Automatic-regulating ventilation system and ventilation regulating method for polar ship machinery

A ventilation system and automatic adjustment technology, applied in the direction of hull ventilation/heating/cooling, ship components, ship construction, etc., can solve the problems of lowering the temperature of the machine space, reducing the effective flow area of the air inlet shutters, and freezing the shutters, etc. The effect of improving stability and reliability, saving operating costs and reducing mechanical fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

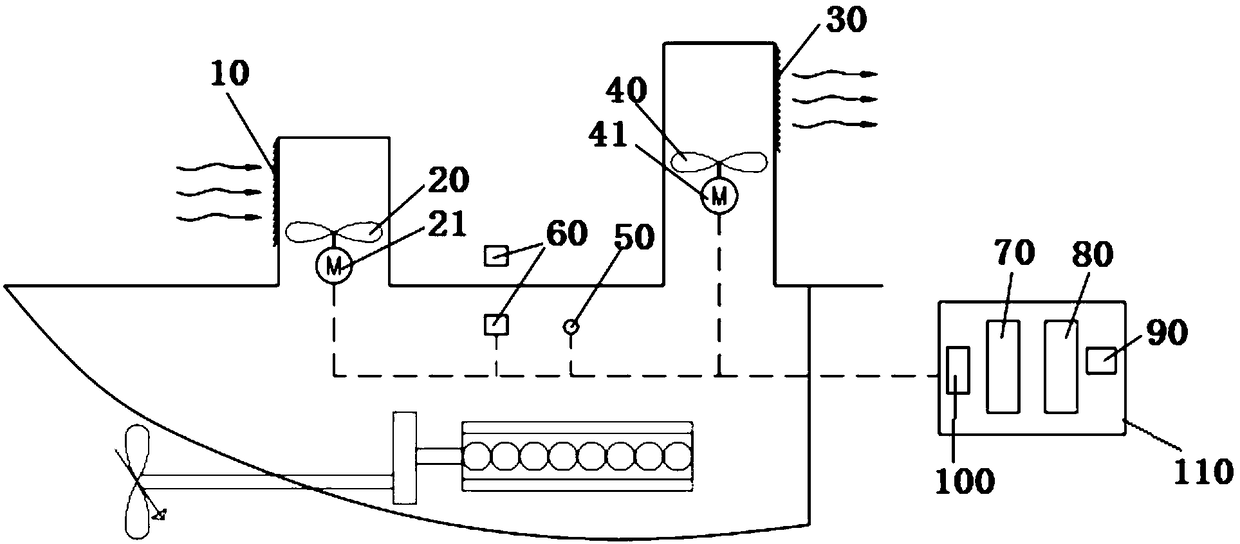

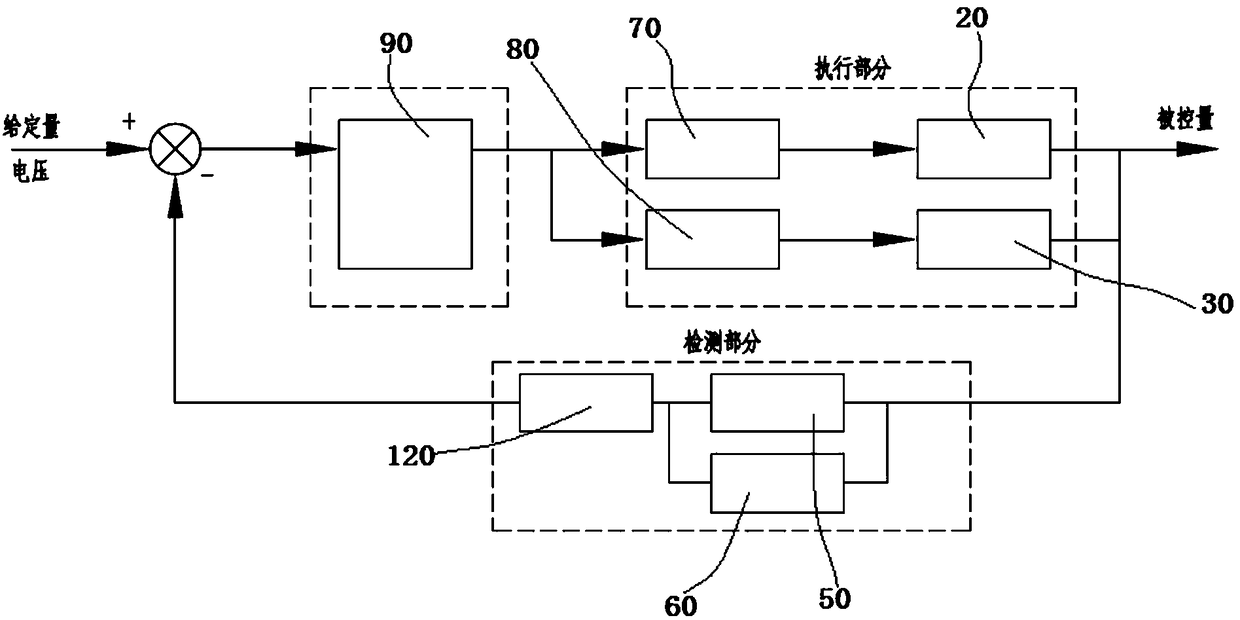

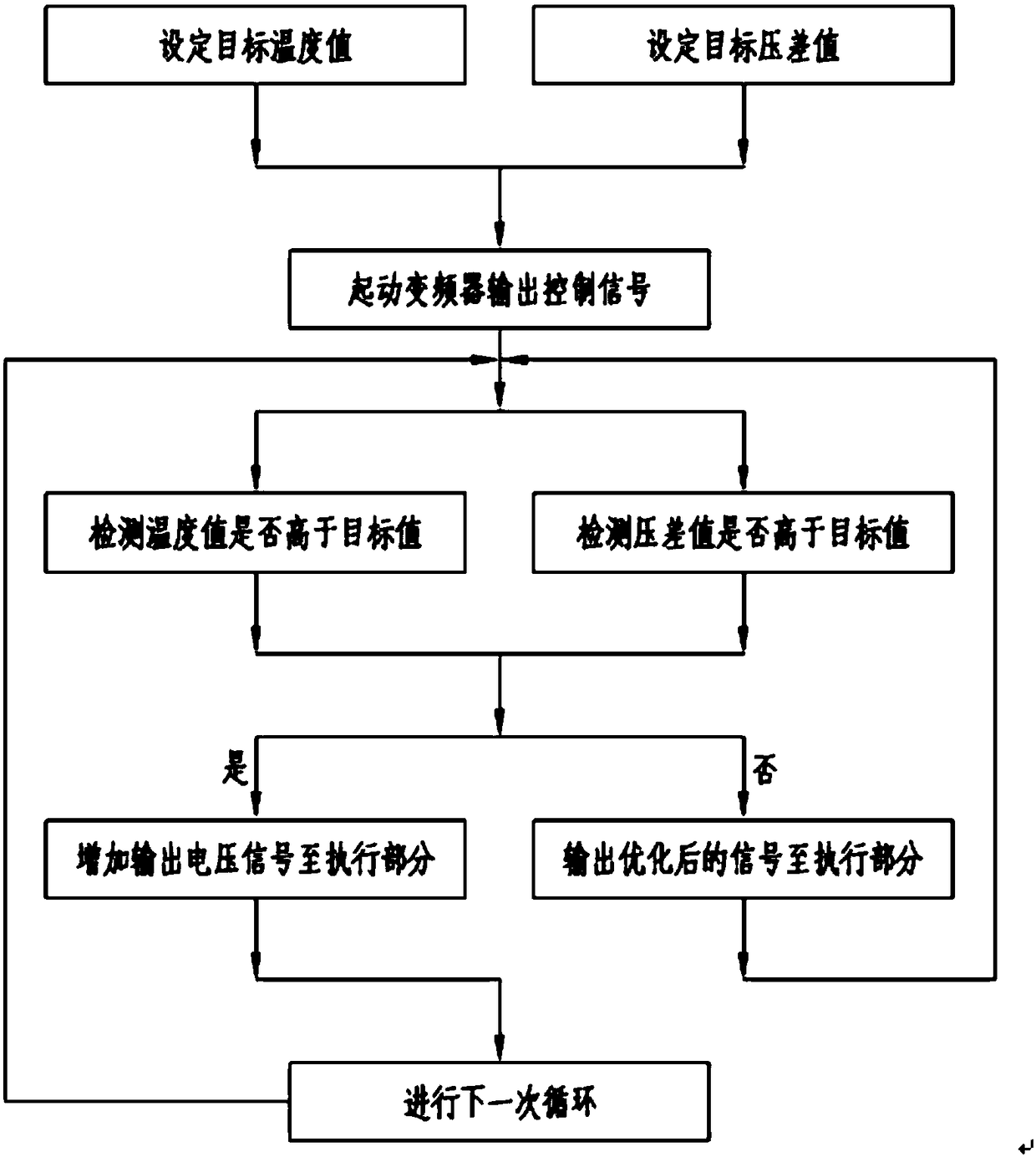

[0047] see figure 1 As shown, the present invention discloses an automatic regulating ventilation system for a polar marine machinery space. The automatic regulating ventilation system includes an air intake louver 10, a blower 20, an exhaust louver 30, an exhaust fan 40, several temperature sensors 50, two pressure sensors 60, A blower frequency converter 70 , an exhaust fan frequency converter 80 , a PLC 90 and a power supply 100 .

[0048] The air intake louver 10 is arranged on the air inlet of the machine space, and the passage inside the air inlet is provided with a blower 20, and the blower 20 is provided with a blower drive motor 21 capable of driving the blower; the air intake louver 10 is made of ordinary weather-tight steel for use in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com