All-solid composite polymer electrolyte and preparation method thereof, and lithium ion battery

A polymer and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of strict preparation and use environment, all-solid-state electrolyte with excellent performance, narrow electrochemical stability window, etc., to achieve scale-up production and good ion conductivity , Excellent effect of interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a first aspect, the present invention provides a method for preparing an all-solid composite polymer electrolyte, comprising the following steps:

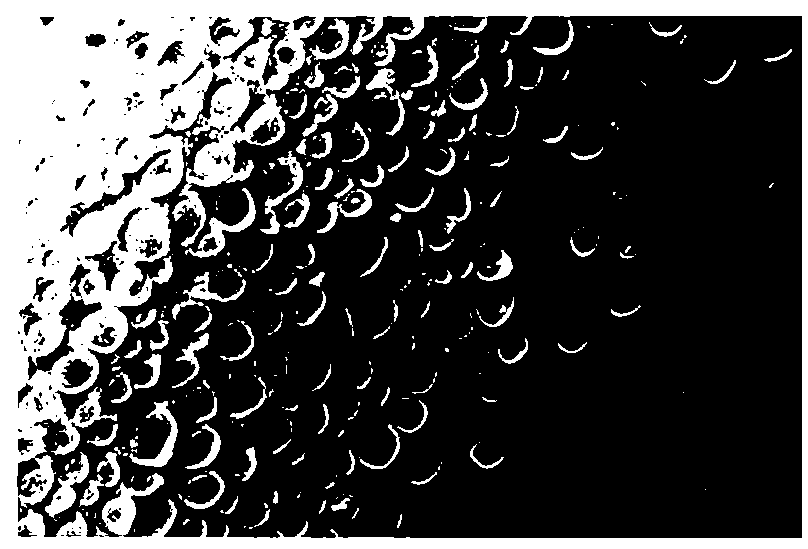

[0038] S1. Preparation of a polymer matrix membrane: After uniformly mixing the first polymer with a solvent, a thin film is formed by a phase inversion method to obtain a polymer matrix membrane with several closely arranged vertical through holes;

[0039] S2. Prepare a thin layer of polymer electrolyte, gradually add inorganic powder, lithium salt, the second polymer and an appropriate amount of additives into the solvent, stir in a glove box filled with argon to form a polymer electrolyte, and then control the moisture, oxygen In a separate environment, scrape-coat the polymer electrolyte to form a film, and then vacuum-dry it after standing at room temperature to obtain a thin polymer electrolyte layer;

[0040] S3. Preparation of composite solid electrolyte by hot-press impregnation: place the polymer electrolyte th...

Embodiment 1

[0066] The preparation method of all-solid-state composite polymer electrolyte, the steps are as follows:

[0067] S1. Prepare a polymer matrix membrane, the polymer matrix membrane has a number of closely arranged vertical through holes; the specific steps are: (1) dissolving polyacrylonitrile (molecular weight: 100,000) in dimethyl sulfoxide, at 60 Stir and mix at ℃ for 3 hours to obtain a uniform and transparent film-forming solution; wherein, the concentration of polyacrylonitrile in the film-forming solution is 5%; (2) scrape-coat the film-forming solution on a glass plate with a thickness of 20 μm; (3 ) Soak the obtained flat film in deionized water for 5 hours, take it out, let it stand at room temperature for 10 hours, transfer it to a refrigerator at 4°C for 24 hours, and then perform freeze-drying treatment for 10 hours to obtain a polymer matrix film;

[0068] S2. Gradually add the inorganic powder LLZTO, lithium bistrifluoromethanesulfonimide, polyethylene oxide (m...

Embodiment 2

[0071] The preparation method of all-solid-state composite polymer electrolyte, the steps are as follows:

[0072] S1. Prepare a polymer matrix membrane, the polymer matrix membrane has a number of closely arranged vertical through holes; the specific steps are: (1) dissolving polyvinylidene fluoride (molecular weight: 50000) in N,N-dimethyl In formamide, stir and mix at 60°C for 3 hours to obtain a uniform and transparent film-forming solution; (2) scrape-coat the film-forming solution on a glass plate with a thickness of 20 μm; (3) place the obtained flat film on a deionized After soaking in water for 5 hours, take it out, let it stand at room temperature for 10 hours, transfer it to a refrigerator at 4°C for 24 hours, and then perform freeze-drying treatment for 10 hours to obtain a polymer matrix film;

[0073] S2. Gradually add inorganic powder silica, lithium hexafluorophosphate, polyvinyl carbonate (molecular weight 100,000) and 5% succinonitrile into acetonitrile solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com