Raster optical modulator with translational reflective mirror and array thereof

A light modulator, translational technology, applied in instruments, optics, optical components, etc., can solve the problems of difficult integration, low GLV effective diffraction area, complex DMD process, etc., to reduce the gap and solve the problem of optical diffraction. , Improve the effect of optical diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

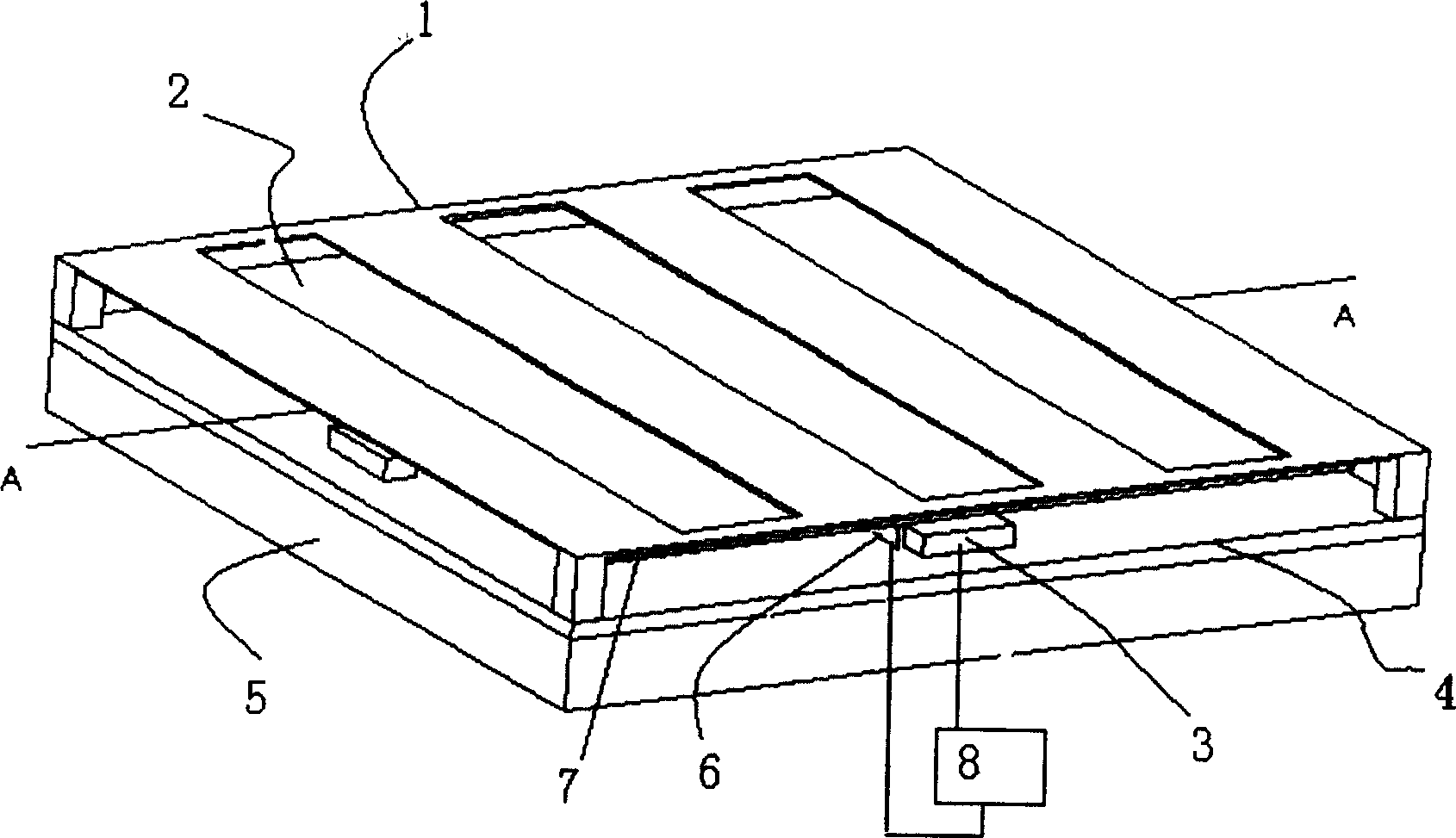

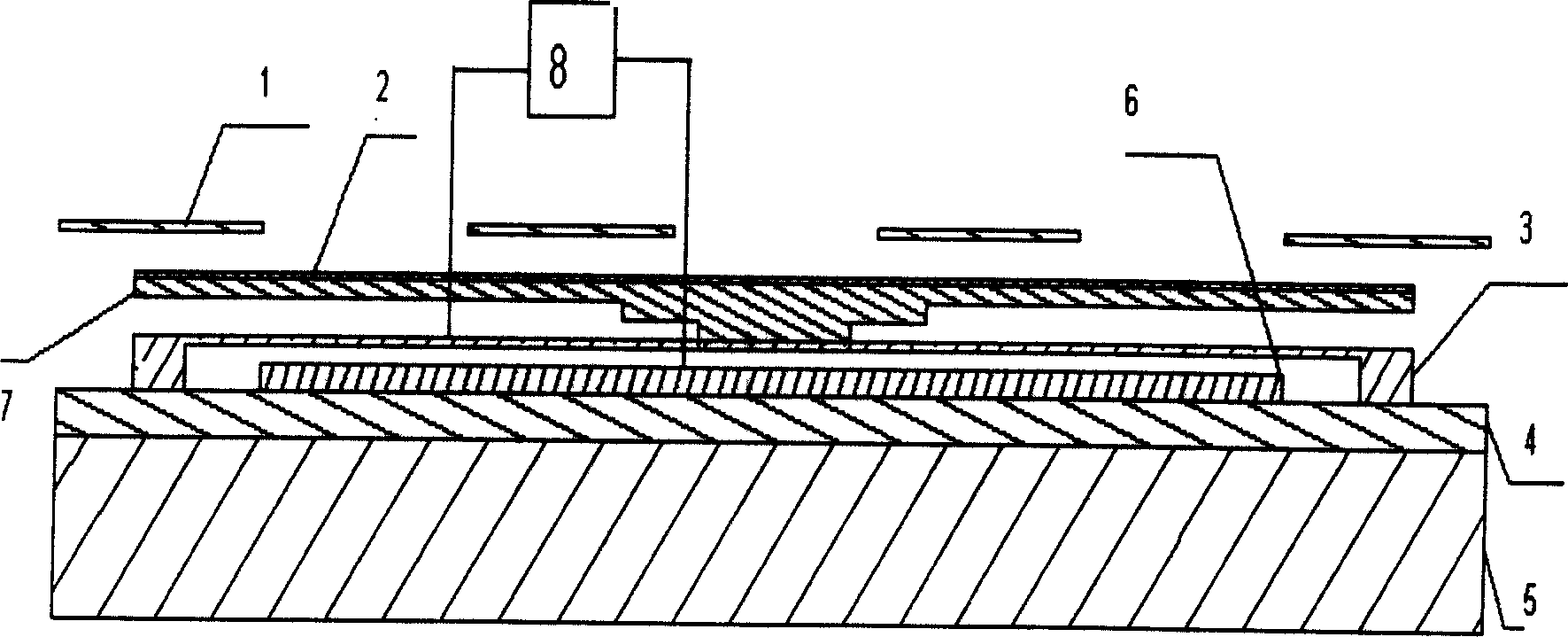

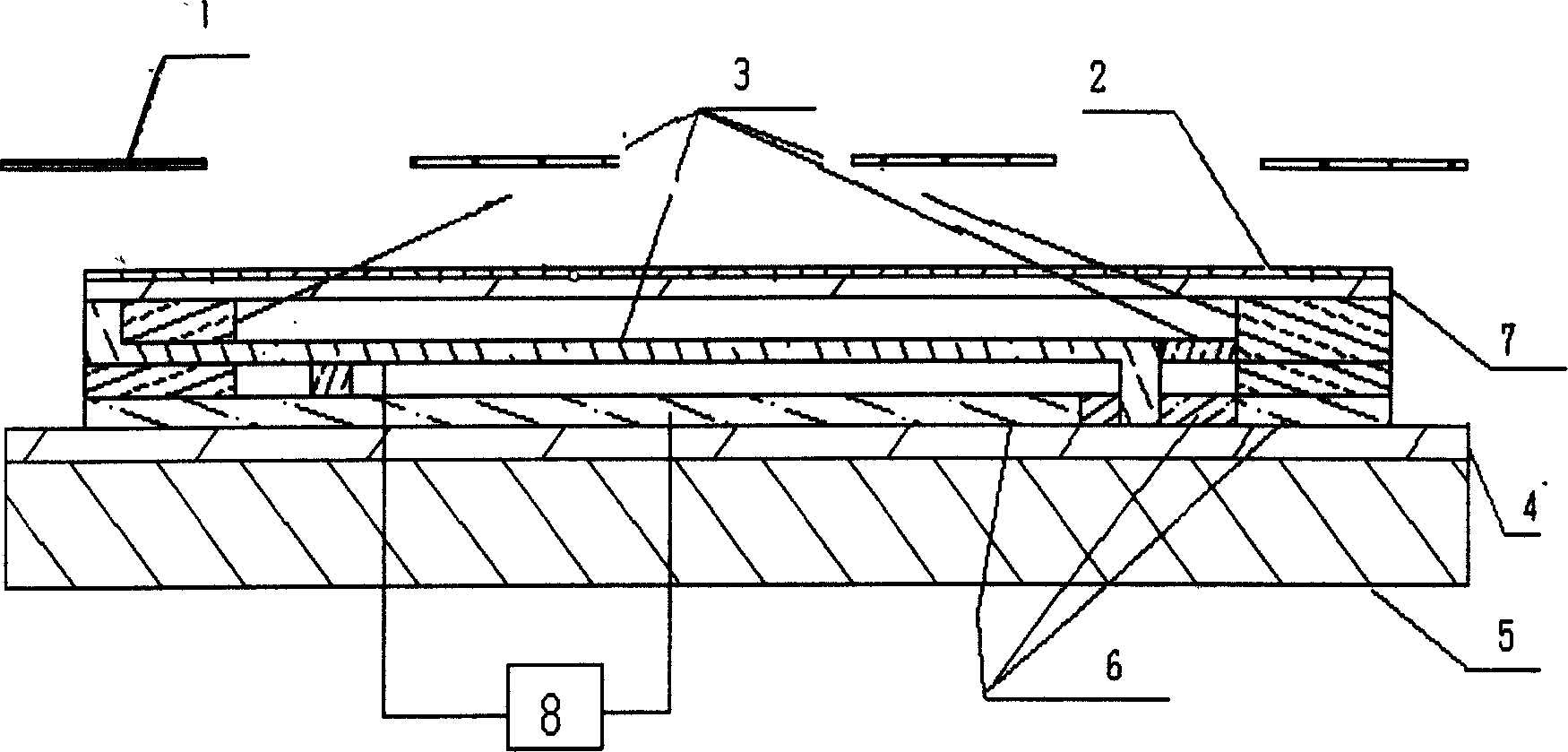

[0039] see figure 1The structure of a single pixel of the reflector-translational grating light modulator includes a fixed grating 1, a reflective surface 2, a support beam 3, an insulating layer 4, a substrate 5, an electrode layer 6, a movable plate 7, and a driving circuit 8. Its production method is as follows: first deposit a layer of silicon oxide on the substrate 5 by using peroxidation technology to form an insulating layer 4, which plays an insulating role; the electrode layer 6 composed of polysilicon material is deposited on this oxide to form an insulating layer 4. into; Utilize sacrificial layer technology, make support beam 3 and movable plate 7; Form capacitive pole plate between support beam 3 and electrode layer 6, the optional material of support beam 3 is many, the present invention adopts silicon nitride plating In the way of double-layer structure of aluminum, single-layer structure of polycrystalline silicon can also be used as the material. The movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com