Grinding wheel special for rail grinding train and manufacturing method of grinding wheel

A technology for grinding trains and grinding wheels, which is applied in the direction of grinding/polishing equipment, grinding devices, manufacturing tools, etc., which can solve the problems of easily burned rails, weak grinding ability, poor self-sharpening, etc., so that it is not easy to block and grind Strong ability, effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

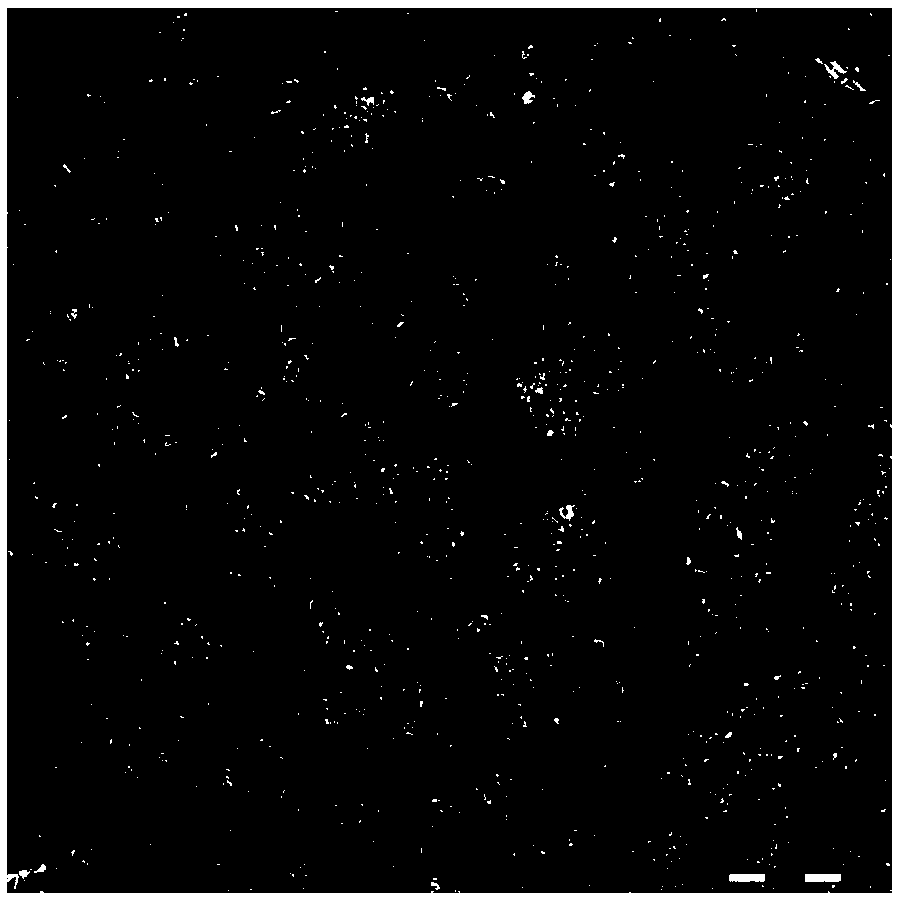

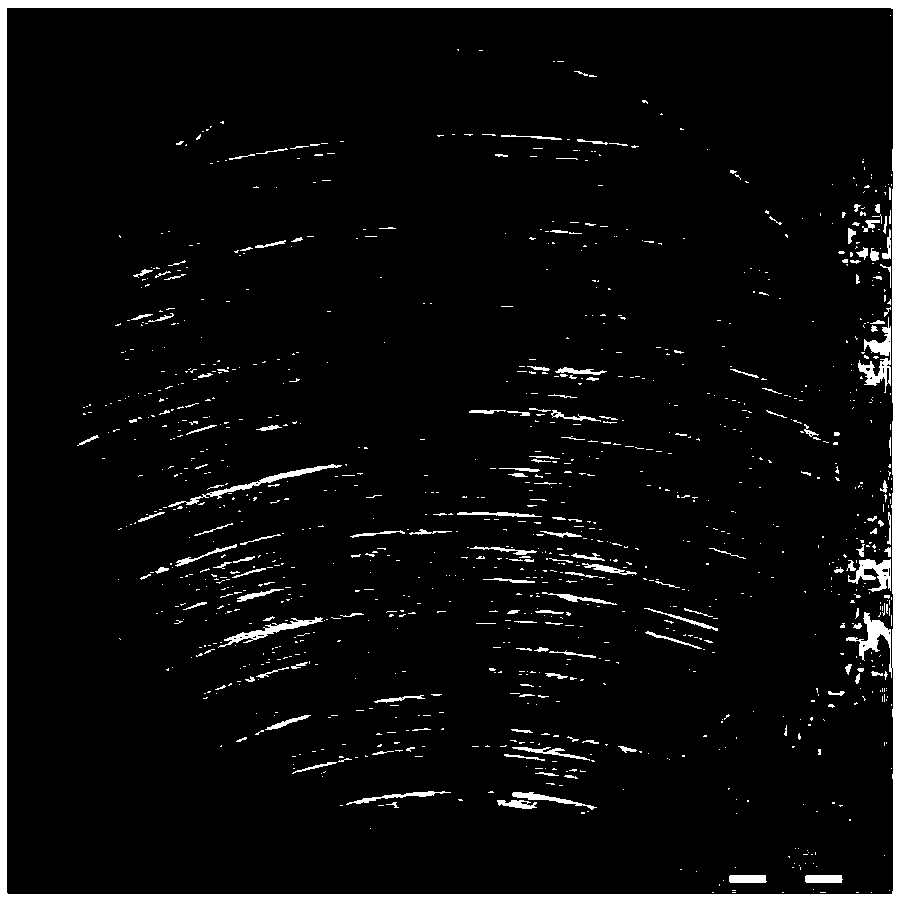

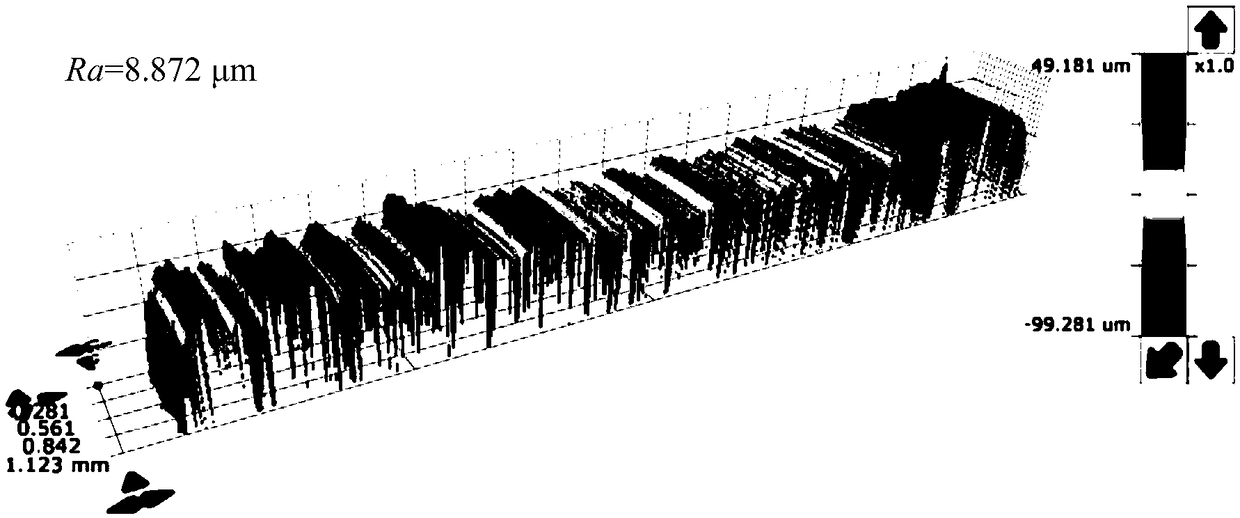

Image

Examples

Embodiment 1

[0043] The special grinding wheel for grinding rails in this embodiment comprises: in parts by weight, 25 parts of modified zirconium corundum, 55 parts of modified brown corundum, 9 parts of mixed resin, 3 parts of alumina hollow balls, 1.5 parts of pyrite powder, ice crystal 1 part of stone powder, 0.5 part of barium sulfate powder, 0.5 part of calcium carbonate powder, 0.5 part of graphite powder, 6 parts of copper powder and 8 parts of fiber reinforced material.

[0044] Wherein the mixed resin comprises 6 parts of polyimide resin powder and 3 parts of epoxy resin liquid.

[0045] The preparation method of the rail grinding train special emery wheel of the present embodiment comprises:

[0046] (1) Mixing

[0047] (11) Pyrite powder, cryolite powder, barium sulfate powder, calcium carbonate powder, graphite powder, copper powder and fiber reinforced material are ground and mixed at a ball-to-material ratio of 1:1 and a rotating speed of 380r / min to obtain a filler;

[00...

Embodiment 2

[0057] The special grinding wheel for grinding rails in this embodiment comprises: in parts by weight, 30 parts of modified zirconium corundum, 45 parts of modified brown corundum, 12 parts of mixed resin, 5 parts of alumina hollow balls, 5 parts of pyrite powder, ice crystal 2 parts of stone powder, 2 parts of barium sulfate powder, 2 parts of calcium carbonate powder, 2 parts of graphite powder, 3 parts of copper powder and 2 parts of fiber reinforced material.

[0058] Wherein the mixed resin comprises 8 parts of phenolic resin powder and 4 parts of water-soluble phenolic resin liquid.

[0059] The preparation method of the rail grinding train special emery wheel of the present embodiment comprises:

[0060] (1) Mixing

[0061] (11) Pyrite powder, cryolite powder, barium sulfate powder, calcium carbonate powder, graphite powder, copper powder and fiber reinforced material are ground and mixed at a ball-to-material ratio of 1:1 and a rotating speed of 400r / min to obtain a f...

Embodiment 3

[0071] The special grinding wheel for grinding rails in this embodiment comprises: in parts by weight, 30 parts of modified zirconium corundum, 35 parts of modified brown corundum, 9 parts of mixed resin, 3 parts of alumina hollow balls, 8 parts of pyrite powder, ice crystal 6 parts of stone powder, 3 parts of barium sulfate powder, 4 parts of calcium carbonate powder, 3 parts of graphite powder, 5 parts of copper powder and 4 parts of fiber reinforced material.

[0072] Wherein the mixed resin comprises 5.5 parts of polyimide resin powder and 3.5 parts of water-soluble phenolic resin liquid.

[0073] The preparation method of the rail grinding train special emery wheel of the present embodiment comprises:

[0074] (1) Mixing

[0075] (11) Pyrite powder, cryolite powder, barium sulfate powder, calcium carbonate powder, graphite powder, copper powder and fiber reinforced material are ground and mixed at a ball-to-material ratio of 1:1 and a rotating speed of 420r / min to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com