Patents

Literature

145 results about "Zirconia alumina" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

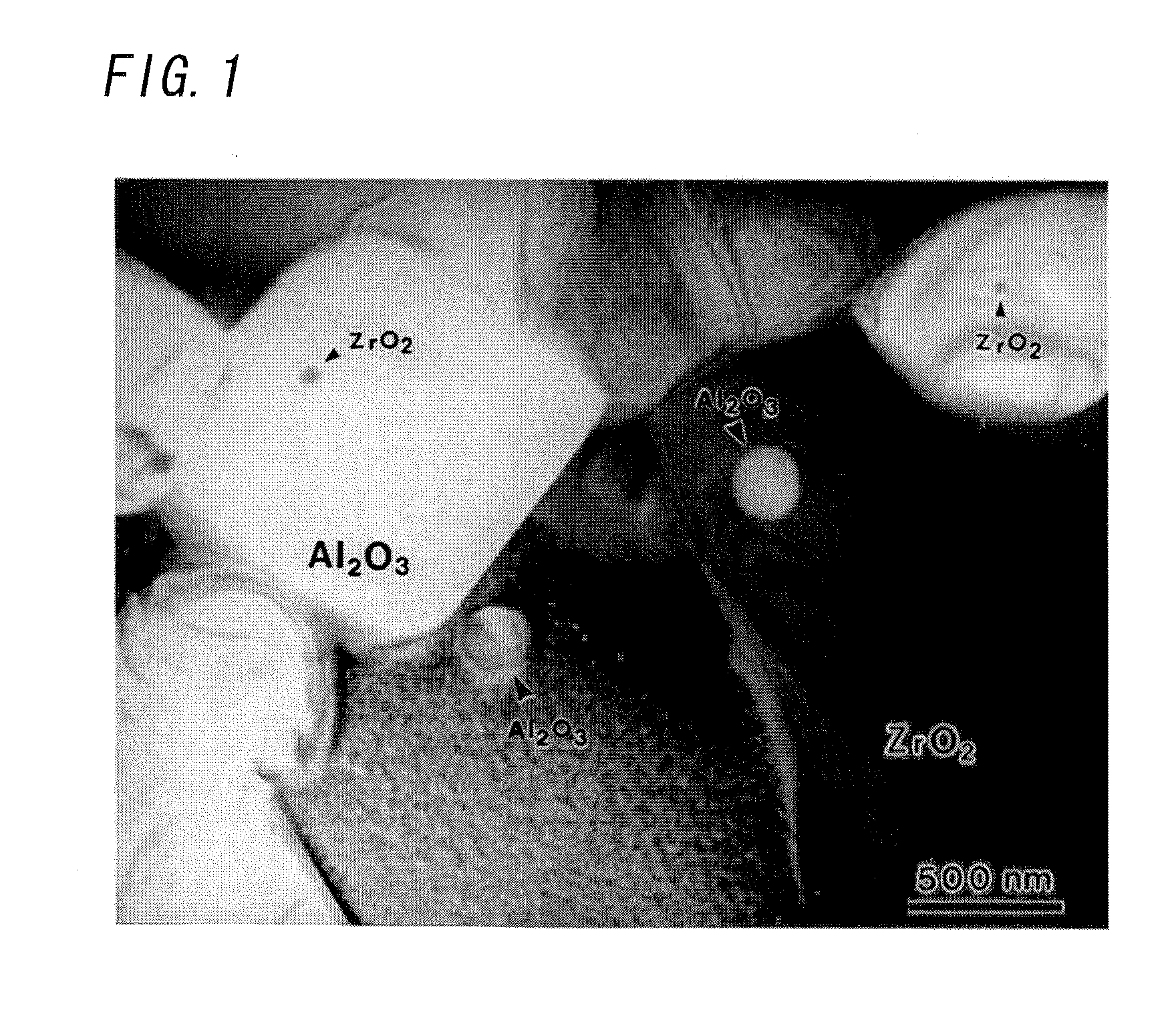

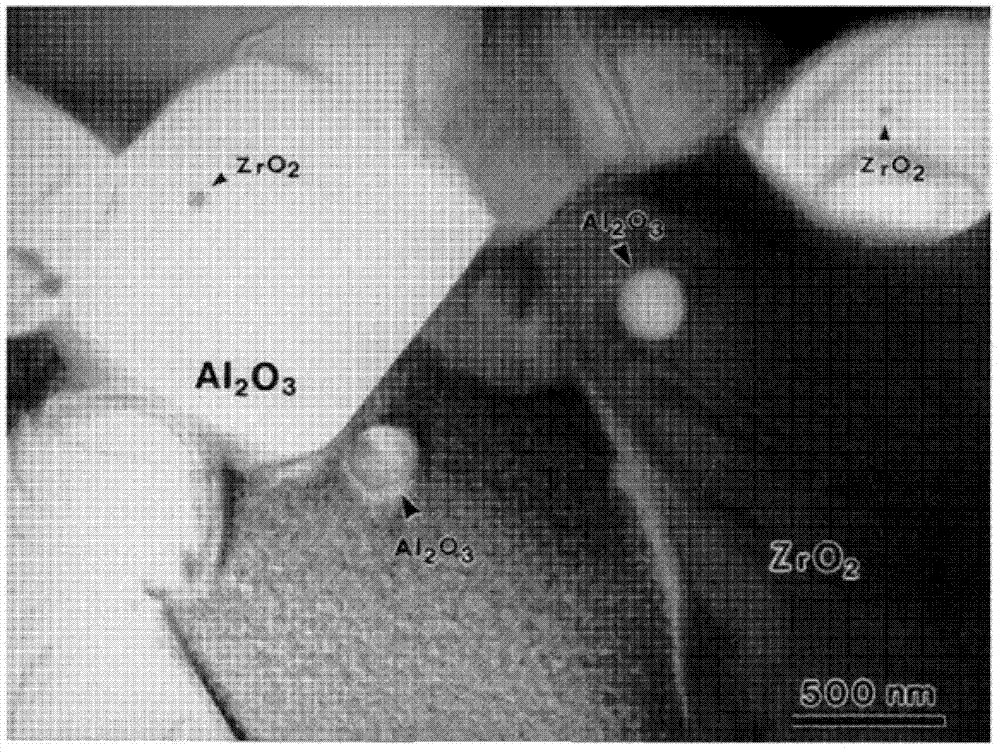

Zirconia alumina is commonly used as a sand-blasting medium. It is typically used as an abrasive in casting and foundry processes. Zirconia alumina is a mixture of zirconium dioxide and aluminium oxide. Zirconia toughened alumina typically consists of alumina with a 10 to 20 percent zirconia concentration, which enhances the toughness of the alumina. To achieve the increase in the composite’s strength, a process known as stress induced transformation toughening takes place. Stress induced transformation toughening results in uniform internal strain, which causes the zirconia structure to crack, and the zirconia particles to switch phases. Because of this phase switch, the amount of zirconia particles increases and creates stresses within the alumina’s structure. These stresses effectively heal the crack and block further cracking—the added zirconia doubles the composite’s strength and enhances toughness between two and four times.

Resin anchoring agent diamond grinding wheel and production method thereof

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

Alkali-Free Composite Sealant Materials for Solid Oxide Fuel Cells

A sealant composition for use in sealing solid oxide fuel cells is provided which comprises a glass component which comprises a mixture of alkali-free inorganic oxides, and an optional filler component dispersed in the glass component, said filler component being up to 40% by weight of the composition. The glass component can include, on a mole basis, 20 to 50% BaO, 1 to 10% Y2P3, 5 to 20% B2O3, 10 to 30% SiO2, 3 to 35% MgO, 2 to 20% CaO, 1 to 10% ZnO, and 0 to 5% ZrO2, and exemplary filler components include zirconia, alumina, barium titanate, strontium titanate, and combinations thereof.

Owner:CUMMINS ENTERPRISE LLC

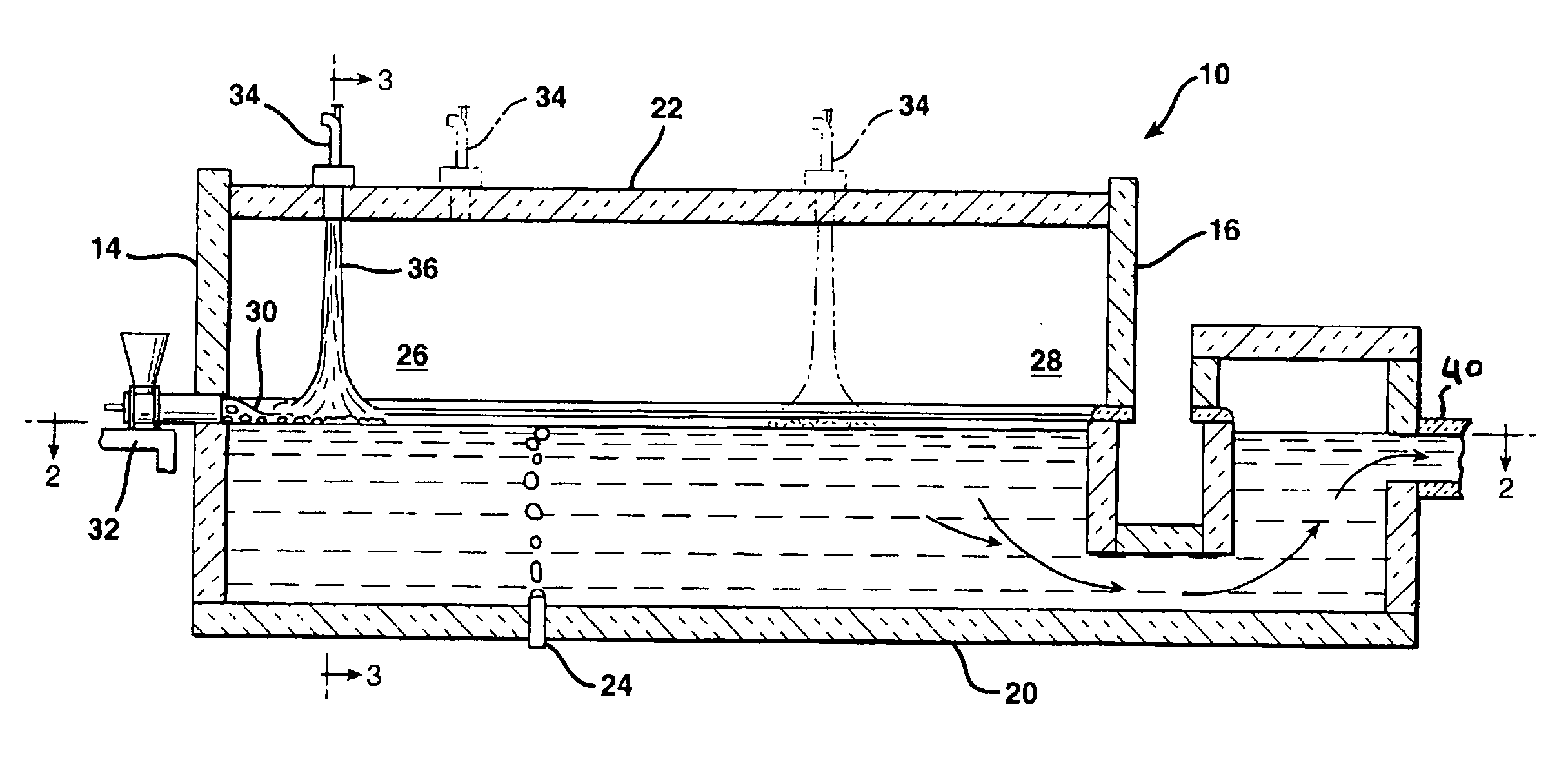

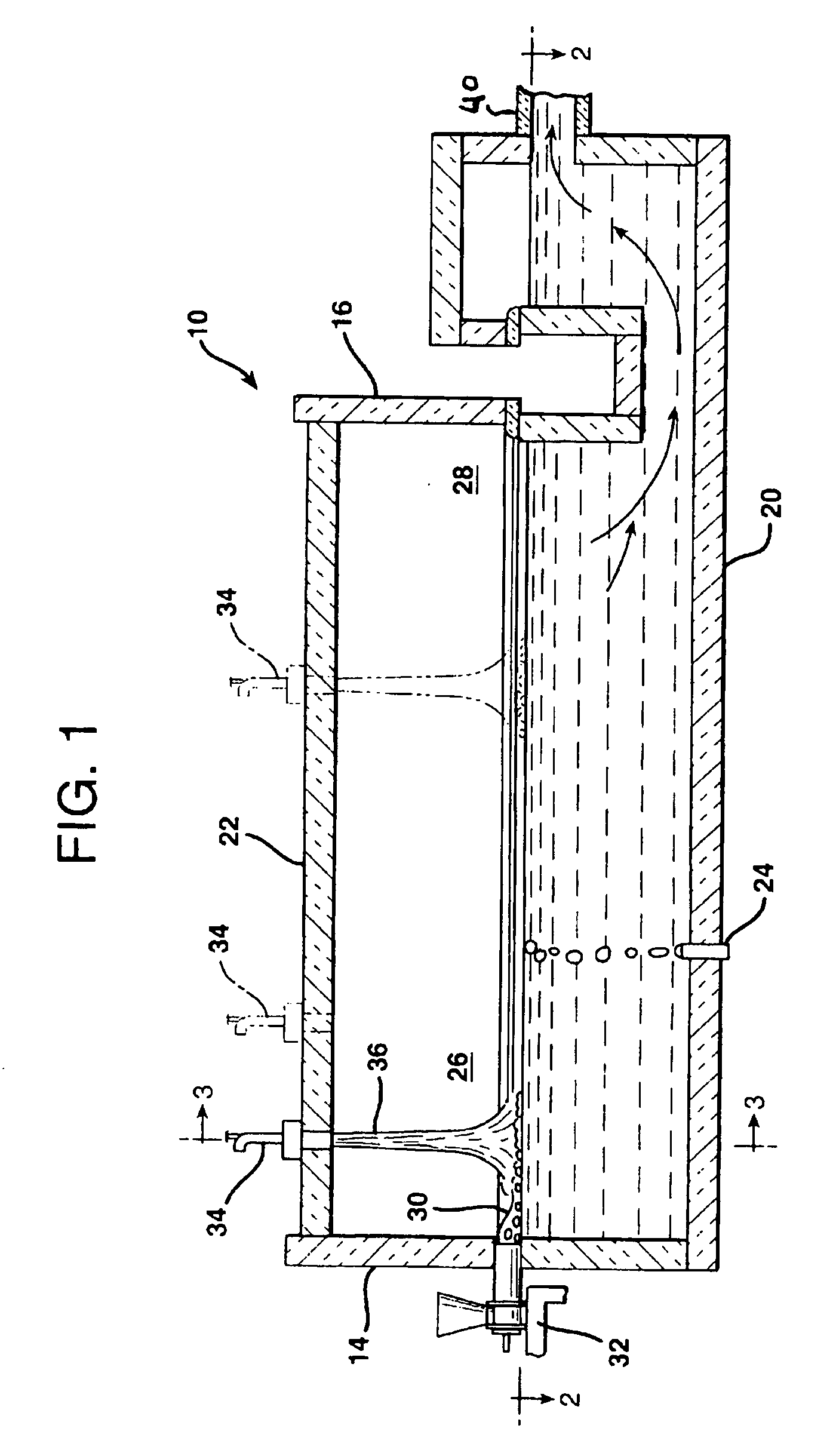

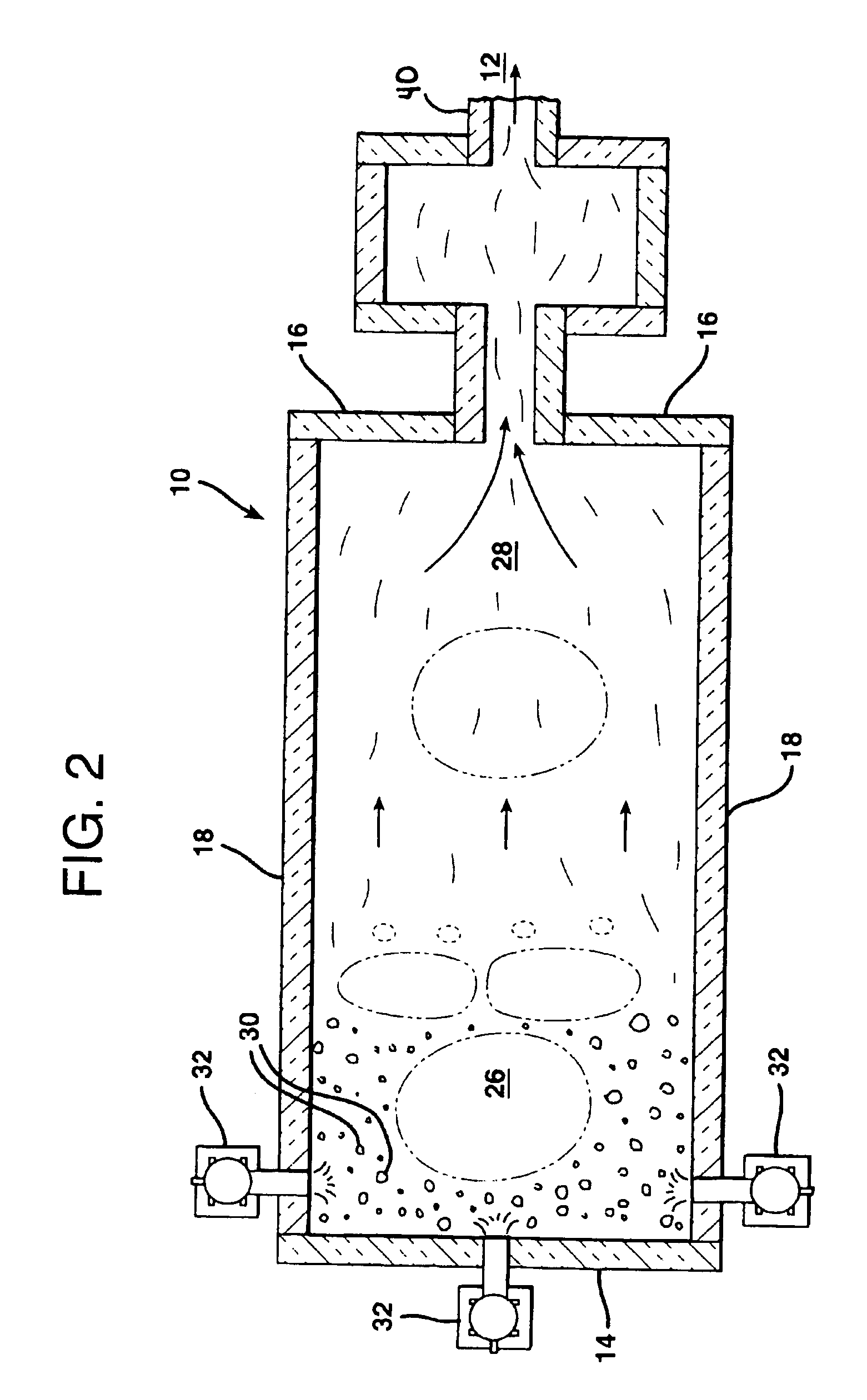

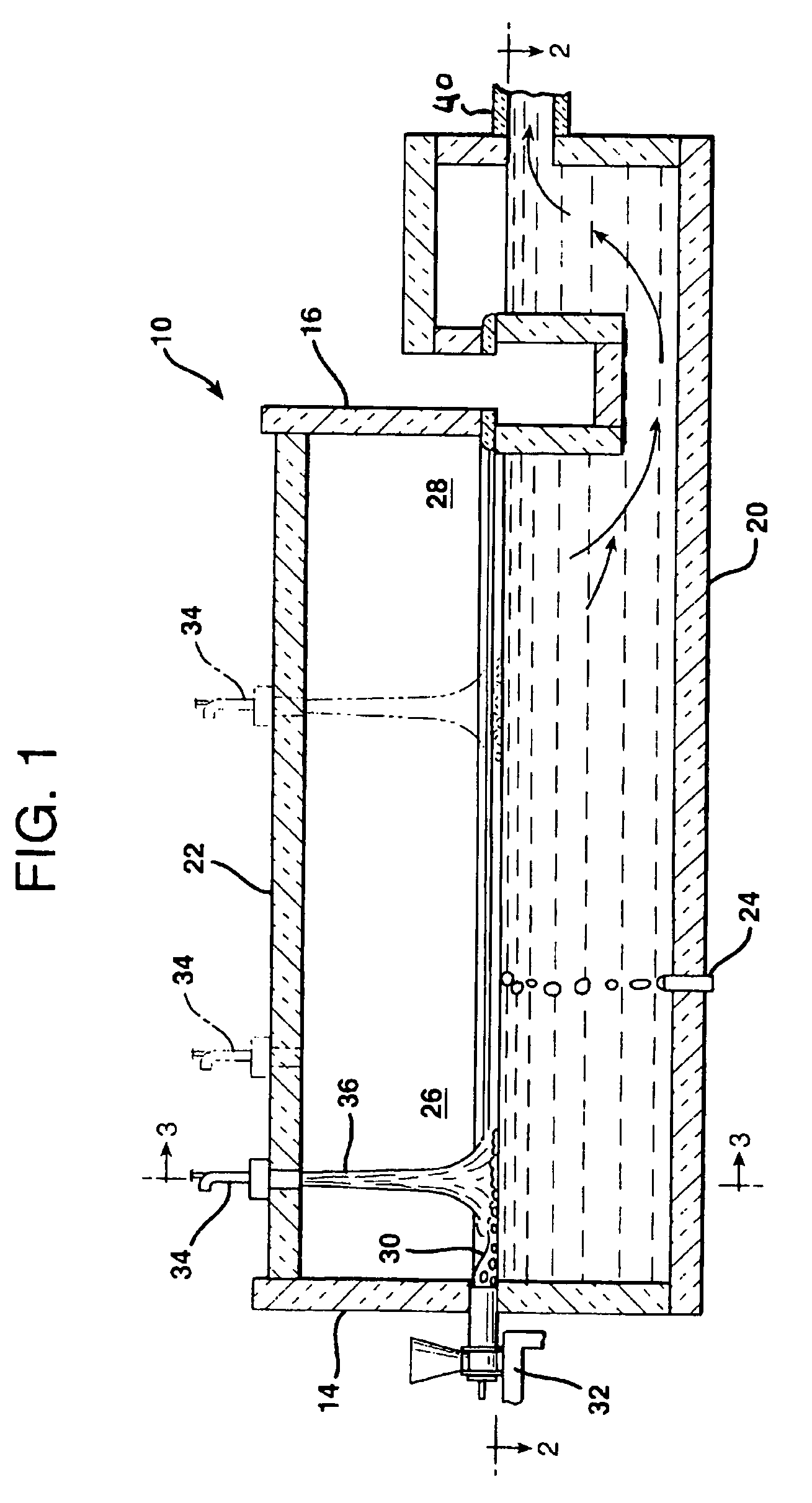

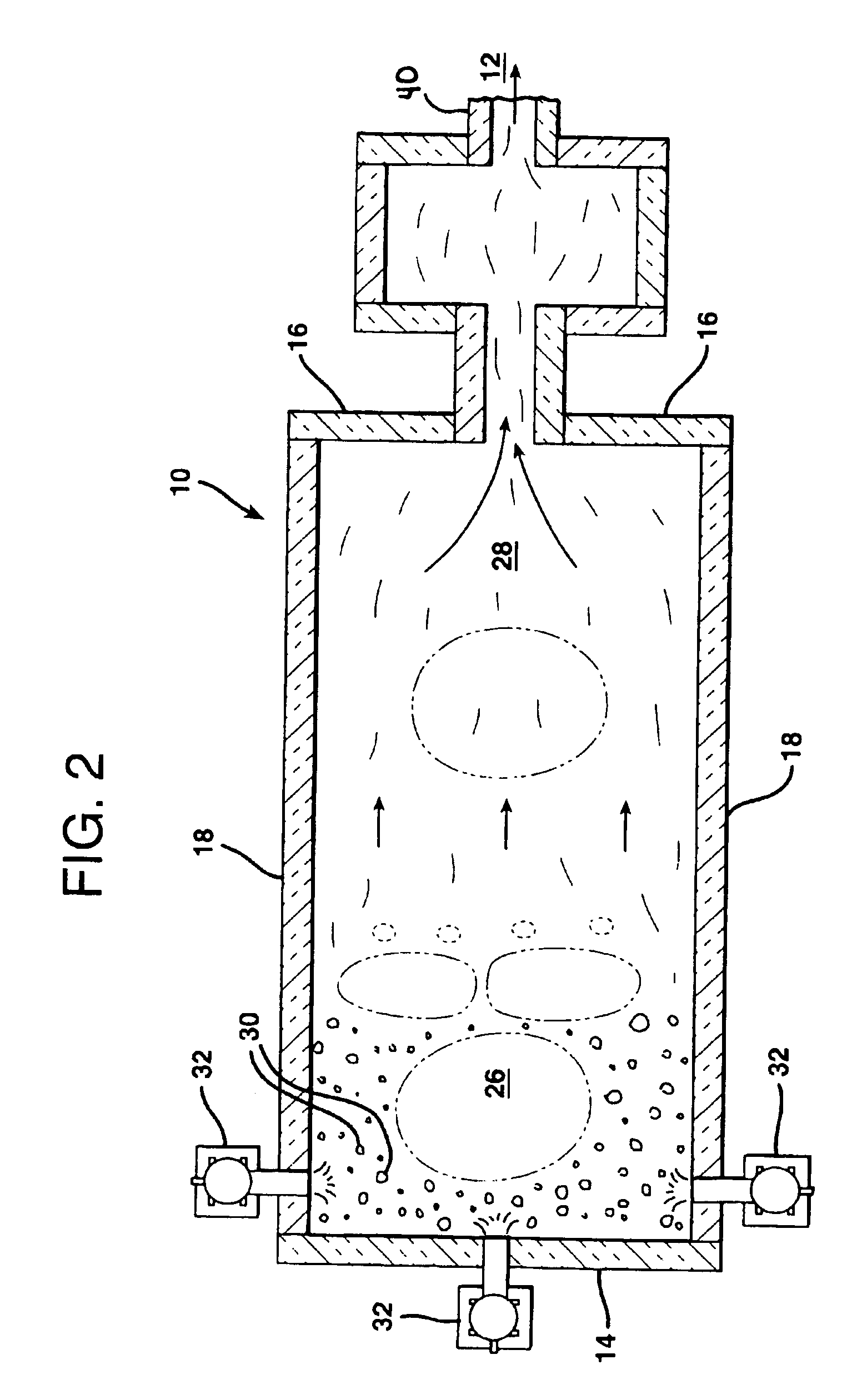

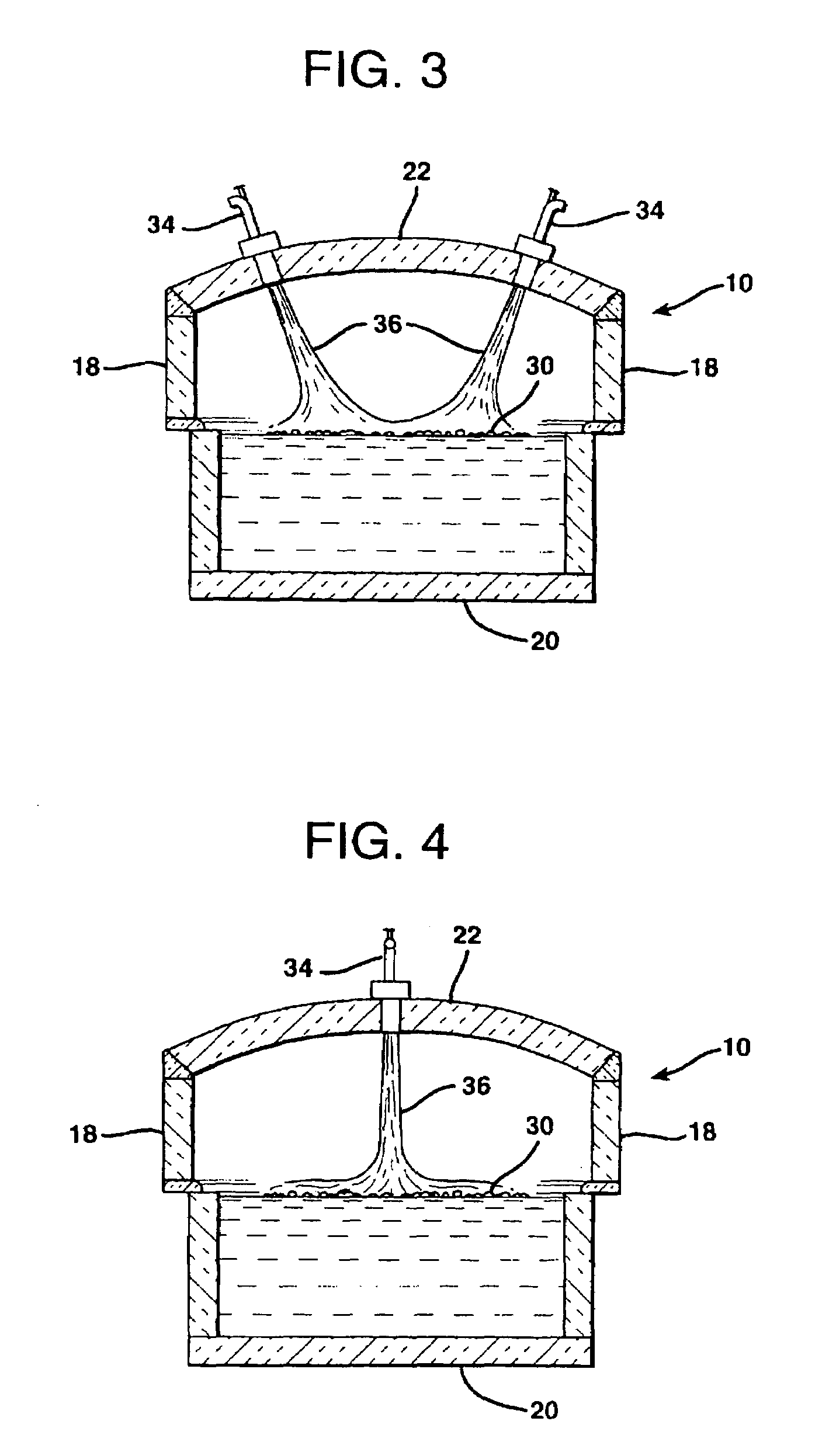

Method of manufacturing high performance glass fibers in a refractory lined melter and fiber formed thereby

ActiveUS20070105701A1Inexpensively formed into glass fiberUse in some applicationCharging furnaceGlass furnace apparatusFiberAlkali metal oxide

A method of forming high strength glass fibers in a refractory lined glass melter is disclosed. The refractory fined melter is suited to the batch compositions disclosed for the formation high modulus, and high-strength glass fibers. The glass composition for use in the method of the present invention is up to about 70.5 Weight % SiO2, 24.5 weight % Al2O3, 22 weight % alkaline earth oxides and may include small amounts of alkali metal oxides and ZrO2. Oxide based refractories included alumina, chromic oxide, silica, alumina-silica, zircon, zirconia-alumina-silica and combinations thereof. By using oxide based refractory lined furnaces the cost of production of glass fibers is substantially reduced in comparison with the cost of fibers using a platinum lined melting furnace. Fibers formed by the present invention are also disclosed.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

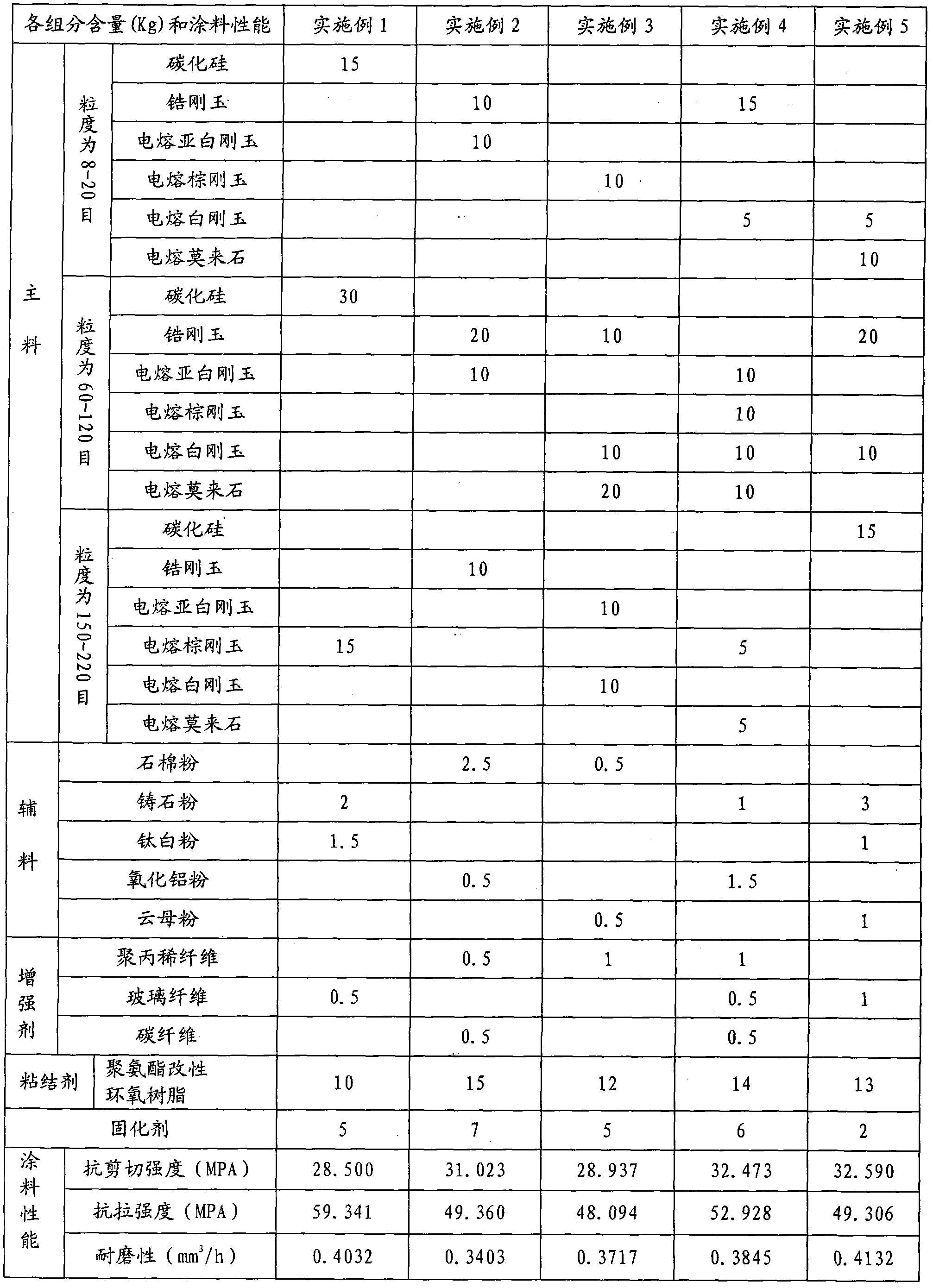

Polymer wear-resistance coating material

ActiveCN102040901AReduce operating costsReduce labor intensityEpoxy resin coatingsEpoxyCarbon fibers

The invention relates to a polymer wear-resistance coating material, which is a coating material consisting of a component A and a component B, wherein the component B is a solidifier, and the weight part of the component B is 2 to 10 percent of that of the component A; the component A consists of 40 to 80 weight parts of a main ingredient which is one or more mixed in random ratio of silicon carbide, fused zirconia alumina, fused sub-white corundum, fused brown aluminium oxide, fused white corundum and fused mullite, 1 to 5 weight parts of an auxiliary material which is one or more mixed in a random ratio of asbestos powder, glass-ceramic powder, titanium white, aluminium oxide powder and mica powder, 0.5 to 2 weight parts of reinforcing agent which is one ore more mixed in a random ratio of polypropylene fibers, glass fibers and carbon fibers, and 10 to 20 weight parts of a bonding agent which is polyurethane modified epoxy resin. The construction and use of the coating material are convenient and quick, the bonding strength of the coating material is high and the use cost of the coating material is low; and the coating material has high wear resistance, corrosion resistance and air corrosion resistance.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Oxidation catalyst with low CO and HC light-off and systems and methods

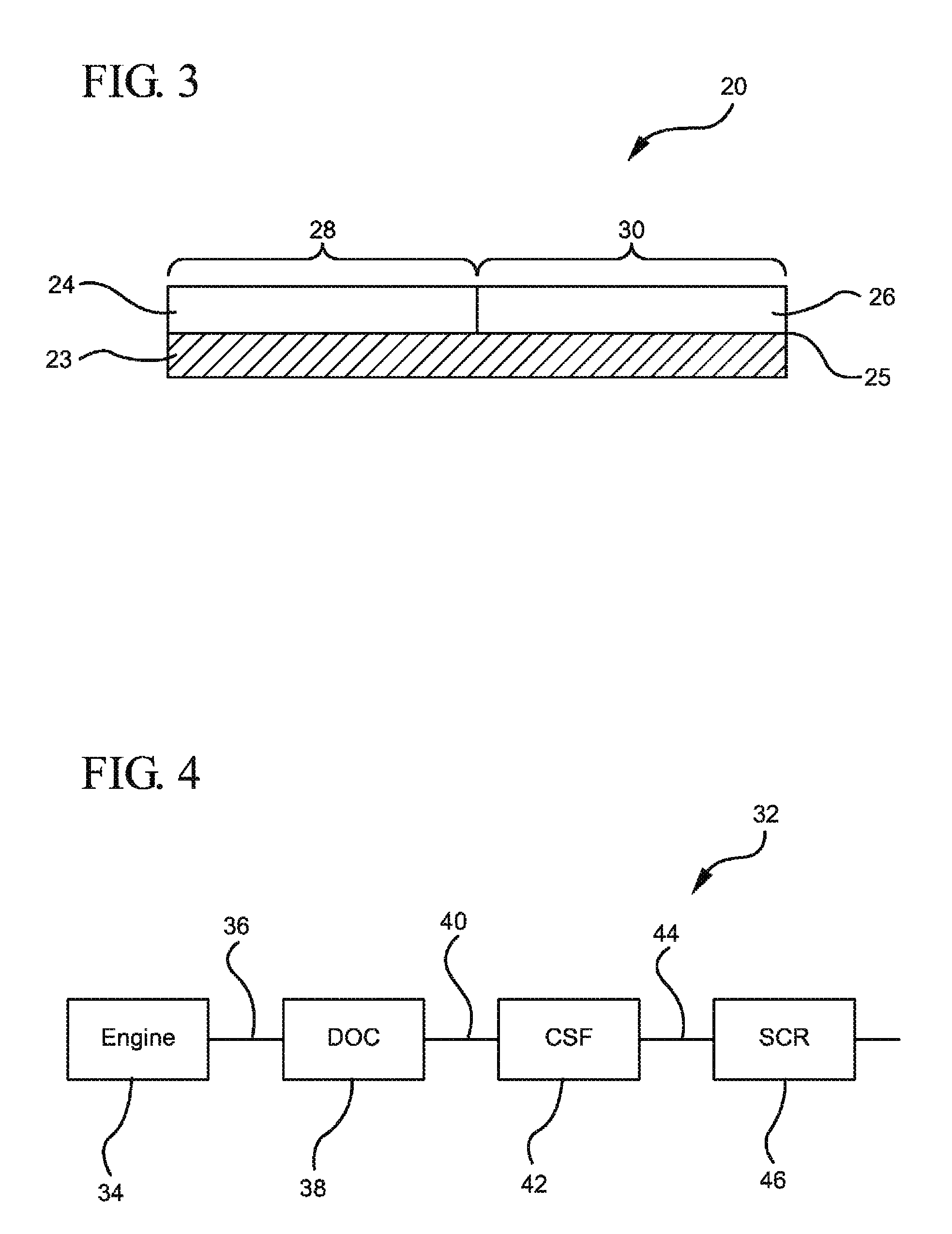

An oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx) from a diesel engine and methods of exhaust gas treatment are disclosed. More particularly, a washcoat composition is disclosed comprising at least two washcoat layers, a first washcoat comprising palladium supported on ceria-zirconia and ceria-zirconia-alumina and a second washcoat containing one or more of platinum and palladium and one or more hydrocarbon storage components. An undercoat may also be included in the catalyst. Also disclosed are method of exhaust gas treatment and diesel exhaust gas treatment systems that include the oxidation catalyst and a downstream soot filter.

Owner:BASF CORP

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

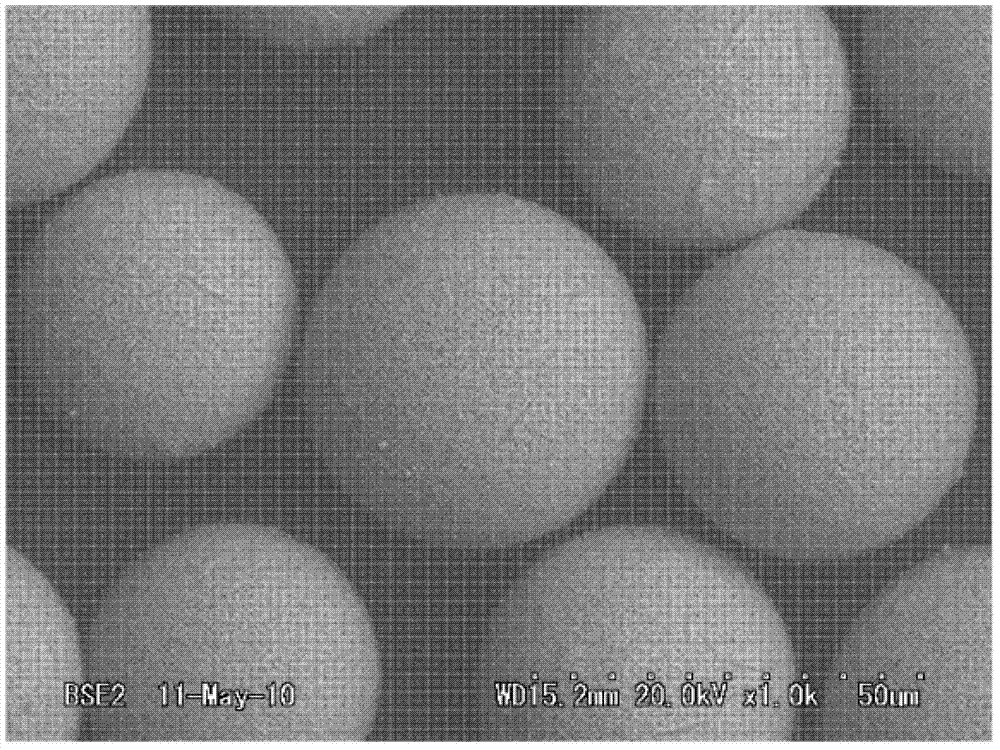

Zr-Al-Si composite ceramic beads with high wear resistance and high strength and processing technique thereof

InactiveCN101723666AAdapt to a wide rangeDensity can be adjusted flexiblyMischmetalComposite ceramic

The invention provides a Zr-Al-Si composite ceramic bead with high wear resistance and high strength and a processing technique thereof. The Zr-Al-Si composite ceramic bead comprises the following components by weight percent: 2-65% of ZrO2, 2-60% of Al2O3, 10-50% of SiO2 and 5% of MgO and mischmetal. The production method comprises the following steps: firstly, evenly mixing zircon sand, zirconia, aluminia, magnesia, kaoline and mischmetal, then carrying out ball milling with a wet method, drying to prepare superfine pulverulent body, rolling and molding, sintering at high temperature, and polishing to obtain the Zr-Al-Si composite ceramic beads with high wear resistance and high strength with the diameter being Phi 0.2mm to Phi 15mm. The prepared ceramic bead has flexibly adjusted density, wide application, wear resistance, stable chemical property and simple process and is easy for scale production.

Owner:许兴康

Process for producing ceria-zirconia-alumina composite oxides and applications thereof

InactiveUS20130108530A1Improved hydrocarbon conversionNitrogen compoundsInternal combustion piston enginesCombustionCerium(IV) oxide

A process for producing a ceria-zirconia-alumina composite oxide is disclosed. The process comprises combining a cerium (IV) compound and a zirconium (IV) compound with a slurry of aluminum oxide at a temperature greater than 40° C. to produce a reaction slurry, then contacting the reaction slurry with a precipitating agent to precipitate insoluble cerium and zirconium compounds onto the aluminum oxide and form cerium-zirconium-aluminum oxide particles, and calcining the cerium-zirconium-aluminum oxide particles to produce a ceria-zirconia-alumina composite oxide. The process to produce ceria-zirconia-alumina composite oxides provides a material having a high oxygen storage / release capacity that is suitable for a catalyst with enhanced cleaning of the exhaust gases from internal combustion engines.

Owner:JOHNSON MATTHEY PLC

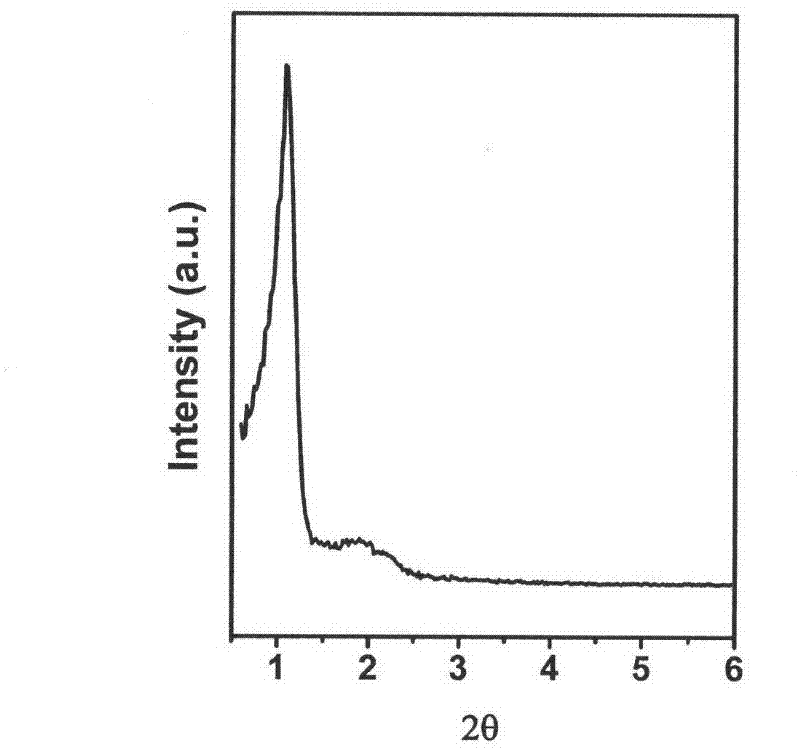

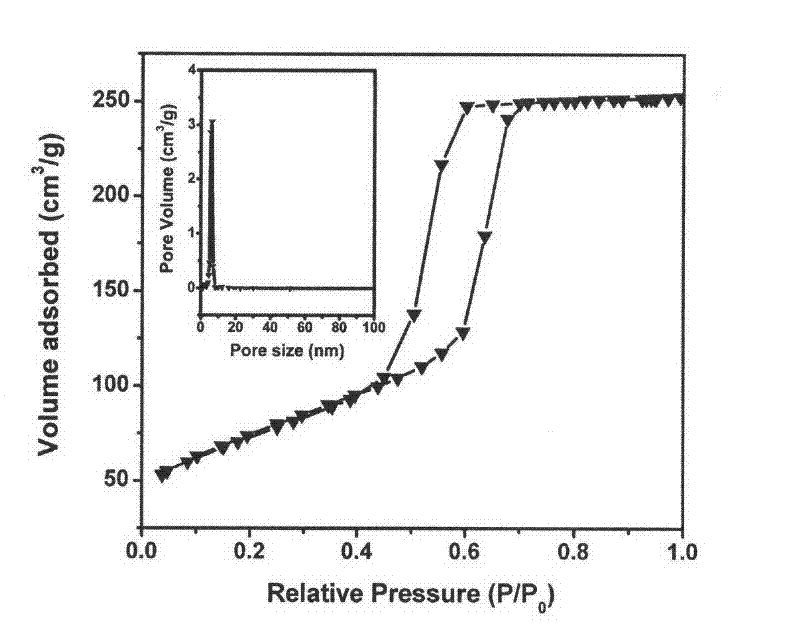

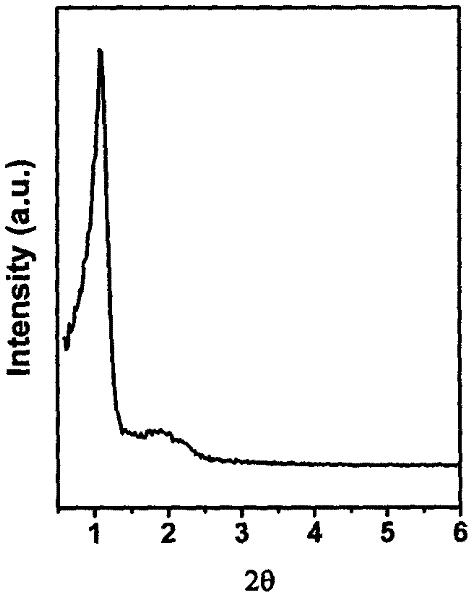

Ordered zirconia-alumina mesoporous material and its preparation method

InactiveCN102380362AEasy to prepareHigh recurrence ratePhysical/chemical process catalystsCarboxylic acidZirconia alumina

The invention relates to an ordered zirconia-alumina mesoporous material and its preparation method, which belongs to the inorganic porous material and catalyst preparation field. The invention is characterized in that the material has a high and ordered mesoporous structure, its mesoporous diameter is 5.0-8.0nm, the specific surface area is 200-300m<2> / g, and the atomic ratio of Zr to Al of the material is 0.1-1.6. The synthetic method comprises the following steps: dissolving a surfactant, organic carboxylic acid and inorganic acid in an ethanol solution containing a little of deionized water according to the ratio of the synthetic material, adding zirconium source and aluminum source while stirring, continuously stirring for certain time, performing solvent volatilization on the reactant, heat treating and high temperature roasting to obtain the ordered zirconia-alumina mesoporous material. The invention has the advantages of simple process, high repetition rate and environmental protection.

Owner:TAIYUAN UNIV OF TECH

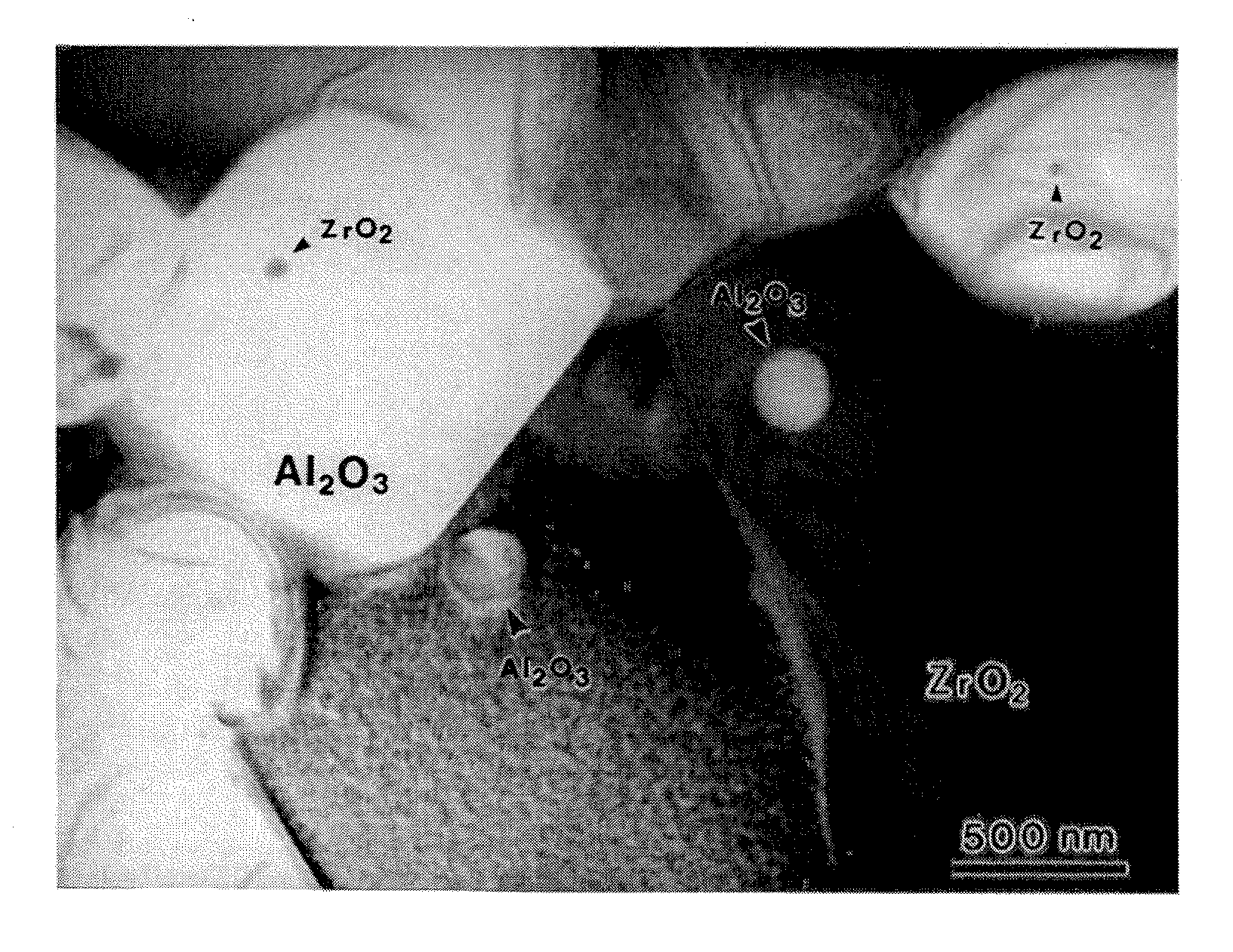

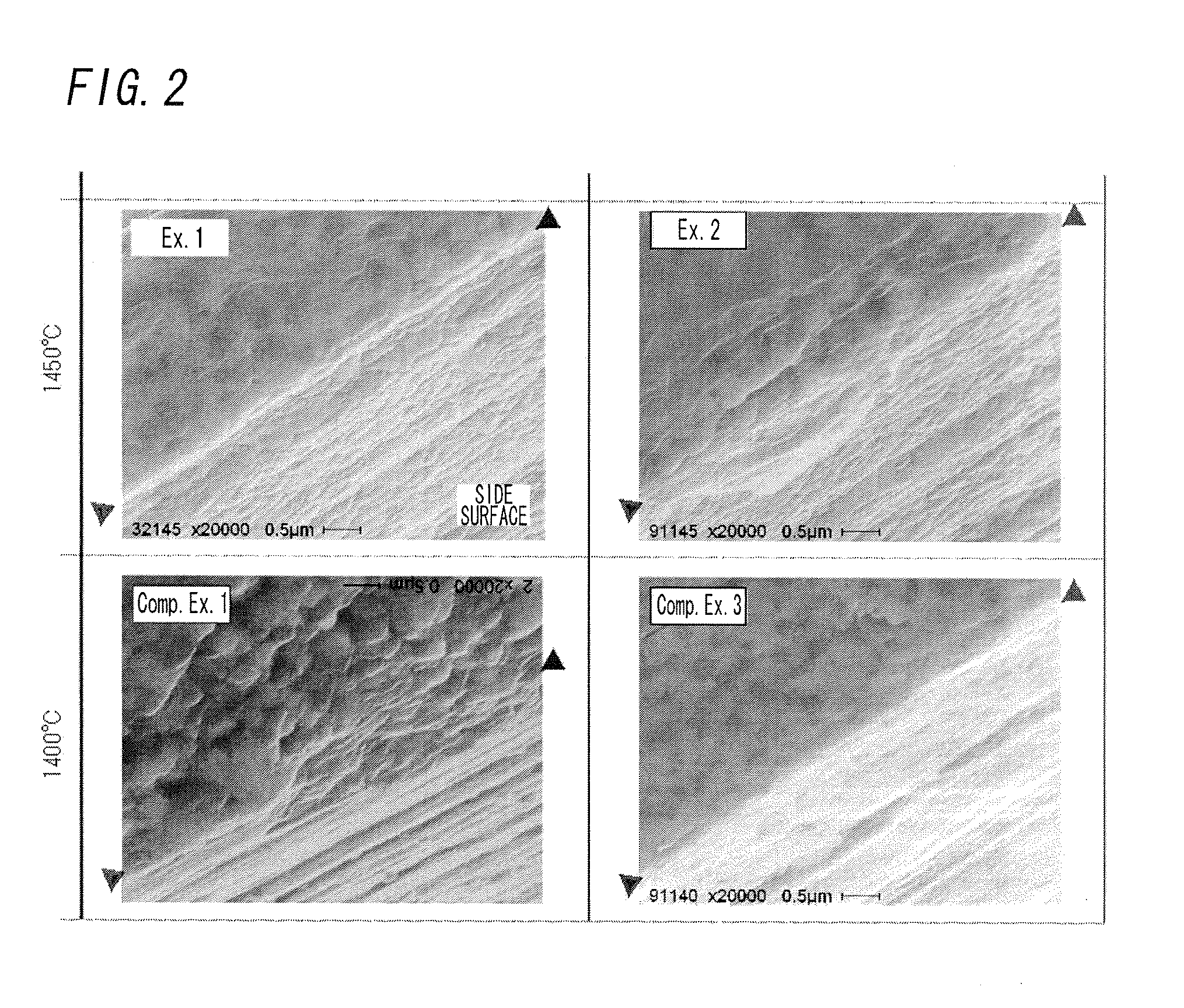

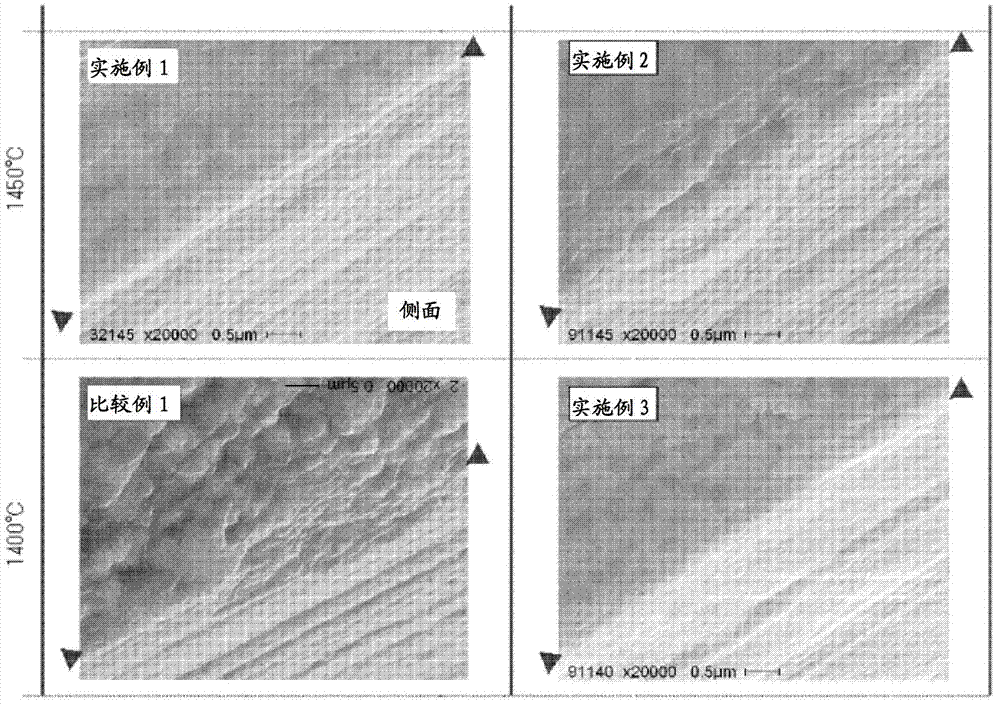

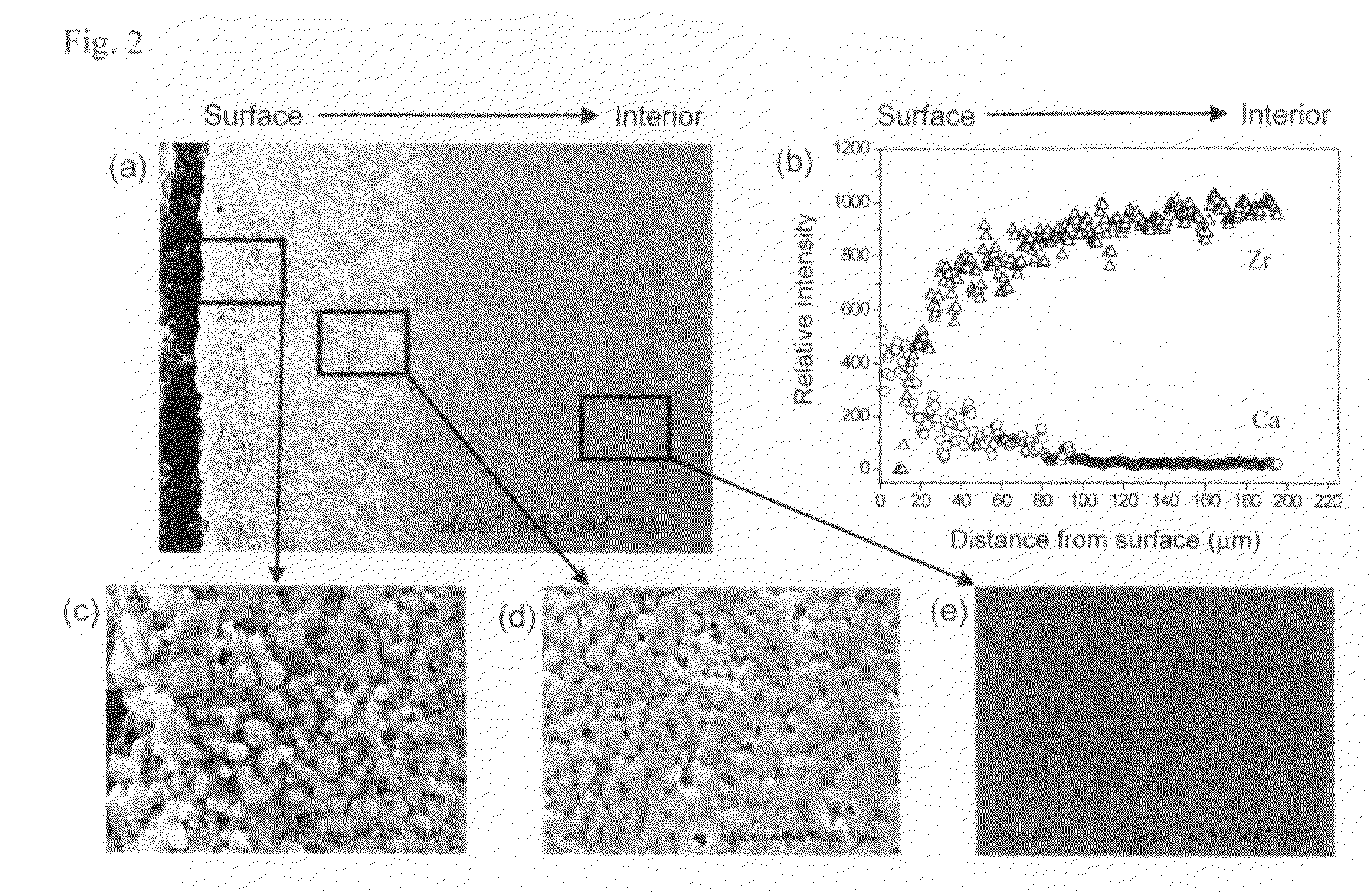

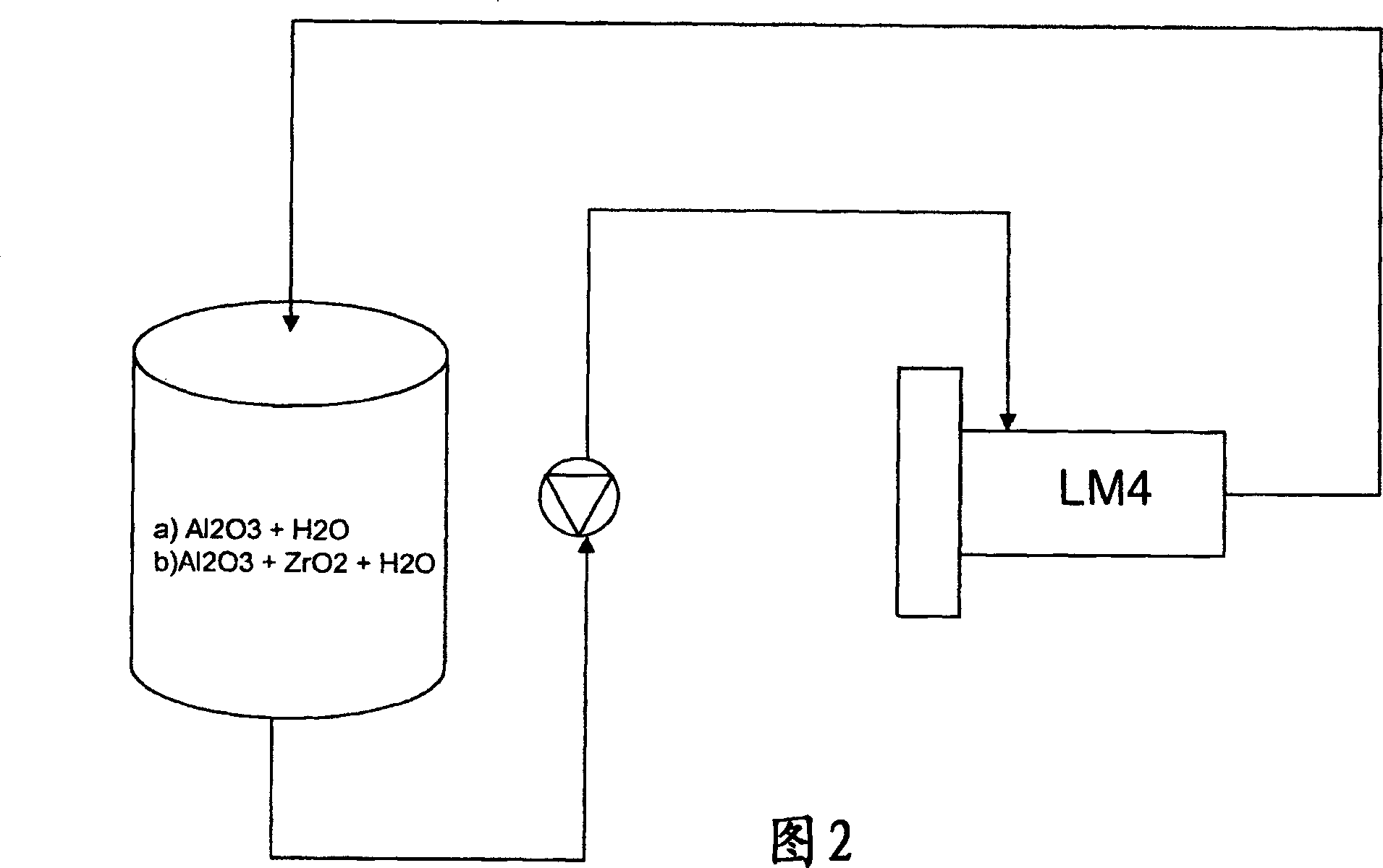

Method for producing zirconia-alumina composite ceramic material, zirconia-alumina composite granulated powder, and zirconia beads

InactiveUS20120295113A1High hardnessImprove wear resistanceMaterial nanotechnologySynthetic resin layered productsComposite ceramicCerium(IV) oxide

The present invention produces a zirconia-alumina composite ceramic material that exhibits an excellent wear resistance and hardness and that resists chipping at the particle edges. The zirconia-alumina composite ceramic material according to the present invention has a composite structure in which zirconia particles are dispersed in alumina particles and the alumina particles are dispersed in the zirconia particles. A first phase is formed of ceria-containing zirconia particles and a second phase is formed of alumina particles. An α-alumina powder having an average particle size of at least 0.1 μm and a γ-alumina powder having an average particle size of 0.01 to 0.1 μm are used in a proportion of 85:15 to 65:35 as the mass ratio for the alumina powder for producing the alumina particles of the second phase.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

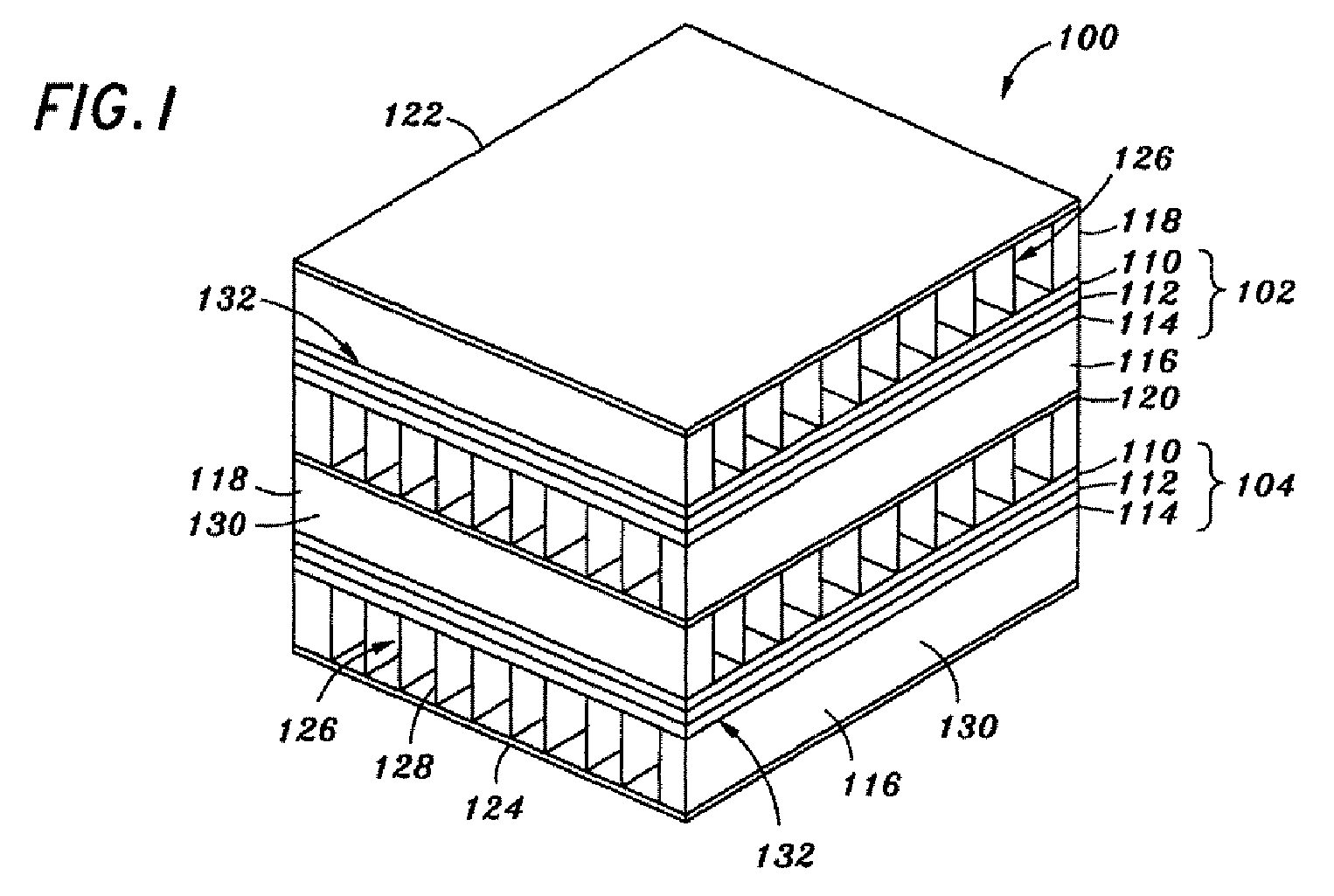

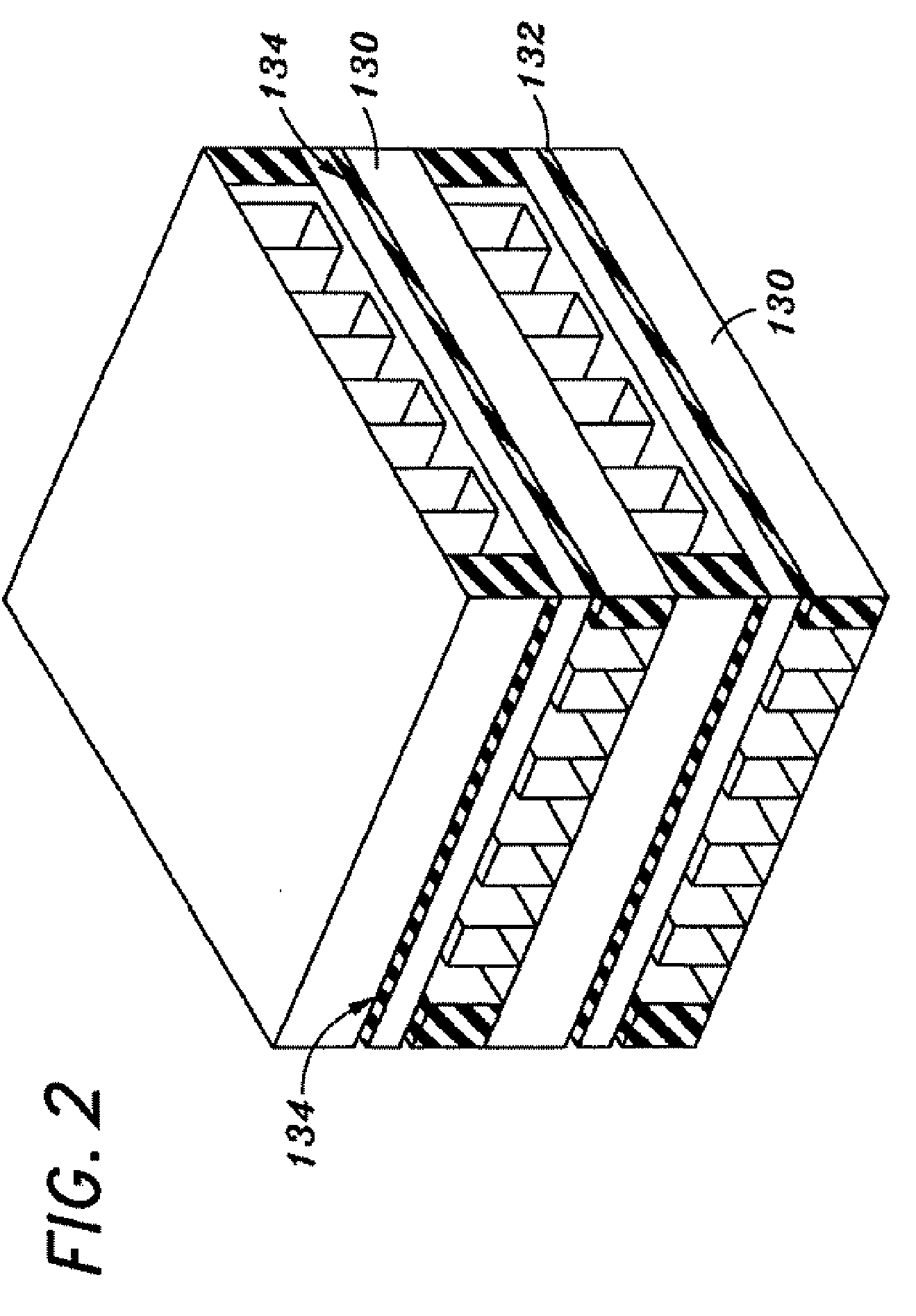

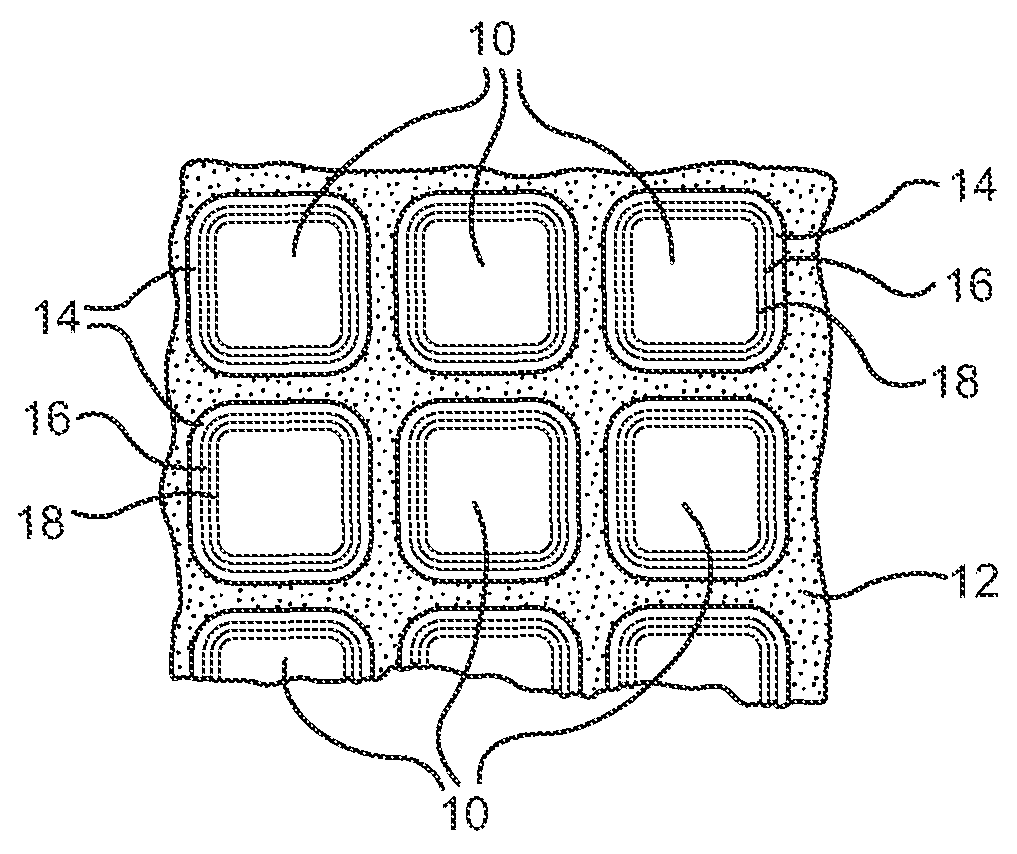

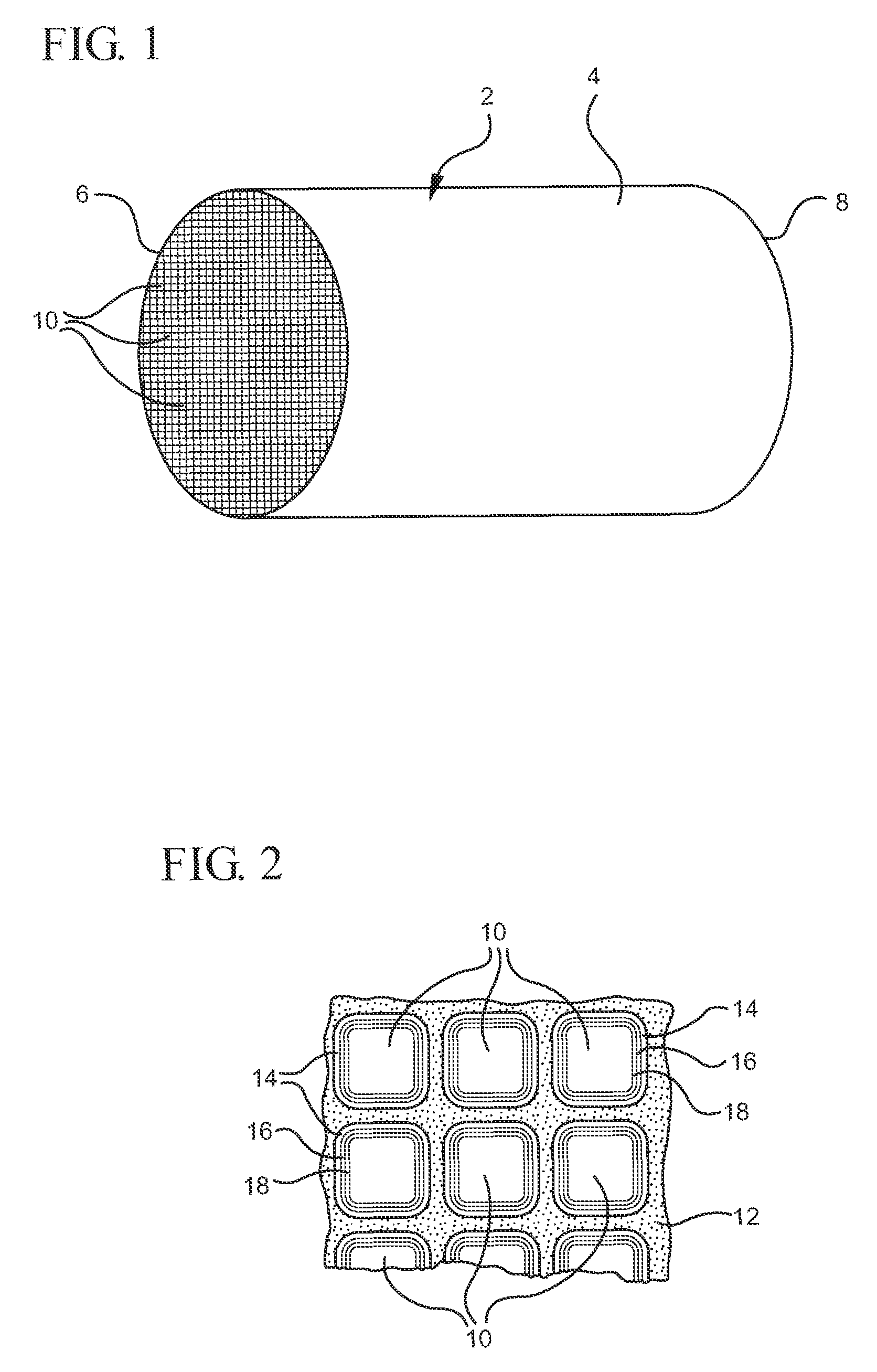

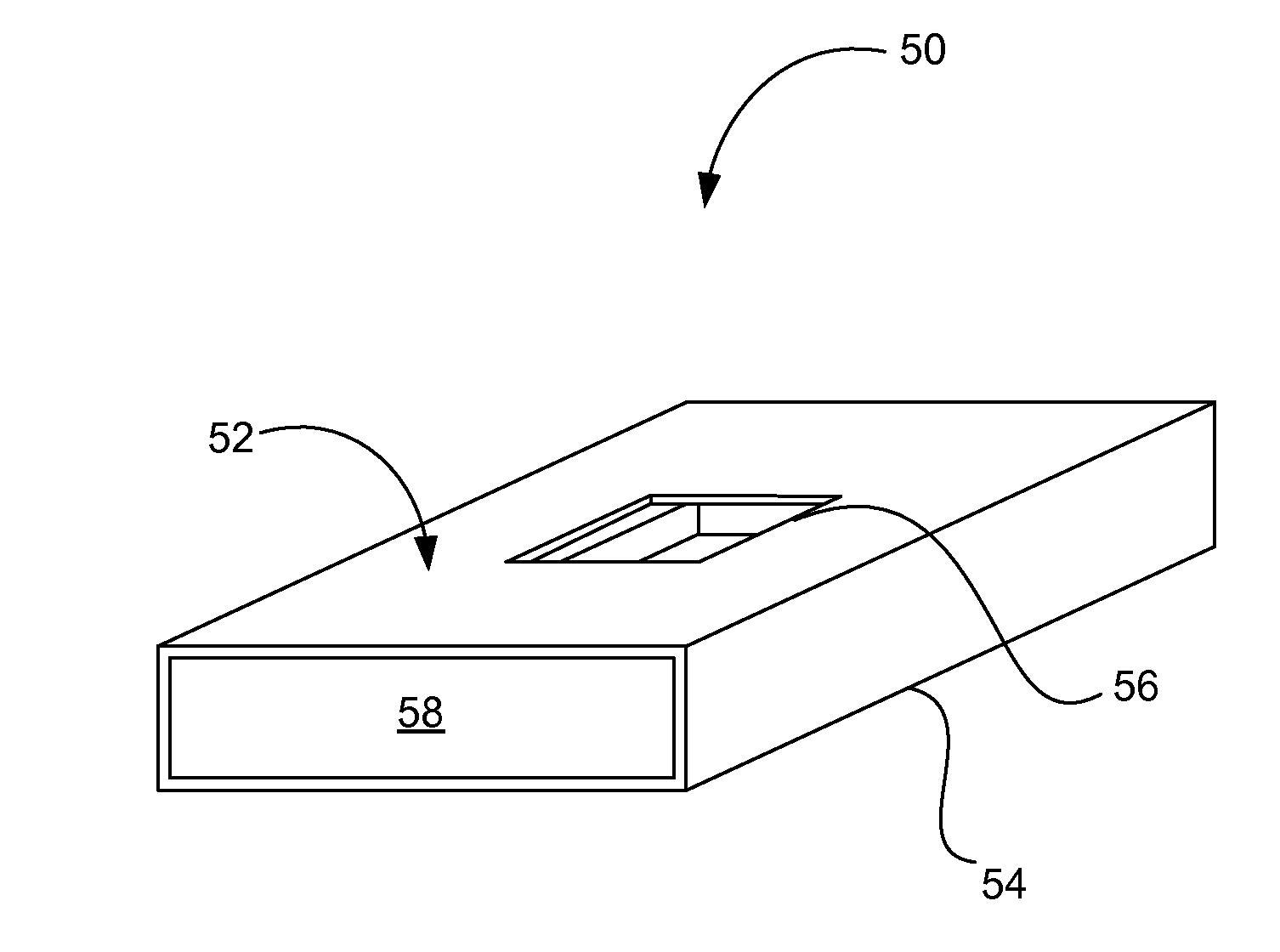

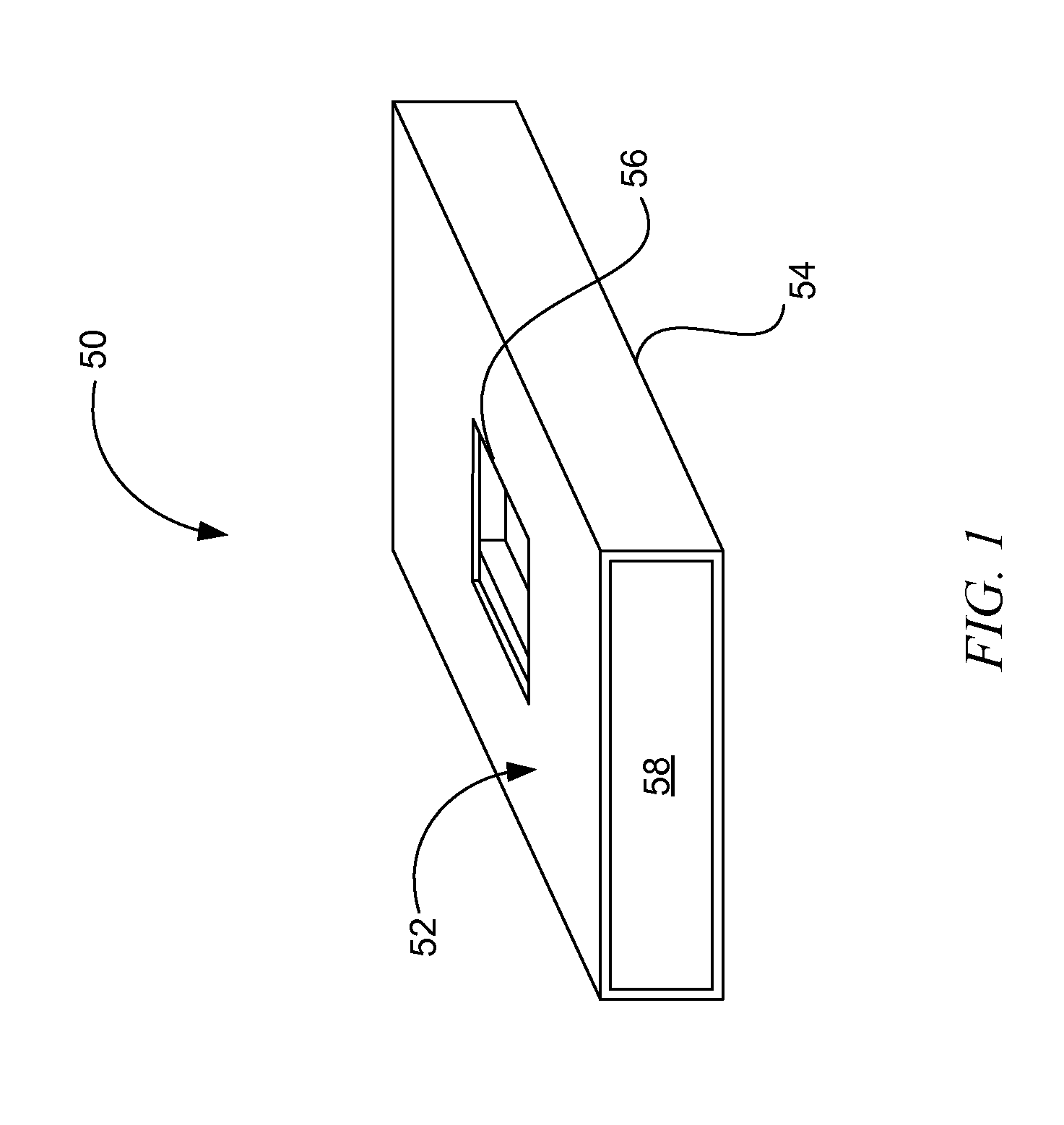

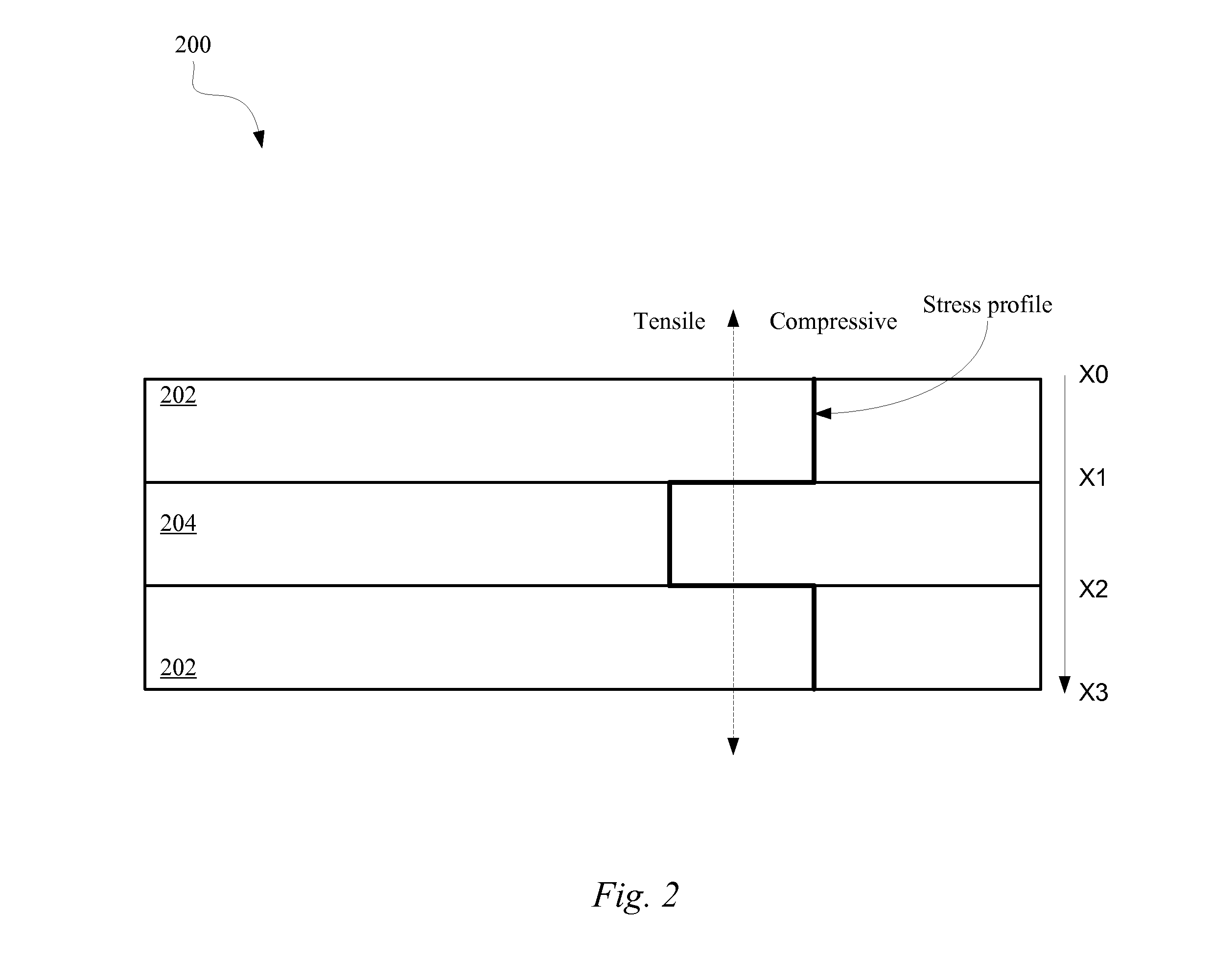

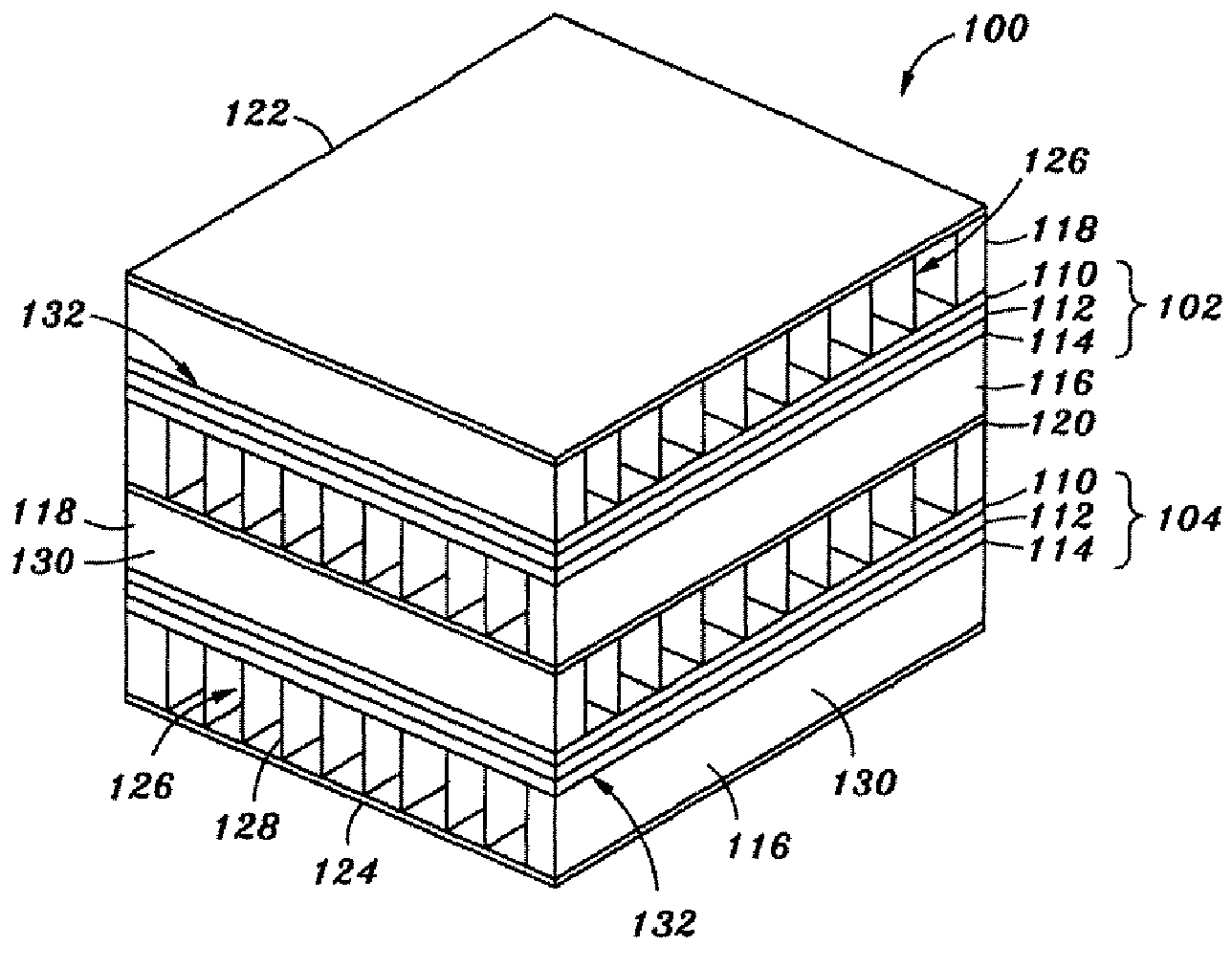

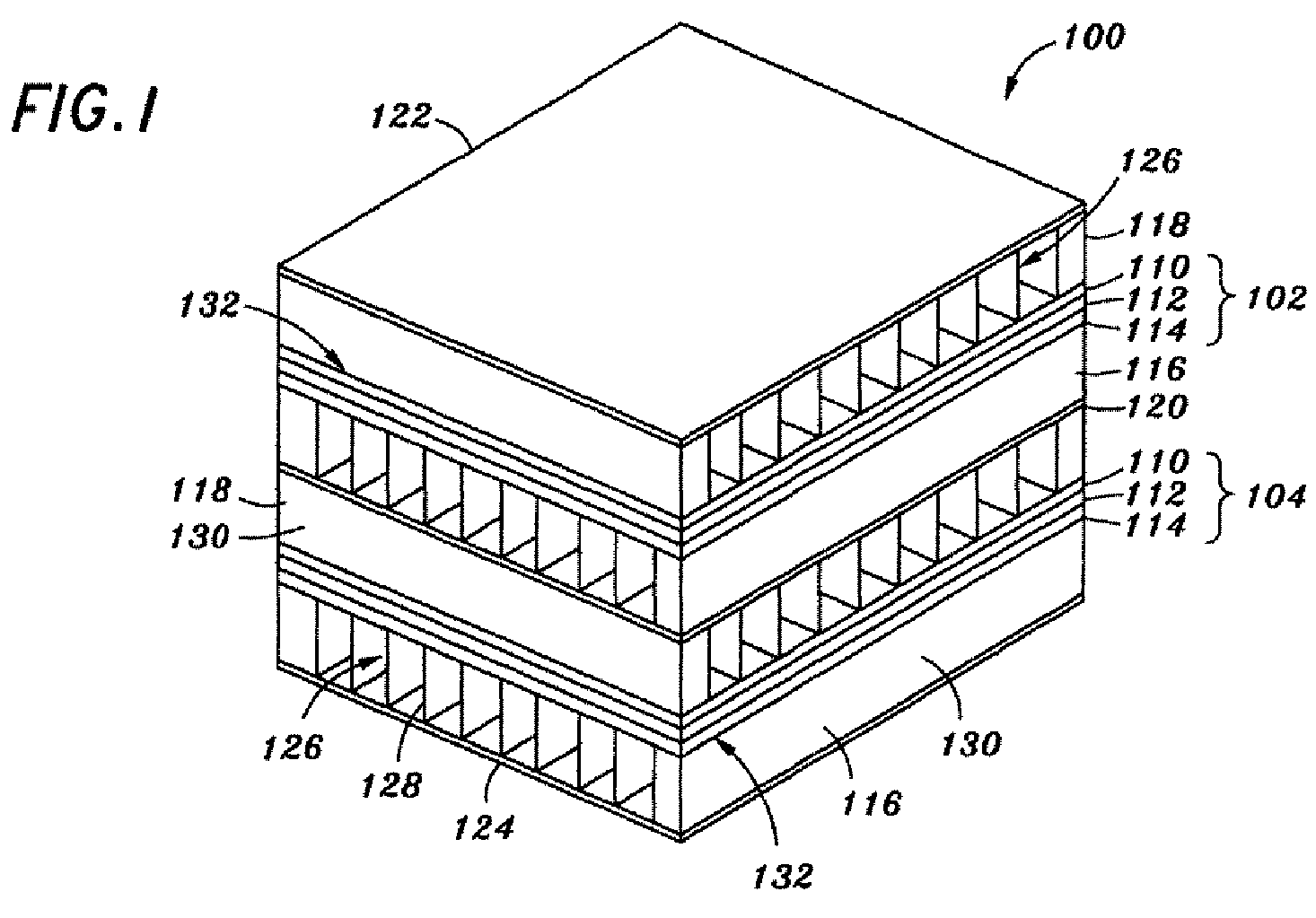

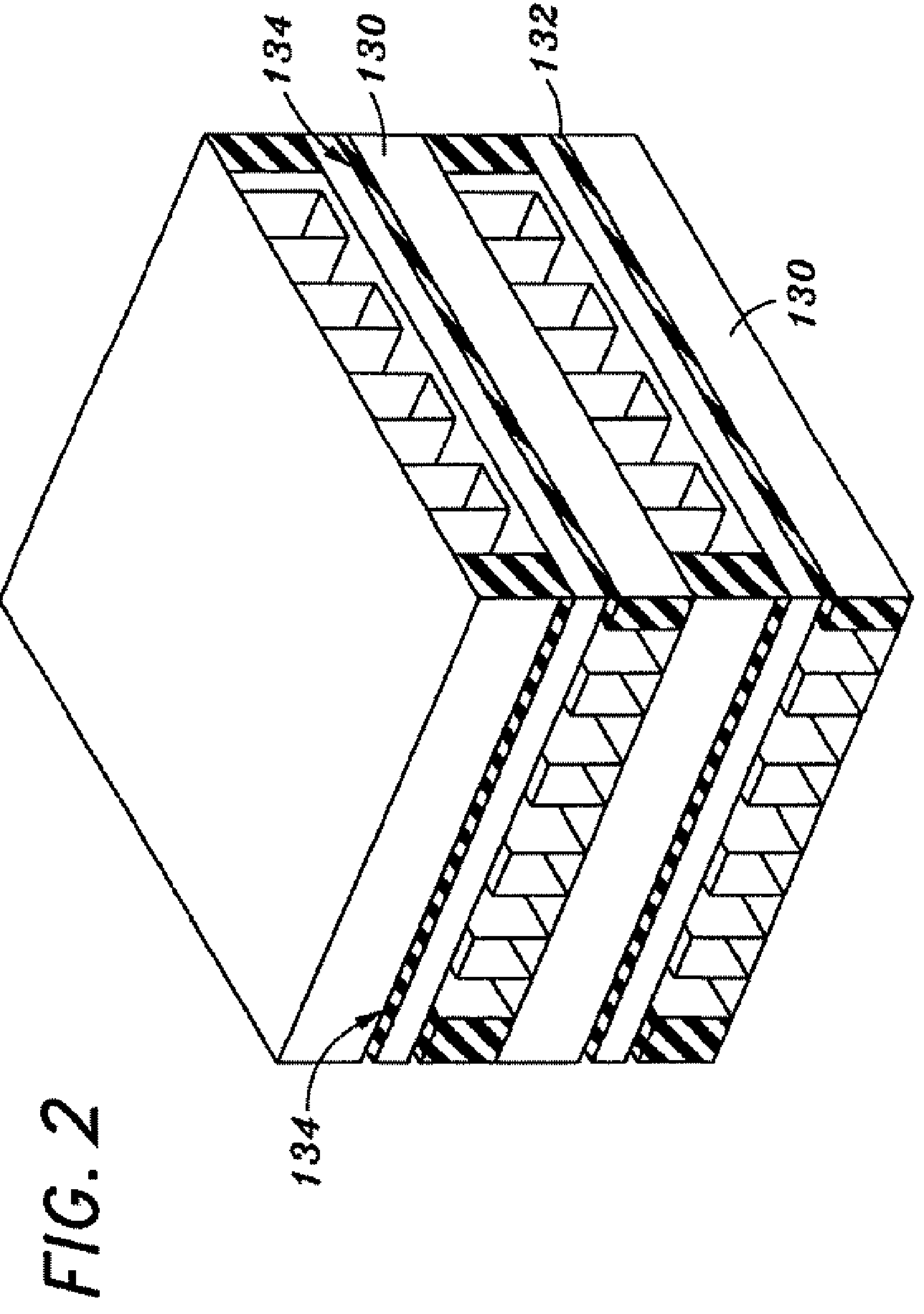

Multi-layered ceramic enclosure

ActiveUS20130078398A1Envelopes/bags making machineryDigital data processing detailsSurface layerThermal expansion

Techniques for fabricating a laminated ceramic housing that can be used for a handheld computing device that includes an enclosure having structural walls formed from a multi-layered ceramic material that can be radio-transparent. The multi-layered ceramic housing can be formed of a plurality of ceramic materials such as zirconia and alumina in any combination. The multi-layer ceramic substrate includes an inner layer and surface layers that sandwich the inner layer. The multi-layer ceramic substrate has an increased transverse strength due to the surface layers having a coefficient of thermal expansion (CTE) that is less than that of the inner layer.

Owner:APPLE INC

Zirconia-alumina composite oxide carrier and method for preparing same

ActiveCN101890377AStrong penetrating powerExtended operating cycleCatalyst carriersCatalyst activation/preparationSolubilityPorosity

The invention discloses a zirconia-alumina composite oxide carrier and a method for preparing the same. The carrier is prepared from a zirconium hydroxide-aluminum hydroxide gel serving as a raw material by using a super-solubility micelle method. Because the gel contains a surfactant and hydrocarbon components, zirconia nanoparticles and alumina nanoparticles formed after dehydration of polymerized zirconium hydroxide and aluminum hydroxide still have rod-like basic structures after shaping and roasting, and the nanoparticles are disorderly stacked into a frame structure. The carrier has large pore volume, large aperture, high porosity, large orifices on outer surface and high pore penetrability, and particularly for high molecules, the carrier can prevent a catalyst from becoming inactivated due to blockage of the orifices, contribute to increasing the deposition of impurities and prolong the operating period of the catalyst because the carrier does not have orifices similar to ink bottle-shaped orifices. The carrier can be used in catalytic reactions comprising high molecular reactants or products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three-way catalyst and its use in exhaust systems

ActiveUS20160228818A1Molecular sieve catalystsInternal combustion piston enginesMolecular sieveHydrocotyle bowlesioides

A three-way catalyst is disclosed. The three-way catalyst comprises a palladium component comprising palladium and a ceria-zirconia-alumina mixed or composite oxide, and also comprises a rhodium component comprising rhodium and a zirconia-containing material. The palladium component and the rhodium component are coated onto a silver-containing extruded molecular sieve substrate. The invention also includes an exhaust system comprising the three-way catalyst. The three-way catalyst results in improved hydrocarbon storage and conversion, in particular during the cold start period.

Owner:JOHNSON MATTHEY PLC

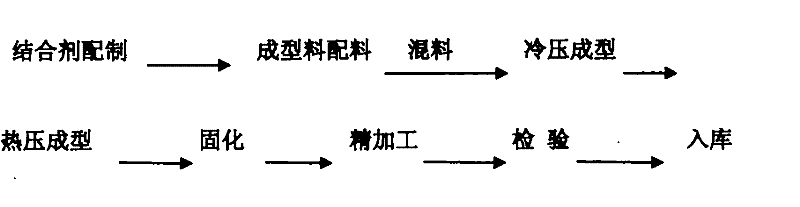

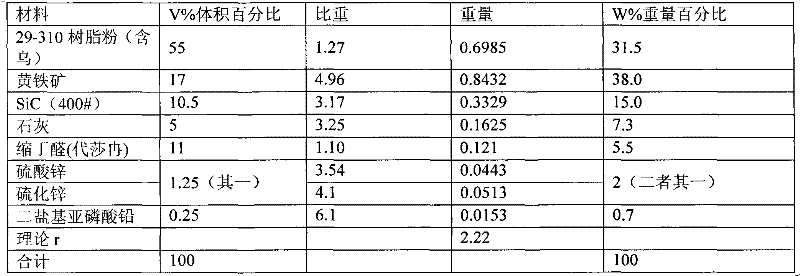

Fiber-reinforced resin abrasive cutting wheel and preparation method thereof

InactiveCN103406837ANot suitable for breakingImprove impact resistanceBonded abrasive wheelsGrinding devicesPolymer scienceIron sulfide

The invention discloses a fiber-reinforced resin abrasive cutting wheel, and relates to the technical field of abrasive wheels. Raw materials comprise 20# white fused alumina, 24# brown fused alumina, 30# fused zirconia alumina, green silicon carbide, liquid resin, phenolic resin powder, calcium carbonate, cryolite, iron sulfide and carbon black, and material mixing, adhesive coating of meshes, superposition pressing forming and drying are carried out to obtain the finished products. The fiber-reinforced resin abrasive cutting wheel has the advantages of being rapid in cutting, grinding and heat dissipation, capable of keeping the end face to be sharp all the time in the process of cutting grinding, and low in cost.

Owner:山东英特磨具股份有限公司

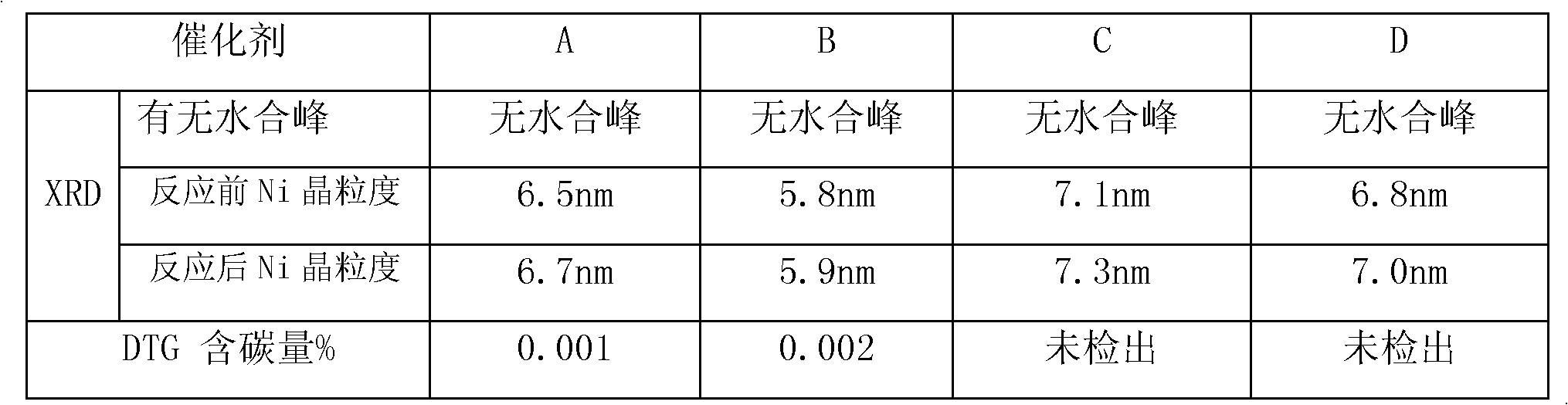

Synthetic methane catalyst and preparation method and application thereof

ActiveCN101920208AApplicable process applicationEasy to manufactureHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The invention provides a synthetic methane catalyst and a preparation method and application thereof. The catalyst is characterized in that: a zirconia or zirconia-alumina composite carrier is taken as a carrier in a catalyst co-precipitation technical process; nickel is taken as an active ingredient; rare earth elements such as La and Ce are added to enhance the activity, selectivity and stability of the catalyst, so that the selectivity of carbon monoxide is over 99 percent; and an appropriate amount of alkali metals and alkaline-earth metals such as Ca, Ba and the like are added to enhance the thermal stability, hydration resistance and anti-carbon performance of the catalyst.

Owner:ENN XINNENG BEIJING TECH

Manufacture formula of rail grinding wheel and manufacture method thereof

InactiveCN102241957AGood self-sharpeningImprove grinding effectOther chemical processesAbrasion apparatusIron powderHeat rejection

The invention relates to a wheel, in particular to a rail grinding wheel, which is formed by mixing, sintering, wrapping, drying and hardening the following components in parts by weight: 70-100 parts of zirconia alumina, 5-8 parts of vulcanized iron powder, 4-8 parts of cryolite, 1-3 parts of calcium carbonate, 1-4 parts of gypsum powder and 7-10 parts of phenolic resin. In the invention, the zirconia alumina is selected as the main material of the rail grinding wheel and the vulcanized iron powder, the cryolite, the calcium carbonate, the gypsum powder and the phenolic resin for heat rejection, heat conduction and reinforcement are added on condition that the cutting force is ensured. The wheel manufactured by the invention not only has the advantages of better self-sharpening performance and grinding performance, higher cutting efficiency and low frequency of burn and crackle when a rail is grinded via the wheel, but also has the advantages of higher strength and good breakage proofness.

Owner:李冰湜

Method of manufacturing high performance glass fibers in a refractory lined melter and fiber formed thereby

ActiveUS7823417B2Inexpensively formed into glass fiberUse in some applicationCharging furnaceGlass furnace apparatusFiberAlkali metal oxide

A method of forming high strength glass fibers in a refractory lined glass melter is disclosed. The refractory lined melter is suited to the batch compositions disclosed for the formation high modulus, and high-strength glass fibers. The glass composition for use in the method of the present invention is up to about 70.5 Weight % SiO2, 24.5 weight % Al2O3, 22 weight % alkaline earth oxides and may include small amounts of alkali metal oxides and ZrO2. Oxide based refractories included alumina, chromic oxide, silica, alumina-silica, zircon, zirconia-alumina-silica and combinations thereof. By using oxide based refractory lined furnaces the cost of production of glass fibers is substantially reduced in comparison with the cost of fibers using a platinum lined melting furnace. Fibers formed by the present invention are also disclosed.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Aluminum alloy surface treatment technology

The invention discloses an aluminum alloy surface treatment technology. The aluminum alloy surface treatment technology comprises the following steps of (1) blasting treatment, specifically, blastingtreatment is conducted on the aluminum alloy surface by utilizing a fused zirconia alumina grinding material, so that oxide skin on the aluminum alloy surface is removed; (2) degreasing treatment, specifically, degreasing treatment is conducted in a degreasing solution; (3) anodic oxidation, specifically, an aluminum alloy base material is placed in a sulfuric acid electrolytic solution with the concentration being 15-20%, and a highly compressed carbon plate serves as a cathode and is placed in the sulfuric acid electrolytic solution to be subjected to anode-cathode electrolysis; (4) water scrubbing; (5) activation treatment; (6) dyeing treatment; and (7) hole sealing treatment. By adopting the aluminum alloy surface treatment technology, a compact protection layer can be formed to protect an aluminum alloy from being corroded and oxidated chemically.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

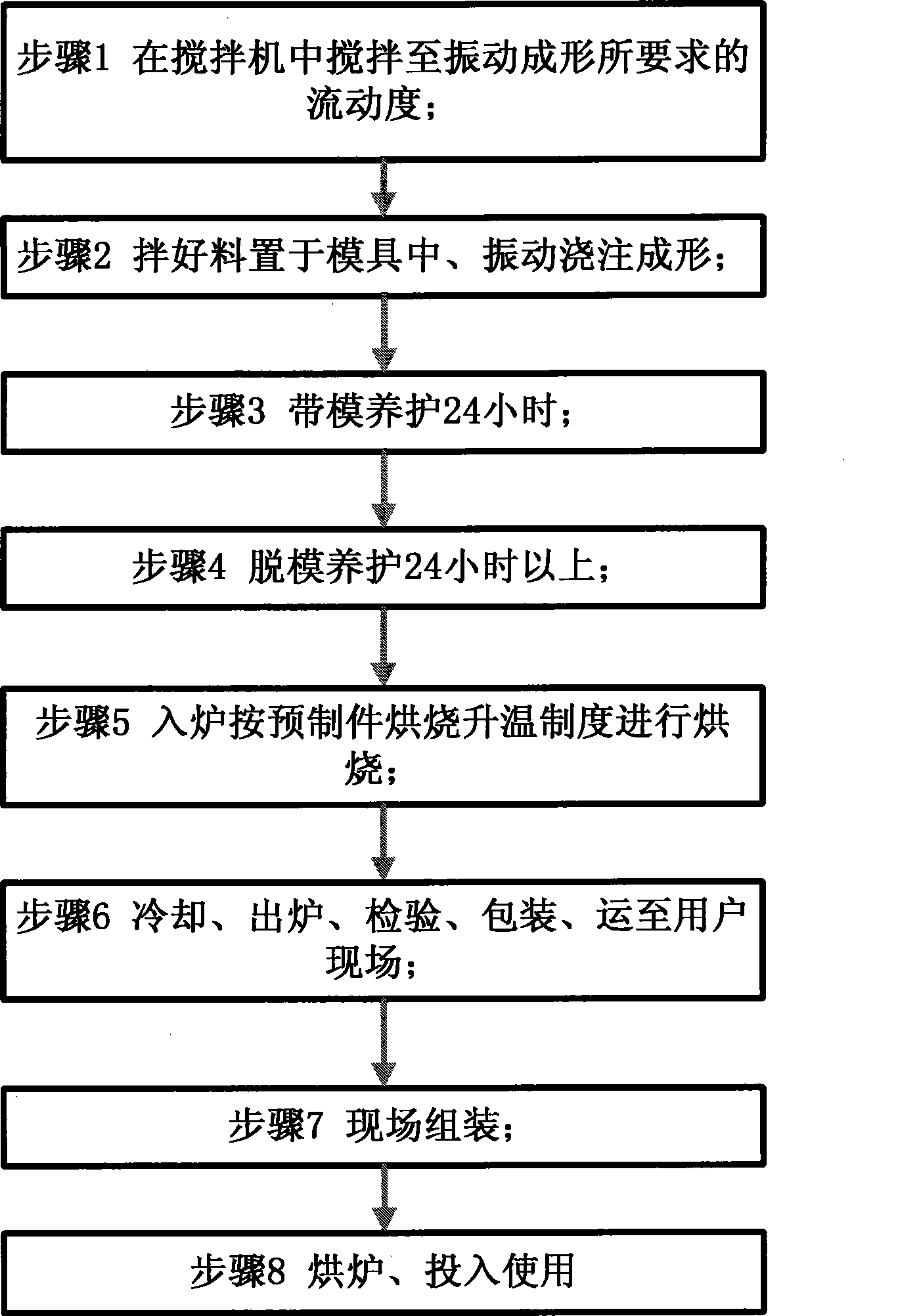

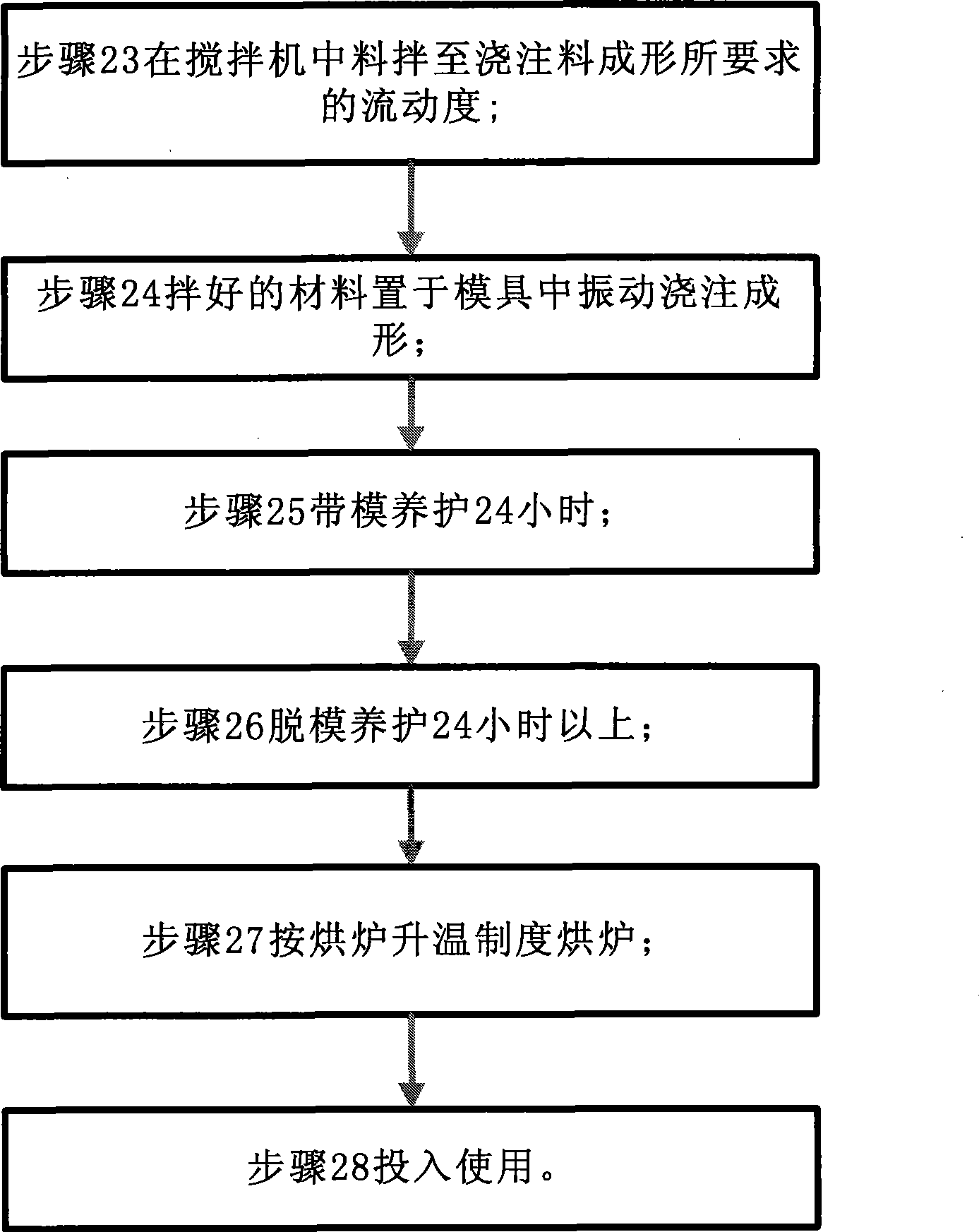

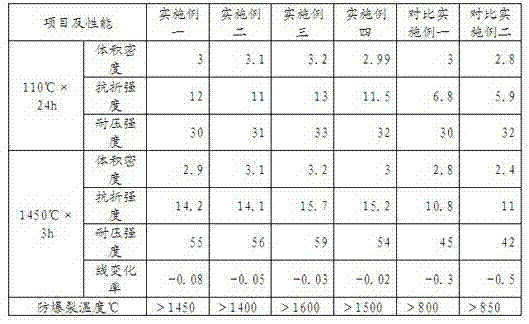

Al2O3/ZrO2 refractory casting material and using method thereof

The invention discloses a mullite combined zirconia-alumina refractory castable material, wherein aggregate consists bauxite chamotte accounting for 50 to 80 percent of the total mass of the aggregate and powder, brown alumina and sub-white corundum; the powder consists of silicon powder, rho-Al2O3 micro powder, sub-white corundum powder, alpha-Al2O3, zirconite powder, white slime, bauxite chamotte powder, high alumina cement and pure calcium aluminate cement; and the additive consists of sodium hexametaphosphate and water. The invention overcomes the defects of poor thermal shock stability and high cost in the prior art, and provides the refractory castable material with good thermal shock stability, short production flow, low cost and convenient use, and the refractory castable material can be widely applied to refractory linings of high and medium temperature furnaces.

Owner:成都蜀冶新材料有限责任公司

Method for producing zirconia-alumina composite ceramic material, zirconia-alumina composite granulated powder, and zirconia beads

InactiveCN102712542AImprove wear resistanceHigh hardnessMaterial nanotechnologyThin material handlingCerium(IV) oxideMetallurgy

Provided is a method for producing a zirconia-alumina composite ceramic material which has excellent abrasion resistance and hardness, and which prevents chipping of particle edges. The zirconia-alumina composite ceramic material has a composite structure of zirconia particles dispersed in alumina particles and alumina particles dispersed in zirconia particles. A first phase is formed of zirconia particles containing ceria and a second phase is formed of alumina particles. a-alumina powder having an average grain size of 0.1 [mu]m or larger and gamma-alumina powder having an average grain size of 0.01 to 0.1 [mu]m are used at a mass ratio of 85:15 to 65:35 as alumina powder for producing the alumina particles of the second phase.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

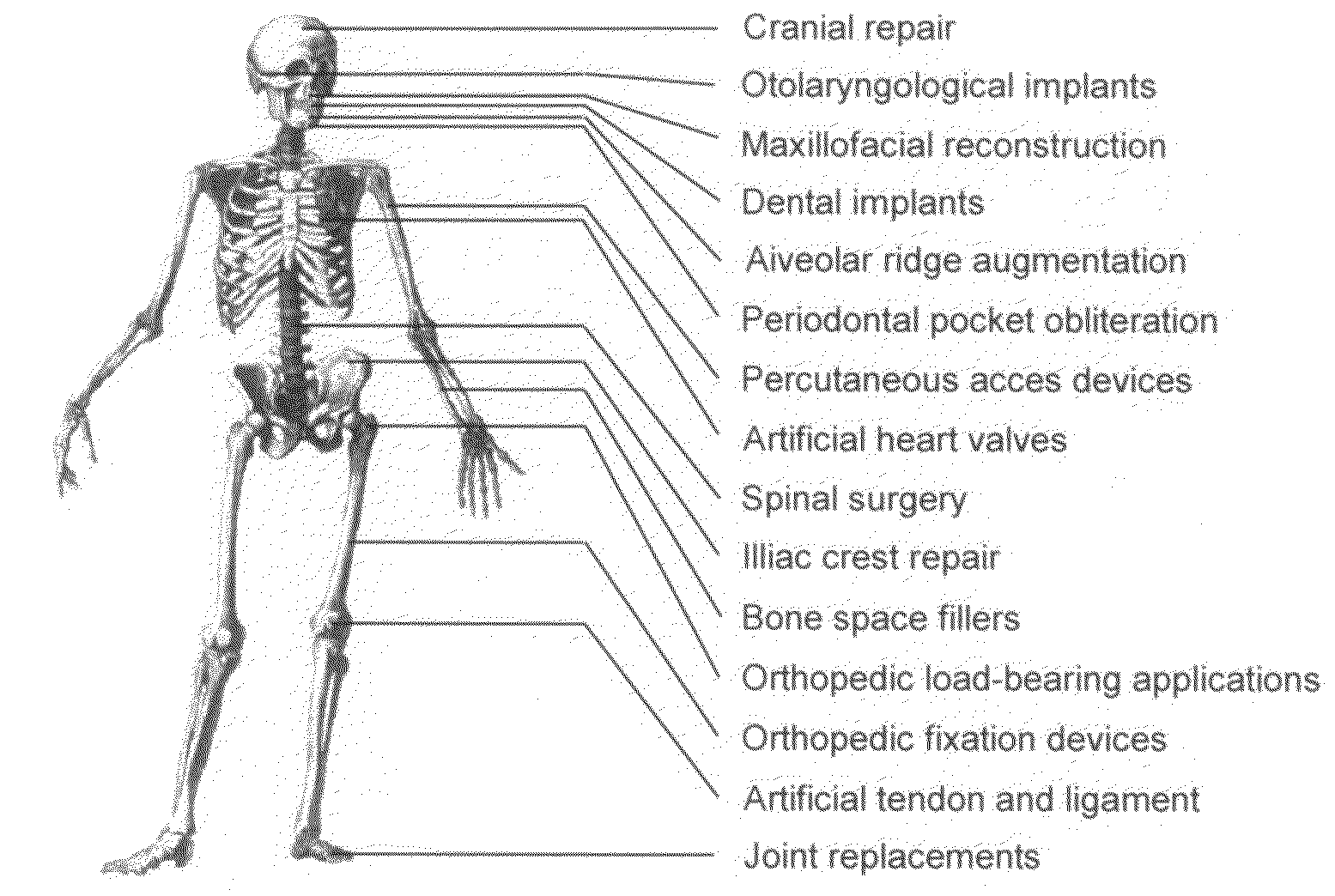

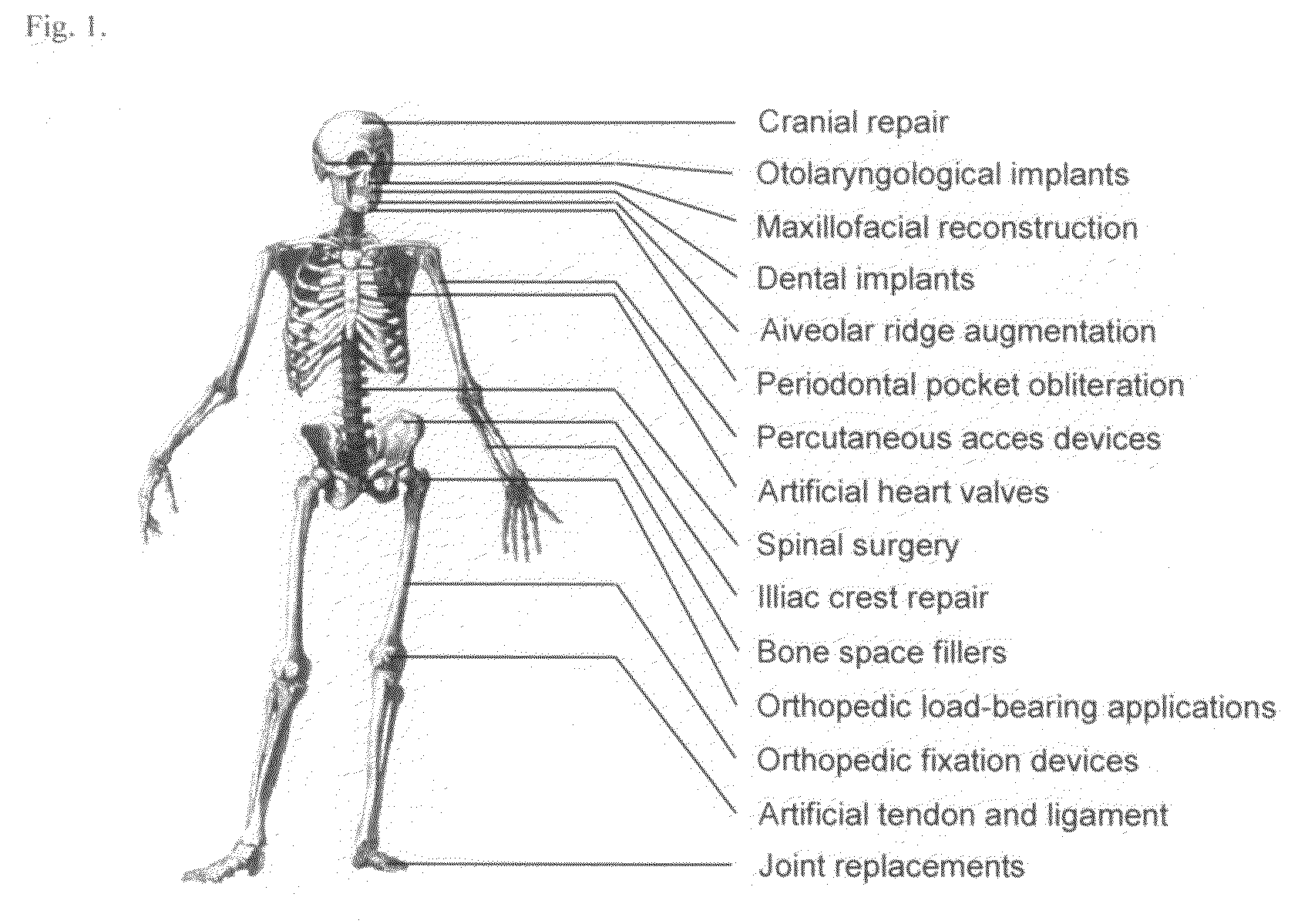

Bioactive graded zirconia-based structures

The present invention provides a functionally graded bioactive glass / ceramic composite structure or bioactive glass / ceramic / bioactive glass sandwich structure for use in such applications as damage resistant, ceramic dental implants, immediate tooth replacement, endodontic posts, orthopedic prostheses, orthopedic stems, bone substitutes, bone screws, plates, and anchors, nonunion fractures repair, alveolar ridge augmentation, missing small bone parts (e.g. fingers, toes, etc), maxilla facial reconstruction, spinal fusion, and scaffolds for bone regeneration, comprising a residual bioactive glass or glass-ceramic layer at all accessible surfaces, followed by an underlying graded glass-ceramic layer, and then an dense interior ceramic. The residual bioactive glass or glass-ceramic layer can be further transformed to a carbonate apatite (CHA) layer by immersing in calcifying solution or simulated body fluid (SBF) with electrolyte composition similar to that of serum. The interior ceramic preferably contains yttria-tetragonal zirconia polycrystal (Y-TZP) or ceria stabilized tetragonal zirconia polycrystal (Ce-TZP) or magnesia stabilized zirconia (Mg-PSZ) or calcia stabilized zirconia (Ca-PSZ) or alumina or zirconia-alumina composites. Further, the invention provides methods for making the same functionally graded bioactive glass / ceramic composite structure or graded bioactive glass / ceramic / bioactive glass sandwich structure.

Owner:NEW YORK UNIV

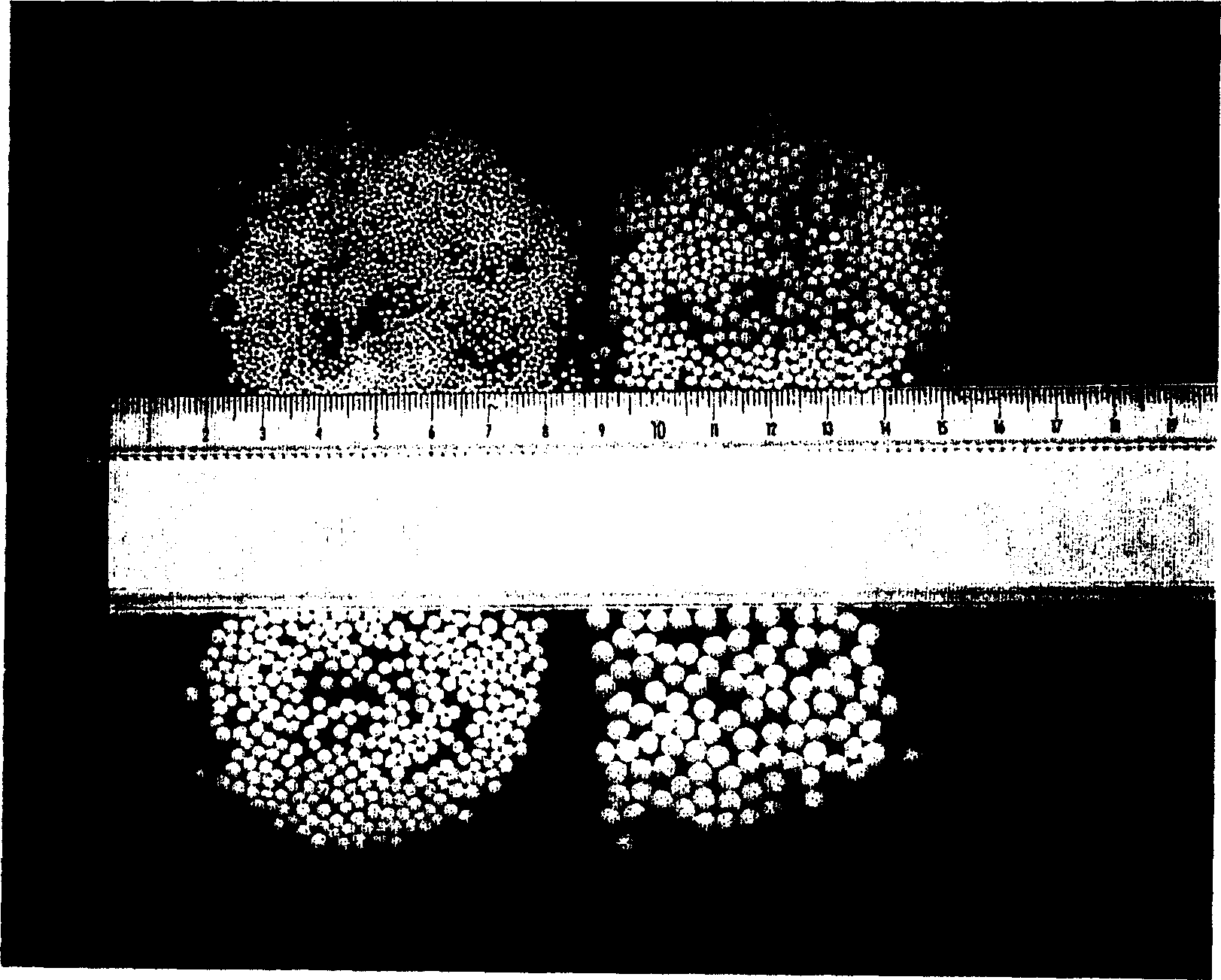

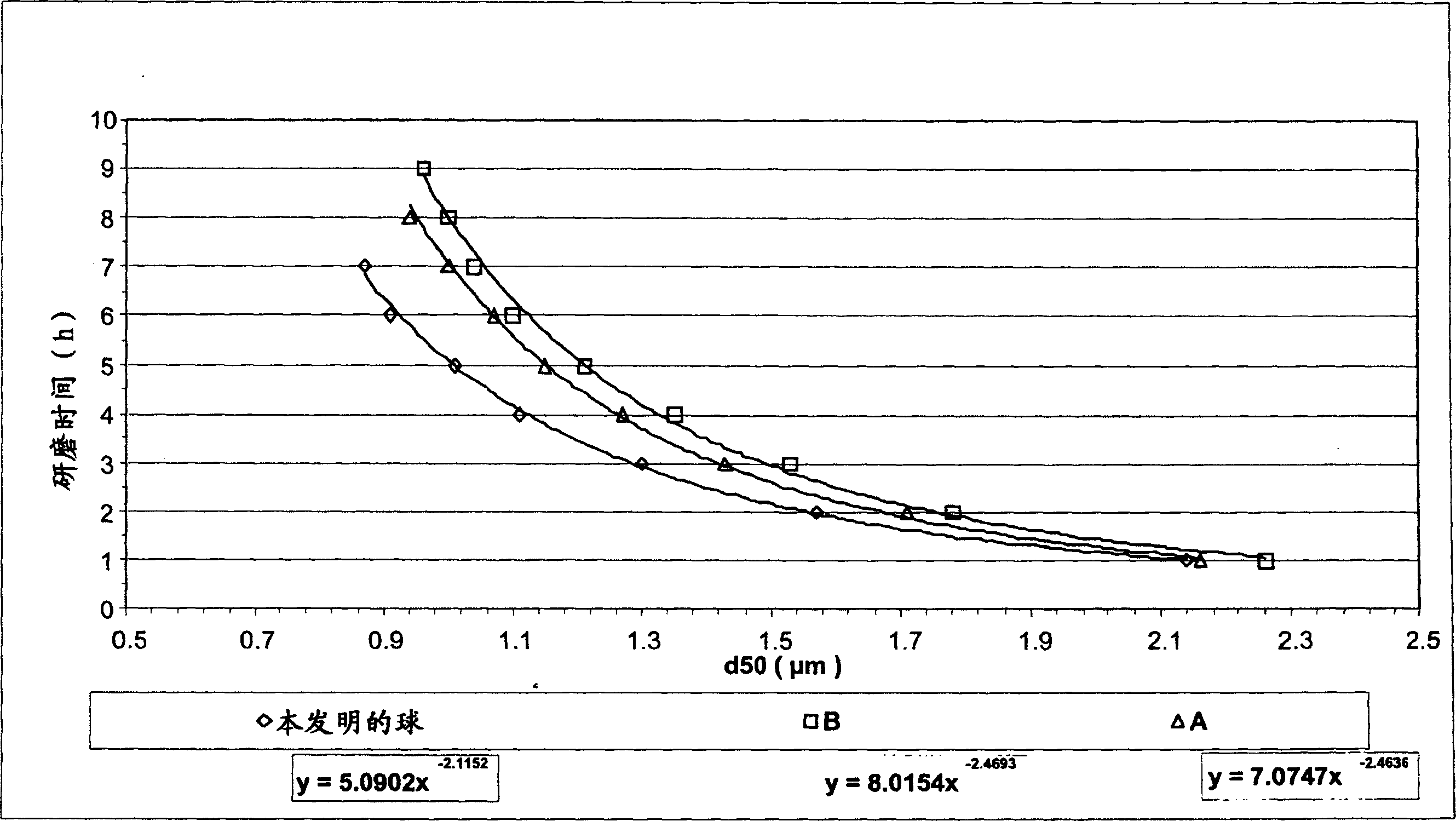

Grinding balls and production method thereof

The invention relates to sintered ceramic grinding balls comprising the following compounds (by wt.-%): 18 to 50 wt.- % mullite (3Al2O3.2SiO2); 9 to 25 wt.- % zirconium (ZrO2 + HfO2) stabilised by 0.5 to 3 wt.- % rare earth oxide; and 25 to 72 wt.- % alumina (Al2O3).

Owner:MAGOTTEAUX INT SA

Alkali-free composite sealant materials for solid oxide fuel cells

A sealant composition for use in sealing solid oxide fuel cells is provided which comprises a glass component which comprises a mixture of alkali-free inorganic oxides, and an optional filler component dispersed in the glass component, said filler component being up to 40% by weight of the composition. The glass component can include, on a mole basis, 20 to 50% BaO, 1 to 10% Y2O3, 5 to 20% B2O3, 10 to 30% SiO2, 3 to 35% MgO, 2 to 20% CaO, 1 to 10% ZnO, and 0 to 5% ZrO2, and exemplary filler components include zirconia, alumina, barium titanate, strontium titanate, and combinations thereof.

Owner:CUMMINS ENTERPRISE LLC

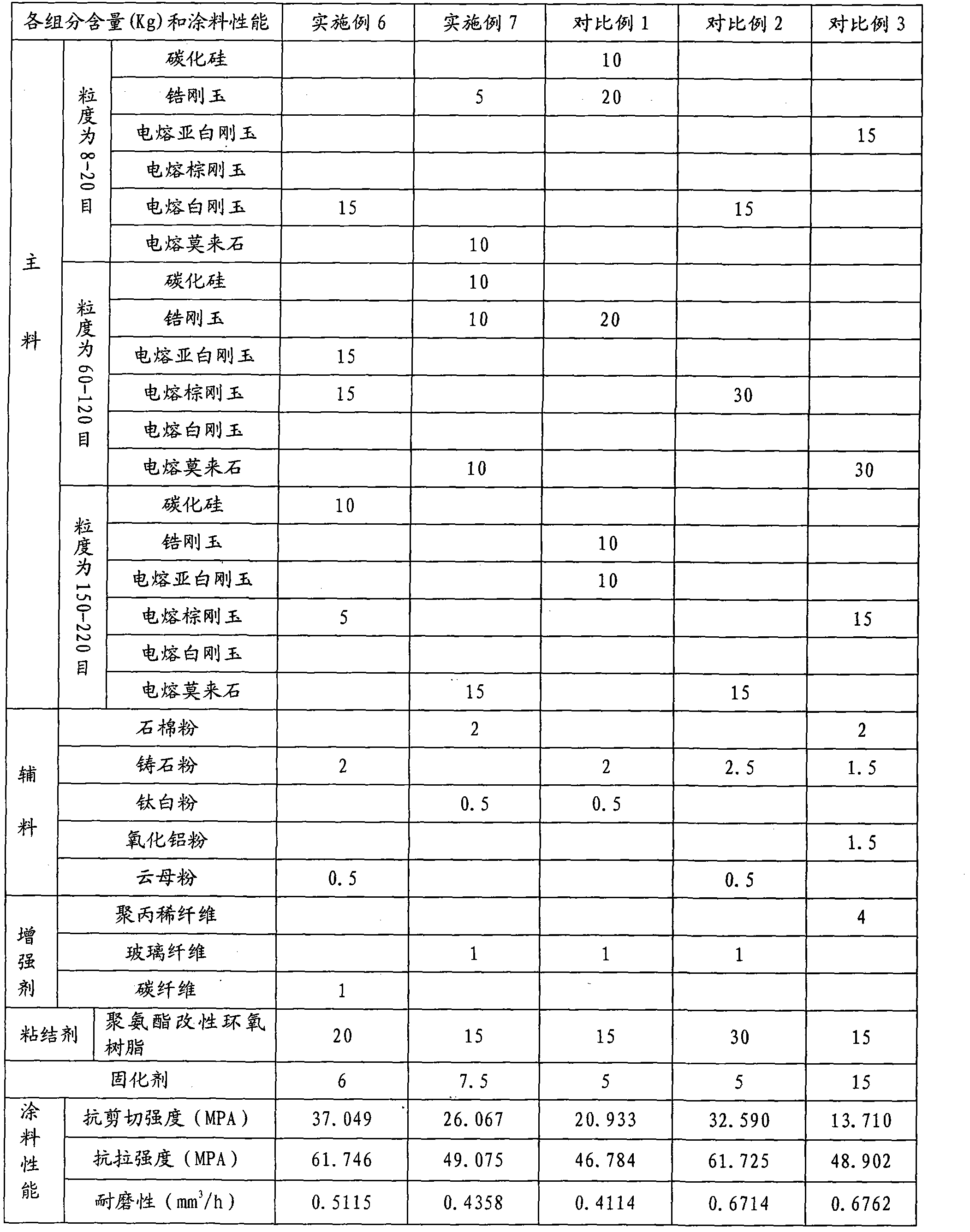

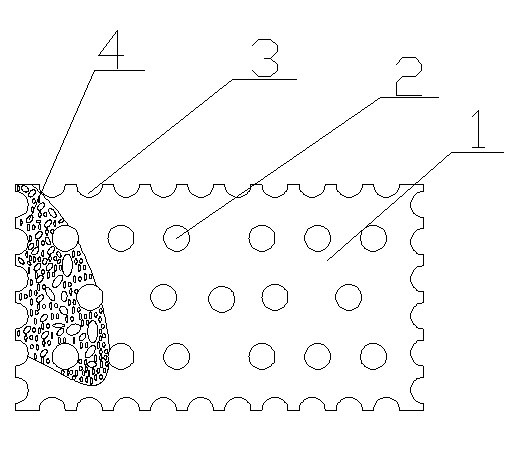

Metal ceramic reinforced body

The invention discloses a metal ceramic reinforced body which is formed by zirconia alumina, Cr-Fe powder and an organic binding agent after being sintered. A plurality of through holes are uniformly arranged on a sintered and moulded block body; the through holes are arranged on the upper end face and the lower end face, and through grooves are arranged on four side faces. According to the metal ceramic reinforced body, grooves at edge portions of two adjacent reinforced bodies form an intact through hole after different reinforced bodies are spliced together, and metal liquid is poured into the through holes, so that metallic phase can infiltrate among ceramic particles and uniformly wrap ceramic phase. Not only toughness and abrasive resistance of product ceramic are enhanced, but also heat-vibration resistance is improved.

Owner:洛阳鹏飞耐磨材料股份有限公司

Grinding wheel special for rail grinding train and manufacturing method of grinding wheel

The invention discloses a grinding wheel special for a rail grinding train and a manufacturing method of the grinding wheel, and relates to the technical field of manufacturing of grinding wheels. Thegrinding wheel special for the rail grinding train comprises, by weight, 25-35 parts of modified zirconia alumina, 35-55 parts of modified brown fused alumina, 9-15 parts of mixed resin, 3-5 parts ofaluminum oxide hollow balls, 1.5-8 parts of pyrite powder, 1-6 parts of cryolite powder, 0.5-5 parts of barium sulfate powder, 0.5-4 parts of calcium carbonate powder, 0.5-4 parts of graphite powder,3-6 parts of copper powder and 1-8 parts of fiber-reinforced materials, wherein the modified zirconia alumina and the modified brown fused alumina are fused alumina zirconia and brown fused alumina which are dried after being soaked in a KH550 alcohol solution with the concentration of 3-10wt%. The grinding wheel special for the rail grinding train is high in strength, good in tenacity, good in self sharpness and high in grinding capacity; blockage is unlikely to occur in the grinding process; a steel rail is unlikely to be burnt in the polishing process; and the steel rail has good surface quality after being polished by the grinding wheel.

Owner:SOUTHWEST JIAOTONG UNIV

Manufacture method of fused cast zirconia-alumina brick

InactiveCN101648811AImprove high temperature resistanceImprove corrosion resistanceBrickEconomic benefits

The invention discloses a manufacture method of a fused cast zirconia-alumina brick. The brick is prepared from 35.69% of zircon sand, 15.3% of zirconia, 47.01% of powdered alumina and 2% of sodium carbonate. The manufacture method comprises the following steps: 1. weighing the raw materials in weight percent and then evenly mixing; 2. adding the mixed raw materials after the furnace temperature rises to 1850 DEG C, and then heating up to melt for 90 minutes; 3. keeping the temperature for 30 minutes after the furnace temperature rises to 2780-2800 DEG C, and then carrying out secondary oxygenblowing; 4. lowering the furnace temperature to 1860-1880 DEG C for casting after the oxygen blowing, and carrying out deep gas discharge and afterteeming of a casting solution in a mouldboard; 5. and annealing. The brick has obvious high temperature resistance and erosion-resistant performance when being used on a glass kiln; compared with the original zircon corundum bricks, the service life ofthe fused cast zirconia-alumina brick is prolonged by two years, thereby bringing considerable economic benefits to users. The fused cast zirconia-alumina brick receives authorization and trust fromexperts and clients of dozens of countries, such as Japan, Britain, France, India and the like.

Owner:ZHENGZHOU XINGUANGSE REFRACTORY

Blast furnace tapping channel castable

InactiveCN102775165AStrong volume stability at high temperatureImproved thermal shock stabilityFiberSodium phosphates

The invention relates to a blast furnace tapping channel castable and belongs to the field of refractory castable. The blast furnace tapping channel castable comprises the following components in part by weight: 40-50 parts of alumina, 15-30 parts of sintered tabular corundum, 10-15 parts of andalusite, 1-8 parts of alumina hollow ball, 3-10 parts of electric smelting zirconia, 10-25 parts of alumina micro powder, 8-12 parts of ferro silicon nitride, 3-10 parts of alumina micro powder, 4-8 parts of alumina and silica sol composite suspension, 1-2 parts of nano ceramic powder, 0.1-0.3 part of mixture of sodium tripolyphosphate and sodium hexametaphosphate and 0.3-0.4 part of explosion-proof fiber. A blast furnace tapping channel with long service life and low melting loss rate can be prepared by the blast furnace tapping channel castable.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

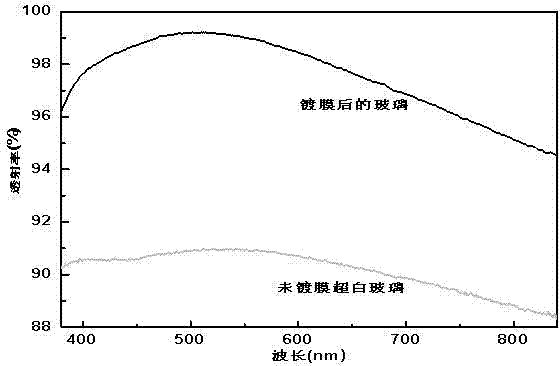

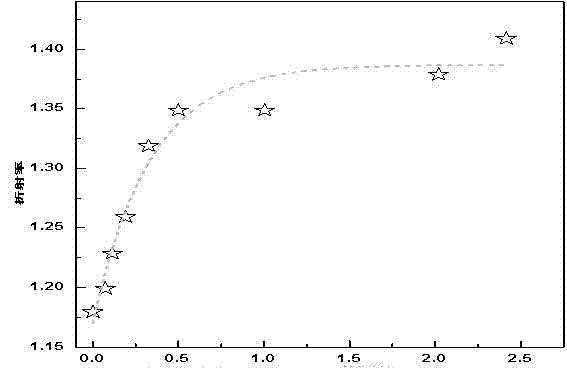

Preparation method of antireflection film applicable to different bases

InactiveCN103757618AWide range of refractive index controlImprove anti-reflection effectSolid/suspension decomposition chemical coatingMicro structureRefractive index

The invention relates to a preparation method of an antireflection film applicable to different bases, and provides an antireflection film material matched with the refractive indexes of the bases. The refractive index of the film is mainly obtained in a manner of compounding sols with different micro-structures or the sols with different materials. The sols are selected from one or combination of two of titanium oxide, hafnium oxide, zirconia, alumina, silicon oxide and the like. The method has the advantages that a large-area and irregular shape substrate can be coated, large-scale production is facilitated, the cost is low, and the like.

Owner:TONGJI UNIV

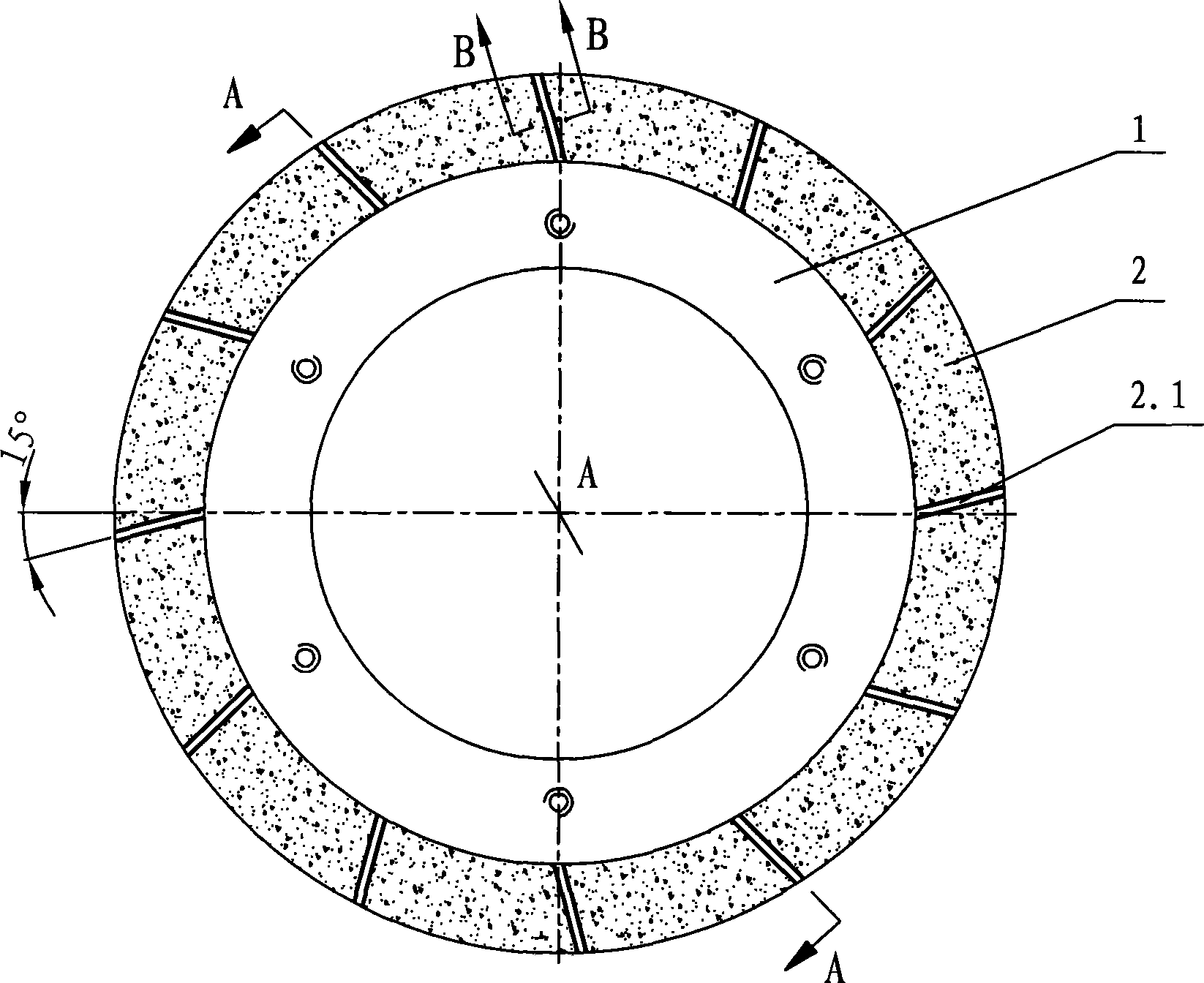

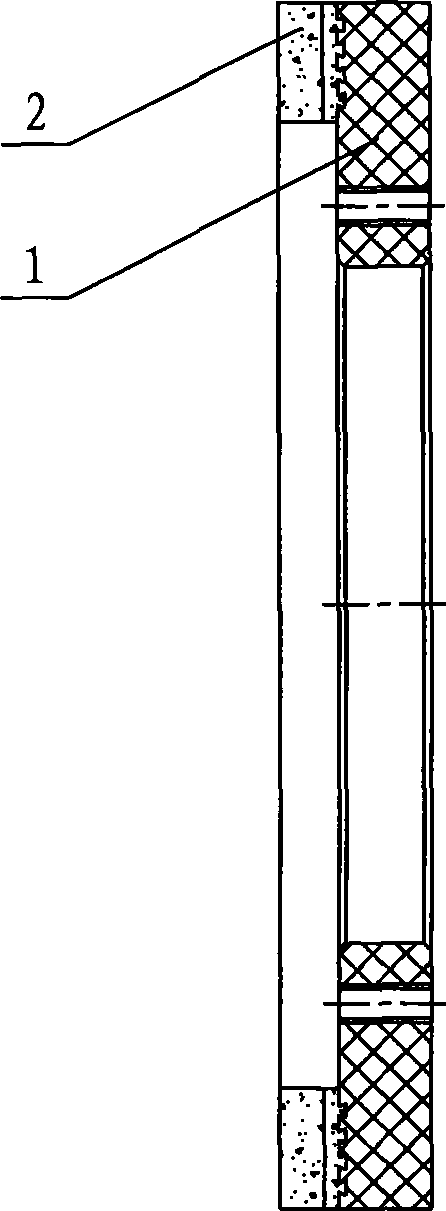

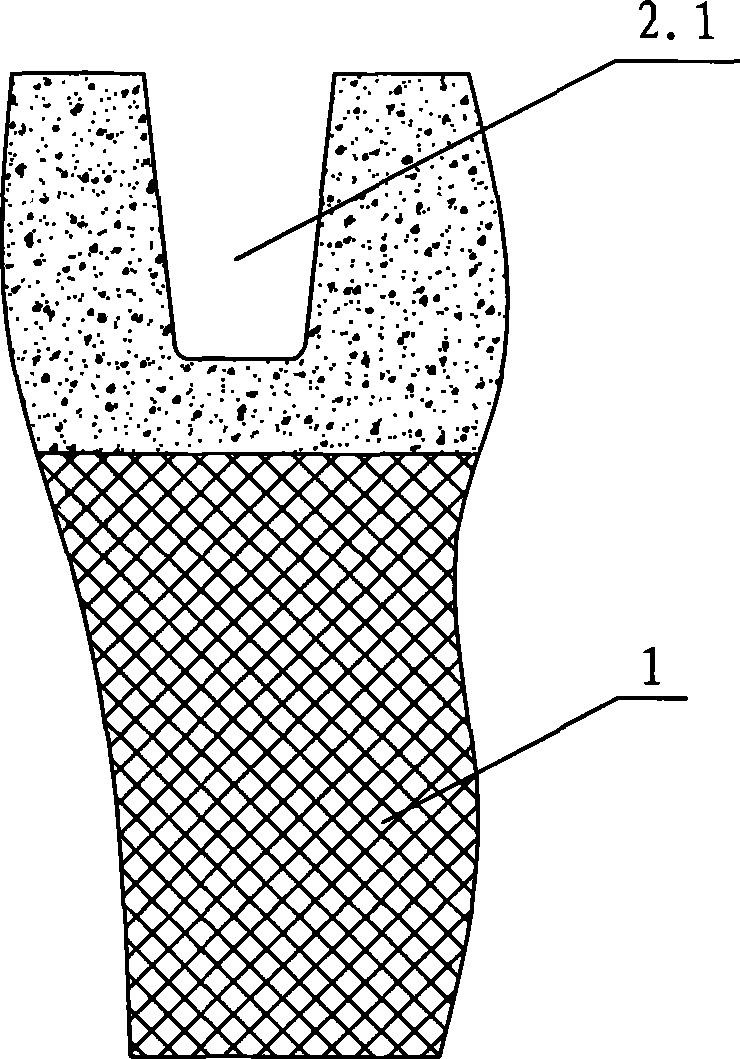

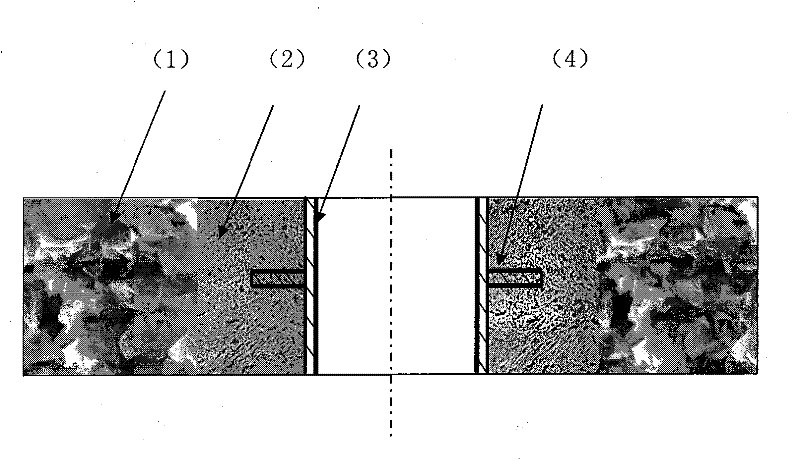

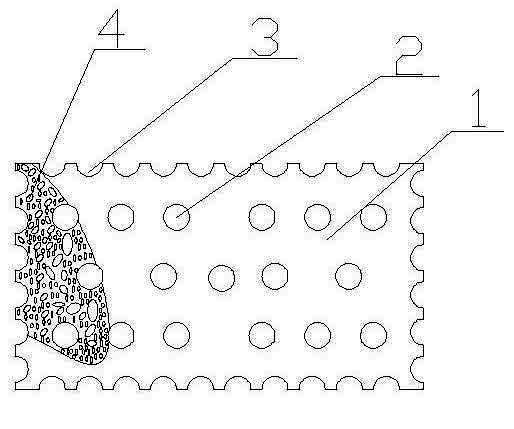

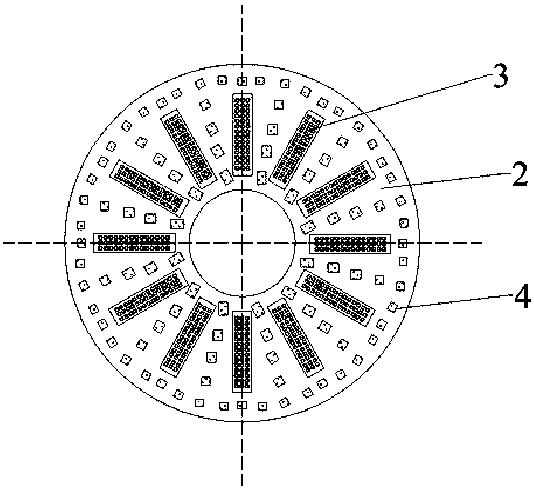

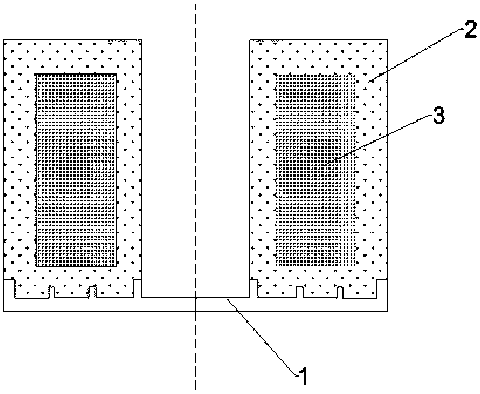

Ultra-hard abrasive ceramic agglomerate and resin zirconia alumina composite grinding wheel

InactiveCN108188950AHigh hardnessImprove sharpnessBonded abrasive wheelsGrinding devicesZirconia aluminaGrinding wheel

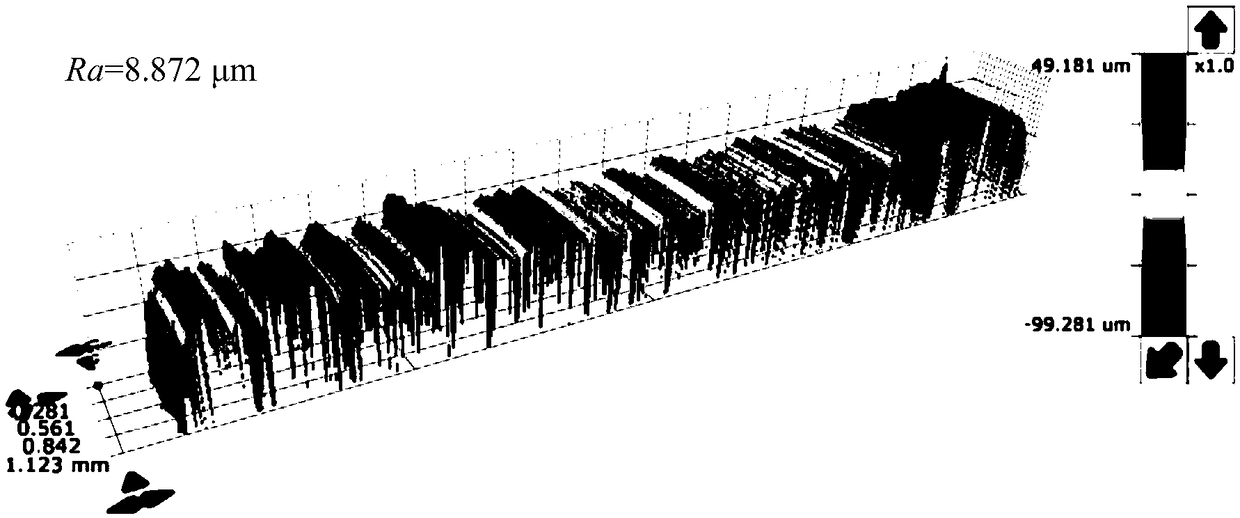

The invention discloses a manufacturing method of an ultra-hard abrasive ceramic agglomerate and resin zirconia alumina composite grinding wheel special for grinding of a railway rail. A base body anda working layer of the grinding wheel are included; the working layer of the grinding wheel is formed by compositing of ceramic bond ultra-hard abrasive (including diamond and cubic boron nitrite) agglomerate and a resin bond zirconia alumina abrasive layer; and the pieces of ceramic bond agglomerate are distributed in resin bonds at intervals with the equal angle, and the interval angle is 10-15degrees. According to the manufactured grinding wheel, by utilizing the advantages that diamond abrasives have ultrahigh hardness and sharpness, cubic boron nitrite abrasives are low in friction coefficient, excellent in heat stability and not liable to react with ferrous metal and combining the high toughness of the resin bonds and zirconia alumina abrasives, the sharpness of the grinding wheelfor grinding the rail s improved obviously, the working life of the grinding wheel is prolonged obviously, the burn injury bluing phenomenon of the surface of the rail due to grinding is prevented effectively, and the surface quality of the ground rail is improved significantly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Refractory aggregate for refractory brick manufactured through recycling investment casting old shell powder and processing method thereof

InactiveCN102951916AComply with refractory aggregate requirementsReduce pollutionInvestment castingFire brick

The invention relates to a refractory aggregate for a refractory brick manufactured through recycling investment casting old shell powder and a processing method thereof. The invention adopts refractory materials, which are the old shell powder manufactured through recycling old shells; the old shell powder is powder which is air dried and high-temperature roasted, and has small linear deformation and completely combusted organic matters; the old shell powder is processed to be the refractory aggregate for manufacturing the refractory brick; and the main components of the refractory aggregate for manufacturing the refractory brick are zirconium oxide, aluminum oxide and silicon oxide. The processing method comprises the following steps of: adopting the investment casting old shells as raw materials; sorting, classifying, dehydrating, deironing, first crushing, and processing to form powder in a manufacturing and processing process; screening, and secondary deironing to obtain oversize products and screen underflows; and classifying the oversize products and the screen underflows to obtain the qualified refractory aggregate for manufacturing the refractory brick. The processing method has the advantages of novel conception, simple and convenient method, and convenience in implementation.

Owner:柳薇

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com