Force dispersion type cold-rolled shipment interlayer padding

A force-dissipating and force-dissipating layer technology, applied in layered products, ship accessories, transportation and packaging, etc., can solve the problems of weight of briquette straw, product damage, and inability to reduce costs, and achieve good elastic buffering effect. , The effect of improving the strength of the scattered force and reducing the cost of cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

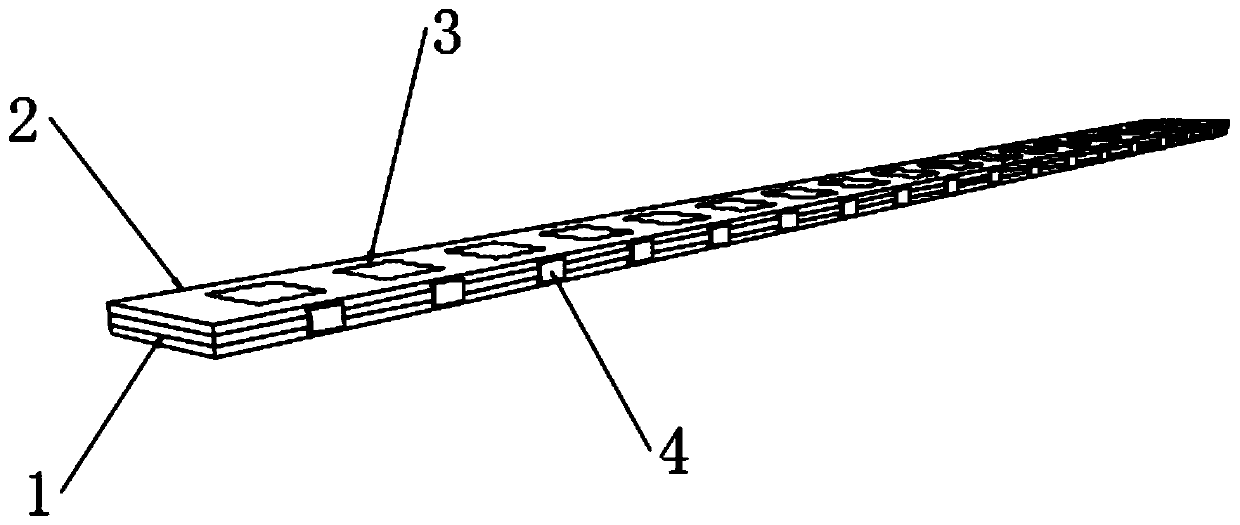

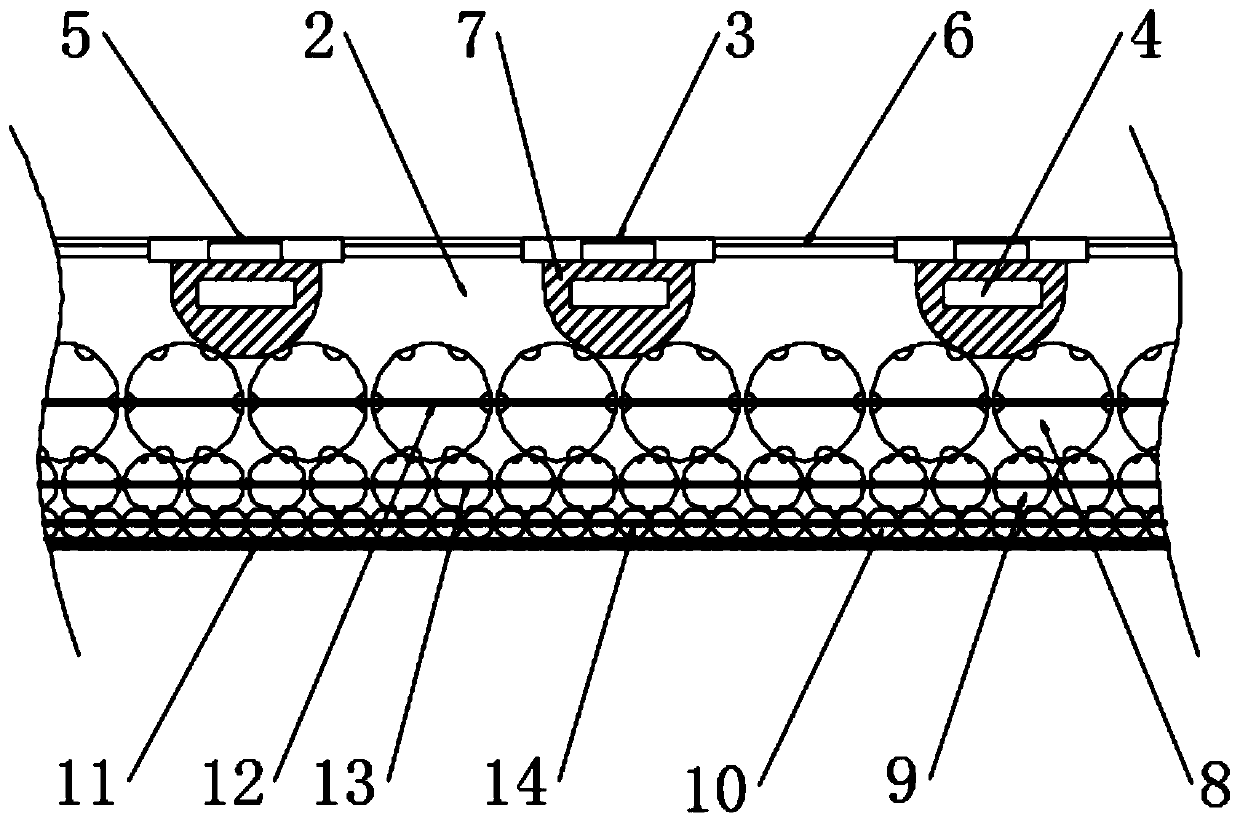

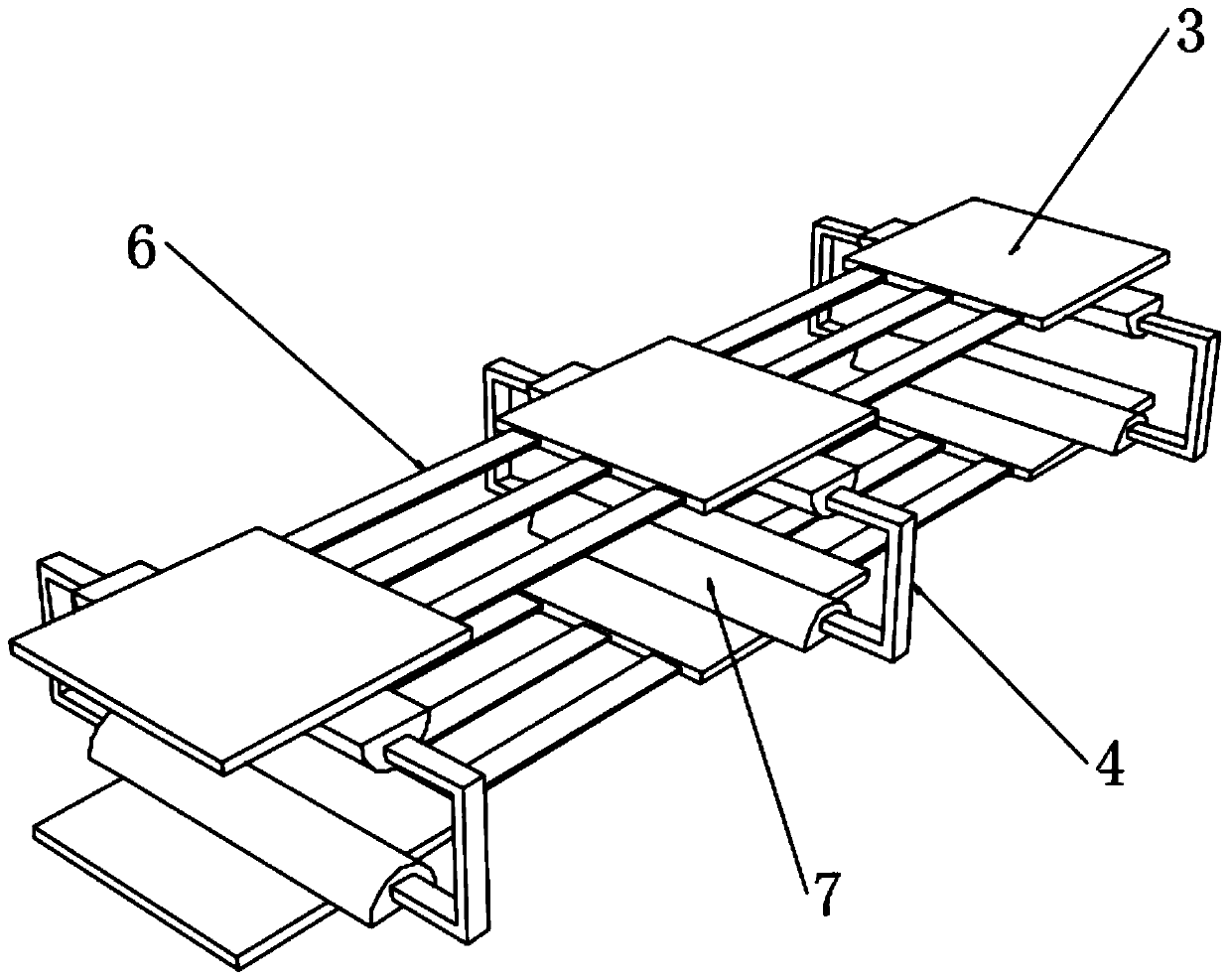

[0039] see figure 1 , a loose-force type cold roll shipping interlayer padding, comprising a fiber splint 1, the upper and lower ends of the fiber splint 1 are bonded with a gel-like sponge layer 2, and the fiber splint 1 is formed by bonding three layers of polyester fiber boards, Colloidal sponge layer 2 is composed of two layers of colloidal high-density sponge, which not only has a certain strength, but also has high softness to meet the binding of export products. It has good protection and recovery effects and can be used frequently. The colloidal sponge layer 2 The outer surface is inlaid with multiple evenly distributed surface force transmission sheets 3, which can protect the surface of the gel sponge layer 2 to a certain extent, and are not easy to be indented and damaged. Please refer to figure 1 , a plurality of elastic connecting bands 6 are fixedly connected between the adjacent surface force transmission pieces 3, and the elastic connecting bands 6 are hidden i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com