Patents

Literature

185 results about "Cast stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast stone or reconstructed stone is a concrete masonry form of artificial stone which simulates natural-cut stone. It is used for architectural features: trim, or ornament; facing buildings or other structures; statuary; and for garden ornaments. Cast stone can be made from white and/or grey cements, manufactured or natural sands, crushed stone or natural gravels, and colored with mineral coloring pigments. Cast stone may replace such common natural building stones as limestone, brownstone, sandstone, bluestone, granite, slate, coral, and travertine.

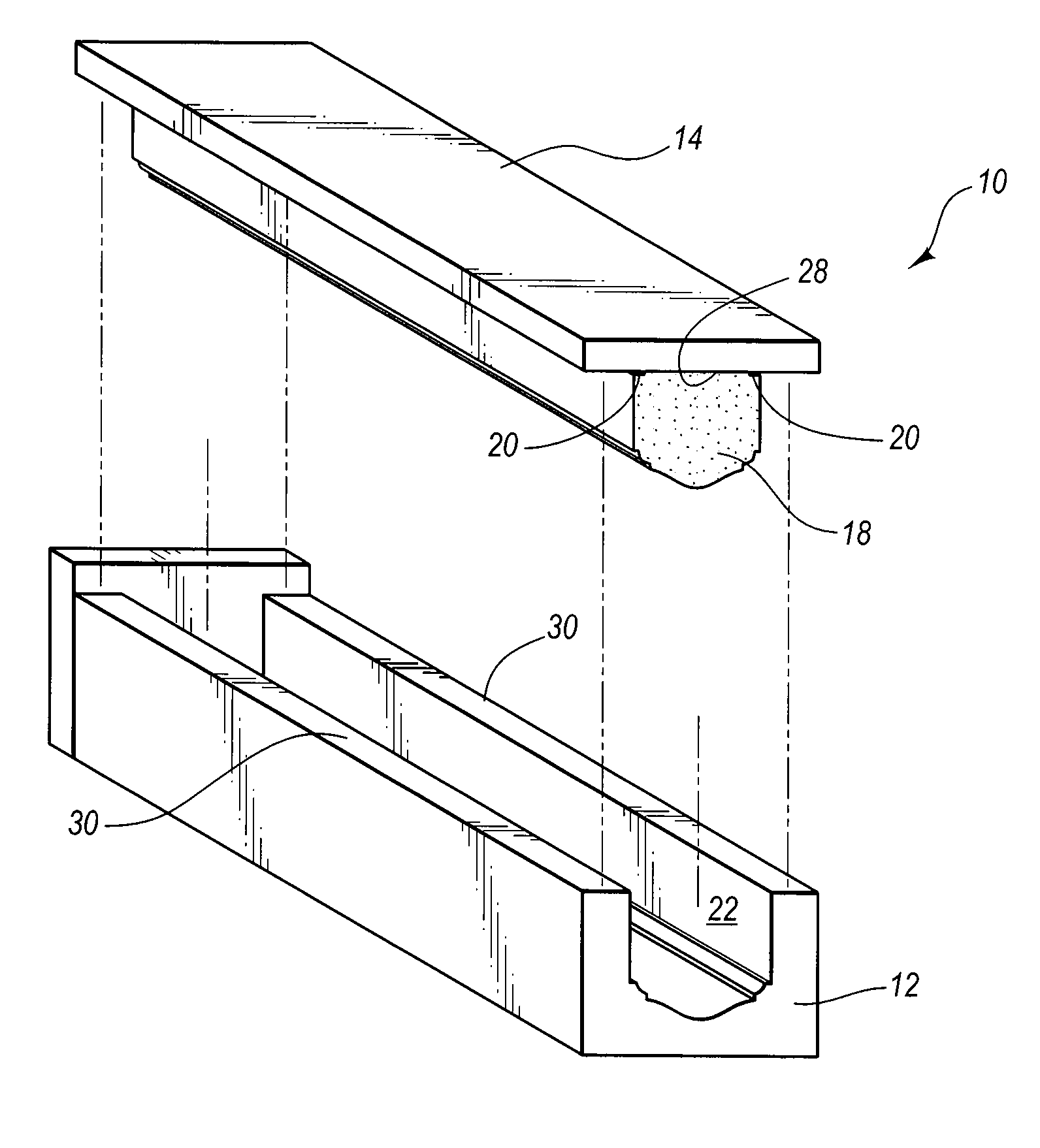

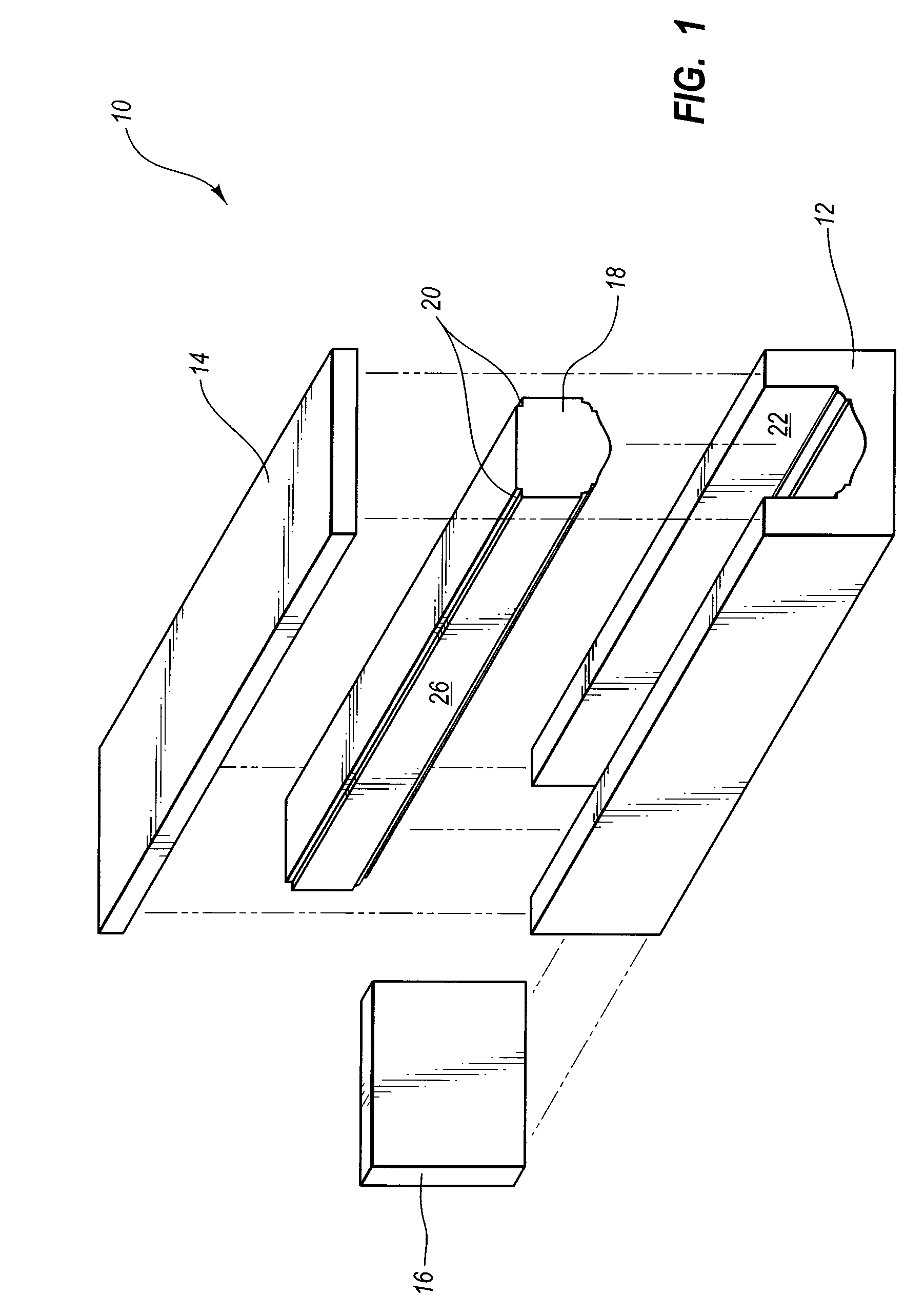

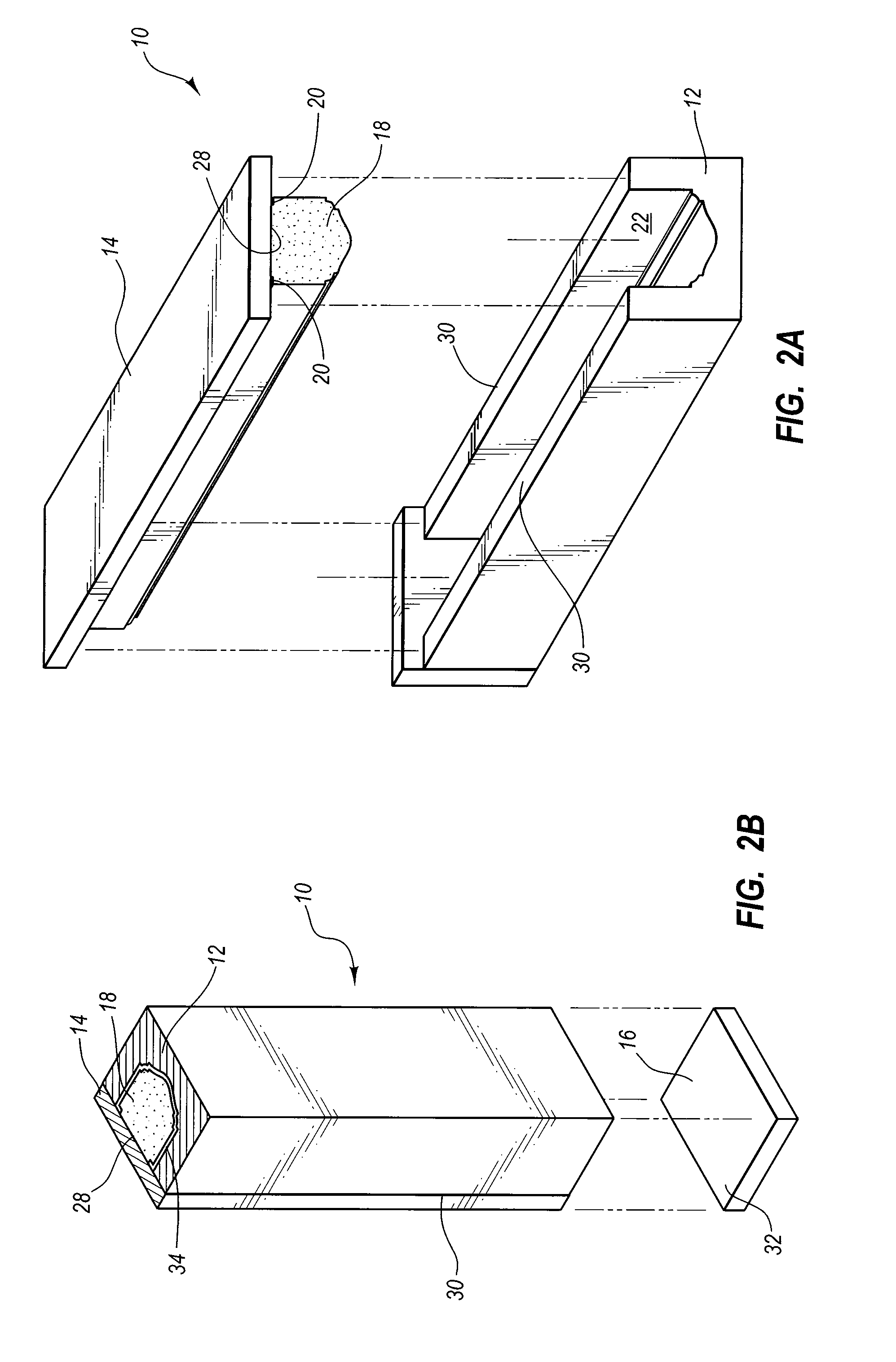

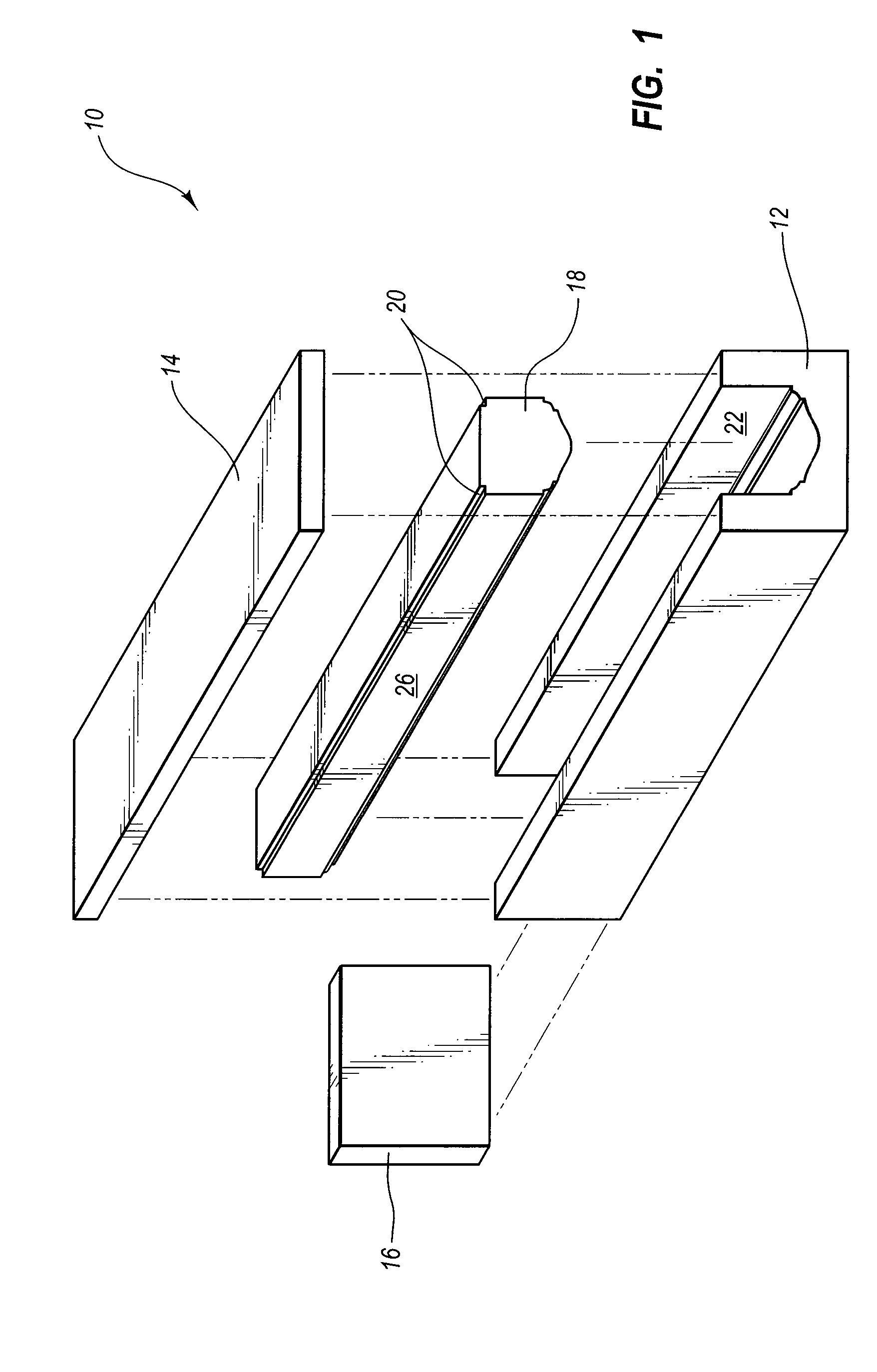

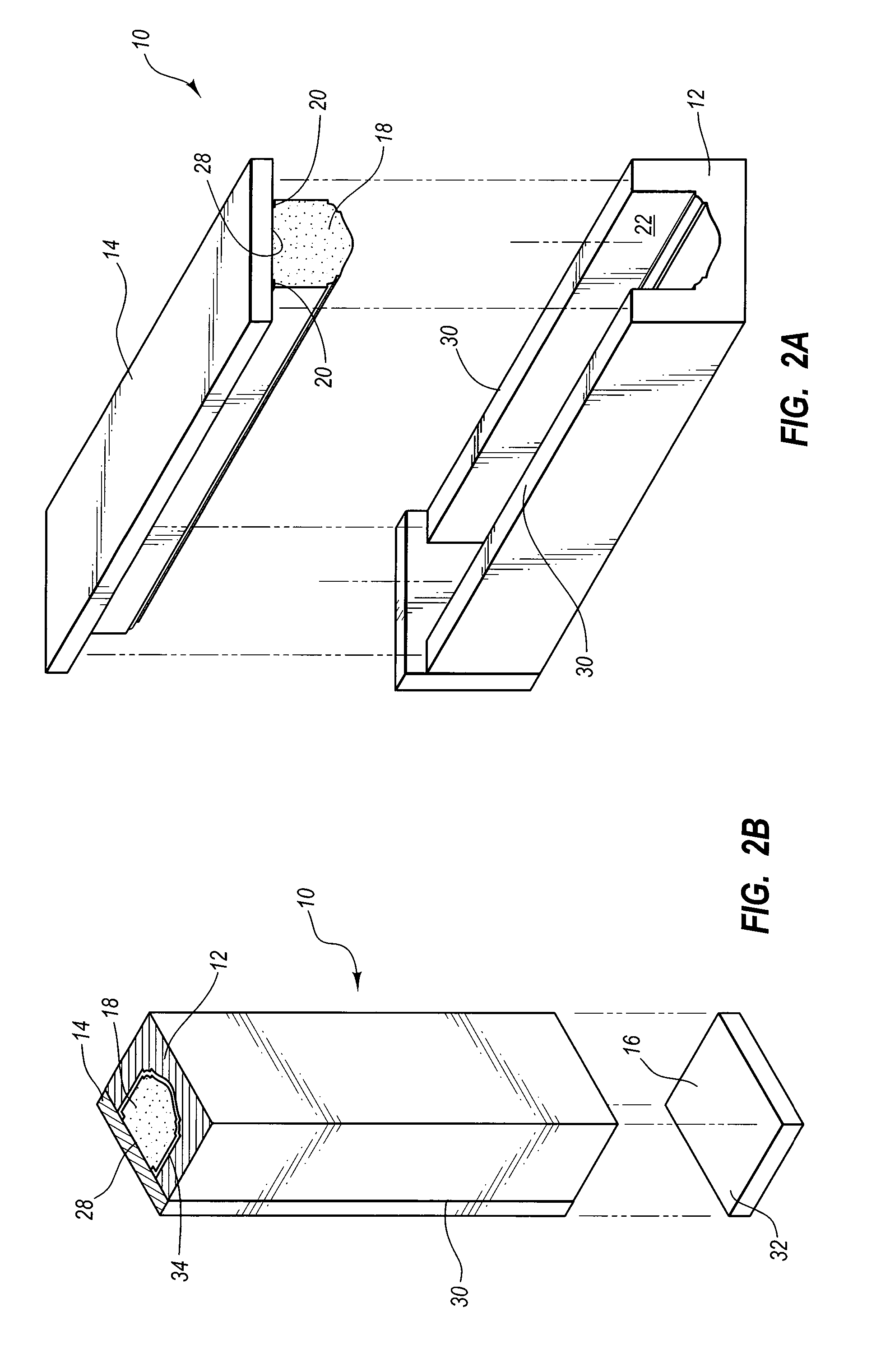

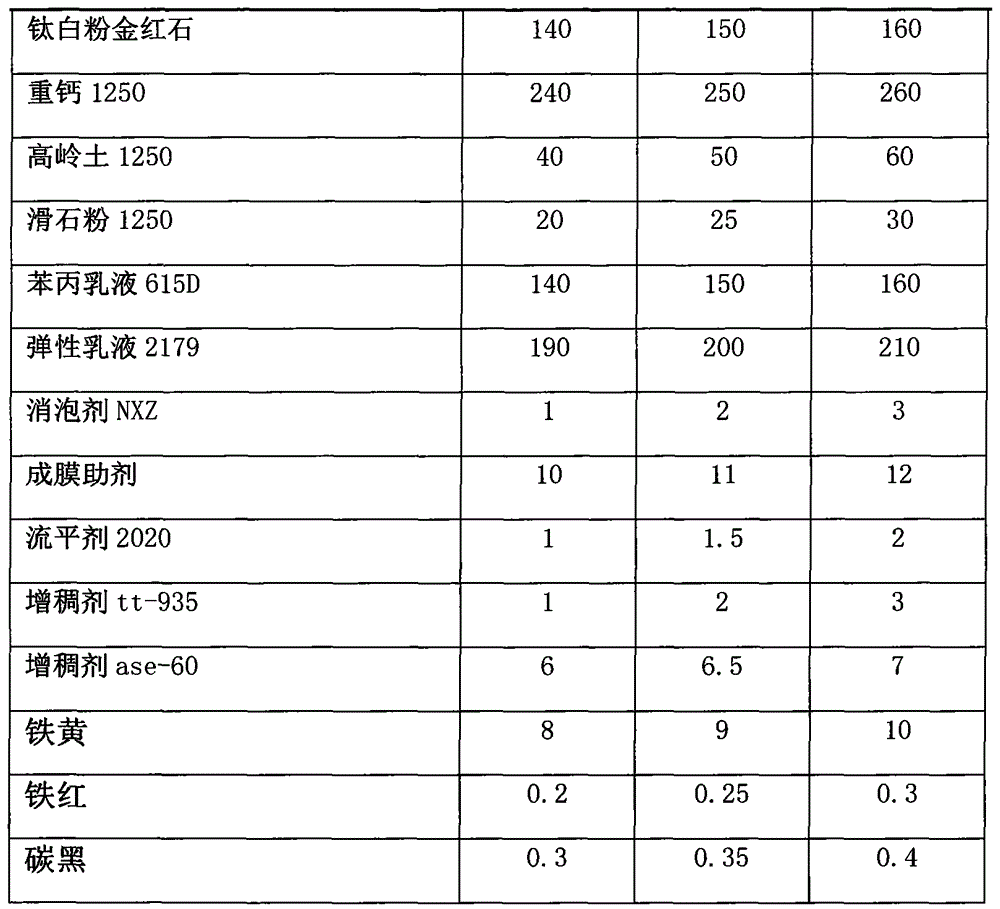

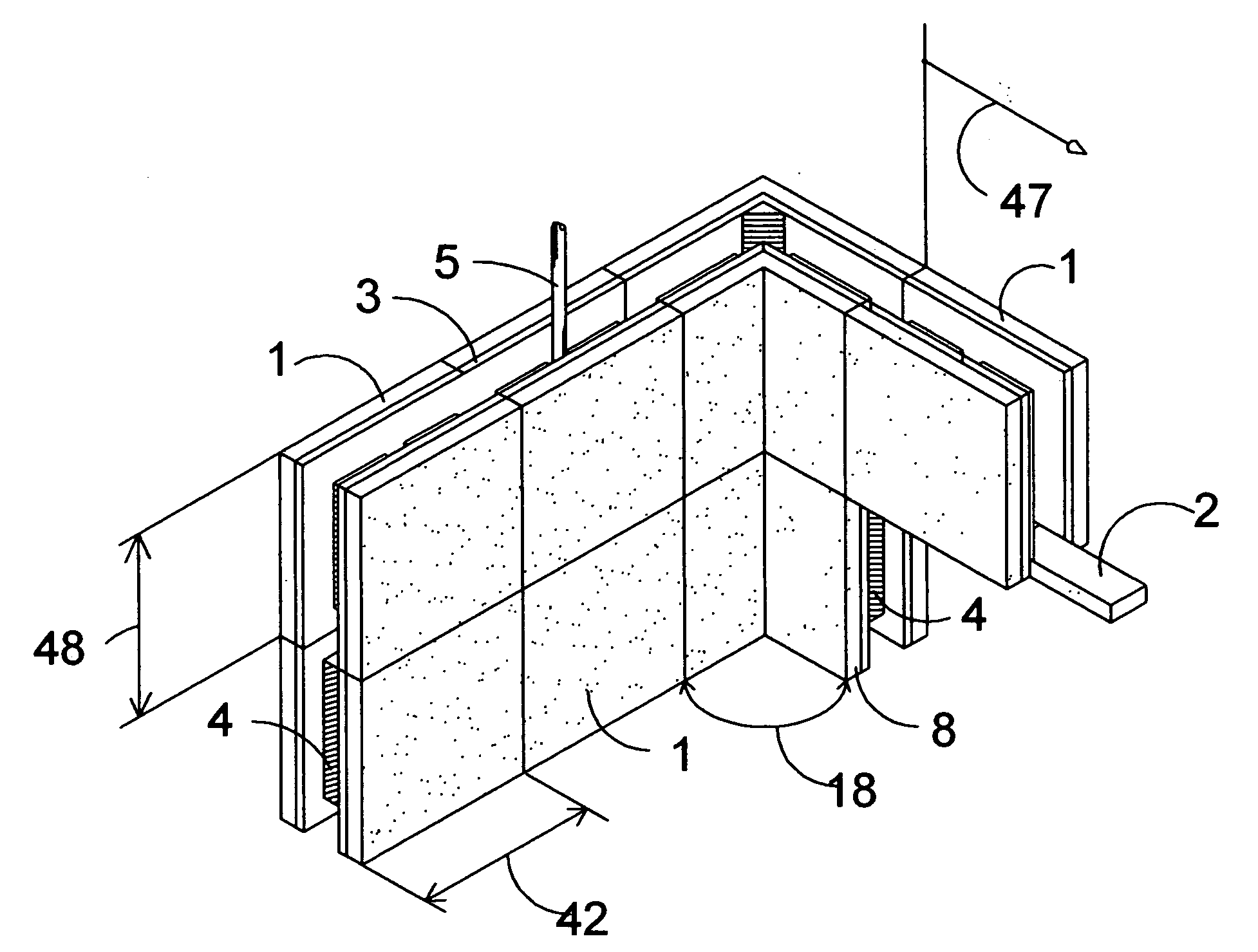

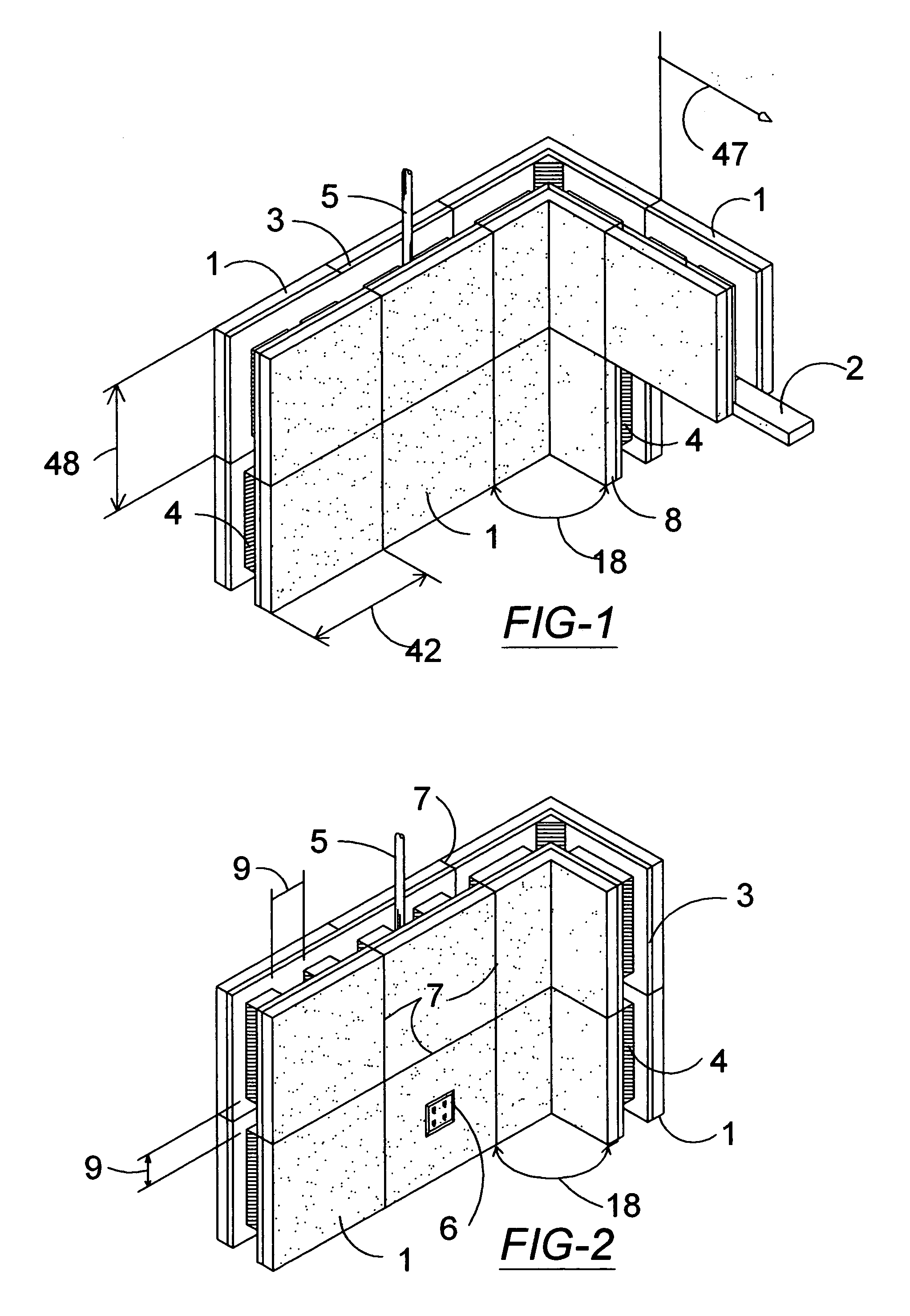

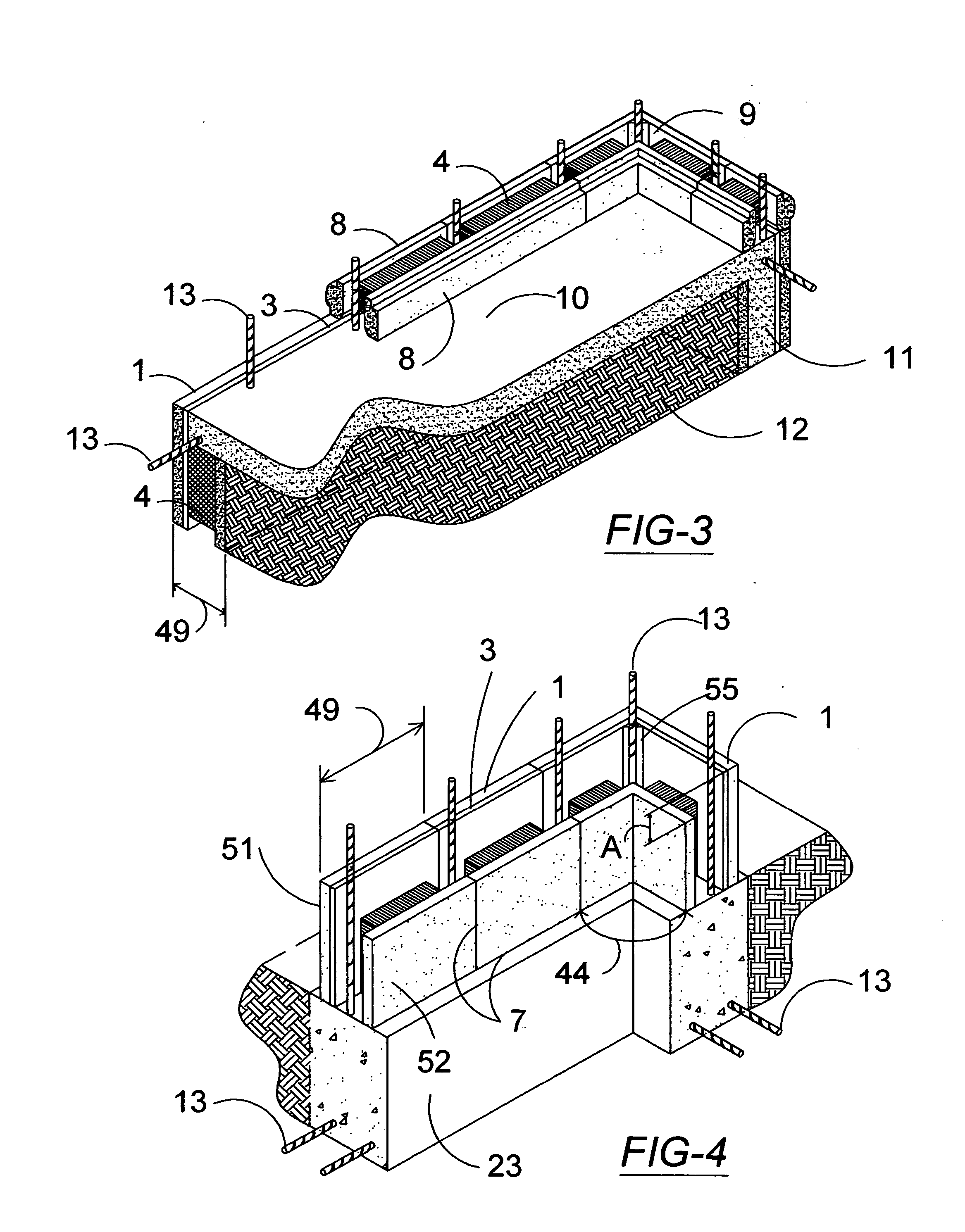

Molded stone architectural product having a foam core

InactiveUS20070157537A1Stable supportWeight controlConstruction materialFloorsBuilding productFoamcore

An architectural cast stone product for use in building construction, which has a unitary shell made of a molded cementitious material that partially surrounds and is affixed to a foam core. The architectural cast stone product has a mounting surface including an exposed surface of the foam core and an exposed surface of the shell. The architectural cast stone product is made by obtaining a front pattern having a desired surface configuration for the architectural cast stone product, obtaining a foam core, affixing the foam core to a backer, affixing the front pattern to the backer that together form a mold, pouring a cementitious material into the mold and into contact with the foam core, at least partially curing the cementitious material to form the architectural cast stone product, and removing the front pattern and backer from the architectural cast stone product.

Owner:E KHASHOGGI INDS +1

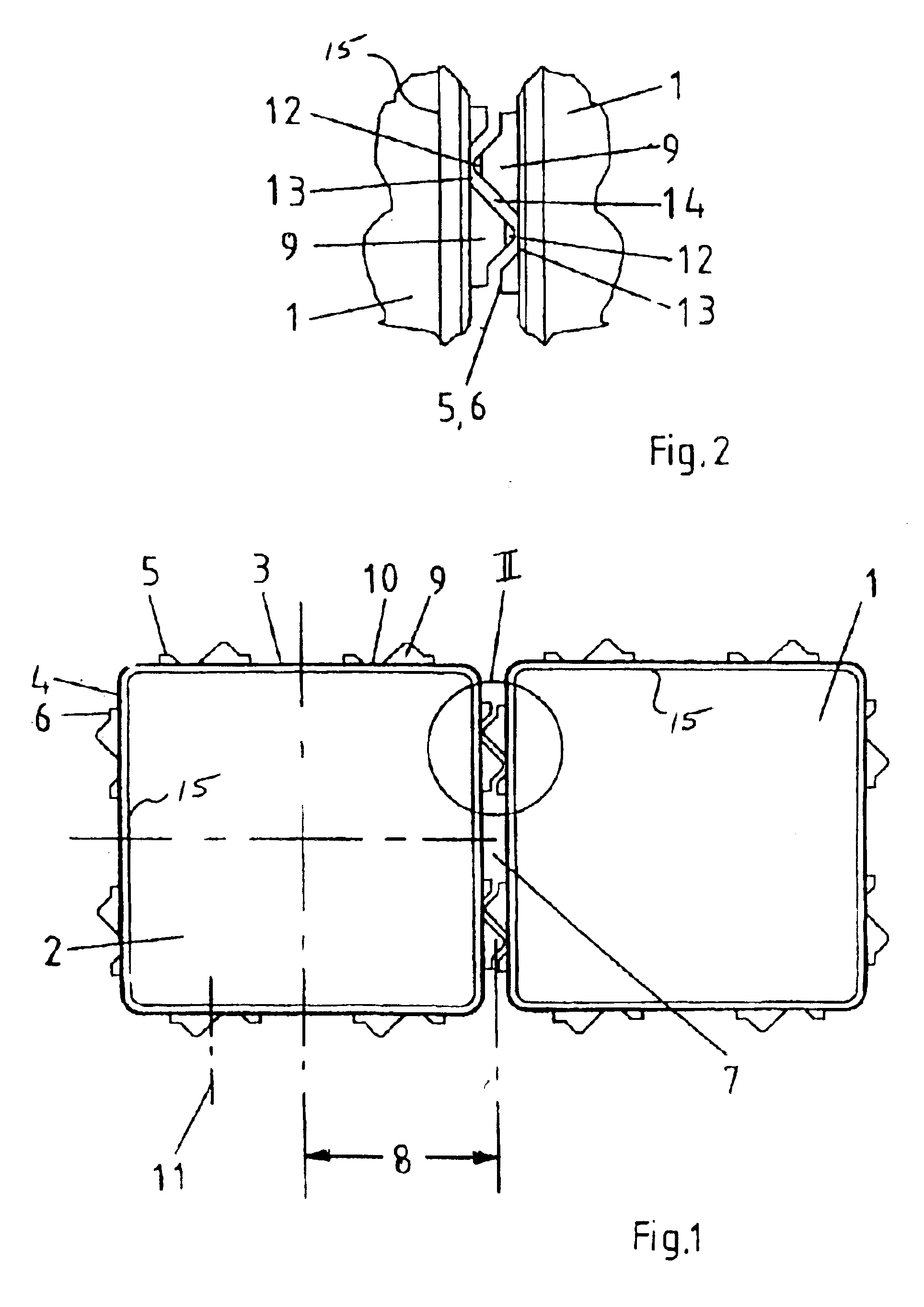

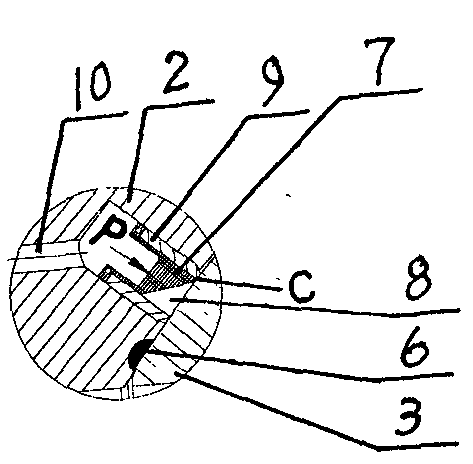

Cast stone for fixing exterior traffic surfaces

There has been disclosed a cast stone (1) for securing traffic areas outdoors, with the stone (1) bearing at least one pair consisting of a protrusion (9) and an adjacent recess (10) substantially matching the form of the protrusion of the adjoining laid stone (1). It is provided that the tip of the protrusion (9) and the bottom (13) of the recess (10) have an integrally moulded layer (12) of material facing away from the associated lateral face (3, 4).

Owner:F VON LANGSDORFF LICENSING

Microcrystalline glass and preparation method thereof

The invention relates to a kind of microcrystalline glass and a preparation method thereof. The preparation raw materials include 10-90wt% of iron, vanadium and titanium-containing tailings, 5-50wt% of fluorite tailings, 1-50wt% of dolomite and 0-20wt% of soda ash. The preparation method of the microcrystalline glass comprises the following steps: uniformly mixing and fusing raw materials in proportion so as to obtain fused glass fluid; and shaping the fused glass fluid, then cooling the shaped glass fluid, and carrying out heat treatment on the obtained product so as to obtain the microcrystalline glass. The microcrystalline glass provided by the invention can be widely used for manufacturing high wear-resisting, acid and alkali erosion resistant and impact resistant products, and the performance of the microcrystalline glass is far higher than that of cast stone, thereby not only solving the pollution problem of tailings and manufacturing high-technical-content and high value-added products.

Owner:承德华富玻璃技术工程有限公司

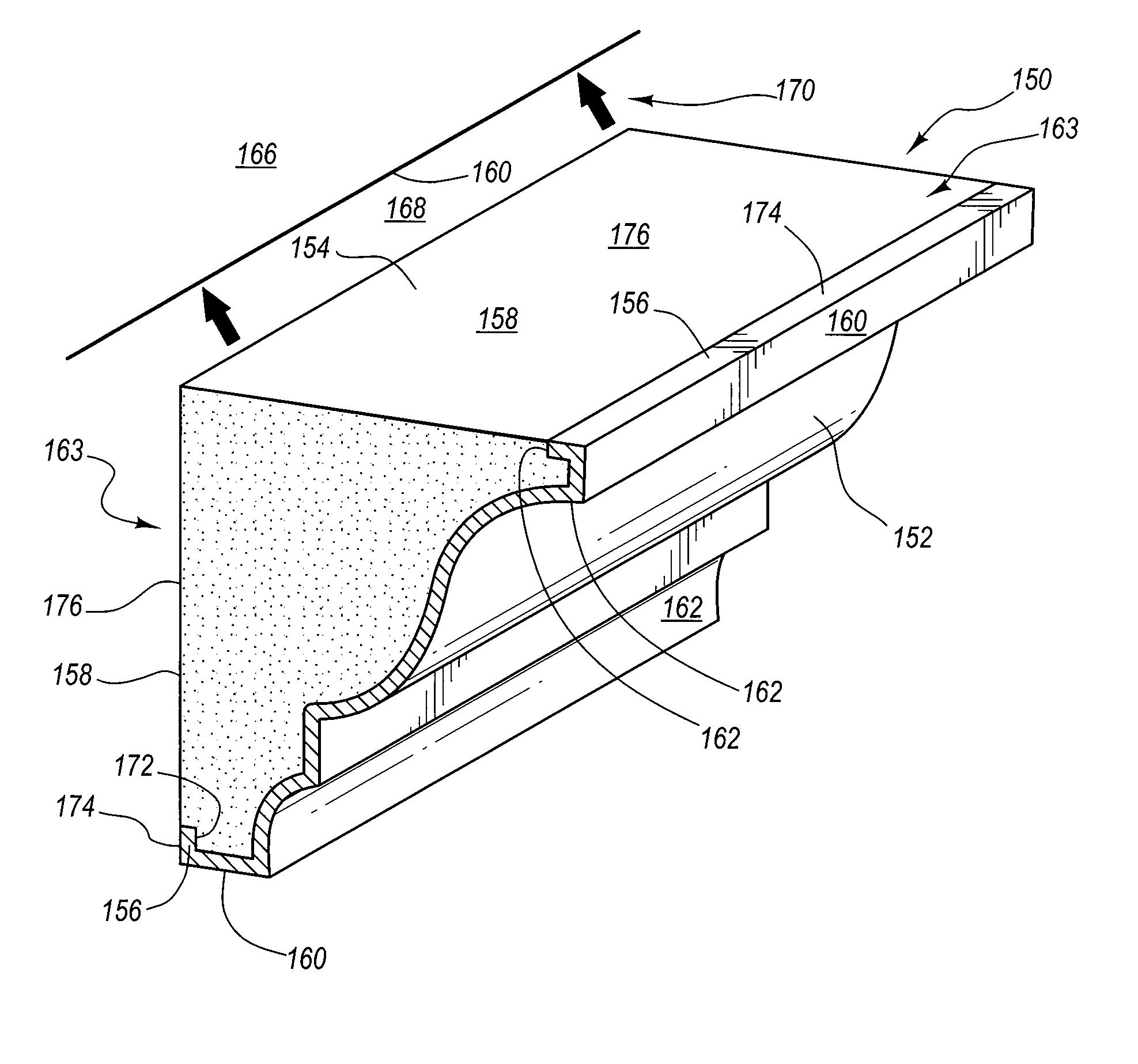

Molded stone architectural product having a foam core

InactiveUS20070175139A1Weight controlStable supportBuilding componentsSurface layering apparatusSurface finishBuilding product

An architectural cast stone product for use in building construction has a unitary shell made of a molded cementitious material that partially surrounds and is affixed to a foam core. The architectural cast stone product has a mounting surface including an exposed surface of the foam core and an exposed surface of the shell. The architectural cast stone product is made by obtaining a front pattern having a desired surface configuration for the architectural cast stone product, obtaining a foam core, affixing the foam core to a backer, affixing the front pattern to the backer that together form a mold, pouring a cementitious material into the mold and into contact with the foam core, at least partially curing the cementitious material to form the architectural cast stone product, and removing the front pattern and backer from the architectural cast stone product. The architectural cast stone product may optionally be surface finished, such as by sanding or polishing, to yield a desired surface finish.

Owner:E KHASHOGGI INDS

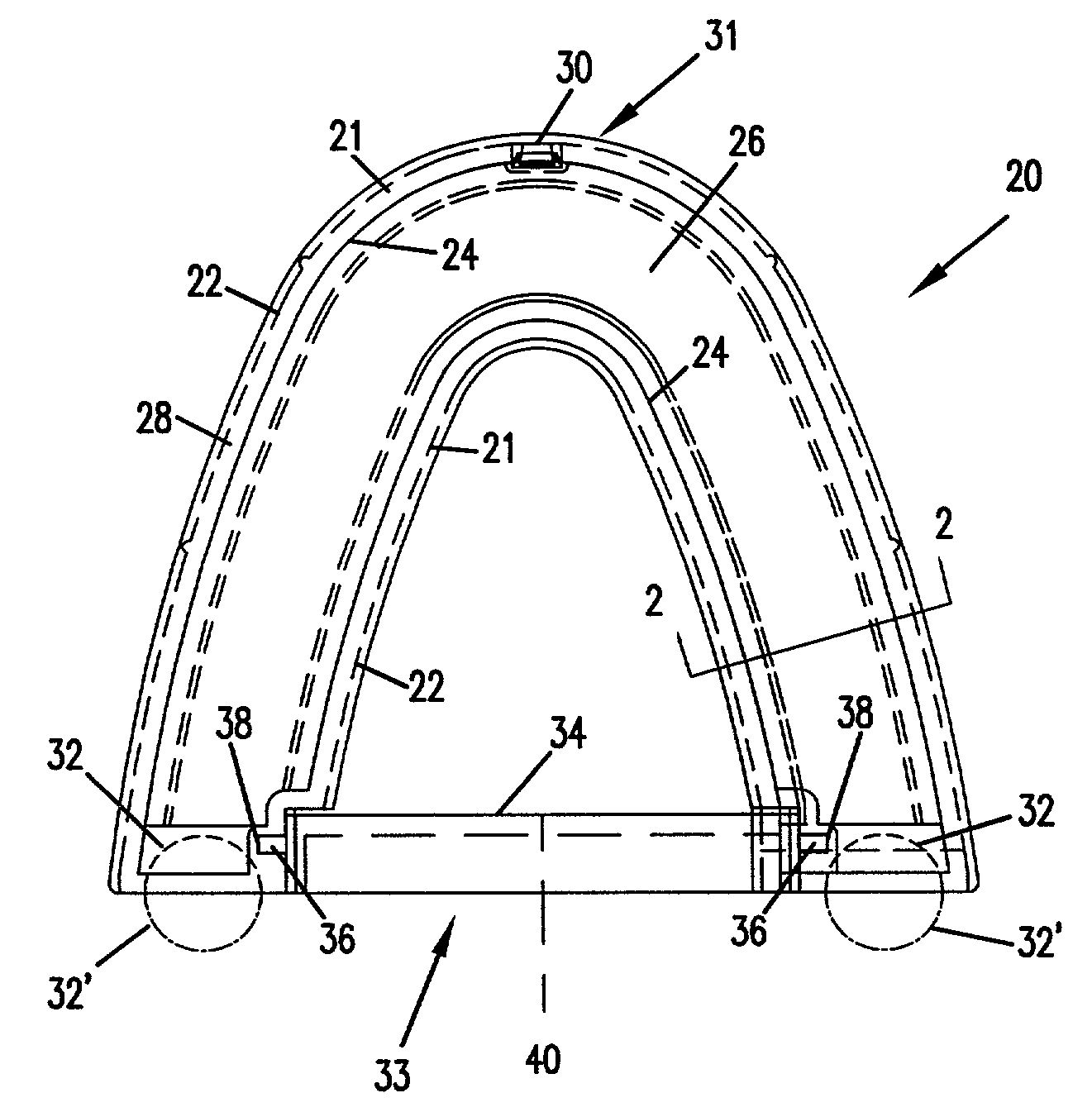

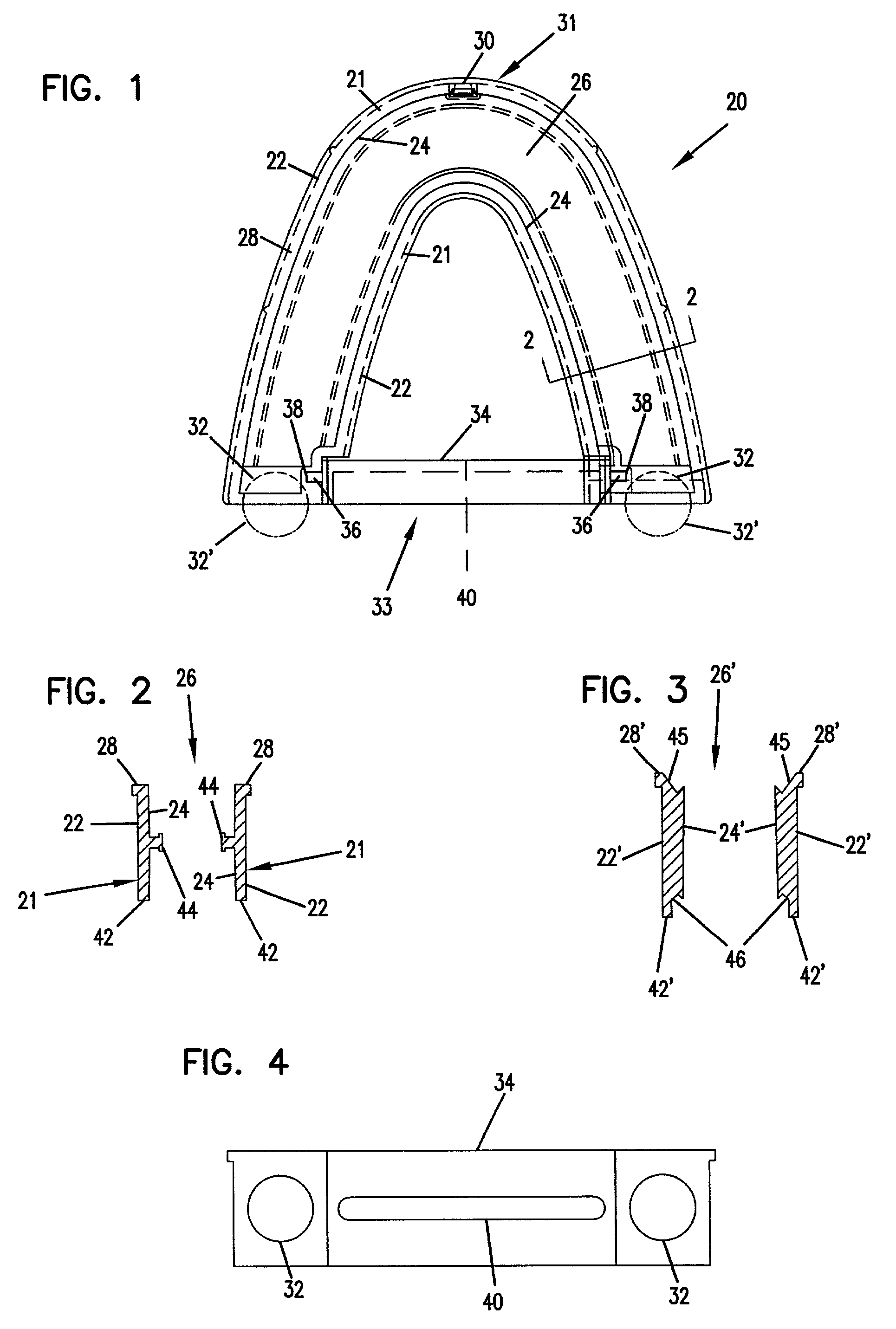

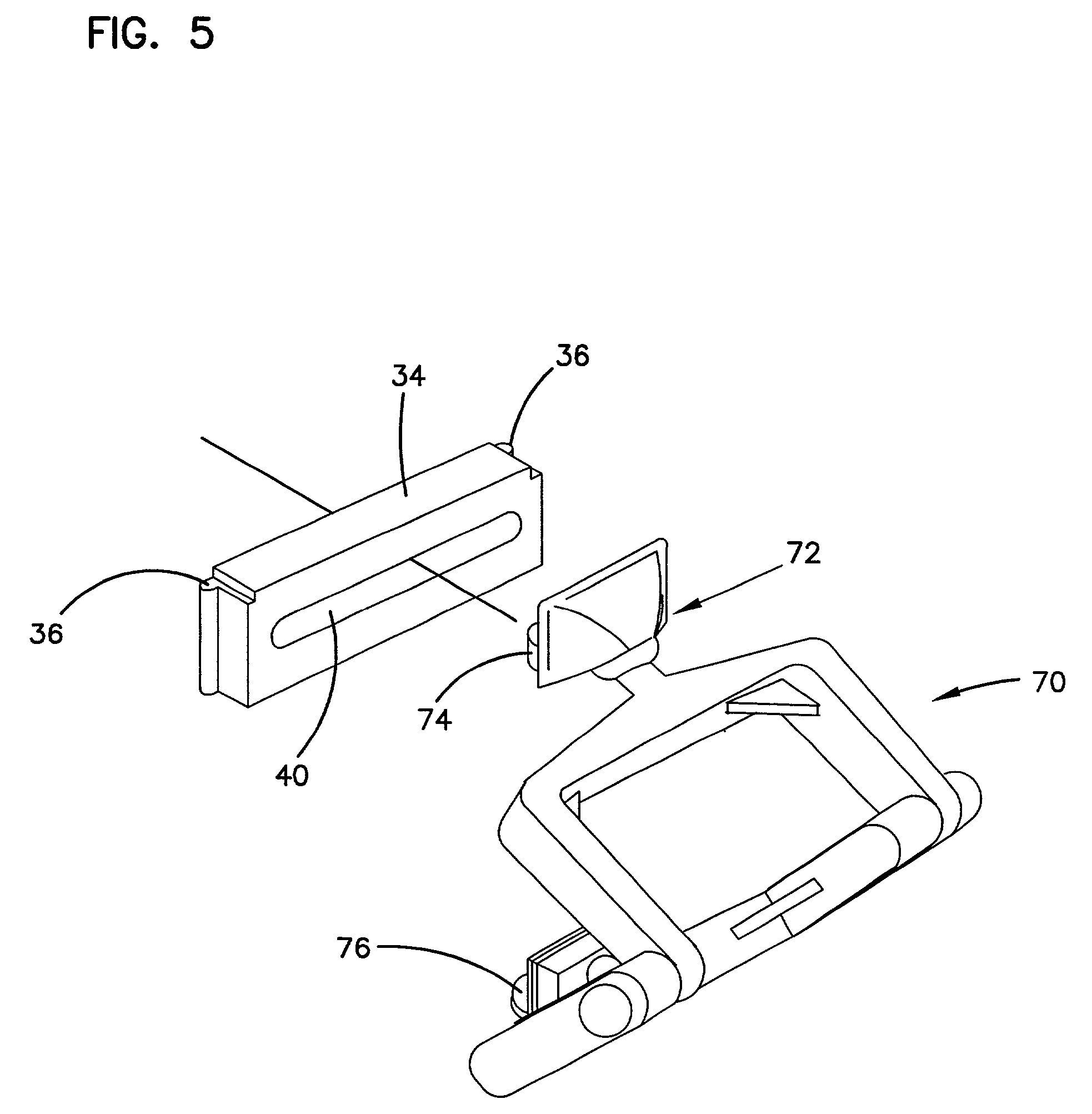

Encased stone dental model base body and method

InactiveUS7044734B2Quality improvementShorten the timeImpression capsDental articulatorsDental ArticulatorsMaterials science

A dental model base having a cast stone core and method for making same. The stone core is cast within an encasement member. The encasement member is adapted for connection to an articulator.

Owner:HUFFMAN RONALD E

Iron-based powder metallurgy friction material

The invention discloses an iron-based powder metallurgic friction material, which consists of the following components by weight percentage: copper powder (Cu) 8 to 13 percent, molybdenum powder (Mo) 3 to 7 percent, nickel powder (Ni) 1 to 3 percent, lead powder (Pb) 2 to 6 percent, graphite (C) 9 to 14 percent, molybdenum disulfide (MoS2) 2 to 5 percent, cast stone 2 to 5 percent, silicon carbide (SiC) 1 to 4 percent, mullite (3Al2O3*2SiO2) 5 to 8 percent, and iron powder in balance. The friction material has the advantages of high friction efficiency, less wear rate and excellent high temperature performance, and is suitable for braking middle and heavy airplanes, engineering vehicles and artillery.

Owner:BEIJING BEI MO GAO KE FRICTION MATERIAL

Lightweight cast stone composition and method

InactiveUS20050183632A1Good colorEasy to cutLayered productsCeramic shaping apparatusPortland cementMaterials science

A moldable cast stone composition for use in making lightweight decorative features for attachment to an interior or exterior surface includes: (a) from about 30 to about 65% of foam beads having an average diameter of between about 1 / 32 and about ⅛ inch; (b) from about 10 to about 25% of a cementitious material; (c) from about 5 to about 20% of a Portland cement; (d) from about 5 to about 15% of an acrylic bonding primer; and (e) the balance being water. A method of making lightweight cast stone decorative features is also included.

Owner:STURRE DARYL JOSEPH

Dosage for producing micro crystal glass or cast stone from iron containing metallurgical waste slag and its method

The present invention relates to material composition and method of producing microcrystalline glass or cast stone with iron containing metallurgical slag, relates to the method of recovering and melting metallurgical slag, and aims at recovering iron containing slag, utilizing its iron in melting cast iron or steel, melting the slag into microcrystalline glass or cast stone, raising resource utilization rate and lowering environmental pollution. The iron containing metallurgical slag used as main material accounts for 45-65 wt%; and the supplementary material accounts 44-55 wt%. The supplementary material includes compounded material, reductant, crystal kernel agent and deairing agent; and the compounded material consists of quartzite, limestone and bauxite, or consists of coal gangue and cinder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Heatproof anticorrosion wear resistant powdery paint, preparation method and application

ActiveCN103073972AImprove anti-corrosion performanceHigh temperature resistanceLiquid surface applicatorsAnti-corrosive paintsPotassium perfluorobutanesulfonatePolyvinyl butyral

The invention relates to a heatproof anticorrosion wear resistant powdery paint, a preparation method and an application. The powdery paint comprises the following raw materials by weight: 80-100 parts of phenol novolac epoxy, 25-35 parts of bisphenol A-epoxy resin matrix, 4.0-5.5 parts of dicyandiamide, 80-120 parts of cast stone powder, 10-40 partsof polypropylene, 5-8 parts of graphite, 5-8 parts of component A, 2-5 parts of aluminum hydroxide, 1-3 parts of magnesium oxide, 5-7 parts of ethyl lactate, 1-3 parts of polyvinyl butyral, 5-8 parts of copper oxide, 1-5 parts of carbon nanotube, 0.1-2 parts of 2,4,5-trichlorobenzene sulfonate, 0.2-1 part of potassium perfluorobutanesulfonate and 0.1-0.4 parts of phenylsulfonyl benzene sulfonic acid potassium. According to the invention, phenol novolac epoxy is taken as a base, the bisphenol A-epoxy resin matrix is added, the carbon nanotube is added in the anticorrosion paint, the heatproof and anticorrosion performances of the paint can be enhanced, and the coating process is simple.

Owner:BEIJING SINOPERM TECH

Formula and process for powder metallurgy

The invention provides a formula and a process for powder metallurgy. The formula comprises Fe-based powder, machinability improving powder and a free lubricant; the Fe-based powder comprises, by weight, 7 to 14% of copper powder (Cu), 2 to 8% of molybdenum powder (Mo), 0.5 to 3.5% of nickel powder (Ni), 1 to 7% of aluminum powder (Pb), 8 to 16% of graphite (C), 1 to 5.5% of molybdenum disulfide (MoS2), 1.5 to 5% of cast stone, 0.5 to 5% of silicon carbide (SiC) and 4 to 9% of mullite (3Al2O3.2SiO2), with the balance being iron powder, the machinability improving powder is composed of calcium phosphate compounds, and the free lubricant contains at least one selected from the group consisting of thermoplastic resin powder, zinc stearate and lithium stearate.

Owner:王萍

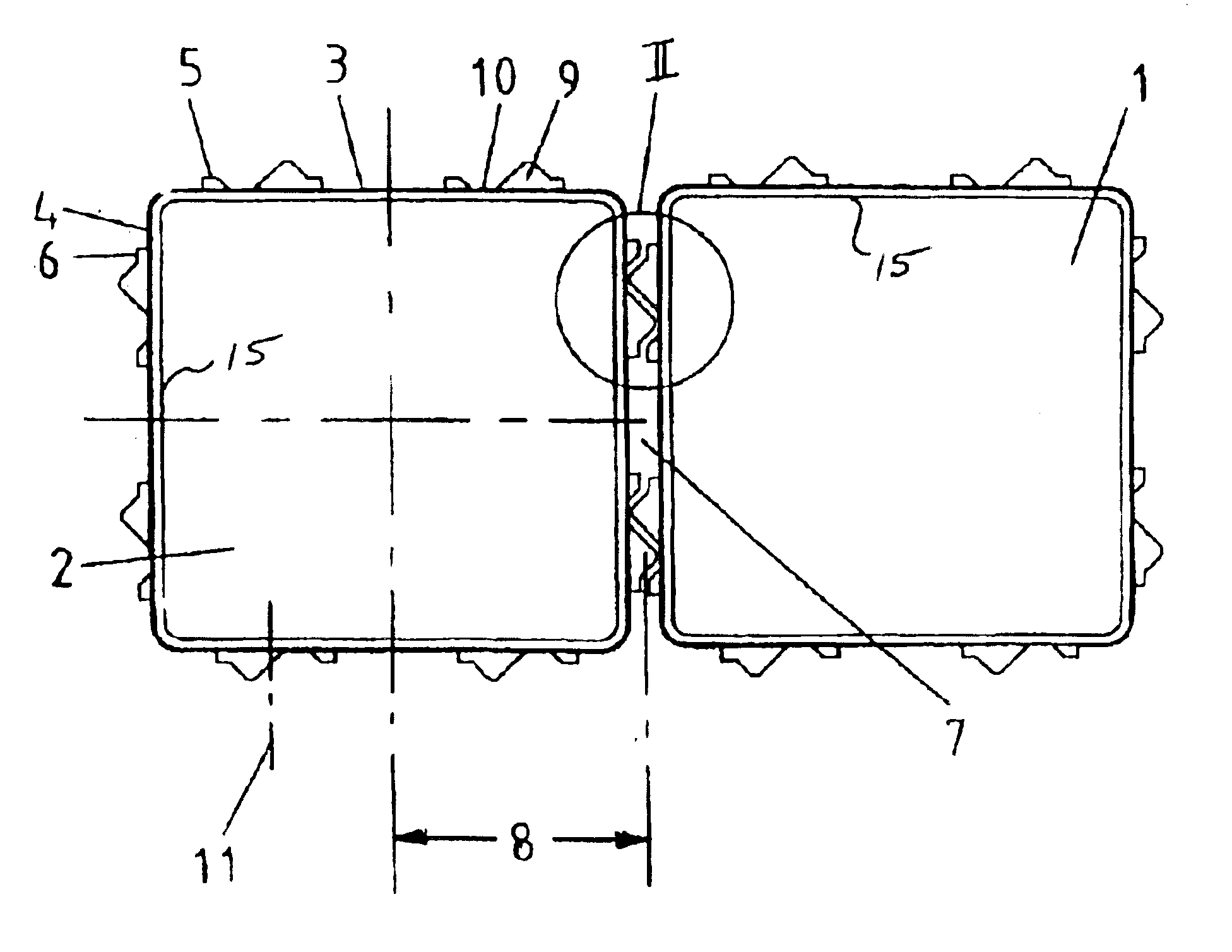

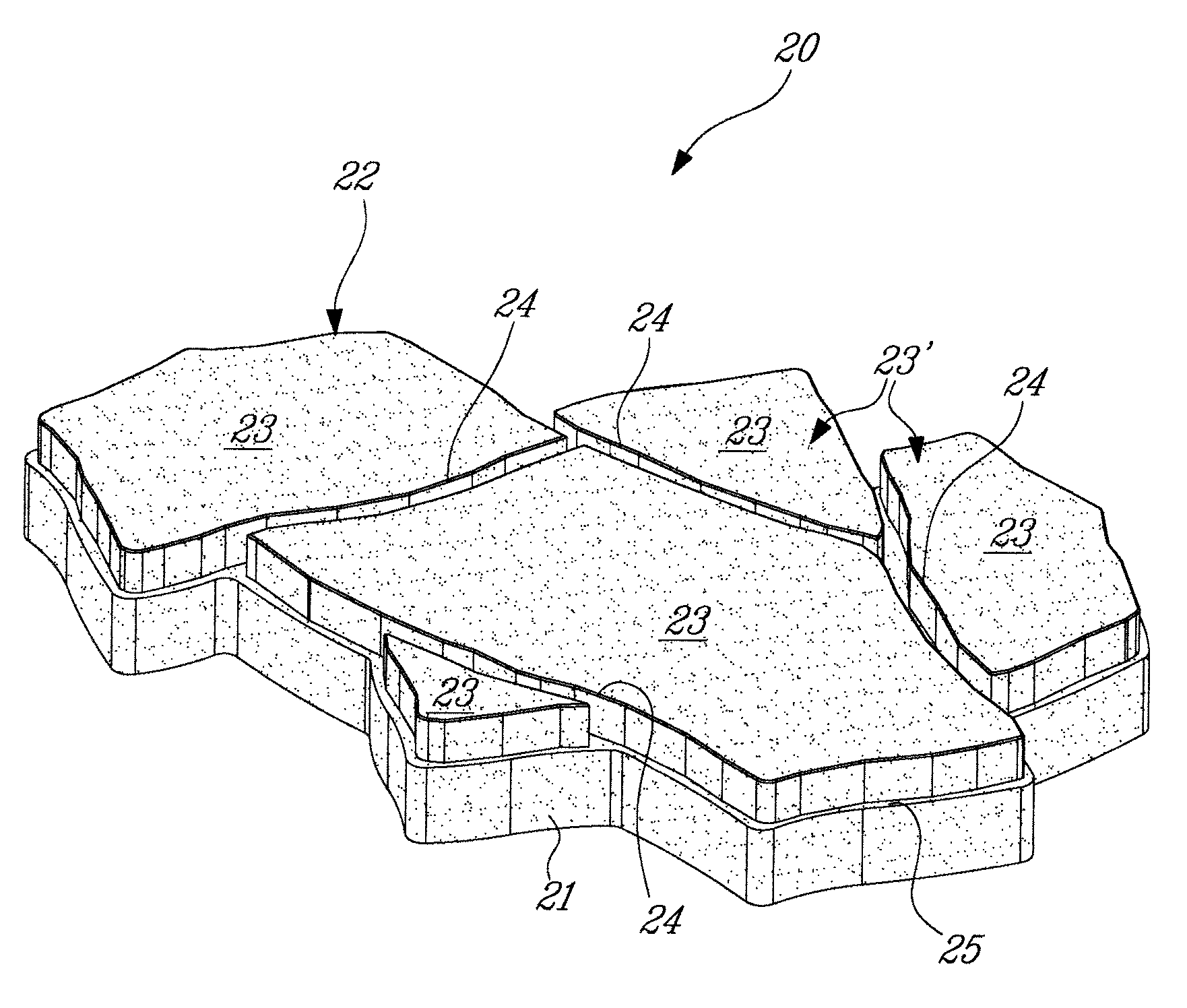

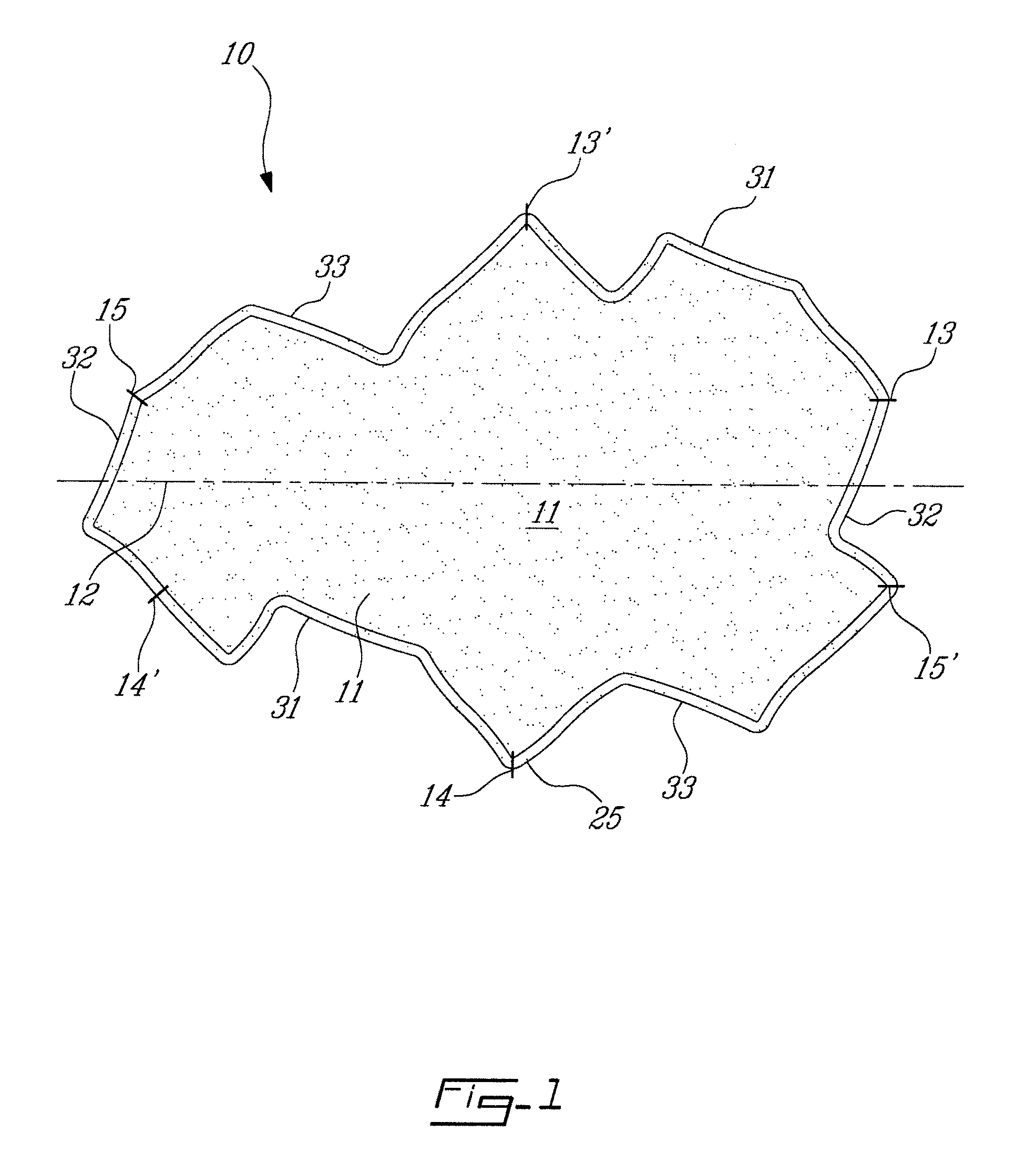

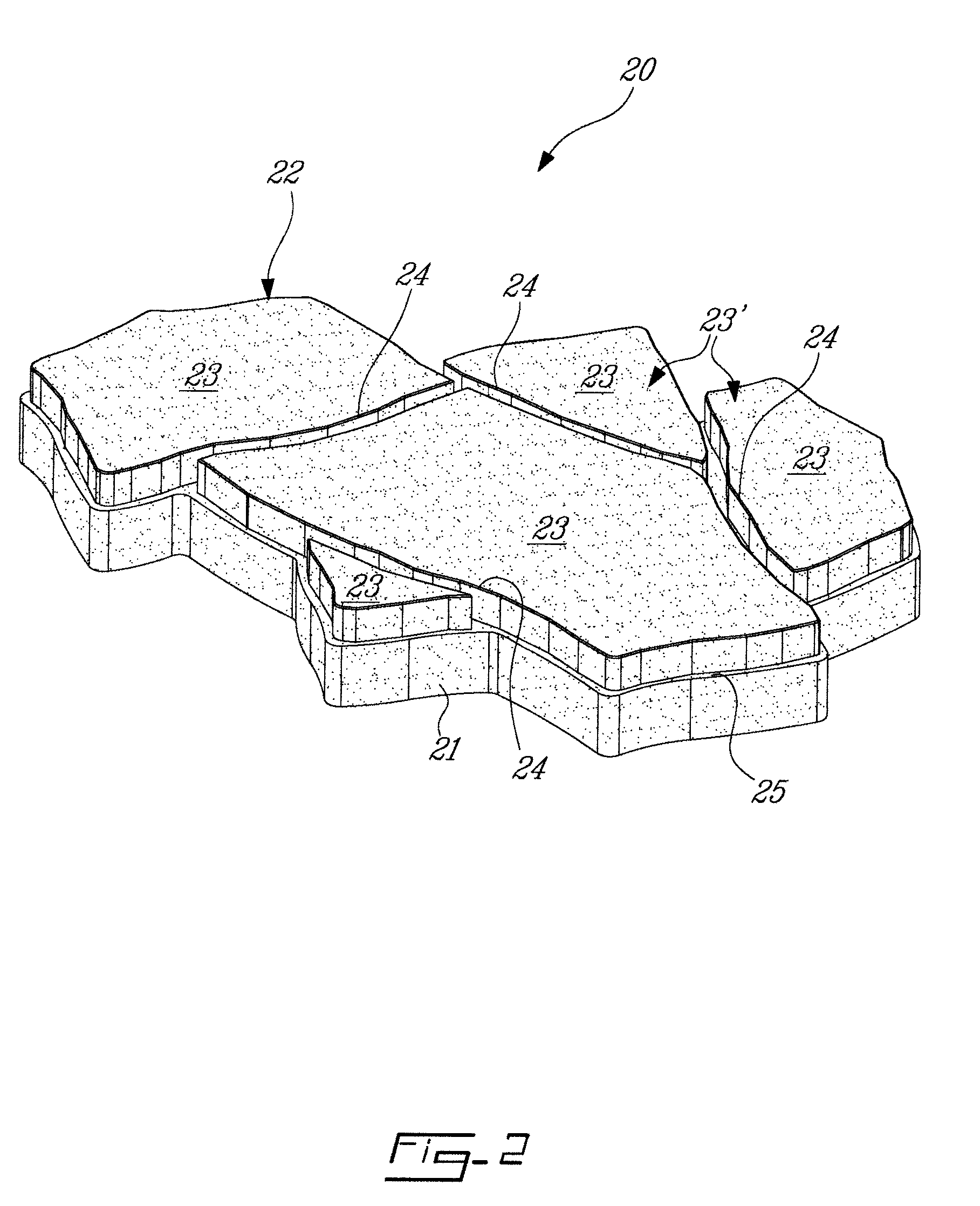

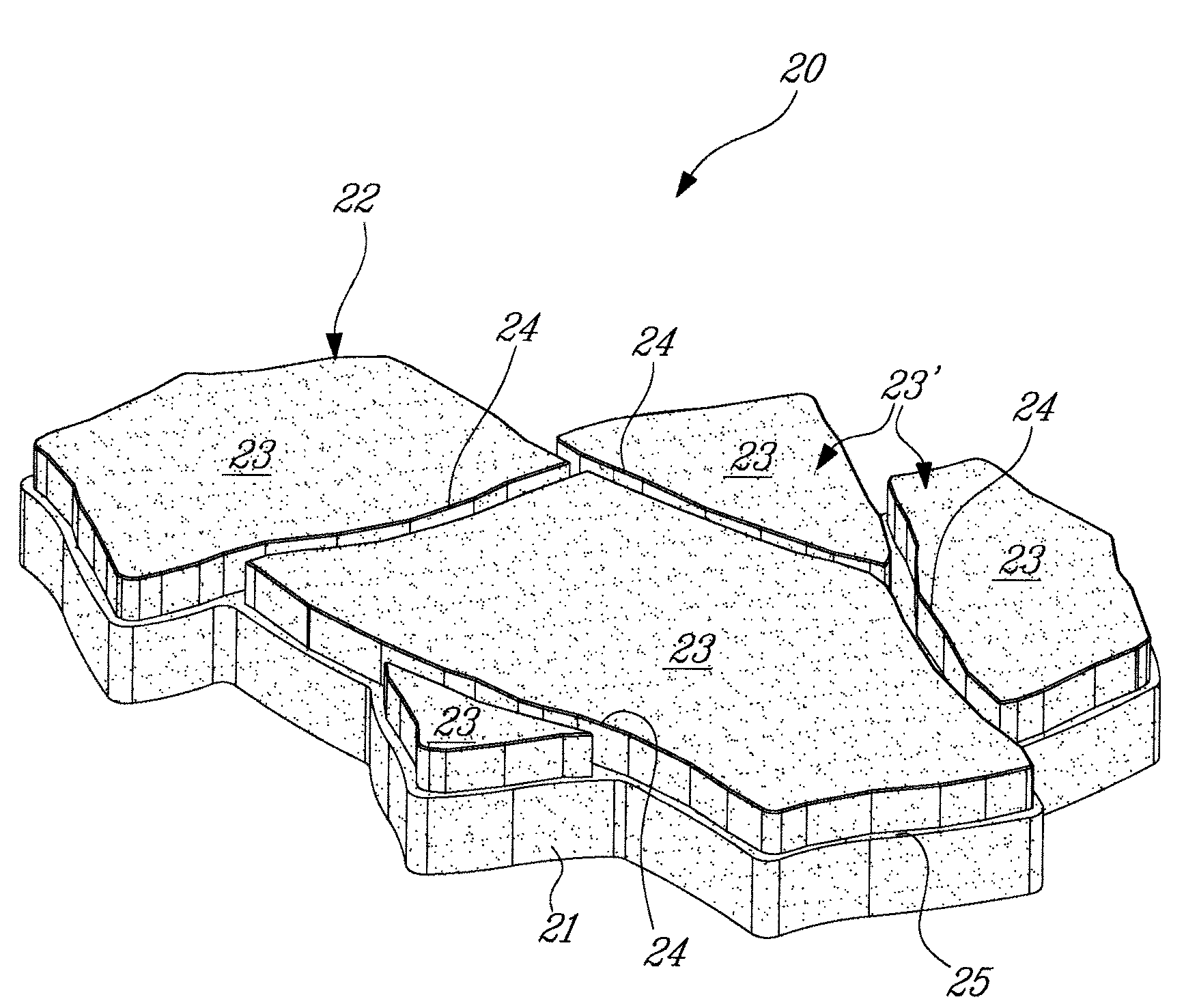

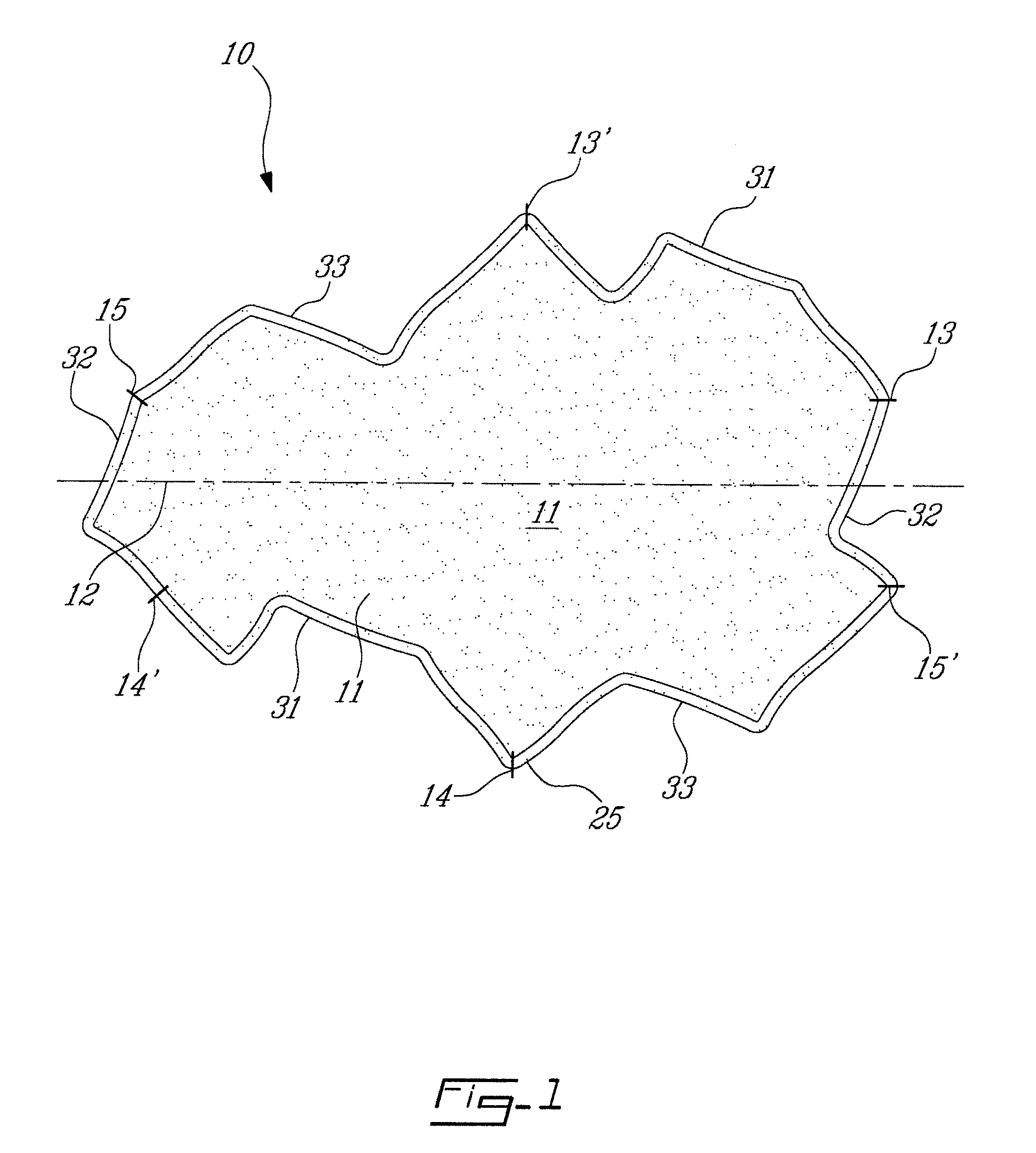

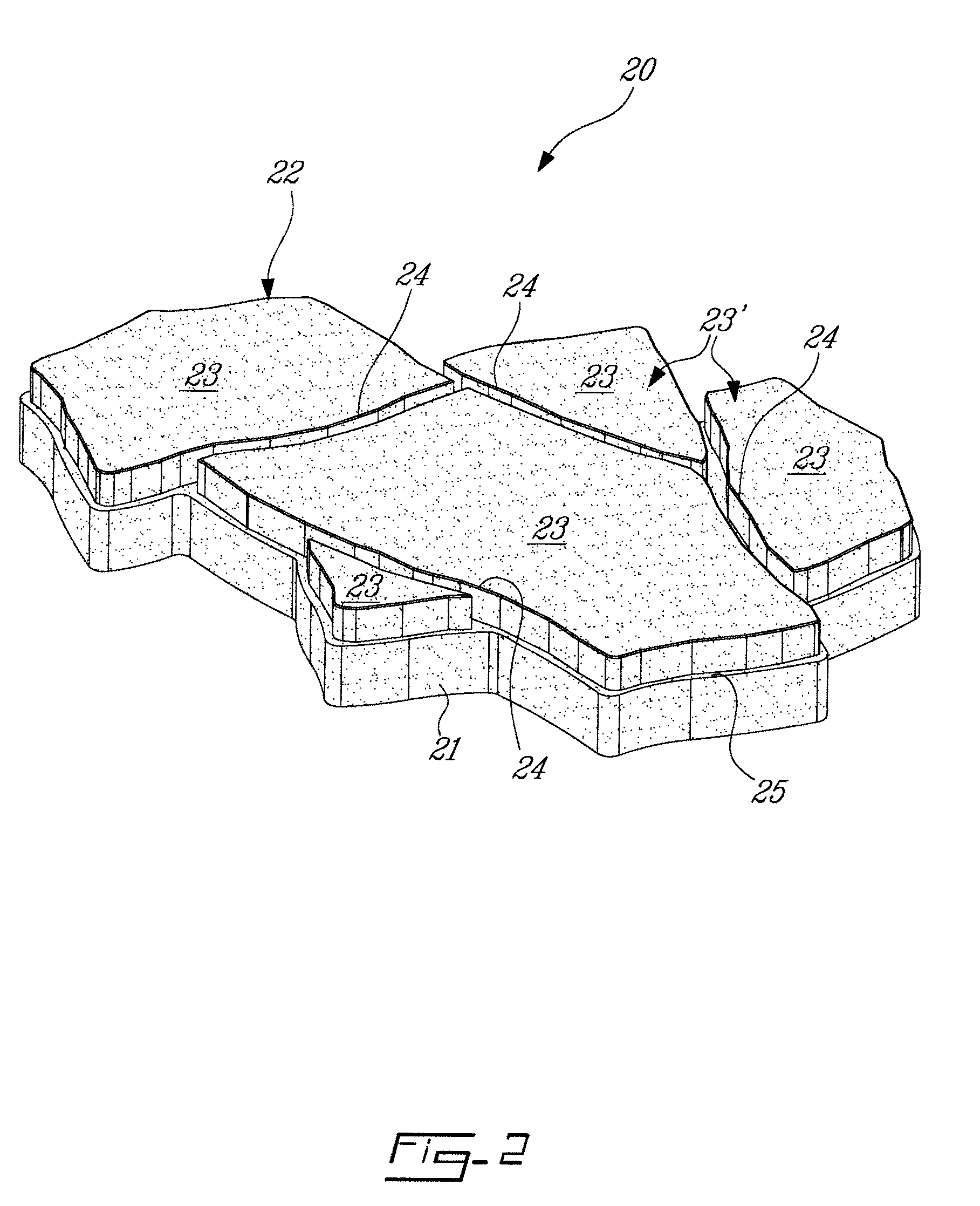

Paving stone and method

A concrete cast stone resembling a flagstone for use with other ones of the concrete cast stones for covering a surface. The concrete cast stone comprising a body having a peripheral contour of non-repetitive jagged shape for interlocking engagement of a plurality of the concrete cast stone. The peripheral contour defining a distinguishable orientation with interlocking side sections and part-interlocking side sections such that said concrete cast stones placed side-by-side interlock by one or a combination of (1) matching the interlocking side sections in a linear arrangement of the concrete cast stones, and (2) matching the part-interlocking side sections in a herringbone arrangement. A method for assembling the concrete cast stone is also provided.

Owner:TECHO BLOC

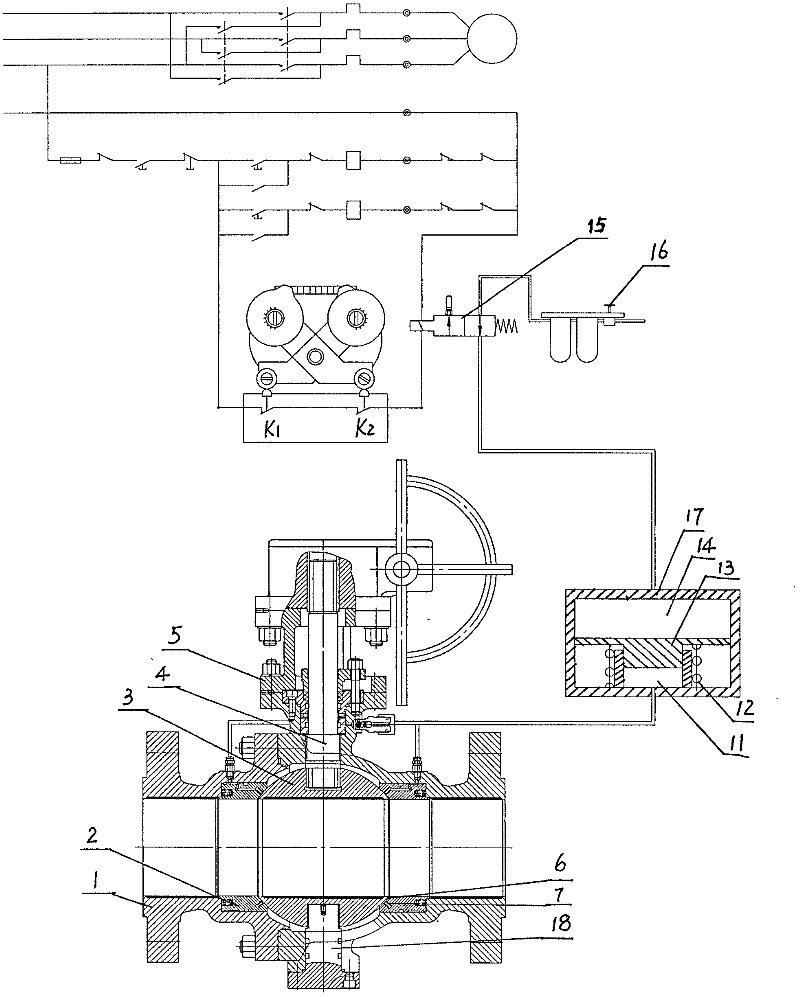

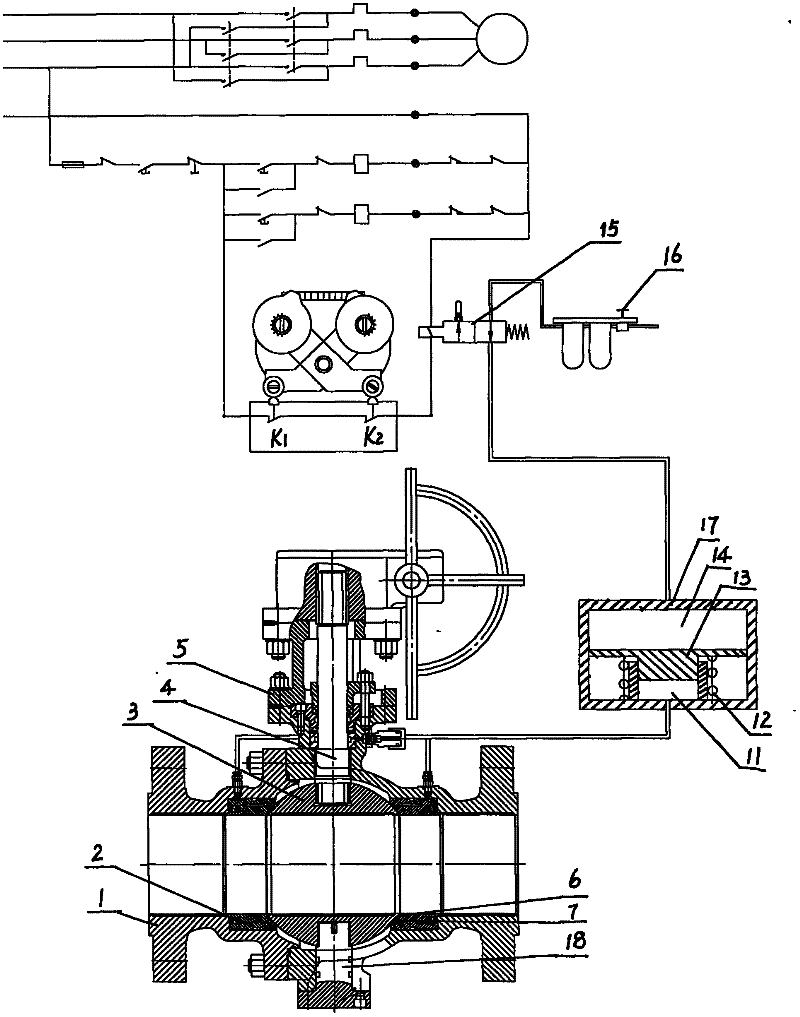

Cast stone ball valve with combined seal

The invention relates to a cast stone ball valve with combined sealing, which includes a valve body, a floating valve seat, a valve cover, a valve stem, and a ball. The sealing surface of the floating valve seat is a combined sealing surface composed of a hard sealing surface and a soft sealing surface. The soft sealing surface is a pressure-filled U-shaped ring, and its two sides are positioned in the annular groove of the floating valve seat with two side rings. The U-shaped pressure chamber communicates with the piston hydraulic chamber, and the piston air pressure chamber passes through The two-position solenoid valve and the regulating valve are connected to the air pressure source. The working coil of the two-position solenoid valve is connected to the power supply through the series branch of the valve closing position switch and the valve opening position switch. The closed and fully open positions are disconnected, and a return spring is installed between the piston and the piston cylinder on the side of the piston hydraulic chamber. The contact area between the medium and the soft sealing surface is small, which has the advantages of stable and reliable sealing performance and long service life. It is suitable for opening and closing devices of slurry and dry ash pipeline systems in power plants, mines, metallurgy, and chemical industries.

Owner:BOTELI VALVE GROUP

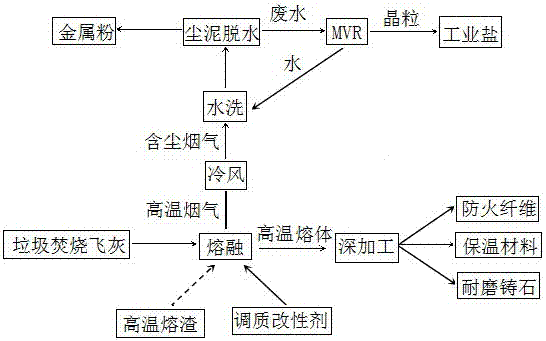

Waste incineration fly ash melting recycling treatment method

ActiveCN107055588AAvoid sources that need to consume large amounts of waterReduce riskZinc oxides/hydroxidesGlass rolling apparatusFiberThermal insulation

The invention discloses a waste incineration fly ash melting recycling treatment method, which comprises the steps of conveying waste incineration fly ash into an electrical heating melting furnace through a sealed pipe, meanwhile, adding a hardening and tempering modifying agent into the electrical heating melting furnace, melting the waste incineration fly ash and the hardening and tempering modifying agent through the electrical heating melting furnace, and obtaining high-temperature flue gas and high-temperature melt; blending the melted high-temperature flue gas with cold air for cooling, and washing the cooled dusty flue gas; carrying out dust mud dewatering on a substance obtained after washing, obtaining metal powder insoluble in water, and treating residual substances soluble in water into industrial salt crystal particles by adopting an MVR process; carrying out deep processing treatment on the high-temperature melt, and obtaining fireproofing fiber, thermal insulation materials or wear-resisting cast stones. According to the waste incineration fly ash melting recycling treatment method provided by the invention, the method has no need to consume a lot of water resources but only utilizes a process with low water consumption, so that the cost for extracting and purifying industrial salt is reduced; in addition, the extracted industrial salt has no risk of mixing with a heavy metal substance, and meets the requirement on producing multiple recycling products.

Owner:KUNSHAN YUSHUN ENVIRONMENTAL PROTECTION TECH CO LTD

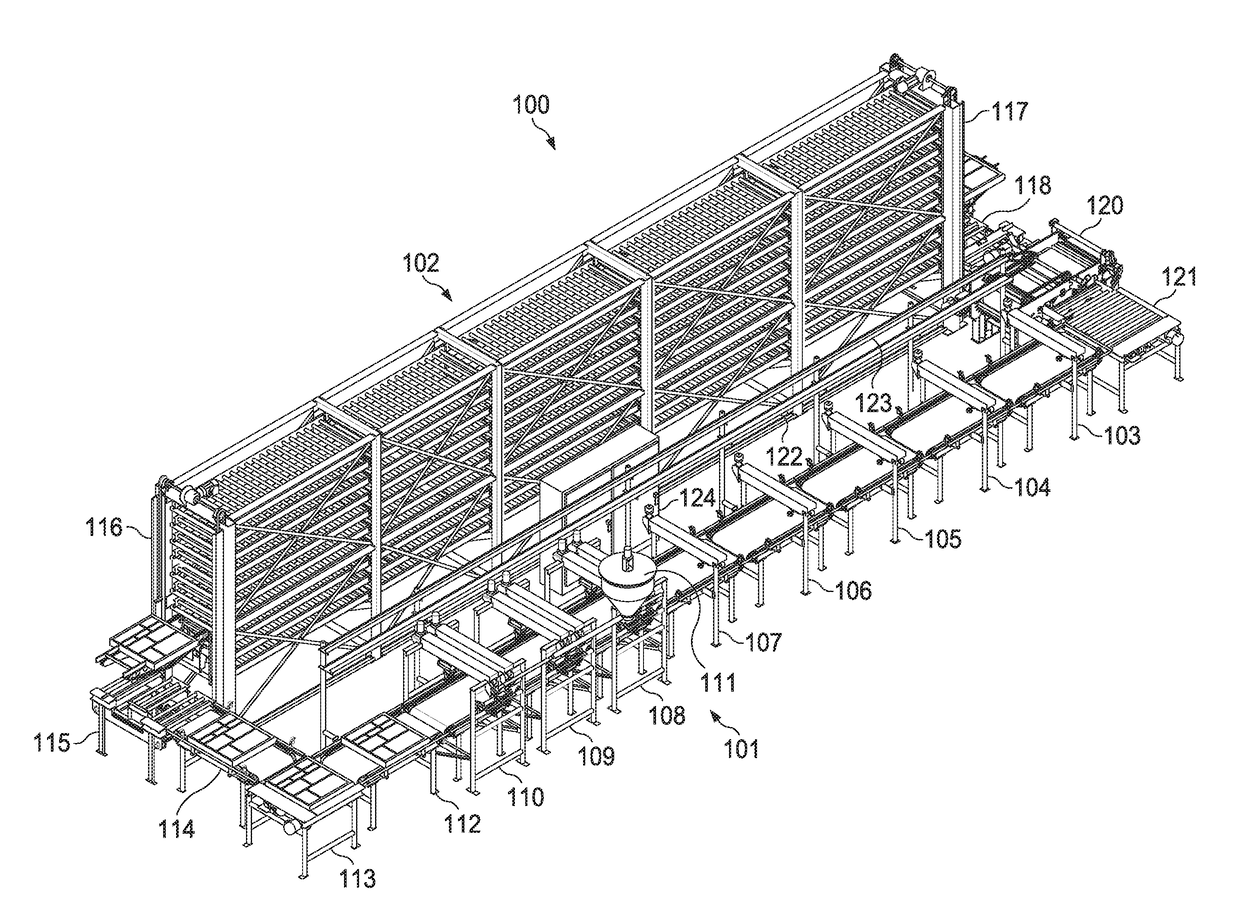

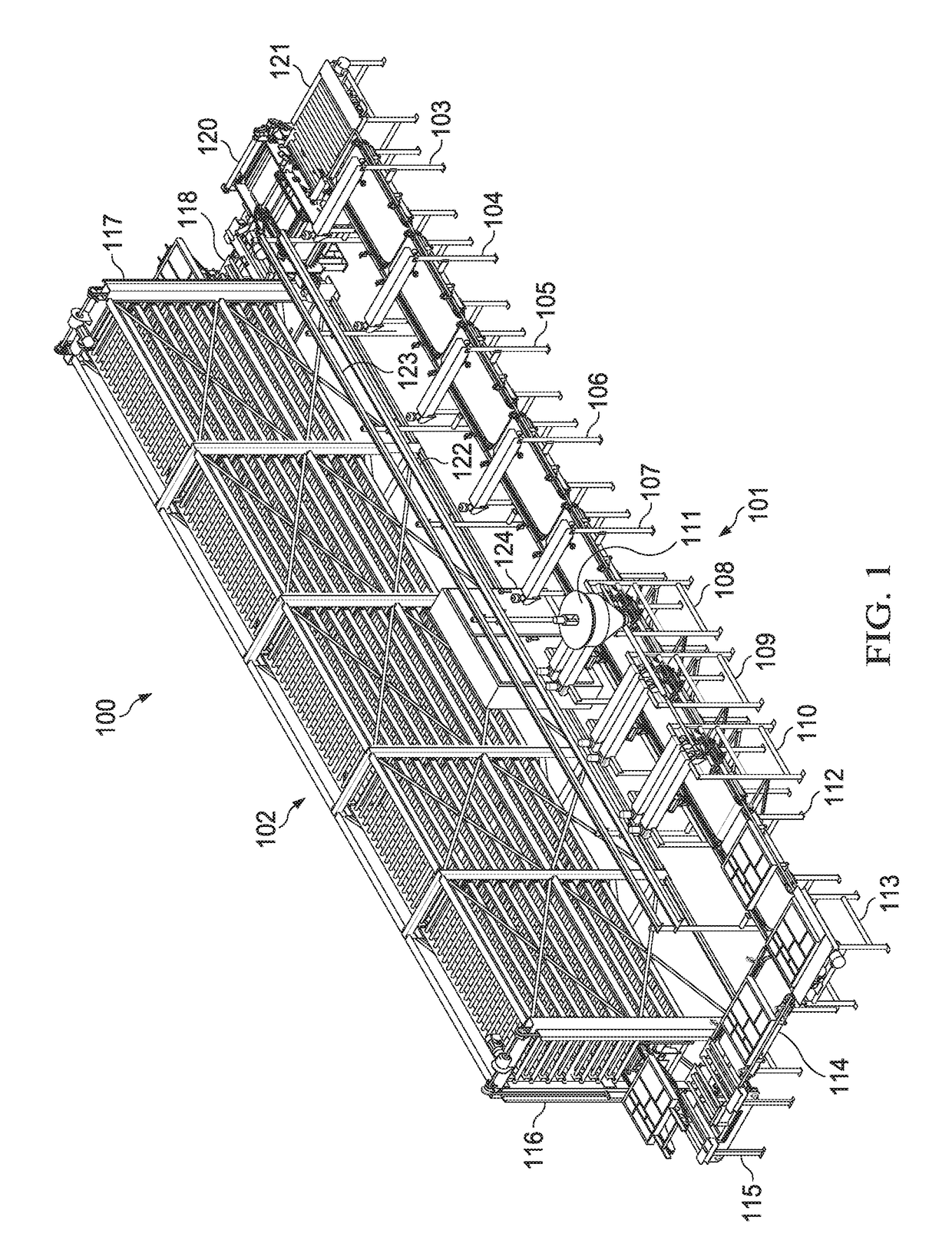

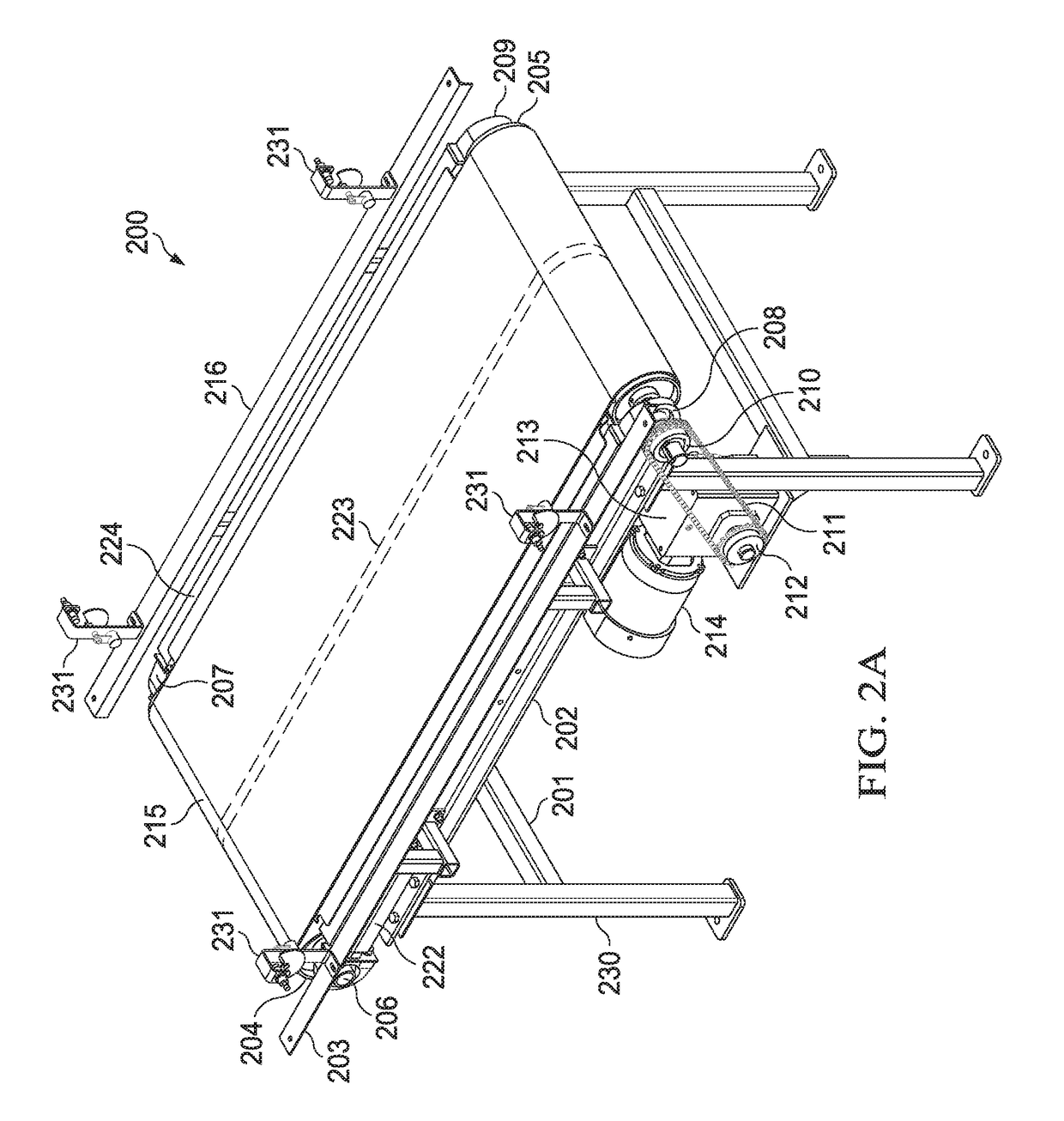

System and method for conveyor rack and elevator

A system and method for manufacturing a set of cast stones includes a set of spray stations, a set of fill stations, a set of vibration tables, a drying rack, and a demolder connected to the drying rack. A controller is connected to each of the set of spray stations, the set of fill stations, the set of vibration tables, the drying rack, and the demolder, each of which has a set of sensors connected to the controller. The set of spray stations include a set of release stations and a set of color stations. A mold is sprayed with a release product, a set of colors, and then filled with a cementitious material. Once vibrated, the cementitious material is dried to form the set of cast stones, which is then automatically released from the mold utilizing the demolder.

Owner:WEICK STEVEN HOWARD

Method for producing microcrystalline cast stone by reducing secondary slag subjected to iron removal by utilizing molten-state nickel slag

The invention discloses a method for performing molten-state tempering on secondary slag subjected to iron removal by directly utilizing molten-state nickel slag and directly producing microcrystalline cast stone. The method comprises the following steps of: reducing the secondary slag subjected to iron removal by the molten-state nickel slag, directly discharging the slag into an electric heating equalizing basin in a hot charging mode, adding a component regulator, a clarifying agent and a nucleating agent, keeping the temperature at the process temperature of not less than 1,450 DEG C, and removing the produced dross and bubbles during the temperature keeping period, so that the materials are fully clarified and are equalized into molten mass; performing casting molding when the viscosity of the melt is 10-100Pa.s; performing microcrystalline treatment on the molded object at the nucleating temperature of 630-800 DEG C, and keeping the temperature of 0.5-3 hours, wherein the temperature rise rate is 5-10 DEG C per minute, the crystallization temperature is 900-1,000 DEG C, maintaining the temperature for 0.5-3 hours, wherein the cooling rate is 5-10 DEG C per minute, or performing furnace cooling to obtain industrial microcrystalline cast stone.

Owner:JINCHUAN GROUP LIMITED +1

Paving stone and method

A concrete cast stone resembling a flagstone for use with other ones of the concrete cast stones for covering a surface. The concrete cast stone comprising a body having a peripheral contour of non-repetitive jagged shape for interlocking engagement of a plurality of the concrete cast stone. The peripheral contour defining a distinguishable orientation with interlocking side sections and part-interlocking side sections such that said concrete cast stones placed side-by-side interlock by one or a combination of (1) matching the interlocking side sections in a linear arrangement of the concrete cast stones, and (2) matching the part-interlocking side sections in a herringbone arrangement. A method for assembling the concrete cast stone is also provided.

Owner:TECHO BLOC

Heat-insulation type concrete for civil construction and preparation method thereof

The invention discloses heat-insulation type concrete for civil construction and belongs to the technical field of concrete. The heat-insulation type concrete is prepared from the following raw materials in parts by weight: 90 to 100 parts of cement, 20 to 25 parts of fly ash, 40 to 50 parts of fine sand, 10 to 20 parts of ceramsite, 5 to 8 parts of cast stone powder, 6 to 9 parts of zeolite powder, 60 to 70 parts of water, 1 to 2 parts of fiber, 0.5 to 1 part of a waterproof agent, 1 to 3 parts of a de-foaming agent, 0.2 to 0.8 part of a suspension agent and 0.1 to 0.2 part of an activating agent. The invention further discloses a preparation method of the heat-insulation type concrete for the civil construction. The heat-insulation type concrete for the civil construction is simple to prepare and has relatively excellent waterproof, fireproof and heat-insulation capabilities.

Owner:山东励仙电力工程有限公司

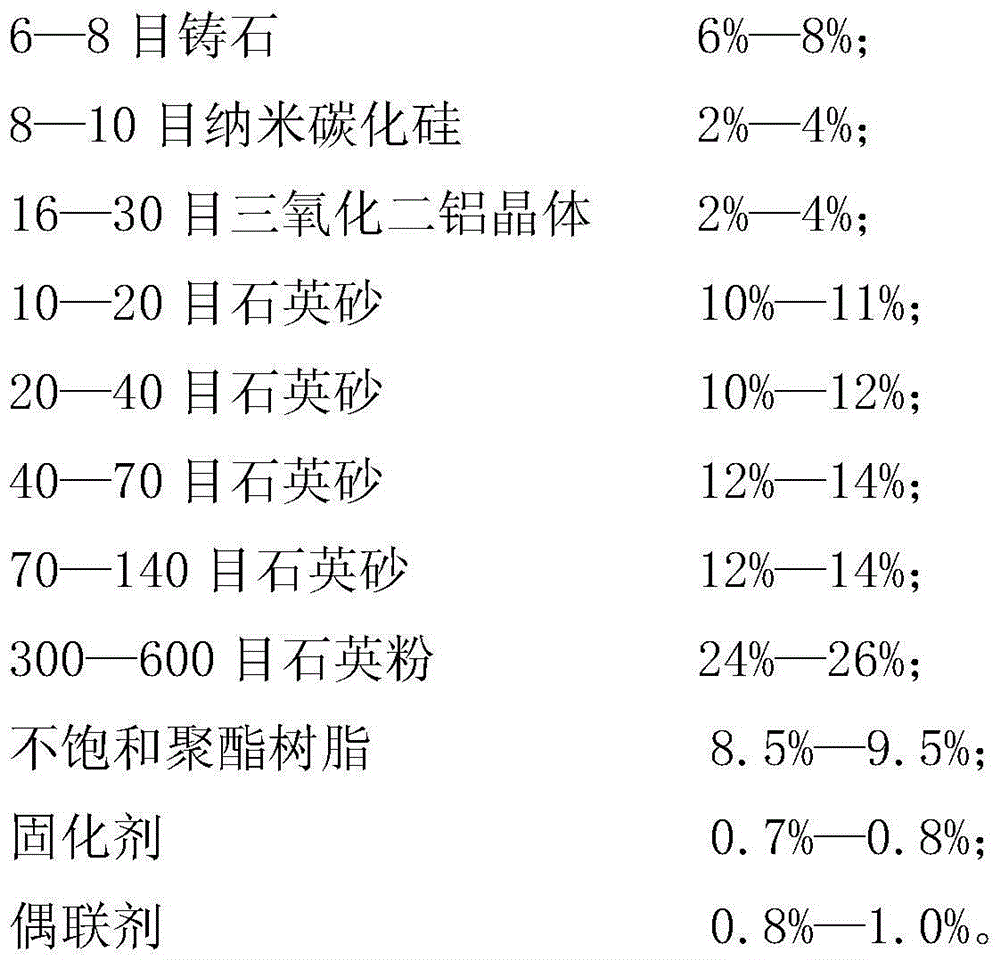

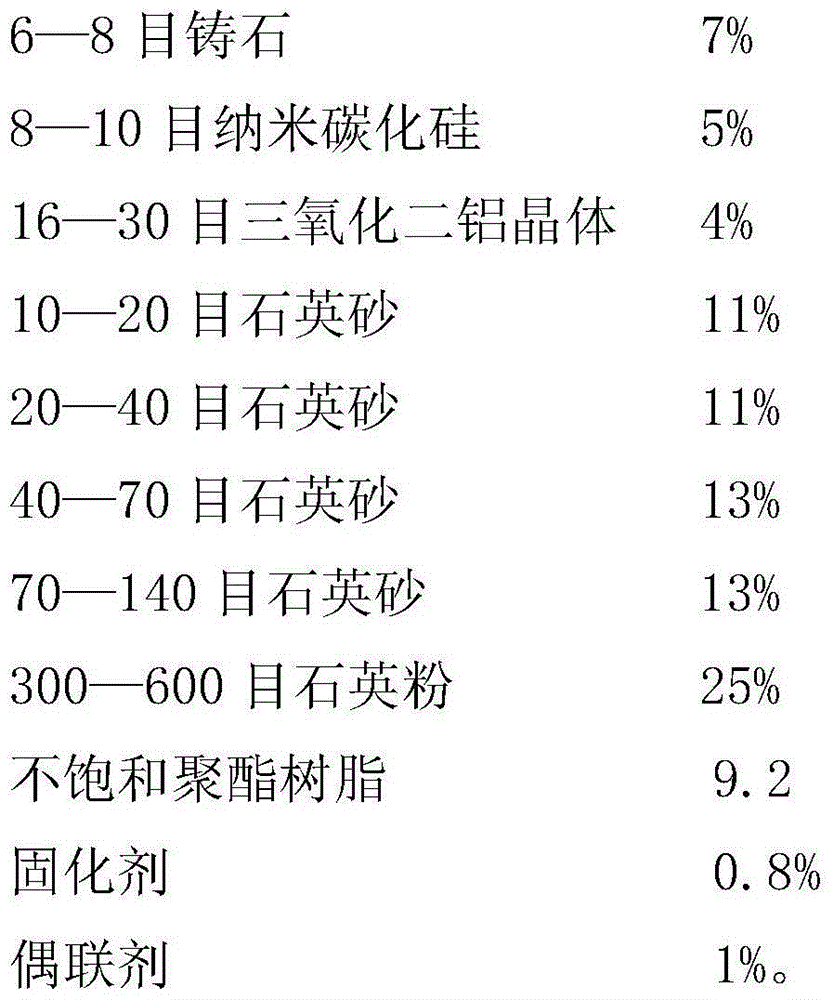

Artificial quartzite plate and preparation method thereof

Owner:新疆雅美石开发进出口有限公司

Anti-corrosive anti-abrasion coating powder for metal pipeline

InactiveCN101503593AQuality improvementLow costAnti-corrosive paintsPowdery paintsPolyvinyl butyralEpoxy

The invention discloses a corrosion protection abrasionproof coating powder used for a metallic pipe. The coating powder takes home-made epoxy powder E12 and metlbond modified epoxy as a main body, takes dicyandiamide and sebacic dihydrazide as curing agents, adopts polyvinyl butyral and ultrahigh molecular weight polyethylene for toughening and levelling the powder, and adopts silicon carbide, cast stone powder and graphite for the support of antifriction self lubrication. The unique abrasionproof corrosion protection powder coating is formed by an energy-saving manufacturing process and hot melt painting. The coating powder emphasizes the abrasionproof characteristic based on the stress laid on the corrosion protection powder performance, is used for strengthening the inner wall surface abrasionproof function of a pumping well oil pipe in an oil field caused by the eccentric wear of a sucker rod, and is extensionally used for metallic parts needing the strengthened abrasionproof function in a corrosive environment.

Owner:TIANJIN XINTE COATING TECH

Multicolor component adhesive system

InactiveUS20080300321A1Wide color spectrumBiocideNon-macromolecular adhesive additivesFilling materialsAdhesive

The present invention relates to a multicolor component adhesive system based on at least two miscible polymerizable components and a curative component, said system being suitable for providing an adhesive having any desired color. The present invention further relates to the use of the adhesive produced on the basis of the multicolor component adhesive system as an adhesive compound, jointing compound, repair material and / or filling material, preferably for plastics, more particularly cast stone, mineral substrates, more particularly natural stone, ceramic, earthenware, porcelain, metals and / or wood, and also to a method of producing the adhesive.

Owner:AKEMI CHEM TECHN SPEZIALFAB

Foam concrete for civil engineering

InactiveCN109776054AStrong mechanical resistanceHigh strengthCeramicwareFoam concreteTitanium fluoride

The invention discloses foam concrete for civil engineering. The foam concrete is prepared from, 50-70 parts of ordinary Portland cement, 20-30 parts of aggregate, 0.8-1.6 parts of a foaming agent, 0.5-1 part of a fiber expanding agent, 1.3-5 parts of high-activity titanium fluoride, 8-15 parts of fly ash, 3-8 parts of graphene oxide, 3-7.2 parts of an acrylate emulsion, 0.1-0.32 part of diethylenetriamine sodium penta-carboxylic ester, 1.5-2.5 parts of calcium carbonate whiskers, 1.5-2.3 parts of cast stone powder, 4-5.8 parts of an ethylene-acrylic emulsion, 0.01-0.03 part of hydroxypropyl methyl cellulose, 0.3-1.3 parts of sulphoaluminate clinker, 0.3-0.5 part of triethanolamine, 0.5-0.7 part of polyether imine, 0.7-1.3 parts of a water reducing agent and 20-30 parts of water. The obtained foam concrete has excellent compression resistance and crack resistance.

Owner:EASTERN GANSU UNIVERSITY

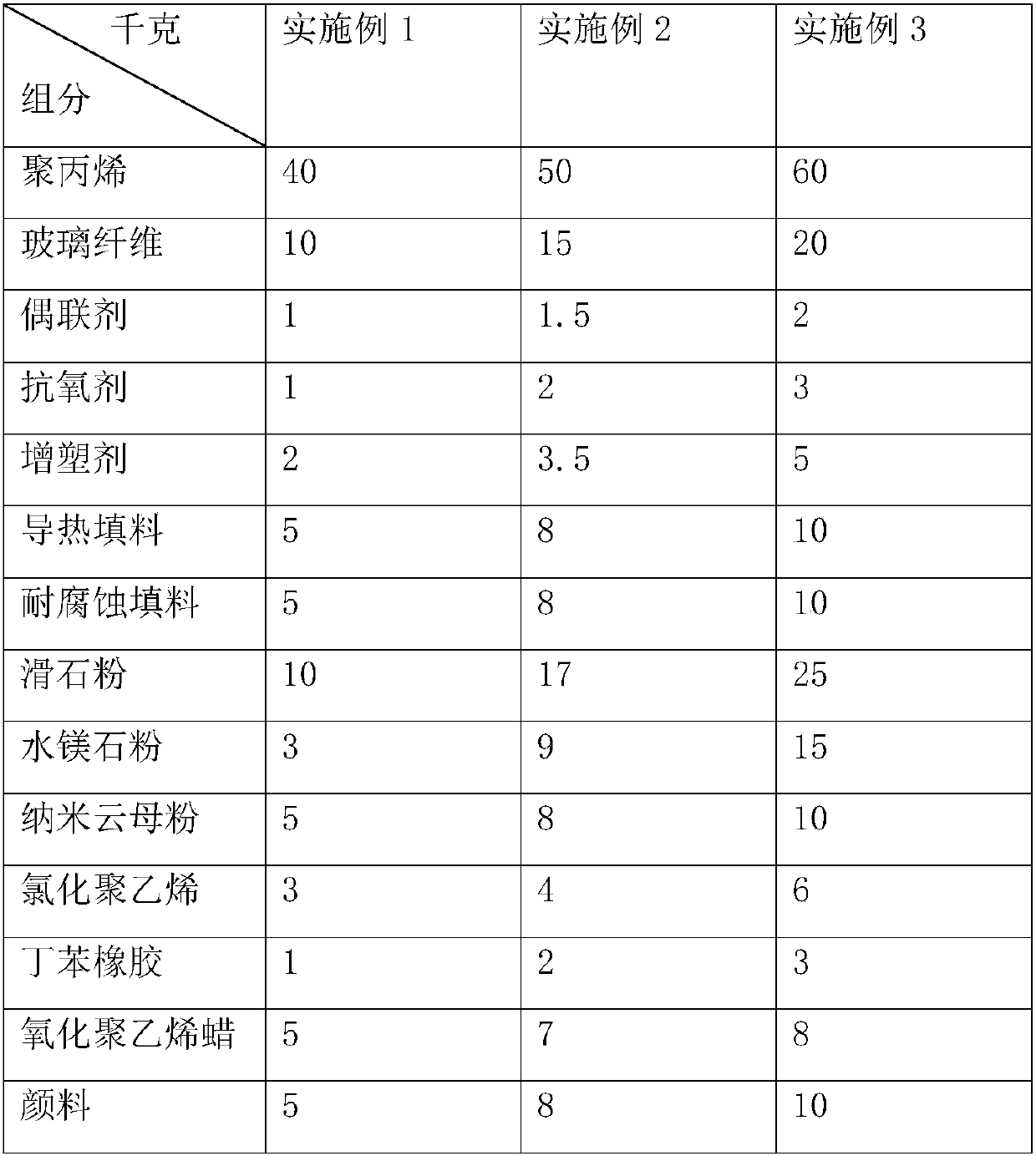

High-heat-dissipation corrosion-resistant flame-retardant MPP corrugated pipe and preparation method thereof

The invention discloses a high-heat-dissipation corrosion-resistant flame-retardant MPP corrugated pipe and a preparation method thereof. The high-heat-dissipation corrosion-resistant flame-retardantMPP corrugated pipe comprises polypropylene, glass fibers, a coupling agent, an antioxidant, a plasticizer, heat-conducting filler, corrosion-resistant filler, talcum powder, brucite powder, nano micapowder, chlorinated polyethylene, styrene-butadiene rubber, oxidized polyethylene wax and a pigment. The heat-conducting filler comprises zirconium oxide powder, silicon carbide, iron powder, steel wool, graphene, an epoxy resin adhesive, a polyvinyl alcohol solution and polyphenyl ether; the corrosion-resistant filler comprises cast stone powder, ceramic micro-powder, calcium bicarbonate, vinylresin emulsion and silicon micropowder. The high-heat-dissipation corrosion-resistant flame-retardant MPP corrugated pipe has the advantages of good heat dissipation properties, good flame retardancyand excellent corrosion resistance.

Owner:深圳市深捷通管业发展有限公司

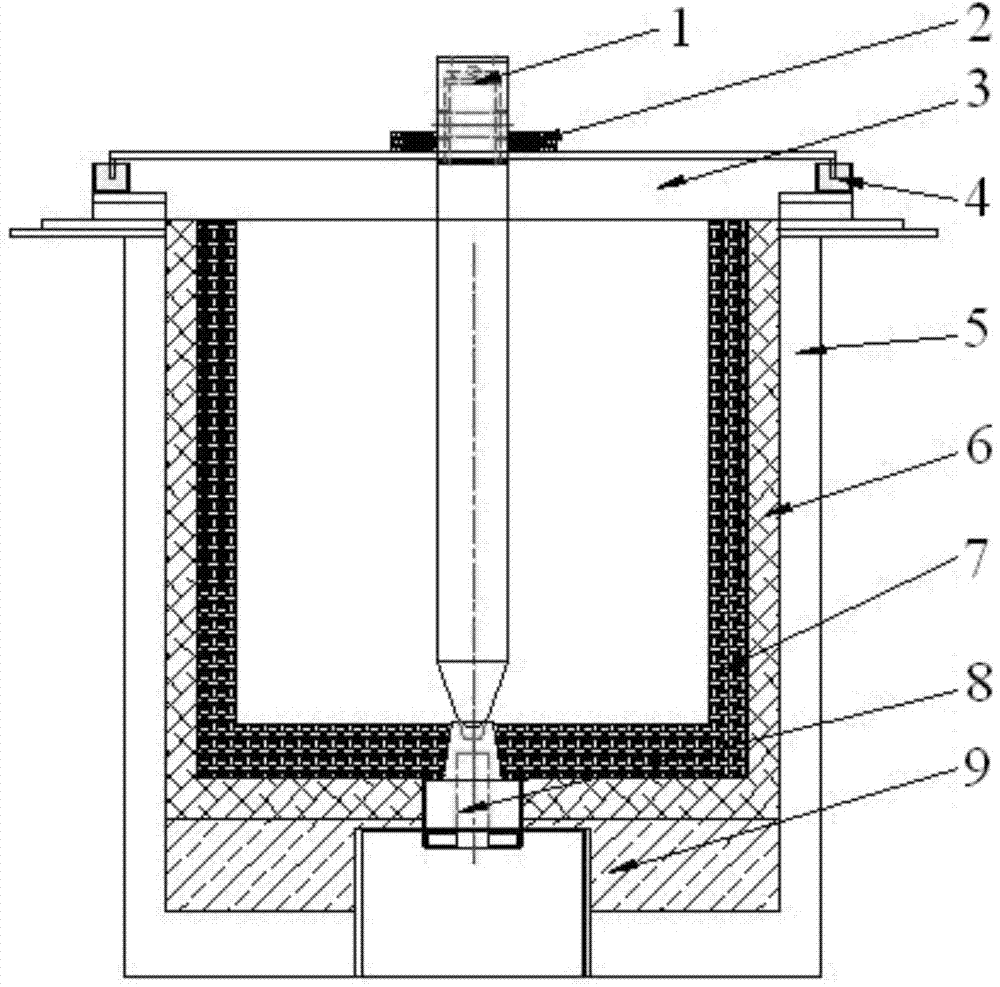

Crucible used for producing slag wool, rock wool, glass ceramic and cast stone products in induction furnace

ActiveCN103575103AImprove power densityHigh electrothermal efficiencyCrucible furnacesMelting tankSlag

The invention discloses a crucible used for producing slag wool, rock wool, glass ceramic and cast stone products in an induction furnace. The crucible is a graphite crucible, is mounted on the innermost side of a hearth of the induction furnace, and serves as a fireproof working face of a molten bath; and a high-fireproofness and high-slag-resistance composite ramming material is filled and compacted among the graphite crucible, an induction furnace coil and a furnace bottom precast fireproof filling material. The crucible has the following advantages that the power density and the electrothermal efficiency of the induction furnace can be improved greatly; leakage and waste of an electromagnetic field can be reduced; the heating is rapider and more uniform; the production efficiency and the quality of a melt can be improved; the fireproofness is higher; the impermeability, the acid resistance and the alkali resistance are better; pollution to the melt can be reduced; mechanical sealing, nitrogen protection, inert gas protection and combustible gas protection ensure that the crucible and a stopper are free from burning loss; under normal use, the service life of a furnace lining exceeds one year; sand sealing can ensure that the hearth is kept sealed when a furnace cover is rotated; and the crucible can meet a requirement of mechanical stirring of the melt.

Owner:WUHU XINXING DUCTILE IRON PIPES

Antibacterial anti-corrosive heat dissipation coating

InactiveCN103756420AImprove adhesionImprove protectionAntifouling/underwater paintsPaints with biocidesSilanesTributyl citrate

The invention discloses an antibacterial anti-corrosive heat dissipation coating which is prepared from the following raw materials in parts by weight: 80-86 parts of high-density polyethylene, 1-2 parts of N,N'-m-phenylene bismaleimide, 1-2 parts of chlorophenasic acid, 5-6 parts of acetyl tributyl citrate, 1-2 parts of dimethyl sulfoxide, 1-2 parts of ammonium dihydrogen phosphate, 2-3 parts of EVA (Ethylene-Vinyl Acetate) resin, 1-2 parts of 3-glycidyl ether oxy-propyl trimethoxy silane, 0.4-1 part of ferrous sulfate, 2-4 parts of cast stone powder, 7-12 parts of light calcium carbonate and 8-10 parts of a modified filler. Because the raw materials including the chlorophenasic acid and the like are added into the powder coating, the antibacterial and anti-corrosive effects of a finished coating product are greatly improved; the coating disclosed by the invention also has an excellent cohesiveness, a high adhesive force to a base material, a good protectiveness, and a good heat dissipation performance.

Owner:WUHU BAOYI AMUSEMENT EQUIP

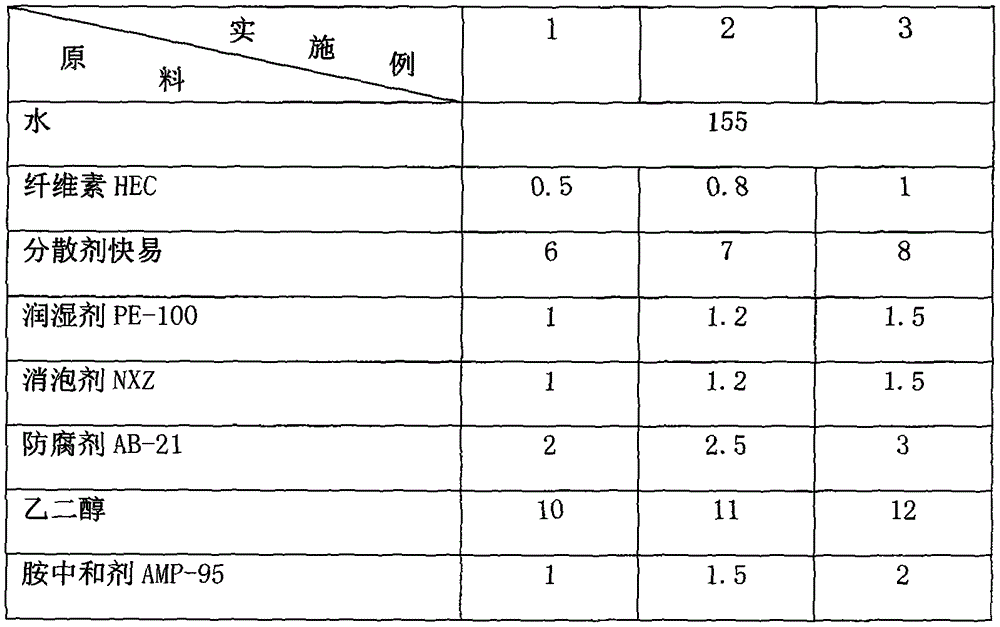

Multi-color imitation marble decorative plate and production method thereof

ActiveCN104612342ARealistic effectVariety of colorsAntifouling/underwater paintsCovering/liningsCrack resistanceWeight range

The invention discloses a multi-color imitation marble decorative plate and a production method thereof. The production method comprises the steps that basal plane treatment is conducted, wherein dirt, dust and last hardening substances on a sample plate are cleared away, and honeycombed cavities and surface cracks on the sample plate are filled and leveled up; base coating is conducted, wherein a roller or a brush or a pneumatic spray gun is utilized to spray alkali-resistant transparent primer on the sample plate after the basal plane treatment, and the coating weight ranges from 0.13 kg / m2 to 0.15 kg / m2; middle coating is conducted, wherein the roller or the brush or the pneumatic spray gun is utilized to spray colorful base coat after the base coating, and the coating weight ranges from 0.2 kg / m2 to 0.35 kg / m2; water in water multi-color coating is conducted, wherein a dedicated spray gun for the water in water multi-color coating is utilized, and the coating weight ranges from 0.35 kg / m2 to 0.6 kg / m2. According to the production method of the multi-color imitation marble decorative plate, the living effect of the appearance of the multi-color imitation marble decorative plate is achieved; the durability and color retention of multi-color cast stone are stabilized; the spray repair is achieved, the effect is not influenced, the lightweight and safety are achieved, and the elasticity and crack resistance are achieved.

Owner:青岛鑫光正建筑节能开发股份有限公司

Wear-resistant rocking bed face putty layer material

InactiveCN101260255ALower unit production costOvercome the shortcoming of low actual recovery rate of beneficiationFilling pastesWear resistantSynthetic resin

The invention provides a wear-resistant shaking table surface putty layer material. The invention relates to a surface wear-resistant paint of machinery equipment, in particular to a wear-resistant paint of a gravity mineral processing shaking table surface of metallurgical machinery. The putty layer material of the surface wear-resistant paint of machinery equipment is manufactured by mixing a synthetic resin with a composite wear-resistant filler based on the weight ratio of 1-1.2:1.8-2.2, in addition, curing agent and catalyst are added in the synthetic resin, and the composite wear-resistant filler adopts quartz sand, talcum powder, cast stone powder and silicon carbide fine powder. The shaking table surface putty layer material has the advantages of improving the wear resistance and service life of the shaking table surface, reducing the production cost and lowering the maintenance costs of a user under the condition of ensuring basical invariability of the casting yield for shaking table surface.

Owner:YUNNAN TIN GROUP HLDG

Wear-resistant coating for aluminum alloy doors and windows, and preparation method thereof

InactiveCN107163645AGood acid and alkali resistanceImprove aging resistanceCoatingsEpoxyWear resistant

The invention discloses a wear-resistant coating for aluminum alloy doors and windows, and belongs to the technical field of door and window coatings. The coating comprises, by weight, 20-30 parts of hexafluorobutyl acrylate, 40-50 parts of epoxy resin, 1-2 parts of styrene-butadiene rubber, 23-26 parts of kaolin, 2-4 parts of cast stone powder, 0.5-1.5 parts of silicon nitride, 1-2 parts of alumina, 0.4-0.8 parts of carboxymethylcellulose, 2-3 parts of paraffin, 6-9 parts of carbon black, 1-4 parts of an antifoaming agent, 0.6-1 pars of a coupling agent, 0.4-0.8 parts of an anti-settling agent and 1-2 parts of a diluent. The invention also discloses a preparation method of the wear-resistant coating for aluminum alloy doors and windows. The coating disclosed in the invention has the advantages of simplicity in preparation, excellent wear resistance, excellent resistance to high temperature, excellent corrosion resistance, excellent aging resistance and difficulty in breakage.

Owner:合肥市旺友门窗有限公司

Insulated tile and stone block wall

An insulated tile or stone block wall assembly. The main element is composed of an outer and inner tile or stone facing bonded to an insulating core. The blocks are stacked and adhered together. The core geometry provides voids for forming concrete and placing steel and utilities. The resulting structure is a decorative, structural, and weatherproof finished product that is easy to install and cost effective to build. Drainage channels are provided behind a cast stone or stone facing to prevent water intrusion. The block insulation shapes are easy to cut making expensive molds unnecessary.

Owner:MORRIS RICHARD D

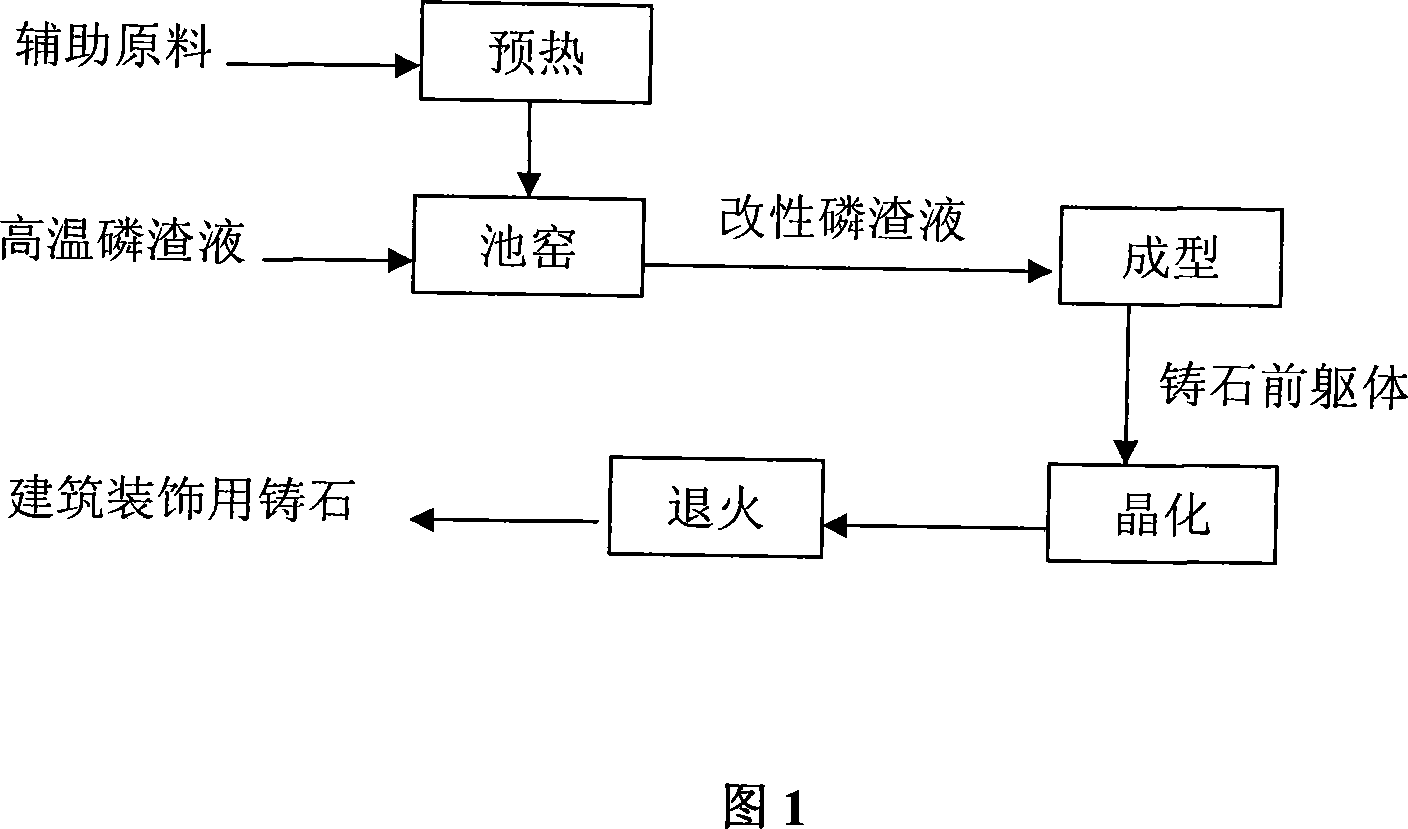

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

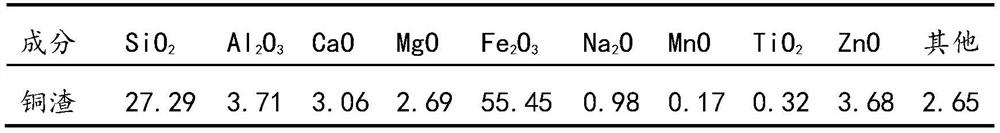

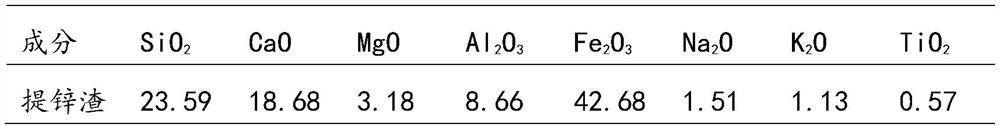

Method for preparing artificial stone from iron-containing slag obtained in pyrometallurgucal process

The invention provides a method for preparing artificial stone from iron-containing slag obtained in a pyrometallurgucal process, belonging to the technical field of energy-saving, environment-friendly and efficient utilization of iron-containing slag obtained through the pyrometallurgucal process. According to the method, a modifier with a mass percentage content of 0.1-10% is added into the iron-containing slag obtained through the pyrometallurgucal process, extra heating is not needed, and the modifier containing alkali metal oxide is directly melted through the waste heat of the slag, or aslag atmosphere is controlled in a gas blowing assisting mode at the same time; the modified slag is subjected to heat preservation for 10-60 min at a temperature higher than 1150 DEG C, then formingis conducted, and heat treatment is conducted so as to obtain the artificial stone; and a main crystal phase in the artificial stone is magnetite, and the mass percentages of the components of the artificial stone are that the mass percentage of Na2O+K2O is more than 0.5% and less than 8%, and the mass percentage of Fe2O3 is more than 25% and less than 65%. The artificial stone is a black artificial granite stone, a common wear-resistant and corrosion-resistant cast stone product or a functional ceramic material containing magnetite.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com