Moxa cone coiling forming machine

A molding machine and molding mechanism technology, applied to conveyors, heating/cooling reflection point instruments, packaging, etc., can solve the problems of inability to realize large-scale production, inability to shape, store, and transport, lack of shaping, protective layer, etc., to achieve the goal of handling Easy to operate, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

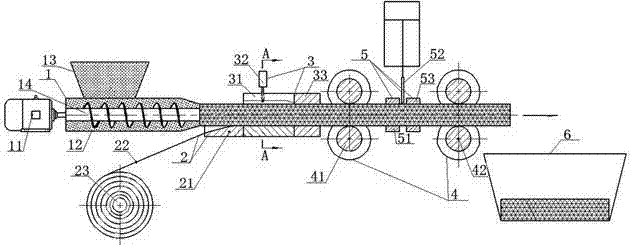

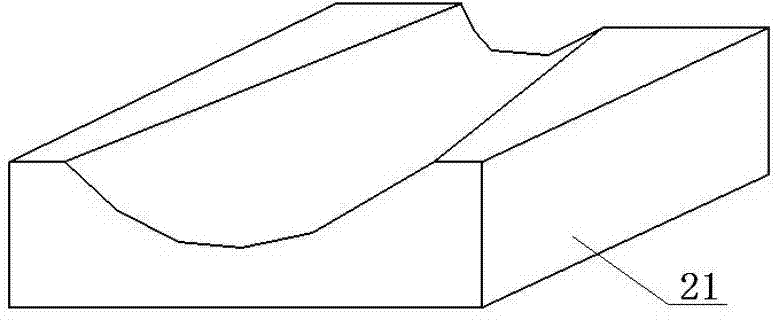

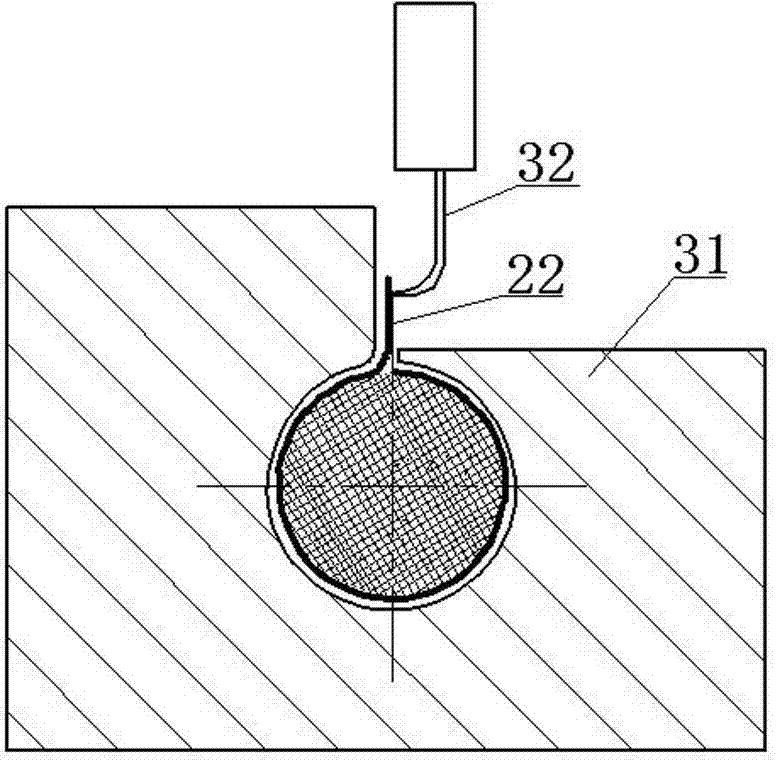

[0019] see figure 1 , figure 2 and image 3 : the present invention is the roll-forming machine of roll paper moxa column, and it comprises the screw feeding mechanism 1 that arranges sequentially from front to back, paper tape wrapping mechanism 2, gluing forming mechanism 3, moxa column traction mechanism 4, Shearing mechanism 5 and storage box 6, promptly these mechanisms of the present invention have constituted a rolling paper moxa post production line of continuous production, are used for successively compacting loose moxa velvet to form naked moxa post, along with the delivery roll of naked moxa post Making paper tape, sealing the paper tape so that the naked moxa pillars are wrapped, outputting the formed roll paper moxa pillars, cutting them to the required length, and storing them. In view of the fact that the moxa pillar structure processed by the present invention is relatively "fragile", the moxa pillar passing grooves of the above-mentioned mechanisms (except...

Embodiment 2

[0028] Other structures of this embodiment are the same as those of Embodiment 1, except that the sealing ring of the gluing forming mechanism is a half-ring structure, and its button cover is at the rear end of the gluing guide plate.

Embodiment 3

[0030] Other structures of this embodiment are the same as those of Embodiment 1, except that each group of traction rollers of the moxa-pillar traction mechanism is mainly composed of a cylindrical (or inner arc-shaped) idler roller. This kind of moxa pillar traction mechanism only plays the role of supporting and conveying, and the traction and orthopedic effects are limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com