Patents

Literature

300 results about "Paper pallet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

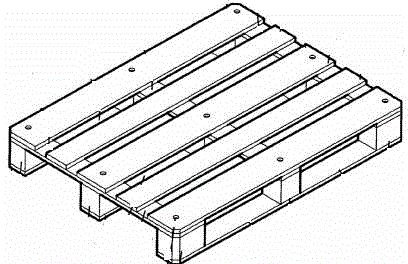

Paper pallets, or ecopallets, are shipping or display pallets made from paperboard.

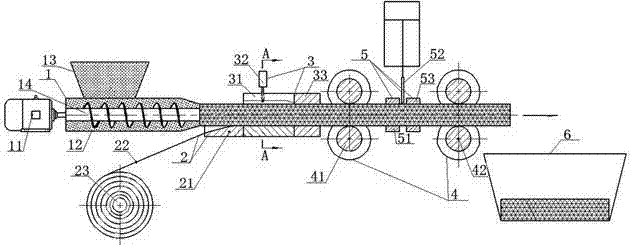

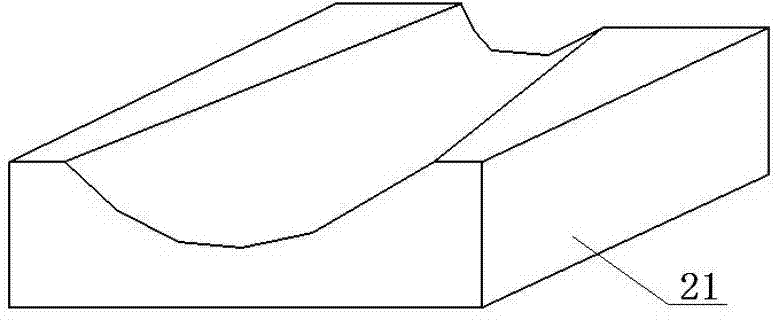

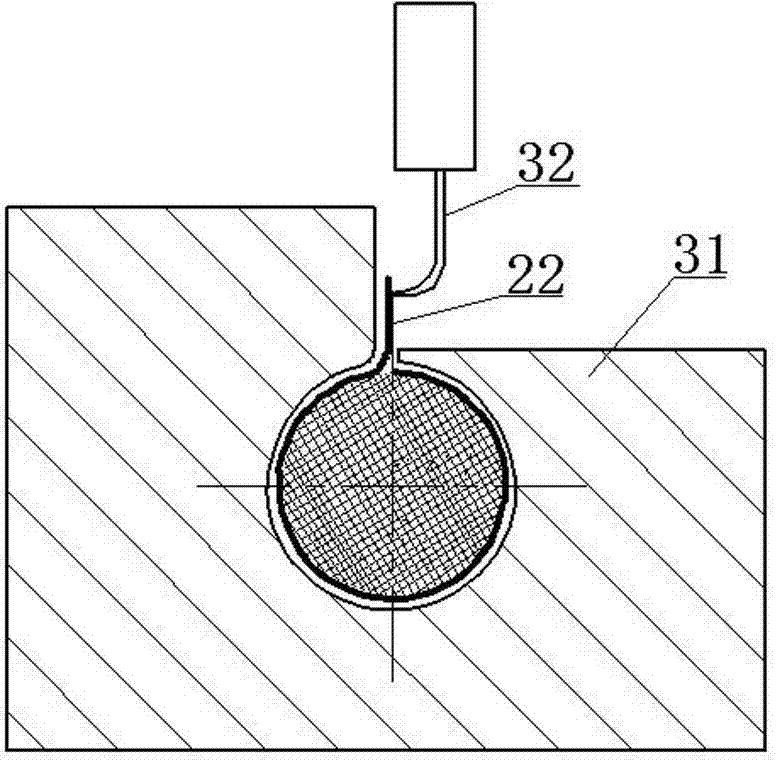

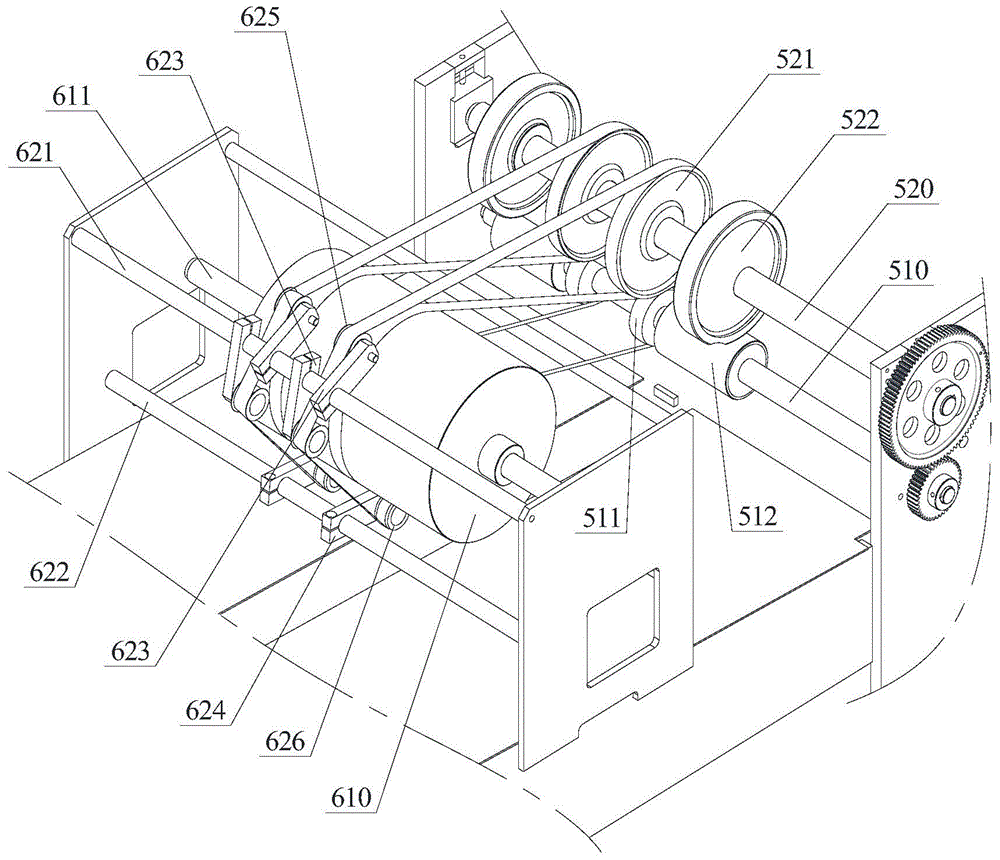

Moxa cone coiling forming machine

ActiveCN104490593AImprove medicinal qualityEasy to operateDevices for heating/cooling reflex pointsConveyorsRolling paperMolding machine

The invention discloses a moxa cone coiling forming machine which comprises a spiral conveying mechanism, a paper tape winding mechanism, a gluing and forming mechanism and a shearing mechanism which are arranged in sequence, wherein the spiral conveying mechanism is used for forming a naked moxa cone; the paper tape winding mechanism mainly consists of a paper coiling disc and a paper tape; a conical guide groove of which the front part is large and the rear part is small is formed in the paper coiling disc; the width of the paper tape is greater than the perimeter of the naked moxa cone; the paper tape is paved inside the conical guide groove in the paper coiling disc in a dynamic conveying manner; the gluing and forming mechanism mainly consists of a gluing machine and a sealing ring; the gluing machine is used for gluing the paper tape; the sealing ring is used for shifting, guiding and compacting the glued paper tape when the paper tape is dynamically conveyed, so as to coil and seal the paper tape; the shearing mechanism is used for shearing the coiled and formed moxa cone output from the gluing and forming mechanism. The moxa cone coiling forming machine is capable of automatically and continuously producing coiled paper moxa cones and is applicable to large-scale in-batch production, the whole production process is clean, sanitary, free of pollution, high in production efficiency and low in cost, and the formed moxa cones are high in medicinal quality.

Owner:SICHUAN ENG TECHN COLLEGE

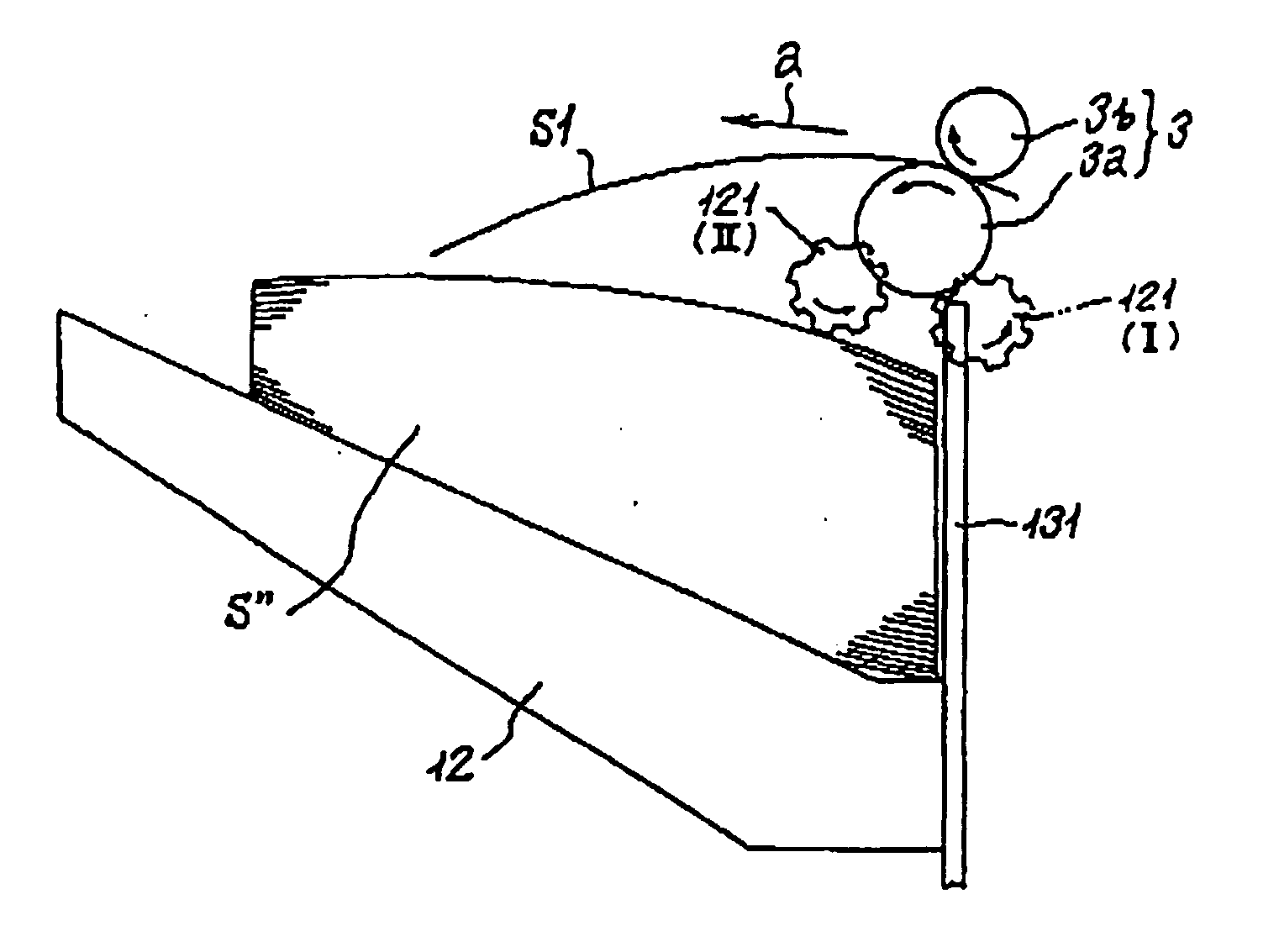

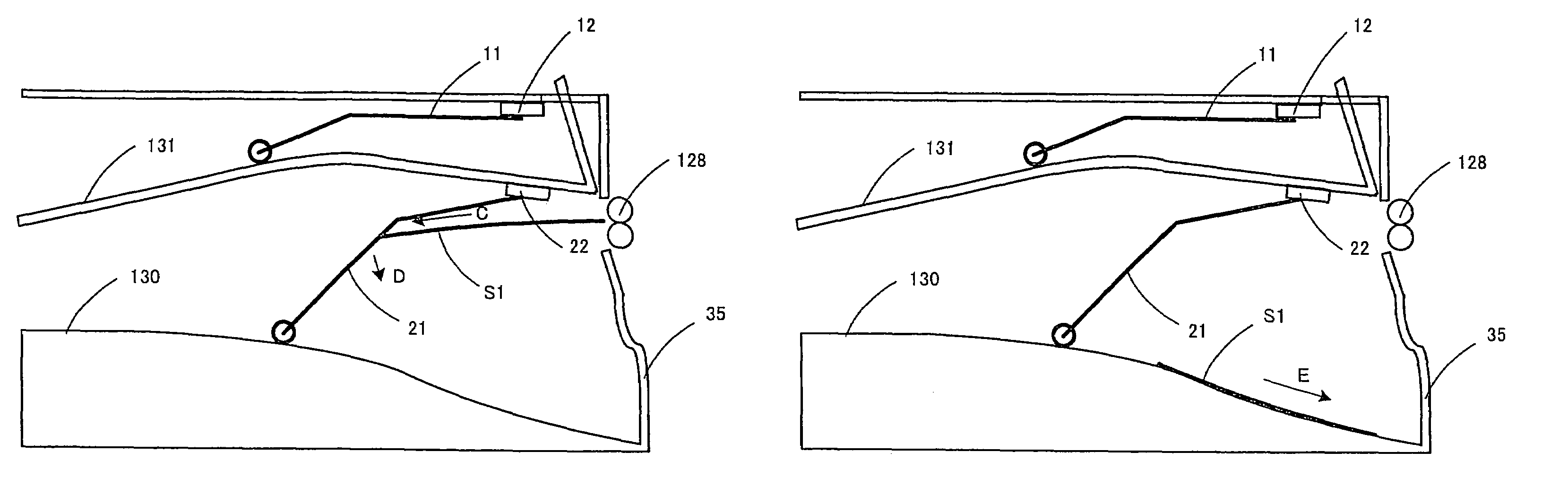

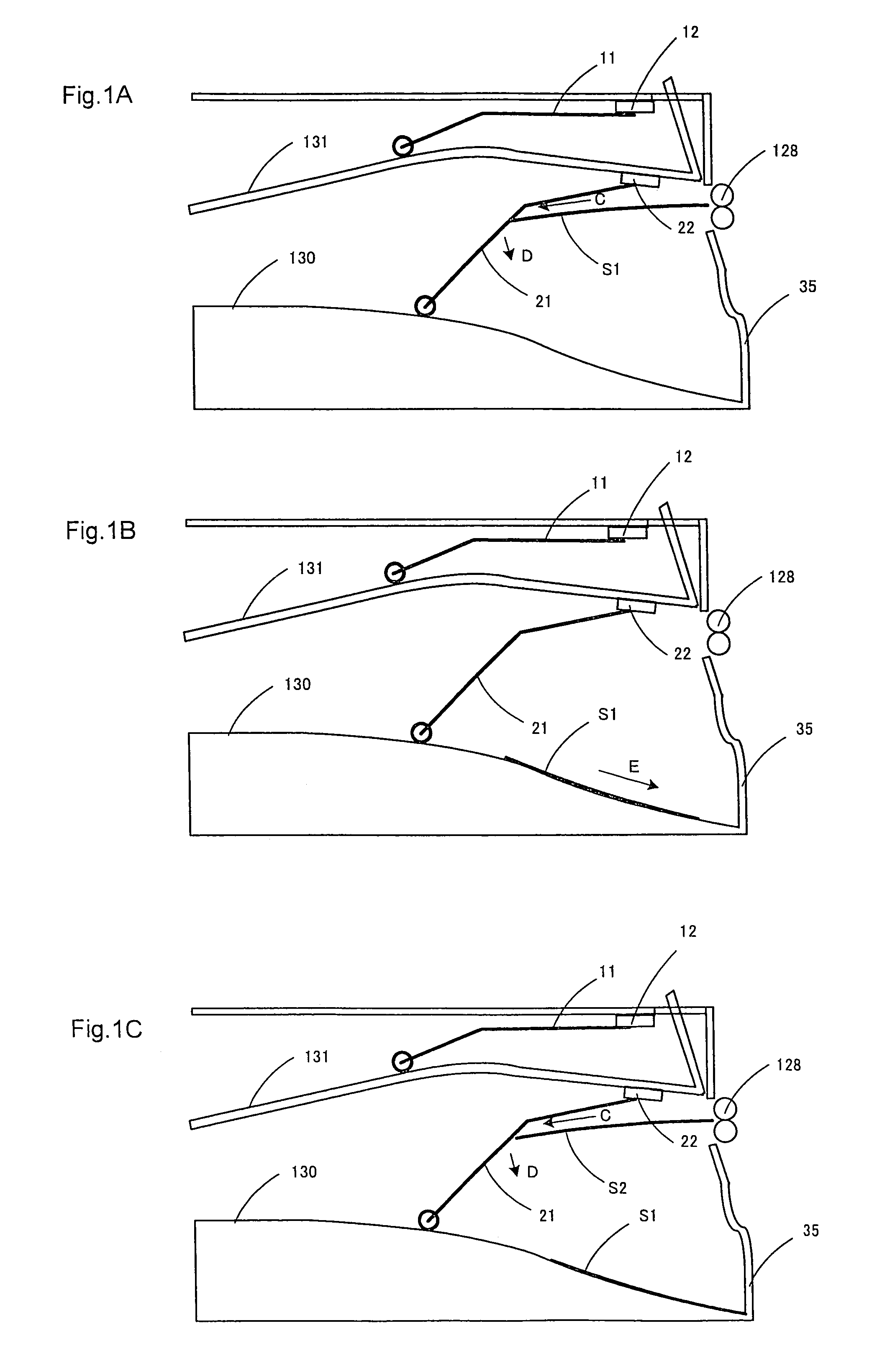

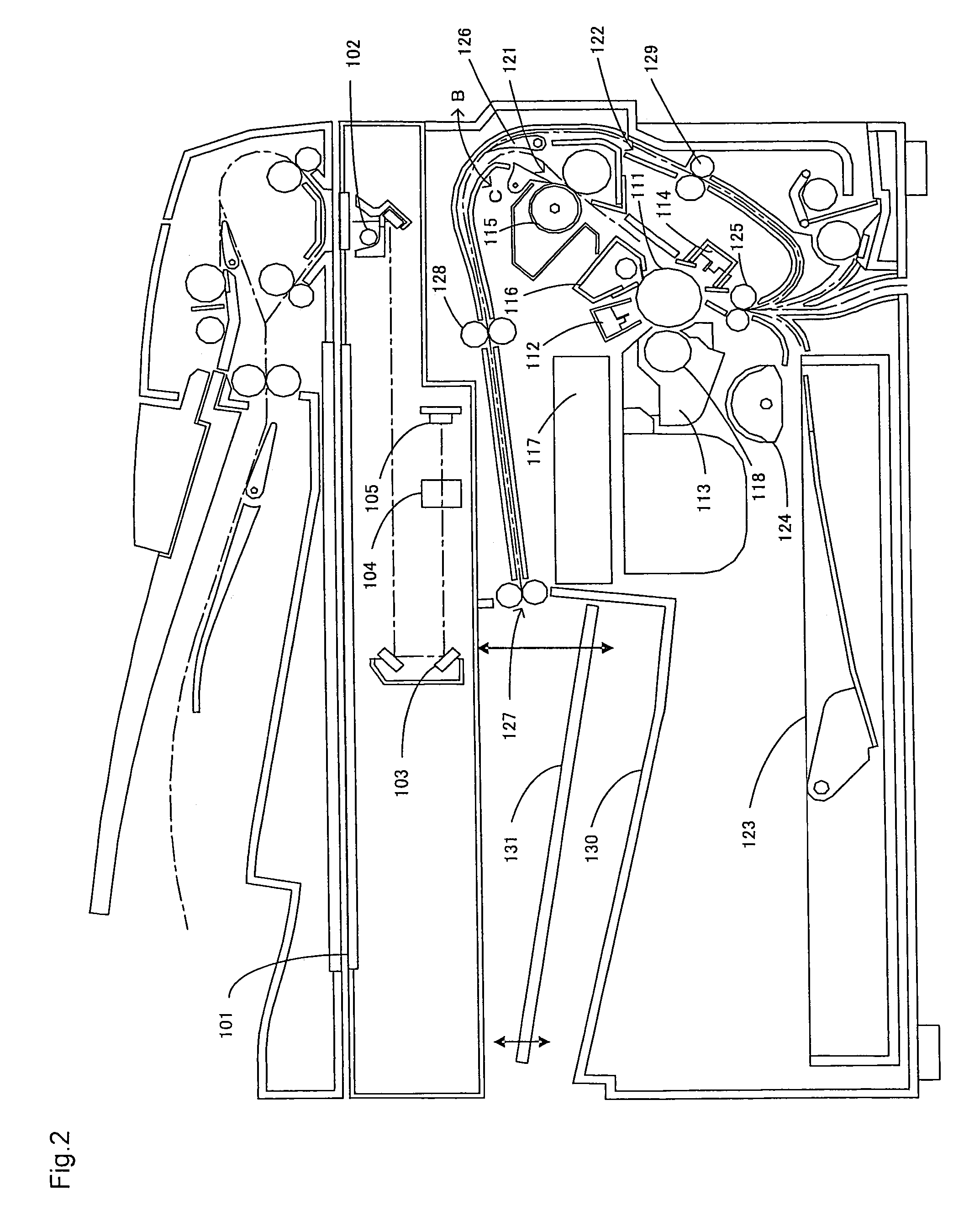

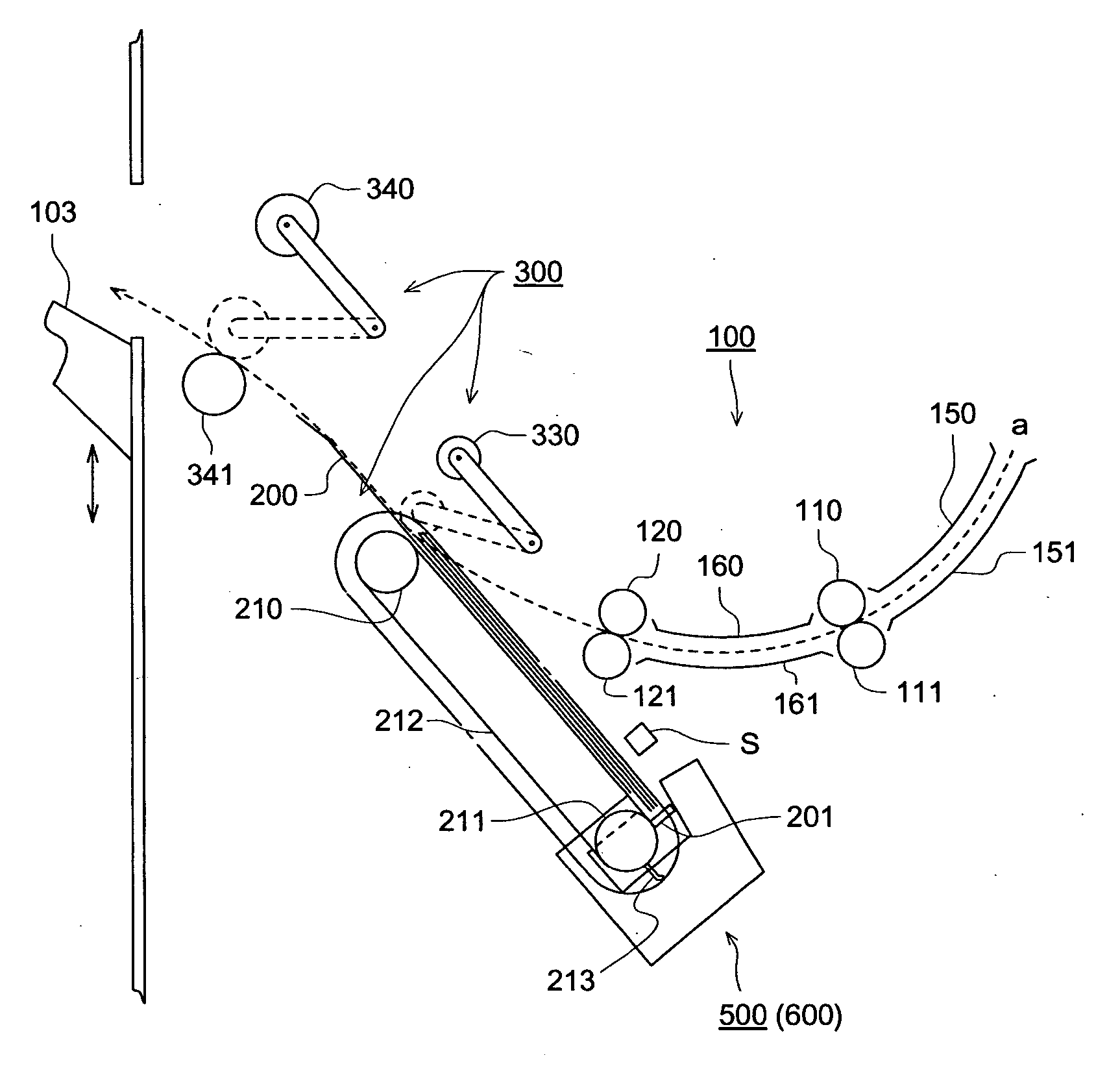

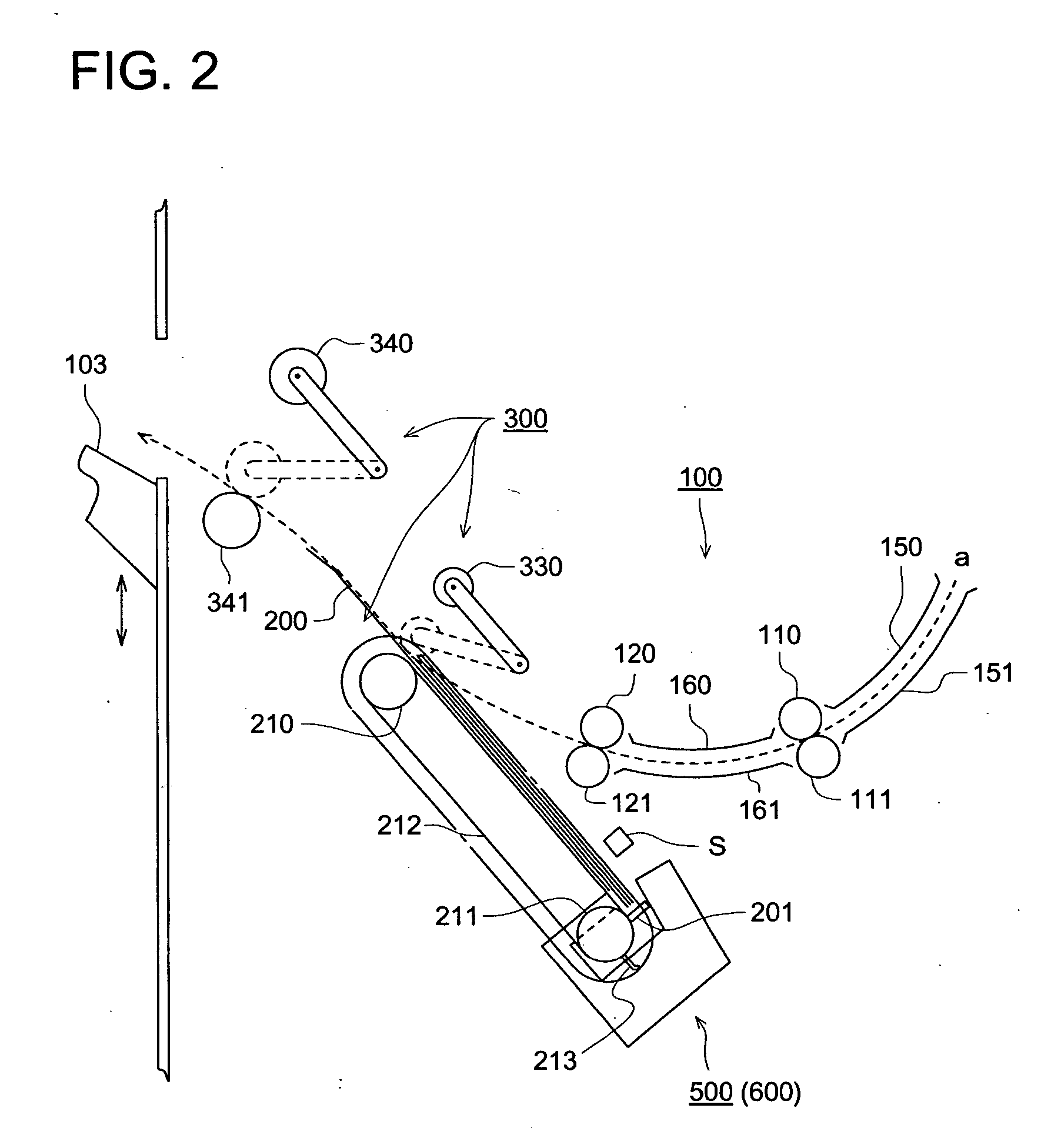

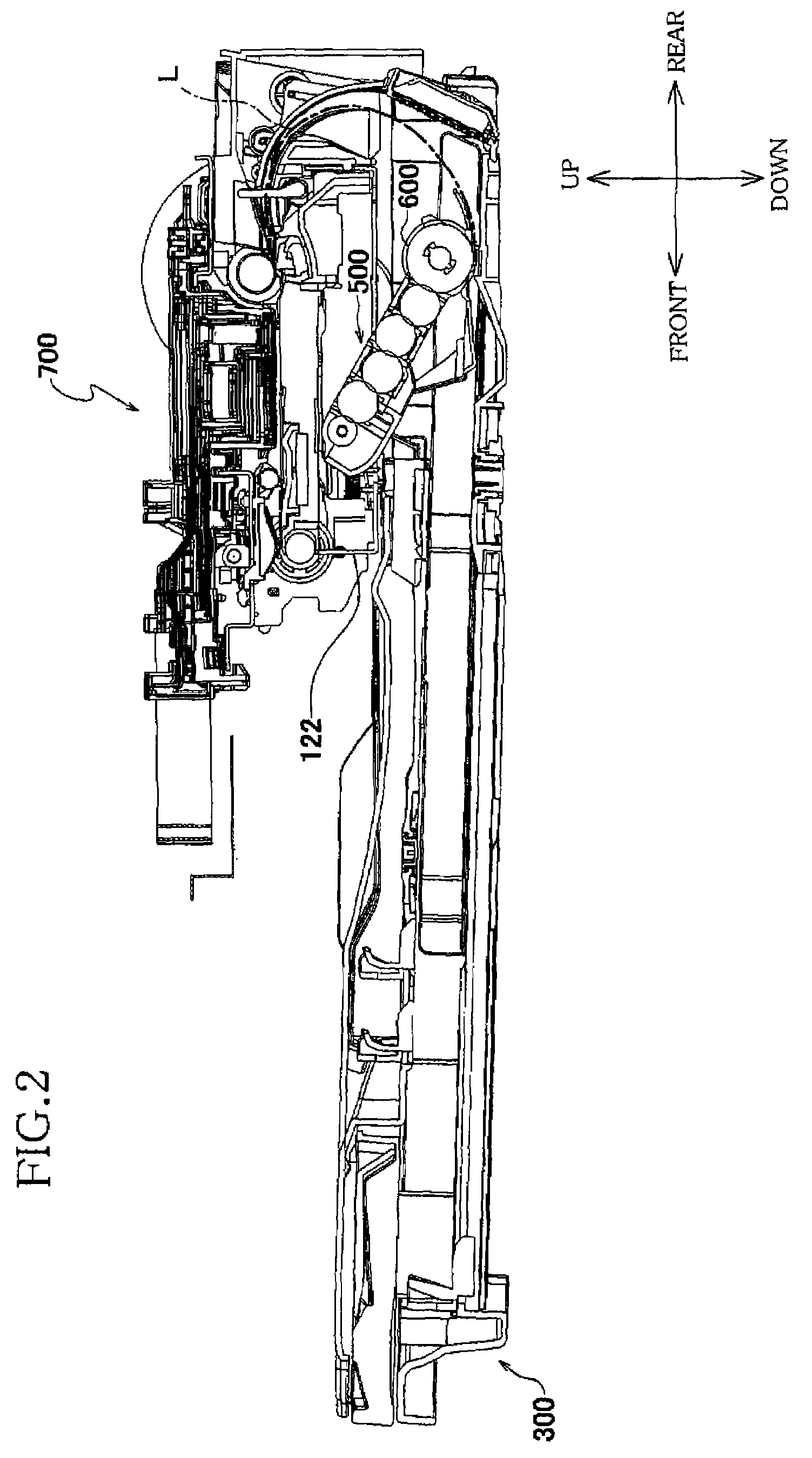

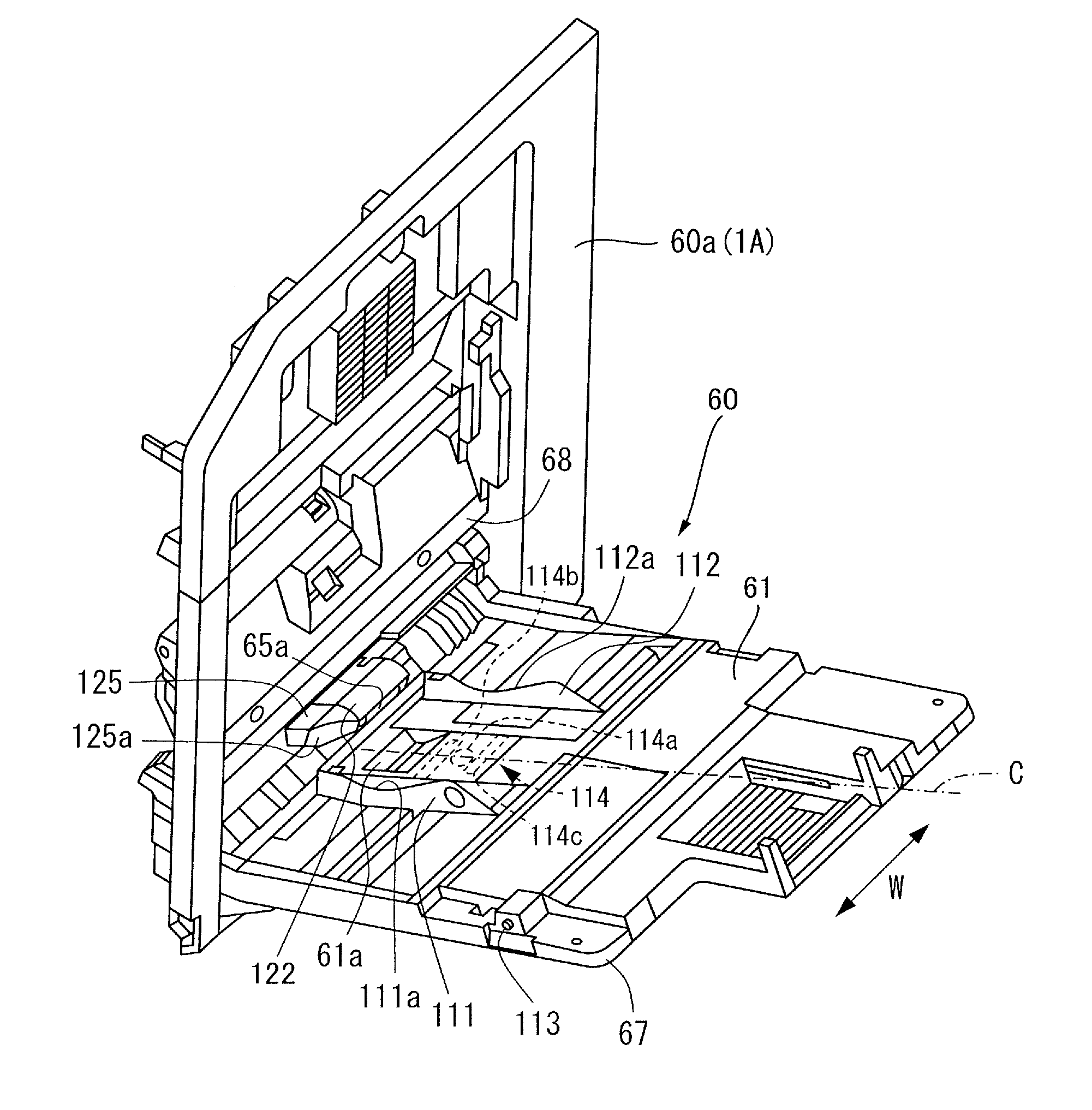

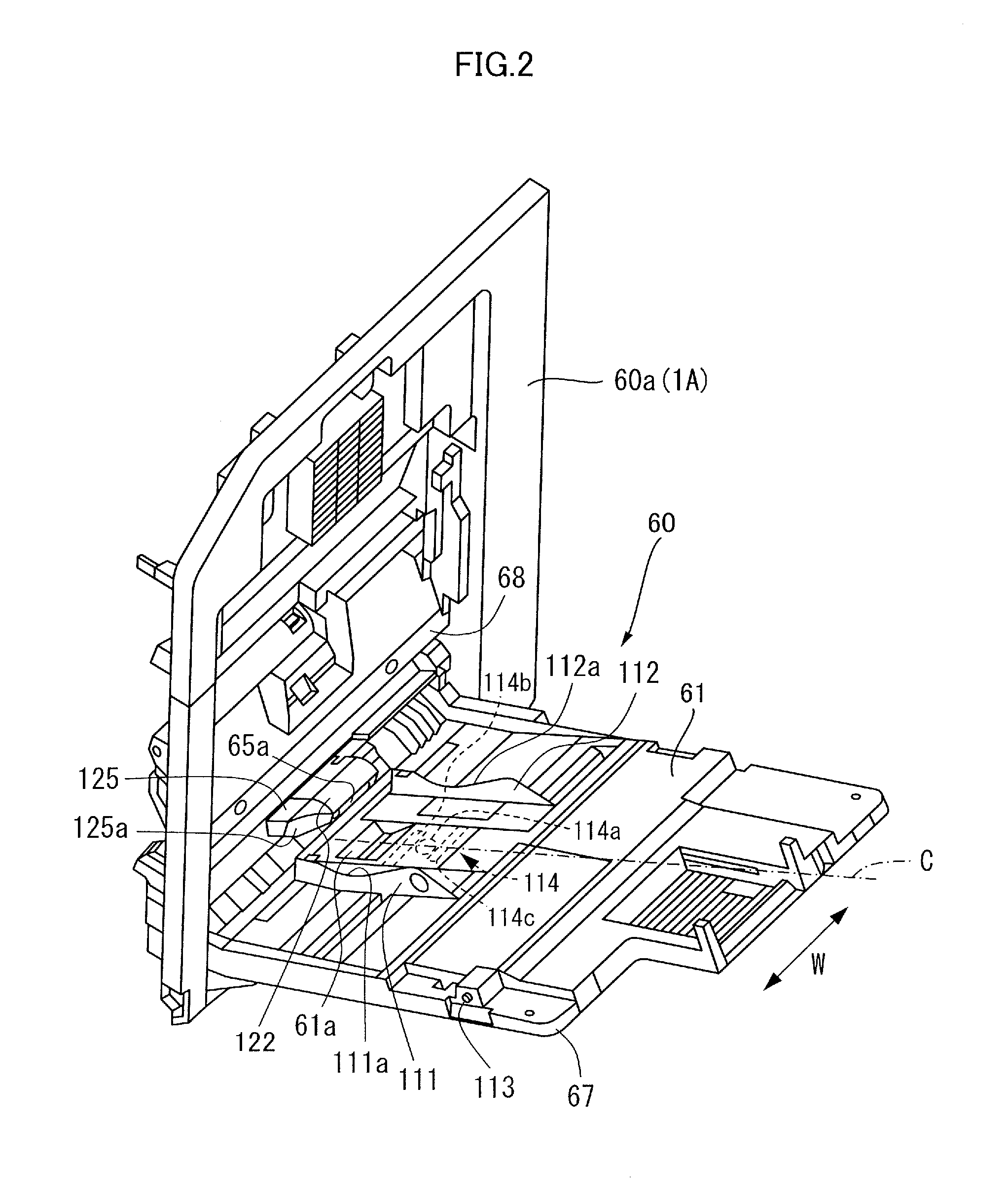

Sheet-like medium alignment apparatus

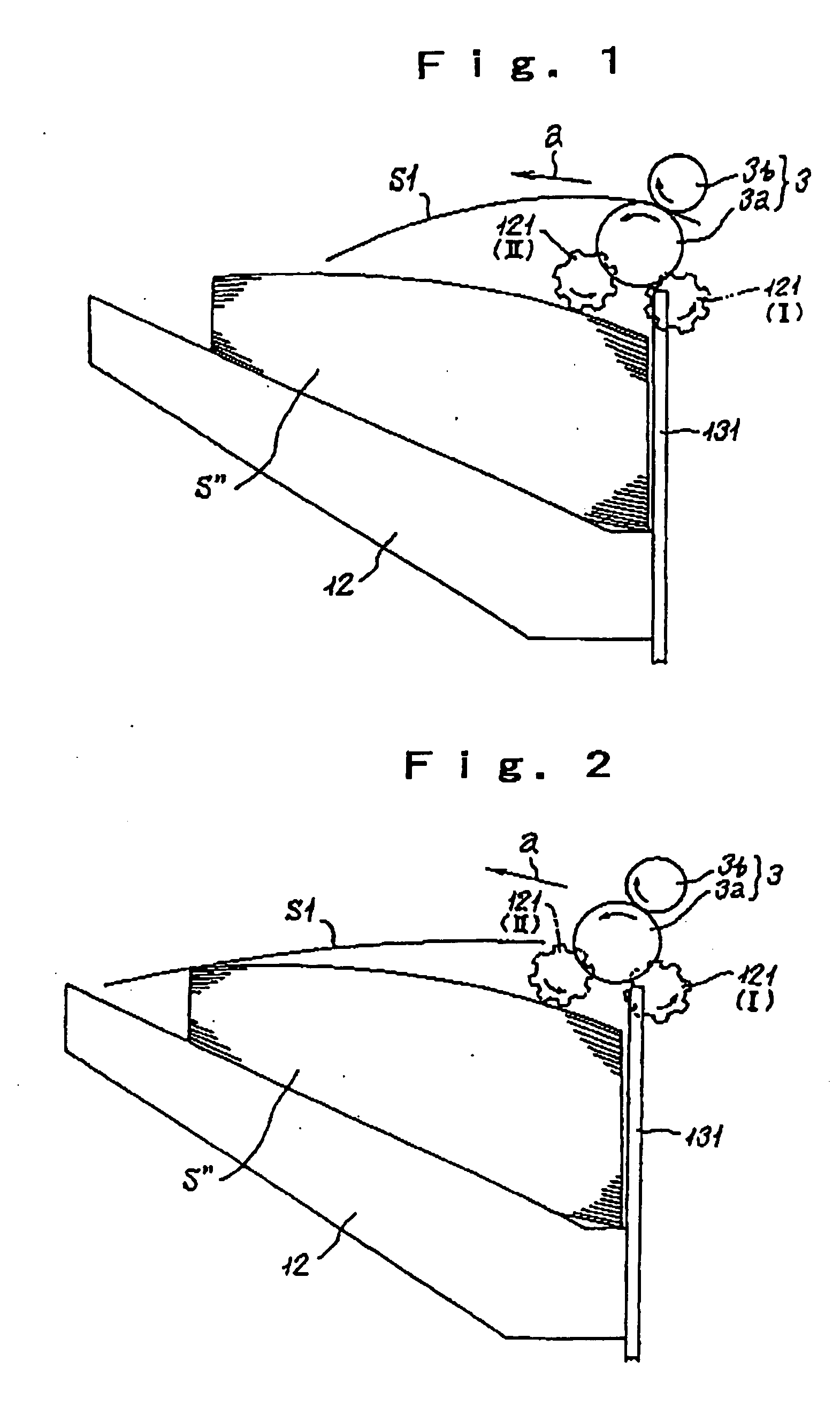

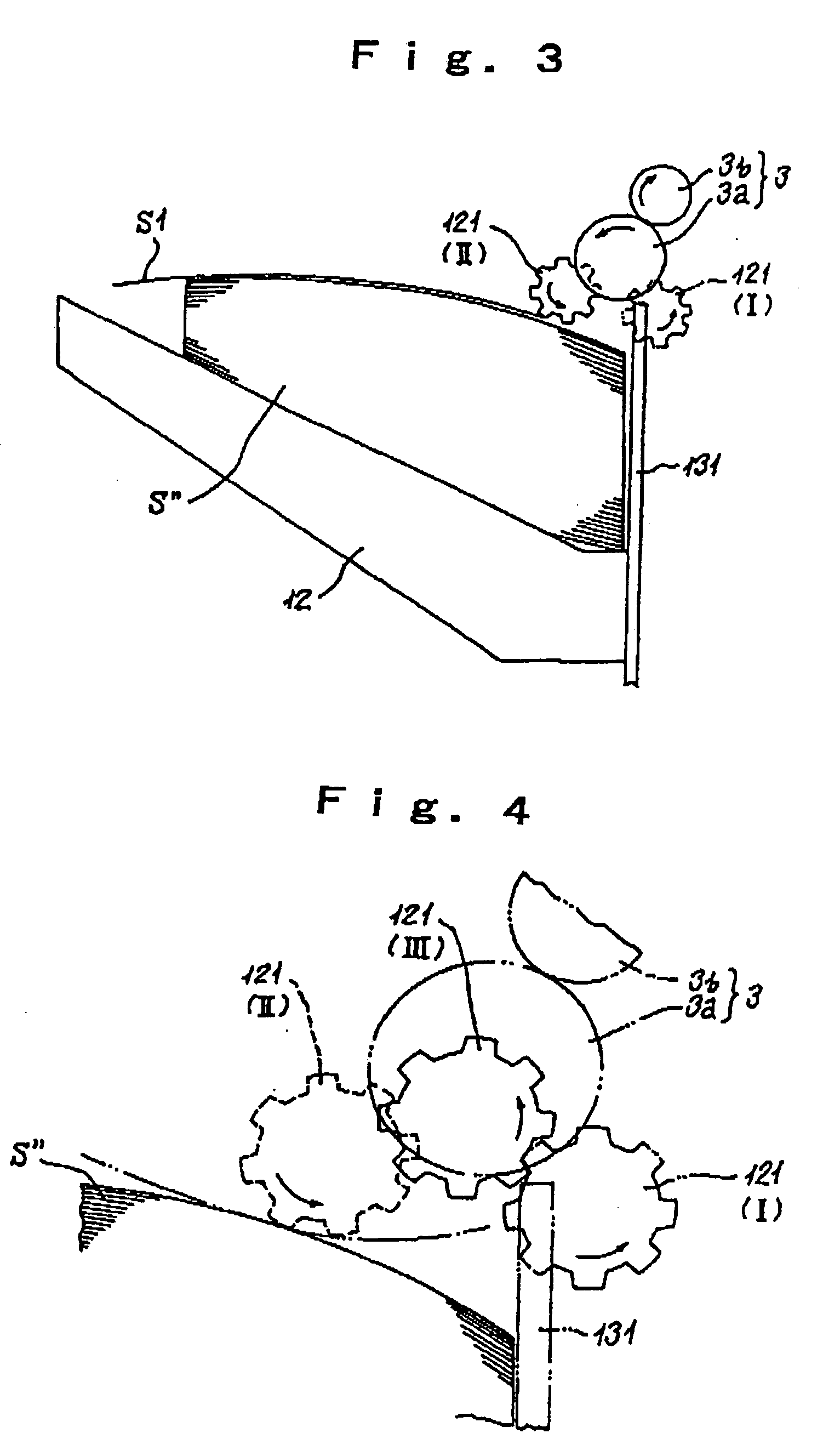

InactiveUS20050067764A1Easy to stackImprove accuracyRegistering devicesFunction indicatorsLeading edgeTrailing edge

To ensure that the leading edge of the sheet ejected onto a tray 12 does not push and move loaded sheets in advance, loaded sheets are retained at position (II) by a retaining roller. A roller (returning roller in this case) 121 for applying external force to a sheet S ejected onto the tray 12 and moving the sheet toward a end face 131 for alignment is displaced to a different position in the direction of ejection “a”, thereby firmly gripping the trailing edge of the sheet S ejected on the tray 12.

Owner:RICOH KK

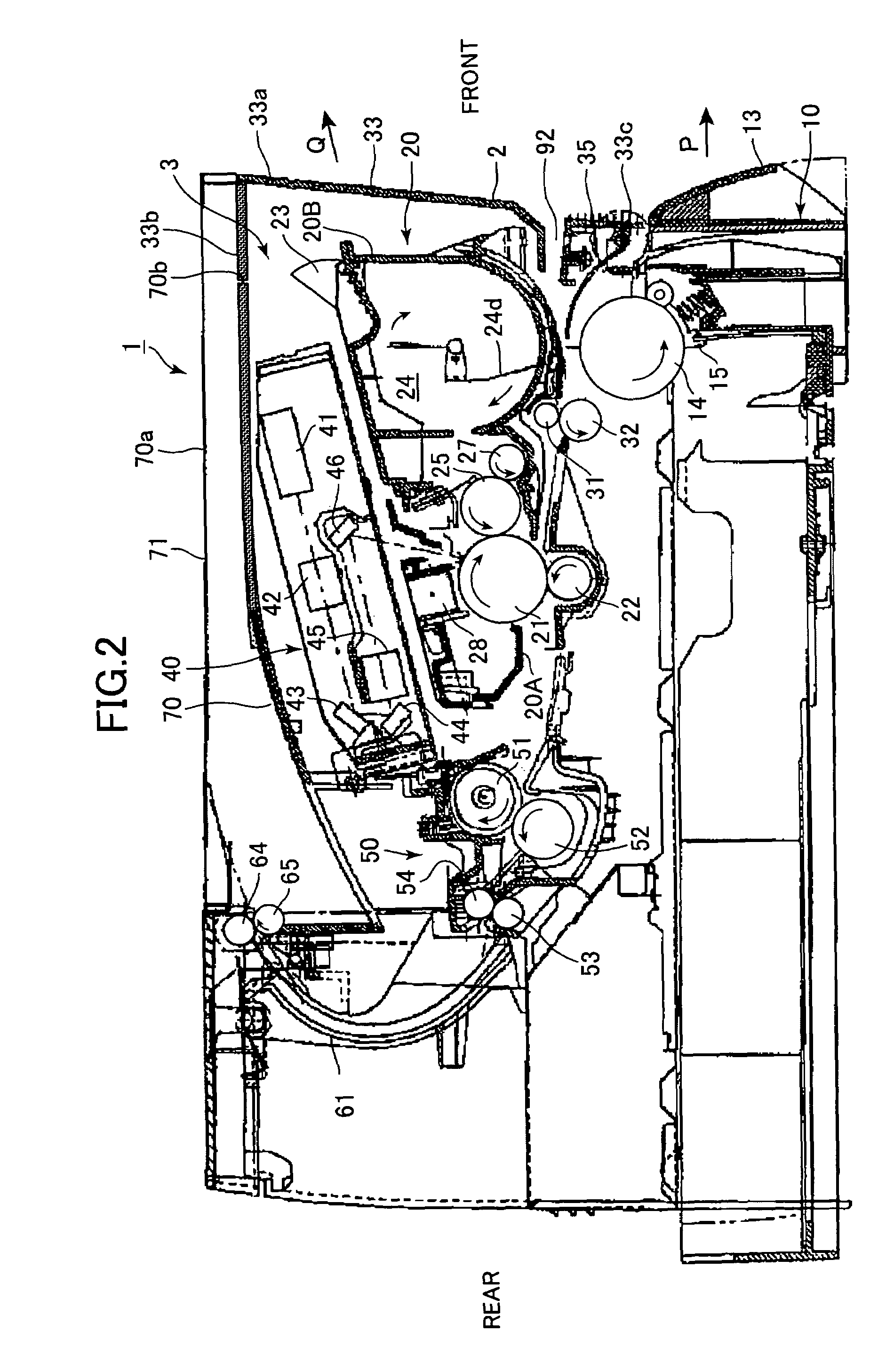

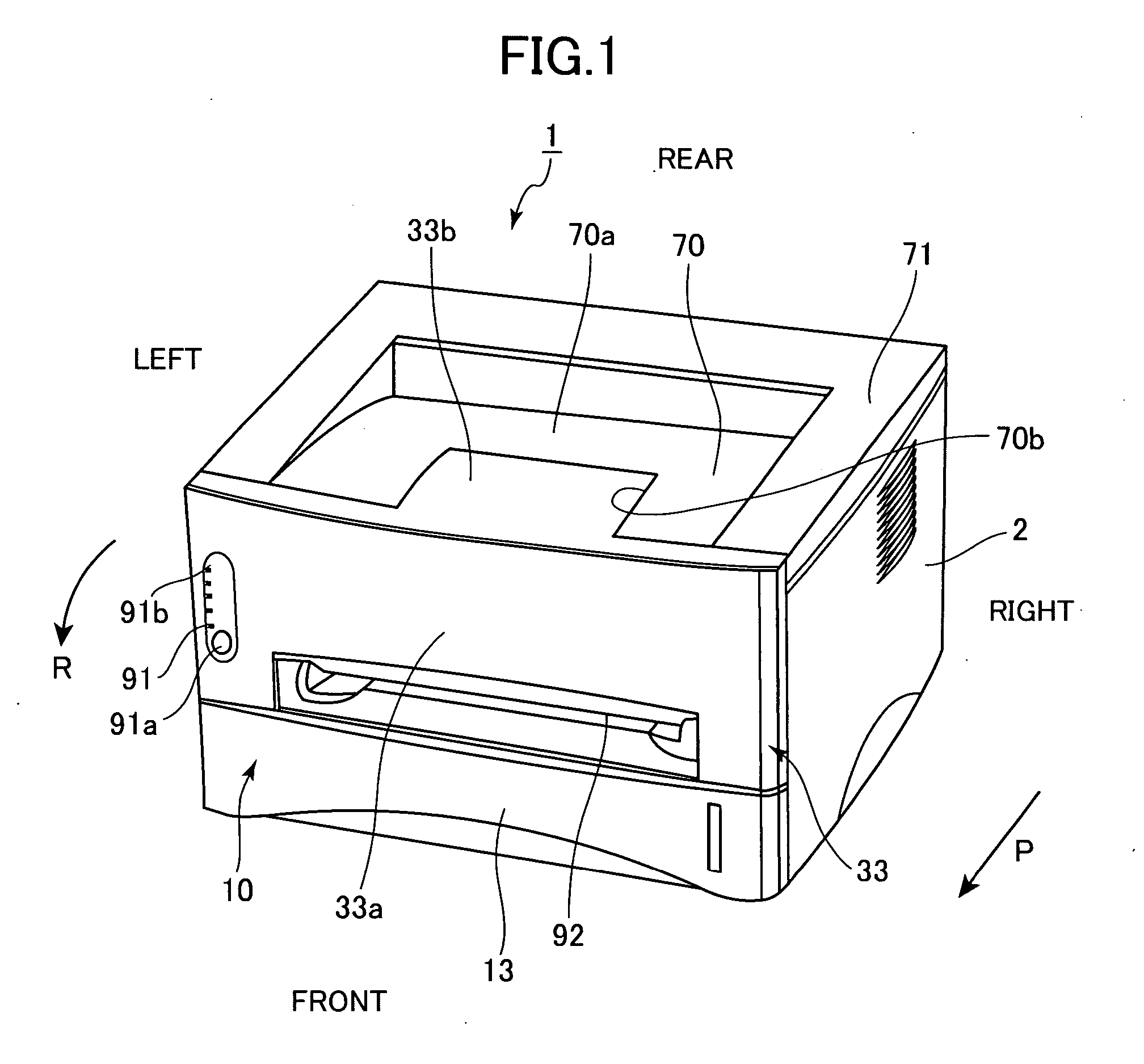

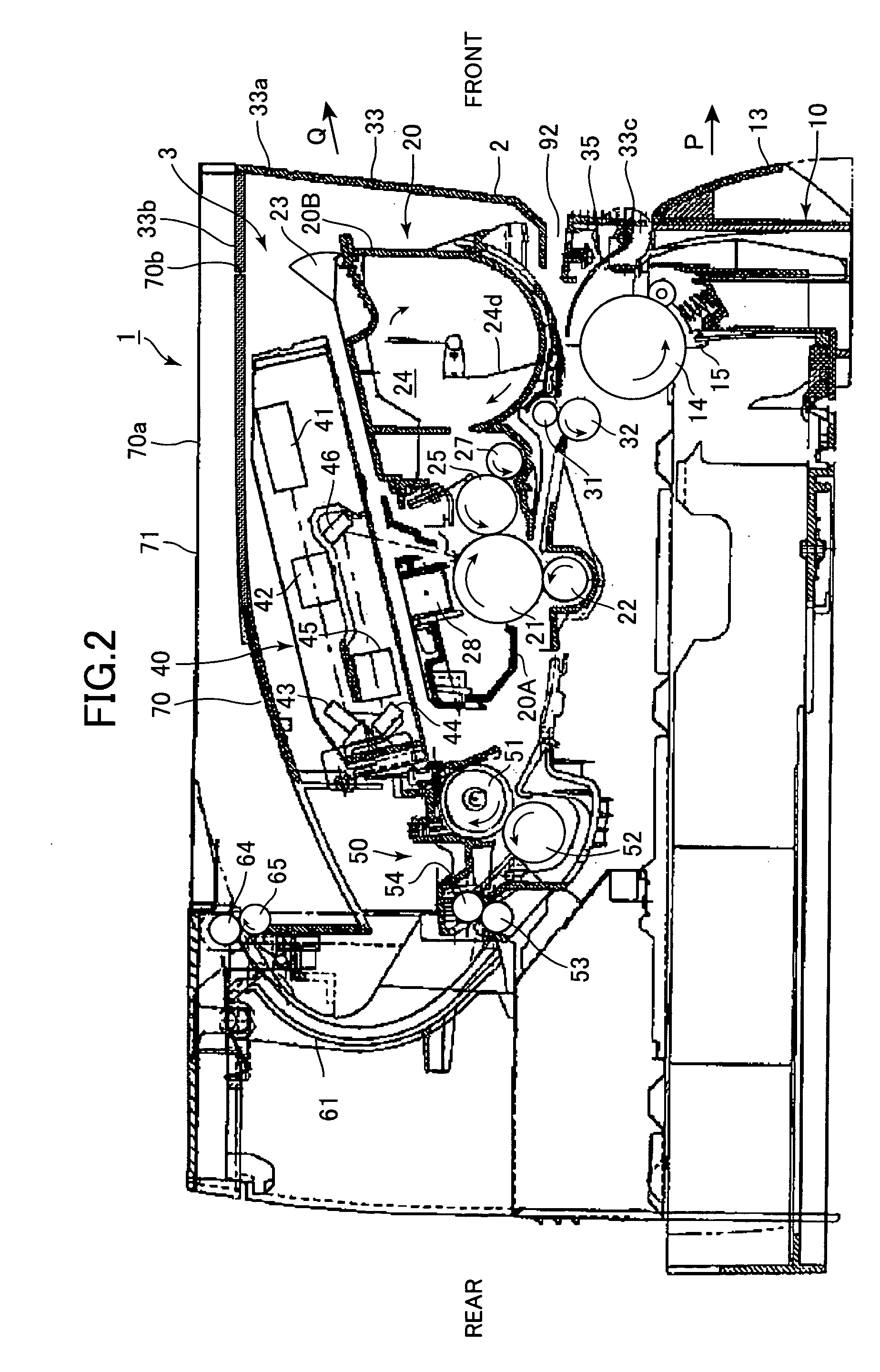

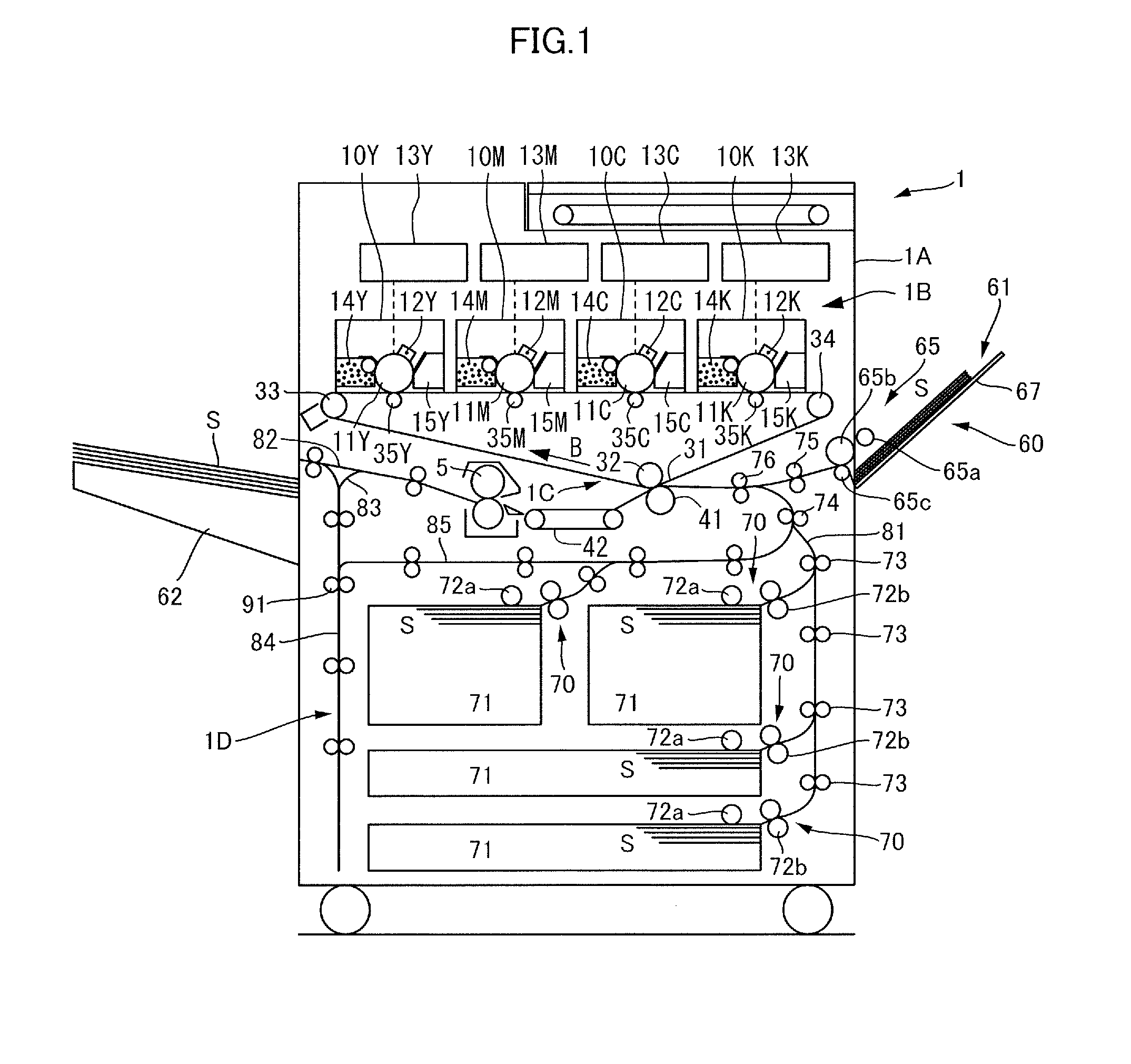

Image forming device

Owner:BROTHER KOGYO KK

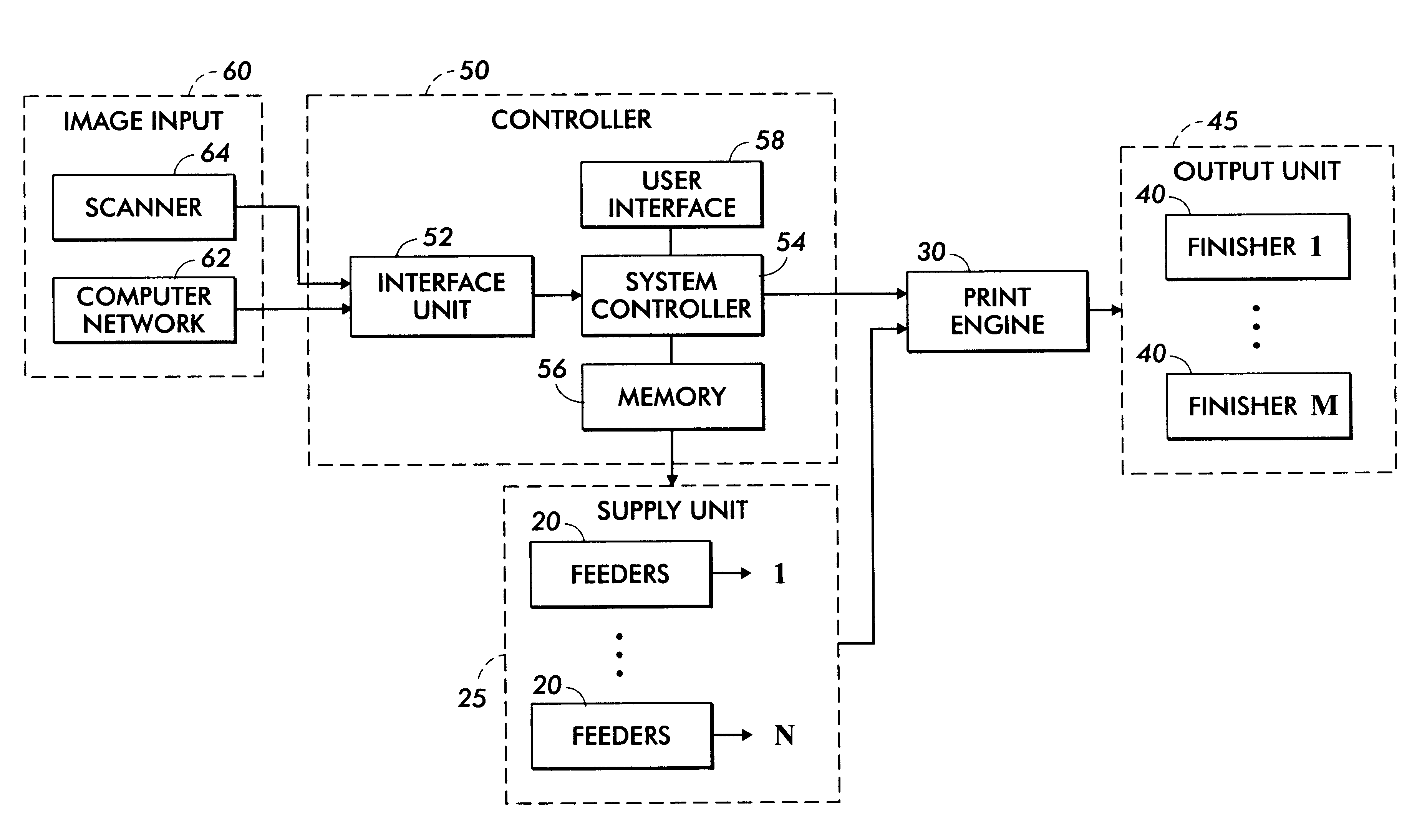

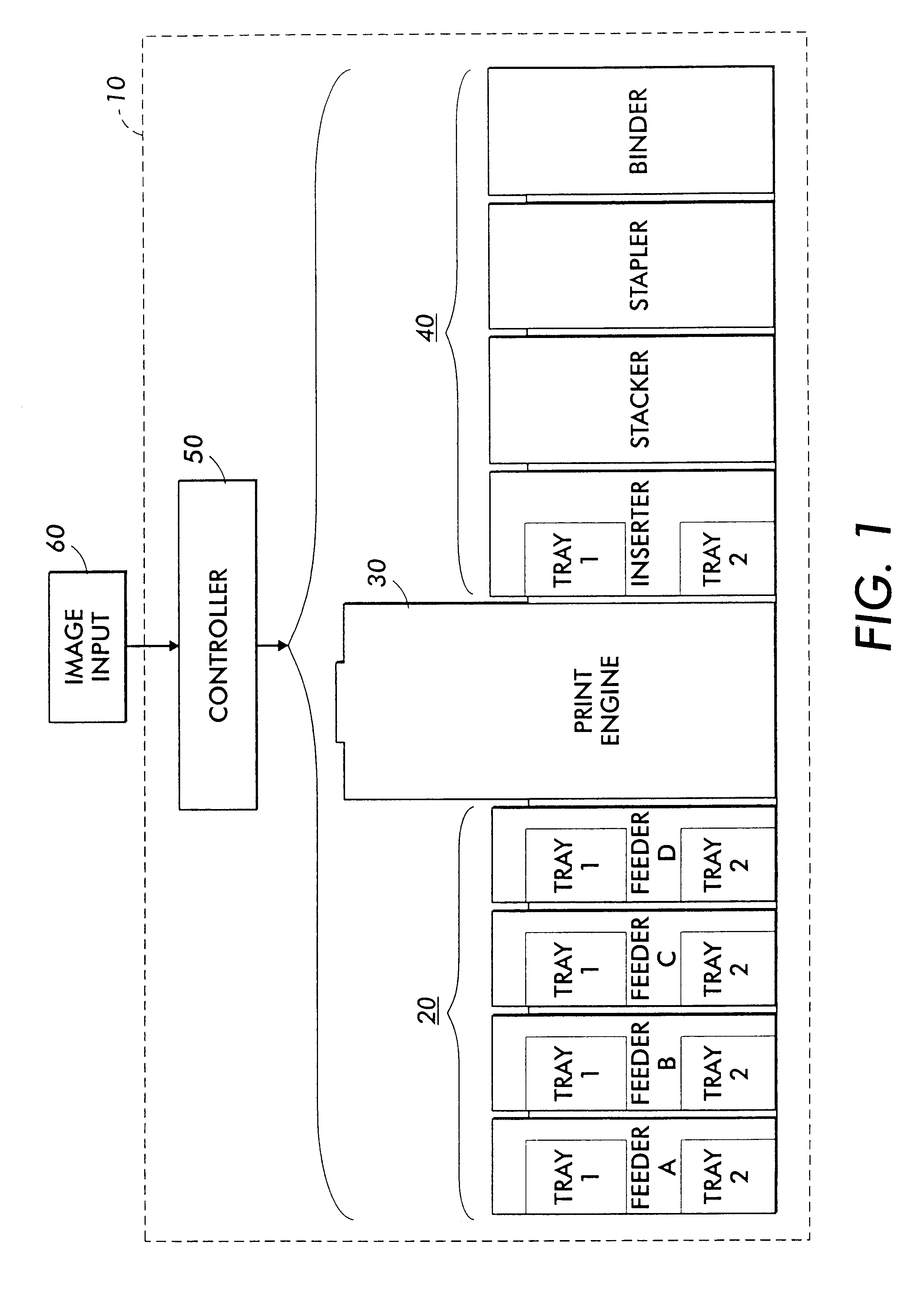

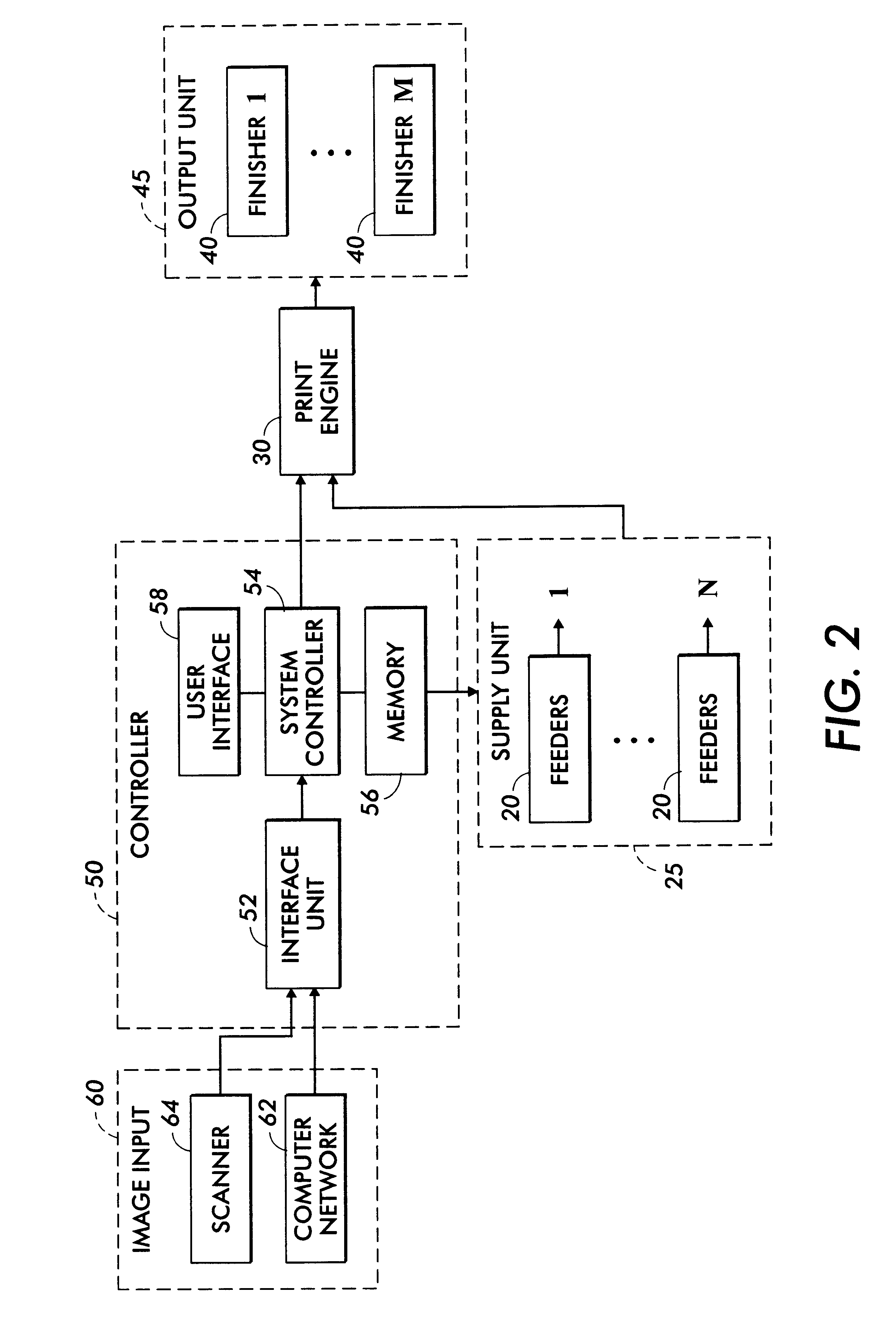

Method for accelerating paper tray programming

InactiveUS6762856B2Speed up the processReduce the possibilityDigitally marking record carriersDigital computer detailsPrint mediaEngineering

A printing system with one or more discrete print media trays, a marking engine and a controller in which prints are produced from a plurality of print jobs by using the controller to control delivery of print media sheets from the one or more discrete print media trays to the marking engine, each of the plurality of print jobs including a plurality of the predefined print media attributes; the one or more discrete print media trays respectively including the print media sheets having a plurality of print media attributes, a method for programming the one or more discrete print media trays, including selecting one print job of the a plurality of print jobs; correlating the plurality of the predefined printed attributes of the selected one of the plurality of print jobs to the plurality of print media attributes of the print media sheets stored in the at two discrete print media trays; and if the plurality of the predefined printed attributes do not correlate with the plurality of print media attributes of the print media stored one of the one or more discrete print media trays, assigning one or more of the plurality of the predefined printed attributes to one of the one or more discrete print media trays.

Owner:XEROX CORP

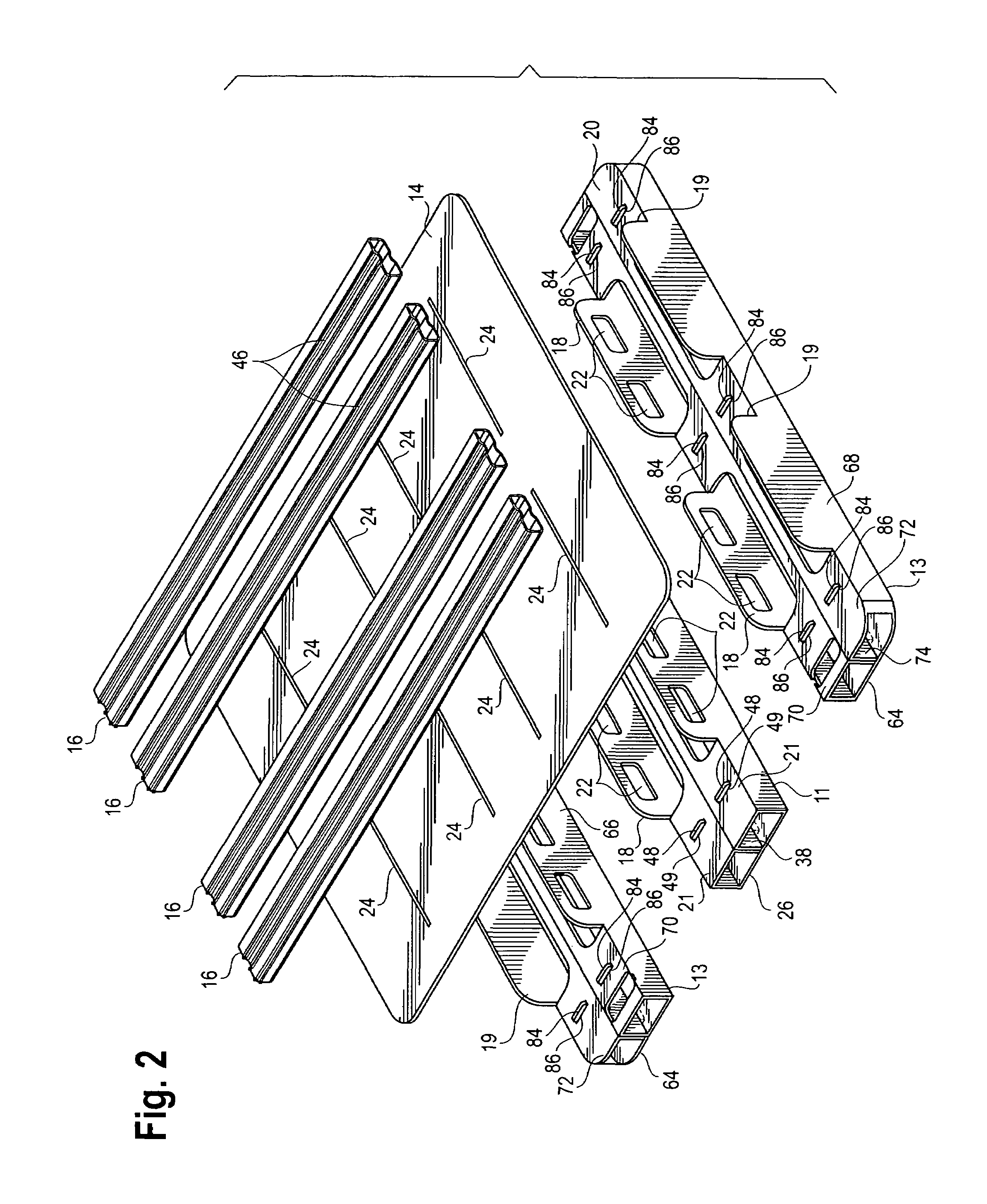

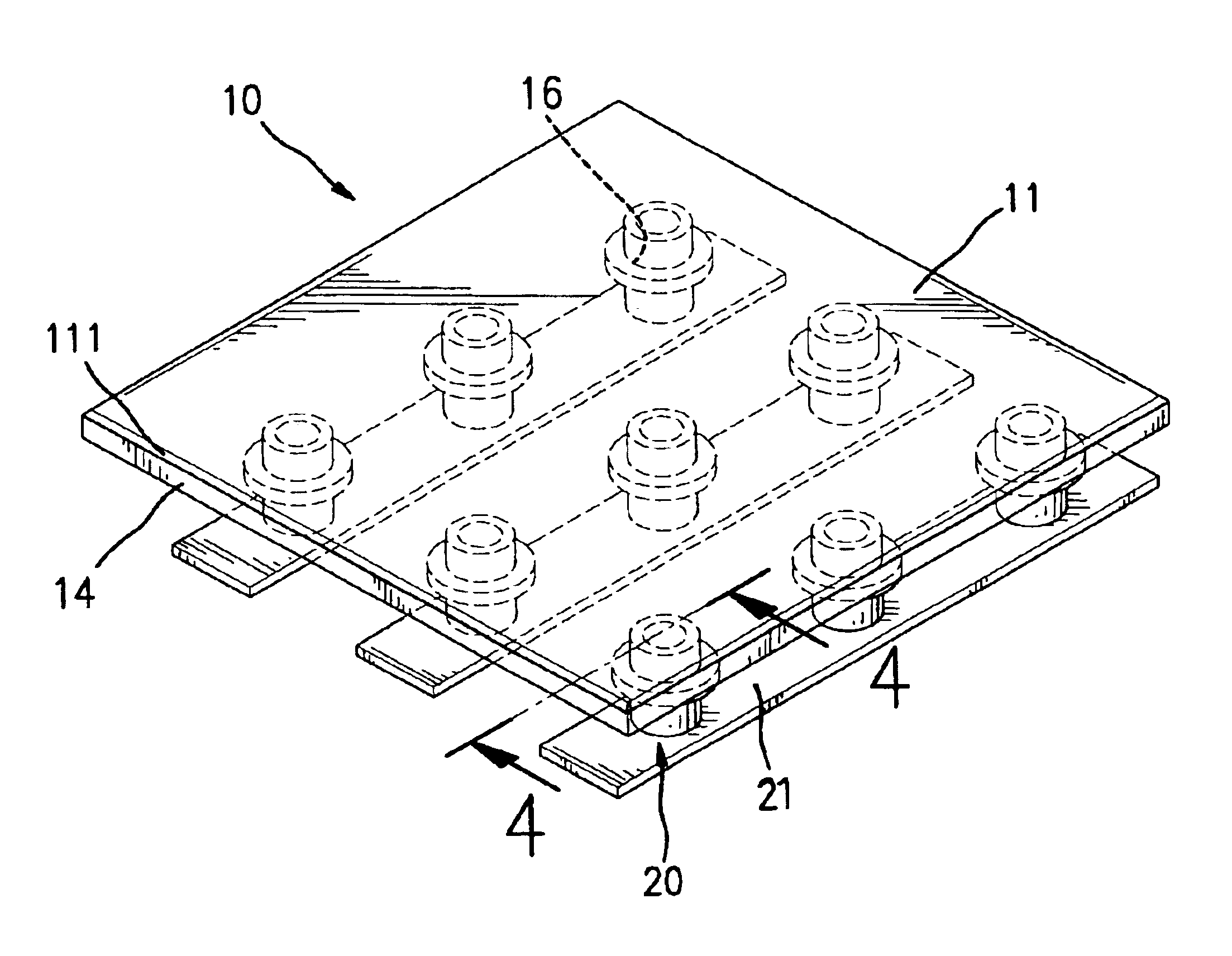

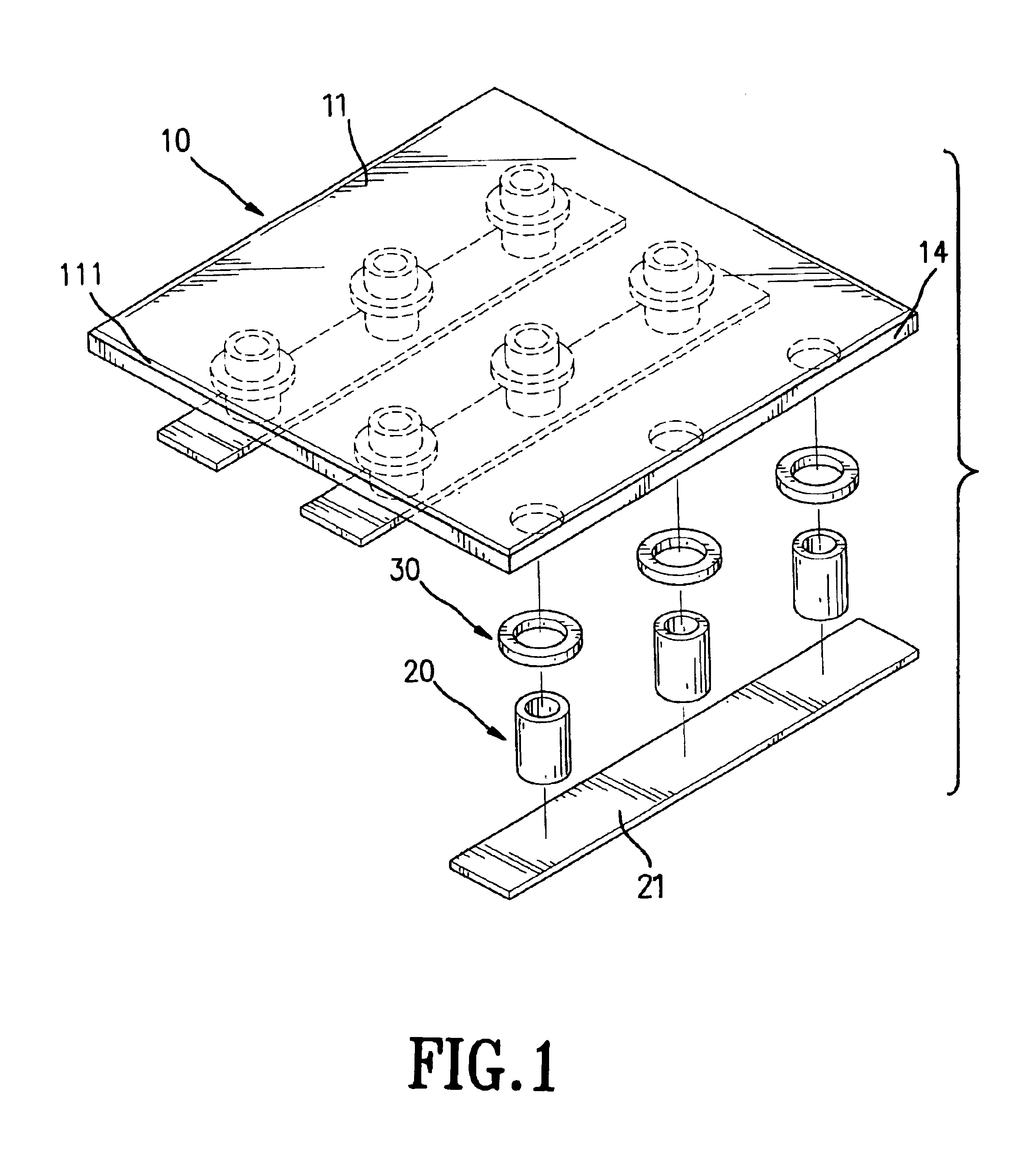

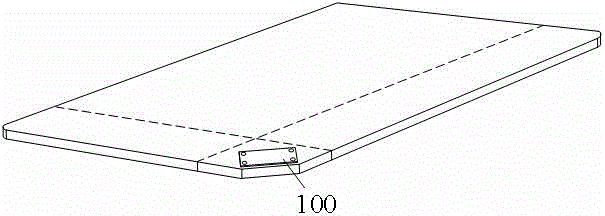

Leg assembly for paper pallet

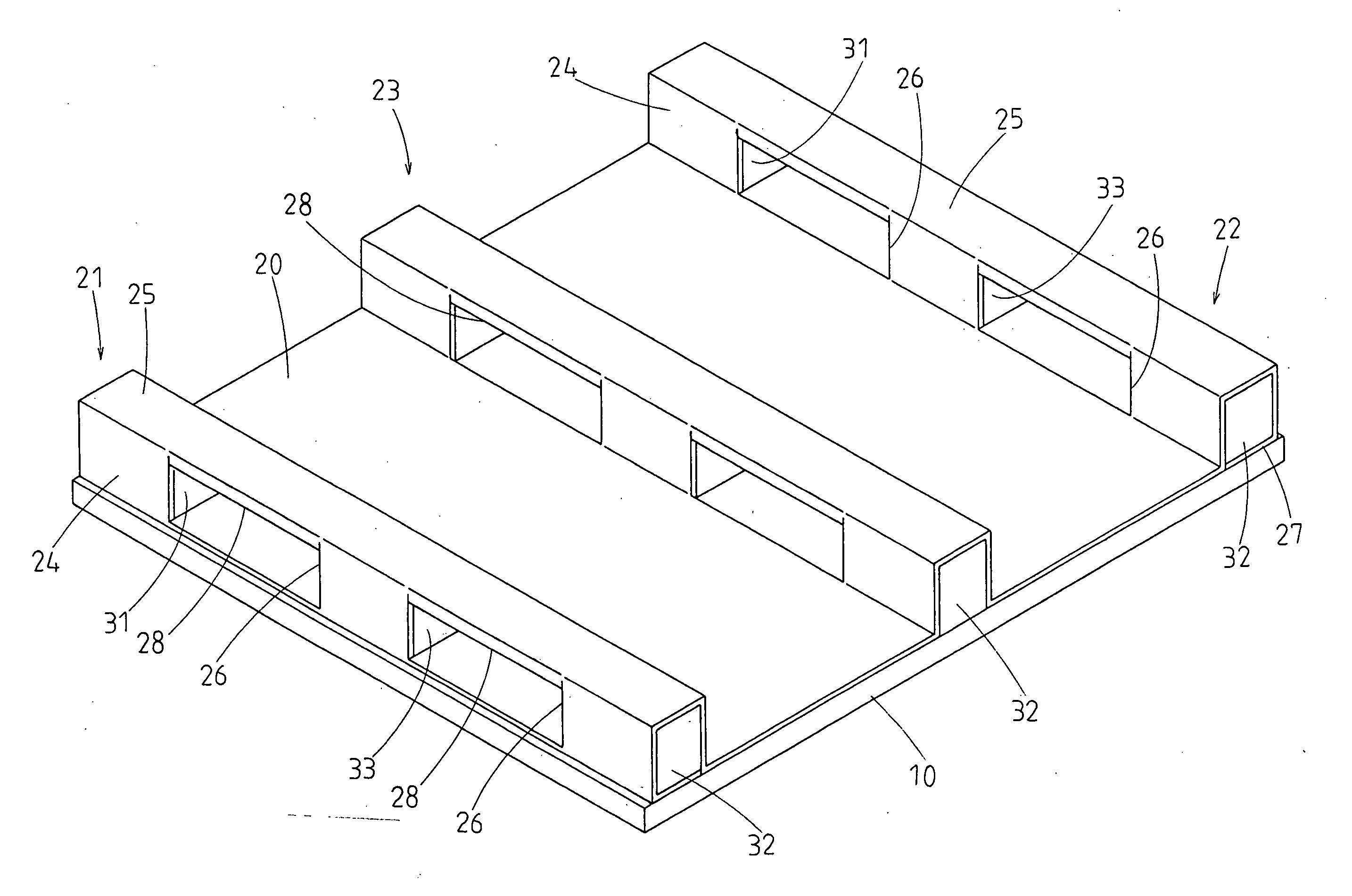

A pallet includes a top plate and a leg assembly fixed below the top plate. The leg assembly includes a bottom plate fixed below the top plate. The bottom plate includes three receiving sections spaced from one another. Each receiving section includes two longitudinal sides and a bottom side. Three supporting blocks are mounted in each receiving section and spaced from one another. Each longitudinal side of each receiving section includes two transverse openings. Each transverse opening on each receiving section is located between two of the supporting blocks adjacent to each other.

Owner:CHEN FU MEI

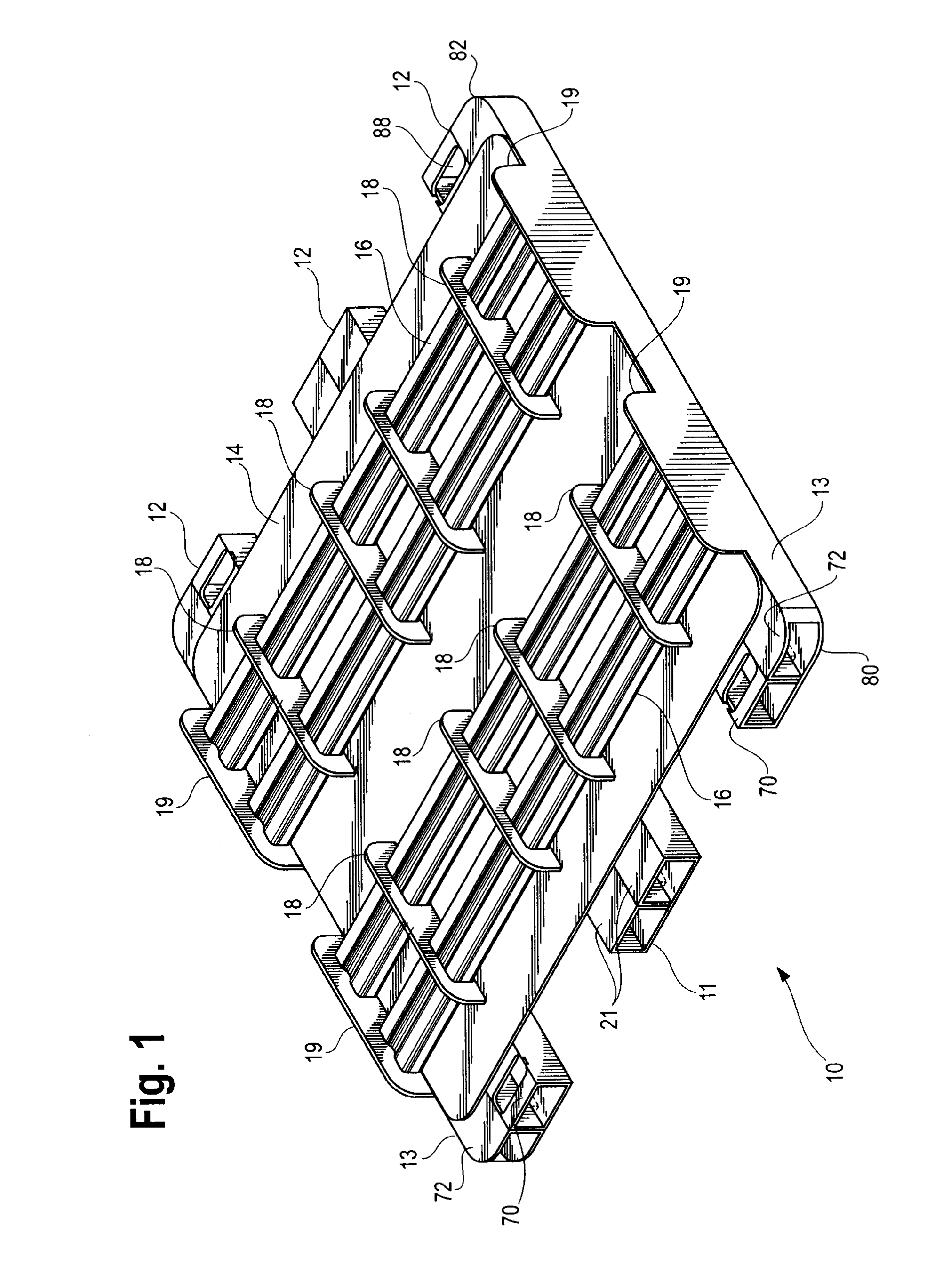

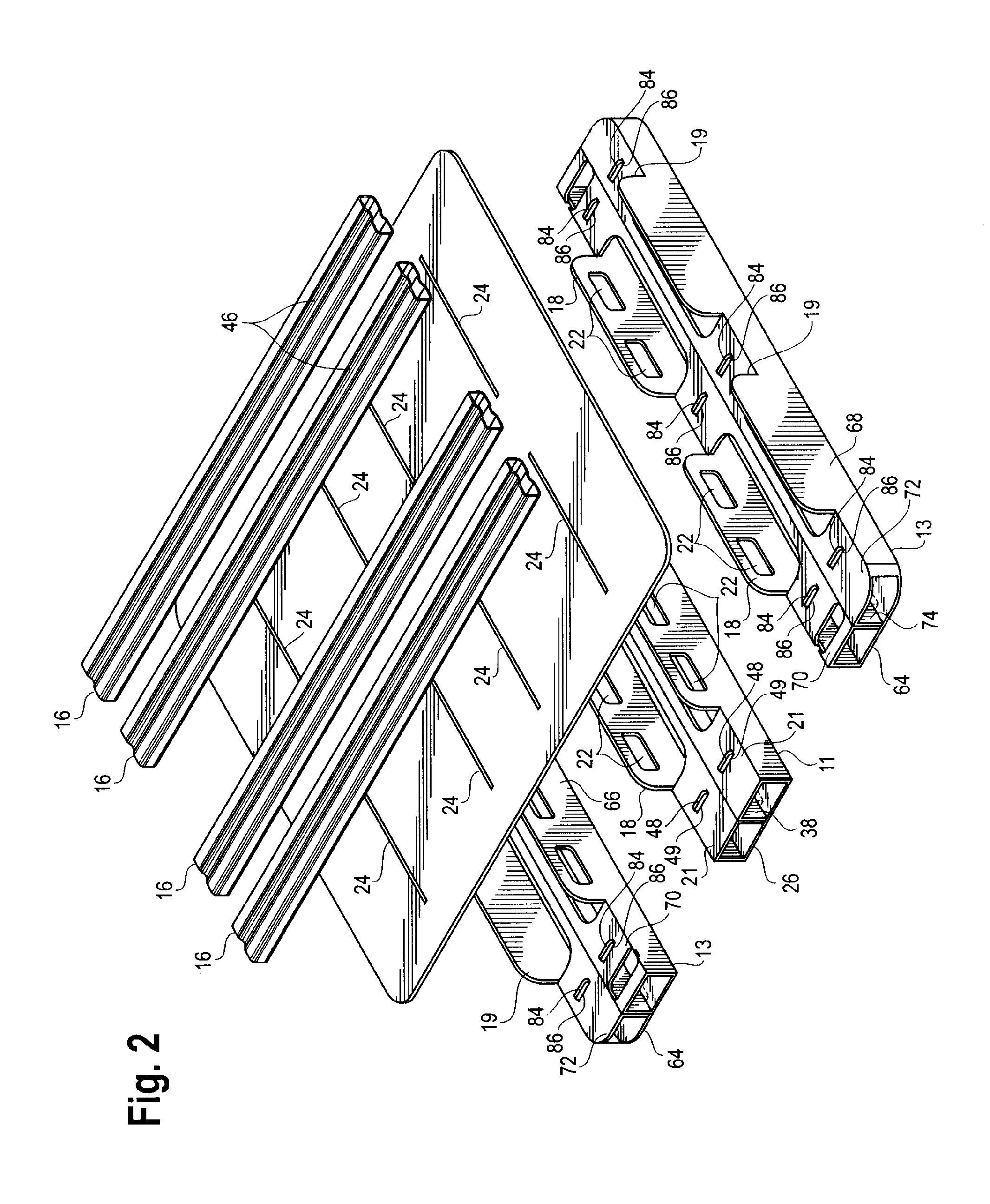

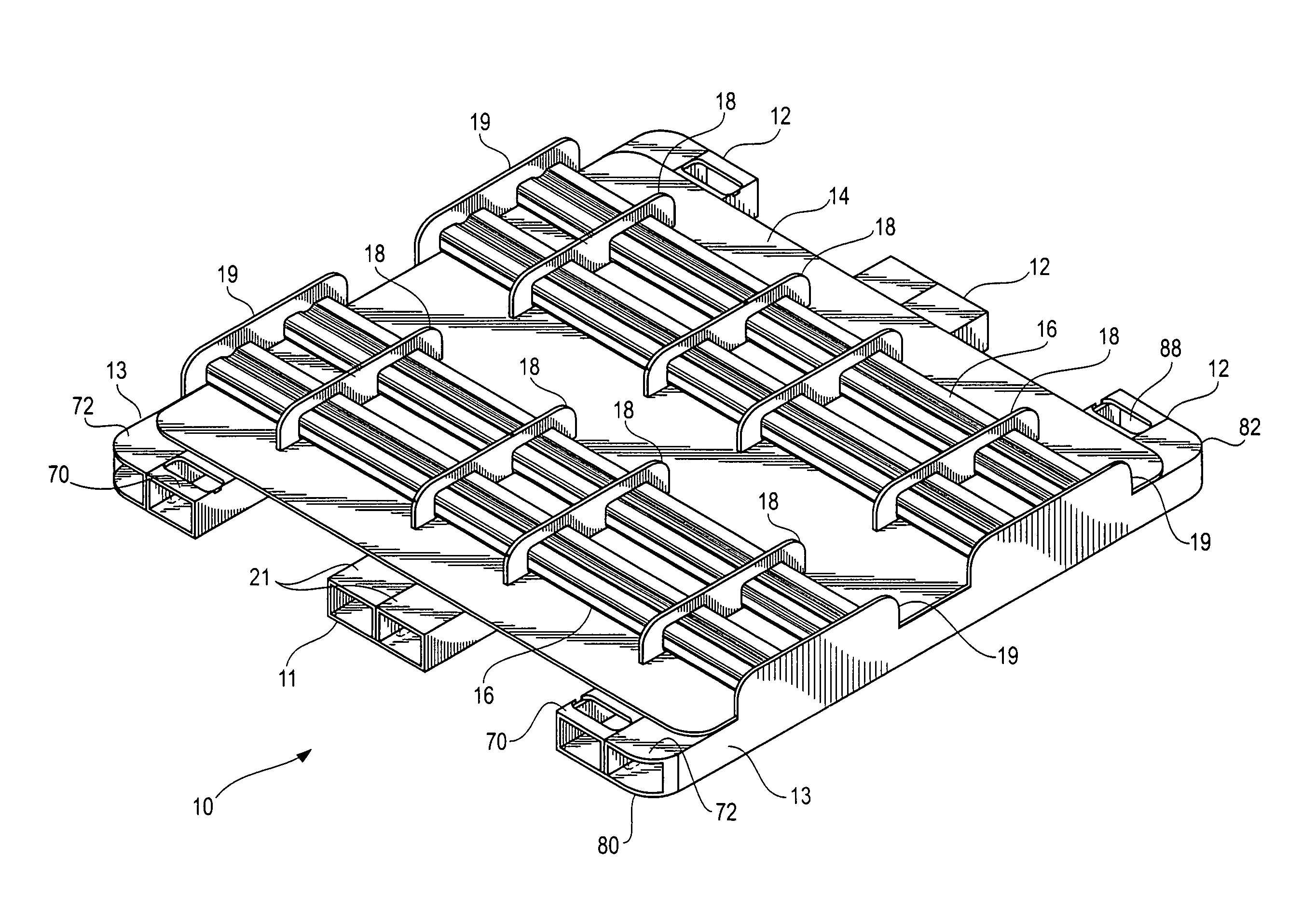

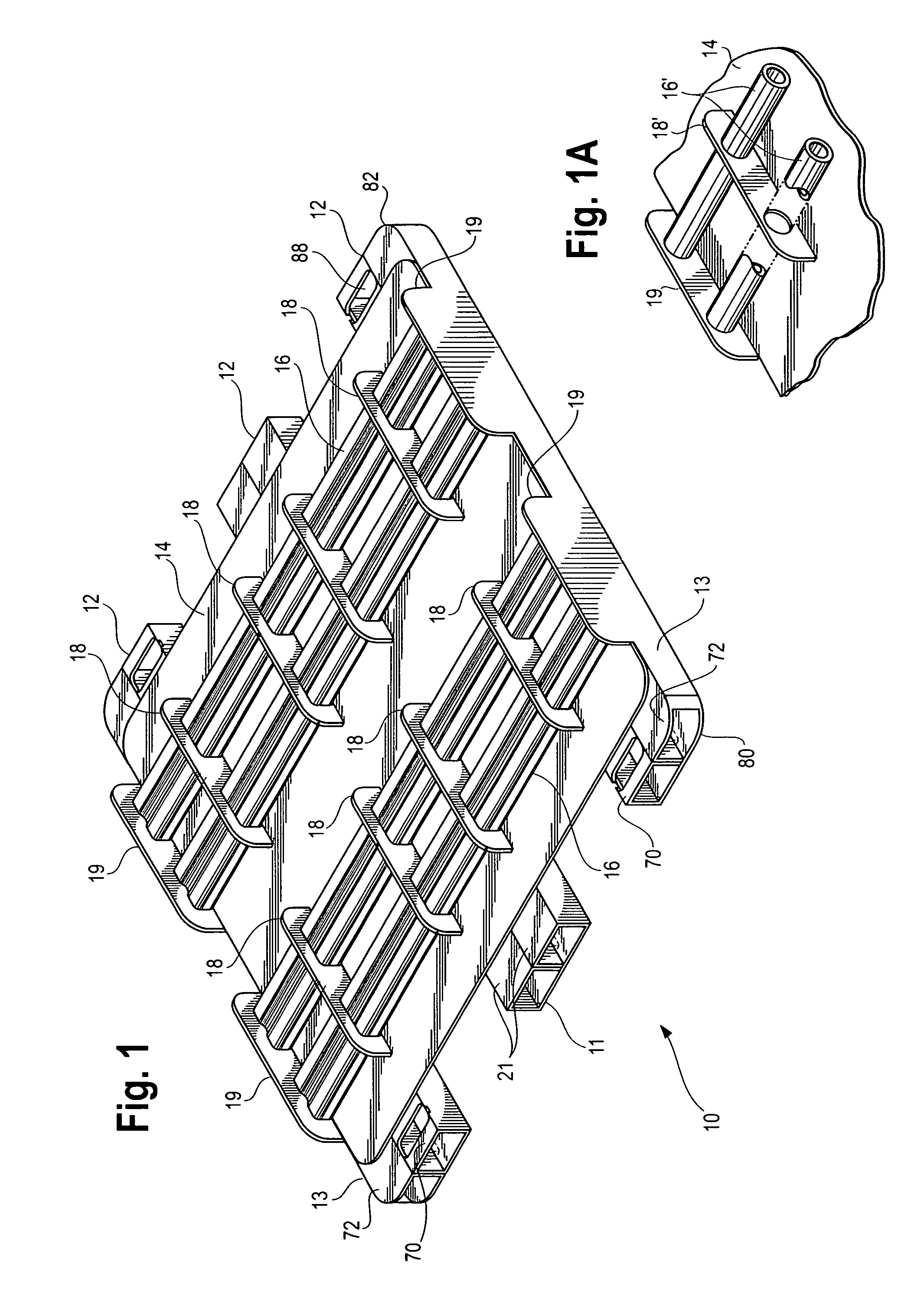

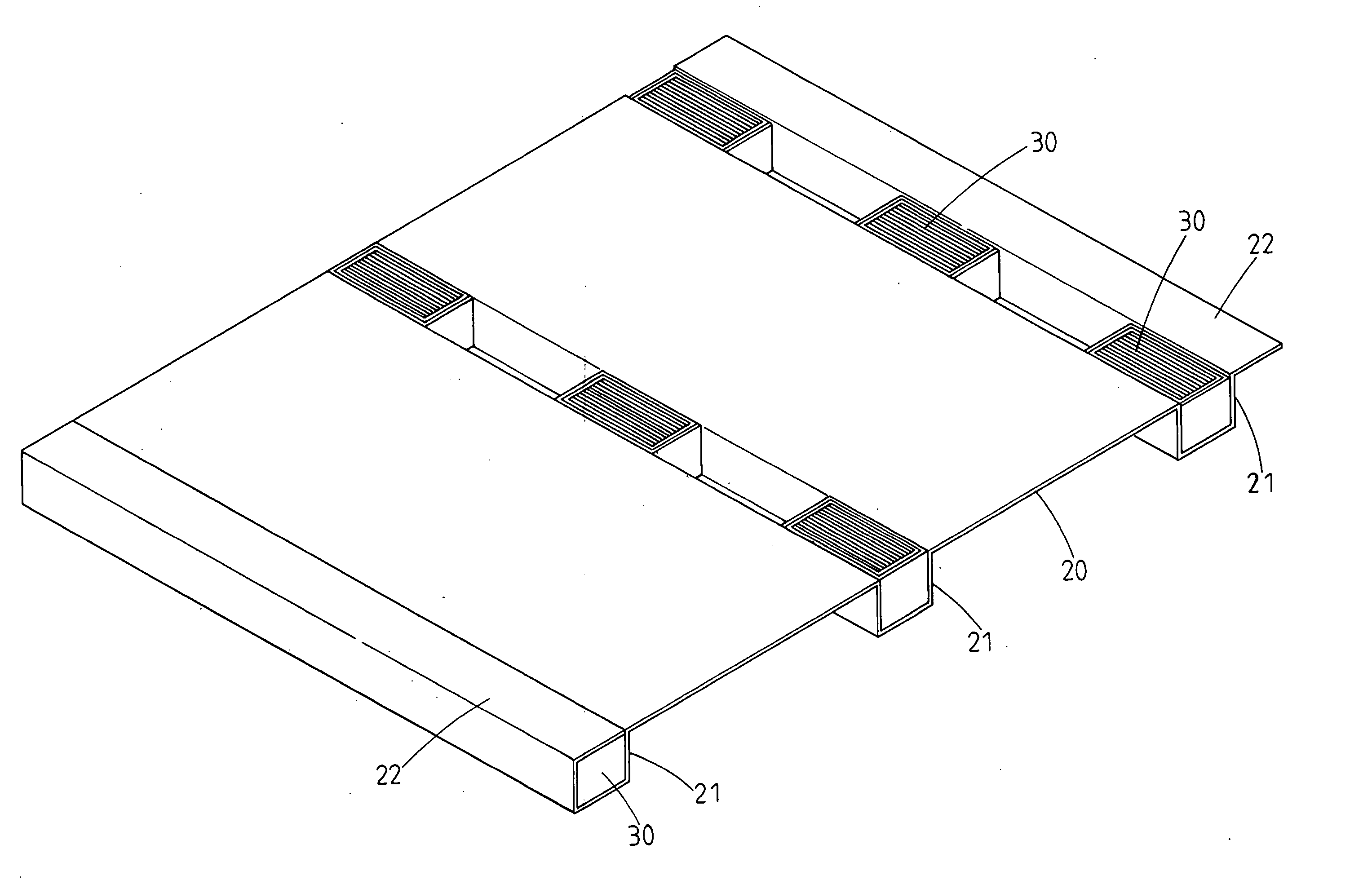

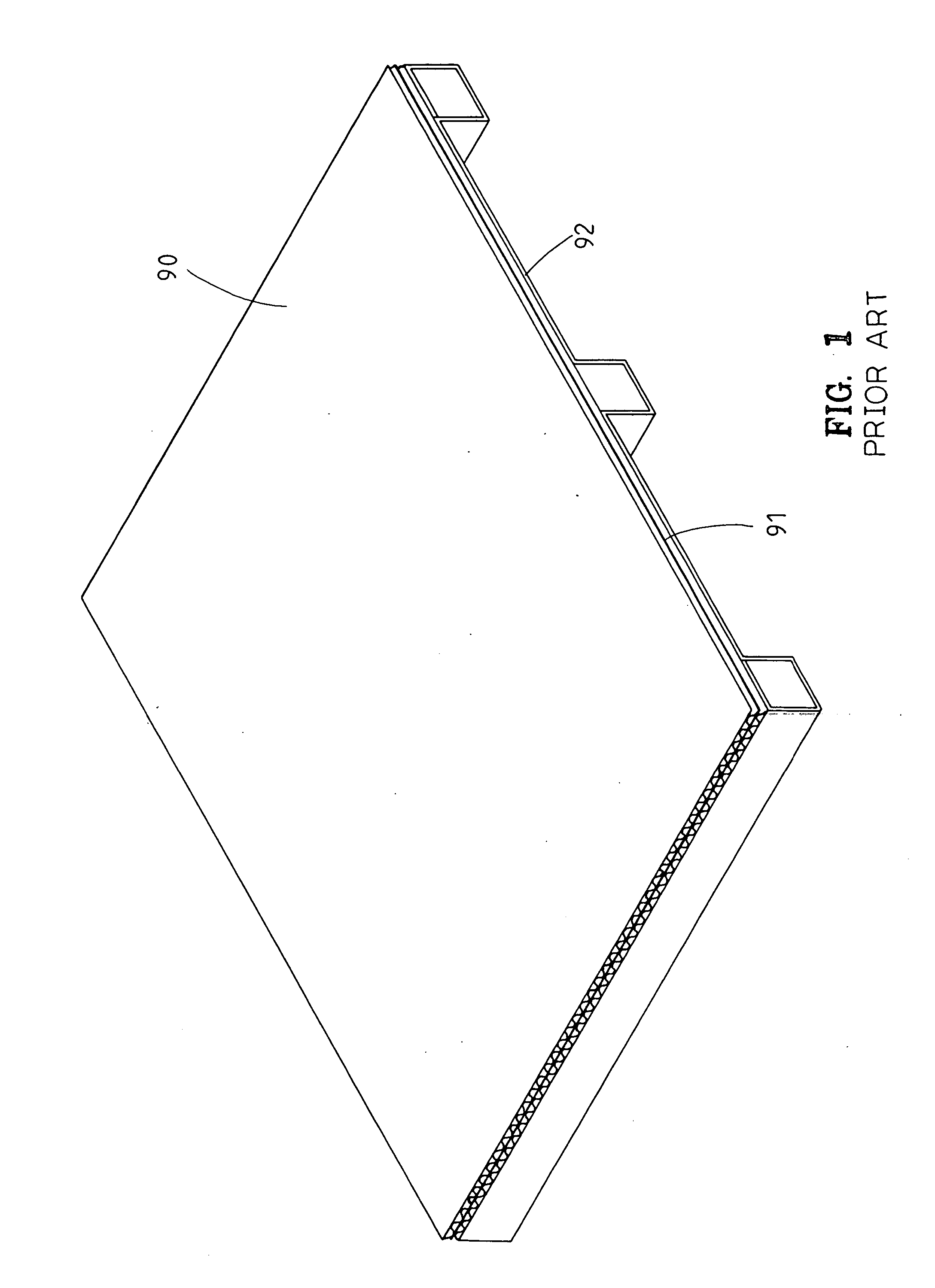

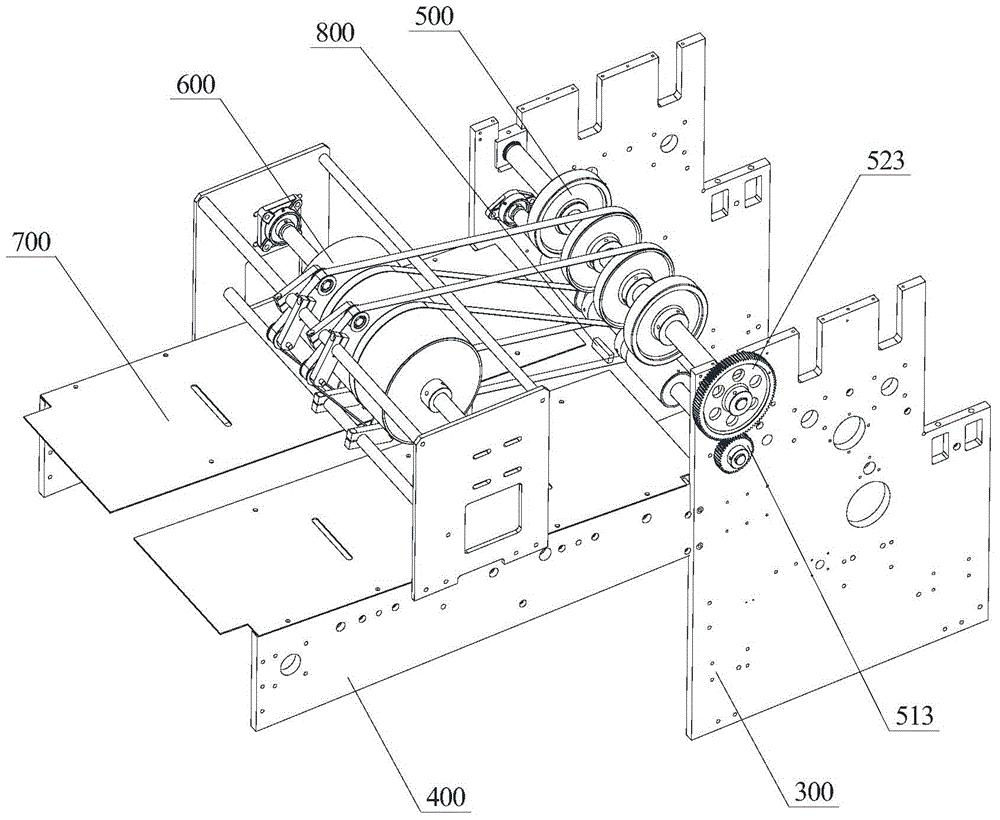

Single use disposable pallet

A single use disposable, recyclable paper pallet for supporting products during storage and shipping is provided. The pallet comprises a corrugated panel resting on multiple, parallel corrugated runners locked together by lateral supports. The runners are made from blanks folded into elongated open-ended box-like shapes. The folded runners have perforated tabs that extend upwards from the top surface of the runners and configured to receive the lateral supports. The lateral supports are formed from a sheet of convolutely wound, formed laminated paper and provide lateral strength so the pallet can be handled with a clamp truck.

Owner:SONOCO DEV INC

Single use disposable pallet

A single use disposable, recyclable paper pallet for supporting products during storage and shipping is provided. The pallet comprises a corrugated panel resting on multiple, parallel corrugated runners locked together by lateral supports. The runners are made from blanks folded into elongated open-ended box-like shapes. The folded runners have perforated tabs that extend upwards from the top surface of the runners and configured to receive the lateral supports. The lateral supports are formed from a sheet of convolutely wound, formed laminated paper and provide lateral strength so the pallet can be handled with a clamp truck.

Owner:SONOCO DEV INC

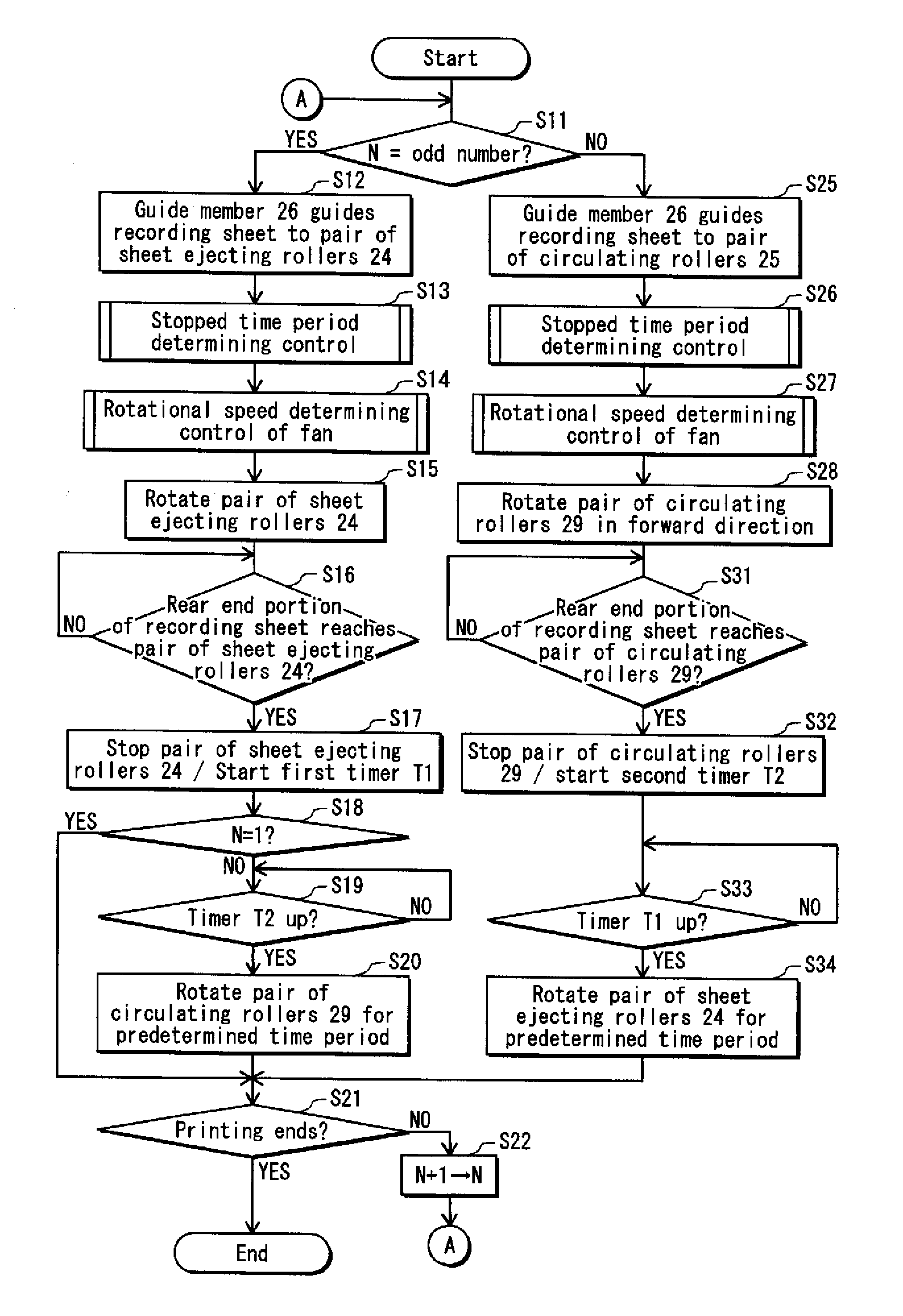

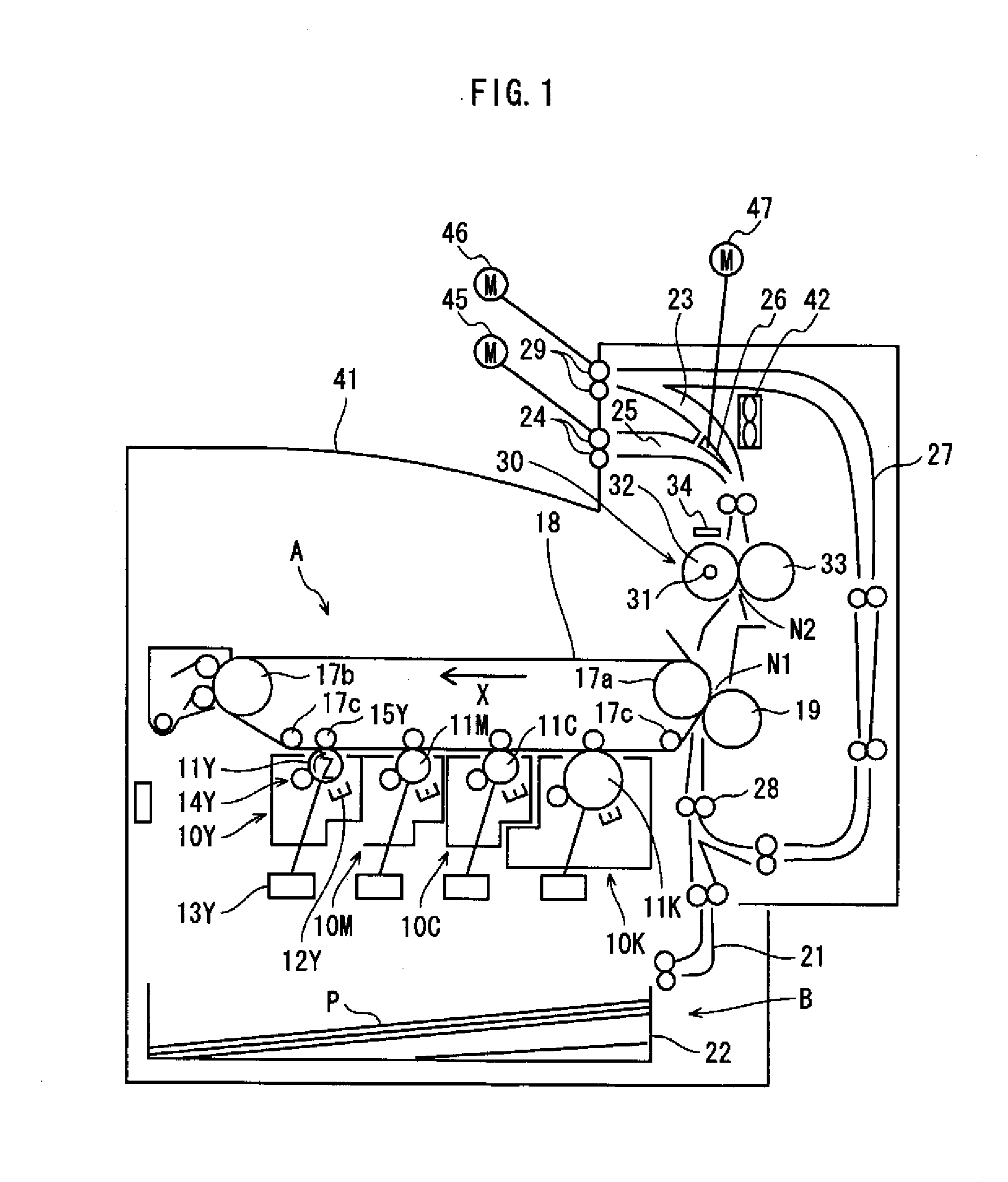

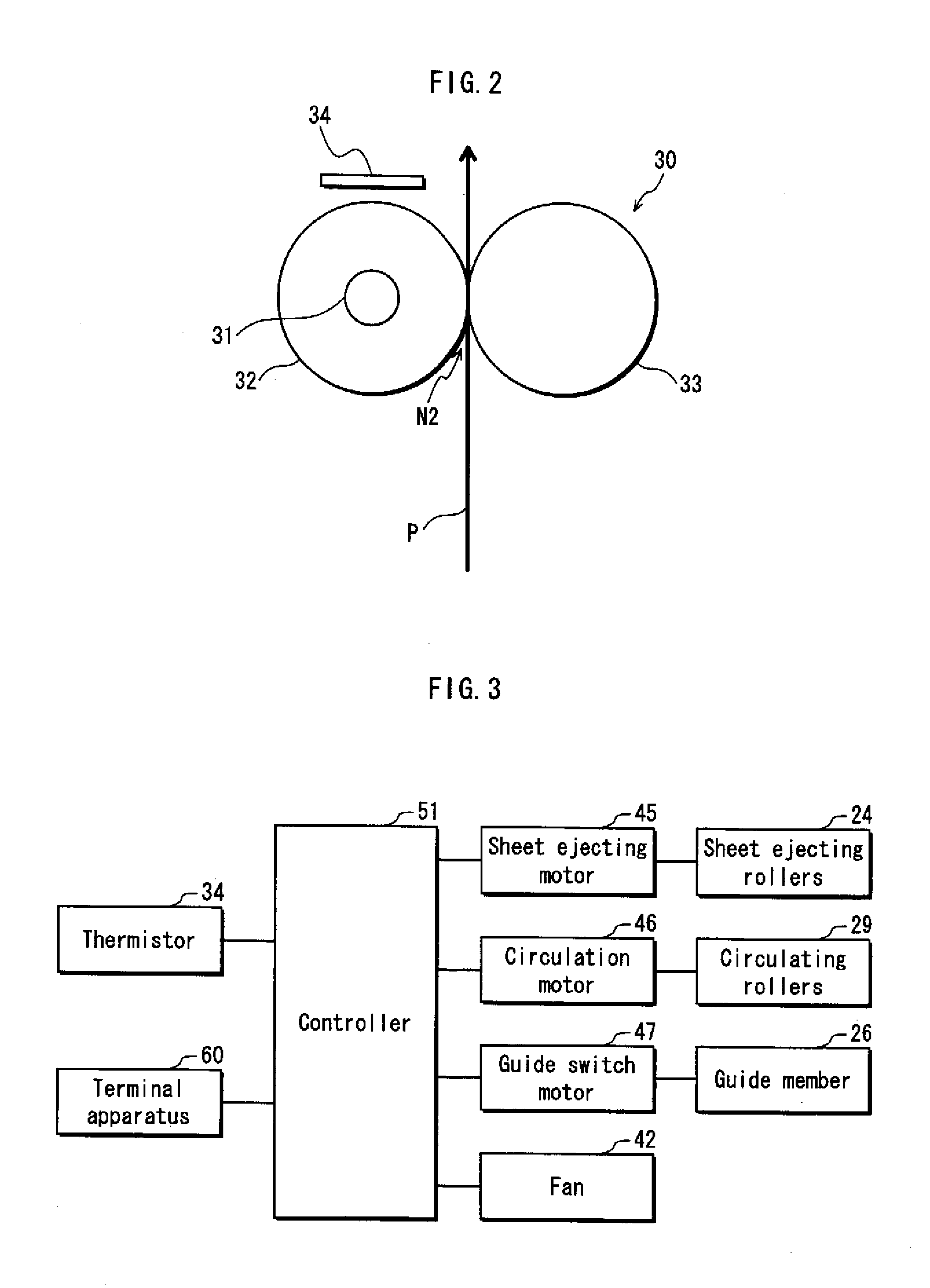

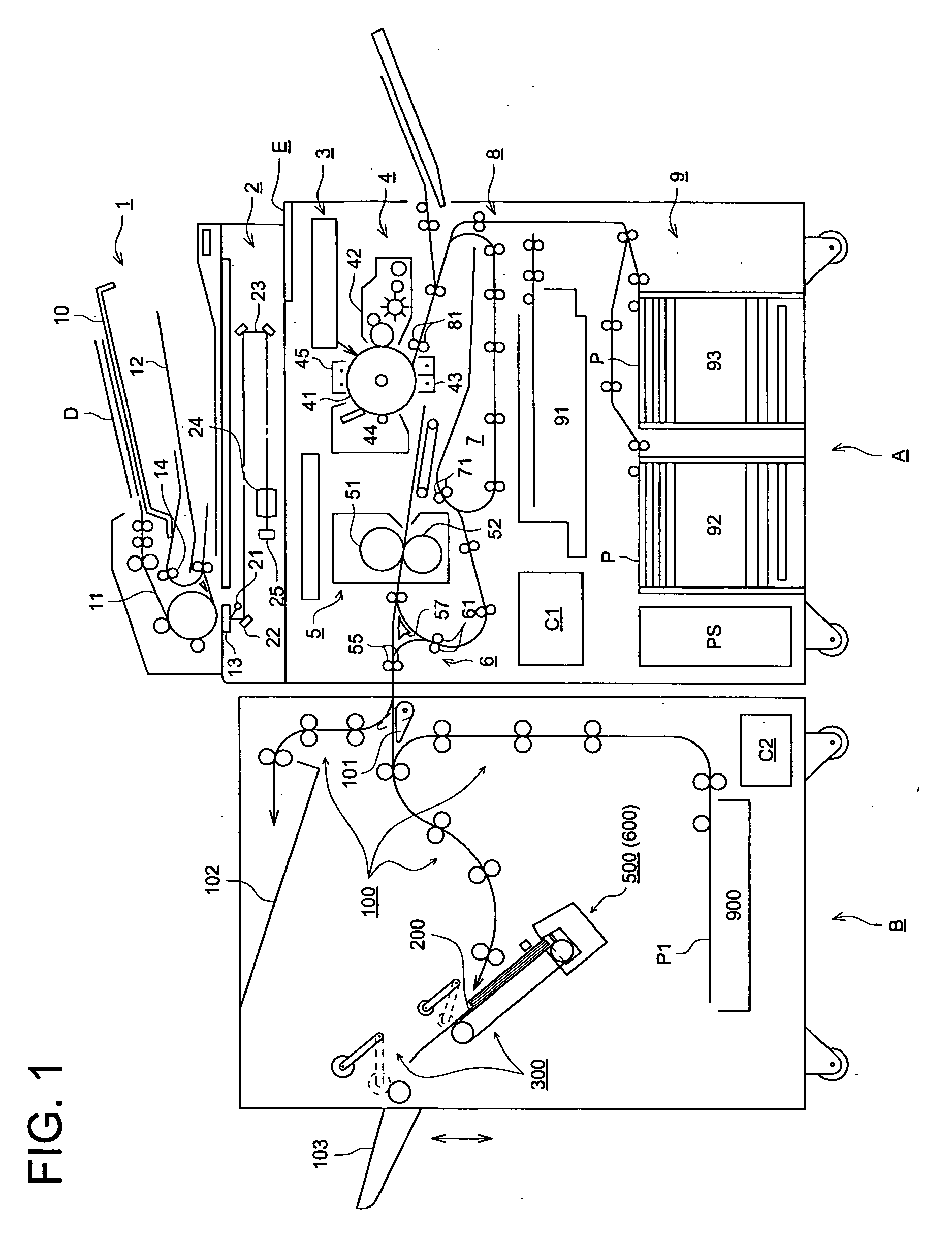

Image forming apparatus

ActiveUS20120070215A1Without reduction of printing efficiency and economic efficiencyDry imageElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

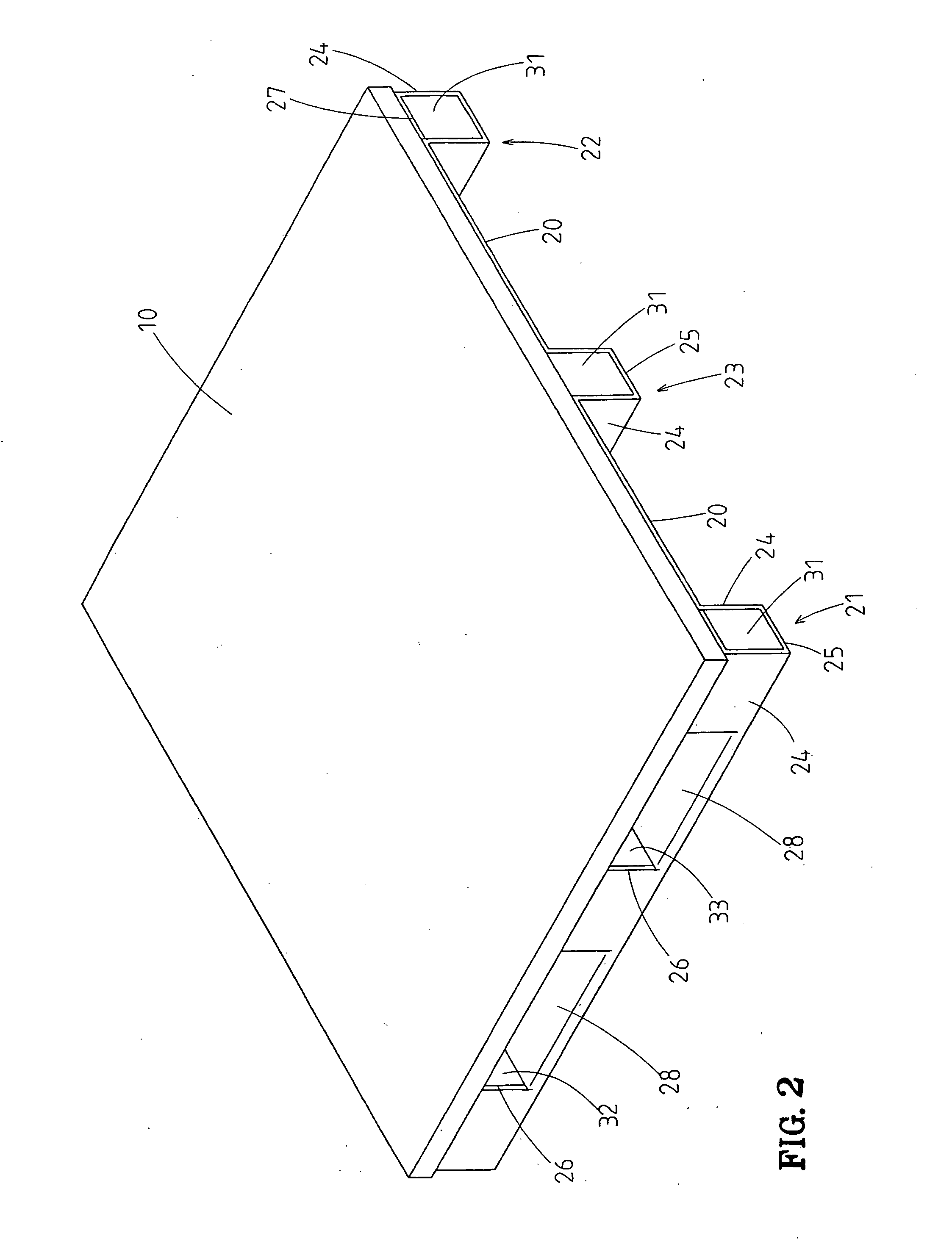

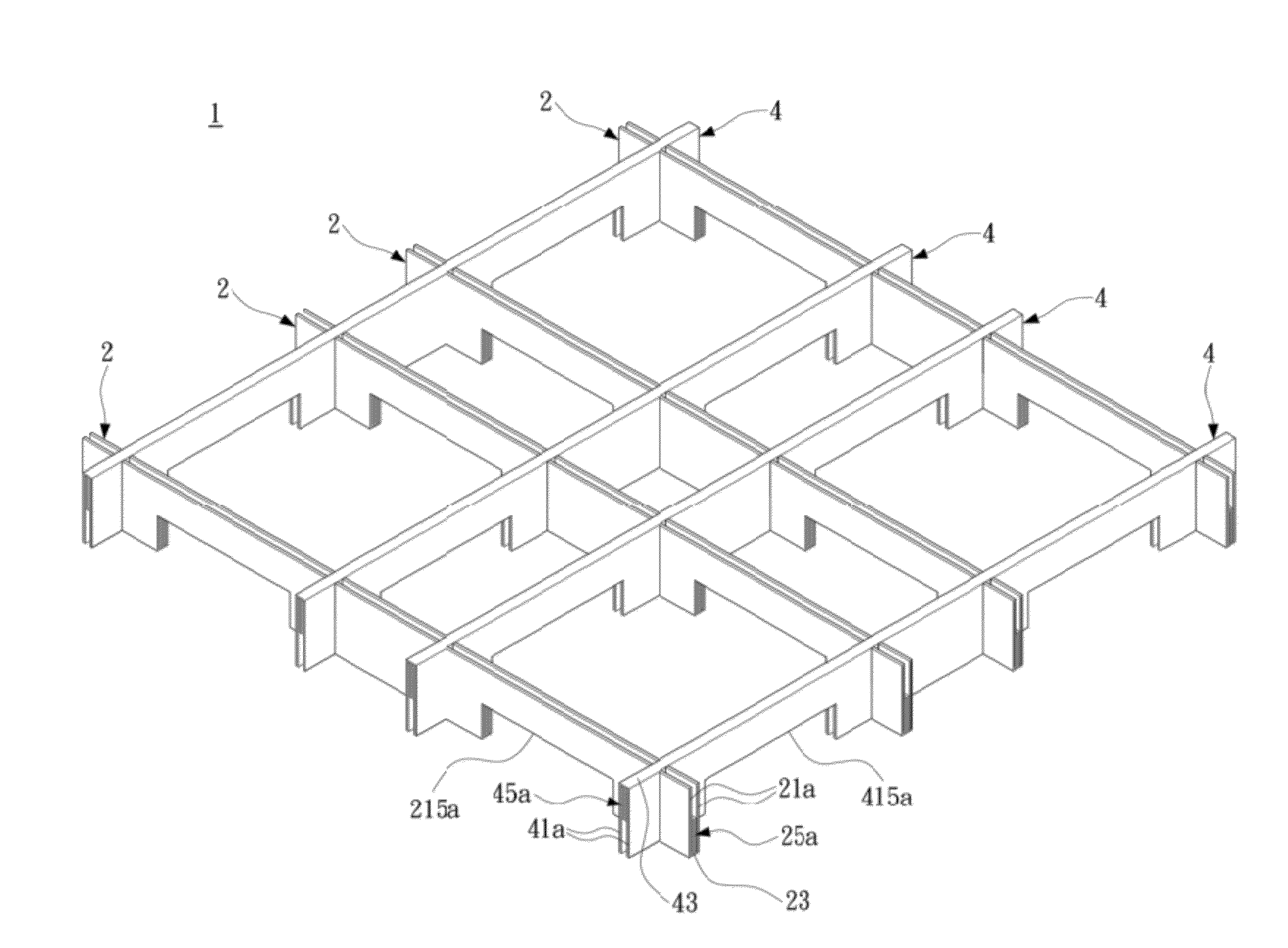

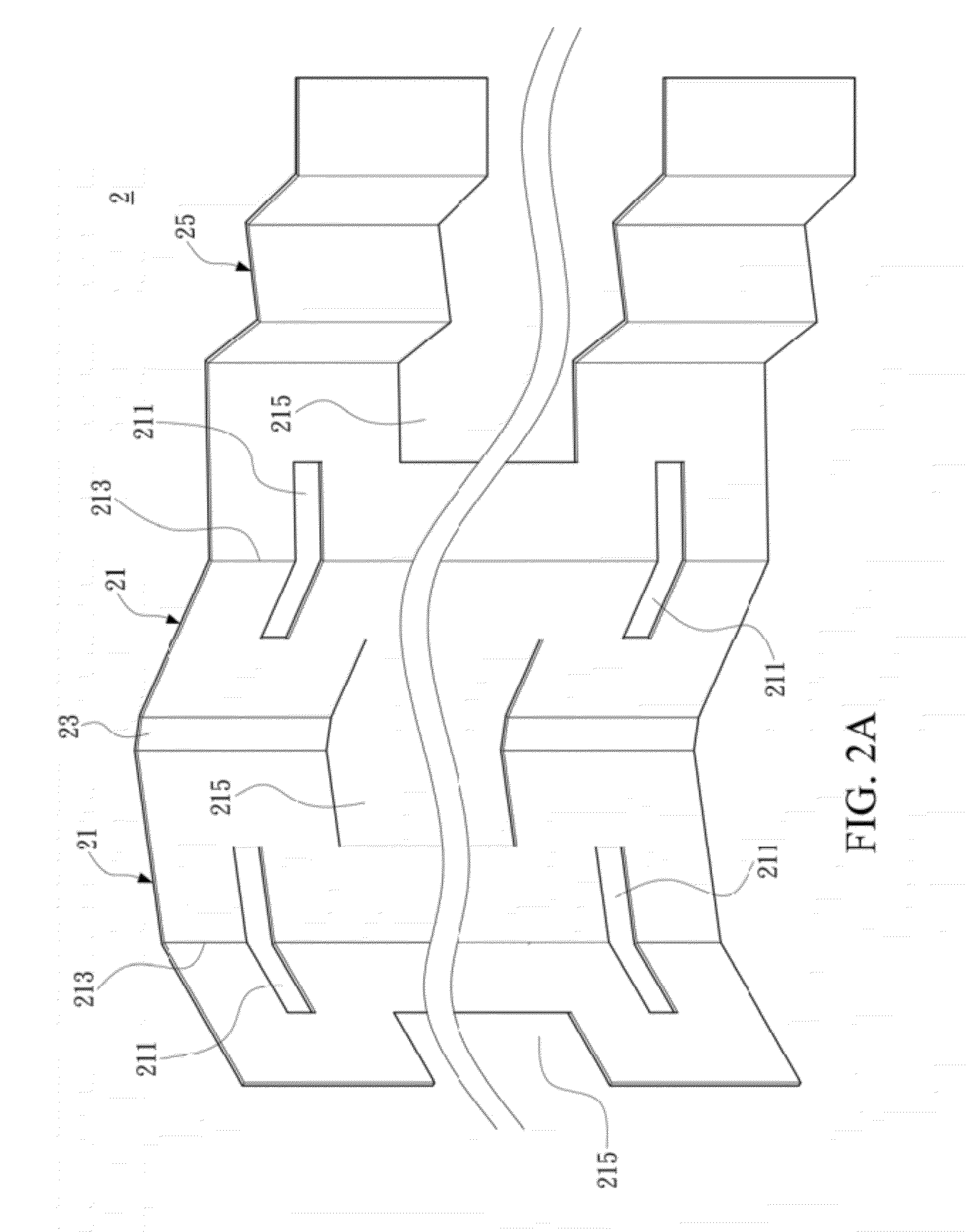

Paper pallet structure

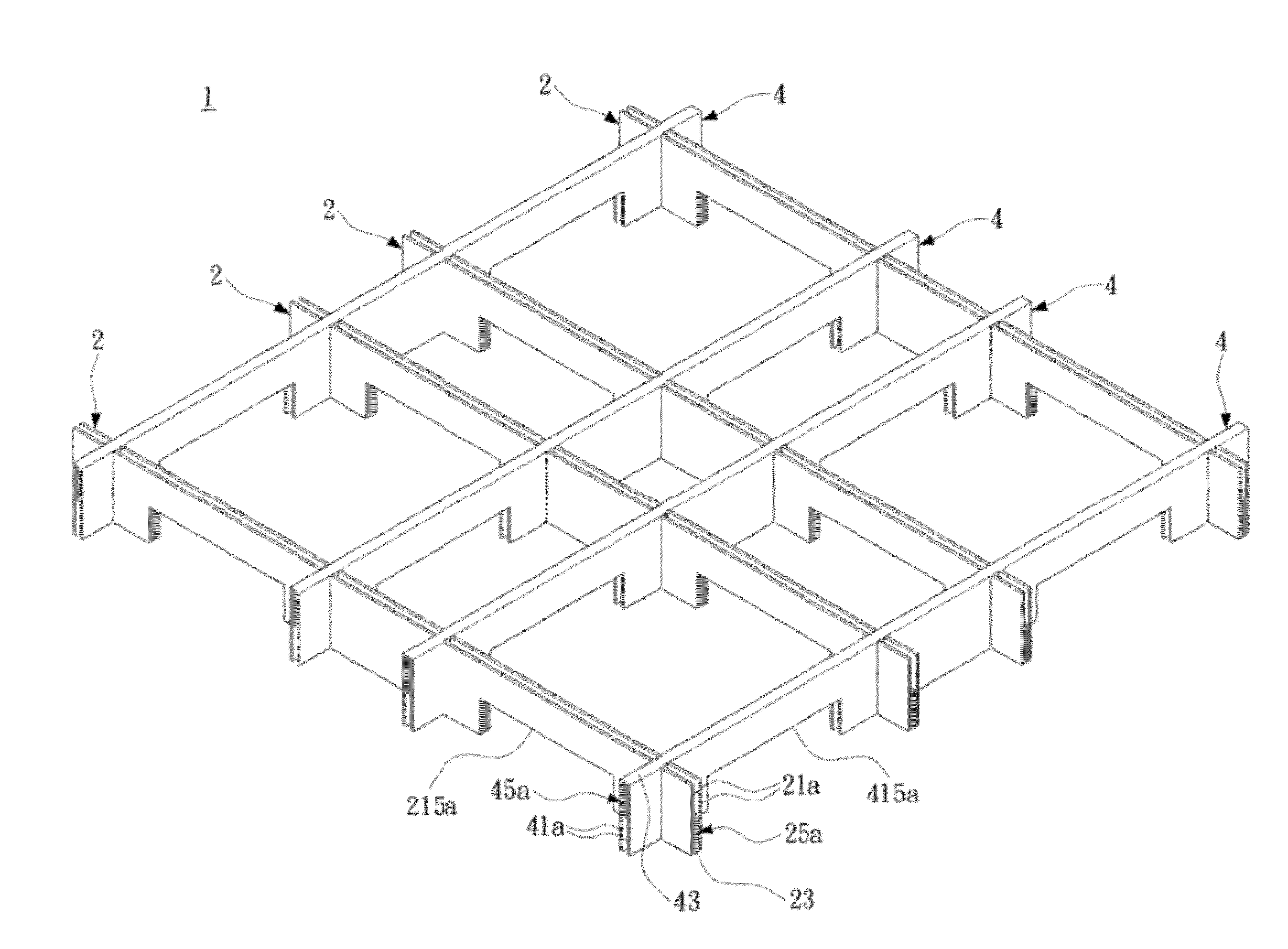

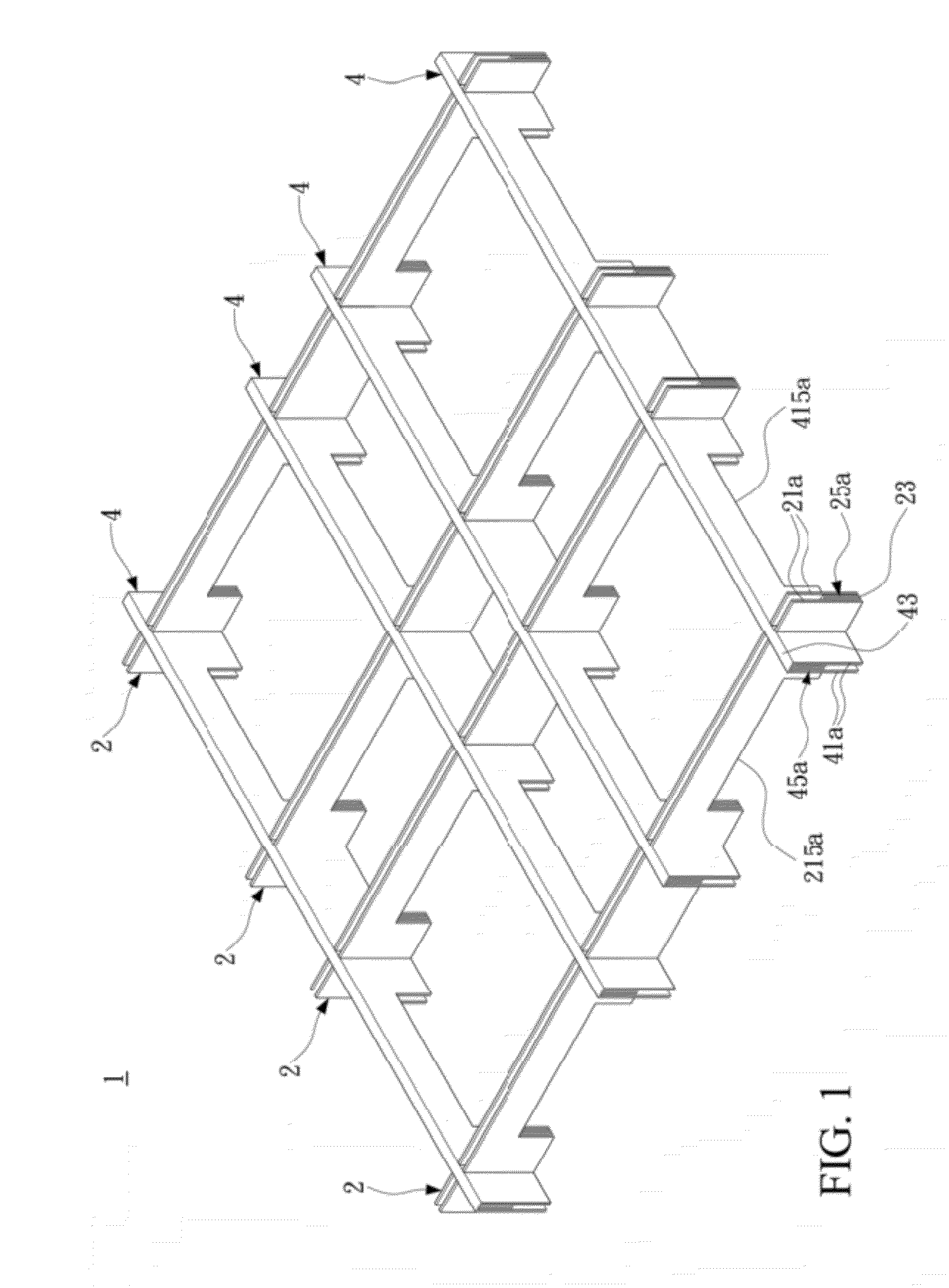

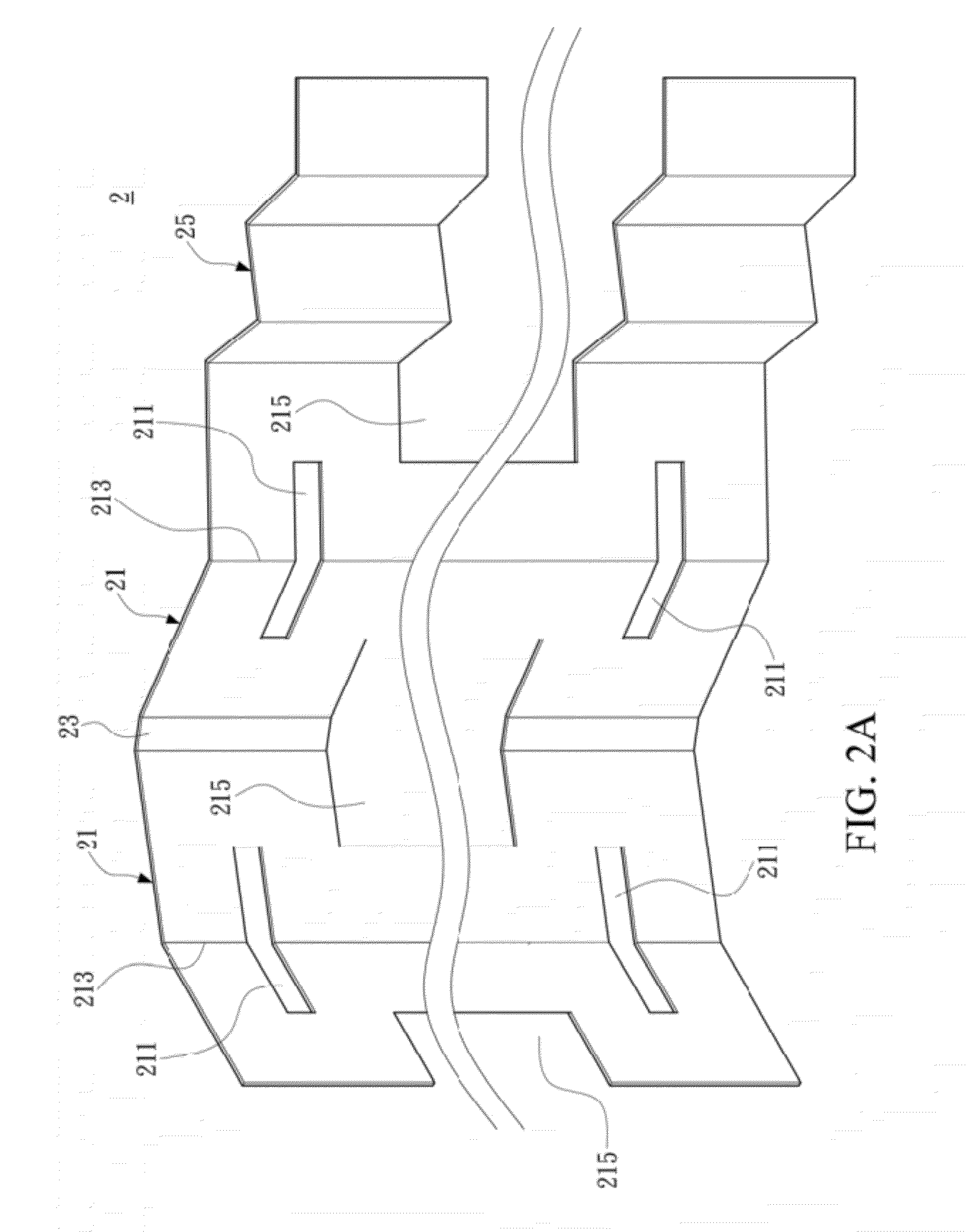

A paper pallet structure, includes a plurality of first sheet bodies and a plurality of second sheet bodies, the first sheet body is bent to form two wing portions, a first connecting portion connected to the two wing portions, and a first supporting portion positioned between the two first wing portions and coming into abutting contact with the first connecting portion, and the second sheet body is bent to form two wing portions, a second connecting portion connected to the two wing portions, and a second supporting portion positioned between the two second wing portions and coming into abutting contact with the second connecting portion. The first wing portion and the second wing portion respectively have first engagement portions and second engagement portions, and the first engagement portions are engaged with the second engagement portions to position the first sheet body and the second sheet body perpendicular to each other.

Owner:AIR BAG PACKING +1

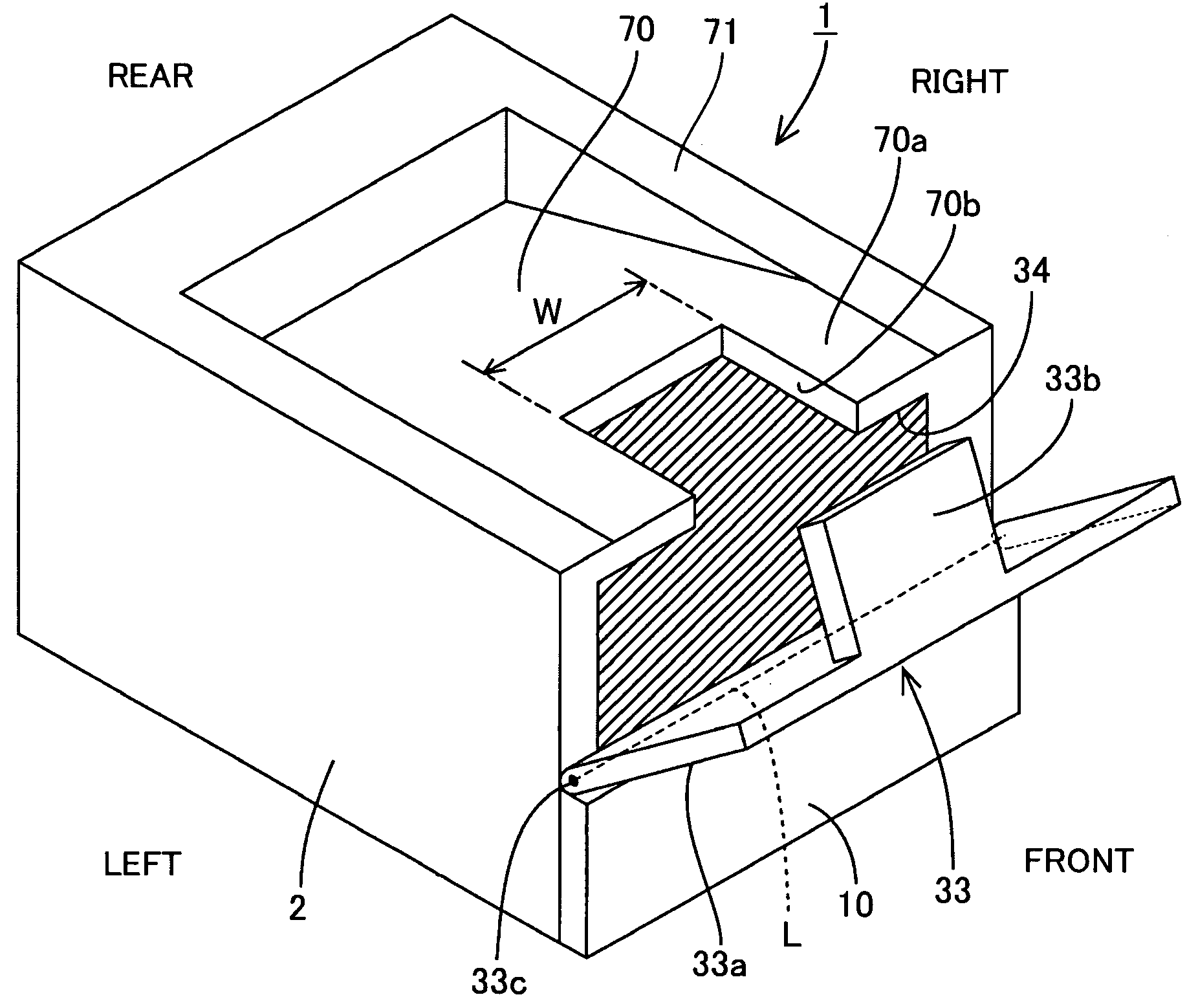

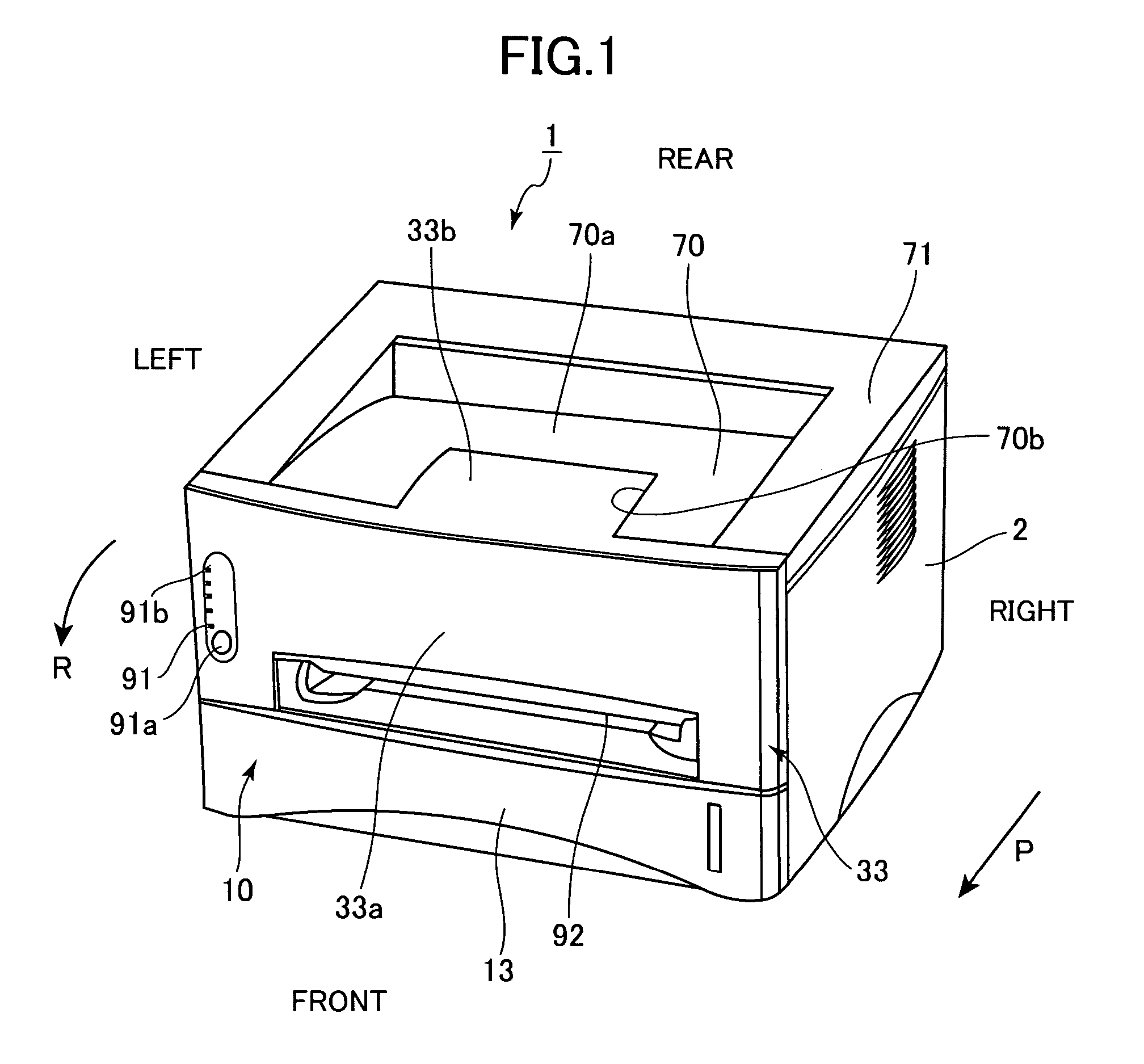

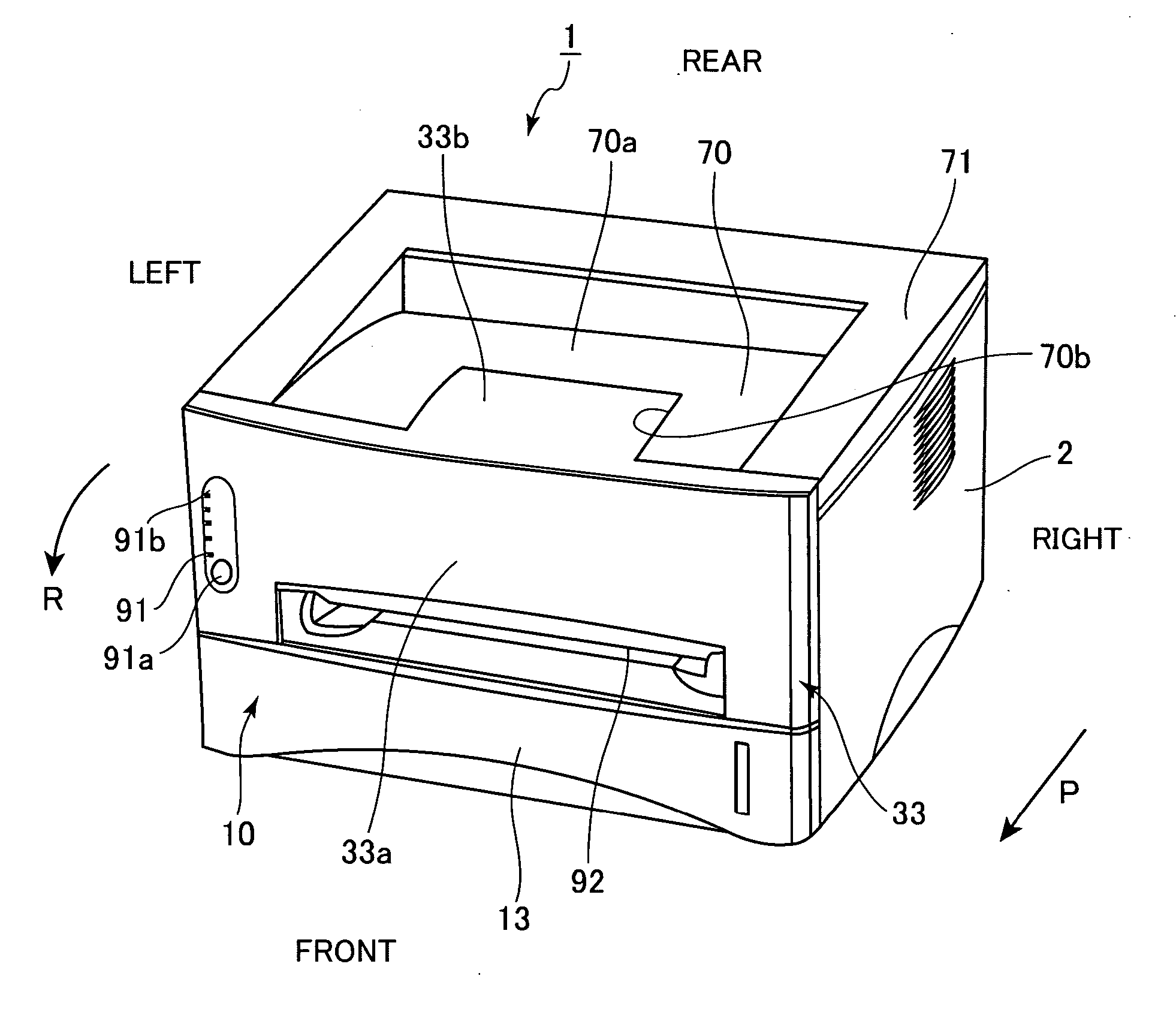

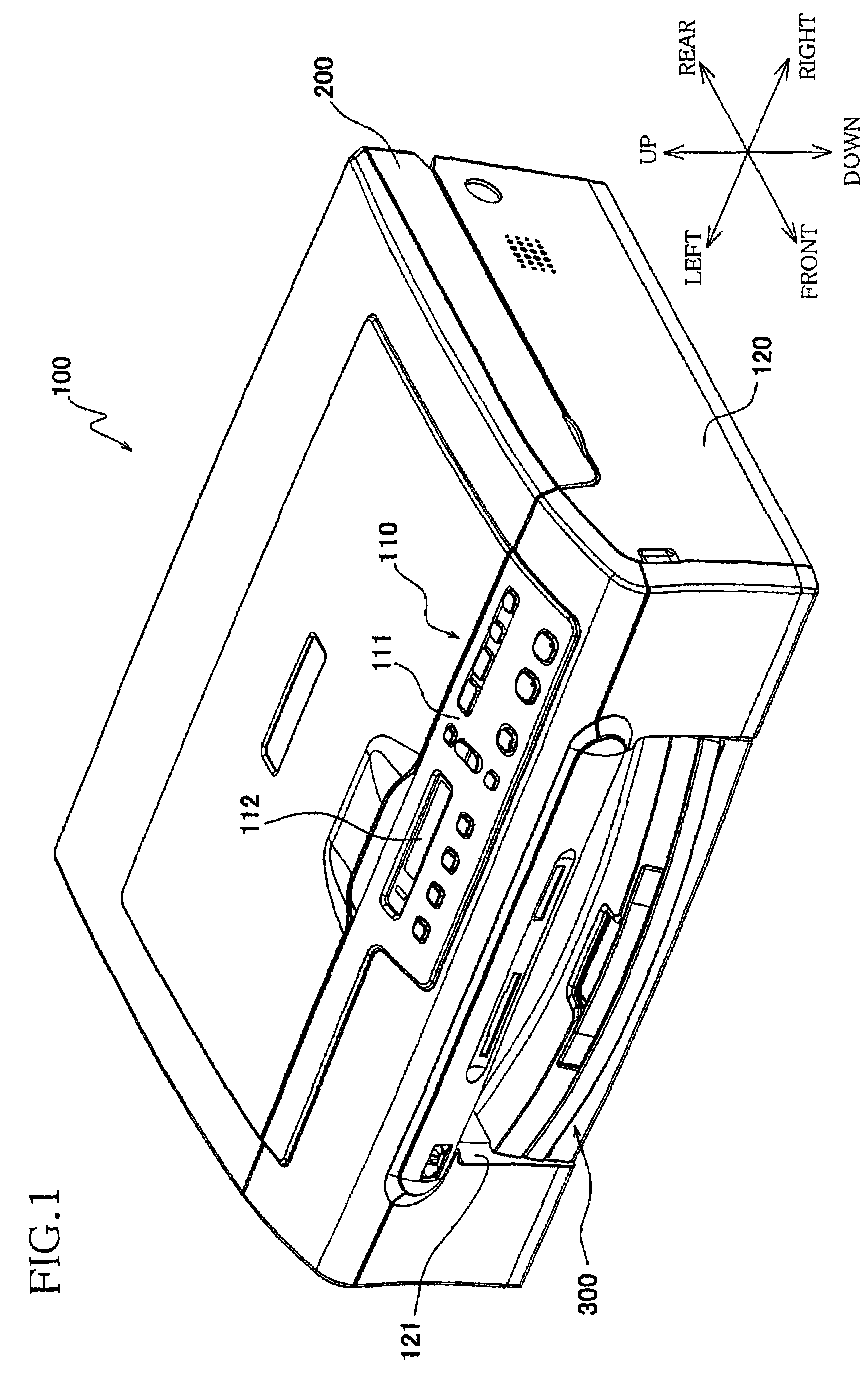

Image forming device

ActiveUS20050141947A1Small surface areaUnstable supportTypewritersElectrography/magnetographyComputer printingImage formation

A laser beam printer includes a casing with a discharge tray disposed on the top surface of the casing. A cutout part is formed in the top surface of the casing and an opening is formed in the front surface of the casing for facilitating mounting and removal of a process cartridge. The opening can be closed with a cover. When the cover is in a closed position, a top cover part of the cover blocks the cutout part. At this time, the top cover part and a main discharge tray part of the discharge tray are adjacent to one another and function to support paper. When the cover is in an open position, the cutout part is exposed; the top cover part is separated from the main discharge tray part; and the paper is supported by the main discharge tray alone.

Owner:BROTHER KOGYO KK

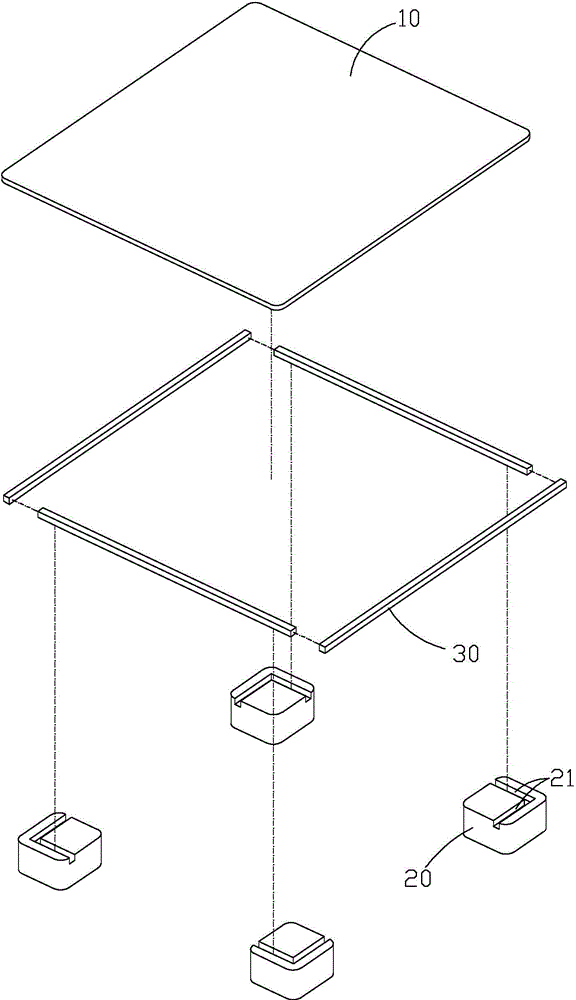

Pallet structure

A pallet structure comprises a bearing body, a plurality of foot bases and a plurality of support rods. The foot bases are arranged on selected positions at the bottom of the bearing body. A plurality of installing grooves are formed in the top surface of each foot base. The support rods are disposed on the corresponding foot bases. The two ends of the support rods are fastened in the installing grooves of the foot bases tightly. By using the design that the support rods are tightly fastened in the installing grooves of the foot bases, various pallets with different bearing capacities can be made conveniently and rapidly. The pallet is formed by combining the plastic bearing body, the plastic foot bases and the metal support rods, so that the pallet is free of shortcomings of wood pallets, plastic pallets, metal pallets and paper pallets.

Owner:INNVALLEY GRP LTD

Printer paper tray

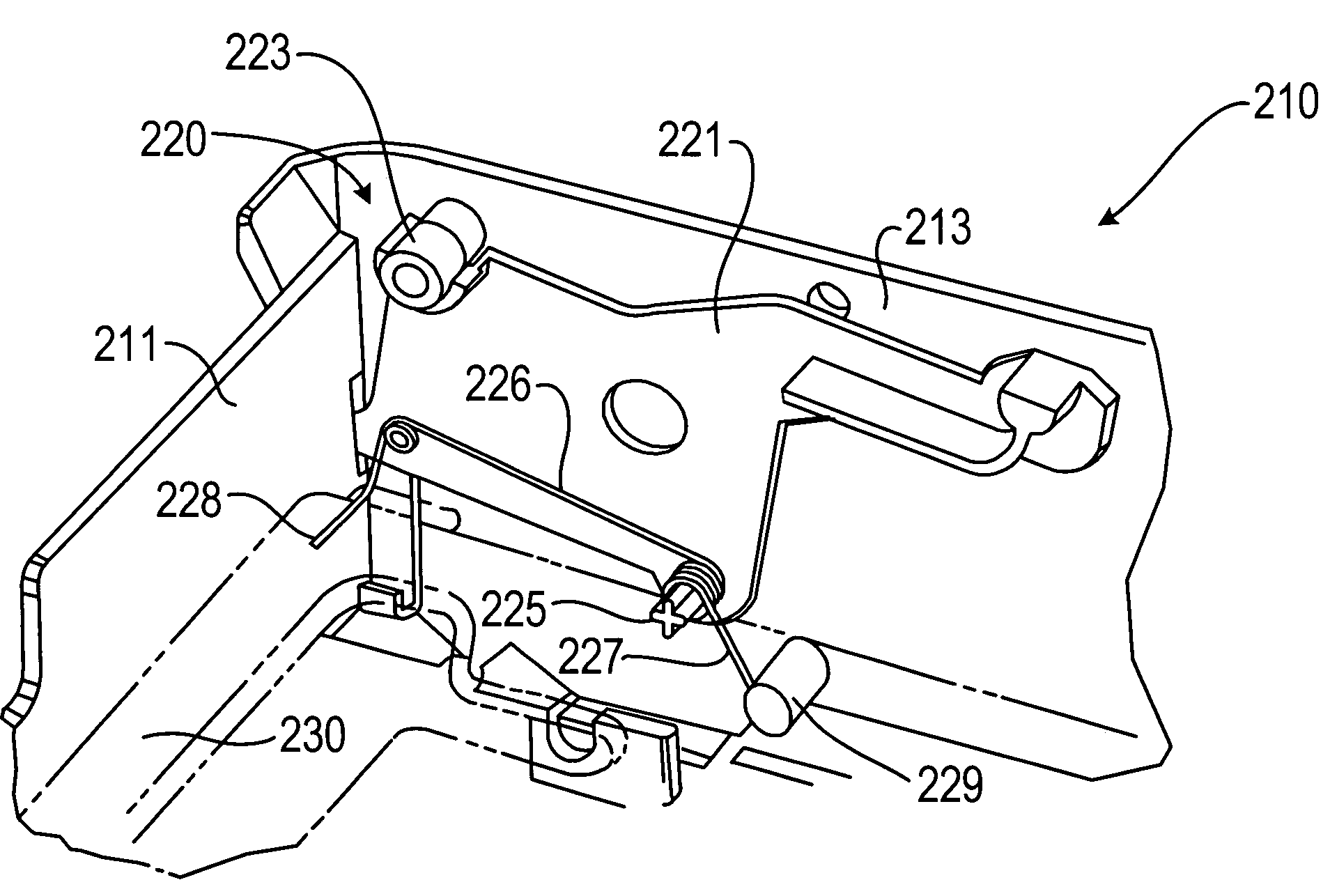

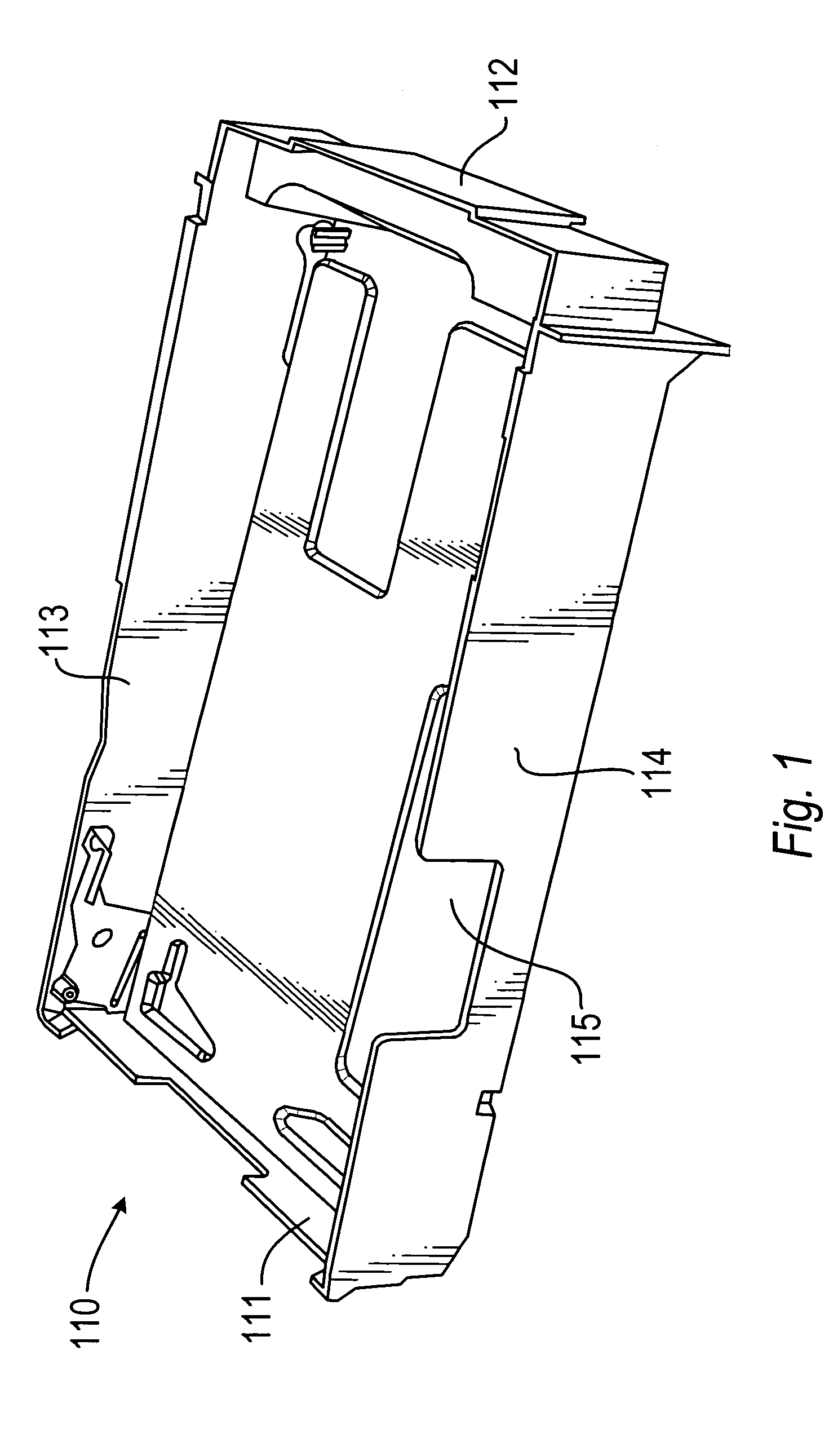

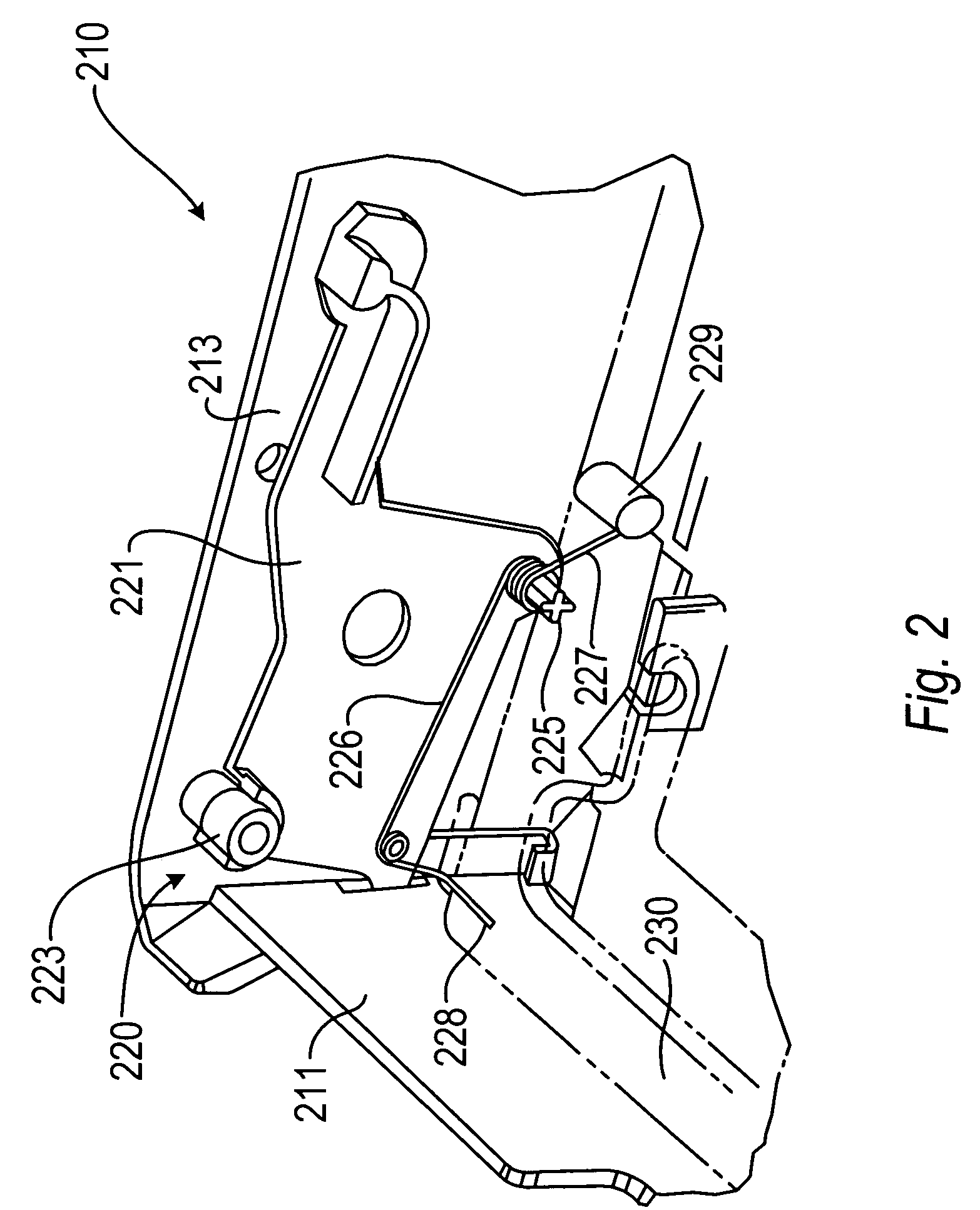

A paper tray (110, 210, 310, 410, 510, 610, 710, 810) for holding a stack of sheets of paper in a printer (540, 640, 740, 840) is provided. The paper tray includes an actuator (221, 421, 521, 621, 721, 821), which is moveable between an engaged position by insertion of the tray into the printer and a refilling position by at least partial removal of the tray from the printer. A paper supporting plate (230, 330, 430, 530, 630, 730, 830) is moveably coupled to the actuator. The paper supporting plate supports the stack of paper so that a sheet furthest away from the paper supporting plate is in a picking position available for picking by the printer, when the actuator is in the engaged position. The actuator is coupled to the paper supporting plate so as to move the paper supporting plate away from the picking position when the actuator is moved into the refilling position.

Owner:HEWLETT PACKARD DEV CO LP

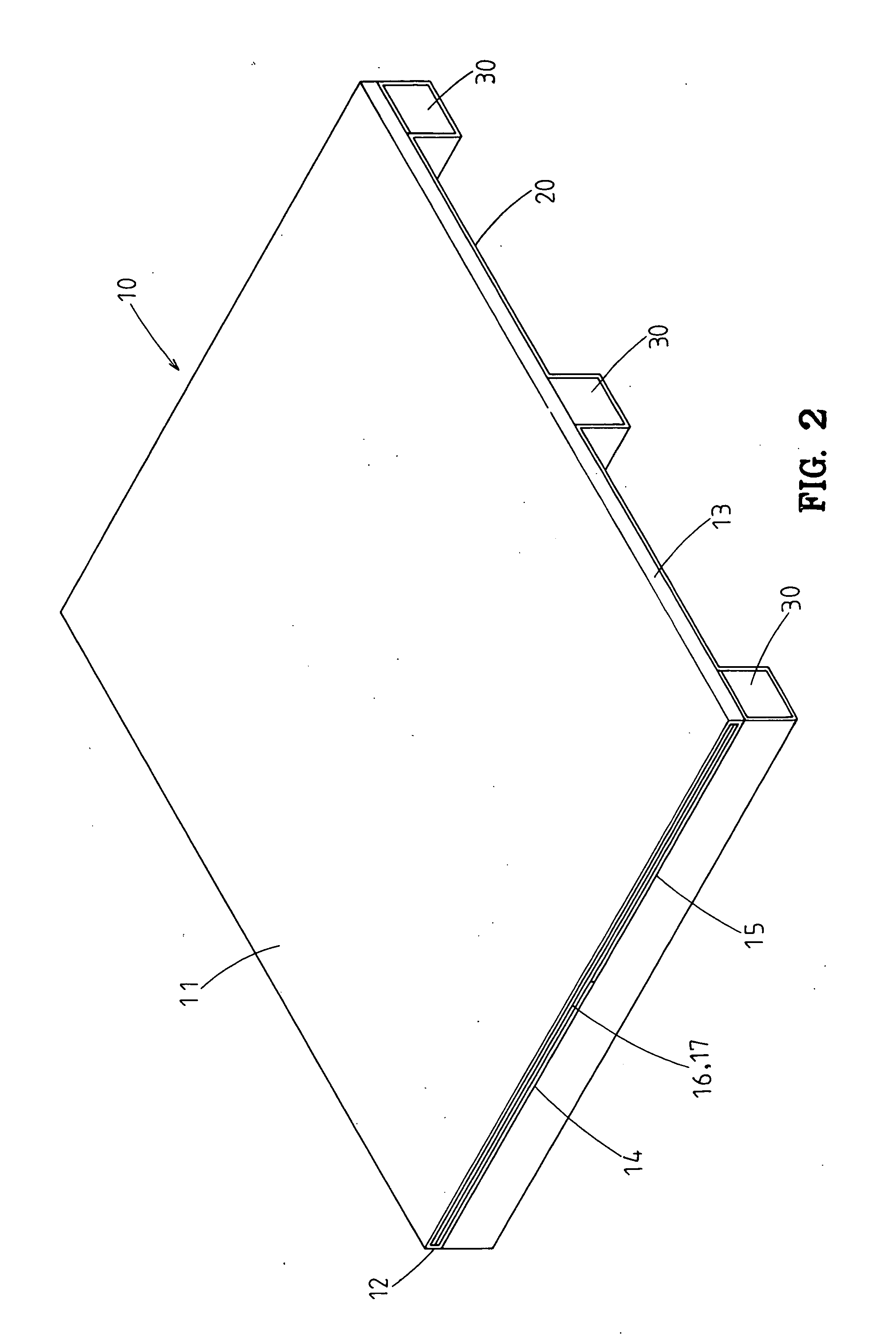

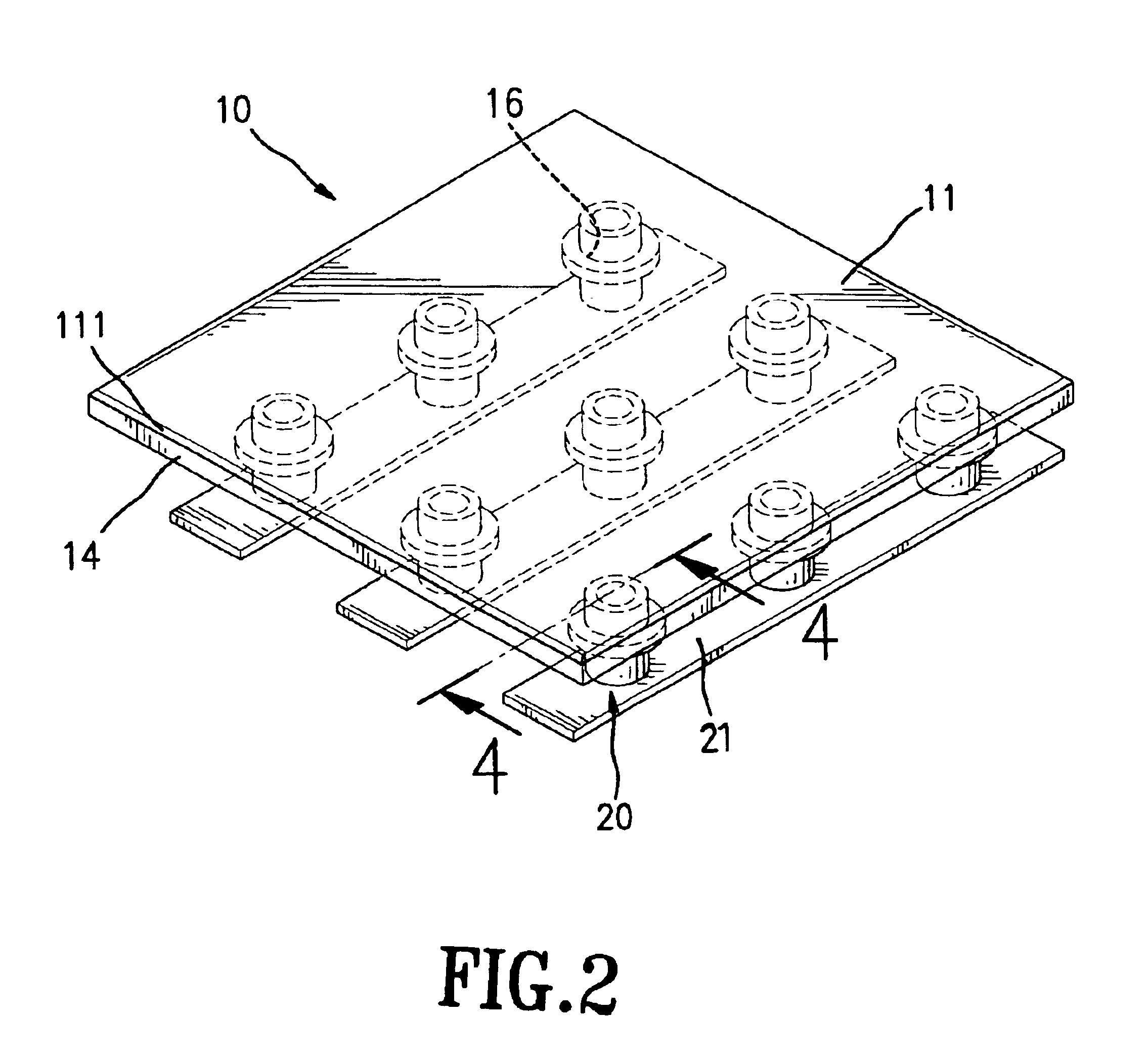

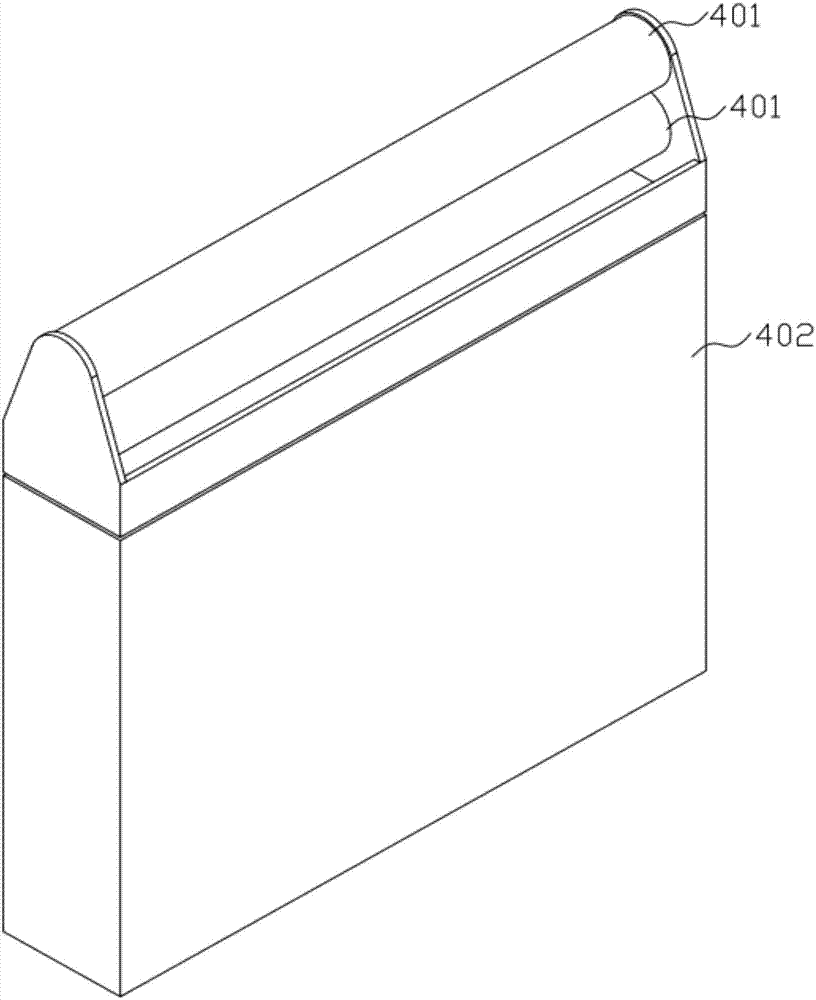

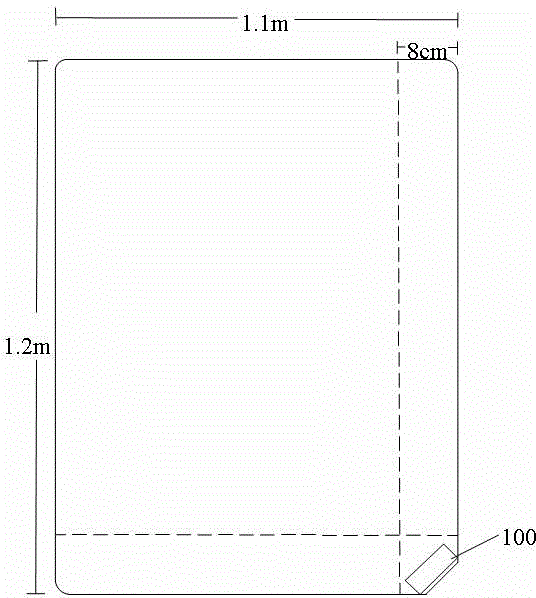

Paper pallet

A pallet includes a top plate, a bottom plate fixed below the main plate, and a plurality of spaces mounted below a general plane of the bottom plate. The top plate includes a main section and two enveloping sections respectively on two sides of the main section of the top plate. A protective folding section is provided between each enveloping section and the main section of the top plate. At least one reinforcing plate is sandwiched between the main section of the top plate and the enveloping sections of the top plate. The protective folding sections form front and rear edges of the pallet, preventing damage to the pallet during use.

Owner:CHEN FU MEI

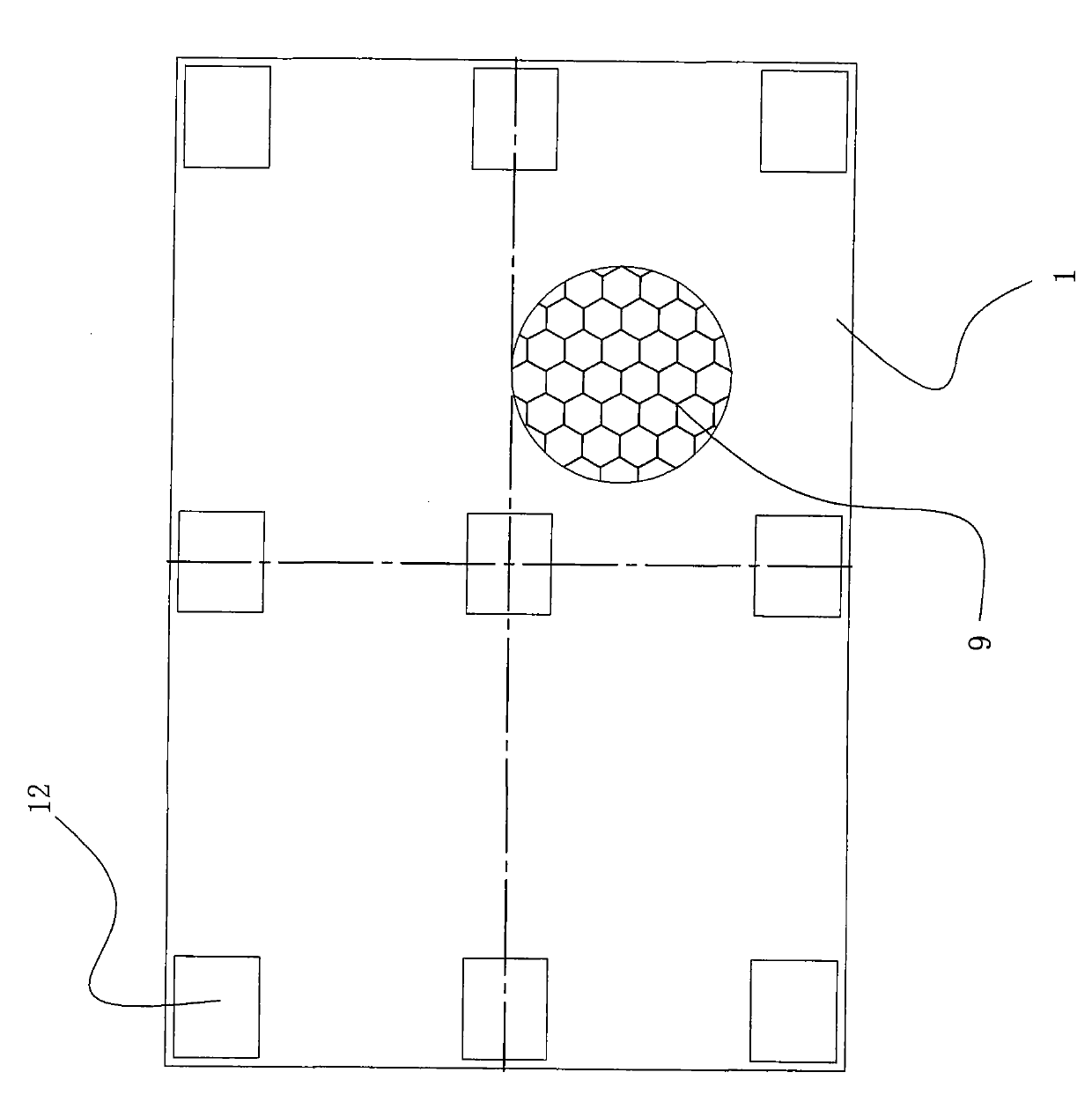

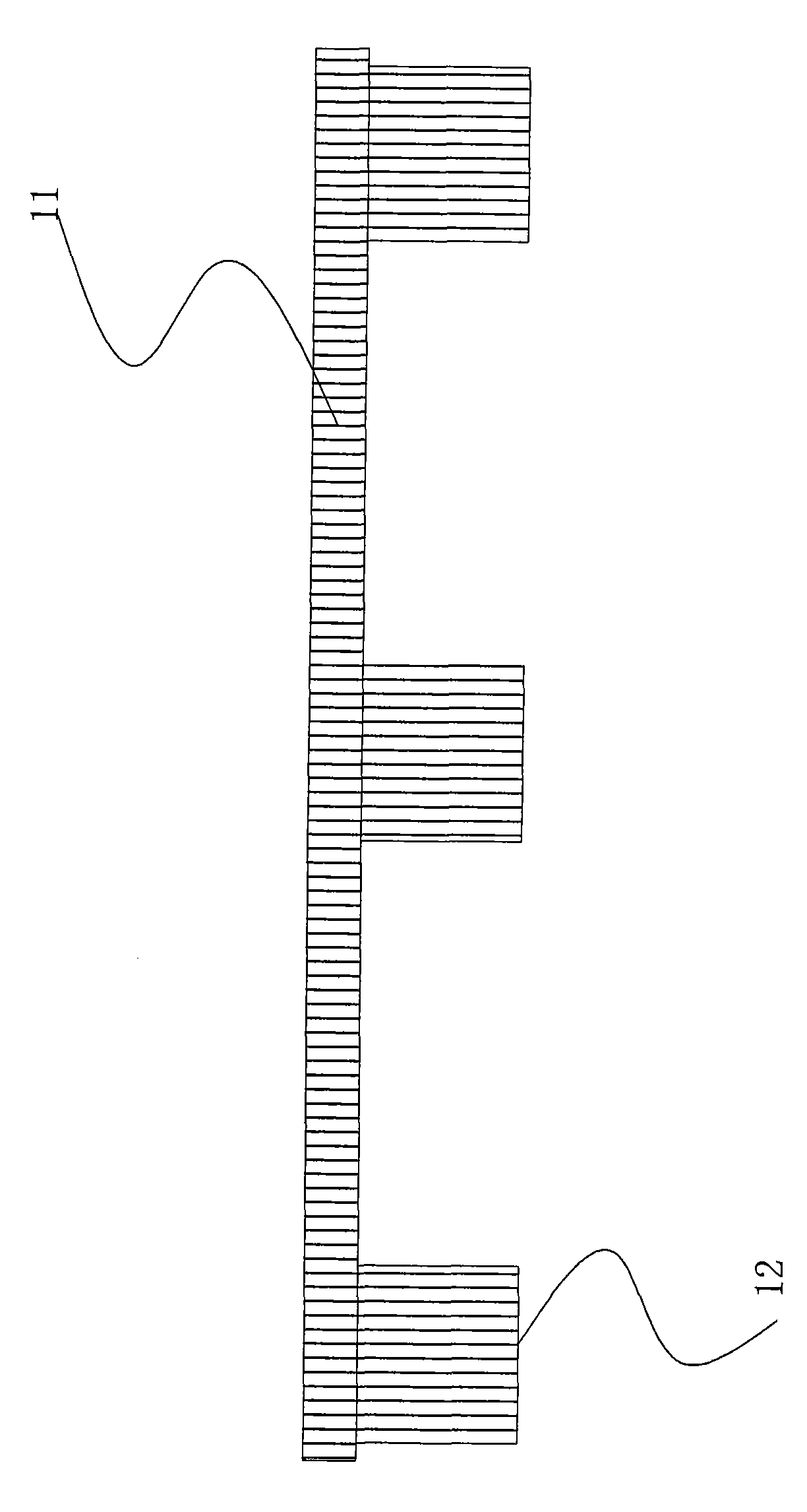

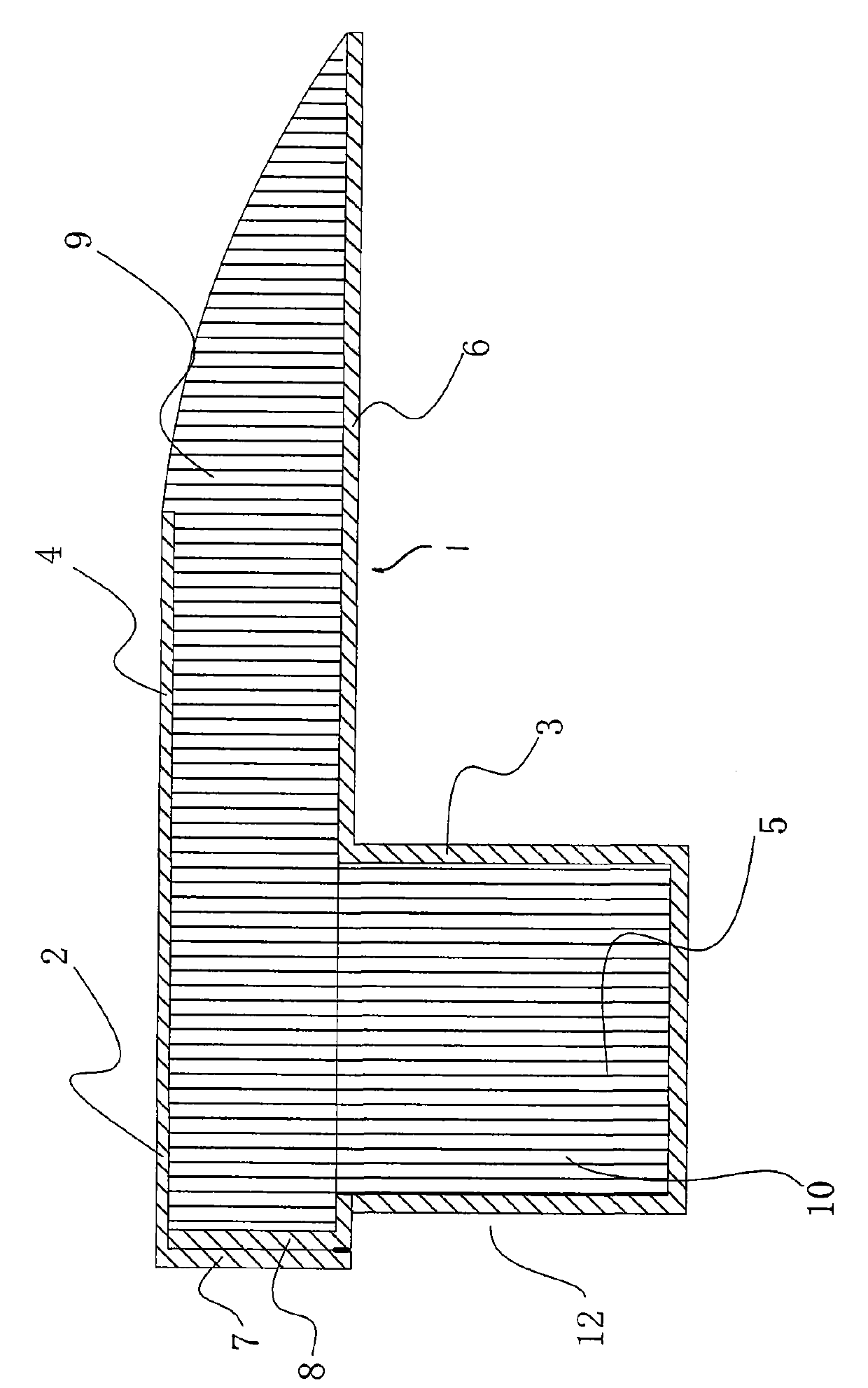

Paper pallet

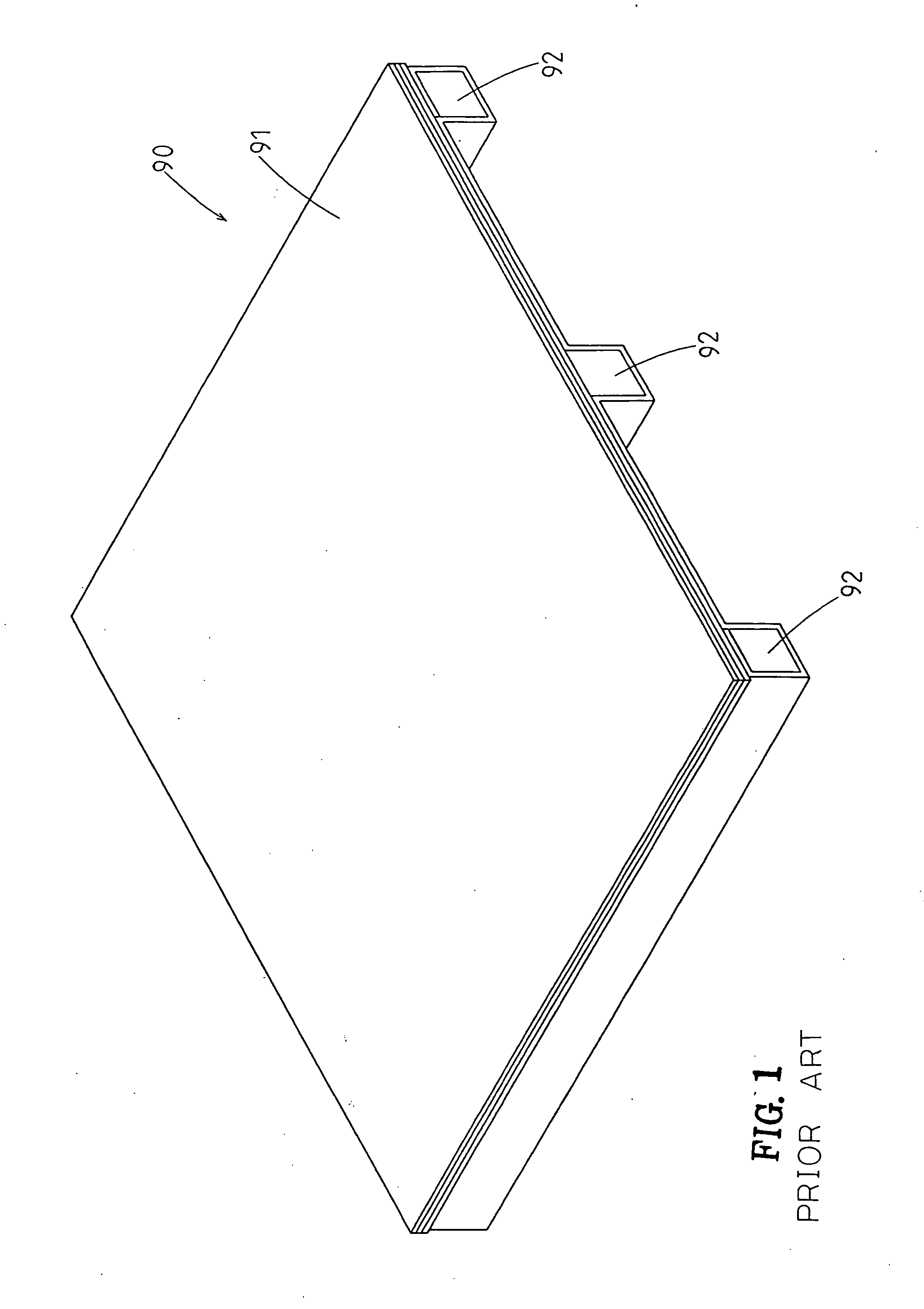

InactiveUS6817586B1Improve structural strengthStands/trestlesKitchen equipmentInterior spaceEngineering

A pallet has a supporting board, multiple supporters, multiple reinforcing rings and a base. The supporting board is rectangular and is made of paper. The supporting board has a top, a bottom, four sides, an inner space and a honeycomb-like baffle. The honeycomb-like baffle is received in the inner space and is formed between the top and the bottom. The supporters are made of paper and are securely attached to the bottom of the supporting board. The reinforcing rings are made of paper, and securely mounted respectively around the supporters and abut against the bottom of the supporting board. The base is made of paper and is securely attached to the bottoms of the supporters. Accordingly, the pallet is light and is convenient to assemble and to transport.

Owner:LIN CHING CHIANG

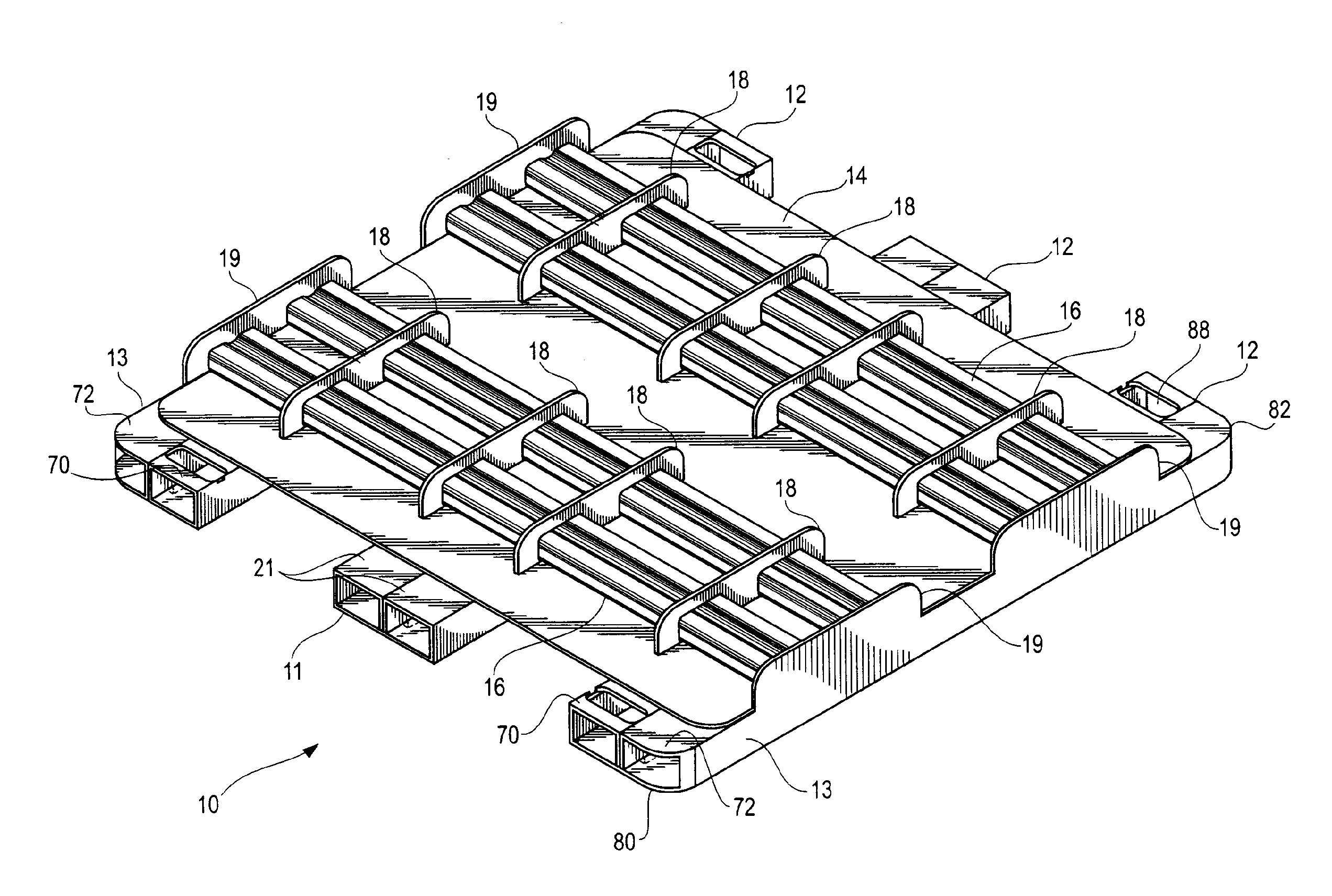

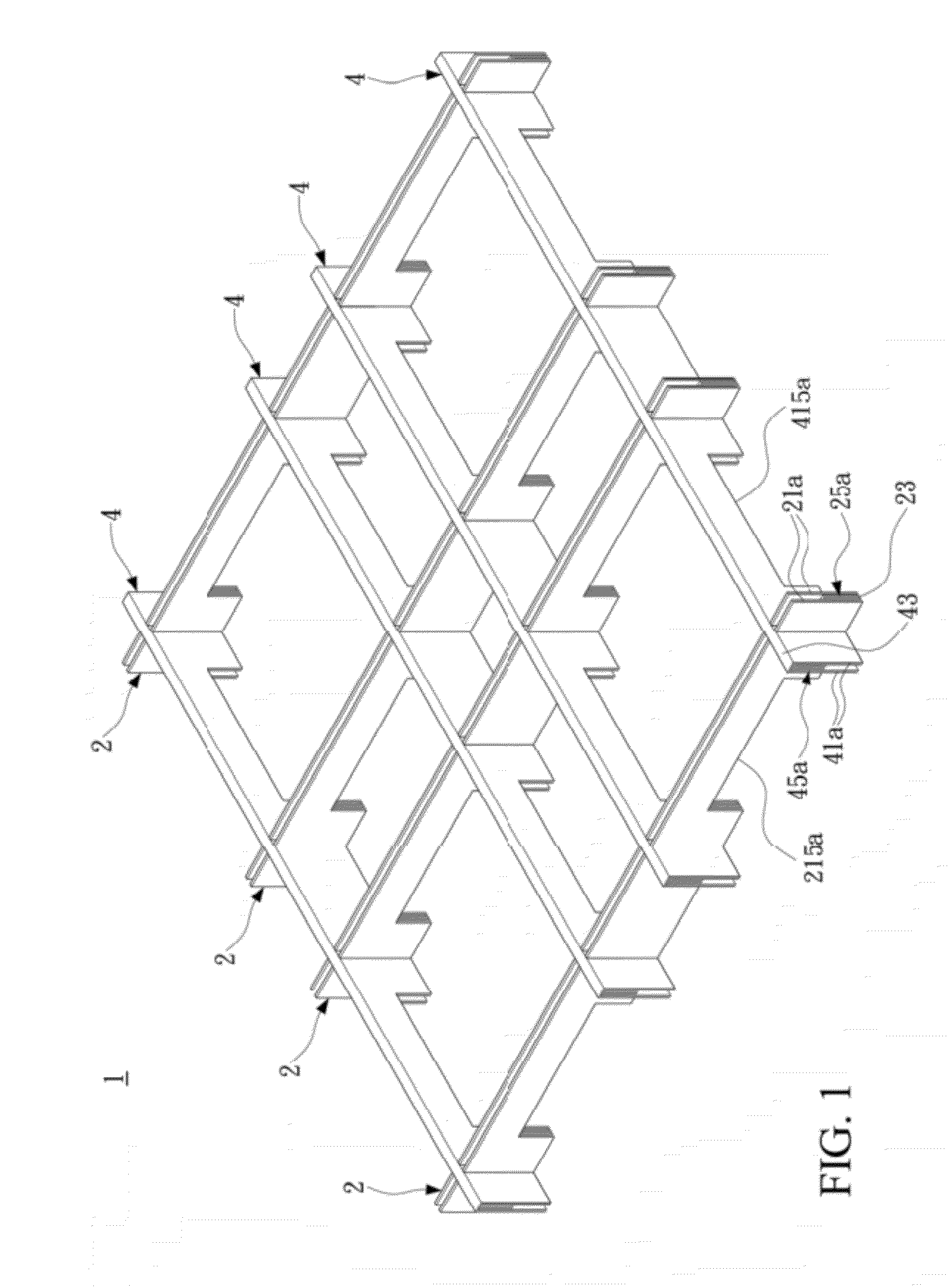

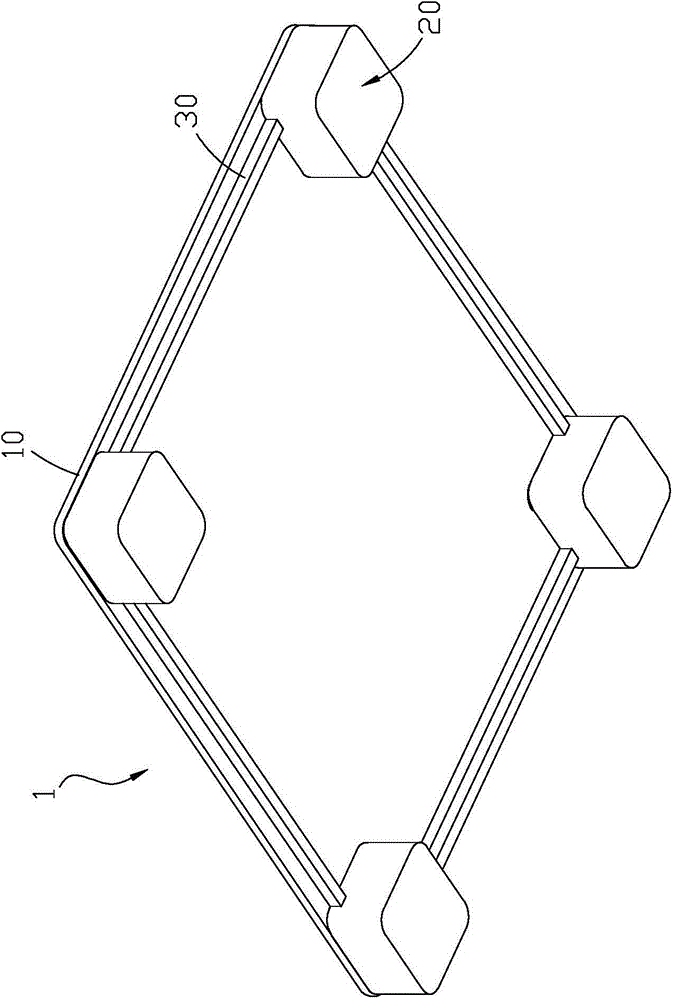

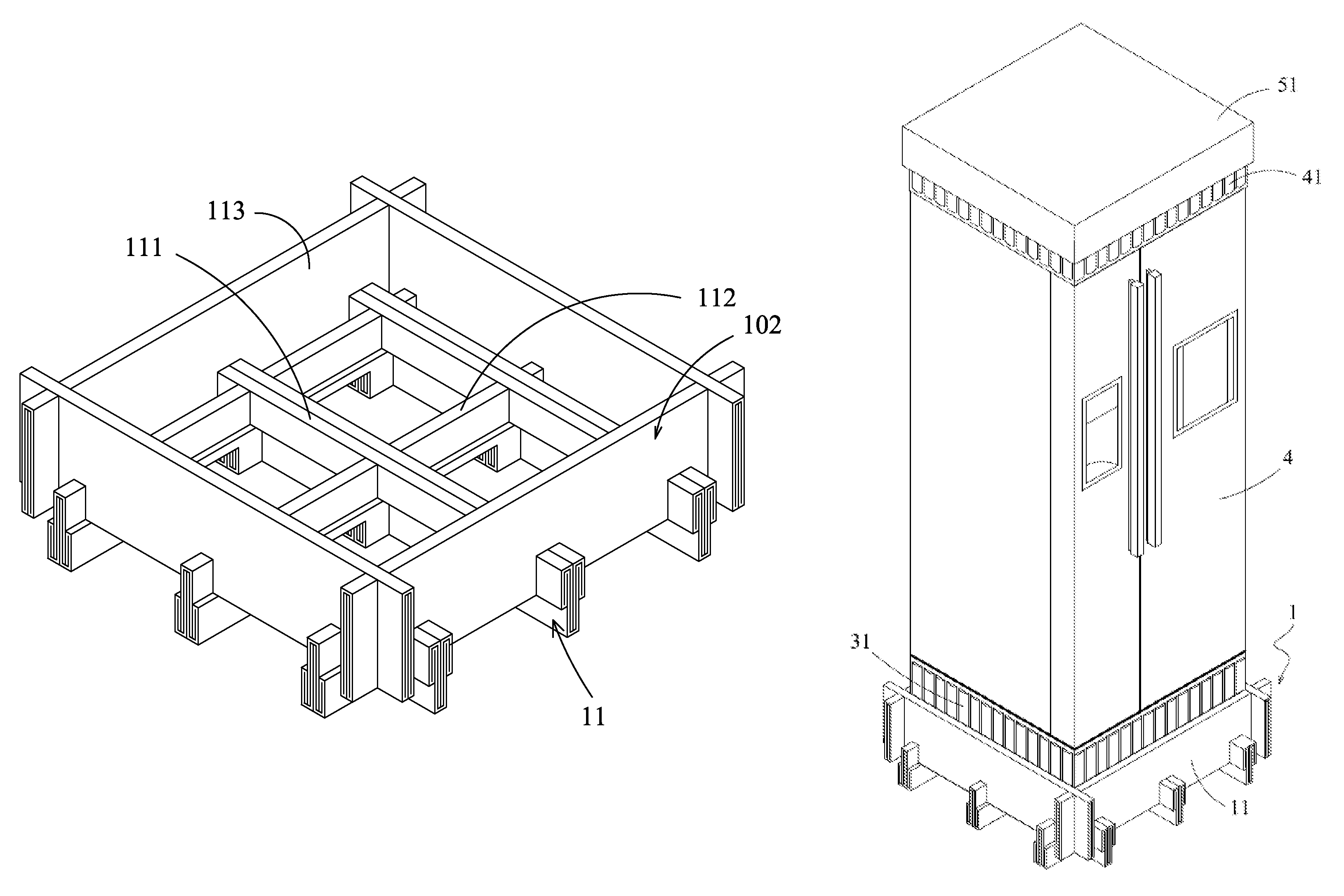

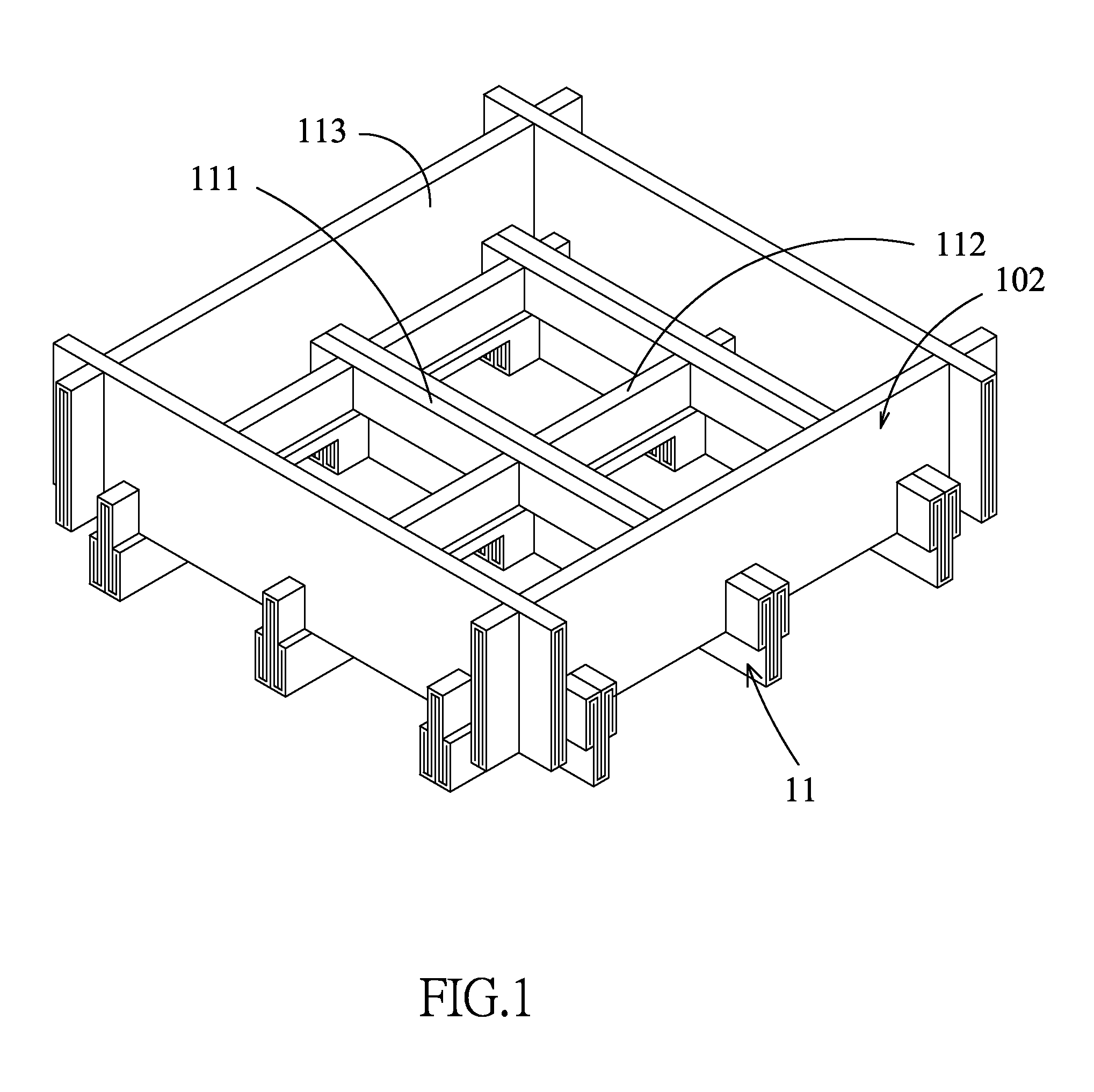

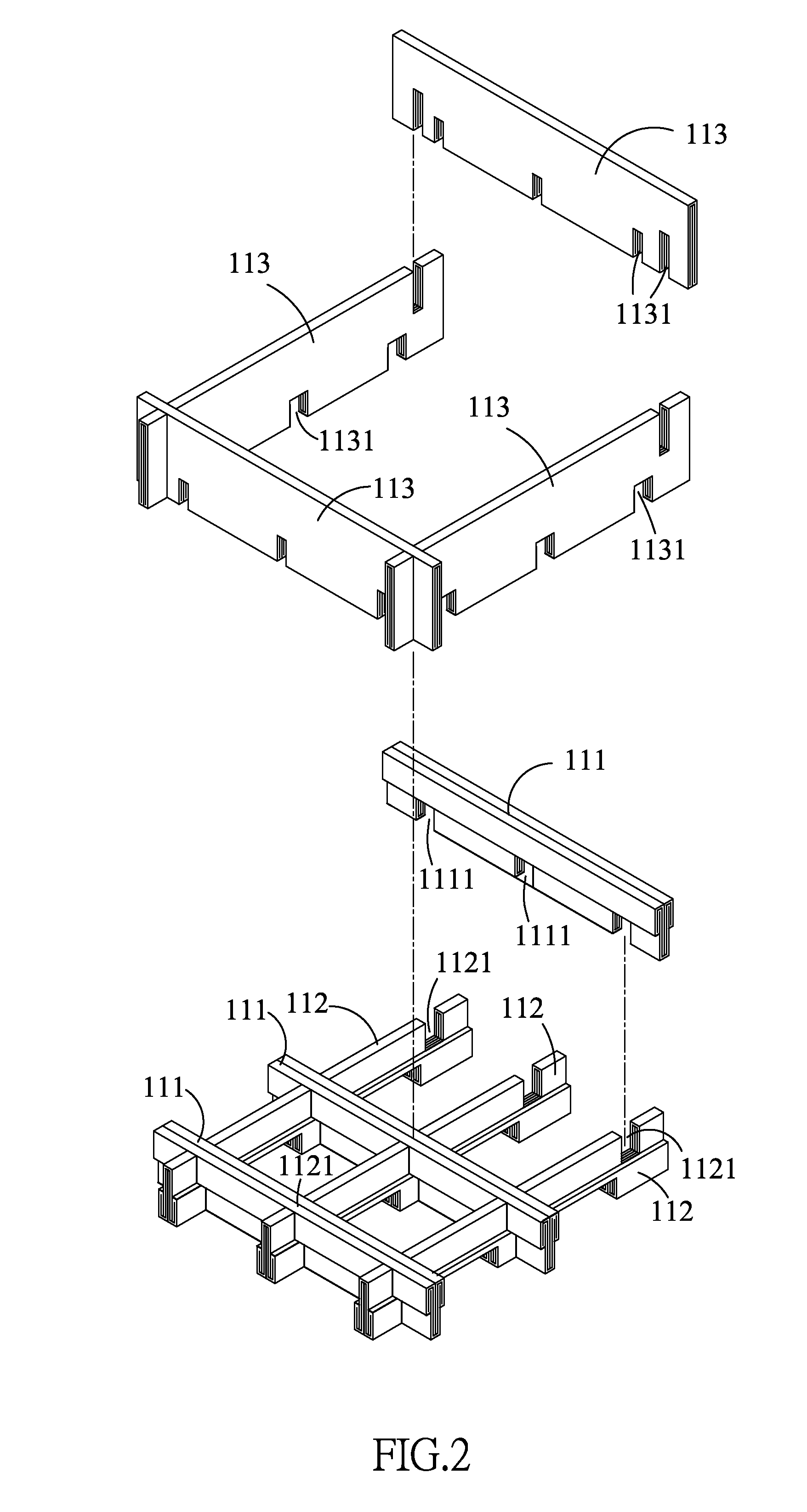

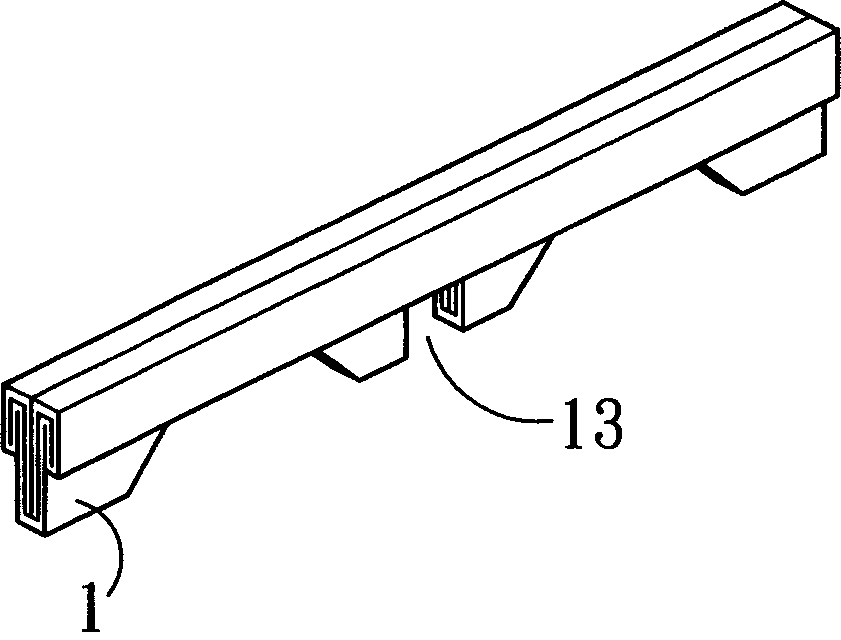

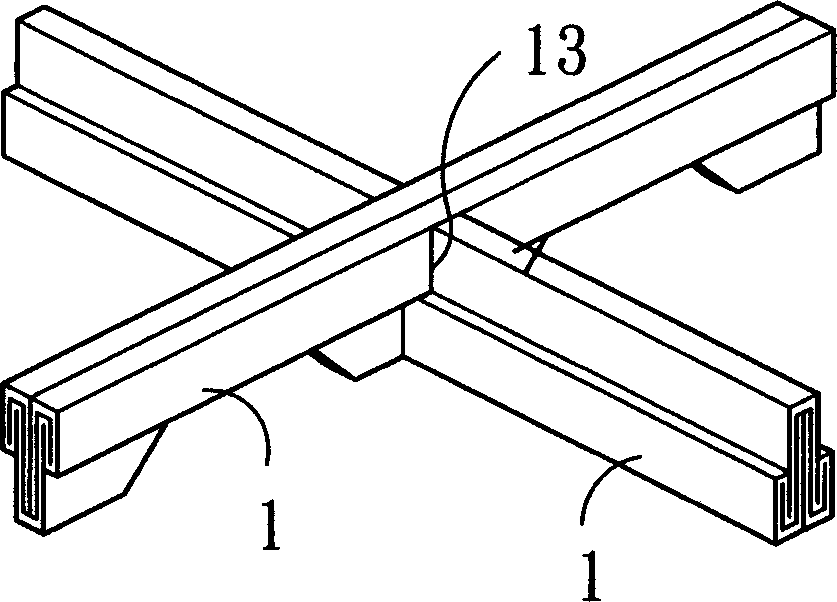

Paper pallet for packaging

InactiveUS8127929B1Improve protectionReduce manufacturing costOther accessoriesContainer/bottle contructionPaper sheetSet distance

A paper pallet for packaging comprising: a load bearing base and a packaging protective frame, wherein the load bearing base is composed of a plurality of vertical supporting components and a plurality of horizontal supporting components. The load bearing base is composed of the vertical supporting components and the horizontal supporting components intersecting and subsequently interlocking with each other, and the packaging protective frame is composed of a plurality of side boards. Therefore, the side boards intersect and subsequently interlock with each other to form a packaging protective frame, which is inlaid at a set distance from the edge around the load bearing base to form a paper pallet for packaging. Thus, the paper pallet for packaging is formed by combining the packaging protective frame with the load bearing base to become the packaging box for delivering goods.

Owner:LUSNGWEN +1

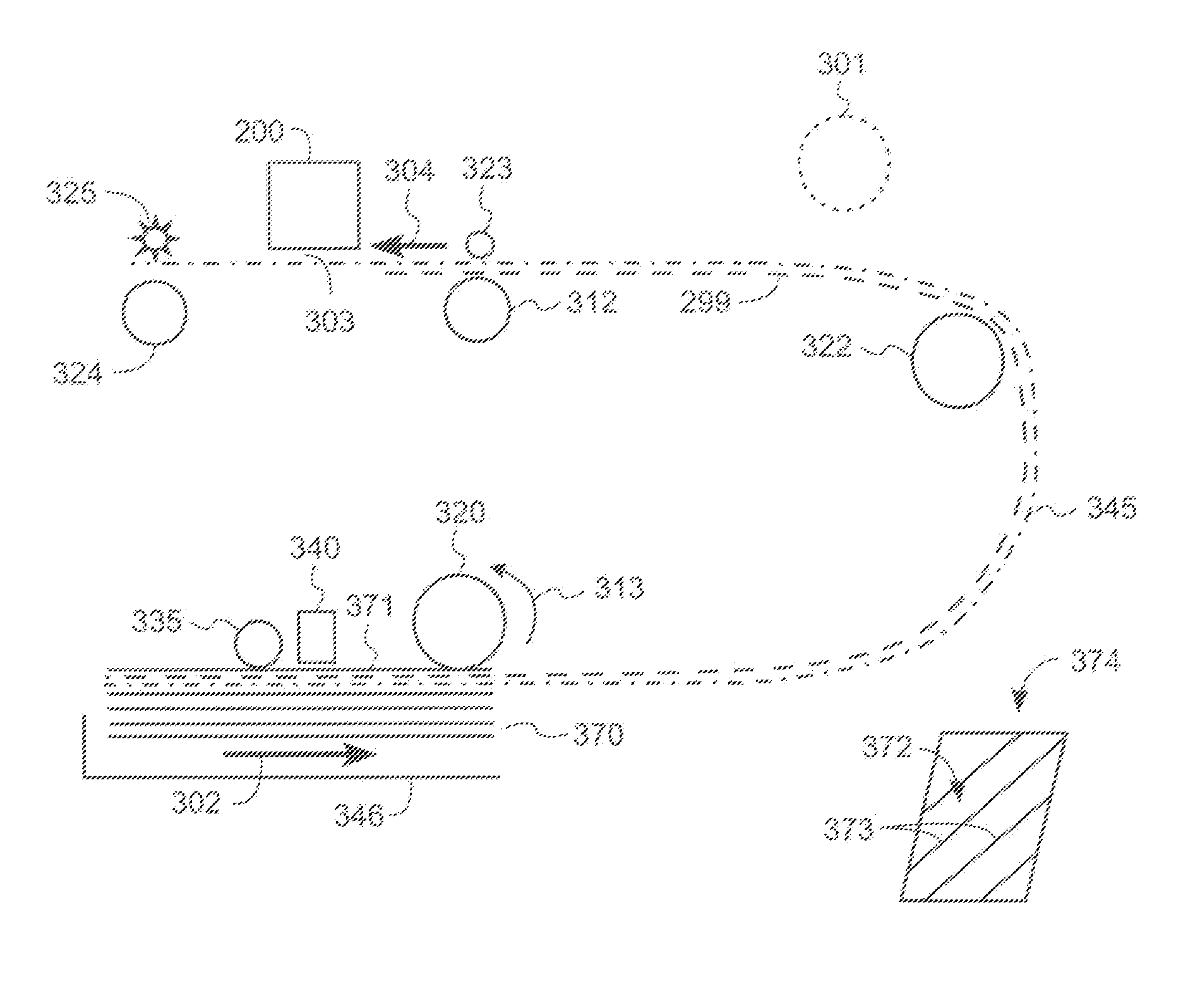

Sheet finisher and control method thereof

InactiveUS20060022395A1Reduce frequencyReduce system performanceElectrographic process apparatusPile receiversEngineeringPaper sheet

A sheet finisher includes: a sheet stacker for stacking sheets outputted from an image forming apparatus to form a sheet bundle; a binder for binding the sheet bundle stacked on the sheet stacker; an ejection device for ejecting out of the sheet finisher at least one of the sheet bundle stacked on the sheet stacker and the sheet bundle which has been bound; an ejection tray for stacking the ejected sheet bundle or the bound sheet bundle sequentially; and a controller for controlling the ejection device to make the bound sheet bundle to wait on the sheet stacker, to make a sheet outputted from the apparatus which have not been bound to stack sequentially on the bound sheet bundle, and to make the bound sheet bundle and the sheet stacked on the bound sheet bundle as a unit to eject to the ejection tray.

Owner:KONICA MINOLTA BUSINESS TECH INC

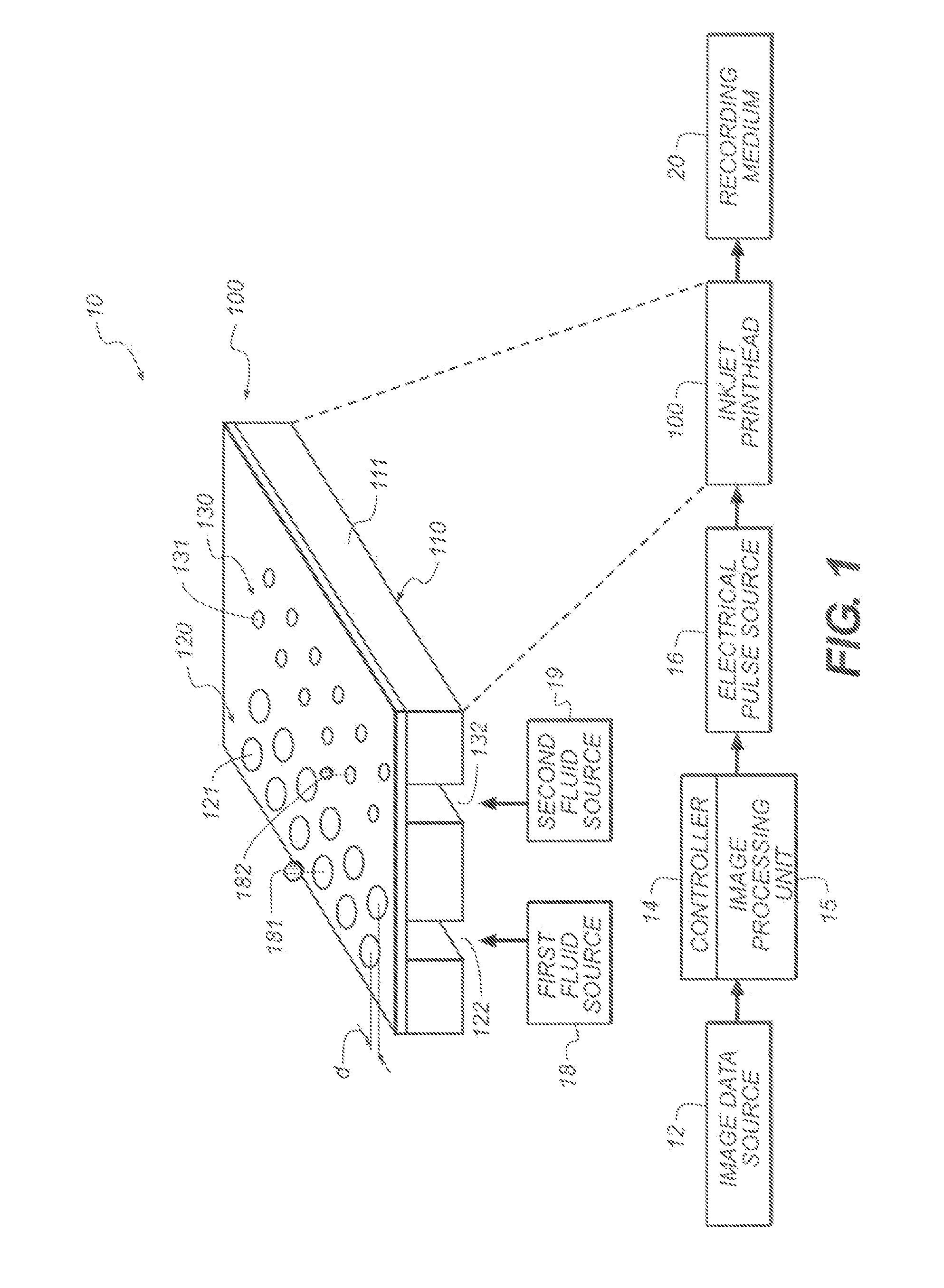

Optical sensor for printer media motion detection

InactiveUS20120069075A1Accurate measurementQuick checkOther printing apparatusPrint mediaPulp and paper industry

An inkjet printer includes a paper tray for holding print media; a pick-up roller for moving the print media along at least a portion of a pre-print zone of a paper transport path; a light source disposed along the pre-print zone of the paper transport path that directs light toward a non-print side of the print media for illuminating the non-print side of the print media; and an array sensor that receives reflected light from the non-print side of the print media; wherein data from the sensor is used to determine an amount of motion of the print media in the pre-print zone.

Owner:EASTMAN KODAK CO

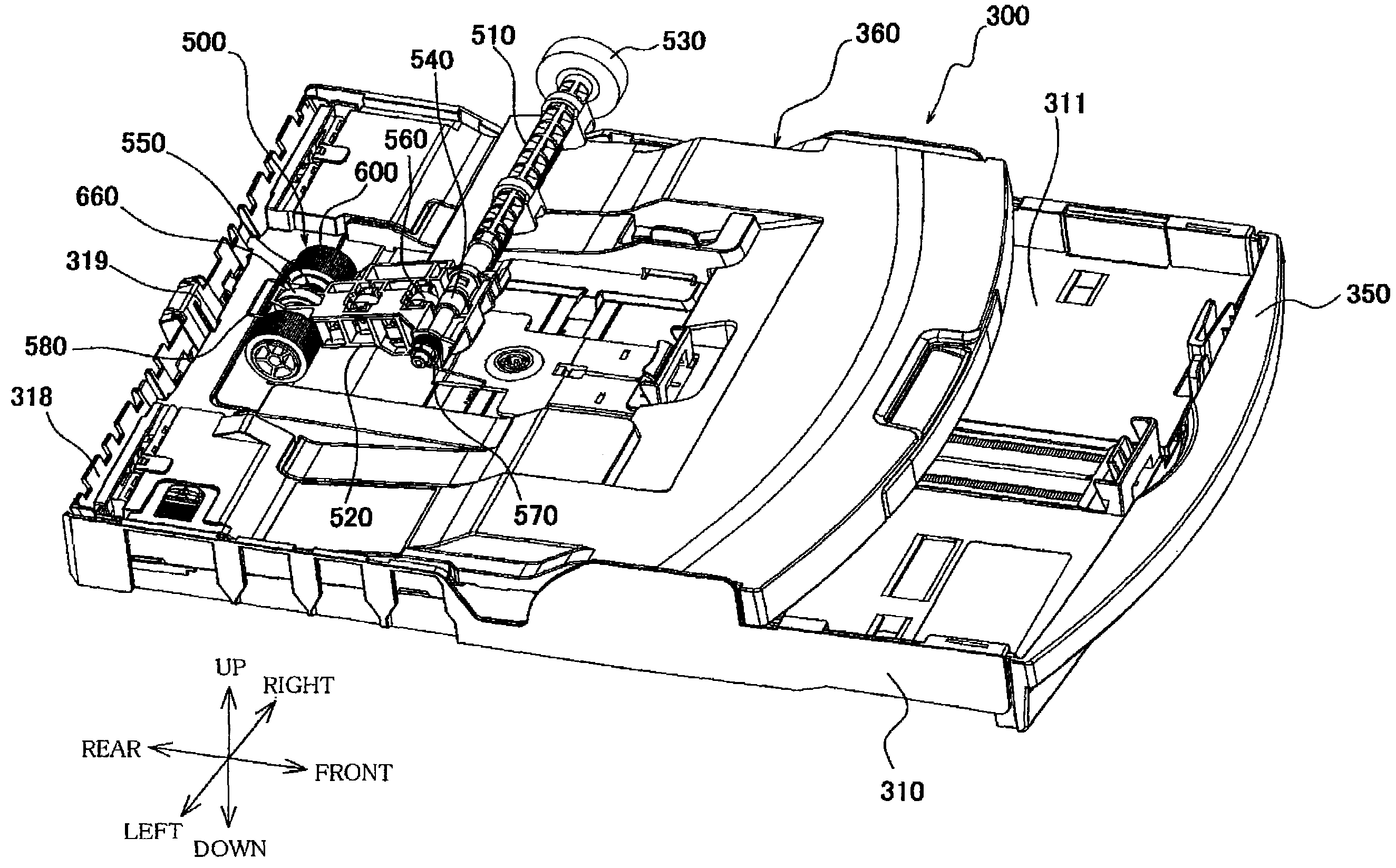

Sheet tray device and image forming apparatus having the sheet tray device

ActiveUS7748692B2Prevent rotationPrevent removalOther printing apparatusArticle feedersImage formationPaper sheet

Owner:BROTHER KOGYO KK

Paper-plastic pallet

InactiveCN102085937AMake up for deficienciesManufacturing flexibilityRigid containersHoneycombPaperboard

The invention discloses a paper-plastic pallet which comprises a pallet main body, wherein the pallet main body at least comprises a panel and a block which is connected to the lower part of the panel. The paper-plastic pallet disclosed by the invention is characterized in that the main body part of the panel adopts a honeycomb paperboard; and the honeycomb paperboard is hermetically arranged in the inner cavity of the plastic shell of the pallet main body. Thus, the paper-plastic pallet makes up the defect of simple materials of a plastic pallet and a paper pallet and combines the respective advantages, thereby increasing the practicability.

Owner:梁国宝

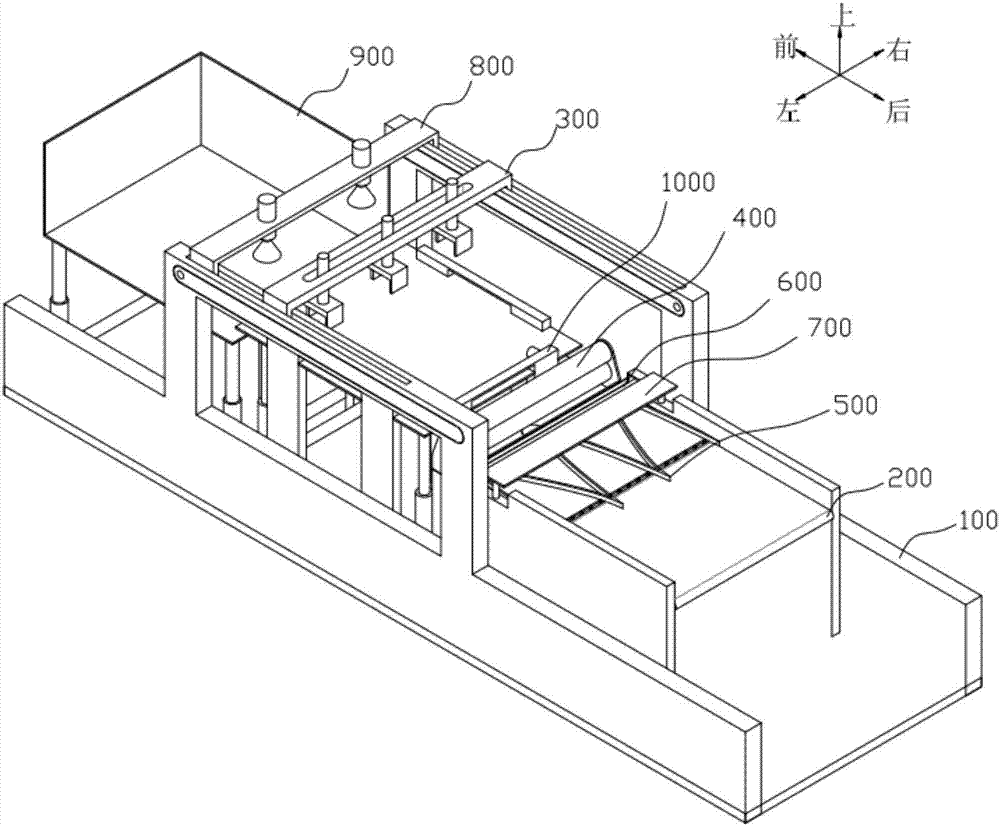

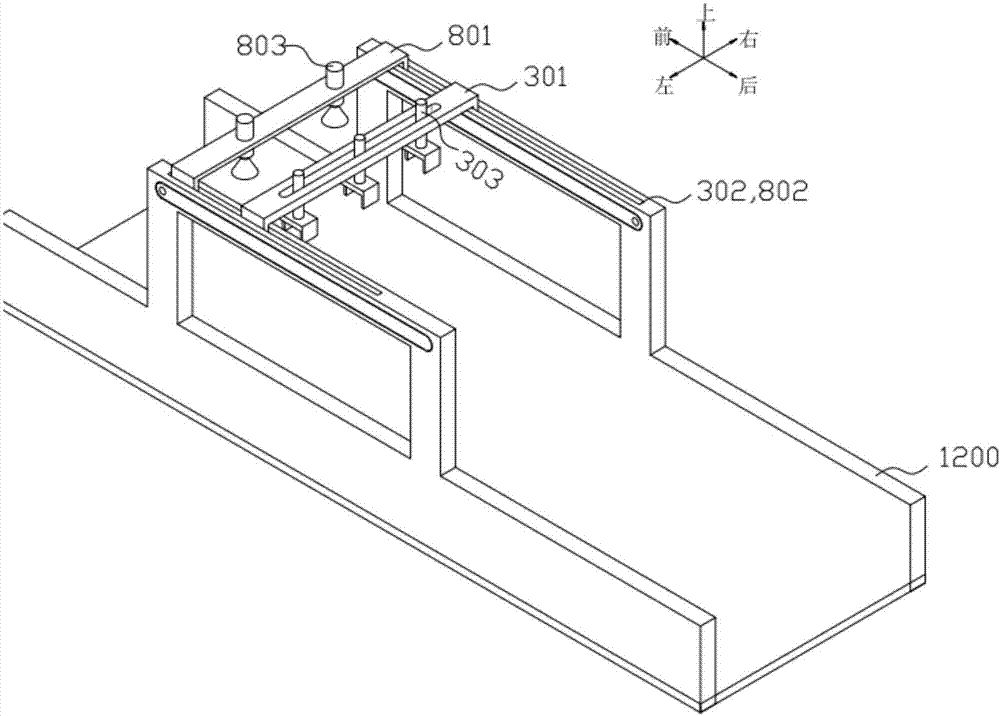

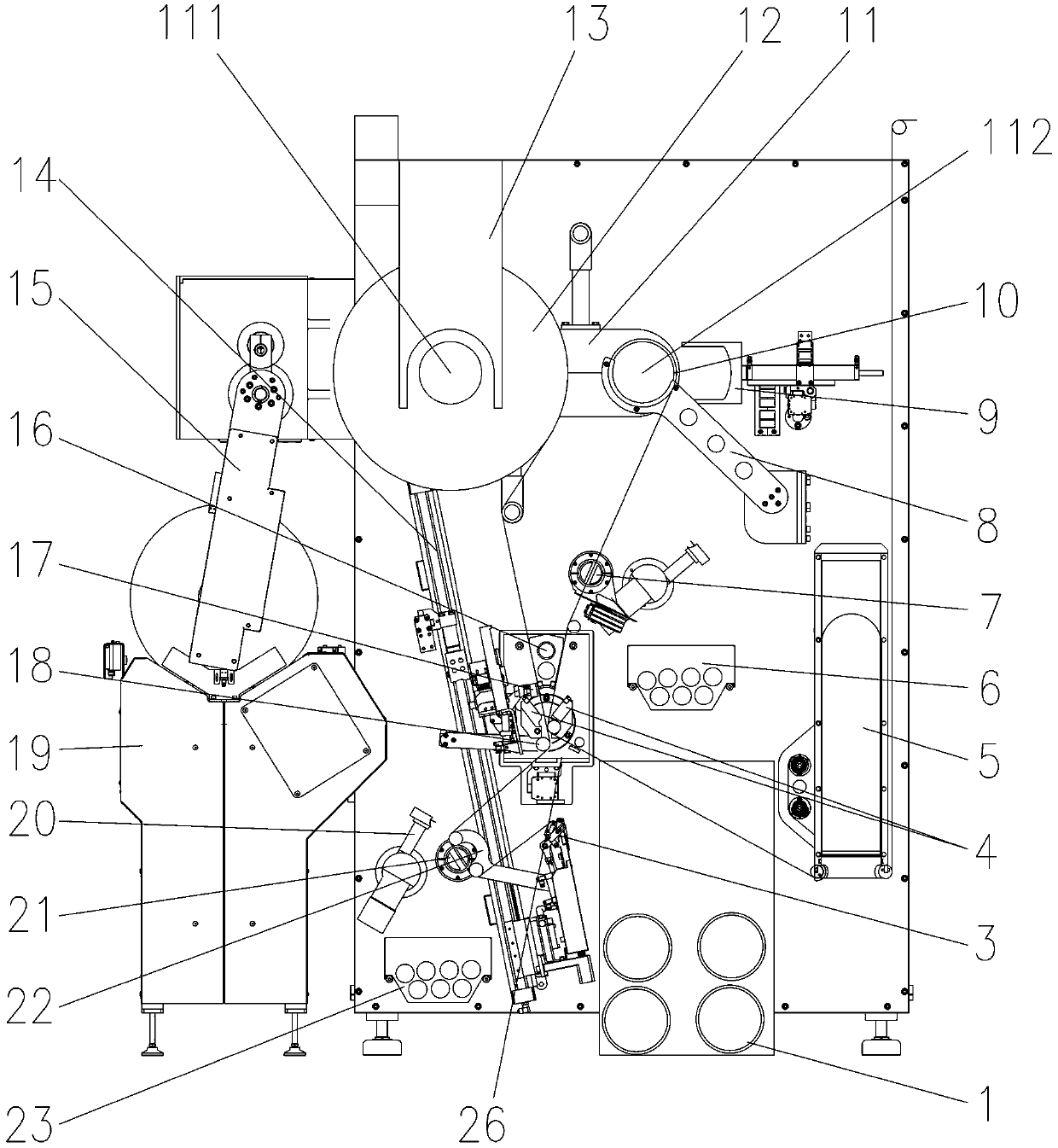

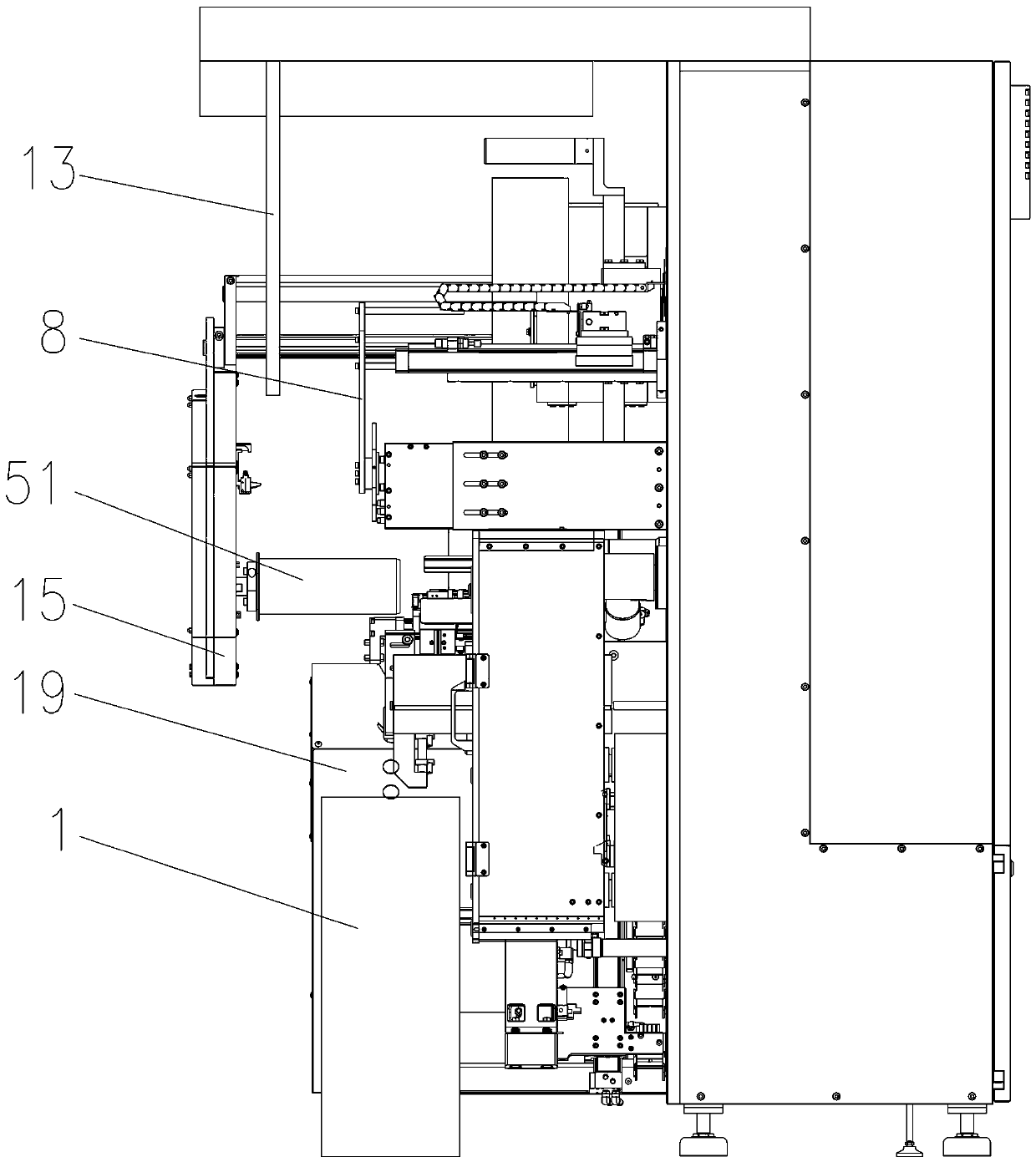

Automatic assembling device for paper pallets

PendingCN107128015AIncrease productivityQuality improvementPaper/cardboard articlesCardboardIndustrial engineering

The invention relates to the field of automatic assembling, and discloses an automatic assembling device for paper pallets. The automatic assembling device for the paper pallets is characterized in that the automatic assembling device comprises a conveying unit, a clamping unit, a brushing unit and a control unit; the conveying unit is mounted on a working table and conveys bottom feet to a first preset position; the clamping unit can conduct reciprocating sliding relative to the working table and clamps at least one bottom foot placed on the first preset position to a second preset position on a cardboard; the brushing unit is located at the side, close to the conveying unit, of the first preset position, and brushes glue onto the bottom feet clamped by the clamping unit; and the conveying unit, the brushing unit and the clamping unit are all connected with the control unit. According to the automatic assembling device for the paper pallets, automatic conveying, clamping and glue brushing of the bottom feet are achieved through the device; the clamping device drives the bottom feet to move and be pasted on second preset positions on the cardboard, so that automatic binding assembling of the cardboard and the bottom feet is achieved; and the production efficiency is enhanced, the quality of products can be controlled better, and the labor cost and the management cost are saved.

Owner:DONGGUAN MYS ENVIRONMENTAL PROTECTION TECH

Plastic slip sheet based on RFID and picking-up, placing and information reading method thereof

ActiveCN104129550ATake and place smoothlyHigh tensile strengthContainer decorationsLevel indicationsElectromagnetic interferenceEngineering

The invention discloses a plastic slip sheet based on RFID and a picking-up, placing and information reading method thereof. The plastic slip sheet is a rectangular thin plate made of high density polyethylene materials, and two adjacent side edges of the rectangular thin plate are provided with folded edges respectively. The plastic slip sheet is made of the high polymer materials, has the advantages of being thin, high in tensile strength and free of electromagnetic interference, solves the problems that an existing plastic pallet is thick and heavy and occupies large space, and a paper pallet is not water-proof, and can be widely applied to transfer of various goods. In addition, a special pull-and-push device is designed to match with the plastic slip sheet, and the plastic slip sheet is smoothly picked up and placed, so that a guarantee is provided for application of the plastic slip sheet.

Owner:RICE BRANCH SHENZHEN CEREALS GRP

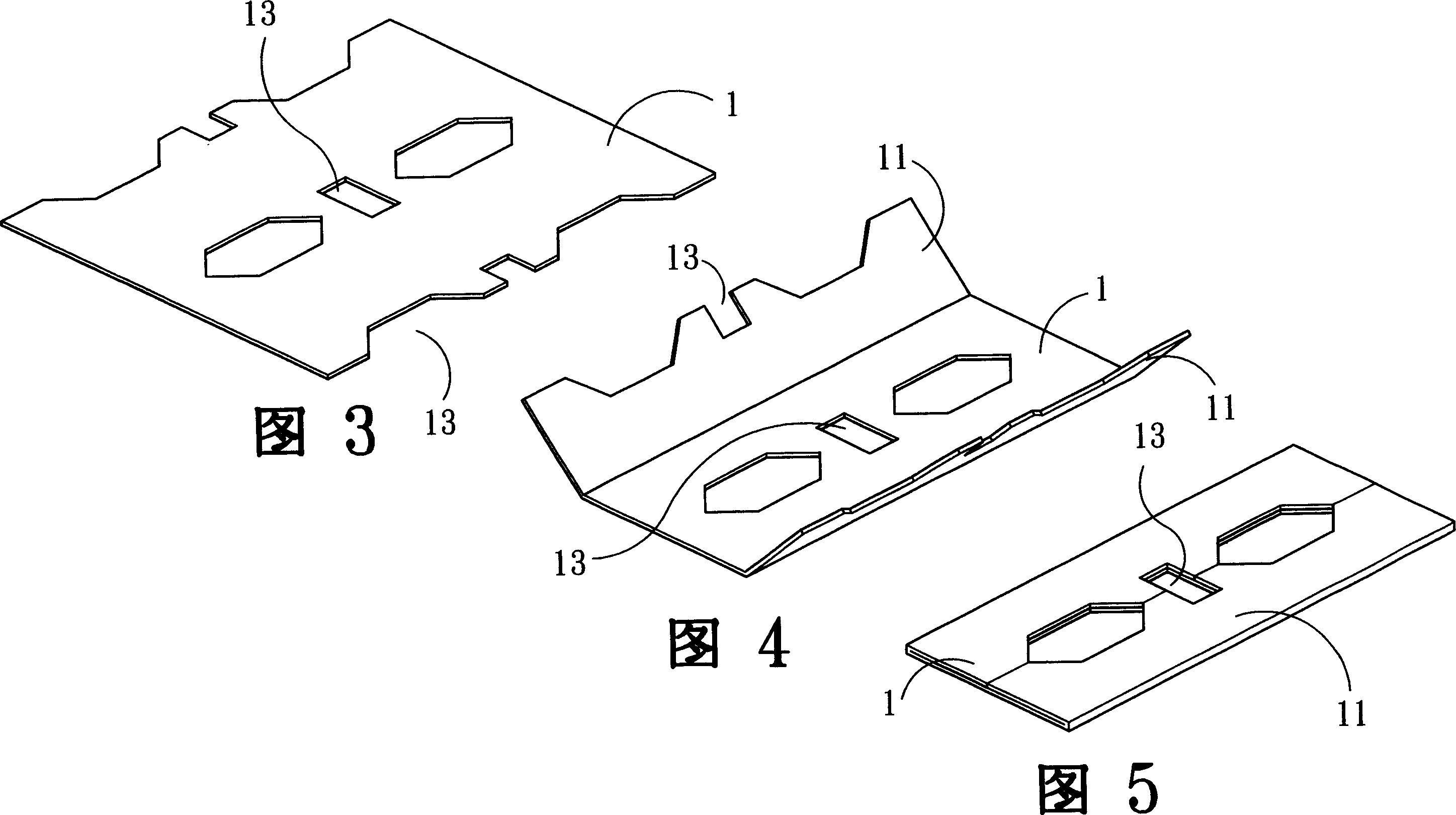

Paper pallet folding method

The invention relates to a method for folding paper pallet with a paper plate, comprising following steps: folding paper plate into middle from two sides, stitching, doubling whole paper plate according to central line, the thickness of formed sectional plane is the four-layer paper plate material, buckling to two sides the paper end to form T-sectional structure with expanded top for stale support function.

Owner:洪正娟

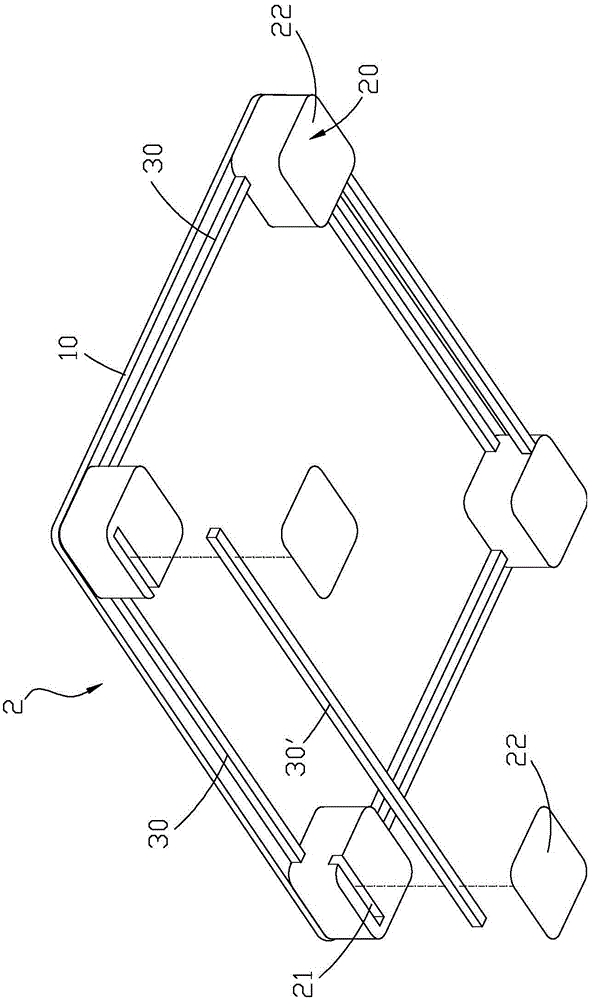

Paper pallet structure

InactiveUS8291836B2Increased load-bearing capacitySimple structureRigid containersPaper palletAerospace engineering

Owner:AIR BAG PACKING +1

Paper feed tray with image scanning function and printer thereof

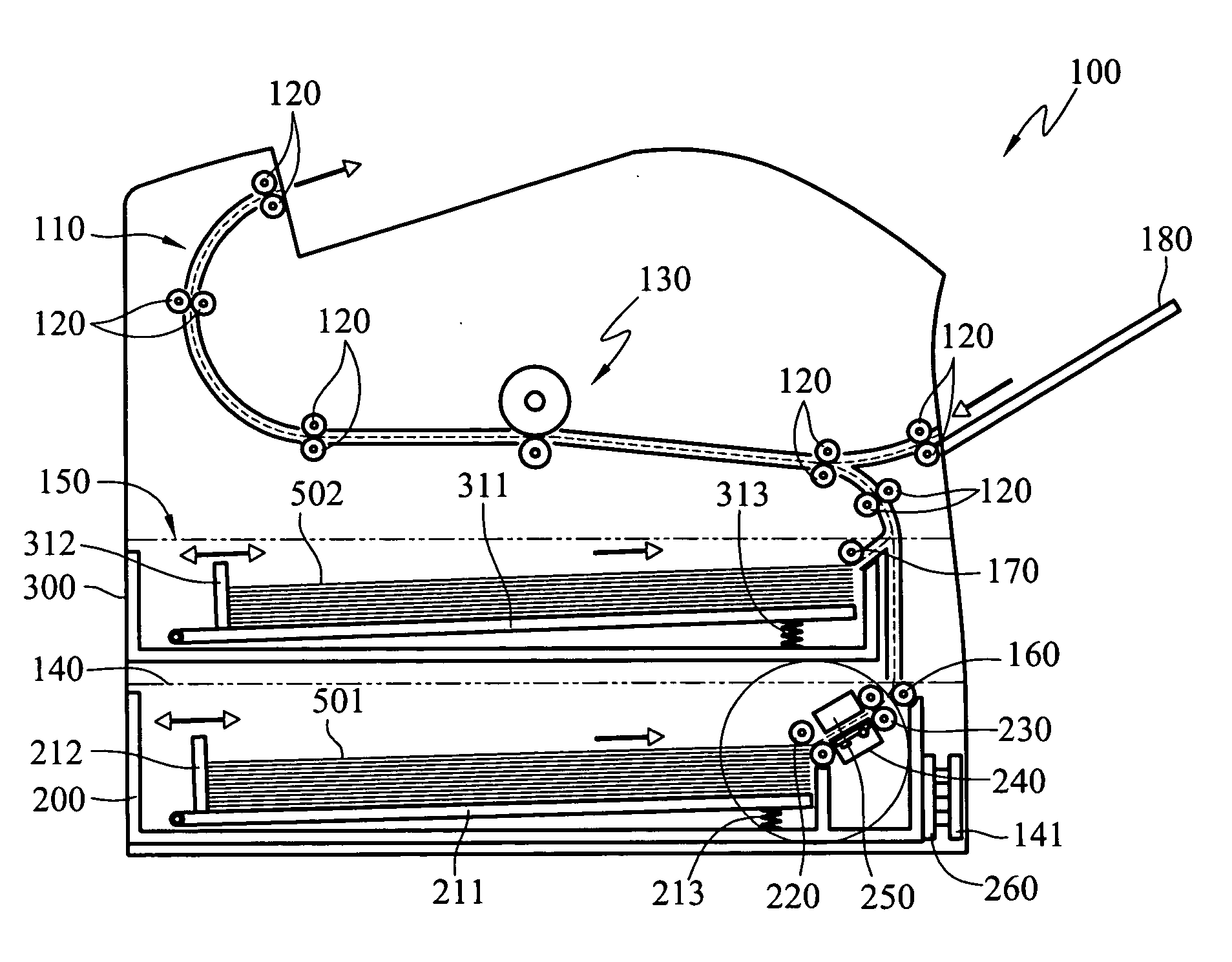

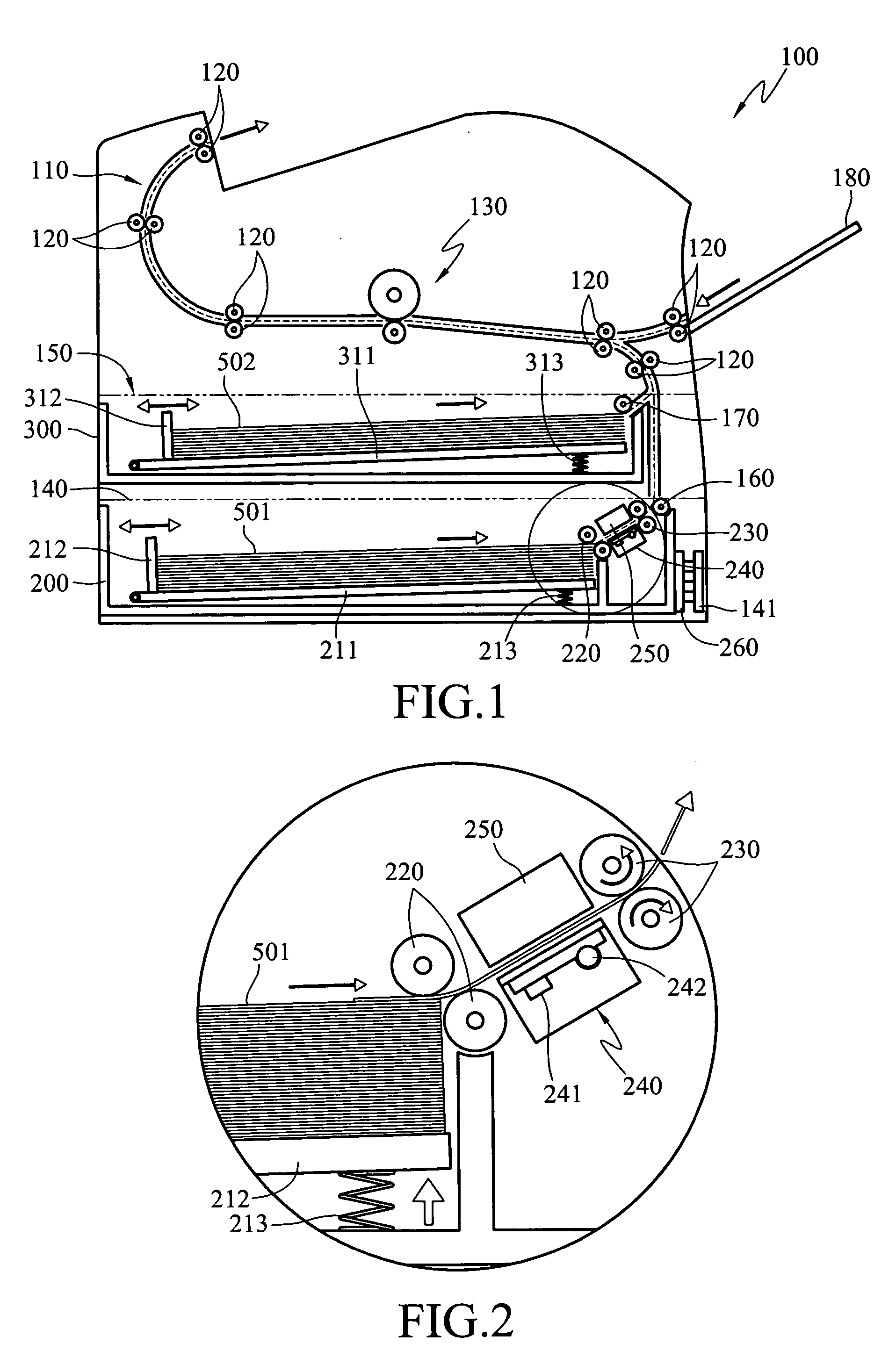

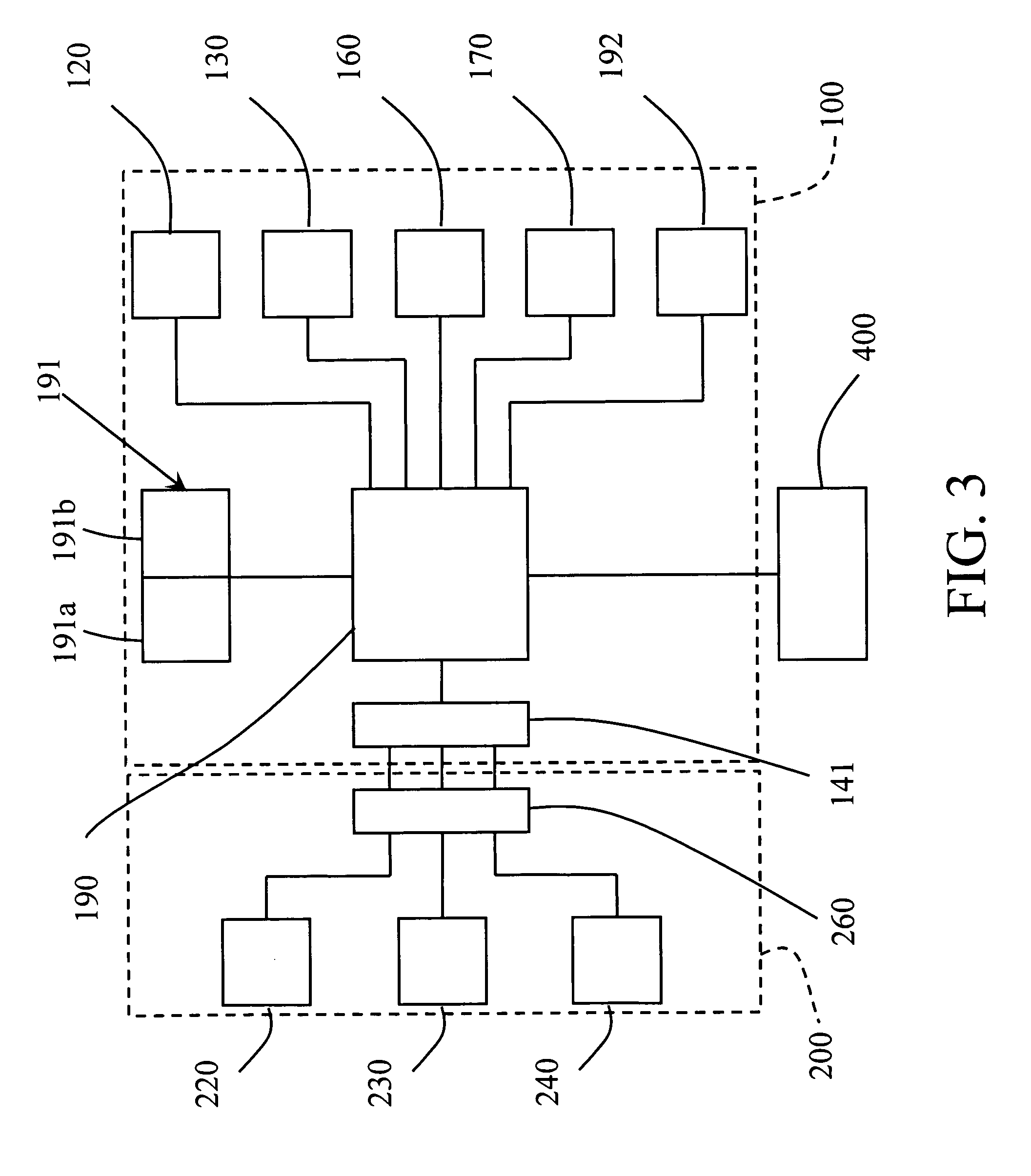

InactiveUS20070057428A1Quickly dismountedEasy to integrateArticle feedersArticle separationPaper palletEngineering

A paper feed tray with the image scanning function of a printer includes a set of paper feed rollers, a set of paper exit rollers, and an optical scanning module. The optical scanning module is located between the set of paper feed rollers and the set of paper exit rollers, wherein the paper feed rollers grab documents waiting for being scanned and transfer the documents through the image scanning module. Each of the documents is scanned by the image scanning module and then transferred out of the printer by the paper exit rollers. Hence the printer with the paper feed tray may serve as an image scanning apparatus.

Owner:LITE ON TECH CORP

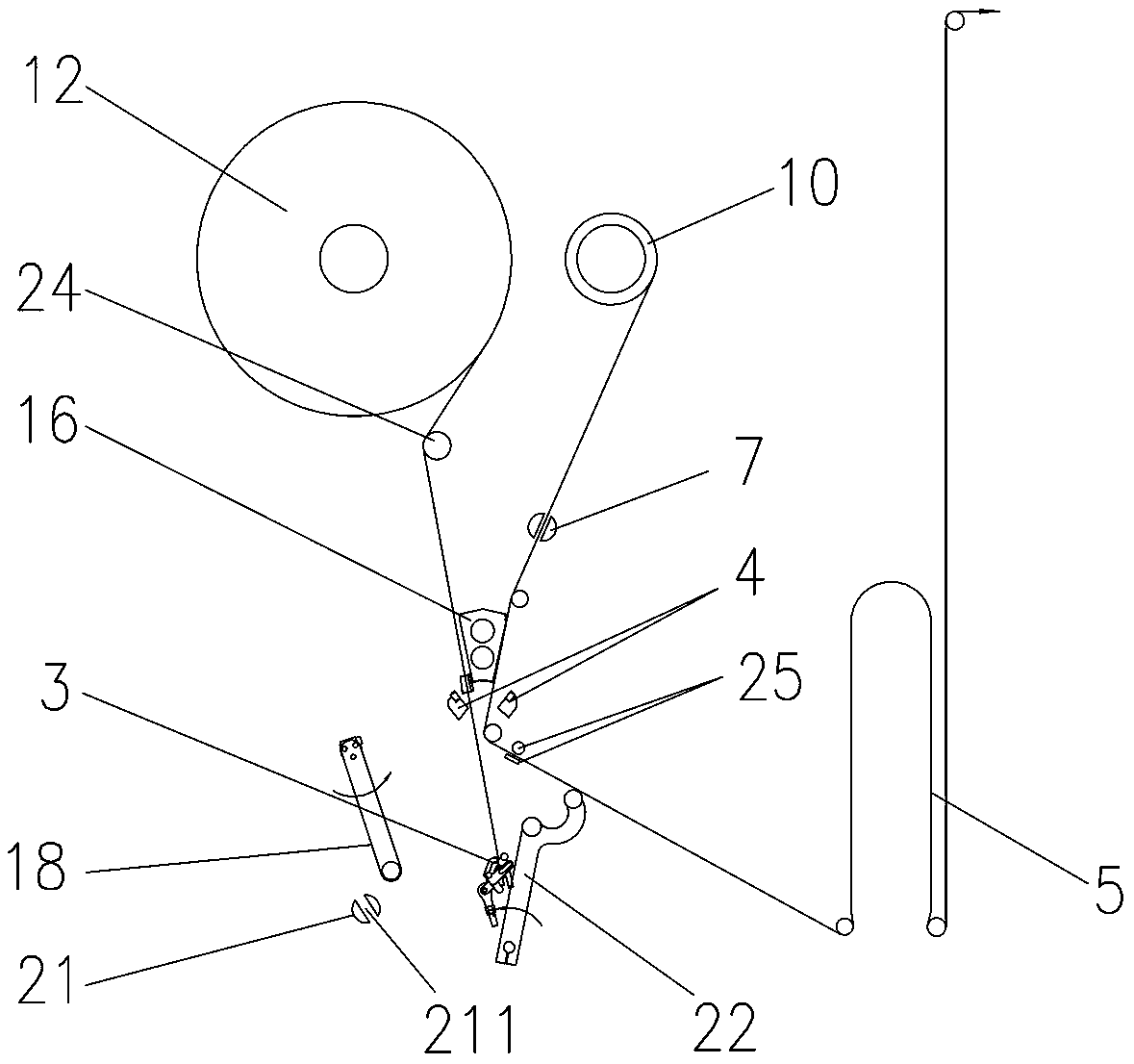

Whole-roll paper reel feeding device of packing machine

ActiveCN107804729ARealize non-stop replacementHighlight substantive featuresWebs handlingBobbinRolling paper

The invention provides a whole-roll paper reel feeding device of a packing machine. The device comprises a paper roll rotary table and a bobbin paper splicing device, wherein a first paper roll is arranged on one end of the paper roll rotary table; a second paper roll is arranged on the other end of the paper roll rotary table; the first paper roll is driven by a first servo motor to rotate; the second paper roll is driven by a second servo motor to rotate; through the rotation of the paper roll rotary table, the first paper roll and the second paper roll can alternatively appear on a left paper roll position and a right paper roll position; the bobbin paper splicing device comprises a fixed cutting tool, a swinging cutting tool and a packaging tape frame. The whole-roll paper reel feedingdevice of the packing machine has the advantages of scientific design, high automation degree, high feeding efficiency, and low human cost.

Owner:XUCHANG TOBACCO MACHINERY

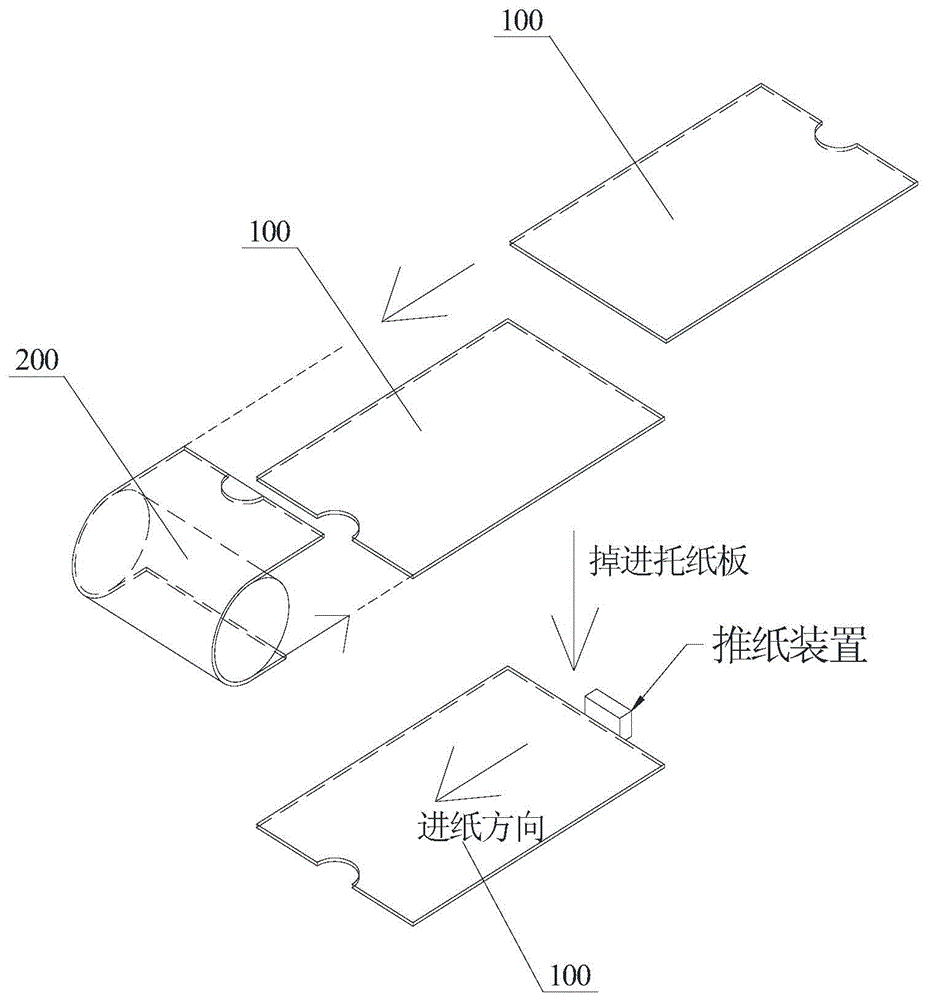

Hand bag forming machine and bag body turning device thereof

ActiveCN104476820ARealize automatic continuous operationIncrease productivityBag making operationsFlexible containers manufactureDrive wheelDrive shaft

The invention discloses a hand bag forming machine and a bag body turning device thereof. The bag body turning device comprises an input mechanism, a turning mechanism and an output mechanism, the input mechanism comprises a first roller set, the first roller set comprises a driving shaft and a driven shaft, a plurality of driving wheels and feed rollers are axially and parallelly arranged on the driving shaft, a plurality of driven wheels and paper pressing rollers are axially, parallelly and correspondingly arranged on the driven wheels, the turning mechanism comprises a second roller set, the second roller set comprises a turning roller and a guide wheel mechanism, a lower endless belt surrounds the driving wheels and the turning roller, an upper endless belt surrounds the driven wheels and the guide wheel mechanism, the upper endless belt and the lower endless belt convey a bag body inputted by the input mechanism to the turning roller for turning, and the output mechanism comprises a paper tray and a paper pushing device for pushing the bag body out of the paper tray. By the aid of the turning mechanism, the bag body with an upper opening folded is turned and then outputted to a bottom sticking procedure, so that the hand bag forming machine automatically and continuously runs, and the production efficiency of hand bags is greatly improved.

Owner:WENZHOU ZENBO PRINTING MACHINERY

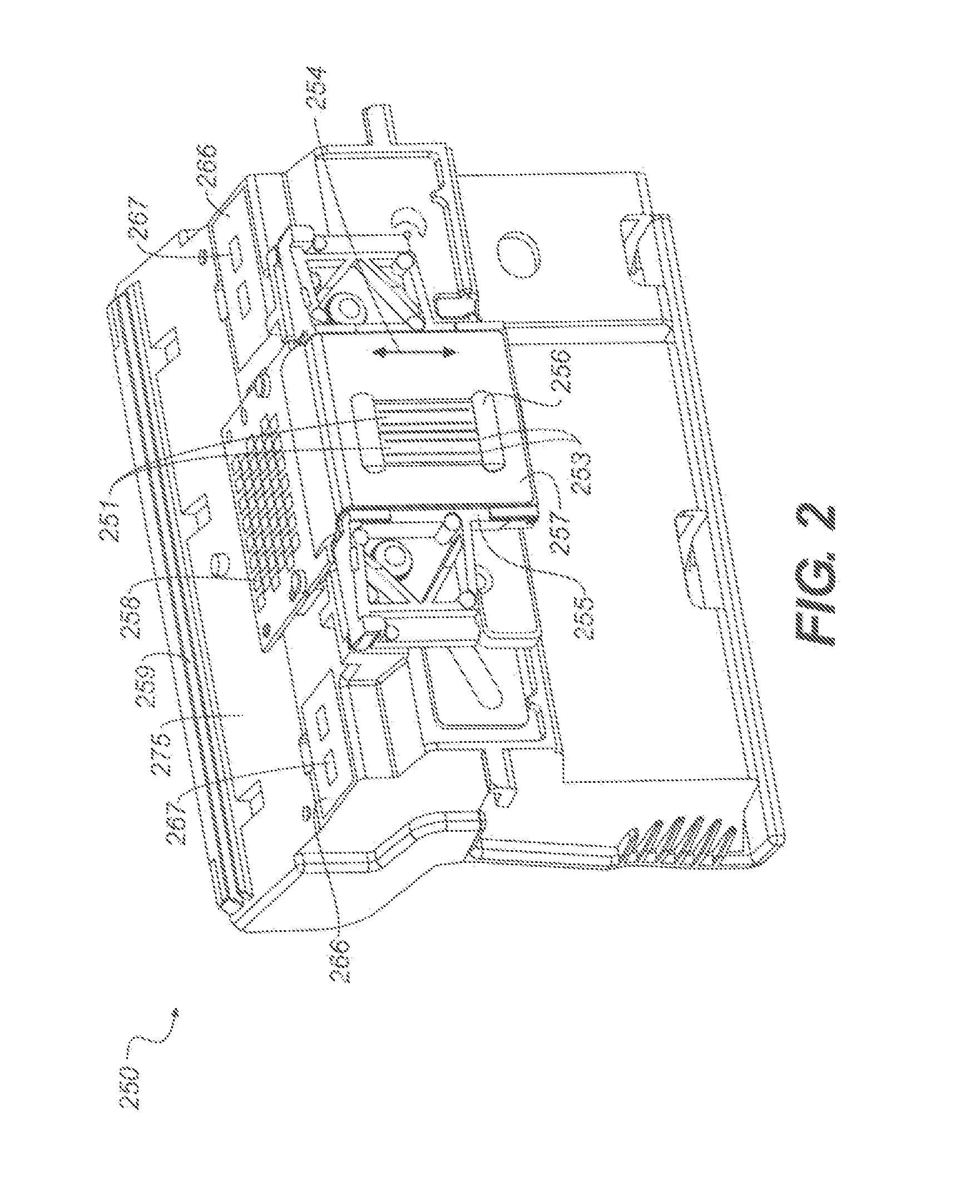

Sheet feeding apparatus and image forming apparatus

Owner:CANON KK

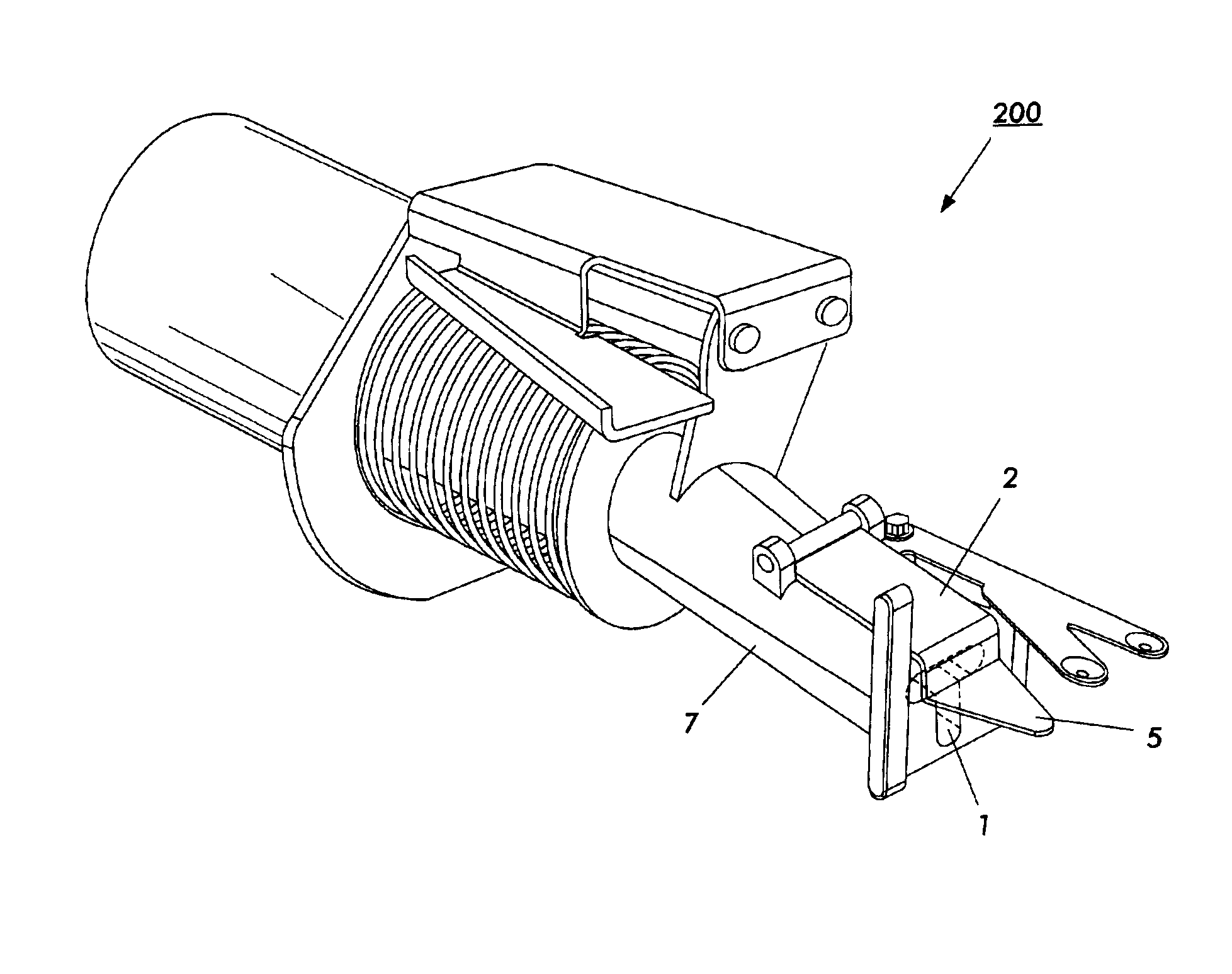

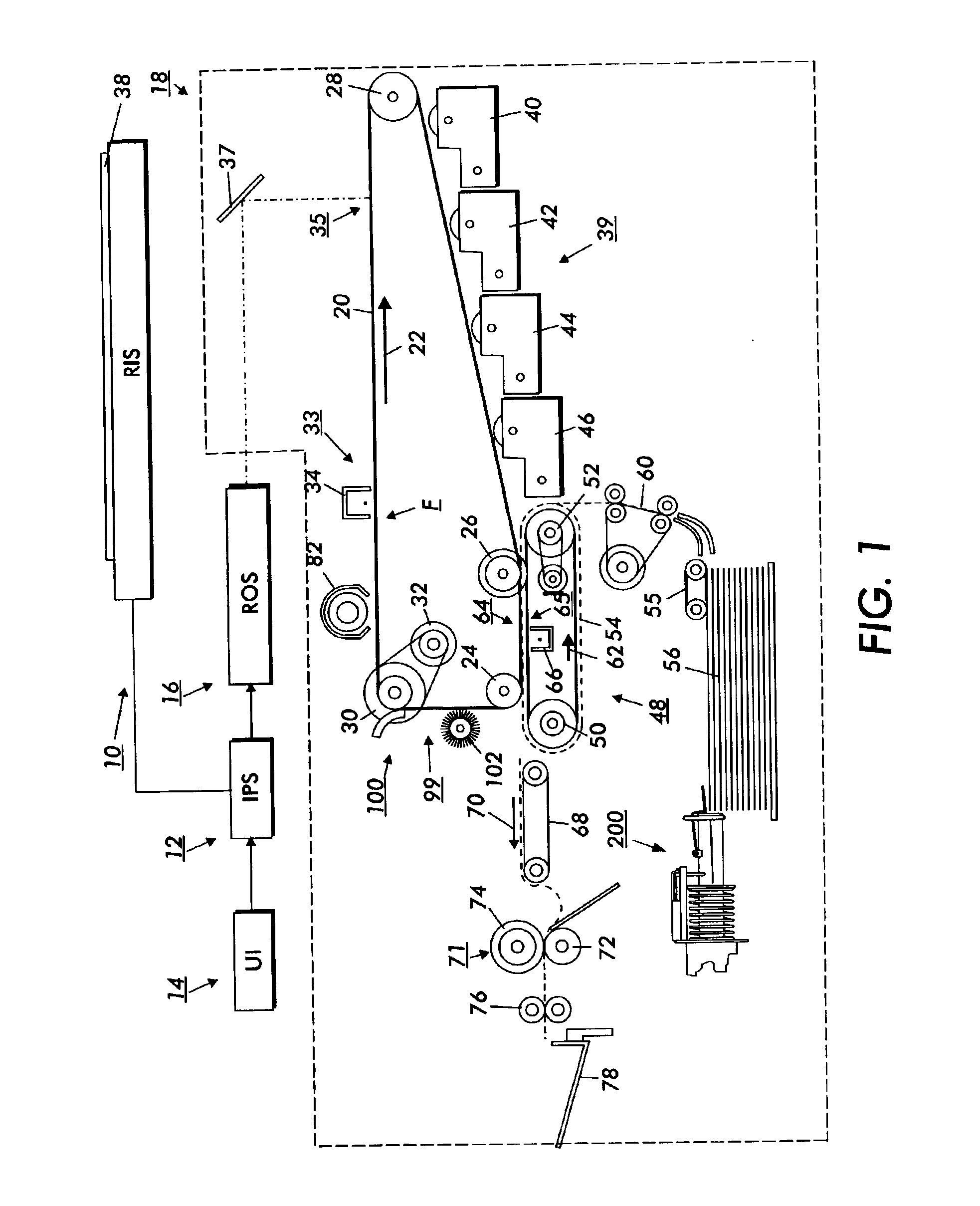

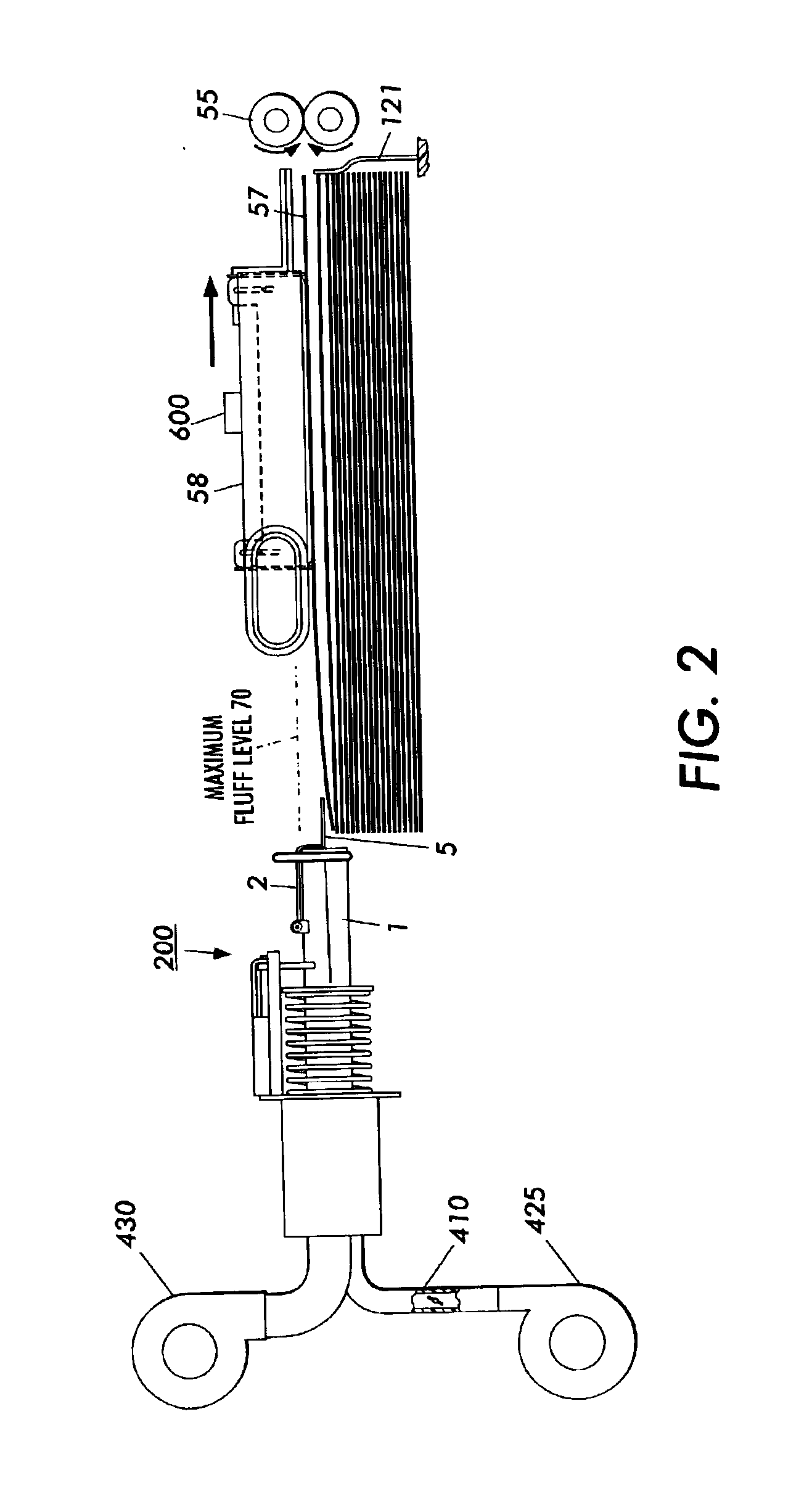

Sheet feeding apparatus having an adaptive air fluffer

A sheet feeding apparatus for feeding a stack of sheets in a direction of movement to a process station, including: a sheet tray for holding the stack of sheets; an air plenum, positioned above the stack of sheets, for picking up a sheet from the stack of sheets when a vacuum force in the air plenum; a paper fluffer for blowing air between individual sheets in the stack, the paper fluffer having means for adjusting air flow between individual sheets.

Owner:XEROX CORP

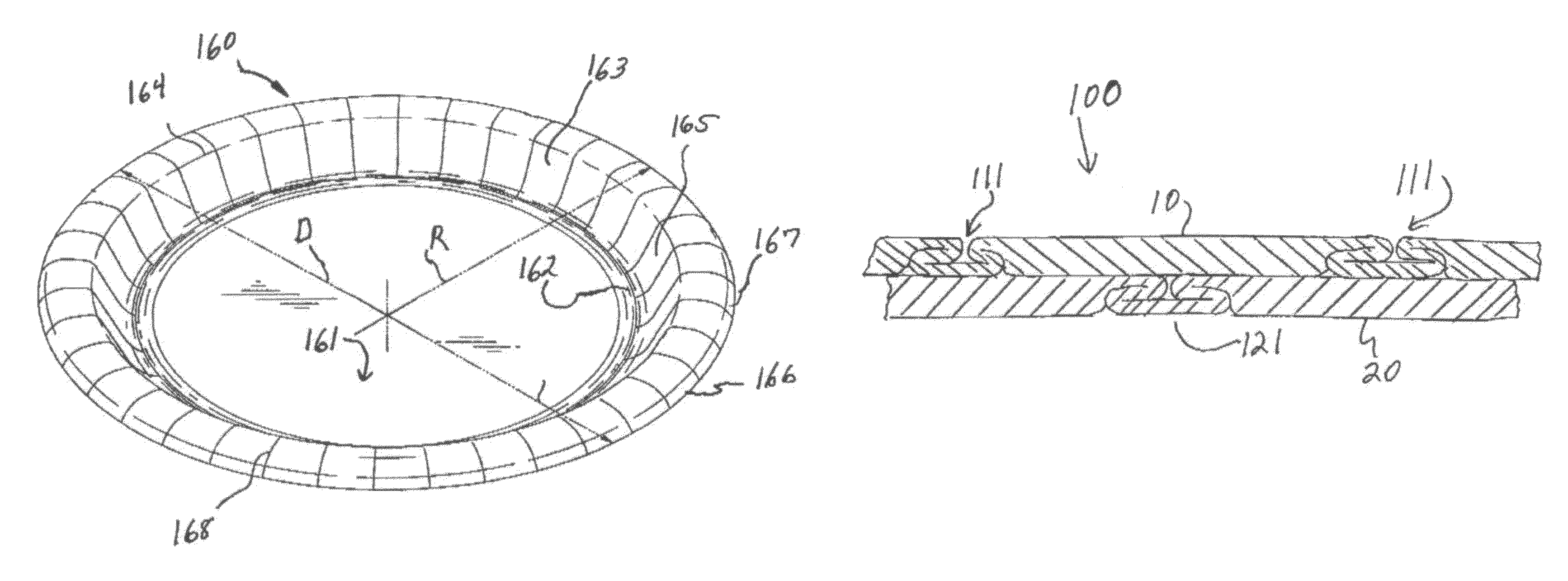

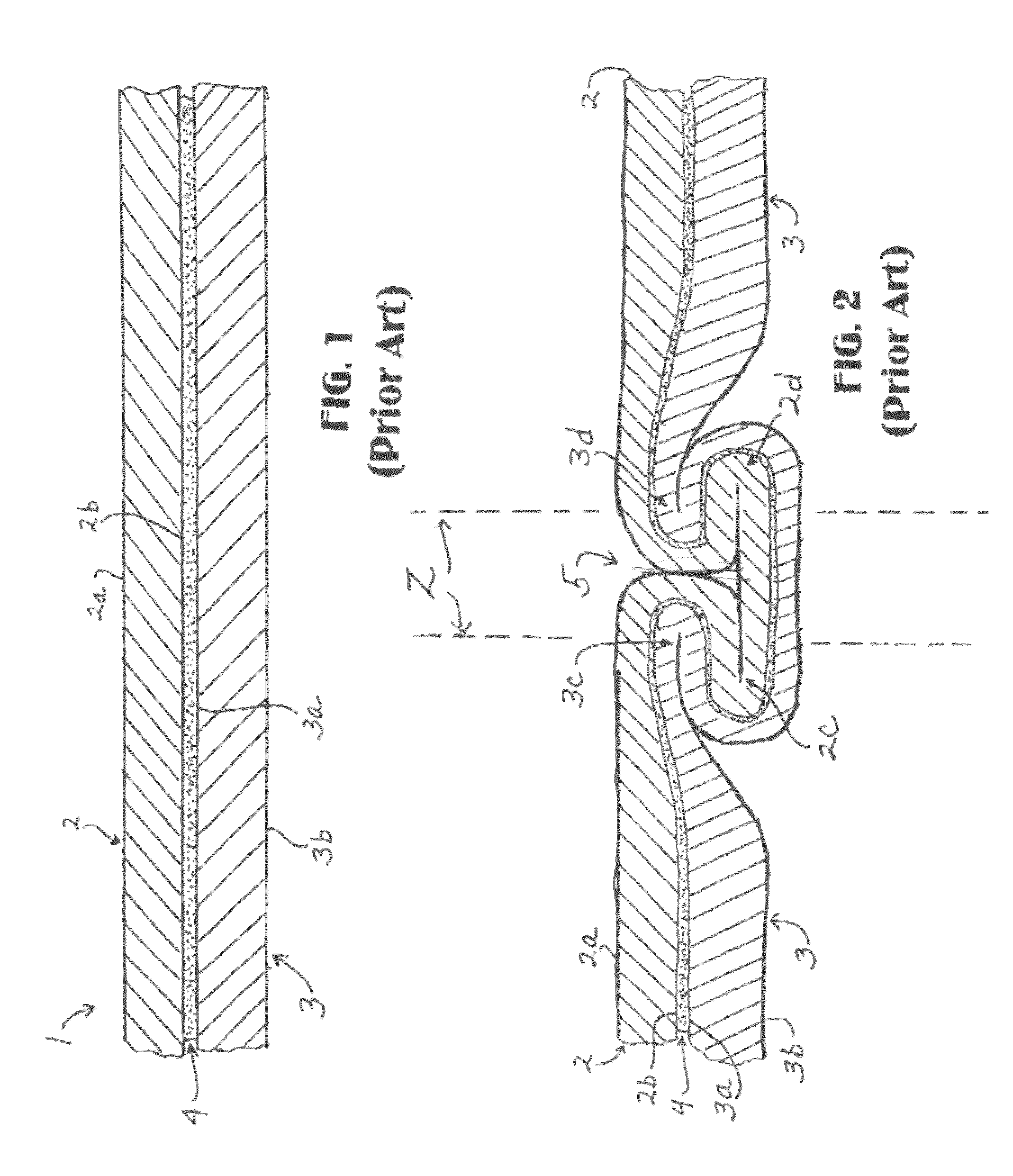

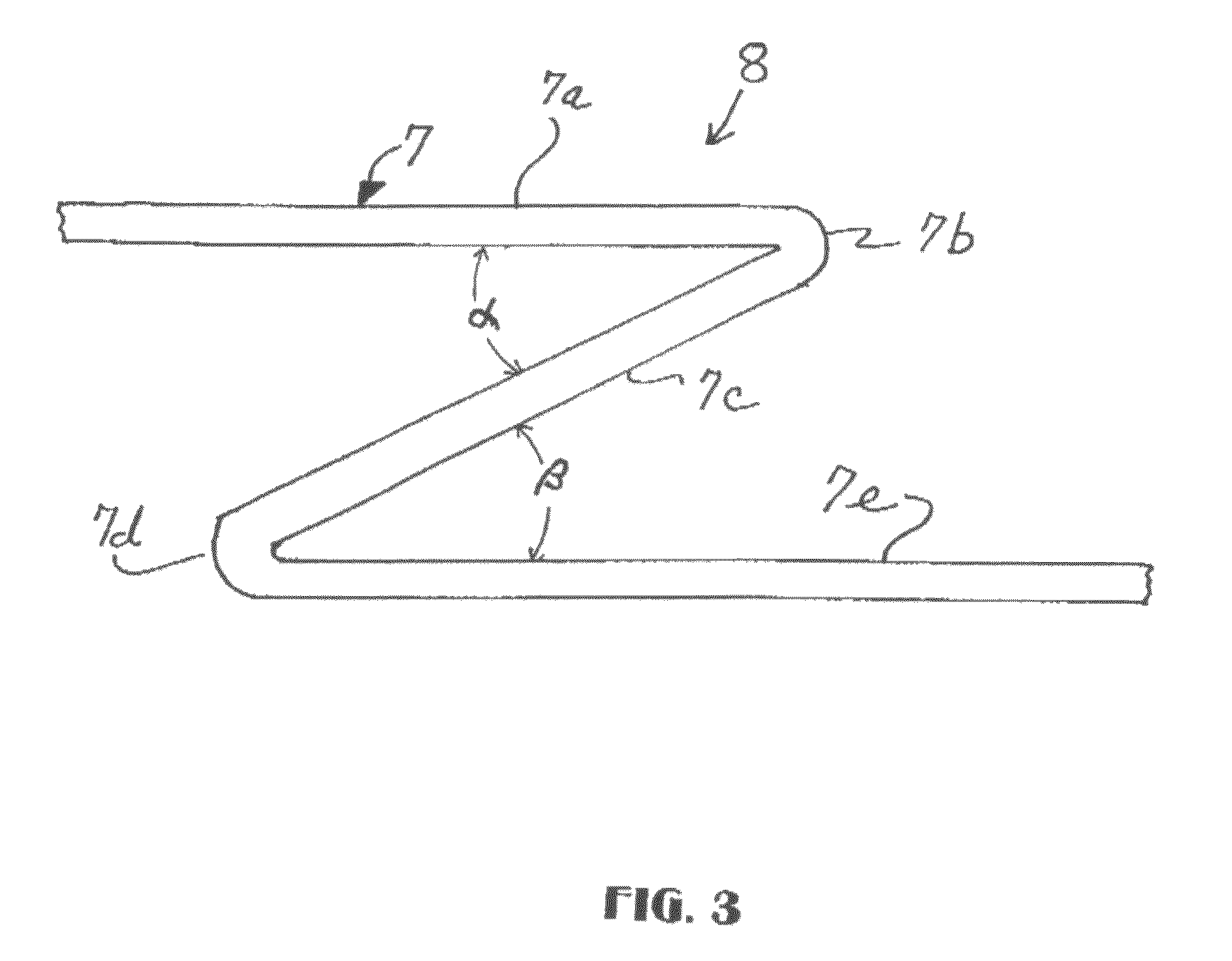

Method for in-die lamination of plural layers of material and paper-containing product made thereby

A method for making a multilayered paper-containing product, for example a paper plate or tray, includes assembling two or more sheets of paper-containing material cut into blanks. The blanks are pressed together and shaped in a die, usually with a bonding agent being used to secure the blanks. Pleats are formed in the curved portion of the shaped product. However, the pleats on each blank are formed independently so that the folded region formed in the pleats are arranged in a staggered array and are not interleaved with the pleats of the other blank.

Owner:GPCP IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com