Insulated tile and stone block wall

a technology of insulated tiles and stone blocks, applied in the field of insulated tile and stone block walls, can solve the problems of insufficient space for concrete filling, inability to provide a thin wall, and increase the cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

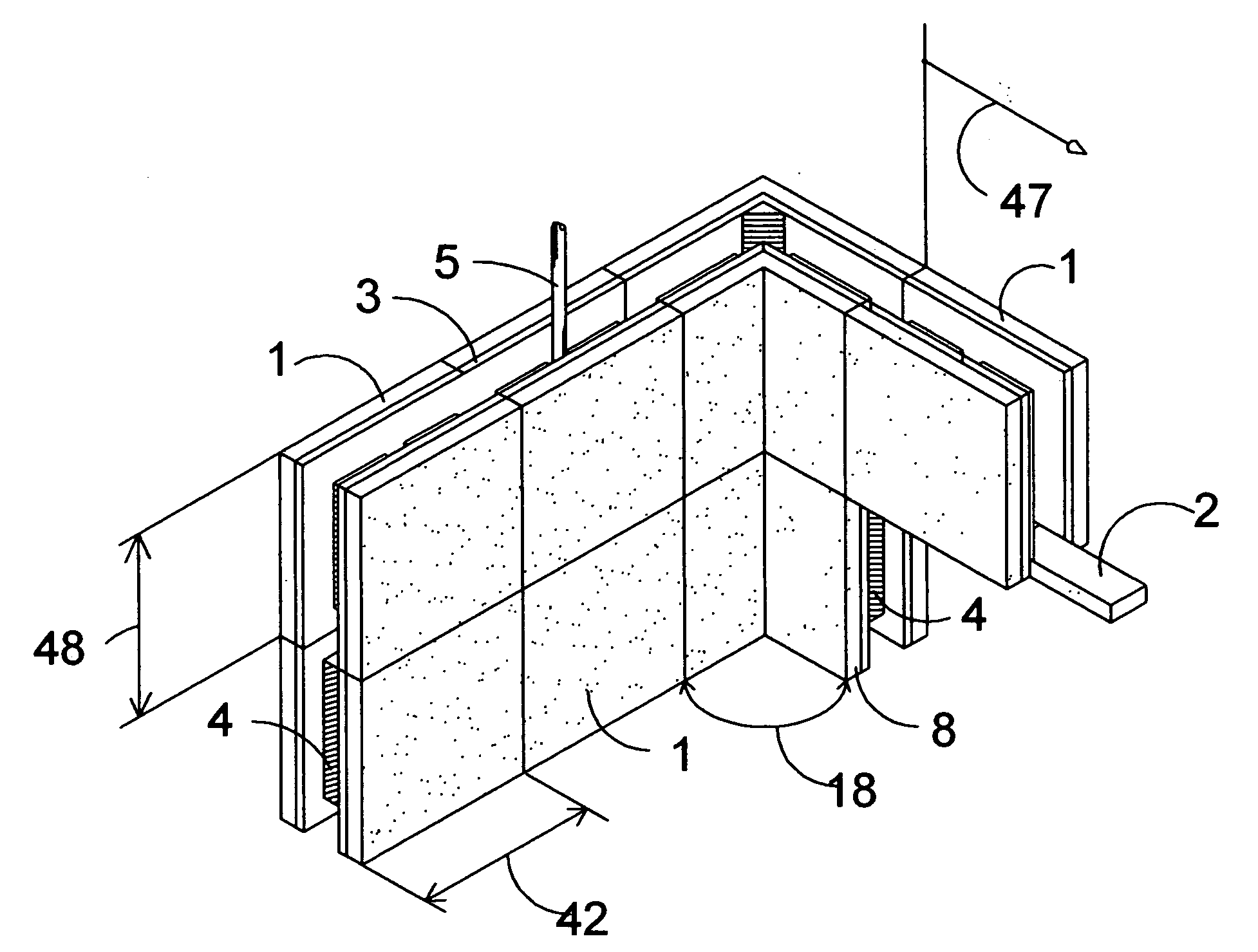

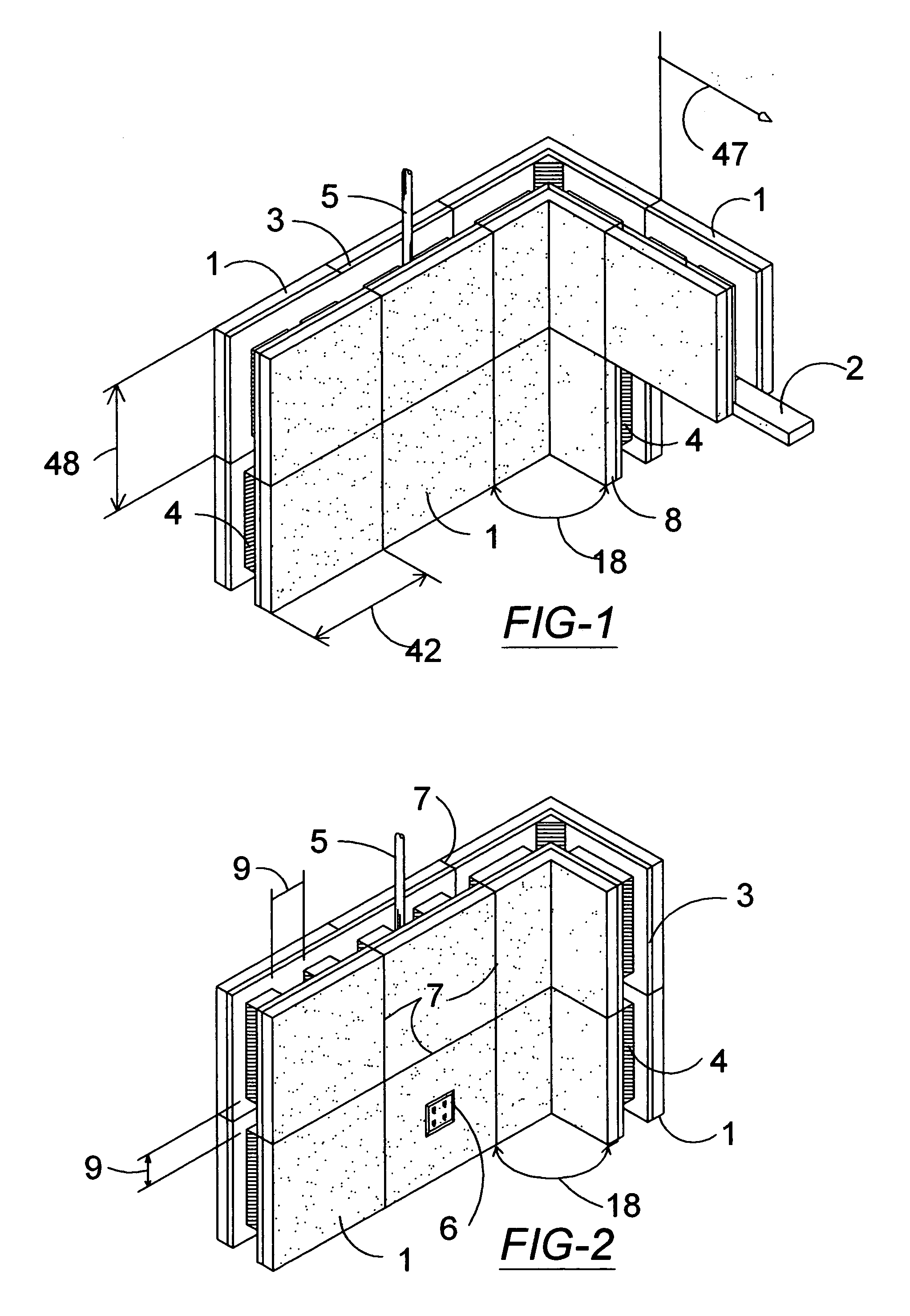

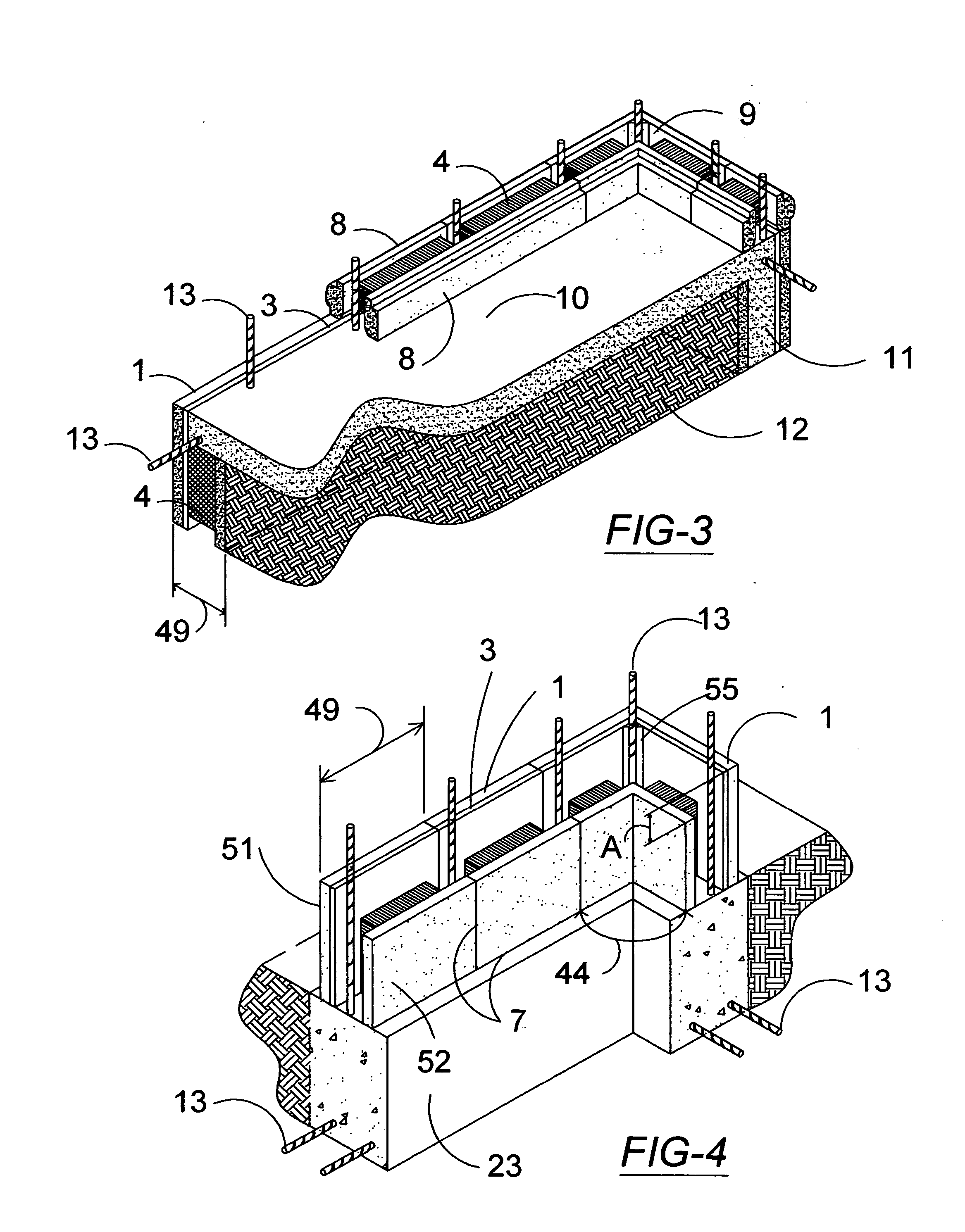

[0039] The preferred embodiment of the present invention consists of an assembly of insulated tile, stone, or cast stone concrete form blocks that when combined together provide a decorative finished wall system and insulation, FIG. 10.

[0040]FIG. 1 shows an isometric view of assembled insulated tile concrete forms from the tie beam 48 and down one course of block. The tile face 1, is laminated to the extruded polystyrene rigid insulation 3 by a polyurethane glue or other adhesive means. The rigid insulation 3 is then laminated to expanded polystyrene rigid insulation 4 by polyurethane glue or other adhesive means. The other side of the block 42 of the preferred embodiment is symmetrically laminated the same way. Each of the tile and insulation components are substantially rectangular in three dimensions. The center insulation (EPS) or expanded polystyrene 4. Utilities 5 have been accommodated for by a vertical run at the center of each block 42 by creating a vertical space between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com