Patents

Literature

62 results about "Lithium imide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium imide is an inorganic compound with the chemical formula Li₂NH. This white solid can be formed by a reaction between lithium amide and lithium hydride. The product is light-sensitive and can undergo disproportionation to form lithium nitride, which is characteristically red.

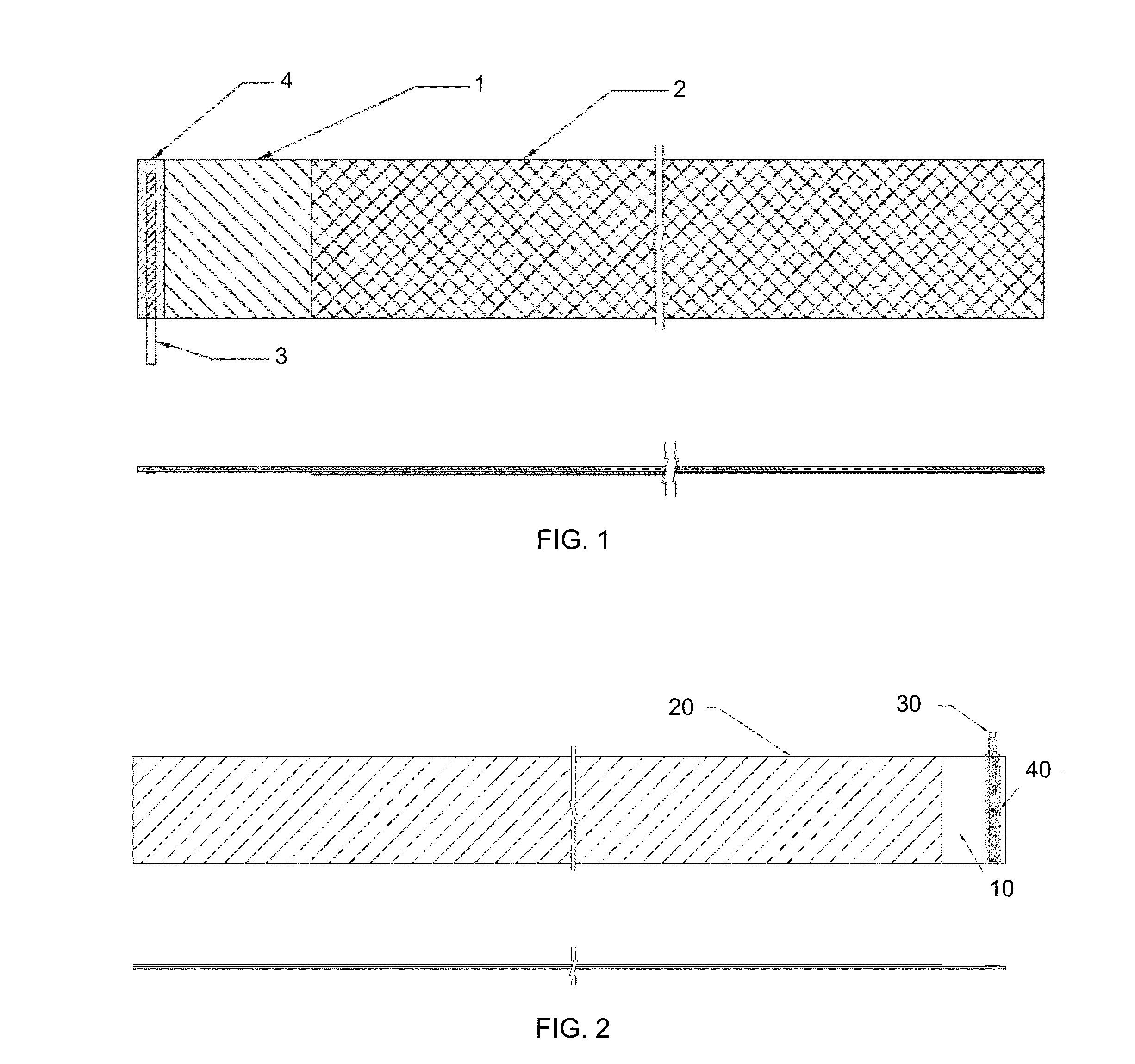

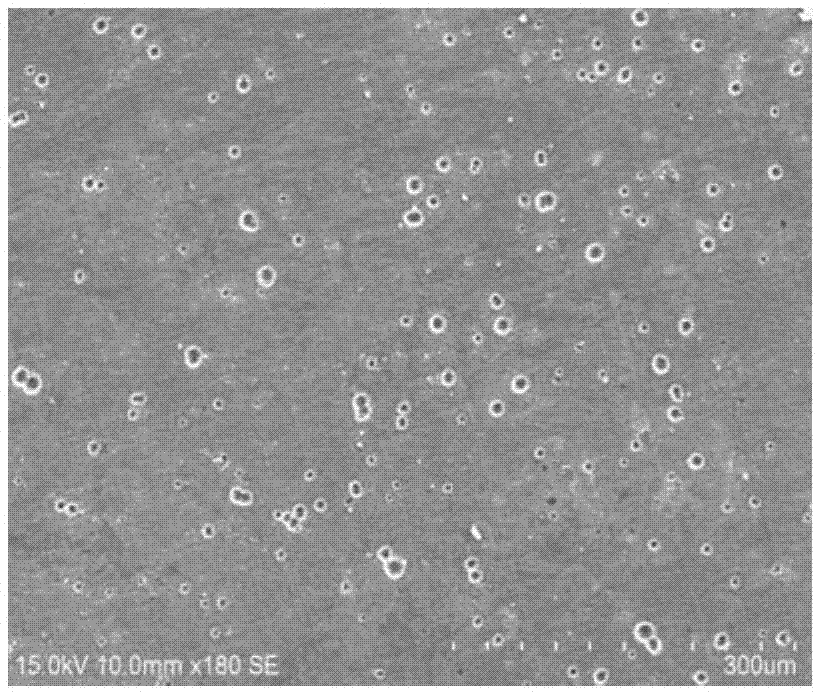

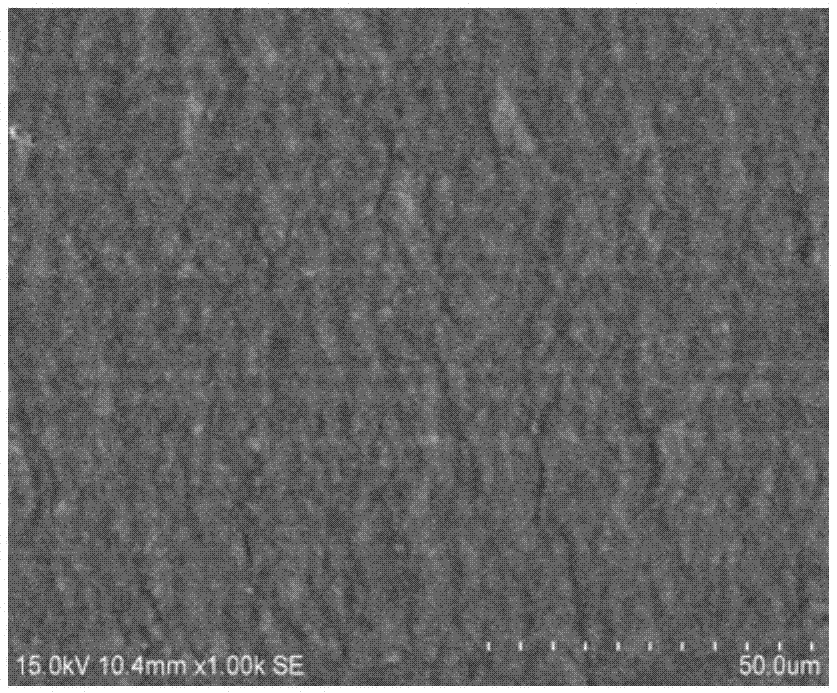

High performance lithium or lithium ion cell

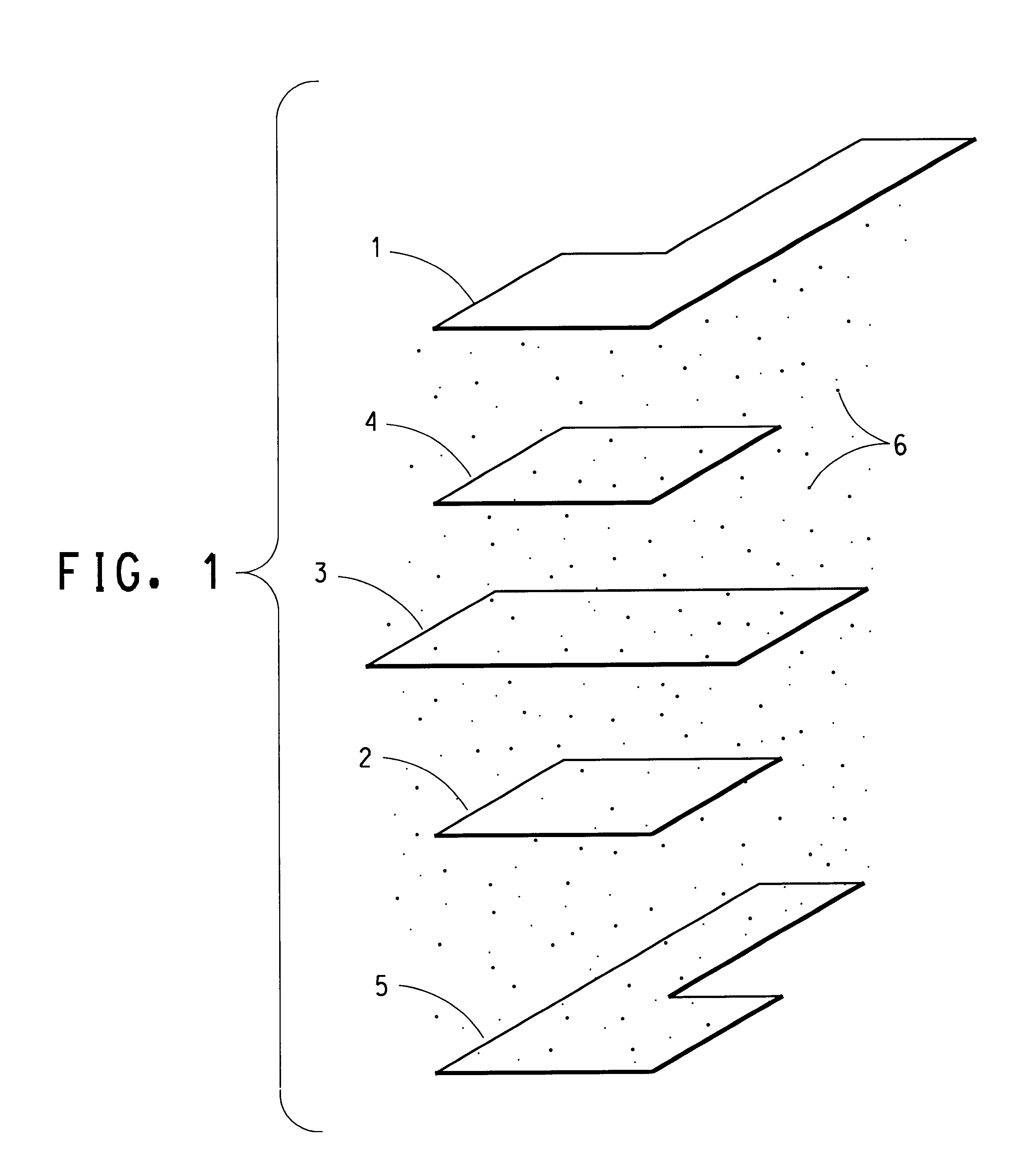

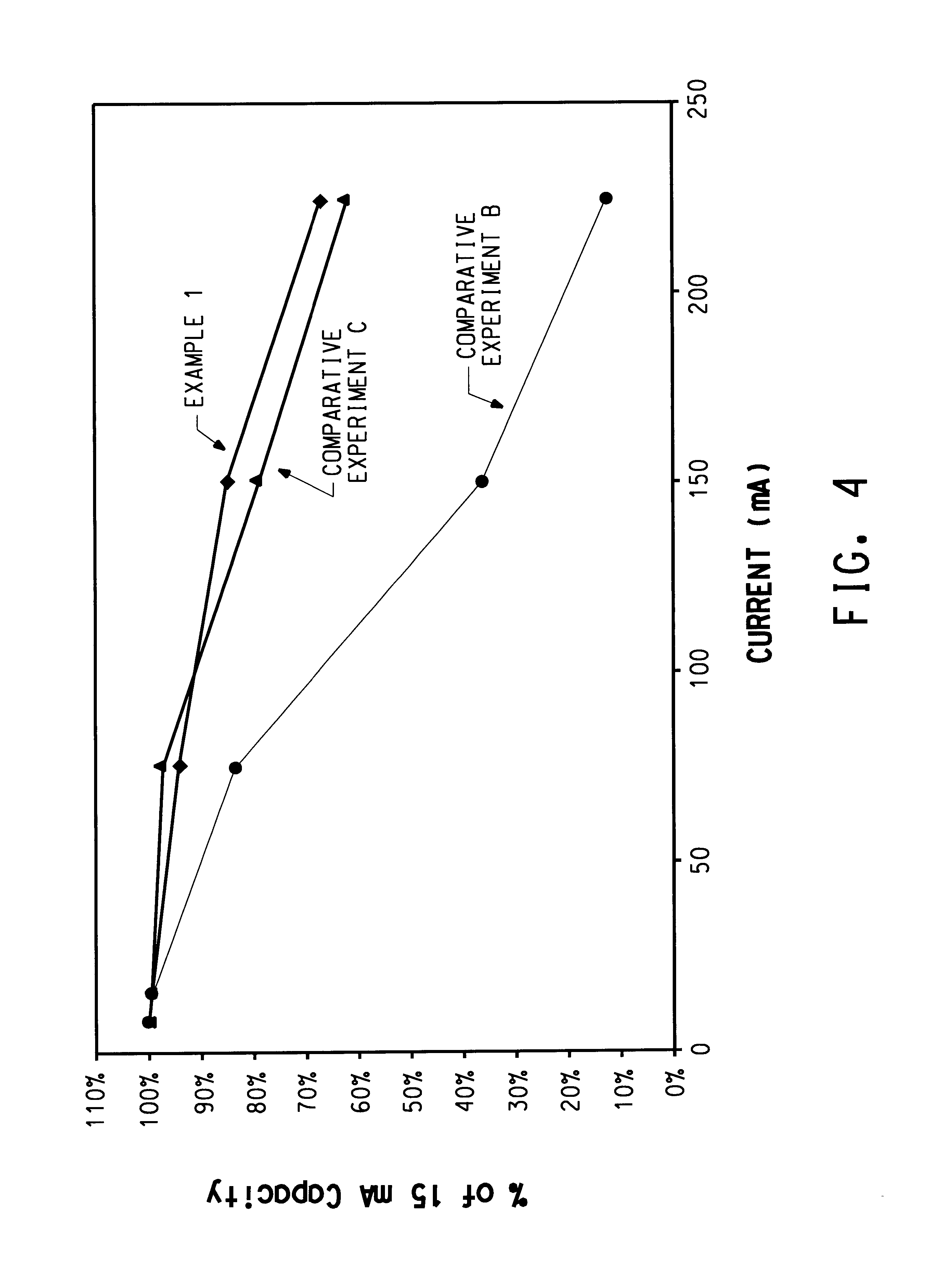

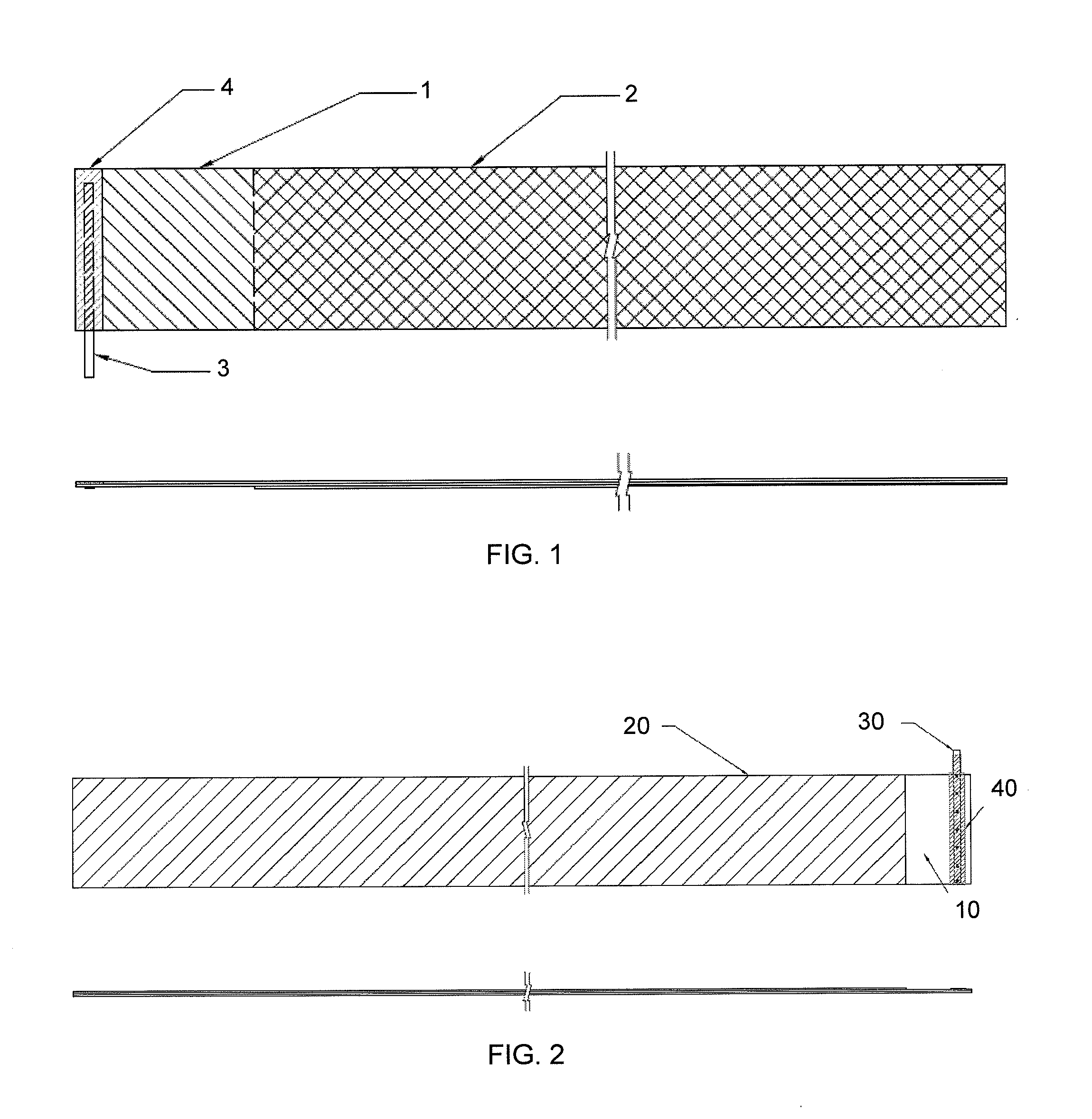

Graphite sheeting having a thickness of less than 250 micrometers and in-plane conductivity of at least 100 S / cm when employed as a cathode current collector in a lithium or lithium ion cell containing a fluorinated lithium imide or methide electrolyte salt imparts high thermal resistance, excellent electrochemical stability, and surprisingly high capacity retention at high rates of discharge.

Owner:A123 SYSTEMS LLC

High performance lithium or lithium ion cell

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

High performance lithium or lithium ion cell

Graphite sheeting having a thickness of less than 250 micrometers and in-plane conductivity of at least 100 S / cm when employed as a cathode current collector in a lithium or lithium ion cell containing a fluorinated lithium imide or methide electrolyte salt imparts high thermal resistance, excellent electrochemical stability, and surprisingly high capacity retention at high rates of discharge.

Owner:DAI HONGLI

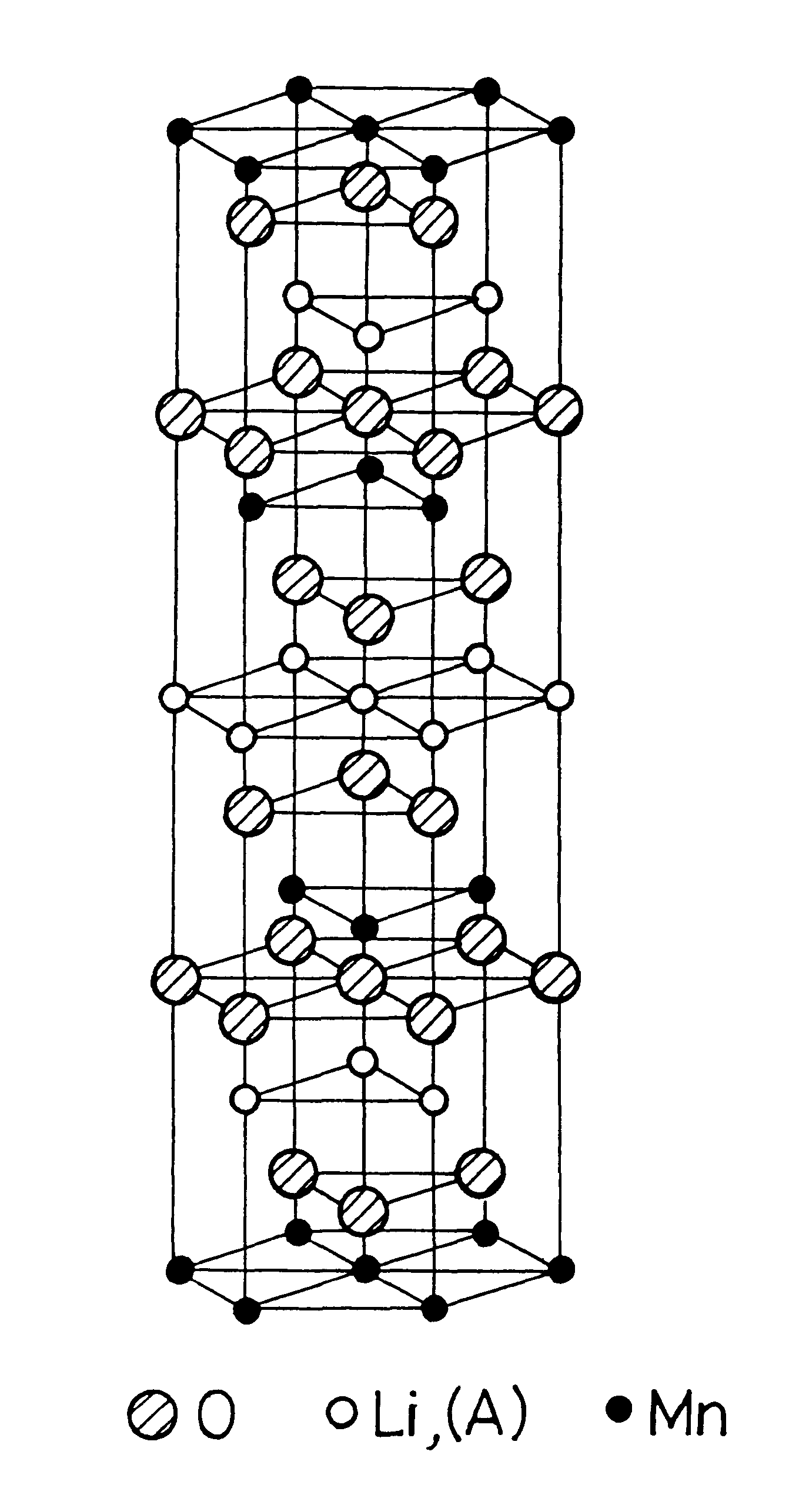

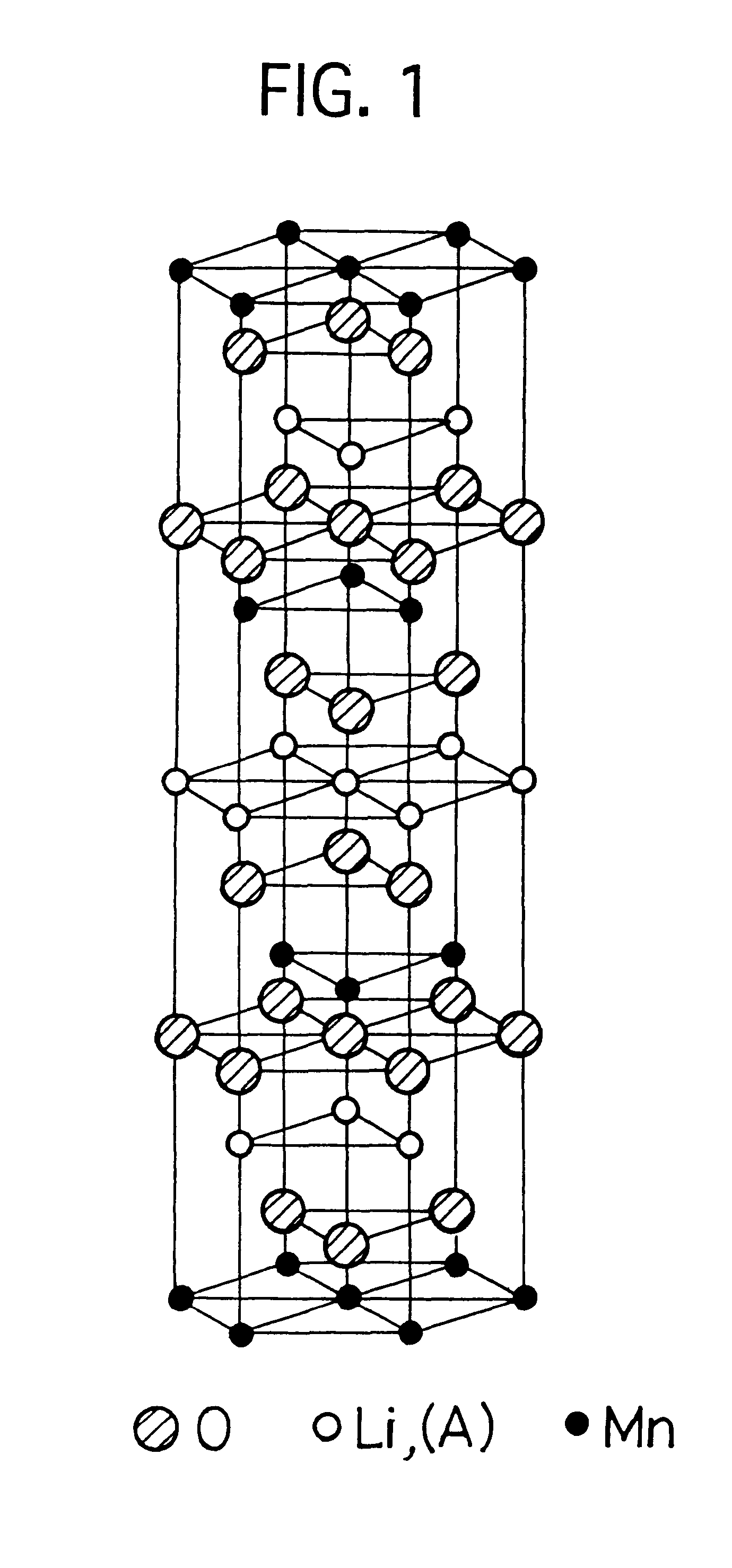

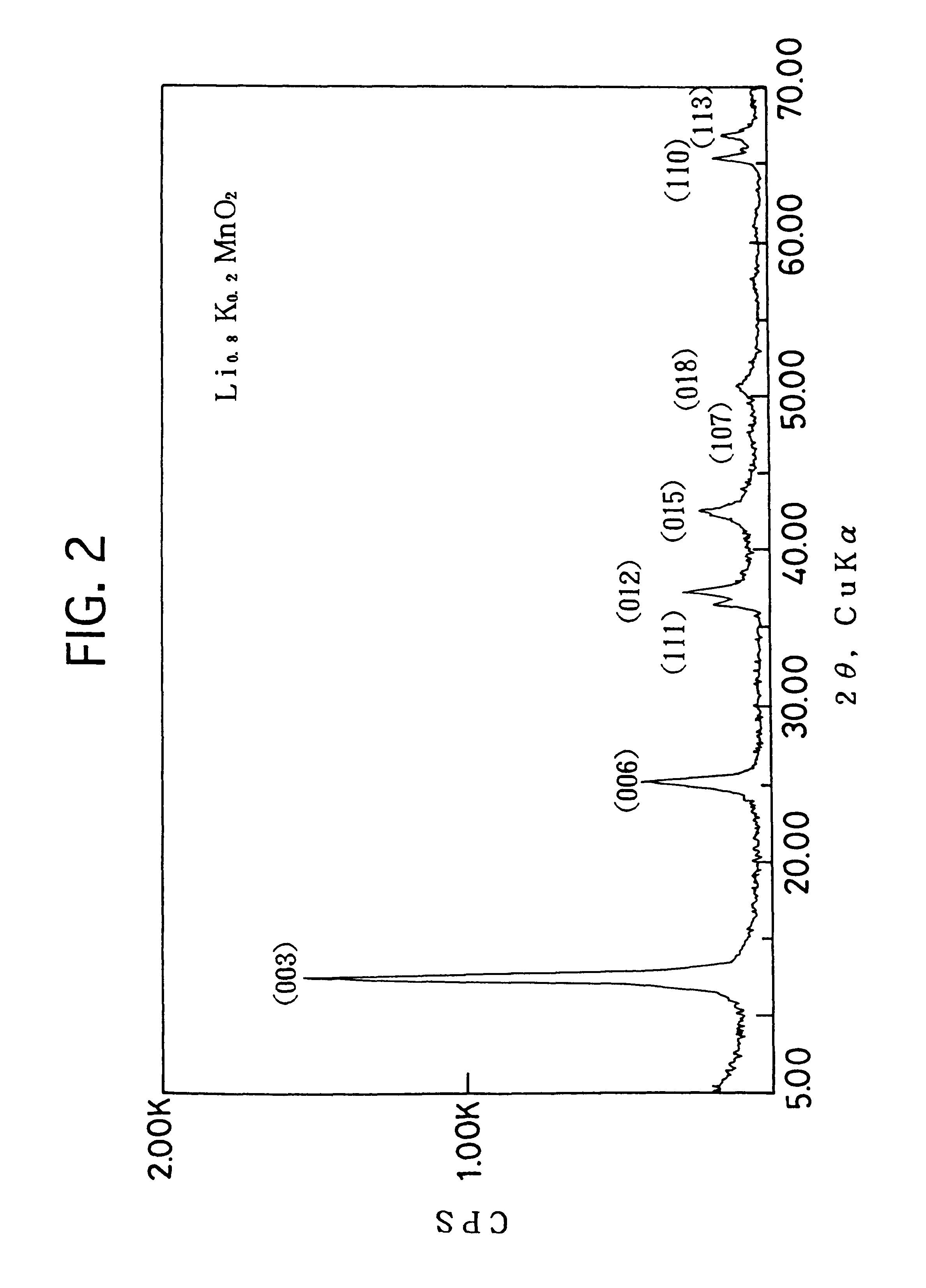

Lithium manganese composite oxide for lithium secondary battery cathode active material, manufacturing method thereof, and lithium secondary battery using the composite oxide as cathode active material

InactiveUS6306542B1Secondary cellsNon-aqueous electrolyte accumulator electrodesLayered structureLithium imide

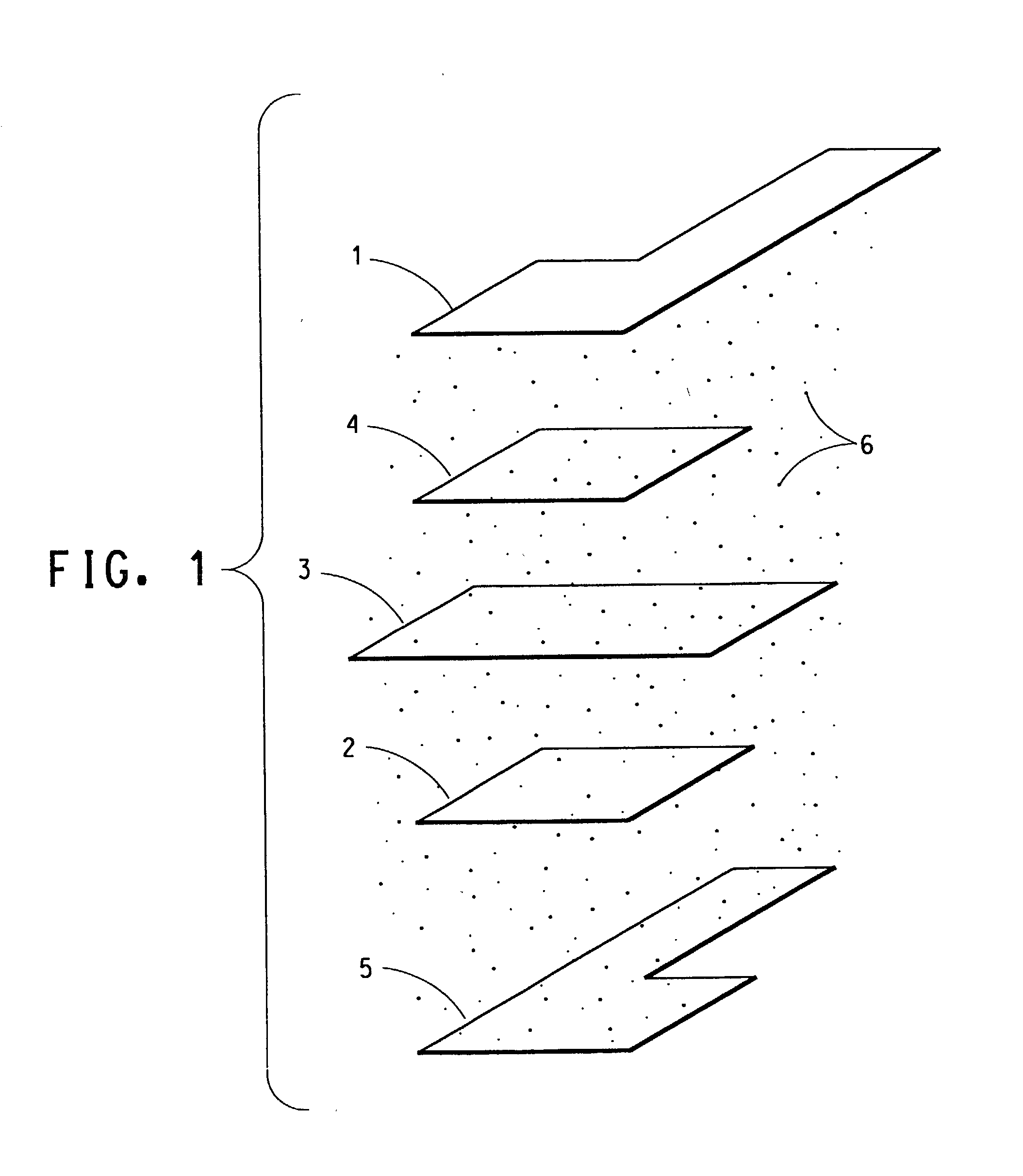

One of the most important subject of the present invention is to provide a new lithium manganese composite oxide which does not include the cobalt which is few as the resource and expensive.For the above purpose, a lithium manganese composite oxide for a lithium secondary battery cathode active material represented by a composition formula of Li1-x Ax MnO2 (A is an alkali metal except for Li:0<x<1) and having a layered structure with a rock salt type ordered cations is adopted.According to the lithium manganese composite oxide, the crystal structure is stabilized since the lithium site of the layered structure LiMnO2 is replaced by the atom of alkali metal element having larger ionic diameter than the lithium ion. Accordingly, not only large discharge capacity is maintained but the cycle characteristic is excellent. In addition, since the lithium manganese composite oxide does not include the cobalt, it can be manufactured in low cost.The present invention can also provide a simple and cheap manufacturing method of the above lithium manganese composite oxide, and a cheap lithium secondary battery which uses the above lithium manganese composite oxide as the cathode active material.

Owner:TOYOTA CENT RES & DEV LAB INC

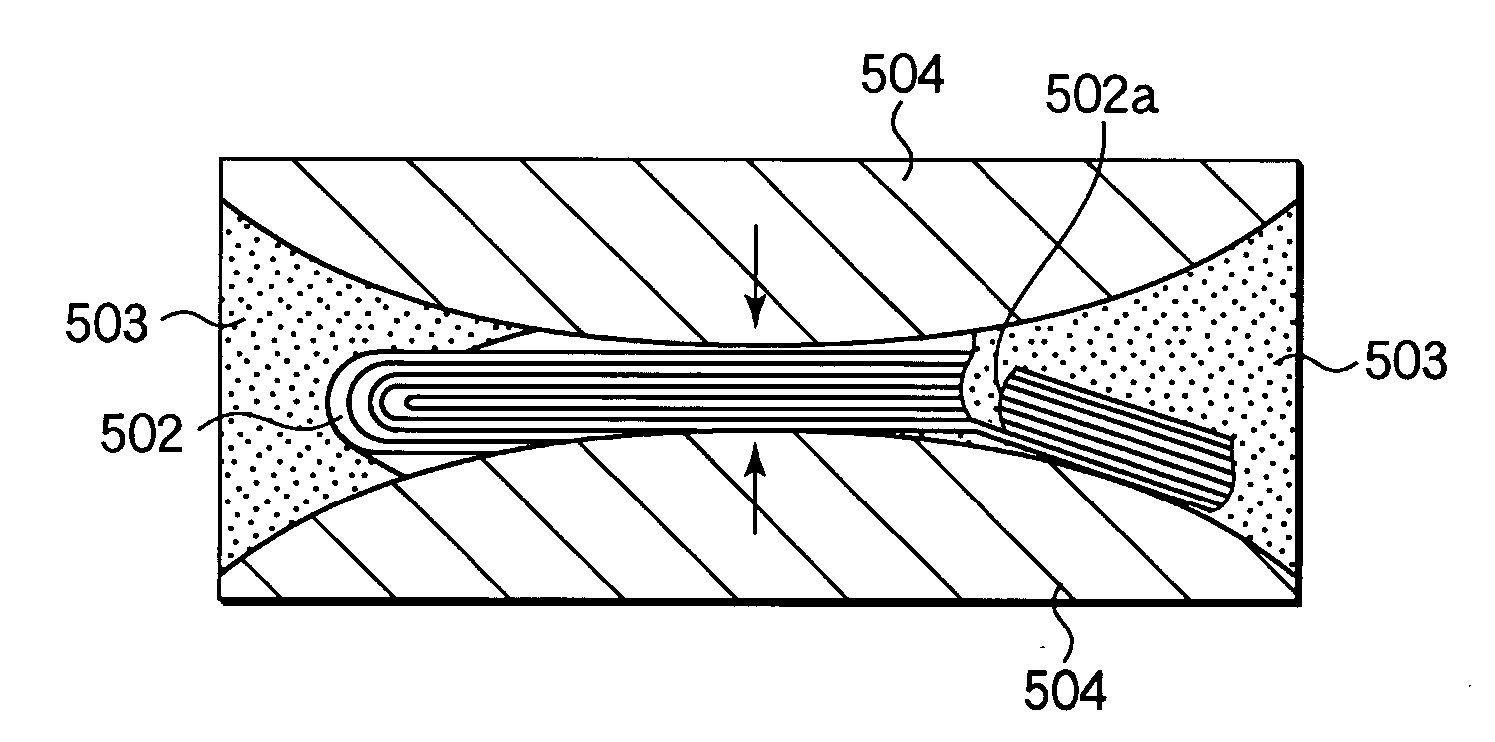

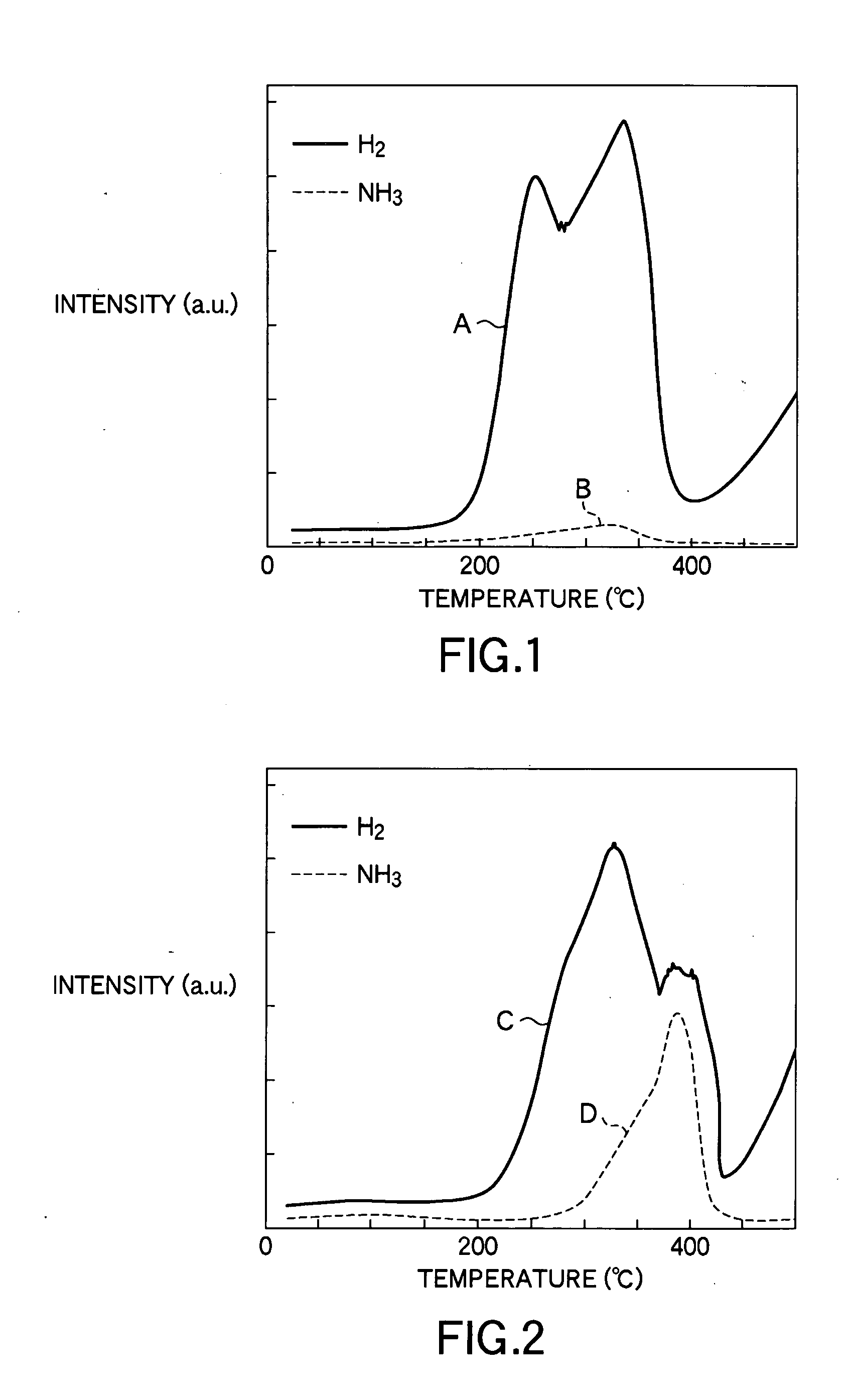

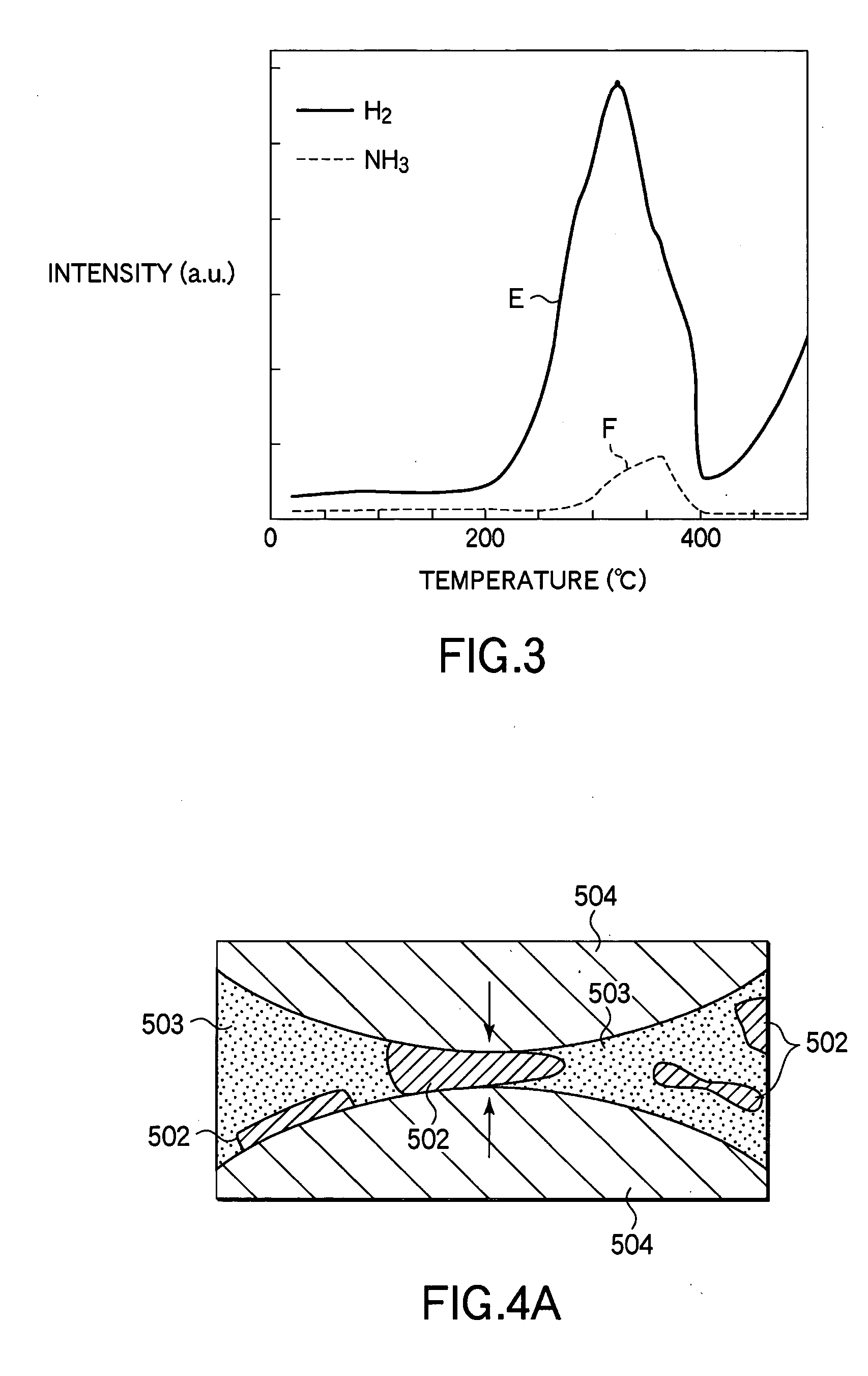

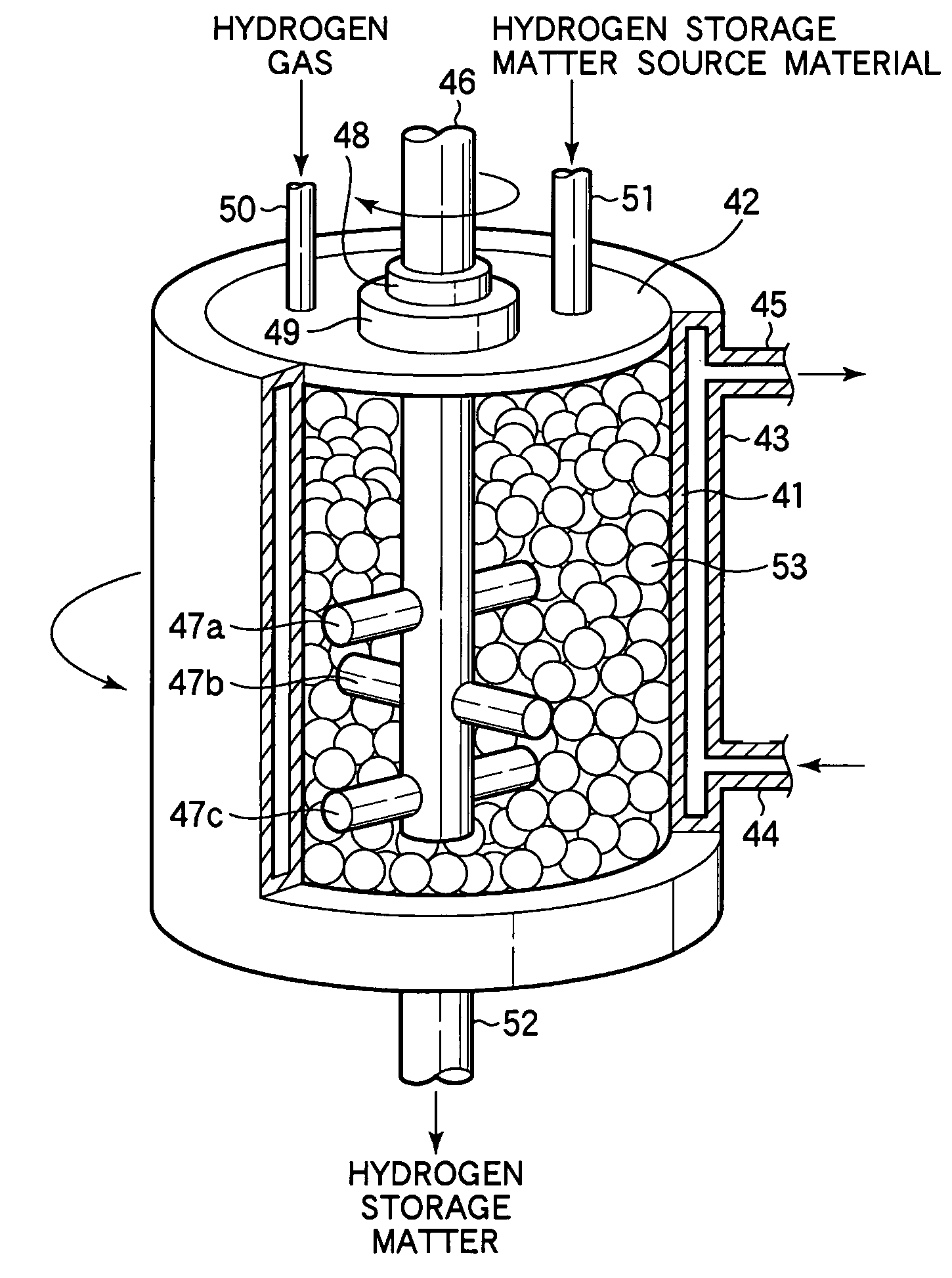

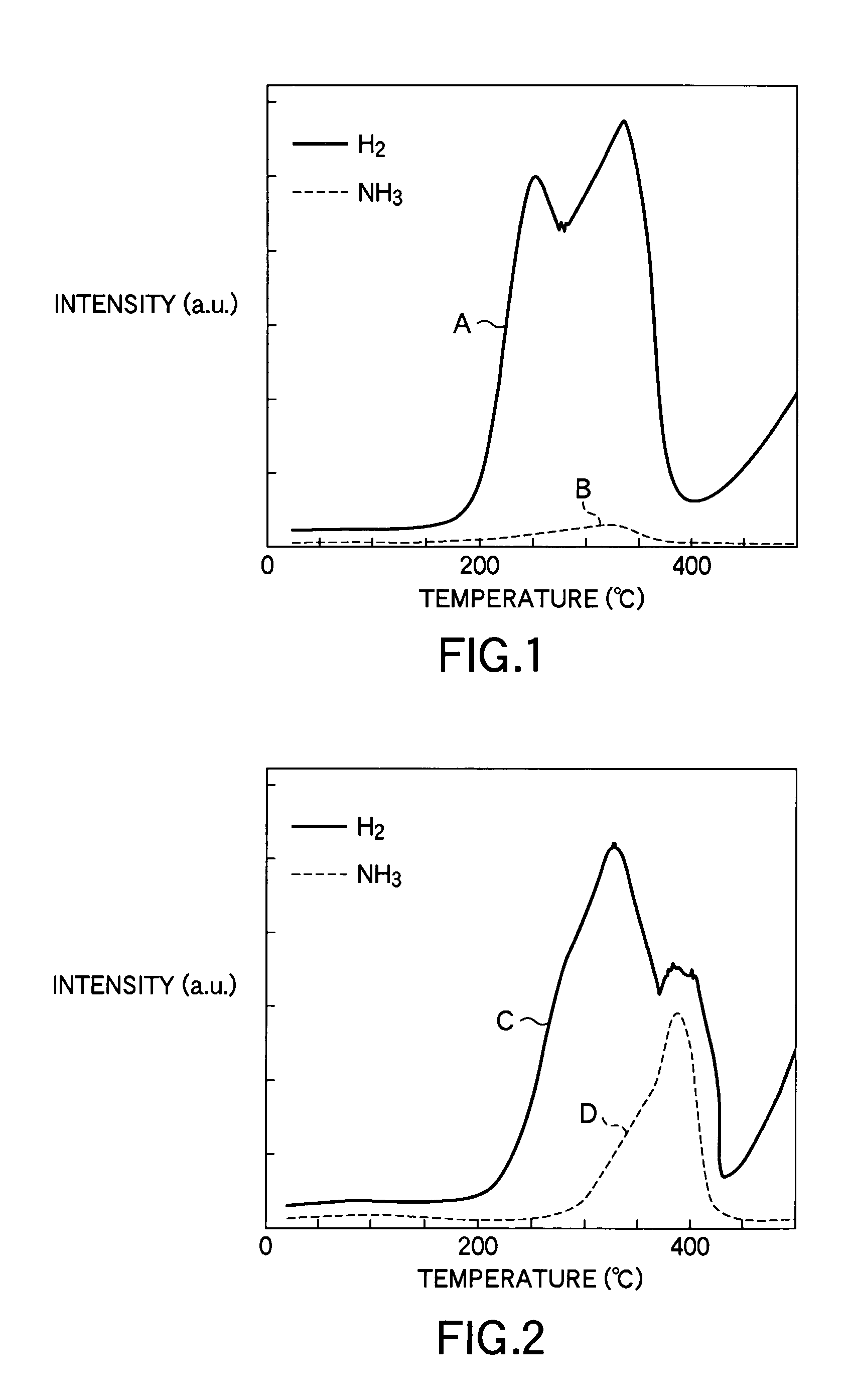

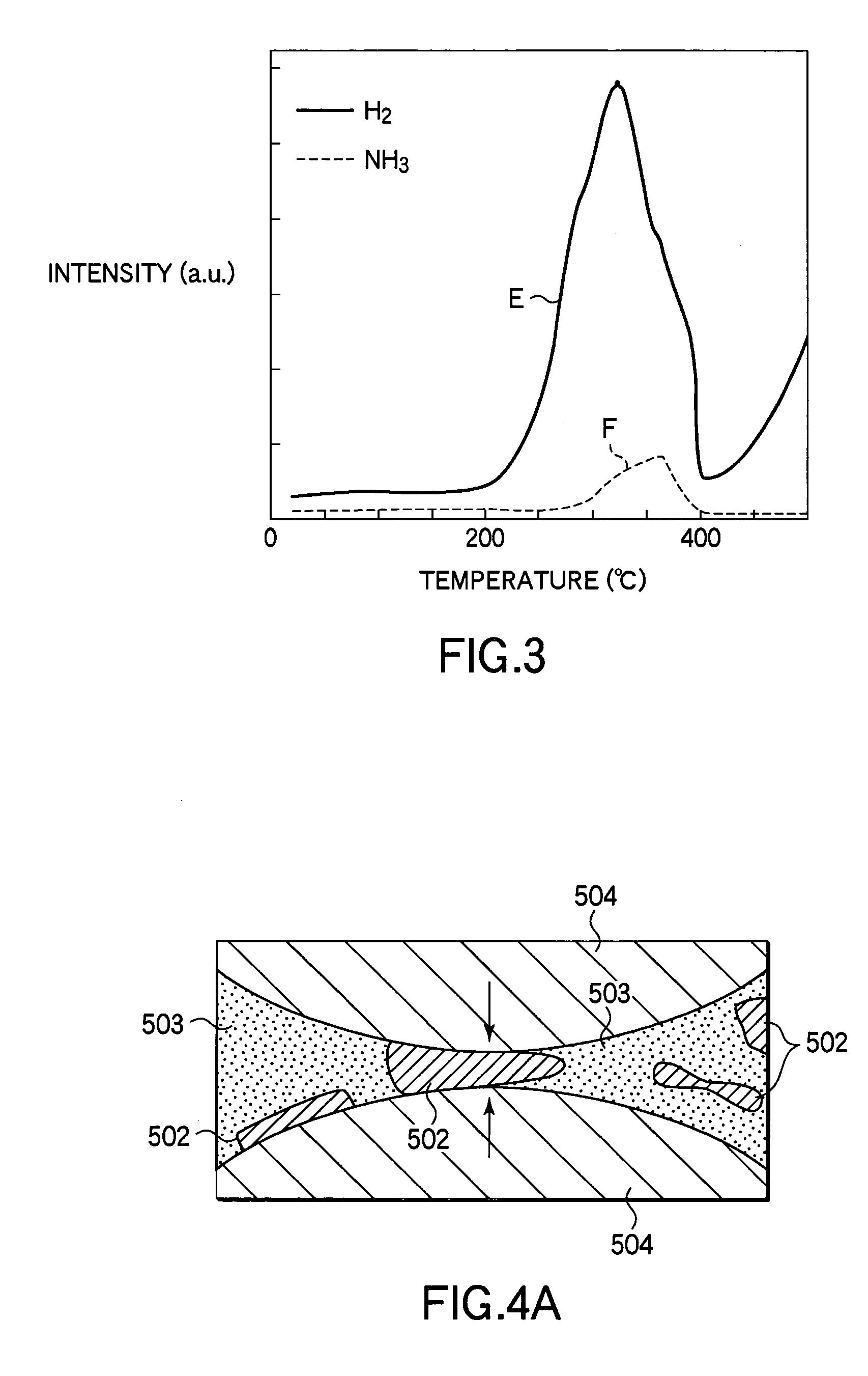

Hydrogen storage matter and manufacturing method and apparatus for the same

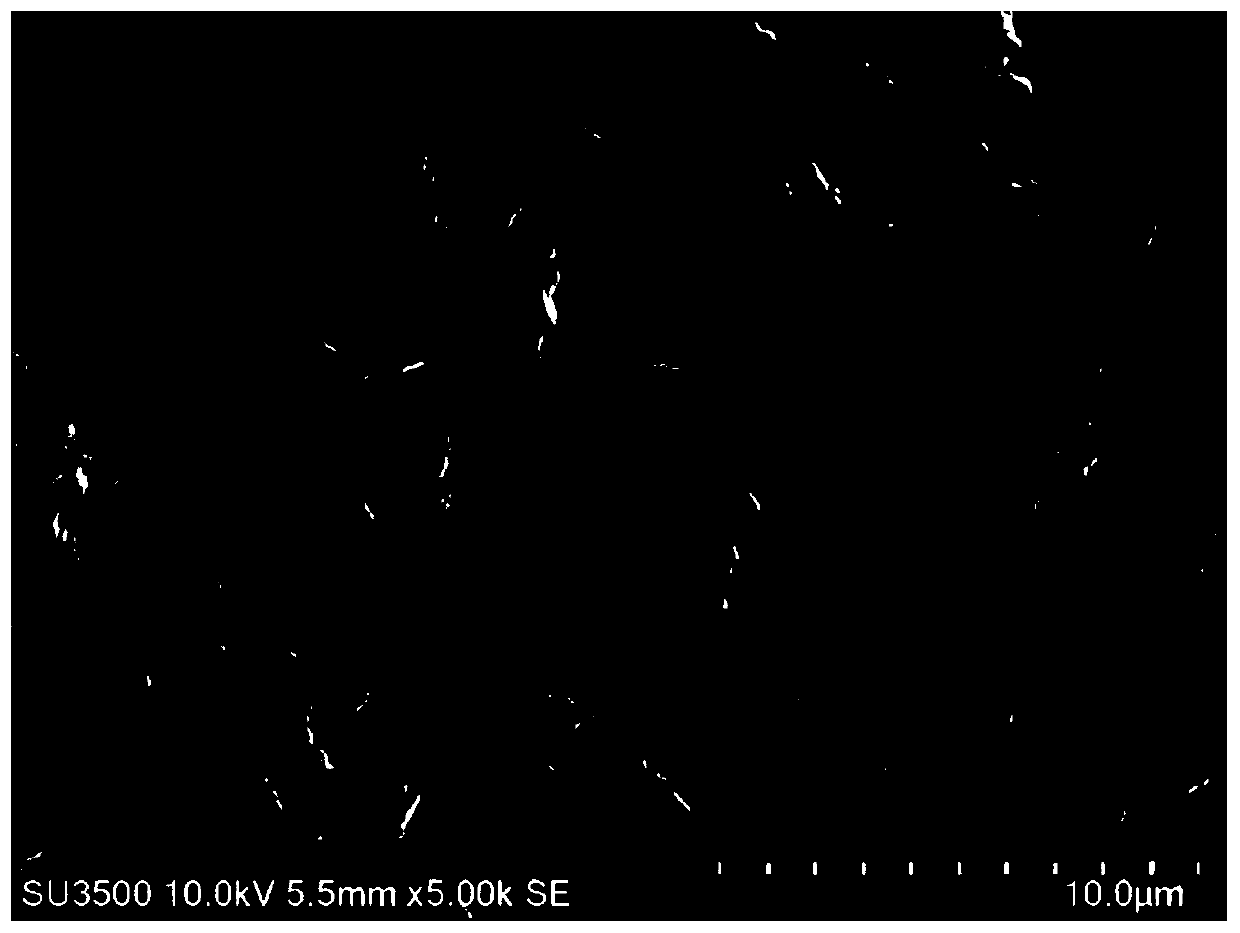

InactiveUS20060127304A1Improve efficiencyIncrease storage capacityMaterial nanotechnologyPhysical/chemical process catalystsLithium compoundNanostructure

A hydrogen storage matter contains at least a nano-structured and organized lithium imide compound precursor complex. In the hydrogen stroge matter, the lithium imide compound precursor complex has been nano-structured and organized by mixing fine powder lithium amide with fine powder lithium hydride at a predetermined ratio to prepare a mixture as a starting material, and then processing the mixture by a predetermined complex formation processing method.

Owner:HIROSHIMA UNIVERSITY +1

High performance lithium or lithium ion cell

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

Lithium secondary battery

InactiveUS20030077517A1Improve reliabilityCell electrodesOrganic electrolyte cellsHigh rateFluorine containing

Lithium batteries having excellent high rate characteristics and low-temperature characteristics, and less in evolution of gases and superior in discharge characteristics are provided by using LiCoO2 mixed with CaO or Cr2O3 or the like as an active material of positive electrode in combination with a non-aqueous electrolyte containing a mixed electrolyte salt comprising both a fluorine-containing inorganic anion lithium salt and a lithium imide salt.

Owner:PANASONIC CORP

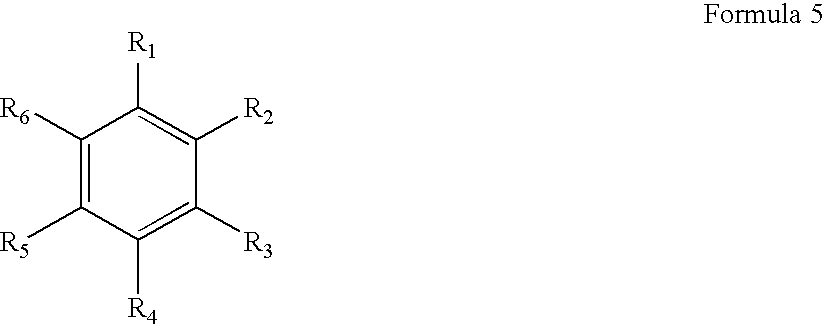

Rechargeable lithium battery

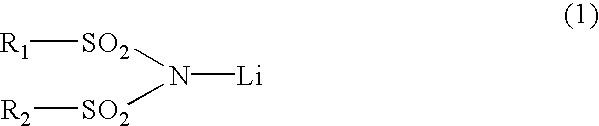

ActiveUS20080118835A1Easy to optimizeSilver accumulatorsFinal product manufactureRare-earth elementAlkaline earth metal

The rechargeable lithium battery includes a positive electrode which includes a positive active material, a negative electrode, and an electrolyte which includes a non-aqueous organic solvent and a lithium salt. The positive active material includes a core including at least one of a compound represented by Formula 1 and a compound represented by Formula 2, and a surface-treatment layer which is formed on the core and includes a compound represented by Formula 3. The lithium salt includes LiPF6 and a lithium imide-based compound.LiaNibCocMndMeO2 (1)LihMn2MiO4 (2)M′xPyOz (3)wherein each of M and M′ is independently selected from the group consisting of an alkali metal, an alkaline-earth metal, a Group 13 element, a Group 14 element, a transition element, a rare earth element, and combinations thereof, 0.95≦a≦1.1, 0≦b≦0.999, 0≦c≦0.999, 0≦d≦0.999, 0.001≦e≦0.2, 0.95≦h≦1.1, 0.001≦i≦0.2, 1≦y≦4, 0≦y≦7, and 2≦z≦30.

Owner:SAMSUNG SDI CO LTD

Electrolyte

InactiveCN102185156AThe group ratio is reasonableReasonable ratioSecondary cellsHigh energyMethyl carbonate

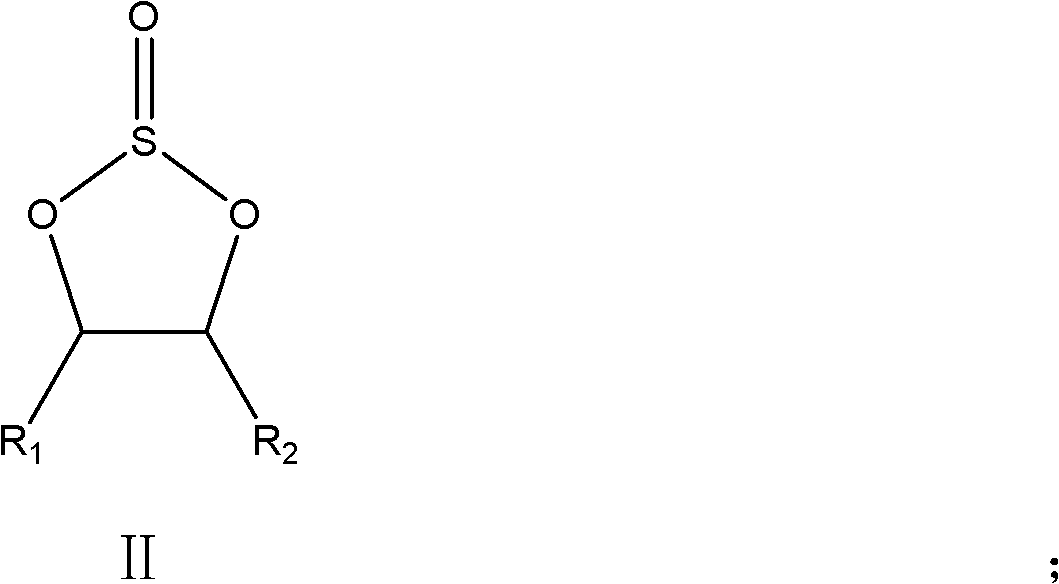

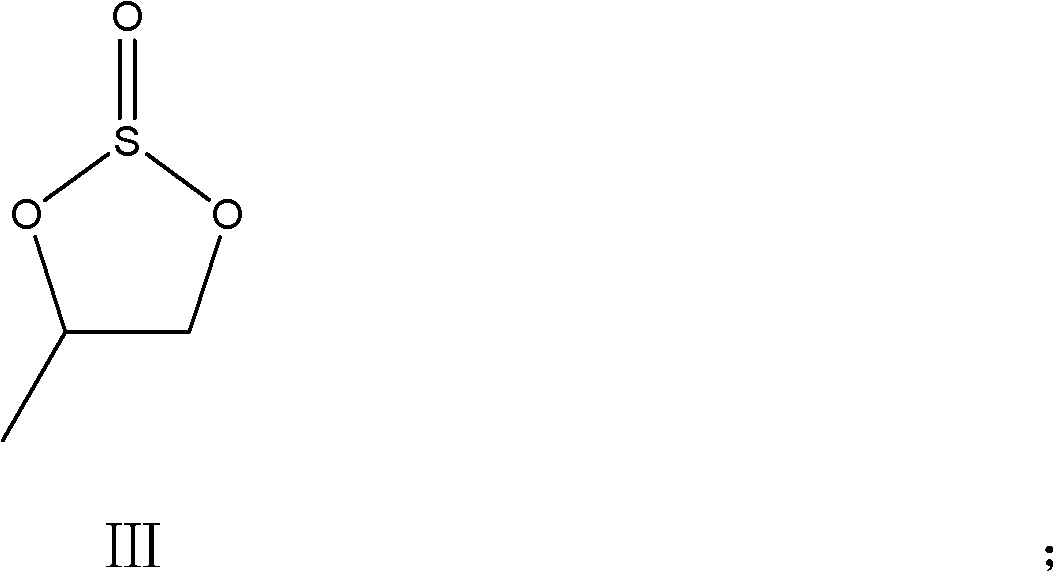

The invention relates to electrolyte, belonging to the technical field of material chemistry and high energy batteries. The electrolyte consists of an organic solvent, an additive and lithium salt, wherein the organic solvent is one or a mixture of ethylene carbonate, ethyl methyl carbonate, methyl-carbonate or diethyl carbonate; the additive is sulfurous ester; and the lithium salt is selected from lithium perchlorate, lithium hexafluorophosphate, lithium tetrafluoroborate, perfluoroalkyl lithium sulfonate, perfluoroalkyl sulfoacid imide lithium, annular perfluoroalkyl di(sulfonyl)lithium imide, perfluoroalkyl acyl sulfonate lithium methide, organic boric acid ester lithium, organic lithium phosphate or organic aluminic acid ester lithium. Due to the adoption of the electrolyte, a layer of stable solid electrolyte phase boundary face film can be formed on the surface of a graphite electrode, the compatibility between the electrolyte and an electrode material is improved, the temperature suitability of the electrolyte material is expanded through proportion optimization, and the cycle performance, rate capability and temperature suitability of a lithium secondary battery using the electrolyte can be effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

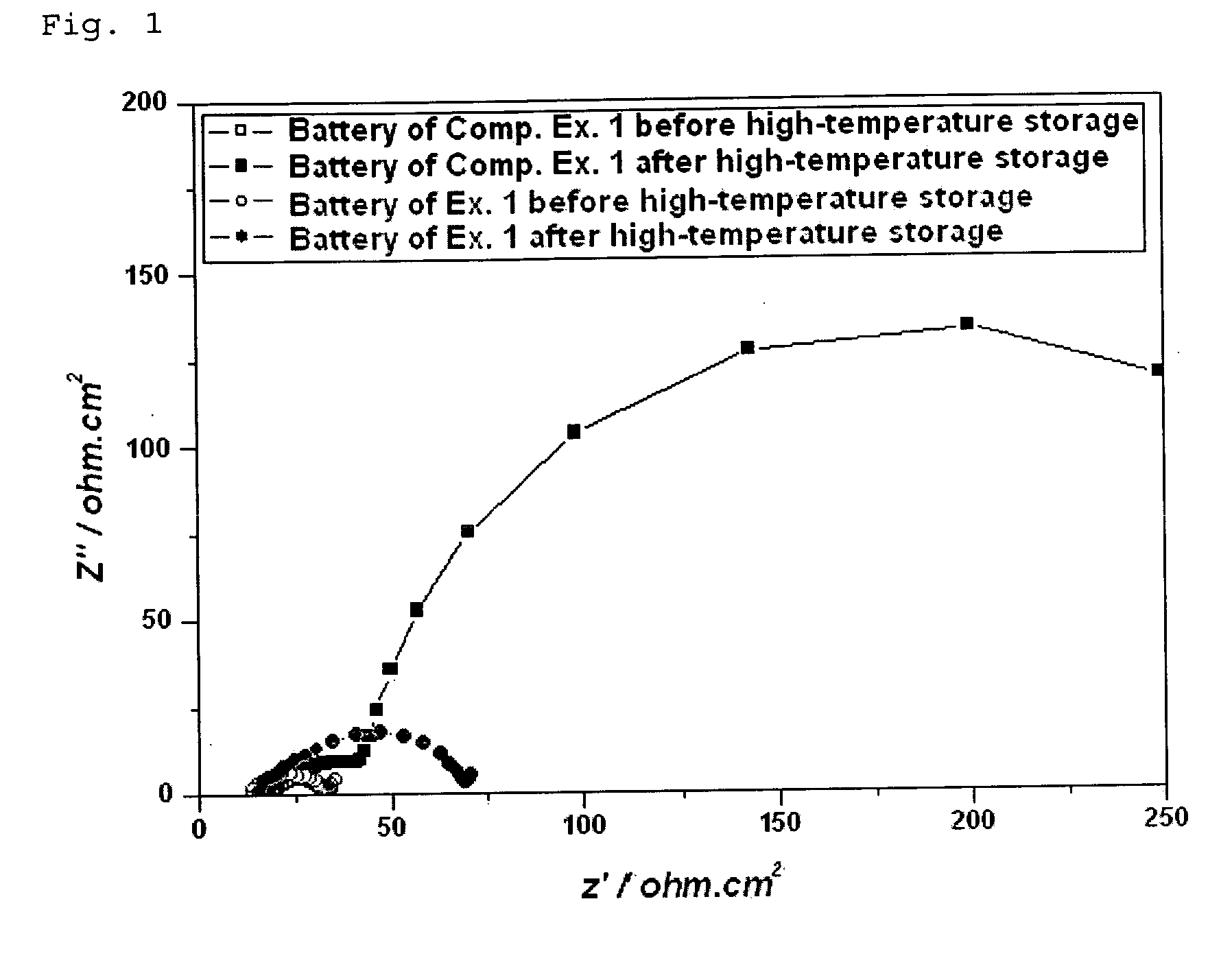

Lithium secondary battery with high performance

InactiveUS20060194119A1Inhibit side effectsPad sawsOrganic electrolyte cellsInorganic saltsOrganic solvent

Disclosed is a lithium secondary battery comprising: (a) a cathode; (b) an anode; (c) a separator; and (d) a non-aqueous electrolyte comprising a lithium salt and an organic solvent, wherein the cathode comprises a cathode active material, doped with at least one element selected from the group consisting of Sn, Al and Zr, or containing the element in the form of a solid solution, and the non-aqueous electrolyte comprises a lithium-containing inorganic salt and a lithium imide salt dissociated in at least one organic solvent including gamma-butyrolactone (GBL). The lithium secondary battery can minimize side reactions between both electrodes and gamma-butyrolactone (GBL), used as a conventional electrolyte for a battery, and thus can provide high capacity, long service life and improved quality at high-temperature.

Owner:LG CHEM LTD

Lithium secondary battery

InactiveUS6723472B2Improve reliabilityCell electrodesOrganic electrolyte cellsHigh rateLithium-ion battery

Lithium batteries having excellent high rate characteristics and low-temperature characteristics, and less in evolution of gases and superior in discharge characteristics are provided by using LiCoO2 mixed with CaO or Cr2O3 or the like as an active material of positive electrode in combination with a non-aqueous electrolyte containing a mixed electrolyte salt comprising both a fluorine-containing inorganic anion lithium salt and a lithium imide salt.

Owner:PANASONIC CORP

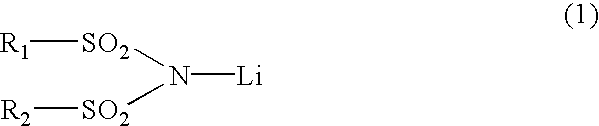

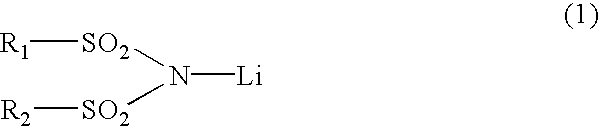

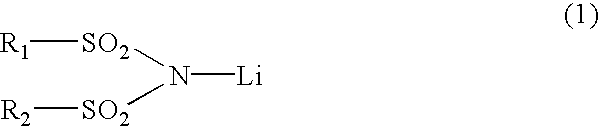

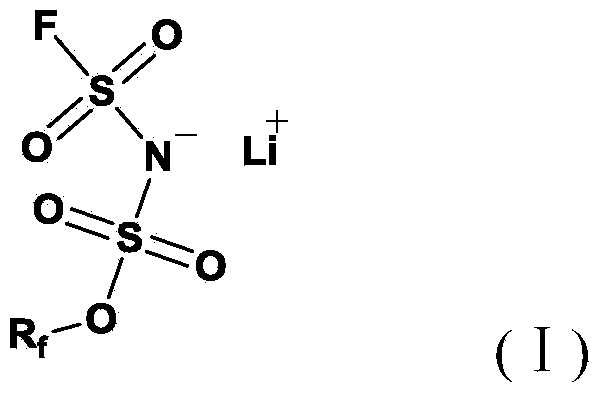

Electrolyte containing lithium imide and battery using electrolyte

ActiveCN105070940AImprove flame retardant propertiesLow viscositySecondary cells servicing/maintenanceAlkaneOrganic solvent

The invention provides electrolyte containing lithium imide. The electrolyte comprises electrolyte lithium salt, lithium imide, a non-aqueous organic solvent and an additive, wherein the lithium imide is phosphonitrile lithium imide; the general molecular formula is as shown in the specification, wherein R1-5 is any one of -OR7 and -Li[NSO2-R6]; R6 is fluorine-containing alkyl with the carbon atom number of 0-8; and R7 is an alkane group with the carbon atom number of 1-10. The phosphonitrile lithium imide has excellent chemical and electrochemical stability, and is compounded with LiPF6 for use; through the complexing effect of phosphonitrile imine anions and PF5, the catalytic decomposition effect on a carbonic ester solvent caused by a strong lewis acid PF5 can be effectively avoided; the heat stability of the electrolyte is improved; and the cycle life and the high-temperature performance of a lithium ion battery are greatly improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

Rechargeable lithium battery

ActiveUS20080206650A1Large capacityImprove cycle lifeOrganic electrolyte cellsSolid electrolyte cellsOrganic solventLithium imide

A rechargeable lithium battery includes a positive electrode including a positive active material being capable of intercalating and deintercalating lithium ions; a negative electrode including a negative active material being capable of intercalating and deintercalating lithium ions; and an electrolyte including a non-aqueous organic solvent and a lithium salt. The positive electrode has a positive active mass density of 3.65 g / cc or more, and the lithium salt includes lithium hexafluorophosphate (LiPF6), lithium tetrafluoroborate (LiBF4), and a lithium imide-based compound. The rechargeable lithium battery has high capacity, excellent cycle-life, and reliability at a high temperature.

Owner:SAMSUNG SDI CO LTD

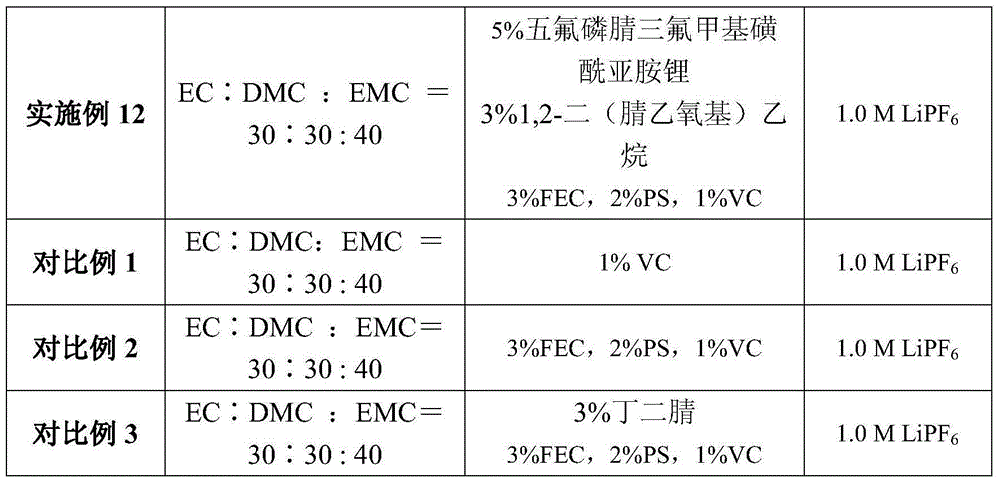

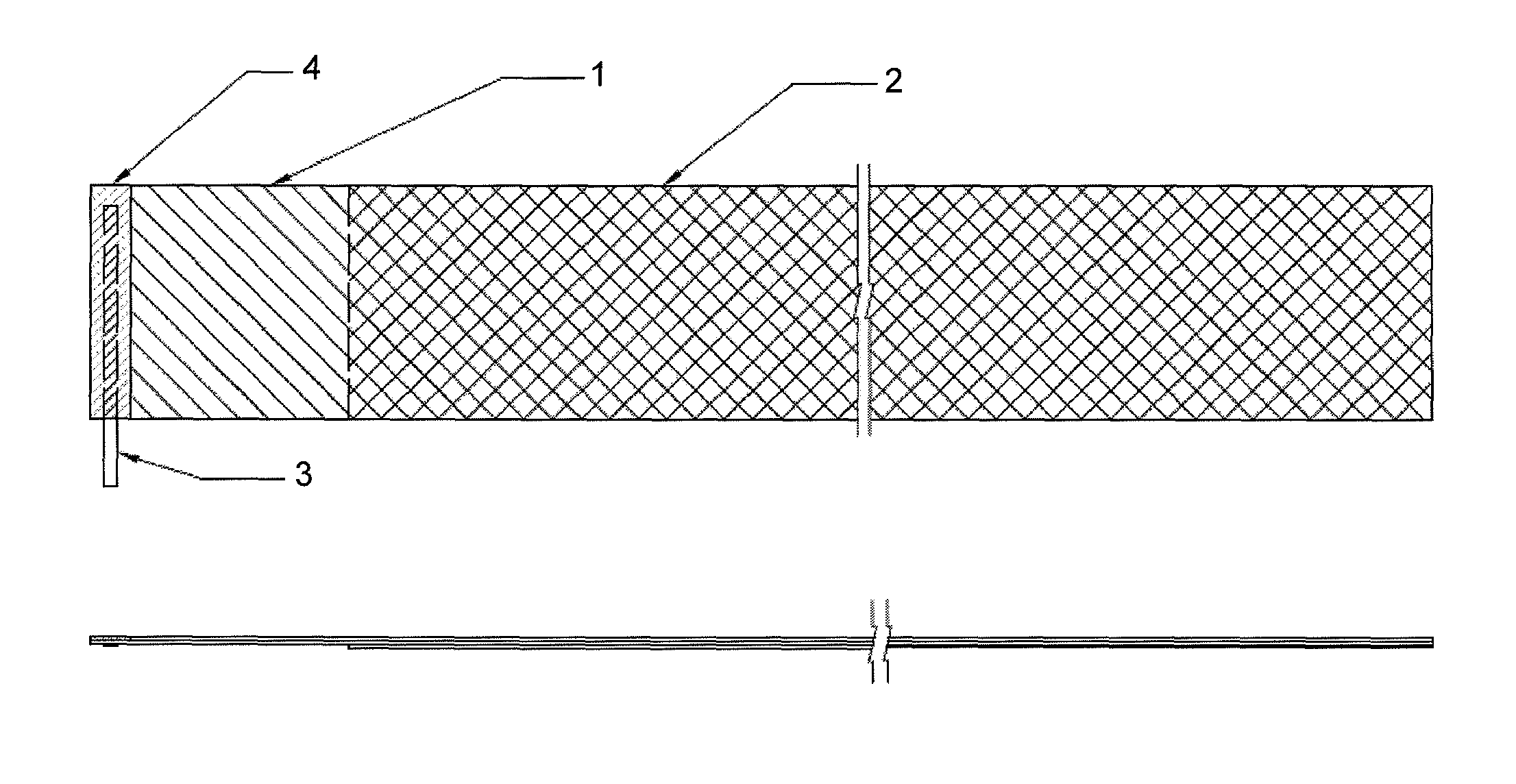

Lithium ion battery electrolyte and lithium ion battery

InactiveCN105449275AImprove securityImprove thermal stabilitySecondary cells servicing/maintenanceTriflic acidSulfonyl fluoride

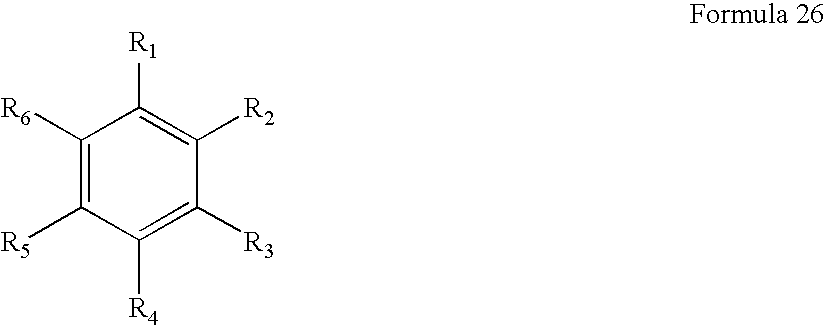

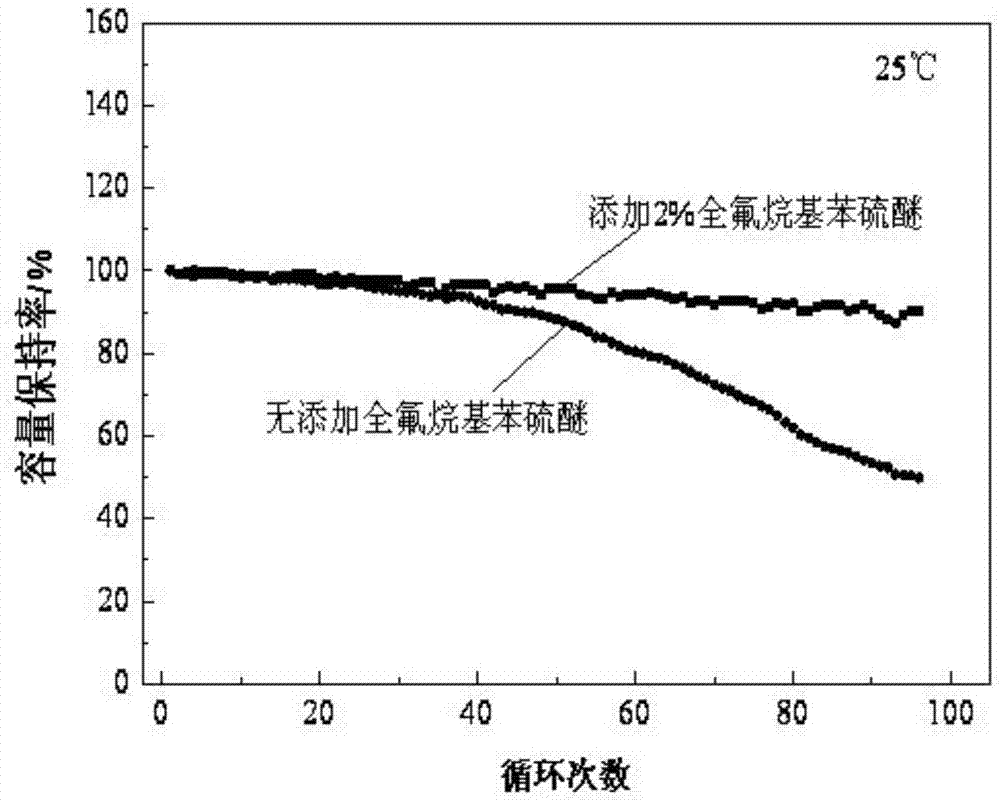

The invention discloses a lithium ion battery electrolyte and a lithium ion battery. The lithium ion batter electrolyte comprises non-aqueous organic solvent, lithium salt, a functional additive, a flame-retardant additive and a negative electrode film-forming agent. According to the scheme of the lithium ion batter electrolyte, perfluoroalkyl diphenyl sulfide is used as the functional additive on the basis of reasonably optimizing the non-aqueous organic solvent, the lithium salt and the negative electrode film-forming agent; the problem that the novel lithium salt corrodes an aluminium current collector can be effectively solved, wherein the novel lithium salt comprises lithium trifluoromethanesulfonate (LiCF3SO3), perfluoroalkyl sulfonyl lithium methide (LiC (CF3SO2)3, bi(trifluoromethyl sulfonyl) lithium imide (LTFSI), bi(sulfonyl fluoride) lithium imide (LiFSI) and the like; the cycling performance of the lithium ion battery is improved; the LiPF6 can be well replaced by the lithium ion battery electrolyte, and the lithium ion battery electrolyte can be widely applied to the secondary lithium ion battery electrolyte, and particularly suitable for lithium ion power batteries for improving the thermal stability of the lithium ion power batteries.

Owner:OPTIMUM BATTERY CO LTD

High performance lithium or lithium ion cell

InactiveUS20120121991A1Electrode carriers/collectorsOrganic electrolyte cellsConductive coatingAlloy

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

Non-aqueous electrolyte for lithium ion battery, and application thereof

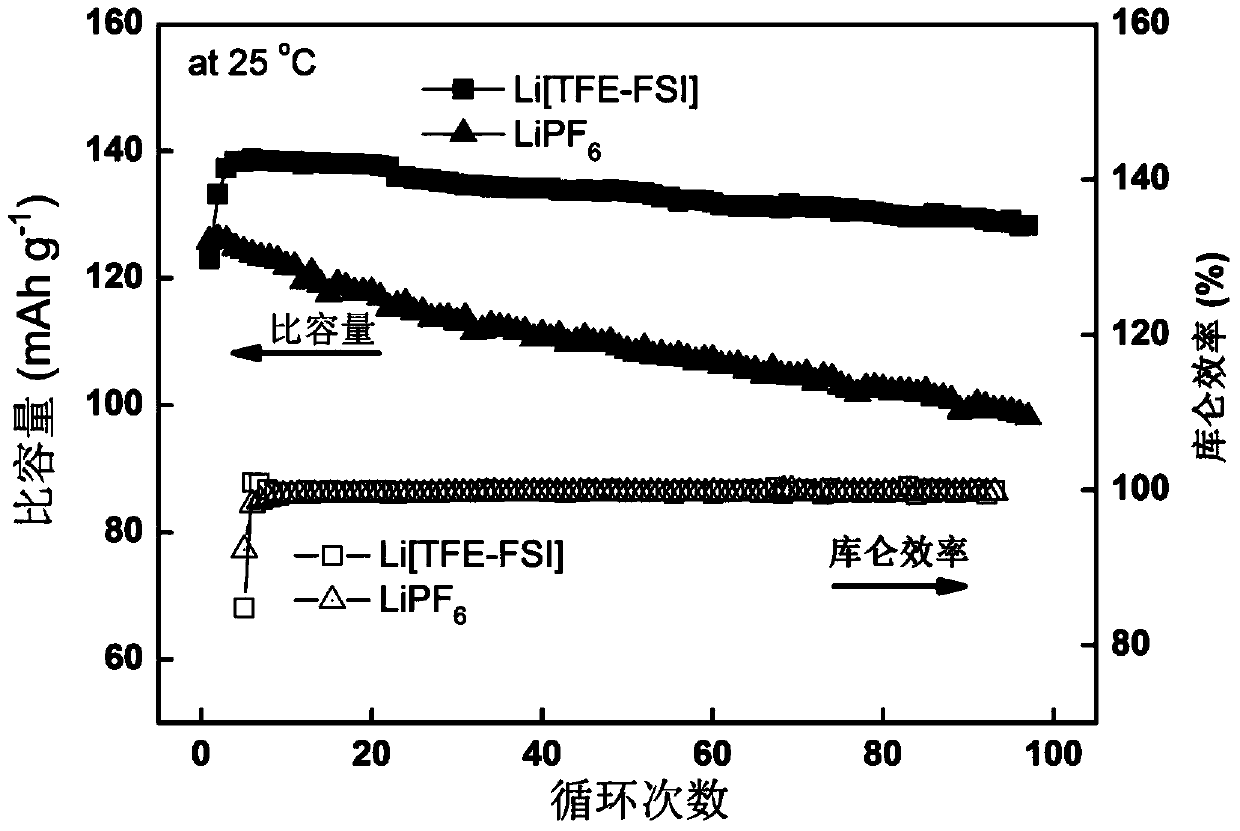

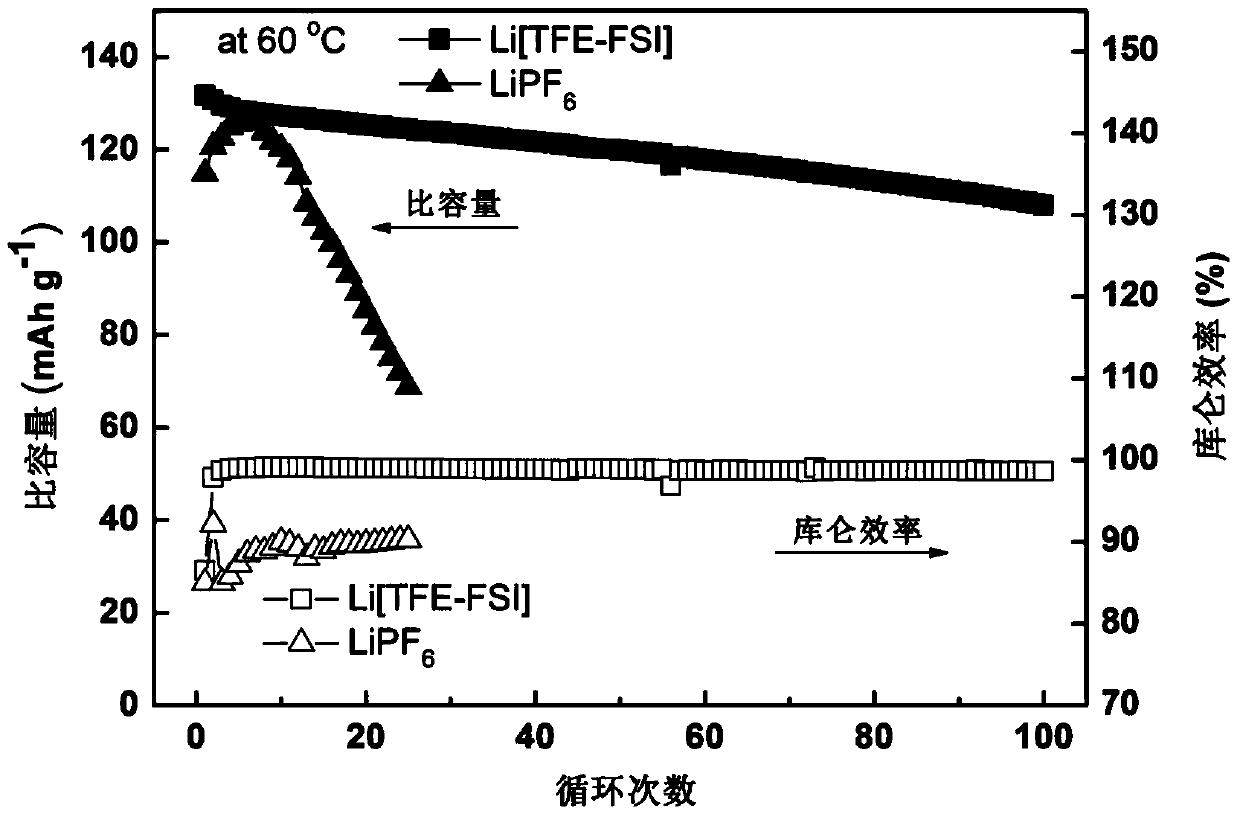

InactiveCN103515650AImprove thermal stabilityStrong redox resistanceSecondary cellsAluminium-ion batteryCarboxylic salt

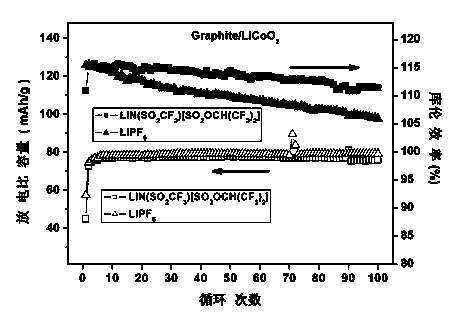

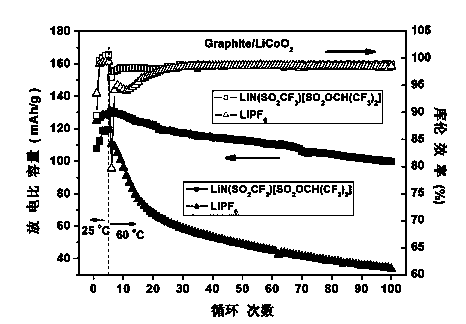

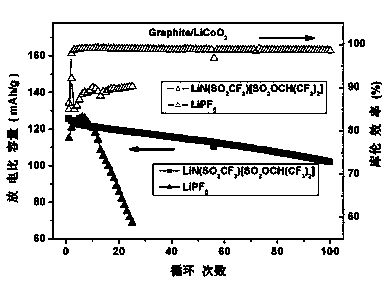

The present invention provides a non-aqueous electrolyte adopting asymmetric (perfluoroalkylsulfonyl) (polyfluoro alkoxy sulfonyl) lithium imide as an electric conduction salt, wherein the non-aqueous electrolyte has characteristics of high thermal stability, strong oxidation reduction resistance, no aluminum foil corrosion and the like. According to the present invention, in the case of no use of any non-aqueous electrolyte functional additive, the lithium ion battery prepared from an non-aqueous electrolyte adopting LiN(SO2CF3)[SO2OCH(CF3)2](LiTFHFSI) as an electric conduction salt and adopting carbonate, cyclic lactone, or carboxylate and the like as a solvent provides more excellent wide temperature work performances, especially high temperature cycle performance and storage performance, compared with the lithium ion battery prepared from the existing LiPF6 electrolyte; and due to excellent characteristics of high thermal stability, insensitivity to water and the like of the used asymmetric (perfluoroalkylsulfonyl) (polyfluoro alkoxy sulfonyl) imide lithium salt, the non-aqueous electrolyte of the present invention has the advantages.

Owner:HUAZHONG UNIV OF SCI & TECH

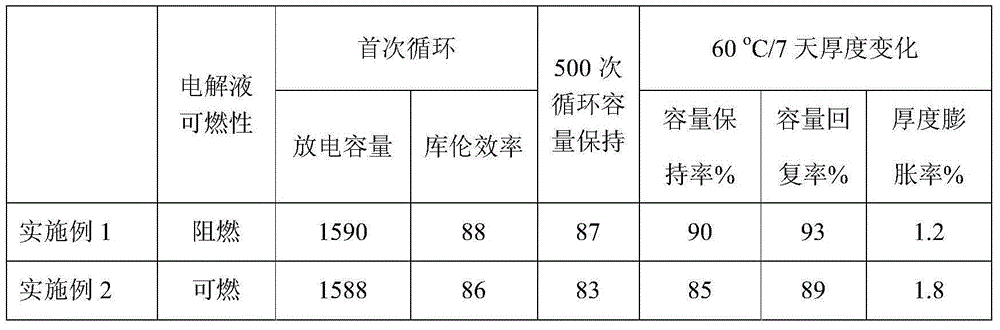

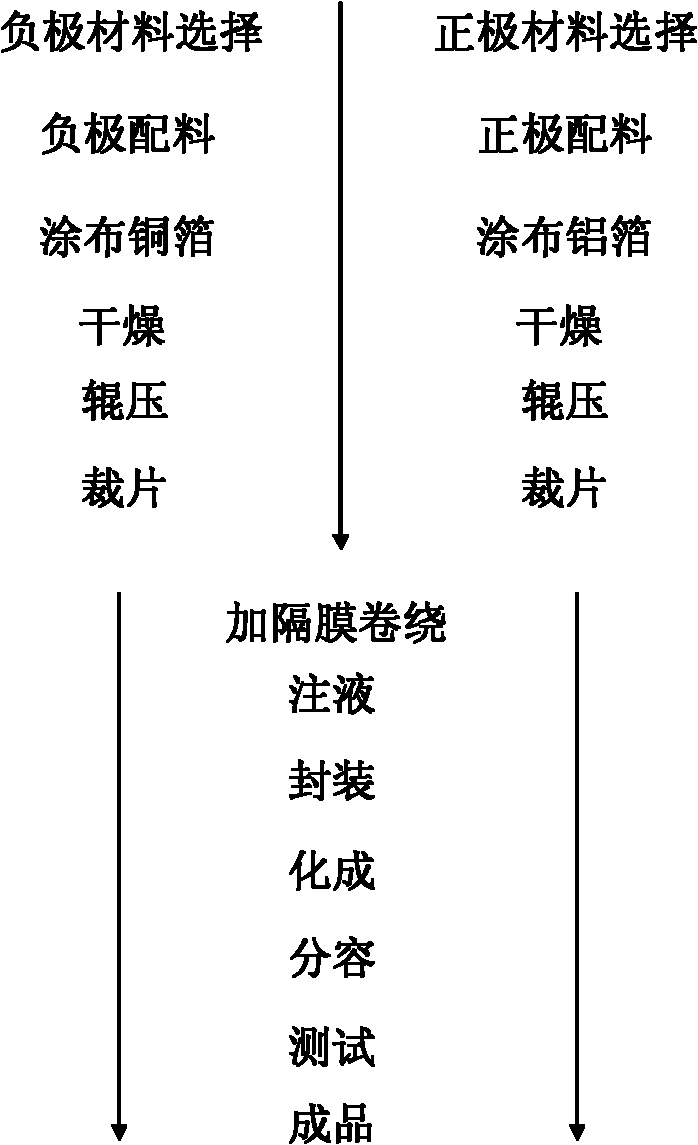

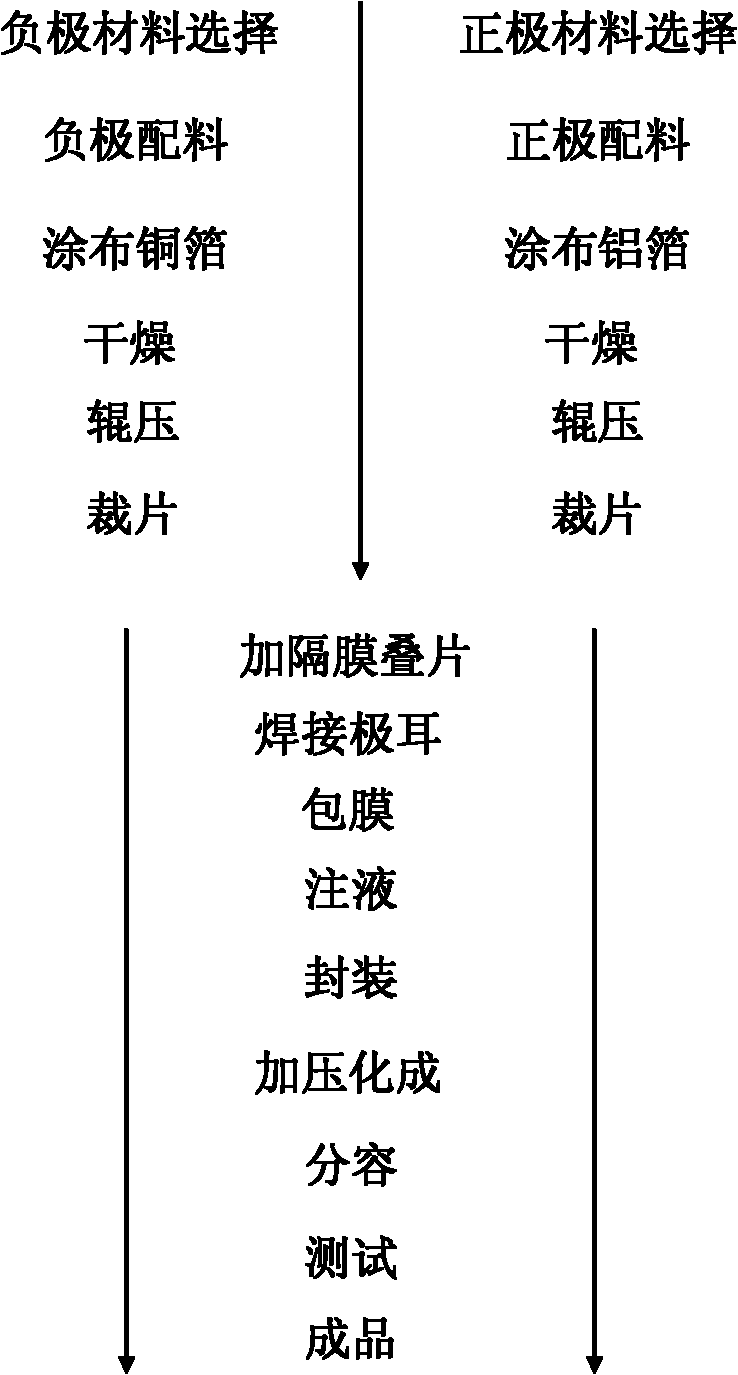

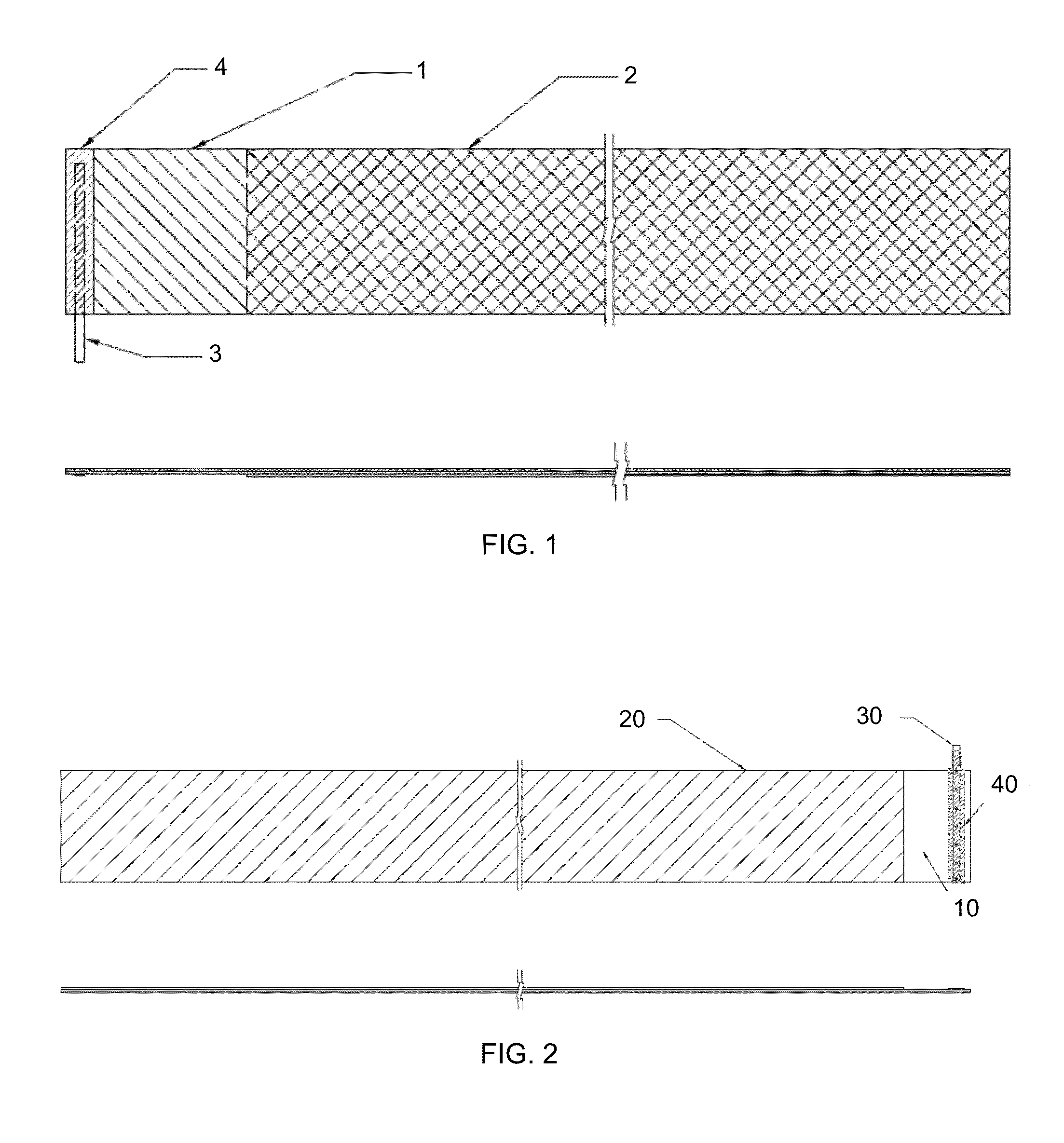

Method for improving energy density of lithium-ion power battery and lithium-ion power battery

ActiveCN104577193AIncrease energy densityImprove battery lifeFinal product manufactureElectrolyte accumulators manufactureLithium imideSolvent

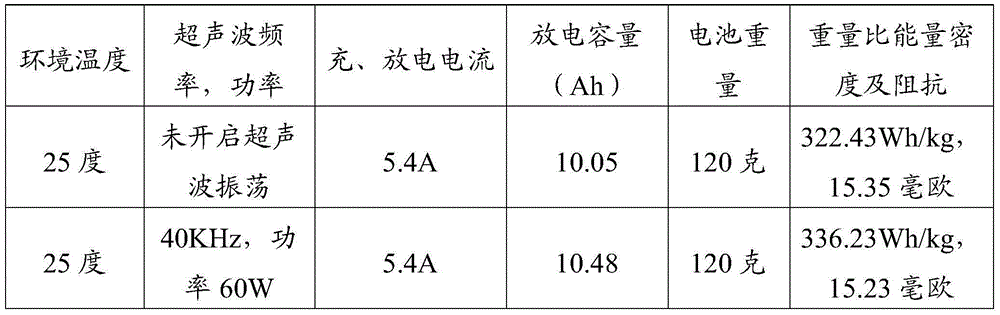

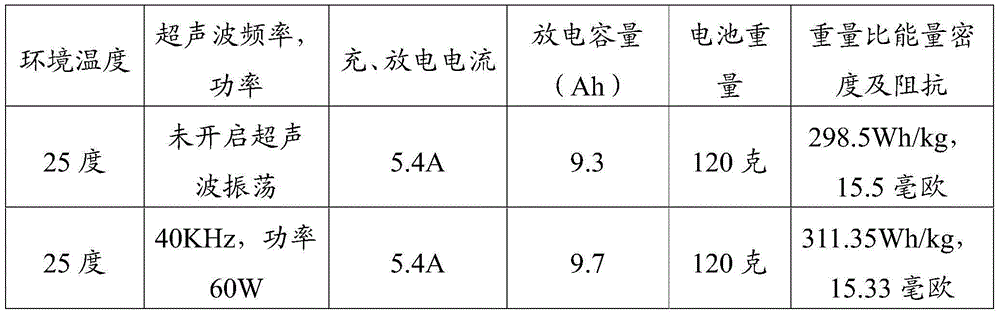

The invention relates to a method for improving energy density of a lithium-ion power battery and the lithium-ion power battery. The surface density or thickness of a positive plate and a negative plate is increased, so that the weight ratio of the amount of a current collector and a diaphragm in the whole battery is correspondingly reduced, the weight ratio of active materials in the whole battery is improved; and therefore, the aim of improving the weight ratio and energy density of the battery is achieved. In addition, by adopting a negative active material with high liquid absorption rate and high liquid retention rate, a copolymer adhesive with a polar group, a carbon-nano-tube conductive agent, electrolyte consisting of a lithium imide salt and a nitrile solvent with 1 or 2 nitrile groups in the molecular structure, and a polyethylene porous membrane coated with alumina ceramics on a single side, the lithium-ion power battery is subjected to high-frequency oscillation by utilizing an ultrasonic high-frequency oscillation technology, so that high power capacity of the battery design is exerted, and the condition that the electrical property and service effect of the battery are reduced due to increase of the surface density of the positive and negative plates is avoided.

Owner:苏州悦钠新能源科技有限公司

Nonaqueous electrolyte containing sulfonyl fluoride imidogen lithium salt as well as application of electrolyte

InactiveCN103794819AImprove thermal stabilityStrong redox resistanceCell electrodesSecondary cellsSulfonyl fluorideLithium-ion battery

The invention discloses nonaqueous electrolyte by taking asymmetrical (sulfonyl fluoride) (multi-fluorine alkoxy sulfonyl) lithium imide as conductive salt. The nonaqueous electrolyte has the characteristics of high thermal stability, high redox resistance, no aluminum foil corrosion and the like. Under the condition of no additive, the electrolyte material and the lithium ion battery electrode material have favorable compatibility; meanwhile, the electrolyte material has better room-temperature and high-temperature circulation stability than LiPF6, and can serve as a nonaqueous electrolyte additive for improving the high-temperature cycle and storage performances based on the LiPF6 electrolyte.

Owner:SUZHOU FLUOLYTE

High performance lithium or lithium ion cell

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

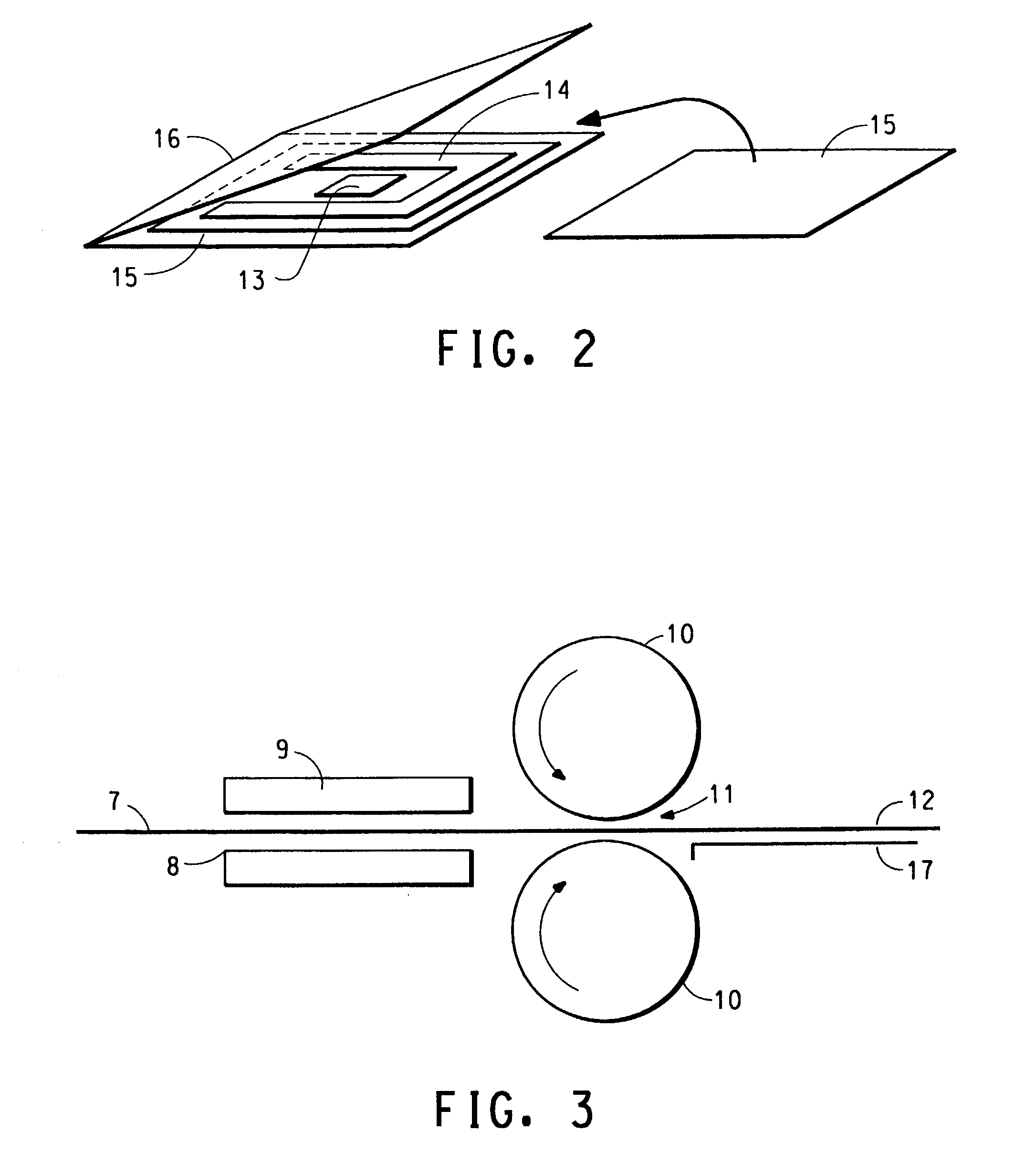

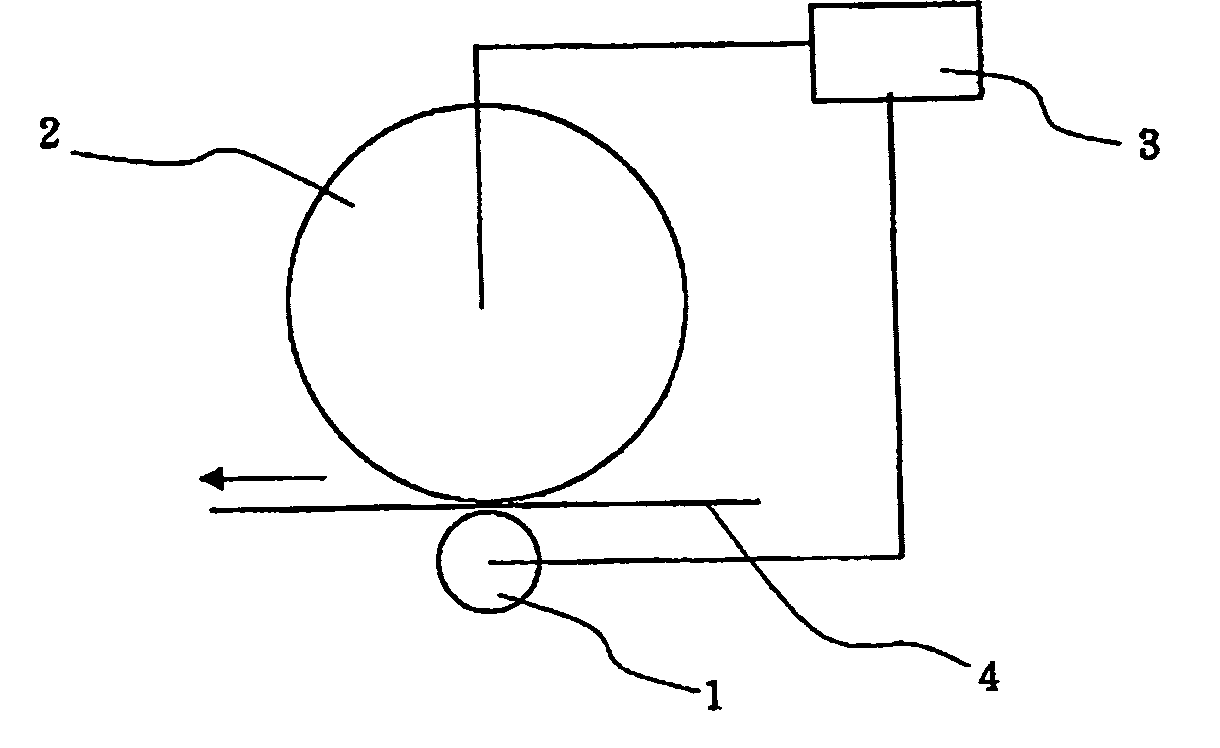

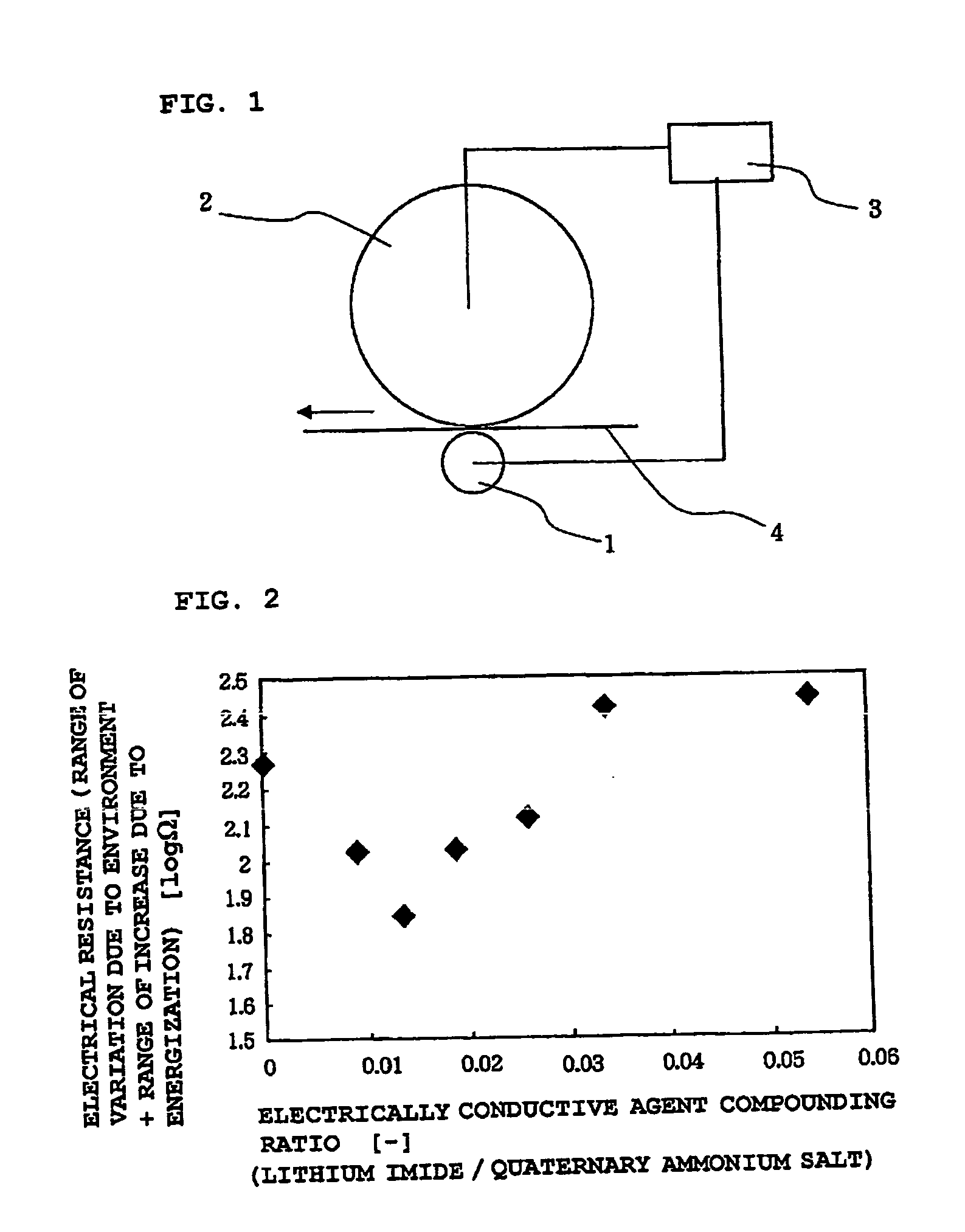

Electrically conductive polymer member, transfer roller, and image forming device

InactiveUS20070152193A1Stable resistance valueEnhanced inhibitory effectConductive materialOrganic conductorsConductive polymerLithium imide

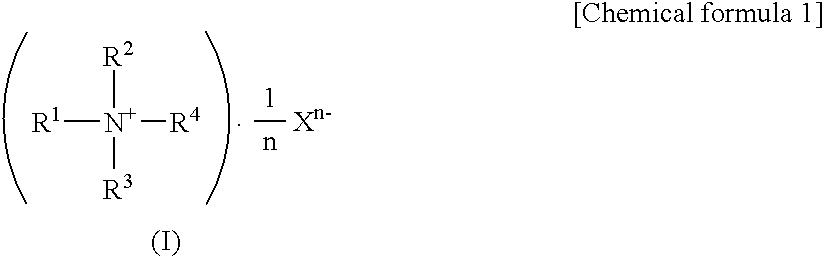

[Object] To provide an electrically conductive polymer member, which can be stably used with a reduced variation in electrical resistance even when its use environment is changed or continuous energization is conducted, and furthermore, a transfer roller and an image forming device, which can stably produce good images by using the electrically conductive polymer member. [Solving Means] An electrically conductive polymer member is formed from an electrically conductive polymer material prepared by adding a quaternary ammonium salt and a lithium imide to a base polymer. When the amounts of compounding of the quaternary ammonium salt and the lithium imide are assumed to be x parts by weight and y parts by weight, respectively, it is preferable that x and y satisfy the following formula: 0.009≦(y / x)≦0.019. A transfer roller and an image forming device are provided with their respective electrically conductive polymer members.

Owner:BRIDGESTONE CORP

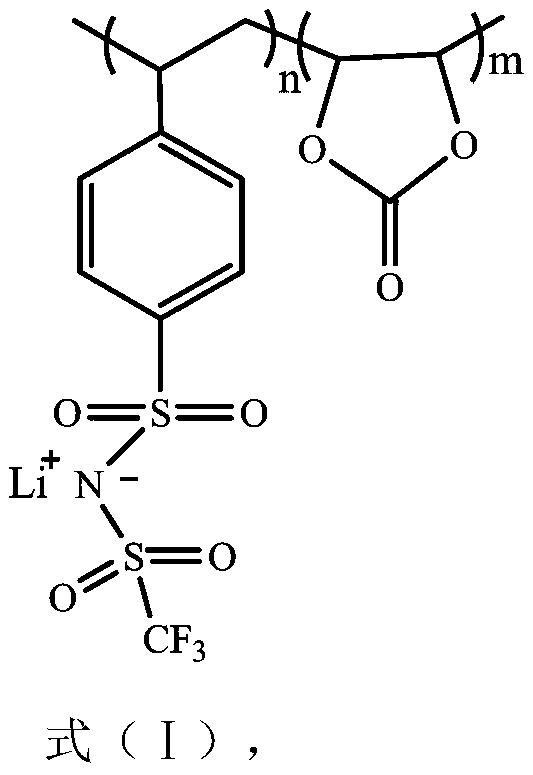

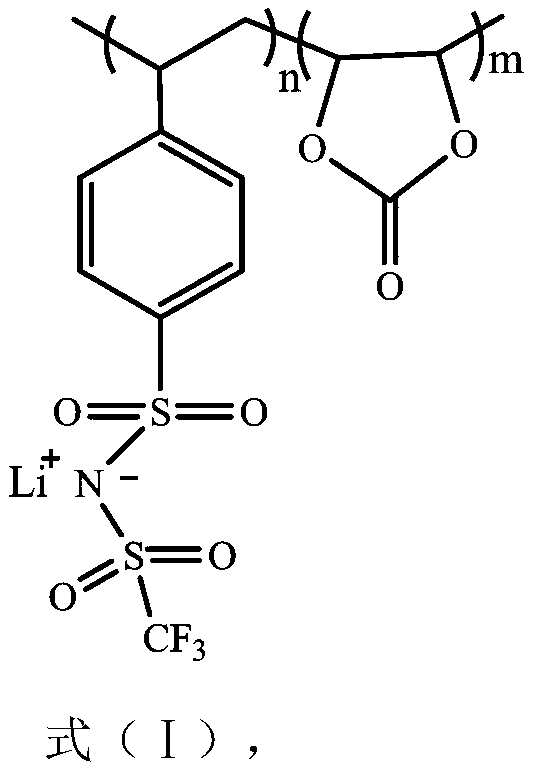

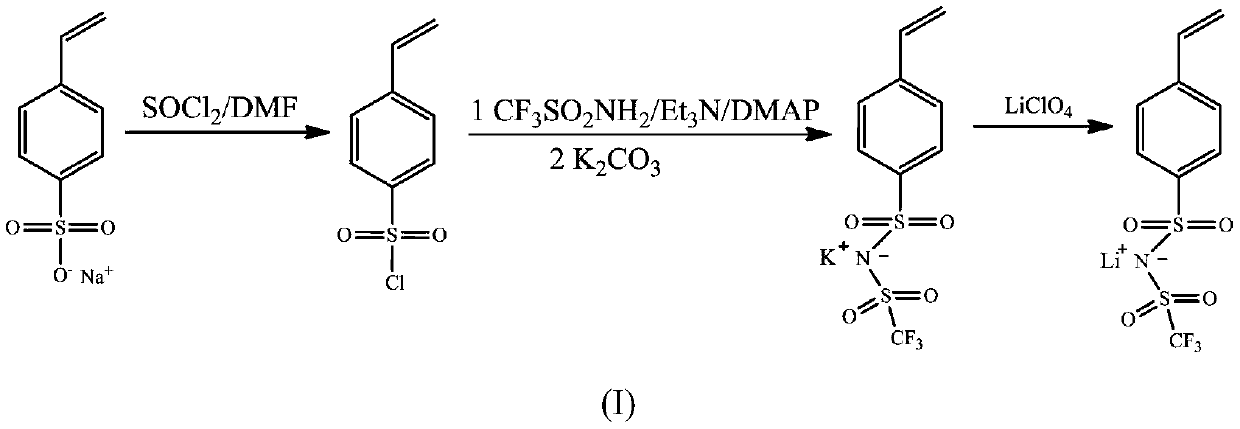

Polyp-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide-polyvinylidene carbonate copolymer and application thereof

The invention belongs to the technical field of polymer synthesis and discloses a polyp-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide-polyvinylidene carbonate copolymer and application thereof. The copolymer is synthesized by the following steps: adding a p-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide monomer, a vinylidene carbonate monomer and a catalyst into a solvent I andperforming polymerization reaction at 70 to 100 DEG C, wherein the p-styrene sulfonyl(trifluoromethyl sulfonyl)lithium imide monomer is prepared by the steps of performing reaction on sodium p-styrenesulfonate and sulfoxide chloride in a solvent at -10 to 25 DEG C, adding an acid-binding agent, an activating agent and trifluoromethyl sulfonamide and performing reaction at -10 to 25 DEG C; addingpotassium carbonate and performing reaction at 25 to 70 DEG C; and adding lithium perchlorate and performing reaction at 25 to 60 DEG C. The copolymer provided by the invention has high lithium ion migration number and room-temperature conductivity, is simple in preparation method, can realize large-scale production and can serve as lithium ion battery electrolyte.

Great-capacity high-power lithium secondary battery and preparation method thereof

InactiveCN102104170AImprove high and low temperature performanceImprove ionic conductivityCell electrodesFinal product manufactureLithiumNew energy

The invention discloses a great-capacity high-power lithium secondary battery comprising a positive electrode, an electrolyte and a negative electrode. The great-capacity high-power lithium secondary battery is characterized in that the electrolyte contains bi-(mefluidide) lithium imide, the positive electrode is selected from a lithium-rich positive electrode material, and the negative electrode is selected from either of H2Ti12O25 or molybdenum dioxide. The invention also discloses a preparation method of the battery. The lithium secondary battery prepared by utilizing the method has high power and capacity and is suitable for lithium ion power and storage batteries in the fields of electric vehicles and new energy.

Owner:CHANGZHOU HECO NEW ENERGY TECH CO LTD

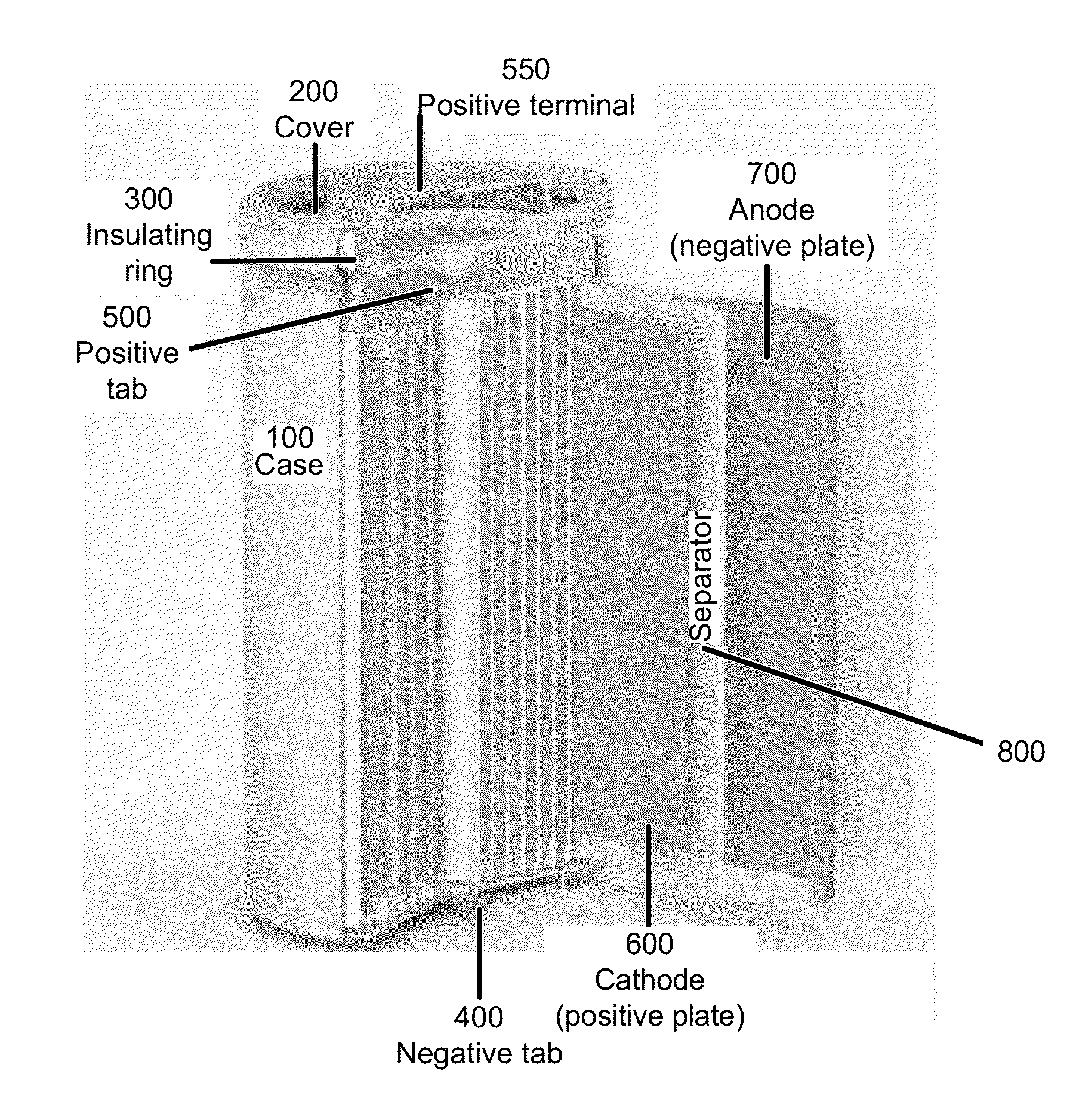

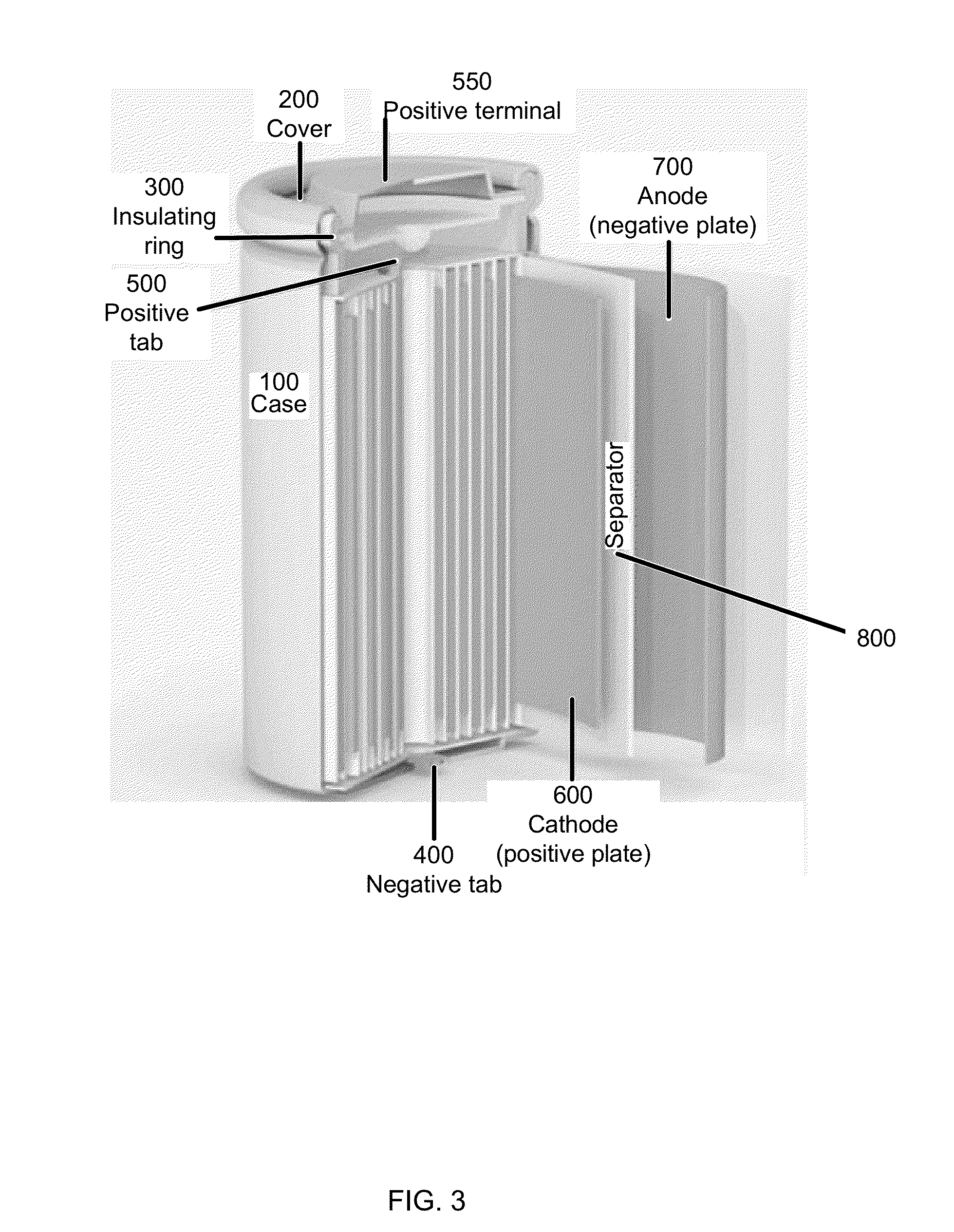

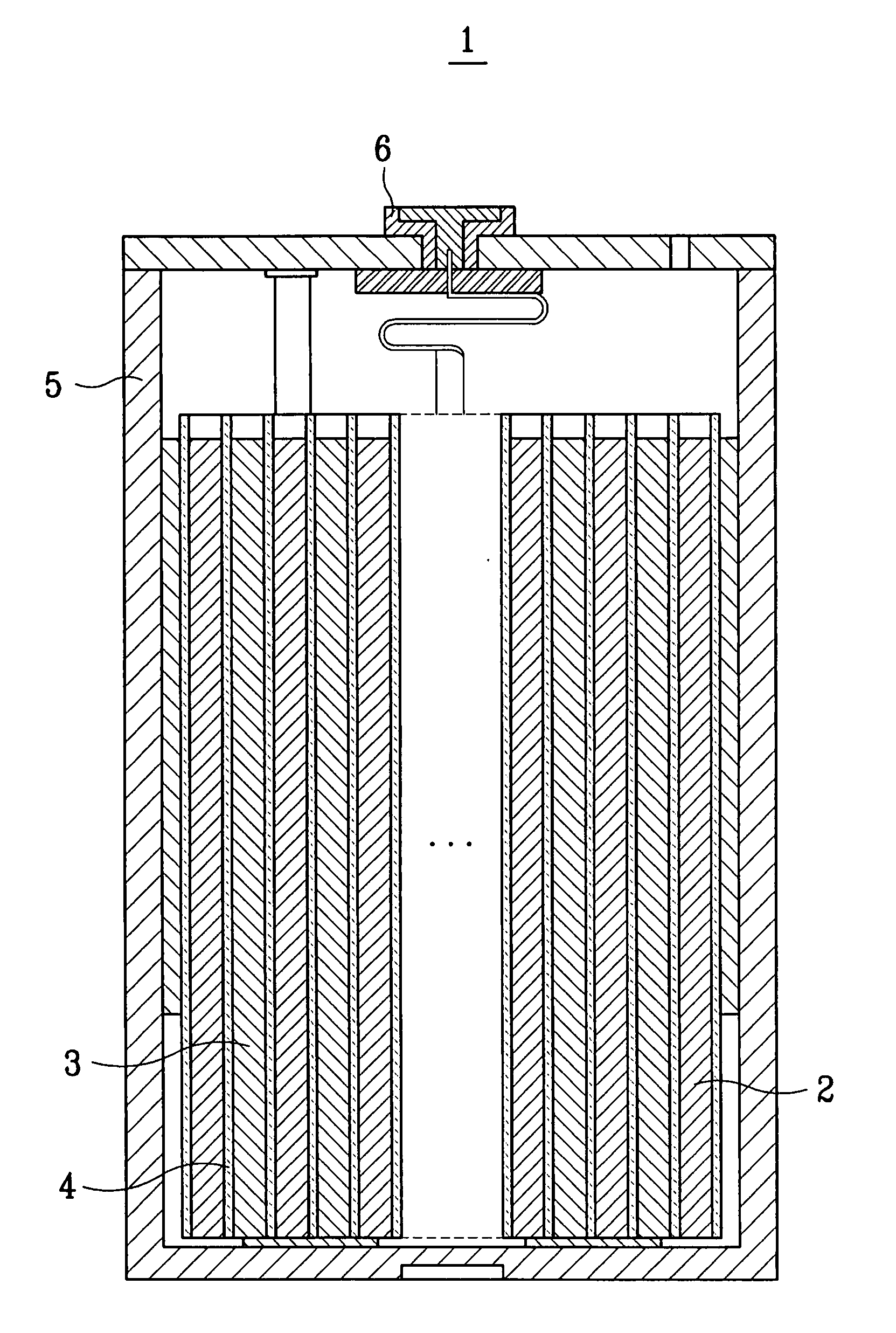

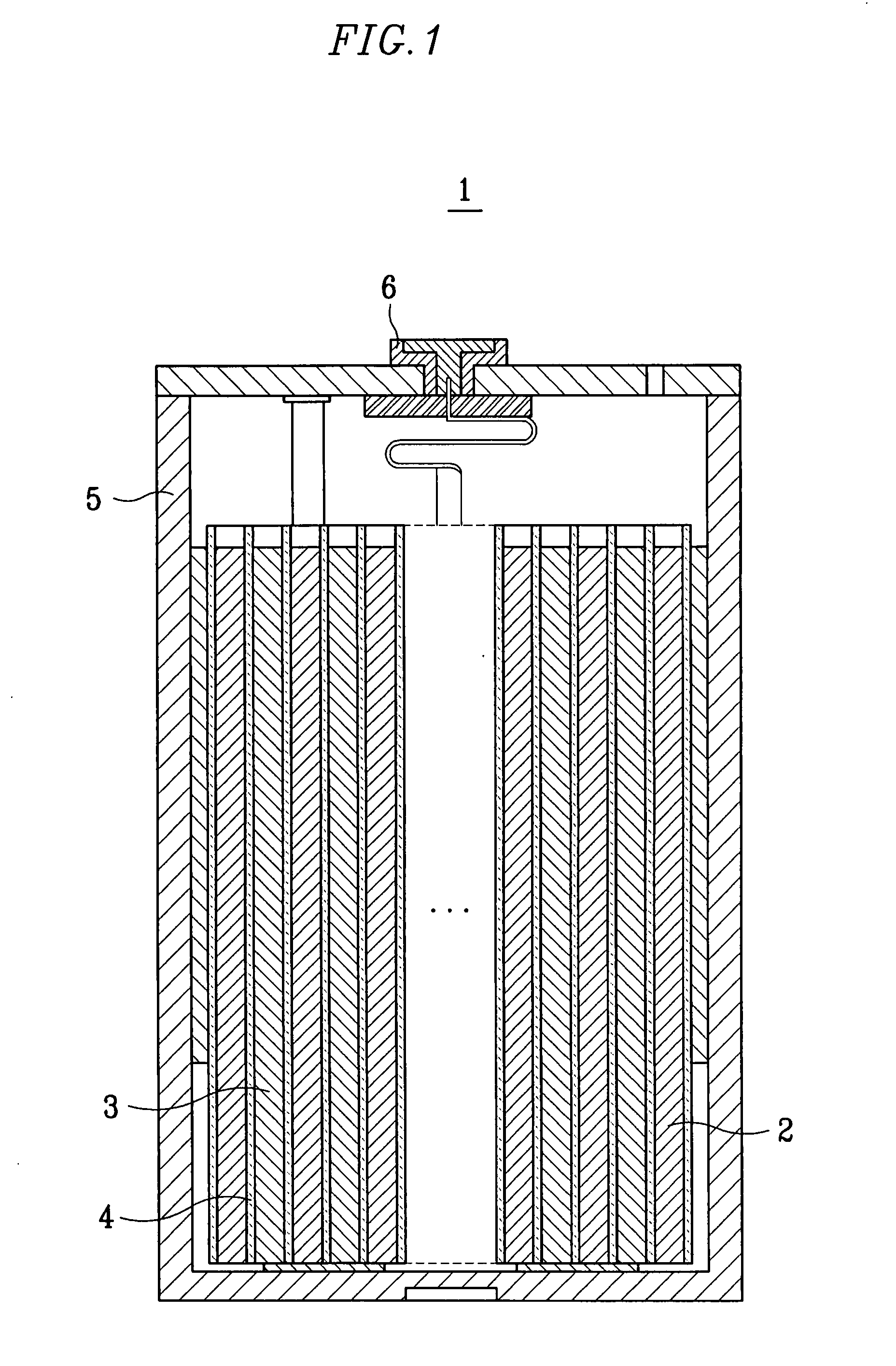

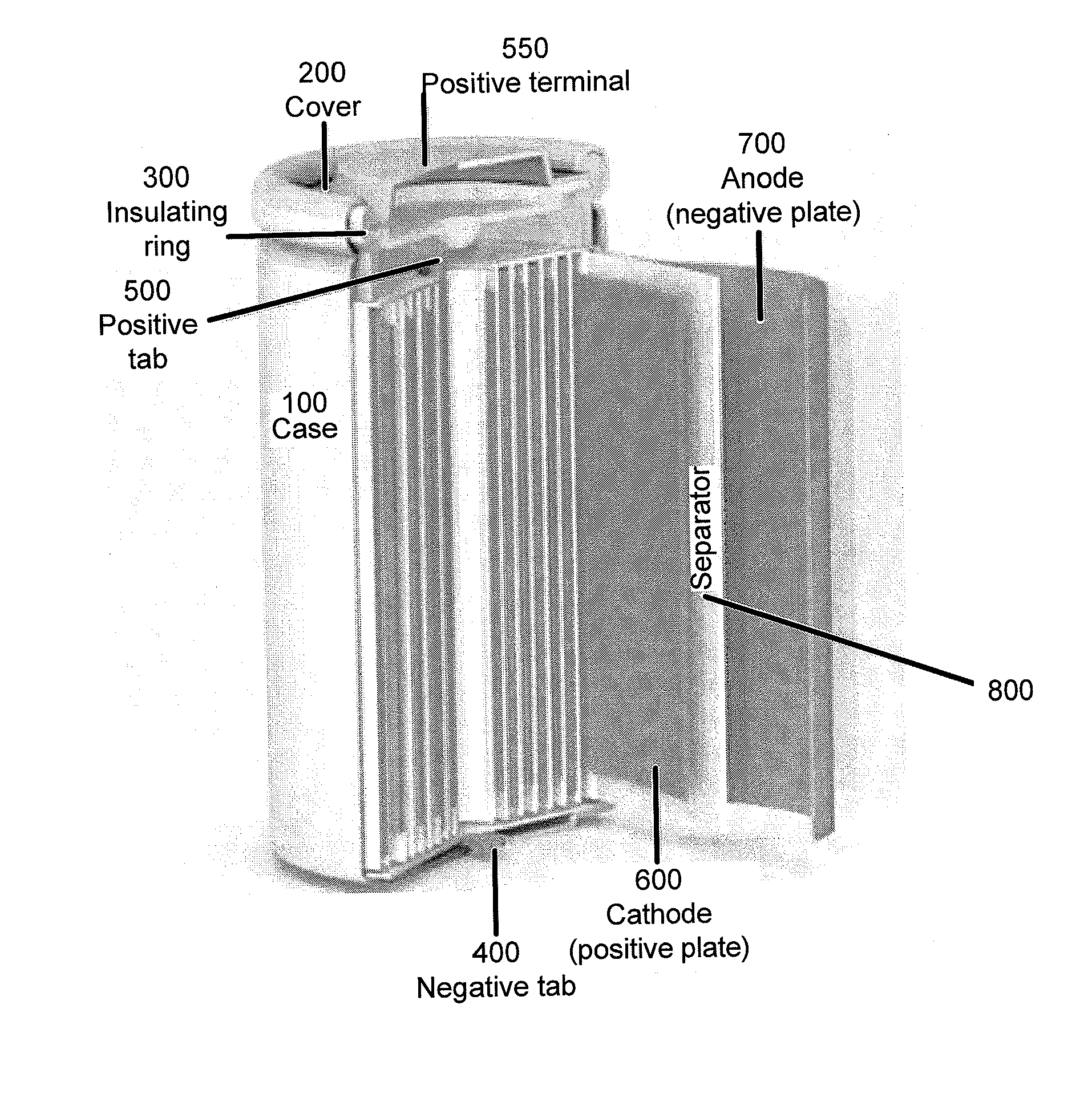

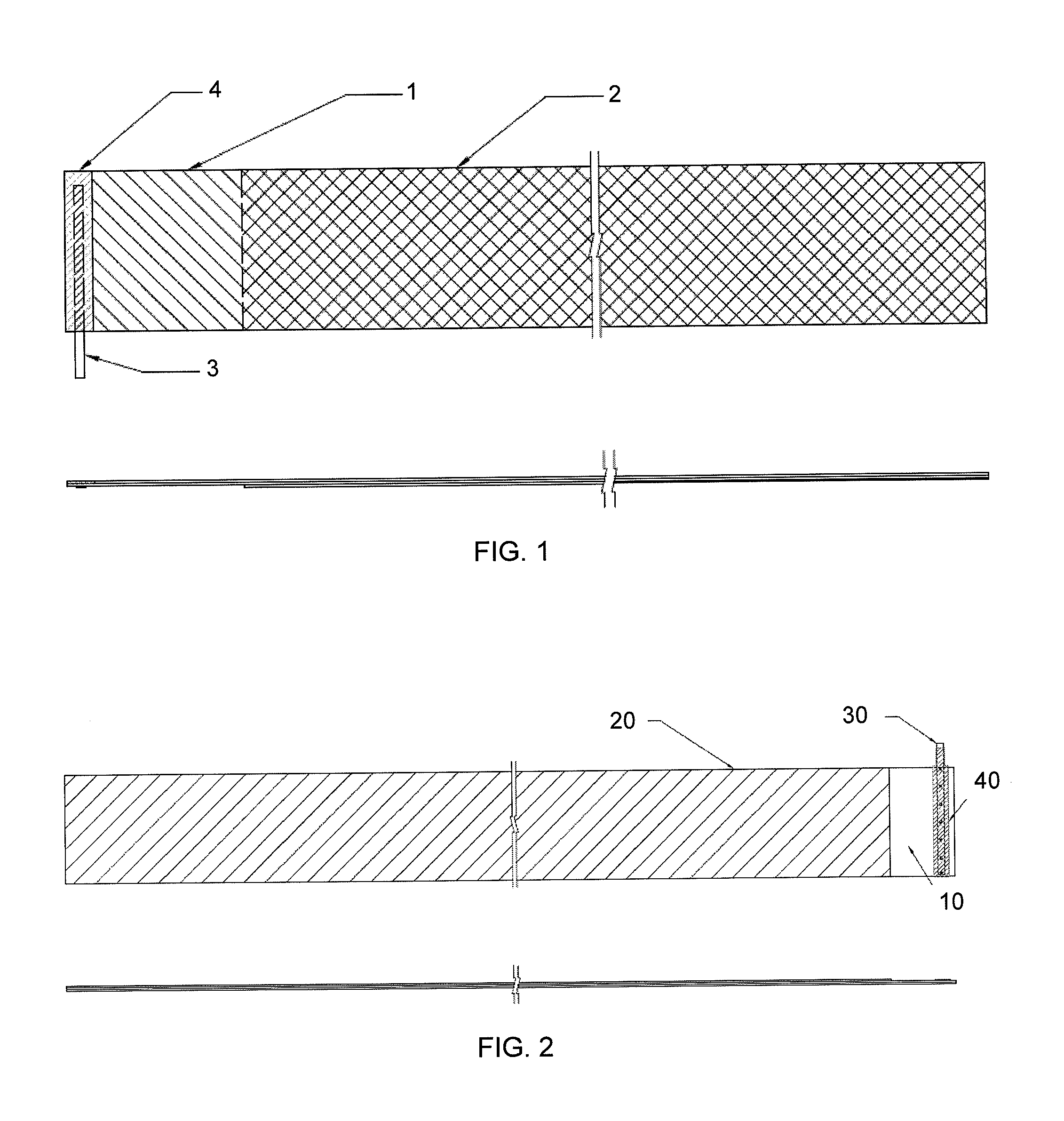

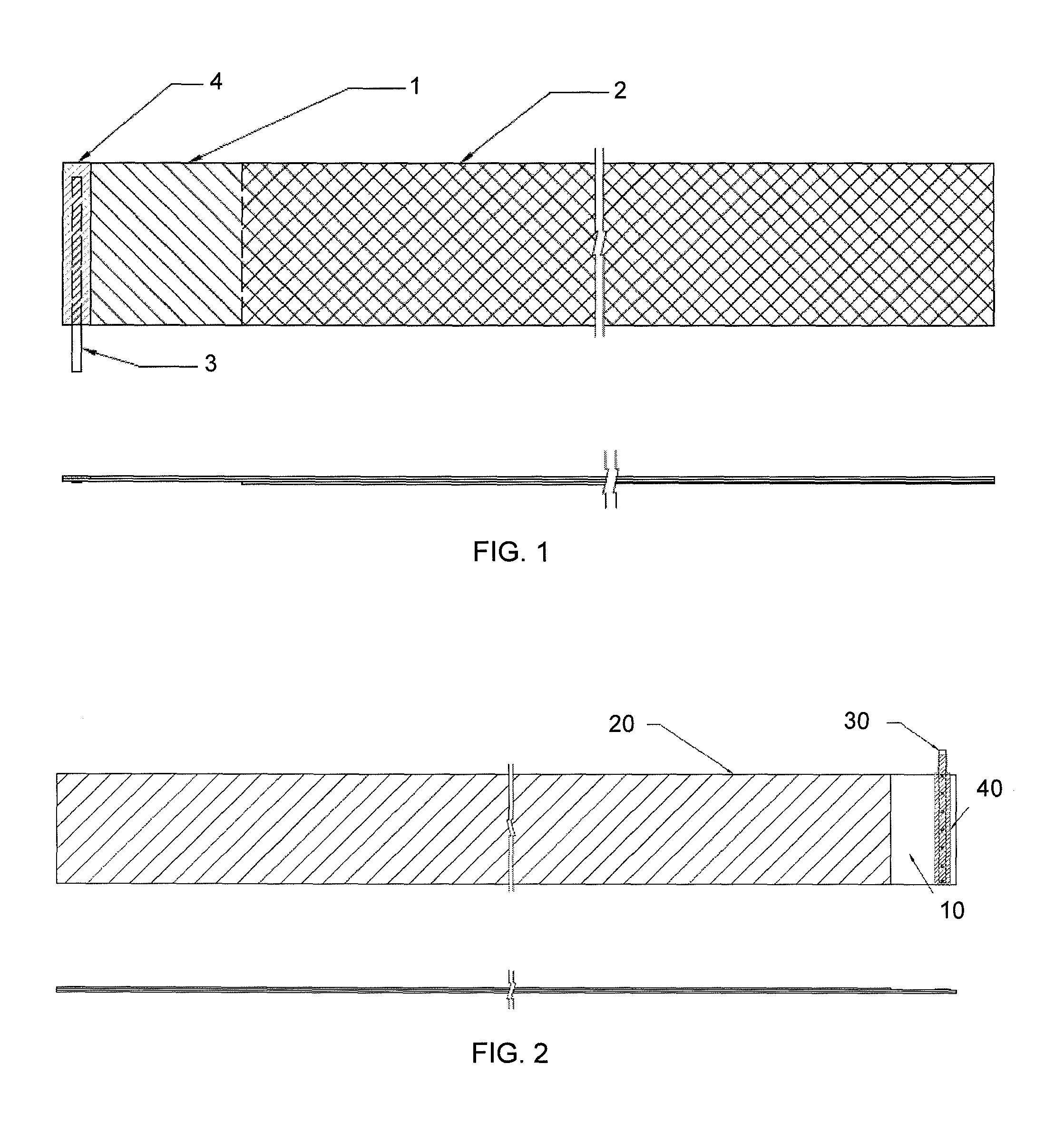

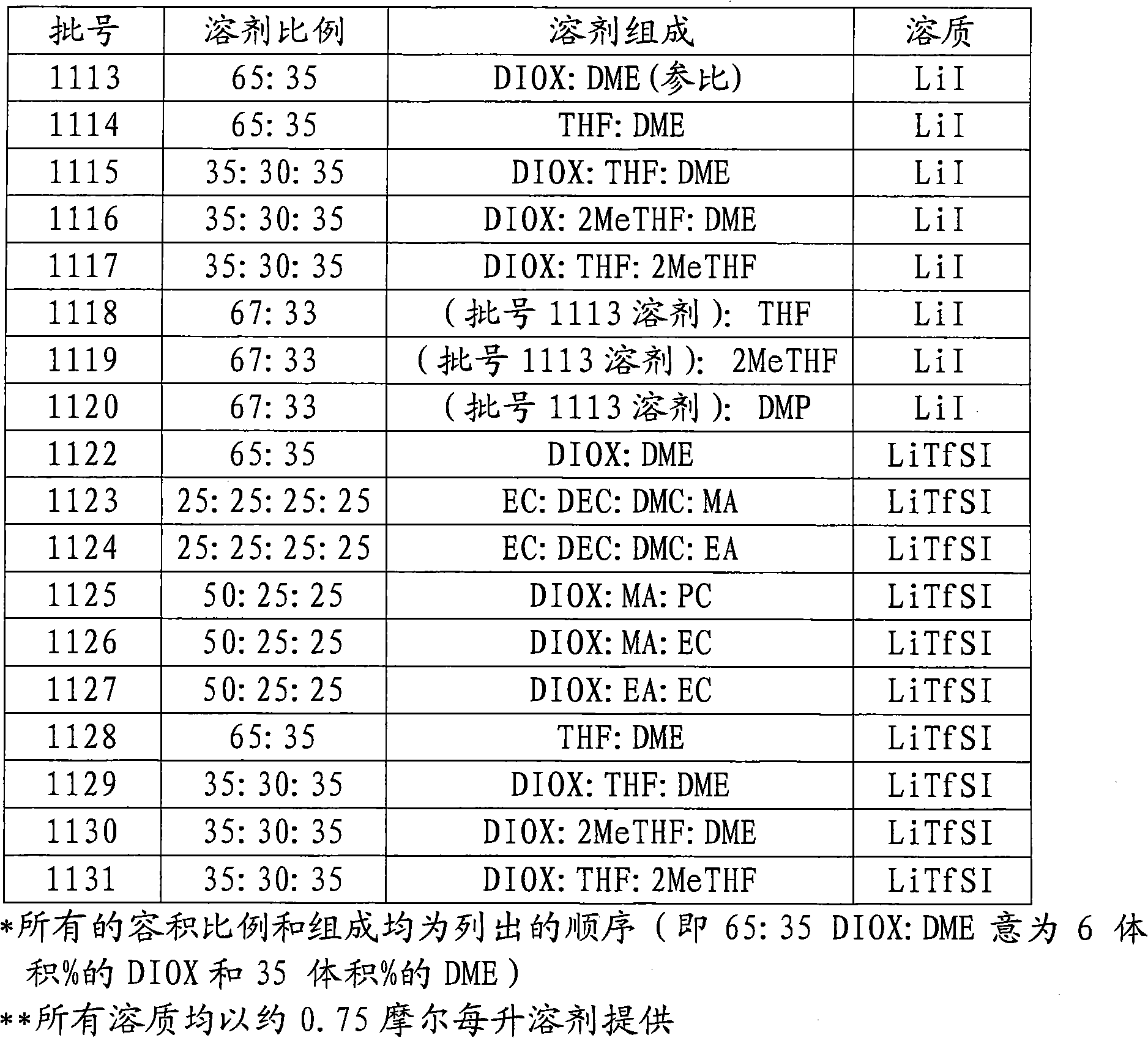

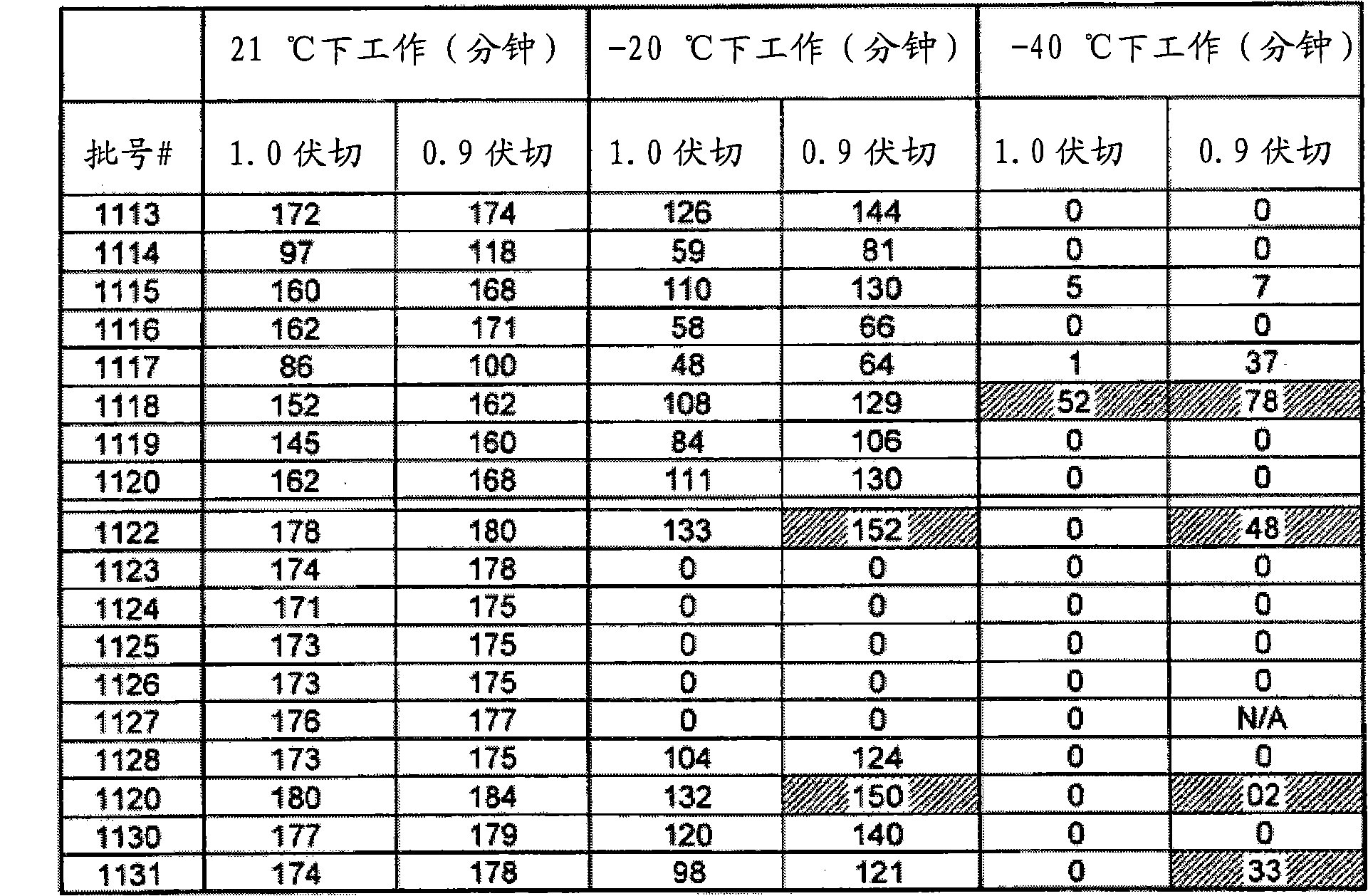

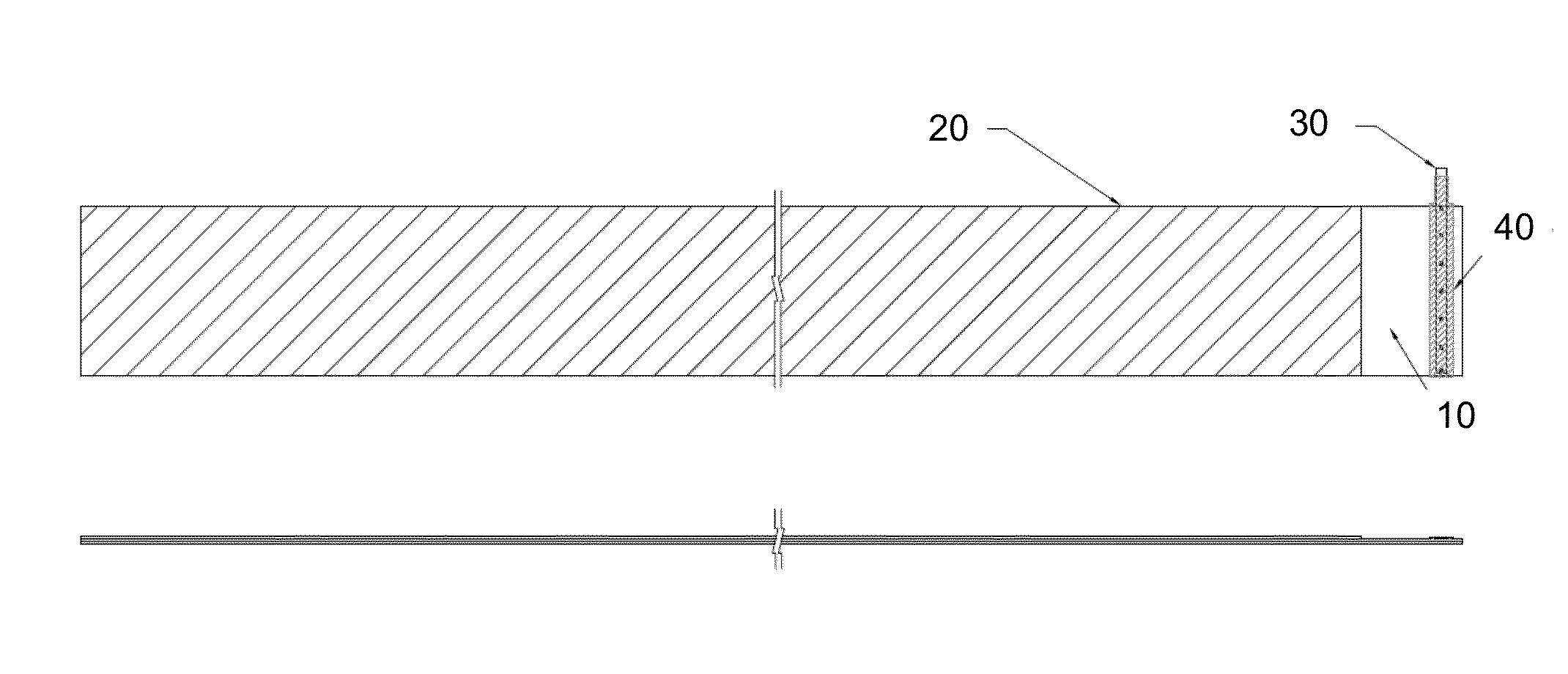

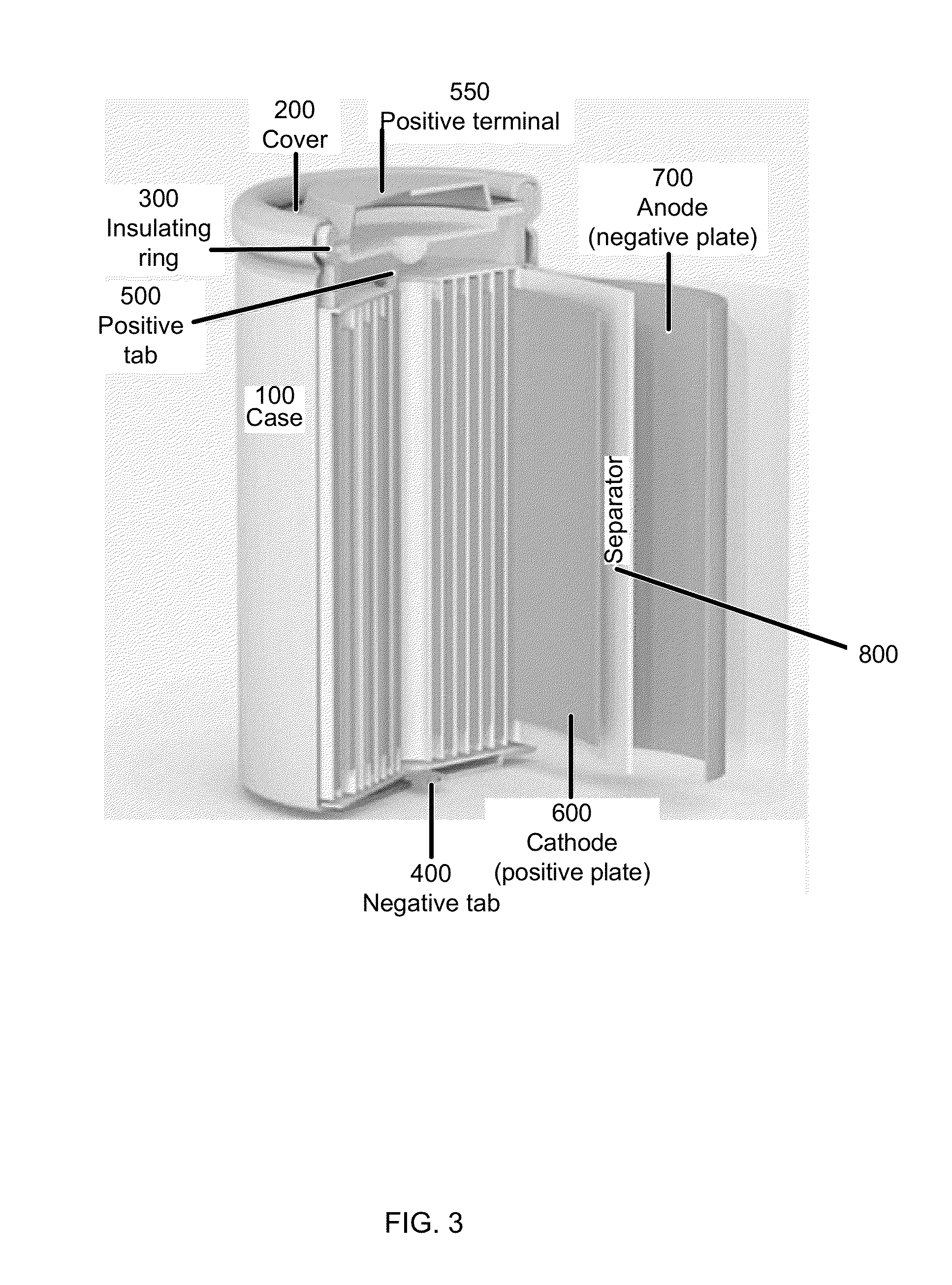

THF-based Electrolyte for Low Temperature Performance in Primary Lithium Batteries

InactiveUS20110117407A1Maximize loadingAvoid coatingCell electrodesSmall-sized cells cases/jacketsElectrical conductorEngineering

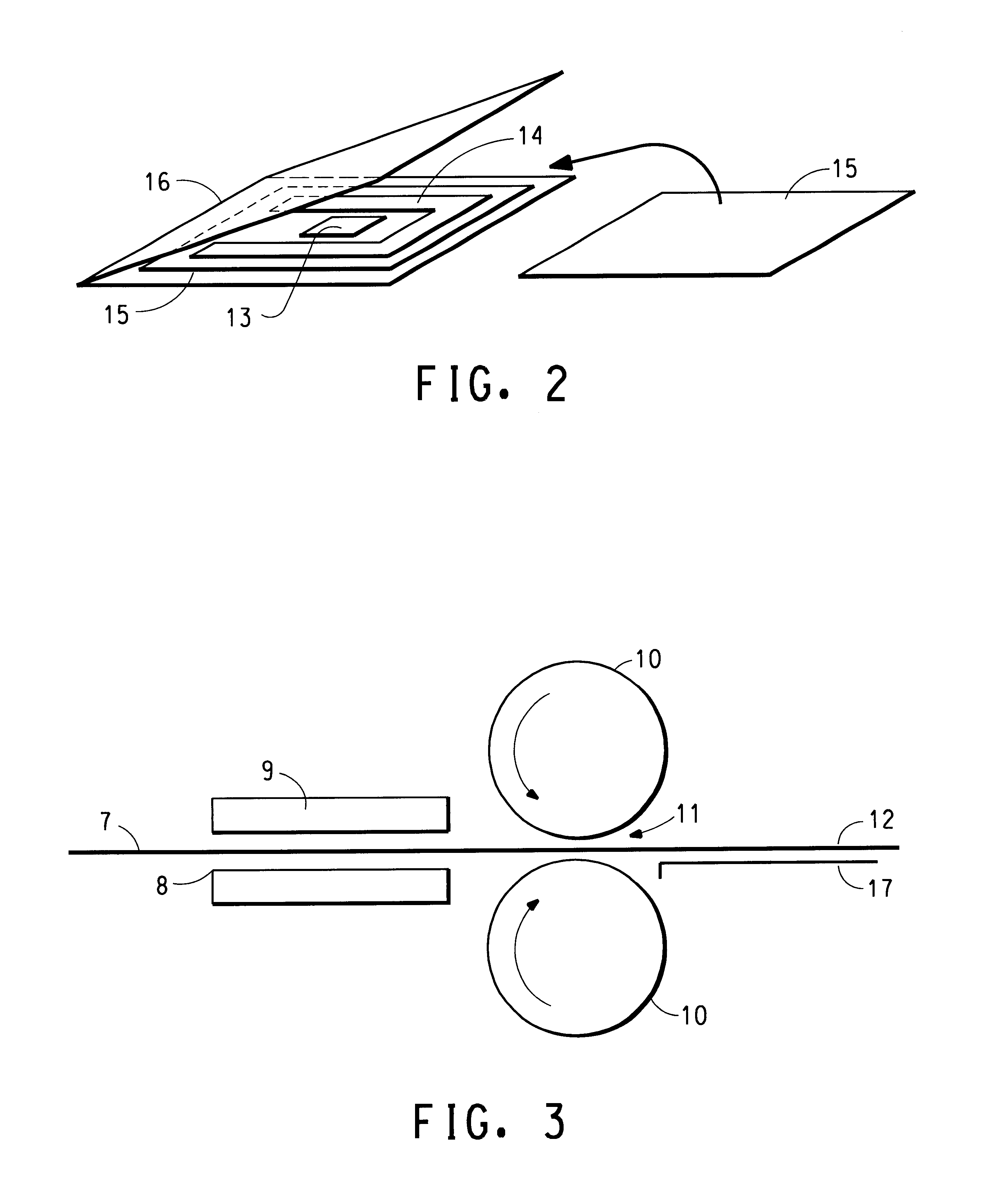

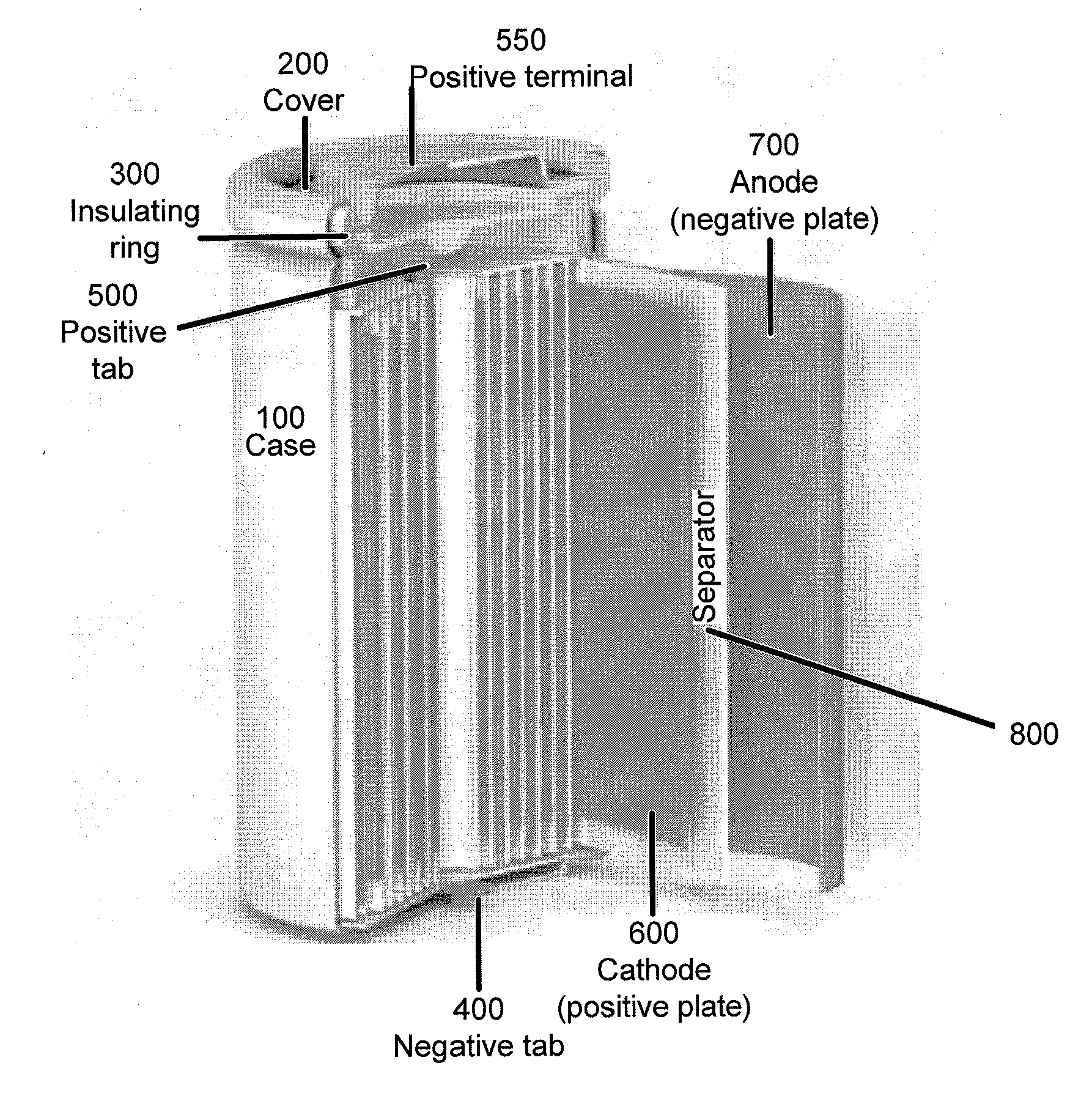

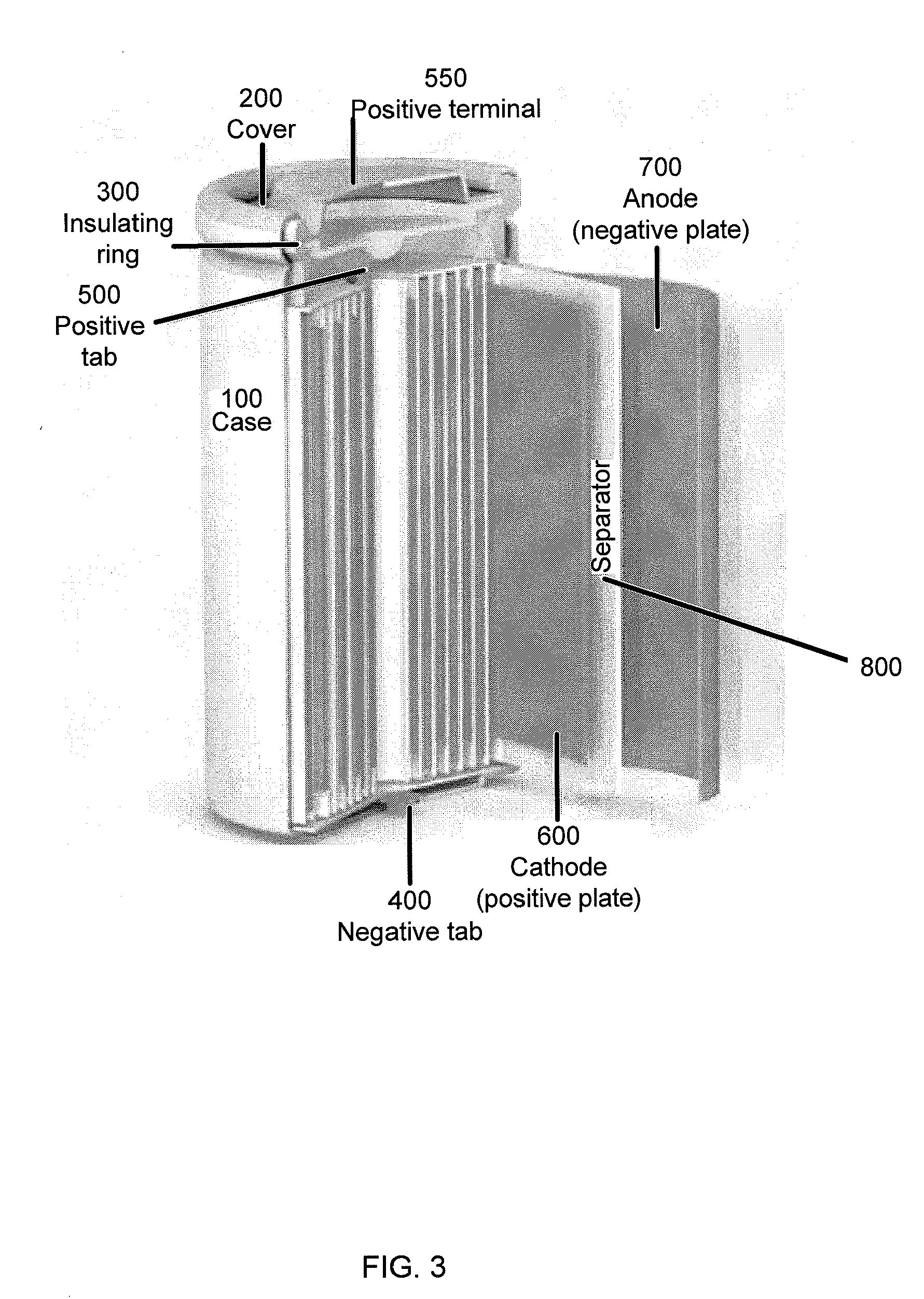

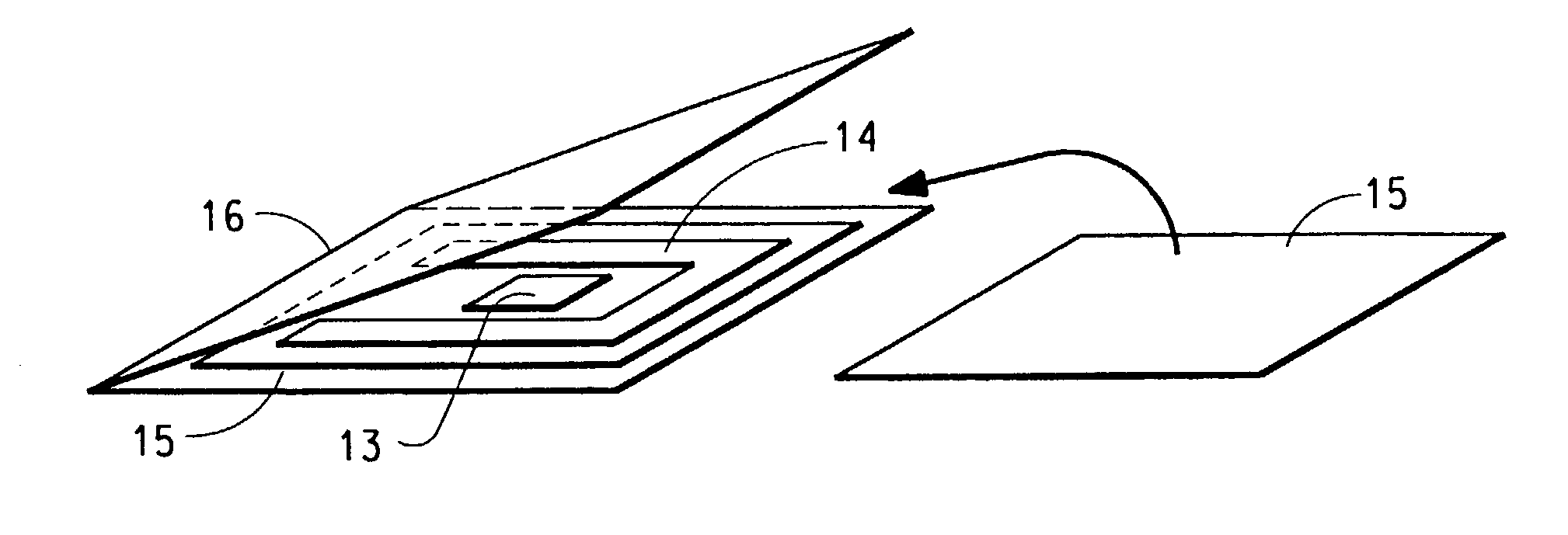

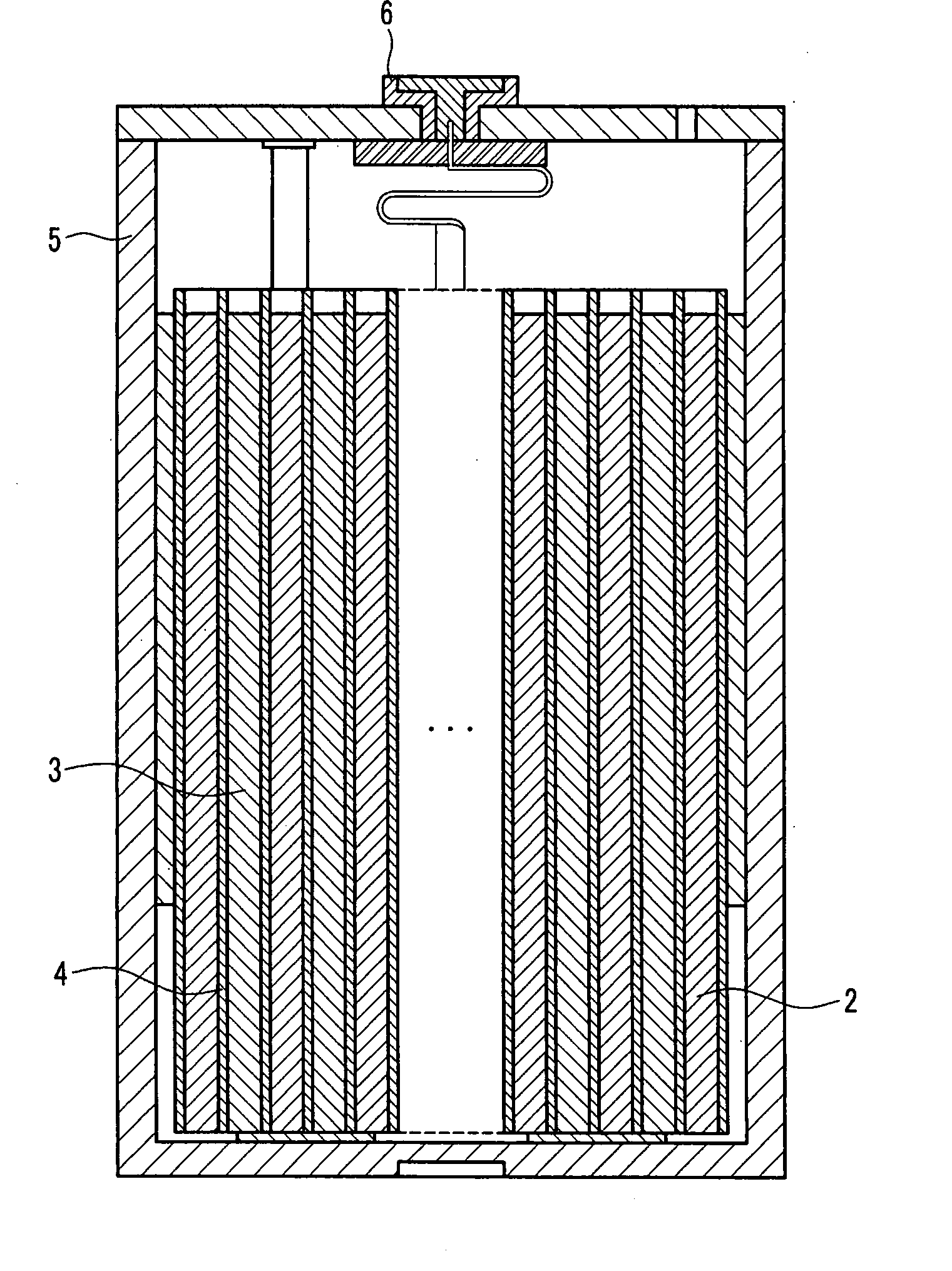

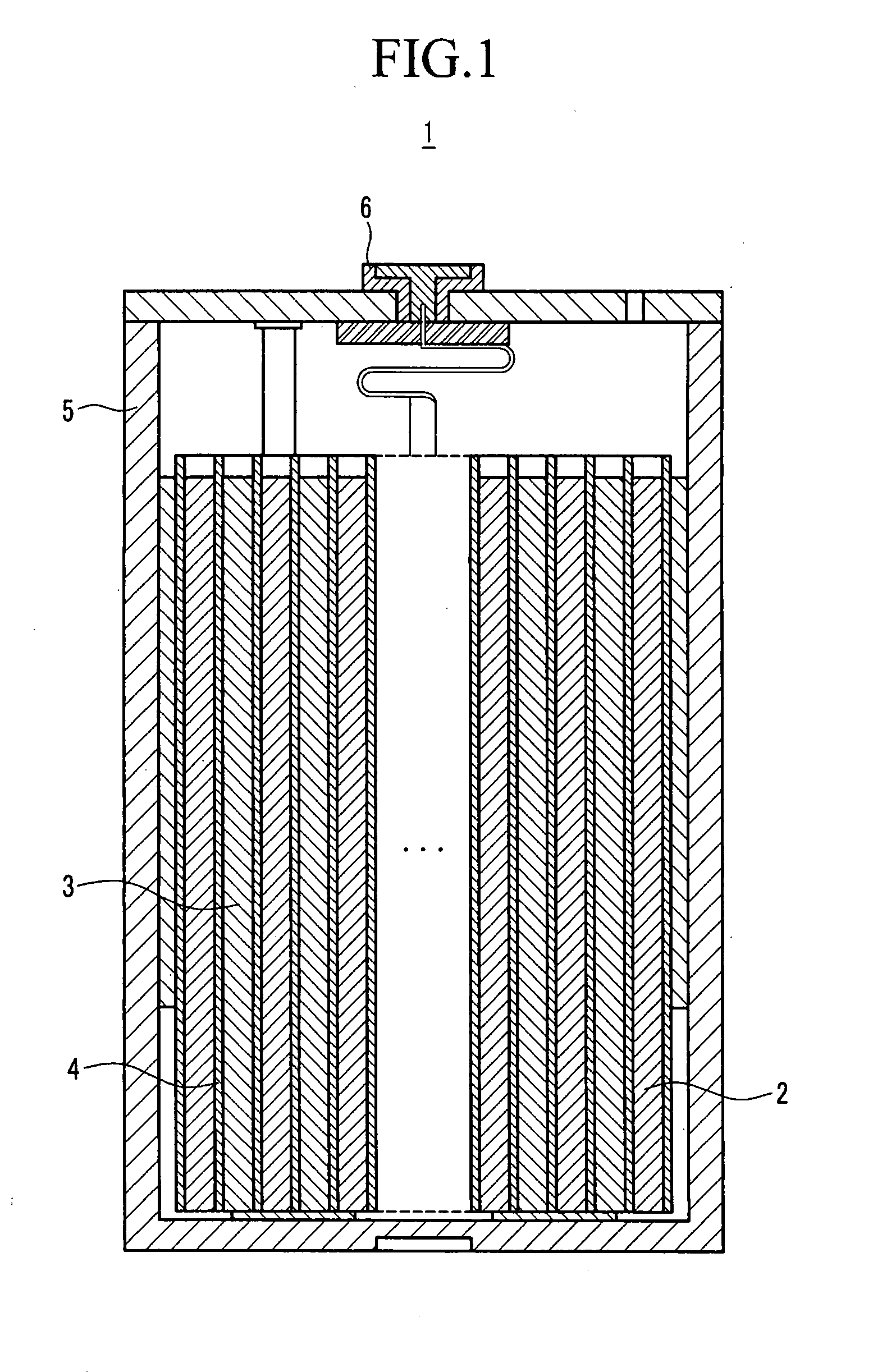

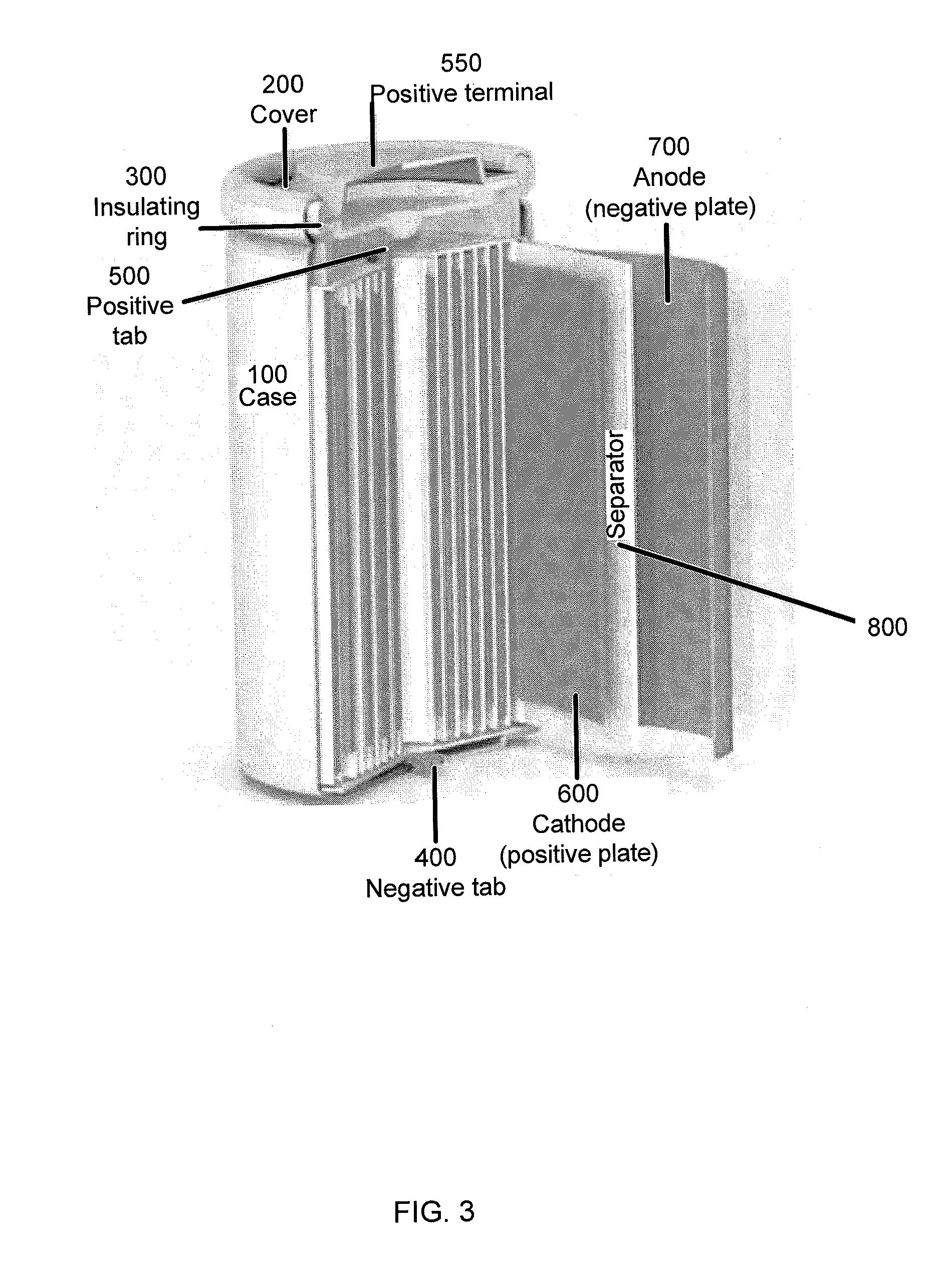

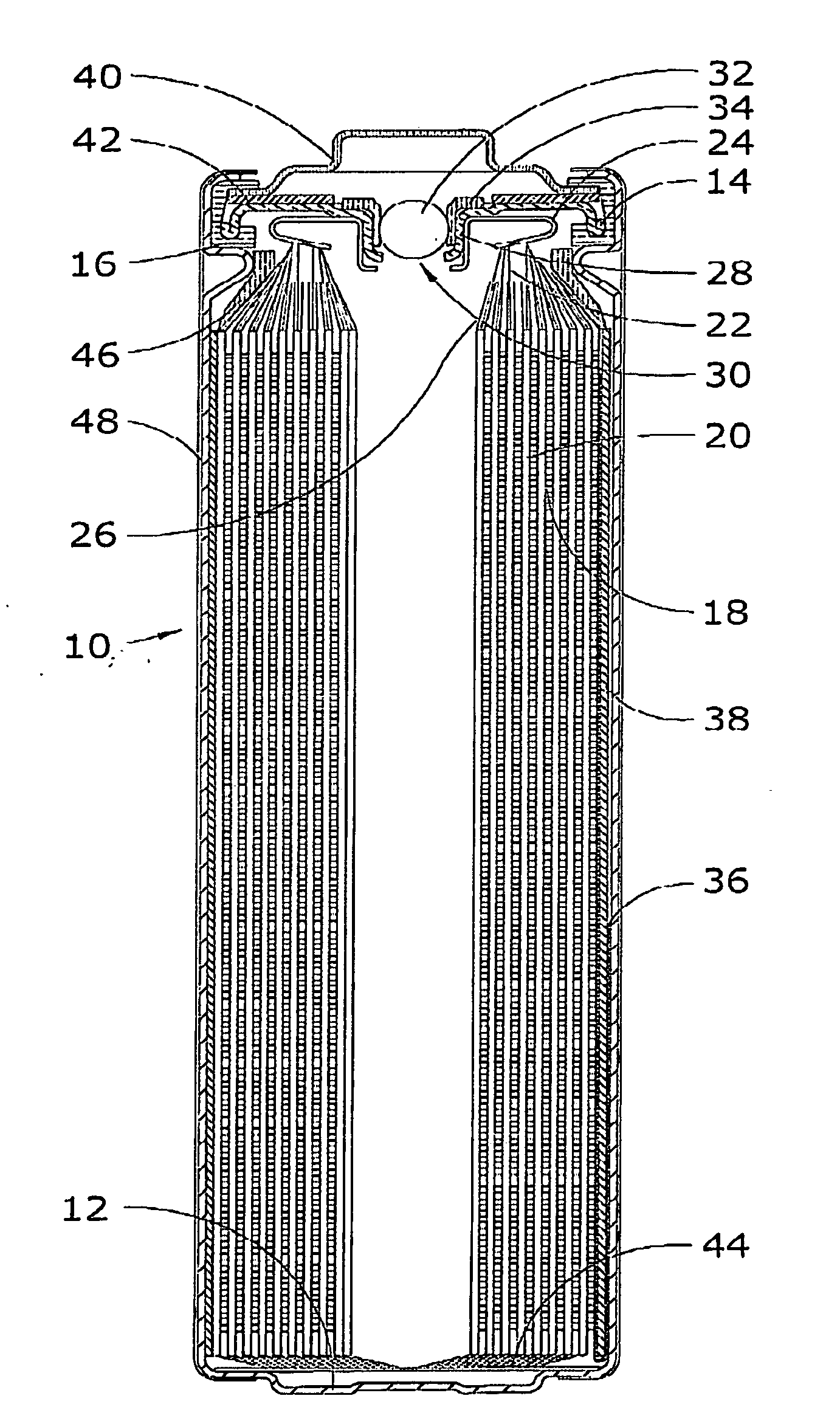

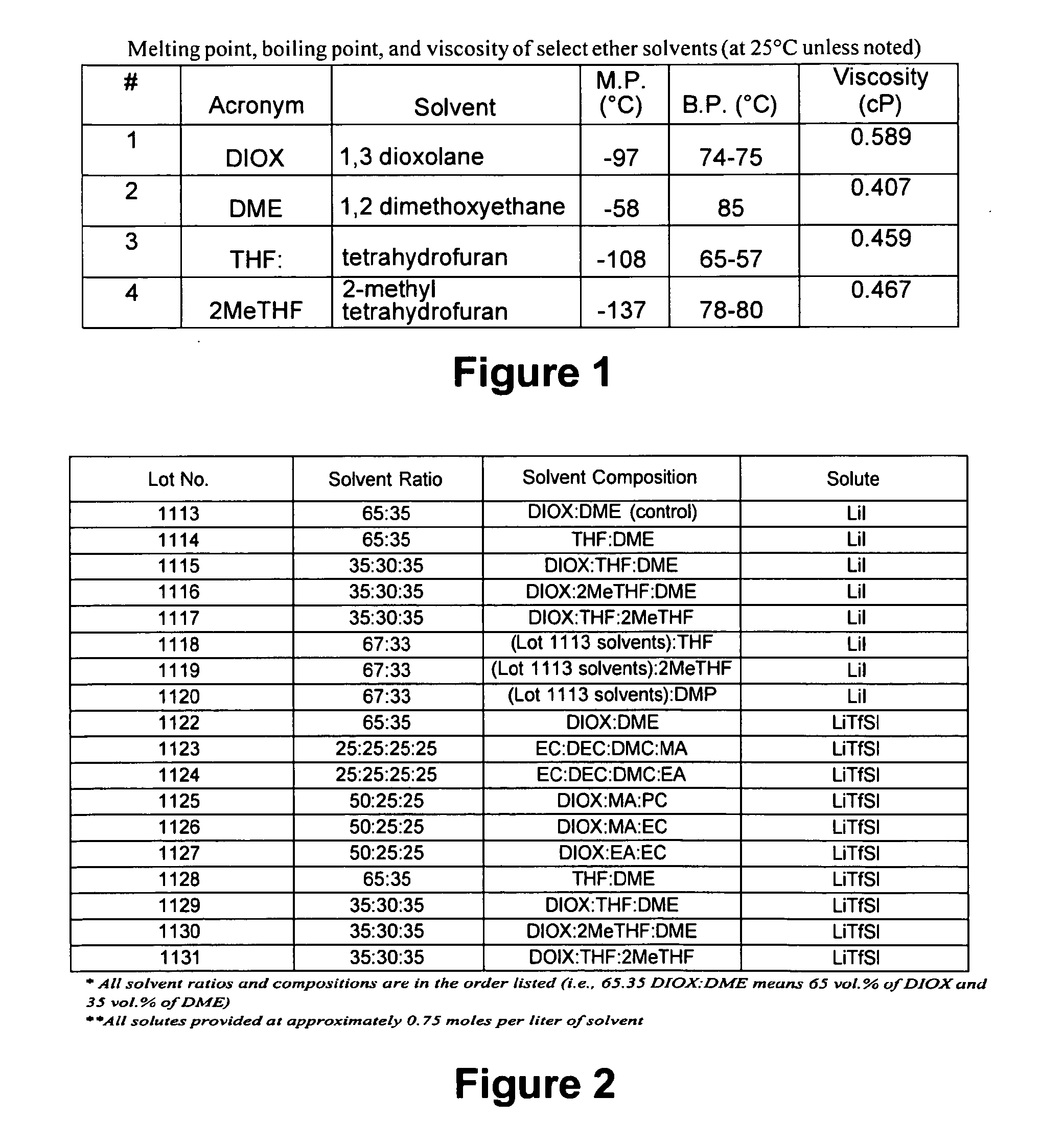

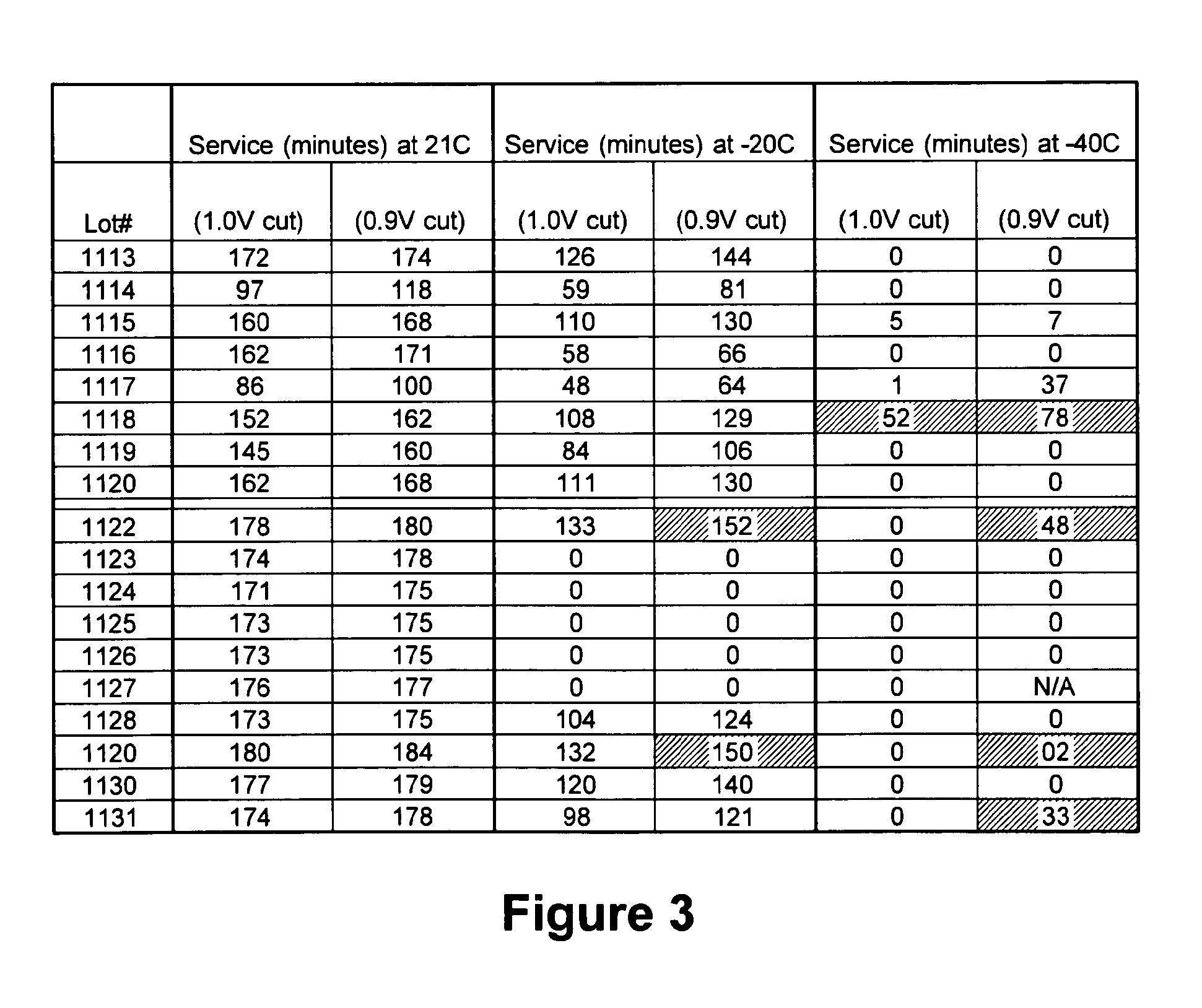

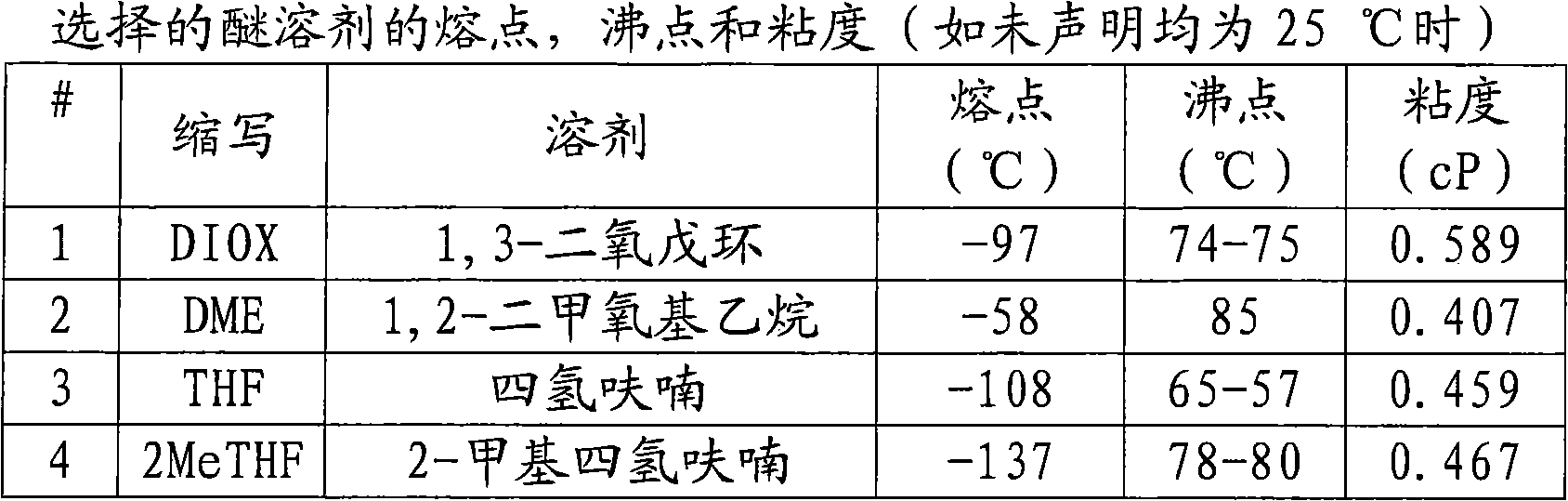

An electrochemical cell (10) showing improved low temperature performance, said electrochemical cell comprises a cylindrical container (12) having an open end; a top cover (14) sealing the open end; a jellyroll electrode assembly disposed inside of the container, the electrode assembly comprising: an anode (18) consisting essentially of lithium or a lithium-based alloy; a cathode (20) consisting of a mix comprising a conductor, a binder and at least 80 wt. % of iron disulfide coated onto a solid foil current collector (22); and a separator (26) disposed between the anode (18) and the cathode (20); and an electrolyte having a solvent blend consisting essentially of 10-95 wt. % of tetrahydrofuran and 5-90 wt % of 1,3-dioxolane- and a solute selected from the group consisting of: lithium imide, lithium jodide and combinations thereof. Alternatively the electrolyte consists essentially of a solute dissolved in tetrahydrofuran, 1,3-dioxolane and 1,2-dimethoxy ethane or the electrolyte has a solvent blend consisting essentially of 10-95 wt % of tetrahydrofuran-based solvent, 5-90 wt % of 1,3-dioxolane and 0-40 wt % of 1,2-dimethoxy ethane and a solute selected from the group consisting of: lithium imide, lithium iodide and combinations thereof.

Owner:EVEREADY BATTERY CO INC

THF-based electrolyte for low temperature performance in primary lithium batteries

InactiveCN102106022AMaximum loadingAvoid stretchingCell electrodesSmall-sized cells cases/jacketsElectrolytic agentElectrical conductor

An electrochemical cell (10) showing improved low temperature performance, said electrochemical cell comprises a cylindrical container (i2) having an open end; a top cover (14) sealing the open end; a jellyroll electrode assembly disposed inside of the container, the electrode assembly comprising: an anode (18) consisting essentially of lithium or a lithium-based alloy; a cathode (20) consisting of a mix comprising a conductor, a binder and at least 80 wt. % of iron disulfide coated onto a solid foil current collector (22); and a separator (26) disposed between the anode (18) and the cathode (20); and an electrolyte having a solvent blend consisting essentially of 10-95 wt.% of tetrahydrofuran and 5-90 wt% of 1, 3-dioxolane- and a solute selected from the group consisting of : lithium imide, lithium jodide and combinations thereof. Alternatively the electrolyte consists essentially of a solute dissolved in tetrahydrofuran, 1, 3-dioxolane and 1, 2 -dime thoxy ethane or the electrolyte has a solvent blend consisting essentially of 10-95 wt% of tetrahydrofuran-based solvent, 5-90 wt% of 1, 3-dioxolane and 0-40 wt% of 1, 2 -dime thoxy ethane and a solute selected from the group consisting of : lithium imide, lithium iodide and combinations thereof.

Owner:ENERGIZER BRANDS

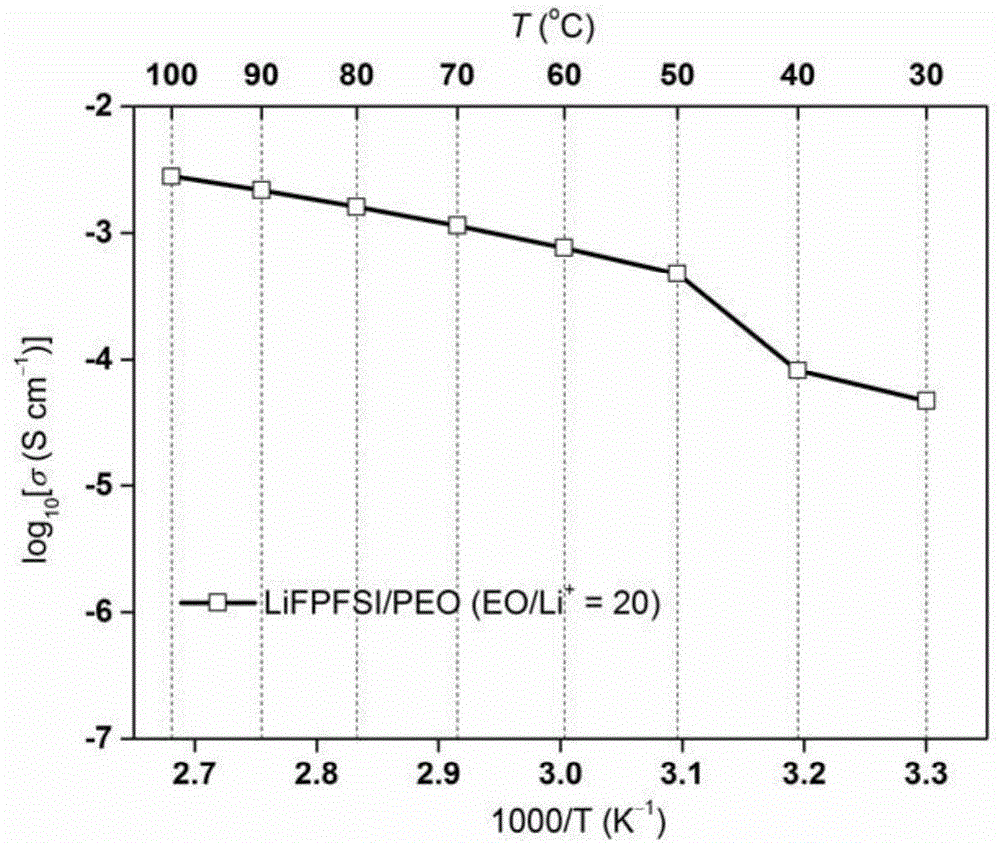

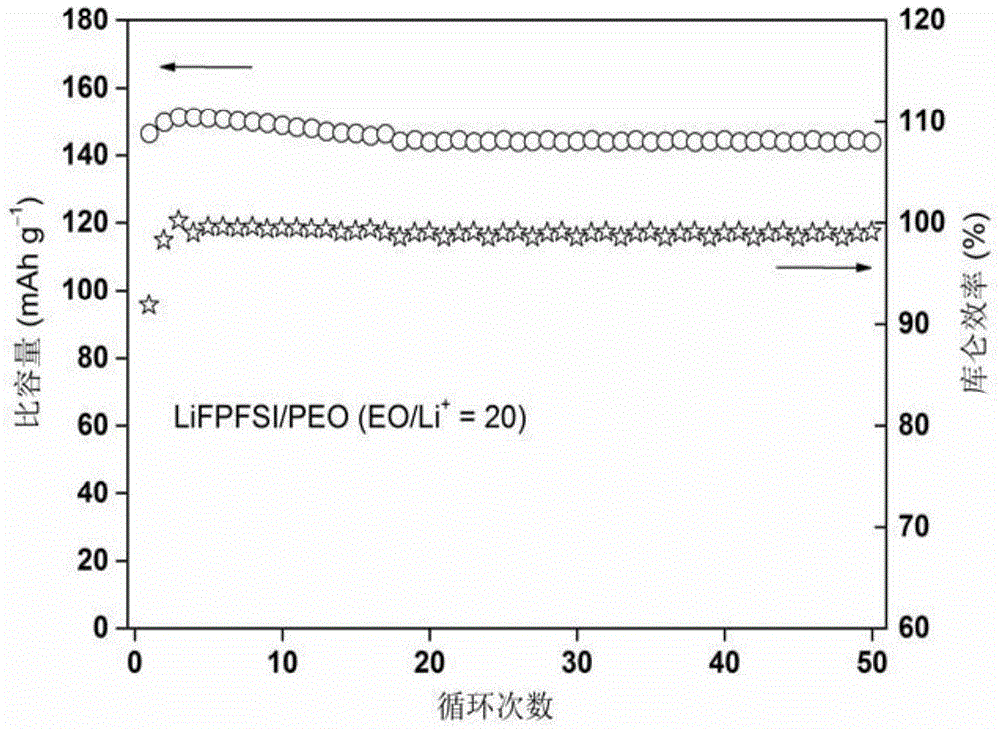

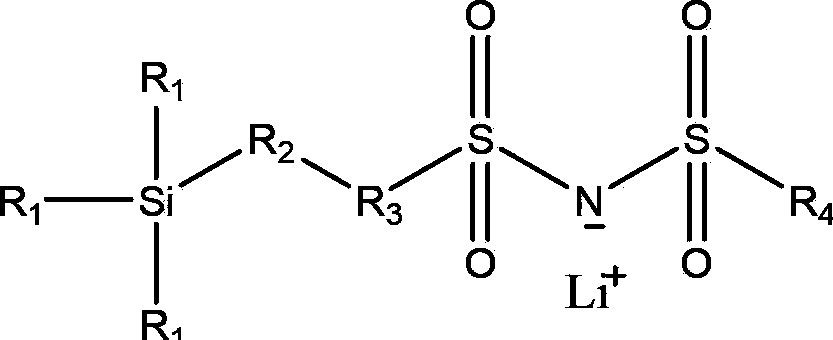

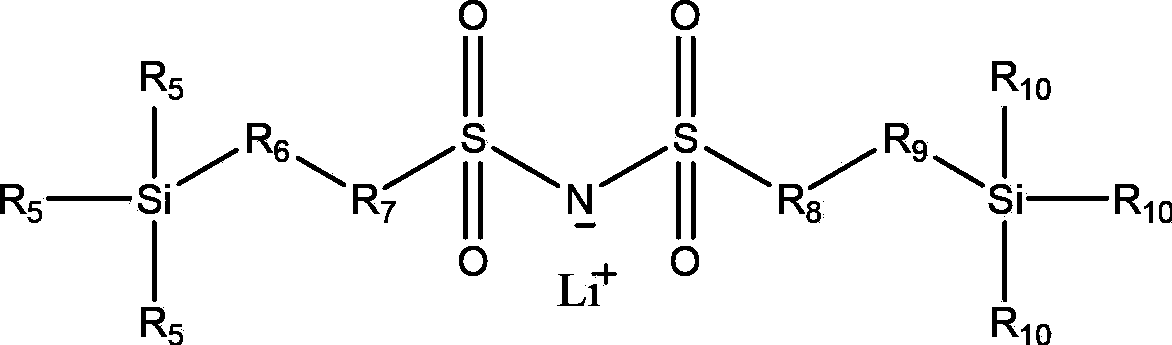

Polymer electrolyte containing lithium imide fluorosulfonate and preparing method of polymer electrolyte

InactiveCN105024094AReduce crystallinityReduce negative charge densityFinal product manufactureLi-accumulatorsPolymer scienceSolar battery

The invention discloses a polymer electrolyte containing lithium imide fluorosulfonate and a preparing method of the polymer electrolyte. The polymer electrolyte prepared by the invention has the advantages that the normal-temperature electric conductivity is high; the vitrification temperature and the crystallinity degree are low; the mechanical intensity and the film forming performance are good; the compatibility with electrode materials is good, and the like. The potential application values are realized in the aspects of lithium (ion) batteries, carbon-base supercapacitors, solar batteries and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydrogen storage matter and manufacturing method and apparatus for the same

InactiveUS7537748B2Improve efficiencyIncrease storage capacityMaterial nanotechnologyAlkali/alkaline-earth/beryllium/magnesium hydridesNanostructureNanometre

A hydrogen storage matter contains at least a nano-structured and organized lithium imide compound precursor complex. In the hydrogen stroge matter, the lithium imide compound precursor complex has been nano-structured and organized by mixing fine powder lithium amide with fine powder lithium hydride at a predetermined ratio to prepare a mixture as a starting material, and then processing the mixture by a predetermined complex formation processing method.

Owner:HIROSHIMA UNIVERSITY +1

High performance lithium or lithium ion cell

InactiveUS9350017B2Electrode carriers/collectorsOrganic electrolyte cellsElectrical batteryConductive coating

Owner:A123 SYSTEMS LLC

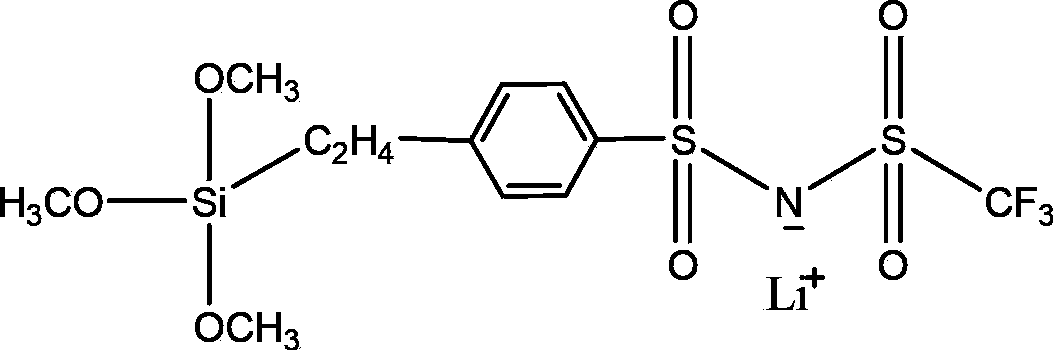

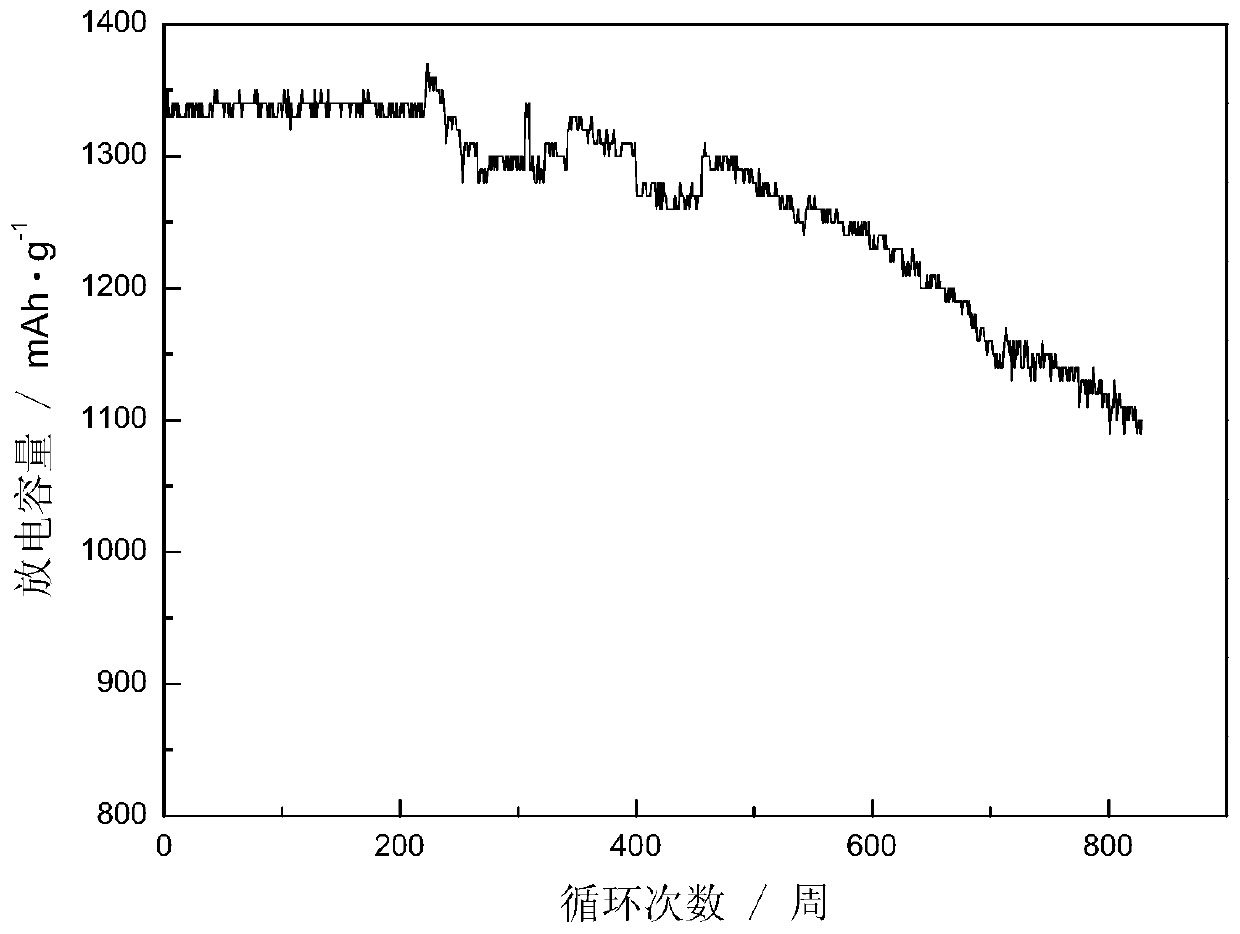

Composite membrane for lithium sulphur battery and preparation method thereof

The invention relates to a composite membrane for a lithium sulphur battery and a preparation method thereof. The composite membrane is prepared from a polypropylene diaphragm, a polyethylene diaphragm, or a polypropylene-polyethylene composite diaphragm and silane lithium imide through hydrolytic polycondensation, the silane lithium imide accounts for 0.1-10wt% of the composite membrane. The composite membrane has better liquid protecting performance, prevents circuit break of the battery in use due to the dry diaphragm, can inhibit generation of cathode lithium dendritic crystals, and has better conductivity; and the preparation method is simple and feasible, the raw materials are easy to obtain, the preparation process for modified membranes is simple and practical and is beneficial to industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Self-healing solid polymer electrolyte for lithium battery and preparation method of solid polymer electrolyte

ActiveCN110224173AImprove solubilityAvoid bringing inSolid electrolytesSecondary cellsSelf-healingSolid state electrolyte

The invention discloses a self-healing solid electrolyte for a lithium battery and a preparation method of the solid electrolyte, and belongs to the technical field of lithium ion batteries. The electrolyte comprises the following components of silyl-terminated polyether, bis (fluorosulfonyl) lithium imide, organic auxiliaries, additives, a first solvent and a second solvent, wherein the first solvent is used for dissolving silyl-terminated polyether and bis (fluorosulfonyl) lithium imide, and the second solvent is used for dissolving the organic auxiliaries; based on 100 parts of total mass of the first solvent and the second solvent, the usage of the silyl-terminated polyether is 25-50 parts; the molar ratio of the mole number of bis (fluorosulfonyl) lithium imide to the mole number of silyl-terminated polyether is 1 to 10-30; the usage of the organic auxiliaries is 1-10 parts; and the usage of the additives is 0-15 parts. By virtue of the novel self-healing solid electrolyte material provided by the invention, the performance of the energy density, the cycle life, the rate discharge and the like of the battery are not lower than those of the existing liquid organic electrolyte.

Owner:TIANNENG SAFT ENERGY JOINT CO

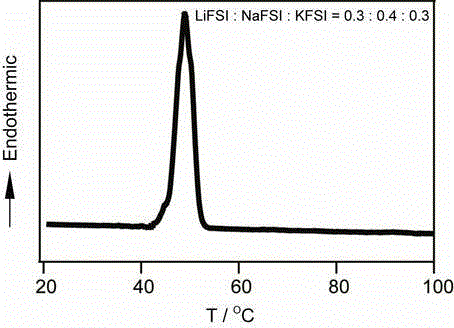

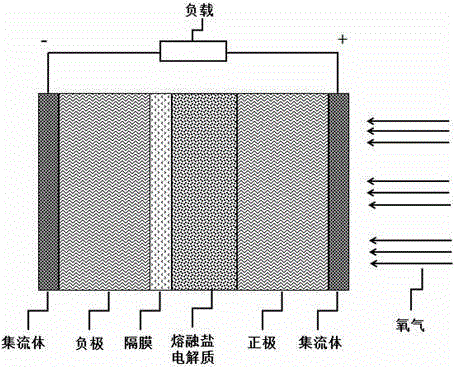

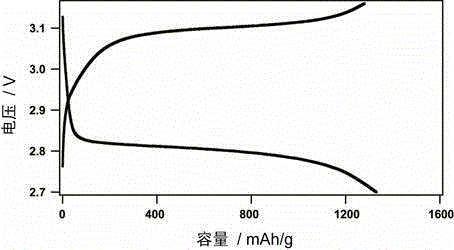

Thermally activated secondary battery using low-temperature molten salt electrolyte

The invention provides a thermally activated secondary battery using a low-temperature molten salt electrolyte based on a lithium / oxygen reaction mechanism. The thermally activated secondary battery comprises the low-temperature molten salt electrolyte, a lithium cathode, an oxygen anode and a diaphragm positioned between the anode and the cathode, wherein the low-temperature molten salt electrolyte consists of alkali metal cations and di(sulfonyl fluoride)imine anions, and particularly consists of di(sulfonyl fluoride)lithium imide and one, two or three of four non-lithium salts, namely, di(sulfonyl fluoride)sodium imide, di(sulfonyl fluoride)potassium imide, di(sulfonyl fluoride)rubidium imide and di(sulfonyl fluoride)cesium imide. The molten salt electrolyte in the invention is in a molten state at the temperature of 40-100 DEG C, and has the advantages of low melting temperature, freeness from volatilization, incombustibility, high chemical stability and high ion conductivity. Charging and discharging reactions are finished on the basis of a lithium / oxygen reaction, so that the problems of high battery working temperature, short working time after activation, low energy density, failure in charging after activation and the like in a conventional thermally activated battery can be effectively solved. The thermally activated secondary battery provided by the invention has wide application prospects in the fields of national defense, industrial use and civil use.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com