Patents

Literature

1367results about "Milling cutting inserts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

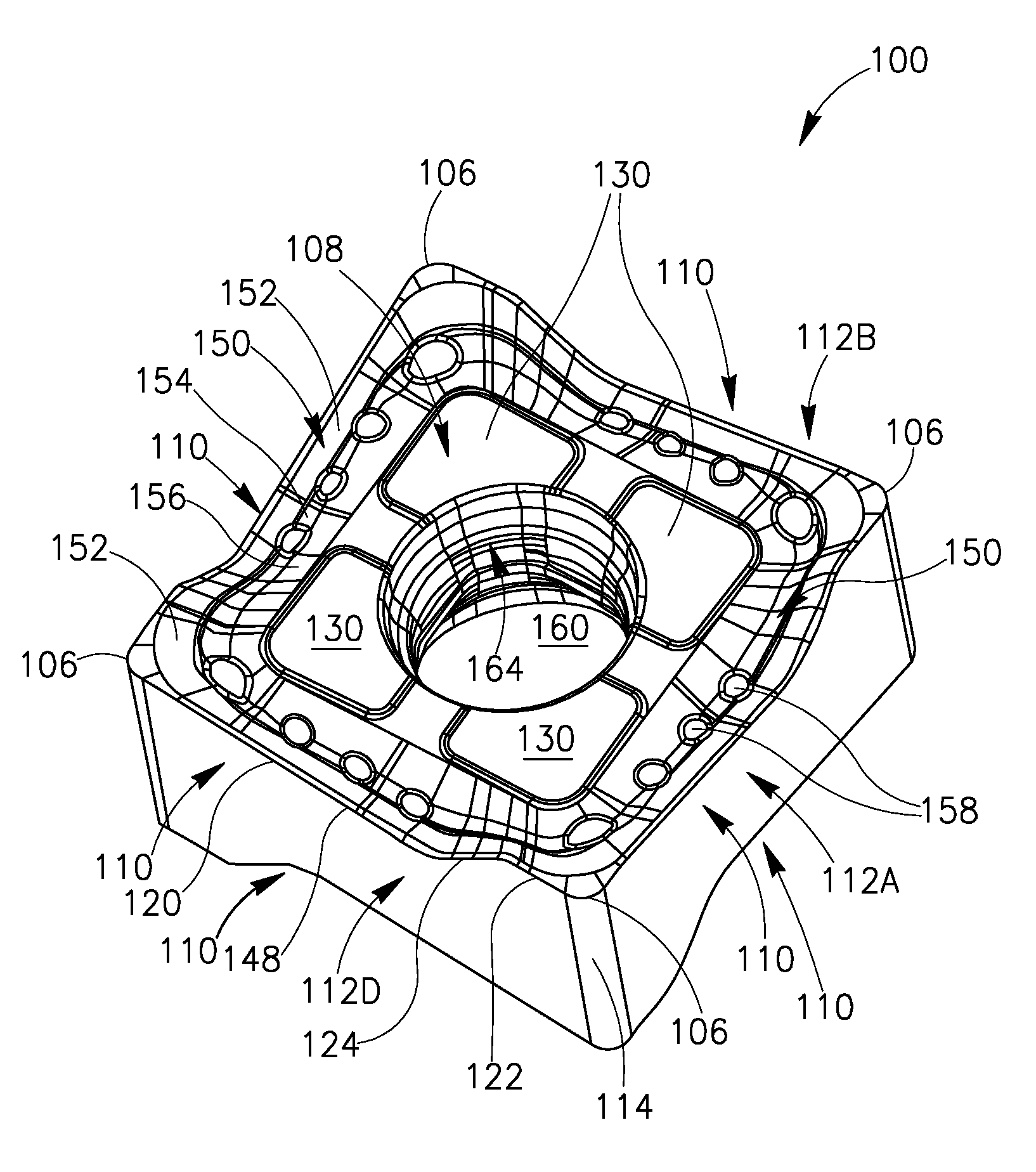

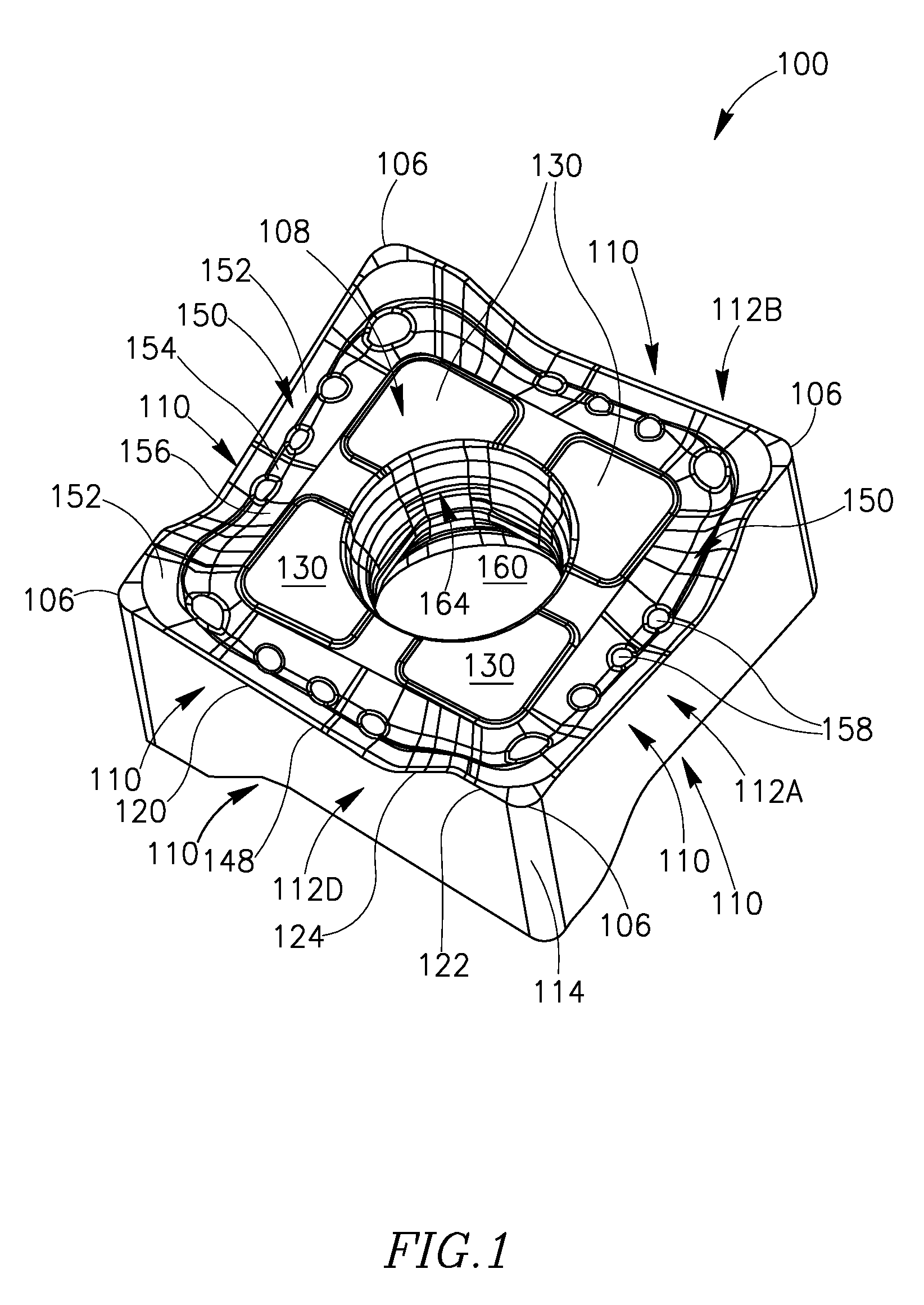

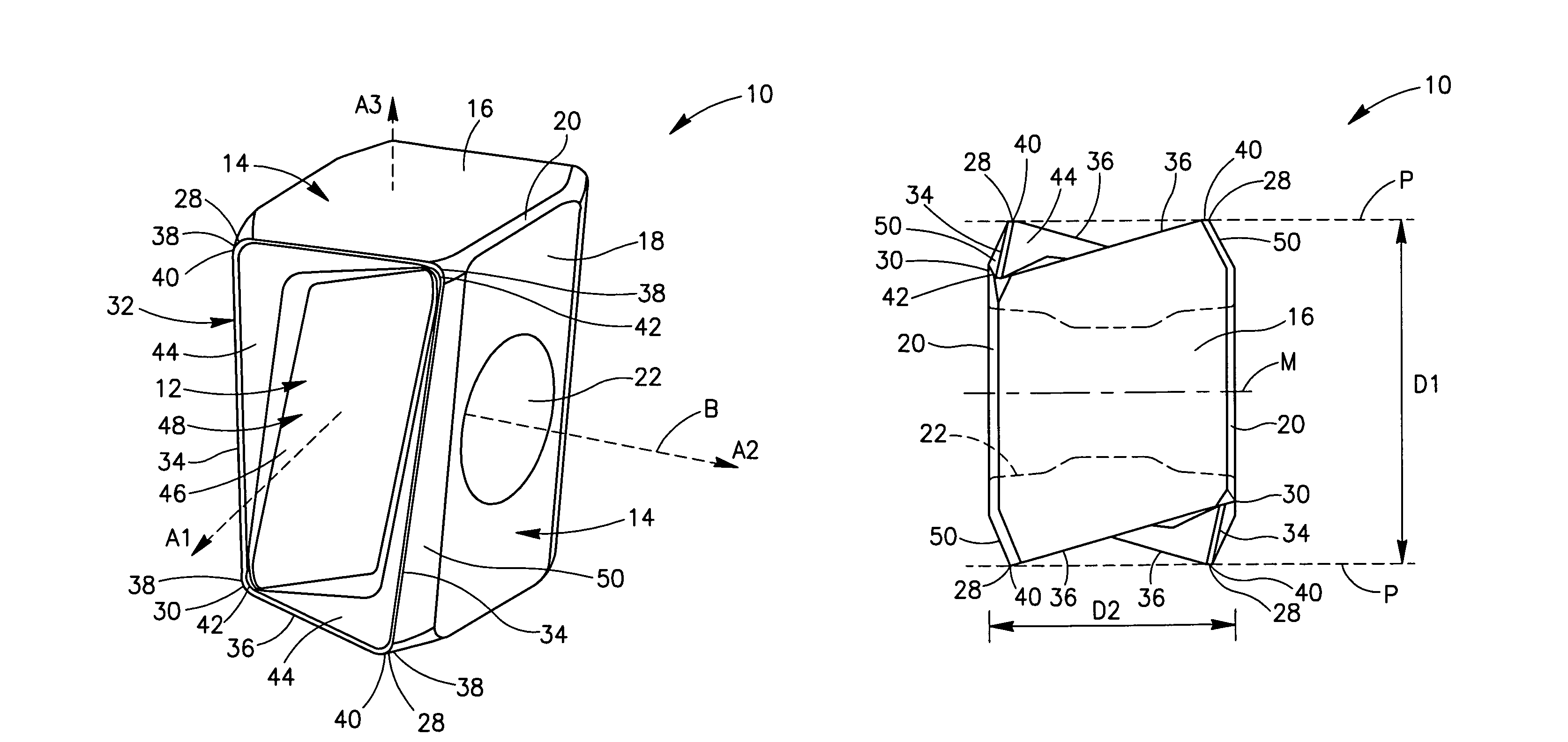

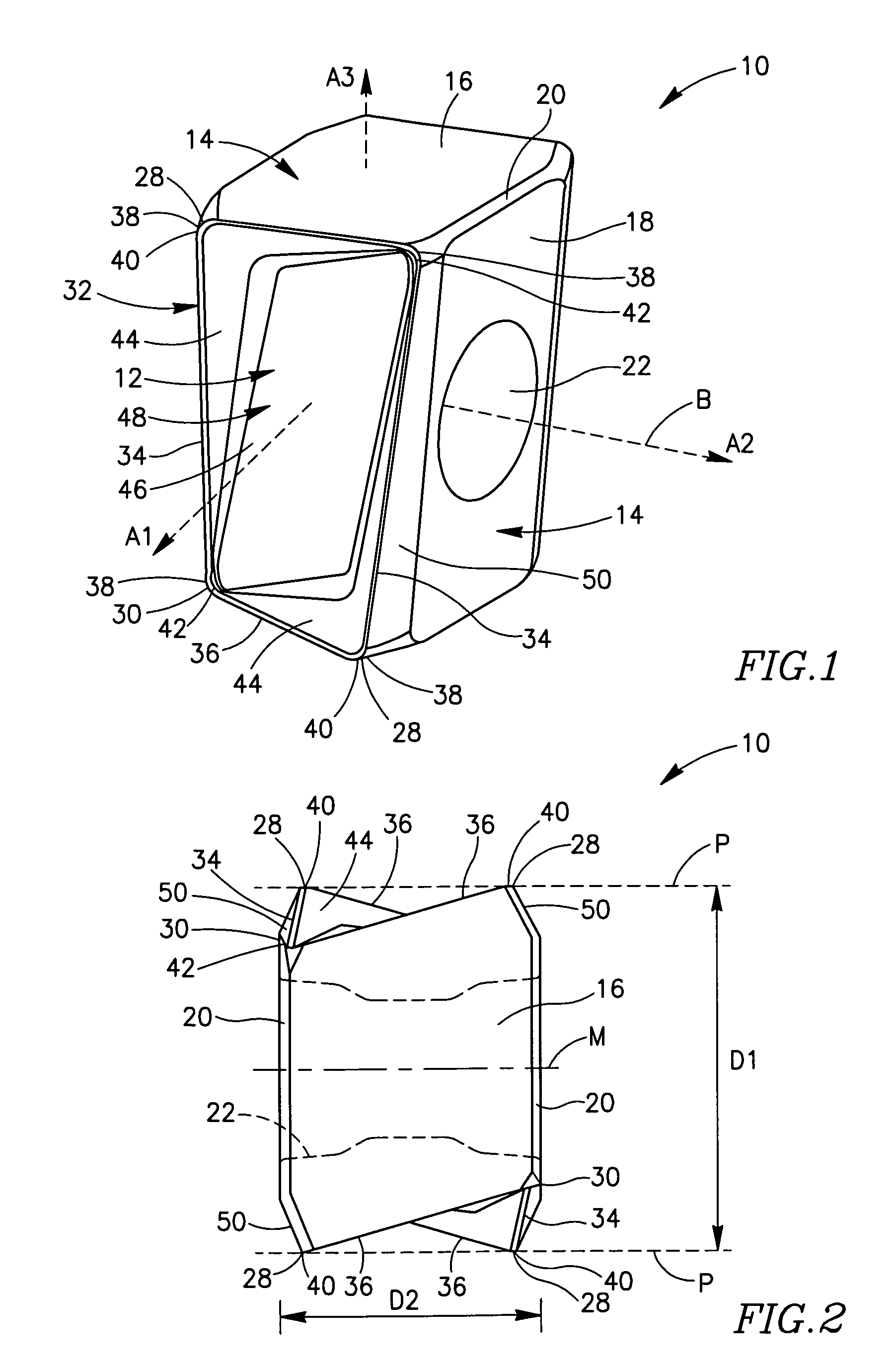

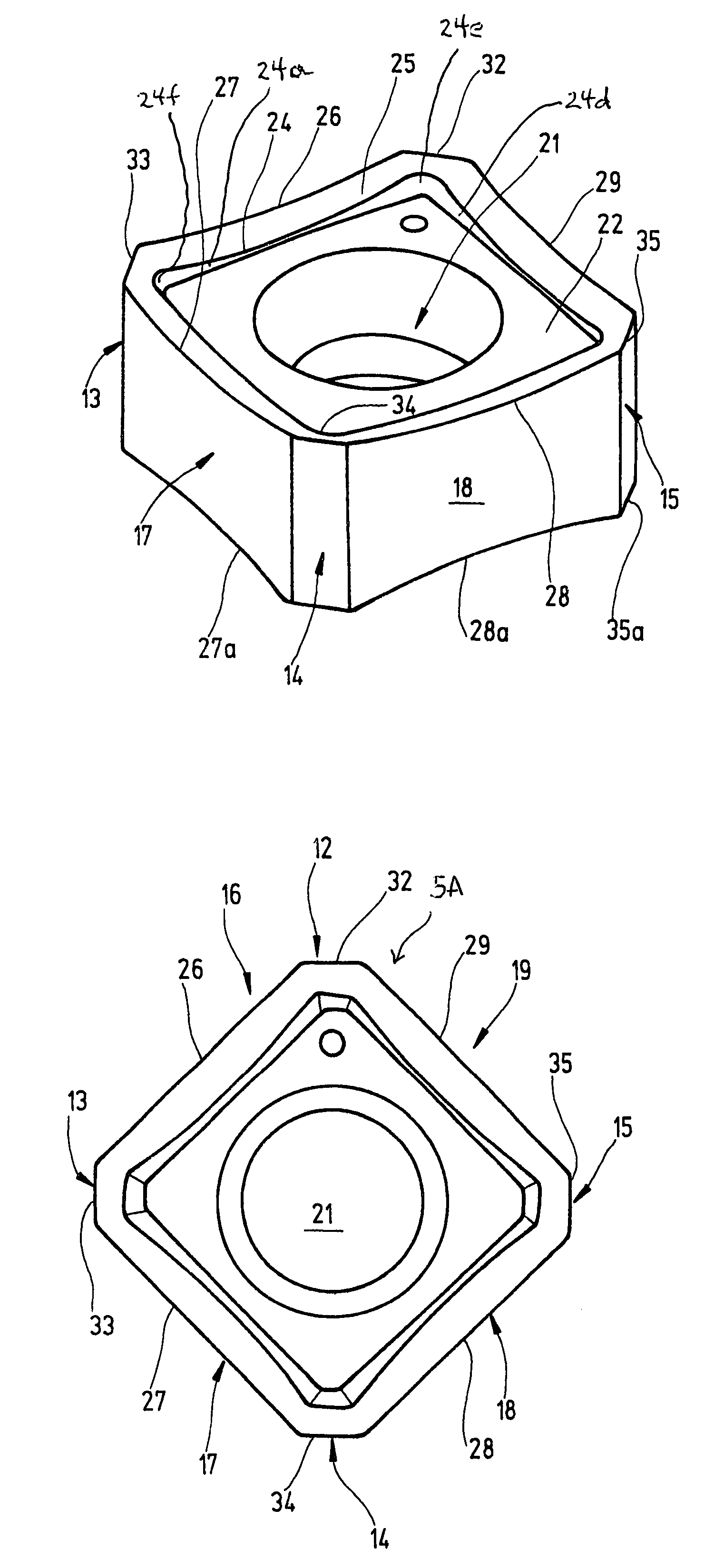

Cutting Insert for a Milling Cutter

ActiveUS20080232912A1Clearance can be providedMilling cuttersShaping cuttersMilling cutterEngineering

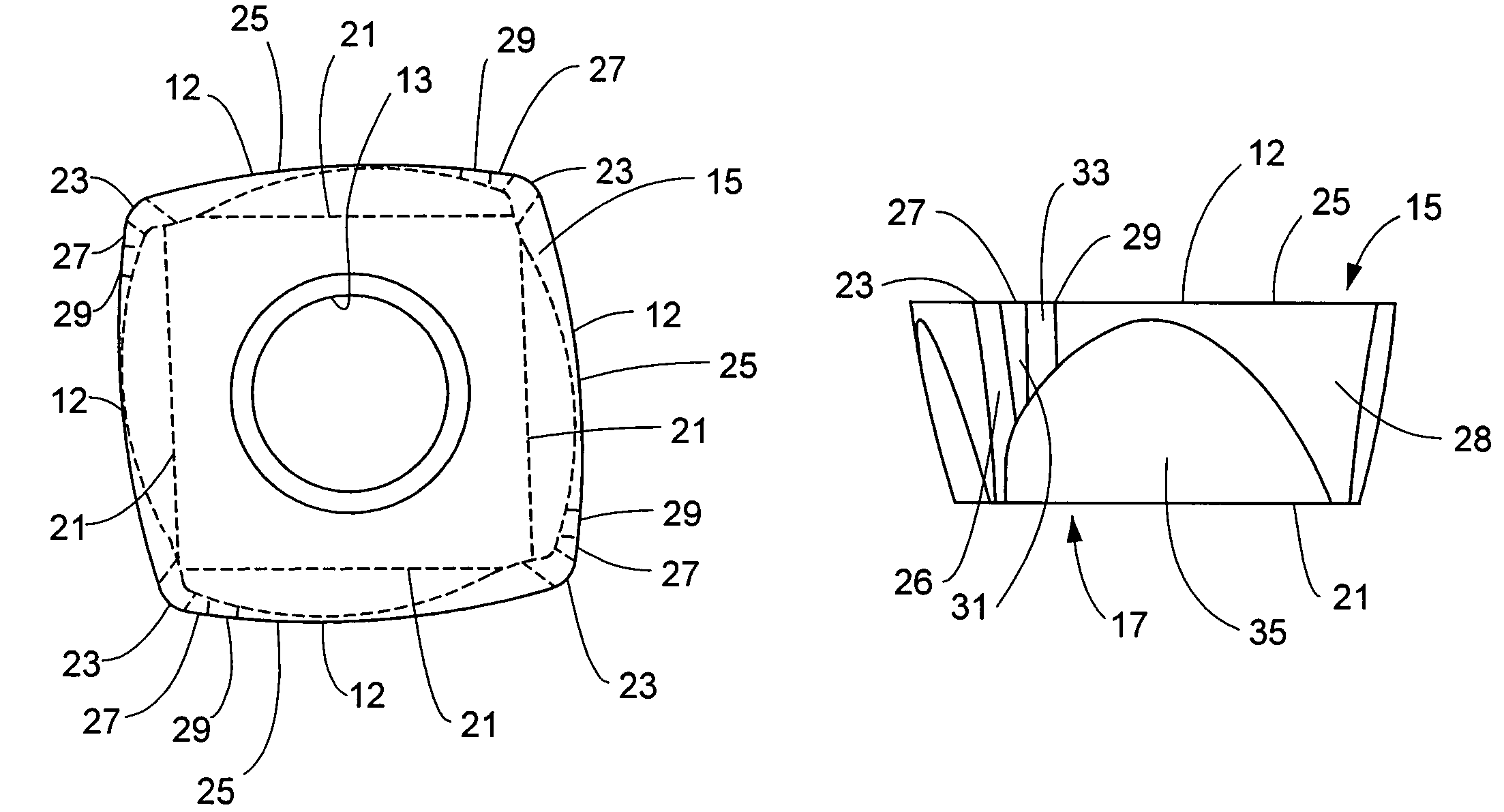

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

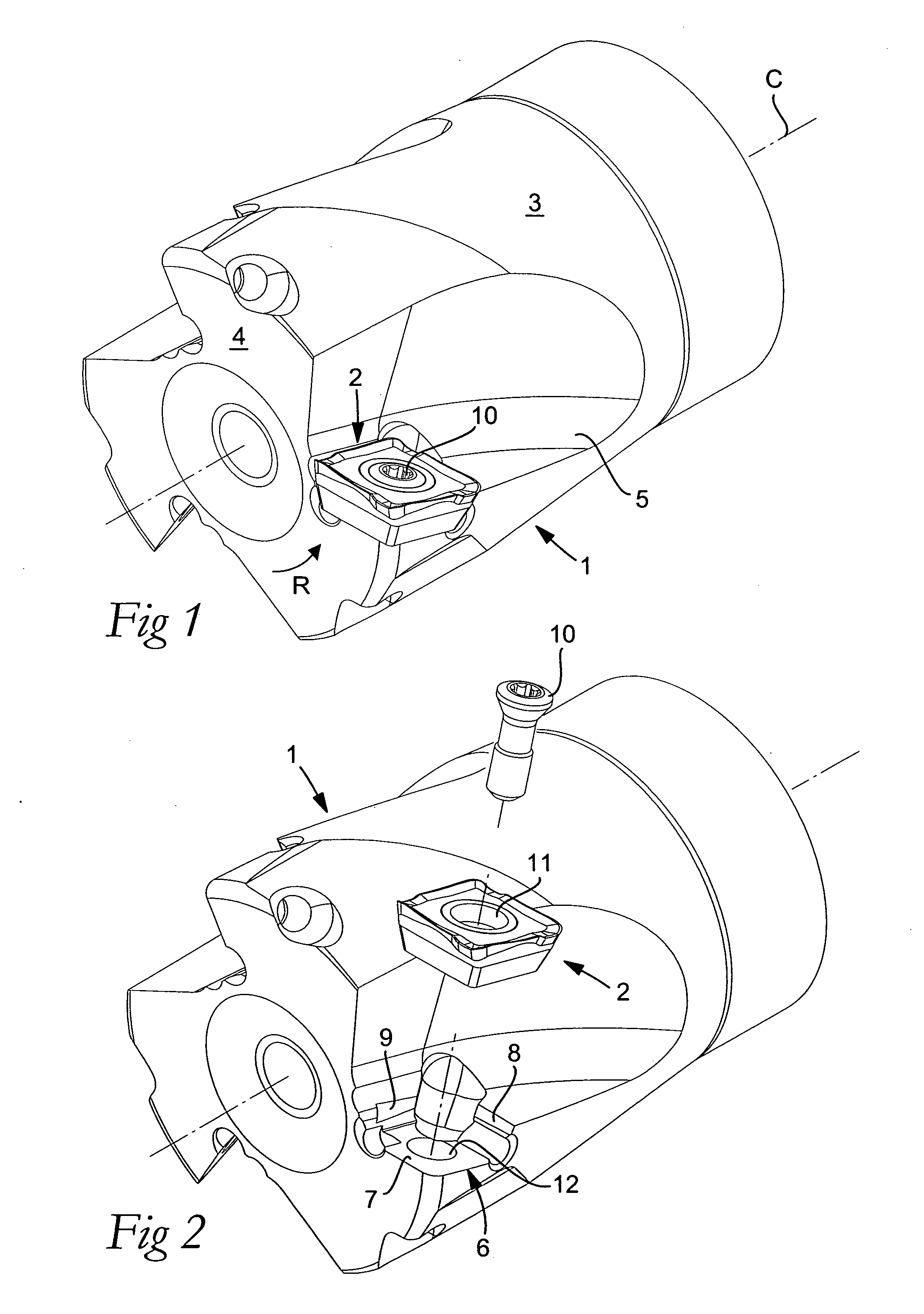

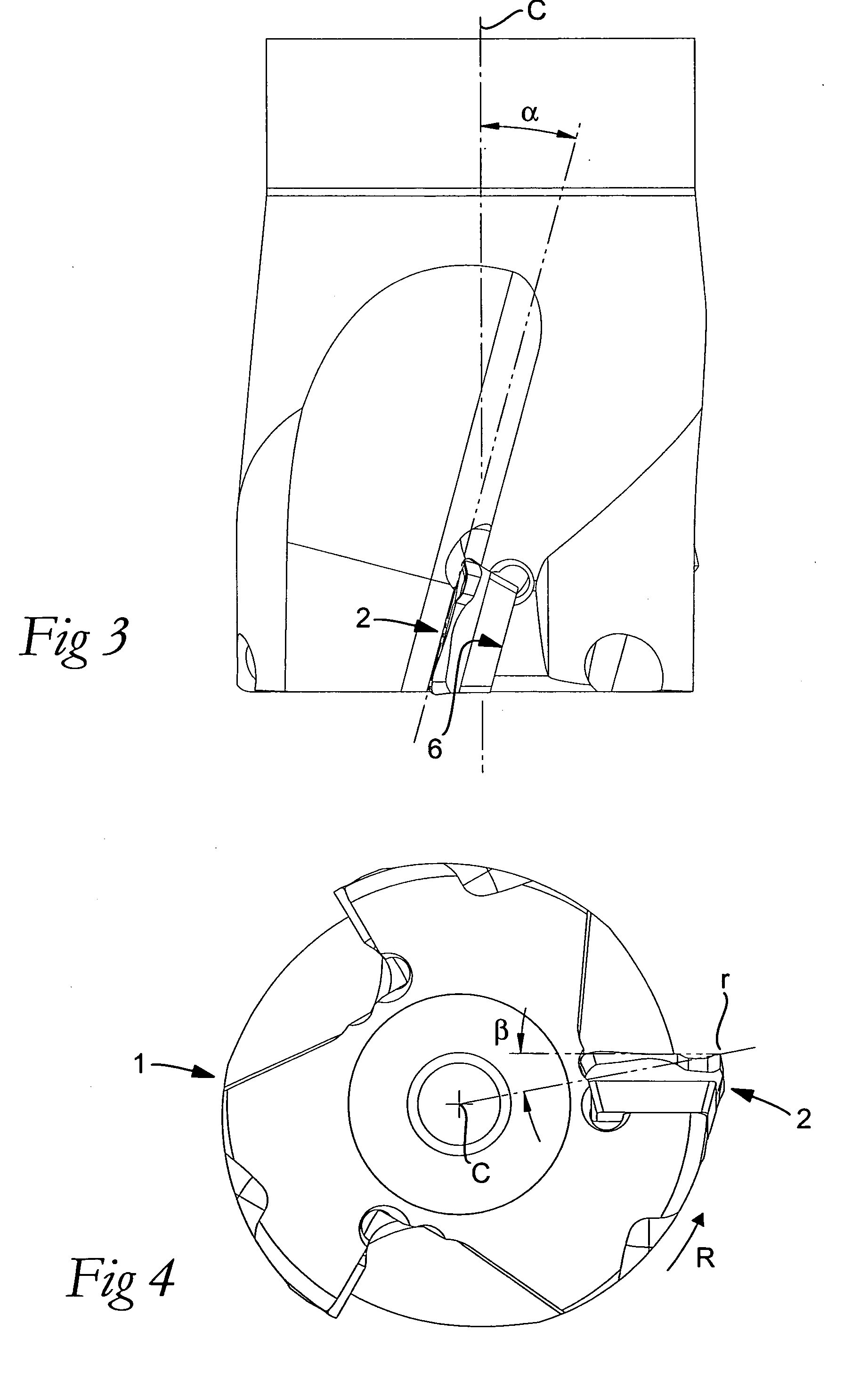

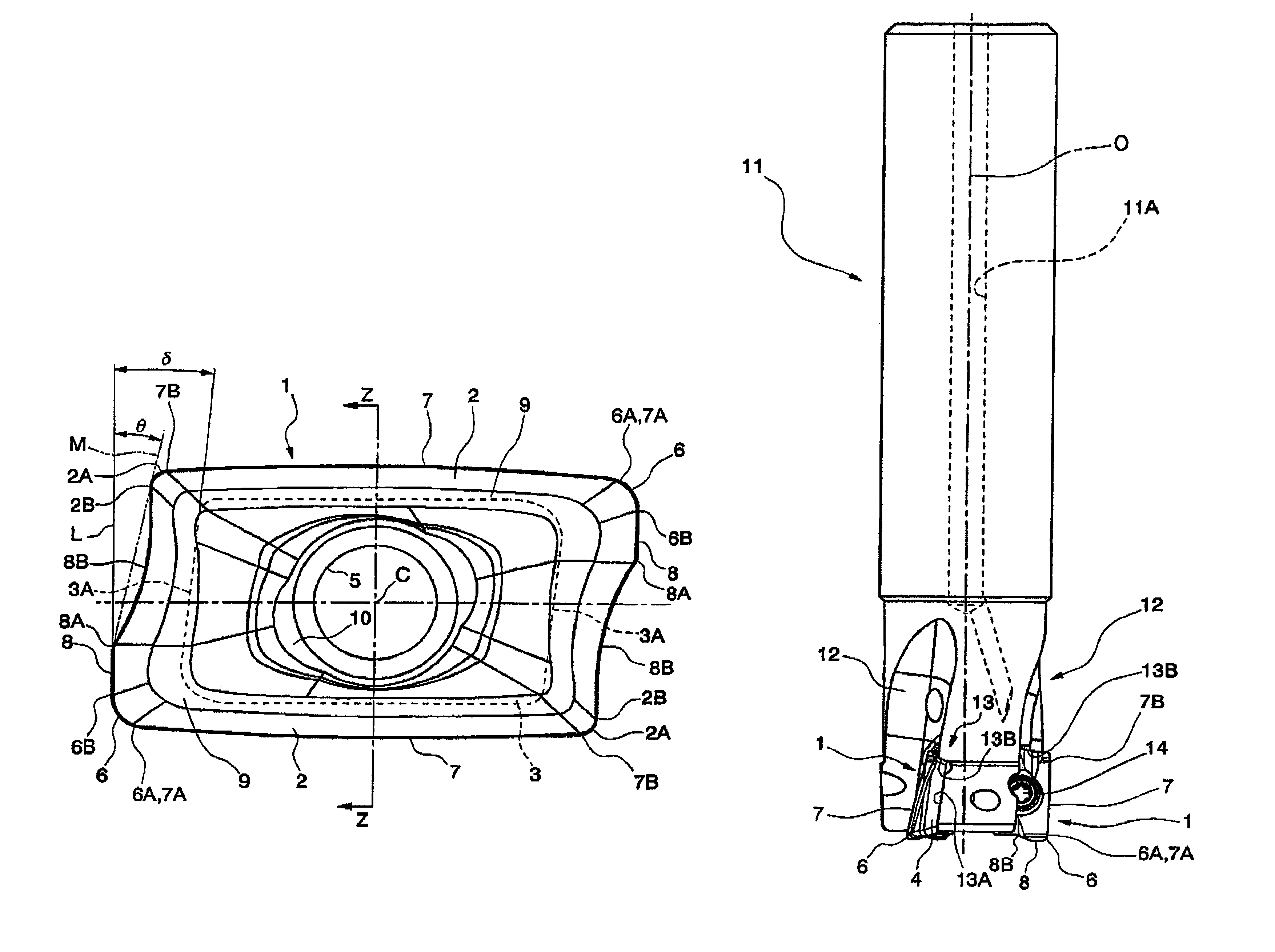

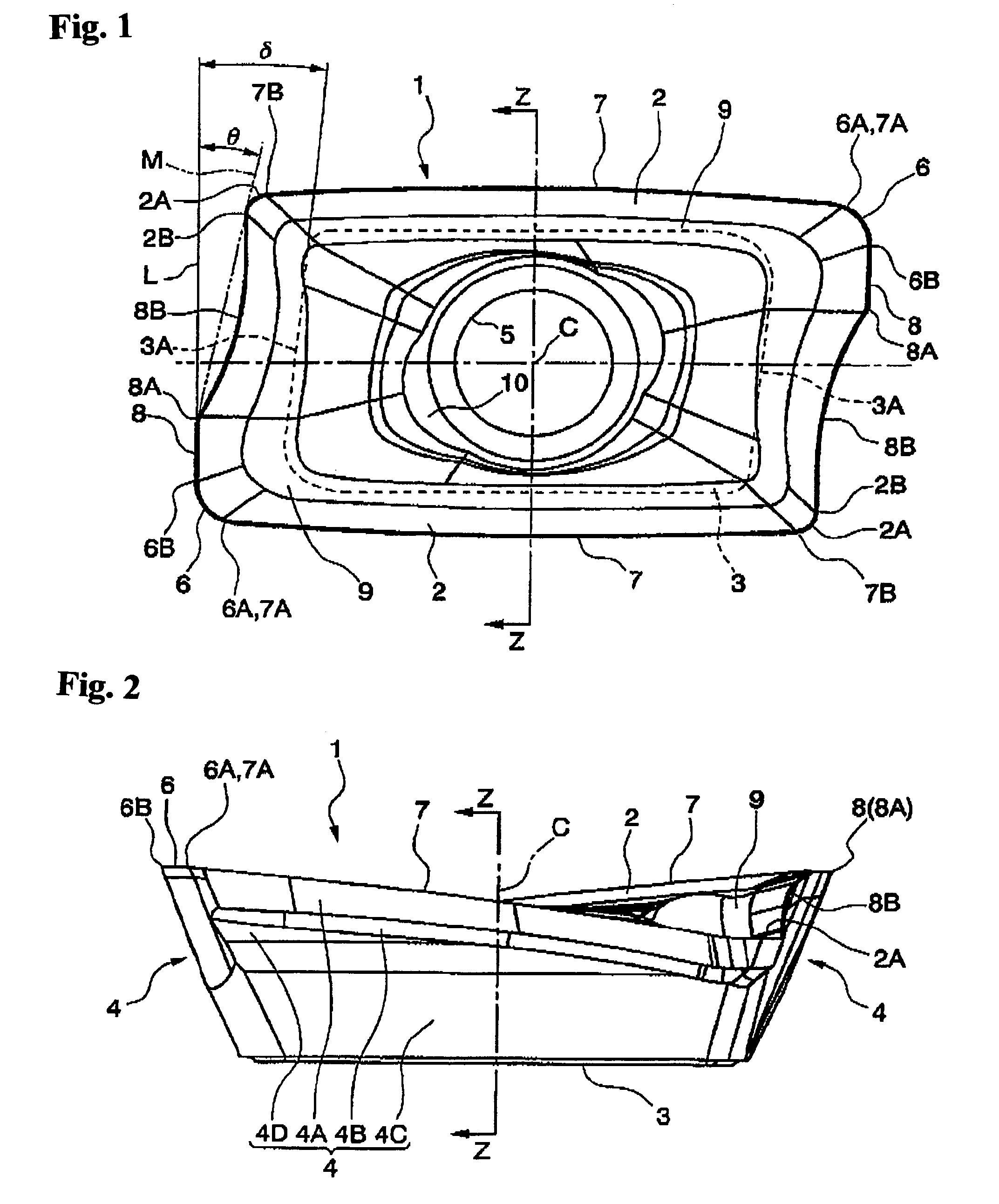

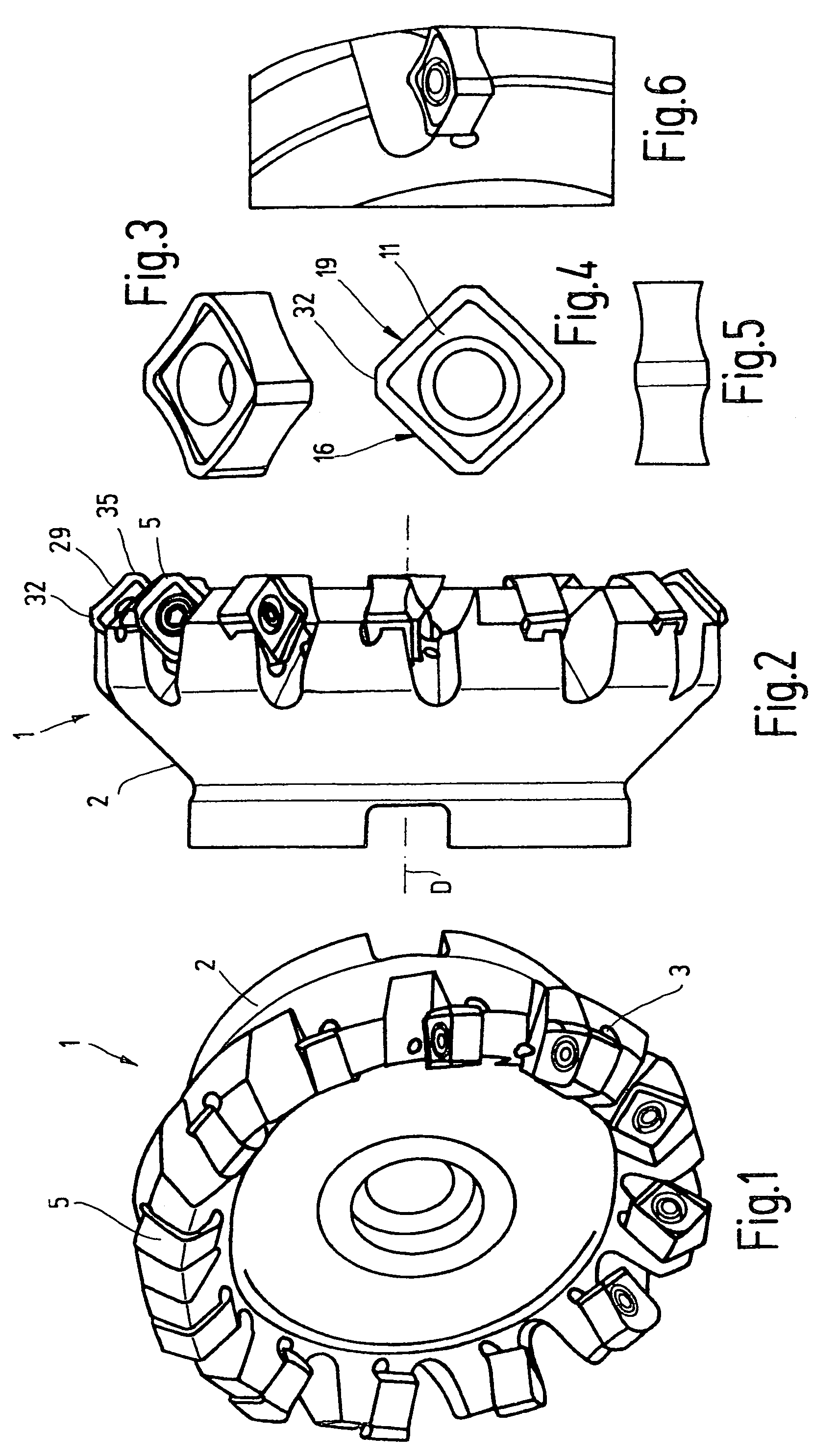

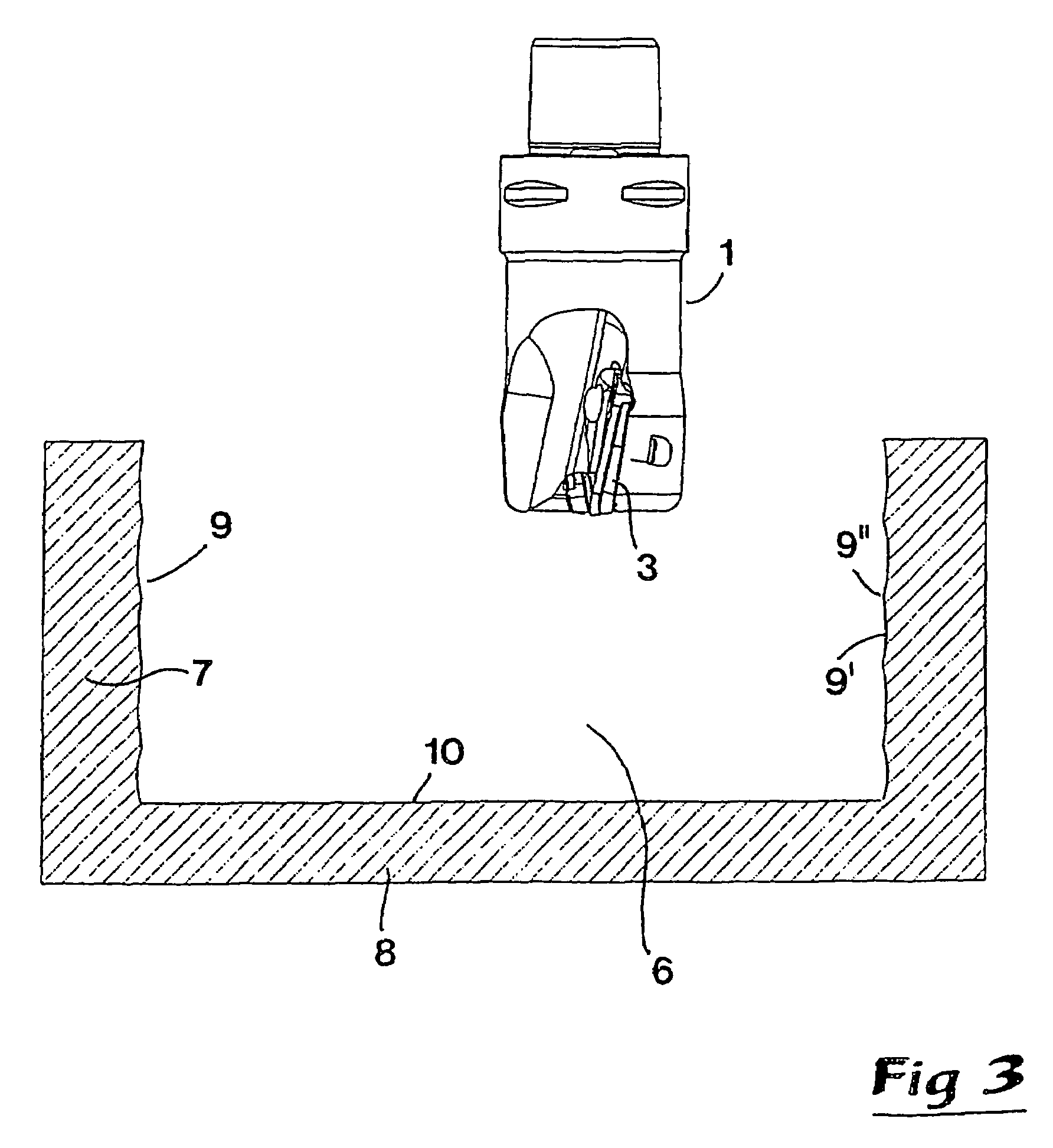

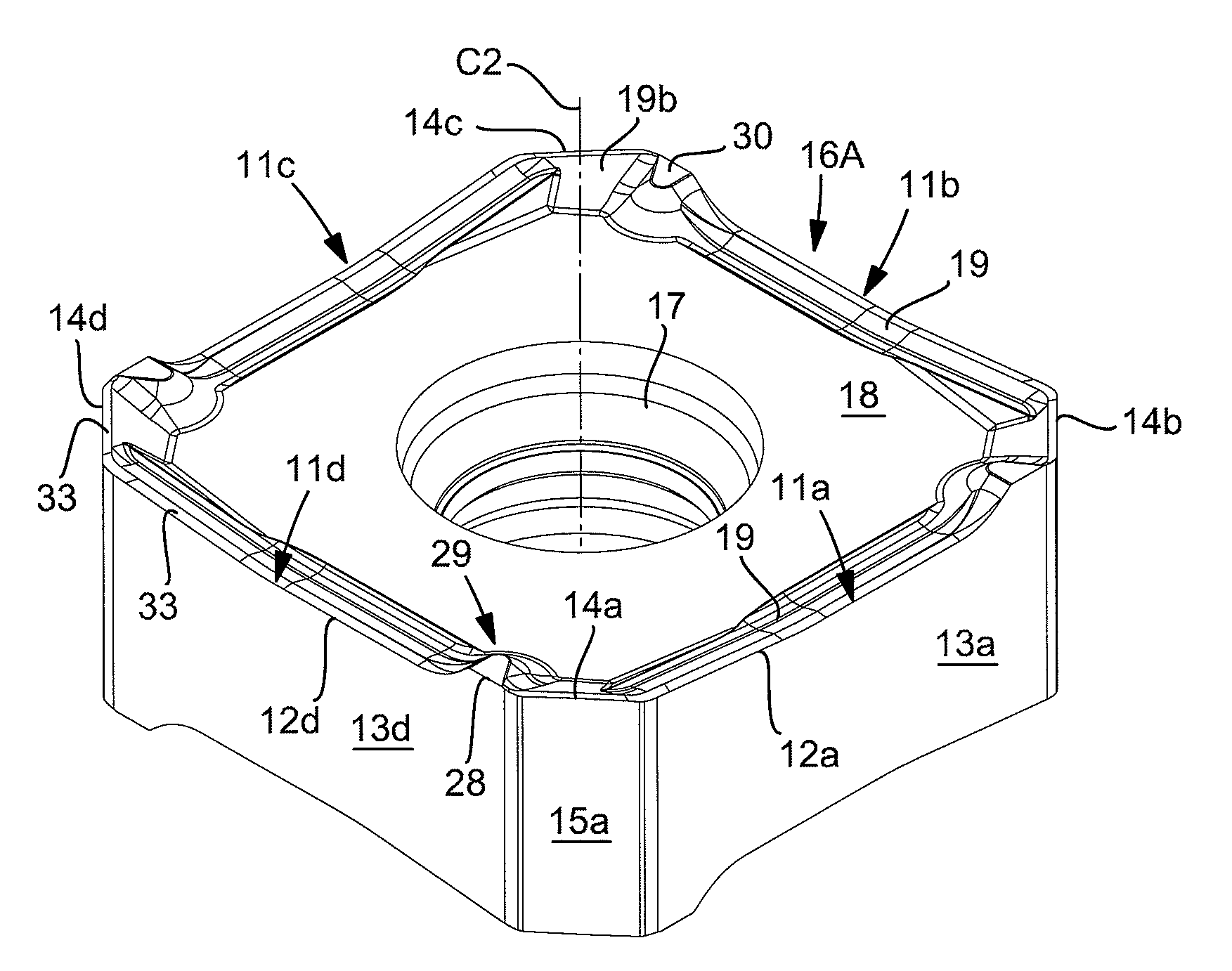

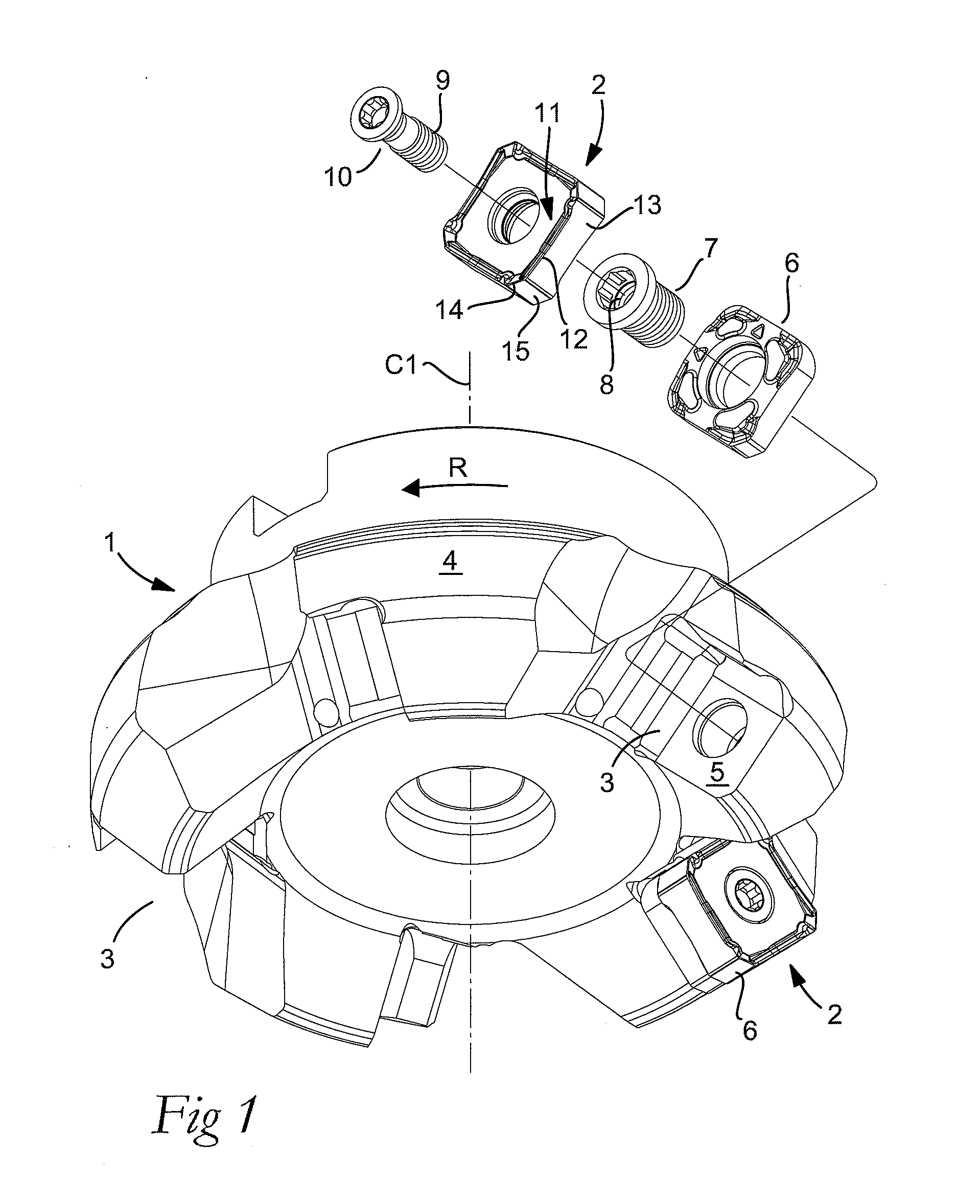

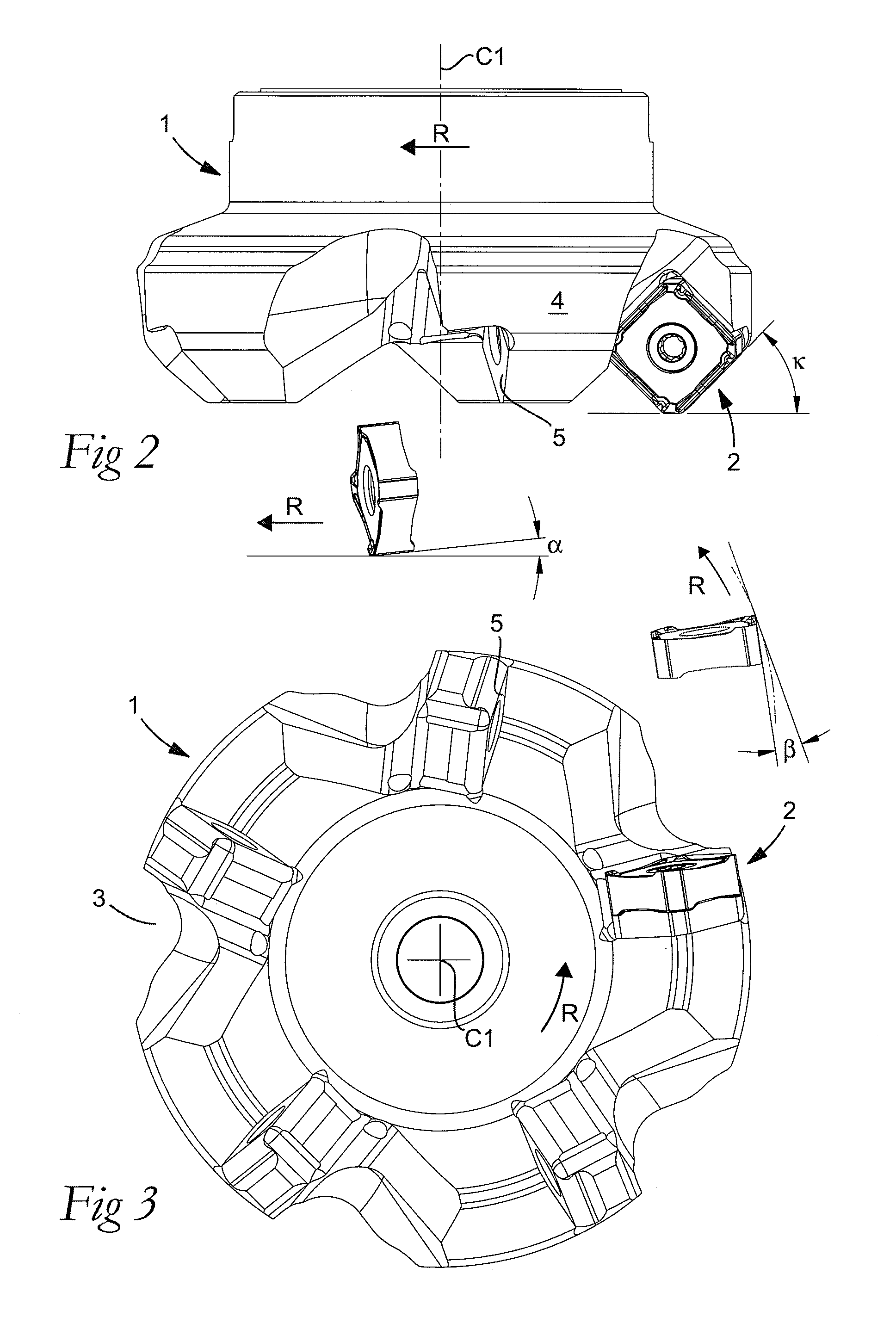

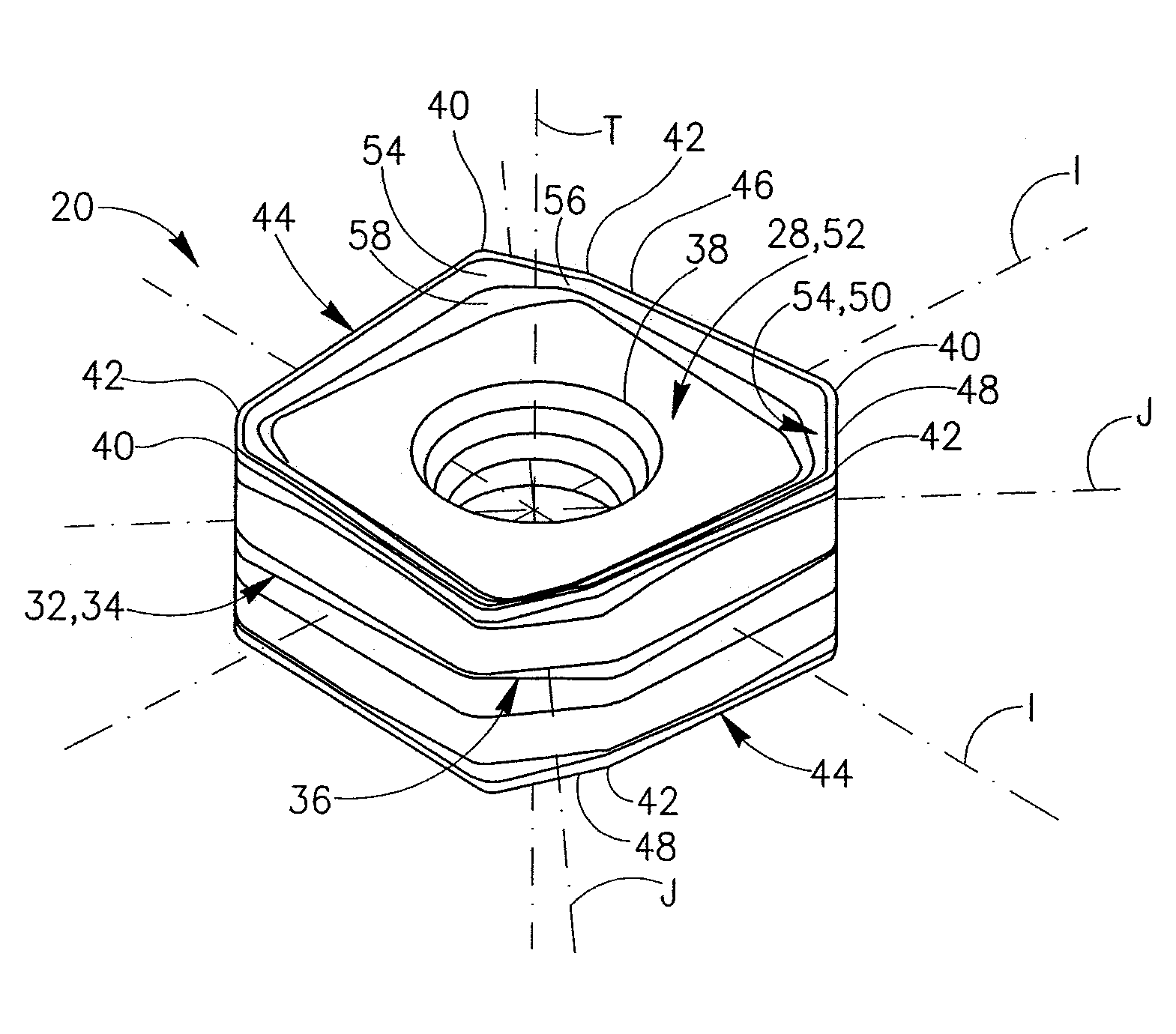

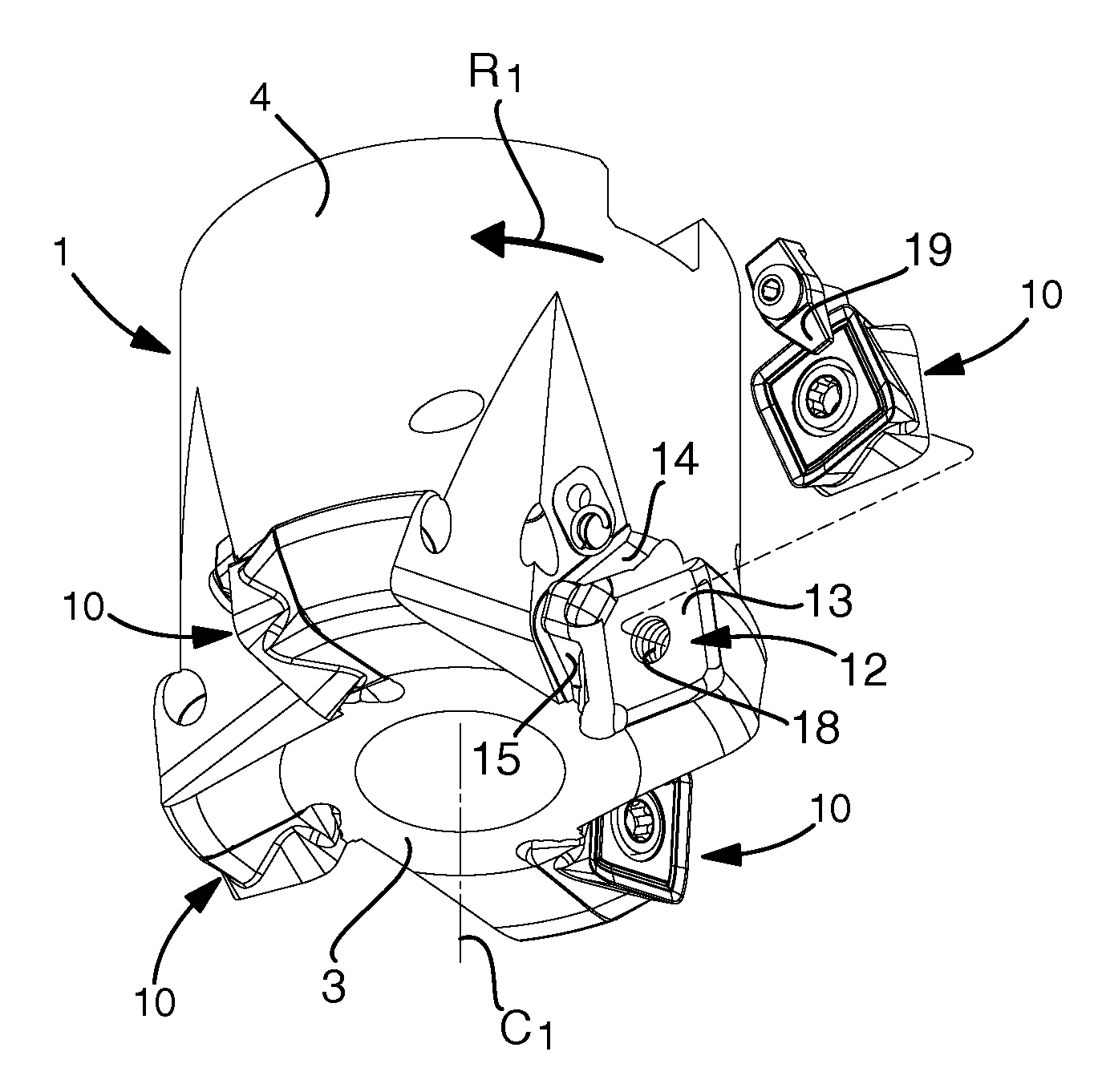

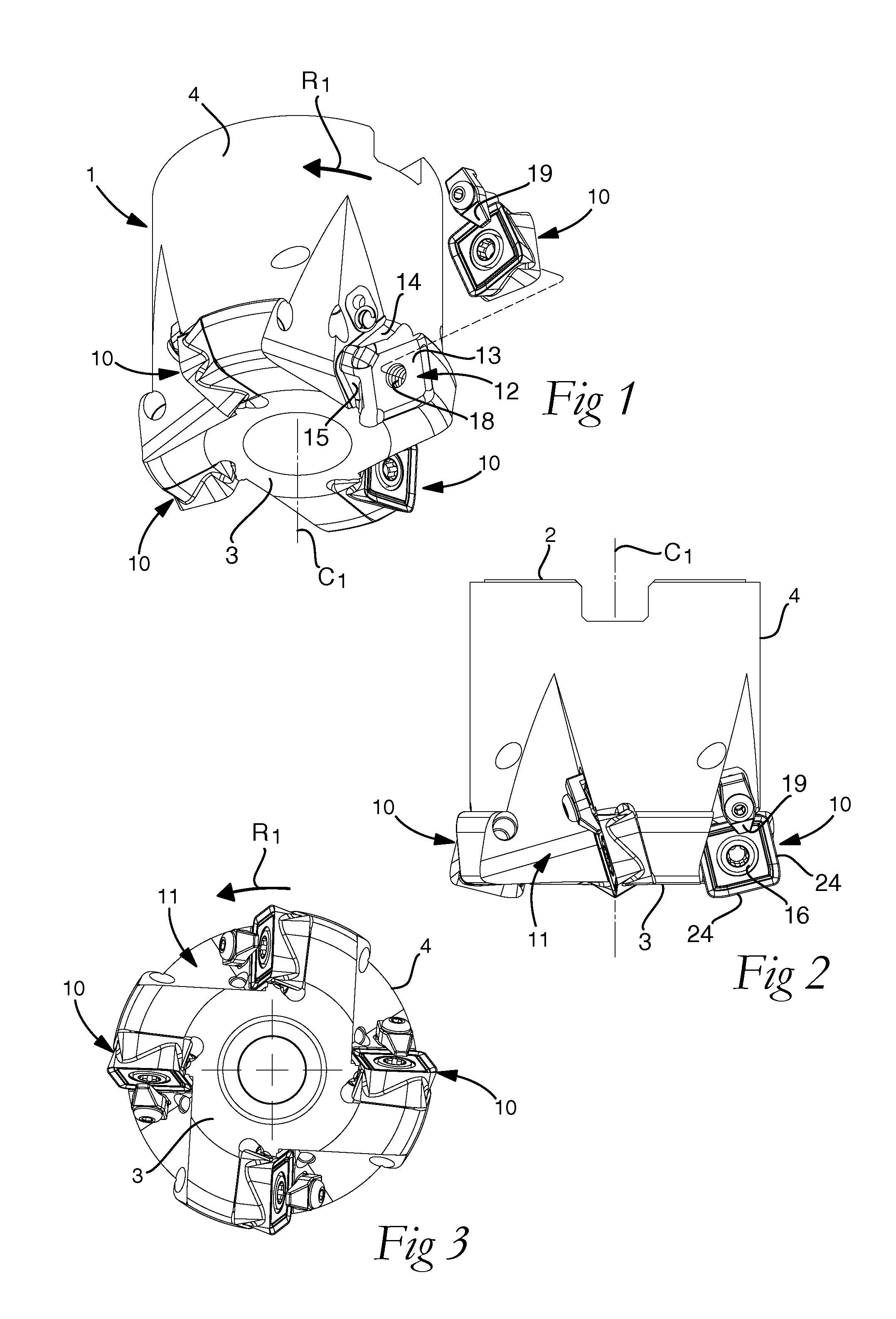

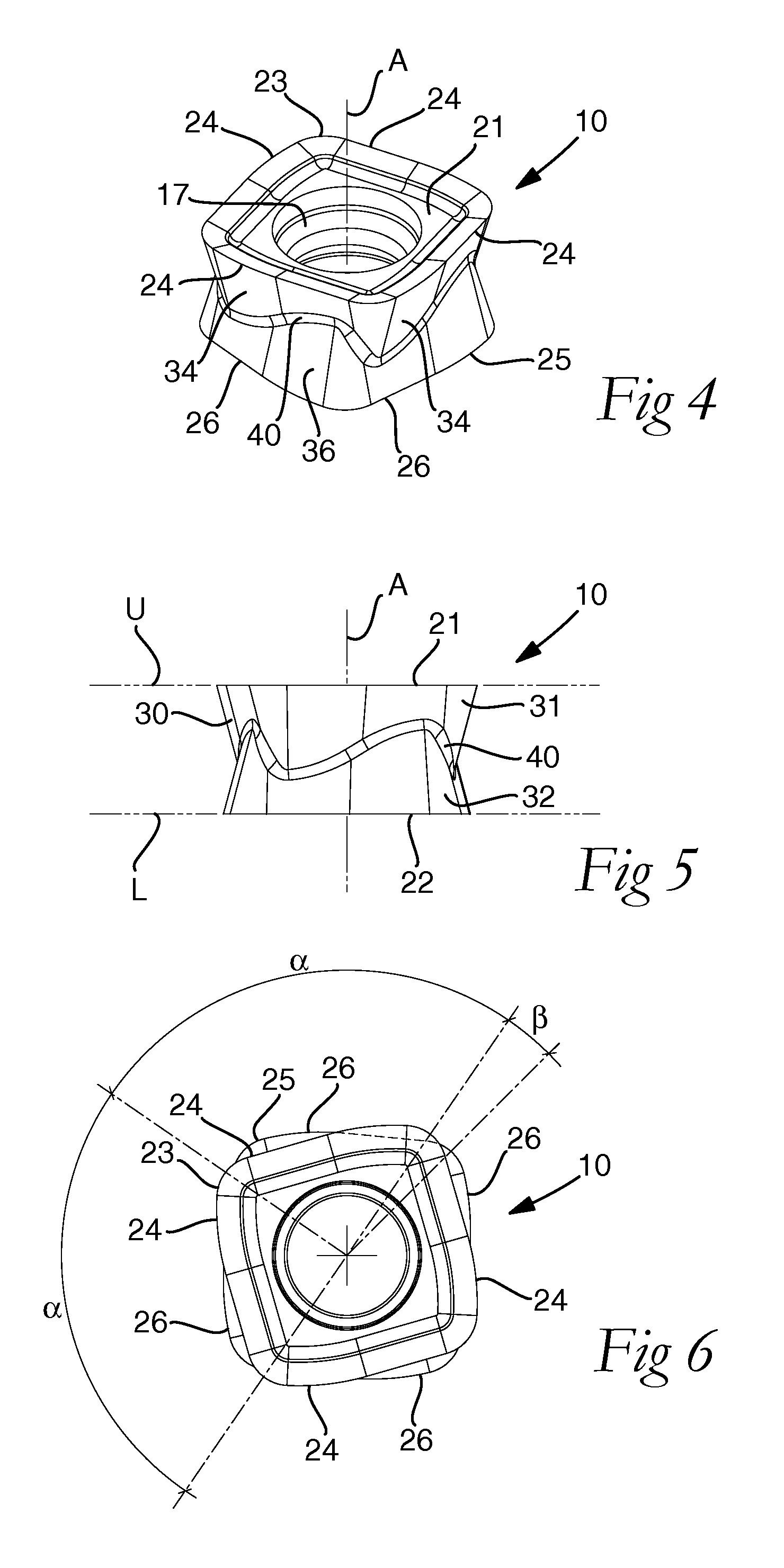

Milling insert and a milling tool

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

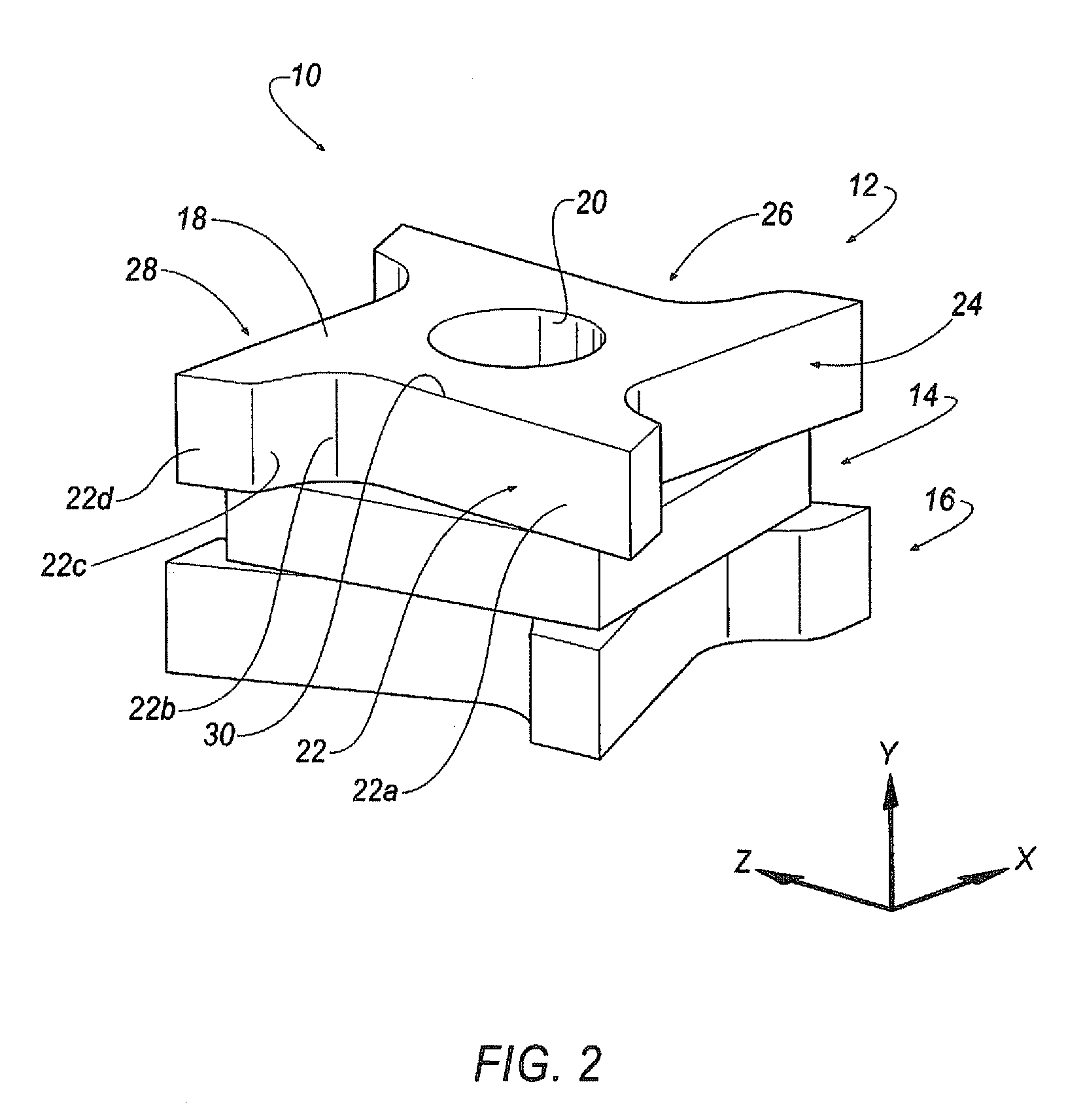

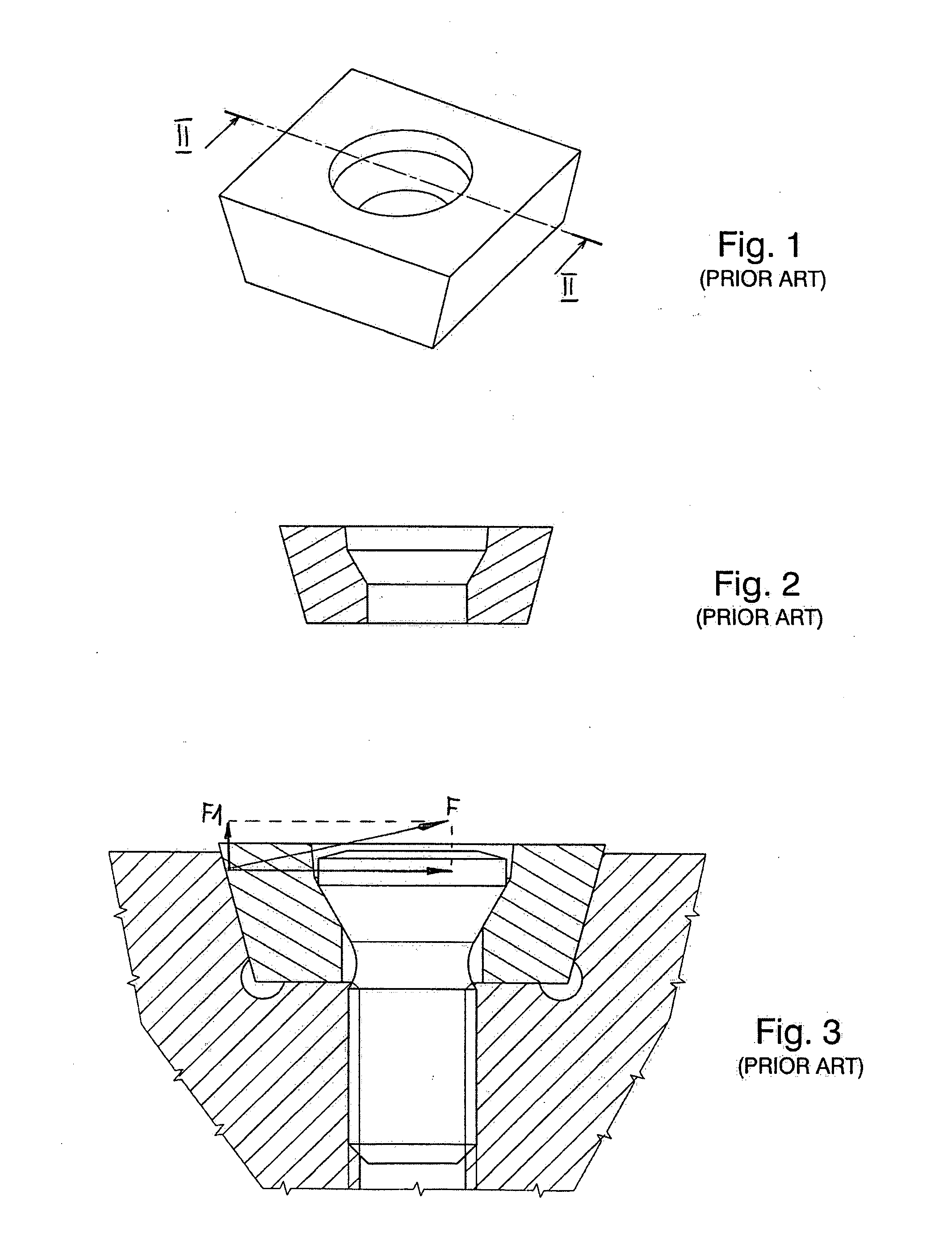

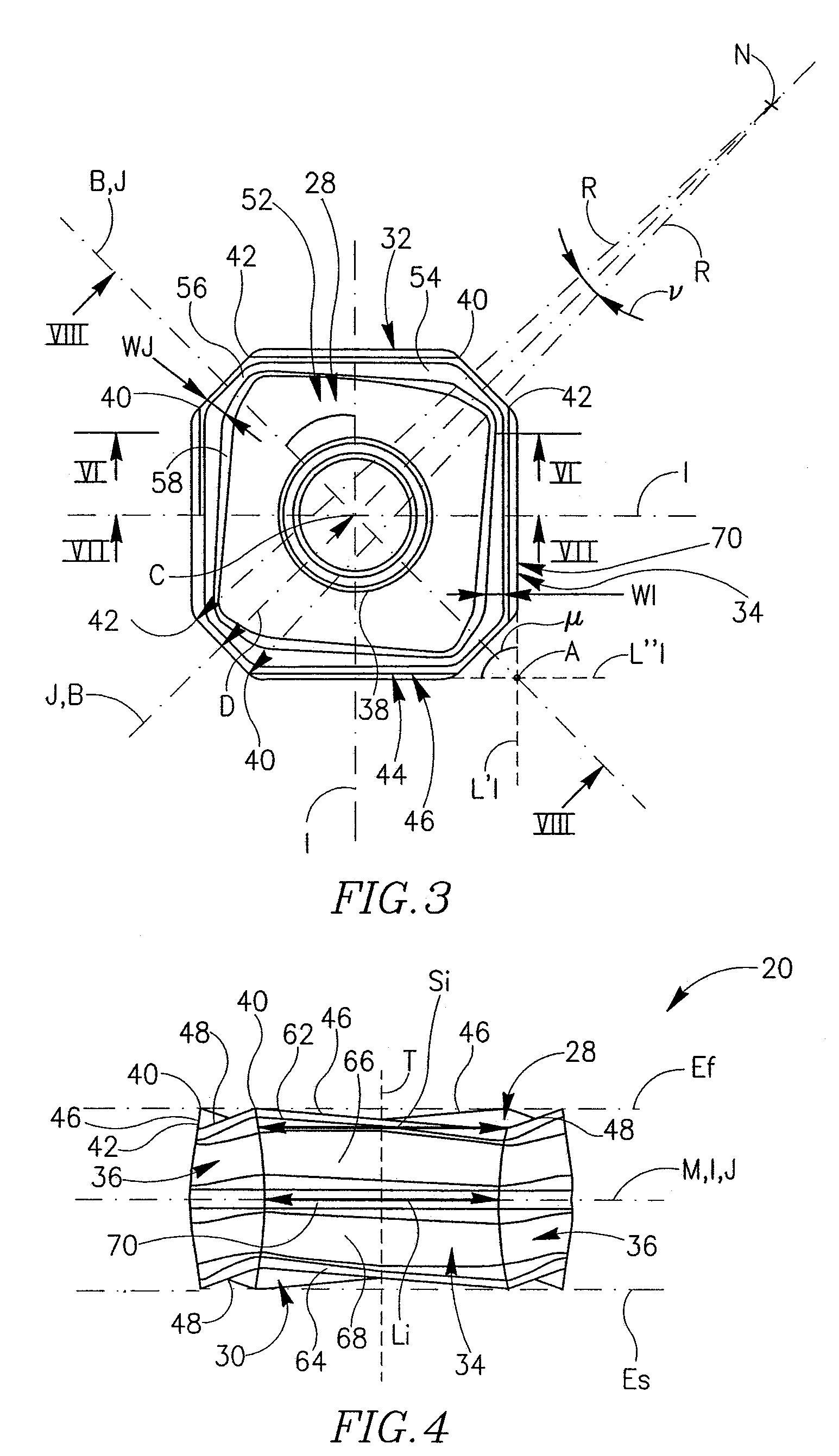

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

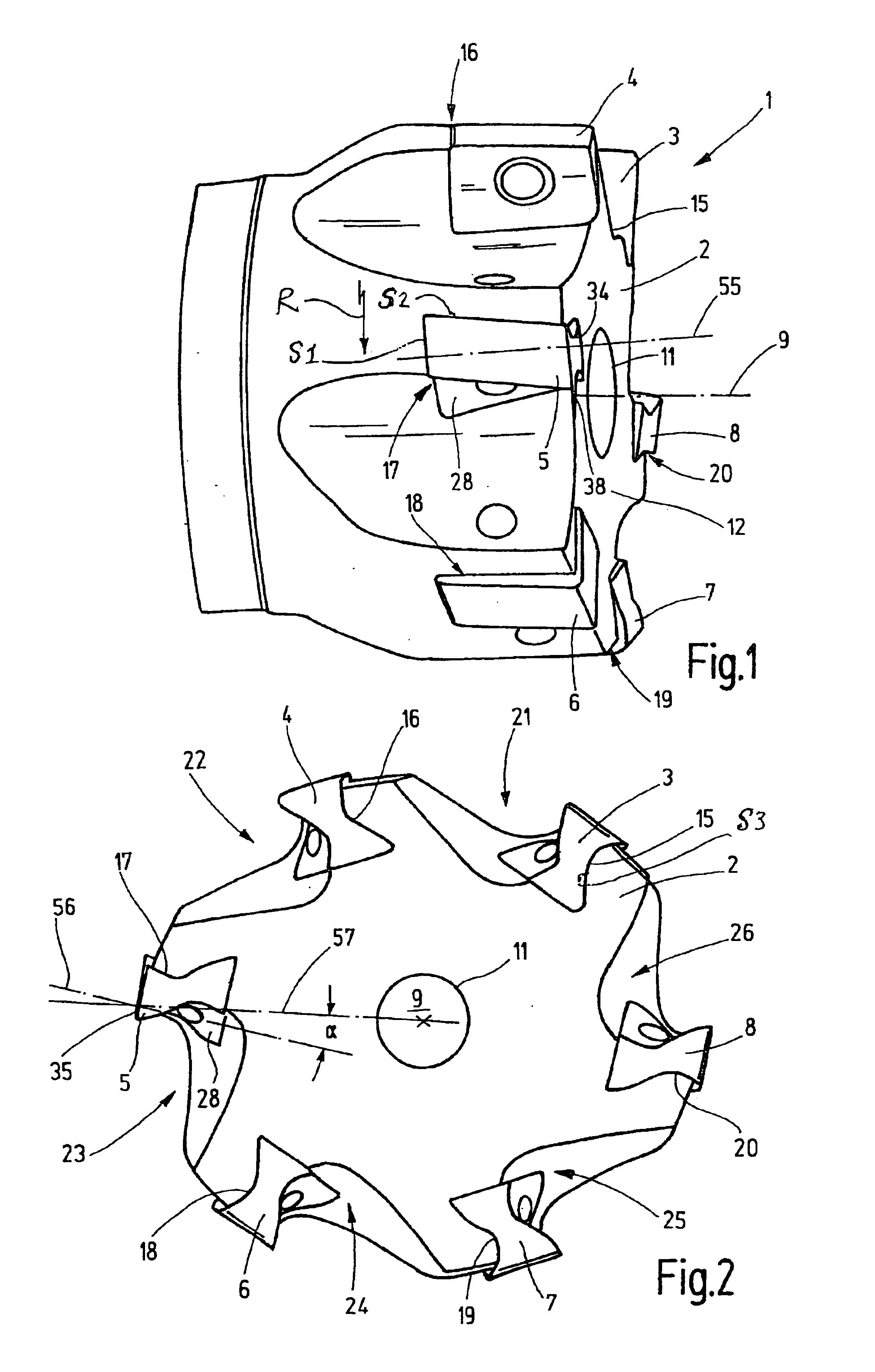

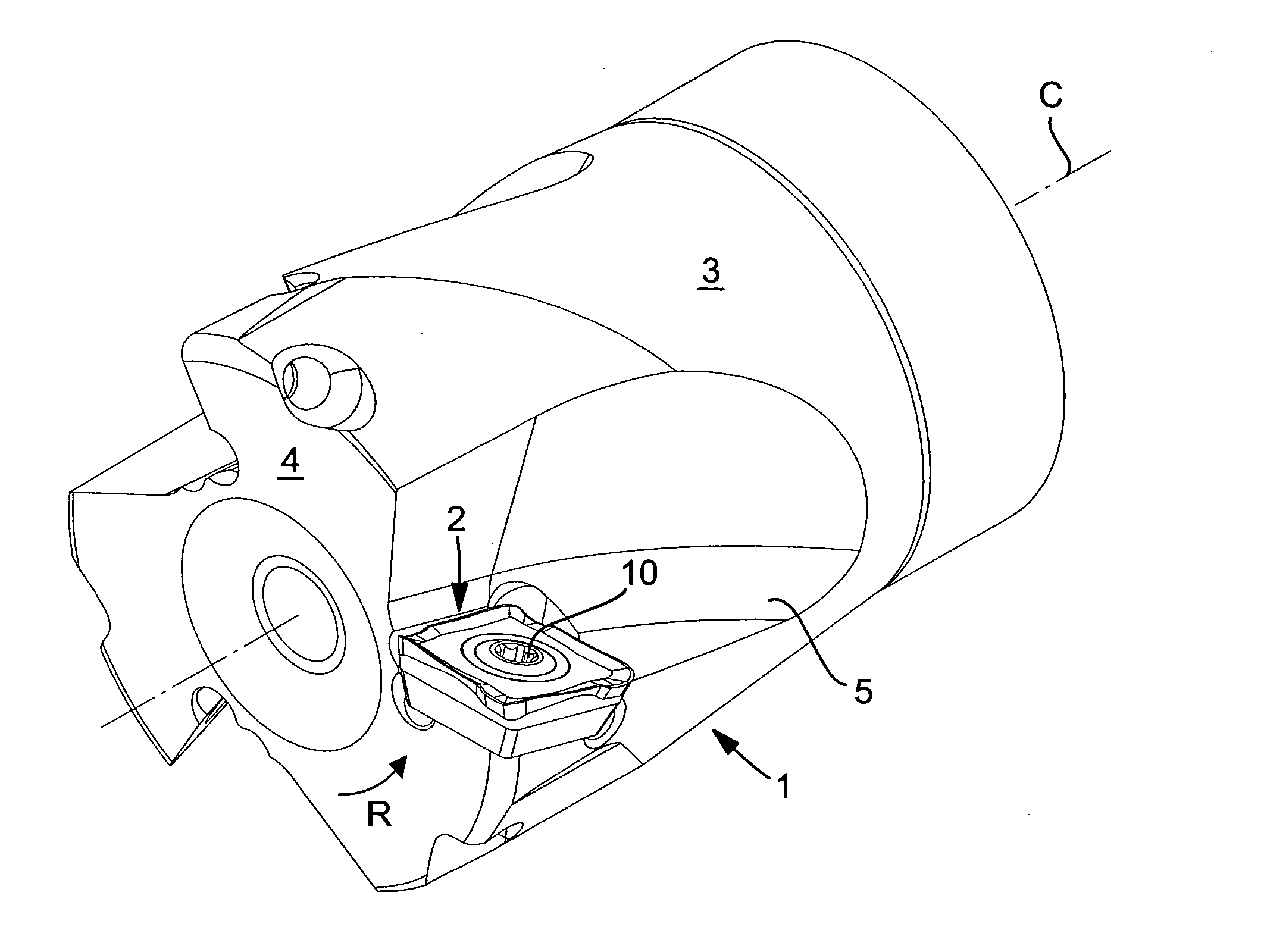

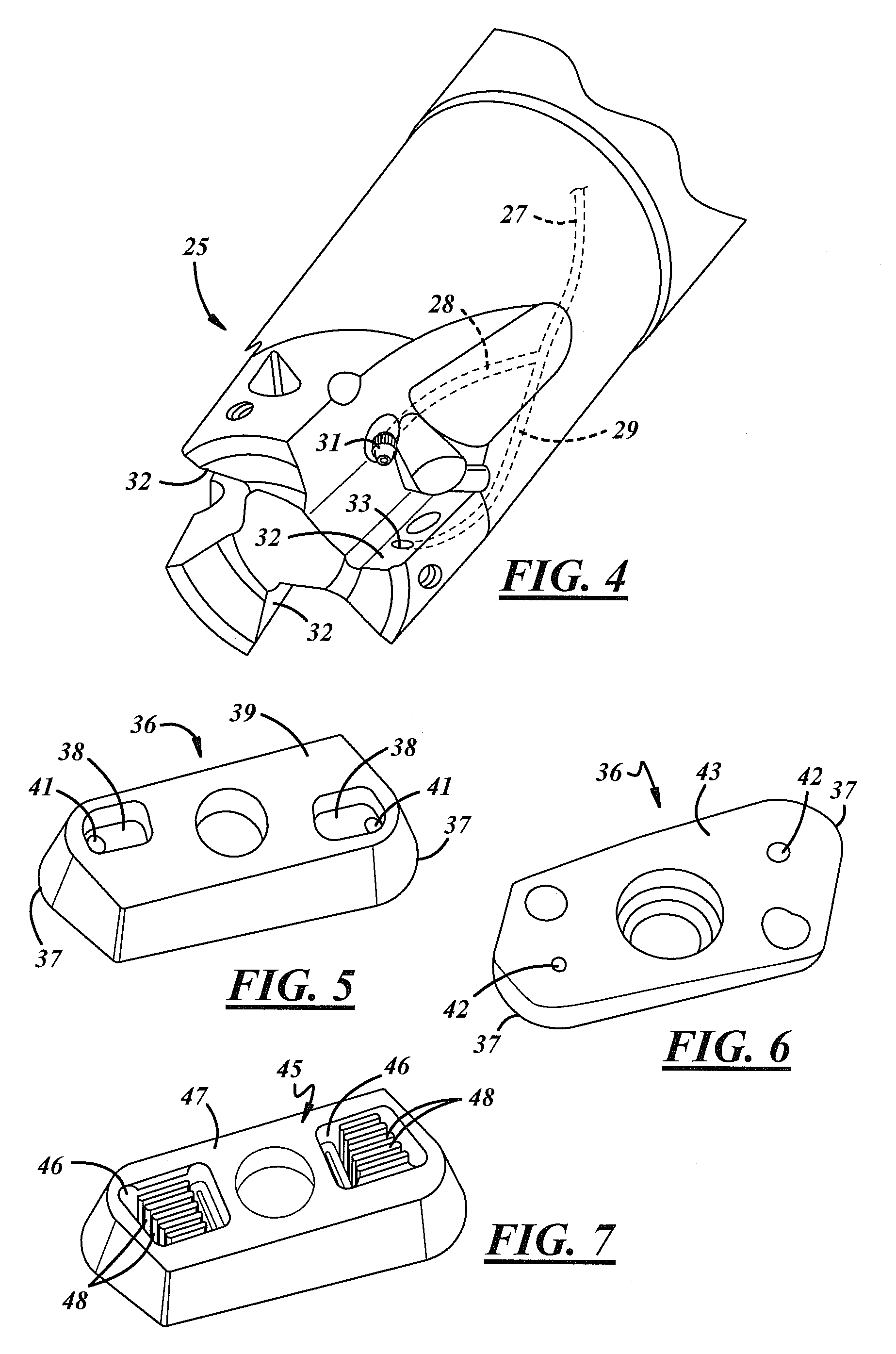

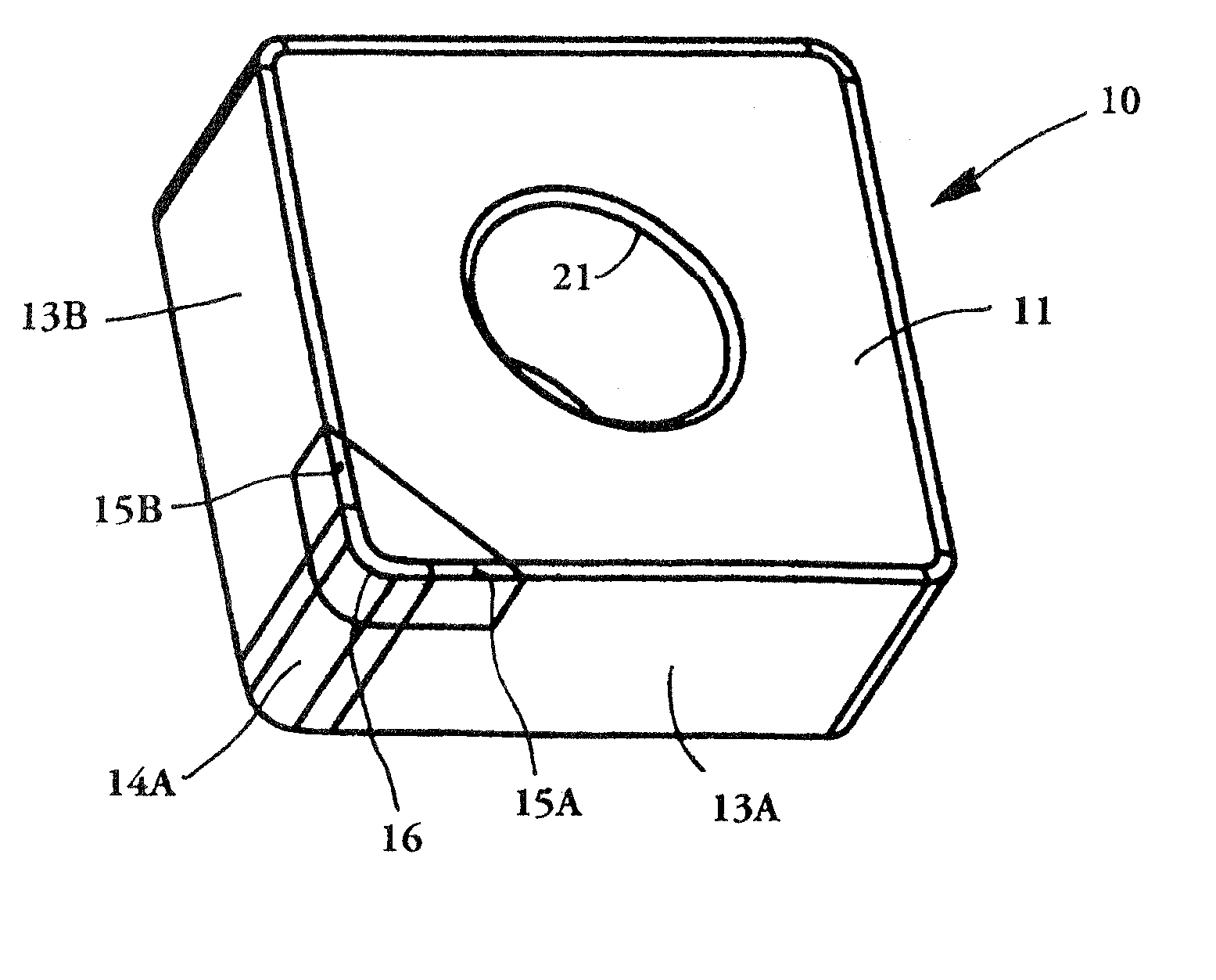

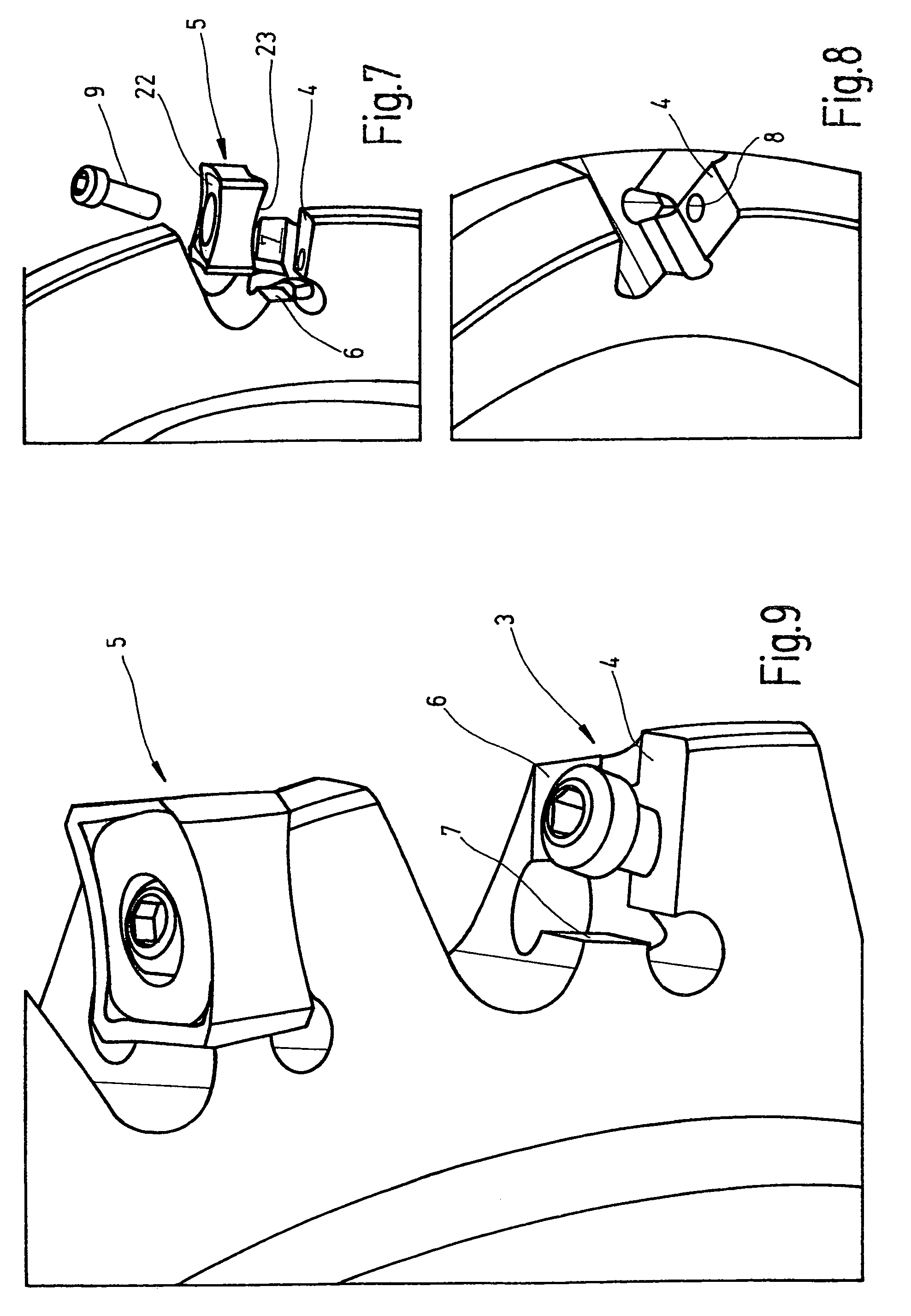

Cutter insert and milling tool

ActiveUS6921233B2Easy to useEasy to manufactureMilling cuttersTurning toolsEngineeringMechanical engineering

A cutter insert for milling tools includes a base body having a base surface, a top surface, and four side surfaces. The four side surfaces, together with each of the base surface and the top surface, define respective cutting edges. The base body is twisted about each of two perpendicular, coplanar axes of the base body. Each side surface has two opposite corner edges that are offset from one another in a direction parallel to a center axis of the base body.

Owner:WALTER AG

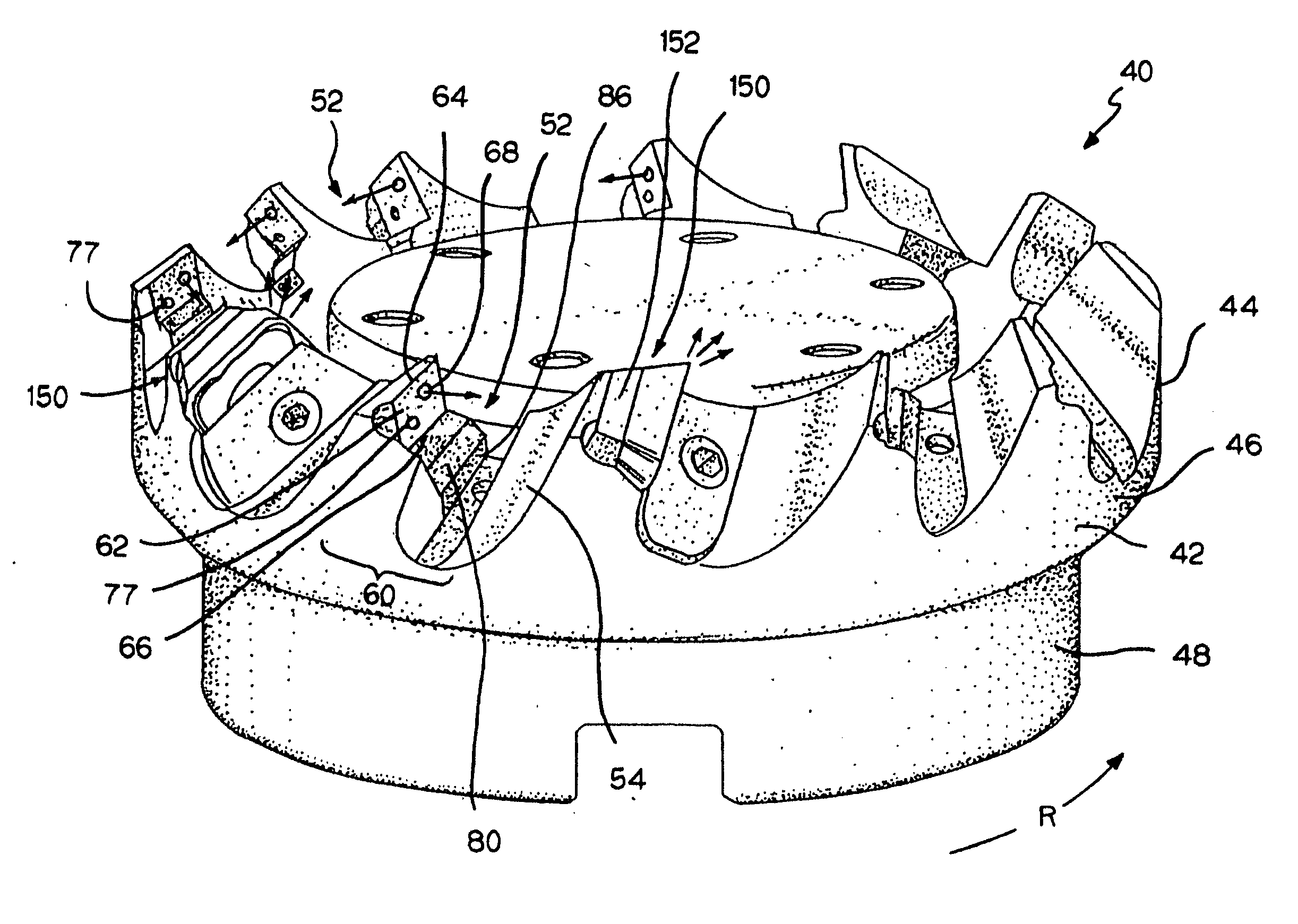

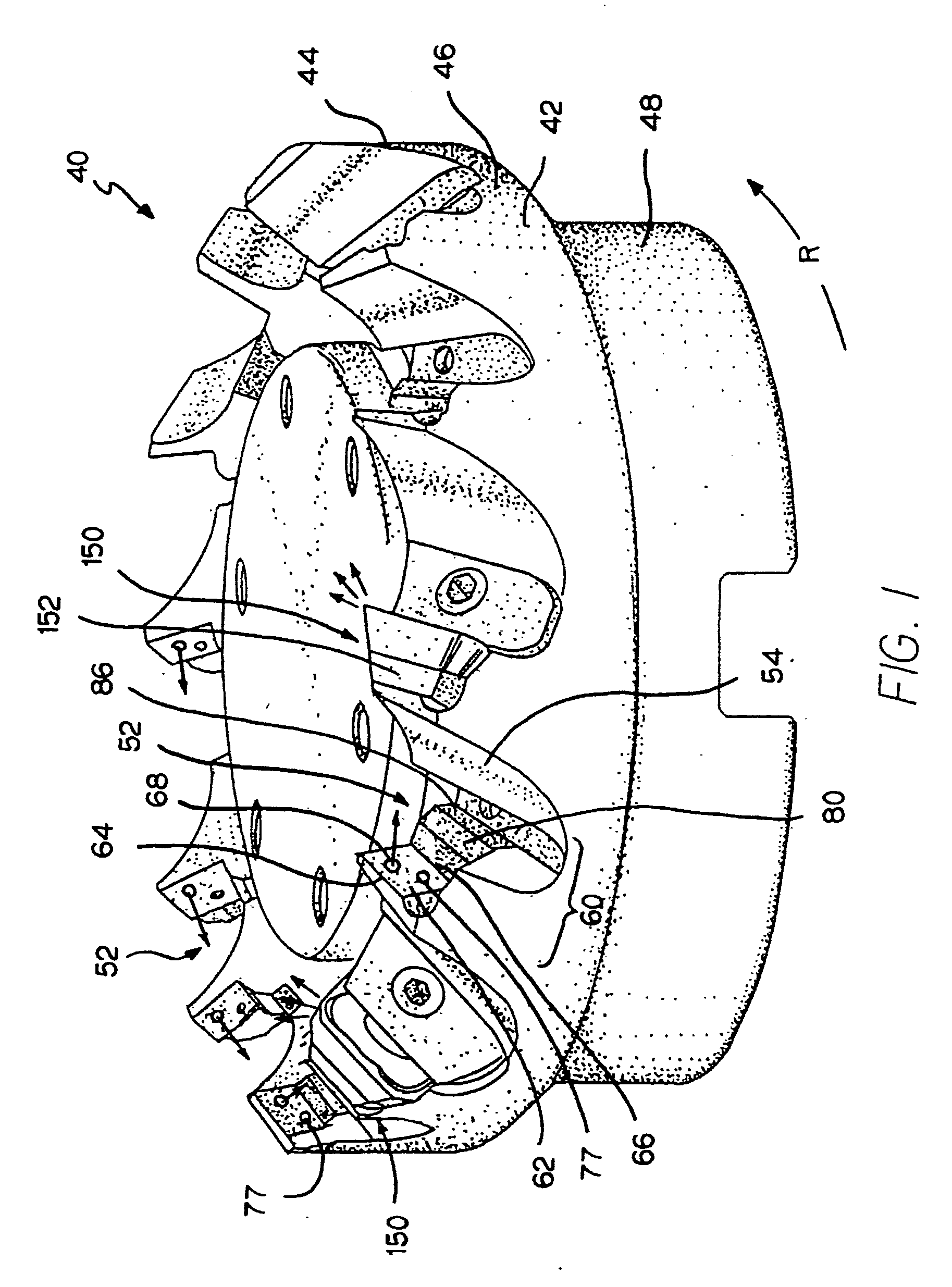

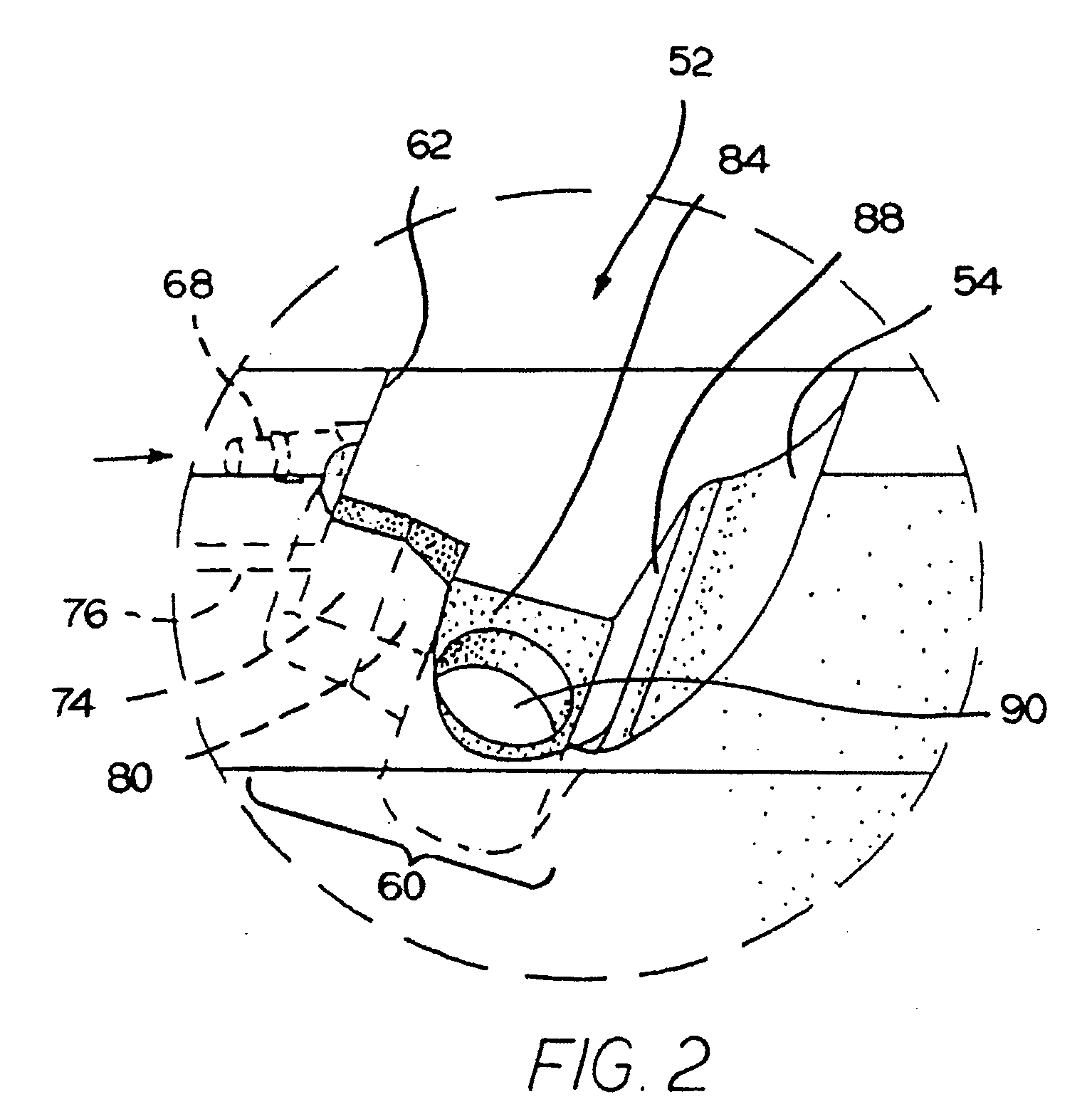

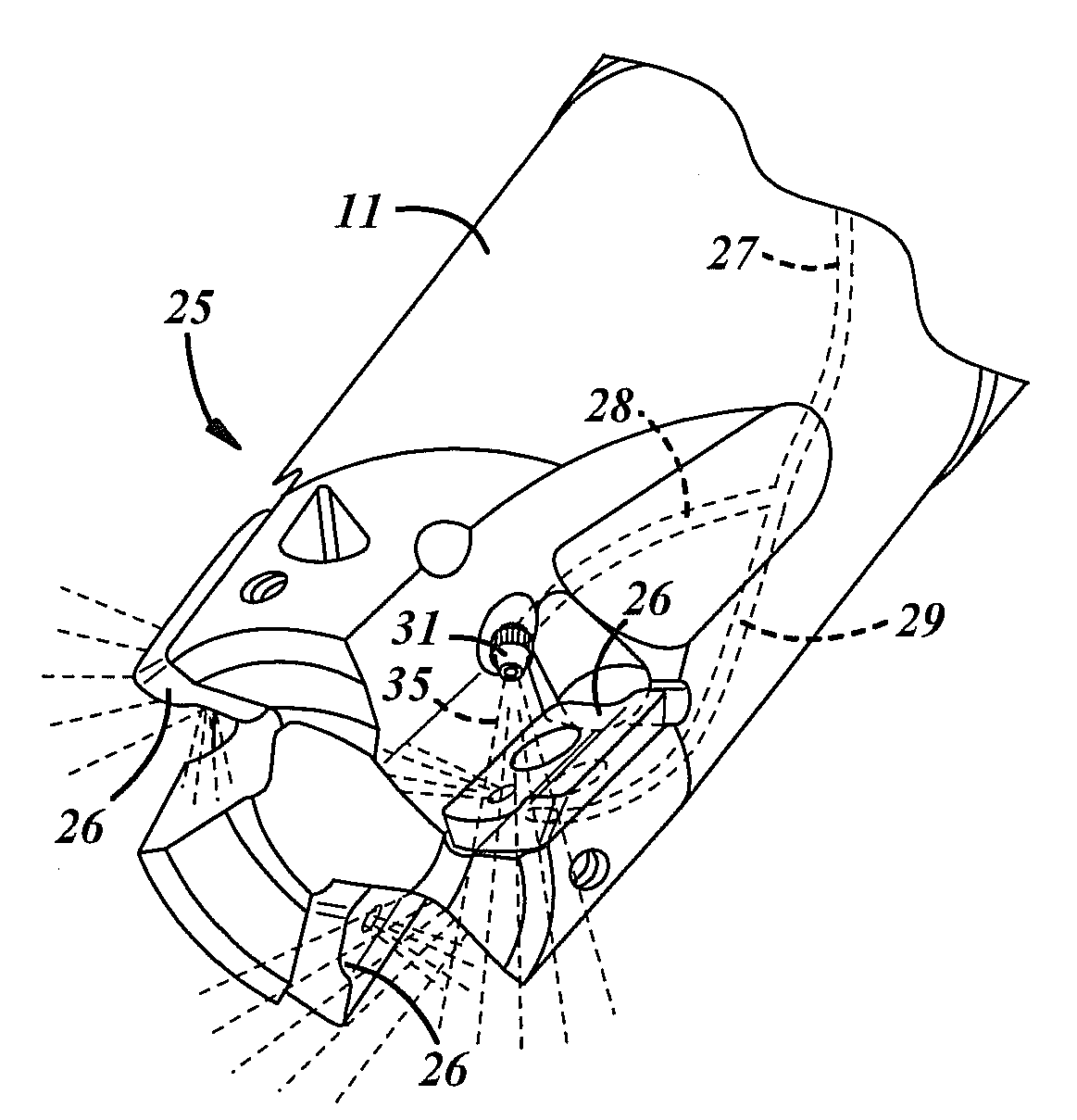

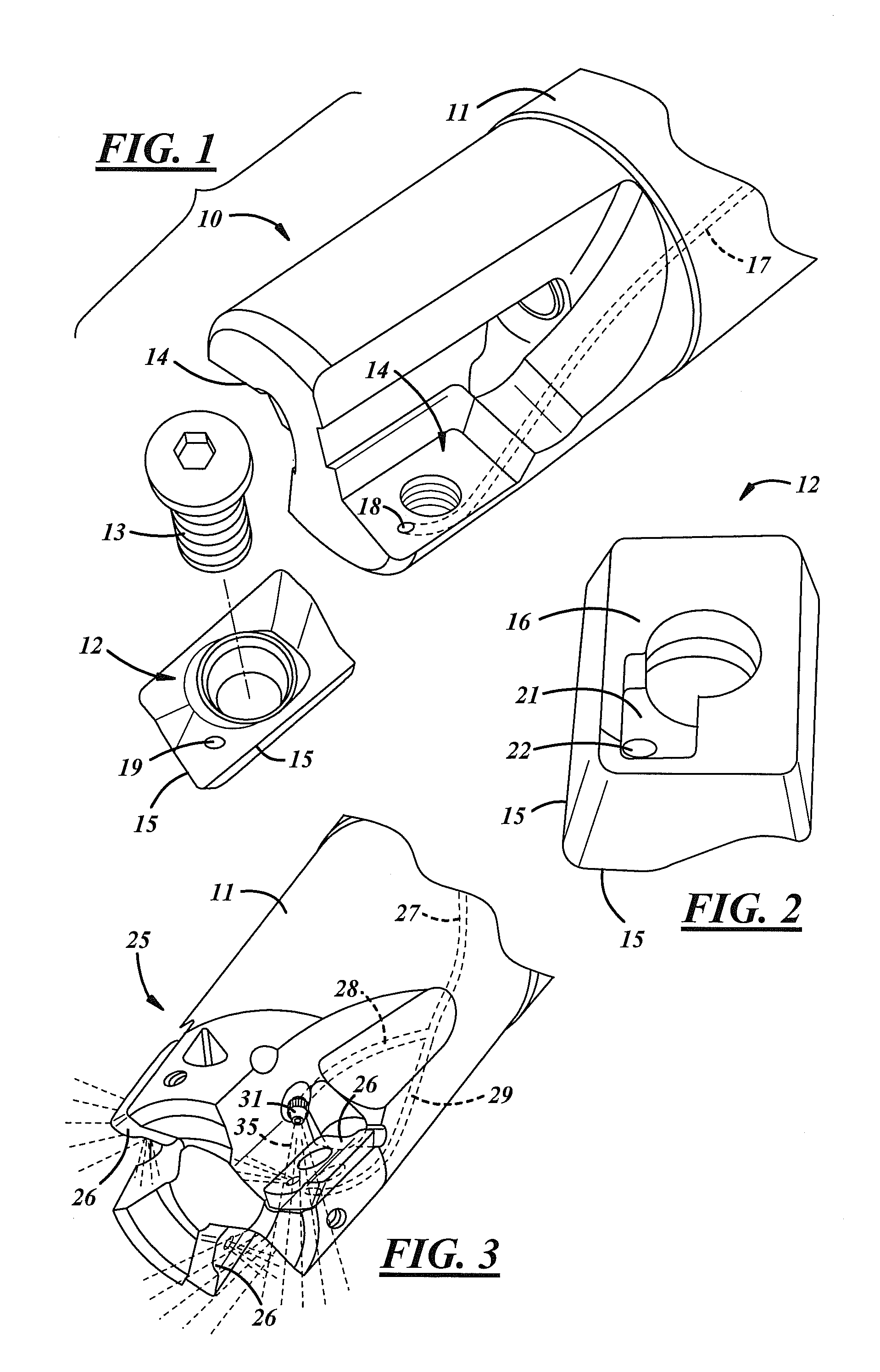

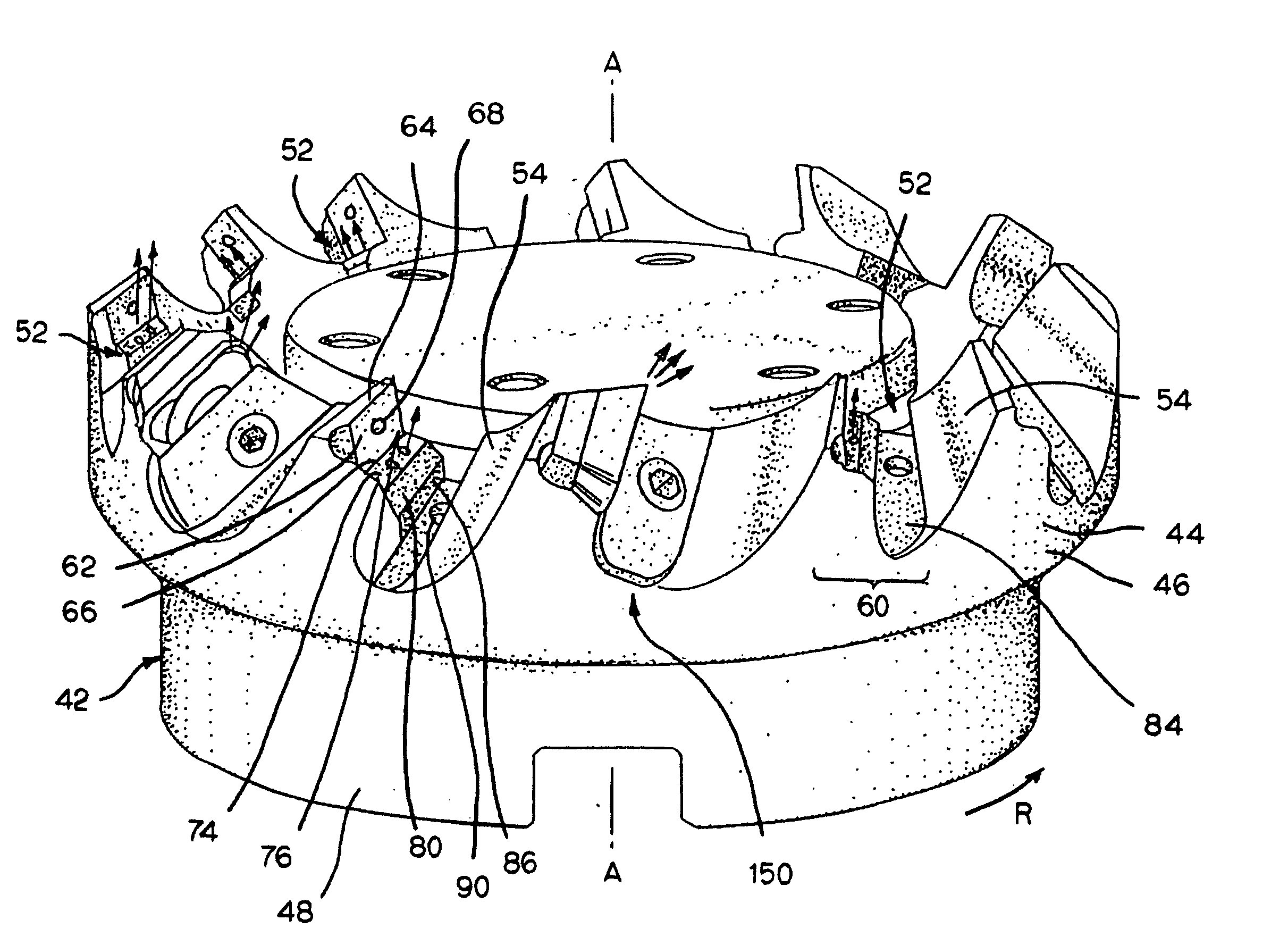

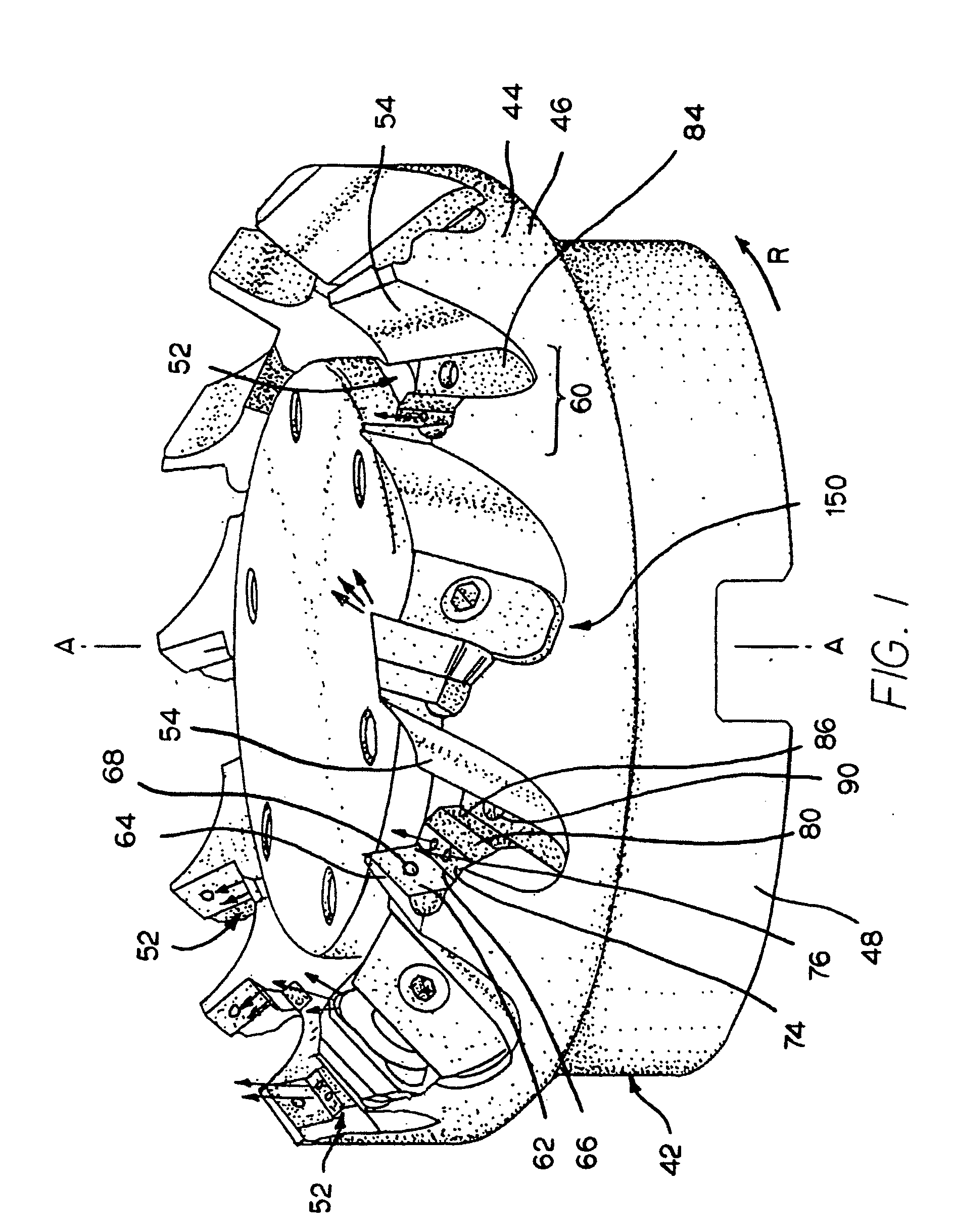

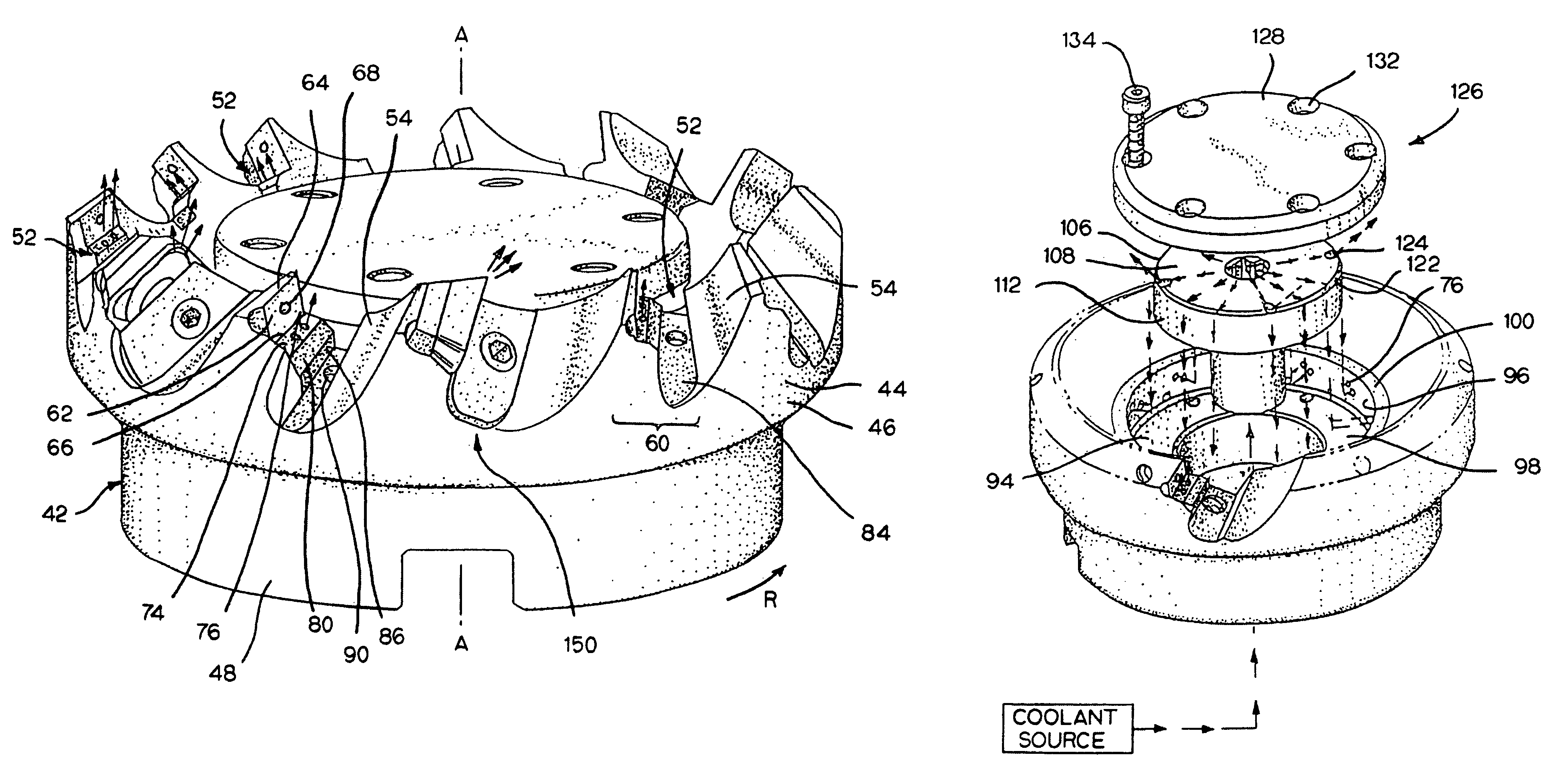

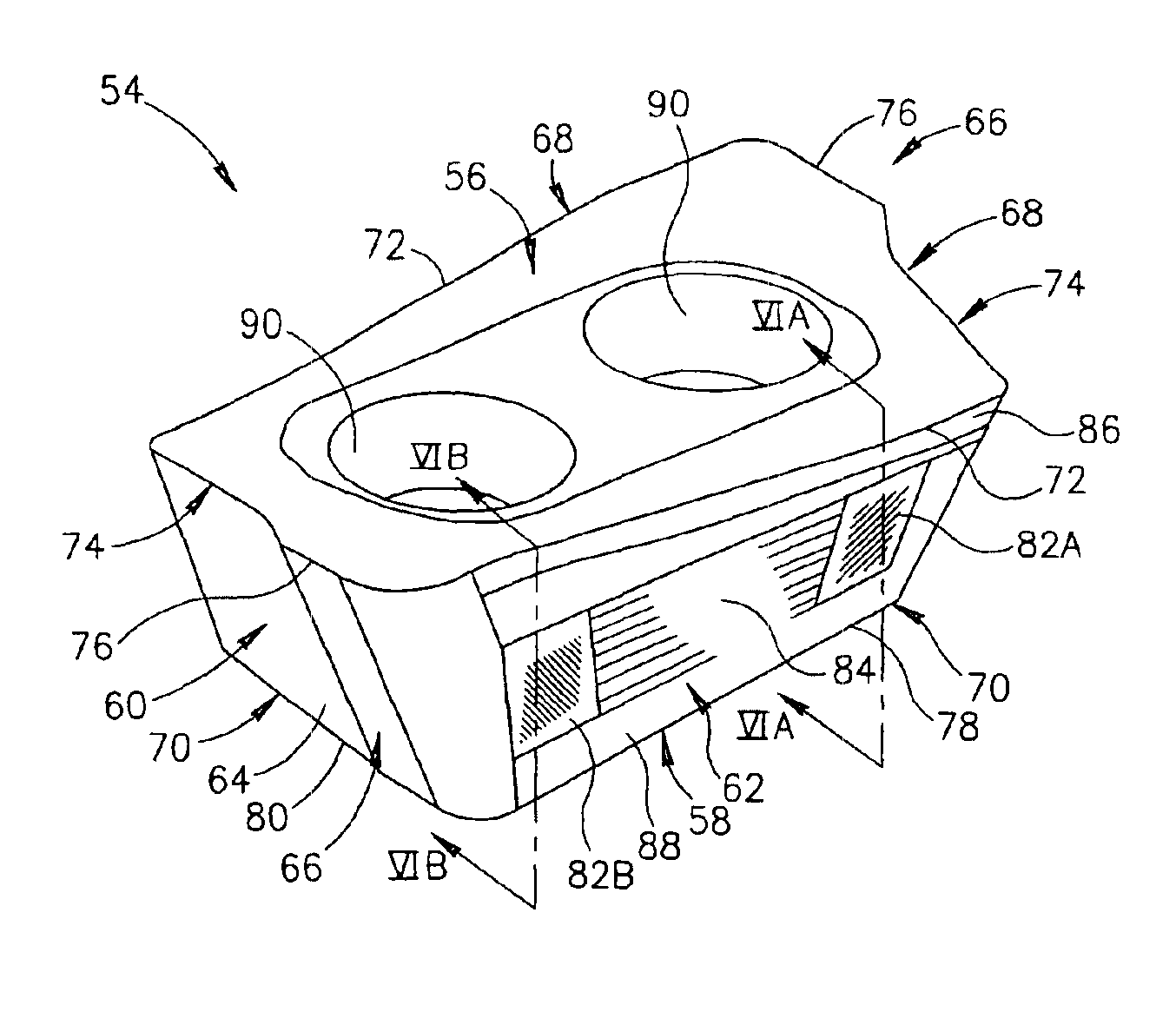

Milling cutter and milling insert with coolant delivery

A cutting insert for use in chipforming and material removal from a workpiece wherein coolant is supplied to the cutting insert from a coolant source. The cutting insert includes at least one discrete cutting location and at least one distinct internal channel that corresponds to the cutting location. The internal channel has an inlet to receive coolant and an outlet to exit coolant. The outlet is proximate to the cutting location, and the inlet is radial inward of the outlet.

Owner:KENNAMETAL INC

Indexable end-milling insert

ActiveUS20080304924A1Good chip formationWorn evenly and slowlyTransportation and packagingMilling cuttersEngineeringKnife blades

An indexable end-milling insert including an underside, an upperside and a plurality of cutting edges that are formed between the upperside and a number of clearance sides and that include a chip-removing main edge as well as a surface-wiping wiper edge. The cutting insert has a square basic shape and includes four main edges and four wiper edges that are countersunk to a lower level than the main edges. The wiper edge is included in a lip projecting in relation to a secondary clearance surface and has a tertiary clearance surface, which laterally transforms into a primary clearance surface. The primary clearance surface has a width that decreases from the two opposite ends thereof toward a section having a smallest width therebetween.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

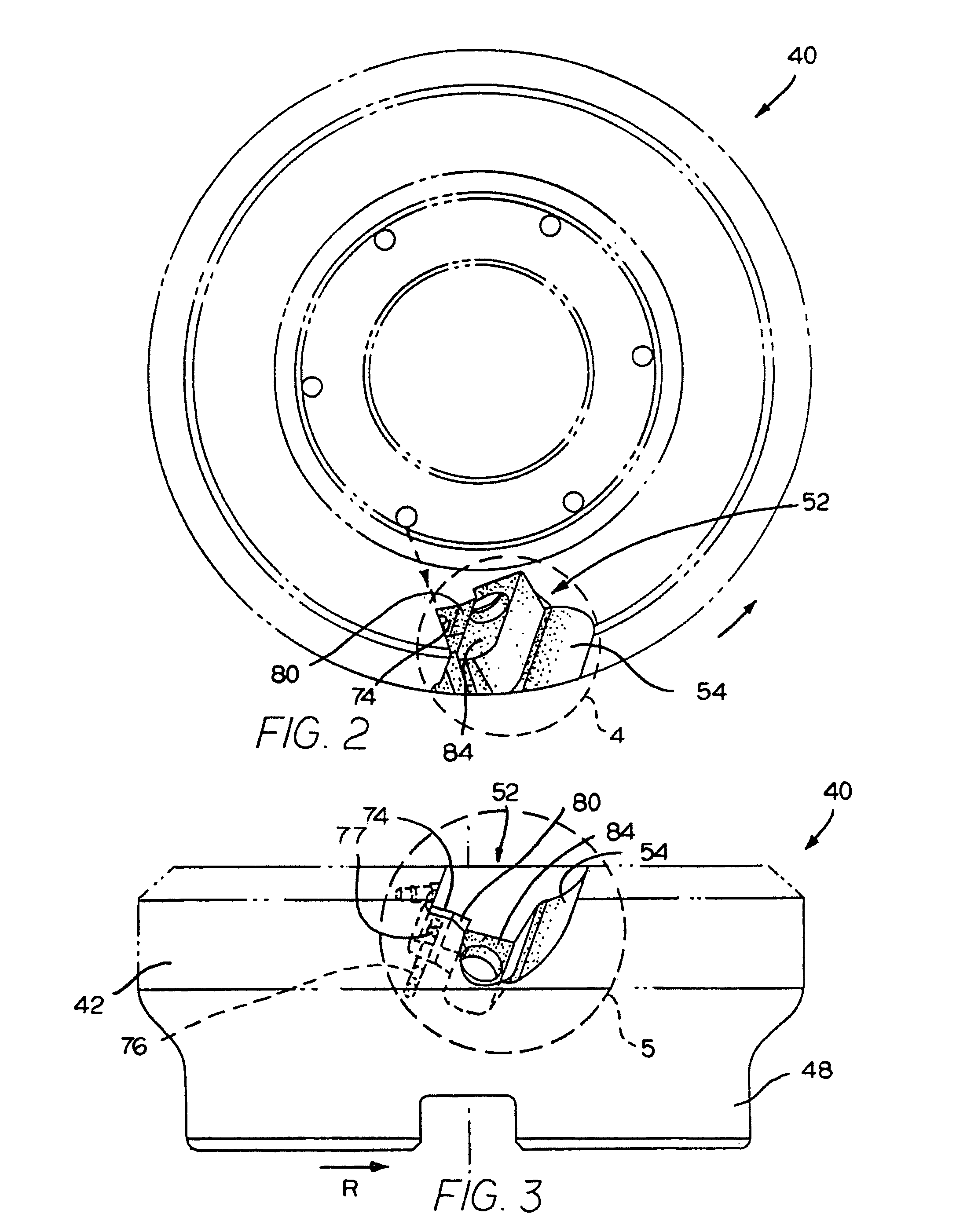

Indirect Cooling of a Rotary Cutting Tool

ActiveUS20100272529A1Dissipate energyMinimization requirementsTransportation and packagingMilling cuttersWorking fluidEngineering

An indirect cooling system for a rotating cutting tool uses a cryogenic coolant that is delivered to a cavity formed on the back surface of the cutting element, providing cooling near the cutting edge of the element. Because the total flow rate of the working fluid is low (less than 0.08 Liters / min / cutting edge), the fluid can be safely vented to atmosphere from the cavity, and as a result, no specialized coolant recovery or ventilation equipment is needed. The cavity may be formed with fins to enhance the heat transfer between the cutting element and the coolant, and coolant may additionally be sprayed directly onto the exterior surface of the element to cool the tool-chip interface. The indirect cooling system may be used for hard to machine metals and composites, as well as the machining of conventional materials without the use of traditional cutting fluids.

Owner:5ME LLC

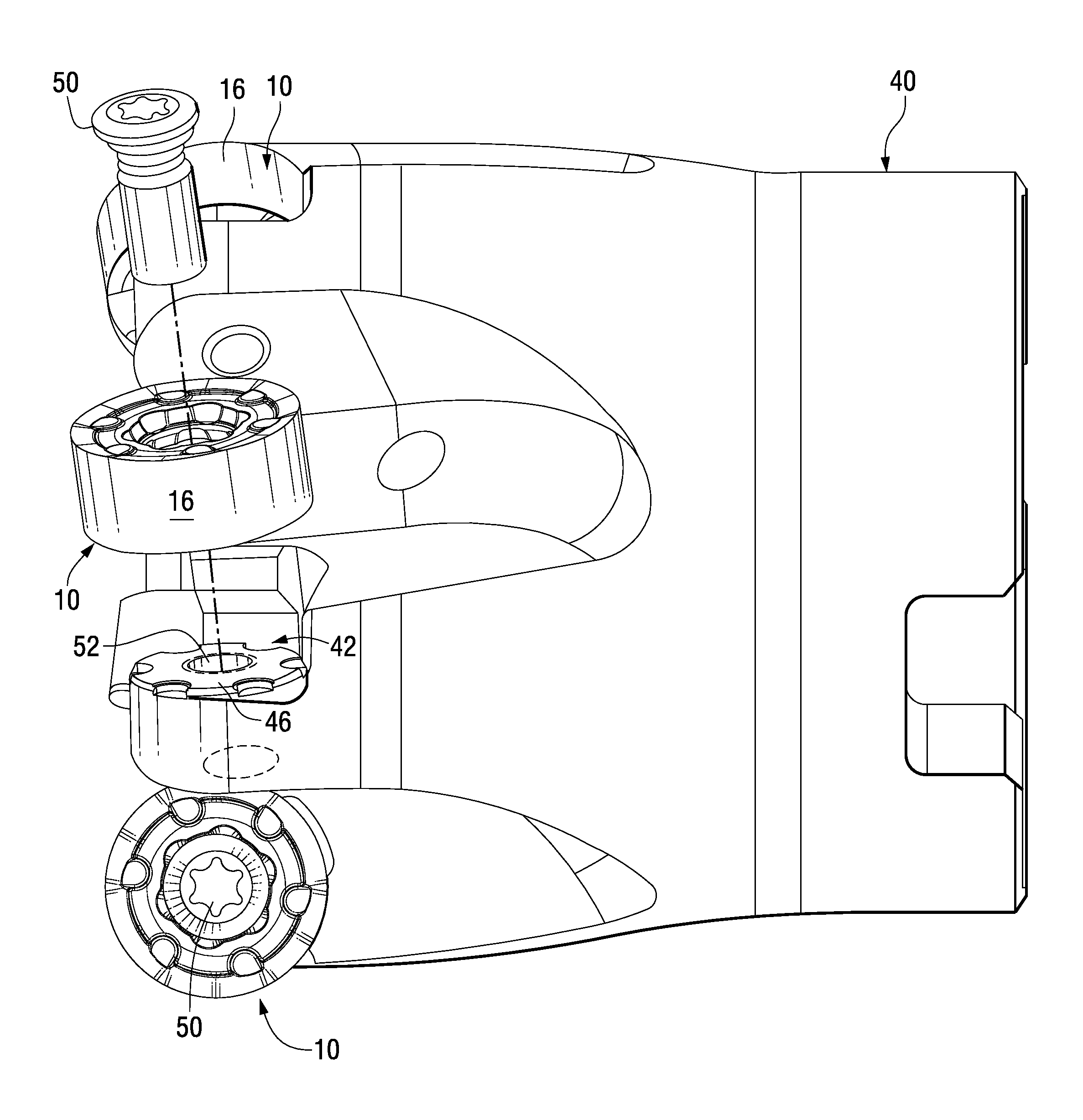

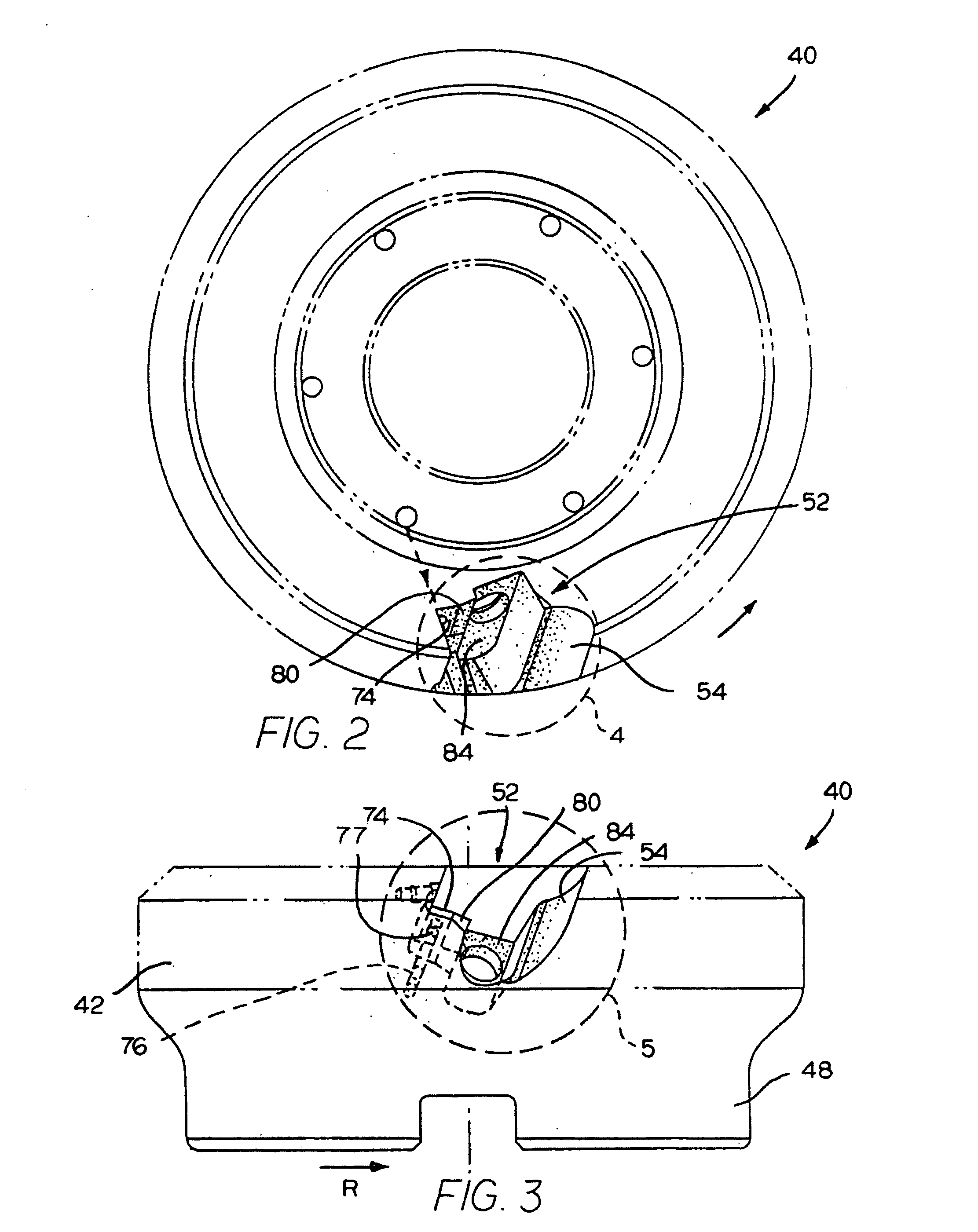

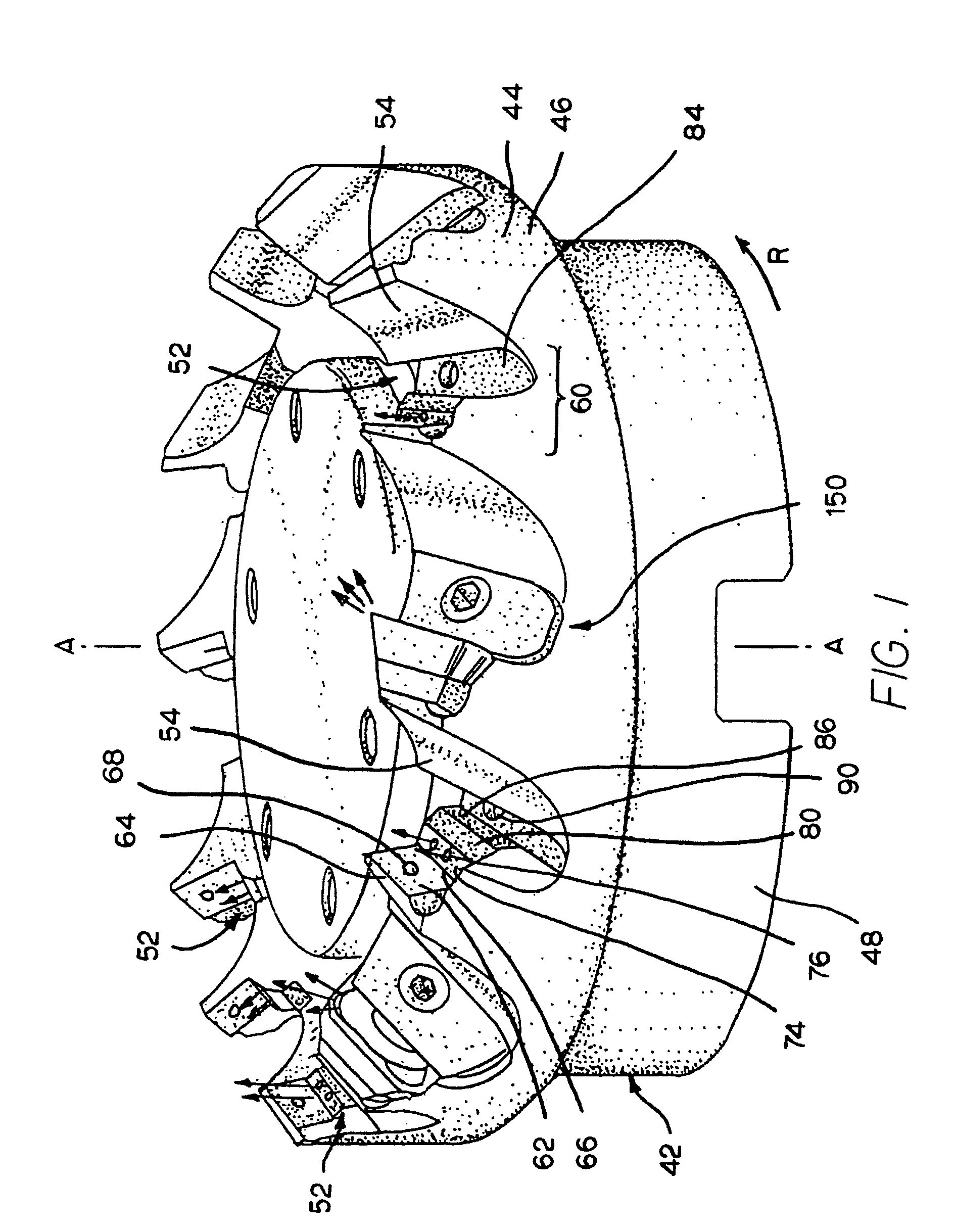

Round Cutting Insert With Anti-Rotation Feature

A round cutting insert with an anti-rotation feature. The round cutting insert includes a plurality of projections formed on a first surface and another plurality of projections formed on an opposing surface. The round cutting insert is reversible and indexable. The round cutting insert is removably received in an insert receiving pocket in a tool body wherein the insert receiving pocket includes a plurality of dimples for receiving one of the plurality of first projections or the plurality of second projections. This arrangement prevents rotation of the round cutting insert while mounted in the insert receiving pocket.

Owner:KENNAMETAL INC

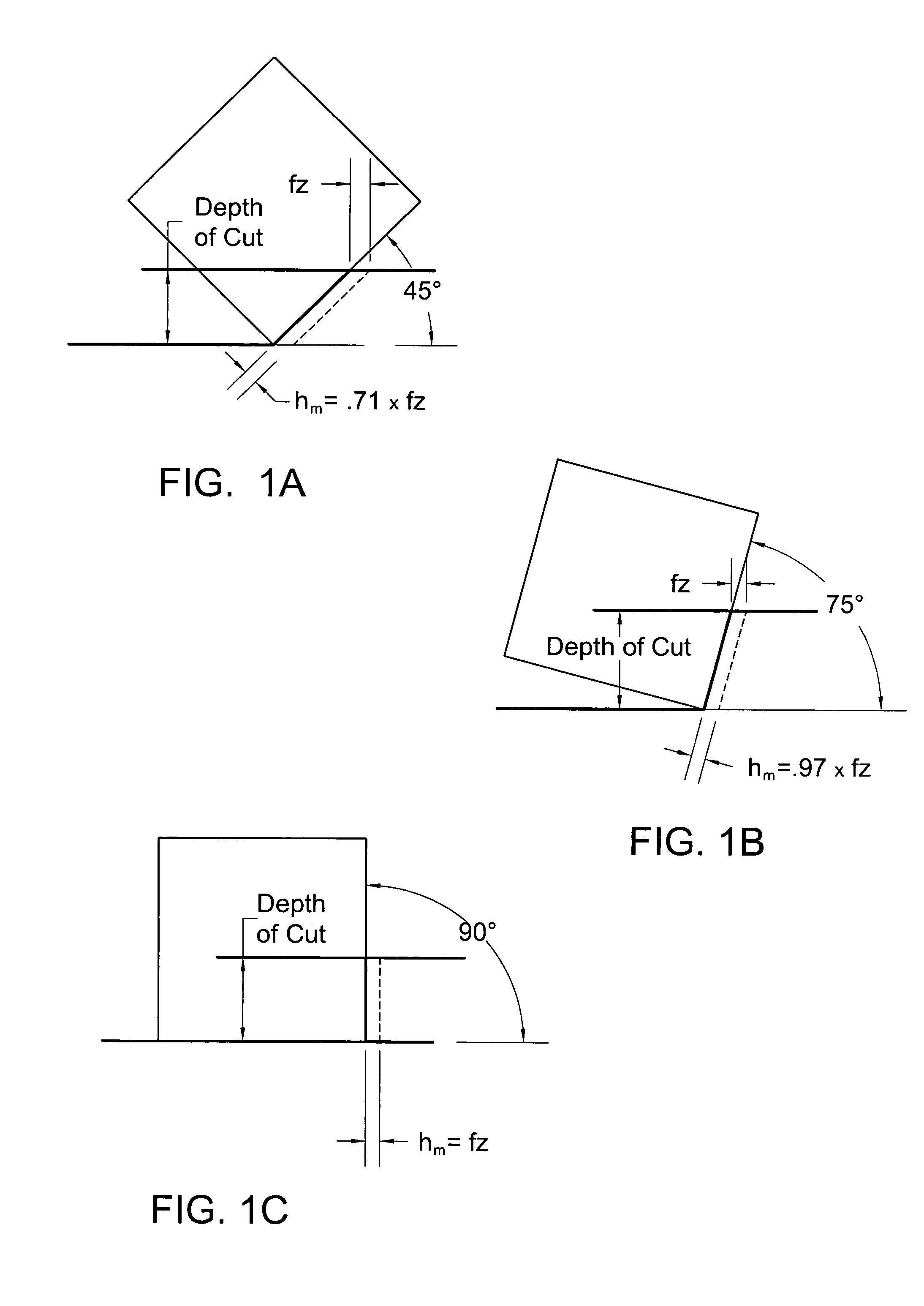

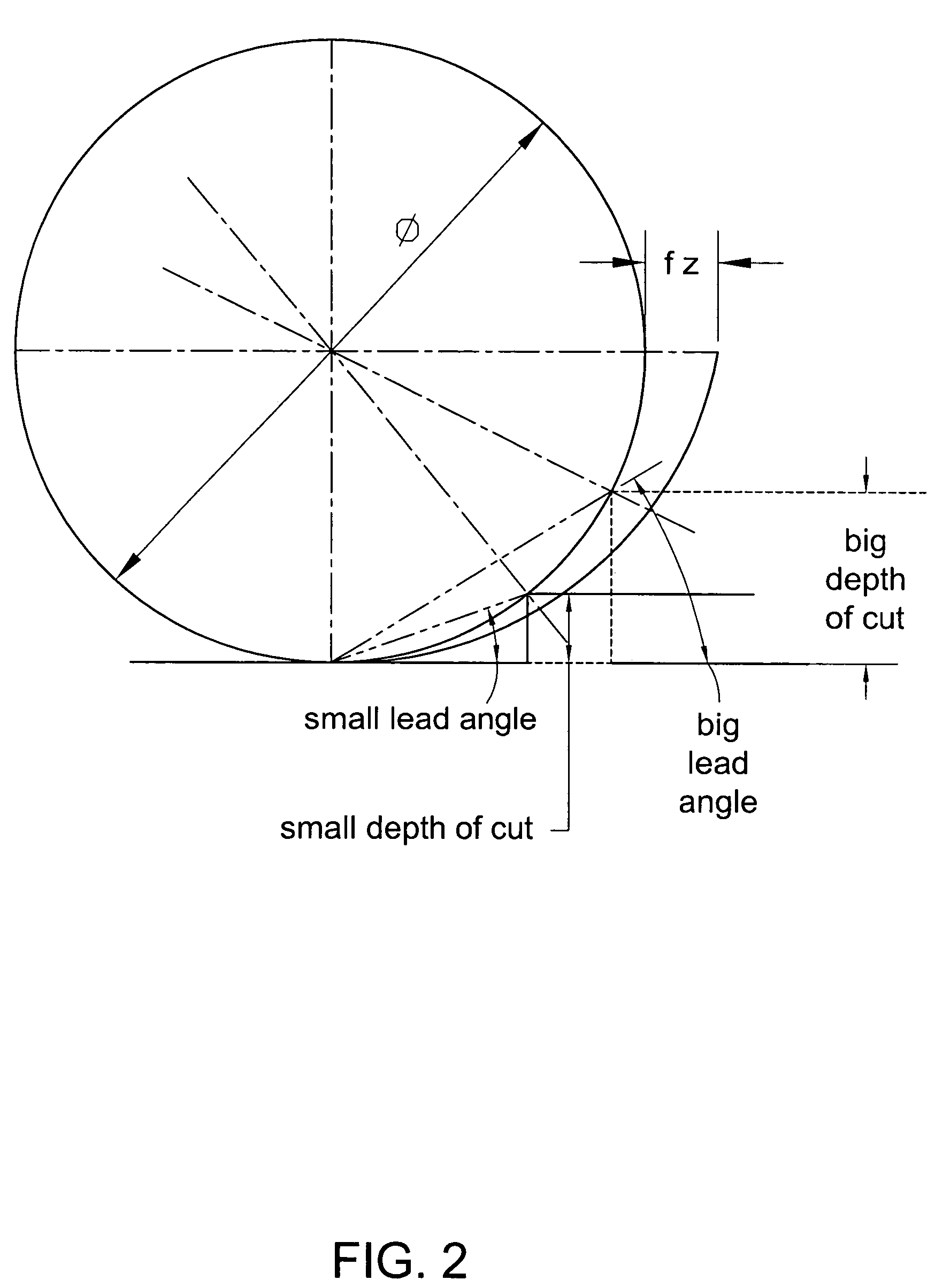

Cutting insert for high feed face milling

InactiveUS7220083B2Increase feed rateReduce forceTransportation and packagingMilling cuttersEllipseEdge strength

A cutting insert for milling operations, such as, face milling, slot milling, plunge milling, and ramping operations. The cutting insert exhibits a combination of favorable cutting edge strength, and unique cutting edge geometry, thus, allowing milling operations at relatively high feed rates. The cutting insert includes at least four cutting edges, wherein at least one of the cutting edges is a convex cutting edge. Certain embodiments of square cutting inserts will have four convex cutting edges which may be connected by nose corners. The convex cutting edge may comprise at least one of a circular arc, a portion of an ellipse, a portion of a parabola, a multi-segment spline curve, a straight line, or combinations of these. Wherein the convex cutting edge comprises a circular arc, the circular arc may have a radius greater than or equal to two times a radius of the largest circle that may be inscribed on the top surface.

Owner:KENNAMETAL INC

A cutting insert

ActiveUS20060228179A1Improve finenessLittle changeCutting insertsWorkpiecesEngineeringMechanical engineering

The present invention relates to a metal cutting insert that is primarily intended for turning operations. The cutting insert comprises an upper surface, a lower surface substantially parallel with said upper surface, and at least three side surfaces extending between said upper and lower surfaces. A transition between two adjacent side surfaces forms a rounded nose radius surface at a cutting insert corner. The cutting insert includes a peripheral land bridging the upper and side surfaces at least at the corner portion at a chamfer angle. An intersection of the land and the nose radius surface forms a nose cutting edge. The nose cutting edge is defined by at least one radius. The cutting corner includes at least one curved wiper edge. The chamfer angle in a cross-section at the nose cutting edge is larger than the chamfer angle in a cross-section a distance away from the nose cutting edge.

Owner:SECO TOOLS AB

Throwaway insert and throwaway-type rotary cutting tool

ActiveUS7040844B1Improve accuracyImprove chip separationMilling cuttersAdverse effect compensationProjection lineCurve line

A tool main cutting edge extends rearward in a rotating direction as it approaches a rear end at the outer periphery. The main cutting edge is a convexly curved line protruding toward the outside of a rake face viewed from the top and another convexly curved line extending toward the seat face, convexly curving from one end of the main cutting edge to the other, viewed from the side. When mounted, an inclination angle defined by the rake face gradually decreases from one end toward the other, and a projection line of a rotation about a rotation axis of the tool forms a convex arc smoothly coming, at a middle portion of the main cutting edge, into contact with a cylindrical surface about the axis and gradually retreats inward from the cylindrical surface as it approaches both ends of the main cutting edge.

Owner:MITSUBISHI MATERIALS CORP

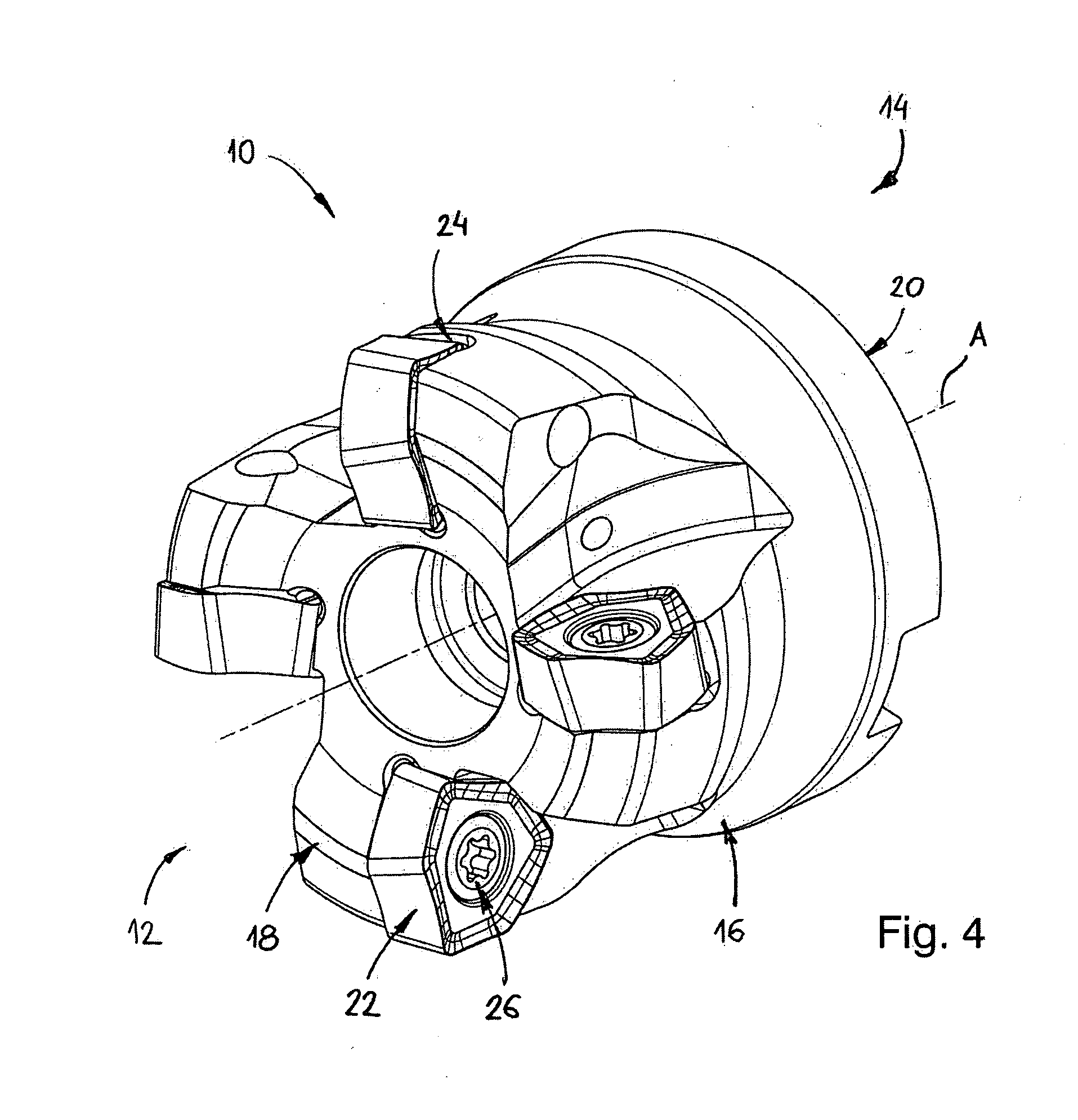

Tangential cutting insert and milling cutter

A tangential cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces and two identical opposing minor side surfaces extending between them. Each end surface has a peripheral edge containing cutting edges and four corners of which two are lowered and two are raised. Each end surface is provided with at least one projecting abutment member having a projecting abutment surface, wherein in a side view of either major side surface, the at least one projecting abutment surface is concave.

Owner:ISCAR LTD

Milling cutter and milling insert with coolant delivery

A cutting insert assembly for use in chipforming and material removal wherein the cutting insert assembly is received in a pocket of a cutter body wherein coolant can flow out of a pocket opening contained in the pocket. The cutting insert assembly includes a cutting insert body that presents at least two discrete cutting locations. The cutting insert body contains a coolant entry passage aligned with the pocket opening for coolant to flow through the coolant entry passage. The cutting insert body has a rake surface that contains at least two of the discrete depressions wherein each one of the discrete depressions corresponds to one of the cutting locations. Each one of the discrete depressions extends toward its corresponding cutting location. The assembly includes a diverter that is positioned adjacent to the cutting insert body wherein the diverter has a receiving opening aligned with the coolant entry passage to receive coolant through the coolant entry passage. The diverter includes a coolant trough in communication with the receiving opening wherein the coolant trough is aligned toward a selected one of the cutting locations whereby the coolant trough and the discrete depression corresponding to the selected cutting location define a conduit for the flow of coolant toward the selected cutting location.

Owner:KENNAMETAL INC

Cutting insert having a rake surface and a plateau surface separated by a step

ActiveUS7306409B2Convenient heightImprove protectionTransportation and packagingMilling cuttersMilling cutterPlateau

A cutting insert intended exemplarily for use in a face-milling cutter, has an all-around extending rake surface which changes into a plateau surface by an uninterrupted step. The step reaches its greatest height in the corner regions of the cutting insert. The rake surface defines a positive rake angle. The step prevents the produced chips from running onto the plateau surface. As a result of such a measure, a smear-on of material onto the plateau surface from a chip is prevented.

Owner:WALTER AG

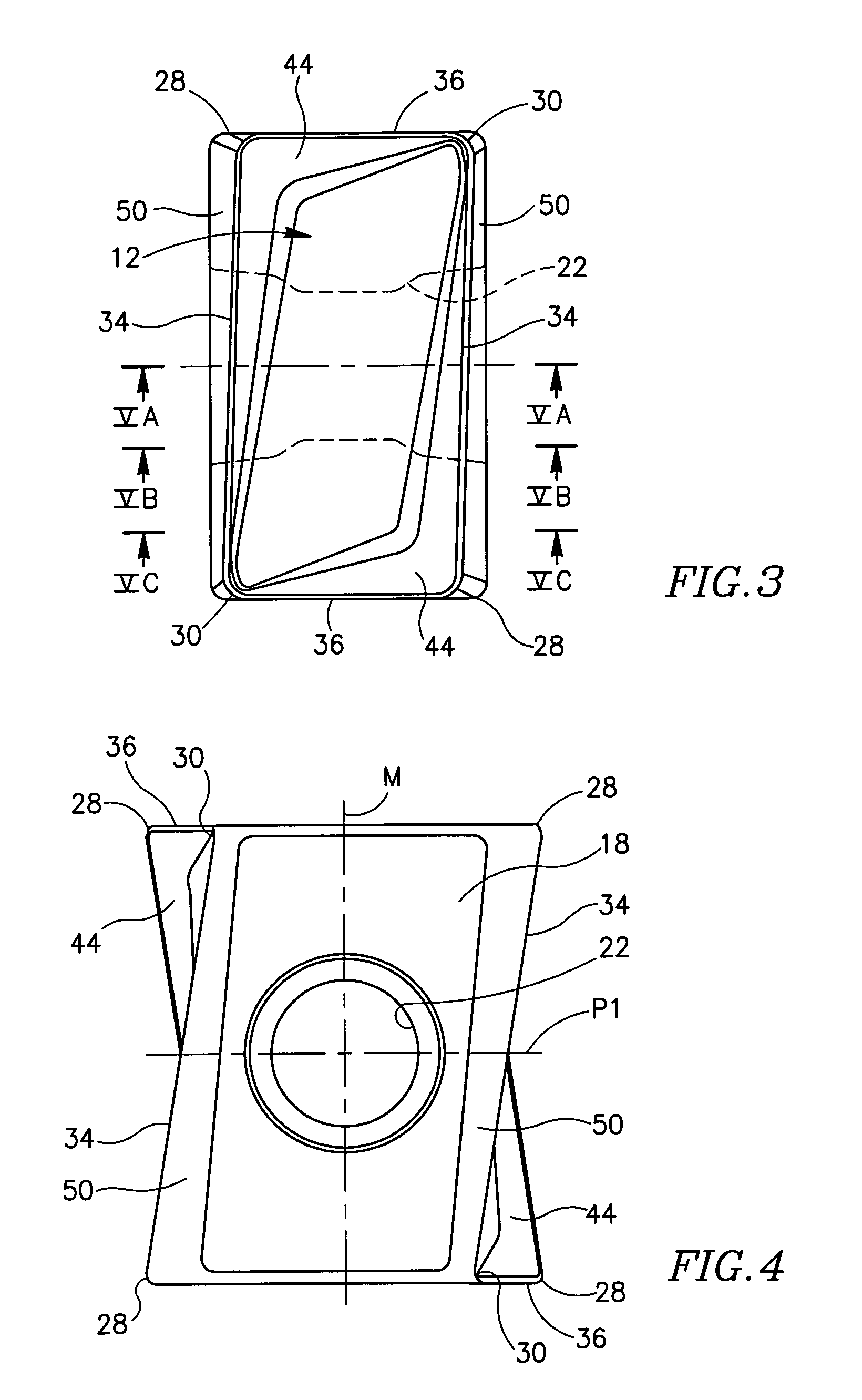

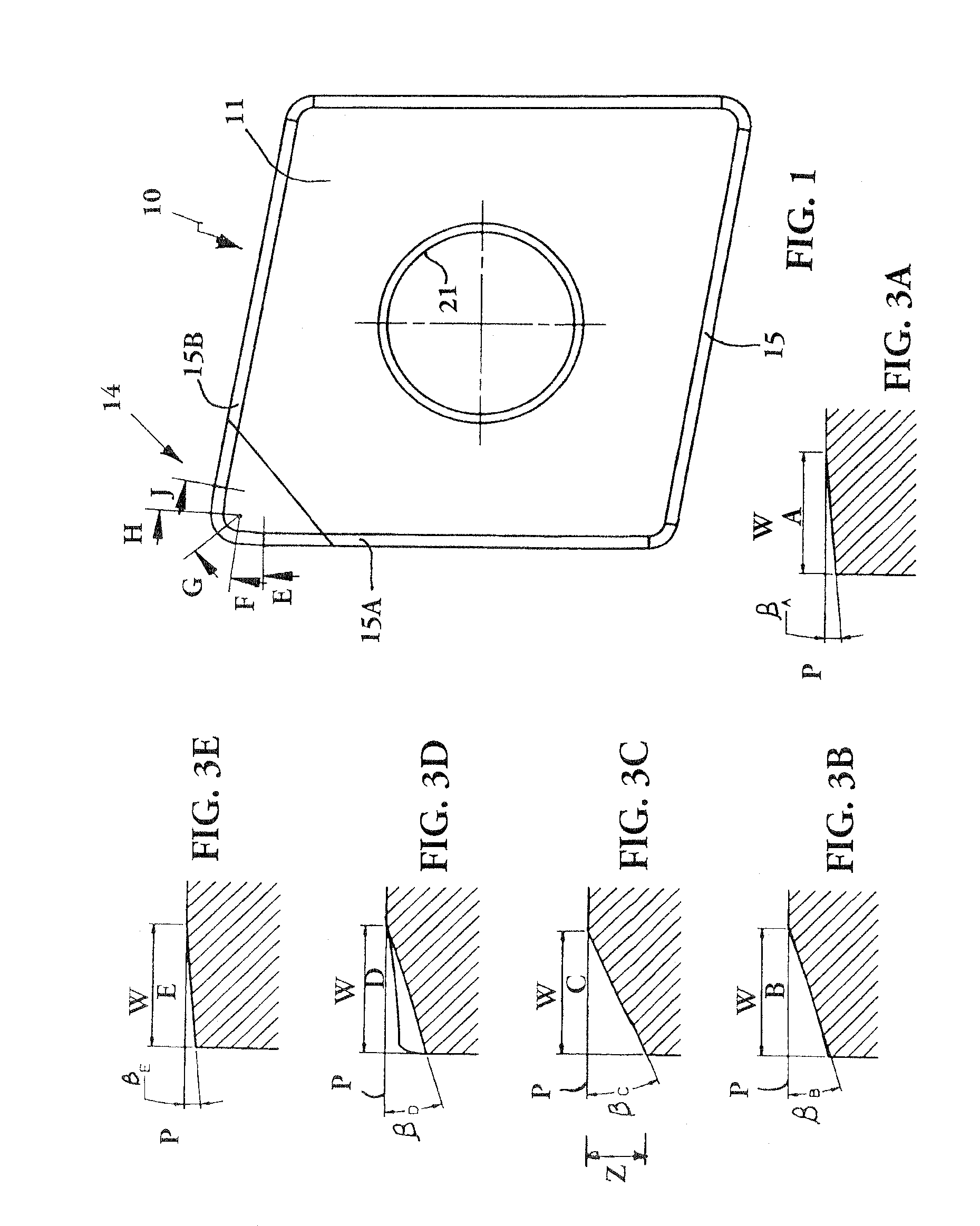

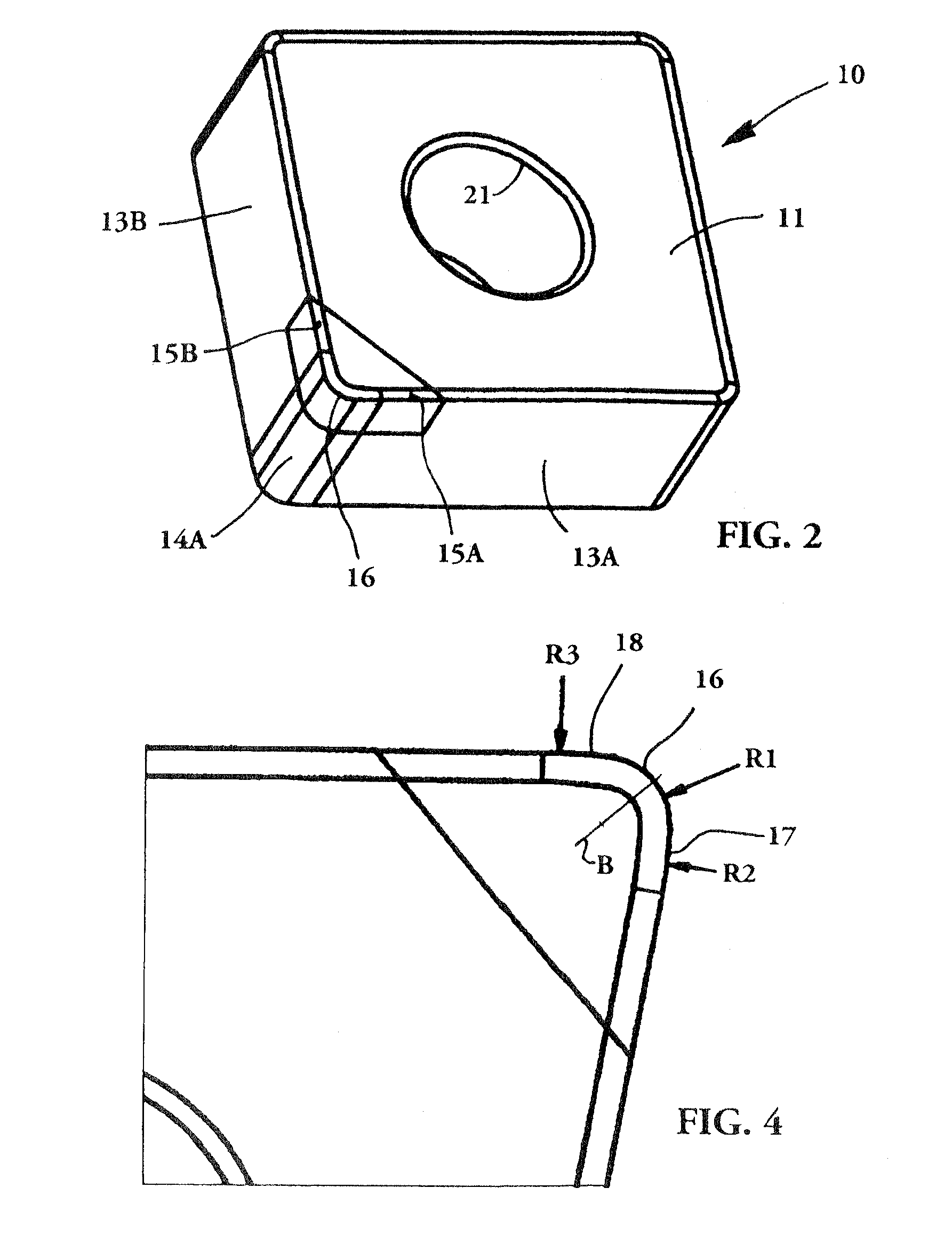

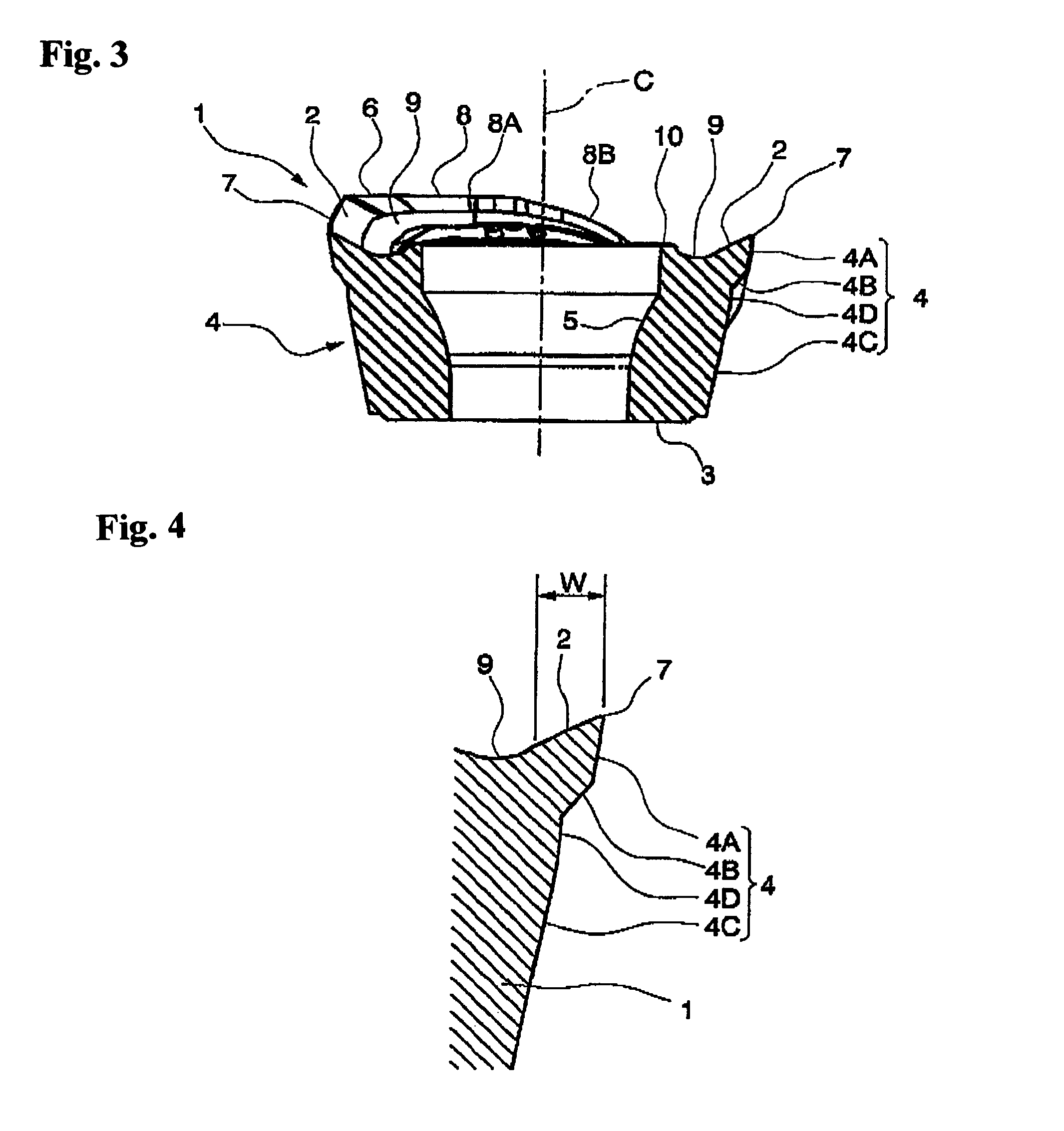

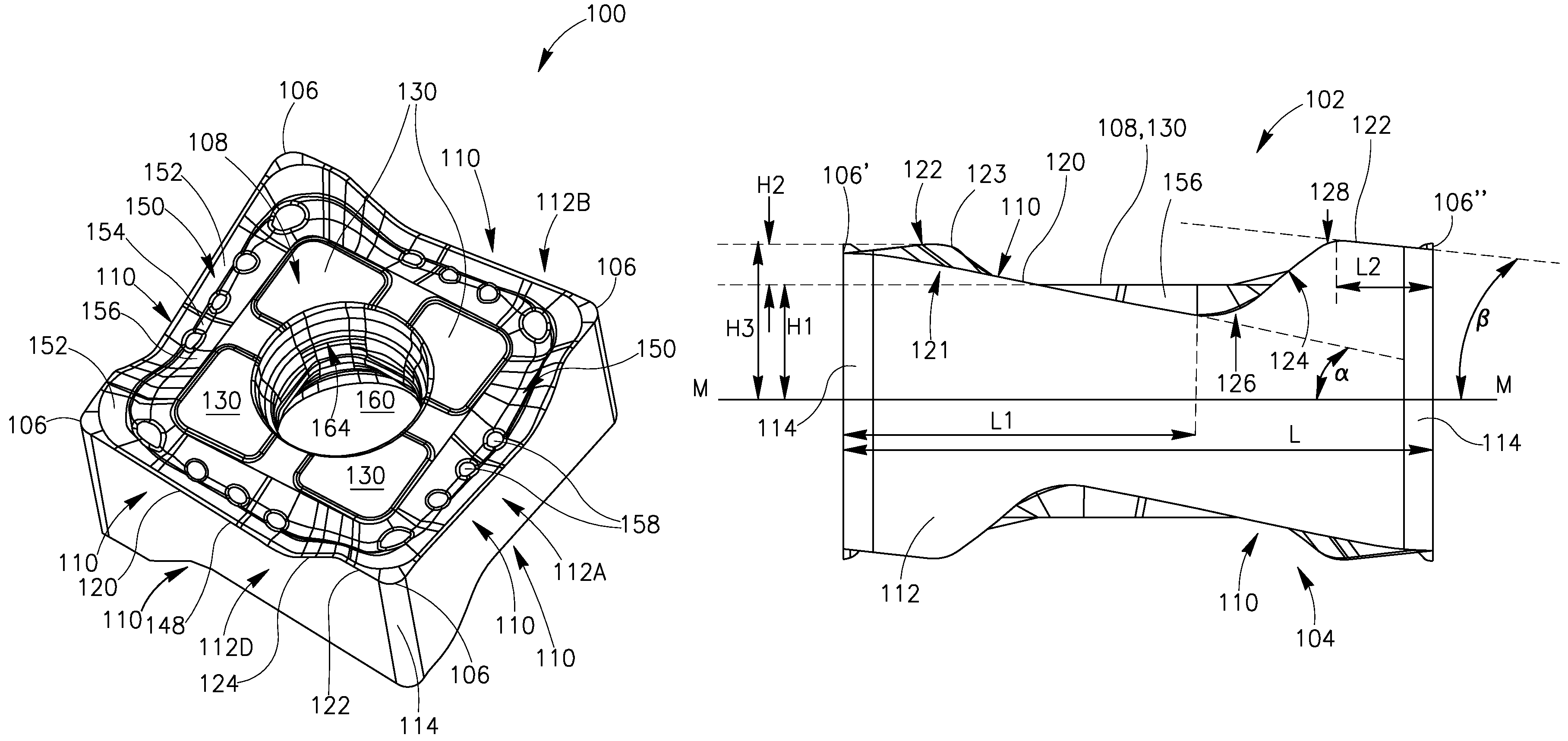

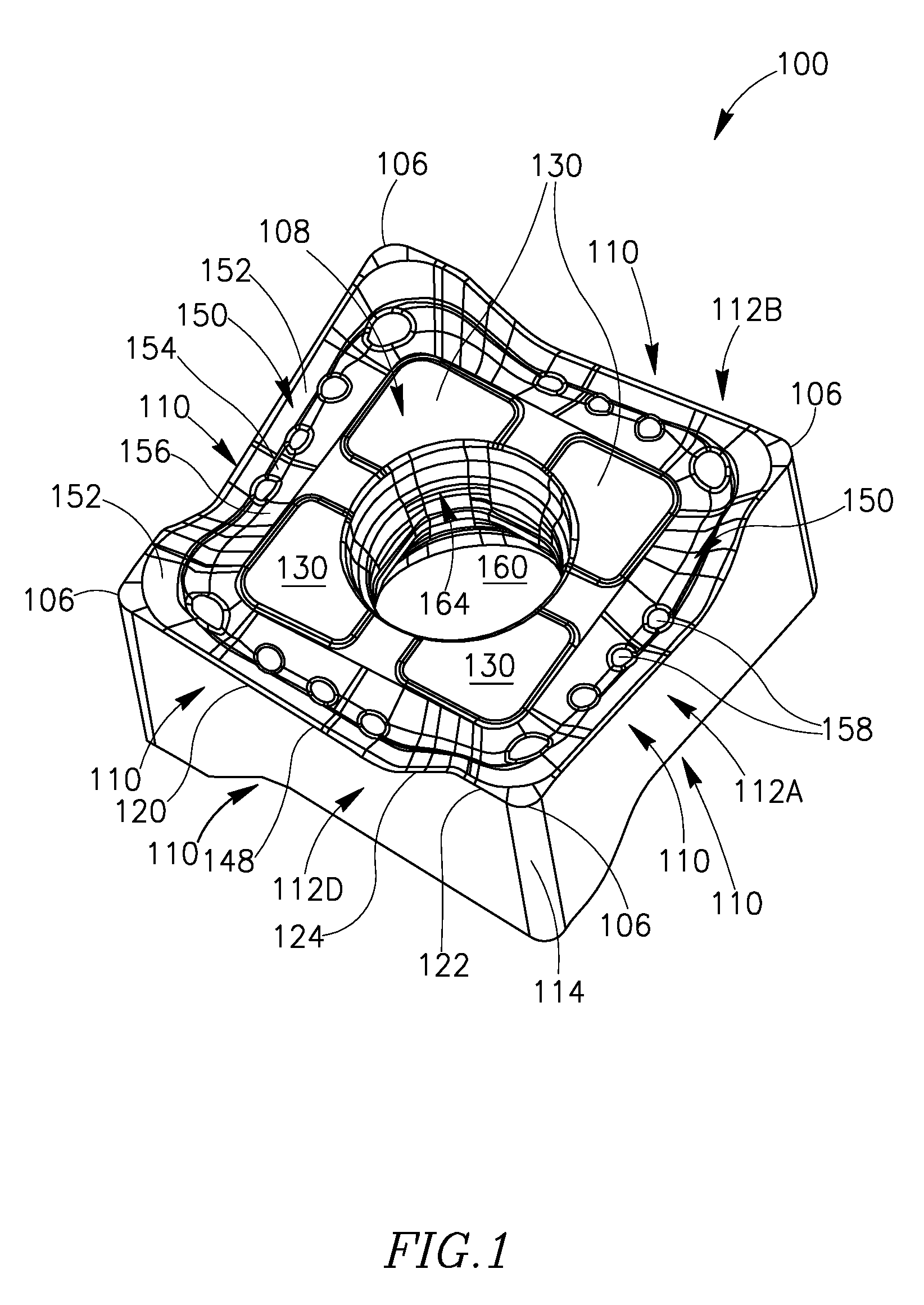

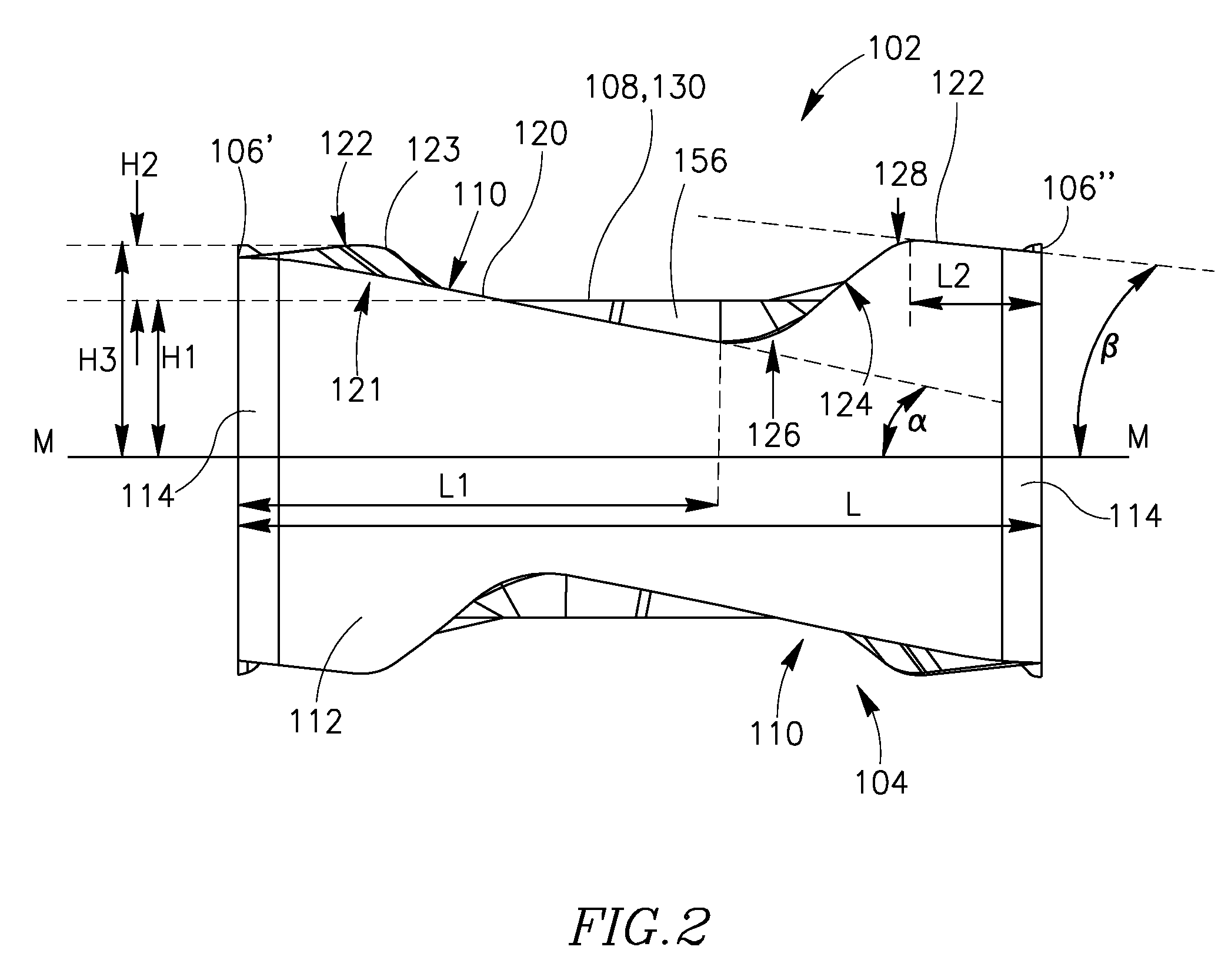

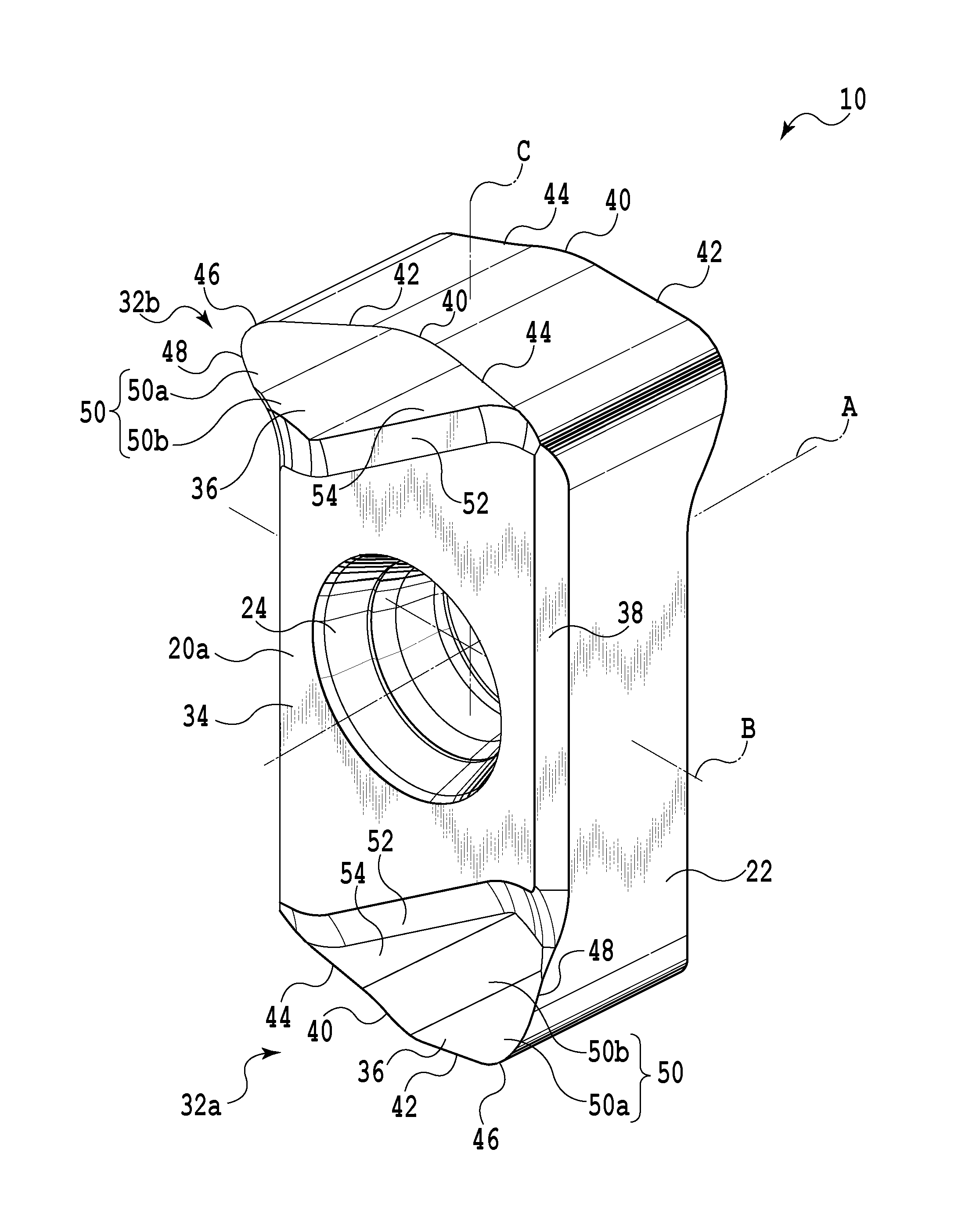

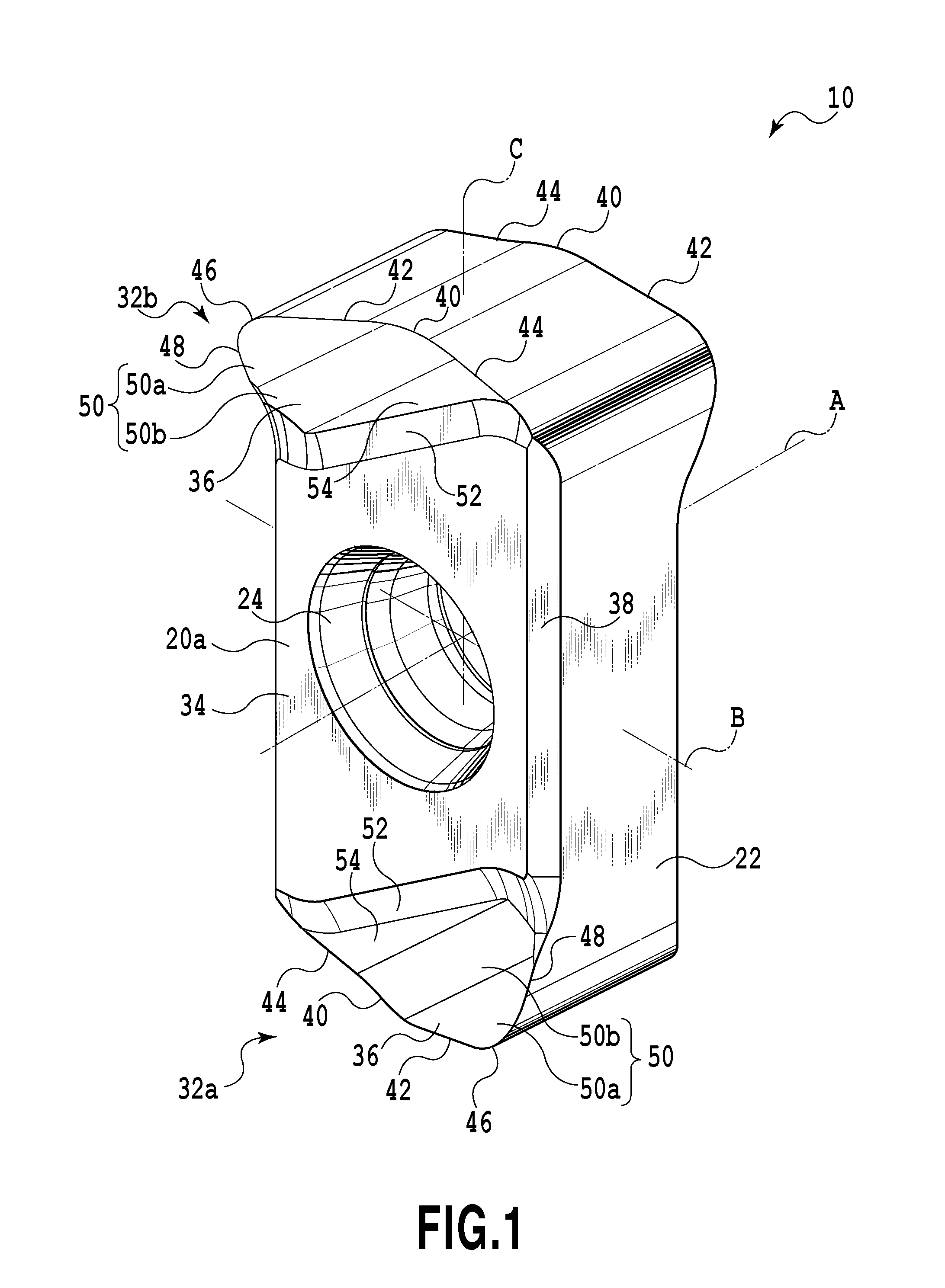

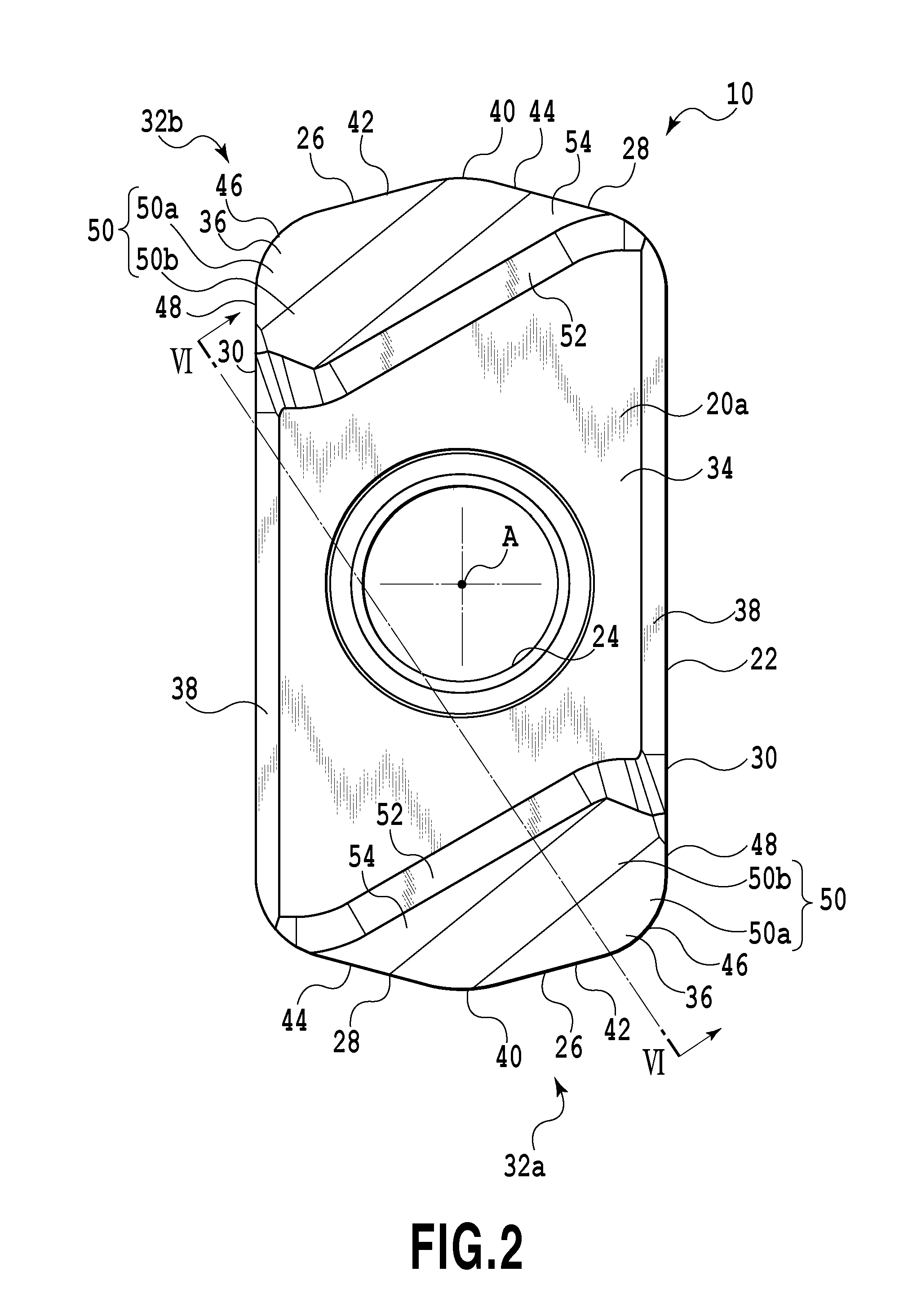

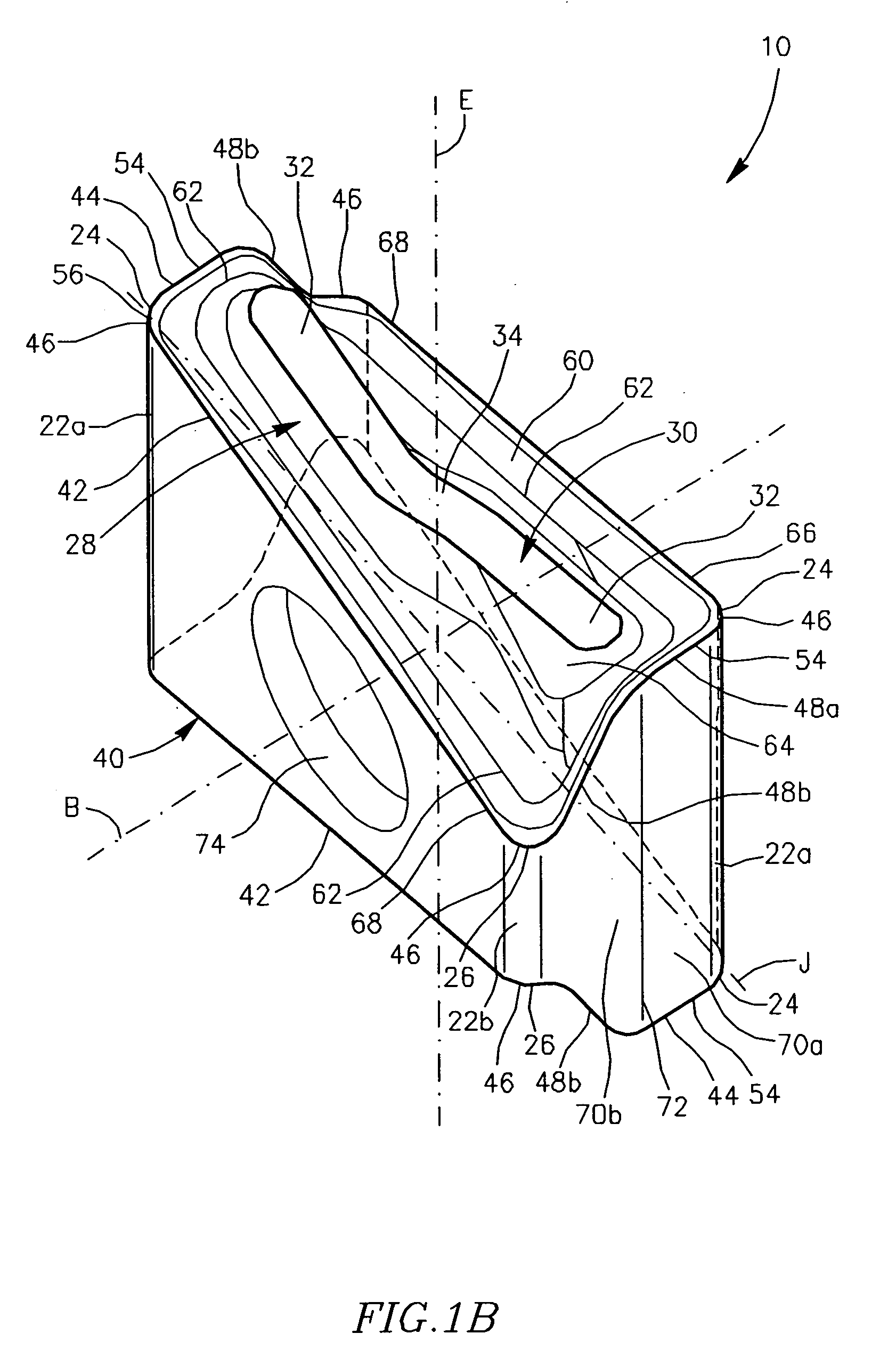

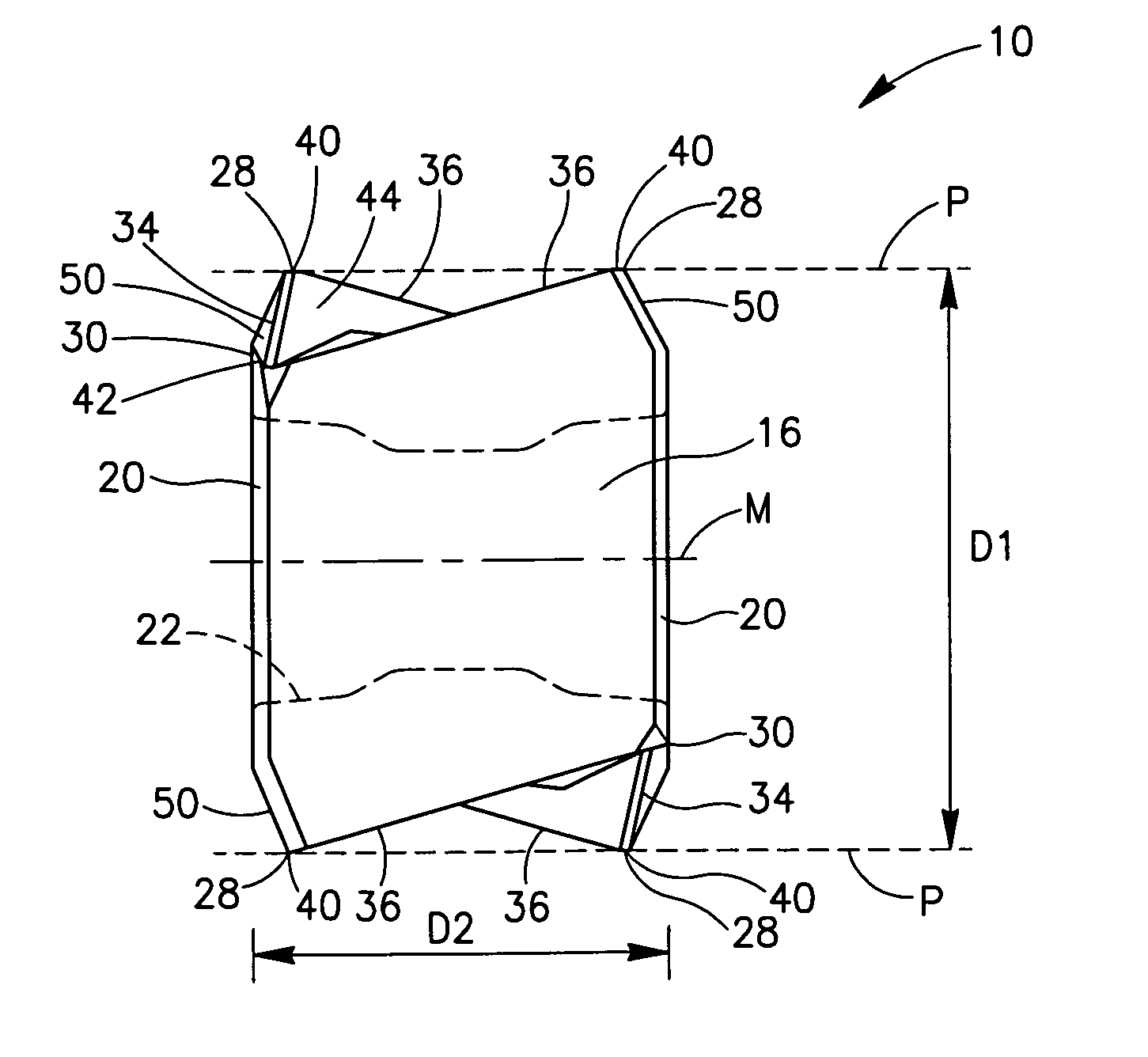

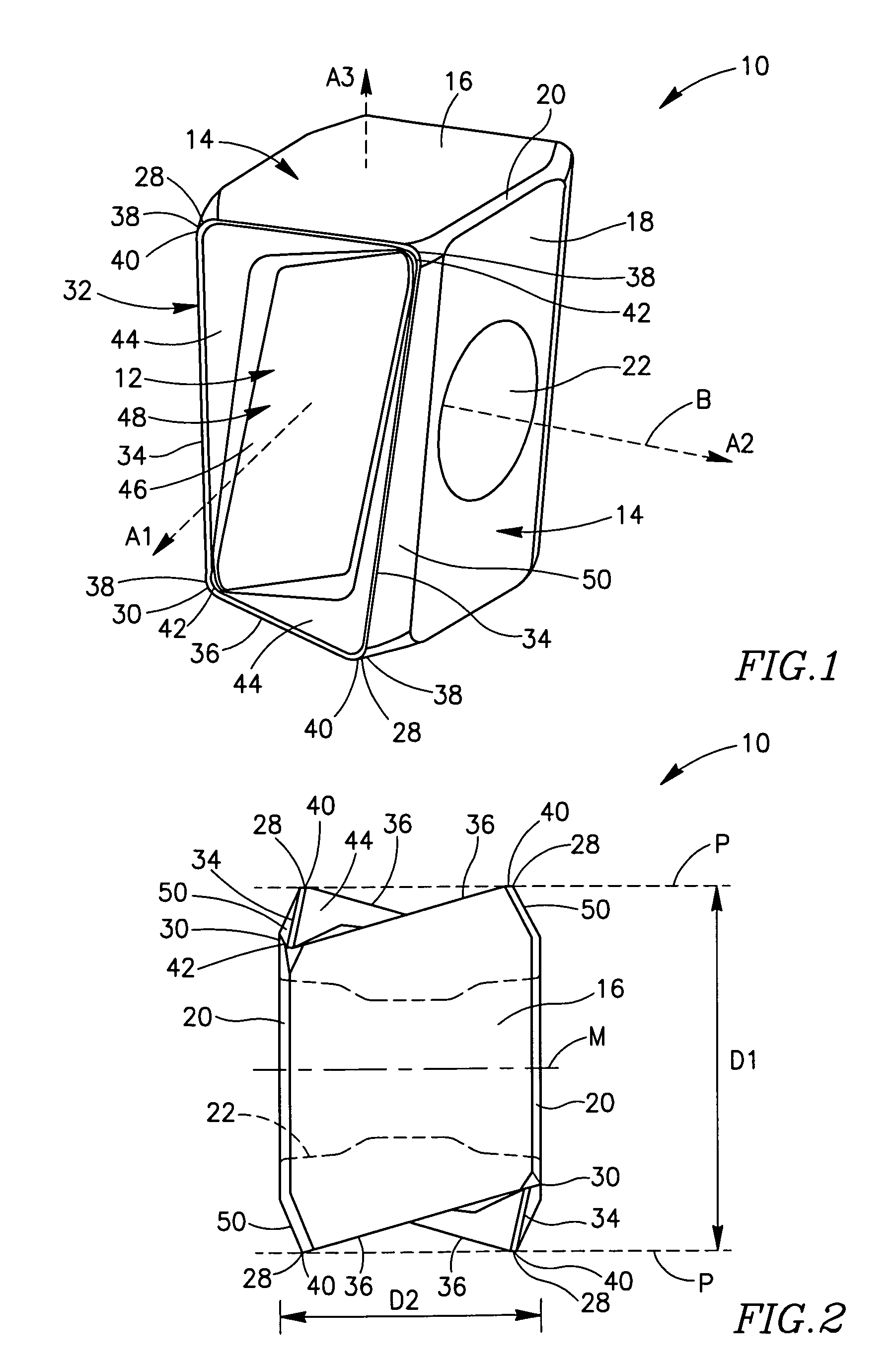

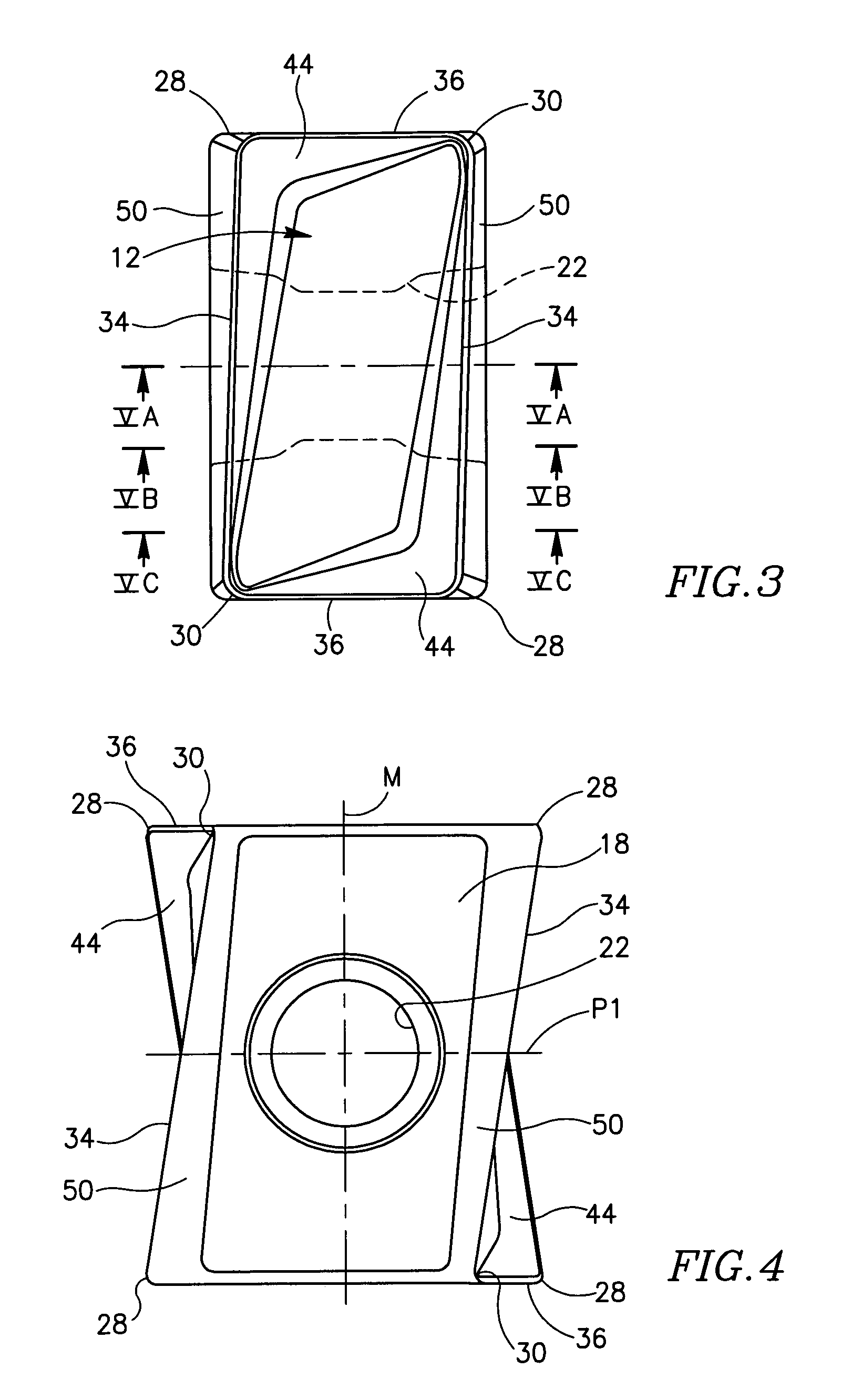

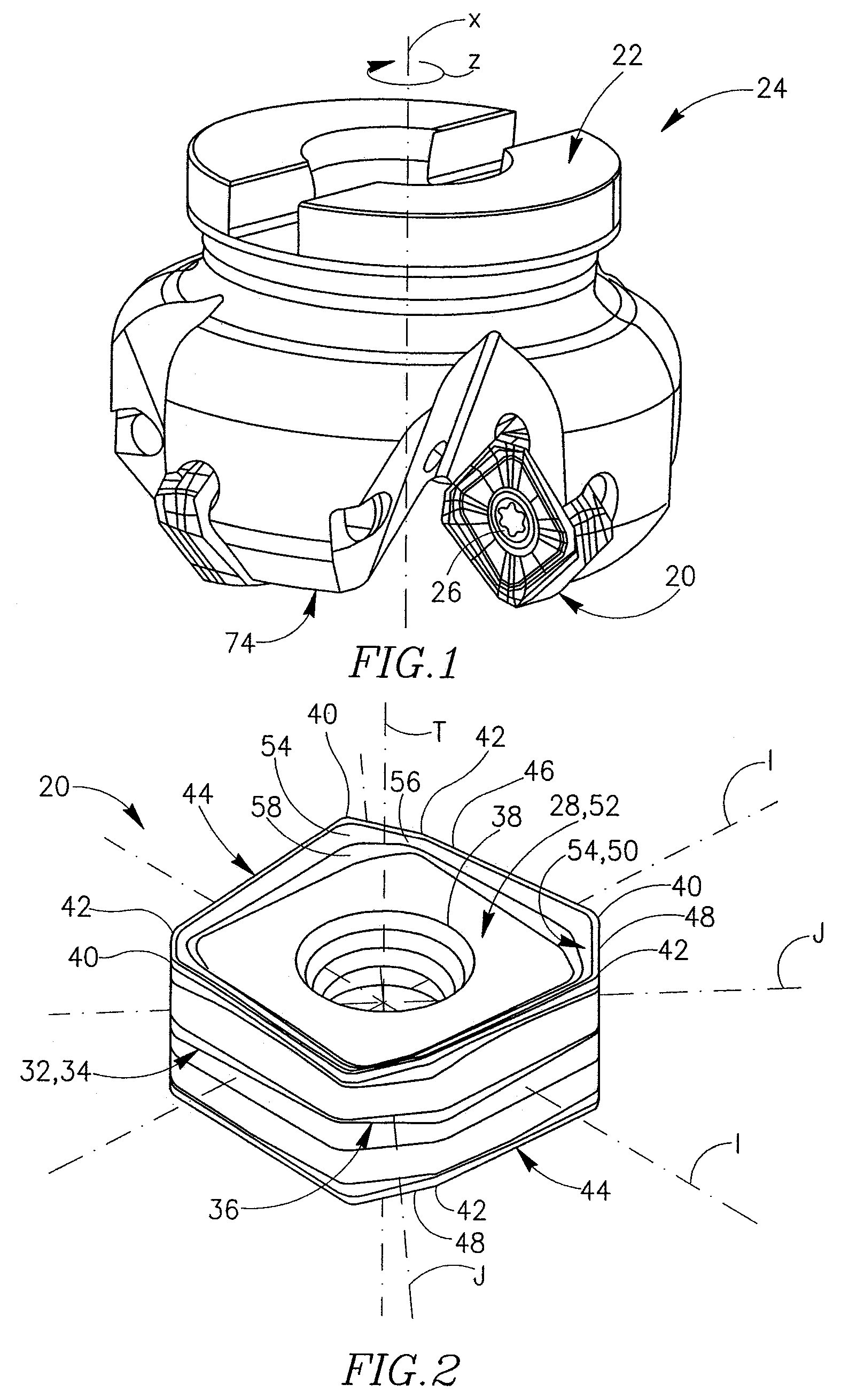

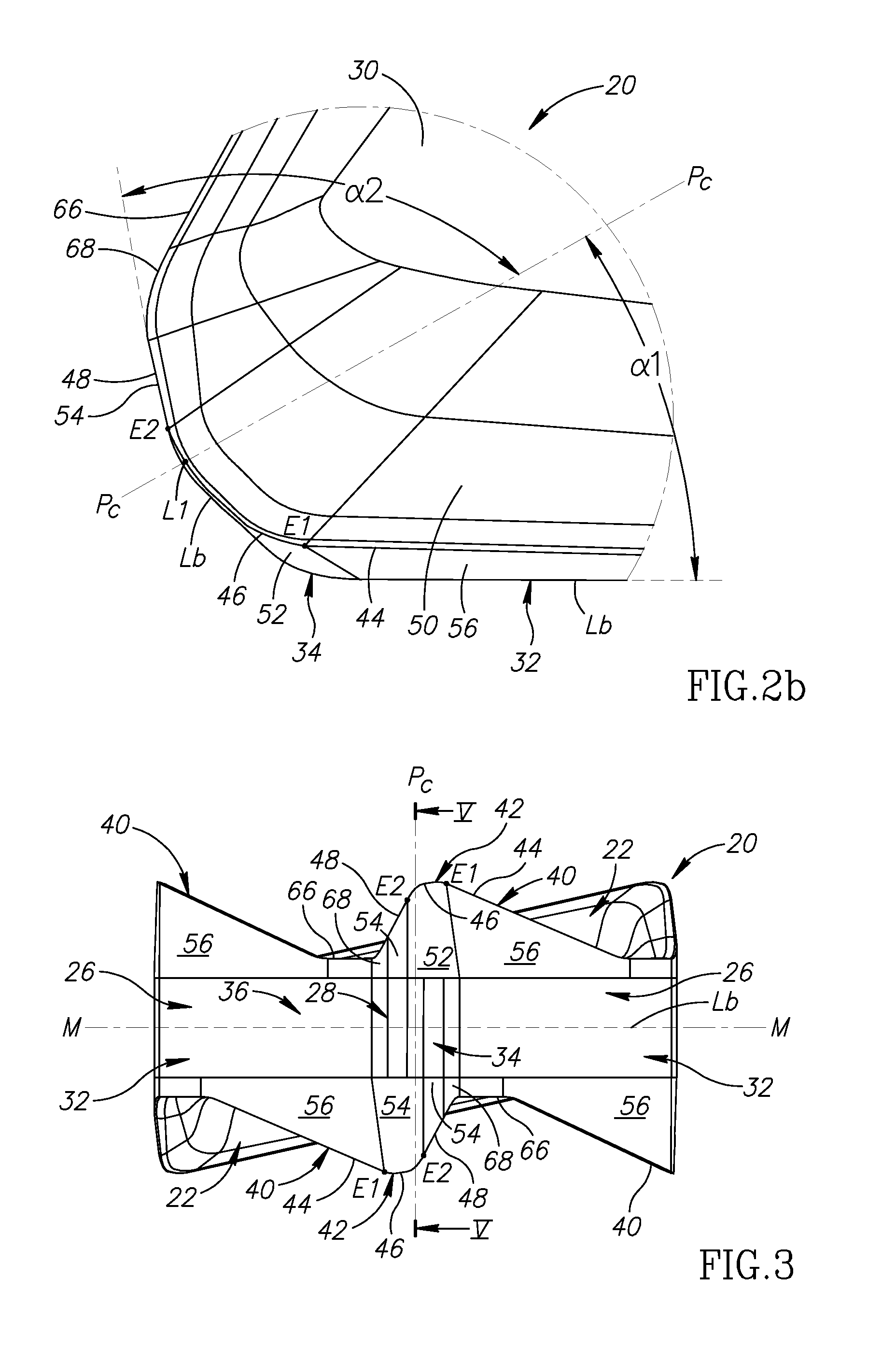

Cutting insert for a milling cutter

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

Milling cutter and milling insert with coolant delivery

Owner:KENNAMETAL INC

Indexable cutting insert with positive axial rake angle and multiple cutting edges

An indexable cutting insert includes a first component with an outer or top surface and side surfaces. A third component is mirror symmetric with respect to the first component about a vertical or y-axis of the cutting insert. A second component is disposed between the first and third components. Multiple cutting edges are defined at an intersection between the side surfaces and the top surface, wherein the cutting edges define a positive axial rake angle. In one embodiment, the first and third components are in the shape of a polygonal with a star appearance, and the second component is in the shape of a square. The first and third components are offset from one another by a first offset angle, while the second component is offset from the first and third components by a second offset angle to allow the cutting insert to be indexable.

Owner:KENNAMETAL INC

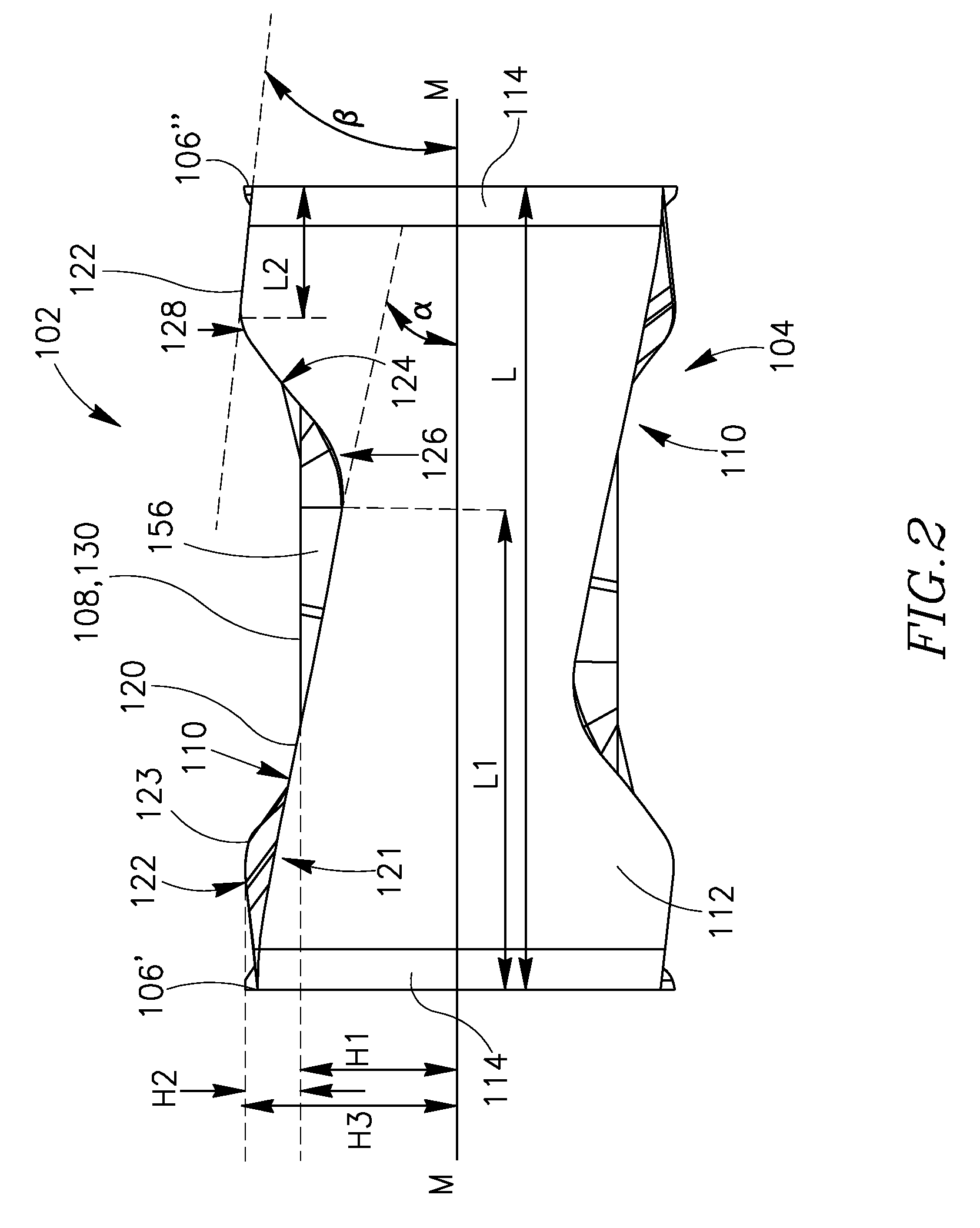

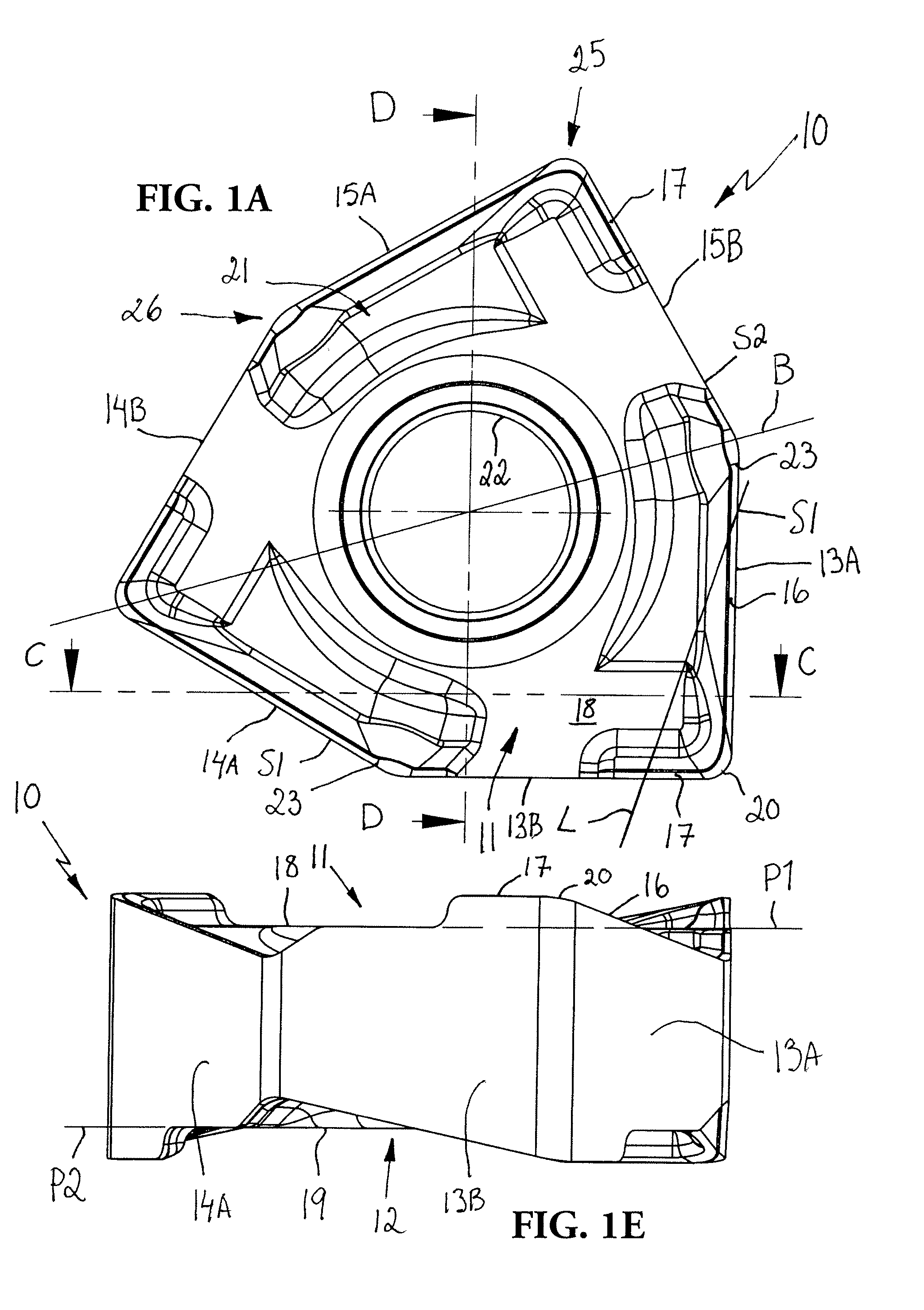

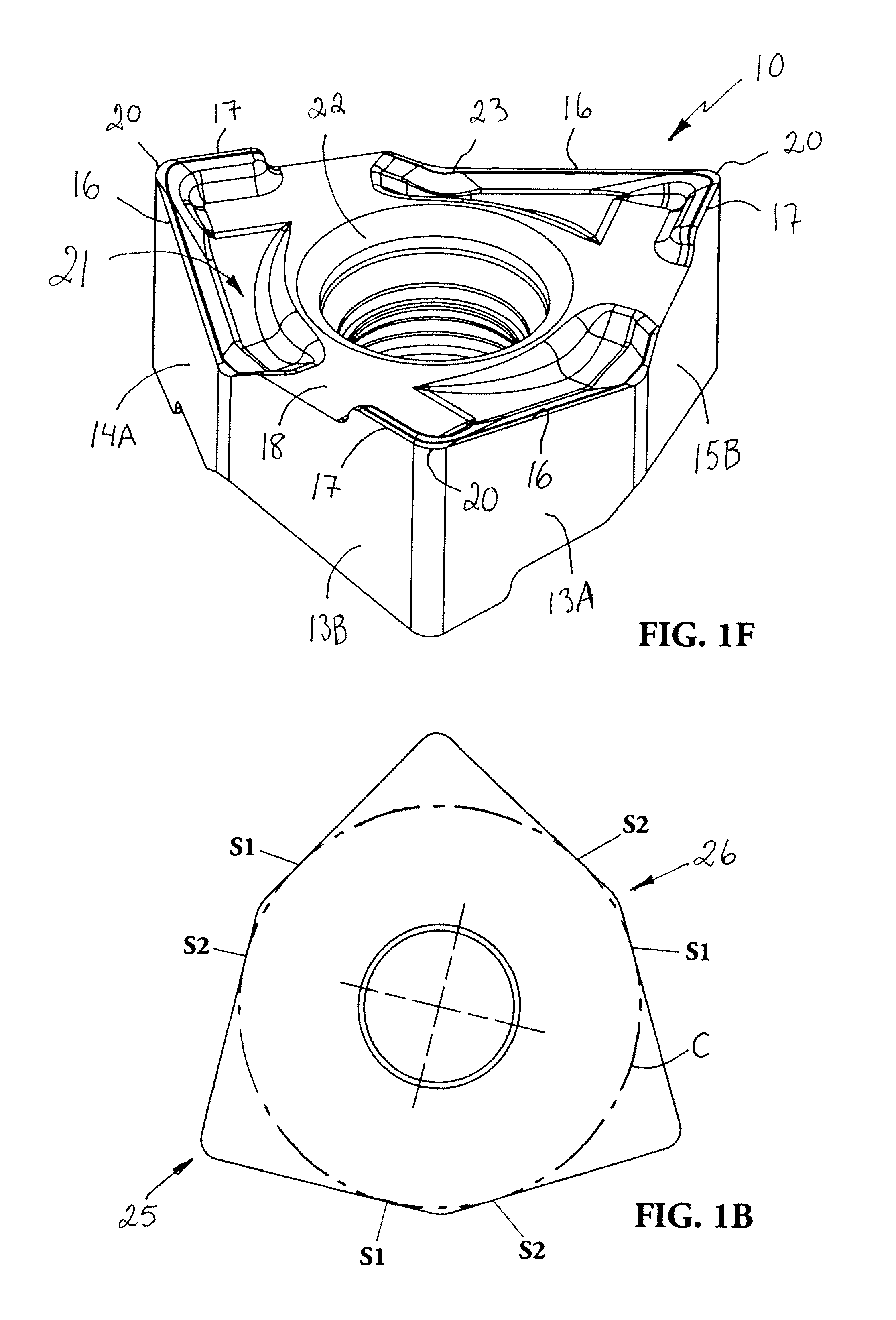

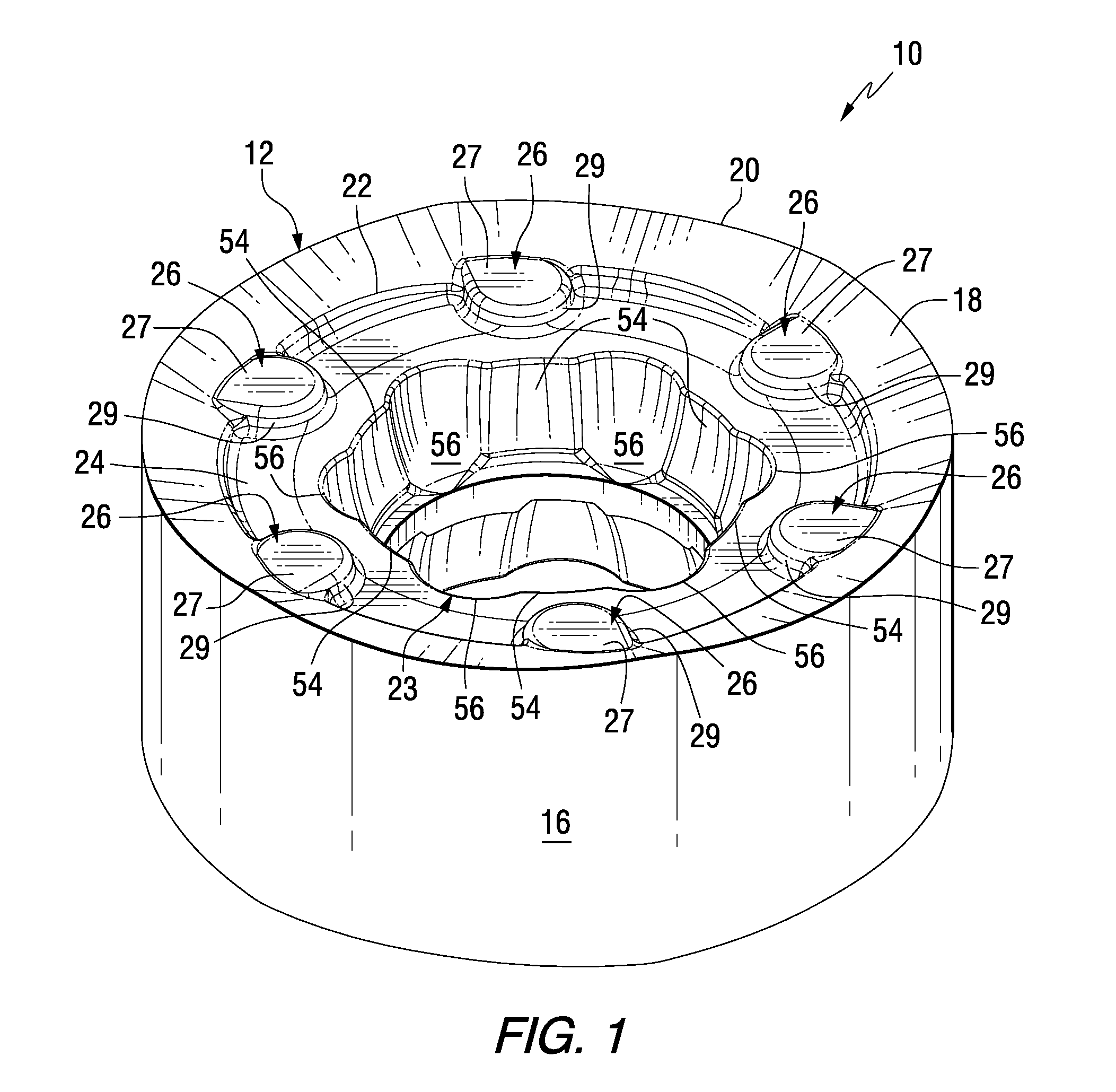

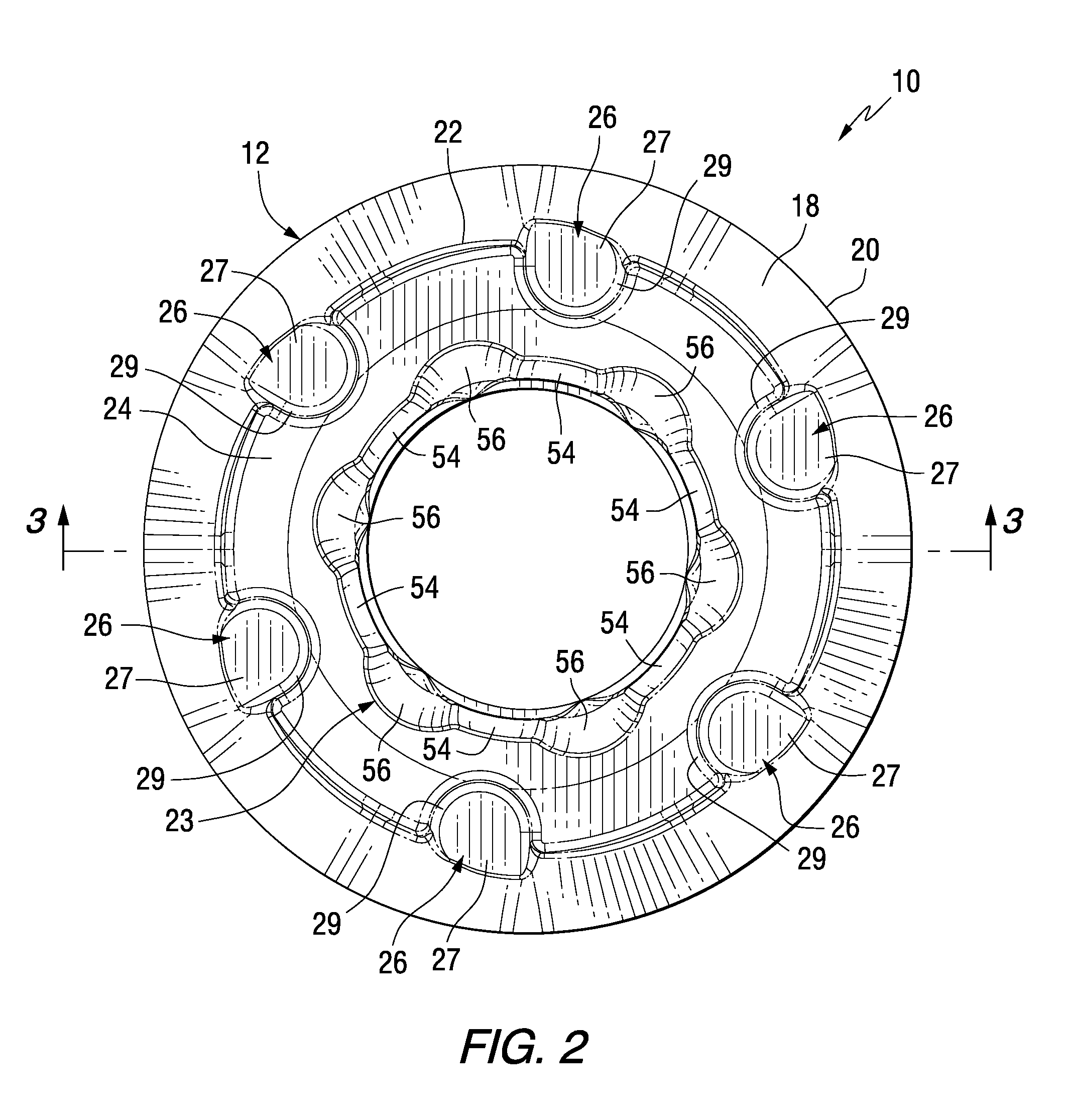

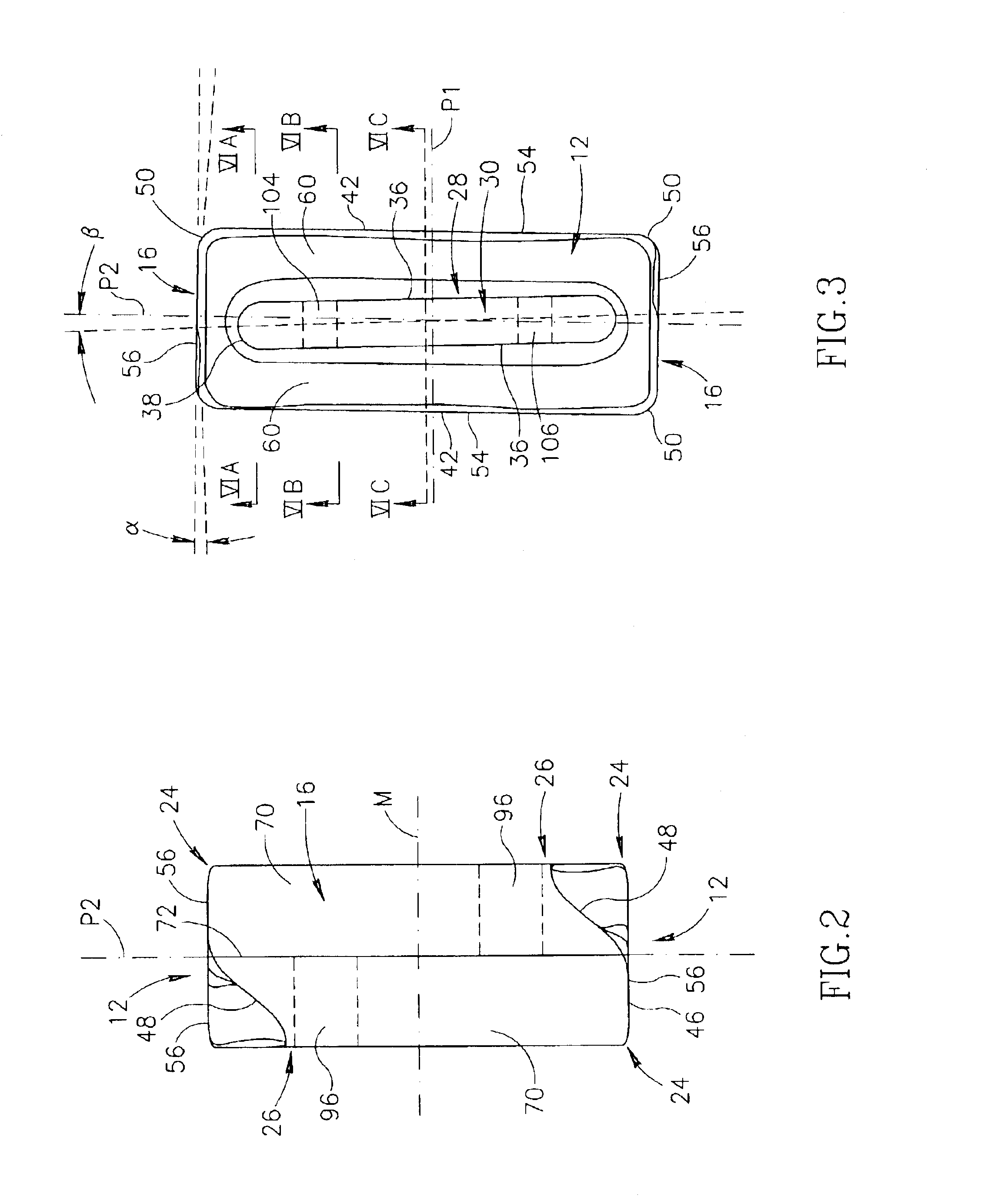

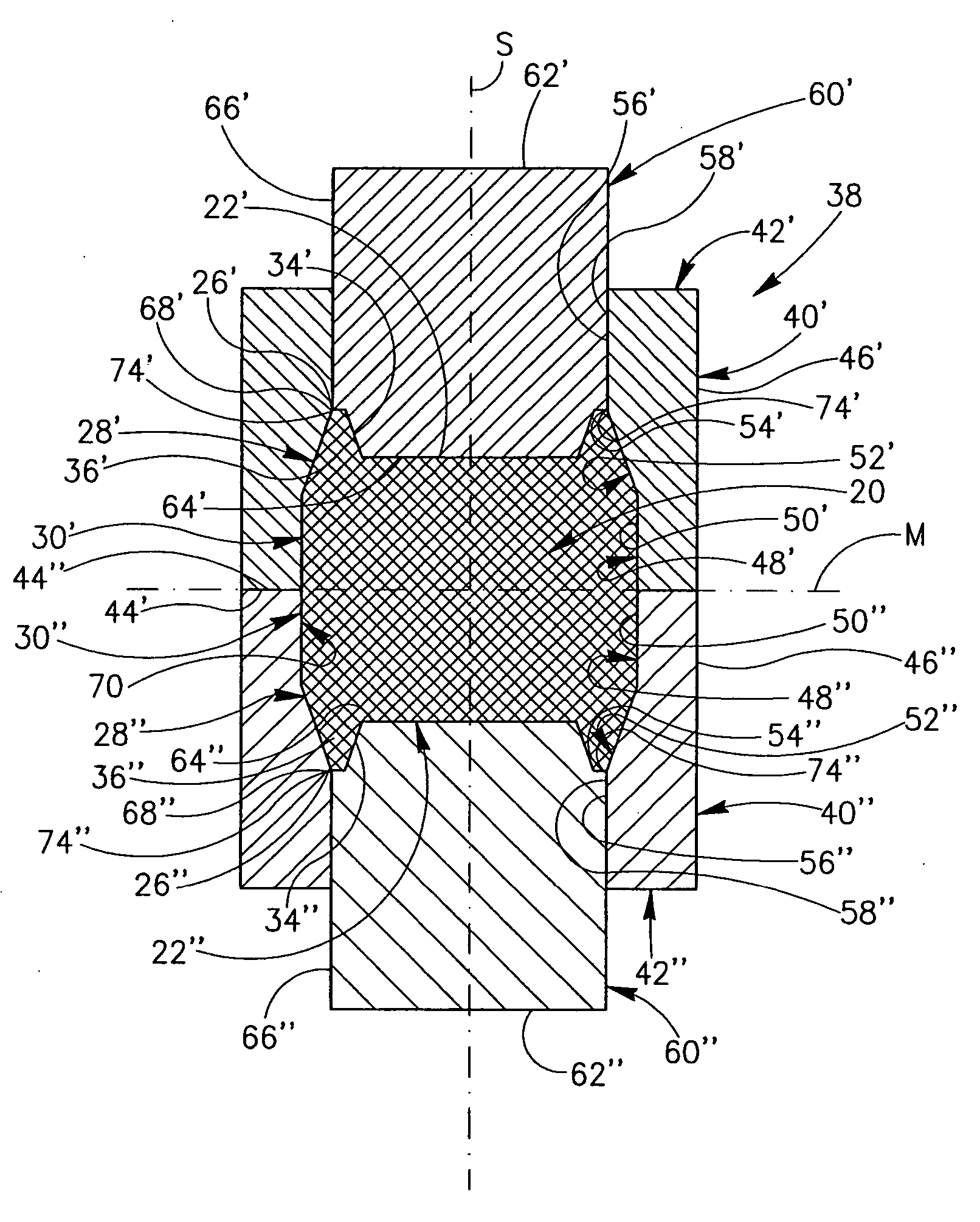

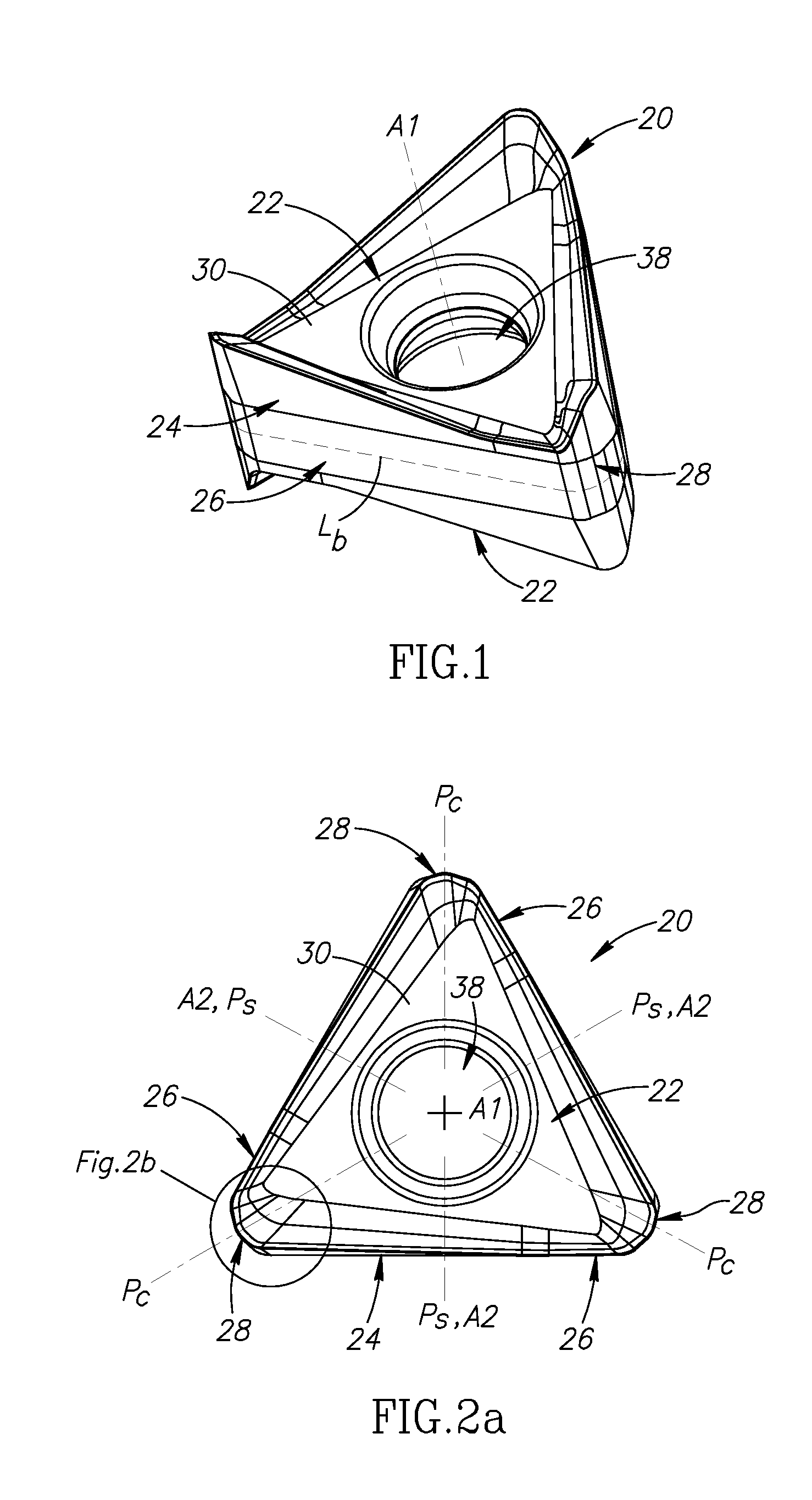

Cutting Insert

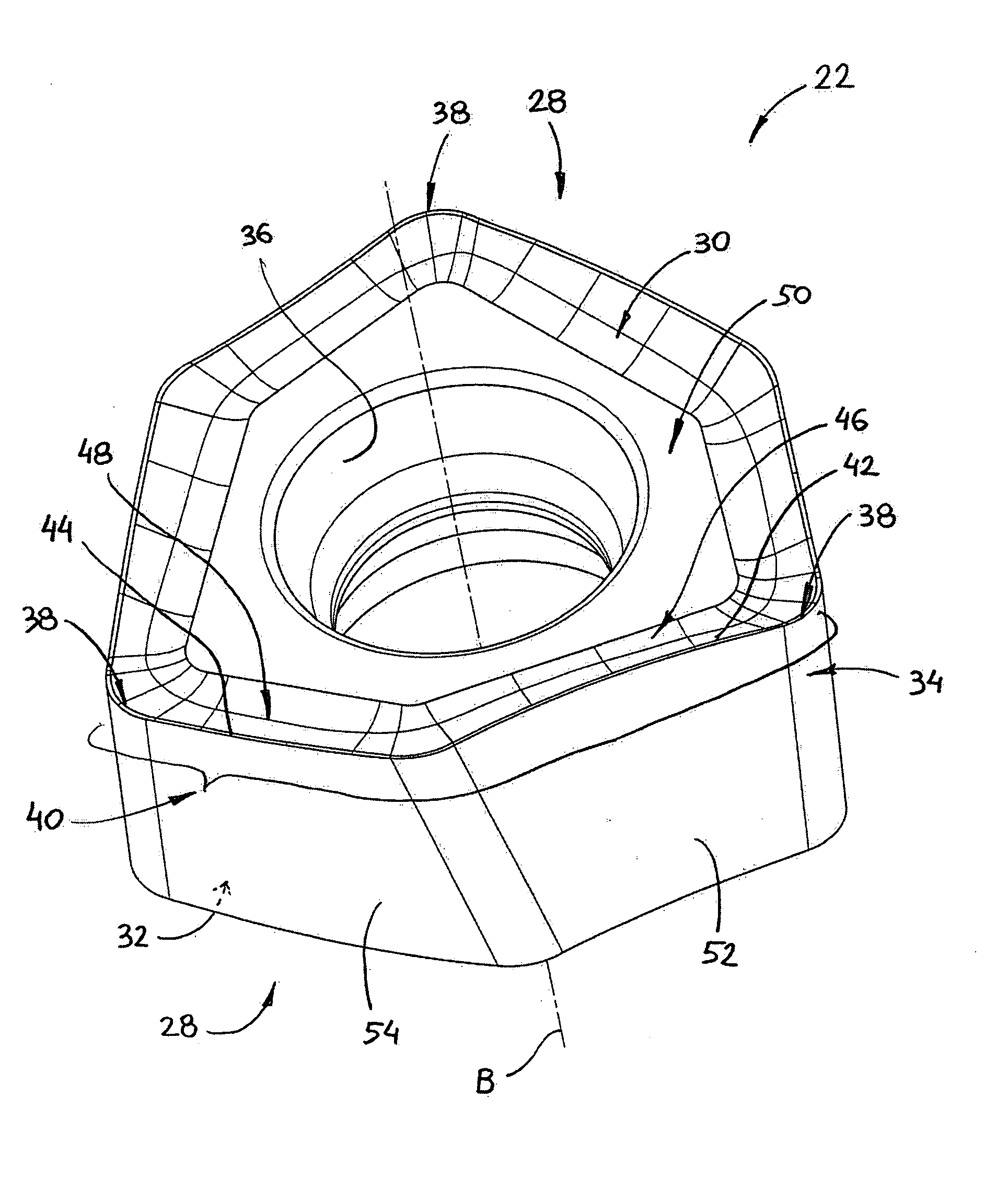

ActiveUS20100080662A1High operating requirementsMilling cuttersShaping cuttersAcute angleMechanical engineering

A cutting insert has a trigonal shape. The cutting insert has a peripheral surface that extends between two opposing identical end surfaces. A median plane (M) bisects the cutting insert between the end surfaces. A through bore extends between the end surfaces. A cutting edge, formed at the intersection of each end surface with the peripheral surface, is divided into three identical cutting sections. Each cutting section is located between two vertexes of the trigonal shape. Each cutting section has a convex primary cutting edge and a concave secondary cutting edge that merge together. An insert tangential abutment surface is located between the cutting edge and the through bore. A primary relief surface forms an insert internal obtuse angle with a first reference plane (P1). A secondary relief surface forms an insert internal acute angle with a second reference plane (P2).

Owner:ISCAR LTD

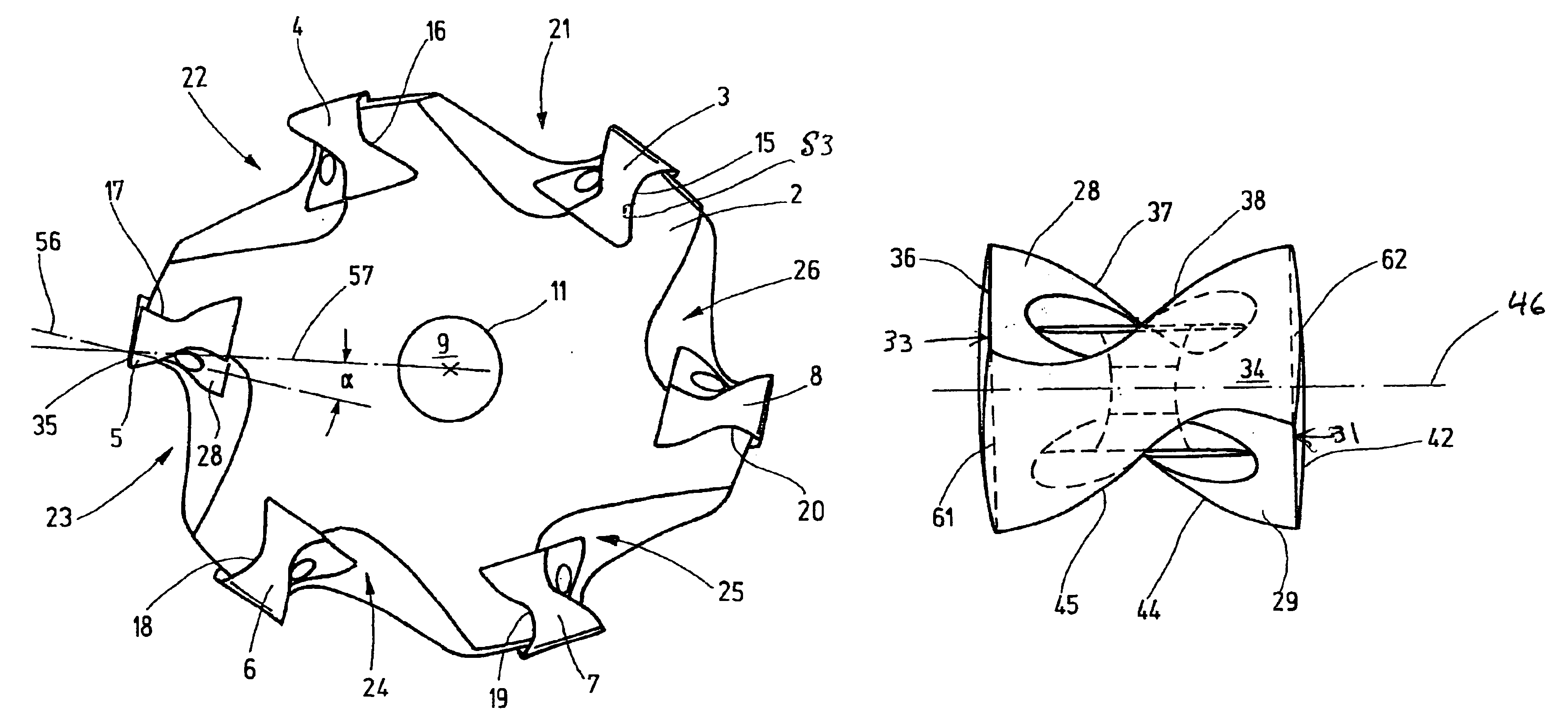

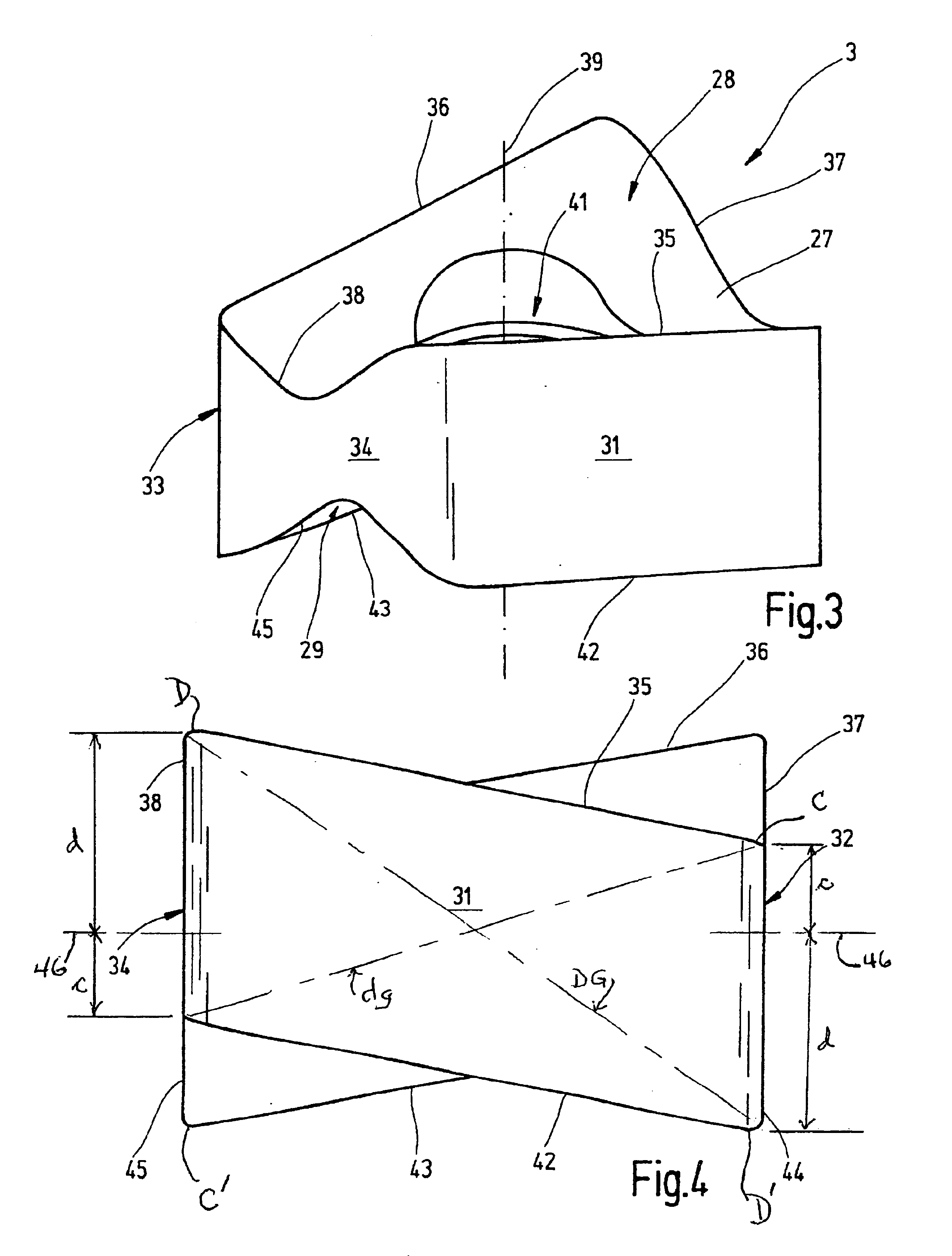

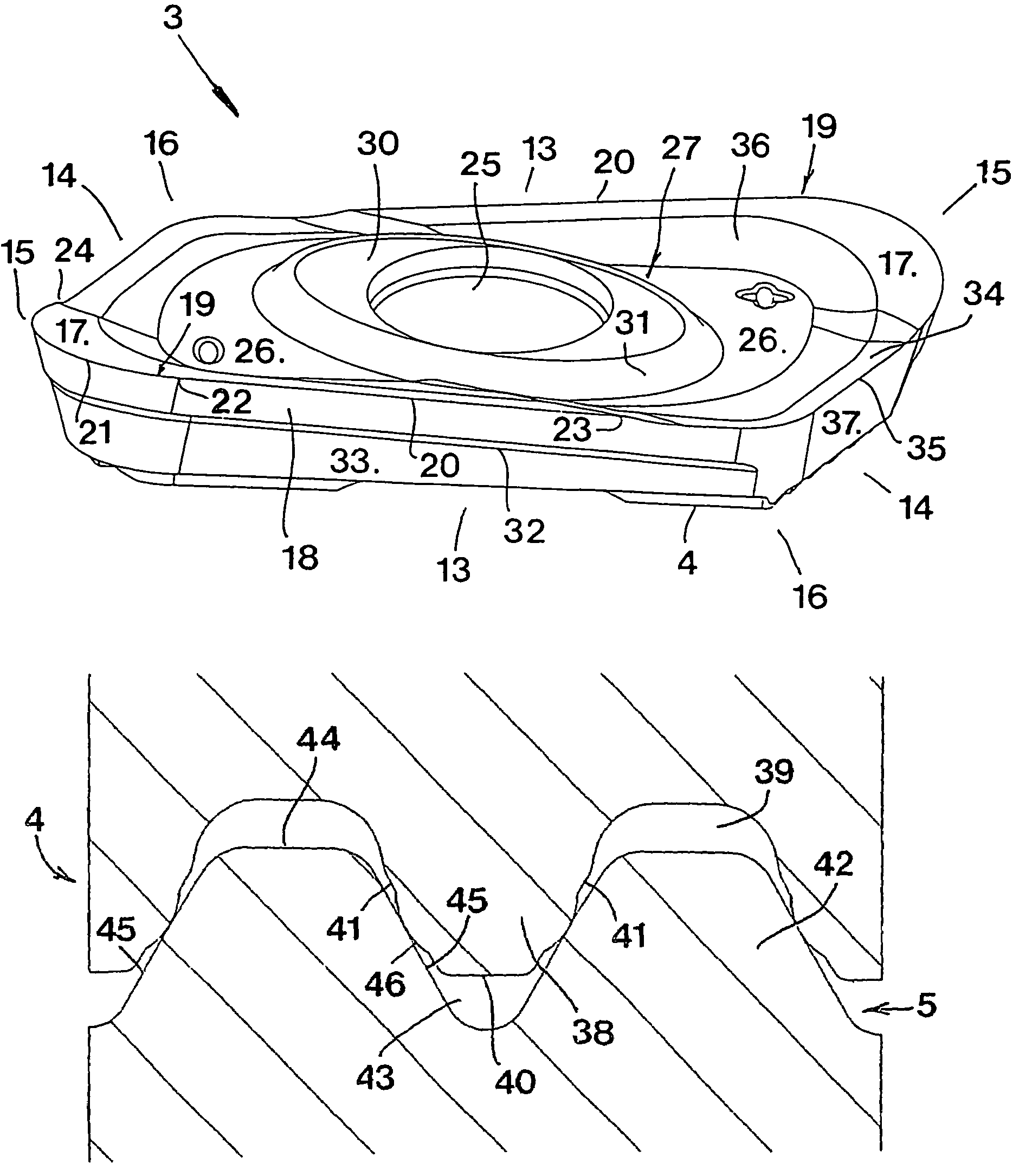

Indexable milling insert

InactiveUS7021871B2Precise positioningReduce energy consumptionTransportation and packagingMilling cuttersRidgeSwarf

The invention relates to an indexable milling insert (3) having a polygonal basic shape, comprising four peripheral sides, which meet each other in pairs in one the one hand two acute corners (15), and on the other hand two obtuse corners (16). Between chip surfaces (17) on the top side of the insert and flank surfaces (18) along the peripheral sides, cutting edges (19) are formed, which individually comprise on the hand a major edge portion (20), and, on the other hand, a rounded minor edge portion (21), formed in connection with an acute corner (15). Characteristic of the invention is the combination that the individual major edge portion (20) is slightly arched and that at least one connecting surface (4) is formed in the bottom side of the insert, of the type that comprises a plurality of parallel ridges spaced-apart by grooves having a cross-section-wise tapering shape and which are intended to co-operate with an analogous connecting surface adjacent to a chip channel in a cutting-insert-carrying milling head.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method and apparatus for manufacturing a cutting insert

A method for manufacturing a cutting insert green body having undercuts includes providing a die cavity formed in closed top and bottom dies; closing a bottom of the die cavity by a bottom punch accommodated in a punch tunnel formed in the bottom die; filling the die cavity with a pre-determined amount of sinterable powder; moving a top punch towards the die cavity through a punch tunnel formed in the top die; compacting the powder by urging the top and bottom punches towards each other, thereby forming the green body; and moving the top die and punch away from the bottom die and punch, thereby enabling removal of the formed green body. An apparatus for manufacturing a cutting insert green body having undercuts includes top and bottom dies which abut each other and top and bottom punches which slide in their respective dies.

Owner:ISCAR LTD

Cutting Insert and Cutting Edge Replaceable Cutting Tool

ActiveUS20120009029A1Degree of freedom is loweredHigh strengthMilling cuttersTurning toolsMechanical engineering

A cutting insert includes two end surfaces each having a main surface usable as an attachment surface to a tool body, a peripheral side surface extending between the two end surfaces and a plurality of cutting edge portions each formed at an intersection between each end surface and the peripheral side surface. Each cutting edge portion includes a corner edge formed at a corner of a related end surface, a major cutting edge extending from one end of the corner edge and extending so as to depart from an intermediate plane defined to be perpendicular to the first axis and to include the second axis, and a minor cutting edge extending from the other end of the corner edge and extending in a direction to approach the intermediate plane.

Owner:TUNGALOY CORP

Milling insert

InactiveUS20090285646A1Reduce risk of damageReduce riskTransportation and packagingMilling cuttersEngineeringSwarf

A milling insert, including an upperside, an underside, and a reference plane parallel to the upperside and the underside. A plurality of indexable cutting edges are formed along a peripheral borderline in transitions between at least the upperside and a number of clearance surfaces. Each cutting edge includes a chip-removing main edge and a surface-wiping secondary edge, the secondary edge forming an obtuse angle with the main edge as viewed in planar view from the upperside. The main edge, from a first end of the main edge adjacent to the secondary edge, first declines toward the underside of the milling insert and then, from a lowest part, rises toward an opposite second end of the main edge. The secondary edge is inclined at an angle (ε) in relation to the reference plane as viewed perpendicularly to the clearance surface of the secondary edge, such that a first end of the secondary edge connected to the main edge is situated on a lower level than the opposite, second end of the secondary edge.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Tangential cutting insert and milling cutter

A tangential milling cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces of a generally isosceles trapezoidal shape and two identical opposing minor side surfaces extending between them is disclosed. Each end surface has a peripheral edge containing cutting edges and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface is provided with an abutment member having an abutment surface. In each cross section of the cutting insert taken in a plane parallel to a minor plane of the cutting insert, the abutment surface is closer to a median plane than a respective leading section of a major cutting edge.

Owner:ISCAR LTD

Cutting insert and milling cutter

A milling cutter has a cutter body having insert pockets, with cutting inserts seated in the insert pockets. Each insert pocket has adjacent side and rear walls generally transverse to a base, the side wall being provided with two spaced apart generally flat and non-coplanar side support surfaces. Each cutting insert has a pair of opposing major side surfaces including two spaced apart generally flat and non-coplanar abutment surfaces. Upper edges of the side support surfaces abut the abutment surfaces.

Owner:ISCAR LTD

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

Cutting insert having cylindrically shaped side surface portions

ActiveUS7232279B2Reduced cutting performanceWithout of to qualityMilling cuttersCutting insertsEngineeringMechanical engineering

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

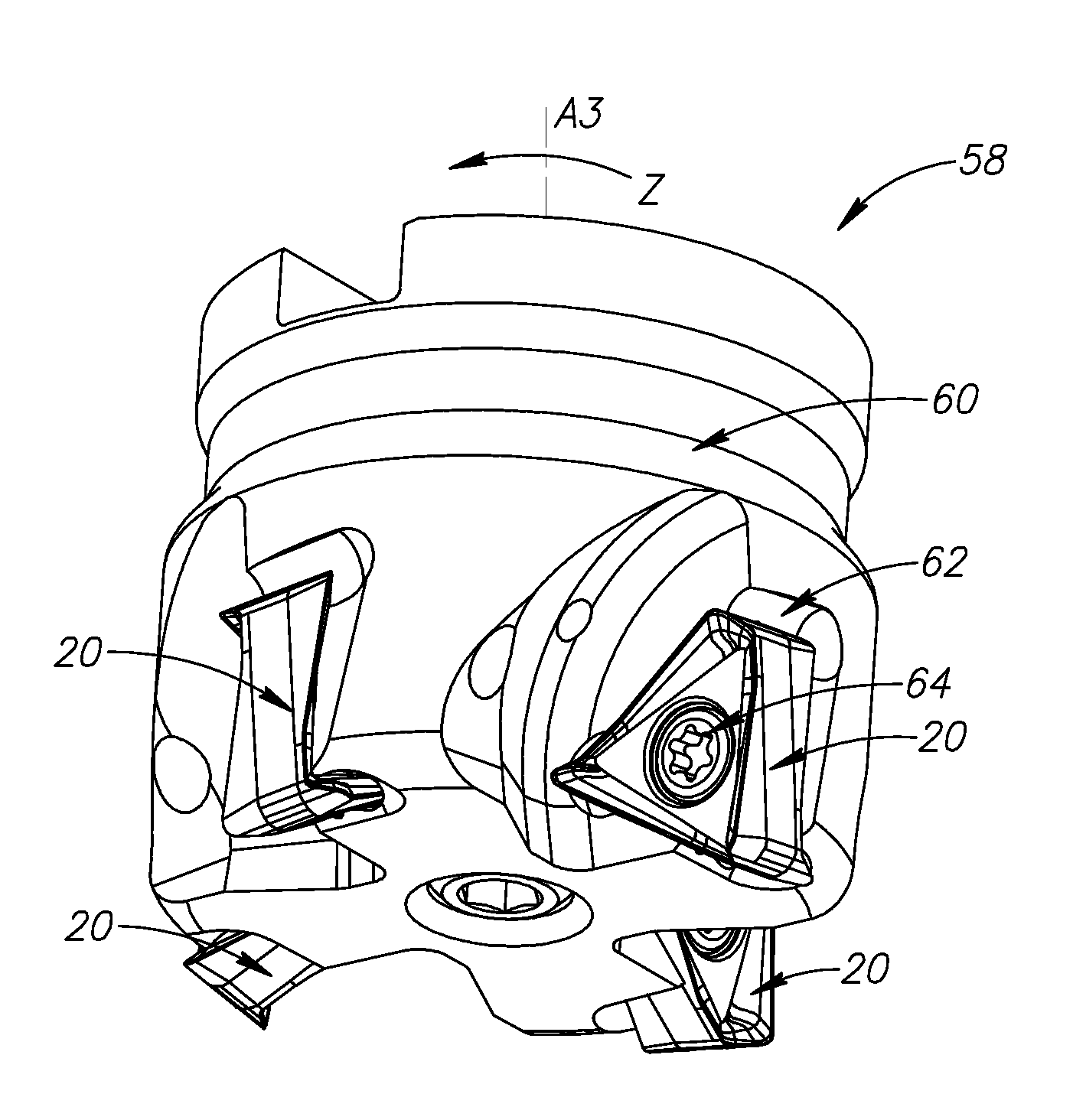

Rotary Cutting Tool and Reversible Cutting Insert Therefor

In a rotary cutting tool used for milling operations, a reversible indexable cutting insert is removably secured in a cutting body. The cutting insert has two opposing end surfaces interconnected by a continuous peripheral surface, including three side surfaces alternating with three corner surfaces. The side and corner surfaces intersect with both end surfaces at side and corner edges, respectively, with each side edge having a major cutting edge, and each corner edge having a corner and minor cutting edge. Each major and minor cutting edge slopes away from first and second end points, respectively, of its mutually associated corner cutting edge, towards a median plane. A first imaginary straight line extending perpendicular to the median plane and intersecting any one of the corner cutting edges at any point along its length except the second end point, passes through the median plane inside an insert boundary line.

Owner:ISCAR LTD

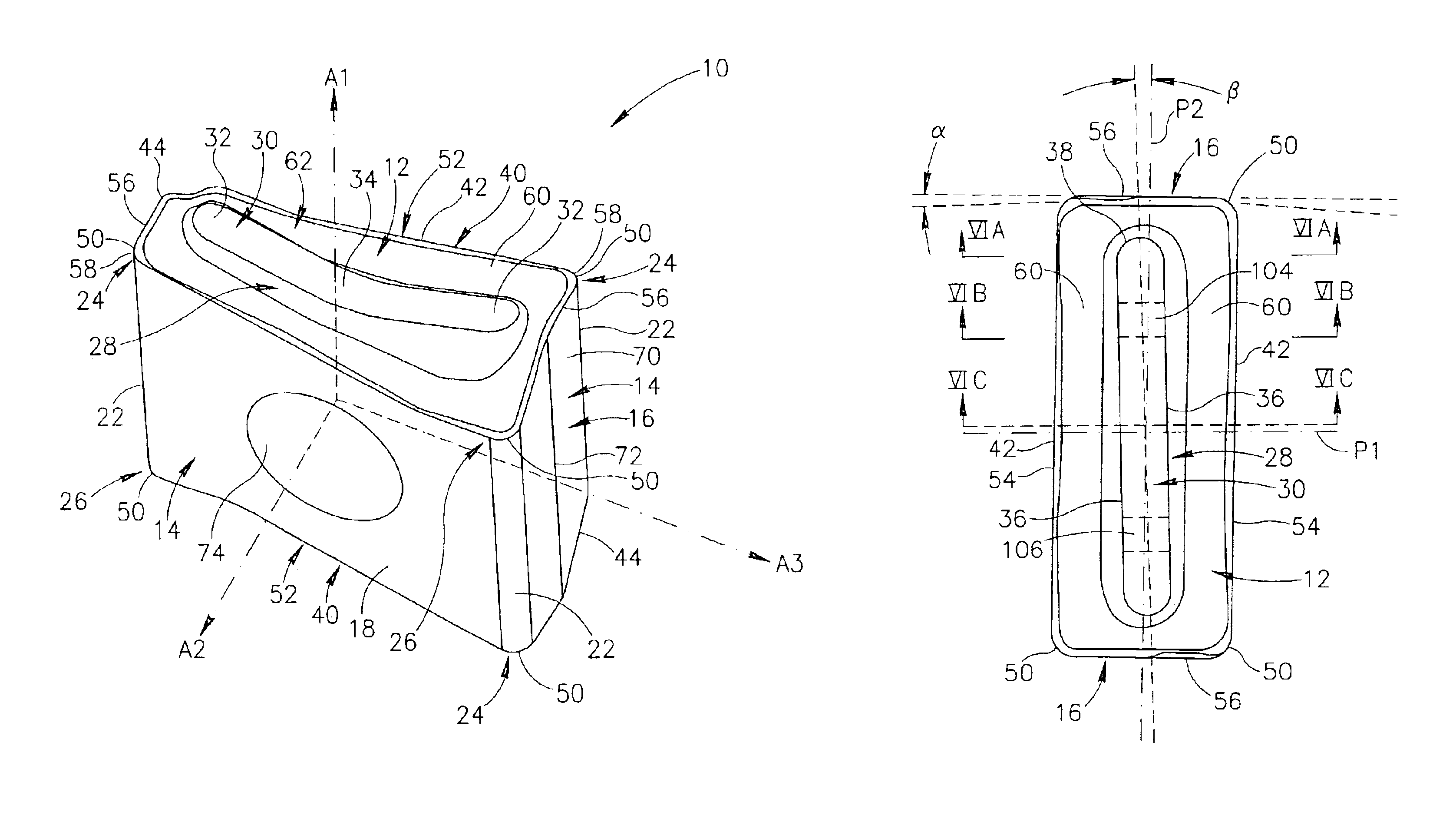

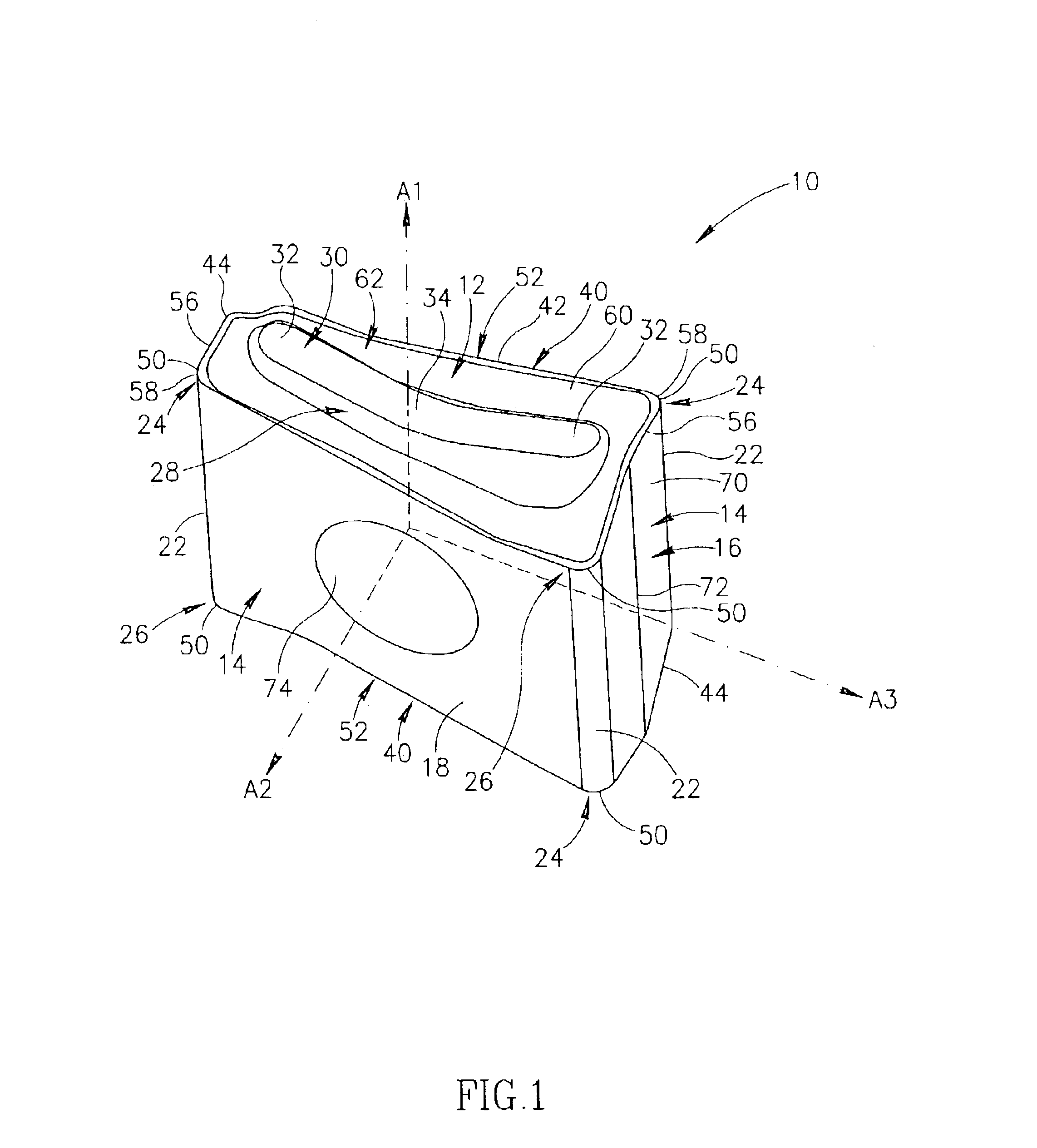

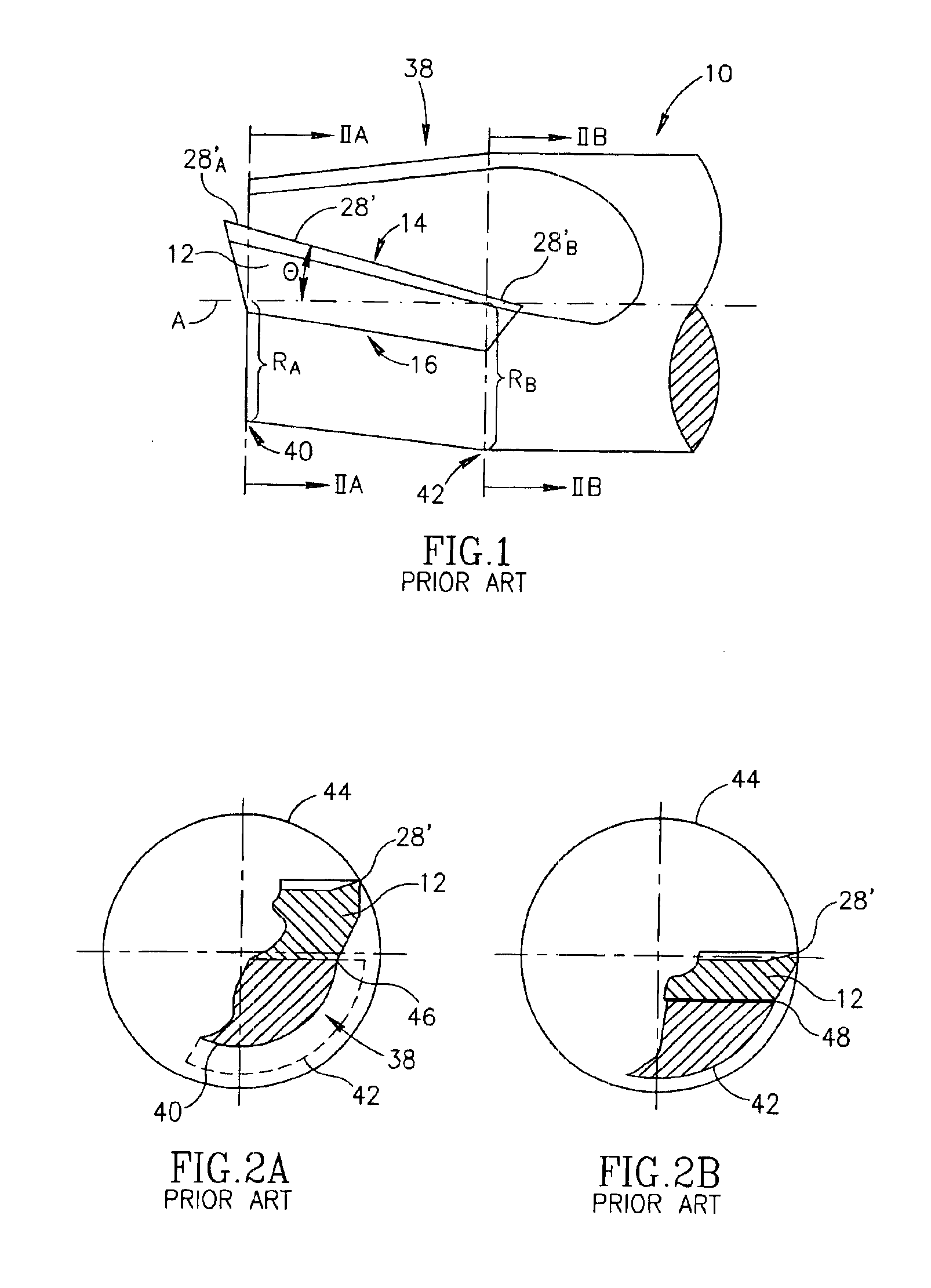

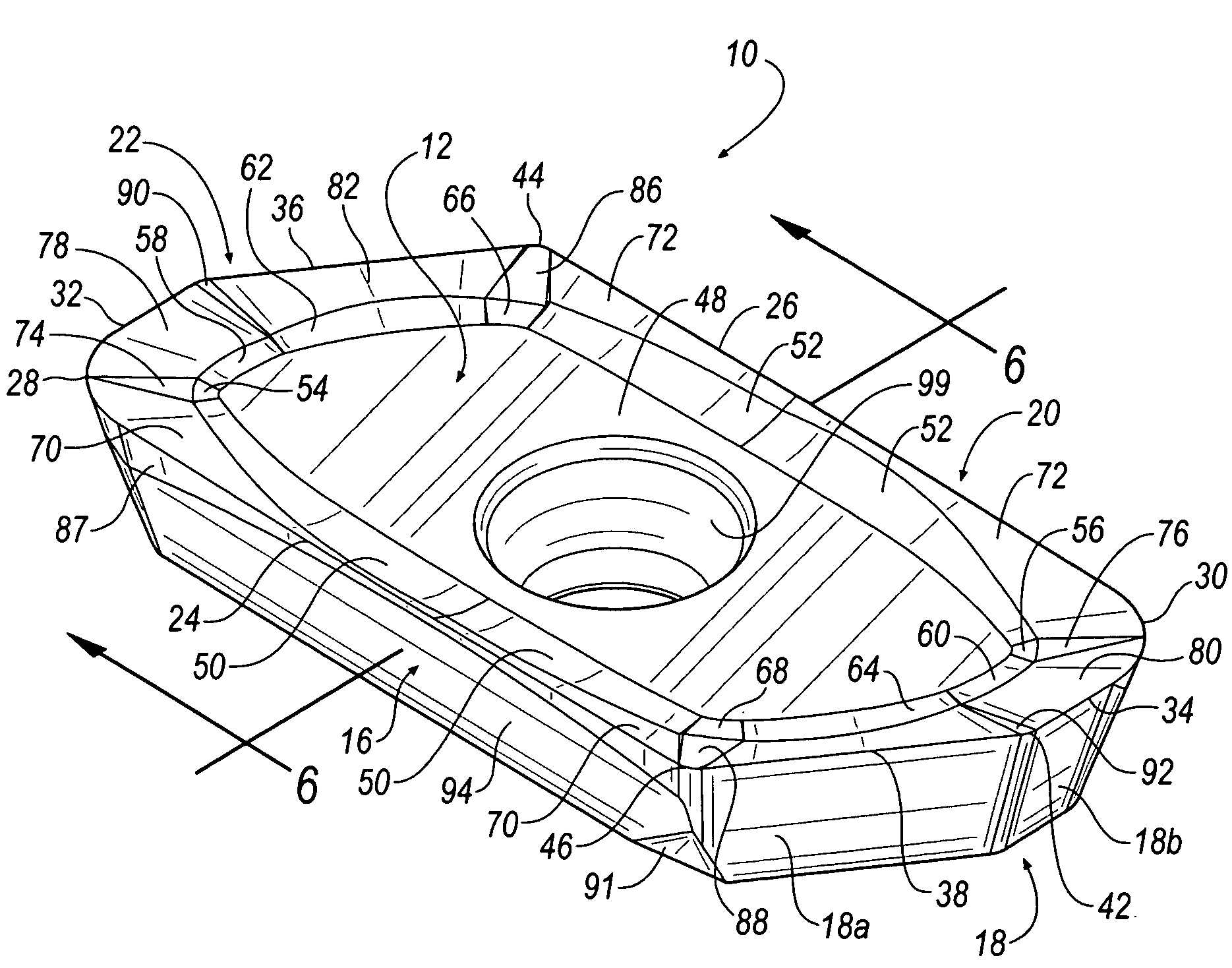

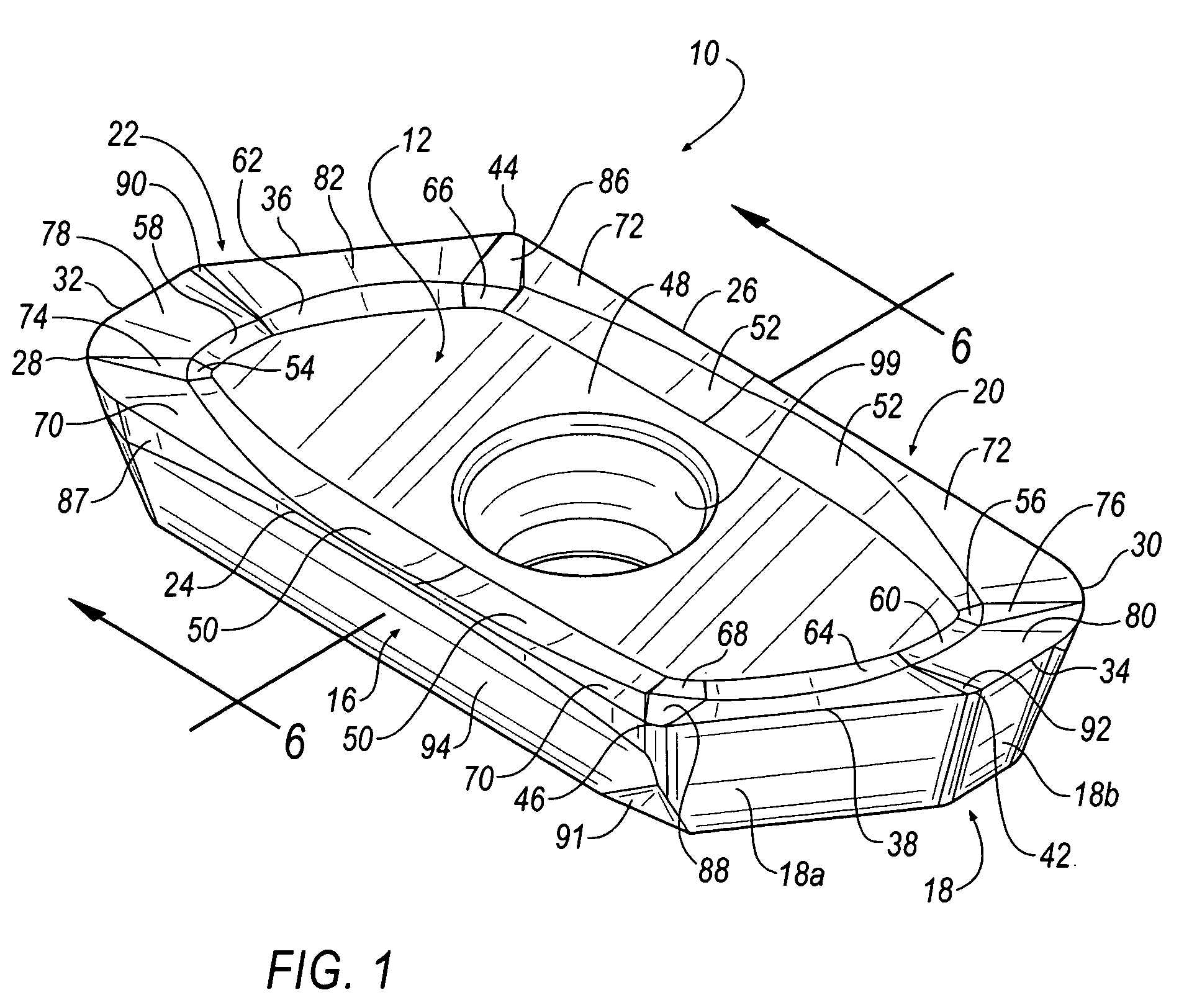

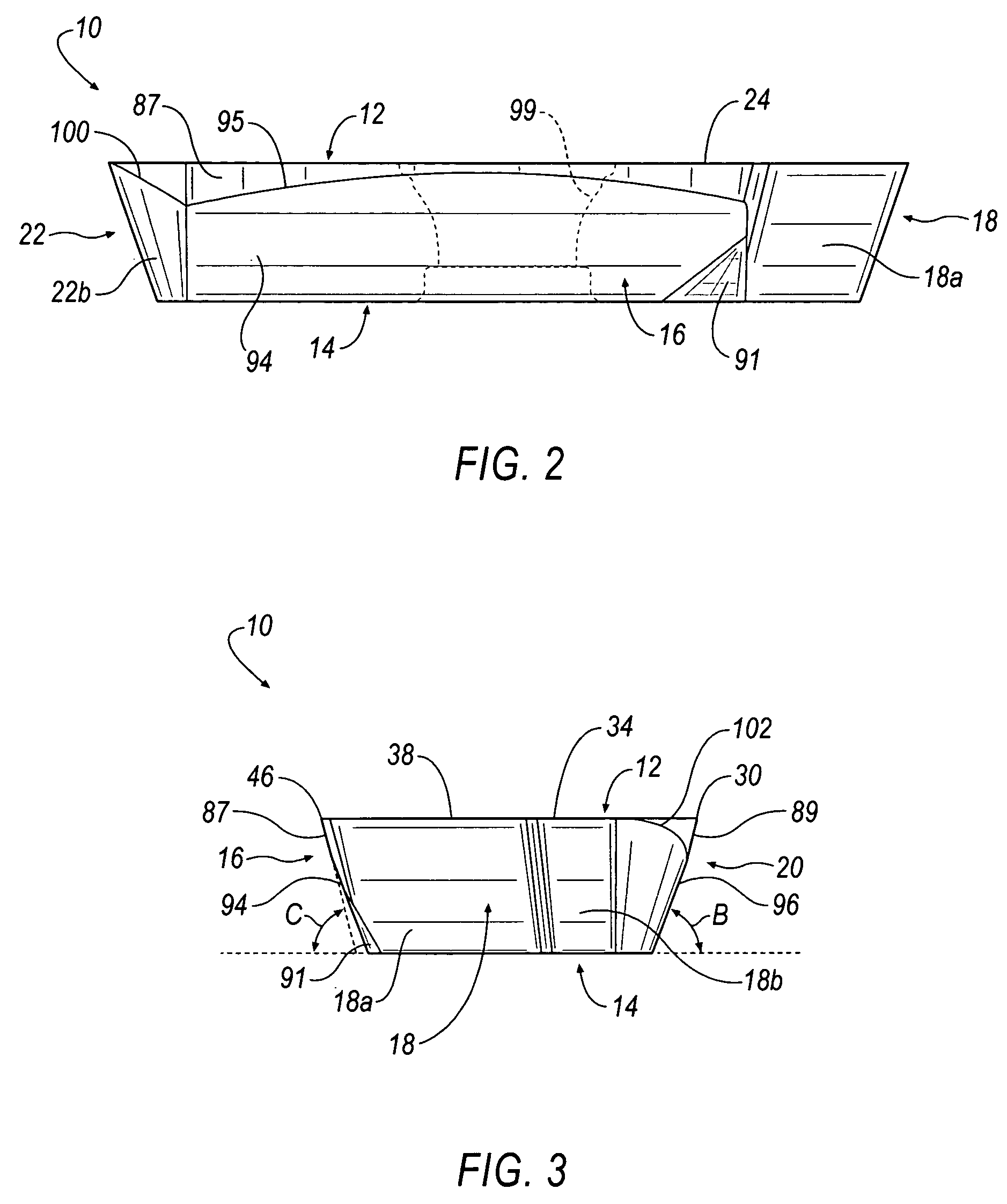

Cutting insert for high-speed milling cutter

An indexable cutting insert (10) having a top surface (12) including a substantially planar central portion (48), a substantially planar bottom surface (14), and a plurality of side surfaces (16, 18, 20, 22). A long cutting edge (24, 26), a corner radius cutting edge (28, 30), a facet radius cutting edge (32, 34), and ramping cutting edge (36, 38) are defined at an intersection between the top surface (12) and one of the side surfaces (16, 18, 20, 22). A margin (87, 89) extends around a nose radius of the cutting insert (10) and blends into a flat surface (94, 96). A margin angle, C, formed by the margins (87, 89) is less than a seating angle, B, formed by the flat surfaces (94, 96). The top surface (12) includes a plurality of upward sloping radius blends (50, 52, 54, 56, 58, 60, 62, 64) extending between the substantially planar central portion (48) and a plurality of upward sloping rake faces (70, 72, 74, 76, 78, 80, 82, 84, 86, 88, 90, 92) extending between a respective radius blend and its respective cutting edge such that the rake face forms an angle, A, of between five and twenty-five degrees with respect to the central portion (48) of the top surface (12).

Owner:KENNAMETAL INC

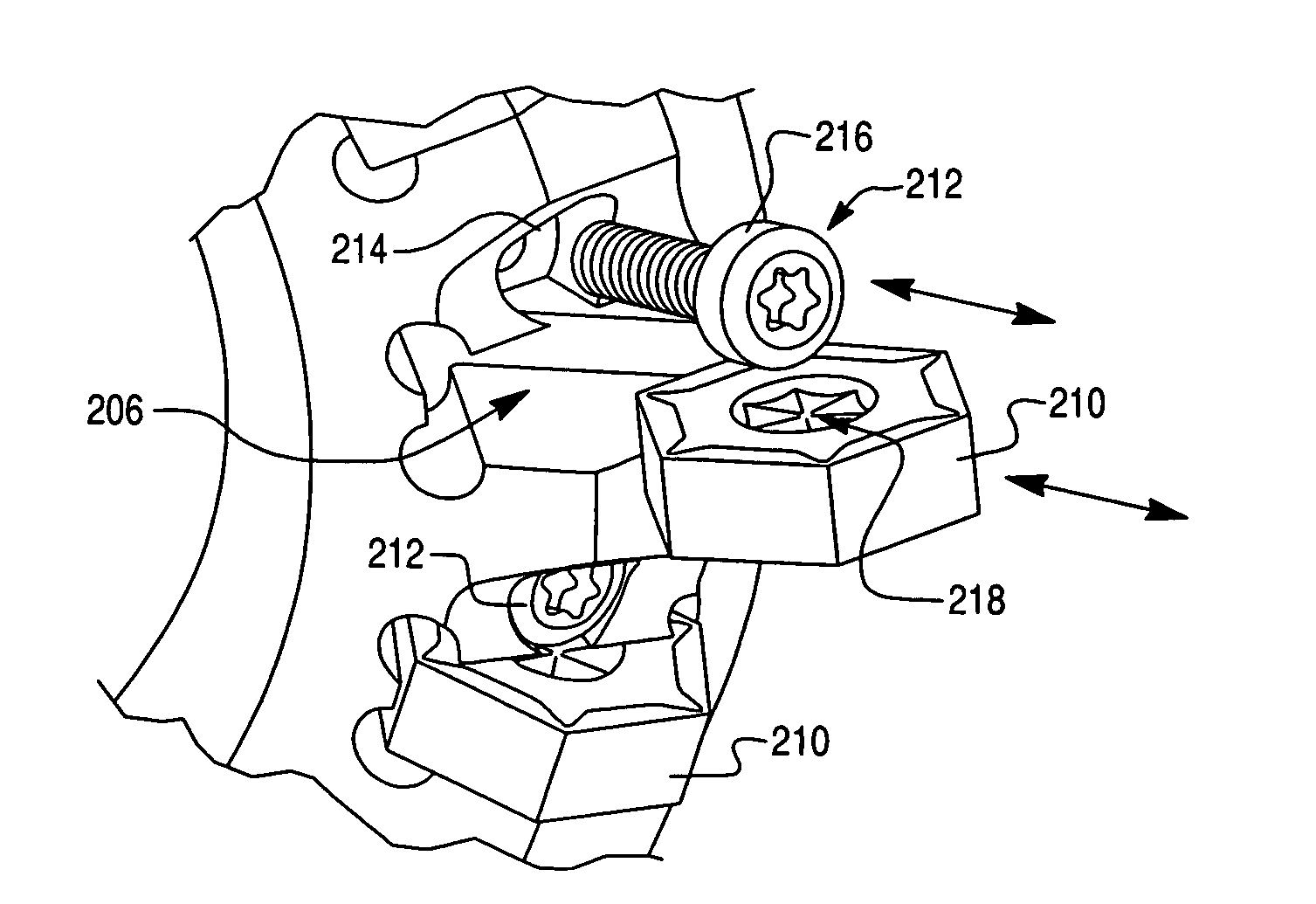

Side locking insert and material removal tool with same

An indexable insert has one or more recesses formed in a frontside or backside surface which receives a surface of the head of a locking screw. When mounted, the insert is forced against respective support surfaces of an insert pocket. The locking screw is threaded into a counterbored tap hole to engage the insert and provide side locating forces and clamping forces to secure the indexable insert in the insert pocket. More particularly, the indexable insert has a shaped surface recess that mates to a complimentarily-shaped surface on the head of a locking screw and secures the indexable insert in multiple dimensions to a seating surface. A material removal tool and a method of mounting the indexable insert are also disclosed.

Owner:SANDVIK TRIANGLE

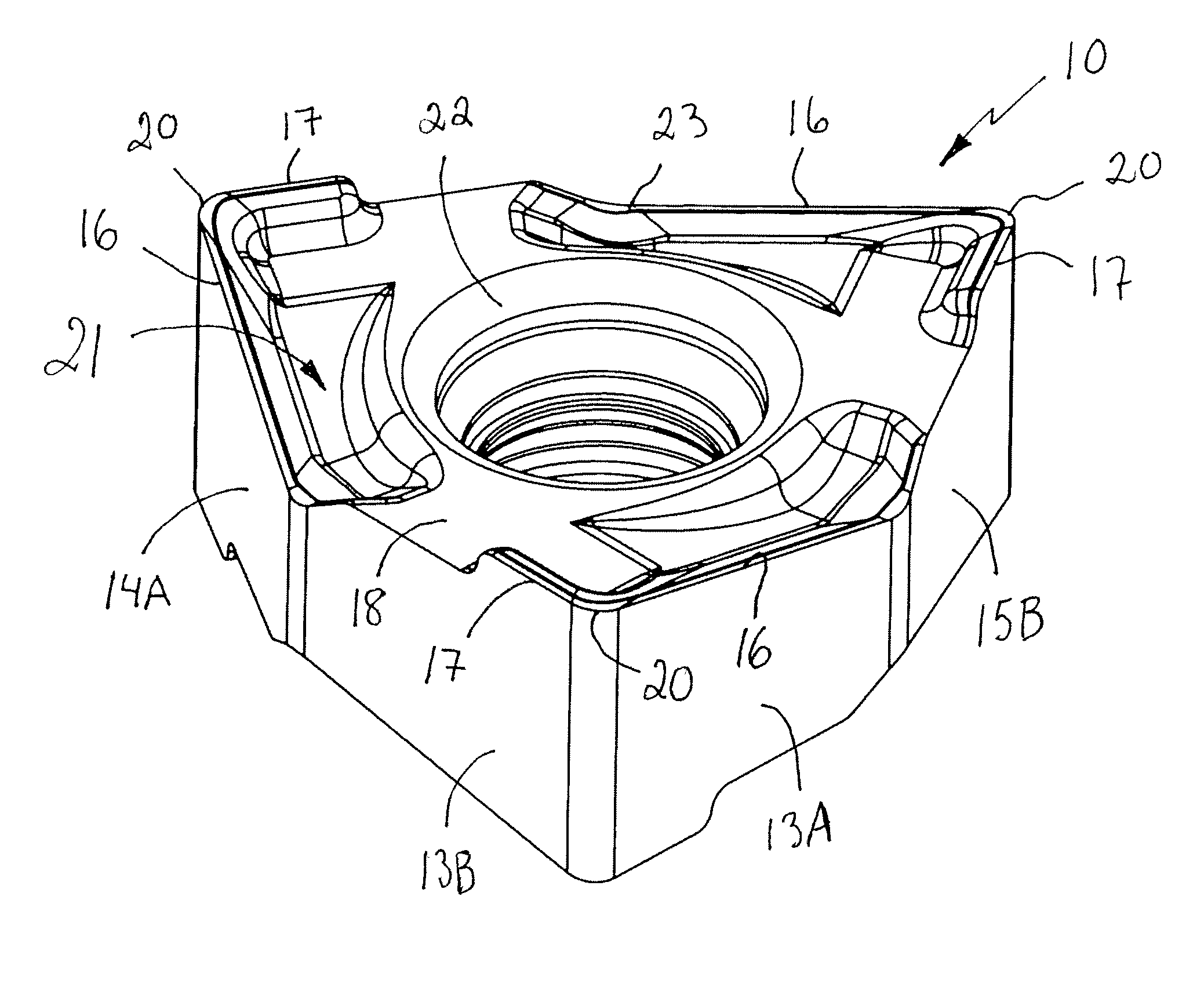

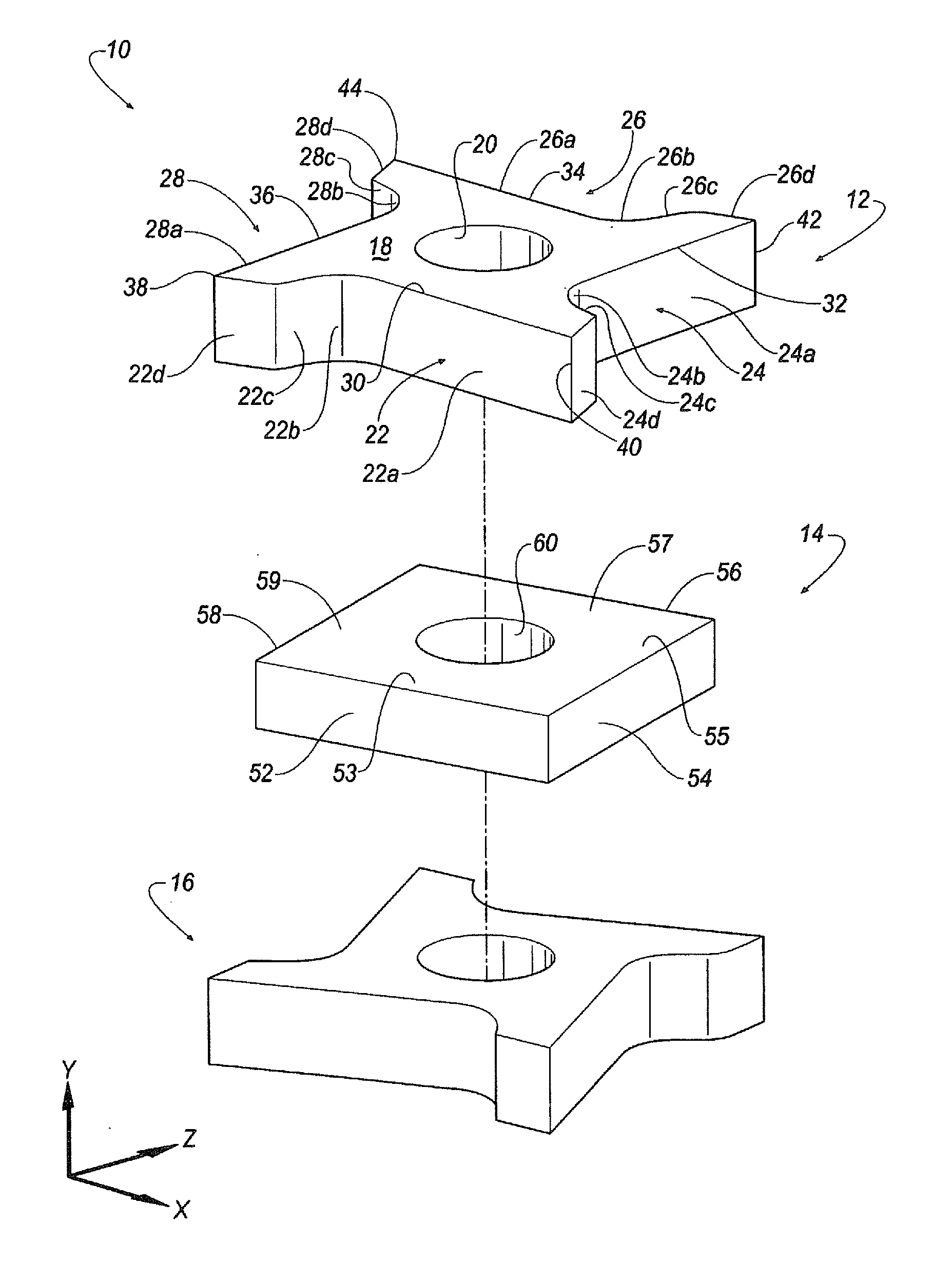

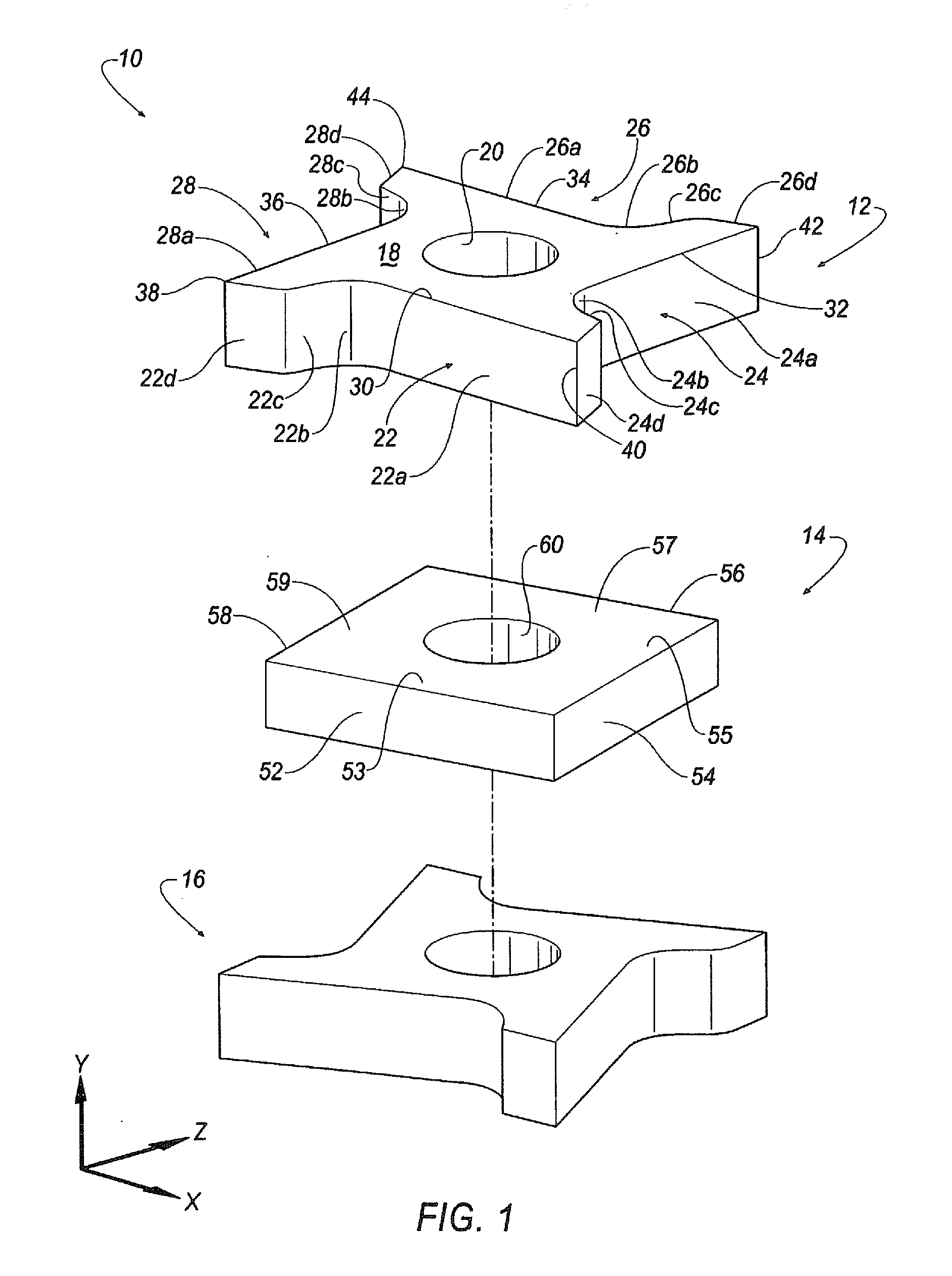

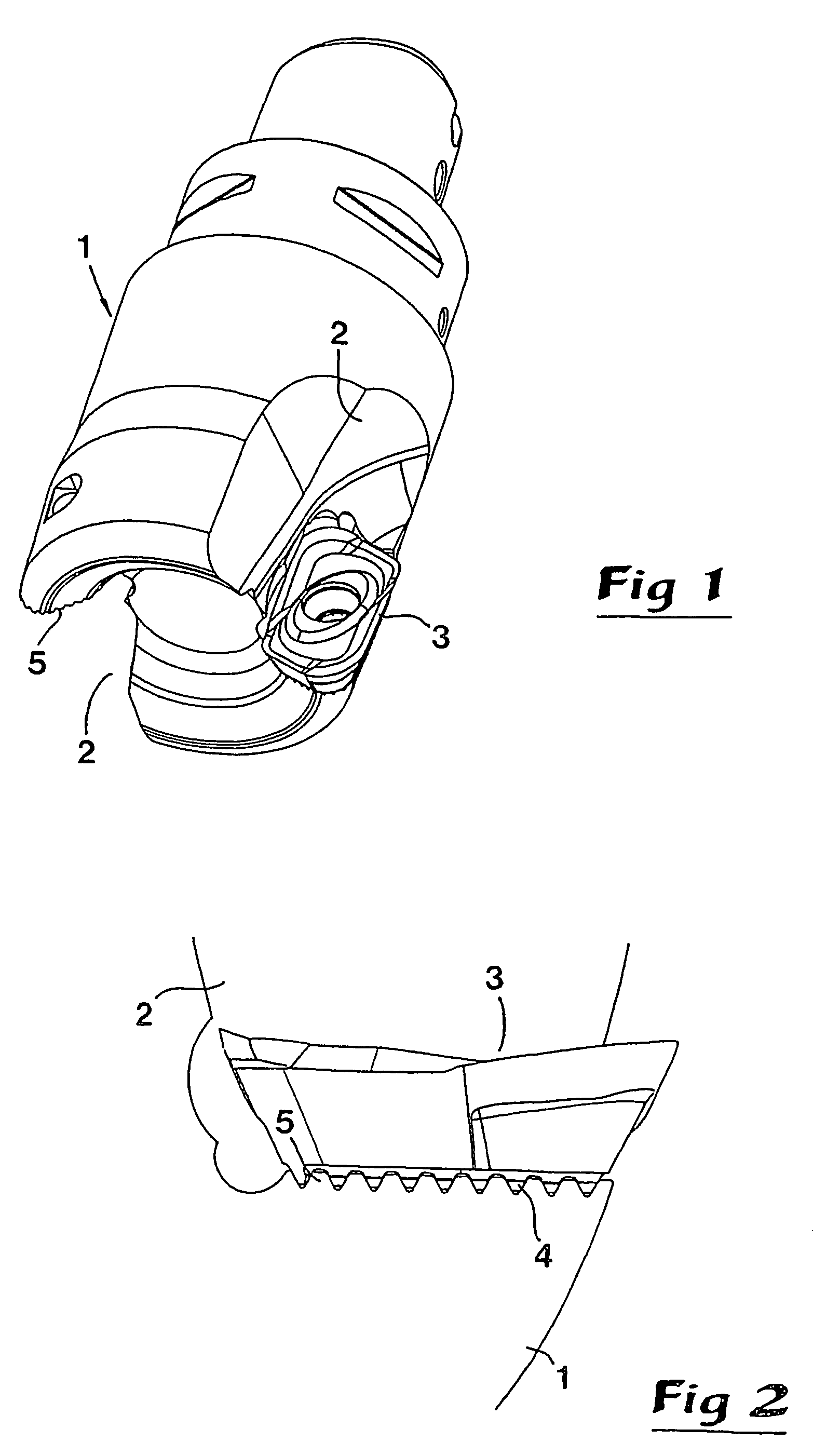

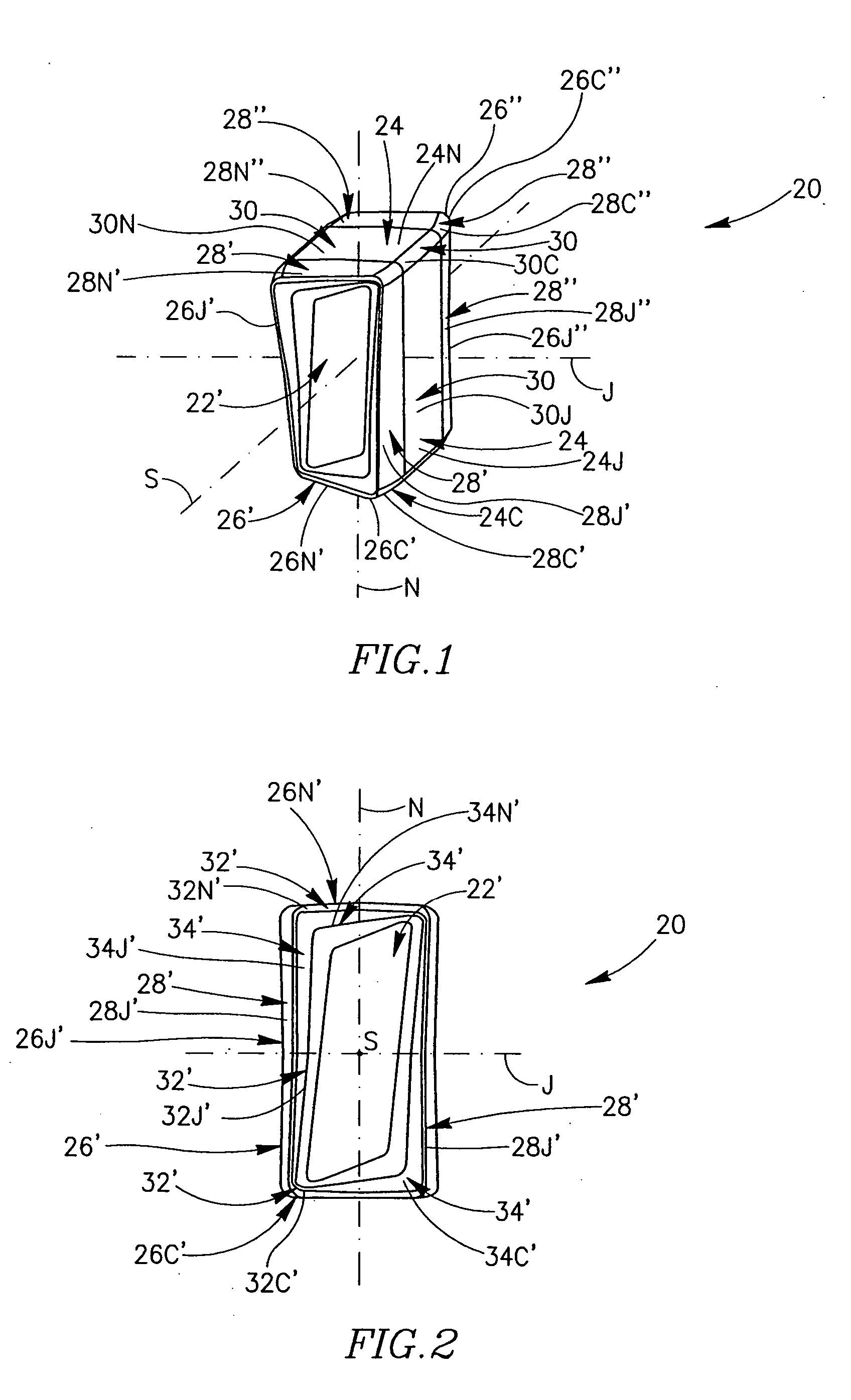

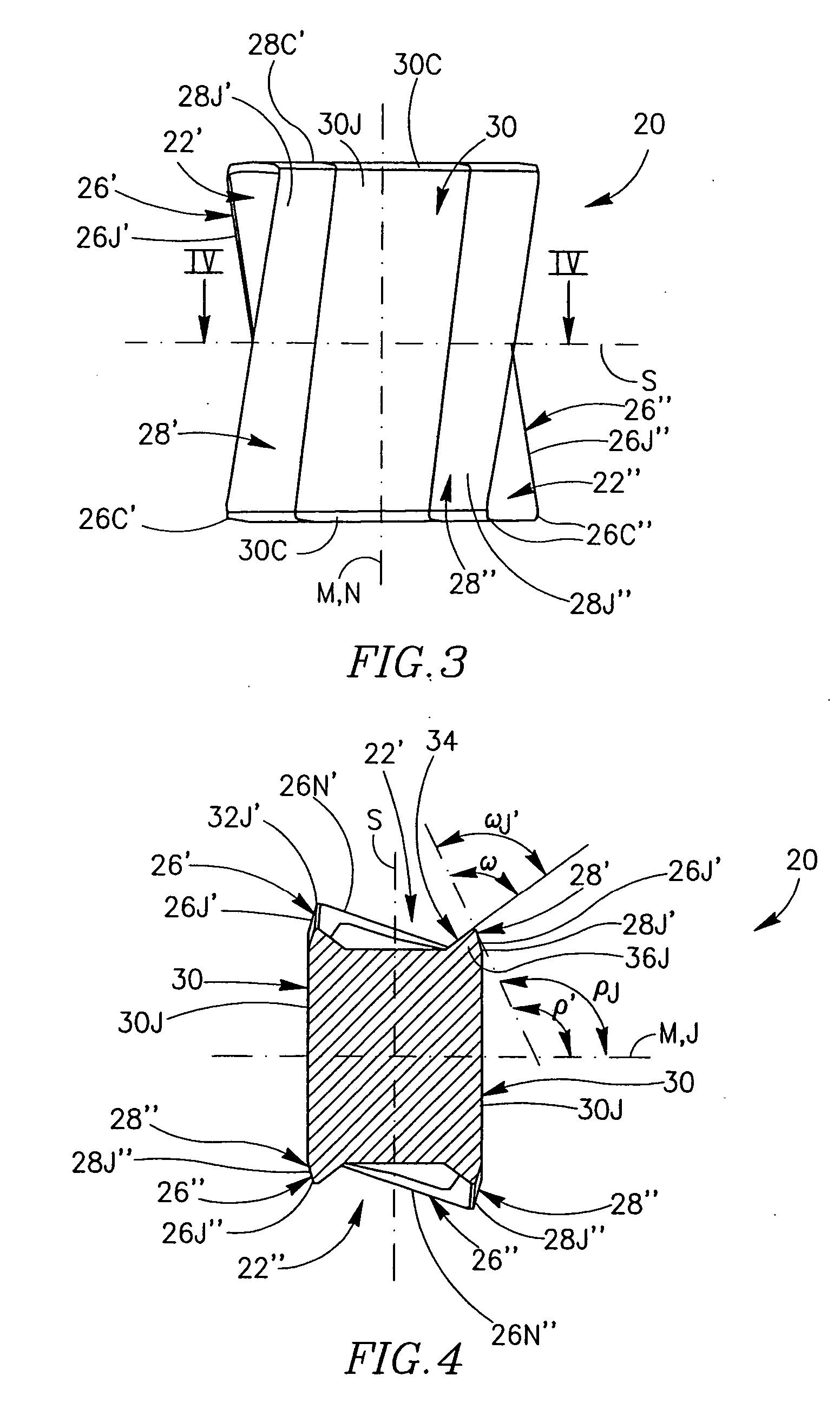

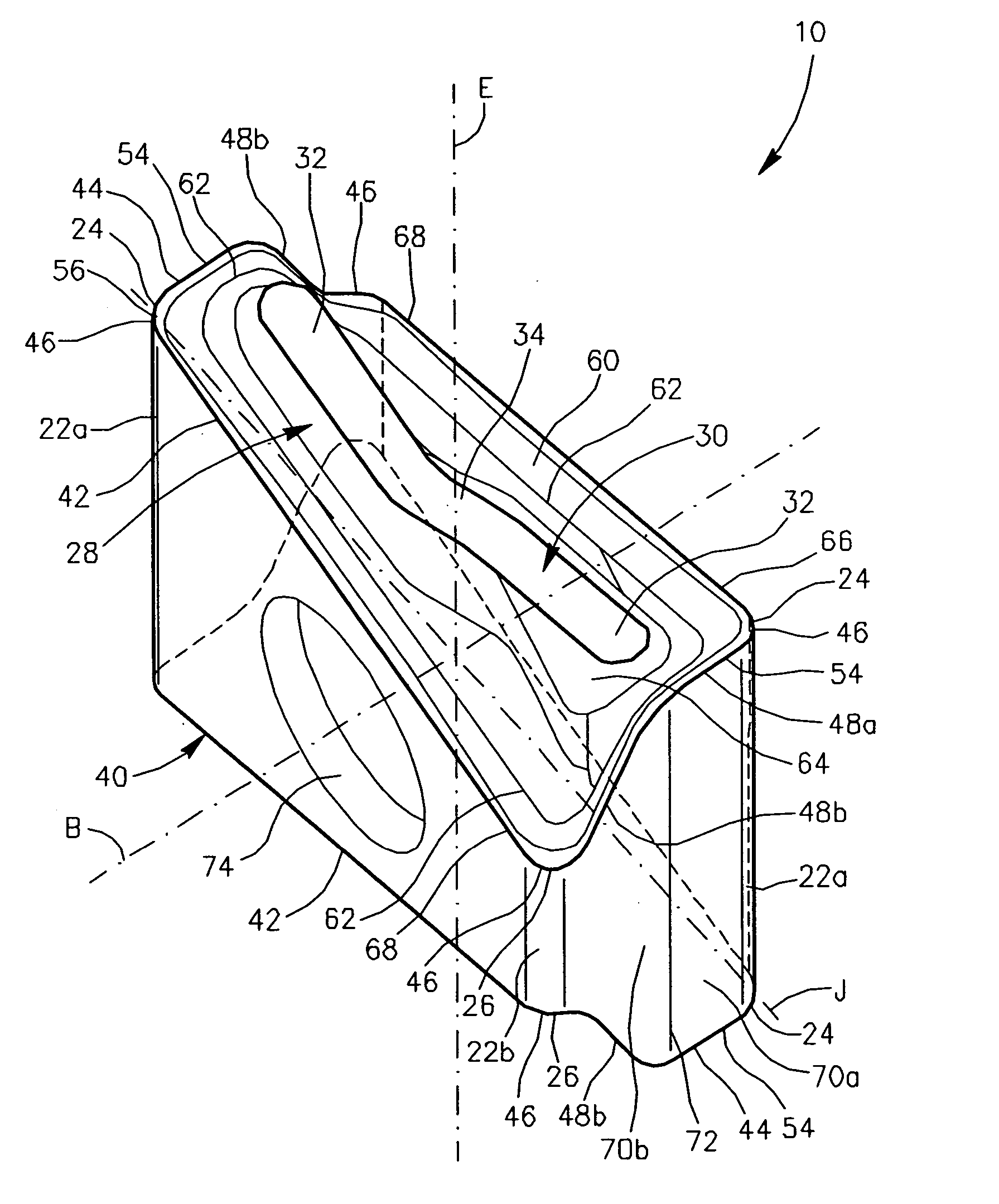

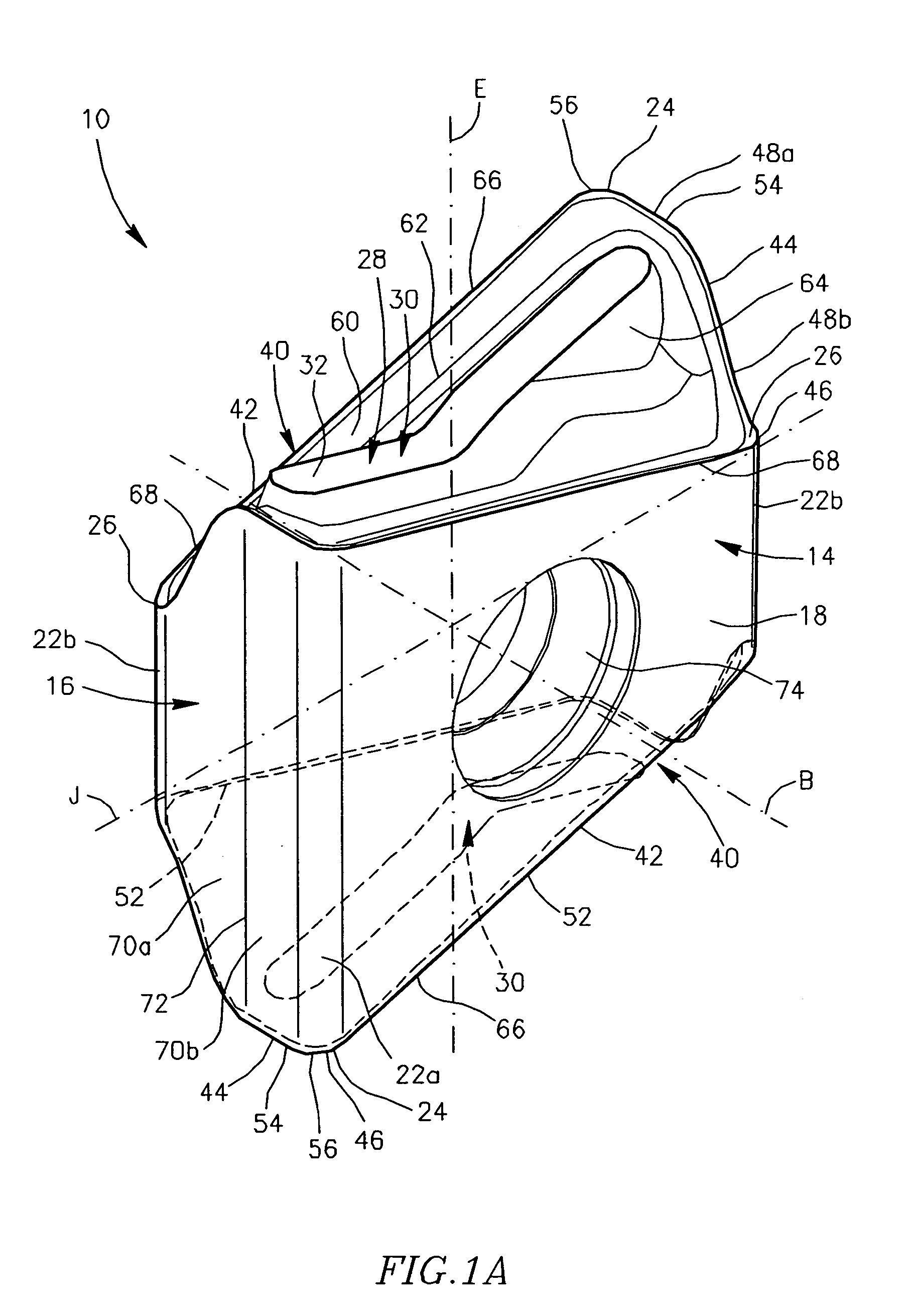

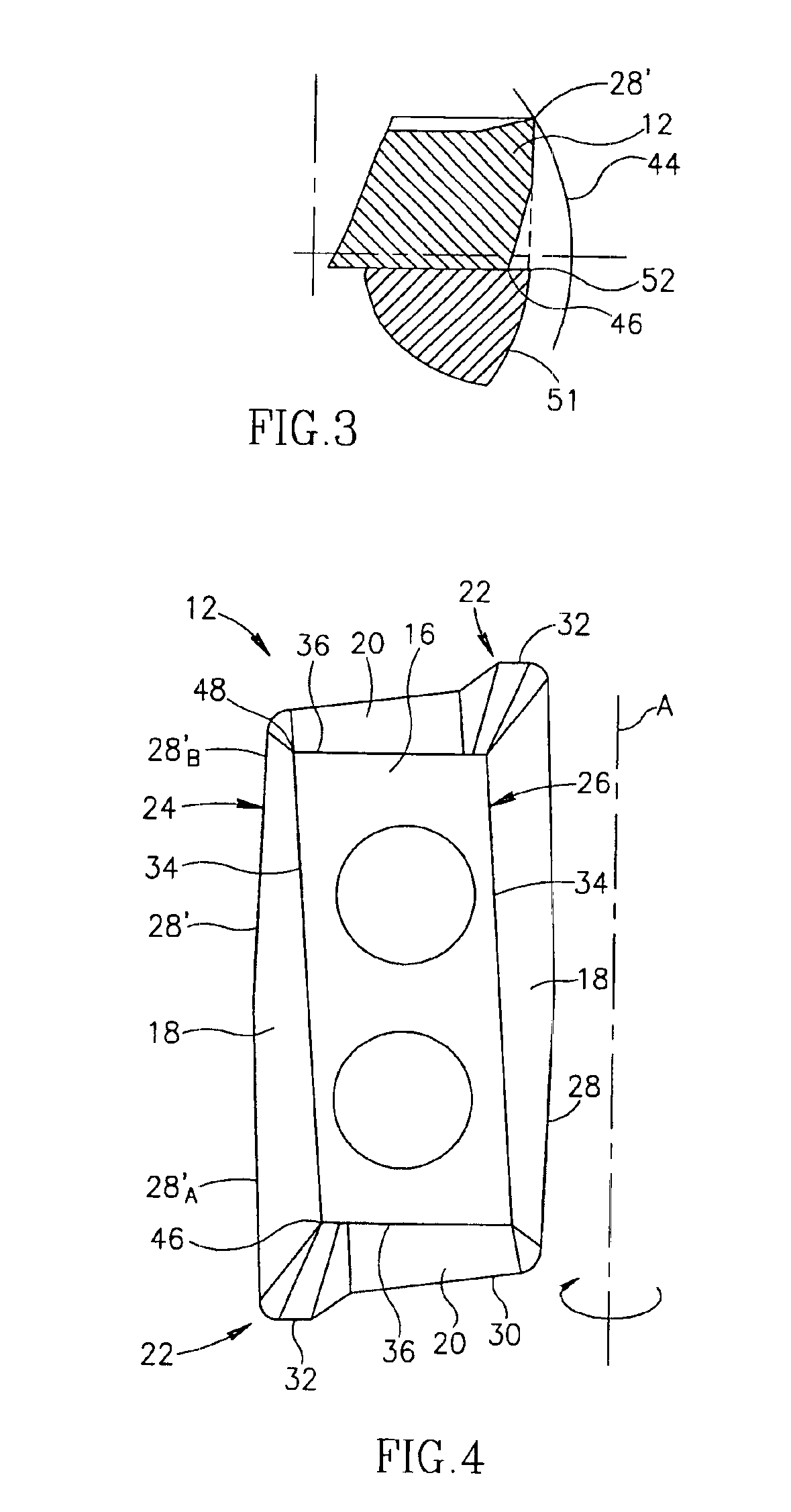

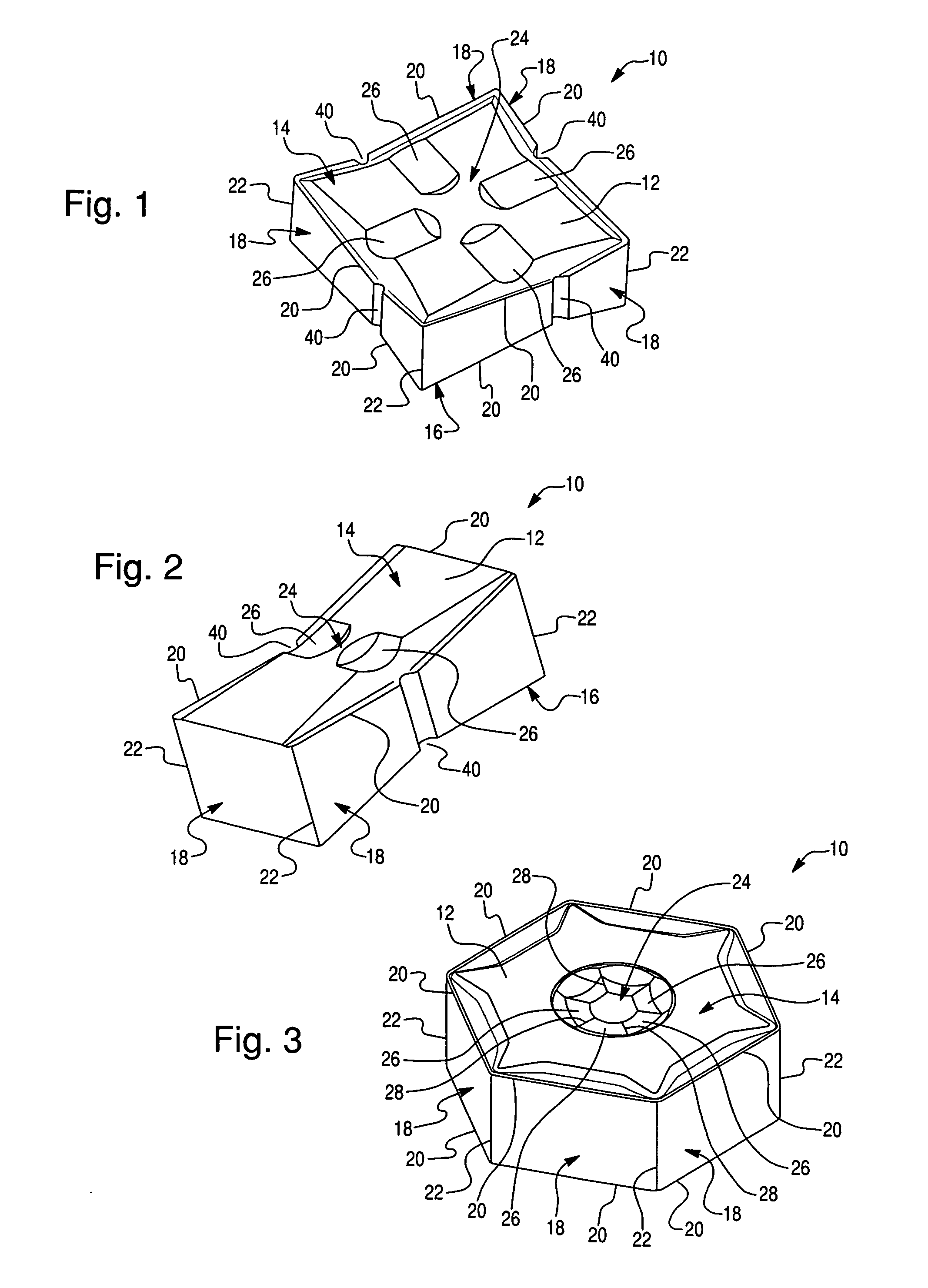

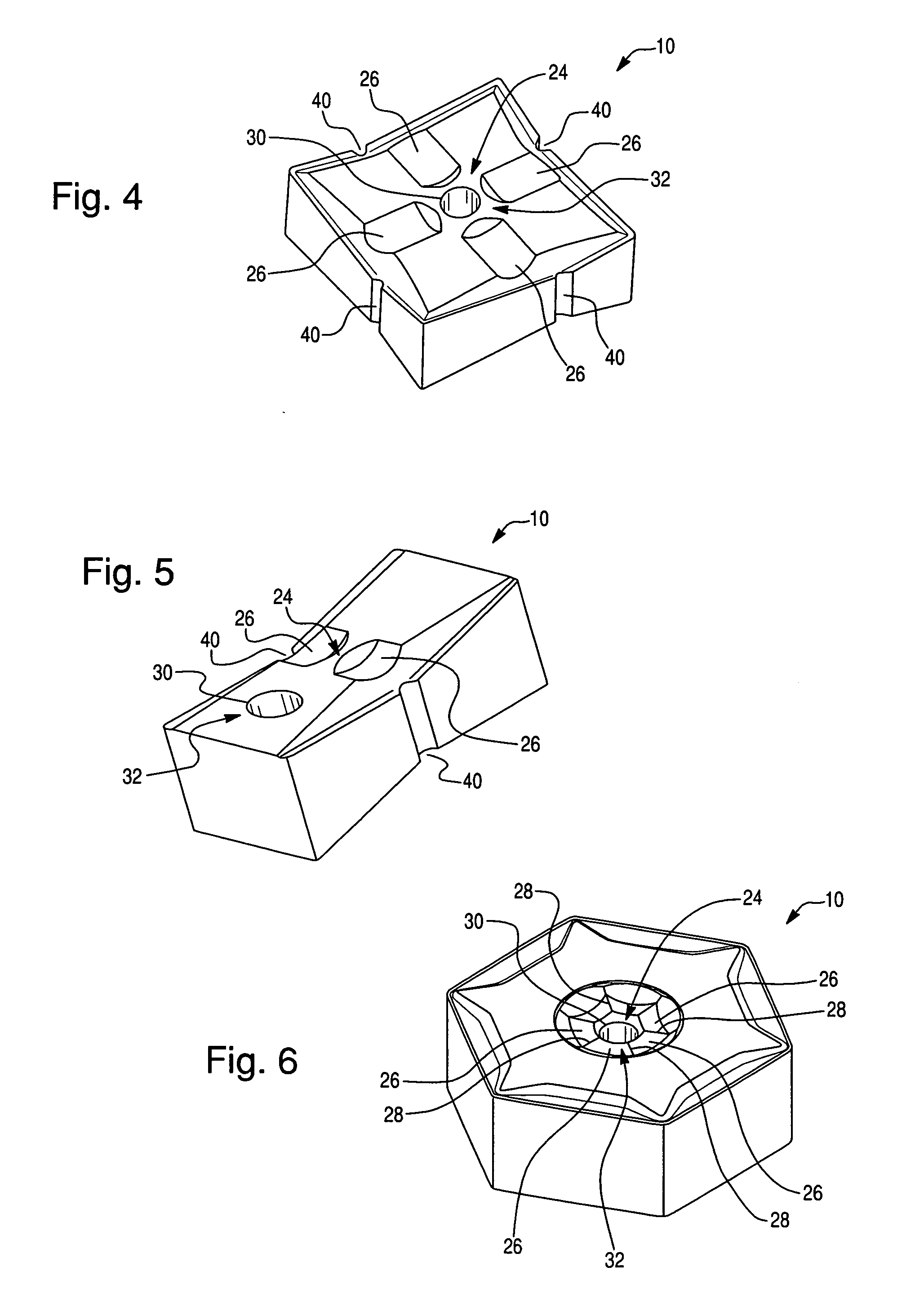

Cutting insert and a milling tool

A cutting insert for face milling and ramping includes an upper side defining an upper extension plane, a lower side defining a lower extension plane parallel with the upper extension plane, and an edge side extending around the cutting insert. A centre axis extends perpendicularly through the upper and lower extension planes. An upper cutting edge forms four upper cutting edge portions having an identical length corresponding to a determined angle with respect to the centre axis. A lower cutting edge forms four lower cutting edge portions (26), having an identical length corresponding to the determined angle with respect to the centre axis. Each upper cutting edge portion is displaced angularly with respect to the centre axis in relation to one of the lower cutting edge portions with a displacement angle being greater than zero and less than the determined angle.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com