Patents

Literature

495results about How to "Guaranteed connection reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

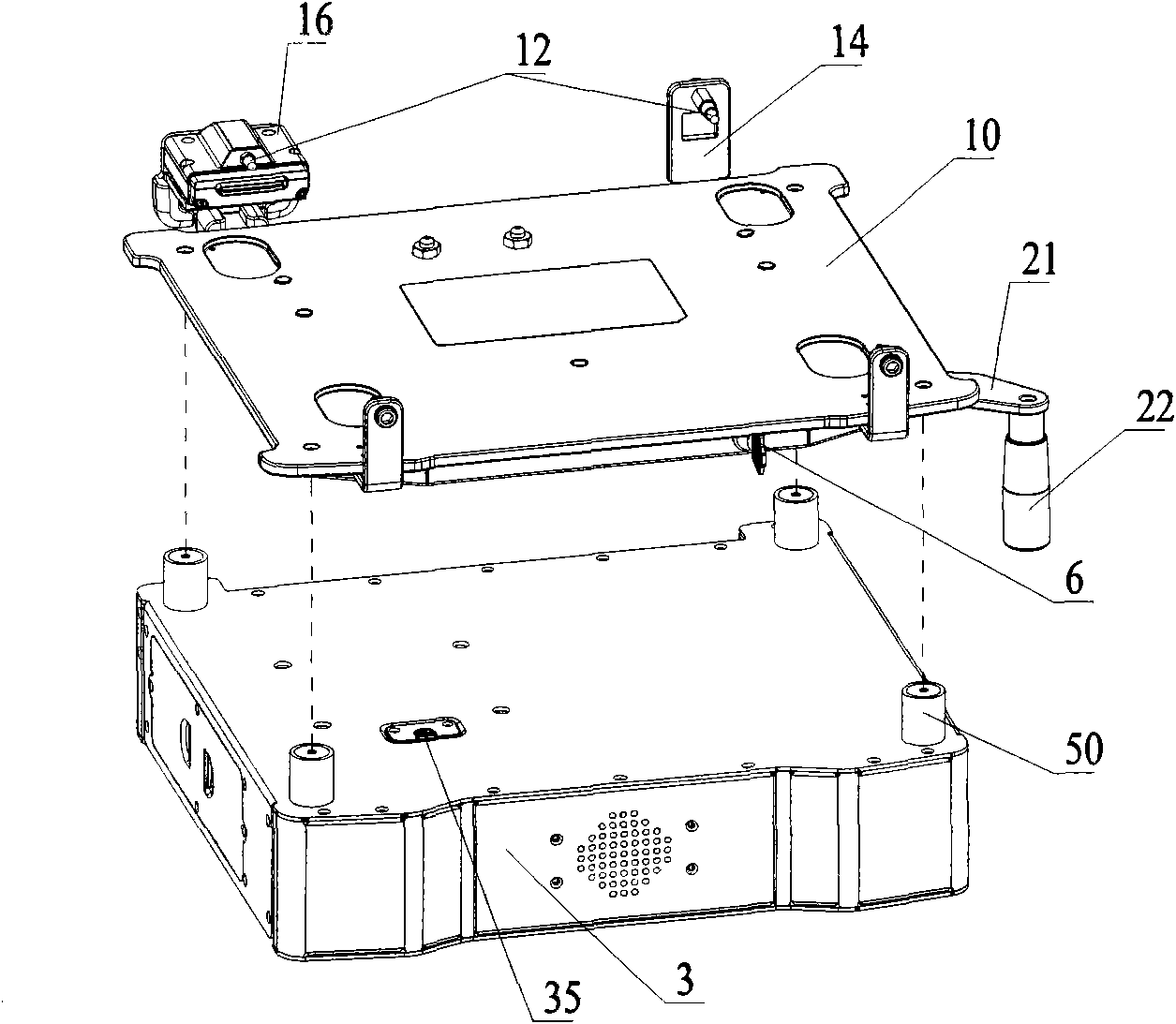

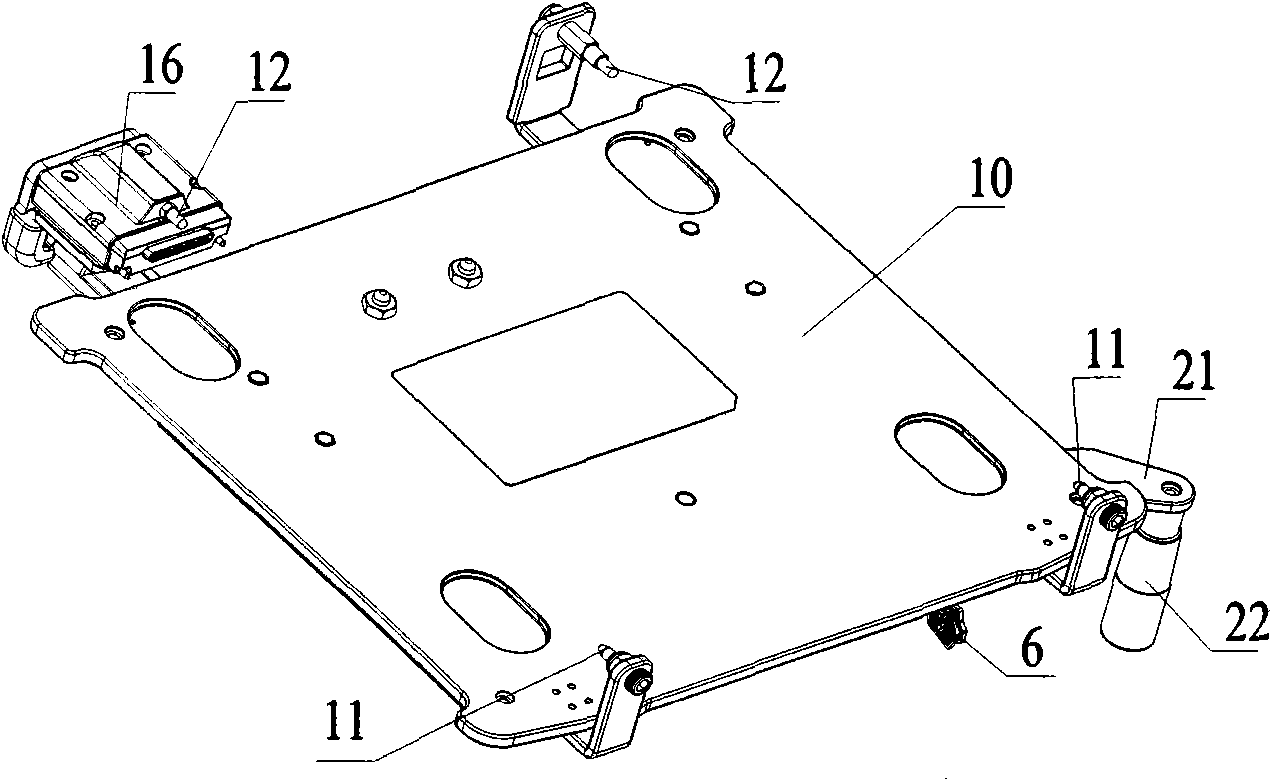

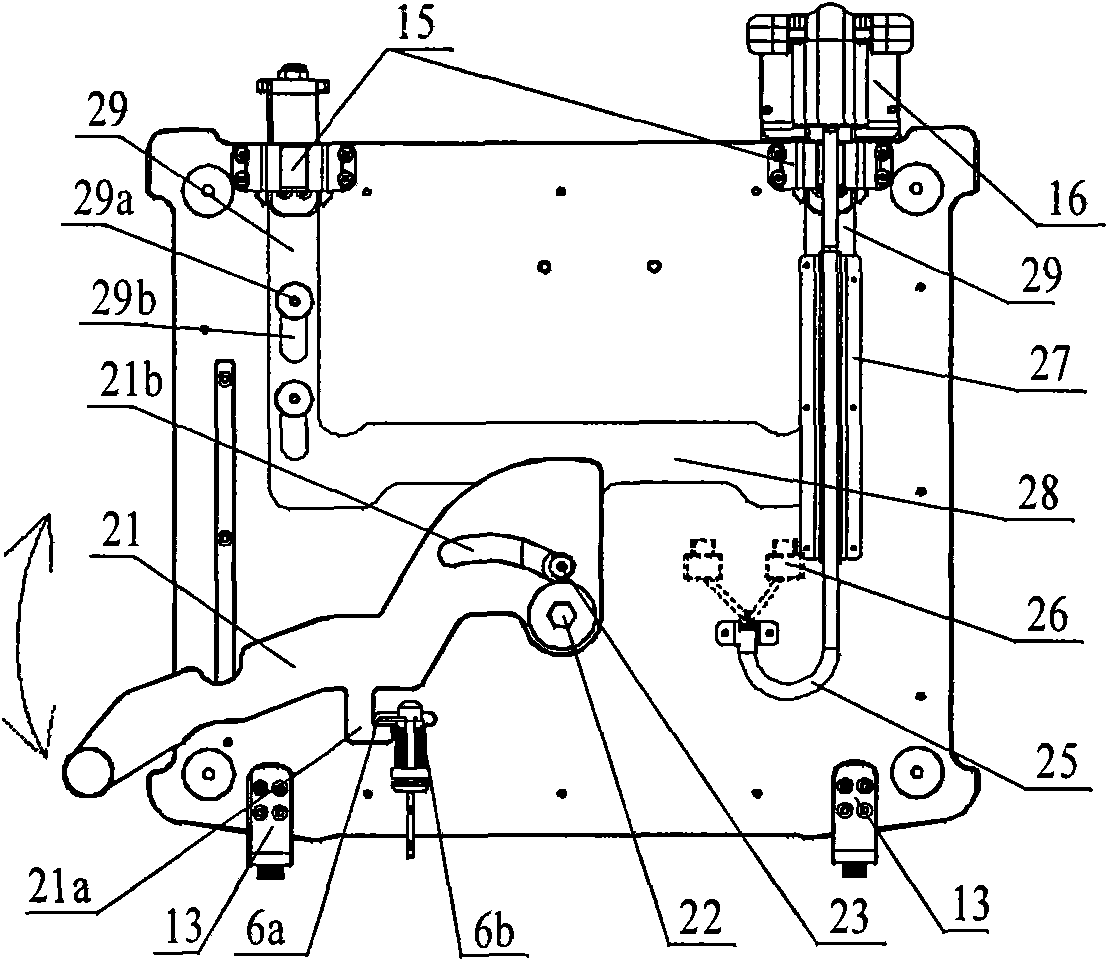

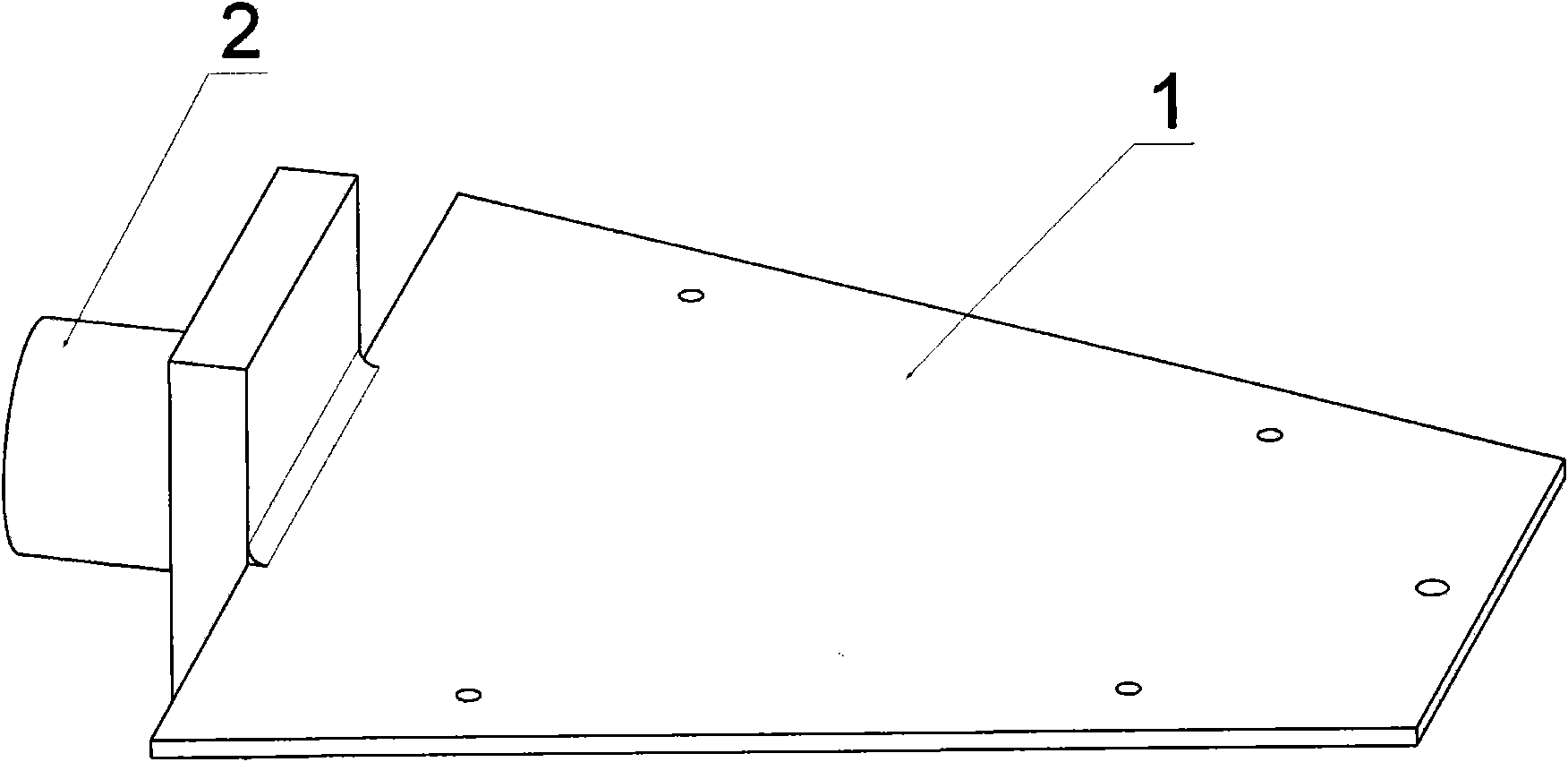

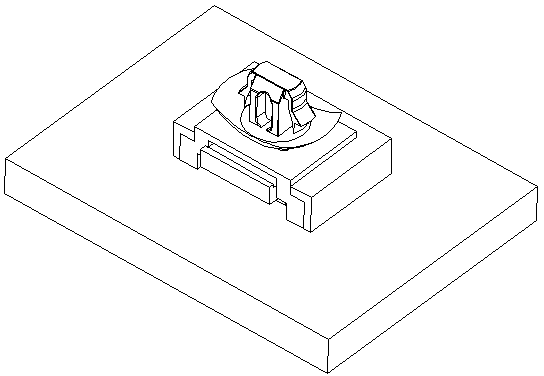

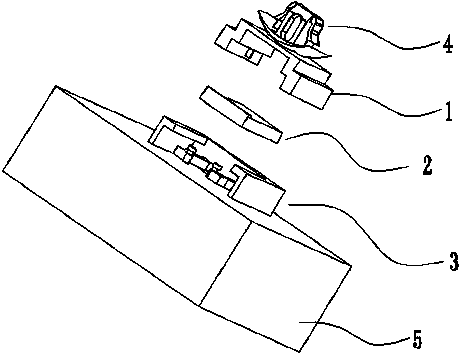

Notebook computer docking station

ActiveCN101930253AFixed way fastFirmly connectedCouplings bases/casesDigital processing power distributionDocking stationComputer engineering

The invention discloses a notebook computer docking station which comprises a host box. A supporting plate for placing a notebook computer is fixed on the host box and provided with a positioning and fixing device which is used for rapidly positioning, clamping and fixing the notebook computer on the supporting plate and is connected with a connector corresponding to a signal output port of the notebook computer, and the connector is aligned to and inserted in the signal output port of the notebook computer after the notebook computer is positioned and fixed on the supporting plate. The notebook computer docking station has the advantages of rapidly positioning the notebook computer, being accurately and reliably abutted with the output port of the notebook computer, being capable of firmly fixing the notebook computer and having prominent anti-vibration and anti-impact capabilities and extended performance.

Owner:深圳市研祥智慧科技股份有限公司

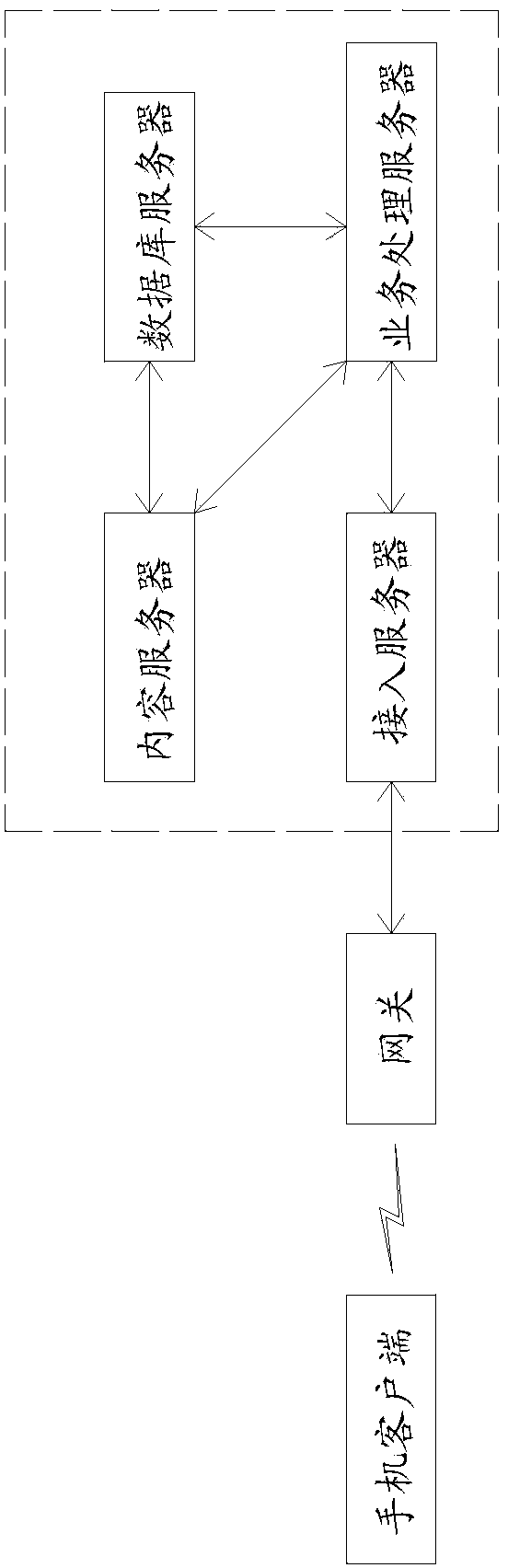

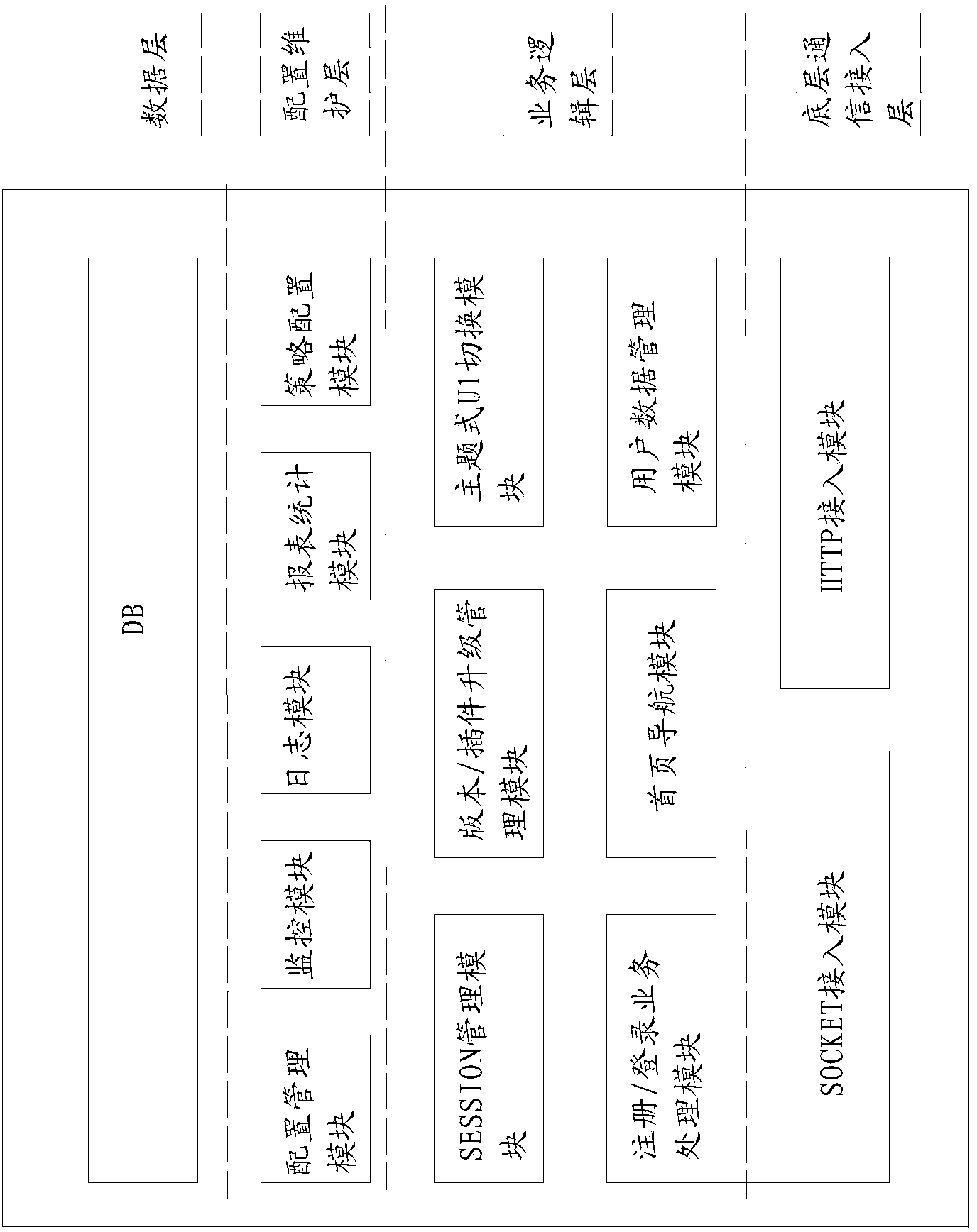

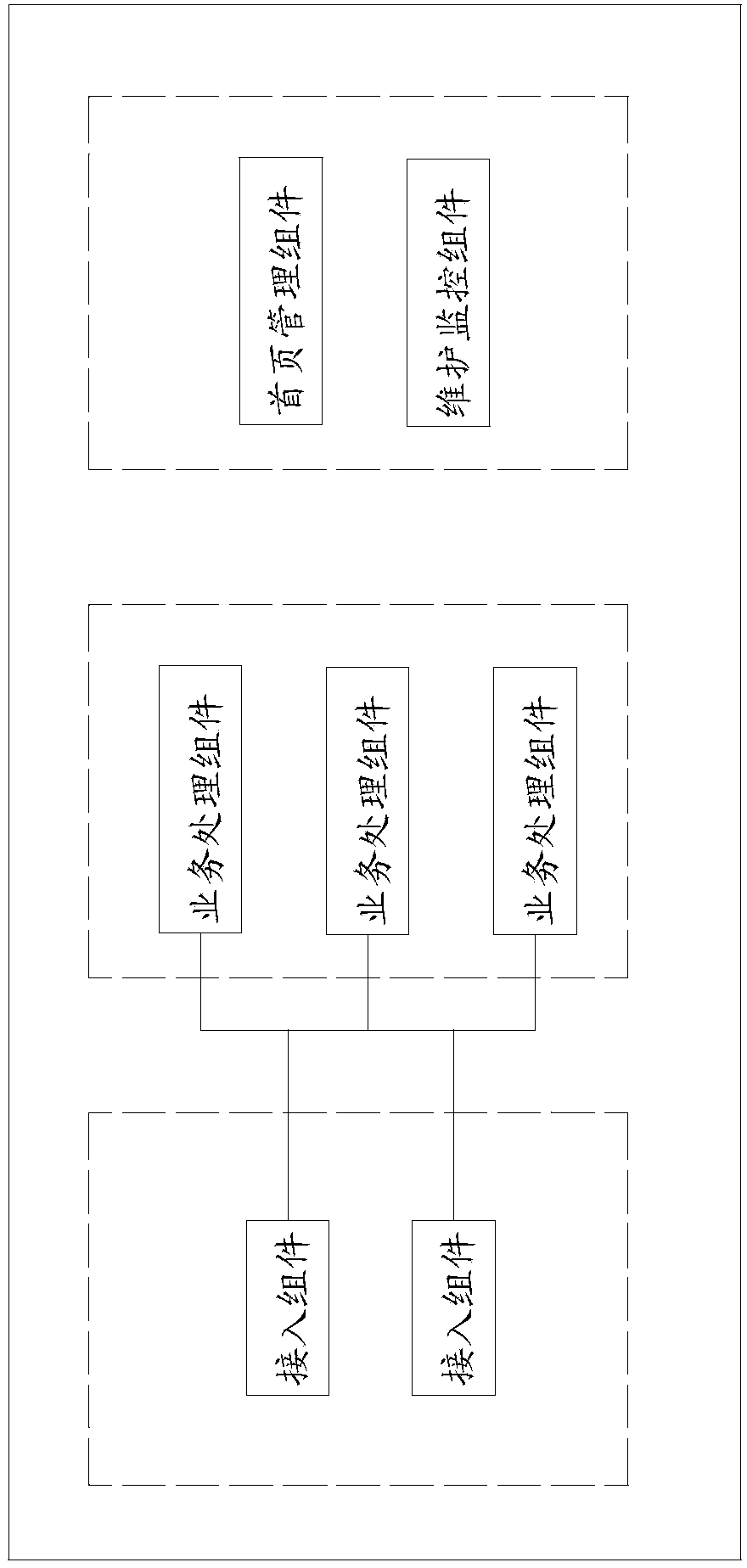

Method for providing large concurrent processing and flow control for mobile phone client sides

InactiveCN103369601AReduce the number of concurrent connectionsGuaranteed connection reliabilityNetwork traffic/resource managementData switching networksData acquisitionClient-side

The invention discloses a method for providing large concurrent processing and flow control for mobile phone client sides, and the method is applied to interaction between the mobile phone client sides and a server cluster. The method includes the steps that step1, the mobile phone client sides send connection requests to an access server in a server cluster, a DNS gets access to the server in a dispatching mode, the DNS and the access server carry out delay detection, when a detected delay is smaller than a strategy parameter, a UDP is adopted for communication of the client sides and the access server, and otherwise, a TCP is used for the communication; step2, the access server receives the requests of the mobile phone client sides and controls the quantity of concurrent requests, if the number of the concurrent requests is larger than a preset value, connection is rejected, and if not, the requests are distributed to a service processing server with the fewest loads; step3, the service processing server receives the service requests distributed by the access server, sorts the service requests according to logging, logout, heartbeat, data collection and page requesting, and then respectively carries out processing according to sorted types of the service requests.

Owner:XIAMEN ZHUOXUN INFORMATION TECH

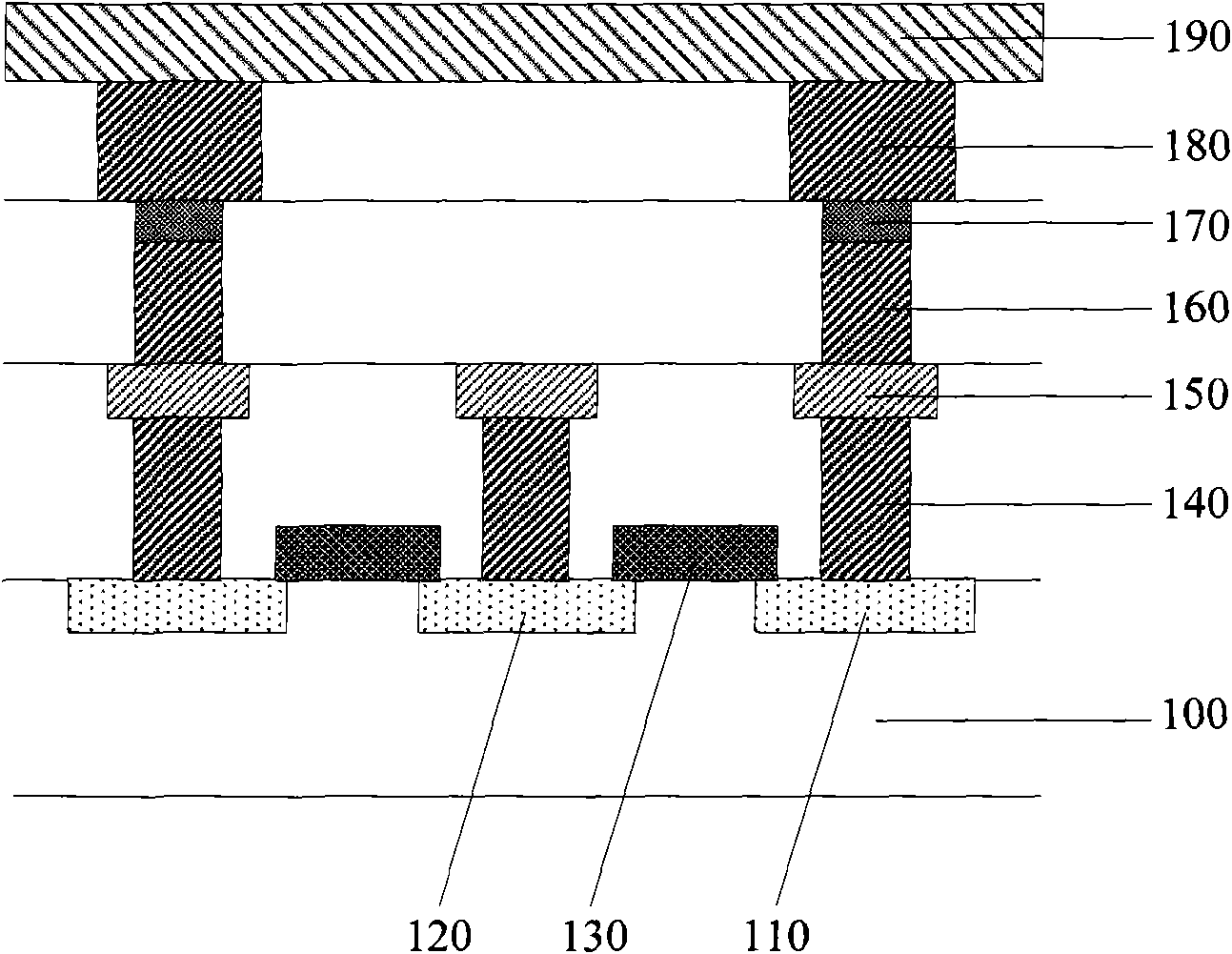

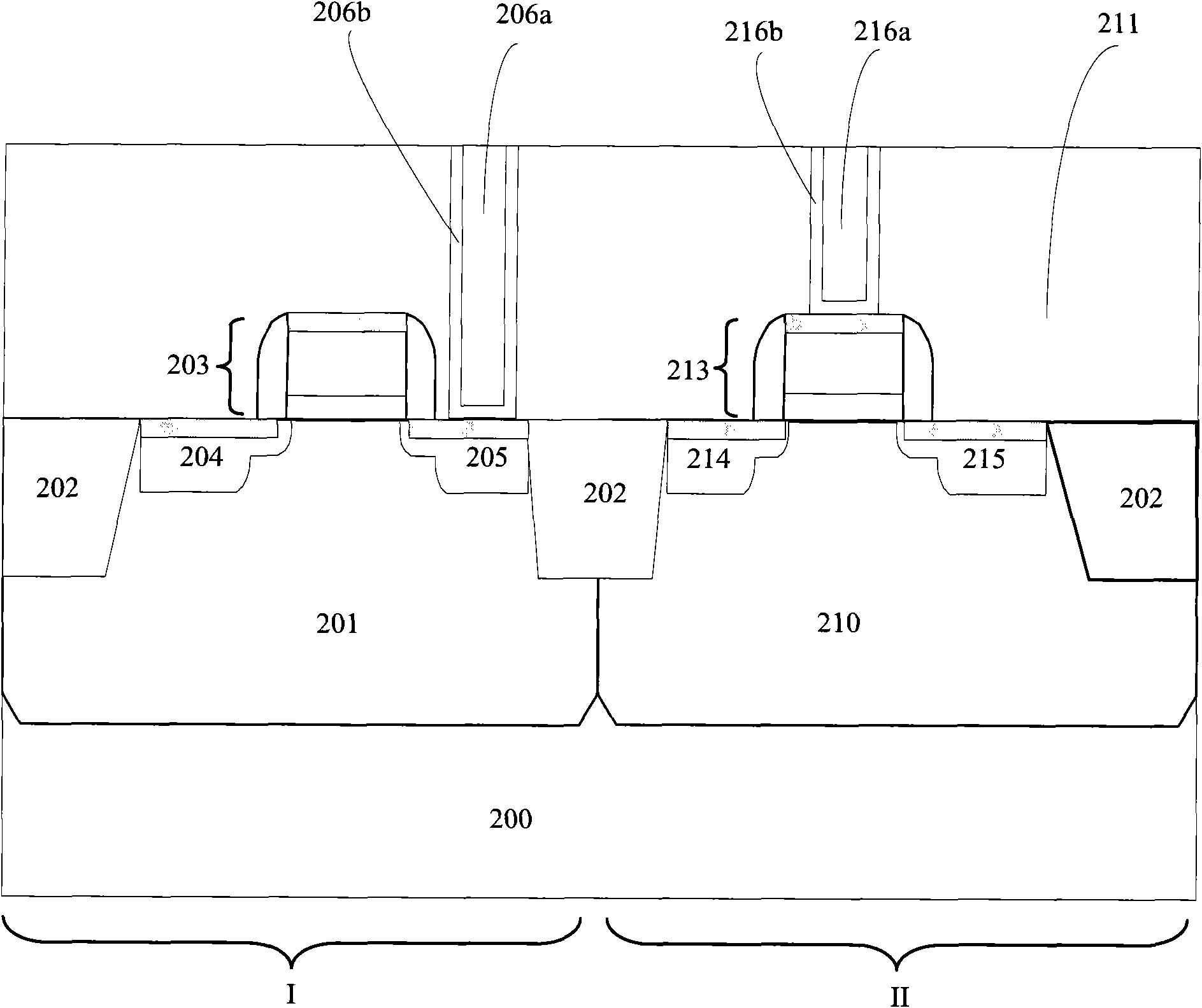

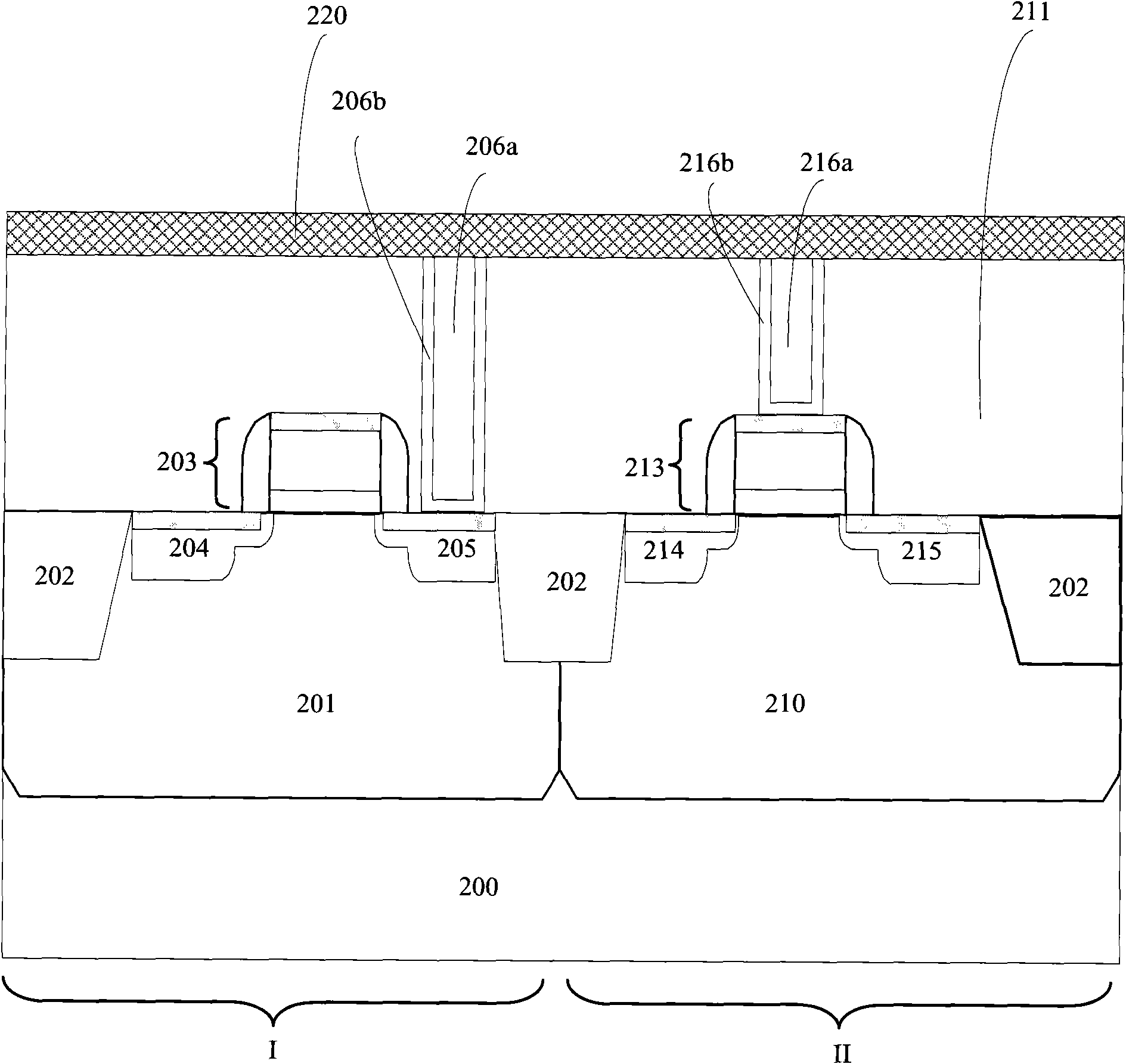

Resistance memory an a method for fabricating integrated circuit with same

ActiveCN101572246ARealize interlayer interconnect structureSimple processSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceCore component

The invention relates to a method for fabricating an integrated circuit with a resistance memory, comprising the following steps: providing an interlaminar dielectric layer comprising a core component area and a peripheral circuit area; forming a first interconnection structure and a second interconnection structure which are respectively formed by a blocking layer and a metal wiring structure in the interlaminar dielectric layer; forming a blocking dielectric layer on the interlaminar dielectric layer; etching the blocking dielectric layer to expose the metal wiring structure of the core component area; forming a first dielectric layer on the metal wiring structure; forming a first conductive layer covering the blocking dielectric layer and the first dielectric layer; forming a masking film on the first conductive layer; etching the first conductive layer and the blocking dielectric layer until the second interconnecting structure is exposed; keeping the first conductive layer and a blocking dielectric layer on the first interconnecting structure; and forming a second conductive layer and a third conductive layer respectively on the first conductive layer and the second interconnecting structure. Due to the adoption of the method for fabricating the integrated circuit with the resistance memory, when the resistance memory is formed, the interlaminar interconnection structures of the core component area and the peripheral circuit area can be also formed.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

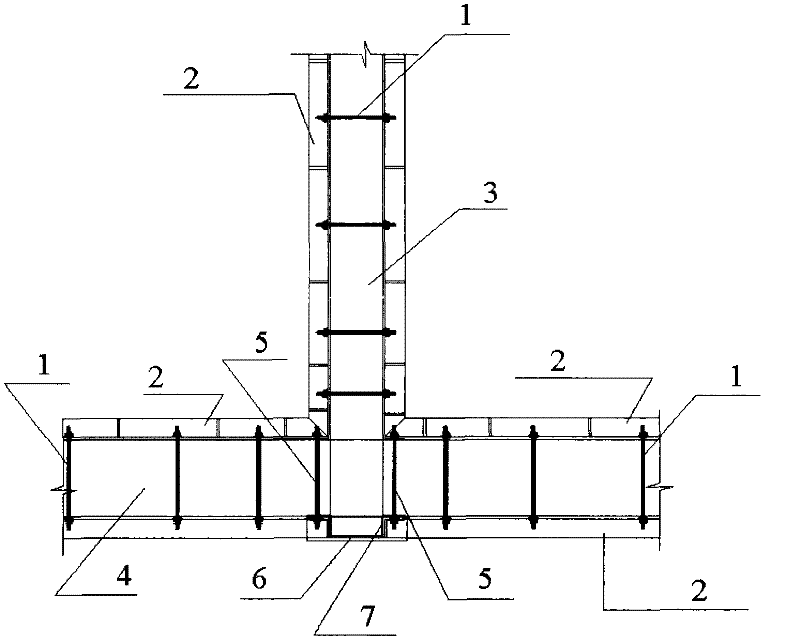

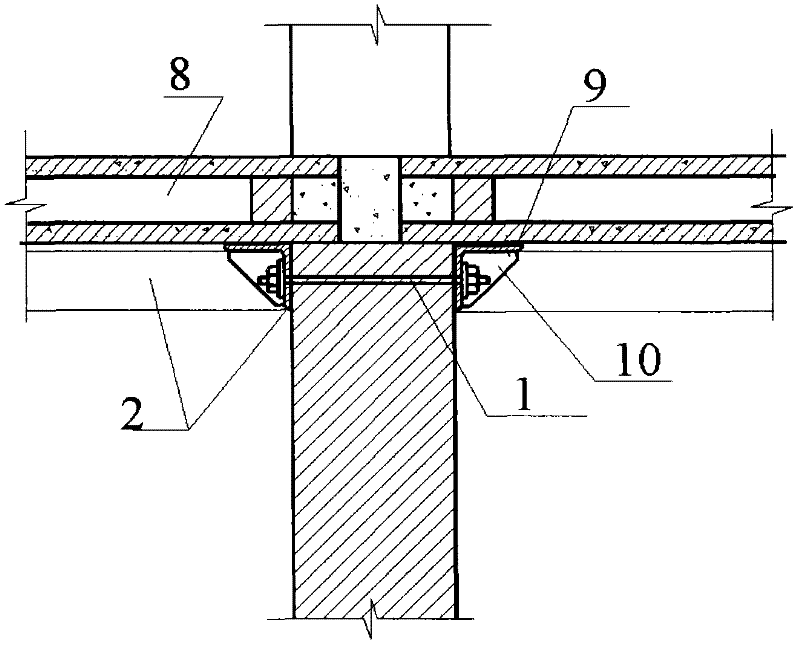

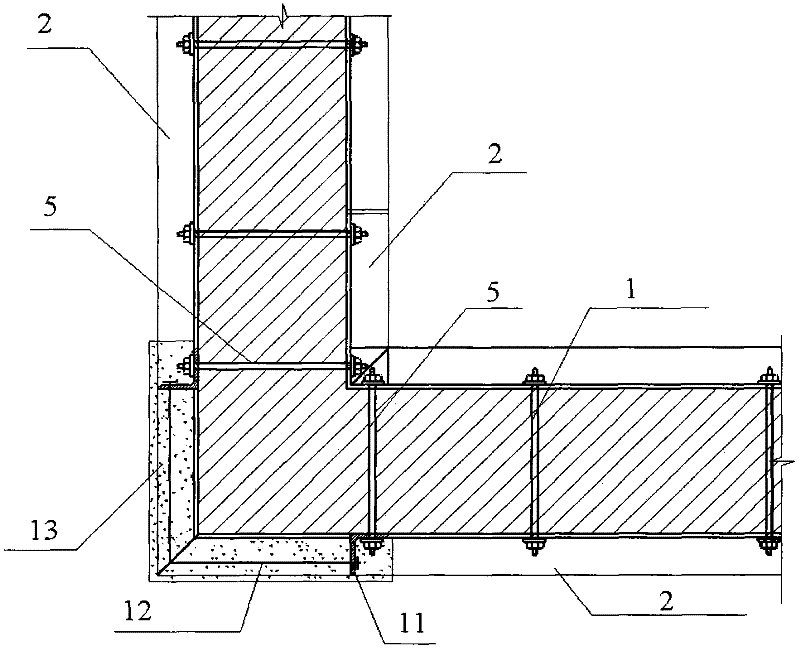

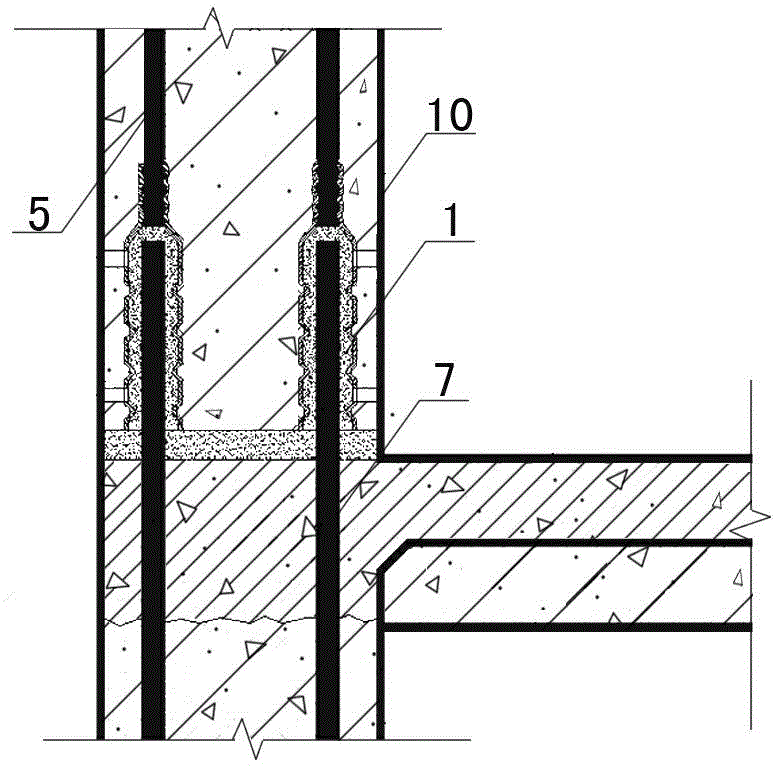

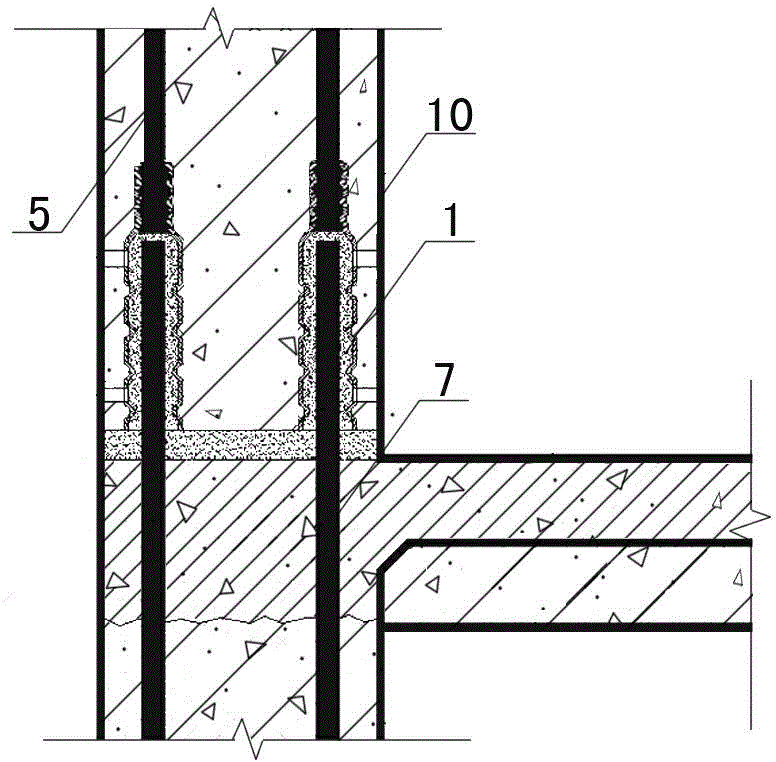

Method for reinforcing brick-concrete structure by utilizing angle steel frame

ActiveCN102561717AConstruction speed safetyBundled reinforcement construction speed is fastBuilding repairsShock proofingEpoxyFloor slab

The invention relates to a method for reinforcing a brick-concrete structure by utilizing an angle steel frame, belonging to the anti-earthquake reinforcement field. According to the method disclosed by the invention, a reliably connected steel frame formed by double-angle steel can replace a ring beam and a structural column, and field bolt assembly connection through factory pre-fabricated components can be realized, thus the safe, environment-friendly and green construction is realized; simultaneously, angle steel, a wall and a pre-fabricated floor slab are connected by bolts and epoxy resin, and the double-angle steel is also can be used as a round hole plate end part support, so that the connection reliability of the pre-fabricated floor slab and the wall is ensured, double functions of the ring beam and a supporting beam are exerted, reinforcement workload and cost are saved, and the original structure and reinforcement components mutually and cooperatively work. According to the method for reinforcing the brick-concrete structure by utilizing the angle steel frame, disclosed by the invention, the binding-type reinforcement construction speed is fast, and the reinforcement construction is safer, so that the method is very suitable for residential buildings.

Owner:贵州建工安顺建筑工程有限公司

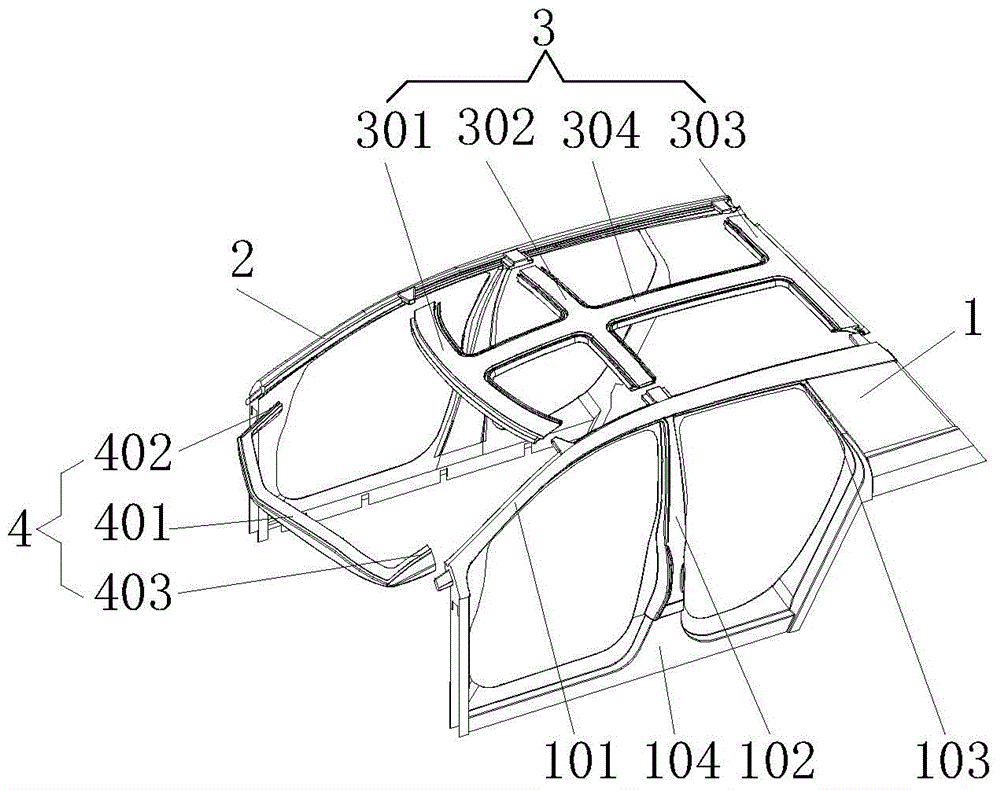

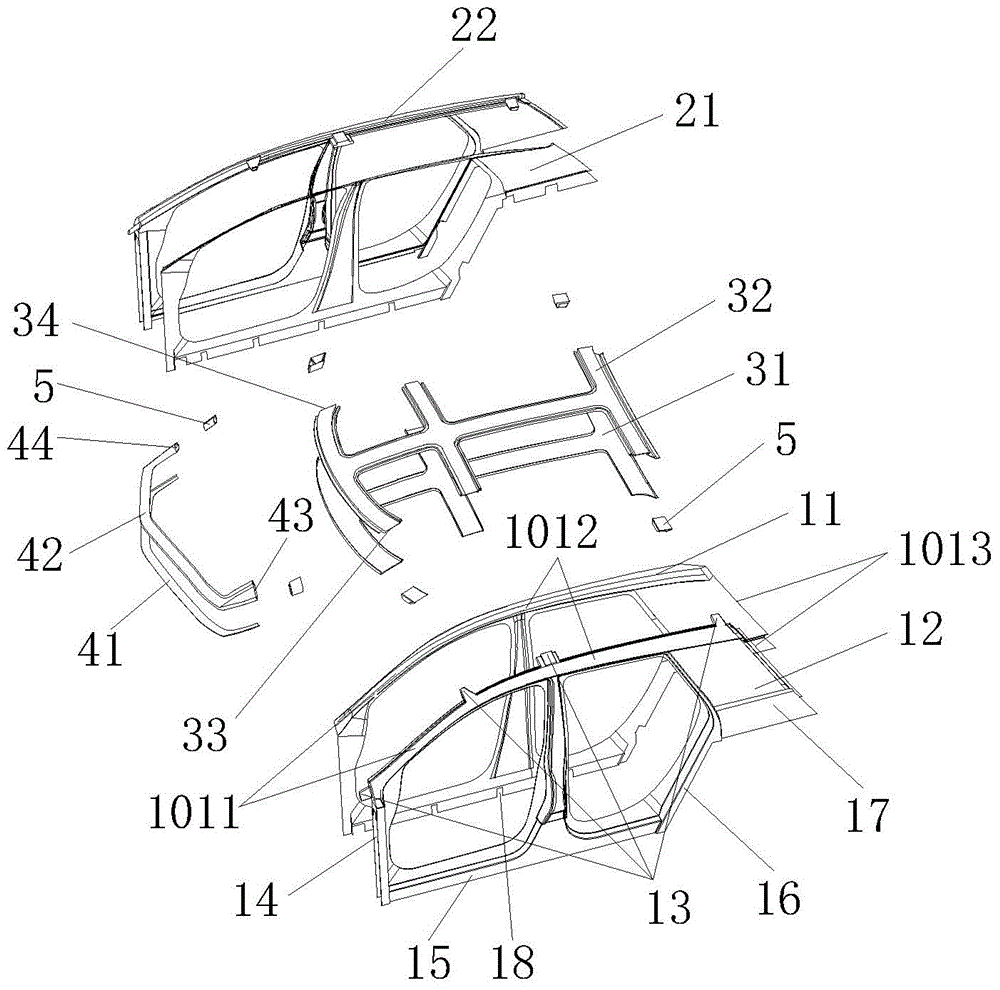

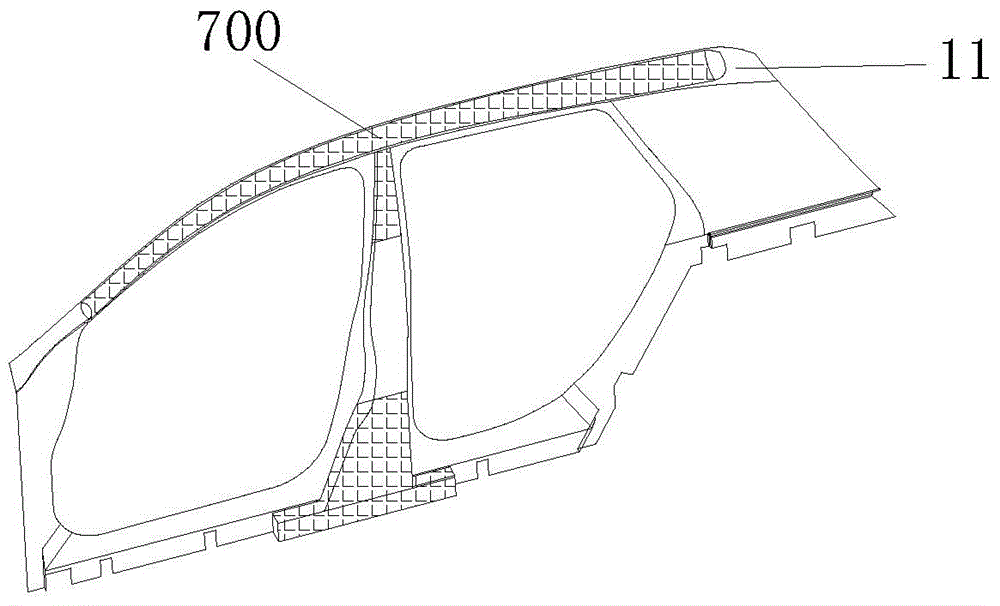

Lightweight electric vehicle body skeleton

InactiveCN103979016AHigh strengthEasy to processSuperstructure subunitsSpatial structureElectric vehicle

The invention relates to the technical field of electric vehicles, in particular to a lightweight electric vehicle body skeleton, which comprises a left side body frame, a right side body frame, a roof and a front glass bracket which are all made of carbon fiber reinforced composite materials, wherein the left side body frame and the right side body frame are respectively assembled with the roof and the front glass bracket in a cementing manner and a bolt fastening manner to form a space cage-shaped tubular body skeleton, each of the four large blocks takes an edge combining area as a piece dividing line and is further divided into an inner piece and an outer piece, and the inner pieces and the outer pieces are connected at the edge combining areas in a cementing manner. The application form of composite materials to the vehicle body is improved from the past single sided board into a double sided tubular space structure, a passenger protecting area is designed into a space cage-shaped skeleton structure, the overall strength of the body skeleton is improved through utilizing the structure characteristics of tubular columns and topological spaces, in addition, the forming efficiency is also considered by adopting the four-large-block and eight-small-piece designing method, and the forming quality is also effectively ensured.

Owner:INST OF DONGGUAN SUN YAT SEN UNIV +1

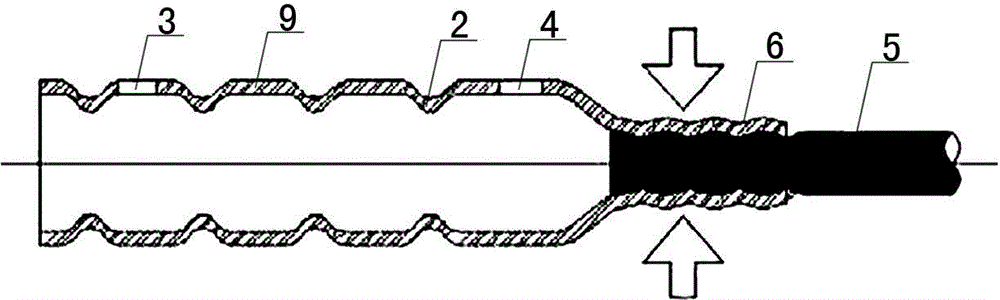

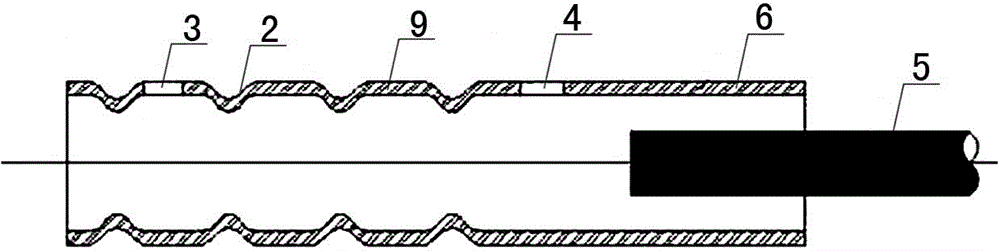

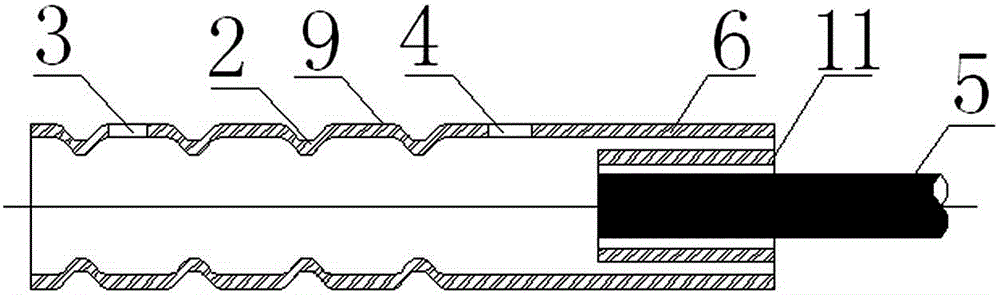

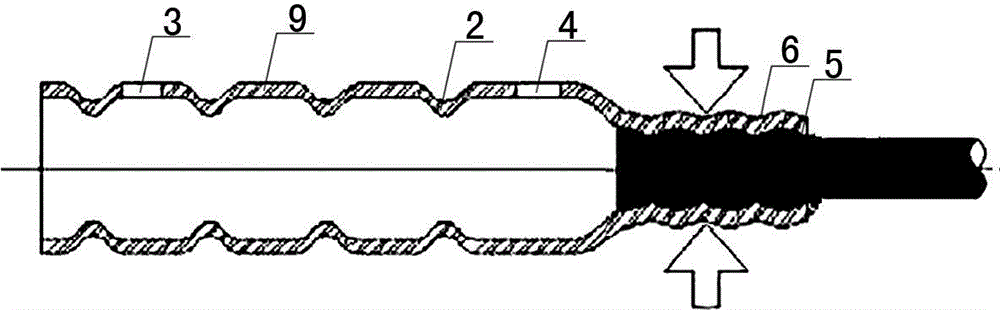

Extrusion semi-grouting reinforcement sleeve, connecting structure and construction method thereof

InactiveCN104563397AAvoid the defect of being too longAvoid the disadvantages of weakening the strength of the sleeveBuilding reinforcementsBuilding material handlingEngineeringSlurry

The invention relates to an extrusion semi-grouting reinforcement bar sleeve, a connecting structure and a construction method thereof. The sleeve is a hot-rolled seamless steel pipe, a grouting hole and a slurry outlet are formed in the tube wall of the sleeve, annular concave bulges are distributed between the grouting hole and the slurry outlet, one end of the sleeve is an extrusion end, the other part of the sleeve is the slurry anchor end, the internal diameter of the extrusion end is equal to the external diameter of each of connected reinforcement bars and is smaller than that of each slurry anchor end, and the grouting hole, the slurry outlet and the annular concave bulges are all positioned at the slurry anchor end. According to the extrusion semi-grouting reinforcement bar sleeve, the connection among the reinforcement bars is realized by the utilization of the semi-grouting reinforcement bar sleeve, one end part of the sleeve is connected with the reinforcement bars by adopting an extrusion connection technology, and the other part of the sleeve is still connected with the reinforcement bars in a grouting way; the extrusion semi-grouting reinforcement bar sleeve can be widely applied to the reinforcement bar connection of precast concrete columns in a multi-high-rise precast concrete frame structure and a shear wall structure or a frame shear wall structure, the horizontal reinforcement bar connection of a precast concrete beam, the reinforcement bar connection of the precast concrete shear wall and the reinforcement bar connection in an existing reinforcement project.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

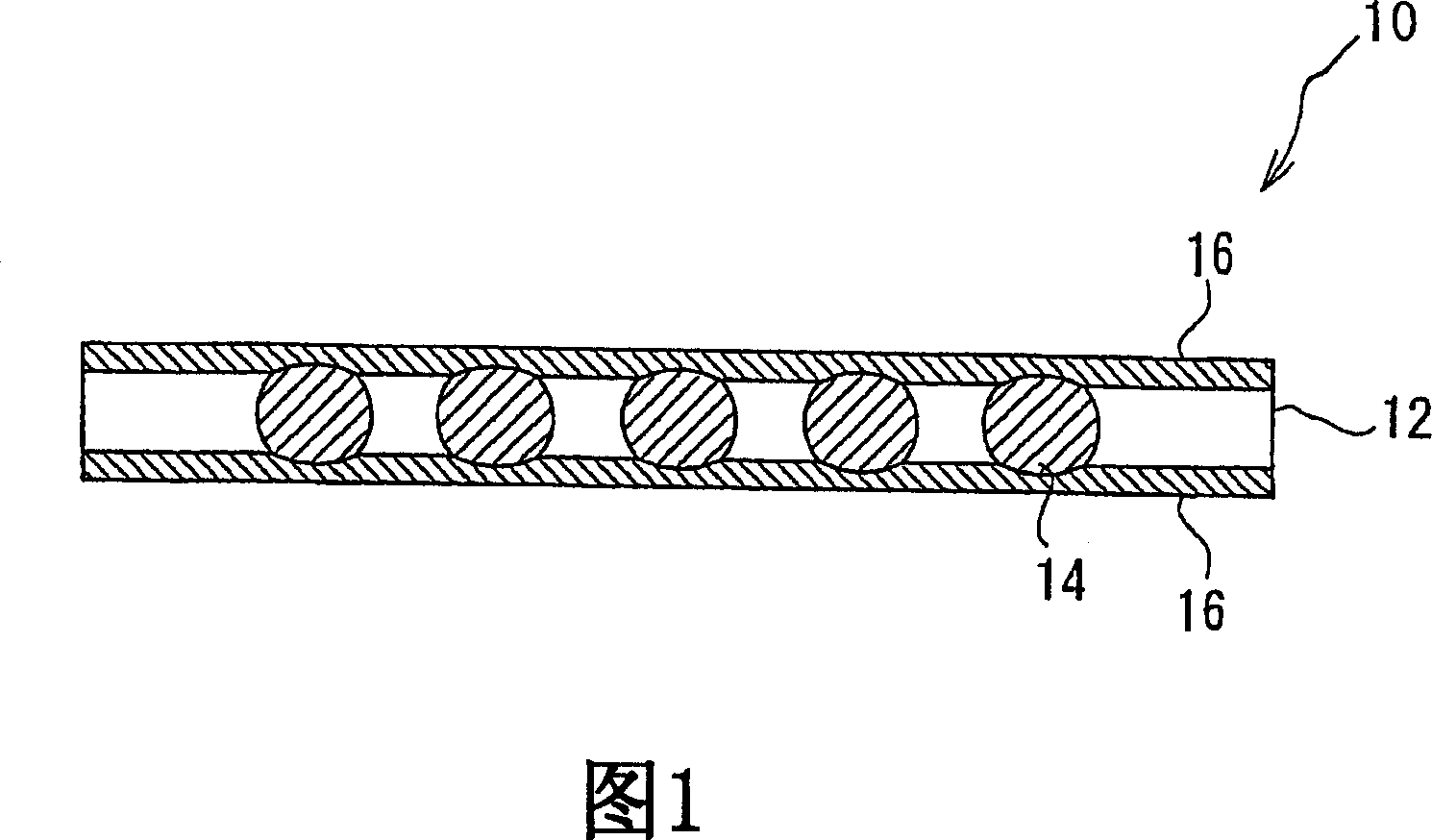

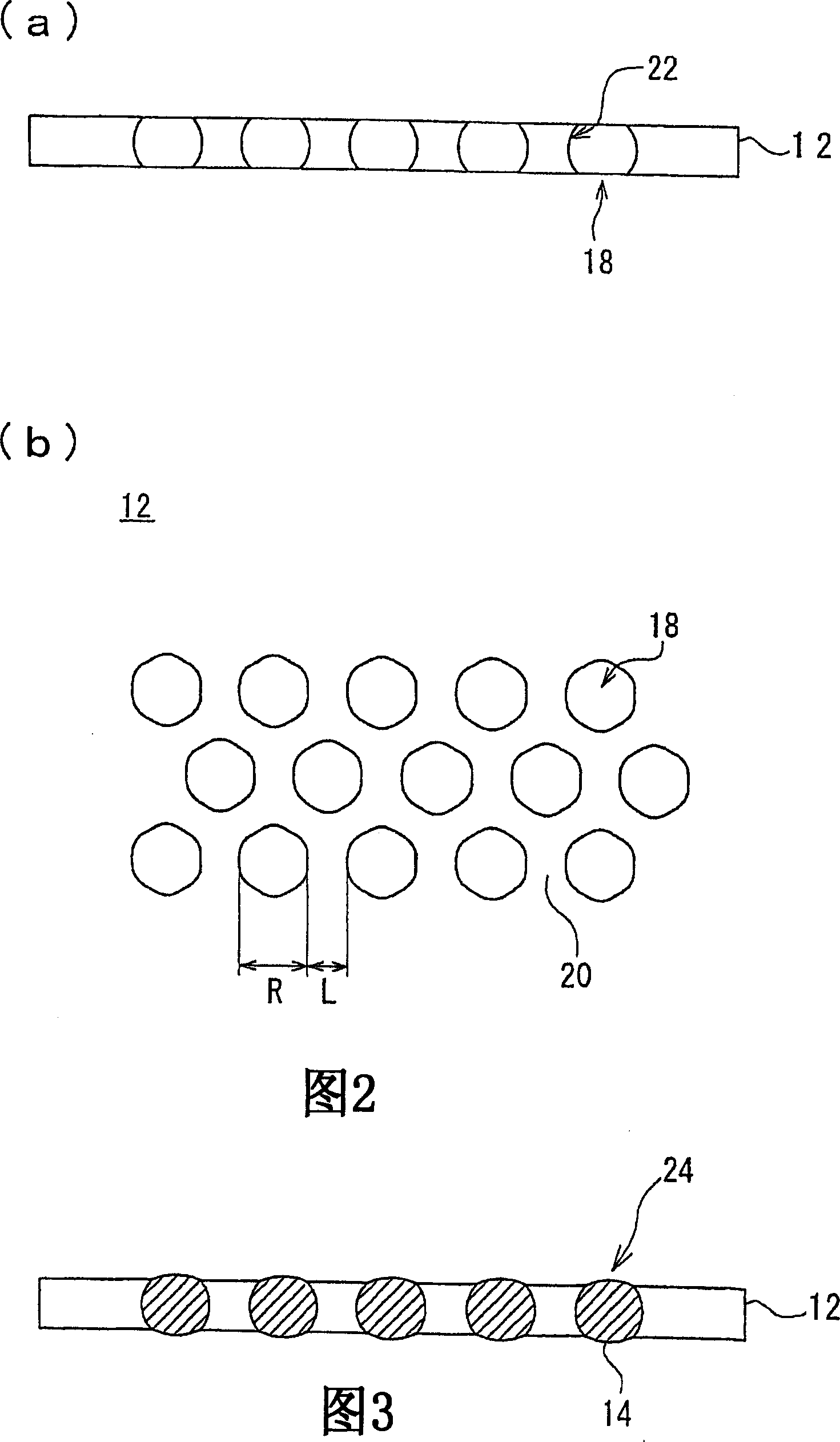

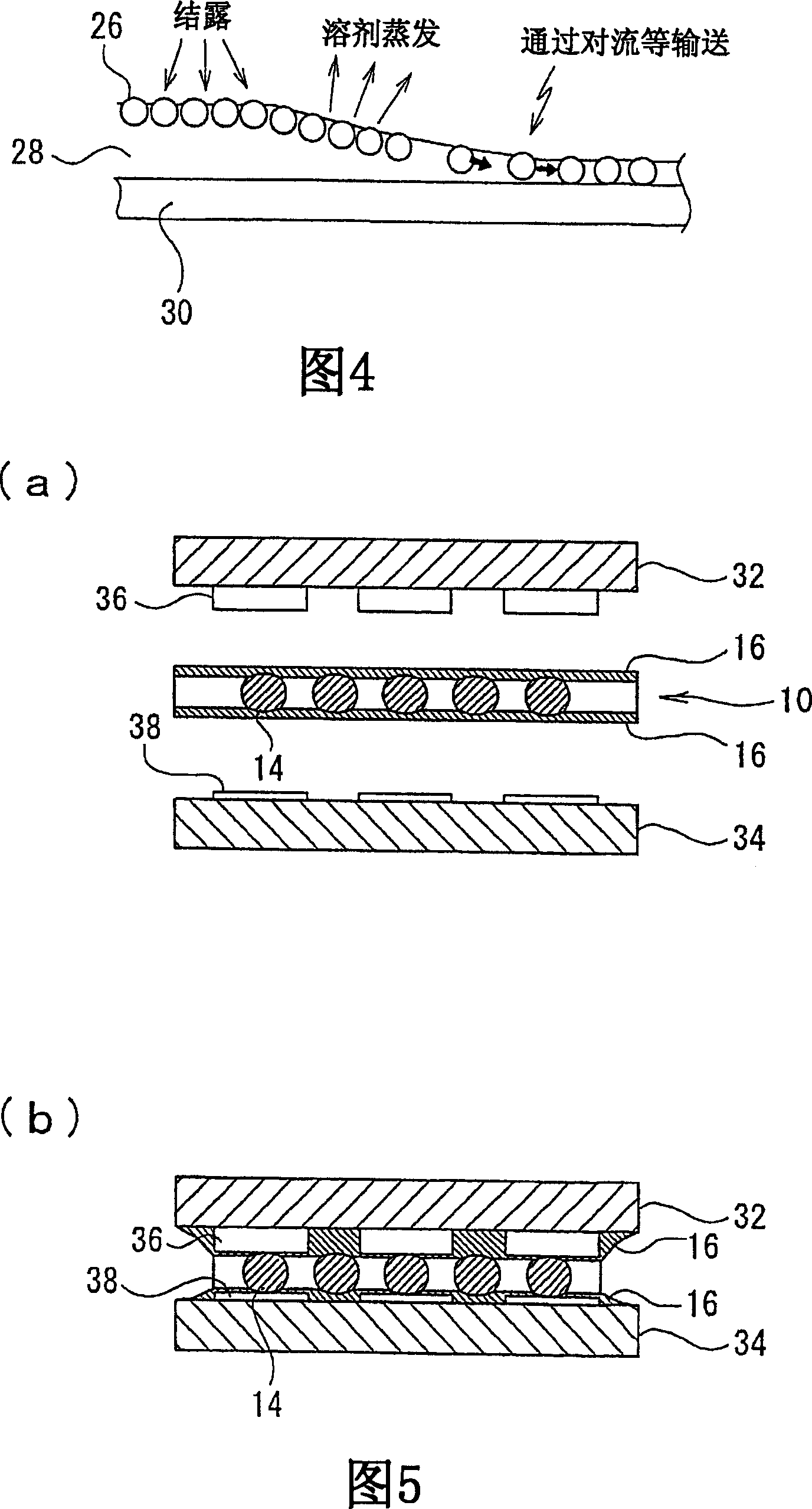

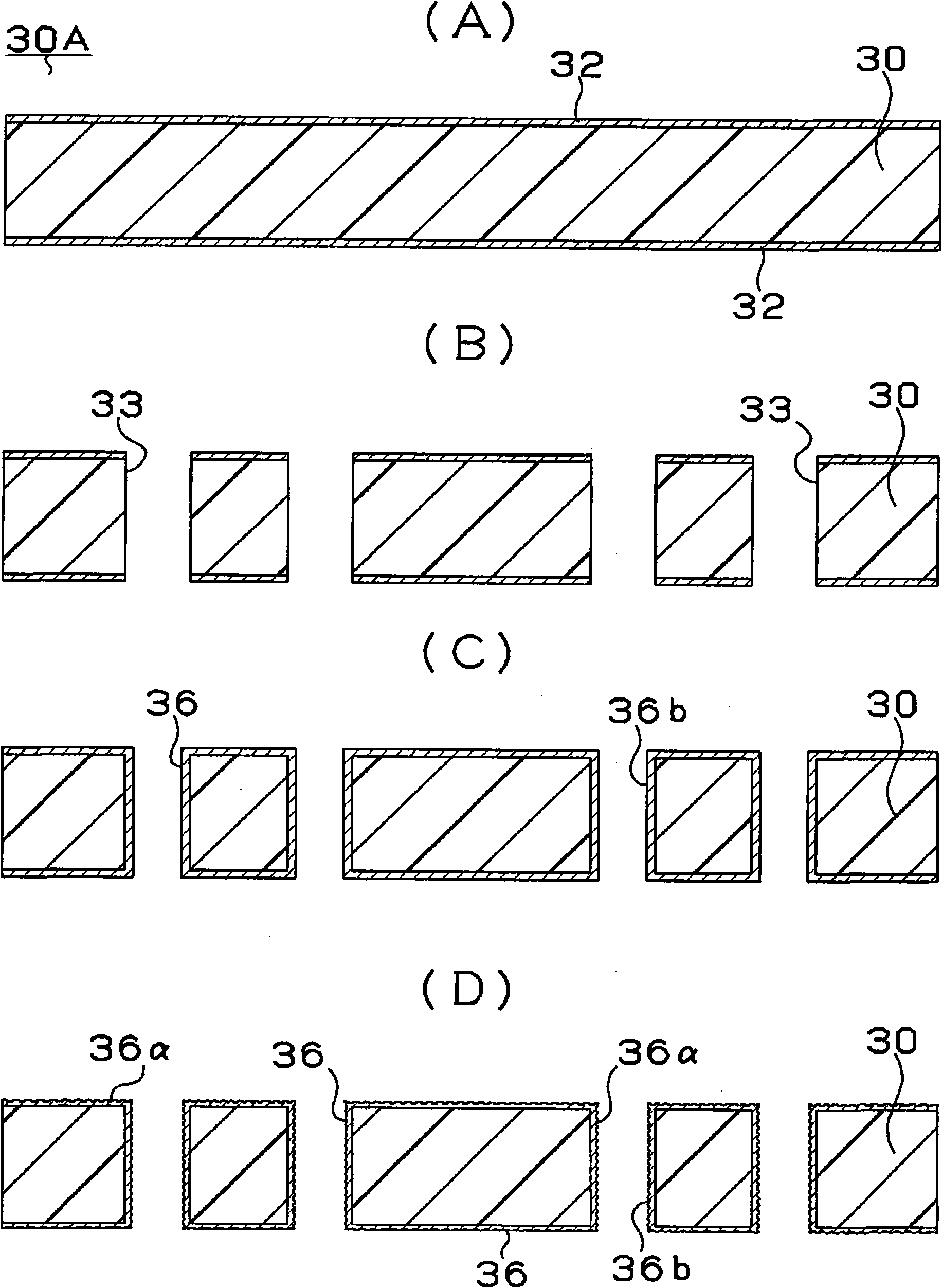

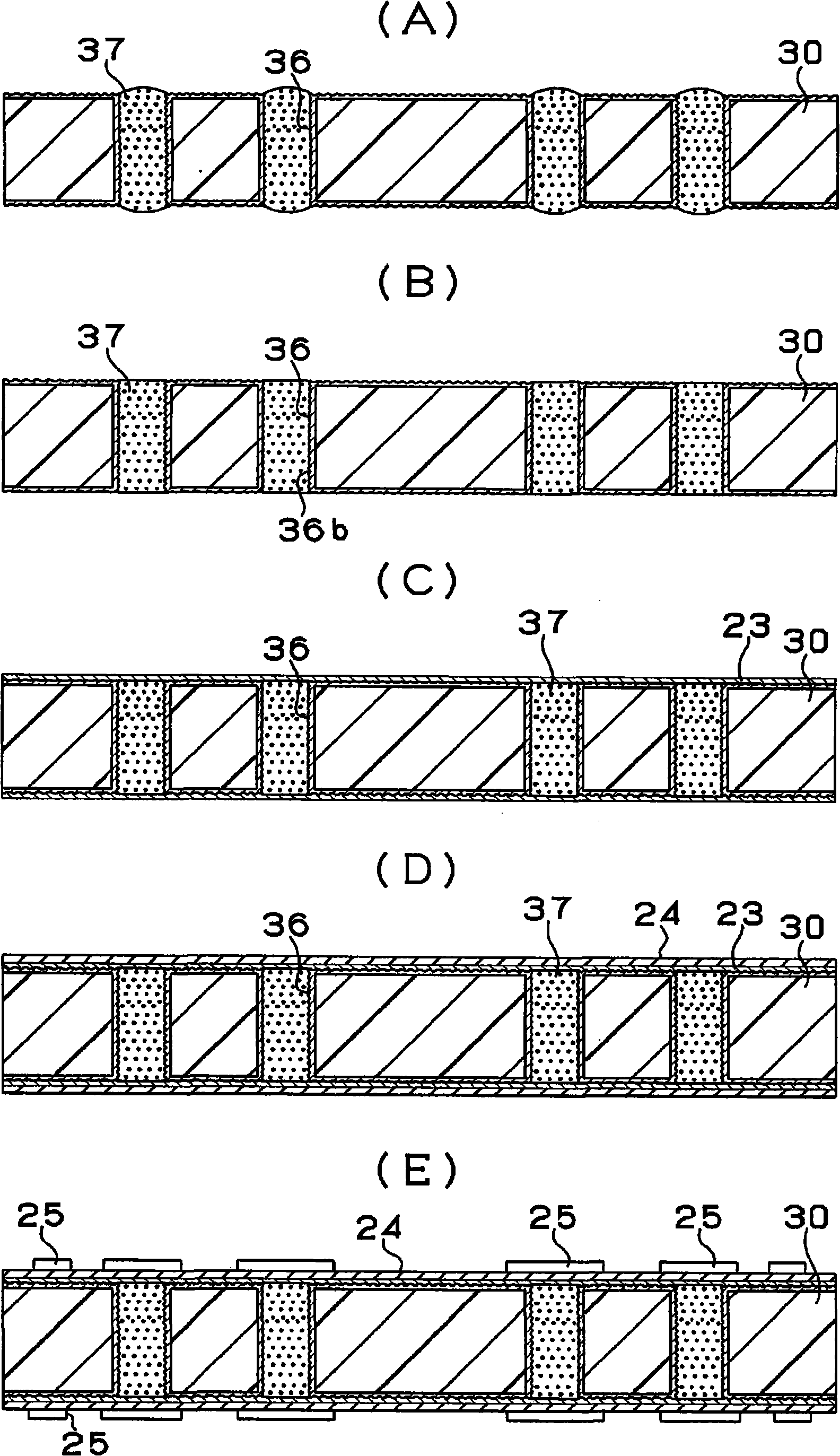

Anisotropic conductive film and manufacturing method thereof

InactiveCN1938904AGuaranteed insulation performanceGuaranteed connection reliabilityLine/current collector detailsNon-insulated conductorsAnisotropic conductive filmOrganic solvent

An anisotropic conductive film, which is applicable to a narrower pitch of an object to be connected, while maintaining connection reliability, is provided at a low cost compared with the conventional ones. A method for manufacturing such anisotropic conductive film is also provided. The anisotropic conductive film is provided with a porous film. The film has many hole parts which penetrate in the film thickness direction, being arranged in a honeycomb state with their inner wall surfaces bent in the external direction, and are formed of a polymer. The film is also provided with a conductive material applied in the holes of the porous film, and an adhesive layer covering the both sides of the porous film. The porous film is formed by a method wherein the polymer is melt in a volatile organic solvent which does not mix with water and a supporting board made by casting the polymer solution is permitted to exist under a high moisture condition.

Owner:SUMITOMO RIKO CO LTD

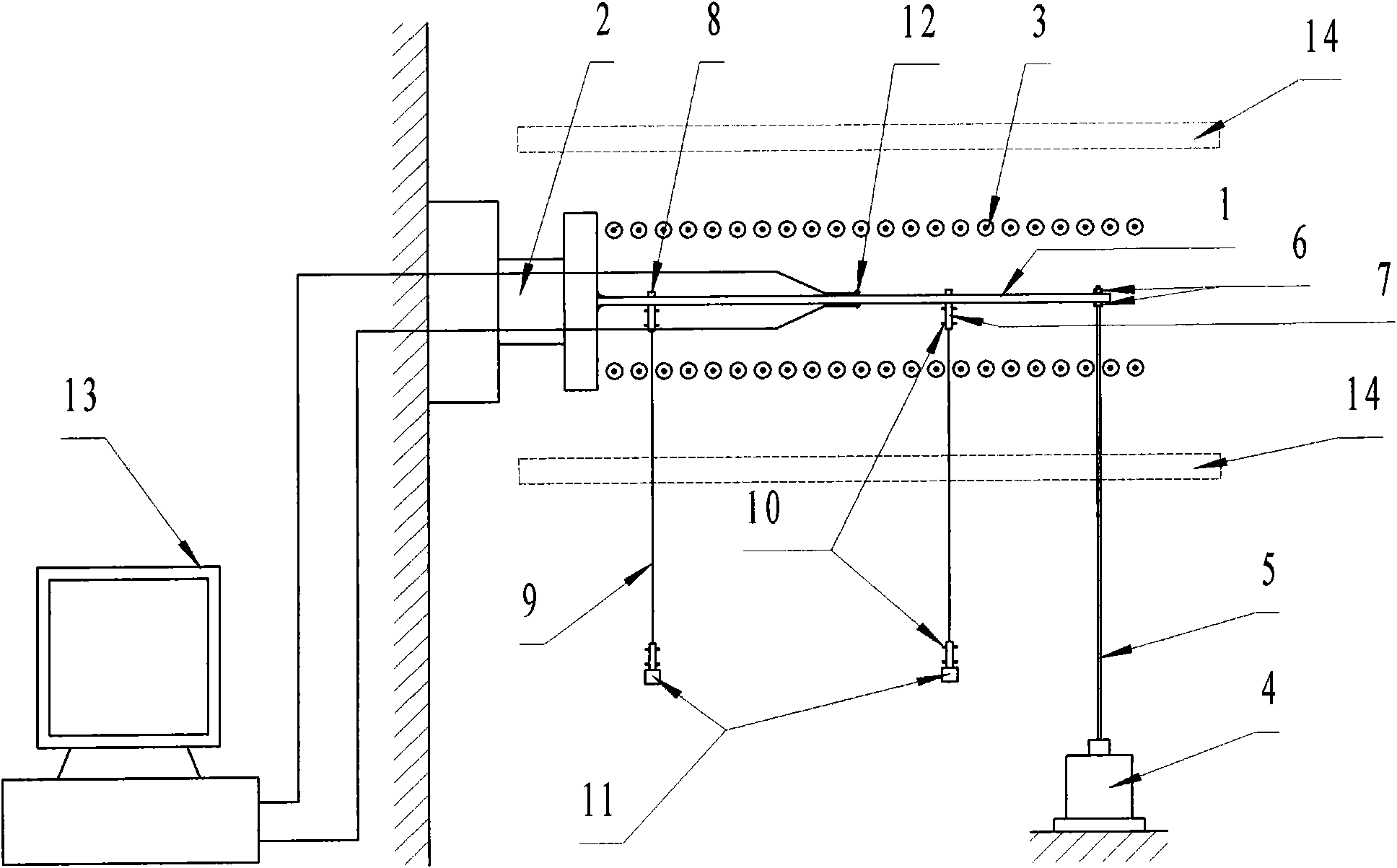

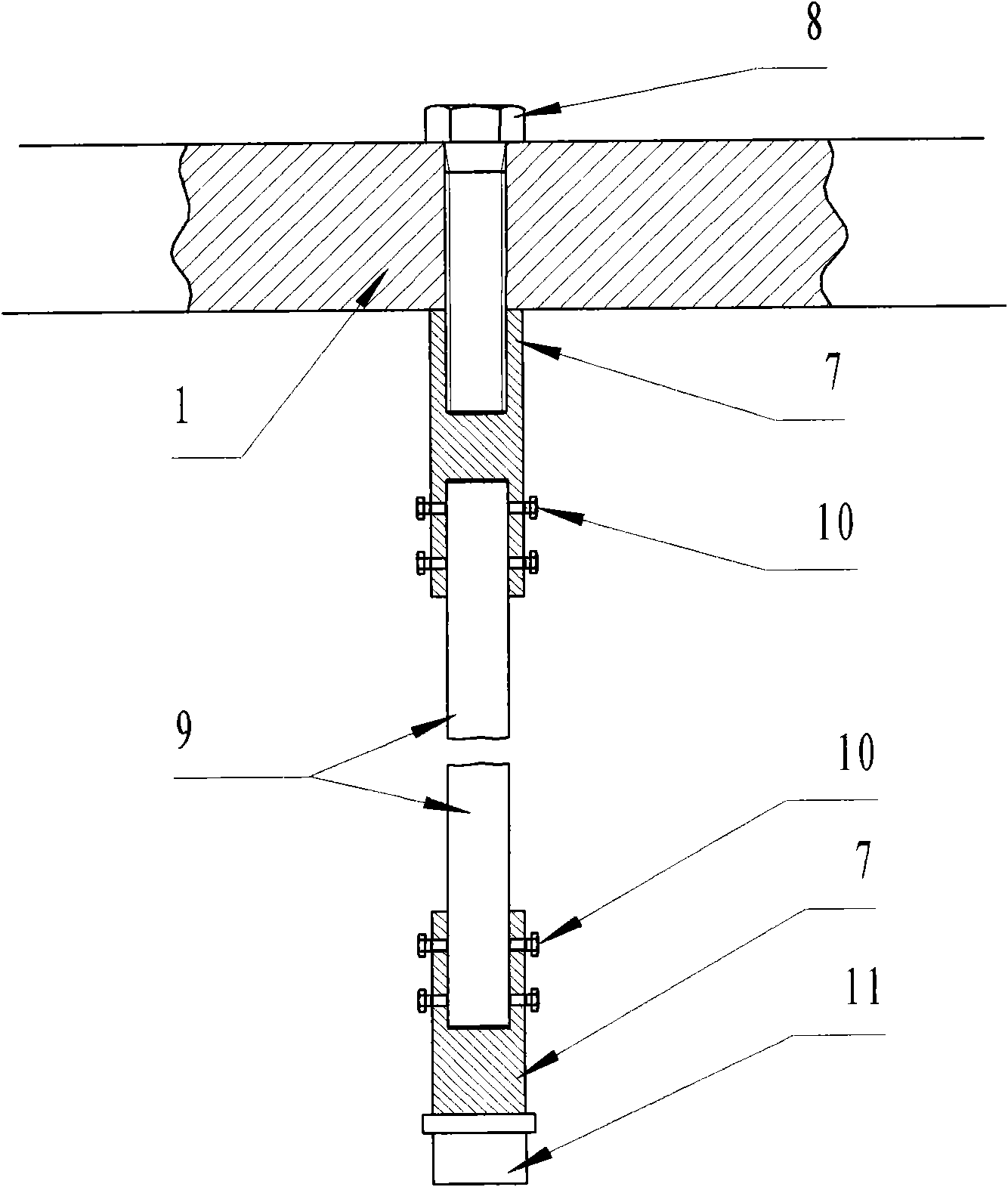

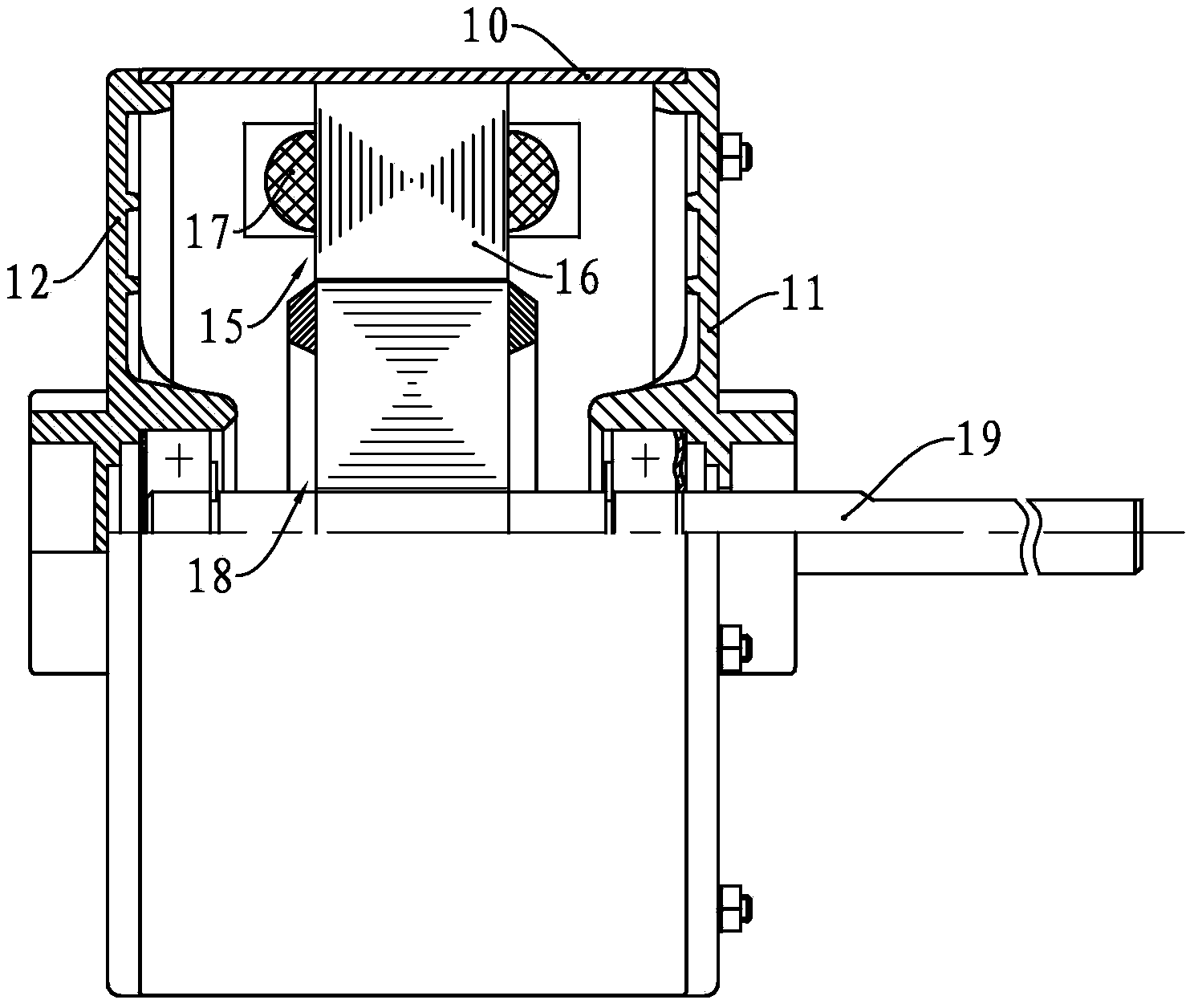

Inherent frequency measuring device for 600 DEG C high-temperature thermal vibration coupling test of high-speed cruise missile airfoil surface

InactiveCN102042870AReduce special requirementsReduce special requirements on temperature environmentSubsonic/sonic/ultrasonic wave measurementSignal onQuartz

The invention discloses an inherent frequency measuring device for 600 DEG C high-temperature thermal vibration coupling test of a high-speed cruise missile airfoil surface. The device comprises a missile airfoil surface structure test piece, a quartz lamp heating array, a vibration exciter, a ceramic extension rod, an acceleration transducer, a computer and a heat insulation baffle plate. In the high-temperature thermal vibration coupling test of the cruise missile airfoil surface, the missile airfoil surface is quickly heated by using the quartz lamp heating array and generates random vibration through the vibration exciter at the same time to form a 600 DEG C high-temperature thermal vibration coupling test environment. The rigid ceramic extension rod with high rigidity and high temperature resistance is arranged on the missile airfoil surface to guide the vibration signals on the missile airfoil surface out of the high-temperature thermal field, and the high-temperature resistant lightweight ceramic fiber heat insulation baffle plate is used for implementing thermal diffusion prevention shielding for the radiation thermal field. The normal temperature acceleration transducer arranged at the cold end of the ceramic extension rod dynamically tracks and measures the vibration signals guided to the missile airfoil structure of the normal temperature zone to acquire the change rule of the inherent frequency of the missile airfoil surface under the high-temperature thermal vibration coupling test environment; and the device provides an effective dynamic high-temperature thermal vibration coupling test means for researching and manufacturing high-speed cruise missiles.

Owner:BEIHANG UNIV

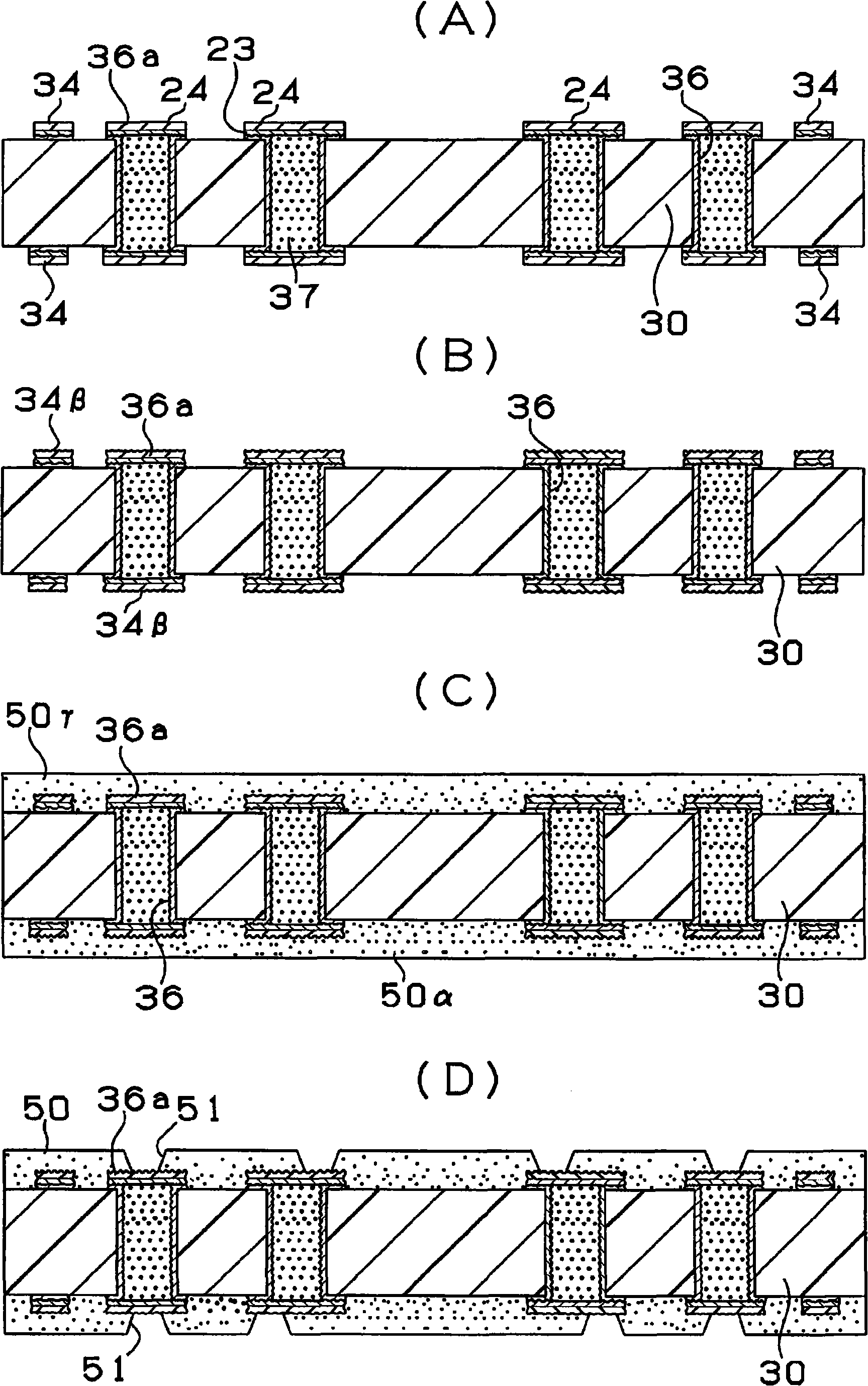

Printed-circuit board, and method for manufacturing the same

InactiveCN101356642AGuaranteed connection reliabilityMake sure to carryPrinted circuit assemblingSemiconductor/solid-state device detailsResistSolder mask

Provided is a method for manufacturing a printed-circuit board, which can form bumps at substantially identical heights on connection pads having different opening diameters of a solder resist. Diametrically-small bumps (78S), which are made high of solder balls (77) mounted in diametrically-small openings (71S) of a solder resist layer (70), are flattened to have the same height as that of the solder bumps (78P) of diametrically-large openings (71P). The solder bumps (78S) of the diametrically small openings (71S) and the solder bumps (78P) of the diametrically large openings (71P) are identical in the solder quantity. No connection occurs at the solder bumps (78S) of the diametrically small openings (71S) so that the connection reliability between an IC chip (90) and a multilayer printed-circuit board (10) can be retained.

Owner:IBIDEN CO LTD

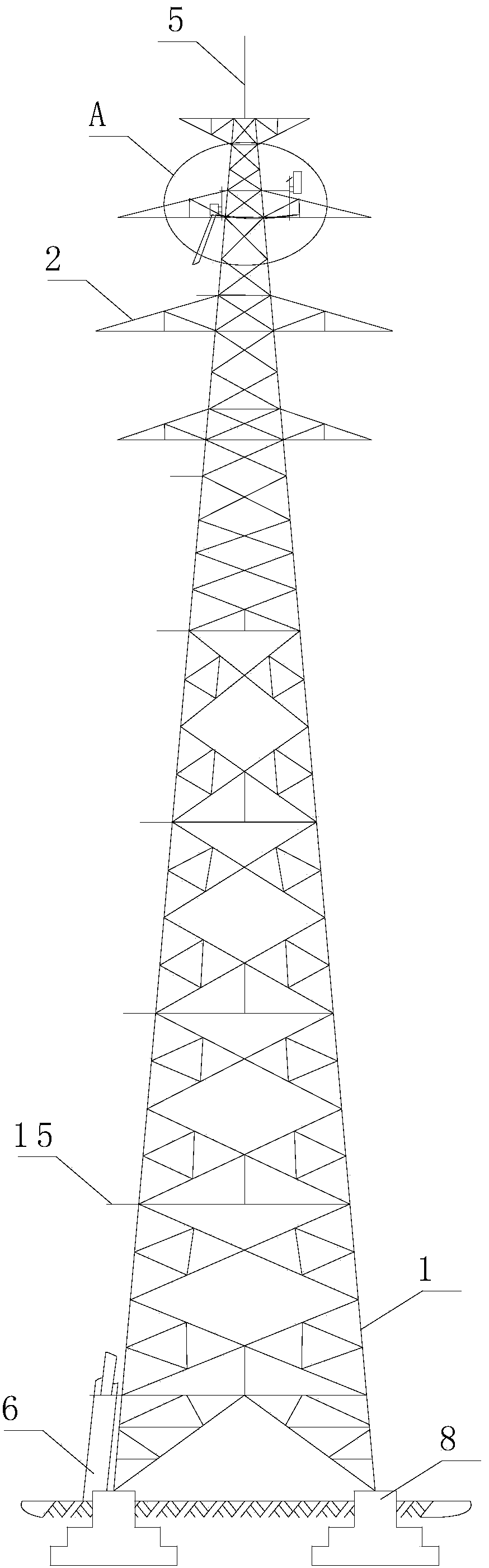

Electric iron tower mounted with 4G antenna

ActiveCN104141406AReduce disengagementGuaranteed connection reliabilityTowersApparatus for overhead lines/cablesLightning rodEngineering

The invention relates to an electric iron tower mounted with an 4G antenna. The electric iron tower comprises an iron tower main body, wherein a first mounting bracket, a second mounting bracket, a lightning rod, a protecting sleeve and a grounding device are arranged on the iron tower main body; a base is arranged at the bottom end of the iron tower main body; the base comprises a soil layer, a thin sand layer, a concrete floor and a macadam layer; the protecting sleeve is inserted into the thin sand layer. The electric iron tower has the advantages that a radio frequency pulling unit RUU and the antenna are respectively fixed on a cross arm at the top of the top end of the iron tower through the first mounting bracket and the second mounting bracket, the lightning rod and the grounding device which are arranged on the iron tower are used for performing lightning protection treatment on the radio frequency pulling unit RUU and the antenna, and the radio frequency pulling unit RUU and the antenna are arranged in a protecting area of the lightning rod, so that the antenna and the radio frequency pulling unit RUU are protected from being damaged, the safety performance is high, the structure is simple, the mounting is convenient, and the base is provided with the soil layer, the thin sand layer, the concrete floor and the macadam layer so that the strength of the base is increased.

Owner:STATE GRID CORP OF CHINA +2

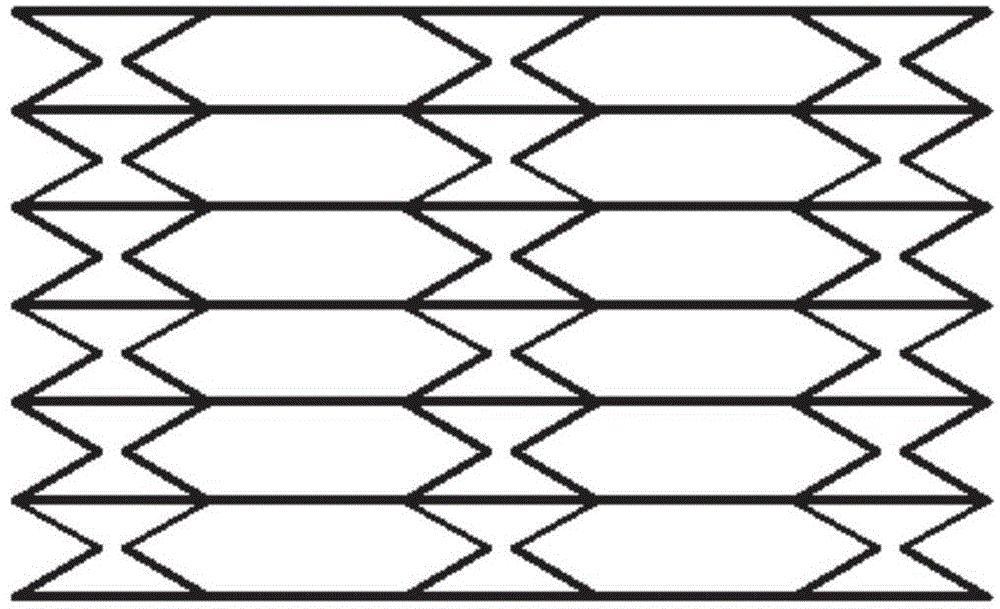

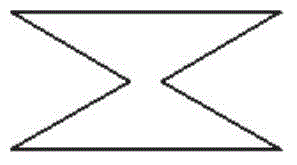

Large-deformation composite material with flexible cellular structure and preparation method of large-deformation composite material

ActiveCN104443346AGood large deformation propertiesHigh bonding strengthFuselage bulkheadsFiberLarge deformation

The invention discloses a large-deformation composite material with a flexible cellular structure and a preparation method of the large-deformation composite material. According to the large-deformation composite material, glass fiber cloth and flexible epoxy resin which need to greatly deform and are used for single-cell cell walls are molded according to a stressing property of the large deformation of the cellular structure; a large deformation function is realized by adopting the flexible epoxy resin; glass fibers and epoxy resin, which have connection effects, of the cell walls are molded; carbon fibers and epoxy resin which have connection effects on single cell lines are molded so that the high rigidity is obtained; and the requirements on bearing out-plane load and keeping the shape of the cellular structure in deformation are met. According to the method, primary paving, and primary curing and molding are adopted, and interface defects caused by secondary paving and curing are avoided; and single-cell inter-line binding force is improved, the process is simplified and the cost is reduced. The composite material with the flexible cellular structure, which is prepared by adopting the method, can be applied to a flexible supporting body of a morphing wing skin or a morphing structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

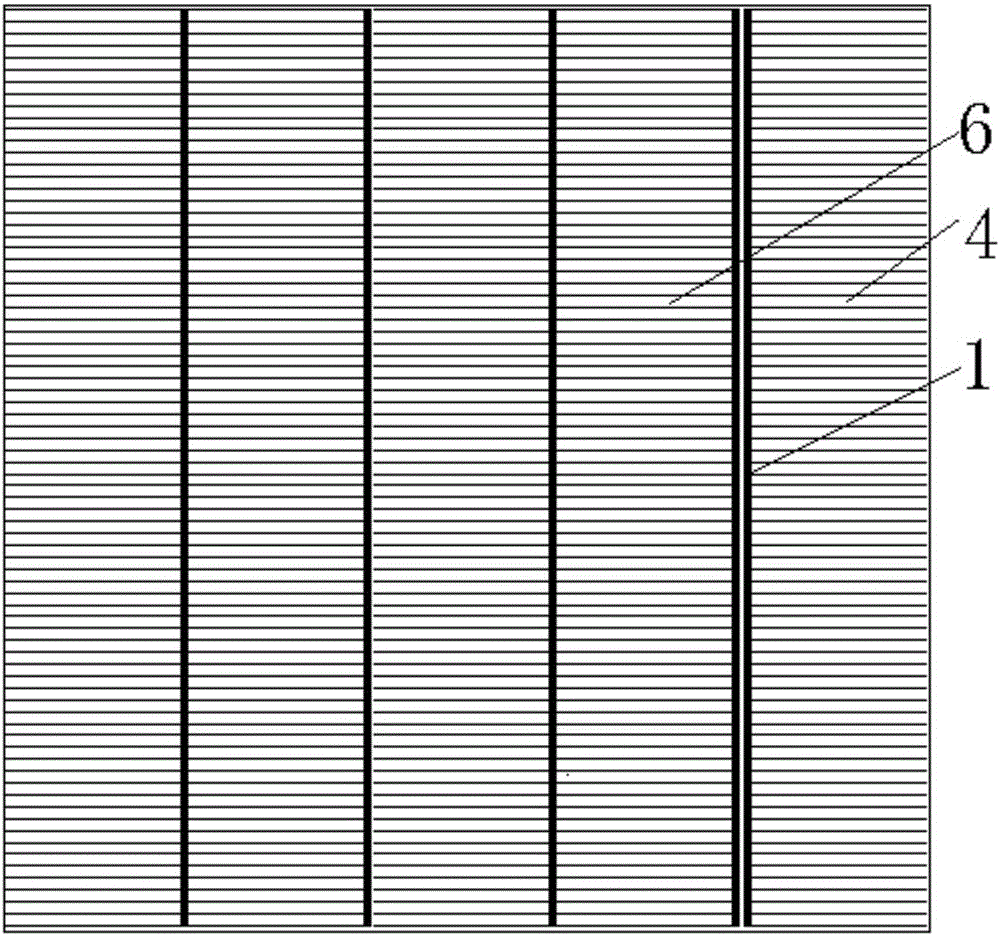

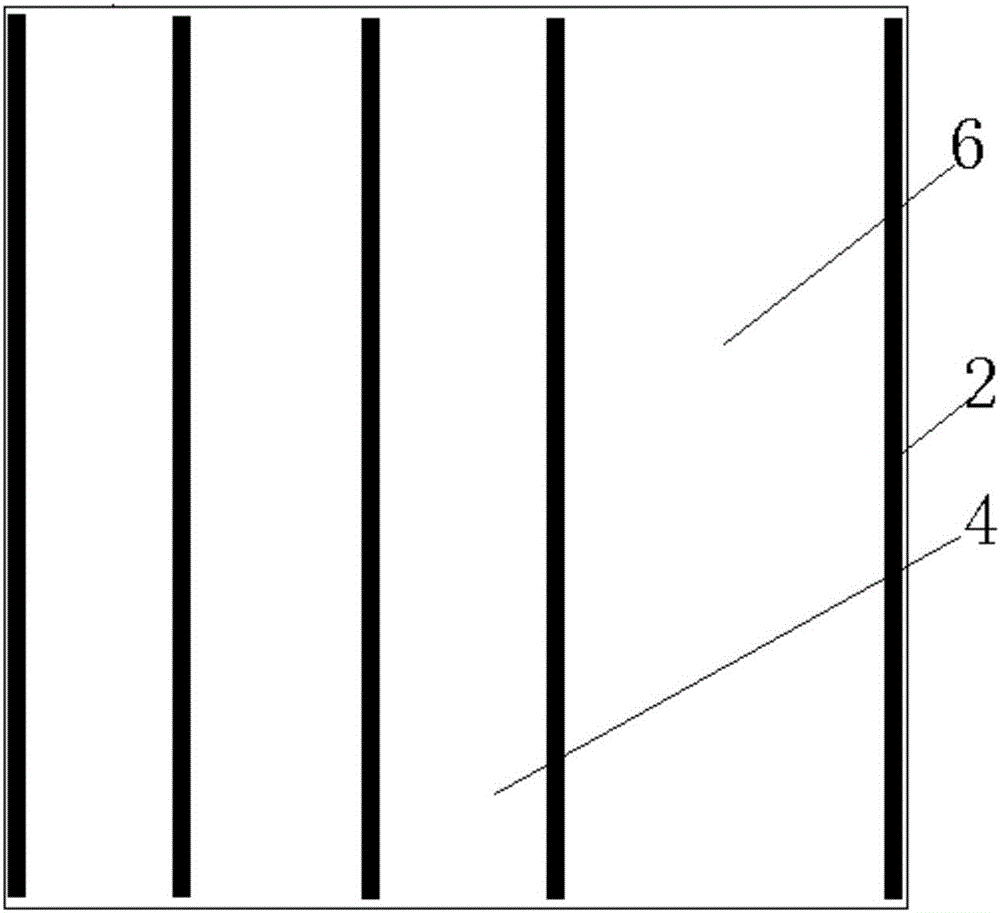

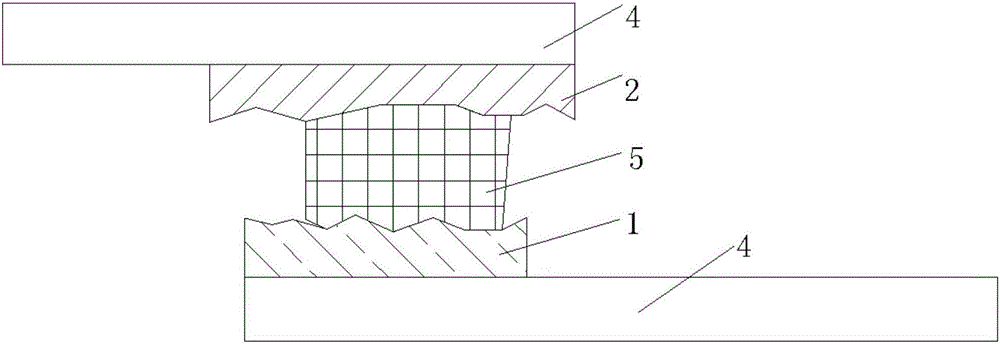

Interconnection structure between solar laminated cells and solar laminated cell

ActiveCN106531829AReliable interconnectionInterconnection is stablePhotovoltaic energy generationSemiconductor devicesElectrical connectionEngineering

The present invention belongs to the technical field of solar cells, and particularly relates to an interconnection structure between solar laminated cells and a solar laminated cell. The interconnection structure is used for sequentially bonding at least two cells and forming a good electrical connection. A front electrode and / or a back electrode of the cell are / is of a hollow structure. The back electrode of the previous cell is connected with the front electrode of the next adjacent cell by using conductive glue, so that a lot of front and back electrode paste is saved, and the cost of the laminated cell is lowered. For a back fragmented hollow design, the interconnection structure also can help reduce the amount of the used conductive glue and the cost of the laminated cell.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Extruded semi-grouting reinforced sleeve with built-in casing, connective structure, and construction method

InactiveCN105178516AReduce workloadImprove work efficiencyBuilding reinforcementsBuilding material handlingConcrete beamsEngineering

Disclosed are an extruded semi-grouting reinforced sleeve with a built-in casing, a connective structure, and a construction method. The sleeve is a hot-rolled seamless steel tube. The wall of the sleeve is provided with a grout inlet and a grout outlet. The sleeve is provided with circular inner projections. One end of the sleeve is an extruded end, and the rest is a grout-anchoring end. The built-in casing is arranged inside the extruded end. The inner diameter of the built-in casing is equal to the outer diameter of a rebar to be connected, and less than the inner diameter of the grout-anchoring end. All of the grout inlet, the grout outlet and the circular inner projections are located at the grout-anchoring end. By the use of the built-in casing, the deformation of the extruded end is lessened to avoid the extruded end being damaged during crimping; the sleeve is widely applicable to the rebar connection of prefabricated concrete columns in multi-storey and high-rise prefabricated assembled concrete frame structures, shear wall structures or frame shear wall structures, as well as the connection of horizontal rebars in prefabricated concrete beams, the connection of rebars in prefabricated concrete shear walls and the connection of rebars in existing reinforcement projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

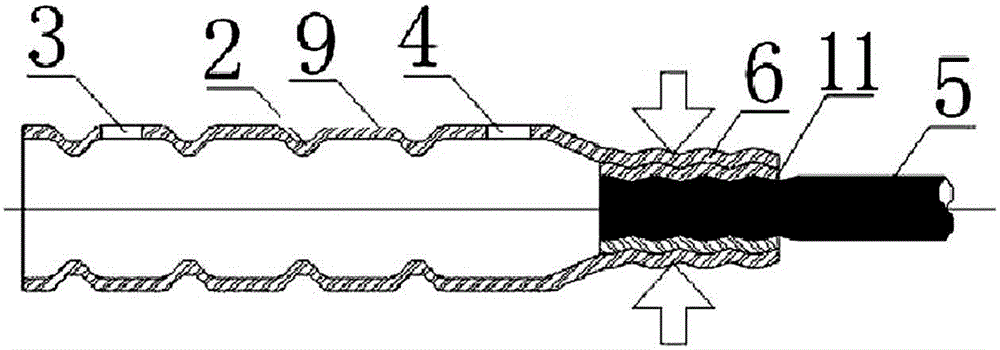

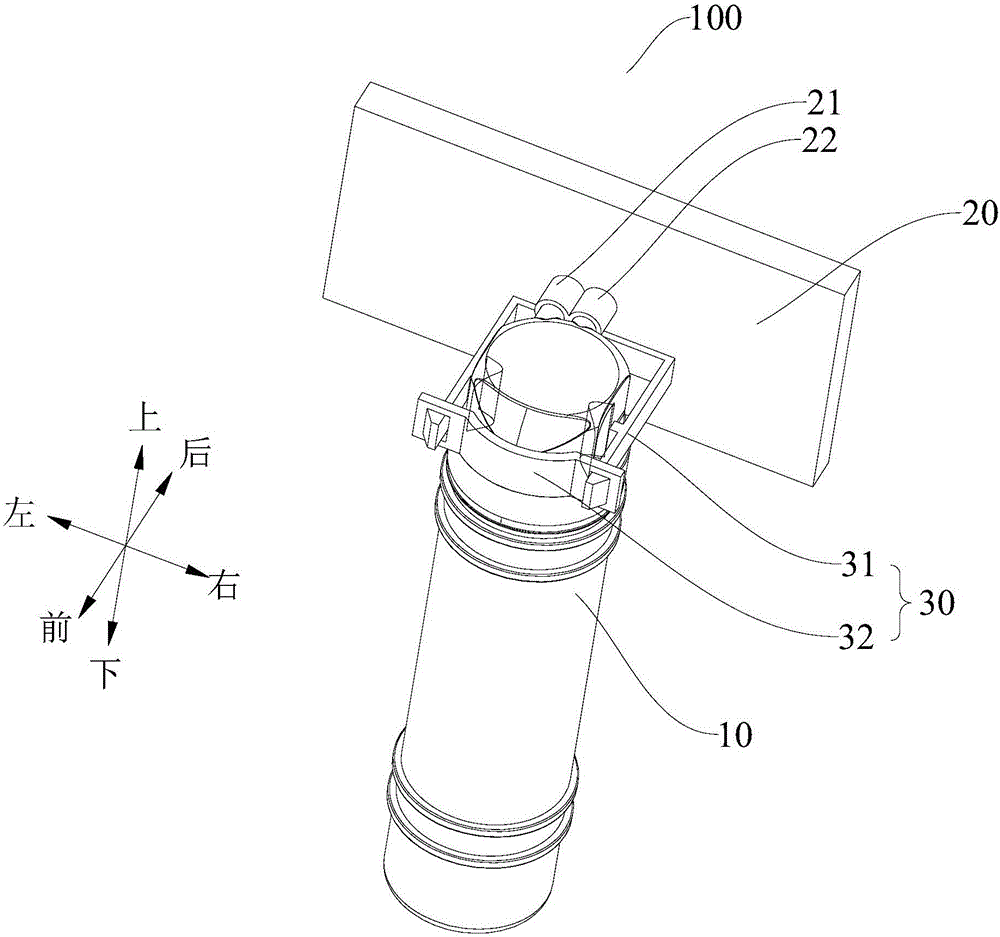

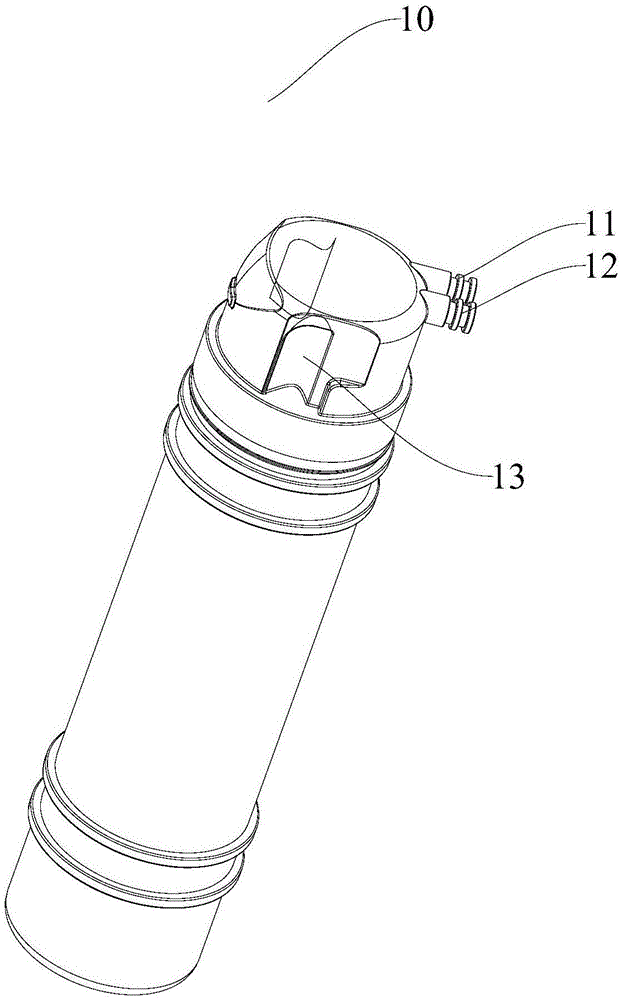

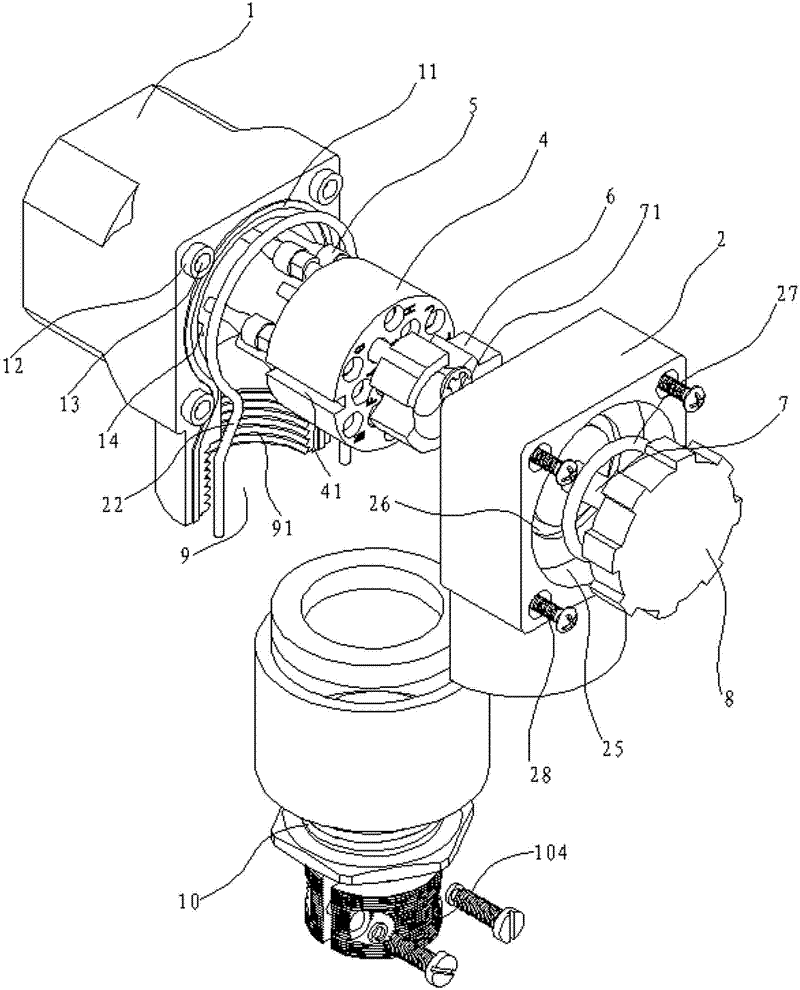

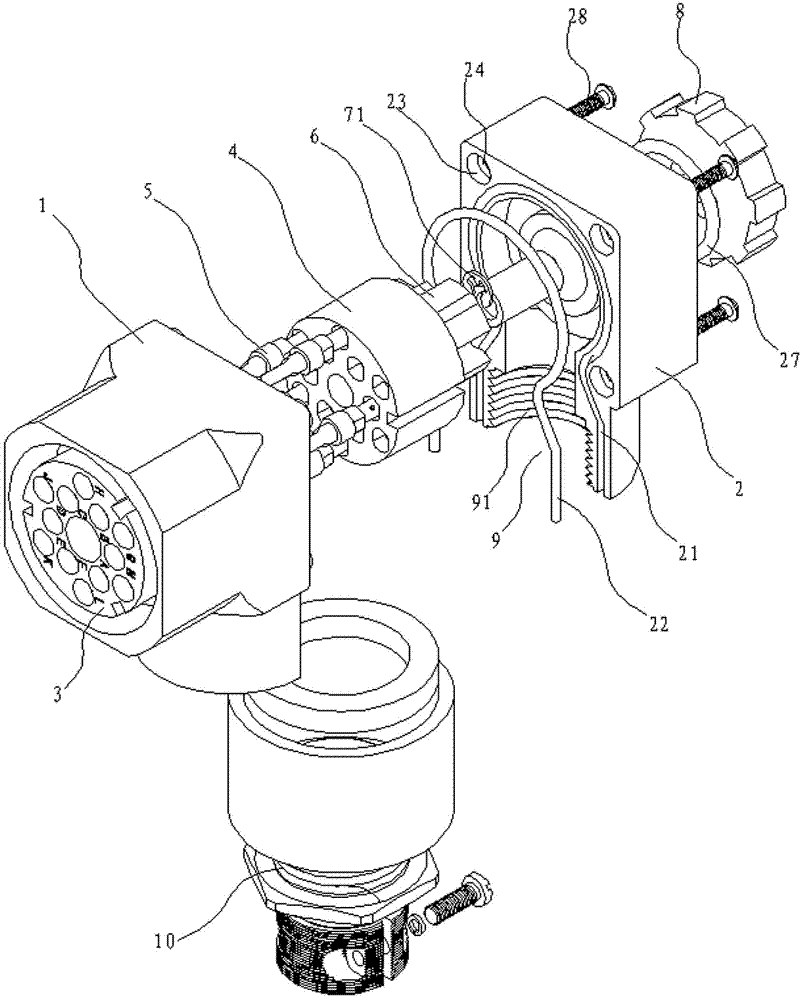

Water purifier

ActiveCN106345168AEasy to fixSimple structureMembrane filtersFiltration separationWorking pressureWaste management

The invention discloses a water purifier. The water purifier comprises a shell, a filter core assembly, a water path board and a filter core fixing structure, wherein the filter core assembly is arranged on the shell and comprises a filter core; a water inlet and a water outlet are formed in the filter core, and the water inlet and the water outlet are respectively formed in the side parts of the filter core; a water path is limited in the water path board, and a direct inserting type filter core interface connected with the water inlet and the water outlet is formed in the water path board; the filter core fixing structure is detachably connected to the water path board or the shell and is connected with the filter core so as to fix the position of the filter core relative to the water path board. According to the water purifier disclosed by the embodiment of the invention, by inserting the filter core in the water path board and fixing the position of the filter core relative to the water path board through the filter core fixing structure, the filter core can be effectively locked, the degree of freedom of the filter core relative to the water path board is limited, and the filter core is further prevented from being thrown away from the water path board due to larger working pressure of the water inlet and the water outlet or the action of an external force, the filter core or the water path board is prevented from being destroyed, the connection reliability is ensured, and the cost is reduced.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

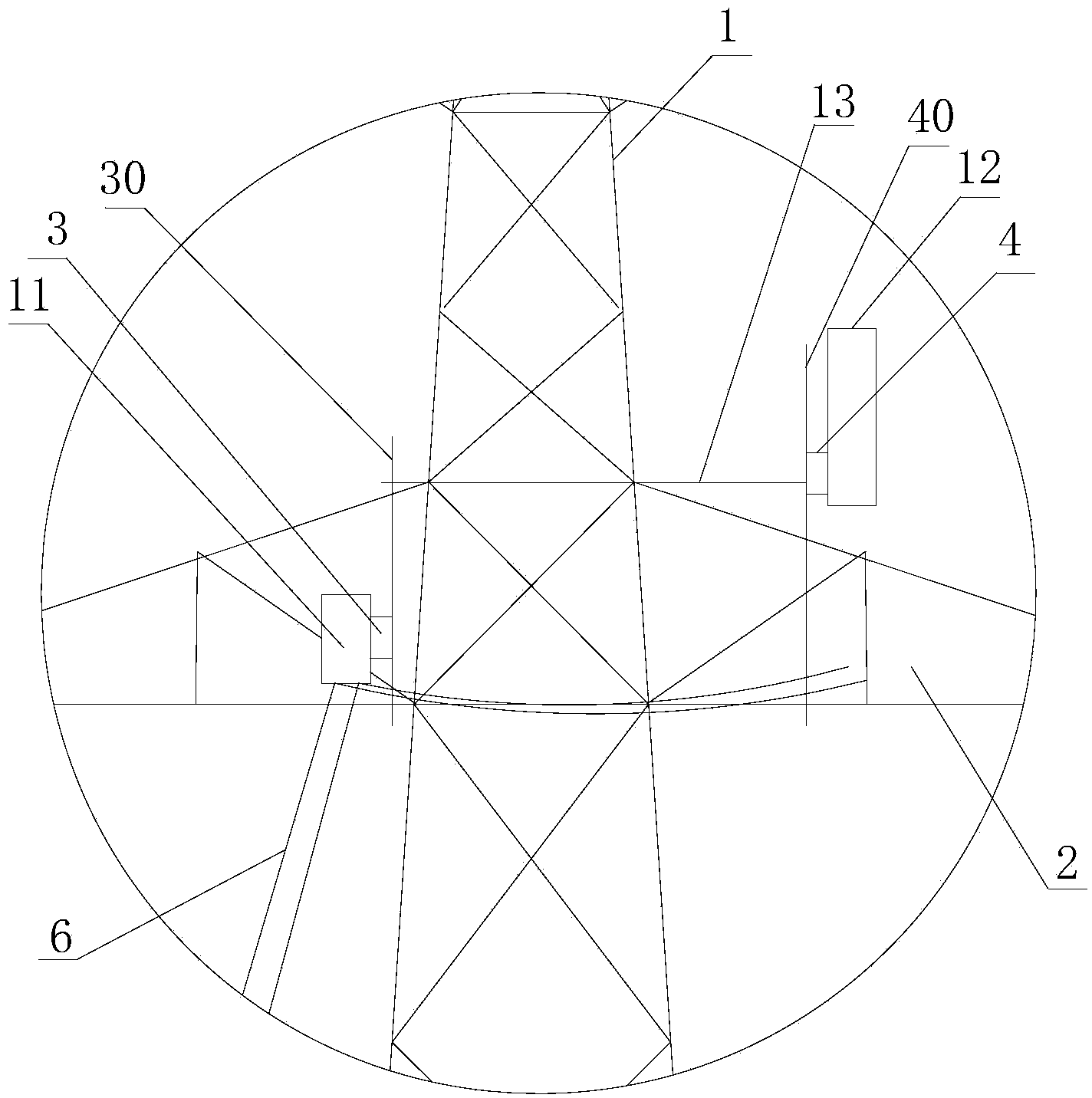

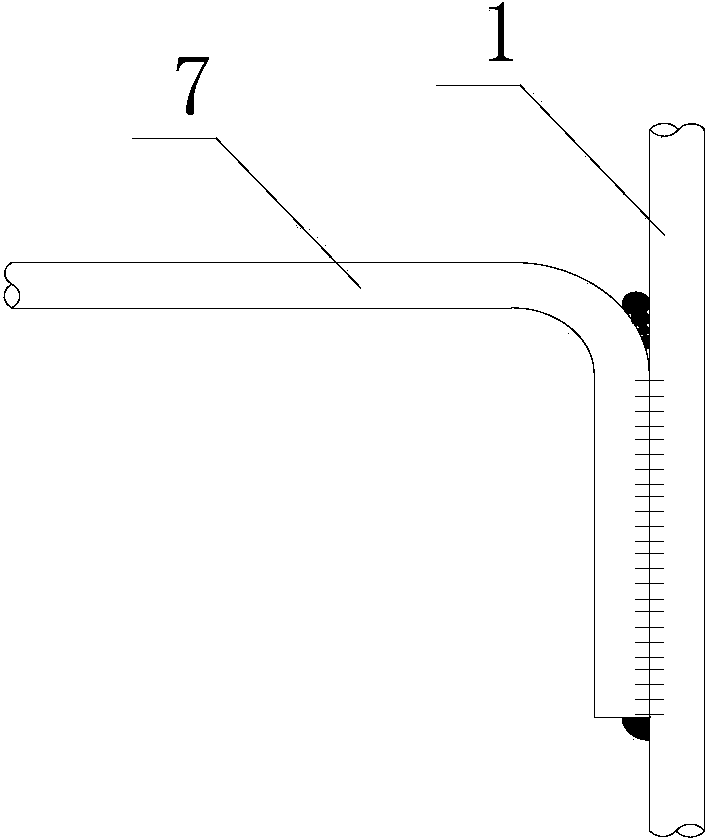

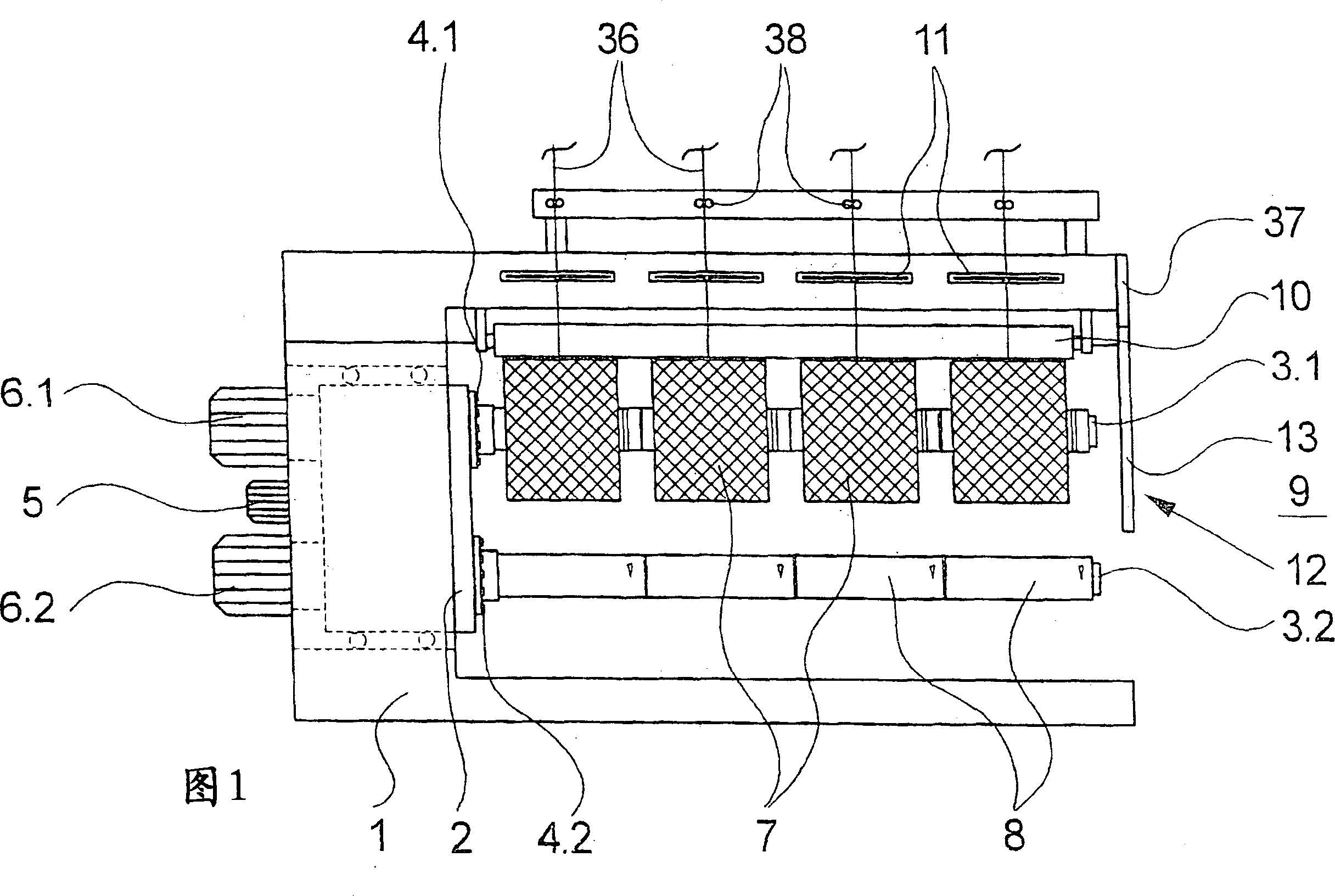

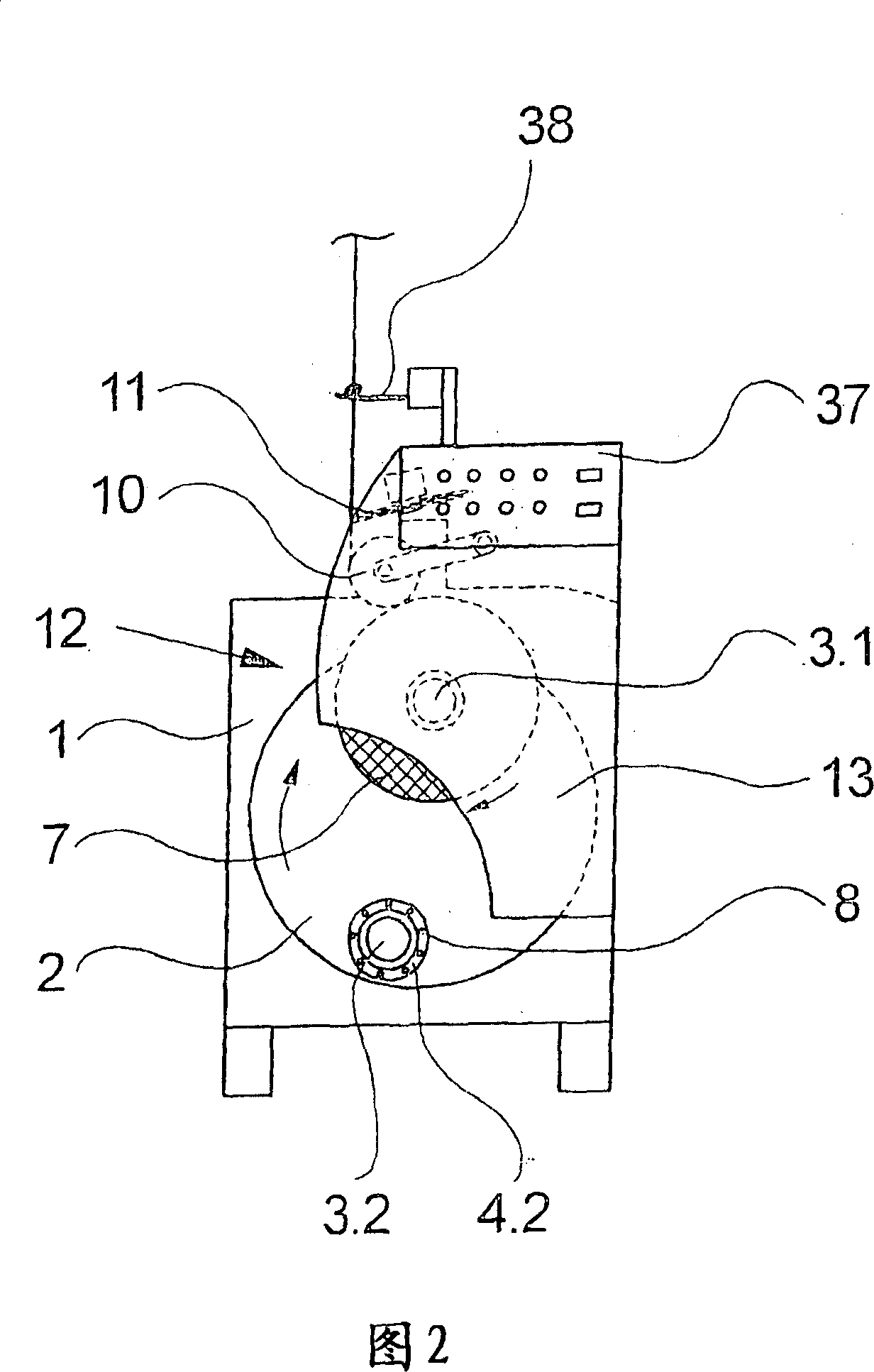

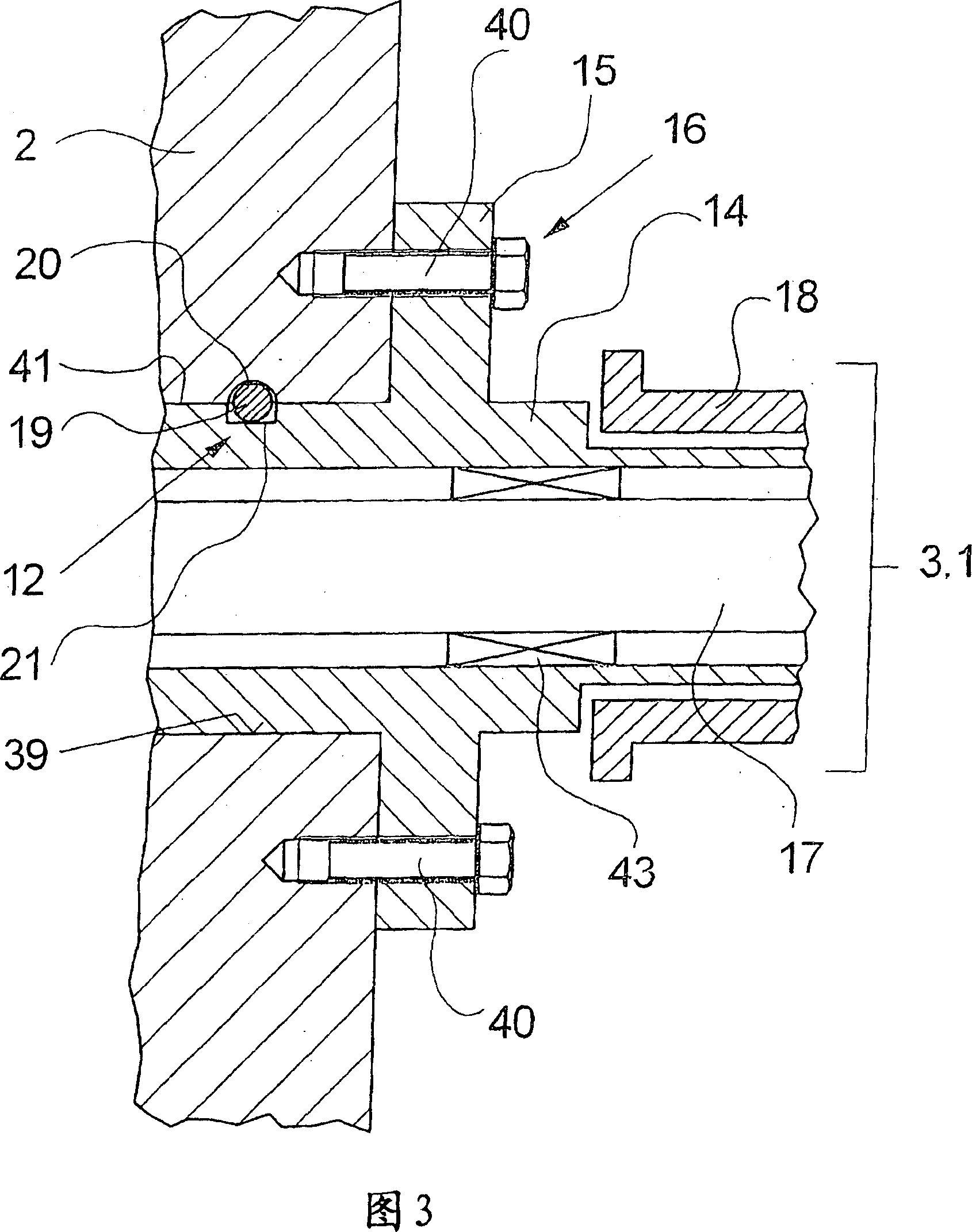

Winding machine

A winding machine is disclosed for continuously winding multiple threads into spools. The winding machine has for that purpose a spool revolver (2) rotatively mounted in a machine frame (1) and bearing two long, cantilevered spool spindles (3.1, 3.2) for receiving the spools. The spool spindles (3.1, 3.2) are alternatively moved by the spool revolver (2) into an operating region for winding the threads and into an exchanging region for removing the fully wound spools. The spool spindles (3.1, 3.2) are rotatively mounted and connected by fastening means (4.1) to the spool revolver (2). In order to prevent the risk of injury to the operator in the event of an operating error and of the resultant overstress, an additional safety means (12) is provided for securing the spool spindles (3.1, 3.2) held in the operating region during their operation.

Owner:OERLIKON TEXTILE GMBH & CO KG

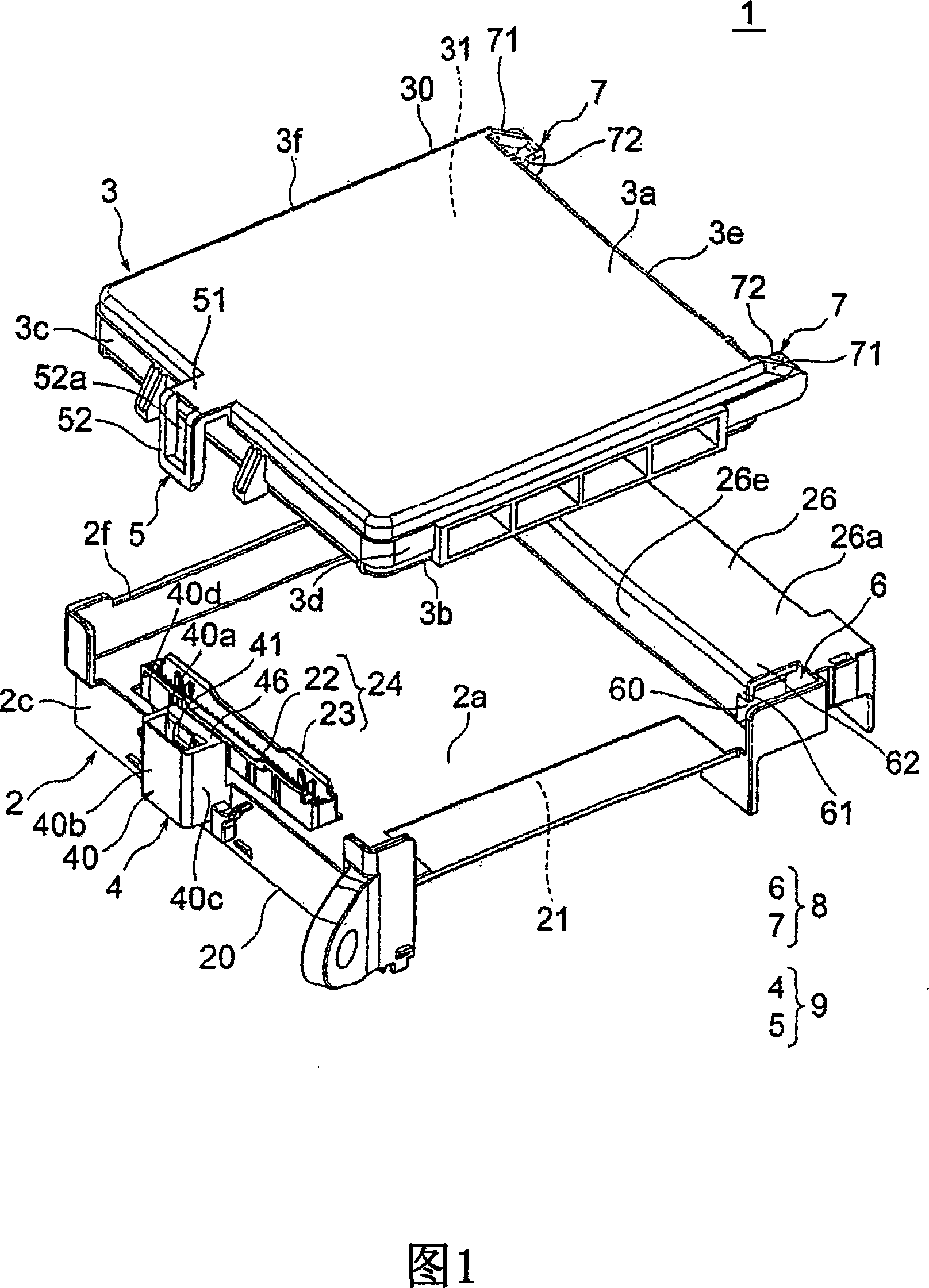

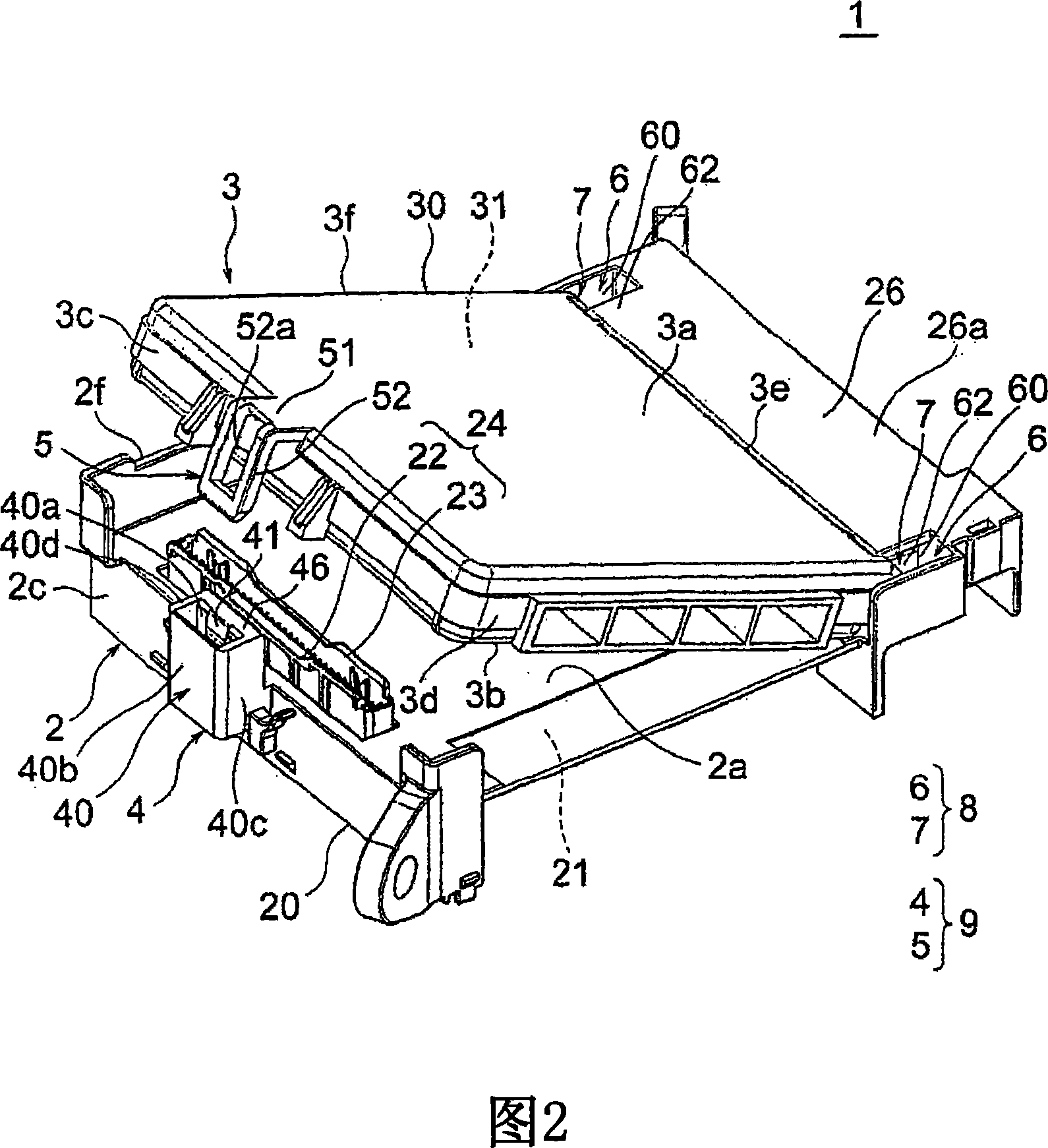

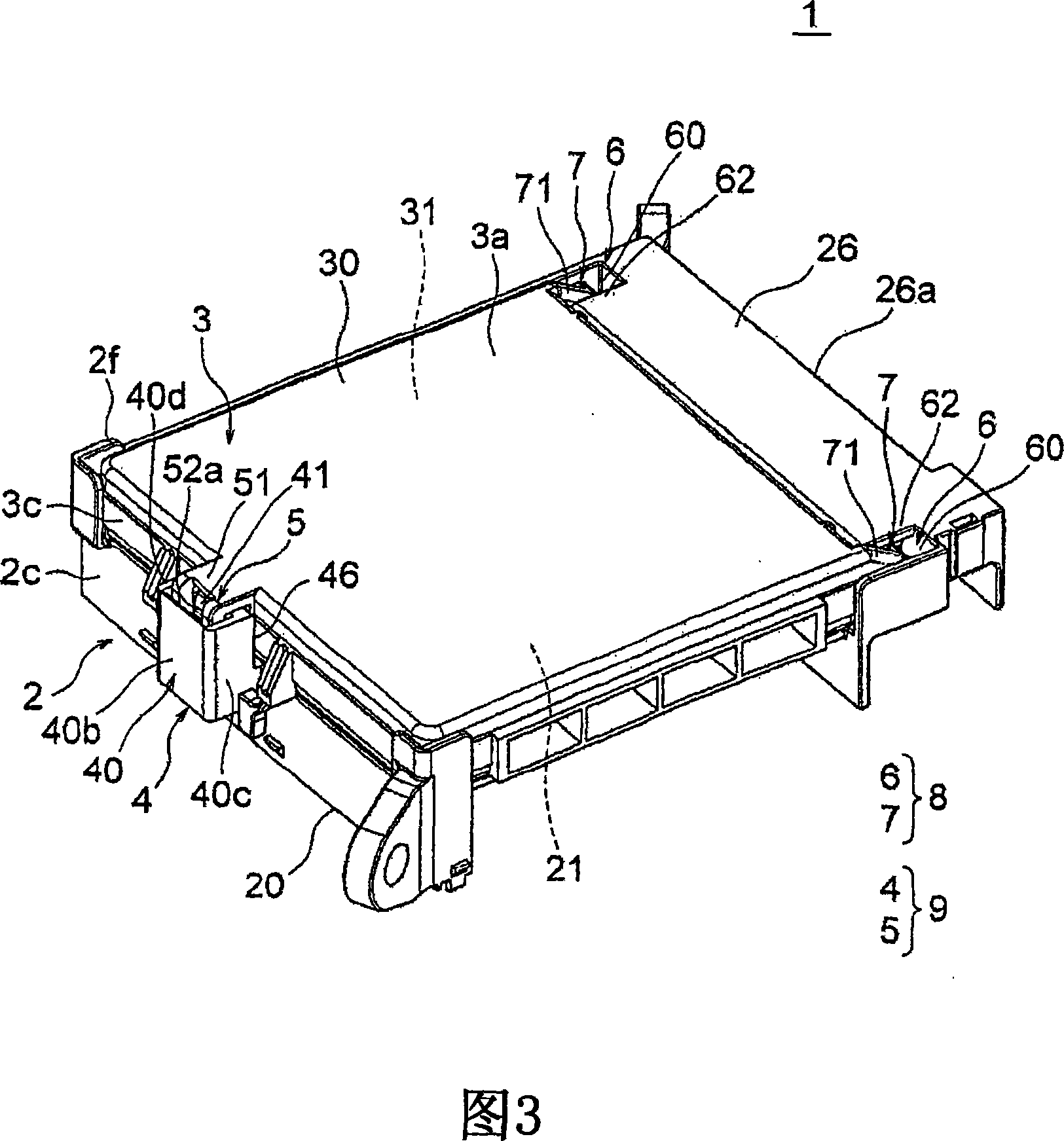

Electrical connection box

An electrical connection box includes a main body, a mounting part connected to the main body, a lock arm provided on one of the main body and the mounting part, and a lock receiving part provided on the other of the main body and the mounting part. The lock arm includes an arm portion and a first engagement portion. The lock receiving portion includes a receiving portion having an insertion portion and a second engagement portion. The receiving portion includes a protrusion protruding from the surface of the receiving portion, the protrusion protruding farther than the second engagement portion protruding from the insertion portion so as to abut on the arm portion so that the lock arm is set at a predetermined position . A gap is formed between the receiving portion and the arm portion when the first engaging portion is engaged with the second engaging portion.

Owner:YAZAKI CORP

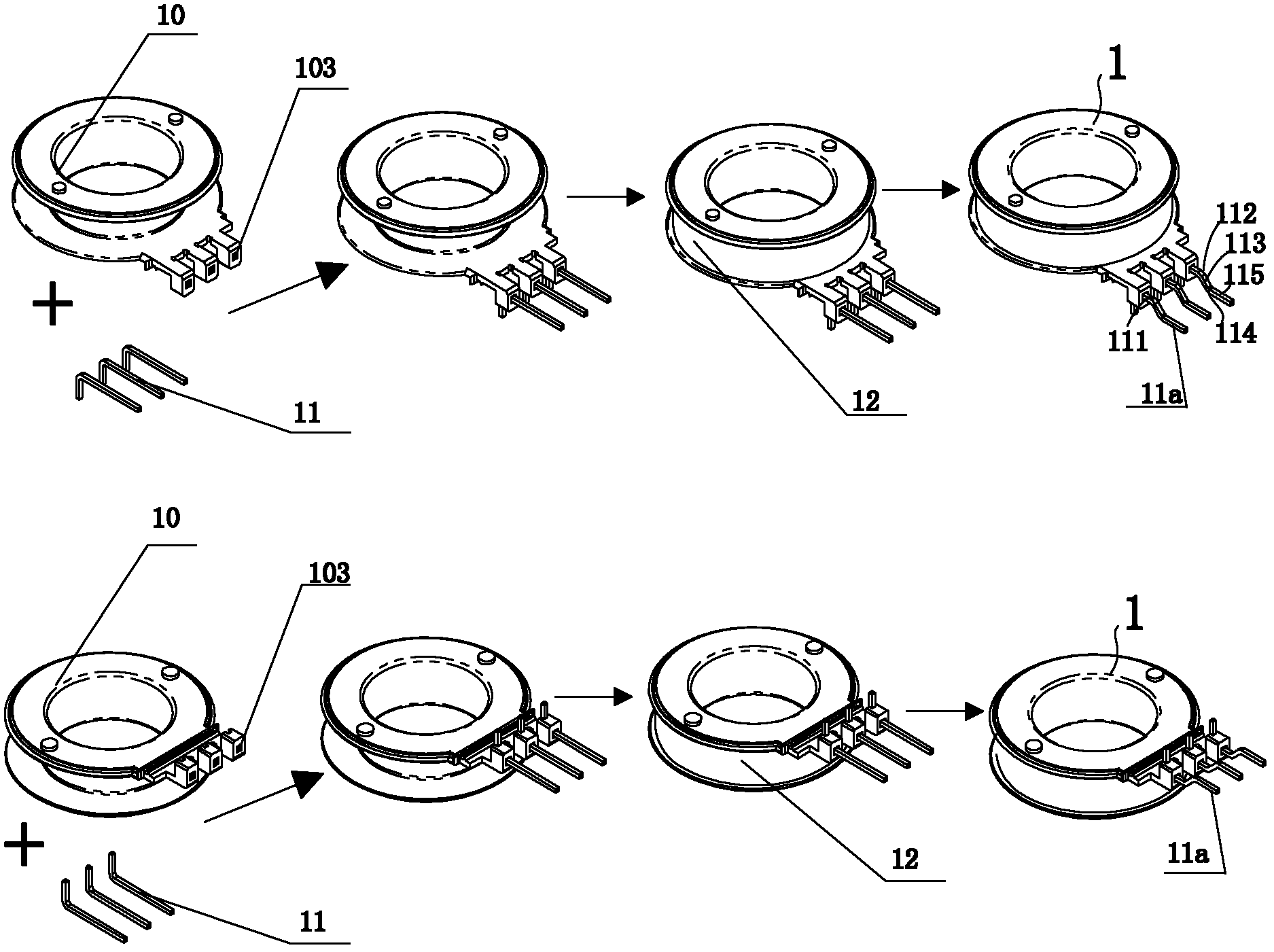

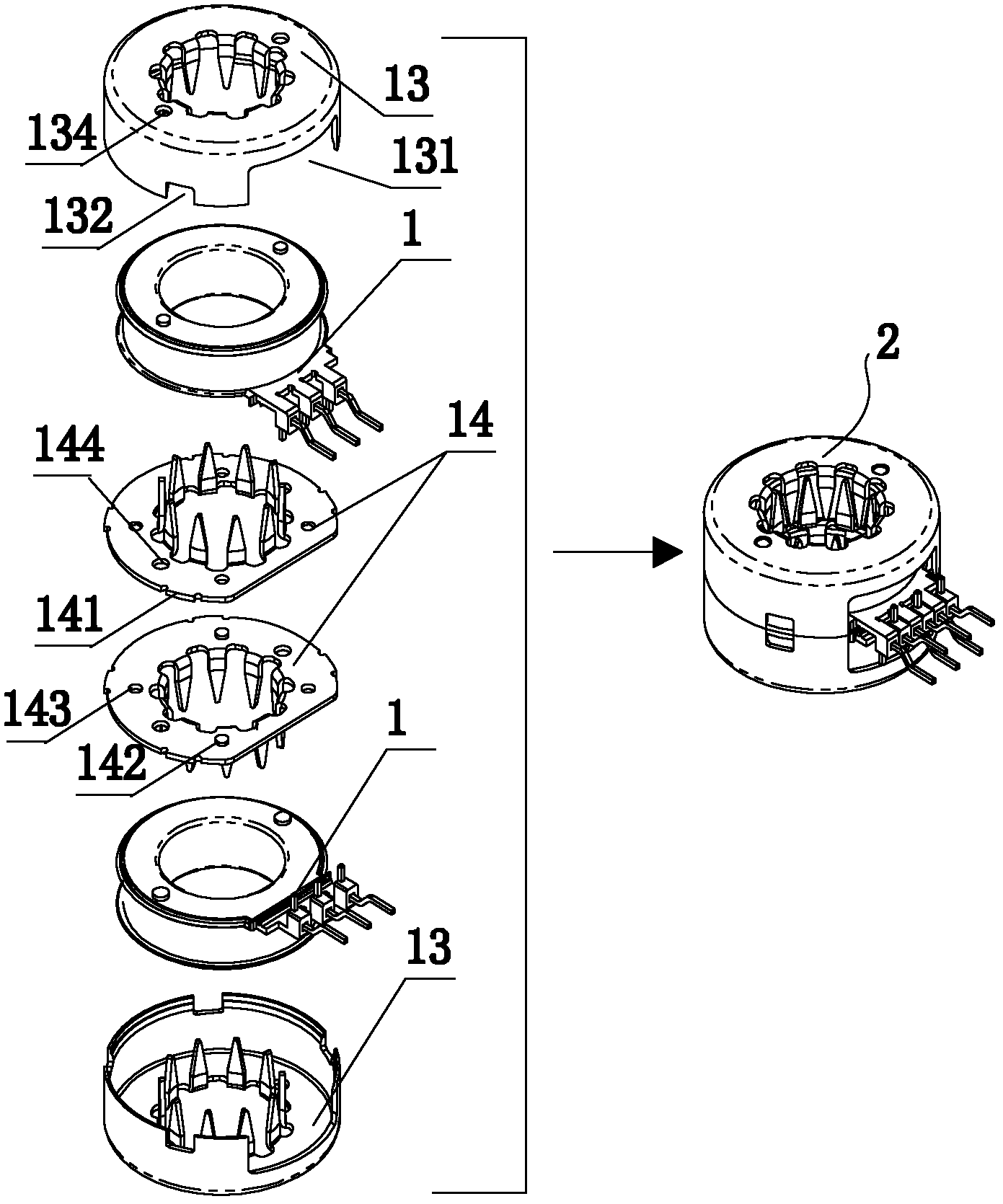

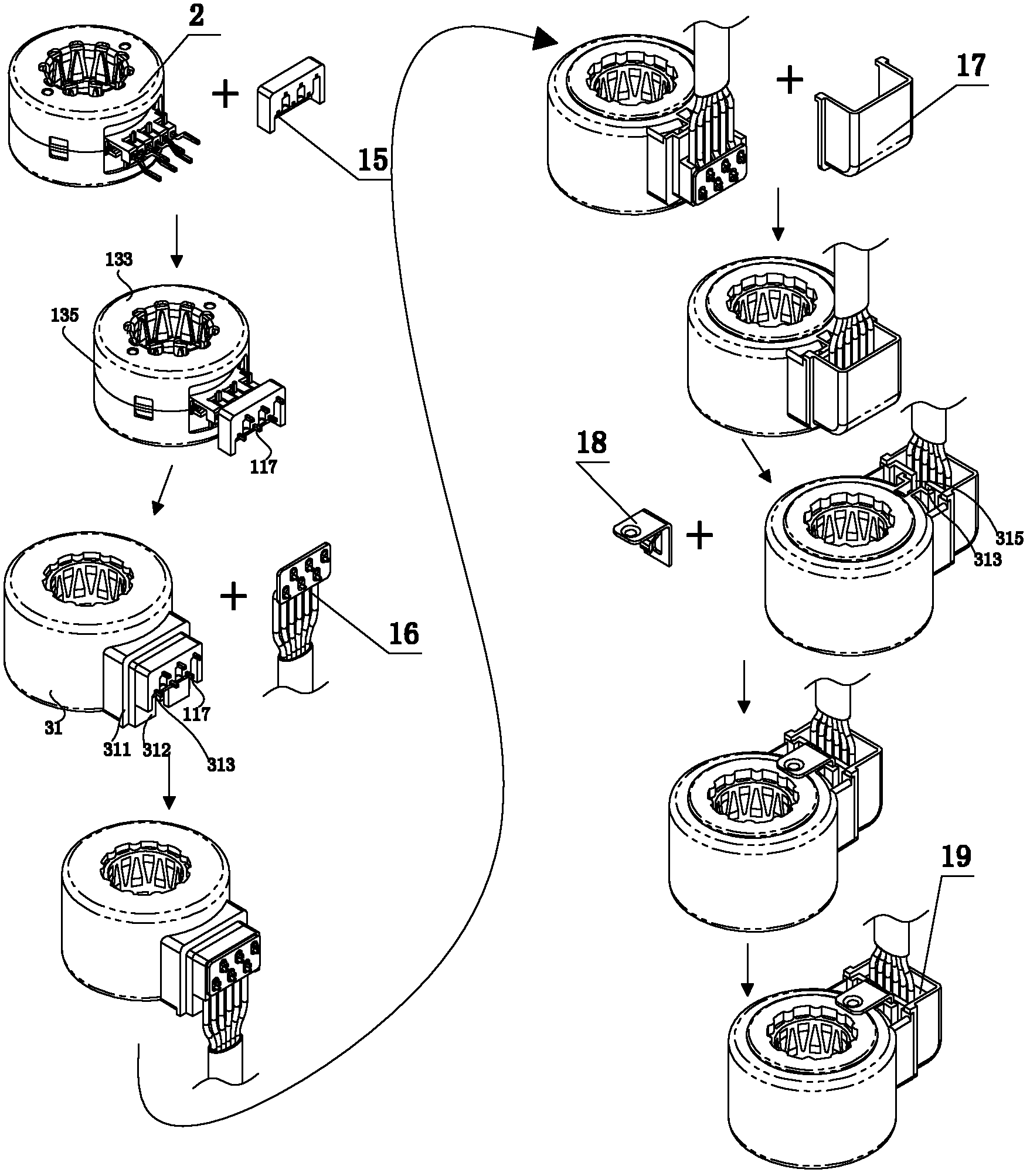

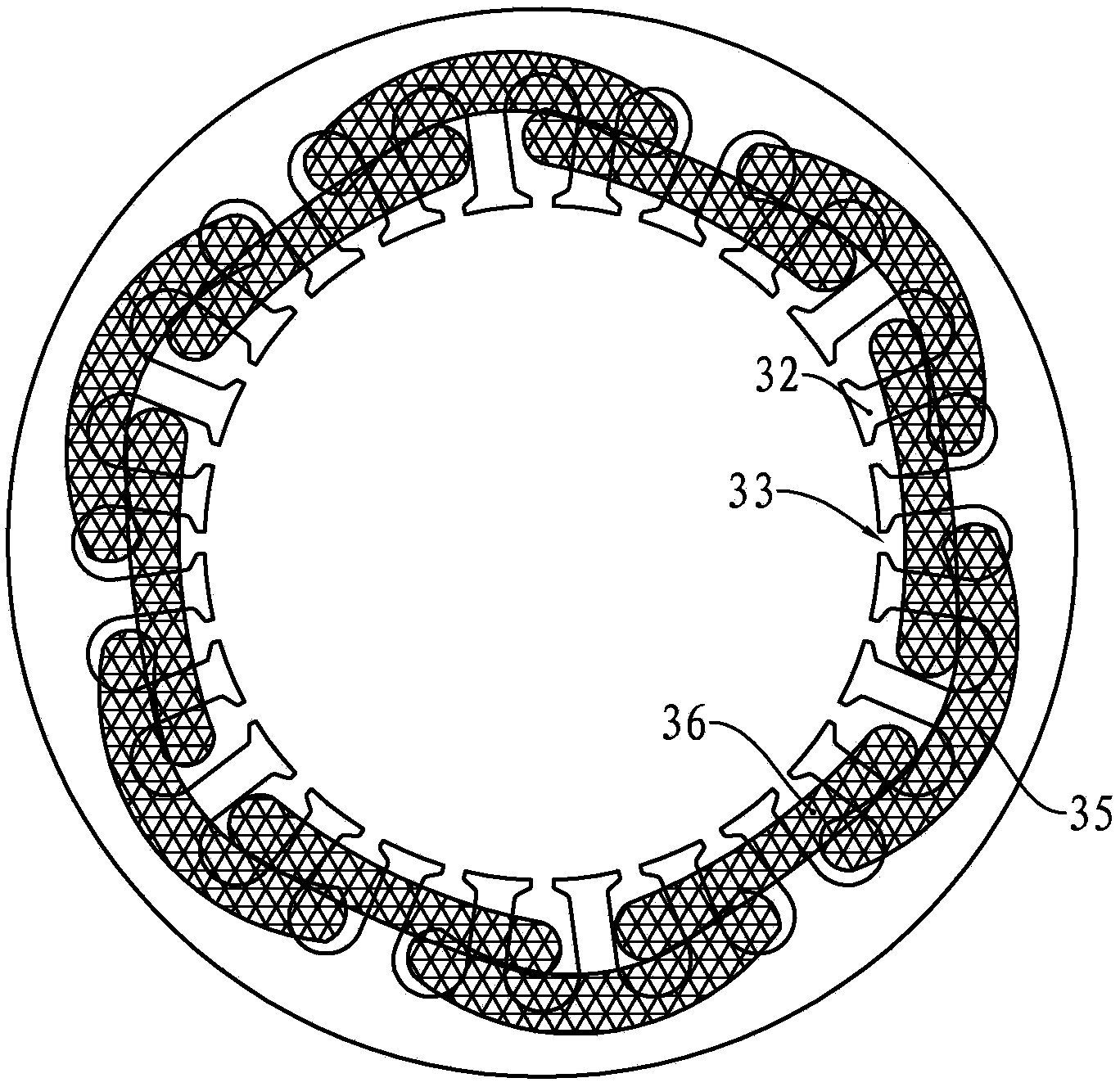

Coil part and manufacturing method therefor

ActiveCN102916514ADoes not affect surface qualityEasy loading and unloadingManufacturing dynamo-electric machinesEfficient regulation technologiesEngineeringElectrical and Electronics engineering

The invention discloses a coil part, which comprises a stator component, wherein the stator component comprises stator shells, electromagnetic polar plates and stator windings, and each stator winding is provided with three contact pins. The coil part also comprises contact pin protection elements, wherein a contact pin holes correspondingly matched with the stator component are arranged on each contact pin protection element, the contact pin on the stator component is inserted into the contact pin hole of the contact pin protection element and exposed out of the outer surface of the contact pin protection element, the contact pin protection element and the stator component are assembled together and then are subjected to injection molding to form a coil injection molding piece, an injection molding layer of the coil injection molding piece is coated with an insulated separation bars of the contact pin protection elements and is not coated on the end part of the contact pin, which stretches out of the contact pin protection element or the outer surface of the contact pin protection element, which is back to the stator component. Based on the coil part, the invention also provides a manufacturing method for the coil part.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

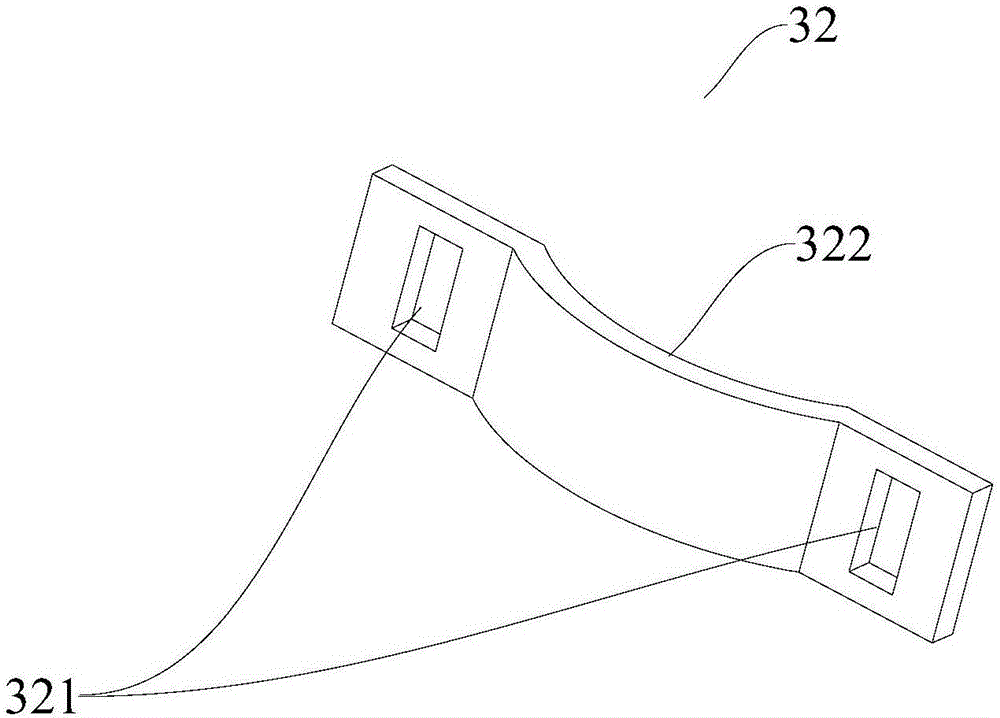

Detachable connecting device and corresponding connecting device of wire harness connector and buckle

ActiveCN104051906ACooperate smoothlyCooperate with solid connection smoothlyCoupling device detailsStructural engineeringMechanical engineering

Owner:曼德汽车零部件(泰州)有限公司

Assembly wall body and installation method

The embodiment of the invention provides an assembly wall body which comprises two wall face units which are oppositely arranged. Each wall face unit comprises a gypsum plate and glass cotton, whereina first vertical keel and a second vertical keel are arranged on the two side edges of the wall face unit correspondingly, a gypsum plate is fixed to the first vertical keel and the second vertical keel through self-tapping screws, the glass cotton is fixed among the gypsum plate, the first vertical keel and the second vertical keel, and the first vertical keel in the wall face unit is connectedwith the second vertical keel of the oppositely-arranged wall face unit through a self-tapping screw; and the width of the first vertical keel is larger than that of the second vertical keel. The embodiment of the invention further provides an installation method of the assembly wall body. The installation method includes the steps that L-shaped keel connecting pieces are installed on a roof and on the ground; the wall face units are connected and fixed to the L-shaped keel connecting pieces; the other wall face unit is connected and fixed to the installed wall face unit through a self-tappingscrew; L-shaped connecting pieces are arranged on the other sides of the wall face units; and the wall face units are sequentially installed to form the whole wall body.

Owner:BEIJING NEW BUILDING MATERIAL

Lora switch detector, device switch detection system and square root extraction method for detector

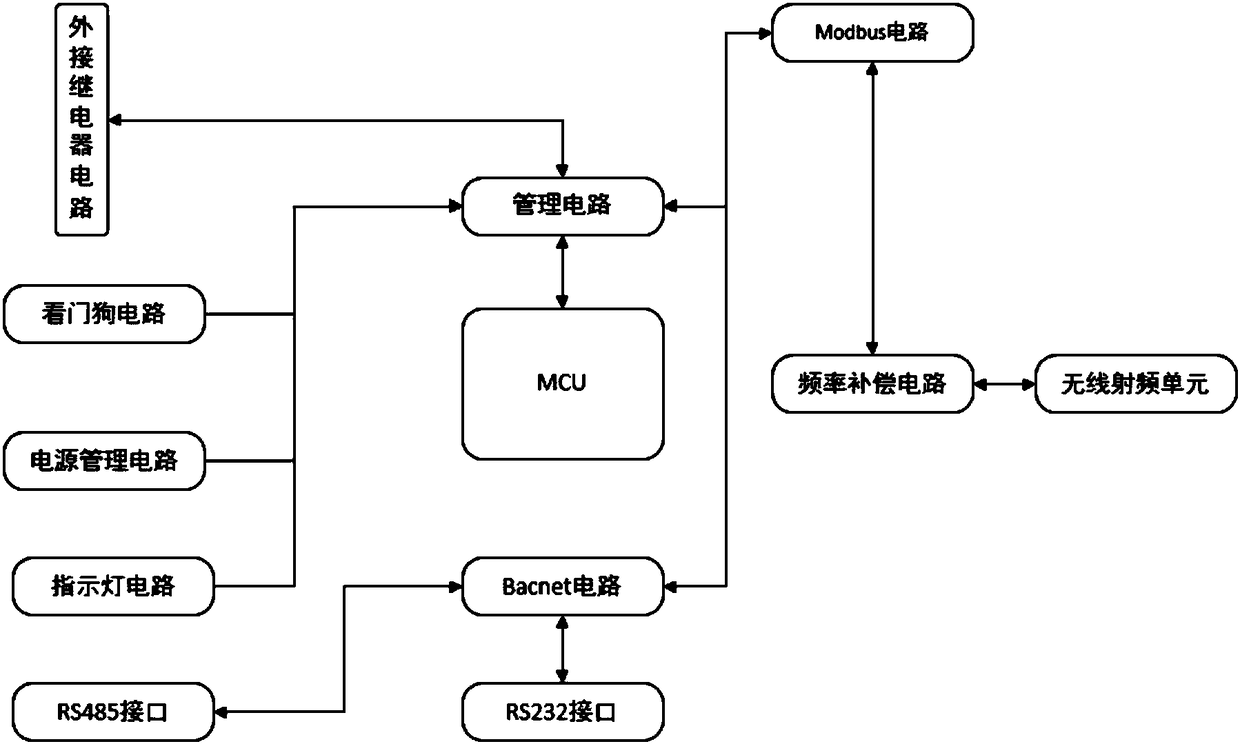

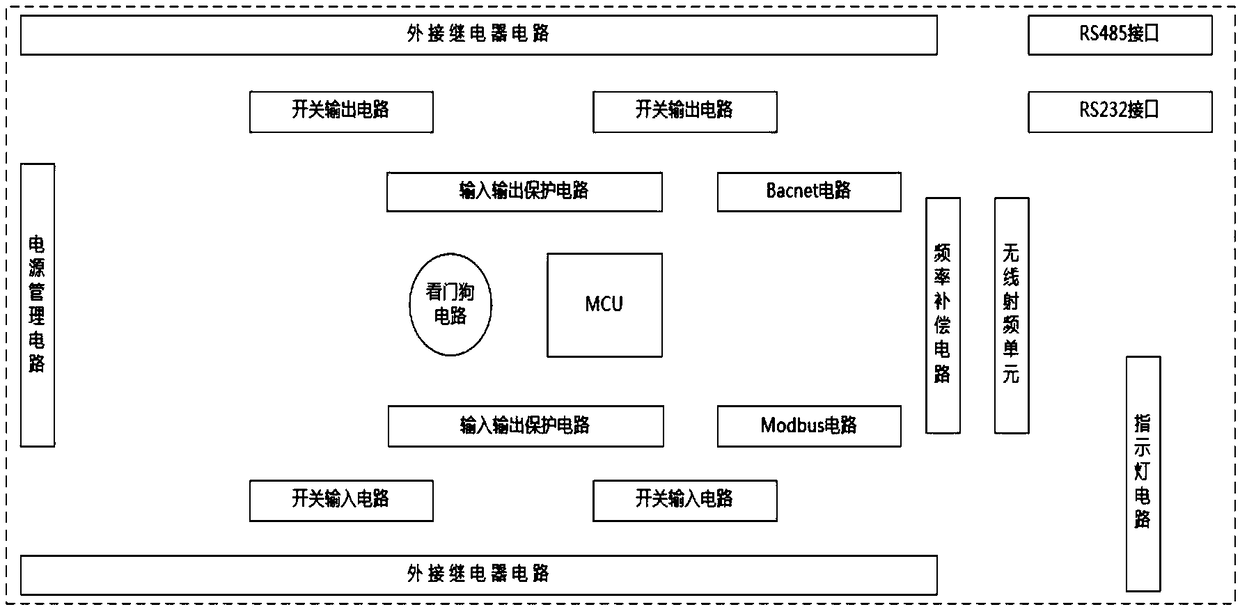

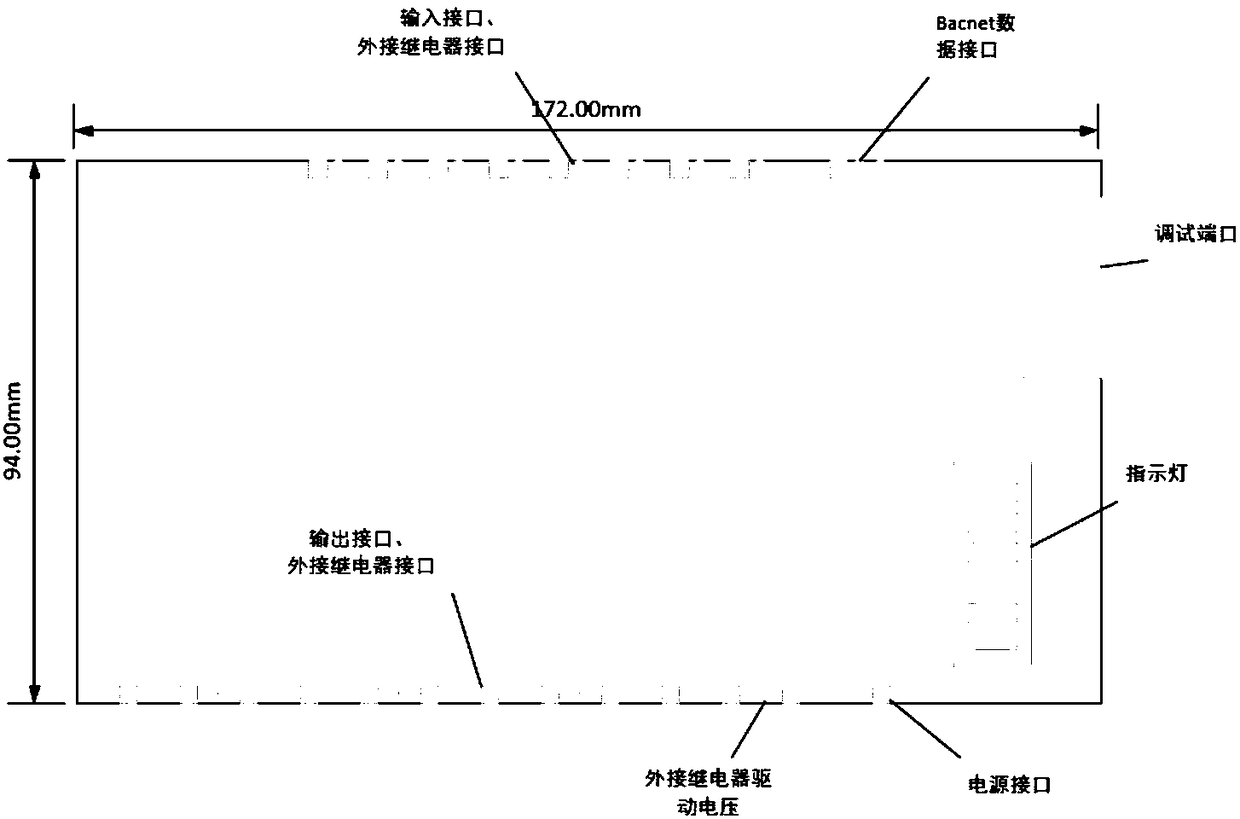

PendingCN108418866AGuaranteed connection reliabilityHigh sensitivityForward error control useFrequency compensationEngineering

The invention provides a Lora switch detector, a device switch detection system, and a signal processing and signal separation method. The detector comprises a shell, an MCU circuit, a radio frequencyunit, a management circuit, a frequency compensation circuit, a Modbus management control circuit, a Bacnet management control circuit, a watchdog circuit, an external relay circuit, an RS232 / RS485 interface, an indicator lamp circuit and power management circuit. The networking device of the Lora switch detector provided by the invention has the advantages of simple structure, stable transmission over a long distance, dynamic network, low power consumption and low cost.

Owner:沈磊

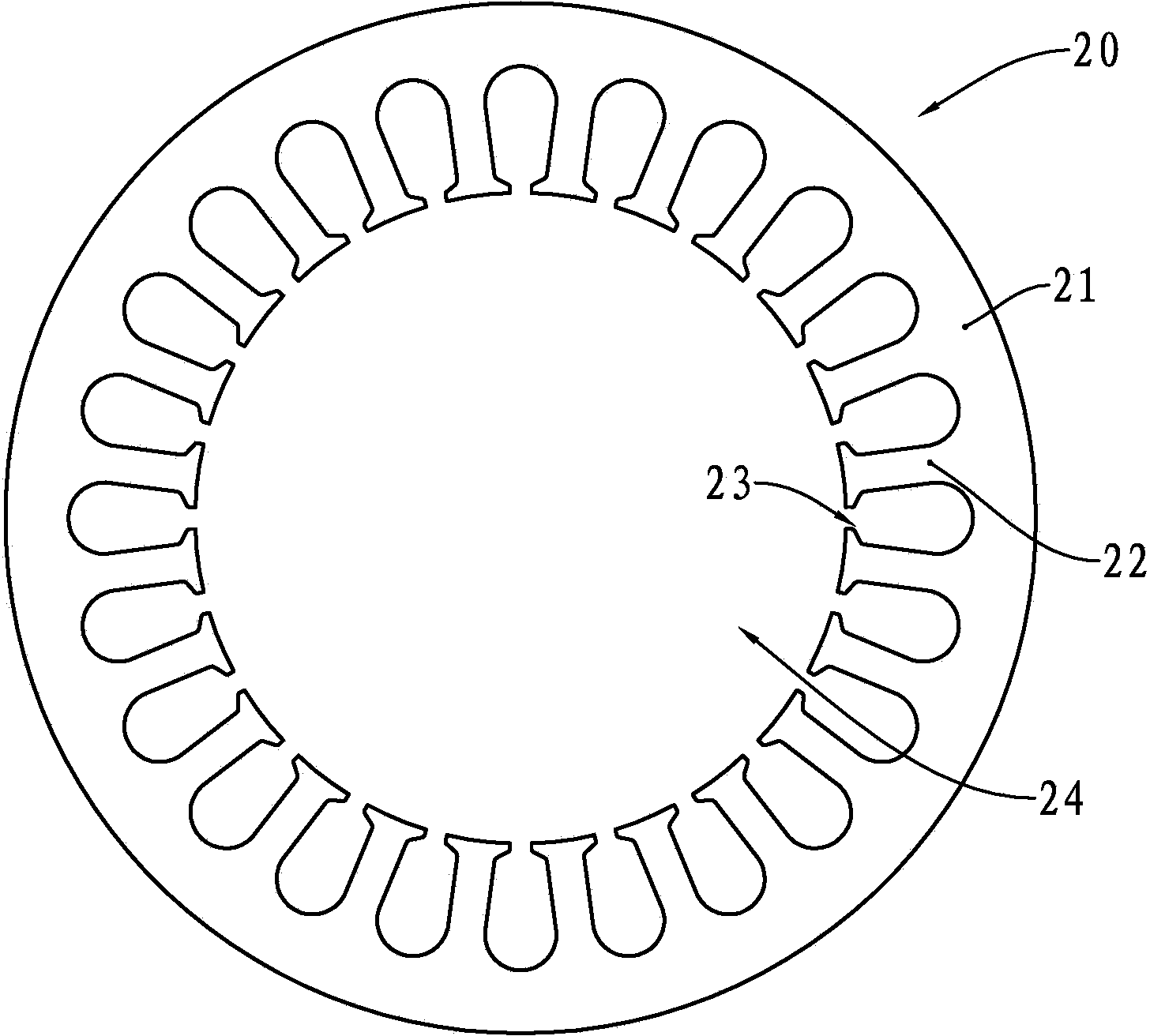

Stator punching piece, stator core and motor

InactiveCN103457365AAvoid breakingSimple structureMagnetic circuit stationary partsPunchingEngineering

The invention provides a stator punching piece, a stator core and a motor. The stator punching piece is provided with an annular yoke part and a tooth part detachably connected with the yoke part. The tooth part is located in the yoke part, a plurality of teeth are circumferentially arranged on the tooth part, tooth roots of every two adjacent teeth are connected through a bridge part, every bridge part is provided with an inner arc close to the circle center of the tooth part and an outer arc far away from the circle center of the tooth part, inner arcs of a plurality of bridge parts are located on a first circumference, outer arcs of the plurality of bridge parts are located on a second circumference, and the first circumference and the second circumference are concentric circles with the circle center of the tooth part serving as the circle center. The stator core is provided with a first tooth part formed by stacking the stator punching pieces. The motor is provided with a stator and a rotor, and the stator comprises the stator core. Flux leakage of the stator core can be reduced, breakage of the stator punching piece from the bridge parts is avoided, and quality of the stator punching piece is improved.

Owner:GREE ELECTRIC APPLIANCES INC +4

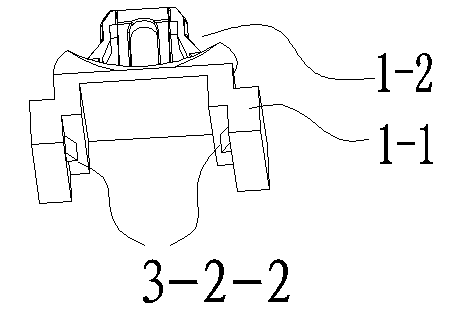

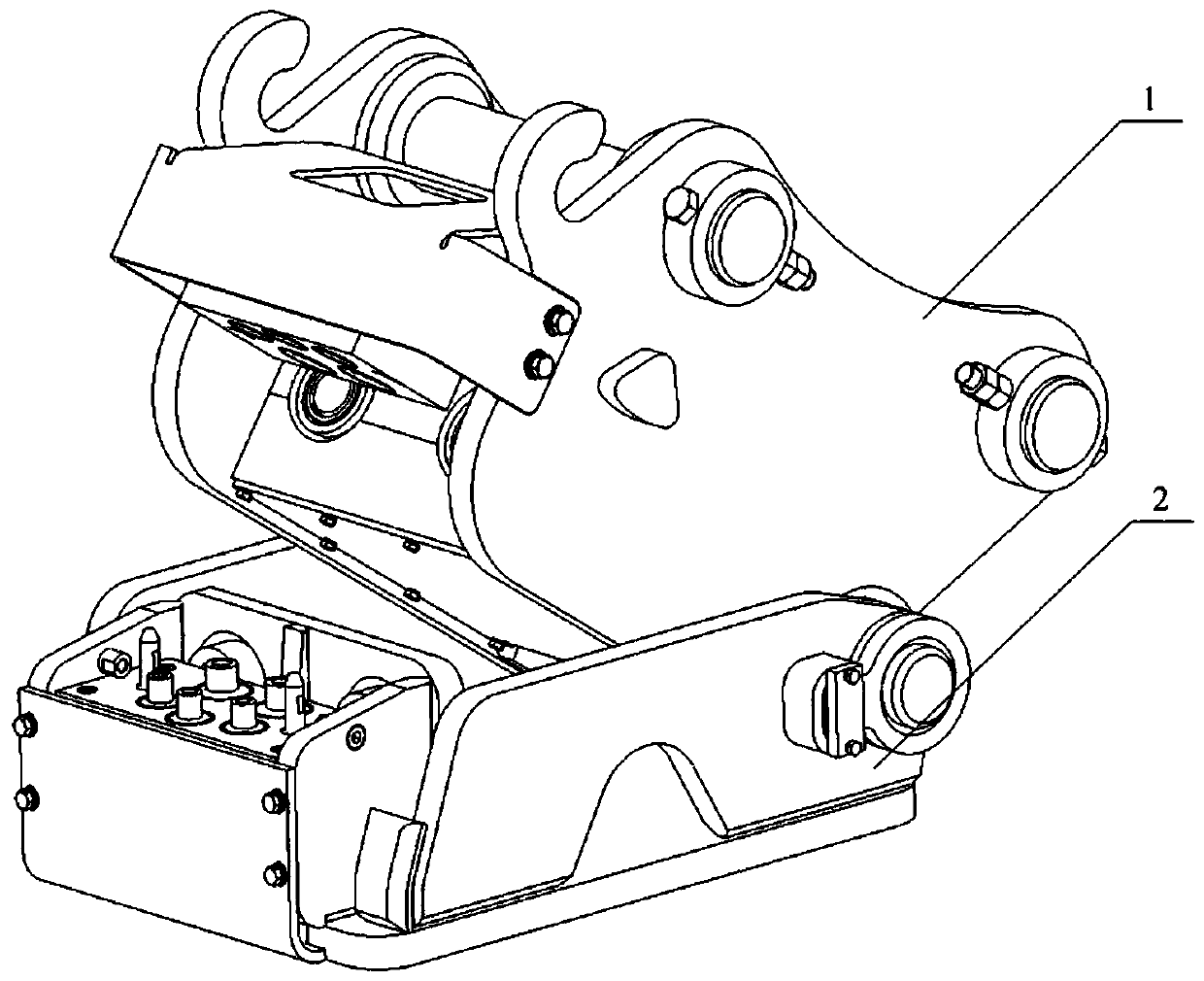

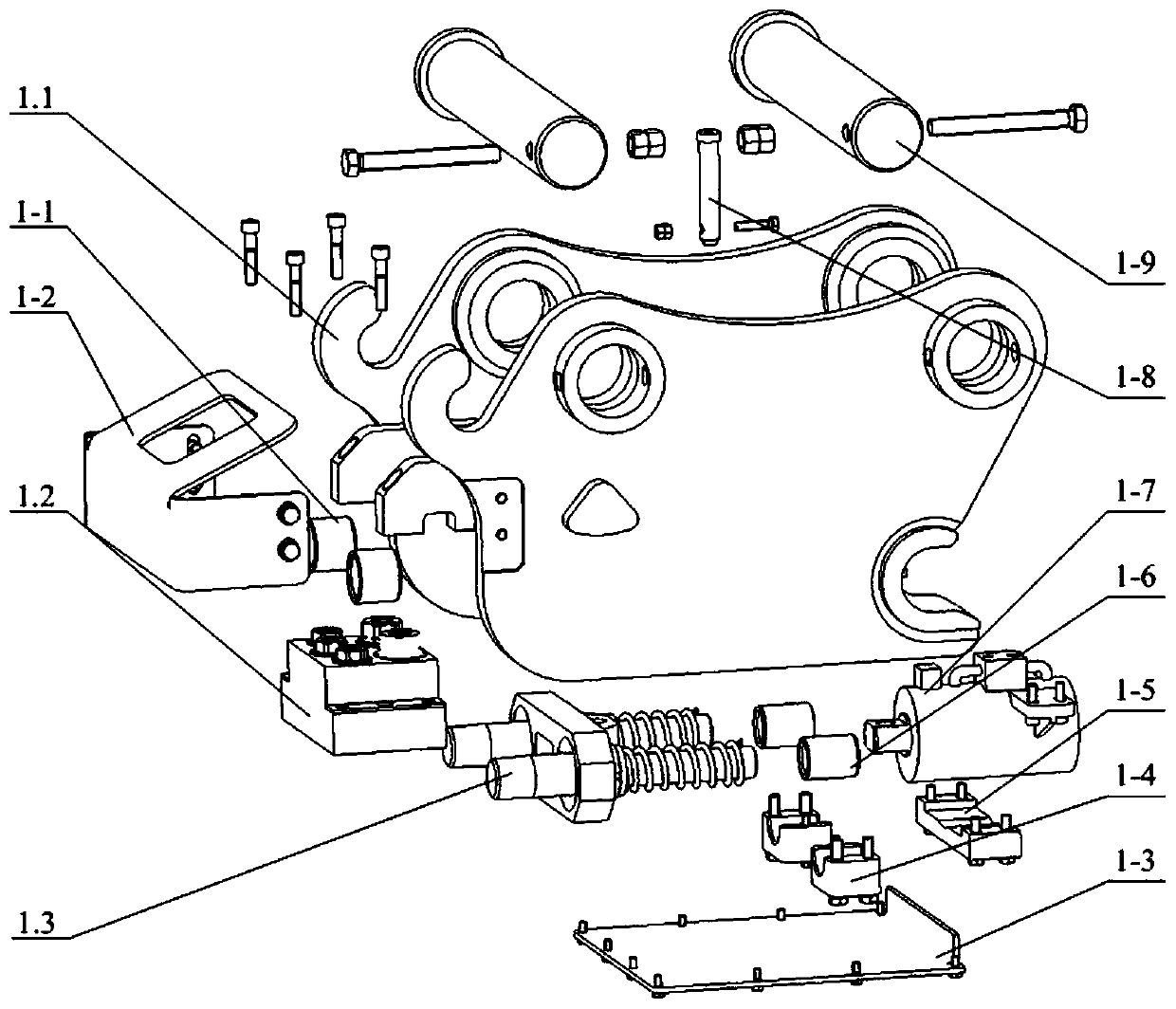

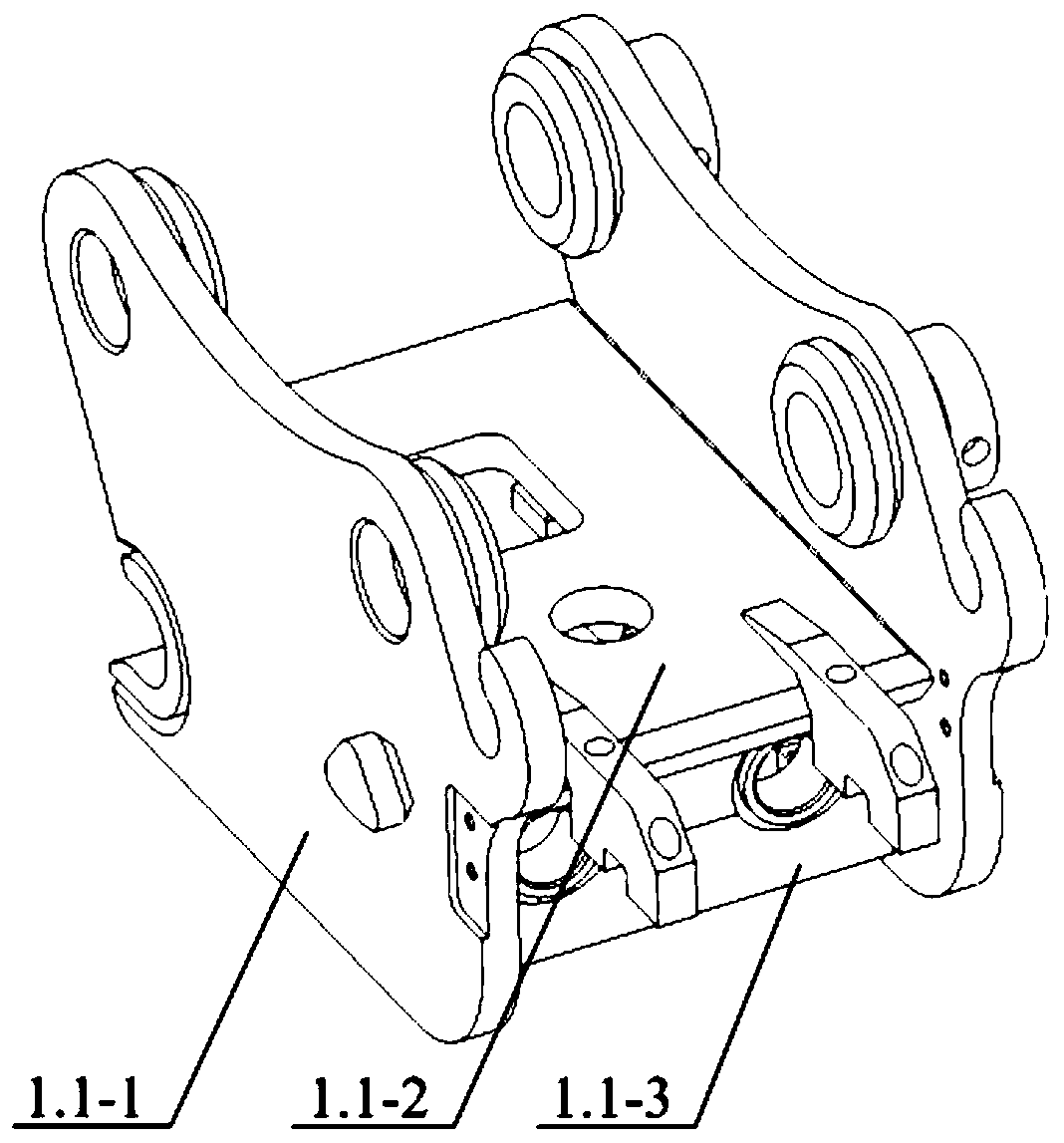

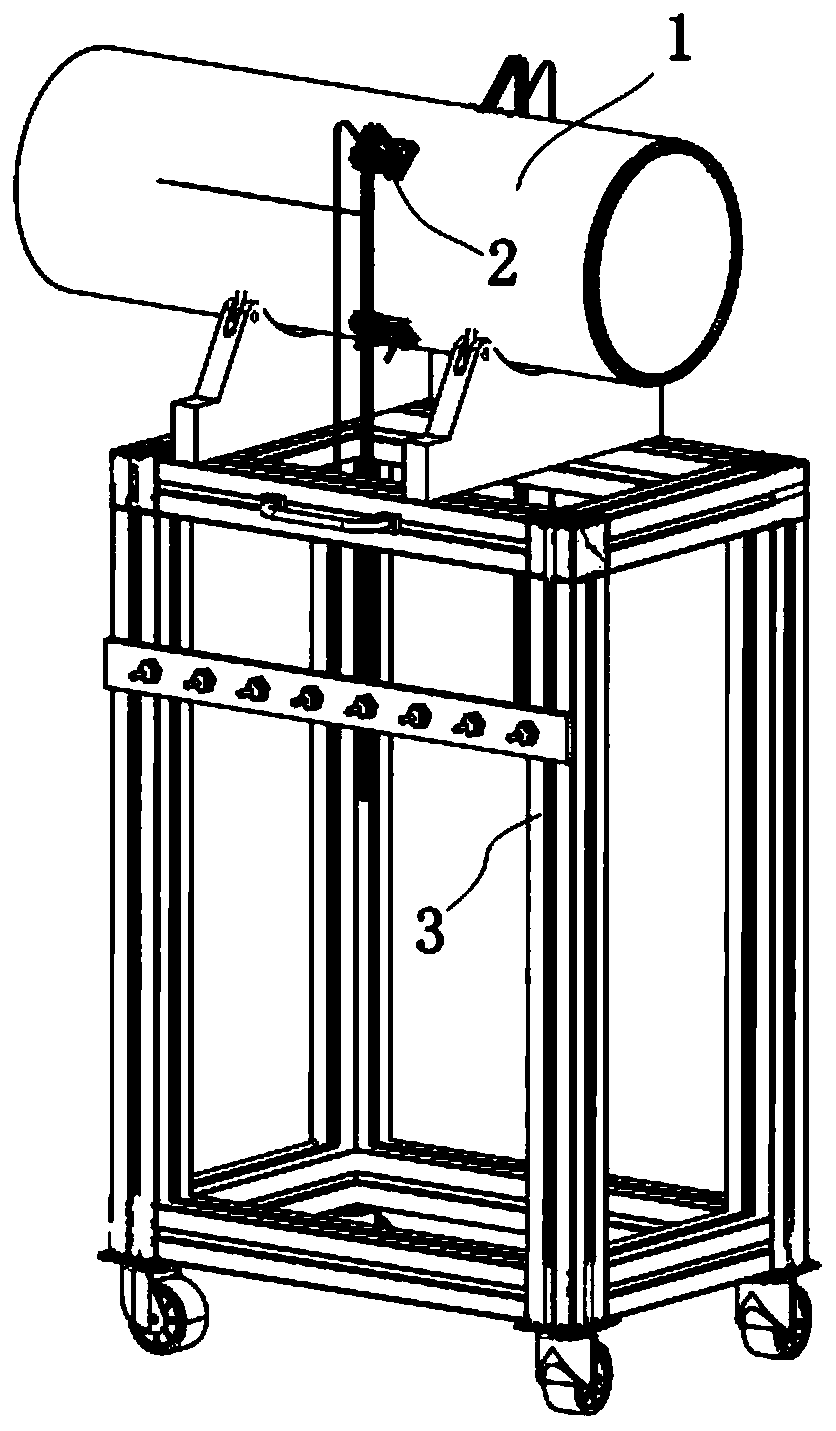

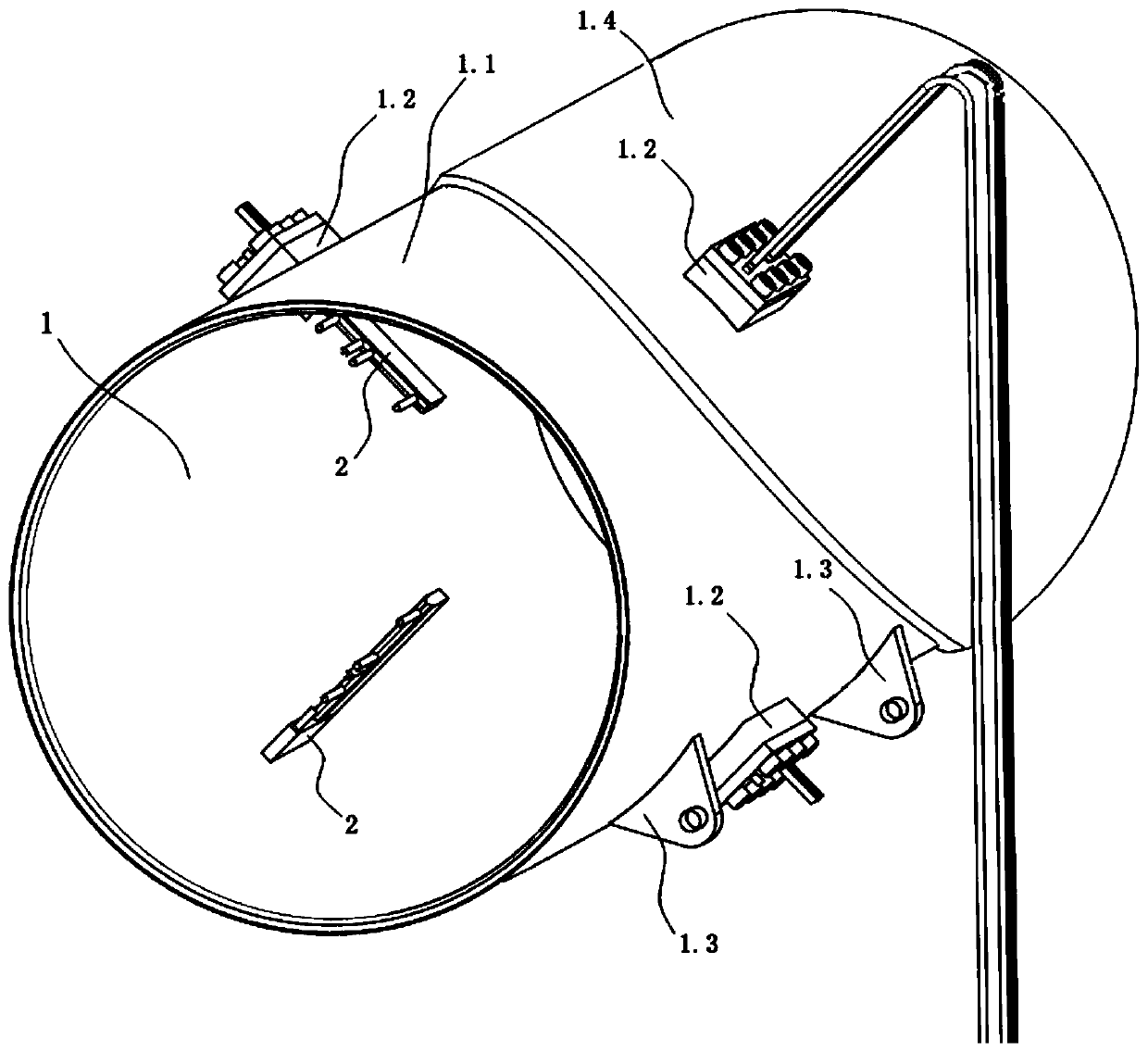

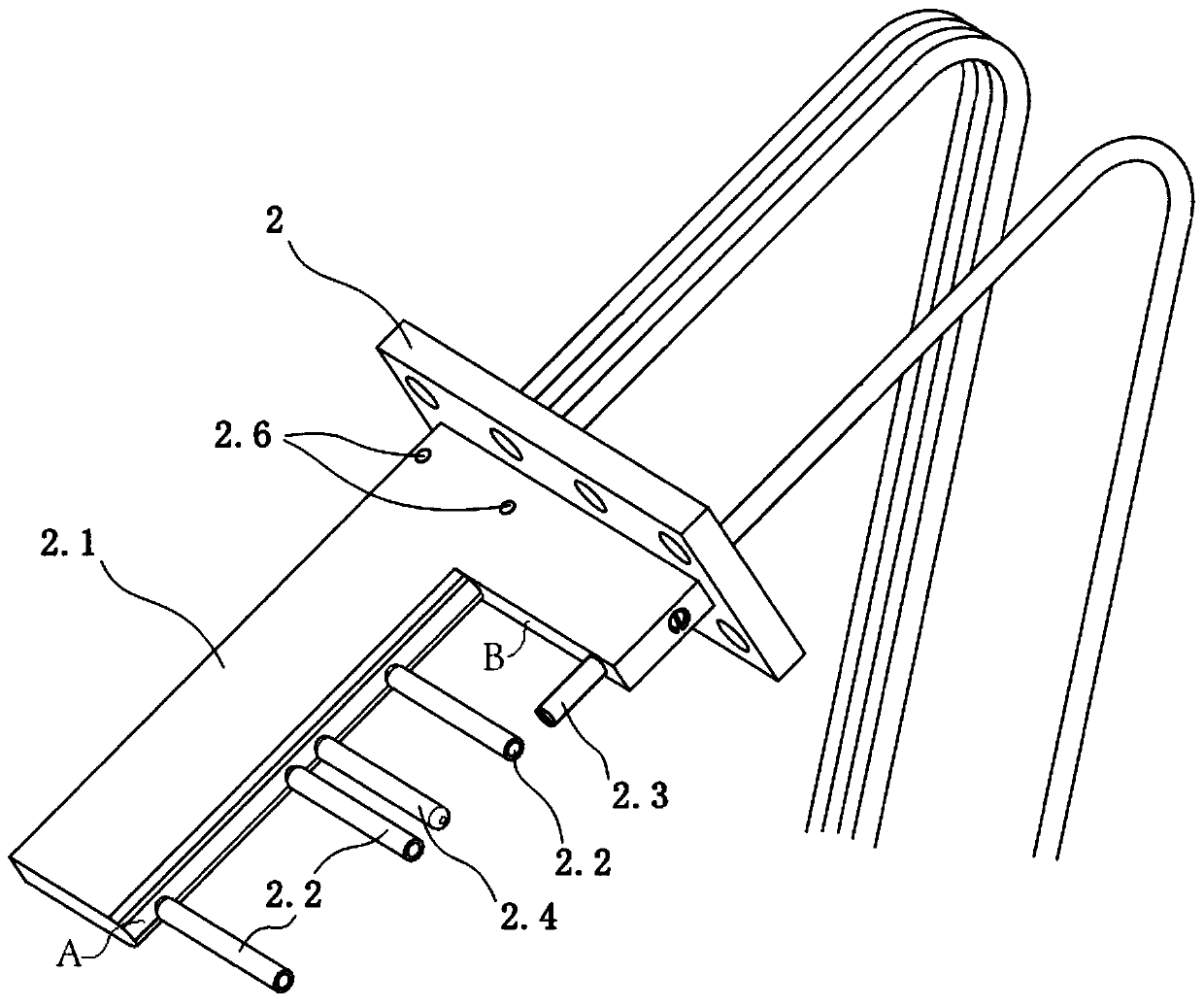

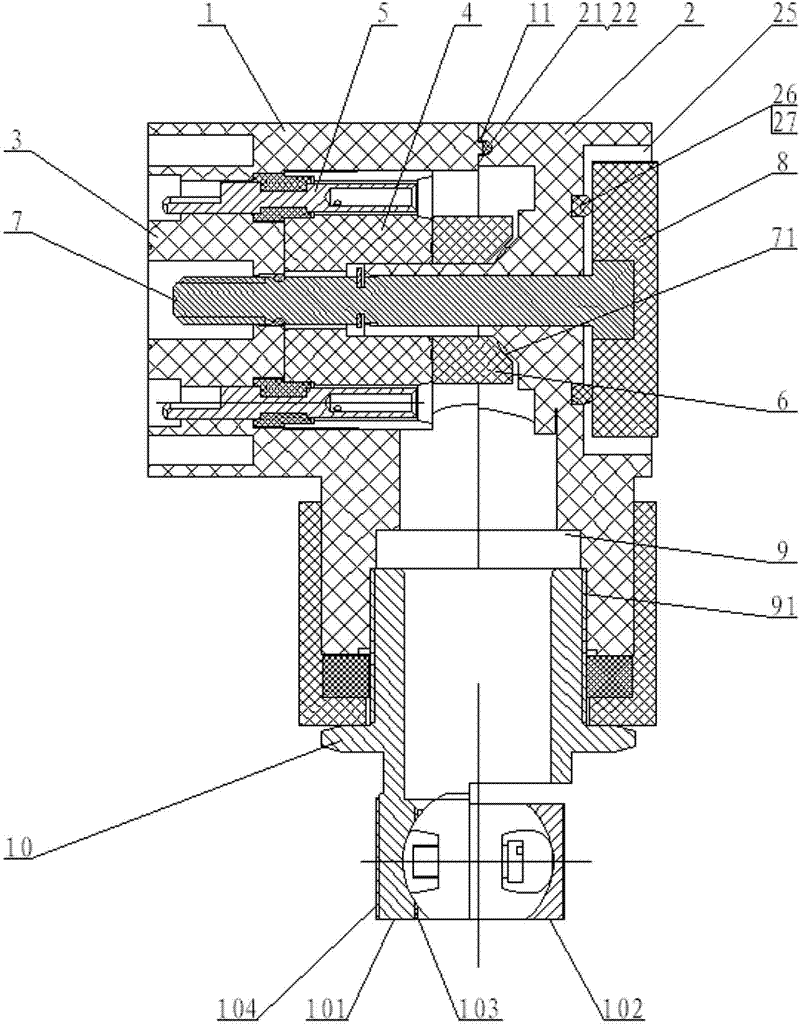

Full-automatic quick replacement device of hydraulic excavator

The invention discloses a full-automatic quick replacement device of a hydraulic excavator. The full-automatic quick replacement device comprises an upper coupling part and a lower coupling part. Theupper coupling part comprises a quick female joint assembly and pin rods capable of being driven by a telescopic oil cylinder to move. The lower coupling part comprises a quick male joint assembly, apin shaft assembly, conic pin cooperation sleeves cooperating with the pin rods and spring lower guide columns. The upper coupling part can be hooked to the pin shaft assembly at one end of the lowercoupling part through a hook-shaped portion at one end of the upper coupling part and rotates around the center axis of the pin shaft assembly, so that quick female joints at the other end of the upper coupling part correspondingly communicate with quick male joints at the other end of the lower coupling part. The pin rods are driven by the telescopic oil cylinder to stretch into the conic pin cooperation sleeves to mechanically lock the upper coupling part and the lower coupling part. Hydraulic connection is achieved through coupling of the quick male joint assembly and the quick female jointassembly, the posture is adjusted through guide of guide columns and adjusting springs, it is ensured that connection is accurate and reliable, and operation is safe.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Aero-engine exhaust measuring device

The invention relates to an aero-engine exhaust measuring device, which belongs to the technical field of aero-engine tests. The aero-engine exhaust measuring device provided by the technical scheme comprises a measuring section and a measuring rake. The measuring section is cylindrical, and the measuring rake is installed on the inner wall of the measuring section. The measuring rake comprises ameasuring rake body, a total pressure probe, a static pressure probe, a temperature probe and a clamping plate. The measuring rake body is of a sheet-shaped structure. A groove is formed in the surface of the measuring rake body. The signal detection ends of the total pressure probe, the static pressure probe and the temperature probe penetrate through the groove and penetrate out of the measuringrake body, and the signal output ends of the total pressure probe, the static pressure probe and the temperature probe penetrate out of the outer wall of the measuring section and are connected witha signal receiving device. The equipment is widely applied to the field of aero-engine tests.

Owner:XIAN XIANGXUN TECH

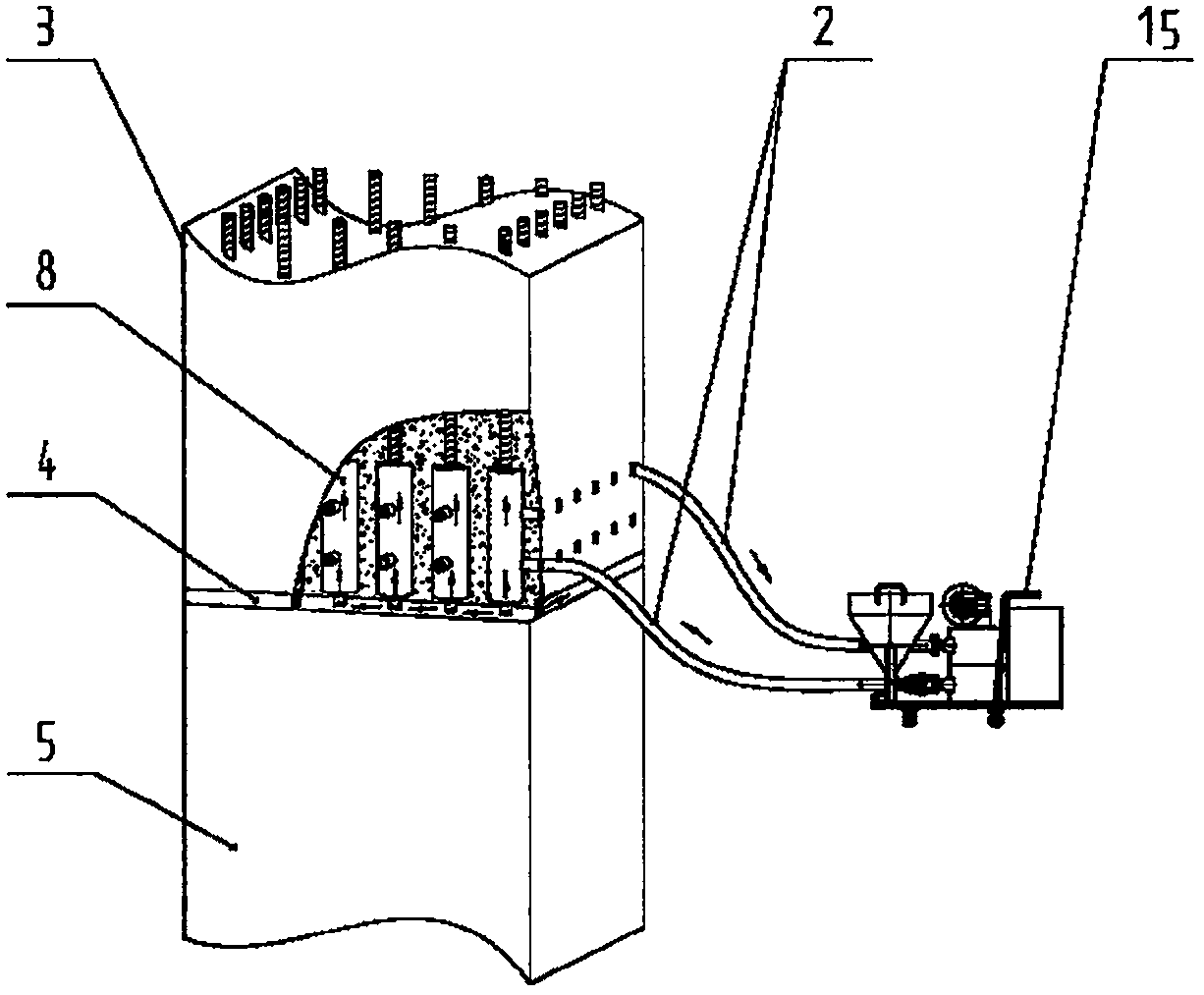

Vacuum negative-pressure grouting method and system

ActiveCN108252521AGuaranteed fullnessGuaranteed reliabilityBuilding material handlingPressure groutingGrout

The invention discloses a vacuum negative-pressure grouting method. Through the effect of vacuum negative-pressure and pressure maintaining grouting, full grouting is achieved, and two machines are combined to carry out the grouting operation. The vacuum negative-pressure grouting method comprises the following steps that through a first grouting machine, a grouting material is conveyed from a grout inlet of a sleeve to a communicating cavity of a connected element and the inner portion of the sleeve by a pipeline; when the grouting material is about to flow out from a post-filling overflow opening of the sleeve, vacuum negative-pressure is formed inside the sleeve by the suction of a second grouting machine at the overflow opening, so that residual air in the sleeve can be sucked out, slurry can leak out secrete free water, and the whole sleeve and the gap area of the communicating cavity are filled with the grouting material; and the first grouting machine continues to perform pressure maintaining grouting at the grout inlet, so that it is guaranteed that the sleeve and the filling parts of the element is full of the grouting material.

Owner:CABR CONSTR MACHINERY TECH +1

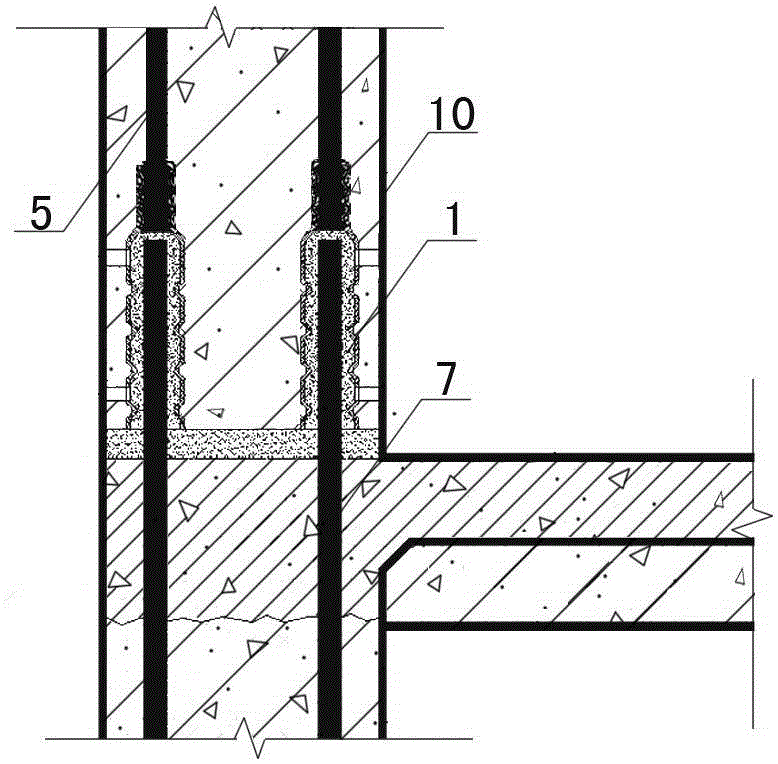

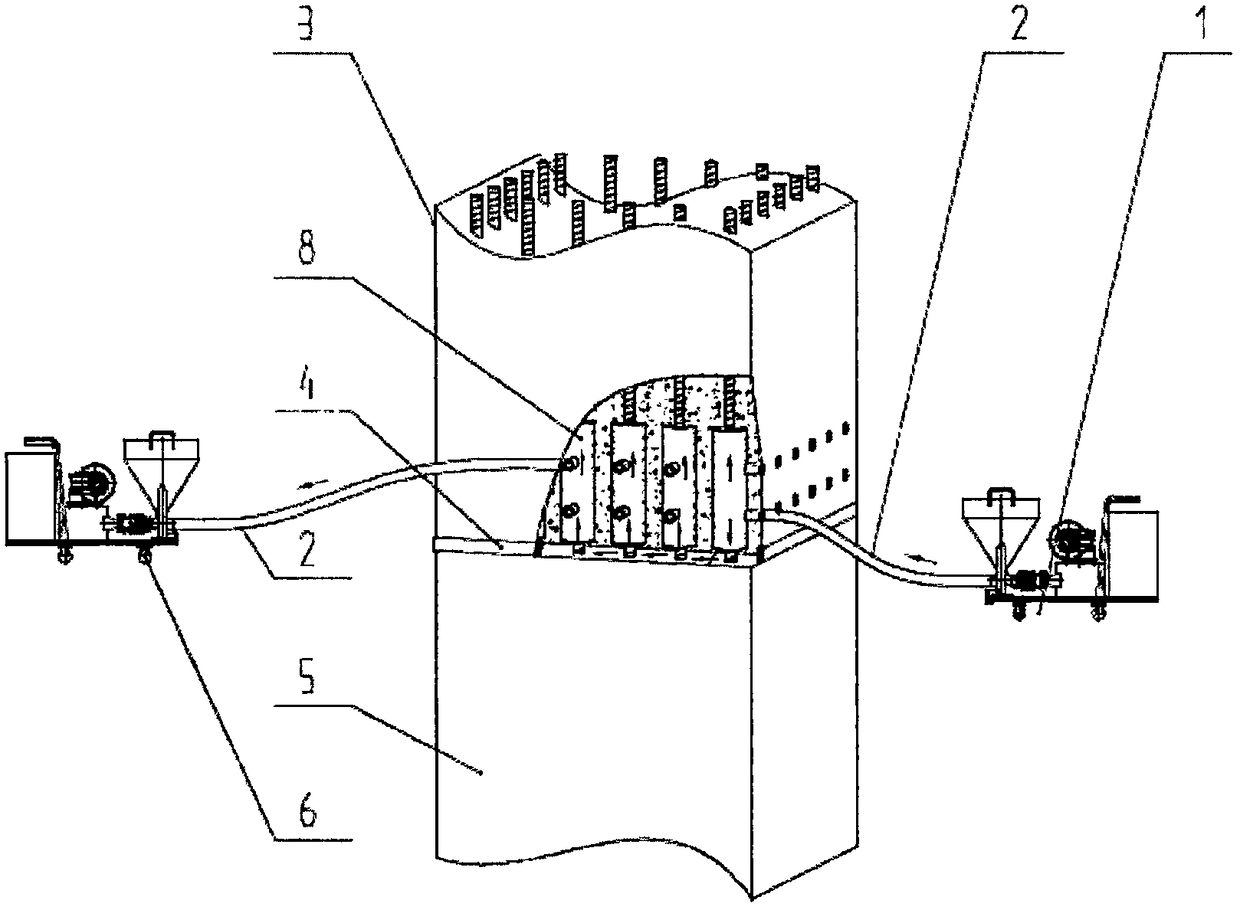

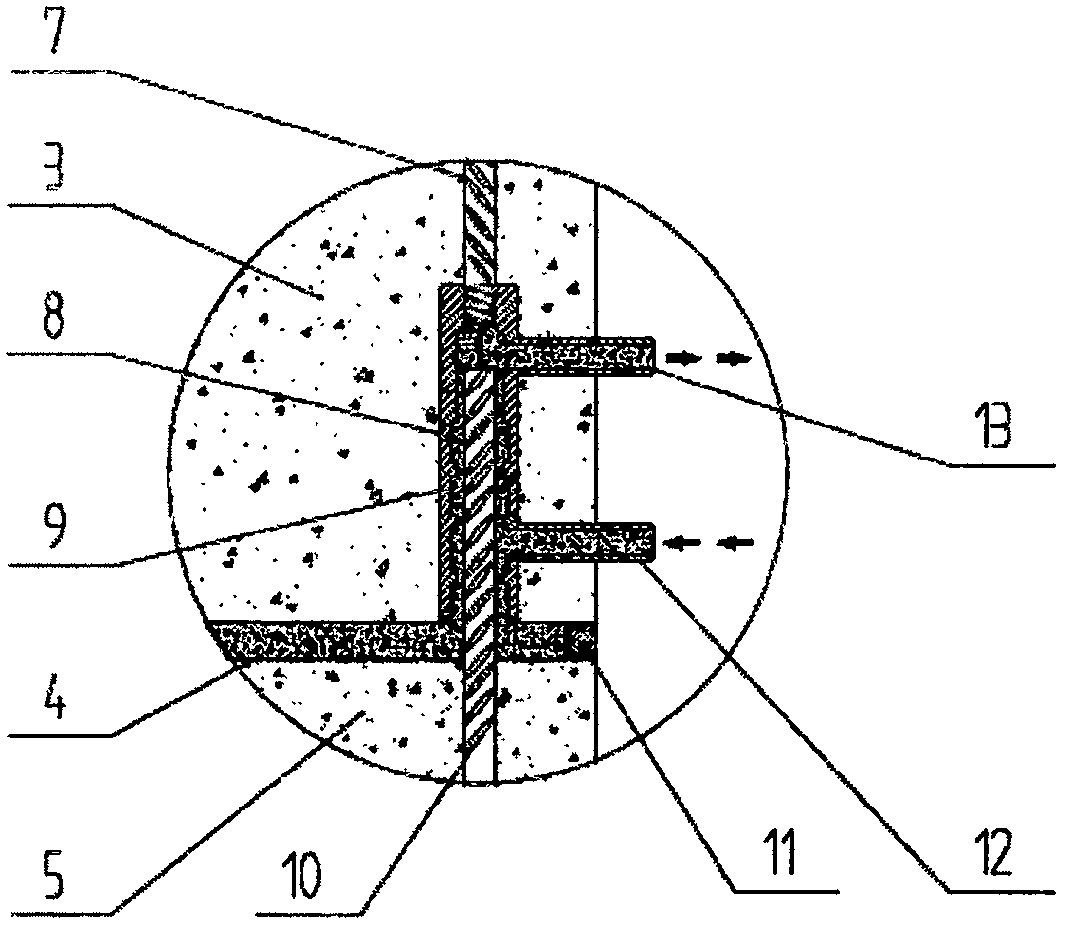

Pier-extruded and half-grouted steel bar sleeve, connecting structure and construction method

InactiveCN104563396AAvoid the defect of being too longAvoid the disadvantages of weakening the strength of the sleeveBuilding reinforcementsConcrete beamsSlurry

The invention provides a pier-extruded and half-grouted steel bar sleeve, a connecting structure and a construction method thereof. The sleeve is a hot-rolling seamless steel pipe, a grouting hole and a slurry discharging hole are formed in the sleeve wall of the sleeve, an annular inner projection is distributed between the grouting hole and the slurry discharging hole, one end of the sleeve is an extrusion end, the rest part is a grouting-anchoring end, the inner diameter of the extrusion end is equal to the outer diameter of connected steel bars and smaller than the inner diameter of the grouting-anchoring end, and the grouting hole, the slurry discharging hole and the annular inner projection are positioned at the grouting-anchoring end. The steel bars are connected through the half-grouted steel bar sleeve, part of one end of the sleeve is connected with the steel bar by an extrusion connection technology, and the other part of the sleeve is still connected with the steel bar in a grouting mode. The connecting structure can be widely applied to the steel bar connection of prefabricated concrete columns in a multi-high-layer prefabricated assembly type concrete framework structure, a shear wall structure or a framework shear wall structure as well as the horizontal steel bar connection of prefabricated concrete beams, the steel bar connection of prefabricated concrete shear walls and steel bar connection in the conventional reinforcing engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

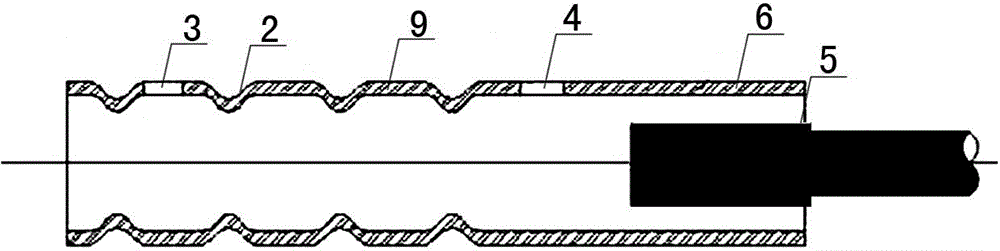

Split type radio frequency coaxial adaptor

ActiveCN103457066AGood electrical performanceGuaranteed connection reliabilitySecuring/insulating coupling contact membersCoupling contact membersRadio frequencyFirst insertion

The invention discloses a split type radio frequency coaxial adaptor which comprises a nut, a casing body, an outer conductor and inner conductors. The casing body comprises an insertion head end and an insertion base end, the outer conductor is arranged in the casing body and is in interference fit with the casing body, the inner conductors are arranged in the outer conductor, and the nut is arranged at the insertion head end of the casing body. The inner conductor comprises a first inner conductor and a second inner conductor, the two ends of the first inner conductor are provided with a first insertion pin and a first insertion hole respectively, the two ends of the second inner conductor are provided with a second insertion pin and a second insertion hole respectively, the first insertion pin is located at the insertion head end of the casing body, the second insertion pin is located in the first insertion hole, and the second insertion hole is located in the insertion base end of the casing body. The processing technology of a radio frequency electric cable adaptor is simplified, production efficiency is improved, production cost is reduced, particularly, such as a split type 1.85mm radio frequency coaxial adaptor, and the voltage standing wave ratio of the adaptor is smaller than or equal to 1.45 under DC-65GHz.

Owner:CAC ELECTRONICS TECH

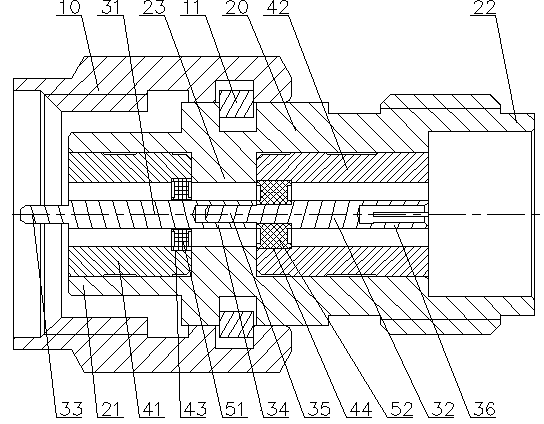

Y63-series special-type electric connector for high-speed rails

ActiveCN102231457AAvoid positional tolerancesImprove sealingRelieving strain on wire connectionSecuring/insulating coupling contact membersElectricityControl system

The invention relates to an Y63-series special-type electric connector for high-speed rails, comprising a shell, an insulator and circular contact elements. The shell comprises a front shell and a back shell, the insulator comprises a front insulator and a back insulator, the front insulator is arranged in the front shell, more than one circular contact element is connected to the back insulator,and the back shell presses out the back insulator between the front shell and the back shell so that the part of more than one circular contact element, which is over the back insulator, is arranged in the front insulator. The front shell and the back shell are connected in series with the front insulator and the back insulator by central screw assemblies to form an electric connecting line with a vertical outside-line opening, and the circular contact elements with hermaphroditic structures, which are inserted on the back insulator, are matched, thus the electric connector has the advantagesof simple and compact structure, stability and firmness in connection, good sealing performance, high switched-on power performance and high safety, and is suitable for train control system responderunits of high-speed rails, underground railways and the like.

Owner:CHINA NORTH IND GRP HANGLIAN TECH CO LTD

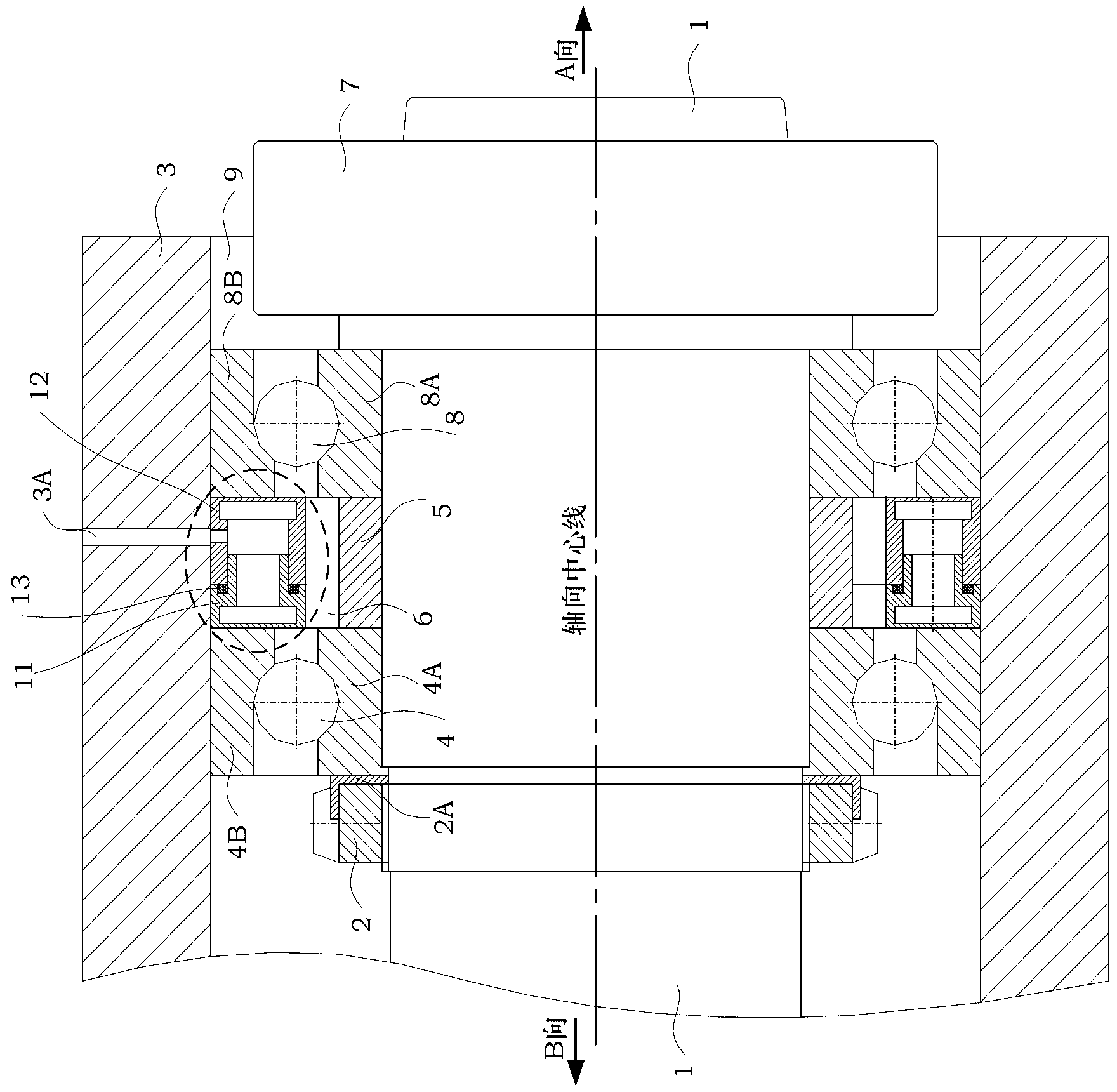

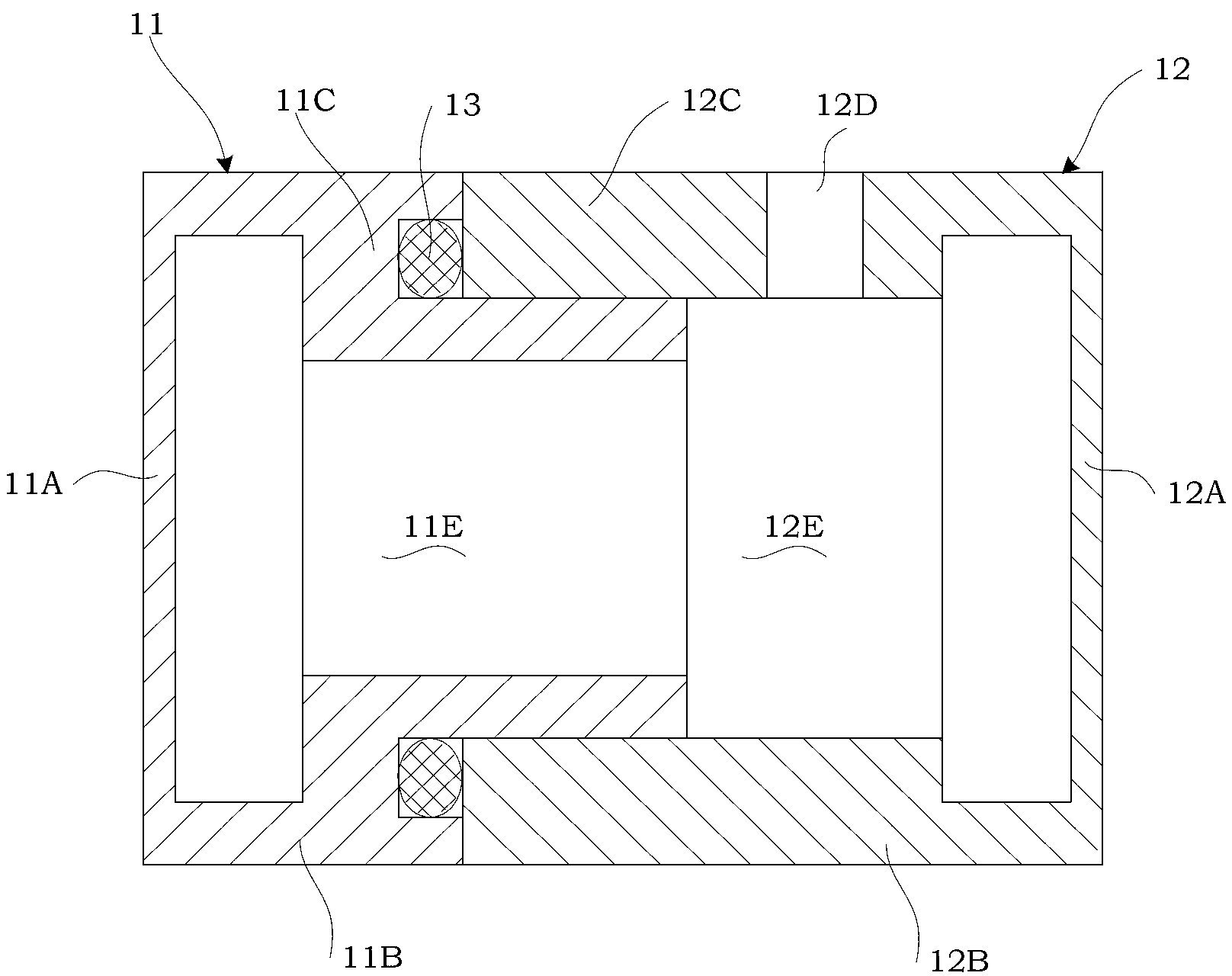

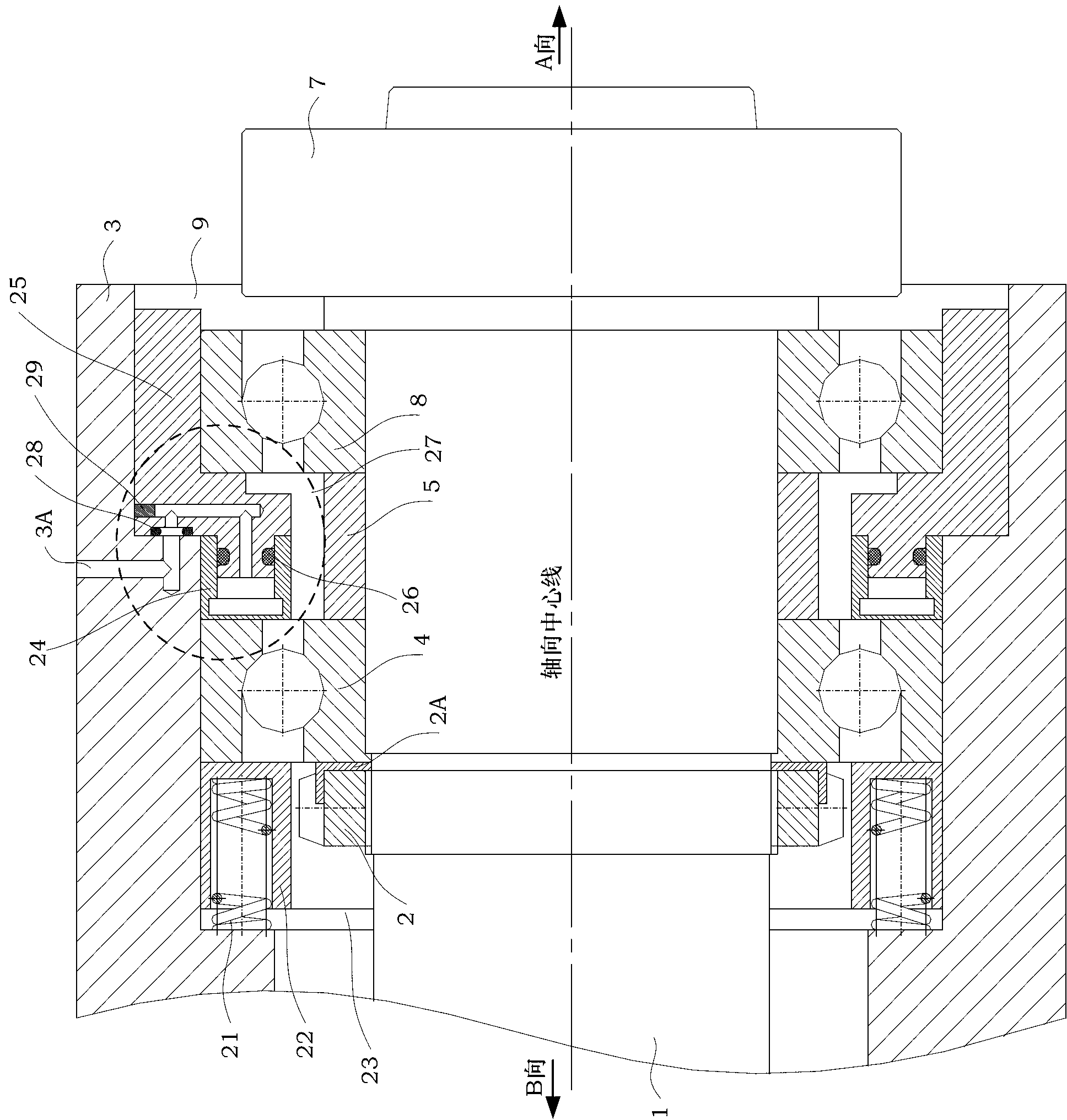

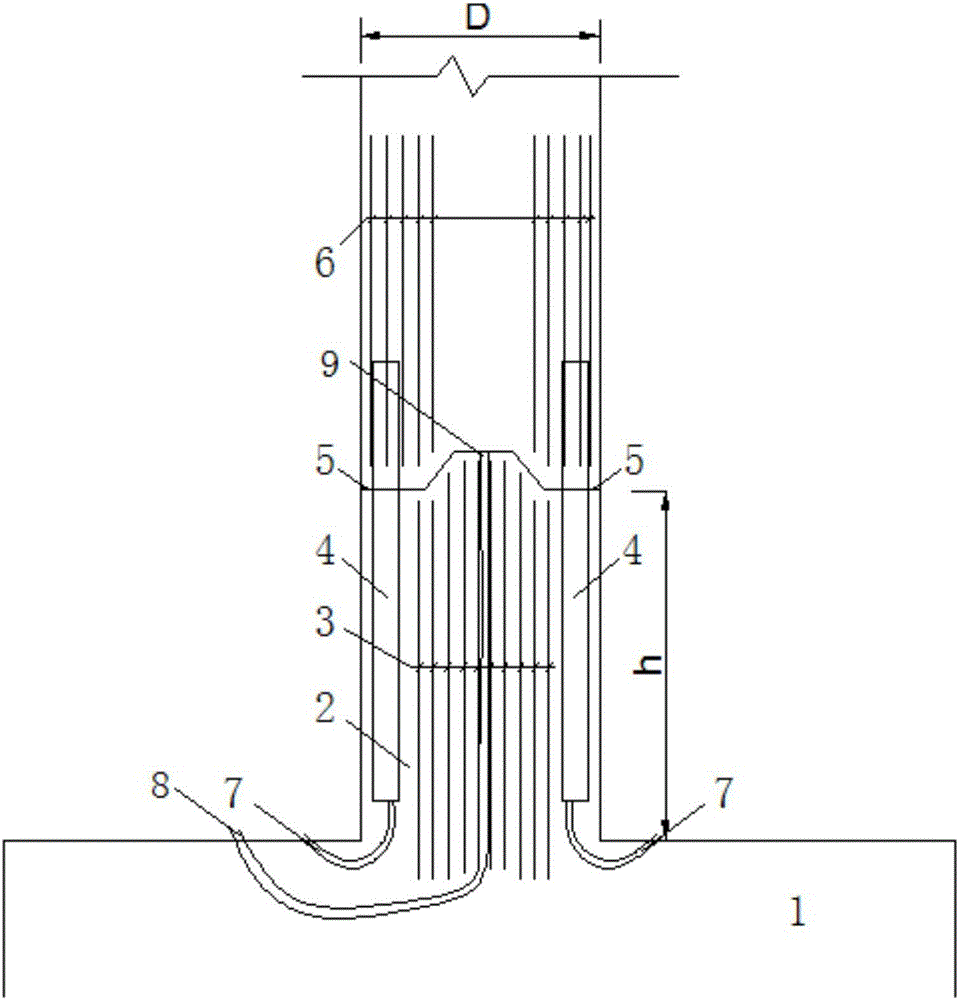

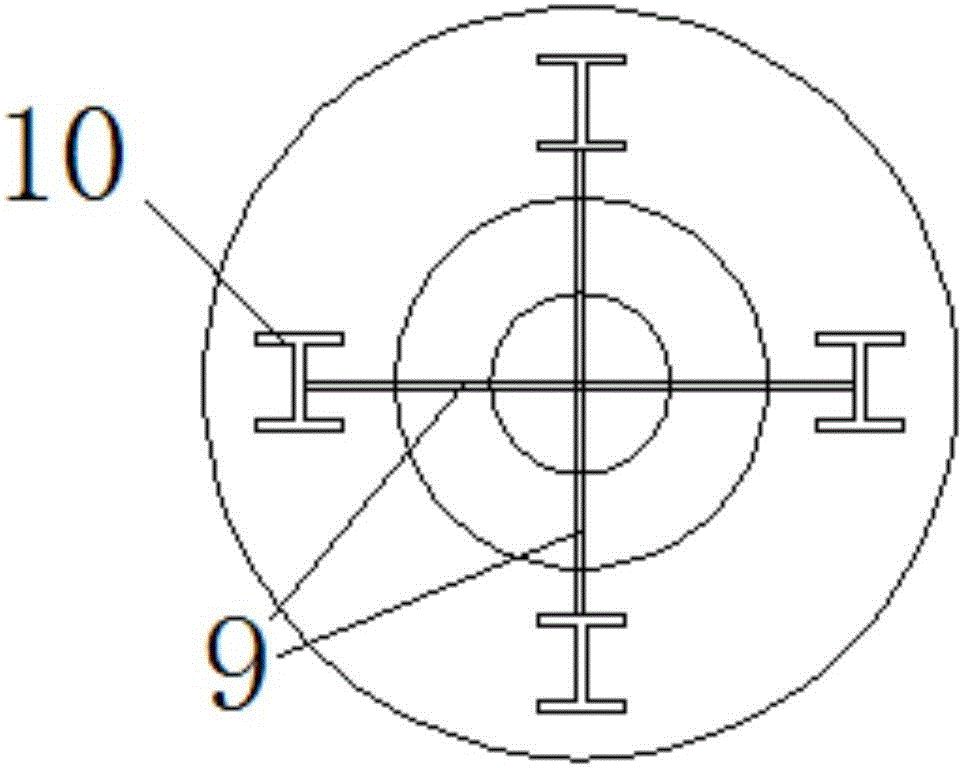

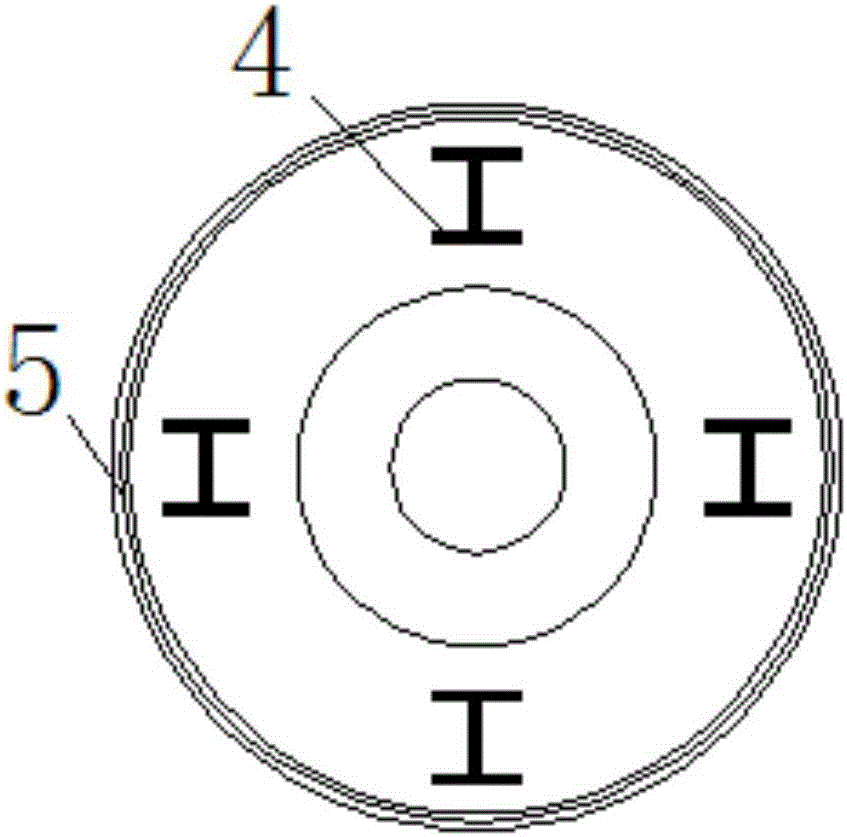

Device capable of improving axial rigidity of main shaft of precision machine tool with adjustable bearing pre-tightening force

InactiveCN103223499AReduce distortionImprove axial stiffnessMetal-working apparatusThin walledLocknut

The invention discloses a device capable of improving axial rigidity of a main shaft of a precision machine tool with an adjustable bearing pre-tightening force. The device comprises a main shaft, a locking nut, a gasket, a box seat, an end cover, a clamp ring, a pre-pressing spring assembly and an improved bearing pre-tightening device, wherein the improved bearing pre-tightening device adopts an annular oil chamber structure formed by transformation of a single-sided thin-walled end surface. The main shaft penetrates through the end cover, the clamp ring, a B bearing, a shaft sleeve, an A bearing, the gasket and the locking nut from one end to the other end sequentially; and the pre-pressing spring assembly and the improved bearing pre-tightening device are mounted between the main shaft and the box seat.According to the device, on one hand, the pre-pressing spring assembly is added on one side of the A bearing to improve the axial rigidity produced when the main shaft moves toward the B direction rightward; and on the other hand, a conventional bearing pre-tightening device mounted between the A bearing and the B bearing is improved, so that on one hand, the improved bearing pre-tightening device can be taken as a support of a D annular oil chamber and an oil way for providing oil, and on the other hand, the improved bearing pre-tightening device can be taken as a support of the B bearing and can achieve radial positioning of the B bearing and axial positioning of the main shaft.

Owner:BEIHANG UNIV

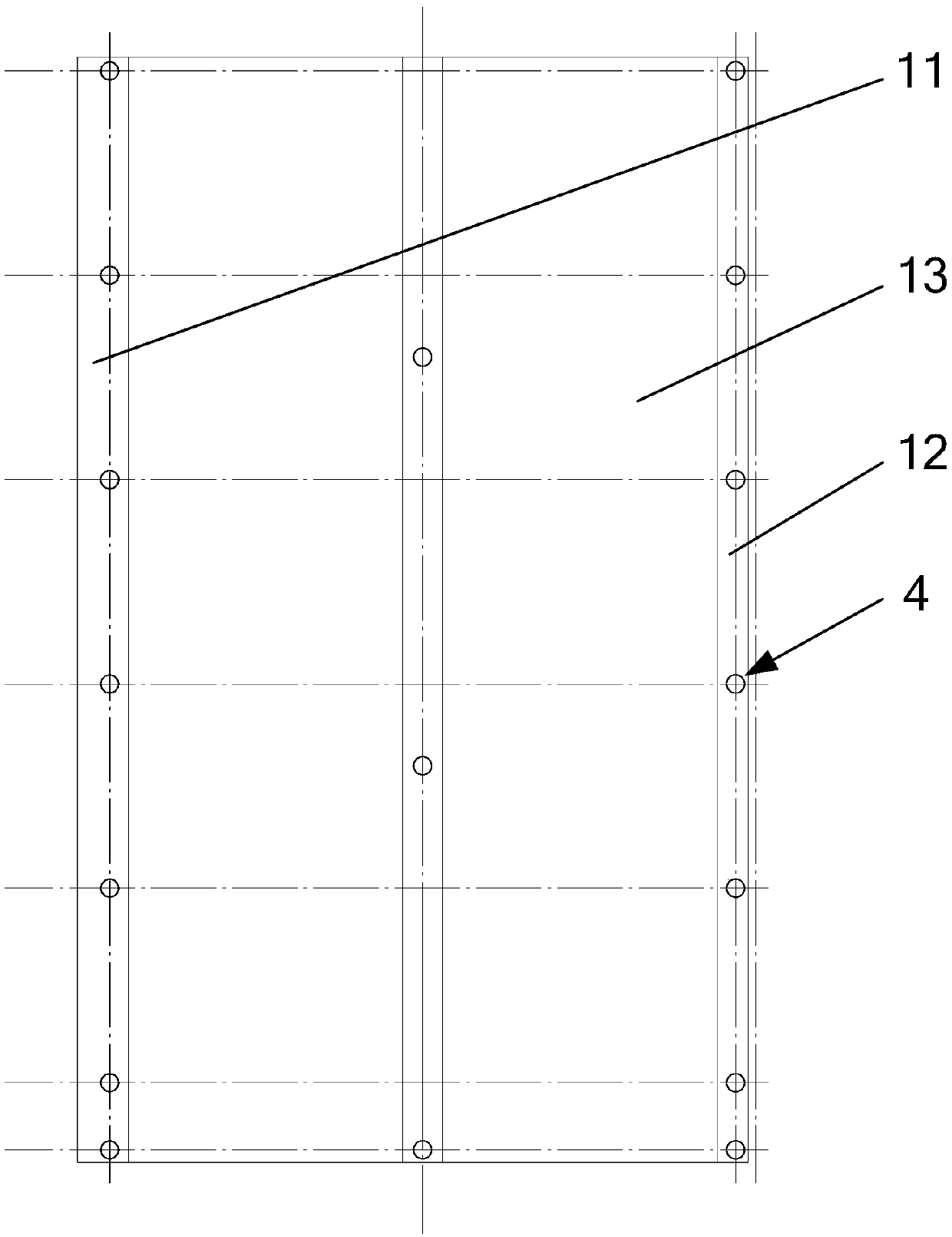

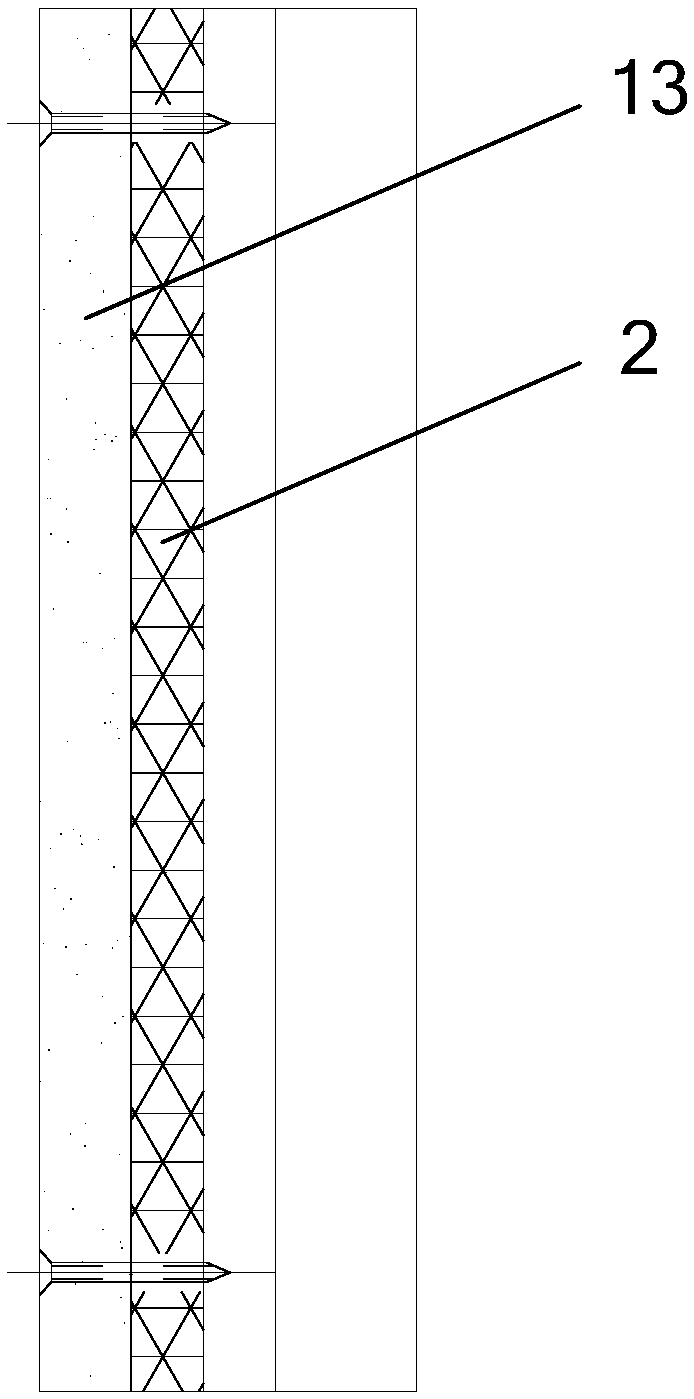

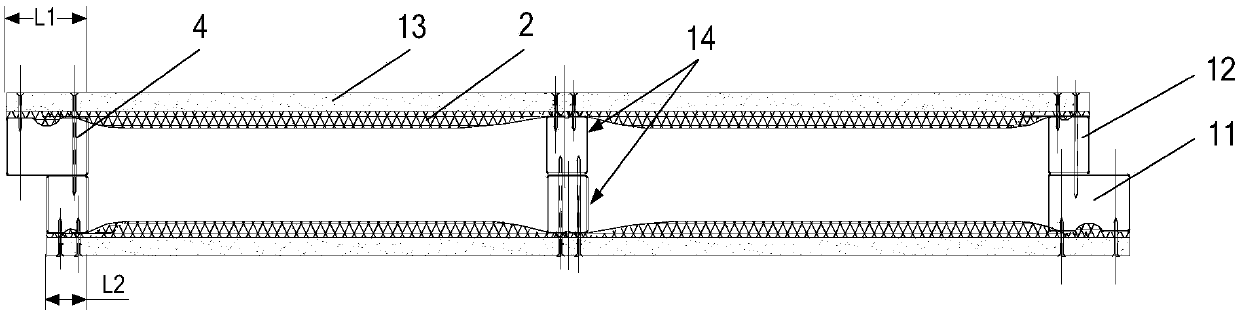

Prefabricated column, pier column structure and construction method

InactiveCN106400678AGuaranteed connection reliabilityClear forceBridge structural detailsBridge erection/assemblyPile capBearing capacity

The invention discloses a prefabricated column, a pier column structure and a construction method. The structure comprises the prefabricated column. The prefabricated column is arranged on a pile cap through a connecting column, the connecting column and the pile cap are constructed in a cast-in-place concrete way, a bulge or a groove is arranged at the bottom of the prefabricated column, the shape of the top of the connecting column is matched with the shape of the bottom of the prefabricated column, steel plates which partially protrude out of the bottom of the prefabricated column are arranged in the prefabricated column in the longitudinal direction, and hole grooves matched with the steel plates are arranged in the connecting column. According to the invention, the prefabricated column and the connecting column are connected through the bulge and the groove, and then connected with the hole grooves through the steel plates, finally the joints are further sealed through grouting pipes and grouting channels, and thus the connection reliability of the pier column structure is effectively guaranteed. The connection structure is clear in stress, the I-shaped steel plates and wedge notches are arranged, so that the shear-bearing capacity of the structure is improved, rubber strips and epoxy mortars ensure the sealing of the joints, and the structure durability is improved.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

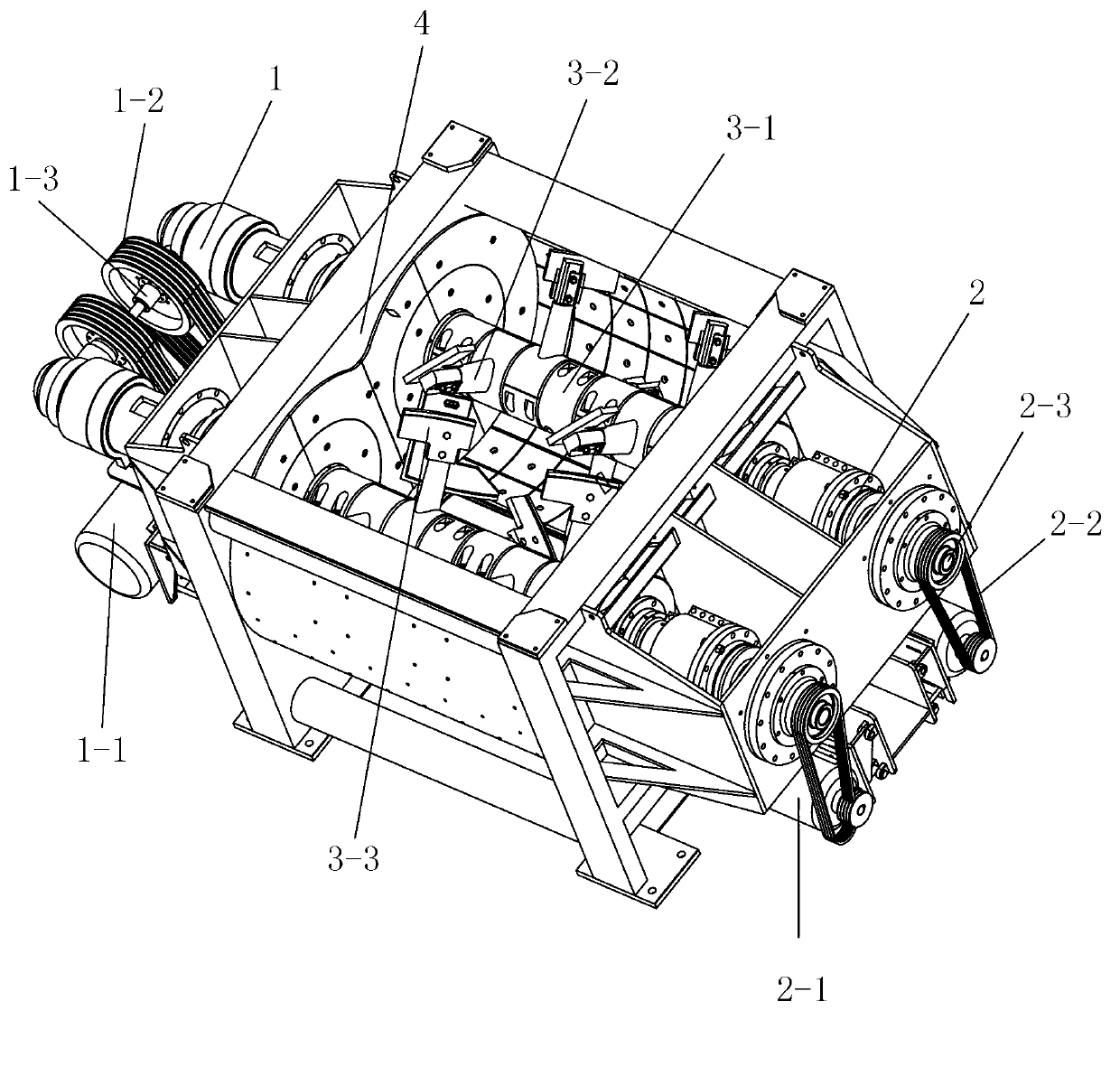

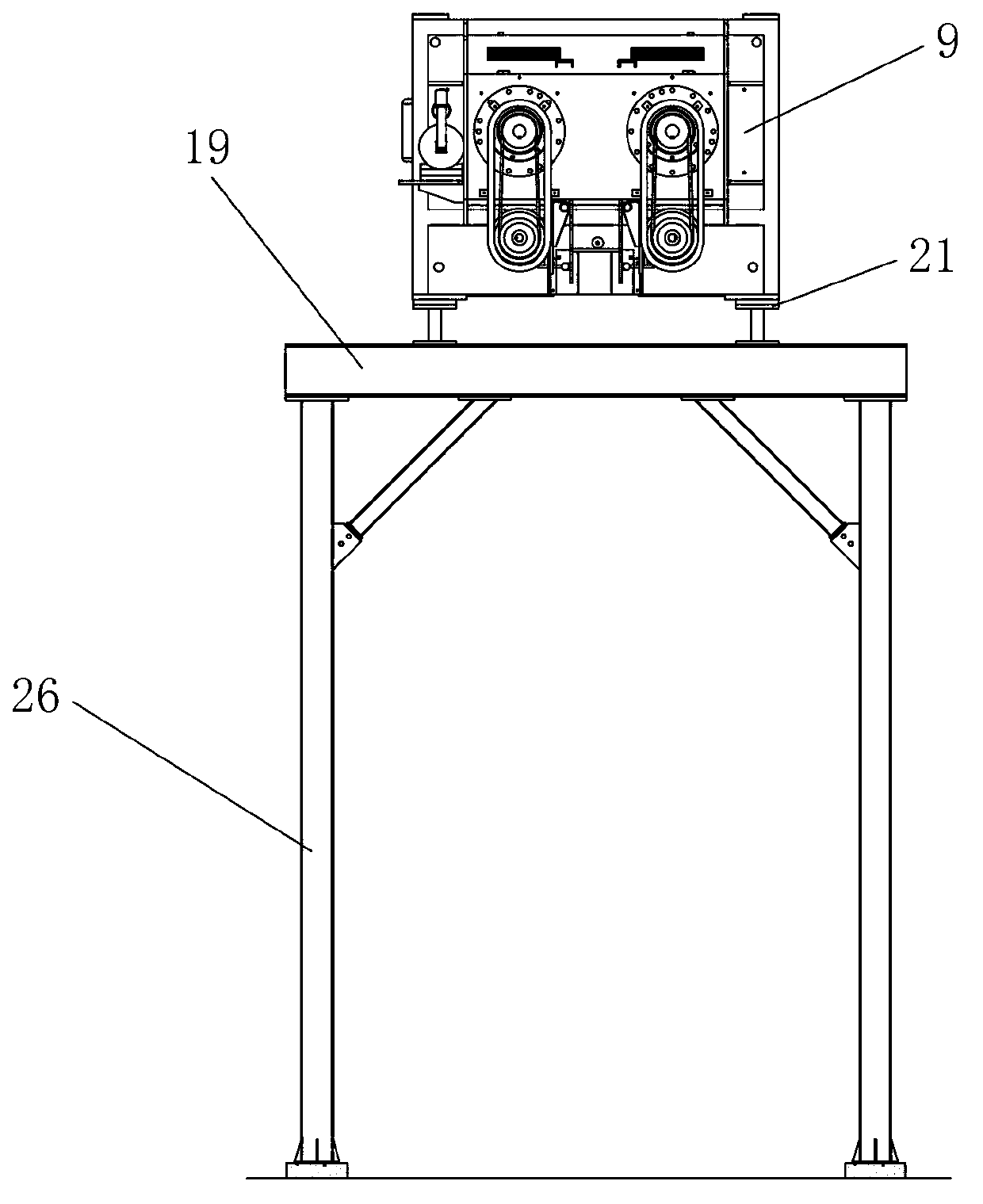

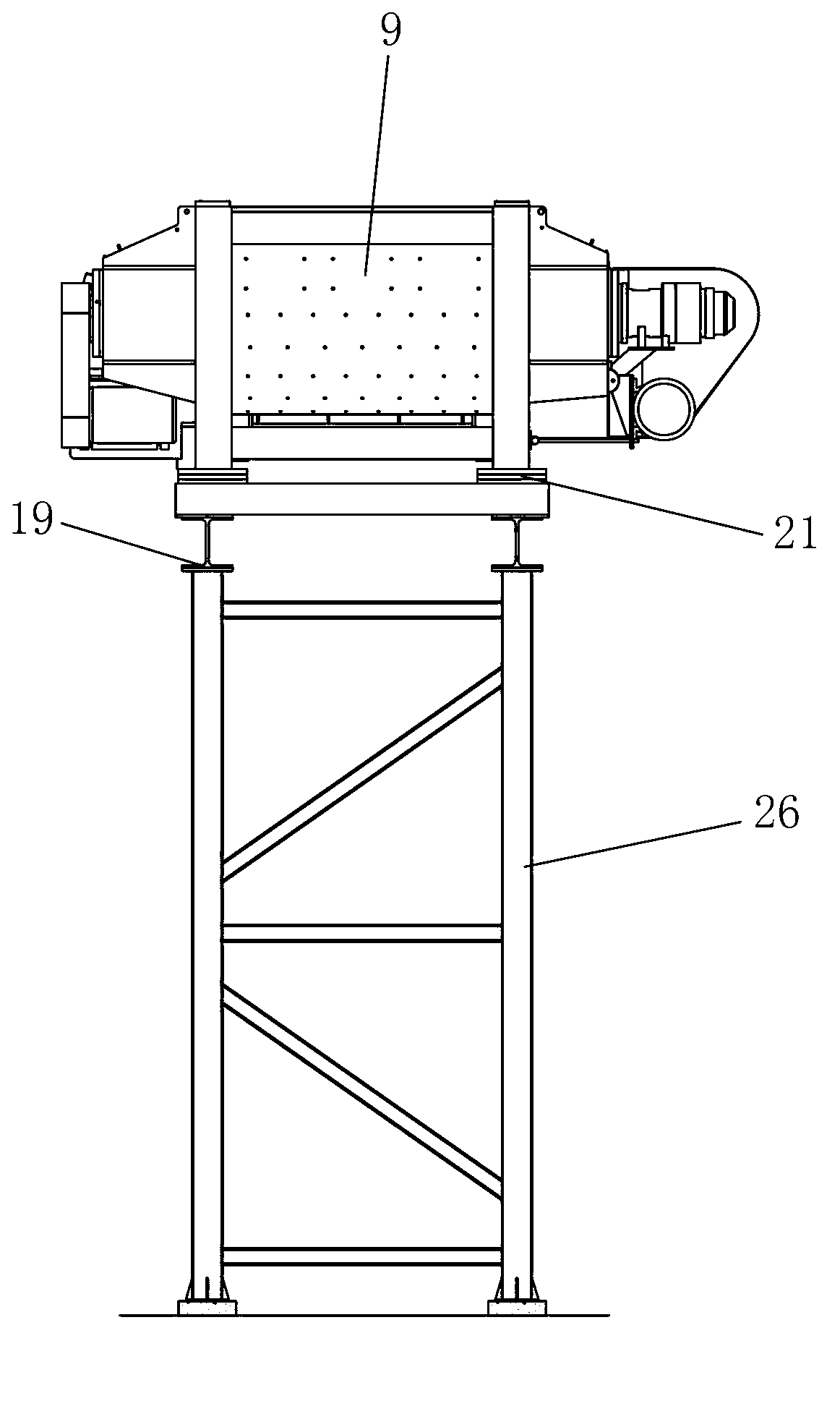

Concrete mixing plant configured with vibration type mixing main engine

ActiveCN103101116AEliminate bad effectsGuaranteed accuracyCement mixing apparatusMixing operation plantCoalWater tanks

The invention discloses a concrete mixing plant configured with a vibration type mixing main engine. The concrete mixing plant configured with the vibration type mixing main engine comprises an aggregate batcher, an aggregate lifting mechanism, a main building platform, a cement chamber, a coal ash chamber, a cement spiral conveyor, a coal ash spiral conveyor, a cement scale, a coal ash scale, a water scale, a water tank, a control chamber, a main engine bracket platform and the vibration type mixing main engine; the main building platform is fixedly supported on a base surface through four main building supporting legs; the main engine bracket platform is arranged at an opening in the center of the main building platform, and is lower than the main building platform; the main engine bracket platform is fixedly supported on the base surface through four bracket platform supporting legs; the four bracket platform supporting legs and the four main building supporting legs form a structure shaped like a Chinese character 'Mu' (means the eye); the vibration type mixing main engine is fixed on the main engine bracket platform; and a rubber damping block is arranged between the vibration type mixing main engine and the main engine bracket platform. The concrete mixing plant configured with the vibration type mixing main engine, provided by the invention, eliminates the influence of the vibration type mixing main engine on the vibration of the main building platform of the mixing plant, so as to ensure the weighing accuracy of the coal ash scale and the water scale, and the safety and the reliability of each connection structure.

Owner:许昌德通混凝土产业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com