Iron-based diamond-impregnated bit for drilling in hard slipping foundation

A diamond-impregnated and diamond-impregnated technology, which is applied in the field of iron-based diamond-impregnated drill bits, achieves less variables, reduces the probability of thermal damage, and is highly targeted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

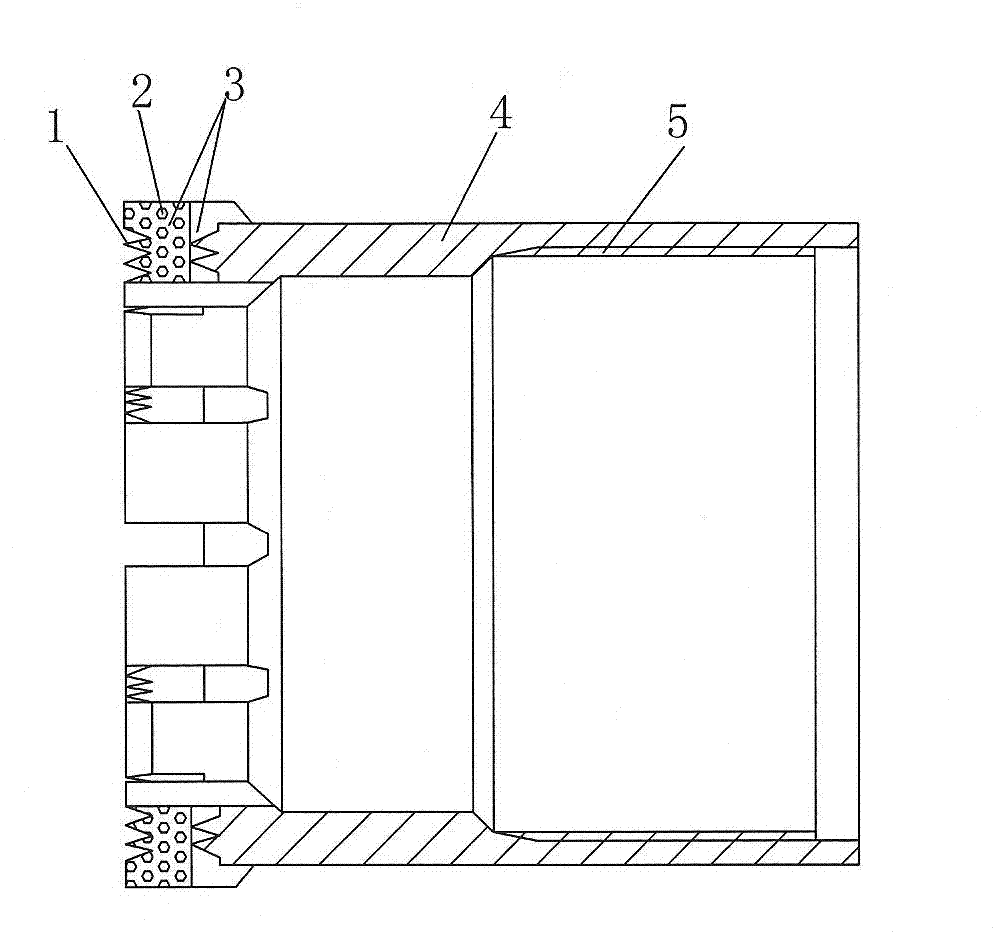

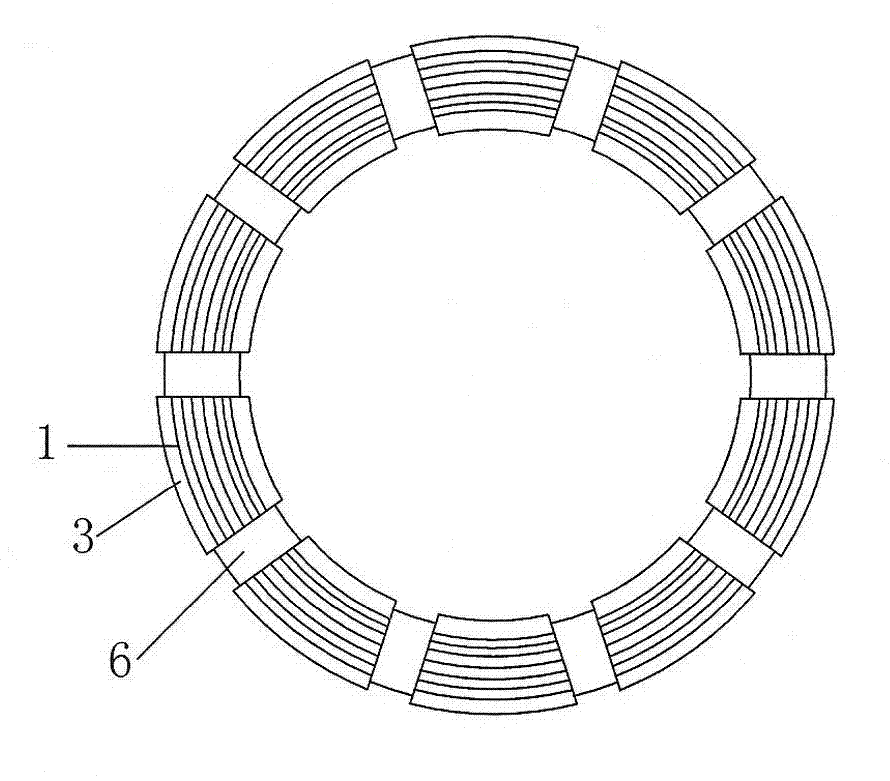

[0021] Select the drill bit size according to the actual drilling design, select the matrix formula, drill bit structure and diamond parameters according to the lithology characteristics of the construction formation, and perform charging calculation, weighing, mixing, charging, steel body alignment, drying, hot pressing Sintering, heat preservation and cooling, later machining, inspection and delivery.

[0022] Now take the drill hole diameter of 76.5mm, formation rock hardness of 6000MPa, weak abrasiveness, and drillability of grade 10~11 granite as an example: iron base is used as the matrix formula, the formula hardness is HRC15±3, and the lip surface of the drill bit is Tine type, as described below.

[0023] 1. Iron-based carcass components (mass percentage): 70% iron powder; 12% zinc powder; 15% 663 bronze powder; 1% manganese powder; 325 mesh.

[0024] 2. Use JR5 type diamond particles, the particle size is 40~45 mesh and 46~50 mesh, and mix according to the mass rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com