Inherent frequency measuring device for 600 DEG C high-temperature thermal vibration coupling test of high-speed cruise missile airfoil surface

A cruise missile and natural frequency technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as redness and softening, high temperature resistant acceleration sensors cannot be used normally, and achieve the effect of reducing special requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

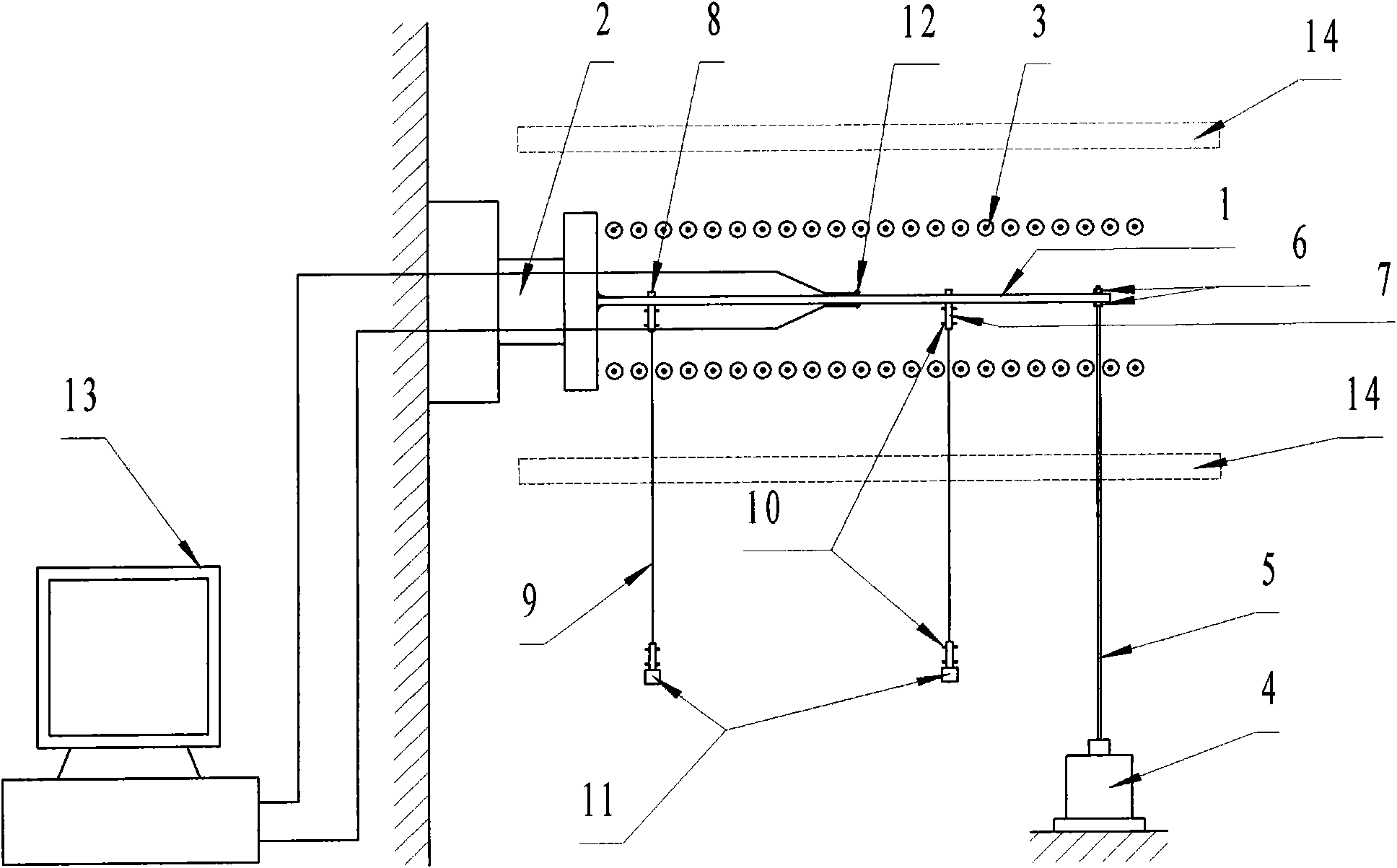

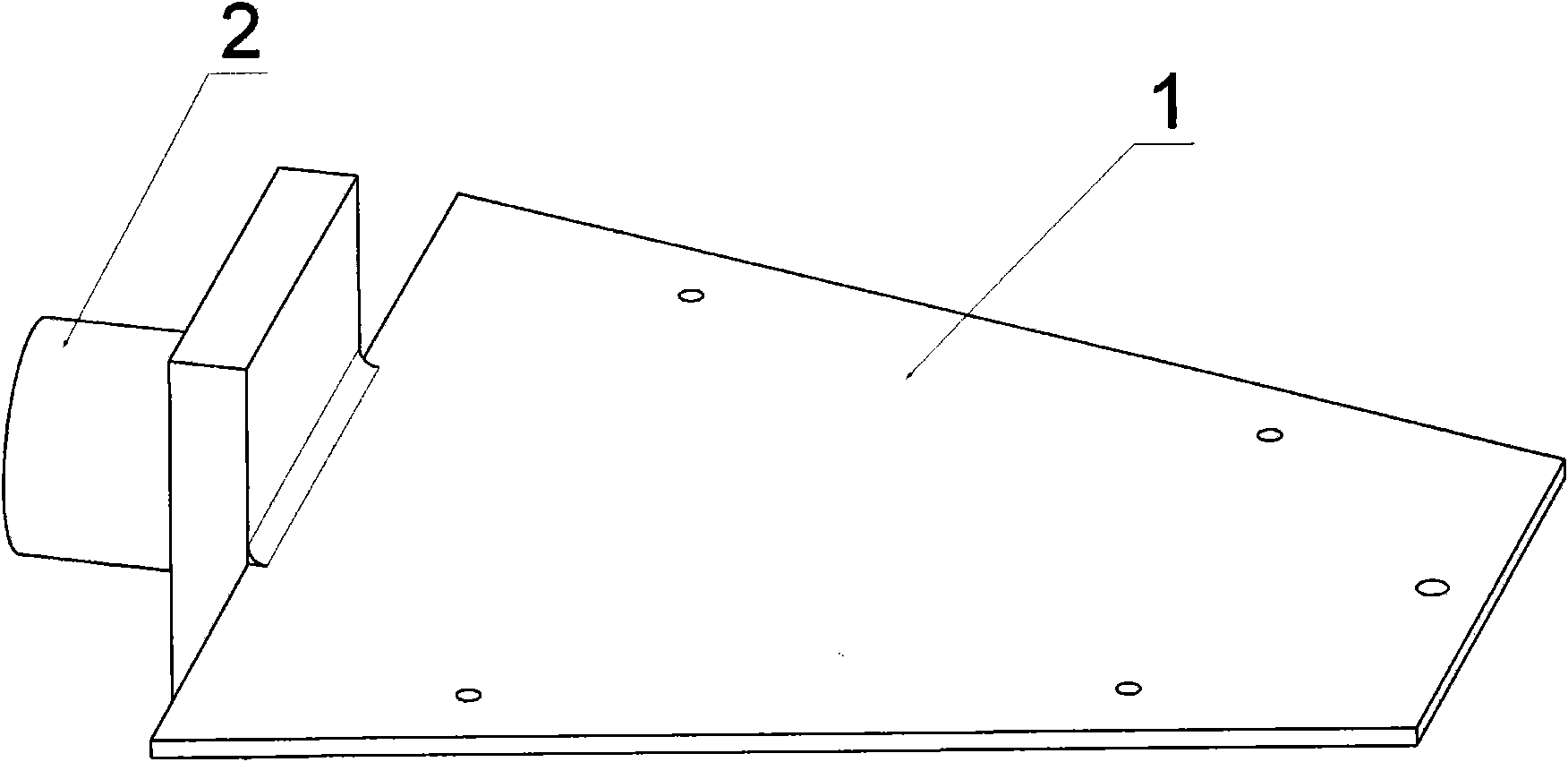

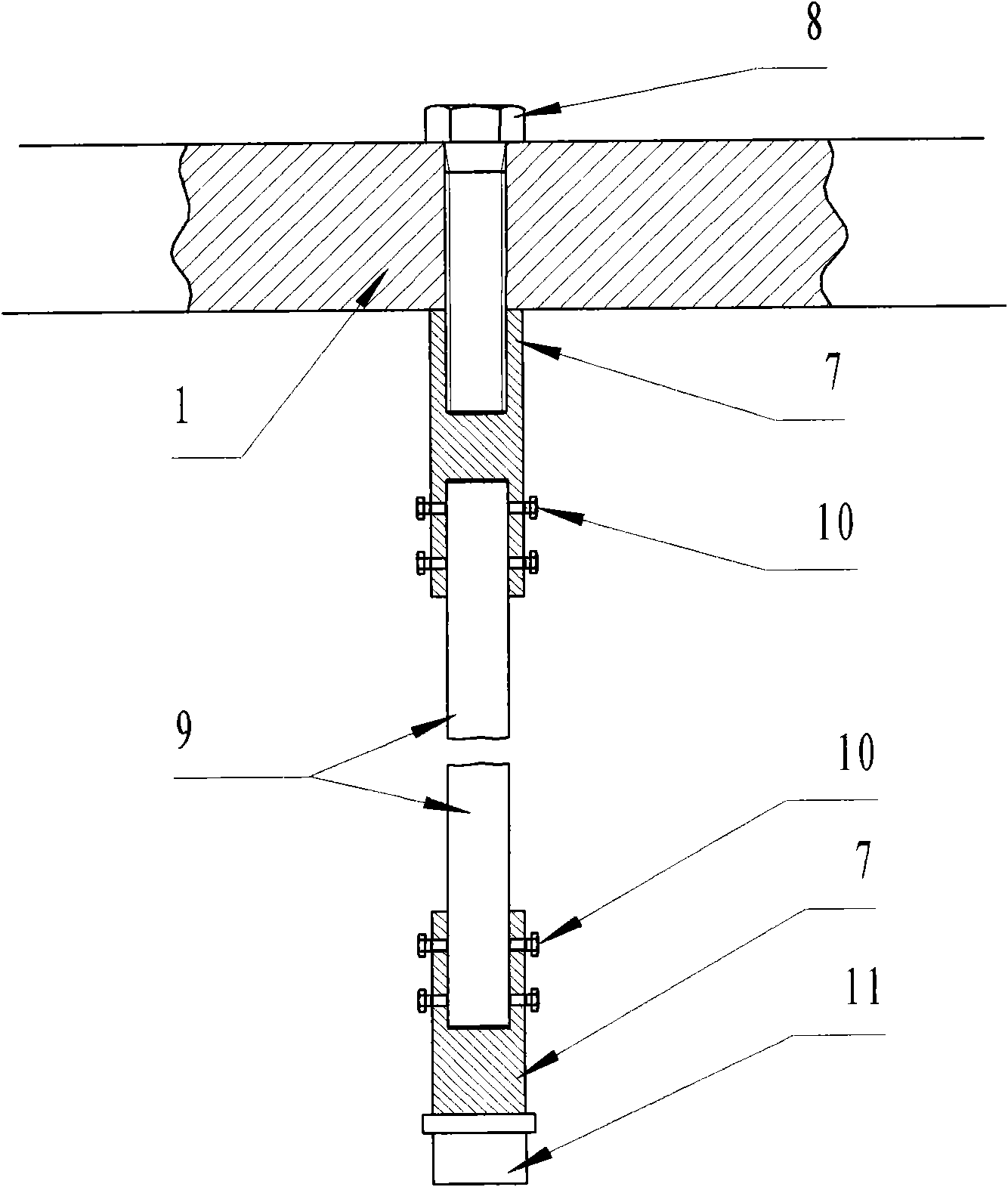

[0022] Such as figure 1 , figure 2 with image 3 As shown, the present invention consists of a missile airfoil structure test piece 1, a fixed support 2, a quartz lamp heating array 3, an exciter 4, an excitation guide rod 5, a locking nut 6, a copper coupling sleeve 7, and a coupling bolt 8. Ceramic extension rod 9, locking bolt 10, acceleration sensor 11, temperature sensor 12, computer 13 and heat insulation baffle 14.

[0023] The metal missile airfoil structure test piece 1 is welded on the fixed support 2, and a row of quartz lamp heating arrays 3 are respectively arranged at a distance of about 50mm from the upper and lower surfaces of the missile airfoil structure test piece 1, and the missile airfoil structure test piece 1 The upper and lower surfaces are heated to simulate the aerodynamic thermal environment of the cruise missile wing during high-speed flight. The vibrator 4 is firmly connected with the missile airfoil structure test piece 1 through the locking n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com