Polymer wear-resistance coating material

A wear-resistant coating and polymer technology, applied in the field of coating materials and wear-resistant coating materials, can solve the problems of reducing the wear resistance of coatings, increasing costs, easy delamination and bubbling, etc., to reduce labor intensity, reduce The effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

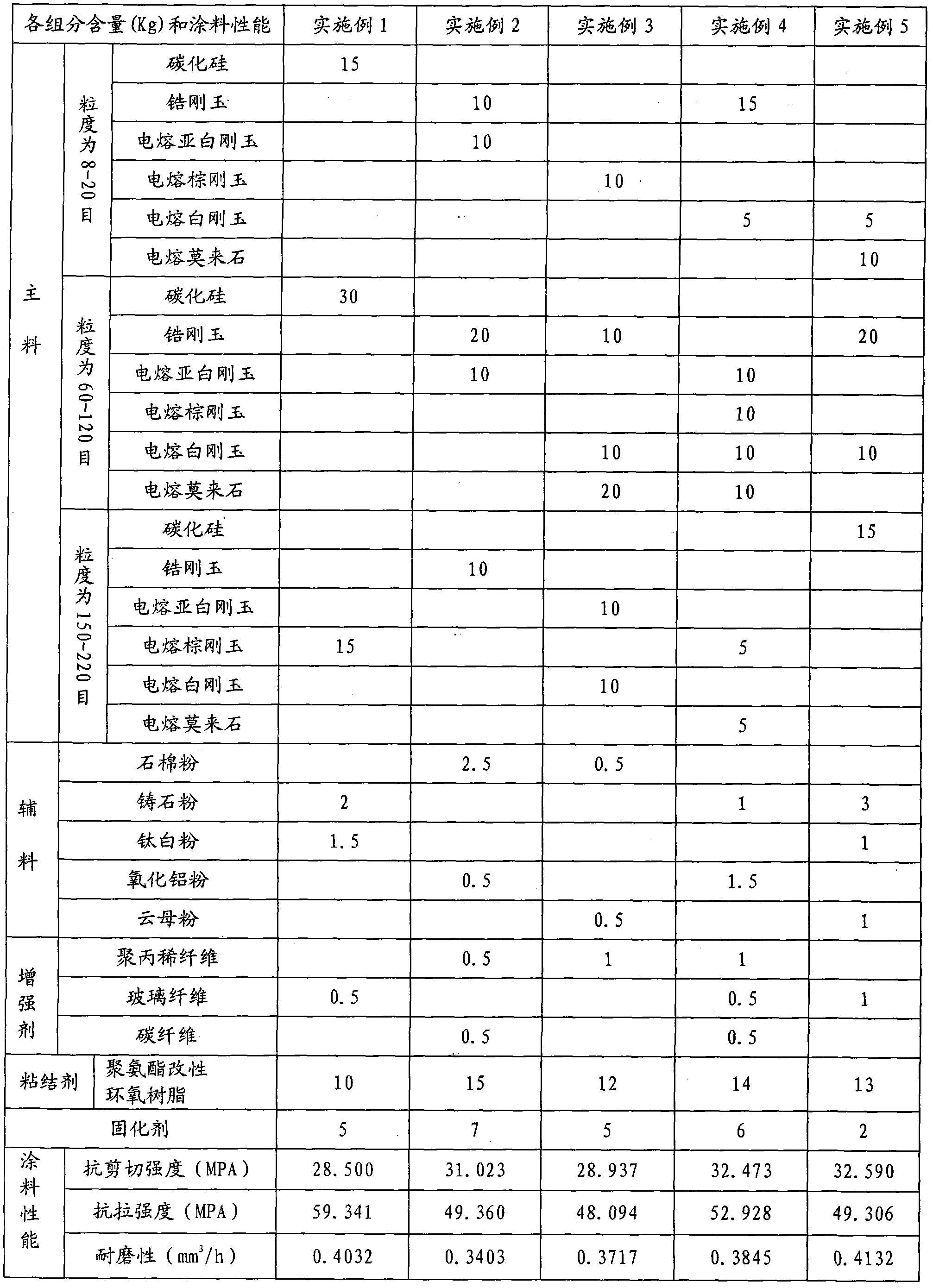

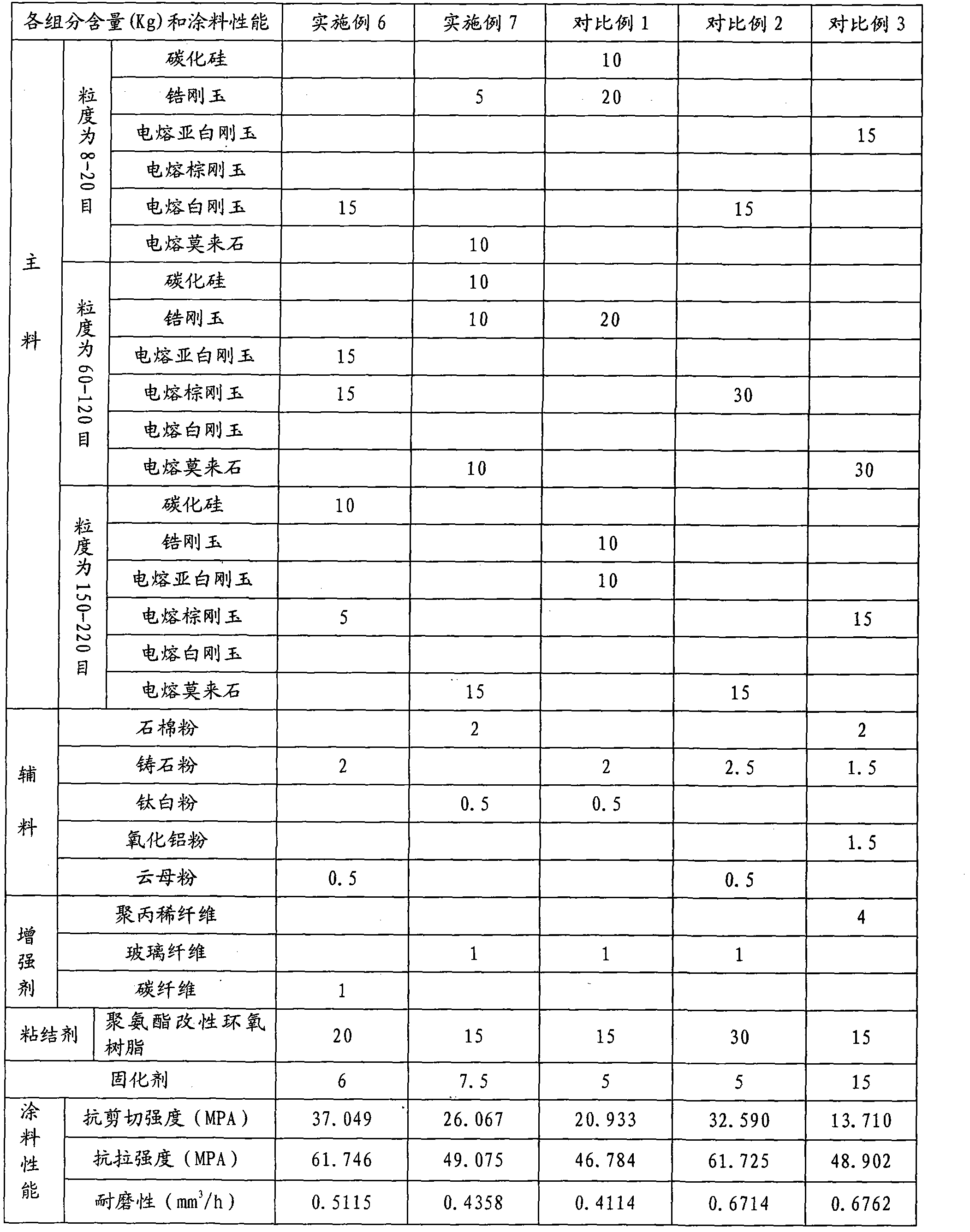

Embodiment 1

[0031] Add the polyurethane modified epoxy resin and main ingredients into the strong mixer according to the weight specified in Table 1 and stir for 5 minutes; then add the auxiliary materials and reinforcing agent into the above-mentioned strong mixer according to the specified weight in Table 1 and stir for 6 minutes to mix evenly to obtain the obtained The A component of the polymer wear-resistant coating material is required, and the A component is put into an iron bucket for use. When construction is used, the surface of the slurry pump that needs to be coated with the wear-resistant coating material is first cleaned and derusted, and then According to the weight listed in the curing agent in Table 1, diaminodiphenylmethane was taken as component B and component A was stirred and mixed uniformly to obtain a polymer wear-resistant coating material. Apply according to the required coating thickness, the application thickness is generally 1-100mm, for the slurry pump, the ap...

Embodiment 2

[0033] Prepare polyurethane modified epoxy resin, preparation method is as follows:

[0034] Add 20 moles of polyether into the reaction kettle, heat it, and when the temperature rises to 110-120°C, vacuumize for 0.6-1.2h, stop vacuuming and heating, and pass N 2 , in order to avoid contact with air, the whole reaction has been kept flowing with N 2, when the temperature drops to 40-50°C, add 20 moles of toluene diisocyanate and react at a temperature of 40°C for 1h, then slowly raise the temperature to 80°C for 2h, and finally raise the temperature to 90°C, and react for 0.5h under this condition , to obtain a PU prepolymer containing terminal NCO groups; add 90 parts by weight of epoxy resin to another reaction kettle, raise the temperature to 100-120°C, start vacuuming for 1-2h, and then introduce N 2 , the whole reaction has been kept feeding N 2 , when the temperature drops to 90-110°C, add 10 parts by weight of the above-reacted prepolymer into the epoxy resin, control...

Embodiment 3

[0037] Repeat the method of Example 1 by the weight of various components specified in Table 1, but the curing agent is changed to m-phenylenediamine, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com