Retractor workbench

A workbench and retractor technology, applied in medical science, surgery and other directions, can solve problems such as insufficient hook body strength, affecting traction effect, and increasing work difficulty for medical personnel, achieving simple process, excellent comprehensive performance, good electrical and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

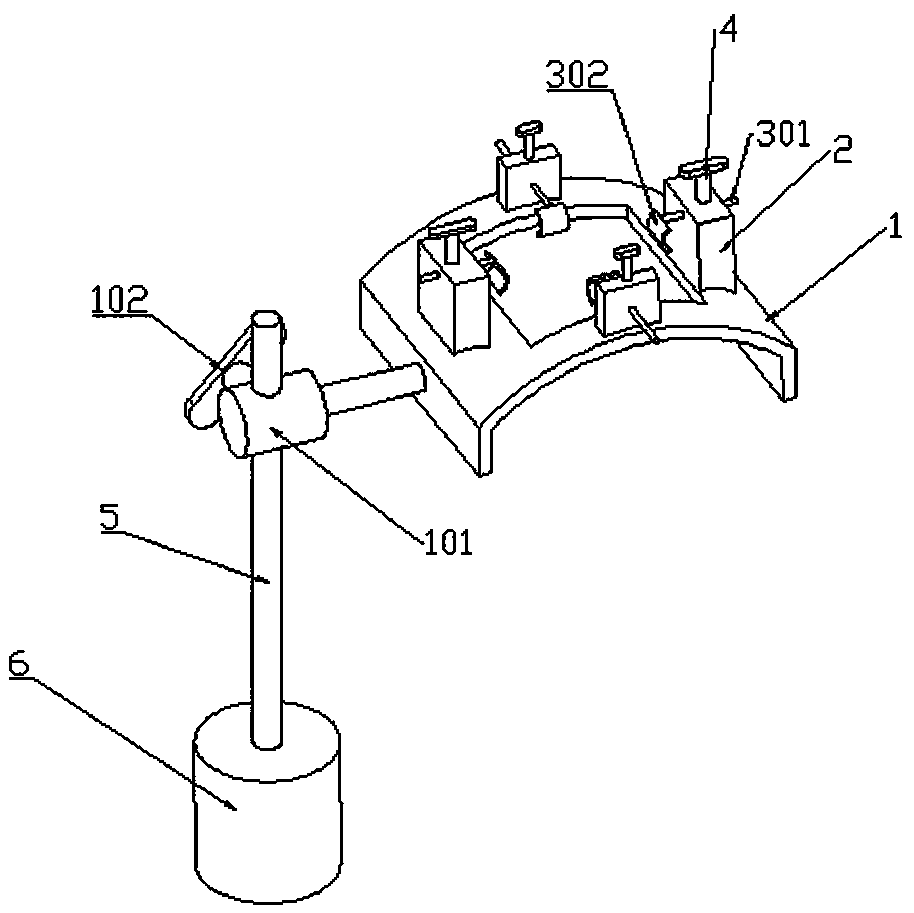

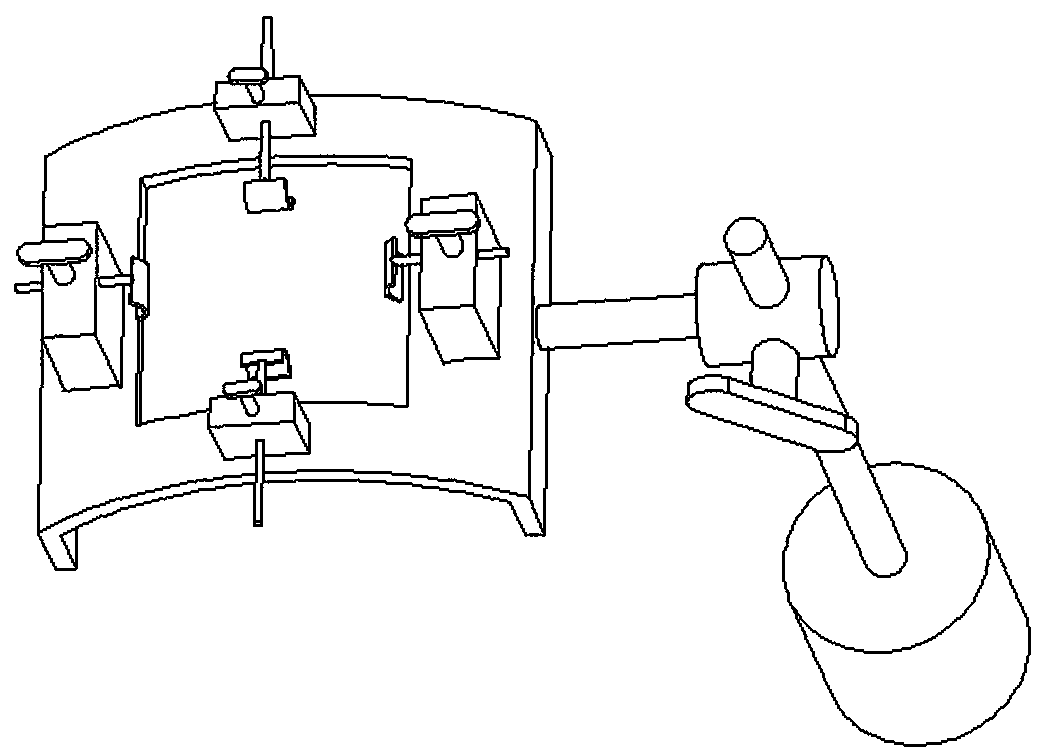

[0028] Specific embodiment 1: as Figure 1-2 As shown, the present invention discloses a retractor workbench, comprising a fixed plate 1, the fixed plate is a hollow structure, the middle is provided with a channel for surgical operation, the bottom of the fixed plate is a groove for placing the patient's body, and the fixed plate is fixed. There are four fixed seats 2 located in different directions on the board. The fixed seat is provided with a rod 301 passing through the fixed seat and a hook 302 at the end of the rod. The rod can move back and forth relative to the fixed seat and pass through the fixed button. 4 is fixed, the fixed plate is connected with the vertical rod through the horizontal rod, and the horizontal rod and the vertical rod are connected 101 through the rotating seat, and the rotating seat can rotate around the vertical shaft of the vertical rod, and can adjust the vertical height and Fixed by the second fixing button 102 , the bottom of the vertical ro...

specific Embodiment 2

[0029] Specific embodiment 2: an in-situ generation of nickel aluminide reinforced copper-based composite material, the preparation method is as follows:

[0030] Step 1, base material preparation, described base material is made of pure aluminum, pure copper raw material;

[0031] Step 2 Weigh the nickel powder and mix it with absolute ethanol and propanol in turn, then mechanically stir respectively, then heat until the ethanol and propanol solutions are all volatilized to obtain nickel powder;

[0032] Step 3: Put the base material in the step 1 into the crucible and put it in the resistance melting furnace, fill the furnace with inert gas protection at the same time, melt at the melting temperature of 1000°C for 12 minutes, then add the alloy total Refining 0.05% hexachloroethane for 5-20 minutes;

[0033] Step 4: Add the nickel powder obtained in Step 2 into the crucible and melt it at 820°C for 12 minutes, then use a water-cooled ultrasonic head to apply it to the molte...

specific Embodiment 3

[0039] Specific embodiment 3: an in-situ generation of nickel aluminide reinforced copper-based composite material, the preparation method is as follows:

[0040] Step 1, base material preparation, described base material is made of pure aluminum, pure copper raw material;

[0041] Step 2 Weigh the nickel powder and mix it with absolute ethanol and propanol in turn, then mechanically stir respectively, then heat until the ethanol and propanol solutions are all volatilized to obtain nickel powder;

[0042] Step 3: Put the base material in the step 1 into the crucible and place it in the resistance melting furnace, fill the furnace with inert gas protection at the same time, melt for 11 minutes at the melting temperature of 800°C, and then add the alloy total Refining 5-20 minutes with 1% hexachloroethane;

[0043] Step 4: Add the nickel powder obtained in Step 2 into the crucible and melt it at 700-950°C for 5-20 minutes, then use a water-cooled ultrasonic head to apply it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com