Spaceflight power bus

A technology of power bus and outer conductor, applied in cables, insulated conductors, conductors, etc., can solve problems such as product incompatibility, and achieve the effects of light weight, excellent mechanical and electrical properties, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

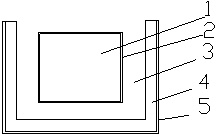

[0013] Control attached figure 1 , aerospace power bus, its structure includes aluminum alloy conductor, aerospace special glue, polyimide tape, wherein aluminum alloy conductor is divided into inner conductor 1, outer conductor 2, between inner conductor 1 and outer conductor 2 is colloid 3, inner conductor 1 The surface of the outer conductor 2 is pasted with A polyimide tape 4 , and the surface of the outer conductor 2 is pasted with B polyimide tape 5 .

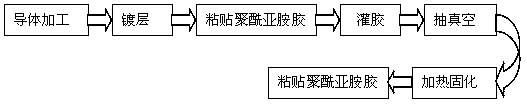

[0014] Control attached figure 2 , a manufacturing method for an aerospace power bus, comprising the following process steps,

[0015] 1) The aluminum alloy conductor is processed by a lathe; the conductor is divided into inner and outer conductors;

[0016] 2) The aluminum alloy conductor is nickel-plated and gold-plated by electroplating, and the appearance is U-shaped;

[0017] 3) Use polytetrafluoroethylene material to process into a U-shaped bracket and put it into the outer conductor;

[0018] 4) Inject the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com