Grinding balls and production method thereof

A production method and technology for grinding balls, which are applied in the production of ceramic materials, grain processing, zirconia, etc., can solve the problems of expensive, undisclosed, technical difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

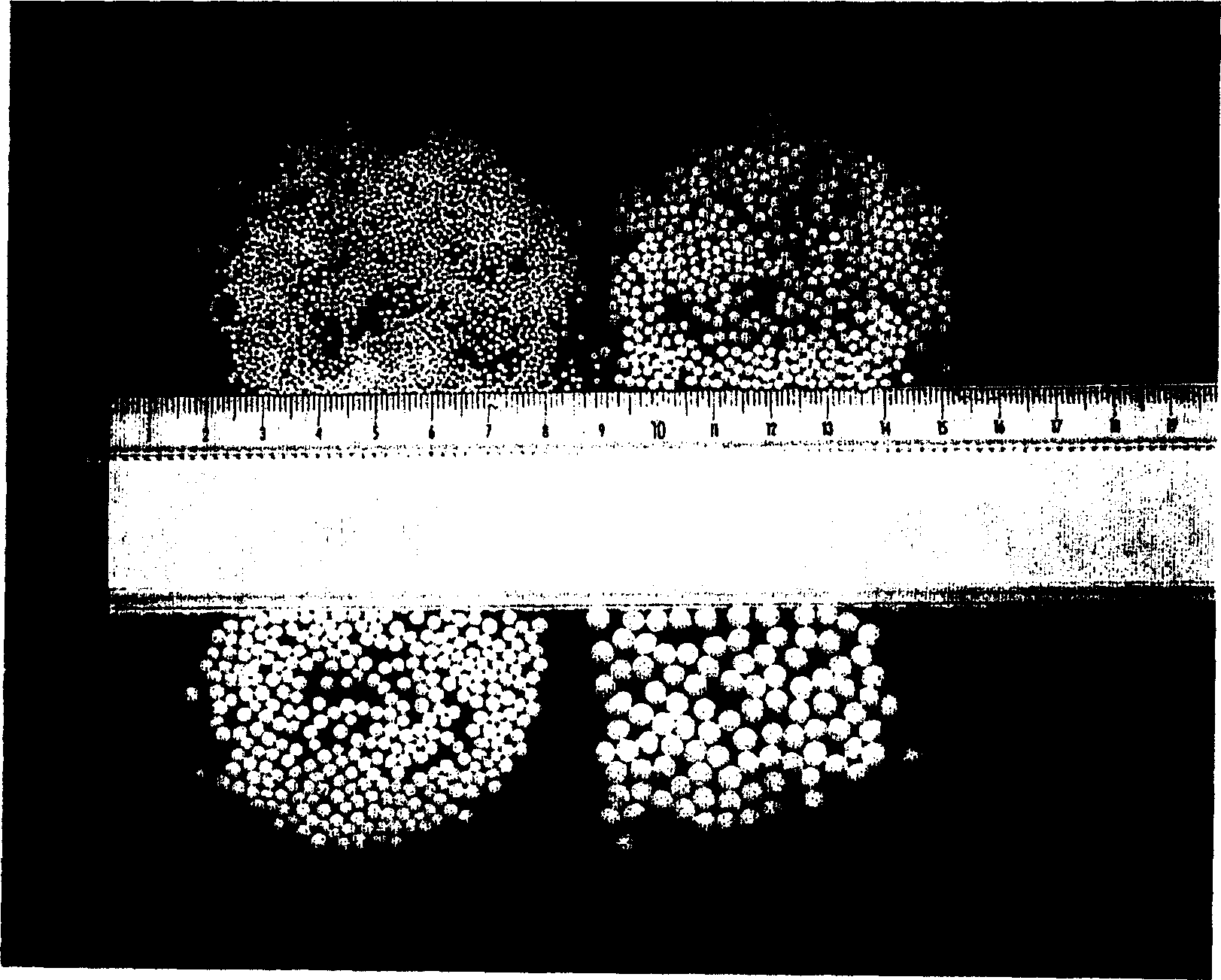

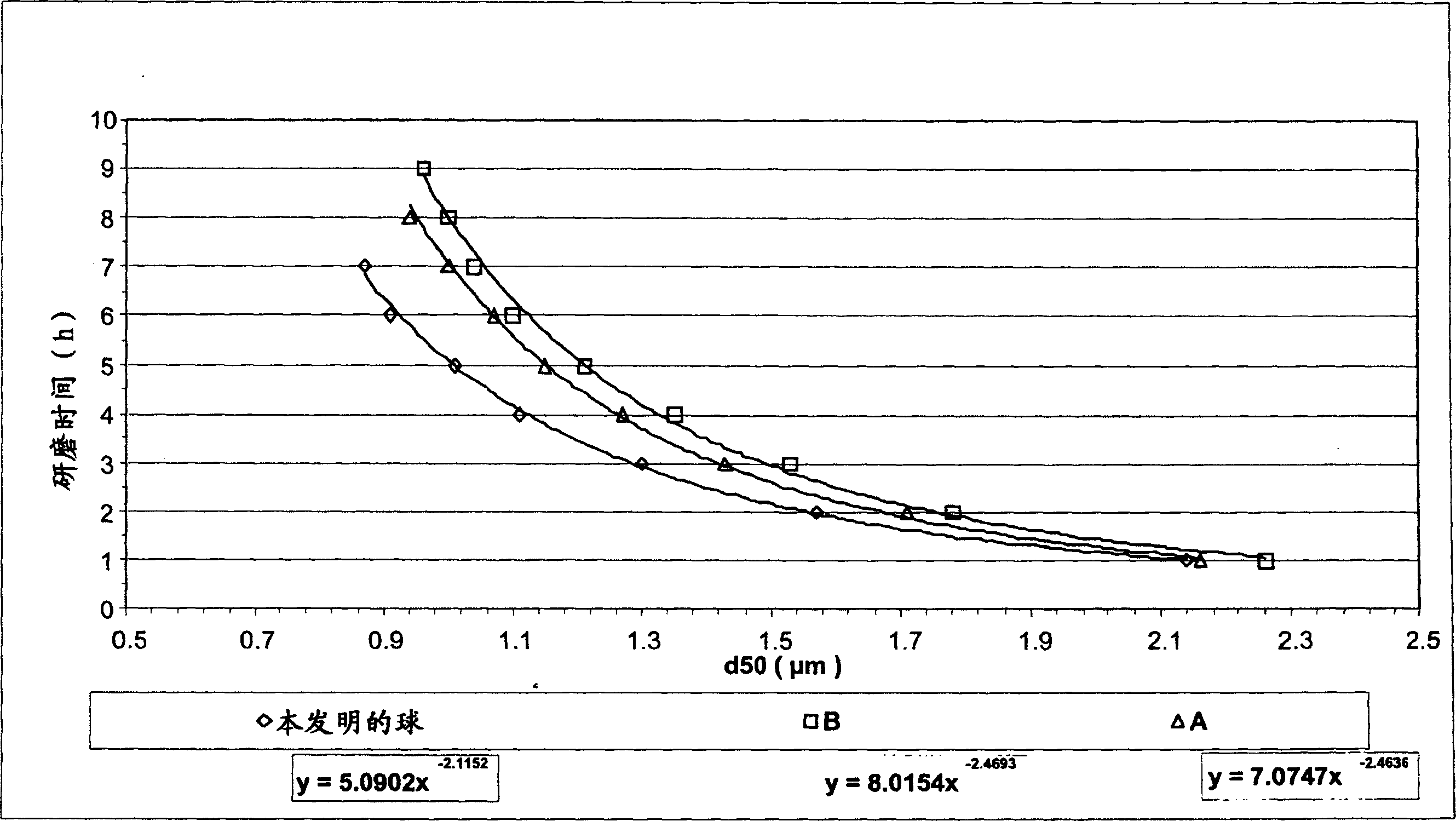

[0082] The present invention relates to balls made of sintered ceramics comprising alumina-zirconia-aluminosilicate, especially alumina-zirconia-mullite. The quality of these balls is higher than that of balls made of alumina, aluminum silicate or alumina-zirconia, and their cost is significantly lower than that of zirconia balls which are very expensive and are used especially as abrasive and / or dispersion media .

[0083] More specifically, the invention relates to balls made of sintered ceramics having the following chemical composition in % by weight:

[0084] -5-40% ZrO 2 +HfO 2 , preferably 9-25%,

[0085] -0.1-10%Y 2 o 3 , preferably 0.5-3%,

[0086] -0.5-20% SiO 2 , preferably 5-12%,

[0087] -40-90%Al 2 o 3 , preferably 60-85%,

[0088] where ZrO 2 / SiO 2 The ratio is greater than or equal to 2, preferably equal to 2,

[0089] -0-5% optional oxide (Na 2 O, CaO, MgO, BaO, ...).

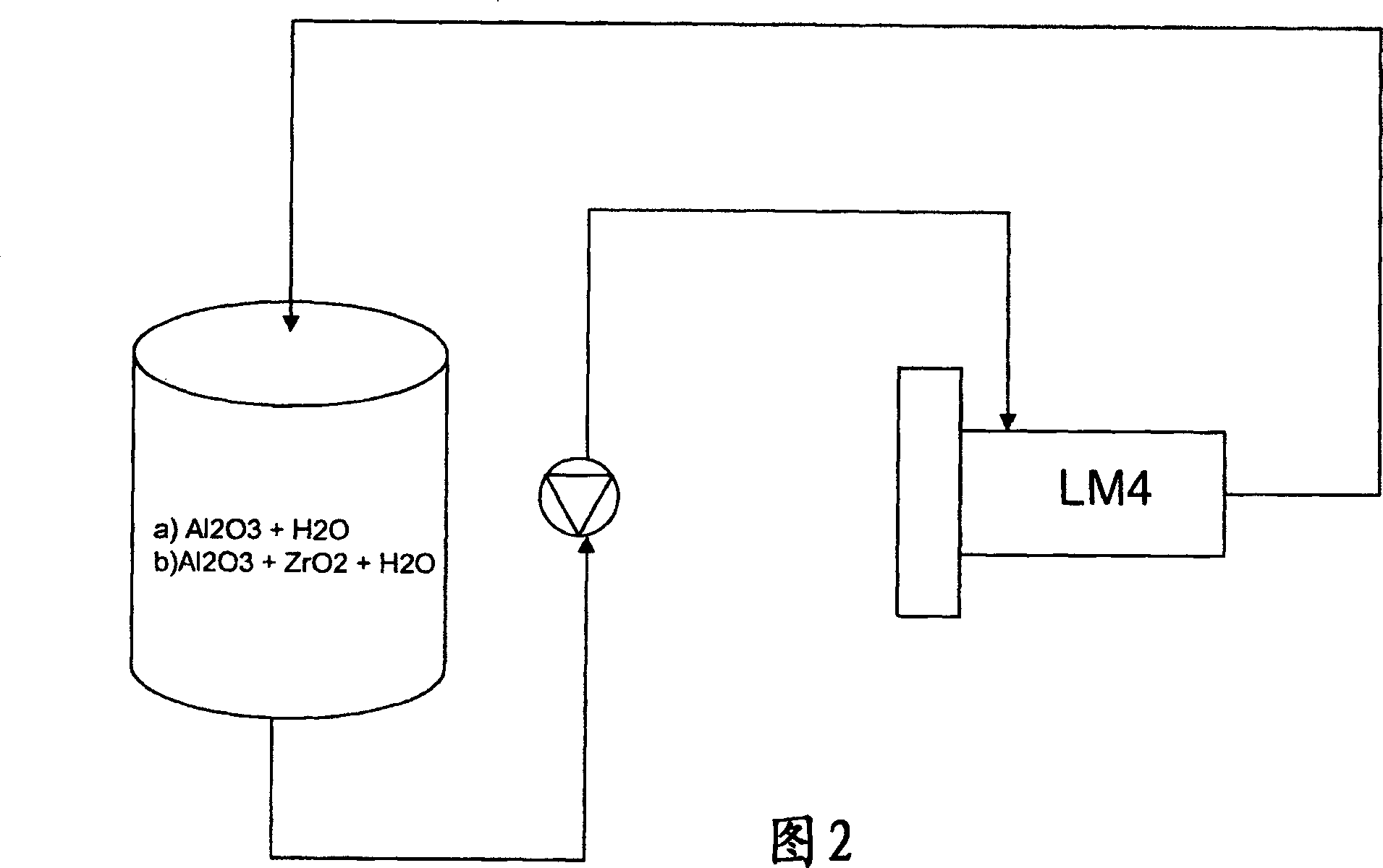

[0090] These balls can be formed by starting from a slurry and / or paste of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com