Insert for roughing and roughing end mill

A technology of inserts and bodies, applied in the field of insert-detachable roughing end mills, can solve the problems of inconsistent cutting edge rotation trajectories, inconsistent waveform rotation trajectories, inconsistent mutual rotation trajectories, etc., to achieve cutting force, cutting resistance, The effect of surface roughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

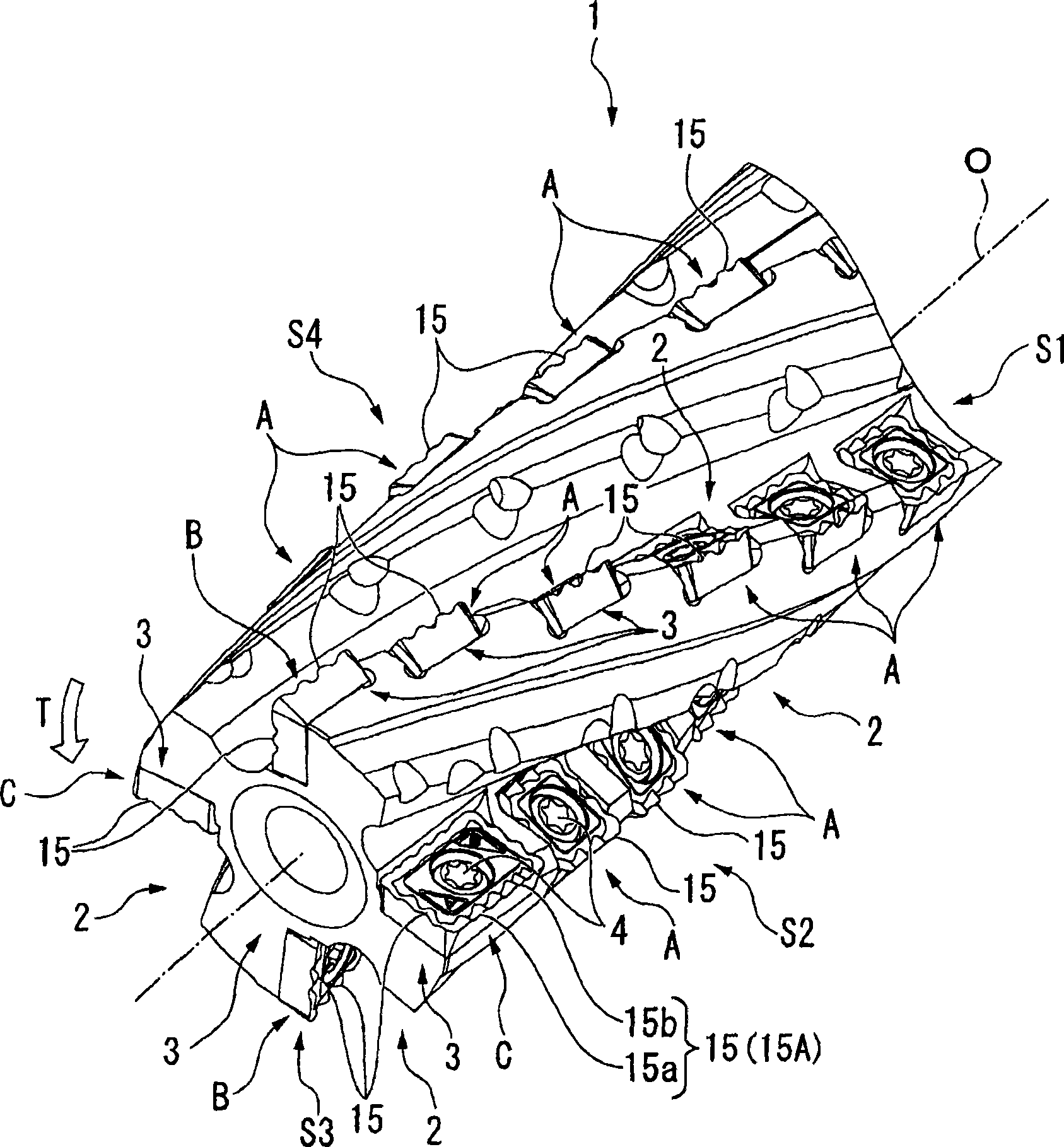

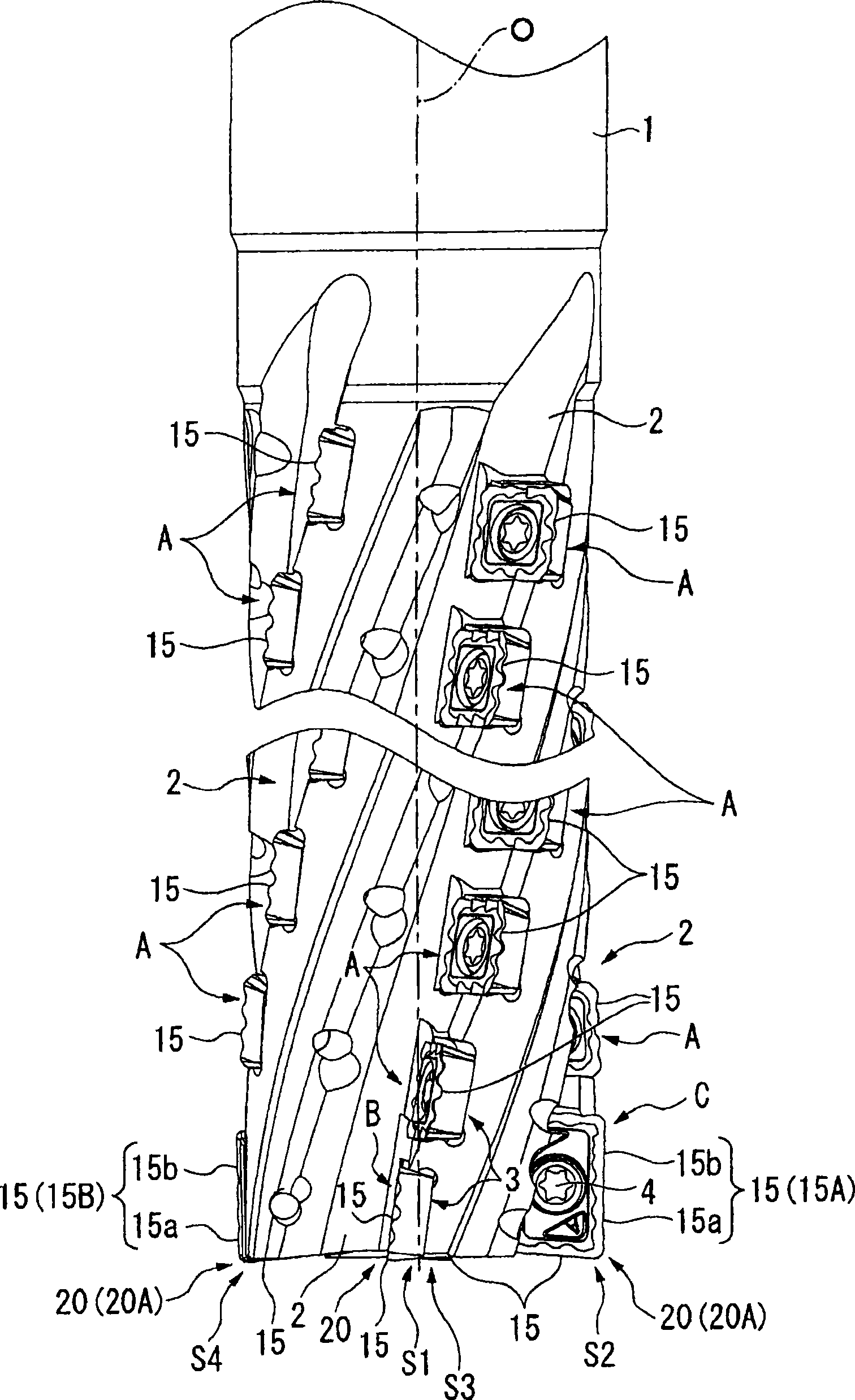

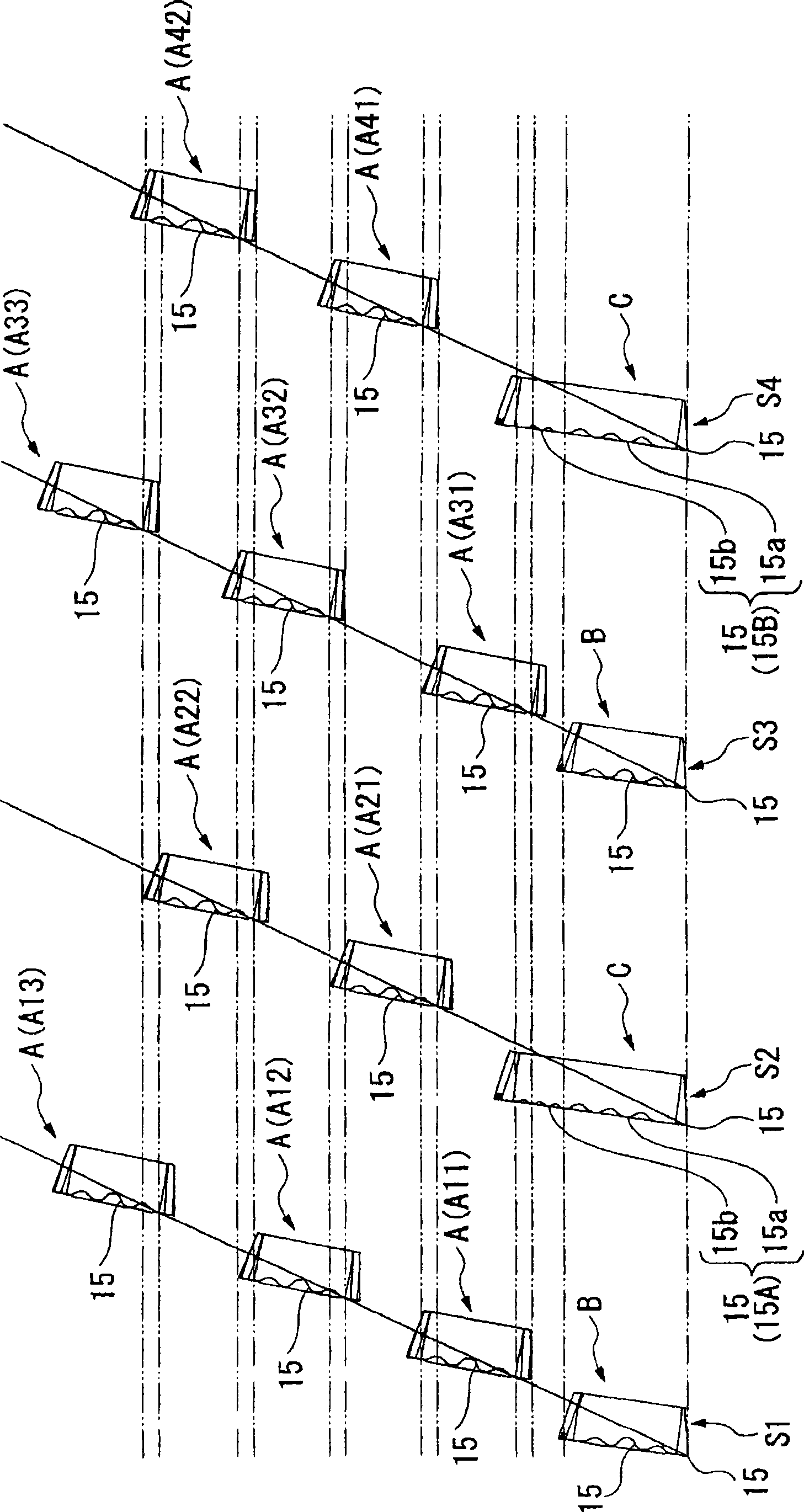

[0057] Figure 1 to Figure 3 One embodiment of the roughing end mill of the present invention is shown. Figure 4 to Figure 8 Blade A shown, Figure 9 to Figure 13 Blade B shown, Figure 14 to Figure 19 The shown insert C is detachably attached to this rough machining end mill, and the insert C is an insert for rough machining according to one embodiment of the present invention. In addition, the other inserts A and B are also inserts for rough machining having wave-shaped cutting edges.

[0058] In the rough machining end mill of this embodiment, the end mill body 1 is formed of steel or the like, and has a substantially cylindrical shape centered on the axis 0. On the outer periphery of the tip part, several lines are formed at equal intervals in the circumferential direction. (Four in this embodiment) Helical chip discharge flutes 2. These chip discharge flutes 2 follow from the front end of the end mill body 1 toward the rear end side in the axis O direction ( figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com