Preparation method and preparation mold of all-solid lithium-sulfur battery

A lithium-sulfur battery, all-solid-state technology, used in lithium batteries, battery electrodes, secondary batteries, etc., can solve problems such as affecting battery discharge capacity, affecting battery reversibility, battery capacity attenuation, etc., to improve rate performance and cycle. performance and rate capability, and the effect of reducing interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing an all-solid-state lithium-sulfur battery, comprising the following steps:

[0032] Step a, preparing solid electrolyte: Put Li2S, P2S5, nano-silicon, and LiF with a mass ratio of 37:28:18:8 into a ball mill jar, for example, weigh 0.37g Li2S, 0.28g P2S5, and 0.18g nano-silicon, Put 0.08g LiF into the ball mill tank, and ball mill at a speed of 510r / min for 24 hours to make an amorphous solid electrolyte intermediate; put the amorphous solid electrolyte intermediate into a metal mold, and powder it under a pressure of 380Mpa Tablet pressing: put the pressed powder into a tube furnace to evacuate and sinter, keep warm at 550°C for 10 hours, and then slowly cool down to room temperature to make a sulfide glass ceramic solid electrolyte; after high-energy ball milling, high-pressure tableting And the high-temperature sintering process prepares the sulfide glass ceramic solid electrolyte-LSIPSF, which reduces the potential difference between the solid...

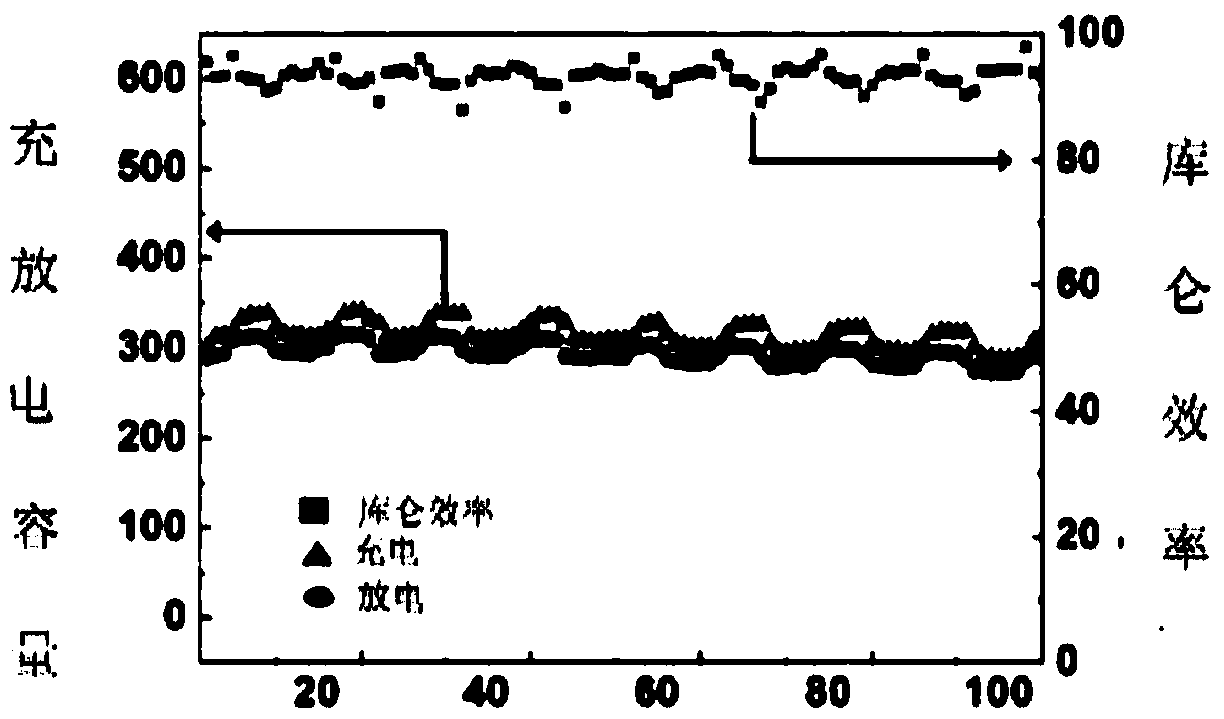

Embodiment 2

[0042] In the above preparation method, the amount of positive electrode material used in step c is 0.15g, that is, the amount of active material of the positive electrode increases, and the same rate condition can have a larger charge and discharge current.

Embodiment 3

[0044] In the above preparation method, the amount of positive electrode material used in step c is 0.20 g, that is, the amount of active material of the positive electrode increases, and the same rate condition can have a larger charge and discharge current.

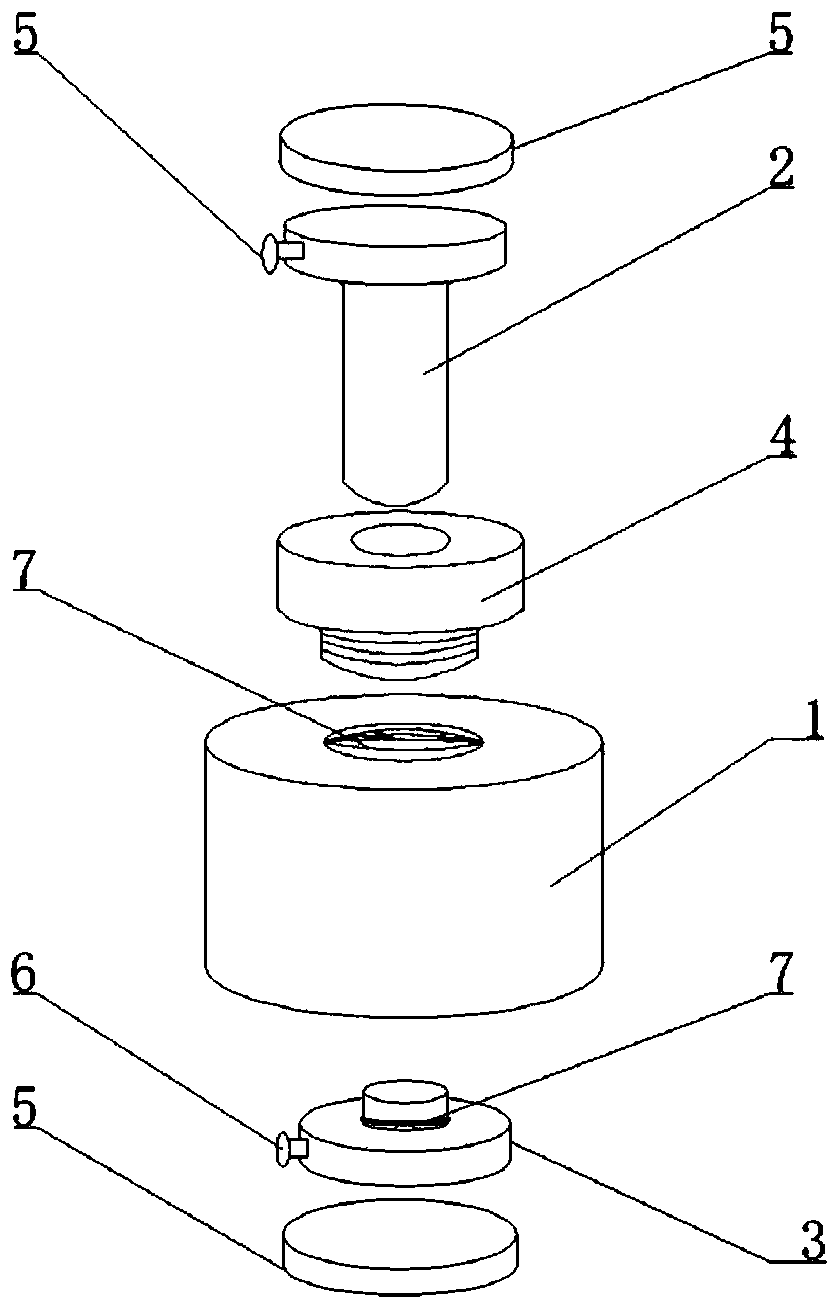

[0045] Such as image 3 As shown, the present invention also provides a mold for preparing an all-solid-state lithium-sulfur battery, including a hollow casing 1, an upper electrode 2, and a lower electrode 3; the upper electrode 2 moves with the casing 1 through a sealing plug 4, and the sealing plug 4 acts as a seal The role is to prevent the electrolyte from contacting with water vapor in the air during the test process, and the lower electrode 3 is flexibly connected to the casing 1; an O-shaped sealing ring 7 is arranged on the inside of the casing 1 and above the lower electrode 3, and the O-shaped sealing ring 7 acts as a fixed electrode and The function of the PTFE sealing plug, the ends of the upper electrode 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com