Patents

Literature

218results about How to "Smooth surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

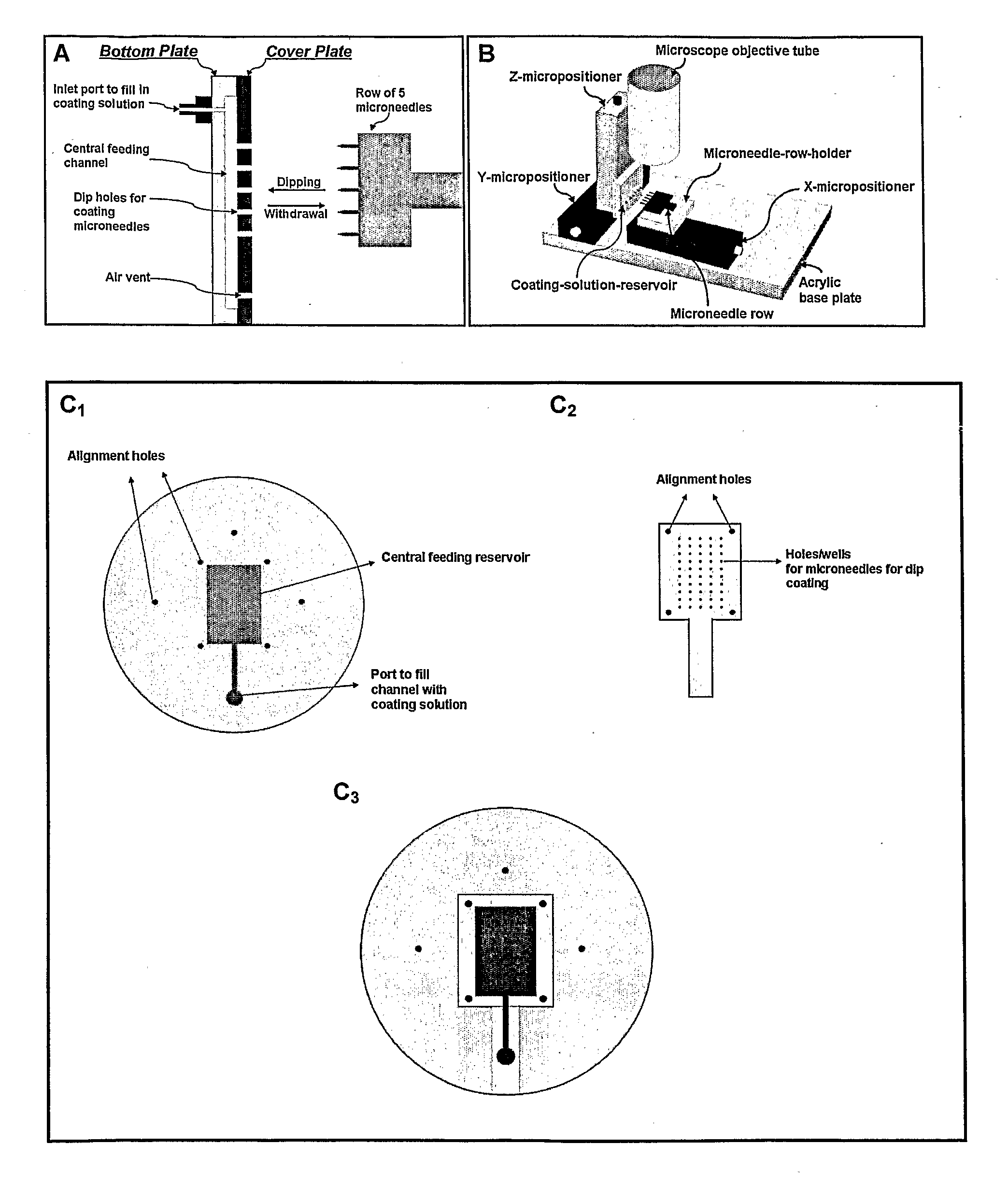

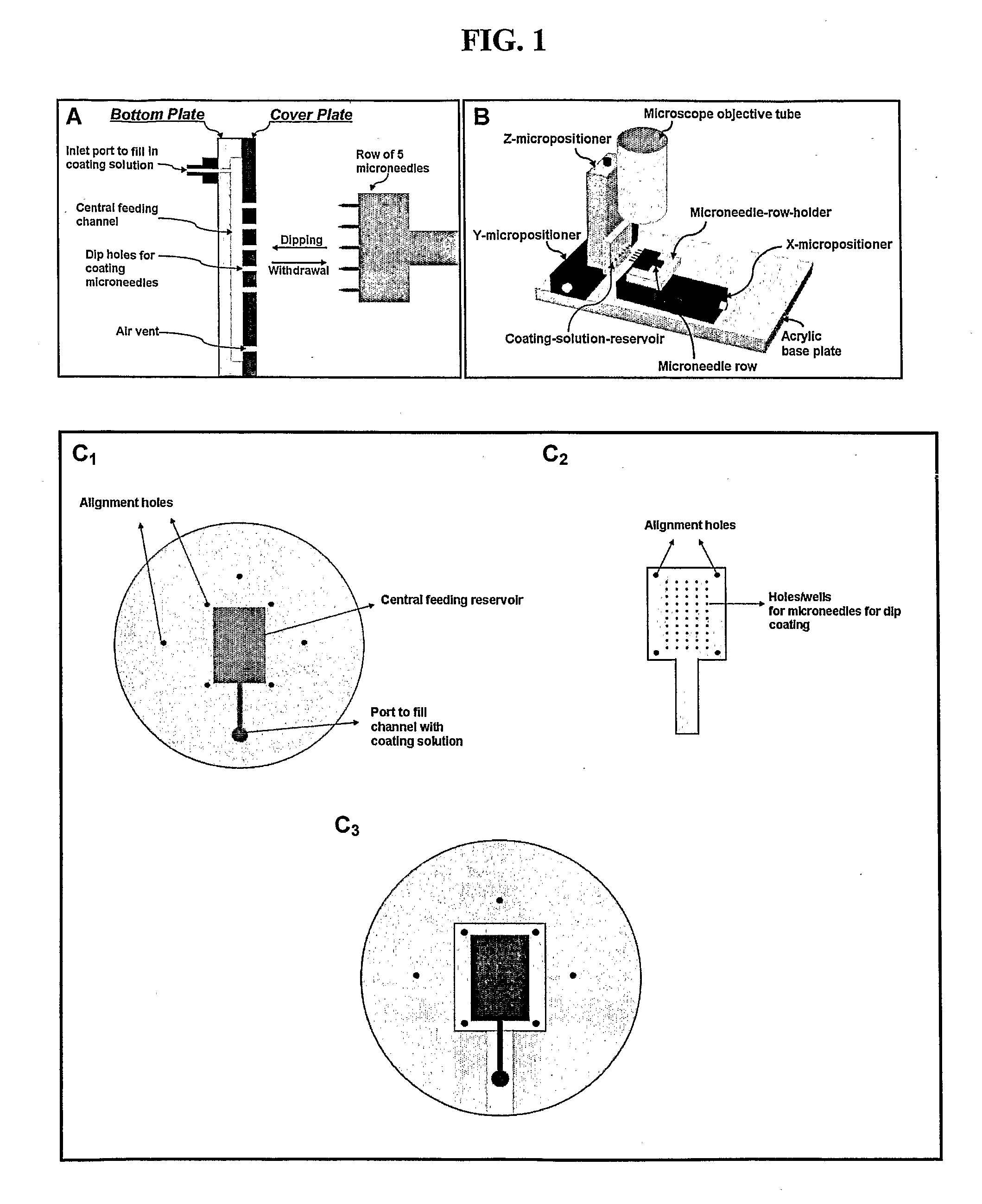

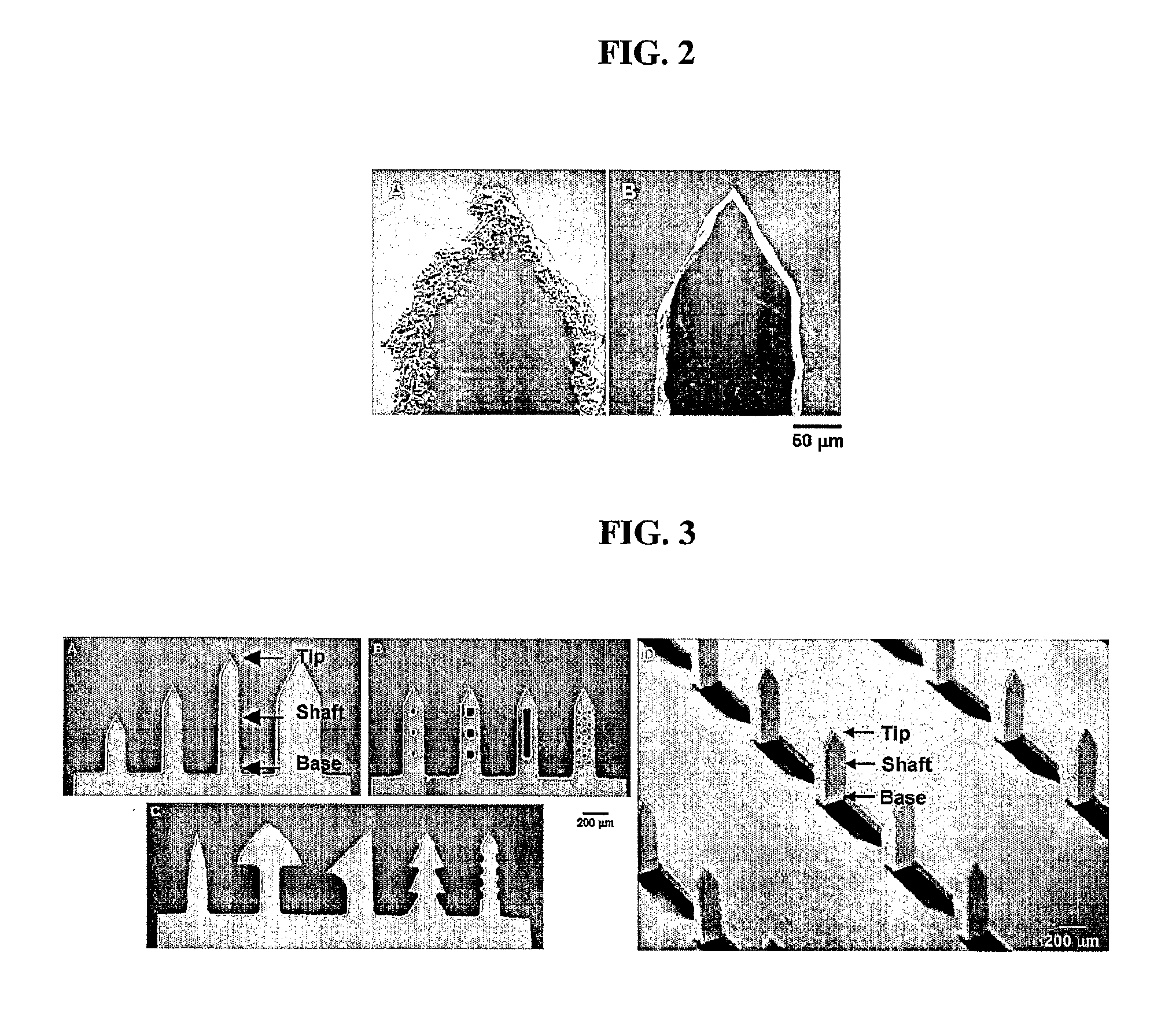

Coated Microstructures and Methods of Manufacture Thereof

Coated microneedle devices and methods of making such devices are provided. In one aspect, a method for coating includes providing a microstructure having at least one surface in need of coating; and applying a coating liquid, which comprises at least one drug, to the at least one surface of the microstructure, wherein the surface energy of the coating liquid is less than the surface energy of the surface of the microstructure. The coating liquid may include a viscosity enhancer and surfactant. Microneedles having heterogeneous coatings, pockets, or both are also provided.

Owner:GEORGIA TECH RES CORP

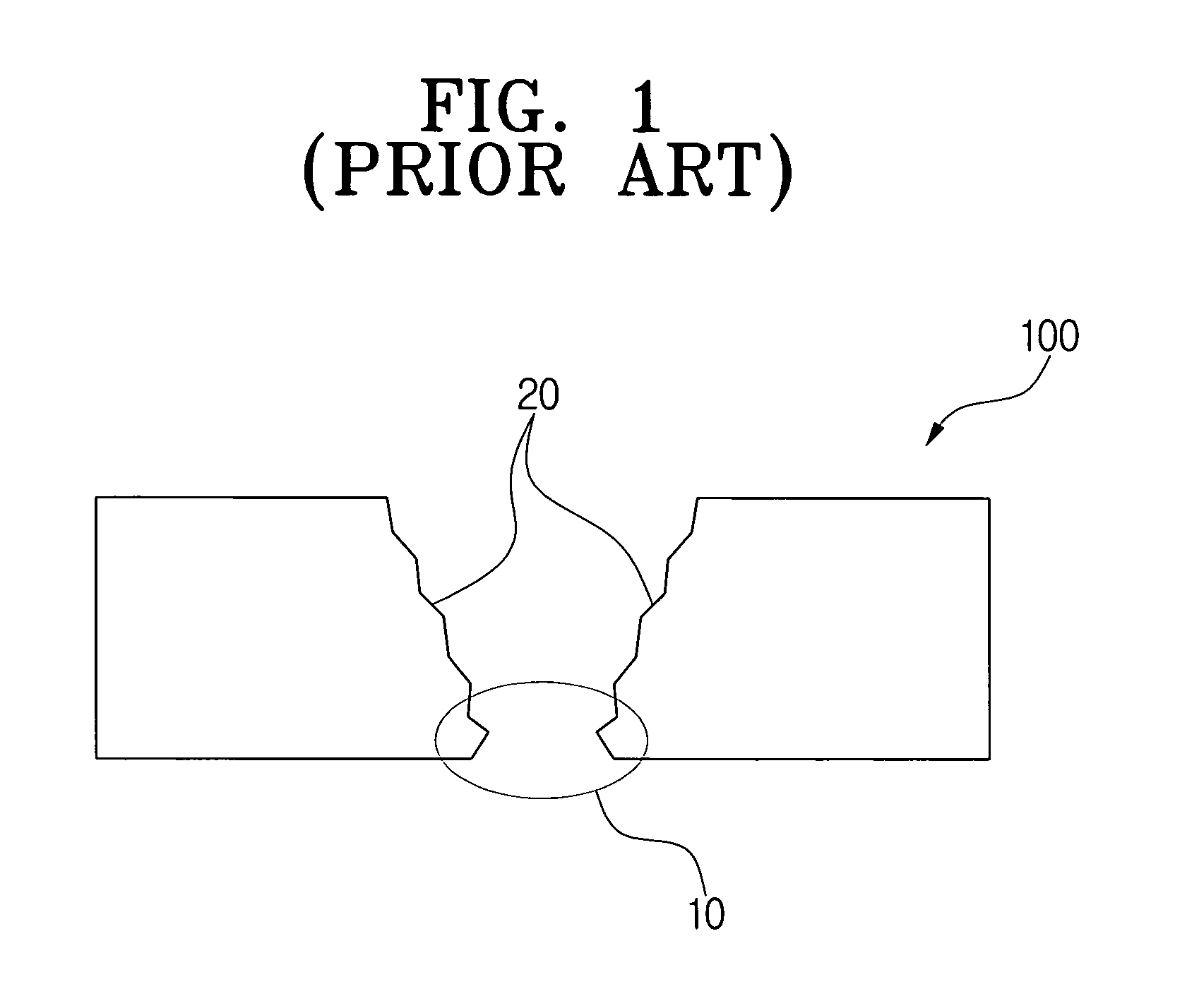

Method of forming a via hole through a glass wafer

ActiveUS7084073B2Smooth surfaceInhibition formationVolume/mass flow by thermal effectsFixed microstructural devicesSmooth surfaceEtching

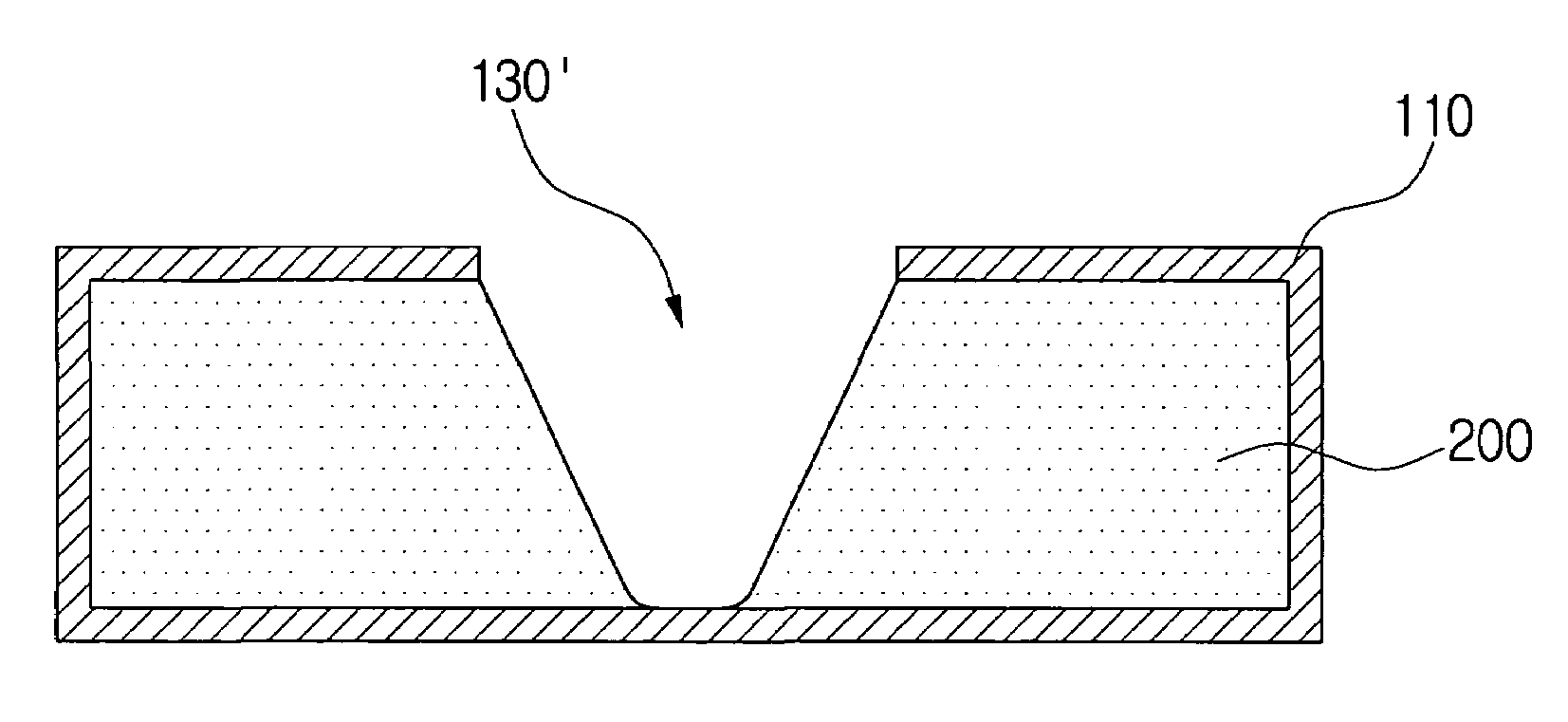

A method of forming a via hole through a glass wafer includes depositing a material layer on an outer surface of the glass wafer, the material layer having a selection ratio higher than that of the glass wafer, forming a via-patterned portion on one side of the material layer, performing a first etching in which the via-patterned portion is etched to form a preliminary via hole, eliminating any remaining patterning material used in the formation of the via-patterned portion, performing a second etching in which the preliminary via hole is etched to form a via hole having a smooth surface and extending through the glass wafer, and eliminating the material layer. The method according to the present invention is able to form a via hole through a glass wafer without allowing formation of an undercut or minute cracks, thereby increasing the yield and reliability of MEMS elements.

Owner:SAMSUNG ELECTRONICS CO LTD

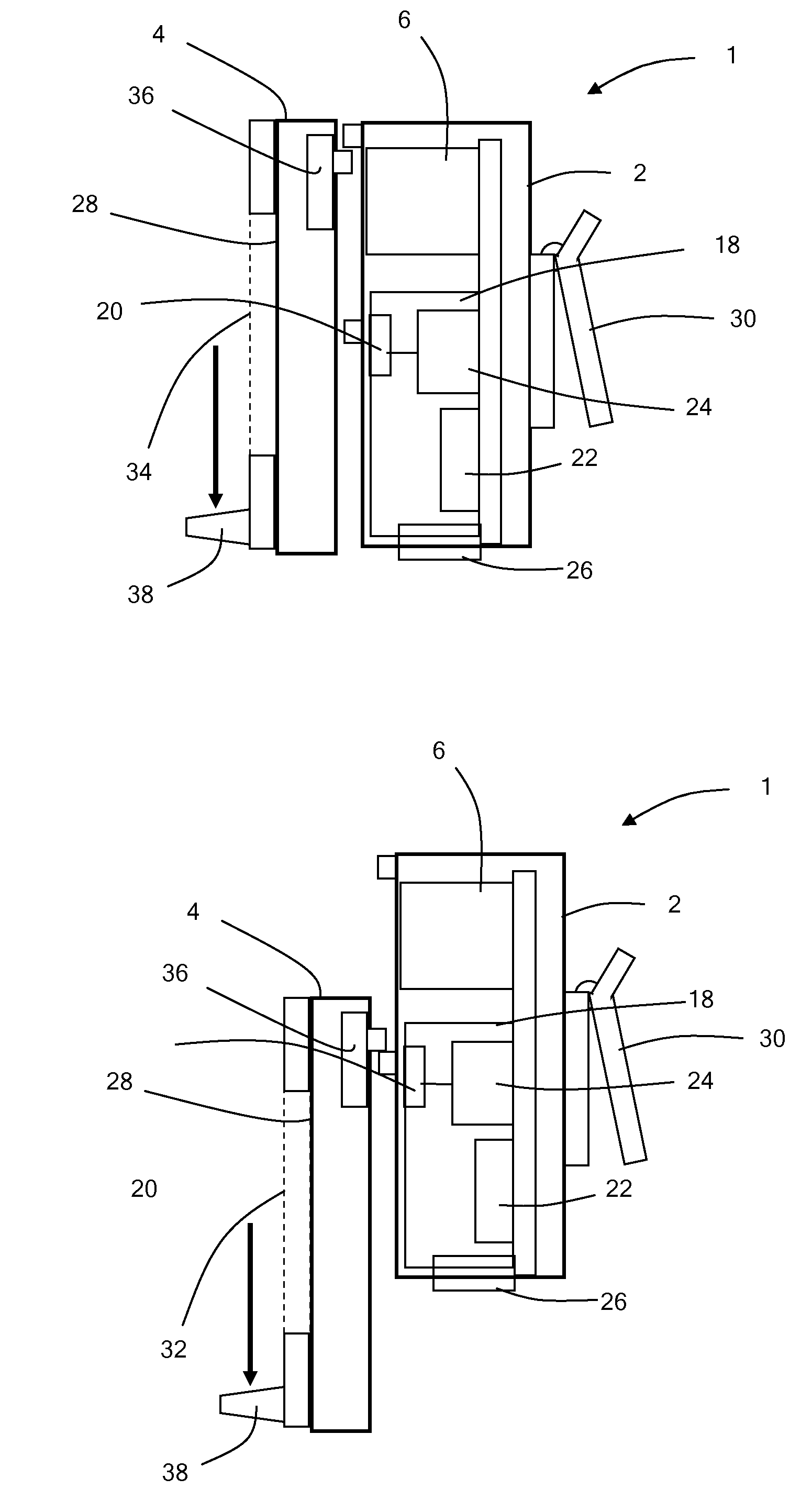

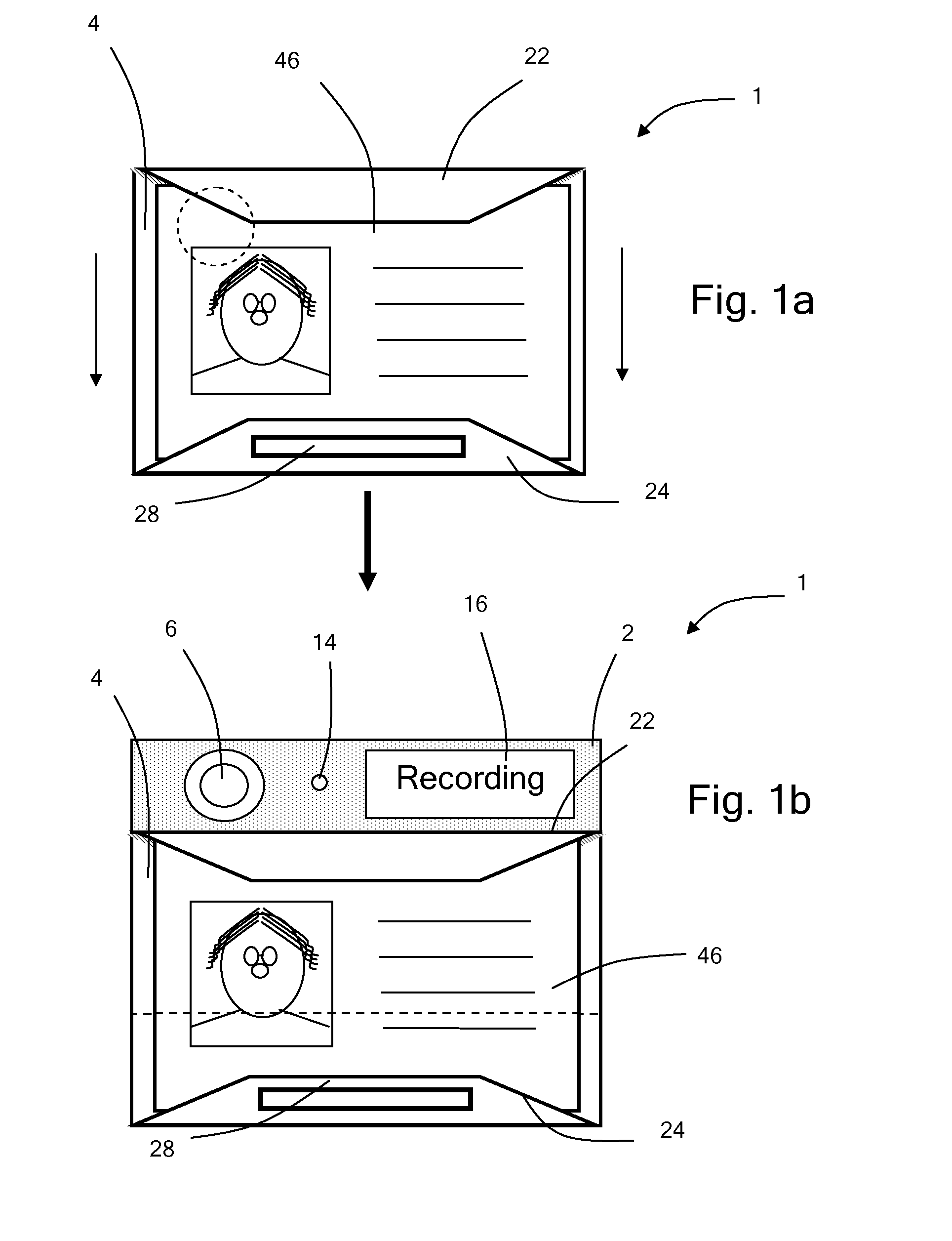

Imaging Recording Apparatus

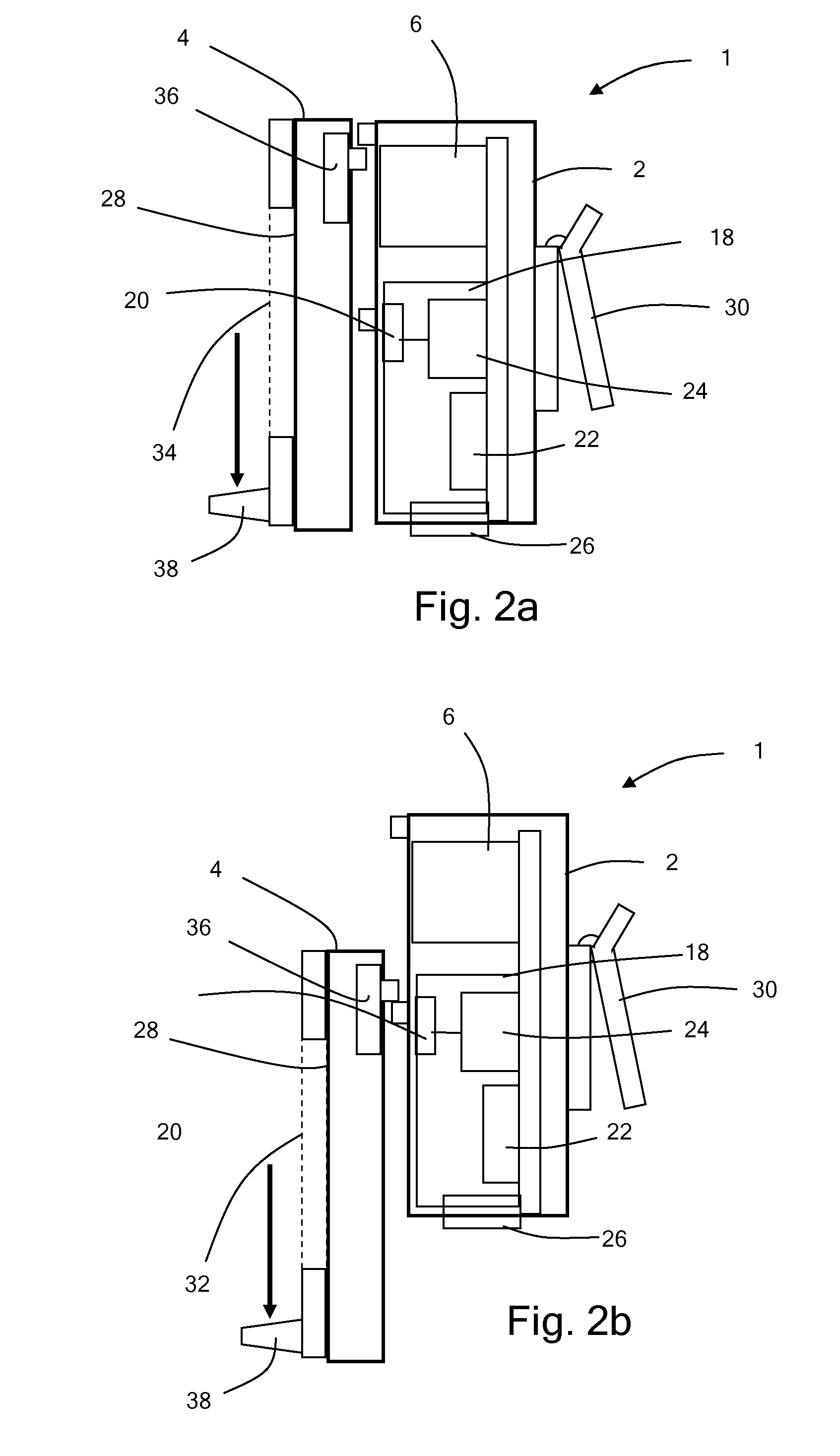

ActiveUS20120120258A1Small operationSmooth surfaceTelevision system detailsPrintersHead movementsImage recording

A body-mountable image capture device comprising a device body and a cover slidably mounted onto the device body, the device body comprising a camera, the cover sliding between a first position and a second position such that in the first position the camera is concealed and in the second position the camera is exposed. The body-mountable image capture device comprises activation means operable to initiate the camera when the cover is in the second position and the camera is exposed. The orientation of the camera is adjustable with respect to that of the device body such that the orientation of the camera can be maintained. The orientation of the camera may be automatically adjusted to keep the field of view generally horizontal. The camera may automatically rotate left and right in a horizontal plane responsive to movement of a head mounted sensor to thereby track a user's head movements.

Owner:EDESIX

Rachael blanket made from Modal cotton

A raschel blanket of modyhr-cotton is prepared form 35-50 wt.% of modyhr, 30-40 wt.% of cotton and 15-30 wt.% of polyester. Its manufacturing process includes warping polyester filament, warping wool yarn blended by modyhr and cotton, weaving for fabric, splitting and opening fine hair, inspecting and sending inspected material to warehouse of semi-finished product.

Owner:上海海欣大津毛织有限公司

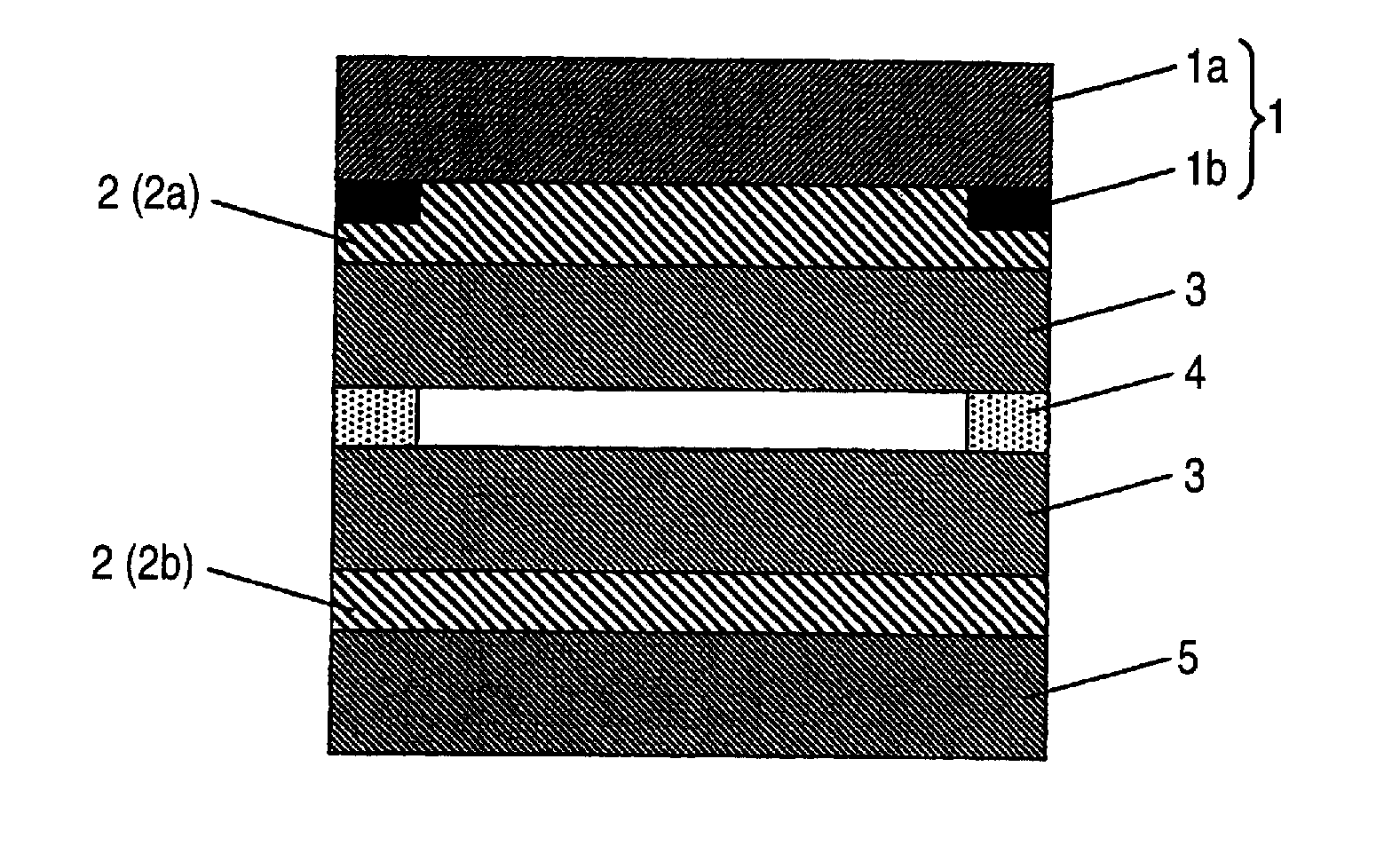

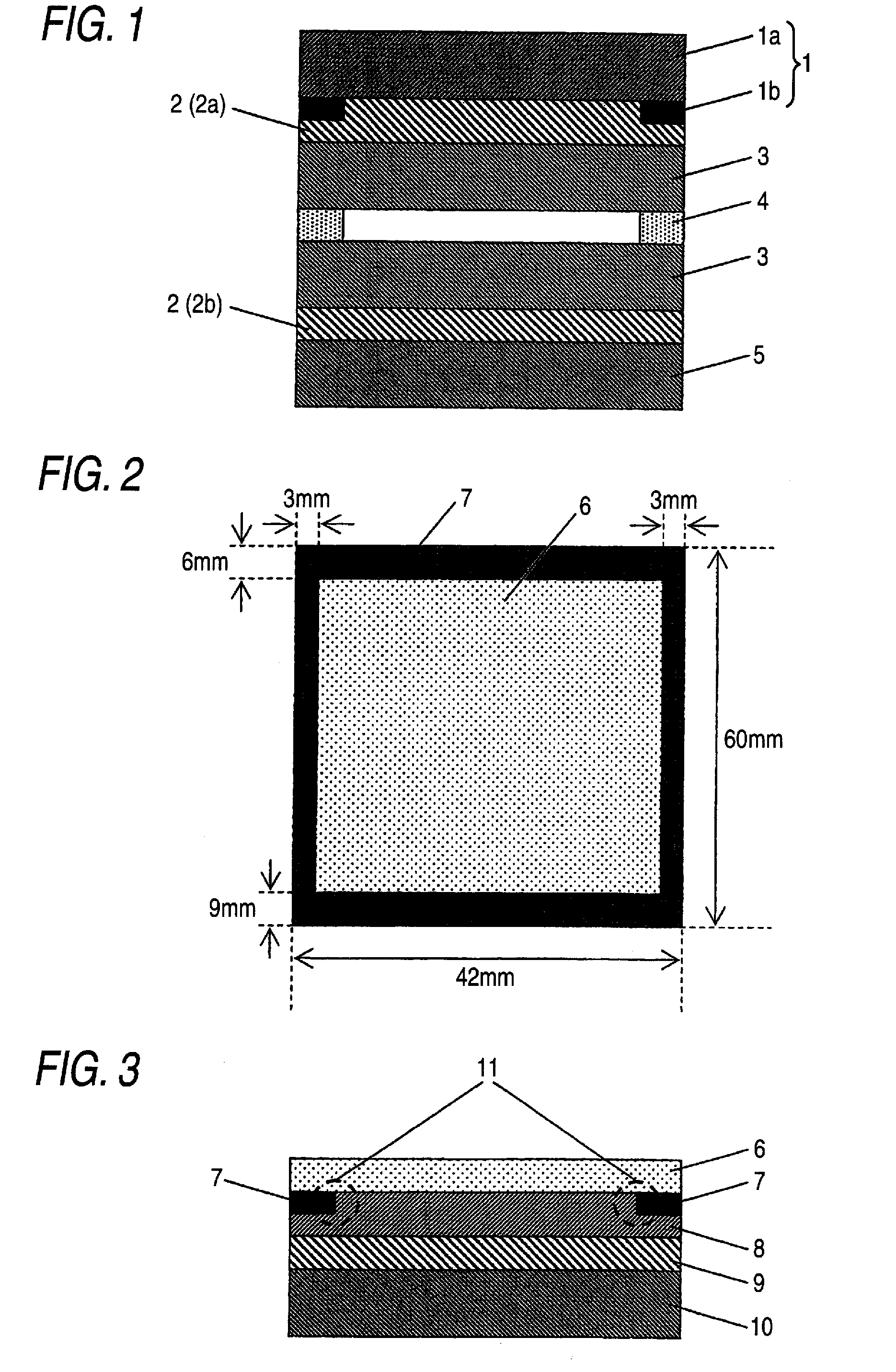

Pressure-sensitive adhesive sheet for optical member adhesion

InactiveUS20100080991A1Excellent in thickness unevenness absorbability and durabilitySmooth surfaceFilm/foil adhesivesSynthetic resin layered productsPressure sensitiveChemistry

The present invention provide a pressure-sensitive adhesive sheet for optical member adhesion, which includes at least an acrylic pressure-sensitive adhesive layer, in which the acrylic pressure-sensitive adhesive layer has a storage modulus at 23° C. of from 1.0×104 Pa to less than 1.0×105 Pa and has a peeling pressure-sensitive adhesive force (with respect to polyethylene terephthalate, 180° peeling) at 80° C. of 2.5 N / 20 mm or more. This pressure-sensitive adhesive sheet is excellent in thickness unevenness absorbability and durability even when the sheet is a thin film.

Owner:NITTO DENKO CORP

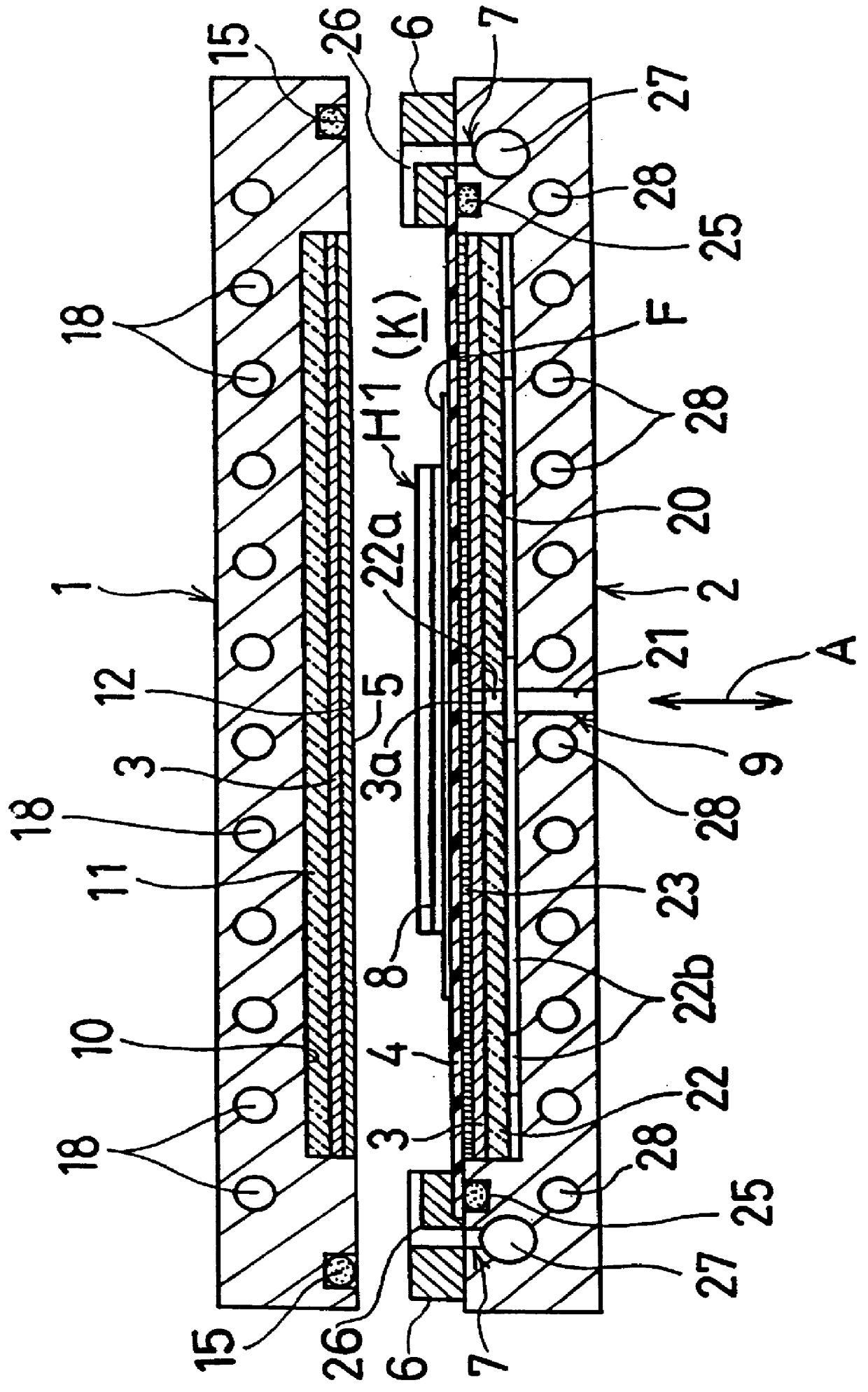

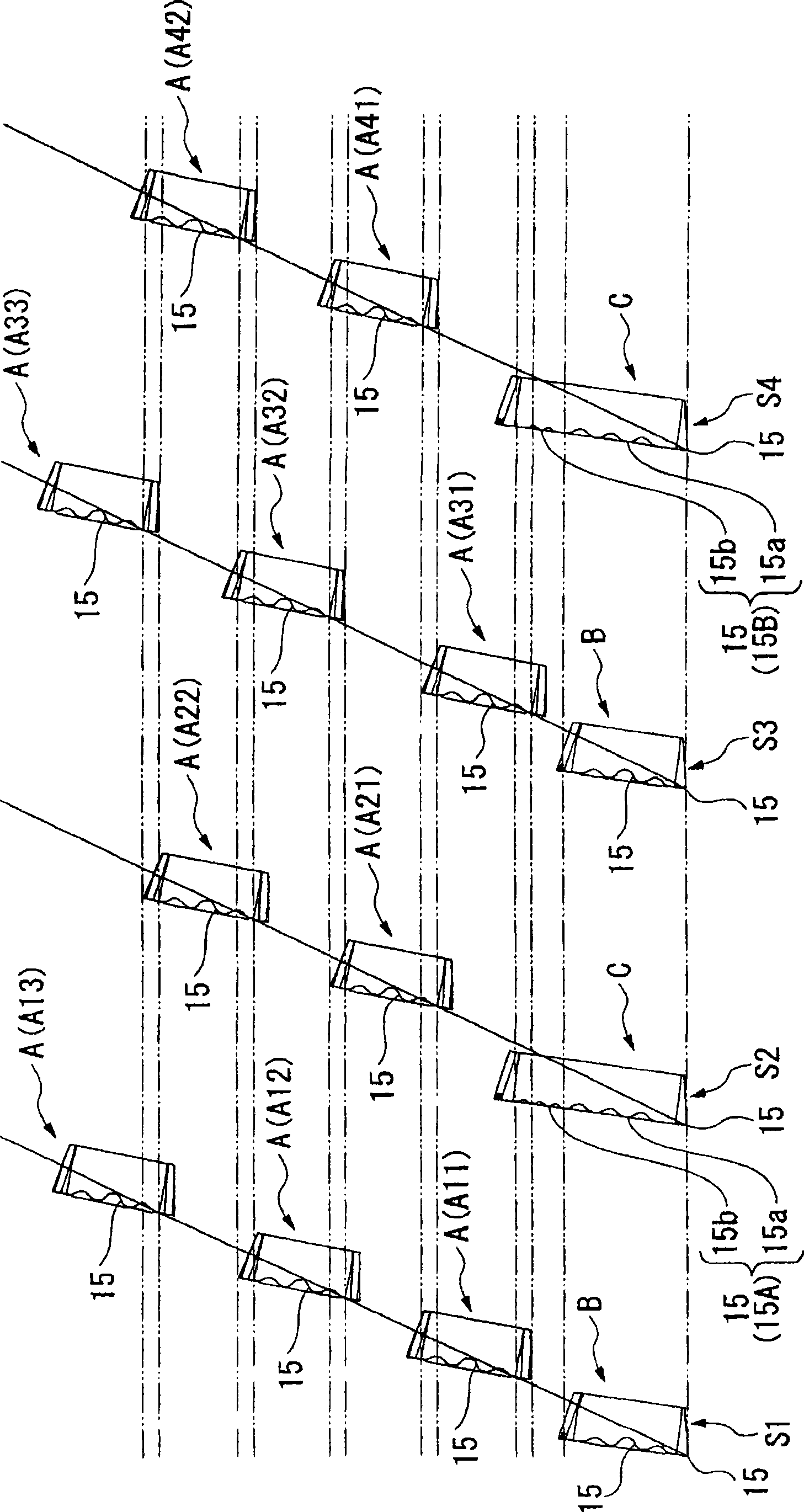

Lamination molding method and an apparatus thereof

InactiveUS6113724ASmooth surfaceAvoid it happening againOther printing matterLaminationEngineeringMechanical engineering

Owner:MEIKI

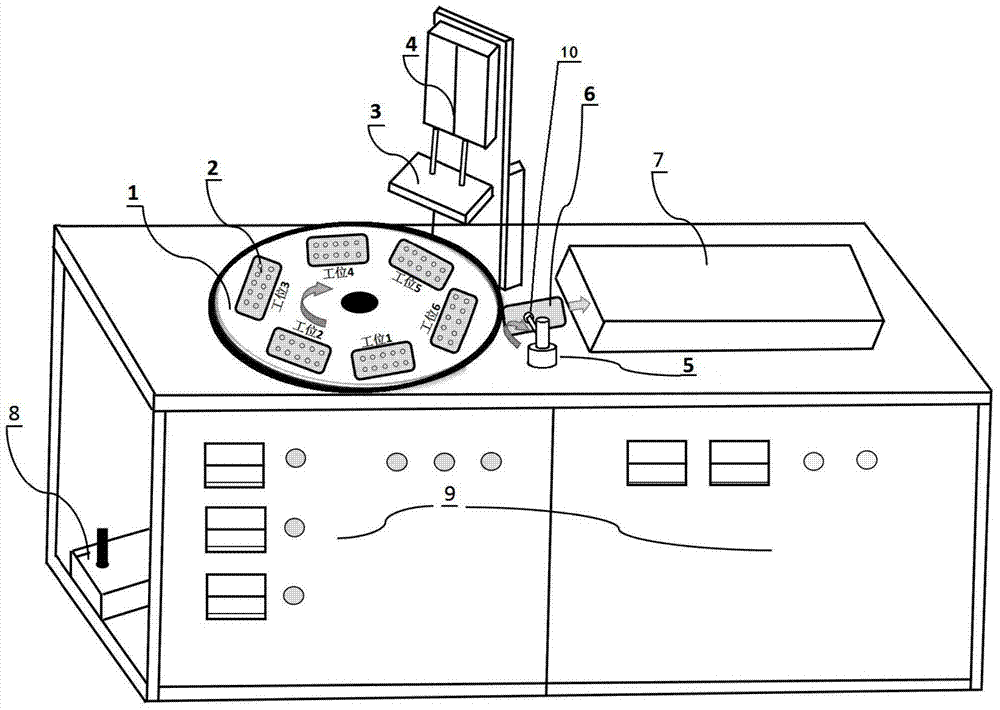

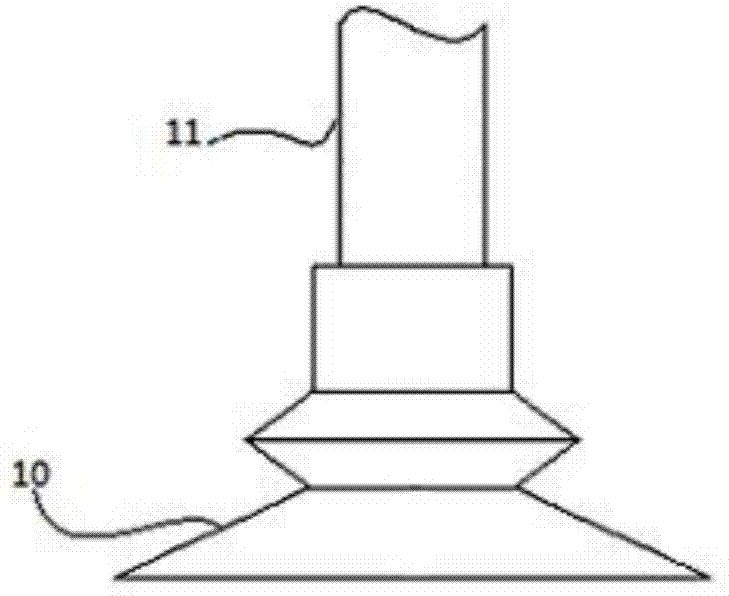

3D Curved ultrathin glass bending and forming device and manufacturing method

ActiveCN104843976ASmooth surfaceReduce stressGlass reforming apparatusGlass productionPhysicsElectrical control

The invention discloses a 3D curved ultrathin glass bending and forming device and a manufacturing method. The device comprises a rotor disc, concave dies, a convex die, a cylinder, a glass transfer mechanism, a tunnel furnace, a vacuum system and an electric control operating system, and a plurality of concave dies are arranged on the rotor disc. By adopting the device, the concave dies and the convex die are quickly heated in different stages; the ultrathin glass is sequentially placed on the concave dies of the rotor disc and is subjected to preheating; when the ultrathin glass rotates and reaches the corresponding work station on the convex die, the convex die is pressed, and a far infrared lamp tube is utilized to quickly heat to the glass softening point; in addition, the ultrathin glass on the concave dies is sucked and the convex die is pressurized by virtue of the vacuum system, so that the ultrathin glass is bended; the ultrathin glass is transferred to the tunnel furnace to be cooled by virtue of the glass transfer mechanism, so that the 3D curved ultrathin glass can be manufactured.

Owner:海程光电科技有限公司

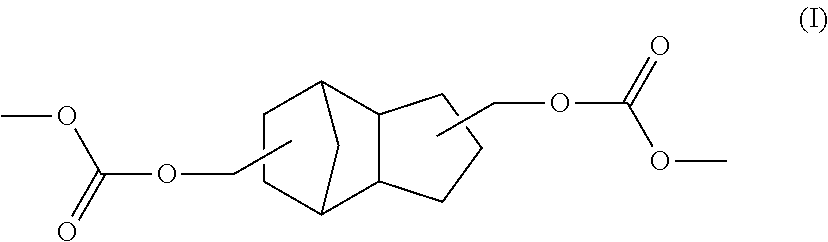

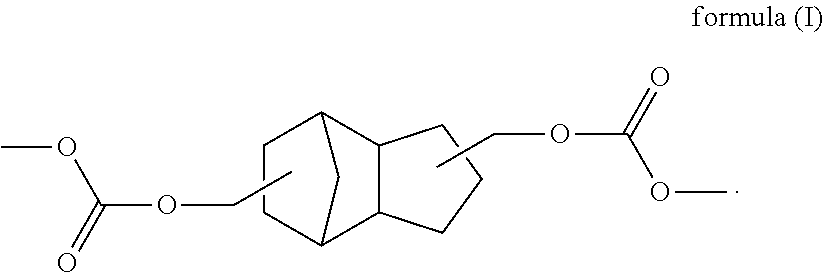

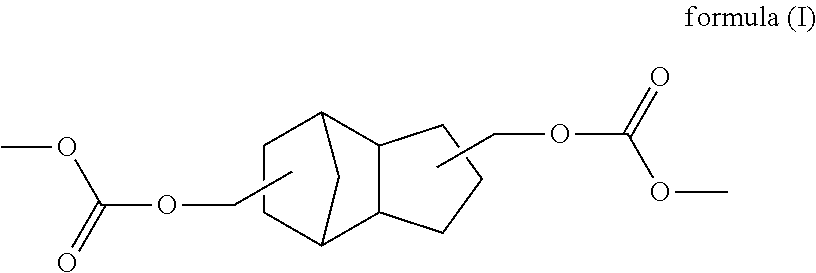

TCD based hydrophilic polyurethane dispersions

InactiveUS8791200B2High hydrophilicitySmooth surfaceAntithrombogenic treatmentPharmaceutical non-active ingredientsPolypropyleneStructural unit

The present invention relates to a polyurethaneurea solution having a polyurethaneurea having a structural unit of the formula (I)and terminated with at least one copolymer unit of the group consisting of a polyethylene oxide, a polypropylene oxide, and mixtures thereof.

Owner:BAYER MATERIALSCIENCE AG

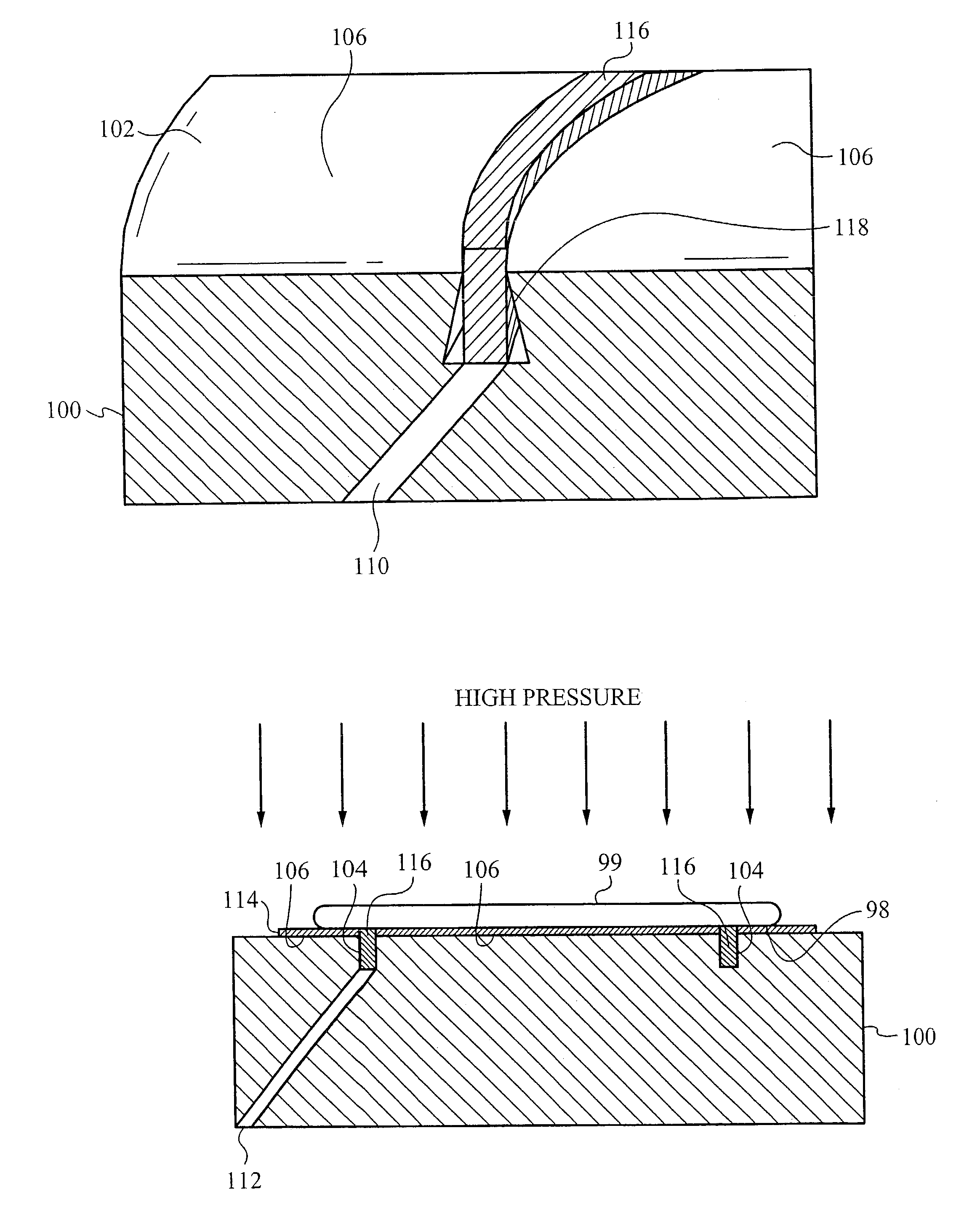

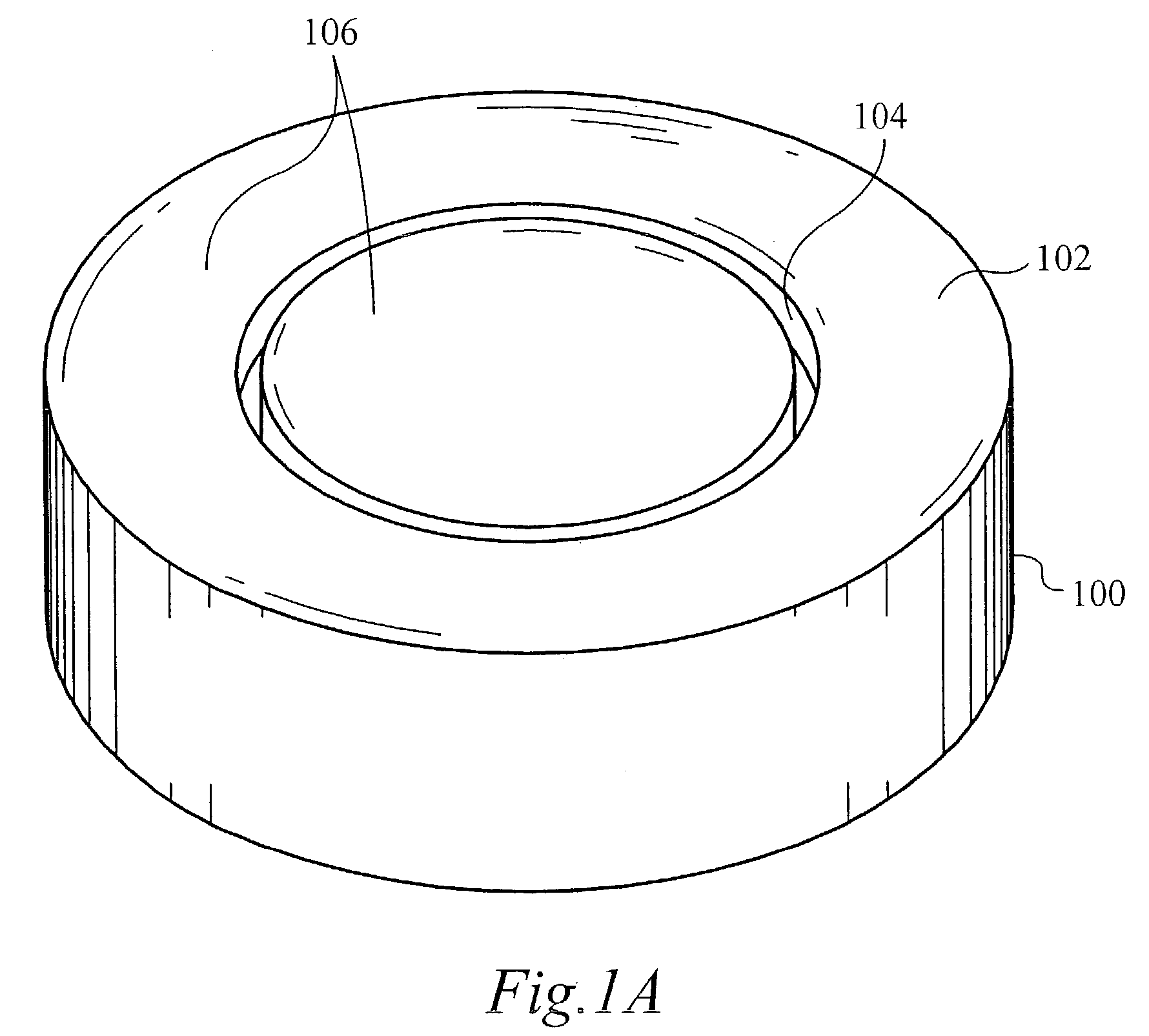

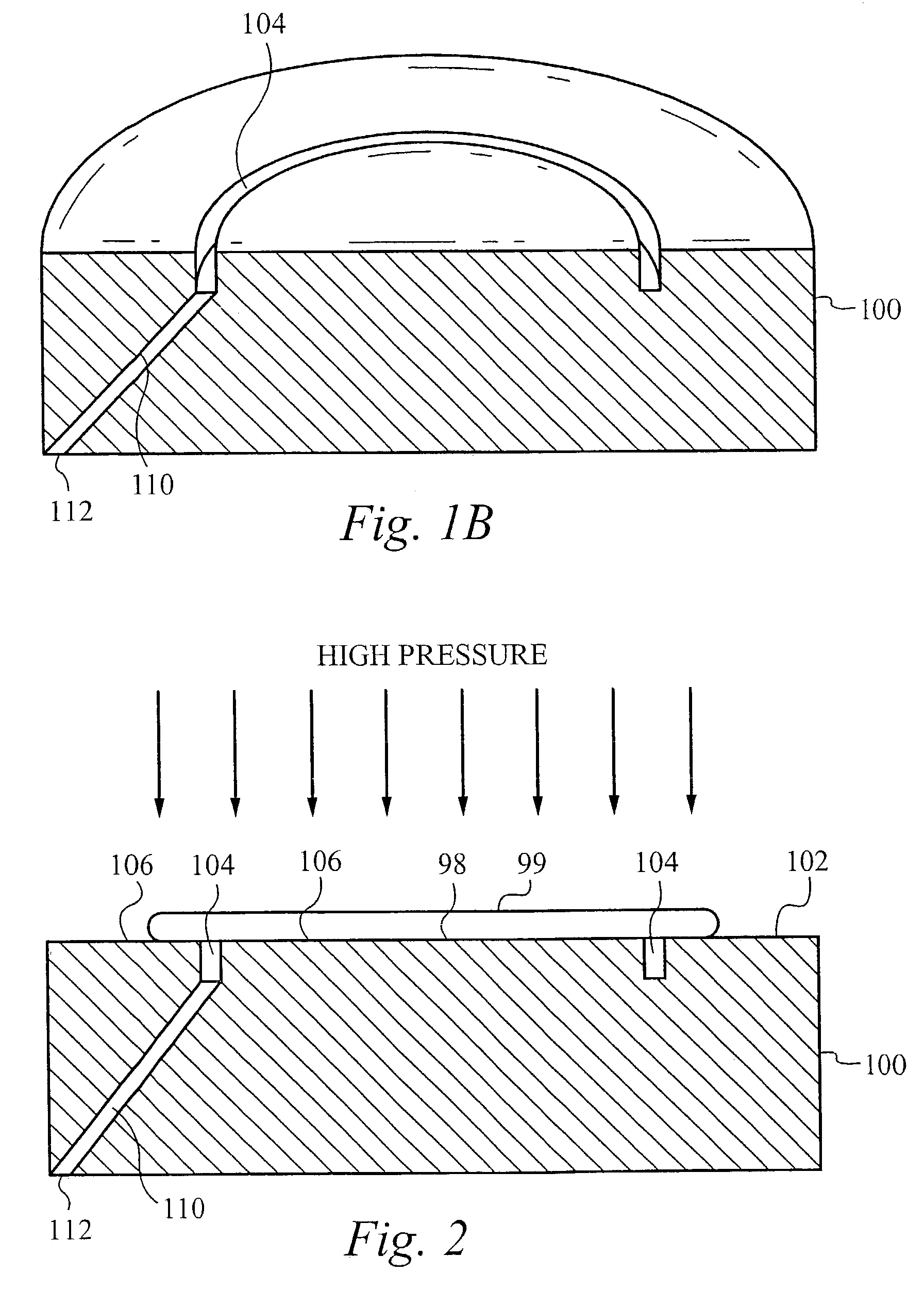

Vacuum chuck utilizing sintered material and method of providing thereof

InactiveUS7021635B2Uniform surfaceSmooth surfaceSleeve/socket jointsSemiconductor/solid-state device manufacturingHigh pressureSemiconductor

A vacuum chuck for holding a semiconductor wafer during high pressure, preferably supercritical, processing comprising: a wafer holding region for holding the wafer; a vacuum region for applying vacuum to a surface of the wafer, the vacuum region within the wafer holding region; and a material, preferably sintered material, applied within the vacuum region, the material configurable to provide a uniform surface between the surface of the wafer and the wafer holding region, wherein the material is configured to allow vacuum to flow therethrough. The vacuum region preferably comprises at least one vacuum groove. Alternatively, the vacuum region includes at least two vacuum grooves that are concentrically configured on the wafer holding region. The vacuum groove alternatively comprises a tapered configuration. Alternatively, a coating material is applied between the wafer surface and the substantially smooth holding region surface, whereby the coating provides a seal between the wafer and the holding region.

Owner:TOKYO ELECTRON LTD

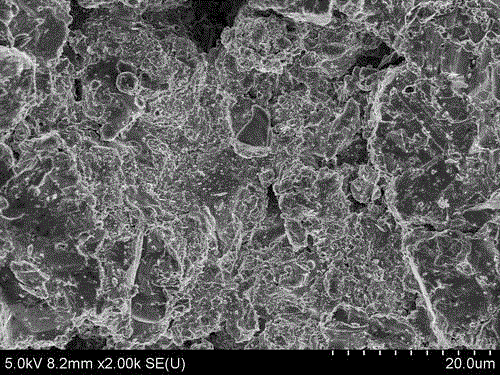

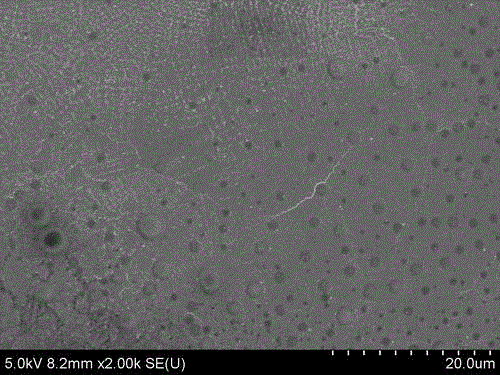

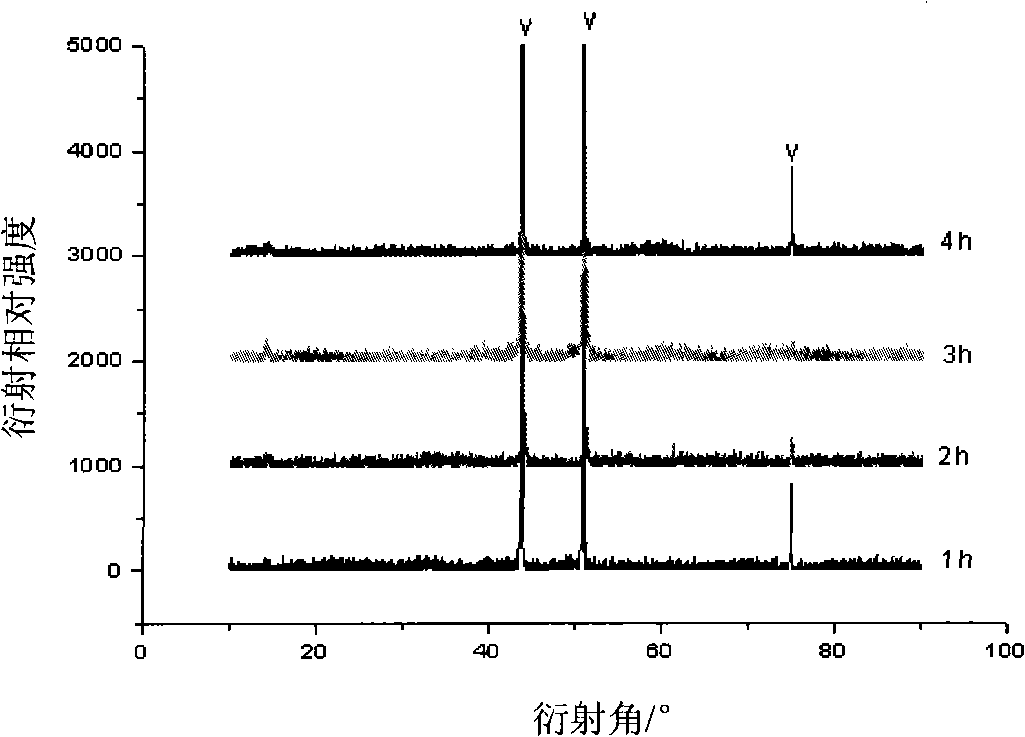

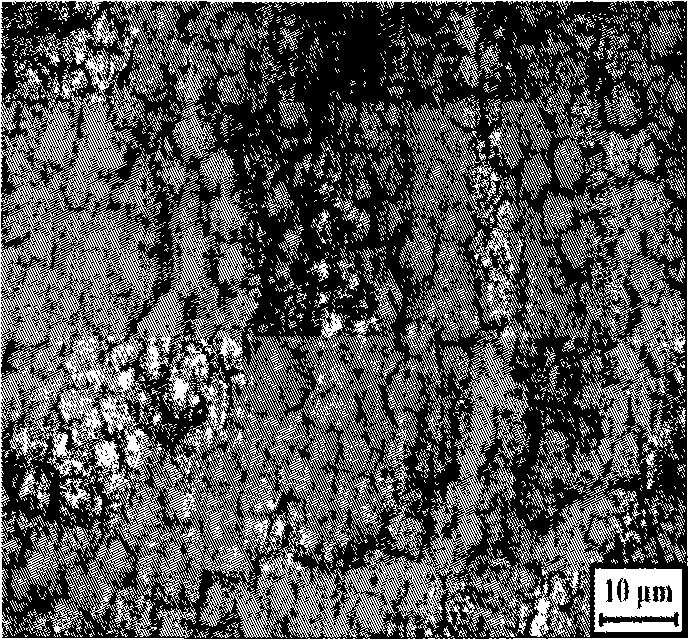

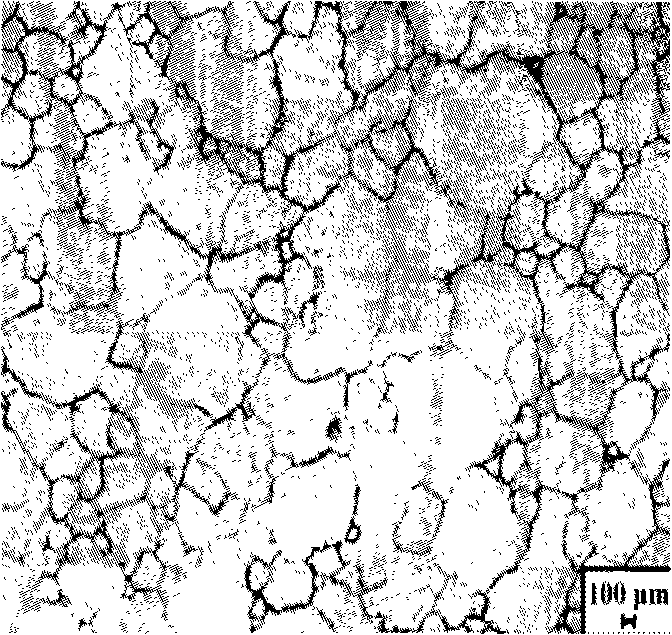

Treatment method for improving oxidation resistance of thermal barrier coating (TBC) bonding layer

InactiveCN102719782AImprove tissue morphology and surface compactnessSmooth surfaceMolten spray coatingSurface finishingVoltage

The invention relates to a treatment method for improving the oxidation resistance of a thermal barrier coating (TBC) bonding layer, and belongs to the technical field of surface treatment and modification of the TBC bonding layer. In the material surface treatment and modification processes, the surface roughness of the TBC bonding layer (MCrAlY) prepared by a plasma spraying method is reduced through high current pulsed electron beam irradiation, and the pores and holes of a coating are reduced, so that the high-temperature oxidation resistance of the TBC bonding layer is improved. Technical conditions are that vacuum degree is 3.5*10<-2>Pa, voltage is 15kV, frequency is 1Hz, pulse width is 50 to 200mu s, energy density is 8 to 18J / cm<2>, and pulse times is 10 to 20. The method has the advantages that the surface roughness of the TBC bonding layer (MCrAlY) prepared by the plasma spraying method is reduced through high current pulsed electron beam irradiation, the pores and holes of the coating are reduced, and penetrated microcracks are avoided, so that the high-temperature oxidation resistance of the TBC bonding layer is effectively improved.

Owner:DALIAN UNIV OF TECH

Manufacturing method of strong twinkling aluminium pastes

ActiveCN101735671ASmooth surfaceNarrow particle size distributionPigment pastesPigment physical treatmentSurface finishingBall mill

The invention discloses a manufacturing method of strong twinkling aluminium pastes. The manufacturing method comprises the following steps: in a vertical stirring mill, adopting glass beads with the diameter being 1.0-5.0mm to serve as milling medium of a ball mill; mixing uniformly the ultrafine spherical aluminium powder with d50 being greater than 8mu m and less than 10mu m, organic solvent and dispersing agent according to the ratio of 20-50:80-200:1-5; ball milling for 20-50h under the rotating speed being 50-200rpm, discharging, filter pressing, introducing the filter liquor to the ball milling procedure for recycling; classifying through fine screening; filter pressing the screened material at each stage by the filter press; blowing dry and reusing; filter pressing and washing through; carrying out surface treatment on the filter cakes entering the mediating procedure; controlling the thickness of the aluminium particles to be 1-2mu m; and packaging to obtain the finished products.

Owner:长沙族兴新材料股份有限公司

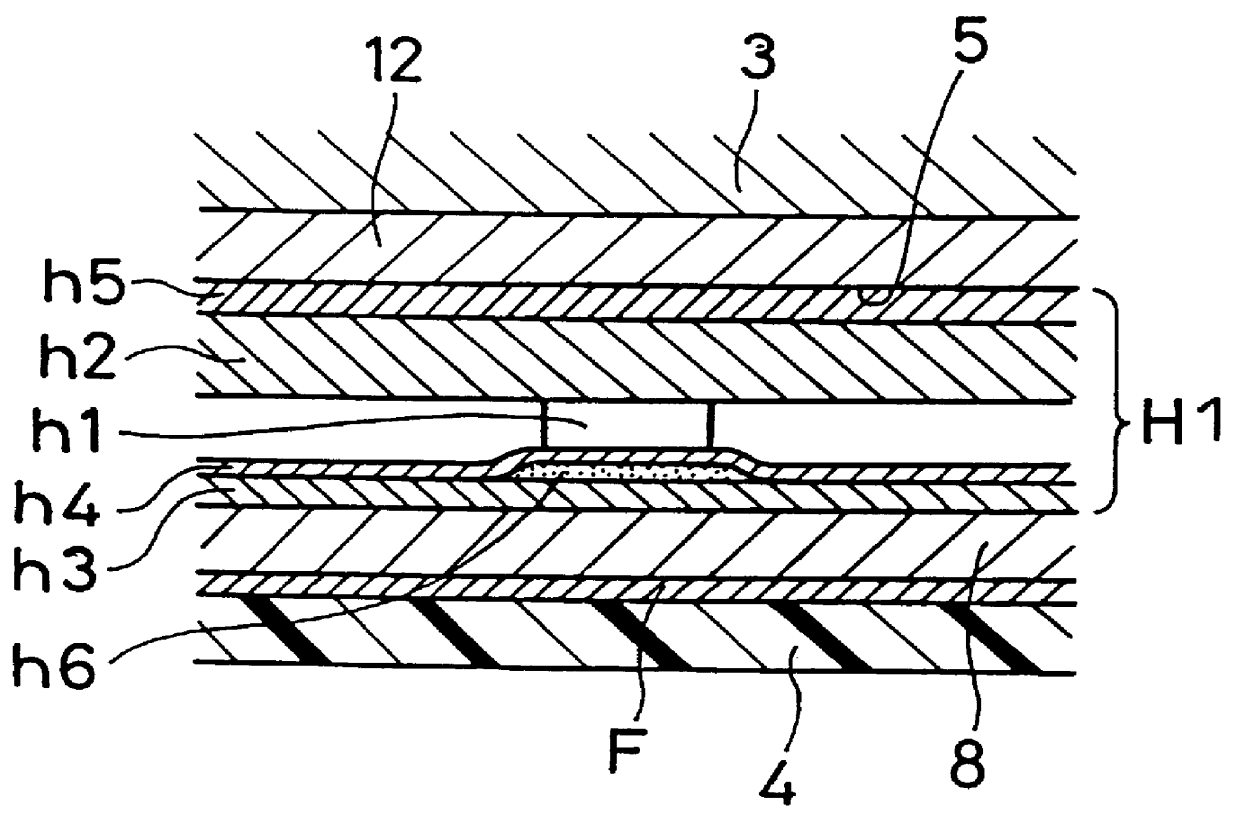

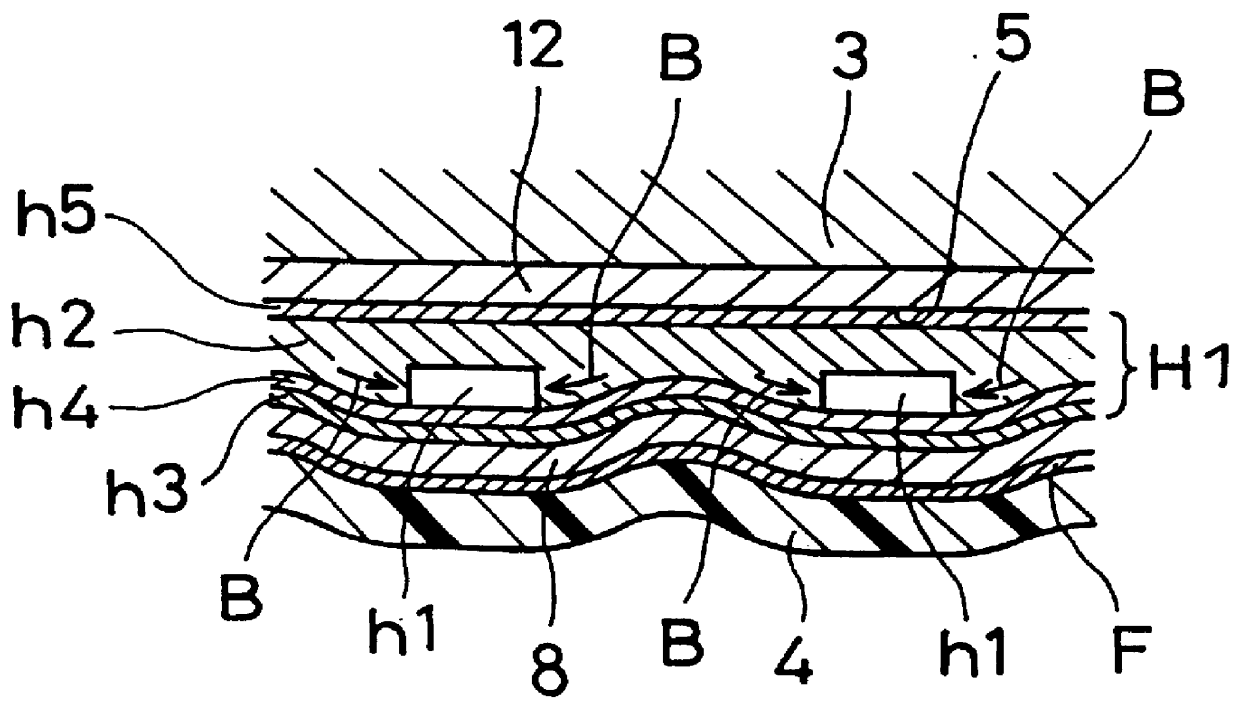

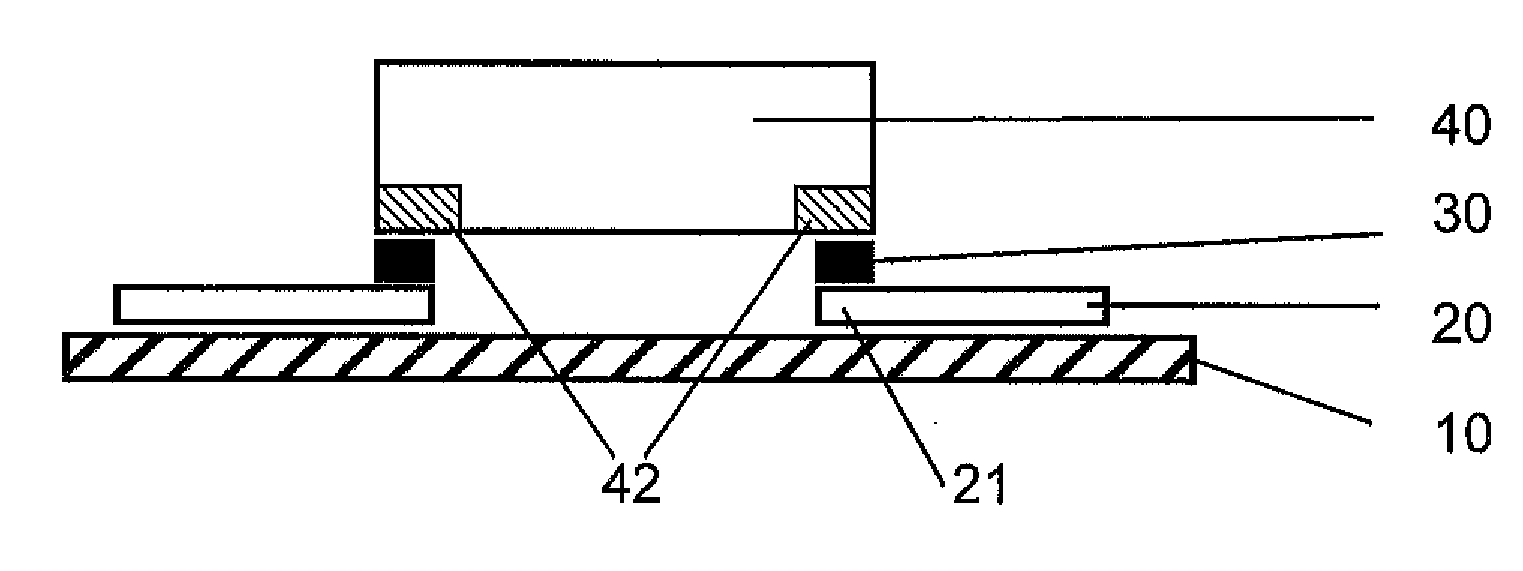

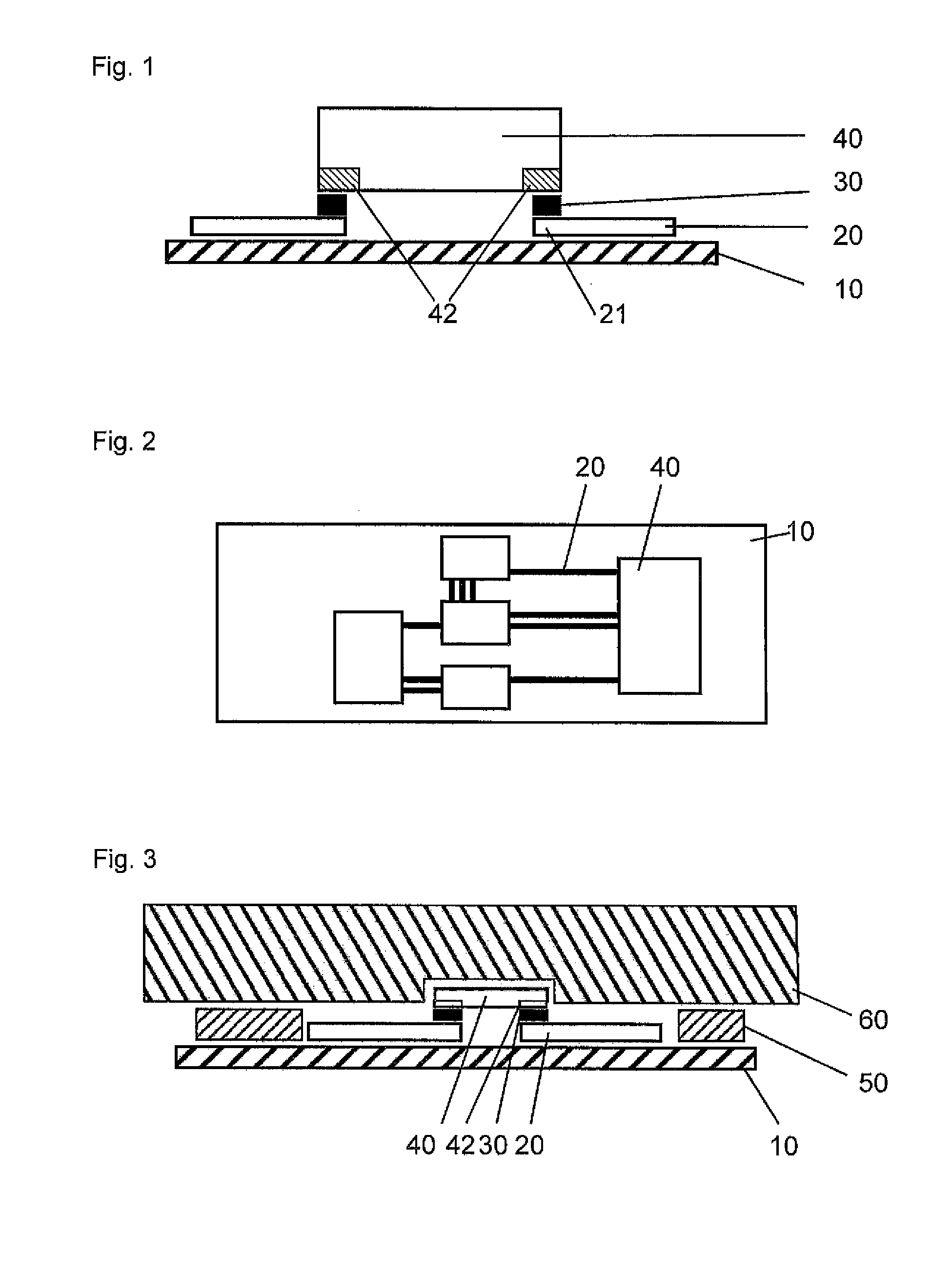

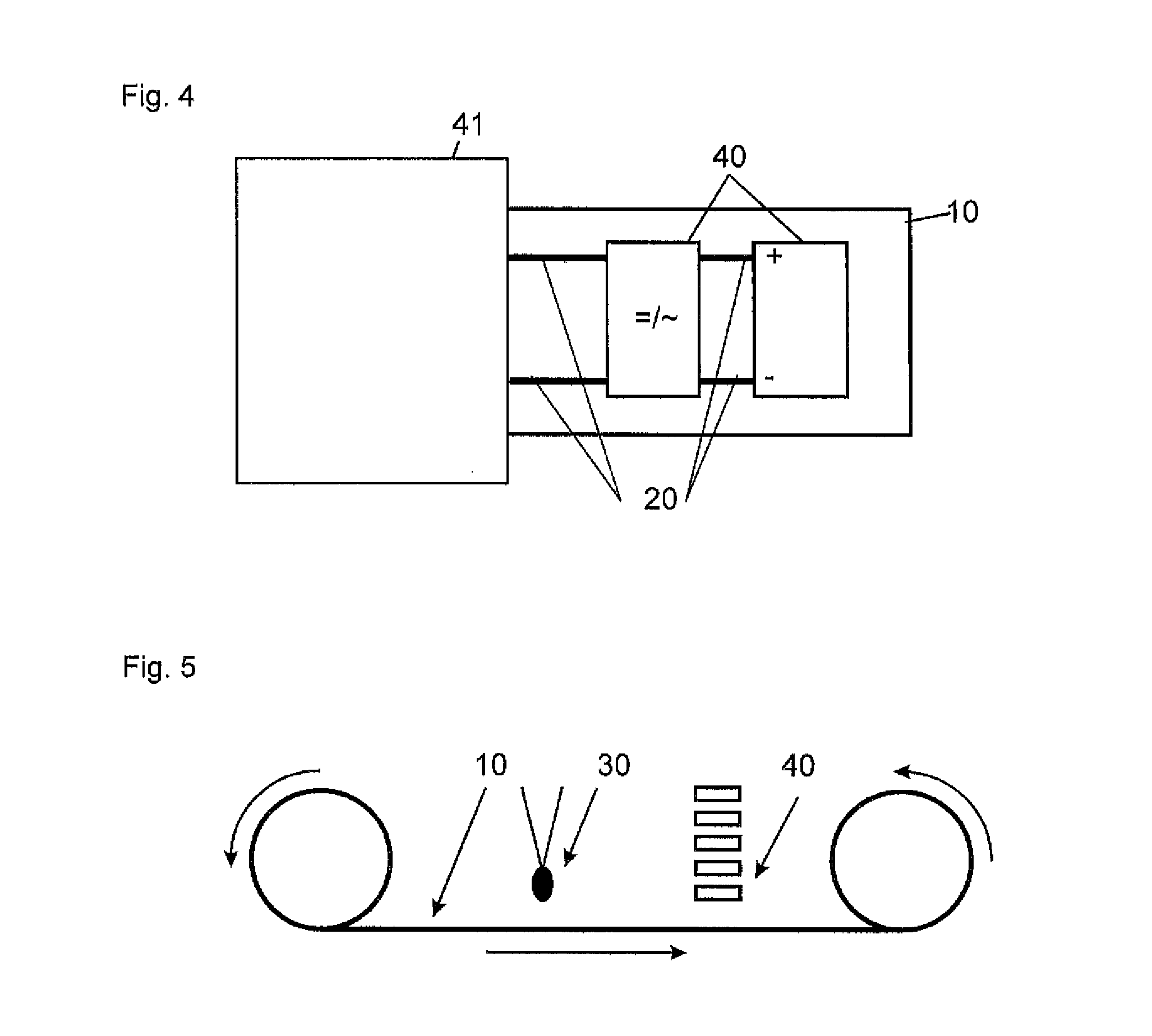

Label having an electronic functional element

InactiveUS20120162945A1Smooth surfaceCost-advantageous and efficientStampsLaminating printed circuit boardsEngineeringElectronic structure

An electronic functional label and a special production process for such a label, which can be equipped with electronic components in very simple, fast, and effective manner, without a soldering process that is connected with high temperatures. For this purpose, a carrier substrate preferably having printed electronic structures is equipped with electronic components by means of an electrically conductive adhesive. The use of special electronic components (sensors and optical / acoustic actors) that interact with their surroundings proves to be particularly advantageous in this connection. High-quality labels, in particular, having surprising interactions can be produced in a simple and cost-advantageous manner.

Owner:SCHREINER GRP GMBH & CO KG

Method for planarizing polysilicon

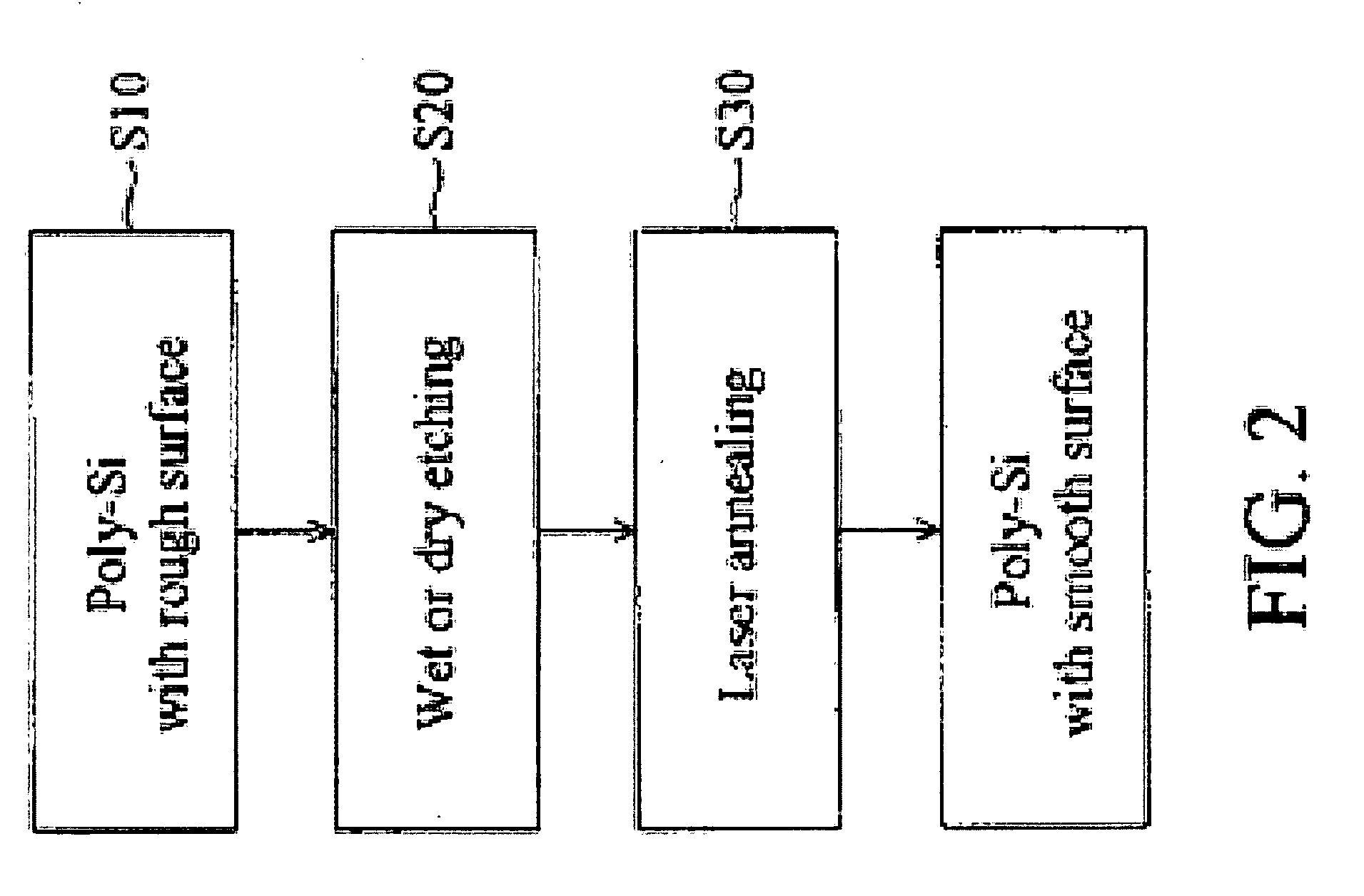

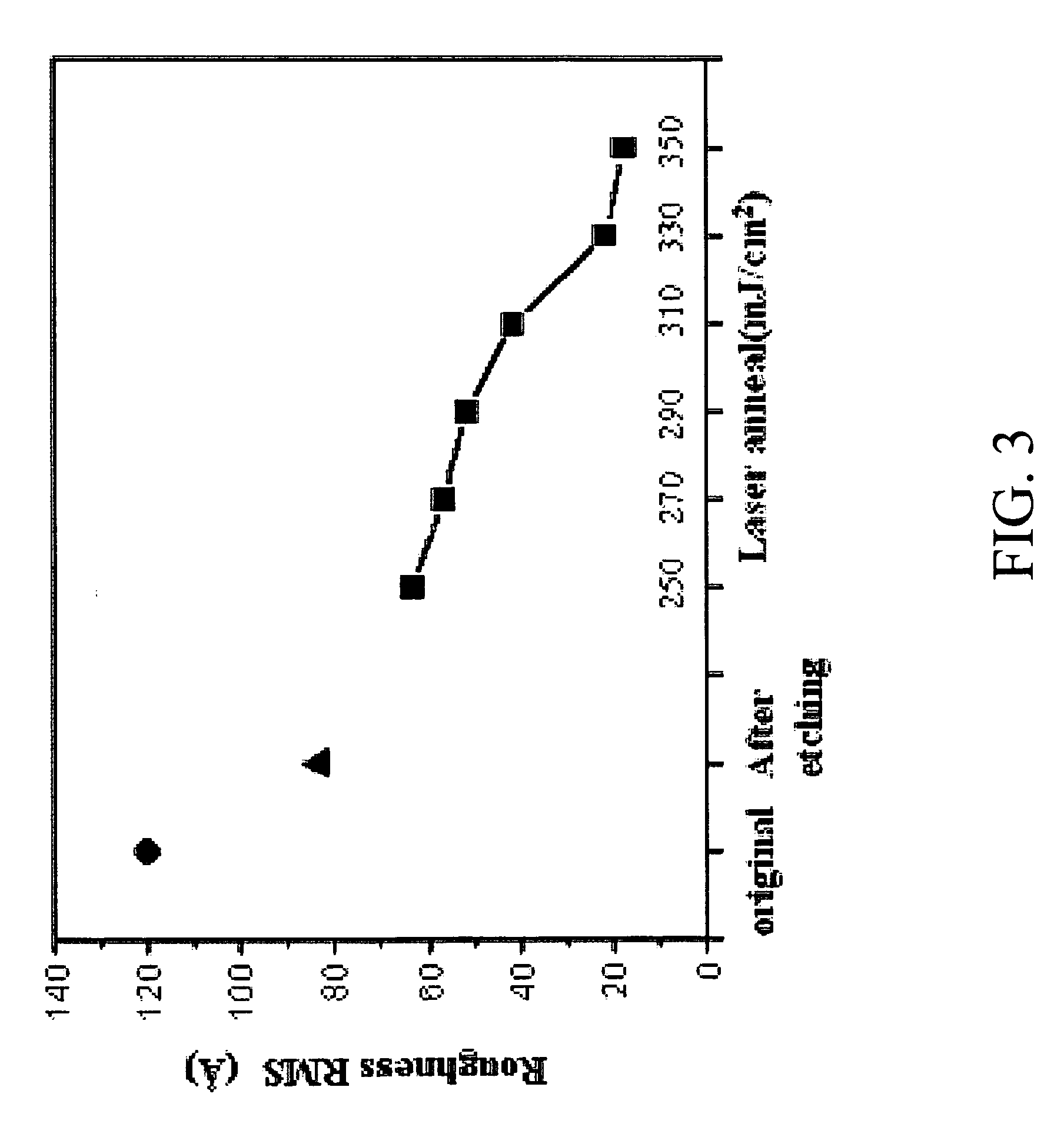

InactiveUS20060043072A1Smooth surfaceLow surface roughnessDecorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsOxide

A method for planarizing polysilicon comprises providing a substrate, forming a dielectric layer on the substrate, forming an amorphous silicon film on the dielectric layer, etching the amorphous silicon film to remove native oxide formed on a surface of the amorphous silicon film, exposing the surface of the amorphous silicon film to a first radiation source to polycrystallize the amorphous silicon film into a polysilicon film, etching the polysilicon film to remove weak bonded silicon formed on a surface of the polysilicon film, and exposing the surface of the polysilicon film to a second radiation source to reflow the polysilicon film.

Owner:IND TECH RES INST

Thermoplastic polyurethane/fiber composite soft cloth and preparation method thereof

InactiveCN104015444ASmoothSmooth surfaceLamination ancillary operationsSynthetic resin layered productsTextileFiber

The invention relates to a piece of thermoplastic polyurethane / fiber composite soft cloth. An intermediate layer is a piece of continuous fiber cloth, an upper surface layer and a lower surface layer are respectively a thermoplastic polyurethane resin layer, and the intermediate layer is connected with the upper surface layer and the lower surface layer through a hot laminating way. The composite soft cloth adopts TPU and fiber fabrics of different types and colors as raw materials, and TPU is bonded with the fabrics in a hot laminating manner, so that the pollution is avoided, the process is simple, the cost is low, the appearance effect is excellent, and the thermoplastic polyurethane / fiber composite soft cloth can be applied to top-grade appearance parts such as cases and vamps.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

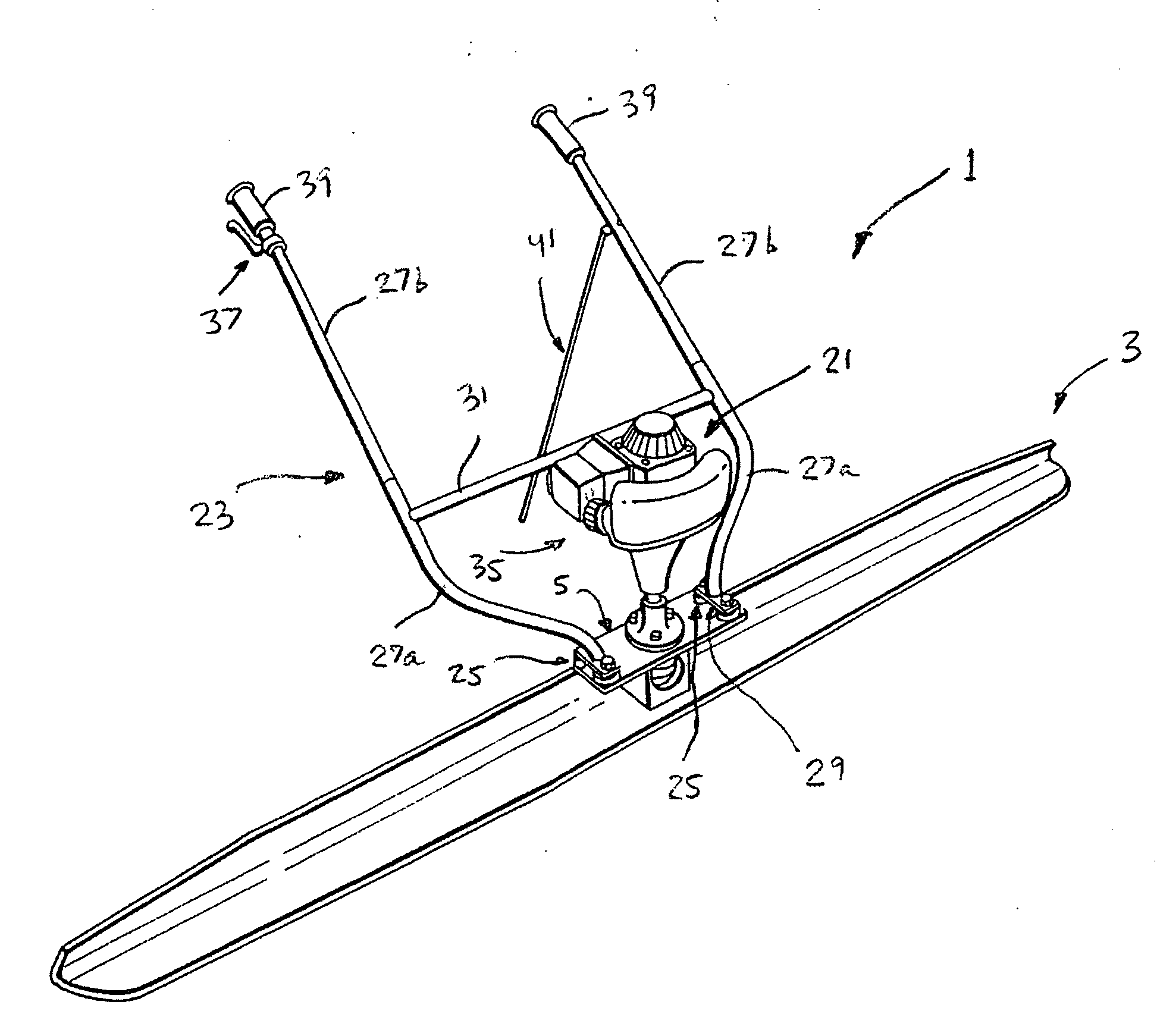

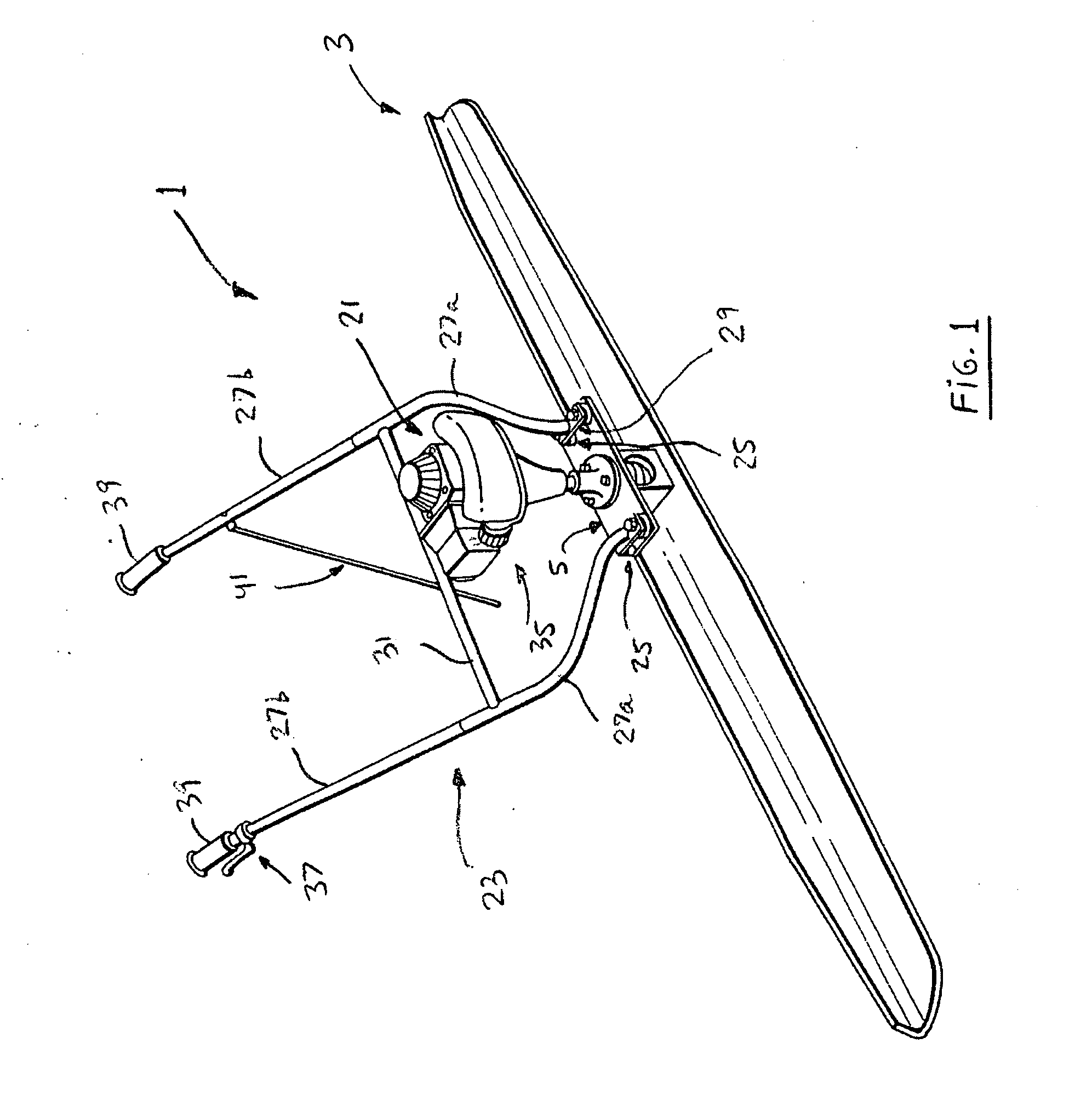

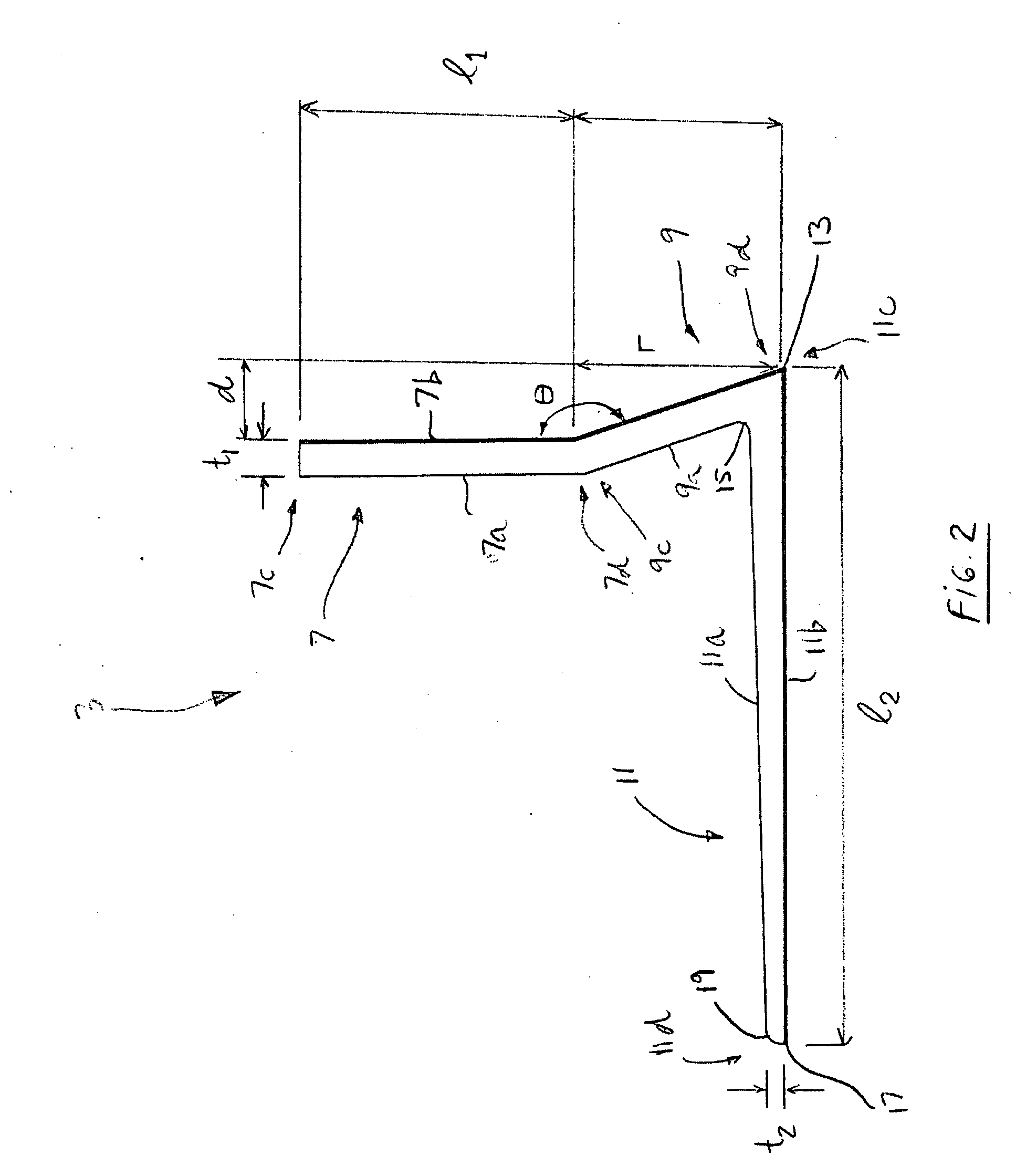

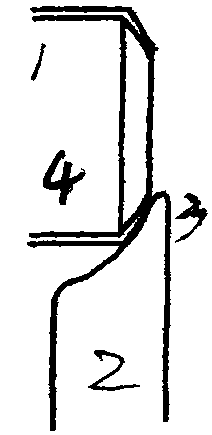

Leveling blade, vibrating screed including the blade, and kit for assembling the same

InactiveUS20060291958A1Smooth surfaceFlat surfaceBuilding constructionsRoads maintainenceScreedEngineering

A leveling blade for mounting onto a support bracket of a vibrating screed, and a vibrating screed including the same. The leveling blade has a substantially vertical portion for mounting onto the support bracket, as well as a substantially slanted portion and a substantially horizontal portion, which results in the leveling blade having a particular profile. The vibrating screed includes also a vibration-generating assembly, being operatively mounted onto the support bracket of the vibrating screed for imparting vibrations to the leveling blade via the support bracket so as to enable to carry out a surfacing of a substantially malleable material with the vibrating screed by passing said leveling blade provided with vibrations about said substantially malleable material. A kit is also provided for assembling such a vibrating screed.

Owner:PIRANDELLO INDS

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

Port sealing process of heating container of electric water heater

The invention relates to a port sealing process of a heating container of an electric water heater, which comprises the following steps: first clamping a fixture for a red copper tube on a machine tool, adopting an edge-less cutter with an arc-shaped side on one end, slowly extruding the edge of the port of the red copper tube which rotates at high speed with the front end of the edge-less cutter so that the port of the red copper tube produces high temperature when rotating at high speed and having point-surface extrusion friction with the front end of the edge-less cutter, and enabling the port to close up inwards with the extension, pressing and stretching characteristics of red copper; forming a new port after the port of the red copper tube closes up inwards, extruding the new port with the arc-shaped end of the edge-less cutter, and so on, keeping closing up inwards until the port is gradually reduced and finally sealed in the center; and the port sealing process of the heating container of the electric water heater has the advantages of simple process, no seam and no welding, can well prevent welding and the oxidation of high-temperature melting points, can achieve attractive overall appearance, and is characterized by higher compressive strength, longer service life and the like.

Owner:陶镇铭 +1

Process for spraying and coating bronze at steel and iron surface using oxygen-acetylene subsonic flame

InactiveCN101187000ASmooth surfaceGood spray coating qualityMolten spray coatingAluminum compositesCorrosion

The invention discloses a technique process which utilizes oxygen-acetylene subsonic flame to spray bronze alloy on steel surface, belonging to the technical field of the spraying of material surface. Firstly, the surface of a steel member is proceeded the treatment of deoiling, derusting and surface roughening, the surface of the steel member is preheated by the oxygen-acetylene subsonic flame, the oxygen-acetylene is employed as combustion flame, compressed air is utilized as powder-feeding air and speed up air, and atomizing particle flow is high-speed sprayed to the member surface by a subsonic spray gun and a compress-swelling spraying nozzle with the structure of spiral gas mixing and spraying-absorbing air inletting. The surface of steel member is firstly sprayed with nickel coated aluminum composite powder which is used to be base coat, then the base coat is sprayed with aluminum bronze layer, and hole-seal treatment is instantly proceeded after being sprayed. The invention has the advantages of high spraying efficiency, high binding intensity of an interface, perfect corrosion resistance, simple operation, beautiful formation of the appearance, low cost, easy popularization and application, and the like. In addition, the technique is in particular adaptable for spraying the surfaces of outdoor large-scale formations or statues.

Owner:SHANDONG UNIV

Hydrophilic polypropylene spun-bonded nonwoven cloth

InactiveCN101130919ANot easy to peel offRetain mechanical and physical propertiesConjugated synthetic polymer artificial filamentsNon-woven fabricsNonwoven fabricPolypropylene

The present invention relates to a hydrophilic polypropylene spun-bonded nonwoven fabric. It is characterized by that it is formed from polypropylene resin and polypropylene hydrophilic mother granules, and its mixing ratio is 94%-98% of polypropylene resin and 2%-6% of polypropylene hydrophilic mother granules.

Owner:SHANGHAI FENGWEI FASHION ACCESSORIES

Method for preparing high interfacial strength nickel-zinc plating steel belt

The invention discloses a preparation method of a high interface strength nickel-zinc plated steel strip, which relates to a steel strip, in particular to a preparation method of a high-performance corrosion resistant nickel-zinc plated steel strip which consists of a nickel-zinc plated thick cladding layer and a low-carbon steel strip which are tightly integrated, and can be used in chemical industry, machinery, communication device and other industries. The cold rolled low-carbon steel is deoiled; the deoiled cold rolled low-carbon steel strip is put in a solution tank, and plated with a zinc layer; the zinc-plated low-carbon steel strip is put in another solution tank to be plated with a nickel layer; the nickel-plated low-carbon steel strip is put in a third solution tank to be passivated; the temperature of the passivated plated nickel-zinc layer steel strip is preserved, and the hydrogen in the plated layer is removed; the plated nickel-zinc layer steel strip with hydrogen removed receives diffusion annealing treatment; the plated nickel-zinc layer steel strip after diffusion annealing receives distressing heat treatment, and the high interface strength plated nickel-zinc steel strip is obtained.

Owner:XIAMEN UNIV

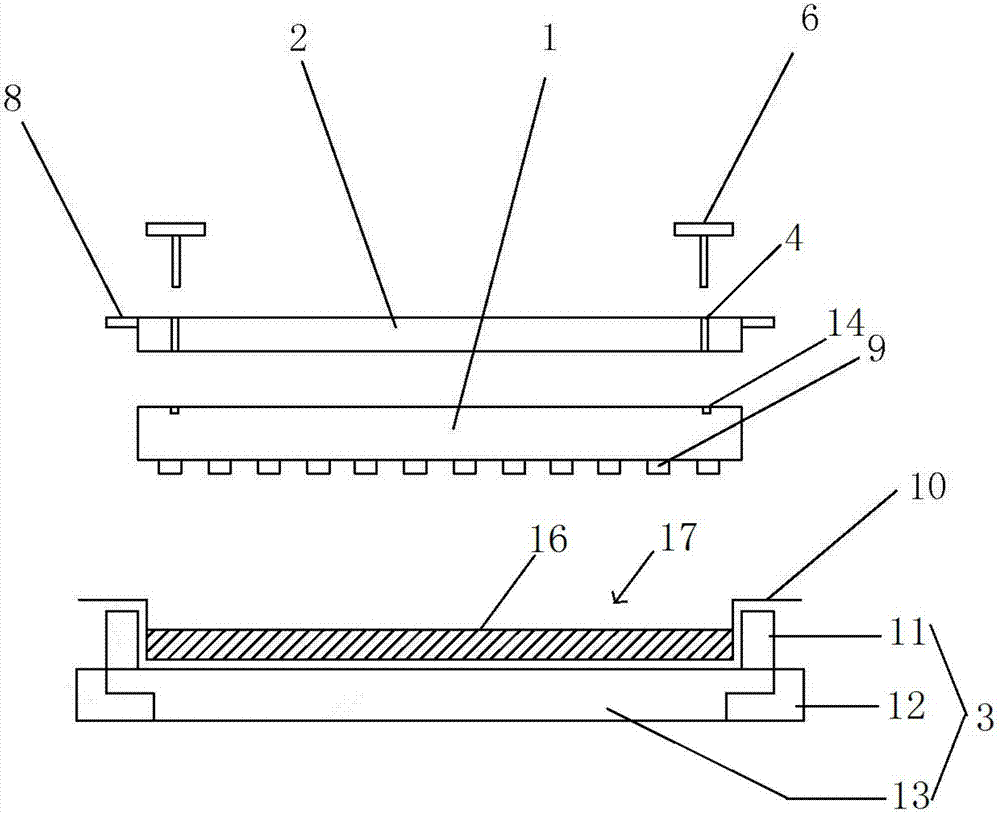

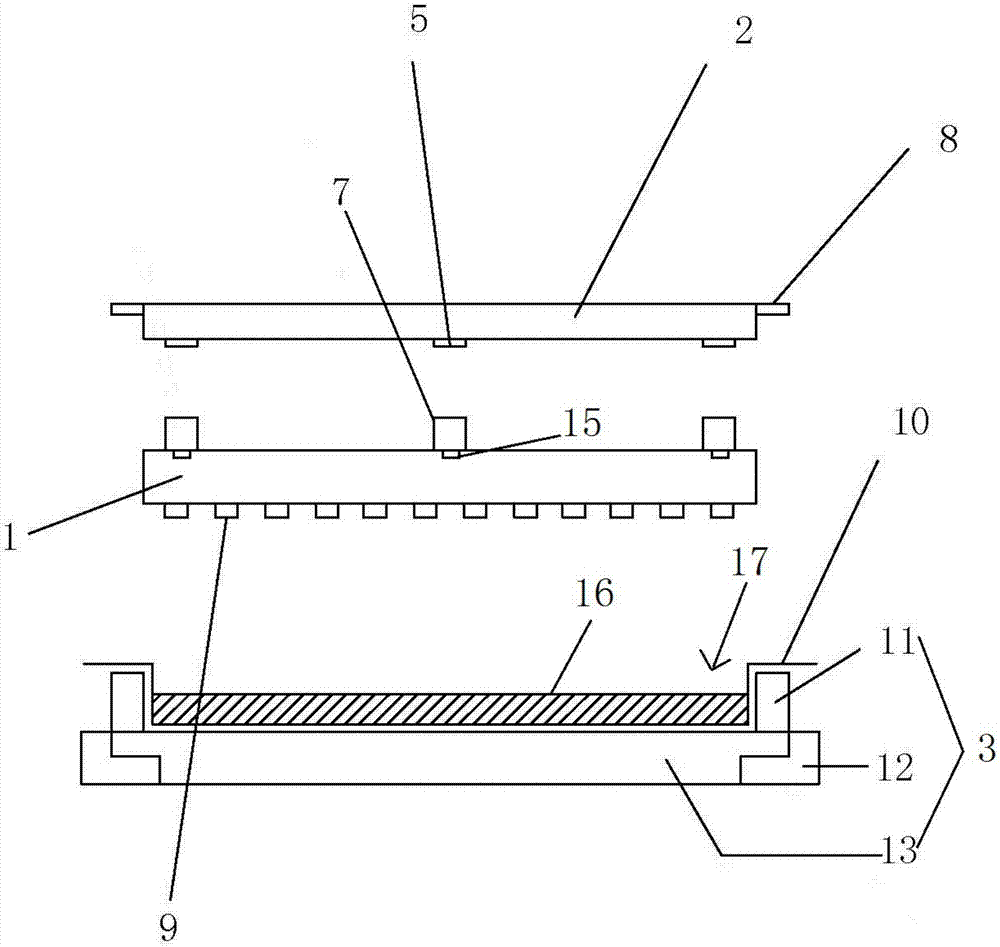

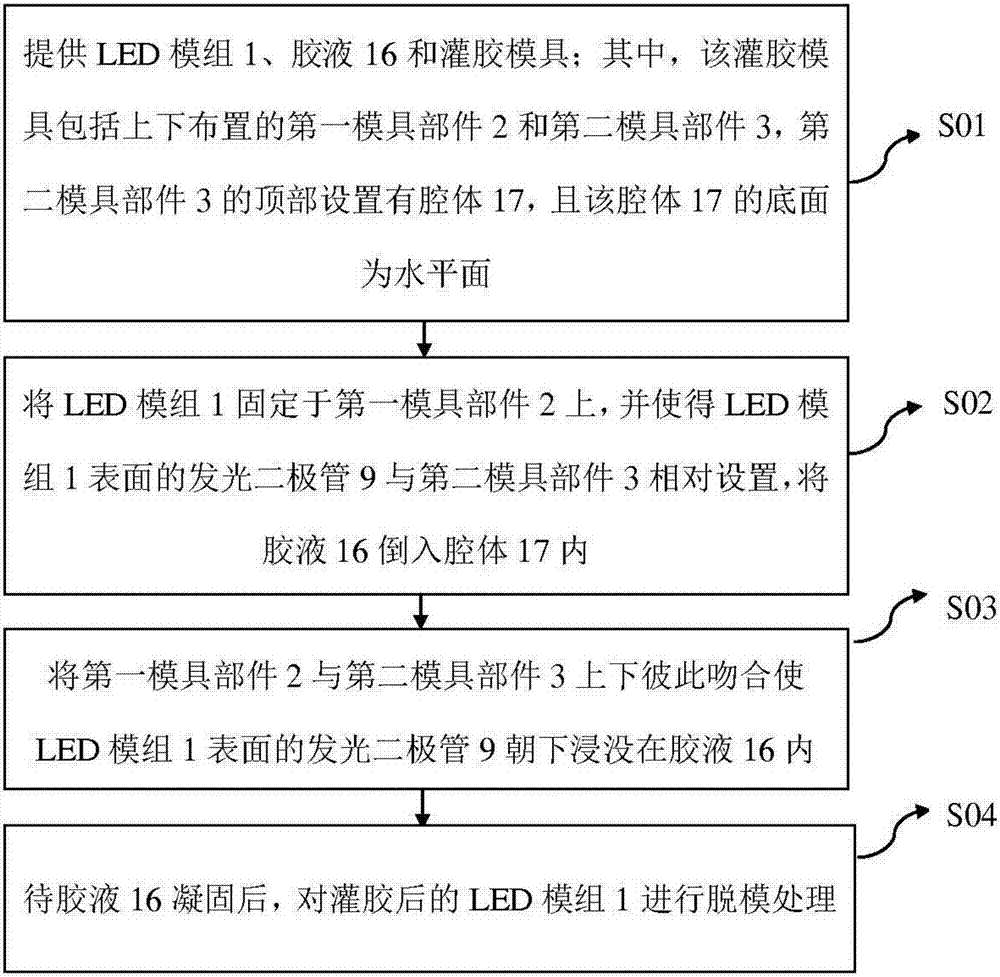

LED module and method for pouring glue on surface of LED module

ActiveCN107335581ASmooth surfaceGood protectionLiquid surface applicatorsCoatingsEngineeringLight-emitting diode

The invention belongs to the technical field of glue pouring, and particularly relates to an LED module and a method for pouring glue on the surface of the LED module. The method for pouring the glue on the surface of the LED module comprises the steps that the LED module, the glue and a glue pouring mold are provided, wherein the glue pouring mold comprises a first mold component and a second mold component which are arranged up and down, a cavity is formed in the top of the second mold component, and the bottom surface of the cavity is a horizon plane; the LED module is fixed to the first mold component, light-emitting diodes on the surface of the LED module are made opposite to the second mold component, and the glue is poured into the mold cavity; the first mold component and the second mold component are matched up and down, so that the light-emitting diodes on the surface of the LED module are made to be downwards immersed in the glue; and after the glue is solidified, the LED module is separated from the mold. According to the LED module and the method for pouring the glue on the surface of the LED module, the surface of a glue layer formed after glue pouring of the LED module is made smooth and flat, the light-emitting diodes are better protected, and polishing is not needed after glue pouring.

Owner:深圳市艾森视讯科技有限公司

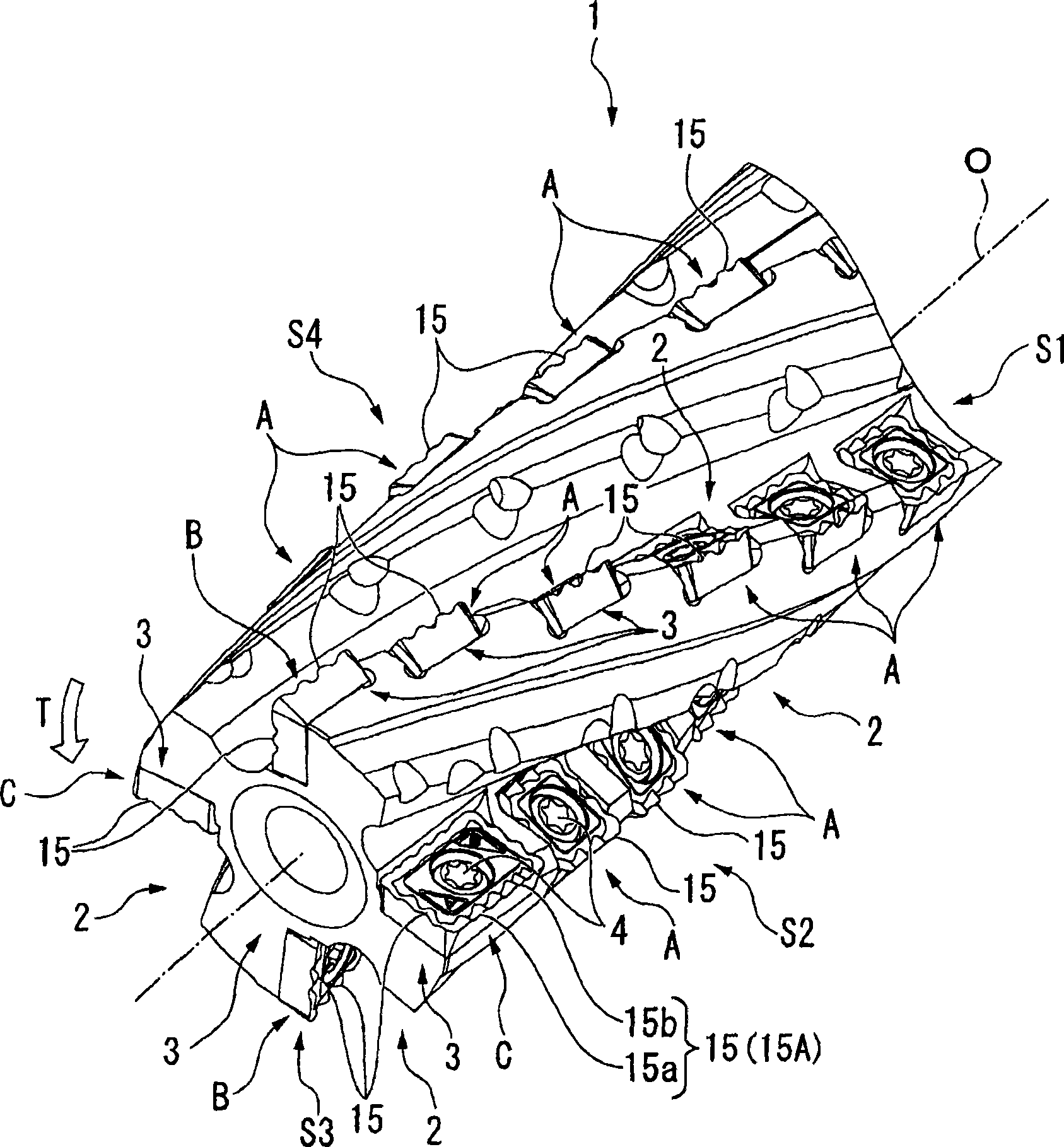

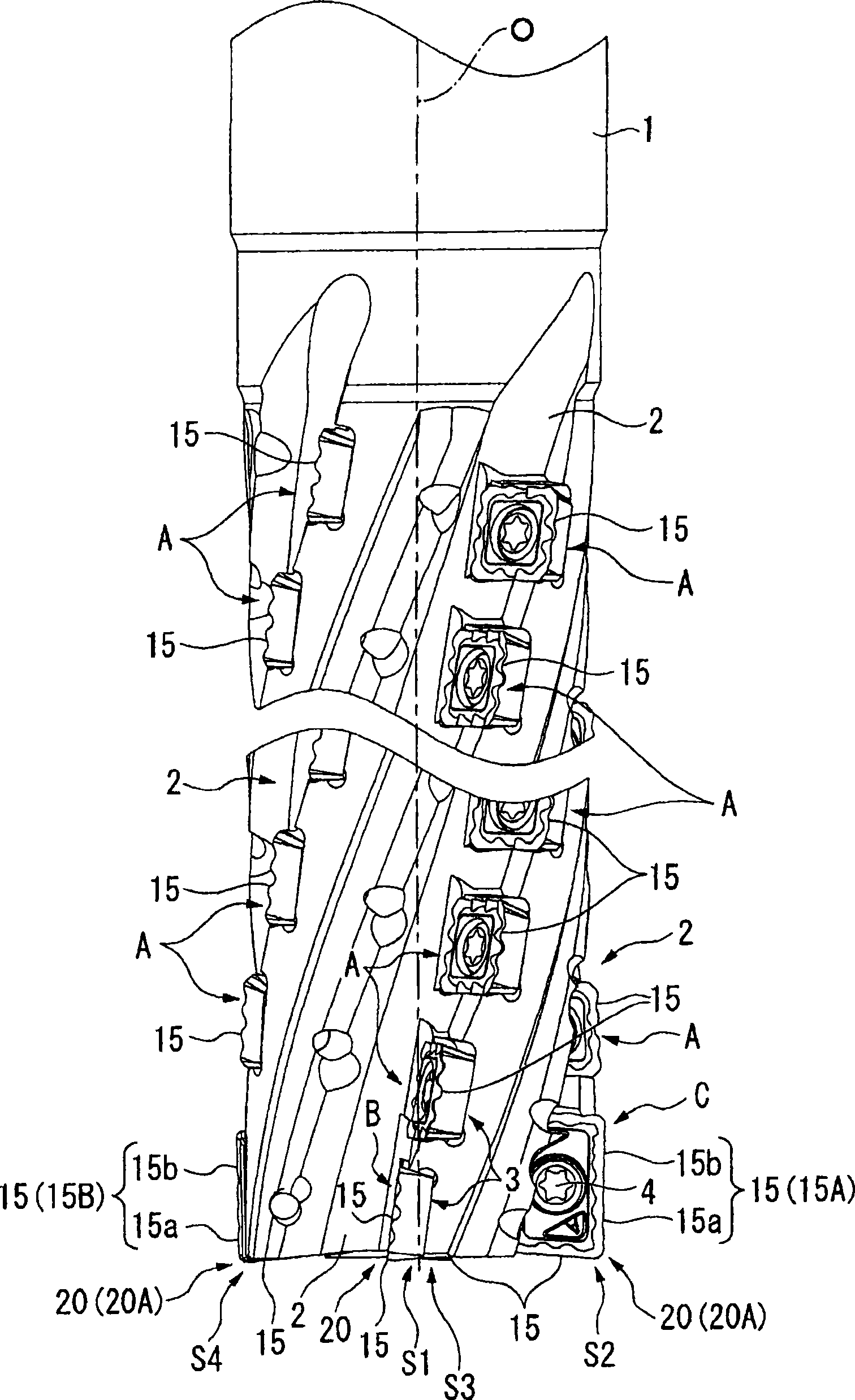

Insert for roughing and roughing end mill

InactiveCN101511514ASmooth cutInconsistent rotation trajectoryRectilinear broachMilling cuttersEngineeringReference line

This roughing insert is provided with an insert body, and a waveform cutting edge which is formed on an intersecting ridge line portion between a rake face and a flank face of the insert body, and which undulates along this intersecting ridge line portion. The waveform cutting edges are formed on the insert body respectively at positions which are rotationally symmetrical at predetermined angularintervals around a reference line of the insert bodies. These waveform cutting edges which are positioned rotationally symmetrically to each other are formed such that, when the insert bodies are rotated by the predetermined angle around the reference line, one or more portions of the waveform cutting edges do not match each other and are mutually asymmetrical.

Owner:MITSUBISHI MATERIALS CORP

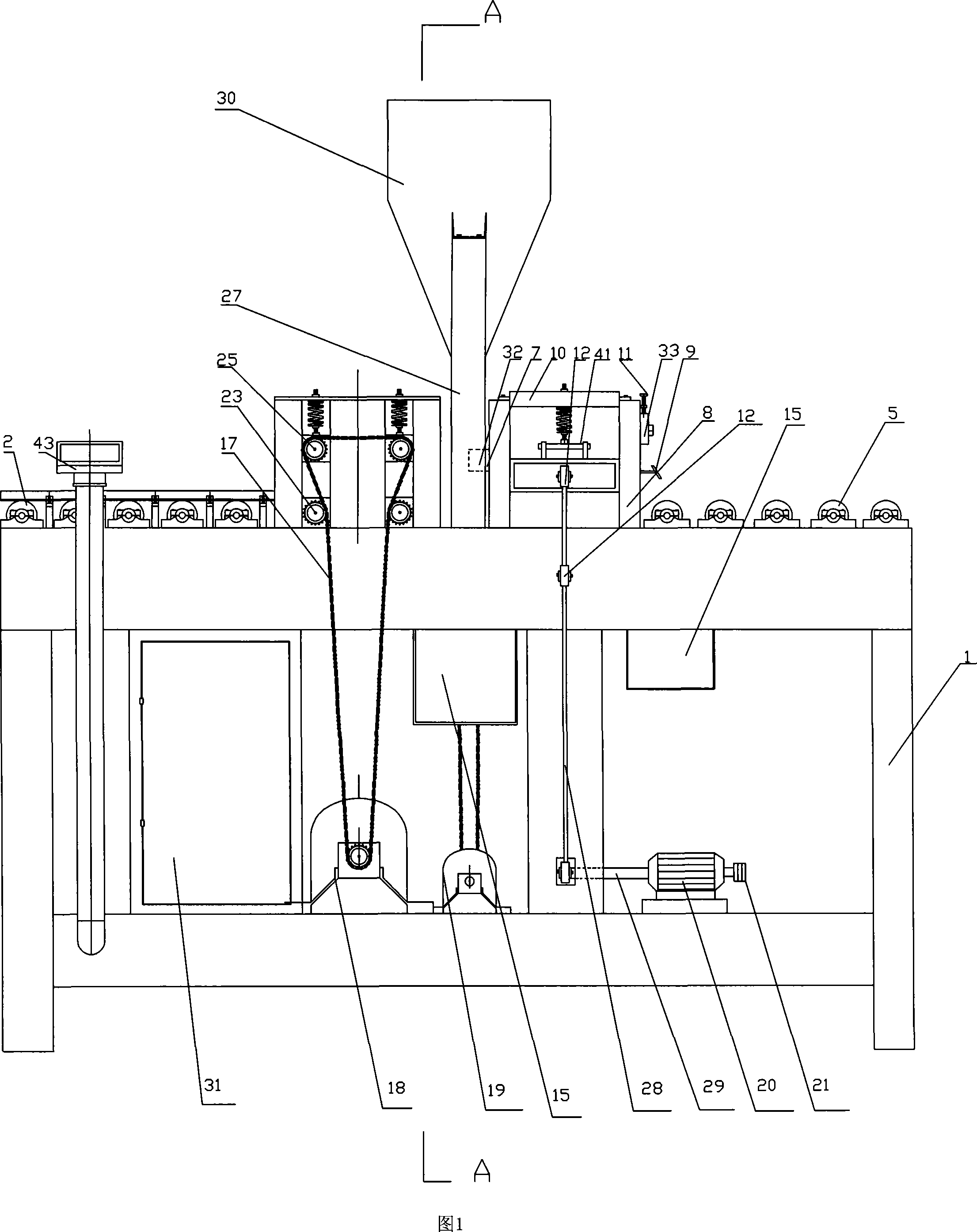

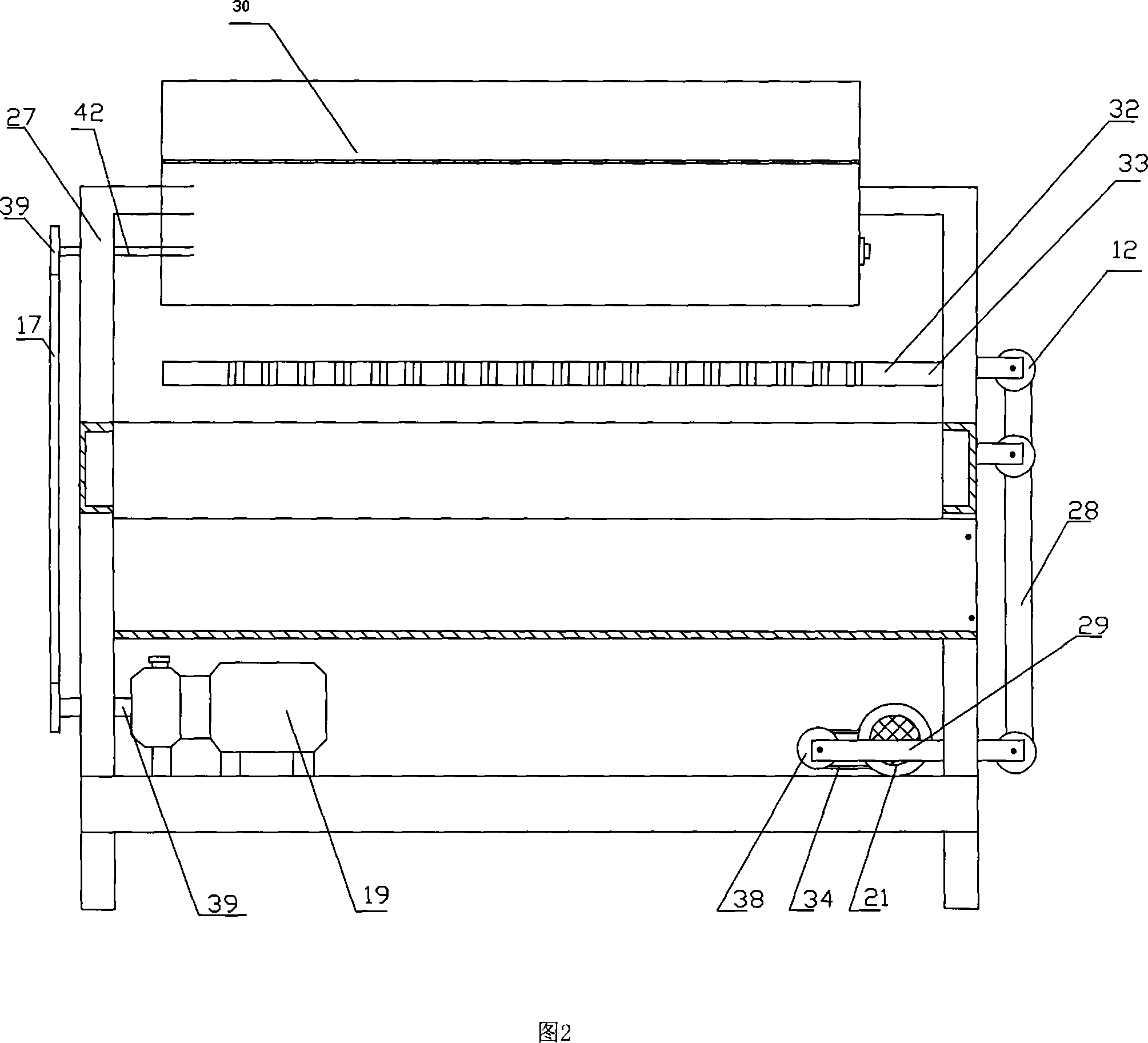

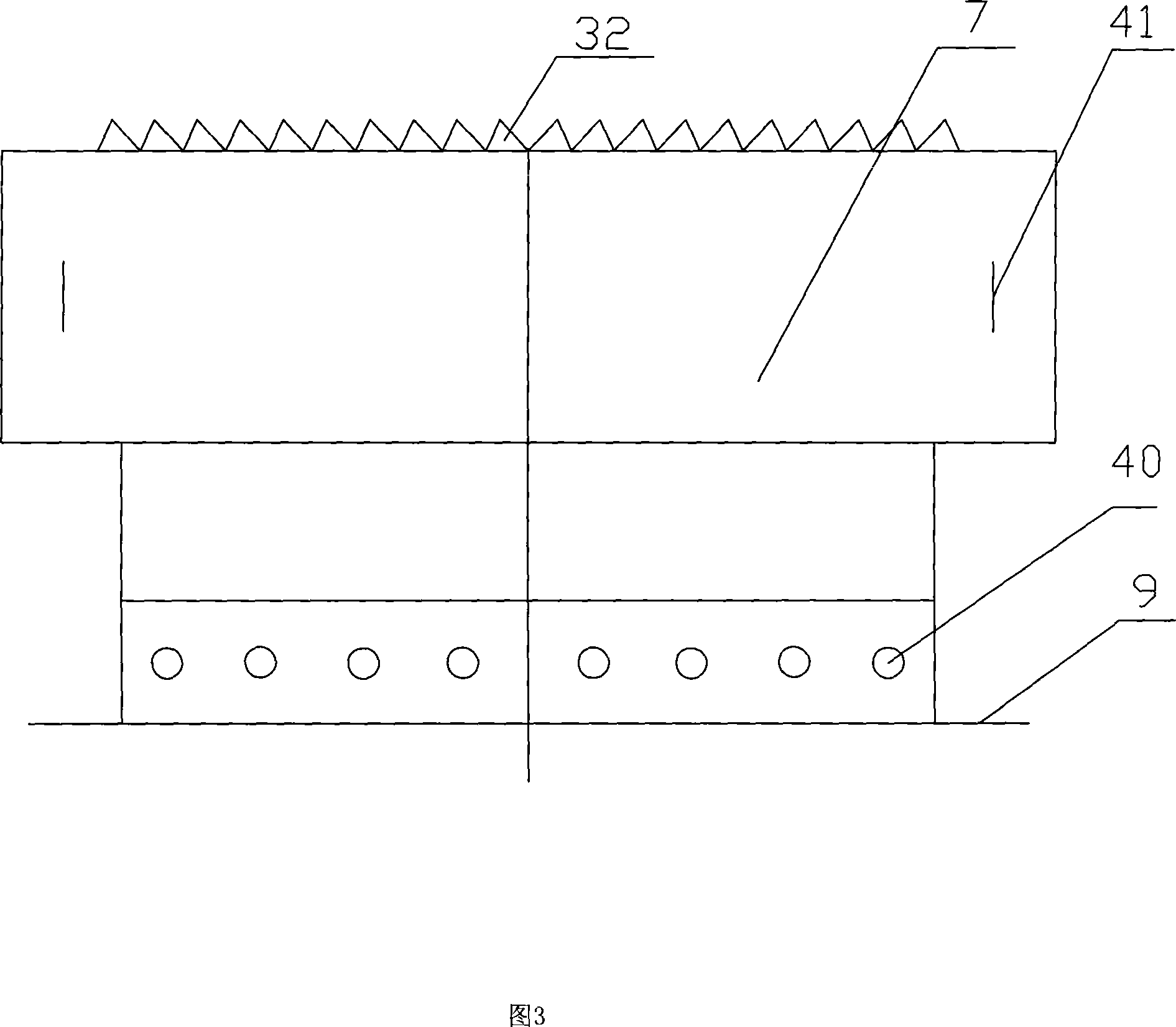

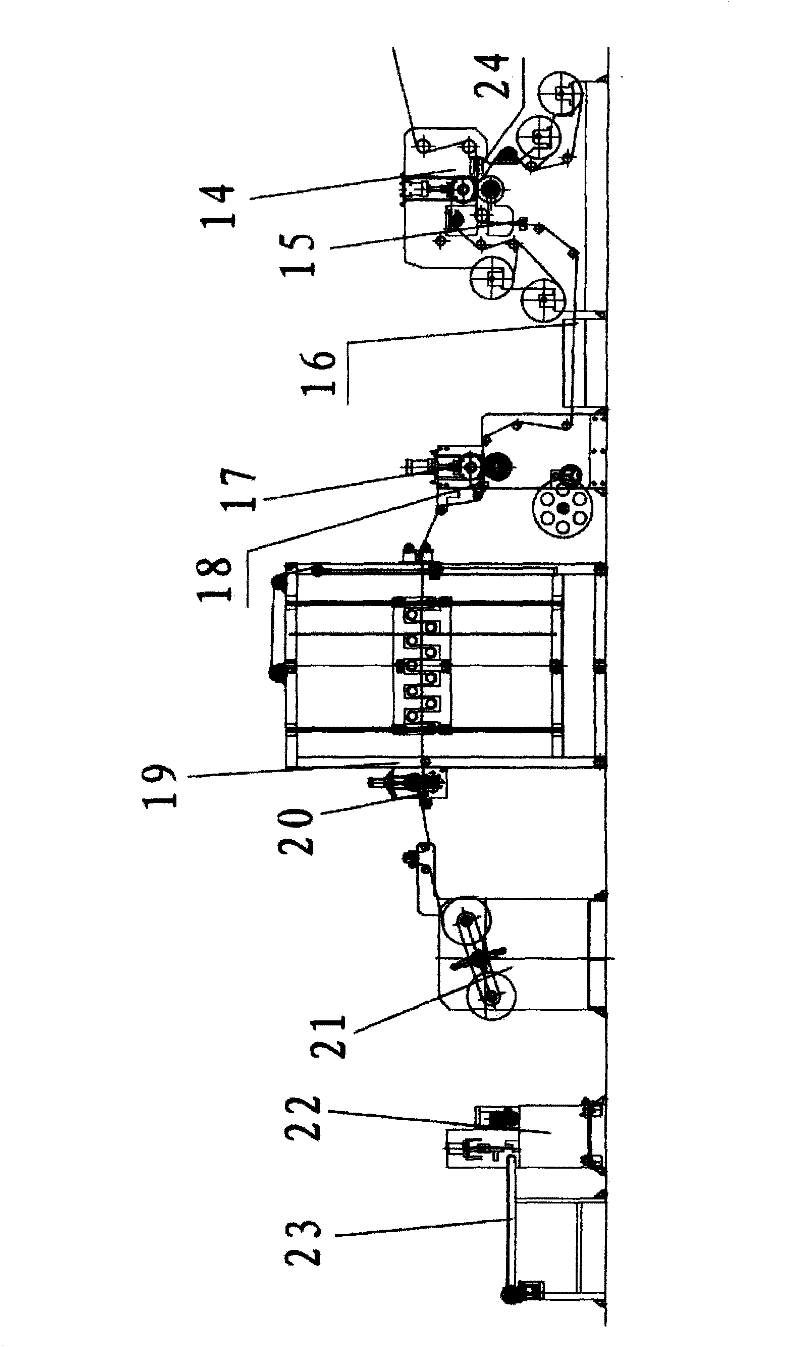

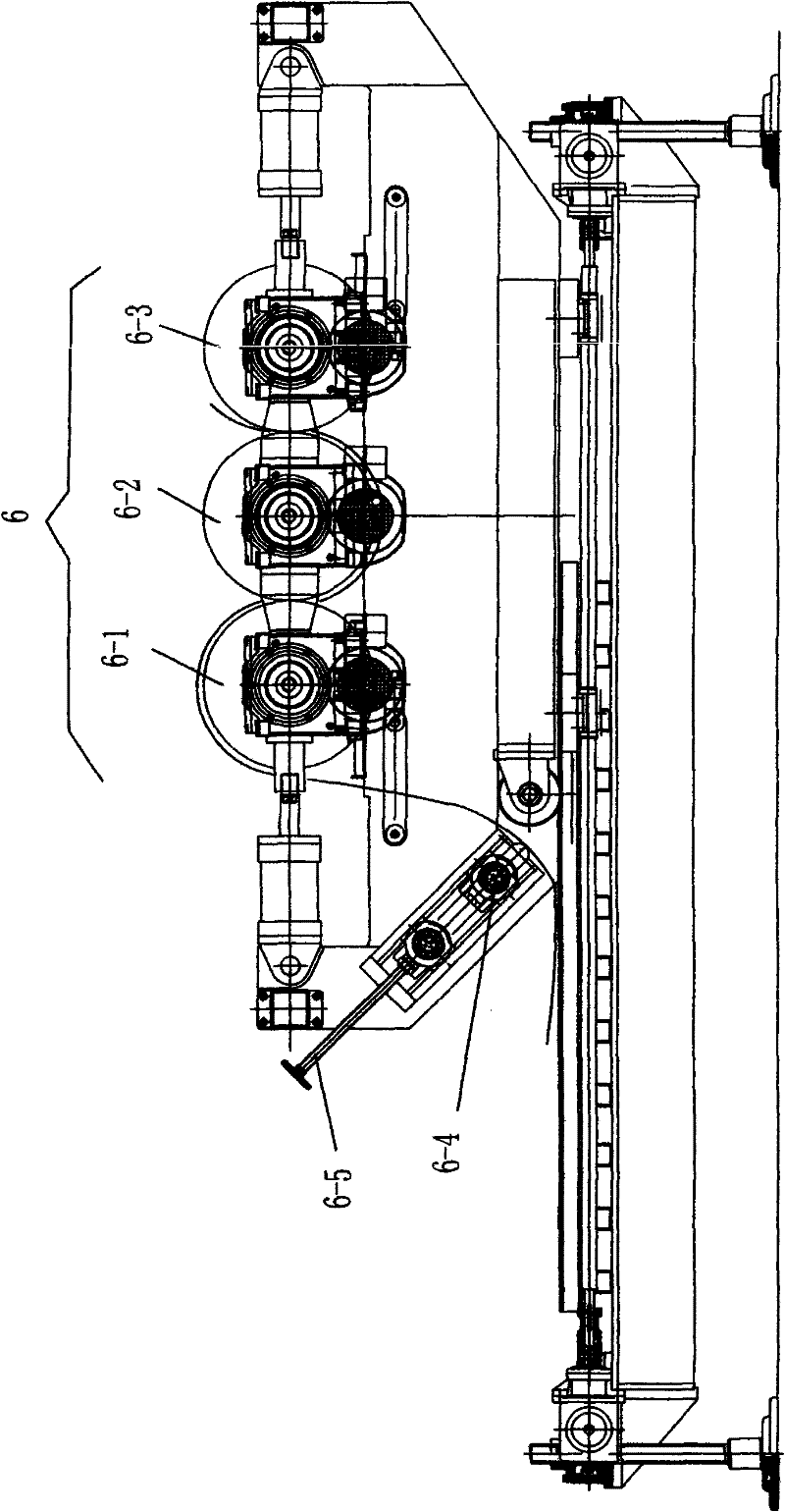

Smoothening machine for sheet material surface

InactiveCN101244575ASmooth surfaceSolve the shortage of putty workersIrregularity removal devicesLeveling effectEngineering

The invention relates to a paint-filler leveling machine for sheet surfaces, which comprises a frame, a feeding device, a scraper device of paint filler, a paint filler box, an electric cabinet and a control cabinet, wherein, the paint filler box is arranged on the frame; the feeding device is arranged in front of the paint filler box; the scraper device of paint filler is arranged behind the paint filler box; the electric cabinet and the control cabinet are arranged on the frame for controlling the feeding device. The paint-filler leveling machine has the advantages of good leveling effect with paint filler, completion at one time, high efficiency and good quality. The paint-filler leveling machine is suitable for block board slabs, block boards, triplex boards and multi-layer boards.

Owner:朱风汉

Fermentation milk of red beet and method for preparing same

InactiveCN1864501ADelicate and smooth tasteMilky and mellowMilk preparationMilk substitutesBifidobacteriumLiver and kidney

The present invention relates to fermented milk with red beet and its preparation process, and belongs to the field of milk product producing technology. The fermented milk with red beet is prepared with red beet, milk, soybean milk, tomato and carrot as main materials, and through adding corrective, stabilizer and flavoring agent, repeated deodorizing, and fermentation via adding bifidobacterium, lactic acid bacteria and other probiotics. The fermented milk with red beet is red, delicious and milk scented, and possesses the health functions of promoting digestion, expelling toxin, strengthening physique, nourishing liver and kidney, resisting cancer, resisting senility, etc.

Owner:章传华

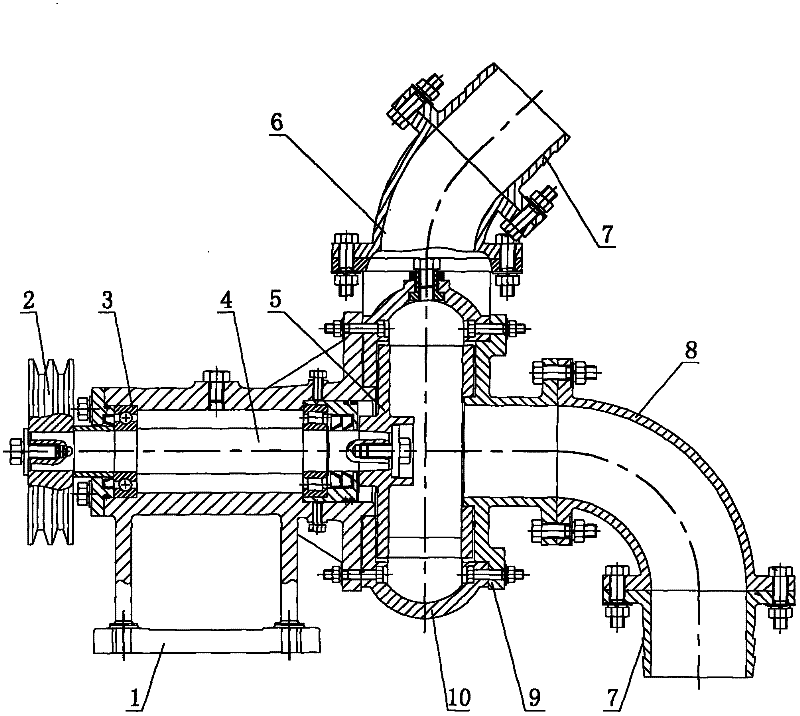

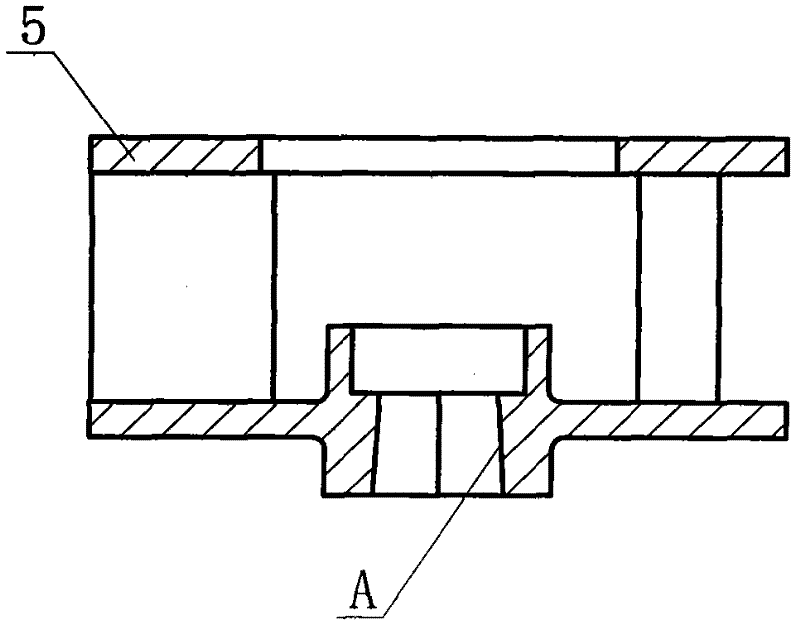

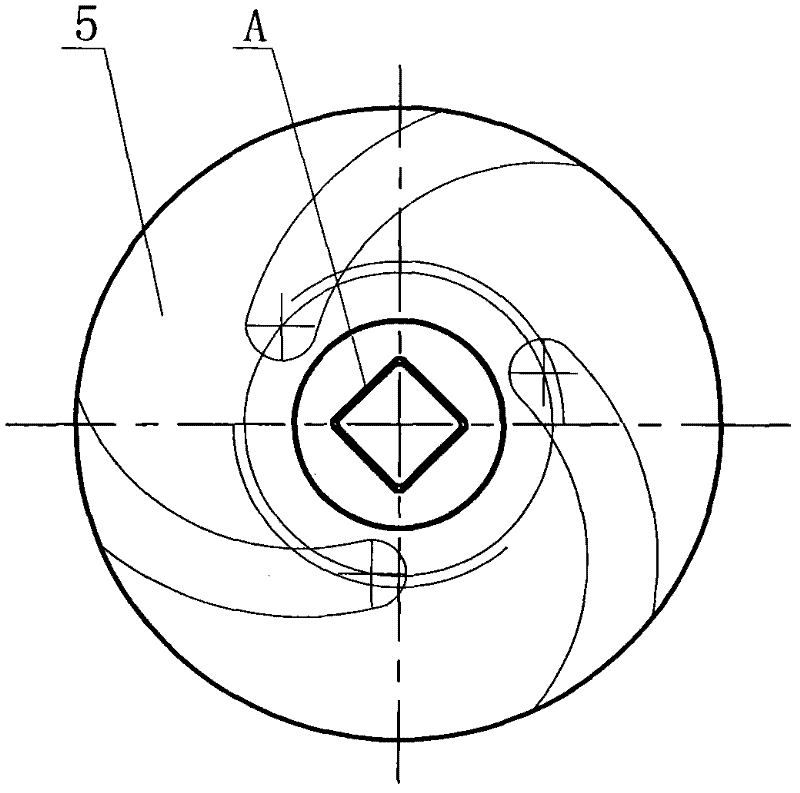

Wear-resisting sand pump and casting method thereof

InactiveCN102235365AQuality improvementGood surface accuracySpecific fluid pumpsFoundry mouldsImpellerDry sand

The invention discloses a method for casting a wear-resisting sand pump. In the wear-resisting sand pump, a pump impeller, a material inlet and a pump body are precisely cast by a vacuum lost mold; a shaft is connected with the pump impeller through an outer cone and an inner cone; and the outer cone and the inner cone are rectangular, prismatic or hexagonal and are fastened by screws. The precise casting method comprises the following process steps of: 1, partitioning a foam material to obtain main parts, and bonding by using an adhesion agent to obtain an integrated model of which the shape is consistent with the main shape of a casting; 2, coating a mica-based coating onto the outer surface of a foam model, and drying; 3, putting the dried foam model into a sand box, filling dry sand into the sand box, and performing three-dimensional oscillation compaction; 4, vacuumizing the sand box by using a vacuum system through negative pressure; 5, pouring molten metallic iron from the feeder head of the sand box to replace the position of a foam-molded model so as to obtain a corresponding main part of the sand pump; and 6, condensing. The wear-resisting sand pump has the characteristics of high casting quality, high surface precision, high rigidity, high wear-resisting property, environment friendliness and the like, and is sanitary, safe and reliable.

Owner:梁汉民

Extrusion production line for optical-grade transparent PC sheet

The invention relates to an extrusion production line for an optical-grade transparent PC sheet, which has a simple structure and high product quality and automation level, and is characterized by orderly comprising a dry loading device, an extruding machine for smelting solid granular PC raw materials into colloidal PC raw materials to be output, a screen-changing device for filtering impurities, a metering pump for quantitatively outputting the colloidal PC materials, a moulding mould for generating the sheets, a three-roller calendar for cleaning the surface of the sheet, a first traction system, a thickness gauge for detecting the thickness of the sheet, a second traction system, a laminating device, an anti-static device, a third traction system, a storage rack, a winder and a cutting machine. The finished PC sheet product achieves optical-grade transparence, and has the advantages of uniform quality, smooth surface and the like.

Owner:安徽嘉好机械制造有限公司

Preparation method of silver dollar-shaped aluminum pigment

ActiveCN102002266ASmooth surfaceNarrow particle size distributionPigment physical treatmentBall millSilver paste

The invention provides a preparation method of a silver dollar-shaped aluminum pigment, which is characterized by comprising the step of carrying out three-stage wet-method ball milling on D50 among aluminum powder with the diameter of 5-8 mum, wherein the diameters of milling balls is within 1.0-3.0 mm, milling balls with the density of 7.0-9.0 g / cm<3> is adopted in the first-stage ball milling,milling balls with the density of 5.0-6.9 g / cm<3> is adopted in the second-stage ball milling, and milling balls with the density of 2.0-4.0 g / cm<3> is adopted in the third-stage ball milling. The surfaces of particles in the tablet-shaped aluminum pigment produced with the method are smooth and clean so that the high glossiness, whiteness and metallic feel of an aluminum-silver paste product areensured.

Owner:长沙族兴新材料股份有限公司

Deplating method for carbon-based thin film on surface of metal workpiece

The invention discloses a deplating method for a carbon-based thin film on the surface of a metal workpiece. Oily pollutants on the surface of the steel-substrate workpiece are removed firstly; then the pretreated workpiece is fixed to a workpiece rack in a vacuum chamber of a vacuum coating system containing a hollow cathode ion source, a gas inlet pipeline for guiding in working gas is mounted, and oxygen plasma is obtained when oxygen is led in; and the surface of the sample is bombarded by the oxygen plasma generated by the ion source, and then the workpiece separated from the carbon-based coating is soaked in a faintly-acid soak solution and then cleanly rinsed. The carbon-based coating can be completely stripped off in the oxygen plasma bombarding process, and the stripping speed can reach 0.5-1.0 micron / h; due to oxidation protection in the carbon-based surface layer stripping process, the positions where the coating is abraded or stripped are protected, and excessive etching of the positions cannot be caused by the proper oxygen ion density and energy.

Owner:广州今泰科技股份有限公司 +1

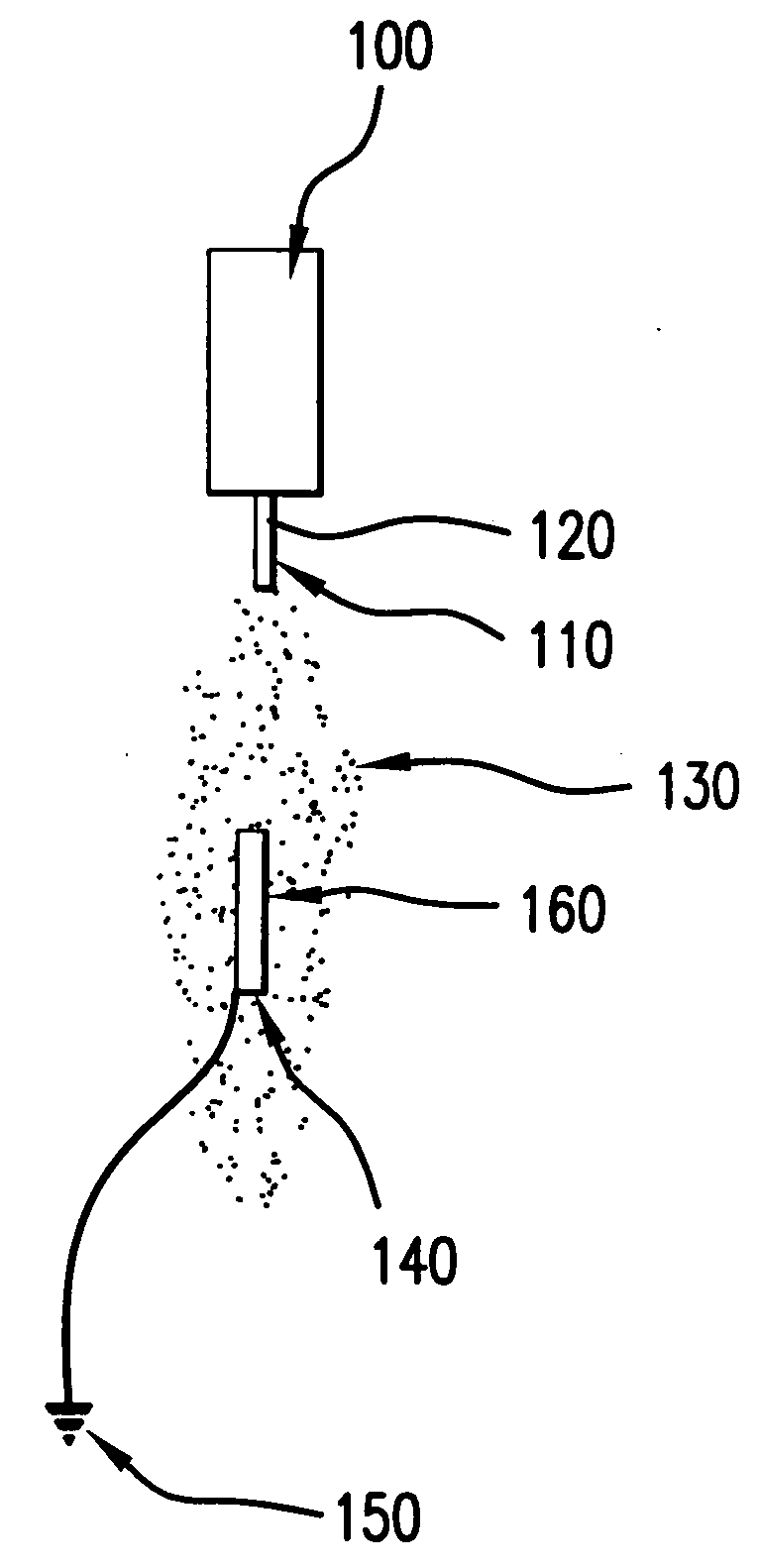

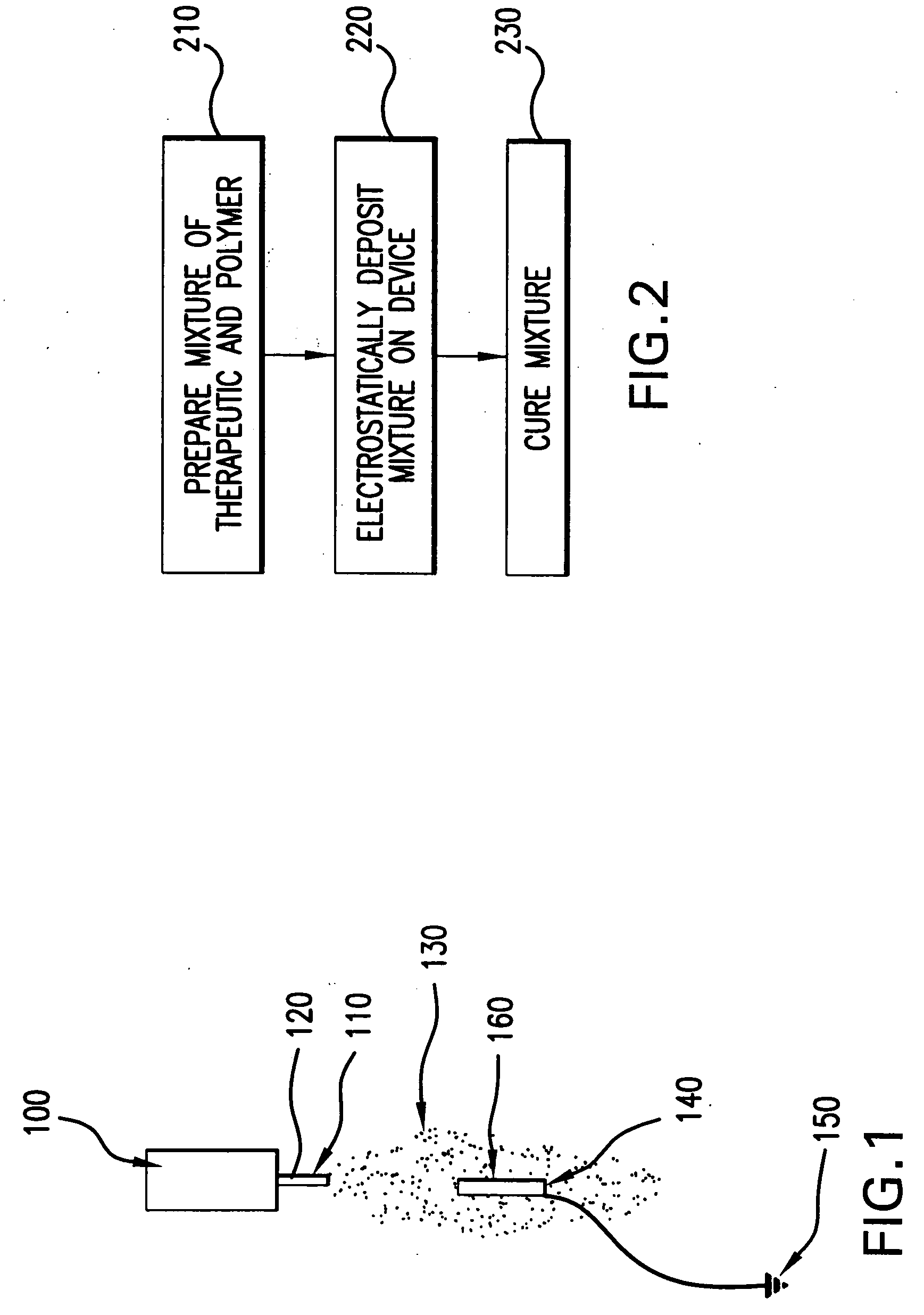

Method of improving the quality and performance of a coating on a coated medical device using a solvent to reflow the coating

A method is provided for coating at least a portion of at least one medical device. The method includes arranging a polymer on the portion of the medical device, arranging a bioactive agent on the portion of the medical device, and spraying, subsequent to the arranging of the polymer and the arranging of the bioactive agent, a solvent on the portion of the medical device. The method may further include selecting a composition of the solvent to achieve a desired agent release response profile for the medical device. A medical appliance is provided having a coating applied by a method that includes arranging a polymer on the portion of the medical device, arranging a bioactive agent on the portion of the medical device, and subsequently spraying a solvent on the portion of the medical device. A method is provided for achieving a desired agent release response profile for a medical device by reflowing the coating with a solvent.

Owner:BOSTON SCI SCIMED INC

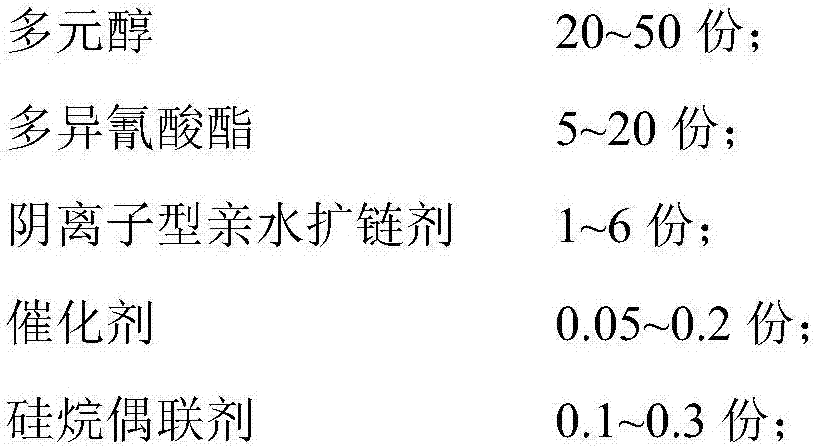

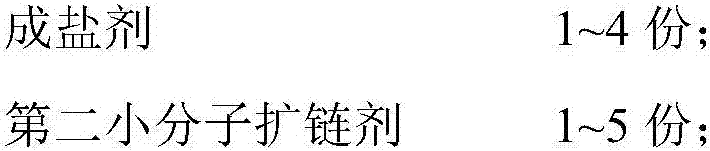

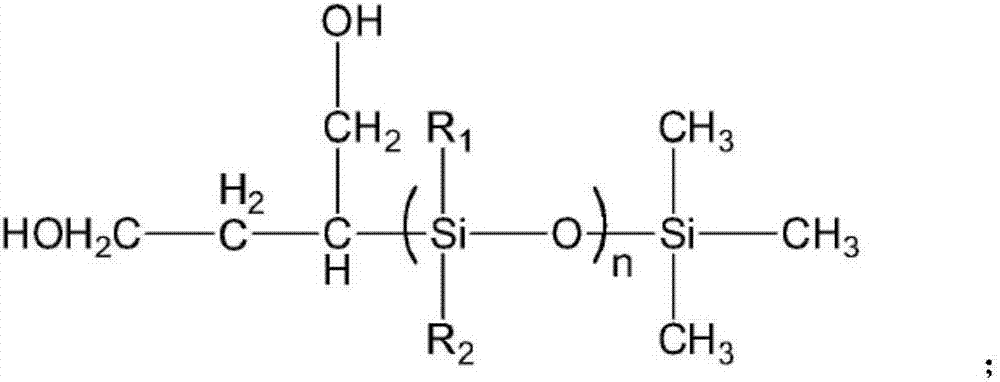

Waterborne polyurethane resin for synthetic leather fabric and preparation method of waterborne polyurethane resin

The invention provides waterborne polyurethane resin for a synthetic leather fabric and a preparation method of the waterborne polyurethane resin. The waterborne polyurethane resin is prepared from the following raw material components in parts by weight: 20 to 50 parts of polyhydric alcohols, 5 to 20 parts of polyisocyanate, 1 to 6 parts of an anionic hydrophilic chain-extending agent, 0.05 to 0.2 part of a catalyst, 0.1 to 0.3 part of a silane coupling agent, 1 to 4 parts of a salt-forming agent and 1 to 5 parts of a second small molecule chain-extending agent, wherein the polyhydric alcohols comprise hydroxyl-terminated polysiloxanediol, polytetrahydrofuran polyol and polycarbonate diol; the weight ratio of the hydroxyl-terminated polysiloxanediol to the polytetrahydrofuran polyol to the polycarbonate diol is (2 to 6) to (10 to 25) to (18 to 30). The waterborne polyurethane resin obtained by the preparation method provided by the invention has the advantages of good alcohol resistance, good normal temperature folding resistance and good wear resistance; a production process of the preparation method provided by the invention is simple; a large amount of toxic or harmful organic solvents in the production process are avoided, so environmental protection and physical and psychological health of a human body are benefited.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com