Magnetically-actuated chemical flow-process pump

A magnetic drive and process pump technology, which is applied in the direction of pumps for special fluids, pumps, and parts of pumping devices for elastic fluids, etc. It can solve the problems of poor hardness, strength and high temperature resistance, poor pressure bearing of parts, and easy bending Deformation and other problems, to achieve good hardness, reduce calorific value, enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

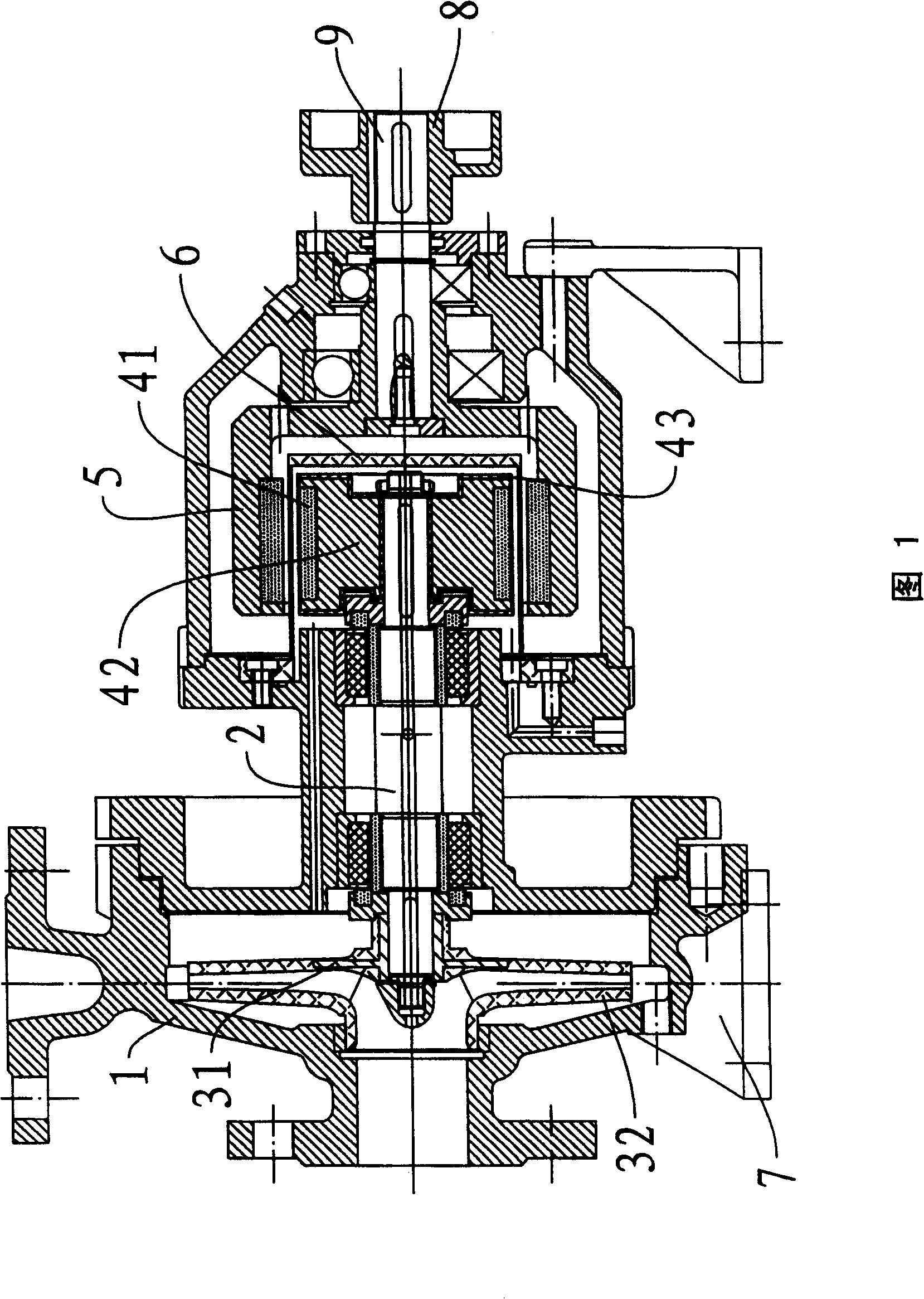

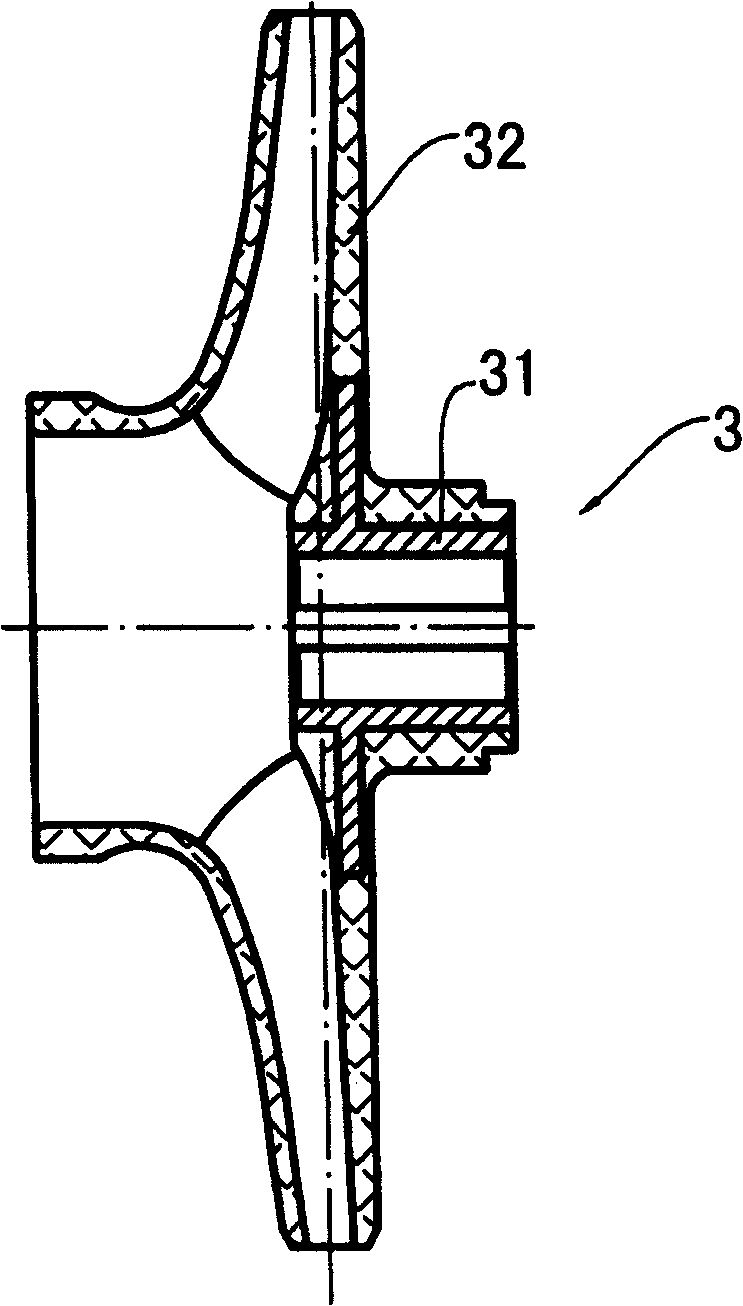

[0018] As shown in Figures 1 to 6, the magnetic drive chemical process pump of the present invention includes a pump casing 1, a pump shaft 2, an impeller 3, an inner coupling 4, a spacer sleeve 6, and a base 7, and the inner layer of the pump shaft 2 The inner layer of the impeller 3 is a metal material 31, and the outer layer is a polyether ether ketone layer 32; the inner layer of the inner coupling 4 is a metal material 42, embedded with a permanent magnet 41, the outer layer is a polyether ether ketone layer 43; the inner layer of the spacer 6 is a polyether ether ketone layer 64, and the outer layer is made of metal.

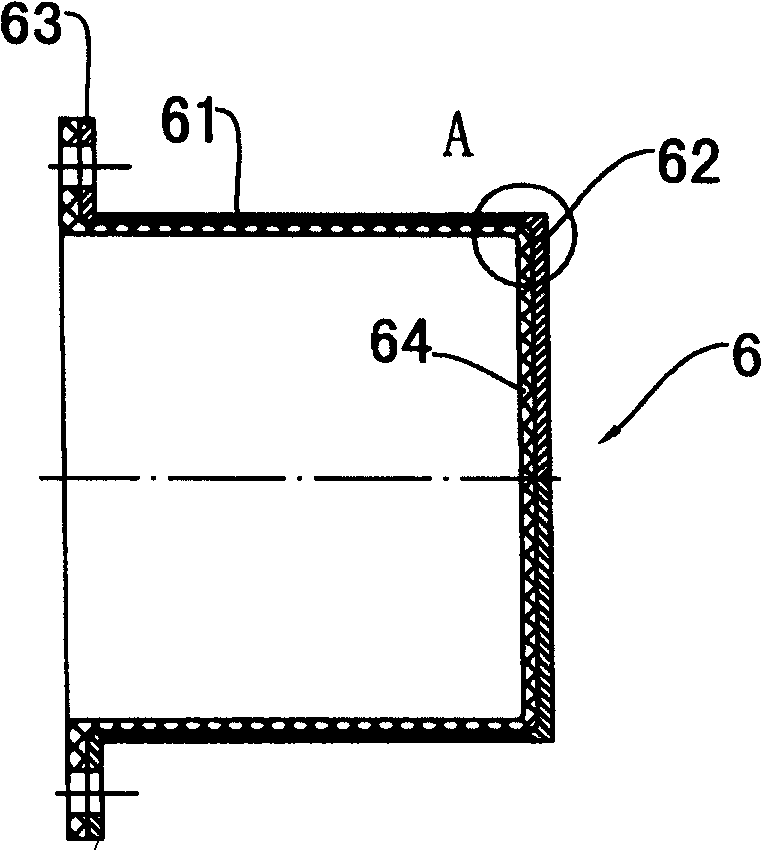

[0019] Such as figure 2 And shown in Fig. 6, the outer layer of the isolation sleeve 6 of the magnetic drive chemical process pump of the present invention is the outer layer middle cylinder 61 that is wound with the metal wire that is coated with insulating varnish on the surface that is reversed " S " shape with cross-section, and its one end A circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com