Patents

Literature

110results about How to "Stable resistance value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

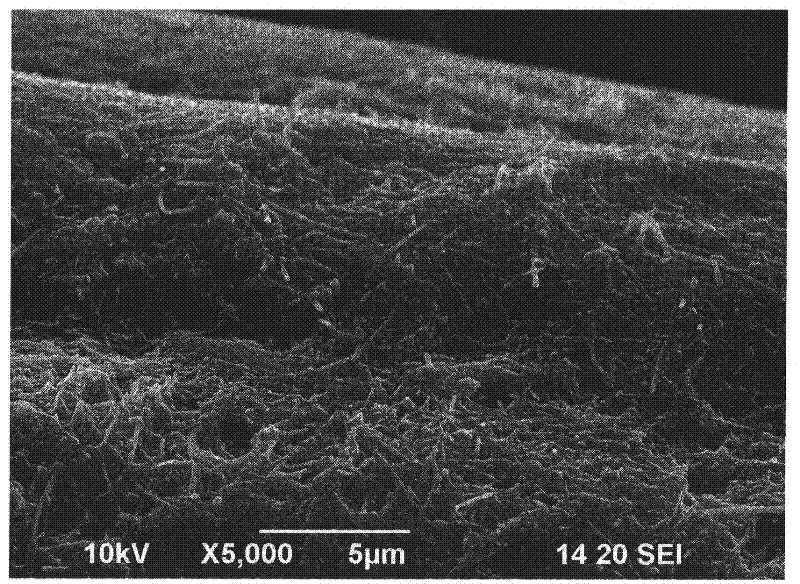

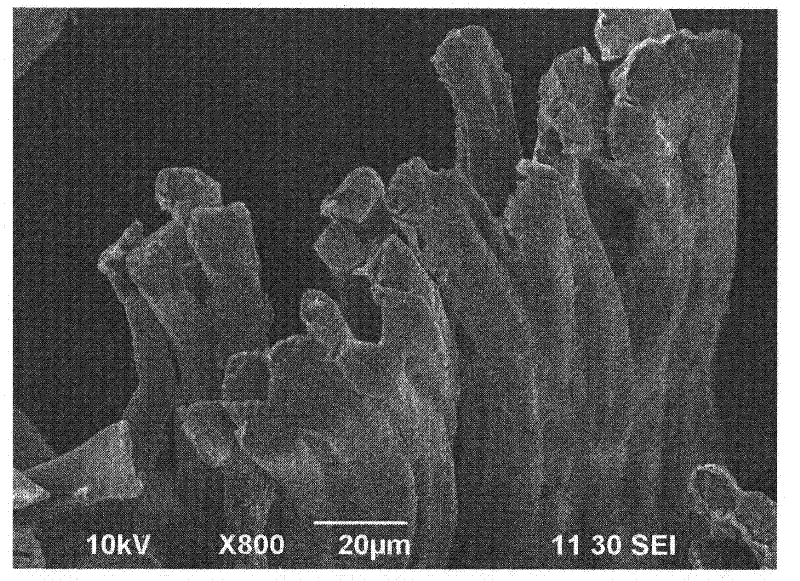

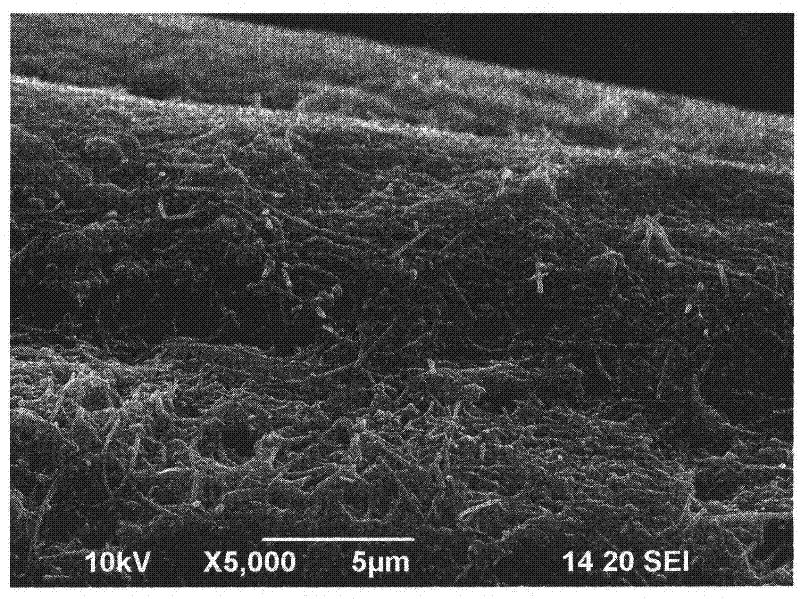

Electroconductive fibers with carbon nanotubes deposited thereon, electroconductive threads, fiber structure, and process for producing same

ActiveCN102131980AImprove conductivityGood flexibilityFibre typesUltrasonic/sonic fibre treatmentPolymer scienceMicrometer

Owner:HOKKAIDO UNIVERSITY +1

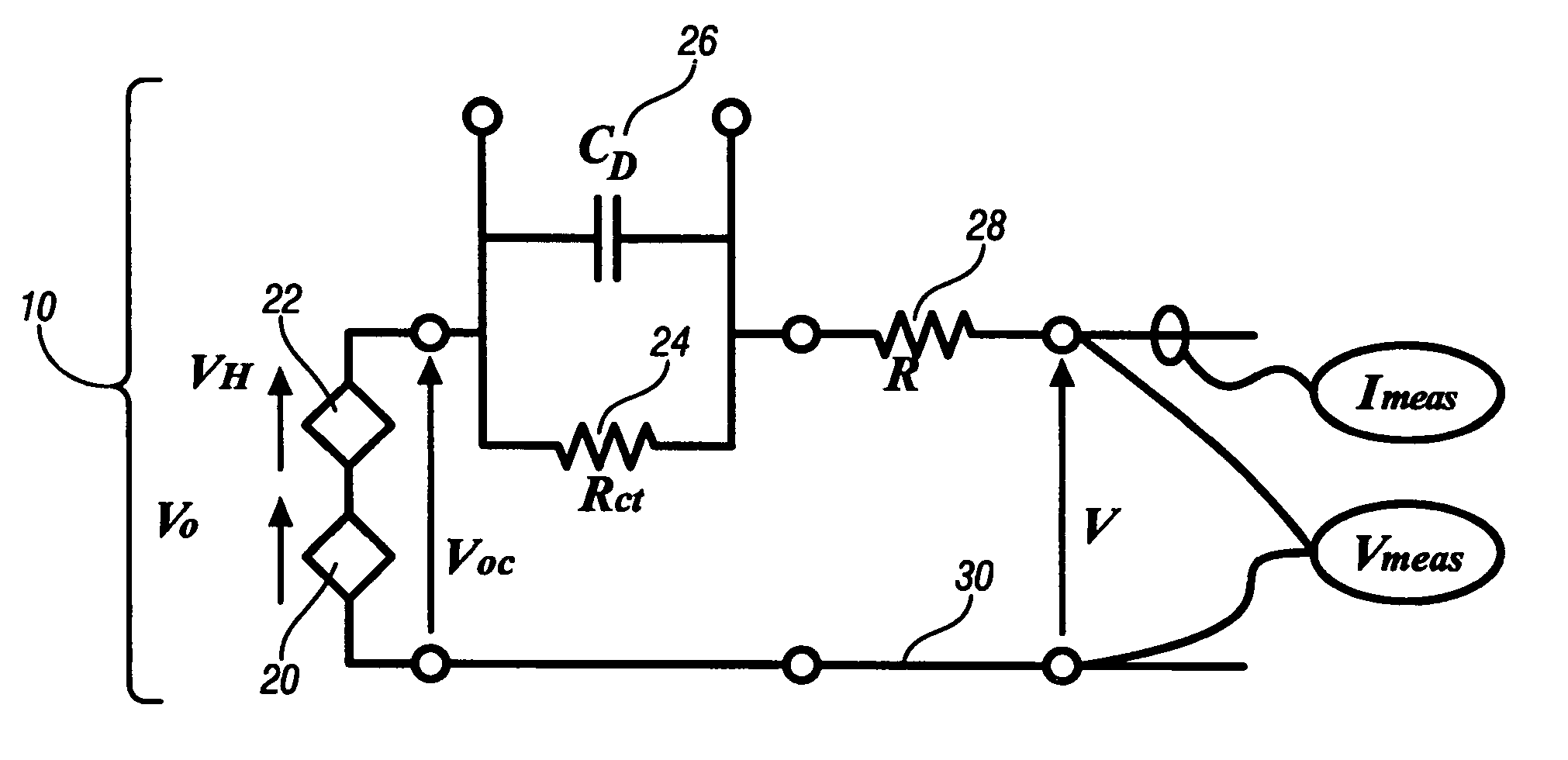

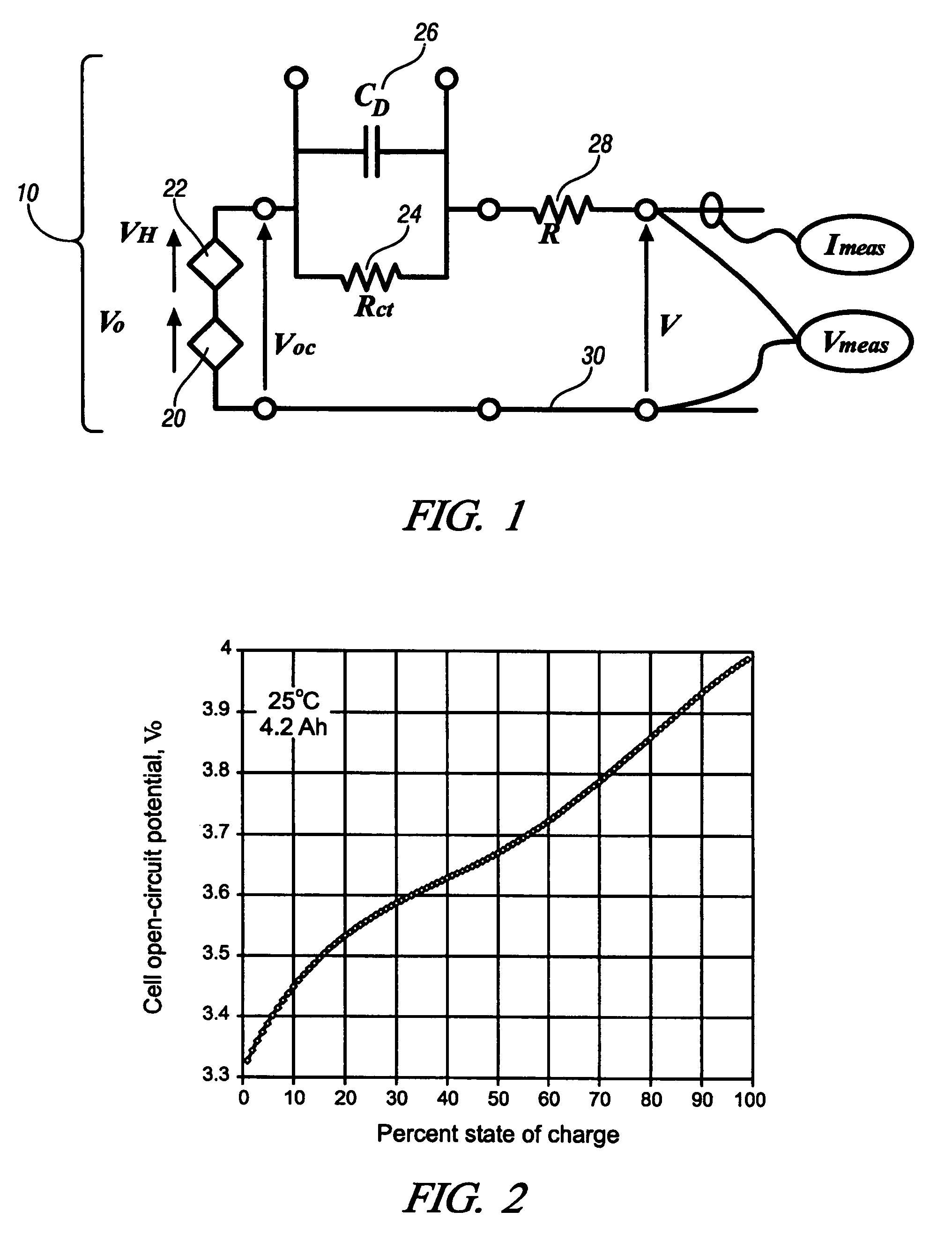

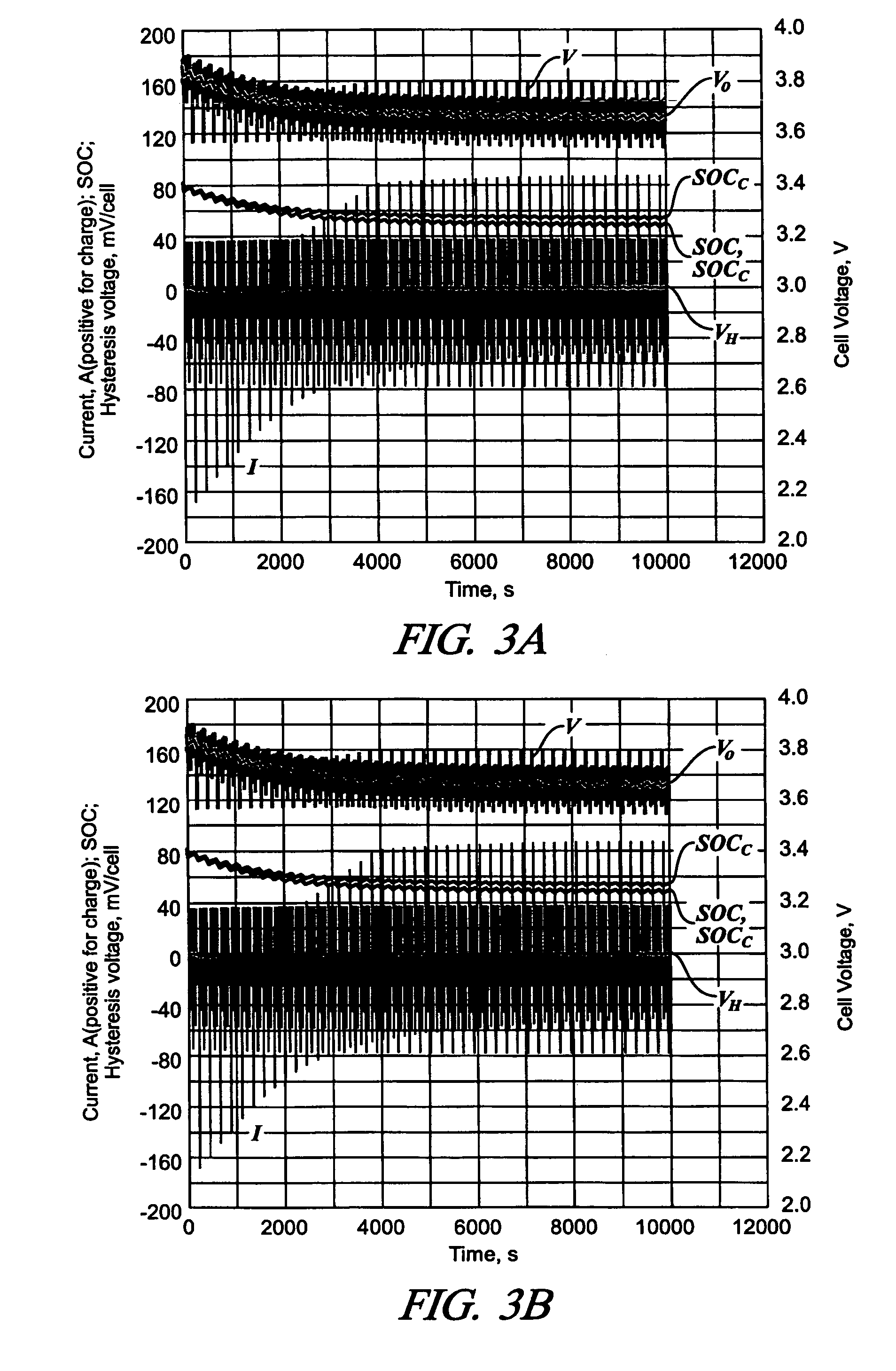

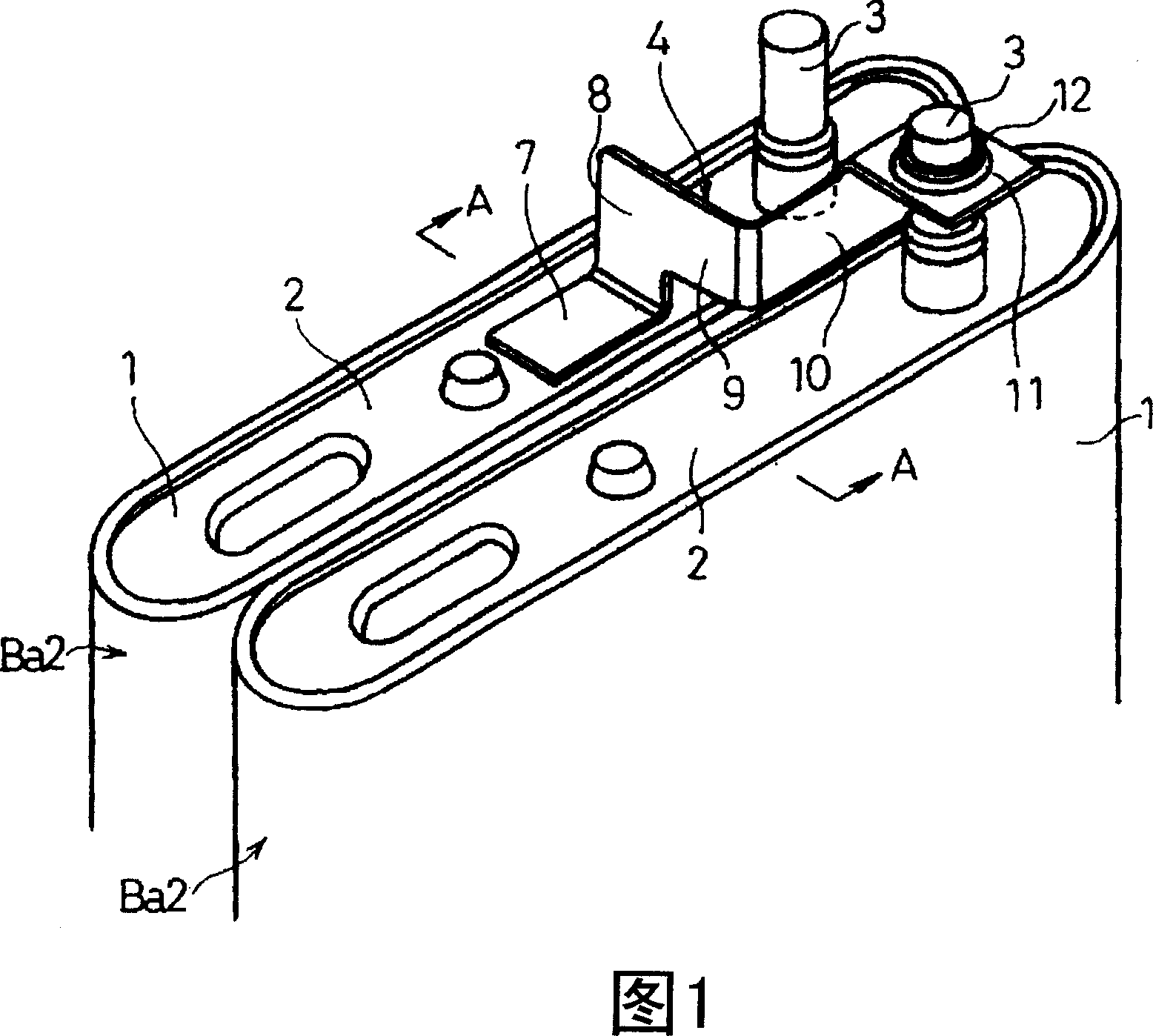

Method for controlling and monitoring using a state estimator having variable forgetting factors

ActiveUS7612532B2Stable resistance valueImprove accuracyBatteries circuit arrangementsElectrical testingAlgorithmForgetting factor

A recursive algorithm is provided for adaptive multi-parameter regression enhanced with forgetting factors unique to each regressed parameter. Applications of this algorithm can include lead acid batteries, nickel-metal hydride batteries, and lithium-ion batteries, among others. A control algorithm is presented, having an arbitrary number of model parameters, each having its own time-weighting factor. A method to determine optimal values for the time-weighting factors is included, to give greater effect to recently obtained data for the determination of a system's state. A methodology of weighted recursive least squares is employed, wherein the time weighting corresponds to the exponential-forgetting formalism. The derived mathematical result does not involve matrix inversion, and the method is iterative, i.e. each parameter is regressed individually at every time step.

Owner:GM GLOBAL TECH OPERATIONS LLC

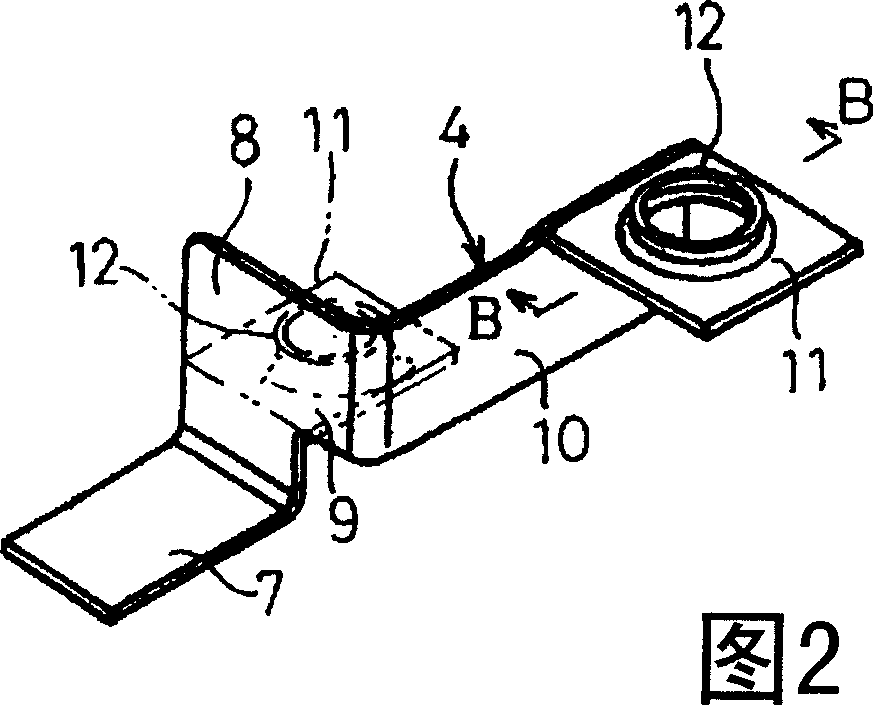

Battery pack

InactiveCN1976095ANo welding defectsEasy to operatePrimary cell to battery groupingSmall-sized cells cases/jacketsElectrical connectionBattery pack

A battery pack is made up of a plurality of flat prismatic batteries arranged face to face, each battery having one electrode terminal protruding from one end face in the height direction of the battery case and this end face or a side face of the battery serving as the other electrode terminal. The connector for electrically connecting adjacent prismatic batteries includes a flat part that is welded to one electrode terminal of one prismatic battery of the adjacent prismatic batteries, and a cylindrical part that is fitted onto and welded to the other electrode terminal of the other prismatic battery. The cylindrical part is formed in an attachment part that extends from the flat part through an upright part in the direction in which the batteries are aligned. The connector enables reliable electrical connection of the prismatic batteries despite possible variation in height of the electrode terminals.

Owner:PANASONIC CORP

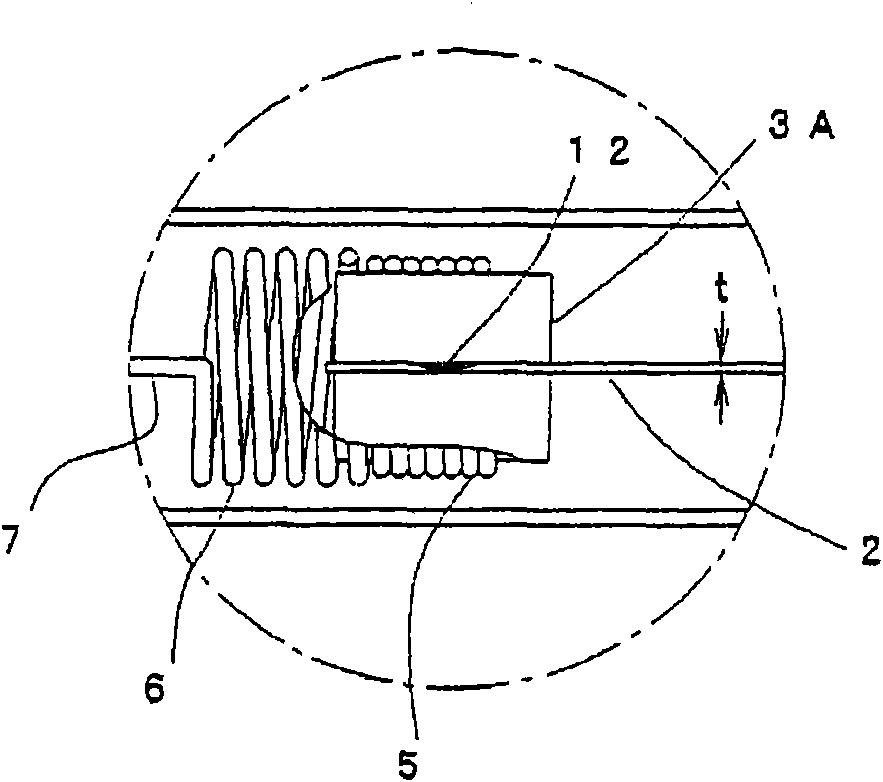

Organic PTC thermistor and making method

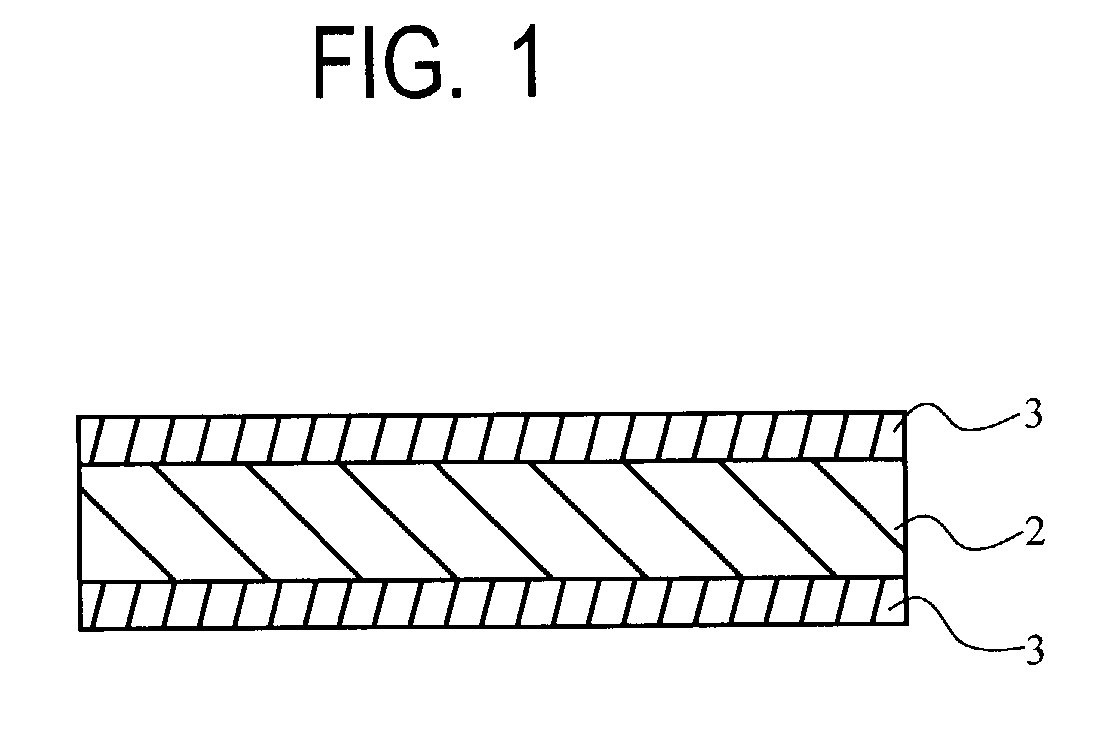

InactiveUS6778062B2Avoid excessive accumulationEasy to separateLiquid surface applicatorsThermometers using electric/magnetic elementsMetal particleMolecular level

In an organic PTC thermistor comprising an organic polymer matrix and conductive metal particles dispersed therein, the conductive metal particles are pretreated with an organic material which is different from the organic polymer matrix, does not covalently bond with the conductive metal particles, and is not compatible at a molecular level with the organic polymer matrix so that an organic material layer covers surfaces of conductive metal particles whereby the stability of thermistor performance is improved.

Owner:TDK CORPARATION

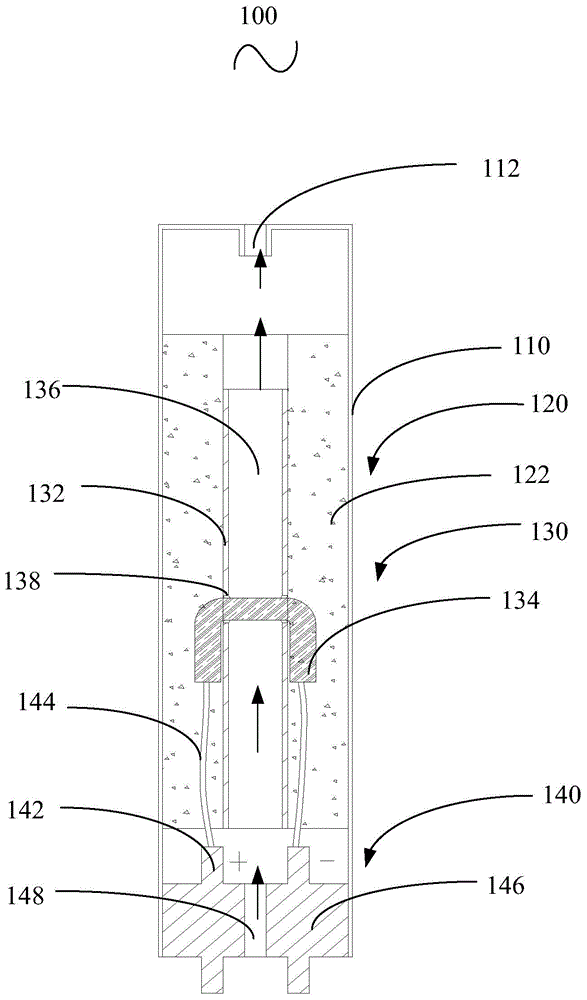

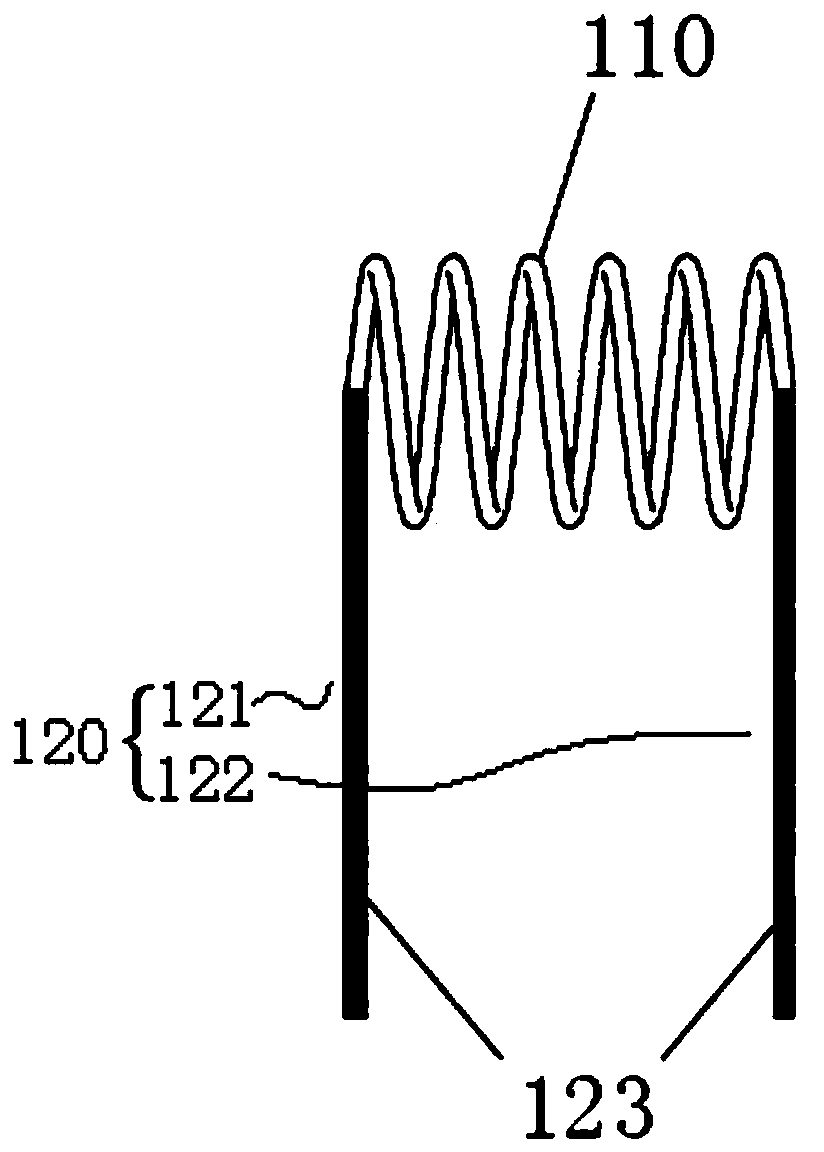

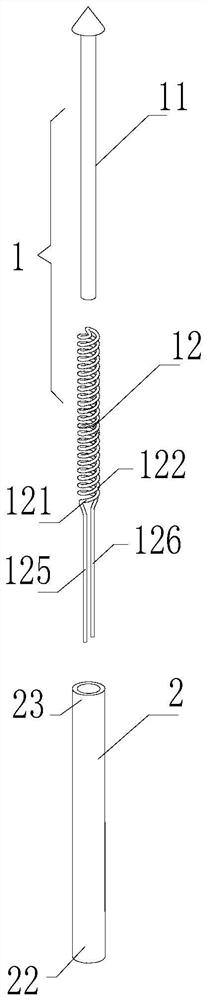

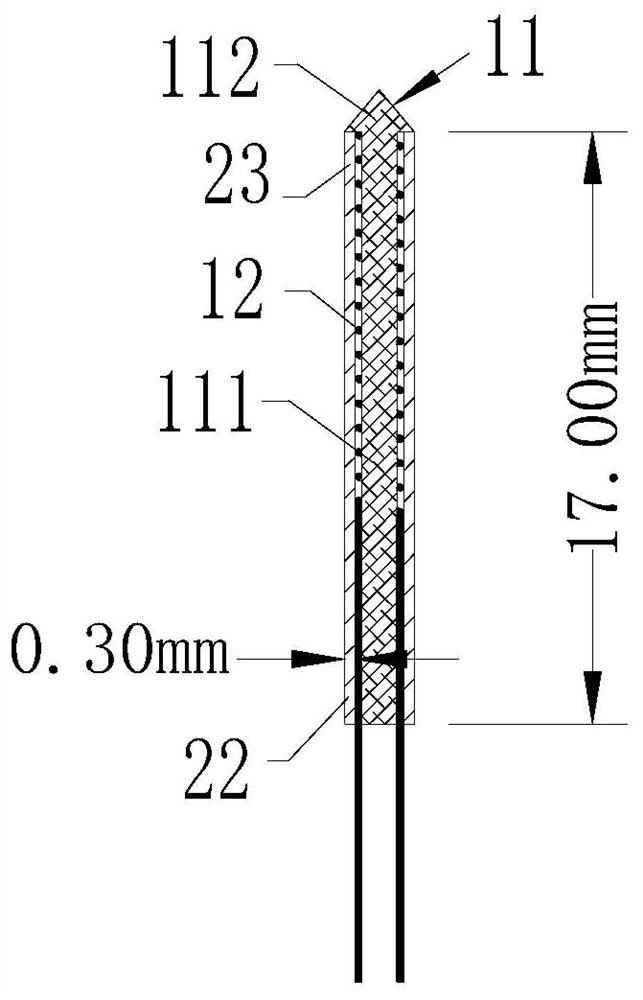

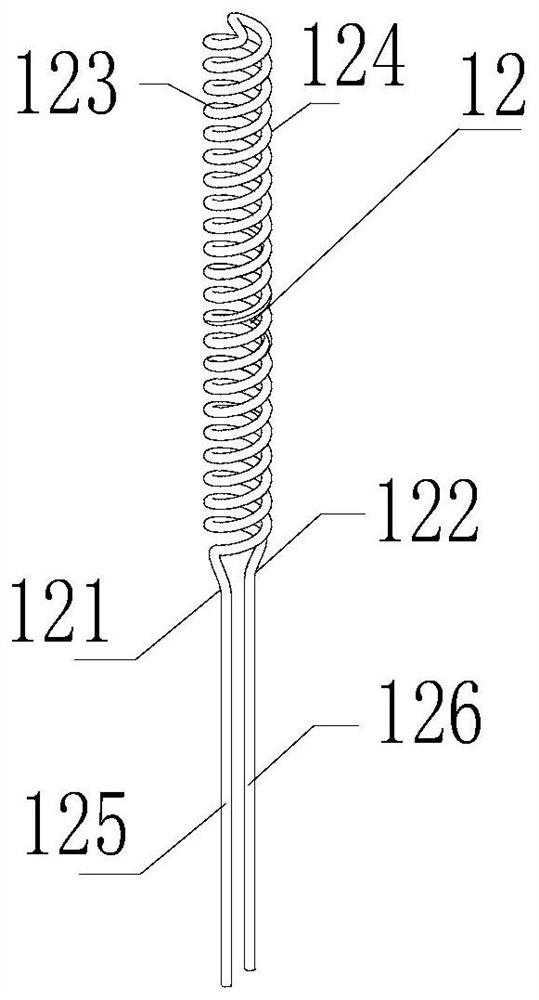

Electronic cigarette

ActiveCN103948172AImprove atomization effectStable resistance valueTobacco devicesEngineeringElectronic cigarette

The invention relates to an electronic cigarette. The electronic cigarette comprises a shell of a hollow structure, wherein an air inlet hole and an air outlet hole are formed in the two ends of the shell, an atomizing assembly is accommodated in the shell and comprises a supporting piece and a flexible heating body, a smoke passage communicated with the air inlet hole and the air outlet hole is formed in the interior of the supporting piece, a through hole communicated with the smoke passage is formed in the supporting piece, the flexible heating body comprises a main body part and a support arm part connected with the main body part, and the main body part penetrates through the through hole and is positioned in the smoke passage; a liquid storage body sleeves the outside of the supporting piece and comprises a liquid storage medium for storing smoke liquid, and the support arm part stretches into the interior of the liquid storage body. The electronic cigarette is simple in structure and simple in assembling process. The flexible heating body has good flexibility, and required shapes can be manufactured according to product shapes, thus the resistance value of the flexible heating body is relatively stable, higher atomization uniformity can be ensured, and the electronic cigarette has a better atomization effect.

Owner:SHENZHEN SMOORE TECH LTD

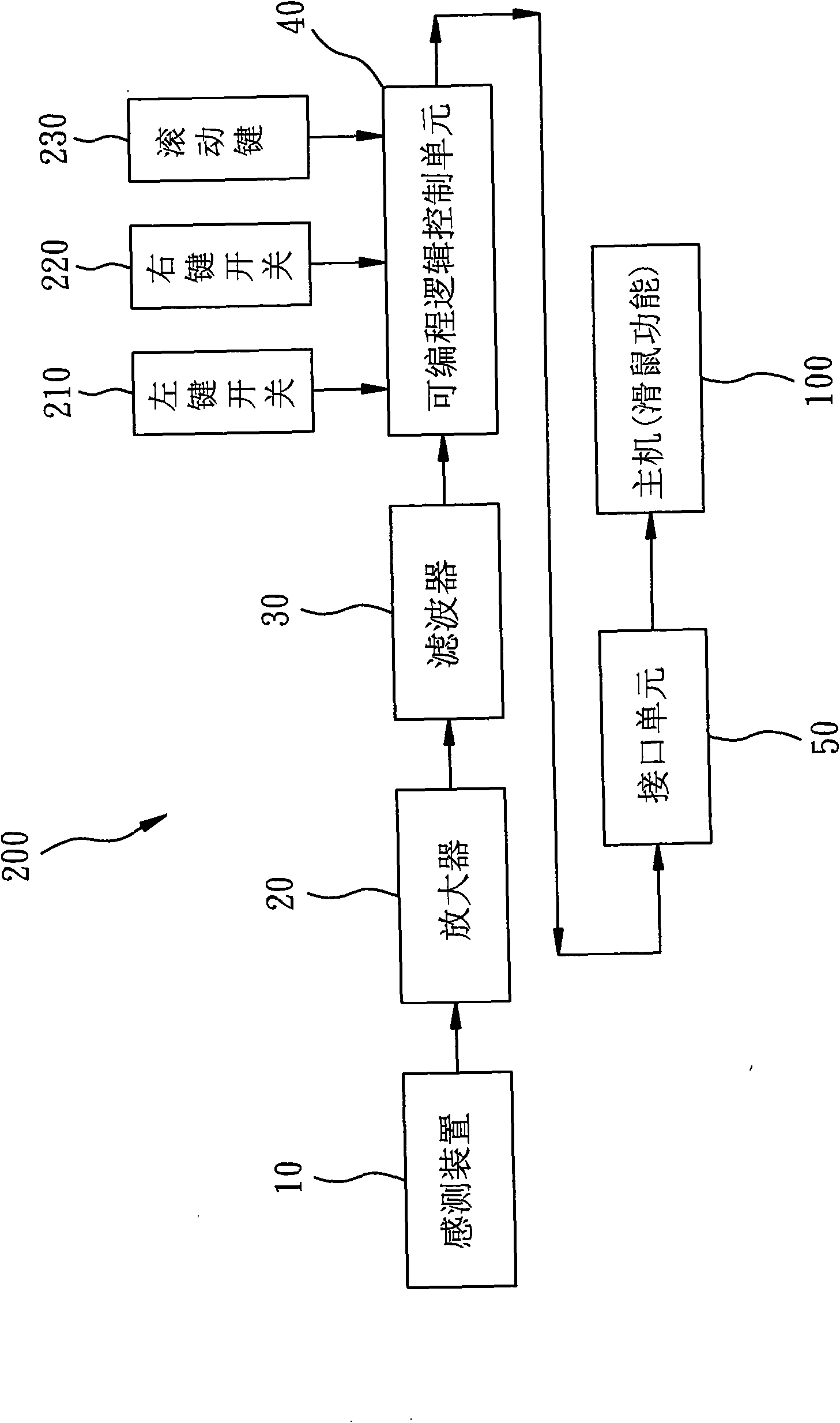

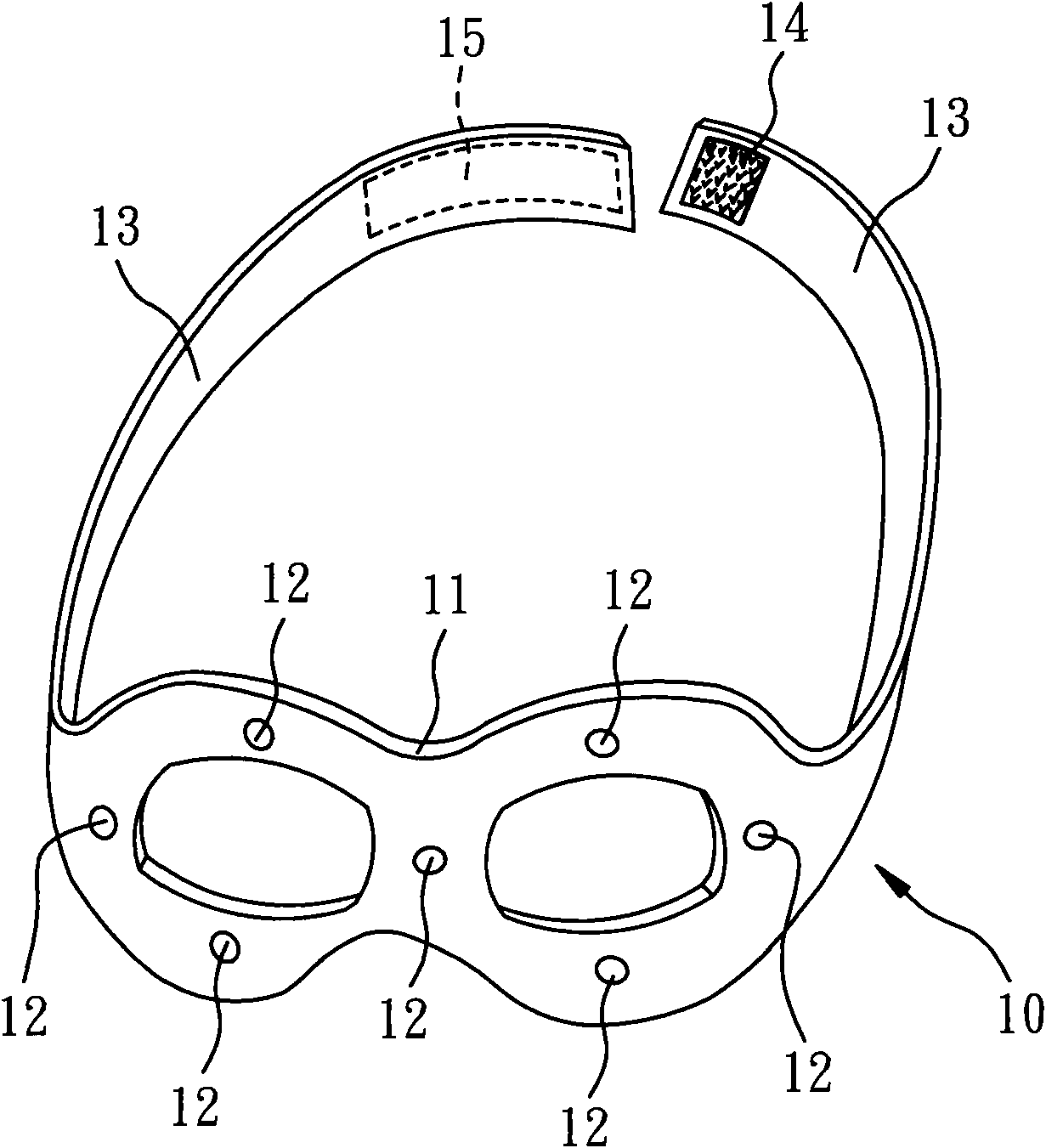

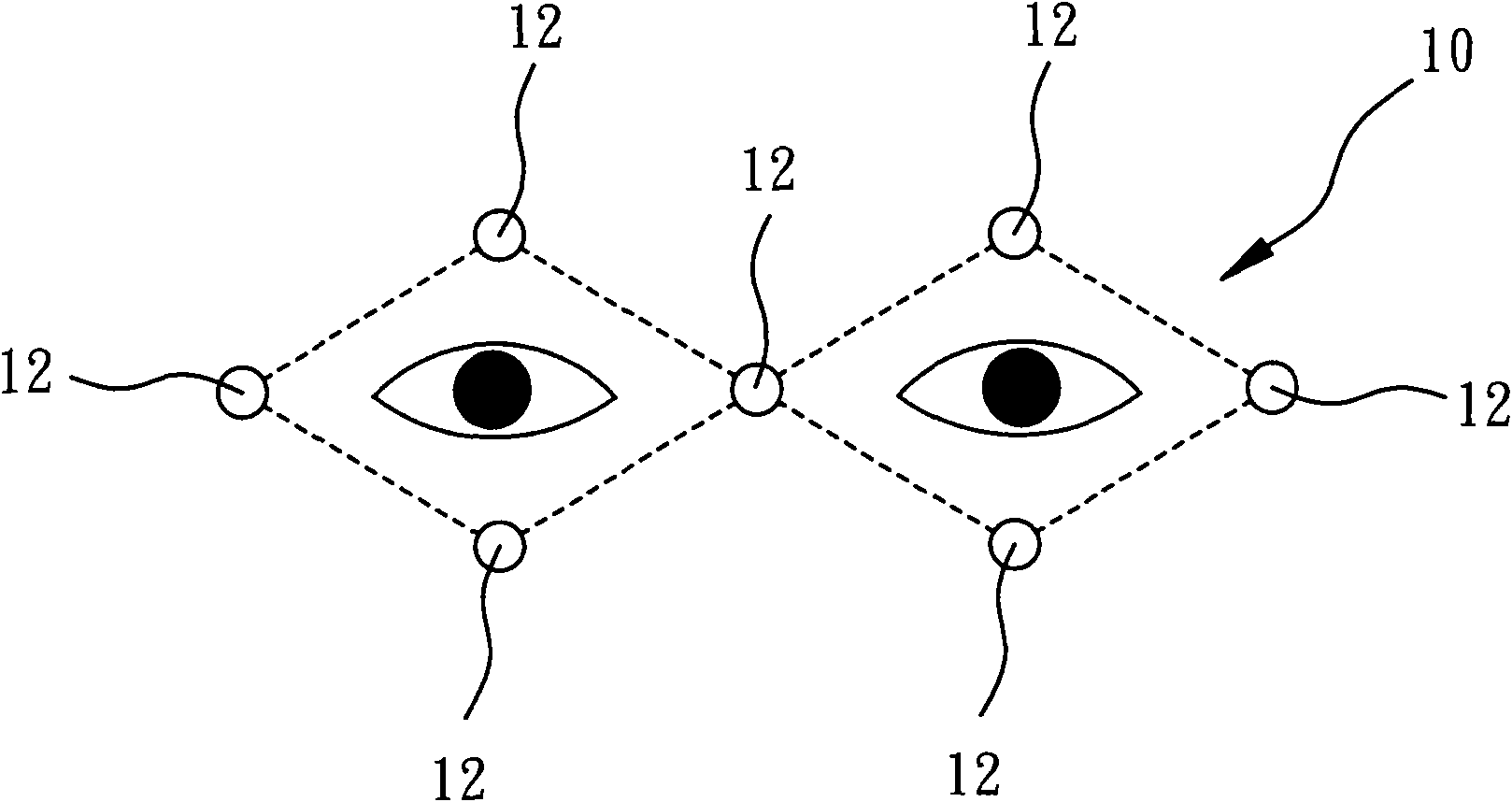

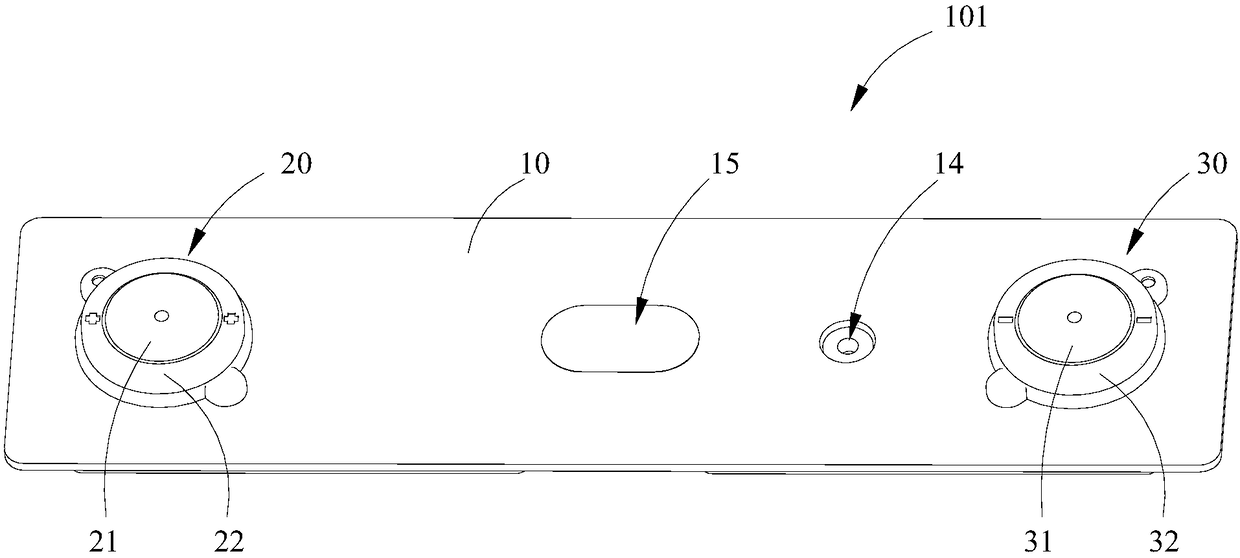

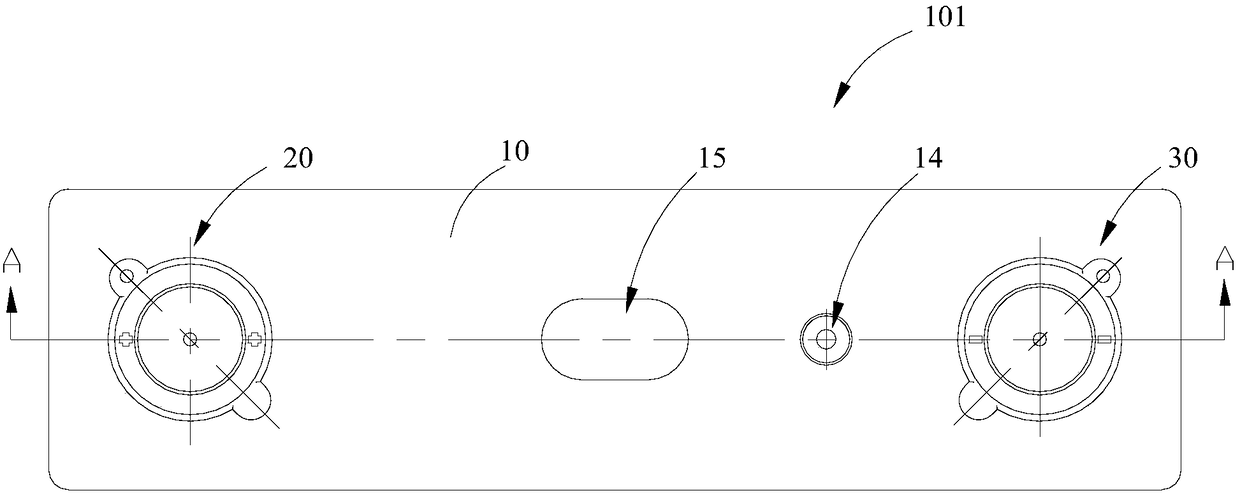

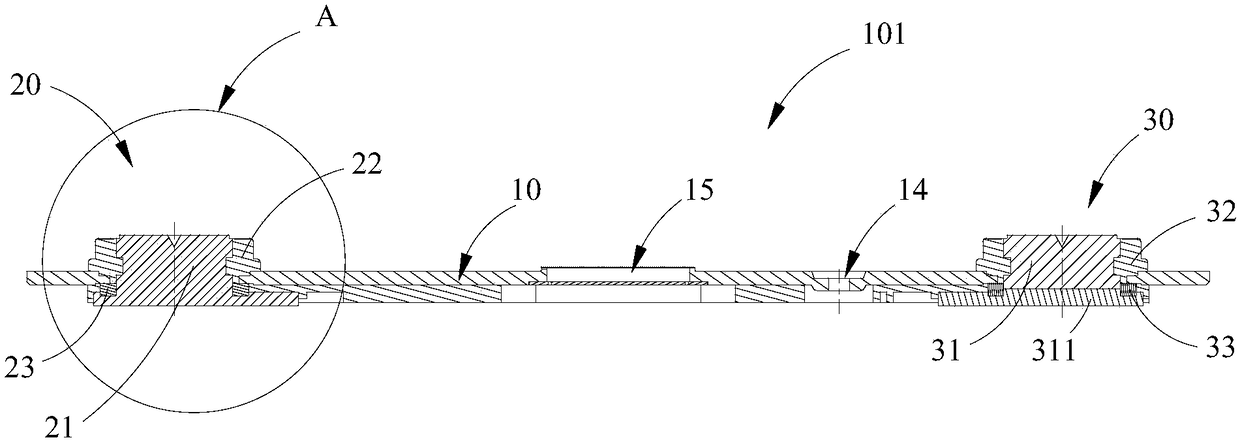

Electrooculogram control system and method for controlling cursor by using eye electricity control system

InactiveCN101995944AEasy to attachStable acquisition of ocular voltage signalInput/output for user-computer interactionGraph readingElectricityHuman body

The invention discloses an electrooculogram control system for control on the basis of relative motion of an eyeball and a head, and a method for controlling a cursor by using the electrooculogram control system. The electrooculogram control system comprises a sensing device and a programmable logical control unit. The sensing device contacts the face of a human body and is used for detecting information on the relative motion of the eyeball and the head so as to respectively convert the information into respective electric-eye movement wave signal of the left eye and the right eye in the longitudinal and transverse directions. The programmable logical unit executes all operation controls and flows in a programming mode, judges and processes the operation controls and flows according to the electric-eye movement wave signal generated by the sensing device so as to control the movement of a mouse cursor and execute (rolling) functions of left, right, upper and lower keys. The method comprises the following steps of: A, setting a visual focus at a position which is different from that of the cursor; B, fixedly staring the position of a target point on a host computer by the visual focus; and C, moving the cursor to the position of the visual focus by using the relative motion of the eyeball and the head.

Owner:仇锐铿

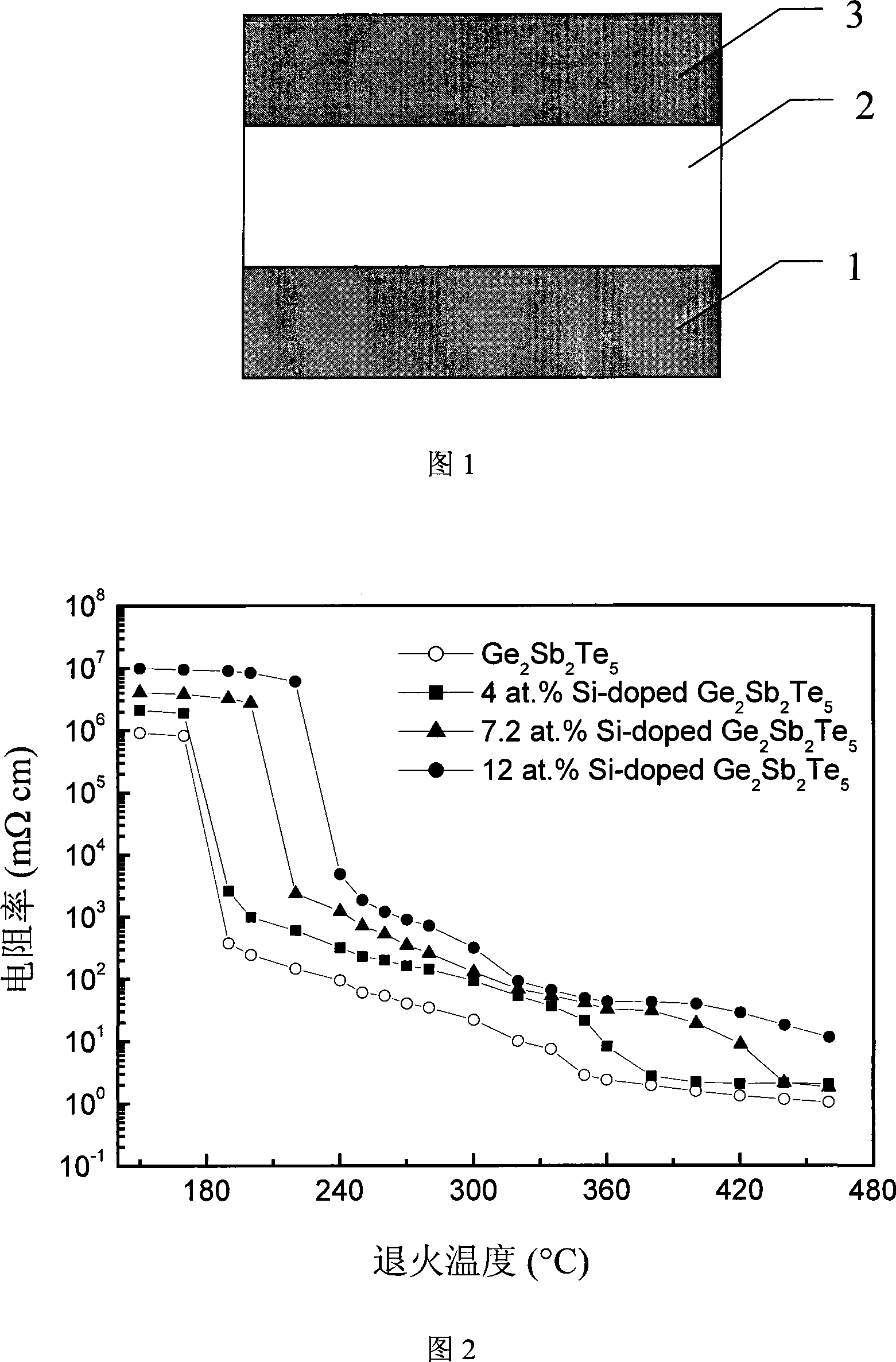

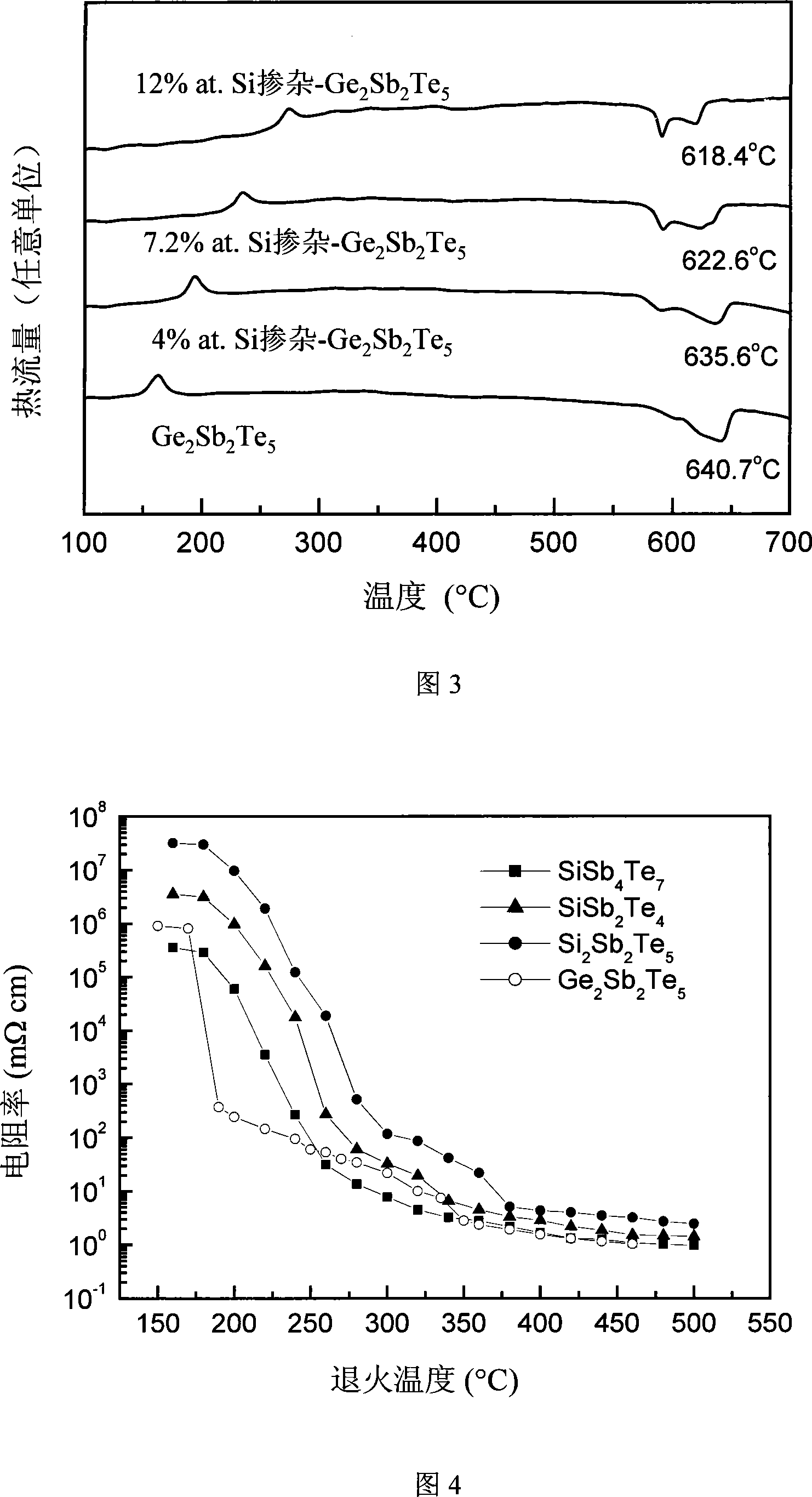

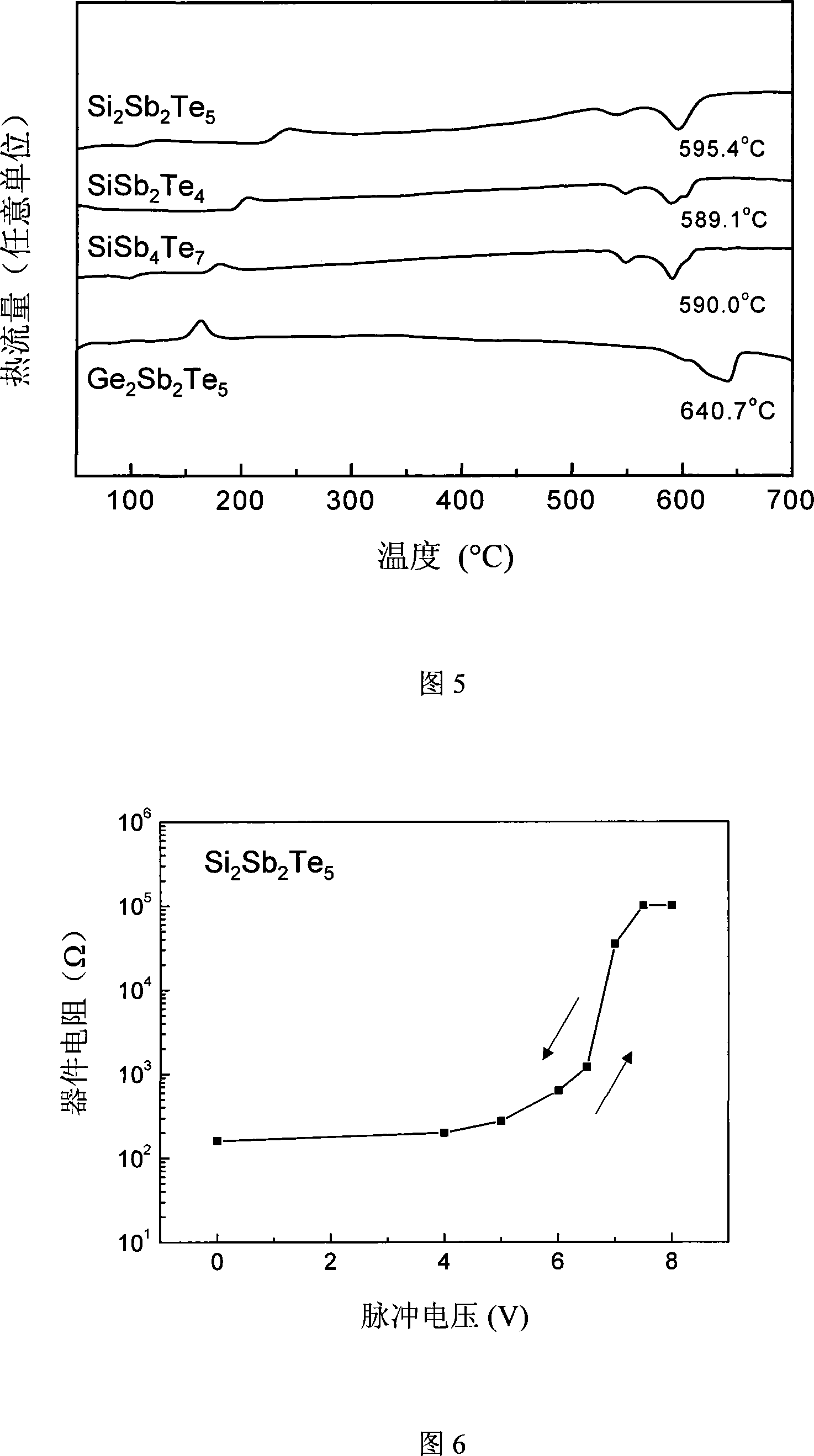

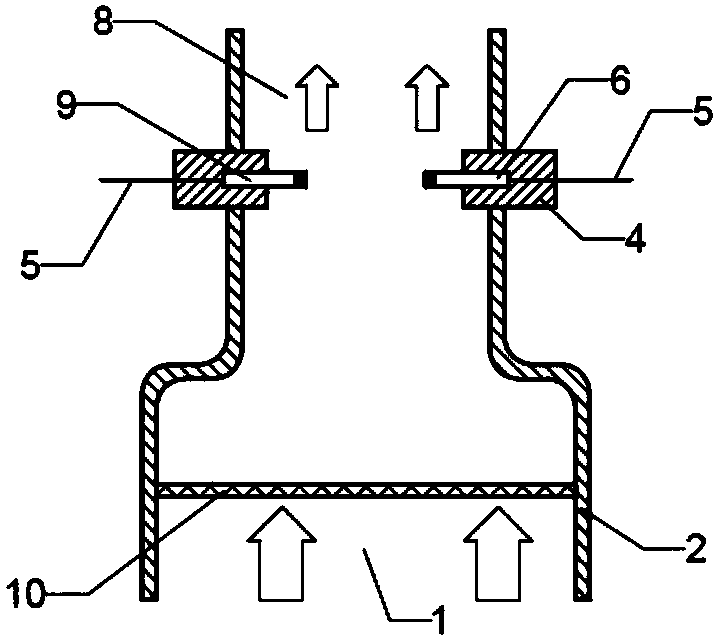

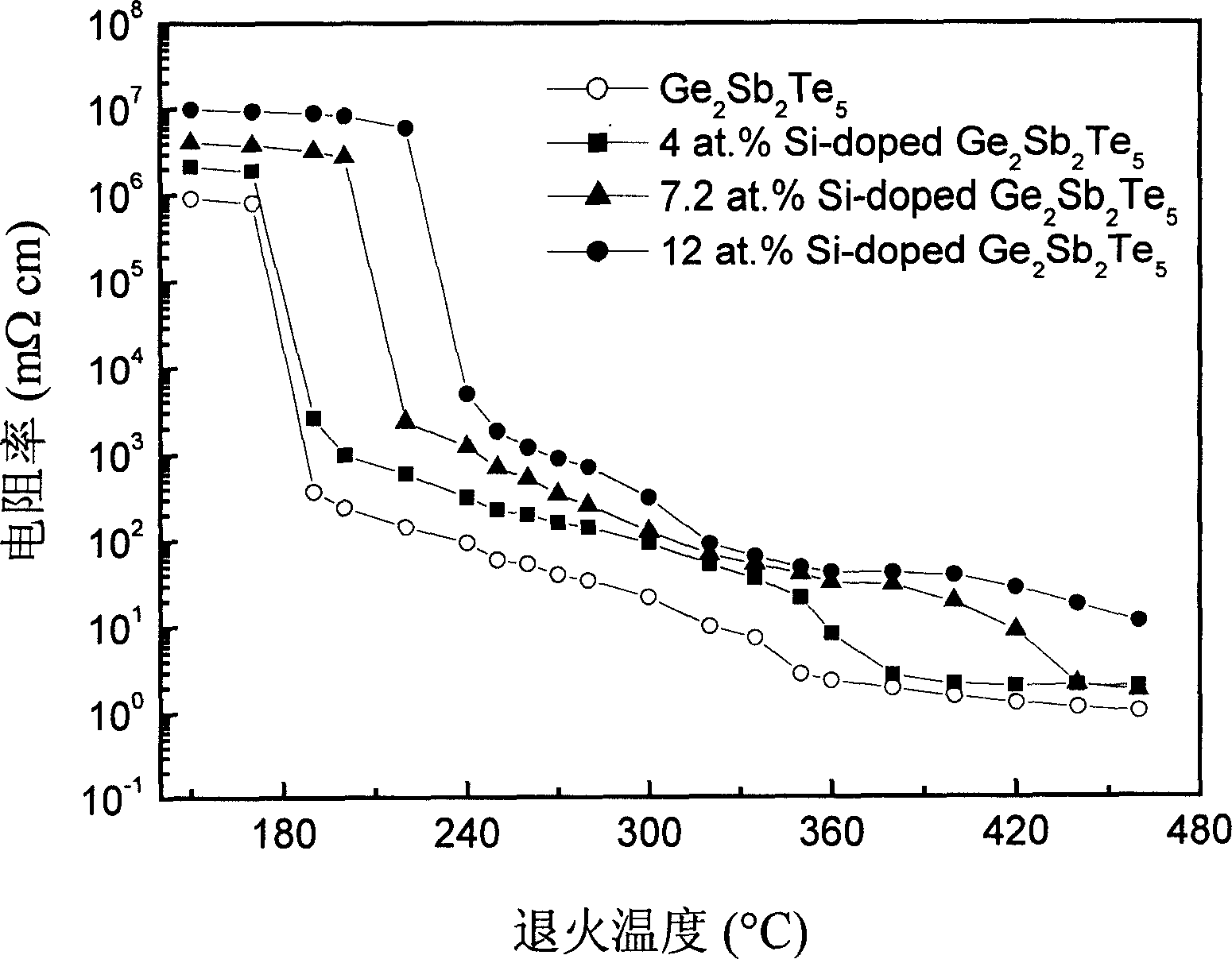

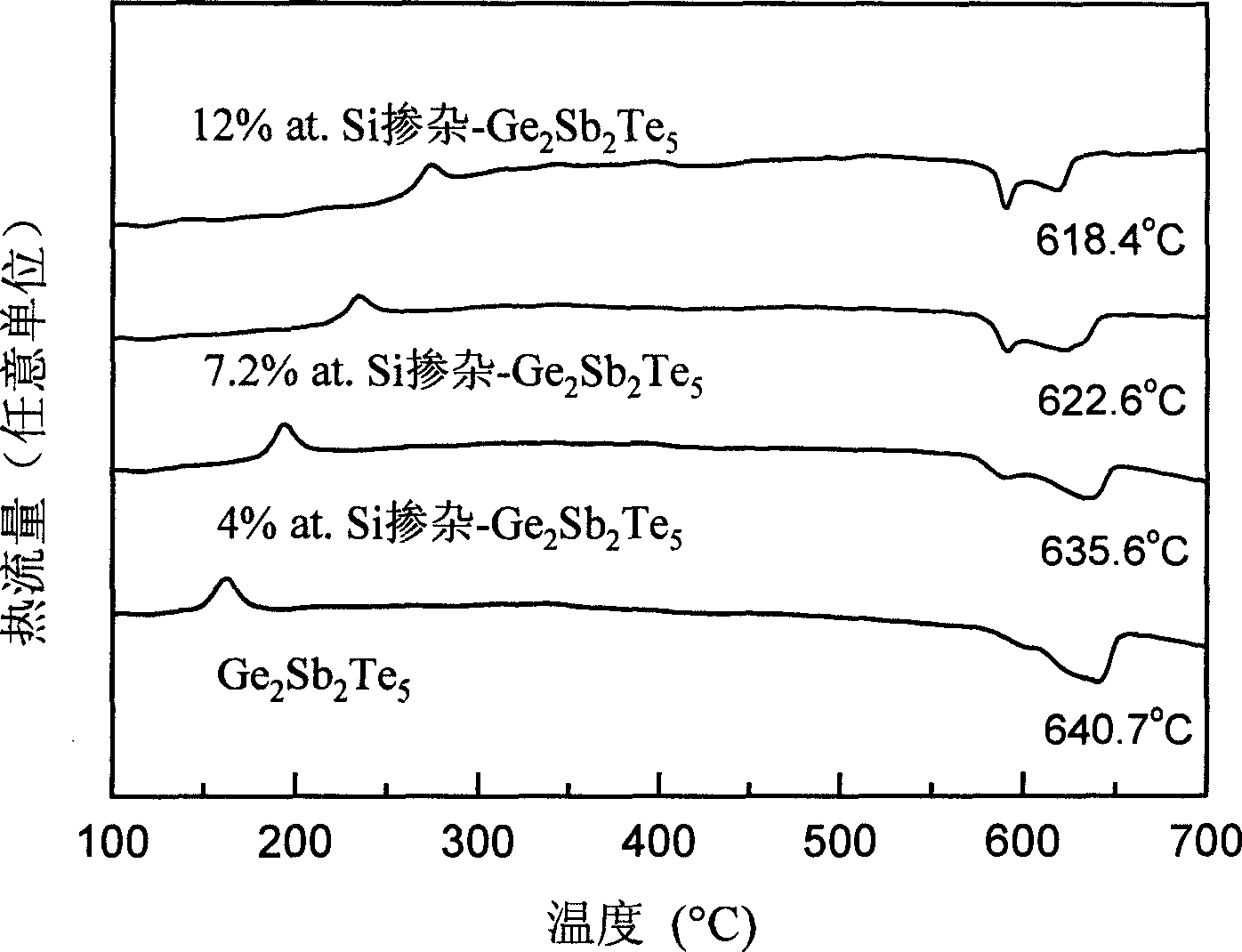

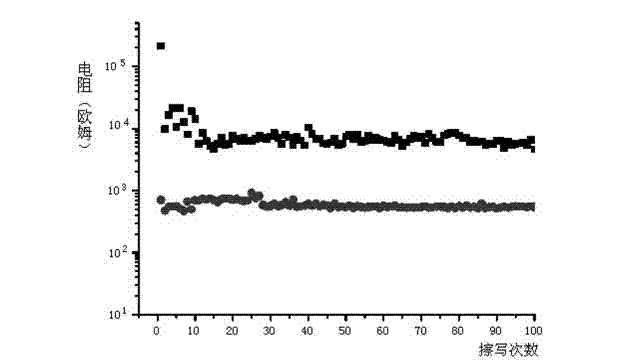

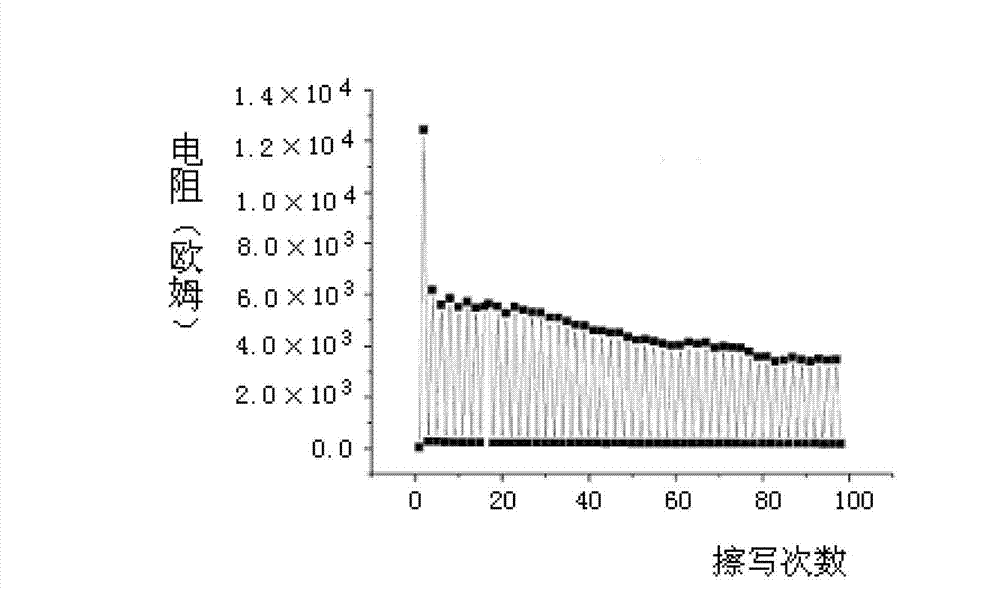

Phase change film material of silicon-adulterated sulfur series for phase change memory

InactiveCN101101965AEasy transferLower write operation currentChalcogenide/metal/alloy compound compositionsElectrical apparatusElectrical resistance and conductancePhase-change memory

The invention is concerned with the phase change film material containing silicon series cluster subject, that is the silicon group subject alloy TeaSibSb100-(a+b) with the a no lesser than 48 but no more than 60, and the b no less than 8 but no more than 40. The invention has the higher crystalline state resistance and non / crystalline resistance change ratio compare to the Ge2Sb2Te5 phase change film, the lower change ratio of the non / crystalline film thickness and melting point. The memorizer including the Si series sulfur group subject phase change film is with the higher ratio sum of the switch stability and it helps the writing operation current.

Owner:SHANGHAI JIAO TONG UNIV +1

Graphene nano steam generation device and cosmetic instrument

PendingCN108479658AStrong dischargeNot easy to accumulate waterChiropractic devicesMedical devicesManufacturing technologyEngineering

Owner:HANGZHOU QINGKE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

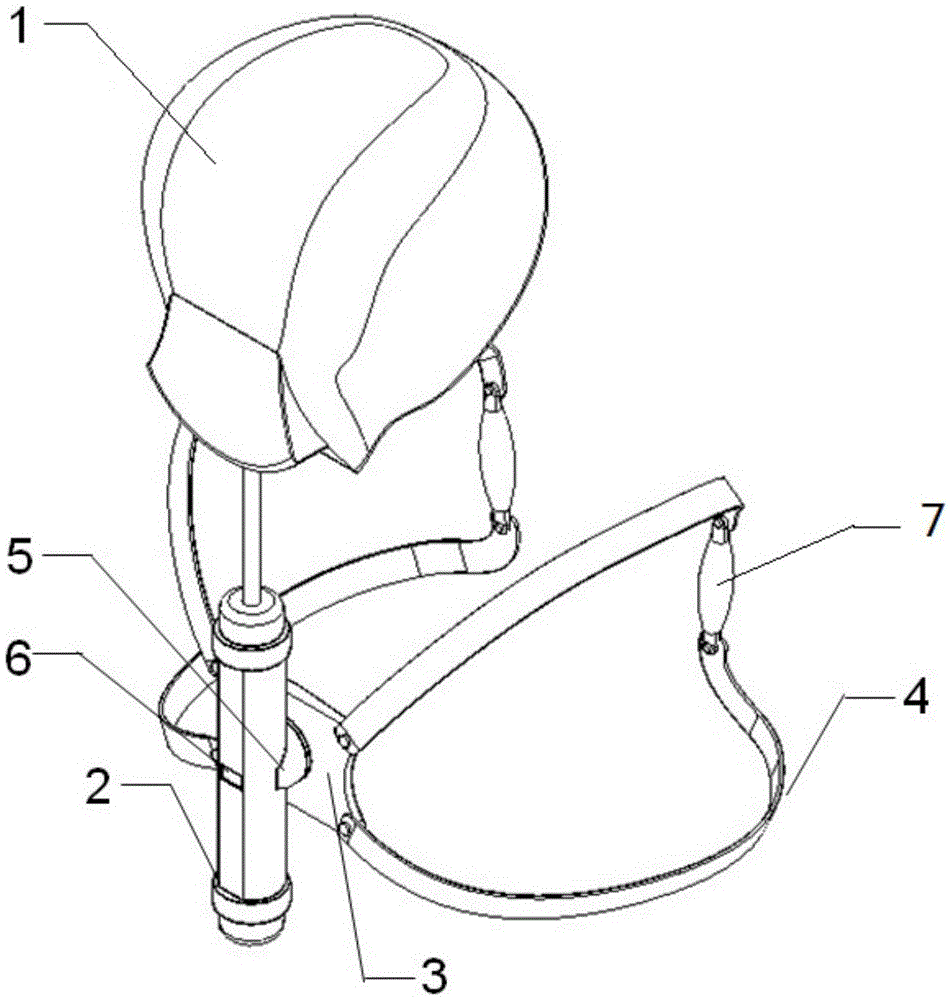

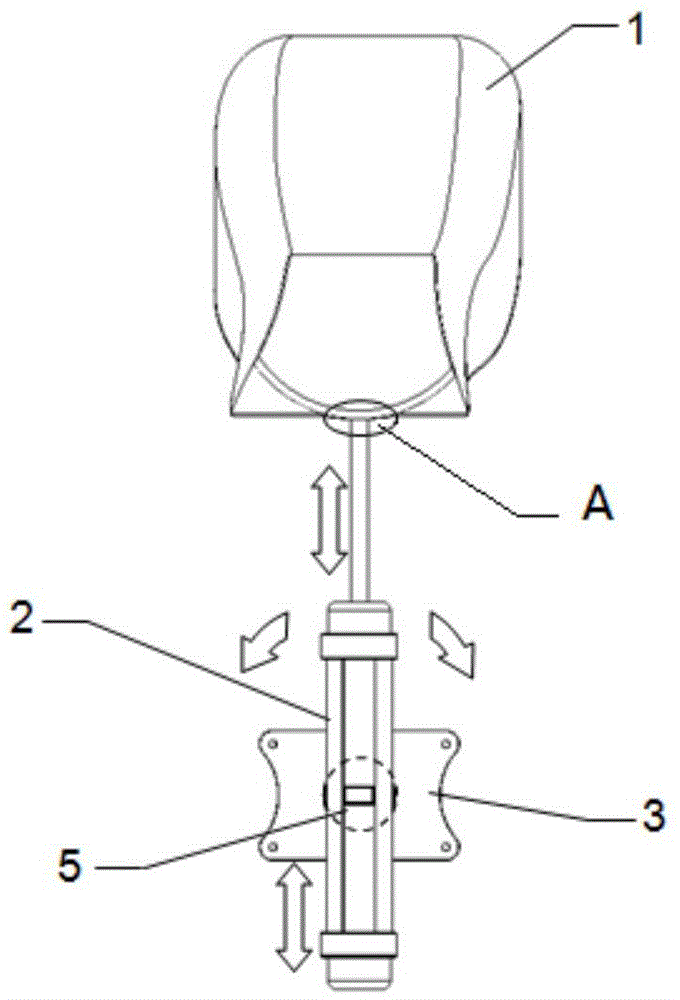

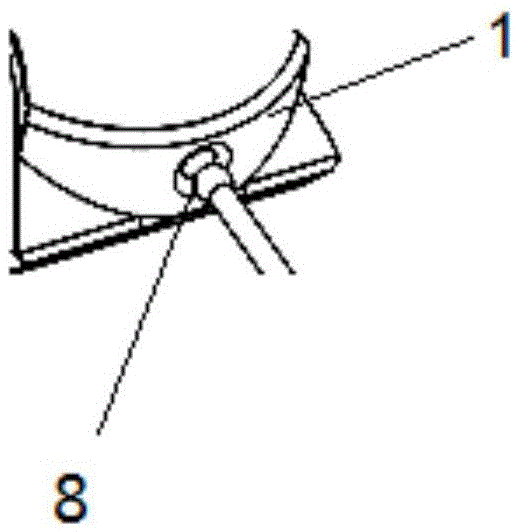

Neck exerciser

InactiveCN105457231AIncrease exerciseRestore physiological curvatureMuscle exercising devicesHuman bodyCervical spondylosis

The invention discloses a neck exerciser. The neck exerciser comprises a head sleeve and further comprises a resistance device and a fixing device. The resistance device is a linear reciprocating movement mechanism. The resistance device comprises a rotating part and a transmission part. The rotating part is fixed to the back of a human body through the fixing device. The transmission part is connected with the head sleeve. During exercise, the head overcomes the resistance of the resistance device, the transmission part performs linear reciprocating movement in the vertical direction through the movement of the head, and the rotating part can reciprocate leftwards and rightwards together with the movement of the head. When the neck exerciser is used, work is done on the resistance device just through the movement of the head, the resistance device reciprocates, the resistance value is stable, the neck muscle group is well exercised, physiological bending of the cervical vertebra can be restored easily, physiological balance of the cervical vertebra is maintained, relapse of cervical spondylosis is prevented, and the neck exerciser has a long-time stable curative effect on various kinds of cervical spondylosis, in particular on neck-type chronic cervical spondylosis.

Owner:林晓东

Organic PTC thermistor and making method

InactiveUS20030091829A1Avoid excessive accumulationEasy to separateLiquid surface applicatorsThermometers using electric/magnetic elementsMolecular levelMetal particle

Owner:TDK CORPARATION

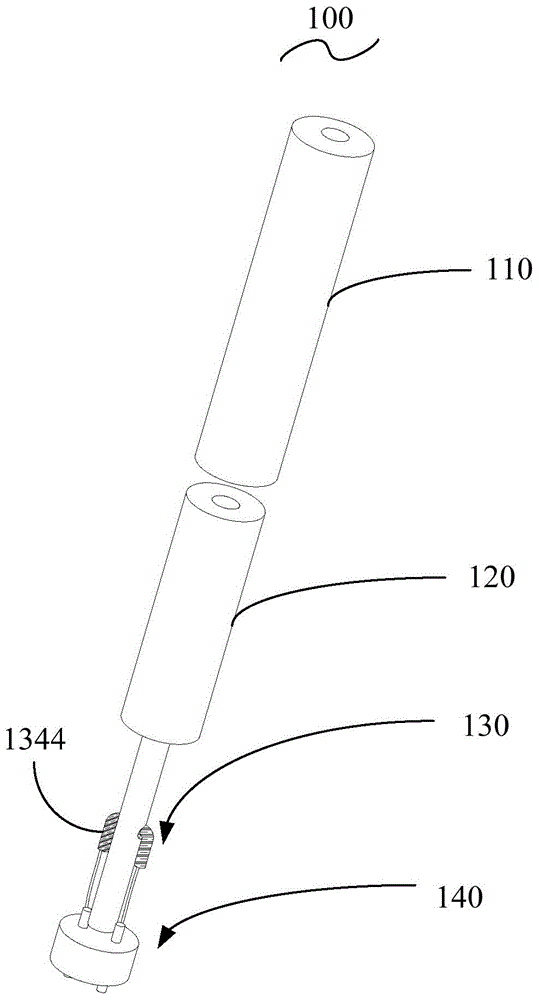

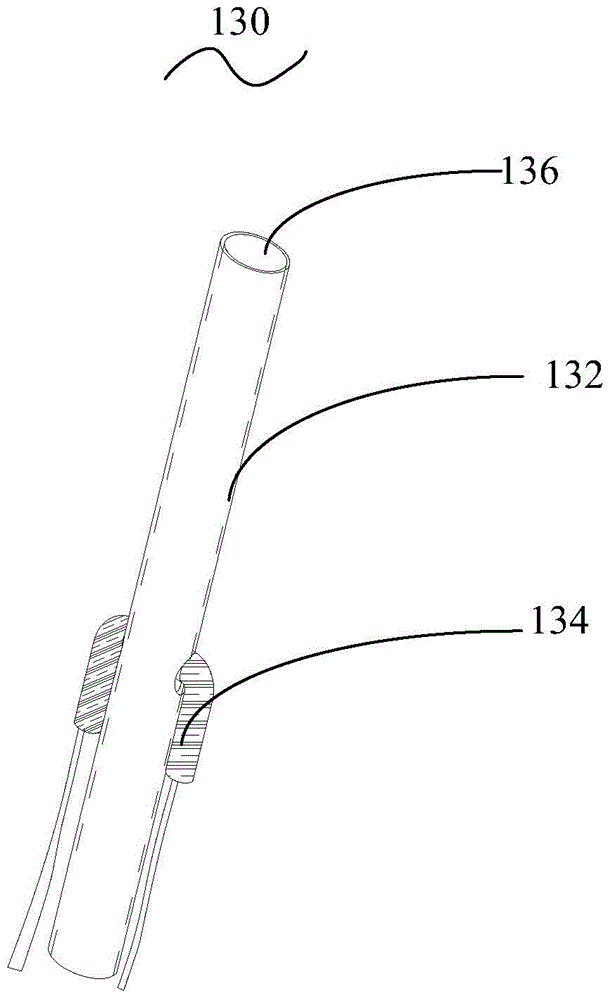

Heating element, electronic cigarette and method for forming heating element

InactiveCN103987142AIncrease productivityStable resistance valueOhmic-resistance electrodesHeater elementsElectrical resistance and conductanceElectronic cigarette

A heating element, electronic cigarette and method for forming heating element. The heating element includes a heating part and a connection part extending along both ends of the heating part so as to form a first connection end and a second connection end, which are electrically connected to a drive circuit respectively. The first connection end, the second connection end and the heating part are integrative, and the first connection end and the second connection end both has a coating covered on outer surface of them respectively. The heating element is integrated designed without any complex technique of the welding or riveting, and via electroplating to form a coating on the heating element instead, the production efficiency of the heating element gets highly improved, costs reduced and a stable resistance value gets obtained in the mass-produced heating elements, involving a consistency in mass production.

Owner:HUIZHOU KIMREE TECH

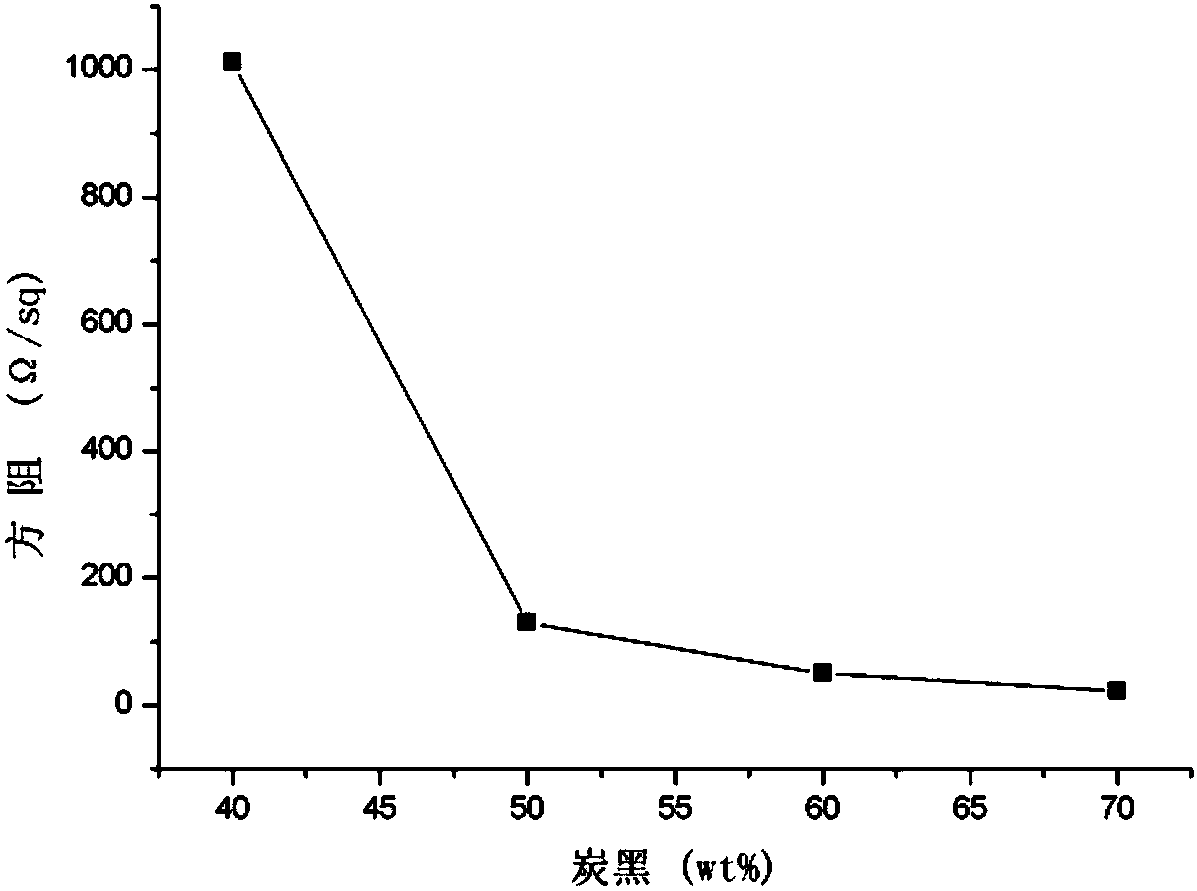

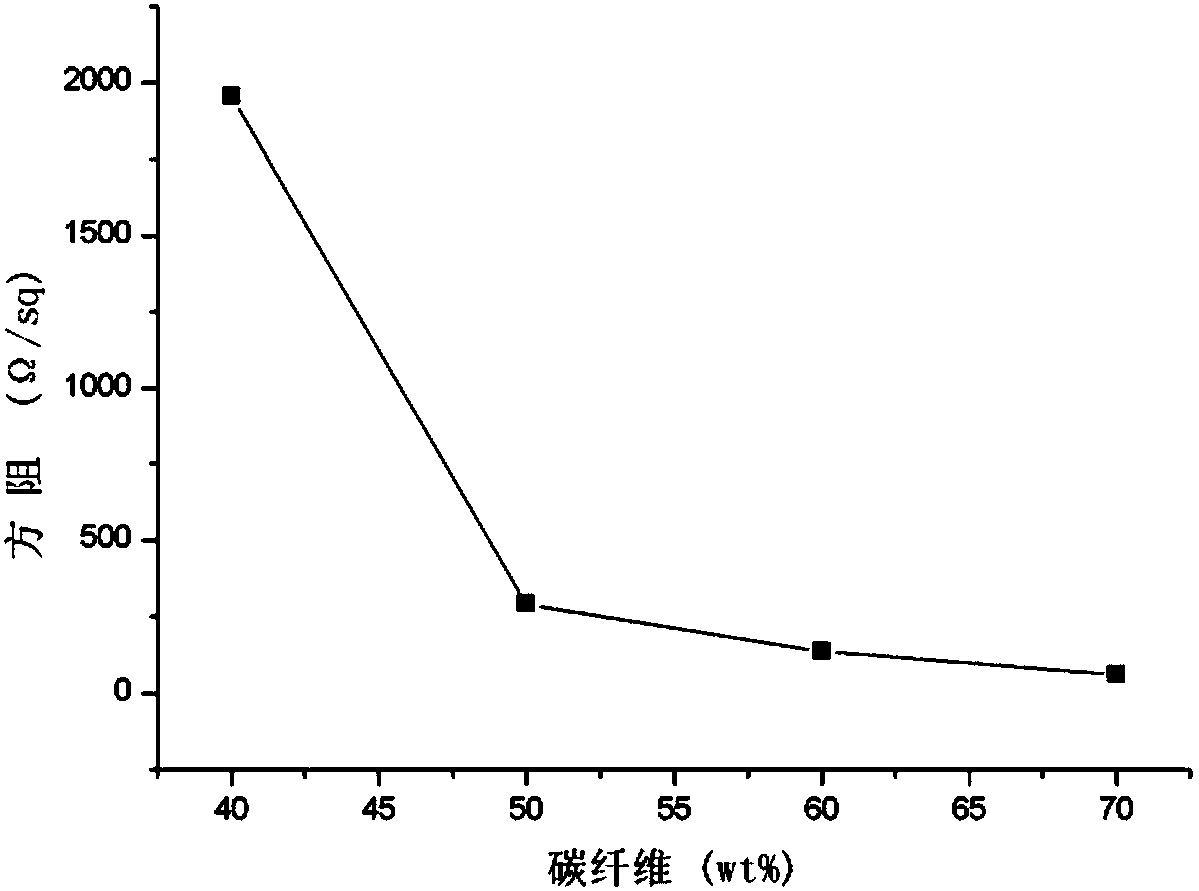

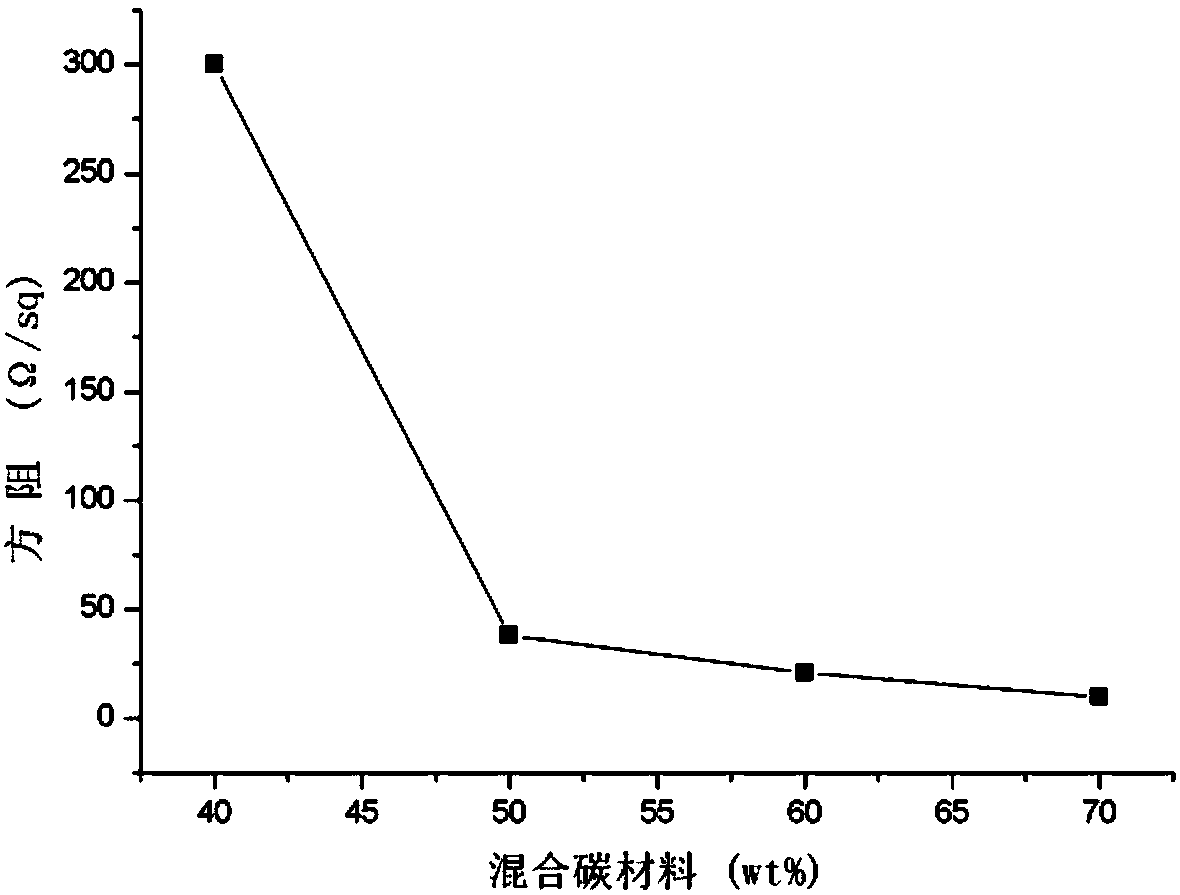

Environment-friendly low-resistance graphene carbon fiber conductive carbon paste and preparation method thereof

InactiveCN108039225AStable resistance valueUniform heating temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureFiberCarbon fibers

The invention relates to the technical field of conductive carbon paste preparation, in particular to environment-friendly low-resistance graphene carbon fiber conductive carbon paste comprising the following components: 30 to 70 parts of resin, 20 to 40 parts of carbon fiber, 1 to 10 parts of graphene microchip, 10 to 30 parts of conductive carbon black, 20 to 50 parts of solvent, 1 to 3 parts ofdispersant, 1 to 3 parts of adhesion promoter, and 1 to 3 parts of defoamer. Thermal conductive carbon paste using graphene and carbon fiber as the main carbon materials has the characteristics of good electrical conductivity, small internal resistance, uniform distribution of carbon material, and easy coating.

Owner:CHANGZHOU XICAI CARBON MATERIAL TECH CO LTD

Grapheneelectrothermal material and preparation method thereof

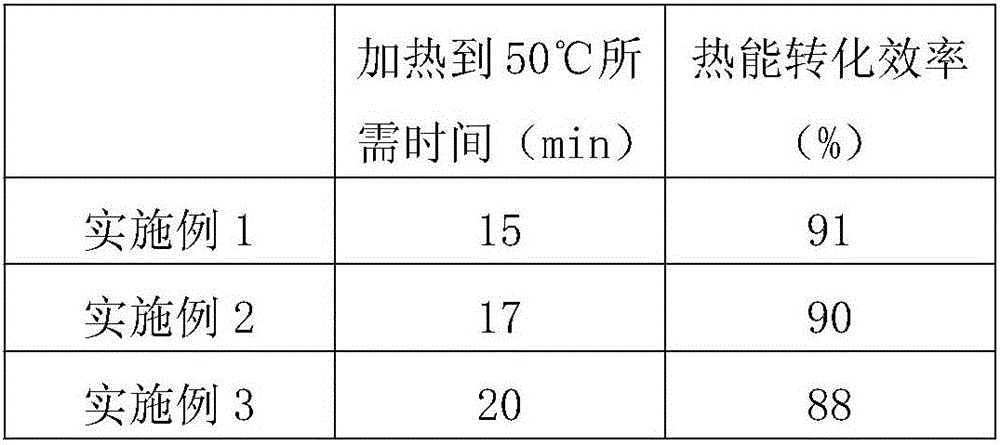

InactiveCN106189085AStable resistance valueImprove power conversion efficiencyChemical industryHeating element materialsEpoxyFiber

The invention discloses a grapheneelectrothermal material, which is prepared from the following components in parts by weight: 60 to 90 parts of polymer matrix, 5 to 10 parts of carbon fiber, 5 to 10 parts of carbon nanotube , 15 to 20 parts of graphene, and 3 to 6 parts of flame retardant. The polymer matrix is one of epoxy resin,silicone rubber and urethane resin. The grapheneelectrothermal material has stable electric resistance value and can uniformly generate heat, the electric energy conversion efficiency is up to over 88%, and the heating time is fast, and15 to 20 minutesgenerally.

Owner:佛山杰致信息科技有限公司

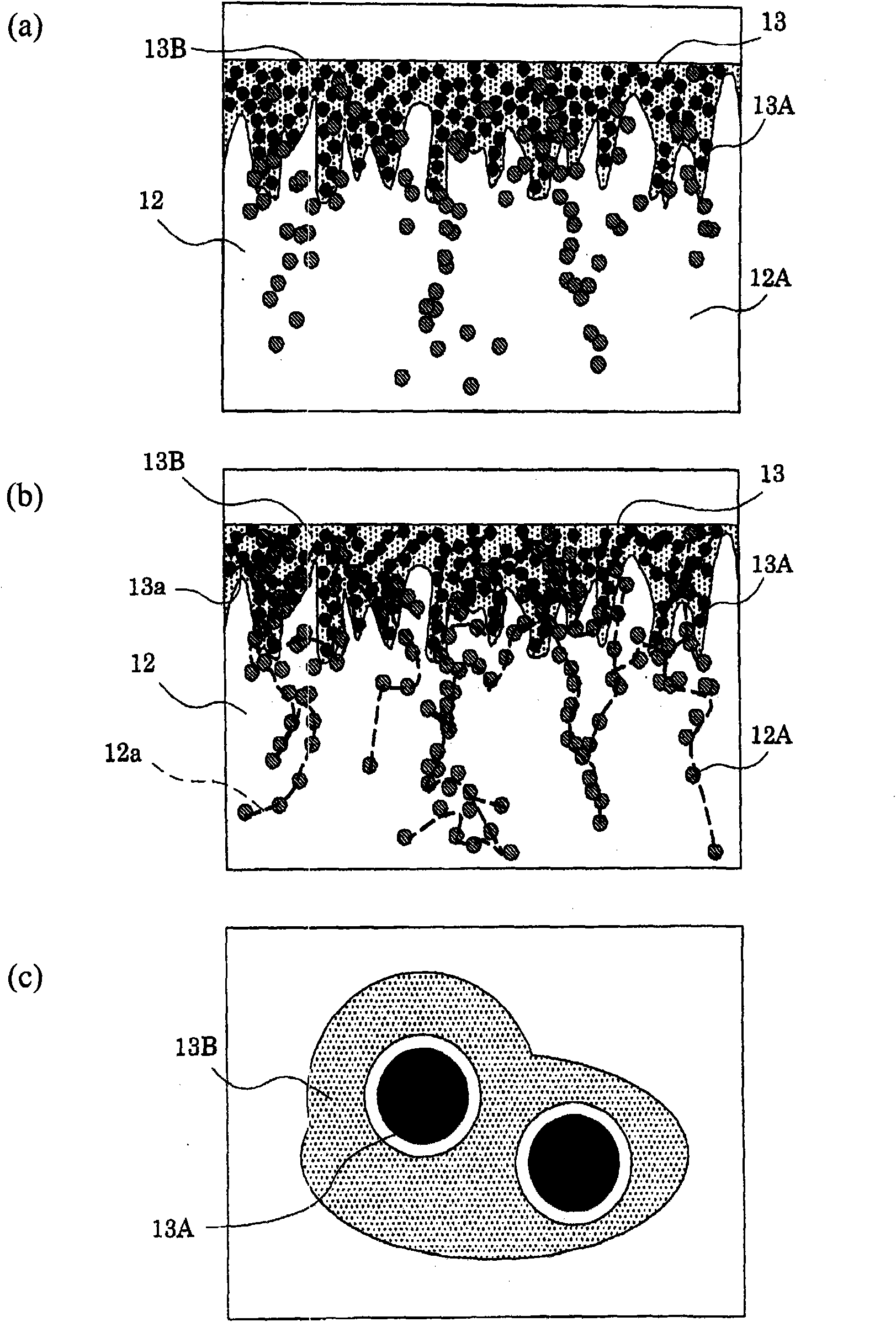

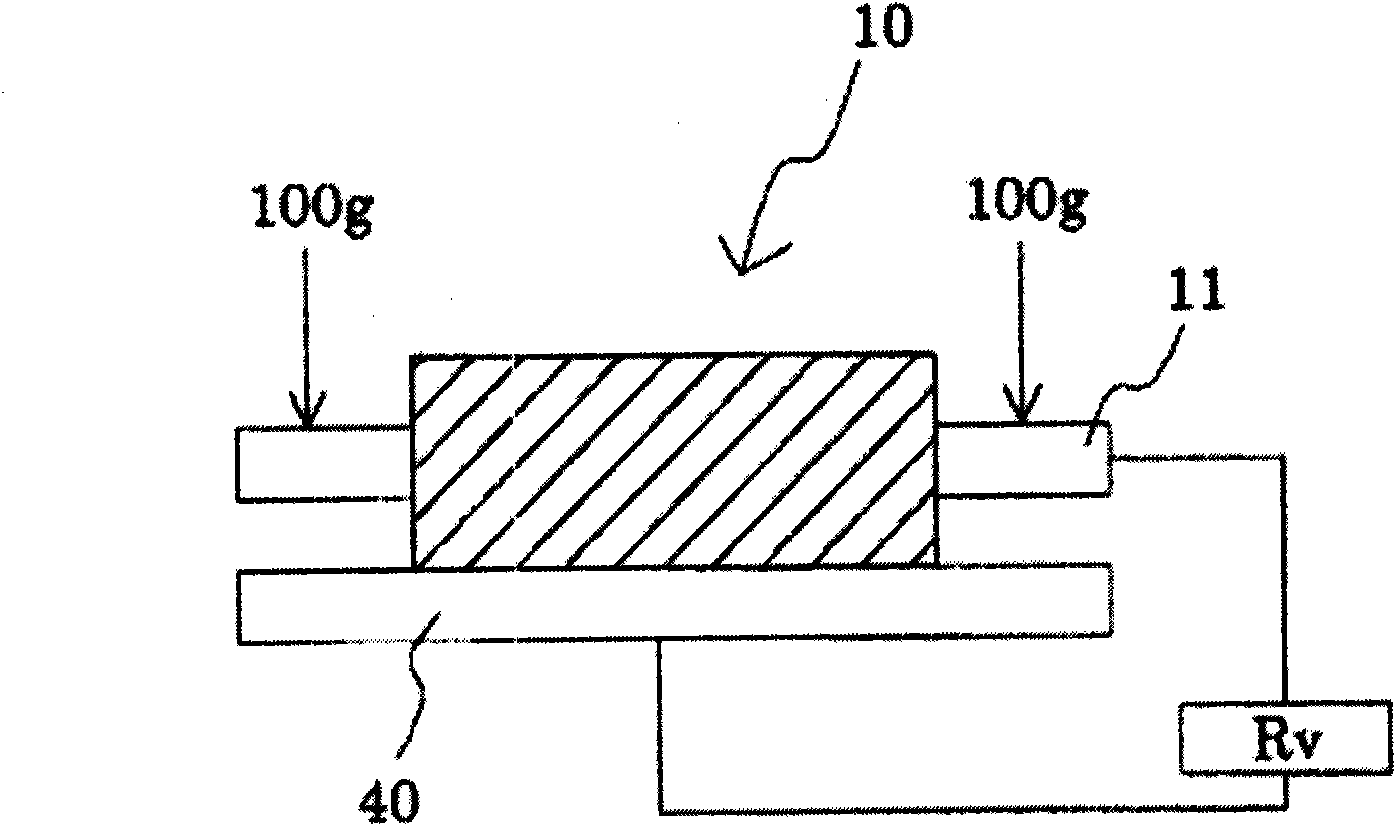

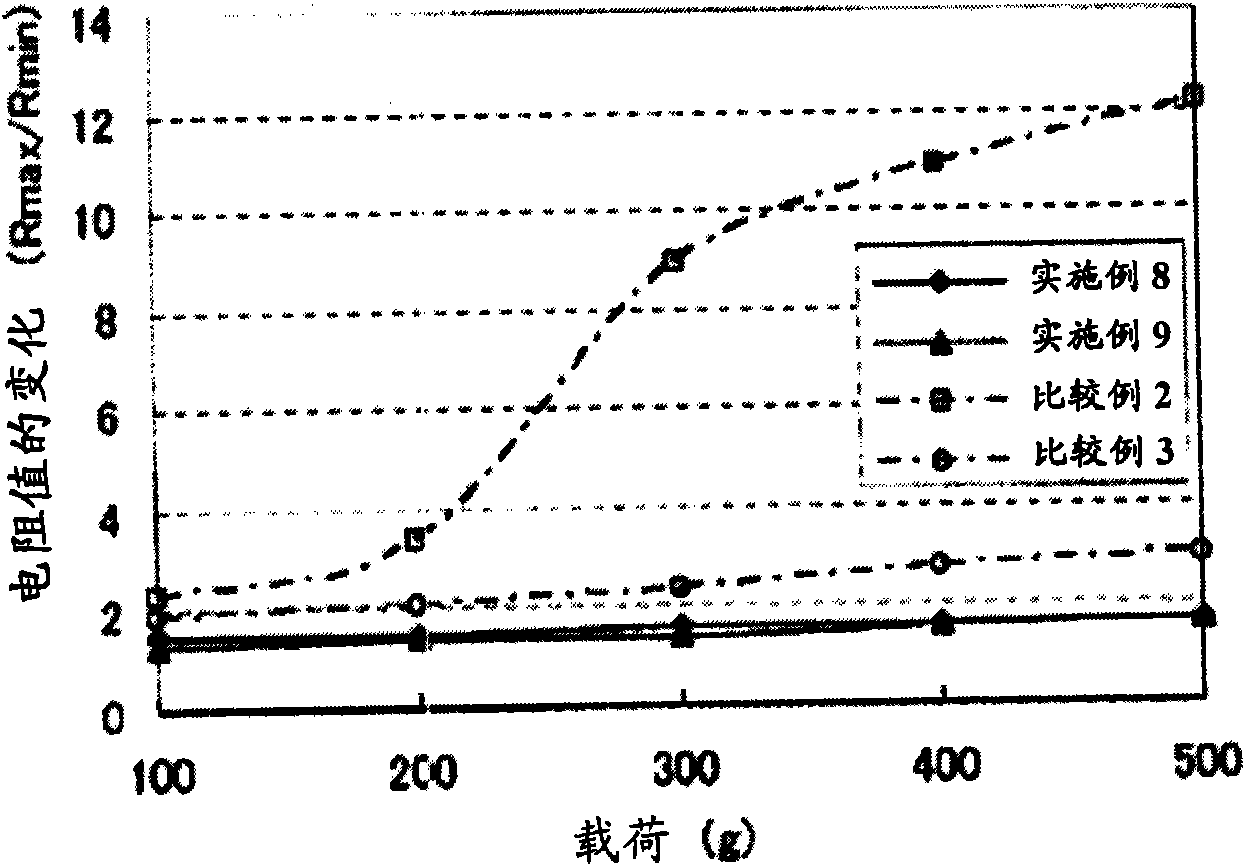

Conductive rubber member

ActiveCN101835604ALower the resistance valueLittle change in resistance valueElectrographic process apparatusRubber layered productsElectrical resistance and conductanceEngineering

Disclosed is a conductive rubber member which is small in variations of electrical resistance and stable in electrical resistance over a long time. Specifically disclosed is a conductive rubber member comprising a surface treated layer in the surface portion of a conductive elastic layer, which is obtained by providing a rubber base with conductivity. The surface treated layer is formed by impregnating the surface portion of the conductive elastic layer with a surface treatment liquid containing a carbon black subjected to a dispersing treatment and an isocyanate compound.

Owner:SYNZTEC

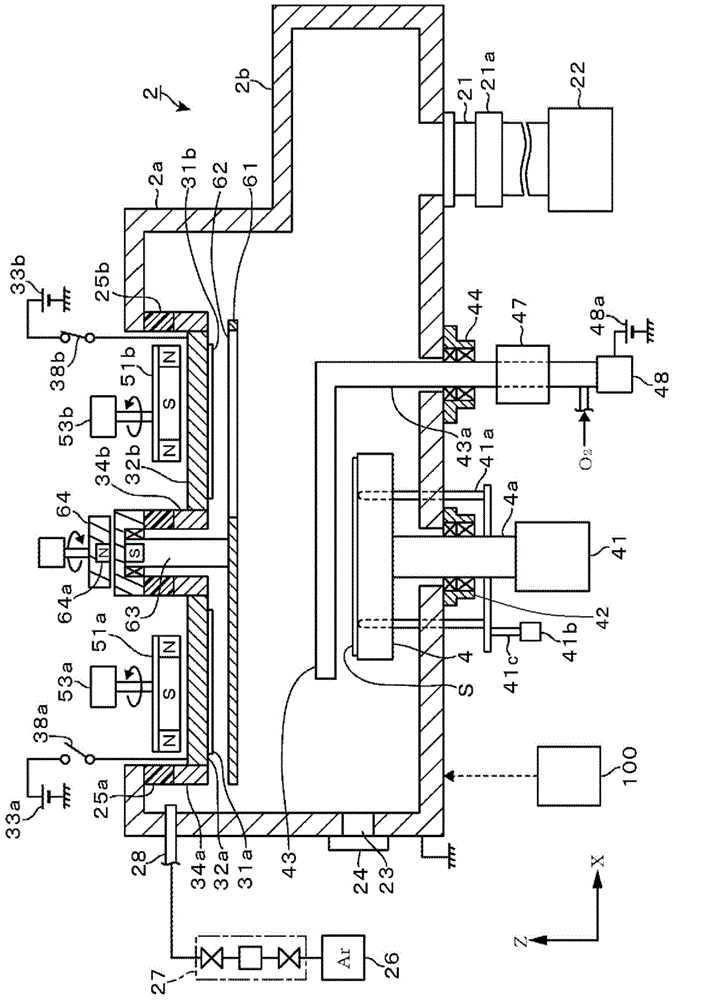

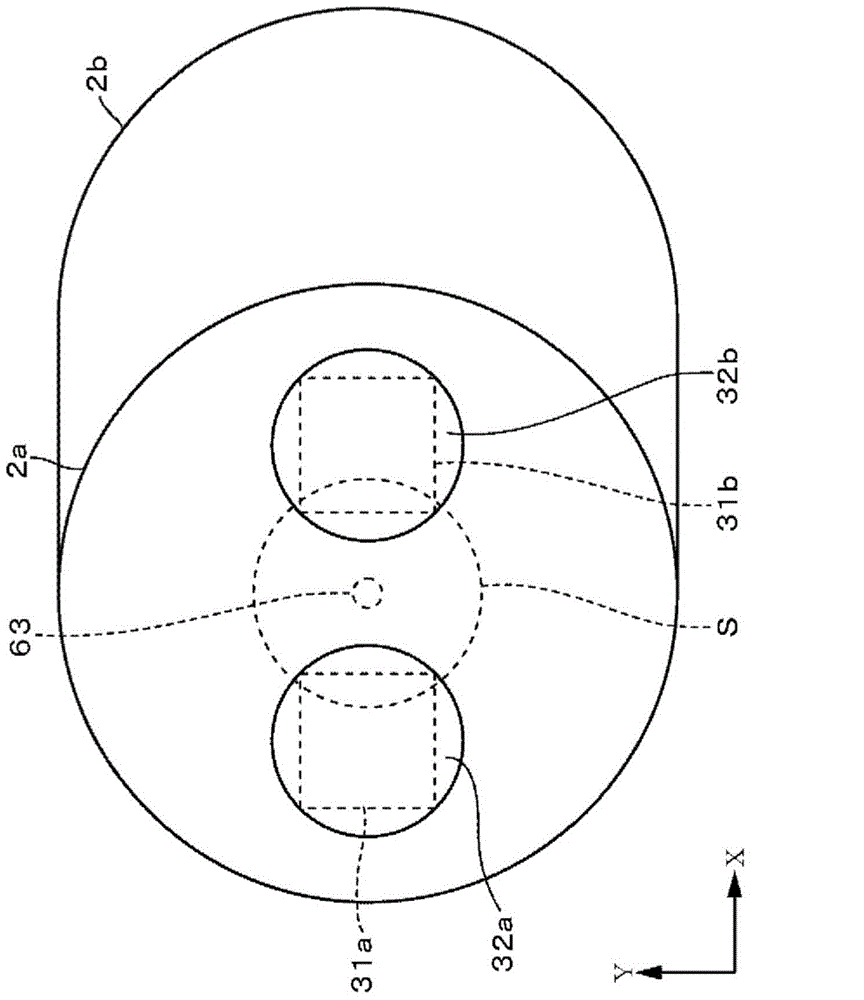

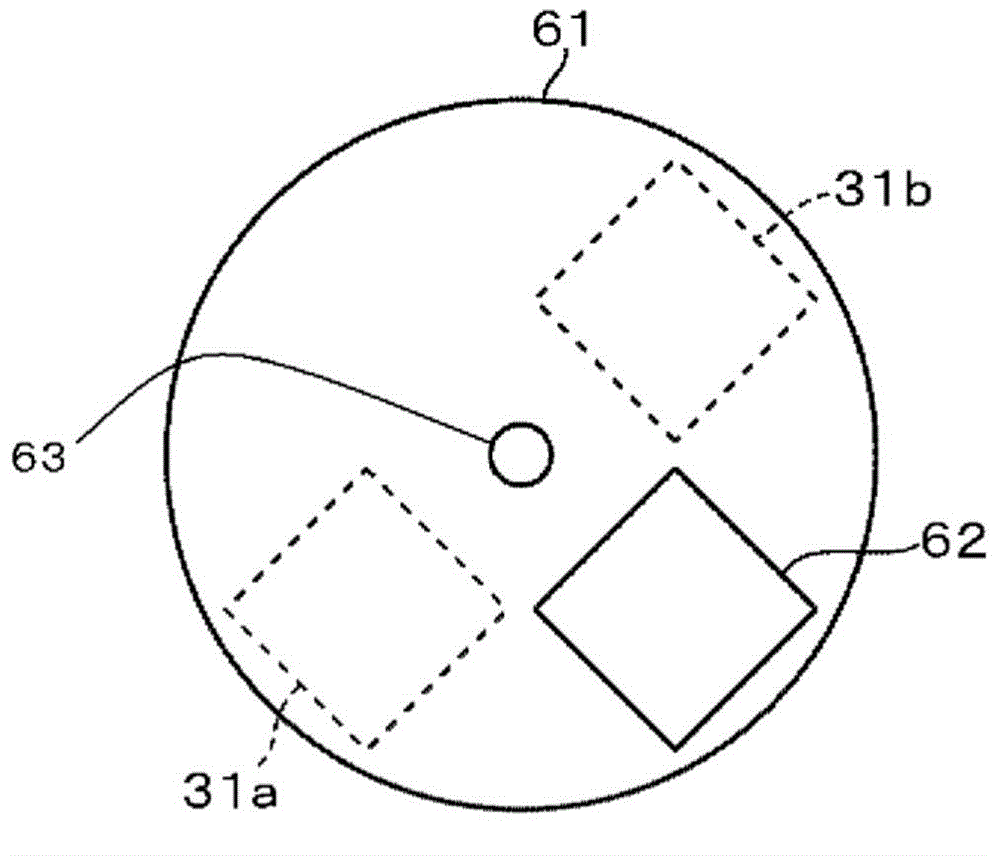

Vacuum-processing apparatus, vacuum-processing method, and storage medium

ActiveCN104350174AOxygen controlStable resistance valueElectric discharge tubesSolid-state devicesSputteringOxygen

[Problem] To provide a processing apparatus and processing method for stabilizing the resistance value of metal oxide film between substrates when a metal oxide film is formed on a substrate. [Solution] A target (31a) composed of a member for absorbing oxygen and a target (31b) composed of metal are disposed inside a vacuum container (2) capable of plasma sputtering, and a substrate (S) is conveyed into the vacuum chamber (2). The substrate (S) is covered with a cover plate (43), the target (31a) is sputtered and formed into a film inside the vacuum chamber (2), and oxygen inside the vacuum chamber (2) is made to adsorb onto the film. The cover plate (43) is moved from above the substrate S, the target (31b) is sputtered, and a metal film is formed on the substrate (S). The required amount of oxygen is fed from the cover plate (43), which has again been moved over the substrate (S), and a metal film is formed into a metal oxide film. The substrate (2) on which the target (31a) has been sputtered, on which oxygen inside the vacuum container (2) has been adsorbed, and on which a metal oxide film has been formed is conveyed out from the interior of the vacuum container (2).

Owner:TOKYO ELECTRON LTD

Silicon-contained series surfur-family compound phase transformation film material for phase transformation memory

InactiveCN1744340AEasy transferLower write operation currentElectrical apparatusHigh resistanceHigh rate

The disclosed materials include three types: (1) alloy firm of TeaSibSbl00-(a+b); (2) firm of (TeaGebSb l00-(a+b) )c Si1oo-c formed from Ge-Sb-Te alloy with Si being doped into; (3) alloy firm of TeaSicGe(b-c)Sb l00-(a+b) obtained by using Si to partially replace Ge in Ge-Sb-Te alloy. Comparing common Ge2Sb2Te5 film of phase change, the invention possesses higher resistance of crystalline state, higher rate of change of amorphous state / crystalline state, lower rate of change of film thickness of amorphous state / crystalline state, and lower melting point. These characters make storage devices of film of phase change containing chalcogenide in Si group possess higher rate of on / off and stability of device. The invention makes for lowering operation current for writing storage devices as well as for realizing storage in multiple values in higher density.

Owner:SHANGHAI JIAO TONG UNIV +1

Preparation and application of graphene heating material realizing low-voltage driving

ActiveCN107880758AWide applicabilityProduce quicklyPolyurea/polyurethane coatingsElectrically-conductive paintsWater basedFiber

A graphene coating contains 5%-30% of aqueous resin, 50%-70% of a graphene dispersion and 10%-30% of a conductive carbon dispersion. Preferably, the graphene coating also contains 0.2%-1% of a wettingdispersant, 0.1%-0.5% of a defoamer, 0.2%-1.0% of a leveling agent, 0.1%-1.0% of a thickener, 0.5%-2% of a solvent and 0-6% of deionized water; preferably, the sum of the components is 100%. The graphene heating coating is a green and environment-friendly water-based coating, and is more environmentally friendly than an existing commercially available oily system. The graphene coating is harmless, environmentally friendly and pollution-free to production workers during coating and use. Little waste water is produced in construction and is easy to treat. The graphene coating is suitable for small-scale production and industrial large-scale production at the same time. The graphene coating has high applicability, can be applied to most polymer films and chemical fiber filaments, and enablescommon polymer materials to have conductive performance. Due to accurate selection of the component materials, graphene and a carbon-based conductive material in the coating, as functional particles,can be fully attached to the polymer surface to form a conductive layer, and the prepared graphene conductive heating material can generate heat quickly, efficiently and uniformly only by switching on a 36V safe voltage. The conductive material prepared with the existing coating technology is stable in resistance value.

Owner:北京烯诺科技有限公司

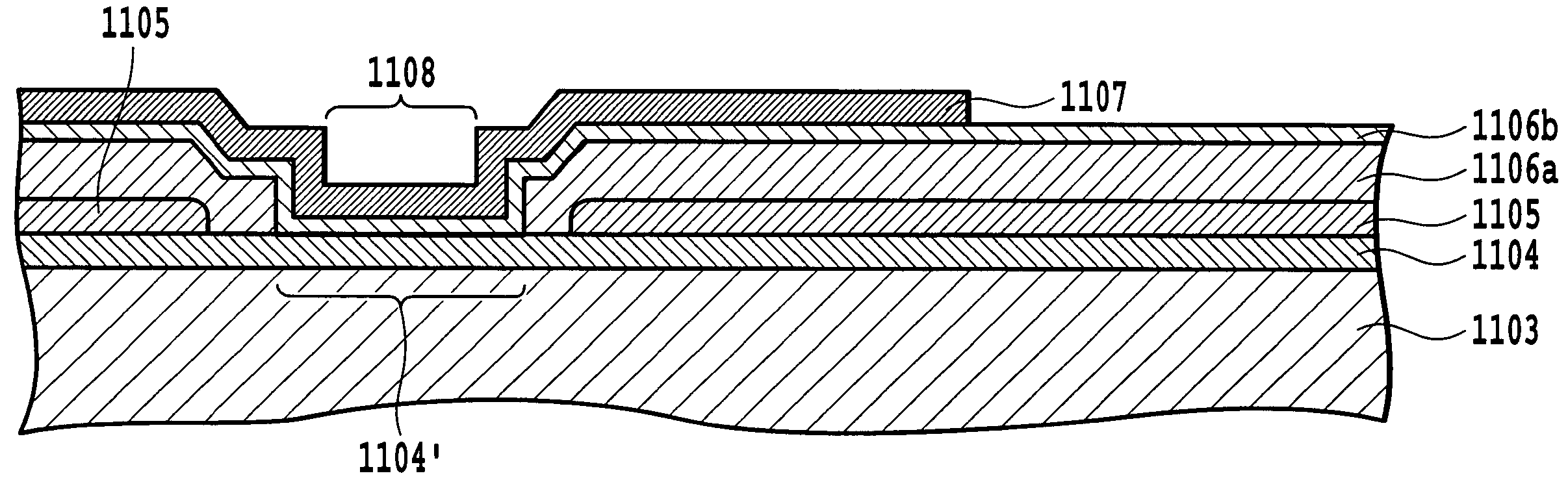

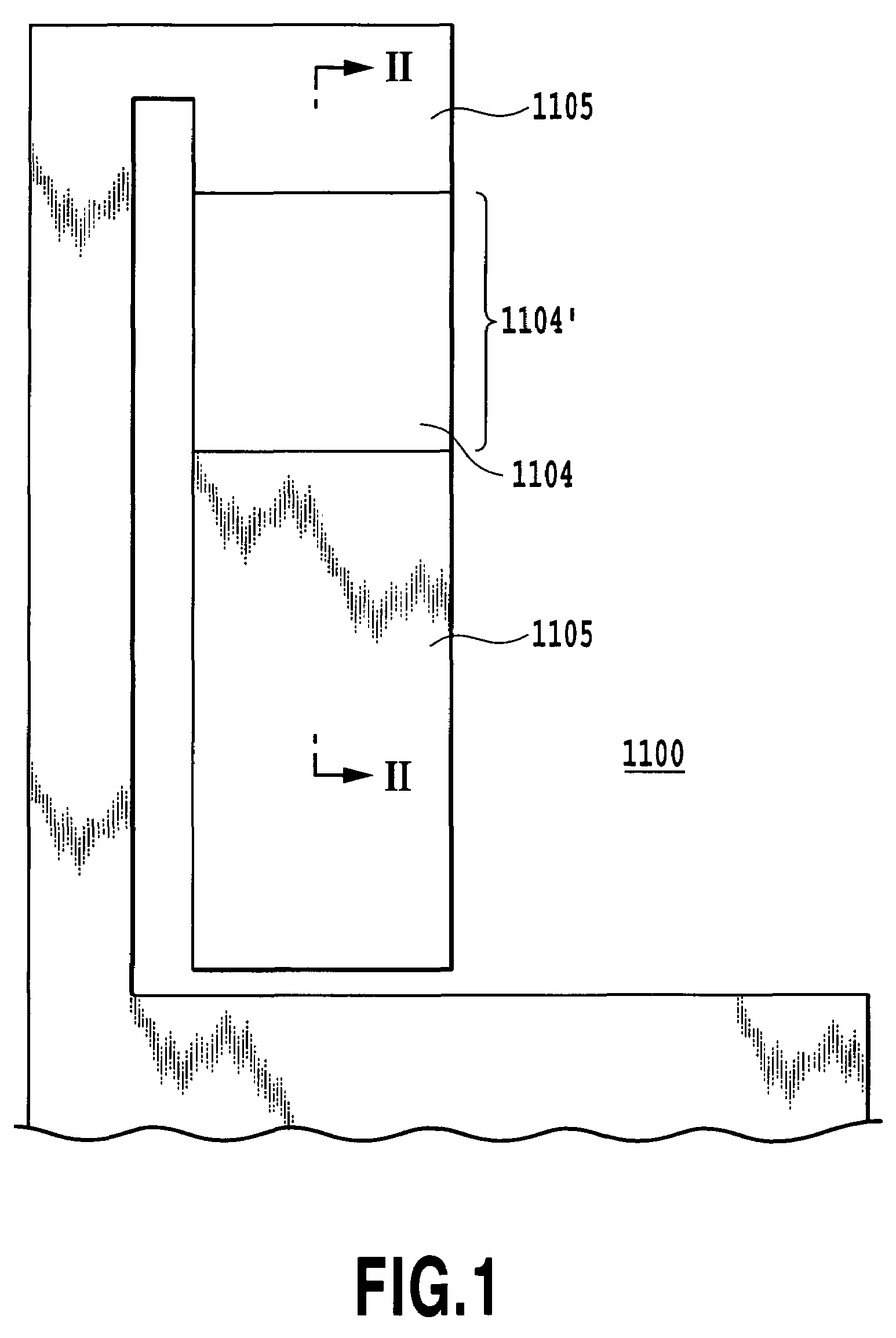

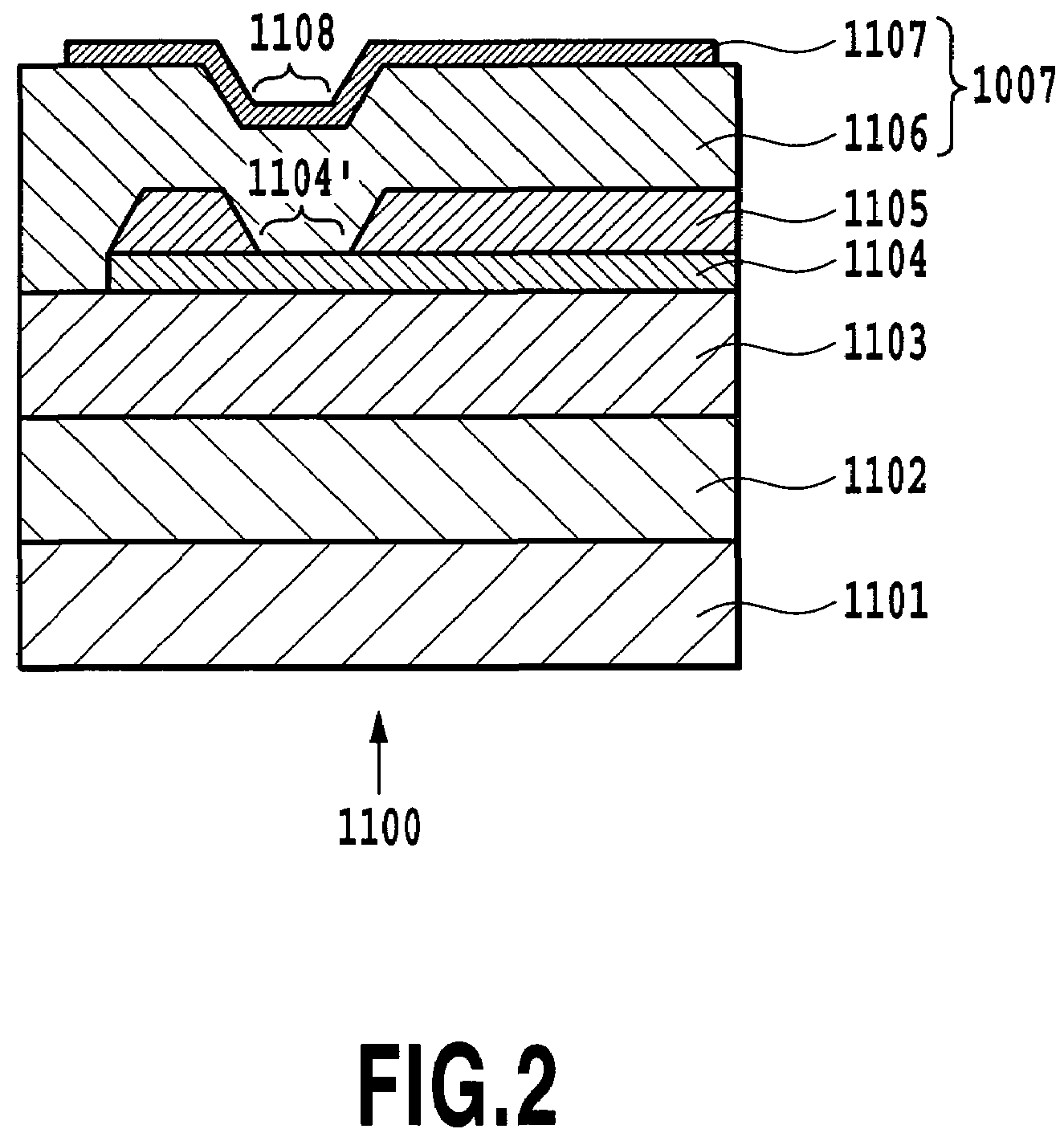

Ink jet head circuit board, method of manufacturing the same and ink jet head using the same

InactiveUS7566116B2Reduce power consumptionReduce volatilityInking apparatusPrinted resistor incorporationThermal energyImaging quality

In an ink jet head circuit board including a heater for generating thermal energy used for ejecting ink in response to application of electricity, a drop in thermal energy efficiency is prevented while reducing an area of the heater to achieve higher-resolution and higher-image-quality printing, and damages on the heater attributable to a manufacturing process are avoided. To achieve this, a resistor layer is disposed on an electrode wire layer; and two protective layers are disposed thereon. Then the upper protective layer is removed in a site above the heater. Accordingly, it is possible to dispose the protective layers without causing a decrease in an effective bubble generating region, and to improve thermal energy efficiency by reducing the effective thickness of the protective layer above the heater. Moreover, the resistor layer is covered with the first protective layer and is thereby prevented from adverse effects in the manufacturing process such as etching processes.

Owner:CANON KK

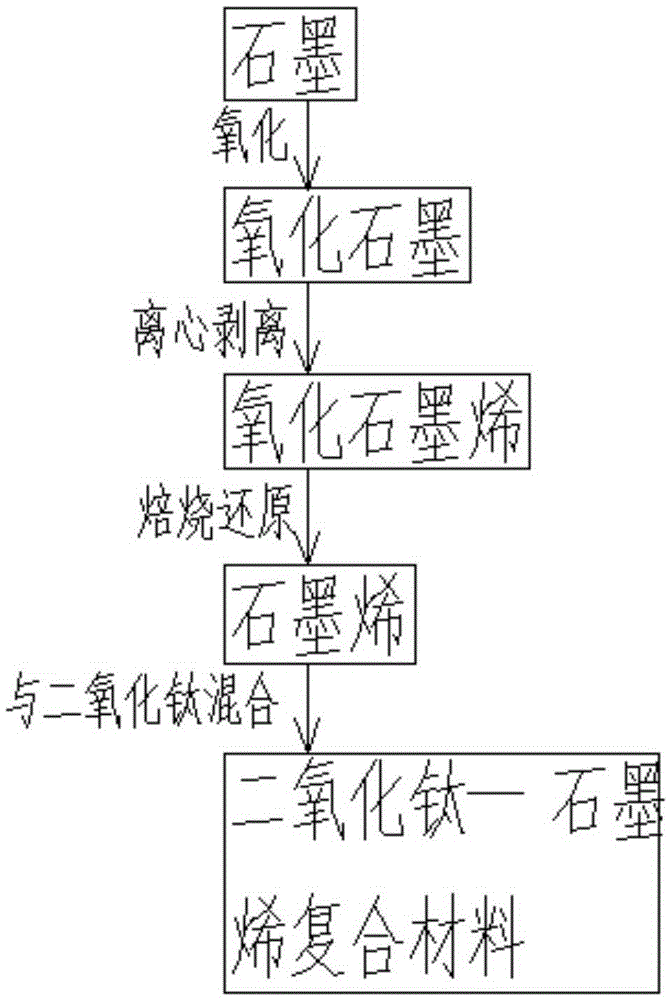

Production technology of nanoscale conductive titanium dioxide

InactiveCN105355320AGood electrical and mechanical propertiesStable resistance valueMaterial nanotechnologyCable/conductor manufactureCvd graphenePotassium permanganate

The invention relates to a production technology of a nanoscale conductive titanium dioxide and belongs to the technical field of titanium dioxide production. The production technology comprises the following steps: reducing oxidized graphene into graphene, mixing the graphene with titanium dioxide, and finally forming a titanium dioxide-graphene composite material; oxidizing graphite powder with concentrated sulfuric acid and potassium permanganate, and forming the oxidized graphene after centrifugal precipitation; drying and grinding the oxidized graphene into powder, respectively putting the oxidized graphene and titanium dioxide powder into absolute ethyl alcohol, dripping an absolute ethyl alcohol dispersion liquid of the oxidized graphene into the absolute ethyl alcohol dispersion liquid of the titanium dioxide, and adding hydrochloric acid and distilled water to obtain a gel product; and carrying out ageing and ultrasonic cleaning, roasting and grinding the gel product, reducing the oxidized graphene into the graphene, and combining with the titanium dioxide to form conductive titanium dioxide. The nanoscale conductive titanium dioxide is applicable to low-temperature preparation of conductive and antistatic equipment, is also applicable to preparation of a variable-temperature sintered powder material of which the high temperature can reach 1600 DEG C and is applicable to popularization and application in related fields.

Owner:HEBEI MILSON TITANIUM DIOXIDE

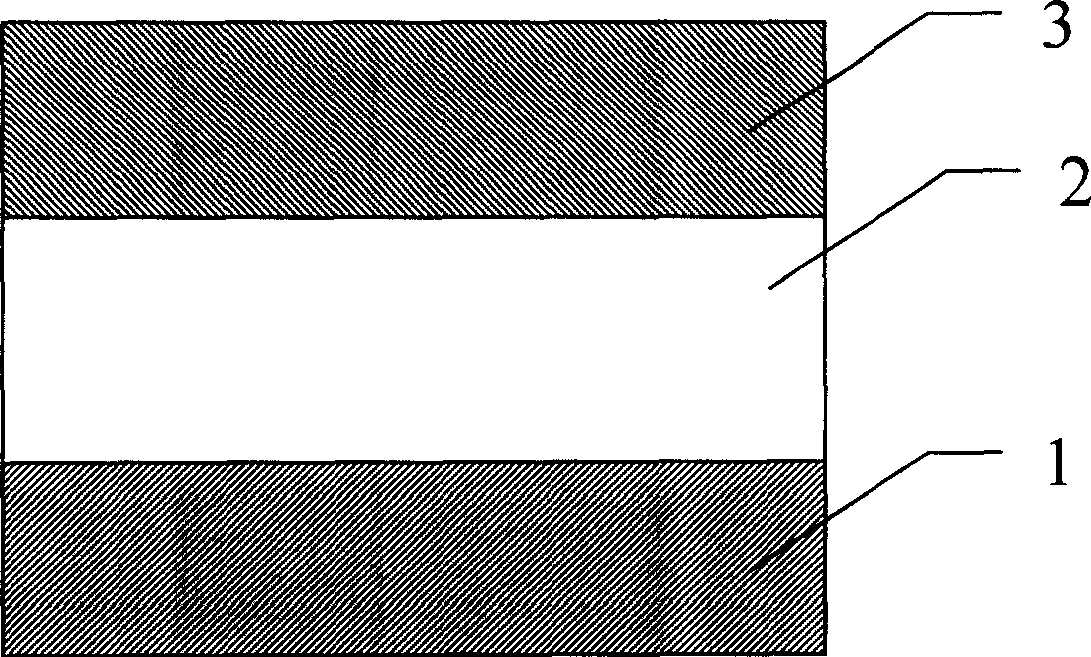

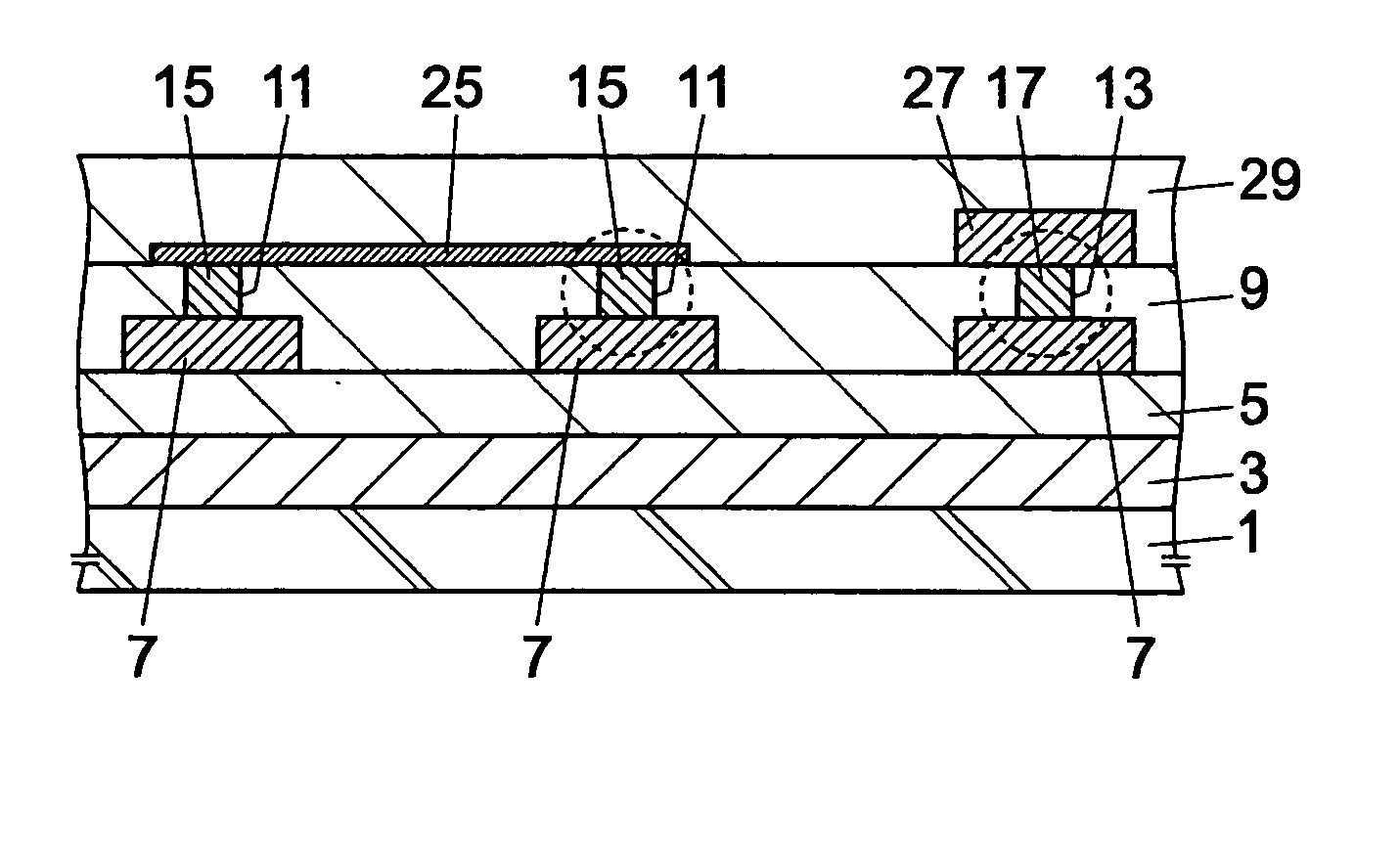

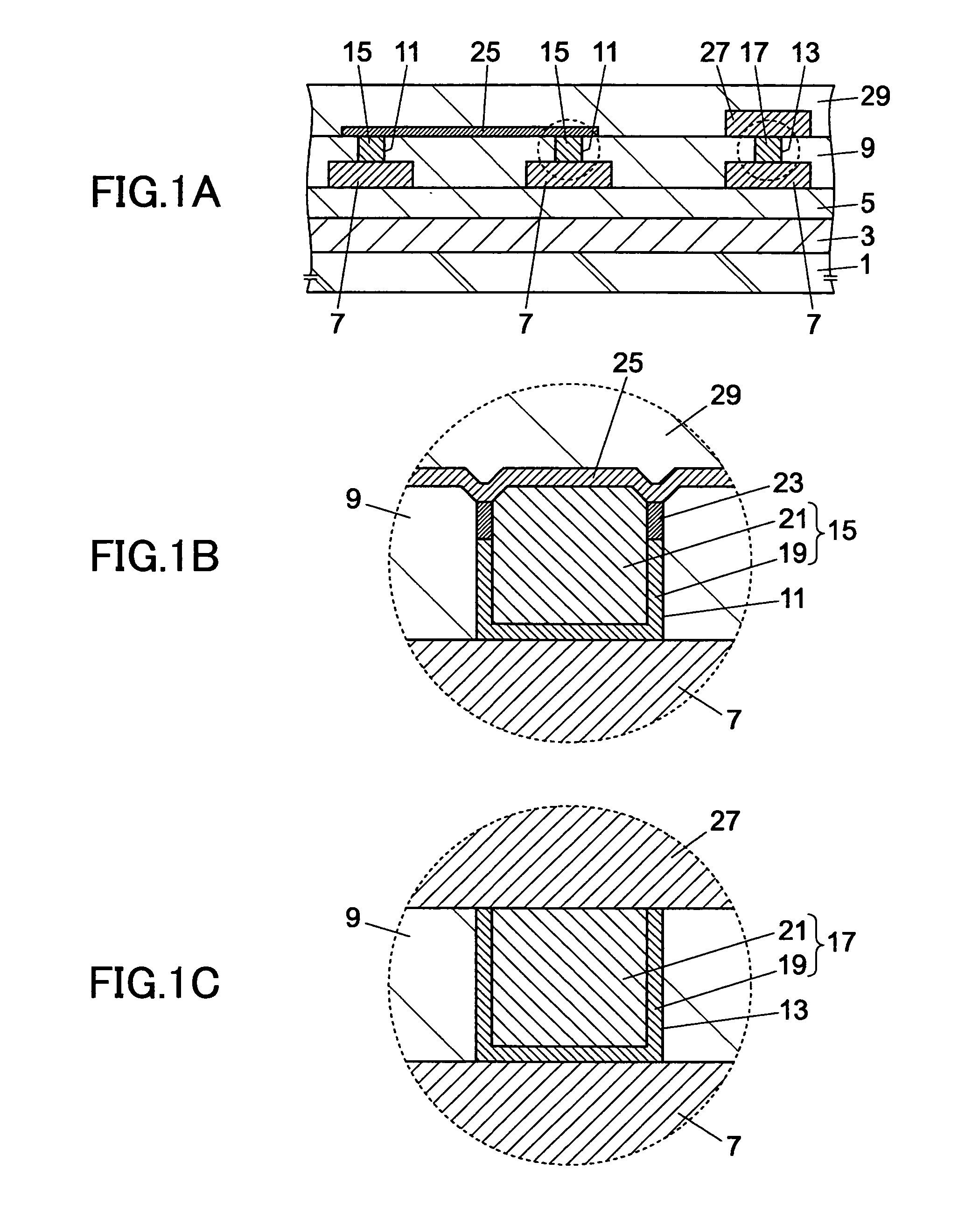

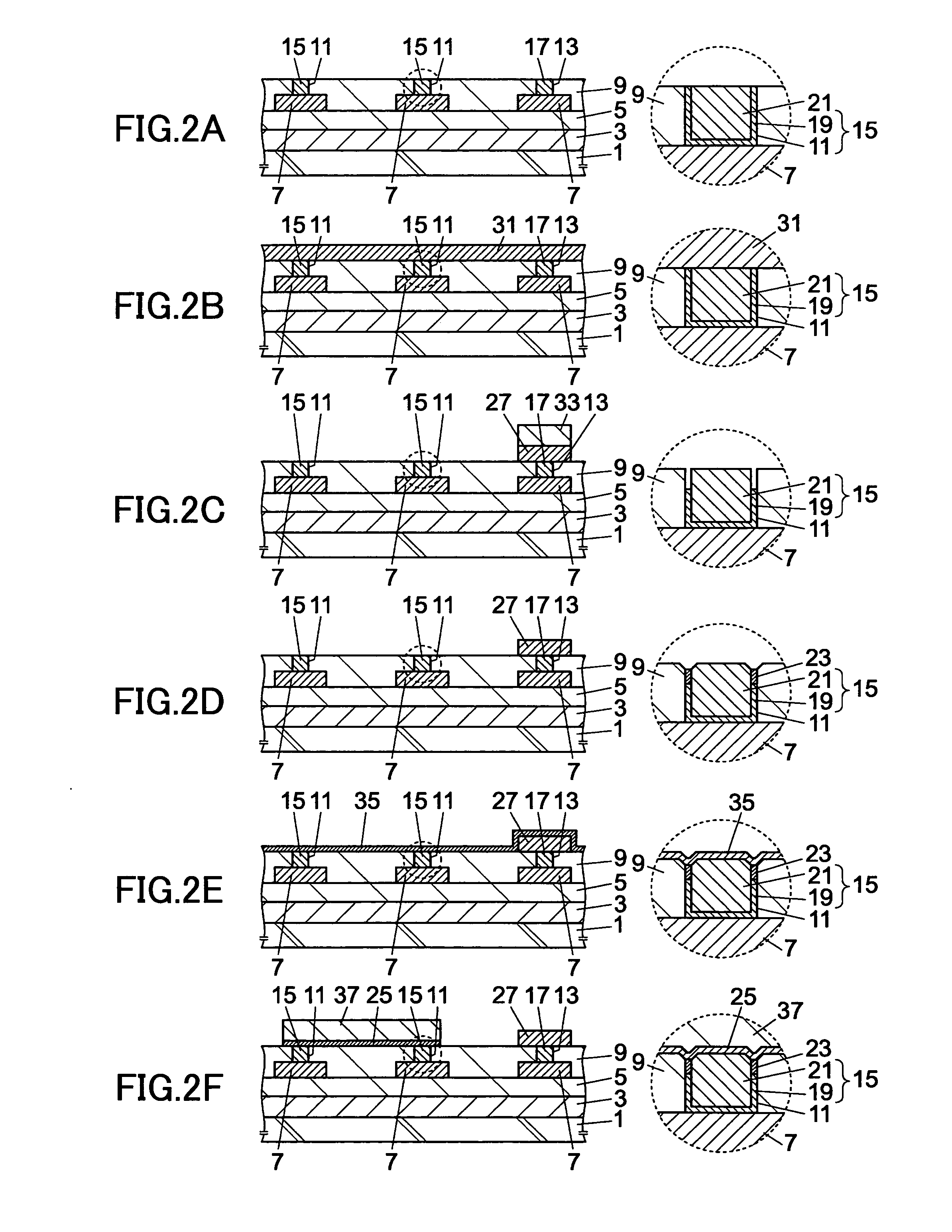

Semiconductor device and fabrication process thereof

ActiveUS20050202219A1Low costShort timeDecorative surface effectsSemiconductor/solid-state device detailsMetal interconnectDevice material

A semiconductor device having a metal thin-film resistance on an insulation film includes first and second contact holes formed in the insulation film, a first conductive plug formed in the first contact hole, a second conductive plug formed in the second contact hole simultaneously to formation of the first conductive plug, a metal thin-film resistance formed on the first conductive plug and on the insulation film, and a metal interconnection pattern formed on the second conductive plug and the insulation film.

Owner:NISSHINBO MICRO DEVICES INC

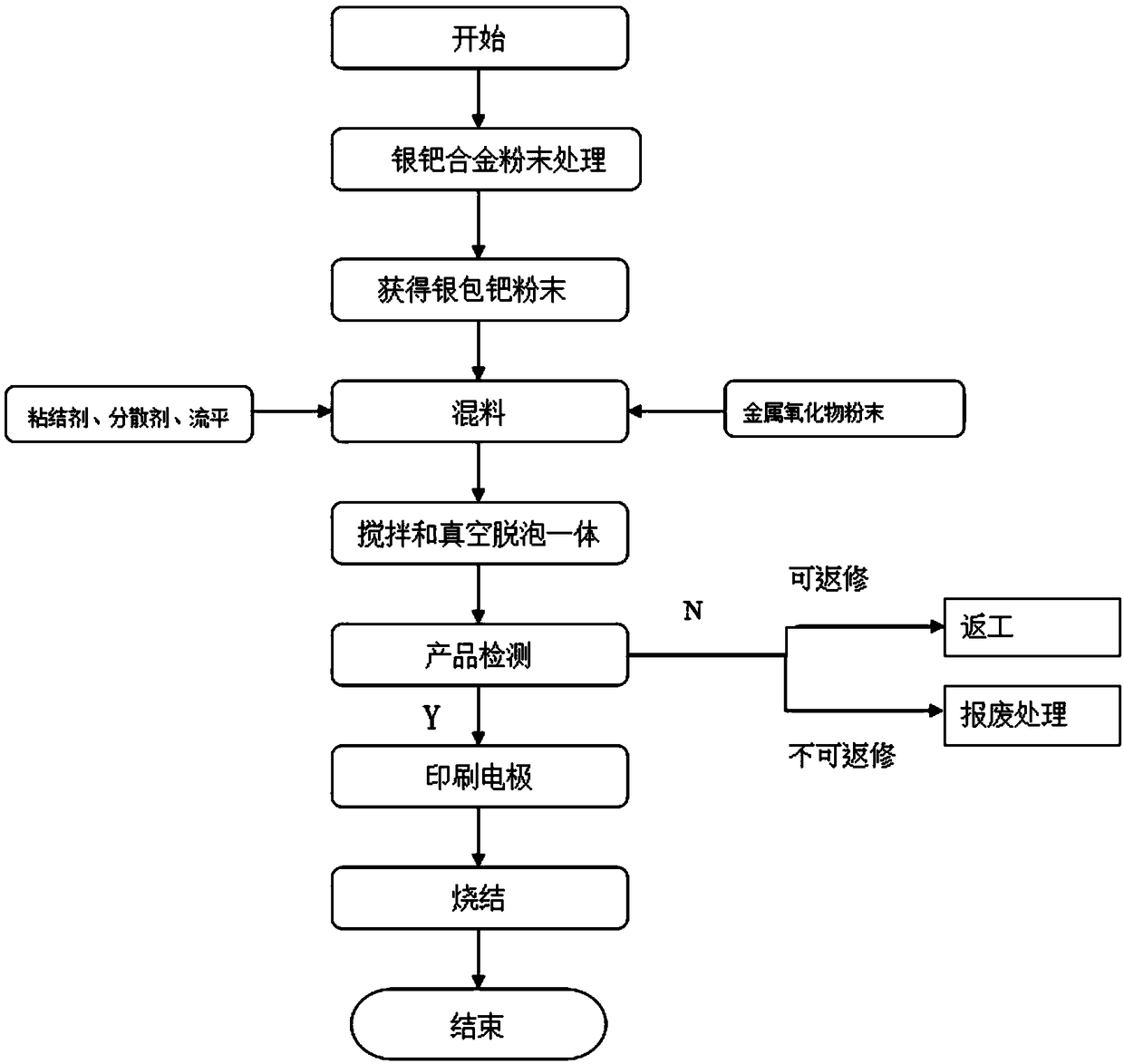

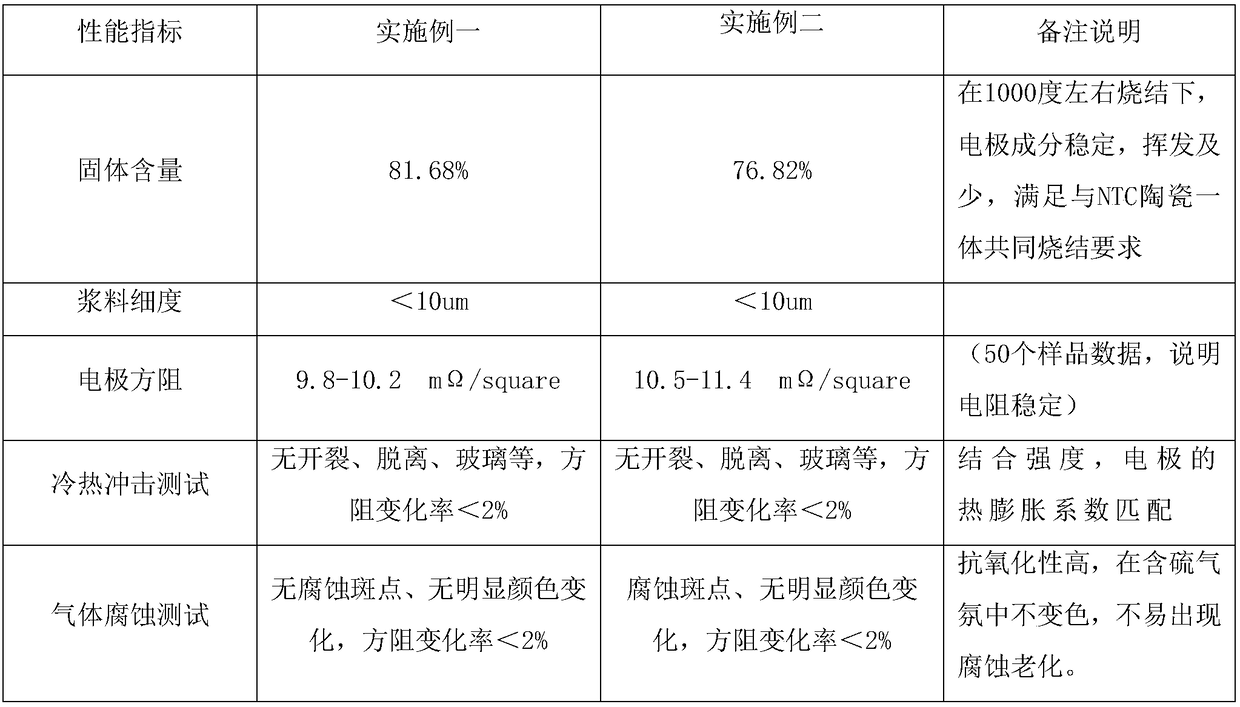

NTC chip electrode paste and method for preparing NTC chip using same

ActiveCN109378105AHigh bonding strengthTightly boundNegative temperature coefficient thermistorsMetal/alloy conductorsNew energyThermal management system

The present application discloses an NTC chip electrode paste and a method for preparing an NTC chip using the same. The NTC chip electrode paste of the present application comprises silver-coated palladium powder used as a conductive agent instead of silver powder. The silver-coated palladium powder of the present application is a silver-added binary alloy with palladium as a matrix, and palladium and silver can be infinitely mutually soluble to form a continuous solid solution with a stable resistance value and good oxidation resistance at room temperature. The oxidation resistance of the solid solution increases with a palladium content increase at a high temperature. The solid solution does not change in color in a sulfur-containing atmosphere, and is not liable to corrosion aging. TheNTC chip prepared by using the electrode paste of the present application has stable resistance, high reliability, good resistance to mechanical vibration and cold and heat shock resistance, can meetthe requirements for high precision, fast response, good consistency and high reliability of a temperature sensors in battery packs, motors, electric control and thermal management systems of new energy vehicles.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

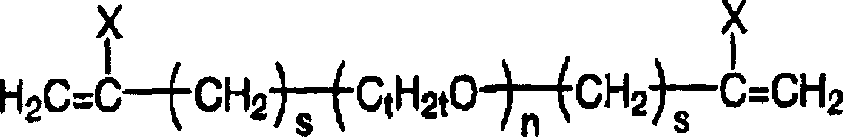

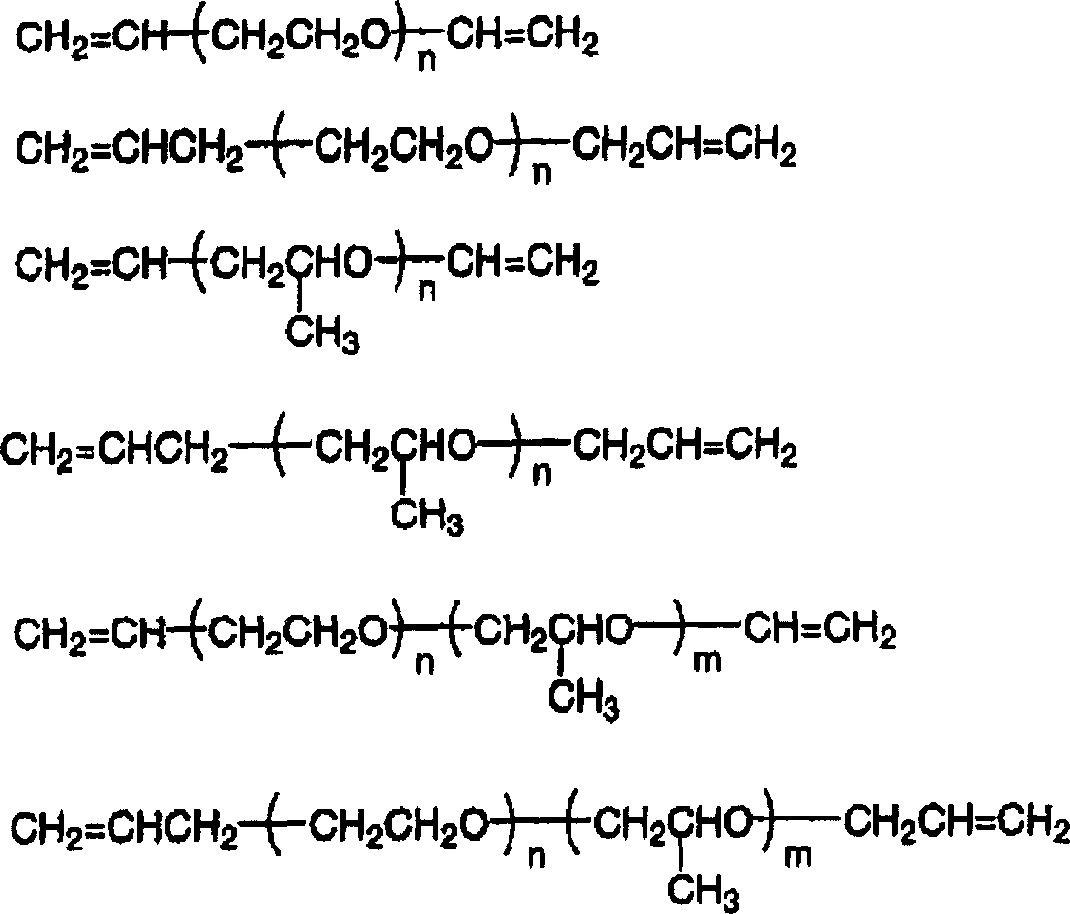

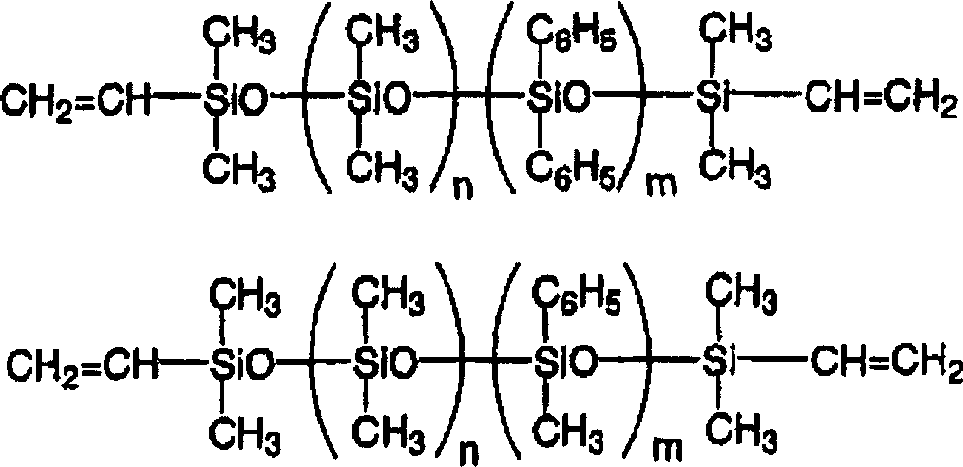

Rubber composition for roller and ionic conductive rubber roller using the composition

InactiveCN1572835AStable resistance valueImprove physical propertiesShaft and bearingsPolyether coatingsHydrogen atomHydrogen

The invention provides an addition-curable rubber composition suitable for manufacturing a rubber for a roll that is free of the tackiness of the rubber surface and oil bleeding and used for electrophotographic image forming apparatuses and the like. The addition-curable rubber composition for the roll contains (A) a polyoxyalkylene having at least two alkenyl groups in the molecule, (B) an organopolysiloxane having at least two alkenyl groups and containing 10-50 mol% of phenyl groups bonded to silicon atoms based on the total organic groups bonded to the silicon atoms, (C) an organohydrogenpolysiloxane having in the molecule at least two hydrogen atoms bonded to silicon atoms, (D) a platinum catalyst, and (E) an ion conductivity imparting agent.

Owner:SHIN ETSU CHEM IND CO LTD

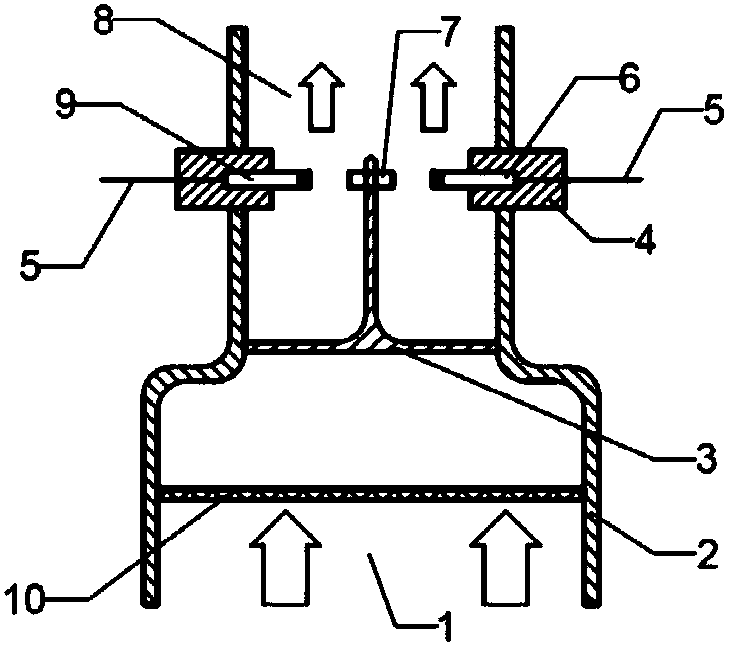

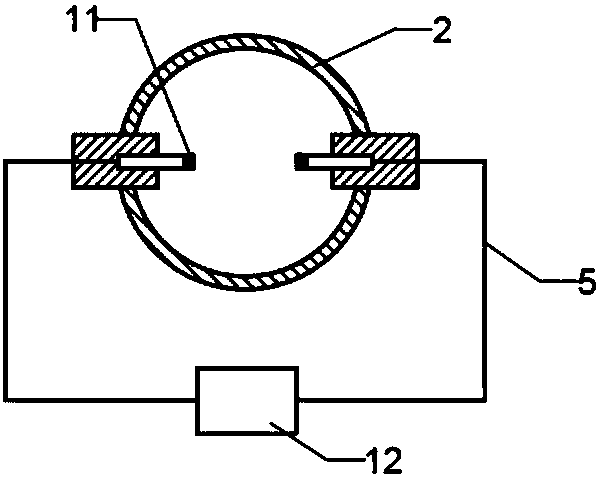

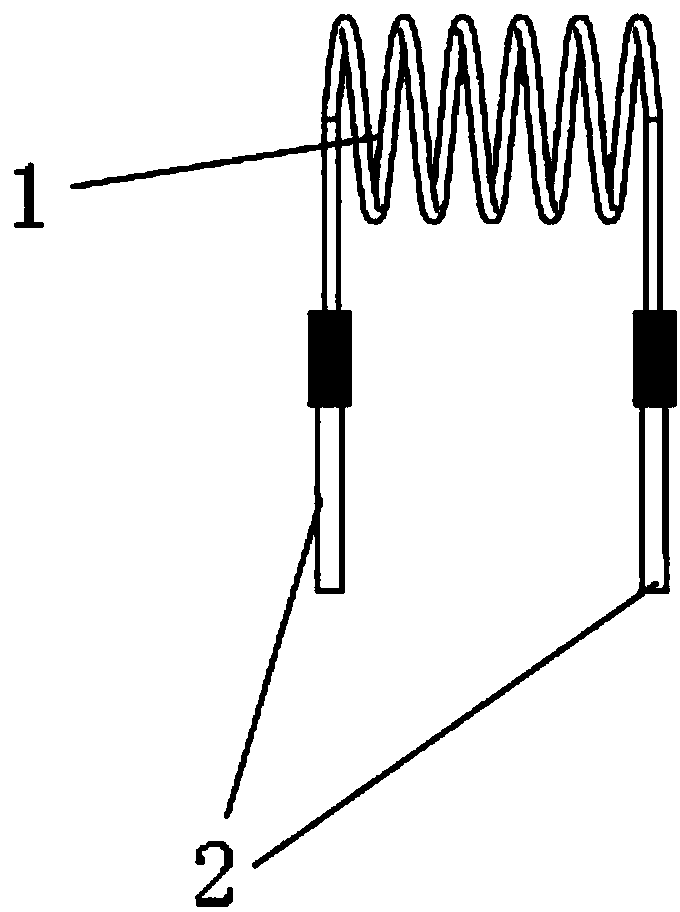

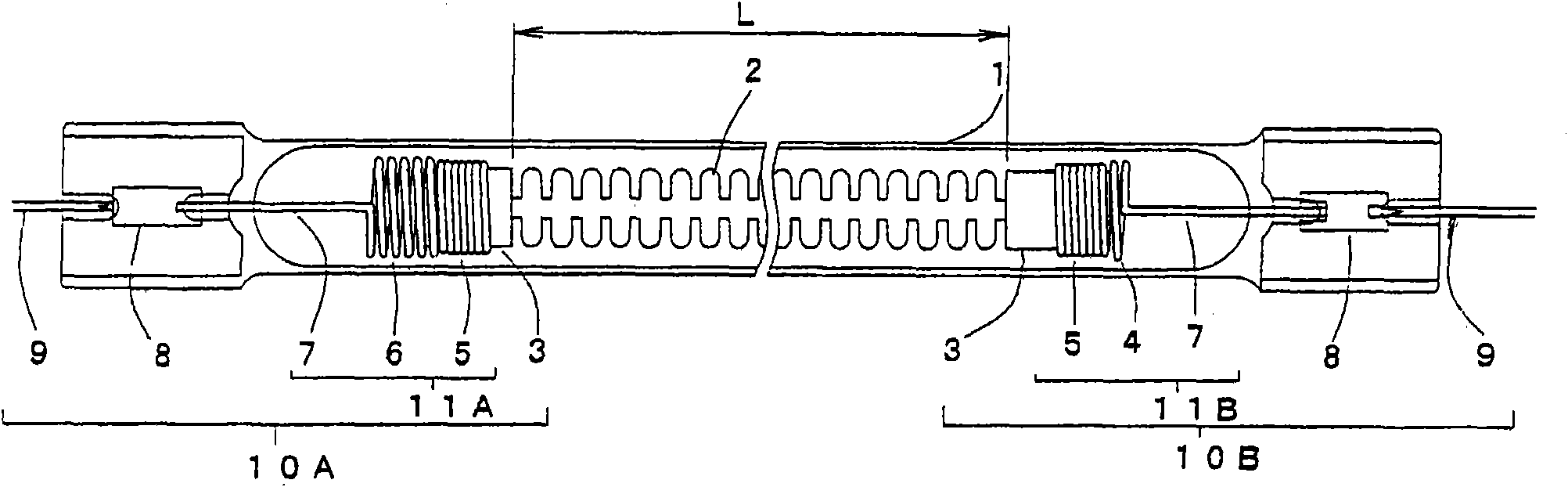

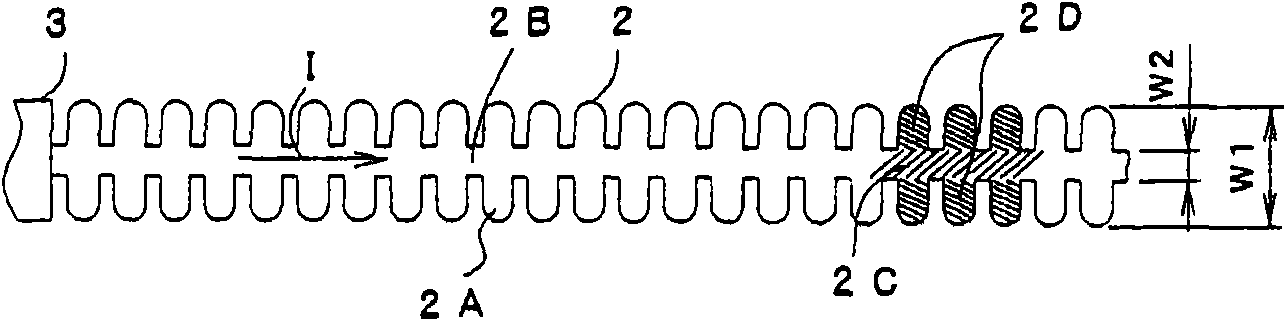

Heat generating body unit and heating apparatus

InactiveCN101589645AIncrease freedomPrevent oxidationHeater elementsHeating element shapesElectric powerDirectivity

Provided are a heat generating body unit, which is small, has high efficiency and directivity, performs uniform heating and starts quickly, and a heating apparatus using such heat generating body unit. A heat generating body (2) in the heat generating body unit is formed of a material having a carbonaceous material as a main component in a film sheet shape, and the heat generating body has equivalent heat conductivity in the planar direction. When power supplying sections (10A, l0B) supply power to facing both ends of the heat generating body (2), the heat generating body (2) in the heat generating body unit generates heat on the entire surface at a high efficiency.

Owner:PANASONIC CORP

Top cover assembly of secondary battery, and secondary battery

ActiveCN108695451AResistor value remains stableUniform compressive stressFinal product manufactureSecondary cells manufactureElectrical batteryElectricity

Owner:CONTEMPORARY AMPEREX TECH CO

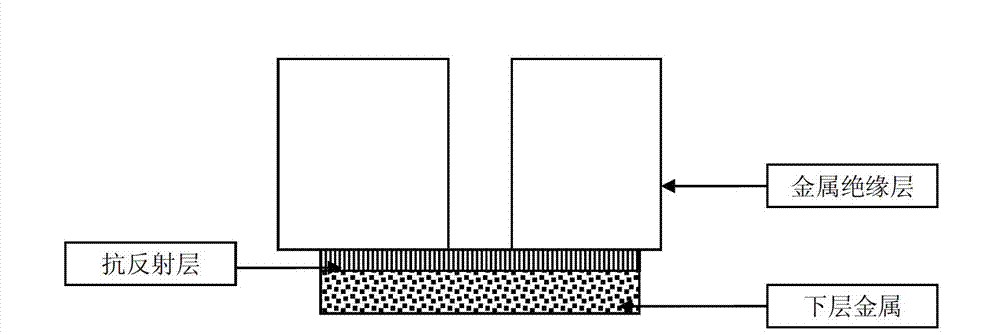

Structure and manufacturing method of semiconductor device

InactiveCN103035837ARapid thermal annealingImproved resistance characteristicsSolid-state devicesSemiconductor devicesMetal-insulator-metalEngineering

The invention discloses a structure of semiconductor device. The structure of the semiconductor device comprises a medal mounted on a lower layer, an anti-reflection layer and a medal insulator formed in sequence on the upper surface of the medal mounted on the lower layer. Medal as a lower electrode is deposited in a through-hole of the medal insulator and a medal oxide layer is formed on the upper end of the lower electrode. A barrier layer made of medals is arranged among the lower electrode, the medal oxide layer, and the side wall of the through-hole. The structure of the semiconductor device is characterized in that a medal aluminum layer deposited on the upper end of the medal insulator and the upper end of the medal oxide layer is further included, the medal aluminum layer is an upper electrode, and medal-insulator-medal is finally formed by the lower electrode, the medal oxide layer, and the medal aluminum layer. The invention further discloses a manufacturing method of semiconductor. Initial resistance can be significantly improved, and the structure and manufacturing method of the semiconductor device has good characteristics of variable resistance.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

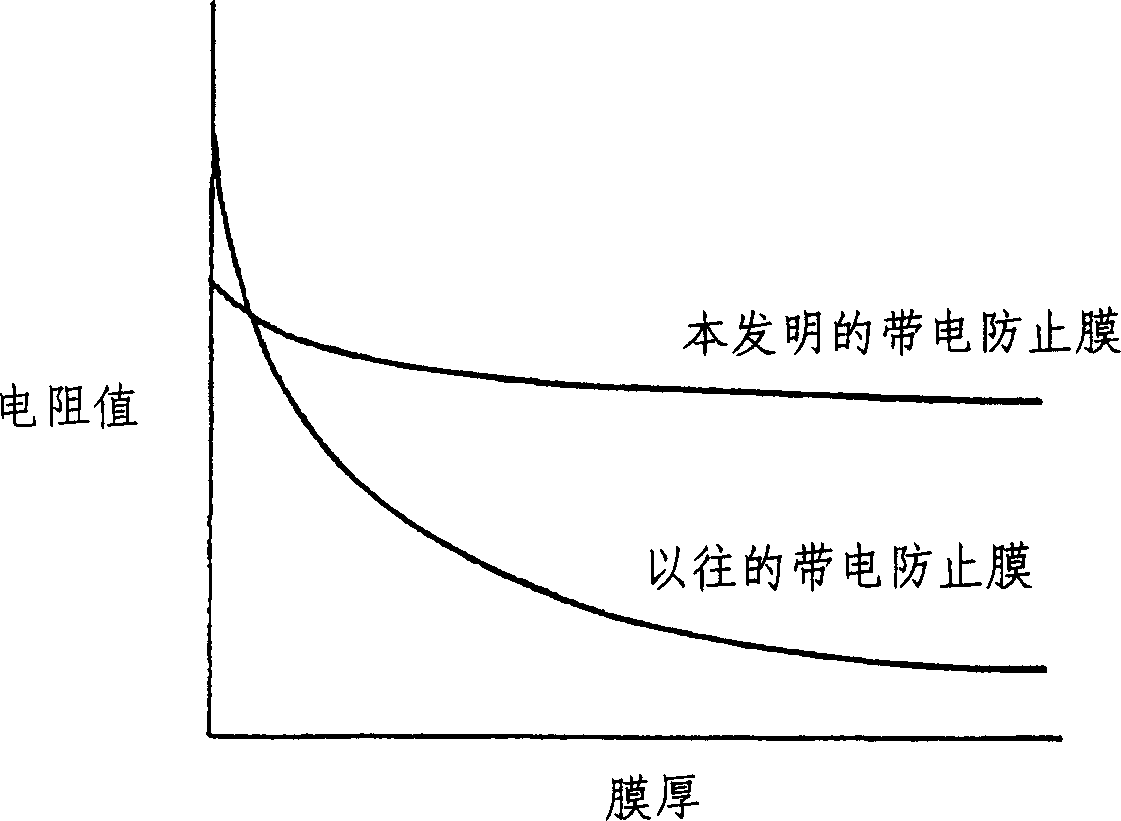

Dispersion for preventing electrification and antistatic film, and image display device

InactiveCN1454250ALittle dependenceStable resistance valueOther chemical processesCathode-ray/electron-beam tube vessels/containersElectrical resistance and conductanceDevice form

The antistatic dispersion liquid contains high-resistance fine particles having an intrinsic resistance value of 106-109 Ω·cm as a main component. This dispersion is applied by a simple method such as spraying or brushing, and then fired. An antistatic film having a stable antistatic property can be obtained with little dependence on the film thickness and the environment of the resistance value. As the high-resistance fine particles, there is a core layer of at least one semiconductive material selected from antimony pentoxide Sb2O5 having a pyrohlore crystal structure, or SnO2, In2O3, Sb2O5, and ZnO2, and a core layer having a semiconducting material selected from SiO2 , TiO2, Al2O3, ZrO2 selected at least one insulating material coating layer particles. This antistatic film does not produce display characteristics due to deformation of orbits of emitted electrons due to voltage application, sparks in the tube, or leakage currents in an image display device formed on the surface of an insulating member disposed in a vacuum envelope. degradation, stable and excellent display characteristics can be achieved.

Owner:KK TOSHIBA

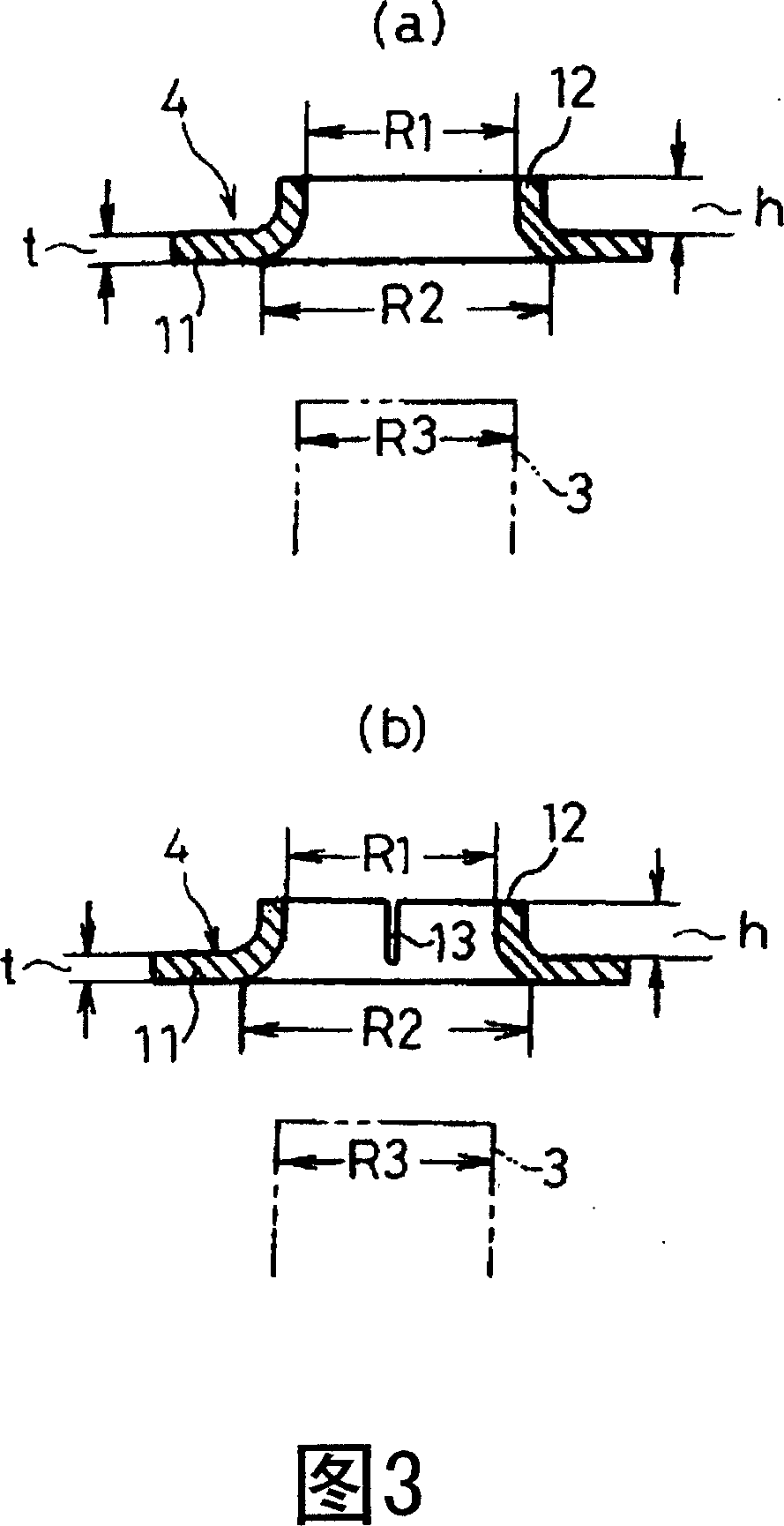

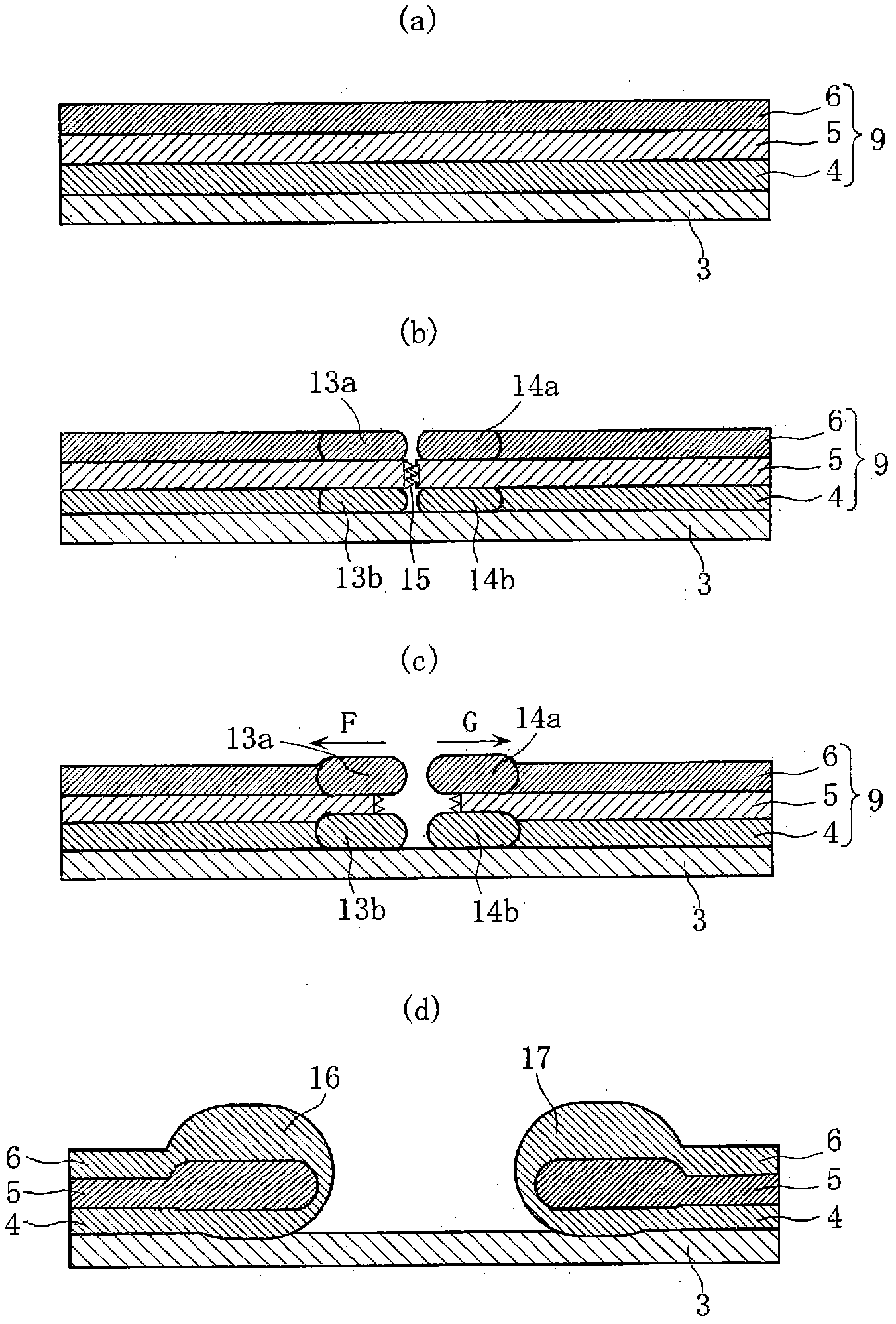

Antifuse device

InactiveCN102341904AEasy to short circuitLower resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductancePower flow

A device body (9) is formed by forming first and second electrode films (4, 6) on the top and bottom surfaces of a dielectric thin film (5)(a). When operating voltage is applied, the heat generated by the current flow causes the first and second electrode films (4, 6) to melt, forming ball parts (13a, 13b, 14a, 14b) and creating a crack (15) in the dielectric thin film (5) as well (b). Further, as the ball parts expand, the dielectric thin film (5) becomes completely divided (c) and the first and second electrode films (4, 6) fuse together in a manner that engulfs the ends of the dielectric thin film (5), thereby forming joined parts (16, 17) and establishing a state of electrical continuity (d). Due to this, after operation, the antifuse device can stably operate with low resistance even when high current is passing, and before operation, can function as an ESD counter device.

Owner:MURATA MFG CO LTD

Aluminum-carbon composite material used for tension-resisting joint fitting and preparing method of aluminum-carbon composite material

The invention provides an aluminum-carbon composite material used for a tension-resisting joint fitting and a preparing method of the aluminum-carbon composite material. Aluminum powder and carbon powder dispersed in an organic solvent are evenly mixed, dried, subjected to ball grinding and pressed into an aluminum-carbon powder block; and the above aluminum-carbon powder block and an aluminum block are used as raw materials to be subjected to smelting, ingot casting, cogging and rolling, and a joint fitting material high in strength and resistant to loosening is obtained. The electric conductivity of the joint fitting prepared through the aluminum-carbon composite material is equivalent to that of pure aluminum. Due to the adding of carbon particles, the hardness, strength and high-temperature loosening resisting performance of the joint fitting are greatly improved. Due to the fact that carbon has very good stability in the atmosphere and does not form an alloy or a compound with aluminum, the corrosion resistance of aluminum is not obviously changed. Preparing steps are simple, operation is convenient, and practicability is high.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Heating component, manufacturing method thereof and aerosol generating device

The invention relates to the technical field of aerosol generating devices, and particularly discloses a heating assembly, which is used for an aerosol generating device, and comprises a shell and a heating element, the shell is internally provided with an accommodating cavity, the first end of the shell is provided with an opening, the opening is communicated with the accommodating cavity, the heating element is arranged in the accommodating cavity from the opening, and a first electrode and a second electrode are arranged at one end of the heating element and extend out of the shell. The heating element is directly assembled on the shell, the manufacturing process is simple, the strength of the heating assembly is improved, the heating wire is heated through heat conduction of the shellinstead of directly heating the aerosol base material in a contact mode, and therefore the heating assembly is safer, healthier and better in atomization effect.

Owner:SHENZHEN JIYOU TECH CO LTD

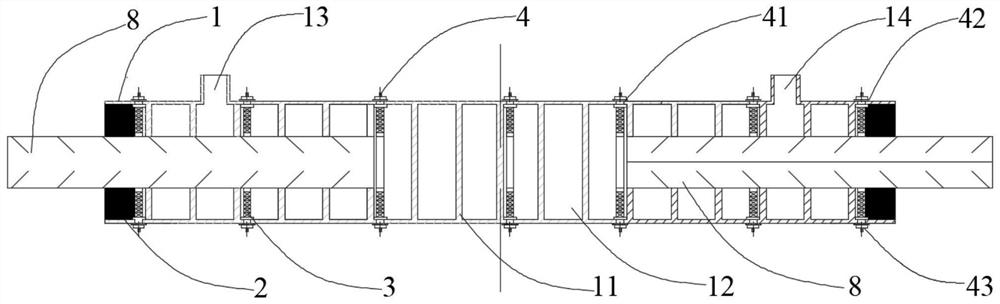

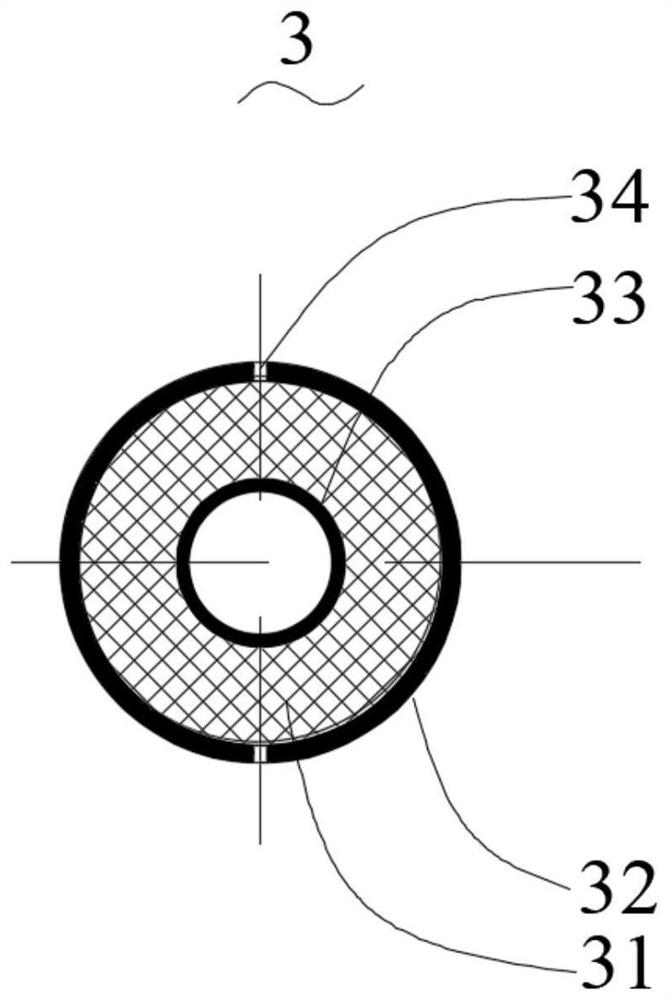

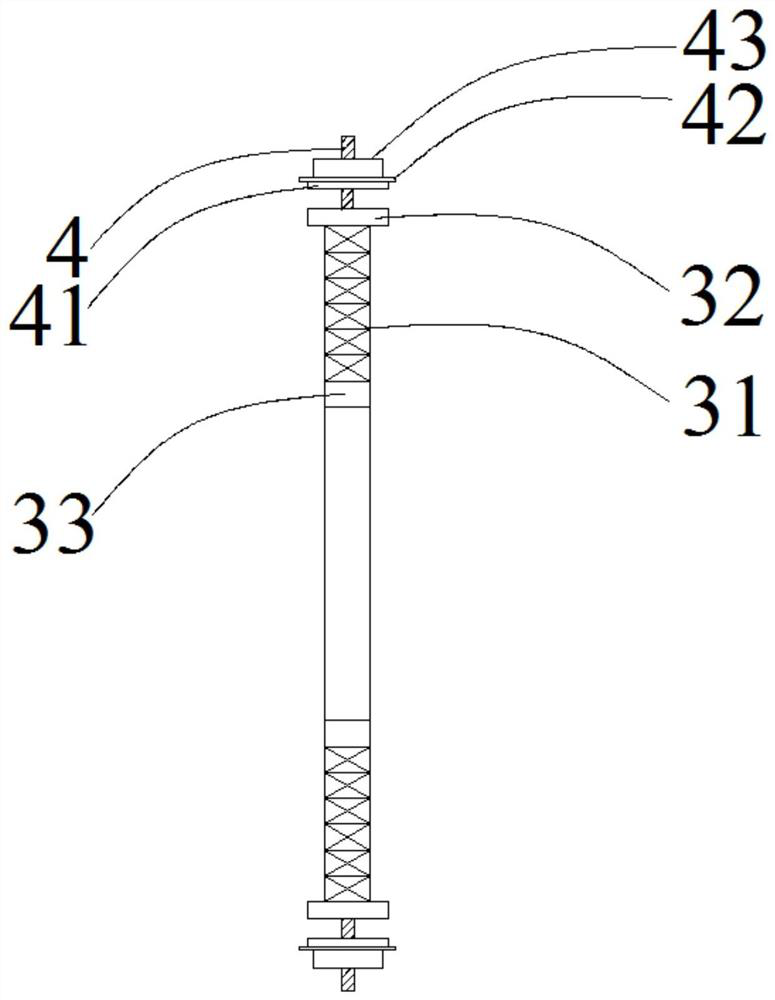

Intelligent grouting bush and saturation and damage position detection device and method thereof

PendingCN112782239AKnow the damage in timeGuarantee the safety of useBuilding reinforcementsMaterial resistanceElectrically conductiveGrout

The invention provides an intelligent grouting bush and a saturation and damage position detection device and method thereof. The intelligent grouting bush comprises a bush body, sealing rings arranged at openings in the two ends of the bush body and at least three conducting sheets arranged in the inner cavity of the bush body, wherein two conducting sheets are located at the two ends of the inner cavity of the bush body respectively, and the other conducting sheets are arranged at intervals in the axis direction of the bush body. According to the invention, the conducting sheets are connected in series with the power supply and the universal meter to form the detection device, so that the resistance of the grouting material can be detected by using the formed conductive loop after the conductive grouting material is injected, and the saturation and unsaturated positions of the grouting material can be detected according to the resistance values of different positions; in the long-term service process of the anchoring body in the grouting bush, the resistance of the anchoring body at different positions is detected, and the damage position of the anchoring body can be effectively judged; and the detection device provided by the invention is simple in structure, the detection method is simple, convenient and feasible, and the application value is relatively high.

Owner:上海宇砼建筑科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com