Patents

Literature

158results about How to "Clearance can be provided" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

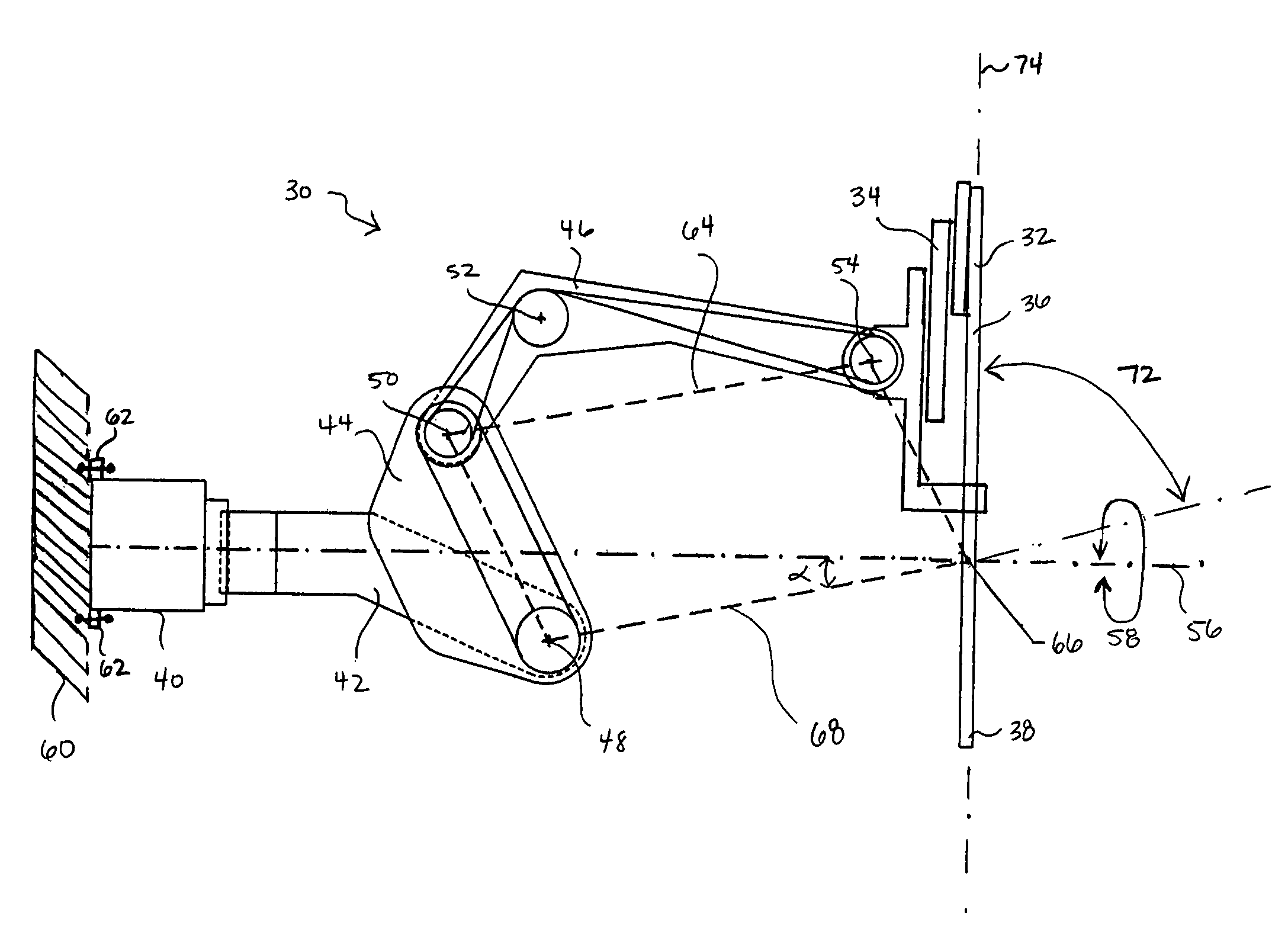

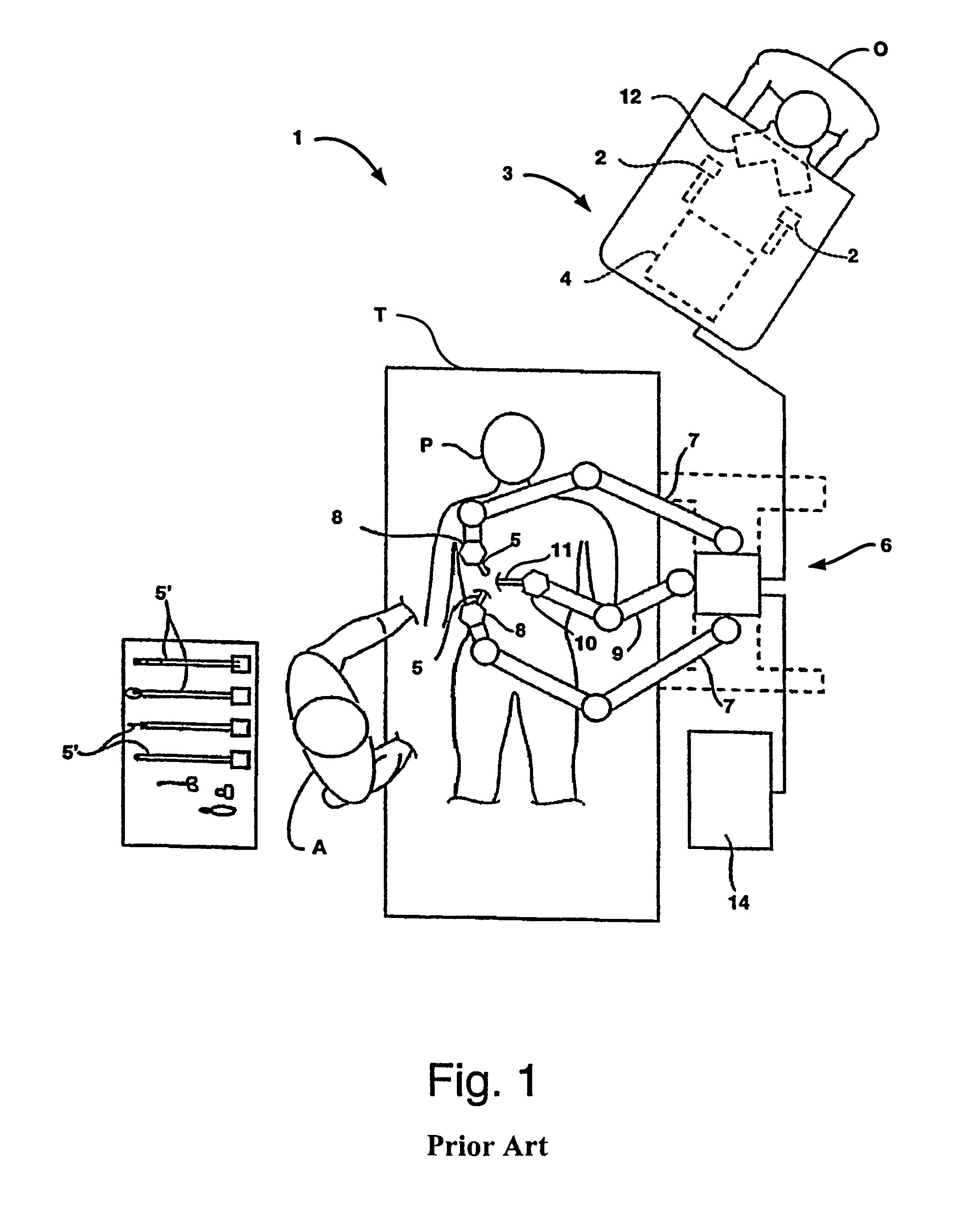

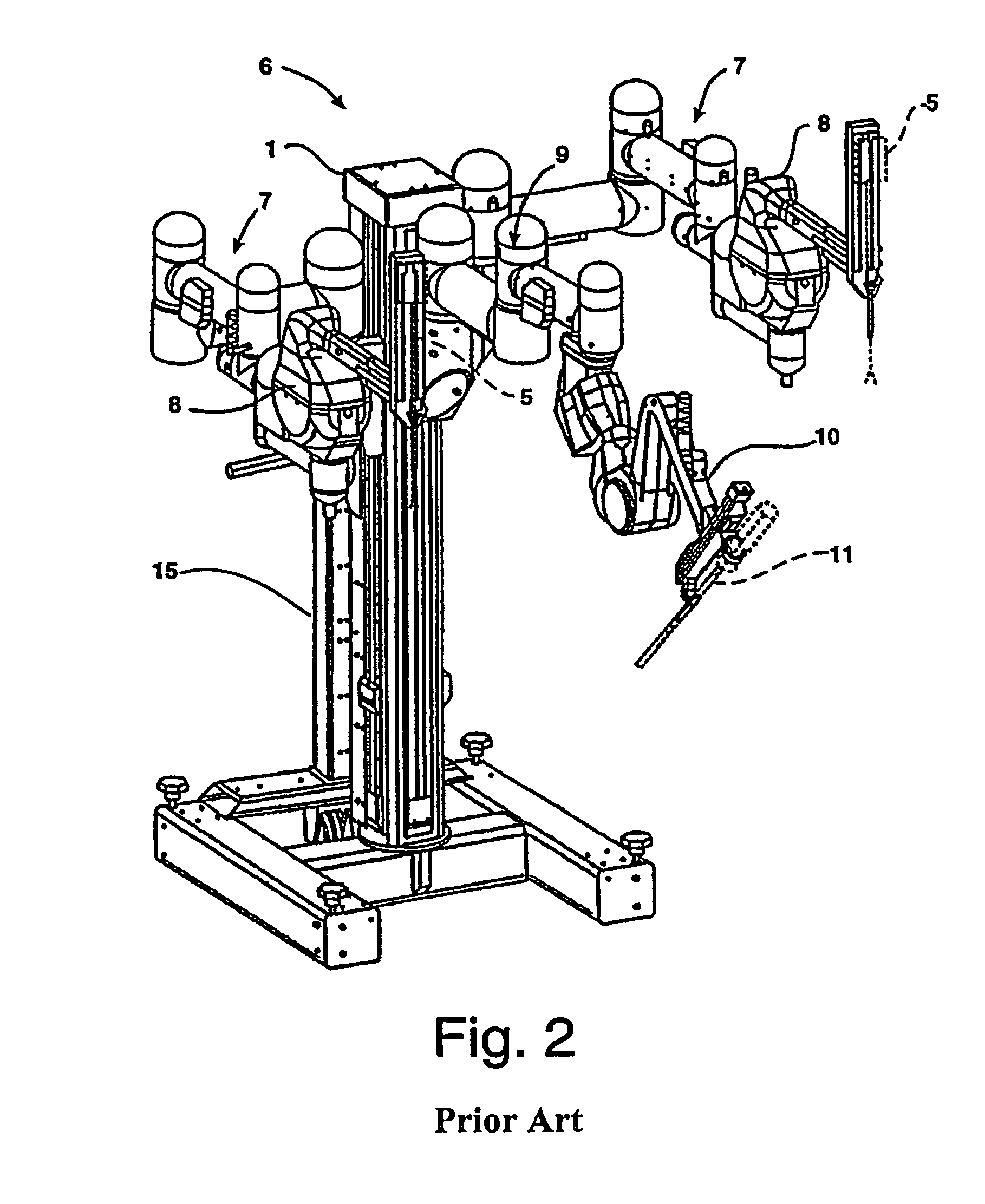

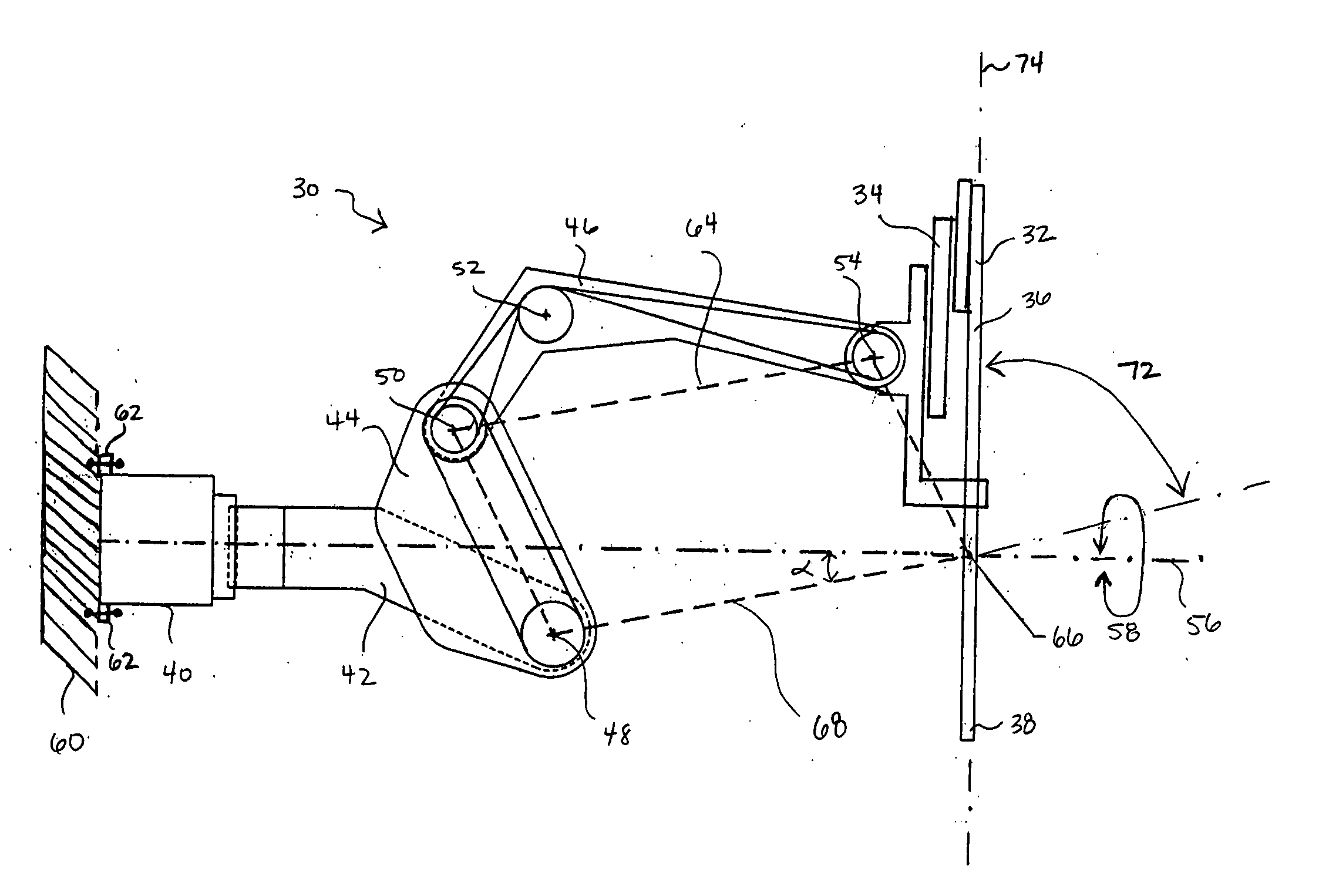

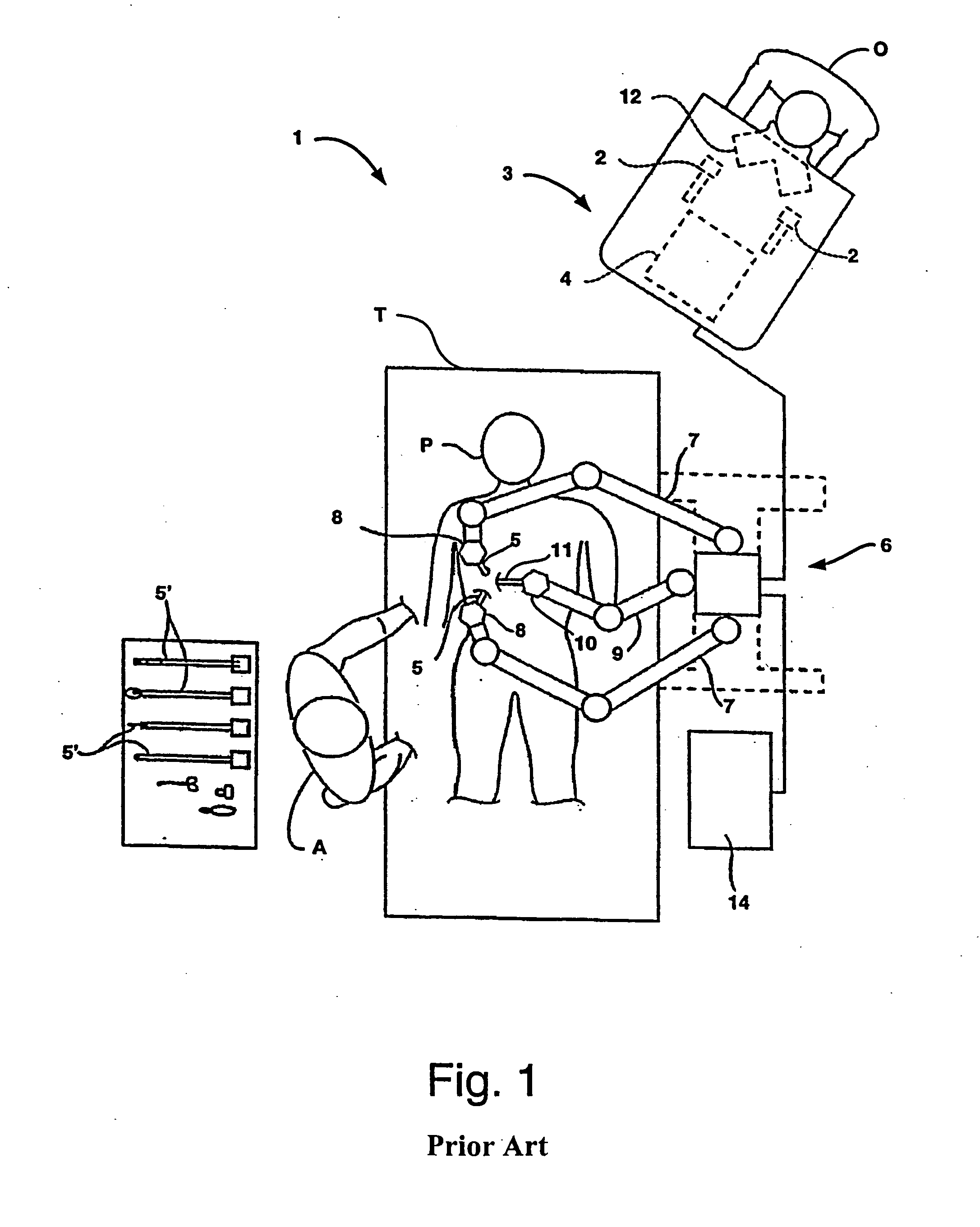

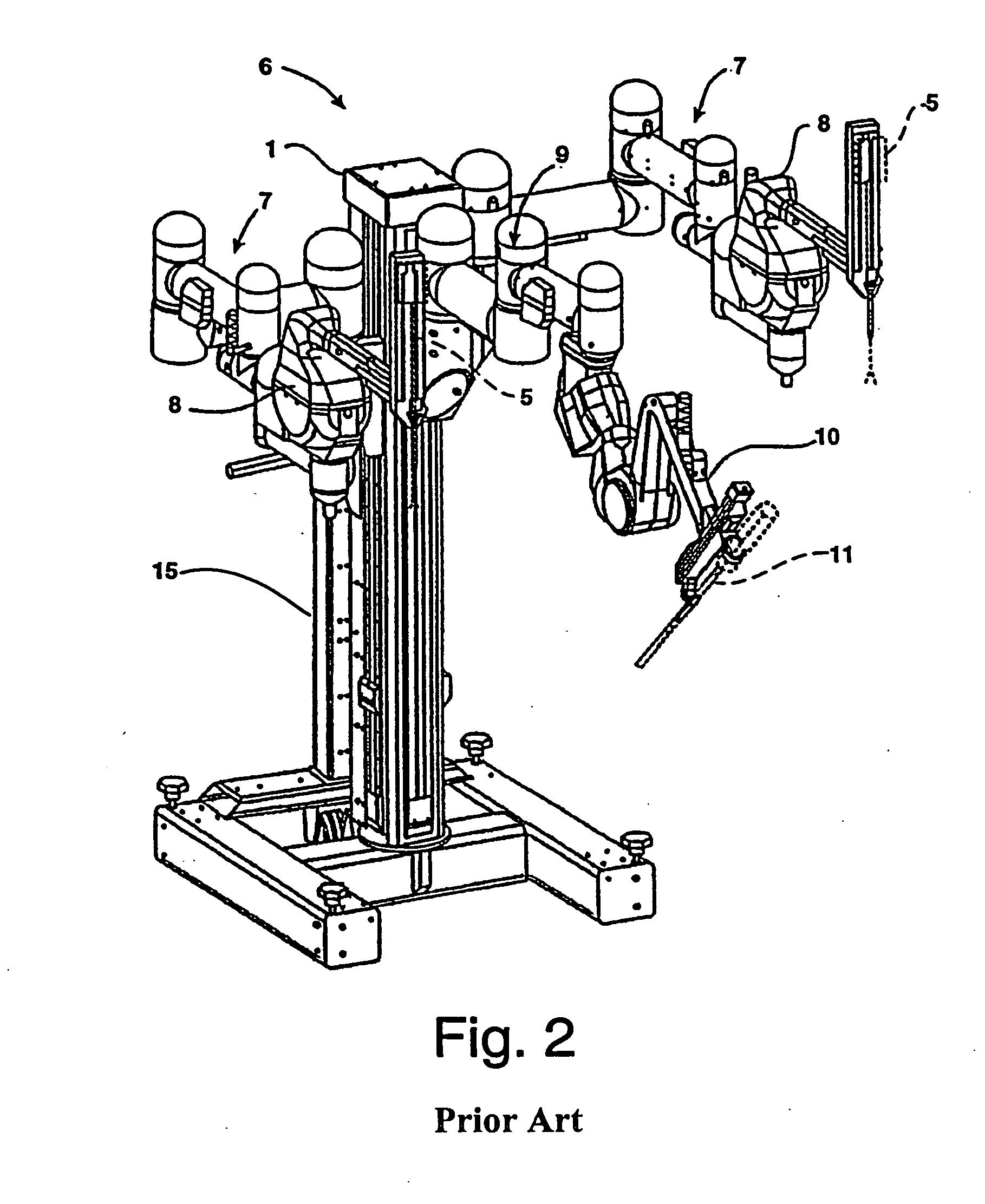

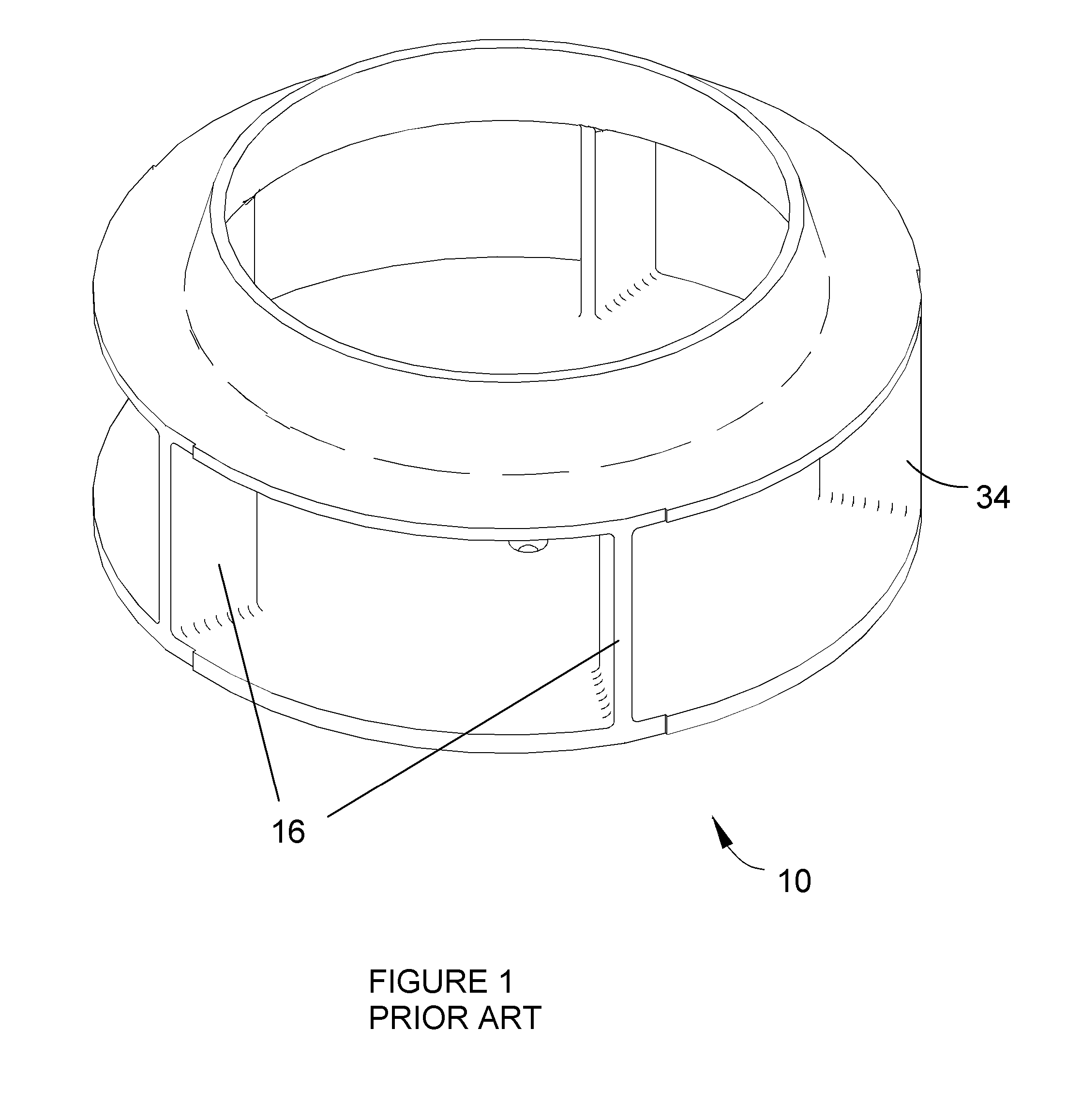

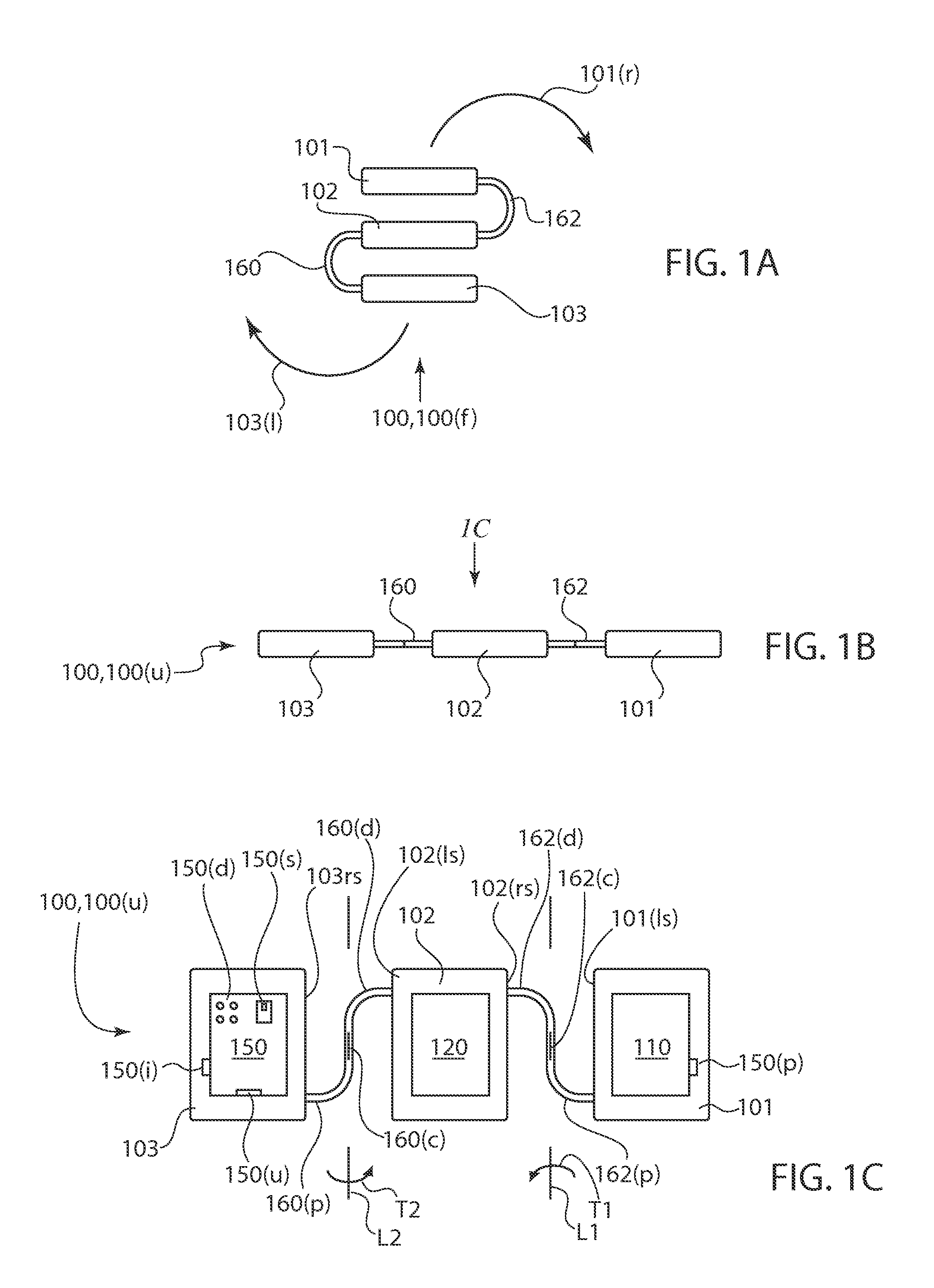

Offset remote center manipulator for robotic surgery

ActiveUS7594912B2Increase rangeReduces overall complexity and size and physical weightMechanical apparatusDiagnosticsEngineeringManipulator

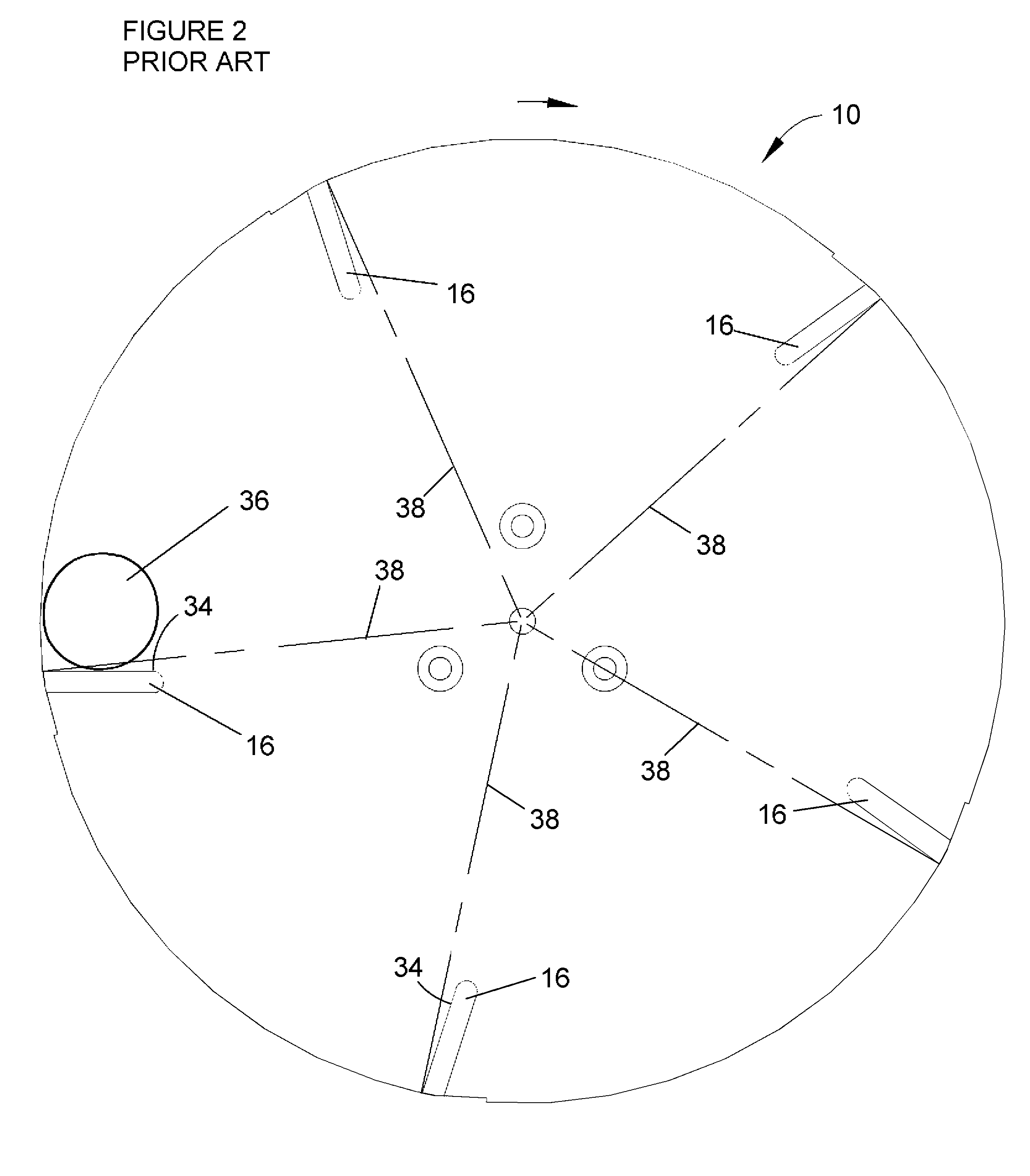

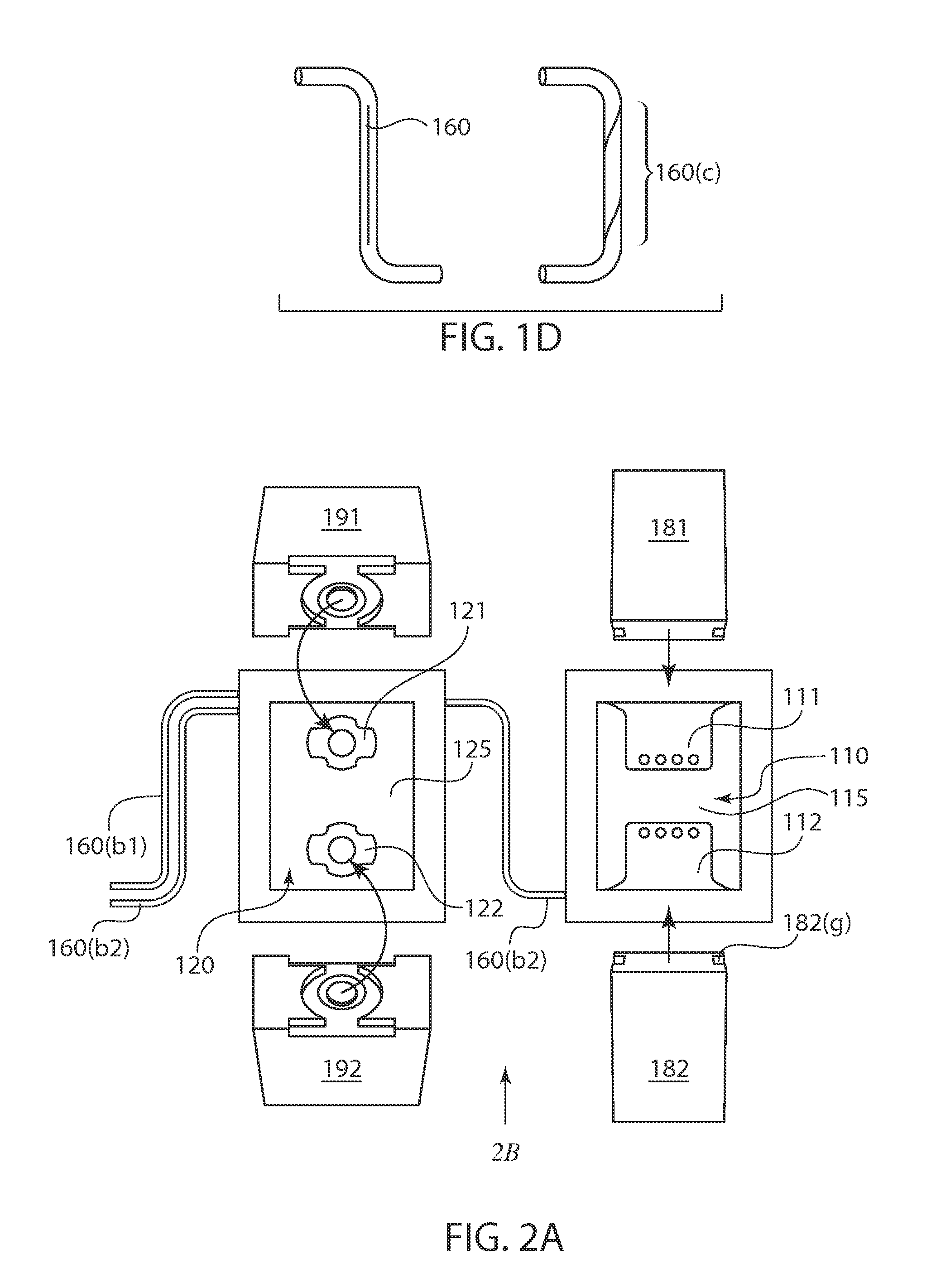

Medical, surgical, and / or robotic devices and systems often including offset remote center parallelogram manipulator linkage assemblies which constrains a position of a surgical instrument during minimally invasive robotic surgery are disclosed. The improved remote center manipulator linkage assembly advantageously enhances the range of instrument motion while at the same time reduces the overall complexity, size, and physical weight of the robotic surgical system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

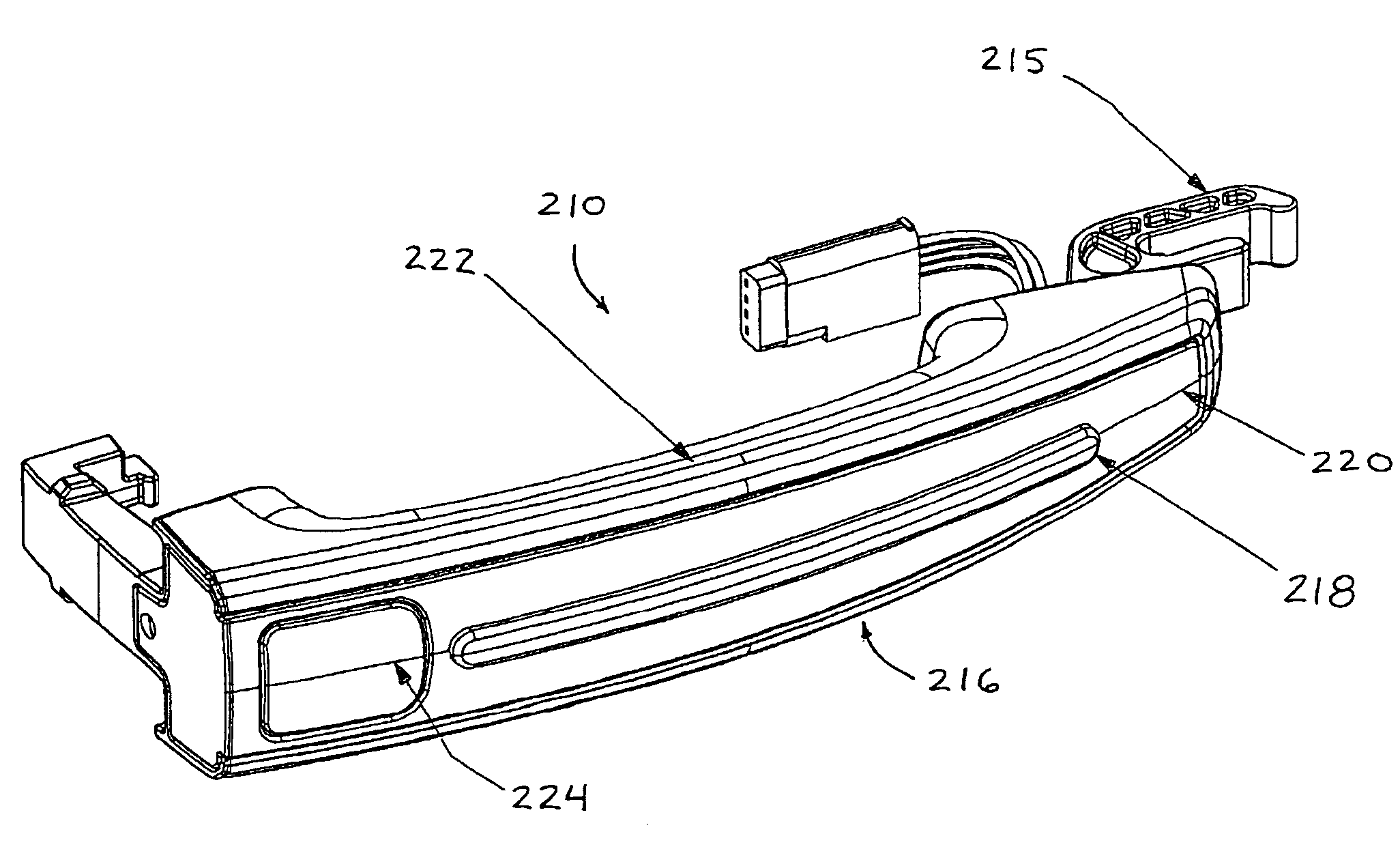

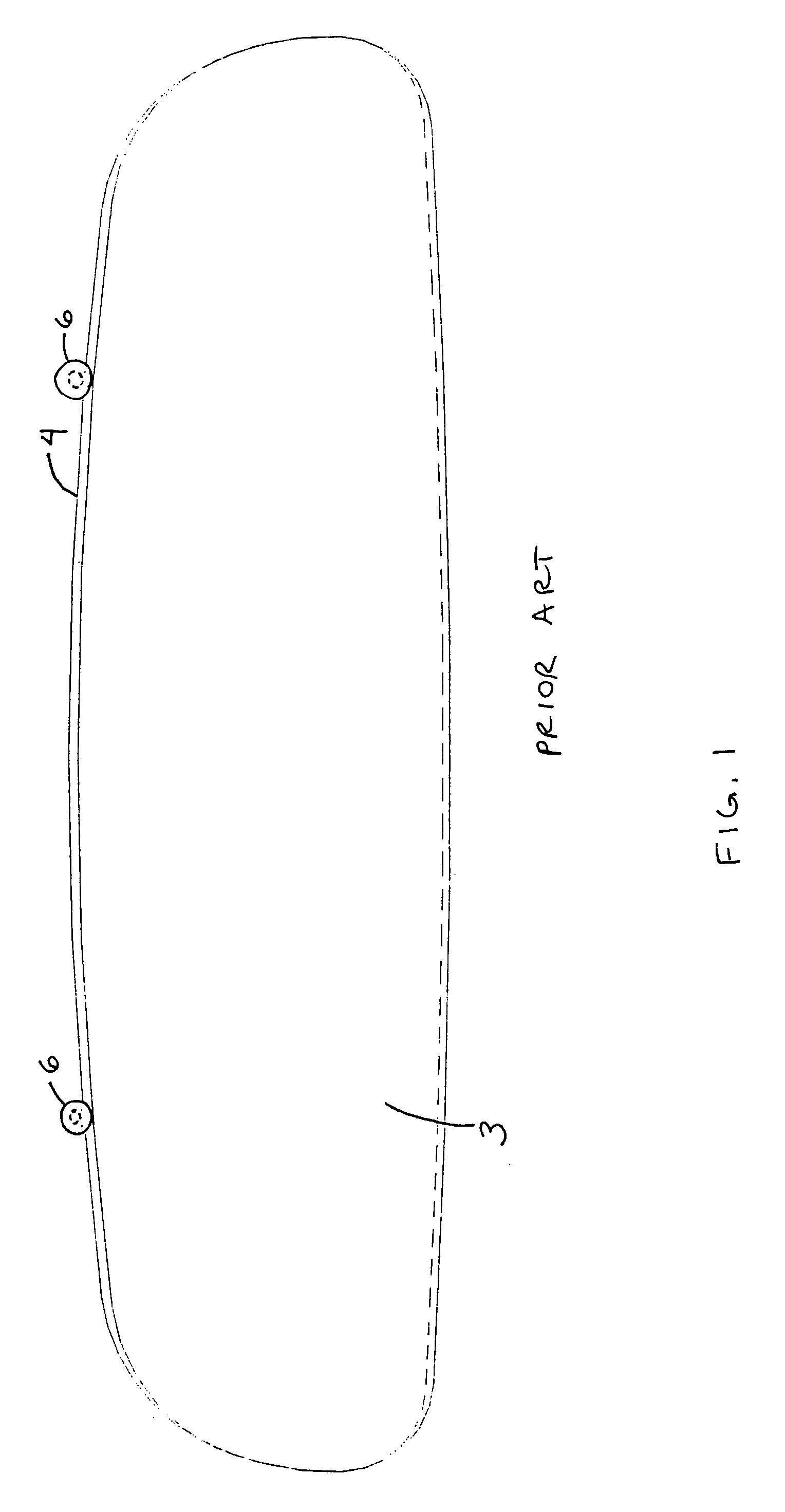

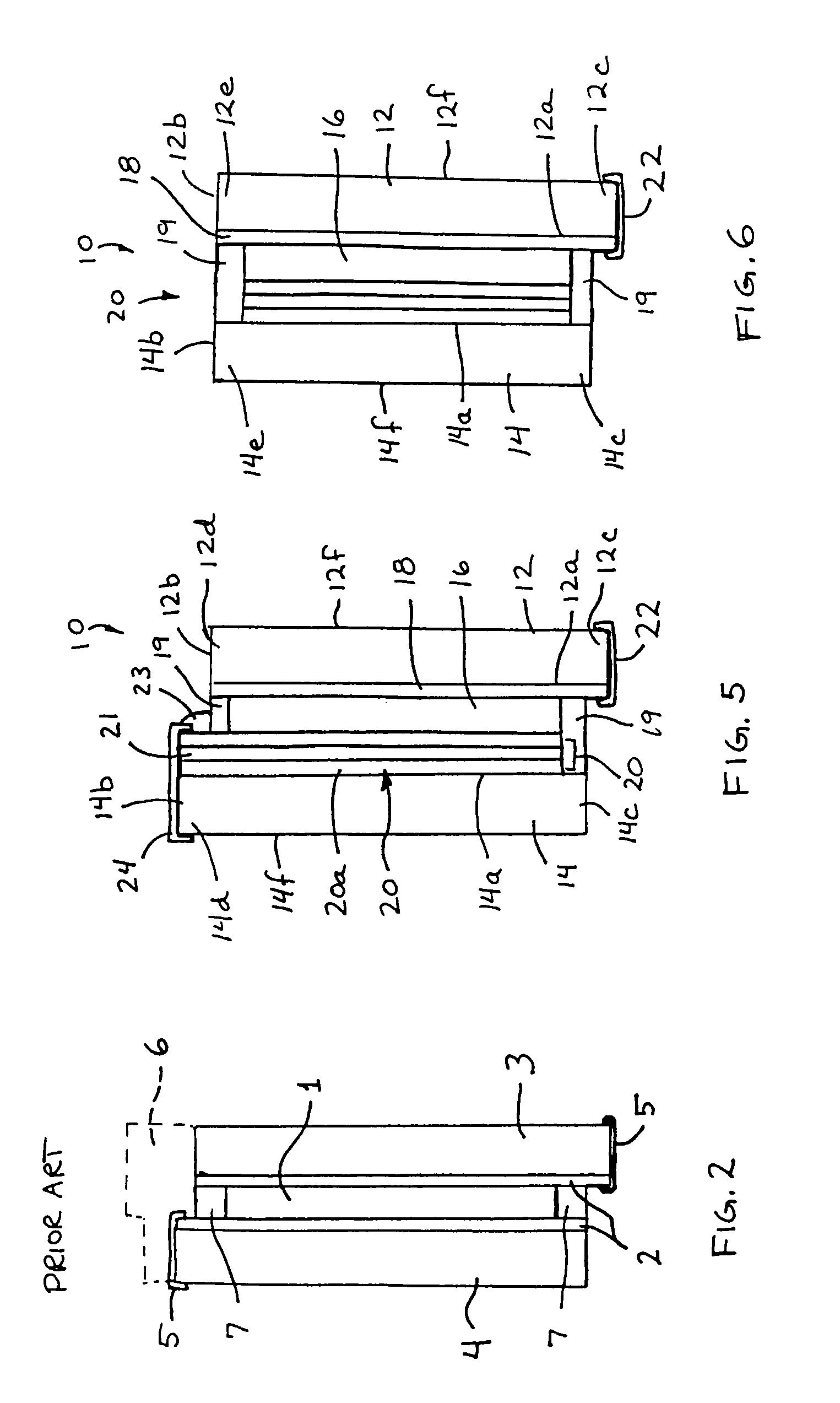

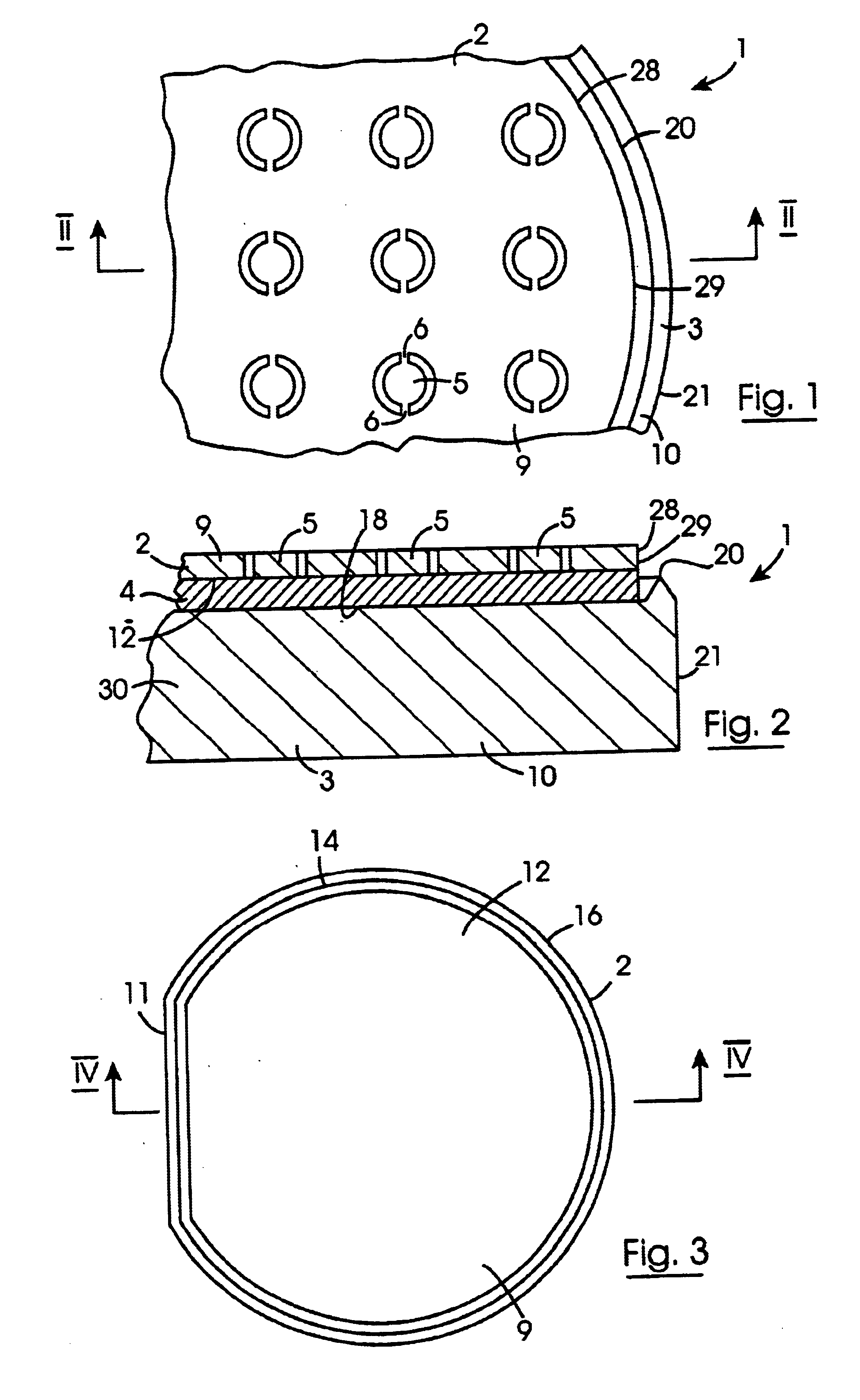

Electro-optic reflective element assembly

InactiveUS7184190B2Easy to assembleClearance can be providedMirrorsNon-linear opticsElectricityElectrical connection

Owner:DONNELLY CORP

Offset remote center manipulator for robotic surgery

ActiveUS20060074406A1Reduce in sizeEnhance rangeMechanical apparatusDiagnosticsManipulatorSurgical instrument

Medical, surgical, and / or robotic devices and systems often including offset remote center parallelogram manipulator linkage assemblies which constrains a position of a surgical instrument during minimally invasive robotic surgery are disclosed. The improved remote center manipulator linkage assembly advantageously enhances the range of instrument motion while at the same time reduces the overall complexity, size, and physical weight of the robotic surgical system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

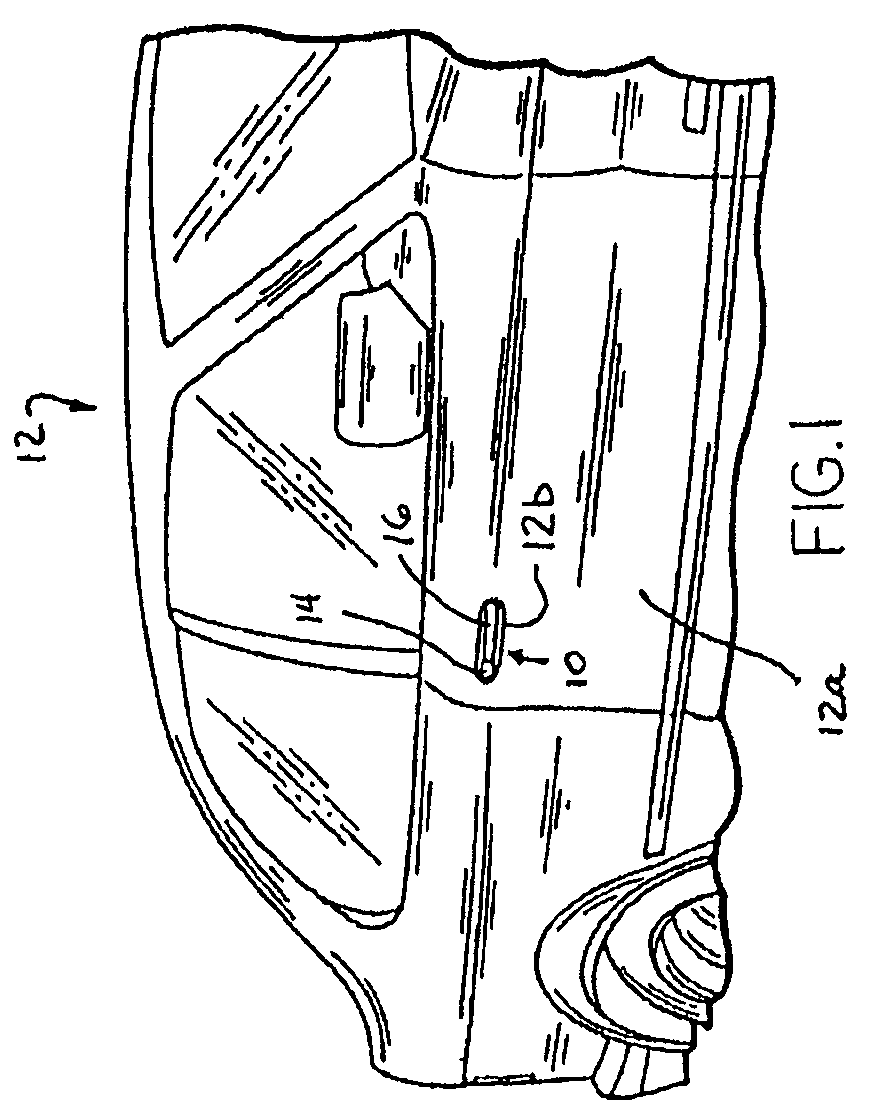

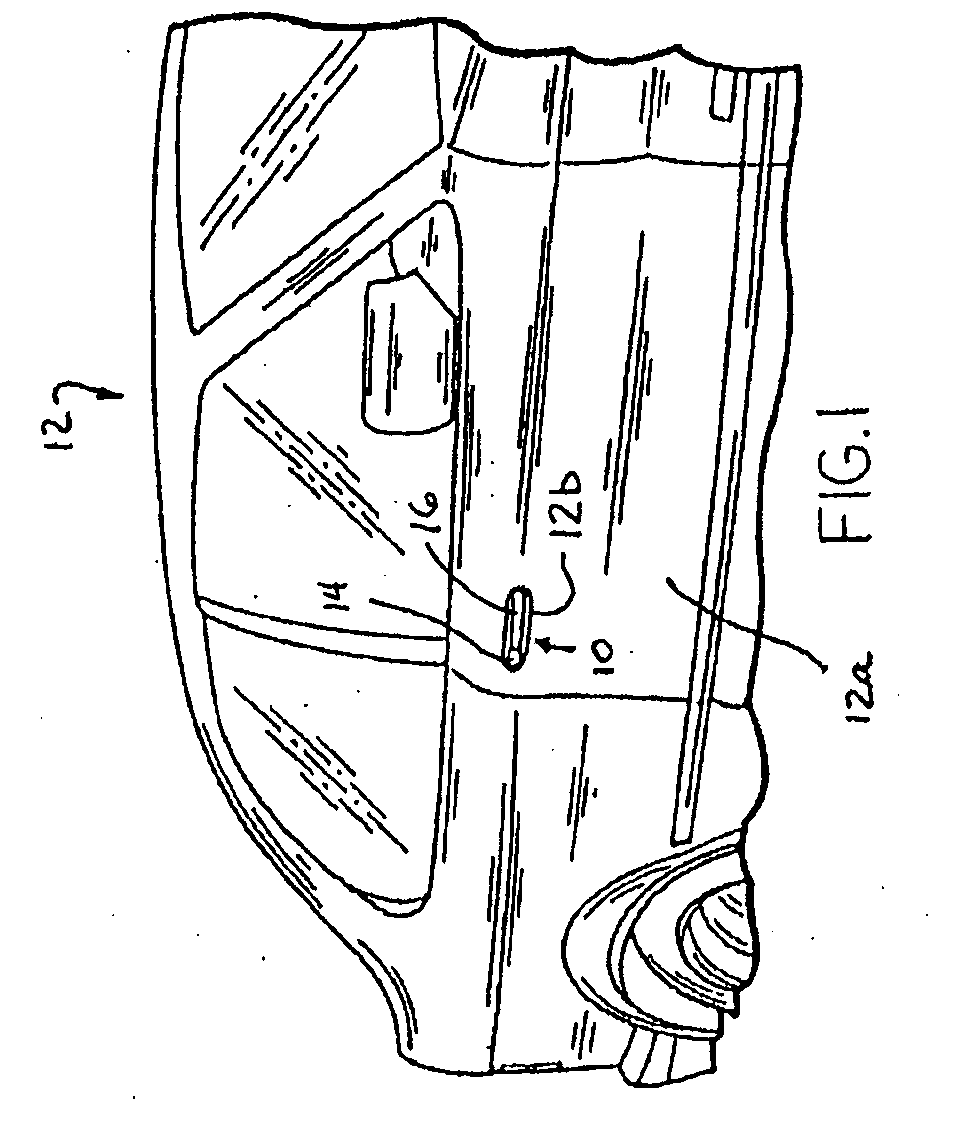

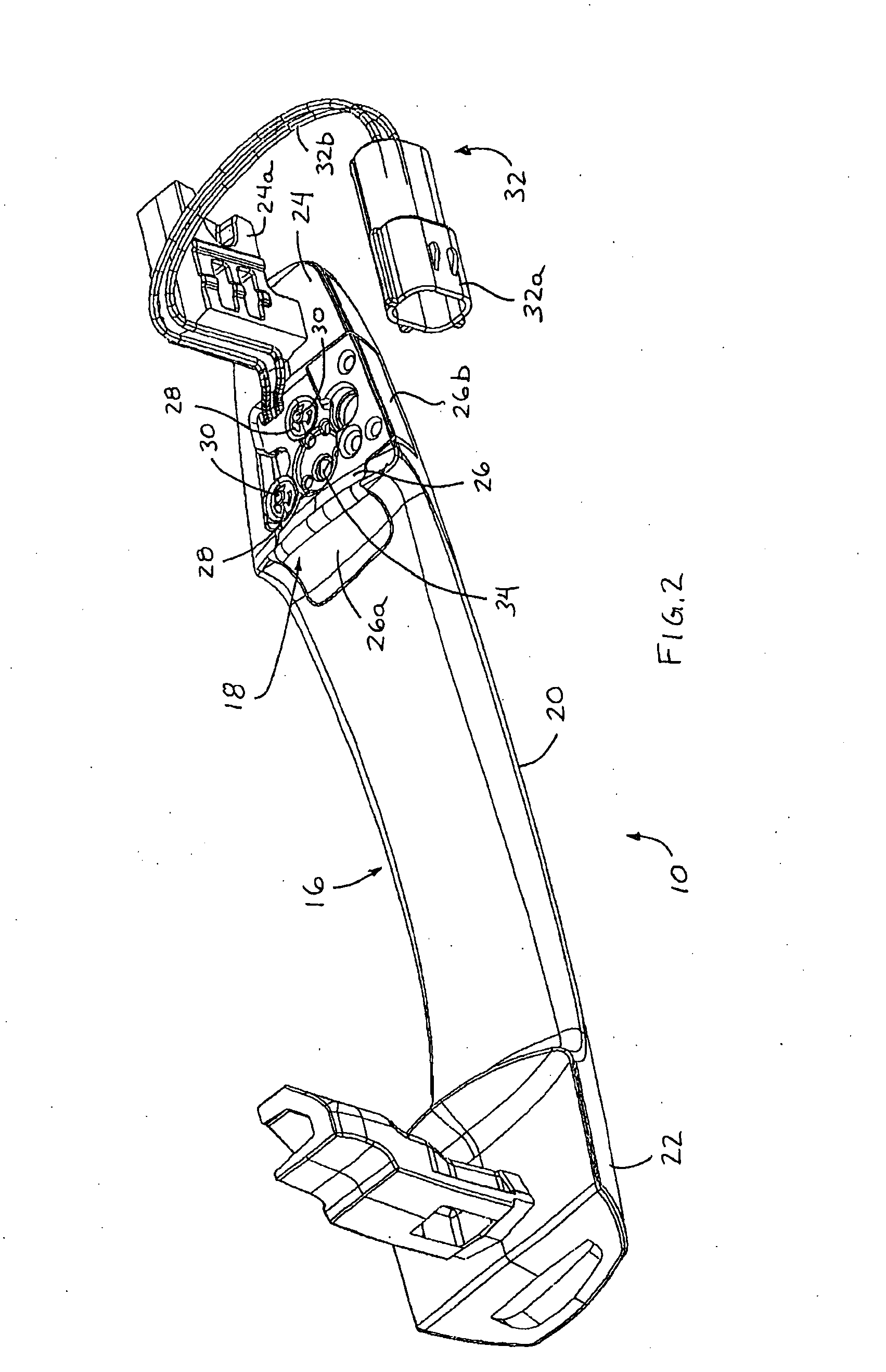

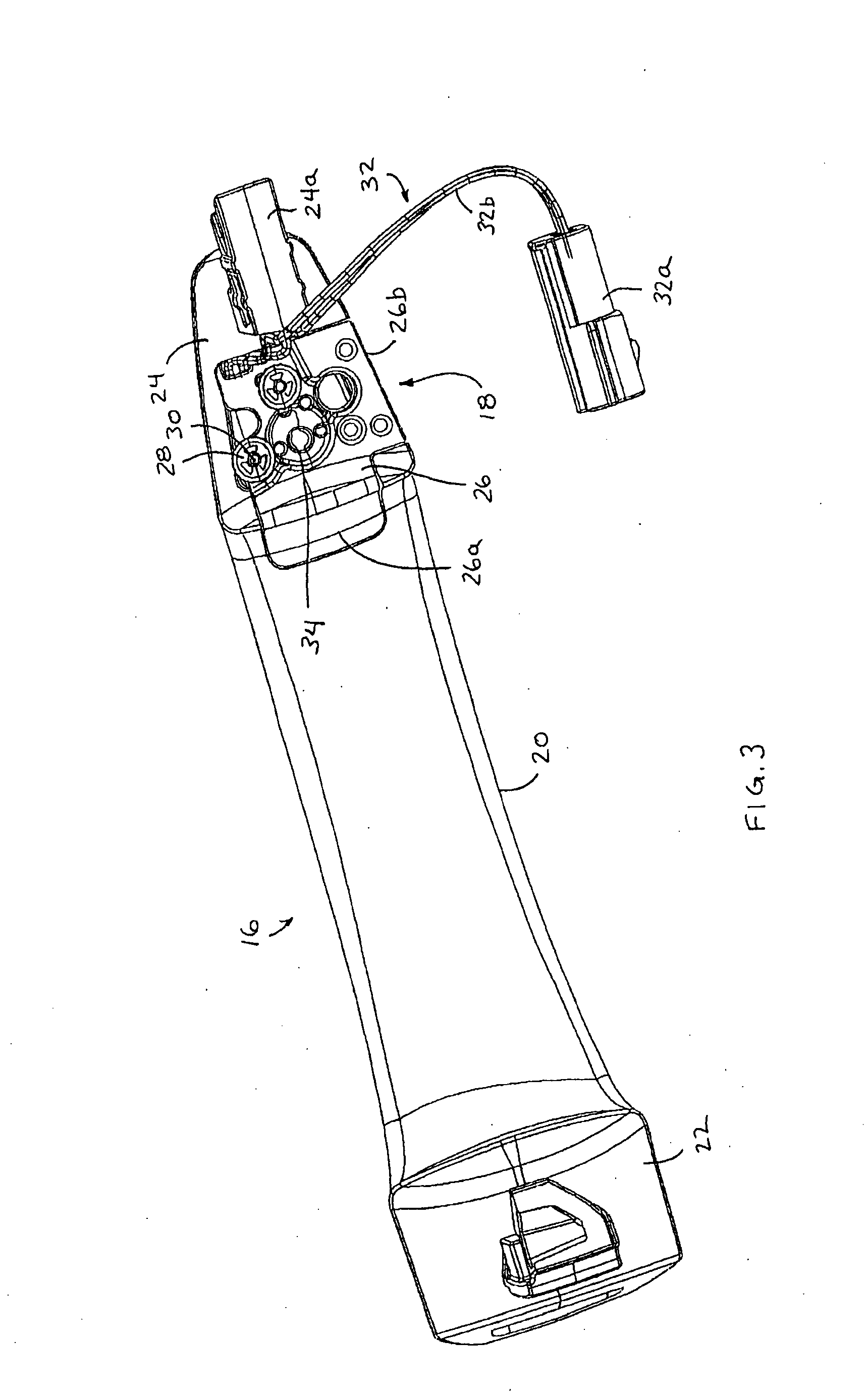

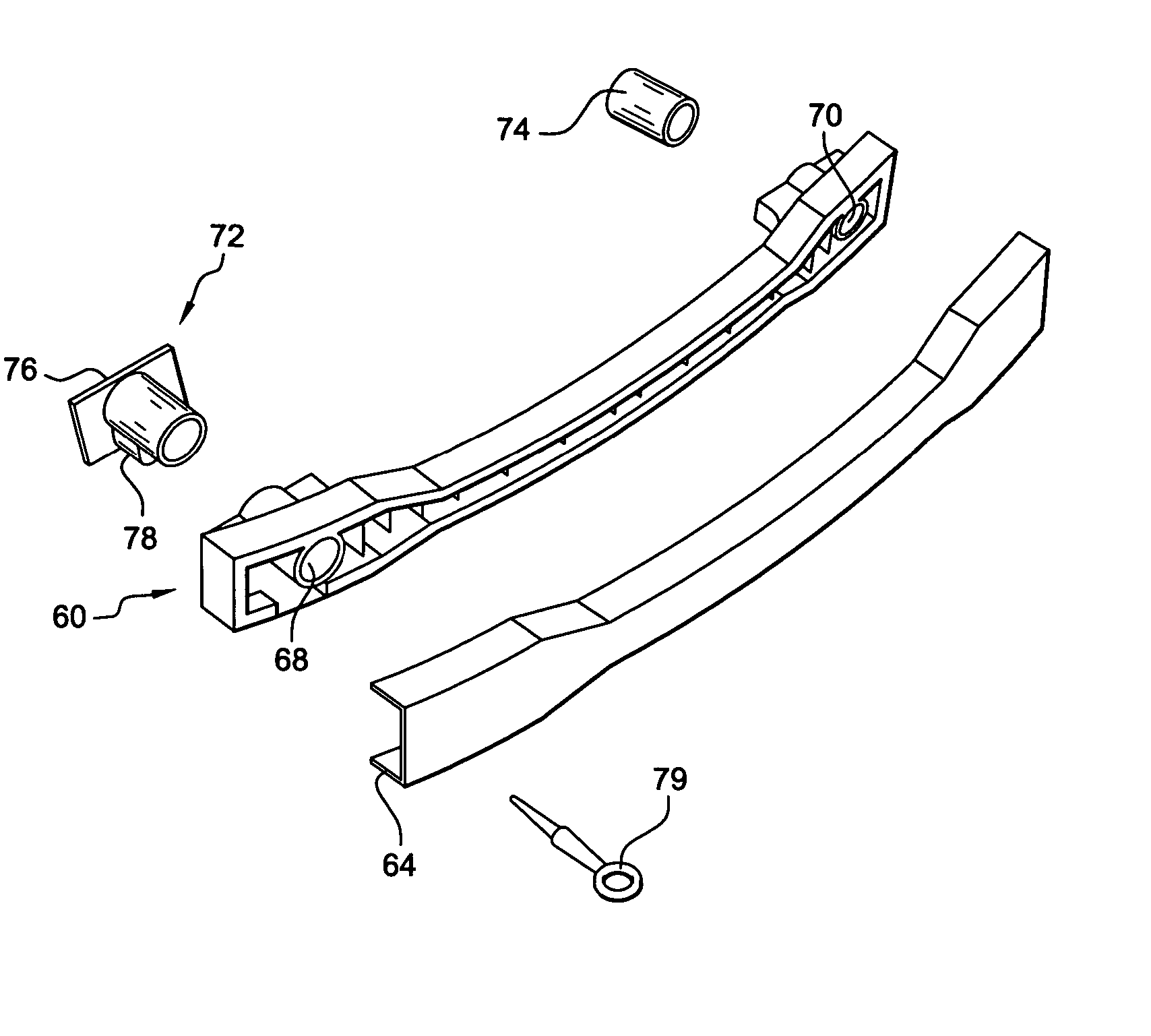

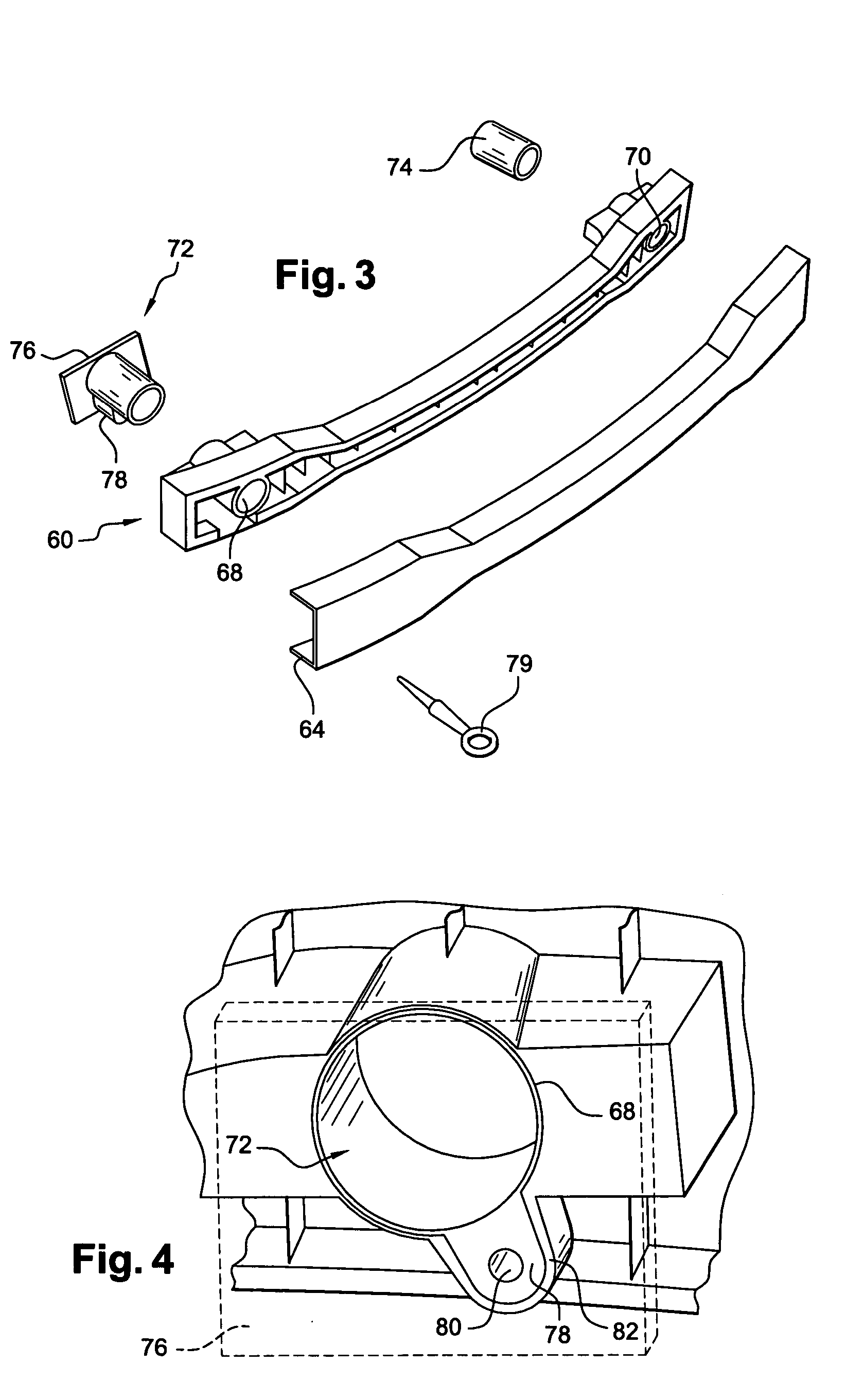

Illumination module for a vehicle

ActiveUS8333492B2Convenient lightingClearance can be providedLighting circuitsVehicle locksComputer graphics (images)Engineering

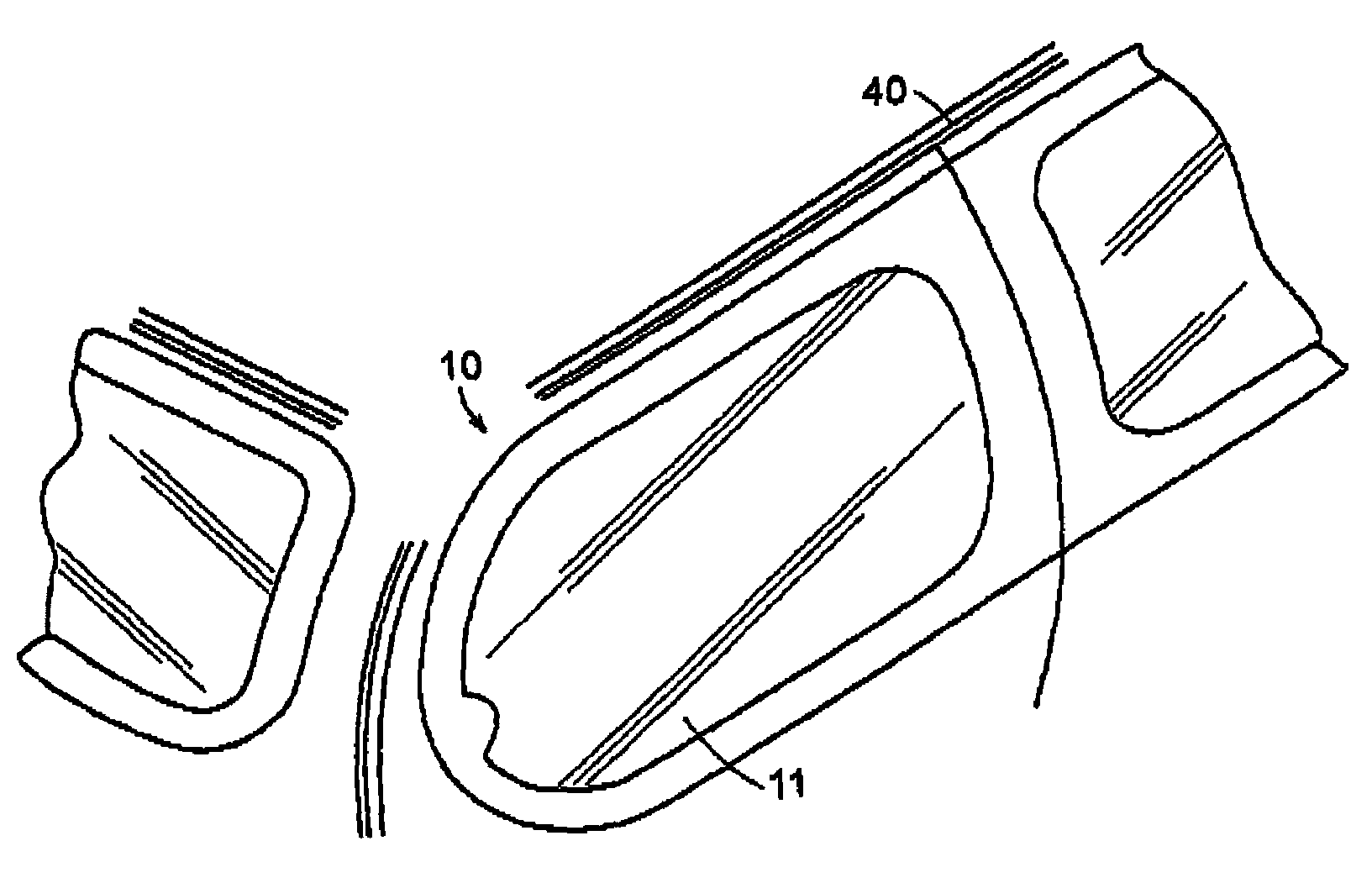

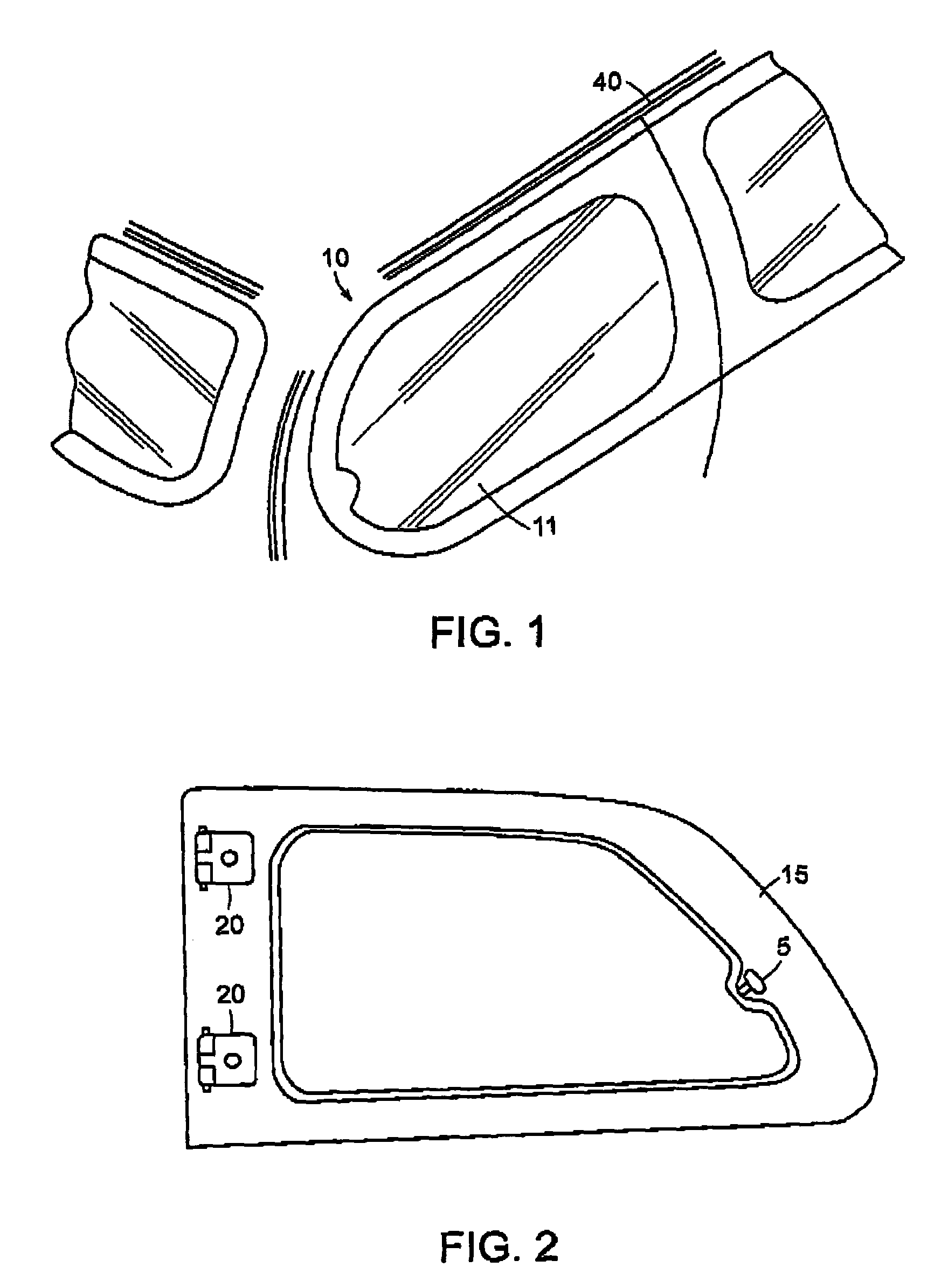

An illumination module for a vehicle includes at least one illumination source for illuminating a target area at the vehicle. The illumination module may be mounted at a handle of a vehicle door and may be operable to illuminate the handle region and / or pocket region of the vehicle door and to illuminate a ground region adjacent to the vehicle and generally below the door handle assembly. The illumination module may include an icon established thereat and the at least one illumination source may back light the icon so that the icon, when the illumination module is activated, is viewable by a person viewing the vehicle. The illumination module may project or direct the illumination toward a targeted area so that the icon is discernible at the targeted area.

Owner:MAGNA MIRRORS OF AMERICA INC

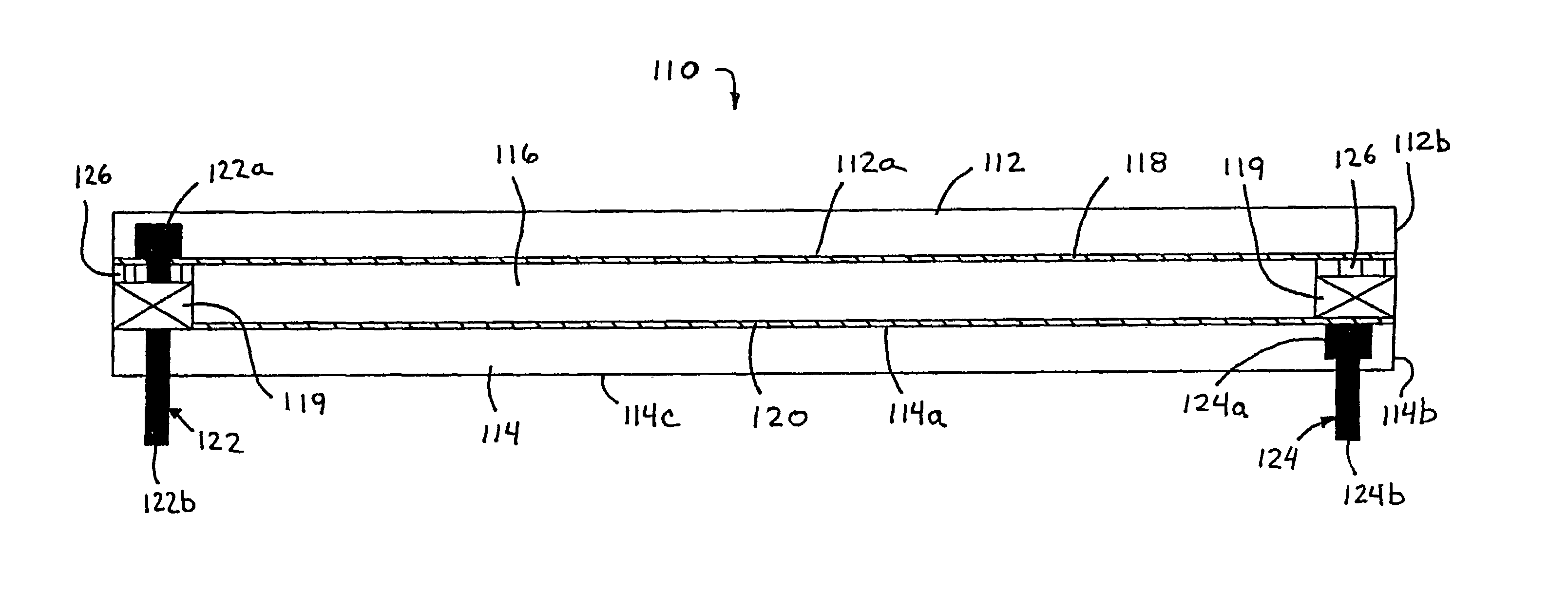

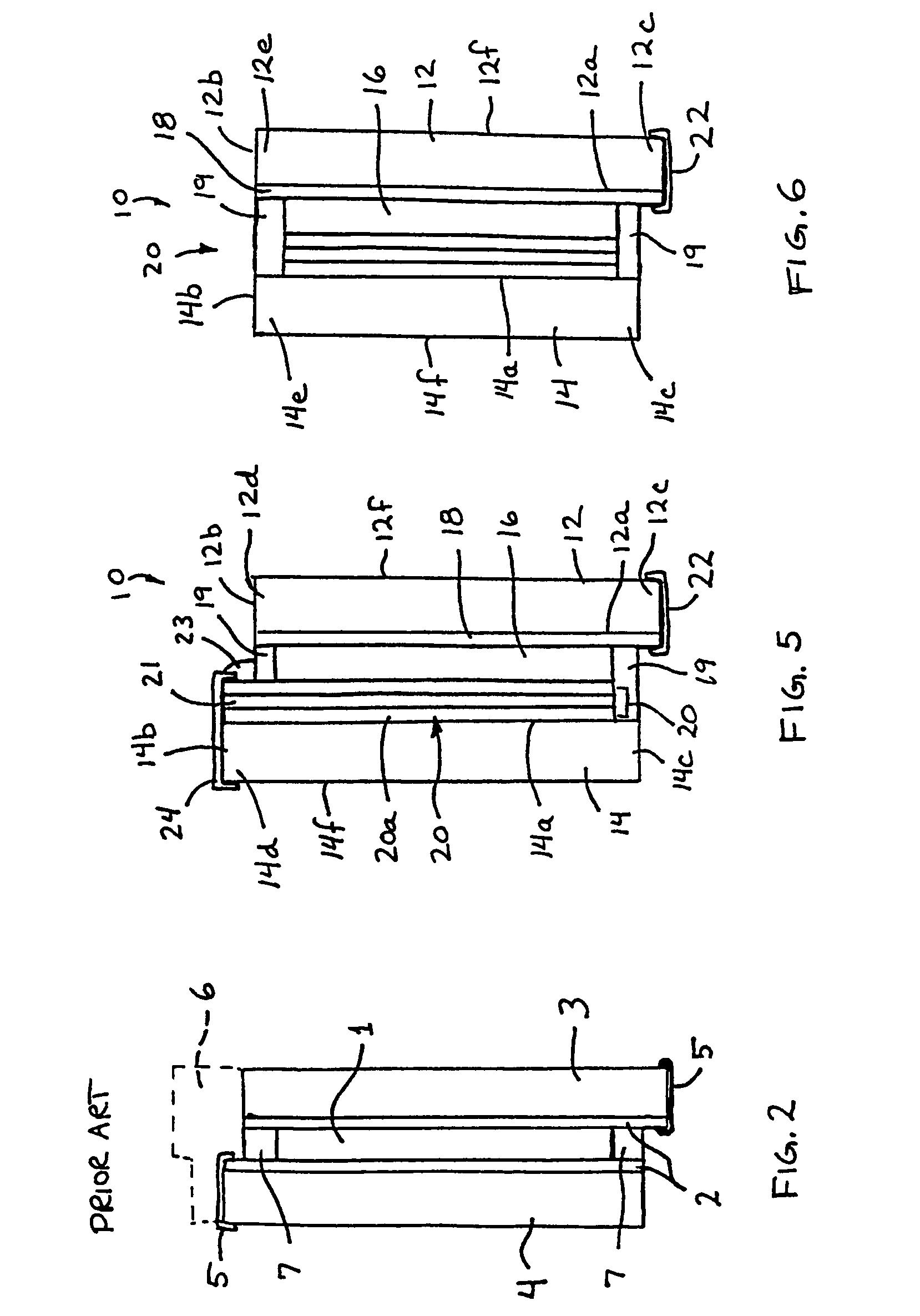

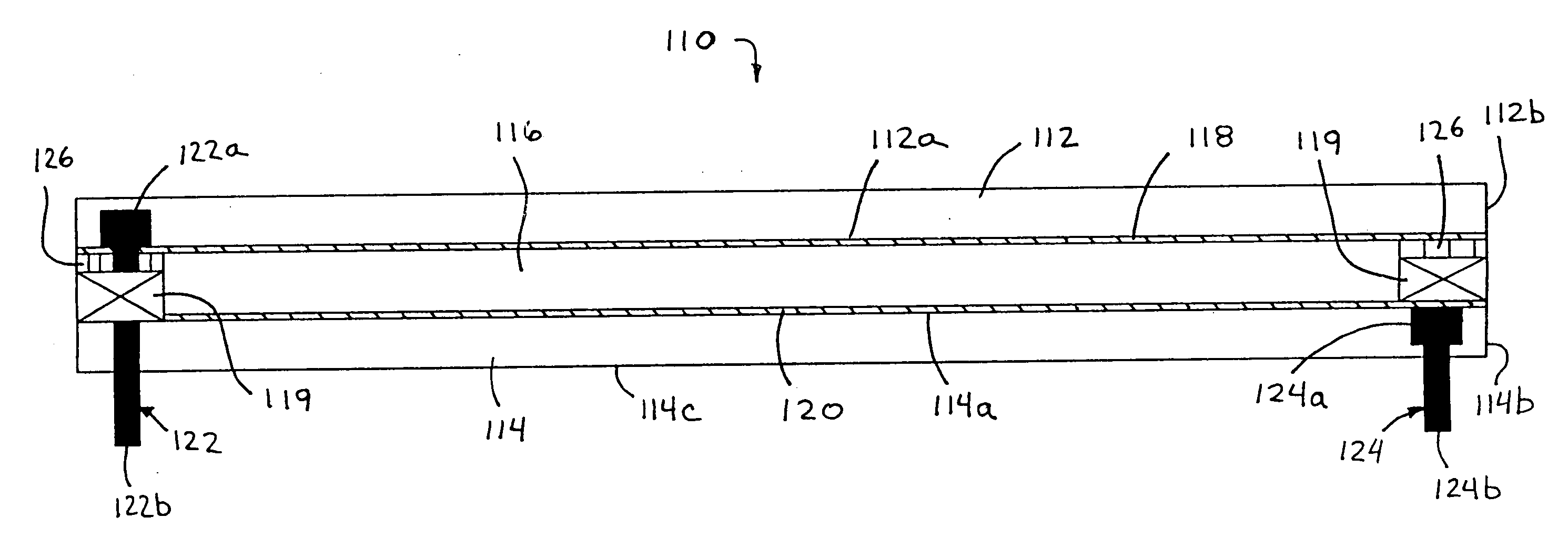

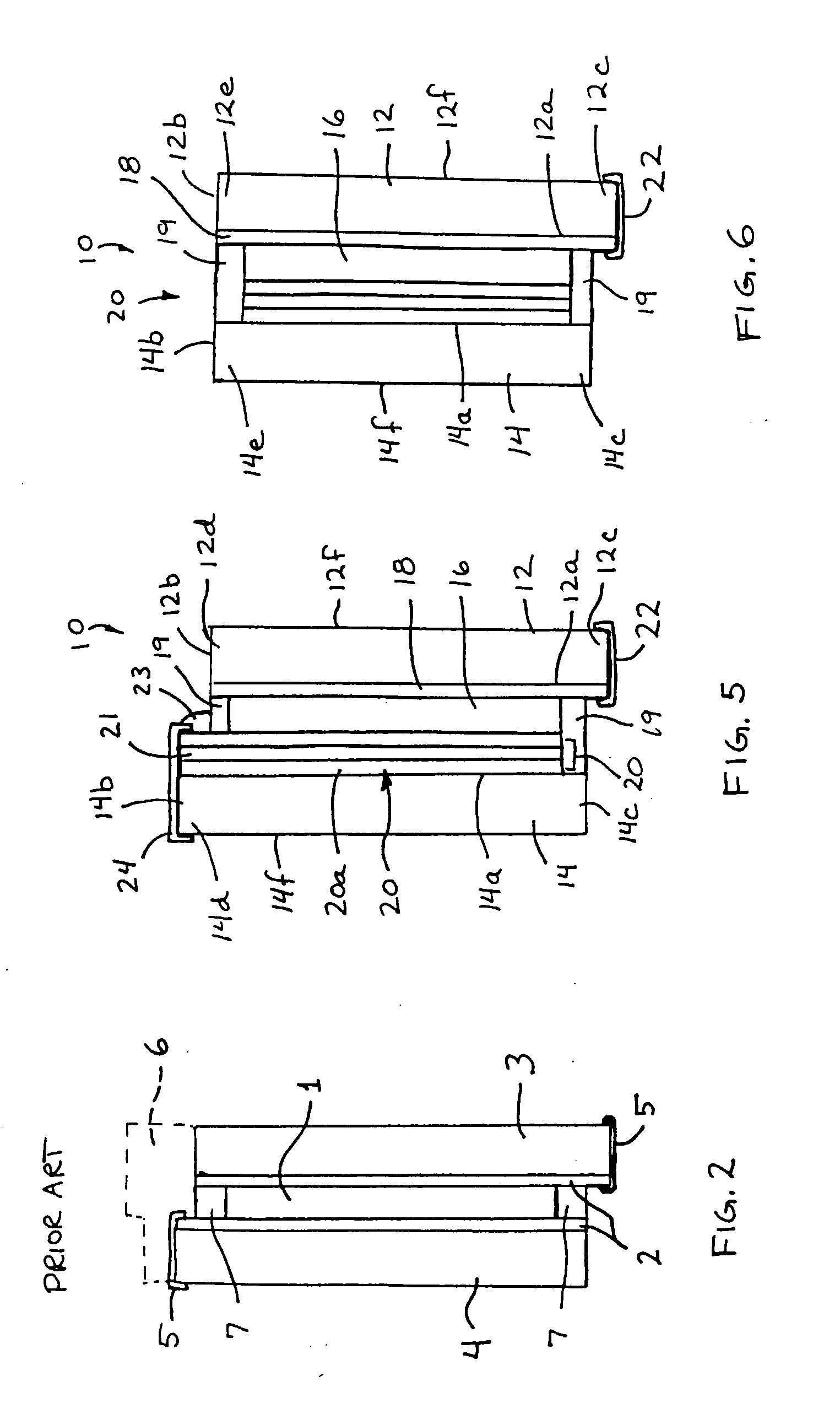

Electro-optic reflective element assembly

InactiveUS7310177B2Easy to assembleClearance can be providedMirrorsElongate light sourcesElectrical conductorElectrical connection

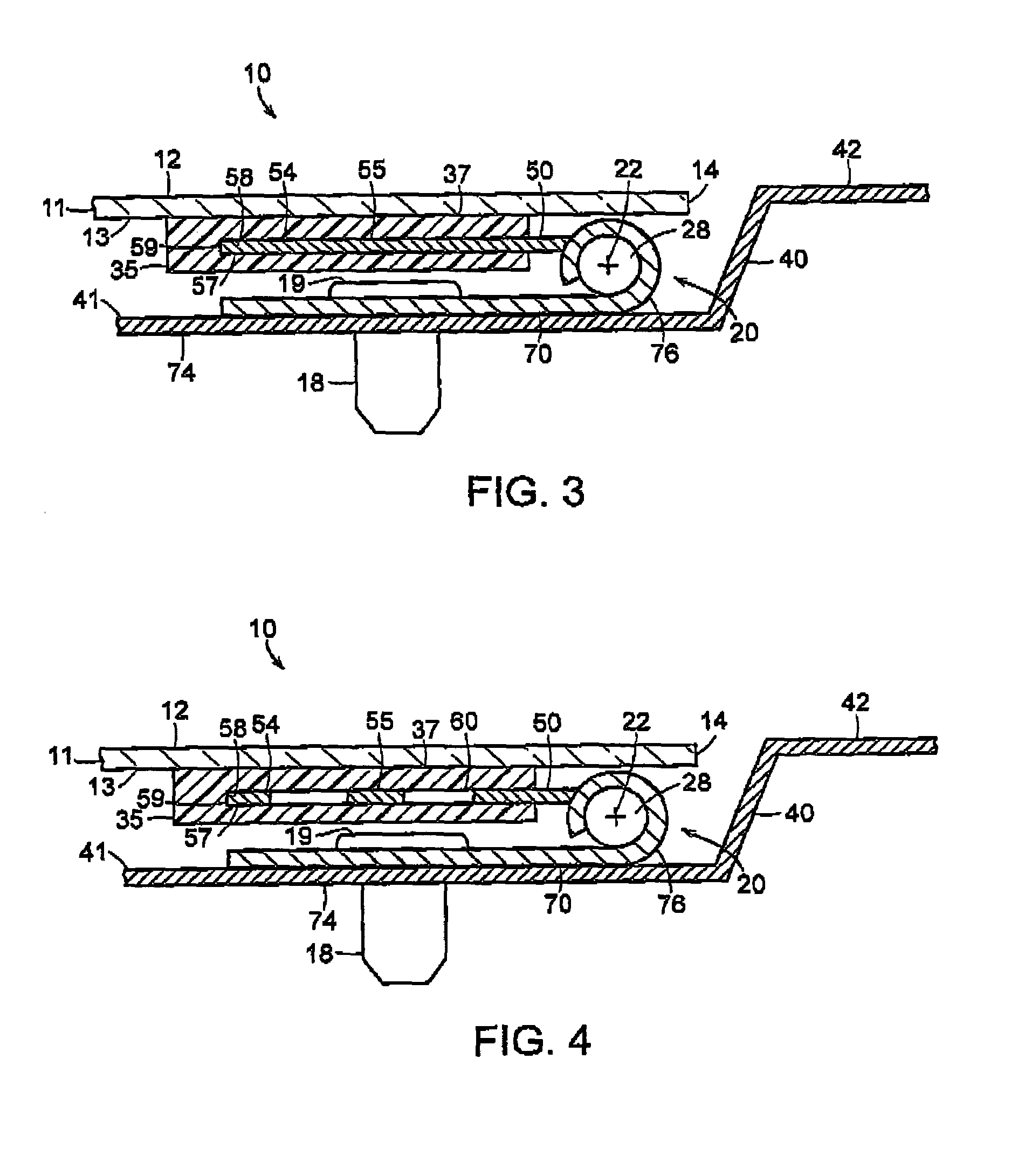

A rearview mirror assembly for a vehicle includes an electro-optic reflective element with an overhang region at an edge region of a first substrate that extends beyond a corresponding edge region of a second substrate. A transparent electrical conductor is disposed at a second surface of the first substrate and a mirror reflector is disposed at a third surface of the second substrate. The mirror reflector includes a tab portion that at least partially encompasses an edge dimension of the second substrate. A non-conductive seal is disposed between the first and second substrates and encompasses at least a portion of the mirror reflector and at least a portion of a non-conductive perimeter region of the third surface. A first electrical connector connects to the transparent electrical conductor via the overhang region and a second electrical connector is in electrical connection with the tab portion of the mirror reflector.

Owner:DONNELLY CORP

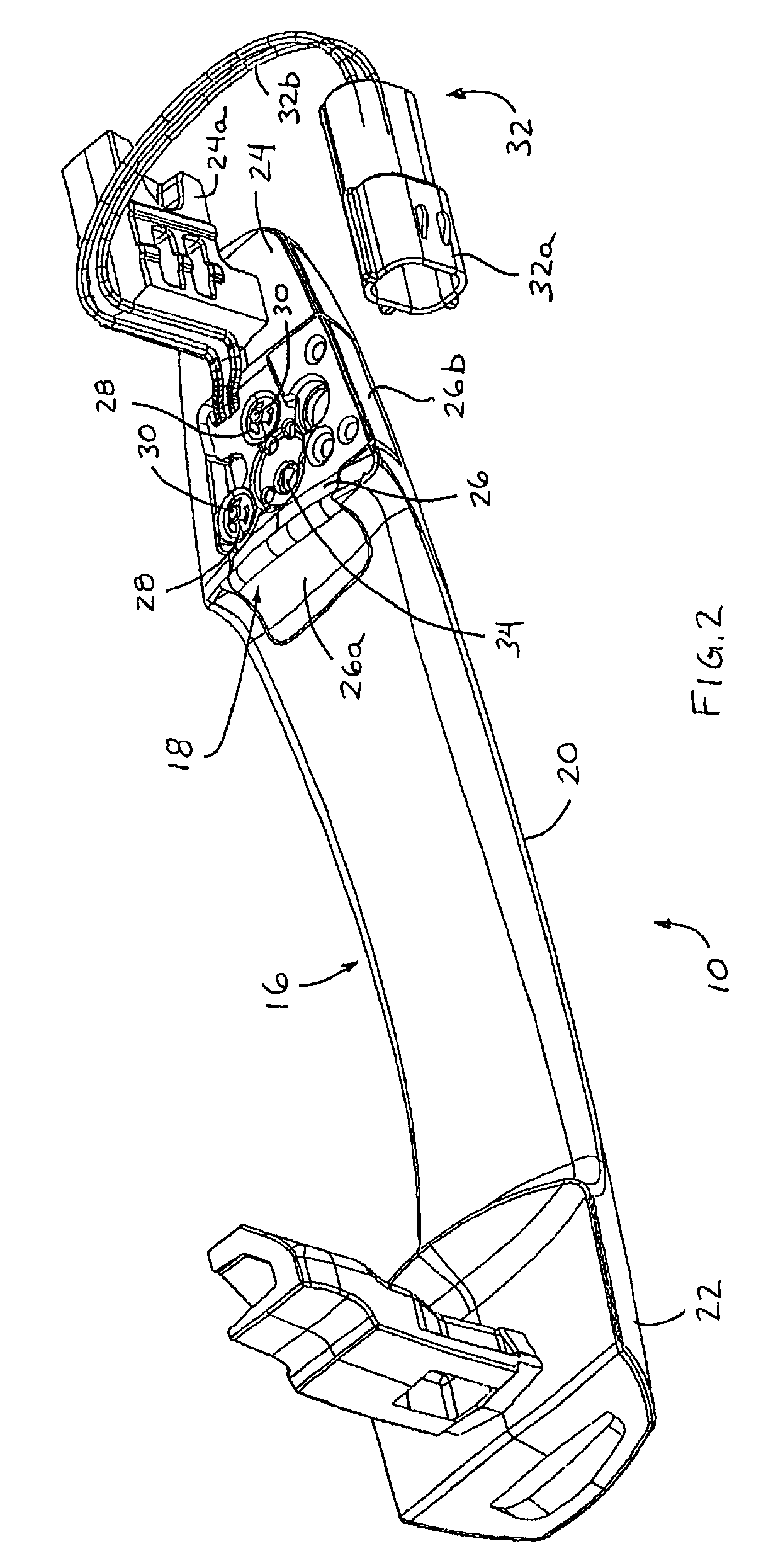

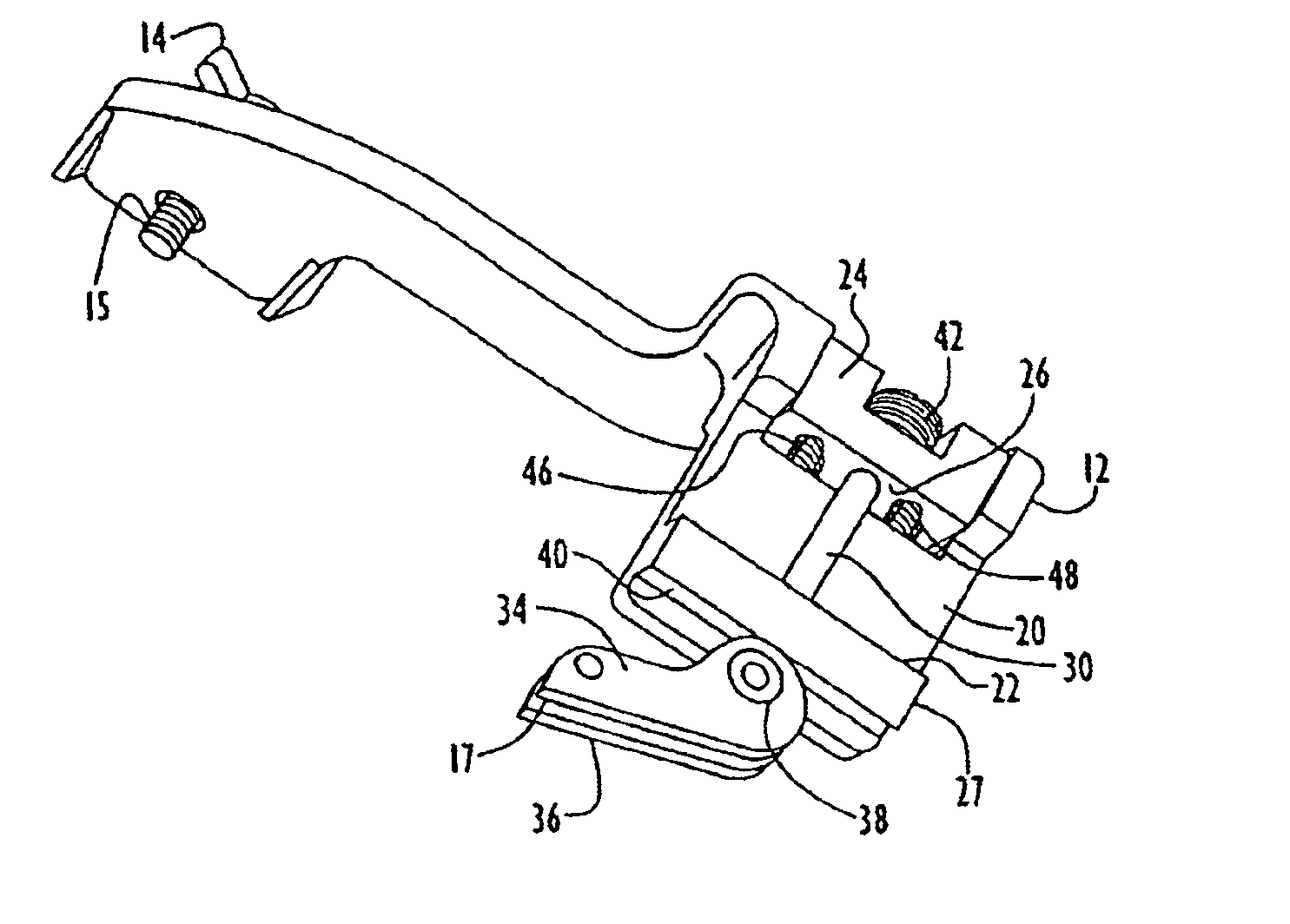

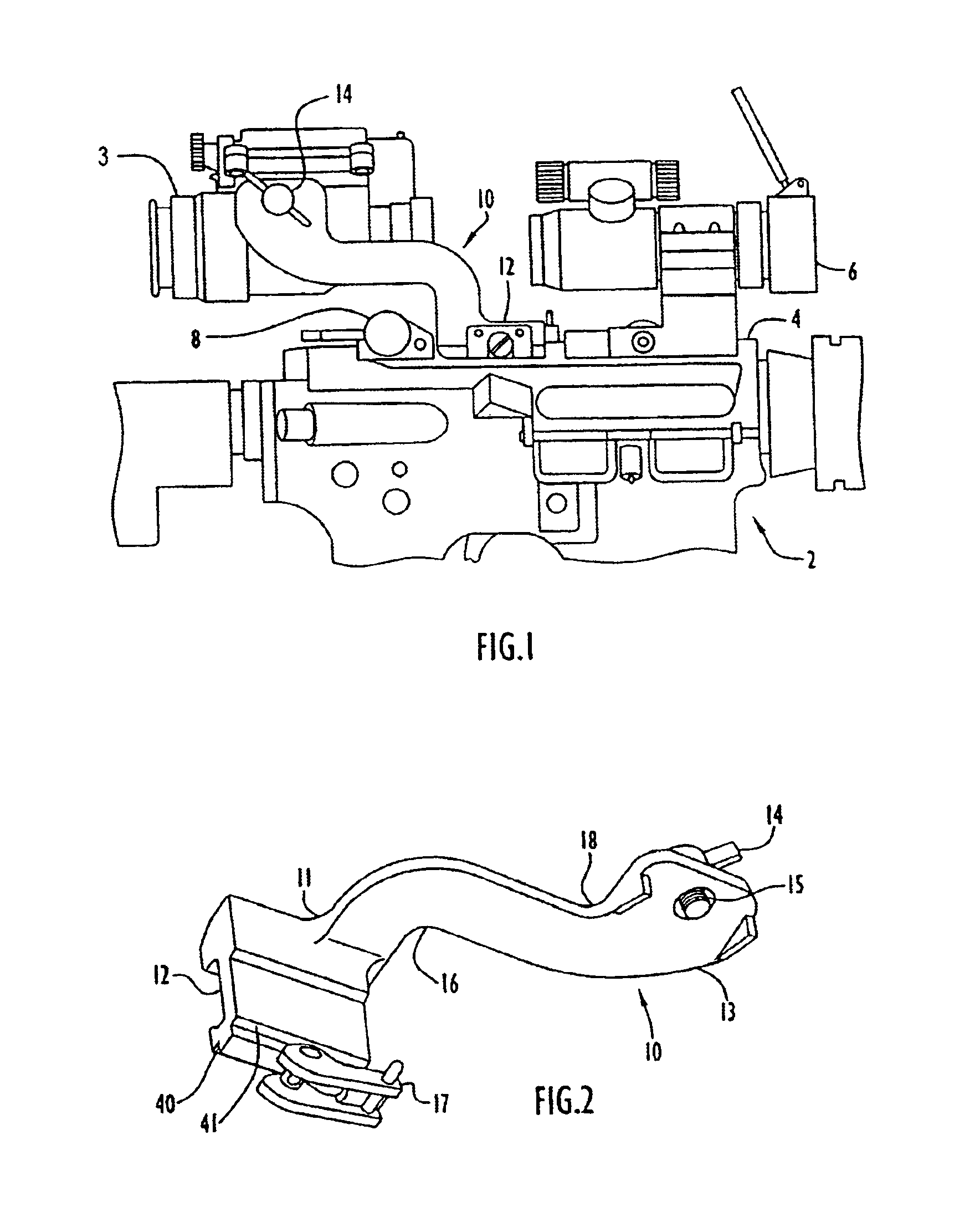

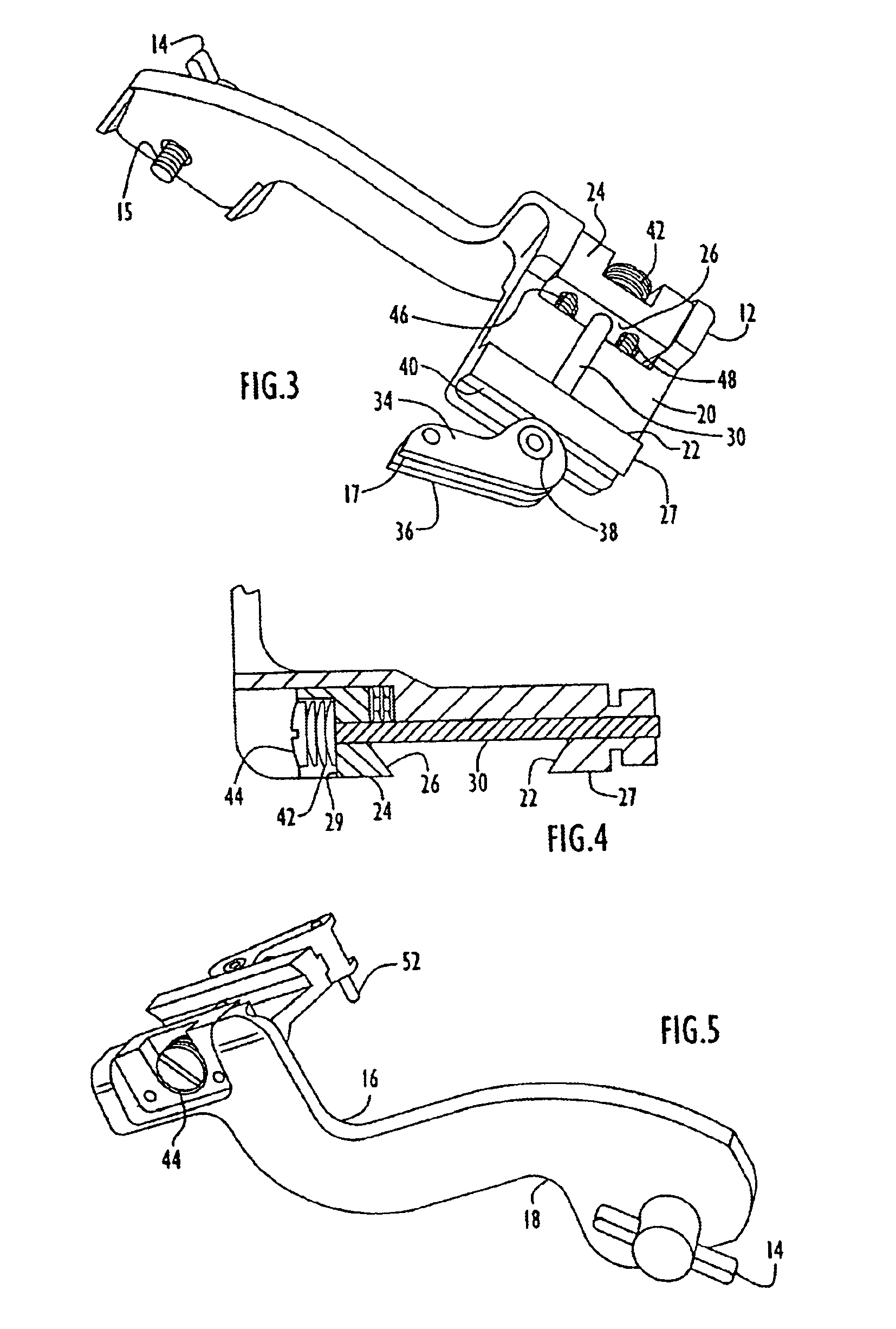

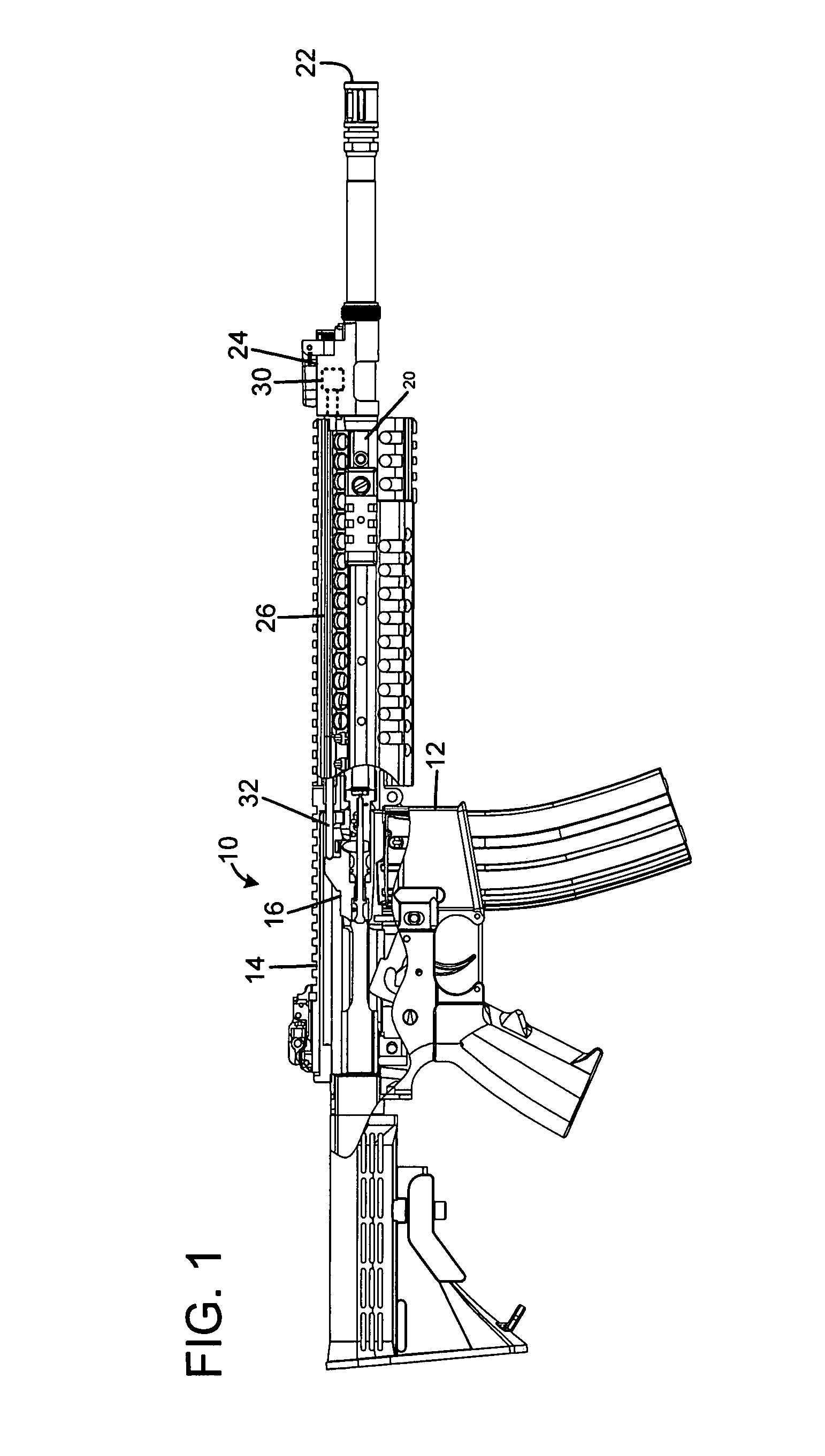

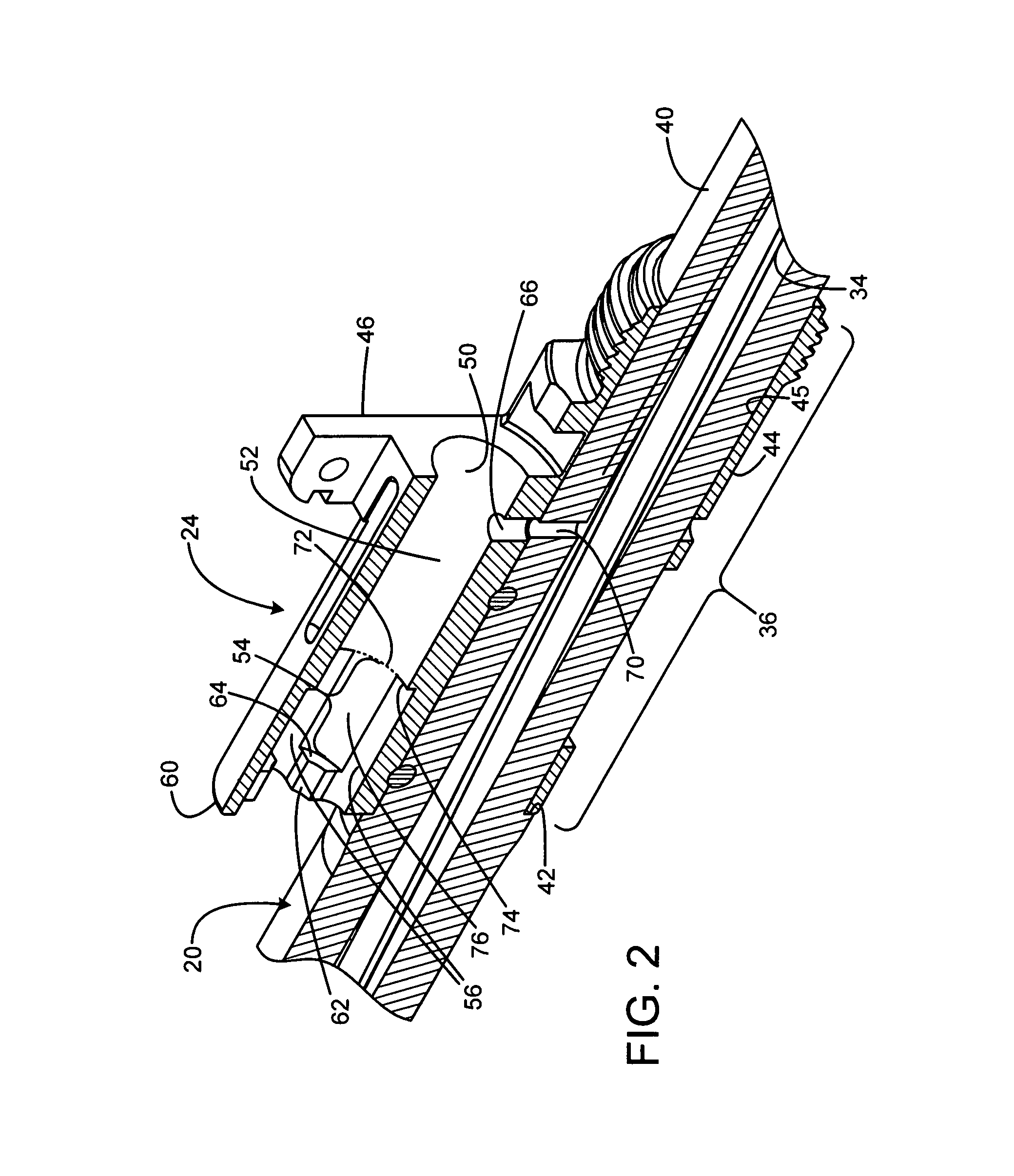

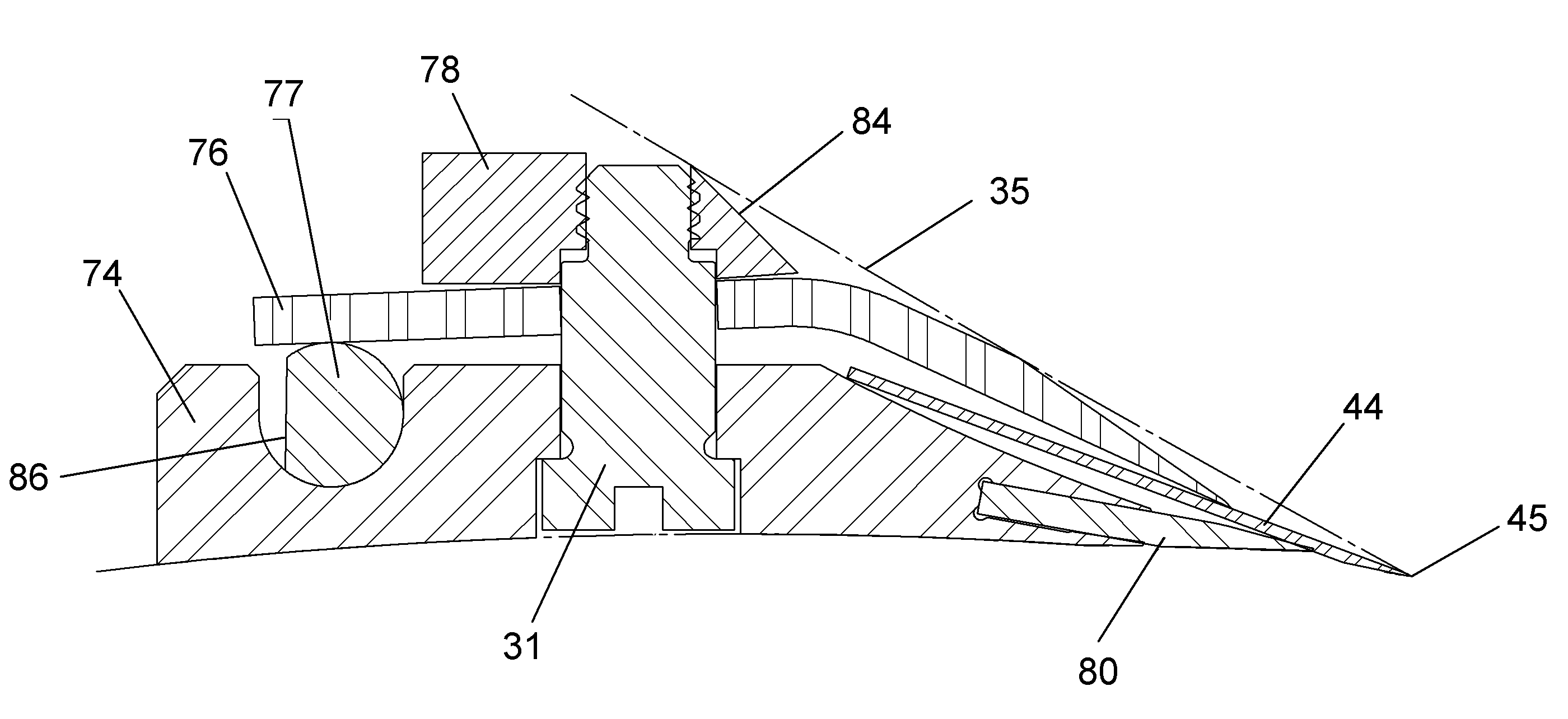

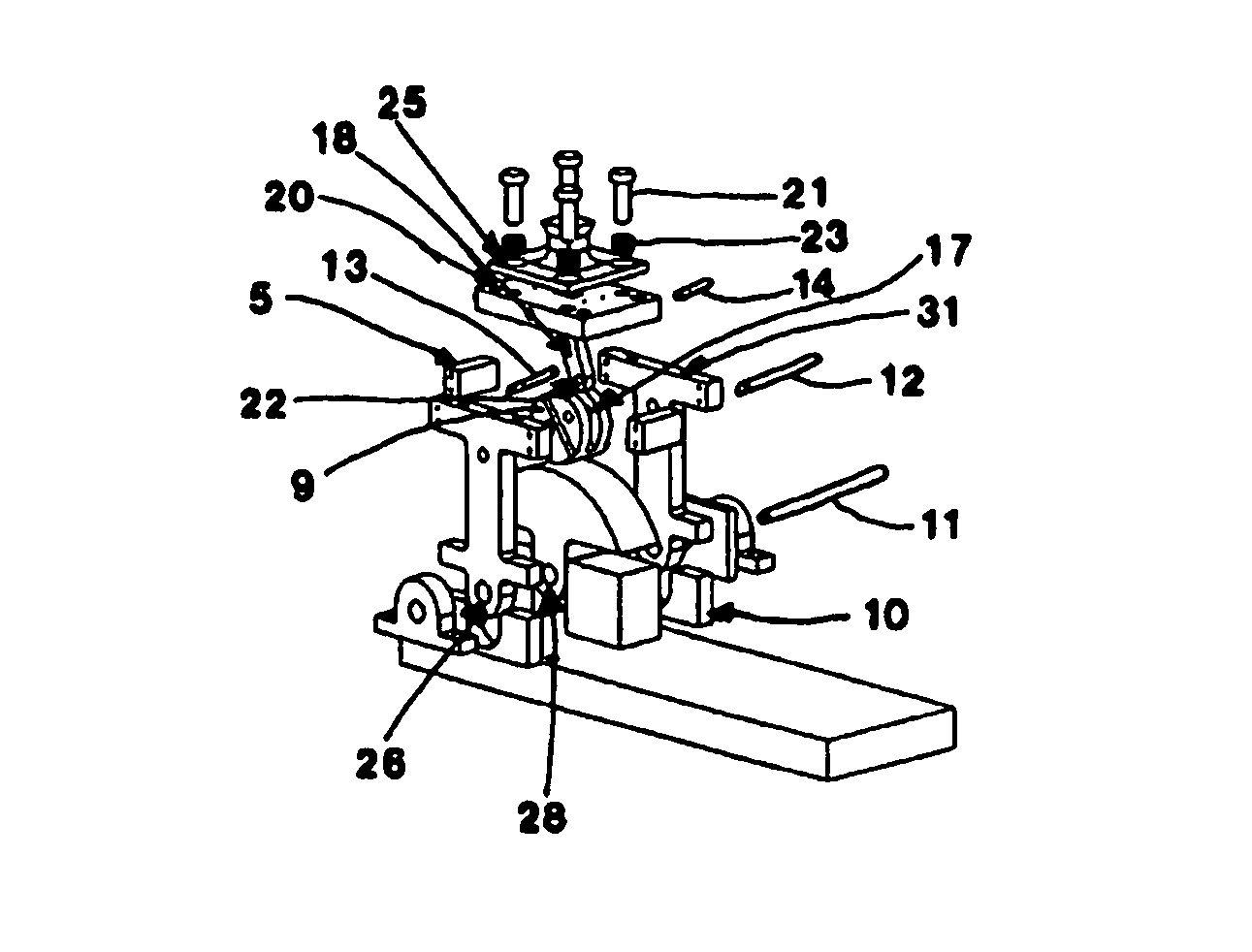

Clamp for weapon mount

InactiveUS6931778B1Clearance can be providedPrecise positioningSighting devicesPistolsBelleville washerCam

A weapon mount for mounting a night vision device to the receiver rail of a weapon. A self-device adjusting cam operated connection device is present at one end region of the mount for attaching to the receiver rail, while the night vision device is connected at the other end region of the mount with a knob operated mounting screw. The knob and mounting screw are a one piece design and the mounting screw is captivated by an E-clip. The cam operated connection device may be adjusted to accommodate different size receiver rails by the provision of compressible means, such as Belleville washers.

Owner:ITT MFG ENTERPRISES LLC

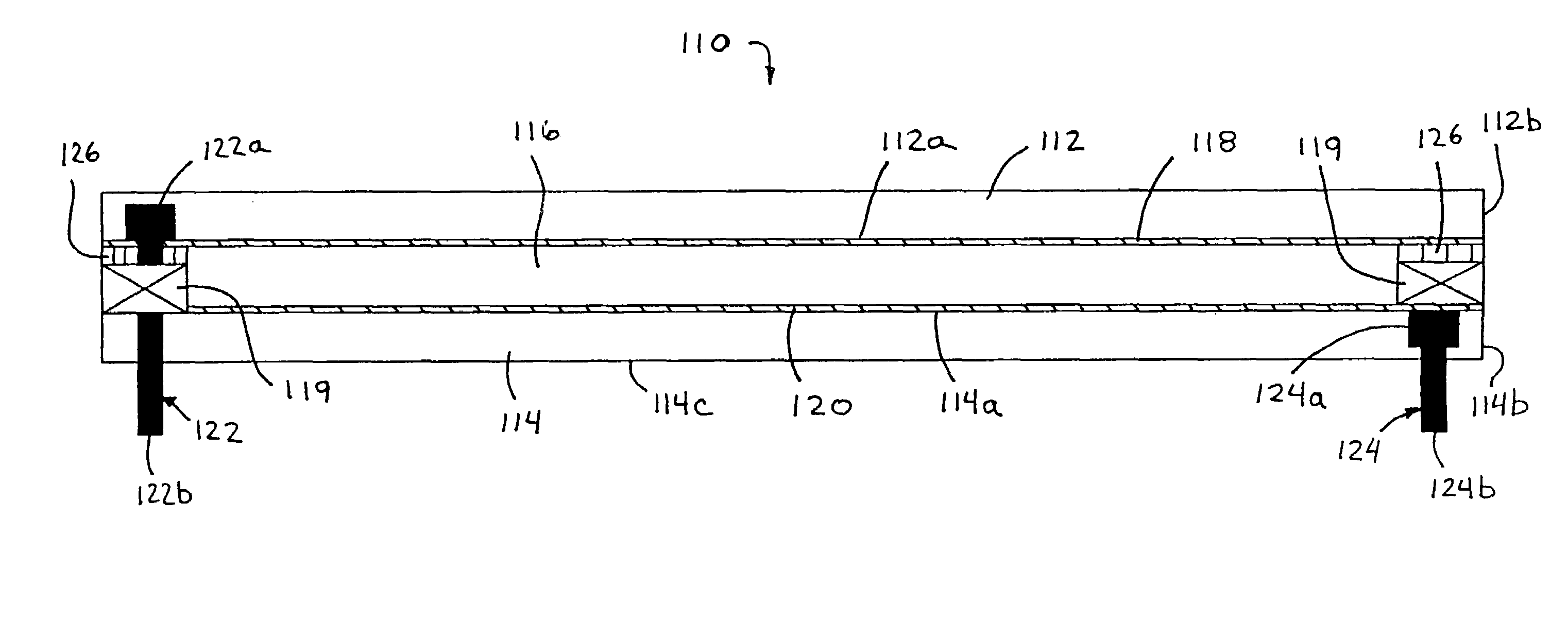

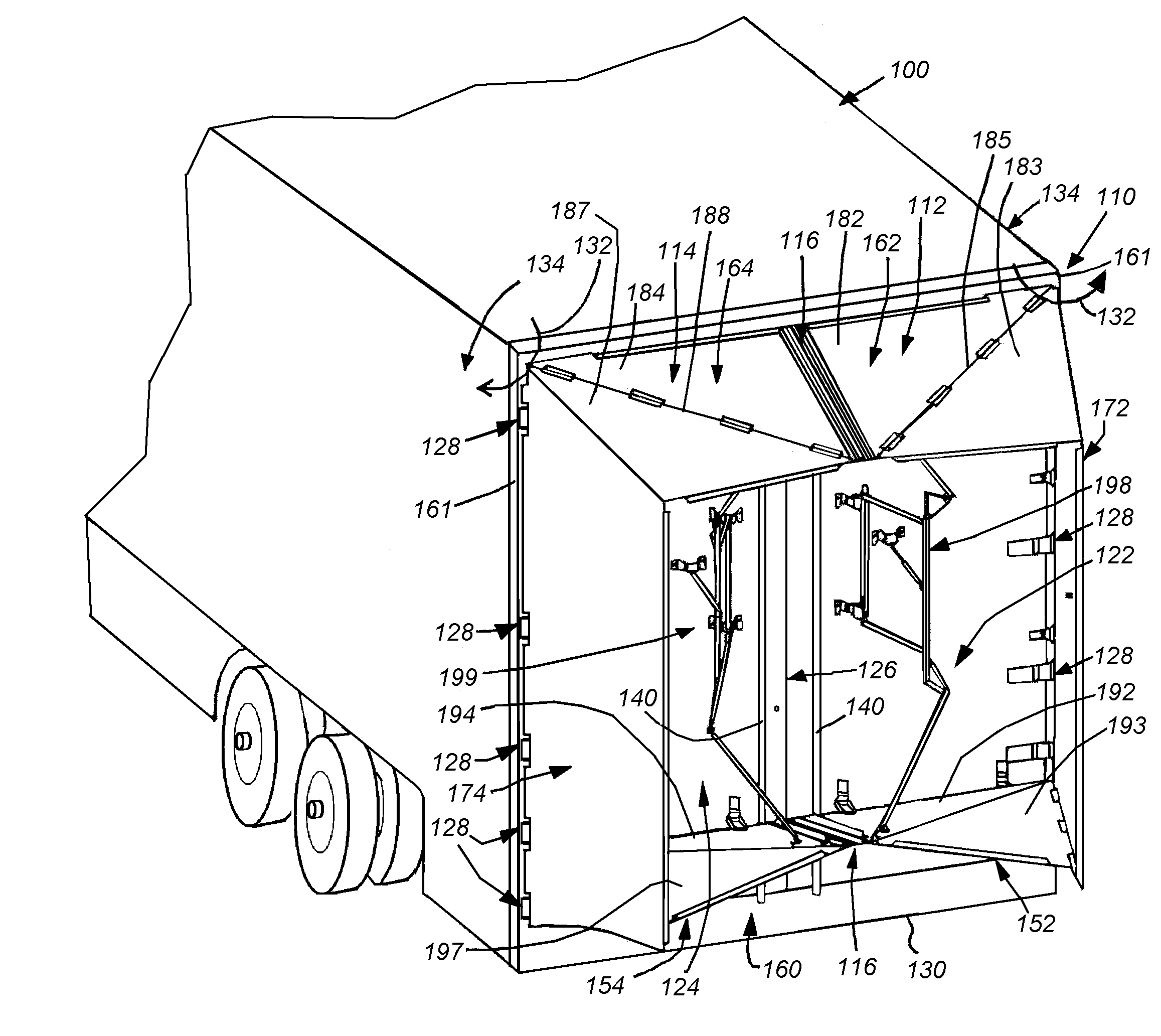

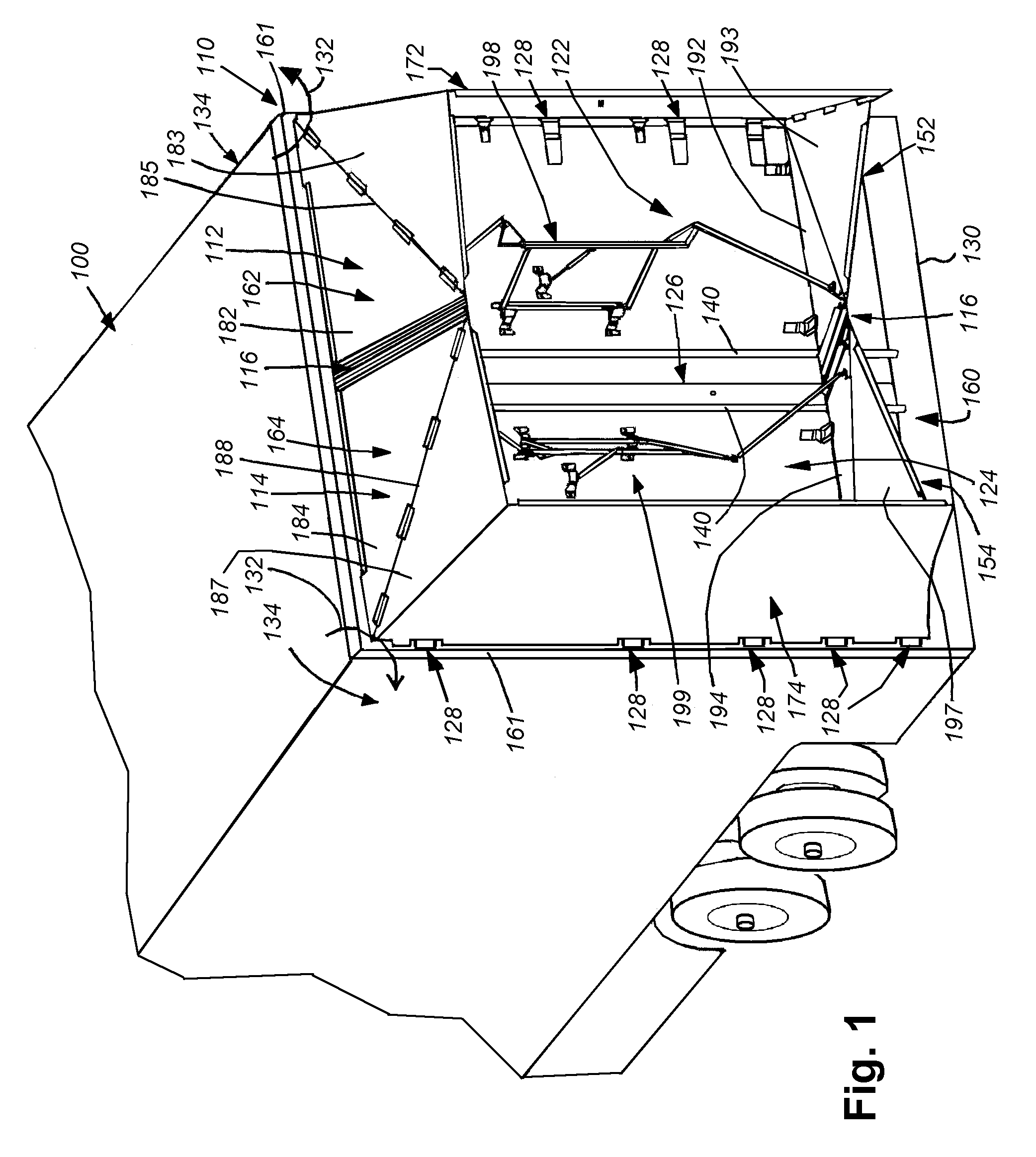

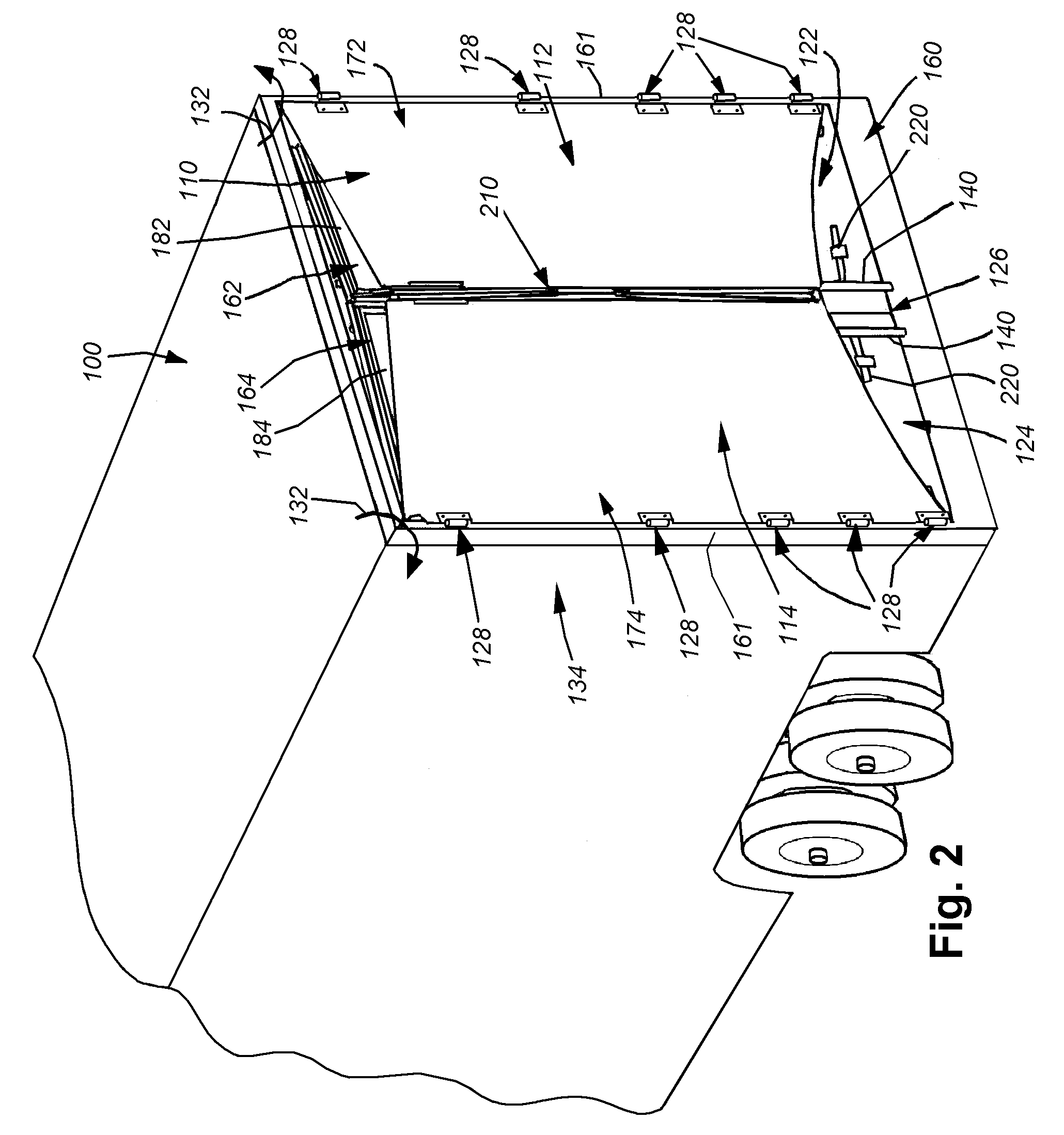

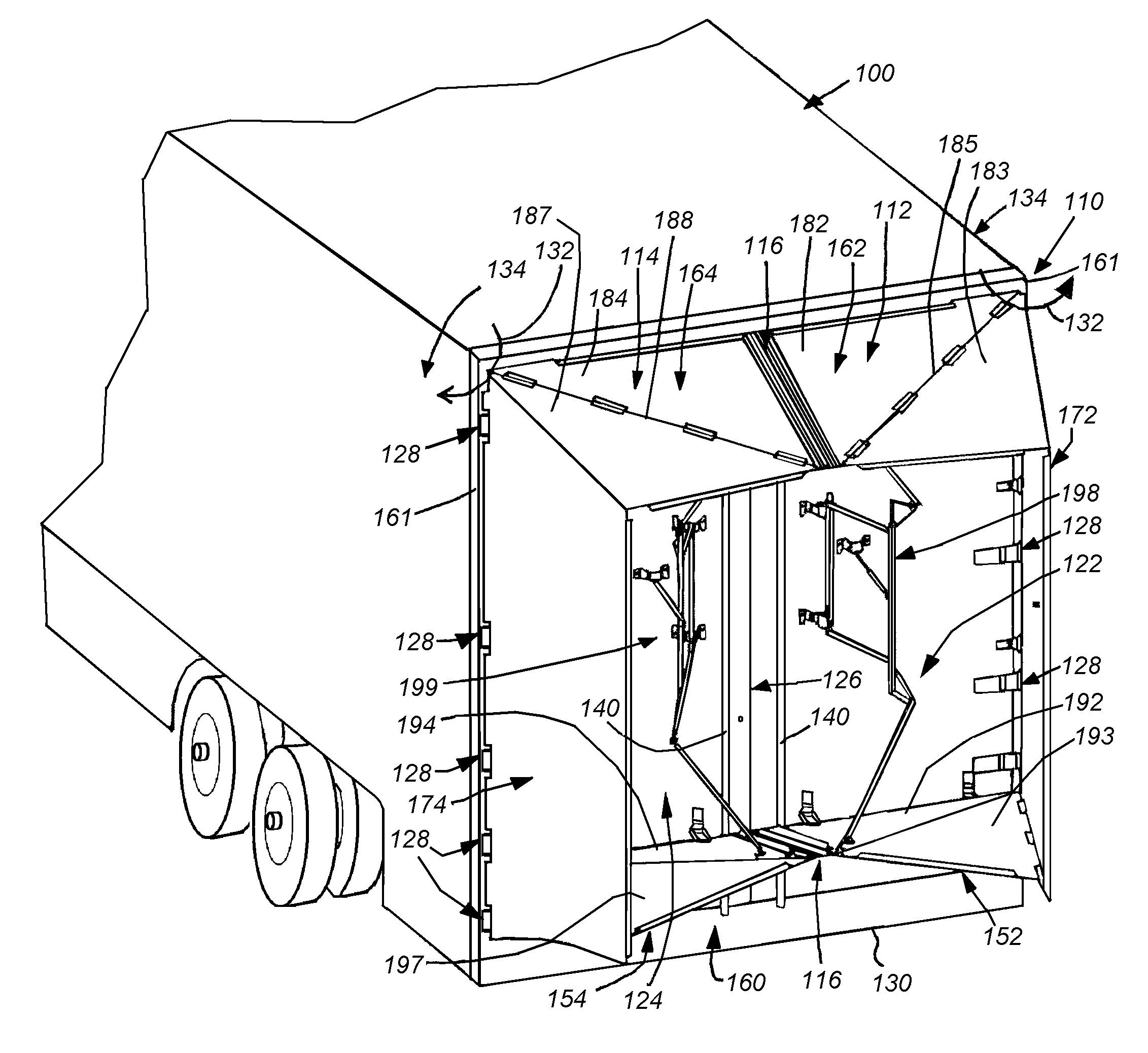

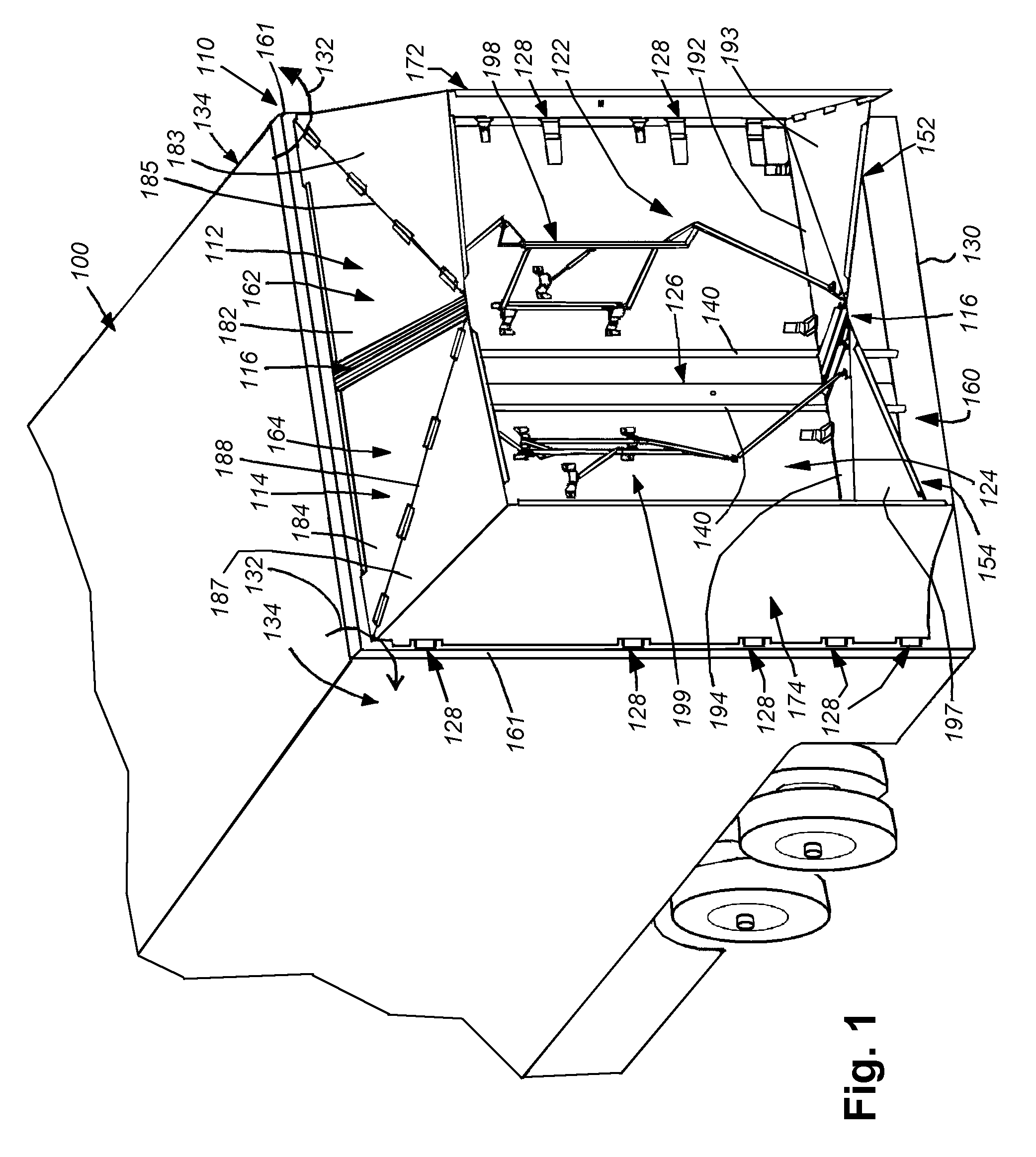

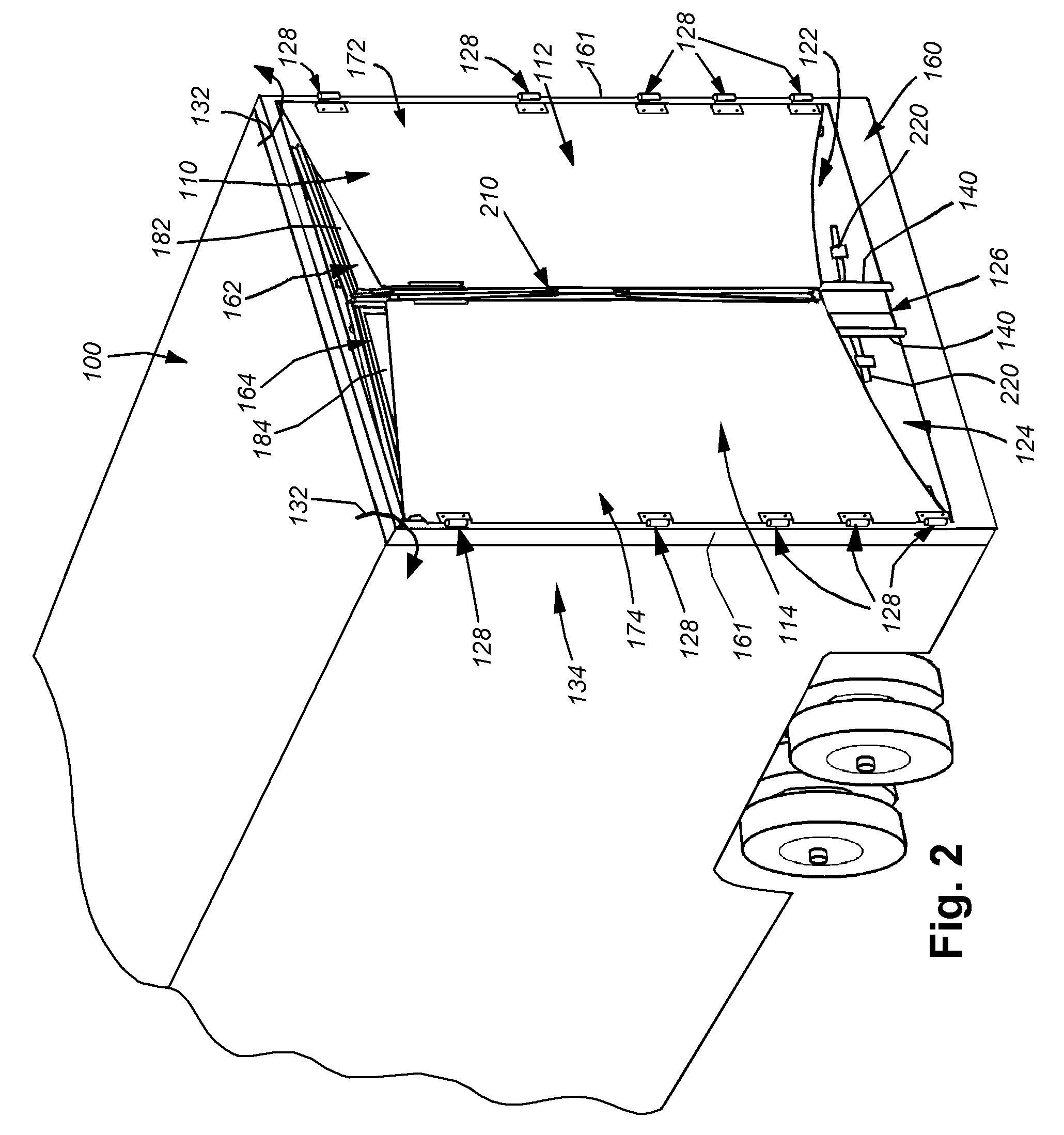

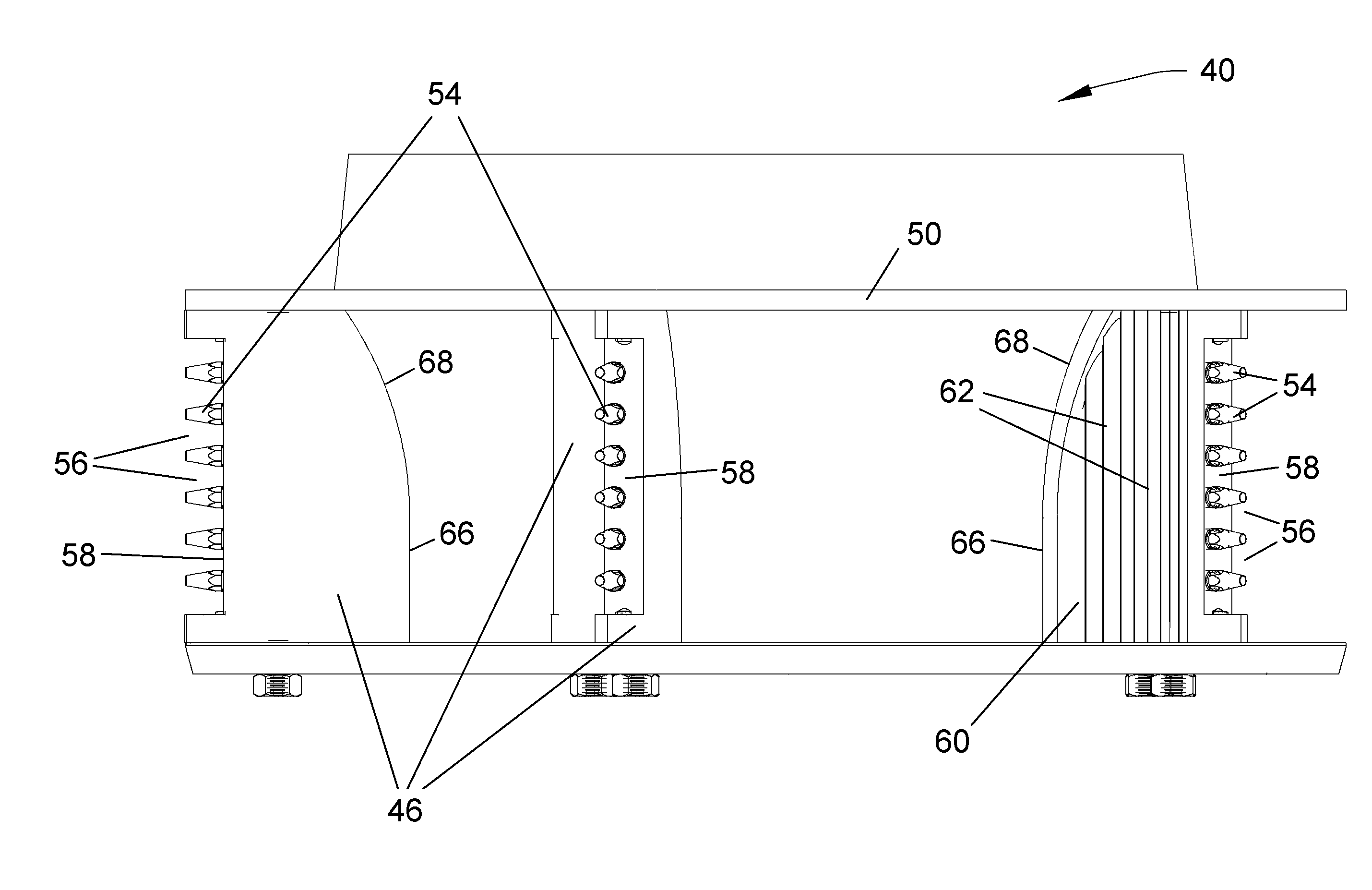

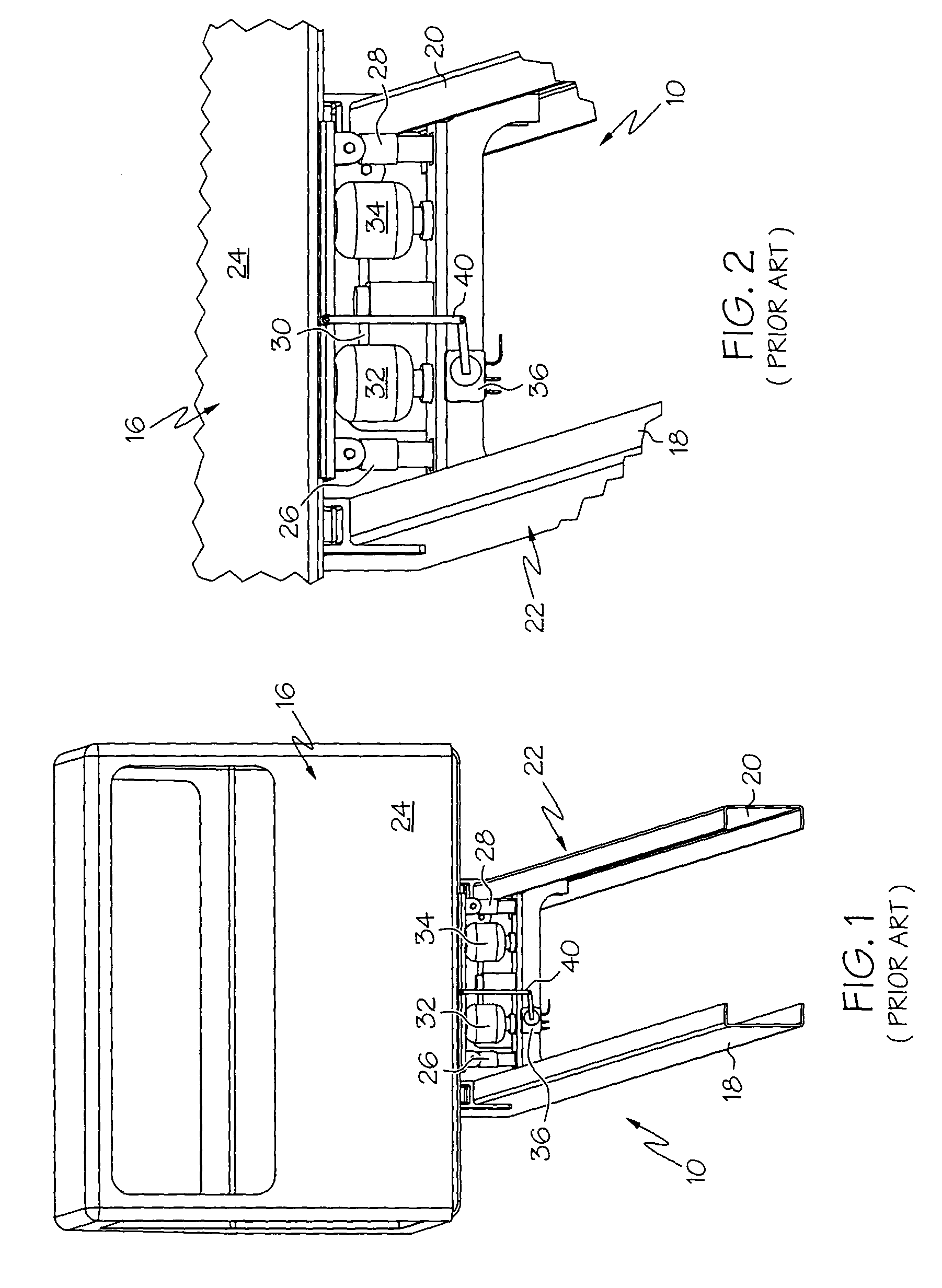

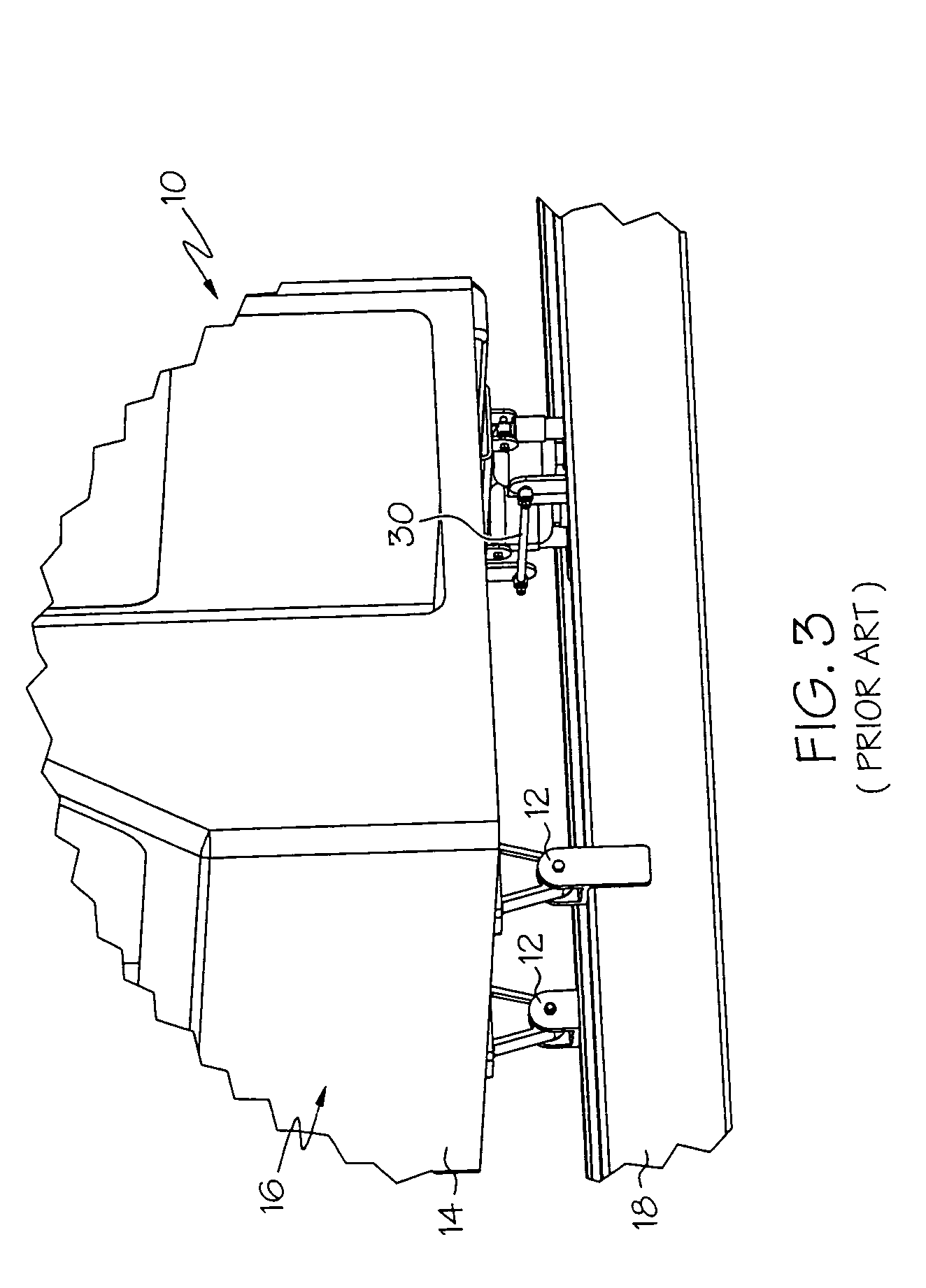

Rear-mounted aerodynamic structure for truck cargo bodies

This invention provides a foldable / retractable and unfoldable / deployable, rearwardly tapered aerodynamic assembly for use on the rear trailer bodies and other vehicles that accommodate dual swing-out doors. The aerodynamic assembly includes a right half mounted on the right hand door and a left half mounted on a left hand door. Each half is constructed with a side panel, top panel and bottom panel, which each form half of an overall tapered box when deployed on the rear of the vehicle, the bottom panels and top panels being sealed together at a pair of overlapping weather seals along the centerline. The panels are relatively thin, but durable, and are joined to each other by resilient strip hinges. The top and bottom panels are also hinged to form two sections along diagonal lines to facilitate folding of all panels in a relatively low-profile stacked orientation. This low profile allows the doors to be swung through approximately 270 degrees to be secured to the sides of the body in a manner that does not interfere with adjacent doors or bodies in, for example a multi-bay loading dock. A swing arm assembly and gas spring biases the panels into a deployed position that can be refolded by grasping the side panel and rotating it inward toward the door surface. The top and bottom panels are partly inwardly folded when deployed to define external valleys using a stop assembly. This ensures that the panels fold readily when desired without the two sections of the panels “locking up”.

Owner:STEMCO PROD INC

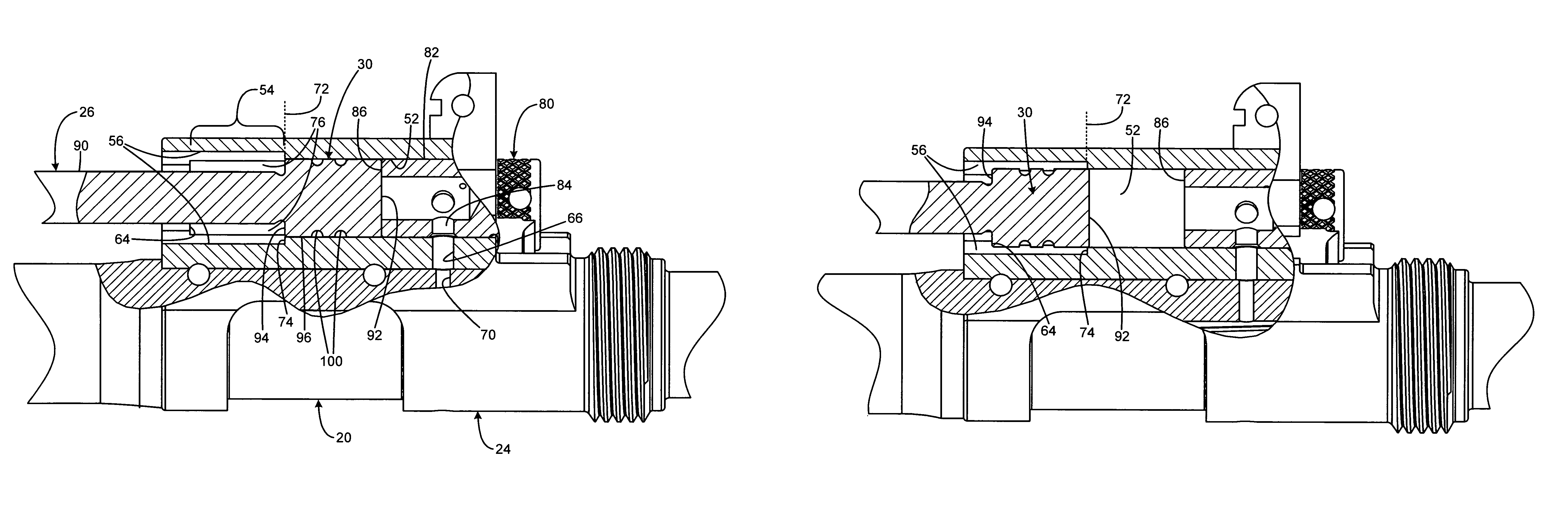

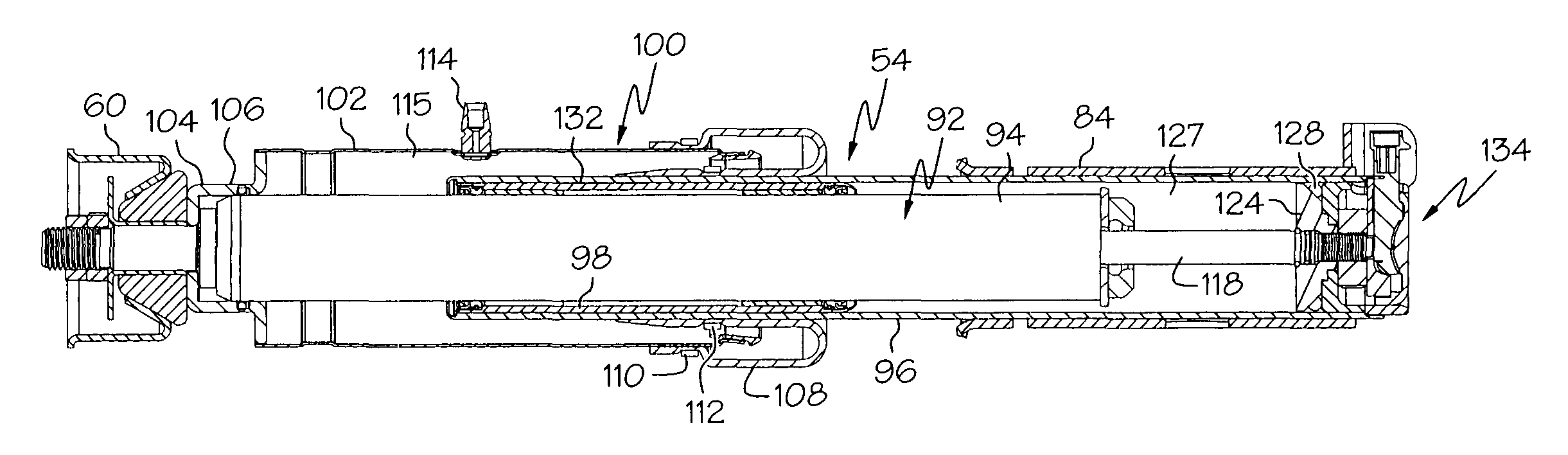

Auto-loading firearm with gas piston facility

ActiveUS7832326B1Prevent accumulationOvercome limitationWeapon cleaningWeapon testingPistonReciprocating motion

A firearm has a body with a bolt assembly reciprocating within the body. A barrel having a bore extends from the body. A gas block with an elongated chamber is connected to the barrel, and a gas passage connects the barrel bore to the gas block chamber. An operating rod has a forward end portion closely received in the gas block chamber and a rear end positioned to operably engage the bolt assembly. The gas block chamber has a forward portion closely receiving the forward end portion of the rod, and the gas block chamber has a rear portion with a profile larger than the forward portion. The forward portion of the rod may be a cylinder, and the rear portion of the gas block chamber may be fluted to provide clearance for flushing out contaminants. The rod may rotate freely to prevent accumulation of contaminants.

Owner:BARRETT FIREARMS MFG INC

Illumination module for a vehicle

ActiveUS20100321946A1Limit hot spot spotLimit spot bright spotLighting circuitsVehicle locksEmbedded systemCar door

An illumination module for a vehicle includes at least one illumination source for illuminating a target area at the vehicle. The illumination module may be mounted at a handle of a vehicle door and may be operable to illuminate the handle region and / or pocket region of the vehicle door and to illuminate a ground region adjacent to the vehicle and generally below the door handle assembly. The illumination module may include an icon established thereat and the at least one illumination source may back light the icon so that the icon, when the illumination module is activated, is viewable by a person viewing the vehicle. The illumination module may project or direct the illumination toward a targeted area so that the icon is discernible at the targeted area.

Owner:MAGNA MIRRORS OF AMERICA INC

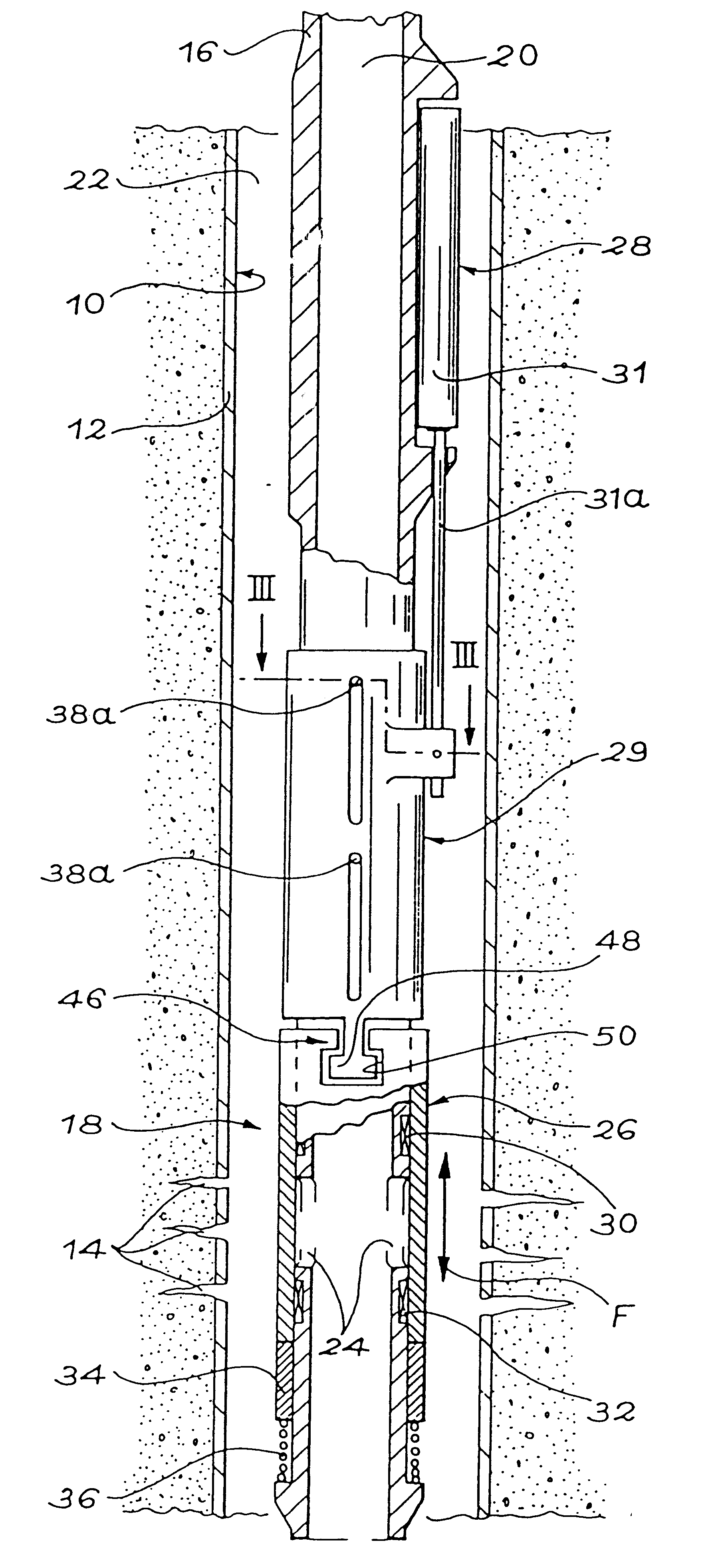

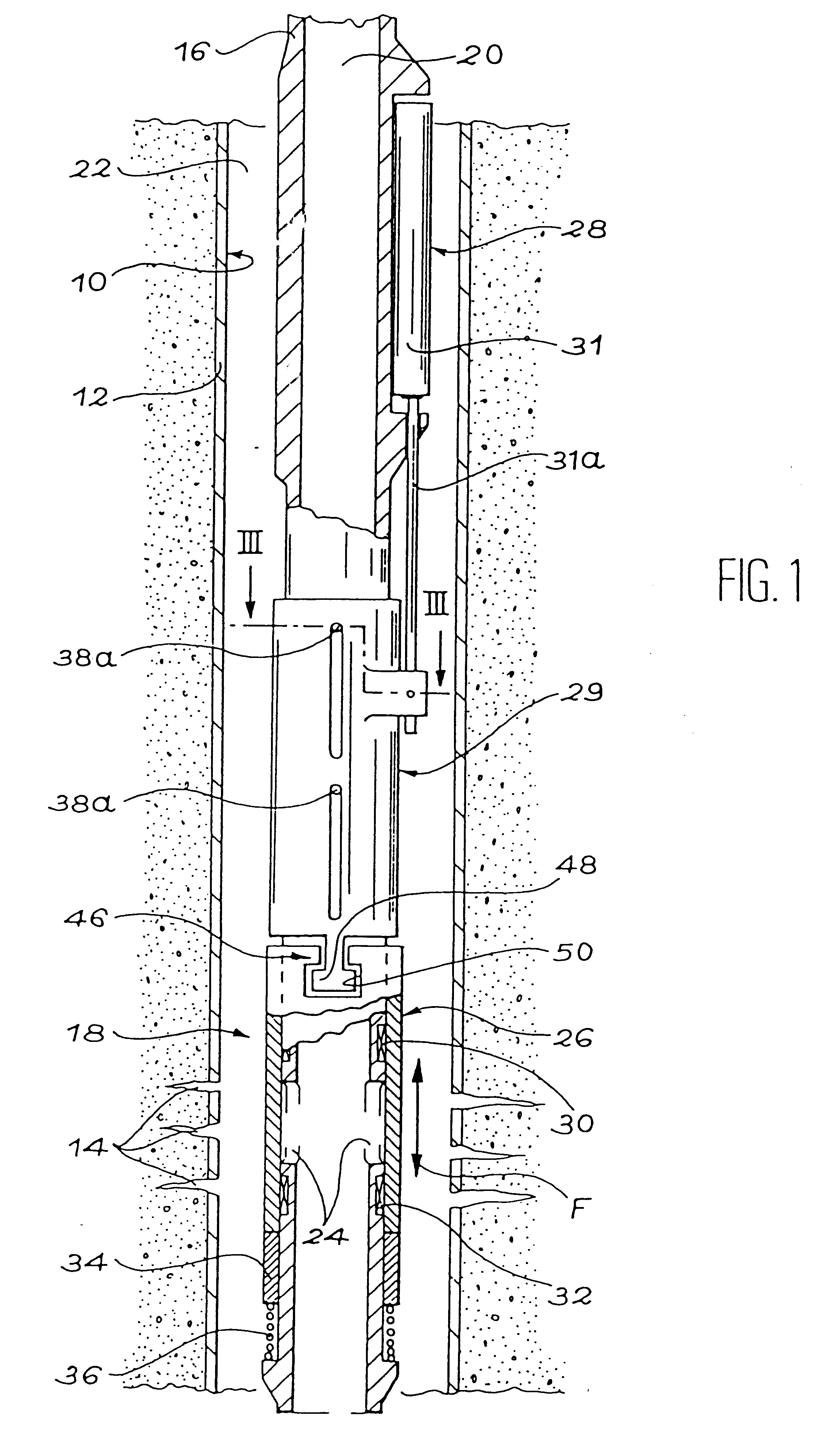

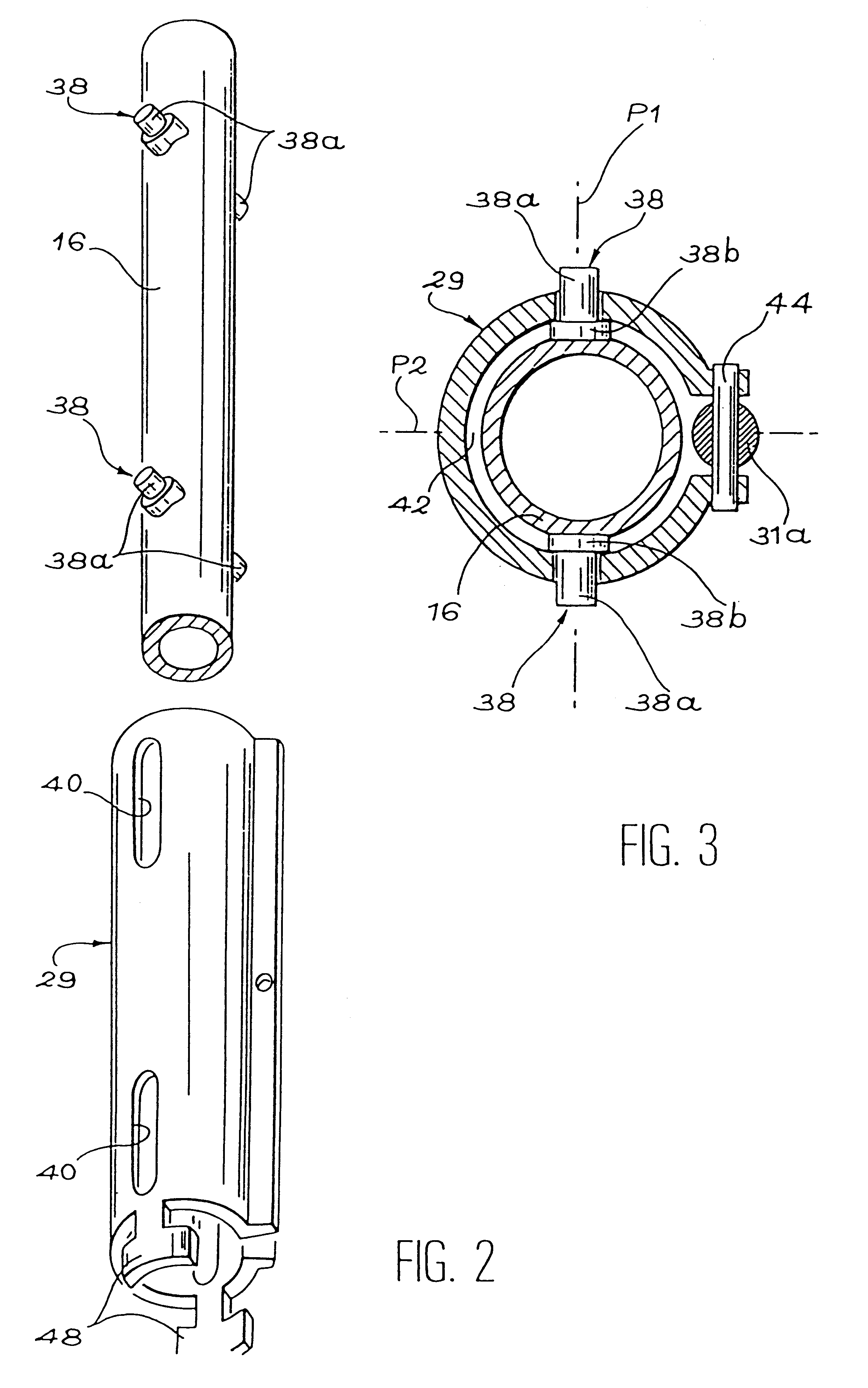

Method and device for downhole flow rate control

InactiveUS6273194B1Extend your lifeImprove reliabilityFluid removalWell/borehole valve arrangementsCouplingActuator

A flow rate control device (18) placed down an oil well in production comprises holes (24) formed in the production tubing (16), a closure sleeve (26) suitable for sliding facing the holes (24), an actuator (31) disposed eccentrically relative to the tubing (16), and an intermediate part (29). The intermediate part (29) is guided on the tubing (16) in a manner such as to withstand the tilting torque due to the eccentricity of the actuator (31). A coupling (46) that is flexible except in the direction in which the sleeve is moved connects the part (29) to the closure sleeve (26) symmetrically about the axis of the tubing (16). The resulting decoupling guarantees that the sleeve (26) is self-centering, which improves the life-span of the device (18) significantly.

Owner:SCHLUMBERGER TECH CORP

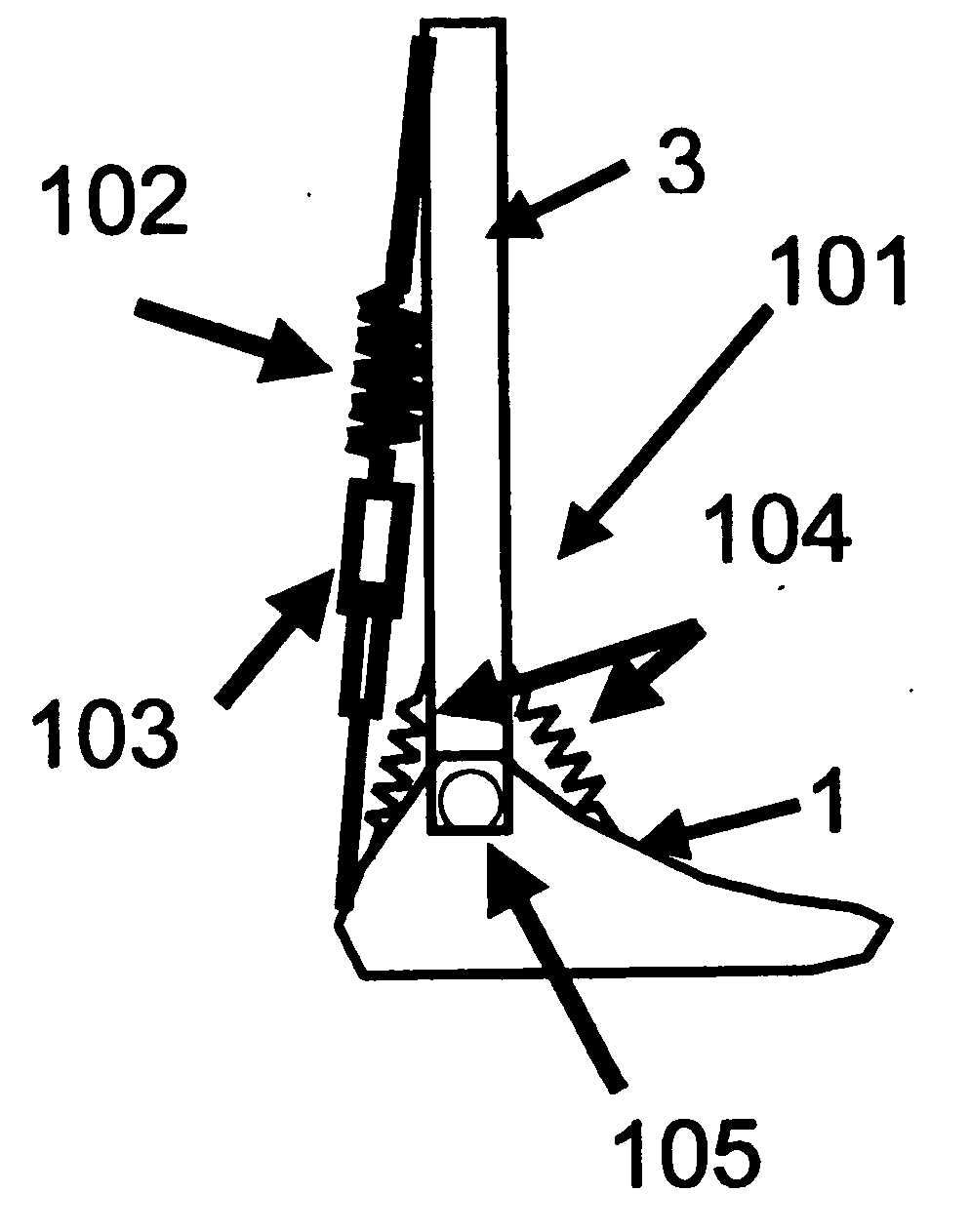

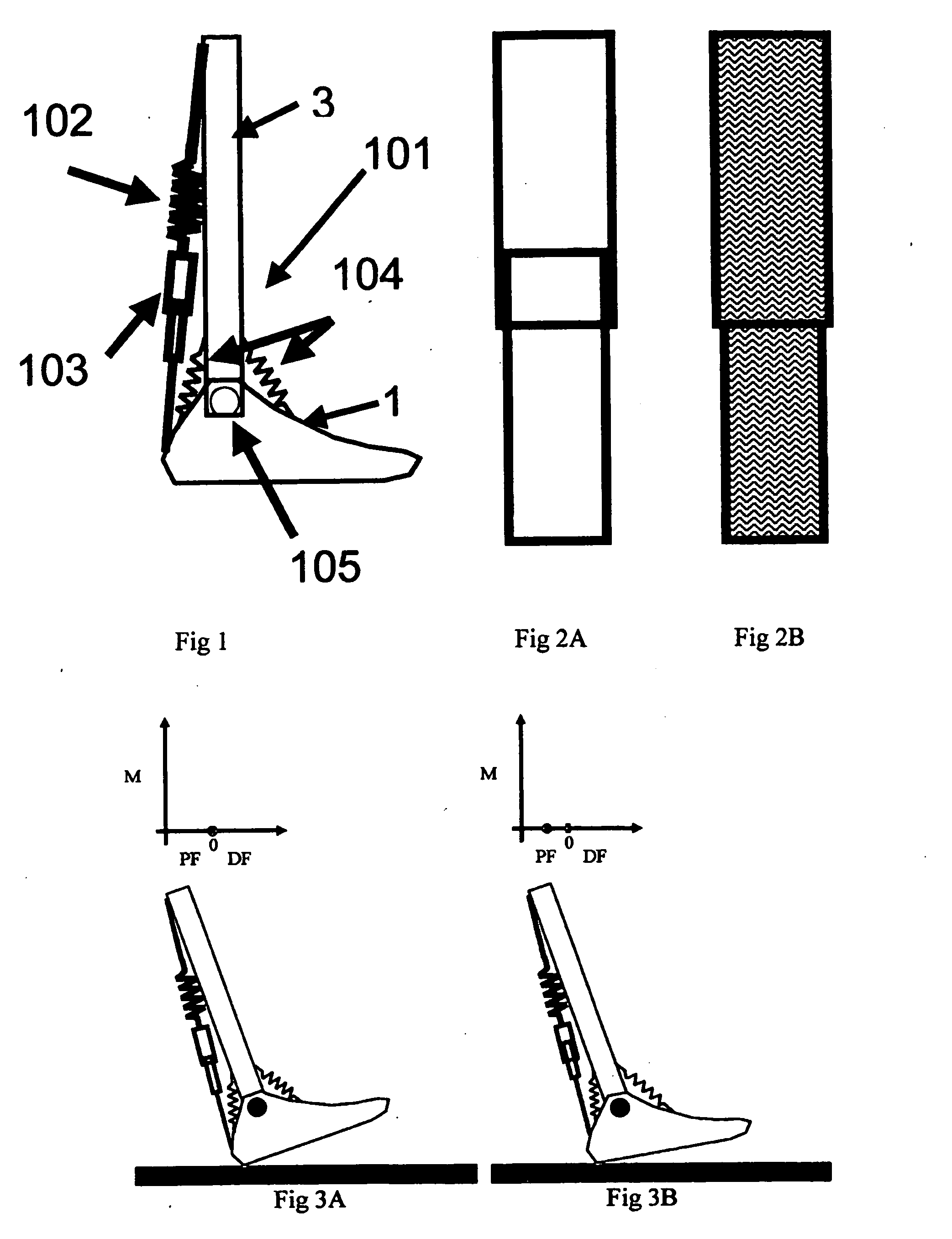

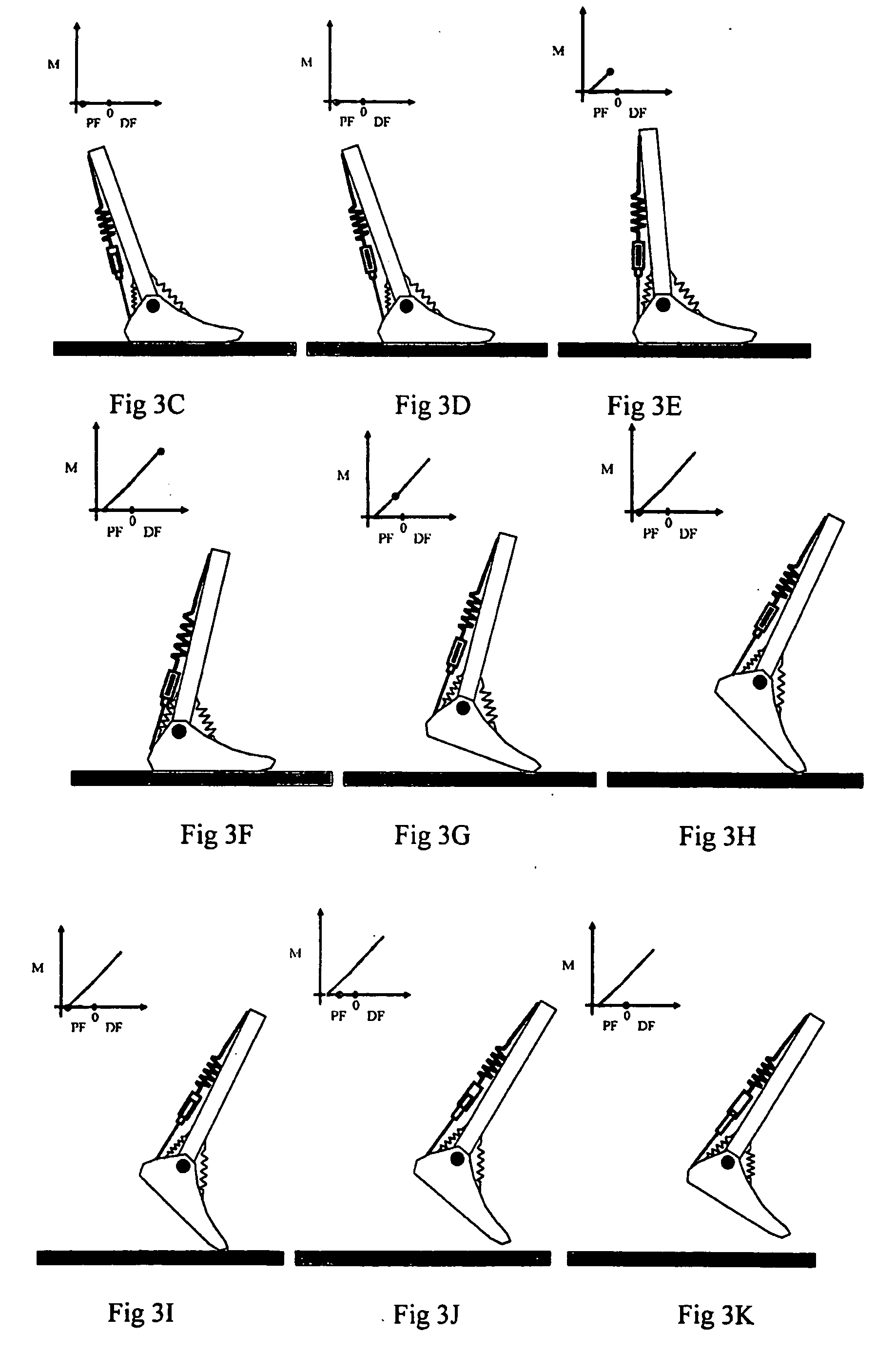

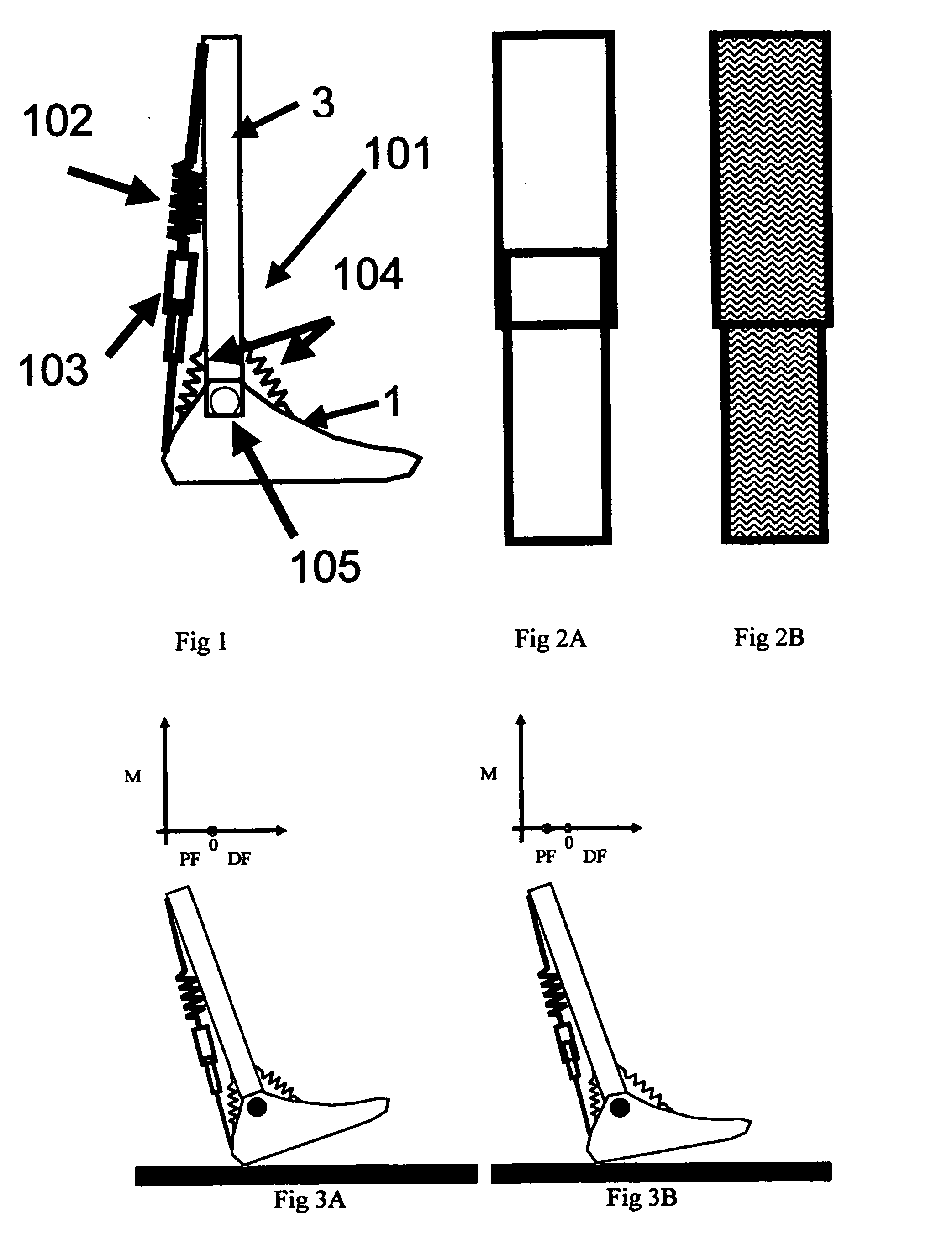

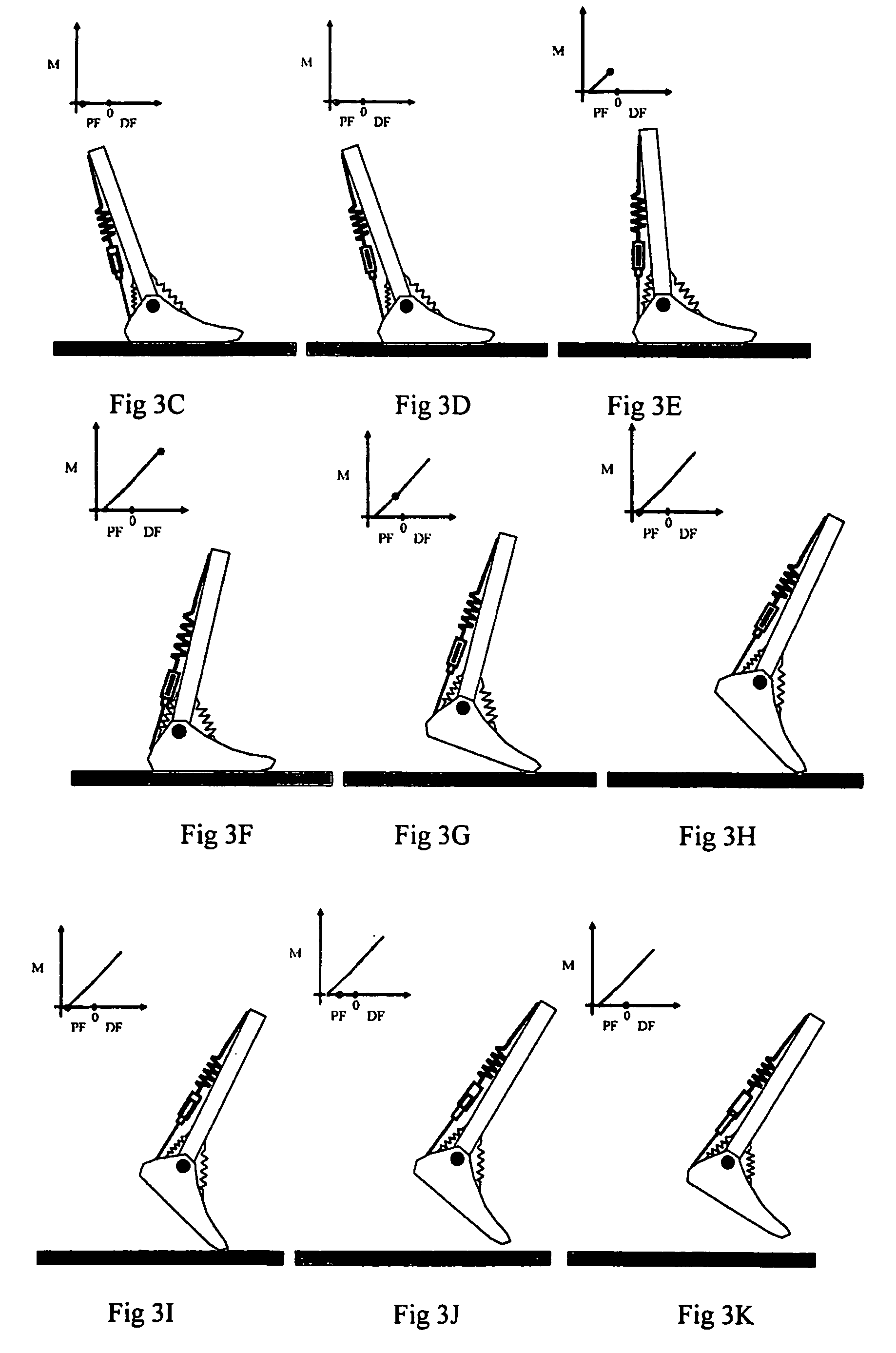

Equilibrium-point prosthetic and orthotic ankle-foot systems, devices, and methods of use

ActiveUS20100185301A1Reduce and prevent likelihoodWeaken energyArtificial legsDiseasePhysical medicine and rehabilitation

The present invention relates to a system for use in rehabilitation and / or physical therapy for the treatment of injury or disease. The system can enable an amputee to proceed over any surface without overbalancing. In particular the system is self-adapting to adjust the torque moment depending upon the motion, the extent of inclination, and the surface topography.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

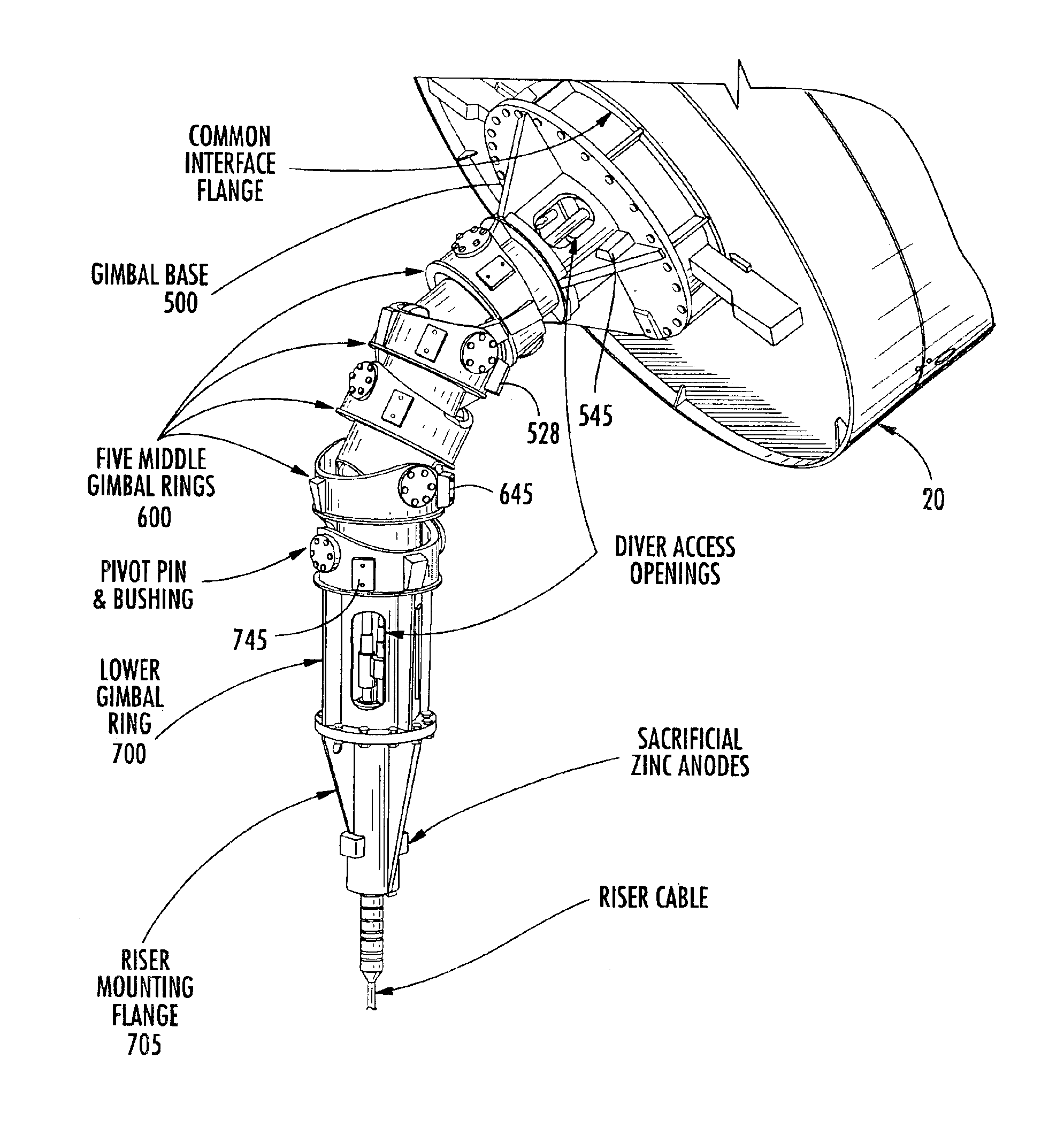

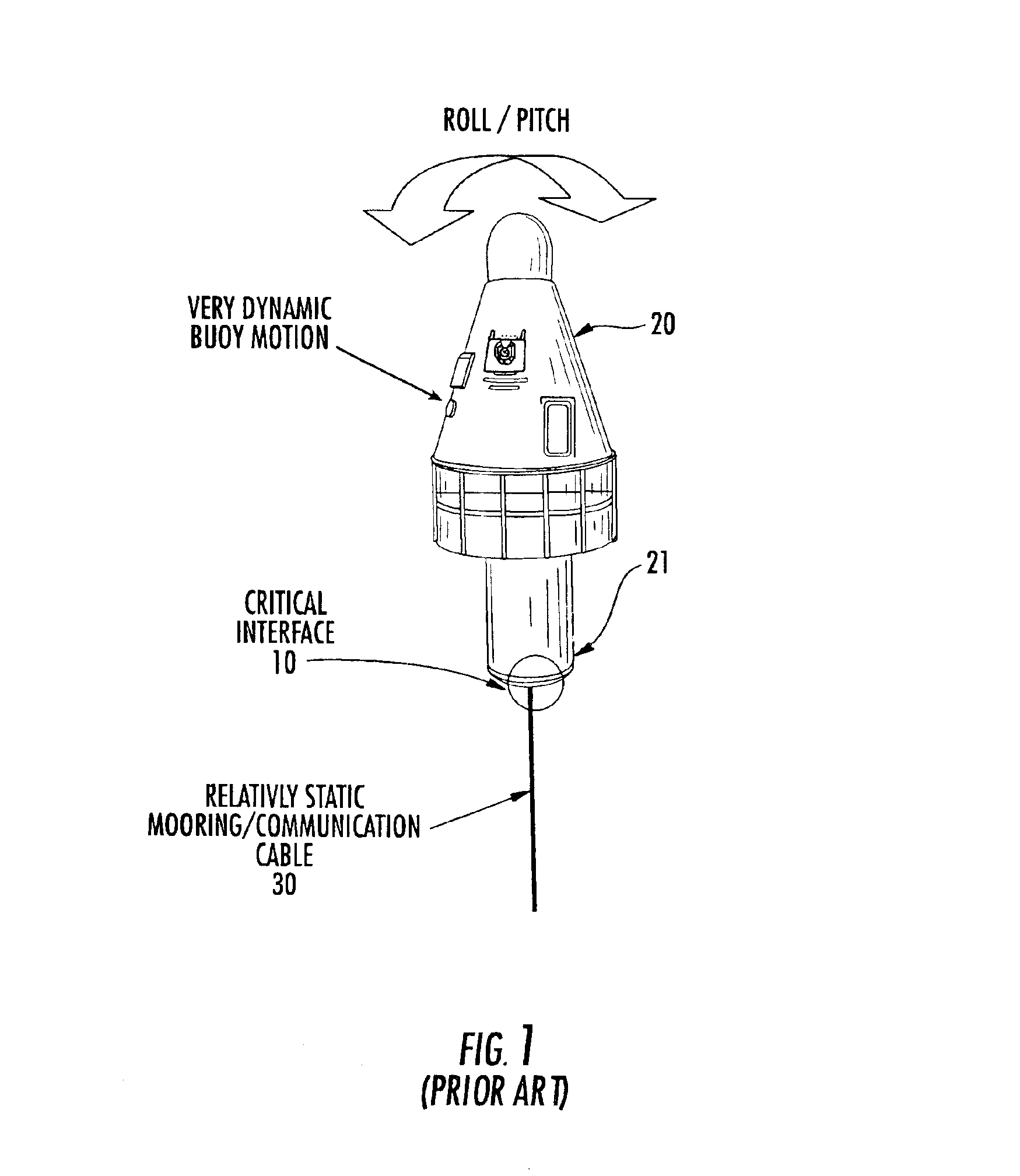

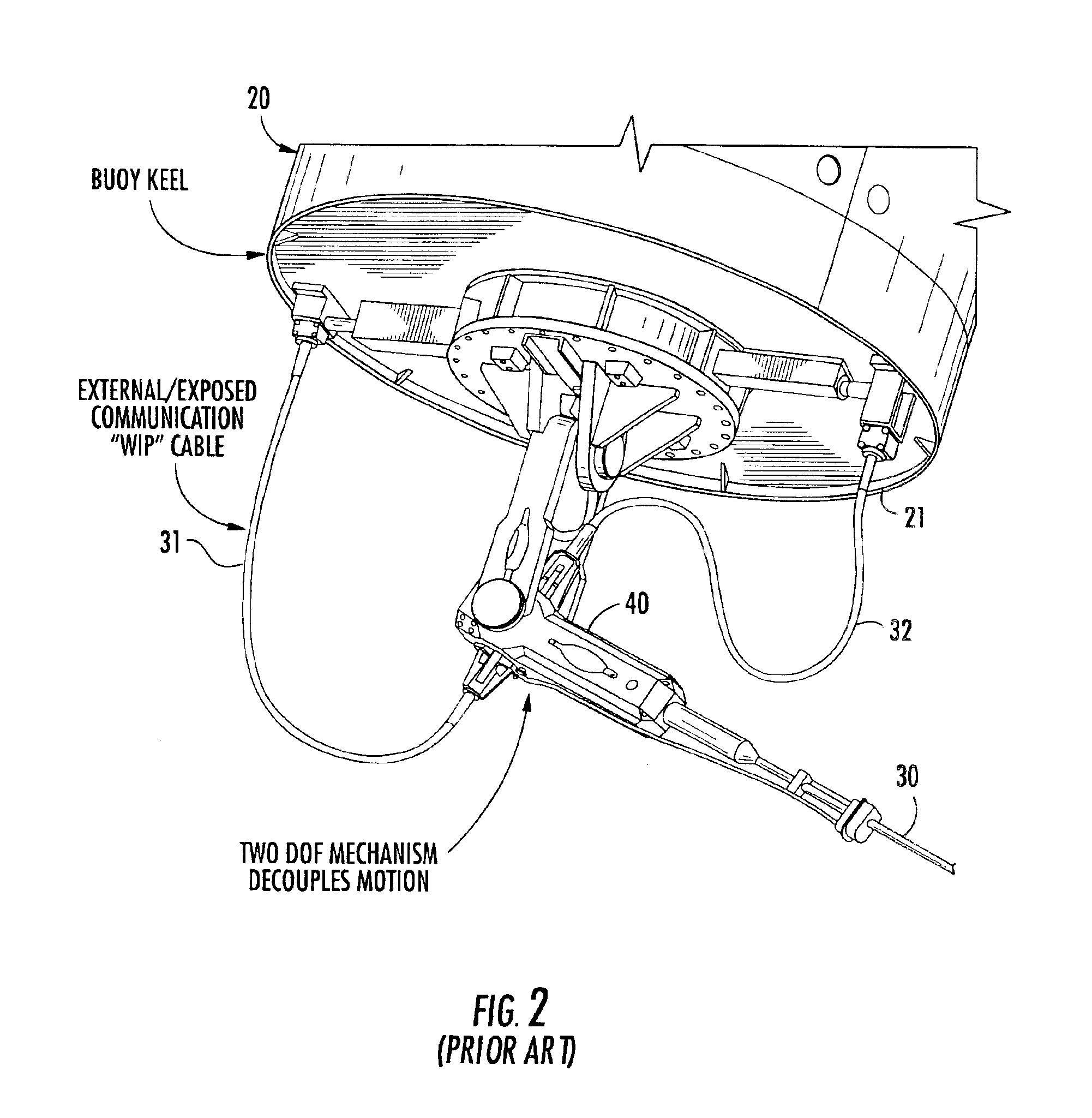

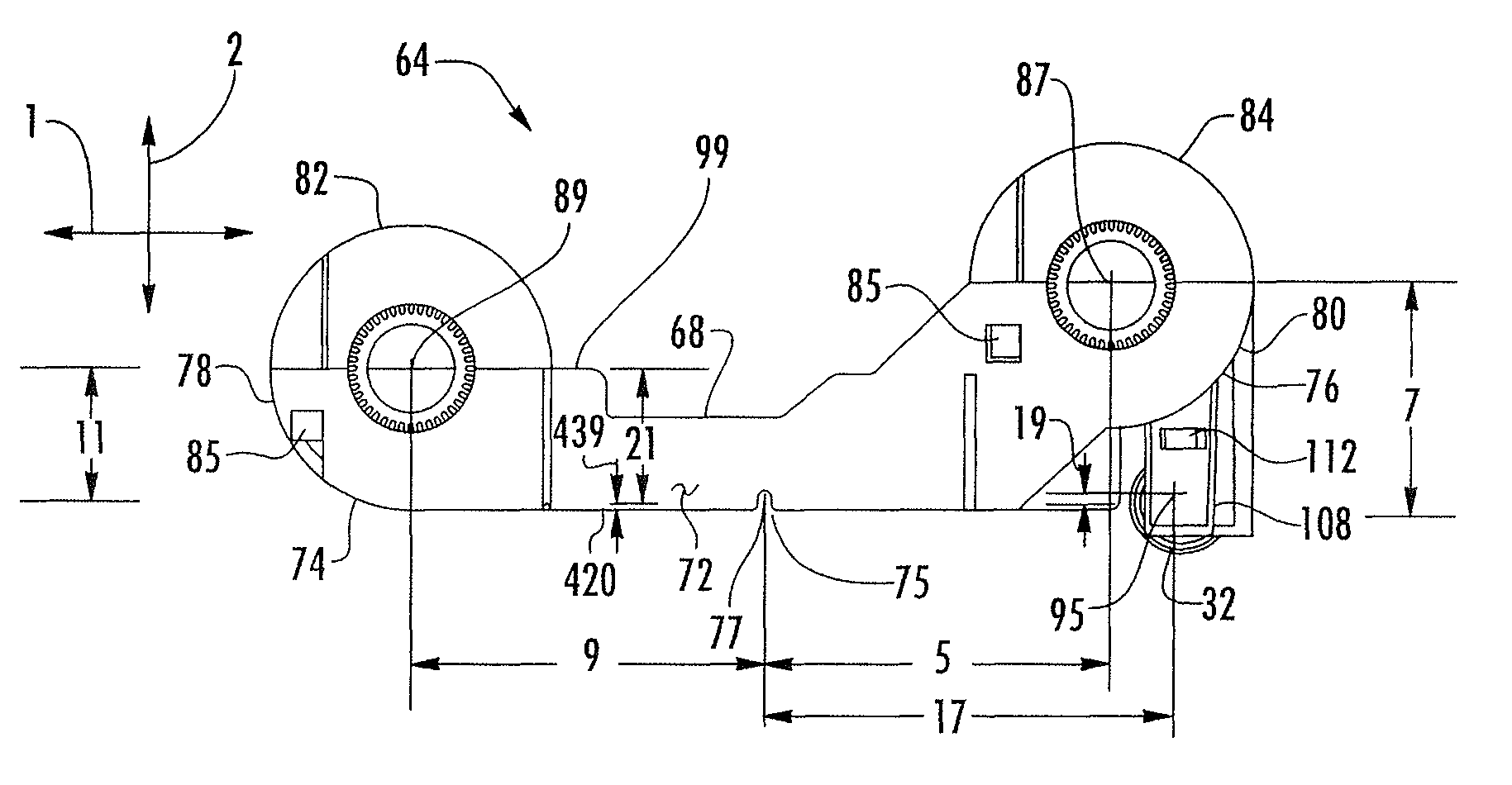

Multi-gimbal marine communication cable to ocean buoy transition interface

InactiveUS6848862B1Clearance can be providedReduce mechanical fatigueCommunication meansService pipe systemsTelecommunications linkCommunication link

A multi-gimbal configured transition protectively interfaces a mooring and communication cable to a communication ocean buoy. The transition interface contains a segmented, flexible sheath formed of a plurality of pivotally interconnected gimbal rings having mutually adjacent interior apertures through which one or more communication link members pass. Successive gimbal rings are orthogonally pivotally interconnected with one another so as to make the flexible sheath flexible in three dimensions. Upper ends of one or more communication link members are connectable with a communication cable connection fixture of the buoy. Lower ends of the communication link members are connectable to communication cable terminal connectors of a terminal end of the mooring cable.

Owner:HARRIS CORP

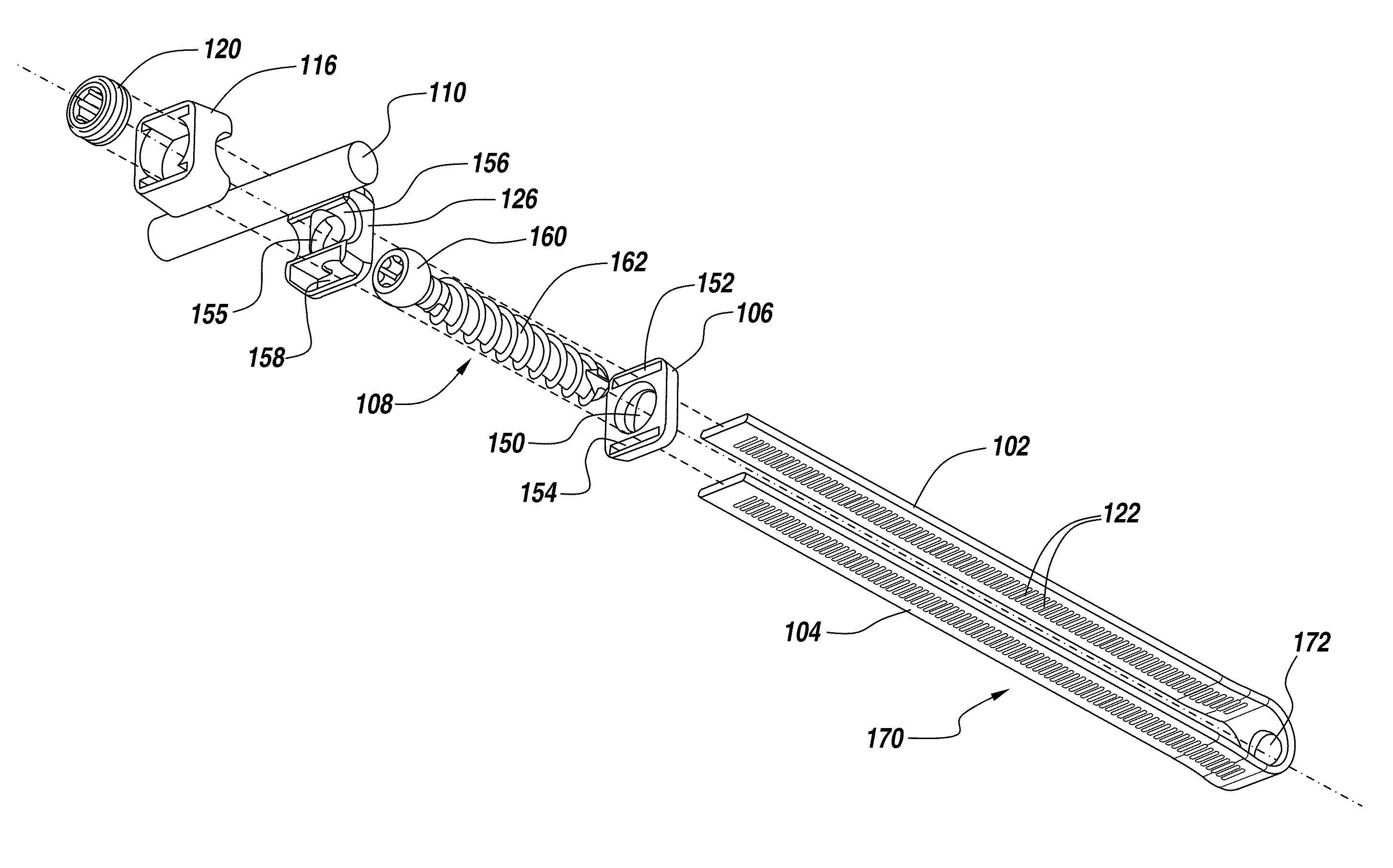

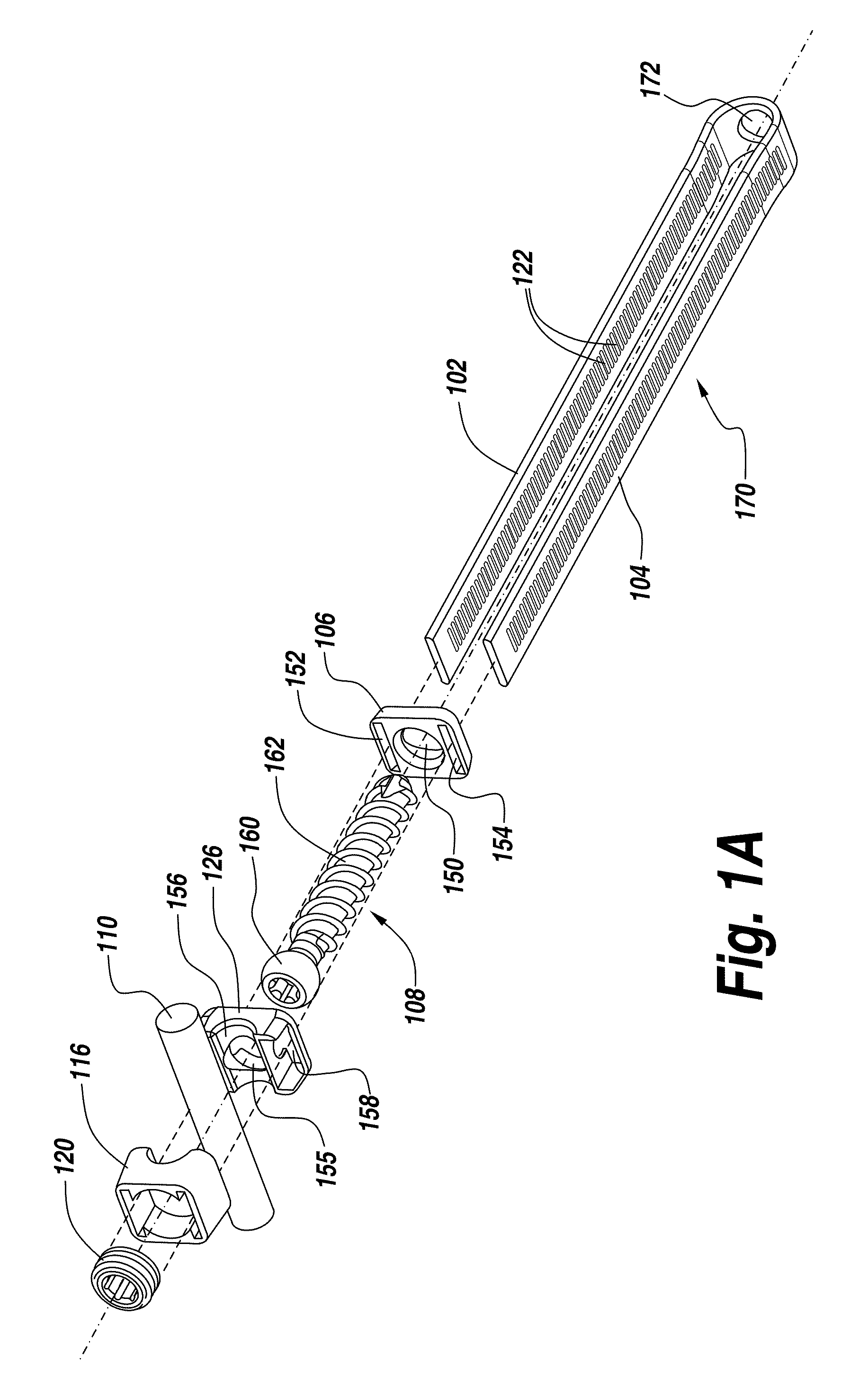

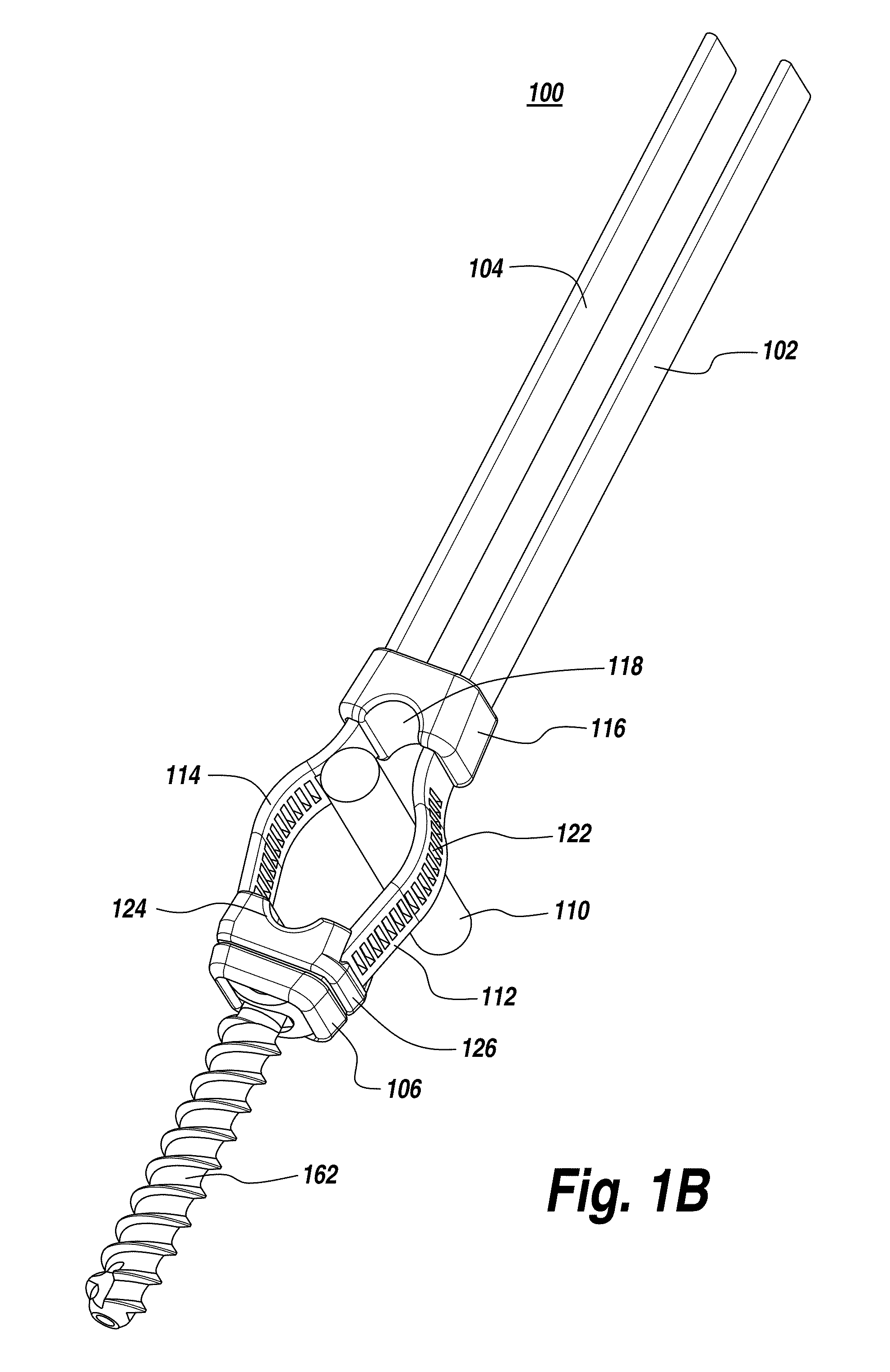

Spinal implant with a flexible extension element

ActiveUS20110093015A1Easy accessControllably implantSuture equipmentsInternal osteosythesisSpinal implantBiomedical engineering

A spinal implant with at least one flexible elongated extension element is provided. The spinal implant has a profile that is lower than standard spinal implants. The spinal implant includes a bone anchor with a head portion and a shaft extending along a longitudinal axis of the bone anchor. A head plate is coupled to the bone anchor. The head plate includes a first elongated extension element and a second elongated extension element. The first elongated extension element and the second elongated extension element may be formed as a single monolithic element that is attached to the head plate by passing through a pair of openings provided on the head plate. At least one of the first elongated extension element and the second elongated extension element is flexible.

Owner:DEPUY SYNTHES PROD INC

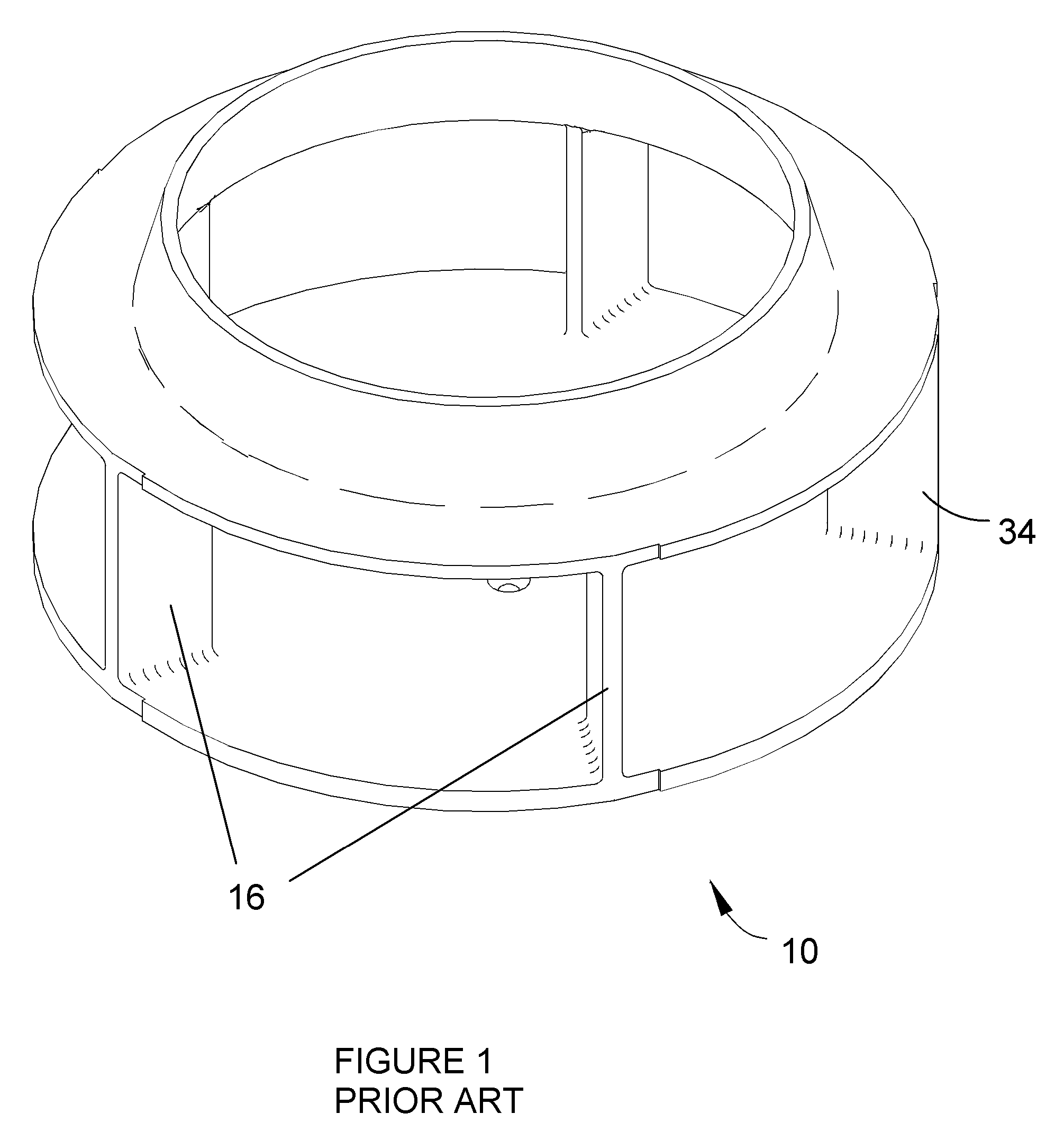

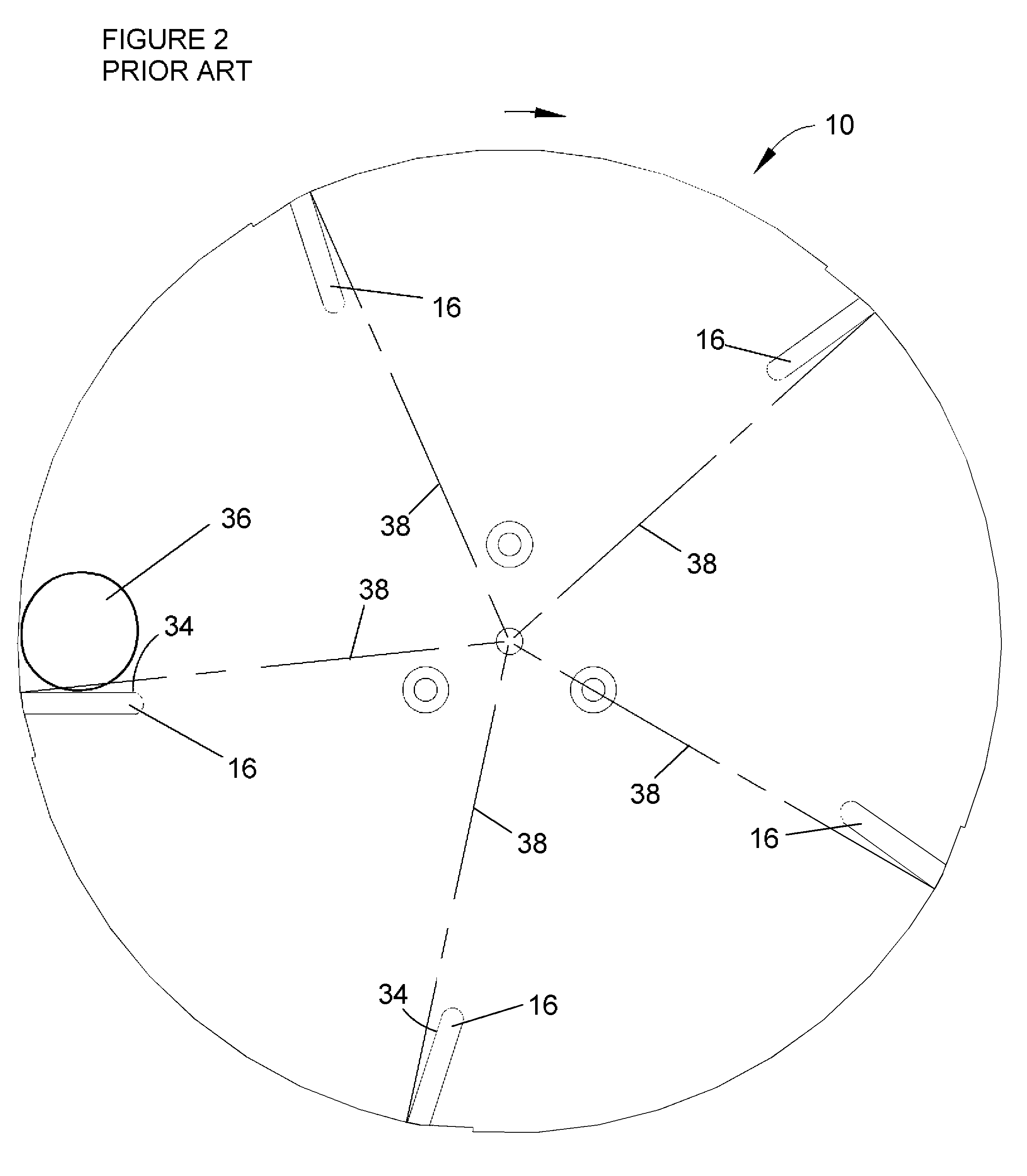

Apparatus for cutting food product

A cutting apparatus having an annular-shaped cutting head and an impeller assembly coaxially mounted for rotation within the cutting head to deliver food products radially outward toward the cutting head. The cutting head has at least one knife extending radially inward toward the impeller assembly. The knife has a cutting edge at a radially innermost extremity and a radially outer face that defines a trajectory plane for slices removed from the products by the cutting edge. The knife is clamped to the cutting head with a clamping feature that provides clearance for slices when traveling the trajectory plane of the knife.

Owner:URSCHEL LAB +1

Rear-mounted aerodynamic structure for truck cargo bodies

This invention provides a foldable / retractable and unfoldable / deployable, rearwardly tapered aerodynamic assembly for use on the rear trailer bodies and other vehicles that accommodate dual swing-out doors. The aerodynamic assembly includes a right half mounted on the right hand door and a left half mounted on a left hand door. Each half is constructed with a side panel, top panel and bottom panel, which each form half of an overall tapered box when deployed on the rear of the vehicle, the bottom panels and top panels being sealed together at a pair of overlapping weather seals along the centerline.

Owner:STEMCO PROD INC

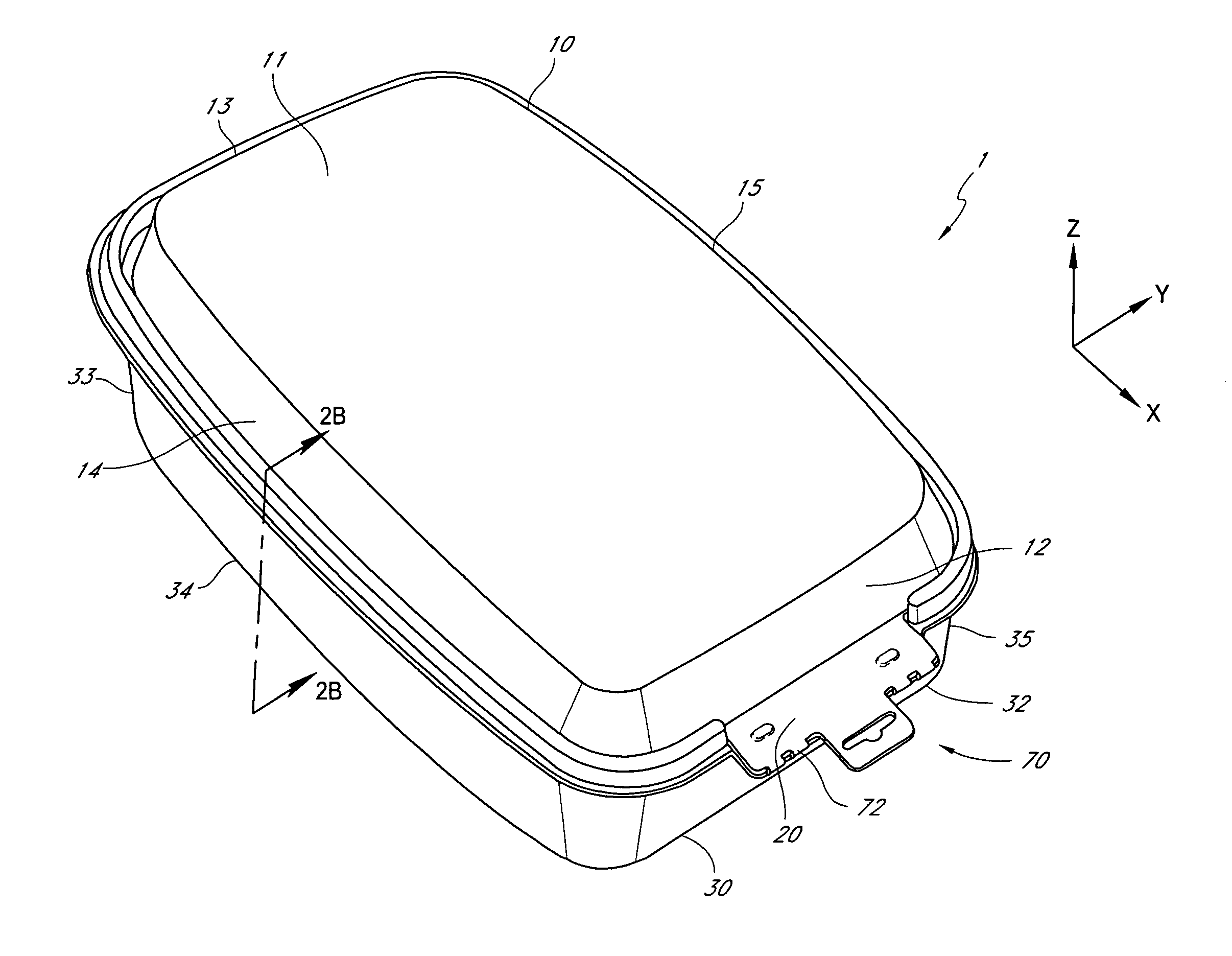

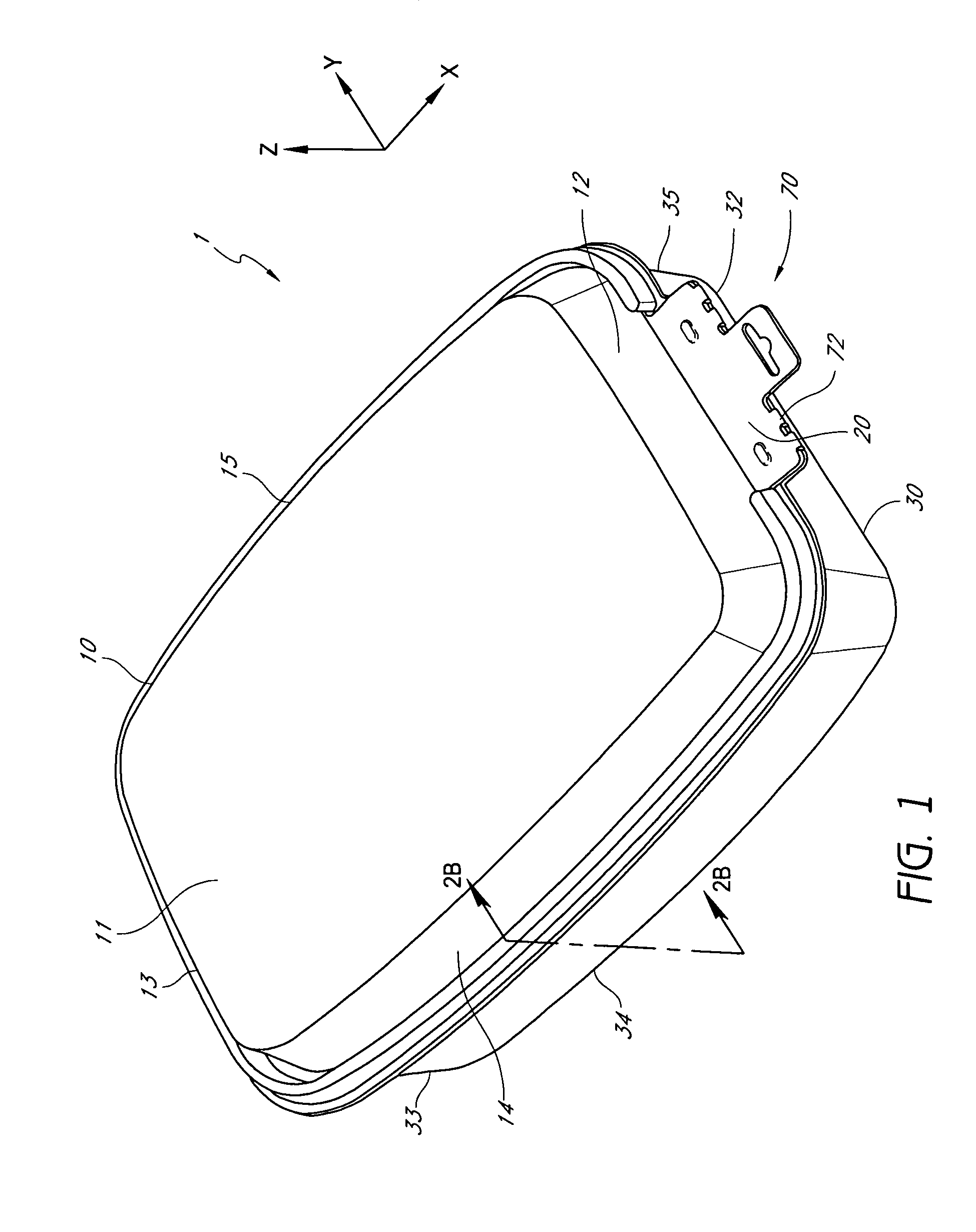

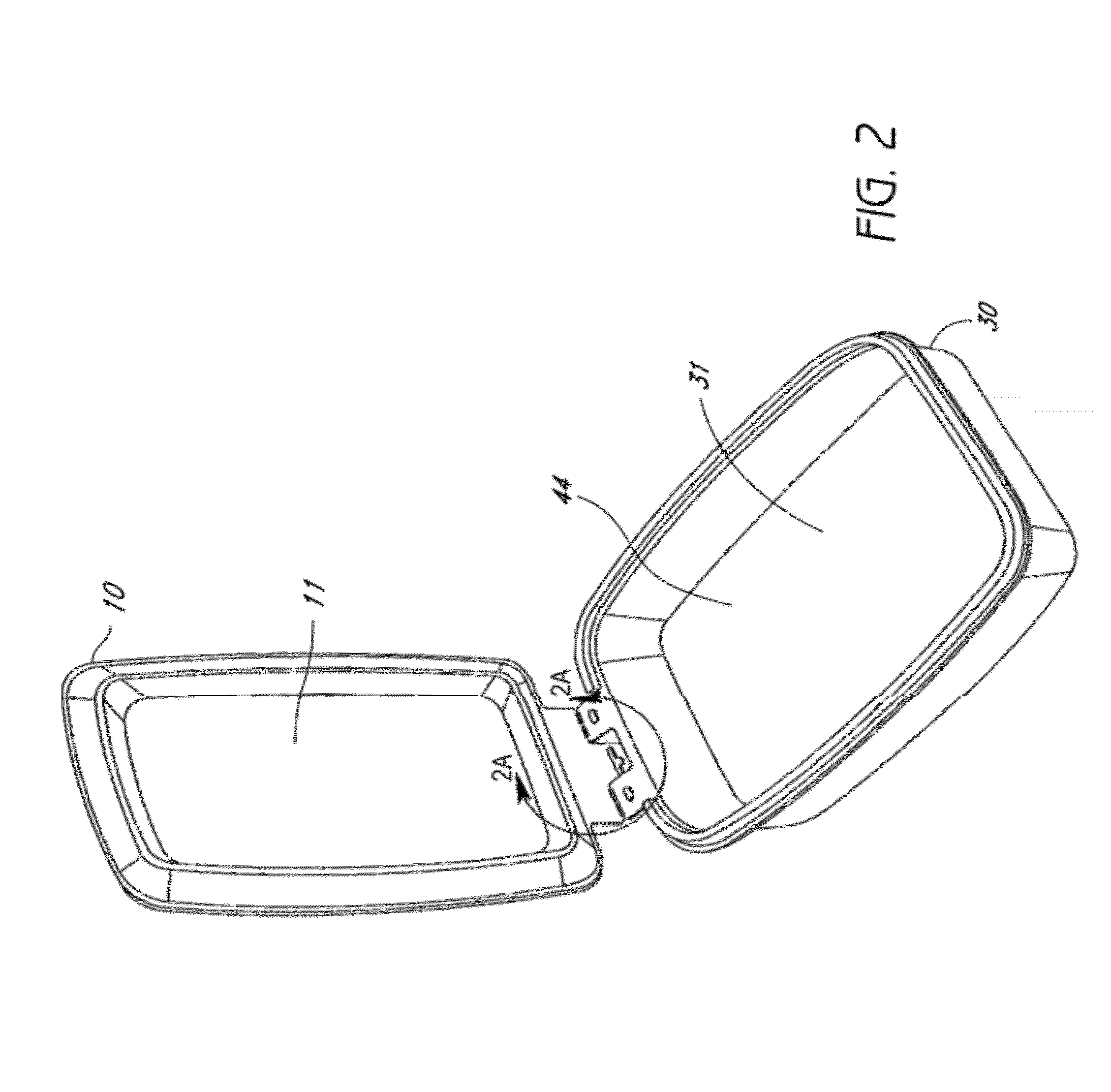

Hangable tamper resistant packaging system

ActiveUS8251249B1Superior hangable packagingEasy to tearDispensing apparatusTable equipmentsEngineeringMechanical engineering

A clam-shell container system can include first and second container pieces that are hingedly connected. The first container piece can include a perimeter and a hangable tab, the hangable tab having an opening configured to receive a rod. The hinge connection can be perforated, such that it breaks upon actuation of the hangable tab to open the container system. The second container piece can include a cutout in proximity to the hinge connection and the hangable tab. Accordingly, the cutout can provide clearance for the rotation of the hangable tab beyond the hinge connection. Further, the second container piece can have a perimeter having a shape substantially similar to the perimeter of the first container piece. The perimeters can form a substantial seal in combination.

Owner:PACTIV PACKAGING

Automobile beam

The invention relates to a motor vehicle beam shell designed to be placed behind a bumper skin, said shell being provided with a recess for receiving a strength member inside it, the strength member being, for example, a strength member made of metal, in particular of aluminum, or a strength member made of a composite material incorporating a metal. The beam is provided with shell cladding which interfits with the shell, thereby forming a hollow body defining a recess for receiving the strength member.

Owner:CO PLASTIC OMNIUM

Electro-optic reflective element assembly

InactiveUS20060098289A1Easy to assembleClearance can be providedMirrorsNon-linear opticsElectricityElectrical connection

An electro-optic reflective element assembly includes a pair of substrates and an electro-optic medium sandwiched therebetween. Each of the pair of substrates includes at least one conductive or semi-conductive layer disposed thereon. The electrical connections may electrically connect to a respective layer and may be electrically isolated from the other layer, such as via non-conductive regions of the substrates and / or deletion lines along one of the conductive layers. The pair of substrates may be positioned relative to one another such that overhang portions of the front substrate extend beyond the corresponding edges of the rear substrate. The overlapping relationship may provide clearance for electrical connection to the conductive layers of the front and rear substrates such that the electrical connections are substantially not viewable through the front substrate.

Owner:DONNELLY CORP

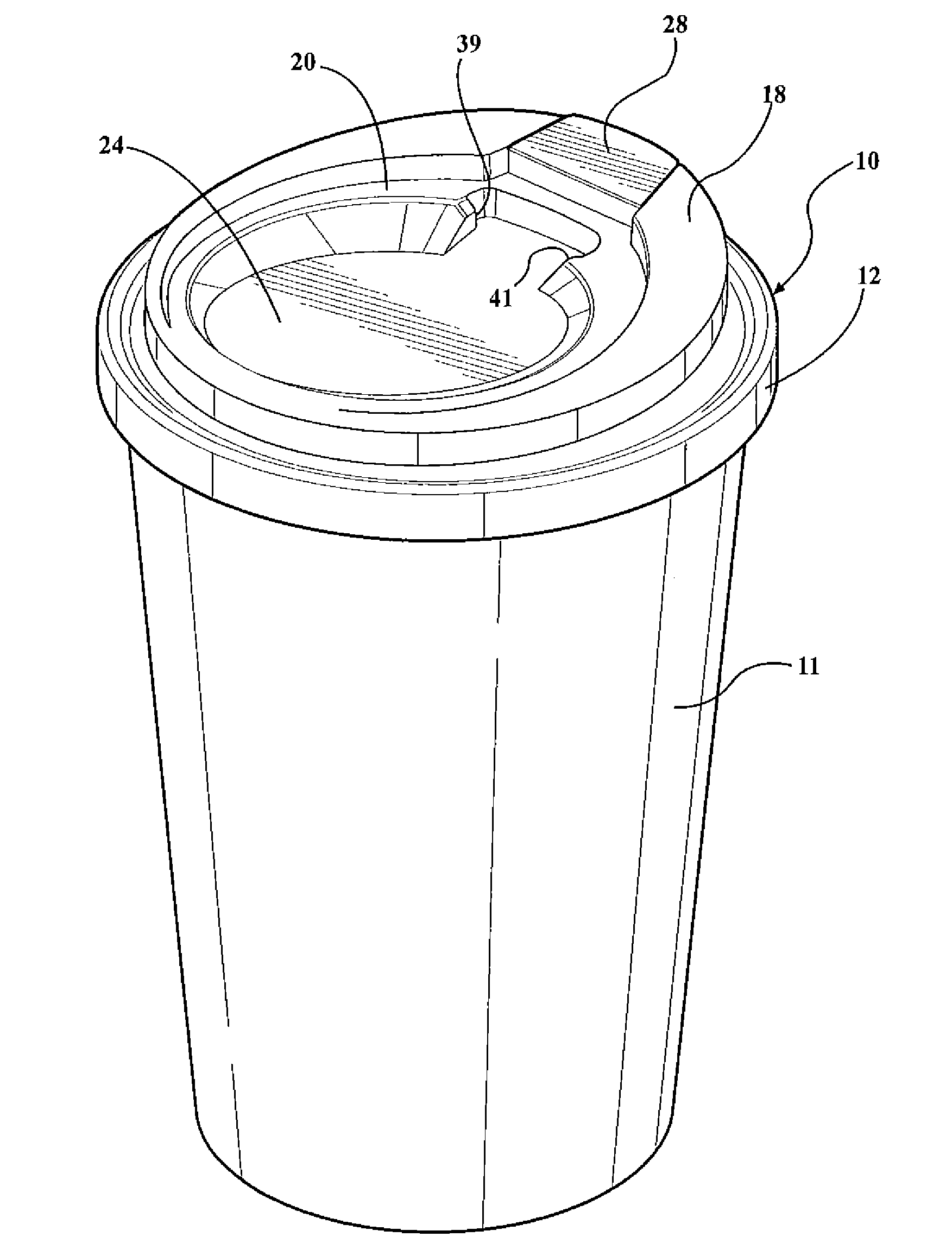

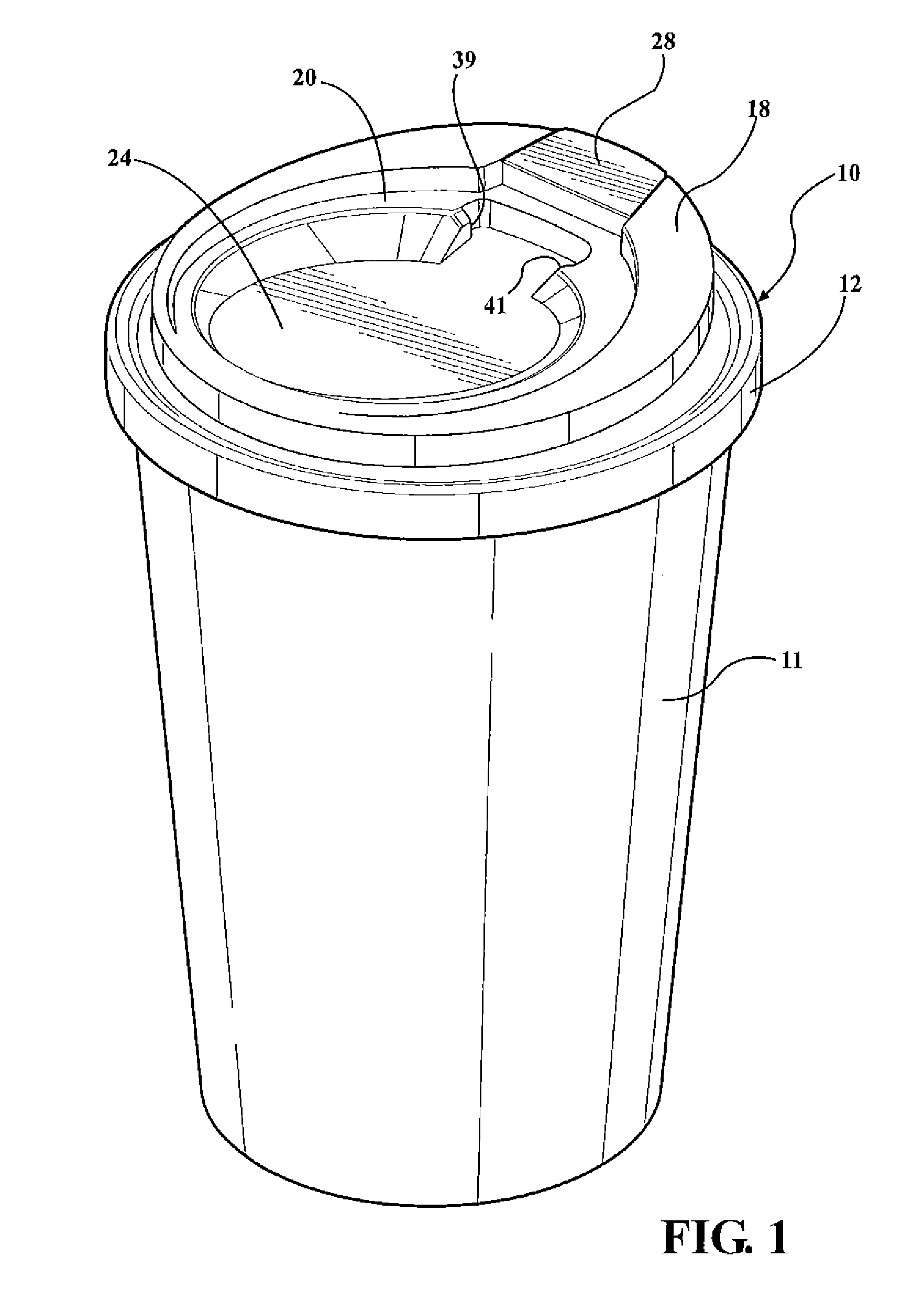

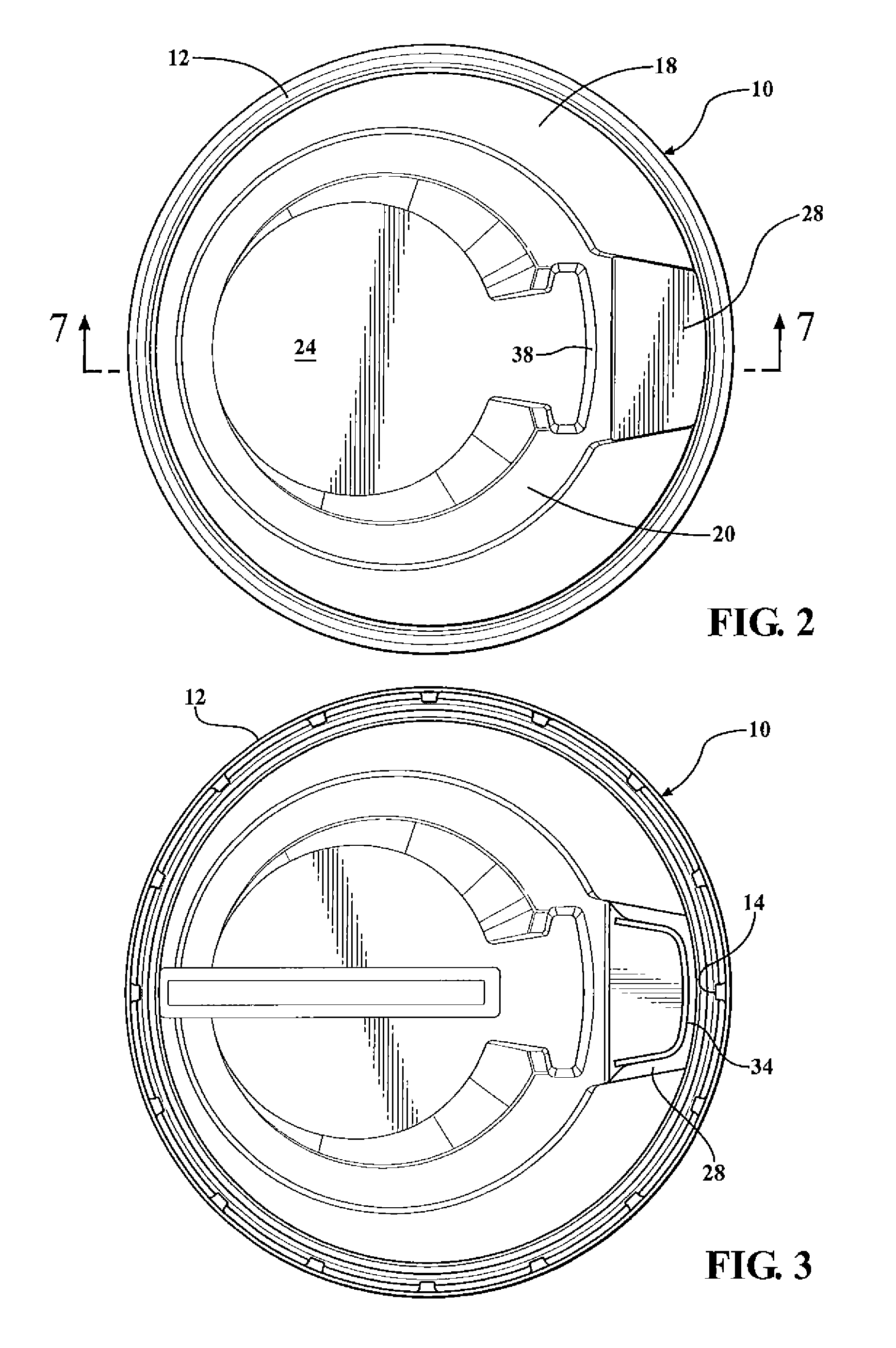

One-piece lock-back lid

ActiveUS20130037558A1Improve sealingOvercome disadvantagesLidsDomestic articlesEngineeringMechanical engineering

A drink-through plastic lid is injection molded in one piece to define a rim structure which snaps onto the rim of a cup and an asymmetric crown having a drink-through opening formed at the high point of an outer deck. An integral hinged flap with a C-shaped seal lip on the inside surface can lock by means of said lip into the drink-through opening when in one condition. The flexible outer edges of the flap latch into a lock-back recess which interrupts an intermediate inner deck formed between the outer crown deck and the floor of a well in the interior area of the lid.

Owner:LETICA

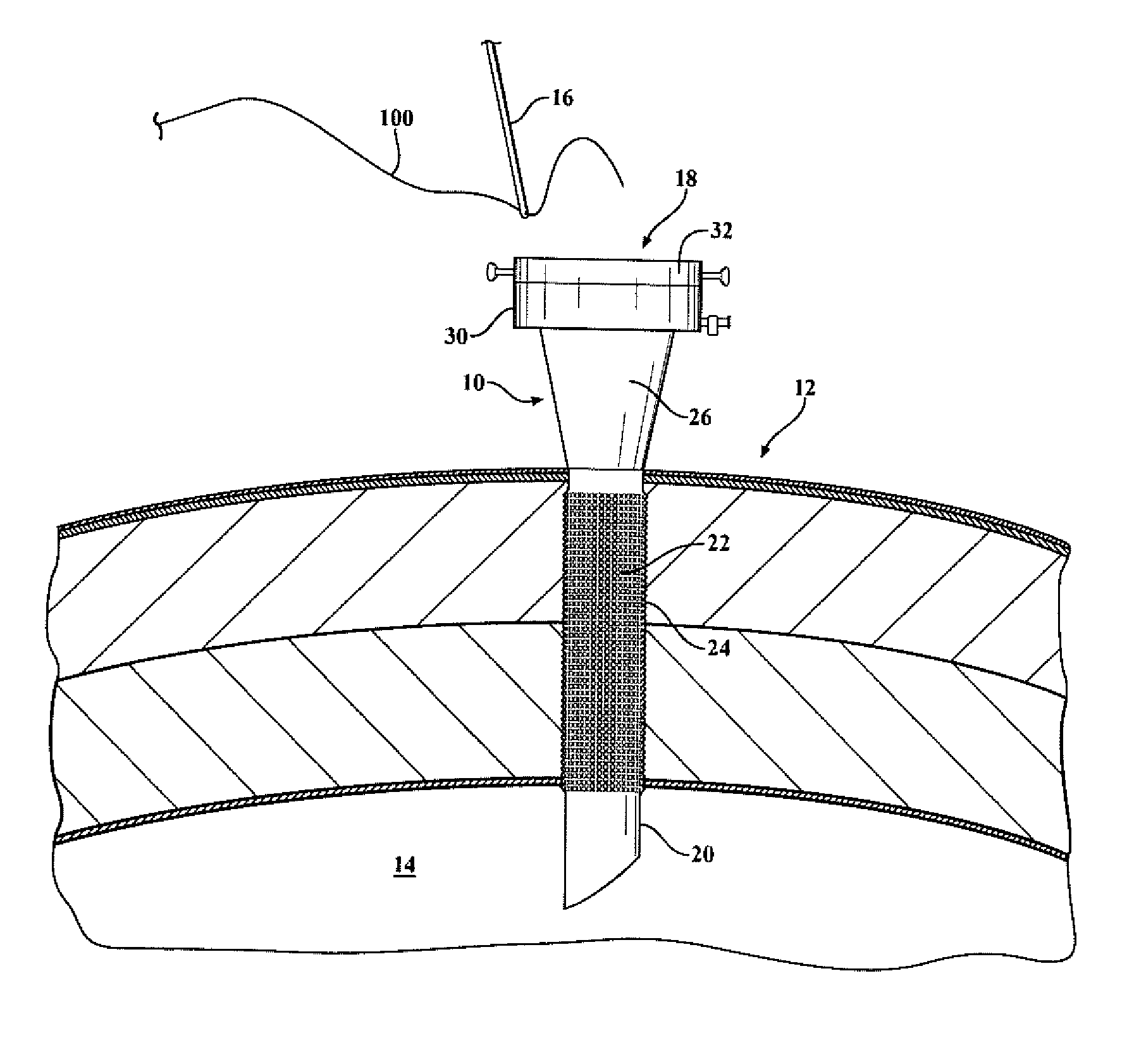

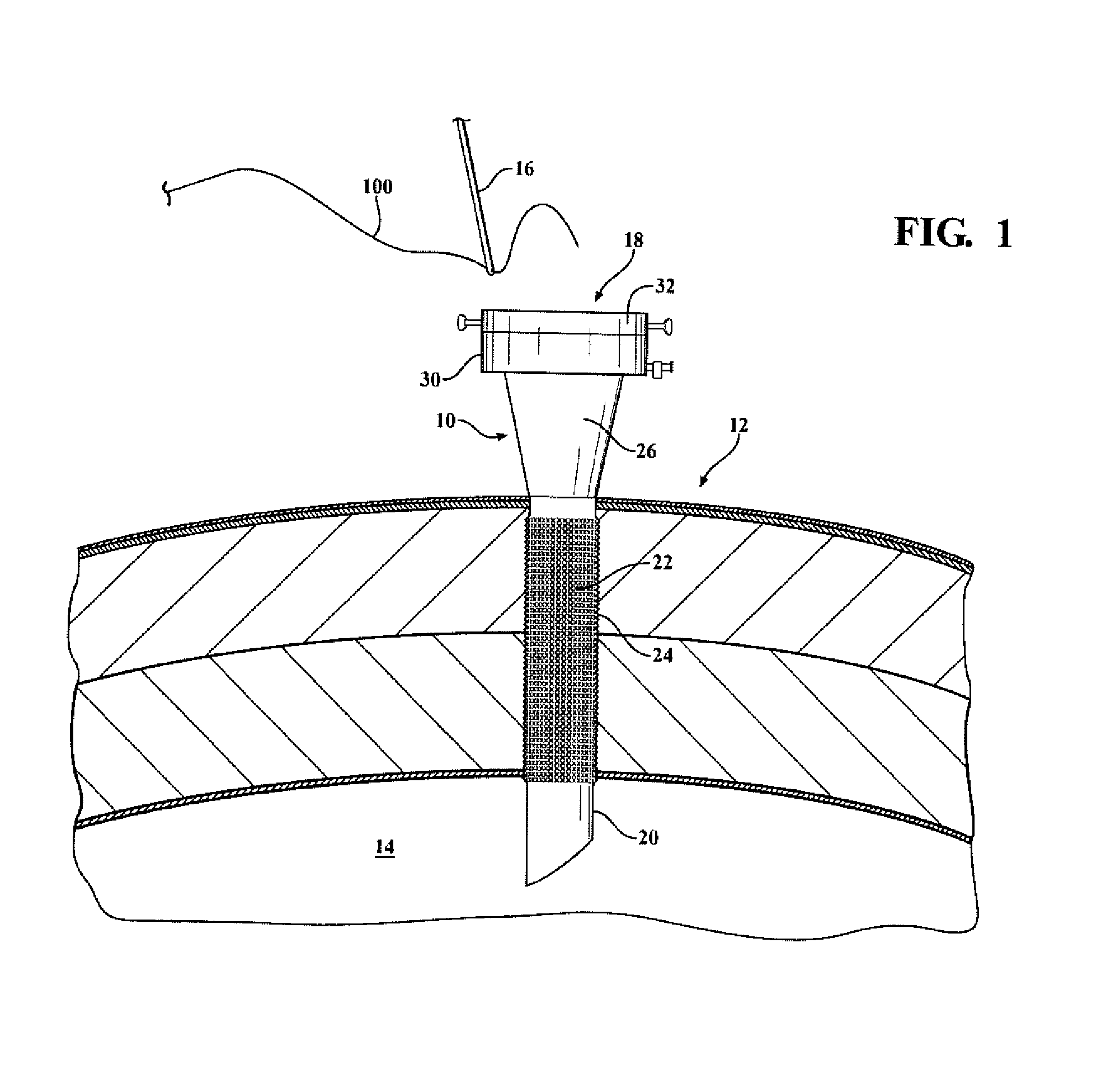

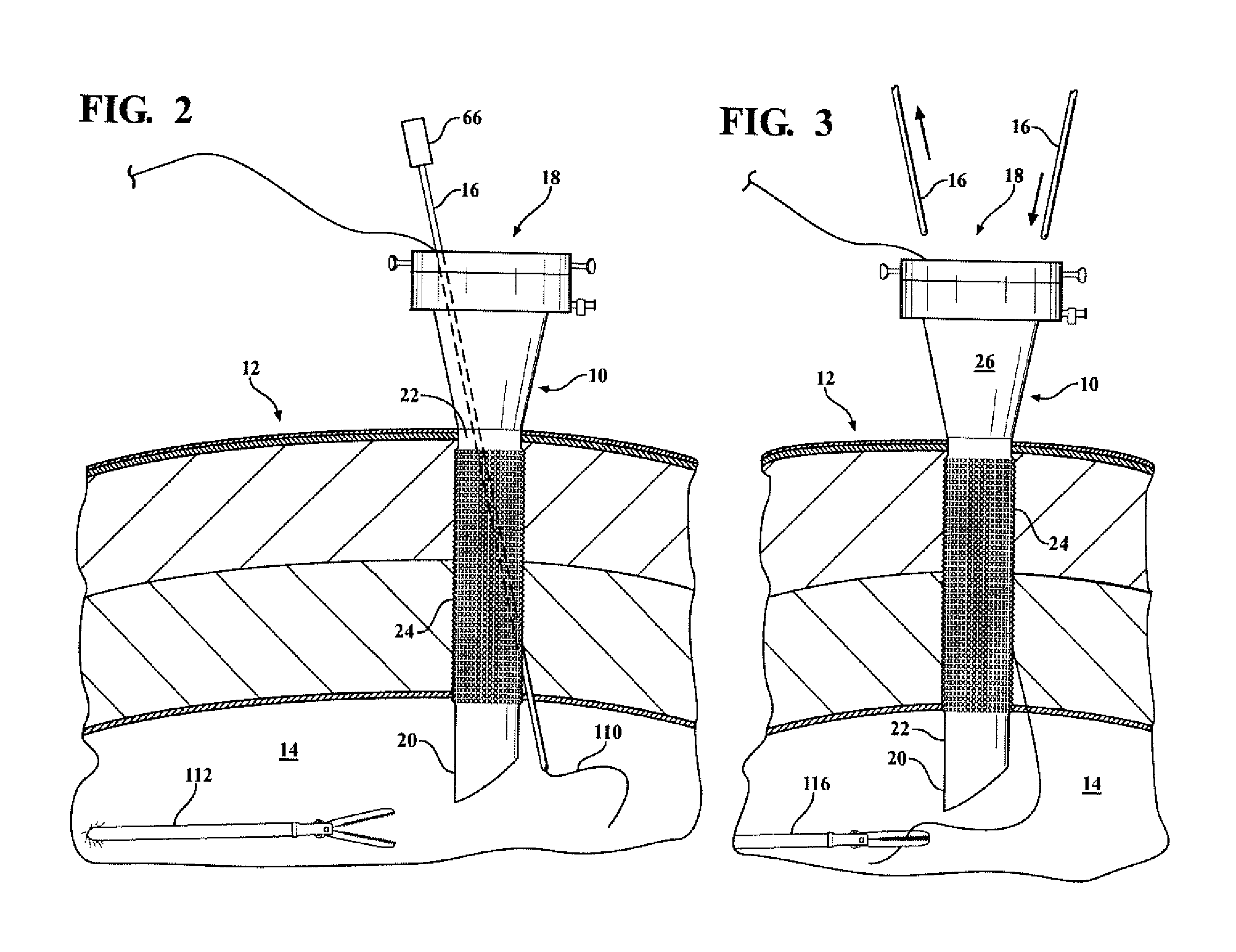

Laparoscopic cannula with suturing capability

InactiveUS20140163323A1Easy to operateClearance can be providedSuture equipmentsCannulasPERITONEOSCOPEBody cavity

A cannula for use in laparoscopic surgery has a central passage which may accept a trocar to create a laparoscopic incision in a body wall to an inner body cavity. A tubular section of the cannula is then pressed into the incision to form a port. After completion of the operation a needle having a blunt distal end with a suture-engaging notch surrounded by a sheath with a sharpened edge is pressed through inclined passages in the side walls of the cannula so as to extend into the body tissue on one side of the cannula and into the body cavity, carrying the suture which is then grasped by an instrument to remove the suture and join it to a needle projecting from the opposite side of the cannula. The needle is then withdrawn so the suture may be knotted on the outer side of the body wall.

Owner:MOHAJER SHOJAEE REZA

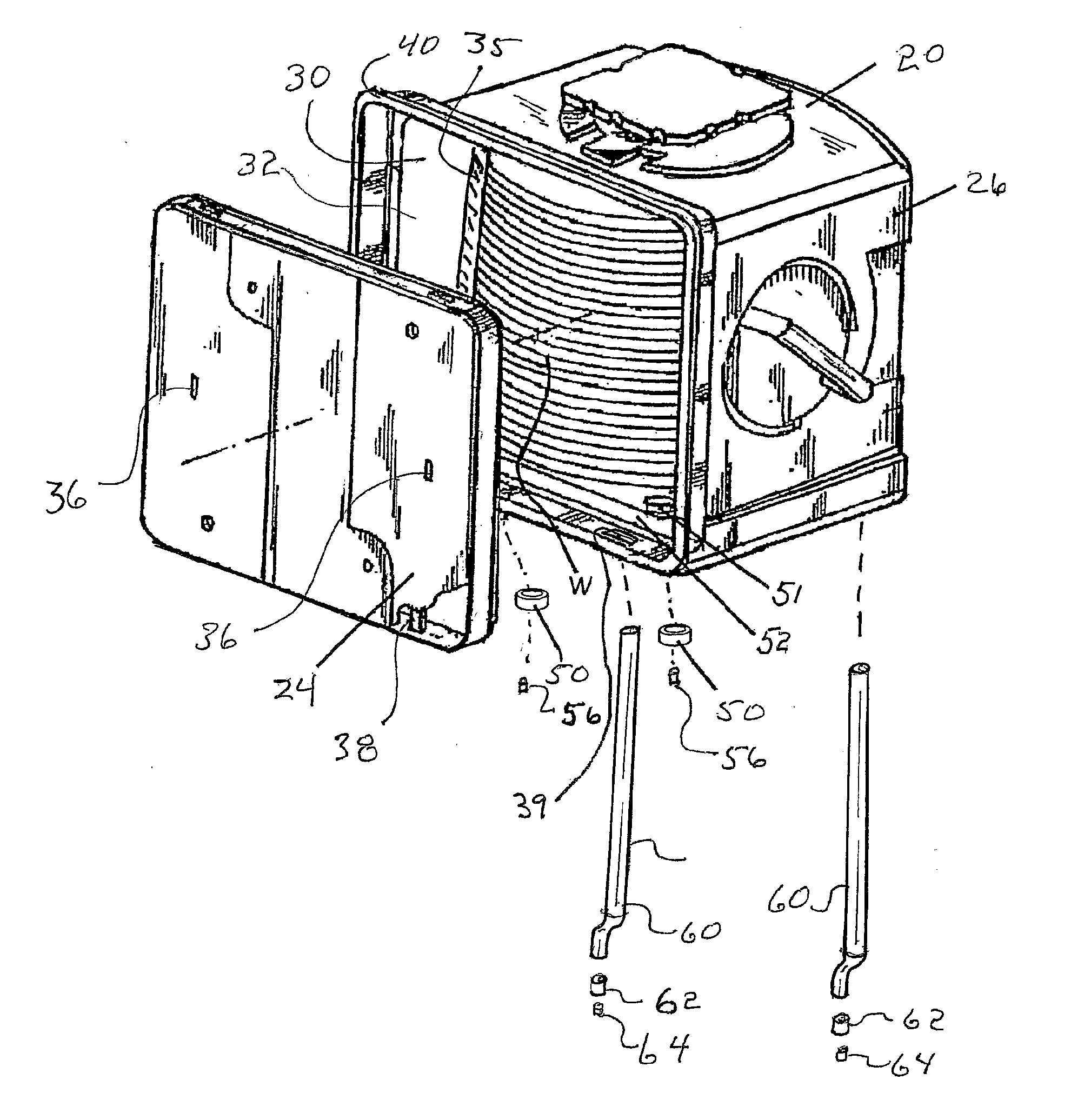

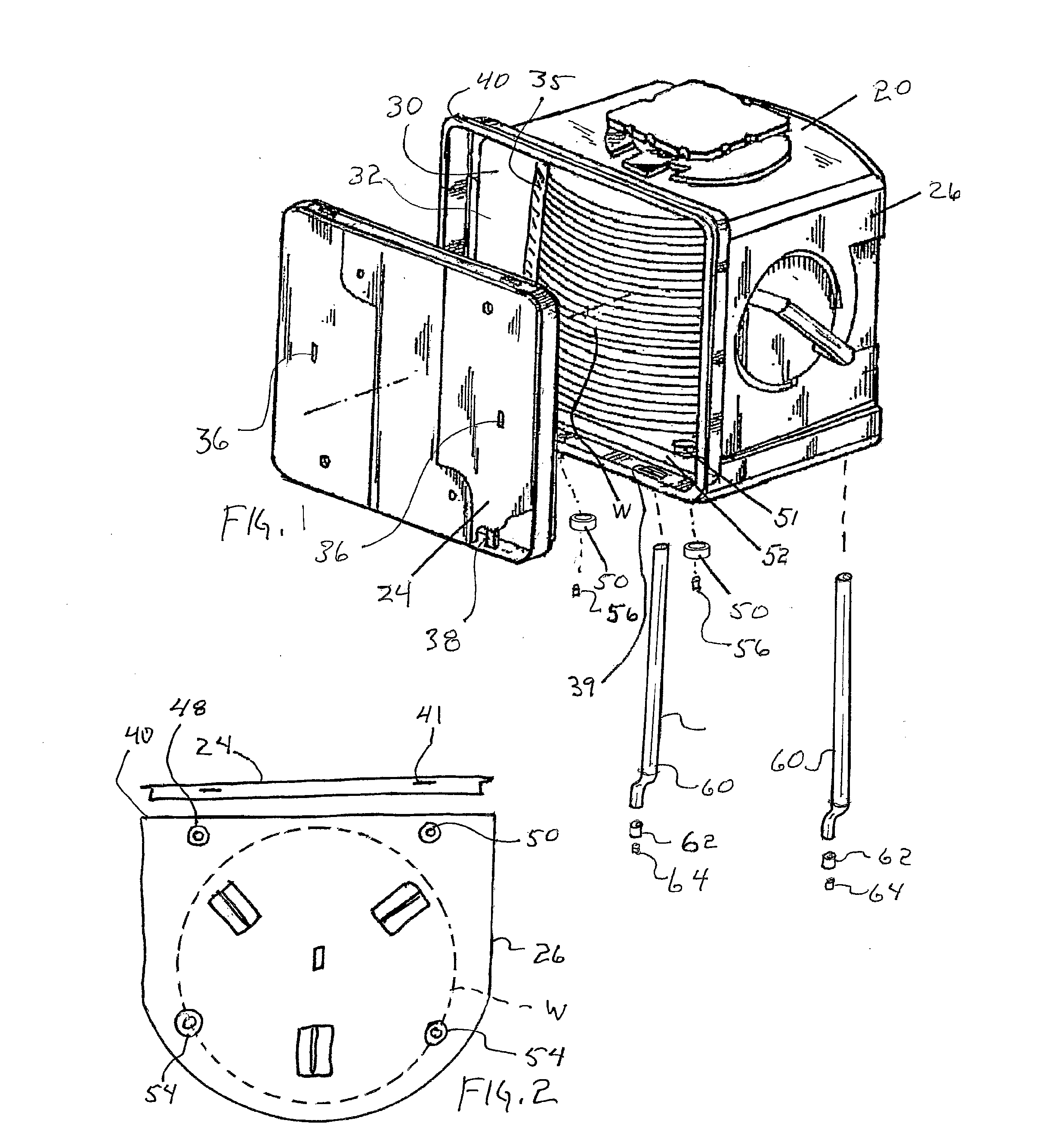

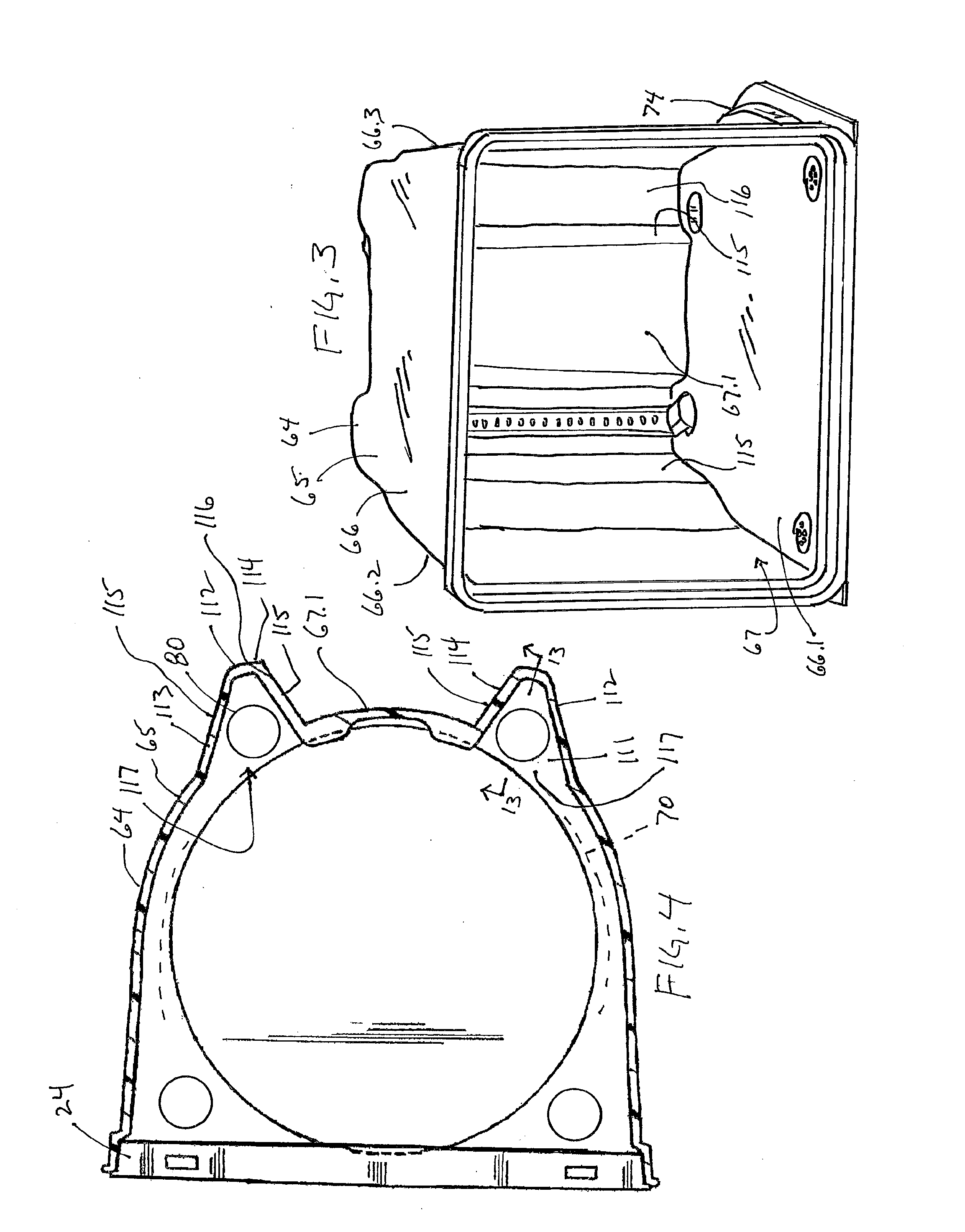

Wafer container with tubular environmental control components

ActiveUS20110114534A1Protected contentSuperior fluid flow characteristicSemiconductor/solid-state device manufacturingOther accessoriesFiltrationEngineering

A wafer container utilizes a rigid polymer tubular tower with slots and a “getter” therein for absorbing and filtering moisture and vapors within the wafer container. The tower preferably utilizes a purge grommet at the base of the container and may have a check valve therein to control the flow direction of gas (including air) into and out of the container and with respect to the tower. The tower is sealingly connected with the grommet. The tower may have a getter media piece rolled in an elongate circular fashion forming or shaped as a tube and disposed within the tower and may have axially extending. The media can provide active and / or passive filtration as well as having capabilities to be recharged. Front opening wafer containers for 300 mm sized wafers generally have a pair of recesses on each of the left and right side in the inside rear of the container portions. These recesses are preferably utilized for elongate towers, such towers extending substantially from a bottom wafer position to a top wafer position. In alternative embodiment, a tubular shape of getter material is exposed within the front opening container without containment of the getter other than at the ends. The tubular getter form is preferably supported at discrete locations to maximize exposure to the internal container environment. A blocker member can selectively close the apertures. An elastomeric cap can facilitate securement of the tubular component in the container portion.

Owner:ENTEGRIS INC

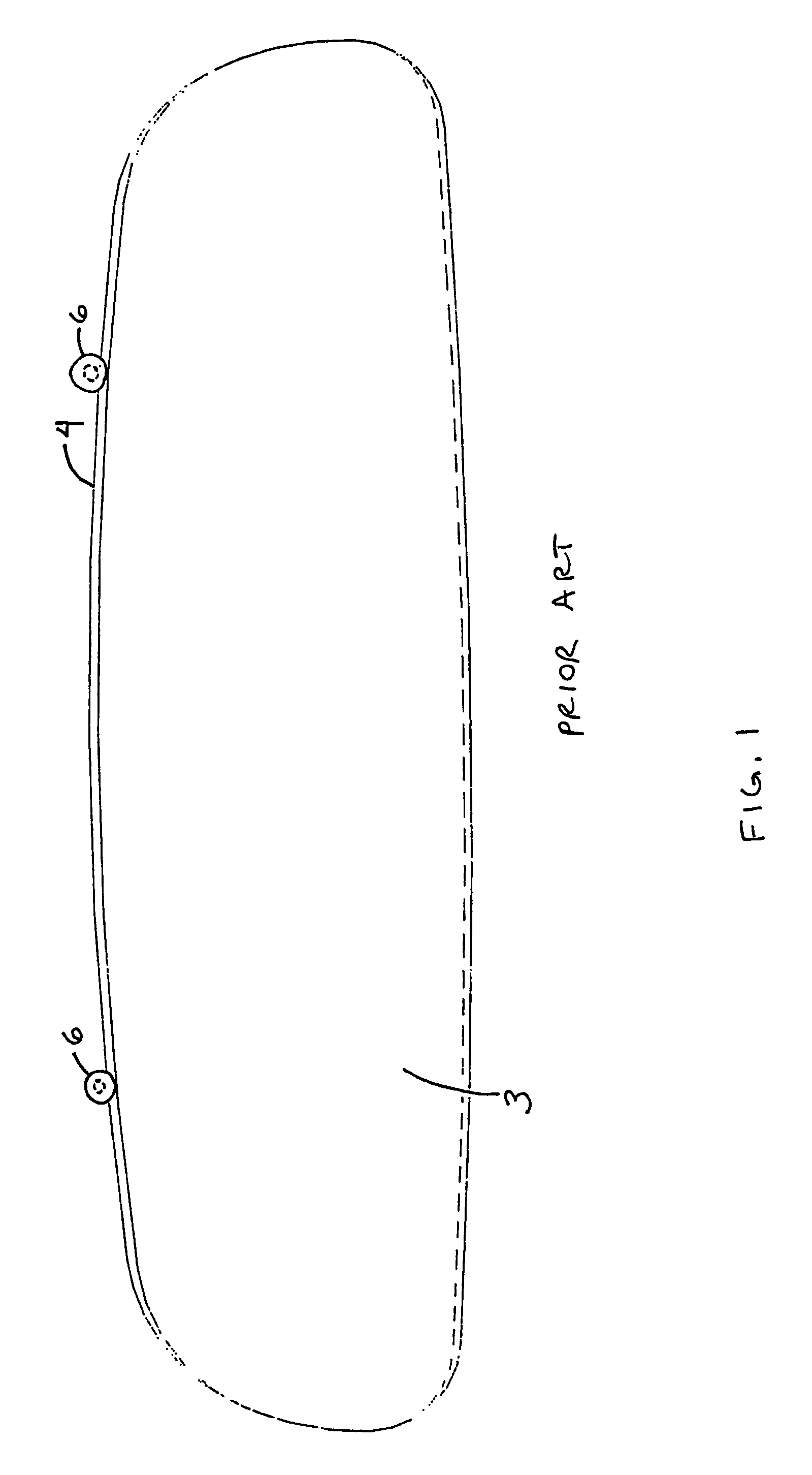

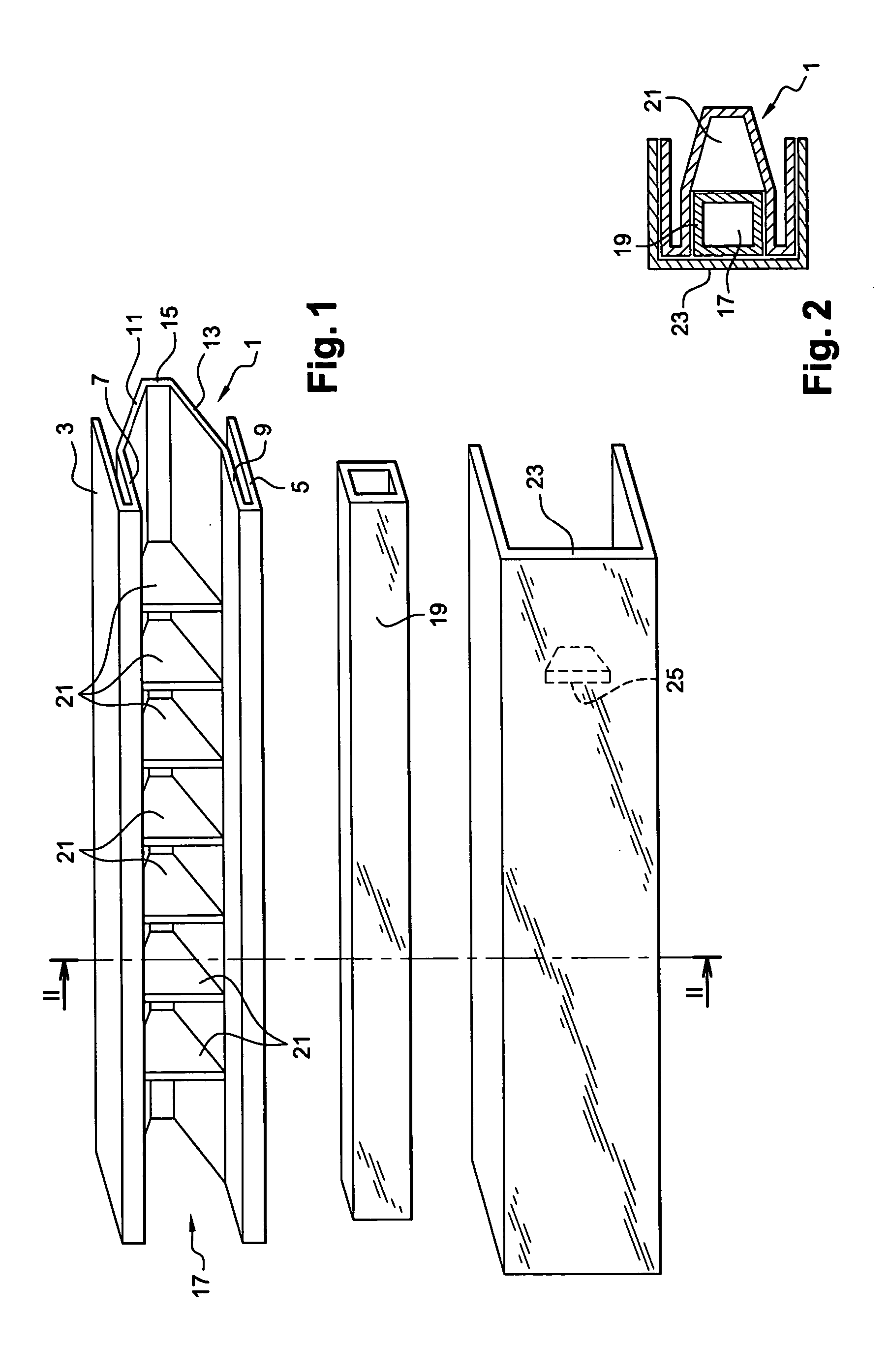

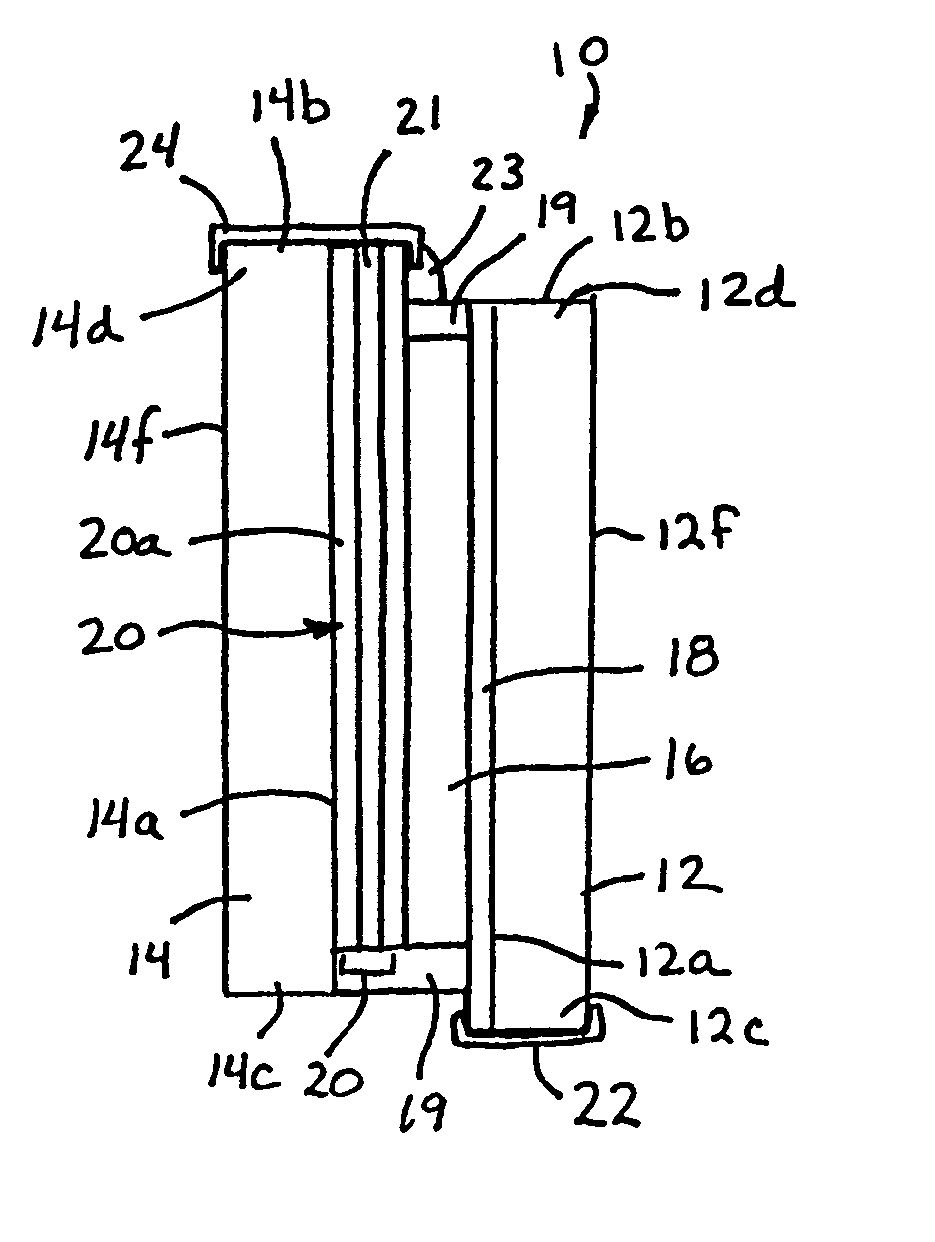

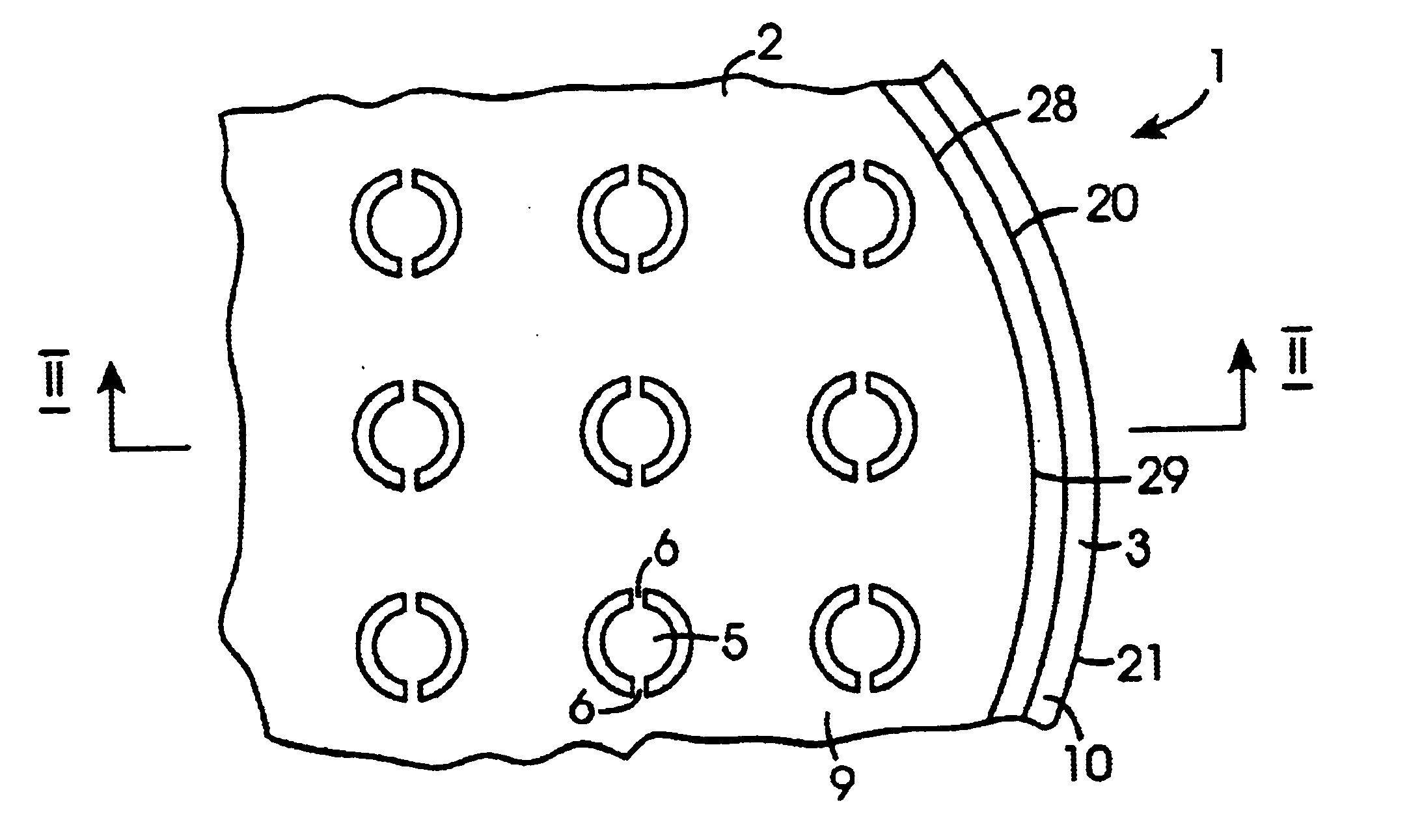

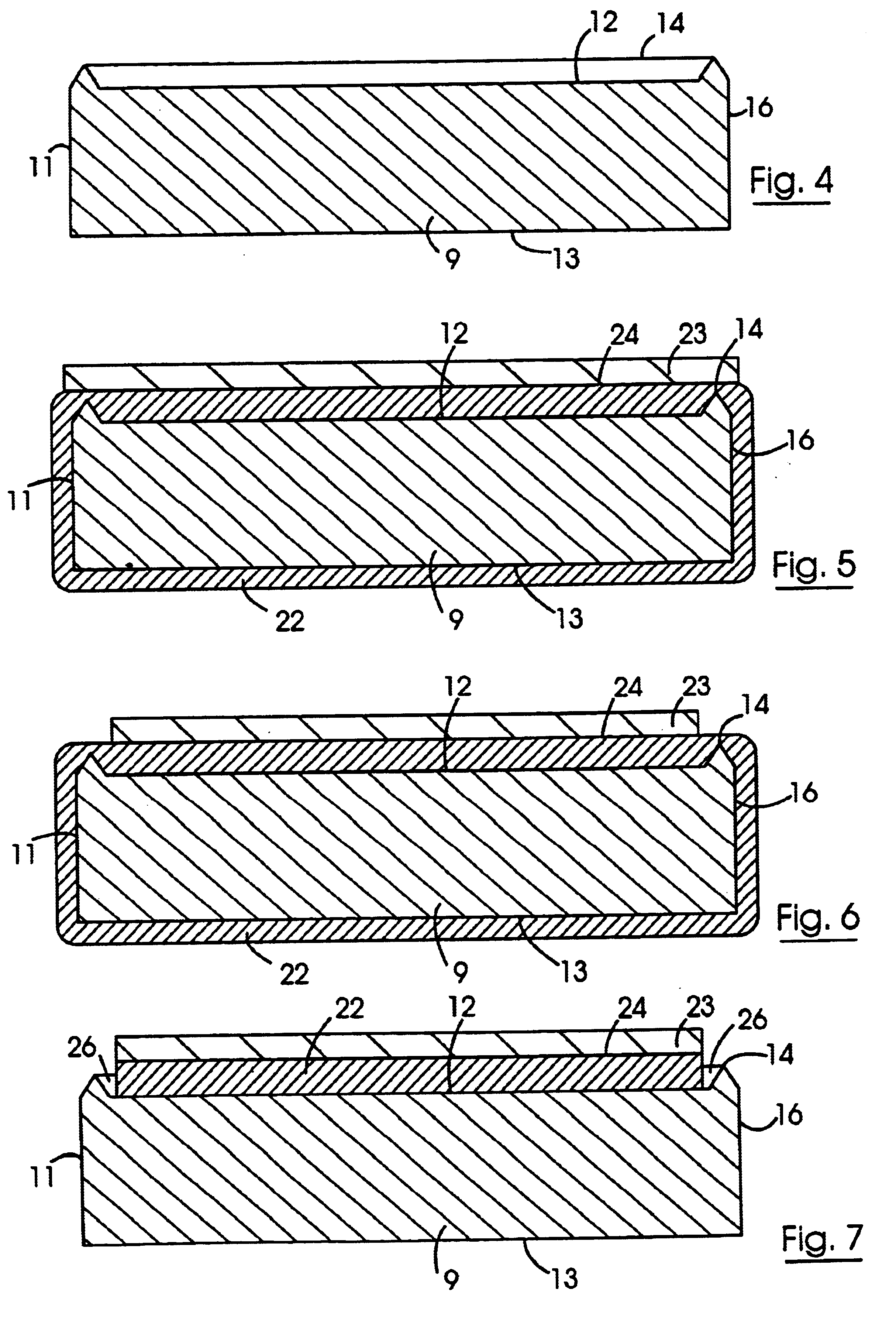

Composite semiconductor wafer and a method for forming the composite semiconductor wafer

InactiveUS6841848B2Improve bindingClearance can be providedDecorative surface effectsSemiconductor/solid-state device detailsEngineeringPhotoresist

A composite SOI semiconductor wafer (1) comprises a device layer (2) and a handle layer (3) with a buried oxide layer (4) located between the device and handle layers (2,3). The device and handle layers (2,3) are formed from device and handle wafers (9,10), respectively. A peripheral ridge (14) extending around a first major surface (12) of the device wafer (9) adjacent the peripheral edge (16) thereof is removed by etching a peripheral recess (25) to a depth (d) into the device wafer (9) prior to bonding the device and handle wafers (9,10), in order to avoid an unbonded peripheral pardon extending around the composite wafer (1). The depth to which the peripheral recess (25) is etched is greater then the final finished thickness t of the device layer (2). An oxide layer (22) is grown on the device water (9) and a photoresist layer (23) on the oxide layer (22) is patterned to define the peripheral recess (25). The oxide layer (22) is etched leaving only a portion of the oxide layer (22) beneath the photoresist layer (23), which subsequently forms the oxide layer (4). The peripheral recess (25) is then etched, and the photoresist layer (23) is removed. The oxide layer (22) is fusion bonded to a first major surface (18) of the handle wafer (10) by a high temperature bond anneal. Thereafter the device layer (2) is machined to its final finished thickness t.

Owner:ANALOG DEVICES INC

Apparatus for cutting food product

ActiveUS7658133B2Minimize compressionGood precisionGrain treatmentsMetal working apparatusImpellerBiomedical engineering

Owner:FRITO LAY NORTH AMERICA INC +1

Articulating window hinges and articulating window assemblies

InactiveUS7024822B2Improve installation strengthImprove gripWindowsEngine sealsEngineeringHinge joint

Articulating window assemblies are provided comprising, in combination, a windowpane and a hinge having a hinge axis. The hinge comprises a first hinge member that cooperates with a second hinge member and optionally with a hinge pin to form a hinge joint. The first hinge member has at least an encapsulation section with at least a first encapsulant void, optionally two or more encapsulant voids. A continuous body of encapsulant overlays at least a portion of an outward-facing surface of the encapsulation section, at least partially fills the first encapsulant void, overlays at least a portion of an inward-facing surface of the encapsulation section and overlaps either at least a portion of an external peripheral edge of the encapsulation section, a portion of a void edge defining a second encapsulation void, or both from both the outward-facing surface and the inward-facing surface. This provides a mechanical grip of the first hinge member by the encapsulant. The encapsulant is further bonded to an inner surface of the windowpane to retain the first hinge member, and thereby the hinge, to the windowpane. The windowpane of the window assemblies provided is therefore adapted to rotate or articulate about the hinge axis relative to the second hinge member. No portion of the hinge extends through or overlays any portion of the outer surface of the windowpane, enabling a flush, streamlined appearance. Also provided are vehicles having an articulating window assembly in accordance with those just described.

Owner:DURA GLOBAL TECH

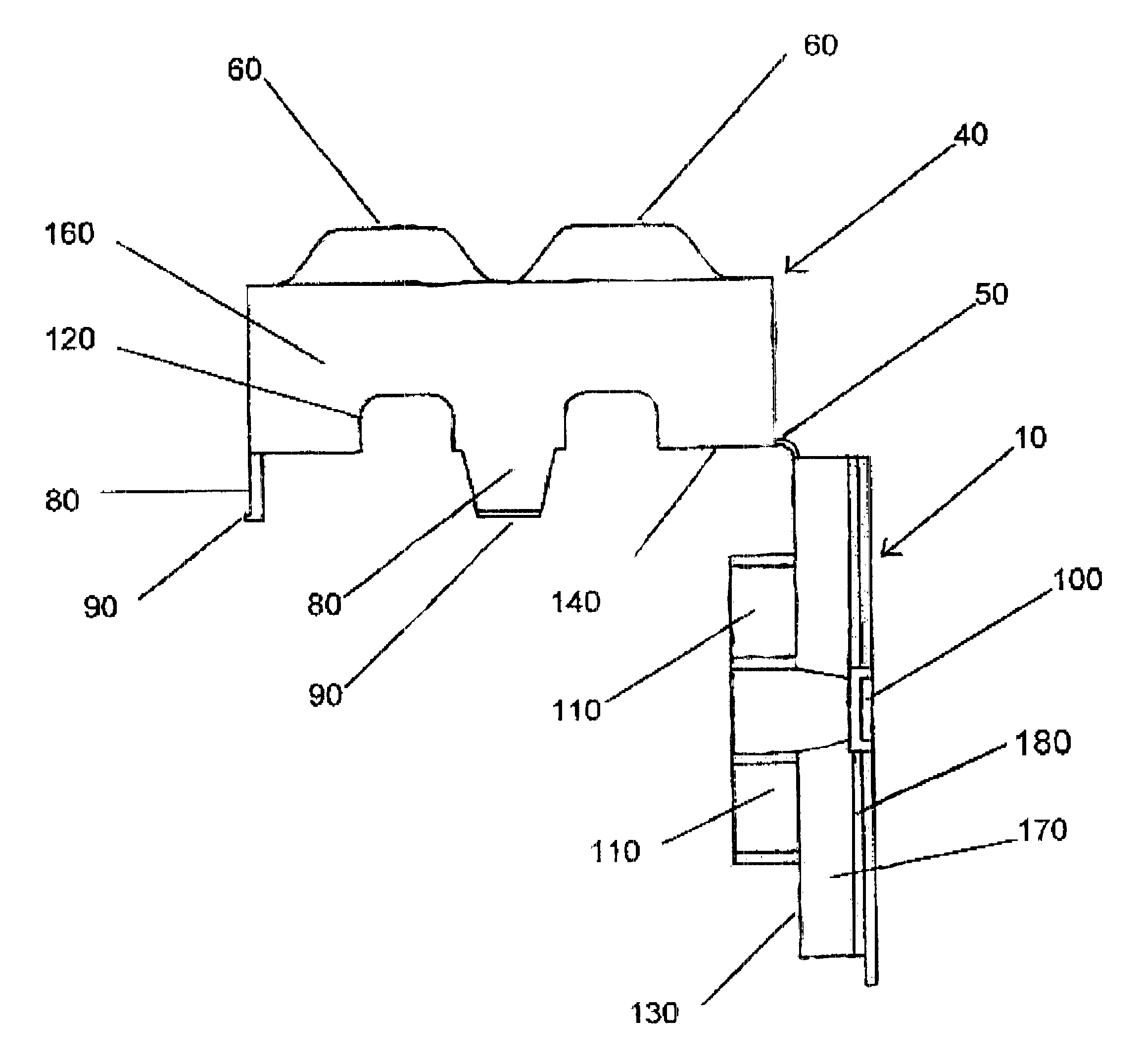

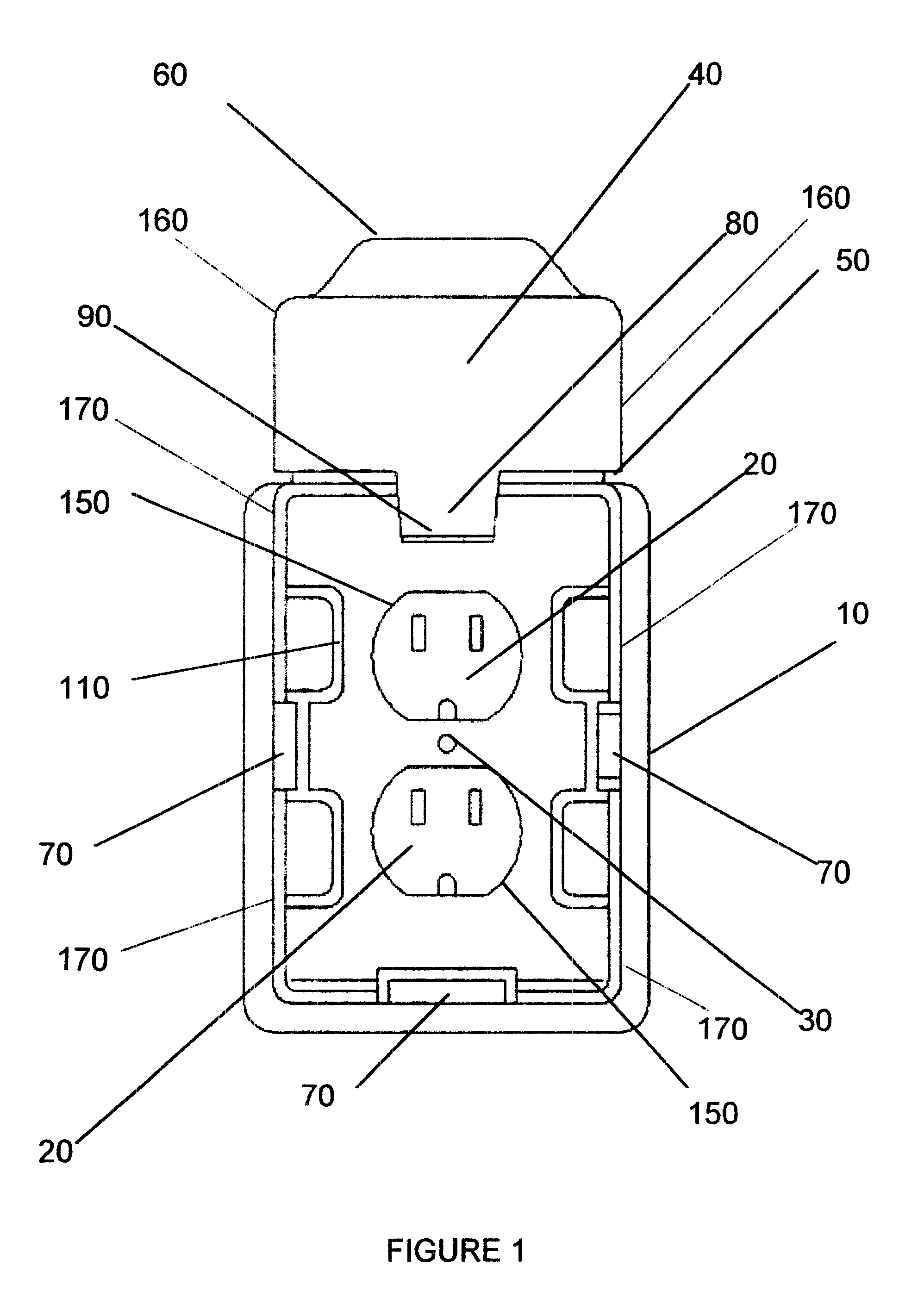

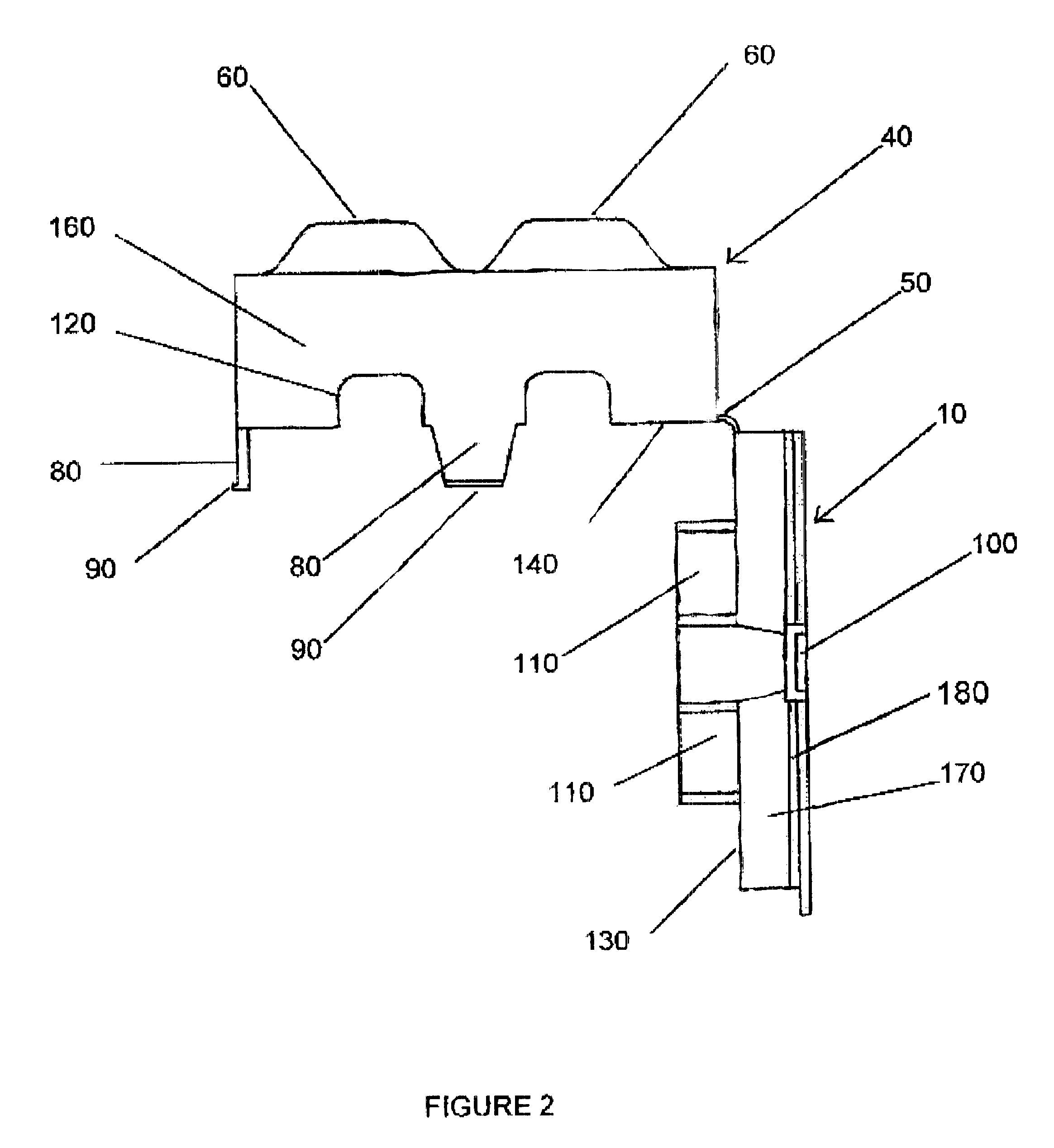

Safety electrical outlet

InactiveUS6649838B1Reduce material volumeGood lookingCasings/cabinets/drawers detailsLive contact access preventionElectricityYoung person

A new and improved safety outlet includes of a one-piece structure which is installed on a standard electrical receptacle in place of a standard receptacle cover. The electrical plugs installed in the outlets of the electrical receptacle are completely enclosed within the fire resistant and electrically insulating structure; baffles are incorporated into the rigid base to prevent an infant or young person from inserting a rigid object through the passages in the structure for electrical cords and thereby preventing contact with the electrical supply voltages; and three tabs spaced on three sides of the cover portion must be simultaneously pressed to allow the structure to be opened for access to the electrical plugs, thereby preventing access to the enclosed region and preventing contact with the electrical supply voltages.

Owner:LOPEZ SR RUDY A +1

Controlled truck cab suspension system

ActiveUS7077226B2Suppress impactReduce vibrationVehicle seatsNon-rotating vibration suppressionAir springTruck

The invention is a suspension system, typically for use between a cab and a truck frame, includes a strut module having a strut and an air spring, and a control module, connected to a source of pressurized air, for sensing a distance between the cab and truck frame and selectively pressurizing the air spring in response to changes in that distance. Preferably, the strut is a McPherson-type strut and the air spring encloses at least a portion of the strut to provide a compact assembly and includes a three point connection to the cab and frame to resist relative lateral movement between the cab and frame. The strut also preferably is a magnetorheological-type damper so that the control module can adjust the damping characteristics of the strut to optimize rider comfort.

Owner:DELPHI TECH INC +1

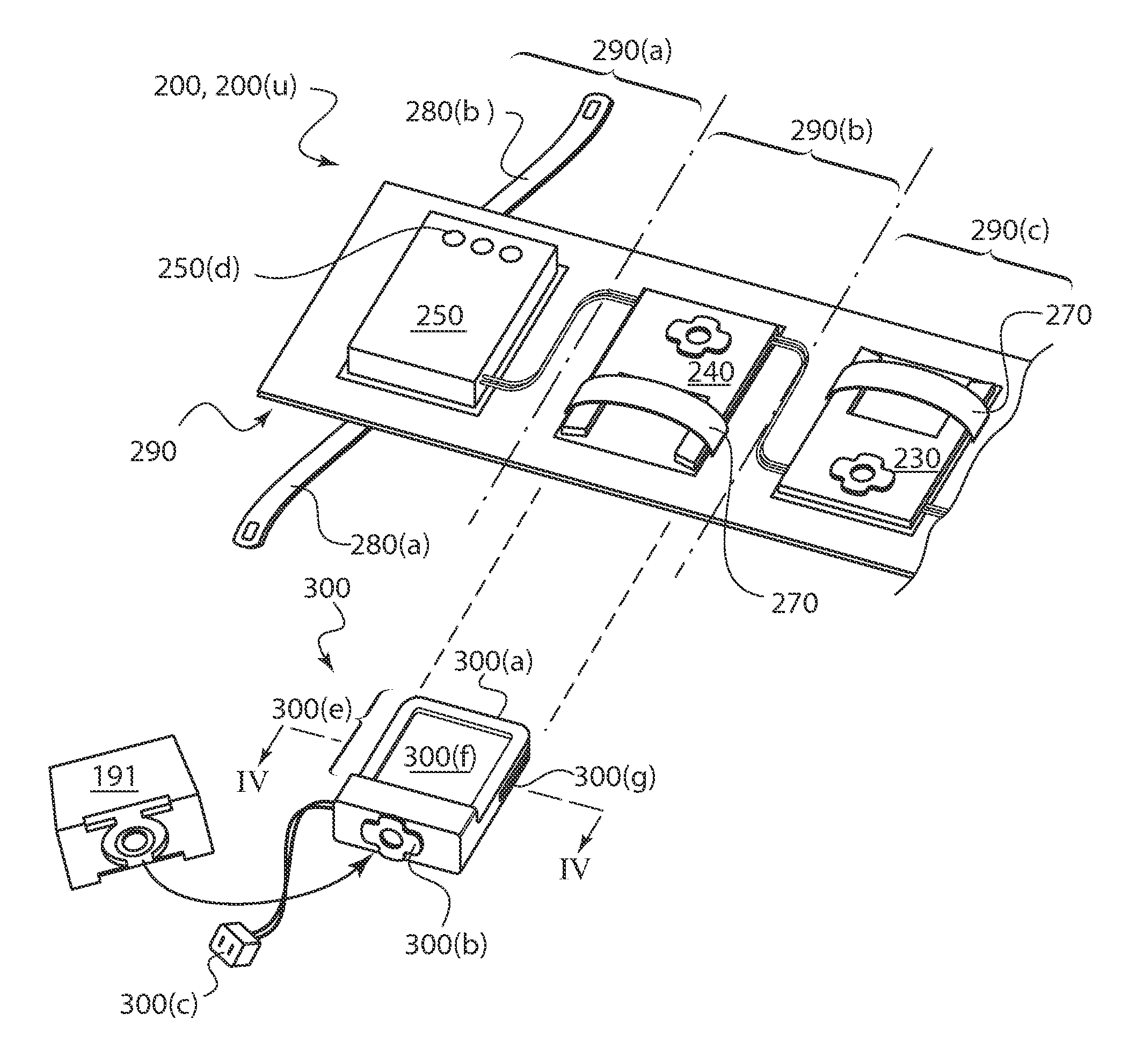

Adapter for foldable battery charger

ActiveUS20140132205A1Improve protectionIncreased durabilityBatteries circuit arrangementsElectric powerBattery chargeElectrical battery

An adapter for a portable battery charging apparatus having two or more battery charging interfaces on separate panels. Wires electrically couple the battery charging apparatuses to a charger unit. The wires are routed for flexibility to fold and unfold the panels. The adapter is configured to nest between two panels of the battery charging apparatus when the panels are stacked together in a compact folded state.

Owner:BREN TRONICS INC

Electro-optic reflective element assembly

ActiveUS20070153356A1Easy to assembleClearance can be providedMirrorsElongate light sourcesElectrical conductorElectrical connection

A rearview mirror assembly for a vehicle includes an electro-optic reflective element with an overhang region at an edge region of a first substrate that extends beyond a corresponding edge region of a second substrate. A transparent electrical conductor is disposed at a second surface of the first substrate and a mirror reflector is disposed at a third surface of the second substrate. The mirror reflector includes a tab portion that at least partially encompasses an edge dimension of the second substrate. A non-conductive seal is disposed between the first and second substrates and encompasses at least a portion of the mirror reflector and at least a portion of a non-conductive perimeter region of the third surface. A first electrical connector connects to the transparent electrical conductor via the overhang region and a second electrical connector is in electrical connection with the tab portion of the mirror reflector.

Owner:DONNELLY CORP

Equilibrium-point prosthetic and orthotic ankle-foot systems and devices

ActiveUS8597369B2Reduce and prevent likelihoodWeaken energyArtificial legsDiseasePhysical medicine and rehabilitation

The present invention relates to a system for use in rehabilitation and / or physical therapy for the treatment of injury or disease. The system can enable an amputee to proceed over any surface without overbalancing. In particular the system is self-adapting to adjust the torque moment depending upon the motion, the extent of inclination, and the surface topography.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

Replaceable ribbon supply and substrate cleaning apparatus

ActiveUS7934881B2Easy to insertInsert smoothlyInk ribbon cartridgesRecording apparatusDetentEngineering

A ribbon cartridge for a printer. The ribbon cartridge includes a frame that supports supply and take-up spools and that has one or more locating features to facilitate its insertion and positioning in a frame of a printer. For example, the ribbon cartridge frame may include a pair of detents defined approximately midway between the two spools to facilitate balanced insertion. The detents are slots with rounded ends that are configured to receive similarly shaped reference protrusions of the printer frame. The cartridge frame may also define a pocket for receiving an identification tag associated with the ribbon cartridge that ensures compatibility with the printer and passage of other information to the printer. In other embodiments, the ribbon cartridge may include a cleaning roller.

Owner:ZEBRA TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com