Waste incineration fly ash melting recycling treatment method

A waste incineration fly ash and treatment method technology, applied in glass forming, glass rolling, alkali metal chloride, etc., can solve the problems of inevitable mixing of heavy metal substances, re-energy-consuming processing, and restrictions, so as to avoid secondary Restore the effects of production, cost reduction, and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

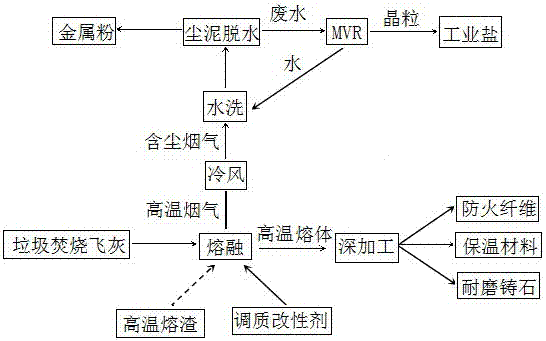

[0031] The following is based on figure 1 The specific embodiment of the present invention is further described:

[0032] see figure 1 , a melting resource treatment method of waste incineration fly ash, comprising:

[0033] Firstly, the waste incineration fly ash is transported to the electric heating furnace through a closed pipeline, and the conditioning modifier is added in the electric heating furnace according to the requirements of the resource-based products, and the waste incineration fly ash and the conditioning modifier Melting treatment. At the same time, when external conditions permit, high-temperature slag can be added to the electric heating furnace to assist in melting. This can not only reduce energy costs, but also replace part of the modifier function, and finally obtain high-temperature flue gas and high-temperature Melt: Let the waste incineration fly ash melt at a high temperature of 1350 ° C ~ 1450 ° C in an electric heating furnace, and the melting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com