Fast water-cooling device and wire hot tinning production equipment

A technology of water cooling device and production equipment, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the physical and mental impact of operators in the workshop environment, the increase of workshop air temperature, the hardness of large-sized copper wires, etc. problems, to achieve the effect of simple internal wiring structure, reduced cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

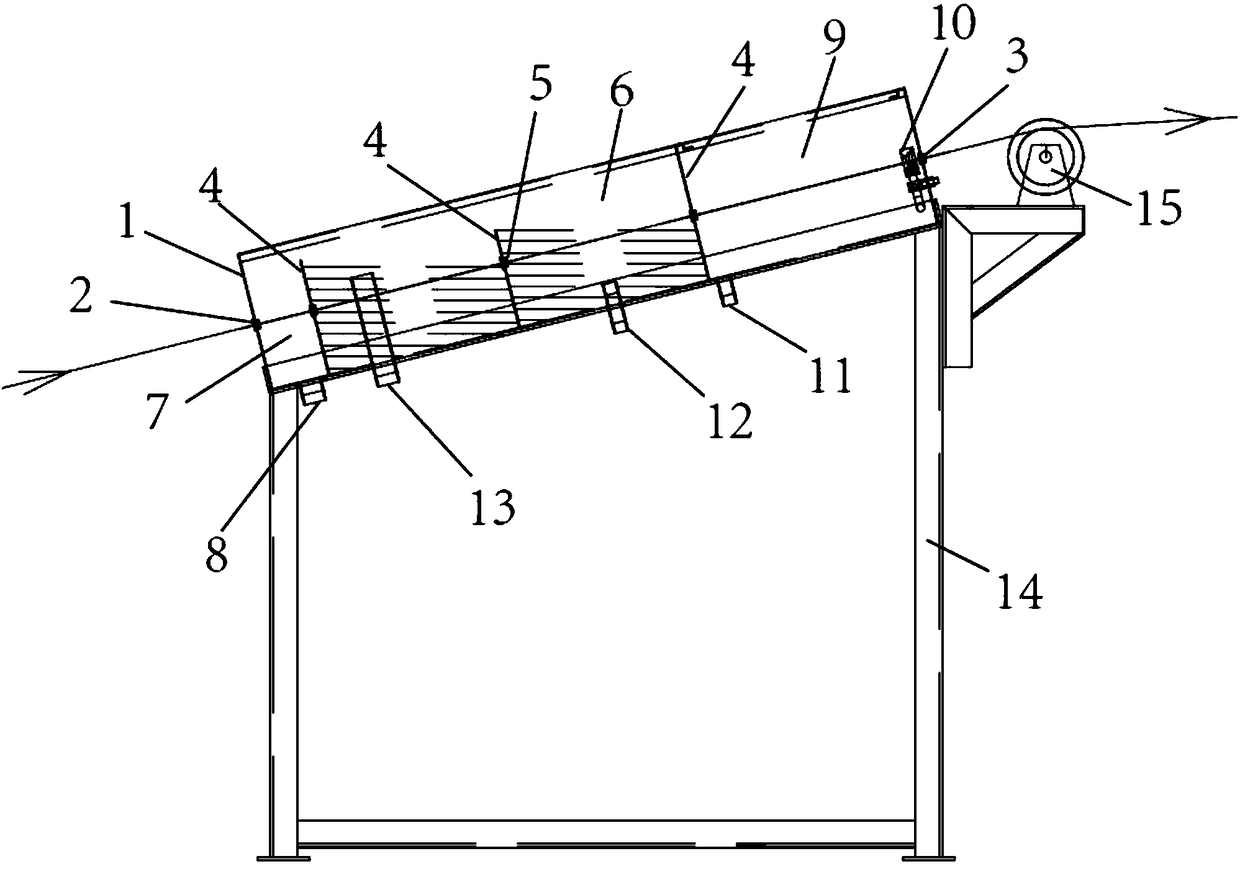

[0024] refer to figure 1 As shown, an embodiment of the hot-dip tinning rapid water cooling device of the present invention includes a water tank 1 arranged obliquely, and the top of the water tank may be open or provided with a tank cover; the two ends of the water tank in the inclined direction are respectively provided with inlets 2 and the wire outlet 3, the wire inlet is arranged on the inclined low end, the wire rod passes through the wire inlet, and passes through the wire outlet; at least two partition plates 4 are arranged in the water tank, and three partitions are used here Take the board as an example. First, there is a wire opening 5 on the partition board, which is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com