Automatic assembling device for paper pallets

An automatic assembly and tray technology, applied to cardboard items, etc., can solve the problems of product reliability limited by manual labor, high labor intensity, and high labor costs, so as to save labor costs and management costs, improve control, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

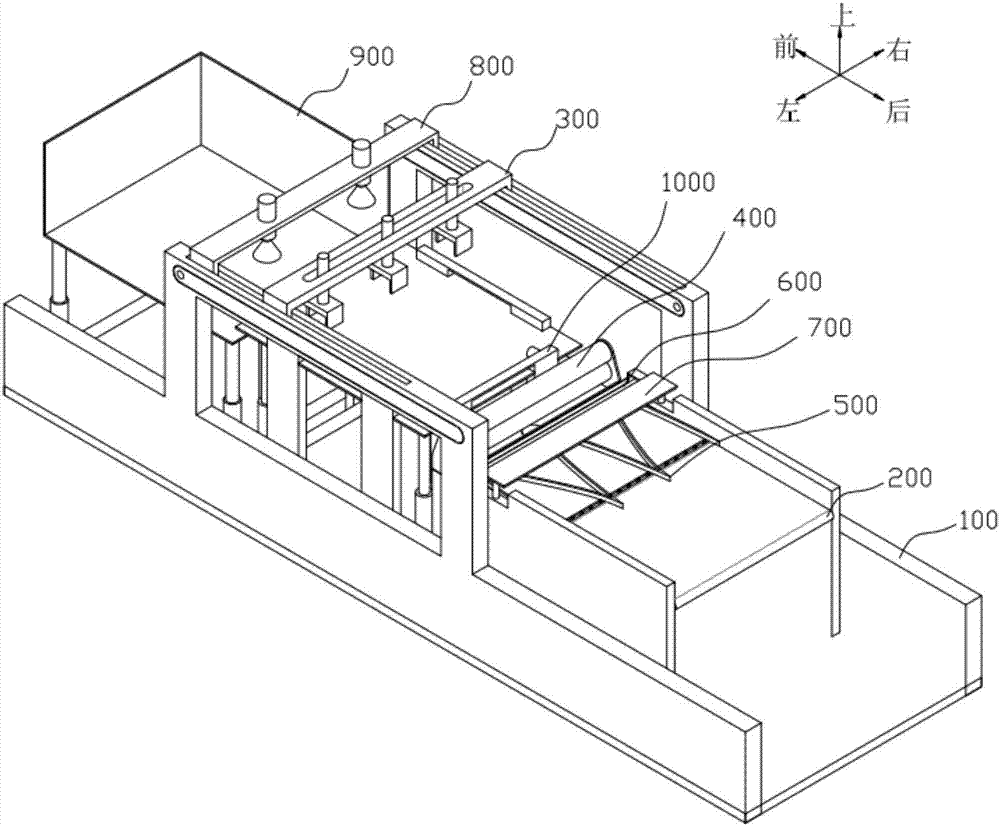

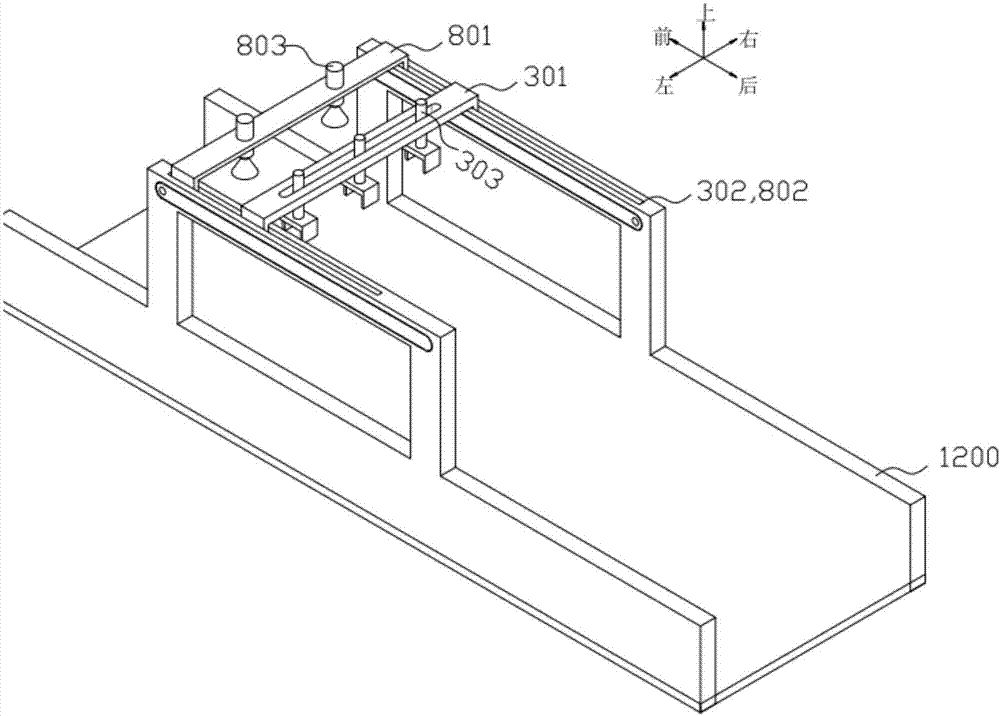

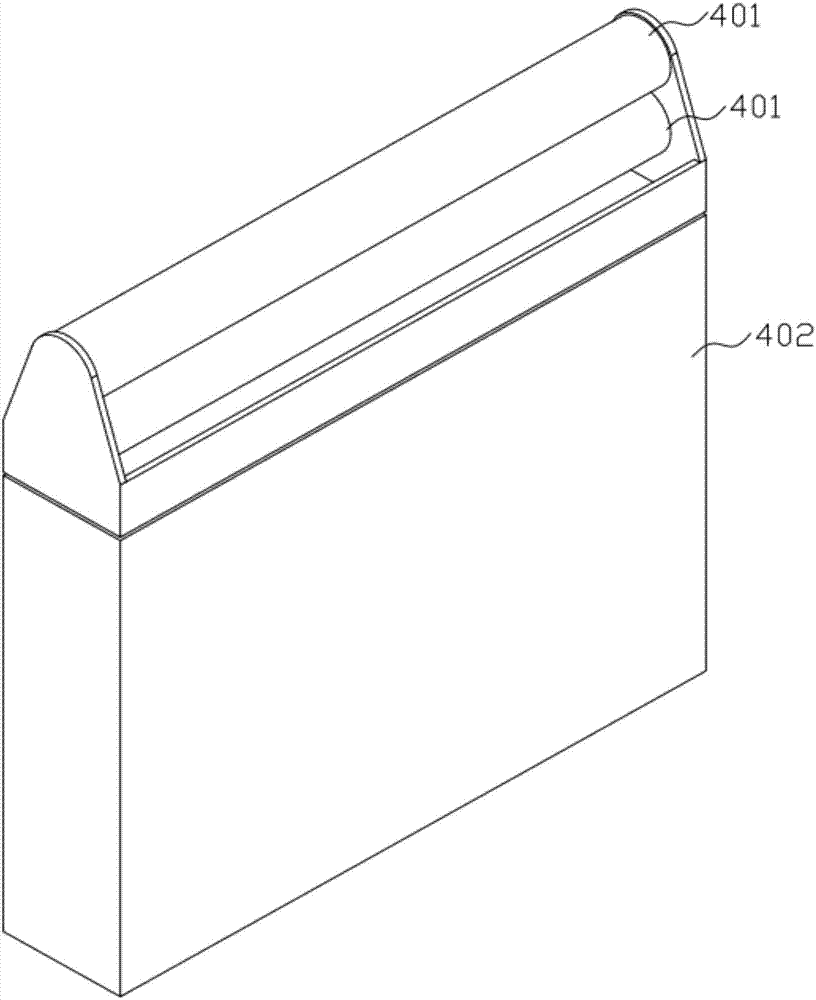

[0038] Such as figure 1 As shown, this embodiment provides an automatic assembly device for paper trays. The paper tray 1100 includes a cardboard 1102 and nine feet 1101 bonded to one side of the cardboard 1102. The feet 1101 are respectively located on two sides of the cardboard. The end and the middle position are evenly and symmetrically arranged, including the workbench 100; the conveying unit 200 is installed on the workbench 100, and transports the feet 1101 to the first preset position; the clamping unit 300 is installed on the workbench 100, and It can slide back and forth relative to the workbench 100, and clamp three feet 1101 placed at the first preset position to the second preset position on the clamping plate 1102; the painting unit 400 is located near the first preset position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com