Artificial quartzite plate and preparation method thereof

A quartz stone slab, artificial technology, applied in the field of building materials, can solve the problems of quartz stone slab pores, uneven distribution of particles on the surface of the slab, uneven surface of the slab, etc., to achieve the effect of improving mechanical energy, increasing hardness, and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

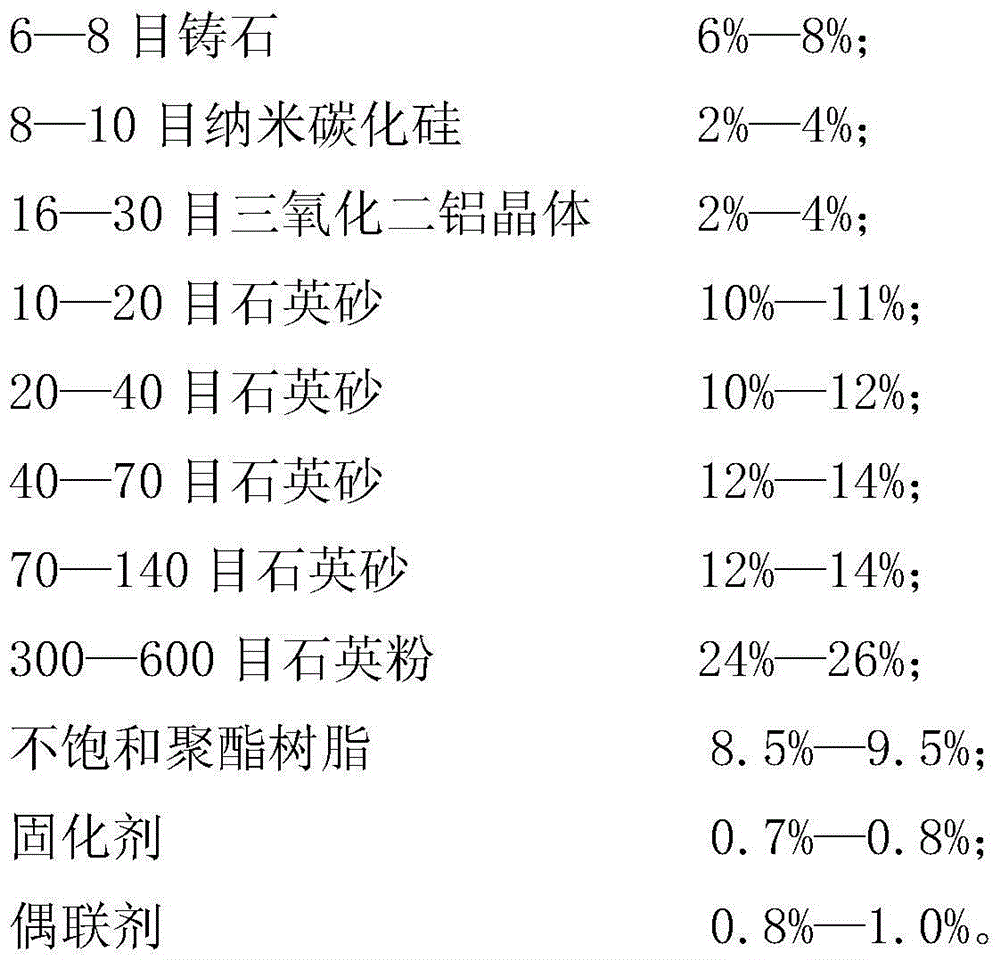

[0046] Artificial quartz slab, its raw material composition is as follows:

[0047] 6-8 mesh cast stone 18.2kg; 8-10 mesh nano silicon carbide 13kg; 16-30 mesh aluminum oxide crystal 10.4kg; 10-20 mesh quartz sand 28.6kg; 20-40 mesh quartz sand 28.6kg; 70 mesh quartz sand 33.8kg; 70-140 mesh quartz sand 33.8kg; 300-600 mesh quartz powder 65kg; unsaturated polyester resin 23.92kg; curing agent (OT) 2.08kg; coupling agent (KH-570) 2.6kg .

[0048] The preparation steps are as follows:

[0049] Weigh the above-mentioned components;

[0050] Add the unsaturated polyester resin into the resin tank, then use an electric heater to raise the temperature in the resin tank to 25°C, then stop heating, use the resin pump to pump the heated resin into the prepared resin barrel, and use the stirring equipment Stir for 15 minutes to make the viscosity reach 900-1000Pa·m / s to obtain an unsaturated polyester resin with high viscosity;

[0051] Add other raw materials except unsaturated pol...

Embodiment 2

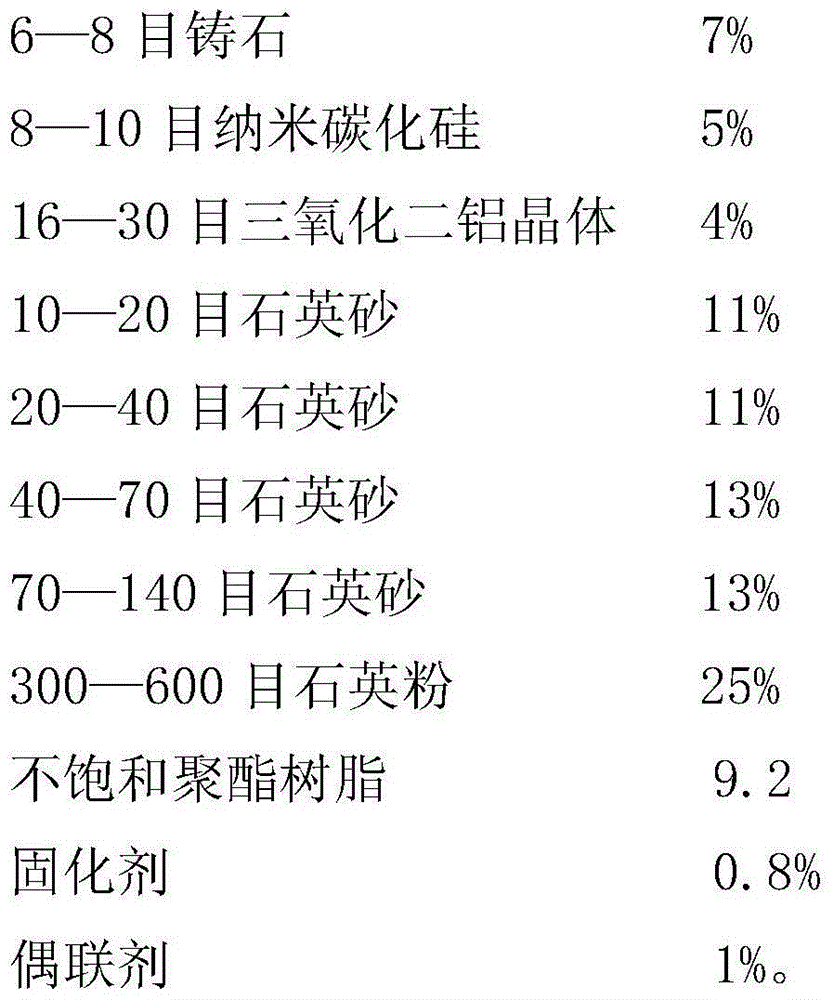

[0056] Artificial quartz slab, its raw material composition is as follows:

[0057] 6-8 mesh cast stone 18.2kg; 8-10 mesh nano silicon carbide 13kg; 16-30 mesh aluminum oxide crystal 10.4kg; 10-20 mesh quartz sand 28.6kg; 20-40 mesh quartz sand 28.6kg; 70 mesh quartz sand 33.8kg; 70-140 mesh quartz sand 33.8kg; 300-600 mesh quartz powder 65kg; unsaturated polyester resin 23.92kg; curing agent (OT) 2.08kg; coupling agent (KH-570) 2.6kg .

[0058] The preparation steps are as follows:

[0059] Weigh the above-mentioned components;

[0060] Add the unsaturated polyester resin to the resin tank, then use water circulation to heat outside the resin tank, the water temperature is 85°C, heat for 10 minutes to make the resin temperature reach 25°C, then stop heating, and use the resin pump to pump the heated resin to the prepared In the resin barrel, use a stirring device to stir for 10 minutes to make the viscosity reach 900-1000Pa m / s, and obtain an unsaturated polyester resin wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com