Crease-resist device for adhesive tape winding

A tape and rewinding roller technology, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve problems such as affecting product quality, easy to produce wrinkles, etc., to achieve stable winding quality, improve product quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

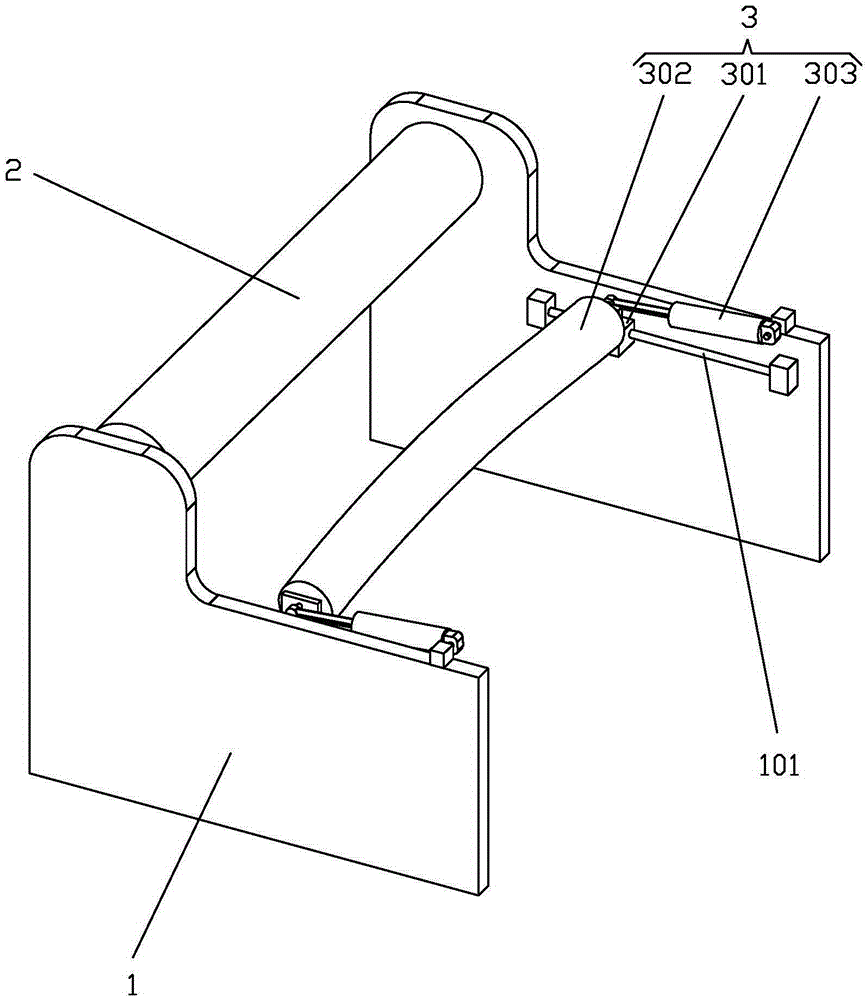

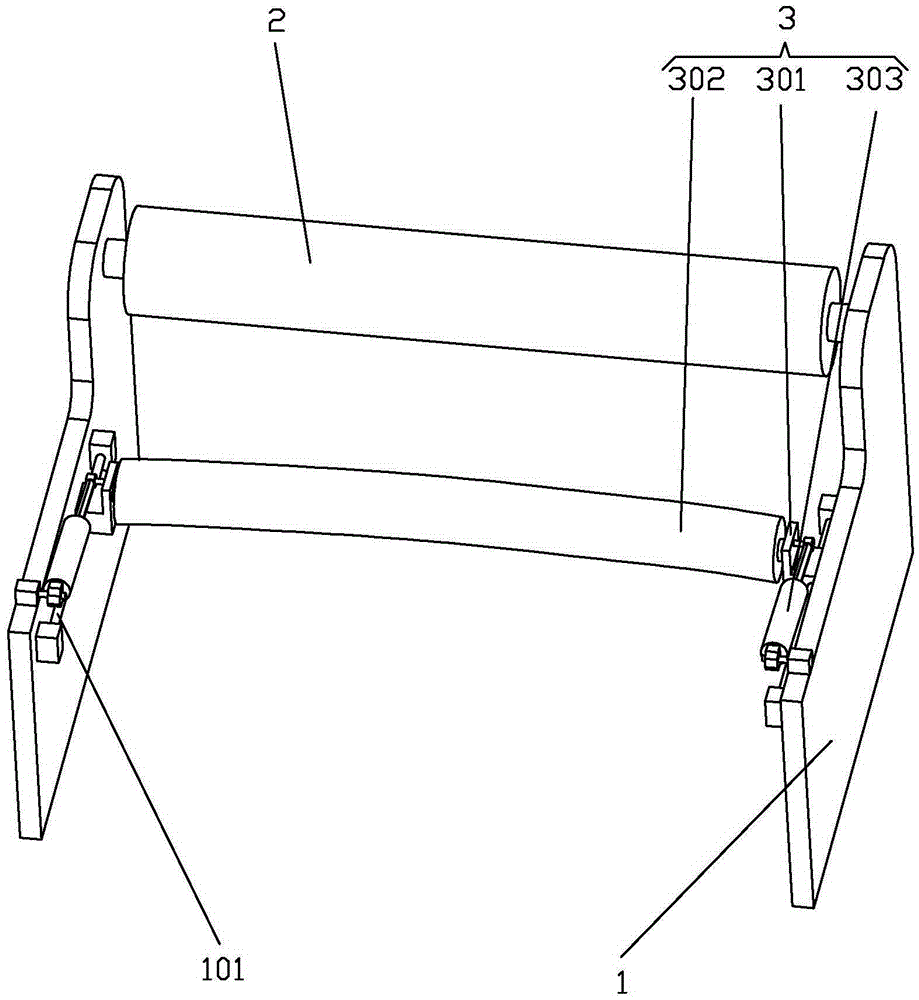

[0014] refer to Figure 1~Figure 2 , a tape rewinding anti-wrinkle device, including a frame 1, a winding roller 2 and an anti-wrinkle mechanism 3, the rewinding roller 2 is rotatably mounted on the rear end of the frame 1, and the anti-wrinkle mechanism 3 includes Two roller bases 301 that are connected to the front end of the frame 1 and can slide back and forth, banana rolls 302 are installed on the two roll bases 301, the surface of the banana rolls 302 is provided with an elastic rubber layer, and the roll bases 301 are also connected There is a power mechanism 303 for propelling it to move. With the above-mentioned structure, the adhesive tape bypasses under the banana roller 302 of the anti-wrinkle mechanism 3 during winding, forming a wrap angle close to 90° on the banana roller 302, and the roller seat 301 is pushed by the power mechanism 303 so that the banana roller 302 maintains pressure on the adhesive tape On the one hand, the tape is tensioned, and on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com