A kind of preparation method of rare earth doping modified polyimide film

A technology of polyimide film and rare earth doping, which is applied in the field of insulating materials to achieve the effects of improving dispersion, improving compatibility and good electrical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

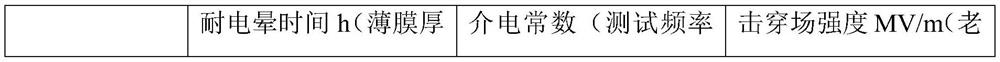

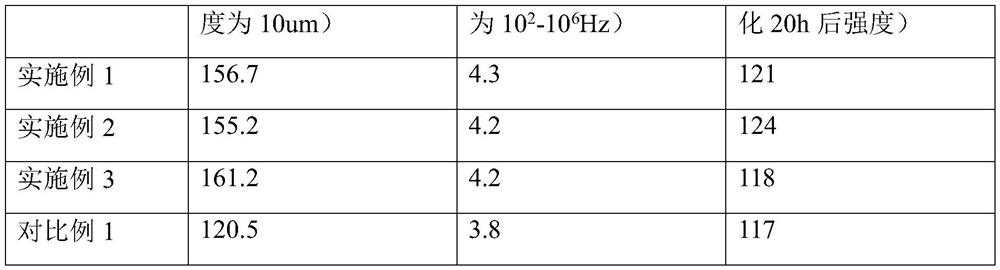

Embodiment 1

[0015] A kind of preparation method of the polyimide film of rare earth doping modification, it is characterized in that, comprises the following steps:

[0016] S1. Add butyl titanate dropwise to the ethanol solution containing ethyl acrylate, and then add Y 2 o 3 ethanol solution, then add a concentration of 20wt% hydrochloric acid ethanol solution, mix and stir at room temperature for 3-8h and then stand still to obtain yttrium-doped TiO 2 Sol;

[0017] S2. Will prepare TiO 2 Put the sol in an oven to dry, grind it into gel powder, heat it up to 200°C at 3°C / min in a muffle furnace, keep it warm for 30 minutes, and then raise the temperature to 500°C at a rate of 5°C / min to obtain yttrium-doped TiO2 Nano powder;

[0018] S3. Add yttrium-doped TiO2 nanopowder and 4,4'-diaminodiphenyl ether to N,N-dimethylacetamide, sonicate for 1h, then add pyromellitic dianhydride in 3 times and stir for 8h to obtain PAA / nanoparticle slurry, wherein, the molar ratio of 4,4'-diaminodiph...

Embodiment 2

[0021] A kind of preparation method of the polyimide film of rare earth doping modification, it is characterized in that, comprises the following steps:

[0022] S1. Add butyl titanate dropwise to the ethanol solution containing ethyl acrylate, and then add Y 2 o 3 ethanol solution, then add a concentration of 25wt% hydrochloric acid ethanol solution, mix and stir at room temperature for 3-8h and then stand still to obtain yttrium-doped TiO 2 Sol;

[0023] S2. Will prepare TiO 2 Put the sol in an oven to dry, grind it into gel powder, heat up to 200°C at 5°C / min in a muffle furnace, keep it warm for 60 minutes, and then raise the temperature to 500°C at a rate of 8°C / min to obtain yttrium-doped TiO2 Nano powder;

[0024] S3. Add yttrium-doped TiO2 nanopowder and 4,4'-diaminodiphenyl ether to N,N-dimethylacetamide, sonicate for 1h, then add pyromellitic dianhydride in 3 times and stir for 4h to obtain PAA / nanoparticle slurry, wherein, the molar ratio of 4,4'-diaminodipheny...

Embodiment 3

[0027] A kind of preparation method of the polyimide film of rare earth doping modification, it is characterized in that, comprises the following steps:

[0028] S1. Add butyl titanate dropwise to the ethanol solution containing ethyl acrylate, and then add Y 2 o 3 ethanol solution, and then add a concentration of 22wt% hydrochloric acid ethanol solution, mix and stir at room temperature for 3-8h and then stand still to obtain yttrium-doped TiO 2 Sol;

[0029] S2. Will prepare TiO 2 Put the sol in an oven to dry, grind into gel powder, heat up to 200°C at 4°C / min in a muffle furnace, keep it warm for 50 minutes, and then raise the temperature to 500°C at a rate of 6°C / min to obtain yttrium-doped TiO2 Nano powder;

[0030] S3. Add yttrium-doped TiO2 nanopowder and 4,4'-diaminodiphenyl ether into N,N-dimethylacetamide, ultrasonicate for 1h, then add pyromellitic dianhydride in 3 times and stir for 6h to obtain PAA / nanoparticle slurry, wherein, the molar ratio of 4,4'-diamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com