Composite structure of locally applying skin on truss and method for analyzing and calculating safety thereof

A technology of local application and combined structure, applied in the direction of truss structure, special data processing application, truss beam, etc., can solve the problem that the potential bearing characteristics of the skin are not fully utilized, the skin effect is not considered, and the skin effect of the roof panel is weakened. and other problems, to achieve the effect of simple, convenient and accurate calculation, small modeling workload, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

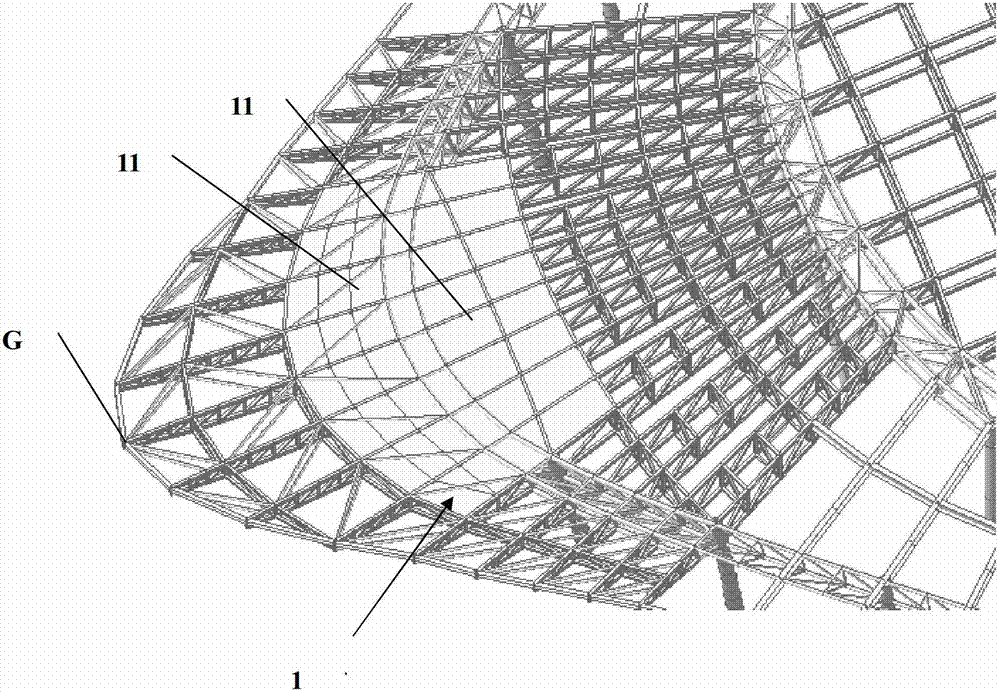

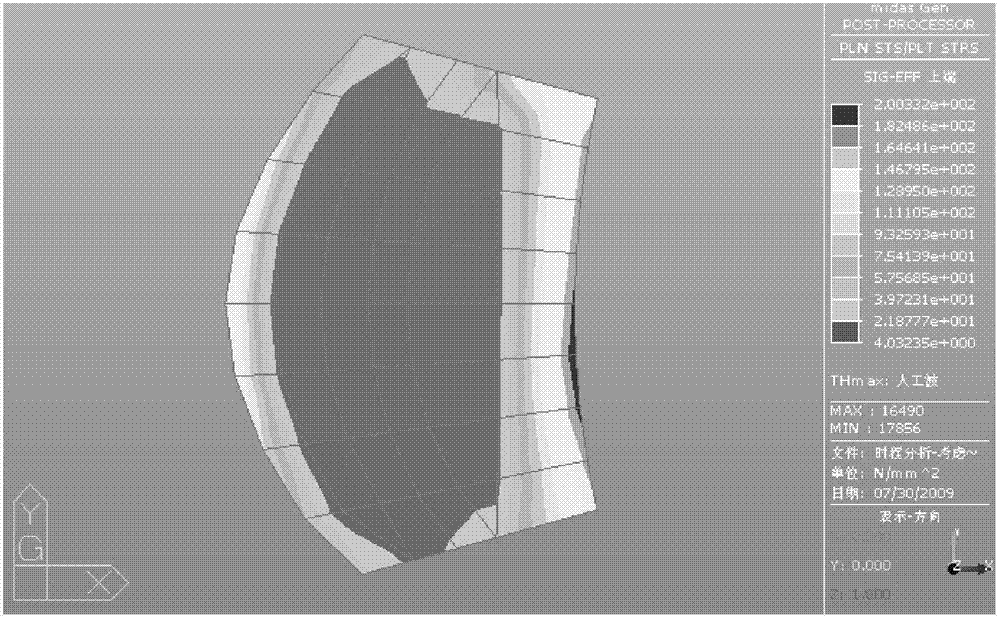

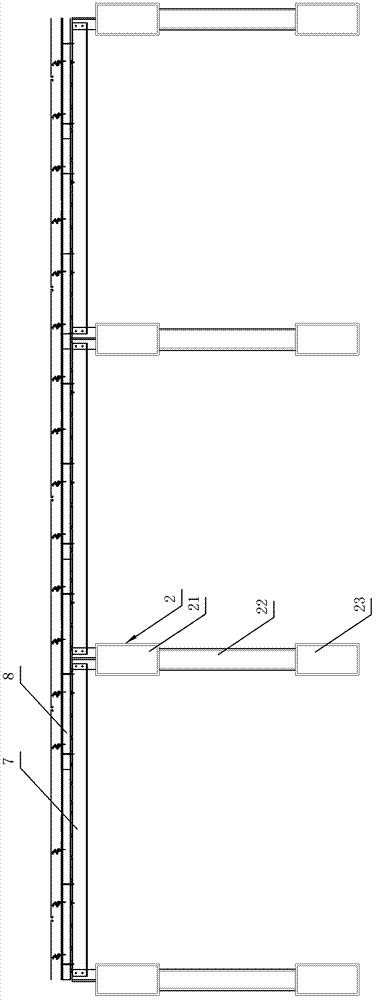

[0068] Such as Figure 1-15 Shown, is the composite structure that a kind of skin of the present invention is partially applied on the truss, comprises truss and purlin, as figure 2 As shown, the truss of this embodiment is a cantilever truss with a length of 23m in the roof steel structure of the gymnasium of the Guangzhou Asian Games in 2010, see Figure 4 , the upper surface of the truss 2 is laid with a skin steel plate 1, the purlin 7 is located above the skin steel plate 1, and the roof panel 8 is arranged on the upper surface of the purlin 7. Specifically, the truss 2 is mainly composed of an upper chord 21 , a web 22 and a lower chord 23 , and the upper surface of the truss 2 refers to the upper flange of the upper chord 21 . After the skin steel plate is set, the stress stiffness of the truss is greatly enhanced, and the bending stiffness of the entire truss is improved, thereby reducing the deflection and stress level of the truss, and it can be used as a reserve f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com