High-heat-dissipation corrosion-resistant flame-retardant MPP corrugated pipe and preparation method thereof

A technology with corrosion resistance and high heat dissipation, applied in the field of power protection pipes, it can solve the problems of short service life of cable insulation, corrosion and rupture of the outer wall of pipes, and reduced service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

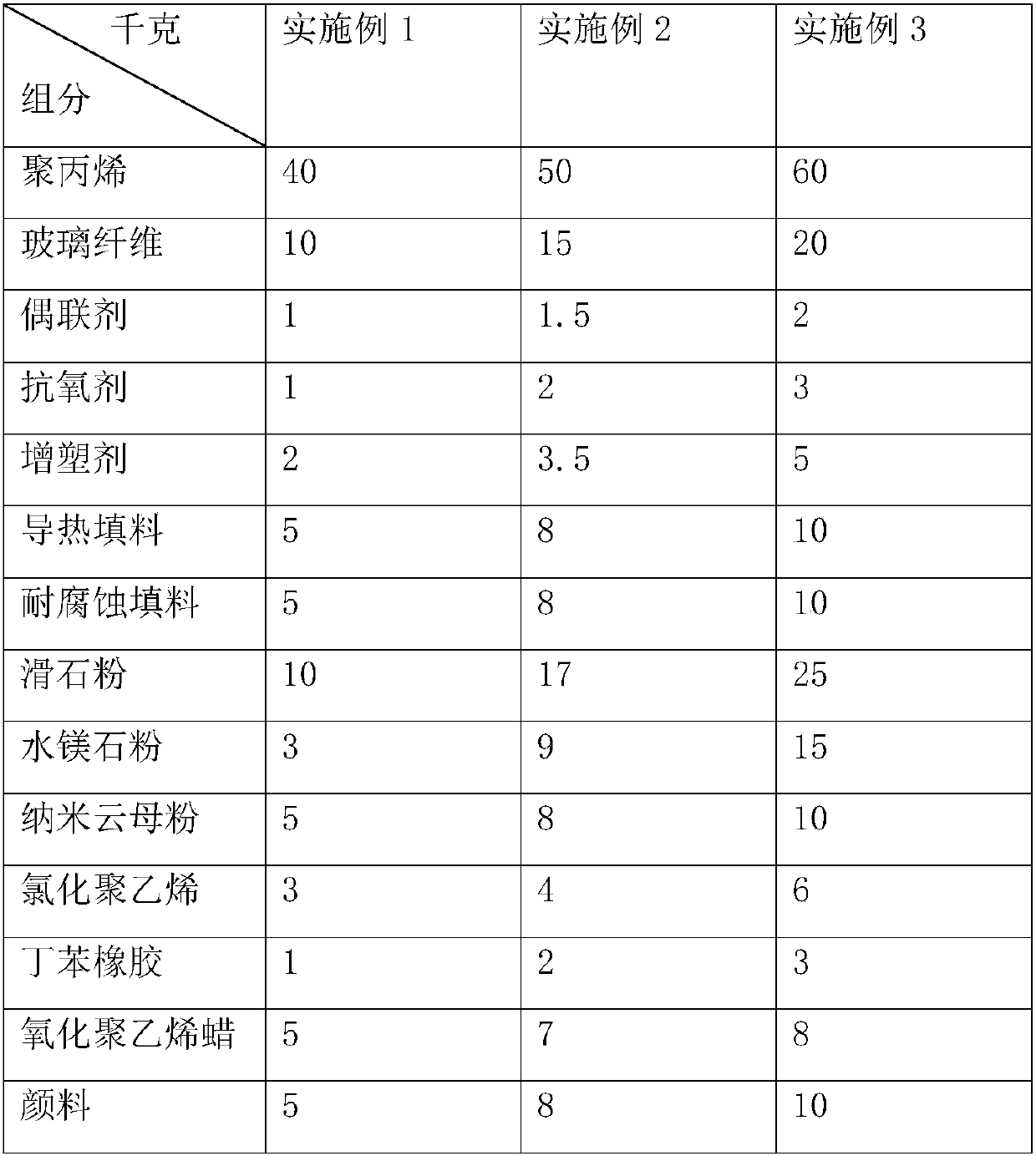

preparation example 1-3

[0032] In the preparation example 1-3, the epoxy resin adhesive is selected from the epoxy resin adhesive sold by Guangzhou Zhongkuang Chemical Co., Ltd. with the product number of 331, and the polyphenylene ether is selected from the model sold by Guangdong Chuangyongjia New Material Co., Ltd. The polyphenylene ether and steel wool of PP0-540Z are selected from Dongguan Dalingshan Meihui Abrasive Material Factory, and the model 1# steel wool and iron powder are selected from Lingshou County Huanlun Mineral Products Processing Factory. The product number is 962 The iron powder and zirconia powder are selected from the zirconia powder of model XS-91 sold by Tengda Chemical Firm in Jinshui District, Zhengzhou City, and the silicon carbide is selected from the silicon carbide and oxide powder of the product number YX099 sold by Qinghe County Yaoxie Metal Material Co., Ltd. The aluminum is selected from the nano-alumina of the model LC-AL2O3 sold by Luoyang Building Materials Archi...

preparation example 1

[0033] Preparation Example 1: (1) Mix 5kg of zirconia powder, 5kg of silicon carbide and 5kg of iron powder, dry at 60°C and ball mill for 10 minutes, soak in 20kg of polyvinyl alcohol solution with a mass fraction of 8% for 20 minutes, and dry Add 3kg epoxy resin adhesive and continue grinding for 10min;

[0034] (2) Cut 10kg of steel wool into small pieces of 2cm, then grind to a particle size of ≤10μm, heat 30kg of polyphenylene ether to 210°C, add the ground steel wool, mix and stir evenly, add 5kg of graphene and step (1) The resultant is ultrasonically oscillated for 30 minutes at a frequency of 25KHz to obtain a thermally conductive filler, wherein the zirconia powder is made by the following method: put zirconia, alumina, and silicon-calcium powder in a ball mill, and wet grind to The particle size is ≤5 μm, dried, pressed and formed, calcined at 1700°C for 2 hours, and crushed so that 60% of the particles in the mixture have a particle size of ≤2 μm, and the mass rati...

preparation example 2

[0035] Preparation Example 2: (1) Mix 8 kg of zirconia powder, 8 kg of silicon carbide and 6 kg of iron powder, dry at 60°C, ball mill for 15 minutes, soak in 23 kg of polyvinyl alcohol solution with a mass fraction of 9% for 25 minutes, dry and add 5kg epoxy resin adhesive, continue to grind for 15min;

[0036] (2) Cut 14kg of steel wool into small pieces of 2.5cm, then grind to a particle size of ≤10μm, heat 35kg of polyphenylene ether to 215°C, add the ground steel wool, mix and stir evenly, add 8kg of graphene and The resulting product of step (1) was ultrasonically oscillated for 40 minutes at a frequency of 28KHz to obtain a thermally conductive filler, wherein the zirconia powder was made by the following method: put zirconia, alumina, and silicon-calcium powder into a ball mill, and wet-mill To a particle size of ≤5 μm, dry, press-molded, calcined at 1800°C for 2.5h, and pulverized so that 65% of the particles in the mixture had a particle size of ≤2 μm, and the mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com