Resin anchoring agent diamond grinding wheel and production method thereof

A diamond grinding wheel and bonding agent technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems of poor adhesion between diamond particles and the substrate, failure to achieve straightness and smoothness, and grinding wheel motor rotation. , to achieve strong self-sharpening, straight and smooth brick edges, and improved and service life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

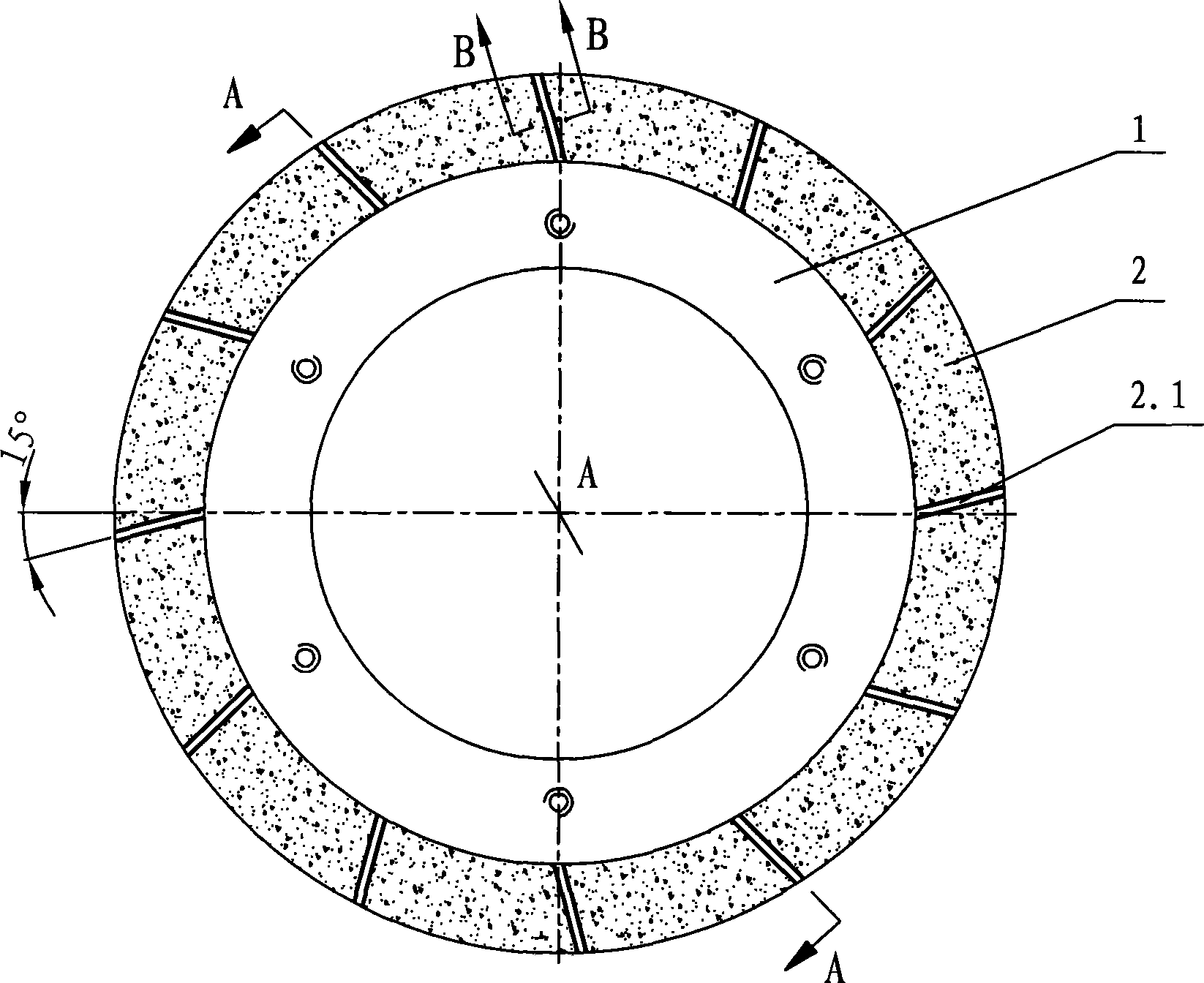

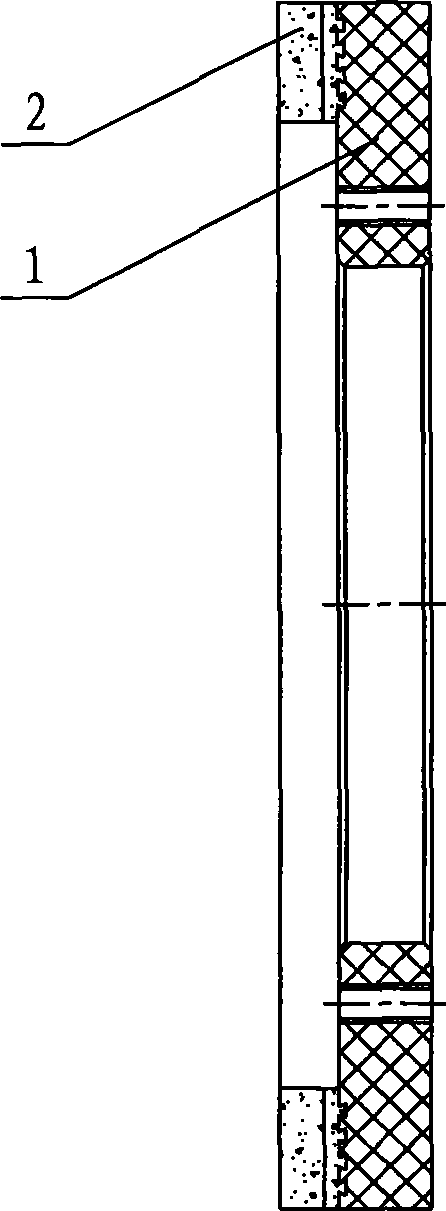

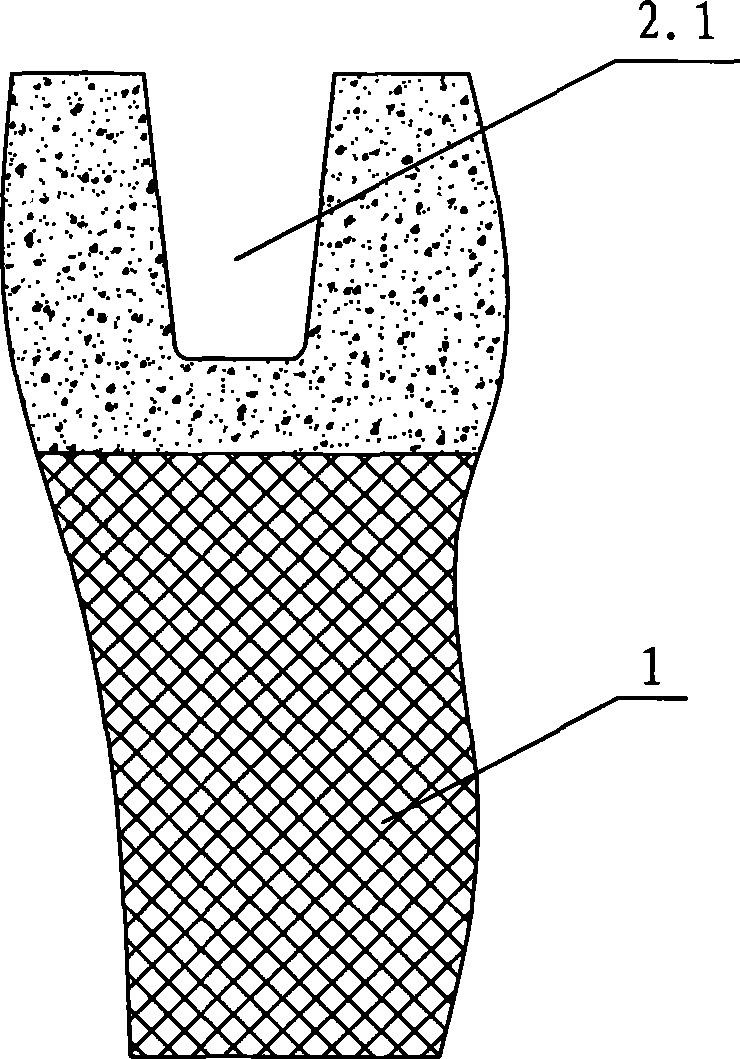

[0032] see Figure 1-Figure 9 , the resin bonded diamond grinding wheel comprises an abrasive layer 2 arranged on a substrate 1, the substrate is a ring-shaped aluminum substrate, the abrasive layer is a ring-shaped resin bond diamond layer, and the abrasive layer is embedded on the substrate and is concentric with it Setting, twelve inclined grooves 2.1 are arranged on the abrasive layer, and the diameter direction of the inclined grooves and the substrate is 12-45°, and the inclined grooves are evenly arranged on the abrasive layer 2, and four annular grooves are arranged on the substrate 1 1.1, the cross-section of the groove is dovetail-shaped.

[0033] The components of the abrasive layer include diamond abrasive, resin bond, auxiliary abrasive, silicon carbide micropowder, copper-clad iron powder and metal oxide fillers, wherein the resin bond is thermosetting polyimide, and the auxiliary abrasive is silicon carbide, A combination of one or more of boron carbide, white ...

no. 2 example

[0055] 1) take by weighing thermosetting polyimide resin 480g, its density is 1.4g / cm , accounting for the volume percentage of the whole abrasive layer is 39.7%,

[0056] 2) take by weighing copper clad iron powder 320g, its density is 8.0g / cm , accounting for the volume percentage of the whole abrasive layer is 4.6%,

[0057] 3) taking by weighing 1000 mesh silicon carbide micropowder 600g, its density is 3.2g / cm3, accounting for the volume percentage of the whole abrasive layer is 21.7%,

[0058] 4) Filler is taken by weighing: chromium oxide 50g powder, its density is 5.21g / cm3, accounts for the volume percent of whole abrasive layer and is 1.1%

[0059] 5) take by weighing diamond abrasive 300g, its density is 3.52g / cm , accounting for the volume percentage of the whole abrasive layer is 9.9%,

[0060] 6) take by weighing auxiliary abrasive material: boron carbide 500g, its density is 2.52g / cm , accounting for the volume percentage of the whole abrasive material layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com