Heat generating body unit and heating apparatus

A heating element unit and heating device technology, applied in the direction of ohmic resistance heating device, electric heating device, heating element, etc., can solve the problems of uneven temperature, cracks, non-flexibility, etc., and achieve the effect of easy design and small efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

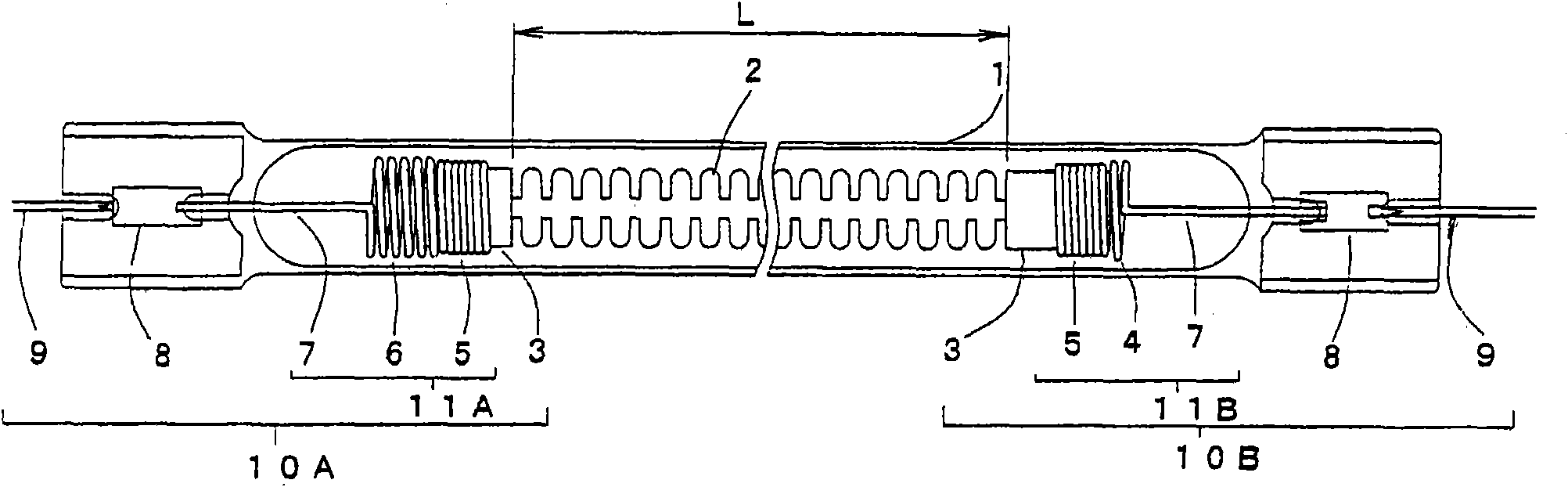

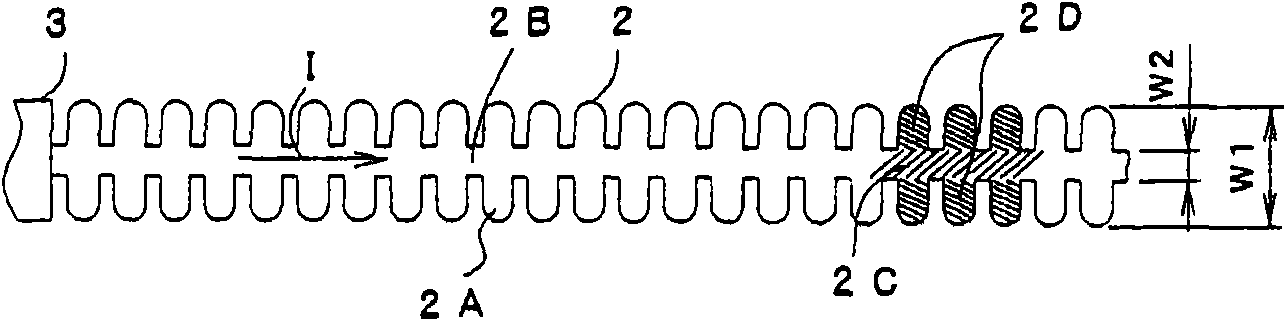

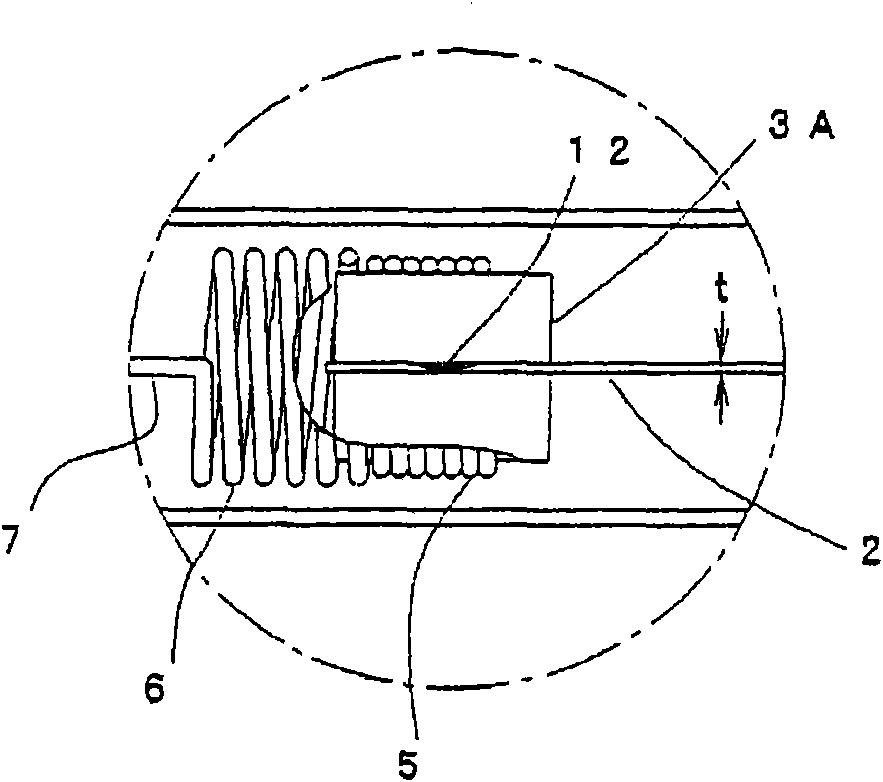

[0052] use Figure 1 ~ Figure 3 , the heat generating unit according to Embodiment 1 of the present invention will be described. figure 1 It is a front view showing the structure of the heat generating unit of Embodiment 1. exist figure 1 In , since the heat generating unit has a long strip shape, its middle part is cut off and omitted, and the vicinity of both end parts is shown. figure 2 It is a front view showing a part of the heat generating body in the heat generating body unit according to the first embodiment. image 3 It is an enlarged view showing a part of the heat generating unit according to Embodiment 1 enlargedly.

[0053] In the heating element unit according to Embodiment 1, the elongated heating element 2 is arranged inside a glass tube 1 made of transparent quartz glass, and the heating element 2 extends along the longitudinal direction of the glass tube 1 . In addition, both ends of the glass tube 1 are welded in a flat shape, and the heating element 2 ...

Embodiment approach 2

[0107] Below, use Figure 5 , and the heat generating unit according to Embodiment 2 of the present invention will be described. Figure 5 It is a front view showing specific examples of various shapes of the heat generating element in the heat generating element unit according to the second embodiment. exist Figure 5 Among the heating elements in , the heating element is long and repeats the same pattern shape, so the right part is omitted.

[0108] The heat generating unit of Embodiment 2 differs from the heat generating unit of Embodiment 1 in the shape of the heat generating body, and is the same as Embodiment 1 in other respects. Therefore, the shape of the heat generating element in the heat generating element unit according to Embodiment 2 will be described, and the description of Embodiment 1 will apply to other components.

[0109] The heat generating element in the heat generating element unit according to Embodiment 2 does not make the temperature distribution u...

Embodiment approach 3

[0119] Below, use Image 6 , and the heat generating unit according to Embodiment 3 of the present invention will be described. Image 6 It is a front view showing specific examples of various shapes of the heat generating element in the heat generating element unit according to the third embodiment. exist Image 6 In , each heating element is in the shape of a strip, which is a repetition of the same pattern shape, so the right part is omitted.

[0120] The heat generating unit of Embodiment 3 differs from the heat generating unit of Embodiment 1 in the shape of the heat generating body, and is the same as Embodiment 1 in other respects. Therefore, the shape of the heat generating element in the heat generating element unit according to Embodiment 3 will be described, and the description of Embodiment 1 will apply to other structural requirements.

[0121] The heat generating element in the heat generating element unit according to Embodiment 3 does not make the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com