Patents

Literature

453 results about "Adamite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adamite is a zinc arsenate hydroxide mineral, Zn₂AsO₄OH. It is a mineral that typically occurs in the oxidized or weathered zone above zinc ore occurrences. Pure adamite is colorless, but usually it possess yellow color due to Fe compounds admixture. Tints of green also occur and are connected with copper substitutions in the mineral structure. Olivenite is a copper arsenate that is isostructural with adamite and there is considerable substitution between zinc and copper resulting in an intermediate called cuproadamite. Zincolivenite is a recently discovered mineral being an intermediate mineral with formula CuZn(AsO₄)(OH). Manganese, cobalt, and nickel also substitute in the structure. An analogous zinc phosphate, tarbuttite, is known.

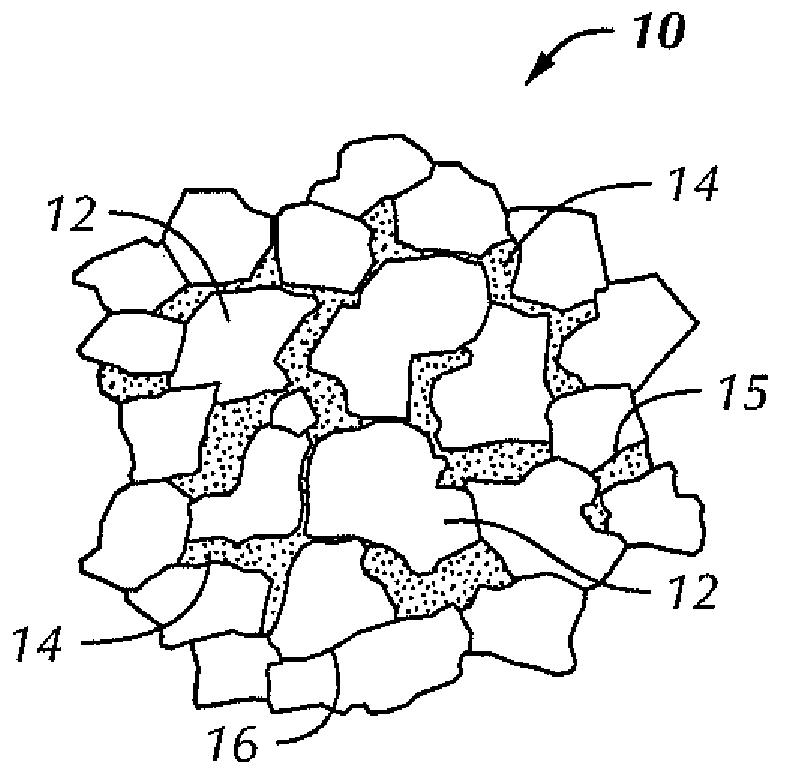

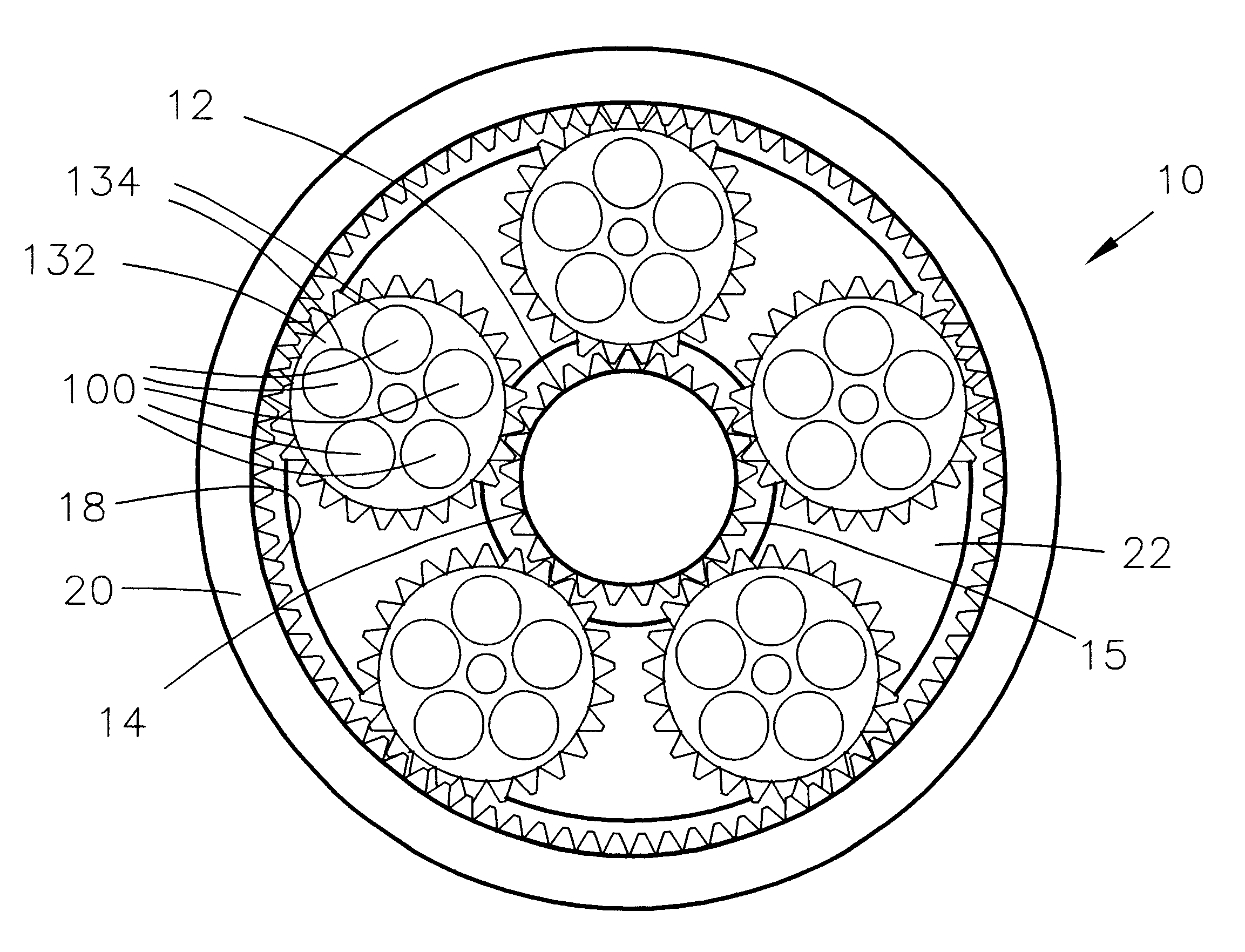

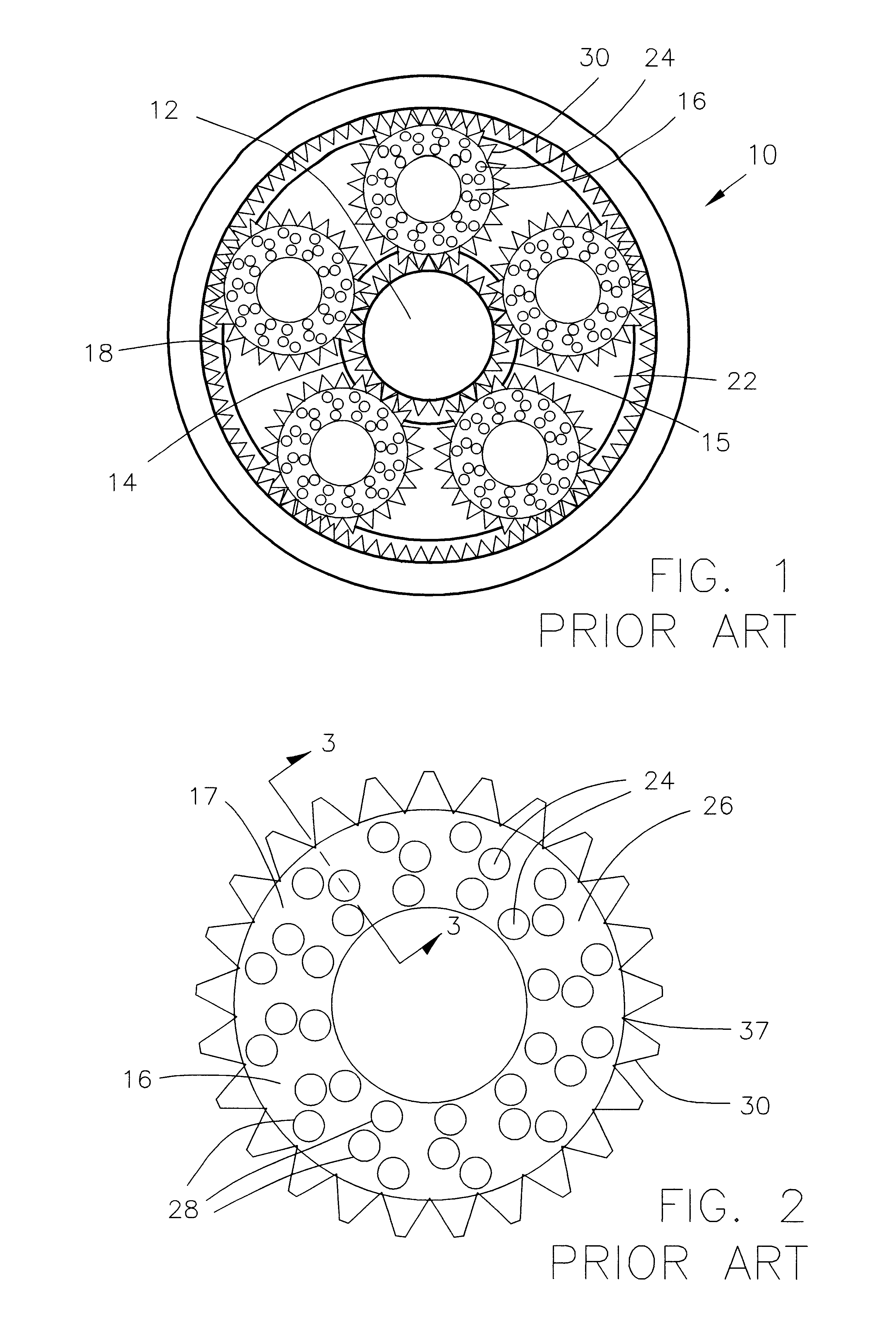

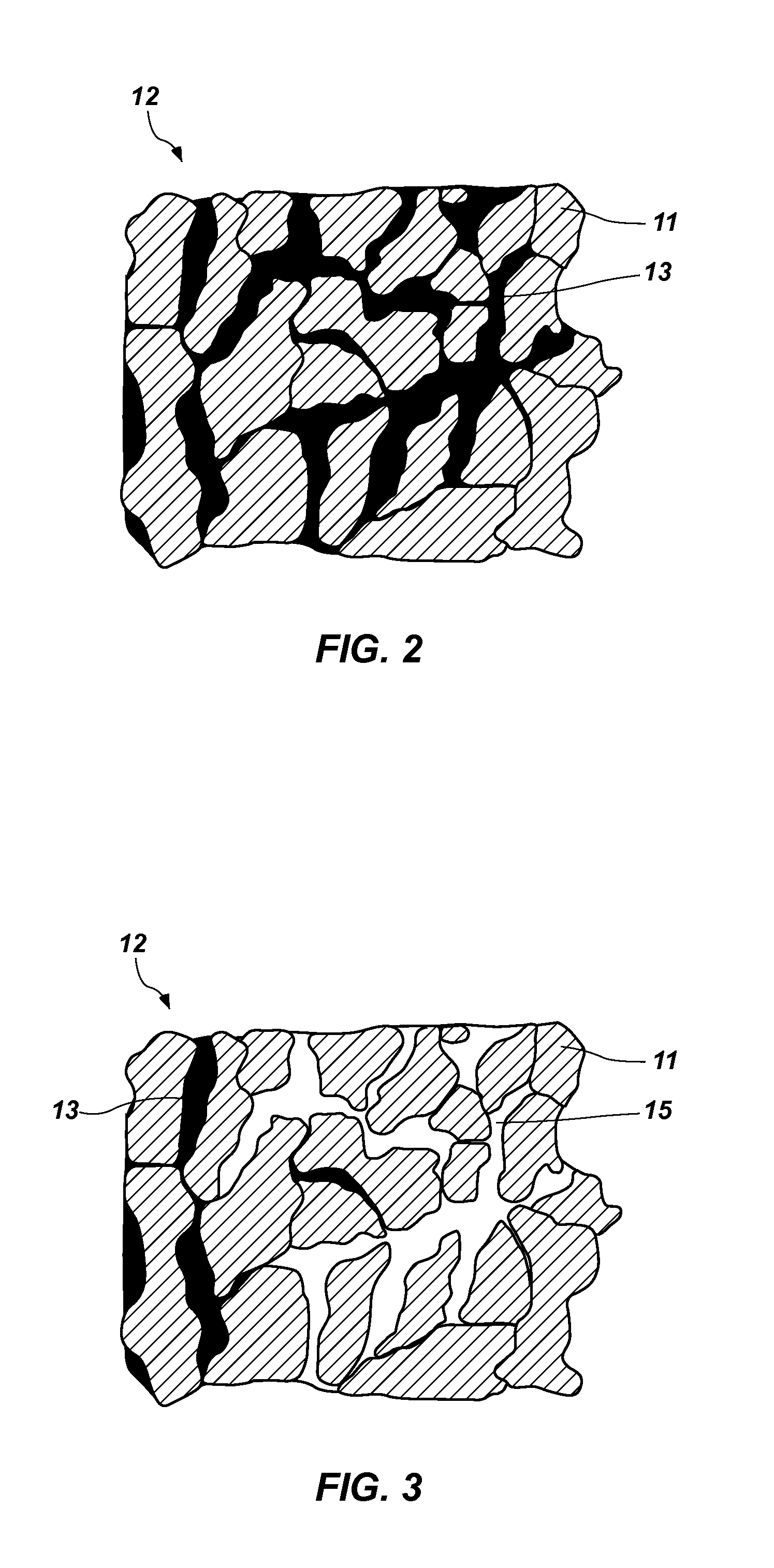

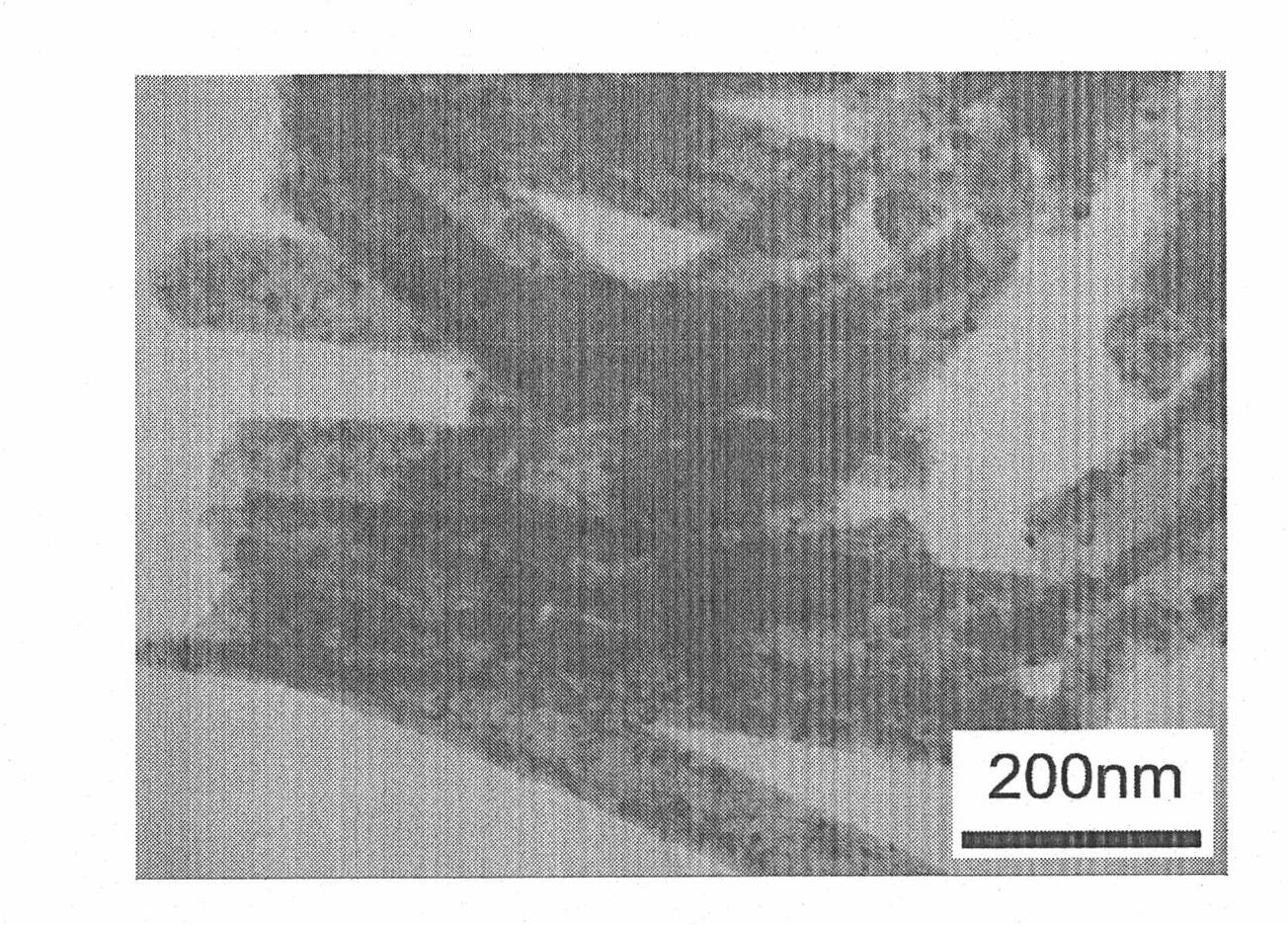

Polycrystalline composites reinforced with elongated nanostructures

A sintered polycrystalline composite for cutting tools that includes a plurality of diamond or cubic boron nitride particles; a plurality of nanotube materials; and a refractory or binder material is disclosed. Methods of forming such polycrystalline composites that include integrating or mixing a plurality of nanotube materials with diamond or cubic boron nitride particle and / or refractory or binder particles are also disclosed.

Owner:SMITH INT INC

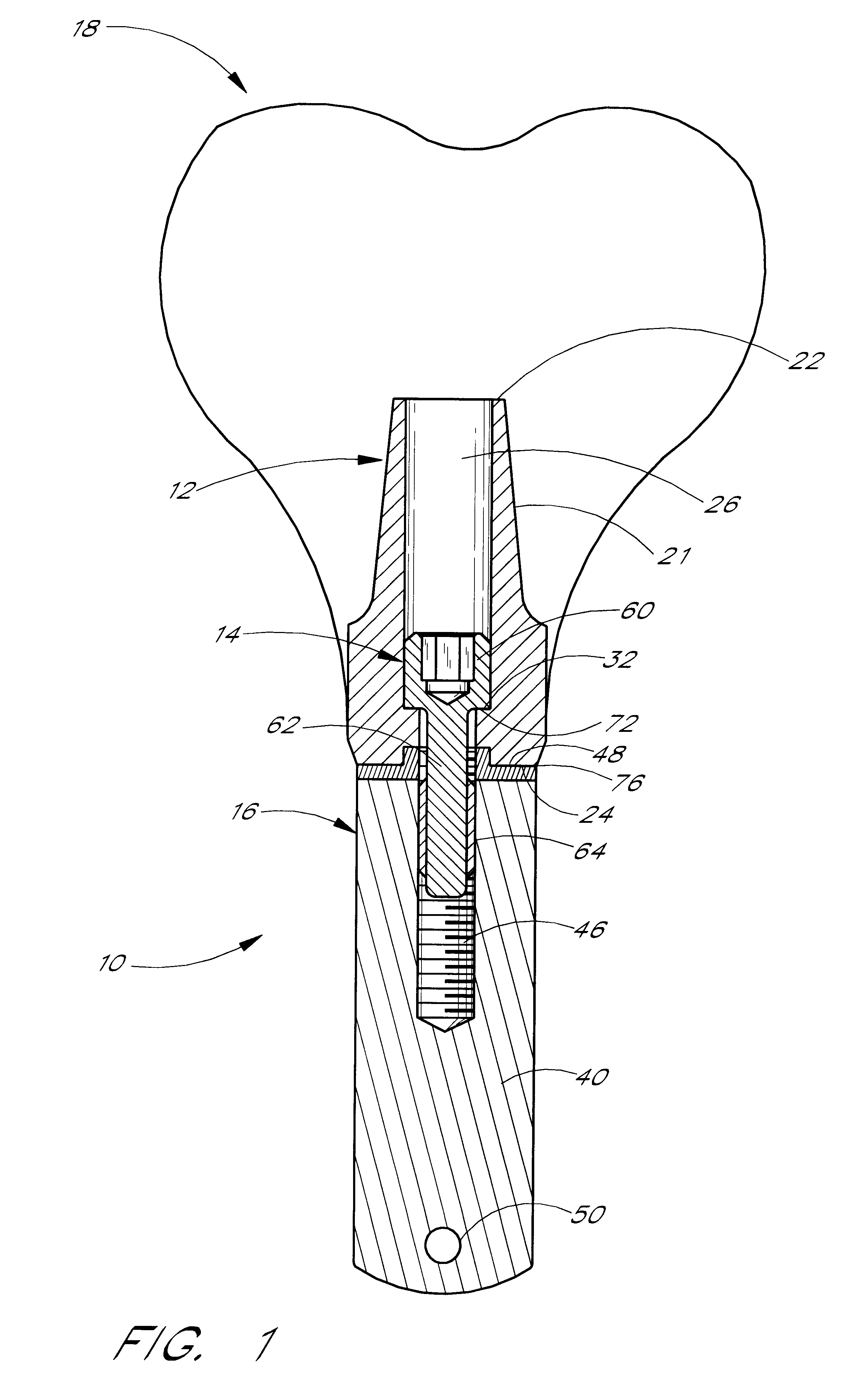

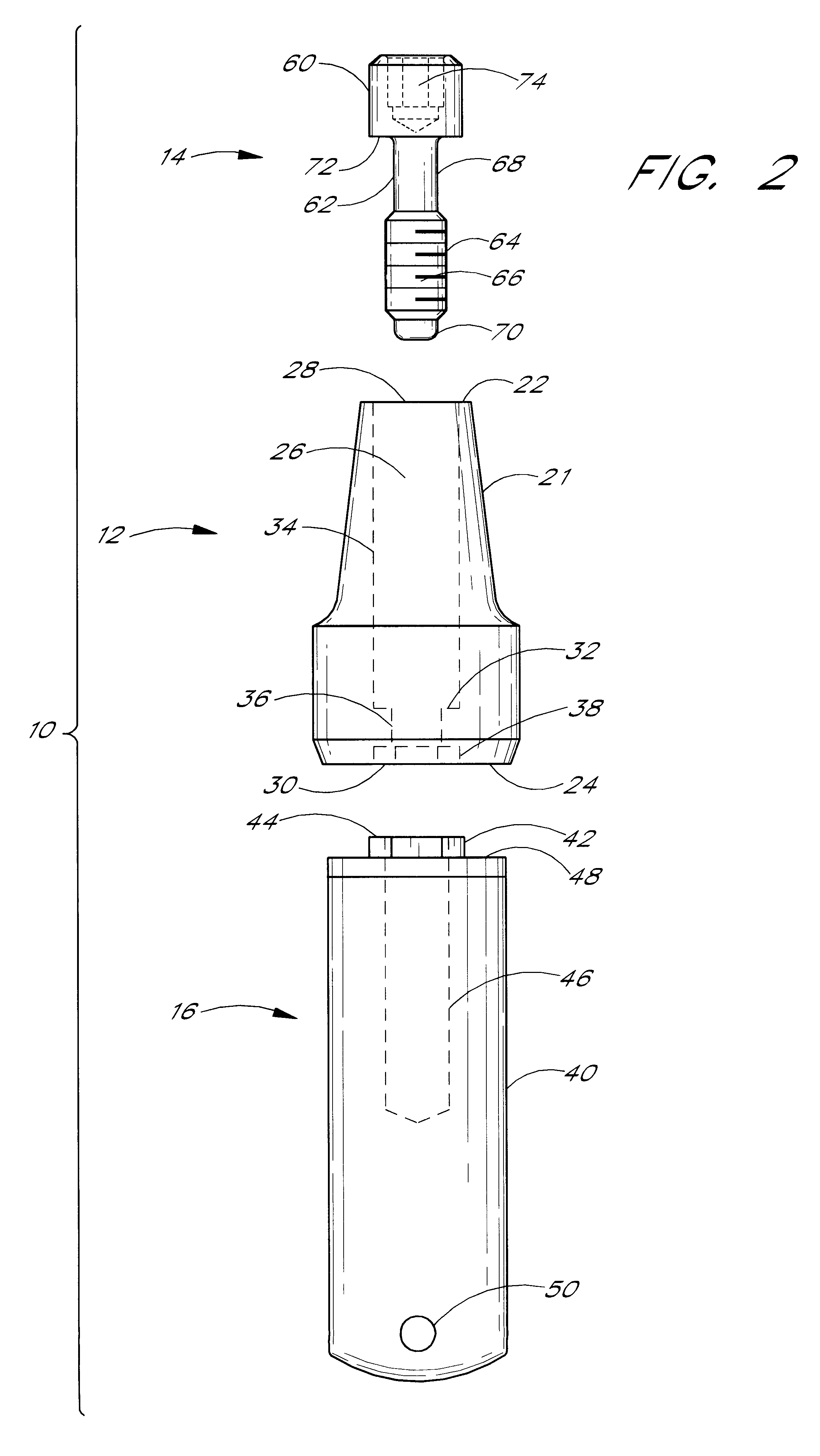

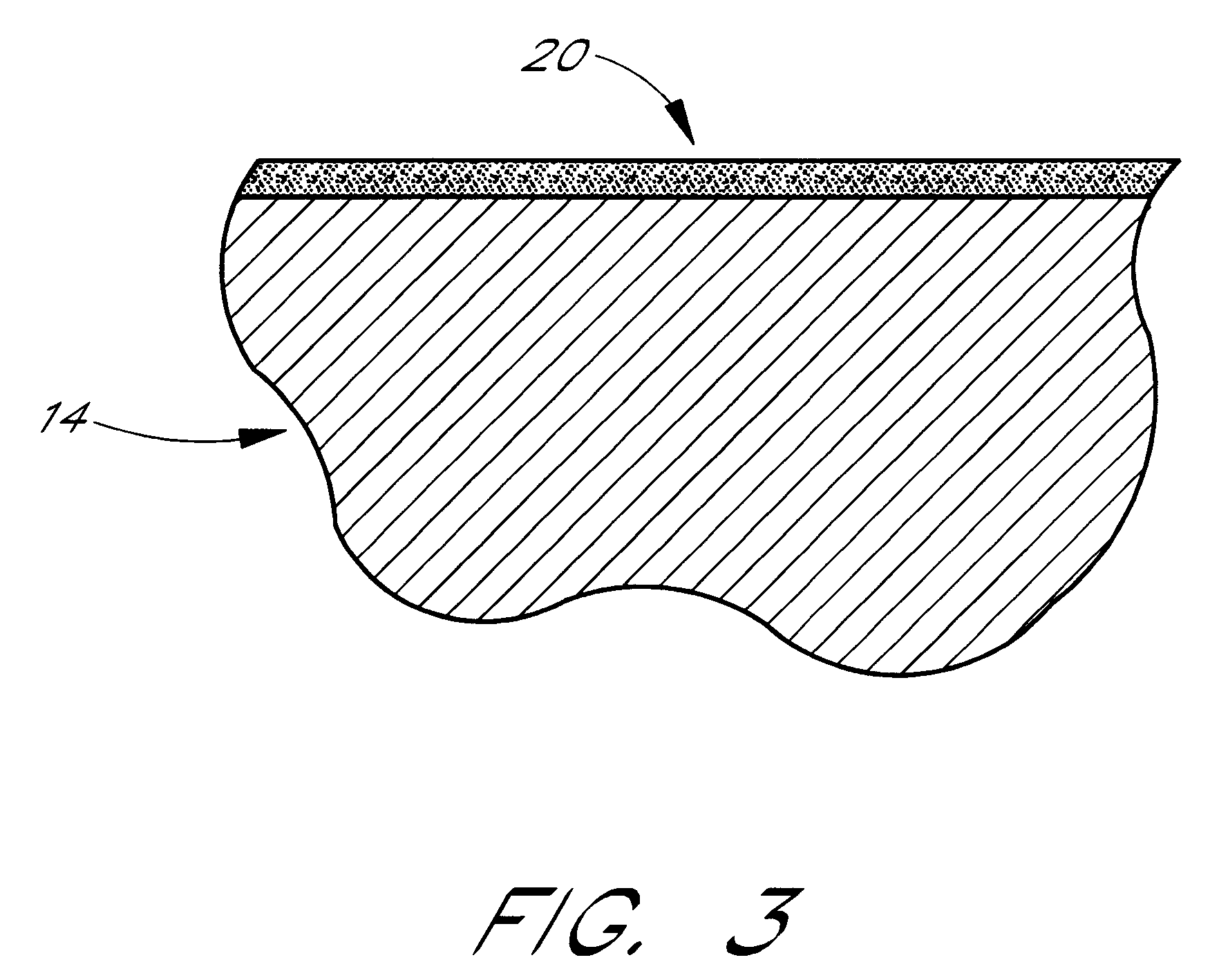

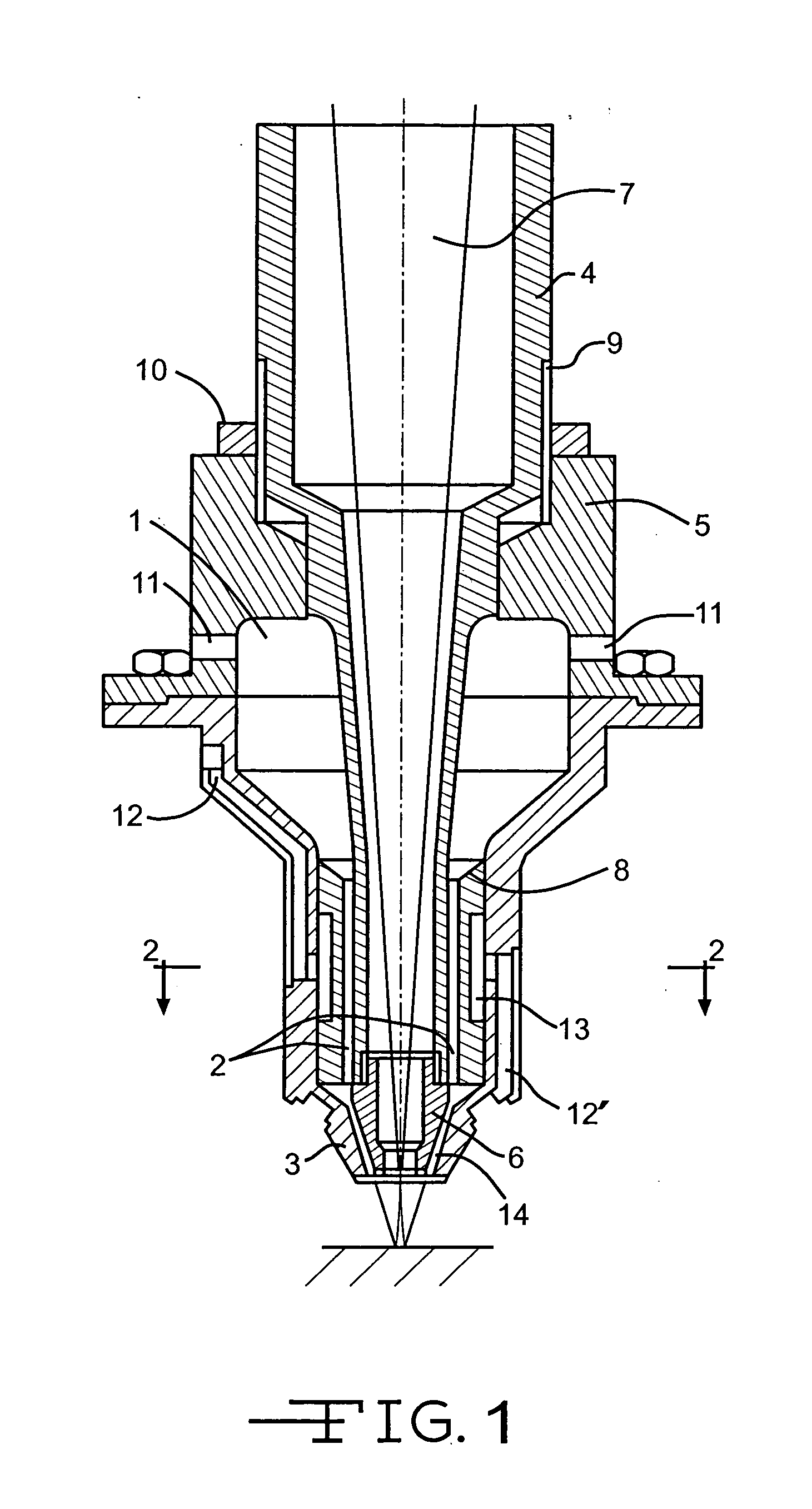

Diamond-like carbon coated dental retaining screws

The invention relates to a coated dental screw for retaining and securing components of a dental prosthetic implant stack. The screw is coated with a hard carbon coating / film to provide a low friction surface finish which advantageously results in improved preloading of the screw, and hence a high clamping force between the components of the dental prosthetic implant stack. The coating can comprise diamond-like carbon (DLC), amorphous diamond, crystalline diamond, or a combination thereof. The dental screw can include abutment retaining screws and prosthesis retaining screws. Other advantages provided by the hard carbon coating include high mechanical surface hardness, biocompatibilty, corrosion resistance, chemical inertness and low cost.

Owner:NOBEL BIOCARE SERVICES AG

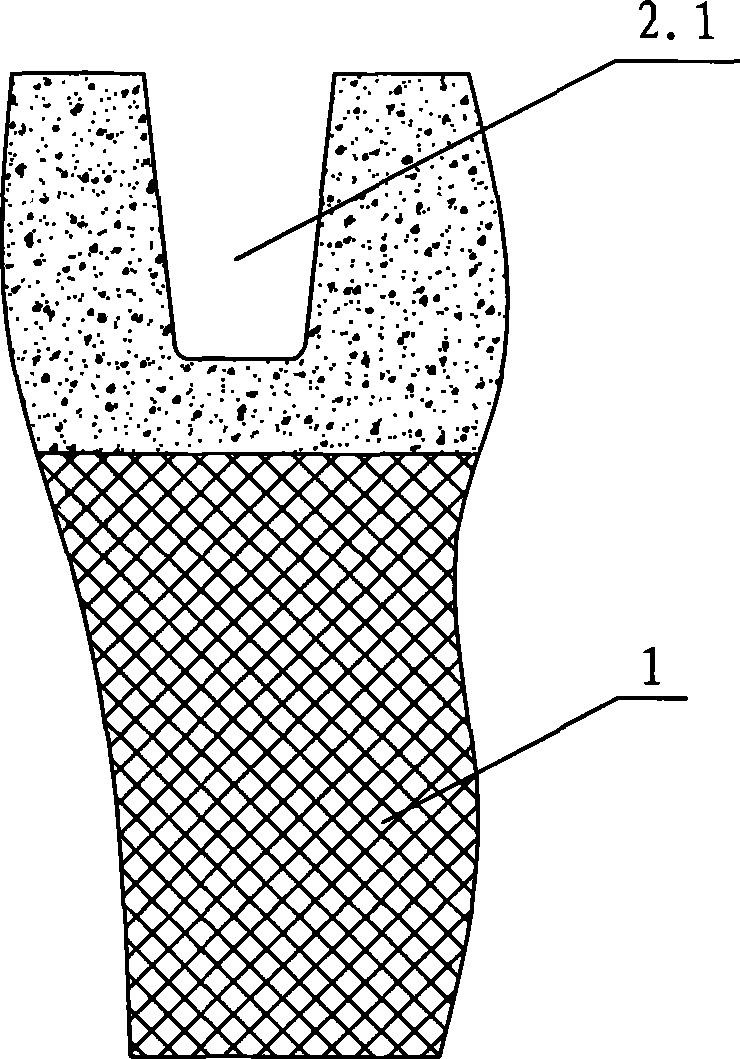

Resin anchoring agent diamond grinding wheel and production method thereof

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

Diamond anode

ActiveUS7359487B1Avoid damageImprove cooling effectX-ray tube laminated targetsX-ray tube anode coolingOptoelectronicsMaterials science

According to one aspect of the invention a robust anode structure and methods of making and using said structure to produce ionizing radiation are disclosed. An ionizing radiation producing layer is bonded to the target side of a highly conductive diamond substrate, by a metal carbide layer. The metal carbide layers improves the strength and durability of the bond, thus improving heat removal from the anode surface and reducing the risk of delaminating the ionizing radiation producing layer, thus reducing degradation and extending the anode's life. A smoothing dopant is alloyed into the radiation producing layer to facilitate keeping the layer surface smooth, thus improving the quality of the x-ray beam emitted from the anode. In an embodiment, the heat sink comprises a metal carbide skeleton cemented diamond material. In another embodiment, the heat sink is bonded to the diamond substrate structure in a high temperature reactive brazing process.

Owner:NOVA MEASURING INSTRUMENTS INC

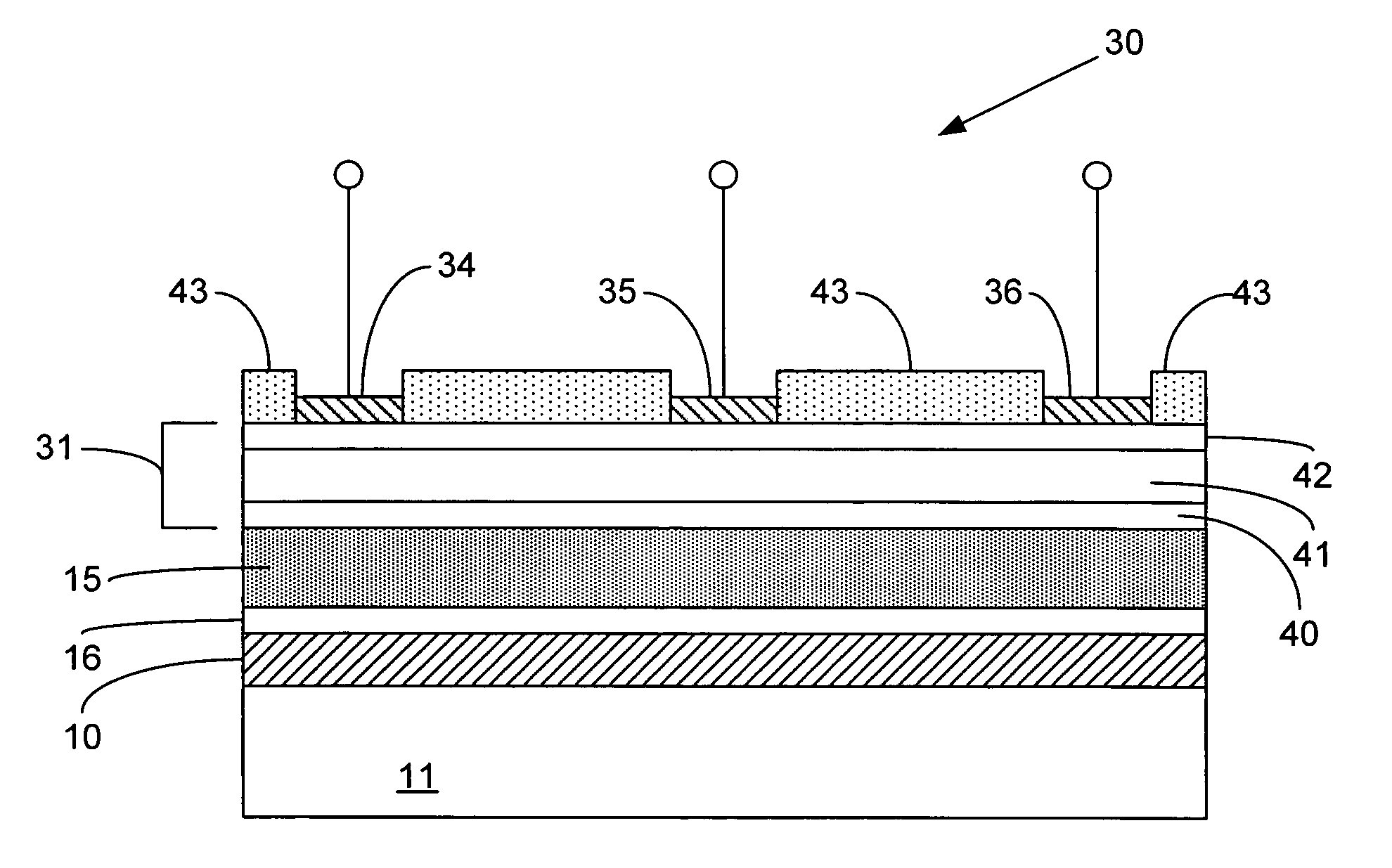

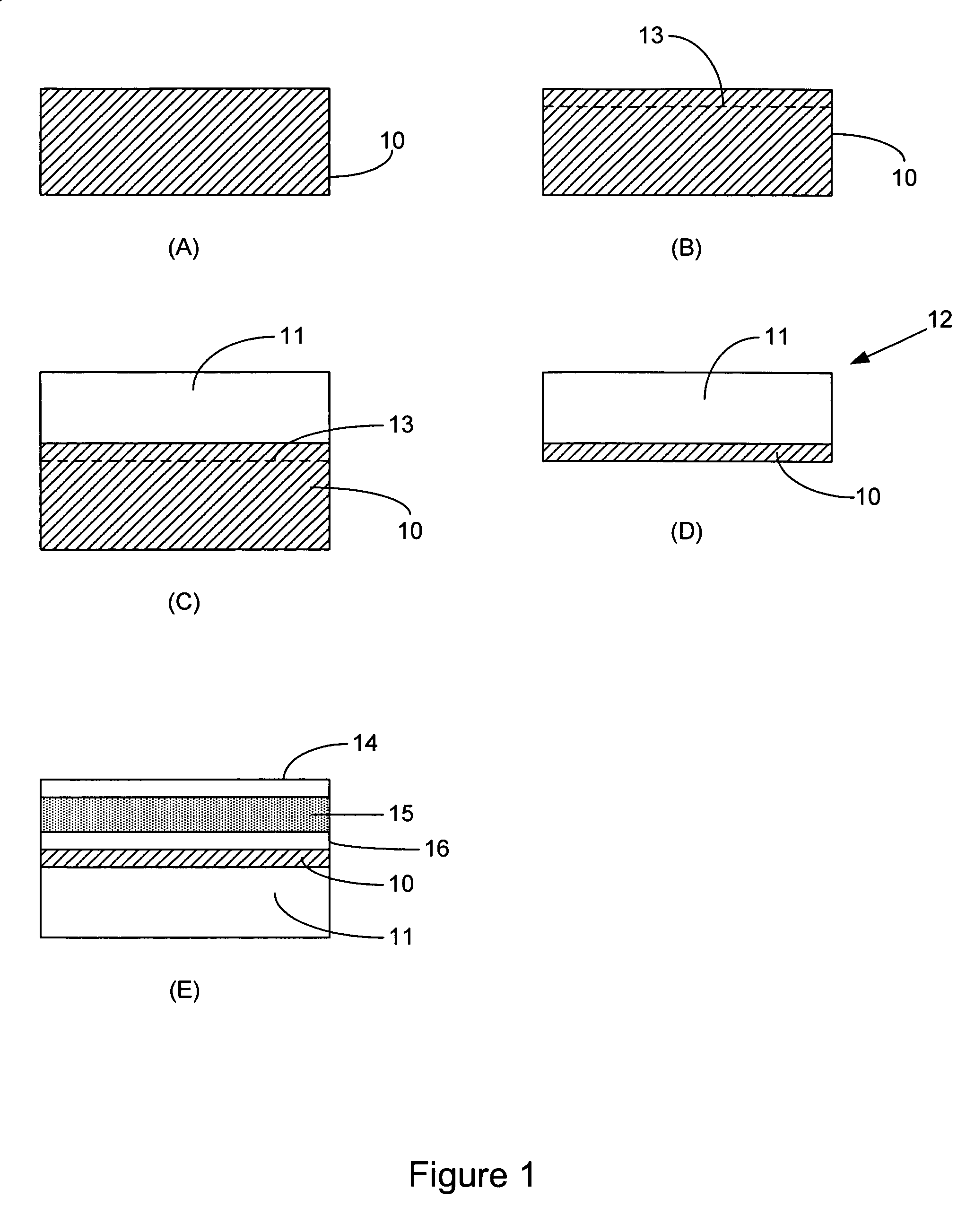

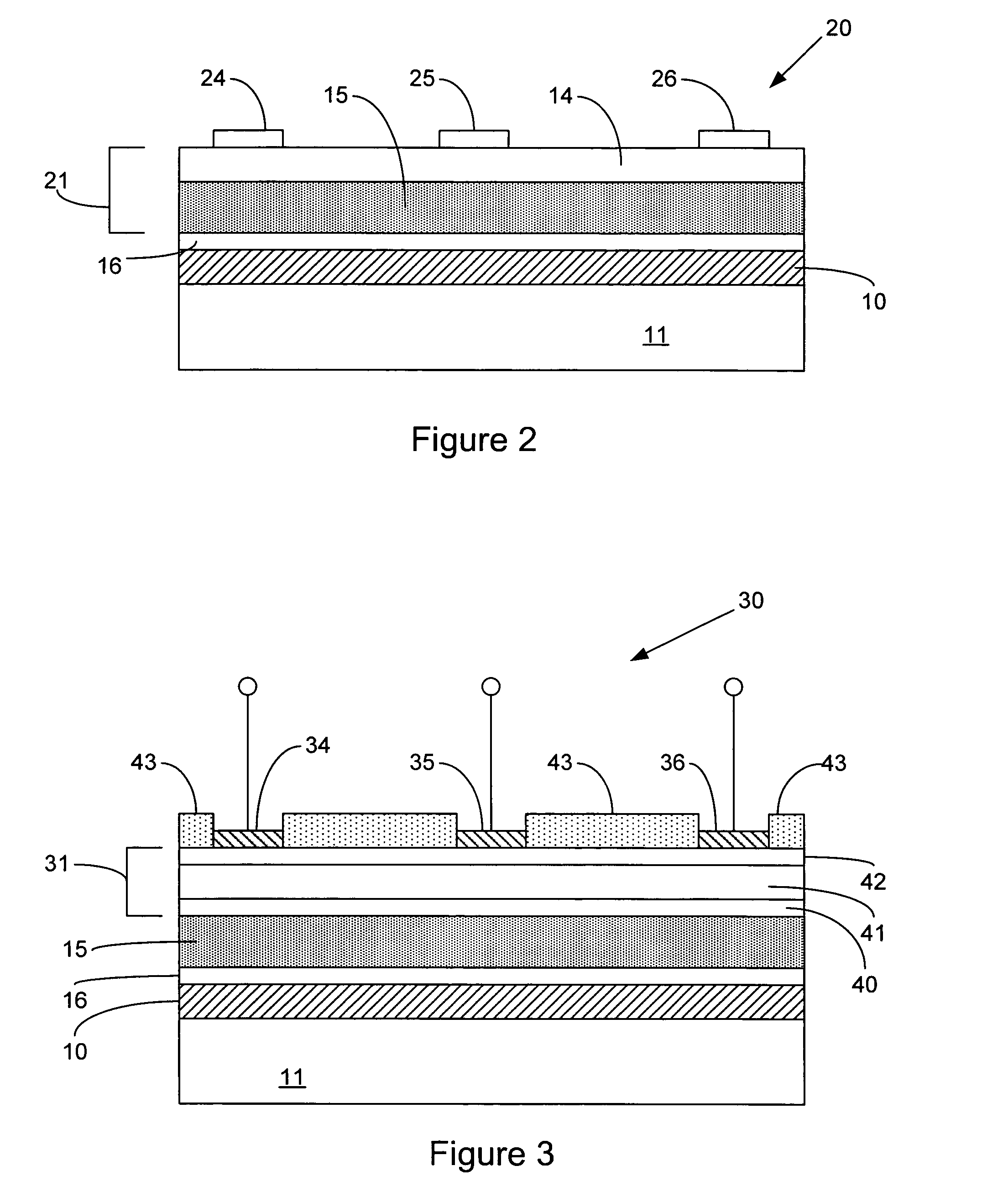

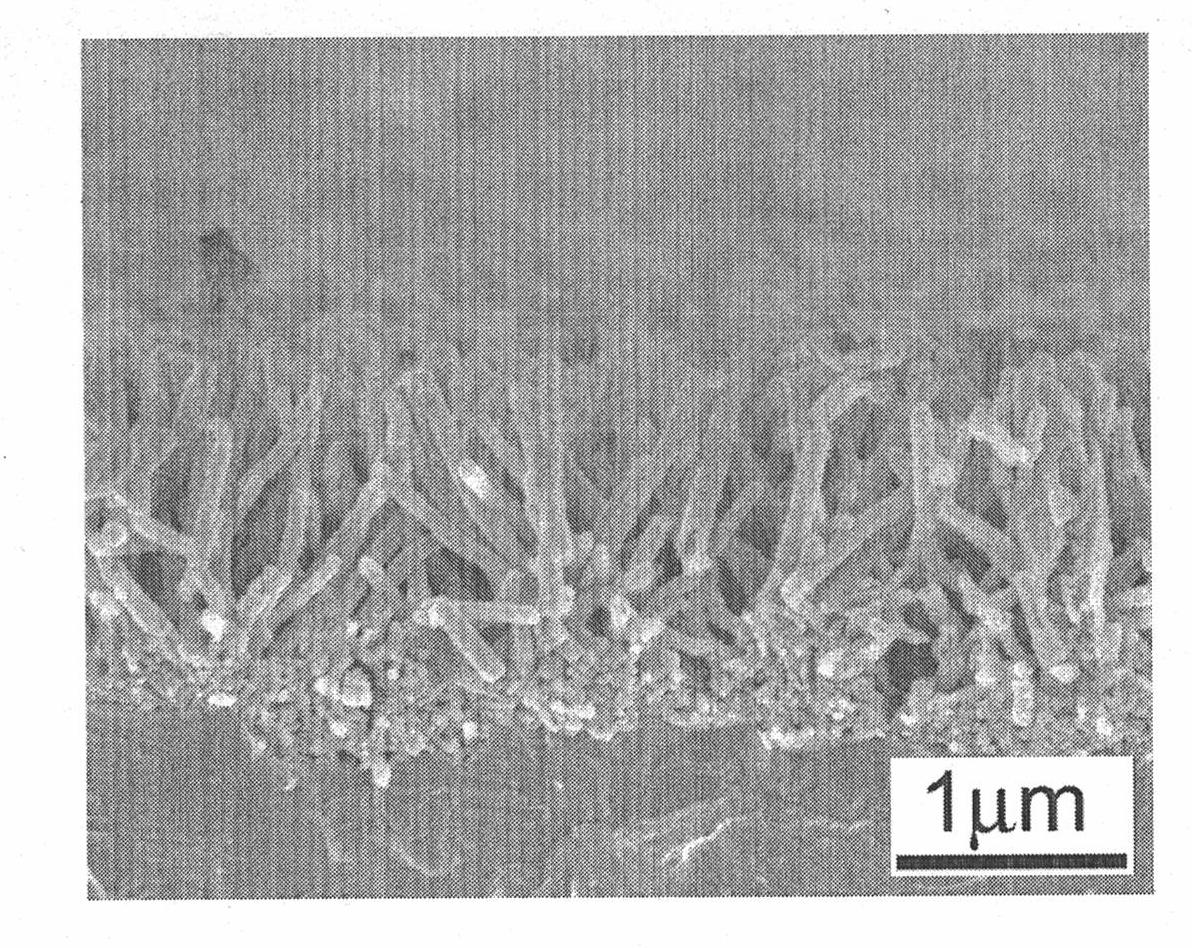

Silicon carbide on diamond substrates and related devices and methods

ActiveUS7033912B2Improve thermal conductivityReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor structure

Owner:WOLFSPEED INC

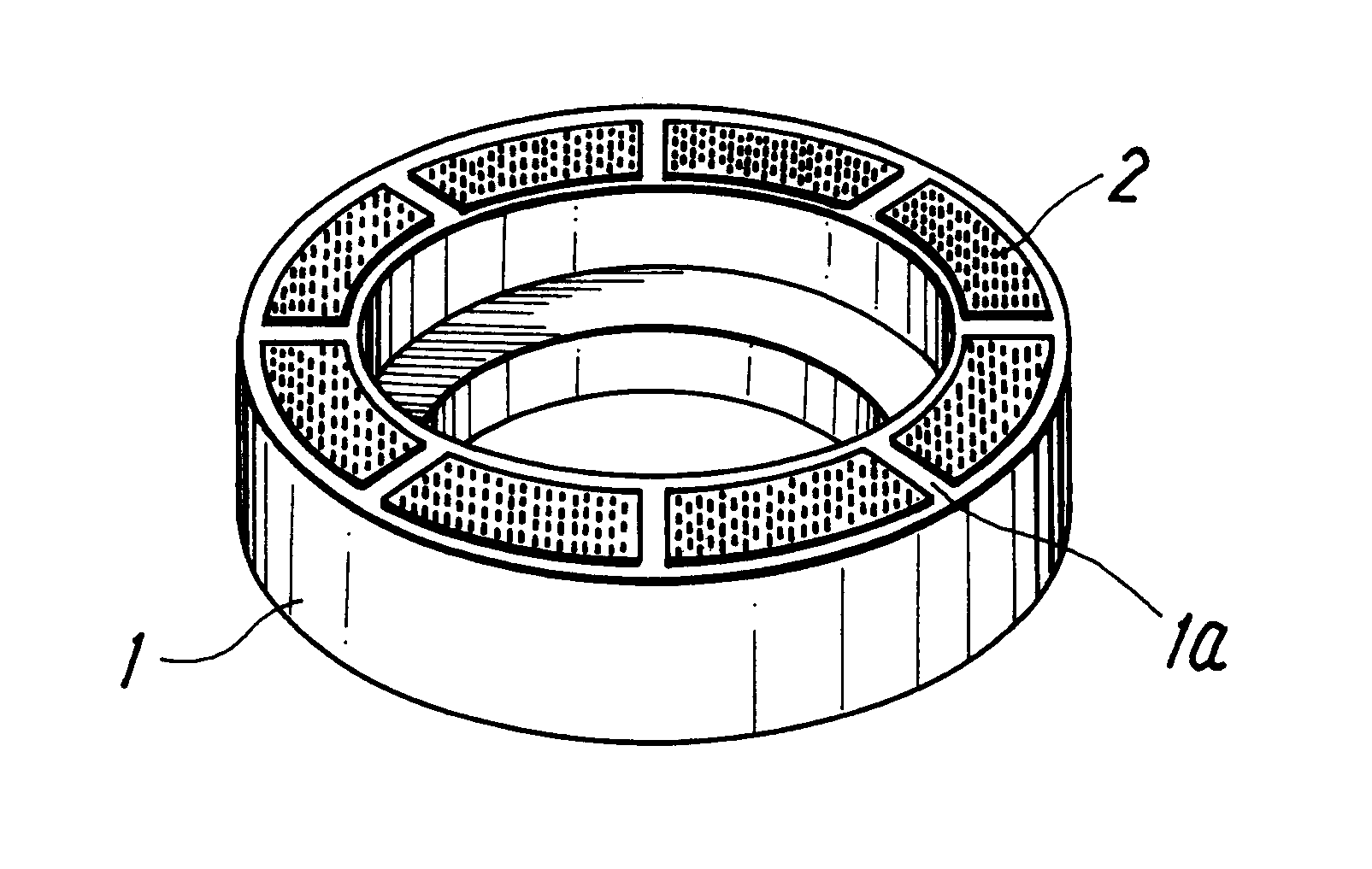

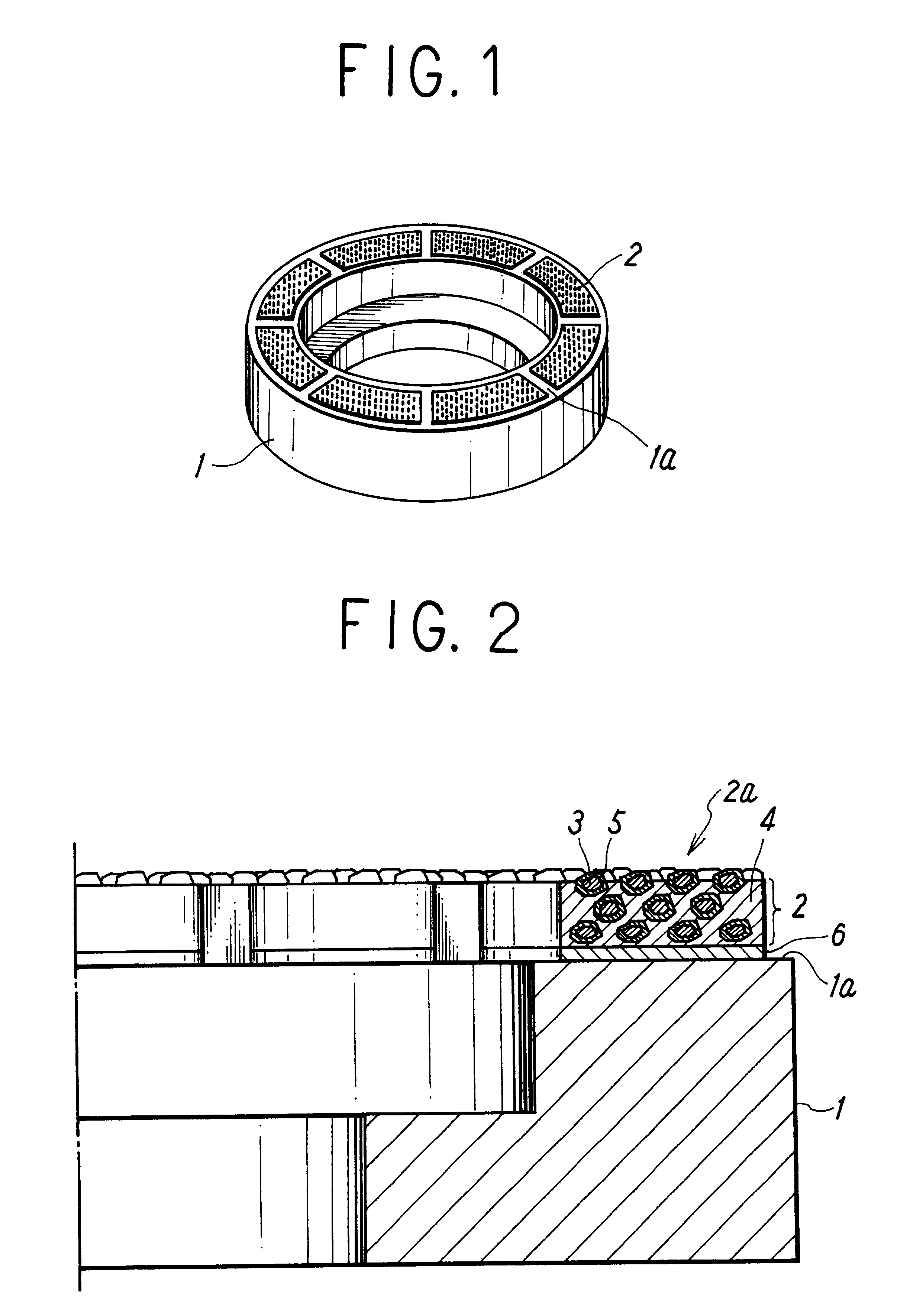

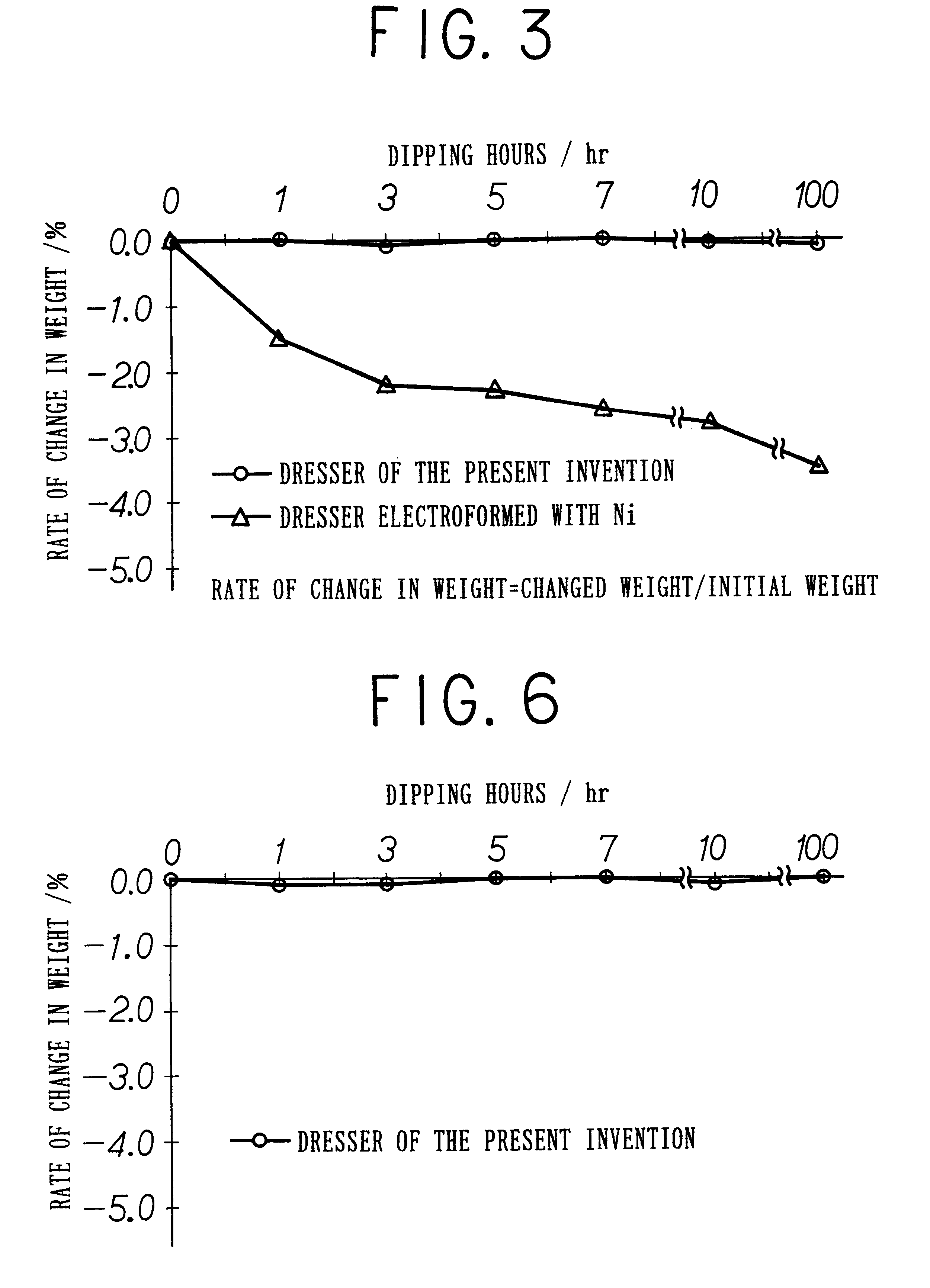

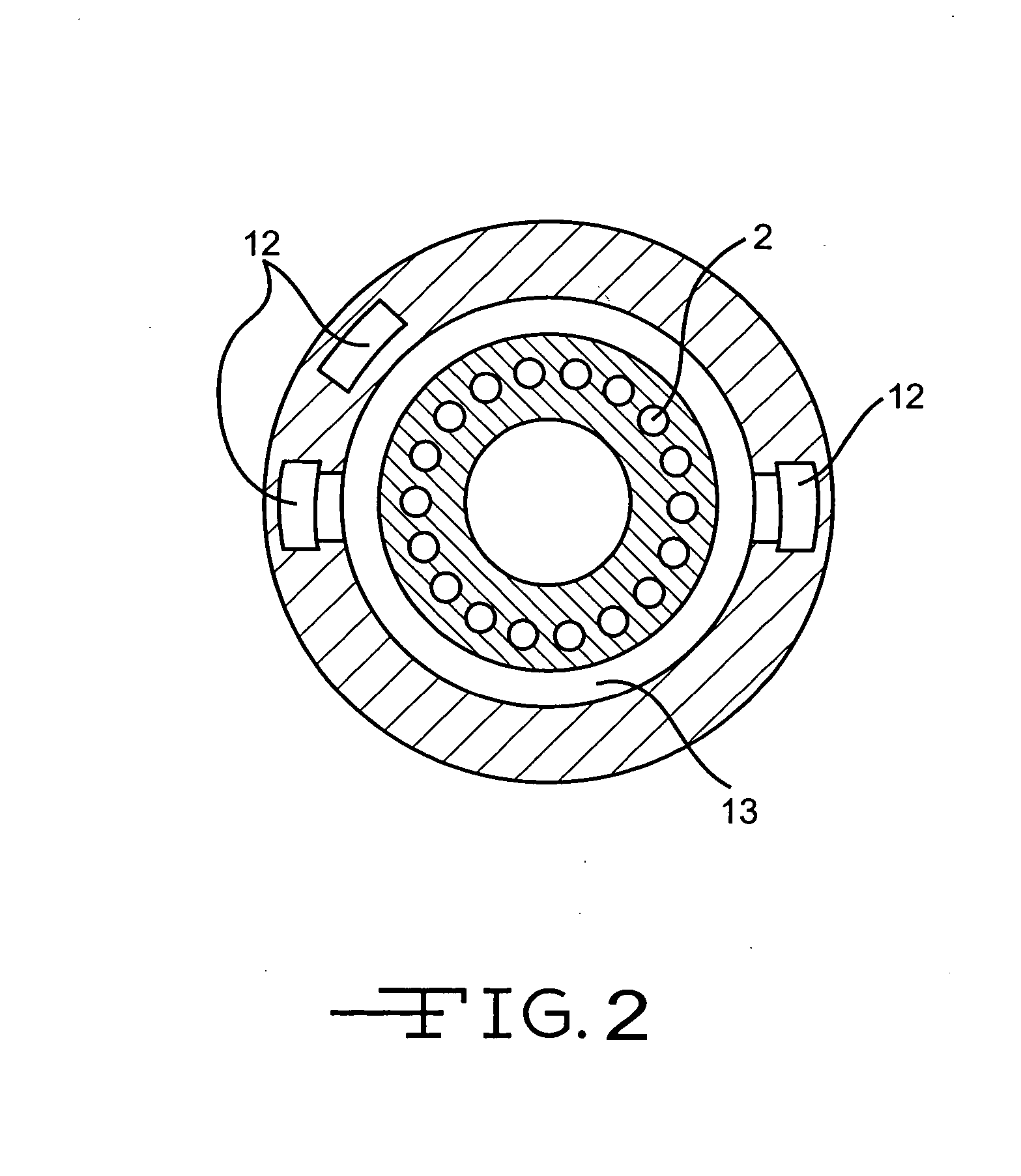

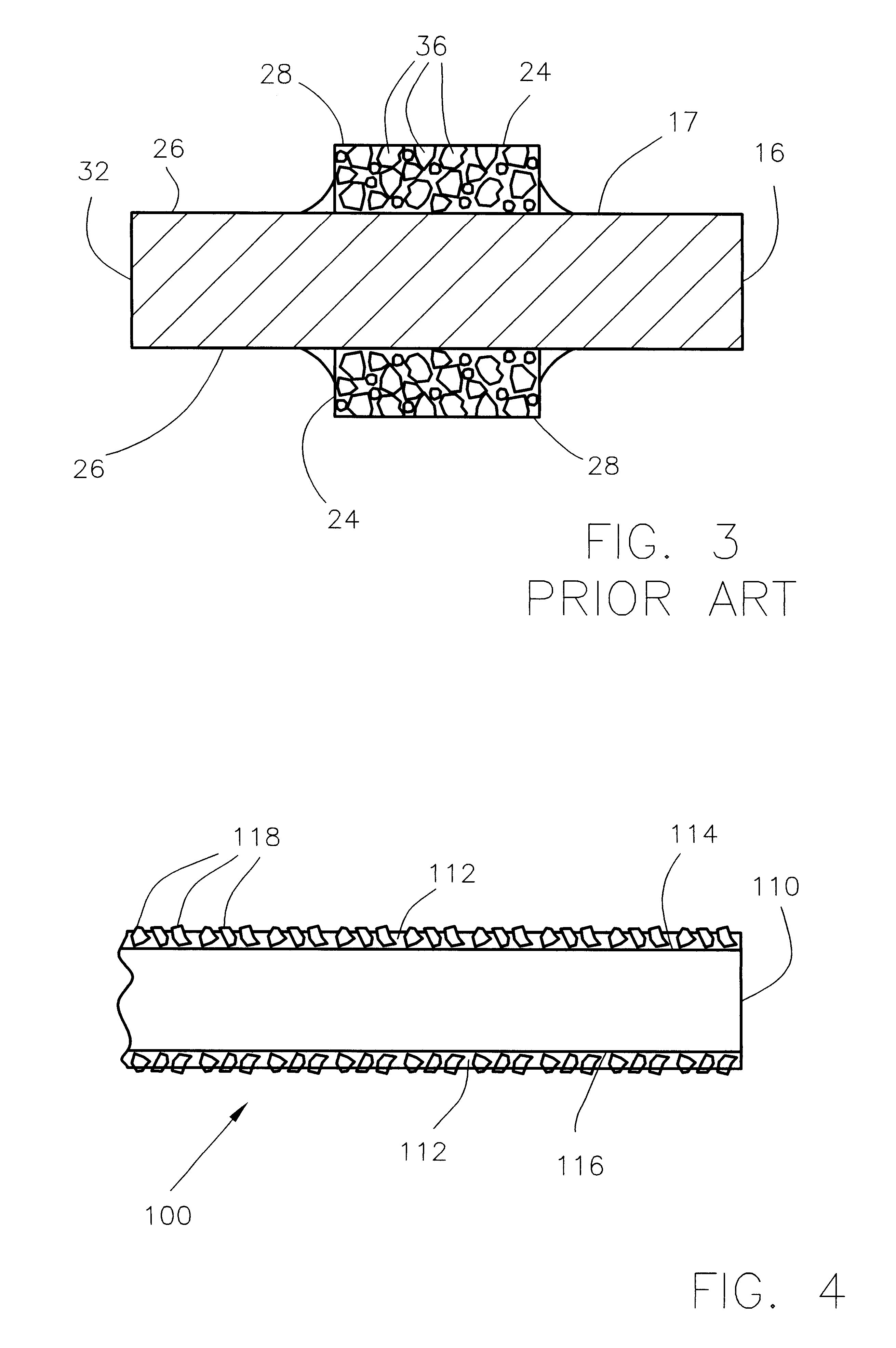

Dresser for polishing cloth and manufacturing method therefor

InactiveUS6293854B1Improve acid resistanceSimplify cleaning stepsGrinding drivesSemiconductor/solid-state device manufacturingSilicon alloyCarbide

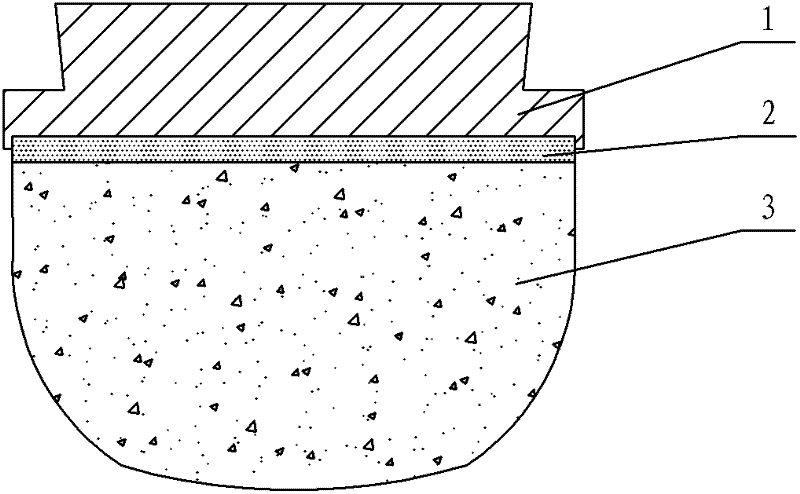

The present invention provides a dresser for a chemical and mechanical polishing cloth wherein a bonding material for retaining diamond grit is not dissolved and contamination of chemical slurry caused by dissolving of metal or peeling-off of diamond grit is prevented from occurring. A sintered product constituting the dressing face 2a is obtained by mixing a bonding material 4 consisting of silicon and / or silicon alloy with diamond grit 3, and forming and sintering the mixture. A carbide film 5 generated by sintering silicon in the bonding material into diamond is formed on the surface of the diamond grit 3. Thereby, the diamond grit is firmly bonded with the bonding material, and the bonding material is not dissolved. As a result, the contamination of the chemical slurry or the peeling-off of the diamond grit is prevented.

Owner:RIIDO

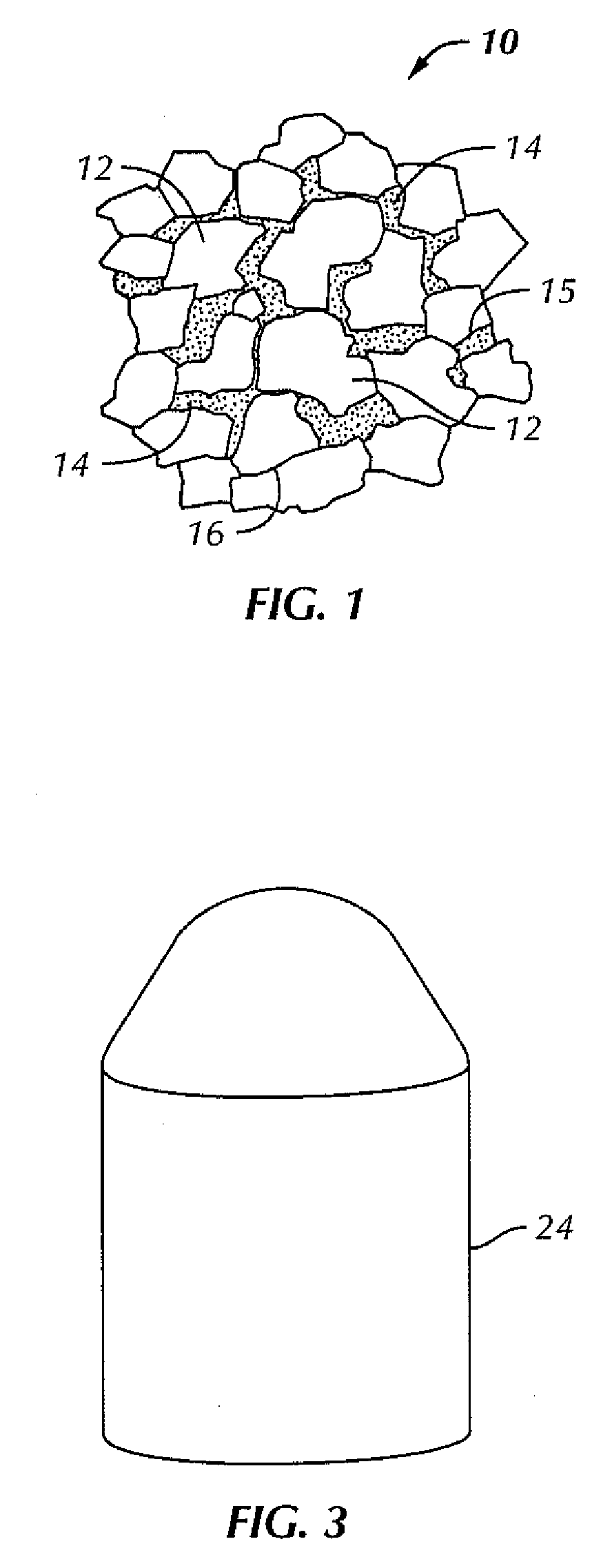

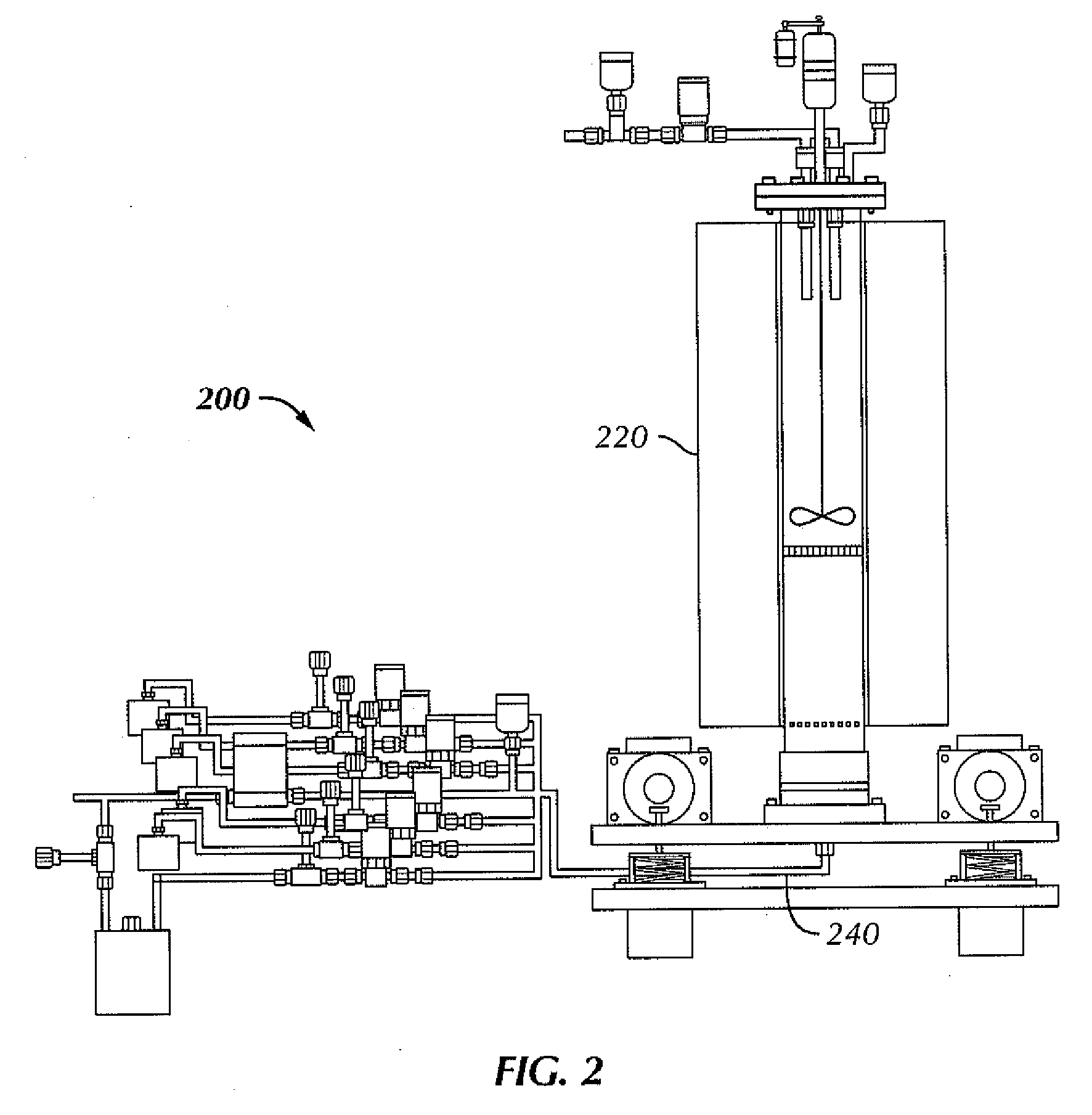

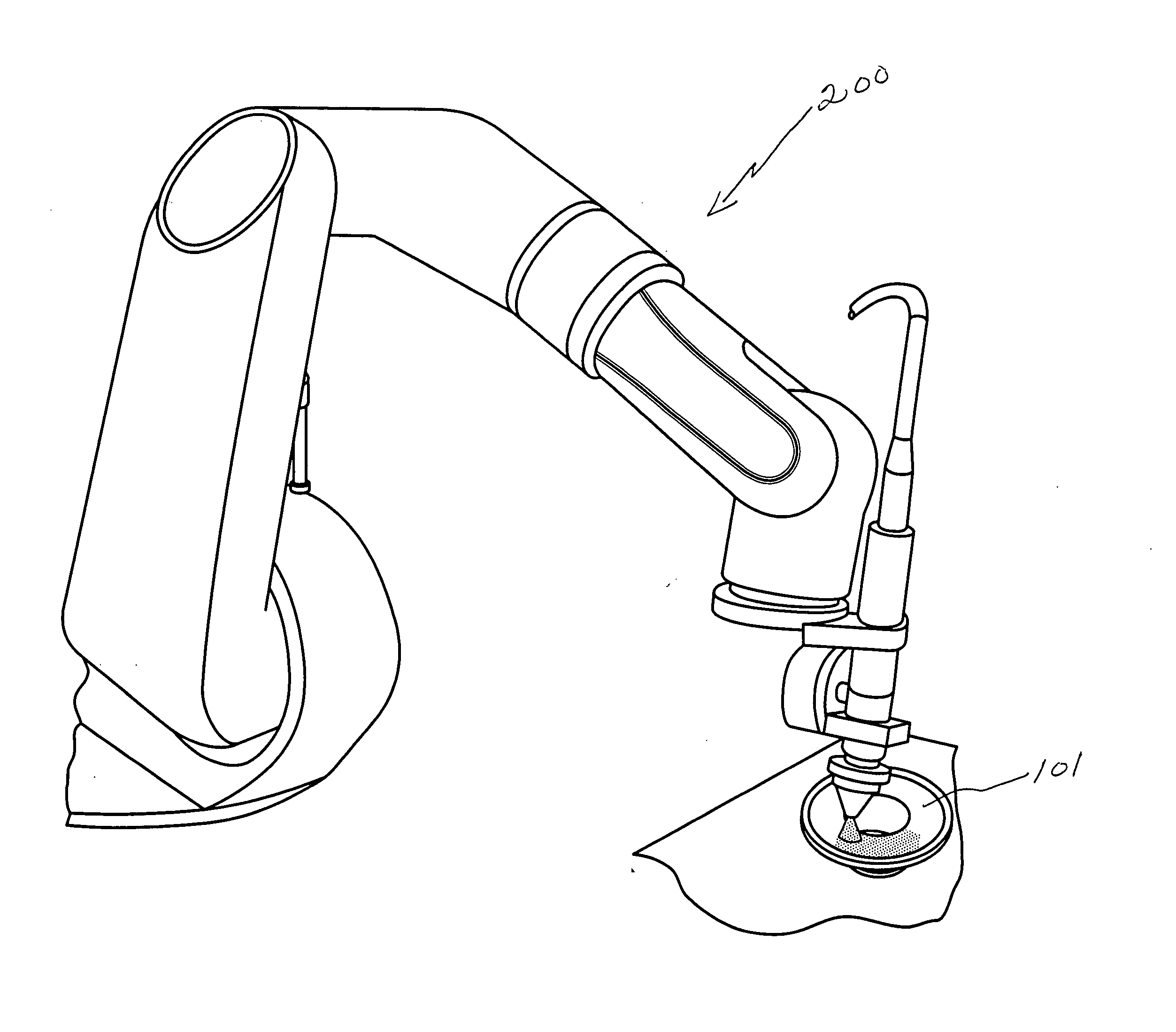

Diamond hard coating of ferrous substrates

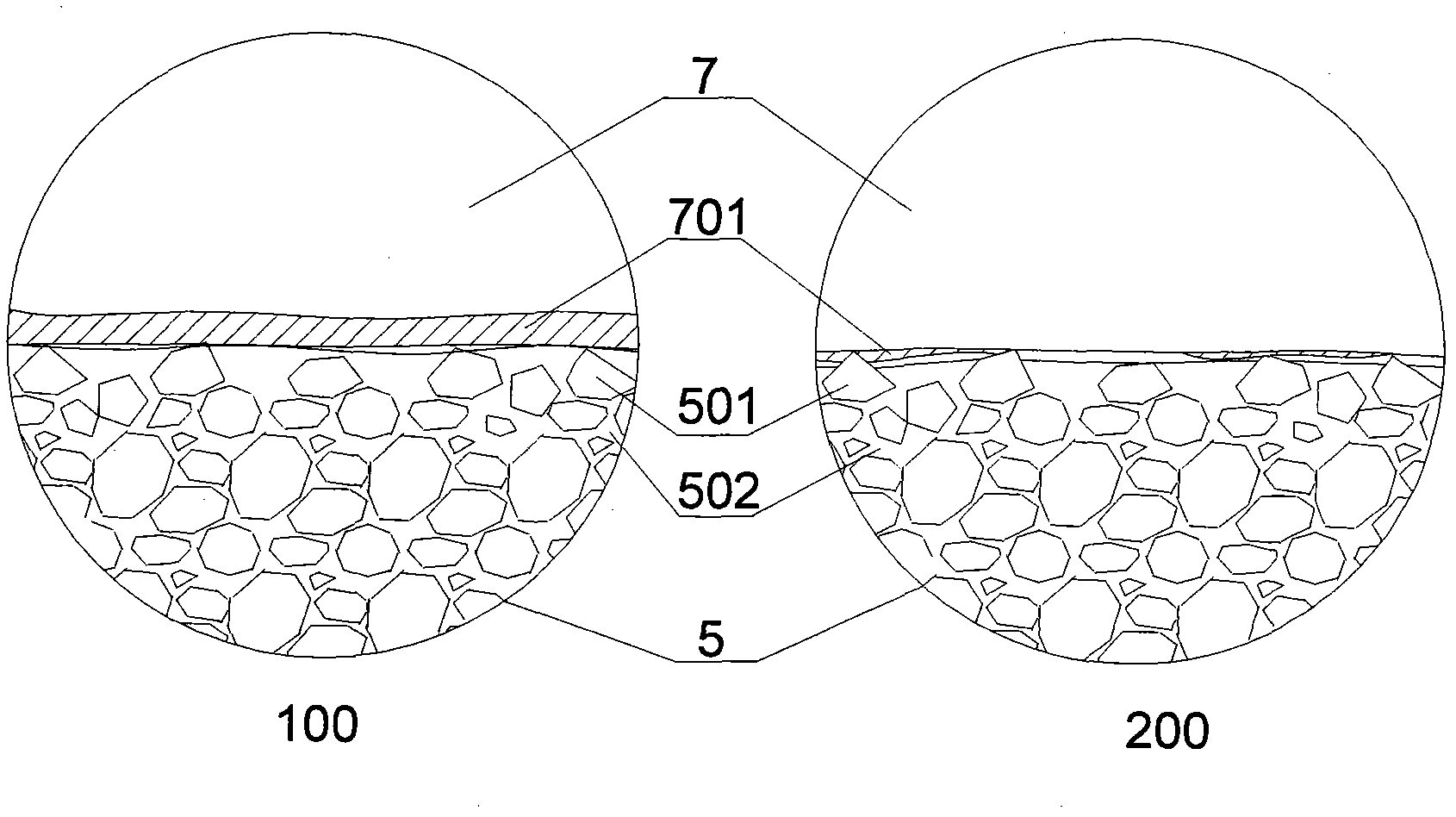

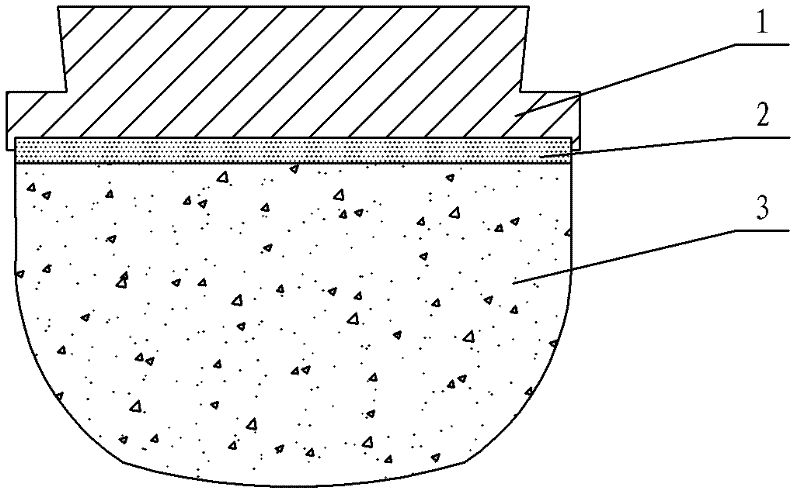

The present invention relates to hard coating of ferrous metal substrates using a laser beam with diamond particles in a metal matrix produced from precursor powders of metals which bond to the diamond particles and to the ferrous substrate. The hard coating is particularly useful for white iron castings for pumps ( 200 ) used in piping tar sand and water mixtures.

Owner:FRAUNHOFER USA

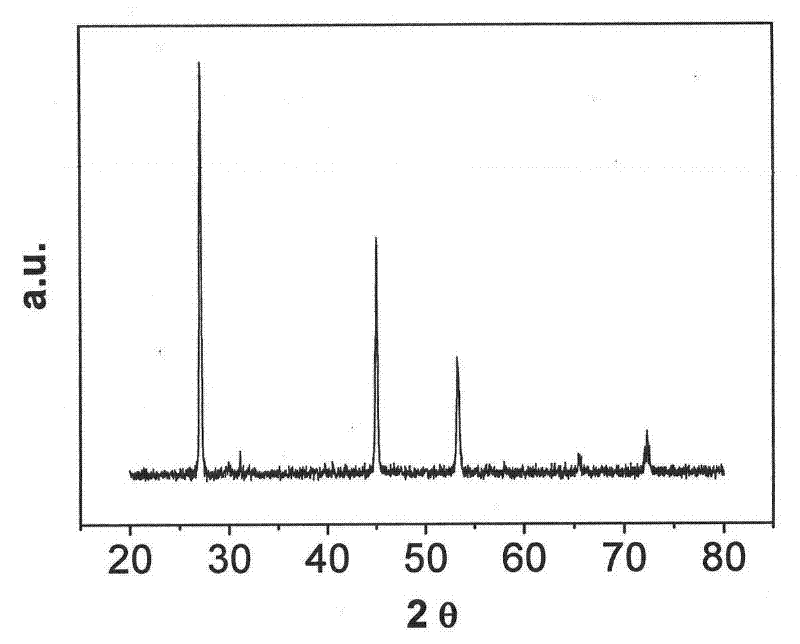

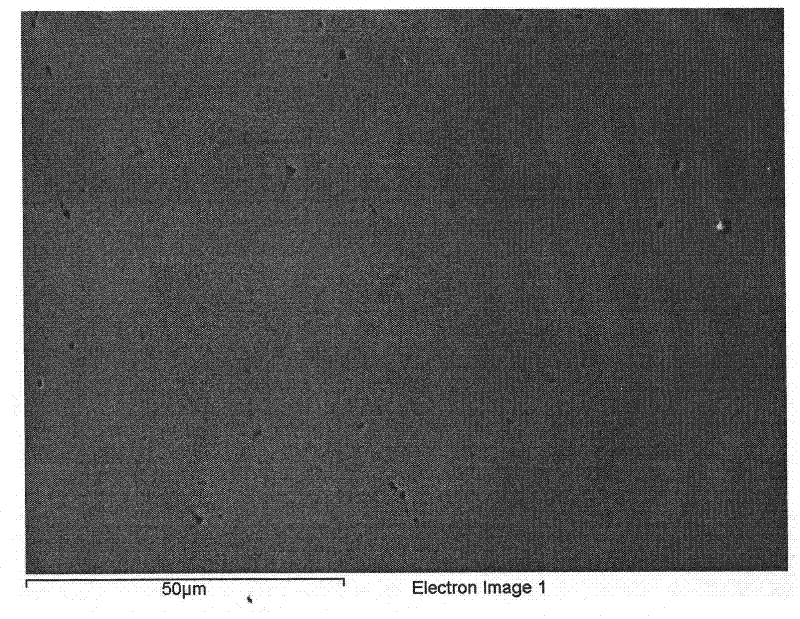

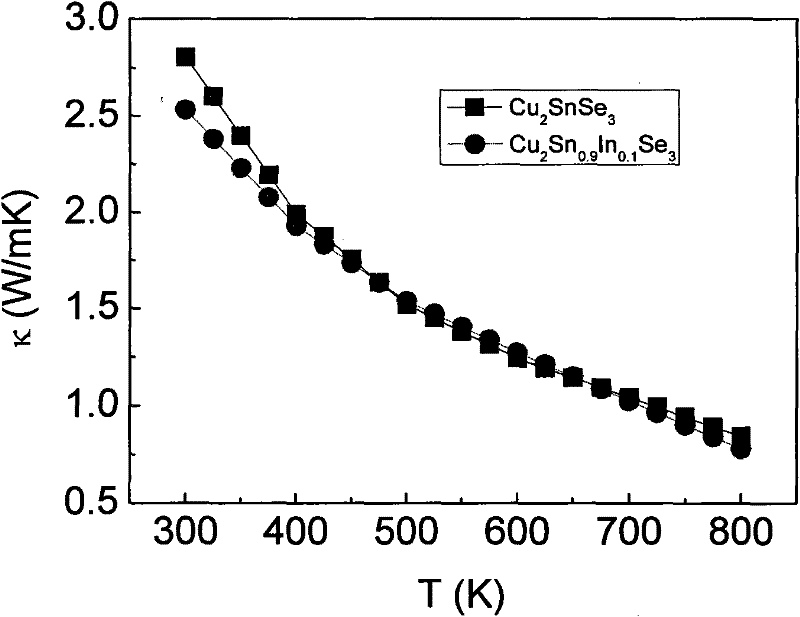

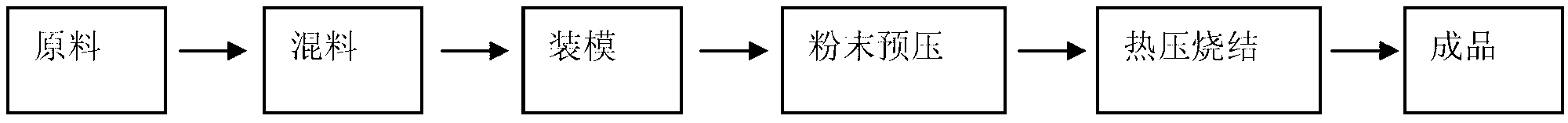

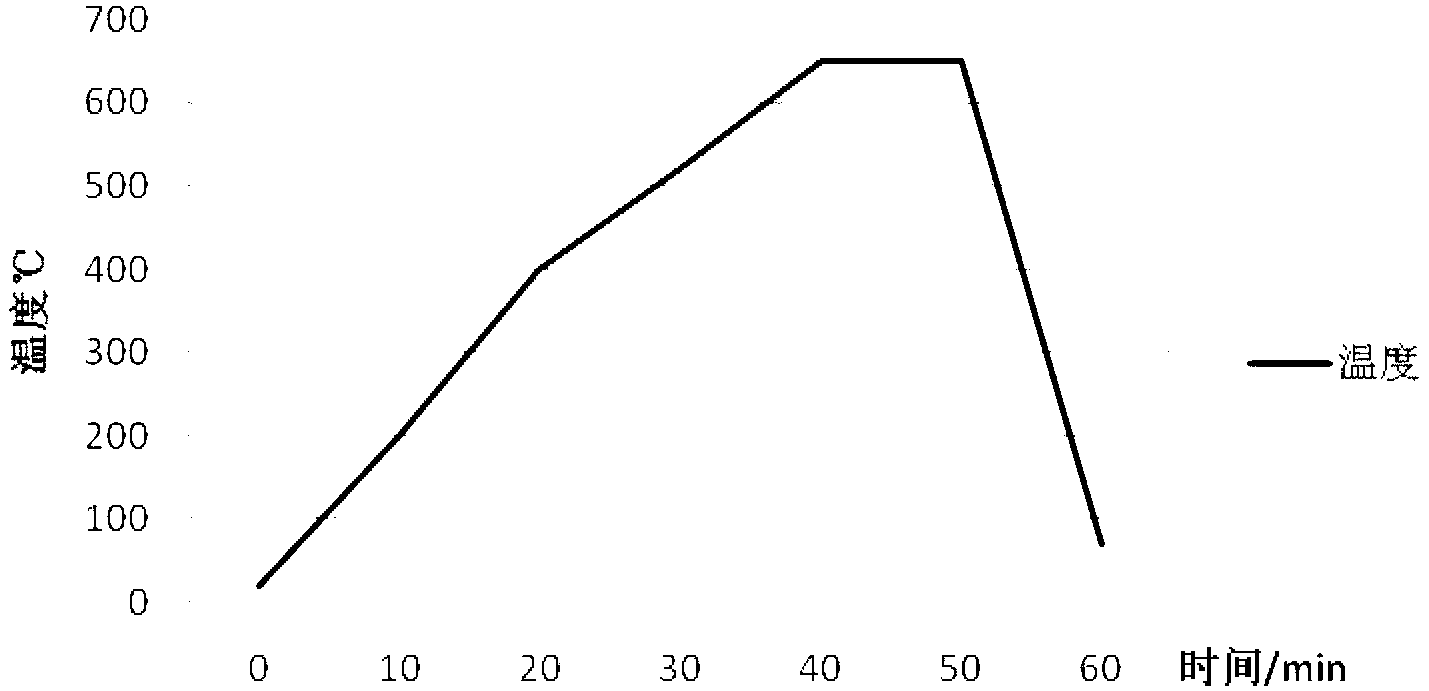

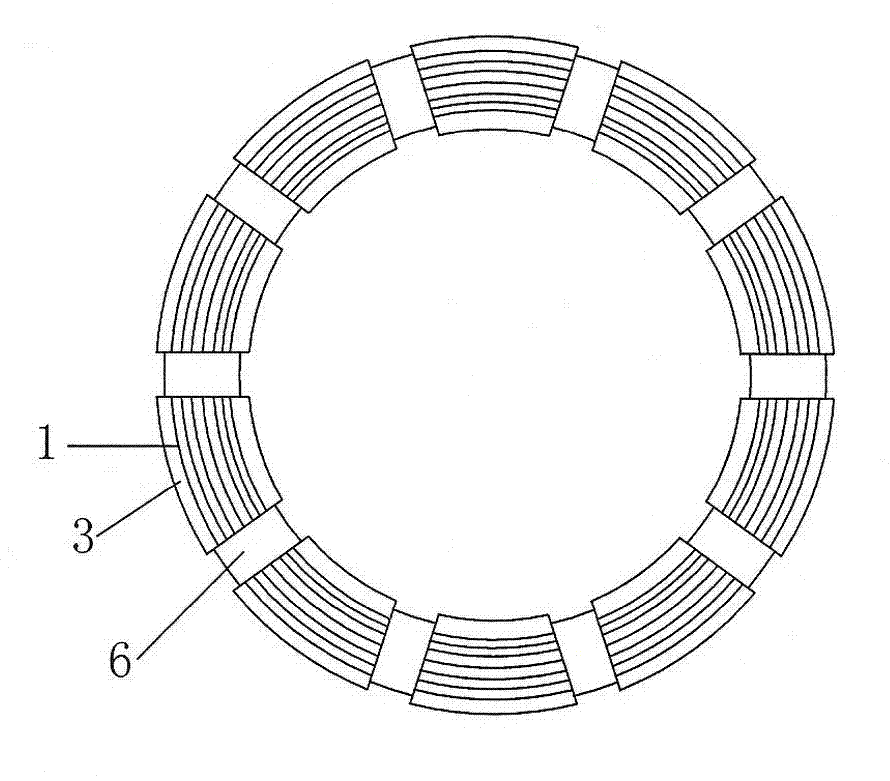

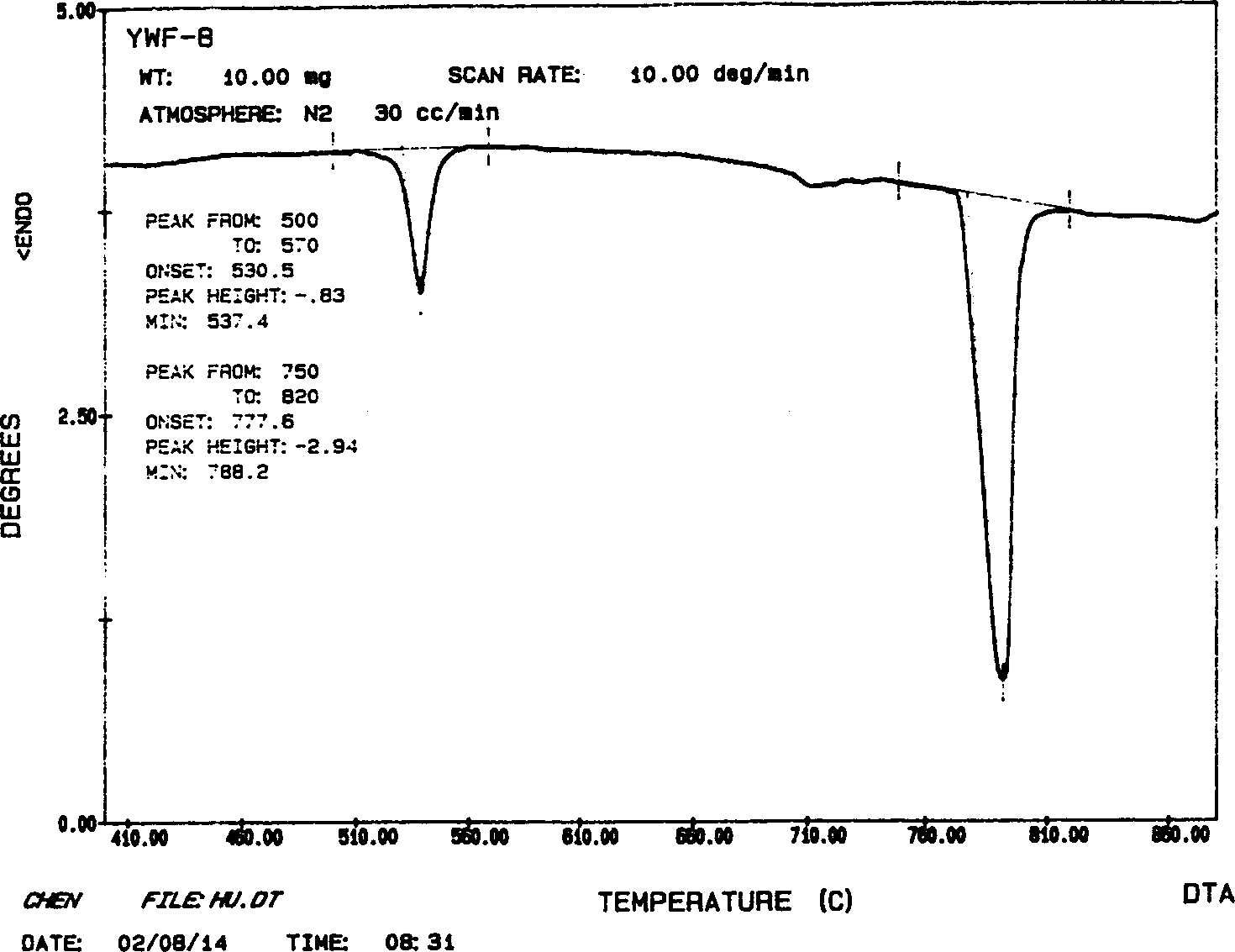

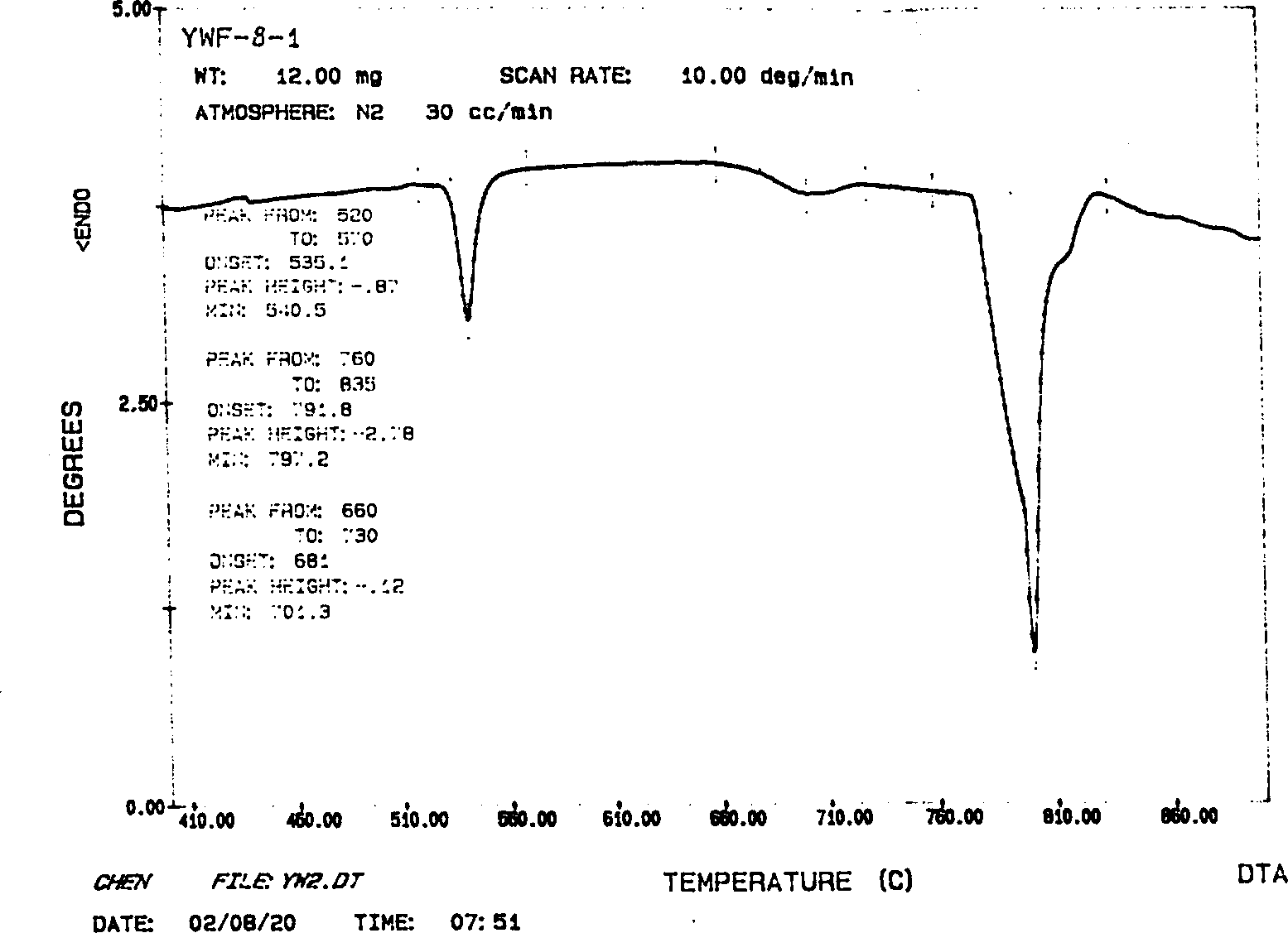

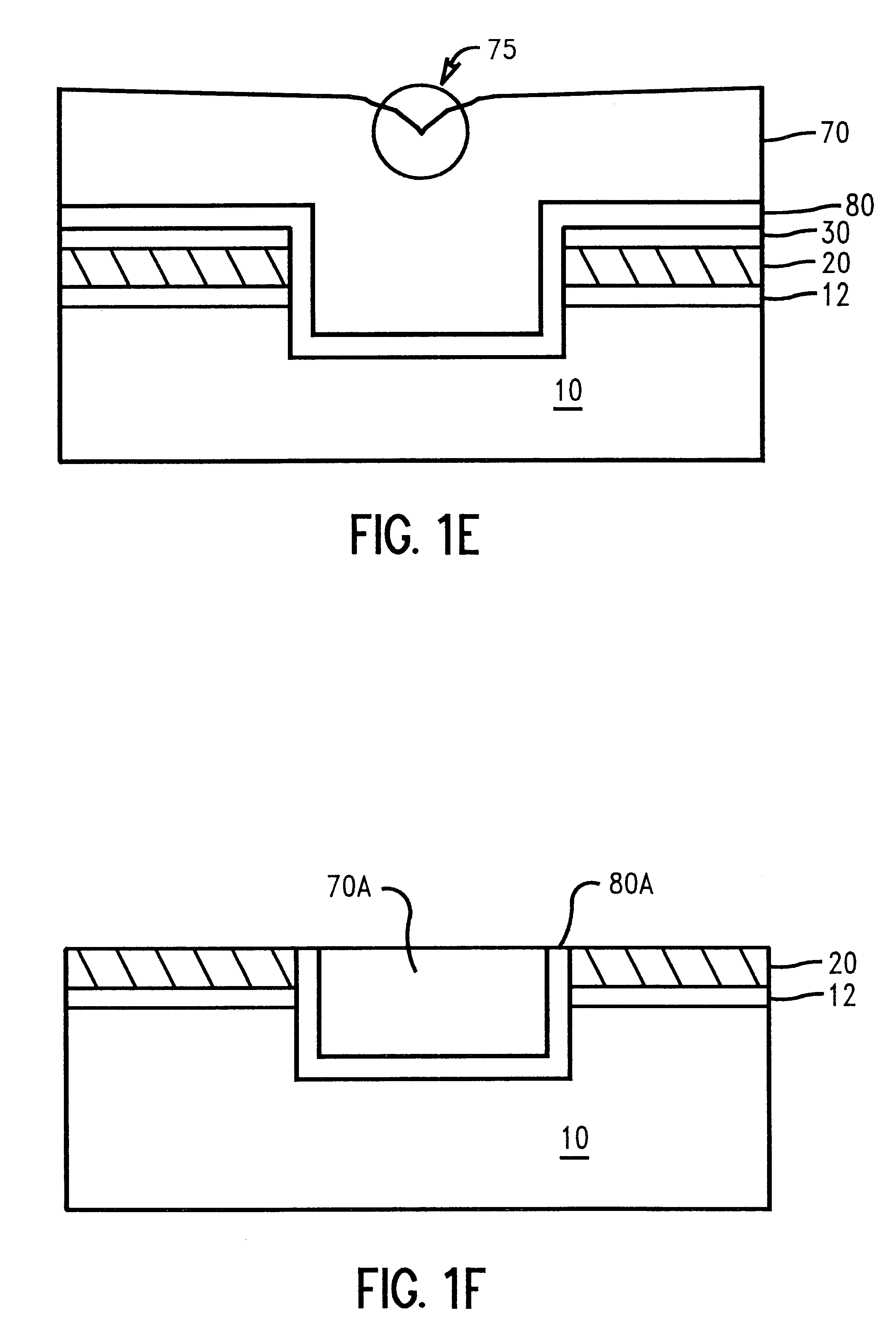

Method for preparing thermoelectric material of ternary diamond structure

ActiveCN102194989AExcellent thermoelectric performanceShort processing timeThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsAdamite

The invention relates to a method for preparing a thermoelectric material of a ternary diamond structure. The method comprises the steps of: raw material preparation, heat-preservation reaction, annealing treatment, spark plasma sintering and the like. In the invention, by applying a fusion-process preparation technology, rapid spark plasma sintering and other methods and controlling technological parameters, the method for preparing the thermoelectric material of the ternary diamond structure is realized and has the advantages of simple and convenient technology, short flow time, high feasibility and good thermoelectric performance, and the thermoelectric material of the ternary diamond structure, prepared with the method provided by the invention, has favorable thermoelectric performance and can be used as a p-type thermoelectric material. The method has the characteristics of simplicity, strong operability, low cost, good industrial prospect and the like.

Owner:中科西卡思(苏州)科技发展有限公司

Online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and preparation method thereof

InactiveCN103009270ALow shrinkageHigh strengthAbrasion apparatusGrinding devicesPolyvinyl alcoholDecomposition

The invention provides an online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and a preparation method thereof and belongs to the technical field of precision grinding pellets. Raw materials of the precision grinding pellet comprise a super-hard abrasive and a metallic bond, wherein the super-hard abrasive is diamond micro-powder; the diamond concentration falls within a range of 75-100 %; and the metallic bond uses a multicomponent alloy bond whose main components are copper powder, tin powder, aluminum powder, copper-clad ball shaped graphite powder, silicon dioxide and ferroferric oxide powder. The preparation method comprises the following steps: uniformly mixing and stirring the diamond micro-powder as well as the copper powder, the tin powder and the aluminum powder; adding polyvinyl alcohol to a mixture and mixing the polyvinyl alcohol and the mixture; adding the silicon dioxide, the copper-clad ball shaped graphite powder and the ferroferric oxide powder to an obtained mixture and mixing these materials and the obtained mixture; filling the mixture into a graphite mold; maintaining the pressure of the graphite mold for 5-10 minutes after pressurizing the graphite mold to 100-250 MPa; and carrying out hot pressing sintering on the graphite mold in a sintering furnace, wherein the sintering atmosphere is ammonia decomposition gas. Through the adoption of the online self-sharpening metallic bond and super-hard abrasive precision grinding pellet provided by the invention, online automatic sharpening can be achieved without blockage and offline repairing.

Owner:BEIJING UNIV OF TECH

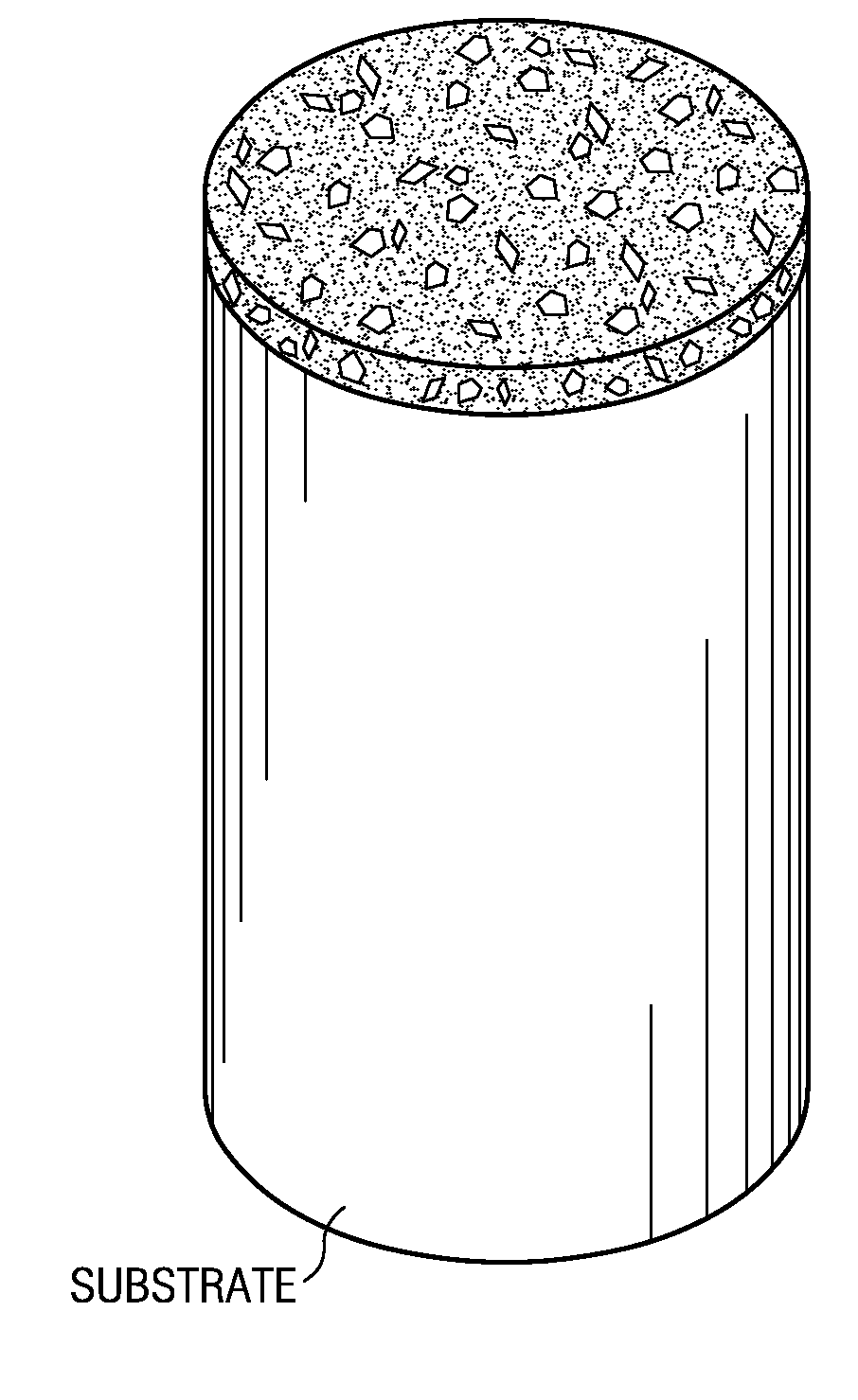

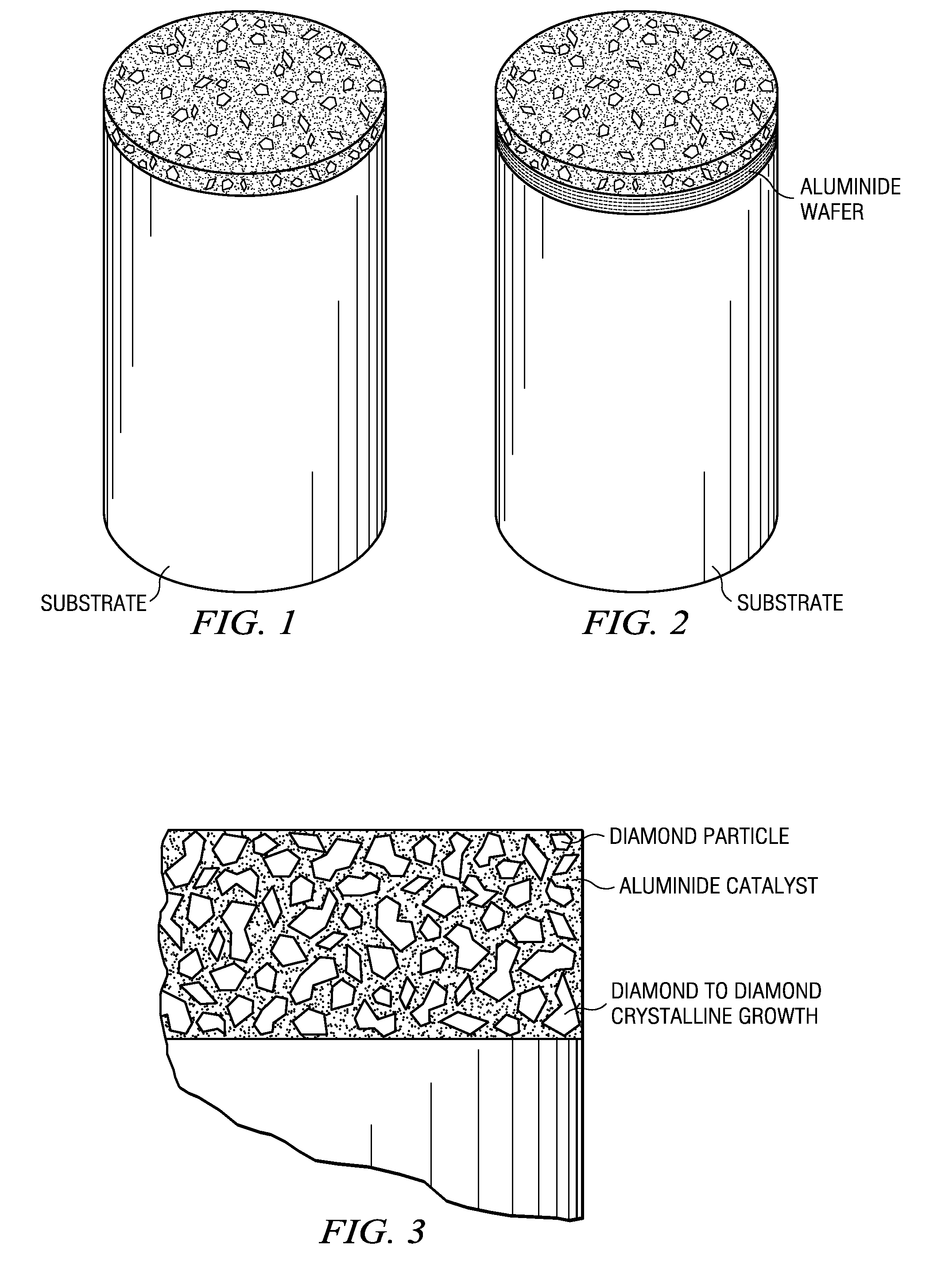

Intermetallic Aluminide Polycrystalline Diamond Compact (PDC) Cutting Elements

InactiveUS20100038148A1Improve heat transfer performanceDissipate quicklyPigmenting treatmentDrill bitsPolycrystalline diamondAdamite

Machining and cutting tools including, but not limited to, rotary drill bits, mining tools, milling tools, wood shredders, reamers and wire dies formed with at least one substrate having a layer of polycrystalline diamond disposed thereon. The polycrystalline diamond layer may be generally described as a polycrystalline diamond compact (PDC) or PDC layer. The PDC may be formed by using an intermetallic aluminide catalyst. One example of such catalyst may include nickel aluminide used to form diamond to diamond bonds between adjacent diamond particles.

Owner:HALLIBURTON ENERGY SERVICES INC

Diamond surface chemical mechanical combined machining method and device thereof

InactiveCN101972979AImprove the efficiency of graphitizationGuaranteed grinding qualityLapping machinesGraphiteAdamite

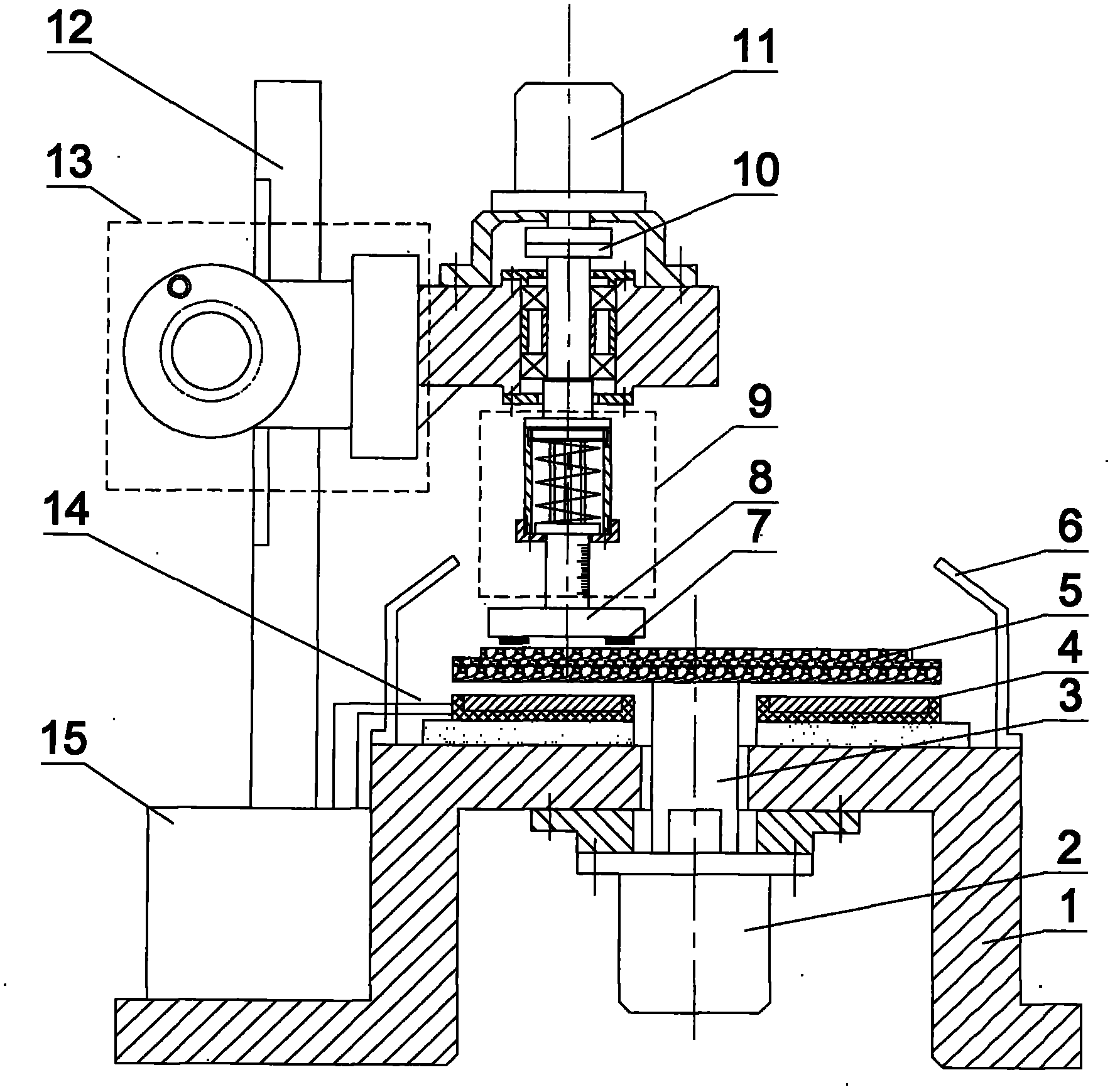

The invention relates to a diamond surface chemical mechanical combined grinding and polishing method. Composite material is adopted as a tool millstone used for grinding and polishing, the tool millstone is heated to appropriate temperature, and then high speed rotational motion is carried out; certain pressure is utilized to press a diamond film / block to be processed onto the surface of the millstone, so that high speed friction is produced between the diamond film / block and the surface of the millstone, and high efficiency grinding and polishing on the surface of the diamond is realized under the chemical-mechanical combined circulation action of friction region. The method adopts a chemical-mechanical combined way, and the grinding process includes a catalytic surface graphitizing process and a mechanical graphite scraping process. In the combined circulation process of chemical action and mechanical action, diamond surface material is efficiently removed. The related device integrates heating and loading functions, a combined millstone is used as a tool millstone, and the beneficial effects include that processing efficiency is high, mechanical acting force is small and processing quality is good. The invention also relates to a diamond surface chemical mechanical combined grinding and polishing device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process of dressing glass disk polishing pads using diamond-coated dressing disks

InactiveUS6254461B1Rapidly but accurately removeEasy to takePolishing machinesGrinding drivesMagnetic memoryCerium

A dressing disk for dressing and reconditioning the polishing pad of a planetary disk polishing machine is fabricated by plating a nickel / diamond matrix layer onto a stainless steel disk wherein the matrix layer thickness is developed or plated to a thickness which leaves exposed about 25 percent of the fine diamond particles, thereby forming a surface that has the look and feel of medium to coarse sandpaper. The dressing disks are inserted into the holes in a disk carrier of a planetary polishing machine and driven by its central rotary drive. While being so driven under a flow of water to carry away abraded particles, a pair of polishing pads are engaged with the disk surfaces and forced together with a loading or down force to cause the disks to abrade or grind away a thin surface layer of the polishing pad, thereby removing glazing and exposing cerium particles embedded in the urethane matrix of the polishing pad to engage the glass disks to be polished to a very smooth surface for use as substrates for magnetic memory disks useable in disk drives.

Owner:IBM CORP

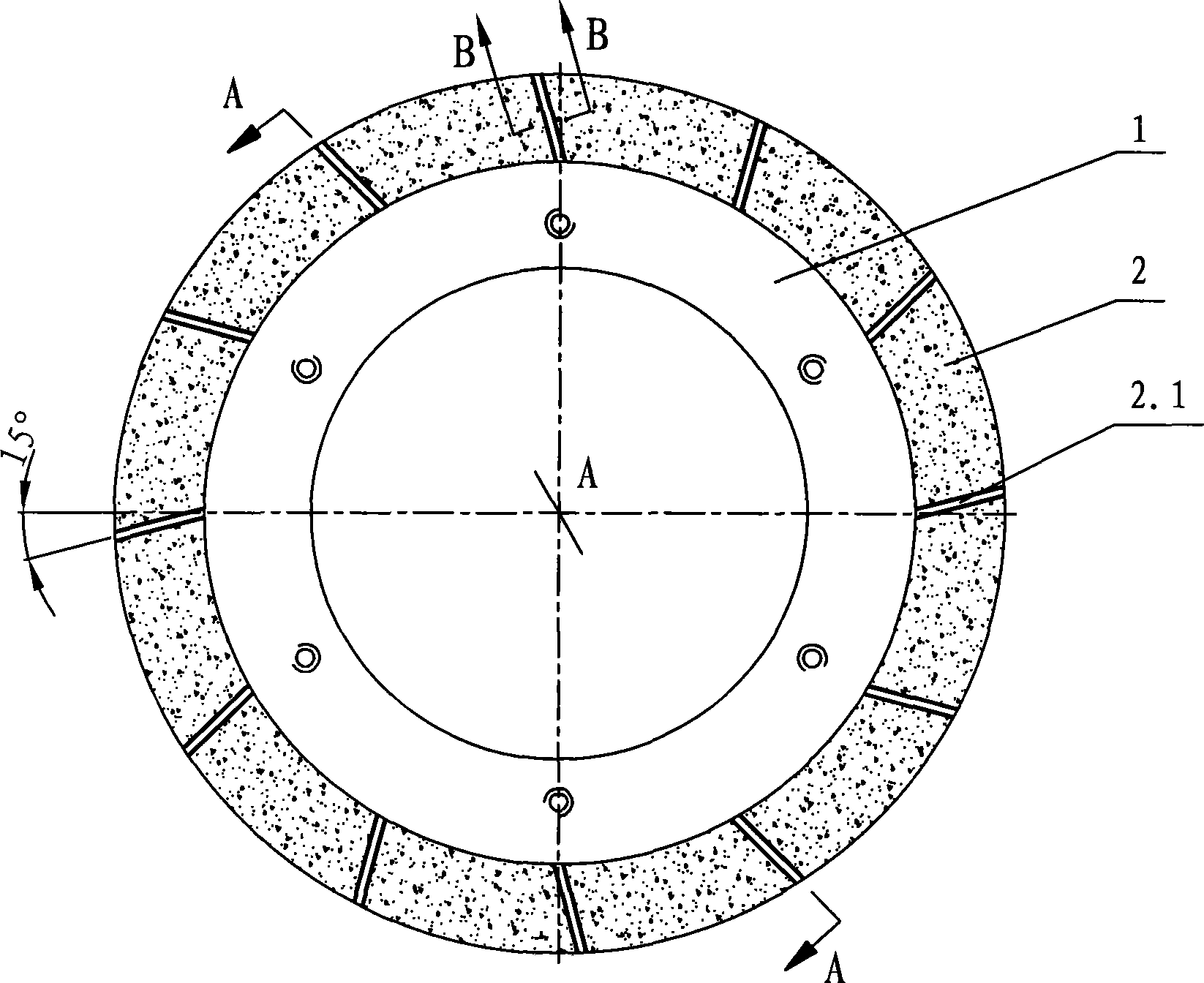

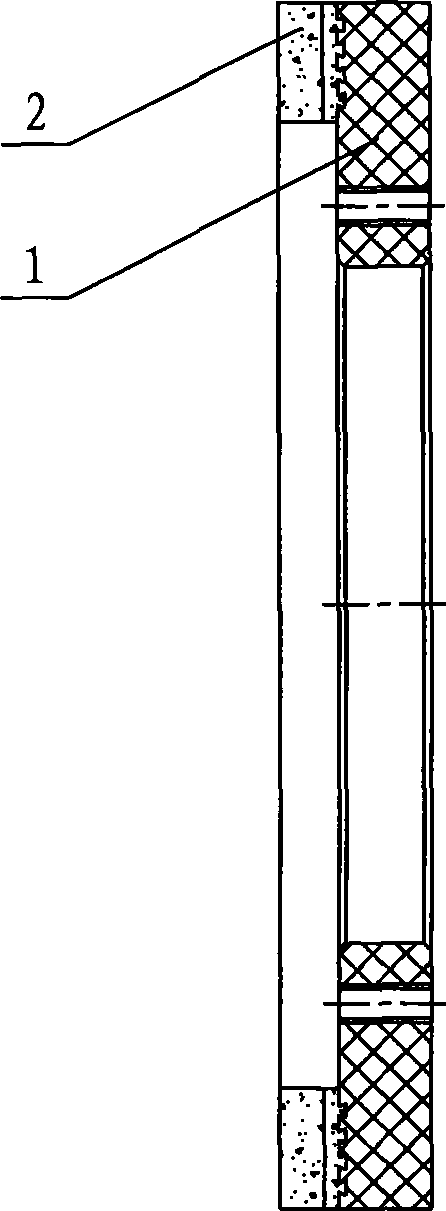

Iron-based diamond-impregnated bit for drilling in hard slipping foundation

The invention discloses an iron-based diamond-impregnated bit for drilling in a hard slipping foundation. An iron-based substrate mixed material provided by the invention is formed by sintering an iron-based matrix and a diamond; the diamond is impregnated in the iron-based matrix; the volume percentage of the content of the diamond is 45-75%, and the grain size is 35-45mu; the iron-based matrix comprises the following components in percentage by mass: 65-72% of iron powder, 10-14% of zinc powder, 14-18% of 663 bronze powder, 1% of manganese powder and 2% of nickel powder; according to the invention, the iron powder with the mass content of about 70% is used for replacing the common tungsten carbide powder, and therefore, the cost of the diamond-impregnated bit is greatly reduced, the sintering temperature is reduced, and the heat damage rate of the diamond is reduced; the iron-based matrix is few in component, less in variable and easy to control; and the iron-based diamond-impregnated bit has higher pertinence and mainly aims to the hard slipping foundations.

Owner:JILIN UNIV

Superhard abrasive grinding wheel of metal binding agent eletrolyzable online, and preparation method

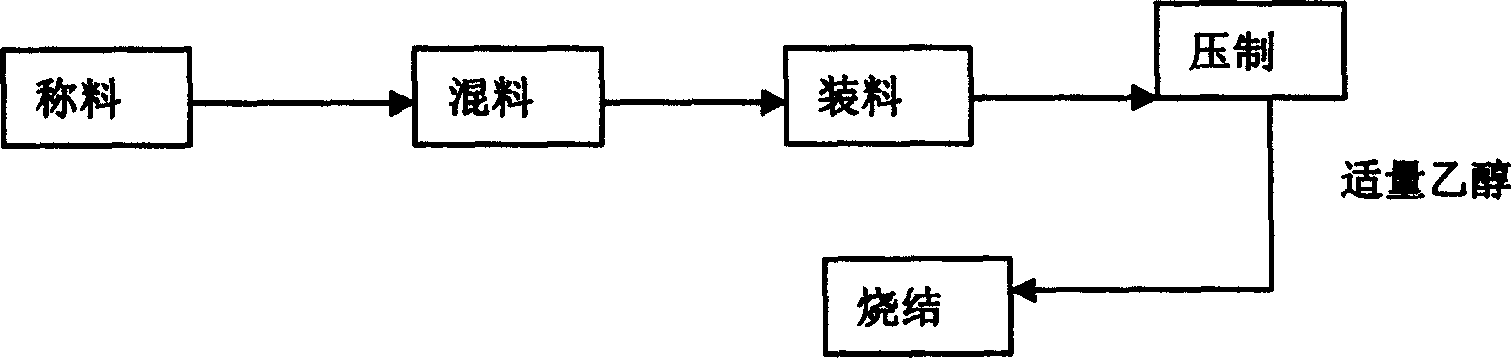

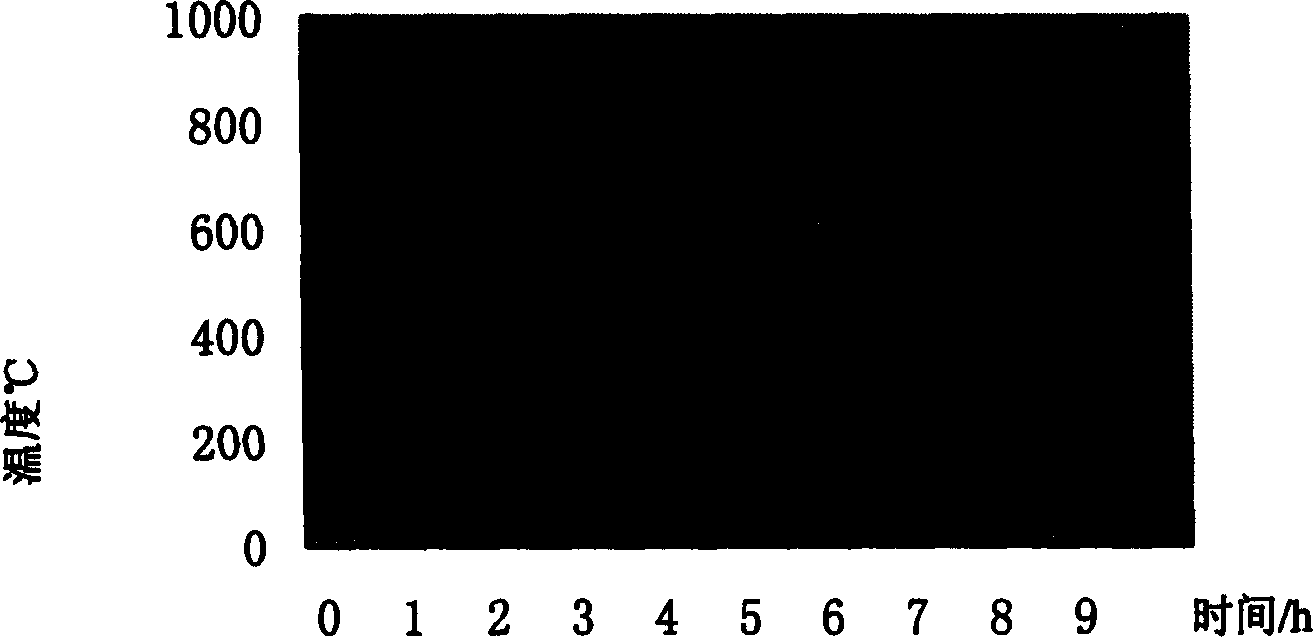

An ultrahard abrasive disk able to be in-line electrolyzed for truing it is prepared from diamond, cubic boron nitride (CBN) and the binder prepared from Fe powder, Cu powder, metal additive and non-metal additive through proportionally mixing diamond, VBN and Fe powder, stirring, adding alcohol, mixing, adding others, stirring, cold die pressing, and sintering in reductive atmosphere.

Owner:BEIJING UNIV OF TECH

Braze filler metal copper base alloy powder for diamond braze welding and its preparation method

The composition of brazing filler metal copper base alloy powder for diamond brazing is formed from (wt%) Sn 16-24%, Ni 7-27%, Cr 1.5-5%, Si 0-3%, B 1-5% and the rest is Cu. Its melting point is 780-840 deg.C, is said range, when brazing the diamond can not be charred or damaged, it possesses good resistance to oxidation and strong imbibition property, is favorable for implementing brazing process and cohesive property of diamond granules.

Owner:胡仁良 +1

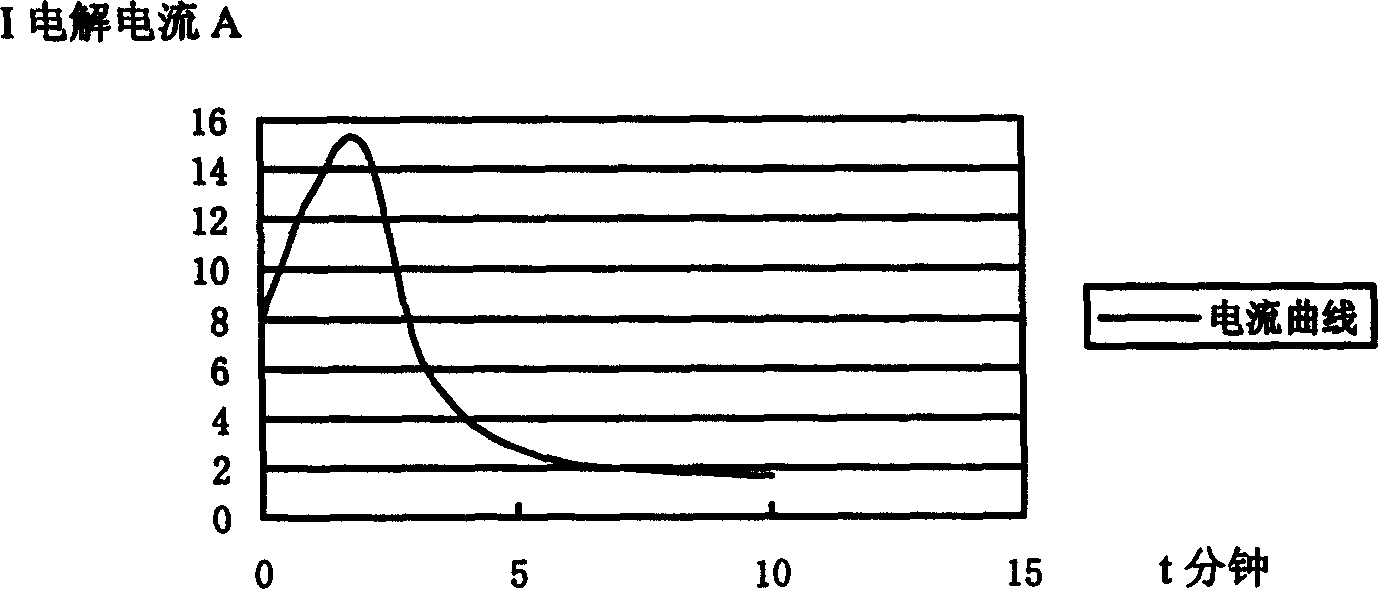

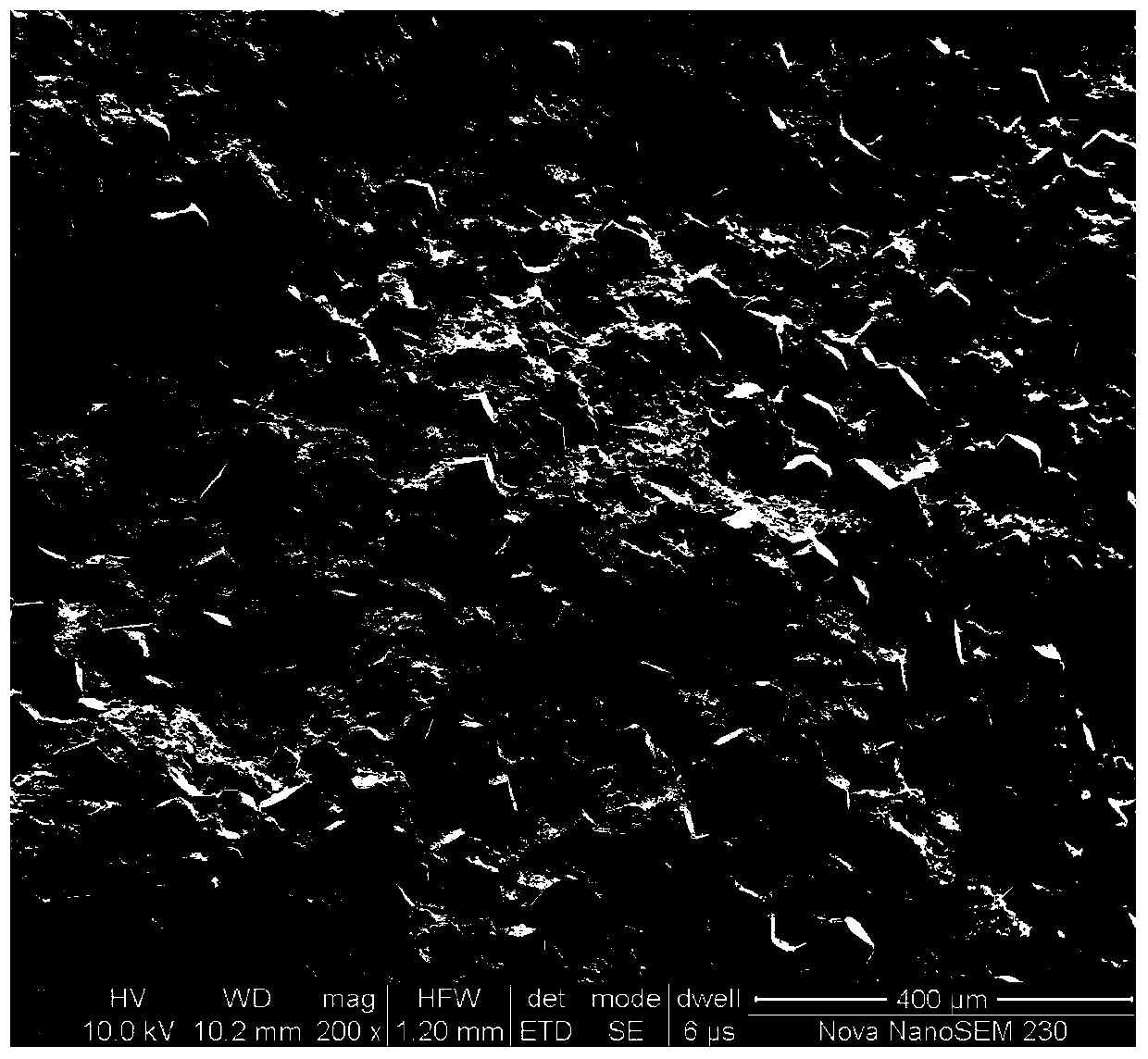

Methods of forming cutting elements by removing metal from interstitial spaces in polycrystalline diamond

ActiveUS20130291447A1Pigmenting treatmentOther chemical processesMetal catalystPolycrystalline diamond

Methods of forming a cutting element include immersing at least a portion of a volume of polycrystalline diamond in a liquid electrolytic solution, applying a voltage between the polycrystalline diamond and a cathode in contact with the liquid electrolytic solution, and removing at least a portion of metal catalyst from interstitial spaces between adjacent diamond grains. The polycrystalline diamond includes interbonded diamond grains and metal catalyst particles in the interstitial spaces between adjacent grains of polycrystalline diamond material. Some methods include forming a barrier over a portion of a volume of polycrystalline diamond and transferring at least a portion of the metal catalyst from a portion of the polycrystalline diamond not covered by the barrier to a liquid electrolyte. Some methods include encapsulating a volume of polycrystalline diamond in a barrier and selectively removing a portion of the barrier from a first portion of the volume of polycrystalline diamond.

Owner:BAKER HUGHES INC

Metal-ceramic bond diamond grinding wheel and production method thereof

ActiveCN103692371AGood self-sharpeningImprove gripAbrasion apparatusGrinding devicesPowder mixtureCopper plating

The invention discloses a novel metal-ceramic bond diamond grinding wheel having the high strength and form-holding property in metal bond grinding wheels and the high self-sharpening property in ceramic bond grinding wheels, and a production method thereof. The metal-ceramic bond diamond grinding wheel is produced by: 1, preparing powder mixture out of 60-70% of copper-plated diamond powder, 15-20% of (W, Ti)C powder, 5-10% of tin powder, and 5-15% of iron group powders; mixing according to the above components and ratio to obtain the powder mixture; 2, forming, namely pressing the powder mixture into blanks by pressure forming; 3, sintering, namely subjecting the blanks to inert atmosphere low-pressure sintering, heating the blanks to 850-1050DEG C during sintering, and holding the temperature for 10-30 minutes. The copper-plated diamond powder is composed of particles with average particle size of 5-80 micrometers, and the particles are composed of diamond cores and copper coatings covering the diamond cores. Inert atmosphere during sintering is 5-10Mpa.

Owner:长沙市萨普新材料有限公司

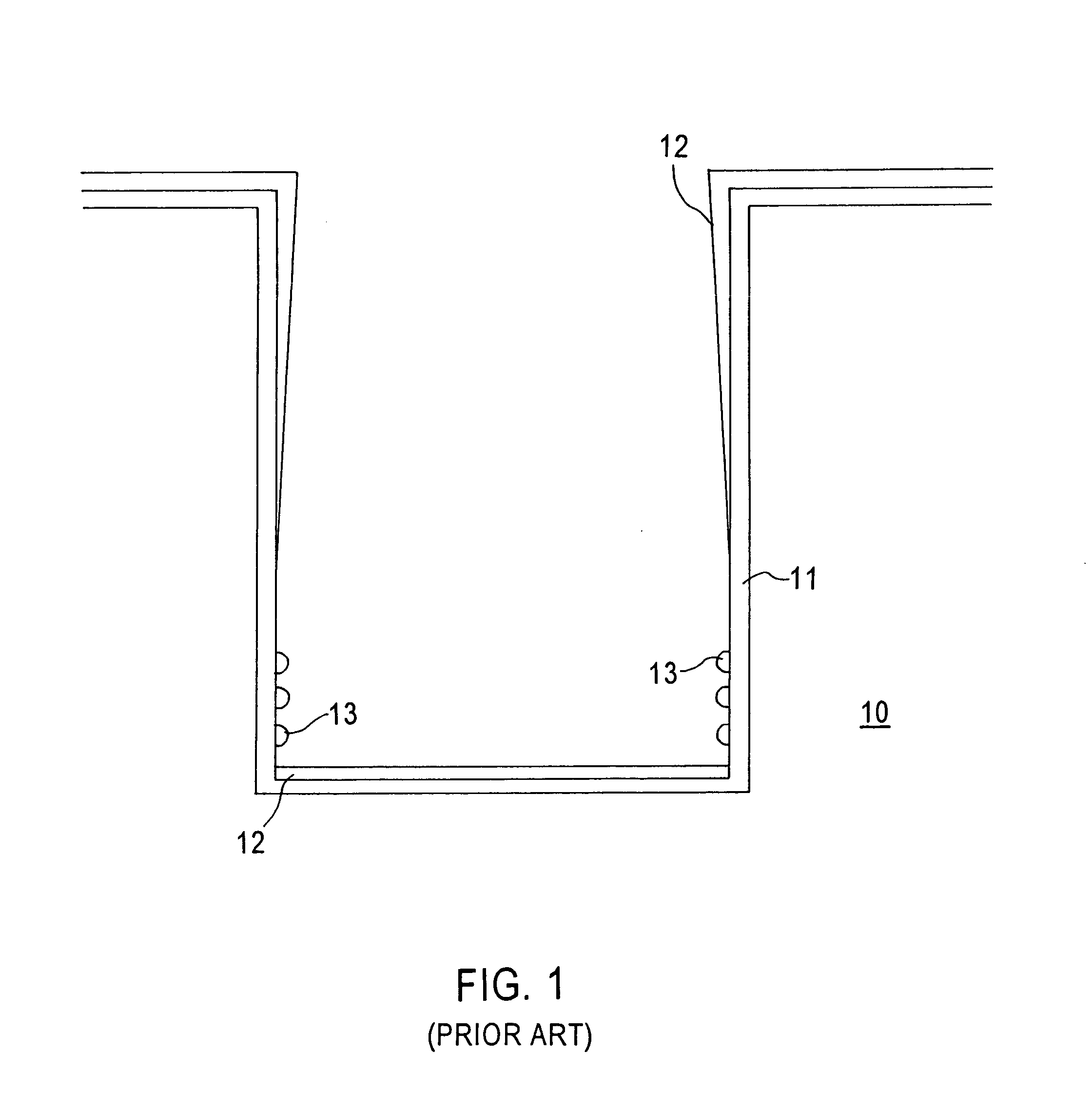

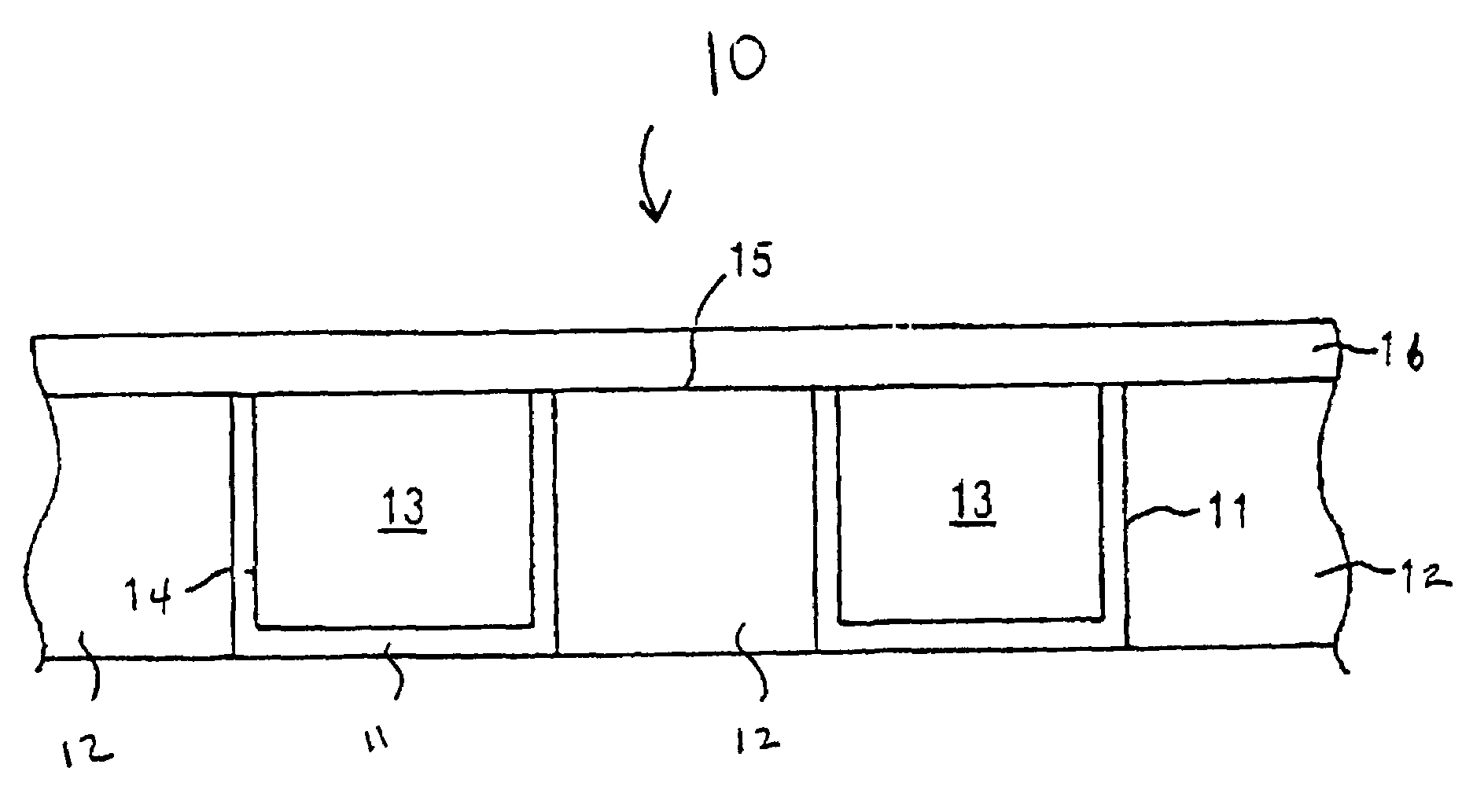

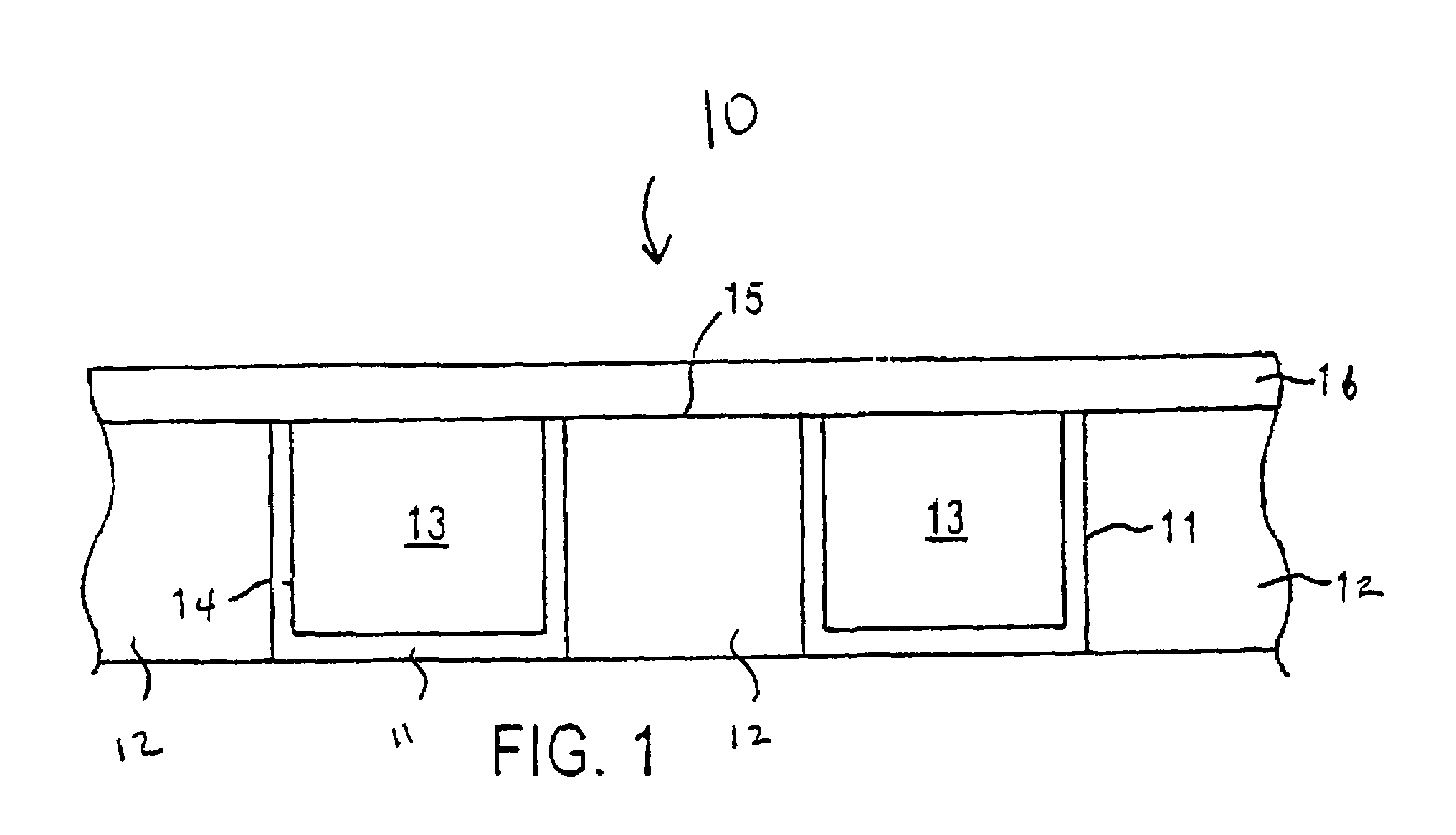

Thermal annealing for Cu seed layer enhancement

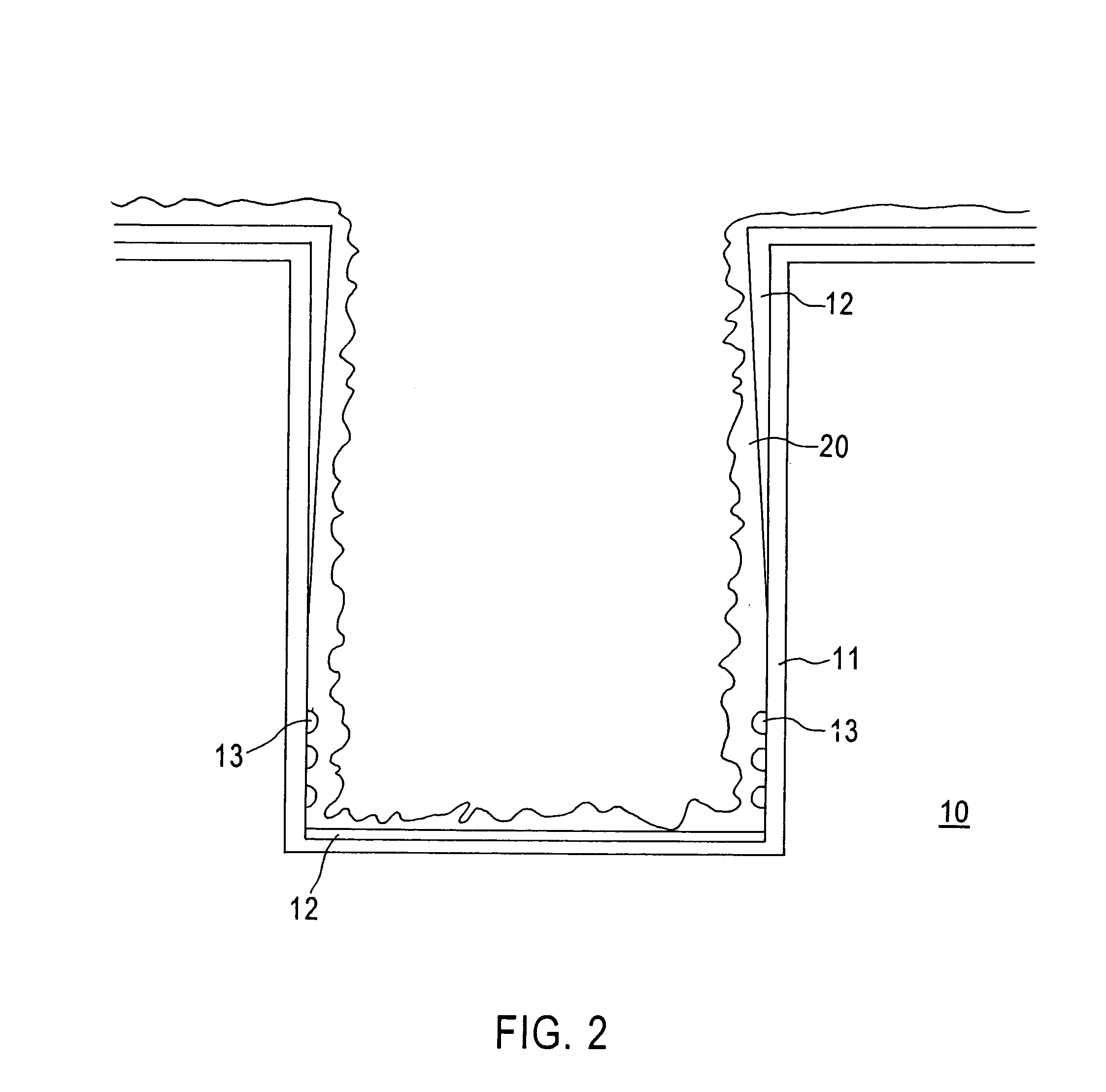

InactiveUS6998337B1Low resistance CuReduce voidsSolid-state devicesSemiconductor/solid-state device manufacturingAdamiteReducing atmosphere

Semiconductor devices with highly reliable Cu interconnects exhibiting reduced resistance are formed by sequentially depositing a seed layer by PVD, depositing a conformal seed layer enhancement film by electroplating, and then thermal annealing the seed layer enhancement film in an inert or reducing atmosphere to expel impurities, enhance film conductivity, reduce film stress, increase film density, and reduce film roughness. Embodiments include single and dual Cu damascene techniques formed in dielectric layers having a dielectric constant no greater than about 3.9.

Owner:ADVANCED MICRO DEVICES INC

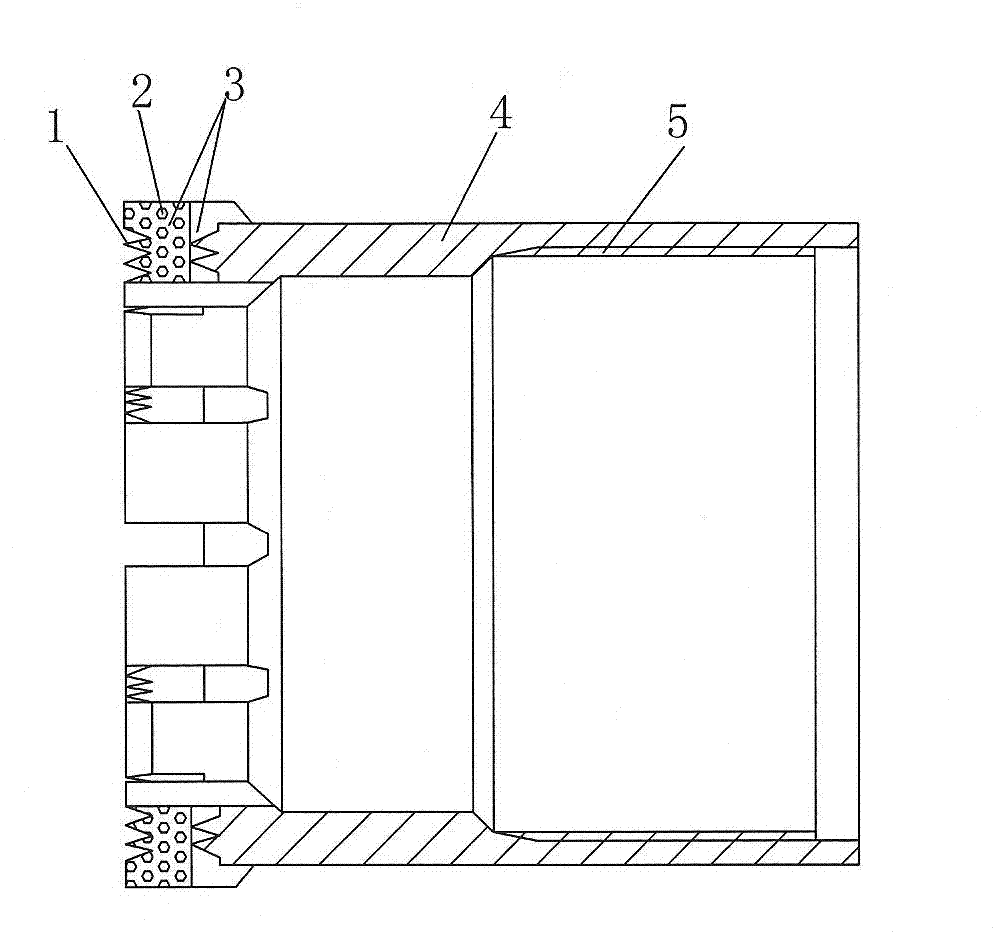

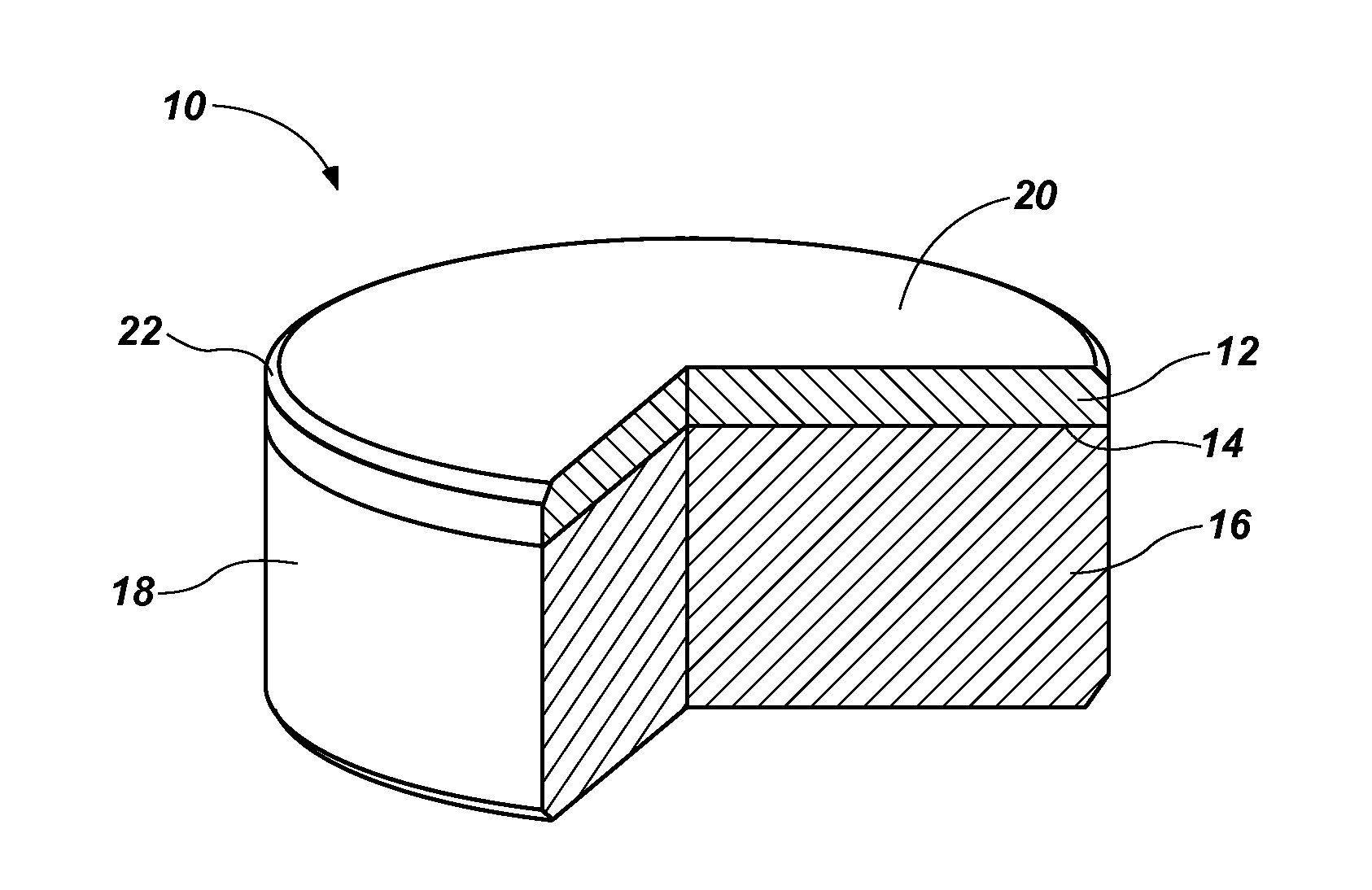

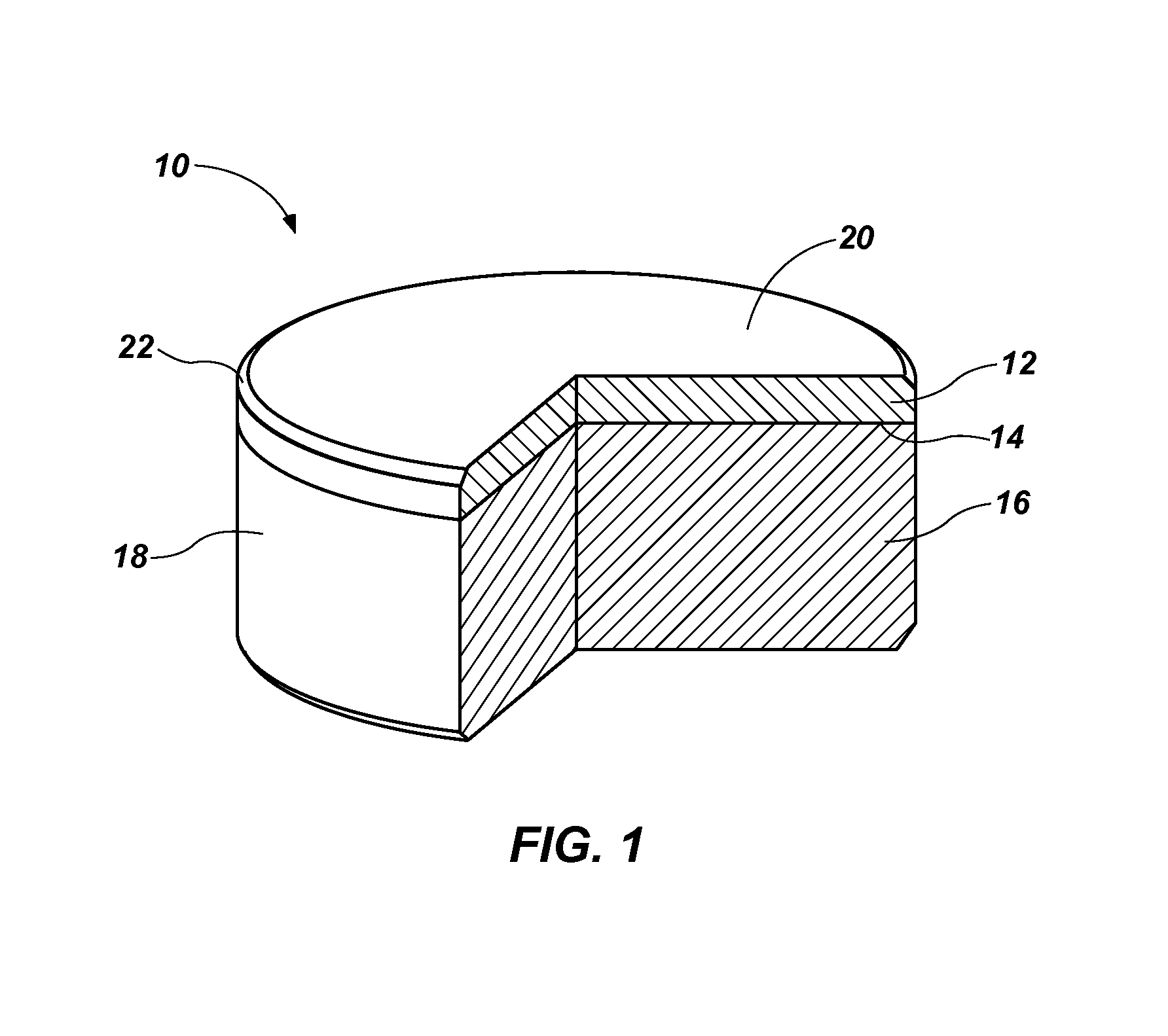

Heat spreader having single layer of diamond particles and associated methods

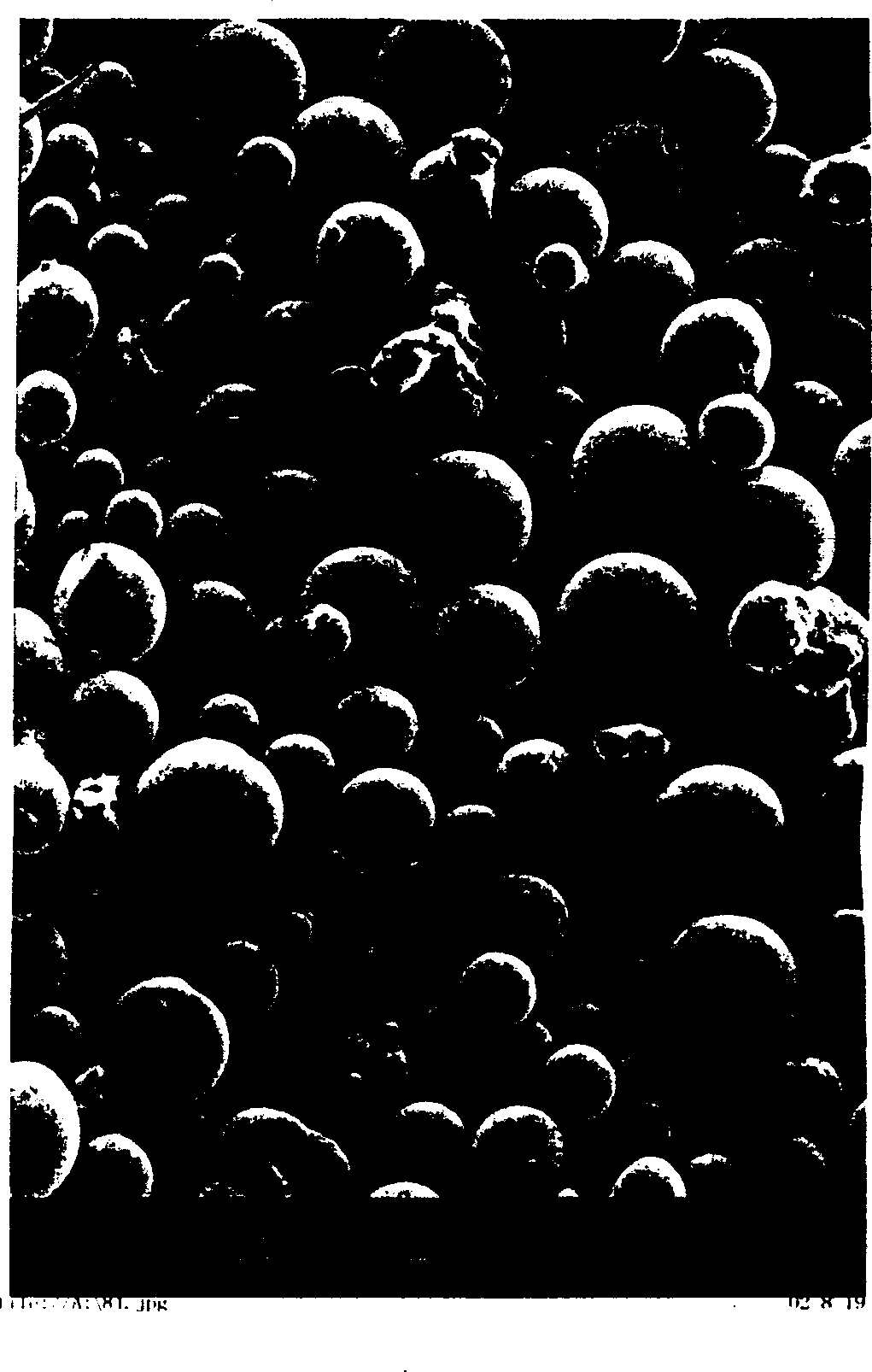

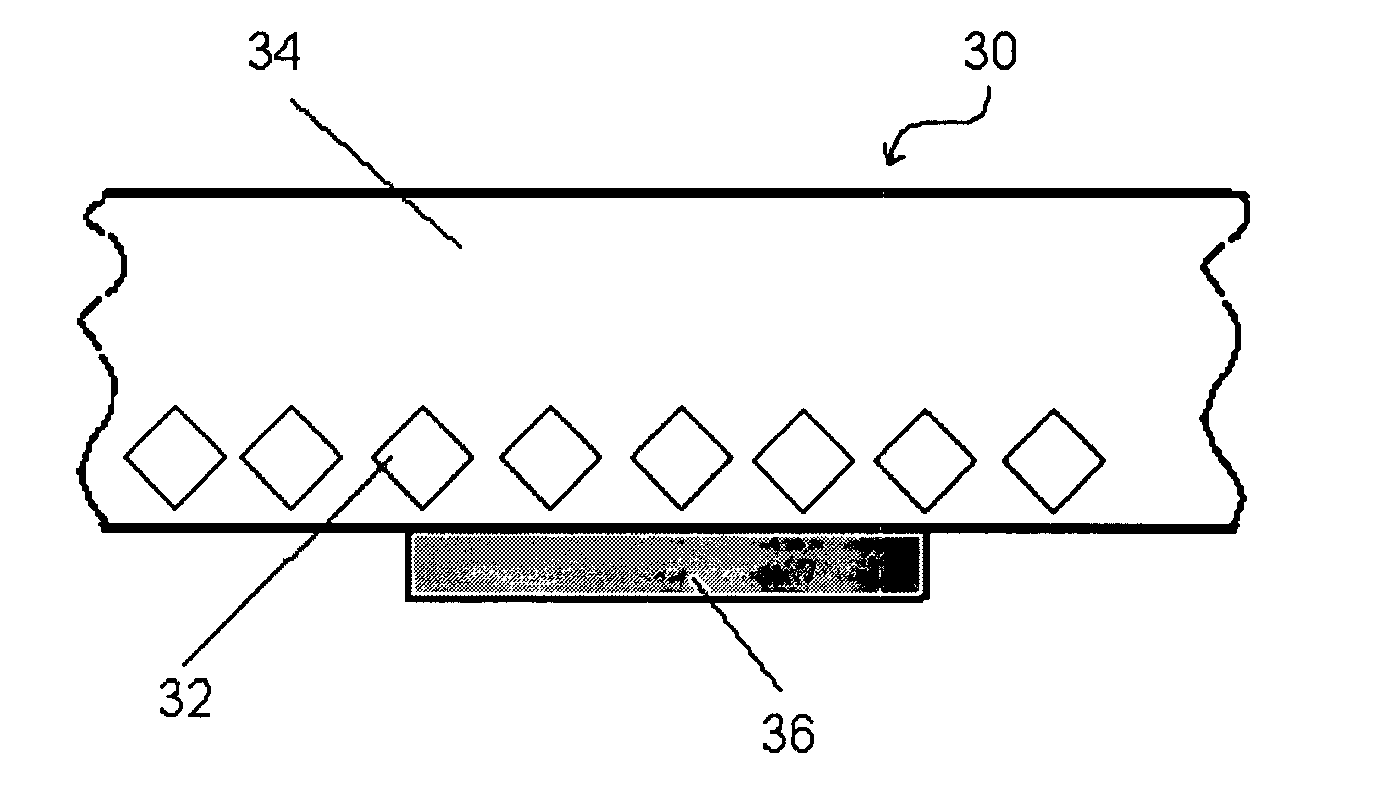

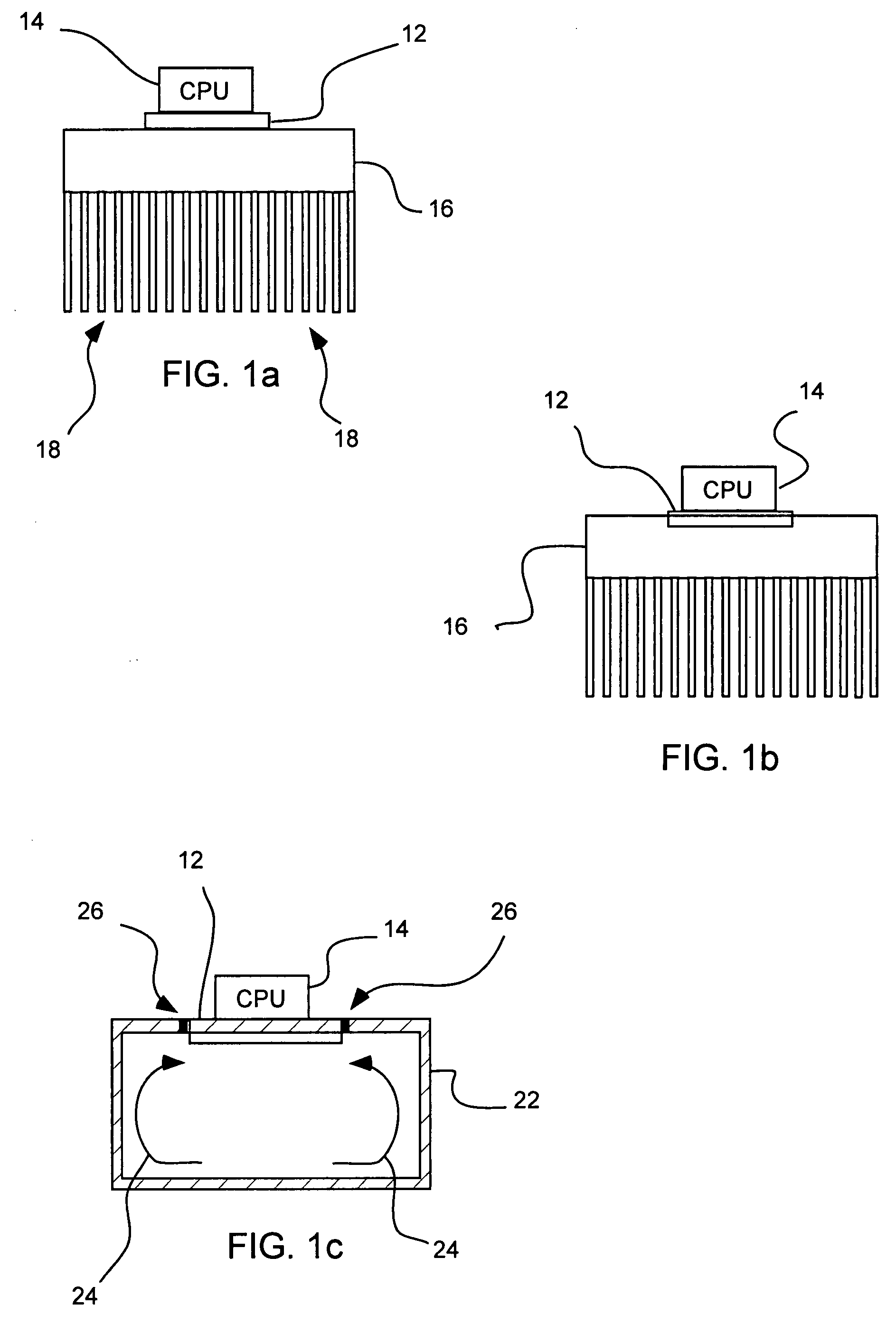

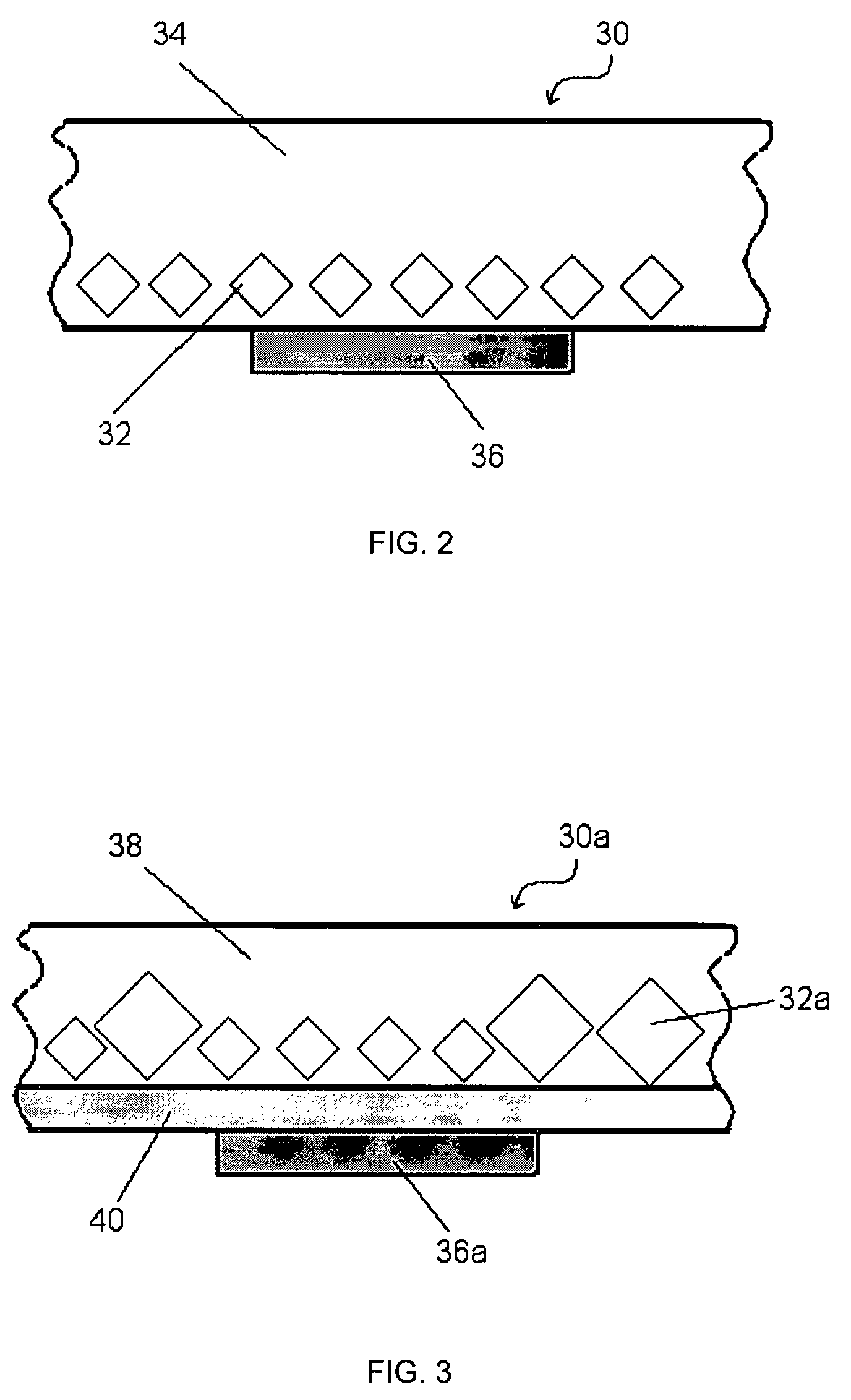

InactiveUS7791188B2Effectively cementIncrease contactSemiconductor/solid-state device detailsSolid-state devicesAdamiteThermal management system

A heat spreader is presented which can provide effective thermal management in a cost effective manner. The heat spreader includes a plurality of diamond particles arranged in a single layer surrounded by a metallic mass. The metallic mass cements the diamond particles together. The layer of diamond particles is a single particle thick. Besides the single layer of diamond particles, the metallic mass has substantially no other diamond particles therein. A thermal management system including a heat source and a heat spreader is also presented, along with methods for making and methods for use of such heat spreaders.

Owner:RITEDIA CORPORATION

Preparation method of composite binding agent diamond grinding wheel

ActiveCN103600308AImprove grinding efficiencyGood self-sharpeningAbrasion apparatusGrinding devicesMaterials scienceTin

The invention discloses a preparation method of a composite binding agent diamond grinding wheel. The method includes the steps of firstly, mixing, by weight, 1-2 parts of phosphorus powder, 10-15 parts of polyimide resin powder, 8-10 parts of tin powder, 35-40 parts of copper powder, 9-11 parts of lead powder and 2-4 parts of zinc powder, and then sieving with a 325-mesh standard sieve to obtain composite binding agent; secondly, mixing, by weight, 10-14 parts of diamond grinding material and 25-45 parts of composite binding agent in a mixing machine, adding, by weight, 1.5-2 parts of acrylic emulsion to continue mixing, and sieving with a 70-mesh standard sieve to obtain grinding wheel mixture; thirdly, placing a steel substrate in a die, filing the grinding wheel mixture in the die, and hot pressing in a hydraulic machine to obtain grinding wheel blank; fourthly, sintering the grinding wheel blank in a sintering furnace; fifthly, machining the sintered grinding wheel blank on a lathe and a grinding machine to obtain the fished composite binding agent diamond grinding wheel. The diamond grinding wheel prepared by the method is high in grinding efficiency, good in self-sharpness, high in rigidity, high in heat resistance, and good in profile maintaining.

Owner:CHANGSHU JULI GRINDING WHEEL

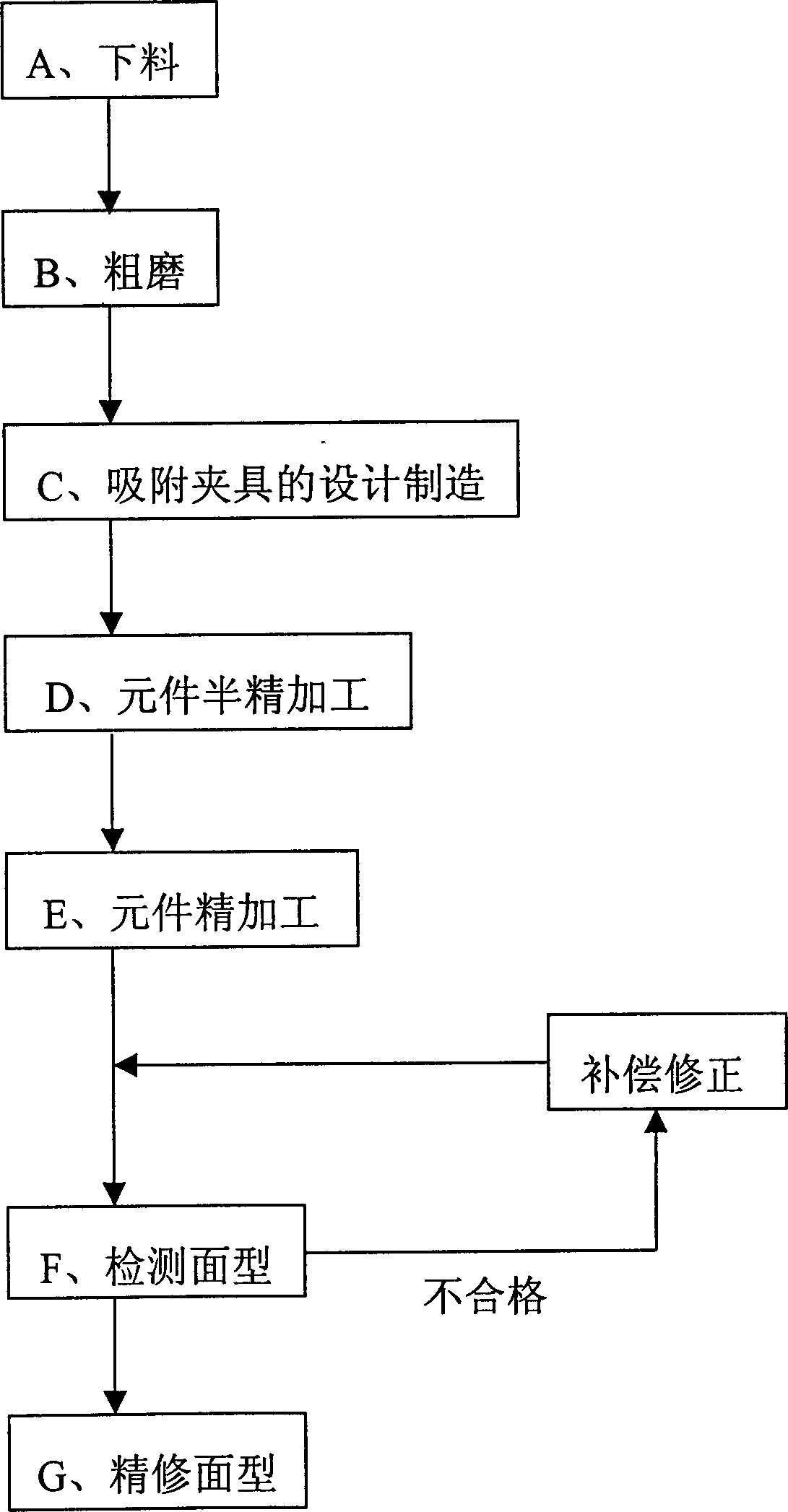

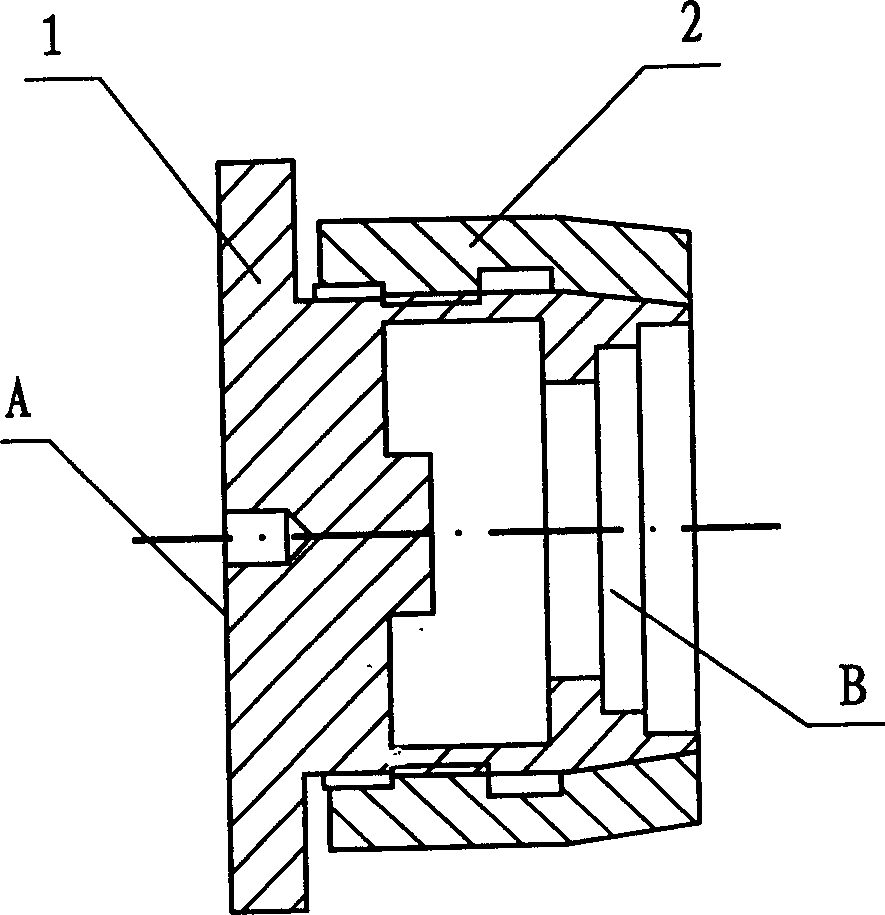

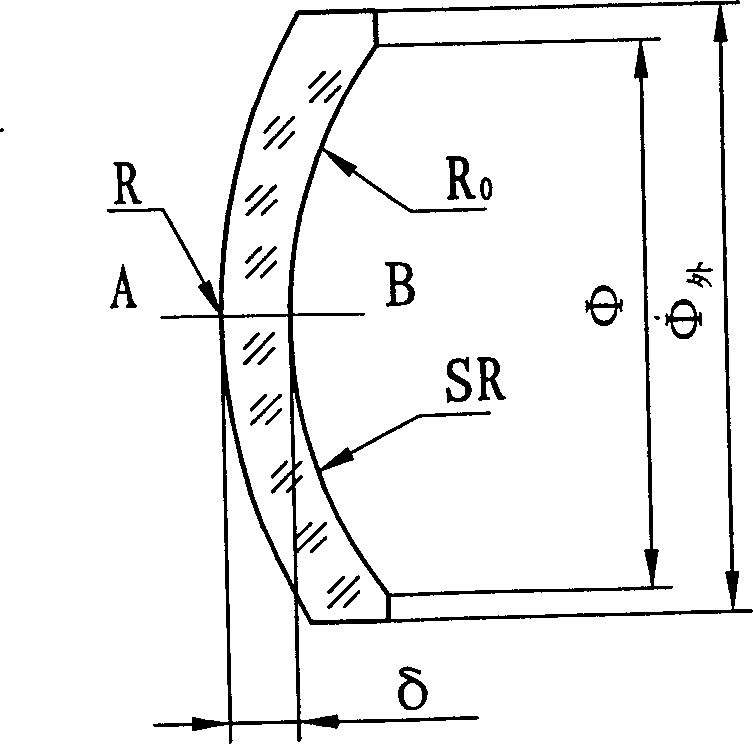

Processing method of germanium single crystal non spherical surface optical element

A technology for machining the non-spherical optical element with monocrystal of Ge features use of numerally controlled lathe and arc diamond cutter. Its technological steps include blanking, coarse grinding, designing and manufacturing attractive fixture, semi-fine machining, fine machining, testing surface type, and trimming. It has high productivity.

Owner:云南北方光学电子集团有限公司

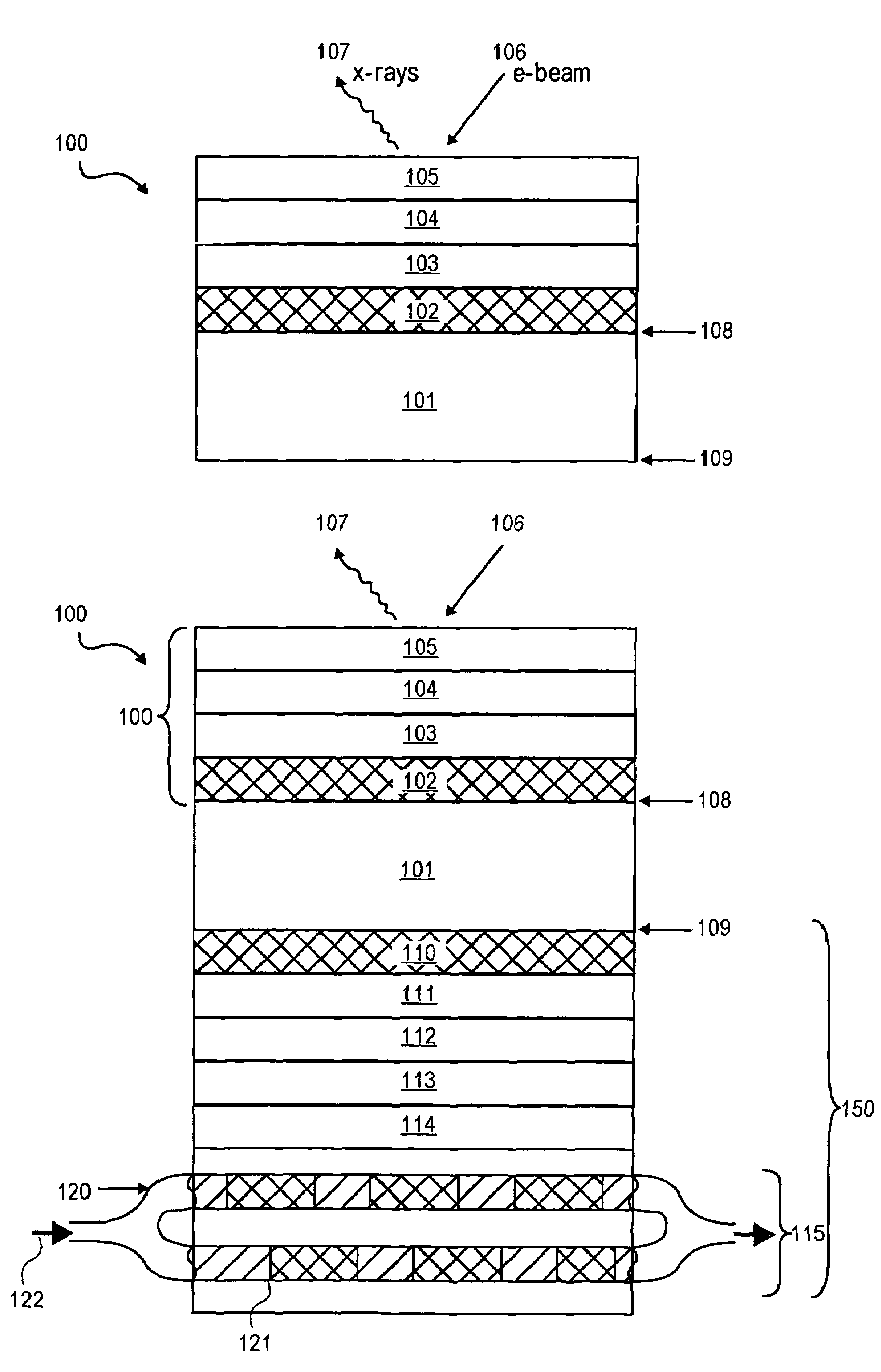

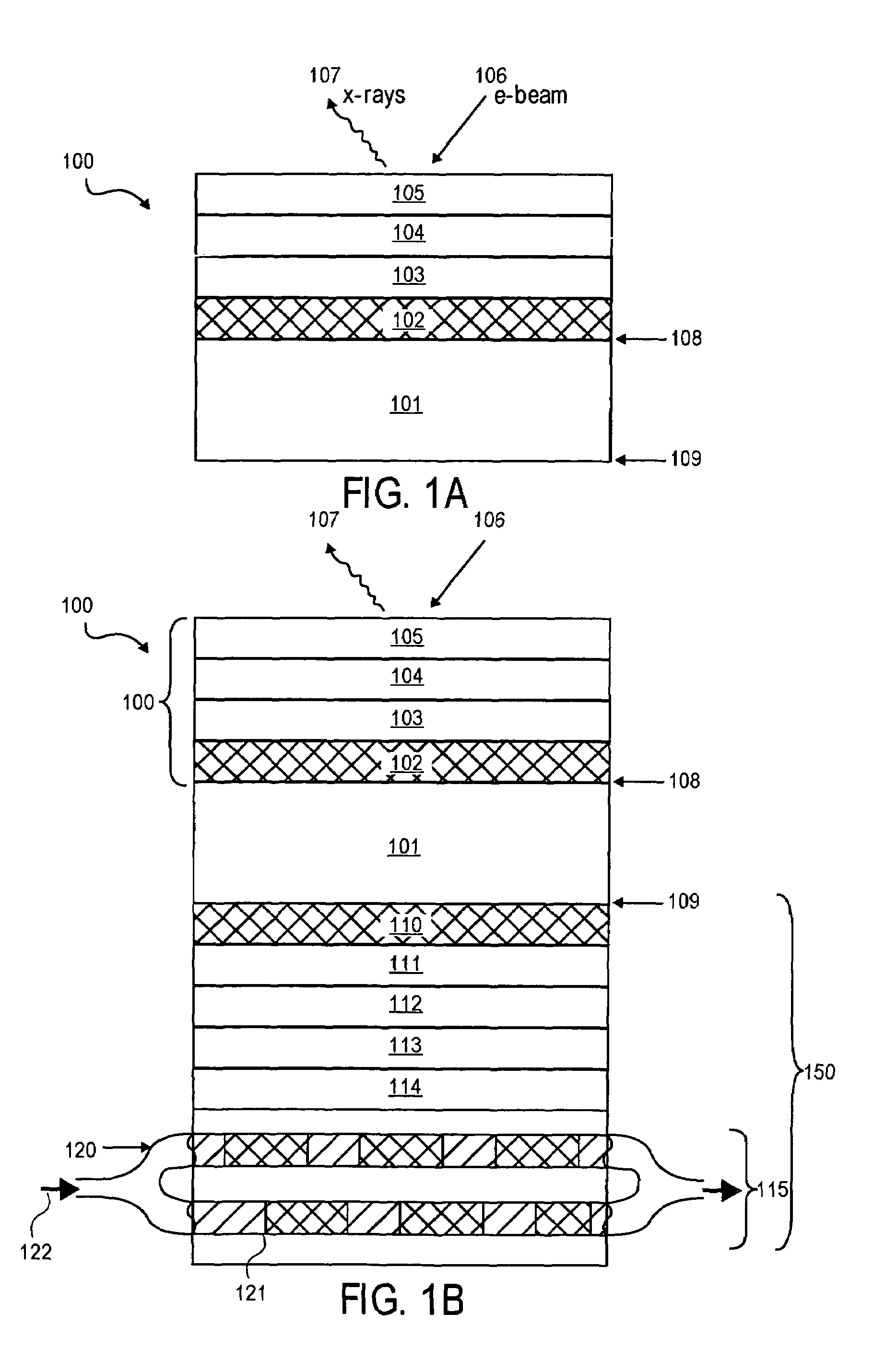

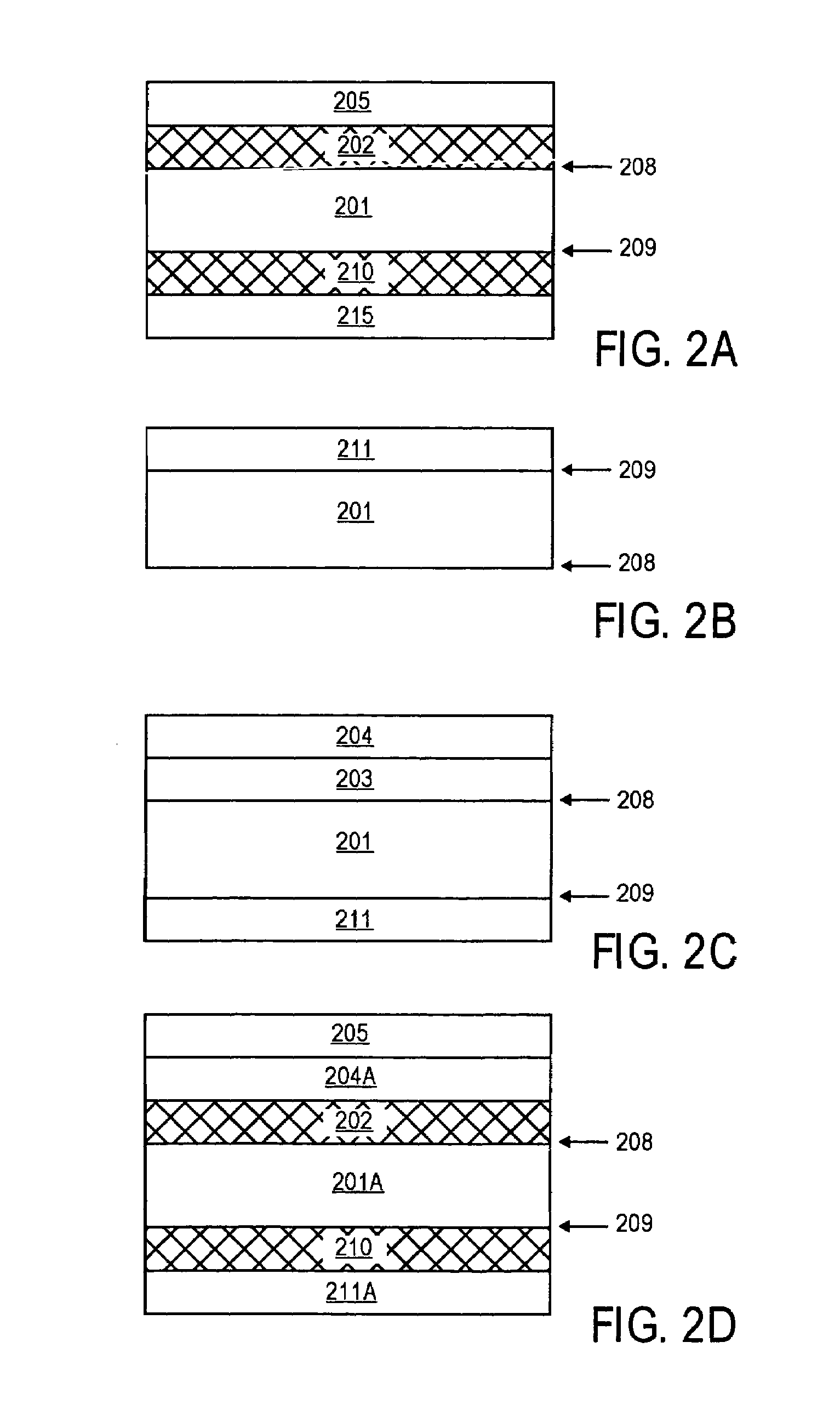

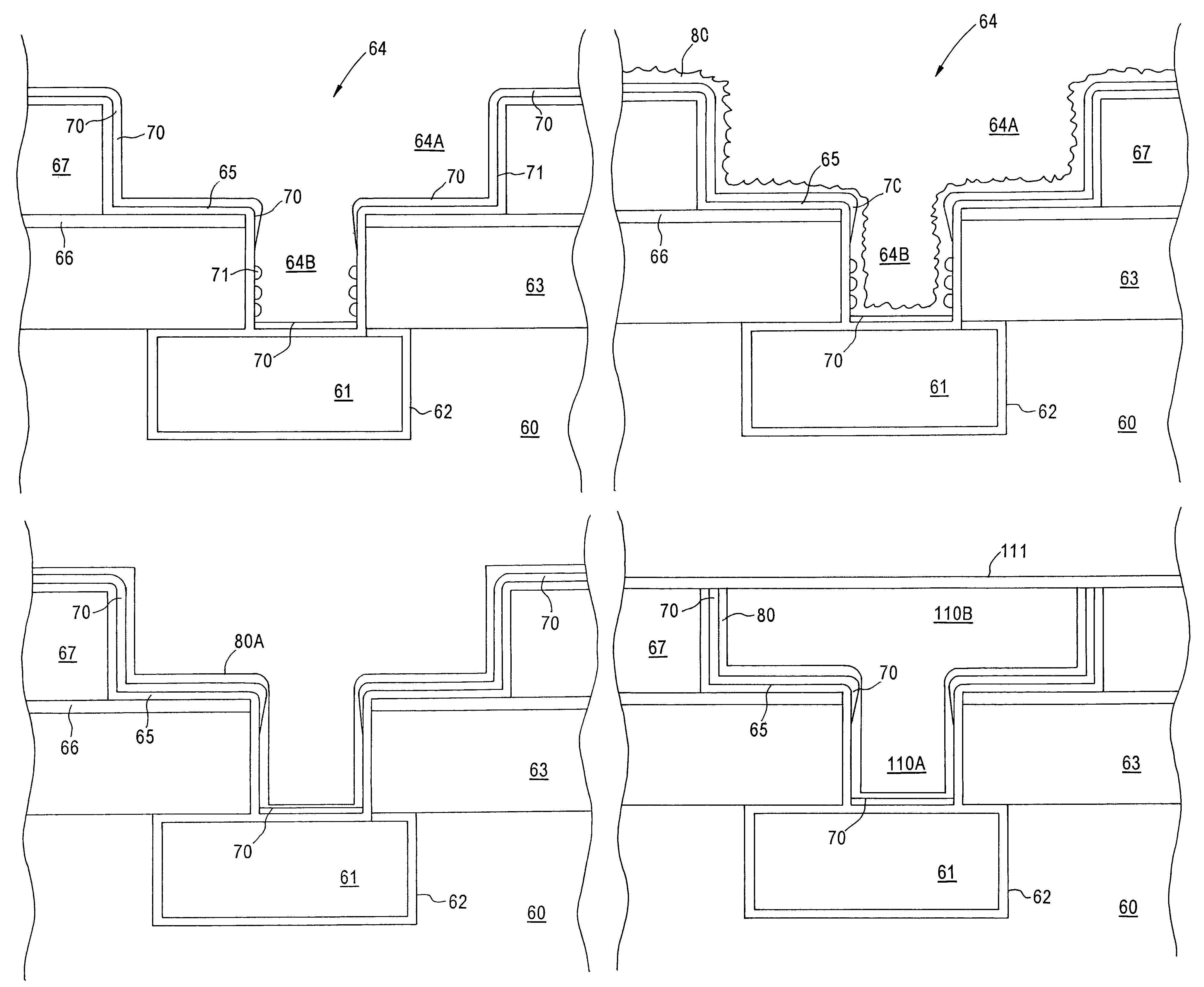

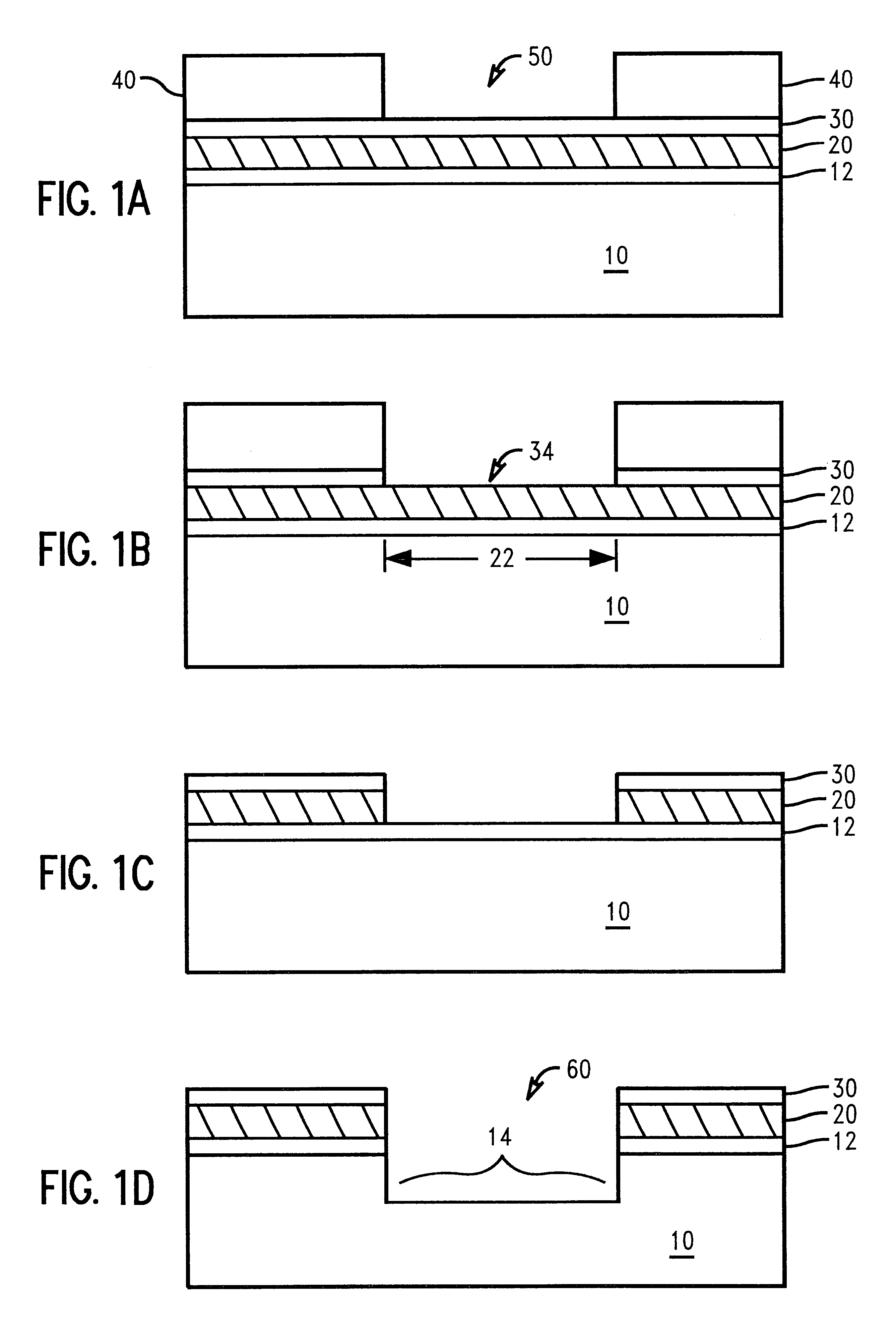

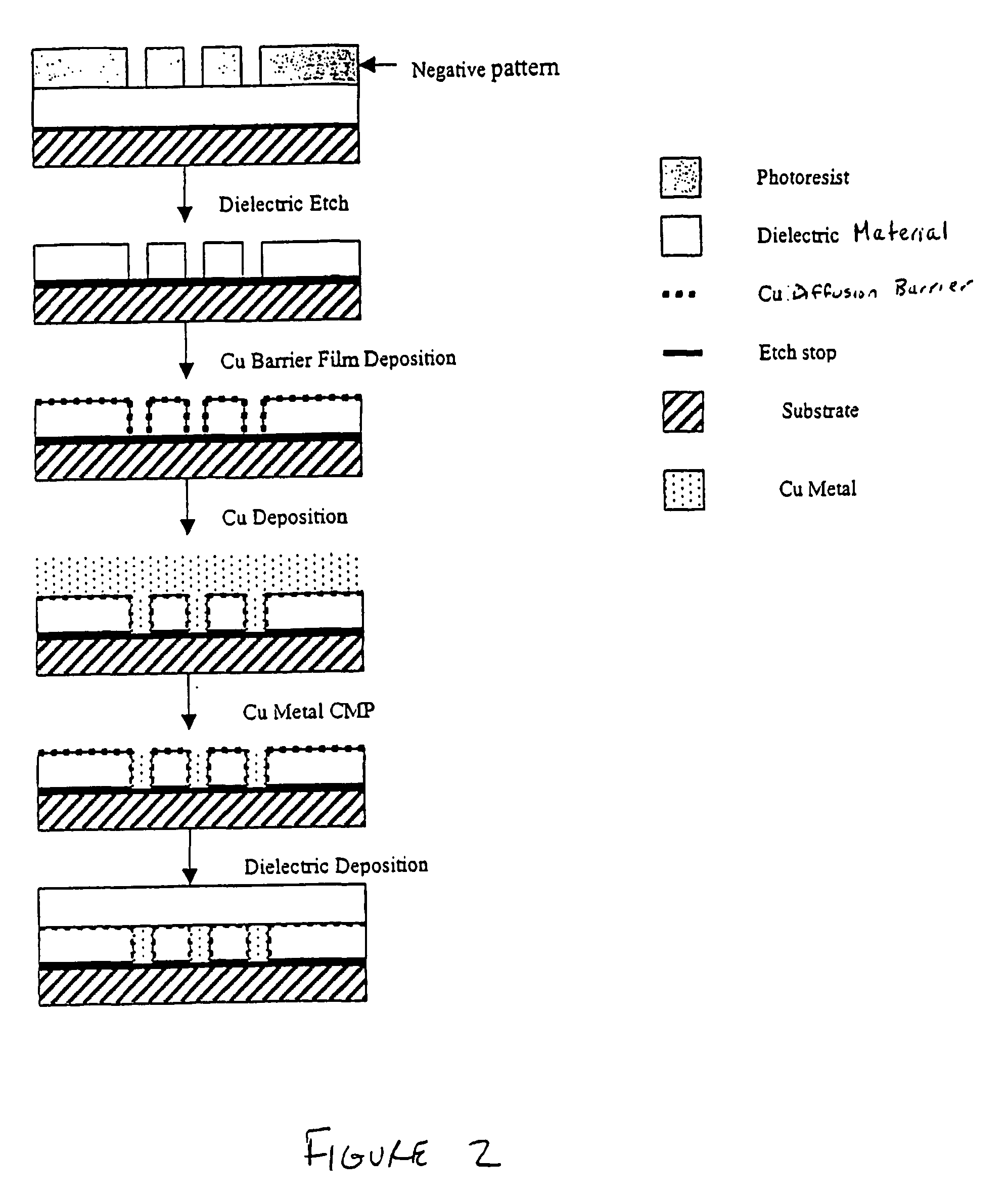

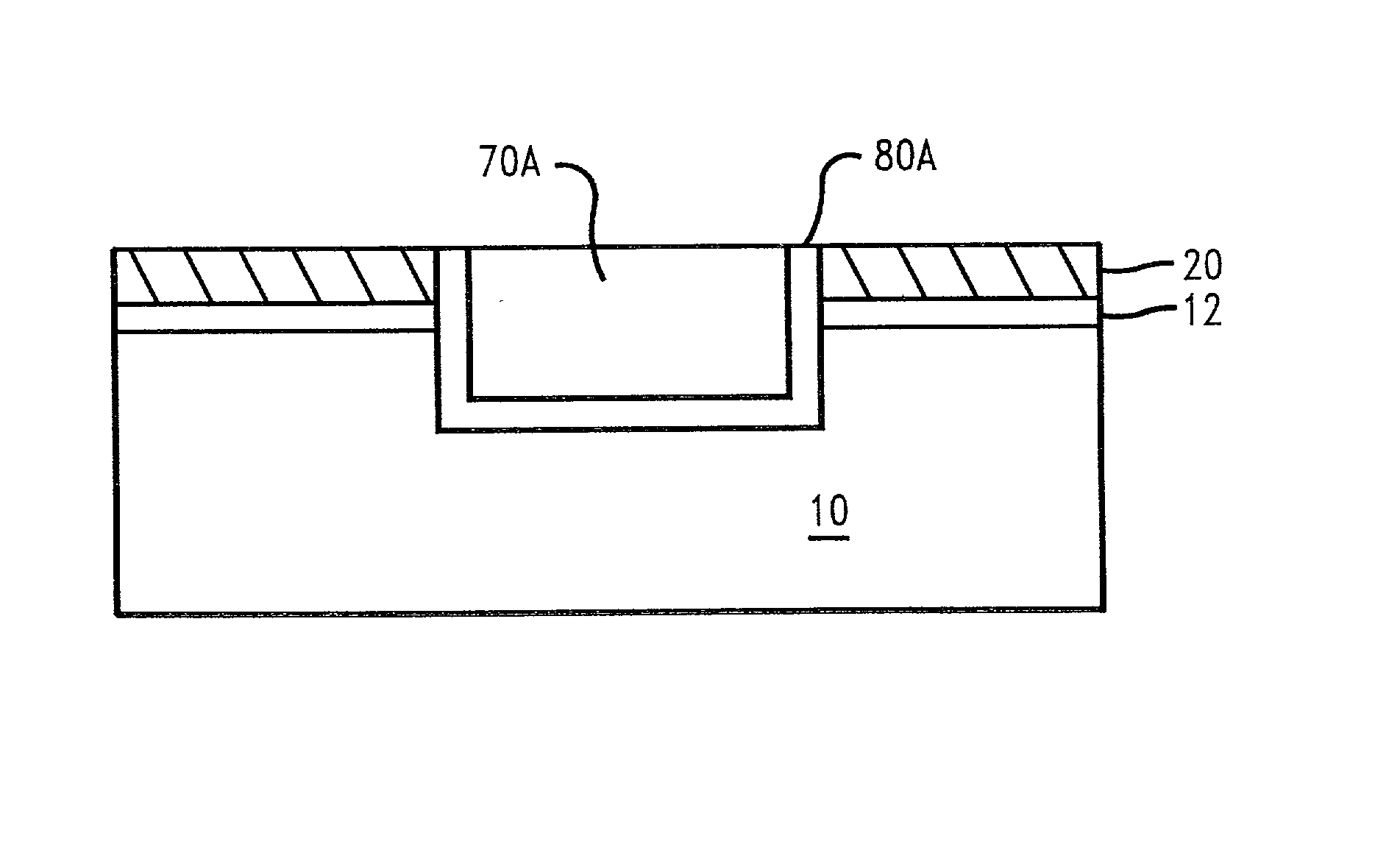

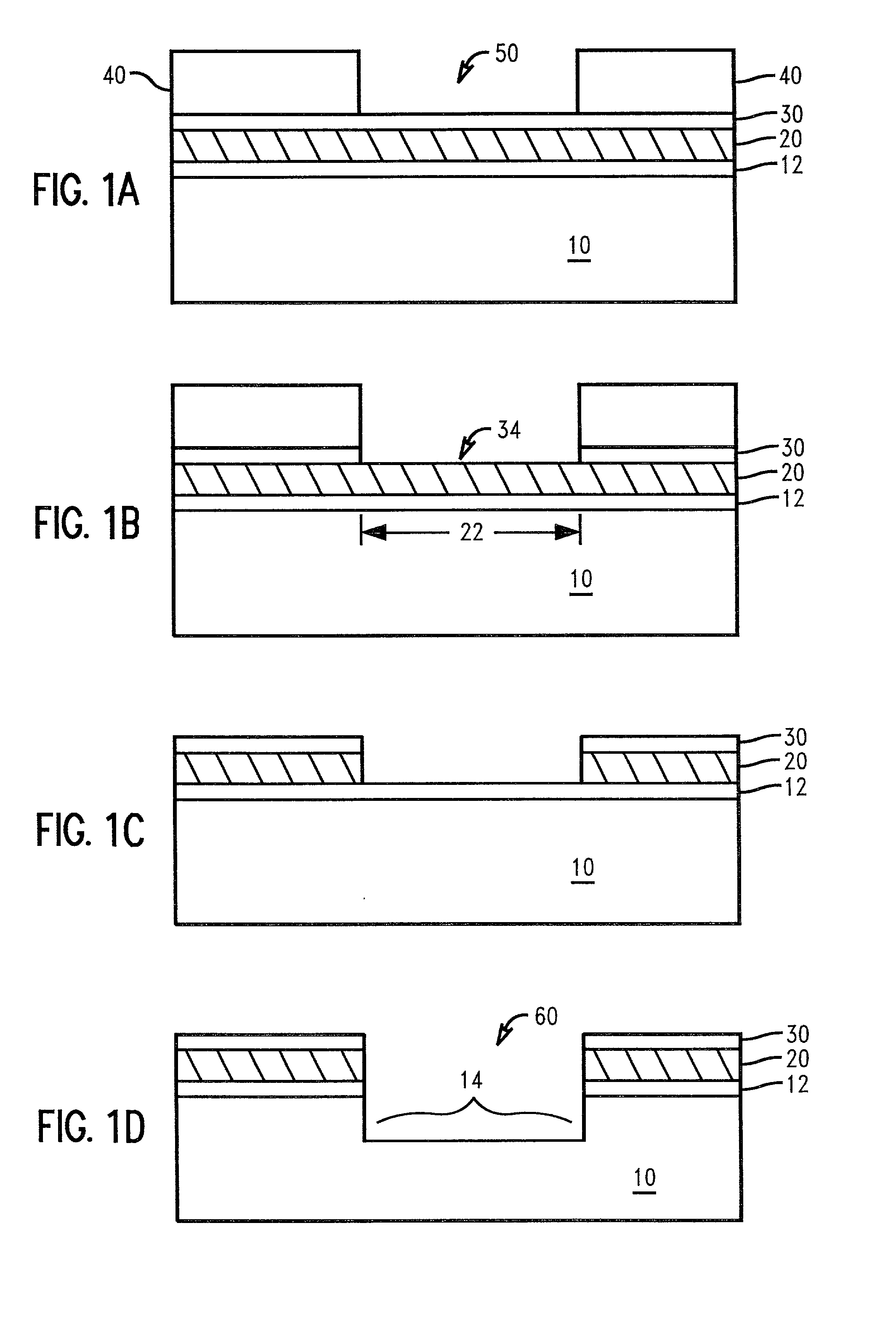

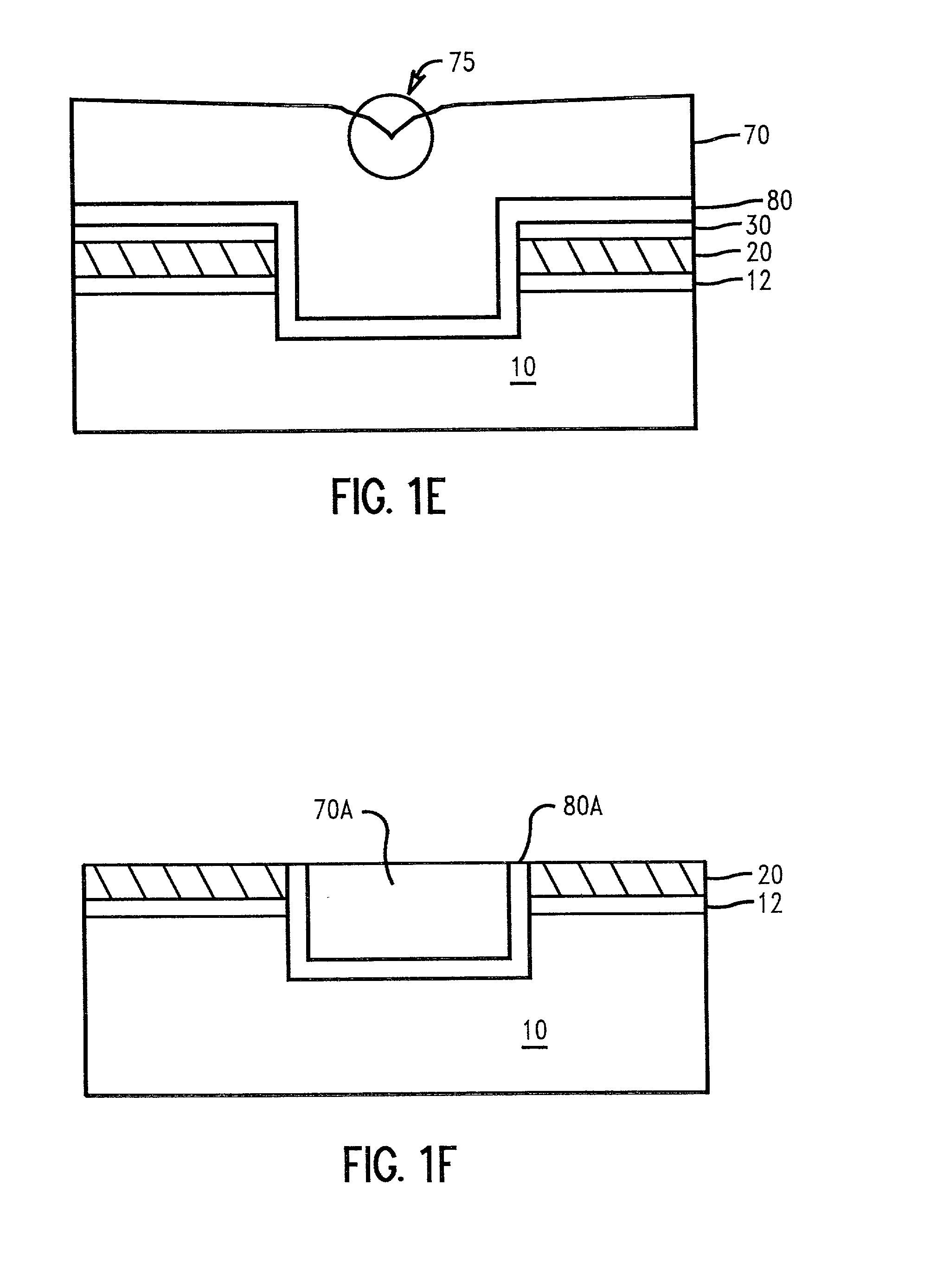

Diamond as a polish-stop layer for chemical-mechanical planarization in a damascene process flow

InactiveUS6348395B1Reduced topographyImprove thermal conductivitySemiconductor/solid-state device manufacturingCarbon layerDiamond-like carbon

A method of using diamond or a diamond-like carbon layer as a polish-stop for patterning a metal level into an inter-level dielectric substrate using a damascene process flow. The diamond or diamond-like carbon layer is deposited onto the surface of the substrate before patterning the metal level. A protective layer is then deposited over the diamond or diamond-like carbon polish-stop layer, wherein such protective layer may act as an additional polish-stop layer. Together, the diamond or diamond-like carbon polish-stop layer and the protective layer are used as a hard-mask for patterning the trenches that will become the metal features, wherein such protective layer protects the diamond or diamond-like carbon polish-stop layer during the patterning process. After deposition of a conductive metal layer, the dielectric substrate is polished to remove excess conductive material, as well as topography. In the polishing process, the diamond or diamond-like carbon polish-stop layer and any remaining protective layer are used as polish-stop layers. The diamond or diamond-like carbon polish-stop layer allows for an improved planar surface, thereby resulting in a sufficient decrease in topography at the surface of the inter-level dielectric.

Owner:QIMONDA +1

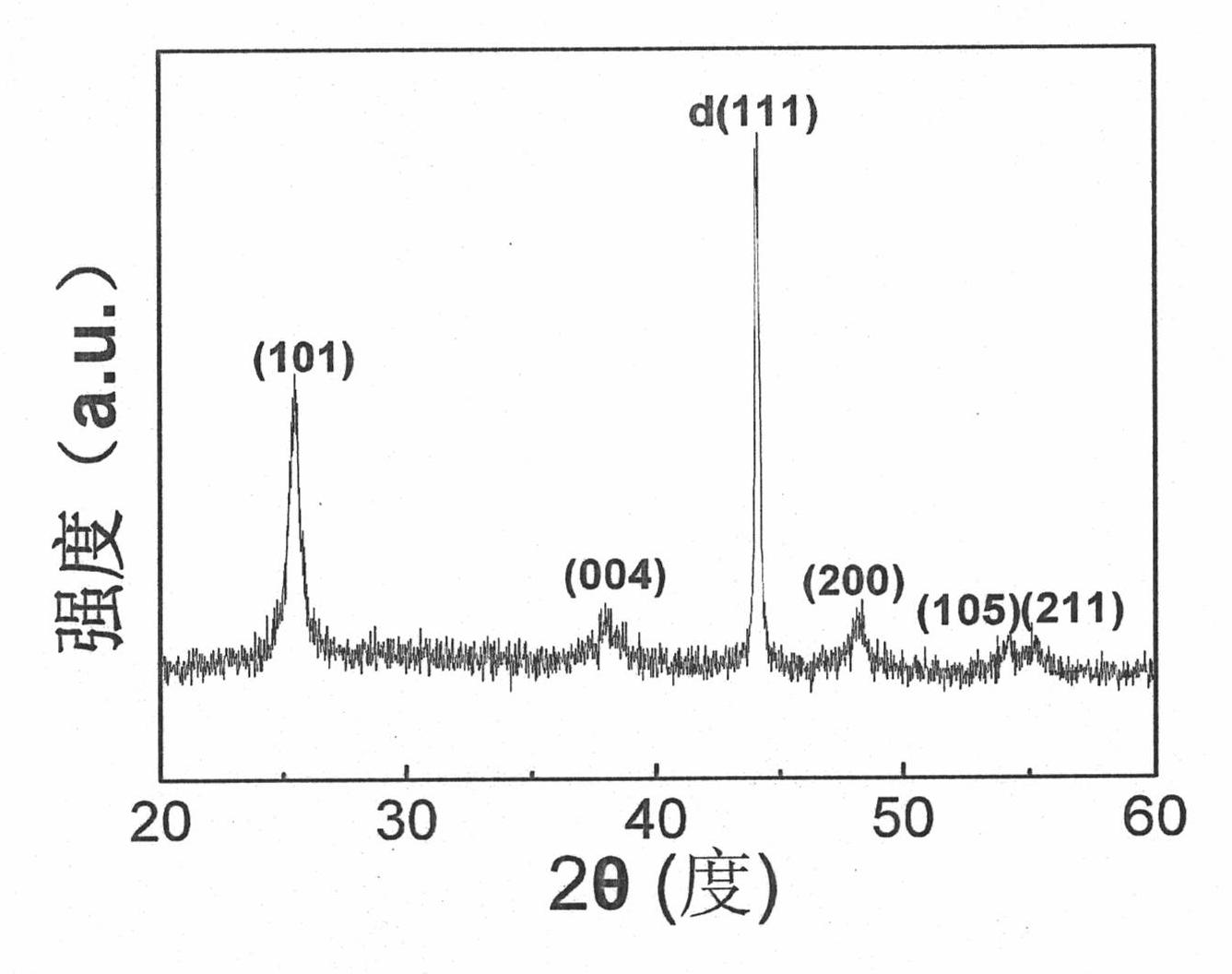

N-shaped titanium oxide nanotube/p-shaped diamond heterojunction photocatalytic material and preparation method

InactiveCN101786026AImprove photocatalytic performanceEasy to separateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionTio2 nanotube

The invention relates to an n-shaped titanium oxide nanotube / p-shaped diamond heterojunction photocatalytic material and a preparation method, belonging to the technical field of photocatalytic materials and the preparation thereof. The photocatalytic material is formed by growing an n-shaped TiO2 nanotube with an anatase structure on a p-shaped diamond. The preparation method comprises the following steps of: 1. growing a boron-doped p-shaped polycrystalline diamond film or boron-doped p-shaped diamond single crystal; 2. sputtering a ZnO seed crystal layer on a p-shaped diamond; 3. growing a ZnO nano rod on the ZnO seed crystal layer in the mixed water solution of zinc acetate and hexamethylene tetramine; and 4. growing the n-shaped TiO2 nanotube on the p-shaped diamond in the mixed solution of ammonium fluorotitanate and boric acid by using the ZnO nano rod as a template. The.TiO2 nanotube is prepared on the diamond by utilizing a liquid-phase synthesis method, thus heterojunction with excellent photocatalytic performance is obtained; and the method is simple, has low cost, and is suitable for large-scale production and application.

Owner:JILIN UNIV

Copper diffusion barriers made of diamond-like nanocomposits doped with metals

InactiveUS7019399B2Semiconductor/solid-state device detailsSolid-state devicesDiffusionCopper interconnect

The invention relatse to a copper diffusion barrier which includes a diamond-like material includes carbon, hydrogen, silicon, oxygen and a metal and is a copper diffusion barrier. Another aspect of the invention relates to an integrated circuit which includes a copper interconnect, a dielectric material and the copper diffusion barrier.

Owner:SULZER METAPLAS

Nano diamond-macromolecular composite abrasive for solidifying abrasive polishing pad

InactiveCN102528648AReduce hardnessAchieving "soft impactAbrasion apparatusLapping toolsEpoxySynthesis methods

The invention provides a method for preparing a diamond-macromolecular composite abrasive. The cores of composite abrasive particles are diamond powder prepared by a mechanical crushing method, an explosive synthesis method or a static pressure method, and the particle diameter range of the powder is 1 to 100 nanometers; the powder serving as the core is modified to form an intermediate transition layer through a silane coupling agent, and the intermediate transition layer is grafted and wrapped to form the composite abrasive by using epoxy resin and polyacrylate, wherein the mass of the silane coupling agent is 0.2 to 2 percent of that of the nano particles; and the mass of the epoxy resin and the polyacrylate is 0.2 to 2 percent of that of inorganic nano particles. The compatibility between the abrasive and a polishing pad base body is improved, and the nano diamond composite abrasive treated by different macromolecules can be selected according to different polishing pad base bodies. By introducing groups to the surface of the diamond abrasive, the bonding force between the diamond abrasive and the polishing pad base body is improved, drop of the diamond abrasive is reduced, and surface damage of a machined workpiece due to drop of the diamond abrasive in the polishing process is prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

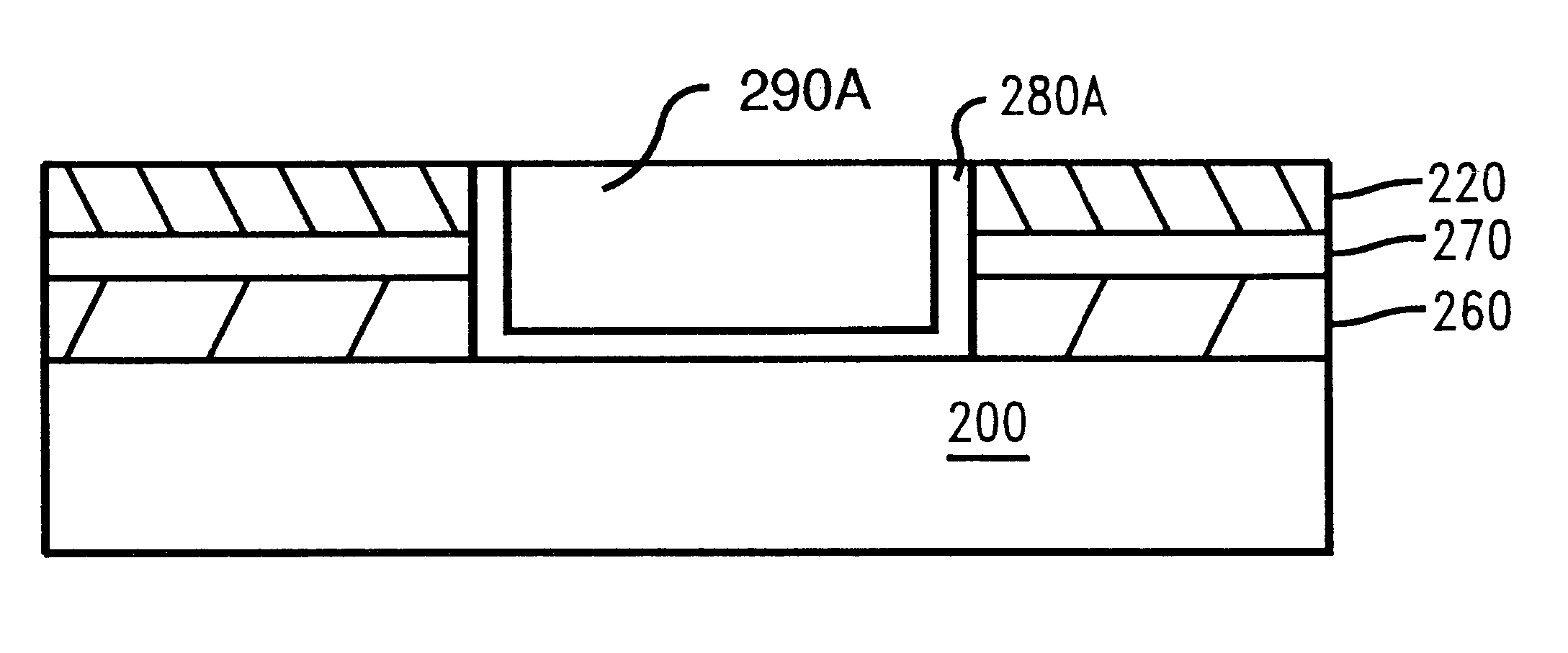

Diamond as a polish-stop layer for chemical-mechanical planarization in a damascene process flow

InactiveUS20020048959A1Improve thermal conductivityImprove abilitiesSemiconductor/solid-state device detailsSolid-state devicesCarbon layerDiamond-like carbon

A method of using diamond or a diamond-like carbon layer as a polish-stop for patterning a metal level into an inter-level dielectric substrate using a damascene process flow. The diamond or diamond-like carbon layer is deposited onto the surface of the substrate before patterning the metal level. A protective layer is then deposited over the diamond or diamond-like carbon polish-stop layer, wherein such protective layer may act as an additional polish-stop layer. Together, the diamond or diamond-like carbon polish-stop layer and the protective layer are used as a hard-mask for patterning the trenches that will become the metal features, wherein such protective layer protects the diamond or diamond-like carbon polish-stop layer during the patterning process. After deposition of a conductive metal layer, the dielectric substrate is polished to remove excess conductive material, as well as topography. In the polishing process, the diamond or diamond-like carbon polish-stop layer and any remaining protective layer are used as polish-stop layers. The diamond or diamond-like carbon polish-stop layer allows for an improved planar surface, thereby resulting in an sufficient decrease in topography at the surface of the inter-level dielectric.

Owner:IBM CORP +1

Wear-resistant diamond polishing grinder and production method thereof

InactiveCN102501186AImprove mechanical propertiesImprove heat resistanceAbrasion apparatusGrinding devicesWear resistantStearic acid

The invention relates to a wear-resistant diamond polishing grinder and a production method thereof. The diamond polishing grinder comprises an abrasive layer arranged on a clamping seat, and the abrasive layer is prepared with raw materials by the following volume percentage: 6.25-15 percent of diamond, 0-15 percent of silicon carbide, 35-60 percent of 200-mesh fine heat-resistant phenolic resin, 10-50 percent of 40-mesh fine carboxylated nitrile rubber, 0.5-1 percent of zinc stearate, 0.5-5 percent of zinc oxide, 0-5 percent of sulfur, 0-5 percent of promoting agent TMTD (tetramethyl thiuram disulfide) and 0-5 percent of stearic acid. A binder in the abrasive layer is prepared by adding carboxylated nitrile rubber into the heat-resistant phenolic resin, and the volume ratio of the heat-resistant phenolic resin and the carboxylated nitrile rubber is 100: (10-100). The particle size of the diamond is of 200-8000 meshes, and the particle size of the silicon carbide is of 200-3000 meshes. The invention has the advantages of good grinding effects, long service life, high polishing speed and low overall cost.

Owner:广东奔朗新材料股份有限公司

Silicified diamond/SiC composite material preparation method

InactiveCN108257925AEnhanced interface bindingIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesMicroparticleThermal expansion

The invention discloses a silicified diamond / SiC composite material preparation method, which belongs to the field of electronic packaging materials. Diamond particles and silicon powder are firstly subjected to wet mixing, sintering is carried out after thorough grinding, the diamond surface and the silicon powder react, and a layer of silicon carbide coating is generated; then, the diamond particles with the surface coated with the silicon carbide and the silicon powder are mixed, an organic binder is added at the same time, grinding is carried out, mixing on a mixer is carried out, and uniform composite particles are obtained; the composite particles are subjected to prepressing and debinding and are transferred to a vacuum infiltration furnace, a silicon burial method is adopted for vacuum infiltration, and a compact diamond / SiC composite material is prepared. The silicon powder is adopted to modify the diamond particles, the interfacial bonding between diamond and silicon is improved, the compactness of the obtained diamond / SiC composite material is more than 95%, the hardness is above HRA 80, the bending strength exceeds 200 MPa, the thermal conductivity reaches 600 W / mK, andthe thermal expansion coefficient 1.5 to 4*10<-6> / K. Thus, multiple products with complex characters, complex curvature and large size can be prepared at one time, the production efficiency is high,and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

Compound metal and ceramic bonding agent diamond grinding wheel

InactiveCN105058248AImprove gripGood self-sharpeningAbrasion apparatusGrinding devicesOxidation resistantLanthanum

The invention relates to the technical field of abrasive grinding of grinding tools, and in particular to a compound metal and ceramic bonding agent diamond grinding wheel. The compound metal and ceramic bonding agent diamond grinding wheel is prepared from, by weight, 50-70 parts of surface titanium-coated diamond abrasive, 4-10 parts of tin powder, 10-20 parts of copper powder, 10-18 parts of aluminum powder, 11-18 parts of silicon dioxide, 5-10 parts of boric oxide, 5-8 parts of zinc oxide, 2-6 parts of calcium oxide, 0.01-1 part of lanthanum powder and 1-4 parts of aluminum oxide. Due to the fact that the surface of diamond is coated with titanium so that oxidization resistance can be achieved; titanium is slowly dissolved in a bonding agent in subsequent reactions and forms a transition layer with the diamond abrasive, and therefore the bonding force of the bonding agent on the abrasive is improved; the lanthanum powder is added so that the mechanical performance of a matrix of the grinding wheel can be effectively improved, and the bonding strength of a matrix material on diamond is improved and strengthened; and the aluminum oxide is added so that the pore forming function can be achieved. The compound metal and ceramic bonding agent diamond grinding wheel maintains the good self-sharpening performance of a ceramic bonding agent grinding wheel and also has the good characteristics of high rigidity and good shape maintenance of a metal bonding agent grinding wheel; and formulas are in cooperation, so that the forming performance of the grinding wheel is good, and the service life is long.

Owner:蓬莱市超硬复合材料有限公司

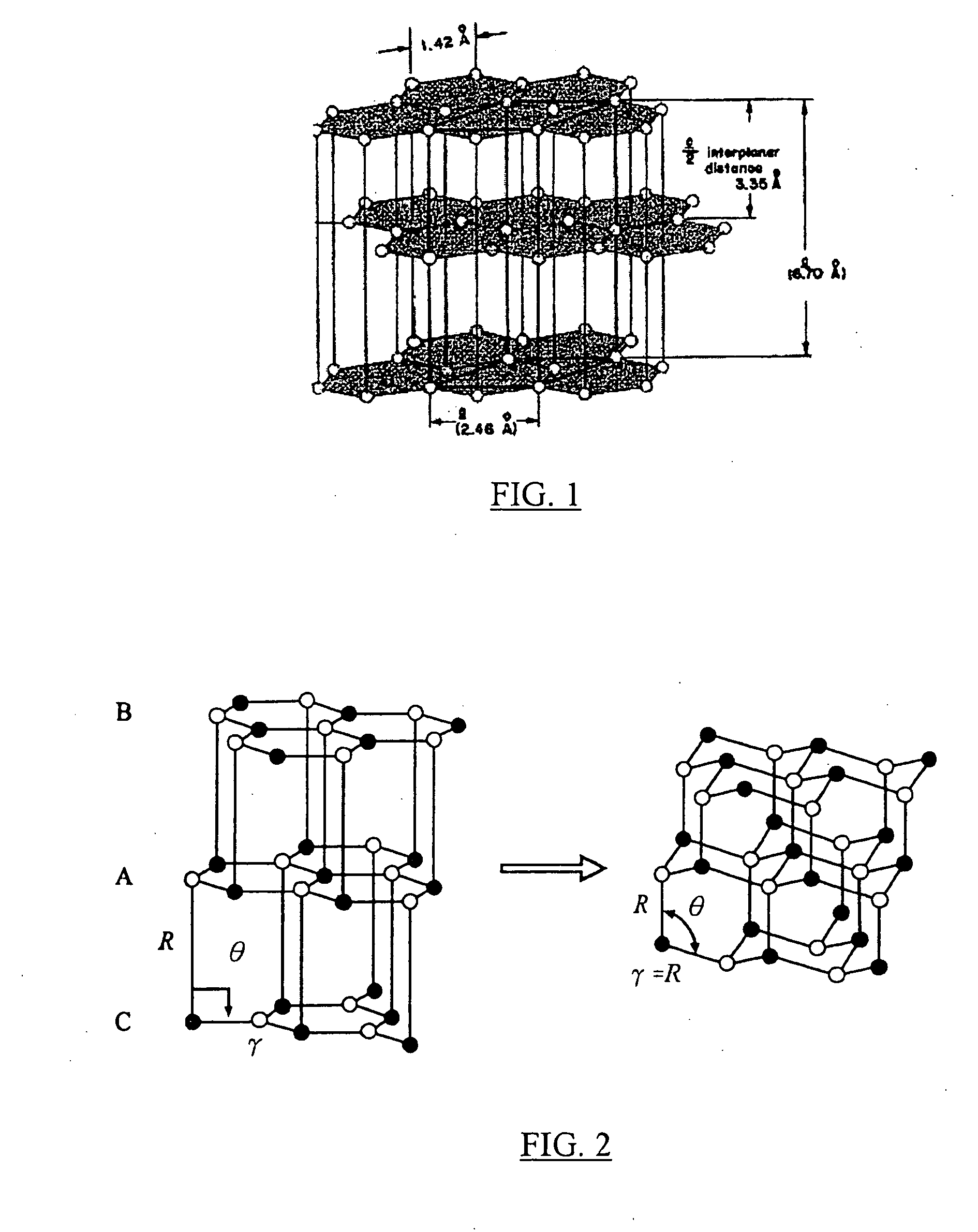

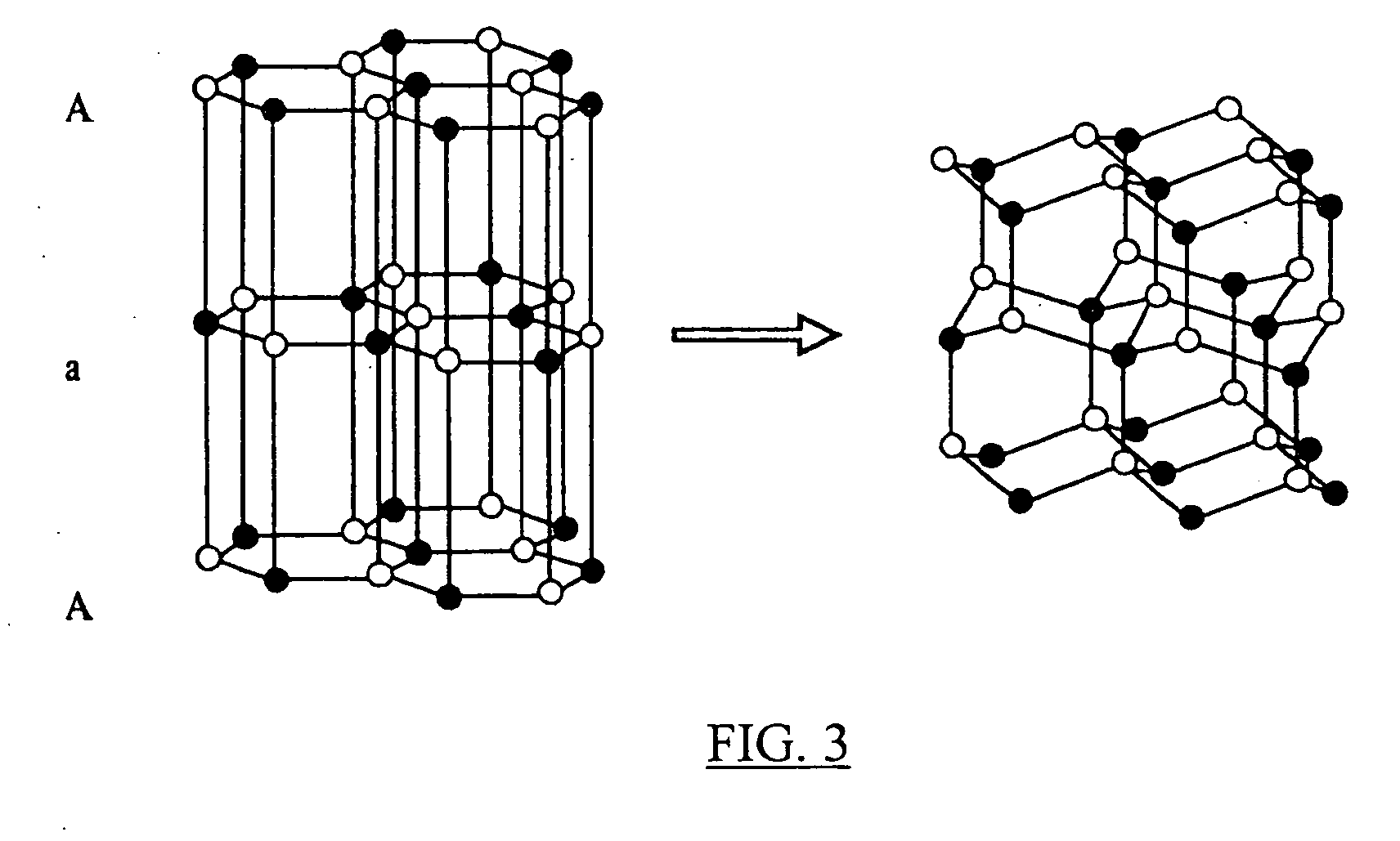

Methods of forming polycrystalline bodies using rhombohedral graphite materials

InactiveUS20060251567A1Improve efficiencyEasy to operateUltra-high pressure processesPorosityParticulates

Methods of synthesizing polycrystalline bodies using rhombohedral graphite materials are disclosed and described. One procedure includes providing a particulate graphite source having a majority of carbon atoms oriented in a rhombohedral polytype configuration. The particulate graphite source can be shaped into a desired shape having a porosity from about 0% to about 30%. A sufficient amount of heat and pressure can be applied to the desired shape to form diamond and consolidate the diamond into a polycrystalline body.

Owner:SUNG CHIEN MIN

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com