Paper pallet folding method

A folding method and technology of paper pallets, applied in the folding field of paper pallets, can solve problems such as inability to carry heavy objects, increased costs, and insufficient carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

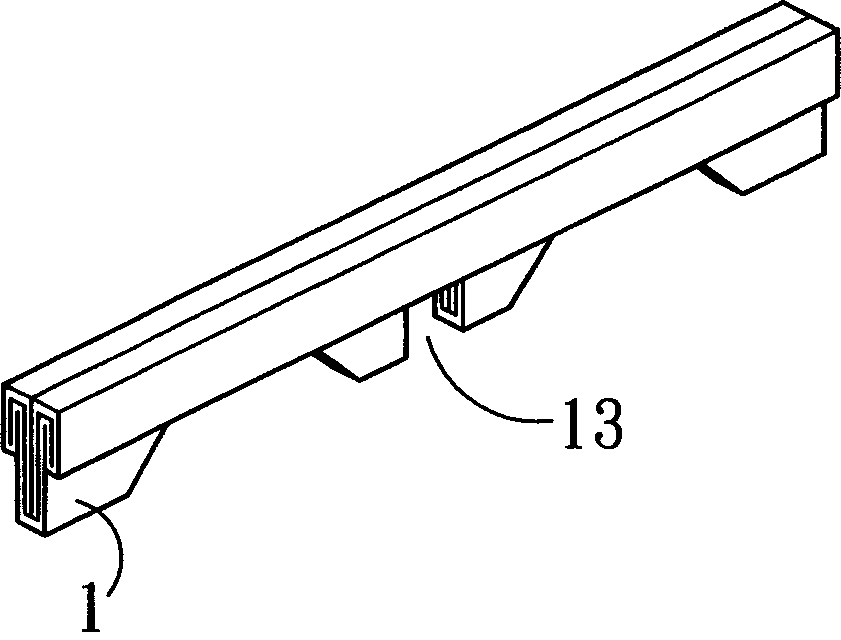

[0031] see figure 1 As shown, the present invention provides a method for folding a paper pallet 1. The paper pallet 1 is formed by folding a cardboard material, and has a T-shaped cross-sectional structure with a thickened top, and a gap 13 is reserved to provide a combined or increase the intensity.

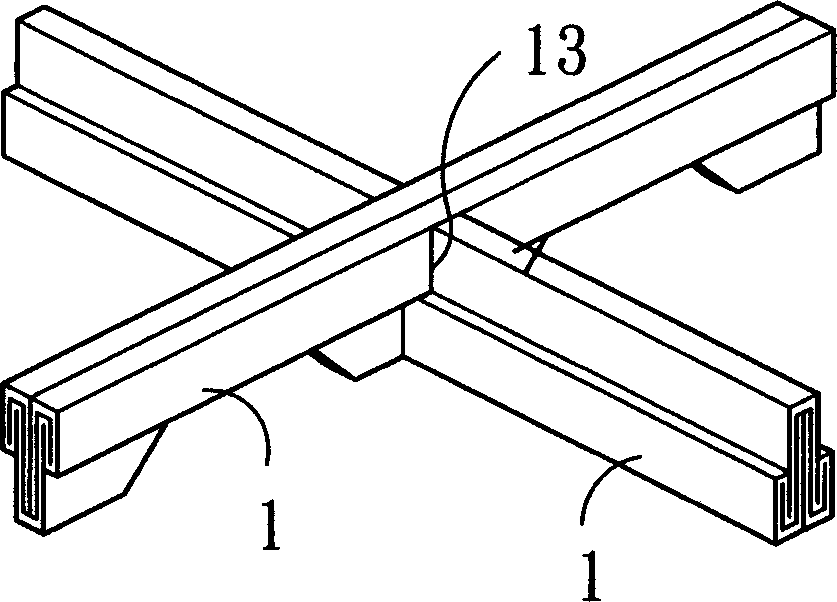

[0032] Such as figure 2 As shown, the aforementioned paper pallet 1 structure can be matched with each other to form Figure 12 The carrier body of the net-shaped paper pallet 1 shown has a relatively large supporting force due to the thickening of the paper pallet 1 itself. And the required gap 13 part of the aforementioned paper pallet 1 itself is to be cut off in advance when the cardboard material is made, and then folded into shape.

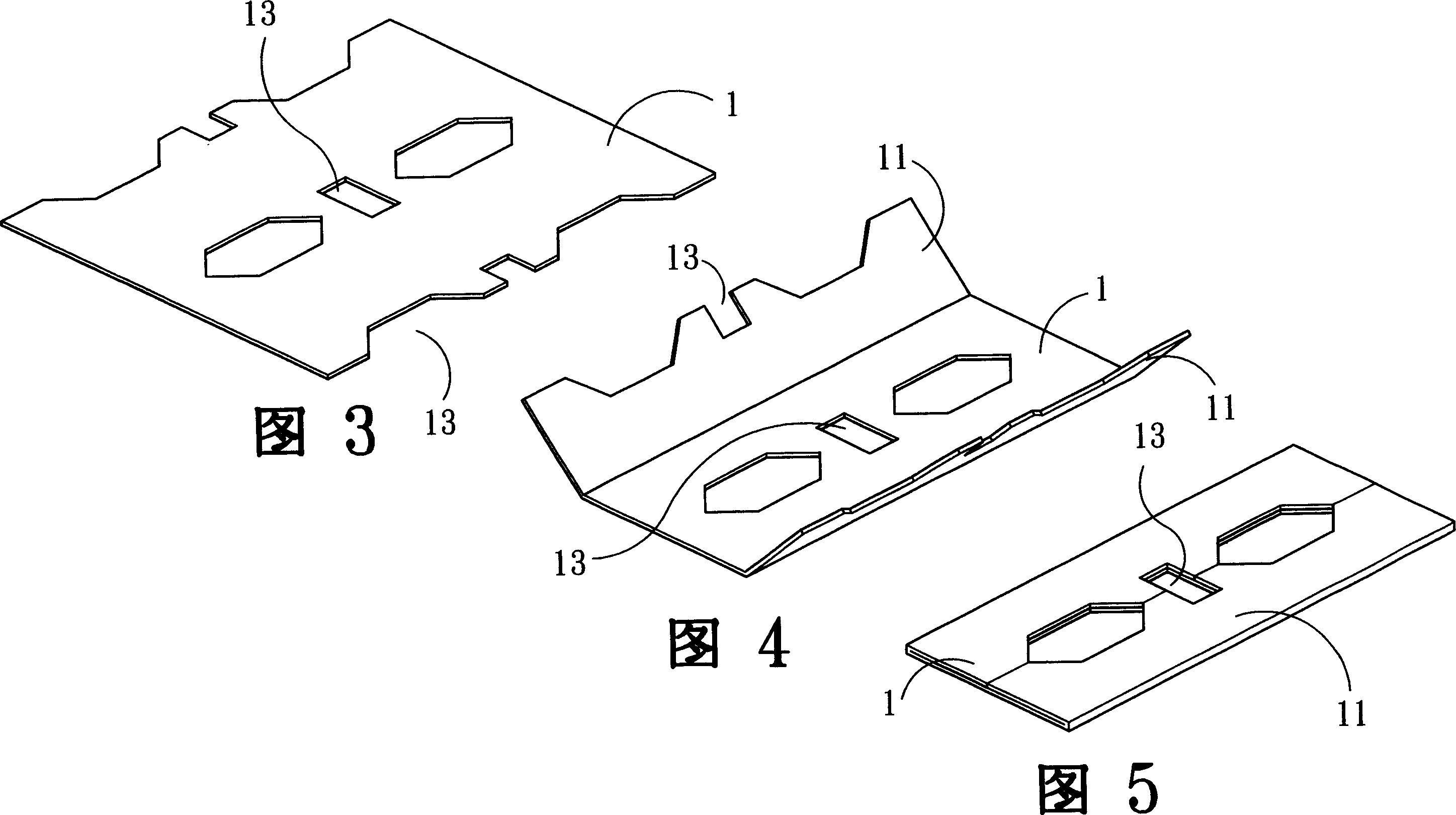

[0033] Please refer to Fig. 3 to Fig. 7, the folding method of the aforementioned paper pallet 1 is to fold and form a cardboard material integrally. Firstly, the two sides 11 of the cardboard material are first folded in the middle, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com