Patents

Literature

649results about How to "Reliable handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

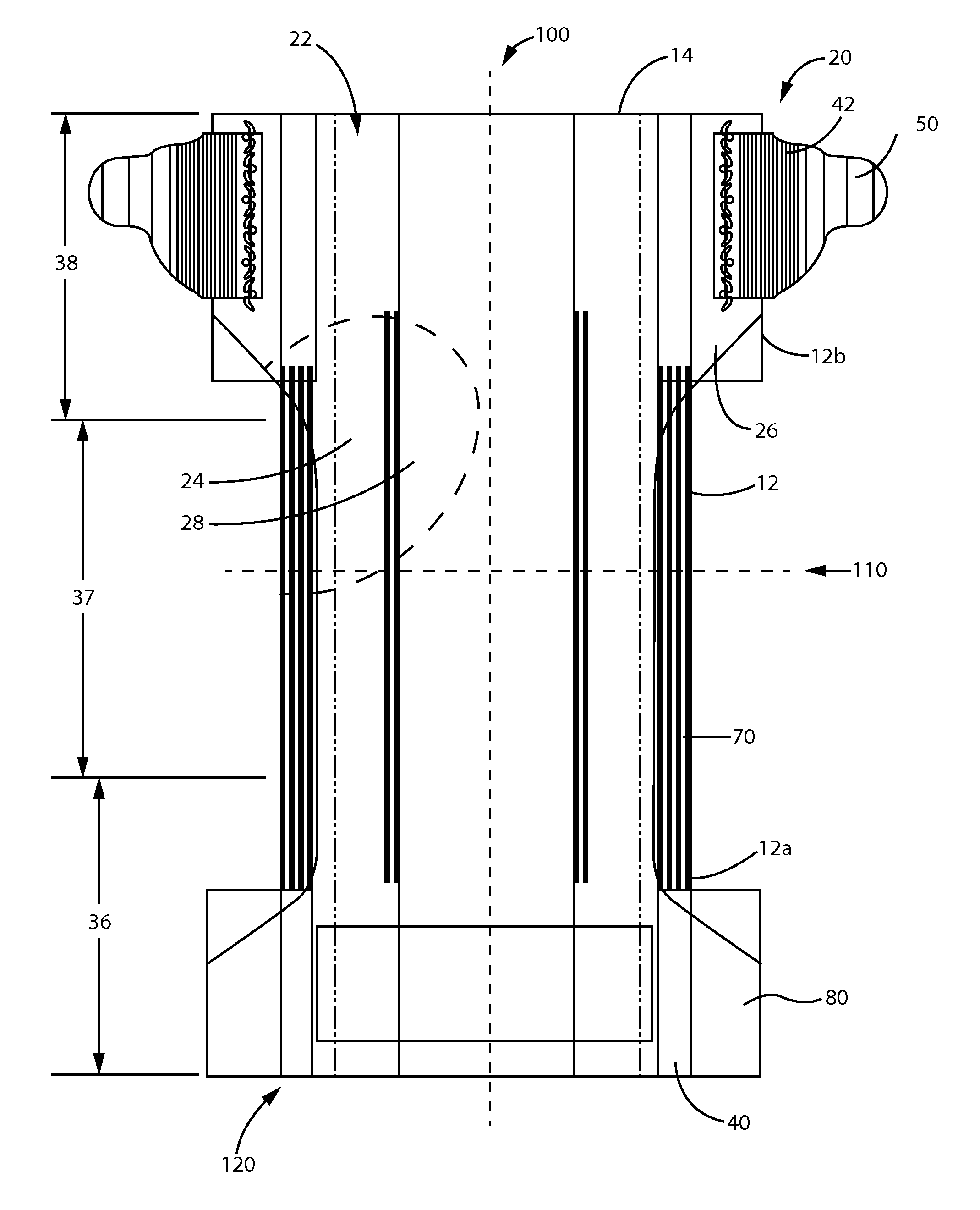

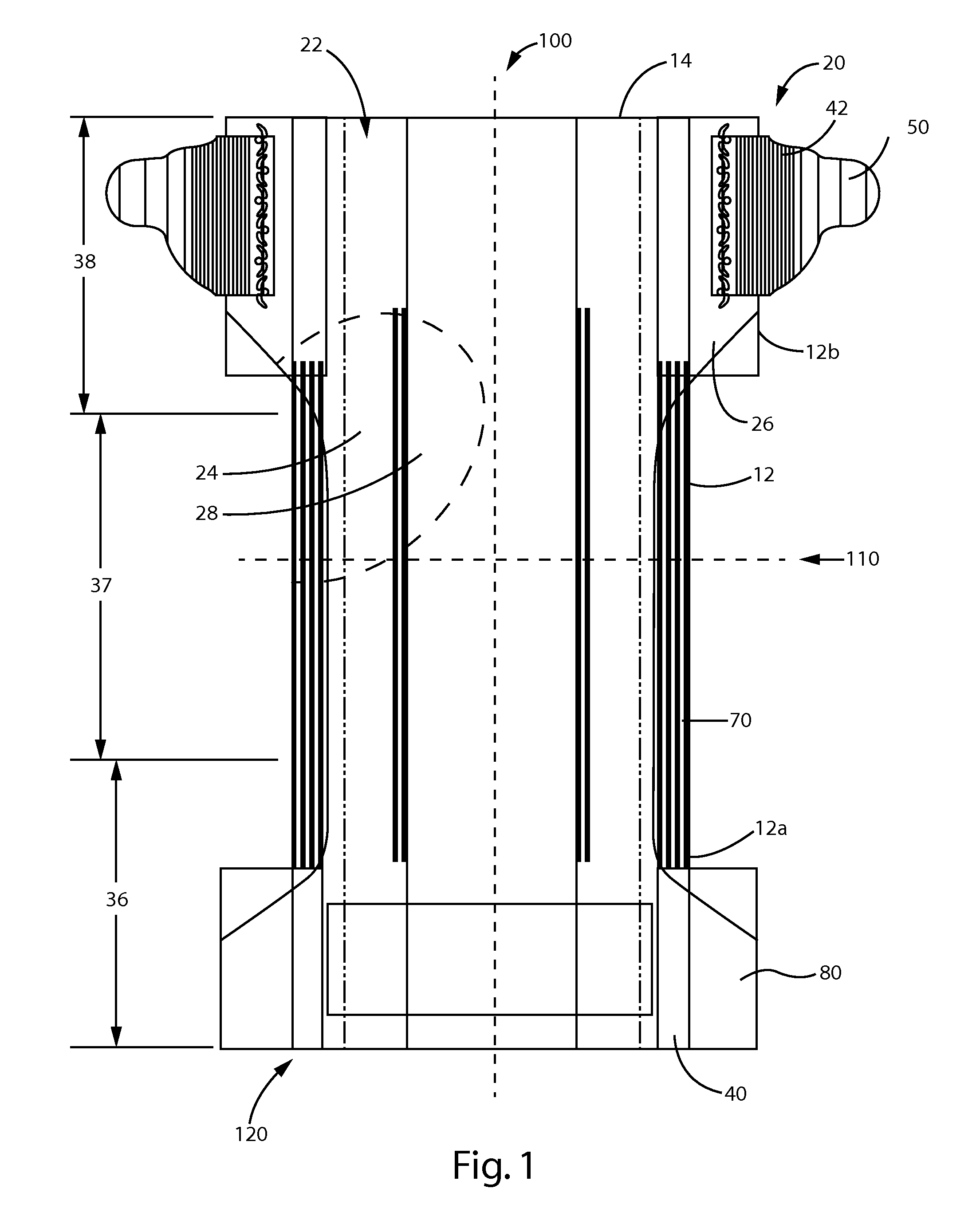

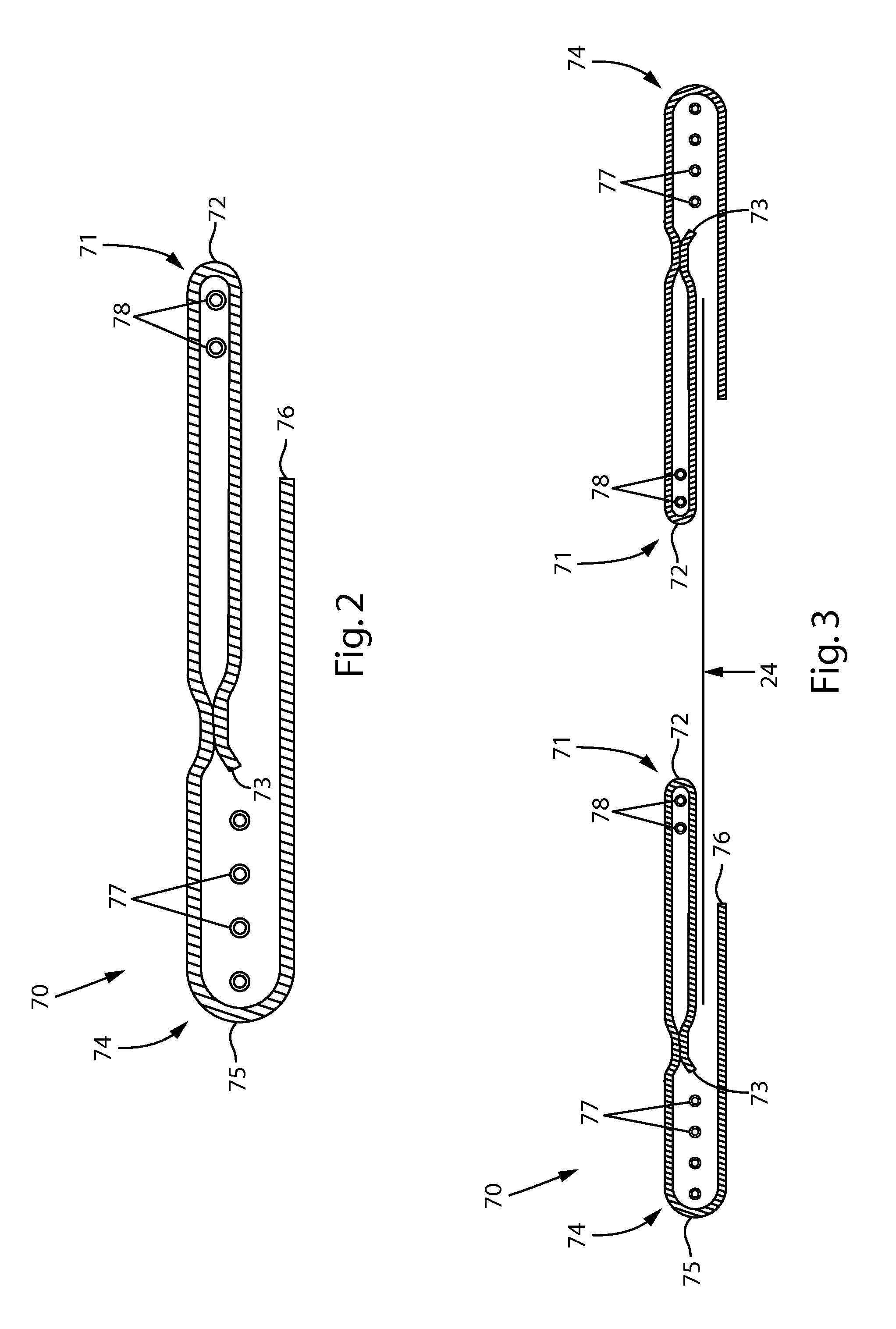

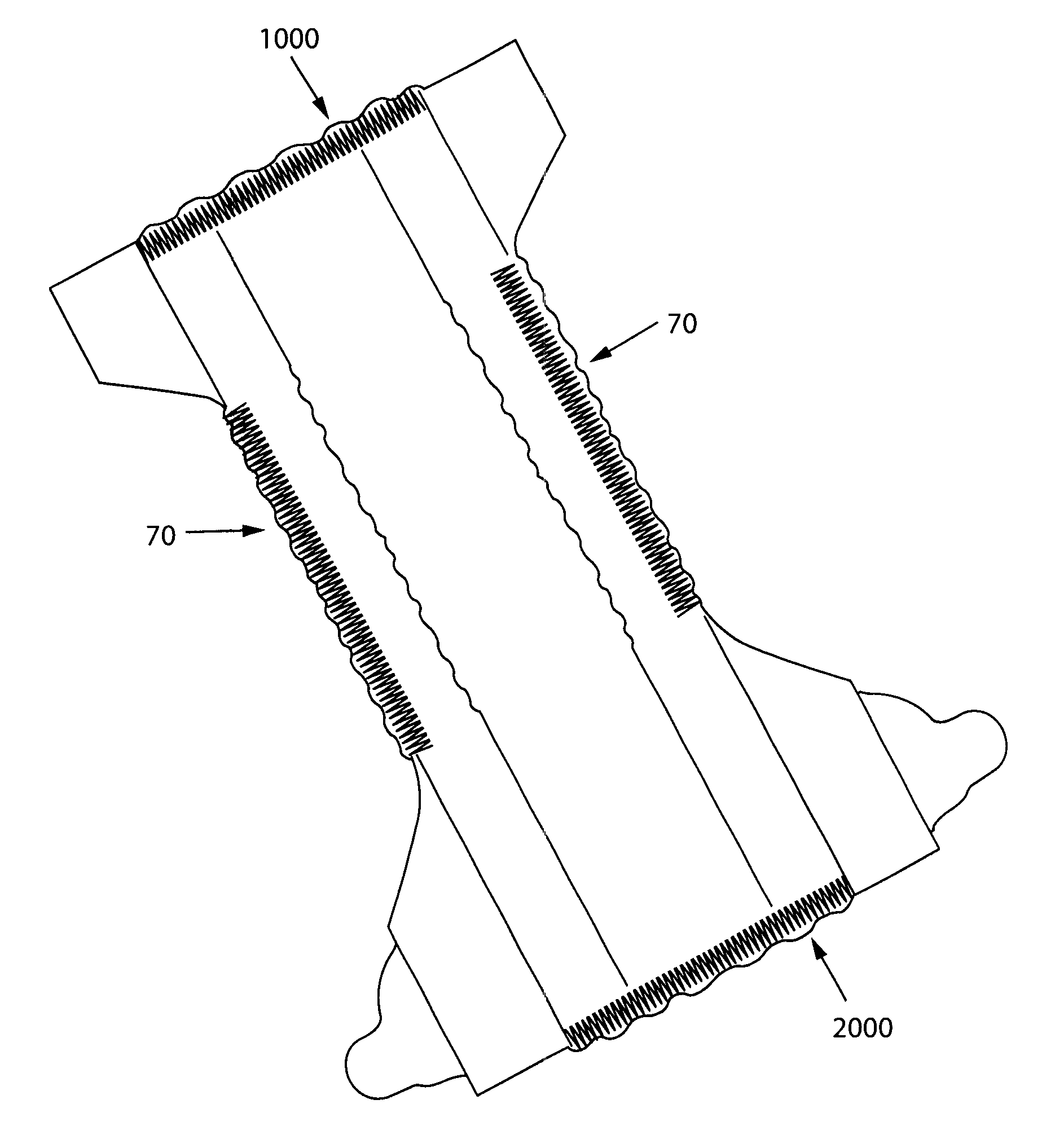

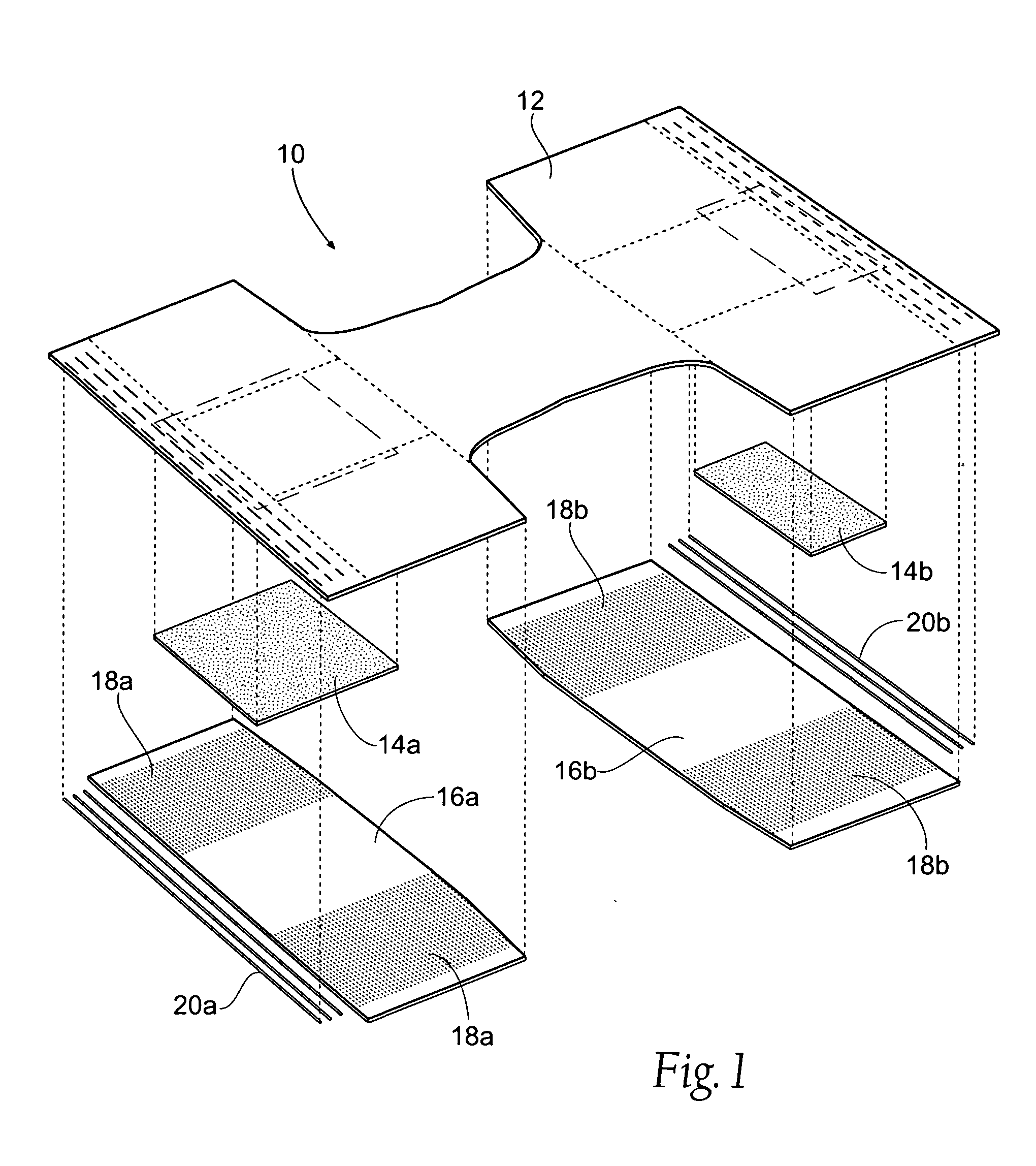

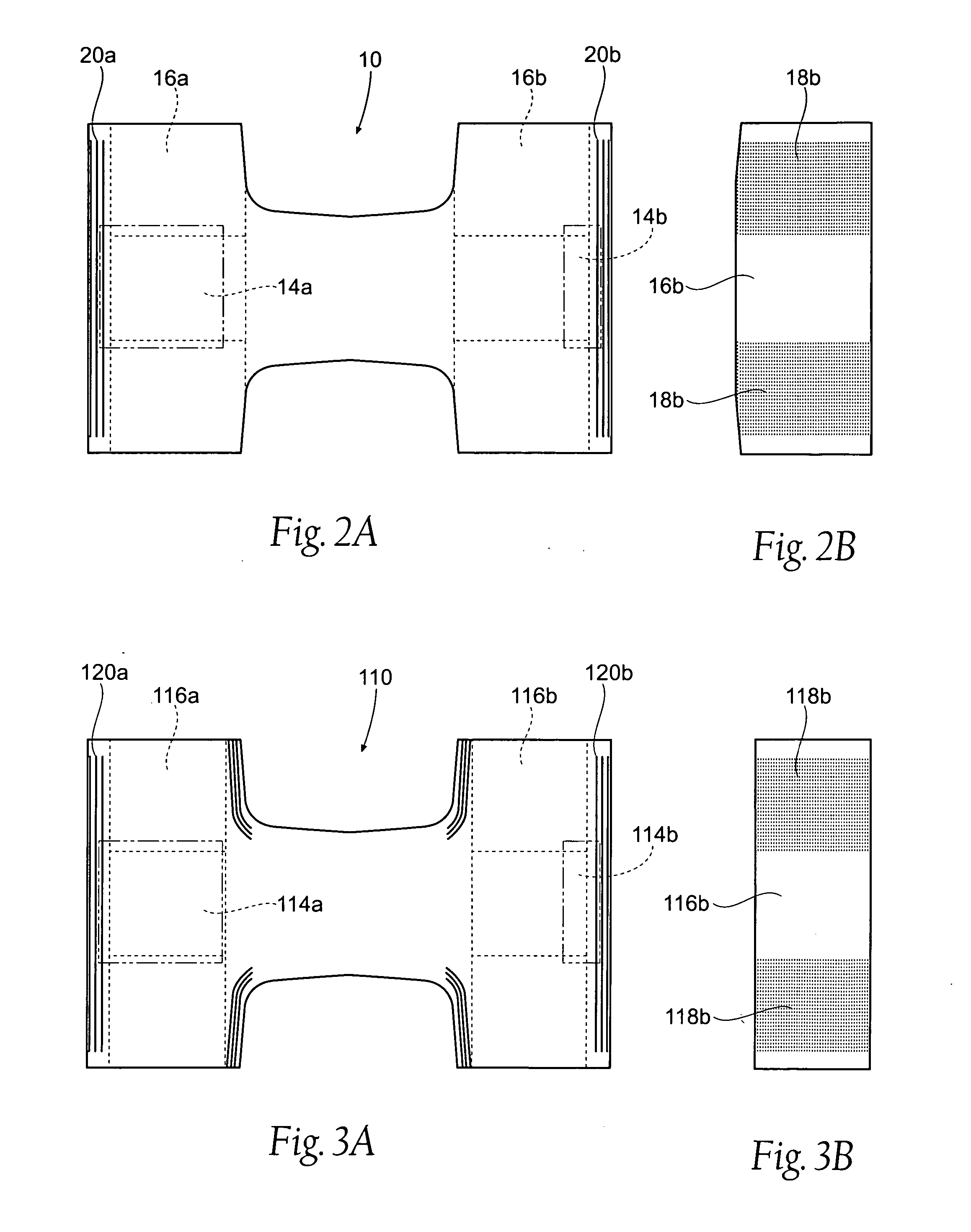

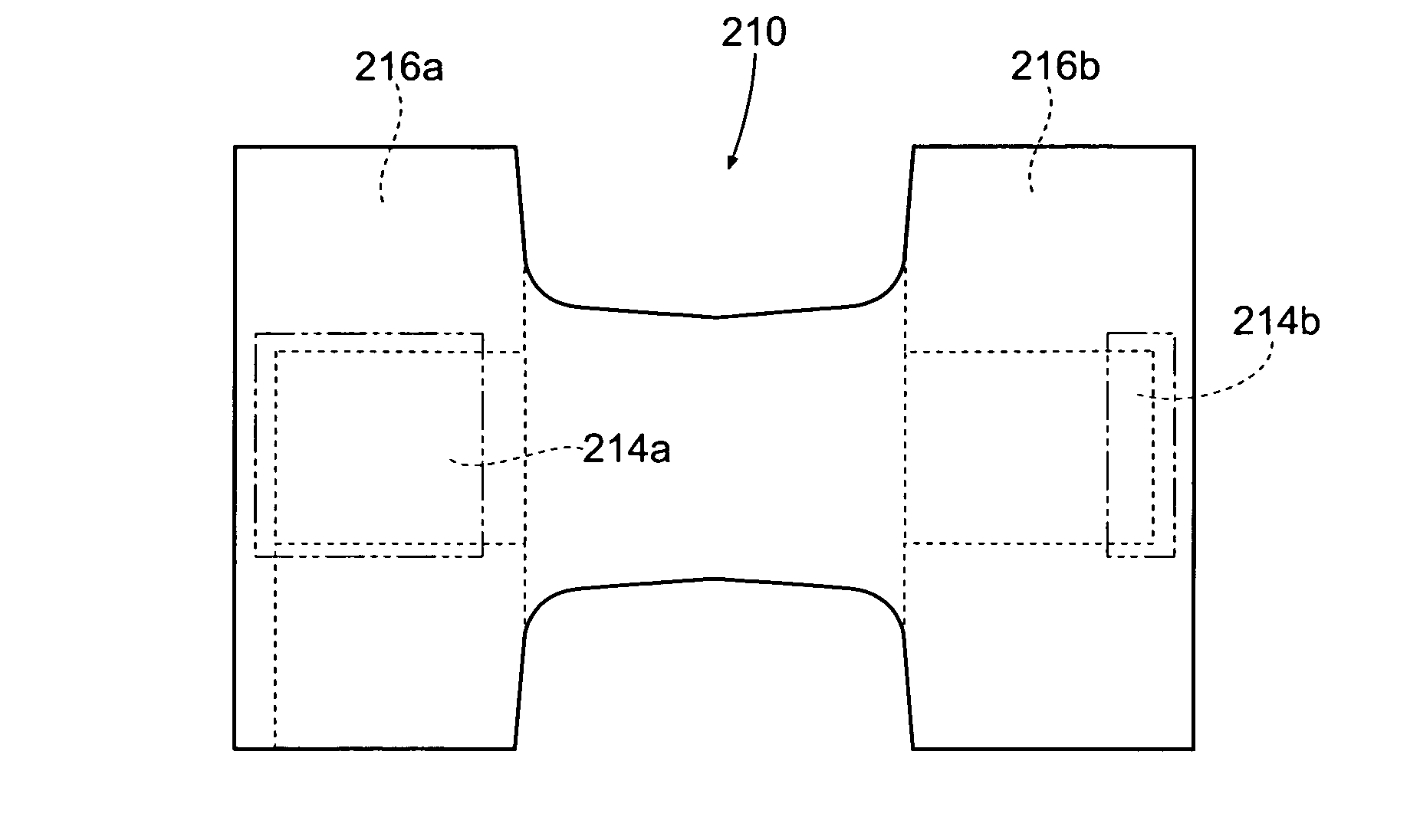

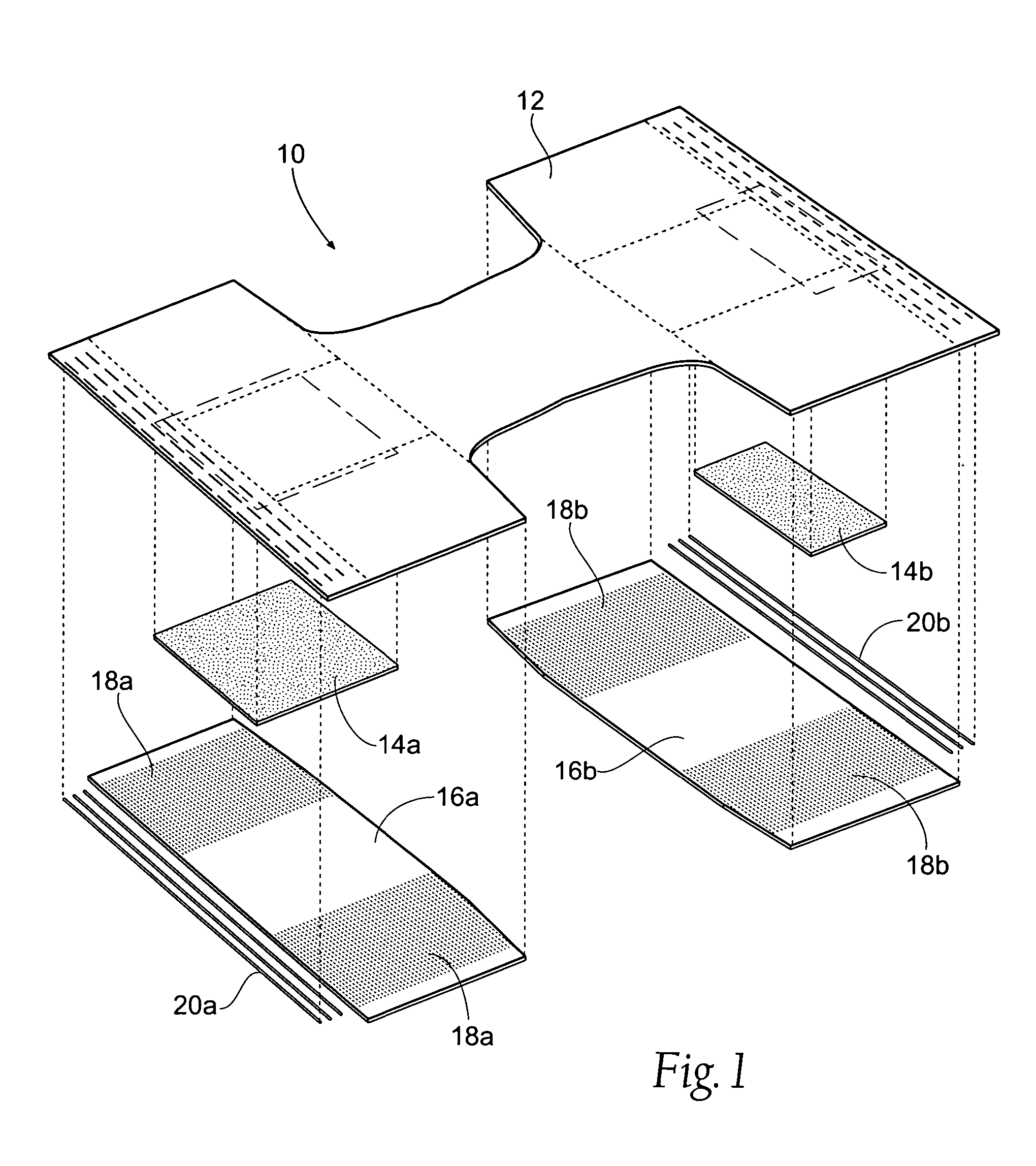

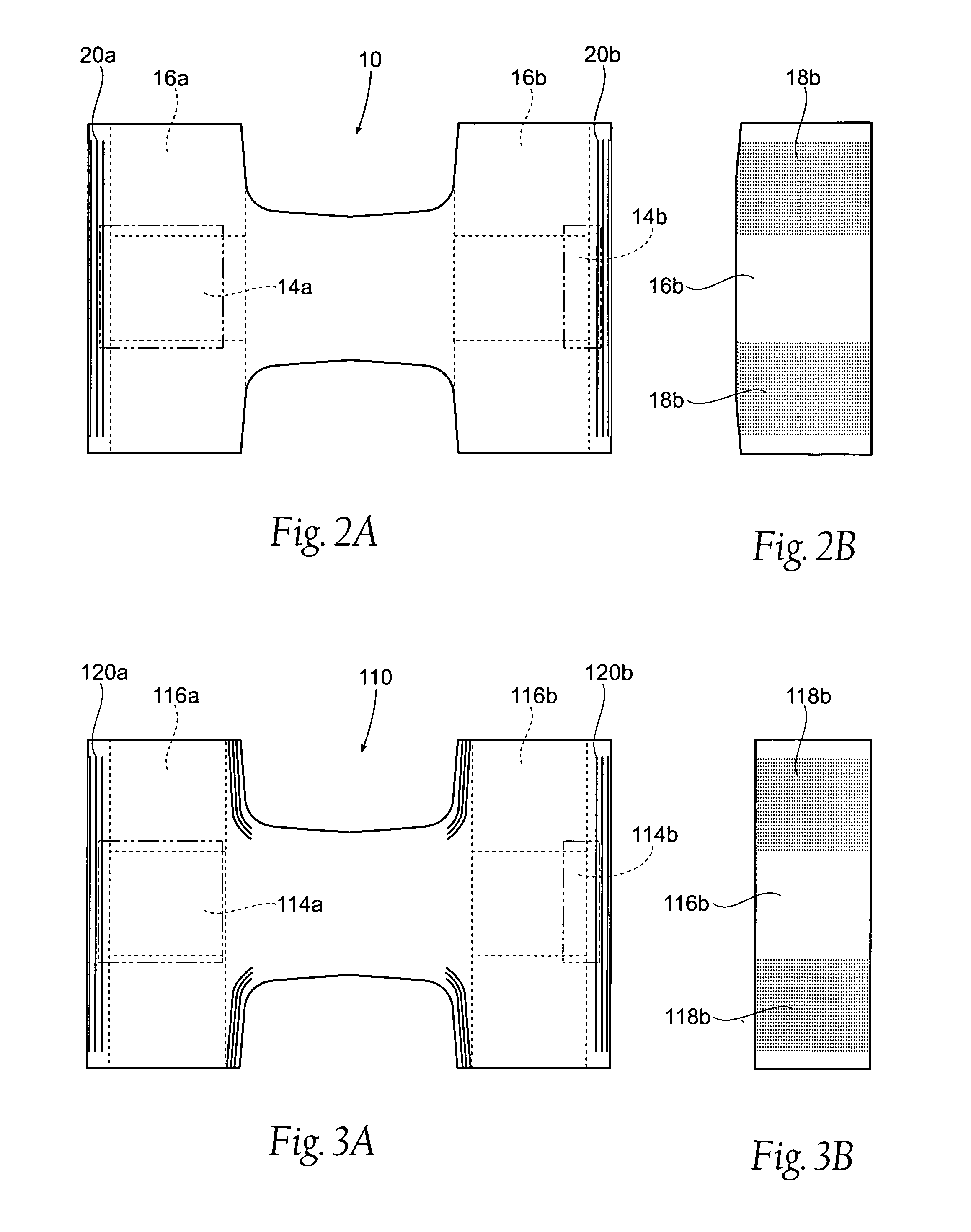

Absorbent Article With Leg Gasketing Cuff

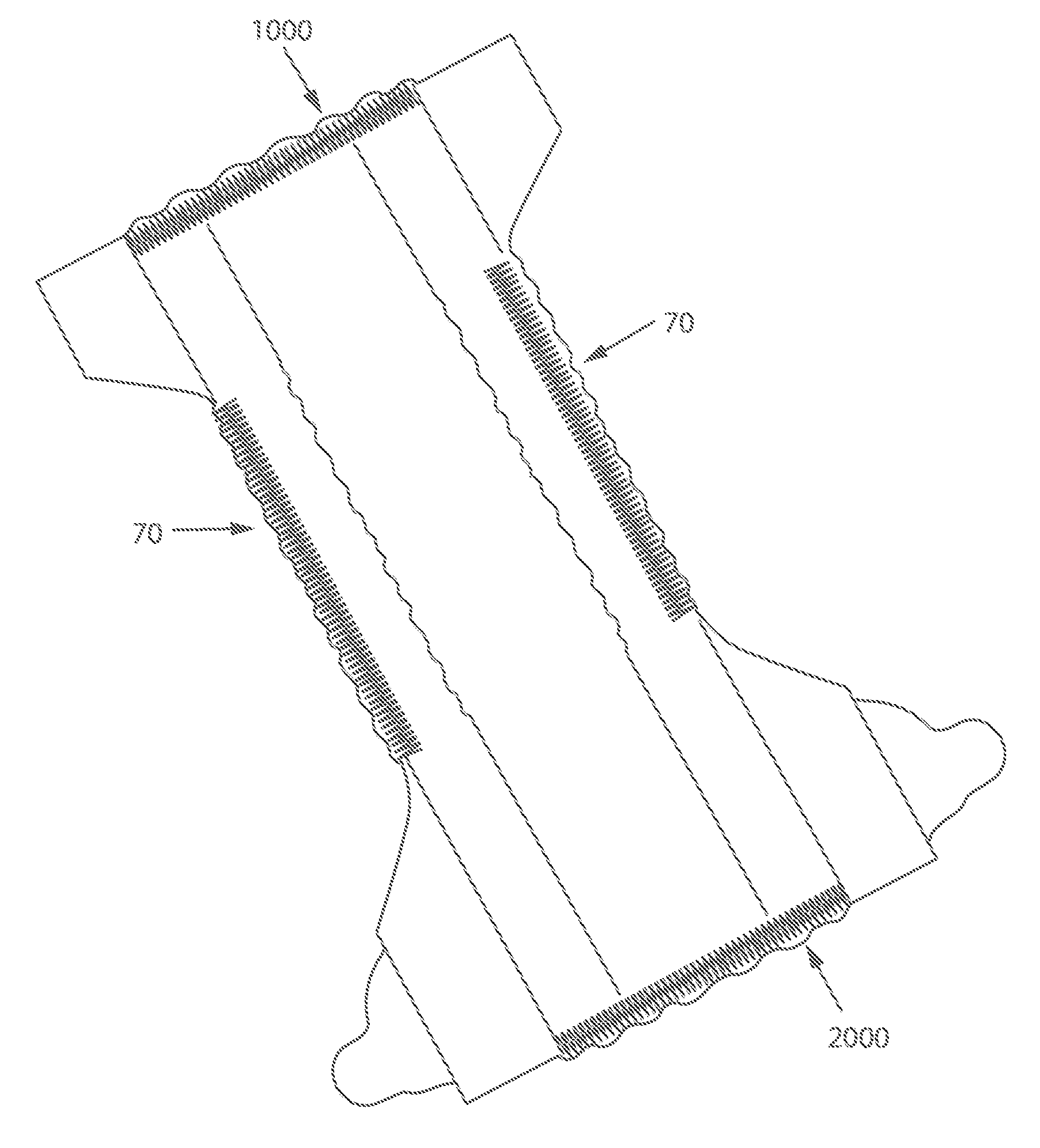

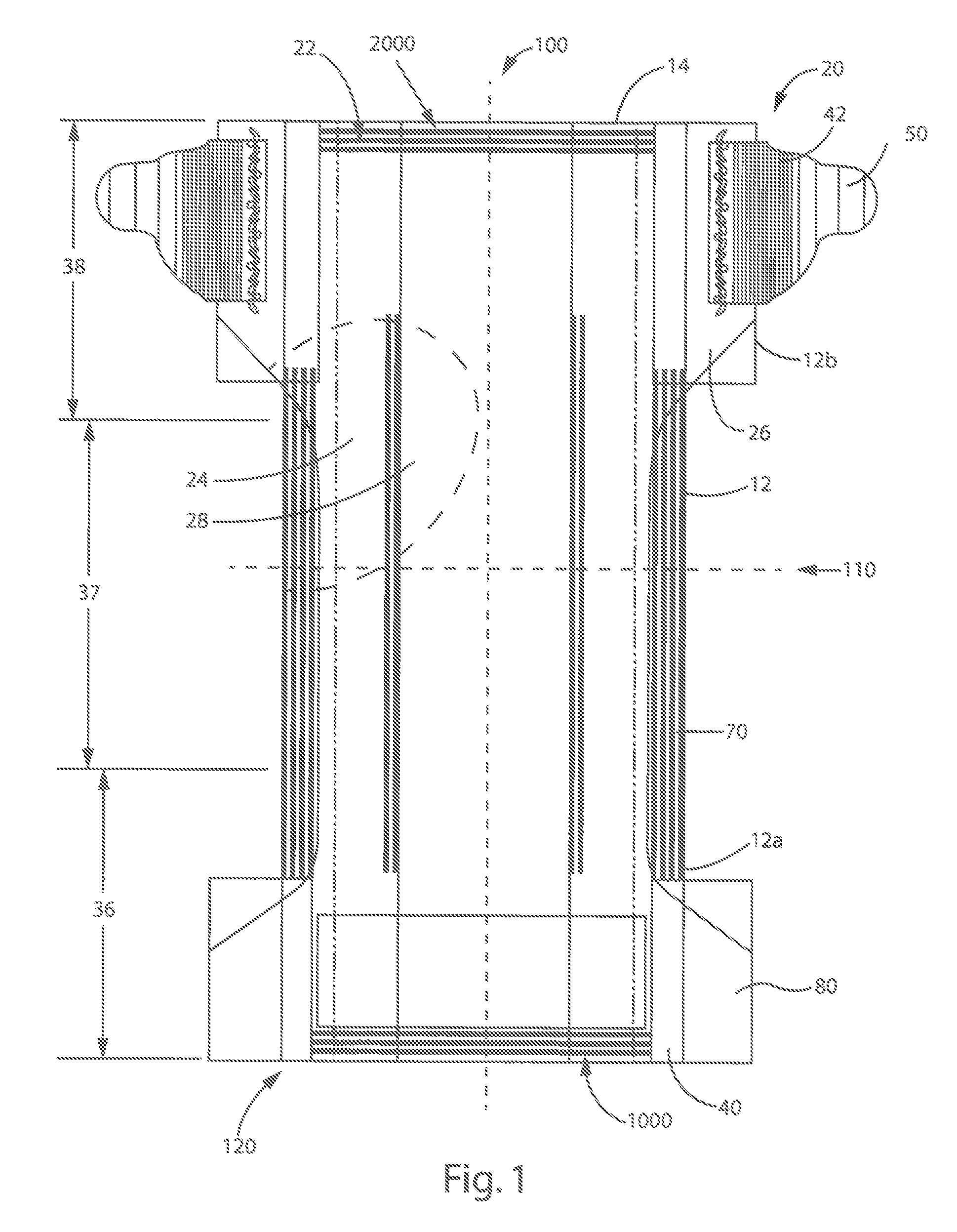

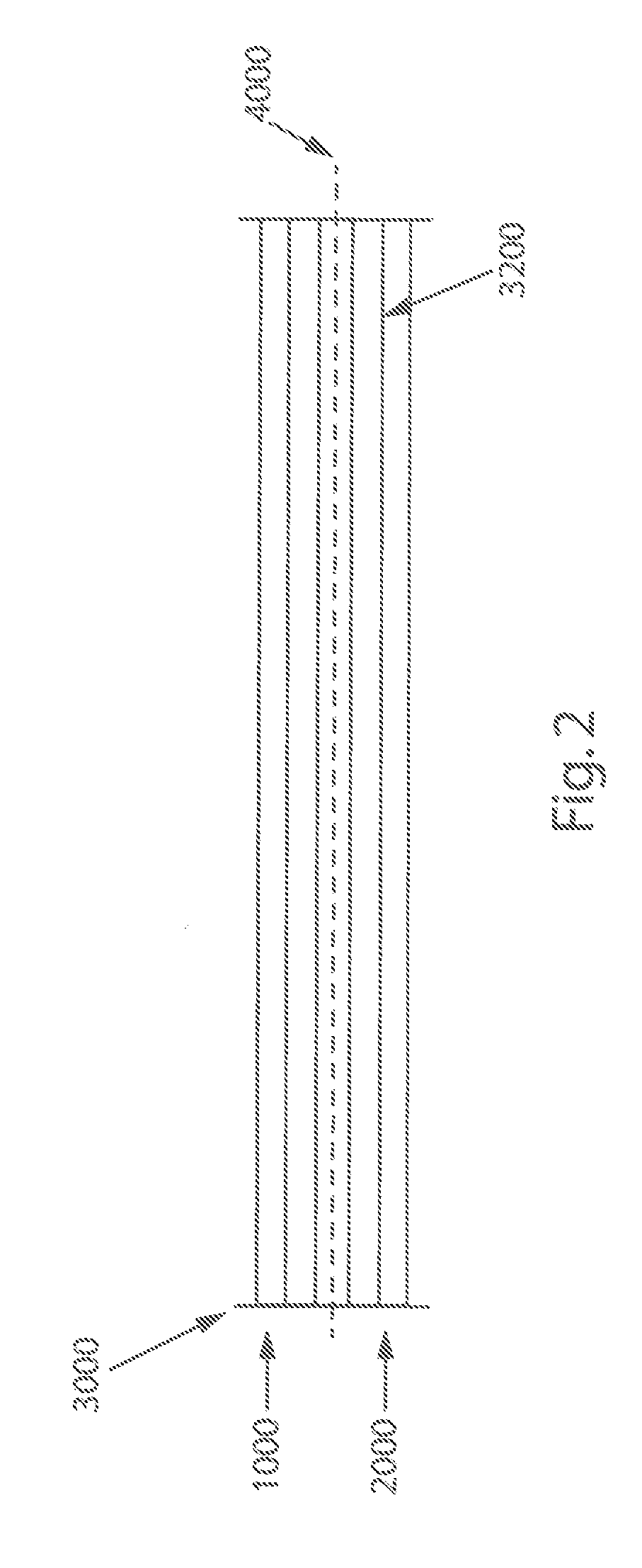

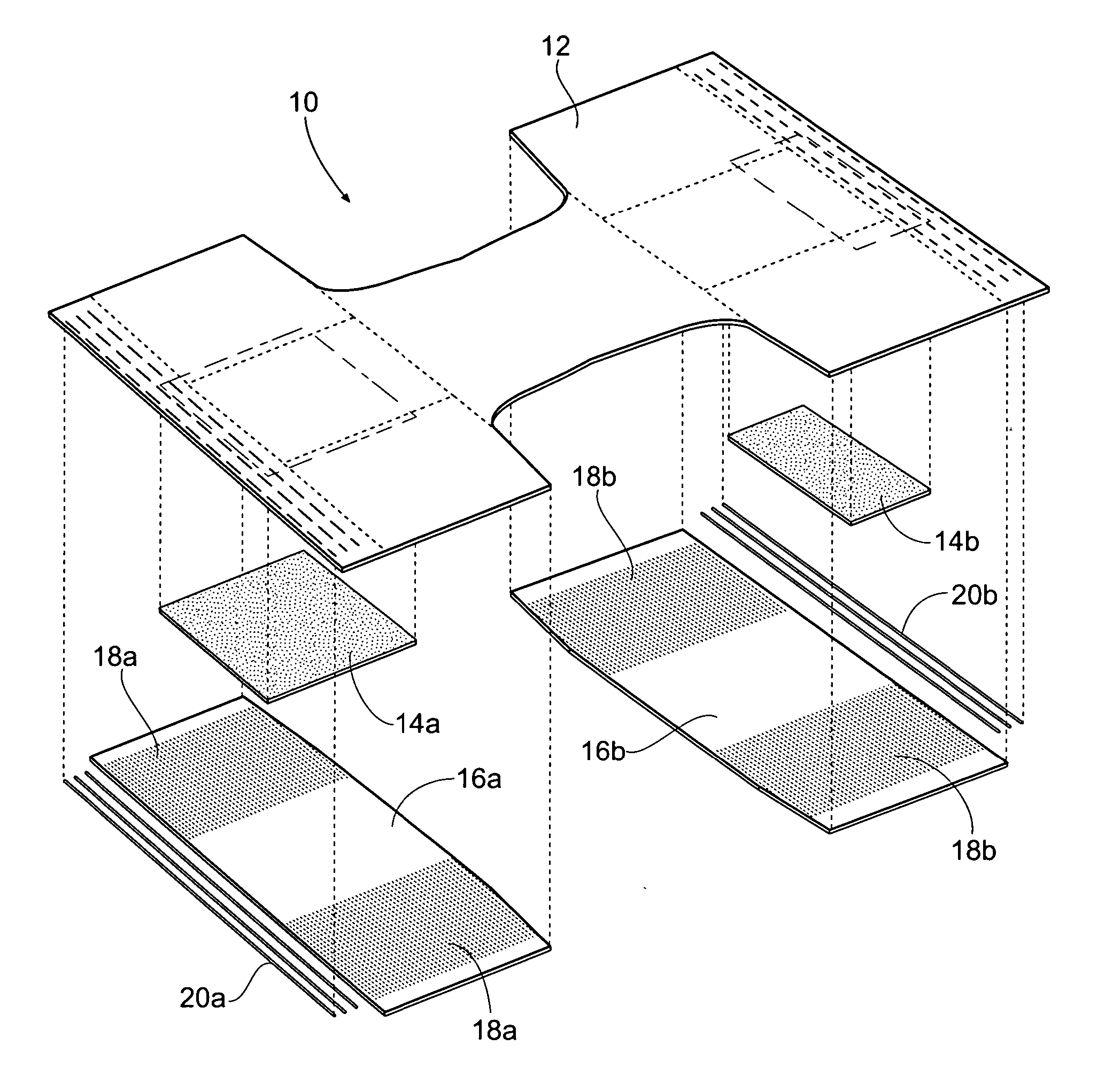

A disposable absorbent article may include a topsheet, a backsheet, an absorbent core disposed between the topsheet and the backsheet, and a leg gasketing system. The leg gasketing system may include an inner cuff and an outer cuff; the inner cuff may include an inner cuff folded edge and an inner cuff material edge and the outer cuff may include an outer cuff folded edge and an outer cuff material edge such that the web of material is folded laterally inward to form the outer cuff folded edge and folded laterally outward to form the inner cuff material edge.

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent article with leg gasketing cuff

A disposable absorbent article may include a topsheet, a backsheet, an absorbent core disposed between the topsheet and the backsheet, and a leg gasketing system. The leg gasketing system may include an inner cuff and an outer cuff; the inner cuff may include an inner cuff folded edge and an inner cuff material edge and the outer cuff may include an outer cuff folded edge and an outer cuff material edge such that the web of material is folded laterally inward to form the outer cuff folded edge and folded laterally outward to form the inner cuff material edge.

Owner:PROCTER & GAMBLE CO

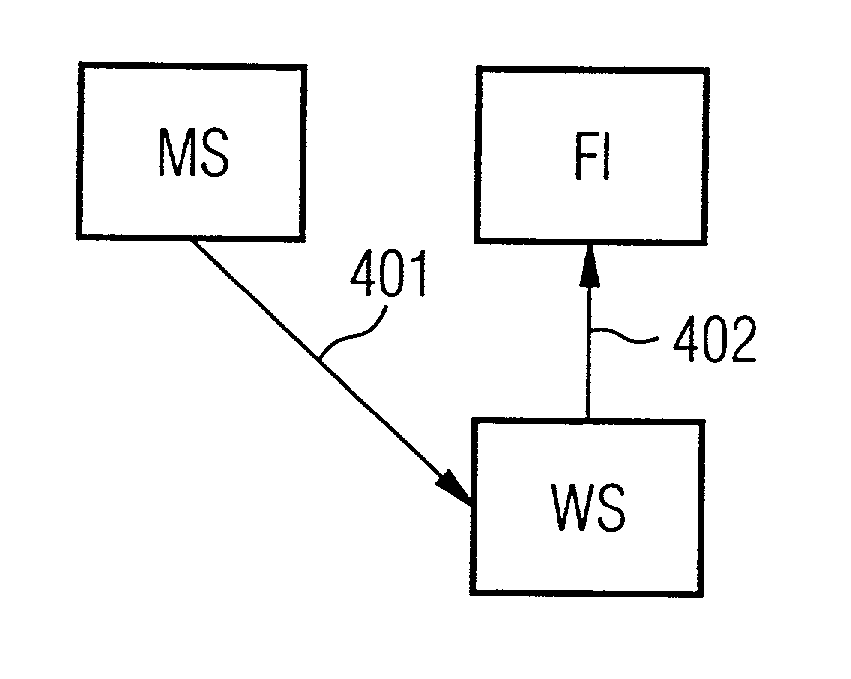

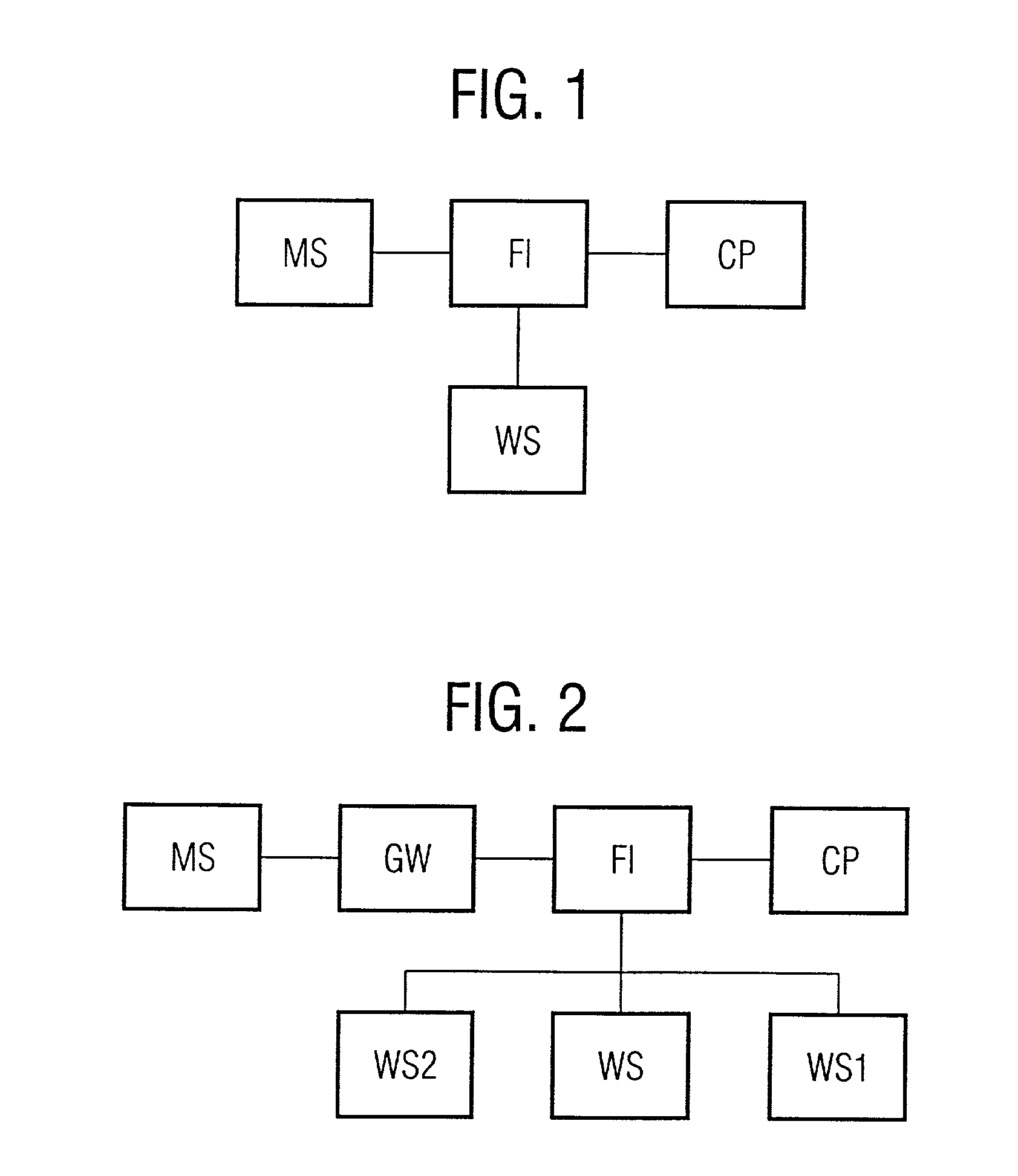

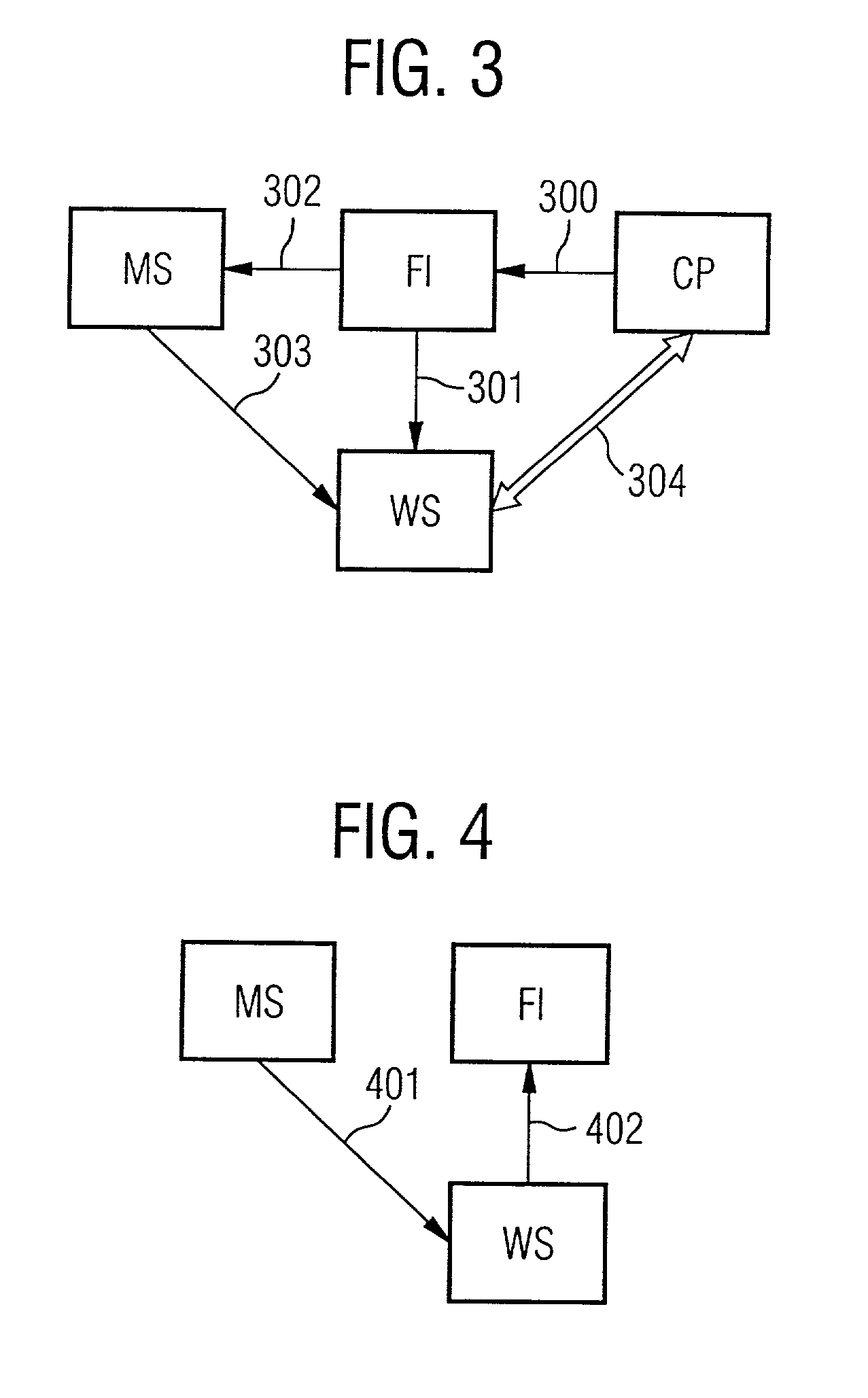

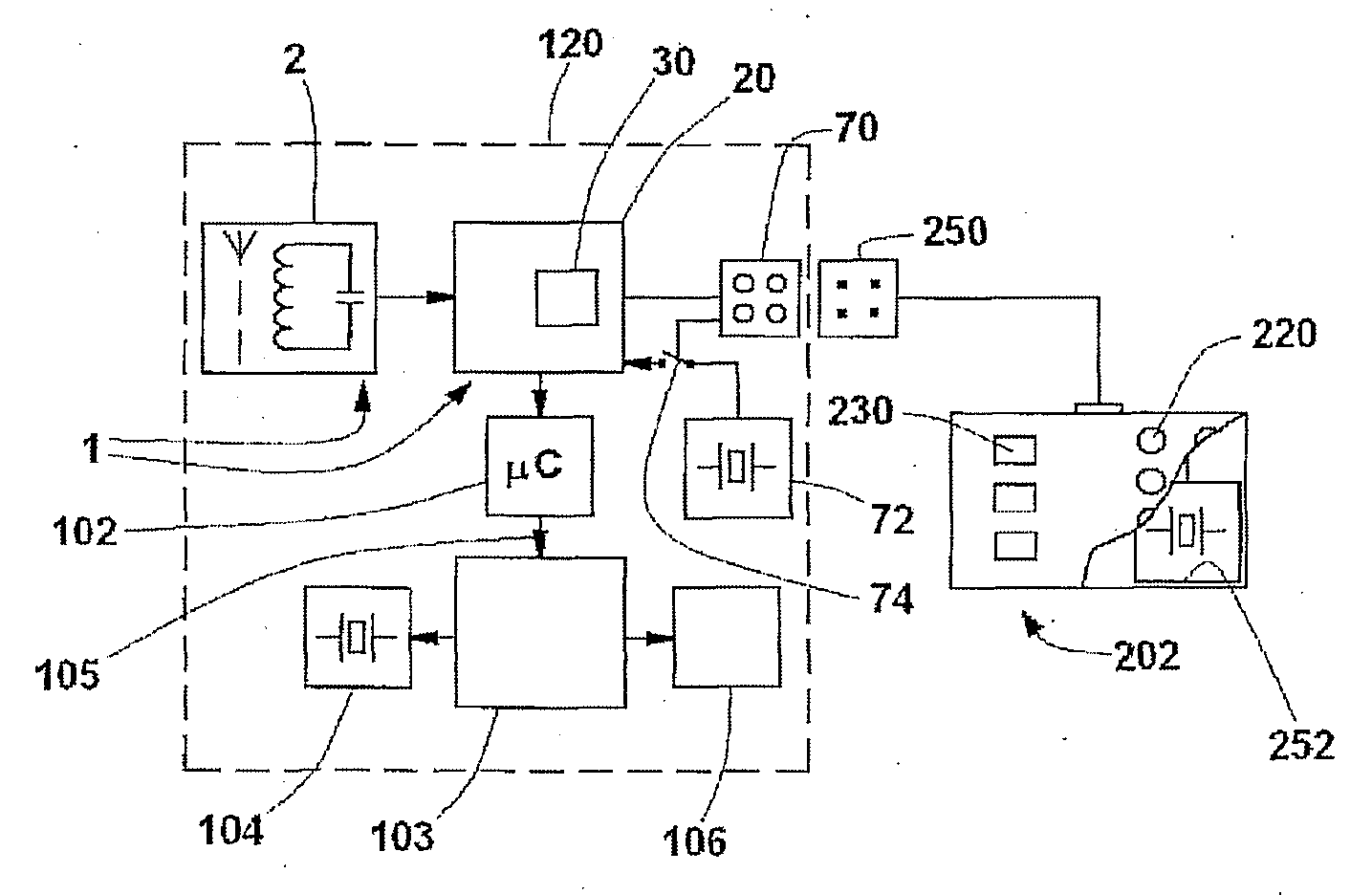

Initiation of an electronic payment transaction

InactiveUS20020052842A1Increase heightReliable payment handlingComplete banking machinesFinancePayment transactionDatabase

The invention relates to a method for initiating an electronic payment transaction. A filter FI receives a payment request 300 and modifies it by adding a transaction identification. It sends the modified payment request 301 to a transaction server WS, and a payment request information 302 containing the transaction identification to a communication terminal MS. The transaction server WS receives the modified payment request 301 and a payment initiation 303 containing an additional transaction identification from the communication terminal MS. The transaction server WS compares the transaction identifications of the modified payment request 301 and the payment initiation 303 and performs the payment transaction 304, if the transaction identifications correspond with each other. The invention moreover relates to a corresponding filter FI and a transaction server WS, to a method for initiating the filter FI and to a computer program for initiating an electronic payment transaction and for initiating the filter FI.

Owner:TELEFON AB LM ERICSSON (PUBL)

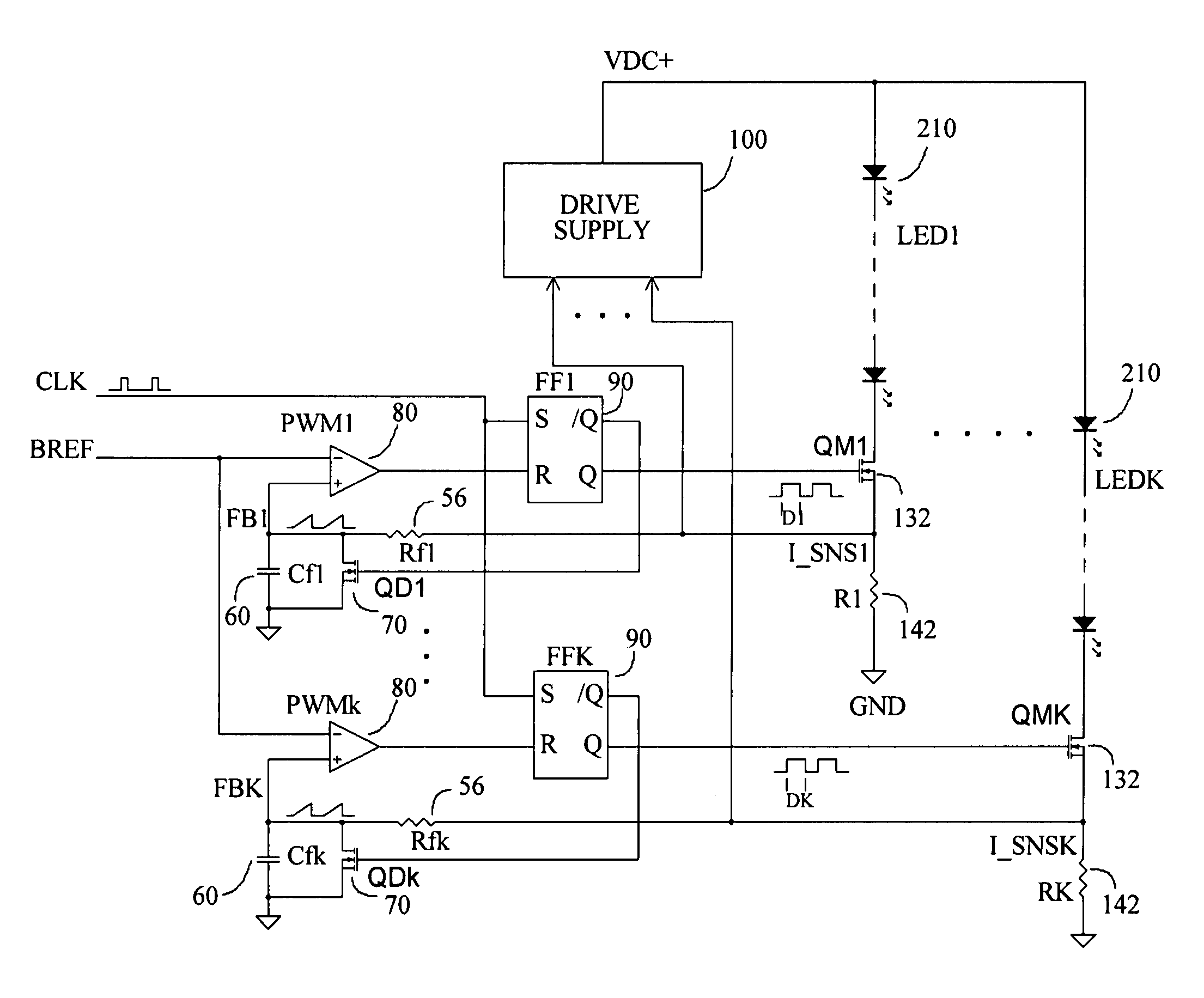

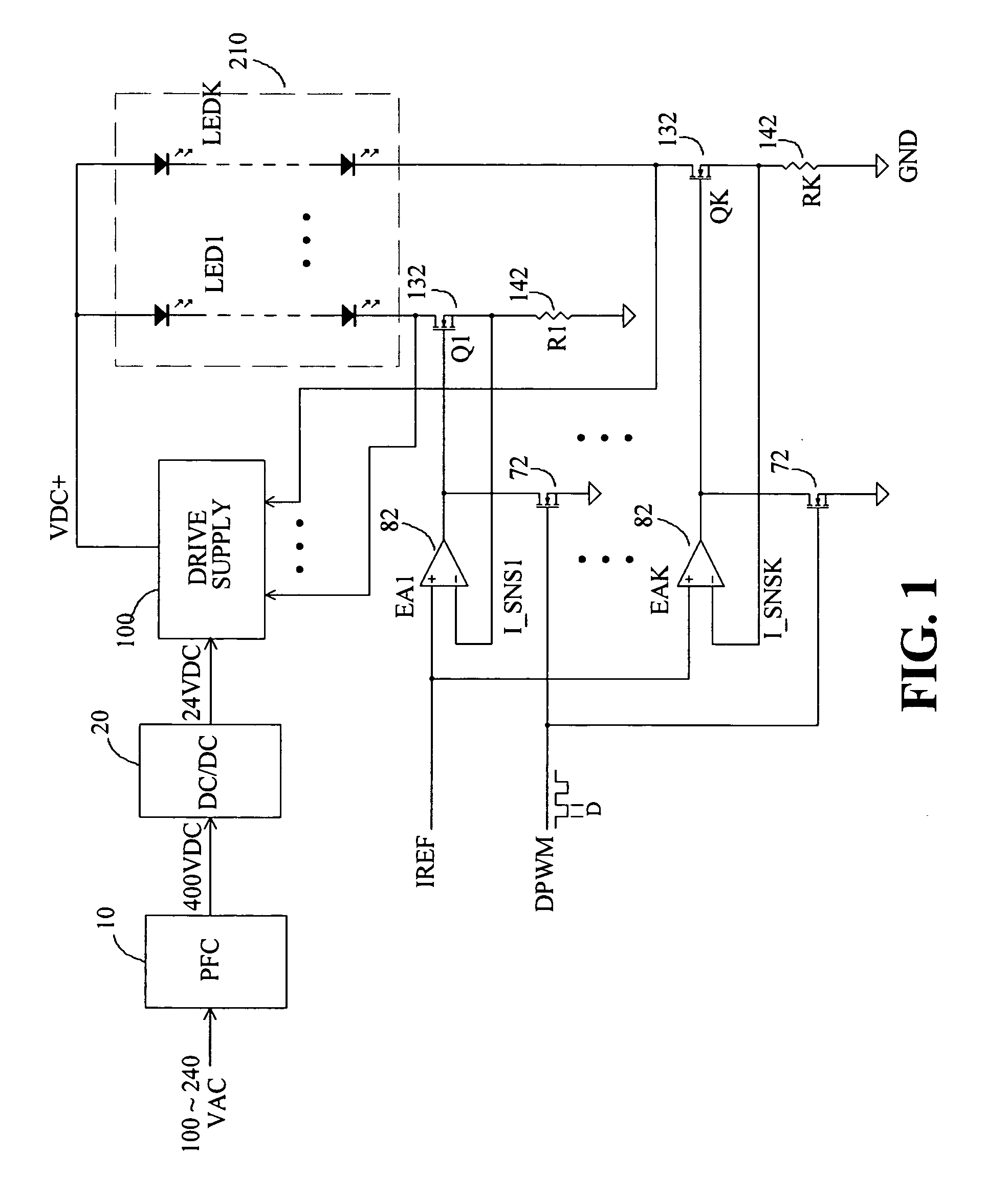

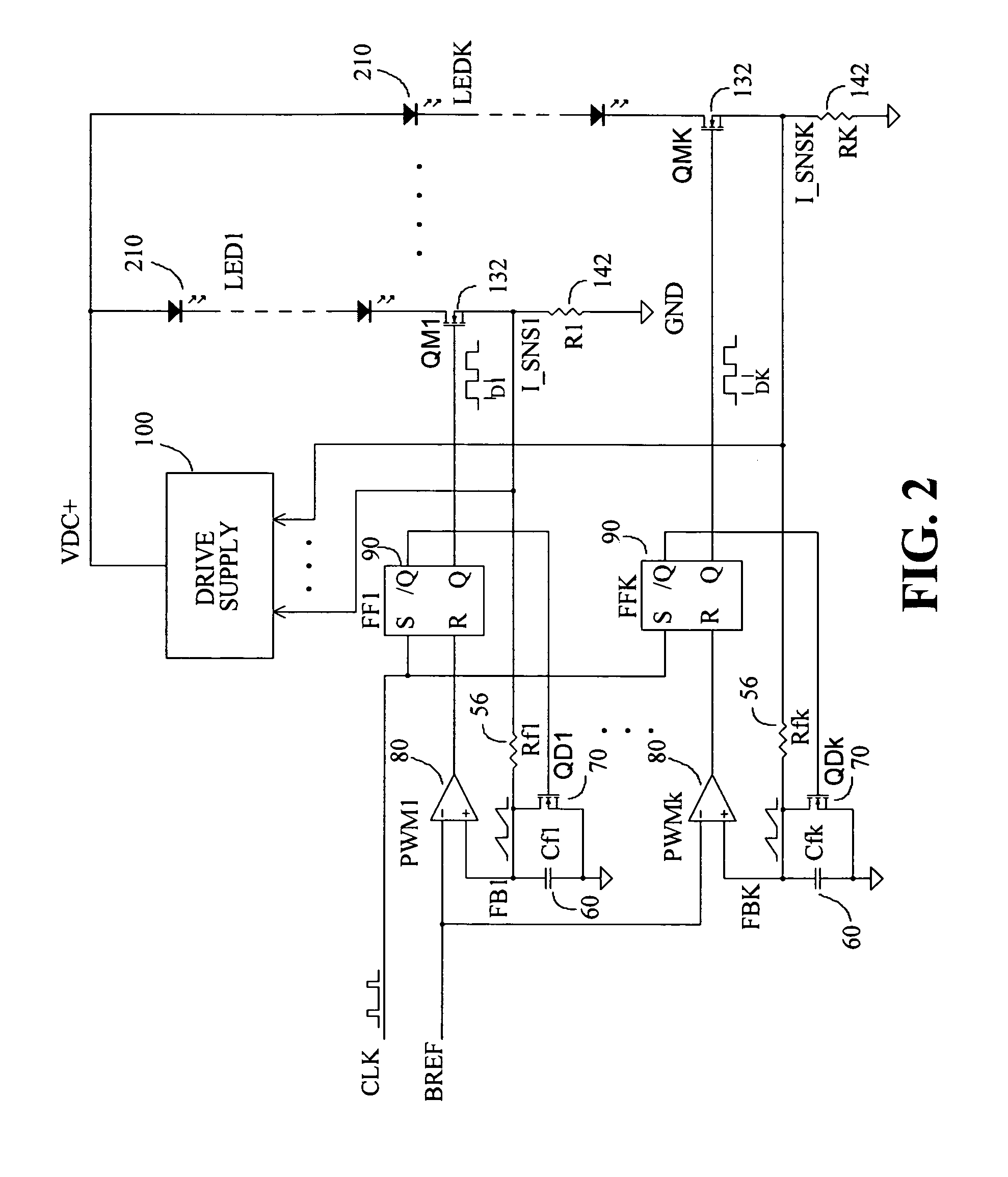

Method and apparatus for driving multiple LED devices

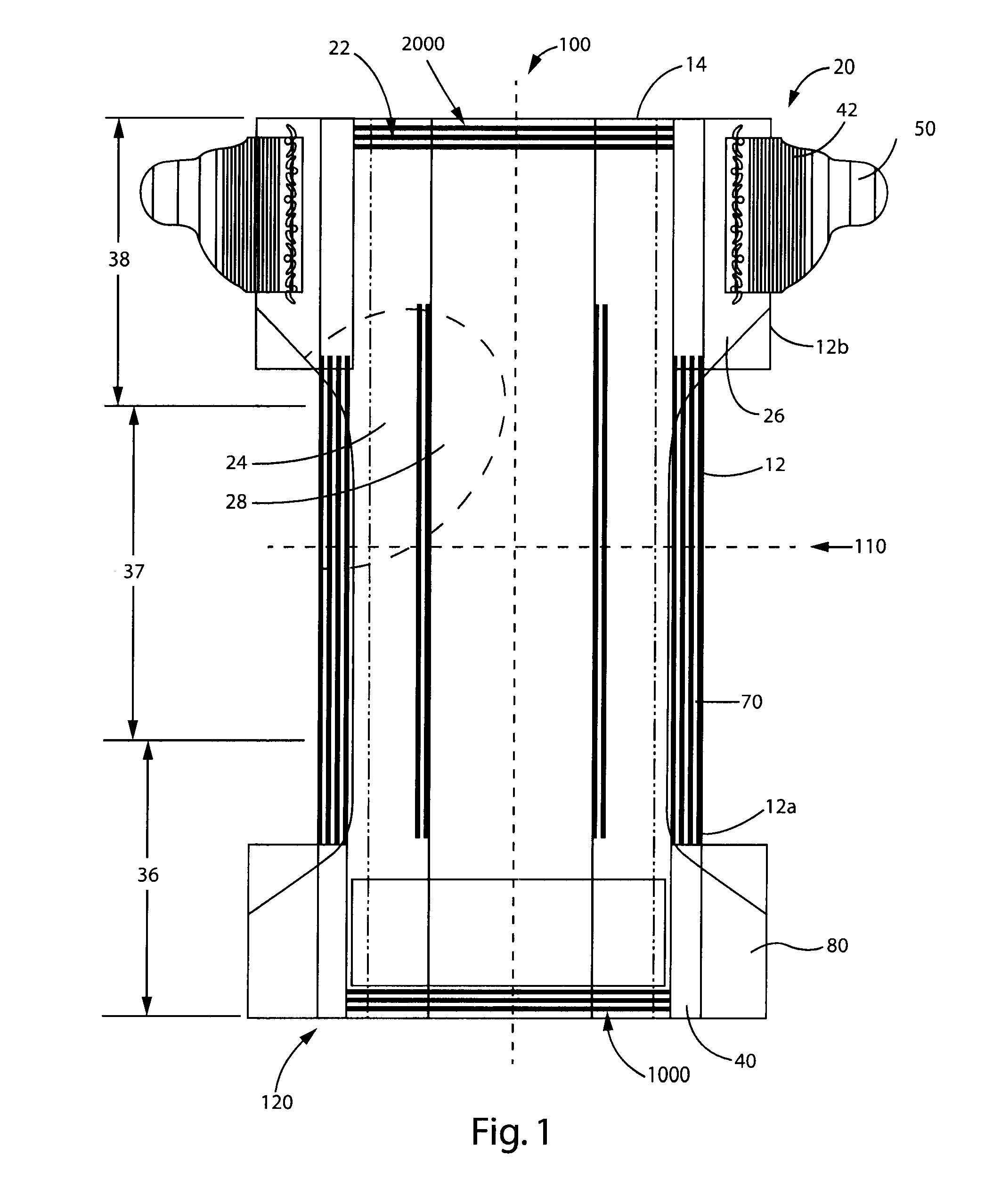

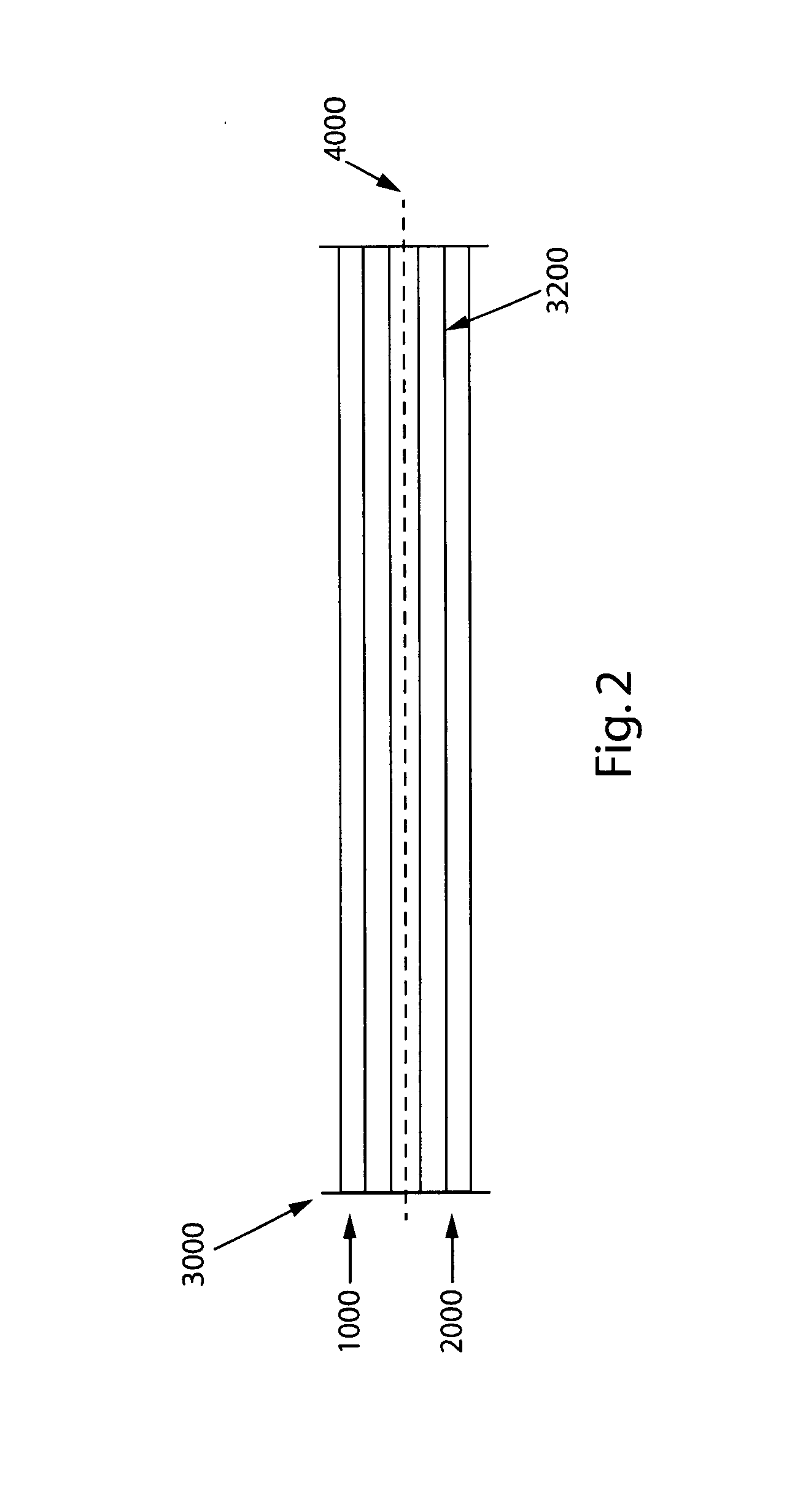

InactiveUS20110068700A1High efficiency circuit operationSimplified power conversion processElectrical apparatusElectroluminescent light sourcesBalancing networkEngineering

A series of methods of driving multiple LED devices with high efficiency balancing technique is disclosed. The regulation of the LED current is accomplished by switching operation to compensate the difference of the LED operating voltage. Reactive components are also employed to construct non-dissipative balancing networks to drive multiple LED strings with low losses. Additionally, a series of concept is presented to drive the LED devices from PFC voltage directly with low cost circuit architecture.

Owner:SUNTEC ENTERPRISES

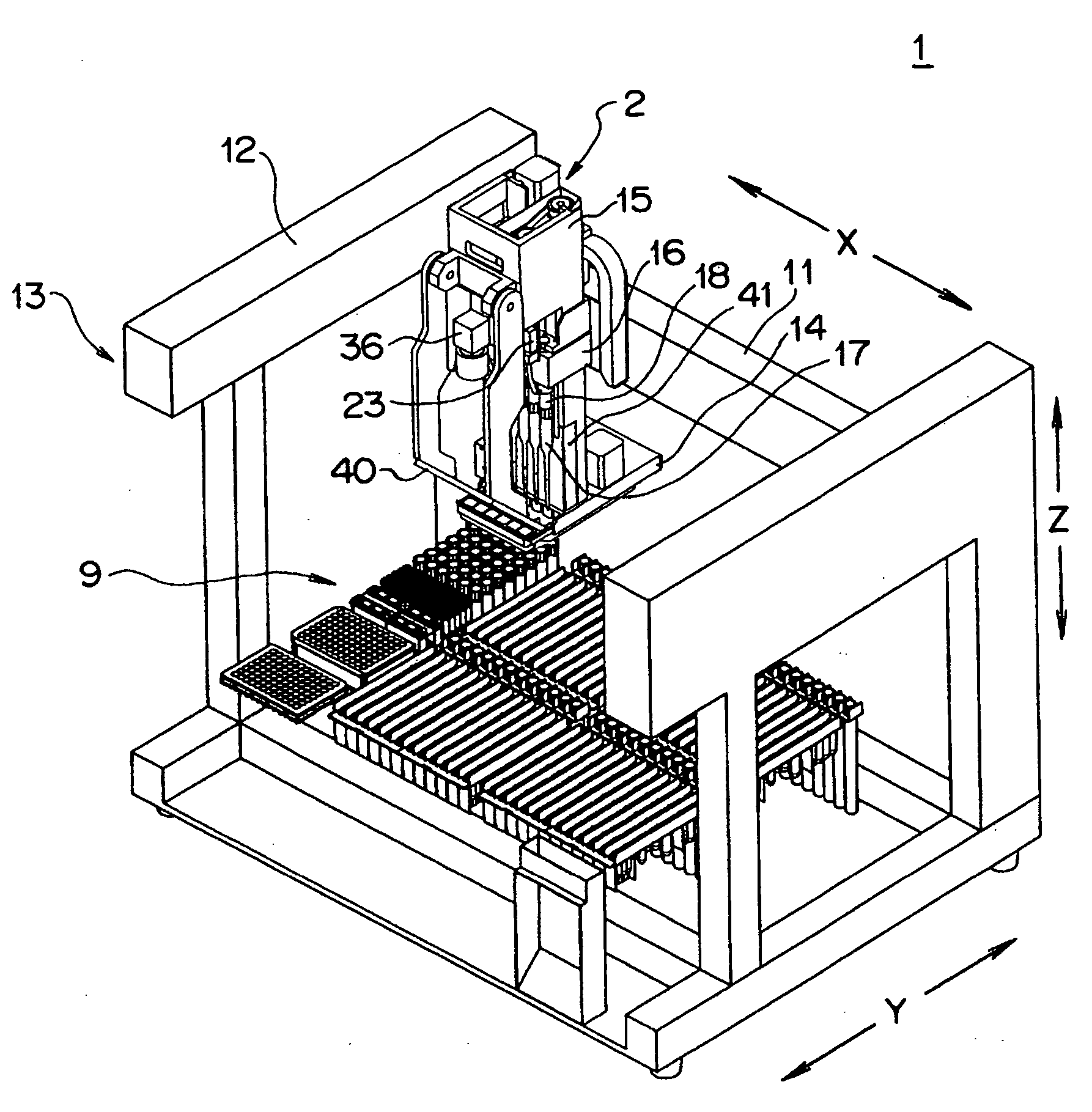

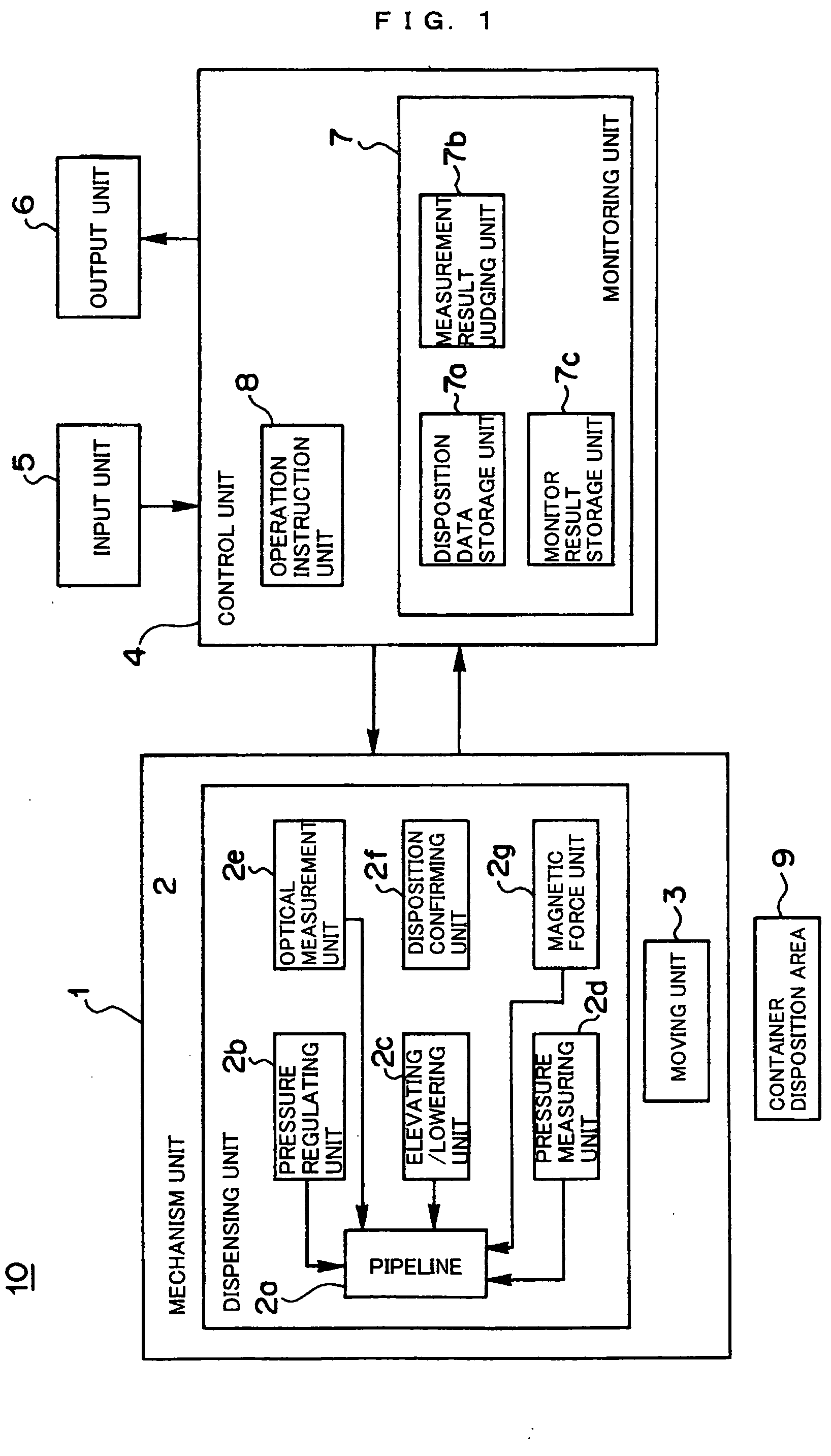

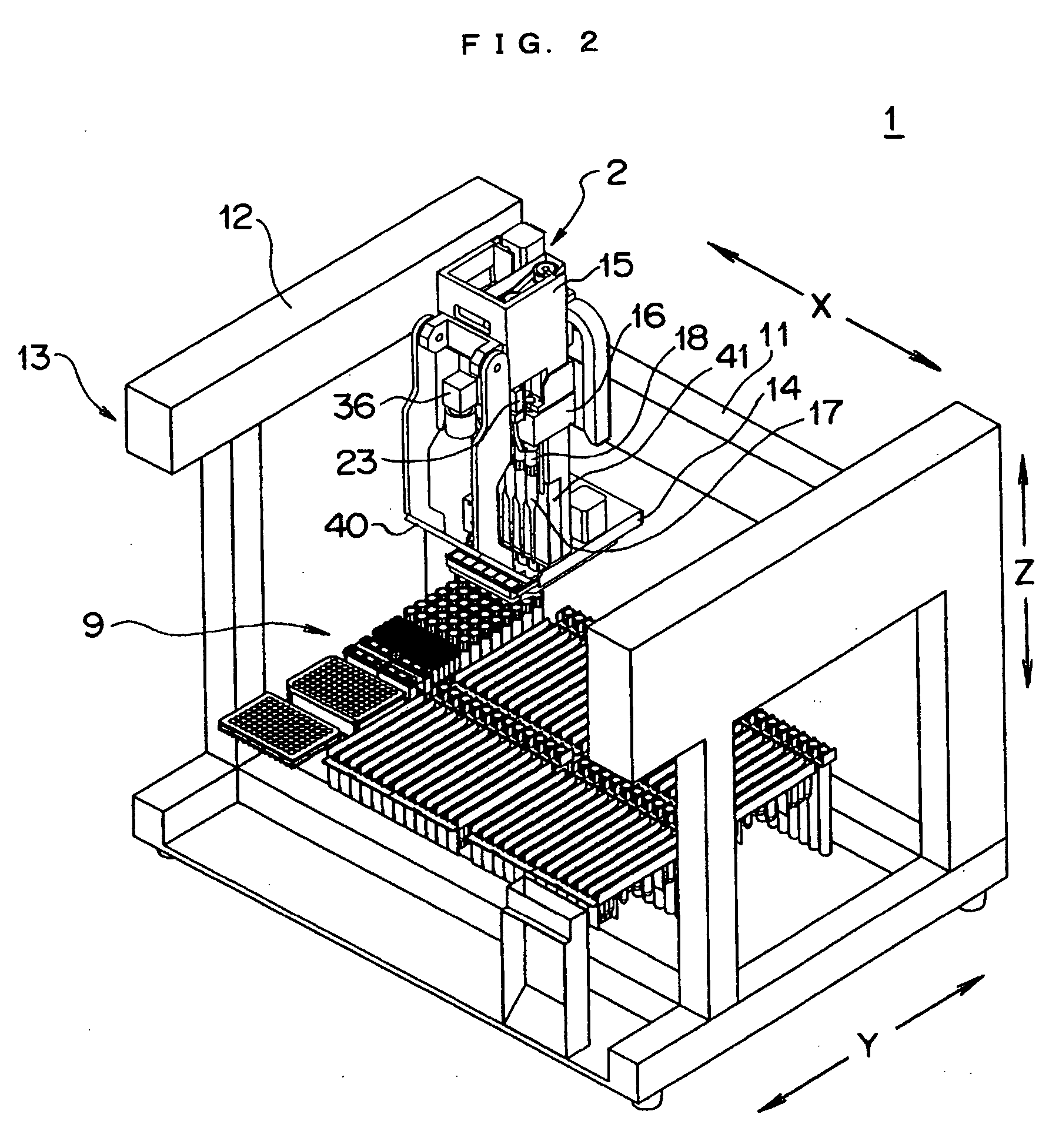

Monitoring function-equipped dispensing system and method of monitoring dispensing device

InactiveUS20060133965A1Ensure correct executionEfficient executionAnalysis using chemical indicatorsLaboratory glasswaresOptical measurementsMonitoring features

A monitoring function-equipped dispensing system and a method of monitoring the dispensing system wherein conditions in a pipeline can be identified accurately and precisely by not only optically measuring conditions in the pipeline, but performing other measurements reinforcing the former. The system comprises: one or more translucent or semi-translucent pipelines; one or more pressure regulating units which respectively regulate the pressures in the pipelines; an elevating / lowering unit which enables the pipelines to be elevated / lowered; a pressure measuring unit which measures the pressures in the respective pipelines when operation instructions are given to the pressure regulating unit; an optical measurement unit which optically measures the conditions of the pipelines above the container disposition area, when operations based on operation instructions including operation instructions to the pressure regulating unit are completed; and a monitoring unit which judges the conditions in the pipelines based on the operation instructions and measurement results of the pressure measuring unit and the optical measurement unit so as to obtain monitoring results that associate the judged results with respective pipelines and the operation instructions.

Owner:UNIVERSAL BIO RESEARCH CO LTD

Absorbent Article With Waistband Having Contraction

A disposable absorbent article comprising a first waist region, a second waist region, a crotch region disposed between the first waist region and second waist region; a first waist edge and a second waist edge; the disposable absorbent article comprising a first waistband near the first waist edge and a second waistband near the second waist edge, wherein the Front-to-Back Delta Chassis Contraction is greater than about 9.0%.

Owner:THE PROCTER & GAMBNE CO

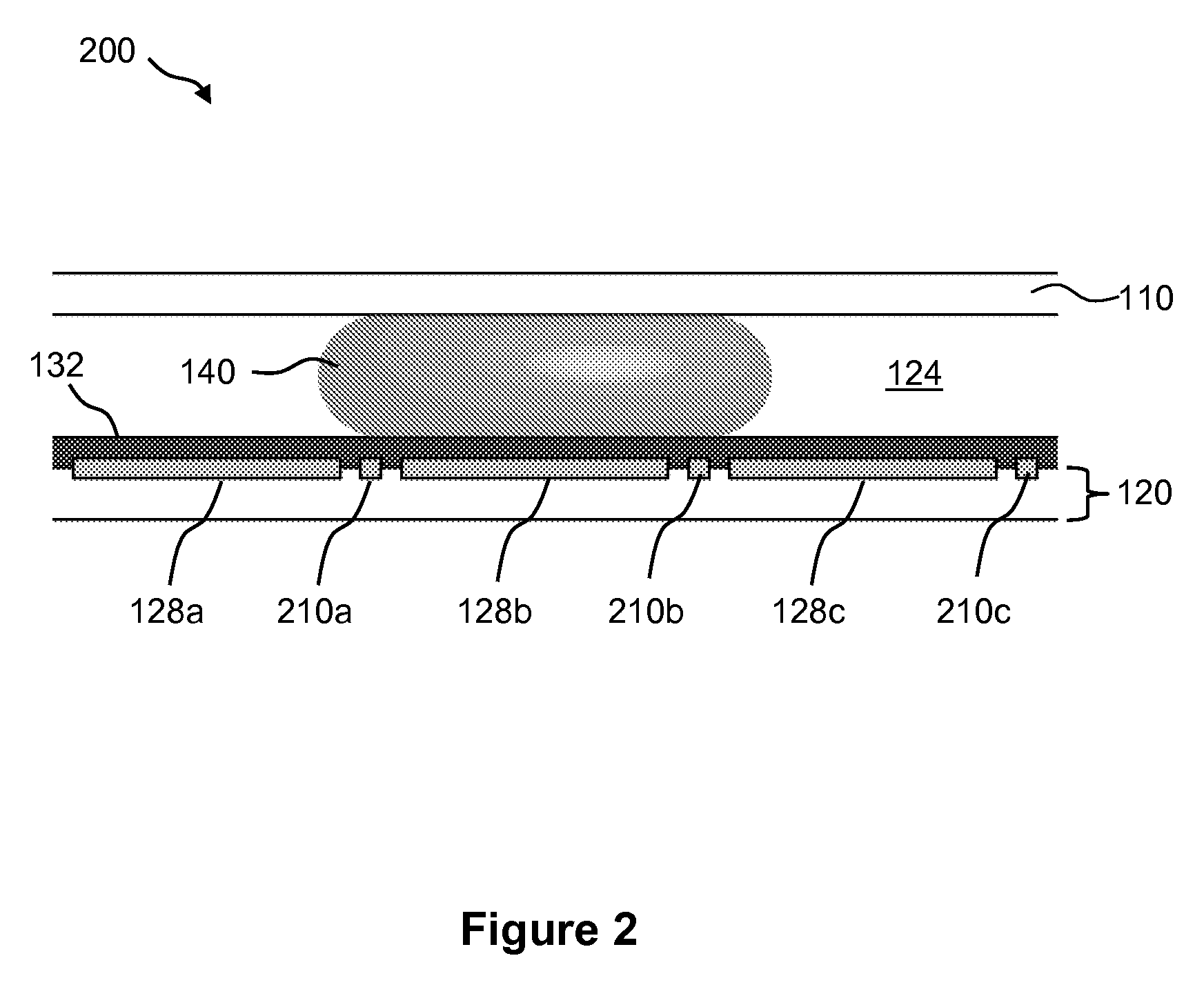

Droplet Actuator Configurations and Methods

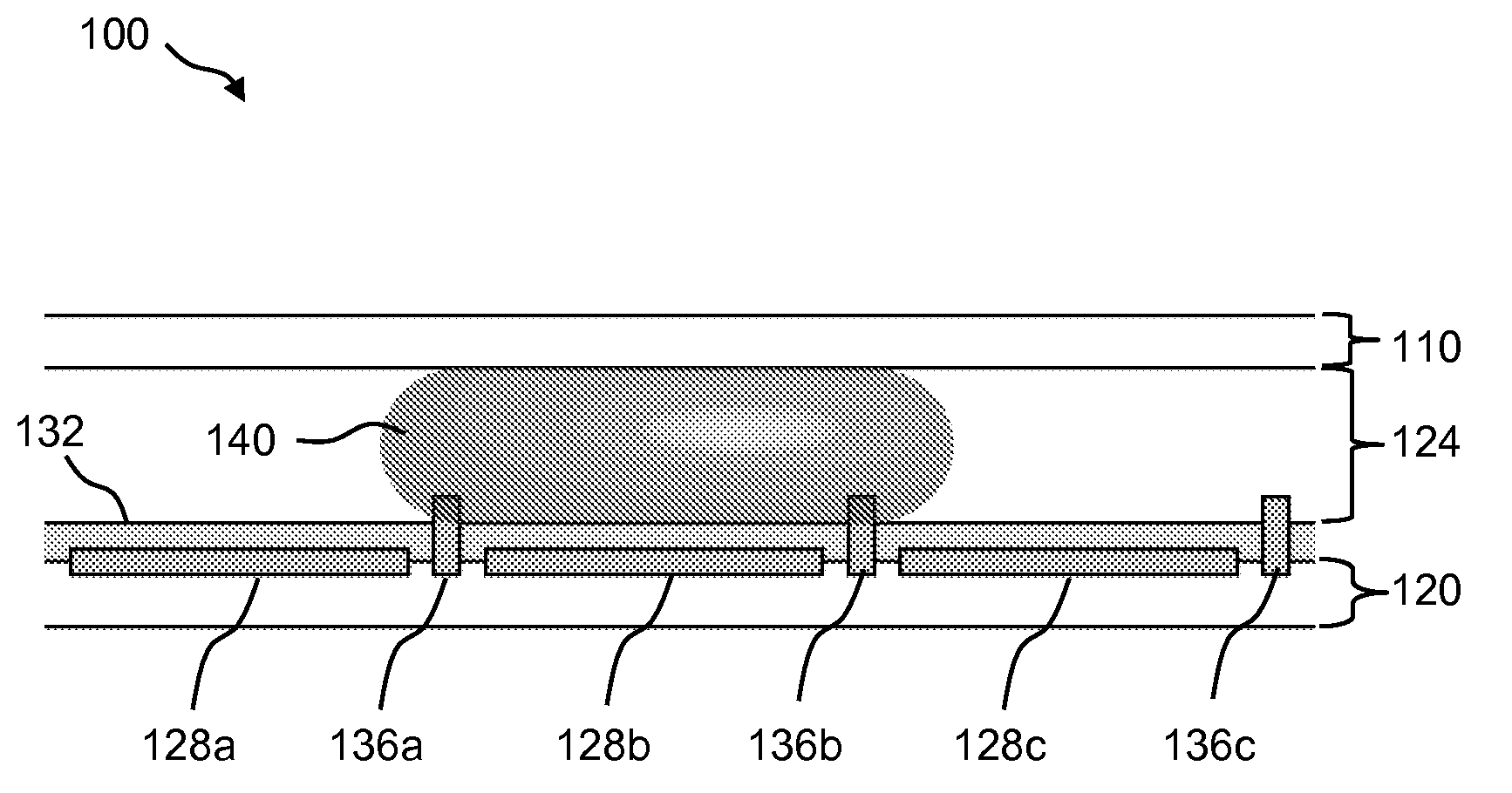

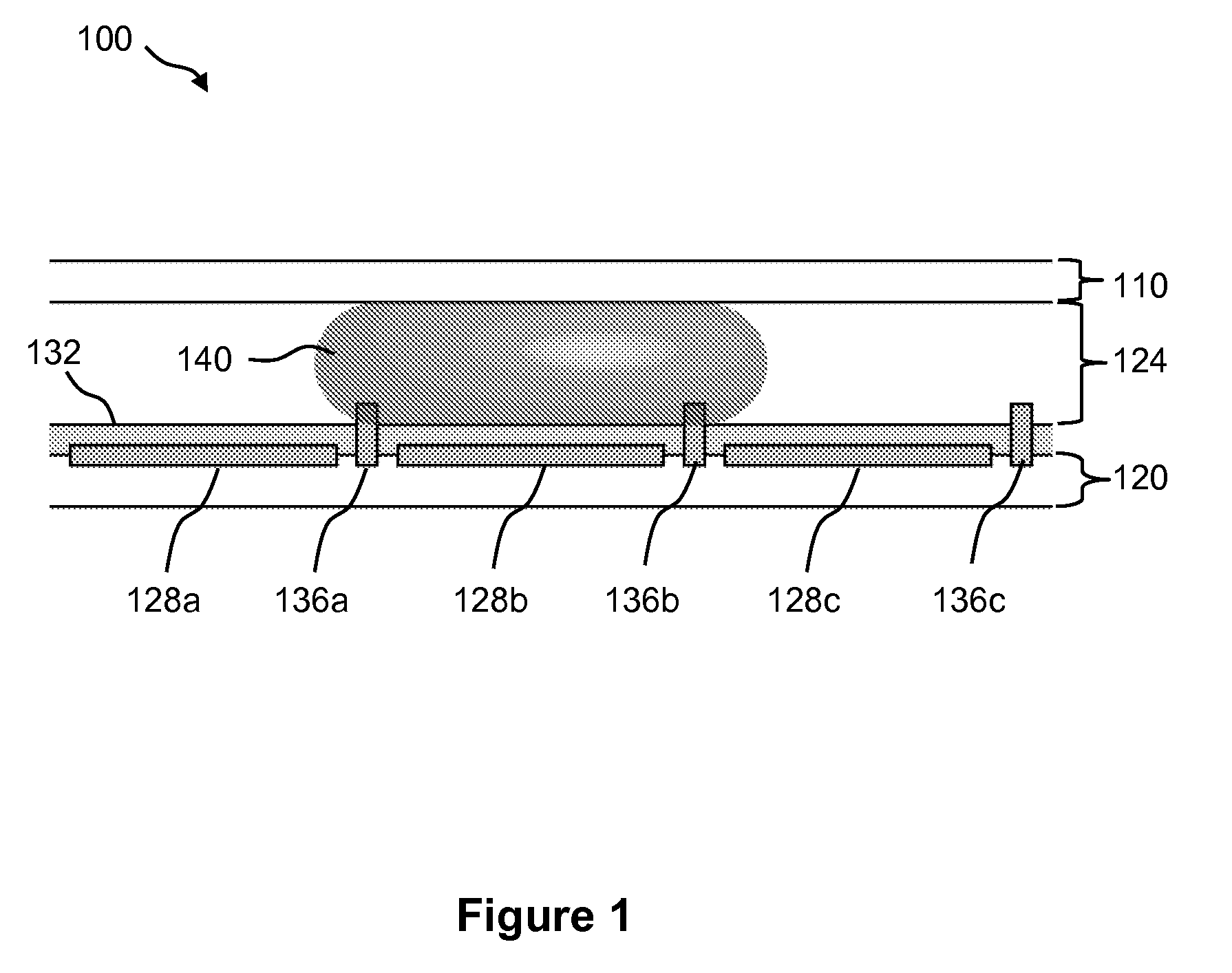

InactiveUS20100307917A1Easy to useFacilitates of propertyElectrostatic separatorsSludge treatmentEngineeringActuator

Droplet actuators for conducting droplet operations, such as droplet transport and droplet dispensing, are provided. In one embodiment, the droplet actuator may include a substrate including, droplet operations electrodes arranged for conducting droplet operations on a surface of the substrate; and reference electrodes associated with the droplet operations electrodes and extending above the surface of the substrate. Other embodiments of droplet actuators and methods of loading and using such droplet actuators are also provided.

Owner:ADVANCED LIQUID LOGIC

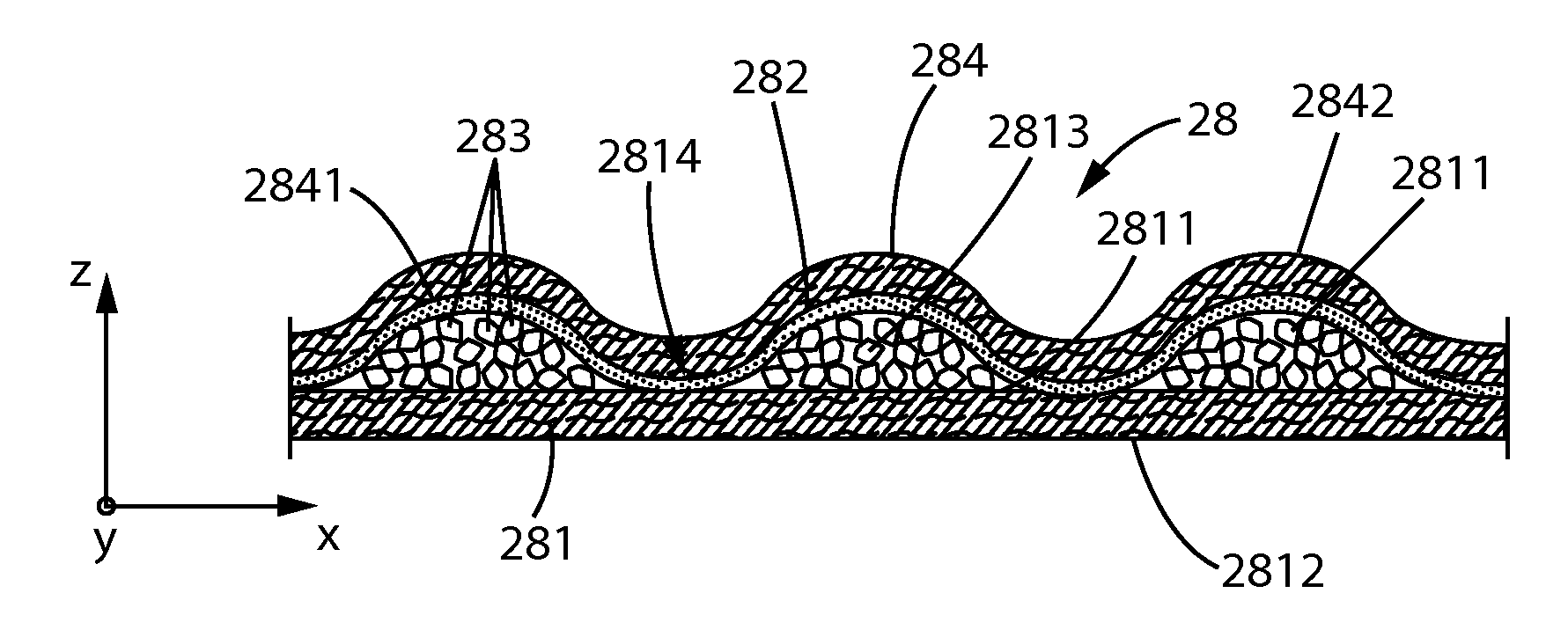

Absorbent Article With A Waistband Having Consolidation

A disposable absorbent article comprising a first waist region, a second waist region, a crotch region disposed between the first waist region and second waist region; a first waist edge and a second waist edge; the disposable absorbent article comprising at least one waistband, wherein the waistband is comprised of a laminate comprising a nonwoven material and at least one elastic strand, wherein the nonwoven material and the least one elastic strand are combined under a first strain and the waistband is attached to the disposable absorbent article under an applied waistband strain, wherein the difference between the first strain and the applied waistband strain results in a waistband having a Full Waistband Consolidation of greater than about 95%.

Owner:THE PROCTER & GAMBLE COMPANY

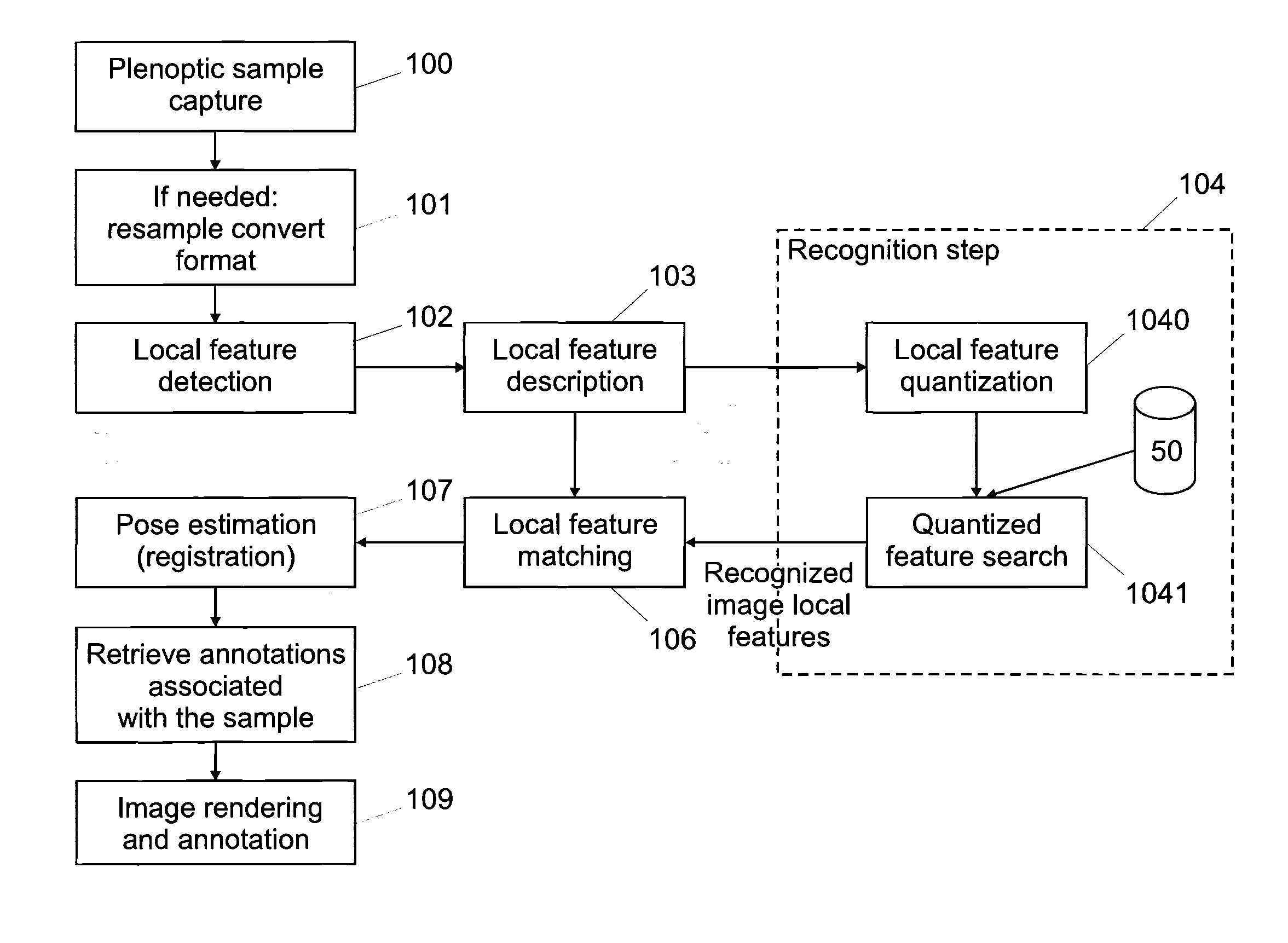

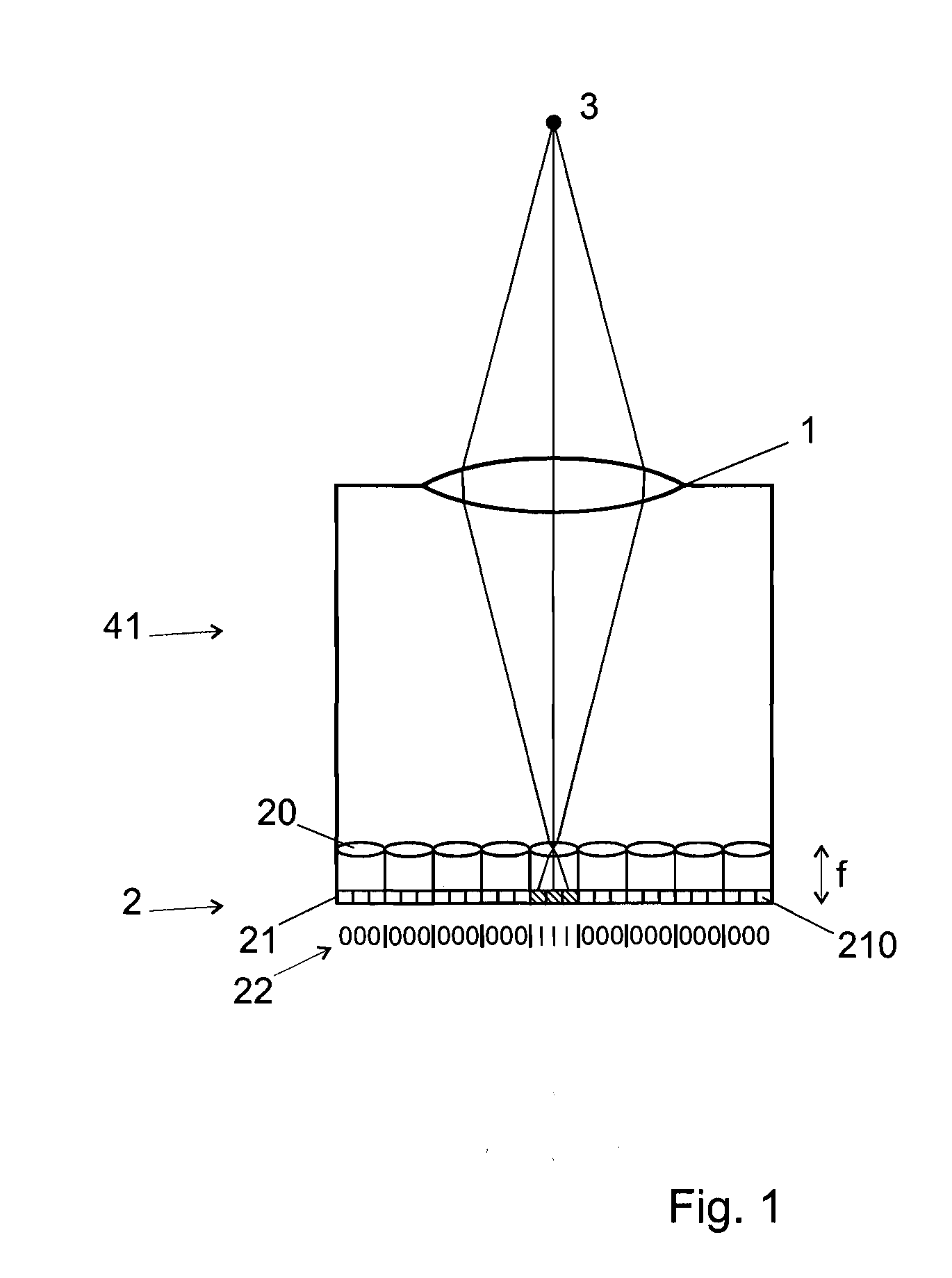

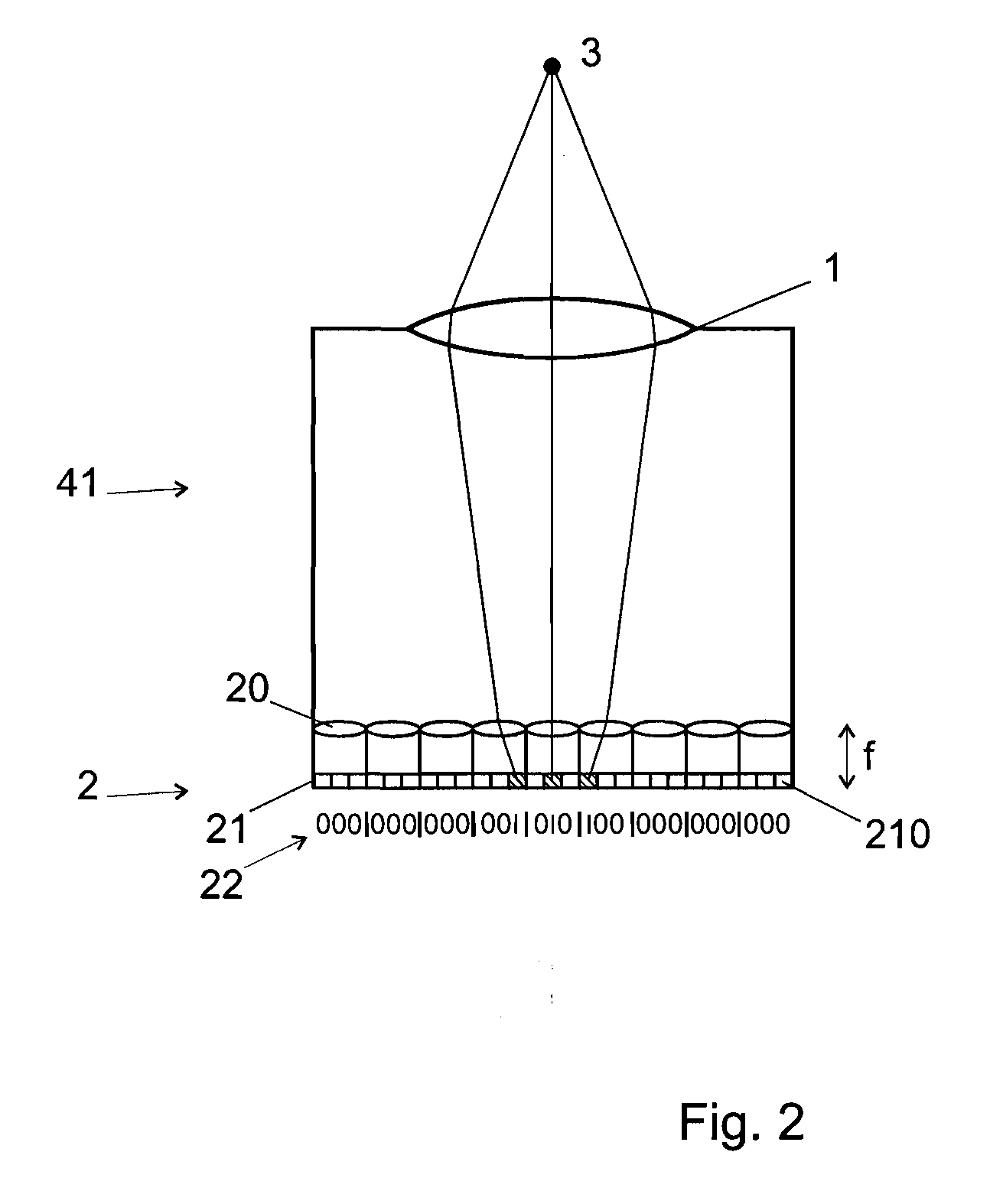

Annotation method and apparatus

ActiveUS20140098191A1Low costEasy to identifyTelevision system detailsColor television detailsImage captureLight field

The present invention relates to an annotating method comprising the steps of:capturing (100) data representing a light field with a plenoptic image capture device (4);matching (101) the captured data with a corresponding reference data;retrieving an annotation associated with an element of said reference data (102);rendering (103) a view generated from said captured data and including at least one annotation.

Owner:BIGTINCAN HLDG LTD

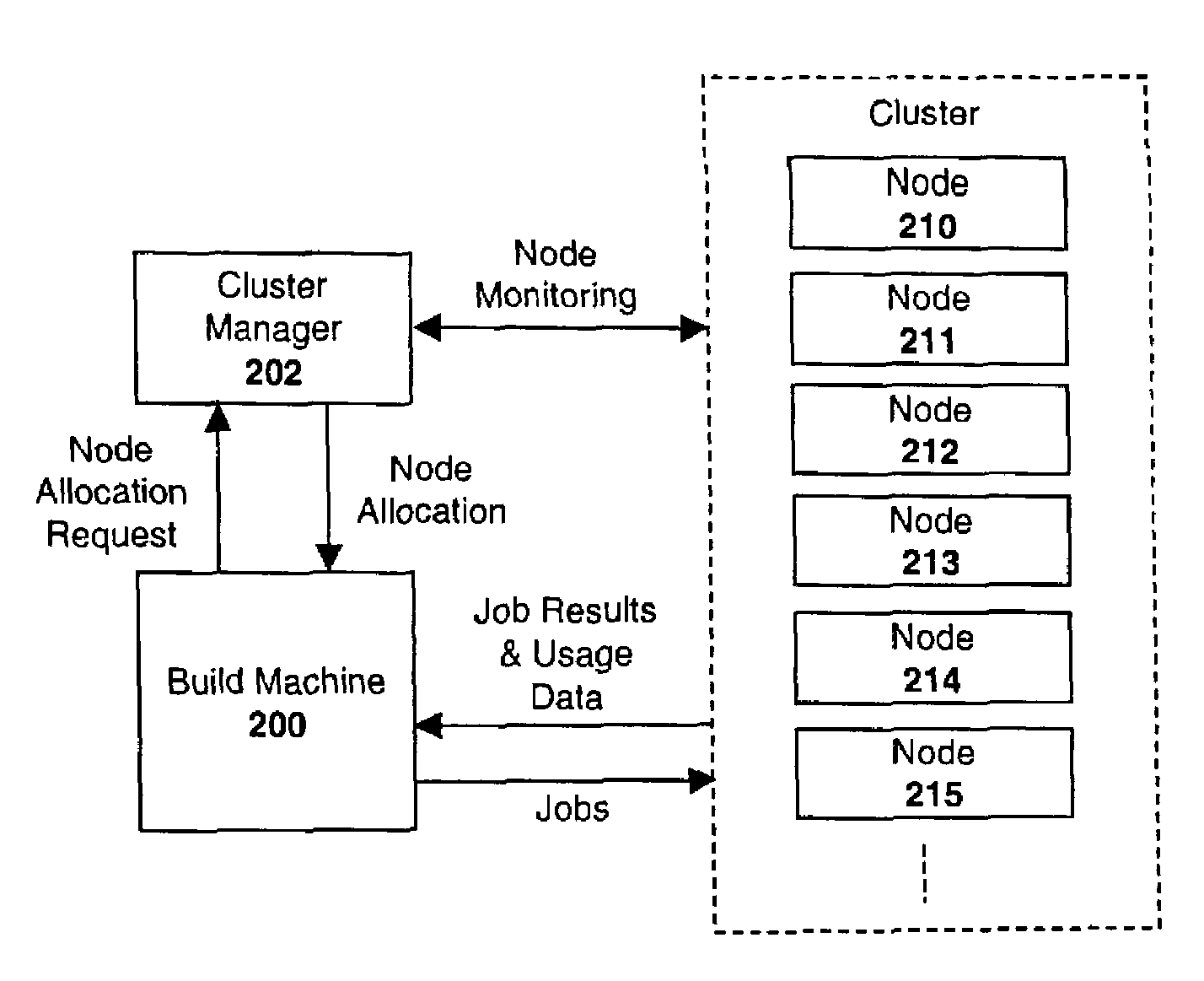

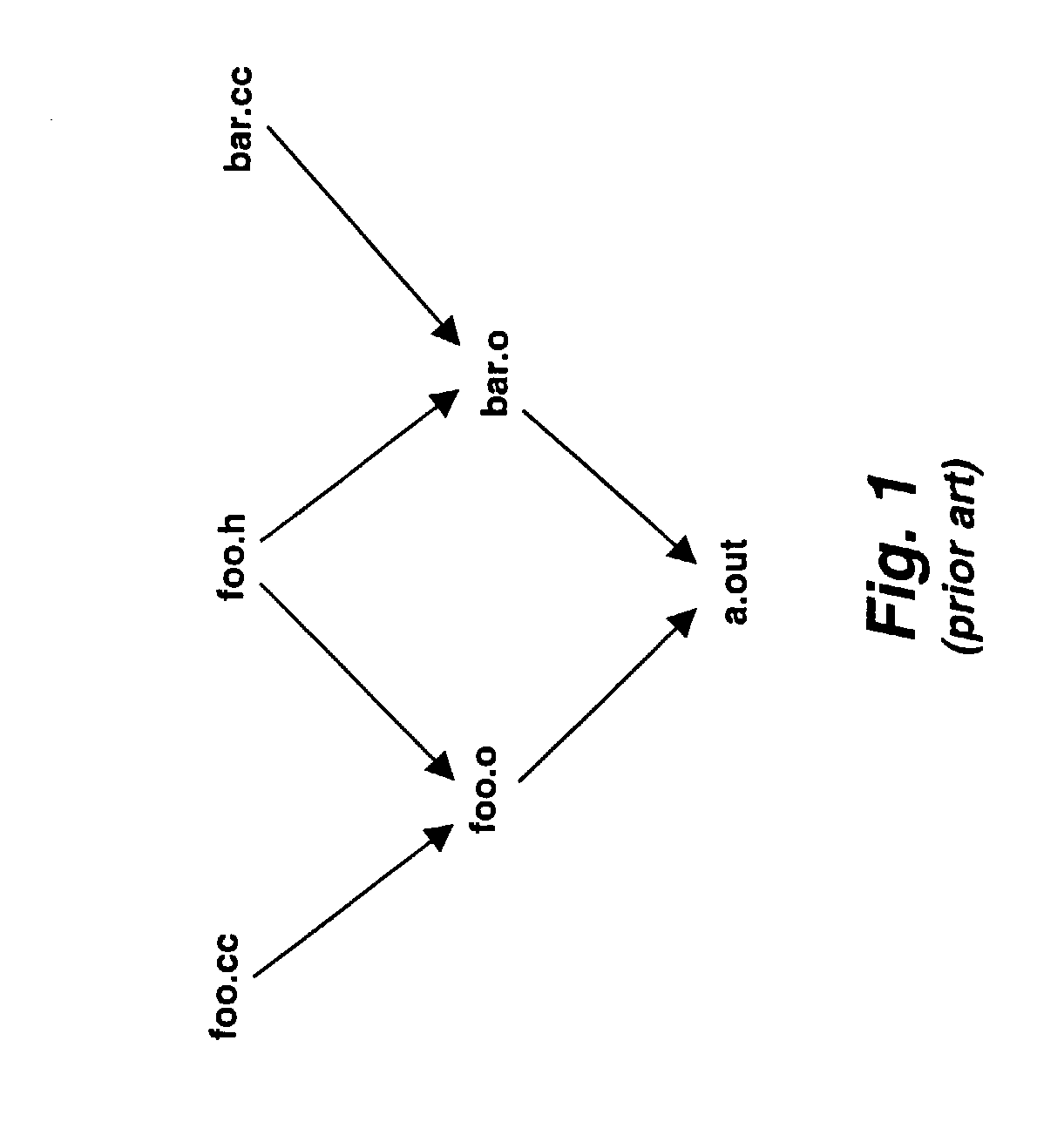

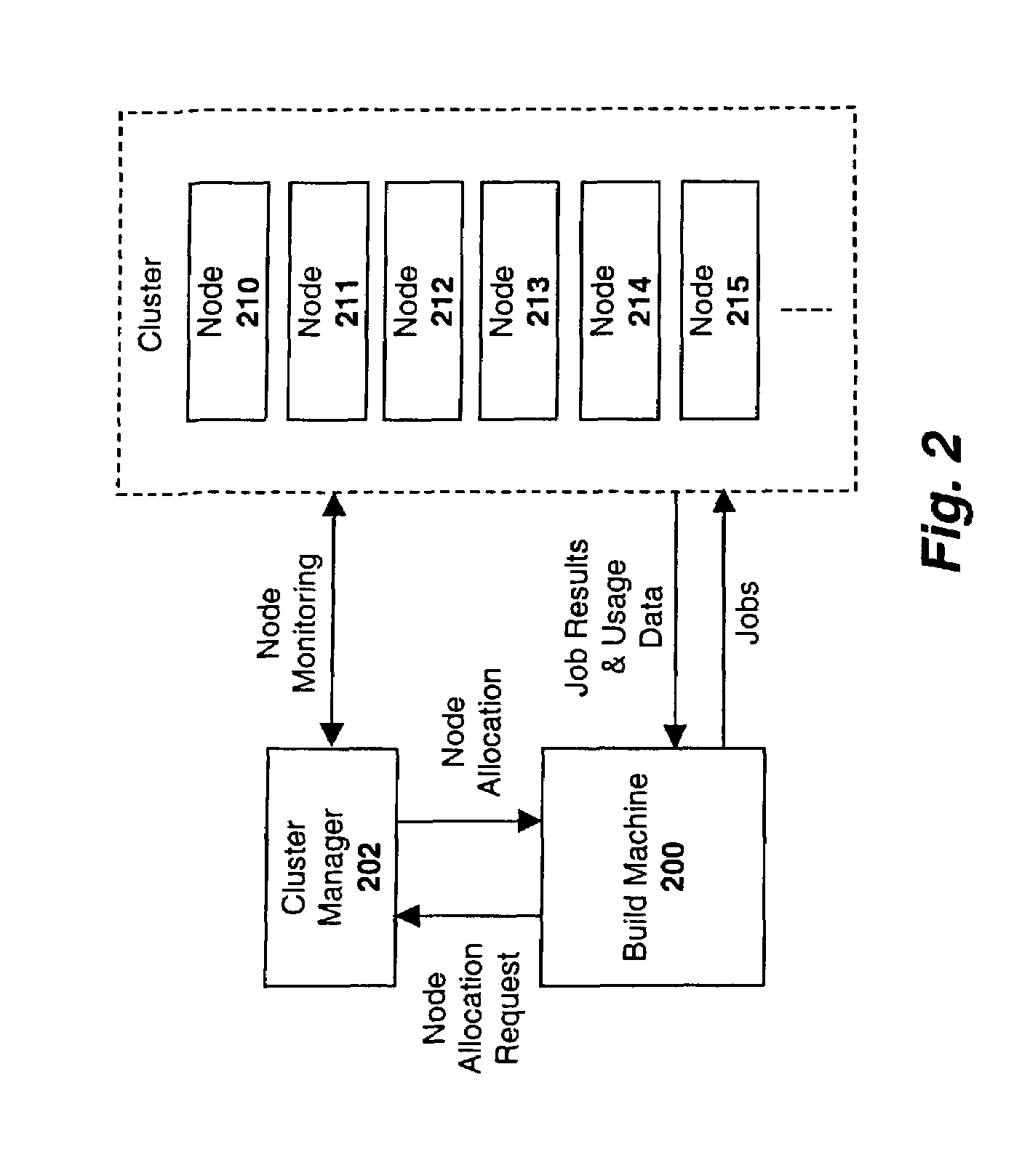

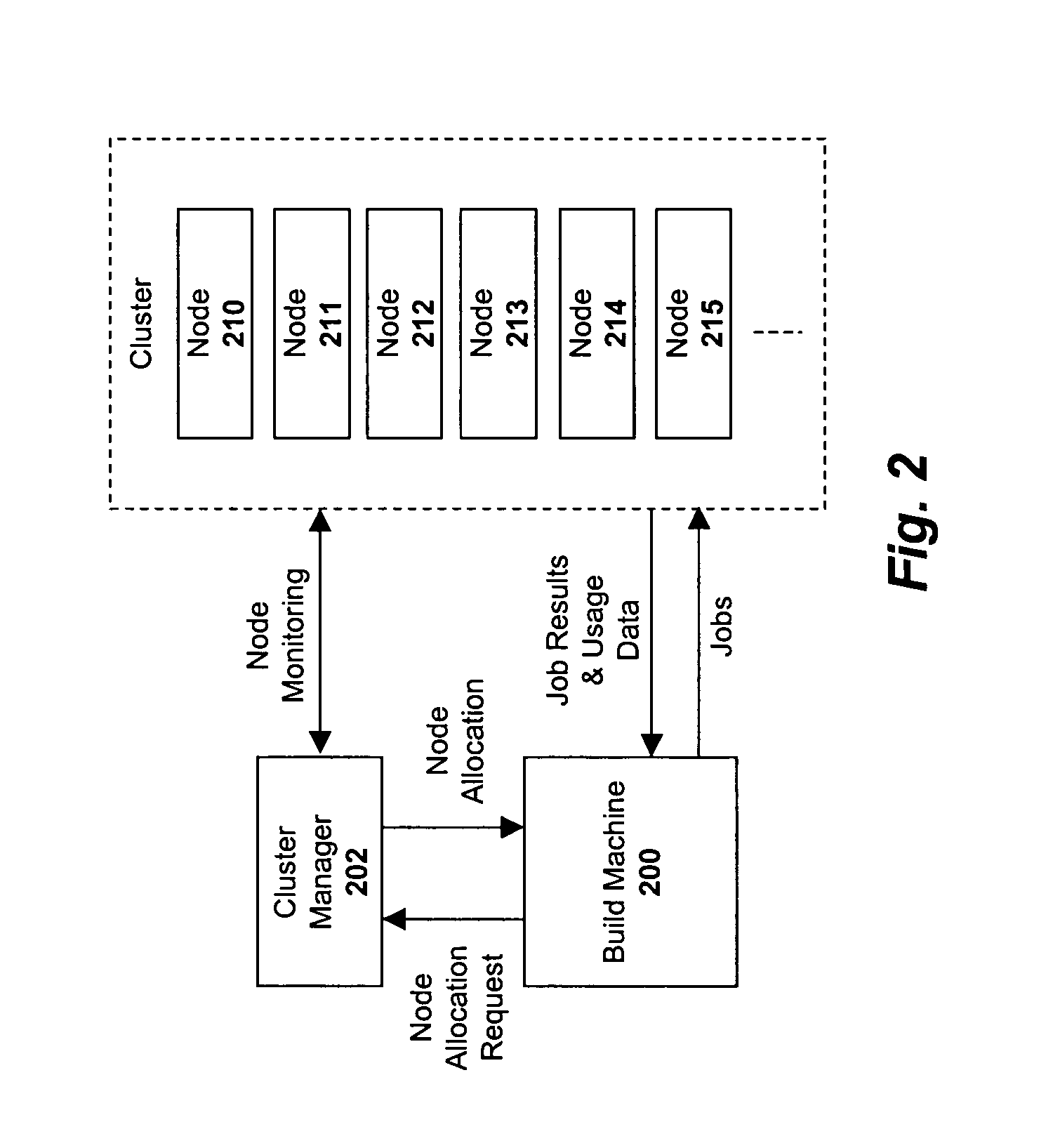

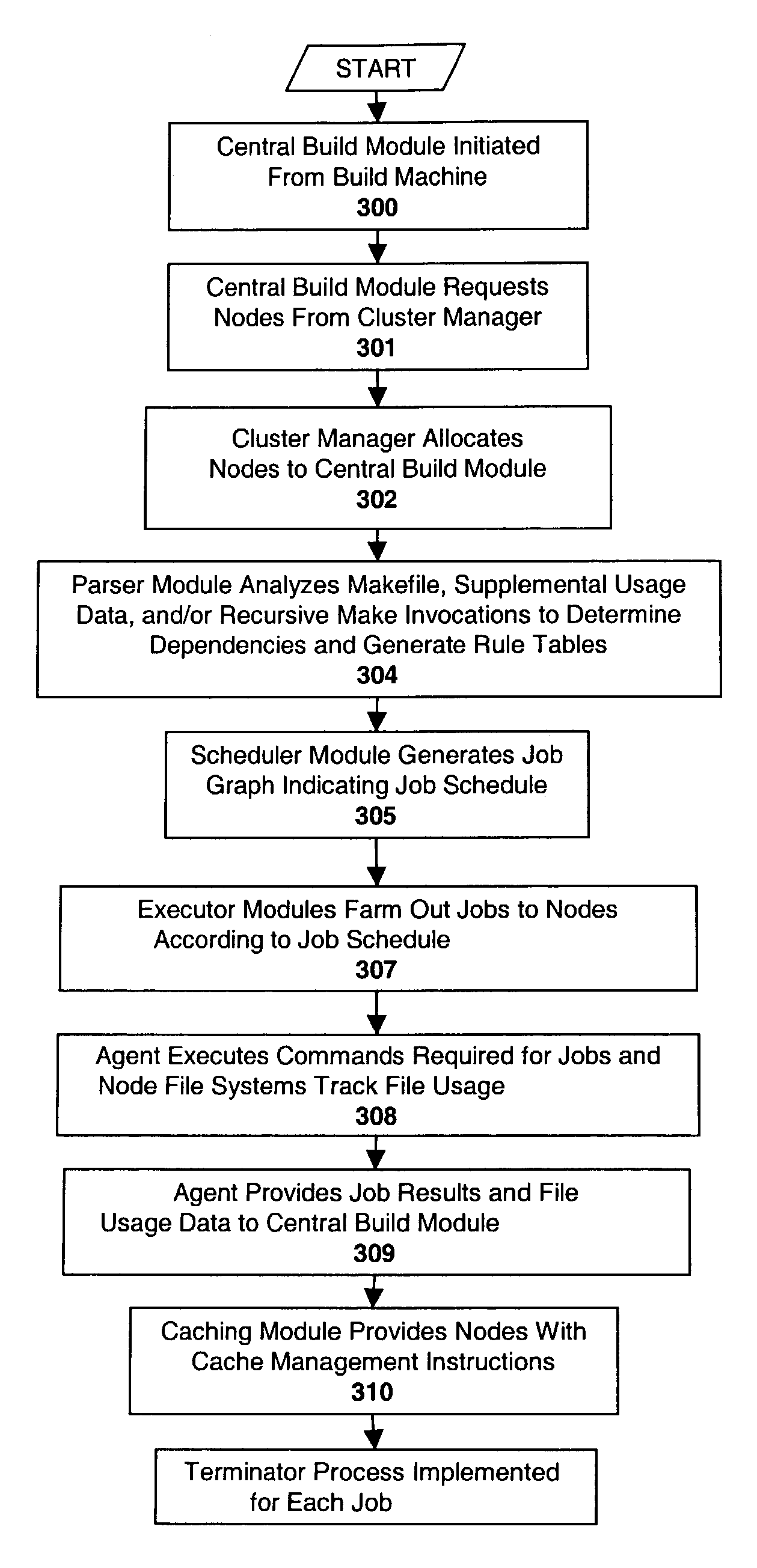

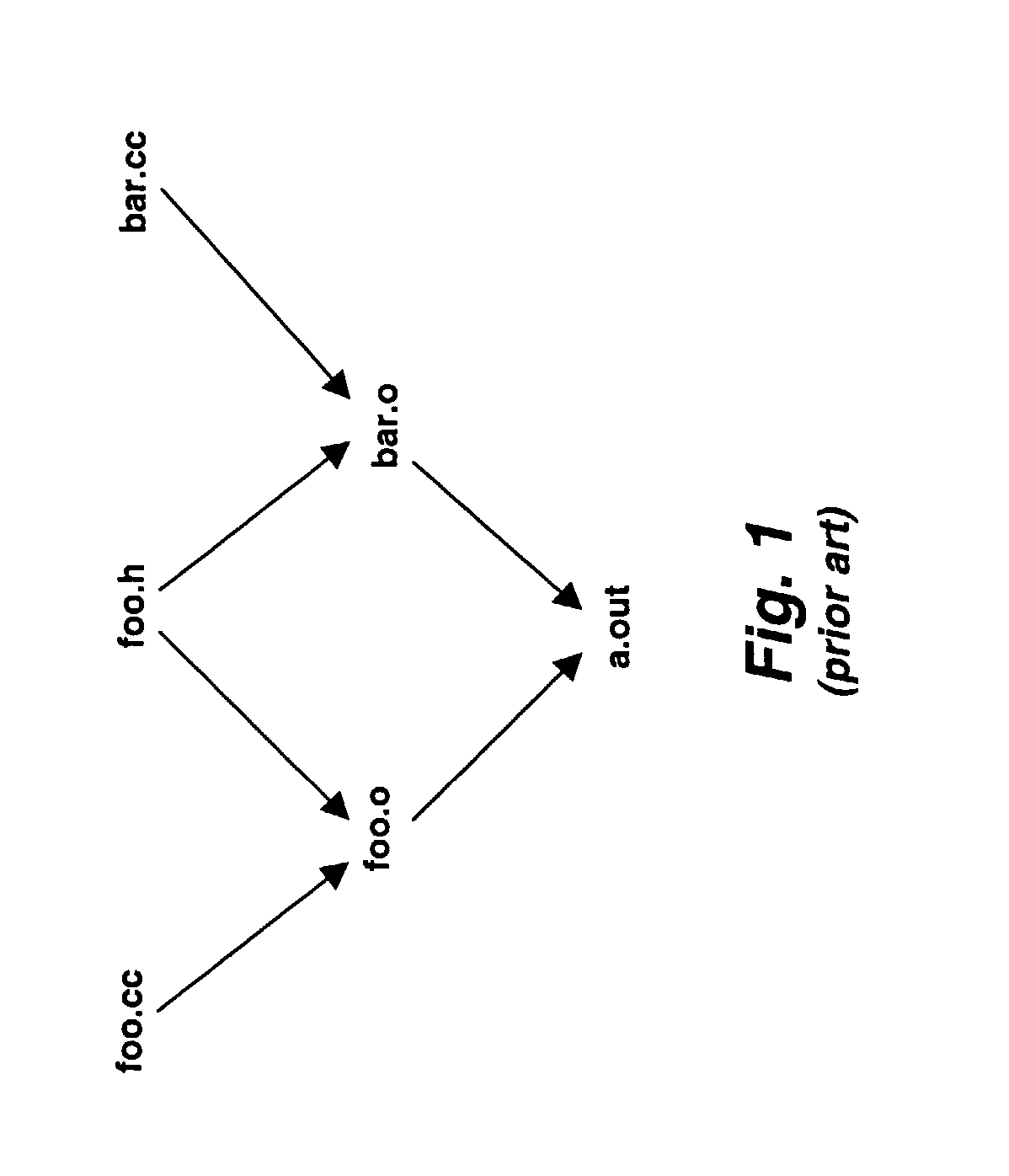

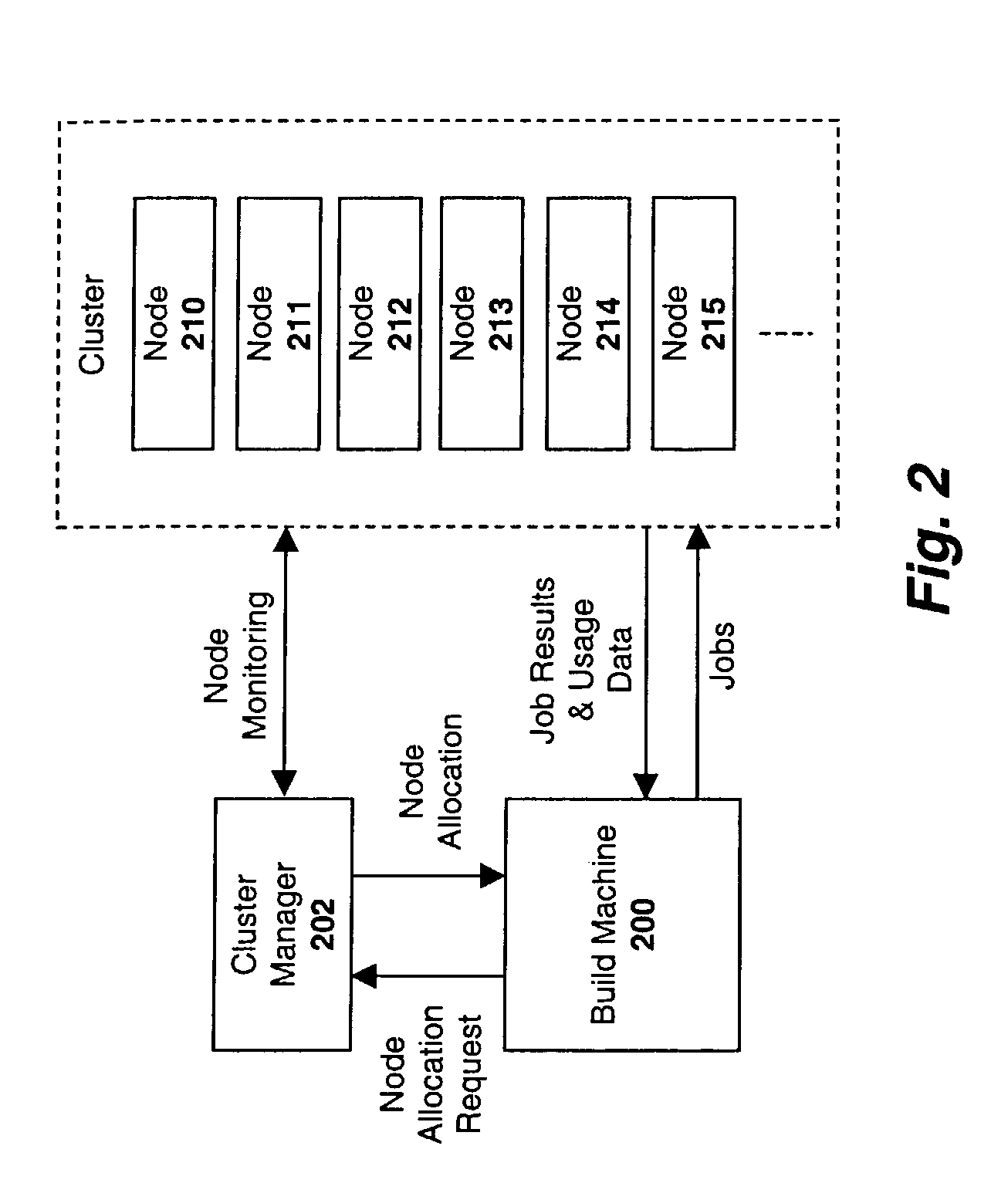

Architecture and method for executing program builds

ActiveUS7676788B1BuildIncreased riskVersion controlDigital computer detailsComputer scienceOperating system

Owner:CLOUDEBEES INC

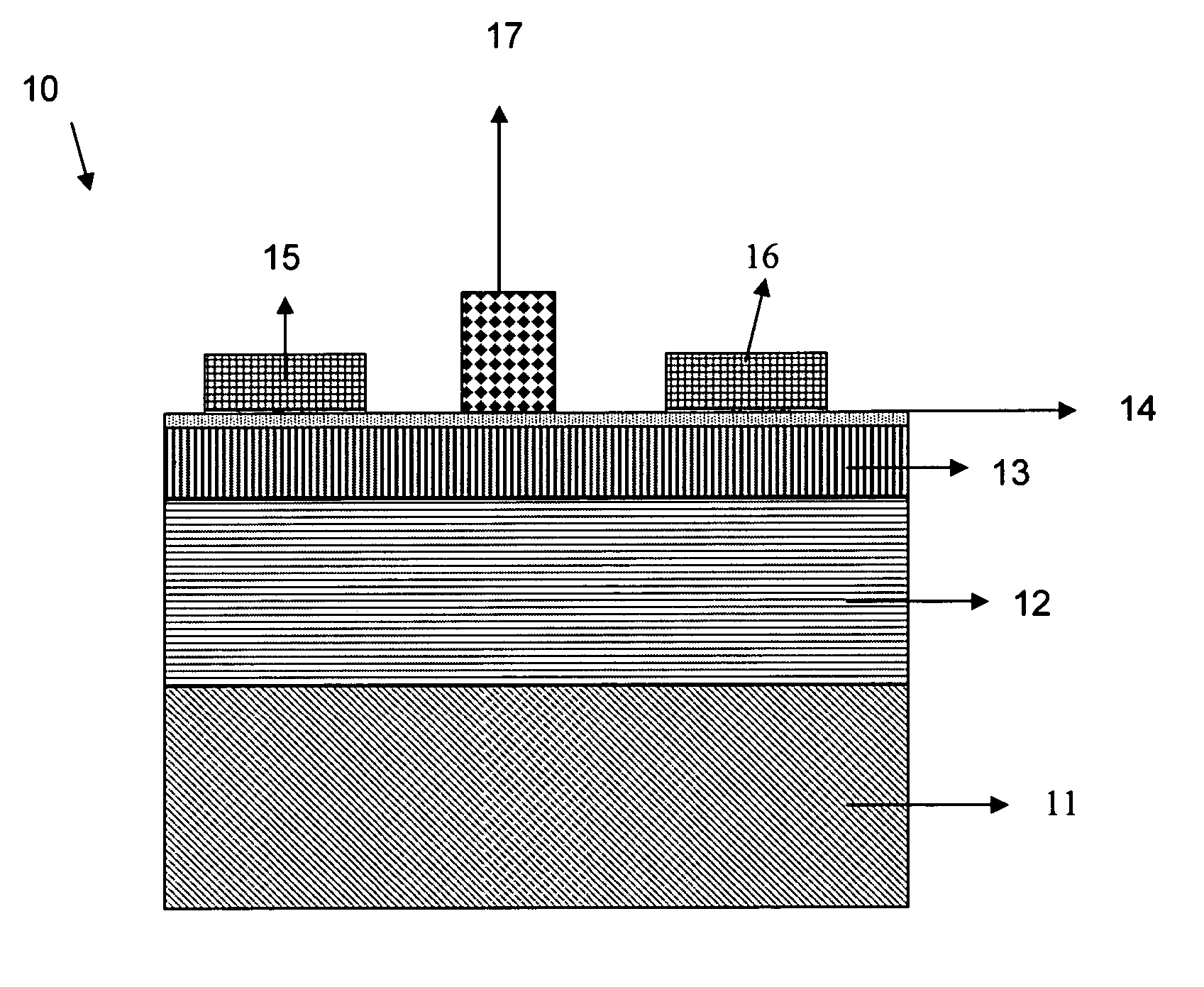

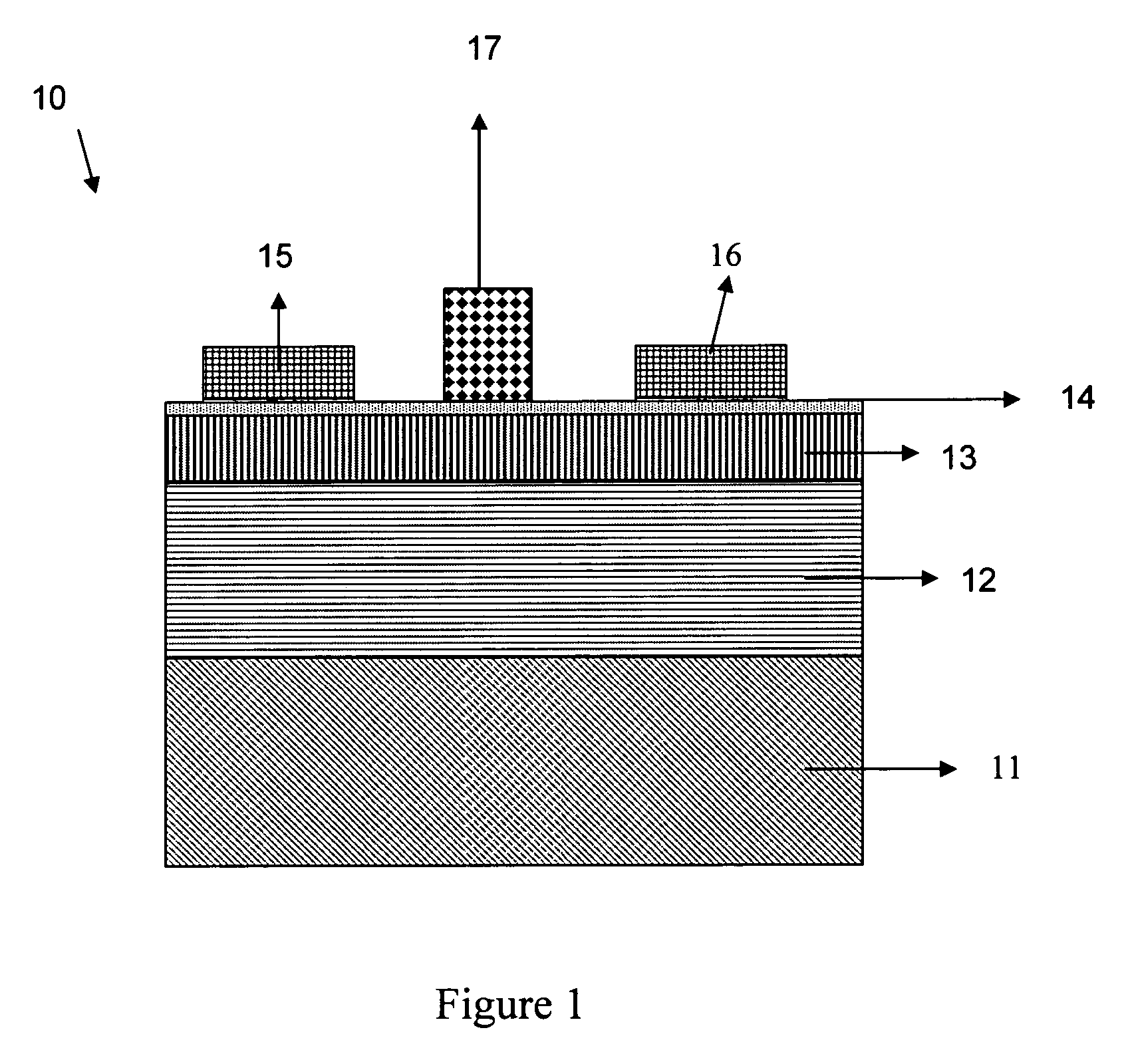

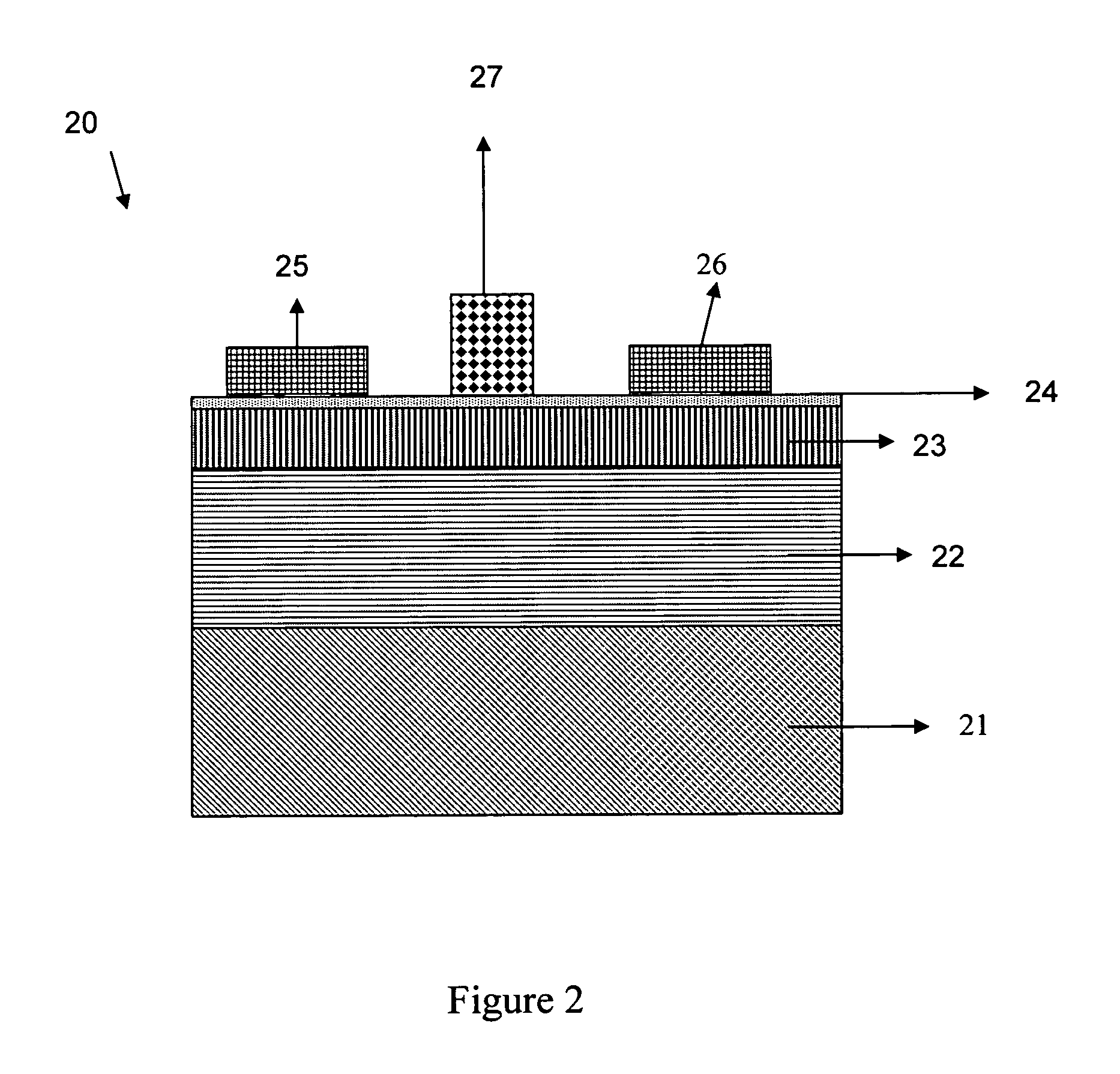

AlGaN/GaN high electron mobility transistor devices

ActiveUS20060006414A1Avoid crackingReduce the appearance of cracksSolid-state devicesSemiconductor/solid-state device manufacturingMESFETCooling down

The present invention recites a new method for manufacturing Group III-N field-effect devices, such as HEMT, MOSHFET, MISHFET devices or MESFET devices, grown by Metal-Organic Vapor Phase Expitaxy, with higher performance (power), by covering the surface with a thin SiN layer on the top AlGaN layer, in the reactor where the growth takes place at high temperature, prior cooling down the structure and loading the sample out of the reactor, as well as a method to produce some HEMT transistors on those heterostructures, by depositing the contact on the surface without any removal of the SiN layer by MOCVD. The present invention recites also a device.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

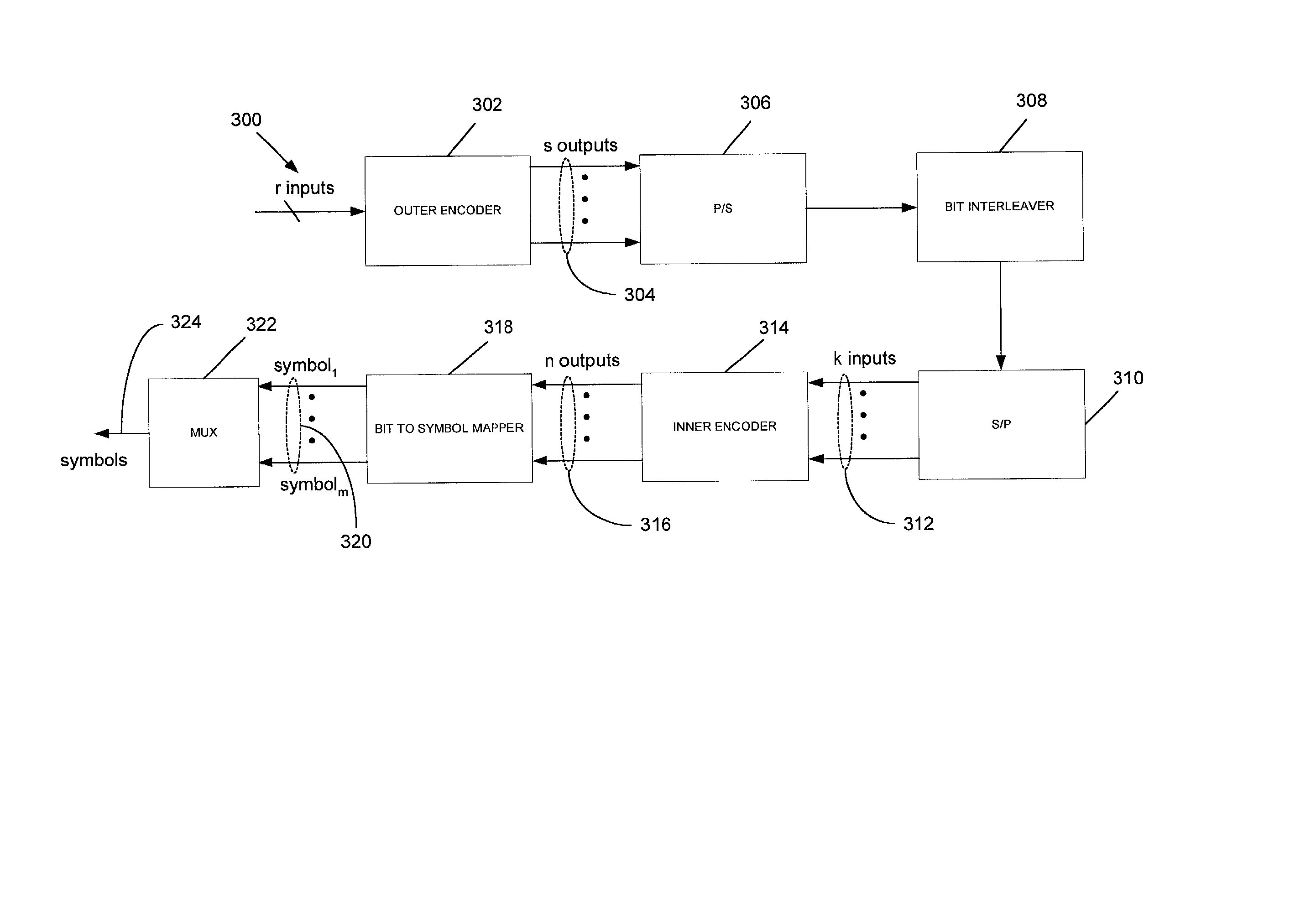

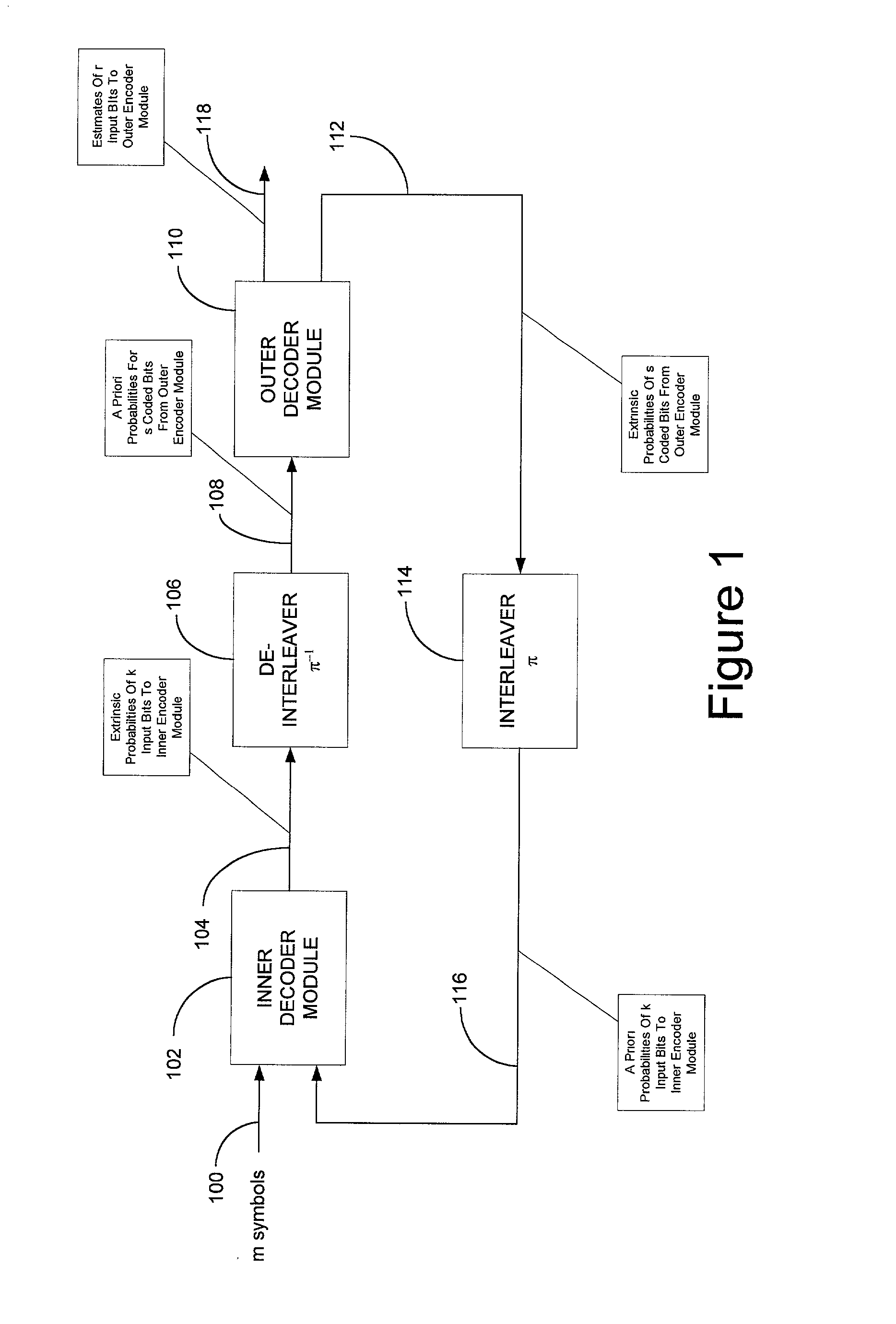

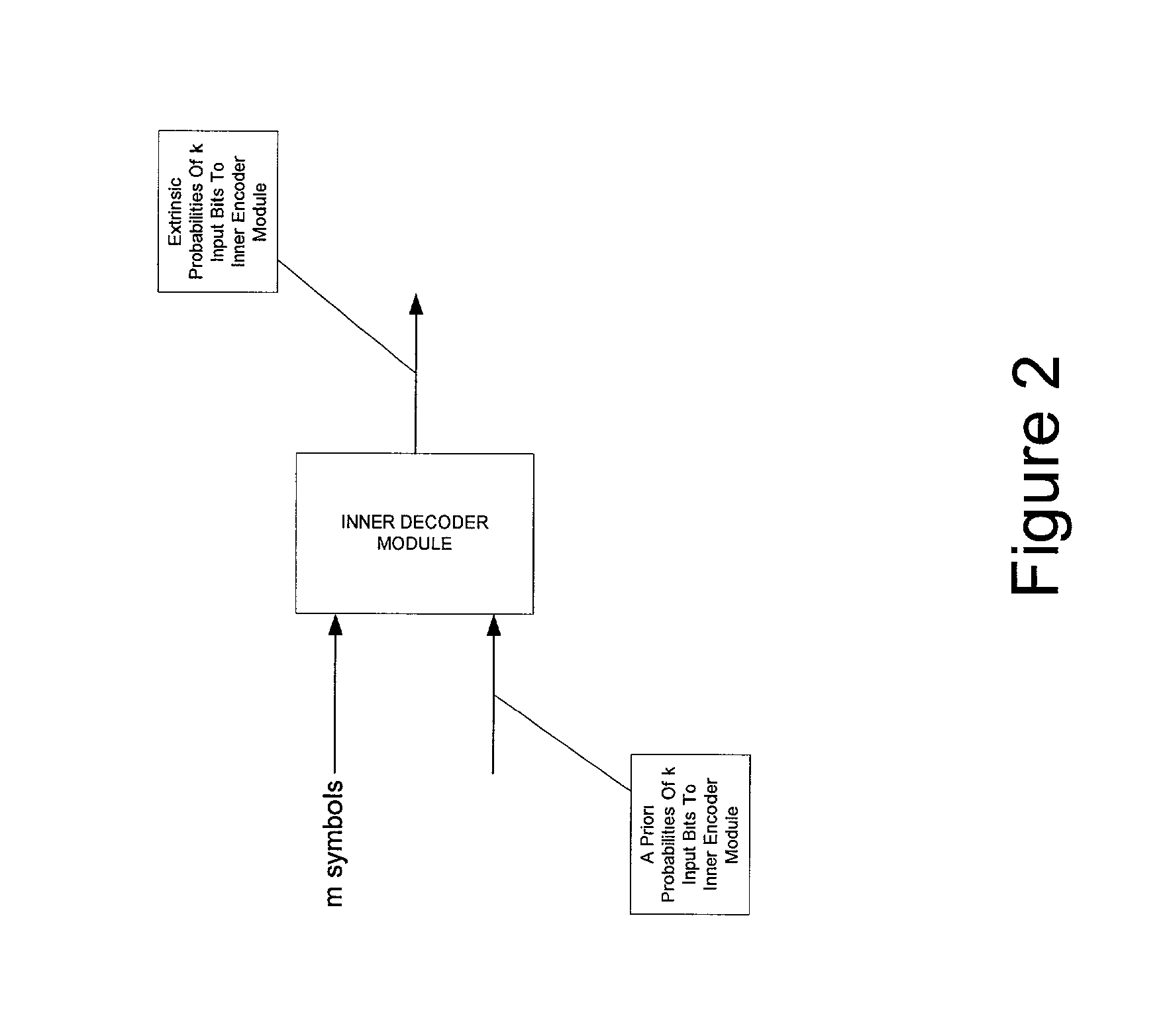

System of and method for decoding trellis codes

ActiveUS20020095640A1Reliable handlingData representation error detection/correctionOther decoding techniquesBranch MetricsOperation mode

Systems and related methods are described for (1) determining one or more state probabilities for one or more states in a trellis representation; (2) determining an estimate of or extrinsic output for one or more bits using a trellis representation; (3) determining a branch metric for a branch in a trellis representation; (4) performing a MAX*2->1 operation; (5) performing a MAX*2p->1 operation, where p is an integer of two or more, through a hierarchical arrangement of MAX*2->1 operations; and (6) computing forward state probabilities in a forward mode of operation and computing backward state probabilities in a backward mode of operation. Combinations of the foregoing are also described.

Owner:ENTROPIC COMM INC

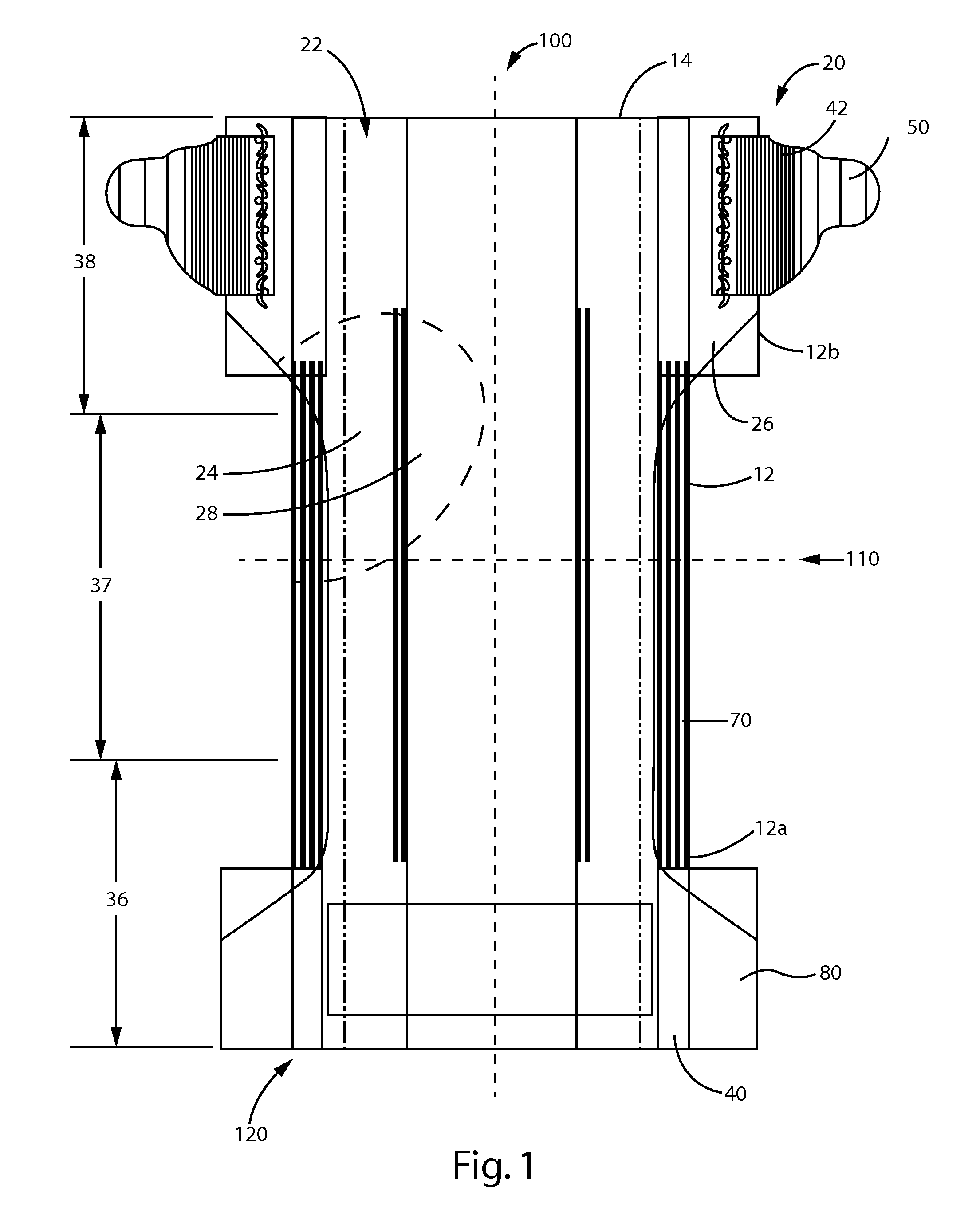

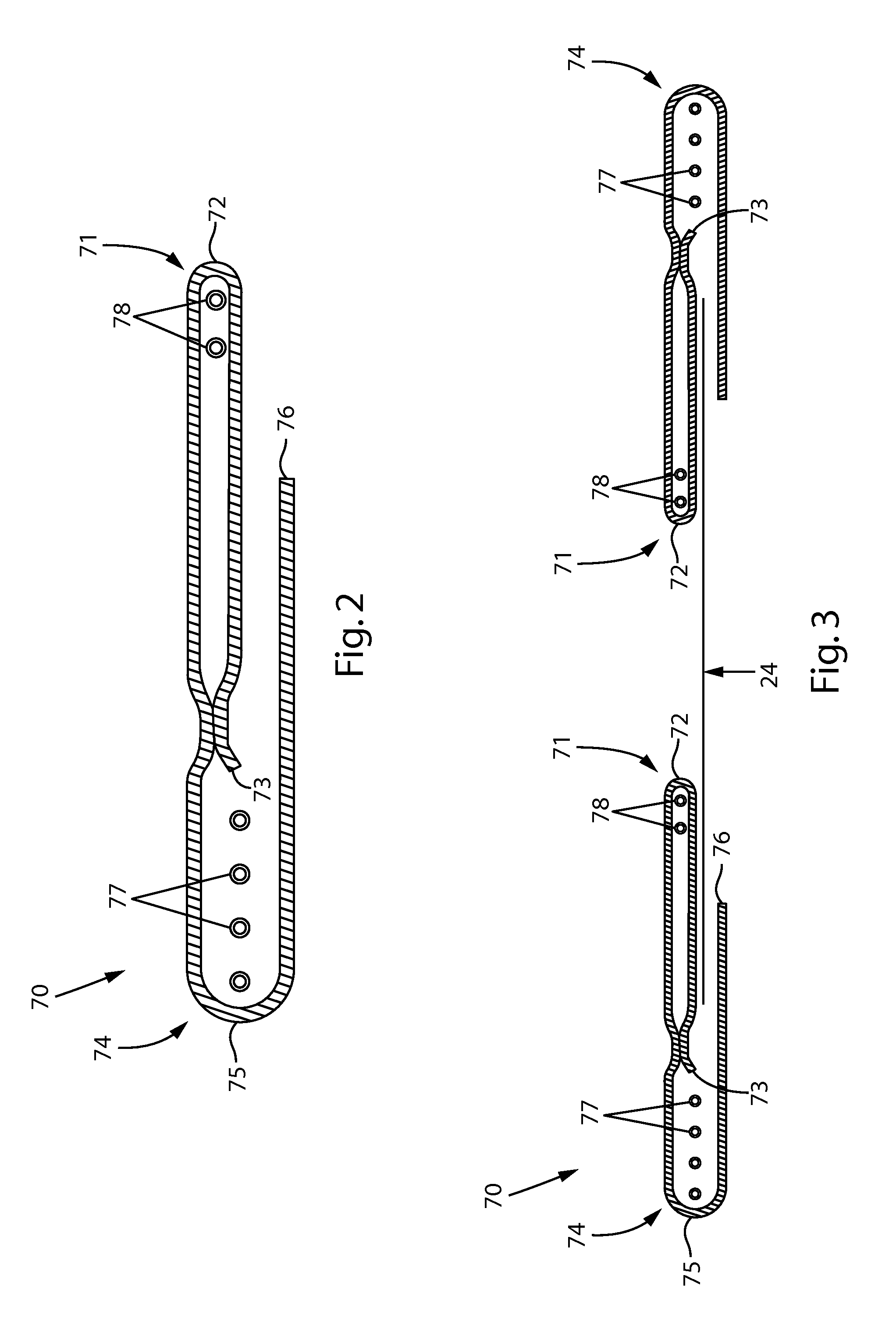

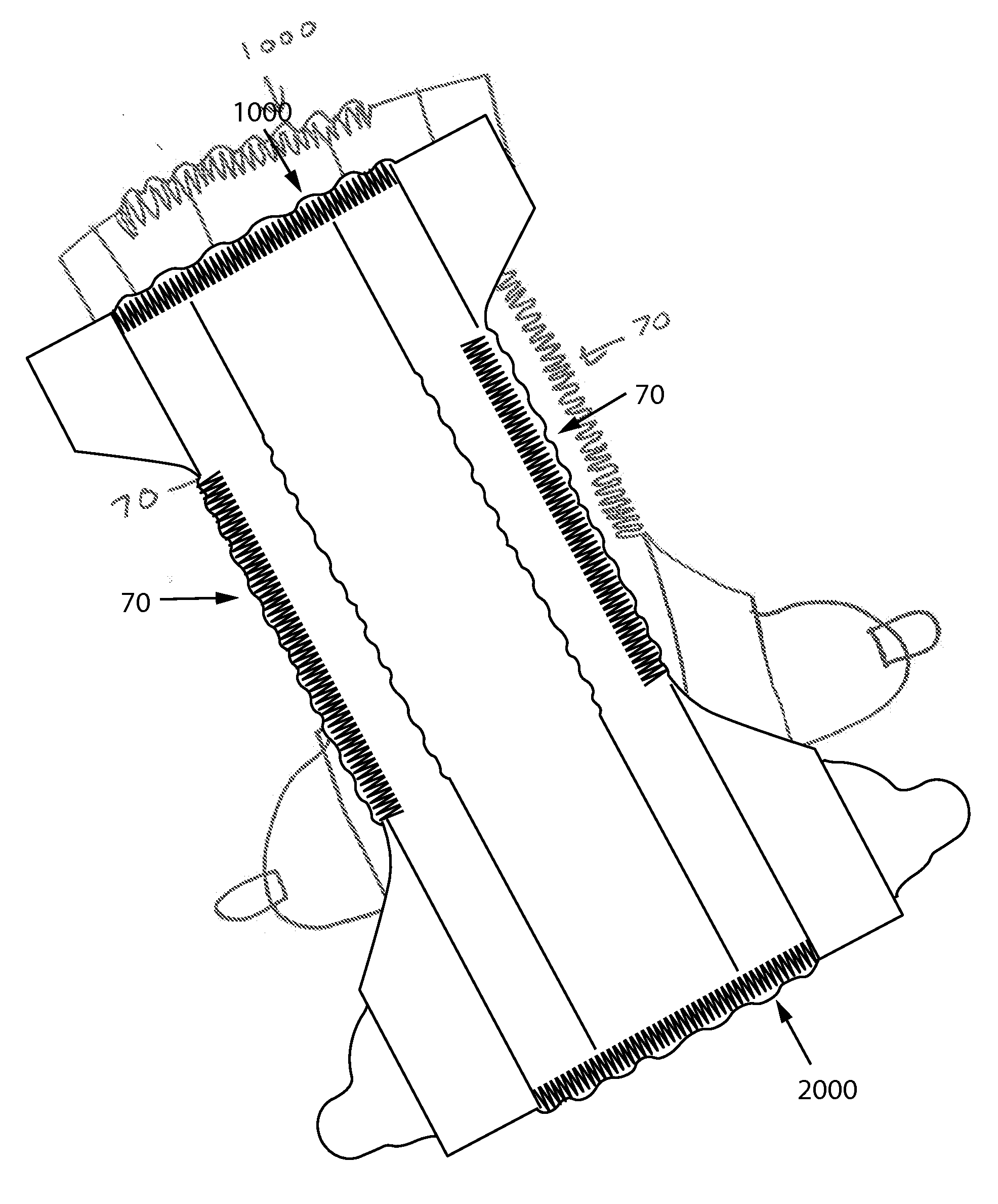

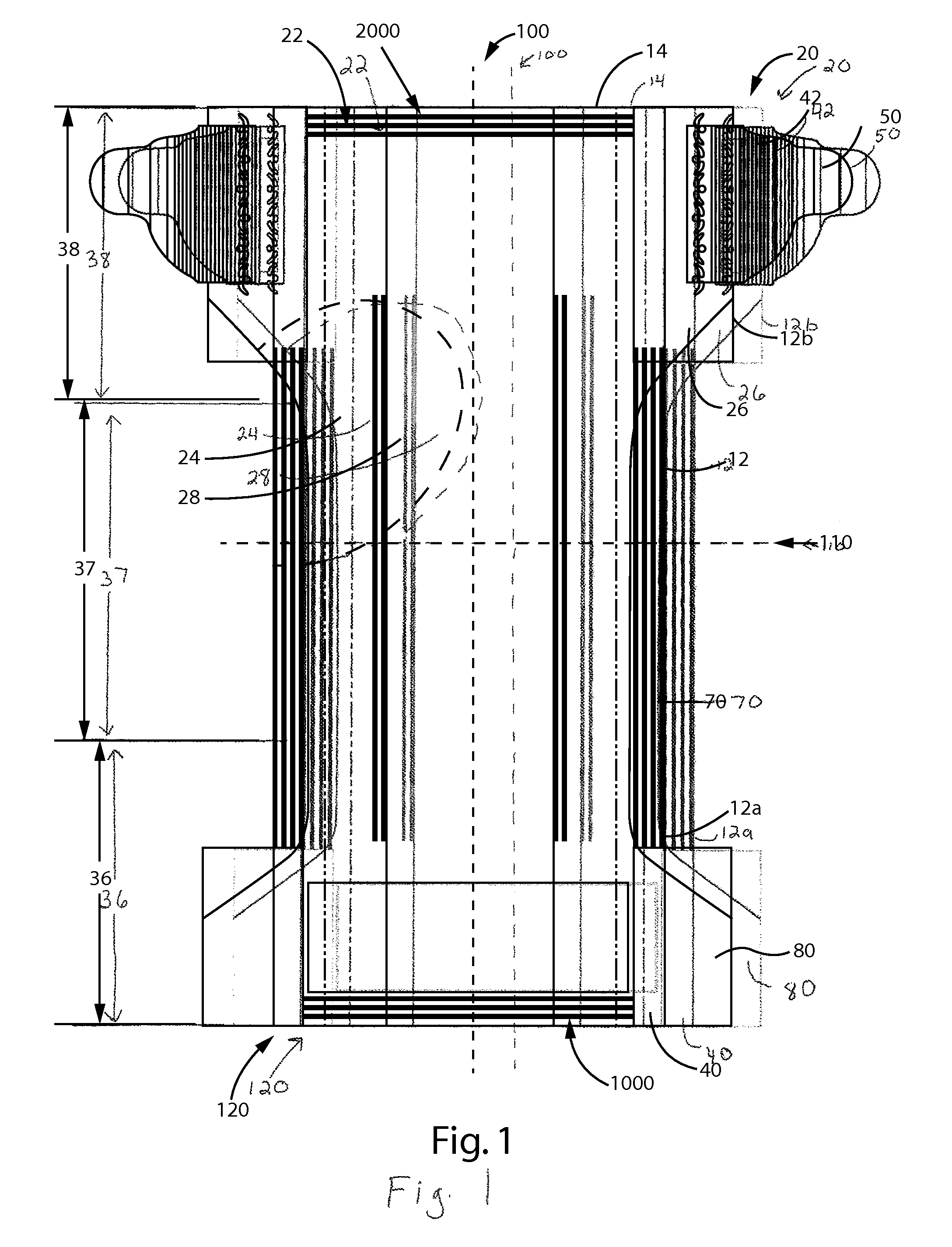

Absorbent Article With A Waistband And Leg Cuff Having Gathers

InactiveUS20120330264A1Reduce needCost-effective designBaby linensTamponsCrotchBiomedical engineering

A disposable absorbent article comprising a first waist region, a second waist region, a crotch region disposed between the first waist region and second waist region; a first waist edge and a second waist edge; and a first longitudinal edge and a second longitudinal edge; the disposable absorbent article comprising a waistband and a leg gasketing system, wherein the waistband has a first gather count and the leg gasketing system has a second gather count such that the ratio of the first gather count to the second gather count is from about 0.75 to about 1.25.

Owner:THE PROCTER & GAMBLE COMPANY

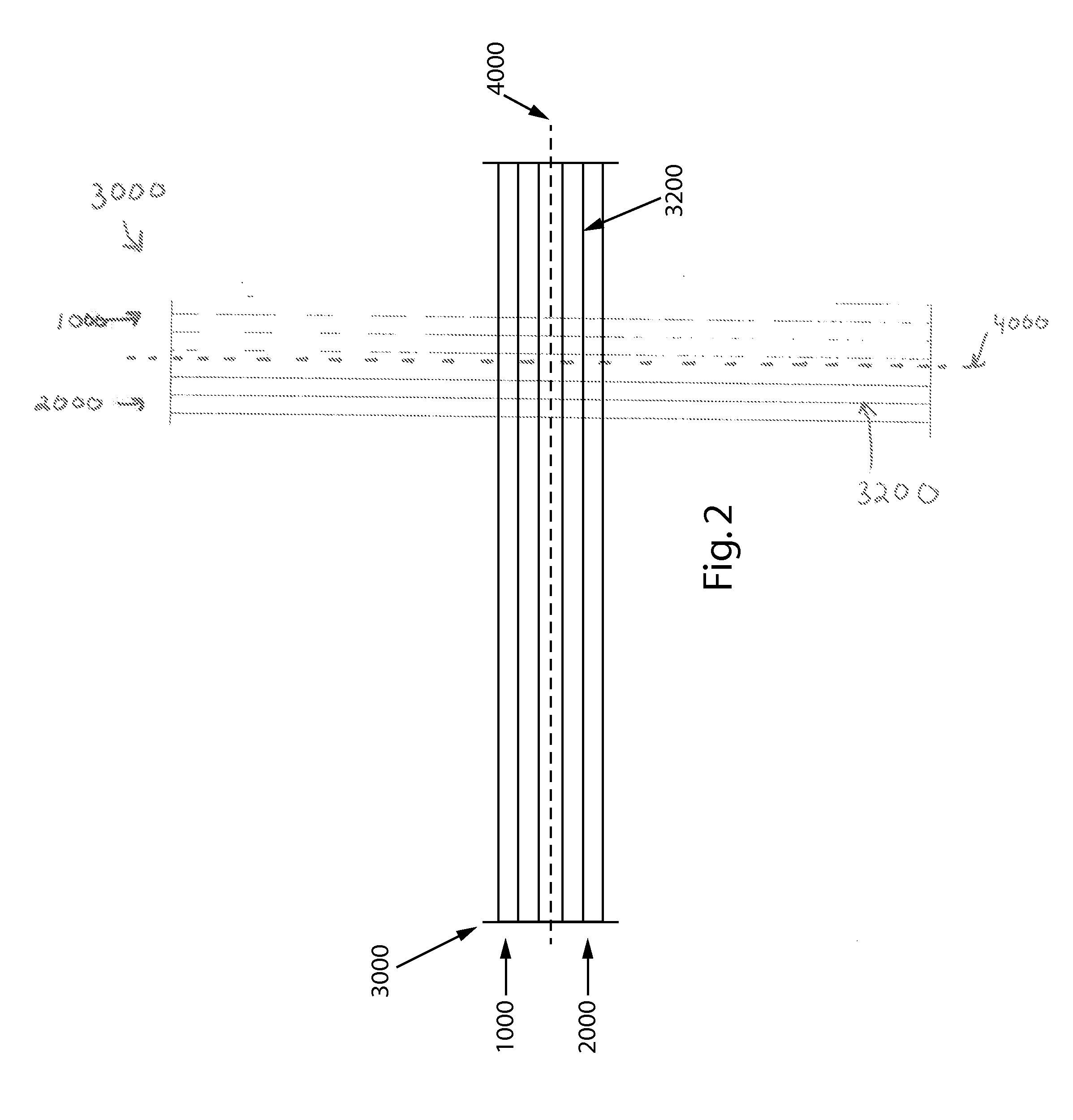

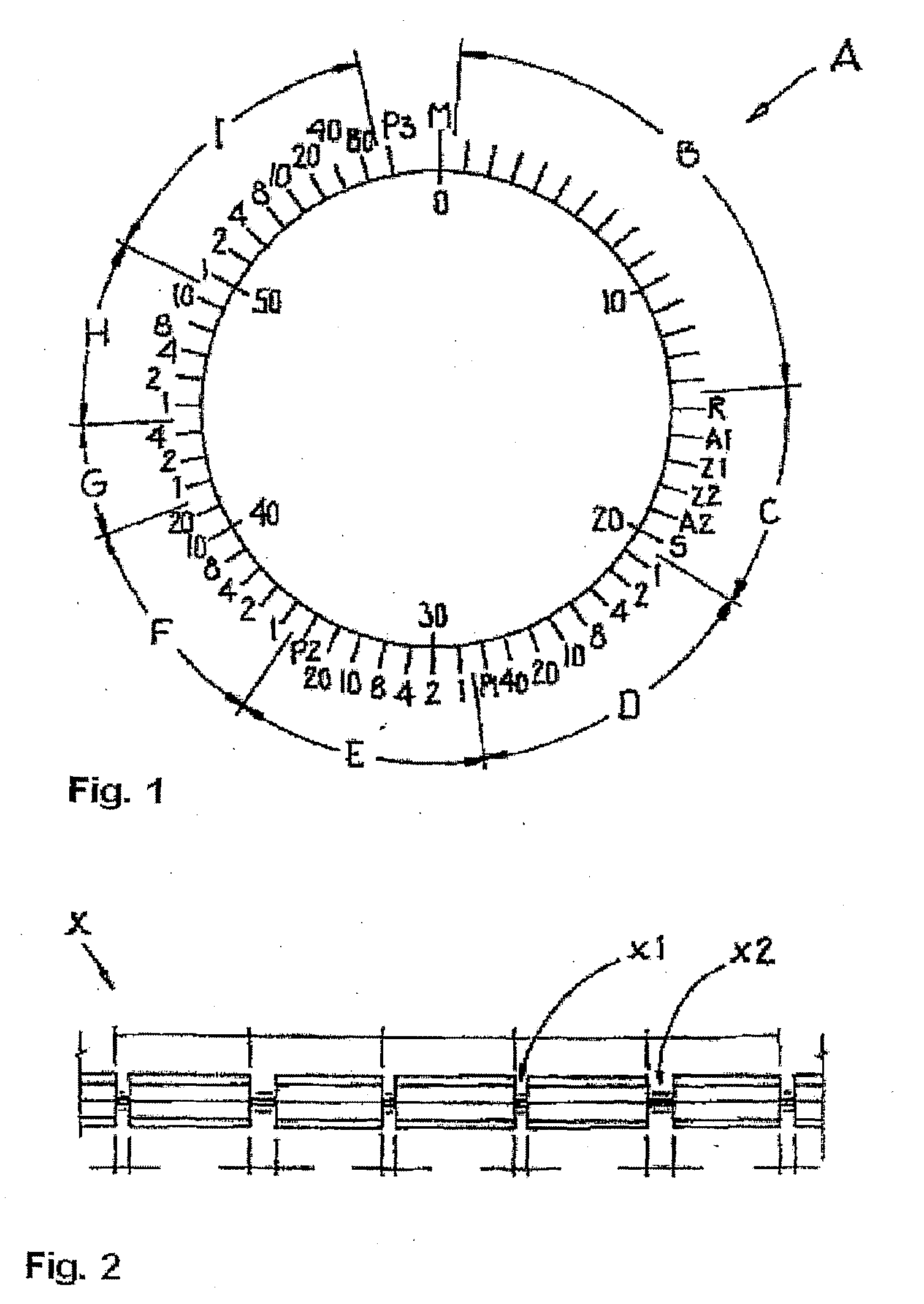

Pants type product and method of making the same

ActiveUS20060224137A1Exemption stepsVisual appearanceLaminationLamination apparatusEngineeringCrotch

A pants type disposable undergarment is provided which is equipped with an elasticized side panel. The side panel is elasticized with elastic film. The elastic film is attached to a nonwoven layer. The elasticized nonwoven layer is then split into two sections. A portion of the elasticized nonwoven layer is then ultrasonically cut to the desired configuration. The elastic film does not traverse the crotch region. Also provided are methods for producing such disposable undergarments.

Owner:CURT G JOA

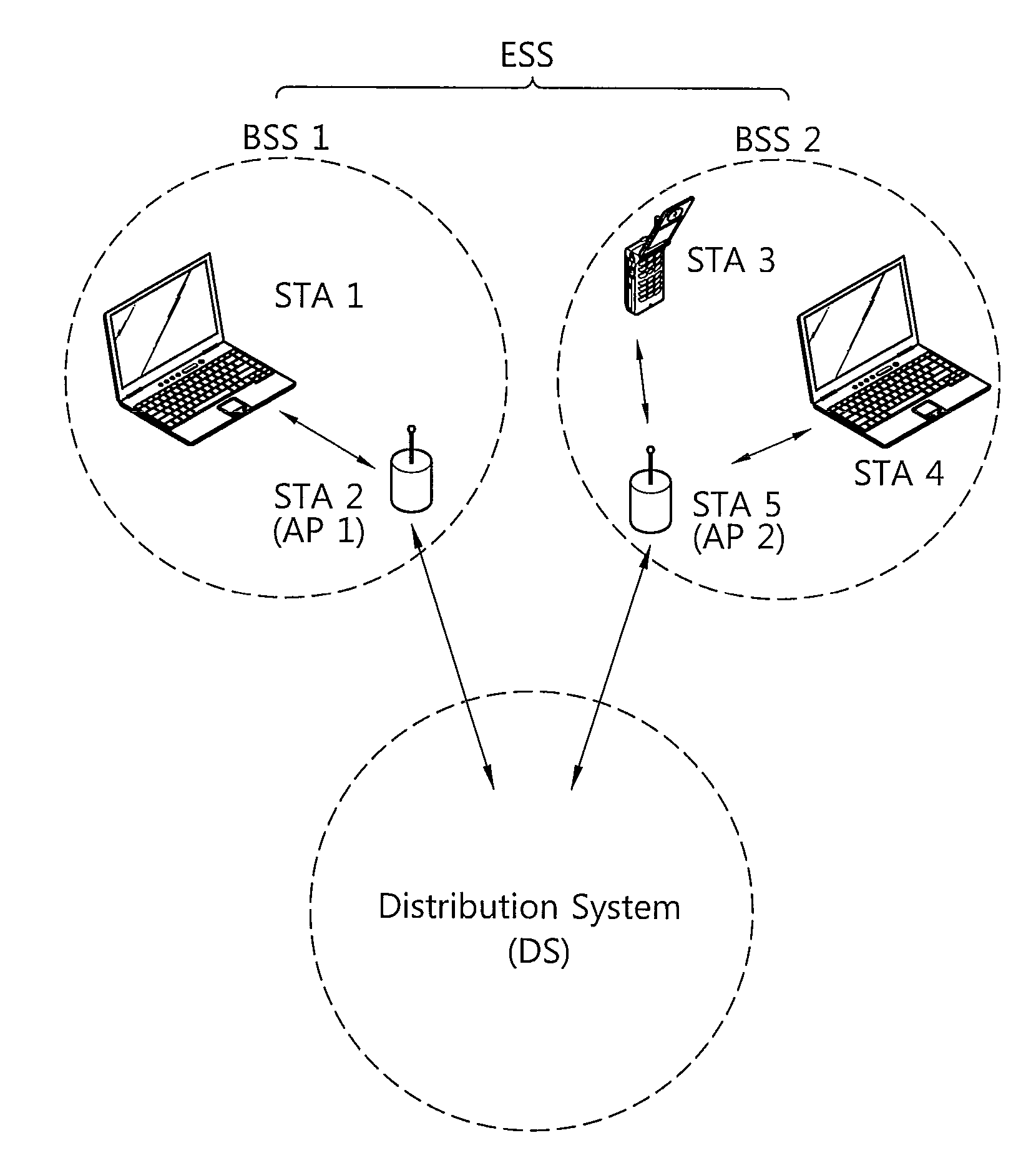

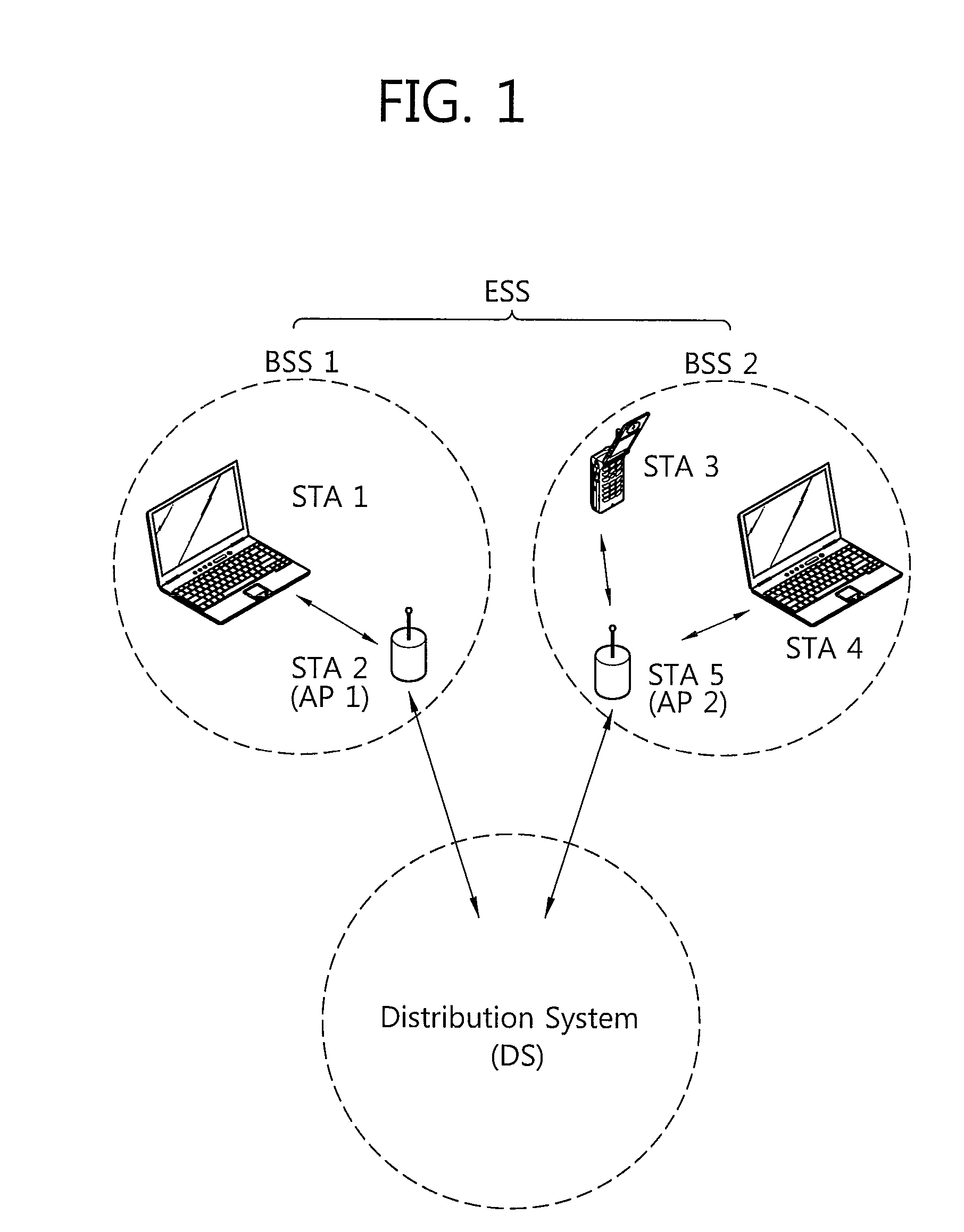

Method and device for transmission opportunity truncation

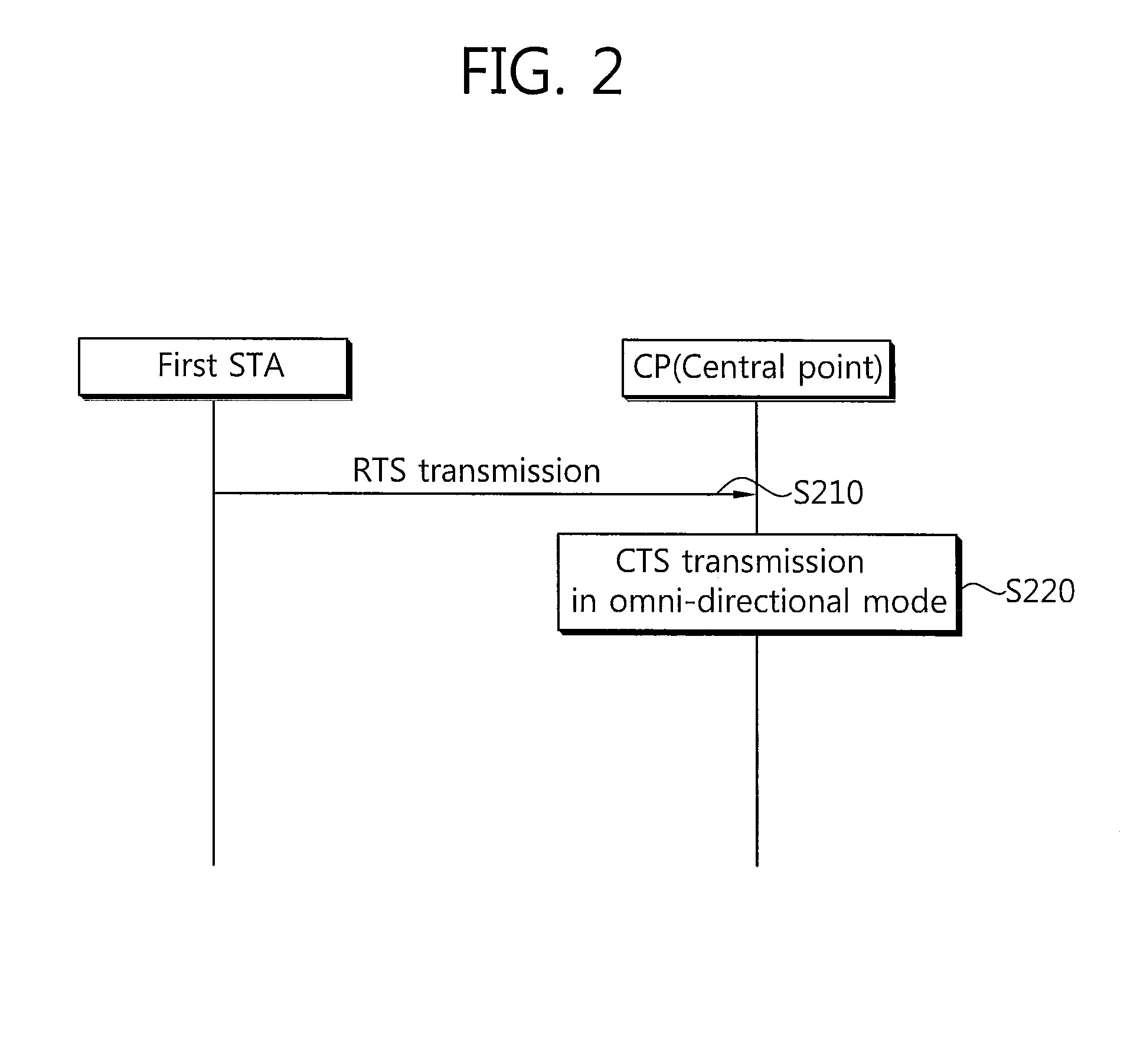

ActiveUS20100135268A1Reduce generationReliable transmission opportunity truncation processError preventionFrequency-division multiplex detailsTransmission opportunityBase station

A method and device for communicating in a contention-based communication network. The method includes upon an early termination of a previously obtained transmission opportunity (TXOP) for communications with one of a mobile device and a base station, transmitting a contention free end (CF-End) frame to the base station for further broadcasting to the network by the base station. Also, a method and device for communicating in a contention-based communication system. The method includes receiving in a base station a first contention free end (CF-End) frame from a first mobile device indicating an early termination of a transmission opportunity (TXOP) previously obtained by the first mobile terminal for communications between the first mobile device and one of the base station and a second mobile device; and omnidirectionally broadcasting a second CF-End frame with a duration field having a value equal to zero.

Owner:LG ELECTRONICS INC

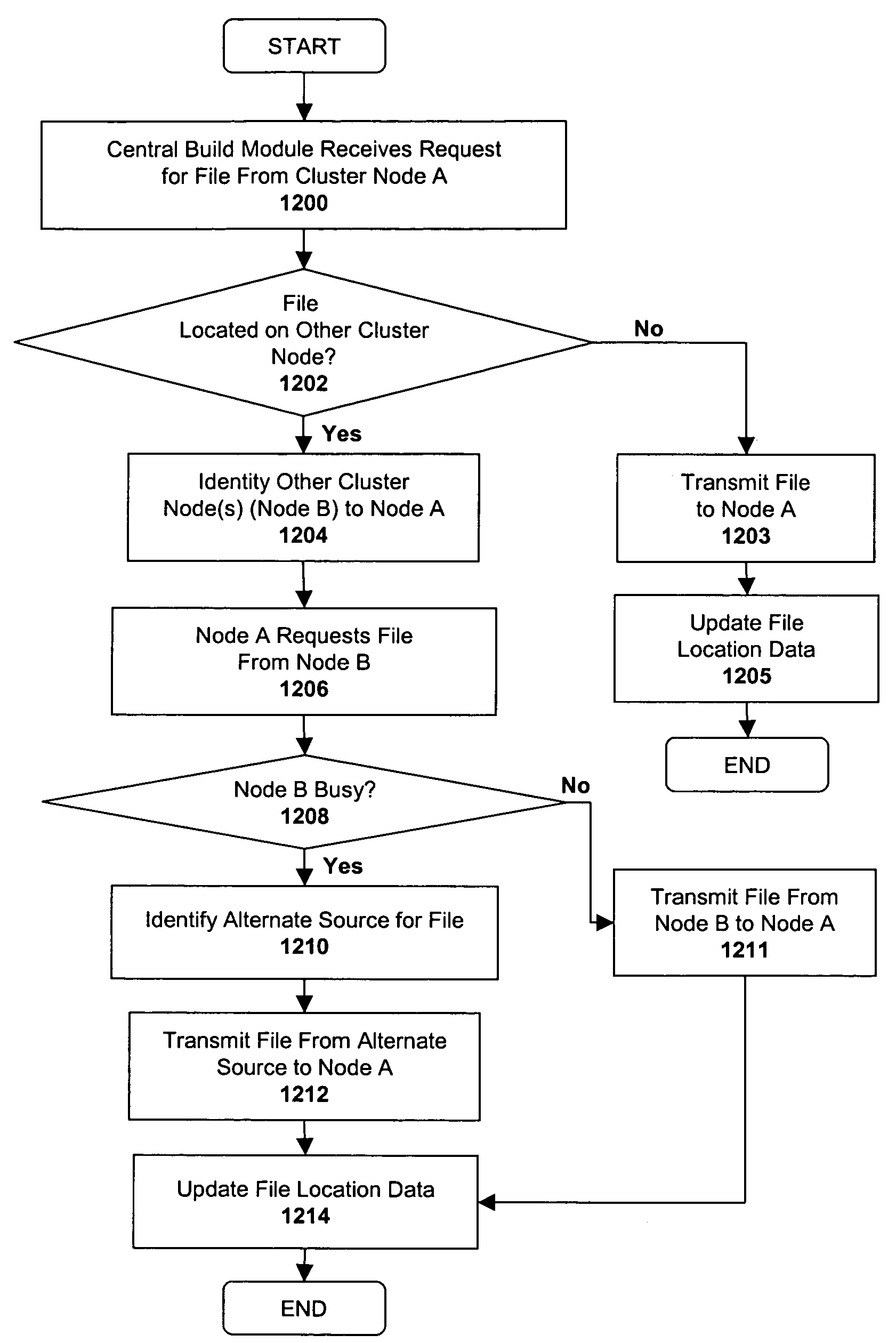

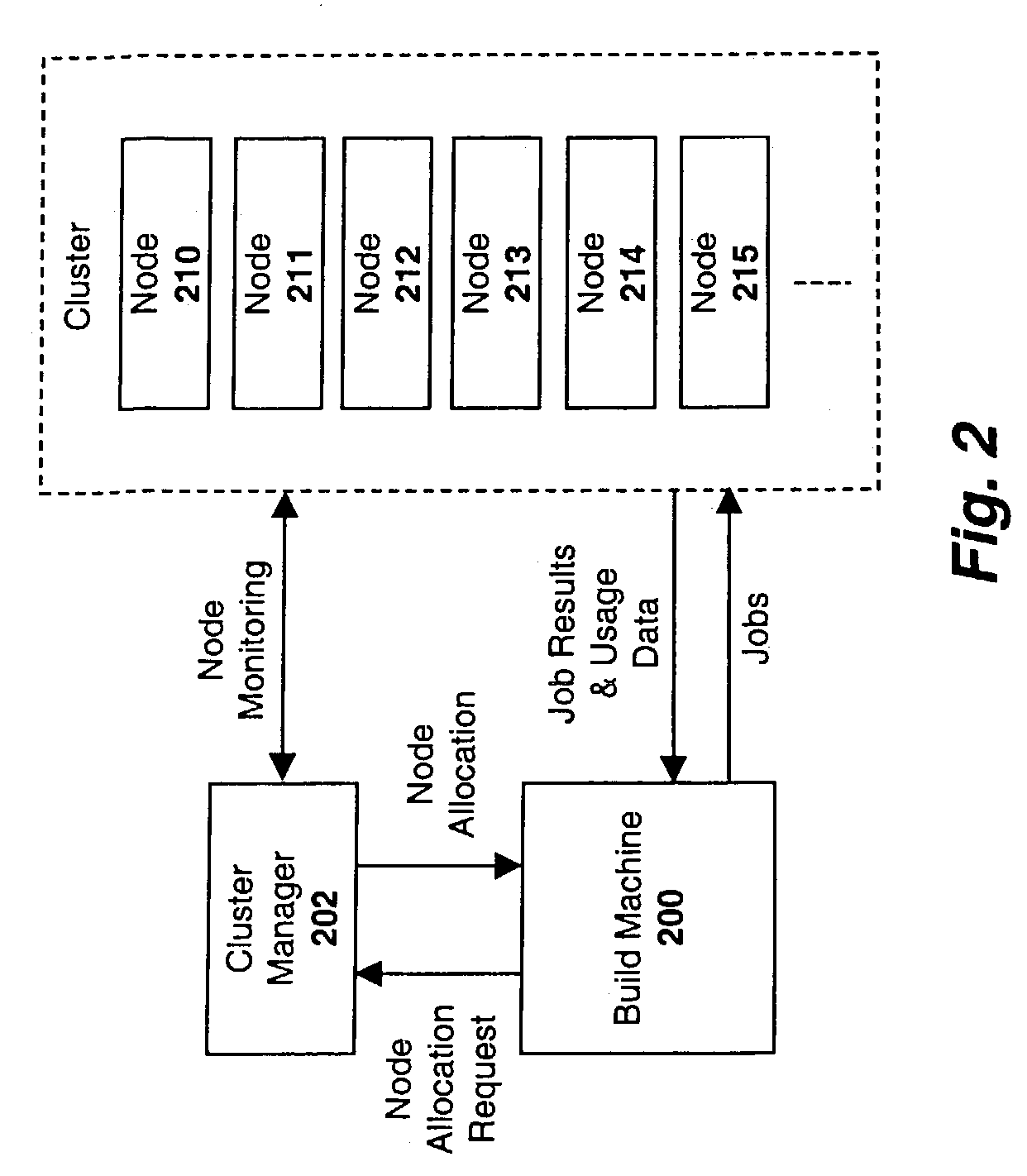

System and method for intelligently distributing source files within a distributed program build architecture

ActiveUS7539976B1BuildIncreased riskVersion controlSpecific program execution arrangementsDistributed sourceDatabase

A method implemented within a distributed build system is described comprising: transmitting a first source file from a program build file repository to a first node, the first node using the source file to generate a target file identified in the build process; receiving a request for the first source file from a second node; and redirecting the second node to retrieve the first source file from the first node rather than from the program build file repository.

Owner:CLOUDBEES INC +1

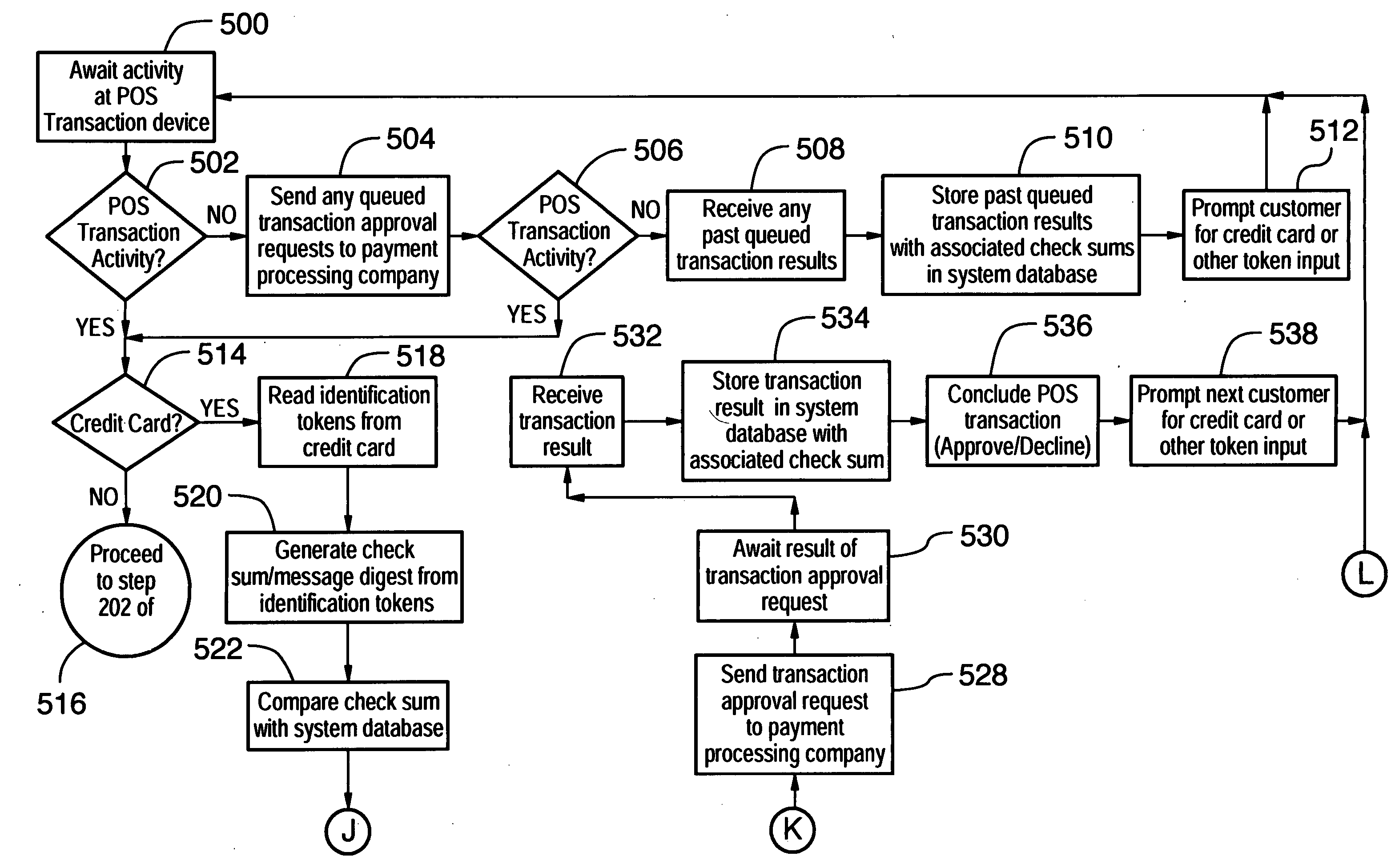

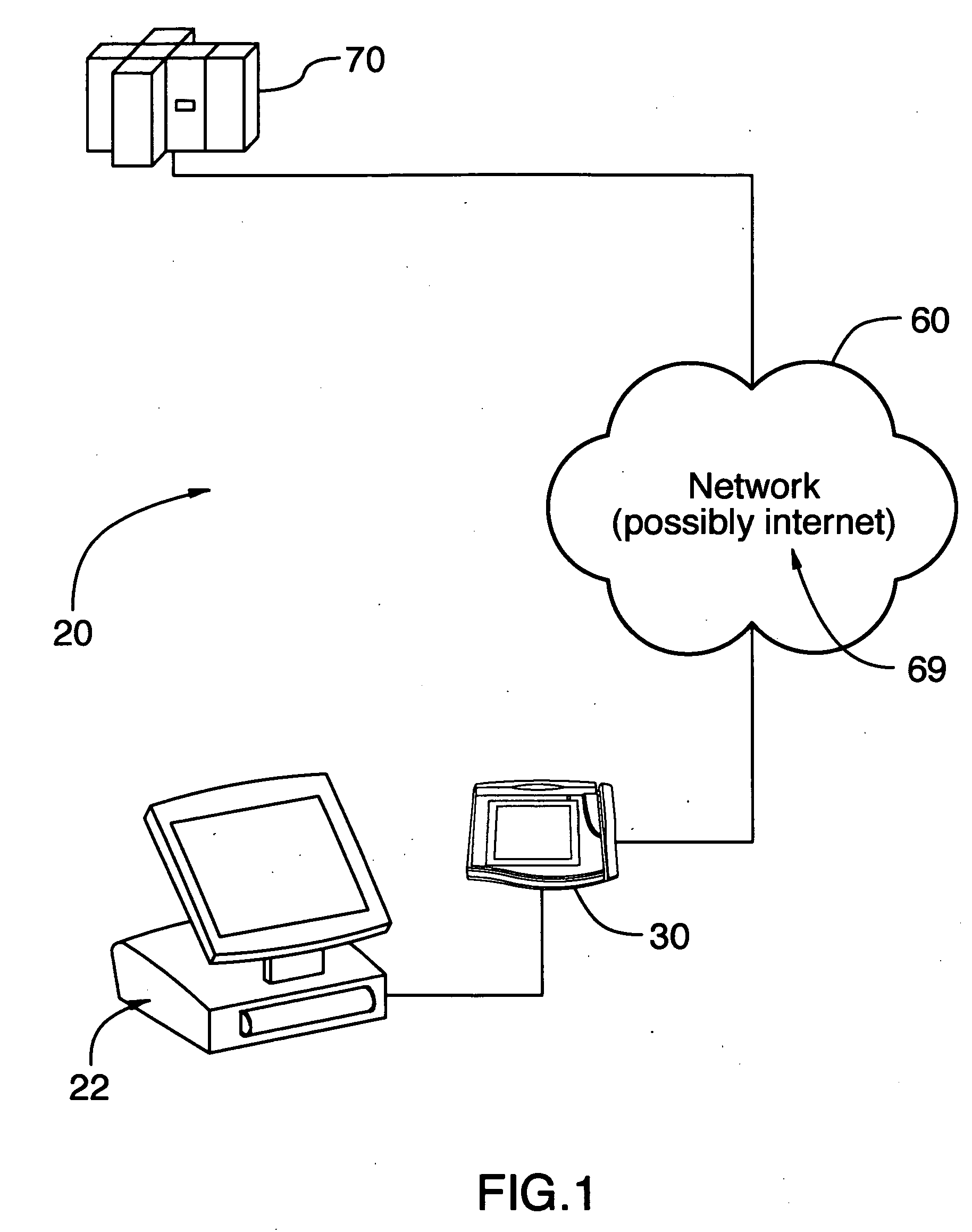

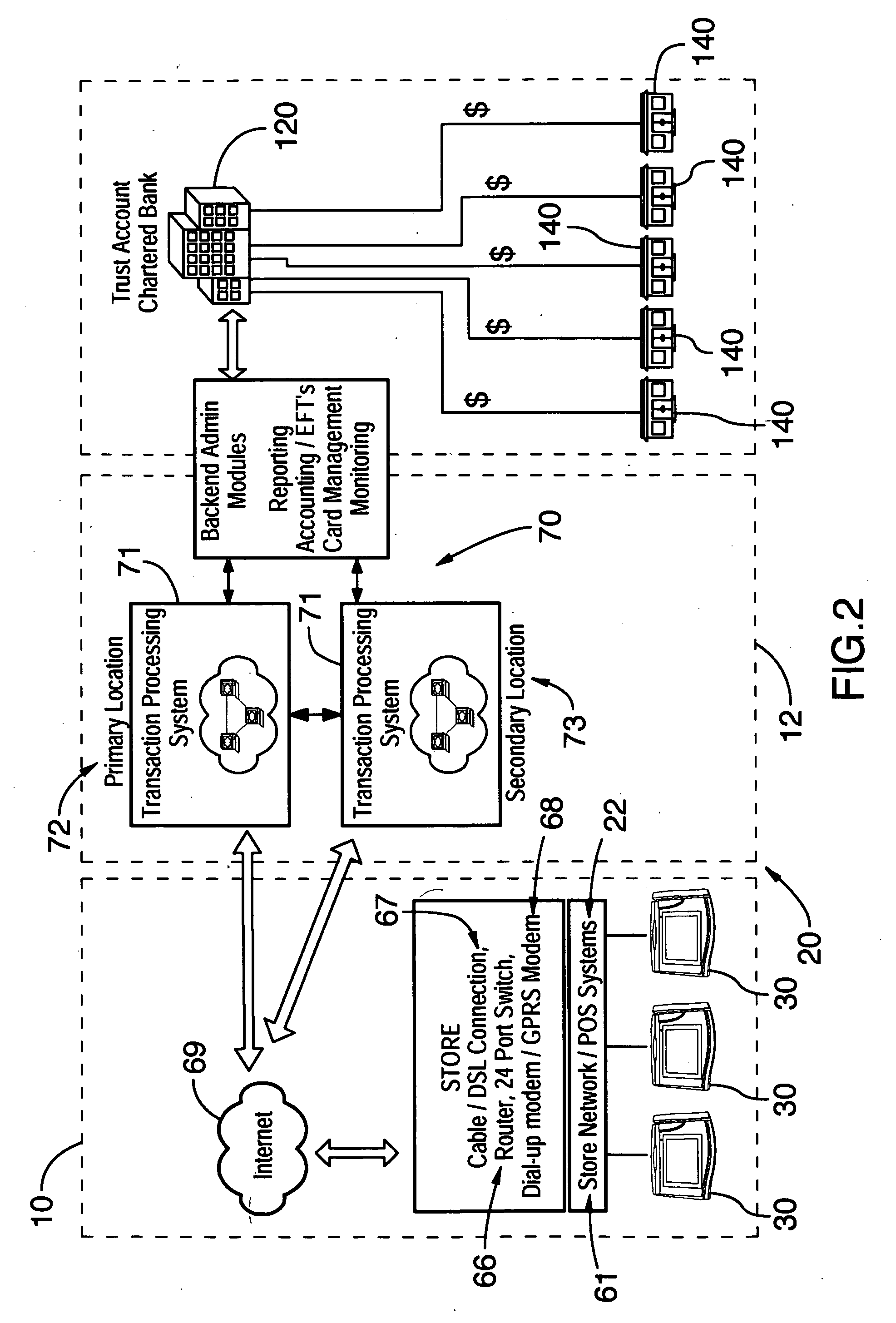

Electronic balance checking and credit approval system for use in conducting electronic transactions

ActiveUS20060229978A1Easy to handleReliable handlingFinancePoint-of-sale network systemsInternet privacyChecksum

An electronic balance checking and credit approval system includes consumer transaction accounts, tokens, input devices, authentication hardware and software, and output devices. The consumer transaction account is held in trust on behalf of a consumer by a credit extending company. The token is specific to and held by the consumer, and includes a consumer account identifier that is associated with the consumer transaction account. The input device receives the consumer account identifier concurrent with a consumer-initiated request for account balance information. The authentication hardware and software verifies the consumer-initiated request and the consumer account identifier and authorizes access to the consumer transaction account. The consumer interface apparatus provides the consumer with a real-time account balance datum that is currently associated with the consumer transaction account. The system also includes a system and method for securely and quickly approving credit card transactions by comparing generated checksums with stored historical transaction results.

Owner:DXSTORM COM

Pants type product and method of making the same

A pants type disposable undergarment is provided which is equipped with an elasticized side panel. The side panel is elasticized with elastic film. The elastic film is attached to a nonwoven layer. The elasticized nonwoven layer is then split into two sections. A portion of the elasticized nonwoven layer is then ultrasonically cut to the desired configuration. The elastic film does not traverse the crotch region. Also provided are methods for producing such disposable undergarments.

Owner:CURT G JOA

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

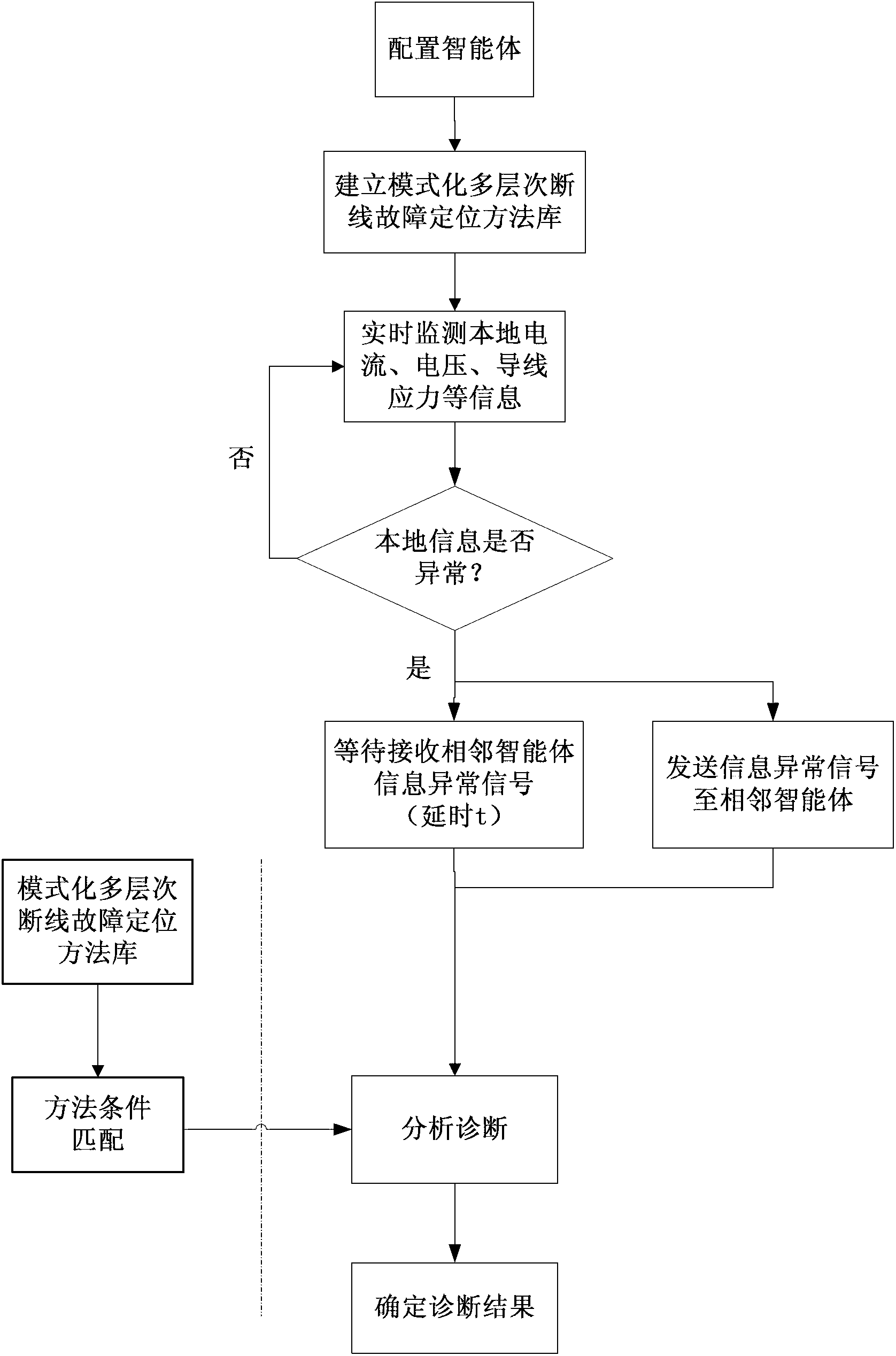

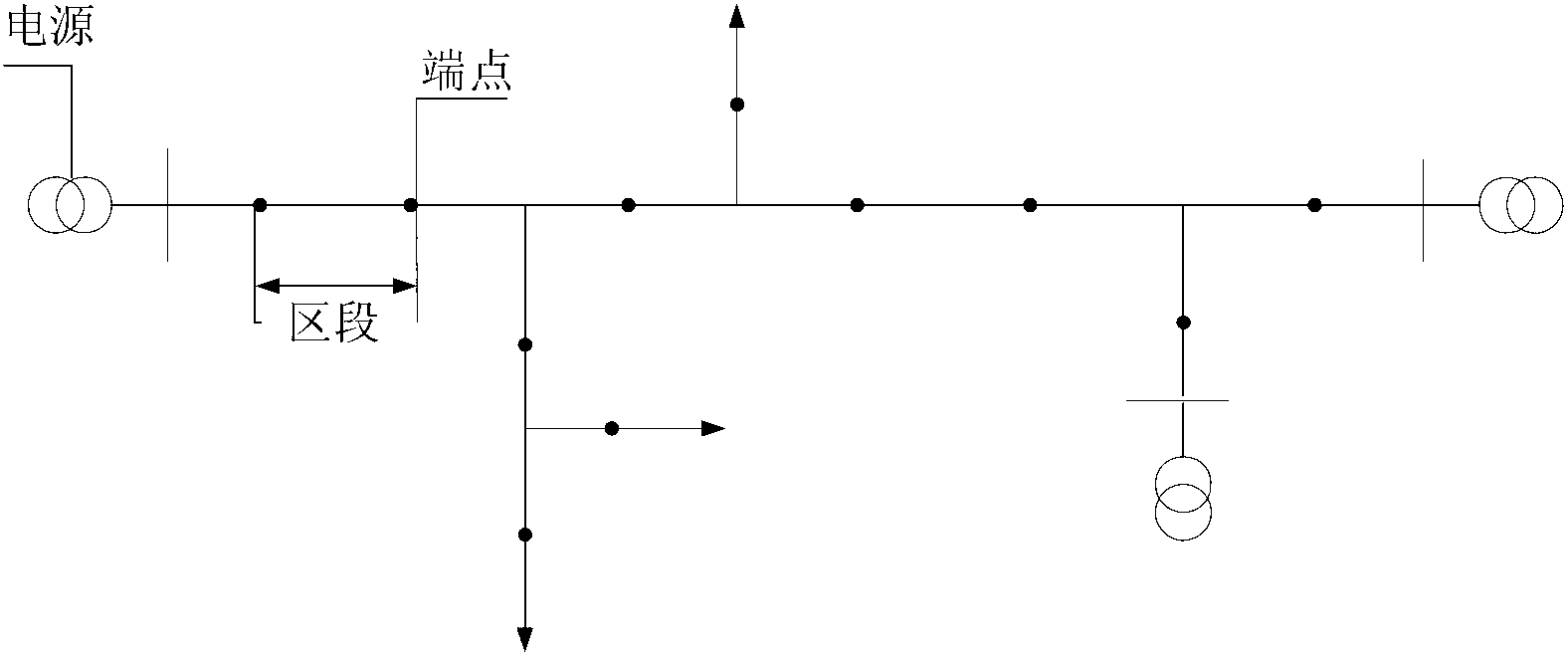

Power distribution network broken line fault location method

ActiveCN102707194AEasy to adapt to various operating modesReliable handlingFault locationInformation technology support systemEngineeringSingle fault

The invention discloses a power distribution network broken line fault location method. According to a structure of a power distribution network and a power supply mode, a local power distribution network line section is divided into a plurality of kinds of typical sections, and characteristics of voltage and load flow of each of endpoints of the typical sections in different broken line faults are proposed. During application, the characteristics of each local line section of the power distribution network are matched with the typical sections, types of the typical sections which the each local line section belongs to are determined, the measured characteristics of the voltage and the load flow of each of the endpoints in the each local line section are matched with the characteristics of the voltage and the load flow of each of the endpoints of the typical sections in the different broken line faults to judge whether the line section has the broken line fault and to judge types of the broken line faults, and the typical sections correspond to the line section. According to the power distribution network broken line fault location method, a modeling rule is used for customizing the method, and the comprehensiveness and the reliability for problem processing are achieved; the customization of the rule is flexible and prone to adapt to a plurality of operating modes of the power distribution network; the location is accurate, and the fault location of sections can be achieved; and human line patrolling is avoided, and the power distribution network broken line fault location method is an ideal method.

Owner:CHINA ELECTRIC POWER RES INST +1

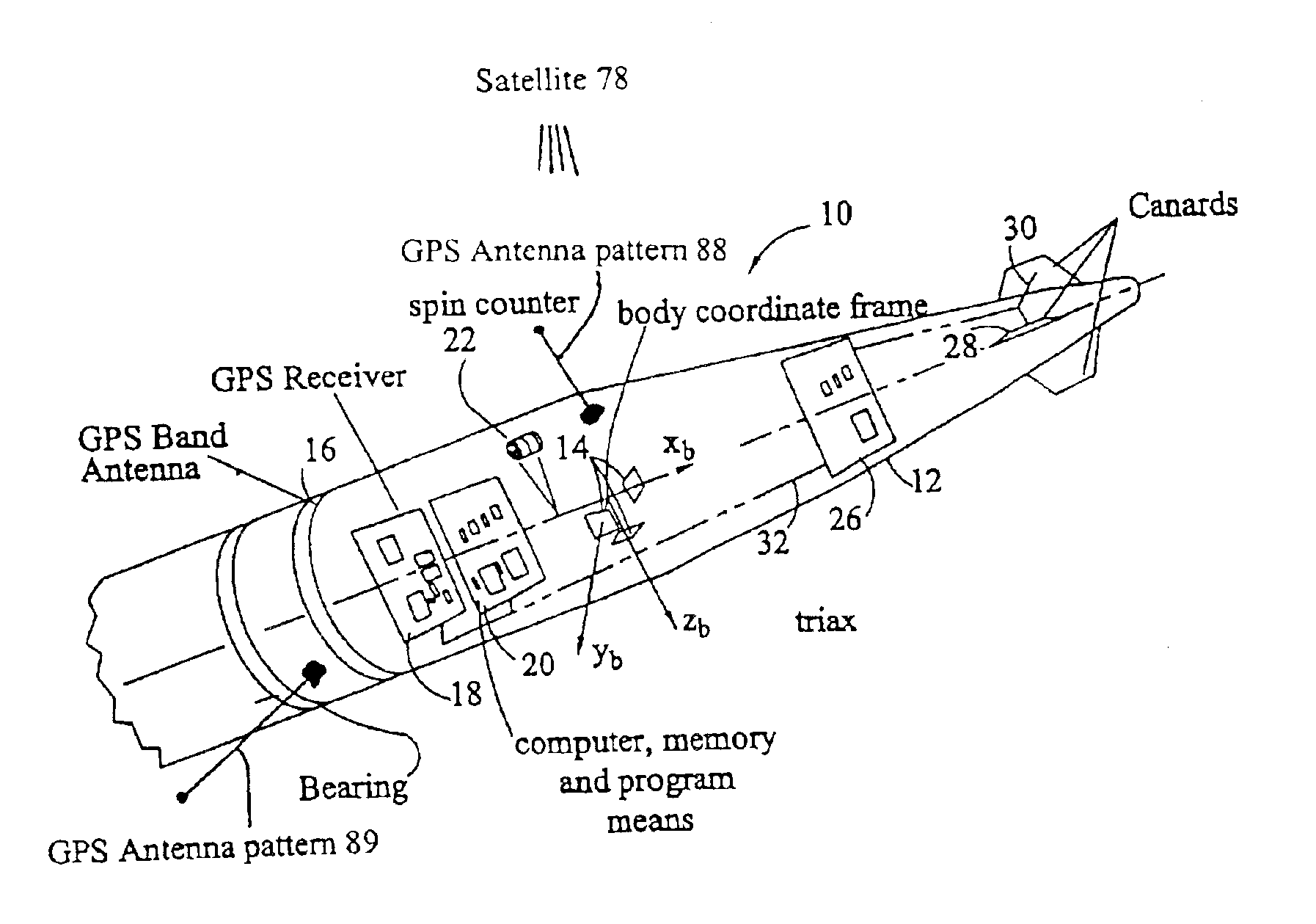

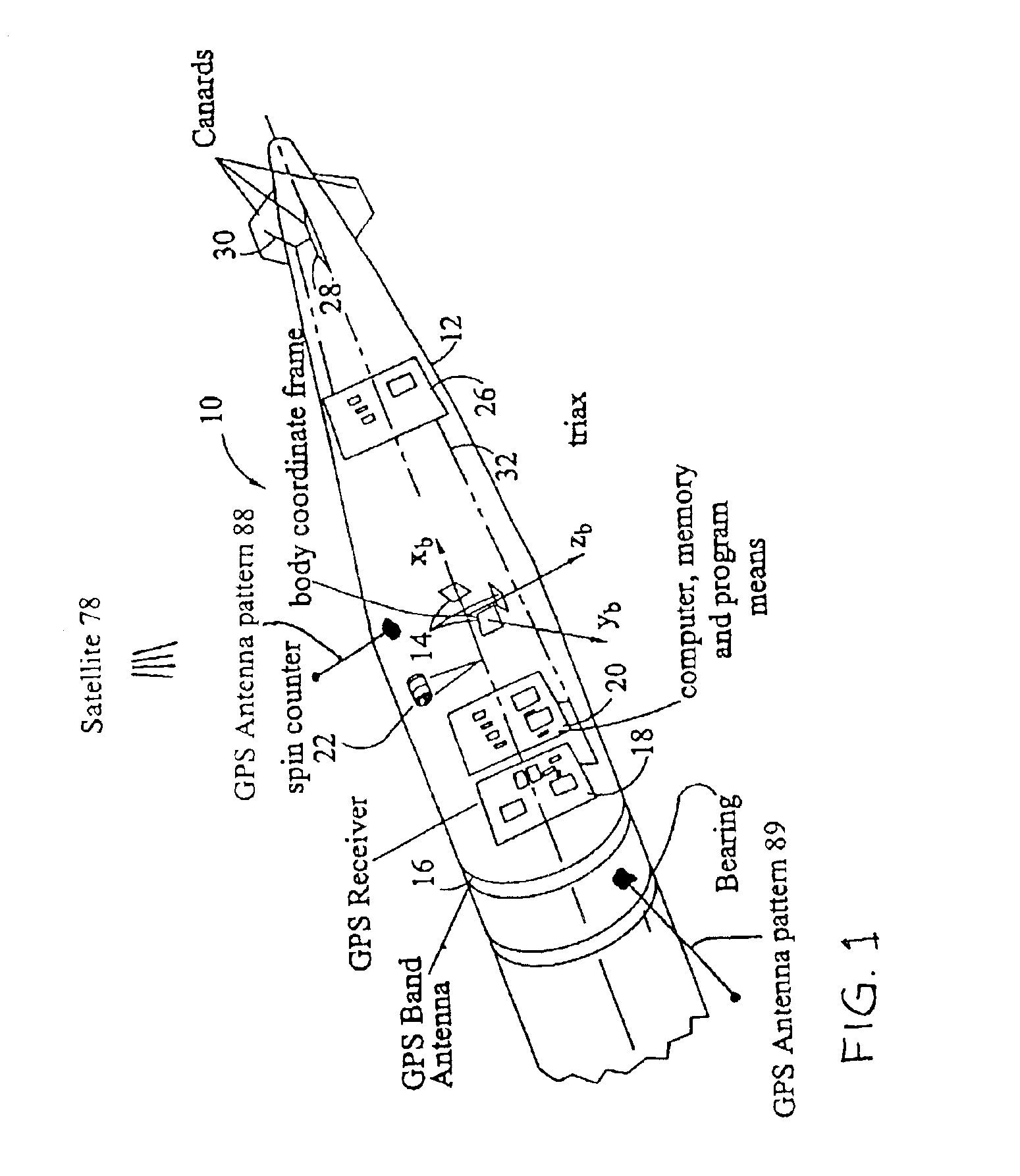

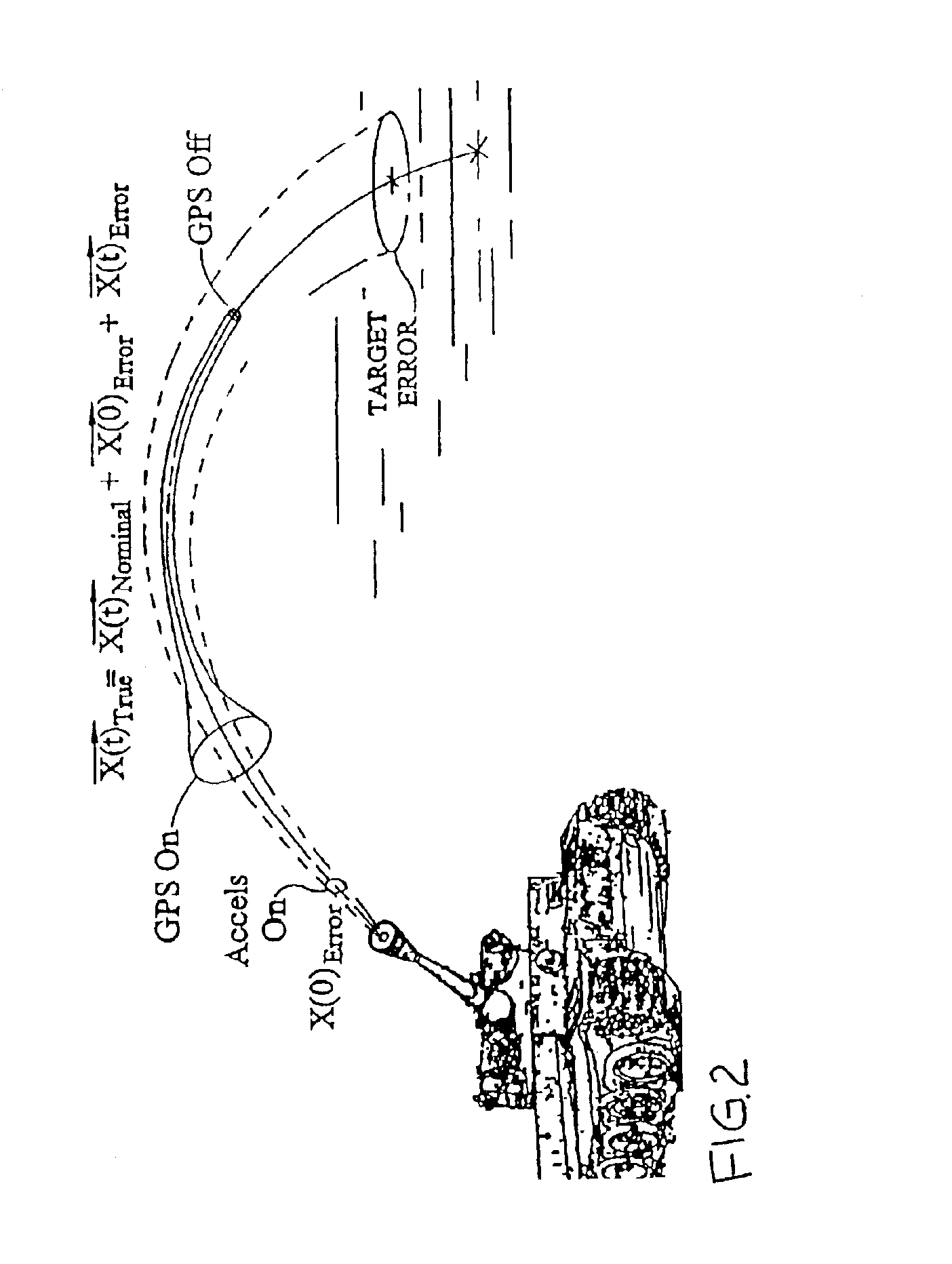

Projectile guidance with accelerometers and a GPS receiver

InactiveUS6883747B2Efficiently guidedGreat relianceDirection controllersPosition fixationGuidance systemAccess time

A projectile guidance system without gyros in which the projectile has an orthogonal body coordinate system. The projectile has a triax of accelerometers providing x, y and z acceleration data measured along the x, y and z axes respectively. A GPS antenna and receiver means provides onboard GPS position and velocity data in earth referenced navigational coordinates. A computer and program means stores and accesses time indexed GPS position and GPS velocity data and transforms x, y and z axis acceleration data from body to navigation coordinates. The program means is responsive to corresponding time indexed acceleration data and to GPS velocity and position data for calculating and outputting an estimated projectile roll, pitch and yaw angle via optimal smoothing techniques with respect to local level for each time index iteration of present position to a flight control system, which actuates a divert propulsion system for guiding the projectile to a predetermined location.

Owner:NORTHROP GRUMMAN SYST CORP +1

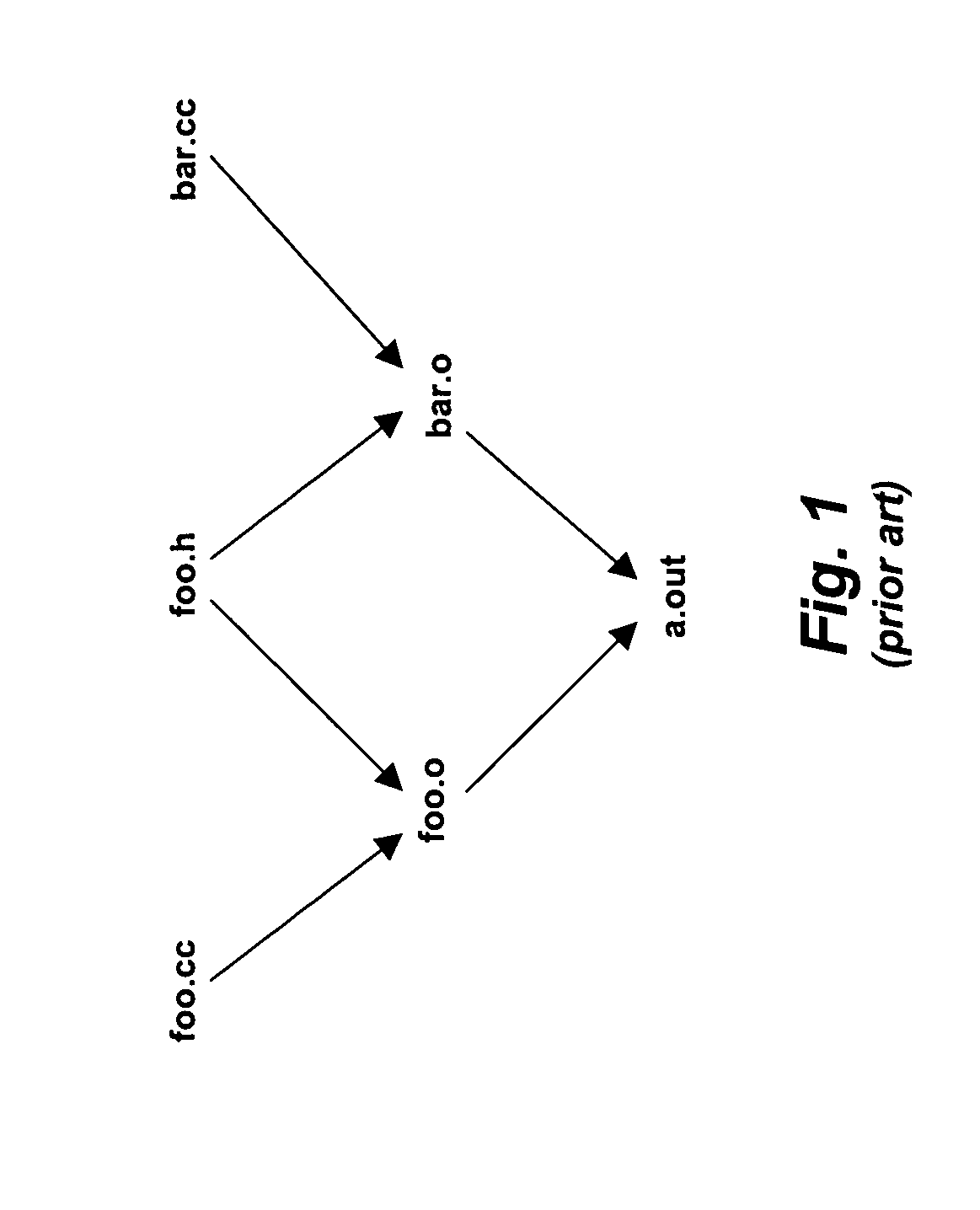

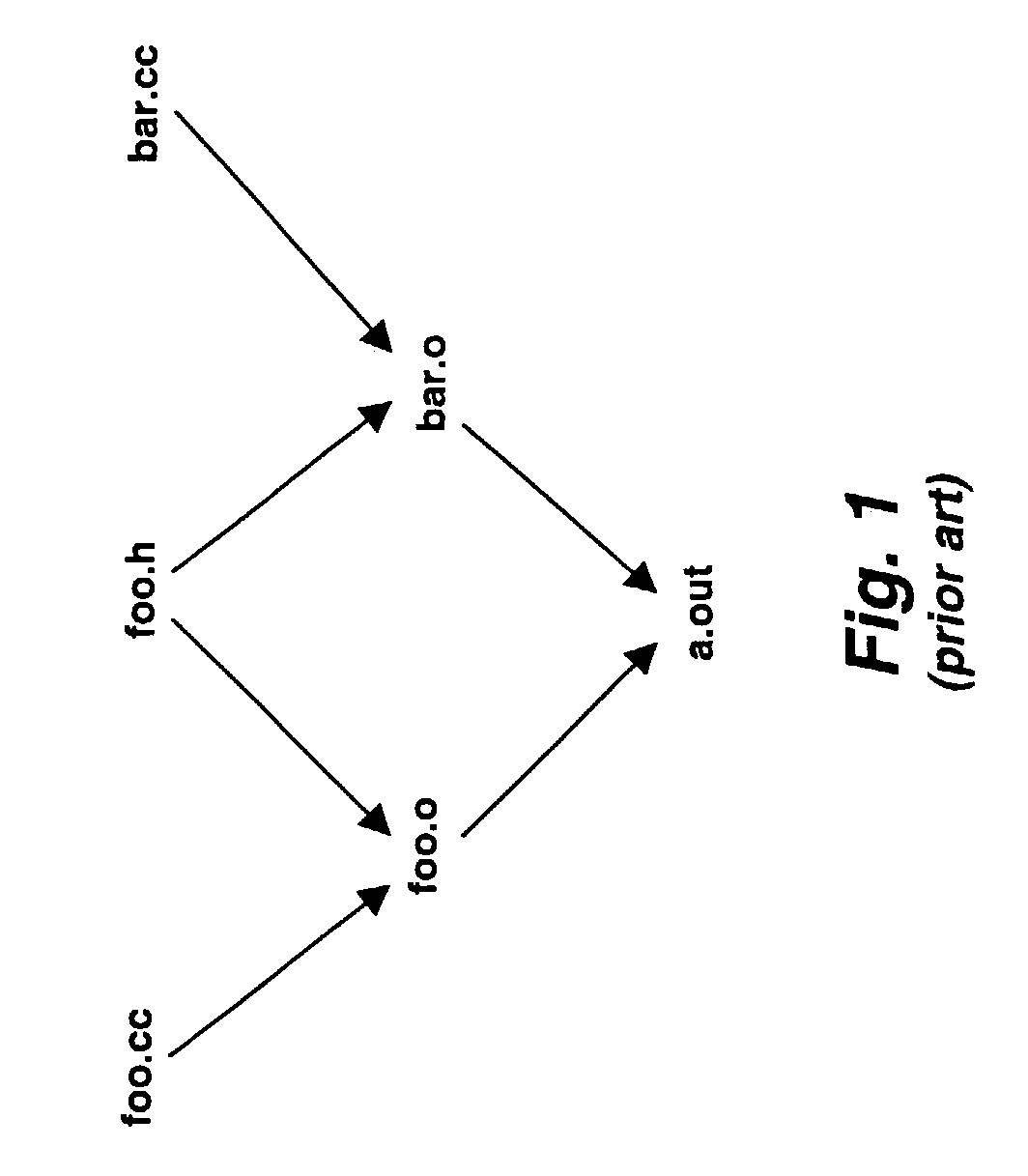

System and method for supplementing program builds with file usage information

ActiveUS7168064B2BuildIncreased riskResource allocationError detection/correctionProgram planningOperating system

A method for executing program builds is described comprising: analyzing file dependency information contained within a first file; scheduling jobs for a program build based on the analysis of the dependency information; executing the jobs according to the schedule; collecting file usage information from each of the jobs; and supplementing the file dependency information with the file usage information.

Owner:CLOUDBEES INC +1

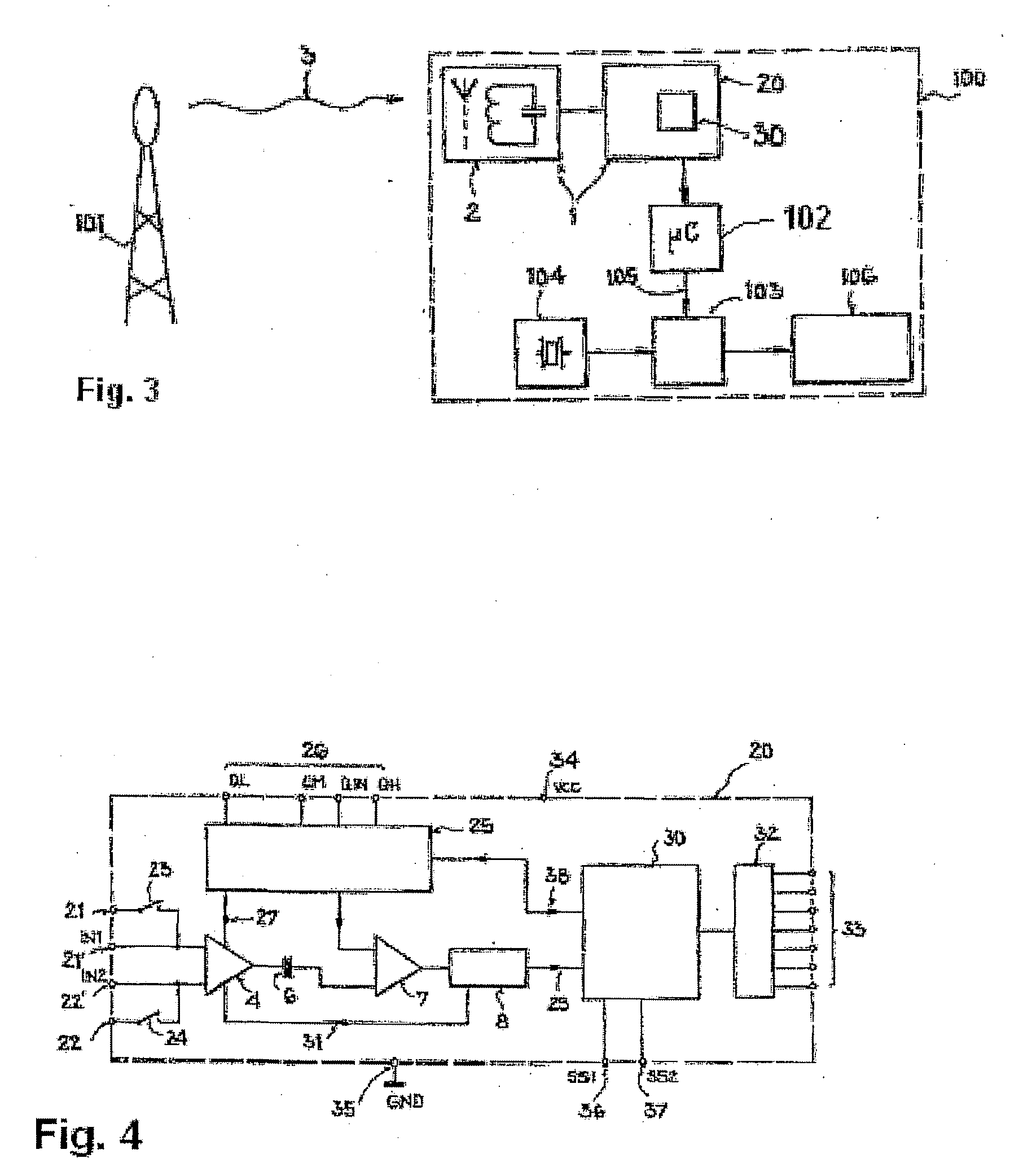

Notification device and method for programming a notification device

InactiveUS20080212416A1Halving of programming timeReduce power consumptionAcoustic time signalsElectric indicationOutput deviceComputer science

A notification device with a time signal receiver is provided that has a receiver for receiving an electromagnetic time signal and processor for processing the time signal and is assigned a signal output device to generate a warning signal, and to a method for programming a notification device comprising a time signal receiver. In the notification device the time signal receiver and / or the signal output device can be set up to generate a warning signal when there is at least one piece of additional information transmitted with the time signal.

Owner:ATMEL GERMANY +1

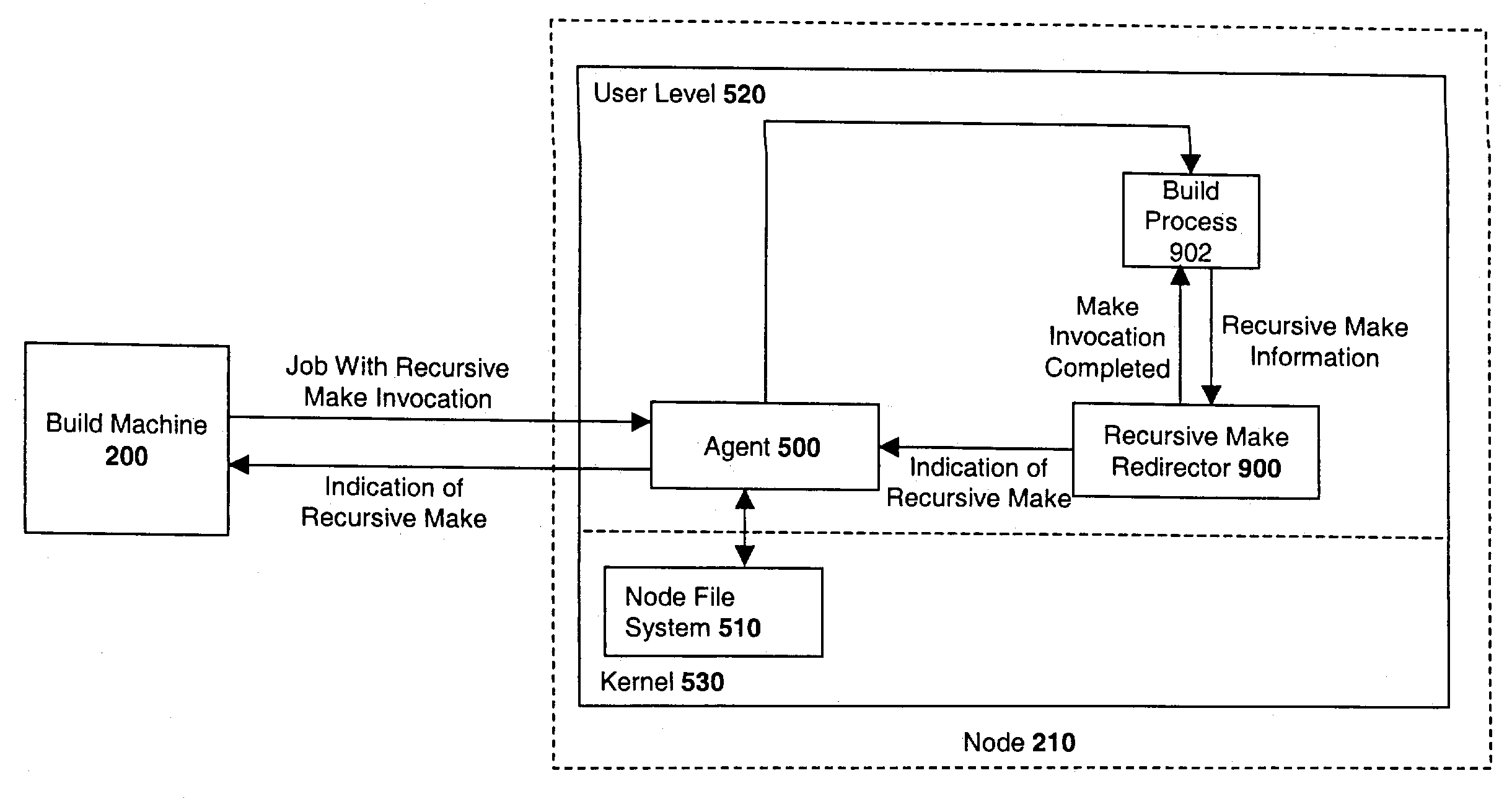

System and method for processing recursive invocations within a program build

ActiveUS7263695B1BuildIncreased riskVersion controlMultiprogramming arrangementsProgram planningParallel computing

A method for executing program builds is described comprising: executing jobs for a program build in parallel according to a first job schedule; detecting a recursive build invocation in one of the jobs; analyzing dependency information associated with the recursive build invocation; and based on the analysis, supplementing the first job schedule with additional job schedule data.

Owner:CLOUDEBEES INC

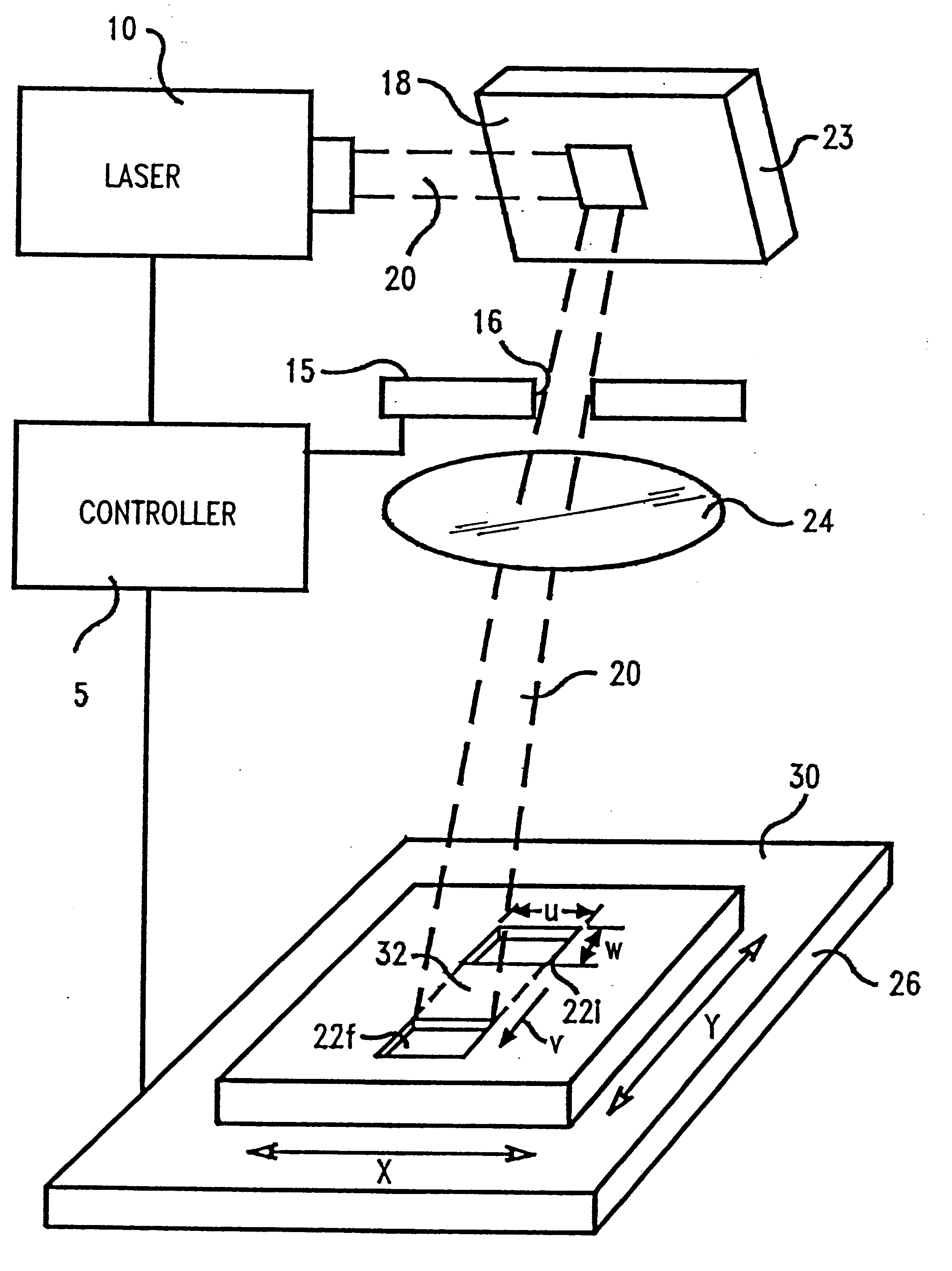

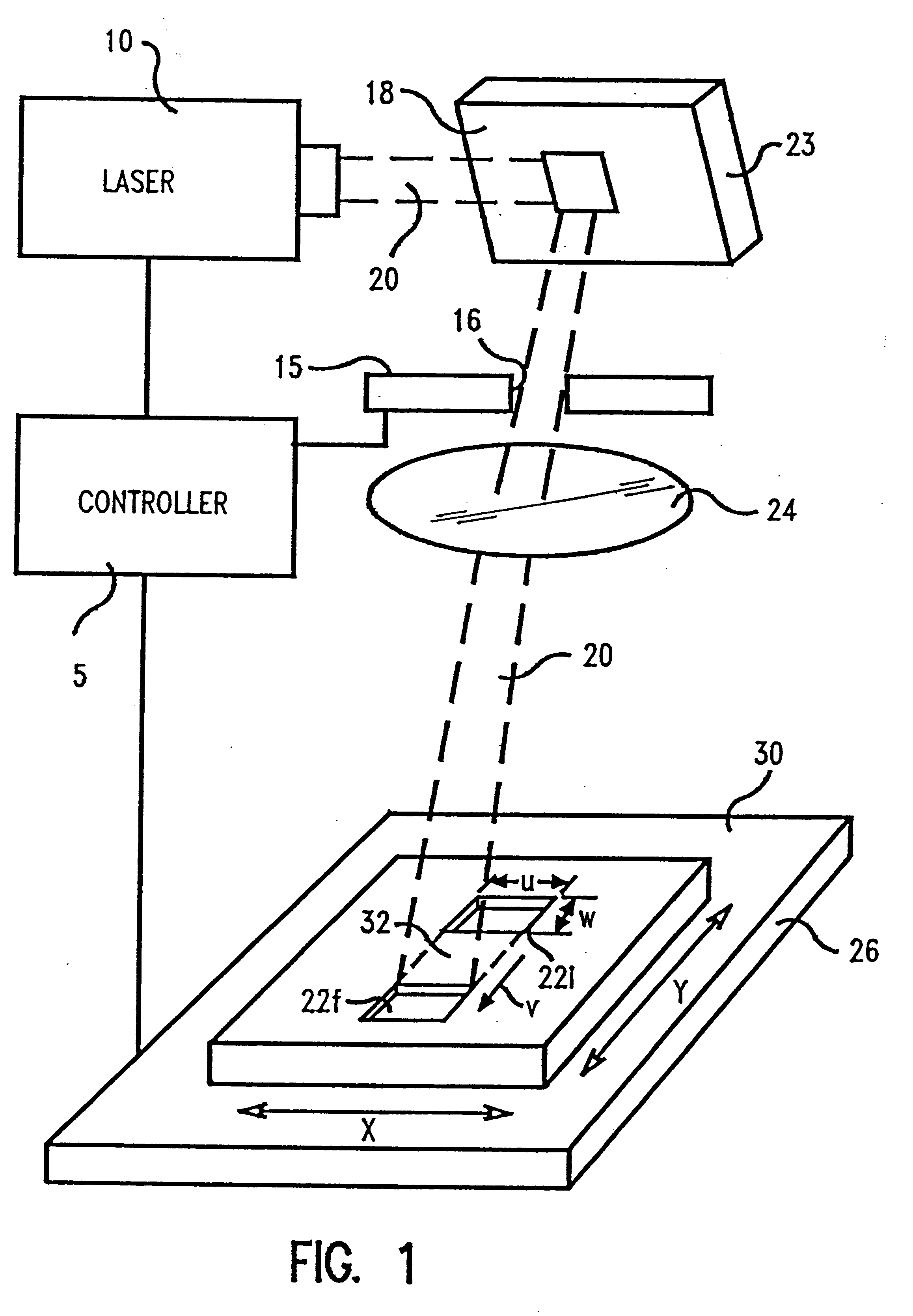

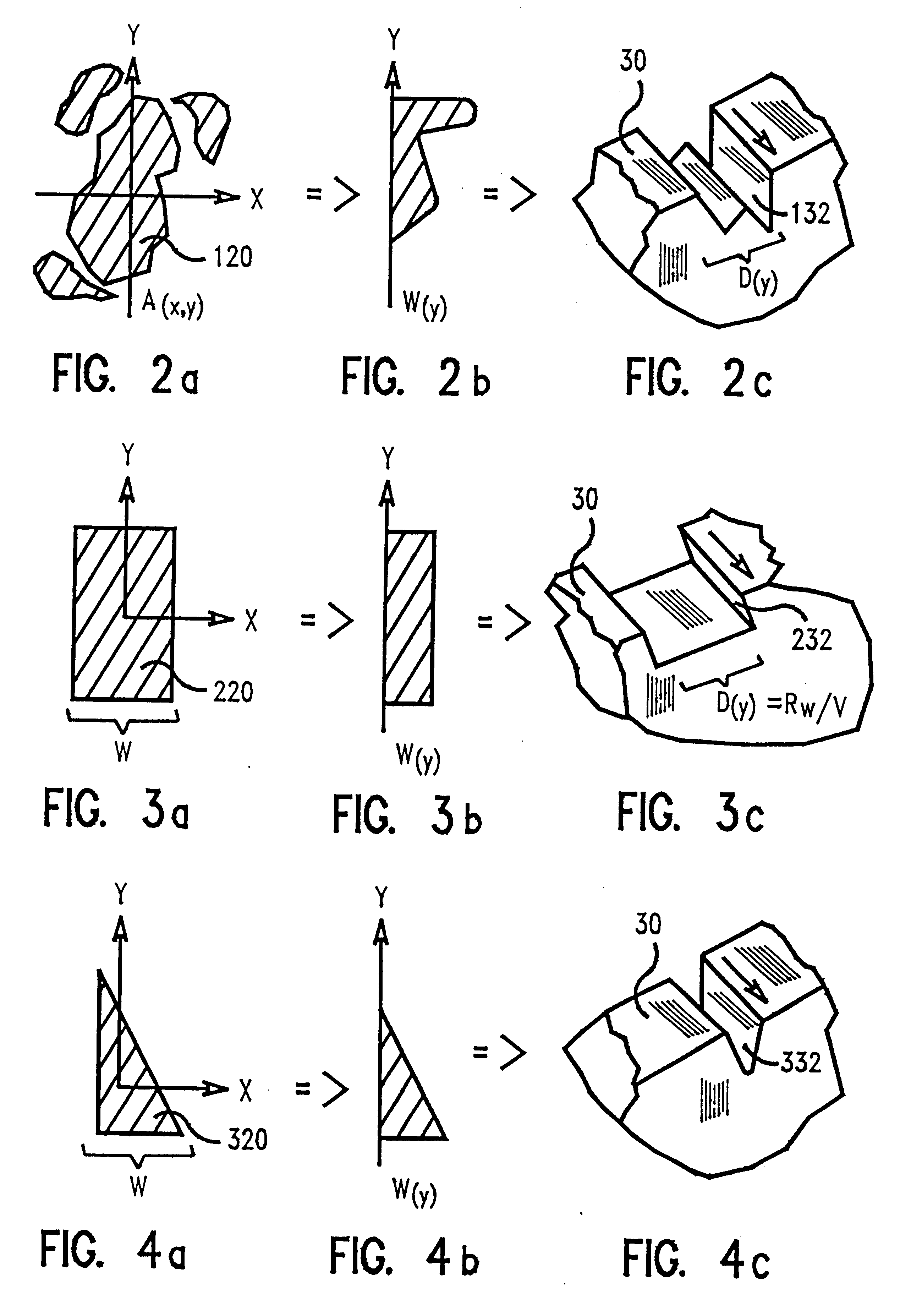

Method for creation of inclined microstructures using a scanned laser image

A system for controlling inclination and depth of ablation of a polymer planar waveguide or semiconductor wafer substrate utilizes a laser which directs the beam at the substrate to ablate portions of the surface thereof and a translatable stage for moving the substrate relative to the beam to create a path of ablated material from the surface. The velocity of the substrate is controlled relative to ablation rate of material from the surface or the dimension of the beam is controlled along the path of ablated material to create a desired inclination and depth of ablated material in the path. The depth of ablated material is a function of the beam width along the path of ablated material, workpiece velocity and ablation rate and is substantially controlled by the formula:where D is the depth of ablated material, R is ablation rate, W is beam dimension along the path of ablated material, and V is workpiece velocity.

Owner:IBM CORP +1

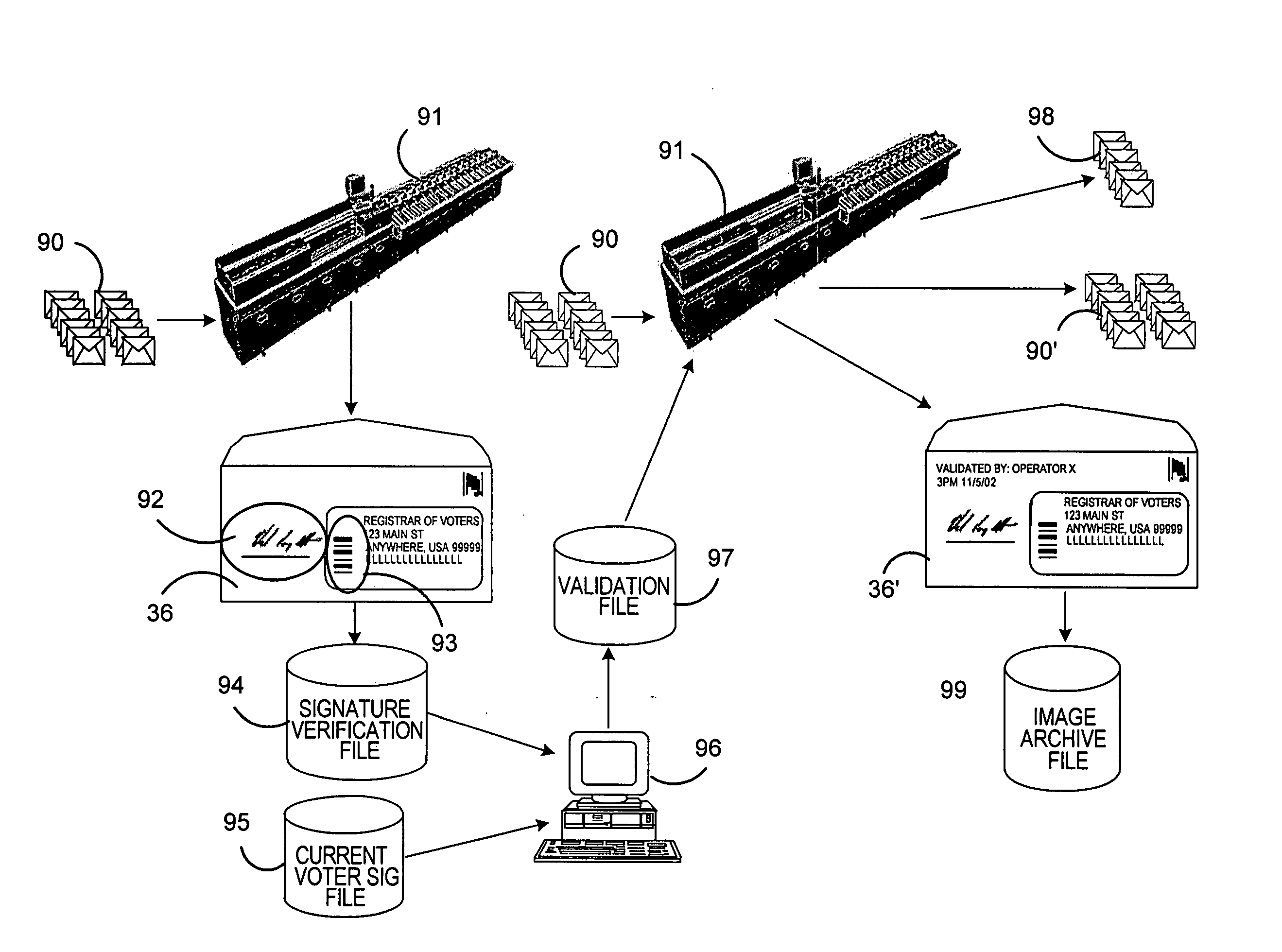

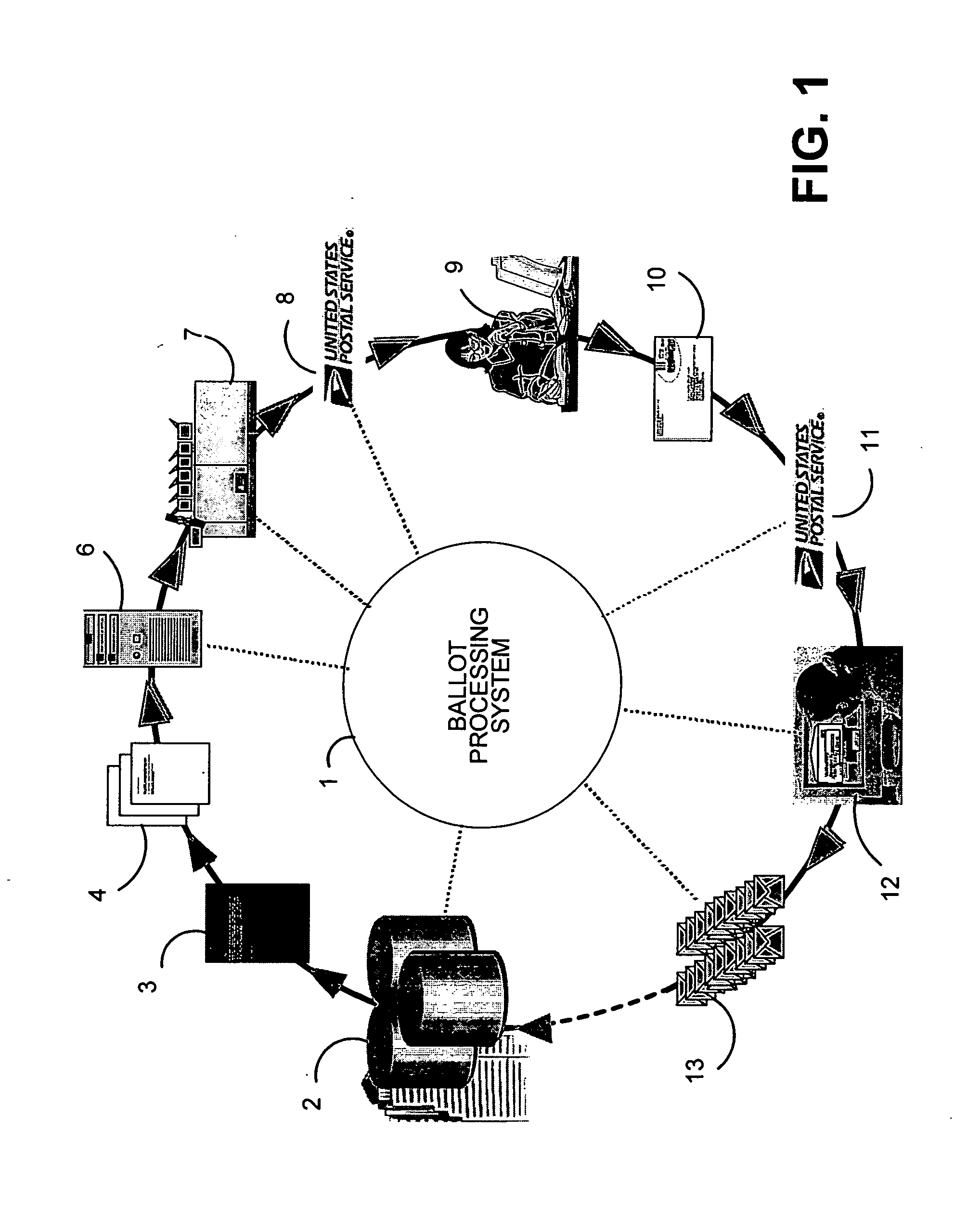

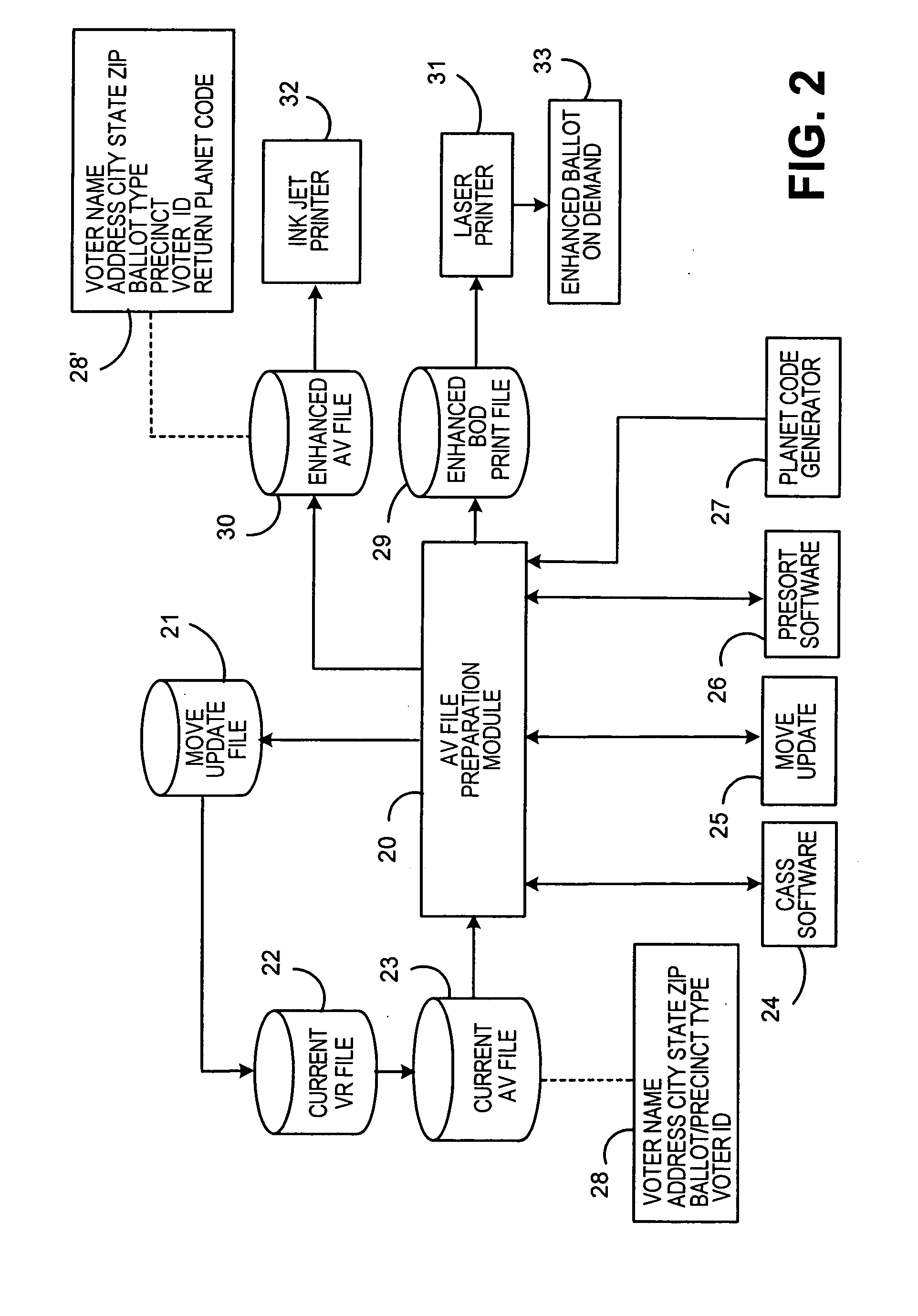

Automated system and method for inbound processing of mailed ballots

ActiveUS20060049252A1Reliable handlingAchieve accountabilityVoting apparatusCo-operative working arrangementsComputer scienceReceipt

A system and method for processing incoming mailed ballot packages having a voter ID code and a verification signature on the envelope and a ballot enclosed within the envelope. Prior to receipt of the incoming ballots voter signatures have been electronically stored and associated with voter ID's. Ballot packages are fed and transported on automated machinery. Voter ID's are scanned and cameras are used for capturing images of the verification signatures from the ballot packages. Based on the scanned voter ID's, electronically stored voter signatures are retrieved. Next, the captured verification signatures are compared with the stored voter signatures corresponding to the scanned voter ID's. A validation file is generated that indicates which ballot packages had verification signatures that were successfully matched with stored voter signatures during the comparing step. Finally, the automated equipment sorts ballot packages using the validation file to separate successfully matched and validated ballot packages from unvalidated ballot packages.

Owner:DMT SOLUTIONS GLOBAL CORP

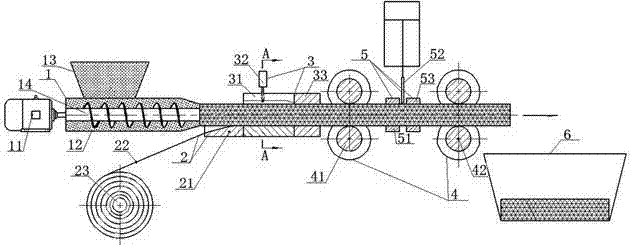

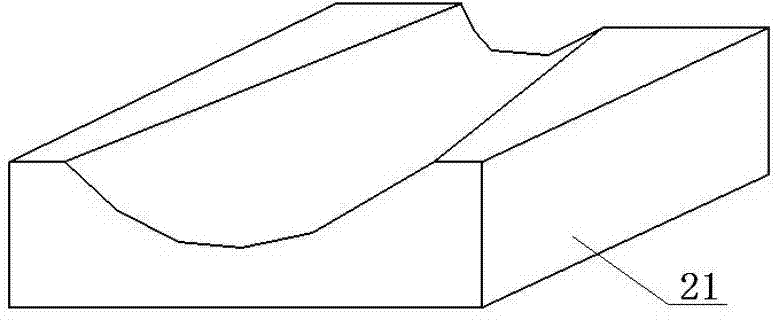

Moxa cone coiling forming machine

ActiveCN104490593AImprove medicinal qualityEasy to operateDevices for heating/cooling reflex pointsConveyorsRolling paperMolding machine

The invention discloses a moxa cone coiling forming machine which comprises a spiral conveying mechanism, a paper tape winding mechanism, a gluing and forming mechanism and a shearing mechanism which are arranged in sequence, wherein the spiral conveying mechanism is used for forming a naked moxa cone; the paper tape winding mechanism mainly consists of a paper coiling disc and a paper tape; a conical guide groove of which the front part is large and the rear part is small is formed in the paper coiling disc; the width of the paper tape is greater than the perimeter of the naked moxa cone; the paper tape is paved inside the conical guide groove in the paper coiling disc in a dynamic conveying manner; the gluing and forming mechanism mainly consists of a gluing machine and a sealing ring; the gluing machine is used for gluing the paper tape; the sealing ring is used for shifting, guiding and compacting the glued paper tape when the paper tape is dynamically conveyed, so as to coil and seal the paper tape; the shearing mechanism is used for shearing the coiled and formed moxa cone output from the gluing and forming mechanism. The moxa cone coiling forming machine is capable of automatically and continuously producing coiled paper moxa cones and is applicable to large-scale in-batch production, the whole production process is clean, sanitary, free of pollution, high in production efficiency and low in cost, and the formed moxa cones are high in medicinal quality.

Owner:SICHUAN ENG TECHN COLLEGE

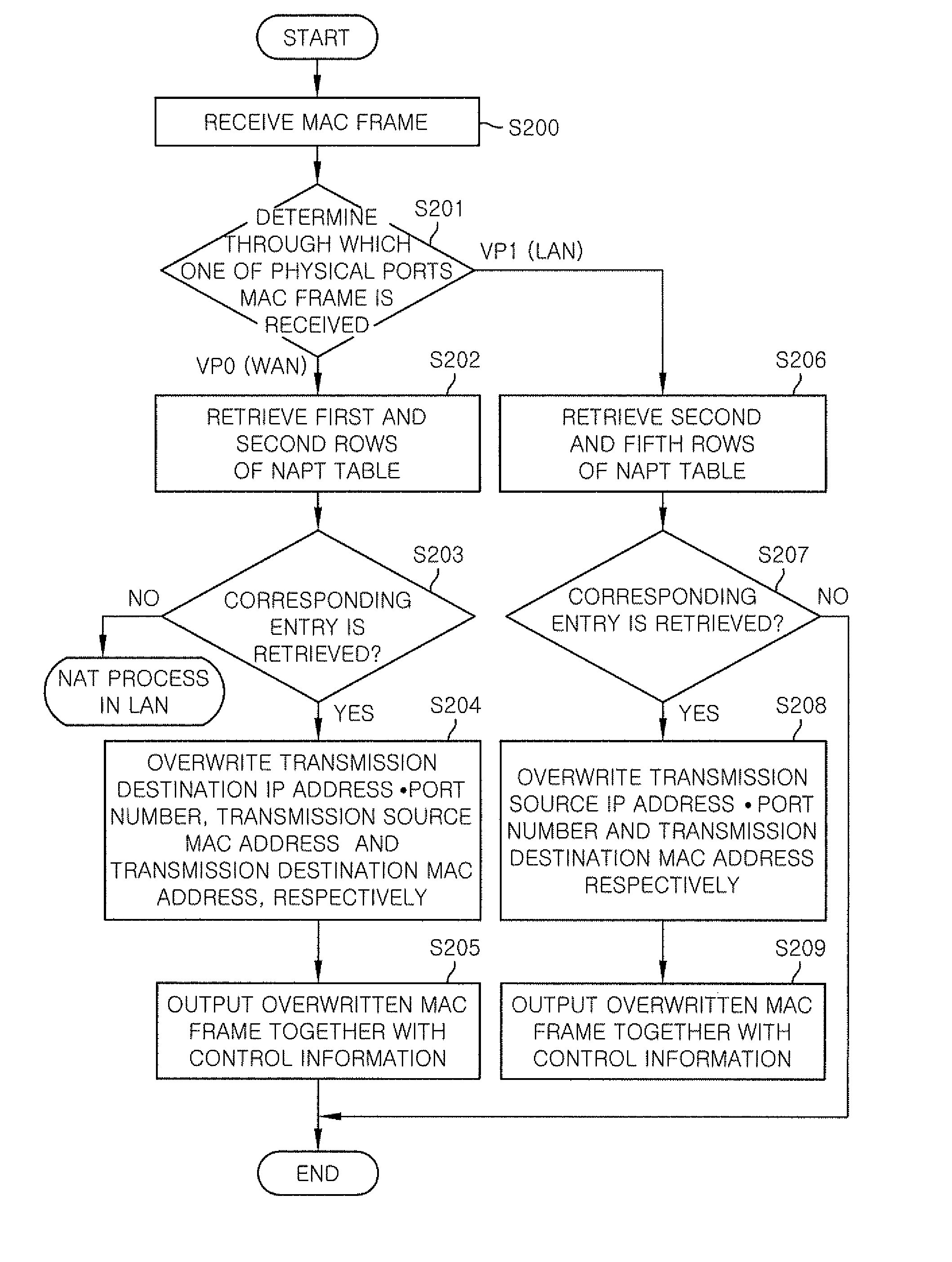

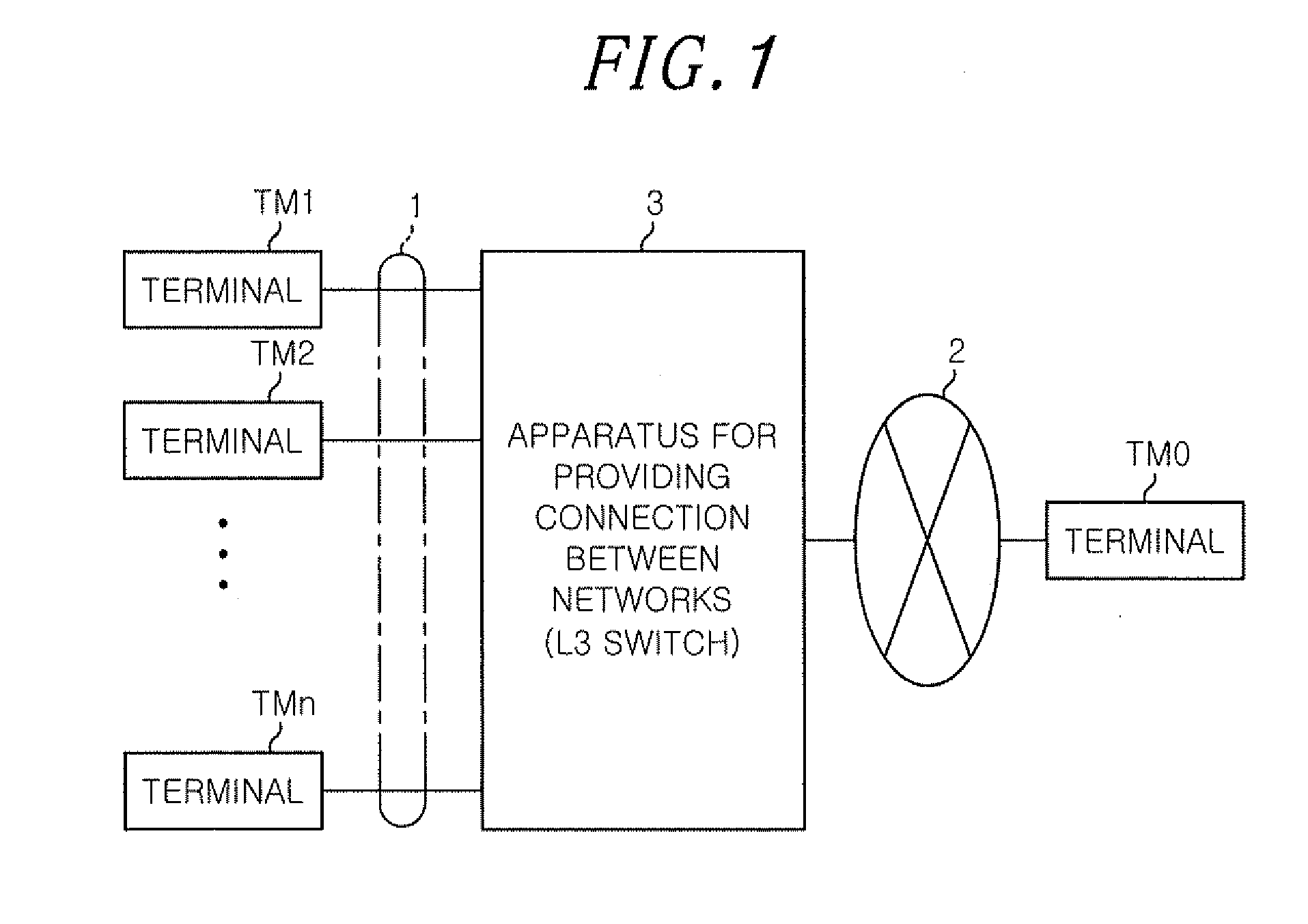

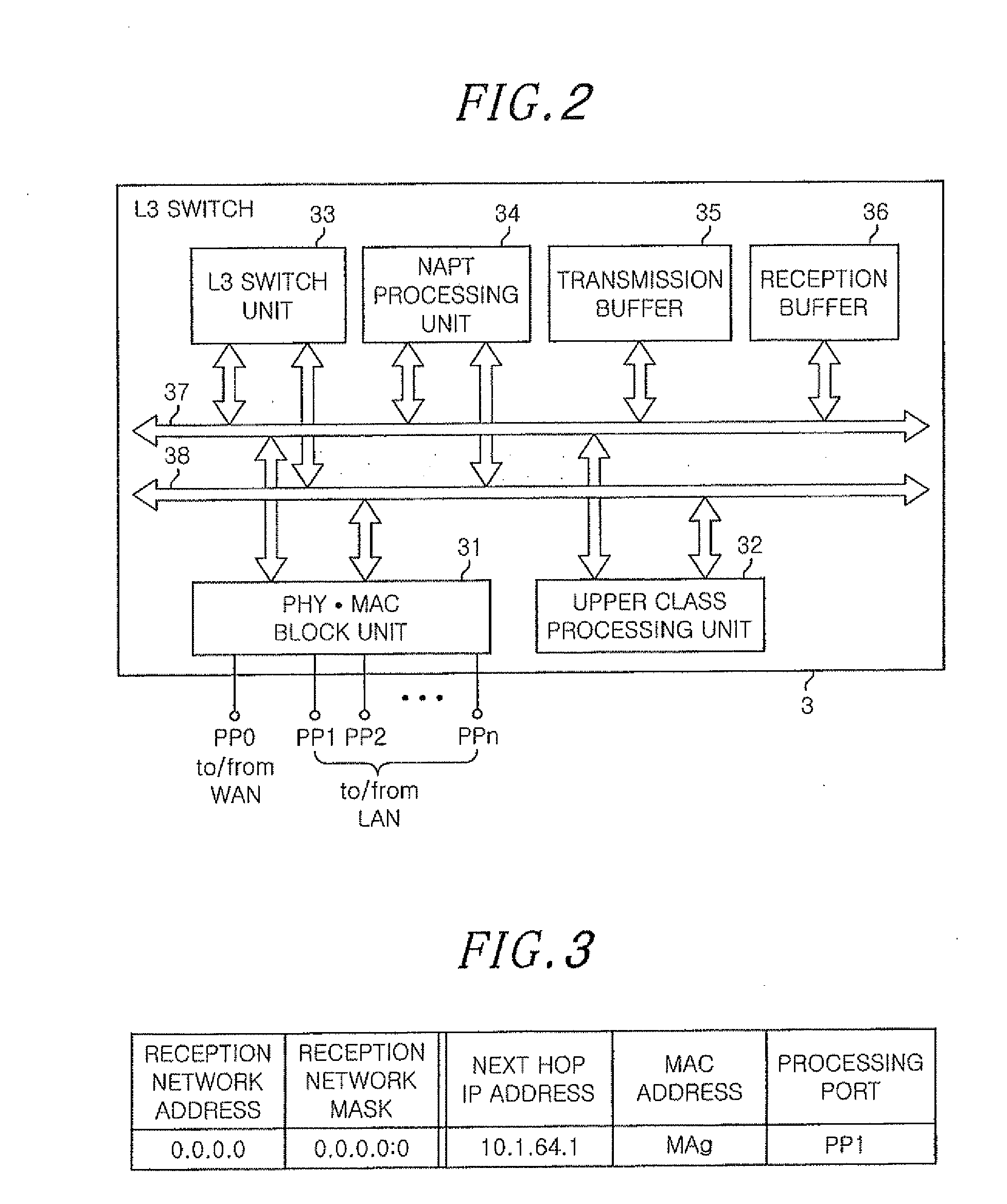

Apparatus for providing connection between networks

ActiveUS20110299538A1Reliable transmissionReduce administrative burdenNetworks interconnectionComputer hardwarePrivate address

When an internal terminal (TM1 to TMn) replaced with another terminal due to the breakdown or the model upgrading and the DHCP function allocates a new private address for the MAC address of the terminal after replacement, the newly allocated private address is managed in association with physical ports (PP1 to PPn) in an expansion NAPT table. Then, in this state, when an IP packet is delivered from an external terminal (TM0) on the side of a WAN(2), the transmission destination address of this IP packet is converted to the private address of the internal terminal after conversion in accordance with the expansion NAPT table using the physical ports as a key.

Owner:KOKUSA ELECTRIC CO LTD

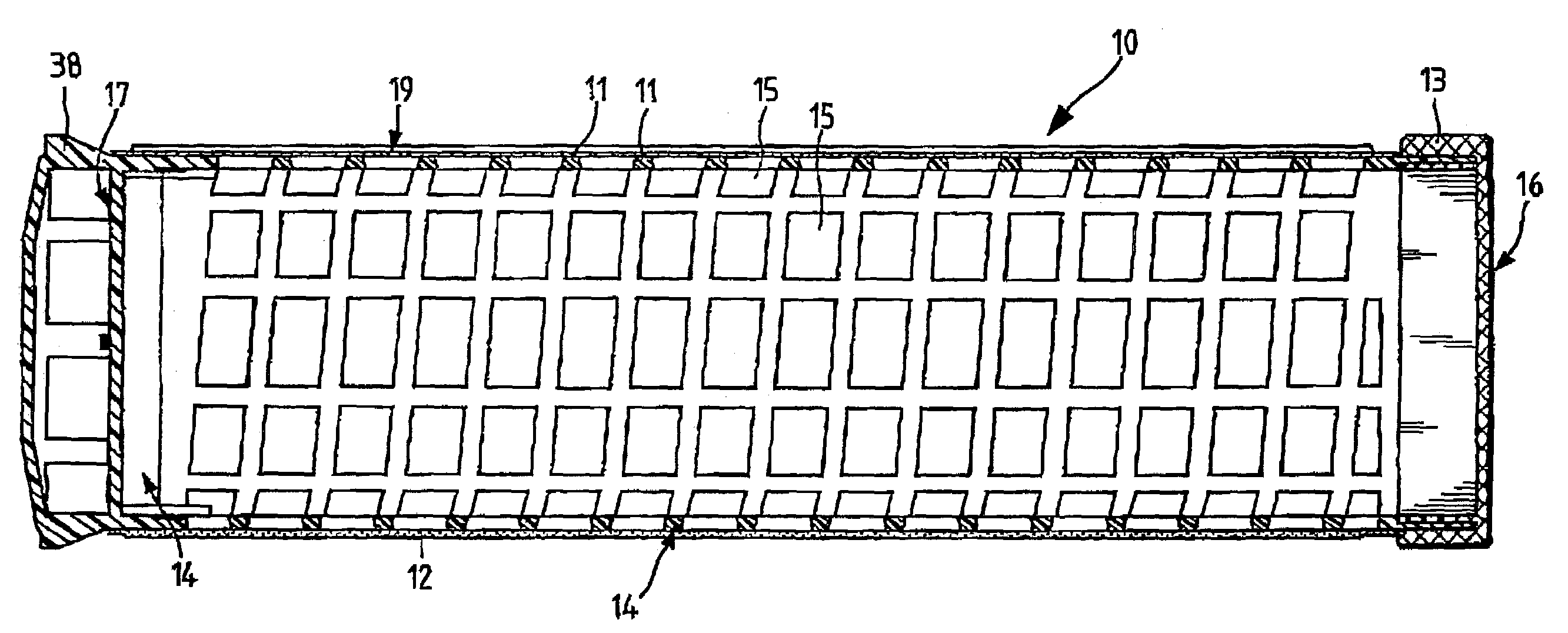

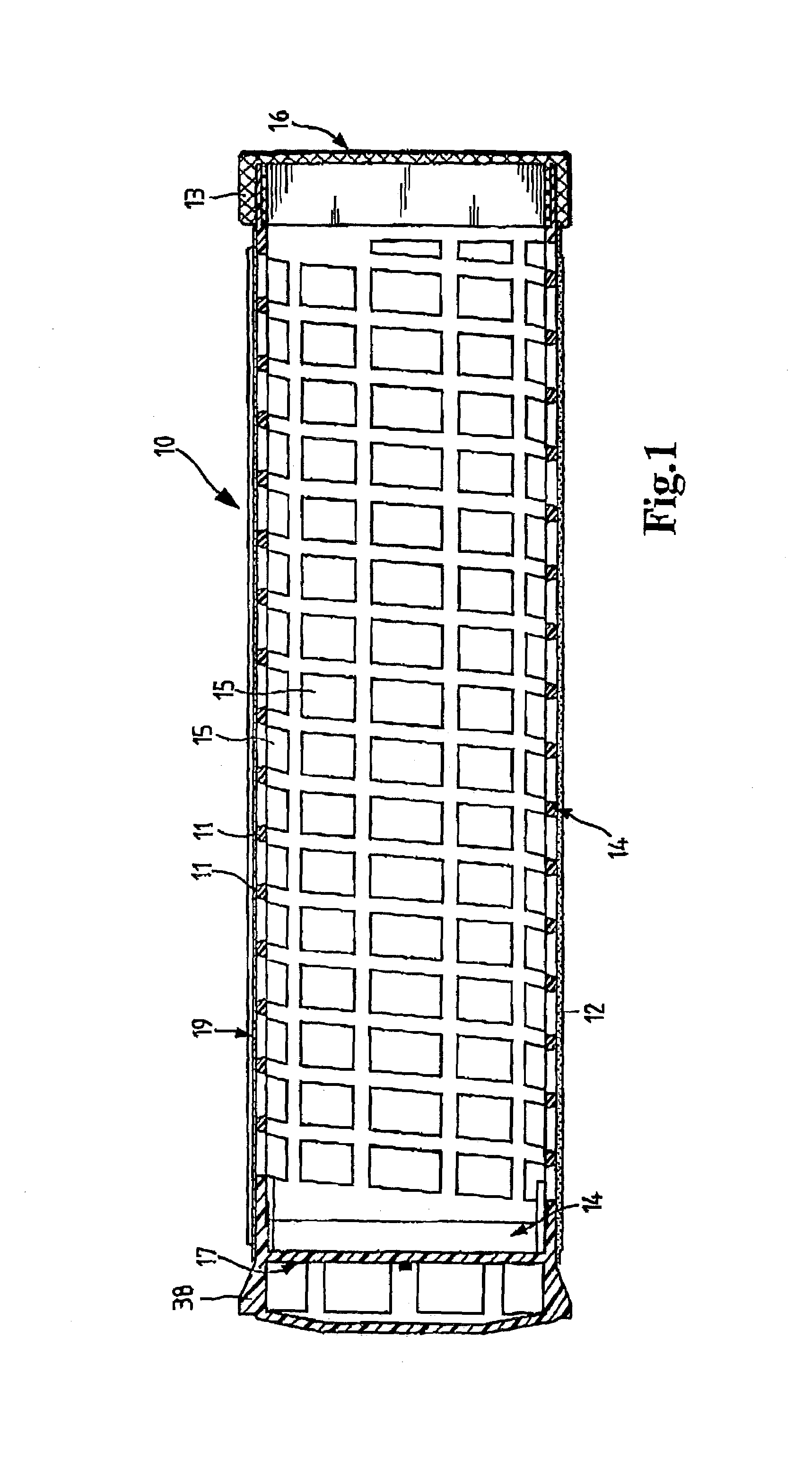

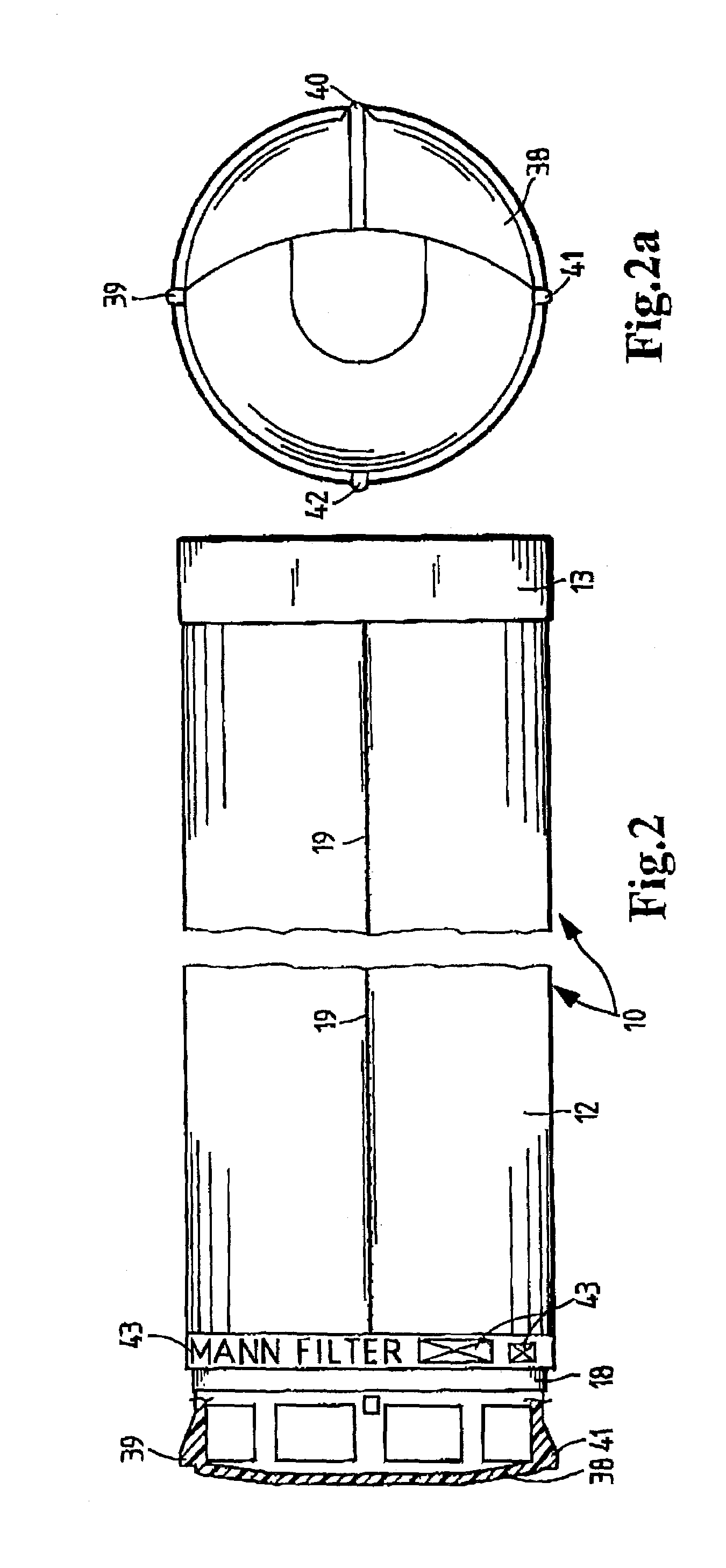

Filter element for filtering a fluid stream

ActiveUS7090708B2Easy to replaceAvoid damageCombination devicesAuxillary pretreatmentFilter mediaEngineering

A filter element for filtering a fluid stream, comprising a cylindrical support body, which is provided with openings and is sealed at one axial end, and a filter medium arranged on the support body. The filter medium is a strip material, which extends over approximately the entire length of the support body, and is wrapped around the circumference of the support body, and the start and the end of the strip material are welded together.

Owner:MANN HUMMEL GMBH

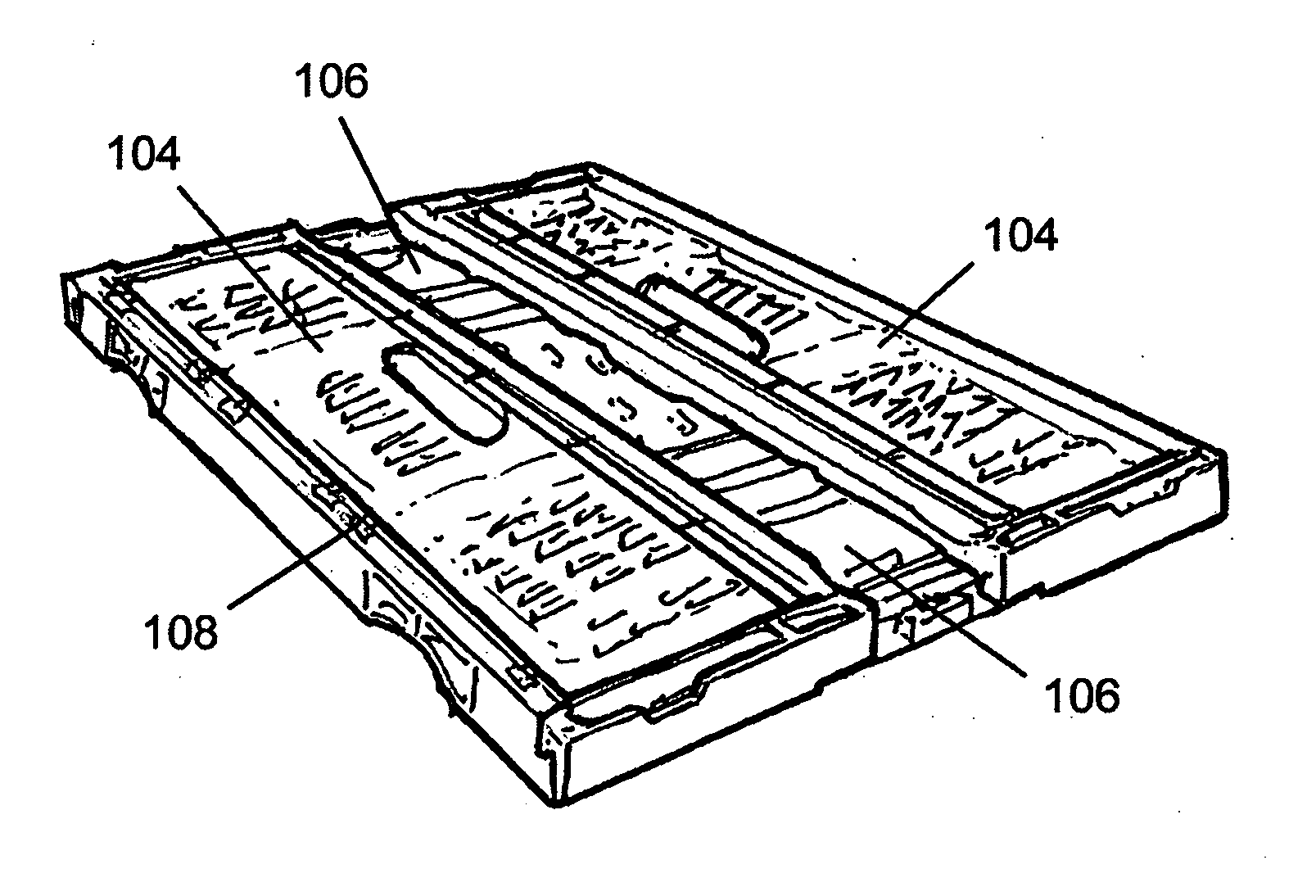

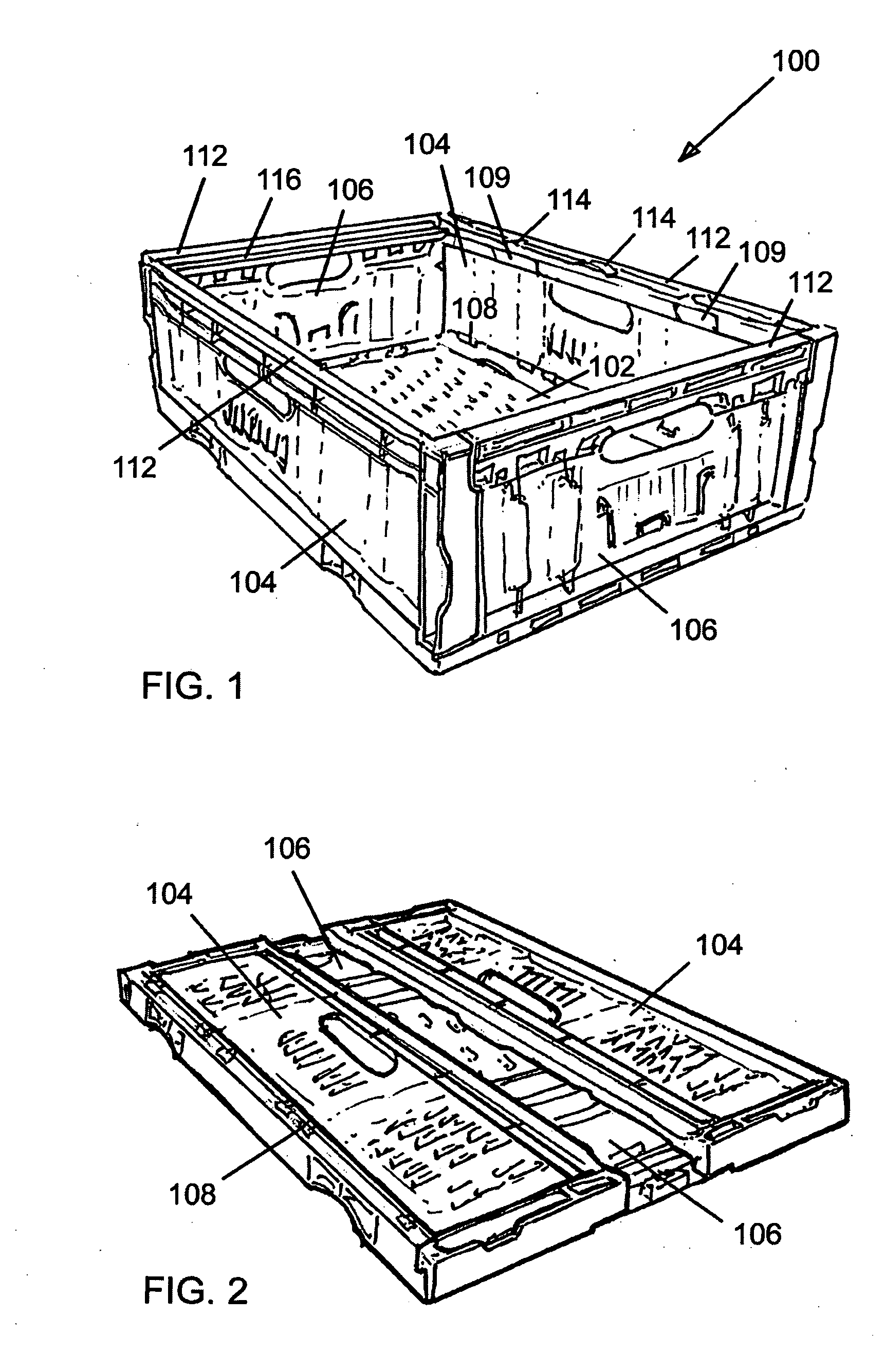

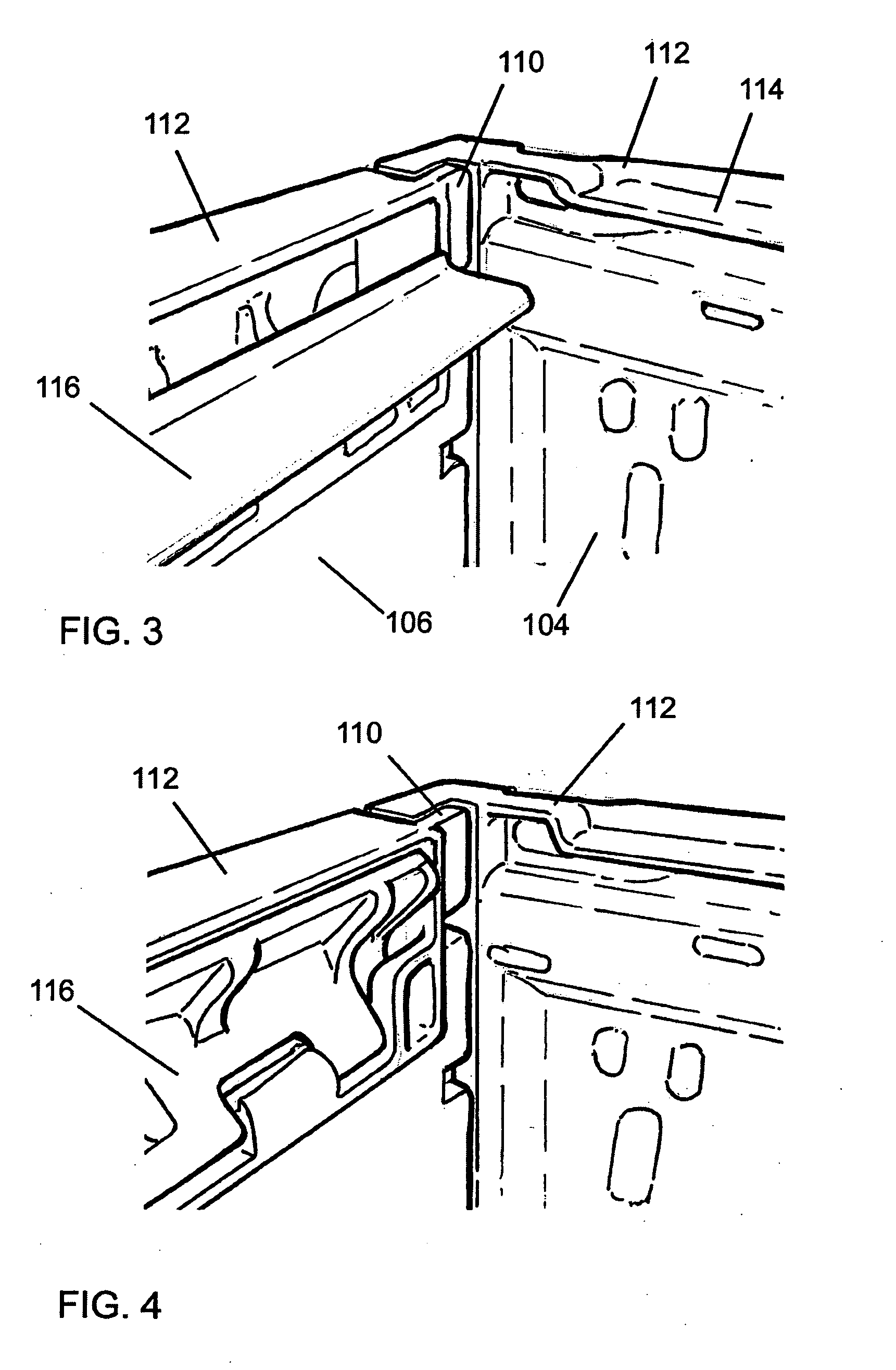

Collapsible container

InactiveUS20070125779A1Prevent unintended collapseReliable handlingRigid containersFree edgeMechanical engineering

A collapsible container that may be configured in a collapsed condition or an erected condition, including a base (102), a pair of side walls (104) and a pair of side walls (106) that are pivotally attached to the base. The walls (104,106) are arranged to lie substantially parallel with the base (102) when collapsed and to stand substantially perpendicular to the base when erected. The free edges of the erected walls define an open mouth. A pair of stacking elements (116) are located adjacent to the free edges of the end walls (106) for supporting the base of another container stacked on the first container. The end walls (106) lie adjacent the base (102) and side walls (104) overlie the end walls when collapsed.

Owner:LINPAC MATERIALS HANDLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com