Composite electrolyte membrane, preparation method thereof and all solid-state lithium battery having same

A composite electrolyte membrane and lithium salt technology, applied in the field of lithium batteries, can solve the problems of complex preparation methods, difficult processing, and low room temperature conductivity, and achieve high room temperature conductivity, good thermal stability, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

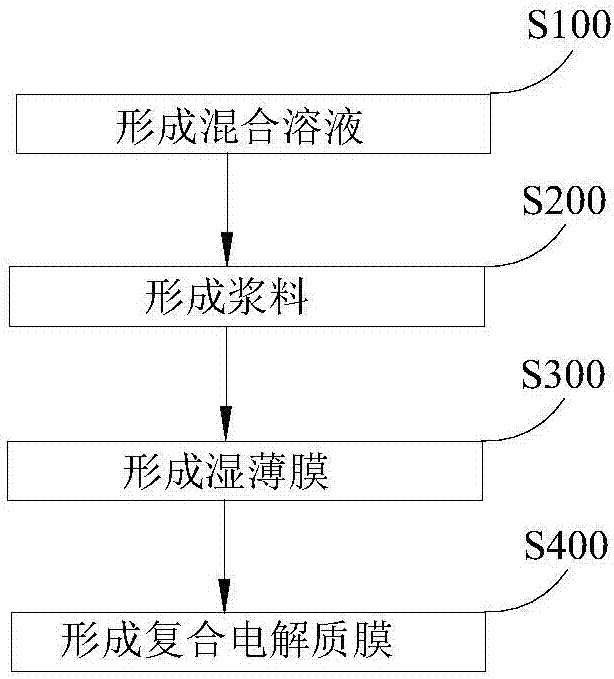

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Preparation of composite electrolyte membrane

[0056] PVDF and LiClO with an average molecular weight of 400,000 4 Dissolved in DMF solvent, stirred for 12h to obtain a mixed solution. Among them, LiClO 4 Accounted for PVDF and LiClO 4 25wt% of the total mass, the concentration of PVDF in the solution is 10wt%. Then, to PVDF and LiClO 4 Li was added to the mixed solution 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , mixed thoroughly to form a slurry. Li 6.75 La 3 Zr 1.75Ta 0.25 o 12 account for Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 10wt% of the total mass of PVDF. Subsequently, the slurry was doctor-bladed onto a glass slide to form a wet film. The wet film was vacuum-dried at 60°C for 24 hours and then taken out to obtain a composite electrolyte membrane.

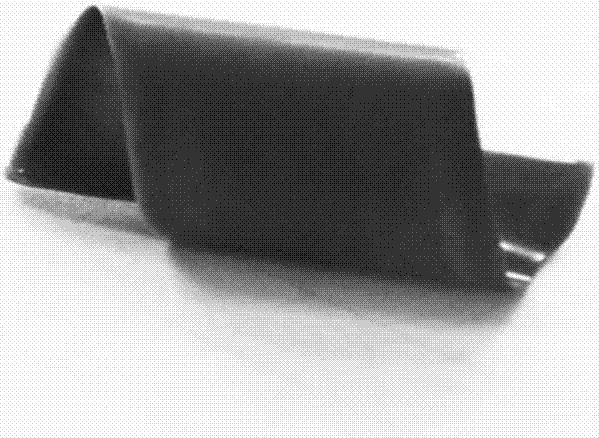

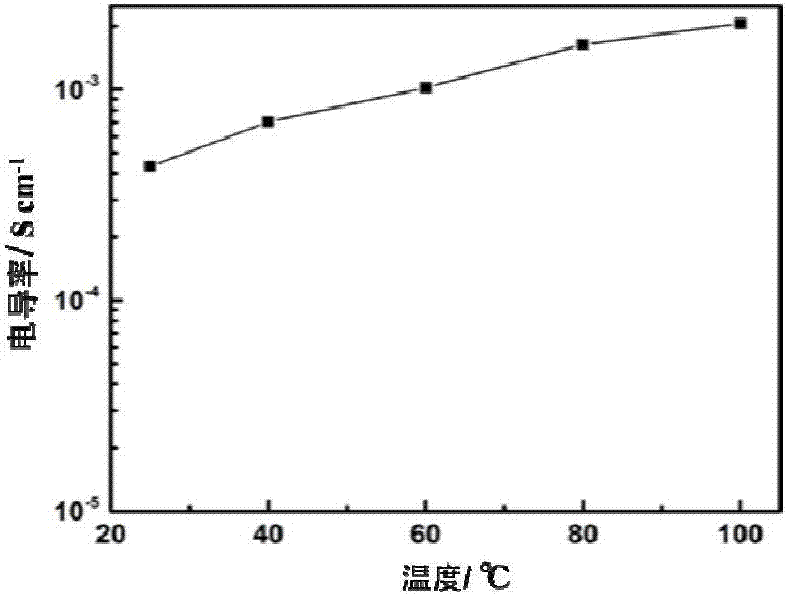

[0057] Such as figure 2 Shown is the physical picture of the composite electrolyte membrane prepared in Example 1. The composite electrolyte membrane has good mechanical properties, easy proce...

Embodiment 2

[0058] Example 2 Preparation of Composite Electrolyte Membrane

[0059] PAN and LiClO with an average molecular weight of 300,000 4 Dissolved in DMF solvent, stirred for 12h to obtain a mixed solution. Among them, LiClO 4 Accounted for PVDF and LiClO 4 25wt% of the total mass, the concentration of PAN in the solution is 10wt%. Then, to PAN and LiClO 4 Li was added to the mixed solution 6.75 La 3 Zr 1.75 Ta 0.25 o 12 , mixed thoroughly to form a slurry. Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 account for Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 20wt% of the total mass of PAN. Subsequently, the slurry was doctor-bladed onto a glass slide to form a wet film. The wet film was vacuum-dried at 60°C for 24 hours and then taken out to obtain a composite electrolyte membrane. The obtained composite electrolyte membrane was heat-pressed at 110 degrees Celsius for half an hour. A composite electrolyte membrane is further obtained.

Embodiment 3

[0060] Embodiment 3: Preparation of composite electrolyte membrane

[0061] PVDF and LiPF with an average molecular weight of 400,000 6 Dissolved in DMF solvent, stirred for 12h to obtain a mixed solution. Among them, LiPF 6 Accounted for PVDF and LiPF 6 25wt% of the total mass, the concentration of PVDF in the solution is 10wt%. Then, to PVDF and LiPF 6 Li was added to the mixed solution 7 La 3 Zr 2 o 12 , mixed thoroughly to form a slurry. Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 account for Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 10wt% of the total mass of PVDF. Subsequently, the slurry was doctor-bladed onto a glass slide to form a wet film. The wet film was vacuum-dried at 60°C for 24 hours and then taken out to obtain a composite electrolyte membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com