Paper-plastic pallet

A tray and paper-plastic technology, applied in rigid containers, containers, packaging, etc., can solve the problems of narrow application range, complicated manufacturing, high price, etc., and achieve the effect of reasonable and practical overall structure, enhanced sturdiness, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

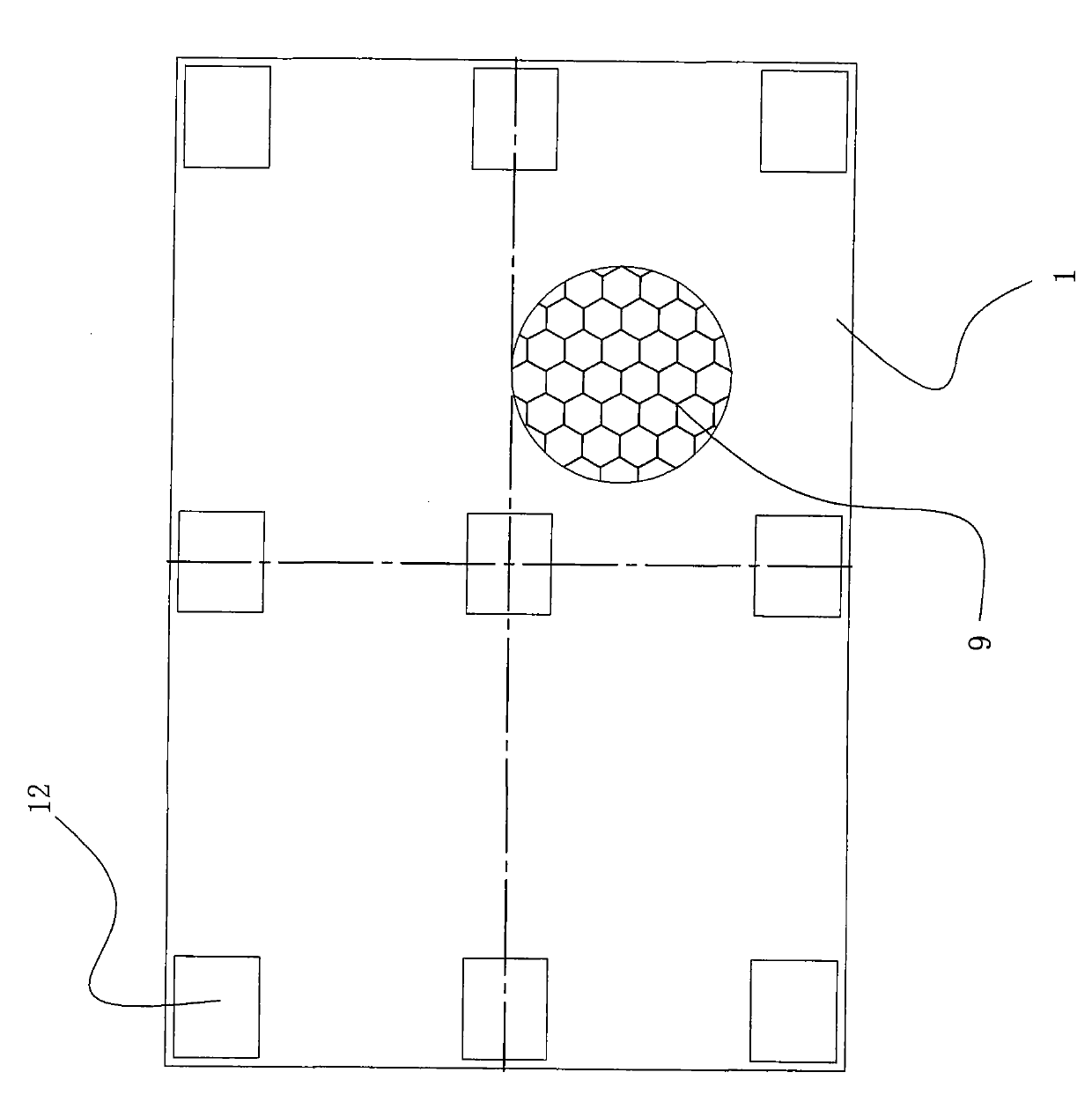

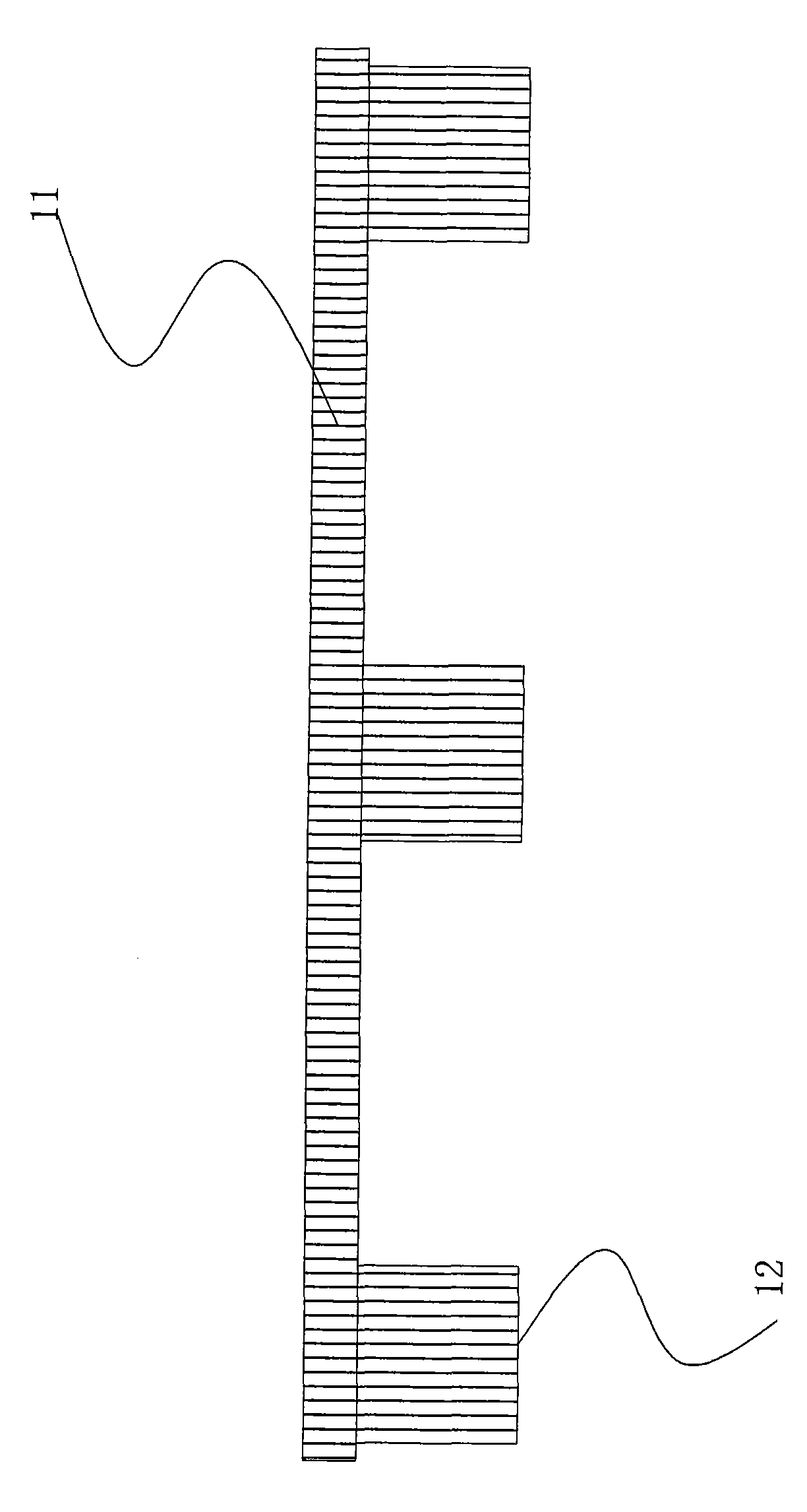

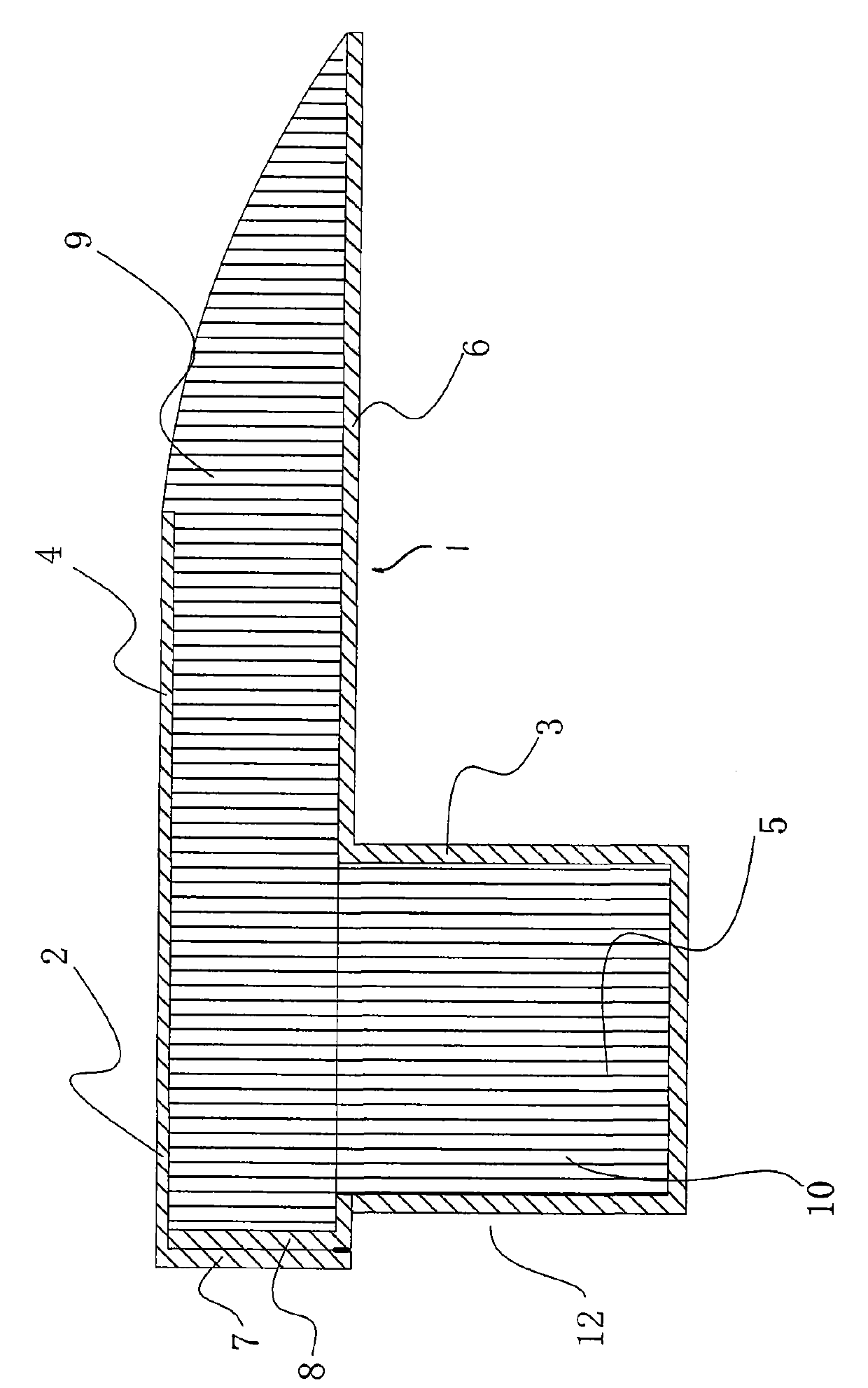

[0030] Such as Figure 1~3 The paper-plastic tray includes a plastic shell 1, the plastic shell 1 includes an upper plastic shell 2 and a lower plastic shell 3, the top 4 of the upper plastic shell 2 is a rectangle, and the lower plastic shell 3 is provided with 9 cavities 5. The concave cavities 5 are distributed in a determinant manner, and the top 6 of the lower plastic shell 3 is also in a rectangular shape as a whole. The side 7 of the upper plastic shell 2 is socketed outside the side 8 of the lower plastic shell 3, and the socket is glued together Fixed or welded, the honeycomb paperboard 9 is fixed and bonded with a glue layer on the top 4 inner surface of the upper plastic shell 2 and the top 6 inner surface of the lower plastic shell 3, and the upper and lower sides of the honeycomb paperboard 9 are compounded with panel paper, so , the top 4 and side 7 of the upper plastic shell 2, the top 6 and side 8 of the lower plastic shell 3 and the honeycomb cardboard 9 toget...

Embodiment 2

[0032] Such as Figure 2~4 The paper-plastic tray includes a plastic shell 1, the plastic shell 1 includes an upper plastic shell 2 and a lower plastic shell 3, the top 4 of the upper plastic shell 2 is a rectangle, and the lower plastic shell 3 is provided with 9 cavities 5. The concave cavities 5 are distributed in a determinant manner. The top 6 of the lower plastic shell 3 is also in a rectangular shape as a whole. The side 7 of the upper plastic shell 2 is socketed outside the side 8 of the lower plastic shell 3, and glue is used to bond the socket. Fixed or welded connection, honeycomb cardboard 9 is directly installed between the inner surface of the top 4 of the upper plastic shell 2 and the inner surface of the top 6 of the lower plastic shell 3, the upper and lower sides of the honeycomb cardboard 9 are compounded with panel paper, and the upper plastic shell 2 The top 4 and side 7 of the lower plastic shell 3, the top 6 and the side 8 and the honeycomb cardboard 9 t...

Embodiment 3

[0034] Such as figure 1 , 2 5. A kind of paper-plastic tray, comprising a plastic shell 1, the plastic shell 1 adopts a plastic-absorbing process to make an integral plastic shell and wraps a honeycomb paperboard 9 and a honeycomb paperboard block 10a in it, the plastic shell 1 The interior is divided into one cavity 14 in the upper part and nine identical concave cavities 5 in the lower part. The concave cavities 5 are distributed in a determinant manner. The upper cavity 14 is filled with honeycomb paperboard 9, and the upper and lower sides of the honeycomb cardboard 9 are compounded with panel paper. The cardboard 9 adopts the glue layer to combine with the surface of the upper cavity 14, so that it constitutes the panel 11 of the paper-plastic tray, and each cavity 5 in the lower part is filled with a honeycomb cardboard block 10a as the main body of the foot, and the honeycomb cardboard block 10a uses The glue layer is closely combined with the surface of the lower cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com