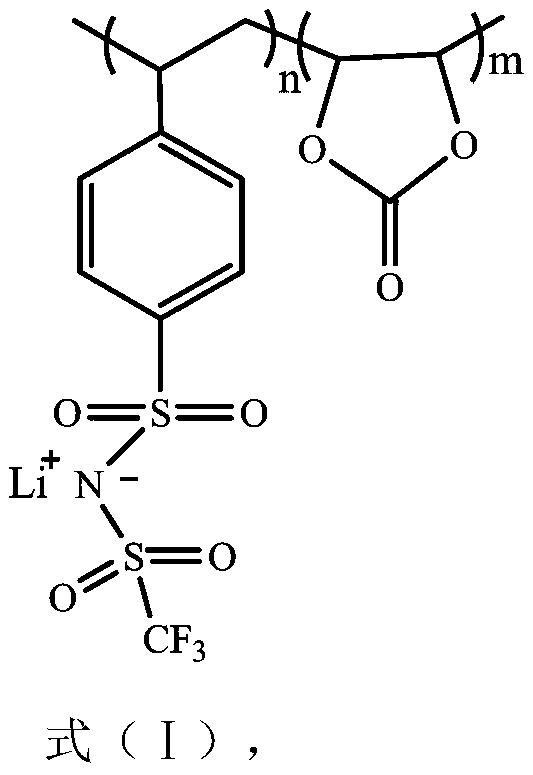

Polyp-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide-polyvinylidene carbonate copolymer and application thereof

A technology of polyvinylene carbonate and trifluoromethylsulfonyl, which is applied in the field of polymer synthesis, can solve the problems of reducing energy efficiency and service life, reducing the stability of charging and discharging current, and poor compatibility of electrode materials. Achieve the effect of improving yield, high lithium ion migration number and room temperature conductivity, and realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

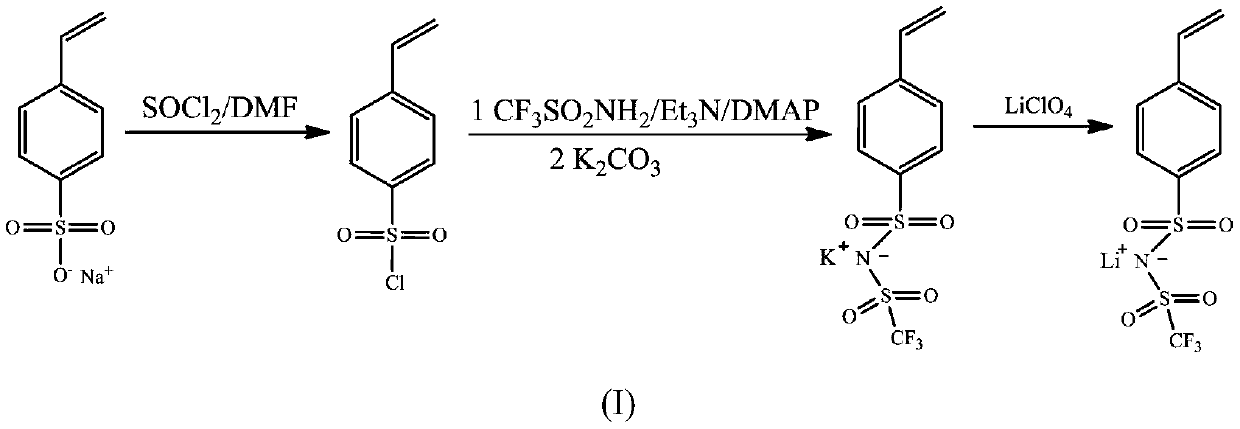

[0033] 1. Weigh 20.6g of sodium p-styrene sulfonate, then add 150ml of N,N-dimethylformamide (DMF) to dissolve it, add 50ml of thionyl chloride dropwise at 0°C, and control it at 60min After the dropwise addition is completed, continue to stir for 2 hours. After stirring at room temperature for 150 minutes, weigh 789 g of ice into a beaker, and pour the solution into it. Add 200ml of diethyl ether to extract, repeat 3 times, dry with anhydrous magnesium sulfate after the extraction is completed; filter with suction, take the suction and spin to remove the filtrate, and dry in vacuo to obtain 19.6g of p-styrenesulfonyl chloride, which is a yellow viscous liquid. Yield 95%.

[0034] 2. Weigh 21.68g of trifluoromethanesulfonamide, 14.25g of triethylamine, 0.42g of 4-dimethylaminopyridine (DMAP) and 120ml of acetonitrile into a round bottom flask. Weigh 19.6g of p-styrenesulfonyl chloride and add 40ml of acetonitrile to dissolve it, drop the p-styrenesulfonyl chloride solution in...

Embodiment 2

[0039] The difference from step 4 in Example 1 is that the reaction time is 12 h, and a P(LiSTFSI50-co-VC50) random copolymer is obtained.

Embodiment 3

[0041]The difference from Step 4 in Example 1 is that the reaction temperature is 90° C., and the P(LiSTFSI50-co-VC50) random copolymer is synthesized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com