Cast stone ball valve with combined seal

A combination of sealing and casting stone technology, which is applied in the direction of valve devices, cocks including cutting devices, engine components, etc., can solve the problems of poor sealing performance, loss of sealing function, short service life, etc., and achieve reduced wear and erosion, and sealing performance Stable, long product life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

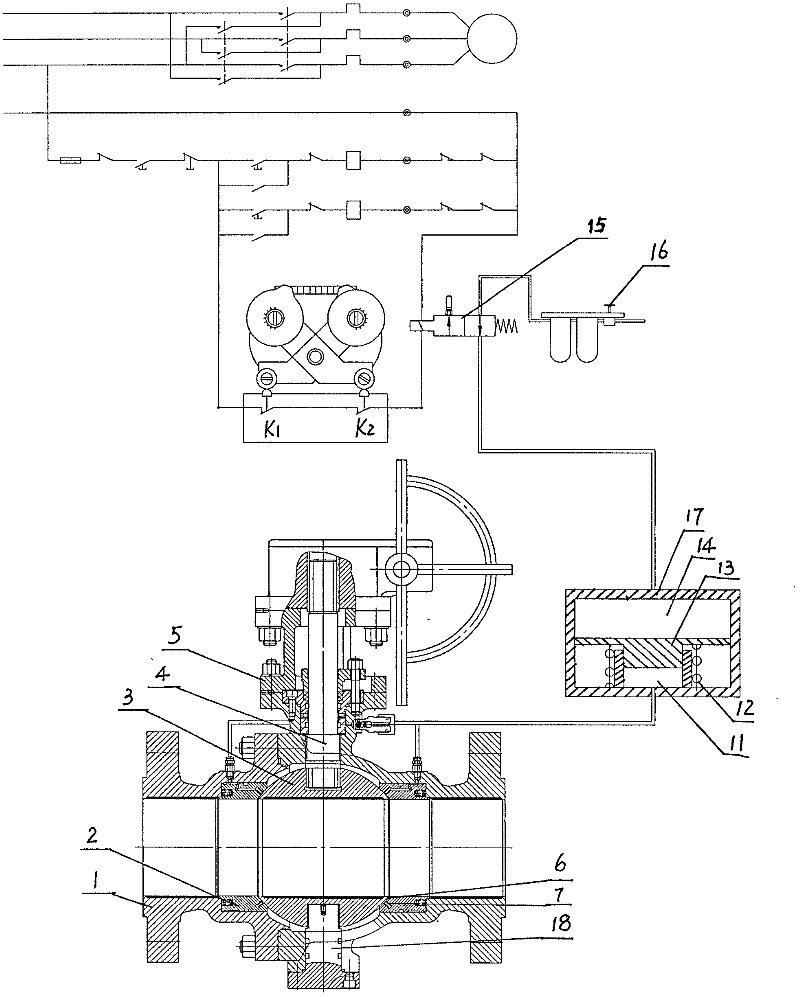

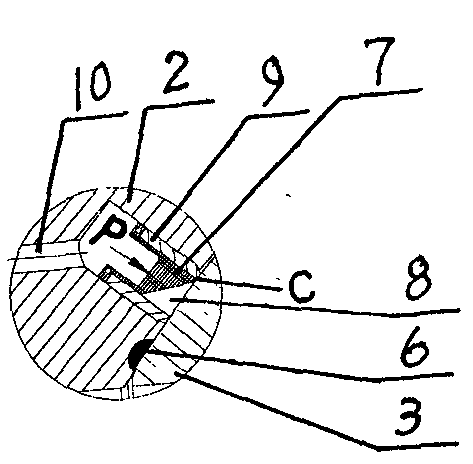

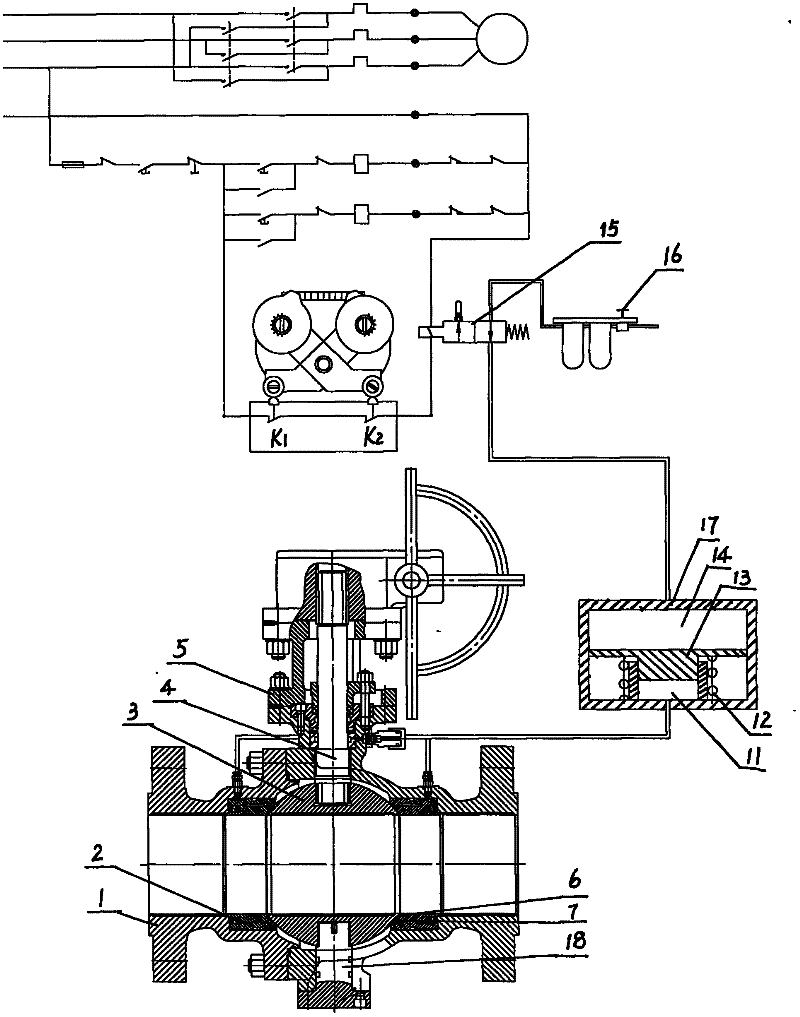

[0009] like figure 1 The shown cast stone ball valve with combined seal includes a valve body 1, a floating valve seat 2, a valve cover 5, a valve stem 4, a ball body 3, a driving mechanism, seals and mounting parts, and the upper end of the ball body 3 is fixedly connected with the valve stem 4. , the lower end of the support rod 18 is positioned in the valve body 1 to form a fixed ball structure. The sealing surface of the floating valve seat 2 is a combined sealing surface composed of a hard sealing surface 6 and a soft sealing surface 7. The hard sealing surface 6 is made of wear-resistant material surfacing on the floating valve seat 2, and has a sealing surface that cooperates with the ball 3. The curved surface can scrape off the dry ash and solid particles on the surface of the sphere 3 during the valve opening process, so as to clean the sealing surface of the sphere 3 . The soft sealing surface 7 is composed of a fluororubber sealing ring installed in the annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com