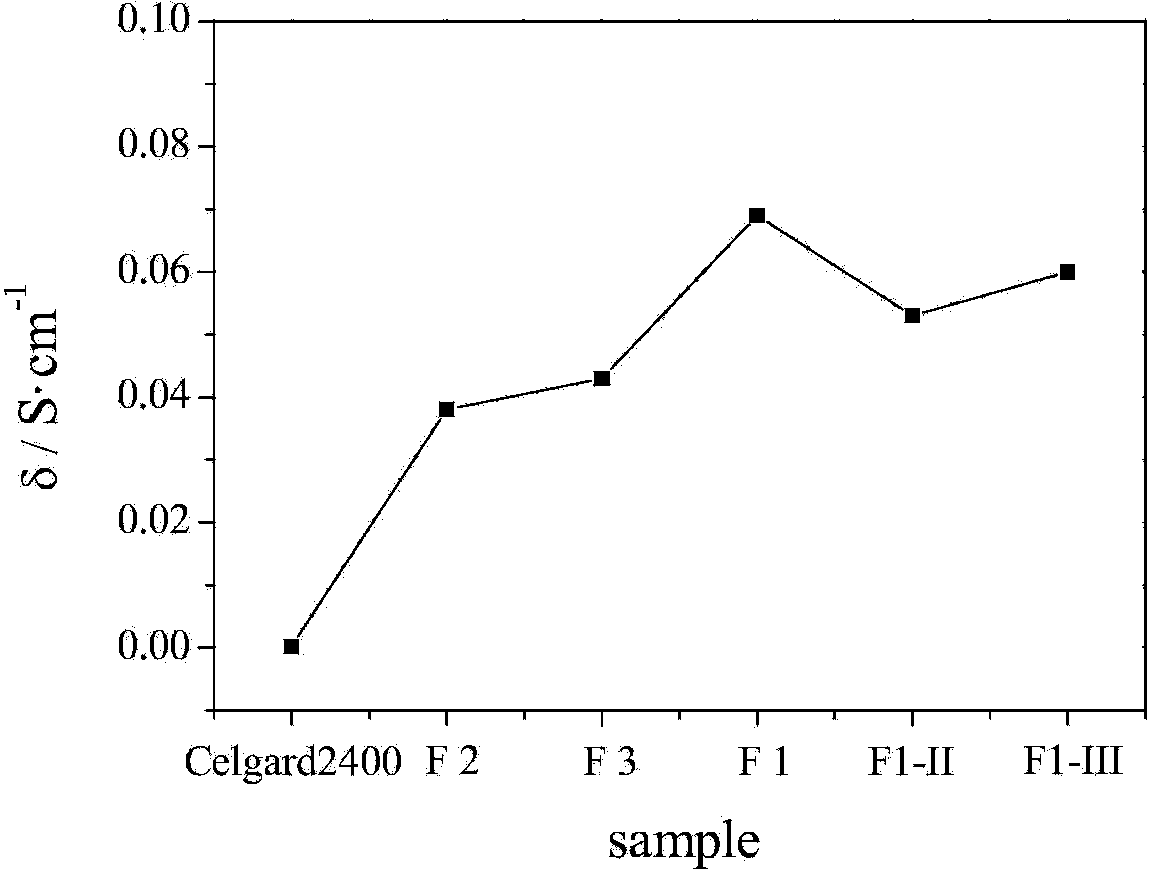

Composite lithium battery diaphragm and preparation method thereof

ActiveCN104183806AImprove interface propertiesHigh conductivity at room temperatureCell seperators/membranes/diaphragms/spacersCoatingsPolypropylene compositesRoom temperature

The invention relates to the technical field of lithium battery diaphragms, and in particular relates to a composite lithium battery diaphragm and a preparation method of the composite lithium battery diaphragm. The composite lithium battery diaphragm comprises a polypropylene base body diaphragm, wherein composite coatings are sprayed on the two surfaces of the polypropylene base body diaphragm, and the composite coating is sol-like mixed solution formed by polymer and sulfonated polyimide, dissolved in solvent proportionally. The preparation method comprises the following steps: firstly, dissolving polymer and sulfonated polyimide in the solvent proportionally to form the sol-like mixed solution; secondly, coating the two surfaces of the polypropylene base body diaphragm by the mixed solution in the step I; and thirdly, drying the polypropylene base body diaphragm coated by the mixed solution in a vacuum drying oven to obtain the polypropylene composite diaphragm finally. The prepared composite diaphragm can improve the room-temperature conductivity, can greatly improve the interfacial property of the anode material and the diaphragm and Li and the diaphragm, and has good cycle performance after being assembled into the battery.

Owner:JIANGSU ANREDA NEW MATERIAL

Colloidal polymer electrolyte for lithium ion cell and its preparing method

InactiveCN1554698AHigh conductivity at room temperatureImprove mechanical propertiesSecondary cell detailsPolymer electrolytesLithium

The colloidal polymer electrolyte system consists of acrylate monomer and its derivative 100 (in weight portions, the same below) including that with functional group 0.4-10; electrolyte liquid 300-1900; initiator 0.2-4 and crosslinking agent 0-5. One of preparation process incldues mixing the components, liquid state filling, polymerizing in the cell chamber to form colloidal polymer electrolyte. The other preparation process includes polymerizing acrylate monomer and its derivative, dissolving the polymer in electrolyte liquid, adding crosslinking agent to mix homogeneously, filling into cell chamber and crosslinking inside the cell chamber to form colloidal polymer electrolyte. The present invention is easy to operate and high in safety, and the prepared electrolyte has excellent comprehensive performance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

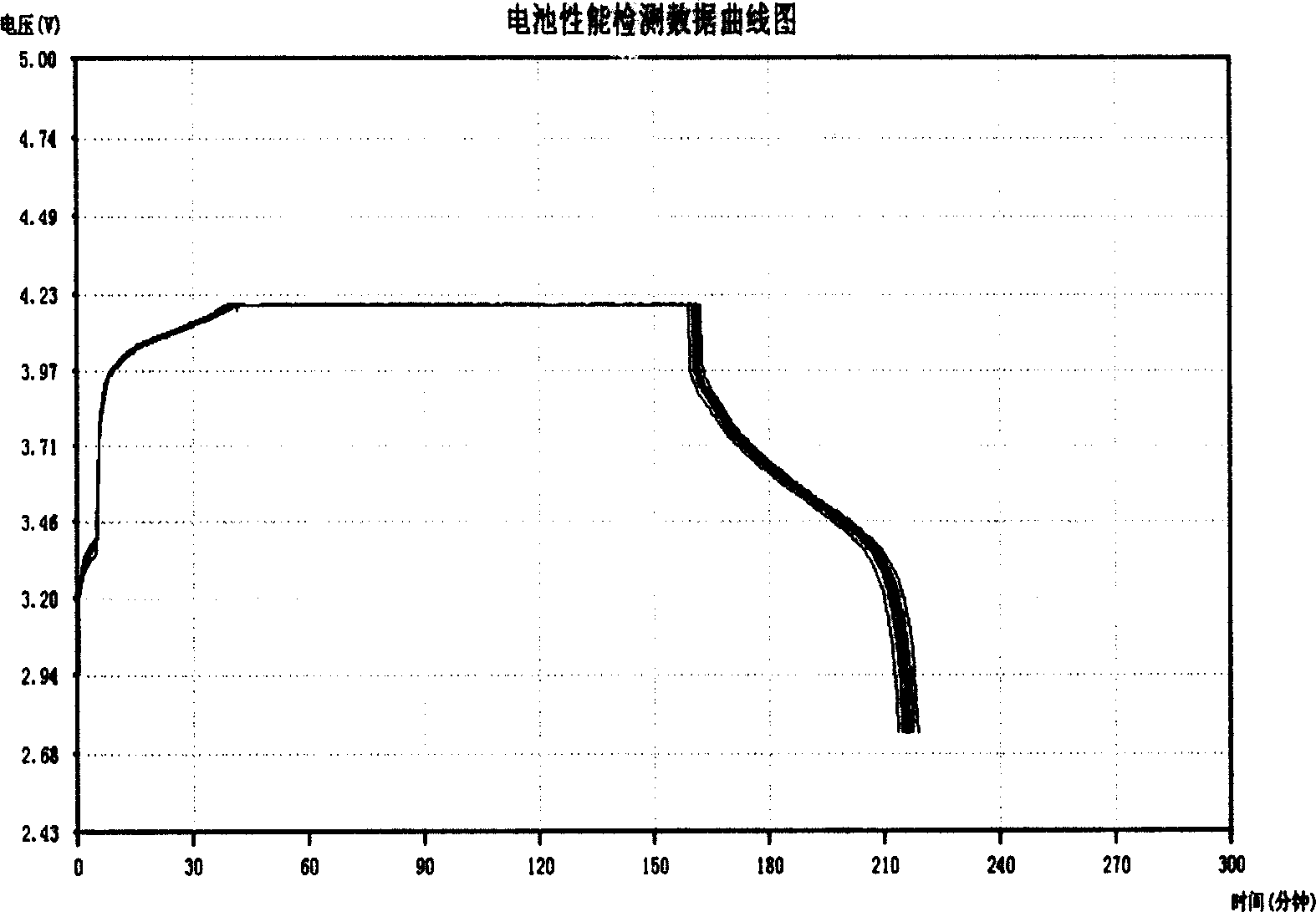

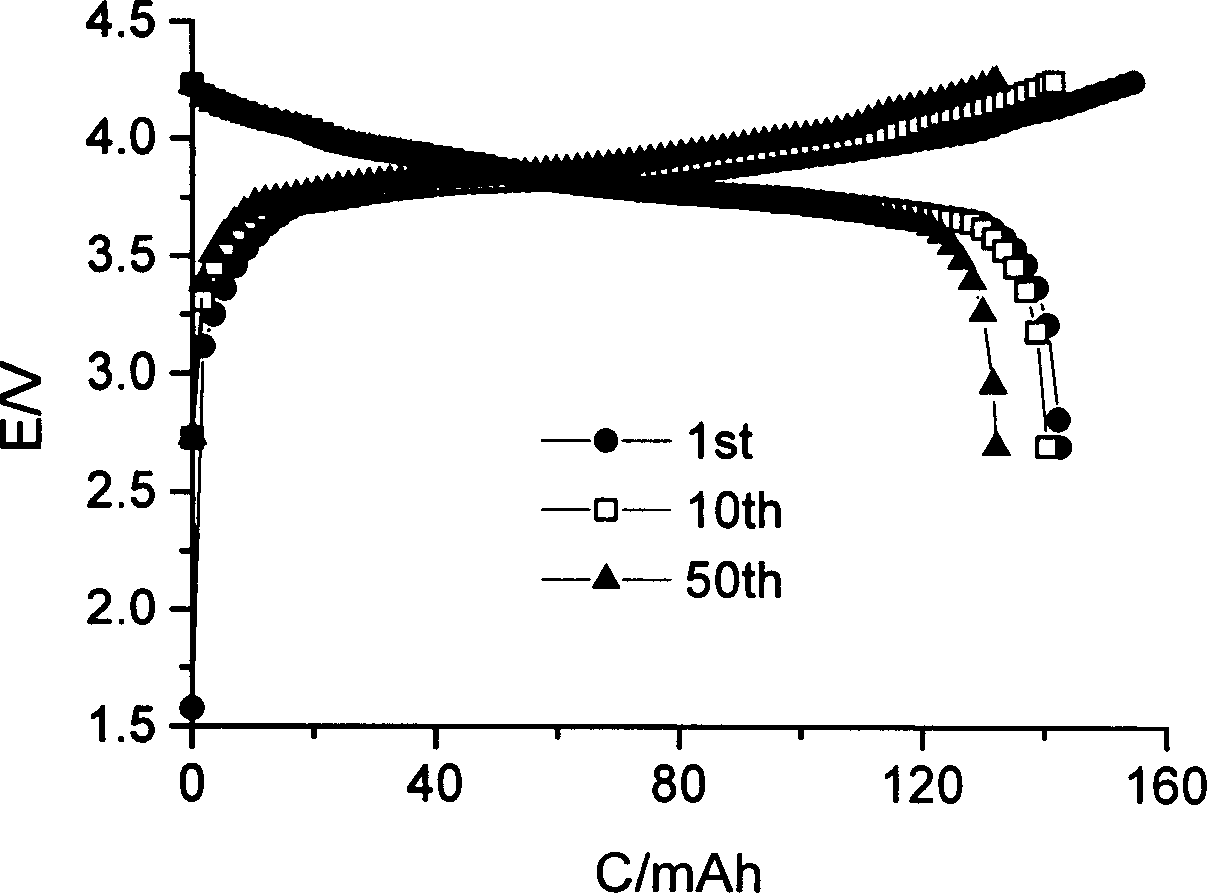

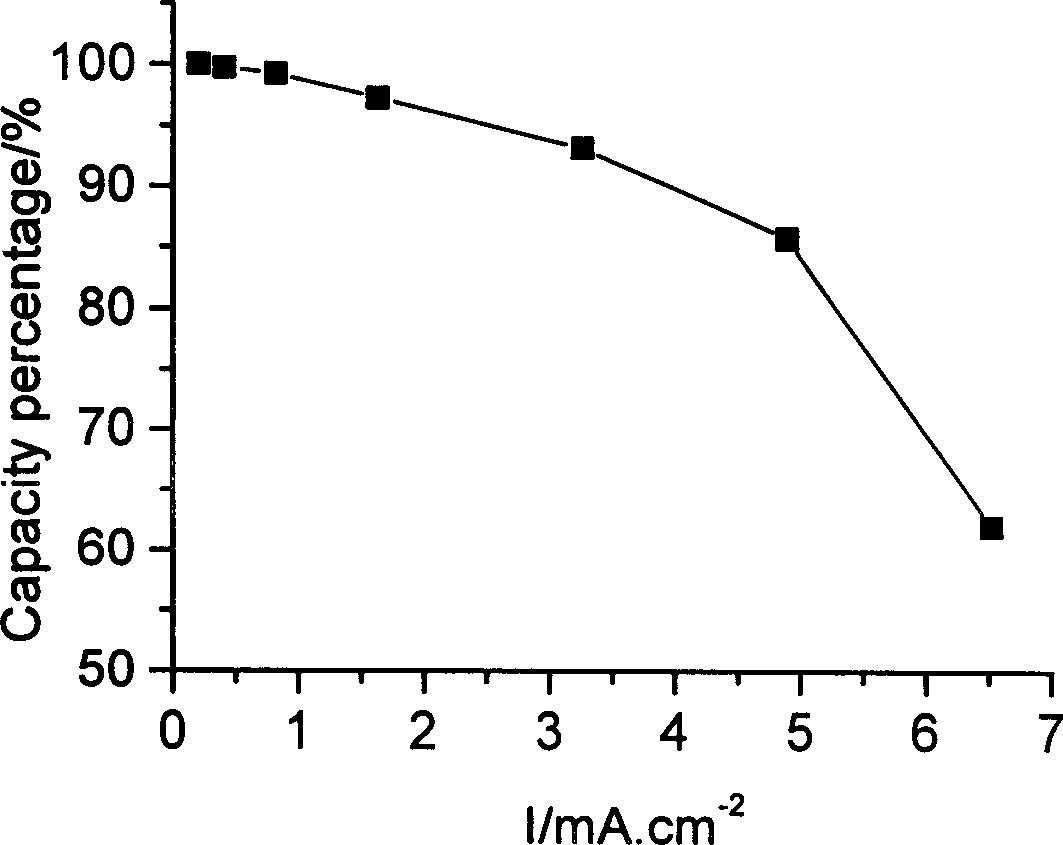

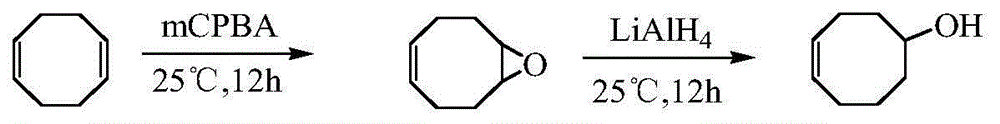

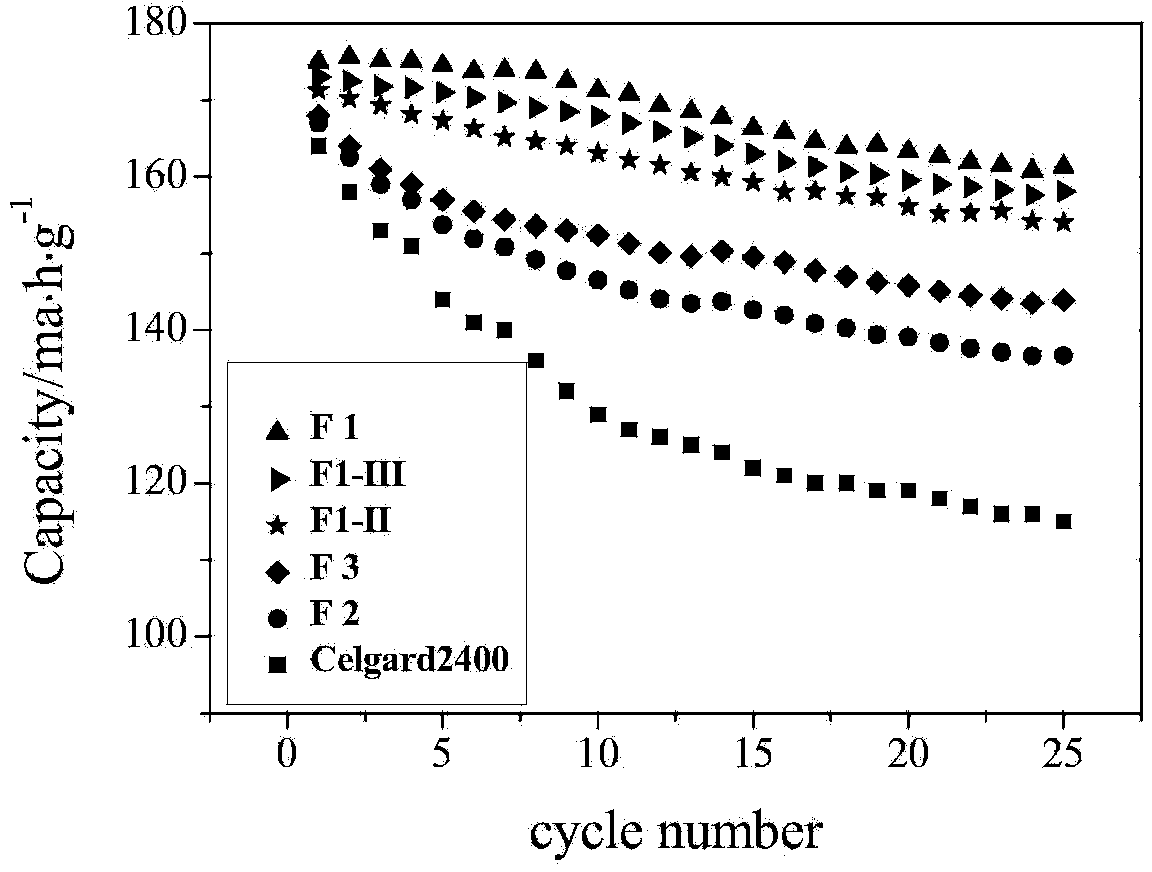

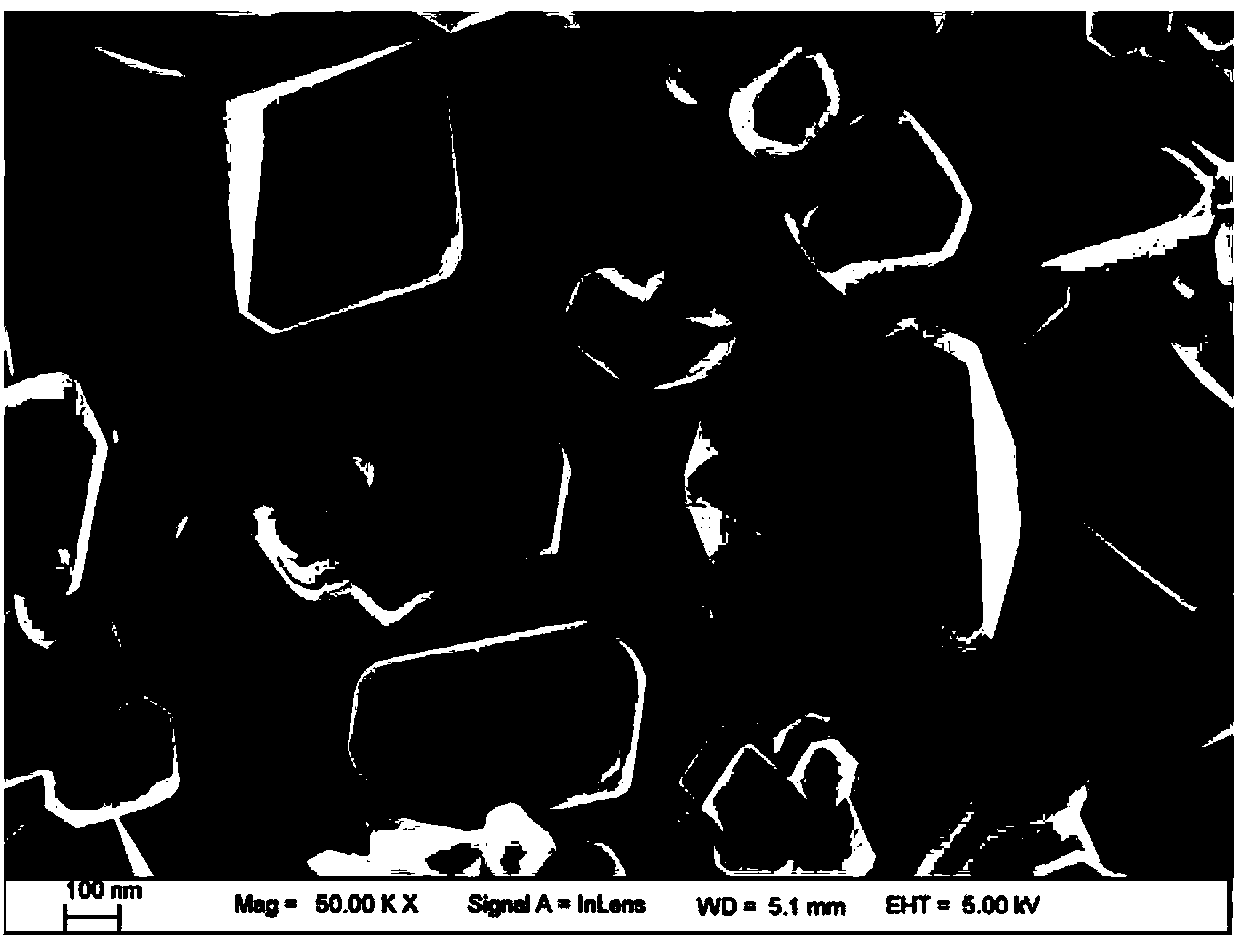

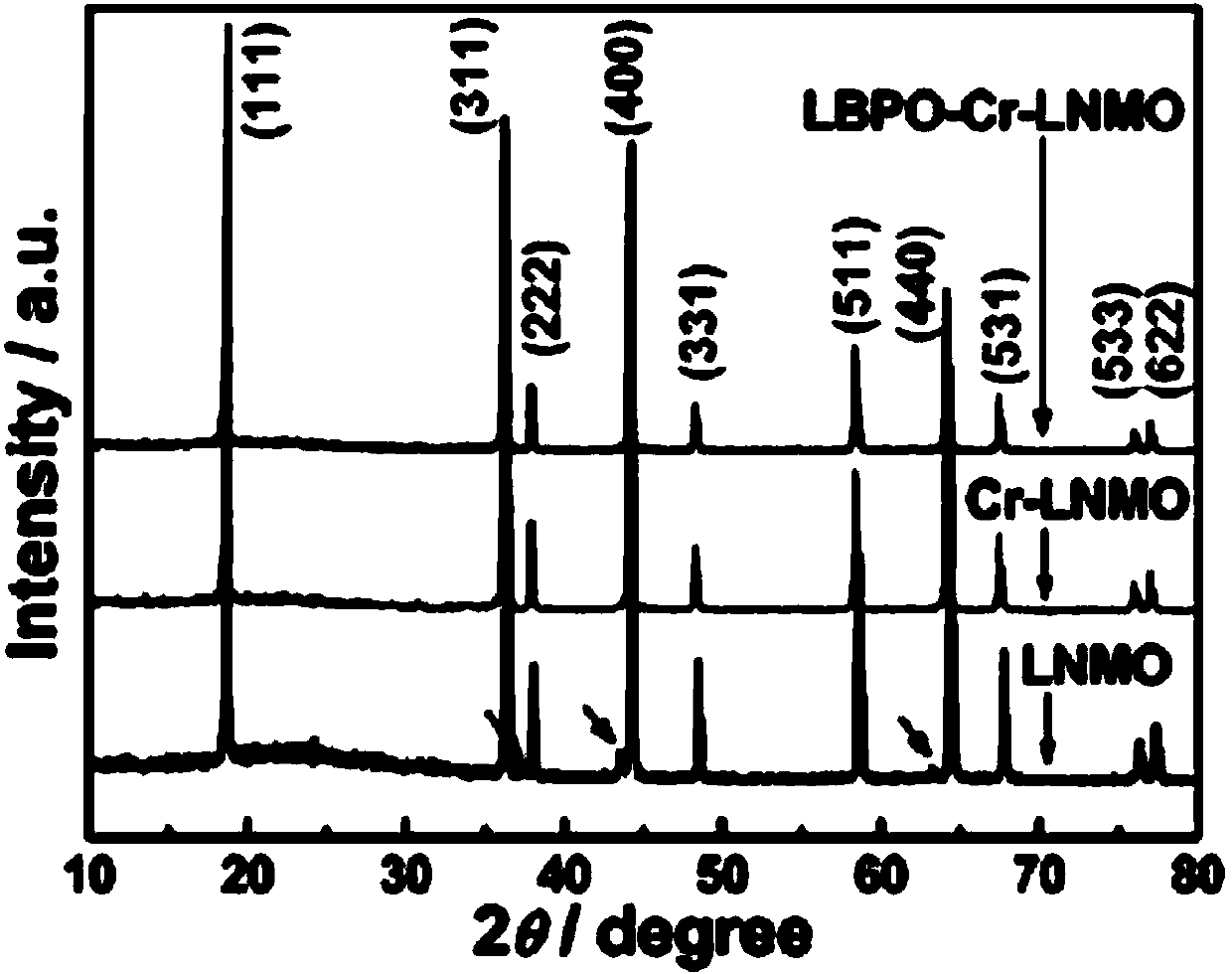

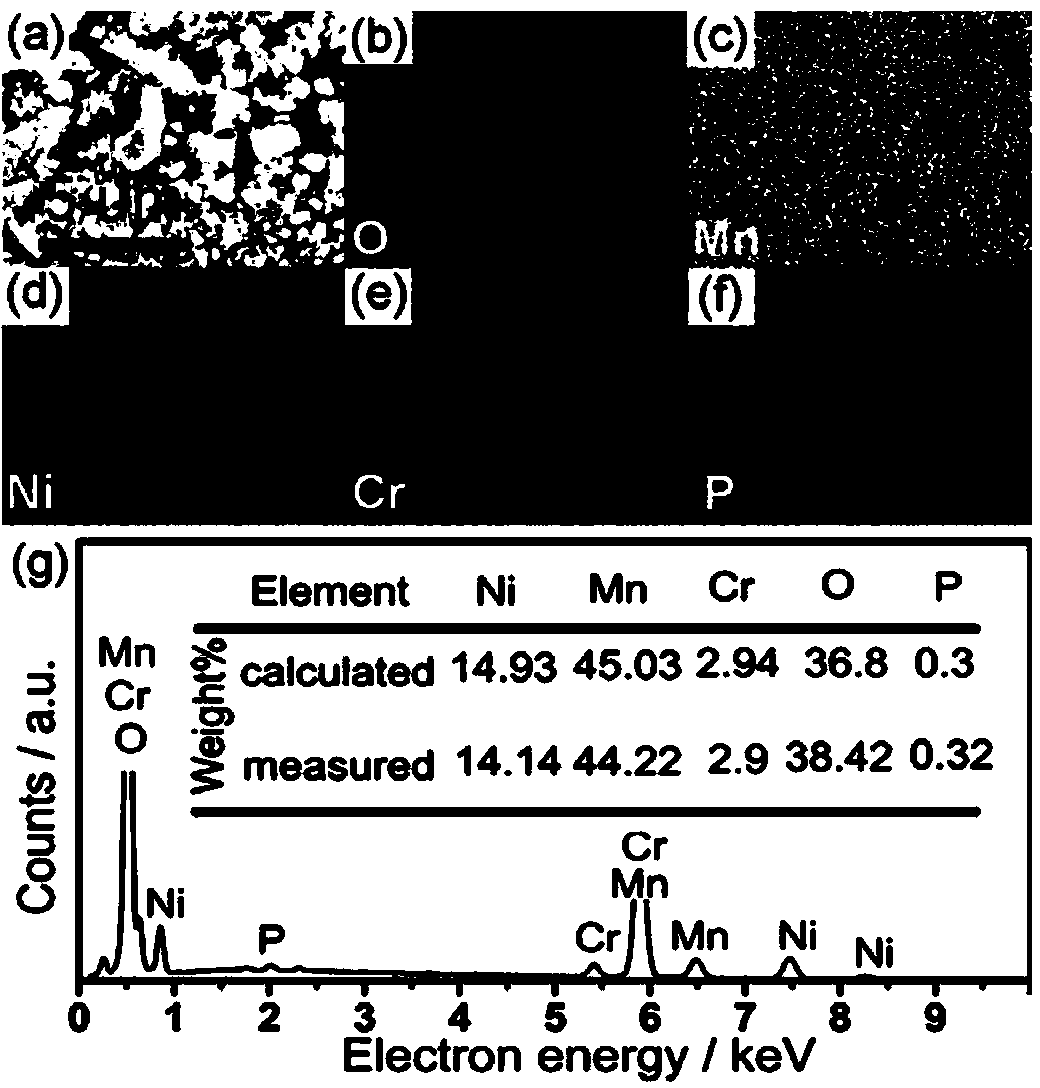

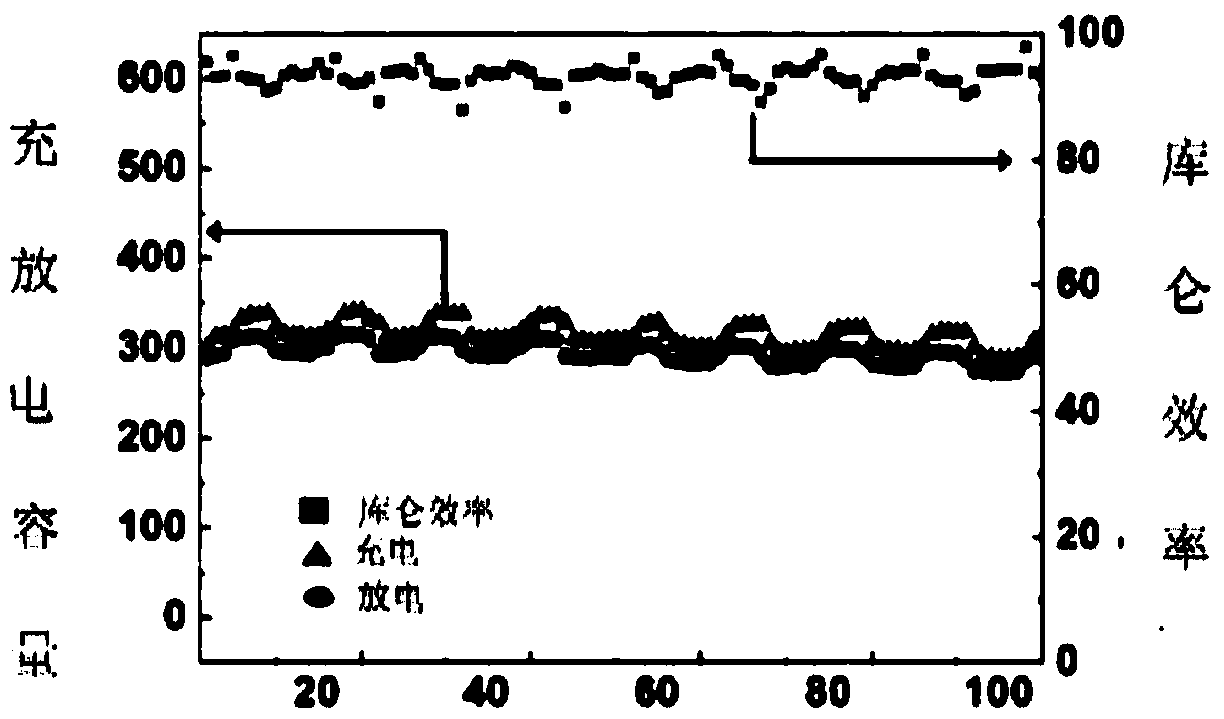

Method for improving performance of electrode material LNMO

ActiveCN103996842AImprove conductivityImprove high current performanceCell electrodesSecondary cellsLithium compoundChromium doping

The invention belongs to the field of an electrode material for a chemical power supply, and particularly relates to a method for improving the performance of a high-voltage electrode material LiNi0.5Mn1.5O4. The method comprises the steps: uniformly mixing a lithium compound, a boron compound and a phosphorus compound to obtain a mixture, uniformly mixing the mixture with LiNi0.5Mn1.5O4 electrode material or chromium-doped LiNi0.5Mn1.5O4 electrode material, sintering the mixture at a high temperature to obtain a LiNi0.5Mn1.5O4 electrode material with surface being coated with Li0.1B0.967PO4. The surface of LNMO is coated with a layer of LBPO, so that not only can the large-current performance be improved, but also the cycling performance can be improved.

Owner:山东鲁顺宏泰新能源科技有限公司

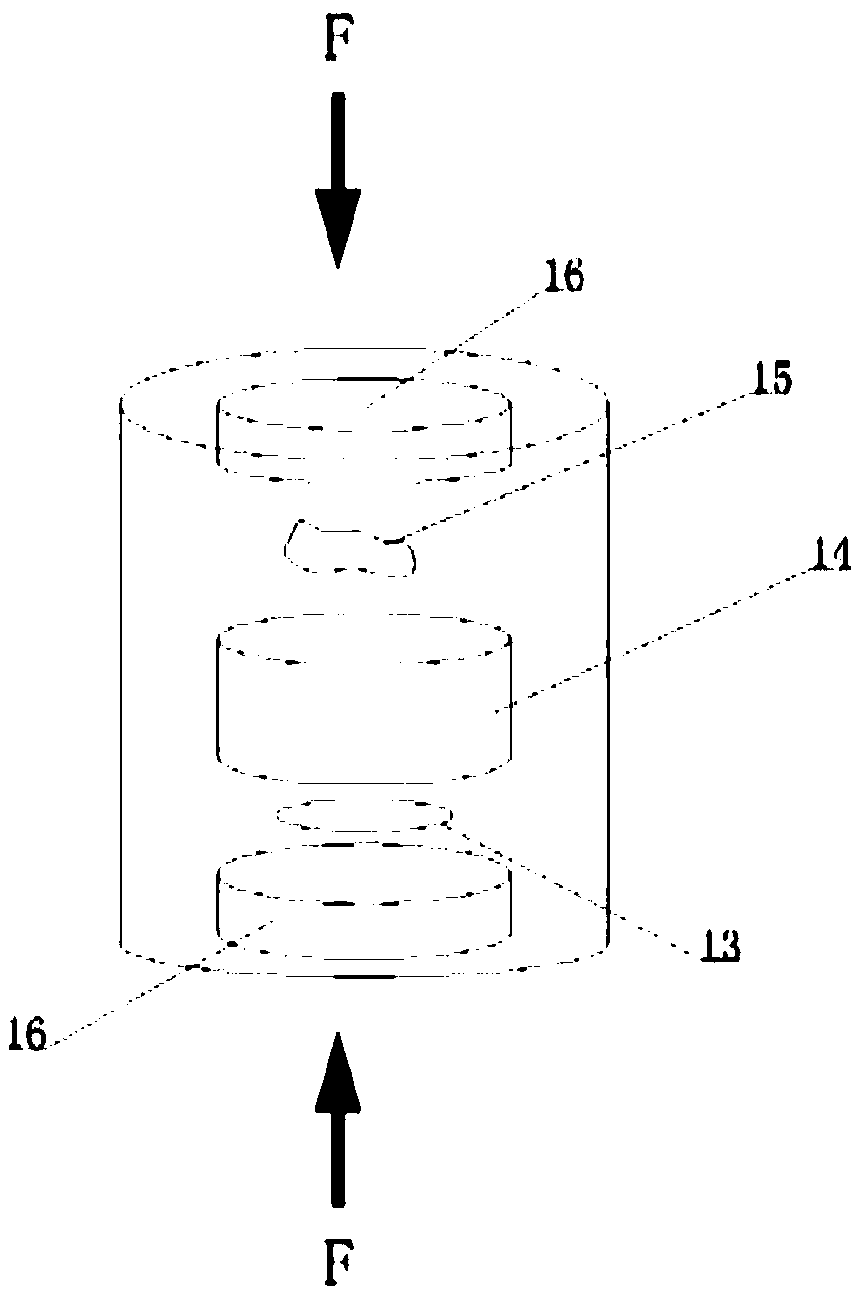

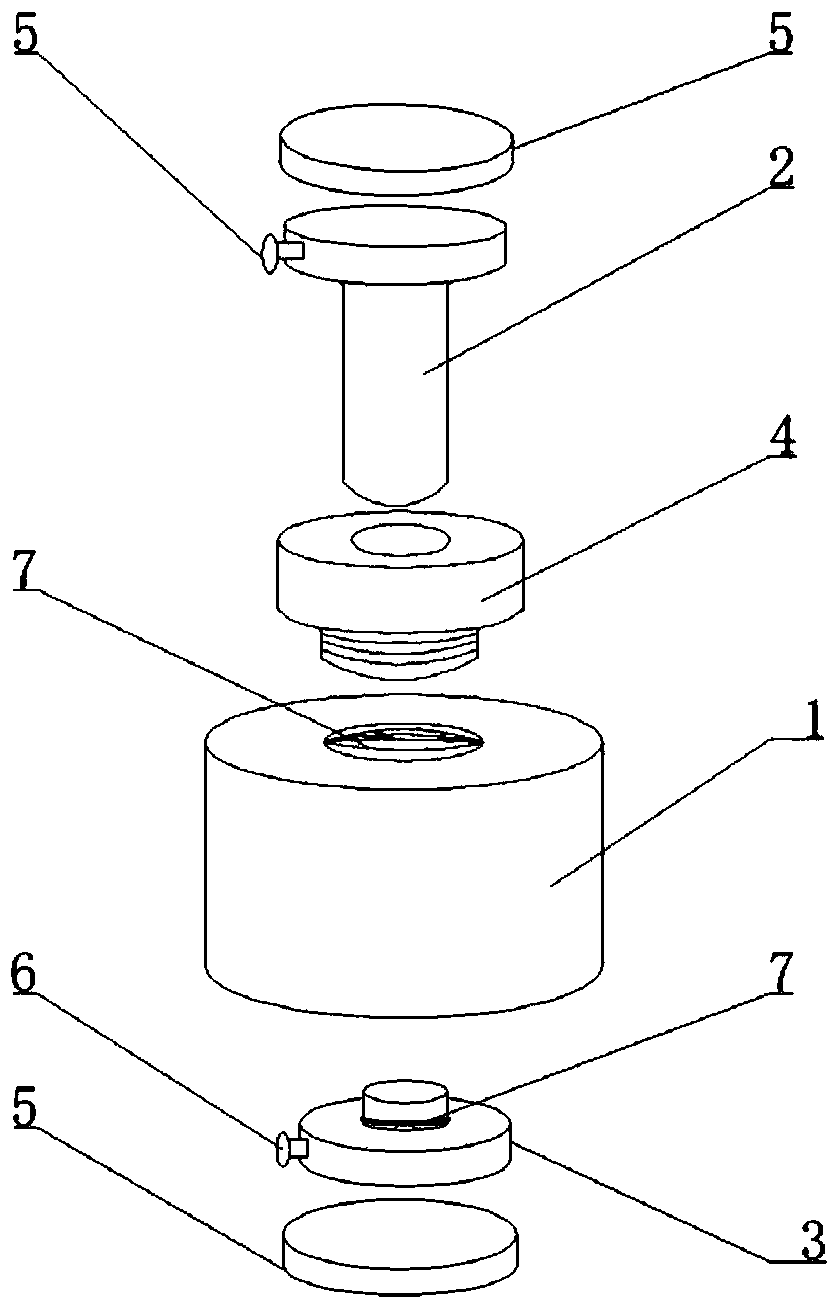

Preparation method and preparation mold of all-solid lithium-sulfur battery

ActiveCN109638360AHigh conductivity at room temperatureReduce manufacturing costCell electrodesFinal product manufactureSolid state electrolyteHigh energy

The invention discloses a preparation method and a preparation mold of an all-solid lithium-sulfur battery. The method of the invention includes the following steps: step a, preparing a solid electrolyte: carrying out high-energy ball milling, high-pressure tabletting and high-temperature sintering on Li2S, P2S5, nano silicon and LiF to prepare a sulfide glass ceramic solid electrolyte; step b, preparing a positive electrode material: carrying out high-temperature heat treatment and multiple times of high-energy ball milling processes on S, active substances and the solid electrolyte preparedin the step a to prepare the positive electrode material; step c, preparing a negative electrode material: carrying out surface treatment on metal lithium sheets to prepare the negative electrode material; and step d, placing the prepared positive electrode material, solid electrolyte and negative electrode material into an all-solid lithium-sulfur battery mold, and adopting a lamination method toprepare the all-solid lithium-sulfur battery. According to the scheme of the invention, the solid electrolyte is used to replace an electrolyte solution, so that a lithium-ion battery is safer, and the solid electrolyte has a good inhibition effect on lithium dendrites, and can also inhibit the shuttle effect and the dissolution of the active substances.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

All-solid composite polymer electrolyte and preparation method thereof, and lithium ion battery

InactiveCN110429344AHigh conductivity at room temperatureImproved interface contactFinal product manufactureElectrolyte accumulators manufacturePolymer scienceSolvent

The invention discloses an all-solid composite polymer electrolyte and a preparation method thereof, and a lithium ion battery. The method comprises the following steps of: S1, preparing a polymer matrix membrane by adopting a phase inversion method, wherein the polymer matrix membrane has a plurality of closely arranged vertical through holes; S2, gradually adding inorganic powder, lithium salt,a second polymer and an appropriate amount of auxiliary agent into a solvent for uniform stirring in an argon-filled glove box to obtain a polymer electrolyte, then, performing scrap coating of the polymer electrolyte in an environment controlled in moisture and oxygen to form a film, performing standing at room temperature to perform vacuum drying to obtain a polymer electrolyte film; and S3, putting the polymer electrolyte film prepared in the S2 at the upper portion of the polymer matrix membrane in the S1, performing melting and hot-pressing of the polymer electrolyte in a vacuum oven at atemperature of 100-350 DEG C into the vertical holes of the polymer matrix membrane. The all-solid composite polymer electrolyte is high in room-temperature conductivity and good in interface contact, has a high modulus and a high voltage window and is simple to prepare and low in cost.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Organic-inorganic composite electrolyte, preparation method thereof, and application in solid lithium ion secondary battery

ActiveCN109301316ANon stickyIncrease stickinessSolid electrolytesSecondary cellsComposite electrolyteOrganic solvent

An organic-inorganic composite electrolyte is disclosed and is composed of a medium-temperature viscoelastic-transformable polymer, lithium salt, and a fast ion conductor ceramic powder, wherein the medium-temperature viscoelastic-transformable polymer includes a hard monomer, a soft monomer containing ethoxyl group, an initiator, and an organic solvent. The organic and inorganic phases of the composite electrolyte film both have ion-conductivity, thus increasing room-temperature conductivity. The organic-inorganic composite electrolyte film has no viscosity at room temperature, so that the film is easy to reel and be composited with an electrode plate in a multilayer manner. The organic-inorganic composite electrolyte is suitable for industrial production.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

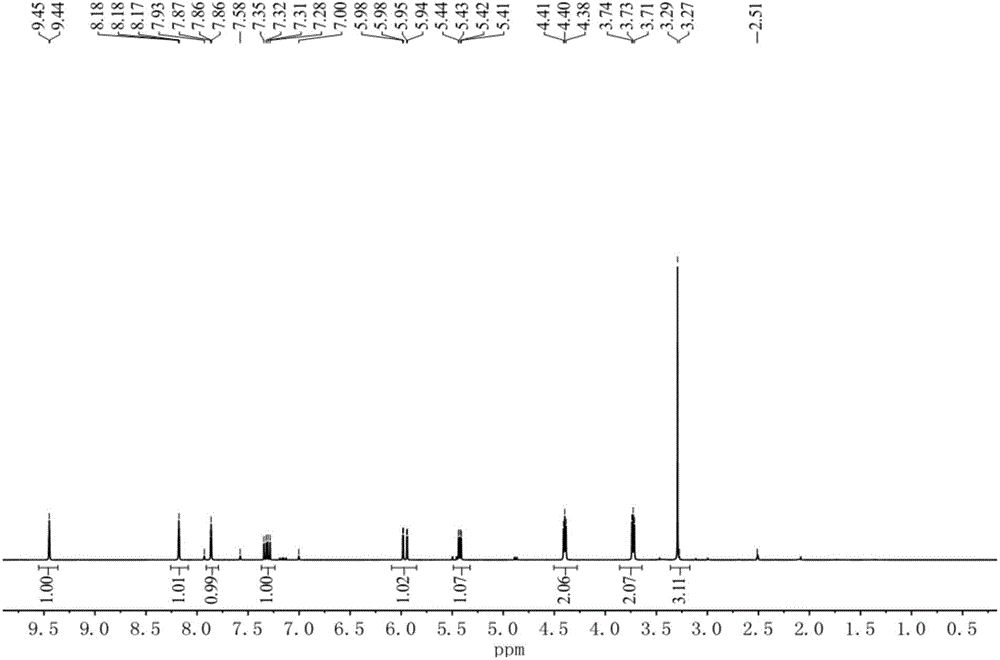

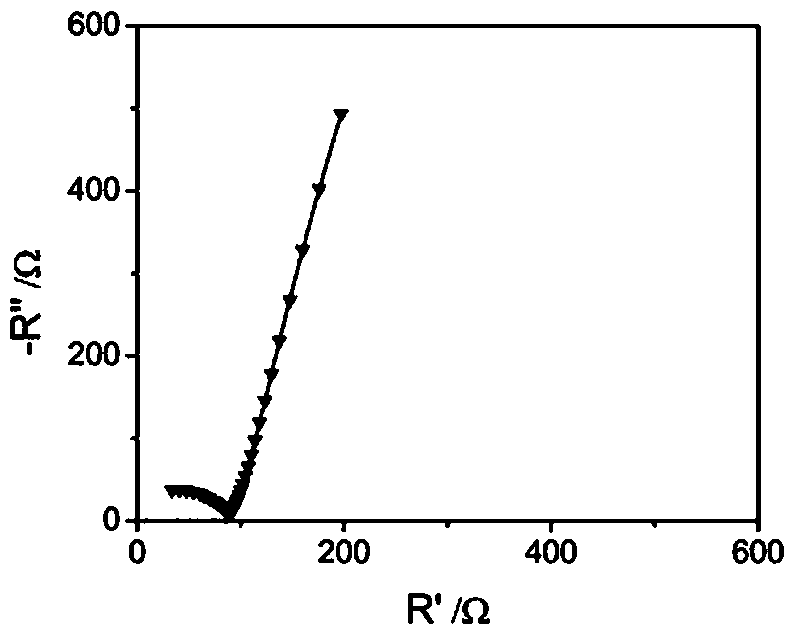

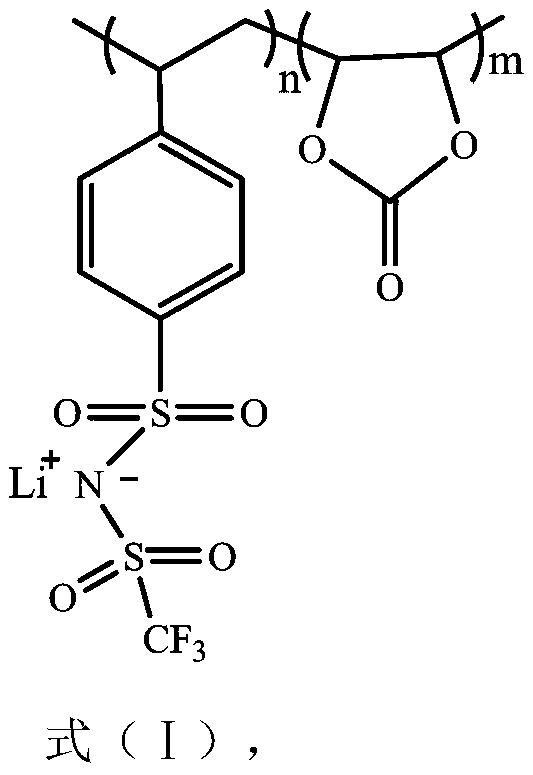

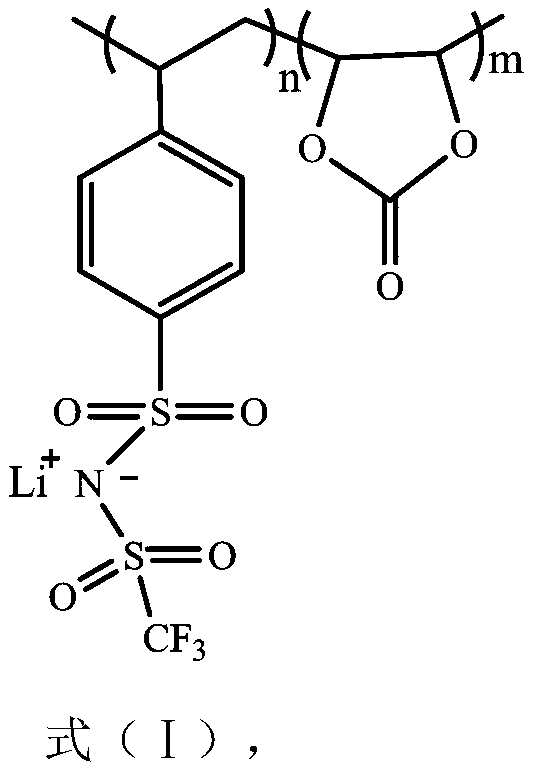

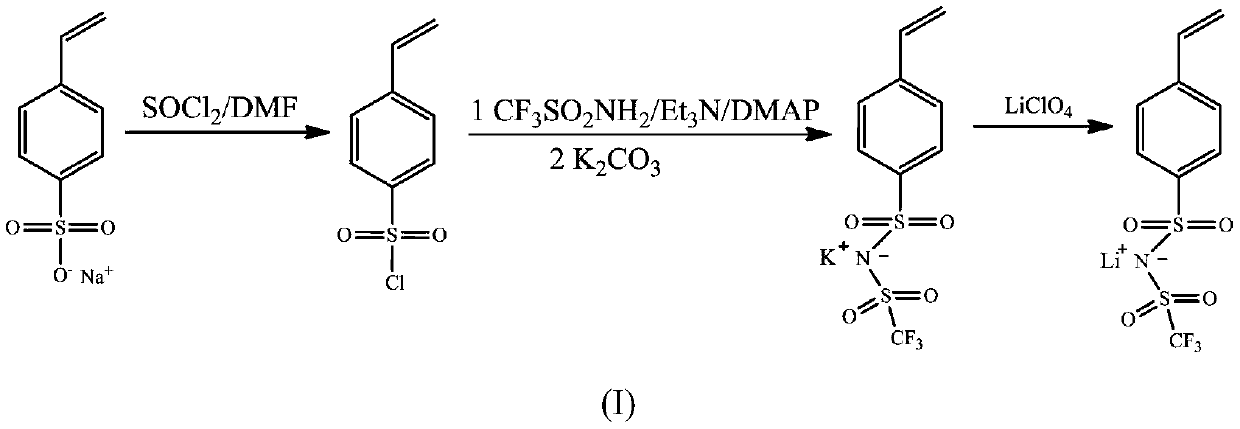

Polyp-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide-polyvinylidene carbonate copolymer and application thereof

The invention belongs to the technical field of polymer synthesis and discloses a polyp-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide-polyvinylidene carbonate copolymer and application thereof. The copolymer is synthesized by the following steps: adding a p-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide monomer, a vinylidene carbonate monomer and a catalyst into a solvent I andperforming polymerization reaction at 70 to 100 DEG C, wherein the p-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide monomer is prepared by the steps of performing reaction on sodium p-styrenesulfonate and sulfoxide chloride in a solvent at -10 to 25 DEG C, adding an acid-binding agent, an activating agent and trifluoromethyl sulfonamide and performing reaction at -10 to 25 DEG C; addingpotassium carbonate and performing reaction at 25 to 70 DEG C; and adding lithium perchlorate and performing reaction at 25 to 60 DEG C. The copolymer provided by the invention has high lithium ion migration number and room-temperature conductivity, is simple in preparation method, can realize large-scale production and can serve as lithium ion battery electrolyte.

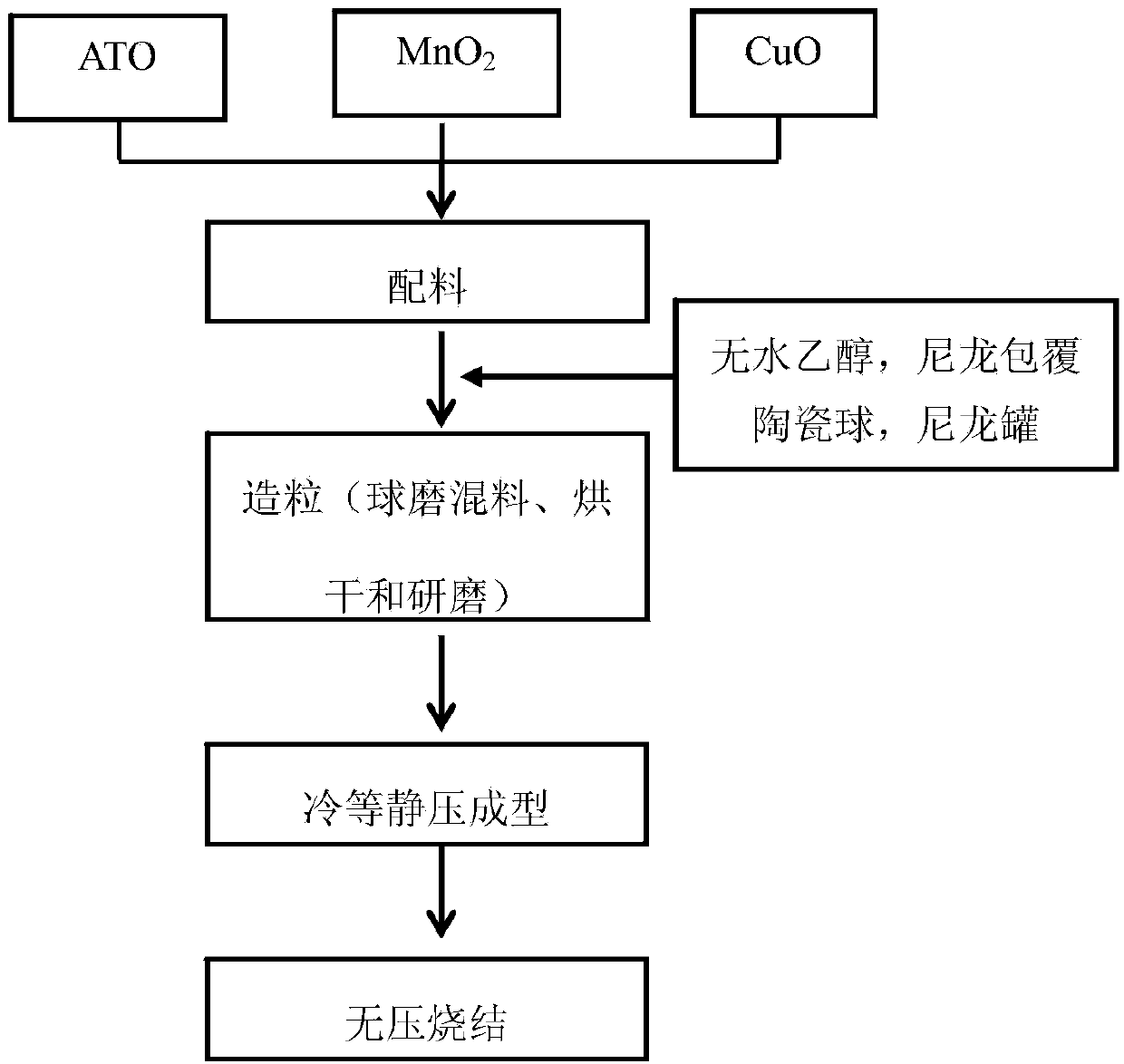

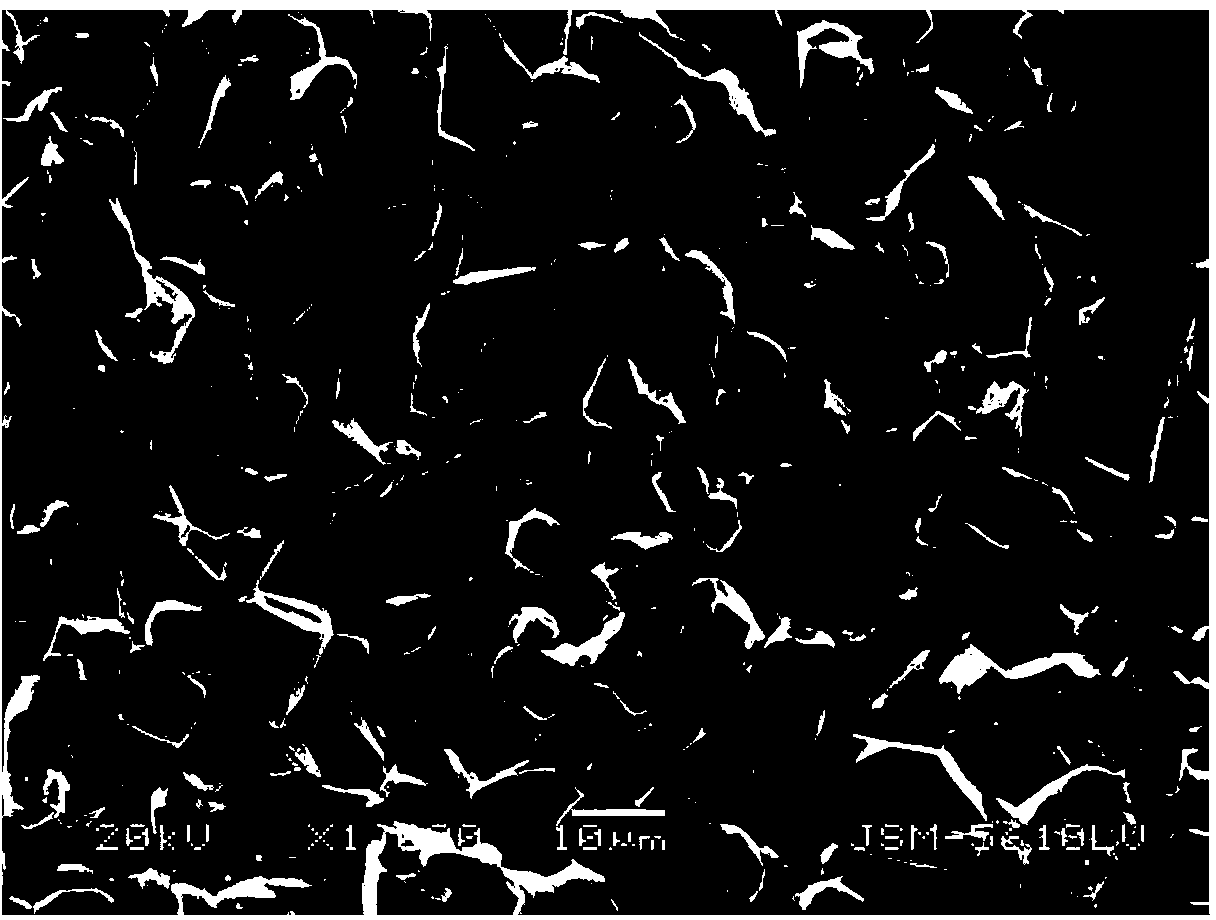

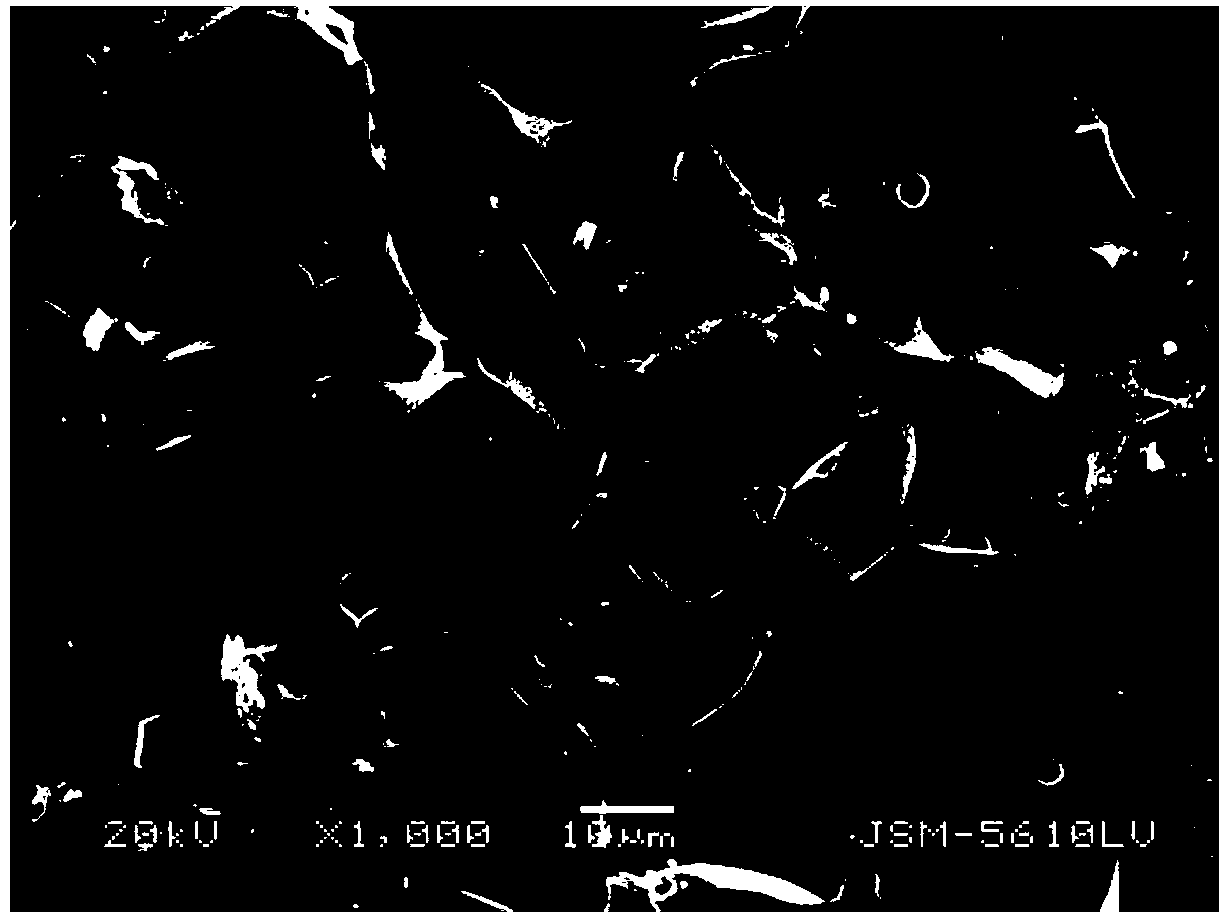

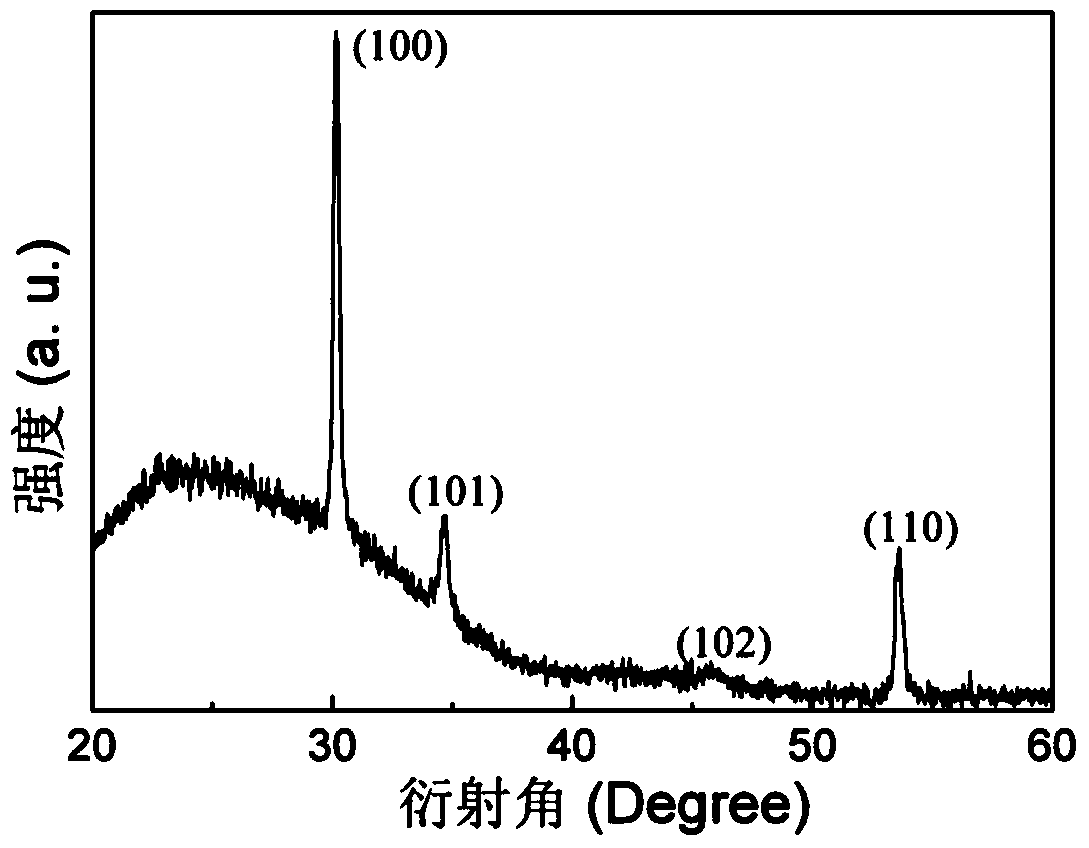

Preparation method of trace element composite doping modified tin antimony oxide (ATO) ceramic target

The invention provides a preparation method of a trace element composite doping modified tin antimony oxide (ATO) ceramic target. The preparation method is characterized by firstly weighing ATO powder with antimony oxide mass percentage of 0.1-1.0% and then respectively weighing manganese oxide and copper oxide powder to serve as composite doping modifying agents according to 0.5-1.0% of the total mass of the ATO powder; ball-milling the powder together with an organic solvent and mixing balls in a mass ratio of (1:1:1)-(1:2:1), putting the obtained slurry into a baking oven to be baked at low temperature until organic solvent evaporation is completed, then grinding the product and sieving the product with an open sieve to obtain mixed powder; after the mixed powder is subjected to intercooling and isostatic pressing in a die, sintering the green body in the air atmosphere by adopting the mode of pressureless sintering, thus obtaining the ceramic target, wherein the heating rate is 0.5-5 DEG C / min, the sintering temperature is 1200-1450 DEG C and the insulating time is 1-10 hours. The obtained modified ATO ceramic target has the advantages of relatively small composite doping amount, high compactness, relatively high normal temperature electrical conductivity and the like.

Owner:WUHAN UNIV OF TECH

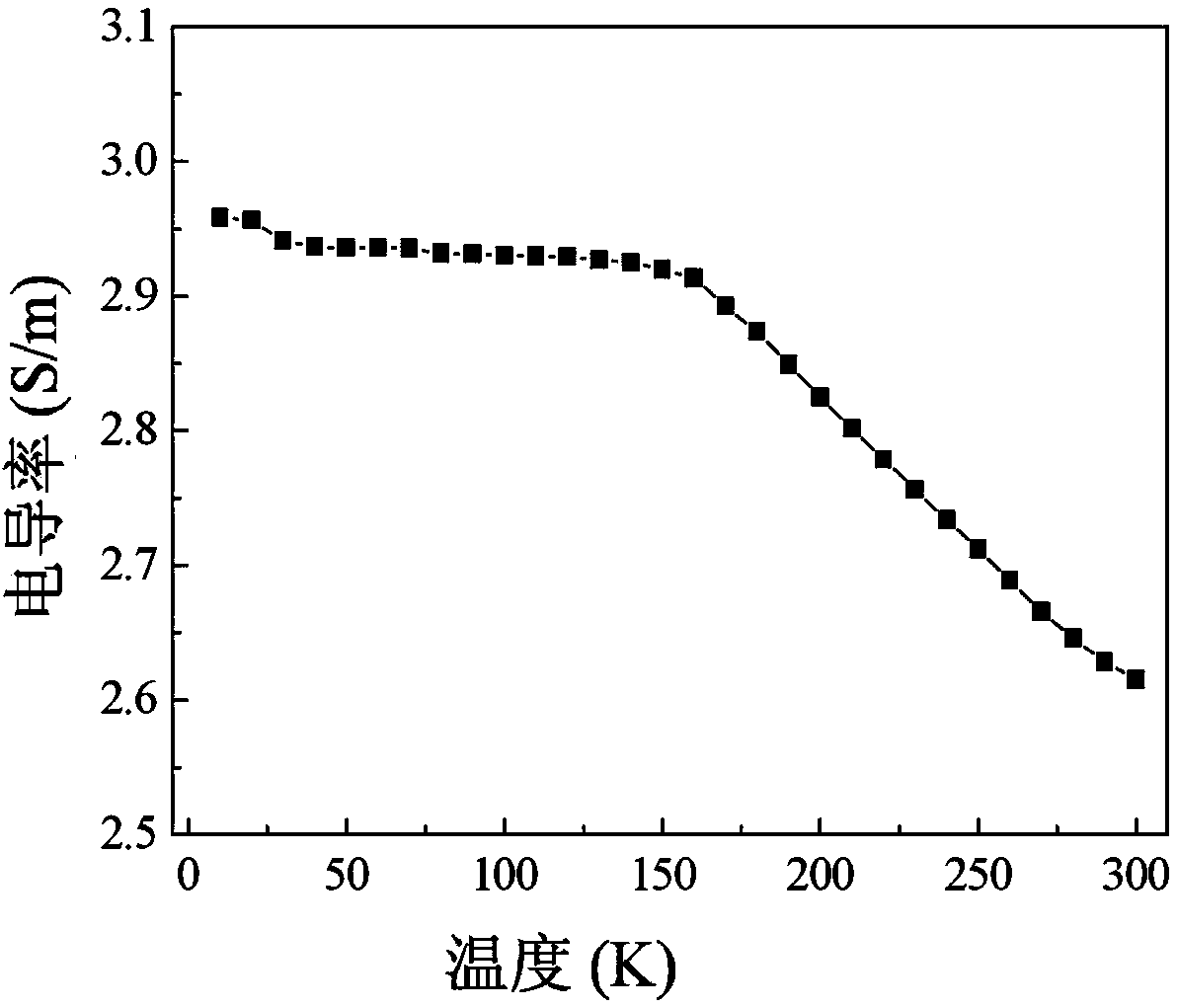

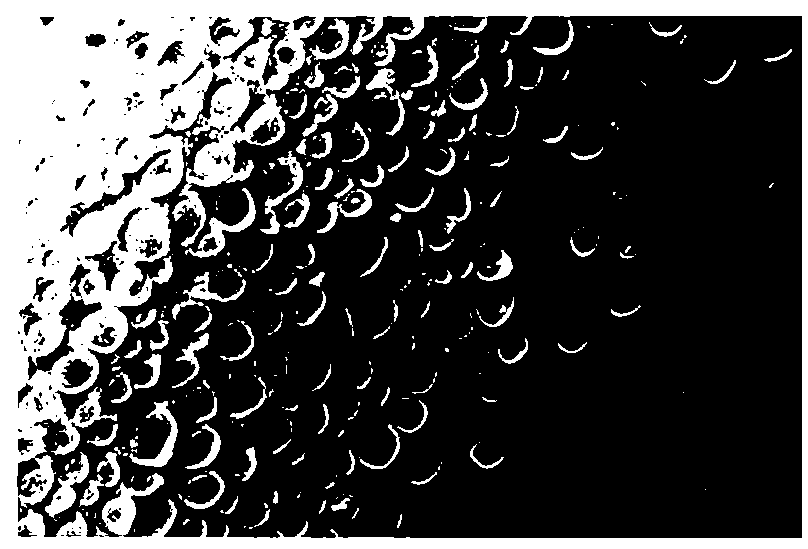

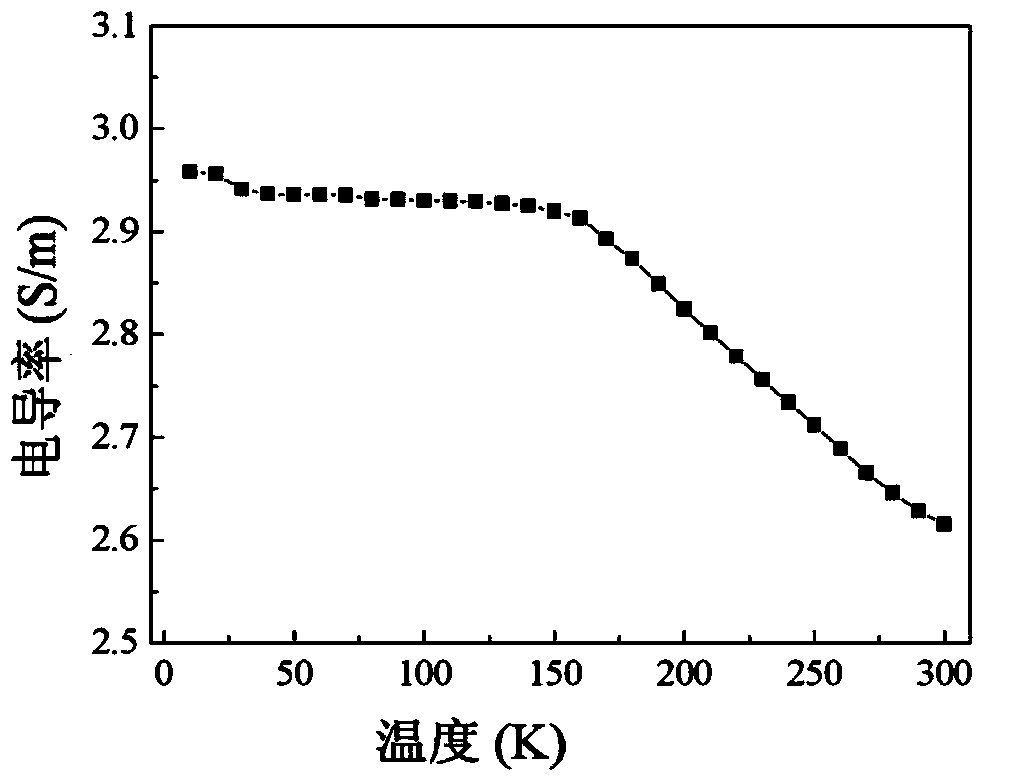

Method for directly synthesizing high conductivity nickel sulfide two-dimension nanosheet array in large scale

ActiveCN103466726AHomogeneous nanostructureHigh conductivity at room temperatureMaterial nanotechnologyNickel sulfidesNickel sulfideRepeatability

The invention discloses a method for directly synthesizing a high conductivity nickel sulfide two-dimension nanosheet array in large scale. The method comprises the first step of synthesizing a xanthogenic acid nickel precursor, and the second step of preparing the nickel sulfide two-dimension nanosheet array, wherein the xanthogenic acid nickel precursor powder is placed into a heating device to be heated to reach the temperature ranging from 160 DEG C to 360 DEG C, the heat preservation is carried out on the xanthogenic acid nickel precursor powder for 10-300 mintues, and then the nickel sulfide two-dimension nanosheet array can be generated on a substrate near the xanthogenic acid nickel precursor. The technological process is simple, parameters are obtained easily and controllably, the repeatability is good, and large-scale industrial production can be achieved. The data result is detailed and accurate, so that the feasibility of the method is fully proven. By means of the technology, the problem that the multi-step processing procedures are commonly complex or the technology period is long or high vacuum equipment is high in cost can be avoided, and an extremely potential candidate scheme is provided for the low-cost and large-scale application of the high conductivity nickel sulfide two-dimension nanosheet array.

Owner:山东百帝气动科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com