Patents

Literature

38results about How to "Reduce mechanical fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

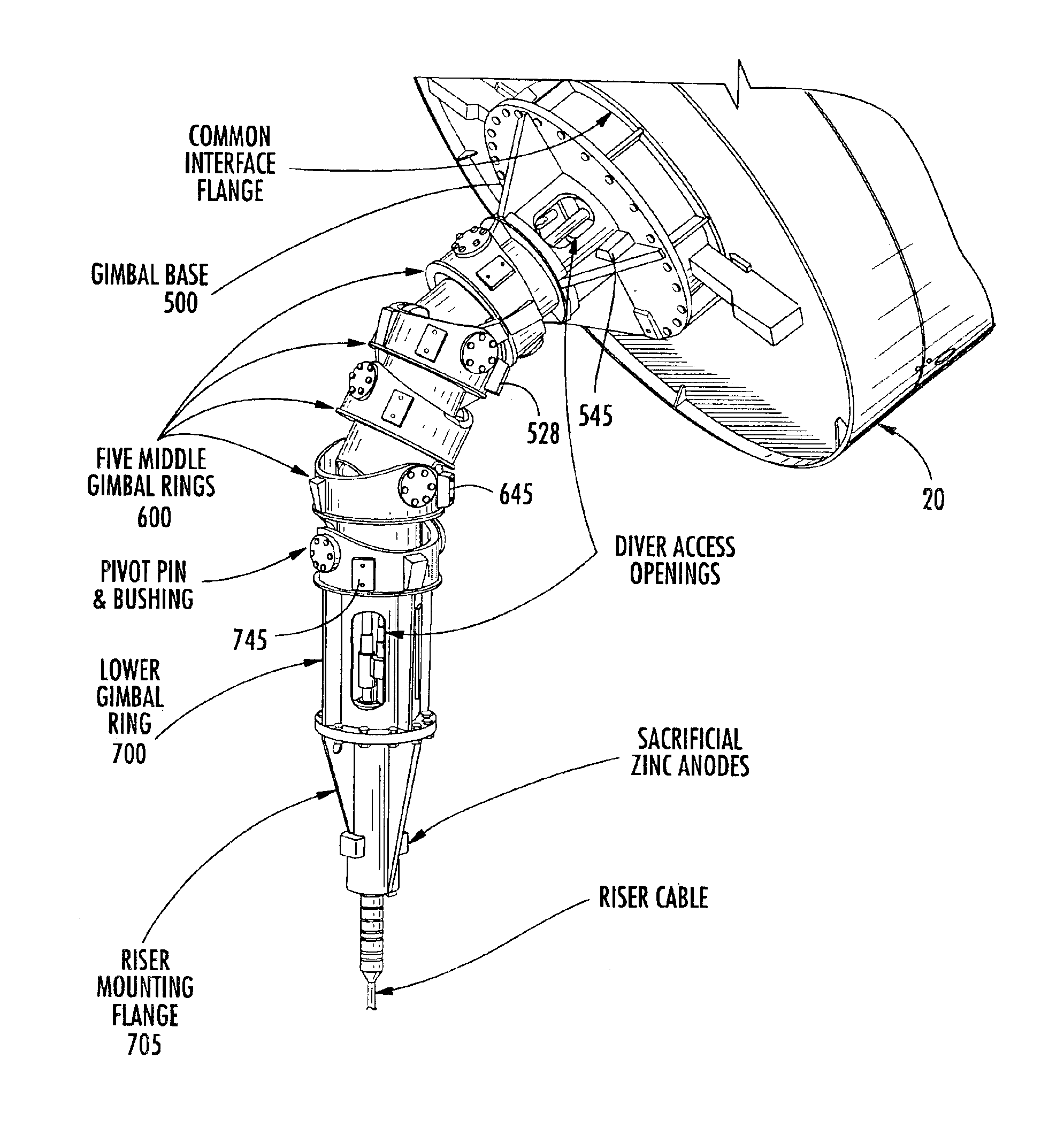

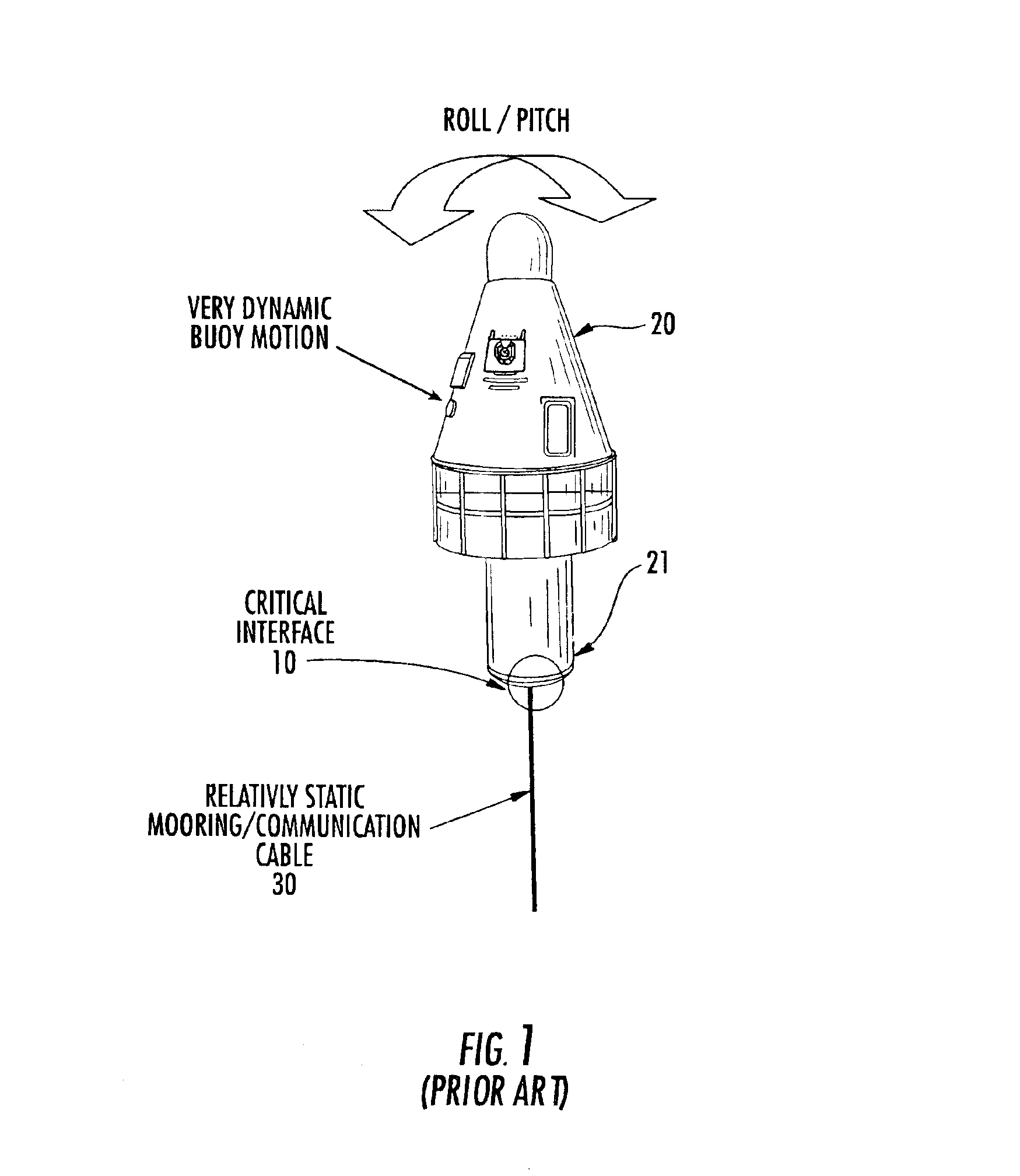

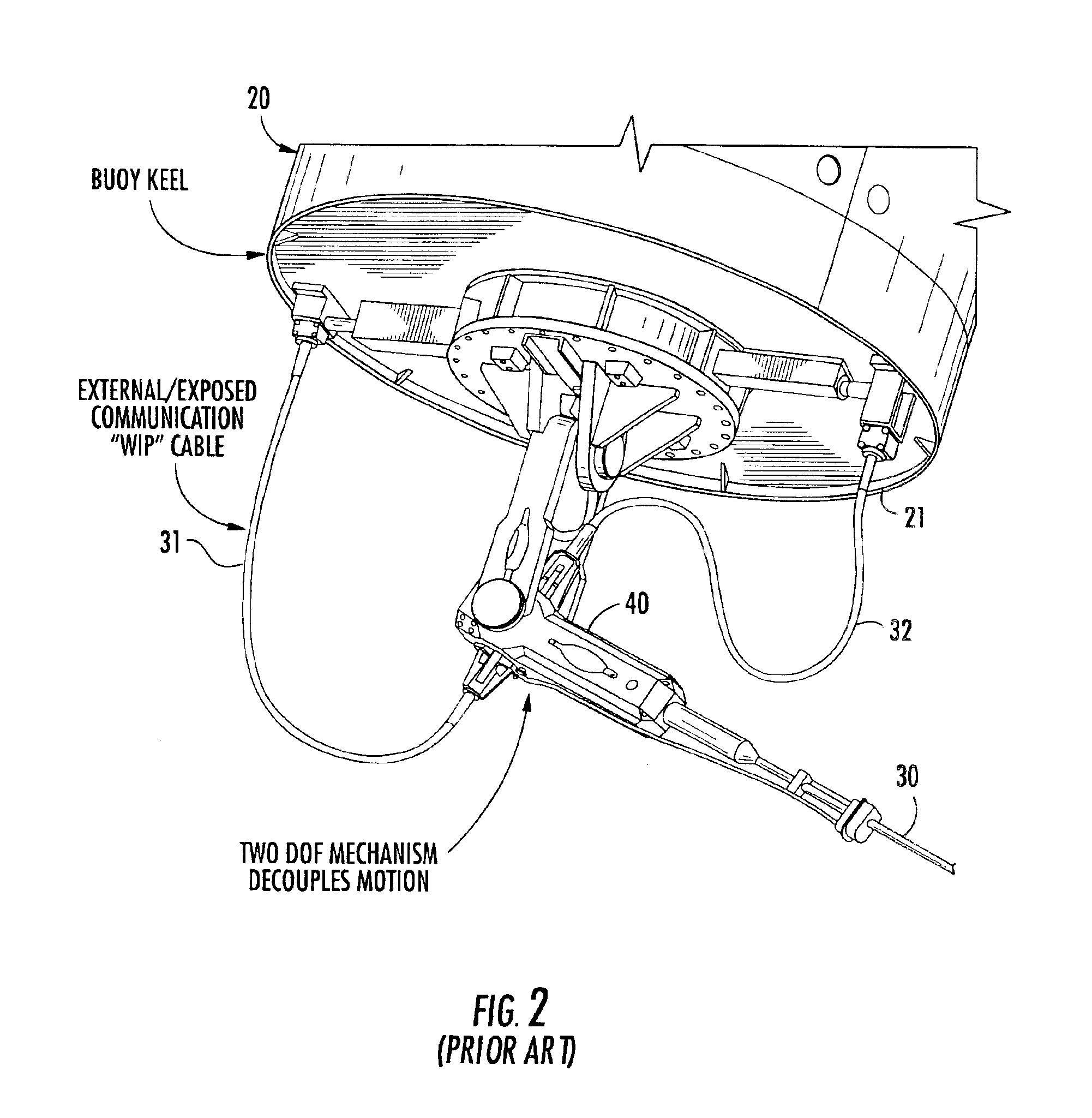

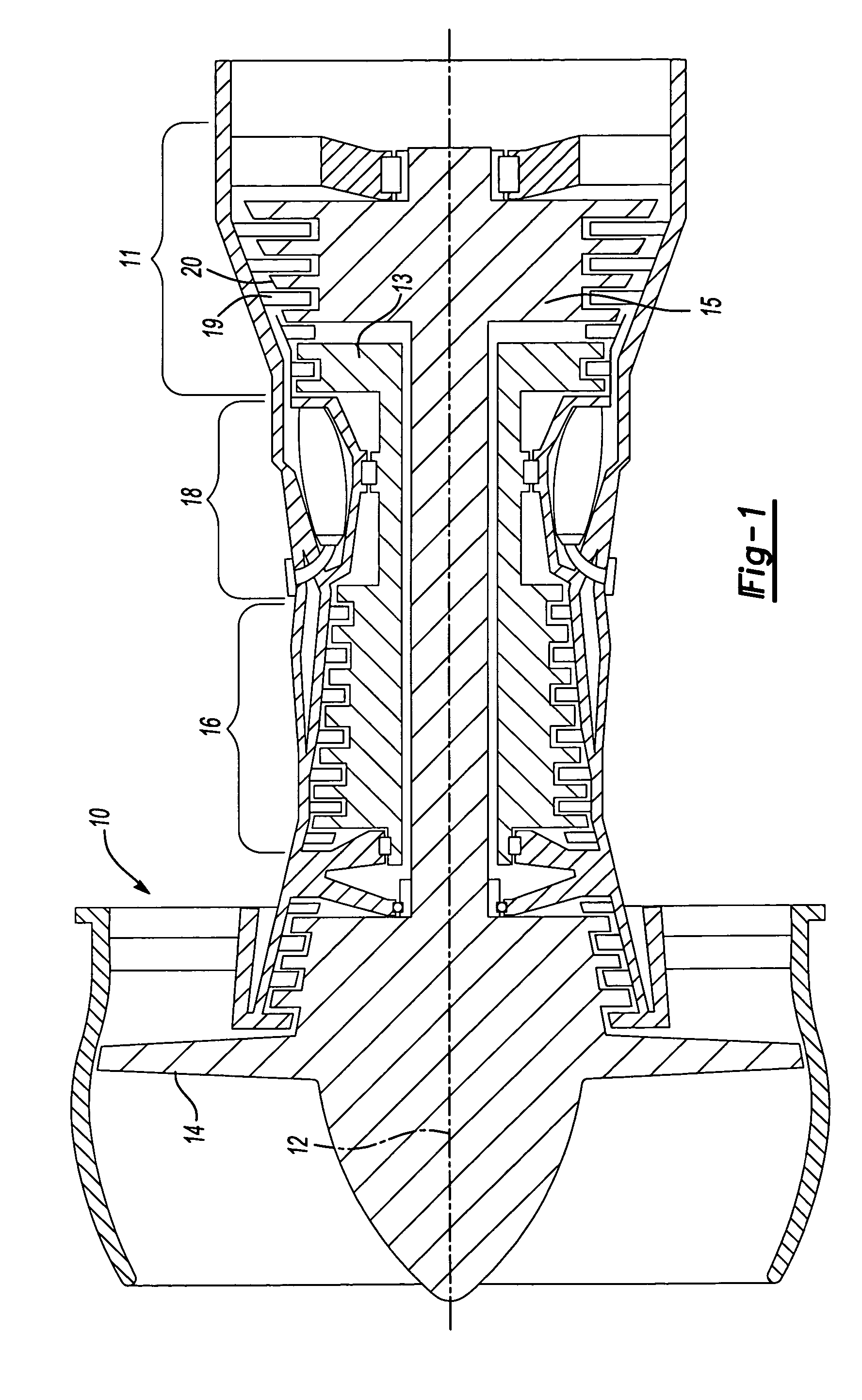

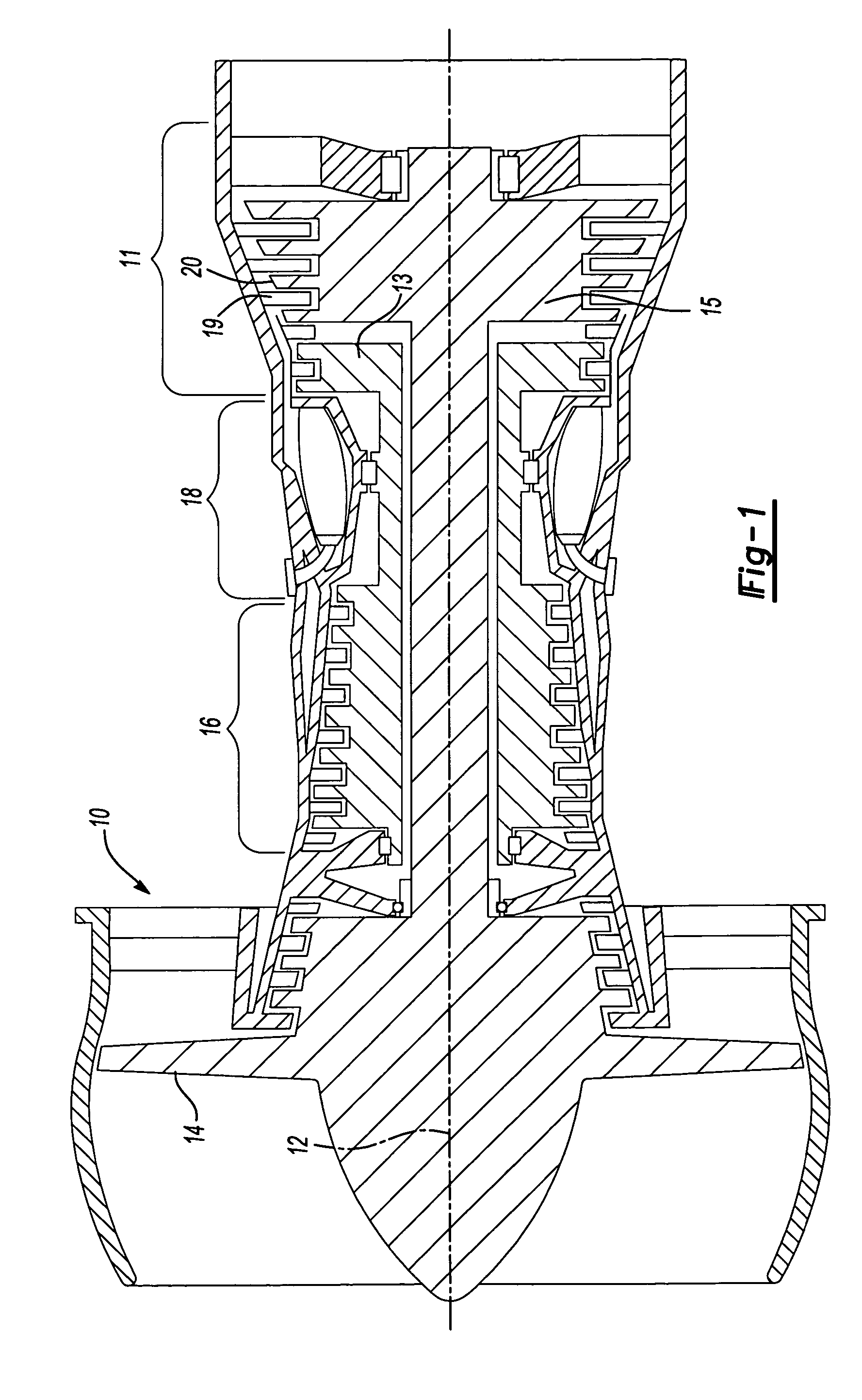

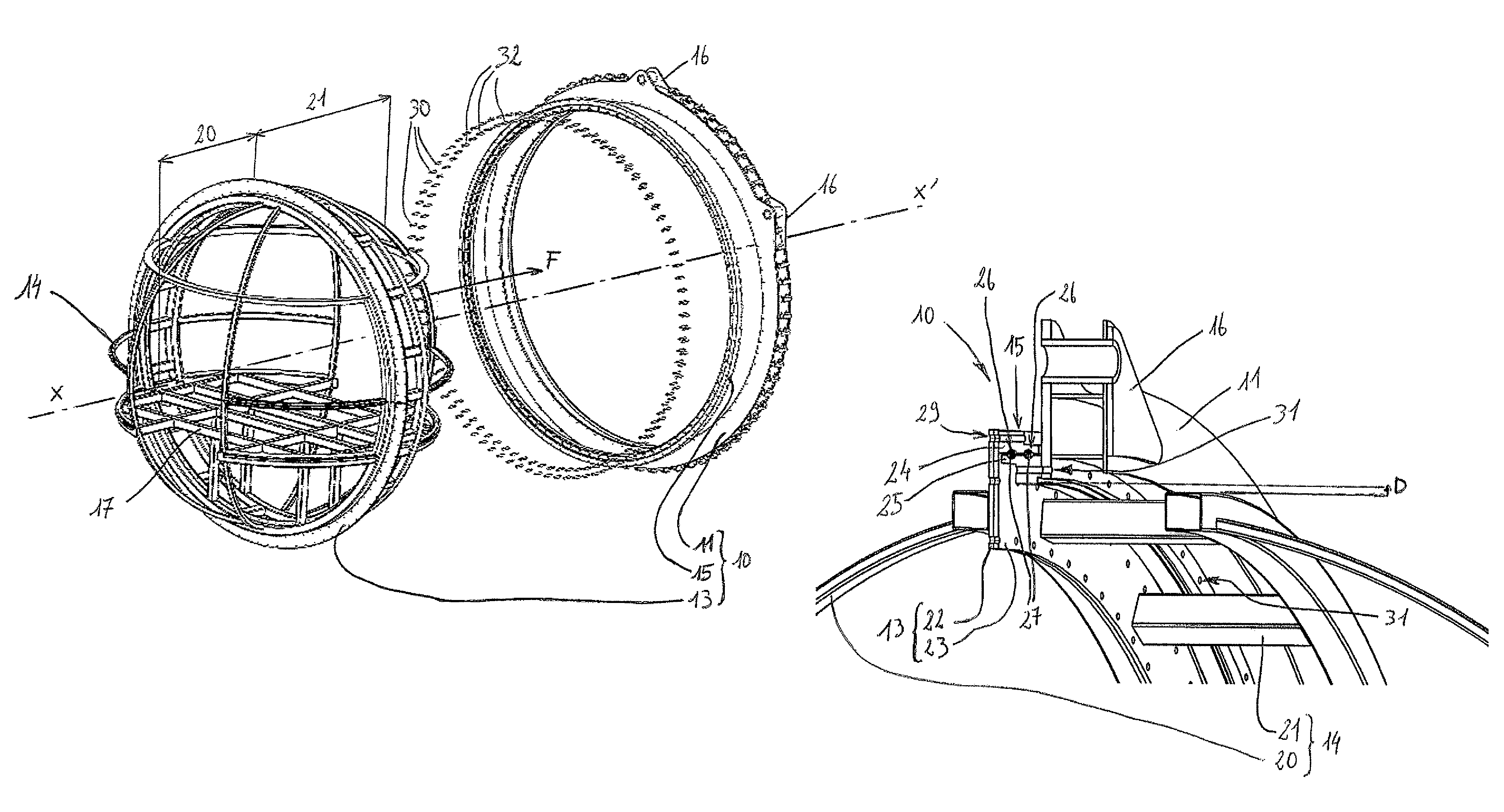

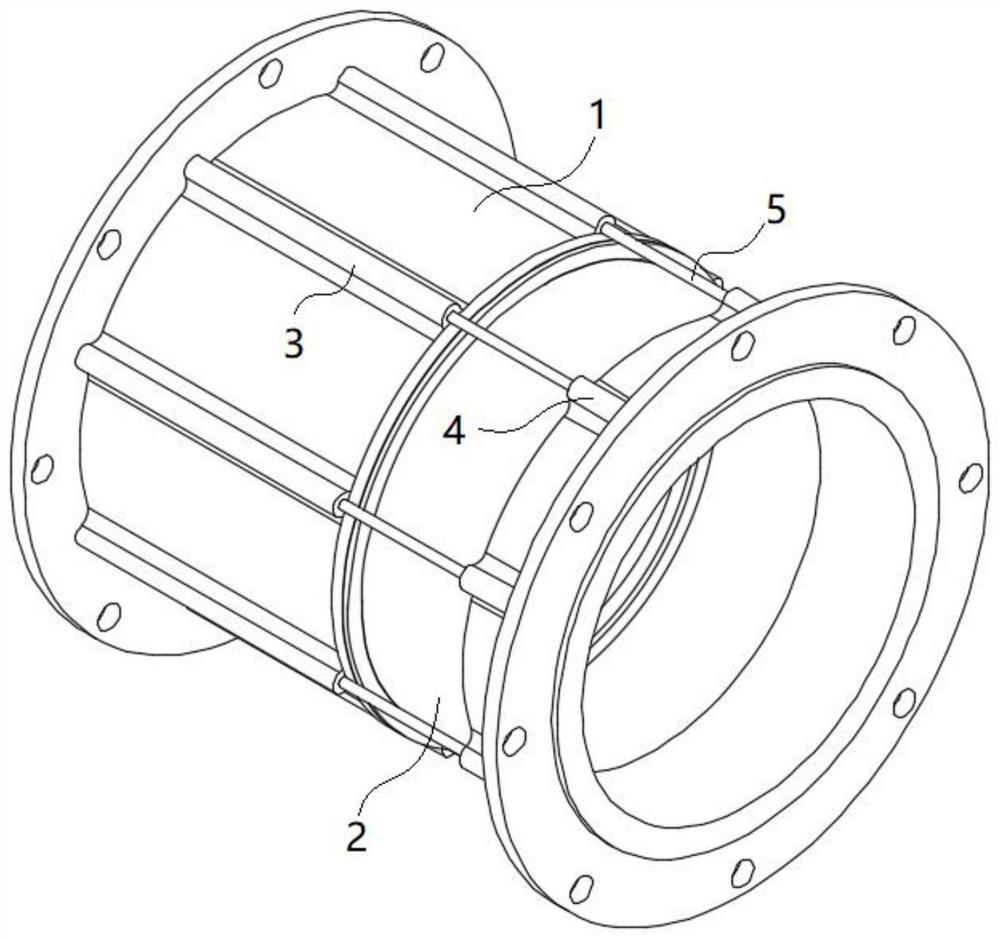

Multi-gimbal marine communication cable to ocean buoy transition interface

InactiveUS6848862B1Clearance can be providedReduce mechanical fatigueCommunication meansService pipe systemsTelecommunications linkCommunication link

A multi-gimbal configured transition protectively interfaces a mooring and communication cable to a communication ocean buoy. The transition interface contains a segmented, flexible sheath formed of a plurality of pivotally interconnected gimbal rings having mutually adjacent interior apertures through which one or more communication link members pass. Successive gimbal rings are orthogonally pivotally interconnected with one another so as to make the flexible sheath flexible in three dimensions. Upper ends of one or more communication link members are connectable with a communication cable connection fixture of the buoy. Lower ends of the communication link members are connectable to communication cable terminal connectors of a terminal end of the mooring cable.

Owner:HARRIS CORP

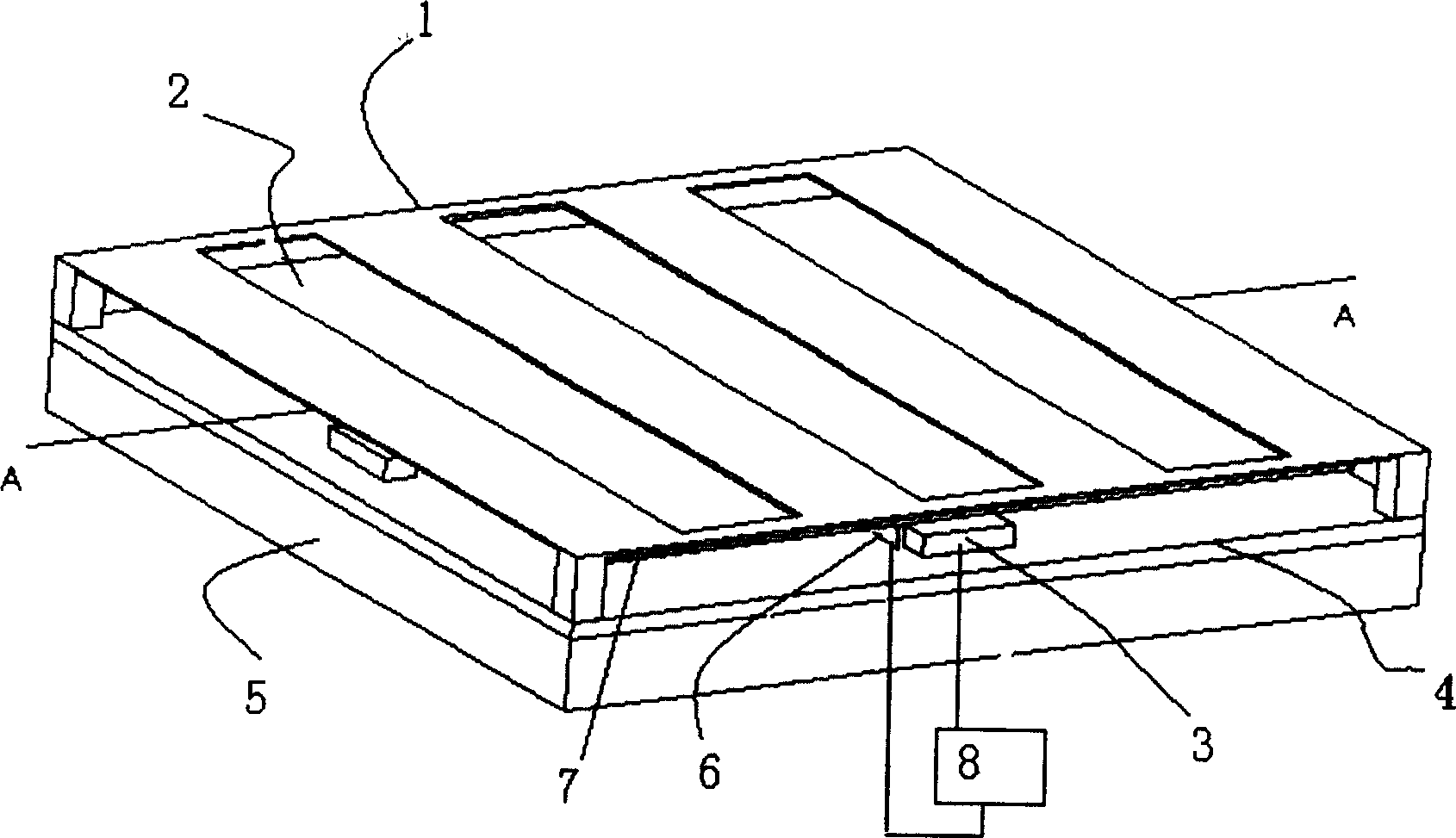

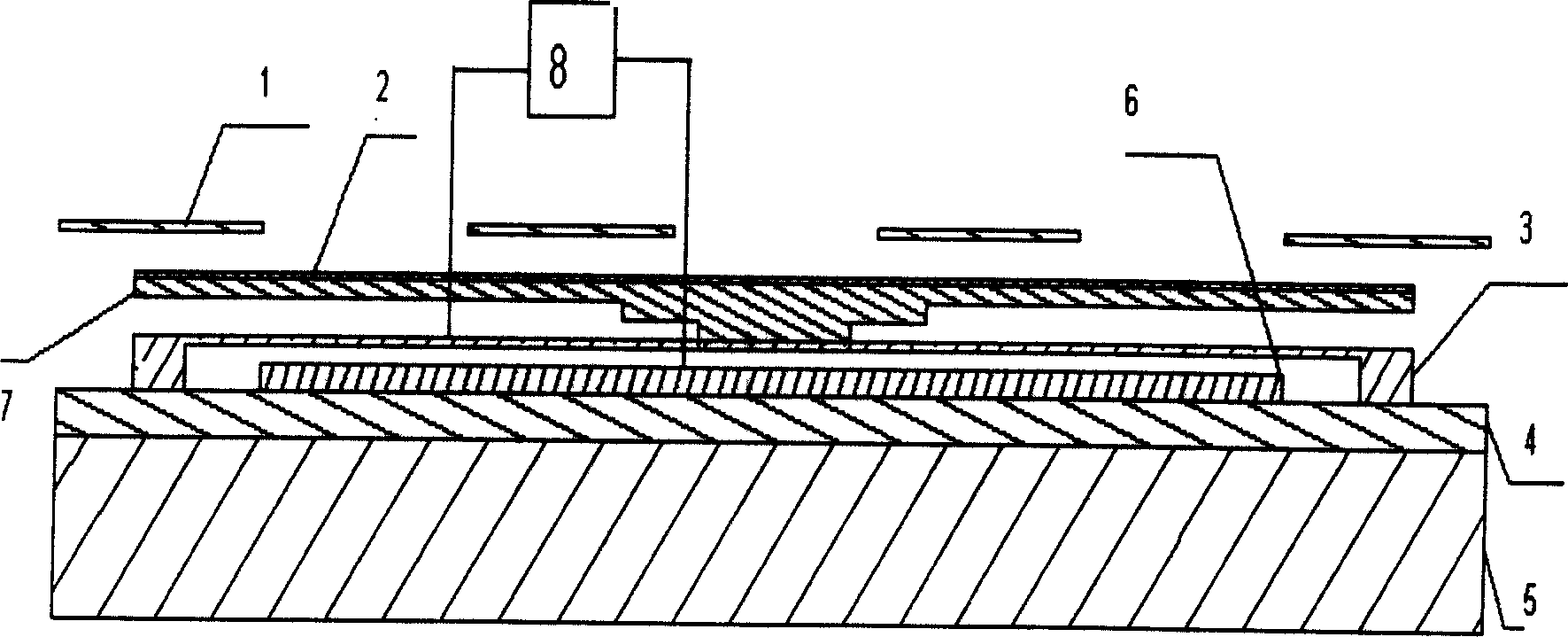

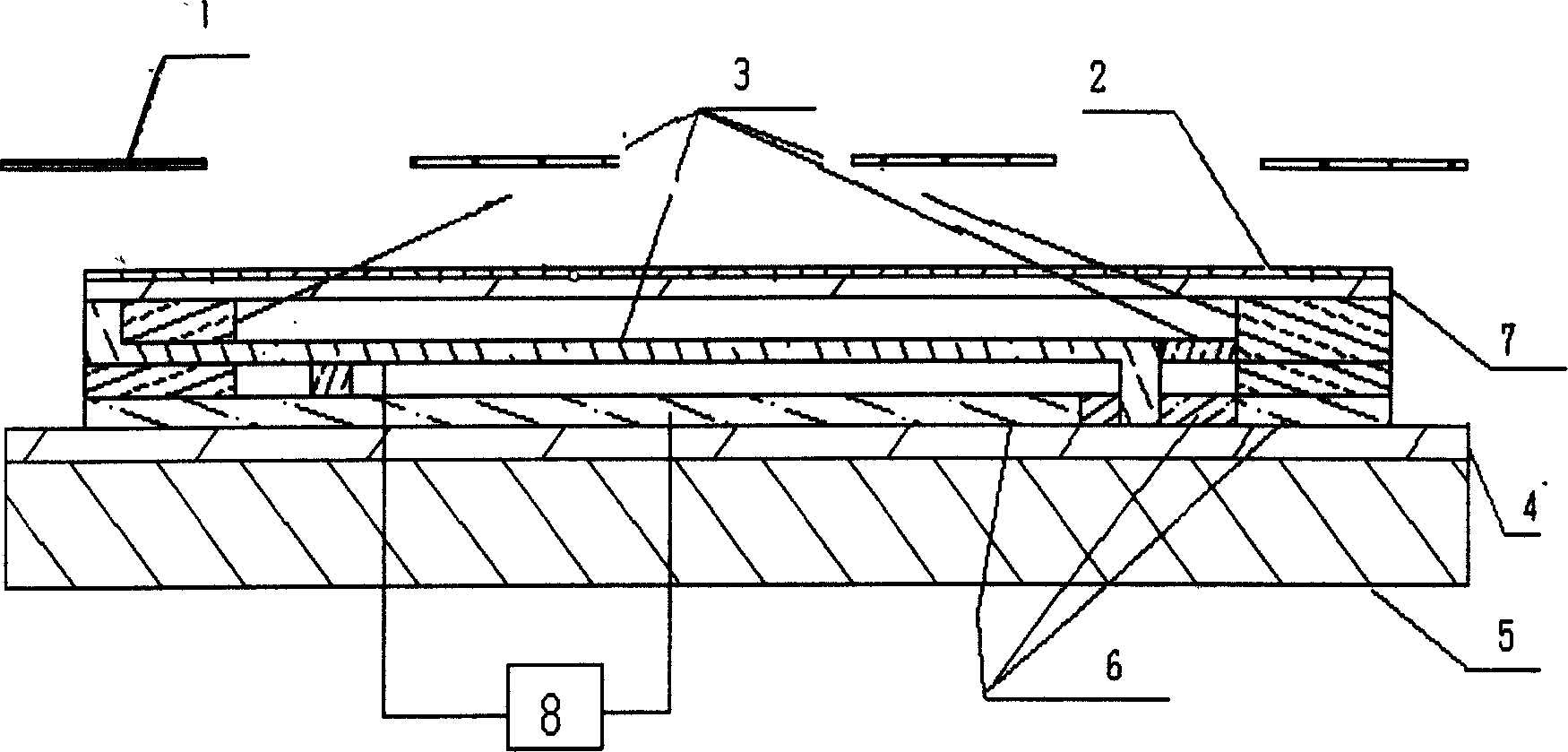

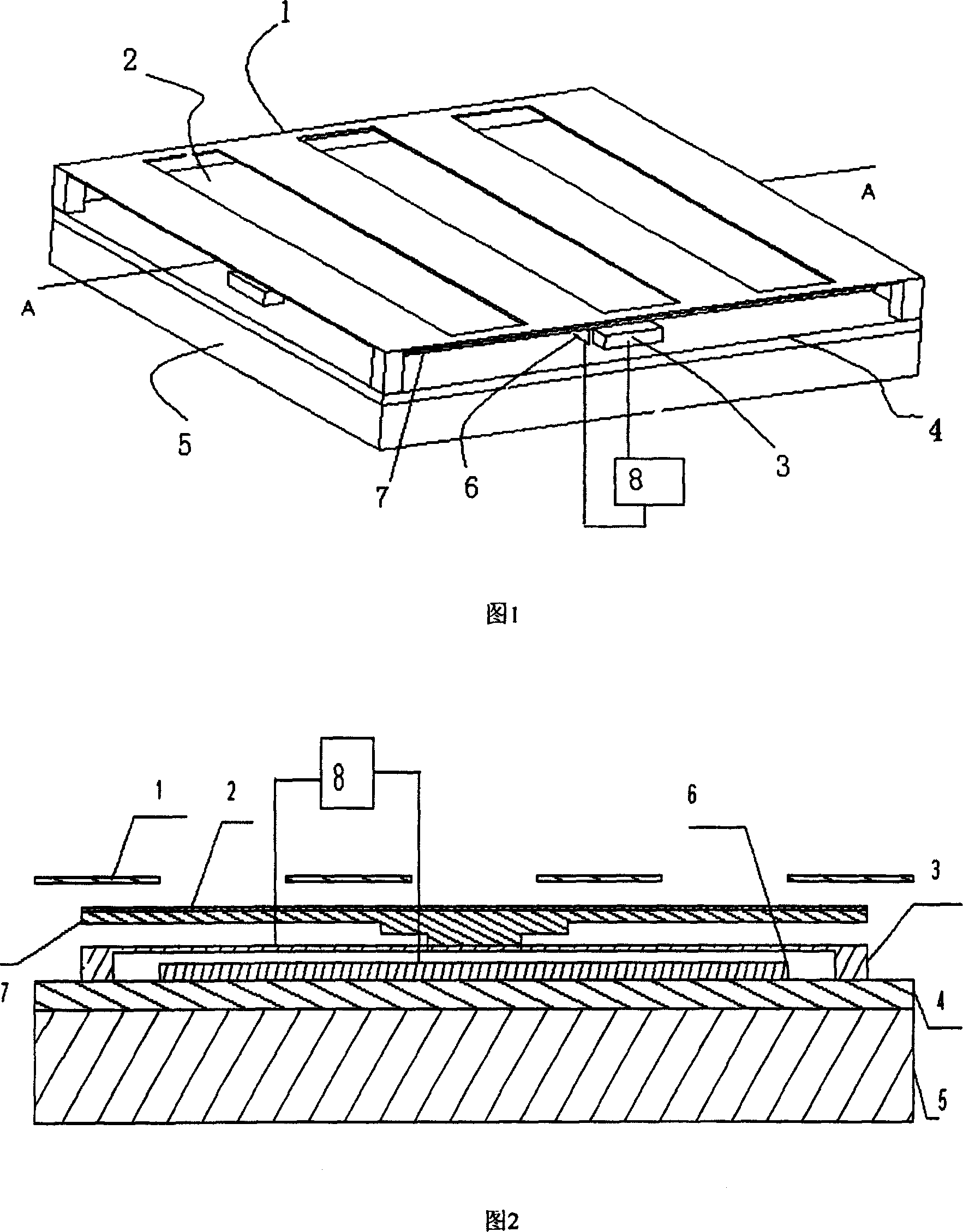

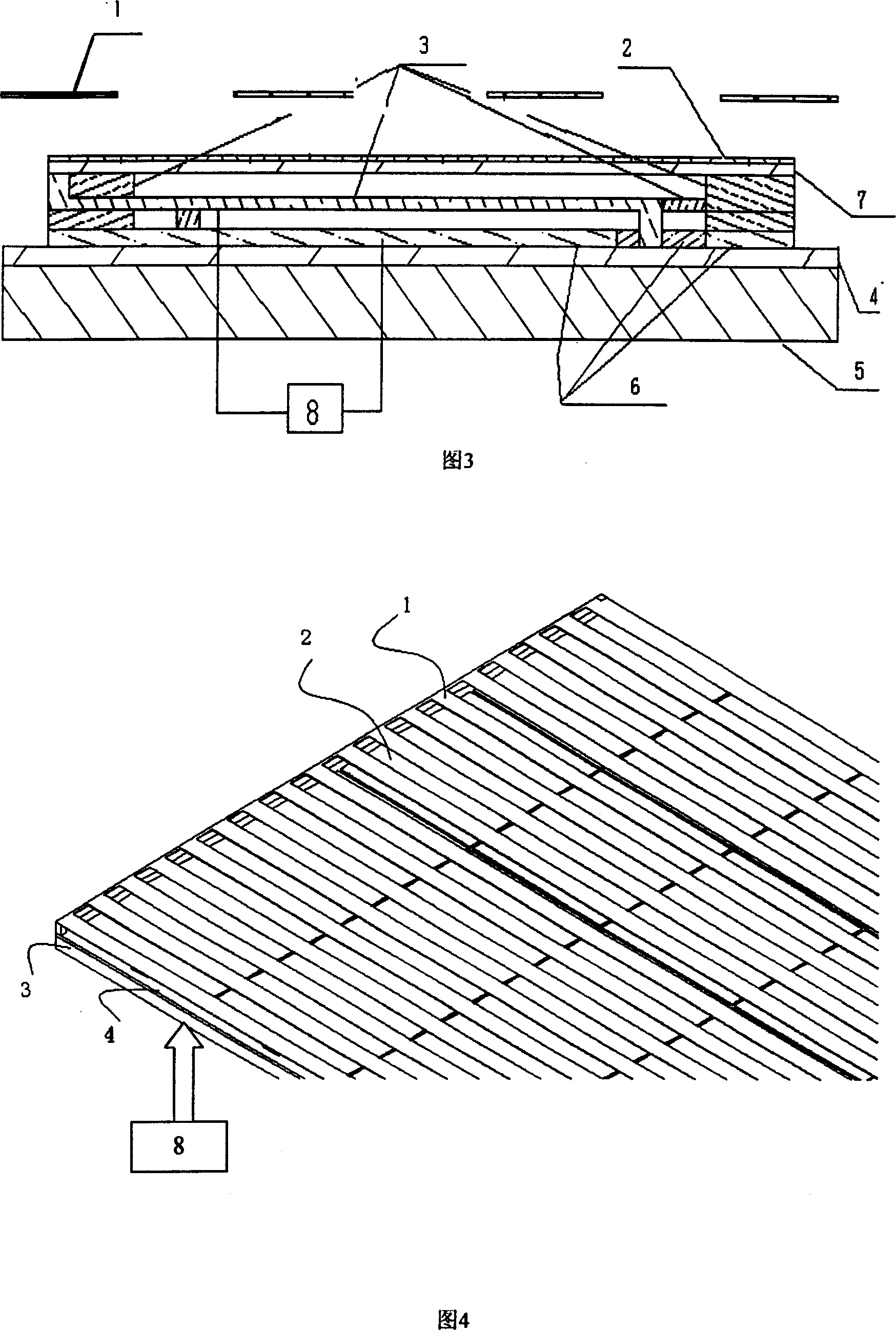

Raster optical modulator with translational reflective mirror and array thereof

InactiveCN1645183AReduce gapImprove optical diffraction efficiencyOptical elementsGratingInsulation layer

A light modulator consists of base, insulation layer, electrode layer, movable flat plate, fixed grating, and cover. It is featured as locating flat plate in the first plane to concentrate light intensity on zero class of diffraction as on voltage and locating it in the second plane to concentrate light intensity on top class of diffraction by driving it to move vertically with voltage in order to realize various modulation for incoming beam for providing different energy distribution of diffraction light.

Owner:CHONGQING UNIV

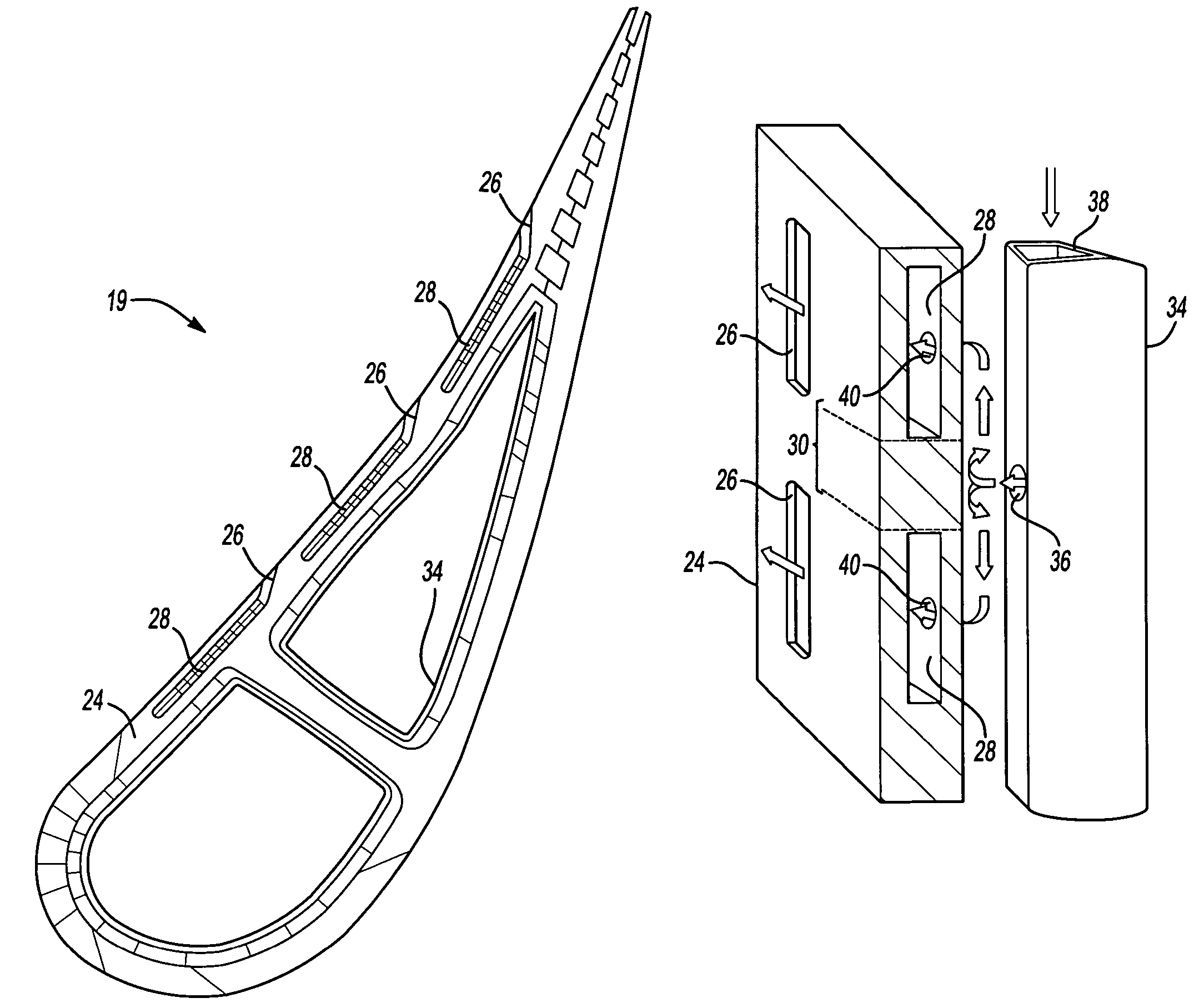

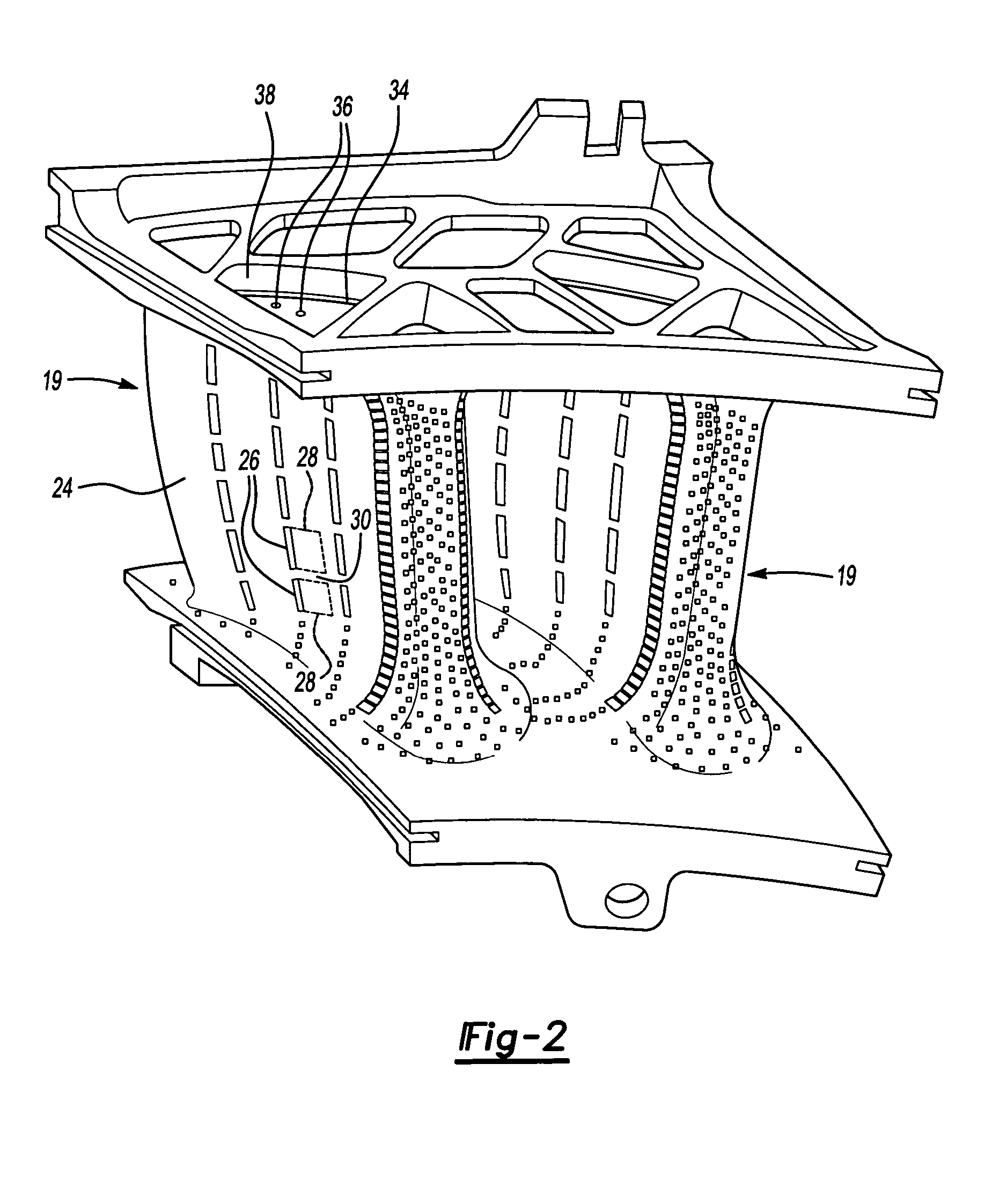

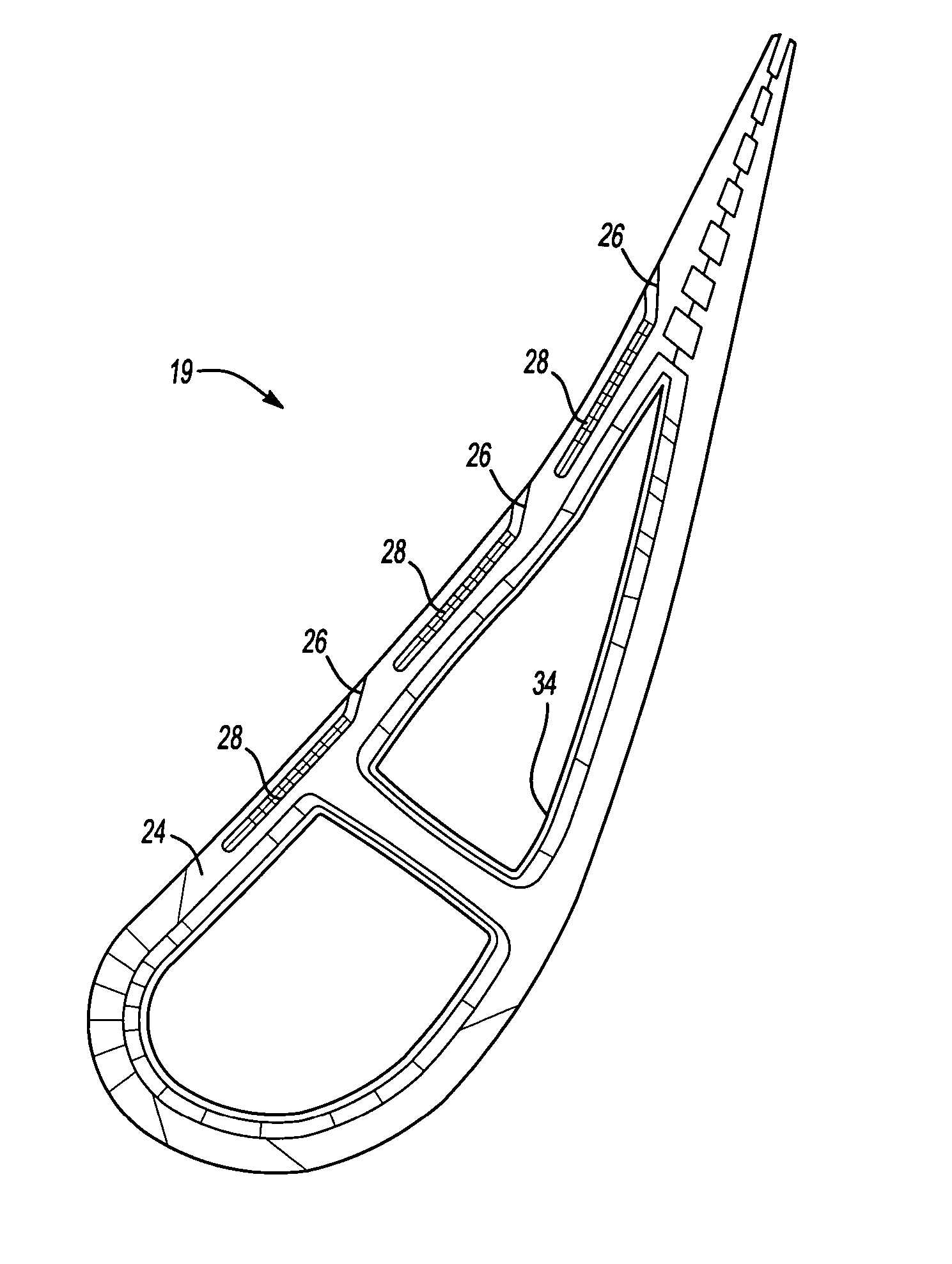

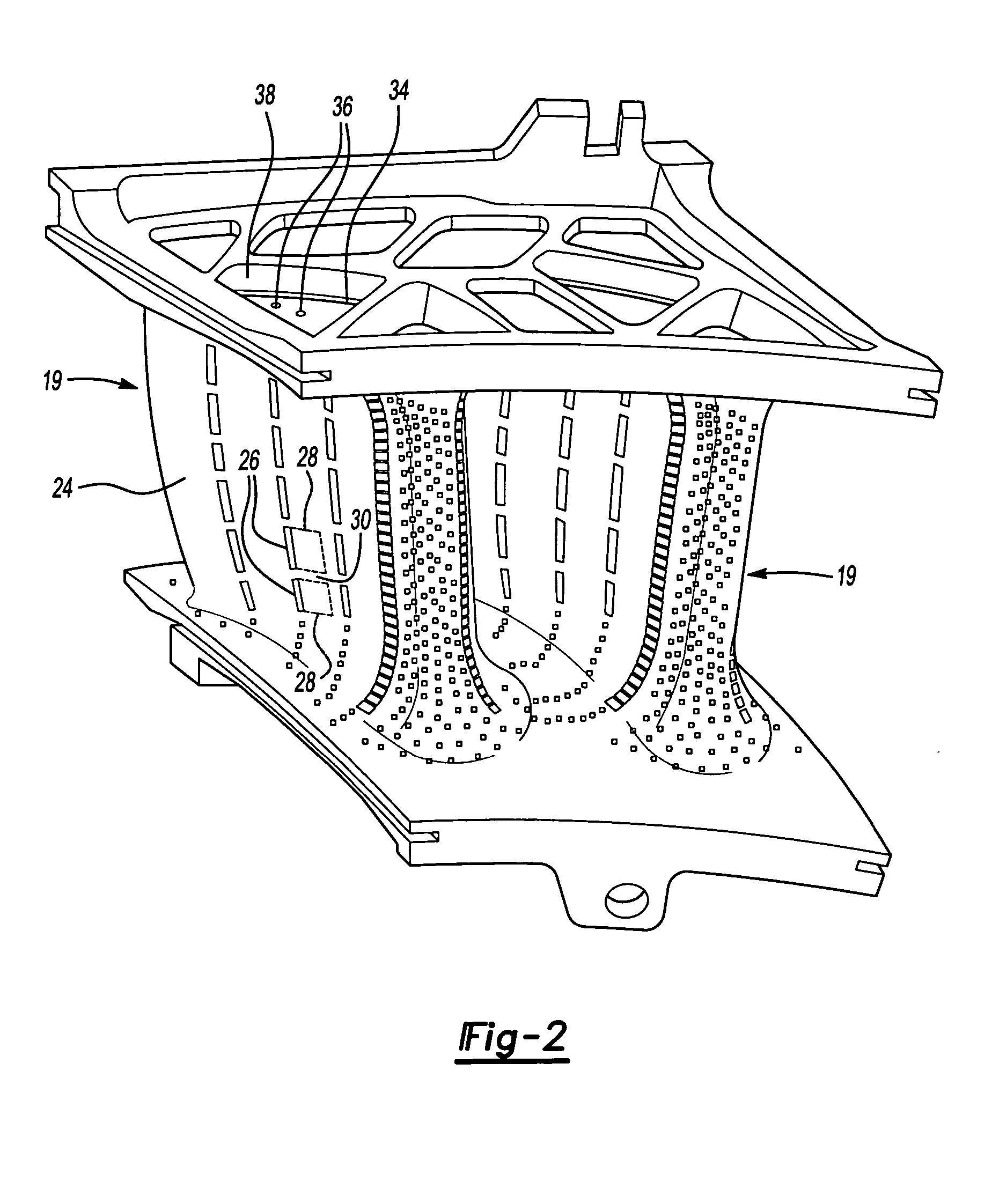

Turbine airfoil with improved cooling

ActiveUS7600966B2Improve cooling effectIncrease temperaturePump componentsEngine fuctionsTurbineCooling fluid

A turbine airfoil includes an outer wall and a plurality of cooling passages or minicores formed in the outer wall. A web separates each adjacent pair of the minicores. In order to provide more effective, even cooling of the airfoil, a baffle inside the airfoil includes a plurality of outlets aligned with the webs. The fluid outlets direct the cooling fluid directly onto the web. The cooling fluid then flows through the minicores and out through exits in the minicores.

Owner:RTX CORP +1

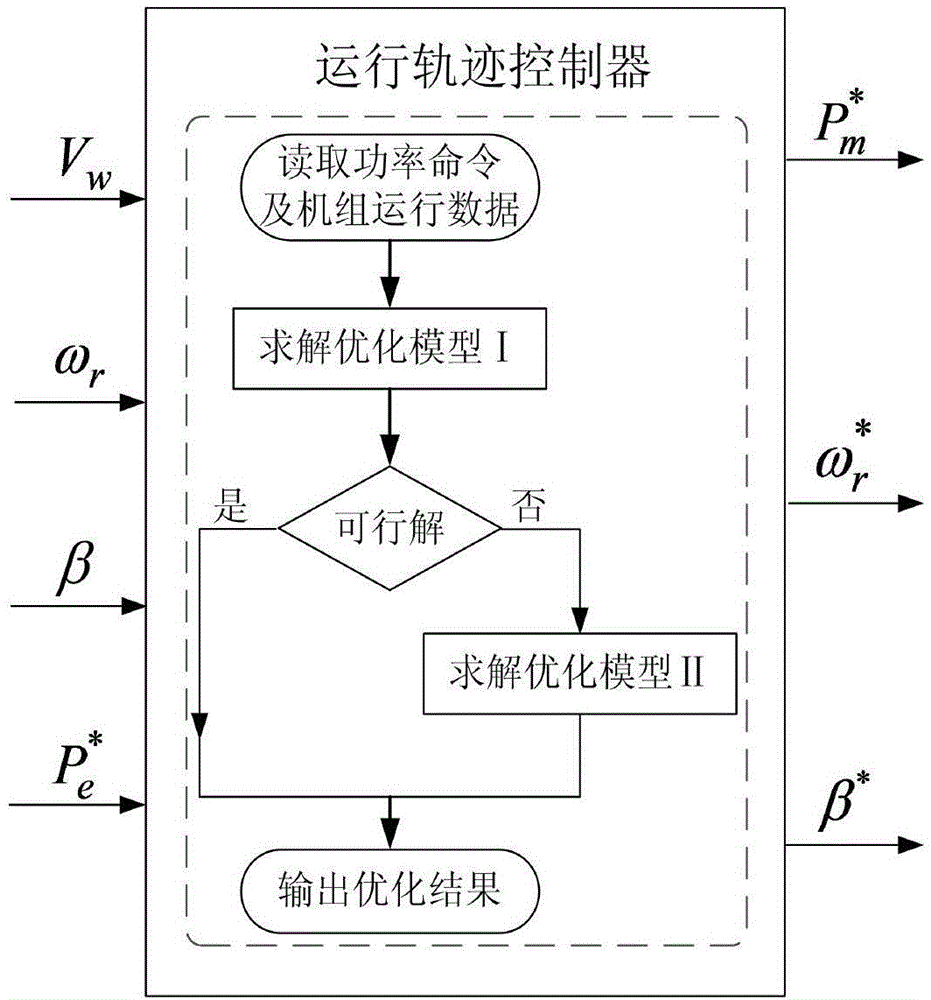

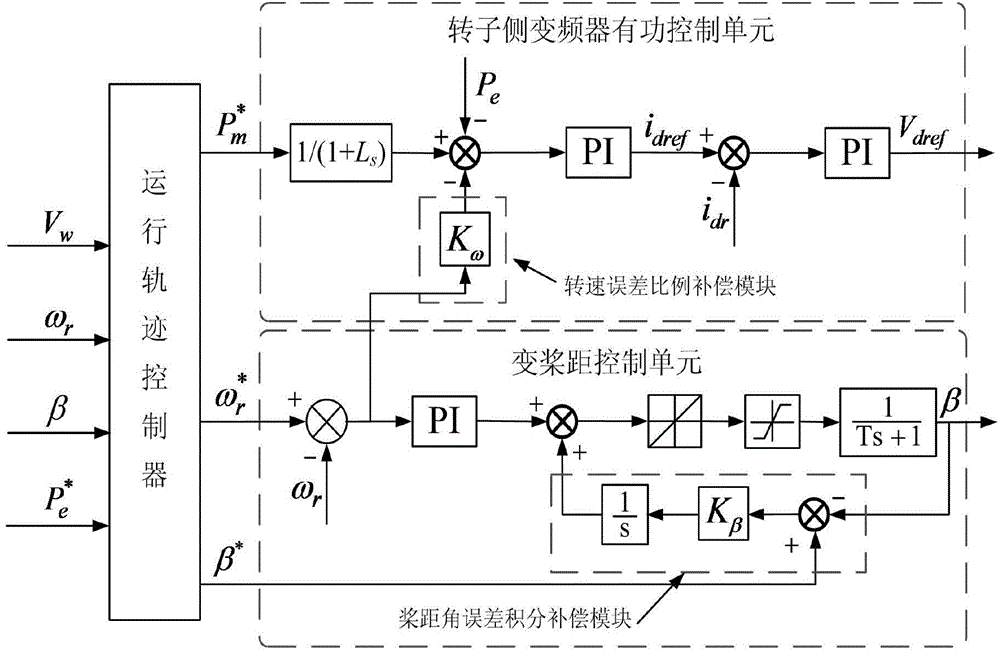

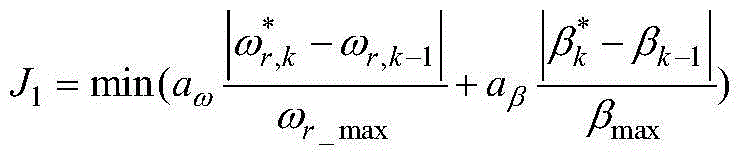

Control method for active power output of doubly-fed wind turbine generator on electricity limitation and wind curtailment working condition

InactiveCN104578181AExtended service lifeOptimal Control StrategySingle network parallel feeding arrangementsWind energy generationElectricityOperating point

The invention relates to a control method for active power output of a doubly-fed wind turbine generator on an electricity limitation and wind curtailment working condition. According to the control method, a generator operating track controller is established, and an operating point transfer track optimization model with the minimum overall adjustment quantity of the rotation speed and the pitch angle of the generator as an objective function and with active balance, the stability of operating points and the like of the generator as constraint conditions is solved in real time so that an optimal transfer track of the generator can be obtained; furthermore, traditional control strategies of a variable pitch system and a rotor-side frequency converter are improved so that the active power of the generator can be adjusted and controlled along the optimal transfer track of the operating points, and an electricity limitation and wind curtailment command of a power grid dispatching department can be completed. The control method is applicable to active power control of the doubly-fed wind turbine generator on the electricity limitation and wind curtailment working condition, the wind turbine generator can accurately execute the electricity limitation and wind curtailment command of the power grid dispatching department, the overall adjustment quantity of the rotation speed and the pitch angle of the generator can be reduced in the operating process, the service life of the generator can be prolonged, and the method has important engineering application value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

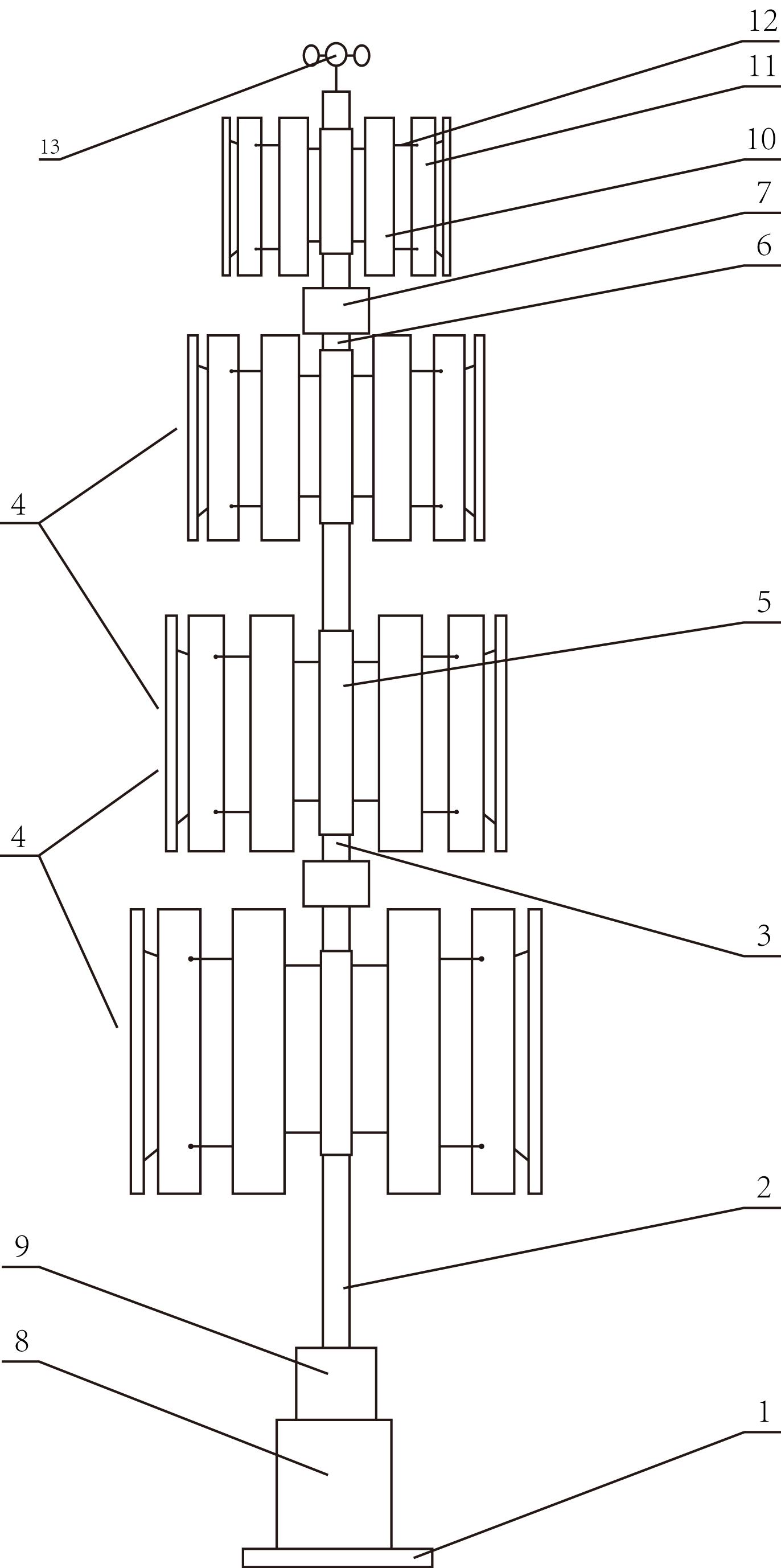

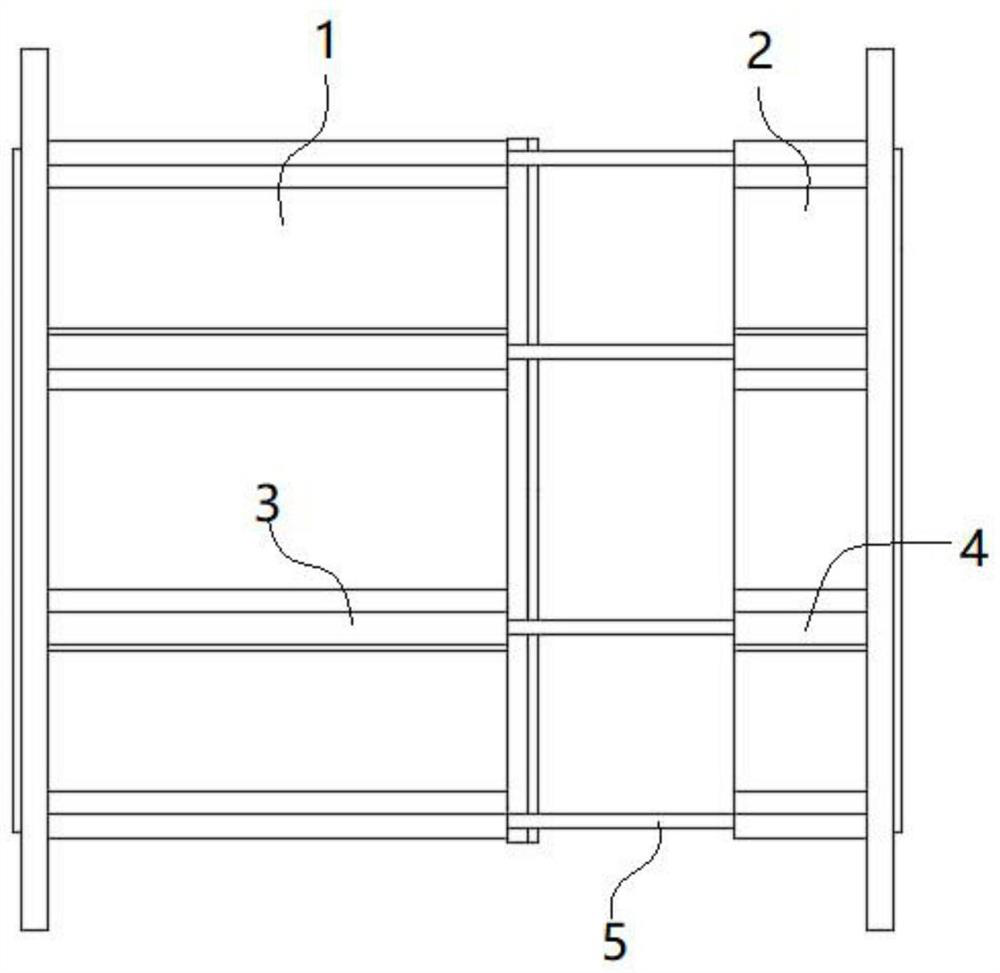

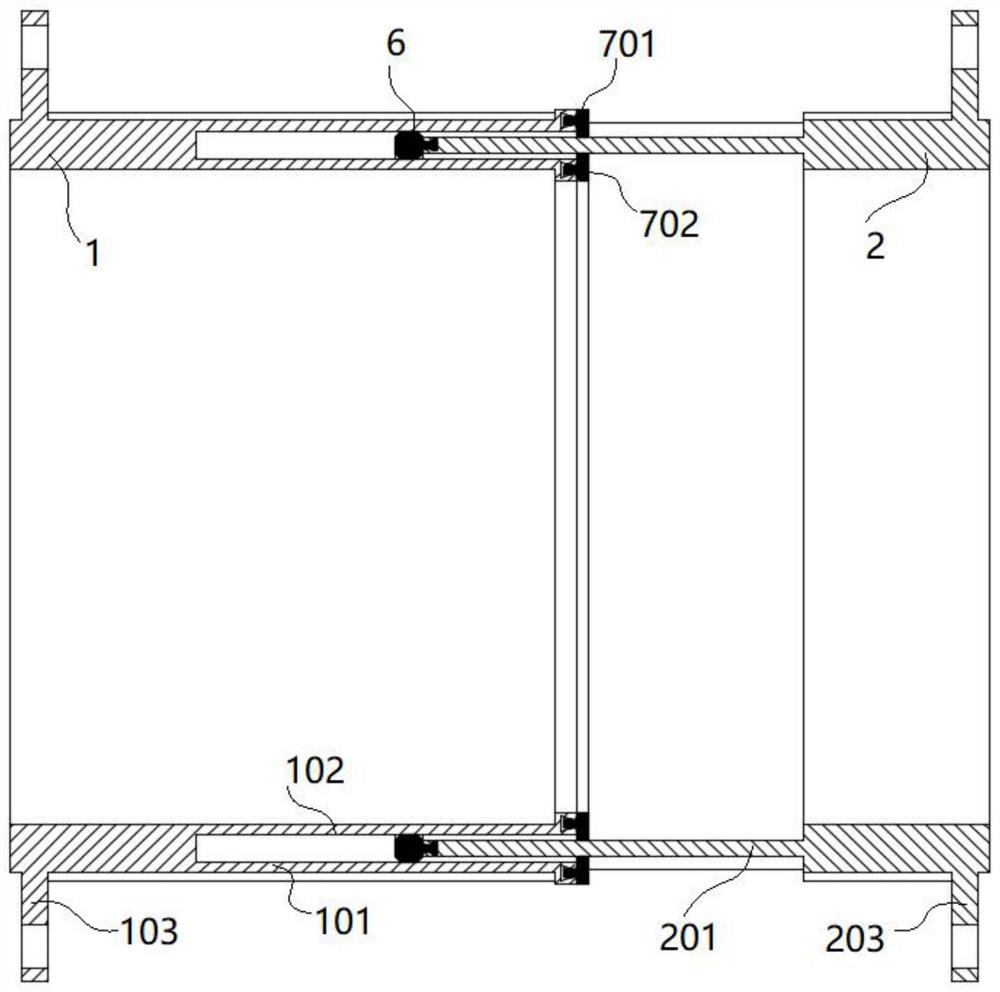

Vertical shaft multi-state dual-blade bidirectional rotation wind driven power generation device and power generation control method thereof

InactiveCN102606411AIncrease wind areaThe flexibility of speed adjustment is convenientWind motor controlWind energy with electric storageAutomotive engineeringWind force

The invention discloses a vertical shaft multi-state dual-blade bidirectional rotation wind driven power generation device which comprises a tower column, wherein an even number of wind wheels are arranged on the tower column; two wind wheels form a group, and a power generation module consisting of a power generator is arranged between the two wind wheels in one group; each wind wheel comprises a wind wheel hub arranged on the tower column and plurality of main blades circumferentially and uniformly arranged on the wind wheel hub through a supporting rod; in each power generation module, the wind wheel hub of one wind wheel is connected with a power generator rotor, and the wind wheel hub of the other wind wheel is connected with a power generator stator; an auxiliary blade is arranged on one side of each main blade; and the auxiliary blades are connected with wind wheel hubs through auxiliary blade angle adjustment rods. Each power generator body and each stator which are integrated rotate around each rotor along opposite directions. Therefore, the rotating speed of each power generator is high, so that the output efficiency is high, and the power generation amount of the unit volume of each wind wheel is increased.

Owner:李新民

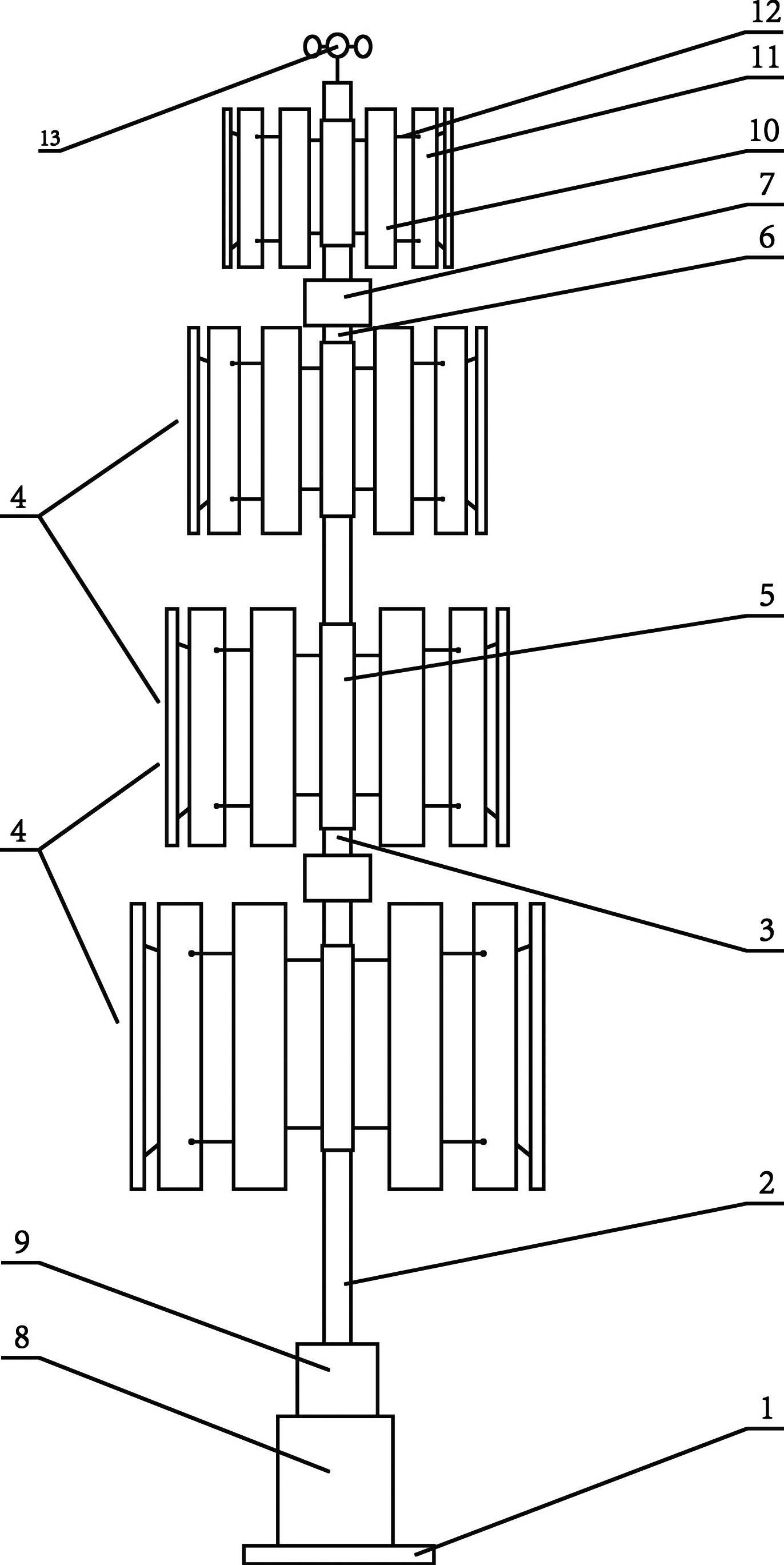

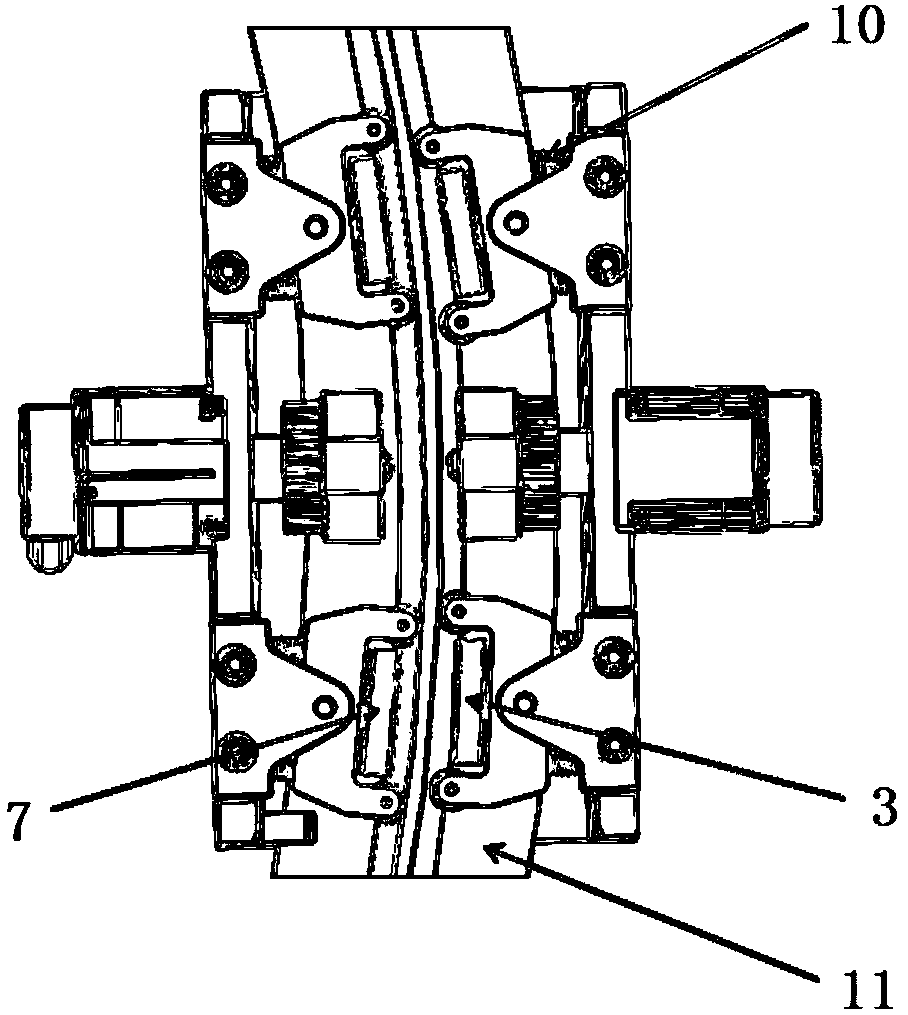

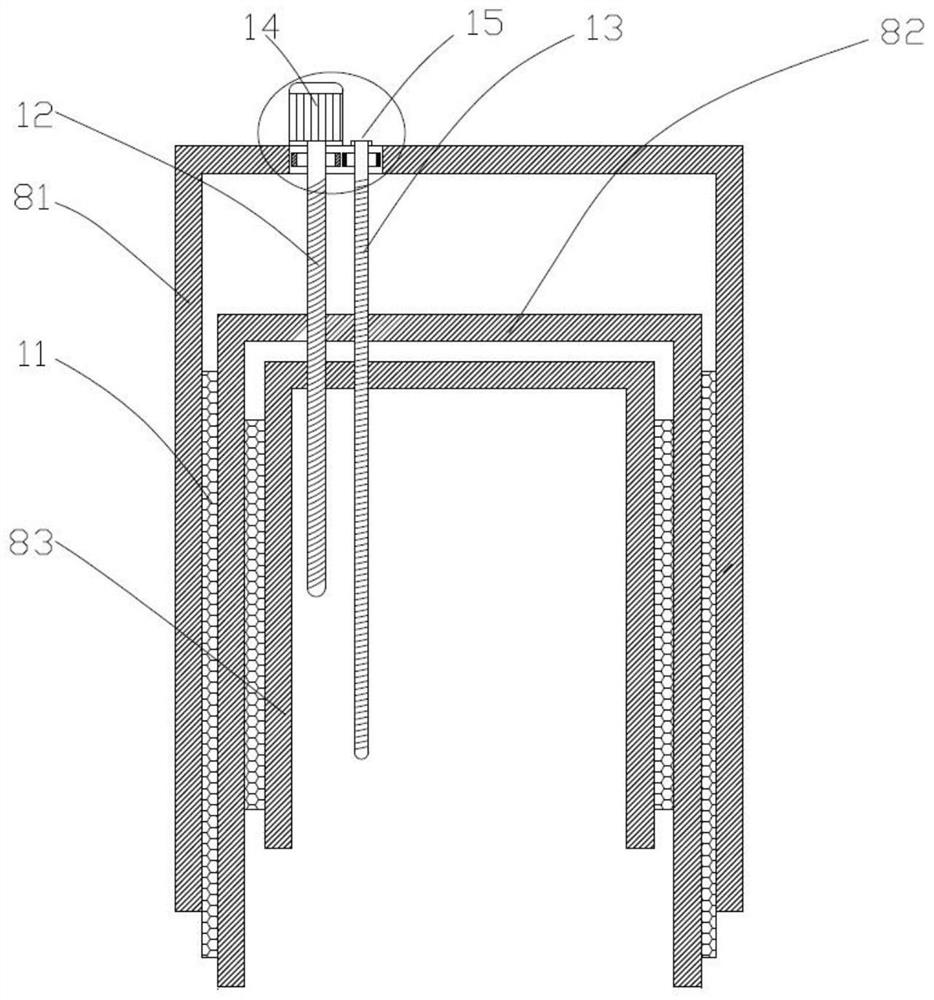

Hanging rail robot slope climbing device capable of realizing small-radius turning

The invention discloses a hanging rail robot slope climbing device capable of realizing small-radius turning. The hanging rail robot slope climbing device comprises a rolling wheel, a guide wheel, a slope climbing damping spring, a turning damping spring, an external framework and a guide wheel fixing support frame, wherein the rolling wheel is connected with a transmission shaft; the guide wheelis used for fixing the position of the whole device on a guide rail; the slope climbing damping spring is connected with the guide wheel fixing support frame and the external framework so as to maintain the vertical relative position of the fixed support frame and the guide rail; the turning damping spring is connected with the guide wheel fixing support frame and the external framework so as to maintain the horizontal relative position of the fixed support frame and the guide rail; the hanging rail robot slope climbing device also comprises a gear; the gear is arranged at the transmission shaft of the rolling wheel; the transmission shaft passes through the external framework. A spring turning clamping mechanism is used, so that the stability can be maintained during the turning and the linear walking of the mechanism.

Owner:山东金惠新达智能制造科技有限公司

Turbine airfoil with improved cooling

ActiveUS20070166161A1Low overall thermal gradientReduce mechanical fatiguePump componentsEngine fuctionsCooling channelCooling fluid

A turbine airfoil includes an outer wall and a plurality of cooling passages or minicores formed in the outer wall. A web separates each adjacent pair of the minicores. In order to provide more effective, even cooling of the airfoil, a baffle inside the airfoil includes a plurality of outlets aligned with the webs. The fluid outlets direct the cooling fluid directly onto the web. The cooling fluid then flows through the minicores and out through exits in the minicores.

Owner:RAYTHEON TECH CORP +1

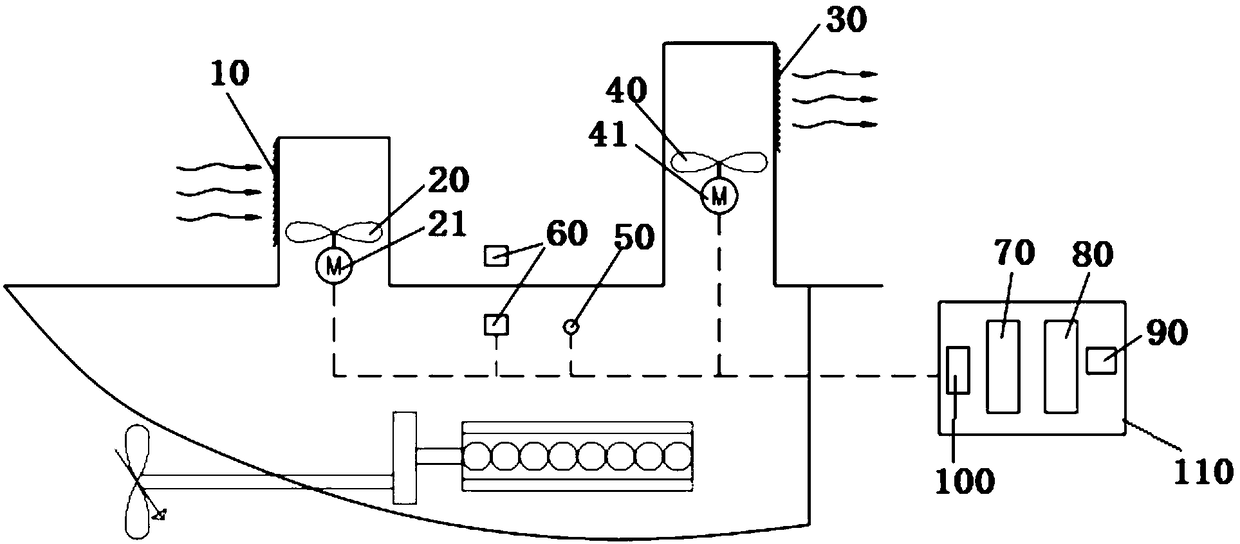

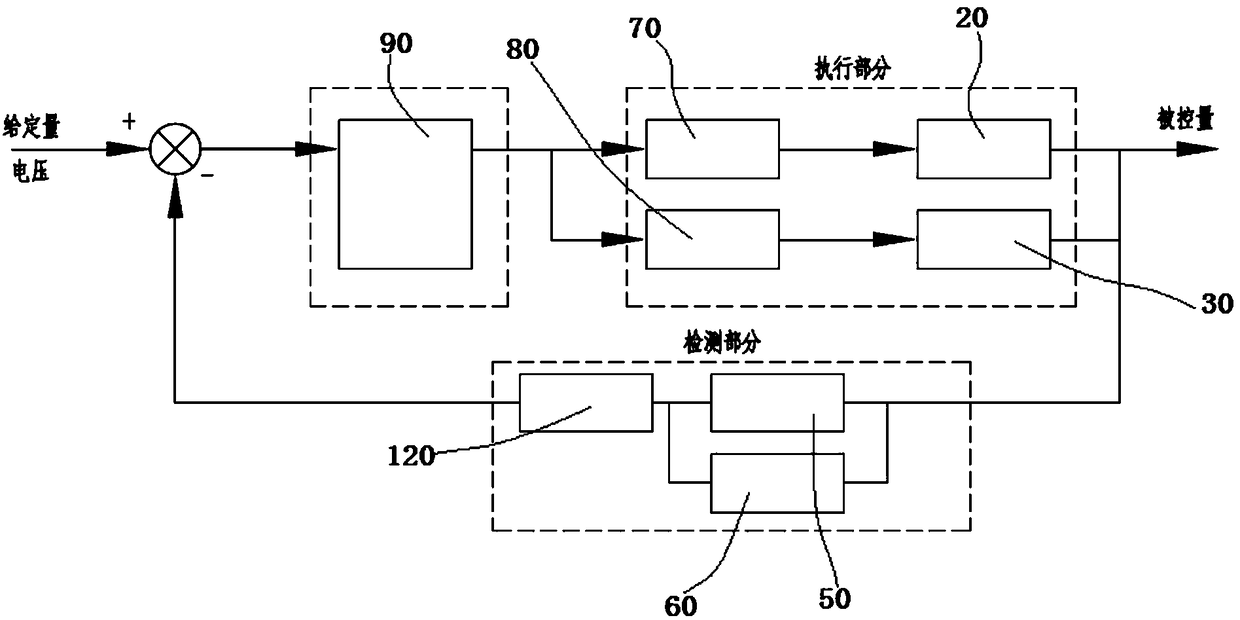

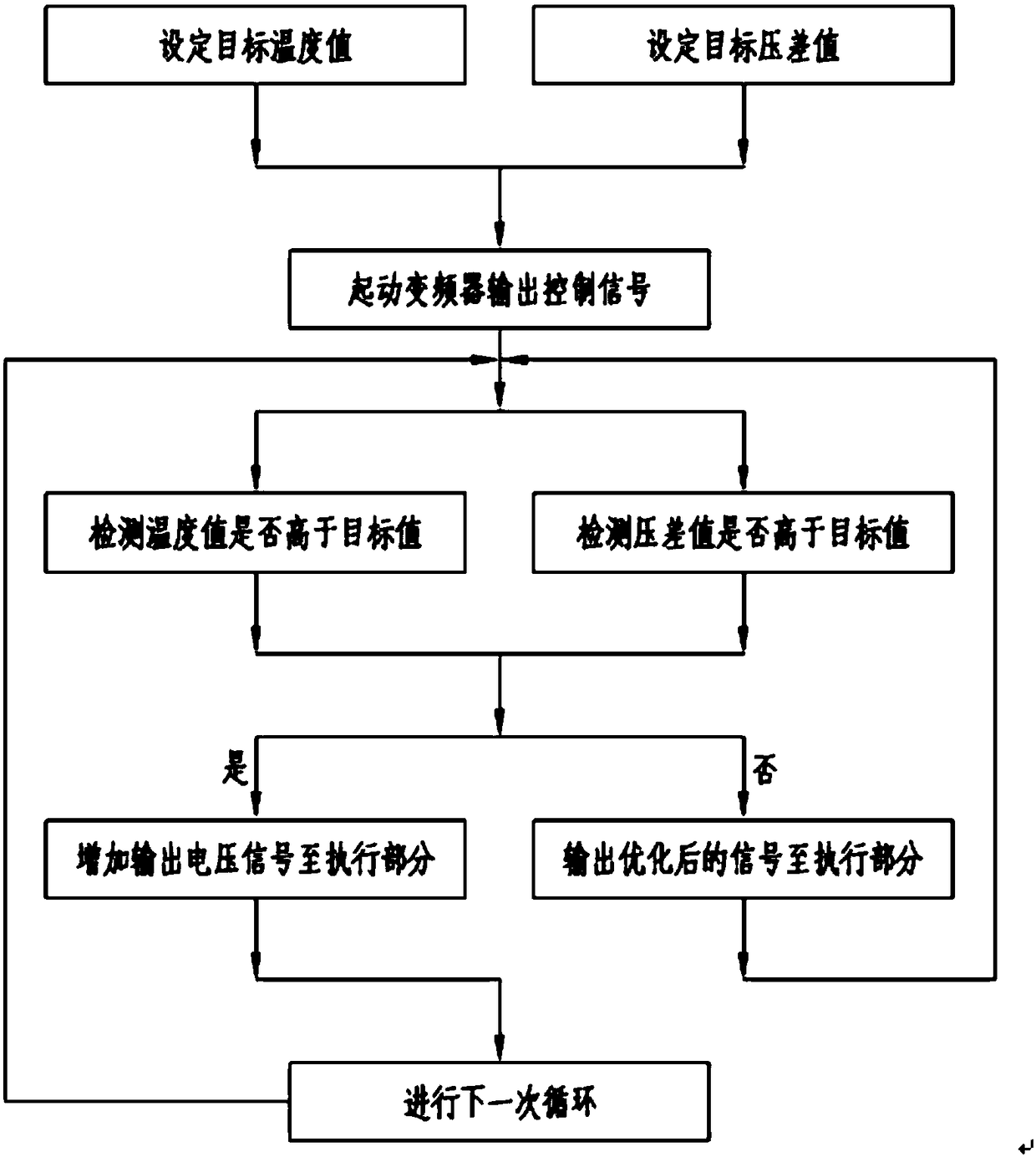

Automatic-regulating ventilation system and ventilation regulating method for polar ship machinery

PendingCN108945380AReduce consumptionReduce operating costsAuxillariesVessel ventillation/heating/coolingPressure differenceControl theory

The invention provides an automatic regulating ventilation system and a ventilation condition method thereof for polar ship machinery. The automatic regulating ventilation system comprises an air inlet shutter, a blower, an exhaust shutter, an exhaust blower, a temperature sensor, a pressure sensor, a blower frequency converter, an exhaust blower frequency converter, a PLC and a power supply. Thetemperature sensor is used for detecting the average temperature in the machine and transmitting the temperature signal to the PLC. Two pressure sensors are used to detect the pressure difference inside and outside the machine and transmit the pressure difference signal to PLC. The blower frequency converter is used for regulating the rotational speed of the blower driving motor; The exhaust fan frequency converter is used for regulating the rotational speed of the exhaust fan driving motor; PLC is used to control the frequency converter of the blower and the frequency converter of the exhaustblower. The power supply is used to power the entire auto-regulating ventilation system. The invention has the advantages of simple structure and convenient use. The PLC automatically adjusts the rotational speed of the fan through continuous circulation collection and control so as to control the temperature at the machine place at the set target value.

Owner:SHANGHAI HECHUANG MARINE ENG CO LTD +1

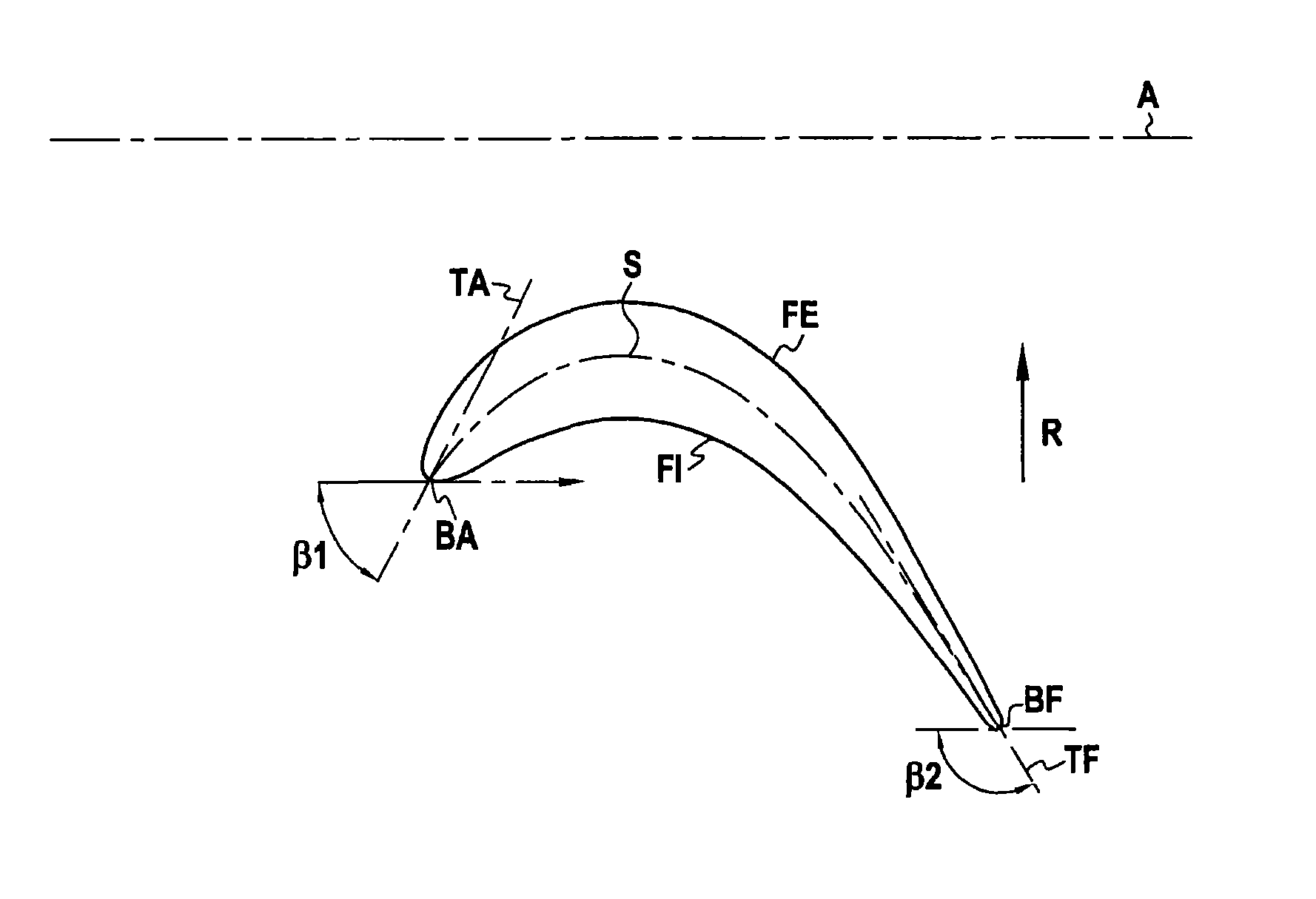

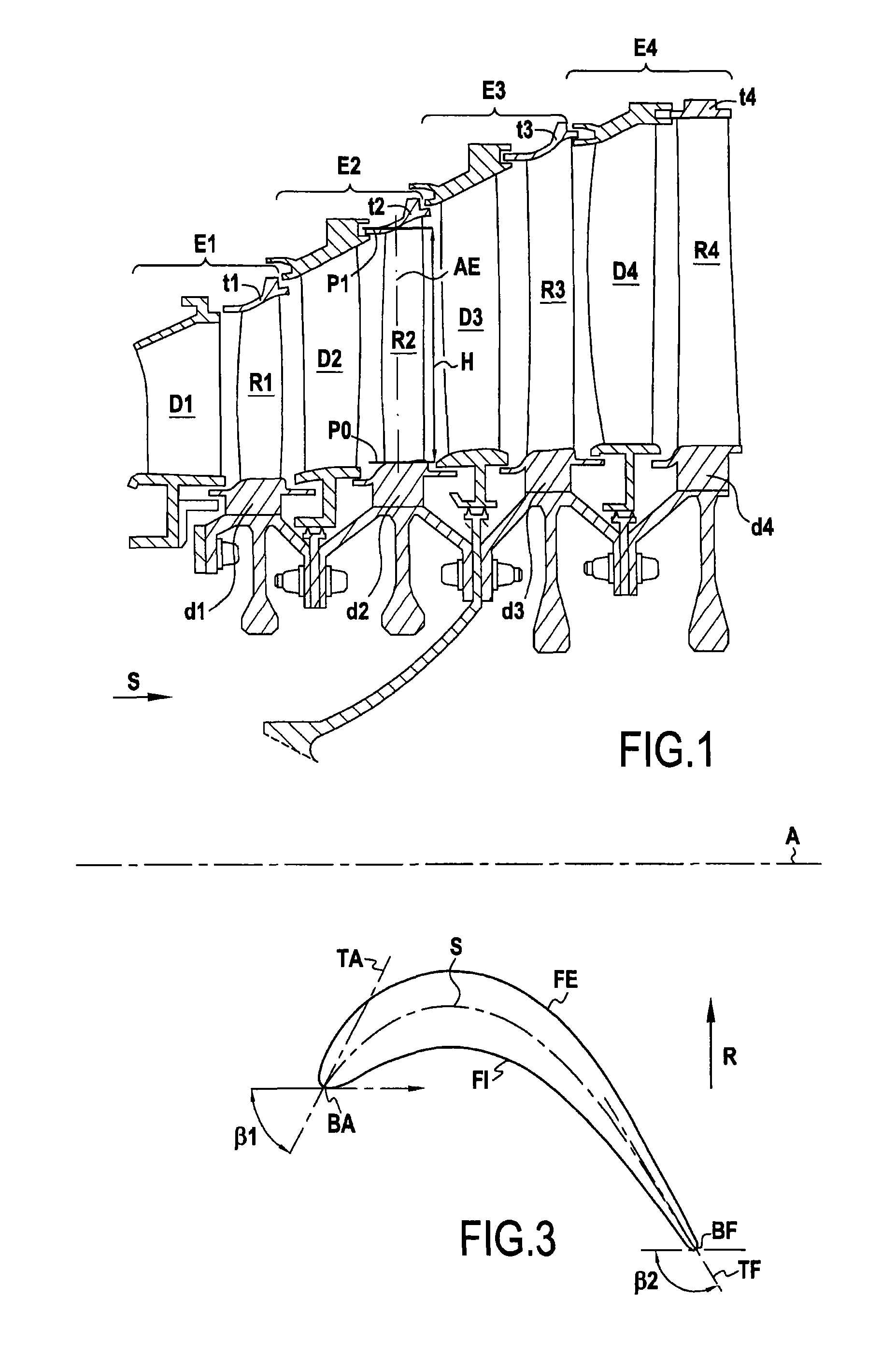

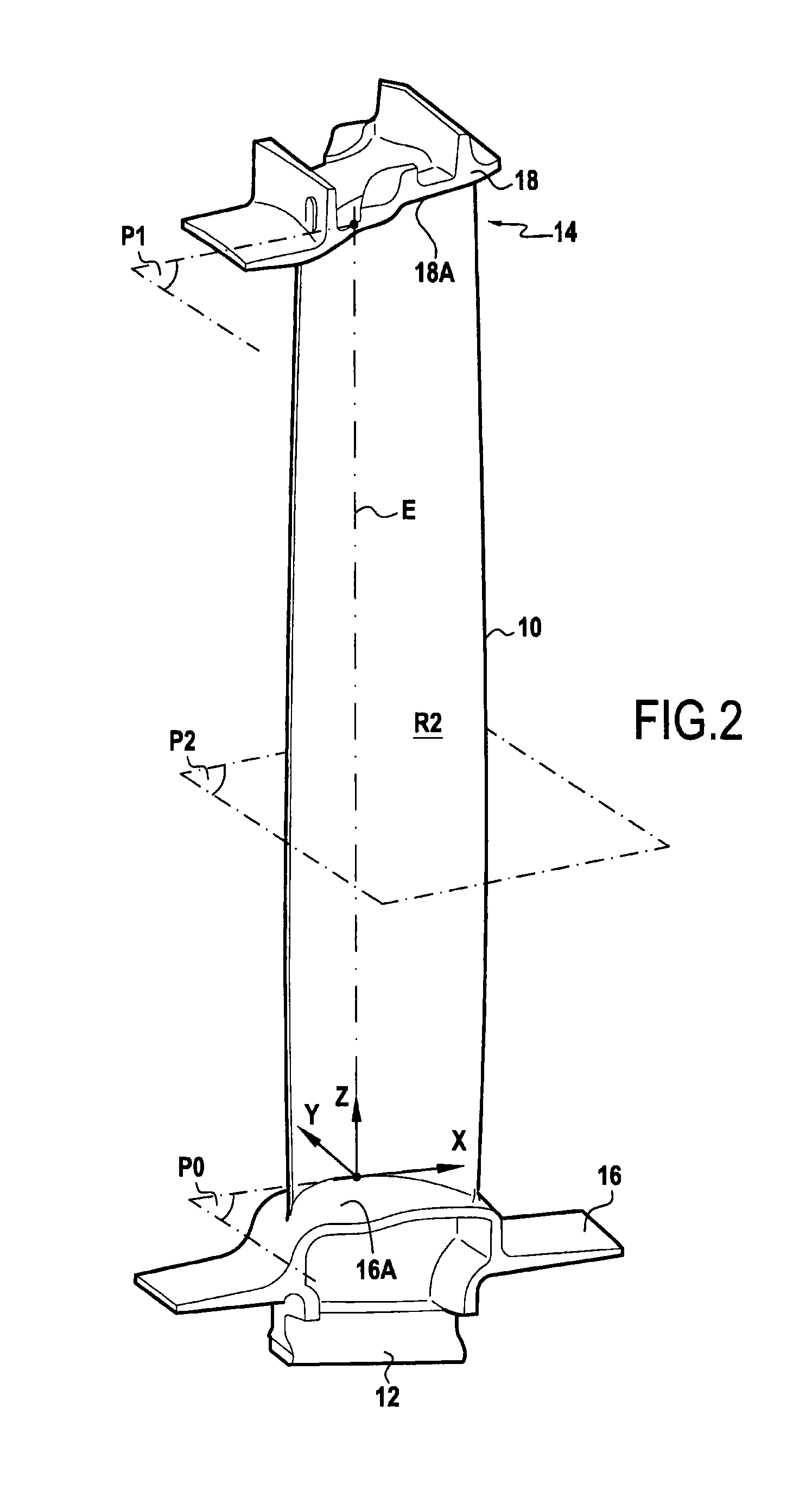

Turbine engine blade

A turbine engine blade having a plurality of blade sections stacked along a radial axis between a root and a tip. Each section extends along a longitudinal axis between a leading edge and a trailing edge, and along a tangential axis between a pressure-side face and a suction-side face. Each section presents a camber line, a deviation defined for each section as the difference between an angle between the tangent to the camber line at the leading edge and the longitudinal axis, and an angle between the tangent to the camber line at the trailing edge and the longitudinal axis. The minimum deviation is at the root of the blade, and the maximum deviation is present at sections situated in the range 0.3H to 0.8H, where H is the height of the blade measured from its root to its tip.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

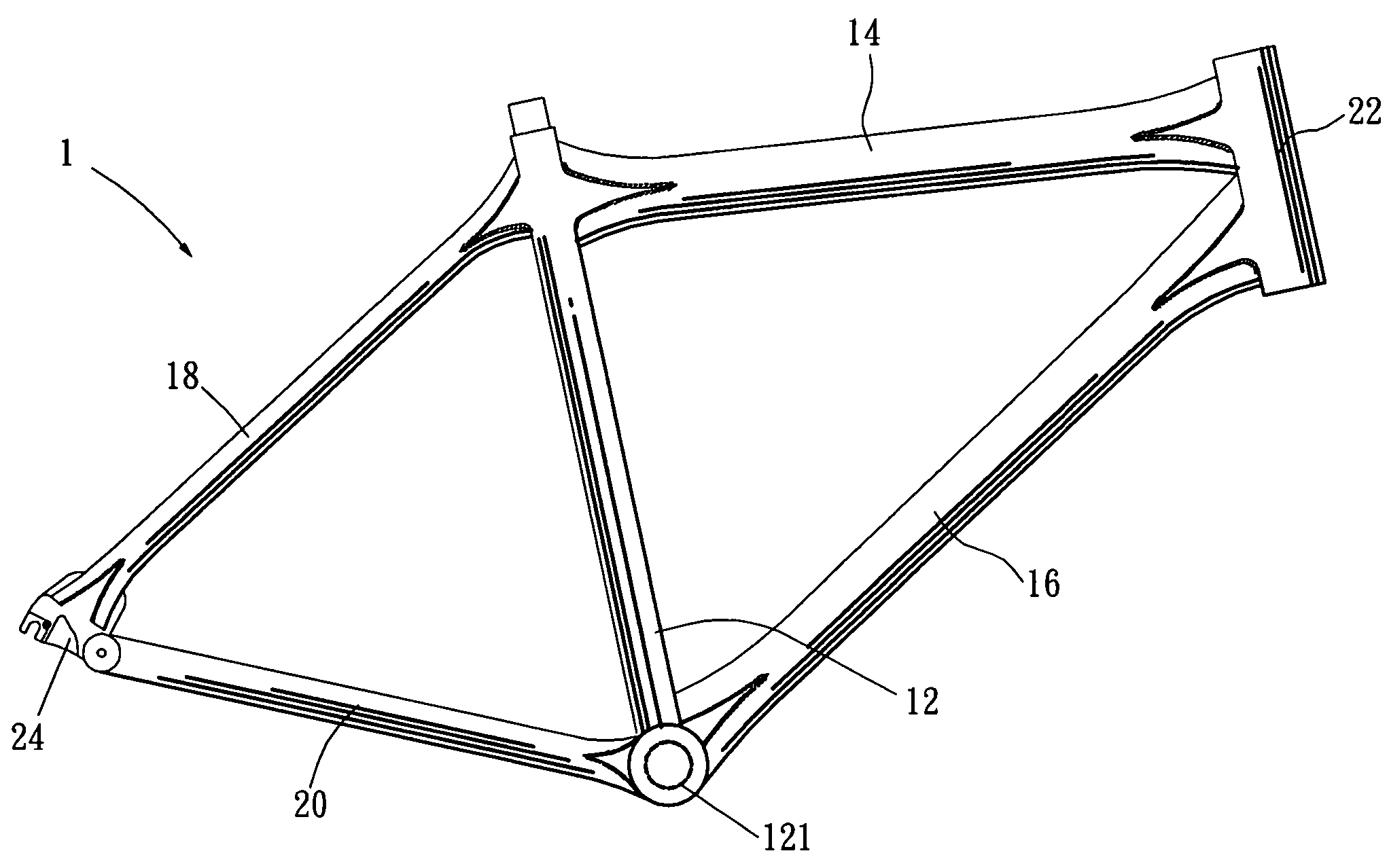

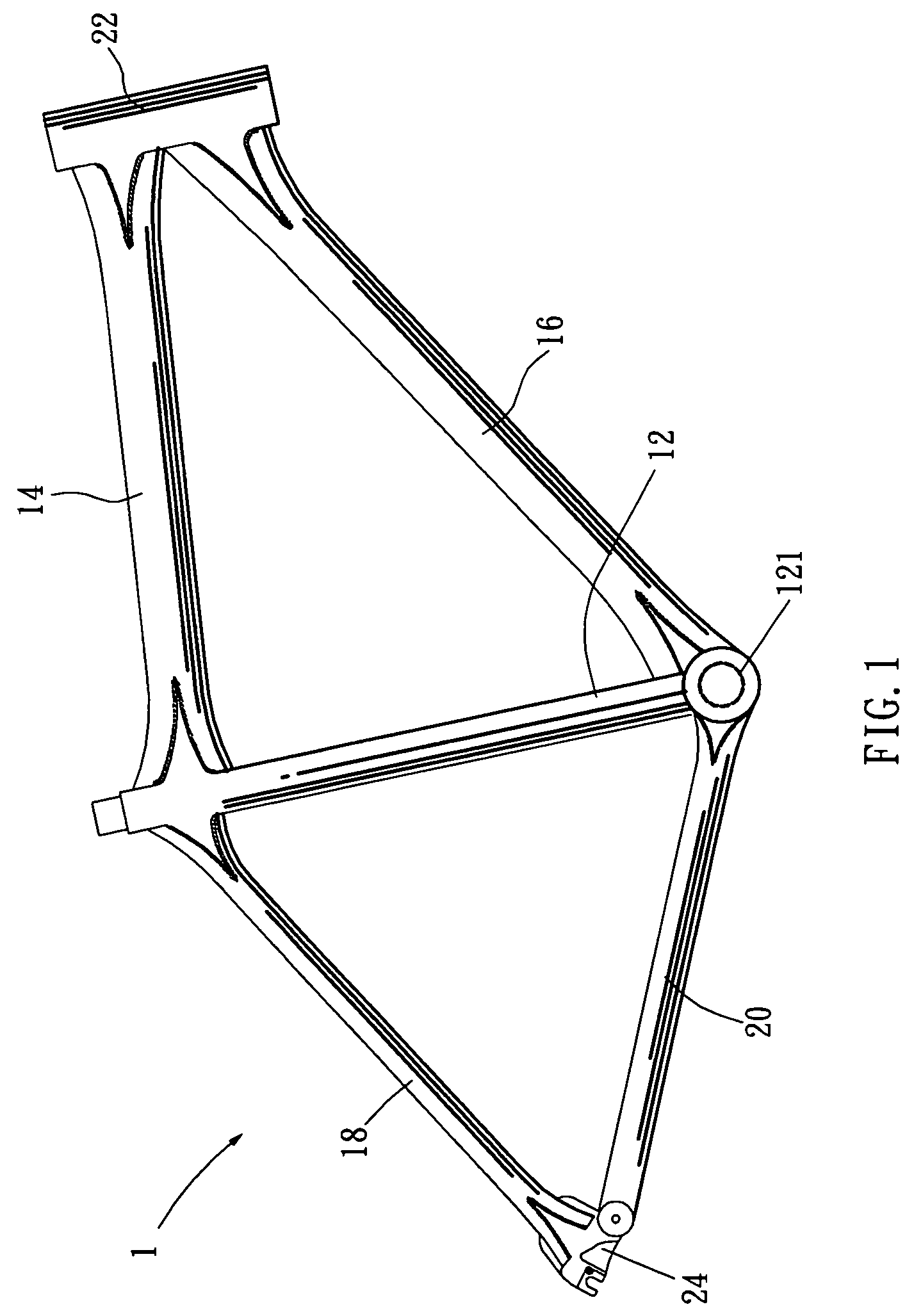

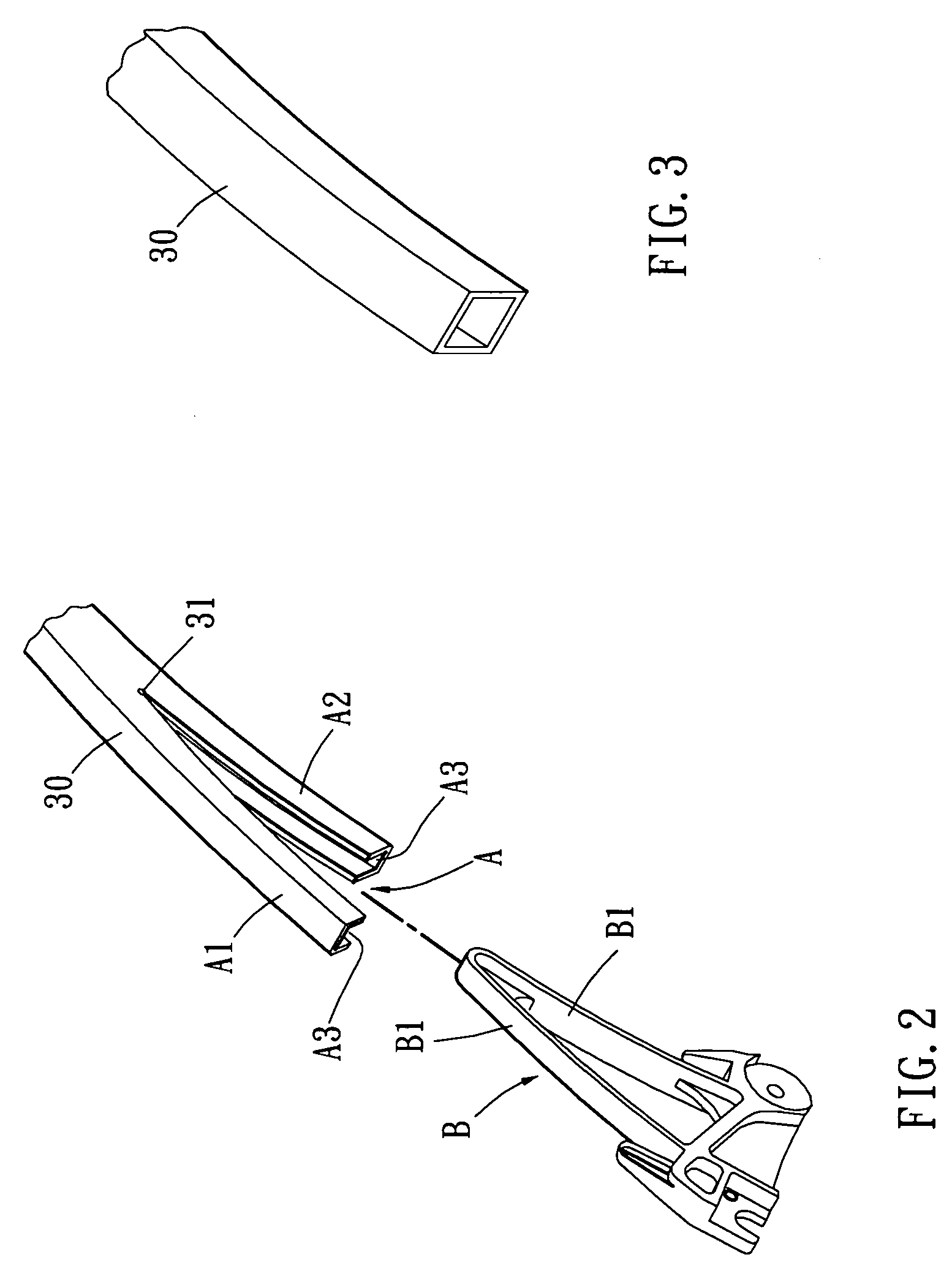

Tube connection assembly of bicycle frame

InactiveUS7390005B2Great combing areaHeavy loadPassenger cyclesWheel based transmissionVehicle frameEngineering

A tube connection assembly of a bicycle frame includes a bi-forked portion formed by a hollow rectangular tube; one end of the rectangular tube being bi-forked as two halves; each half having a positioning groove; and a combining portion formed by two plates which are connected as a shape corresponding to that of the positioning groove and the bi-forked portion so that in assembly the combining portion is assembled to the bi-forked portion; and connection area of the bi-forked portion and combining portion being welded.

Owner:IDEAL BIKE CORP

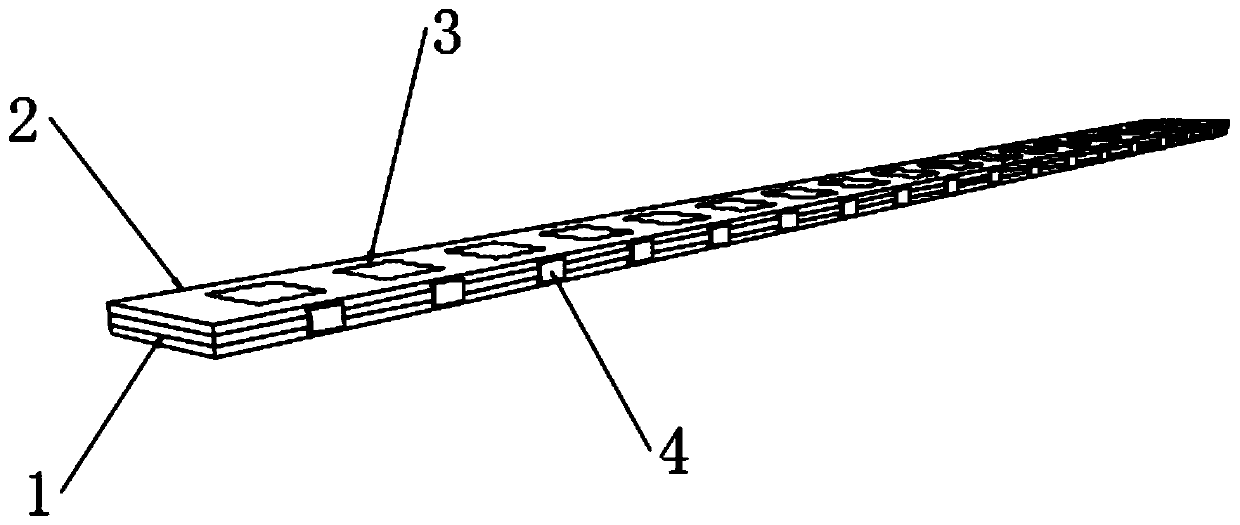

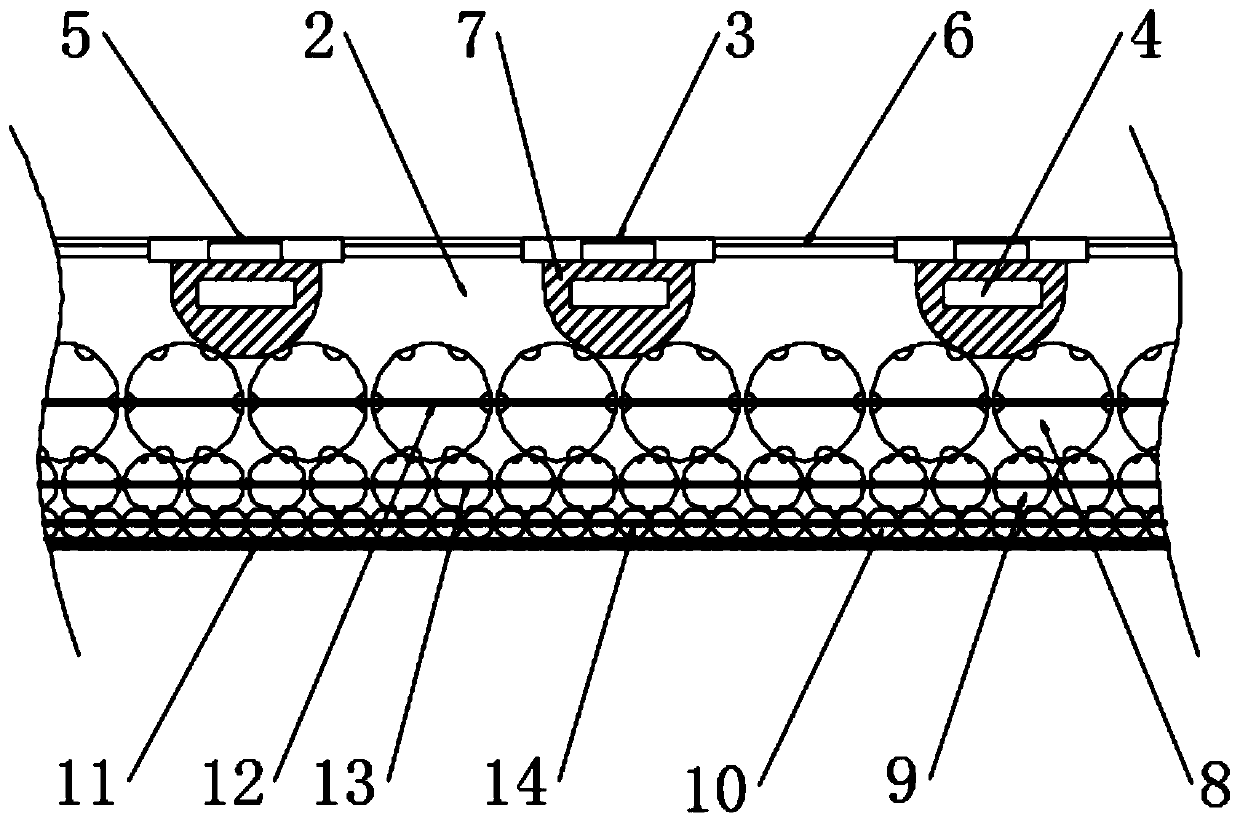

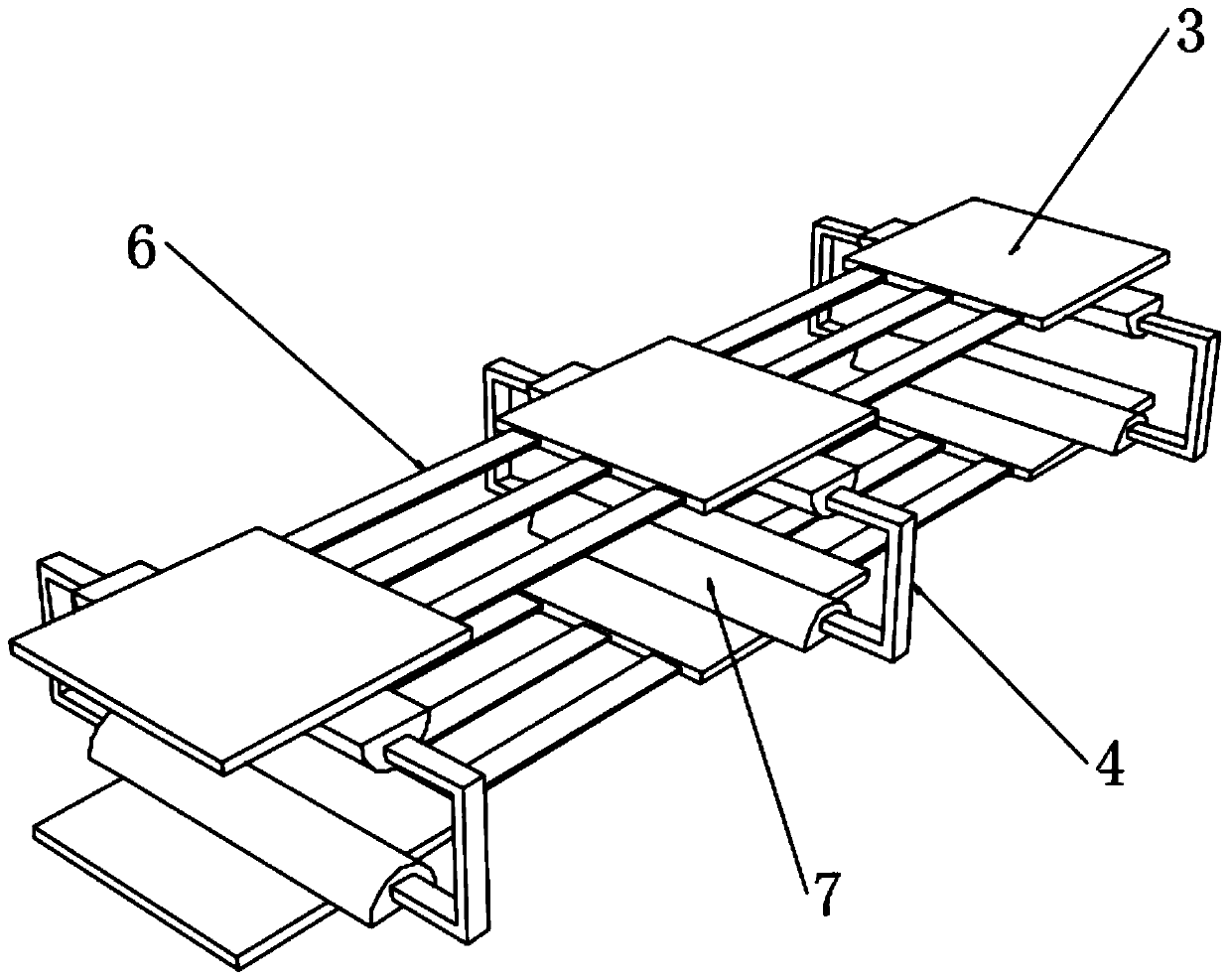

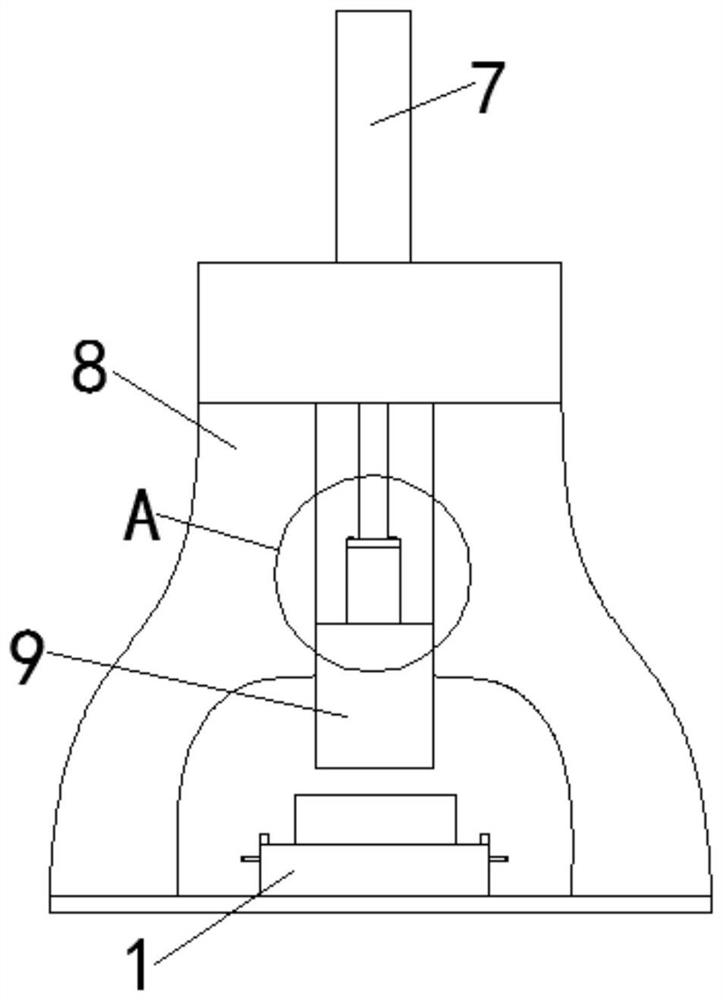

Force dispersion type cold-rolled shipment interlayer padding

PendingCN111216418AImprove the strength of forceReduce padding costsSynthetic resin layered productsVehicle componentsCushioningHigh density

The invention discloses a force dispersion type cold-rolled shipment interlayer padding. A three-layer fiberboard can be used as a core material, two sides of the core material are wrapped with high-density sponges, a composite force dispersion layer is inlaid in the high-density sponge, a force transmission structure arranged on the surface of the sponge is used for pre-dispersing the received force and then transmitting the pre-dispersed force to the composite force dispersion layer, the force is dispersed layer by layer and partially counteracted by utilizing the elasticity of the force dispersion layer itself and the distribution characteristics of a spherical structure, a good cushion protection effect can be achieved on the product, meanwhile, internal optimization is carried out ona single force dispersion layer, a special-shaped net is used for enhancing the integrality of the force dispersion layer, and a special force buffering layer is arranged among force dispersing ballsforming the force dispersion layer. According to the invention, a good elastic buffering effect is kept while the requirements for bundling, winding, cushioning and protection are met, the effect of coping with instantaneous impact hardening protection is also achieved, the force dispersion strength of the force dispersion layers is improved, the reliability of product cushioning and protection isextremely high, and the interlayer padding can be recycled, and the cushioning and protection cost of exported products can be greatly reduced in the long term.

Owner:TAIZHOU YUXIN HOISTING EQUIP

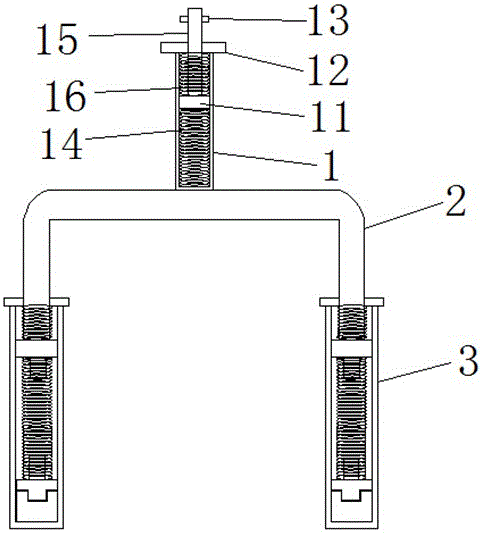

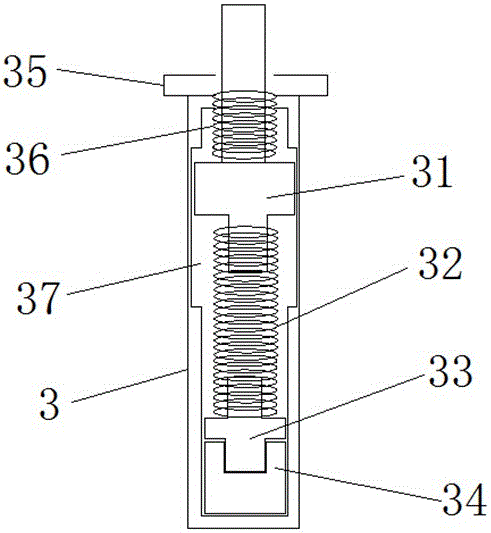

Electric car damping device

InactiveCN105822720AReduce stressImprove stabilityNon-rotating vibration suppressionShock absorbersEngineeringElectric cars

The invention discloses an electric car damping device. The electric car damping device comprises a support, a first damper is fixedly connected to the upper surface of the support, a first spring and a second spring are arranged in the first damper, a sliding block is arranged between the bottom of the first spring and the top of the second spring, a limiting block is fixedly connected to the top of the first damper, a fixed rod is fixedly connected to the middle of the limiting block, and the bottom of the fixed rod penetrates the first spring to be fixedly connected with the sliding block; and a dead bolt is arranged on the top of the fixed rod, second dampers are fixedly connected to the two ends of the bottom of the support through flanges, and each second damper is internally provided with a third spring and a fourth spring. The electric car damping device enables pressure to be shared, the pressure is decreased progressively in a stage-by-stage manner, the damping effect is better, during use, the device is more comfortable, stress of a single spring is small, generation of mechanical fatigue can be relieved, the service life of the springs is prolonged, and the damping device is simple in structure and low in cost.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

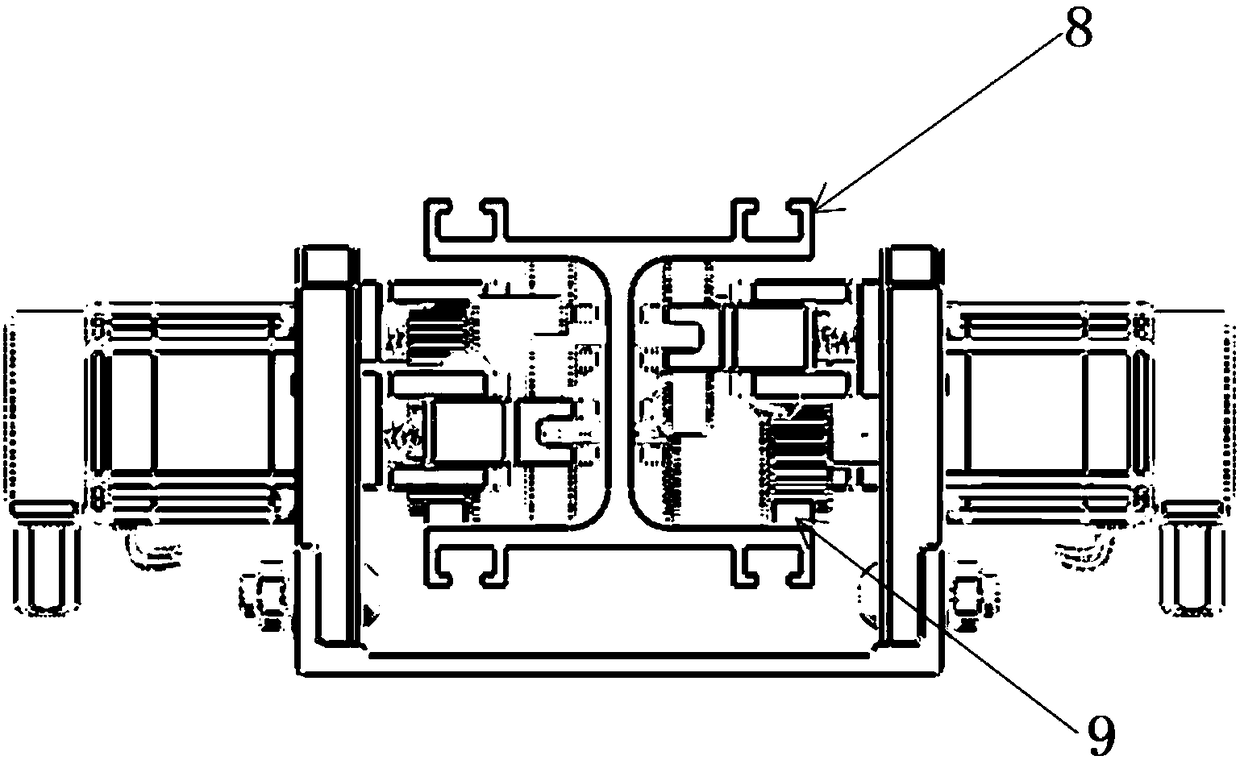

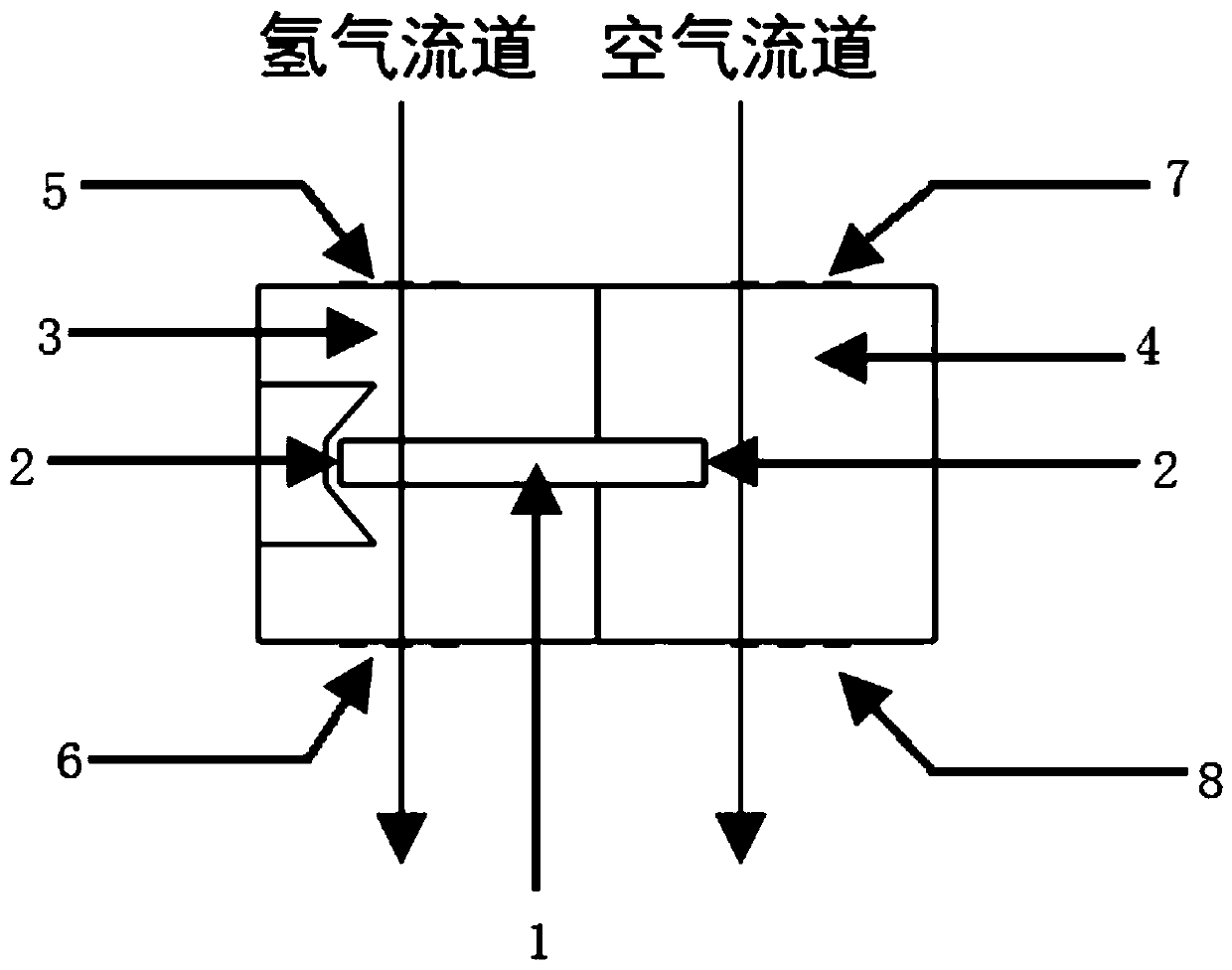

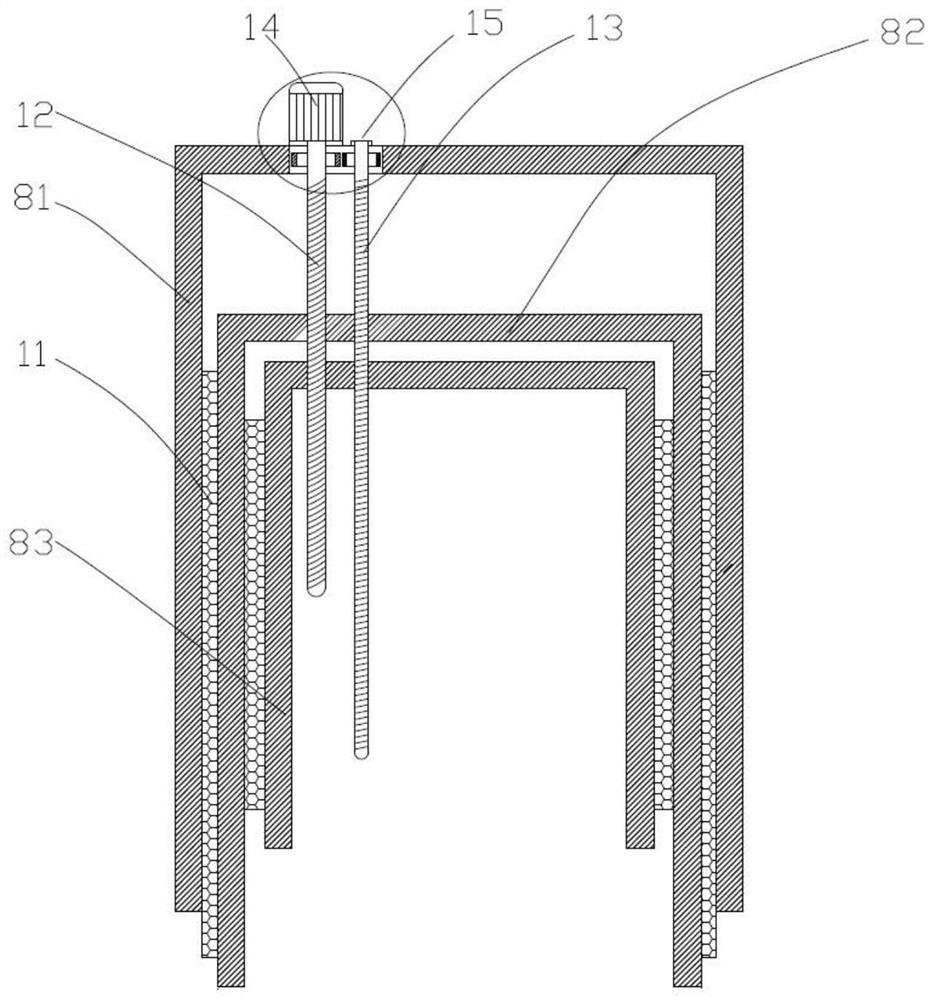

A fuel cell hydrogen-side pressure-regulating device based on pressure sensitive films and a cell

The invention relates to a fuel cell hydrogen-side pressure-regulating device based on pressure sensitive films. The fuel cell hydrogen-side pressure-regulating device comprises a hydraulic container.The hydraulic container is a closed container; and the two ends of the hydraulic container are sealed by the pressure sensitive films respectively. One pressure sensitive film is located in a hydrogen chamber of a fuel cell, and the other pressure sensitive film is located in an air chamber. When the pressure between the hydrogen chamber and the air chamber is balanced or is within a designed pressure difference range, the pressure sensitive films at both ends do not deform; and when the pressure between the hydrogen chamber and the air chamber is higher than the designed pressure difference,the pressure sensitive film in the hydrogen chamber deforms to make a hydrogen flow channel in the hydrogen chamber change to adjust the hydrogen side pressure so as to maintain pressure balance at the hydrogen-air sides. Compared with the prior art, the device adopts a pure mechanical mode and utilizes the hydraulic principle to carry out pressure difference conduction directly to achieve a purpose of pressure balance, so that mechanical fatigue of a proton exchange membrane caused by pressure fluctuation can be effectively reduced.

Owner:上海楞次新能源汽车科技有限公司

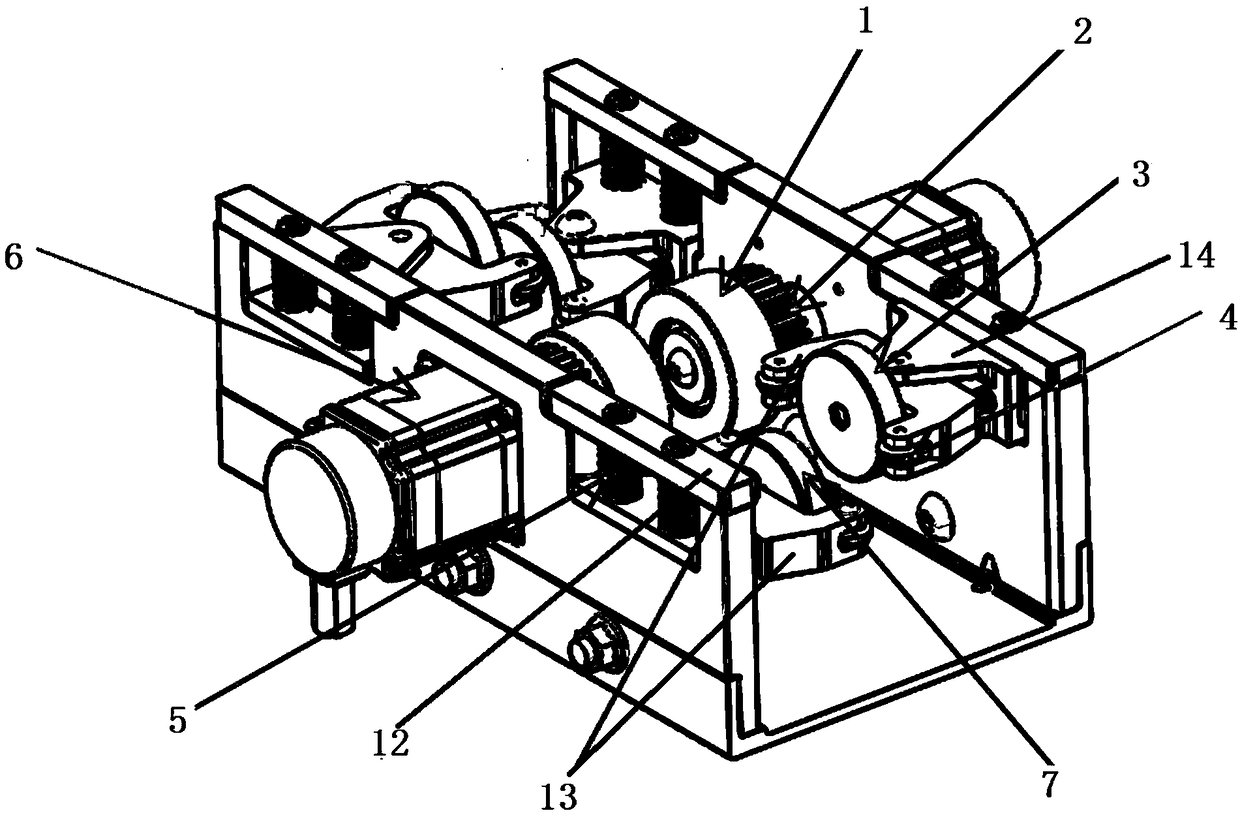

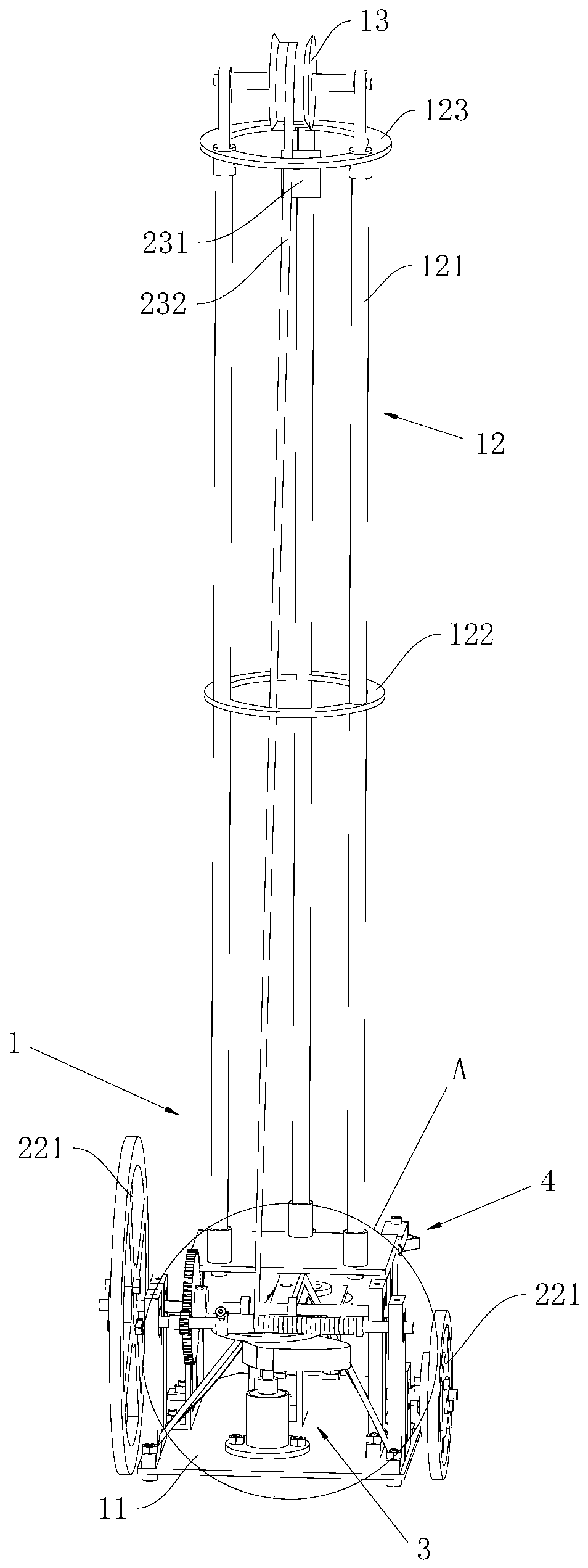

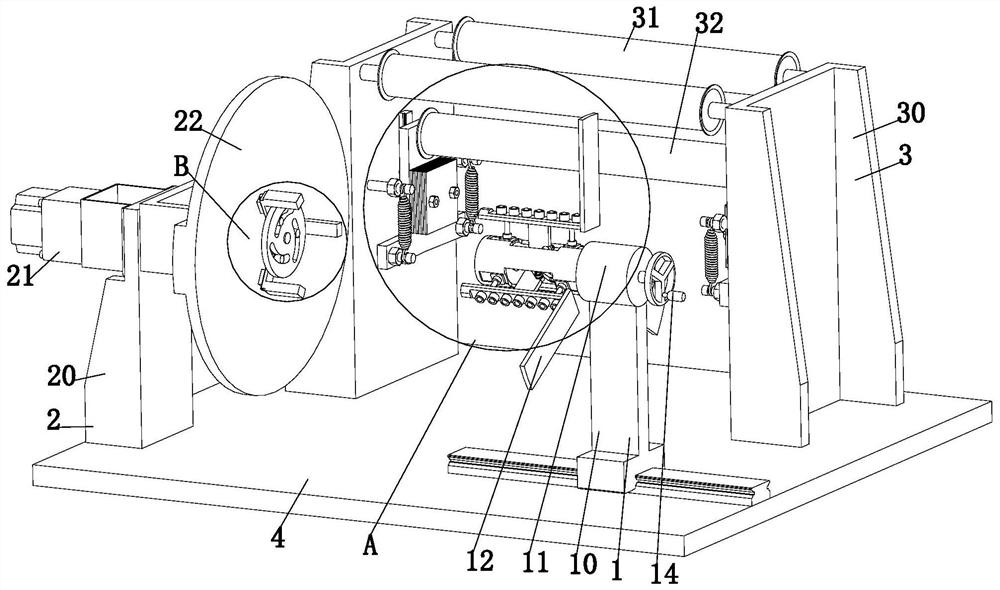

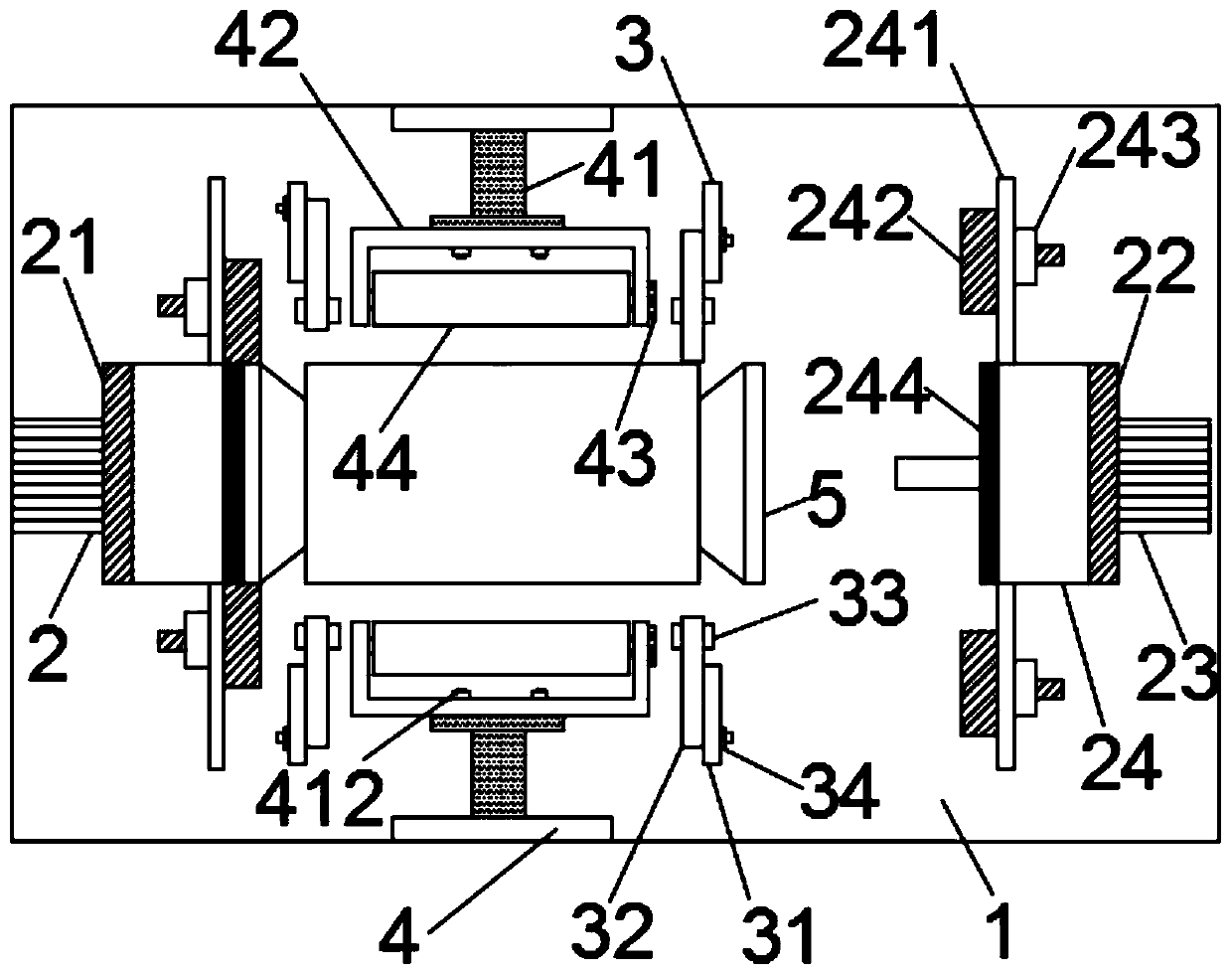

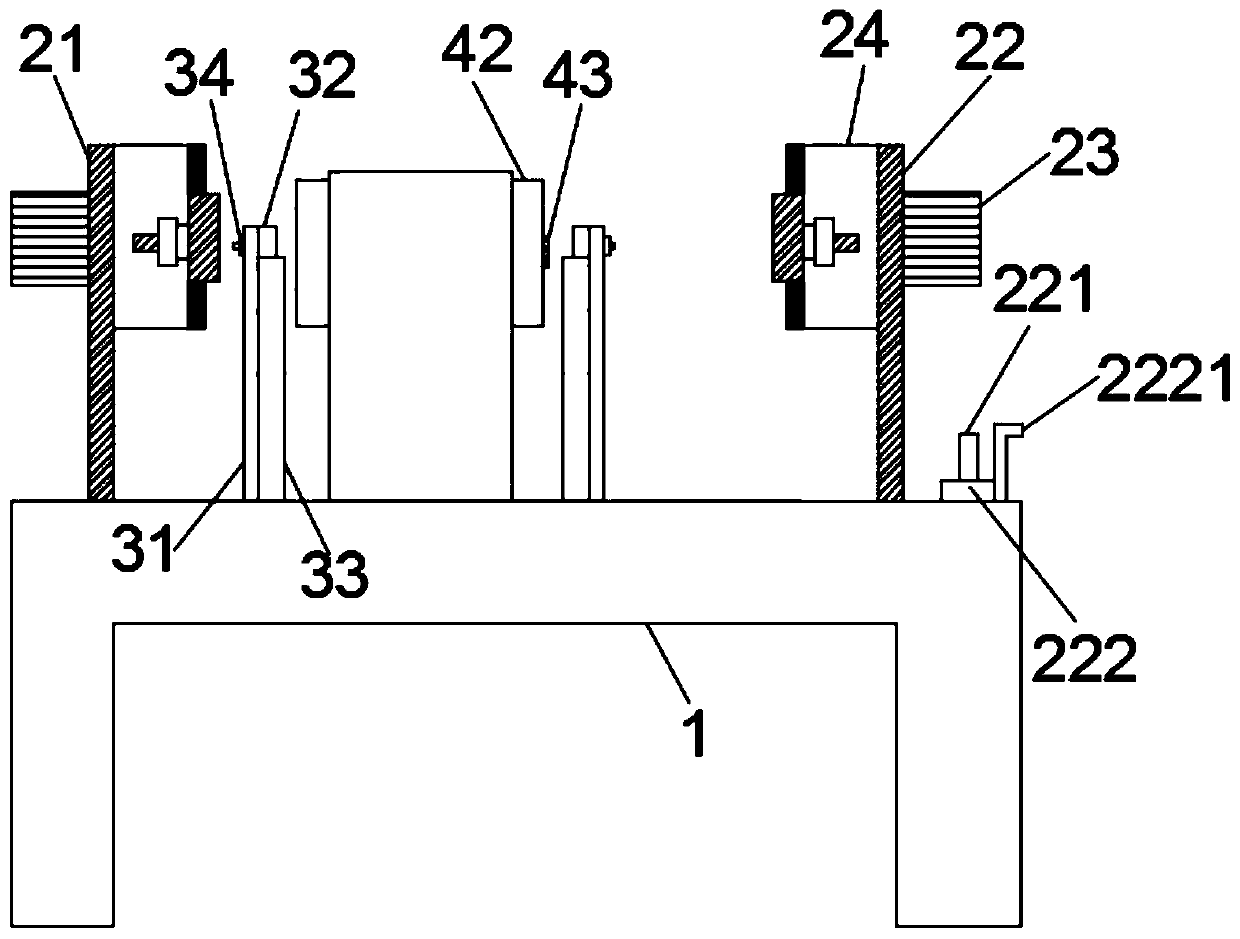

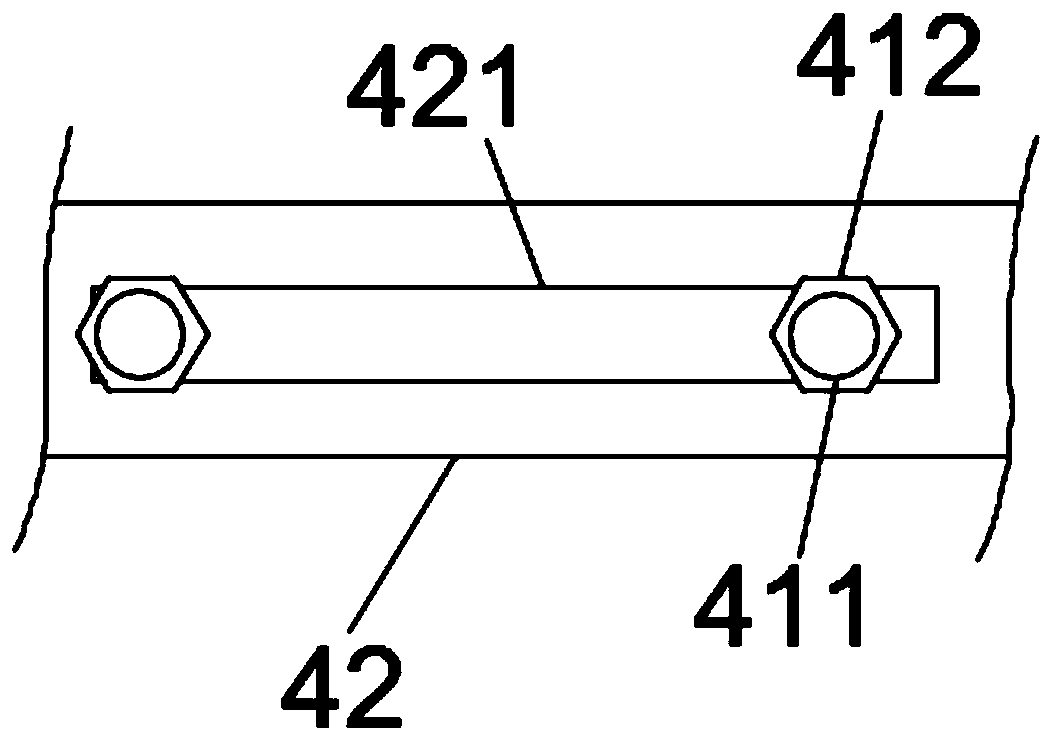

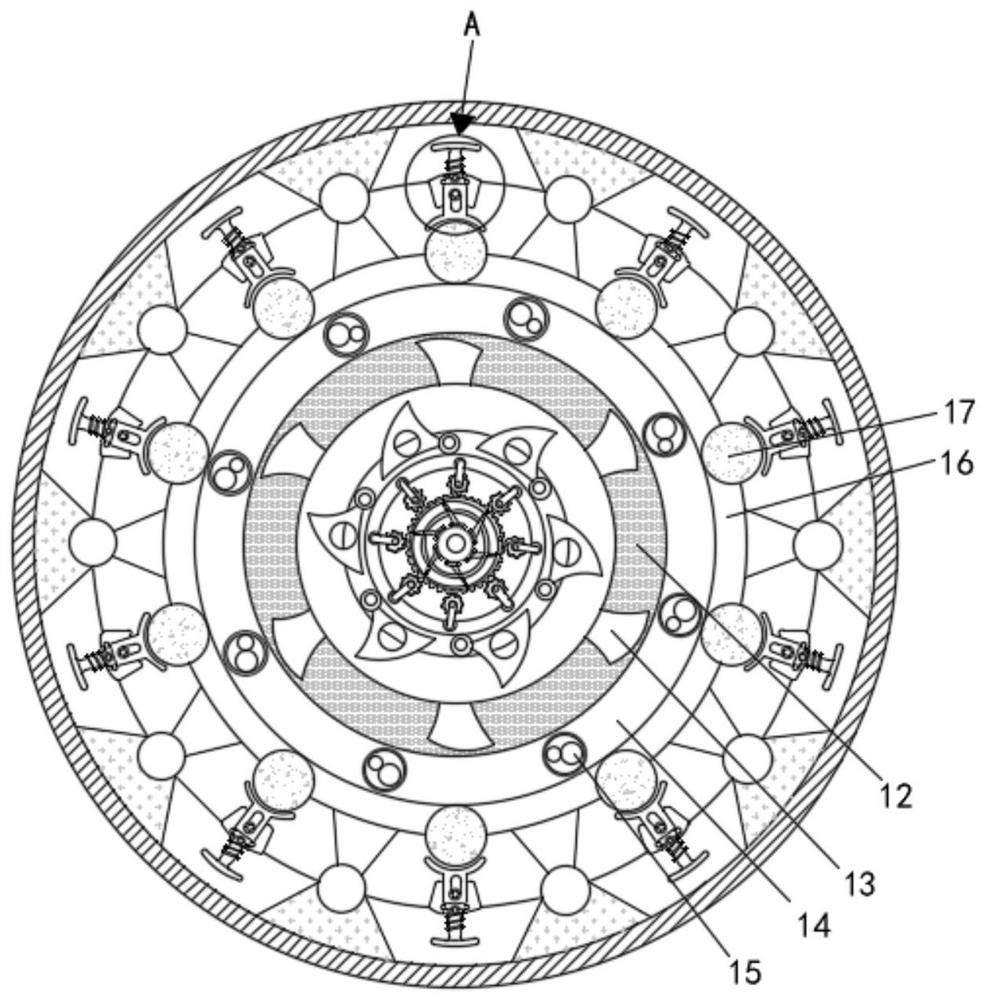

Carbon-free trolley

The invention provides a carbon-free trolley. The problem of difficult adjusting of the deflecting direction of an existing trolley is solved. The carbon-free trolley comprises a trolley frame, a traveling mechanism, a transmission mechanism and a steering mechanism, wherein the traveling mechanism, the transmission mechanism and the steering mechanism are arranged on the trolley frame; the traveling mechanism comprises a front wheel rotatably connected with the trolley frame, rear wheels arranged on the two sides of the trolley frame, and a driving assembly used for driving the rear wheels torotate; and the transmission mechanism comprises a cycle adjusting assembly used for adjusting the transmission cycle, the transmission mechanism is connected with the rear wheels and the steering mechanism, one end of the steering mechanism is connected with the transmission mechanism, the other end of the steering mechanism is connected with the front wheel, the driving assembly drives the rearwheels to rotate so as to drive the transmission mechanism to adjust the deflecting direction of the front wheel connected with the transmission mechanism, and the cycle adjusting assembly changes the transmission cycle to change the steering cycle that the steering mechanism drives the front wheel to deflect. Through cooperation of the traveling mechanism, the transmission mechanism and the steering mechanism, the trolley operates circularly according to a double-8-shaped trajectory and according to the preset requirements, and the trajectory size of the trolley can be adjusted through the cycle adjusting assembly.

Owner:GUANGDONG UNIV OF TECH

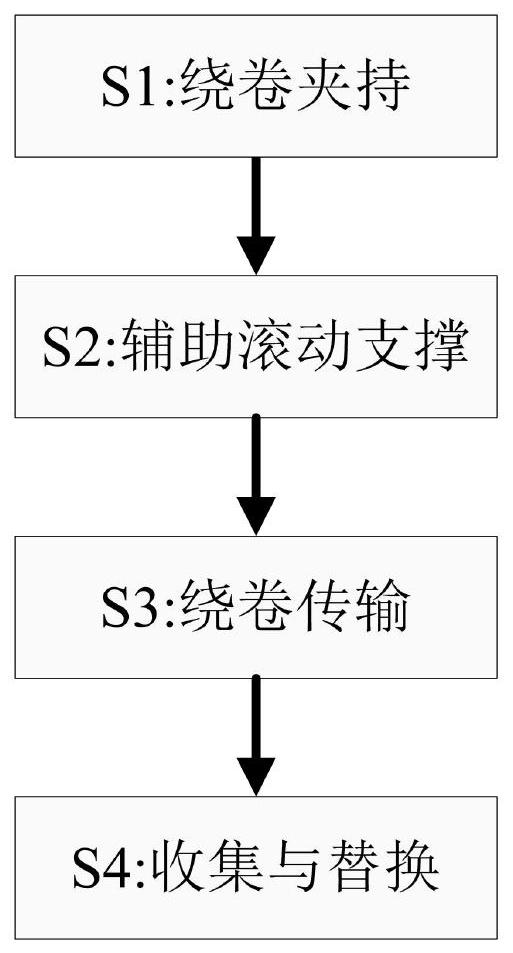

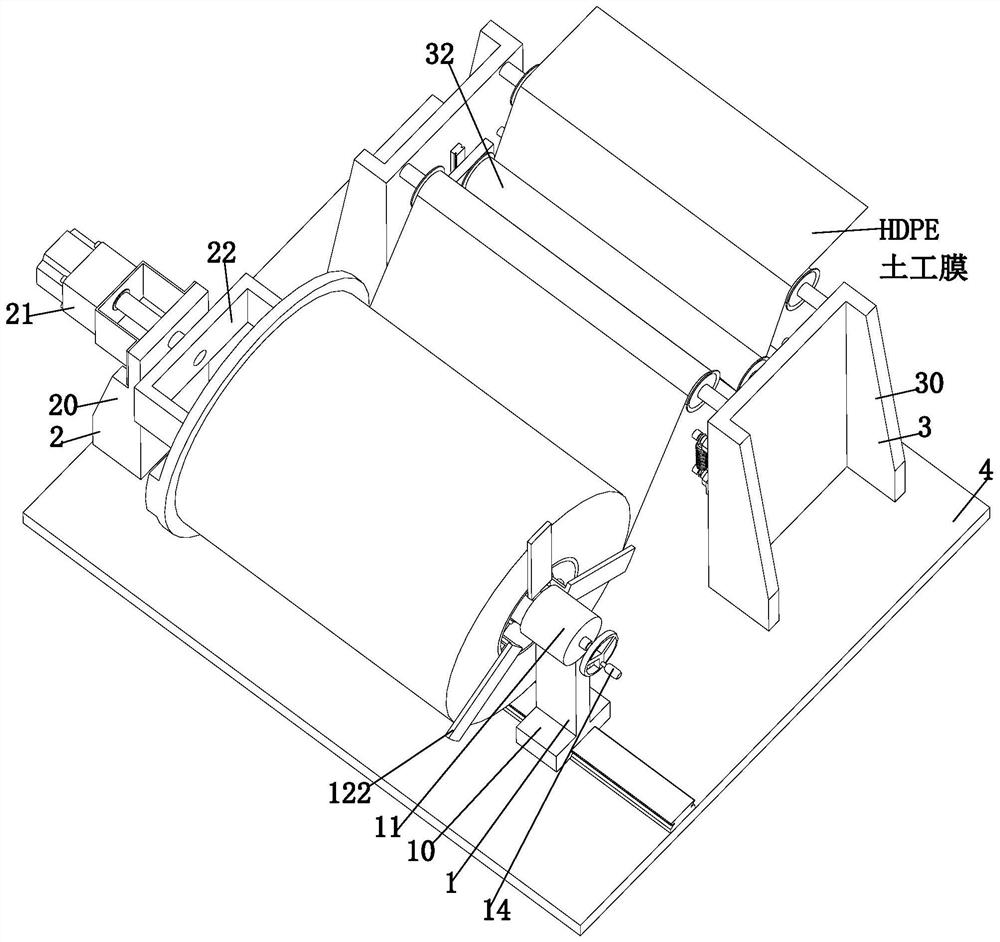

Manufacturing and forming process of HDPE geomembrane

The invention provides a manufacturing and forming process of a HDPE geomembrane. A HDPE geomembrane winding device comprises a guide sliding rolling mechanism, a winding mechanism, a transmission tensioning mechanism, a bottom plate and a winding roller; the transmission tensioning mechanism is installed on the bottom plate, and the winding mechanism and the guide sliding rolling mechanism are arranged right in front of the transmission tensioning mechanism; and the winding mechanism is installed on the bottom plate, the guide sliding rolling mechanism is installed on the bottom plate in a sliding fit mode, and the winding roller is arranged between the winding mechanism and the guide sliding rolling mechanism. The manufacturing and forming process of the HDPE geomembrane solves the problems that the HDPE geomembrane needs to be collected and stored through winding after being produced and manufactured, an existing HDPE geomembrane winding device directly winds the HDPE geomembrane onwinding rollers, wrinkles are likely to be generated in the middle winding process, and the winding work efficiency and the later use quality are seriously affected by the wrinkles on the surfaces ofthe HDPE geomembranes; and in addition, only the winding rollers of the same type can be used, market requirements cannot be met, and negative effects are caused to the production efficiency.

Owner:广州粤科塑胶科技有限公司

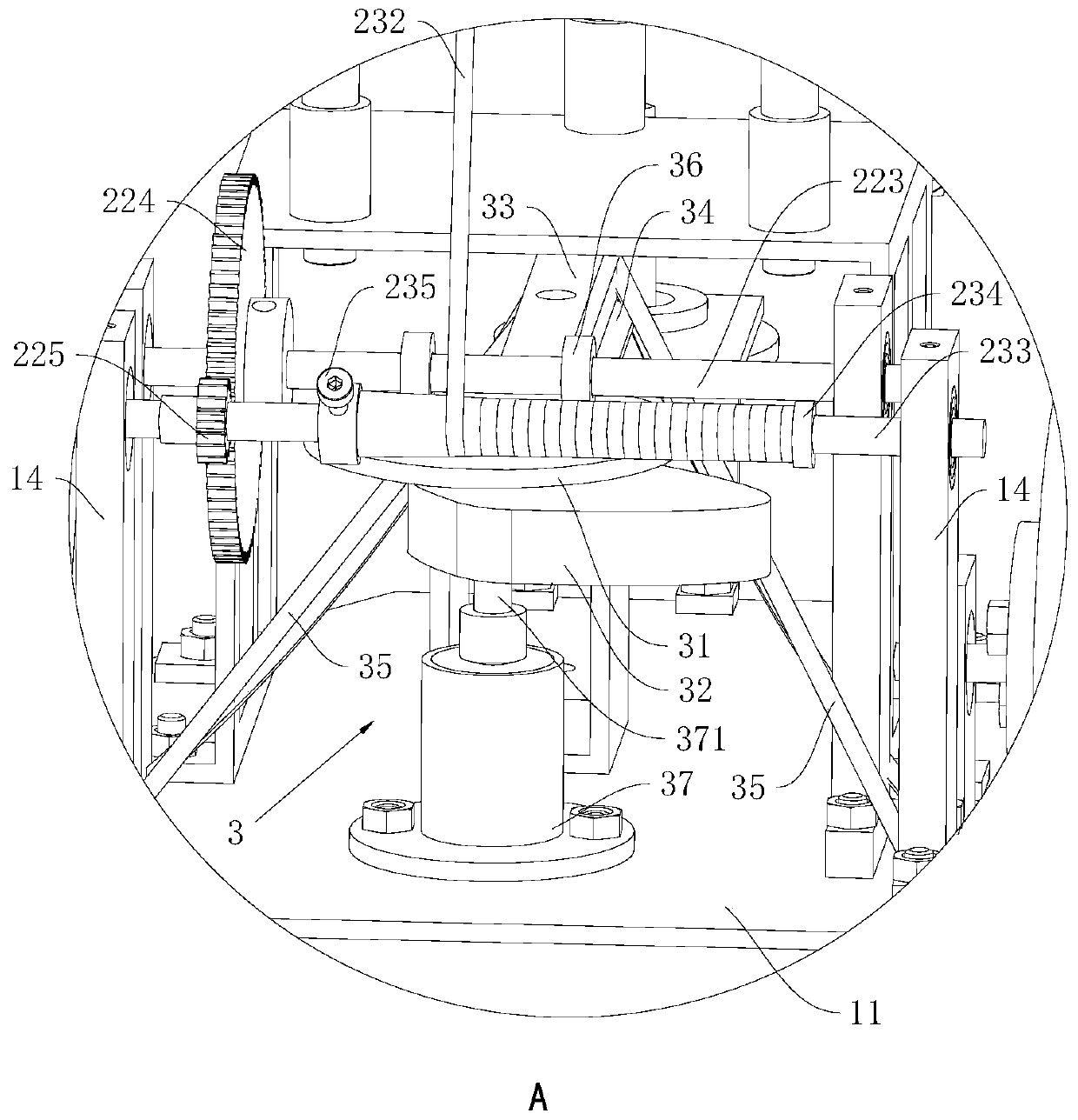

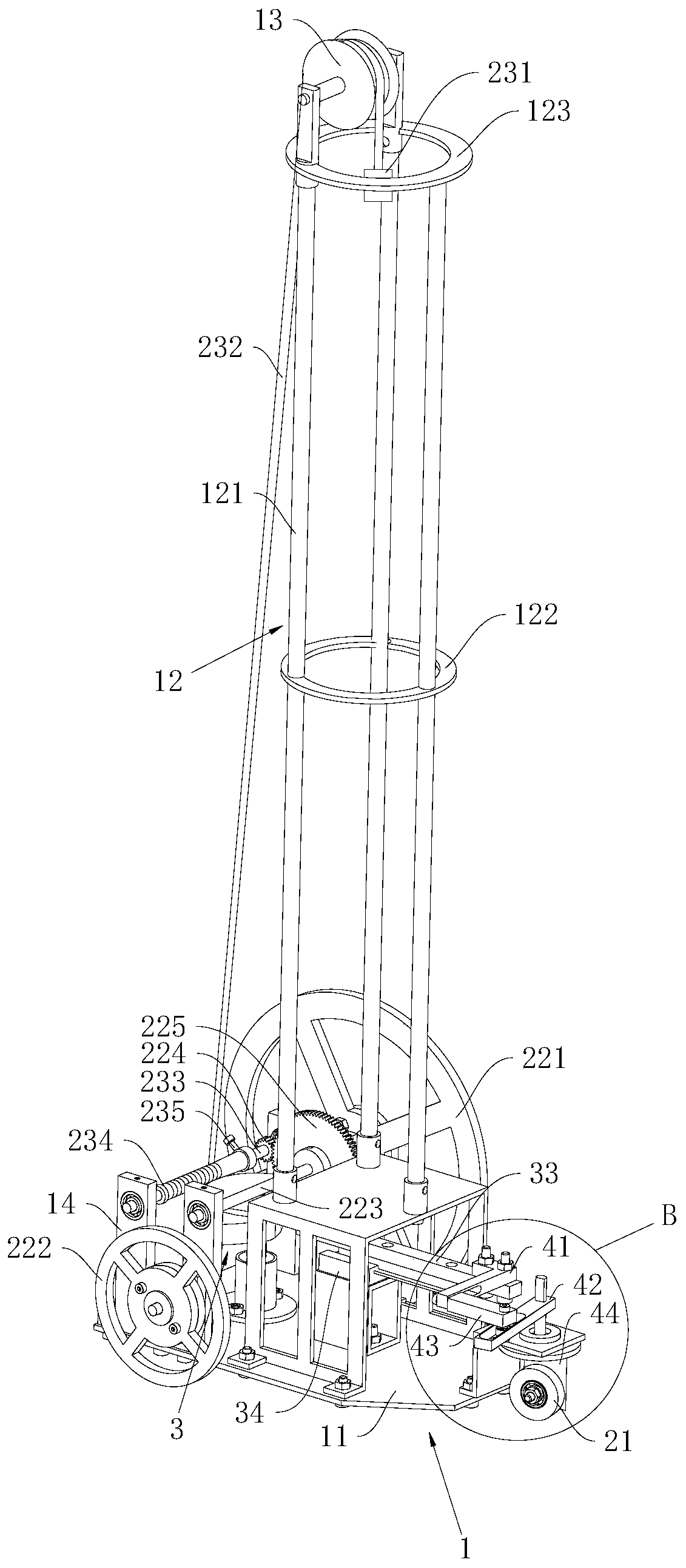

Coil shaping device for motor

InactiveCN111564938AAvoid offsetEnsure shapingManufacturing dynamo-electric machinesElectric machineHydraulic ram

Owner:安徽聚益德电子科技有限公司

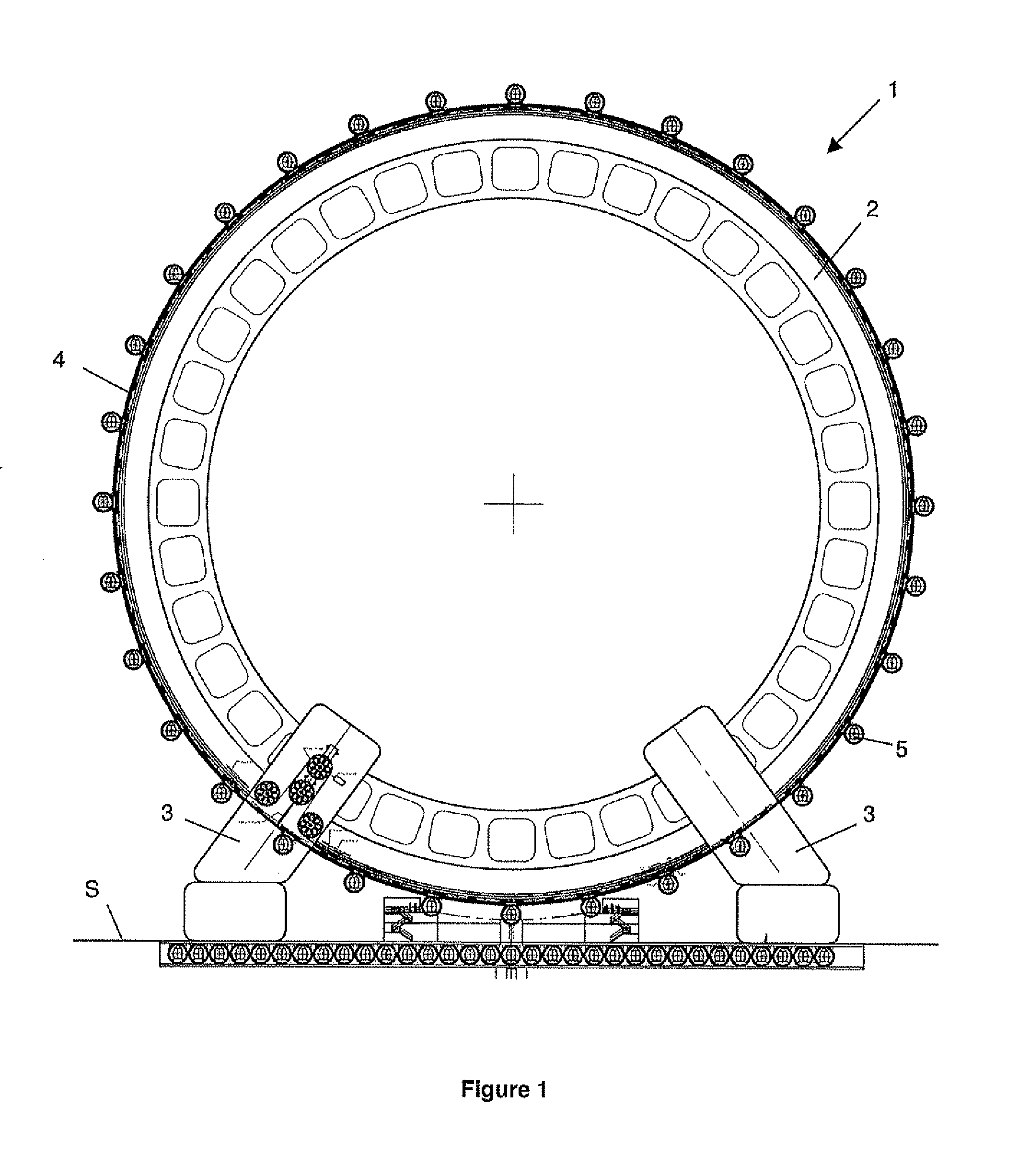

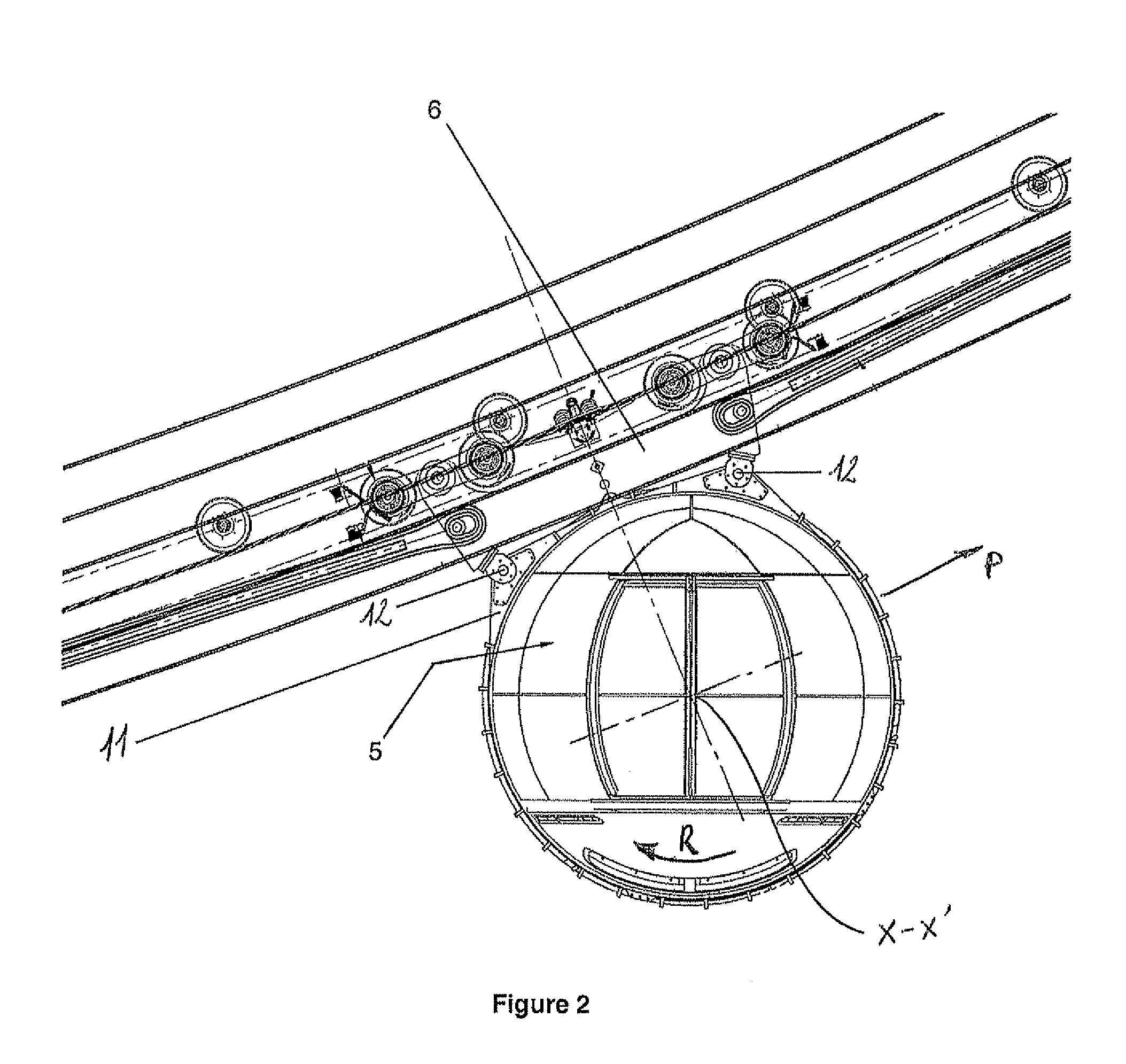

Mobile unit and installation for transportation of at least one passenger

A mobile unit for transportation of at least one passenger comprises a car accommodating this passenger and an assembly device for fitting this car on a mobile support in rotary manner with respect to a substantially horizontal axis of rotation. The assembly device comprises a single first crown rigidly secured to the car and assembled by a bearing to a second crown performing securing to the mobile support.

Owner:SIGMA COMPOSITE

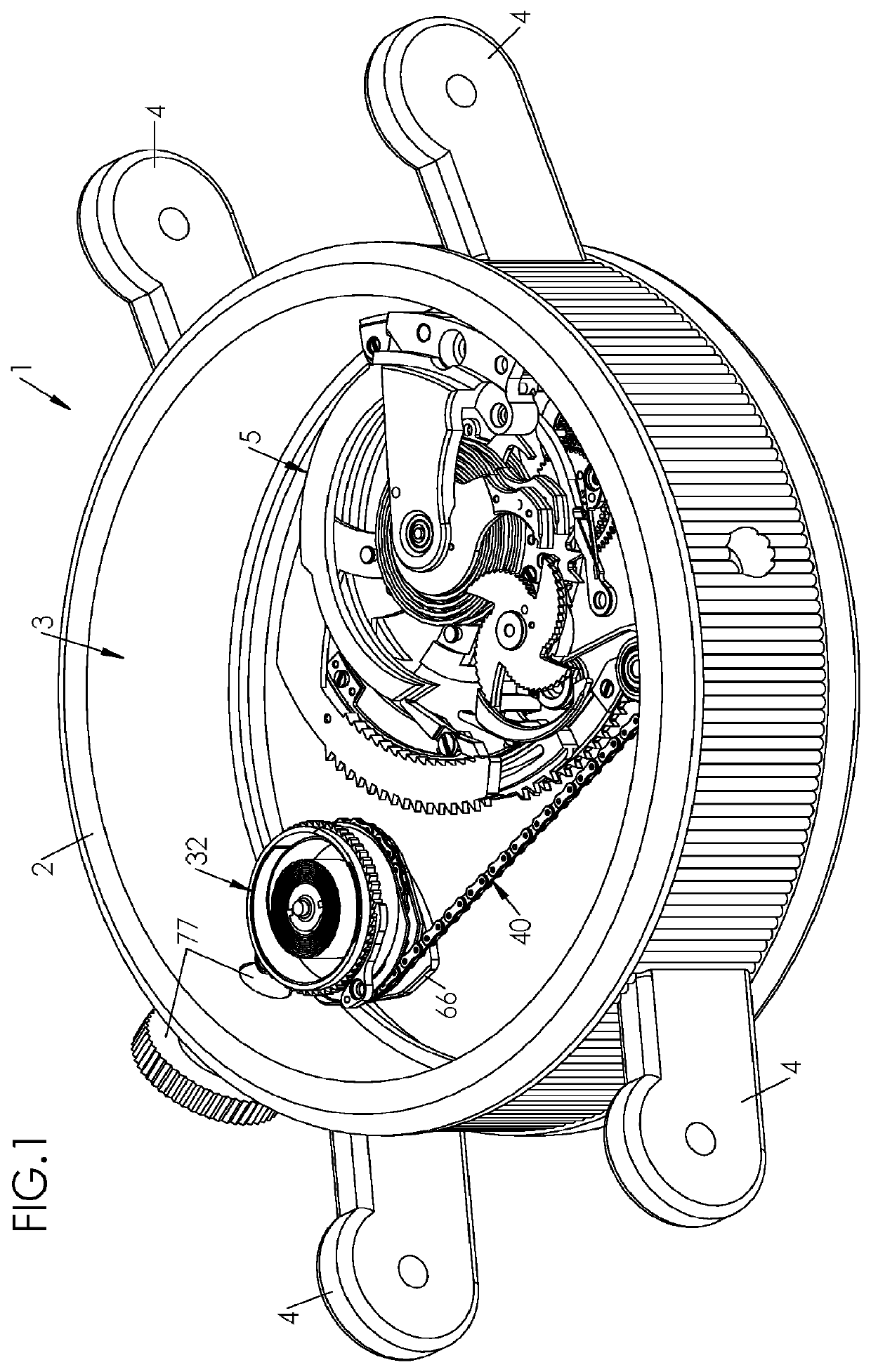

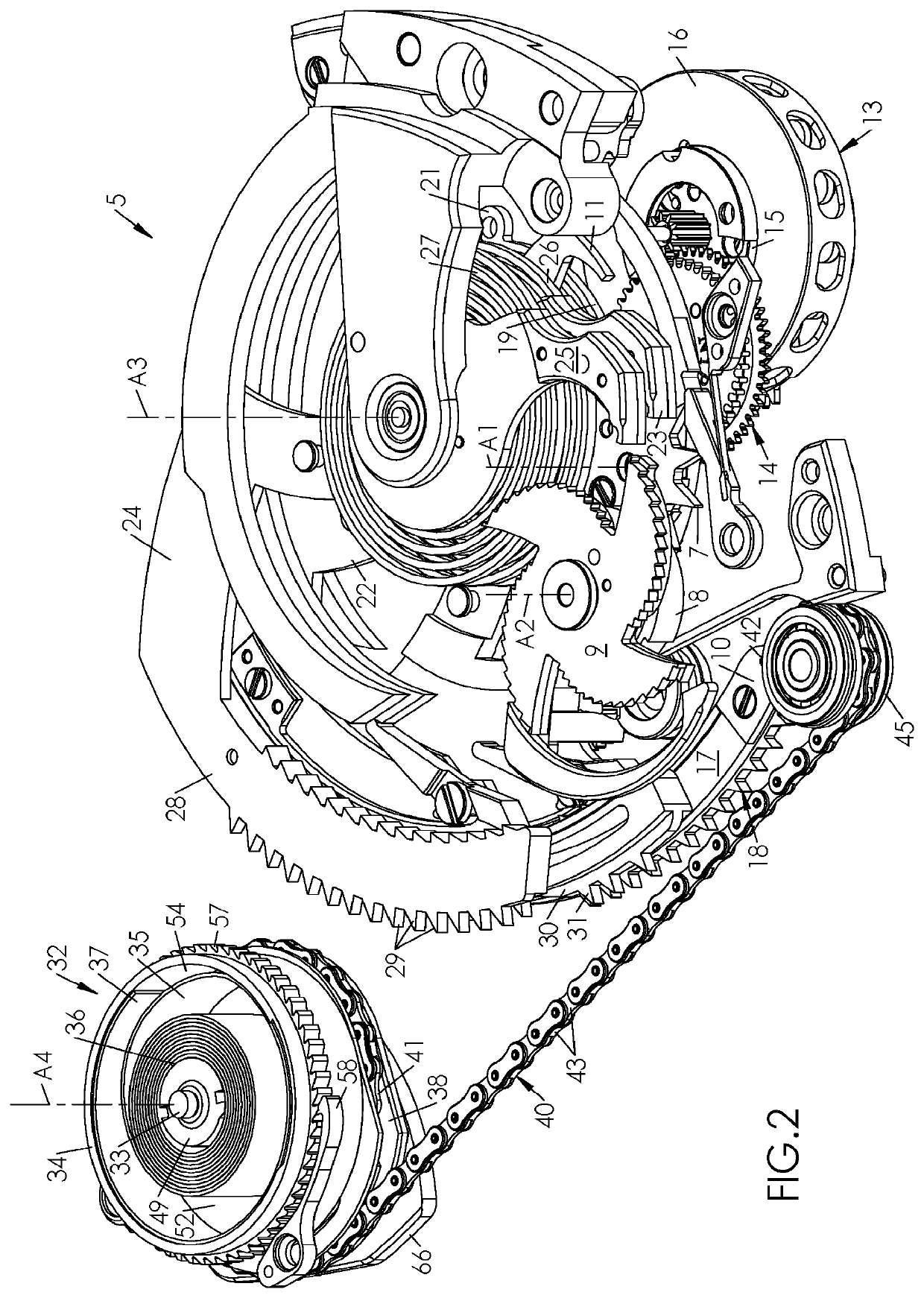

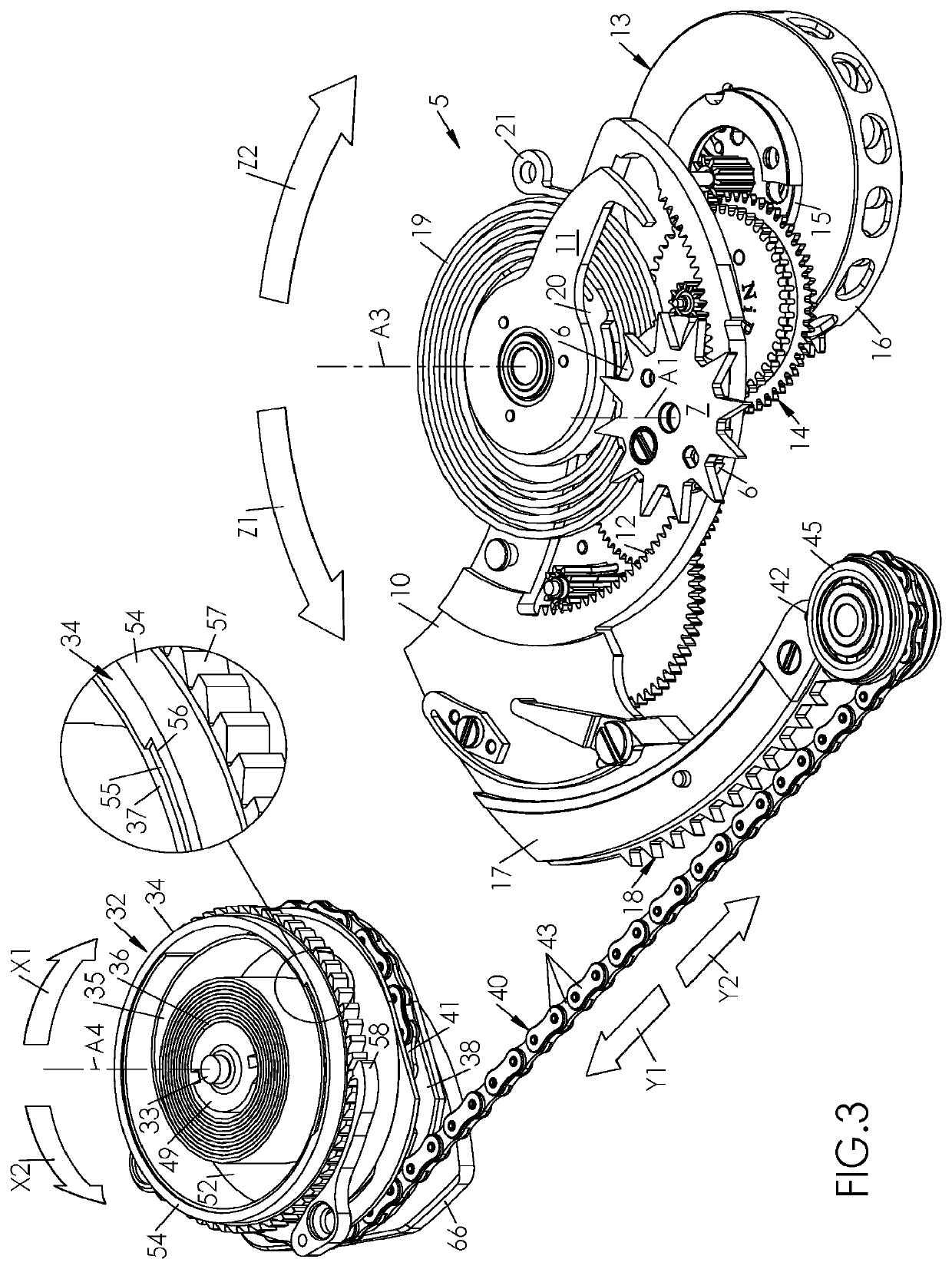

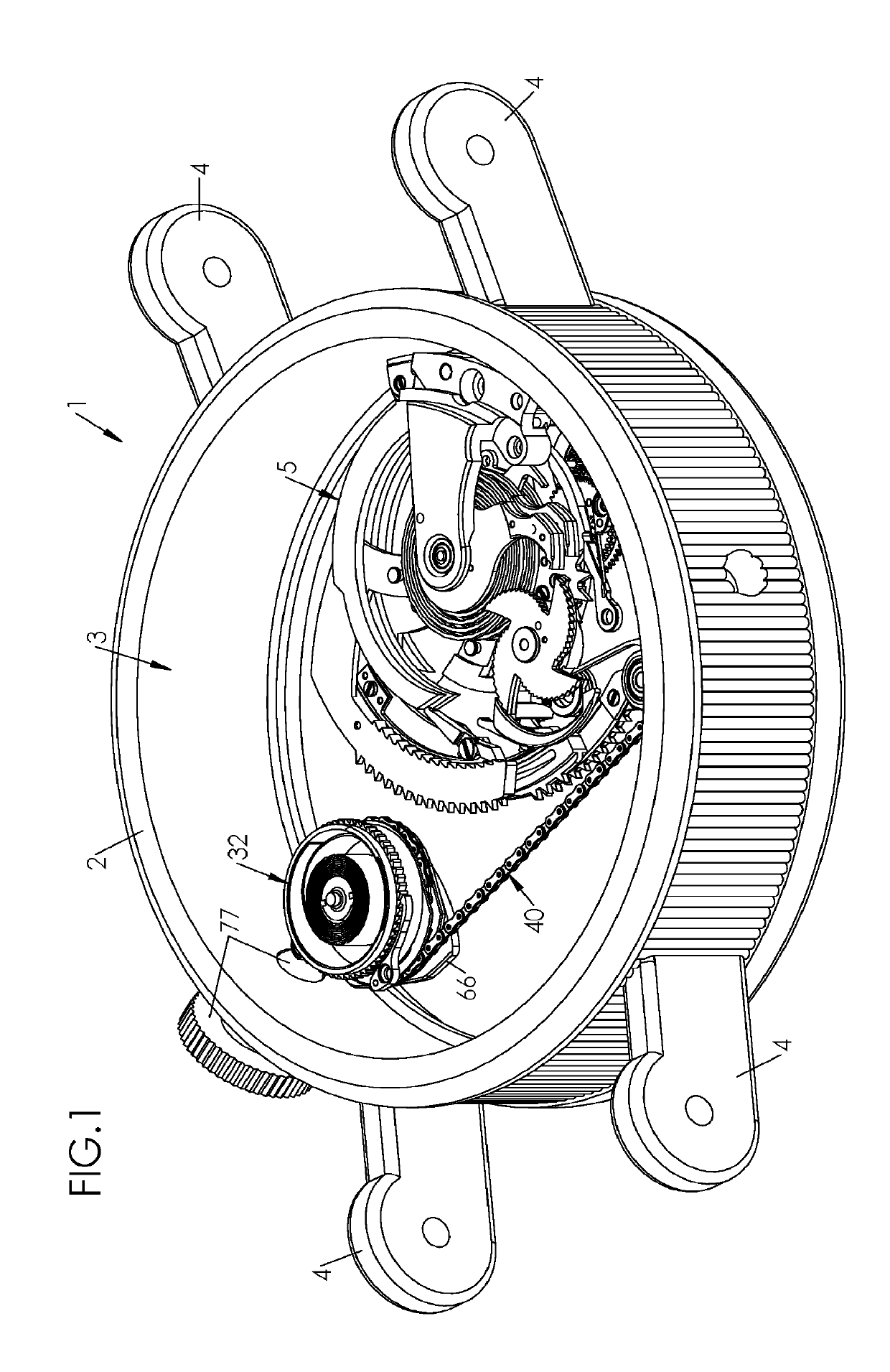

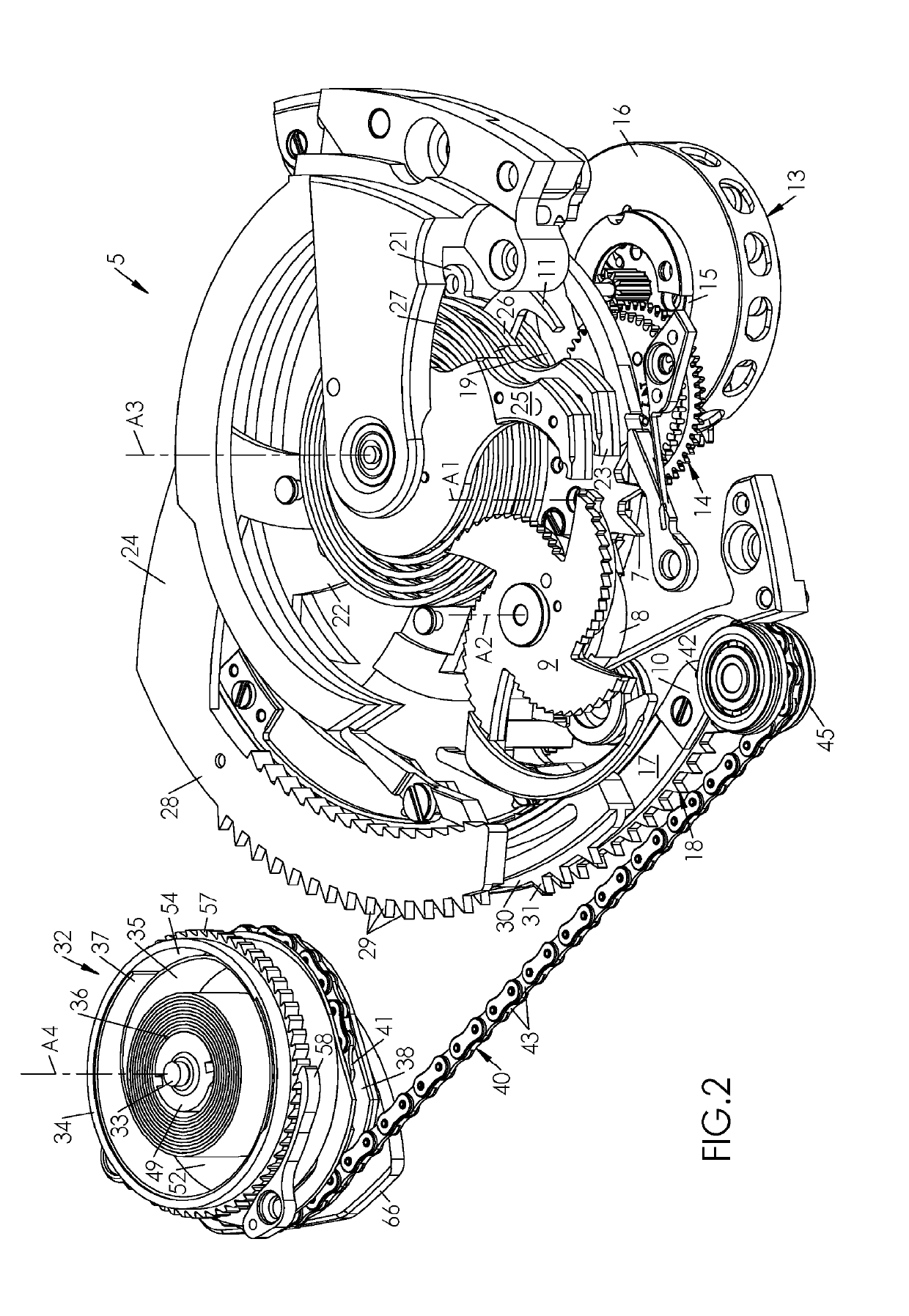

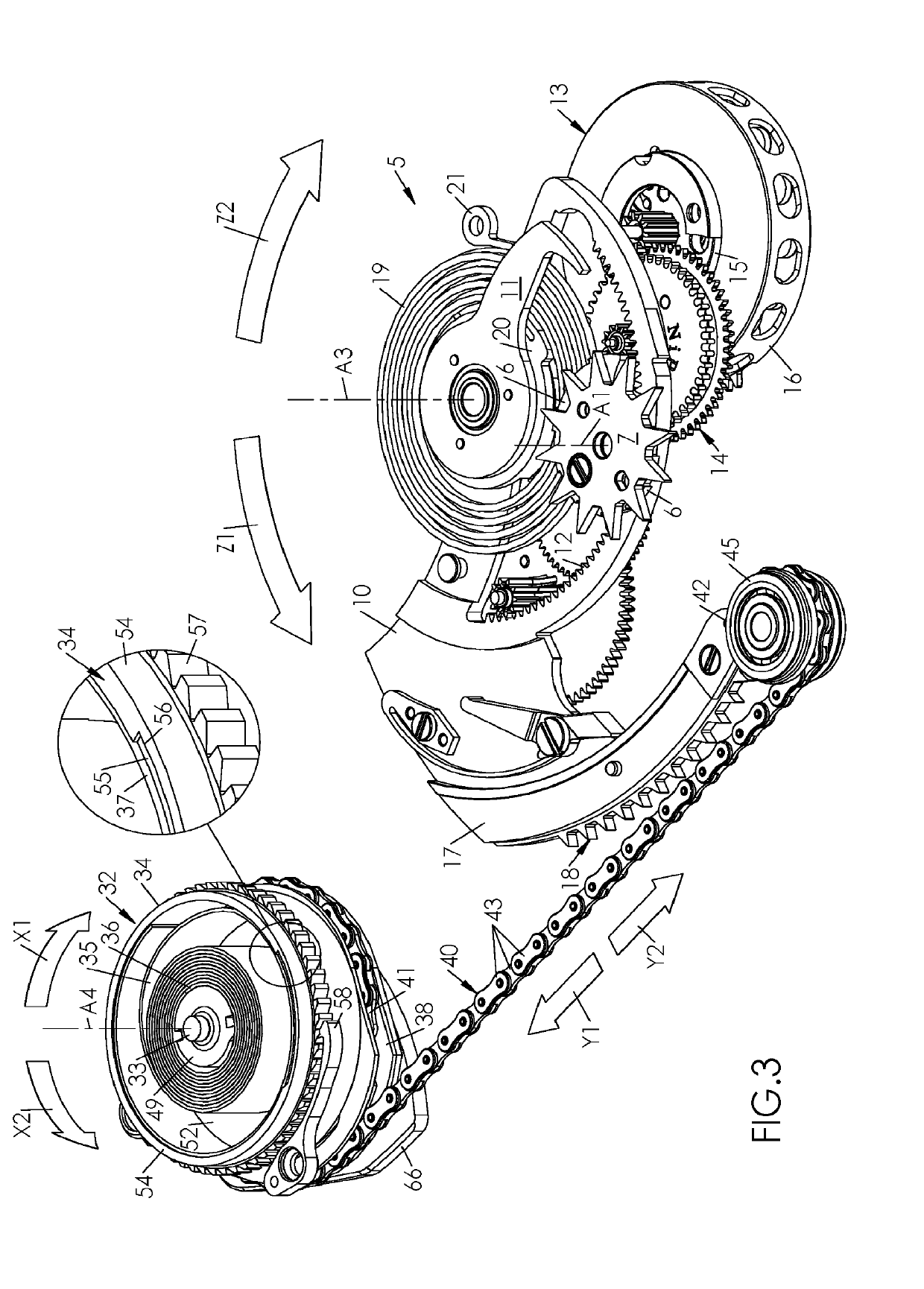

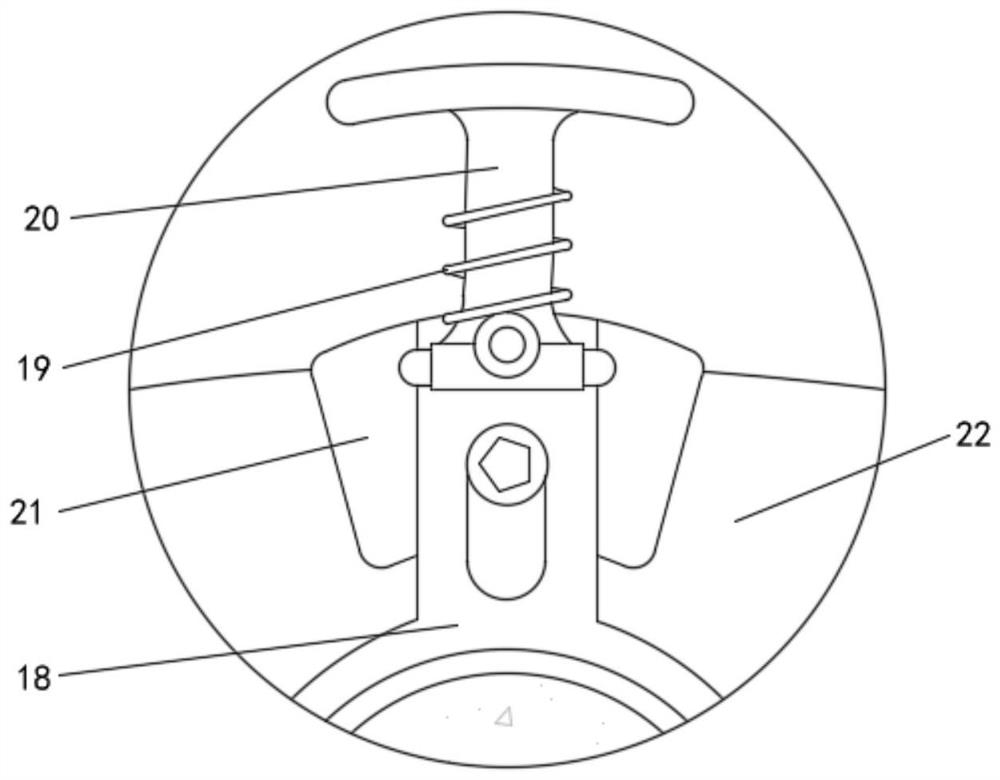

Repeater mechanism with tensioned chain

ActiveUS11073797B2Reduce mechanical fatigueGuaranteed uptimeGearworksAcoustic indicationRatchetControl theory

Owner:MONTRES BREGUET

Repeater mechanism with tensioned chain

ActiveUS20190196409A1Reduce mechanical fatigueReliable operationGearworksAcoustic indicationEngineeringPulley

Repeater mechanism (5), comprising:An hour part (10), which is mobile between a resting position and a reading position;An hour spring (19) which returns the hour part (10) towards its reading position;A chain (40) which is hooked to the hour part (10);A barrel (32) which comprises a shaft (33), a drum (34), a spring (35), a pulley (38) which is mobile in rotation relative to the shaft (33) and on which the chain (40) is hooked, and also a ratchet which is integral in rotation with the barrel shaft (33) and: coupled to the pulley (38) as long as the hour part (10) exerts a traction force on the chain (40);uncoupled from the pulley (38) as soon as this traction force is cancelled out;A pulley spring (38) which is interposed between the ratchet and the pulley (38).

Owner:MONTRES BREGUET

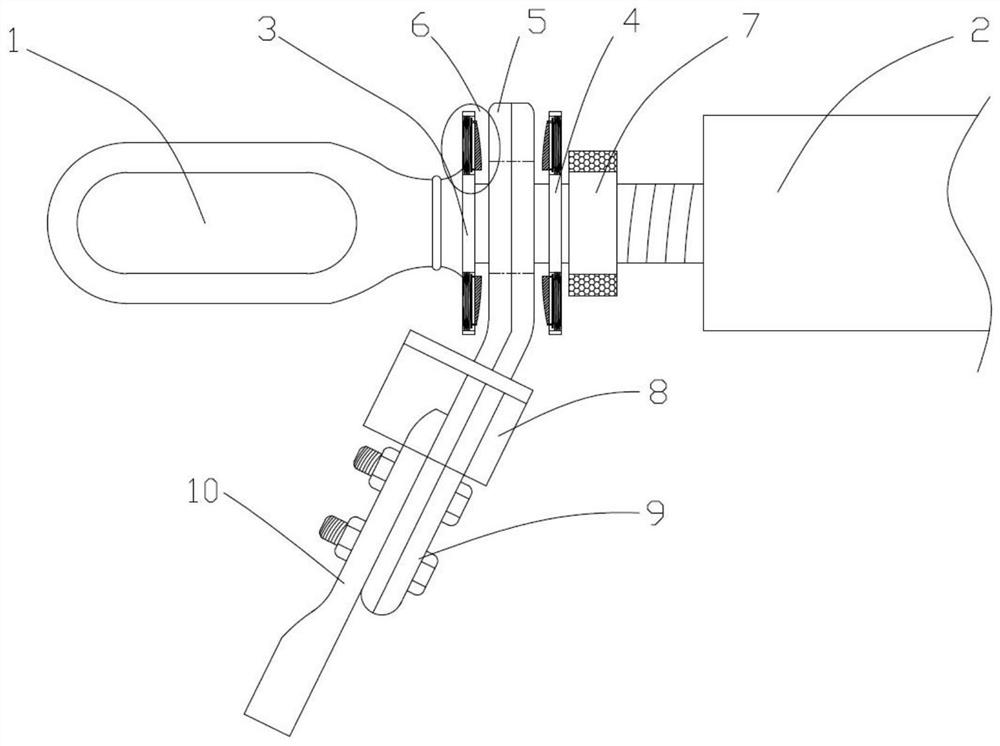

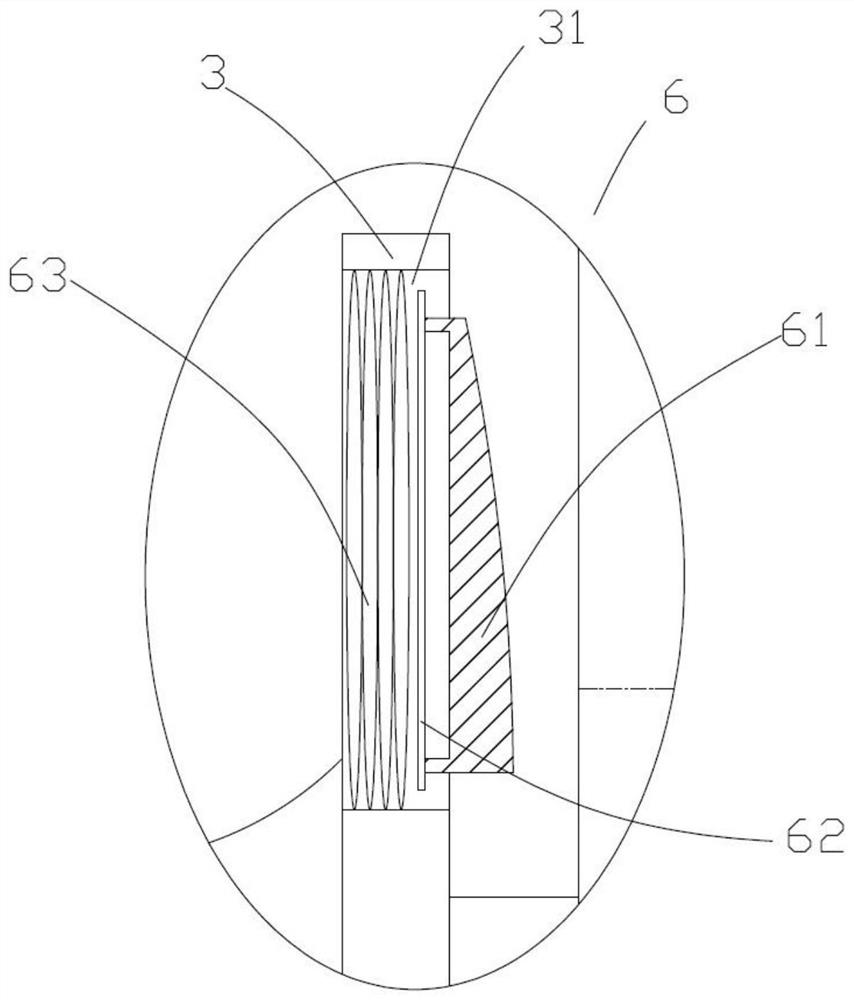

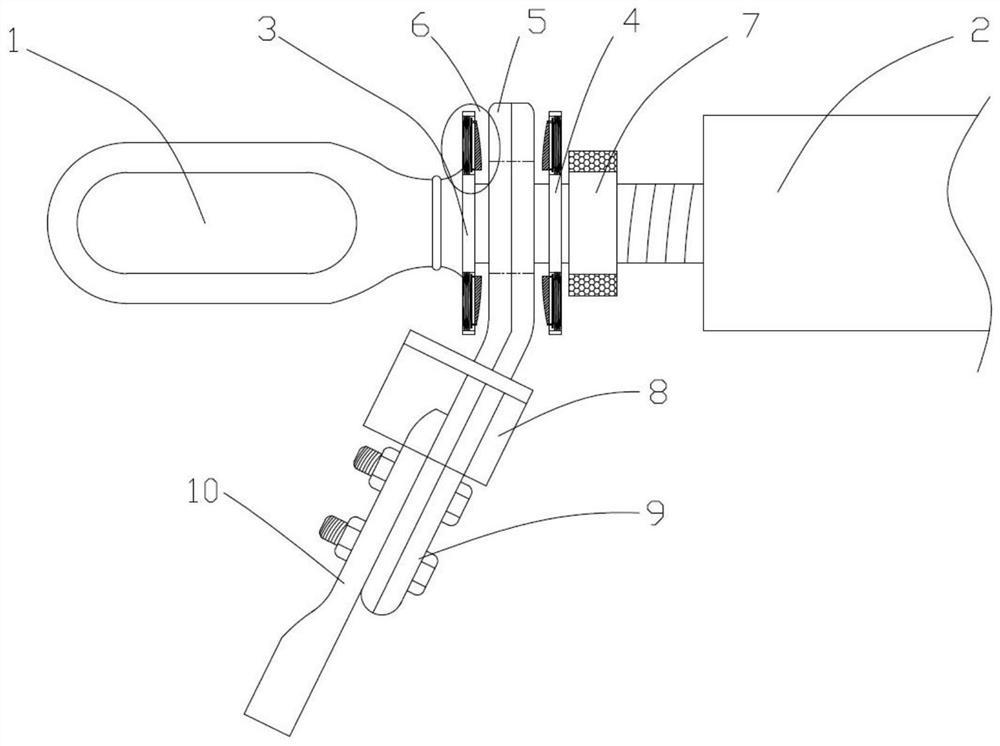

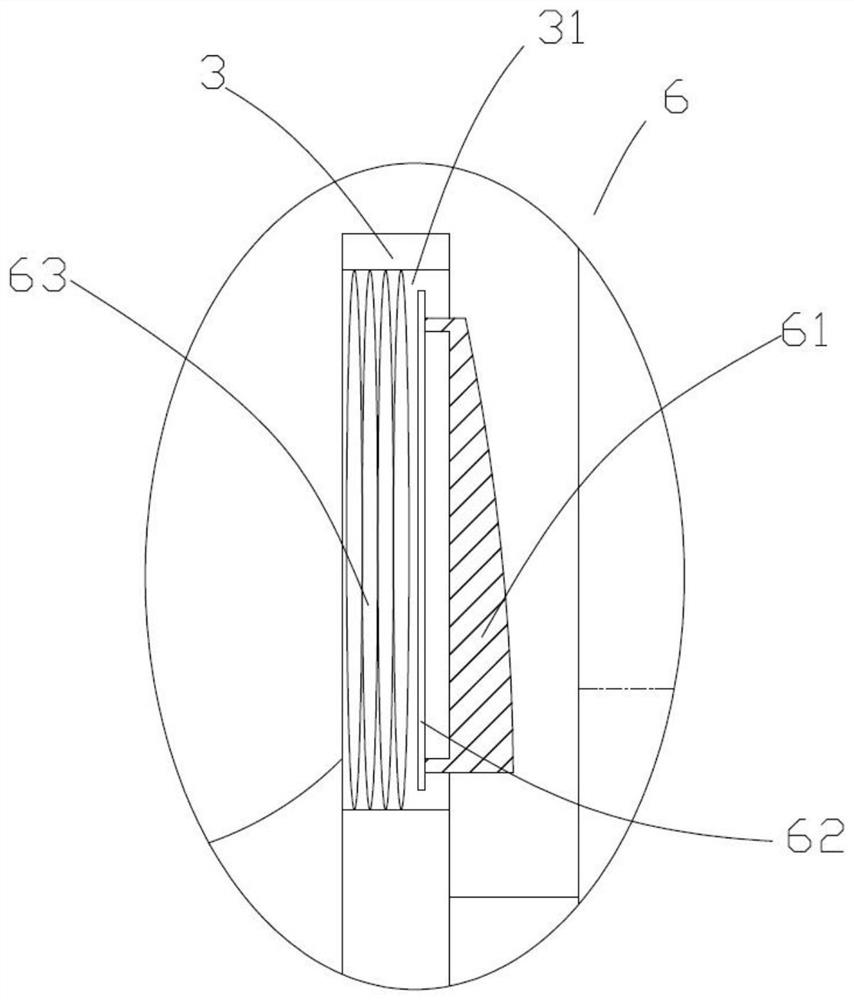

Hydraulic strain clamp

ActiveCN111799734AReduce mechanical fatigueAvoid affecting useAdjusting/maintaining mechanical tensionSuspension arrangements for electric cablesMechanical engineeringElectric power

The invention provides a hydraulic strain clamp. The invention relates to the technical field of electric power fittings. The strain clamp designed by the invention is provided with the buffer devicesfor buffering a mounting plate, the buffer devices are placed on an extrusion plate and are symmetrically arranged, a protection device is further arranged at the joint of a first drainage plate anda second drainage plate, and the protection device can extend and retract to protect the joint of the first drainage plate and the second drainage plate.

Owner:扬州市江华电力器材有限公司

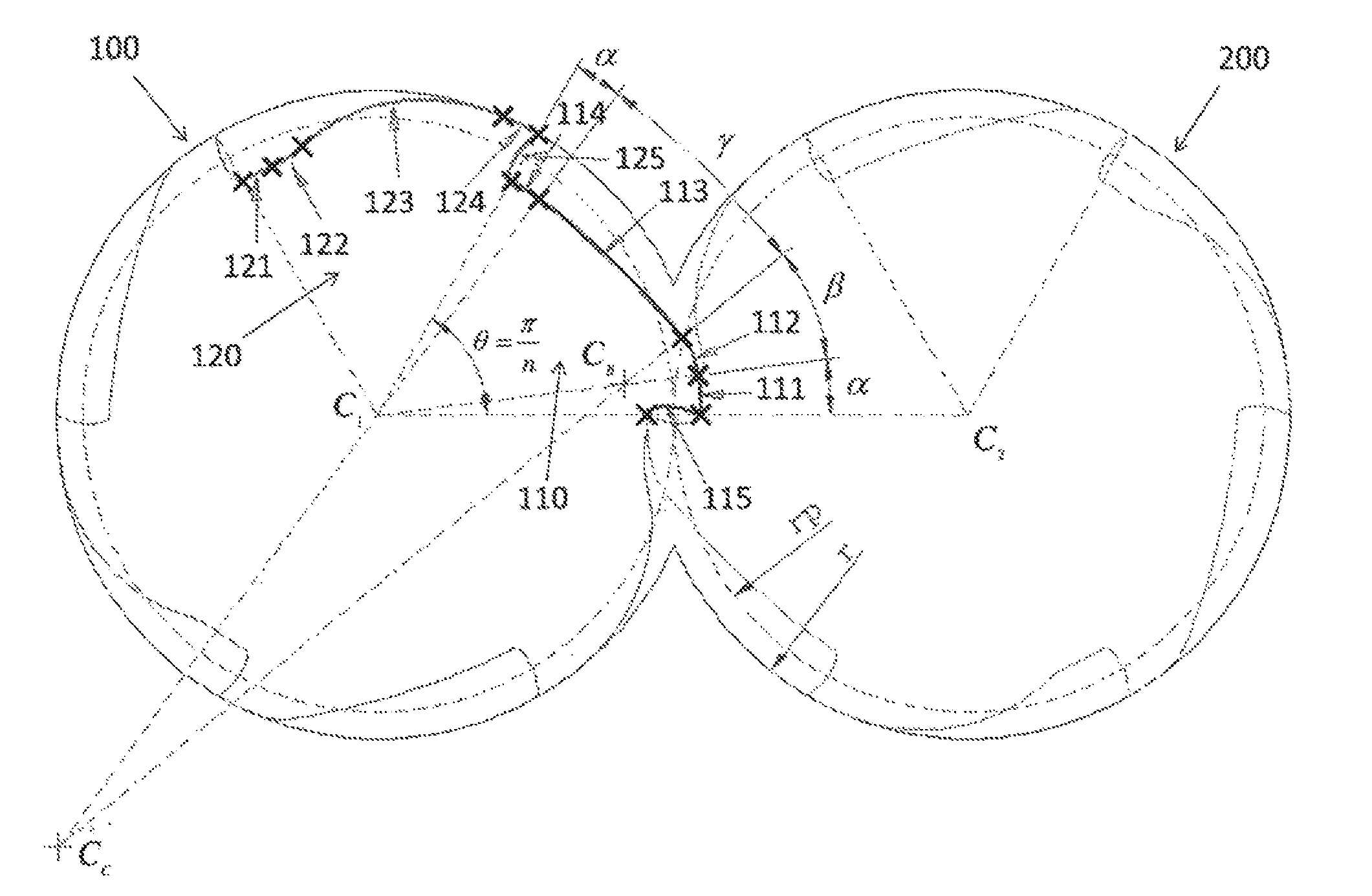

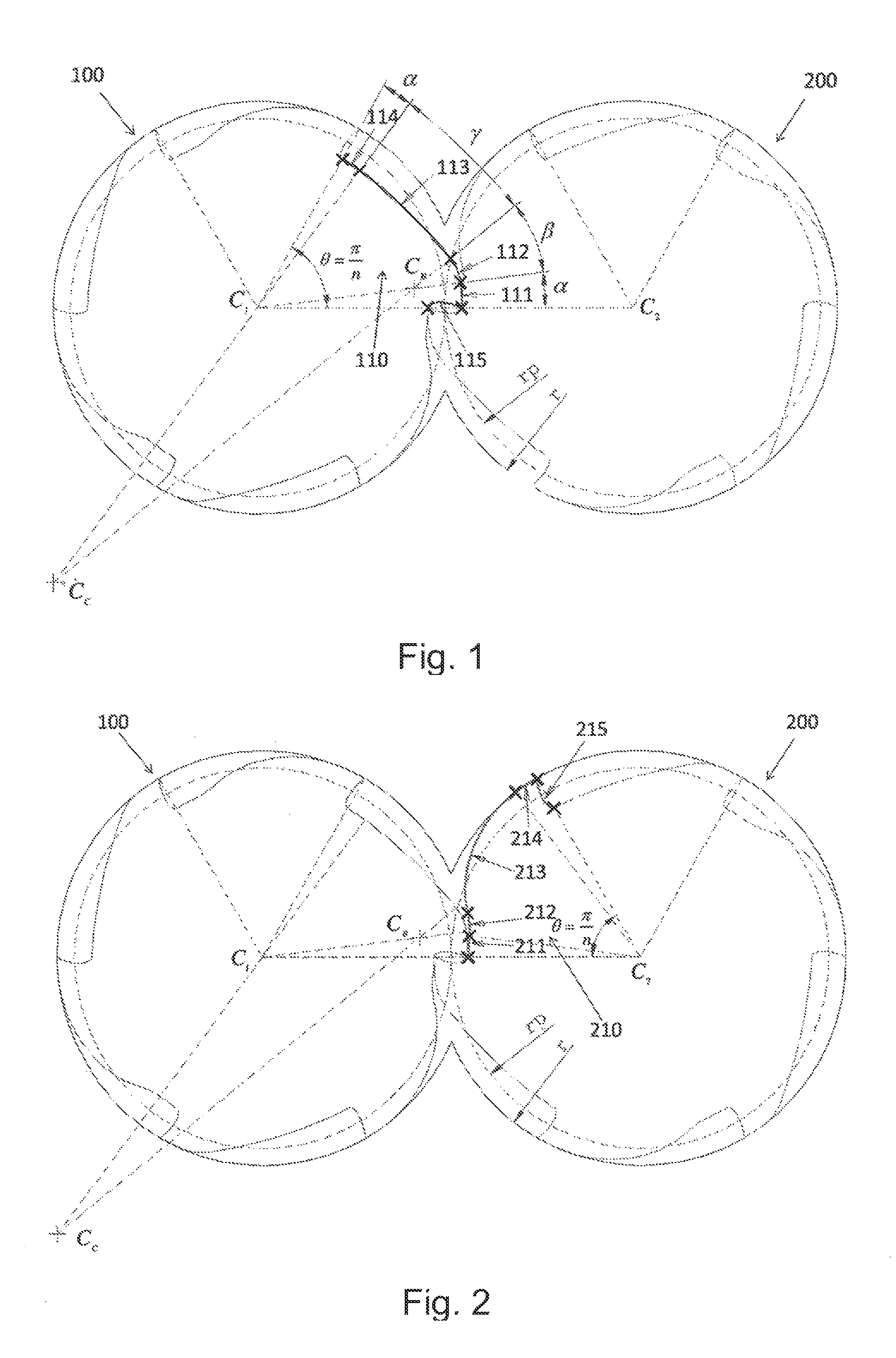

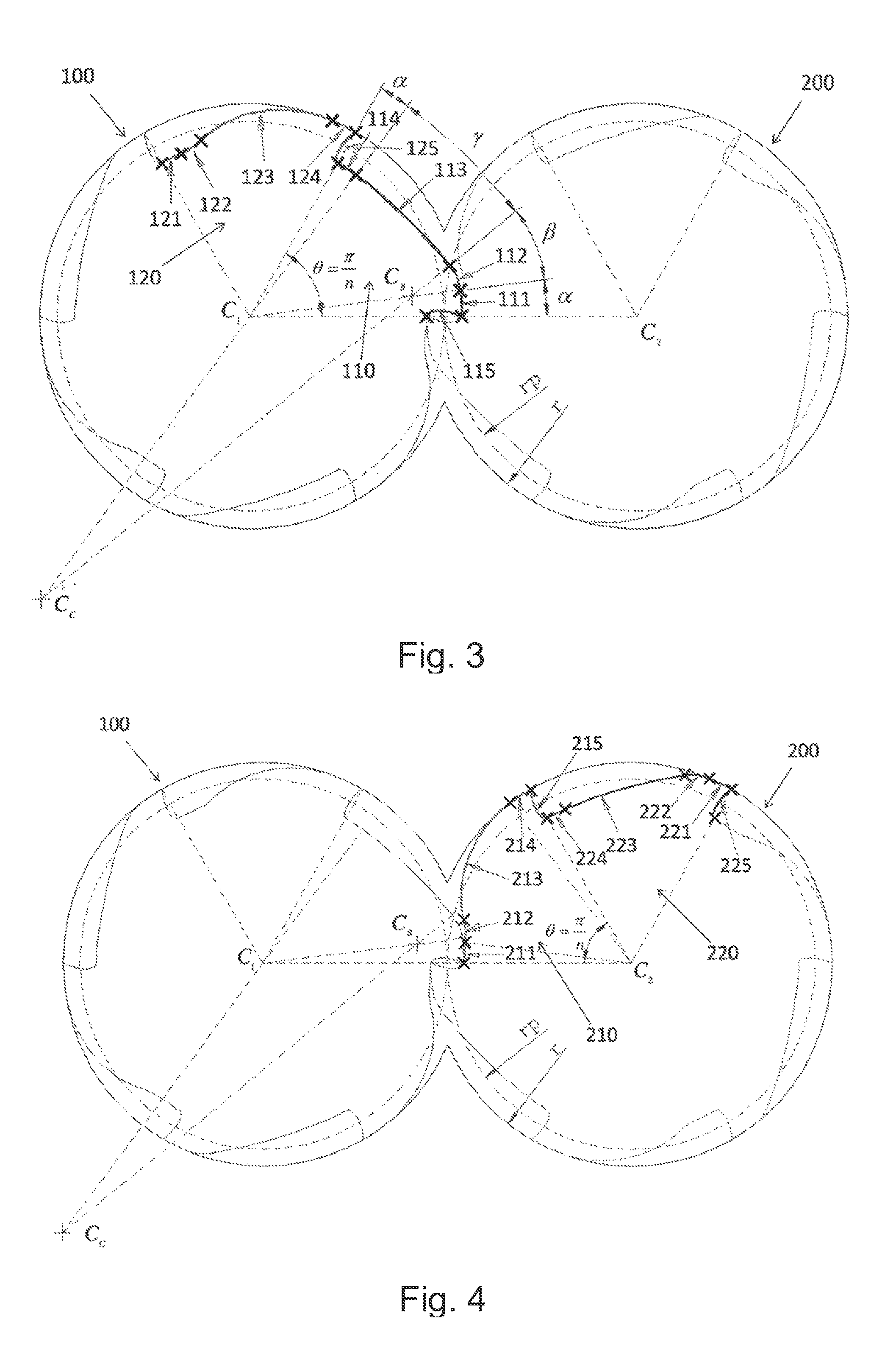

Device of a pair of claw-type rotors having same profiles

ActiveUS8887593B2Extend your lifeAvoid noiseToothed gearingsPortable liftingGeometric relationsEngineering

The present invention is to provide a device of a pair of claw-type rotors having same profiles, the device includes a defined rotor and a conjugate rotor intermeshing with and conjugating to each other. The defined rotor includes a first claw having a cross-section profile having an epicycloid, a first arc, a second arc, a third arc, and a fourth arc all connected together in sequence in a counterclockwise direction. The first, second, third, and fourth arcs are connected with slope continuity, whereby locations of centers, values of radiuses and arc angles of the second and third arcs are capable of being defined in accordance with the slope continuity and geometric relations between the first and fourth arcs. The conjugate rotor has a first claw having a cross-section profile generated by utilizing a conjugate curve corresponding to the first claw of the defined rotor.

Owner:LIUNG FENG INDAL

Telescopic high-pressure pipeline compensator

InactiveCN112524371AStructure independentNo structural deformationAdjustable jointsStructural deformationControl engineering

The invention discloses a telescopic high-pressure pipeline compensator, and relates to the technical field of pipeline compensators. The telescopic high-pressure pipeline compensator comprises a first telescopic part and a second telescopic part, the first telescopic part is used for connecting with a pipeline, and comprises a first pipe body, and an outer pipe shell and an inner pipe shell are arranged on one end face of the first pipe body; a first flange is fixed to the other end face of the first pipe body; the second telescopic part is used for connecting with another pipeline, and comprises a second pipe body, and an inserting pipe shell is located on one end face of the second pipe body, and is in clearance fit with an annular cavity in the first pipe body; and a second flange is fixed to the other end face of the second pipe body. According to the telescopic high-pressure pipeline compensator, relative contraction or extension is achieved through relative sliding connection between the independent first telescopic part pipe body and the second telescopic part pipe body so that the pipeline compensation effect is achieved, and the two pipe bodies are independent in structure; and the pipeline compensator is free of structural deformation, high in bearing pressure, convenient in installation, low in mechanical fatigue and long in service life.

Owner:合肥众甫工业技术有限公司

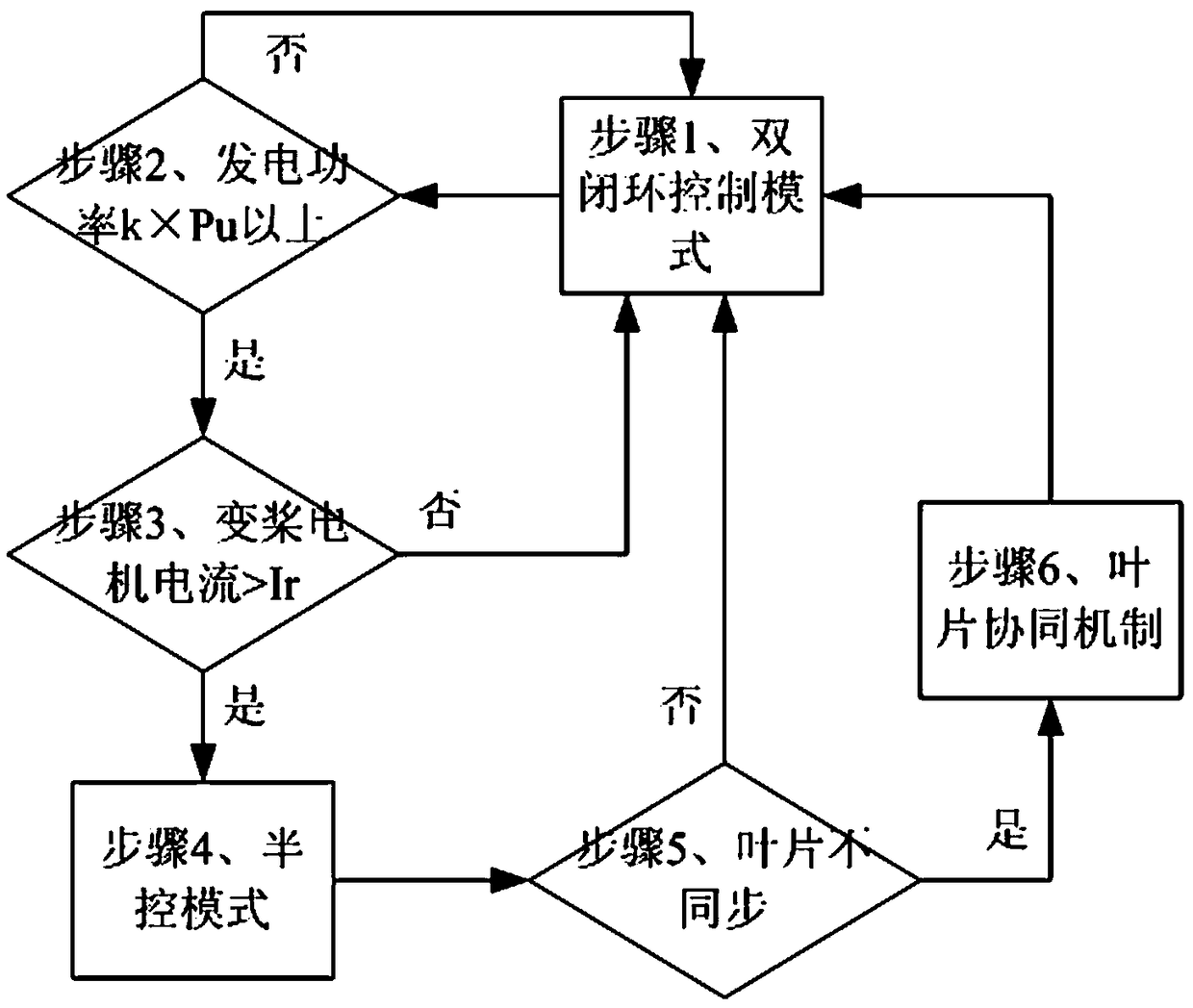

A wind turbine load shedding control method

ActiveCN106499582BReduce mechanical fatigueReduce operating loadWind motor controlMachines/enginesLoad SheddingElectricity

The invention relates to a wind generation set deloading control method. The method comprises the steps that whether a current feedback value of a variable pitch motor is larger than a set parameter value Ir or not is judged at first; if yes, a wind generation set runs in a semi-control mode, in other words, when the practical feedback current of the variable pitch motor is larger than the reference value Ir, the variable pitch motor is controlled to carry out output according to the reference value Ir, and meanwhile, double closed loop control is canceled; after continuous running is carried out for the set time T, whether the phenomenon that blades are nonsynchronous exists or not is judged; and when the angle difference of every two adjacent blades exceeds a set angular deviation, the blades are in the nonsynchronous state, a blade cooperation mechanism is executed, the blade with the largest angle is used as the reference, and the other two blades are controlled to keep the same angle as the blade. Due to the fact that the semi-control mode is added, when large turbulent flow appears, the problems that execution of a variable pitch system lags and the wind generation set is overspeed are solved. The variable pitch nonsynchronous phenomenon existing during operation in the semi-control mode is avoided through the blade cooperation mechanism.

Owner:XEMC WINDPOWER CO LTD

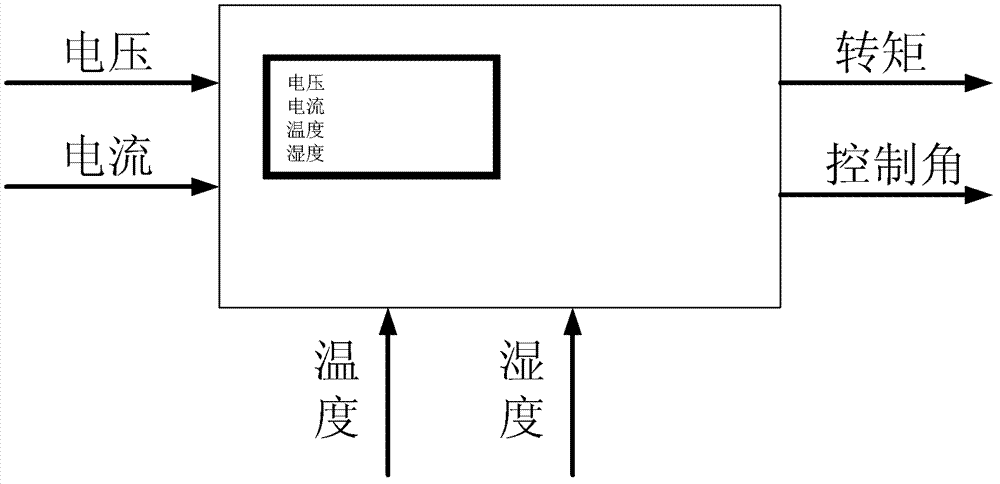

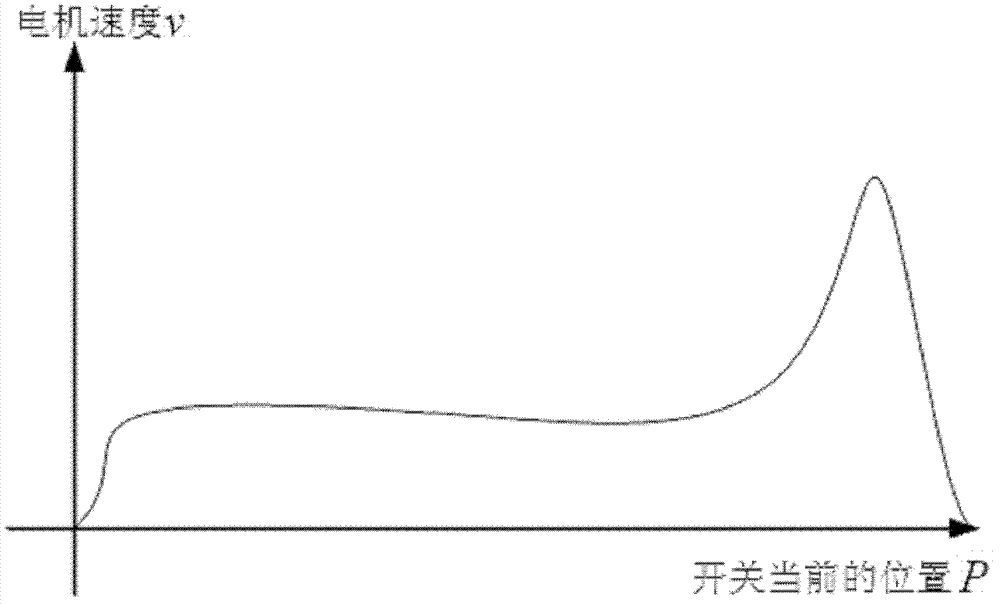

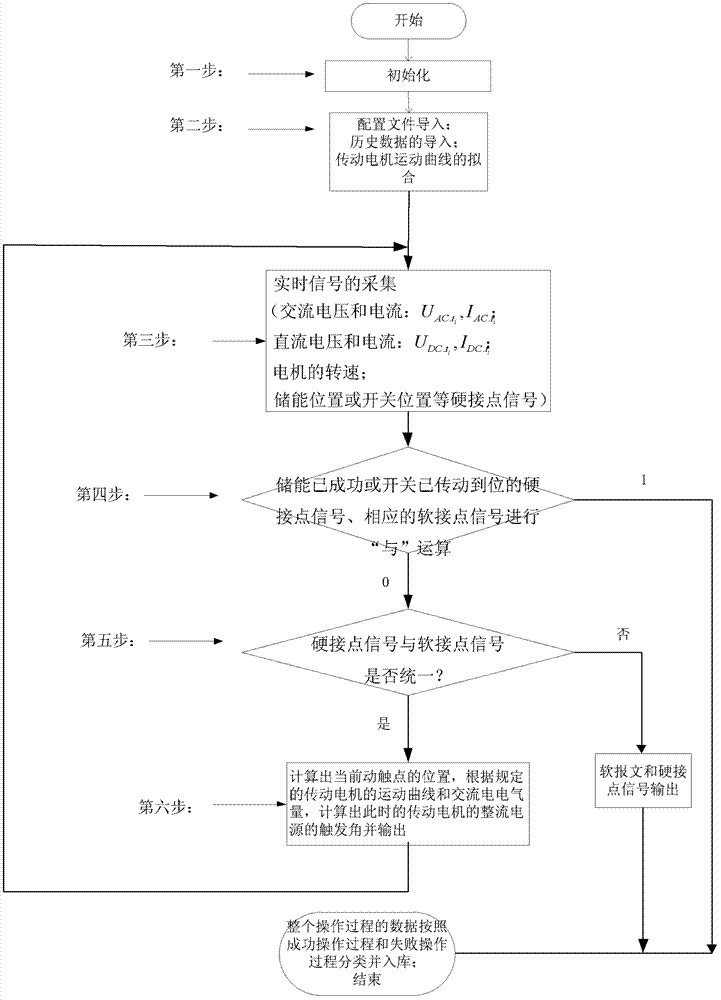

Intelligent control method of electrified operation mechanism of high-voltage switch

ActiveCN103378652BLow residual voltage on load sideLow VFTO amplitudeCircuit arrangementsChange controlHigh pressure

The invention relates to an intelligent control method of an electrified operation mechanism of a high-voltage switch. The method includes the steps of importing configuration files and historical data of a motor to form a stepping curve in the motor transmission and energy storage process in a fitting mode, monitoring the real-time process amount of the motor and the dynamic process of switching on and switching off of the switch, performing analysis in combination with the stepping curve of the transmission motor to obtain a soft contact signal of the position of the switch and a soft contact signal of energy storage of a spring, if the switch operation is not in place and a hard contact signal of the switch is consistent with the soft contact signal, calculating and outputting the position of a movable contact of the switch and the triggering angle of a rectification power supply of the transmission motor, and returning to the step of monitoring the real-time process amount of the motor and the dynamic process of the operation mechanism. While self-diagnosis is achieved, speed changing control is performed on the motor, the phenomena such as coil burnt damage caused by frustration of an operation process or being not in place of the opening state are avoided, and the motor is protected to the maximum. The intelligent operation of the operation mechanism can be achieved without changing the original structure, and the method is easy and convenient to use and high in performance cost ratio.

Owner:SIFANG-TBEA INTELLIGENT ELECTRICAL CO LTD

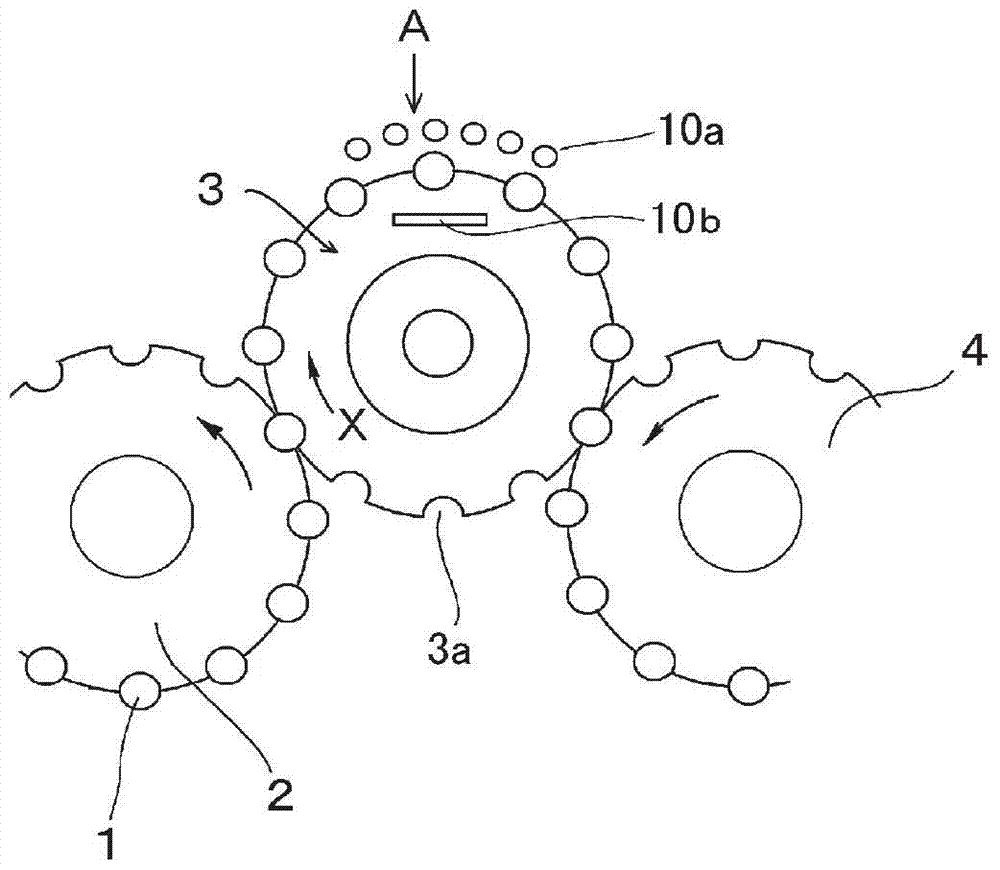

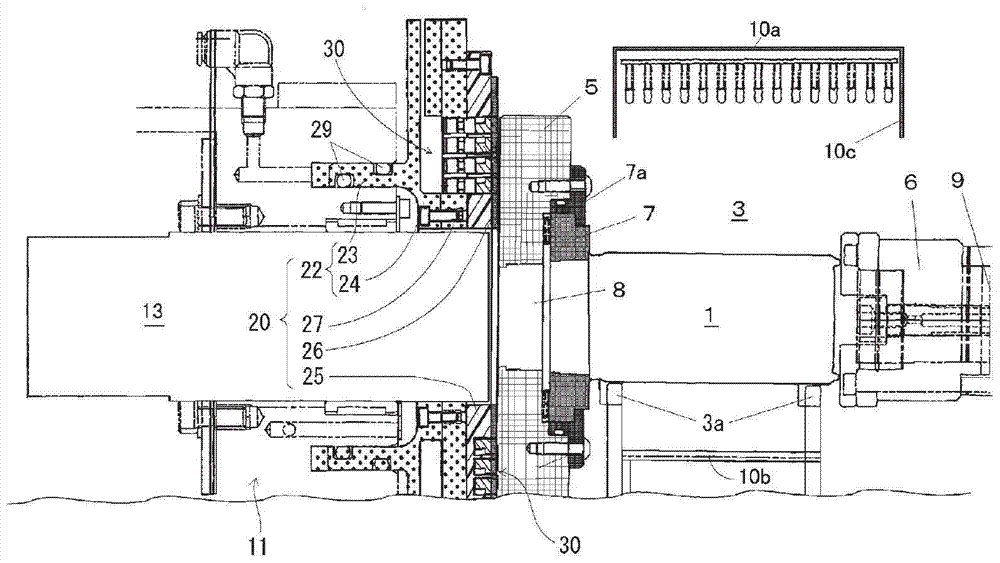

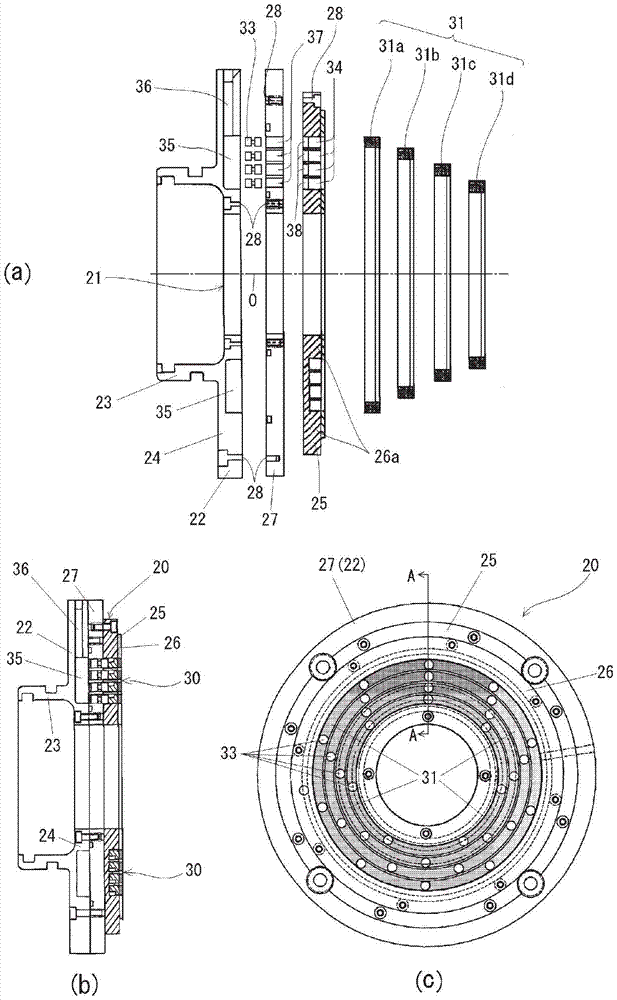

Pinhole inspection device for tanks

ActiveCN104781655BEasy to coverReduce mechanical fatigueOptically investigating flaws/contaminationFluid-tightness measurement using lightPhotodetectorSurface conditions

The pinhole inspection device for cans according to the present invention includes: a rotating plate having a through hole; a movable plate provided on the side of the fixed frame facing the rotating plate; and a can holding member supporting the main body of the can. a photodetector for detecting light leaked into the inside of the can body; and a light source for irradiating light on the outer peripheral surface of the can body, the pinhole inspection device for the can body is characterized in that the movable plate The front surface of the piston member having a through-hole in the center is equipped with an annular plate via a joint member, and a shielding member composed of an annular member formed concentrically with the through-hole is provided on the above-mentioned annular plate. The blocking member is in sliding contact with the rotating plate, thereby effectively preventing disturbance light from reaching the photodetector side through the gap between the movable plate and the rotating plate caused by external force or the surface state of the sealed annular plate and the sliding annular plate. .

Owner:TOYO SEIKAN GRP HLDG LTD

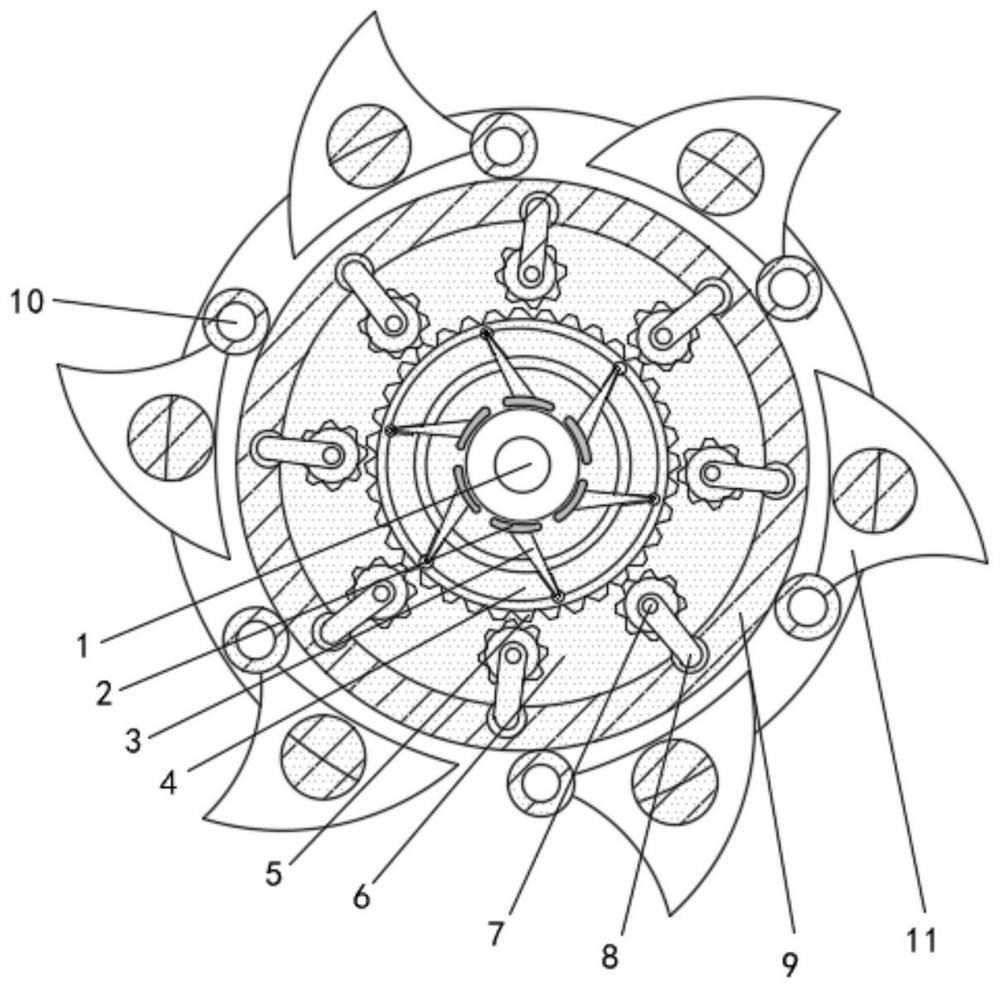

Energy-saving and environment-friendly rigidity improving assembly for steel bar prestress

InactiveCN112538972ARaise stiffness componentsReduces excessive stretchingBuilding material handlingPre stressLinkage (mechanical)

The invention relates to the technical field of steel bar prestress, and discloses an energy-saving and environment-friendly steel bar prestress rigidity improving assembly. The energy-saving and environment-friendly rigidity improving assembly for steel bar prestress comprises a control shaft; a detection block is fixedly connected to the outer side of the control shaft; a conical plate is fixedly connected to the top of the detection block; a synchronous disc is fixedly connected to the top of the conical plate; and outer side teeth are fixedly connected to the outer side of the synchronousdisc. According to the energy-saving and environment-friendly rigidity improving assembly for steel bar prestress, the synchronous disc synchronously rotates along with the control shaft through centrifugal force of the control shaft, a trigger block makes contact with a linkage bin under the action of the centrifugal force, a rolling ball extrudes the outer wall of a rotating ring under the action of the centrifugal force, a movable ball connected to the outer wall of the rotating ring is stressed to be hardened, the size of the movable ball is increased, an extrusion plate and a limiting plate are pushed to move outwards, stall of the control shaft is controlled, excessive stretching of a reinforcing steel bar is reduced, and the mechanical fatigue degree of the reinforcing steel bar isreduced.

Owner:温州山全贸易有限公司

Raster optical modulator with translational reflective mirror and array thereof

InactiveCN100349035CReduce gapImprove optical diffraction efficiencyDiffraction gratingsInsulation layerGrating

A light modulator consists of base, insulation layer, electrode layer, movable flat plate, fixed grating, and cover. It is featured as locating flat plate in the first plane to concentrate light intensity on zero class of diffraction as on voltage and locating it in the second plane to concentrate light intensity on top class of diffraction by driving it to move vertically with voltage in order to realize various modulation for incoming beam for providing different energy distribution of diffraction light.

Owner:CHONGQING UNIV

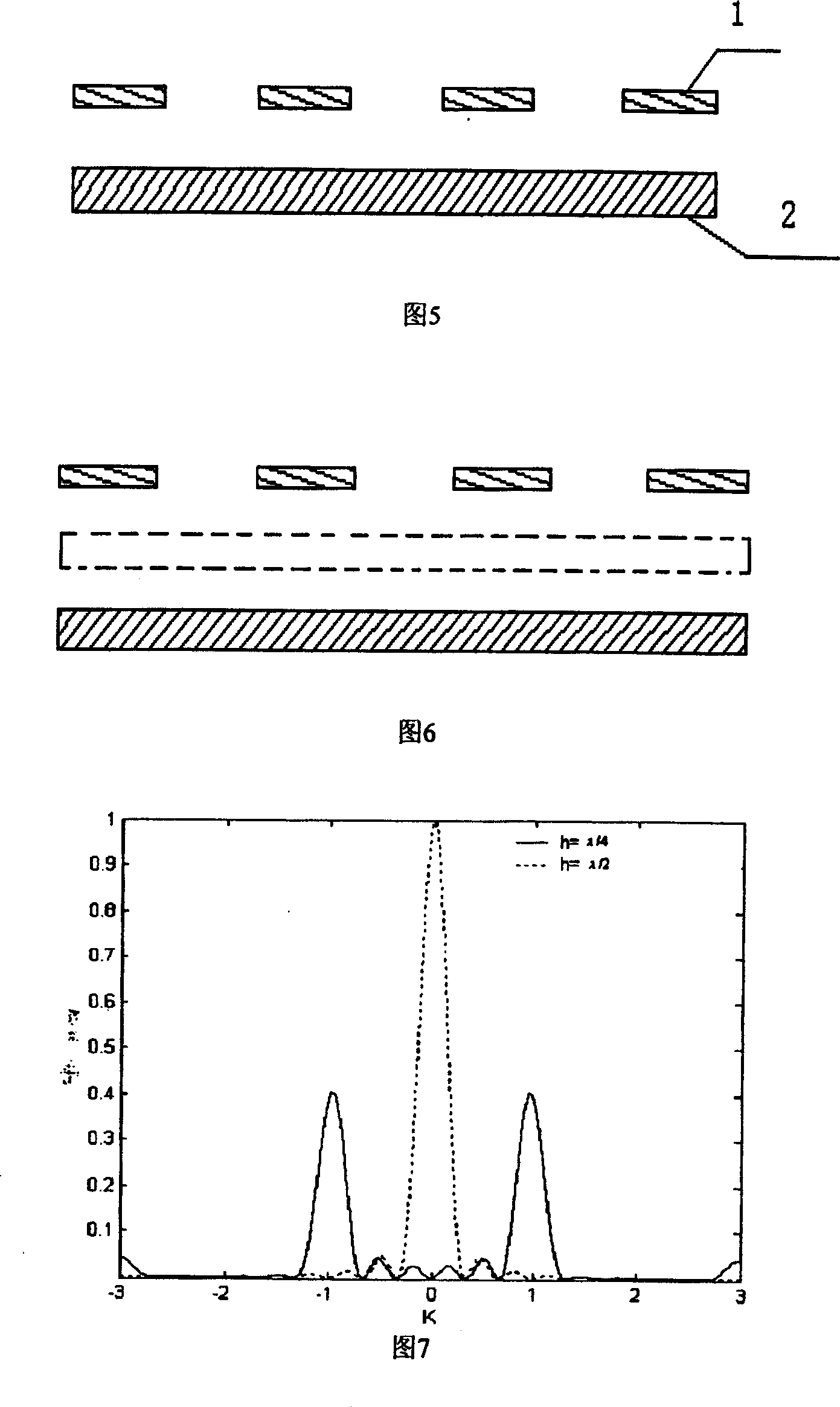

Forging hammer equipment for forging

PendingCN112846022ARelieve structural mechanical fatigueRelieve Mechanical FatigueDrop hammersHammer drivesImpactTelescopic cylinder

The invention discloses forging hammer equipment which comprises a support, a telescopic cylinder, a hammer head, an anvil block and a buffer mechanism, wherein the support comprises a top plate, a bottom plate and two side plates, the two side plates are arranged in a spaced mode, the tops of the two side plates are fixedly connected with the top plate, the bottoms of the two side plates are fixedly connected with the bottom plate, the telescopic cylinder is fixedly and vertically arranged on the top plate, the telescopic end of the telescopic cylinder penetrates through the top plate and is arranged in a gap between the two side plates, the anvil block is arranged on the bottom plate and is arranged right below the telescopic cylinder, the hammer head is arranged in the gap between the two side plates, the hammer head is arranged above the anvil block, and the buffering mechanism is used for buffering an impact force generated by the damping hammer head. The technical problems that damping cannot be achieved and mechanical fatigue cannot be eliminated easily in the prior art are solved.

Owner:DEYANG WANHONG HEAVY FORGING CO LTD

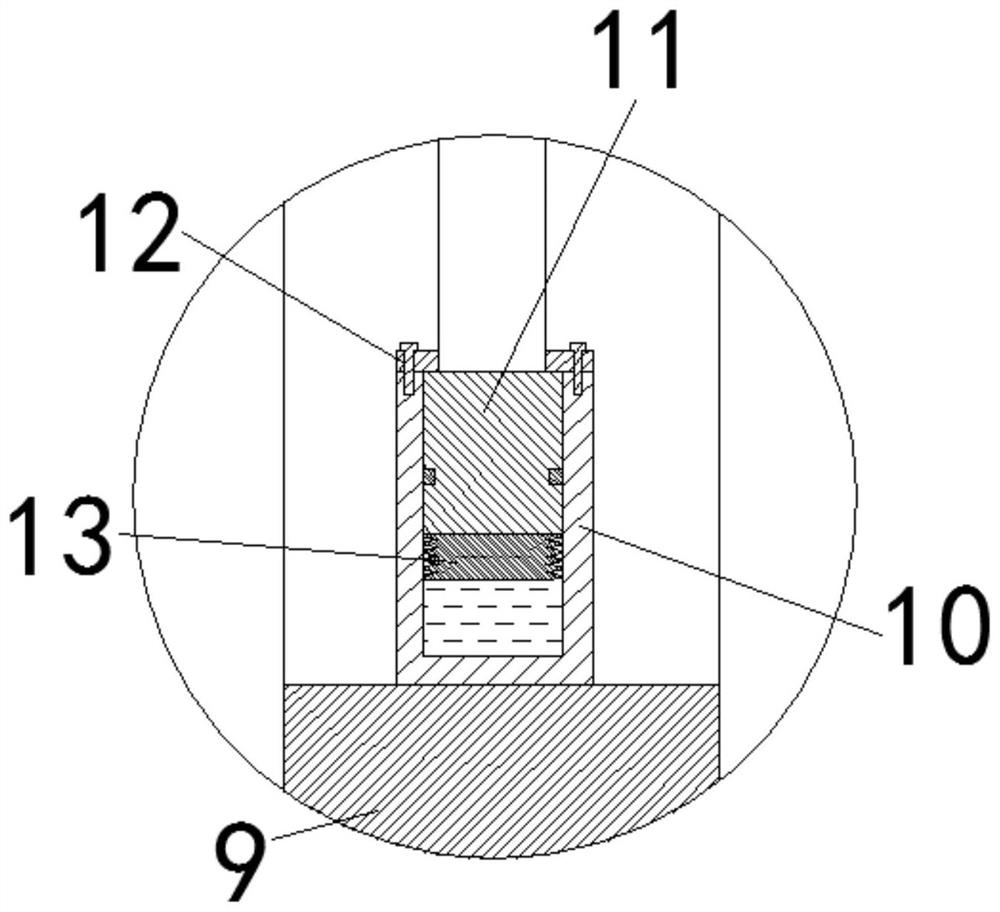

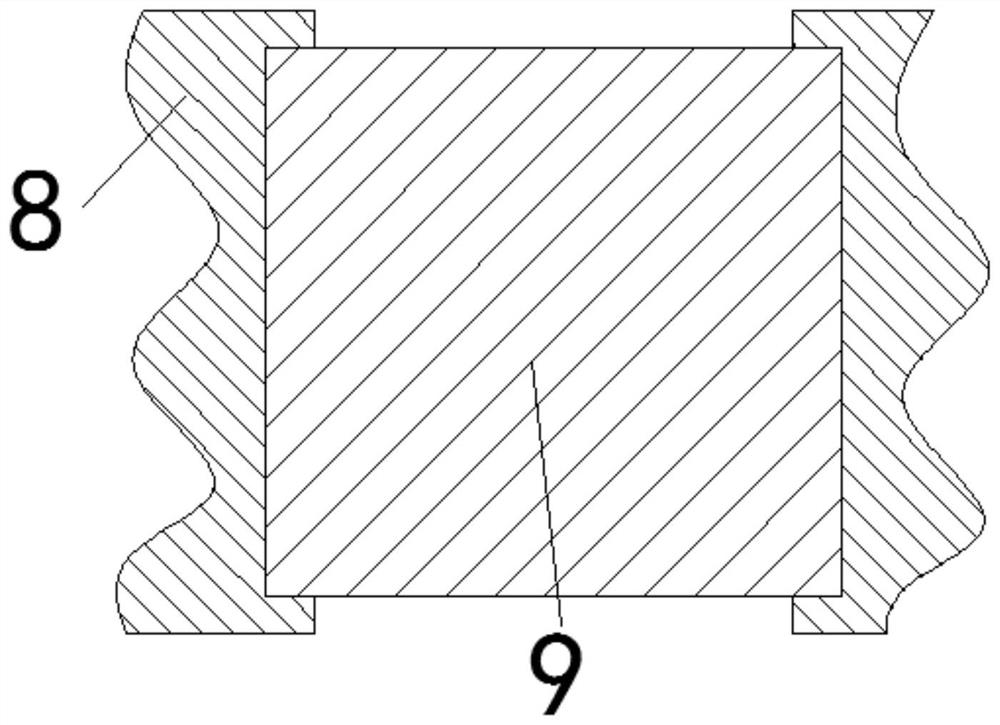

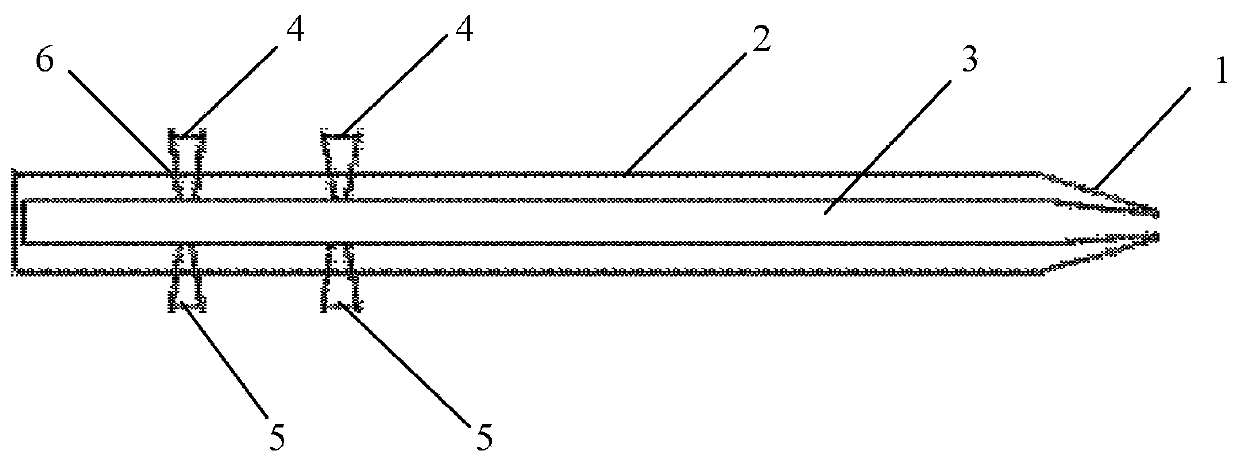

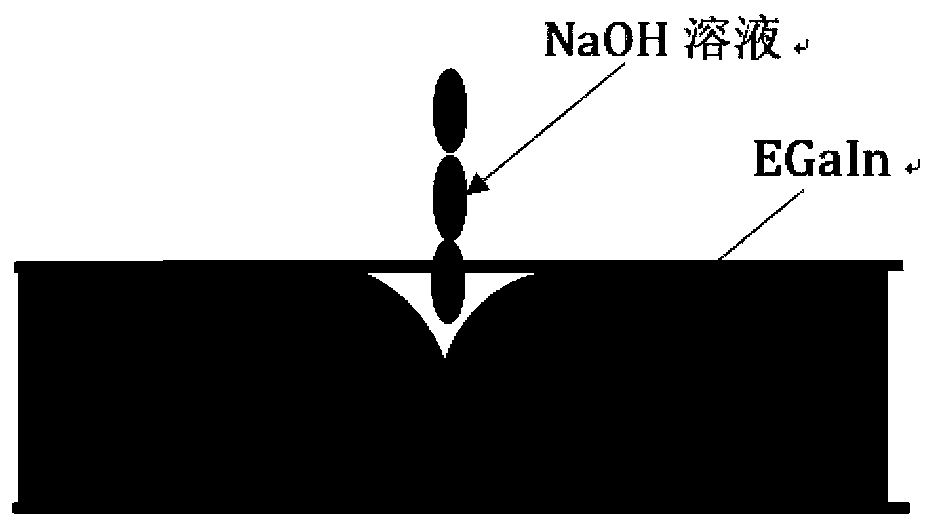

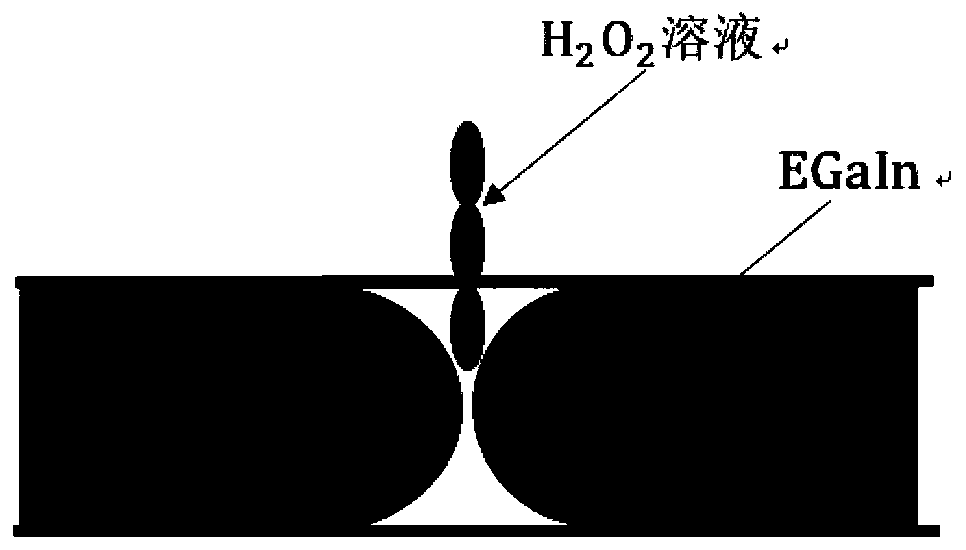

Reconfigurable antenna oscillator and reconfigurable antenna based on liquid gallium indium alloy

ActiveCN110197945BStructural regulationHigh bandwidthSimultaneous aerial operationsRadiating elements structural formsReconfigurable antennaIndium

The invention discloses a reconfigurable antenna element based on a liquid gallium-indium alloy and a reconfigurable antenna. The reconfigurable antenna element comprises a hollow housing and a liquidgallium-indium alloy column in the hollow housing, wherein the hollow housing is provided with a plurality of solution reservoirs and a plurality of adsorbent reservoirs symmetrically distributed with the solution reservoirs; one end of each solution reservoir and one end of each adsorbent reservoir pass through the hollow housing and are in contact with the liquid gallium-indium alloy column; the solution reservoirs selectively contain a NaOH solution or a H2O2 solution; and the adsorbent reservoirs contain a solution adsorbent. The reconfigurable antenna, by the chemical reaction of the solution in the solution reservoirs and the liquid gallium-indium alloy column, changes the effective length of the reconfigurable antenna element and adjusts the structure of the antenna so as to make the antenna compatible with different resonant frequencies and expand the bandwidth of the antenna.

Owner:XIDIAN UNIV

A hydraulic tension clamp

ActiveCN111799734BReduce mechanical fatigueAvoid affecting useAdjusting/maintaining mechanical tensionSuspension arrangements for electric cablesEngineeringMechanical engineering

The invention provides a hydraulic tension clamp, which relates to the technical field of electric power fittings. The tension clamp designed by the invention is provided with a buffer device for buffering a mounting plate. The buffer device is placed on the extrusion plate and is symmetrically arranged. A protection device is also provided at the connection between the first flow guide plate and the second flow guide plate, and the protection device can be extended and retracted to protect the connection between the first flow guide plate and the second flow guide plate.

Owner:扬州市江华电力器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com