Production technology of nanoscale conductive titanium dioxide

A technology of conductive titanium dioxide and production process, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of high degradation rate, inability to achieve optical properties, limited photocatalytic activity of conductive titanium dioxide, etc. problems, to achieve the effects of good electrical conductivity and mechanical properties, widened application range and stable resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

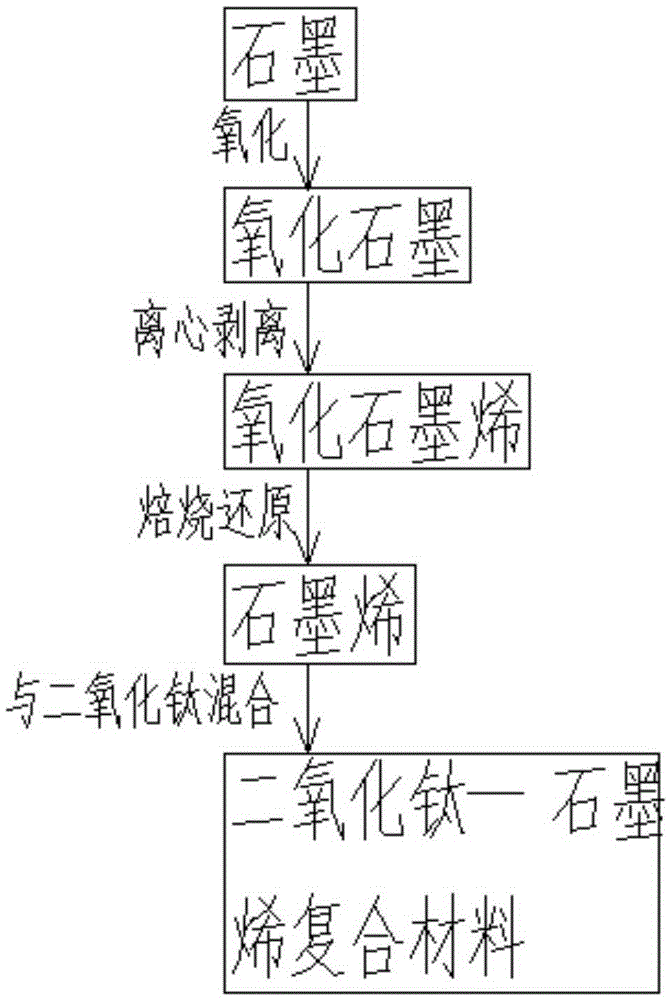

[0024] Concrete embodiment, the specific steps of the production technology of nanoscale conductive titanium dioxide are as follows:

[0025] First, graphene oxide needs to be prepared, and the specific steps of preparation are as follows:

[0026] b1. Pour the concentrated sulfuric acid into a constant temperature magnetic stirrer. Using this stirrer can control the temperature well, so that the mixture has better stability. The concentrated sulfuric acid is first cooled to 0°C in a cold water bath, and then graphite is added while stirring powder and KMnO4, concentrated sulfuric acid, KMnO 4 It is an oxidizing agent that can oxidize graphite into graphite oxide. The mass ratio of graphite powder and KMnO4 is 1:3. Every 22ml of concentrated sulfuric acid needs to add 1g of graphite powder and 3g of KMnO4. The reaction temperature of graphite powder and KMnO4 after adding concentrated sulfuric acid is controlled at 3- 5°C and stirring reaction for 2 hours, the stirring speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com