Patents

Literature

261results about How to "Reasonable and practical structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

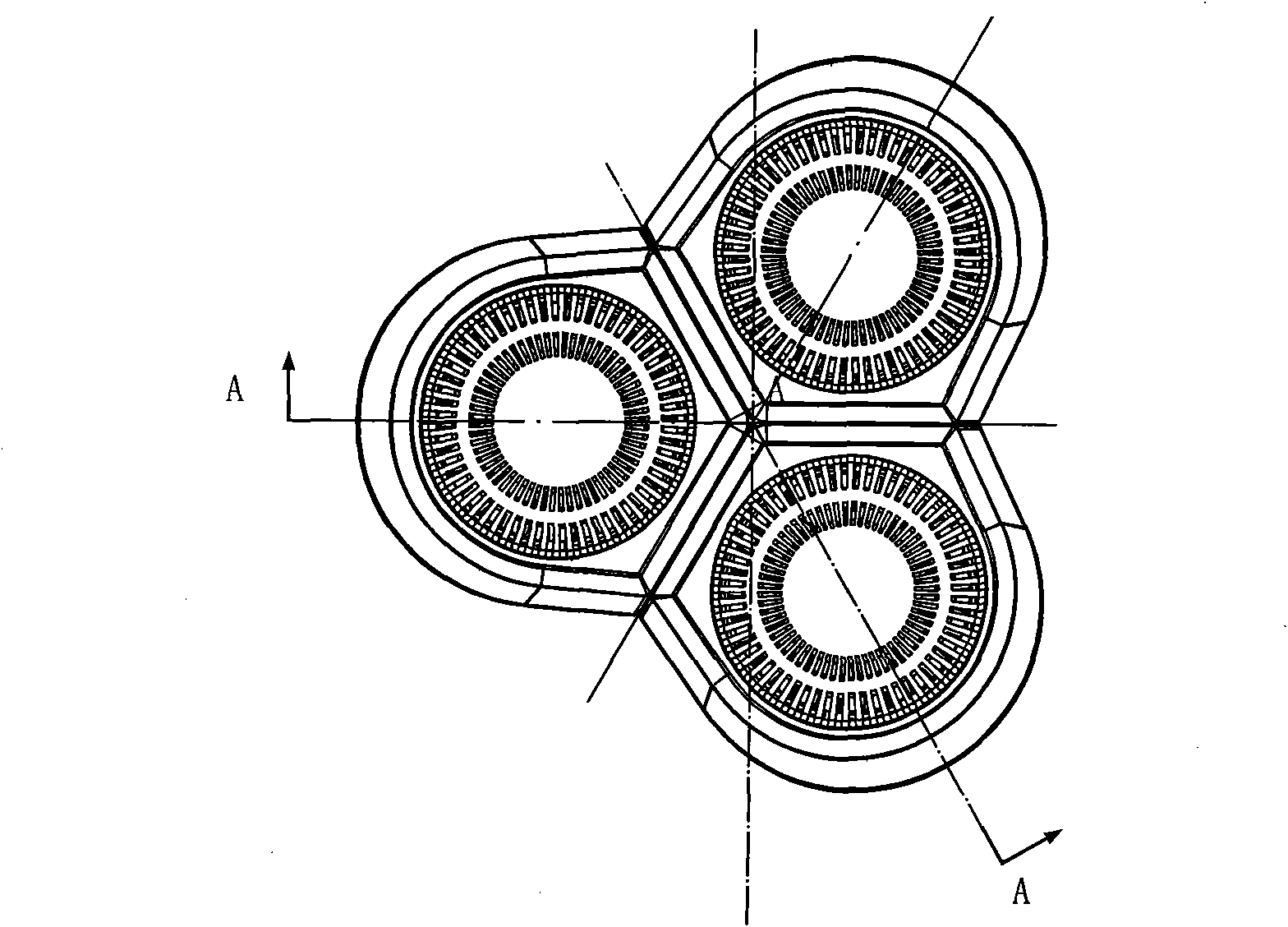

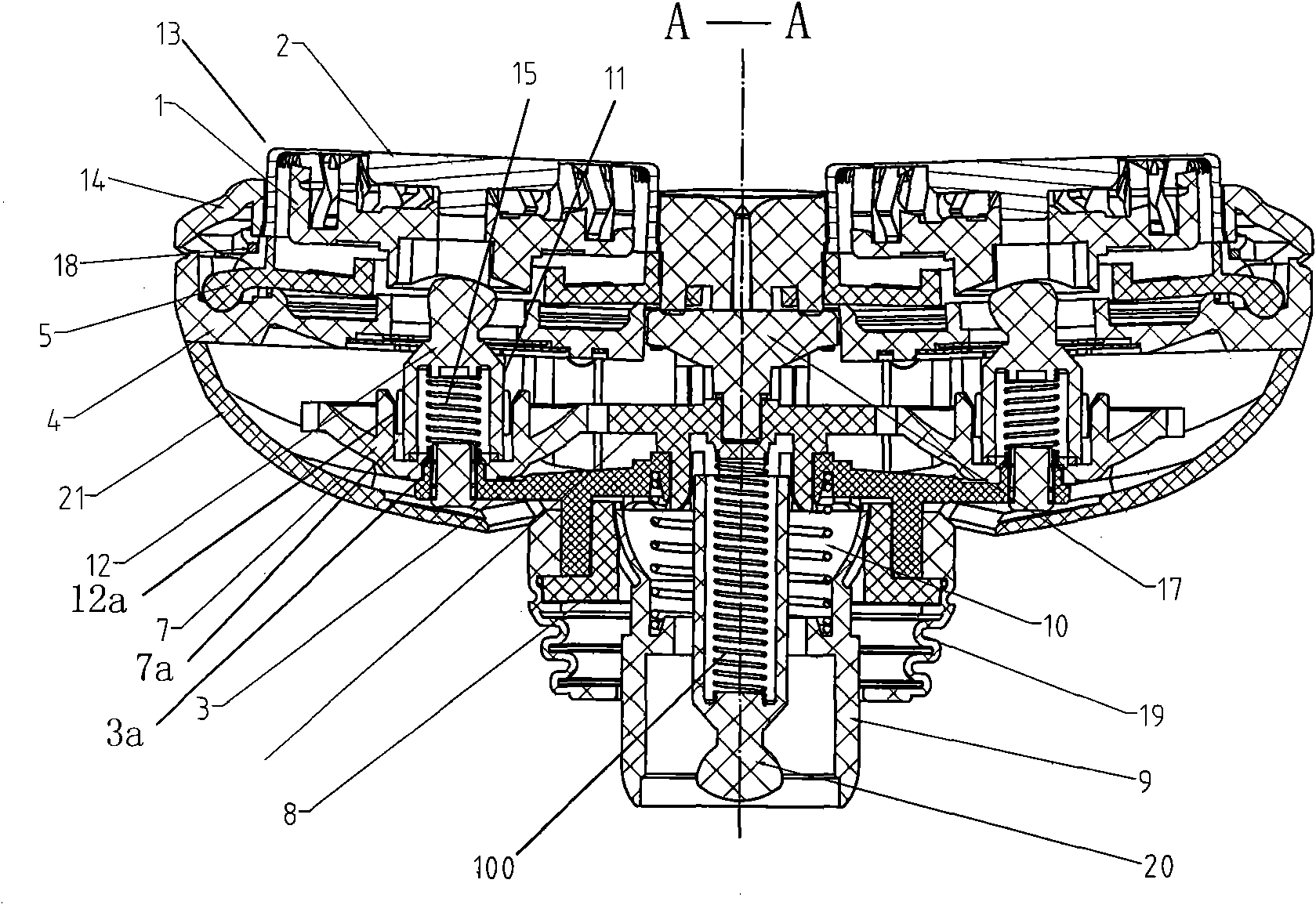

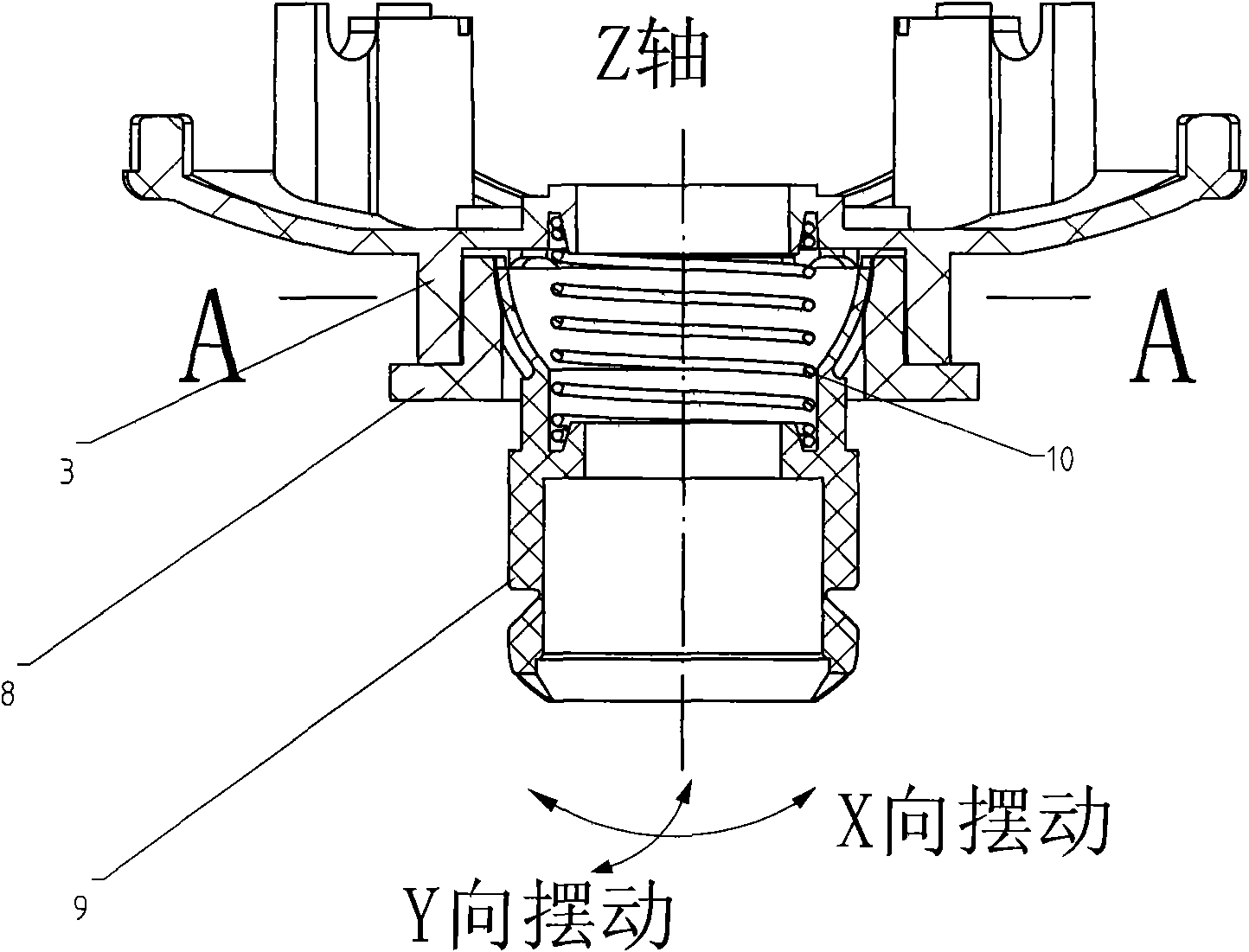

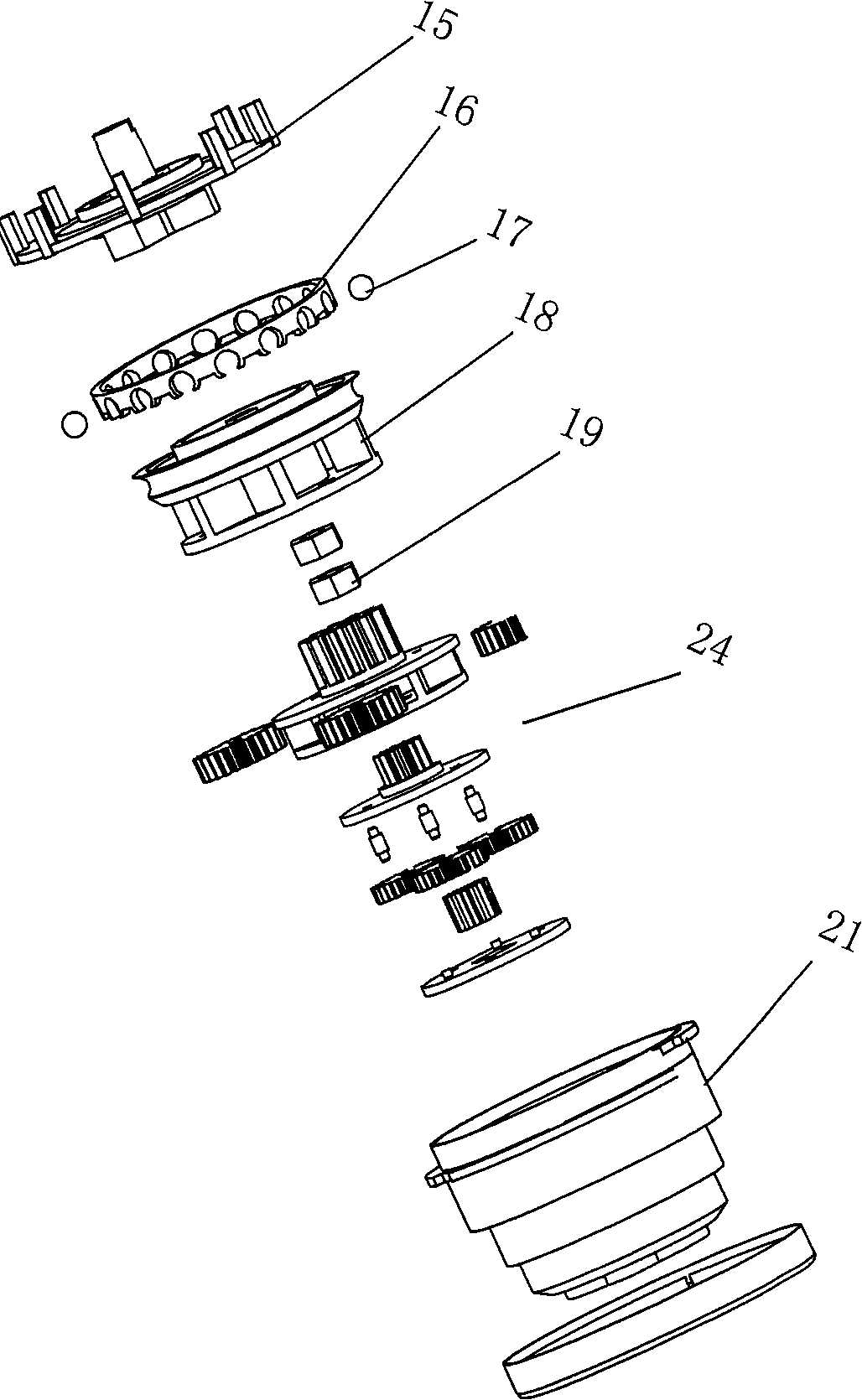

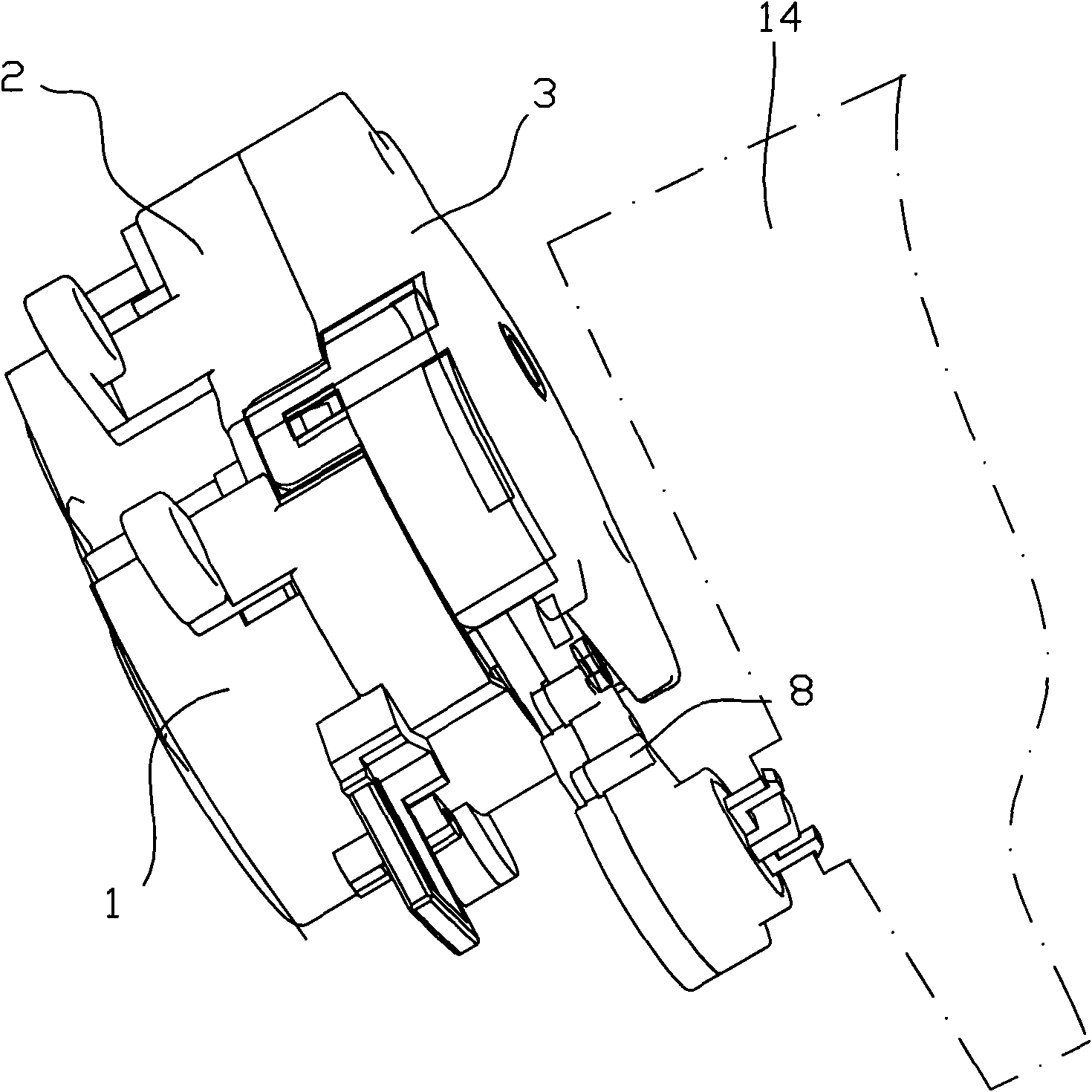

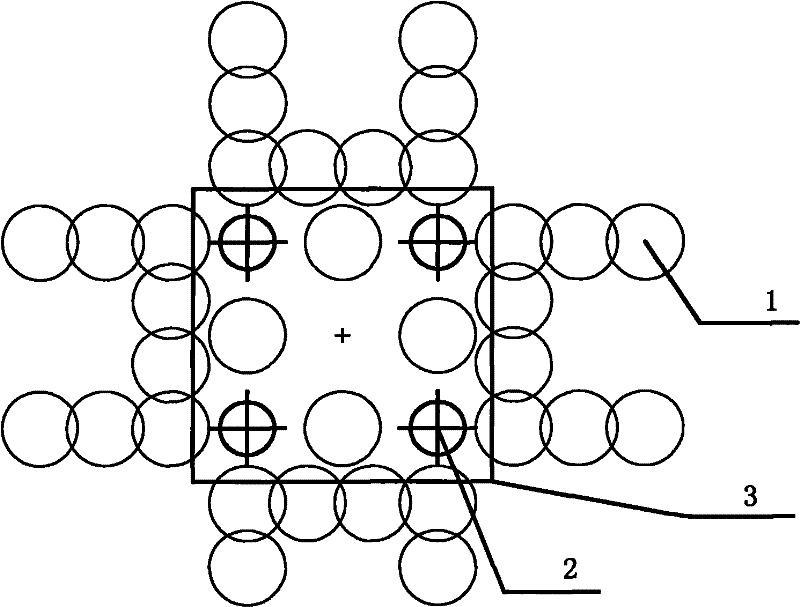

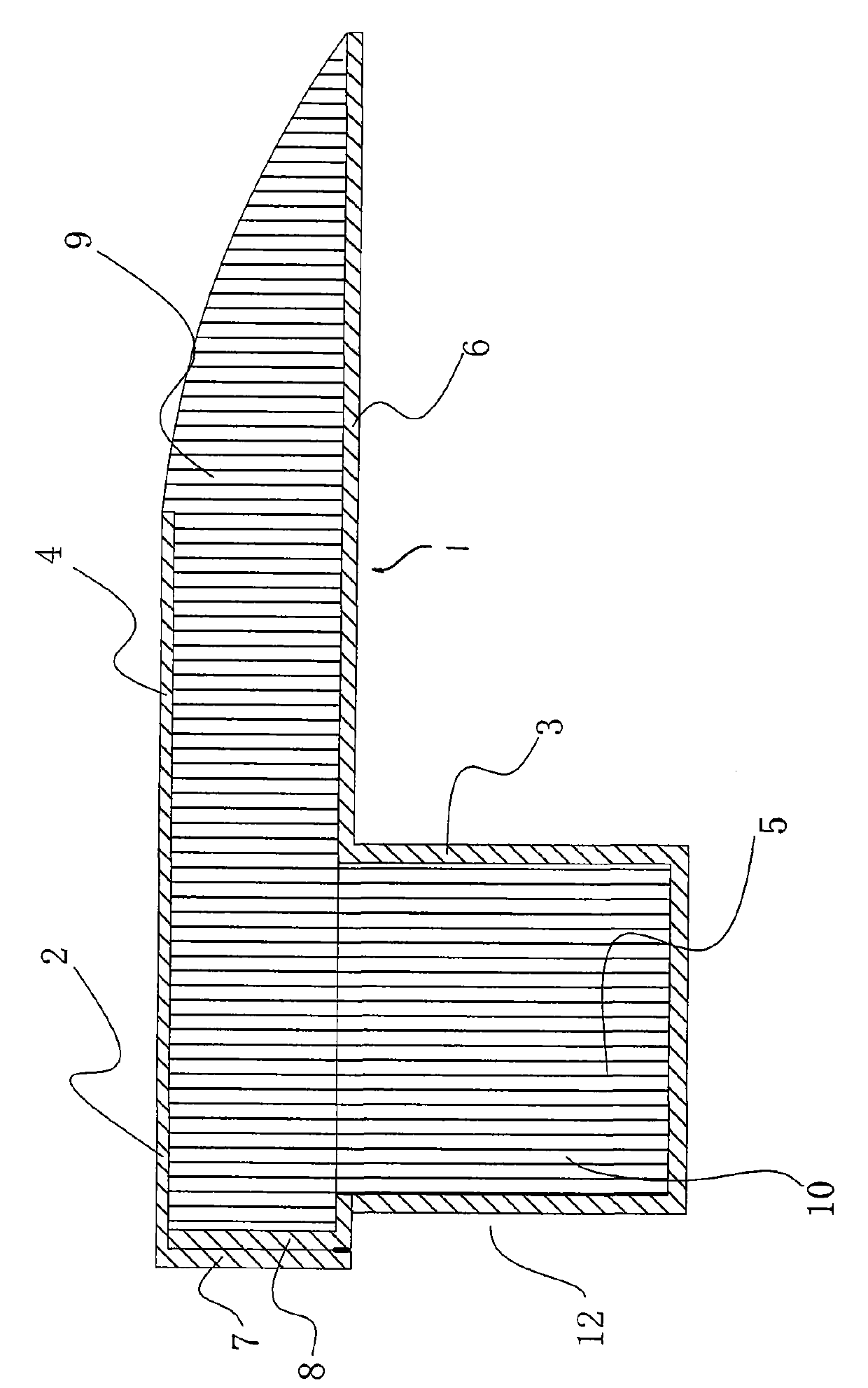

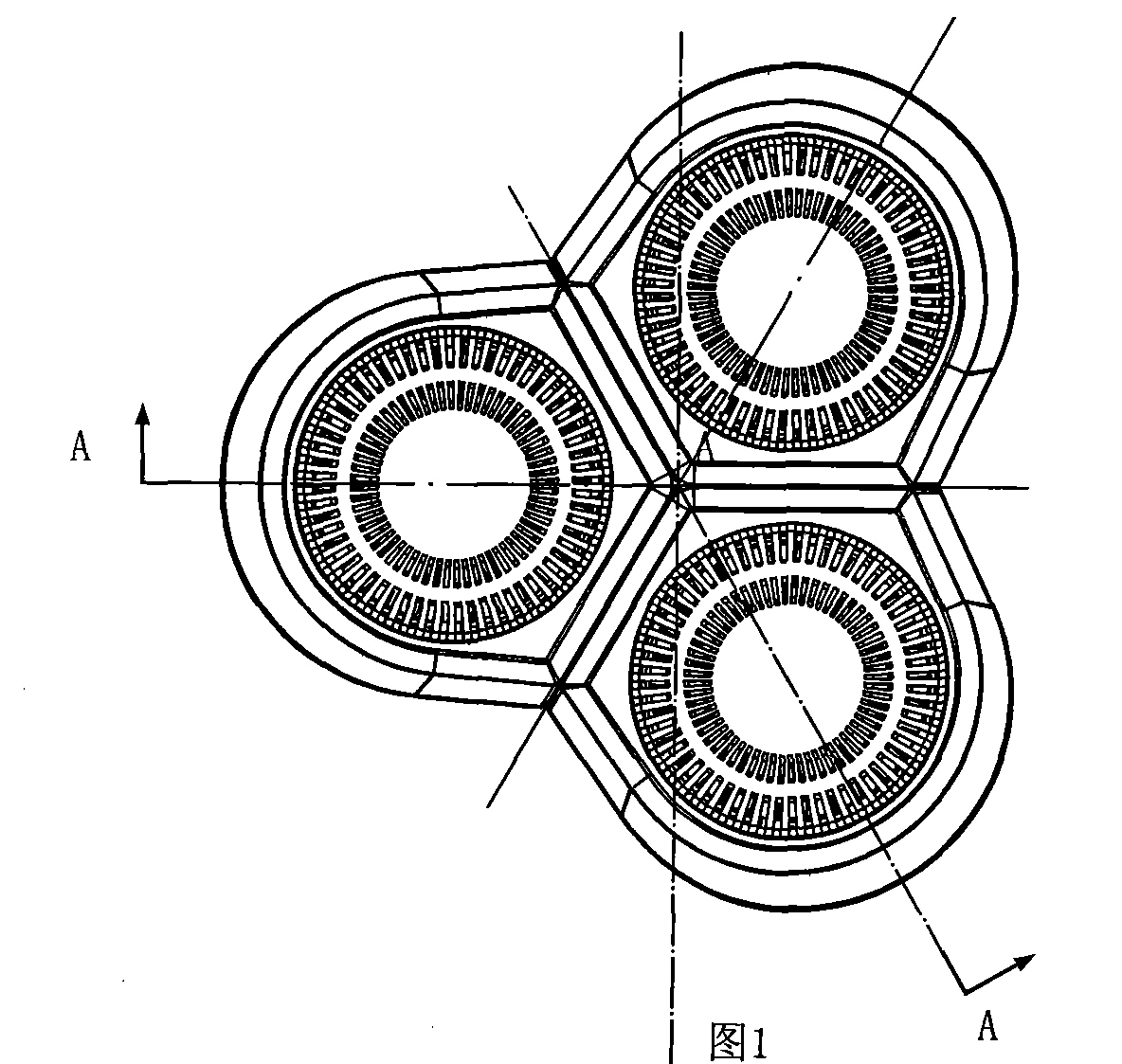

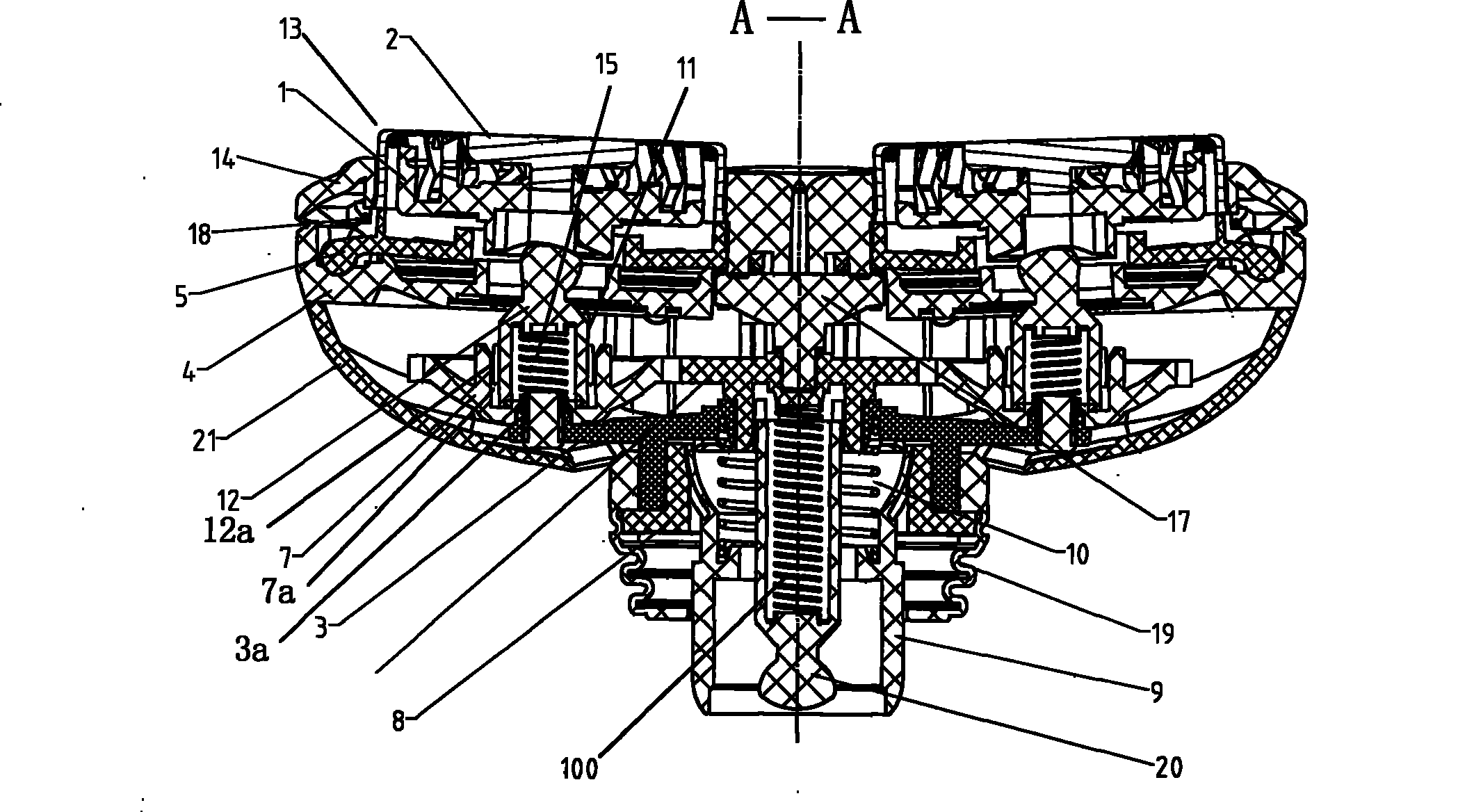

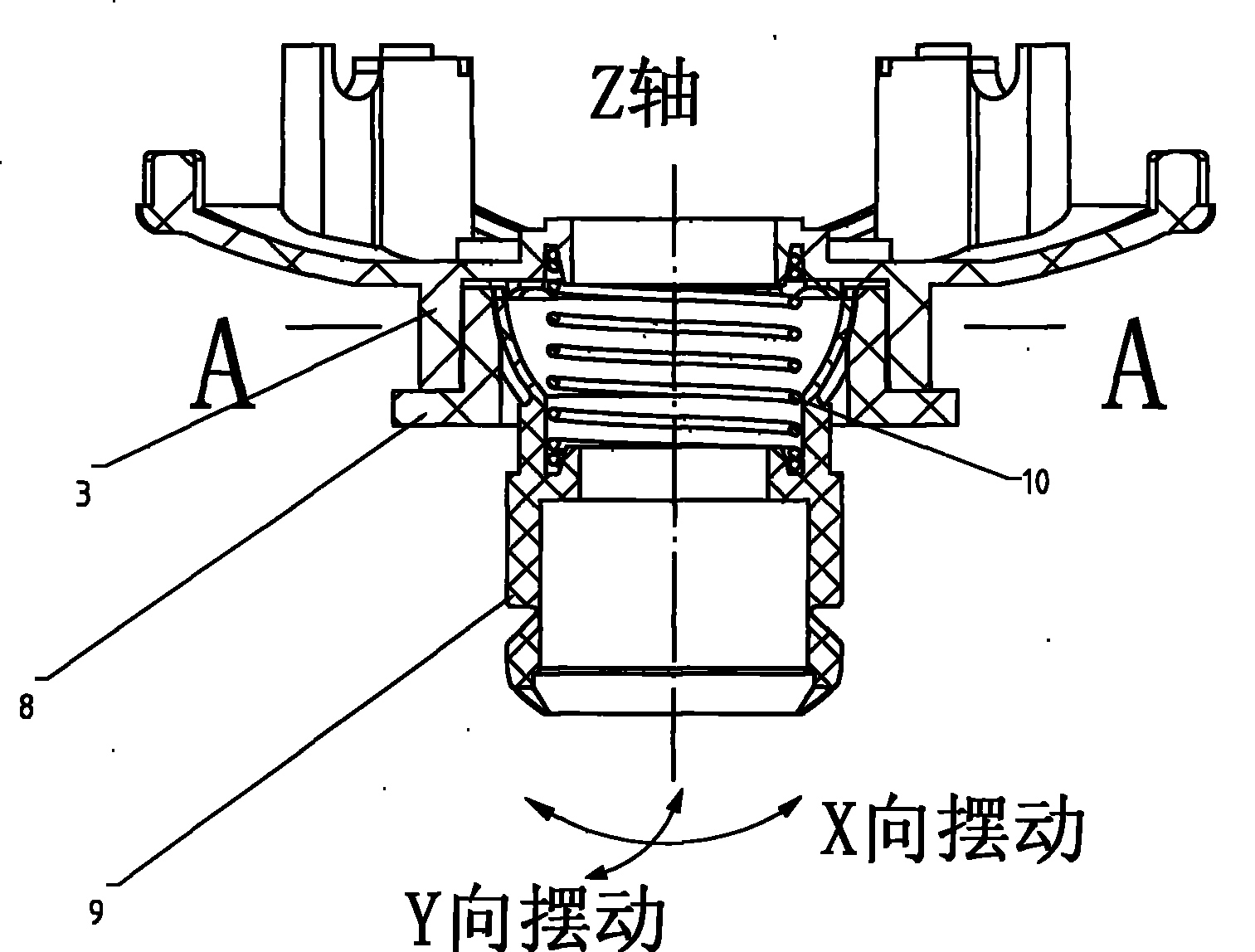

Cutter head structure of detachable electric shaver

InactiveCN101683739AHigh rotational freedomShaving feels goodMetal working apparatusRotational degrees of freedomEngineering

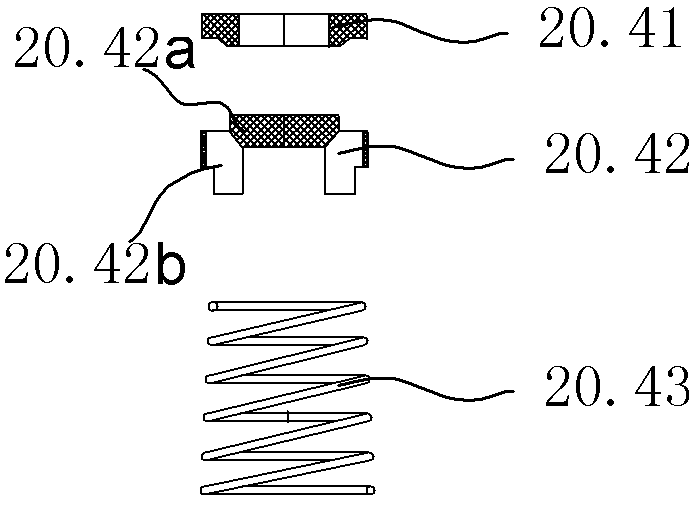

The invention relates to a cutter head structure of a detachable electric shaver, comprising a plurality of cutter blade assemblies capable of rotatably cutting, and the cutter blade assemblies are injoggled connection with a central transmission gearwheel on a main support by respective transmission unit. The cutter head structure is characterized in that the main support is sleeved on the lowercover of the main support, whereas the lower cover of the main support is connected with a cutter blade connecting seat by spherical coordination; and an elastic element is supported between the mainsupport and the cutter blade connecting seat. The cutter head structure has big rotational degree of freedom, simple and practical structure and easy manufacture.

Owner:叶常明

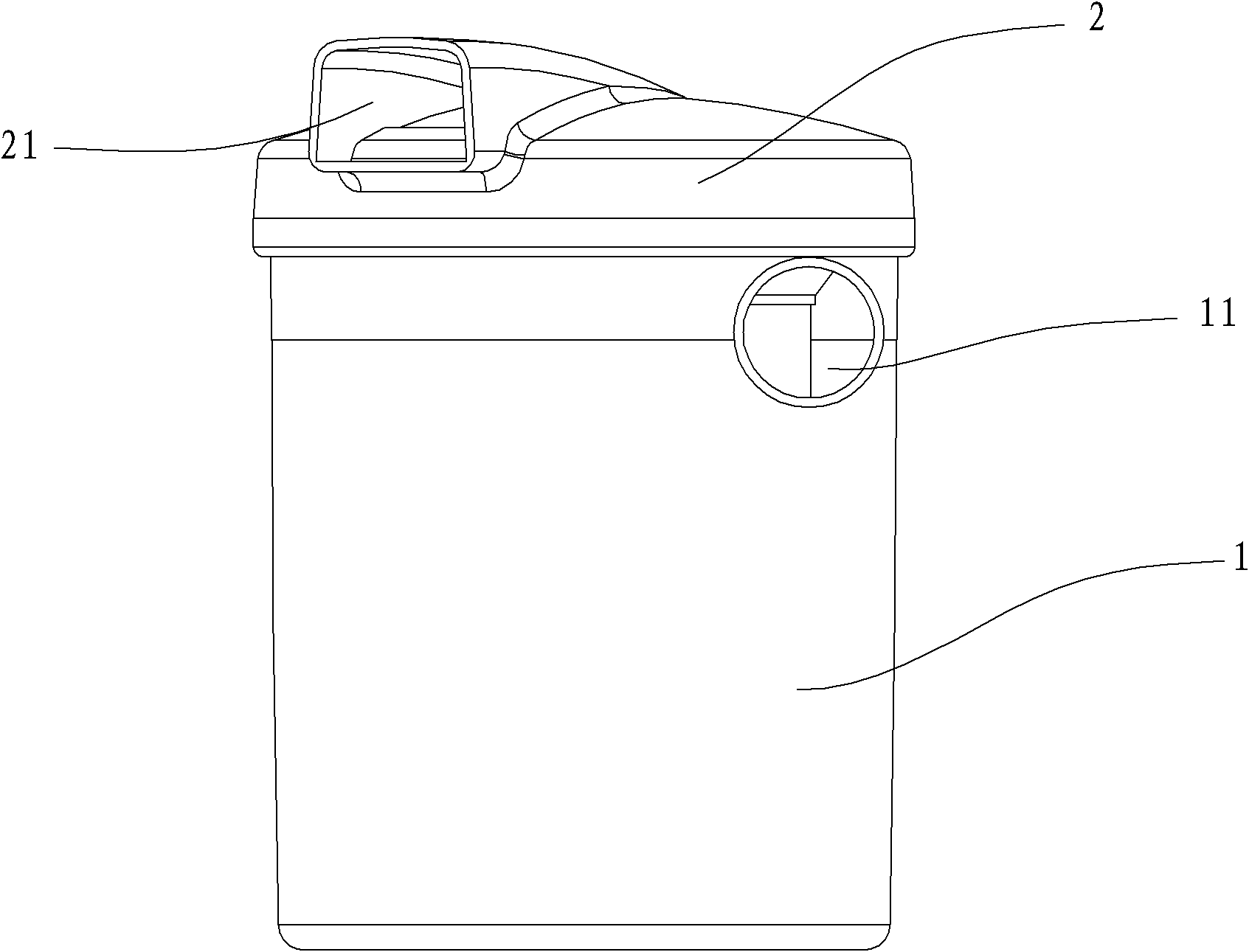

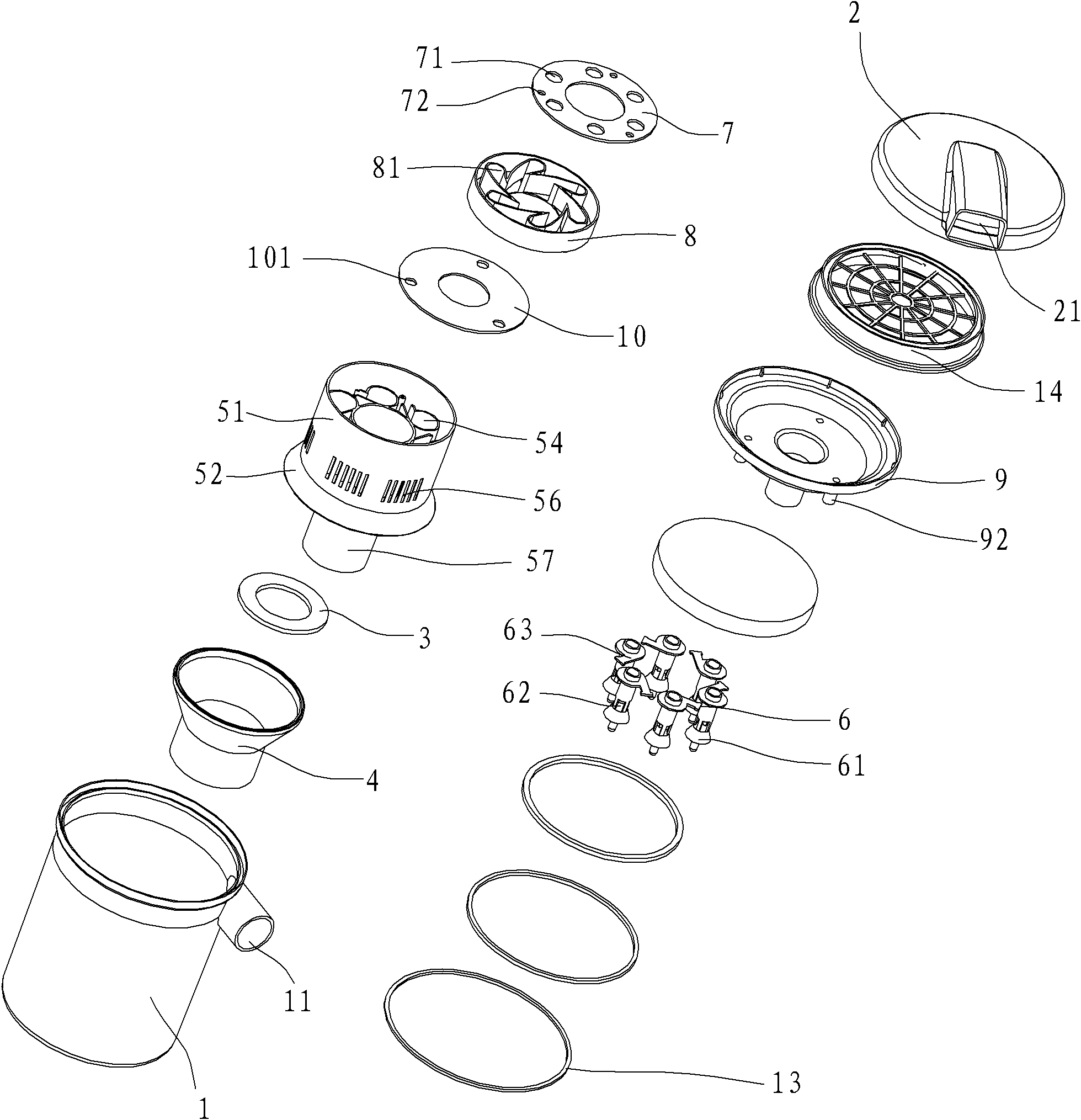

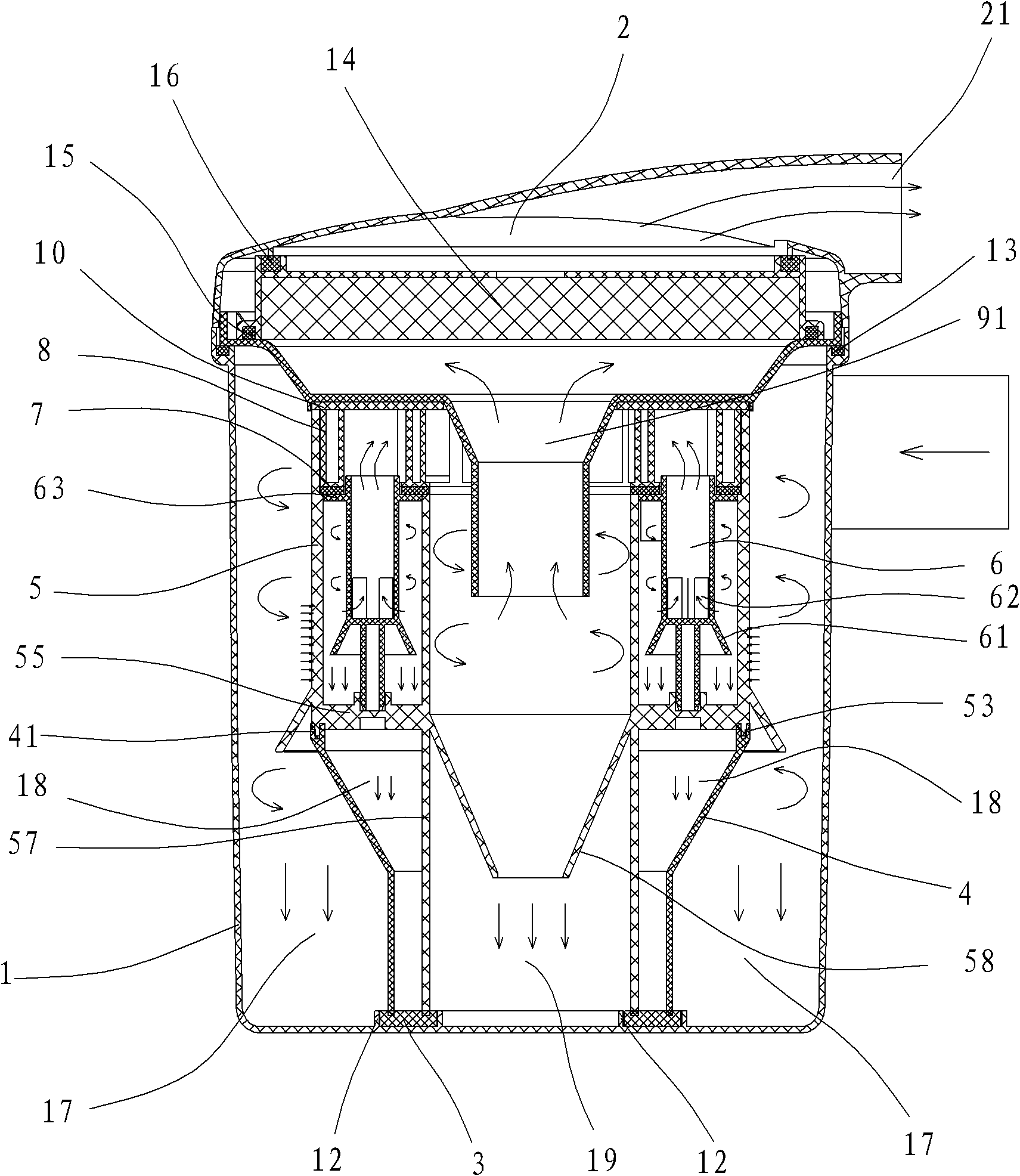

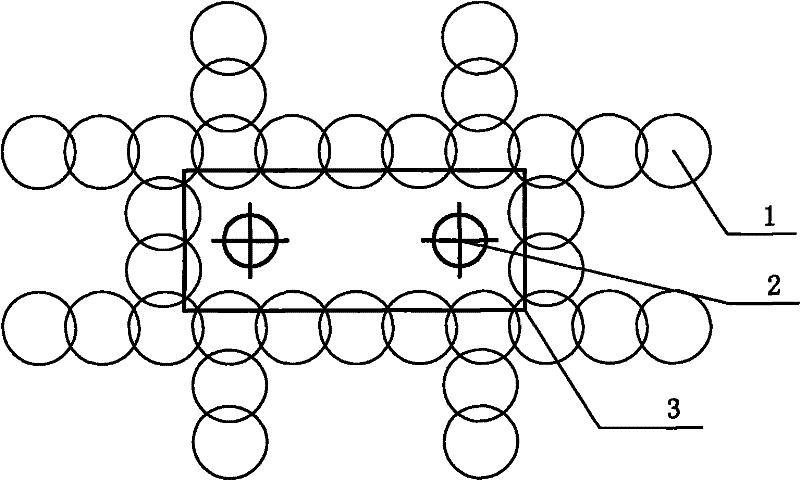

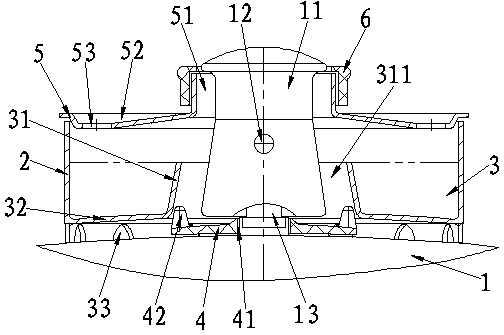

Cyclone separation dust cup of dust collector

InactiveCN102429612AImprove Cyclone Separation EfficiencyHigh Cyclone EfficiencySuction filtersCycloneThree stage

The invention discloses a cyclone separation dust cup of a dust collector, which adopts a rationally-configured three-stage cyclone separation capable of improving the cyclone separation efficiency of the dust cup and enabling the dust to be remained in a dust collecting chamber of the dust cup instead of being conveyed to the fan or being polluted twice. Each stage of cyclone separator is provided with a cone apron edge or a cone surface, with which the air flow is accelerated and then decelerated while entering the oversized space at the lower part; then the dust is deposited instead of being taken away. Compared with cyclone separator having straight barrel, the utility model has better cyclone separation effect.

Owner:胡海荣

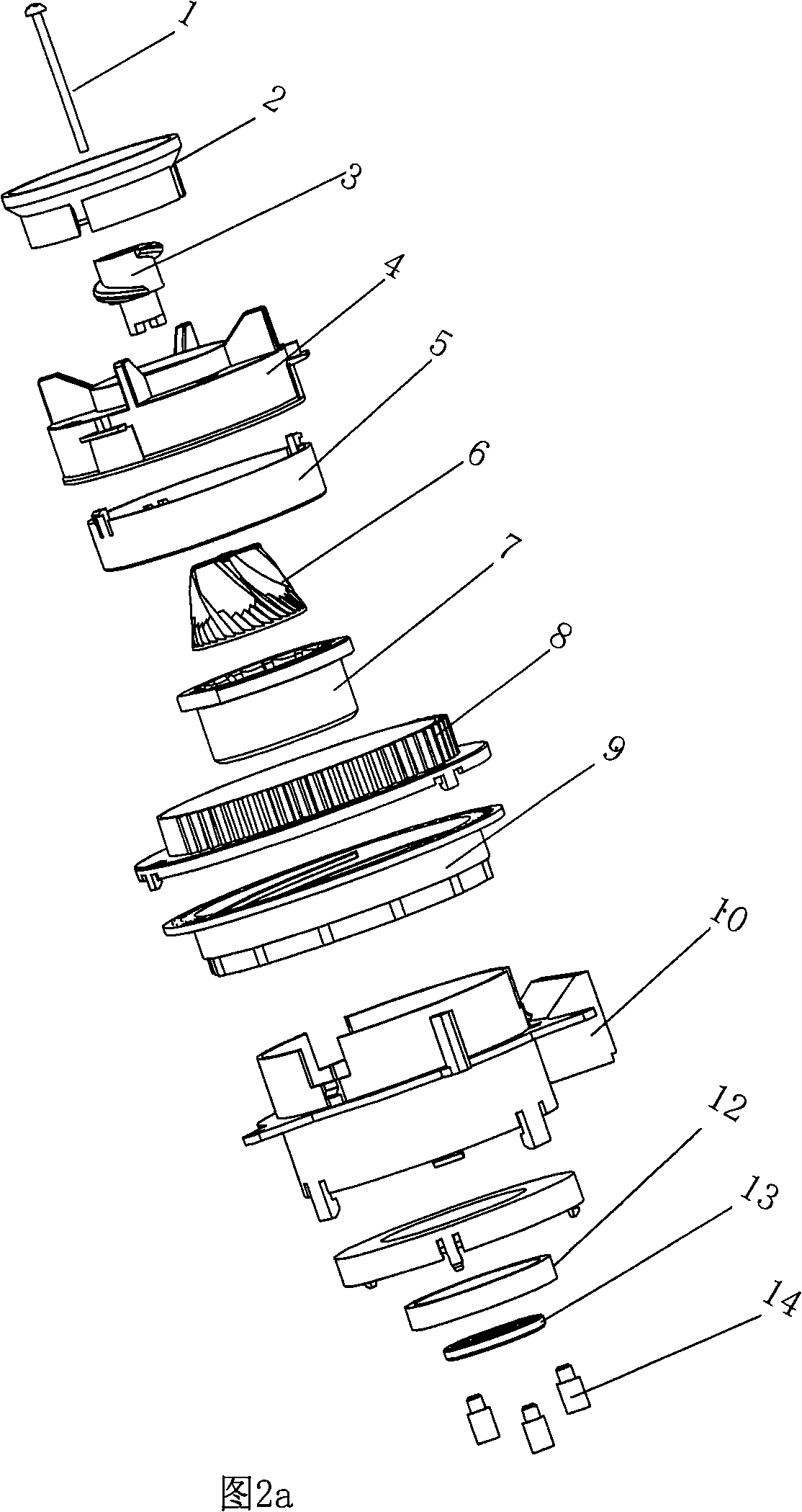

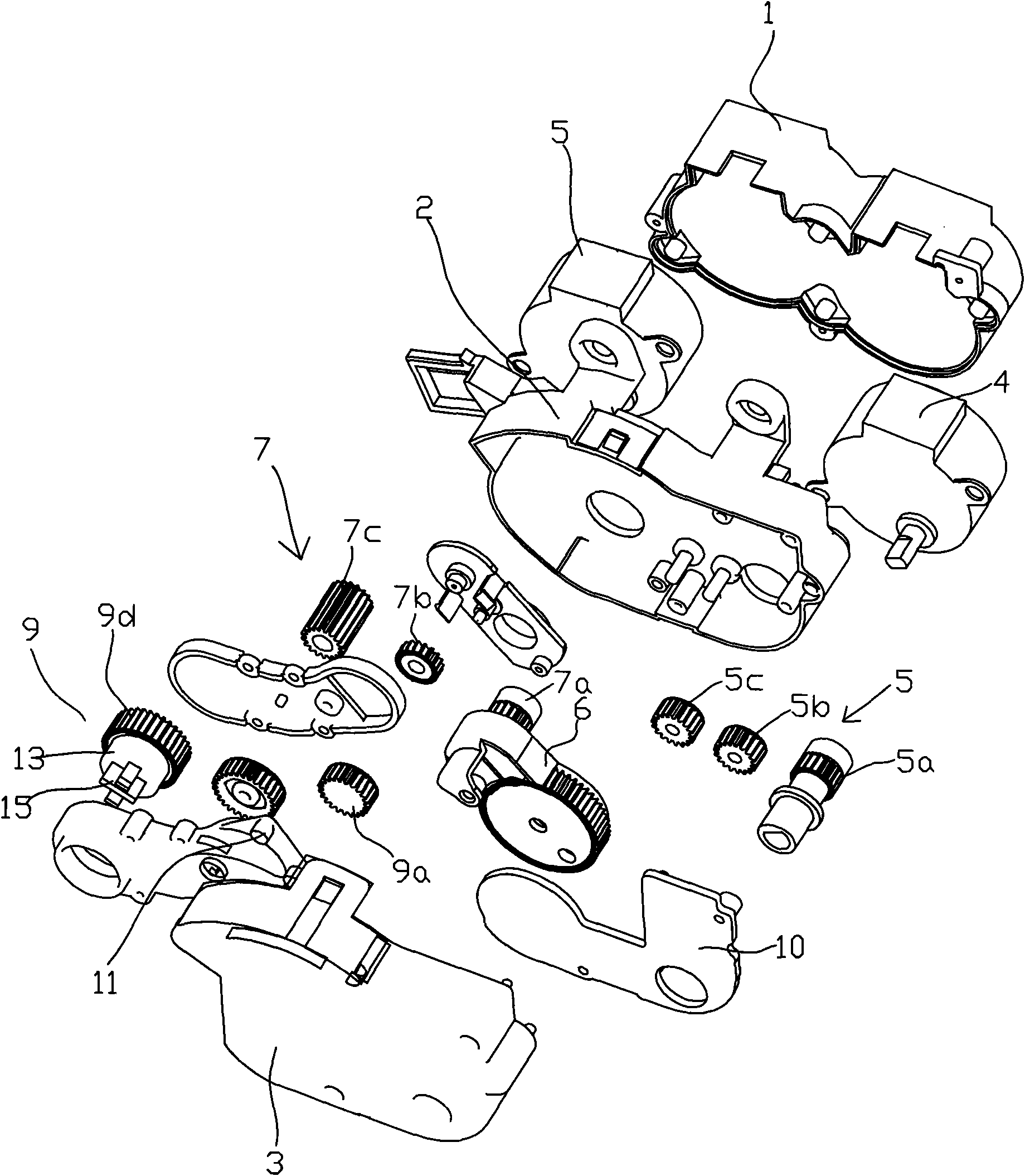

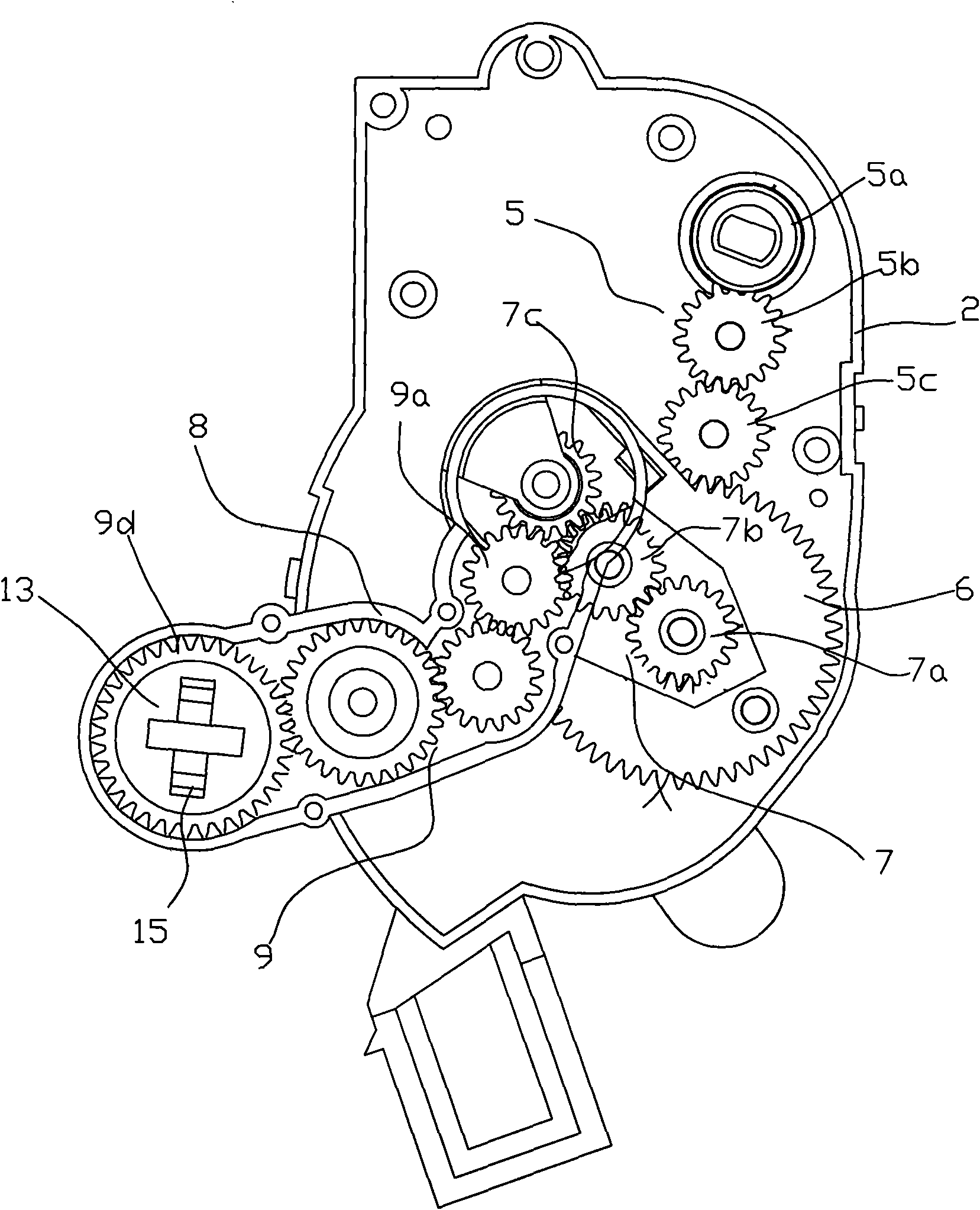

Mill of coffee-making machine

InactiveCN101347313ASmall thermal deformationHigh hardnessCoffee millsSpice millsThermal deformationEngineering

The invention relates to a coffee machine grinder which comprises a grinding head, a cutter head, a cutter cover and a transmission mechanism. The grinding head is installed and fixed at the upper end of a vertical rotating shaft in the grinder, and the underside is provided with the cutter head. The cutter head and the cutter cover arranged in the grinder are in clearance fit. A coffee turnplate is also fixed in the vertical rotating shaft. The lower end of the vertical rotating shaft is connected with the transmission mechanism in a driving way. The coffee machine grinder is characterized in that the cutter head and the cutter cover are made from ceramic material; furthermore, the cutter head is spliced and connected with the coffee turnplate by a positioning pin; an elastic element is supported between the opposite surfaces of the cutter head and the coffee turnplate. The coffee machine grinder is provided with the cutter head and the cutter cover made from ceramic material and is combined with an elastic mechanism to ensure that a cutter head component is hard wearing, resists high temperature and corrosion and has less thermal deformation, high hardness and large strength, so as to ensure that the grinder grinds meals uniformly, outputs meals fast, reduces noise, has reasonable structure and is practical.

Owner:NINGBO HAWK ELECTRICAL APPLIANCE CO LTD

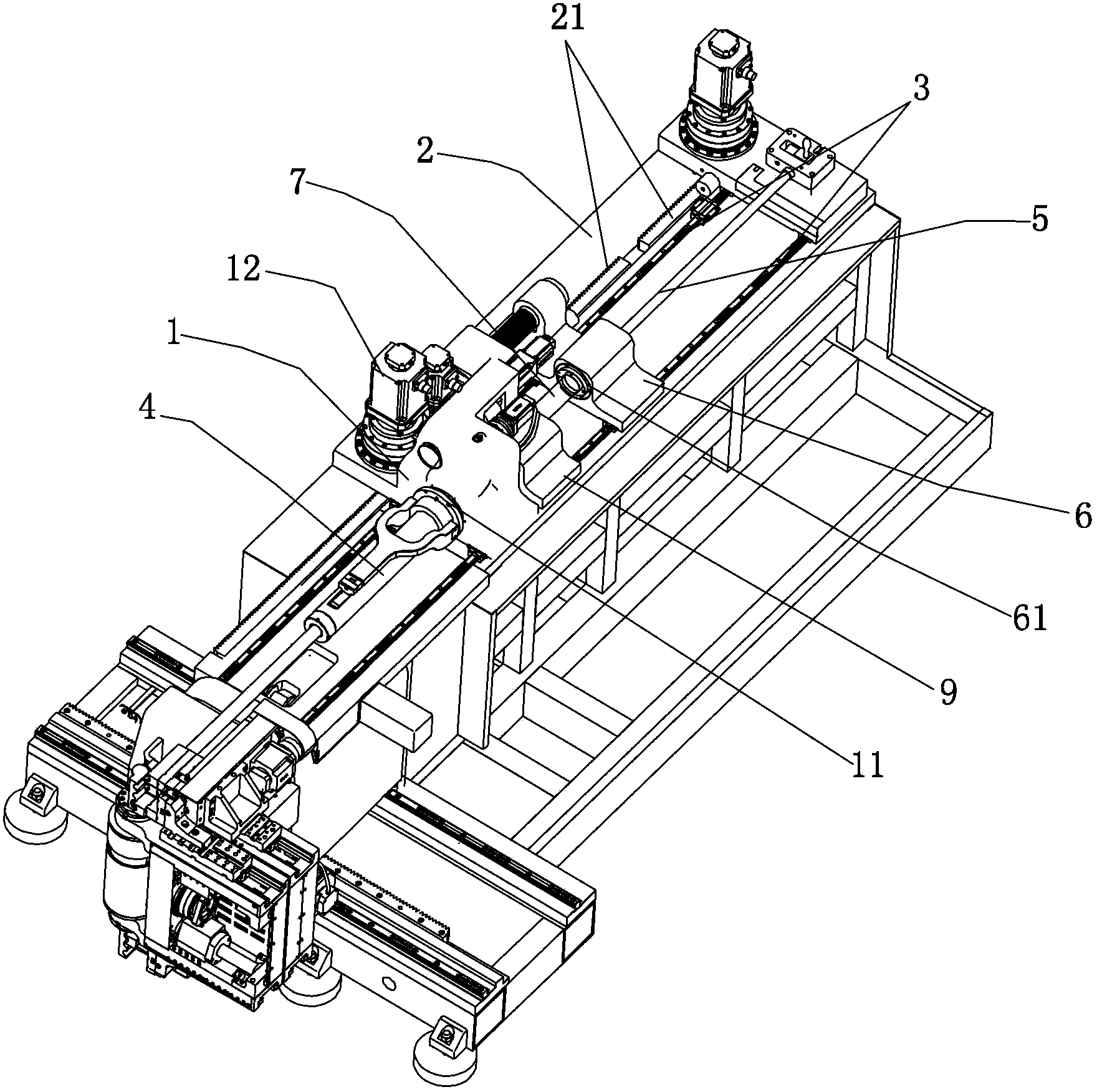

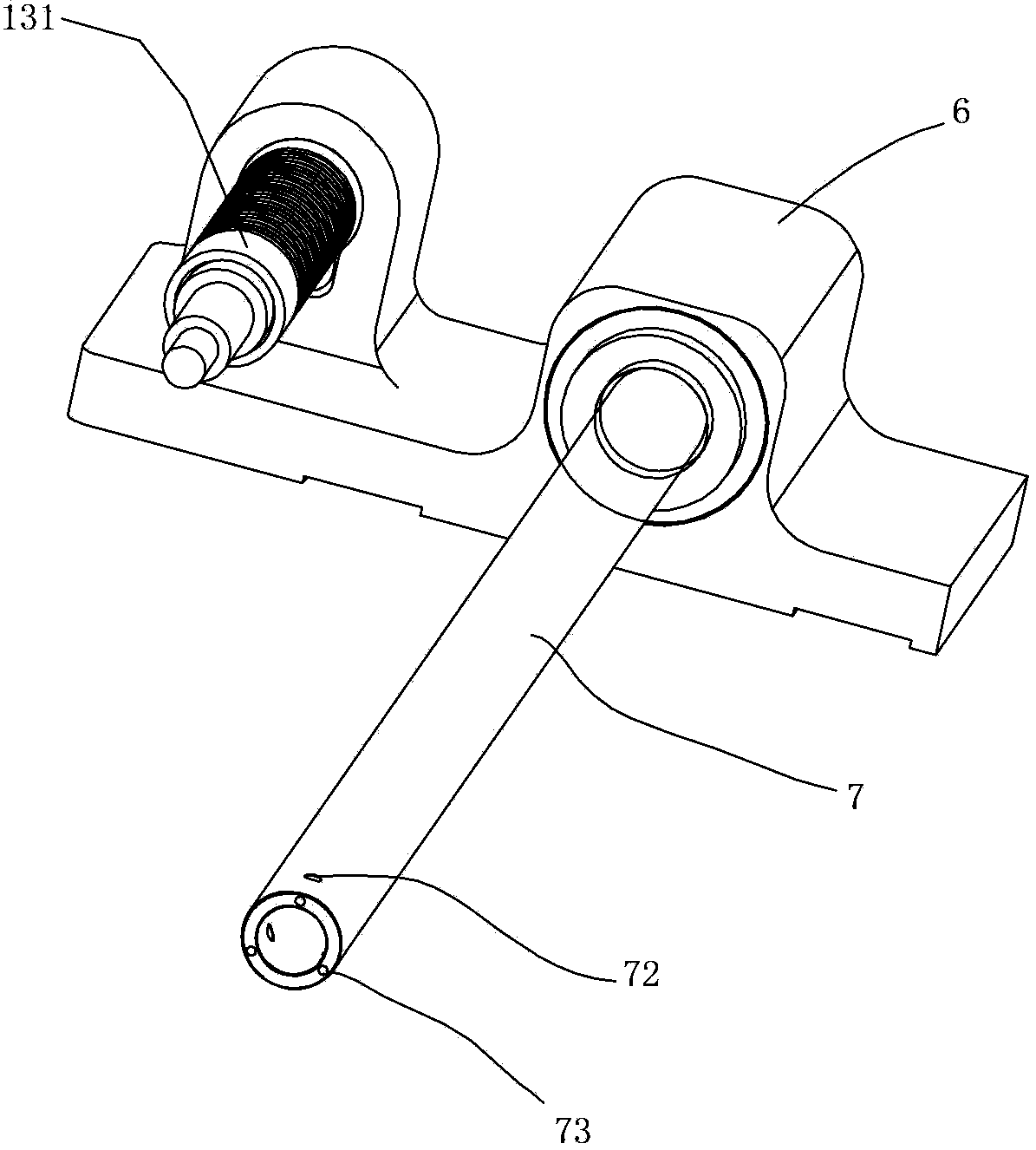

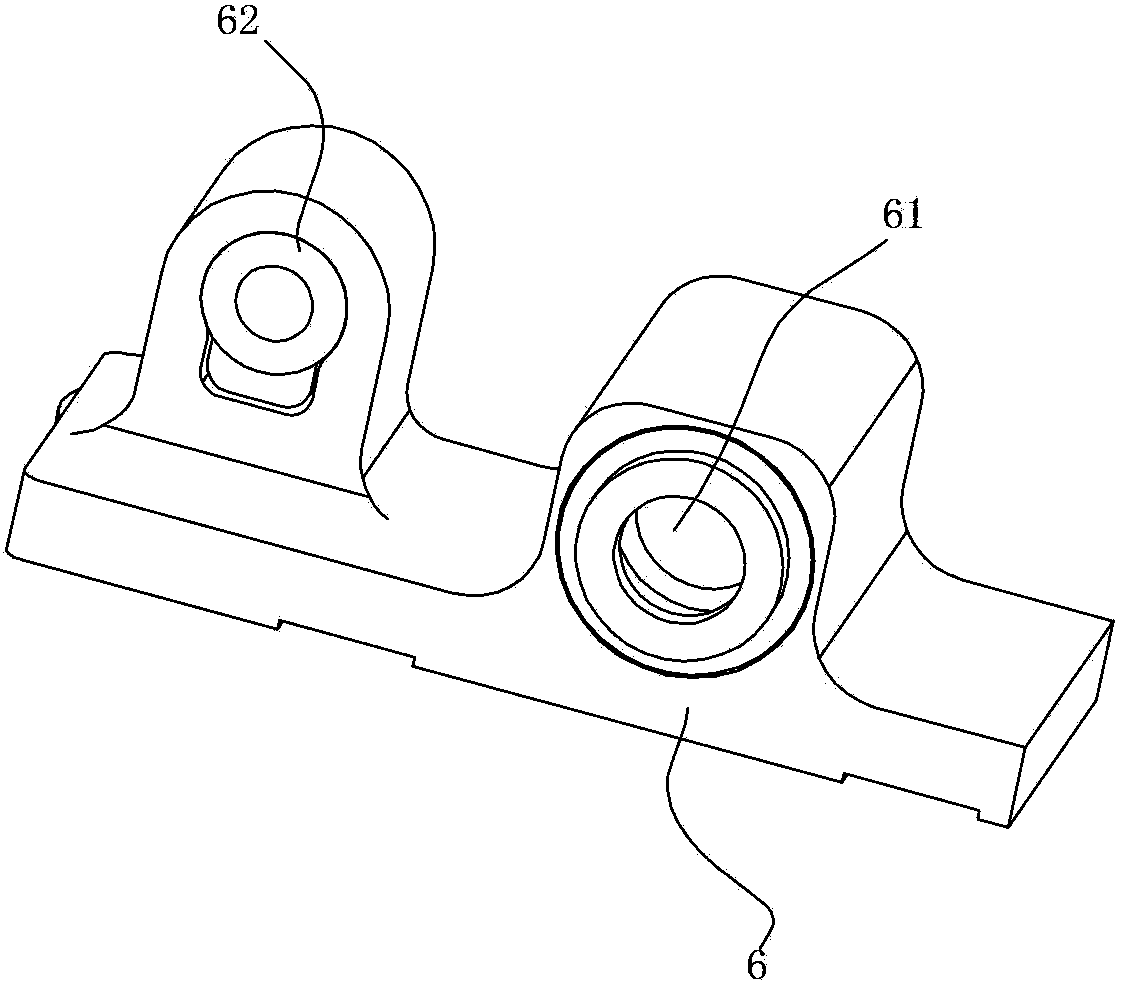

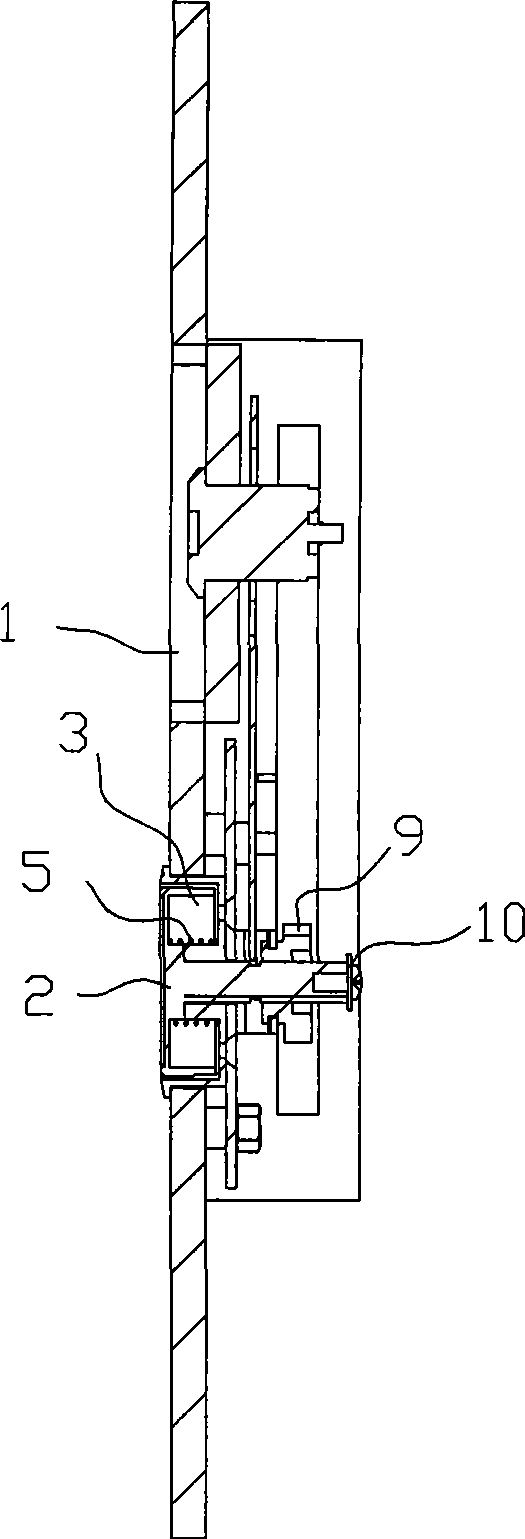

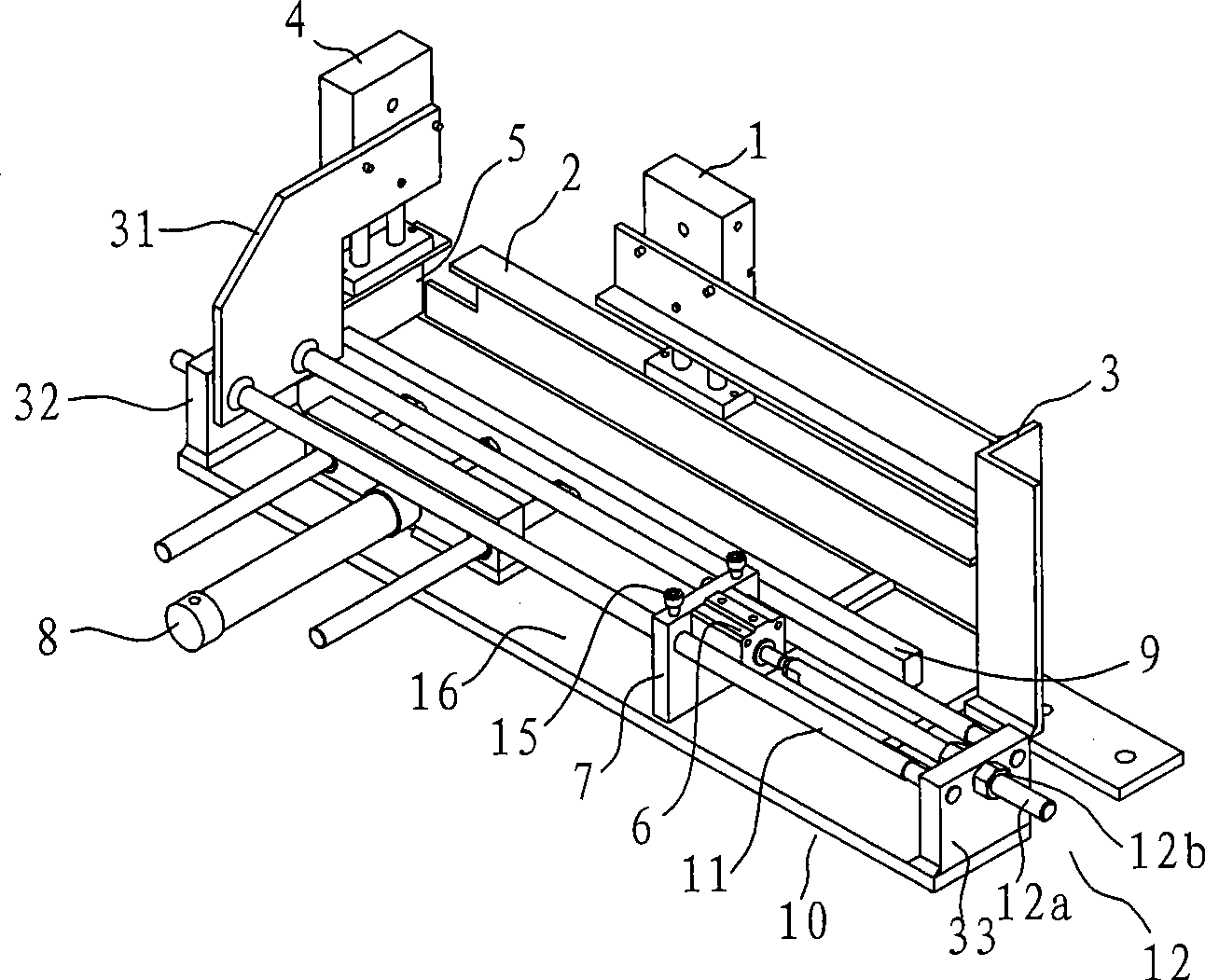

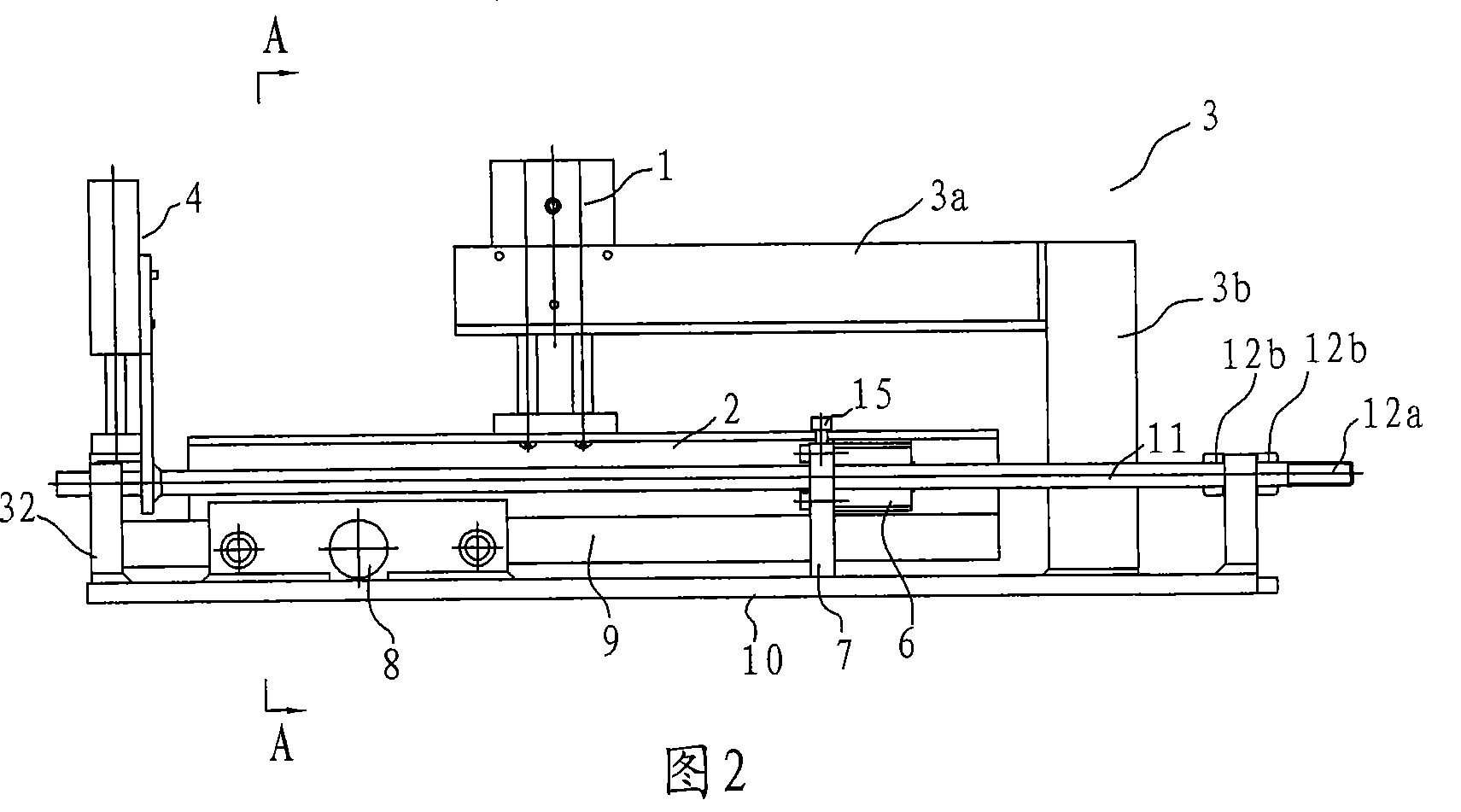

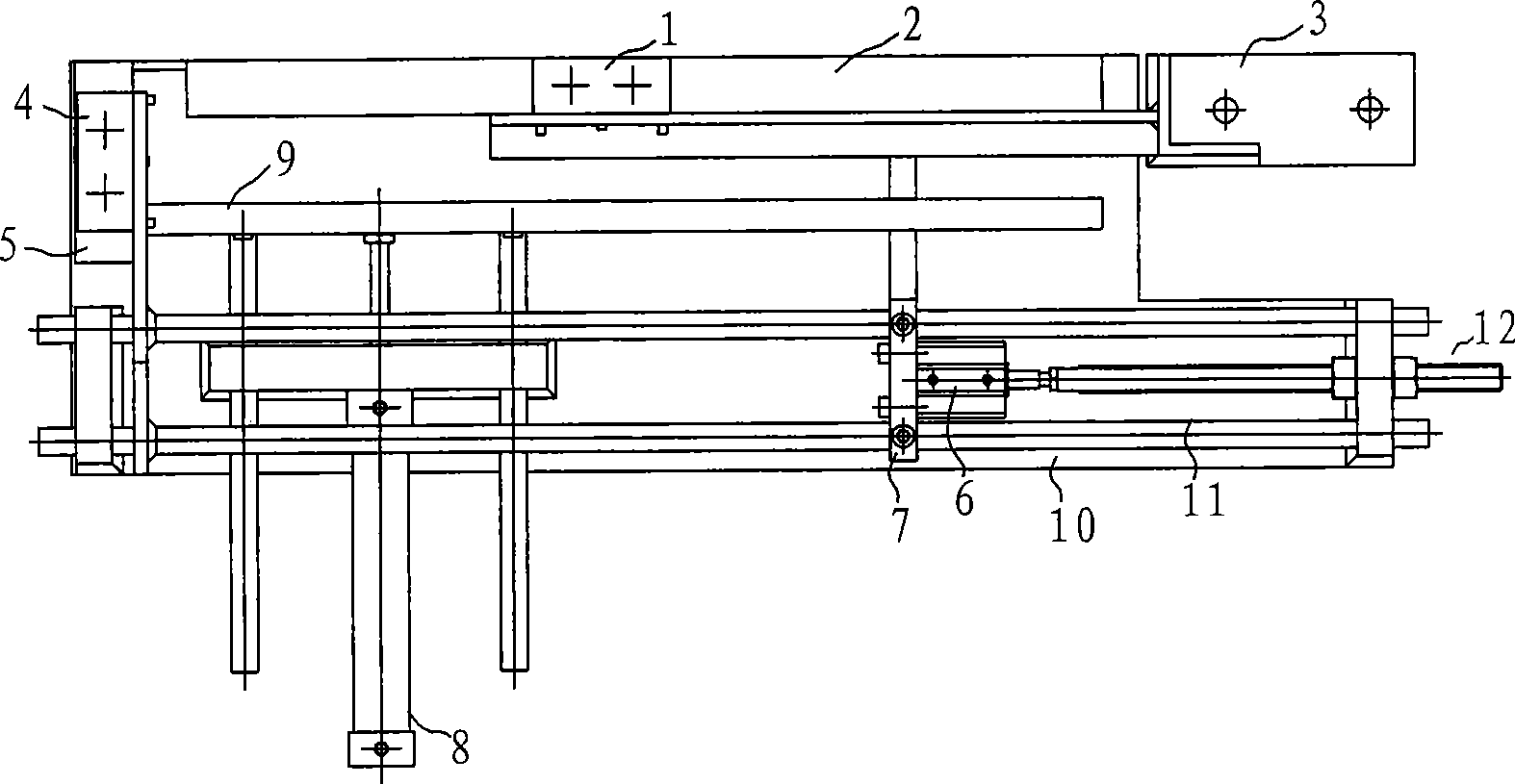

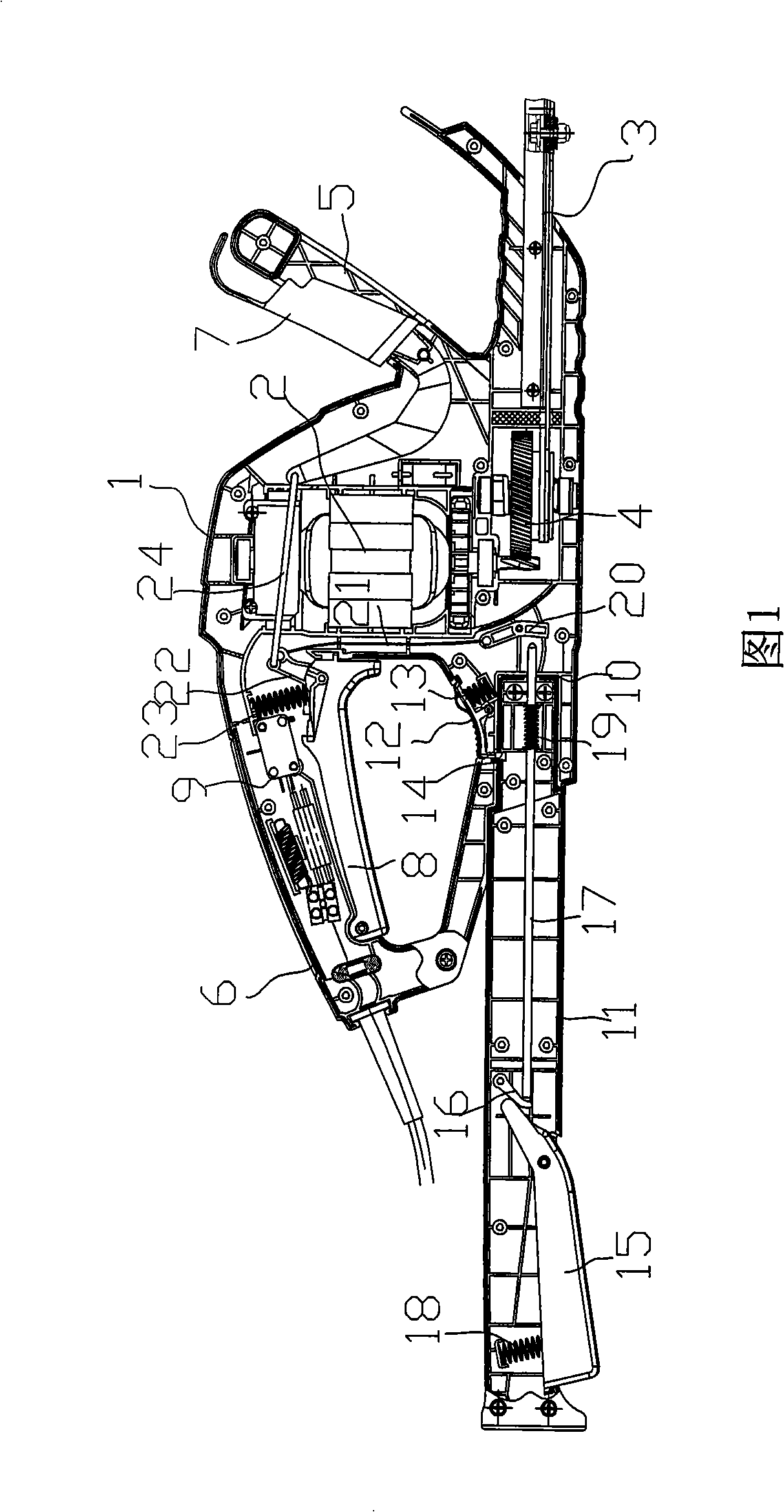

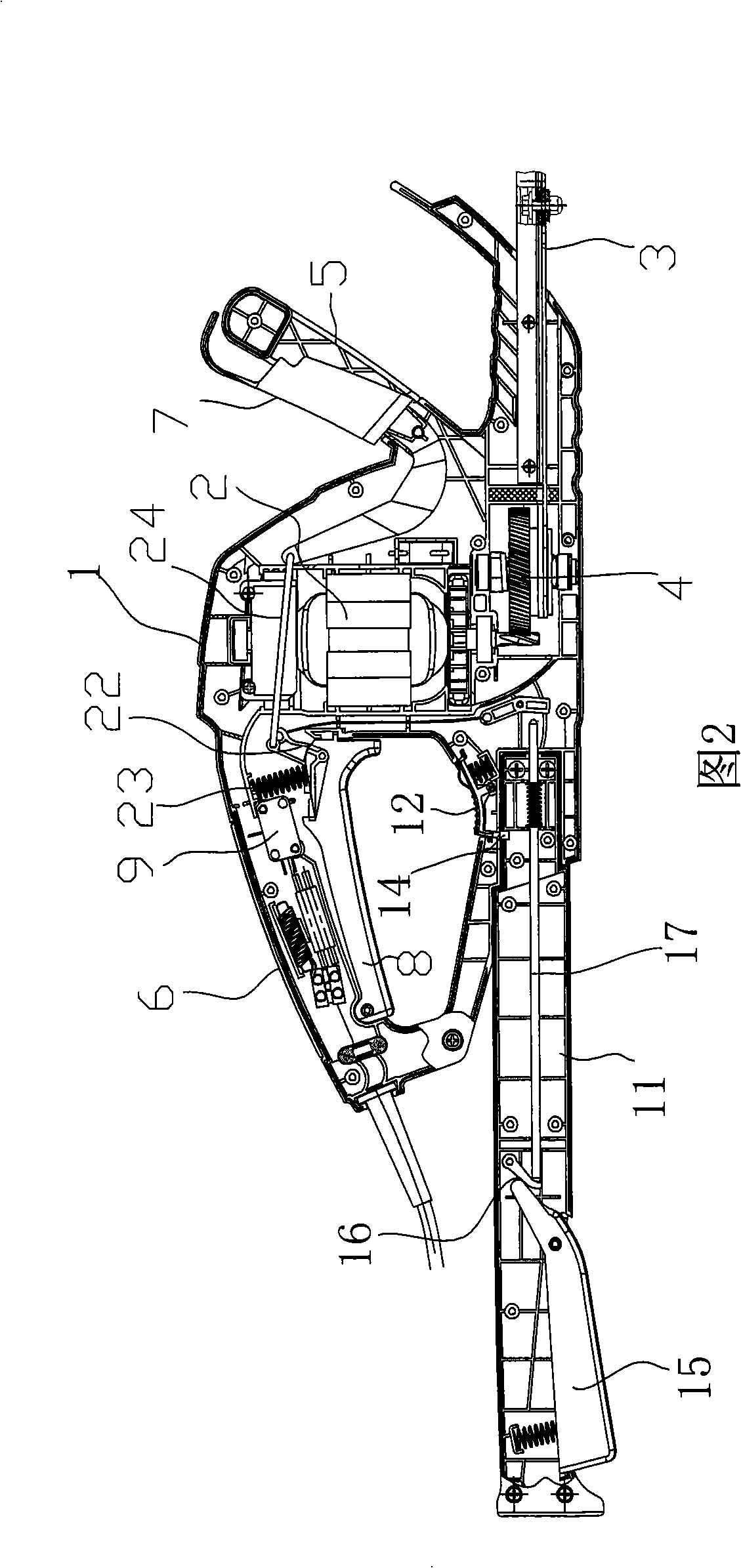

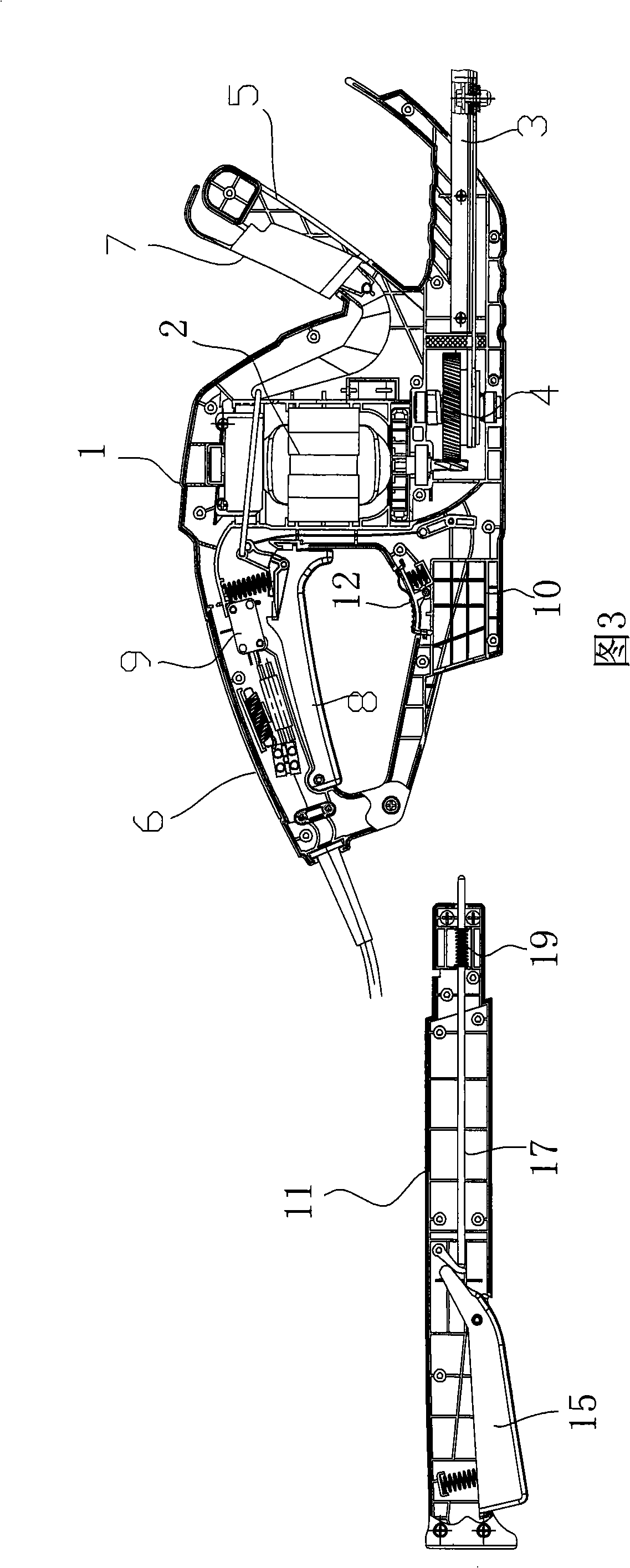

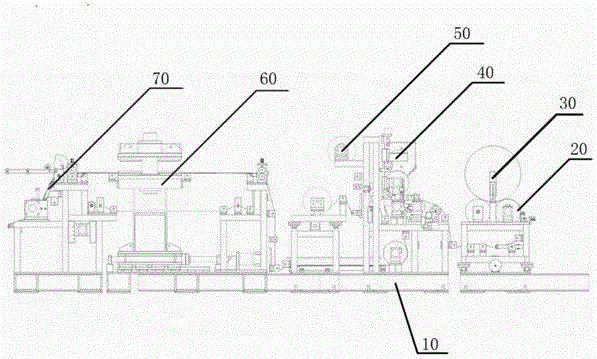

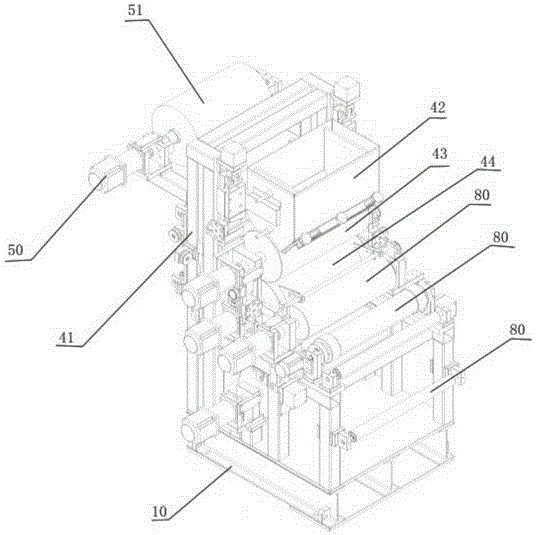

Numerically-controlled pipe bending machine

The invention discloses a numerically-controlled pipe bending machine. The numerically-controlled pipe bending machine is provided with an excess material auxiliary pushing trolley, wherein the excess material auxiliary pushing trolley can push pipe fitting excess materials in a pipe fitting clamping device out, and thus a pipe fitting is fully utilized, and waste is avoided. The numerically-controlled pipe bending machine is further provided with a multifunctional pipe fitting forming die. Due to the fact that the pipe fitting forming die is arranged, punch forming of the pipe fitting can be achieved while pipe bending is achieved, and cutting of the pipe fitting can also be achieved. According to the numerically-controlled pipe bending machine, station switching can be achieved by adjusting the horizontal position of a movable box and the rotation angle of a machine head box, and leftward bending and rightward bending of an integrated pipe fitting can be achieved by controlling the rotating direction of a rotary arm of an elbow pipe; an anti-wrinkle plate of the numerically-controlled pipe bending machine is provided with a lubrication system, and the service life of the anti-wrinkle plate can be prolonged through the lubrication system. The numerically-controlled pipe bending machine has the advantages of being more reasonable in structure, more practical, more comprehensive in function, and capable of improving the utilization rate of materials.

Owner:NINGBO TRIZ AUTOMATIC EQUIP

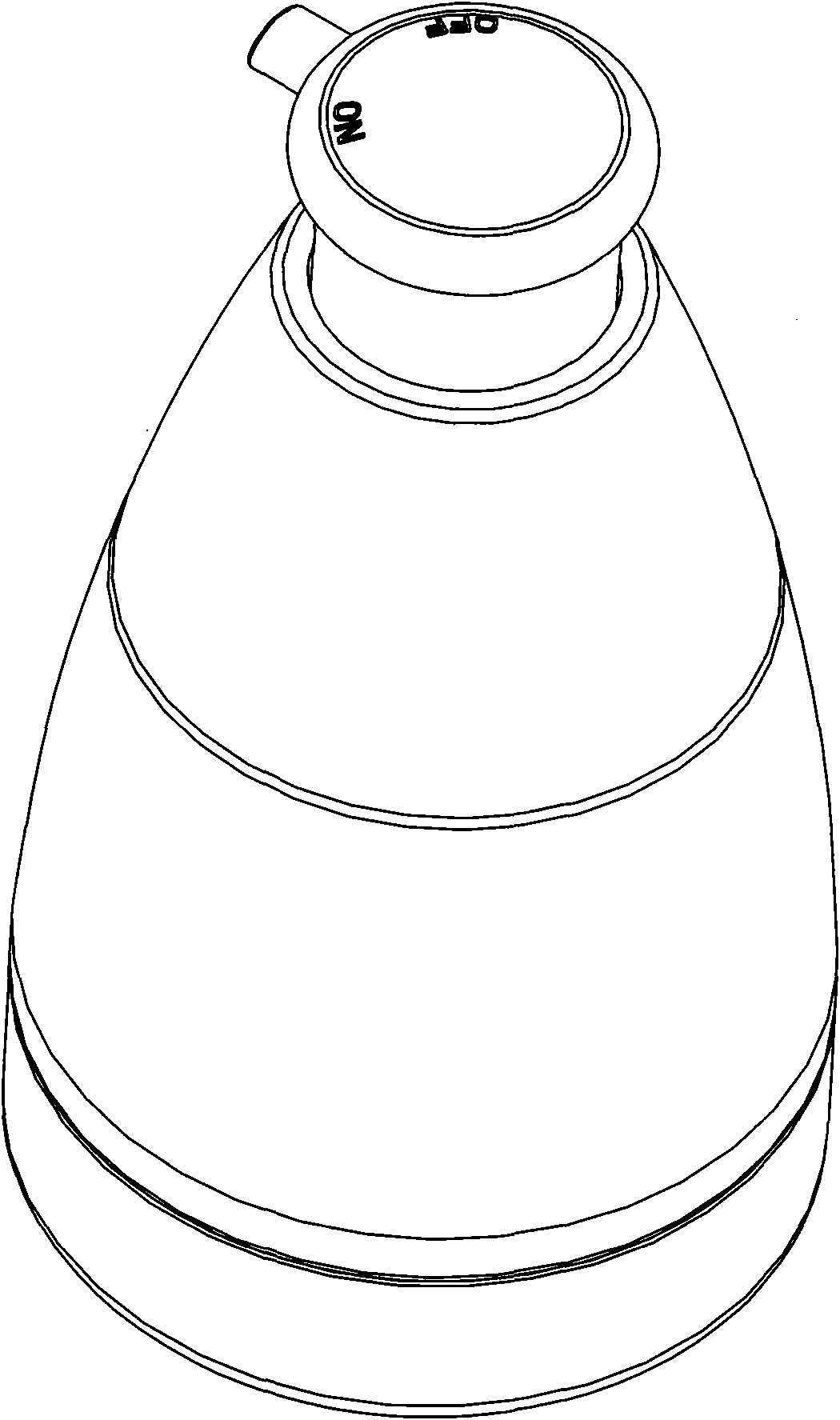

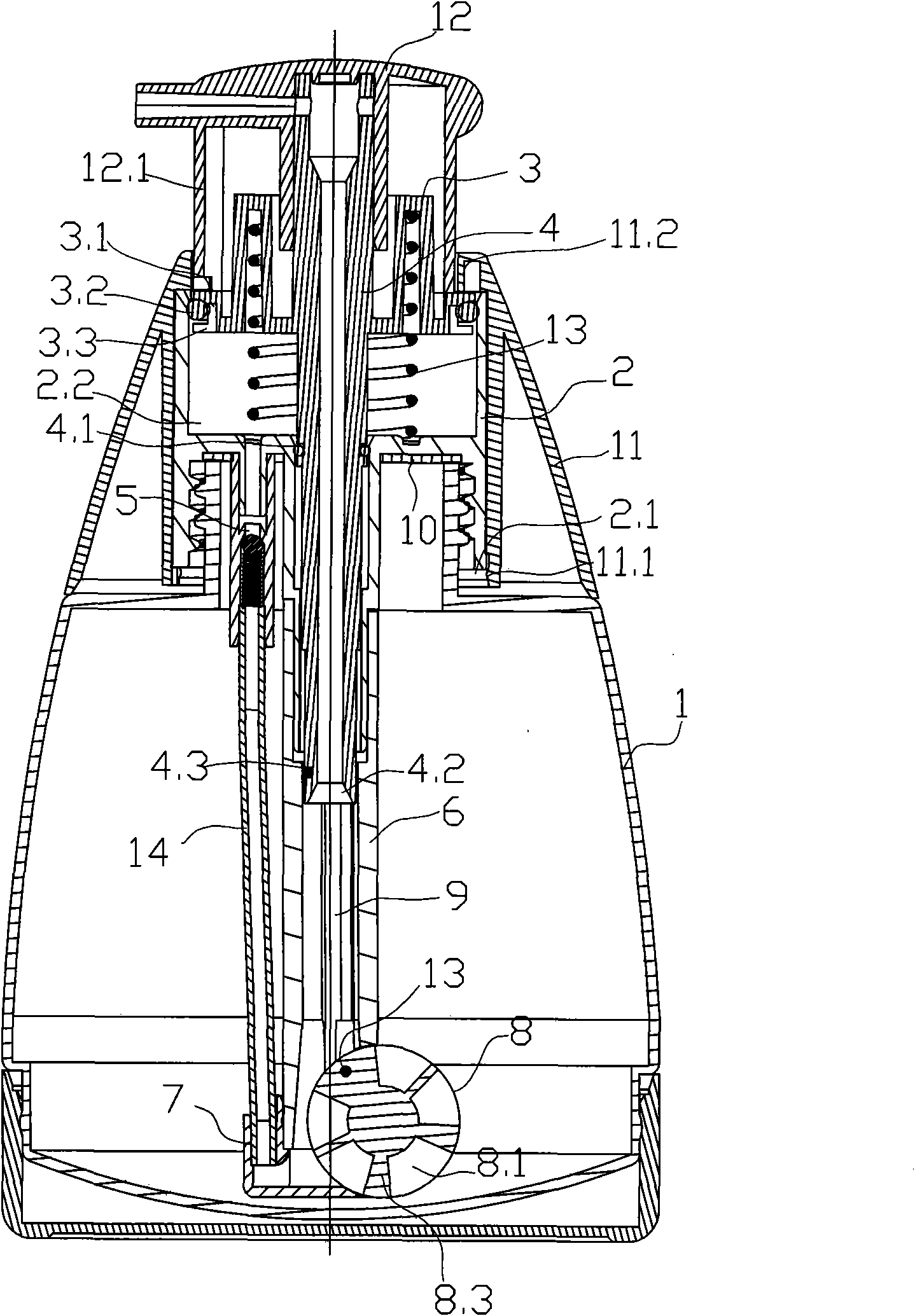

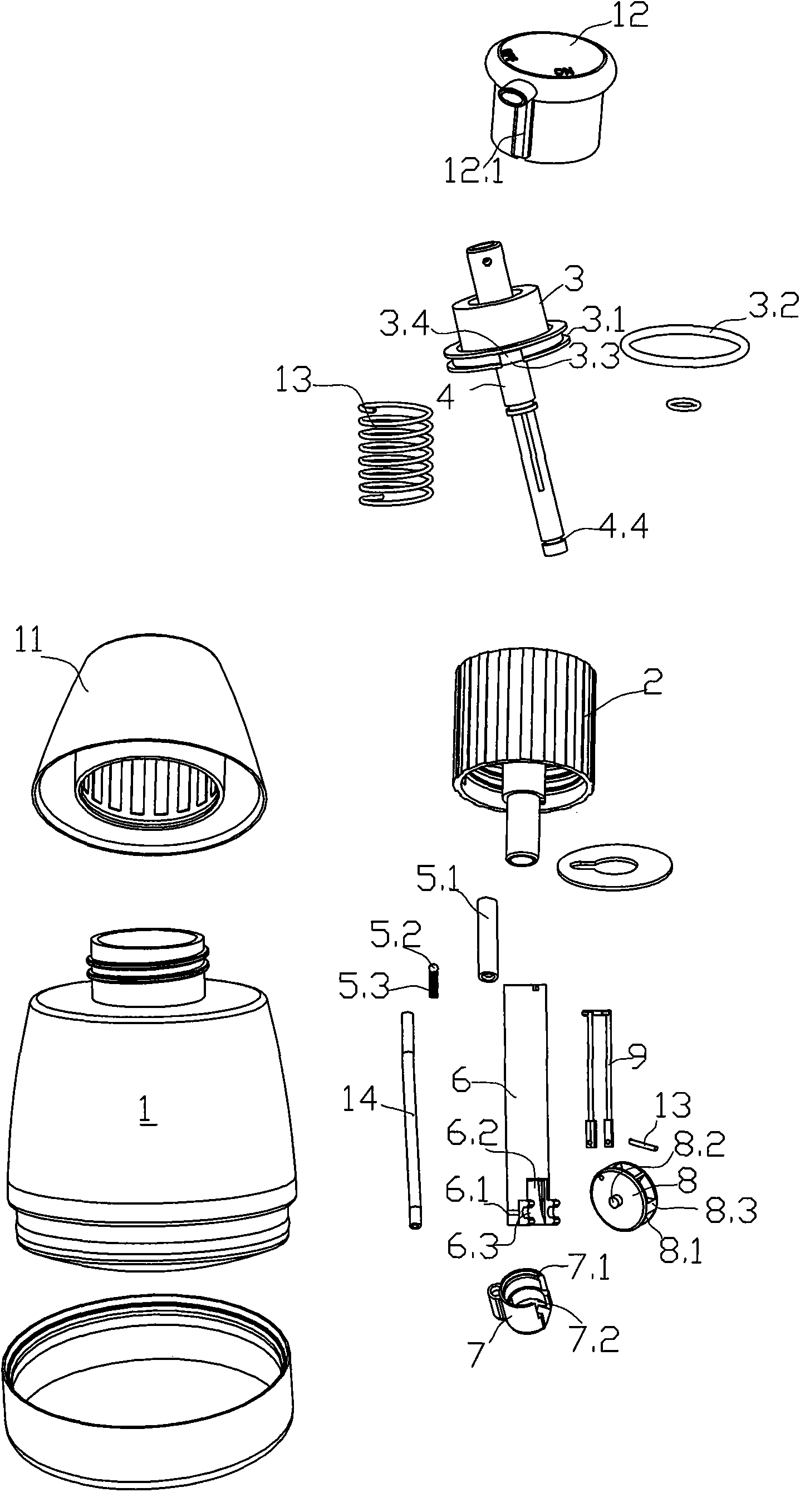

Dry powder pump

ActiveCN101879966AAvoid contactBig contactPowdered material dispensingDischarging meansProduct gasEngineering

The invention relates to a dry powder pump comprising a bottle body, a cap, a piston and an elastic element, wherein an inner cavity of the bottle body is used for containing powder; the cap is connected to a mouth of the bottle body to form a piston cavity; the piston is driven to slide up and down by a head cap and then is limited and installed in the piston cavity to form an air compressing mechanism; and the elastic element makes the piston have a resetting trend. The dry powder pump is characterized in that a one-way valve is arranged in the mouth of the bottle body, an air inlet and the one-way valve is communicated with the piston cavity, and an air outlet of the one-way valve is communicated with the inner cavity of the bottle body; and the upper end of a hollow pipeline is communicated with a nozzle on the head cap, and the lower end of the hollow pipeline passes through the mouth of the bottle body to extend nearby the bottom of the bottle body and is directly or indirectly communicated with the inner cavity of the bottle body. The dry powder pump has the advantages of reasonable and practical structure, favorable sealing performance, convenient operation and use, light weight and convenient carrying and is easy to spray mixed powder and air.

Owner:ZHEJIANG JM IND

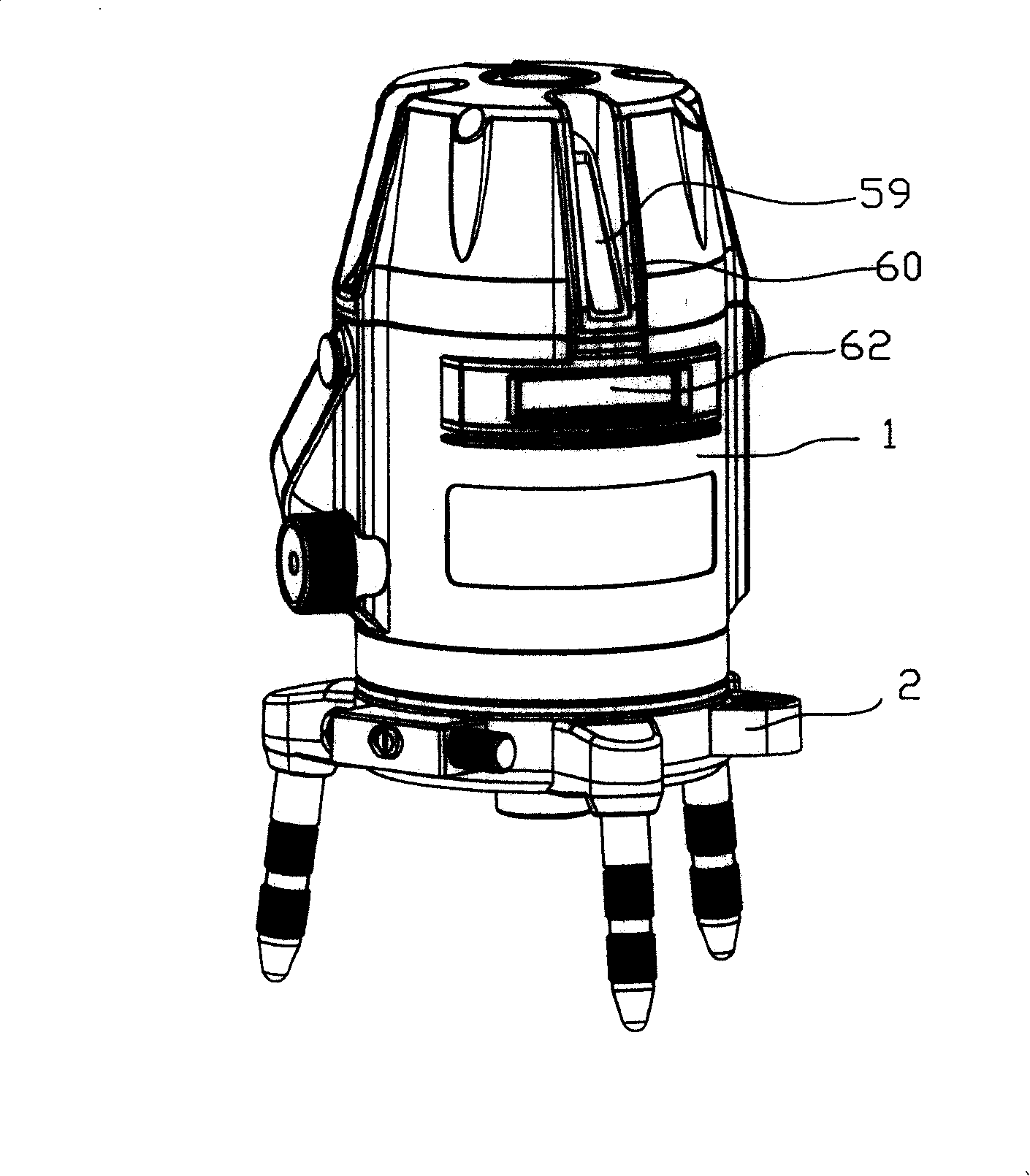

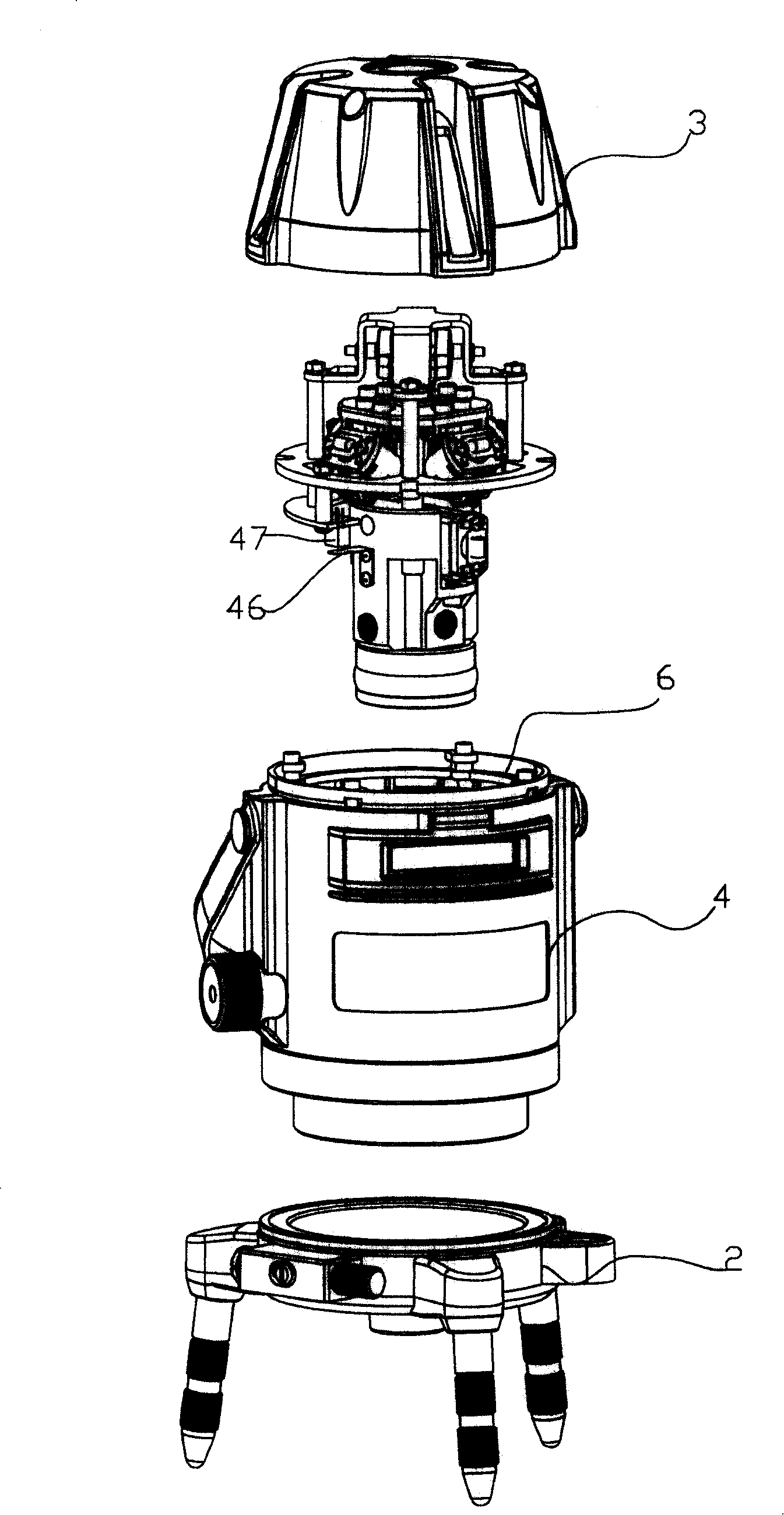

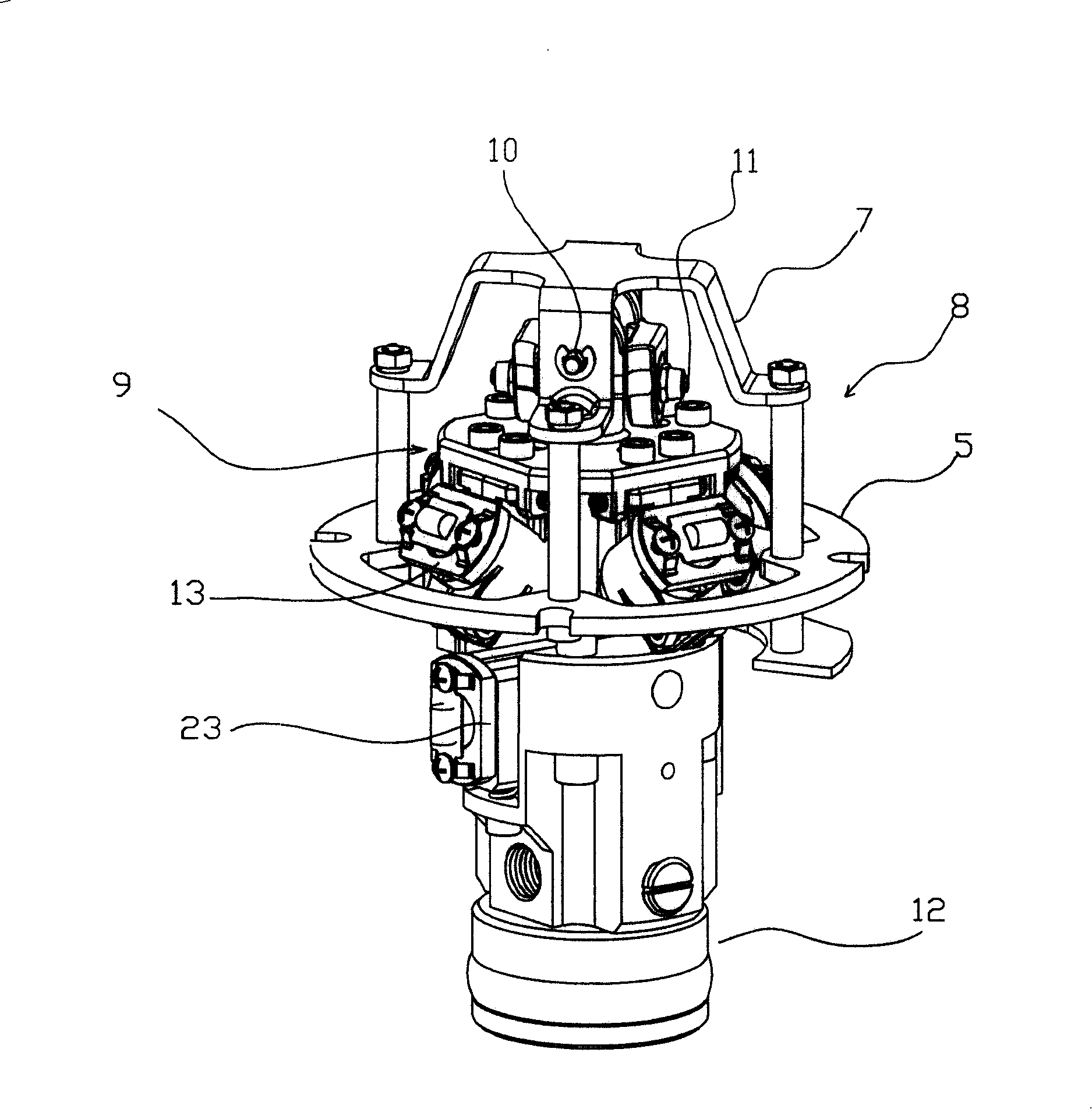

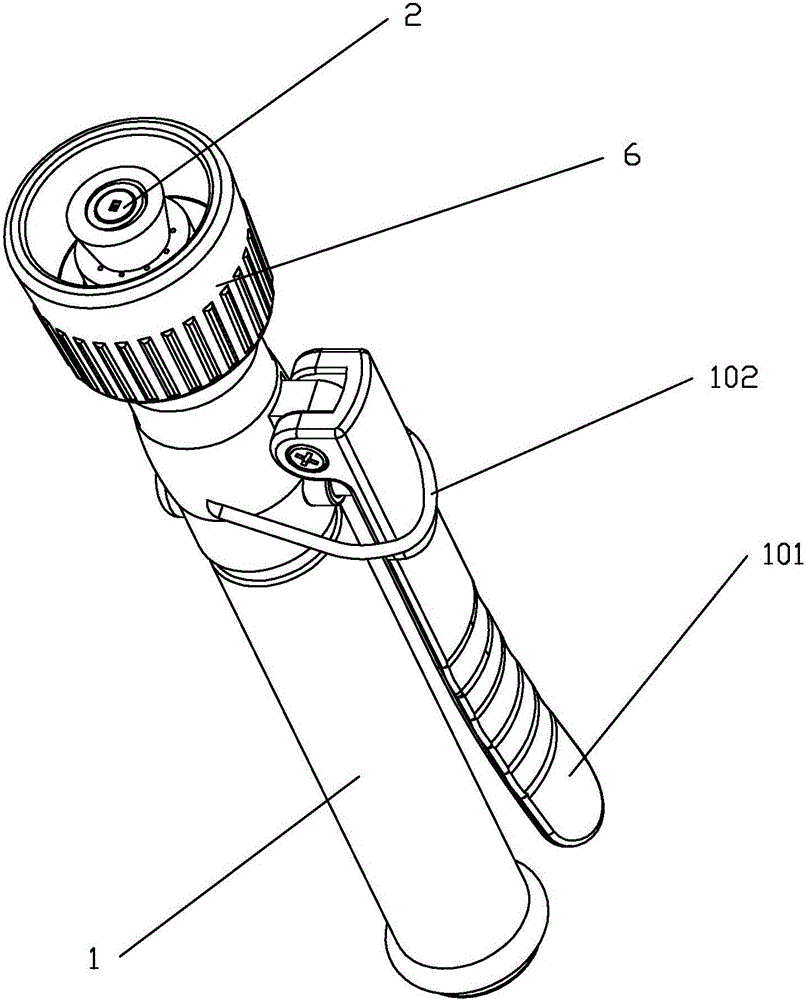

Laser self-adjusting demarcation device

InactiveCN101241008AEasy to adjustReasonable and practical structureSurveying instrumentsSelf-tuningEngineering

The invention relates a laser self-tuning line-vote, which comprises a shell and a base, a heavy hammer part lay automatically is connected and installed on the inside of the shell through the hoisting bodies, four vertical laser head blocks is installed on main part of the heavy hammer part along ring distribution, a vertical line laser head is installed on each laser head block, and the angle between the laser head is 90 degrees, a vertical laser window is installed on the shell targeted, power and control circuit boards are also installed, the invention is characterized in that the vertical laser head blocks are connected through a screw and pegged roof of hoisted bodies, at the same time, a dummy club is installed on both sides of the laser head block by pegged roof, which is connected to the screw, and the vertical laser block is collided by the screw, the invention can lead to four vertical laser head blocks in 90-degree angle, and achieve vertical and horizontal adjustment, and has good regulation, reasonable and practical structure.

Owner:陈建军

Telescopic handle mechanism used in safe

ActiveCN101429831AImprove aestheticsPerformance impactBuilding locksHandle fastenersMechanical engineering

The invention provides a telescopic type handle structure for a safe, which comprises a handle. The handle structure is characterized in that a middle shaft of the handle passes through a mounting hole of a door plate of the safe, and supports an upper spring between the handle and the door plate, the middle part of the middle shaft on the handle is provided with a clamping opening which is in clamping fit with a movable clamping plate, the clamping plate is hanged behind the door plate through the matching structure of a guide hole and a pin, a power-driven part is directly or indirectly in matching connection with the clamping plate, and the rear part of the middle shaft on the handle is provided with an upper limit part. The handle structure has reasonable and practical structure, and can conveniently combine a mechanical lock or an electric lock; moreover, the application range of the handle structure is wider, and the assembly and the use of the handle structure are also quite convenient.

Owner:曹君

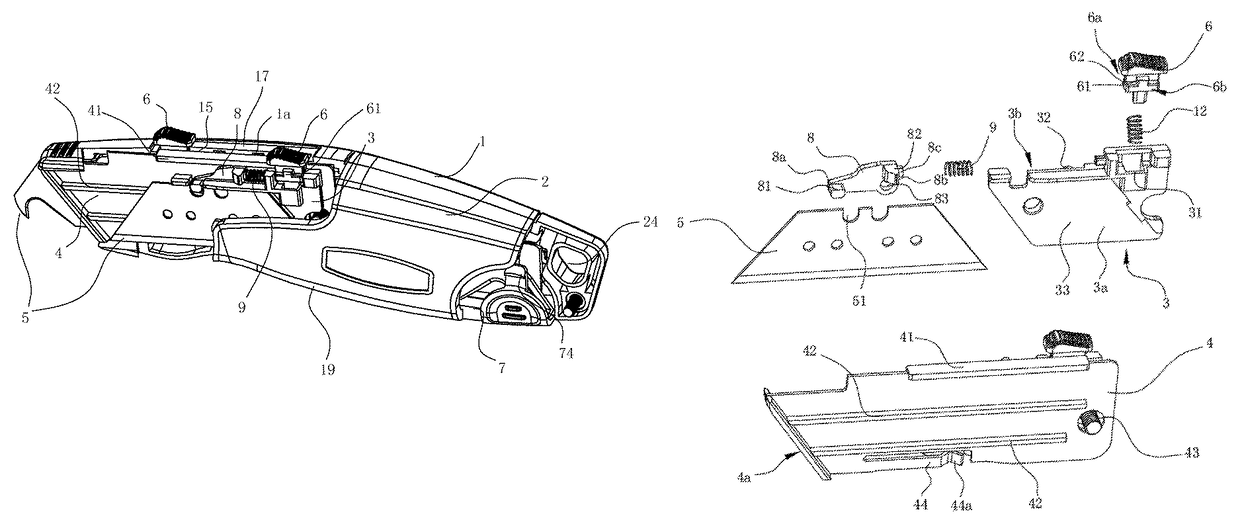

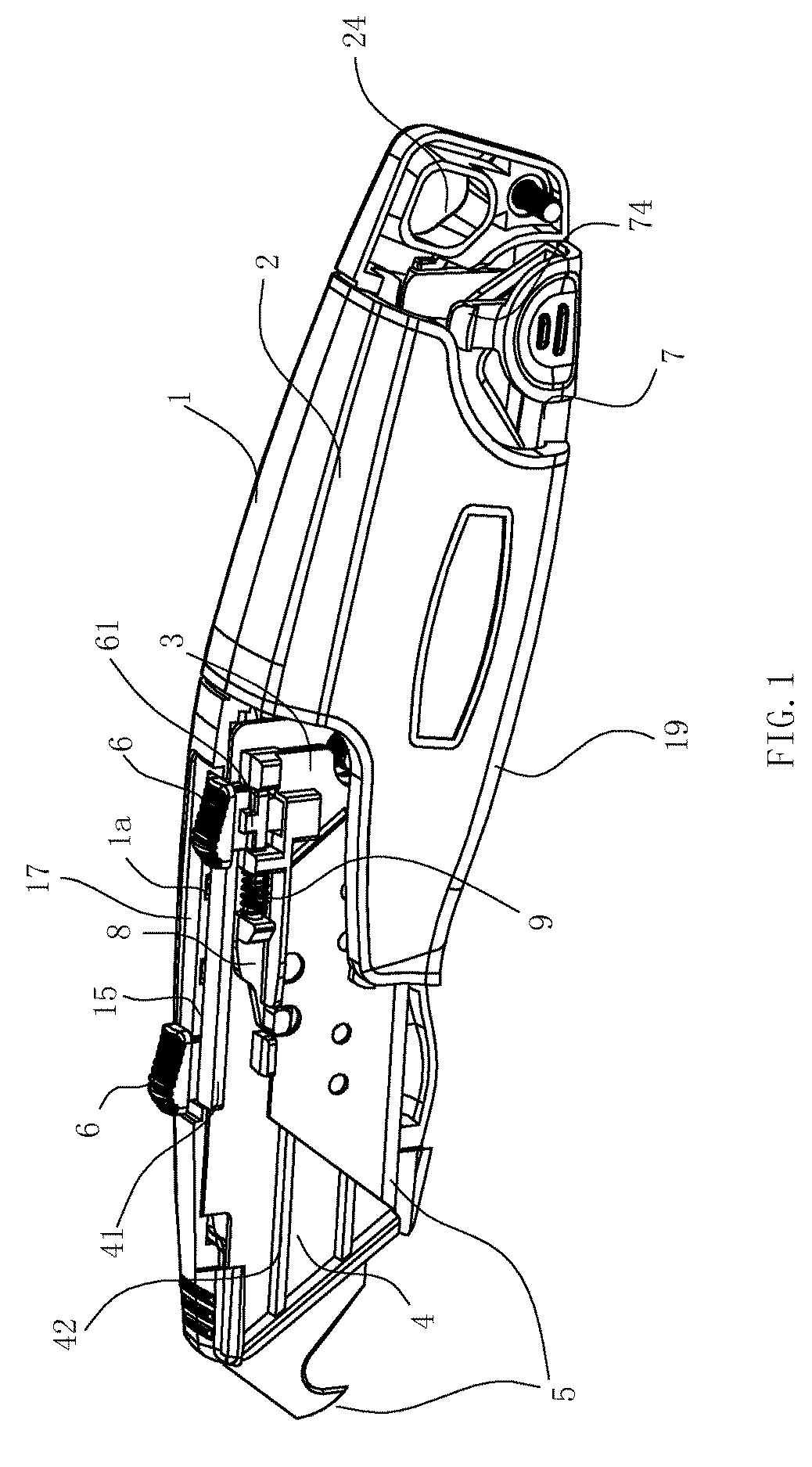

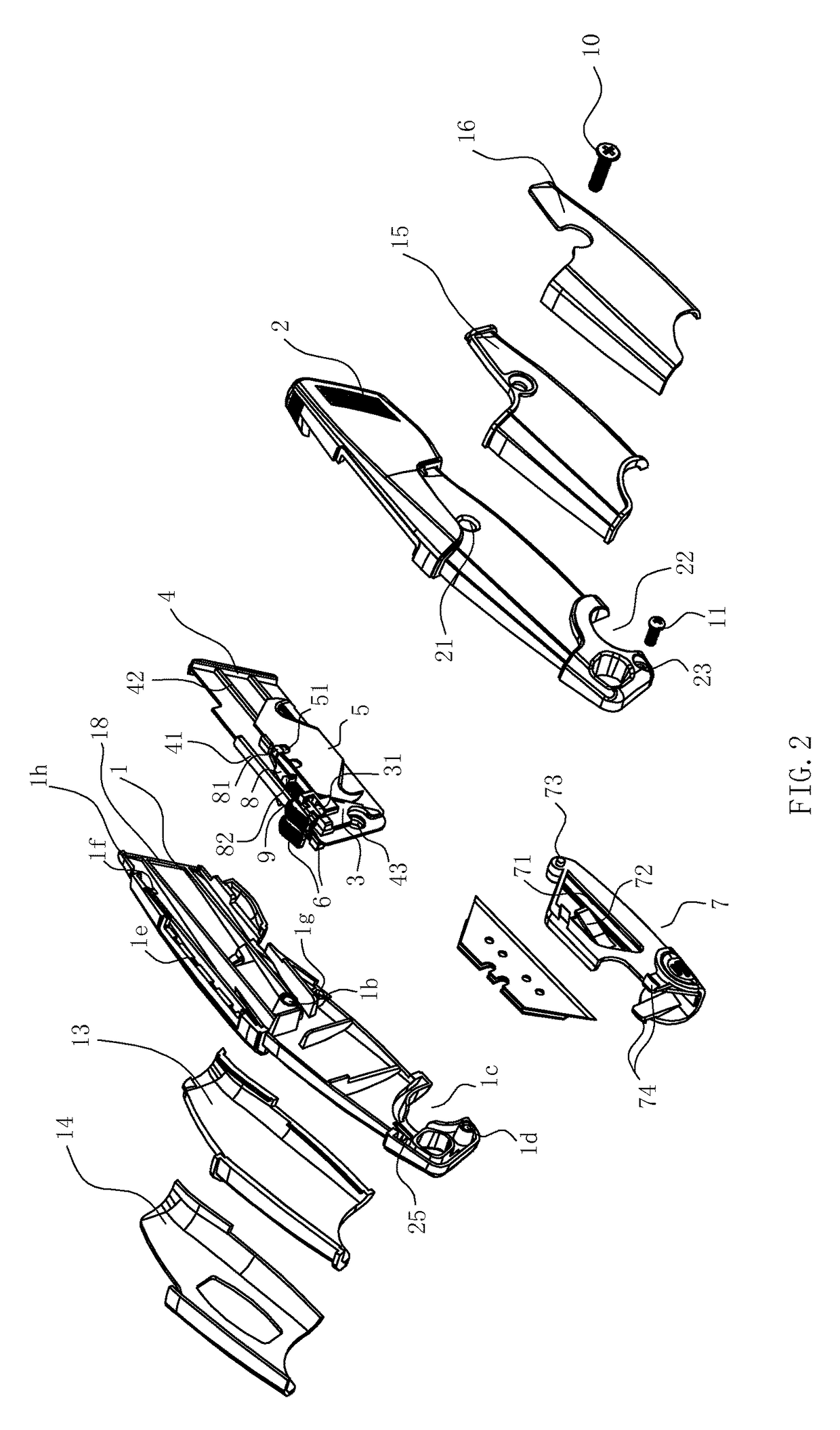

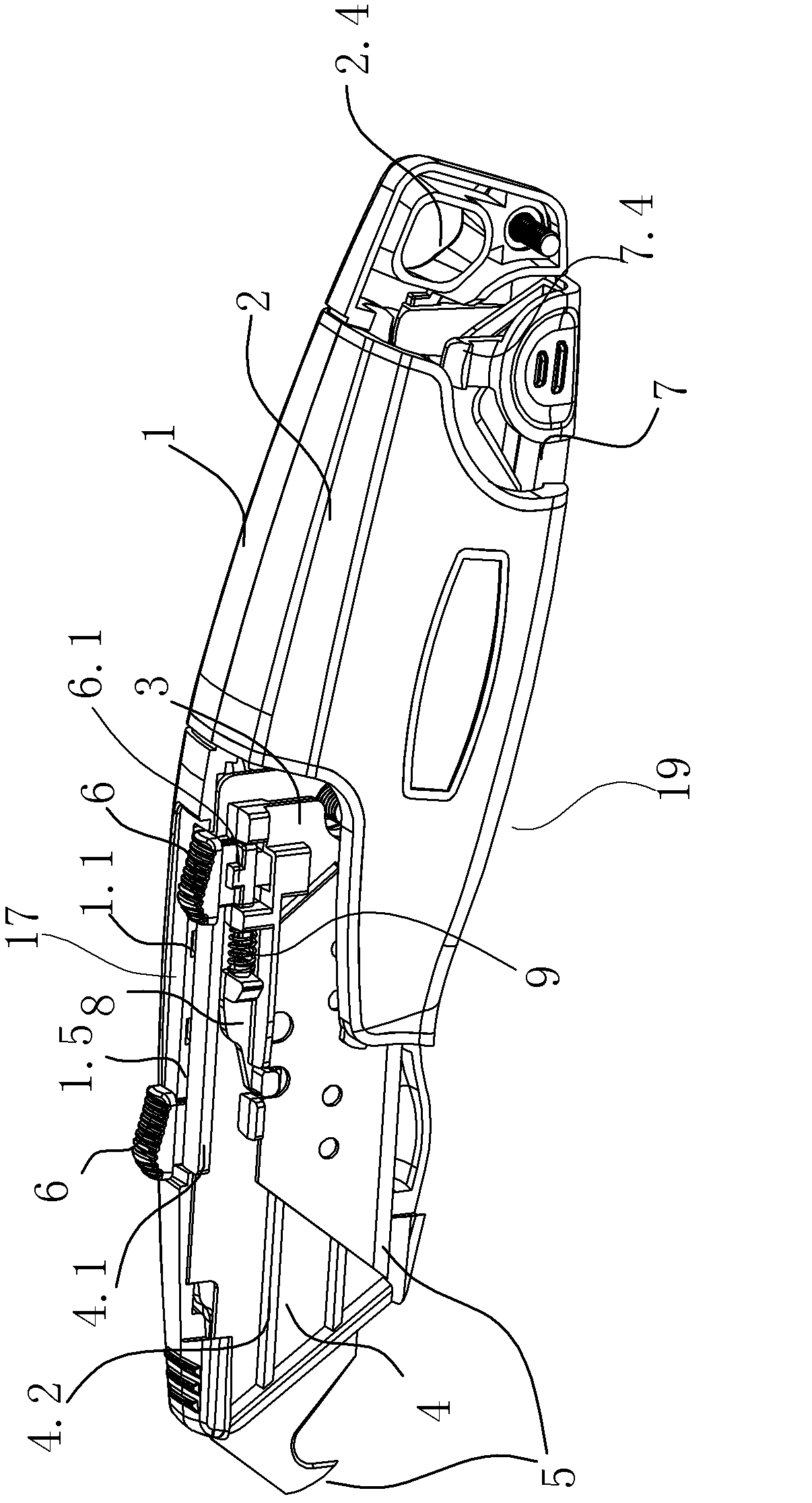

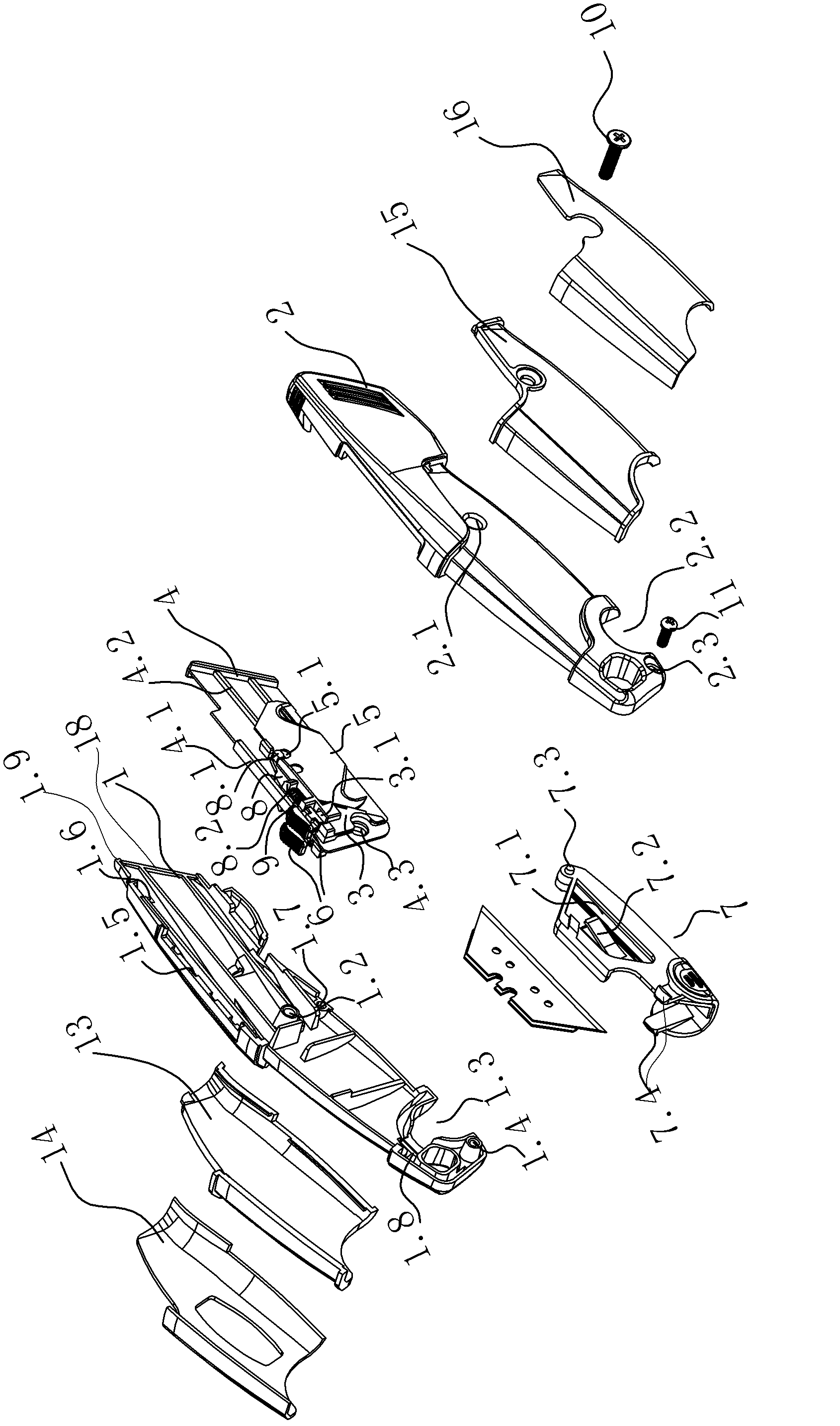

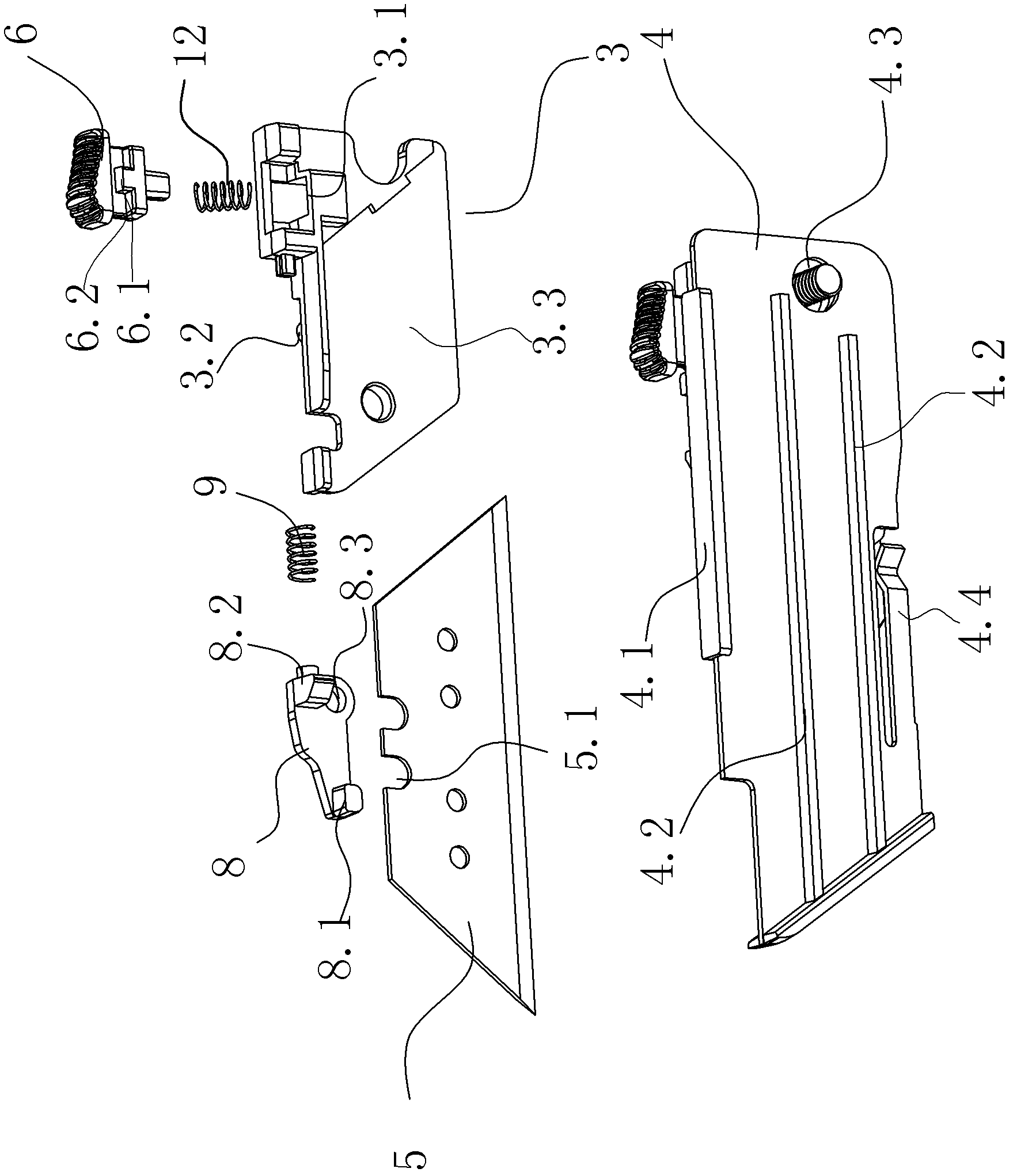

Utility knife

A utility knife including a housing (19), two parallel knife holders slidingly disposed substantially parallel to each other inside the front section of the housing; different blades (5) are positioned on the two knife holders; each push button (6) is movably disposed on top of one knife holder (3); a strip-shaped aperture (17) is provided on top of the inner wall of the housing (19); the strip-shaped aperture has two grooves (1e), parallel to each other, for receiving the two push buttons and for allowing the two push buttons (6) to slide along the two parallel grooves; and a plurality of recesses (1a) are distributed inside each groove; each push button further comprises a snap block (61), when the snap block (61) is inserted into the corresponding recess (1a), the corresponding knife holder (3) and the blade (5) are locked in position.

Owner:ZHEJIANG XINGDA STATIONERY

Air guide mechanism of indoor unit of air conditioner

ActiveCN101676648AGood orientationReduce the limit of rotationAir-flow control membersMechanical engineering

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

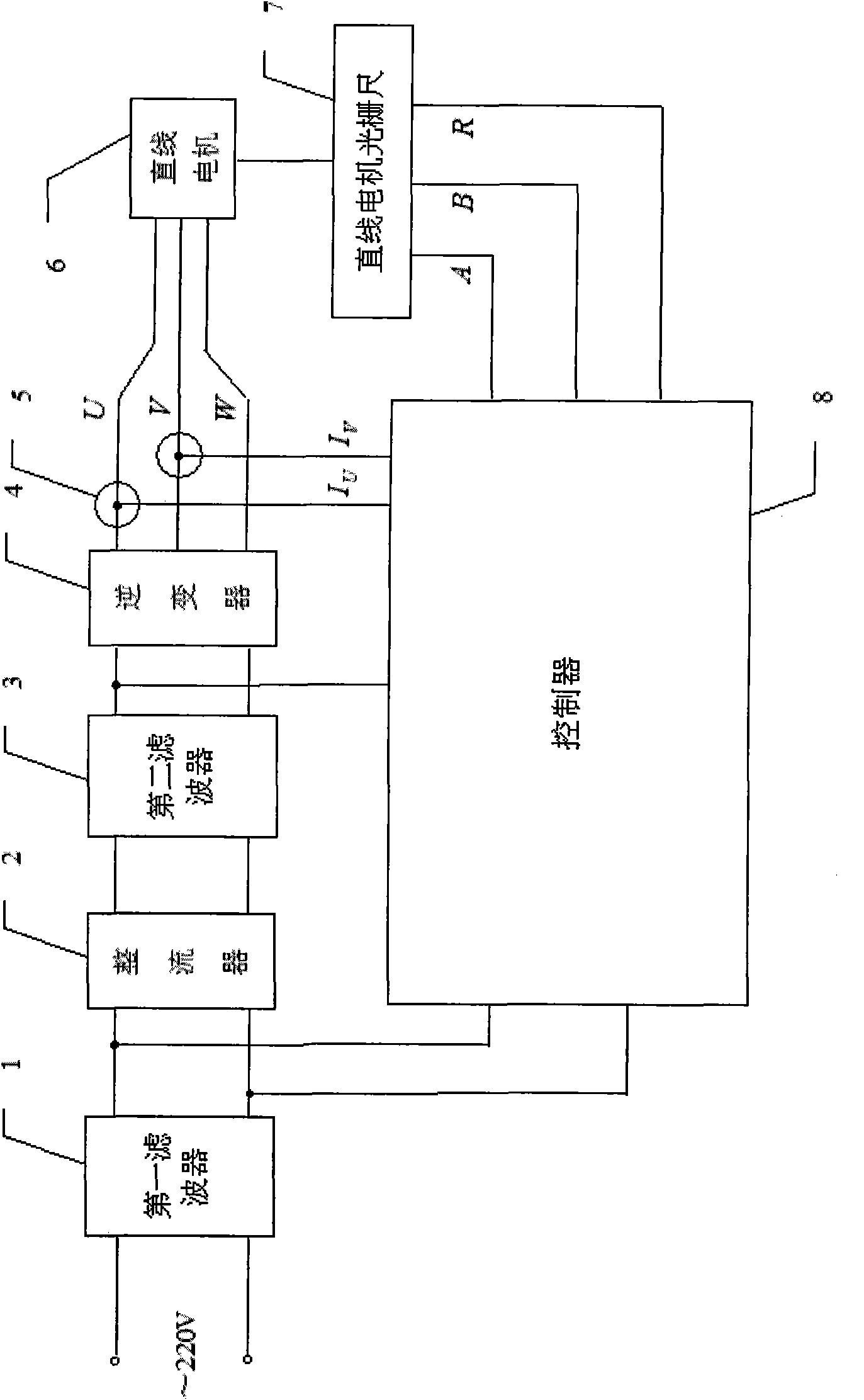

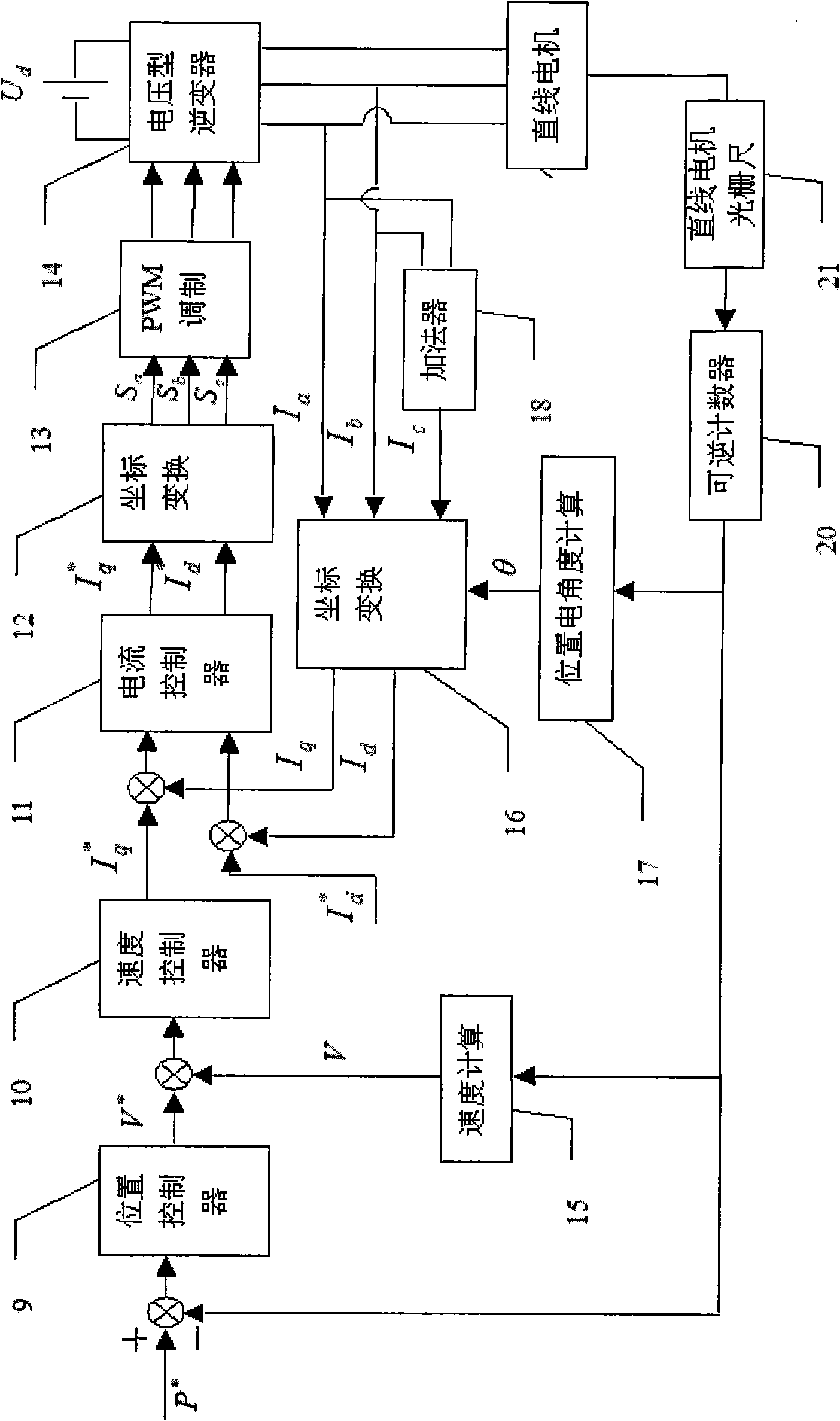

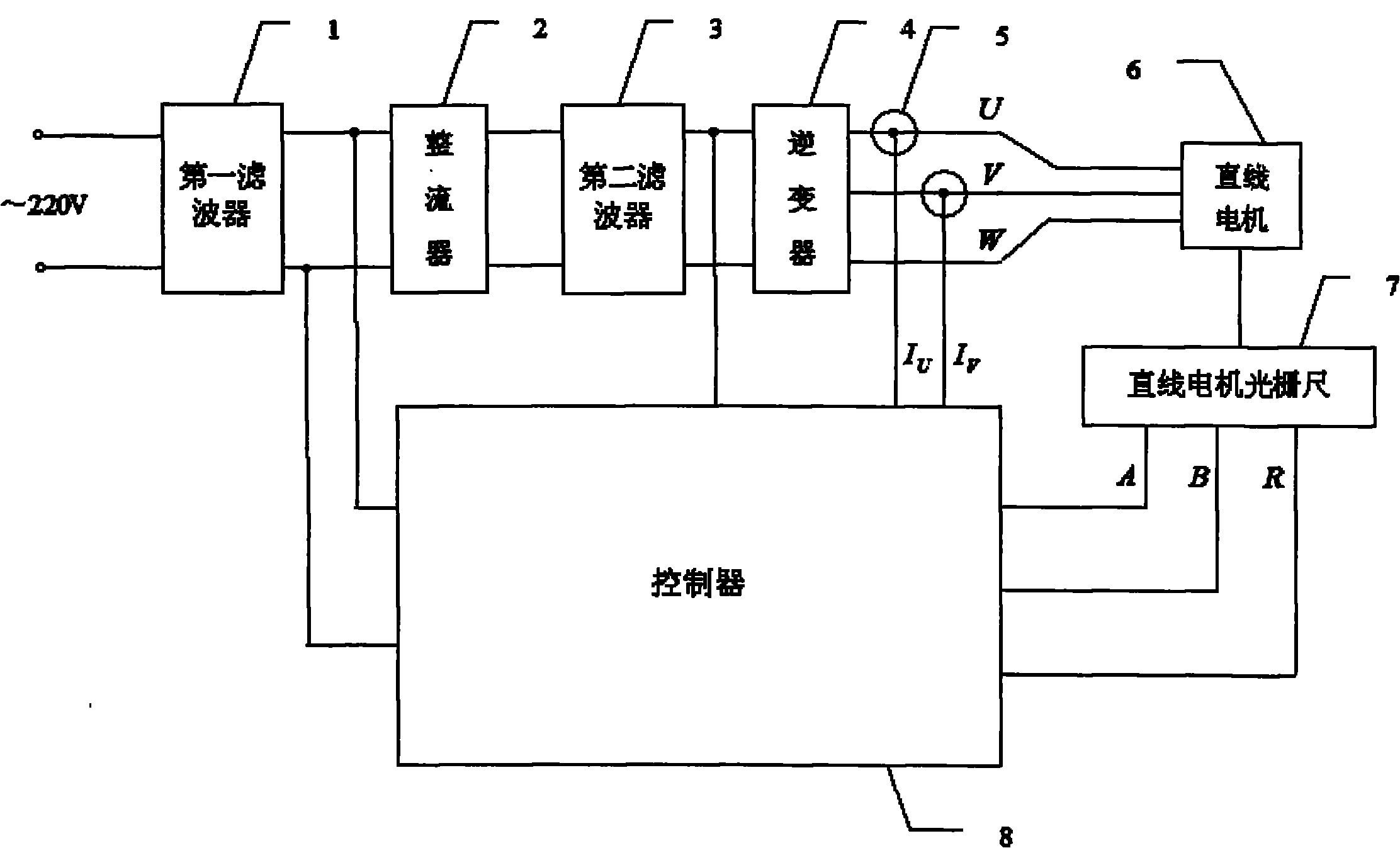

Permanent-magnetic synchronous linear motor driver

InactiveCN101888206AControl thrustControl speedAC motor controlElectronic commutatorsControl signalActive cell

The invention relates to a permanent-magnetic synchronous linear motor driver, which is characterized by comprising a first filer (1) for filtering single-phase utility power, a rectifier (2) for converting alternating current into direct current, a second filter (3) for smoothly processing the direct current, an inverter (4) for converting the direct current into three-phase alternating current to drive a linear motor, a current detection device (5) for detecting the current of the linear motor and a controller (8) for executing precise control of the linear motor and receiving a feedback signal of the linear motor, wherein the controller (8) is used for receiving an analog signal and a power supply voltage signal from the current detection device (5), meanwhile receiving the feedback signal from an active cell position of a grating ruler of the linear motor, performing internal processing on the three data and outputting a control signal to precisely control the motion position and the thrust of the active cell of the linear motor. Compared with the prior art, the driver has the advantage of precisely controlling the thrust, speed and position of the linear motor.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

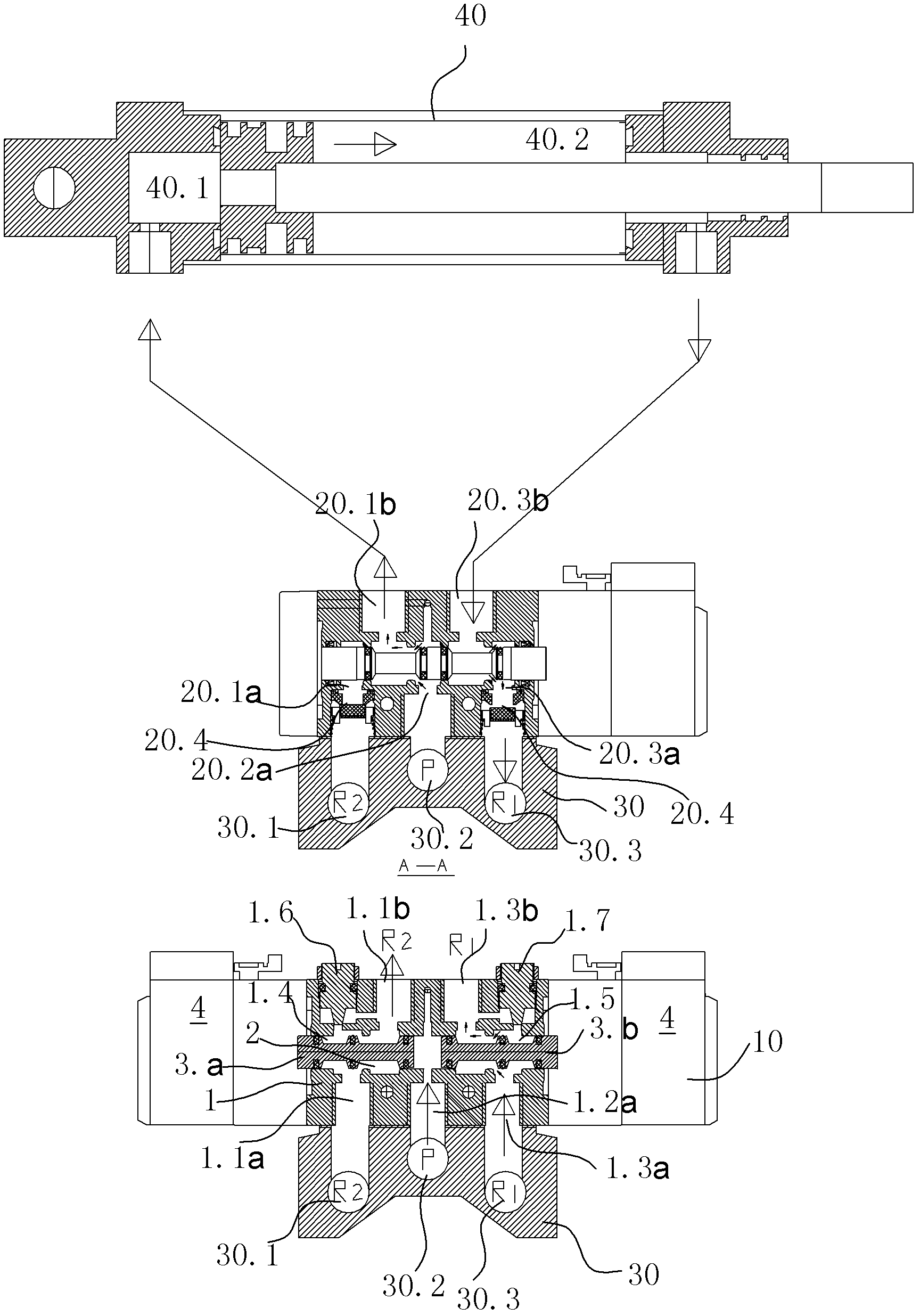

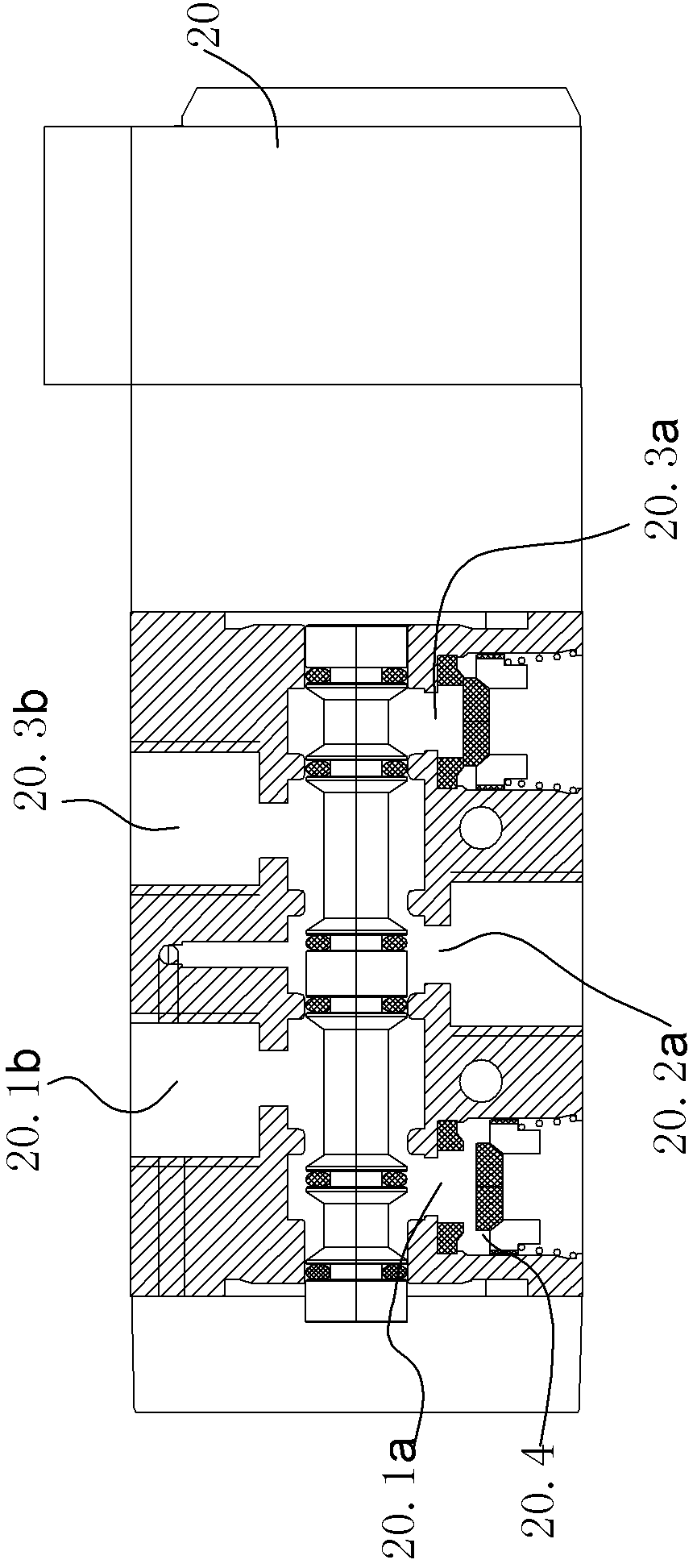

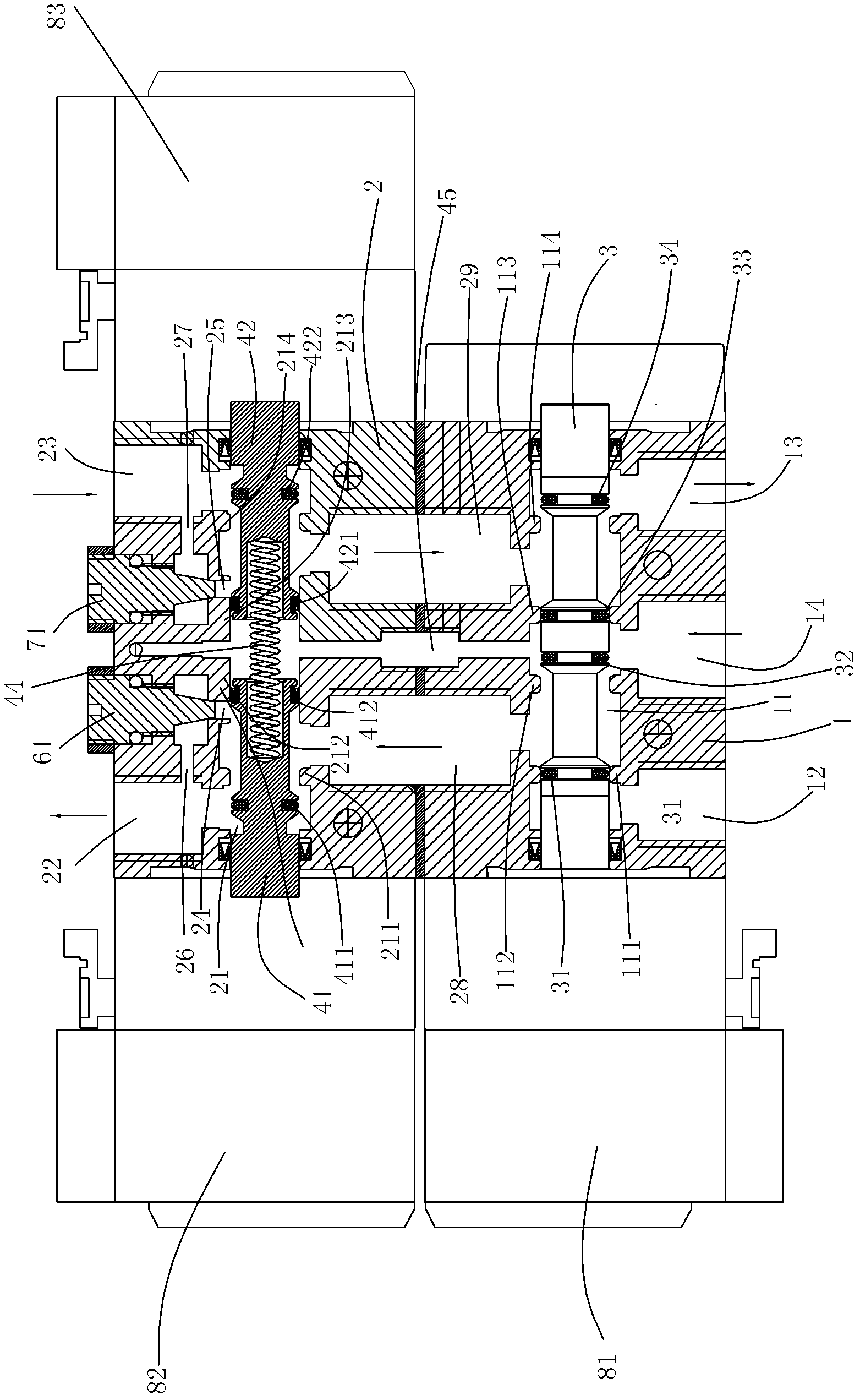

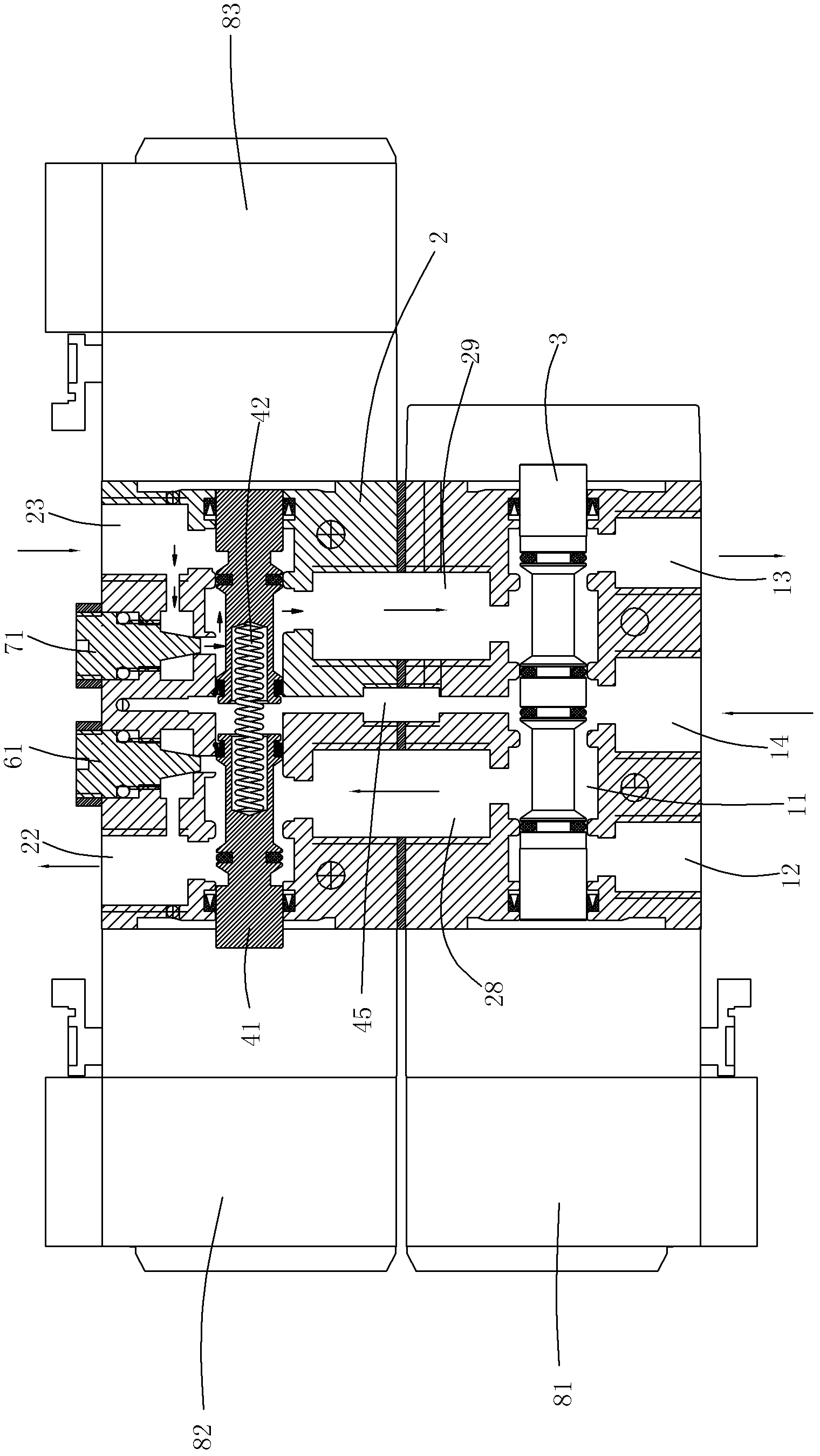

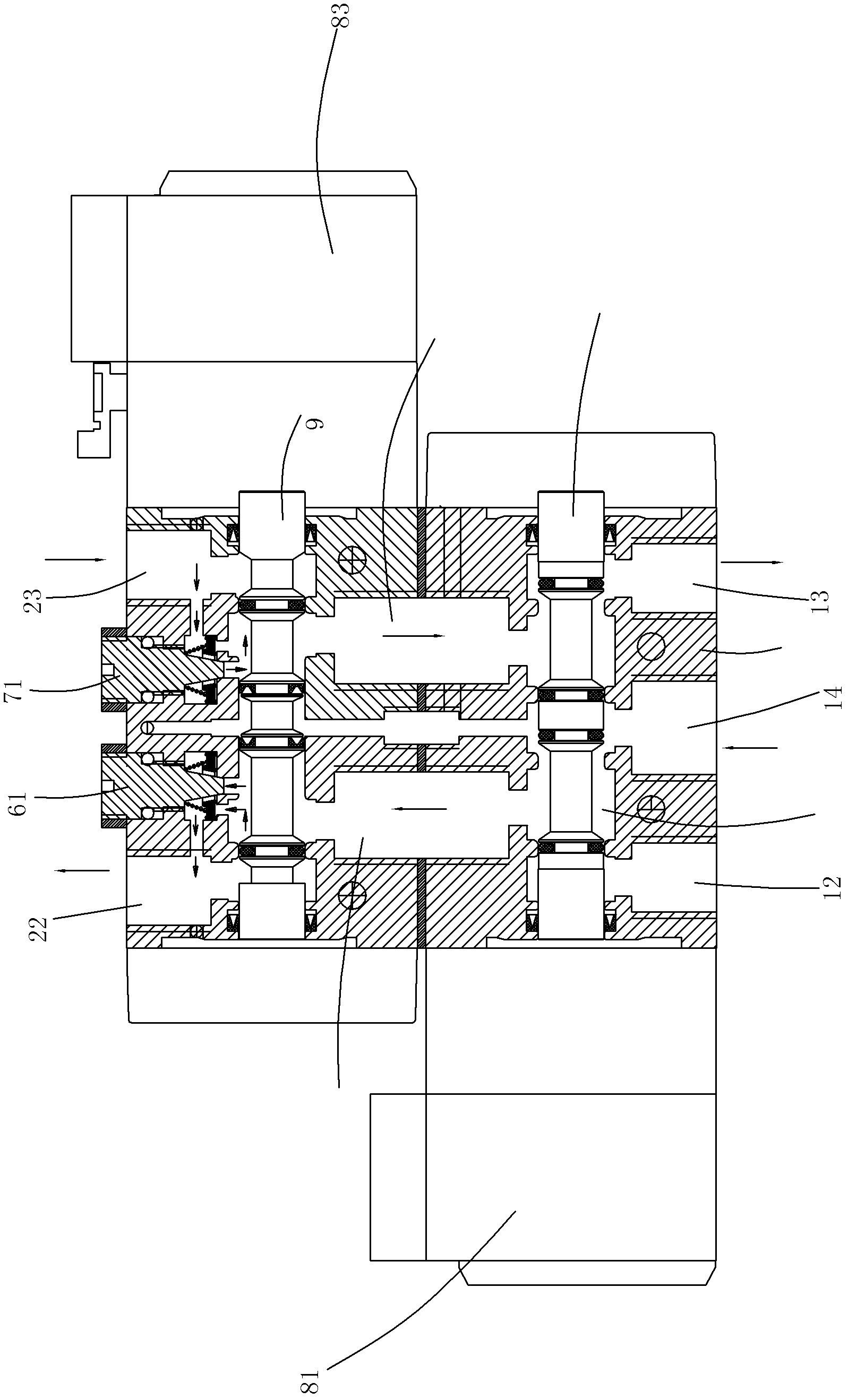

Combined valve

InactiveCN103256404AAvoid mutual influenceAvoid collision wearMultiple way valvesRefluxCylinder block

The invention relates to a combined valve. The combined valve comprises a multifunctional valve, a confluence plate and at least one operation reversing valve, wherein a left opening and a right opening at one side surface of one operation reversing valve are respectively connected to a left cavity and a right cavity of a piston cylinder; a left reflux opening, a middle inlet and a right reflux opening at the other side surface of the operation reversing valve are respectively connected to a left flow channel, a middle flow channel and a right flow channel of the confluence plate; the channels of the left reflux opening and the right reflux opening of the operation reversing valve are respectively provided with a one-way valve; the left reflux opening and the right reflux opening are corresponding connected to a left flow channel and a right flow channel of the confluence plate through respective throttle valves; and the left inlet and right inlet of the multifunctional valve are respectively and correspondingly communicated with a left outlet and a right outlet through respective throttle valves. The combined valve avoids mutual influence among cylinders and collision abrasion to a piston and a cylinder end cover when the piston moves rapidly, prolongs the service life of the piston cylinder efficiently, and guarantees operation safety and stability of the piston cylinder.

Owner:皇甫美蓉

Bottle pushing apparatus

The invention relates to a bottle pushing device, which is characterized in that the bottle pushing device comprises a base for bearing a glass bottle, a front baffle plate, a front cylinder body which is used for driving the front baffle plate to lift and is arranged on a front bracket, a bottle pushing plate arranged at interval with the front baffle plate, a bottle pushing cylinder body for driving the bottle pushing plate to move back and forth, a left baffle plate, a left cylinder body which is used for driving the left baffle plate to lift and is arranged on a left bracket, and a right baffle plate arranged at interval with the left baffle plate. Compared with the prior art, the bottle pushing device has the advantages that the bottle pushing device has simple structure, and deft operation, and greatly improves boxing speed of the glass bottle.

Owner:宁波正力药品包装有限公司

Pruning machine

InactiveCN101331839AAvoid installationEasy to manufactureCuttersCutting implementsElectric machineryEngineering

The invention relates to a pruner. The pruner comprises a shell; a motor is arranged in the shell; a microswitch which can control the work of the motor is installed in the shell or a handgrip; a rear trigger coordinates with a front trigger by the contact of a trigging control mechanism and the microswitch. The pruner is characterized in that a prolonged auxiliary handle is connected to the rear of the lower part of the shell in a discharge way; an auxiliary handle trigger is rotatably articulated at the position of the handgrip at the rear part of the prolonged auxiliary handle; the front end of the auxiliary handle trigger coordinates with and touches a handspike in the prolonged auxiliary handle directly or indirectly; a spring is supported between the handspike and the prolonged auxiliary handle so as to lead the other end of the handspike to touch and coordinate with one end of a dwang articulated in the shell; the other end of the dwang is connected with the triggering control mechanism by an inhaul cable or a connecting bar. The prolonged handle can be disassembled and can prune the gardens with higher height and wider scope without relying on other auxiliary equipment; only a mechanism is adopted for control, thus being safe and reliable.

Owner:沈高明

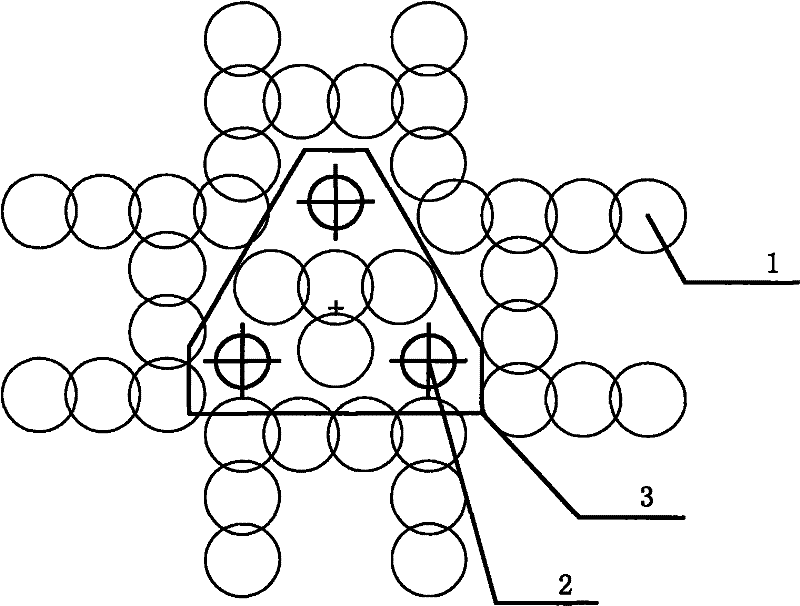

Engineering pile deviation preventing structure of soft soil foundation and pretreatment method

InactiveCN102235008AAvoid misalignmentReasonable and practical structureExcavationsBulkheads/pilesPretreatment methodEngineering

The invention relates to an engineering pile deviation preventing structure of a soft soil foundation and a pretreatment method. The engineering pile deviation preventing structure is characterized in that: a reinforcing structure is arranged on the circumference of an engineering pile, the reinforcing structure comprises a plurality of stirring piles which encircle a bearing platform and are continuously arranged in a grid structure, the stirring piles are flush with the engineering pile, the depths of the stirring piles are 1.2 to 1.4 times depth of a foundation pit, and the reinforcing structure is positioned in a 2 / 3 to 3 / 4 foundation pit range using the center of the foundation pit as a center. The pretreatment method of the engineering pile deviation preventing structure comprises the following steps of: digging a pit slag filling layer in original pile sinking, positioning the stirring piles, preparing cement paste, spouting, stirring and sinking, hoisting, repeating the spouting, stirring and sinking step, repeating hoisting till the orifice, closing and cleaning a stirrer, moving to the next pile, and repeating the processes. Compared with the prior art, the engineering pile deviation preventing structure of the soft soil foundation and the pretreatment method provided by the invention have the advantage of effectively preventing the engineering pile from deviating when the foundation pit of the soft soil foundation is dug.

Owner:ZHEJIANG HONGYU ENG PROSPECTING DESIGN

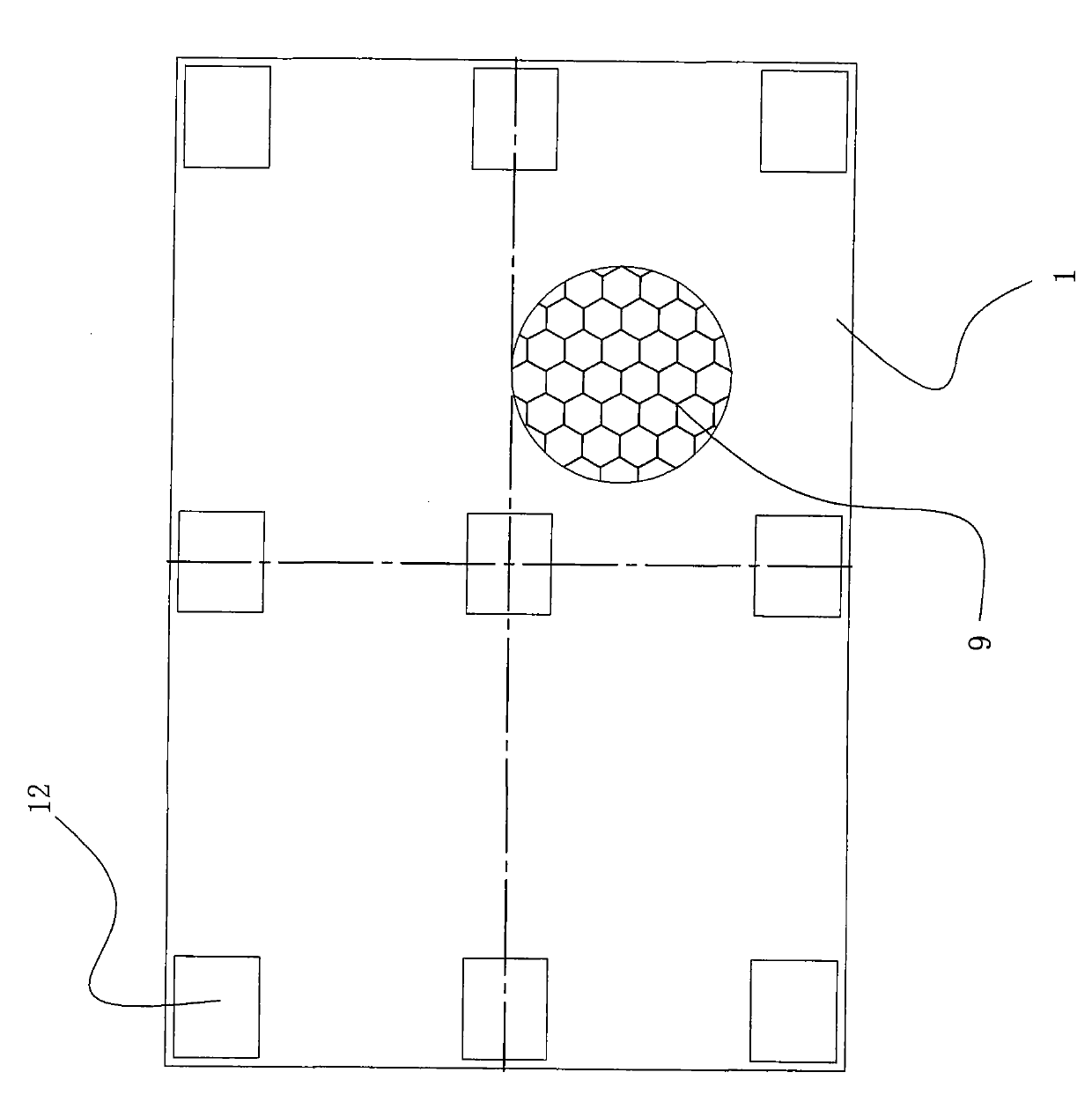

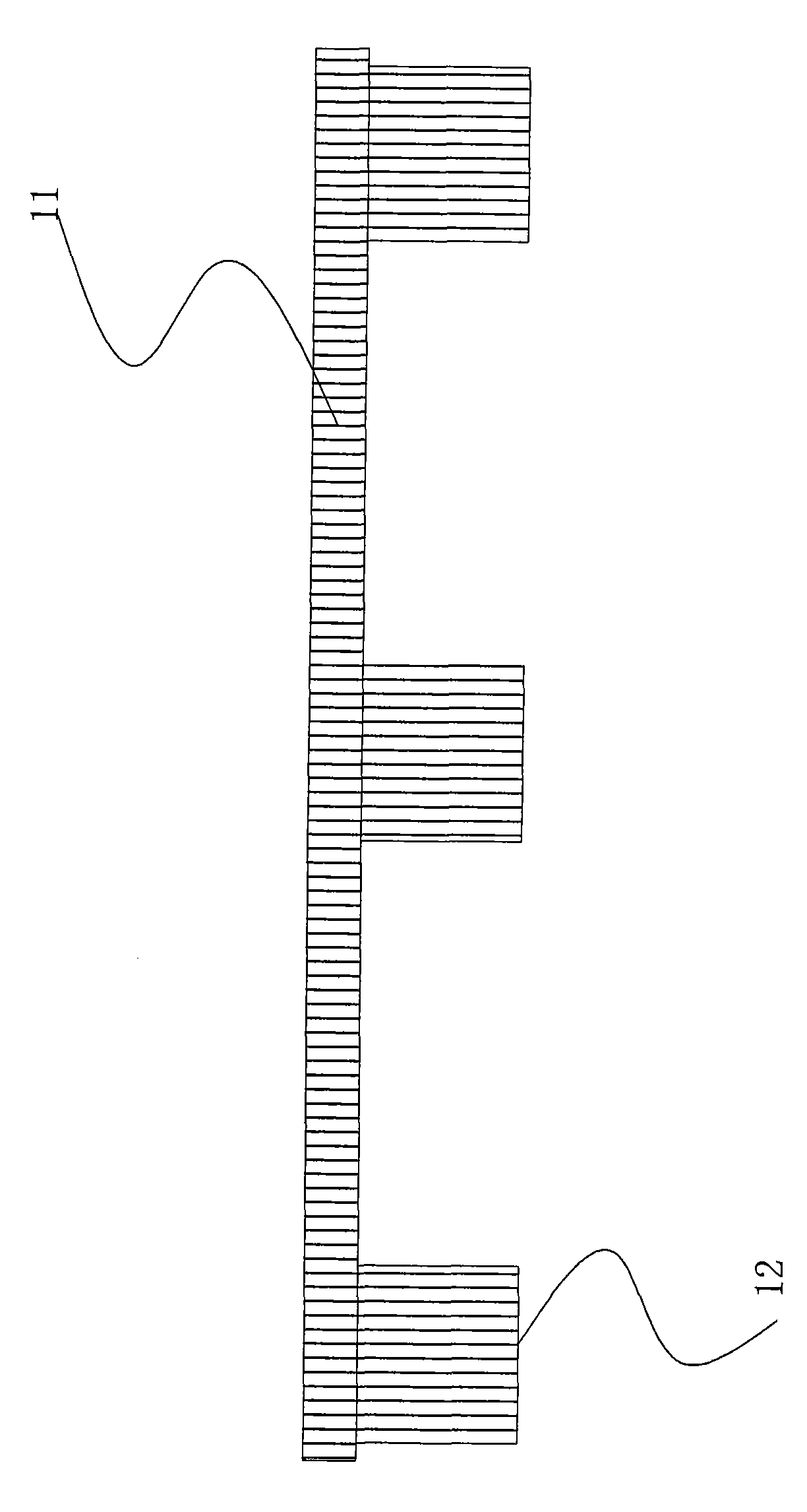

Paper-plastic pallet

InactiveCN102085937AMake up for deficienciesManufacturing flexibilityRigid containersHoneycombPaperboard

The invention discloses a paper-plastic pallet which comprises a pallet main body, wherein the pallet main body at least comprises a panel and a block which is connected to the lower part of the panel. The paper-plastic pallet disclosed by the invention is characterized in that the main body part of the panel adopts a honeycomb paperboard; and the honeycomb paperboard is hermetically arranged in the inner cavity of the plastic shell of the pallet main body. Thus, the paper-plastic pallet makes up the defect of simple materials of a plastic pallet and a paper pallet and combines the respective advantages, thereby increasing the practicability.

Owner:梁国宝

Structure of reversing valve

InactiveCN102359620AGuaranteed running stabilityEasy to operate and controlMultiple way valvesEngineeringMotion resistance

The invention relates to a structure of a reversing valve. The reversing valve comprises a control reversing valve and an action reversing valve, and two groups are matched to realize flow velocity variable control over a pressure medium. Compared with the prior art, the structure of the reversing valve has the advantages that: through a design of a second valve rod and two overflow valves, when a piston moves to be about to contact the end of a piston cylinder, the reflux quantity of the pressure medium is reduced, and the motion resistance of the piston is increased, so that the motion velocity of the piston is reduced, the piston slowly touches the end of the piston cylinder, the piston and the end of the piston cylinder are prevented from being collided and worn when the piston moves at a high speed, the service life of the piston cylinder is effectively prolonged, and the operation safety and stability of the piston cylinder are ensured simultaneously.

Owner:皇甫岳伟

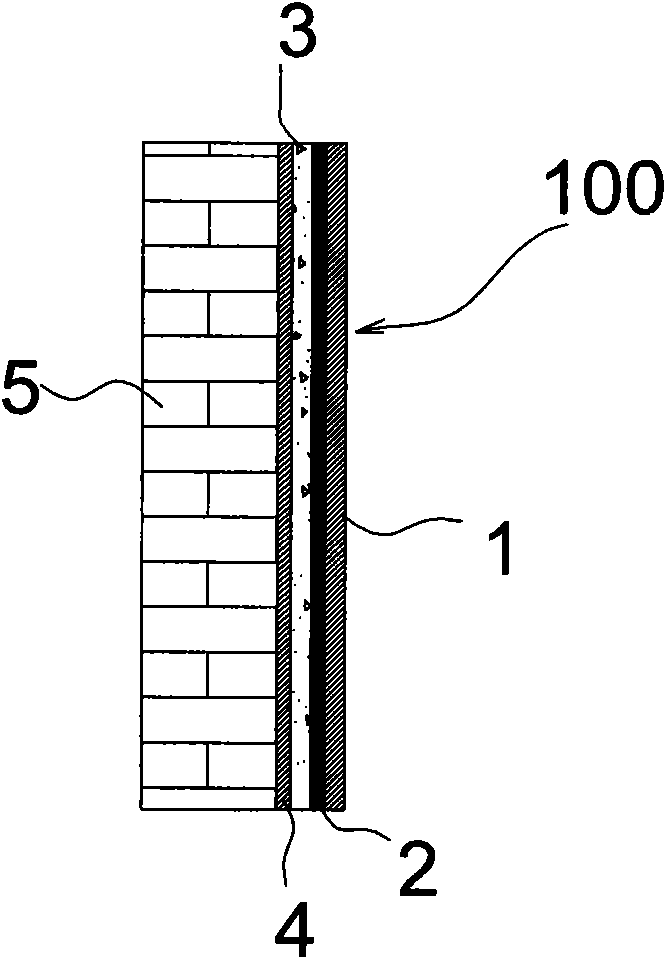

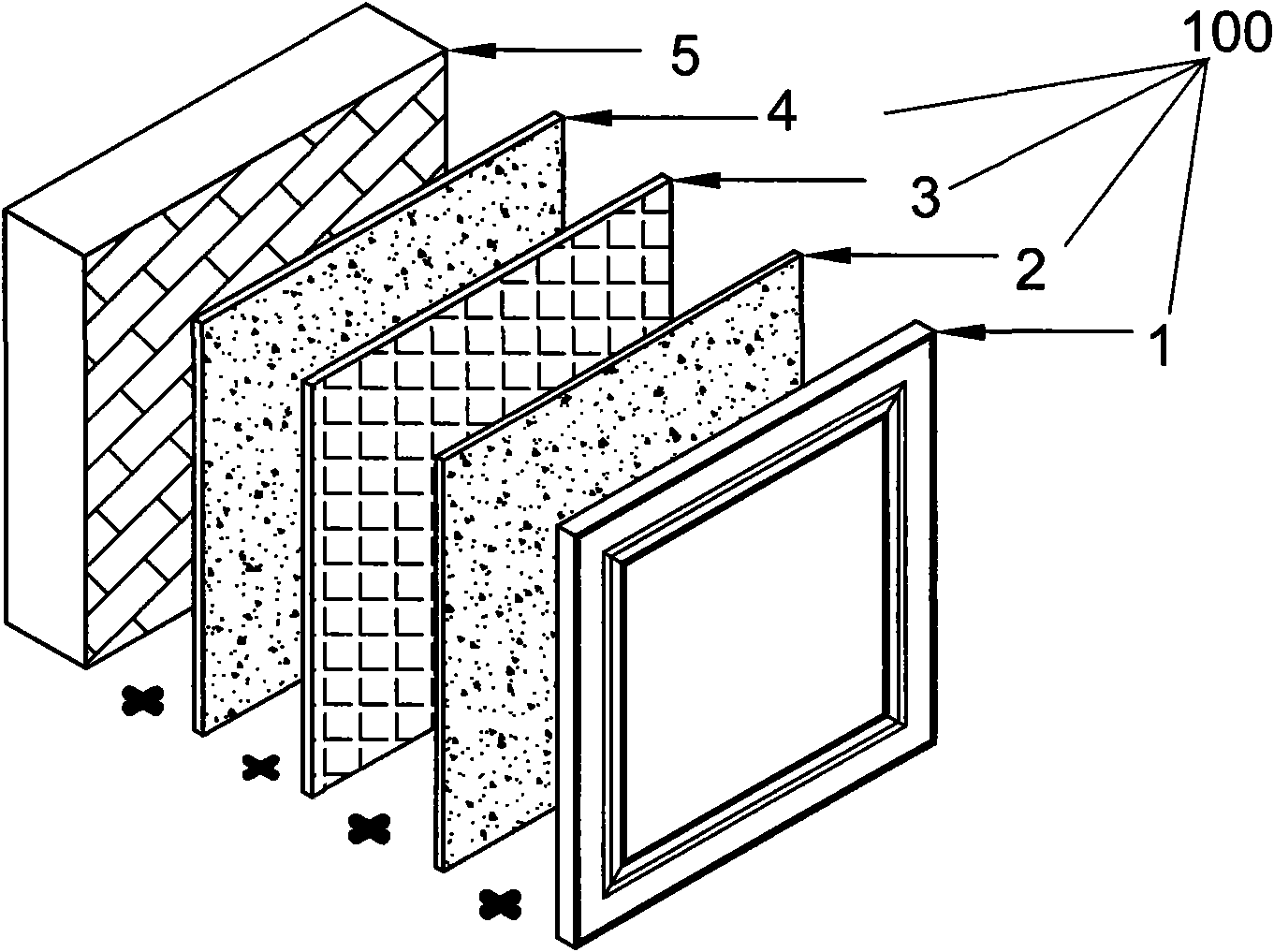

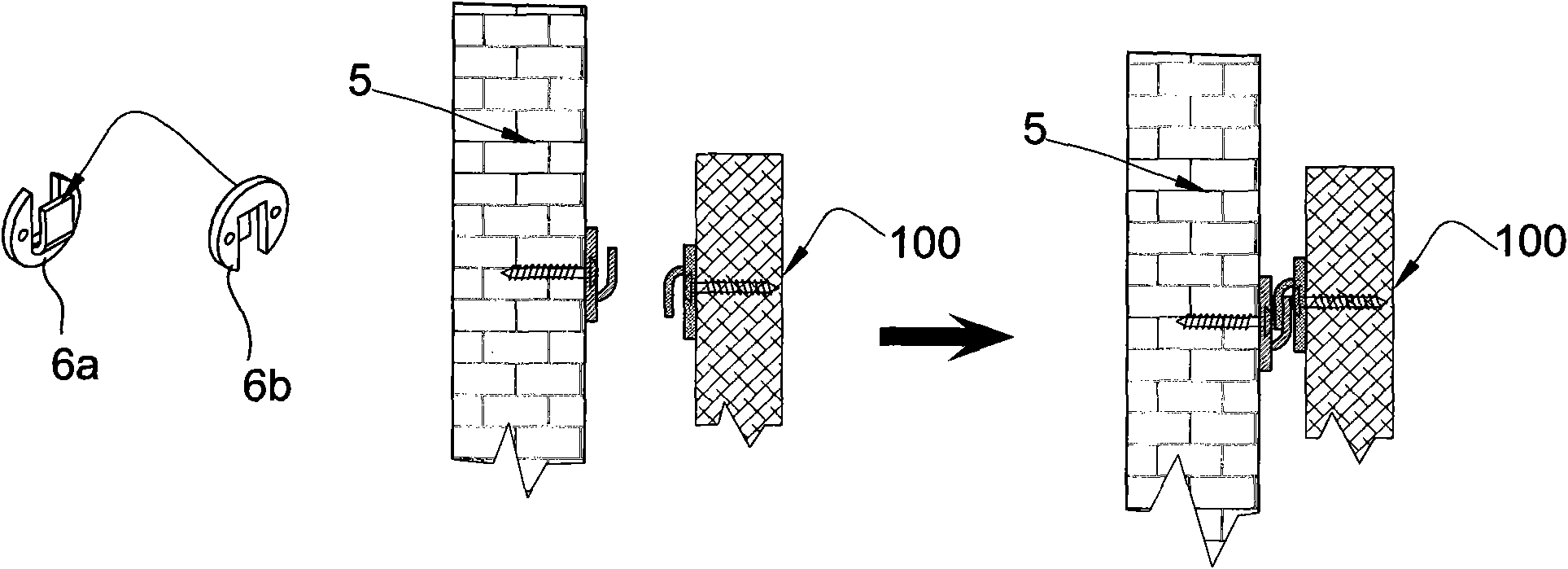

Damp-proof wall protection plate

InactiveCN102400529AEvent replacementReasonable and practical structureCovering/liningsBuilding insulationsEngineeringMoisture

The invention relates to a damp-proof wall protection plate, which comprises a wall protection plate body (100) and is characterized in that the wall protection plate body (100) is sequentially provided with a wall plate (1), a ventilation film layer (2), a porous filling frame layer (3) and a damp-proof film layer (4) from outside to inside, wherein the porous filling frame layer (3) at least comprises moisture absorbing agent powder or block bodies. The damp-proof wall protection plate has the advantages that the structure is reasonable and practical, the assembly and the production are easy, moisture absorbing agents, moisture preserving agents and insecticide on the porous filling frame layer are combined, the damp-proof and environmental-friendly effects are realized, and the porous filling frame layer can be movably replaced in the further improvement, so the performance is improved to the optimum degree, and convenience and high speed are realized.

Owner:应孝华

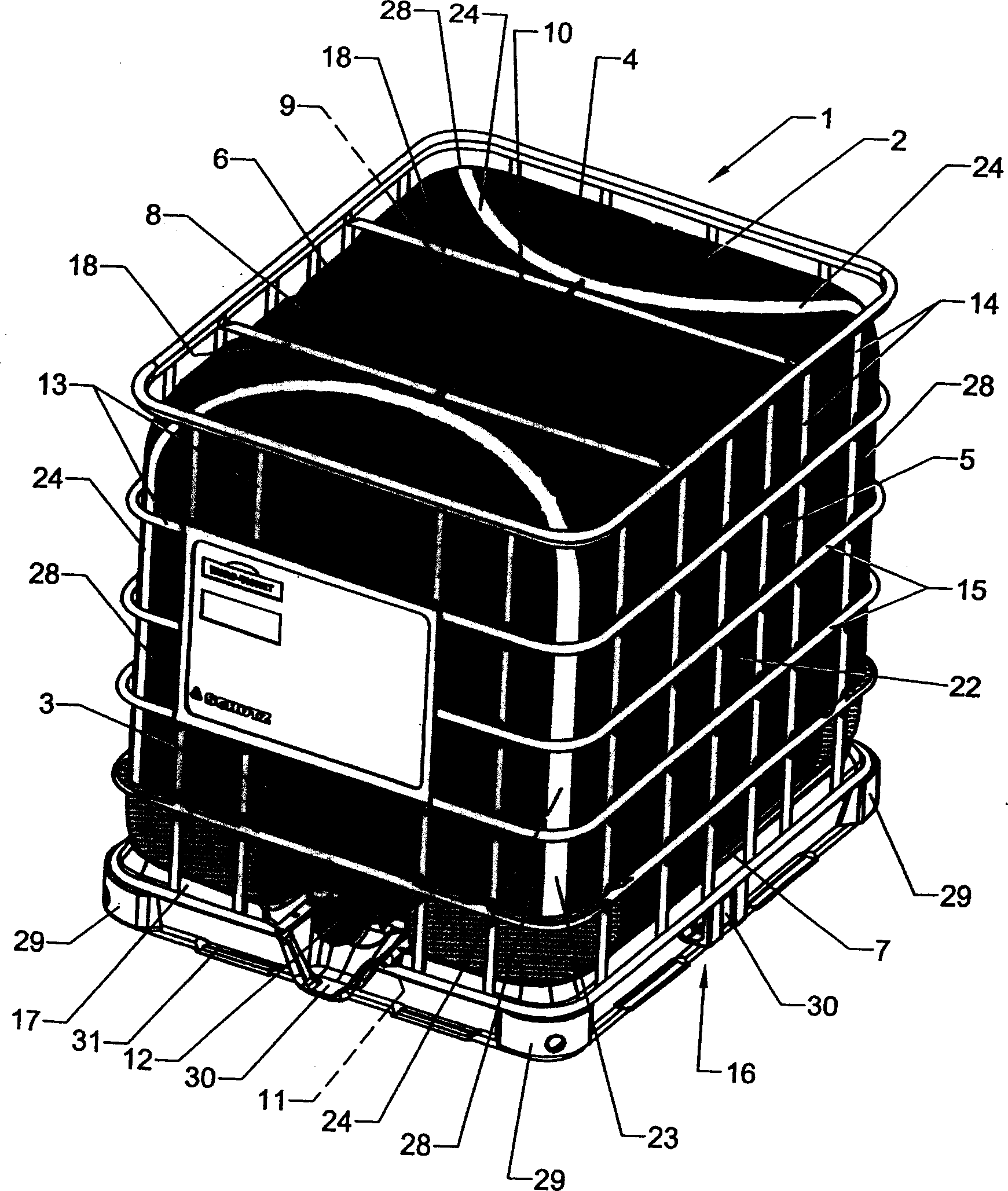

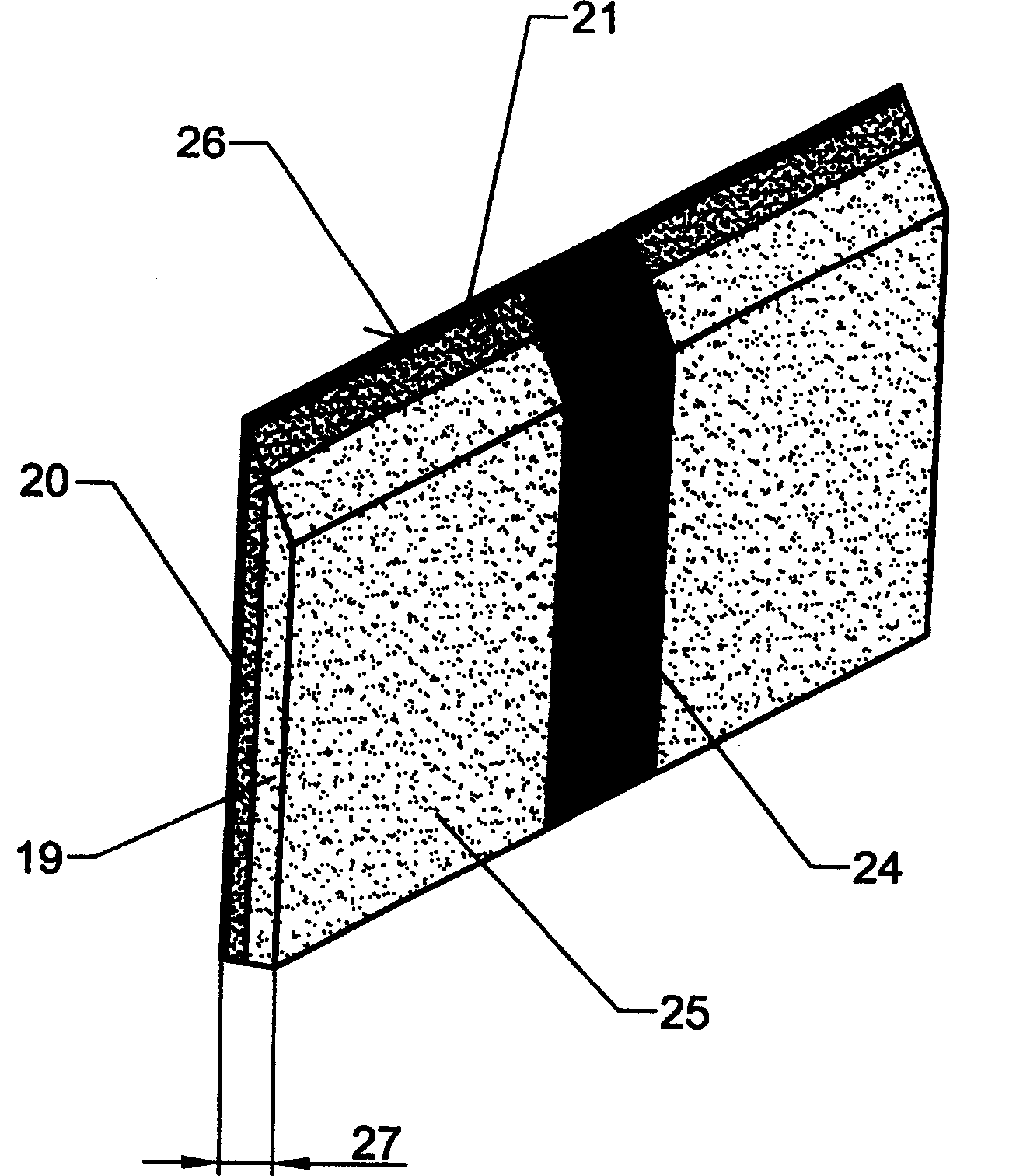

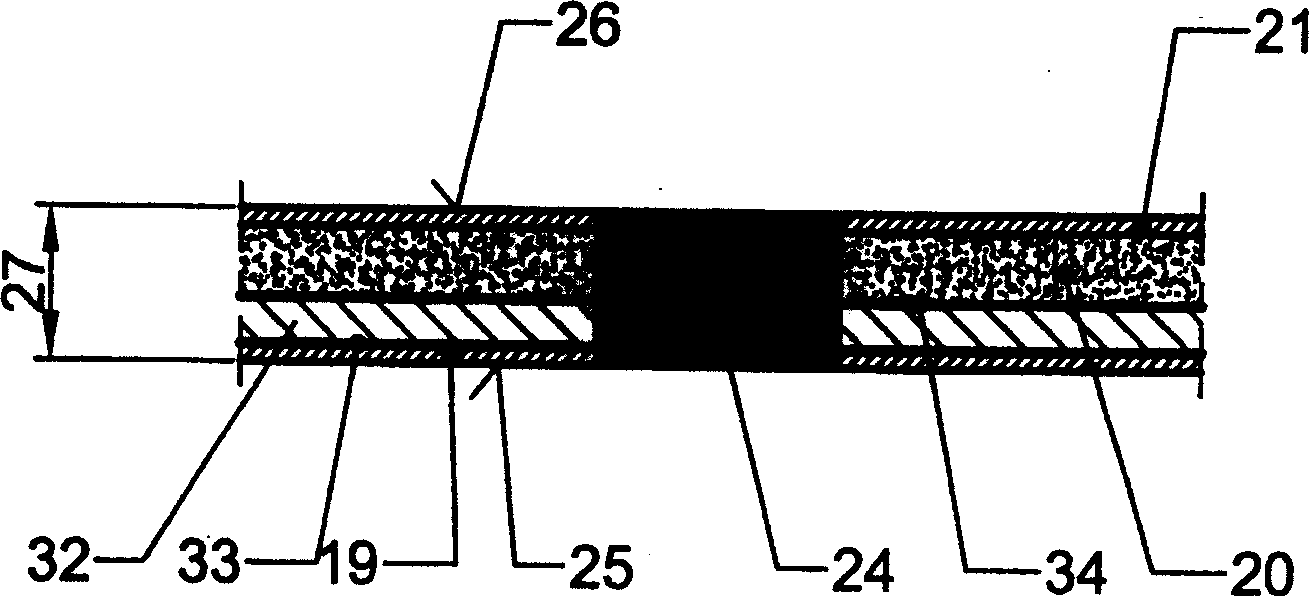

Transport and storage container for liquids and method for manufacturing an inner plastic container of the transport and storage container

InactiveCN1500709AReasonable and practical structureDoes not affect strengthFlexible coversWrappersEngineeringMetal

A conductive protruding pieces (24) made of high density polyethylene containing a conductive carbon black component is integrated into a main body (22) of the plastic-made inner container (2). The protruding pieces form an electric connecting means between the inner surface and the outer surface of the inner of the inner container (2) and its thickness is correspondent with the wall of the inner container (2). Legs (29 and 30) and a leg frame (31) of a seat (16) supporting the inner container (2) is made of a metal or a conductive plastic whereby the transporting and storing container (1) is electrically earthed via the conductive protruding piece (24) and a permanent anti-electrostatic outer layer (21) of the multi-layered plastic-made inner container (2), an outer shell (13) and the seat (16).

Owner:PROTECHNA SA

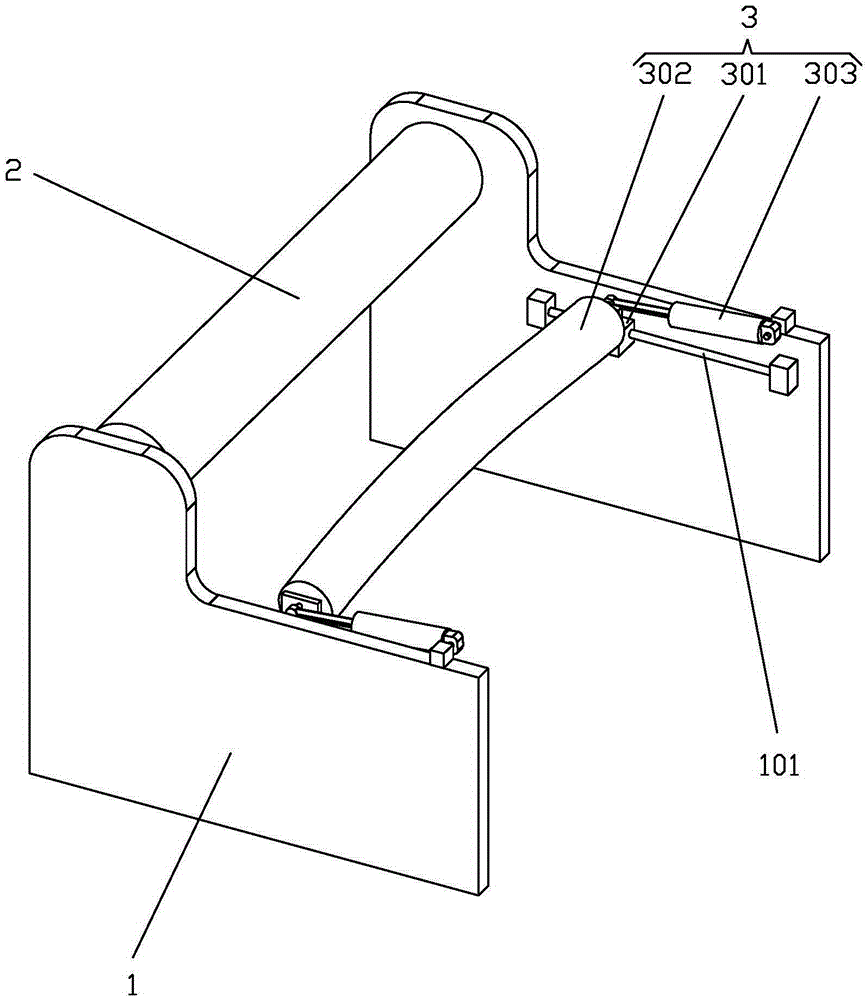

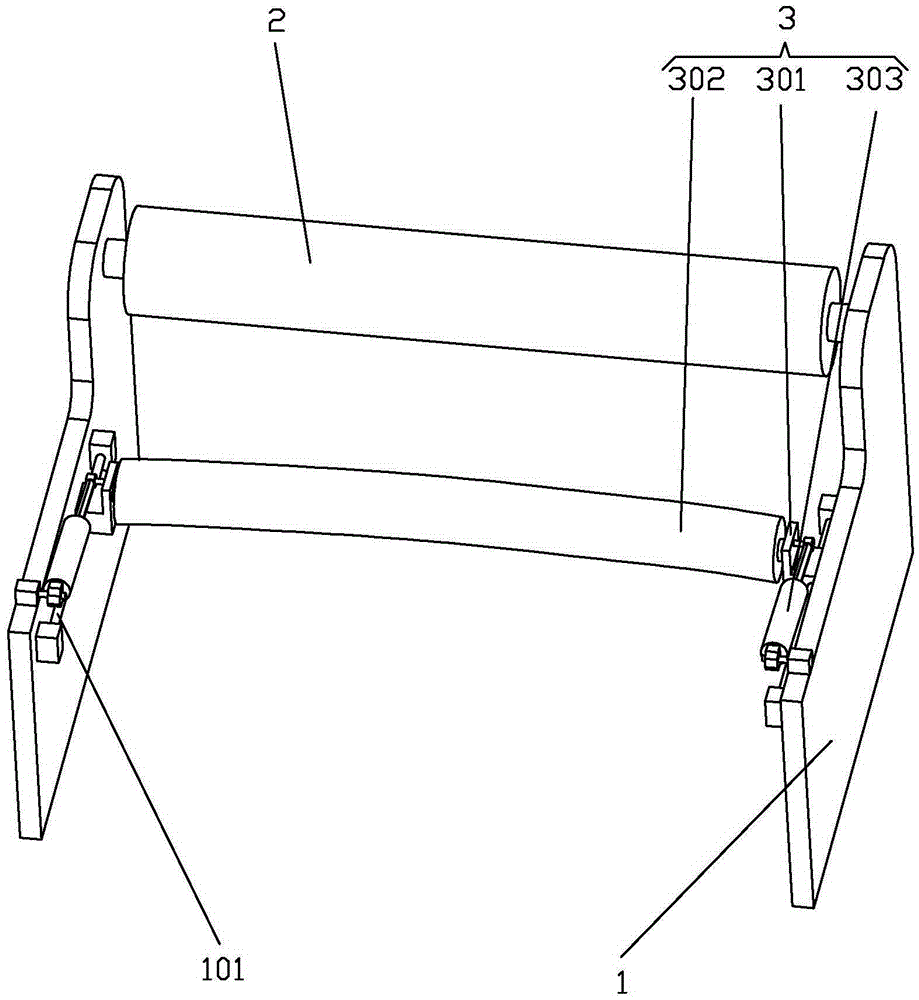

Crease-resist device for adhesive tape winding

The invention discloses a crease-resist device for adhesive tape winding. The crease-resist device comprises a machine frame, a winding roller and a crease-resist mechanism, wherein the winding roller is installed at the rear end of the machine frame in a rotating mode. The crease-resist mechanism comprises two roller bases, the roller bases are connected to the front end of the machine frame and can slide from front to back, a banana-shaped roller is installed on the two roller bases, an elastic rubber layer is arranged on the surface of the banana-shaped roller, and power mechanisms for pushing the roller bases to move are connected to the roller bases. Through the crease-resist mechanism, creases generated in adhesive tape winding are eliminated, and the product quality is improved.

Owner:林英强

Art knife

ActiveCN103381606ATimely replacementEasy to useHand artistic toolsMetal working apparatusEngineeringKnife blades

The invention provides an art knife which comprises a housing and is characterized in that two groups of knife rests are arranged in parallel, the two groups of knife rests are arranged in the cavity in the front part of the housing through a knife rest gasket in a sliding manner respectively, different kinds of blades are arranged on each group of knife rest, a push button, which has a pop-up upward trend, is arranged at the upper end of the knife rest, a strip groove, which is corresponding to the upper edge of the knife rest gasket, is formed in the upper edge of the housing, two parallel push grooves, on which the two push buttons can slide, are formed between the strip groove and the upper edge of the knife rest gasket, and a clamp foot, which is matched with a tap position groove to conduct positioning, is arranged at the side part of the push button, so as to realize the stretch of the blades and the positioning of the tap position. The art knife has a beautiful appearance, is safe to use and convenient to operate, has the functions of an assistant blade and double blades, and can afford different kinds of blades as required, and realize quick blade exchange and tap position positioning.

Owner:ZHEJIANG XINGDA STATIONERY

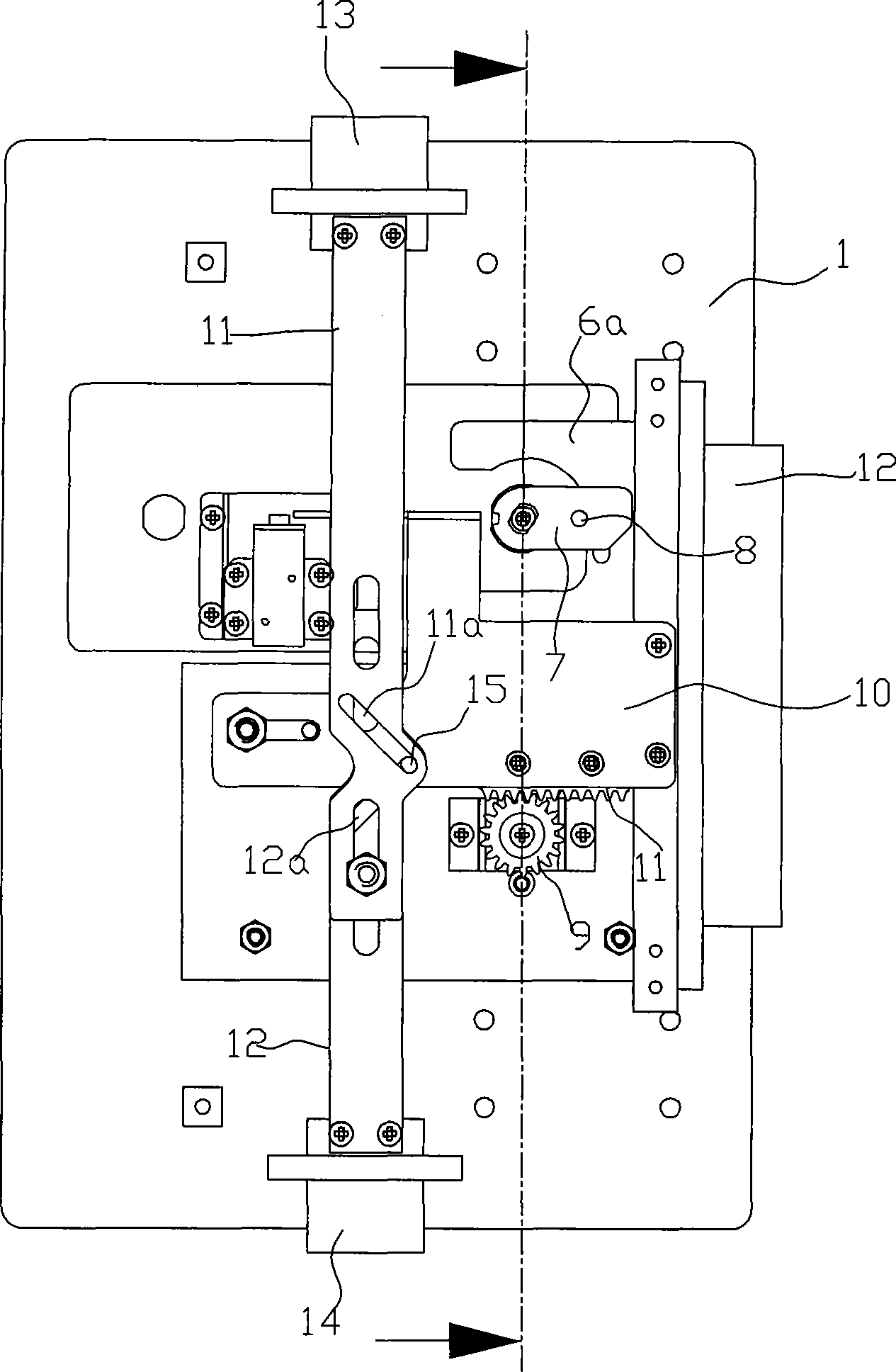

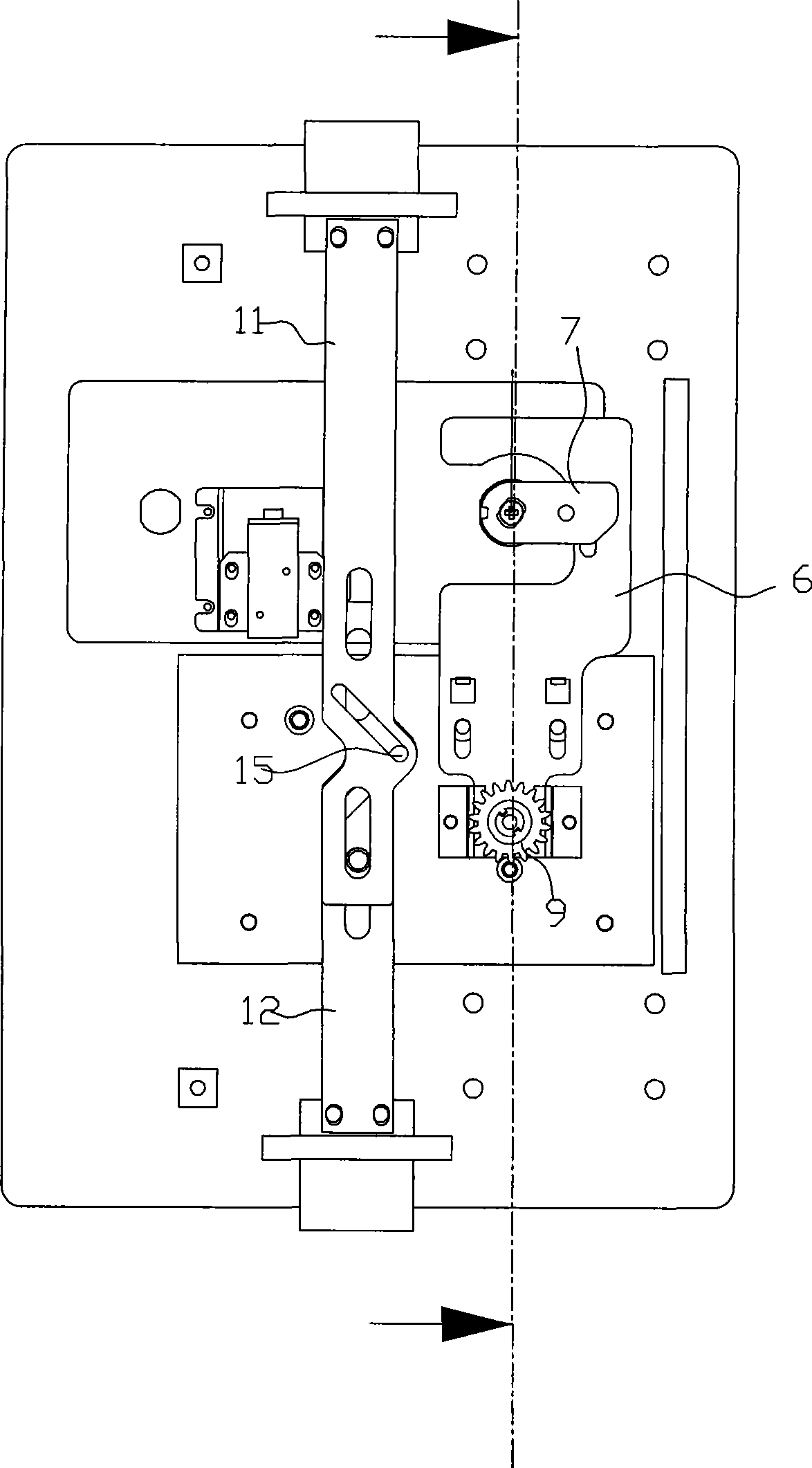

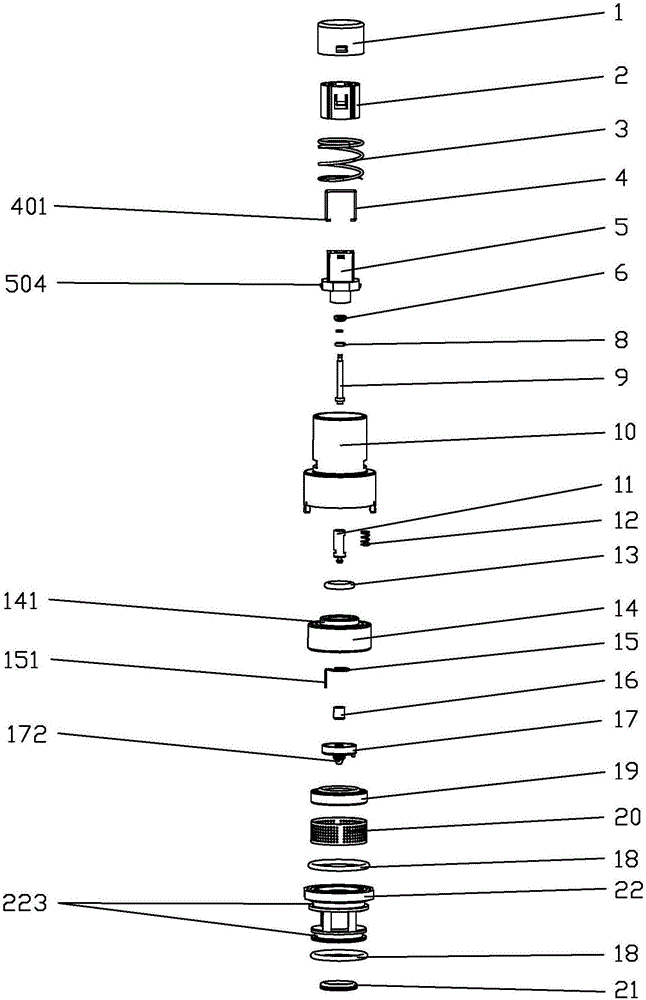

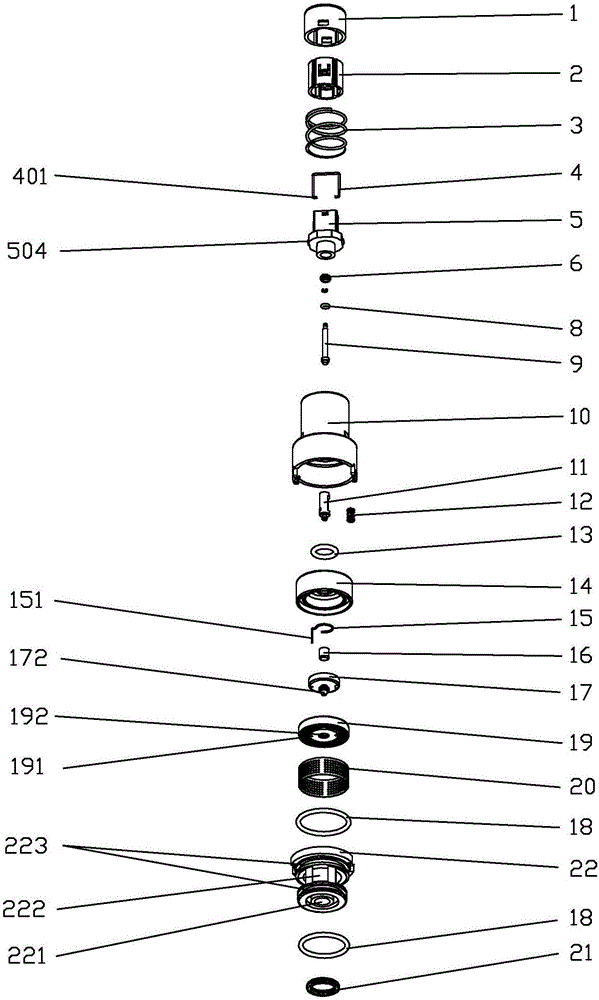

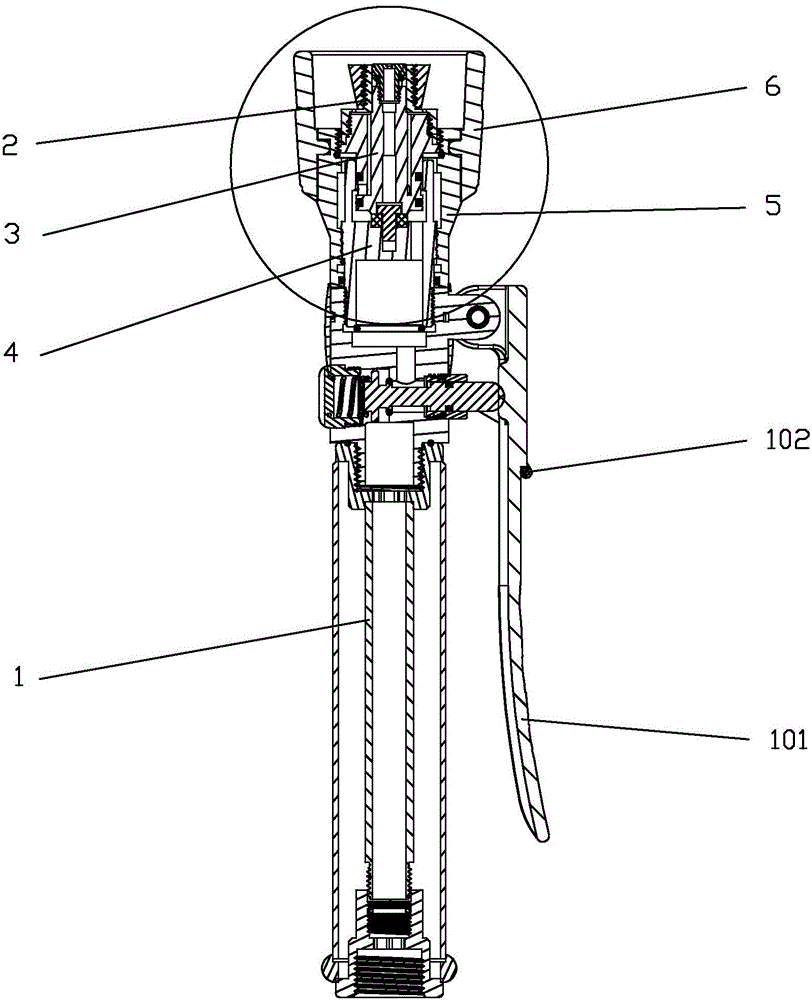

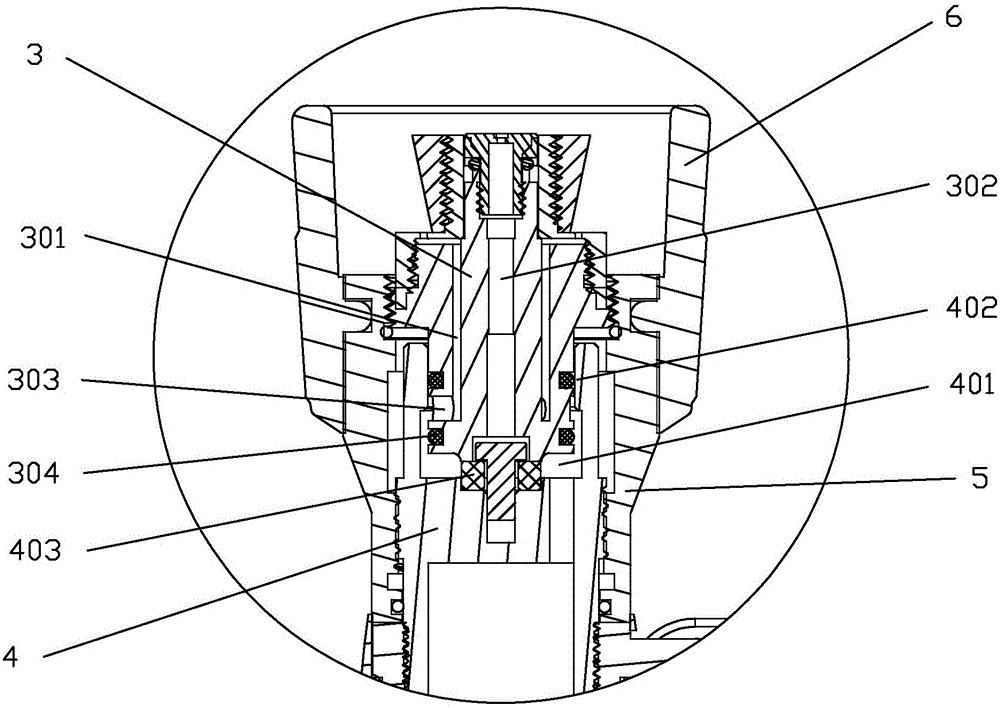

Press key type switch valve core

ActiveCN106352110AReasonable and practical structureSimple structureDiaphragm valvesEngine diaphragmsEngineeringMechanical engineering

The invention discloses a press key type switch valve core, which comprises a casing and a base, wherein the base is arranged at the bottom of the casing, wherein a press key, a gear inner liner, a gear support frame, a linkage small shaft, a water stop spring seat, a water stop press block and a reset spring are arranged inside the casing; a compression spring is arranged between the lower end of the linkage small shaft and the water stop spring seat; the gear support frame is connected with the reset spring and is provided with a gear block used for gear shifting; a penetrated water outlet passage is formed in the middle part of the base; a plurality of water inlet holes communicating with an upper end opening of the water outlet passage are formed on the periphery of the lower part of the base; a filtering screen covers the outer side of the water inlet hole; a diaphragm covers the upper end opening of the water outlet passage; the diaphragm is connected into a whole with a pressure relief base; the middle part of the diaphragm is provided with a water passing passage communicating with the water outlet passage; the diaphragm is provided with a water guide hole communicating with the water inlet hole; the water stop press block downwards moves to press the upper end opening of the water passing passage so as to close the water passing passage.

Owner:GUANGDONG HENT TECH

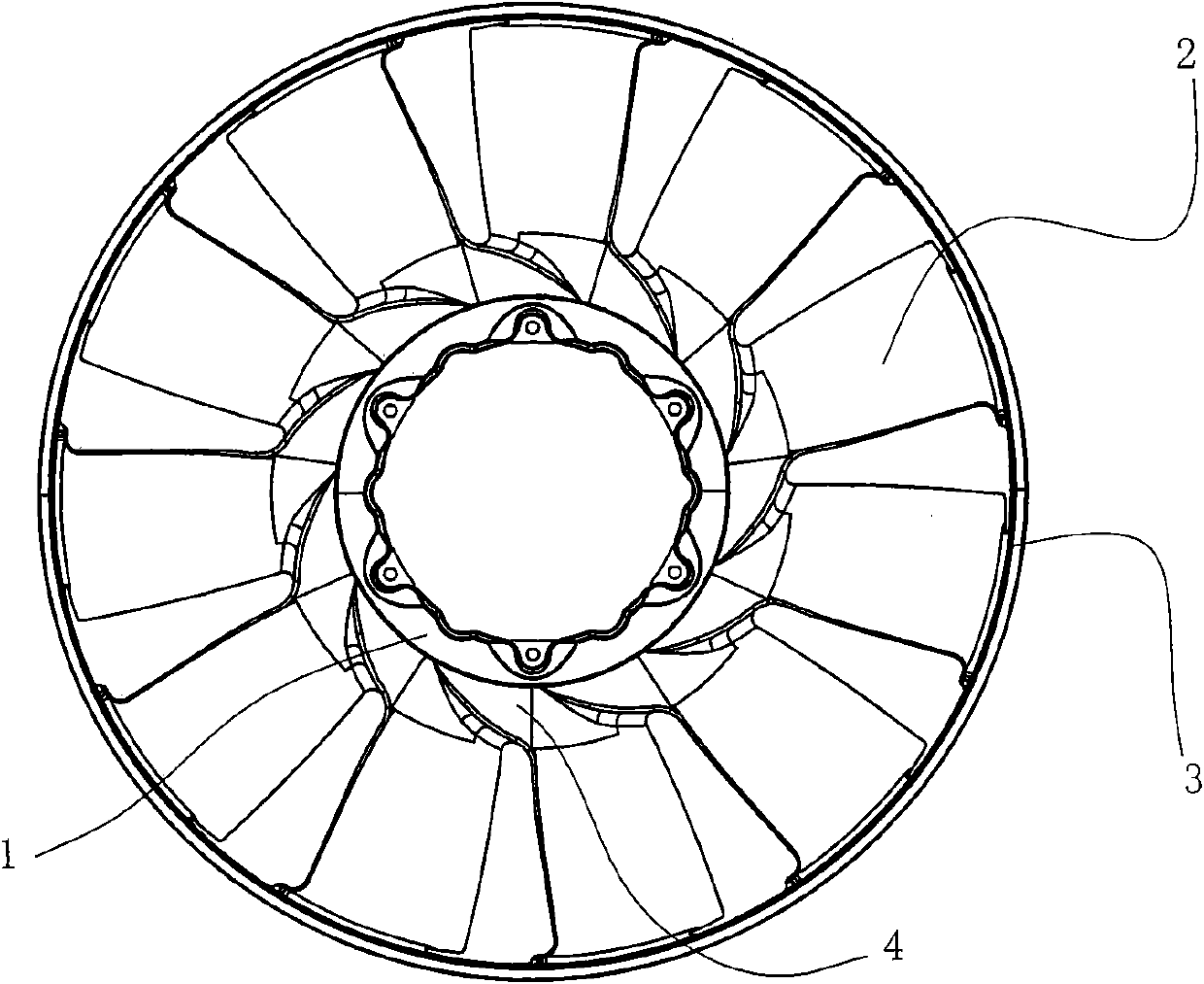

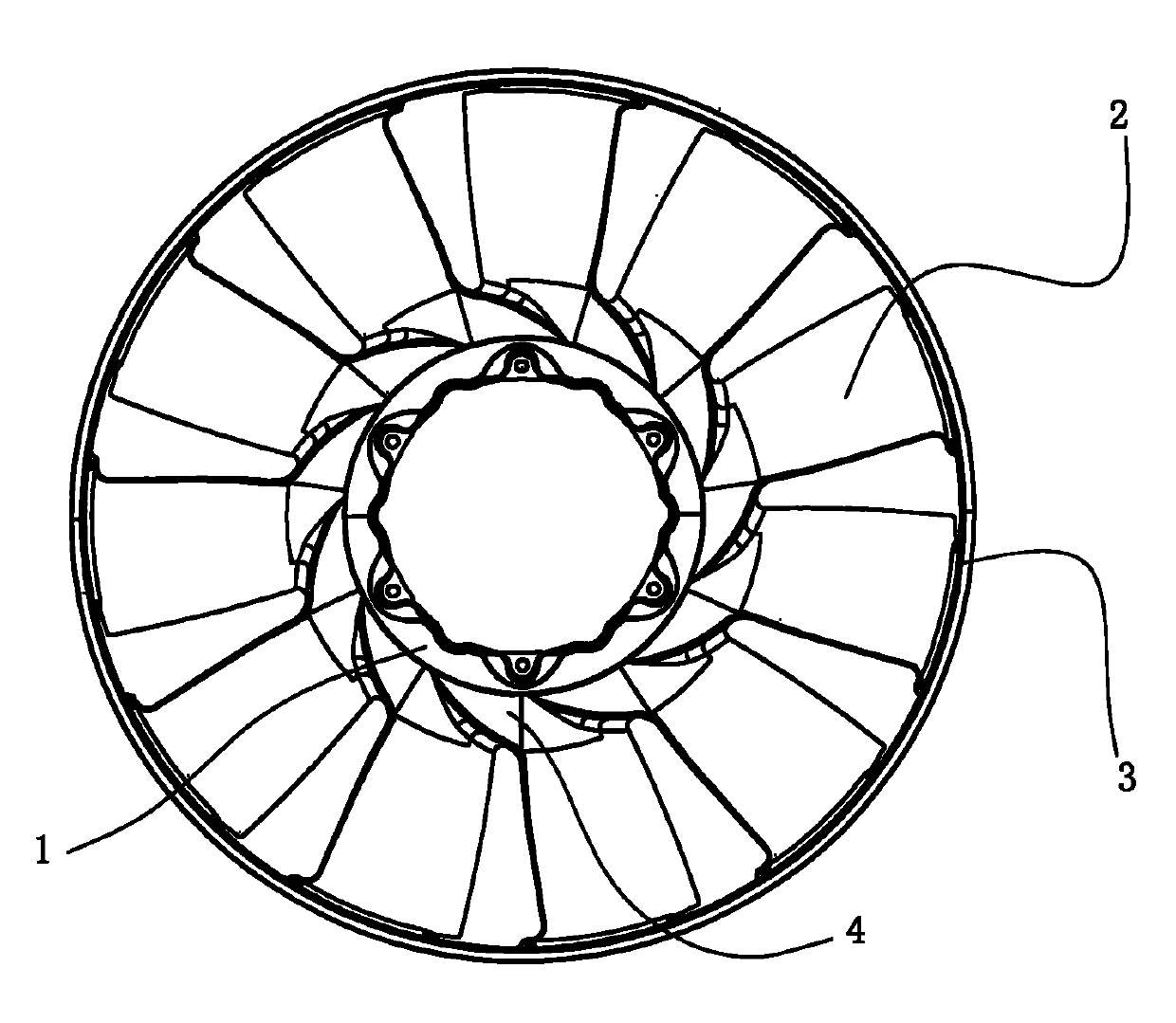

Cooling fan for reinforcing diversion cooling

InactiveCN102086874AImprove efficiencyIncrease flow ratePump componentsPump installationsCooling effectInvolute

The invention discloses a cooling fan for reinforcing diversion cooling. The cooling fan comprises a hub, fan blades and a diversion ring, wherein the fan blades are connected with the diversion ring. The cooling fan is characterized in that: the periphery of the hub is provided with spiral reinforcing ribs; the spiral reinforcing ribs are connected with the bottoms of the fan blades and are distributed at equal intervals along an involute; the direction of the involute corresponds to the rotation direction of the fan; and in the involute, x and y in a parameter equation can be exchanged along with the rotation direction of the fan by the parameter equation under a Qadir coordinate system. Compared with the prior art, the cooling fan has the advantages that: service life is greatly prolonged and a cooling effect is enhanced.

Owner:WARNER SHENGLONG NINGBO CO LTD

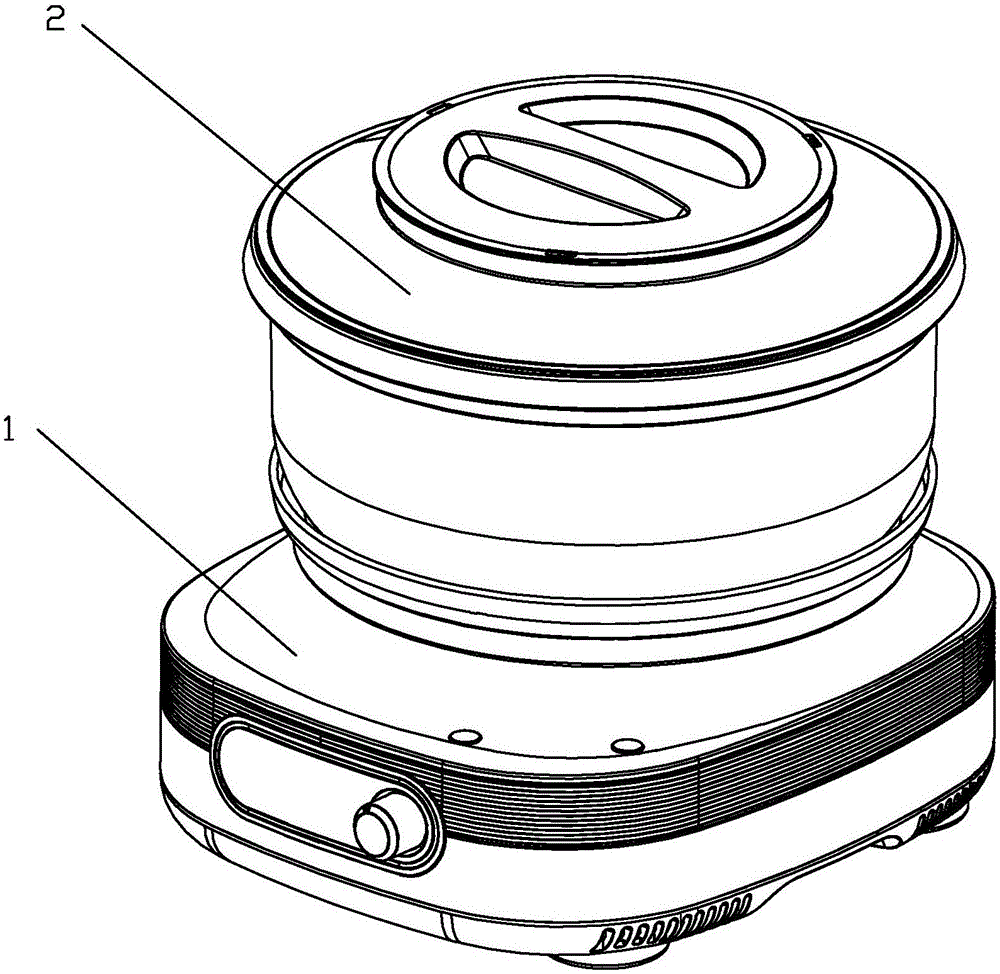

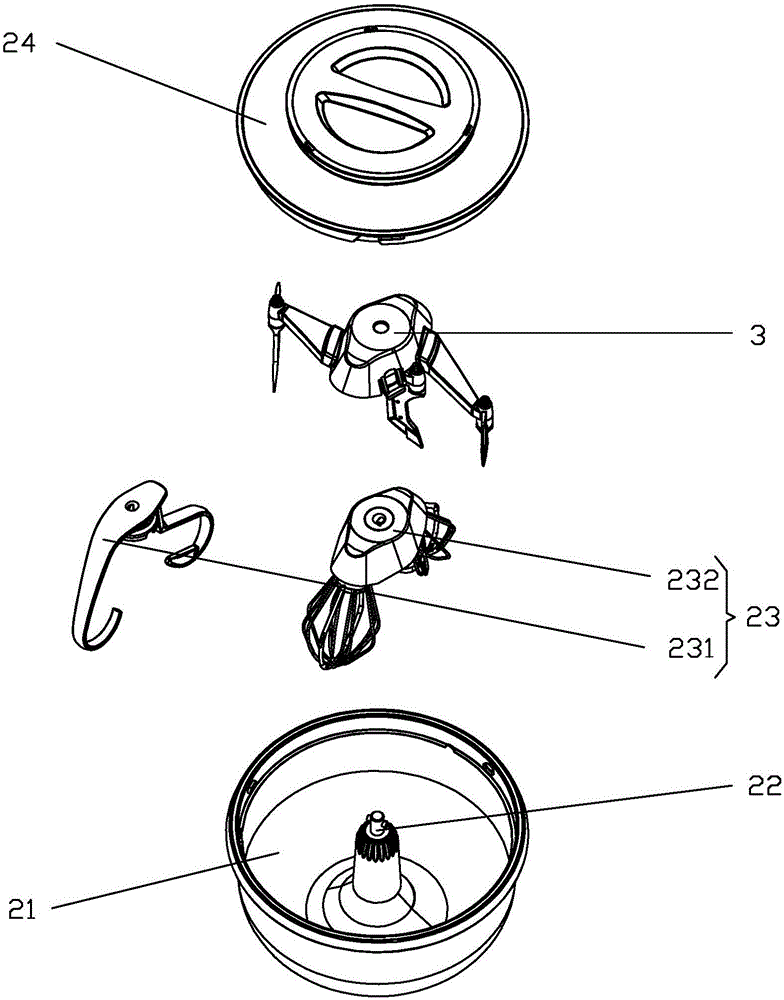

Dough kneading machine

ActiveCN106135332AIncrease usageAvoid wastingMixing/kneading structural elementsRotary stirring mixersDrive shaftEngineering

The invention discloses a dough kneading machine. The dough kneading machine comprises a main machine and a dough kneading assembly mounted on the main machine, wherein a motor is arranged in the main machine, the dough kneading assembly comprises a dough kneading bowl and an upper cover, a drive shaft connected to the motor is arranged in the dough kneading bowl, the drive shaft is connected with a dough kneading device, a detachable scraper device is further connected to the upper end of the dough kneading device, the scraper device is provided with two oppositely disposed bowl wall scrapers to scrape adhesive materials on the inner wall of the dough kneading bowl and a central scraper to scrape adhesive materials on the outer wall of the drive shaft, each bowl wall scraper is provided with an edge fit with the inner wall of the dough kneading bowl, and the central scraper is provided with an edge matched with the shape of the outer wall of the drive shaft. By adopting the dough kneading machine disclosed by the invention, the dough adhered to the inner wall of the dough kneading bowl and the drive shaft can be scraped in time through the scraper device, the wastage is avoided and the cleaning after use is facilitated.

Owner:JIANGMEN HOUSOEN ELECTRIC MFG +1

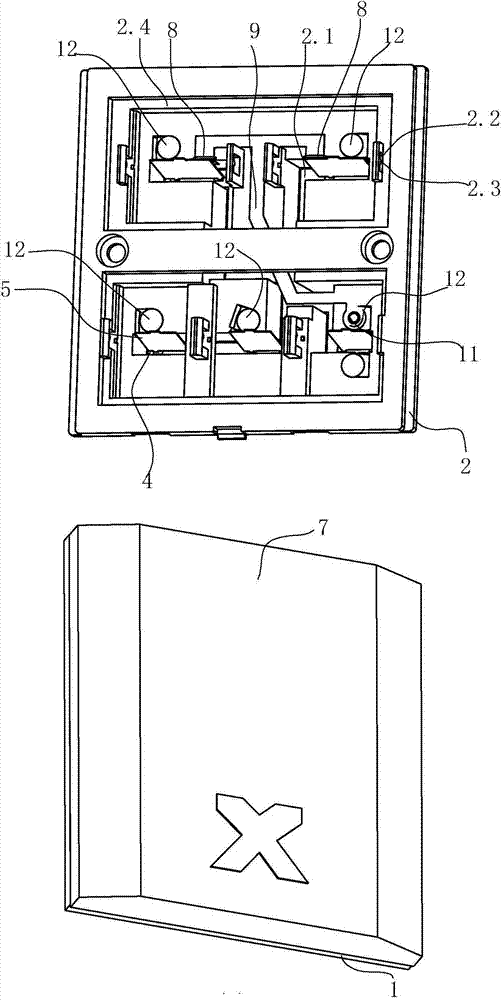

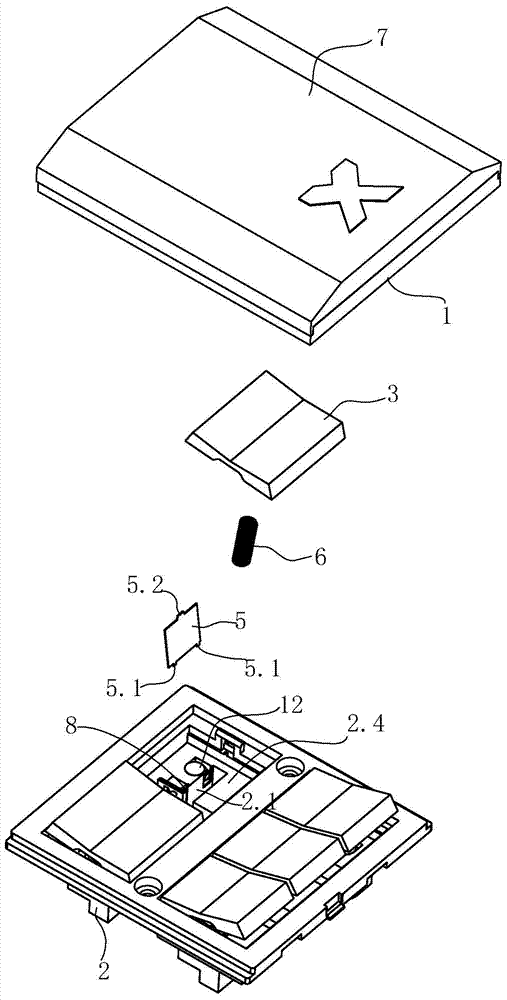

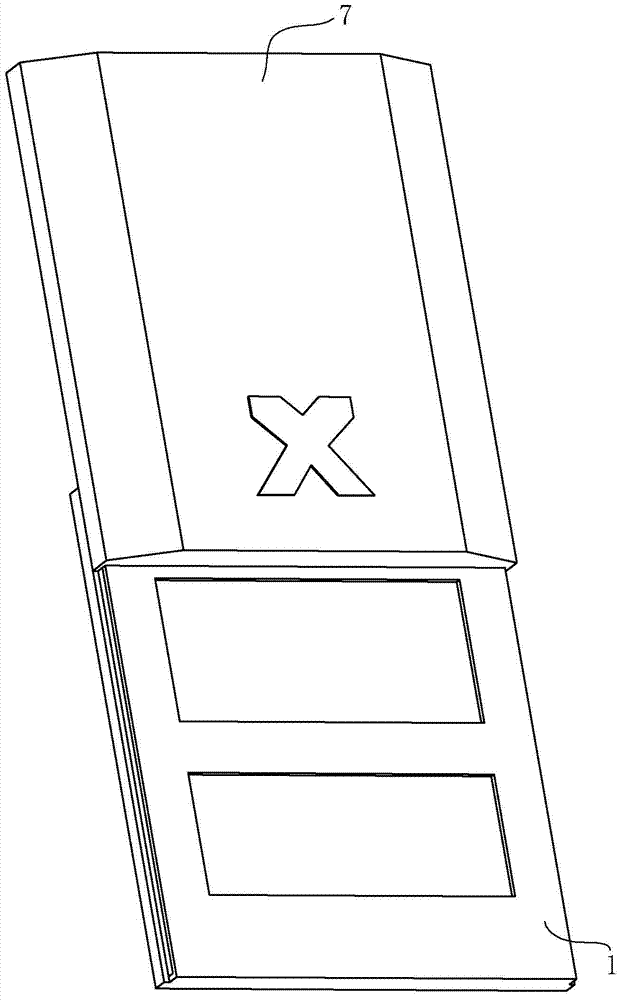

Bathroom master control switch

InactiveCN104517747AReduce loop currentAvoid less badContact surface shape/structureContact electric connectionElectricityPower flow

A bathroom master control switch comprises a panel, a switch base and a switch pressing board. The switch base is internally provided with a plurality of cavities for arranging switch members. The cavities are communicated so that a metal connecting member can be paved on the bottom of each chamber, and the metal connecting member is connected with an input power line through an intermediate connecting column. The metal connecting member is rotatably provided with a metal springboard on the bottom of each cavity. The upper end of each metal springboard is matched with a middle opening of the switch press board, and supports a spring. A metal connecting column is fixed to a side of each cavity, and a wiring hole for being connected with an output power line is arranged below each metal connecting column. Moreover, the contact surfaces of each metal springboard and the corresponding metal connecting column are provided with matching contacts. The bathroom master control switch is characterized in that a metal contact piece for electrical conduction is arranged near the opening of each cavity of the switch base and beside the corresponding metal connecting column for connecting heating devices, each metal contact piece is matched with the metal connecting column beside the metal contact piece, each metal contact piece contacts the corresponding metal springboard to conduct electricity or be separated from the metal springboard, and each metal contact piece and at least one metal connecting column for connecting non-heating devices are connected by a metal connecting piece. The bathroom master control switch of the invention is reasonable in structure and practical, has better current-through performance, and can be protected from burnout.

Owner:许全忠

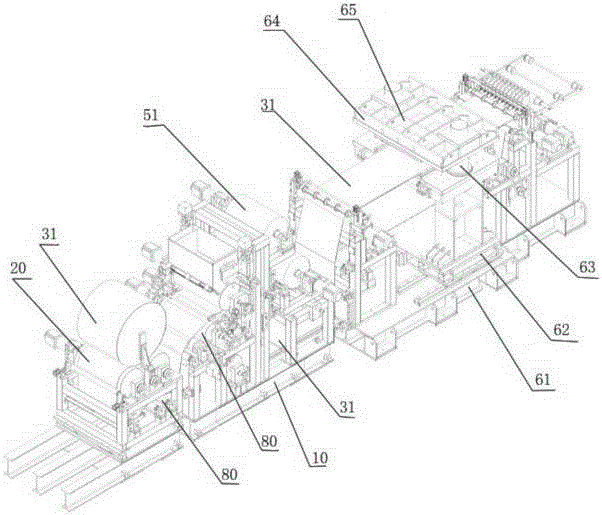

Plaster coating system

InactiveCN106236586ARealize flow mechanized productionQuality assurancePharmaceutical product form changeCoating systemEngineering

The invention provides a plaster coating system. The plaster coating system comprises a rack, a tension-free cloth feeding mechanism, a plaster base cloth roll fixing device, a plaster medicinal material coating mechanism, a transfer film roll fixing device, a plaster base cloth parting mechanism and a plaster slicing mechanism which are arranged on the rack in sequence and a delivery mechanism; the tension-free cloth feeding mechanism is arranged under the plaster base cloth roll fixing device and is tangent to an elastic cloth roll so as to drive the elastic cloth roll to rotate. According to the plaster coating system, the elastic cloth roll completes the process of passive cloth feeding in running friction of the tension-free cloth feeding mechanism, no tensile force exists in the whole cloth feeding process, it is guaranteed that elastic cloth is stable and free of deformation in the cloth feeding process, when the elastic cloth enters the coating phase, coating is smooth and uniform, and the coating quality is guaranteed; the processes of cloth feeding, gumming, parting, slicing and discharging of the elastic cloth can be completed automatically, mechanized flow production of special-shaped plasters is achieved, the structure is reasonable and practical, gumming is uniform, the production efficiency is high, and the quality is good.

Owner:佛山智高机械有限公司

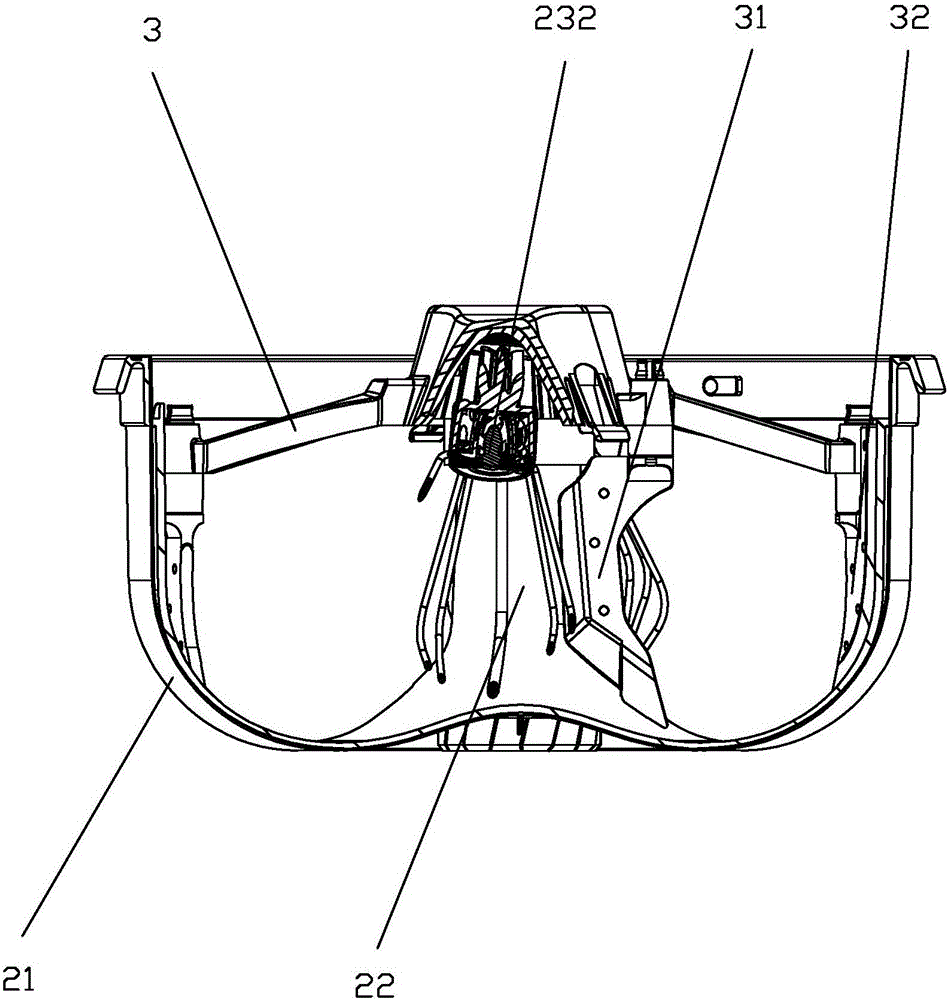

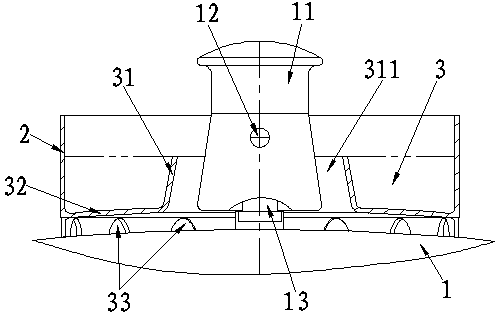

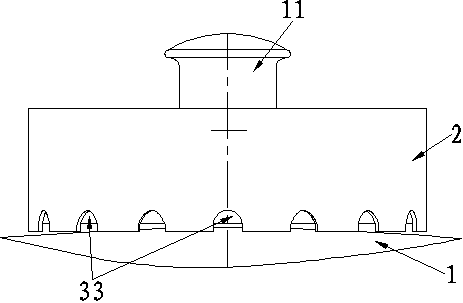

Splashing preventing and oily water collecting device of cooking pressure cooker

InactiveCN103815771AAccumulate free fromSquirt without hindranceBoiling over preventionPressure-cookersOil waterEngineering

The invention provides a splashing preventing and oily water collecting device of a cooking pressure cooker. The splashing preventing and oily water collecting device comprises a cylindrical cover (2). A receiving groove (3) is formed in the lower portion of the cylindrical cover (2); the receiving groove (3) comprises the cylindrical cover (2), an inner ring wall (31) and a groove bottom (32) which are integrated; the cylindrical cover (2) and the receiving groove (3) sleeve the outer periphery of a valve bonnet (11), and the bottom of the cylindrical cover (2) is in contact connection with a cooker lid (1); the peripheral edge of the upper end of the inner ring wall (31) is lower than the lower edge of a bonnet hole (12). The splashing preventing and oily water collecting device has the advantages that splashing preventing, oily water collecting and noise reducing functions can be realized on the premise that the safety use of the pressure cooker is unaffected, and the splashing preventing and oily water collecting device can sleeve the existing pressure cooker to be used at any time; the receiving groove (3) and the cylindrical cover (2) are of integral structures, and accordingly the splashing preventing and oily water collecting device is reasonable and practical in structure, can bring convenience for cooking by the aid of the pressure cooker and is easy to popularize and apply.

Owner:戴永锋

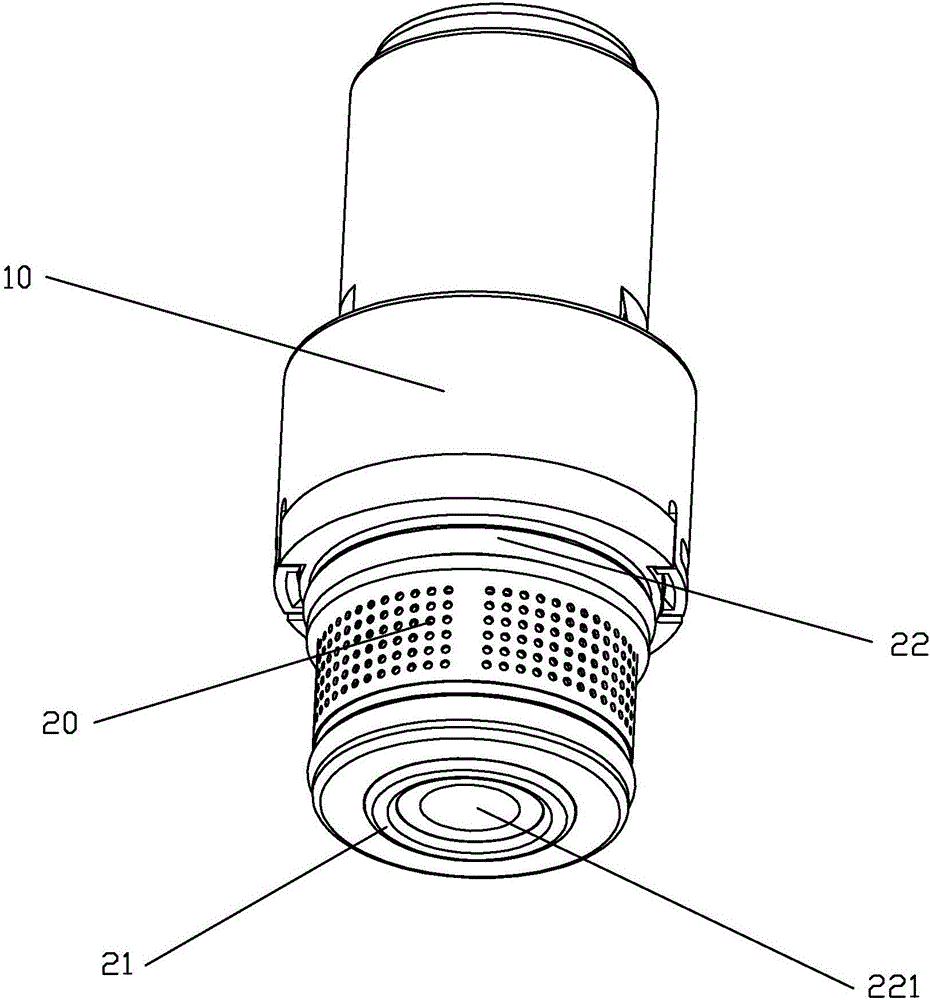

Kitchen shower and kitchen water tap using kitchen shower

ActiveCN105944848AAvoid enteringReasonable and practical structureSpray nozzlesDomestic plumbingEngineeringShower

The invention discloses a kitchen shower which conveniently converts water discharging modes, is compact in structure and easy to use, and a kitchen water tap using the kitchen shower. The kitchen shower comprises a shower body and a shower head with a mist spraying water outlet body and a V-shaped spraying water outlet body, wherein the shower head is provided with a water separator; an annular flow channel and an inner flow channel which separately communicate with the mist spraying water outlet body and the V-shaped spraying water outlet body are formed in the water separator; a plurality of water inlets which communicate with the annular flow channel are circumferentially formed in the lower end of the outer wall of the water separator; a first sealing ring is arranged on the lower sides of the water inlets; a convertor is connected to a water discharging end of the shower body; a water separating cavity communicating with the water discharging end of the shower body is formed in the convertor; the lower end of the water separator is mounted in the water separating cavity and can move up and down; a bulge ring matched with the first sealing ring is arranged at the upper end of the inner wall of the water separating cavity; a sealing gasket which can be used for sealing the inner flow channel is arranged on the bottom surface of the water separating cavity.

Owner:BESTWARE HARDWARE PRODN CO LTD

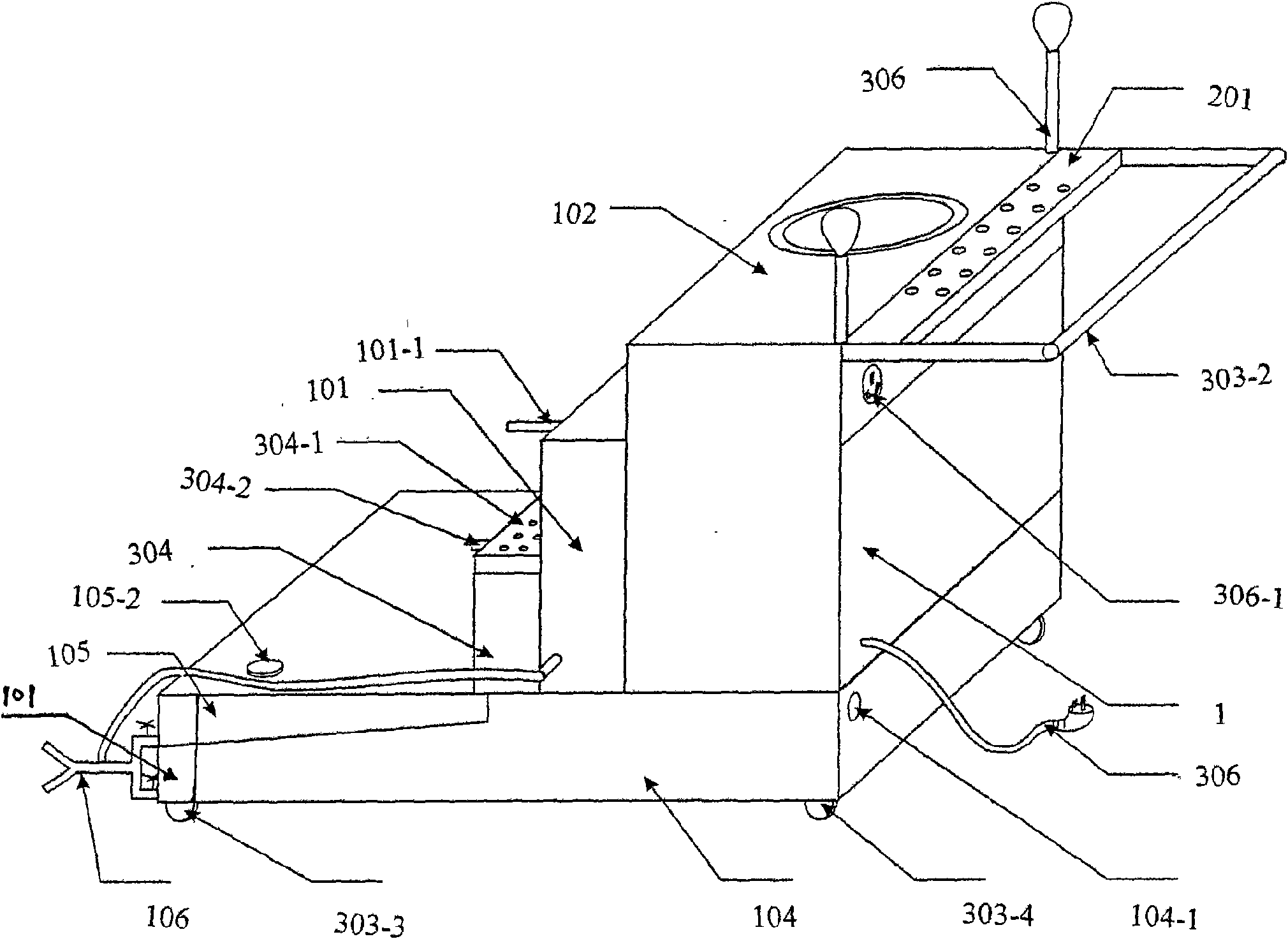

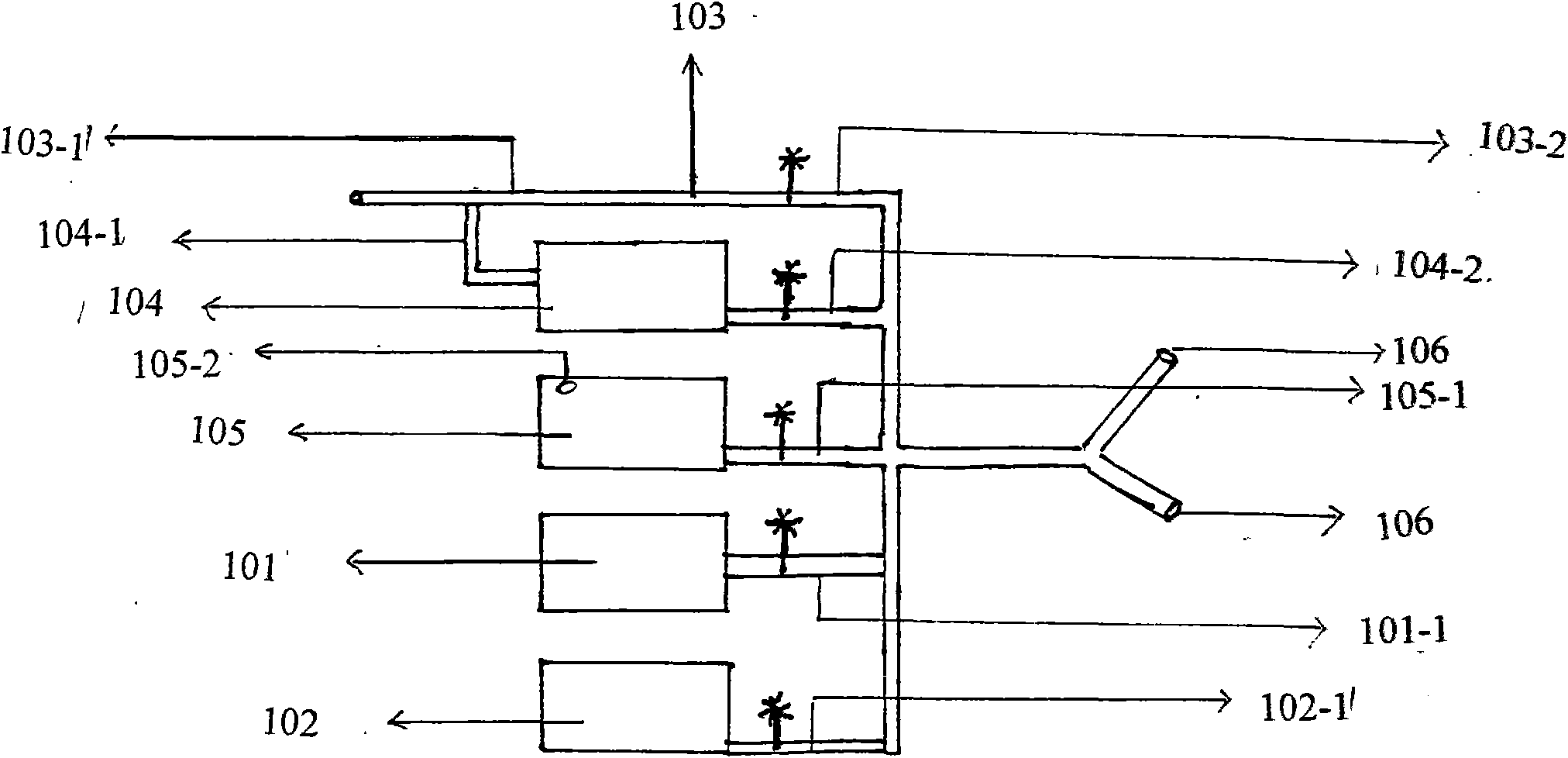

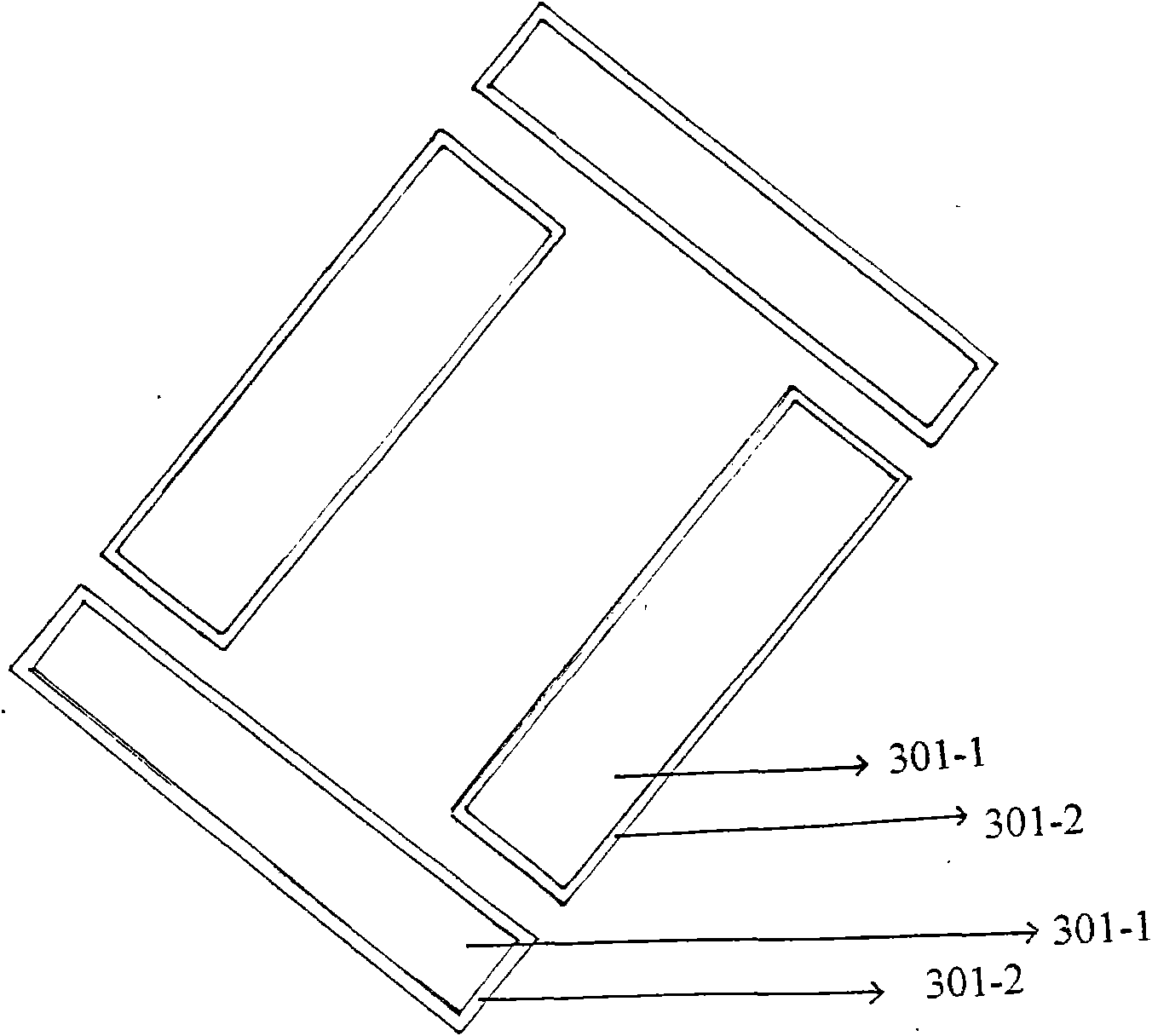

Mobile spraying-collecting car washer

InactiveCN101574959AReasonable and practical structureLow costCleaning apparatus for vehicle exteriorsVehicle frameSprayer

The invention discloses a mobile spraying-collecting car washer, comprising three parts of a spraying-collecting part, a control part and an accessory part; the spraying-collecting part comprises a water sprayer, a water-spraying washing scrubber, a water collector, a water-collecting wiper, an external adapter tube of running water, a clean water tank and a foam tank; the control part comprises an electronic control panel; and the accessory part comprises a waste water collector, an anti-contamination work fence, a chassis, a recycling bin and an illumination lamp bracket. When the car washeris used, a power supply is connected with a running water tap firstly, then a water outlet tube switch of the external adapter tube of running water is turned on by adopting the electronic control panel, the water flows into the water-spraying washing scrubber via a general exit and is sprayed out from a water-spraying hole arranged on the water-spraying washing scrubber, and the original water pressure is hardly lowered down; the water-spraying washing scrubber is provided with fluff and a water form regulating switch, therefore that washing the surface of an object is very flexible and safe, instead of adopting traditional high-pressure car washing every time; after the car is washed, the water drops on the car and the waste water on the ground are removed by the water collector and thewater-collecting wiper, thus improving the speed and safety for washing cars, and achieving stopping with washing at any time and zero-pollution discharge.

Owner:成都易禧科技管理发展有限公司

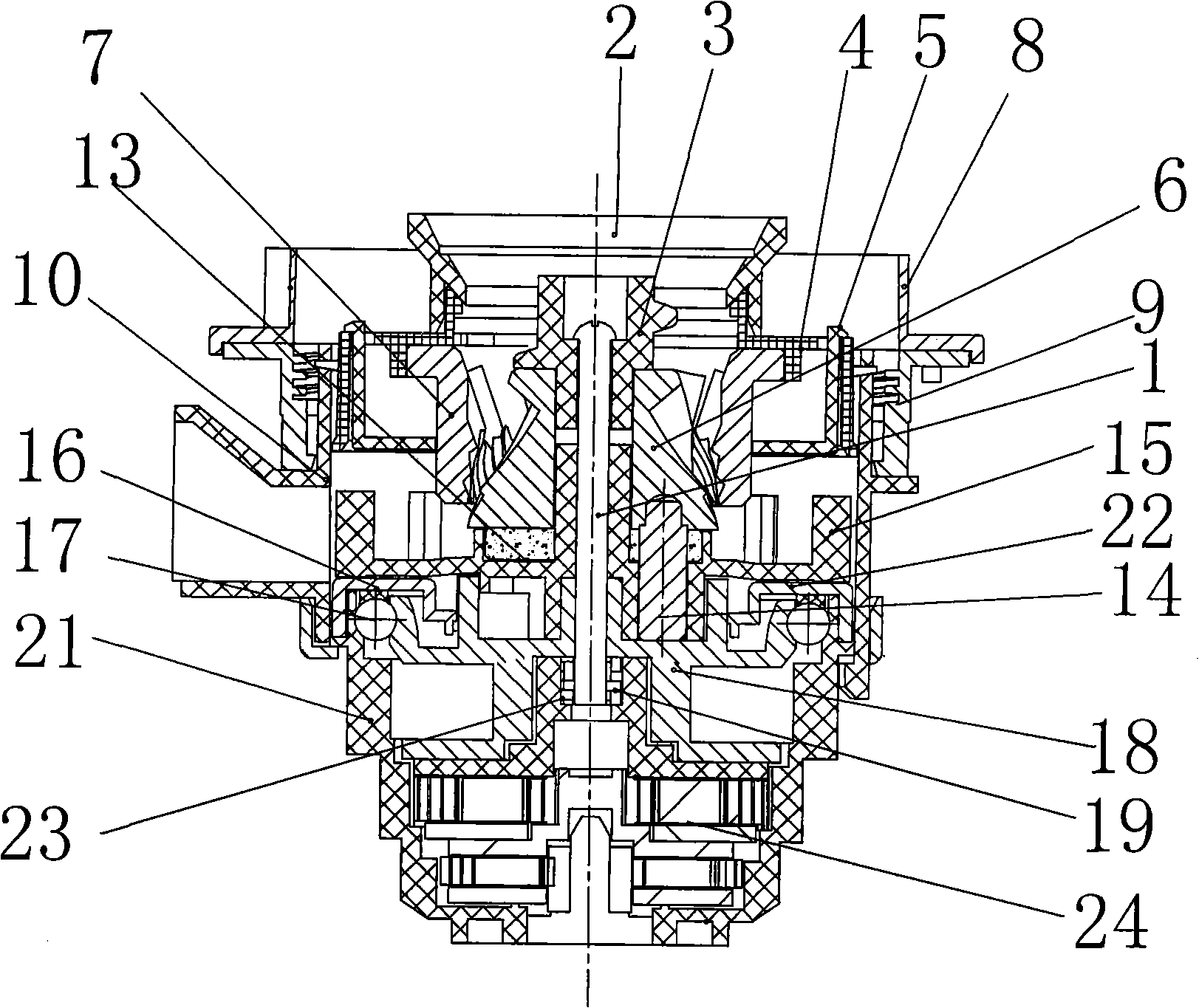

Cutter head structure of detachable electric shaver

InactiveCN101683739BHigh rotational freedomShaving feels goodMetal working apparatusRotational degrees of freedomEngineering

The invention relates to a cutter head structure of a detachable electric shaver, comprising a plurality of cutter blade assemblies capable of rotatably cutting, and the cutter blade assemblies are in joggled connection with a central transmission gearwheel on a main support by respective transmission unit. The cutter head structure is characterized in that the main support is sleeved on the lower cover of the main support, whereas the lower cover of the main support is connected with a cutter blade connecting seat by spherical coordination; and an elastic element is supported between the main support and the cutter blade connecting seat. The cutter head structure has big rotational degree of freedom, simple and practical structure and easy manufacture.

Owner:叶常明

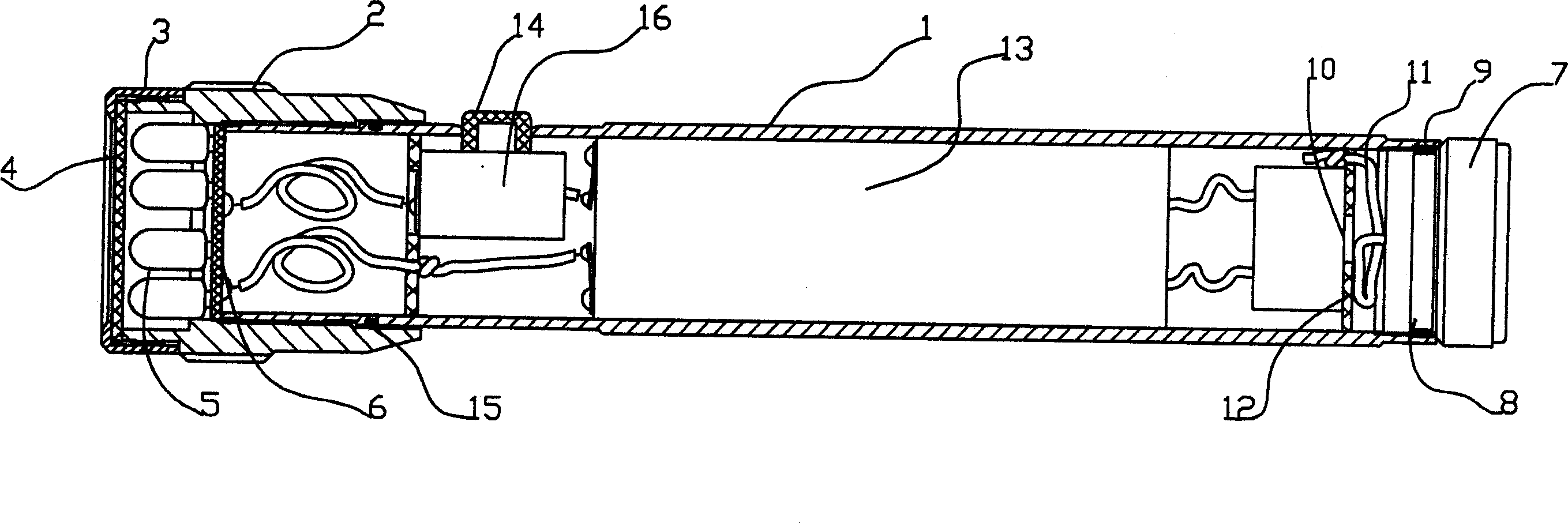

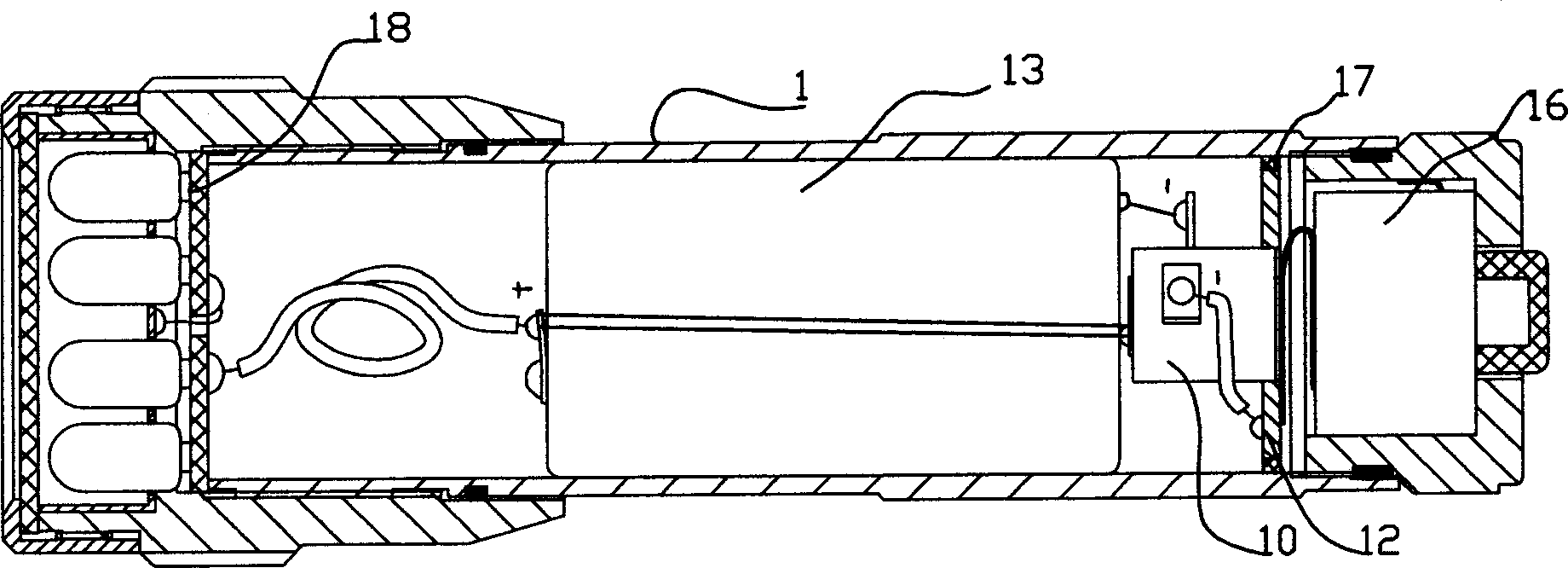

Chargeable flashlight

InactiveCN1804454AAvoid tarnishingAvoid cloggingDomestic lightingPoint-like light sourceForeign matterEngineering

The invention relates to a charge electric torch which comprises a cylinder, a light head, a light base, and a switch. Wherein, the light head is connected to the cylinder inside which the charge battery is arranged as power resource; the electric torch has a switch to control the power resource and a plug connecting the charge battery used to charge. The invention is characterized in that: the end of cylinder can be detachable from an end cap; said plug is fixed near the end. The invention has reasonable structure which can avoid the plug form jam and polluted by outside foreign matters, to prolong the service life and insulate water.

Owner:邵成海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com