Patents

Literature

36 results about "Flagstone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flagstone (flag) is a generic flat stone, sometimes cut in regular rectangular or square shape and usually used for paving slabs or walkways, patios, flooring, fences and roofing. It may be used for memorials, headstones, facades and other construction. The name derives from Middle English flagge meaning turf, perhaps from Old Norse flaga meaning slab or chip.

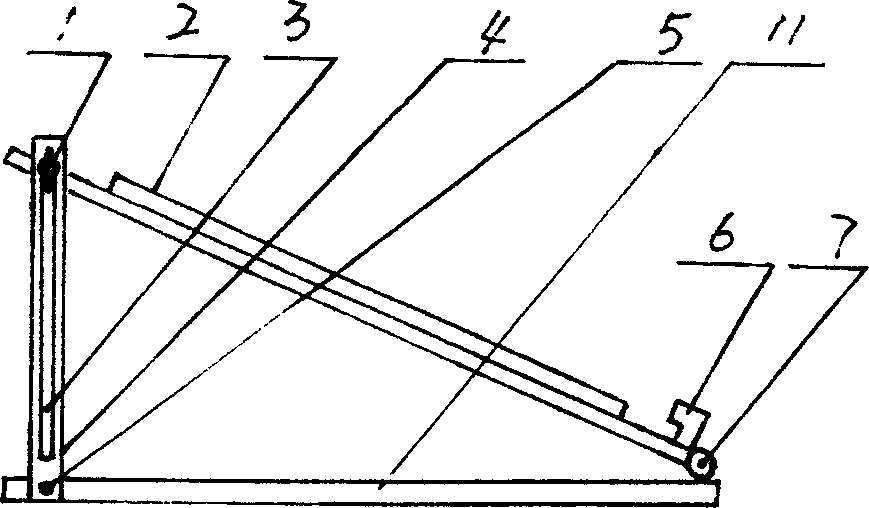

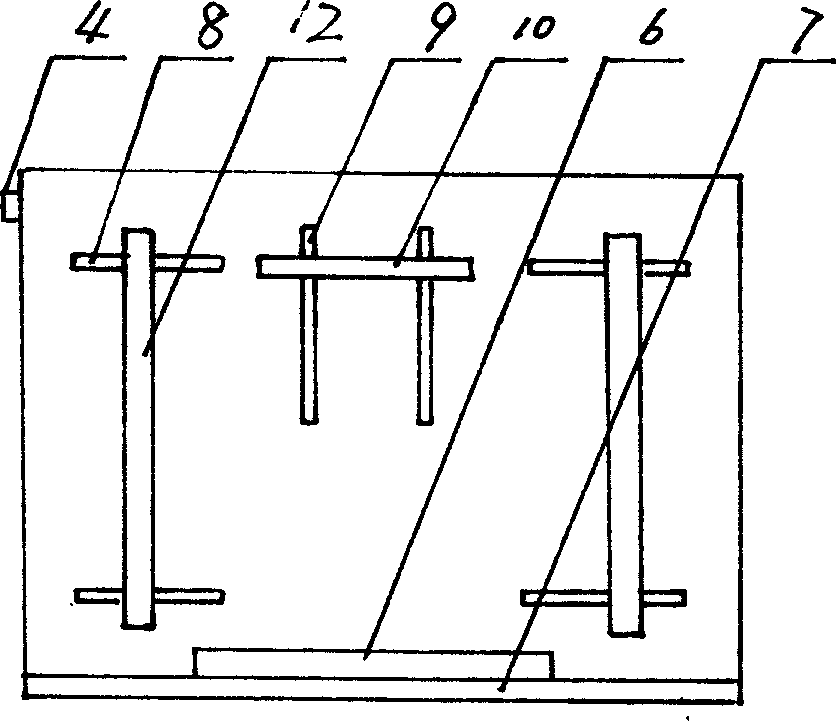

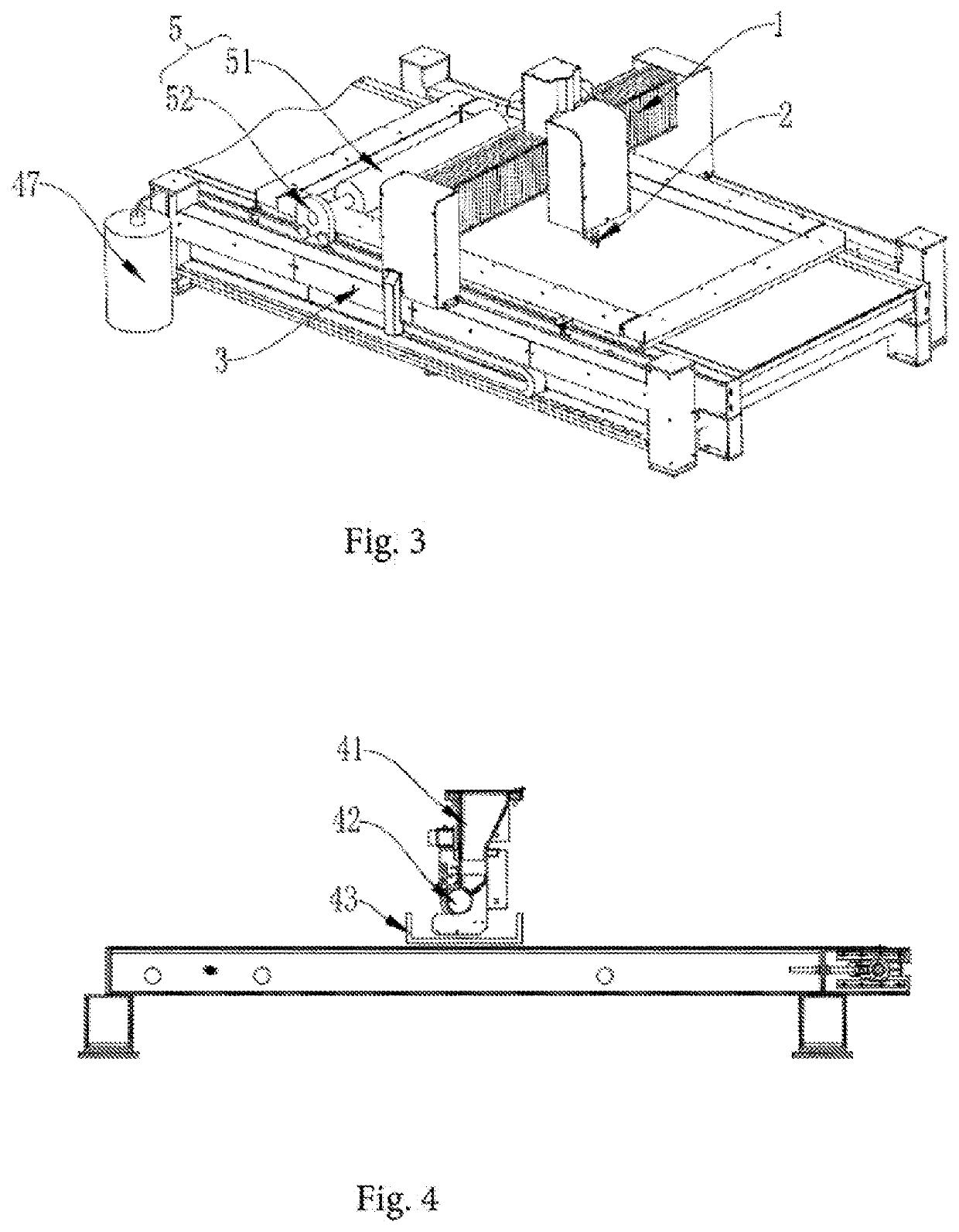

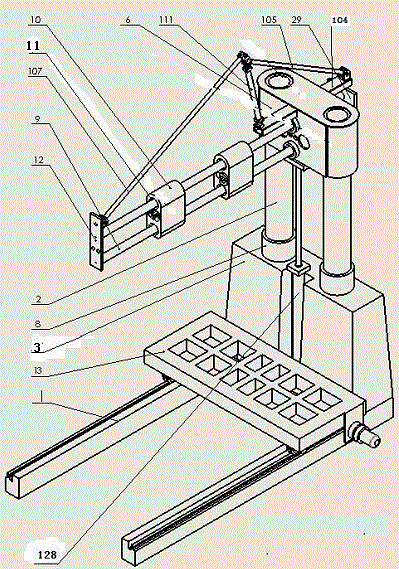

Positioning clamp for machining flagstone surface and method for grinding flagstone surface

InactiveCN1699013AAvoid wear and tear defectsImprove efficiencyEdge grinding machinesPositioning apparatusFlagstoneEngineering

This invention relates to a stone plate processing location jig and a grinding method, which belongs to jig and grinding method field. The location jig is on the table surface of jig borer, and the sheet material is on the clamp and be fasten; the method comprises: adjusting angle regulating stem to make the sheet surface in a needed angle; setting grinding quantity of jig borer; opening jig borer; its bistrique will move automatically downwards to drive the stone plate being grinded until reach to the designed quantity, or the bistrique will move automatically to contact the stone plate, and the table surface shift will force the stone plate being grinded until reach to the designed quantity.

Owner:厉国苗

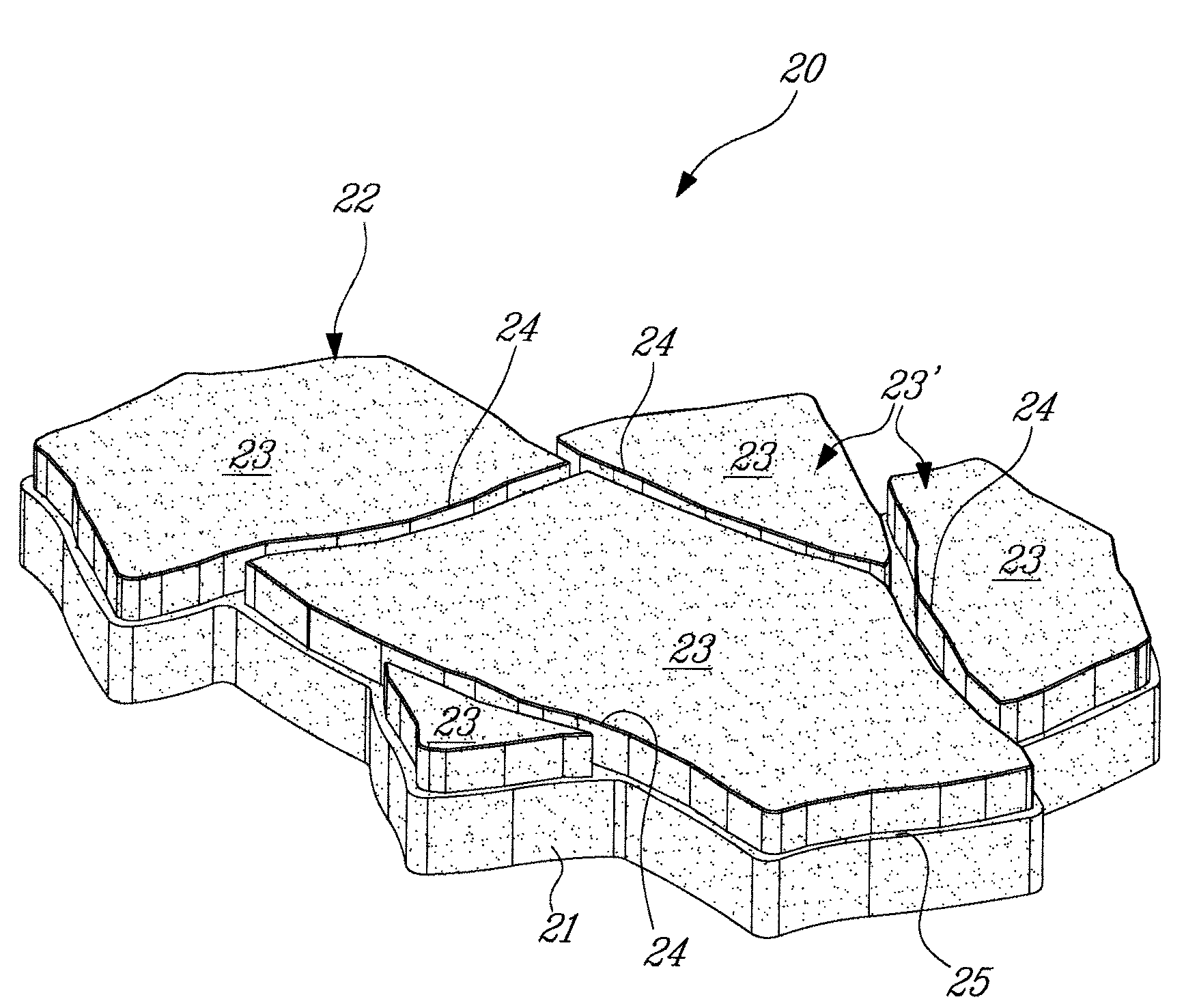

Paving stone and method

A concrete cast stone resembling a flagstone for use with other ones of the concrete cast stones for covering a surface. The concrete cast stone comprising a body having a peripheral contour of non-repetitive jagged shape for interlocking engagement of a plurality of the concrete cast stone. The peripheral contour defining a distinguishable orientation with interlocking side sections and part-interlocking side sections such that said concrete cast stones placed side-by-side interlock by one or a combination of (1) matching the interlocking side sections in a linear arrangement of the concrete cast stones, and (2) matching the part-interlocking side sections in a herringbone arrangement. A method for assembling the concrete cast stone is also provided.

Owner:TECHO BLOC

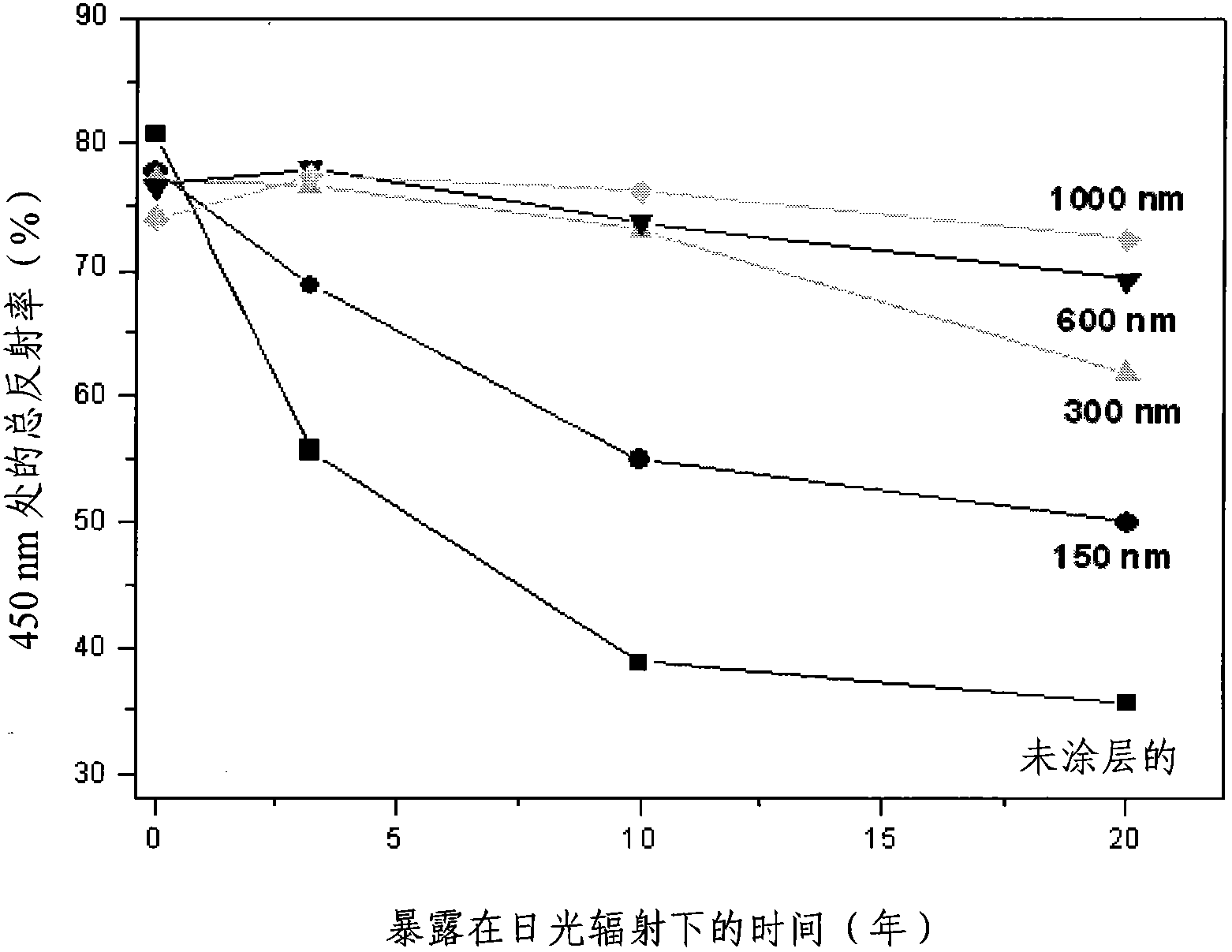

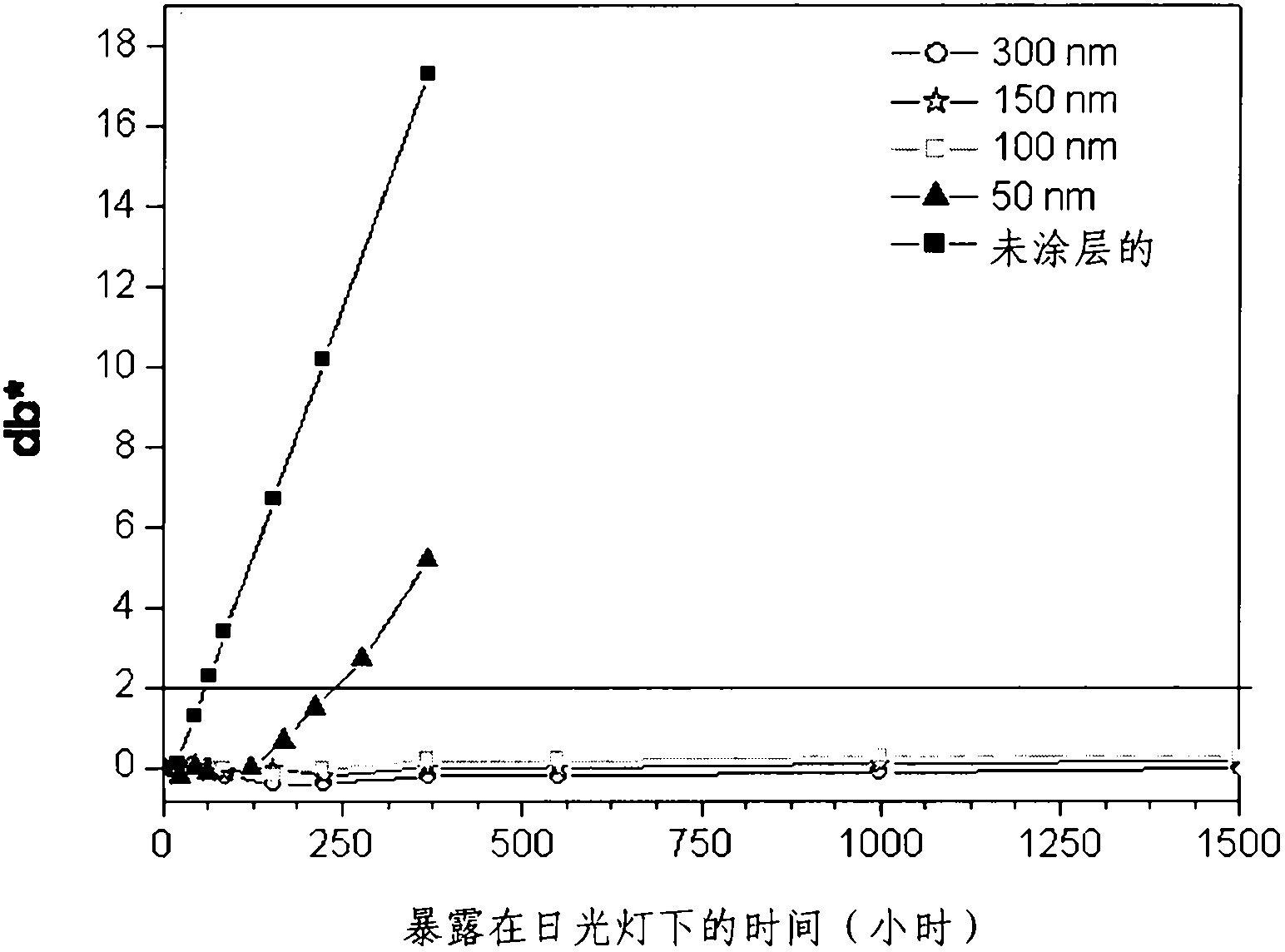

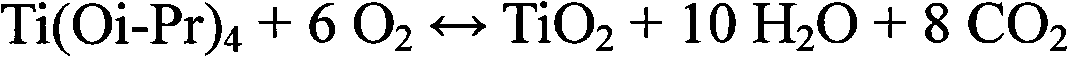

Stone agglomerate slab or flagstone with tio2 or zno coating

InactiveCN102112416AEliminates risk of thermal degradationUniform and controllable thicknessVacuum evaporation coatingSputtering coatingFlagstoneThin membrane

Article in the form of a slab or flagstone fabricated from stone agglomerate coated with thin, transparent films of TiO2 or ZnO, using dry deposition techniques, with a high level of resistance to solar degradation, said article having the form of a slab or flagstone fabricated from stone agglomerate coated with a thin, transparent film of TiO2 and / or ZnO with low or zero photocatalytic activity, said film being deposited by means of dry deposition, physical vapour deposition (PVD) or plasma enhanced chemical vapour deposition (PECVD) techniques. Said article has a high level of resistance to solar degradation, which means that the resulting material is suitable for external environments.

Owner:COSENTINO SA

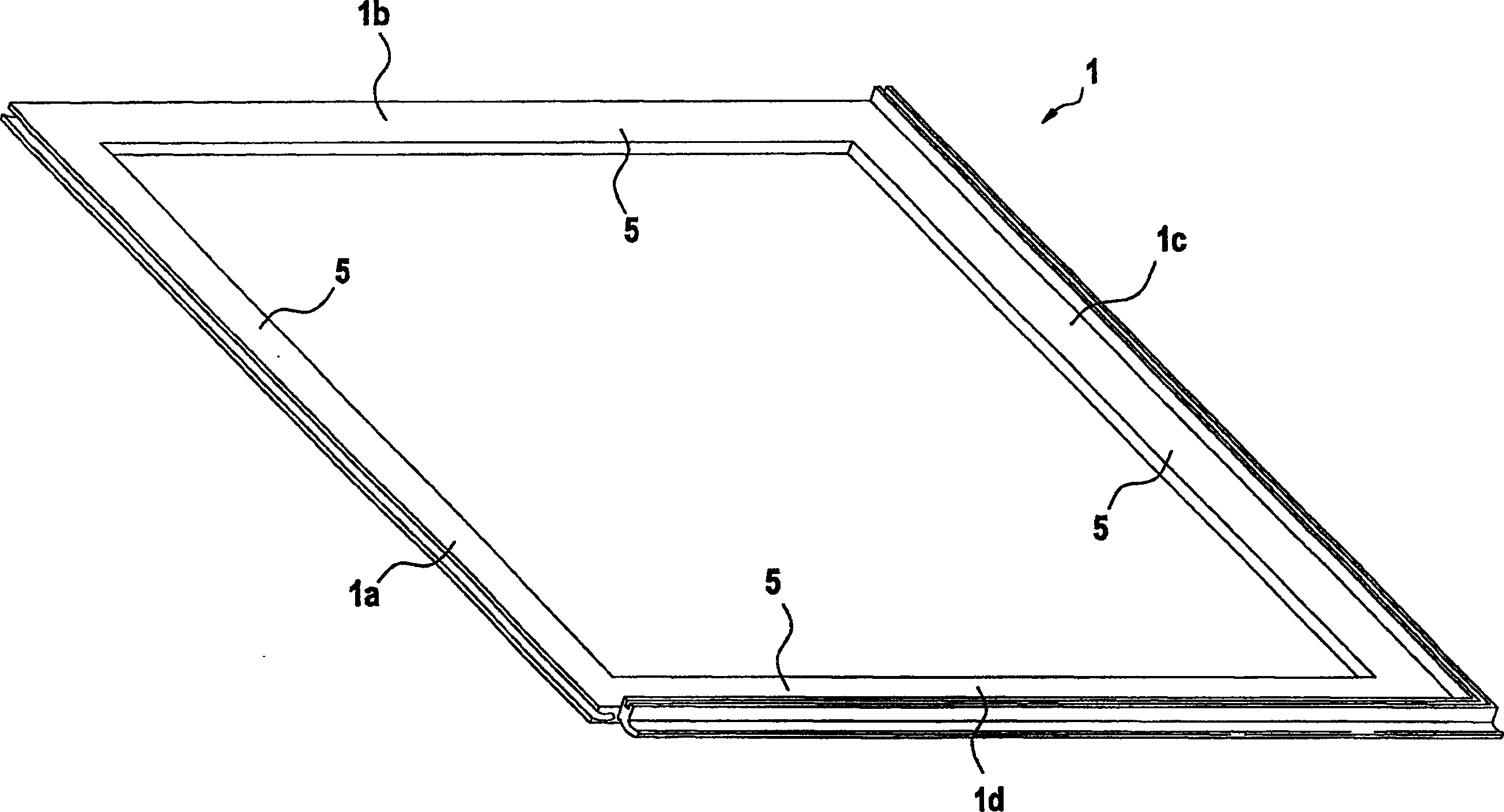

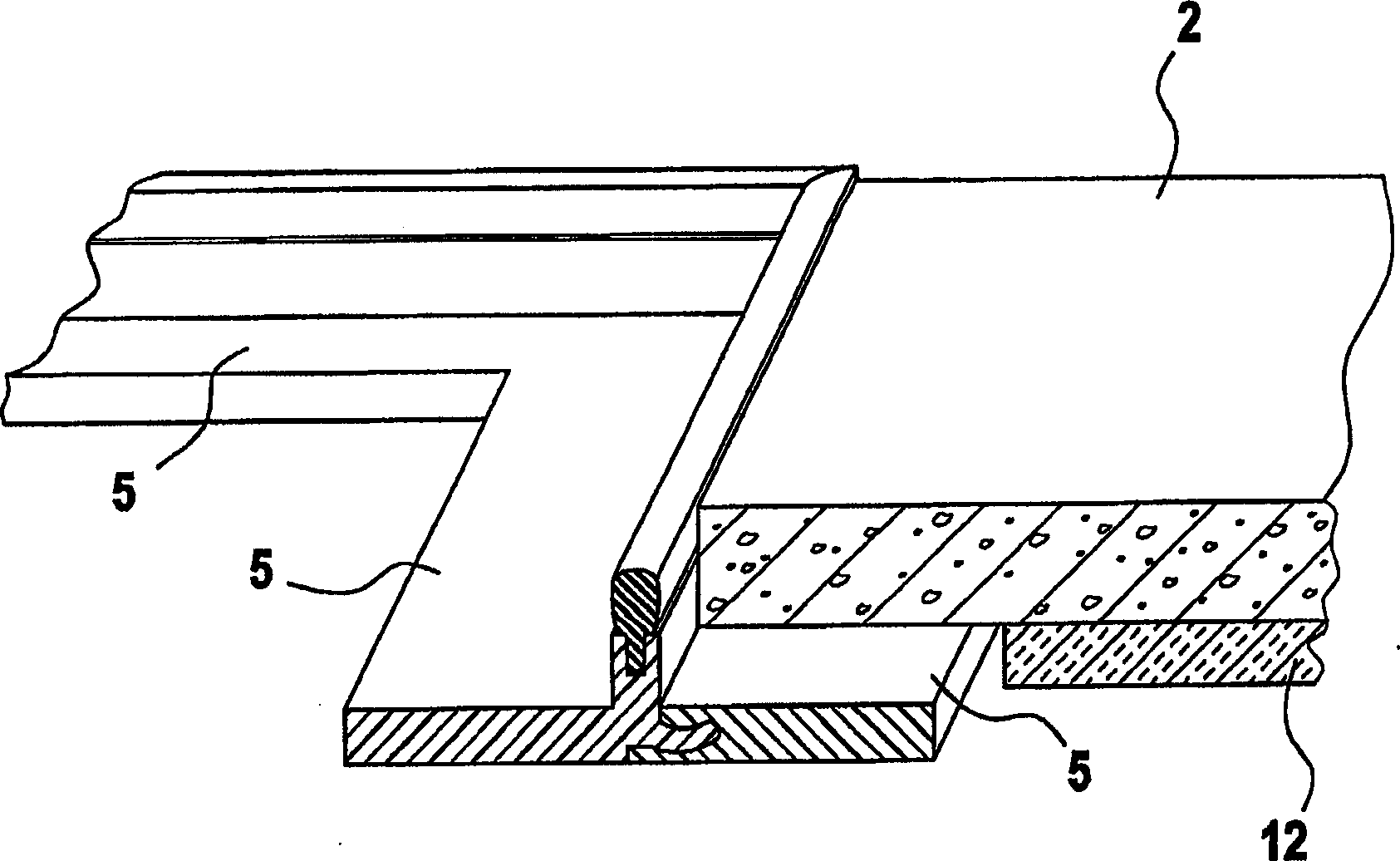

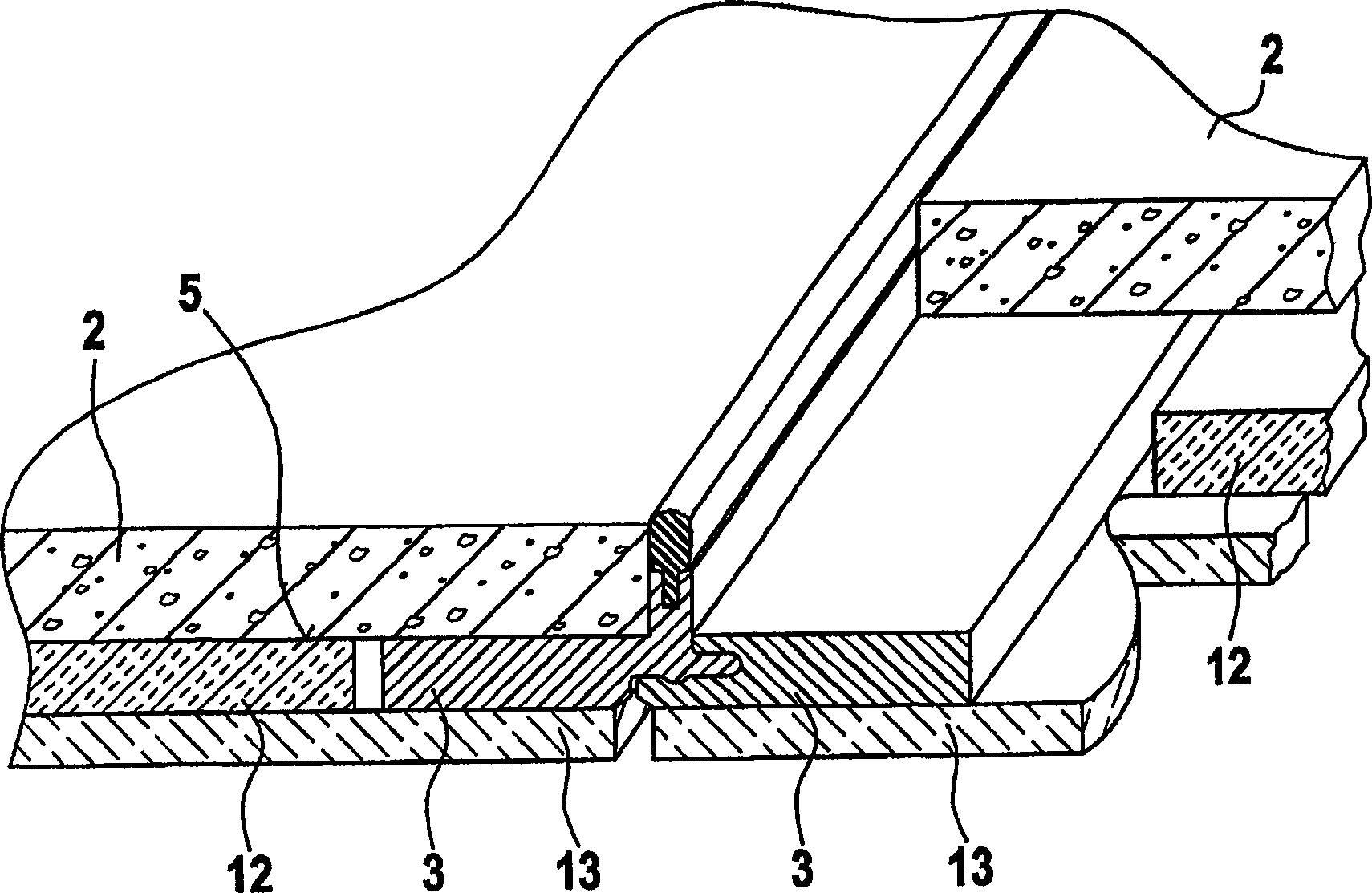

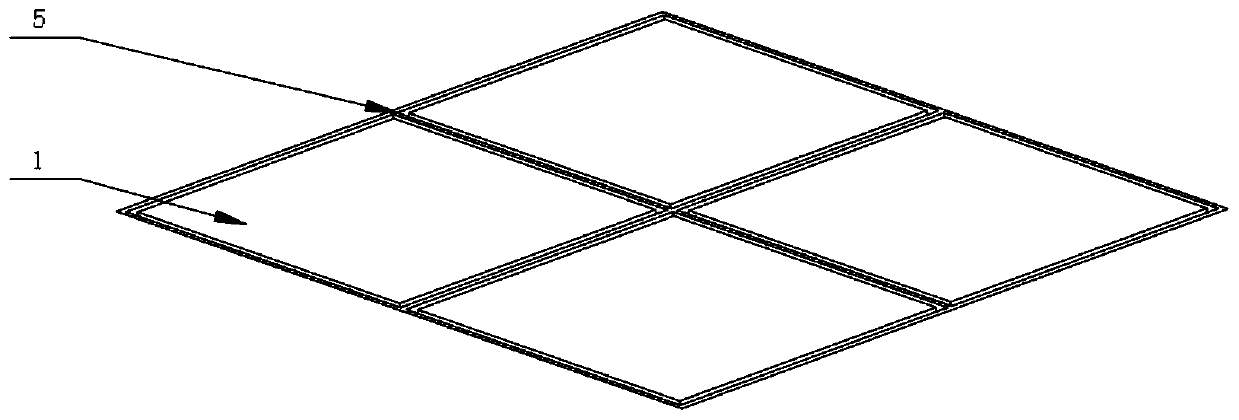

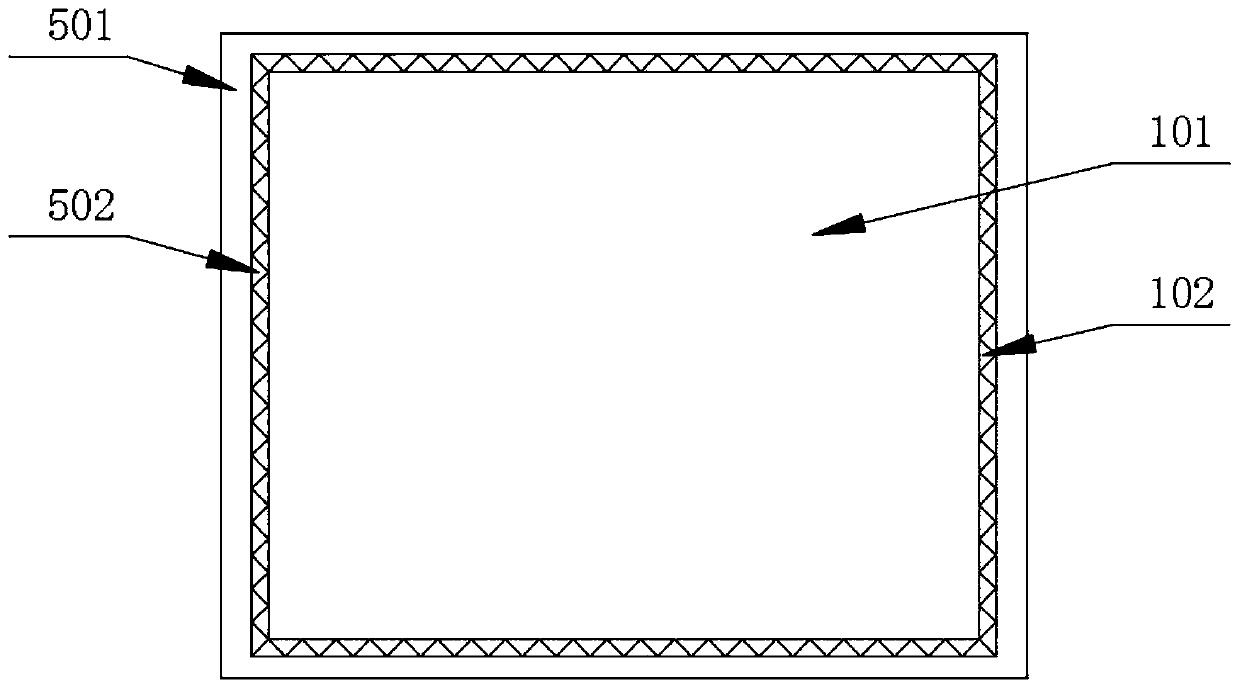

Laying system for floor tiles

InactiveCN1617966AAvoid Plank MistakesQuick and cheap layingCovering/liningsSingle unit pavingsFlagstoneArchitectural engineering

The invention relates to a paving system for tiles, especially flagstones, for paving ceilings, walls, or floors, in which each tile is provided with a paving frame on which the tile rests over at least part of its area. The paving frames comprise, on each of two adjacent (intersecting) limbs, a fin for the accommodation of a rubber-elastic sealing profile that defines the width of the seam.

Owner:CLICKN WALK

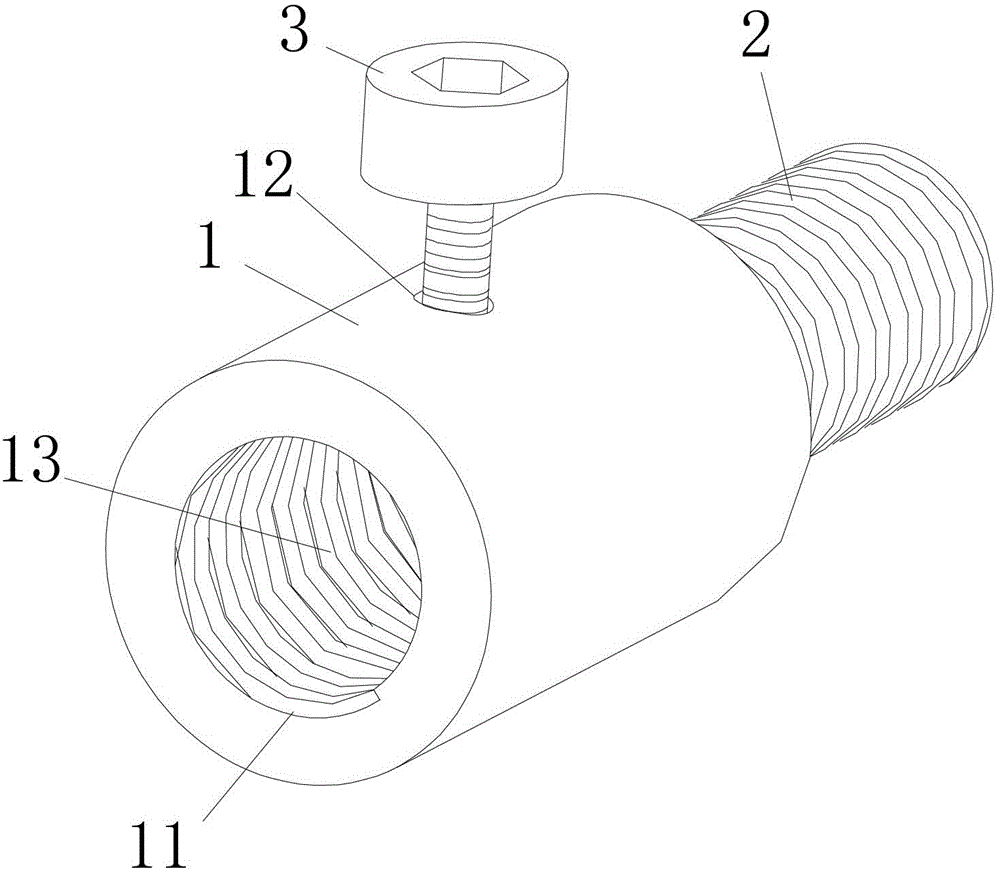

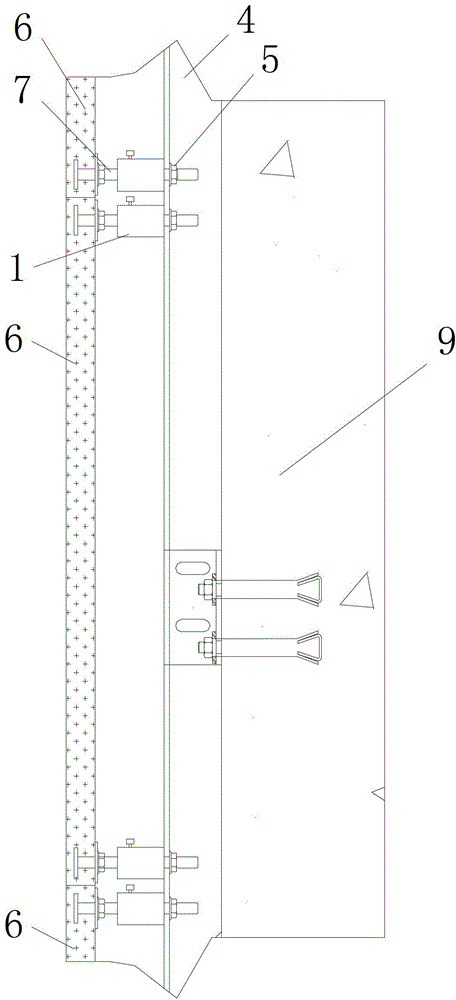

Dry-hanging stone curtain wall mounting and maintaining method and sleeve

The invention discloses a dry-hanging stone curtain wall mounting method which includes the steps: fixedly mounting a keel frame on a wall; fixing a sleeve and the keel frame; adjusting a pressure head screw; moving flagstones with connectors to mounting positions and inserting each connector into a cylinder containing cavity through an opening; rotating the pressure head screw and tightly pressing the connector between the inner wall of the cylinder containing cavity and the pressure head screw; and filling dry-hanging glue into the gap between flagstones to mount a dry-hanging stone curtain wall. The invention provides a dry-hanging stone curtain wall mounting and maintaining method and the sleeve to overcome the shortcomings of the prior art.

Owner:冯文钦

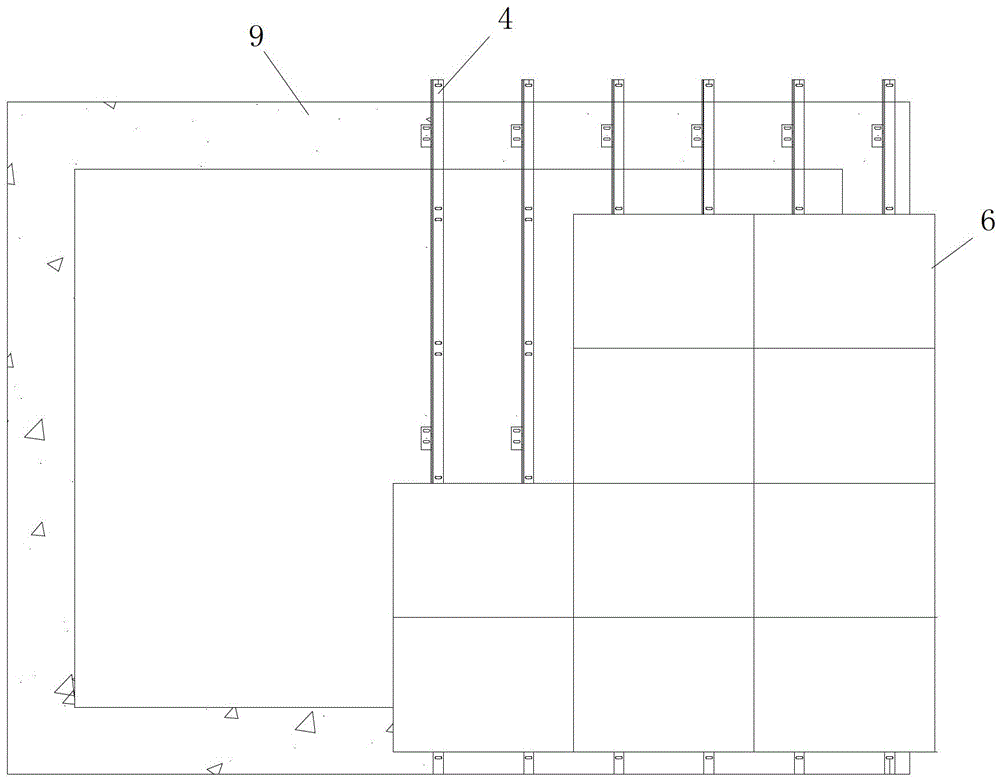

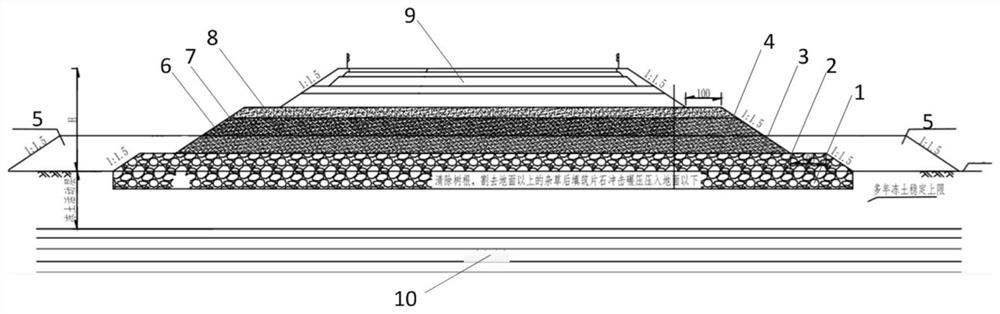

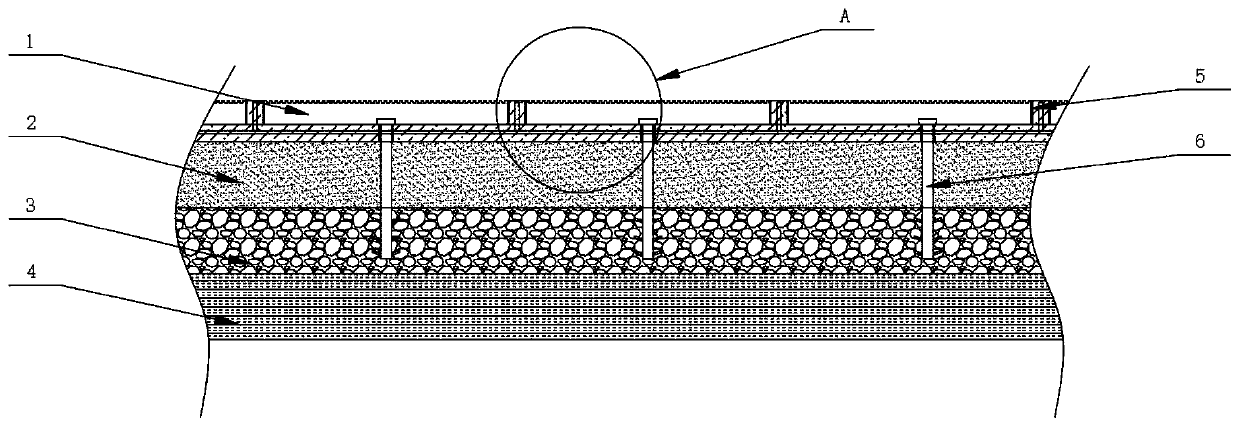

Fill subgrade construction method suitable for water-rich low-lying permafrost region

PendingCN112160208AImprove bearing capacityKeep dryRoadwaysClimate change adaptationFlagstoneSurface water

The invention discloses a fill subgrade construction method suitable for a water-rich low-lying permafrost region. The fill subgrade construction method comprises the following steps of stamping flagstone silt squeezing replacement construction being conducted; filling a rubble layer cooling layer; paving two pieces of cloth and one film; paving a gravel layer; constructing a roadbed slope toe heat preservation protective channel; laying inverted filter geotextile; paving a gravel layer; paving a gravel cushion layer; and loading subgrade filler which is compact in filling and good in water permeability. According to the method, silt is squeezed and replaced by impacting and rolling the rubble layer, the bearing capacity of the foundation is improved, meanwhile, underground water is prevented from rising to roadbed soil under the action of capillary water, and it is guaranteed that the roadbed is dry; the rubble cooling layer being filled, good gaps among rubbles being utilized to formnatural air convection in winter, and the temperature of permafrost being actively reduced; paving a two-cloth one-film impermeable layer to prevent water in the roadbed body from infiltrating into the permafrost region. The water seepage geotextile and the gravel paving layer have high drainage performance, and the roadbed slope toe heat preservation protective channel prevents frost heaving diseases of a slope toe and prevents slope toe surface water from seeping into a roadbed soil body.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE

Processing method of slabstone wall brick

ActiveCN112008899AEasy to handleImprove processing efficiencyEdge grinding machinesGrinding carriagesFlagstoneBrick

The invention provides a processing method of a slabstone wall brick, and belongs to the technical field of wall brick processing. The processing method of the slabstone wall brick is characterized bycomprising the following steps that S1, cutting is conducted, specifically, a stone initial blank is cut into cuboid stone with the preset size, and the cuboid stone is arranged in a processing device; S2, edge chiseling treatment is conducted, specifically, the cuboid stone is sequentially placed on an input mechanism of the processing device, a lifting assembly in the input mechanism drives thecuboid stone to move upwards by a first preset distance, then the four edges of the uppermost part of the cuboid stone are chiseled away through a treatment mechanism, and thus the cuboid stone formsthe shape protruding from the four edges to the middle; and S3, flake chiseling treatment is conducted, specifically, the cuboid stone subjected to edge chiseling treatment is driven by the lifting assembly to continuously move upwards by a second preset distance, then the upper part of the cuboid stone is chiseled off through the treatment mechanism, and thus a stone flake is obtained. The processing method has the advantages of high slabstone wall brick processing efficiency and good in effect.

Owner:海宁金都新能源有限公司

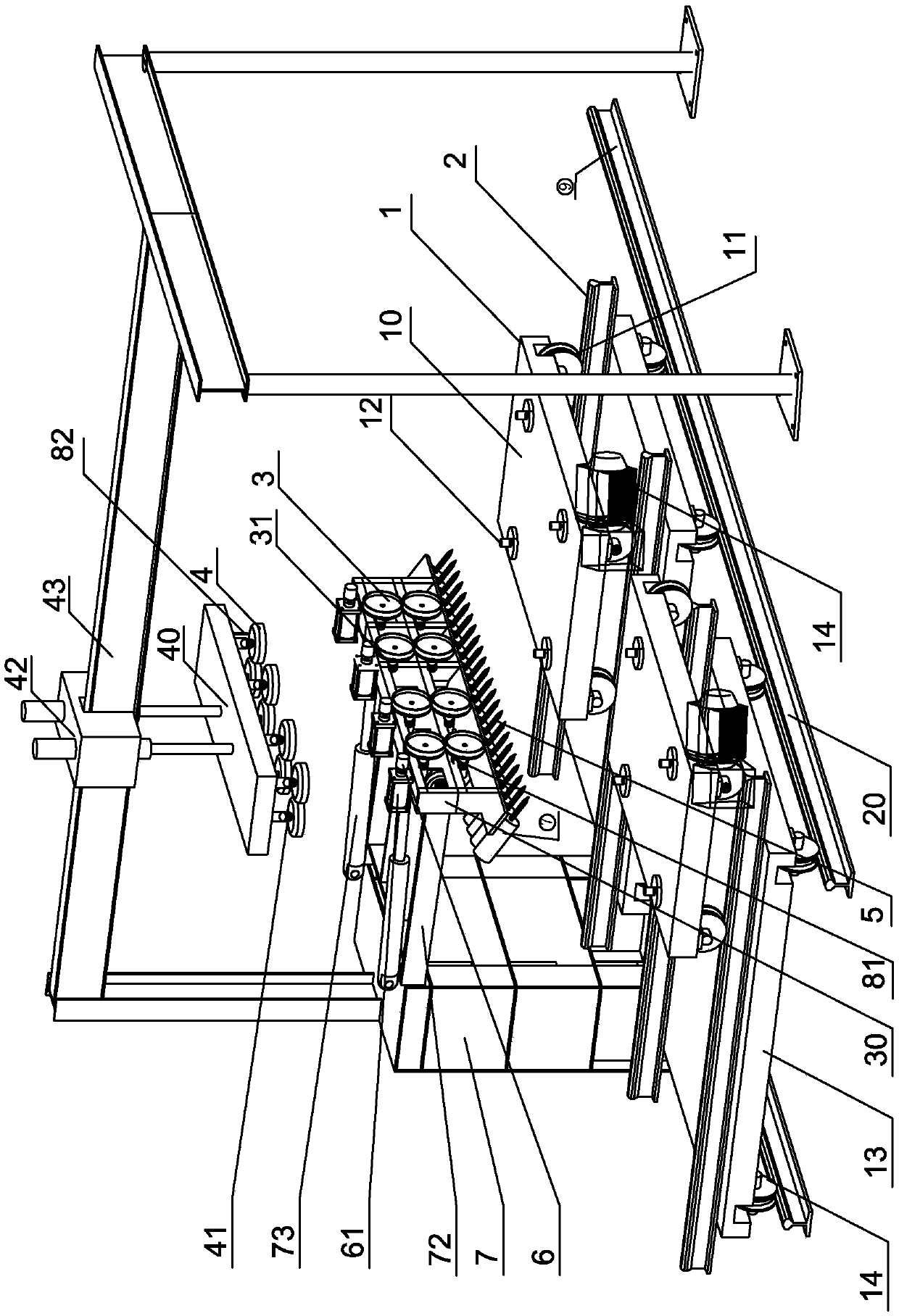

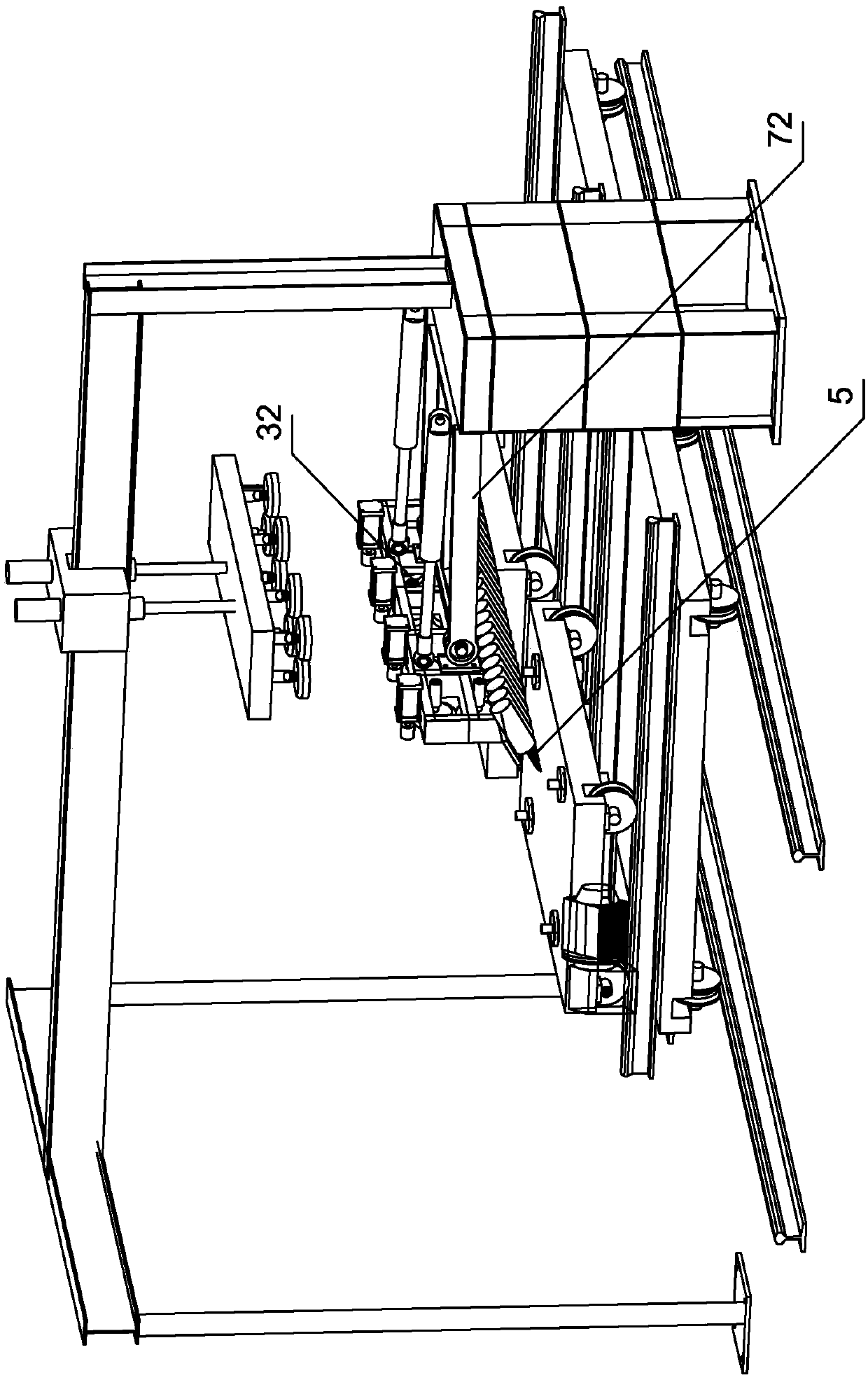

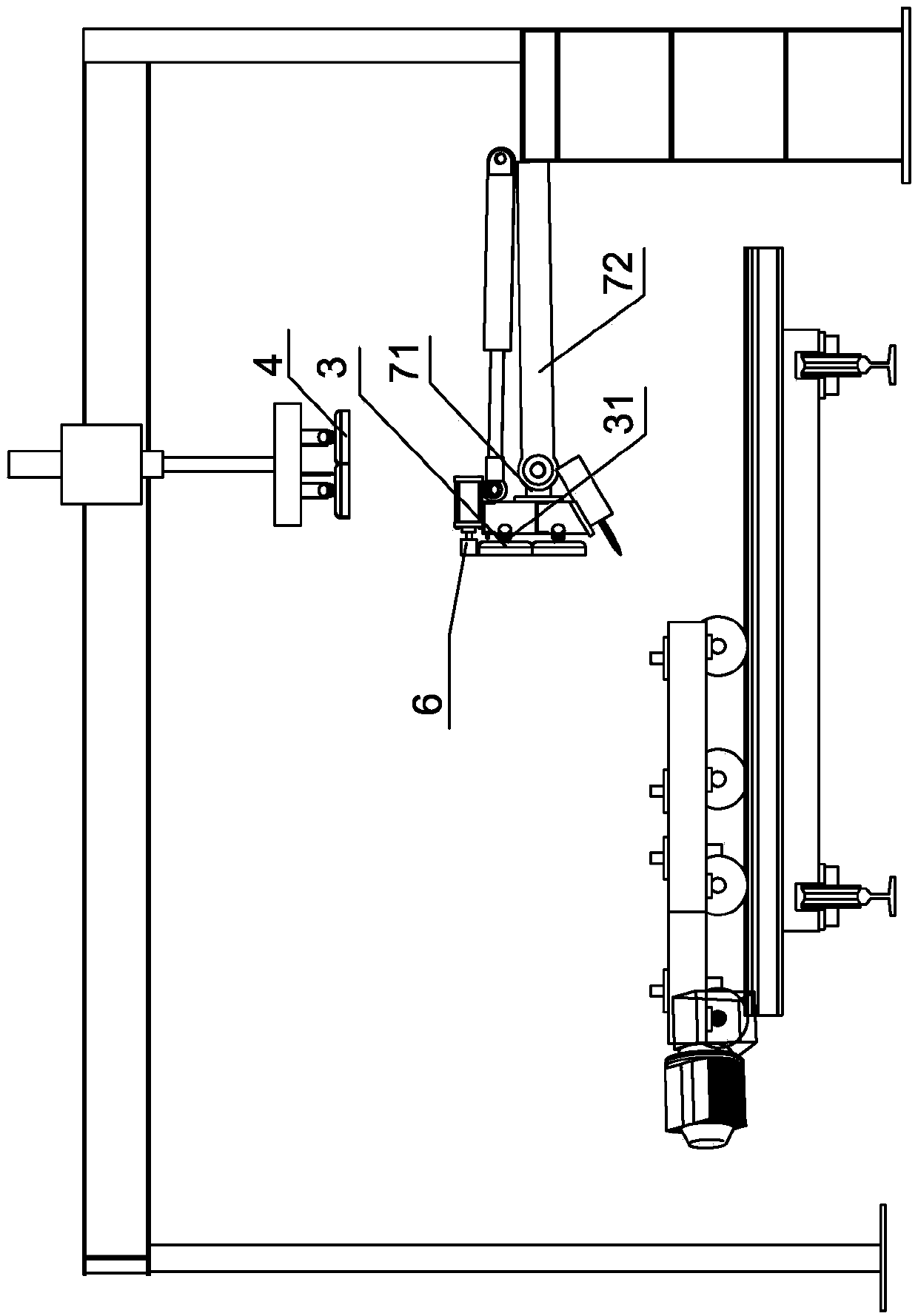

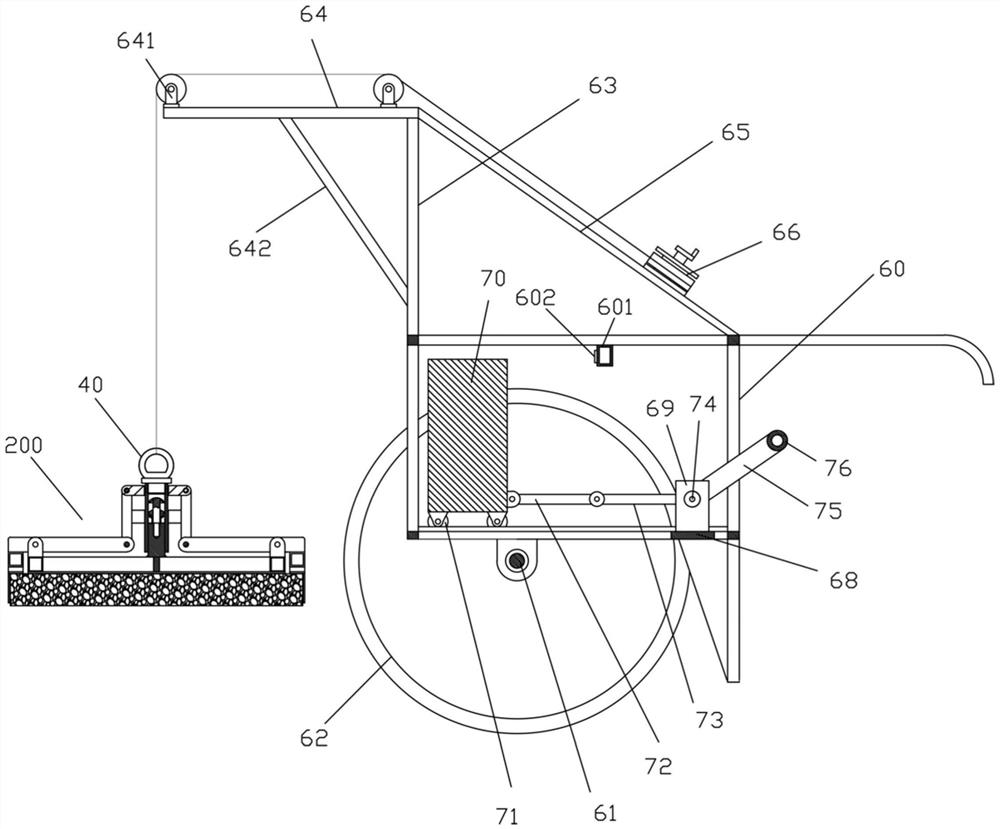

Interlayer mixing apparatus for texturing man-made stone slabs

InactiveUS20200282596A1Improve breathabilitySignificant barrierNatural patternsPress rollersFlagstoneControl system

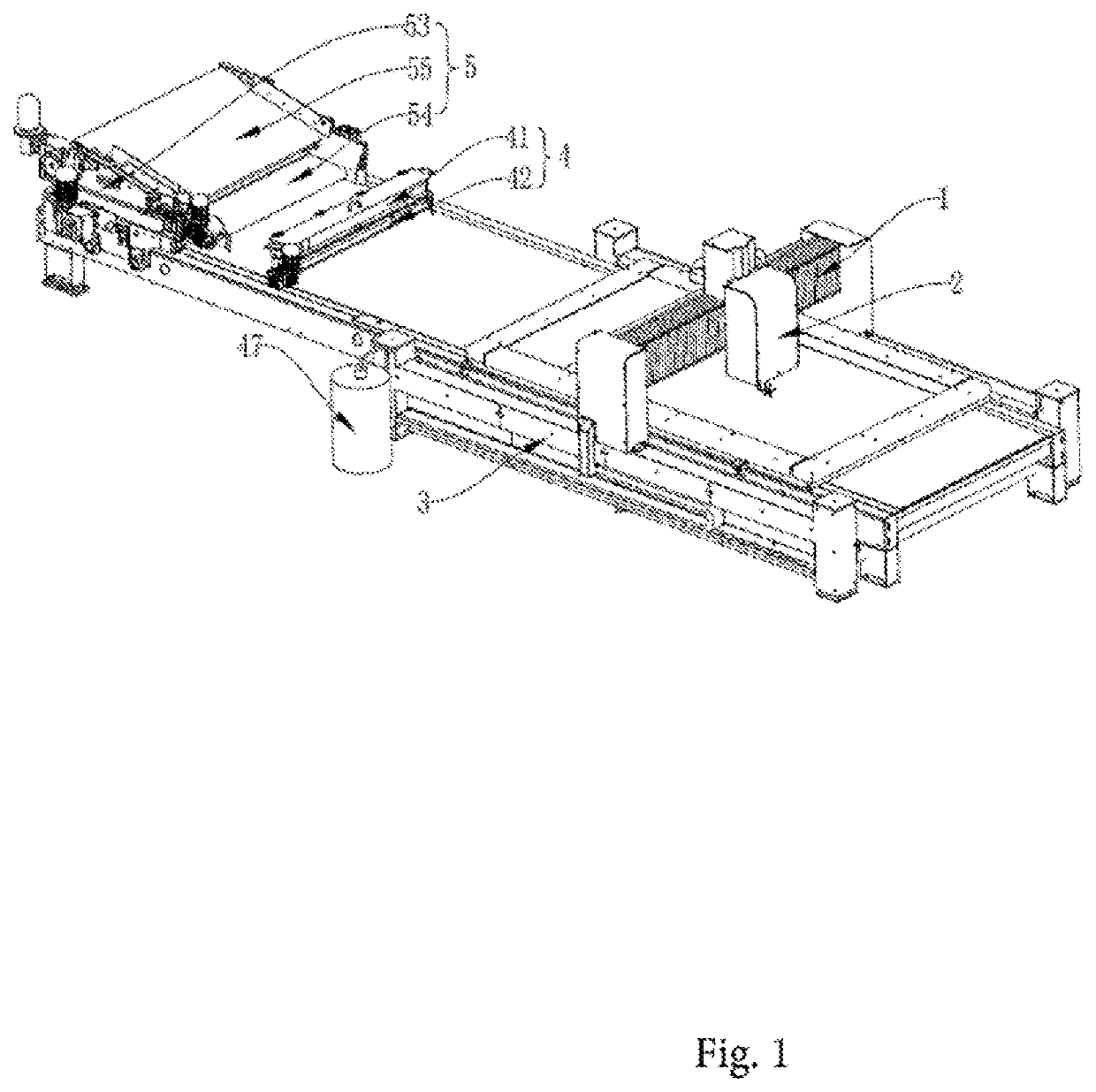

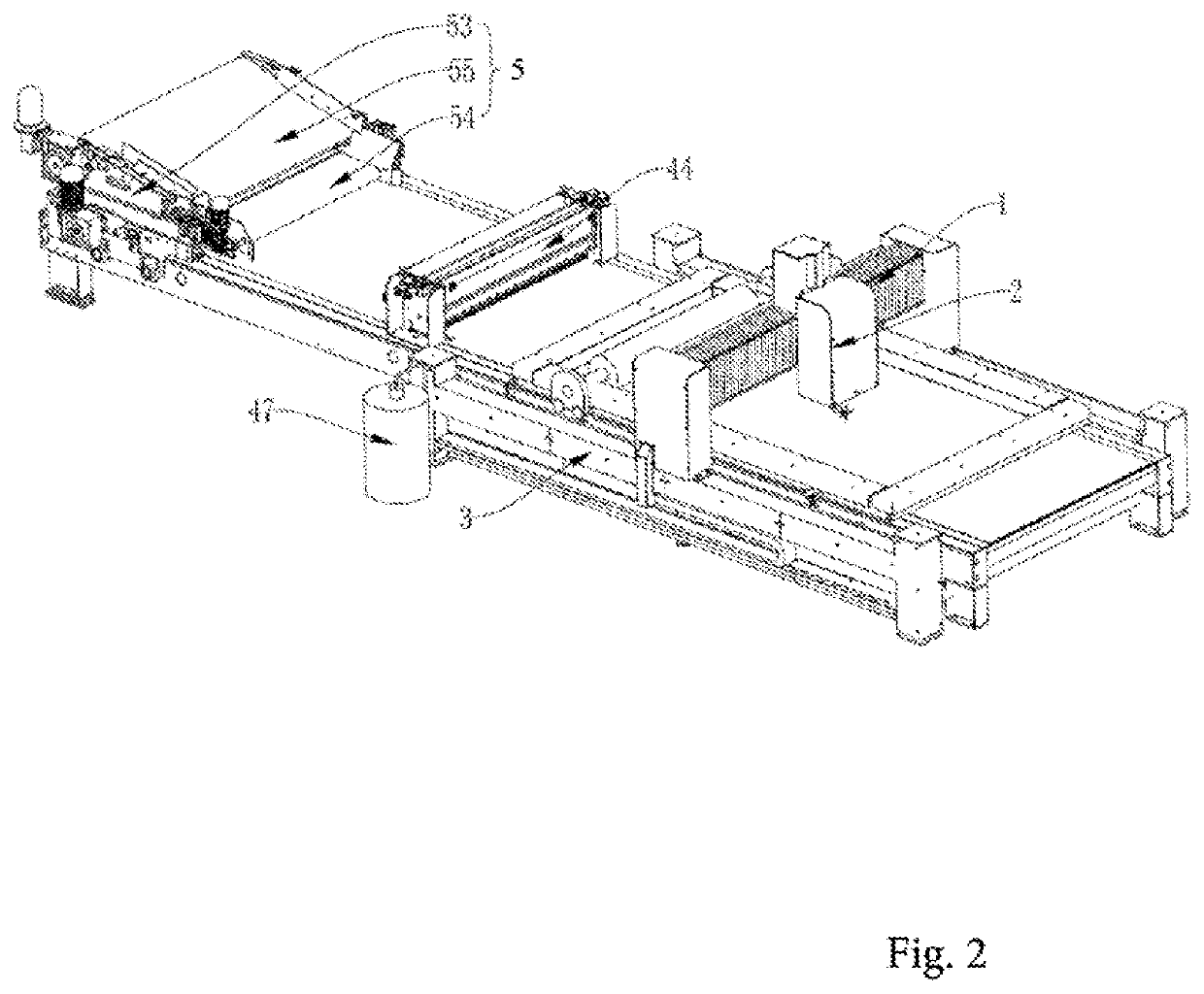

An interlayer mixing apparatus for texturing man-made stone slabs has a pressing assembly, a coloring component, a stirring assembly, a moving assembly, and a control system. A conveyor belt sequentially conveys a slab to working areas of the pressing assembly, the coloring component, and the stirring assembly which are separately connected to the control system. The pressing assembly presses the slab before the pigment and the slab are stirred, so that the texture boundary on the final product is clearer and more complete. The control system moves the moving assembly to position the stirring assembly according to a texture route, while the stirring assembly performs stirring on a part of the surface of the slab, to stir a pigment layer with a raw material layer on the slab.

Owner:VEEGOO TECH CO LTD

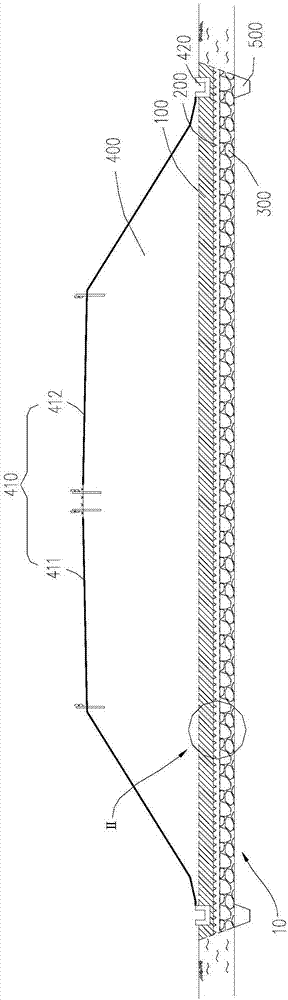

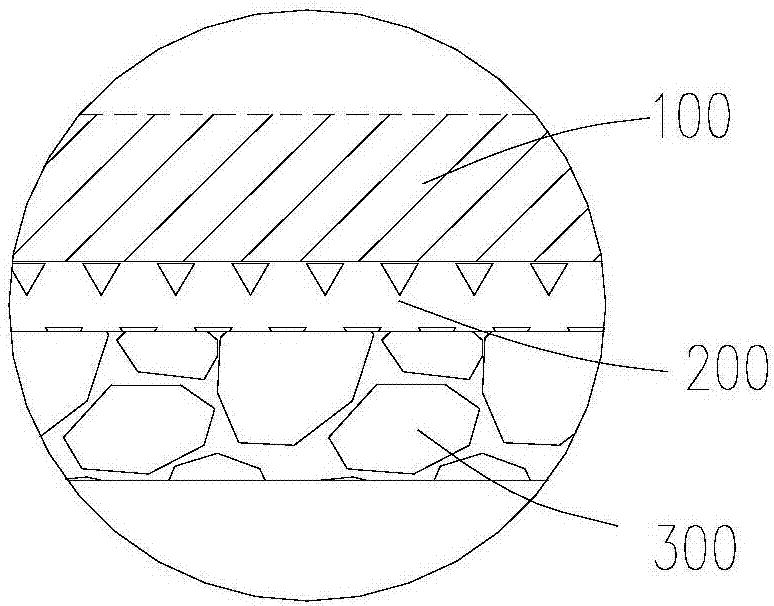

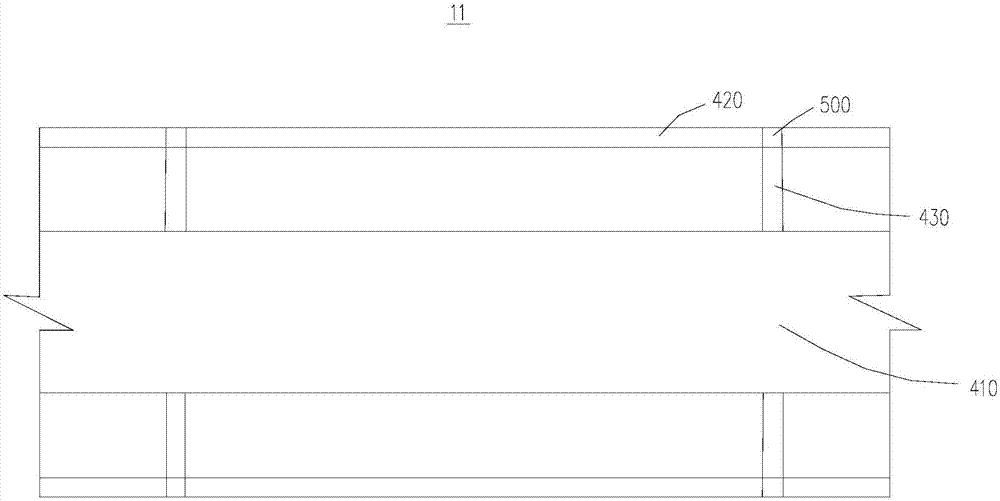

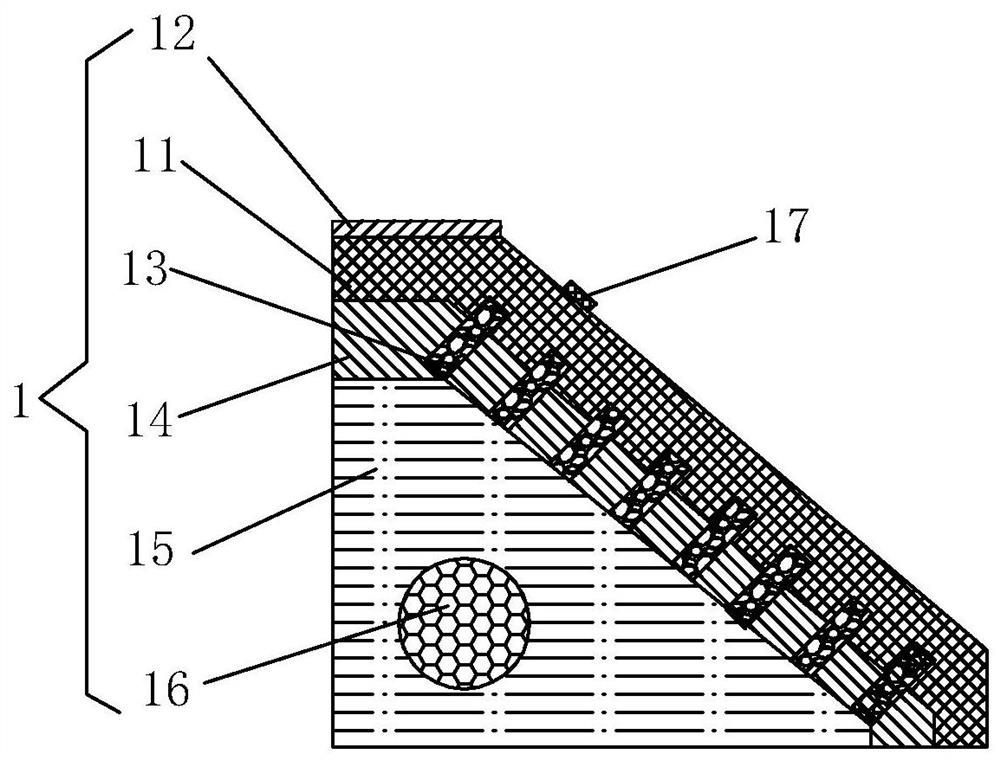

Composite replacing and filling structure and treatment method for valley-type soft soil

PendingCN106978770AImprove the effect of treatmentThe treatment effect can reach a good standardRoadwaysFlagstoneSoil science

The invention provides a composite replacing and filling structure and treatment method for valley-type soft soil, and relates to the field of soft soil foundation treatment. The composite replacing and filling structure suitable for the valley-type soft soil in granite areas can be applied to rapid replacing and filling treatment of the valley-type soft soil in the granite areas, and comprises a granite residual soil layer, a rubble layer and a flagstone layer from top to bottom, wherein flagstones are arranged at the bottom of a foundation pit, rubbles are laid on the flagstones to serve as a transition layer, and the granite residual soil layer is laid on the rubble layer. The invention further provides the treatment method which is applied to the replacing and filling structure for the valley-type soft soil in the granite areas. By adoption of the replacing and filling structure and the treatment method for the valley-type soft soil in the granite areas, the granite residual soil can be excavated fully; and compared with out-purchased materials such as flagstones, rubbles and gravels for replacing and filling of soft soil foundations, replacing and filling cost of the soft soil foundations is reduced, construction time is shortened, and thus good and desirable soft soil foundation treatment effects are achieved.

Owner:GUANGXI COMM PLANNING SURVEYING & DESIGNING INST

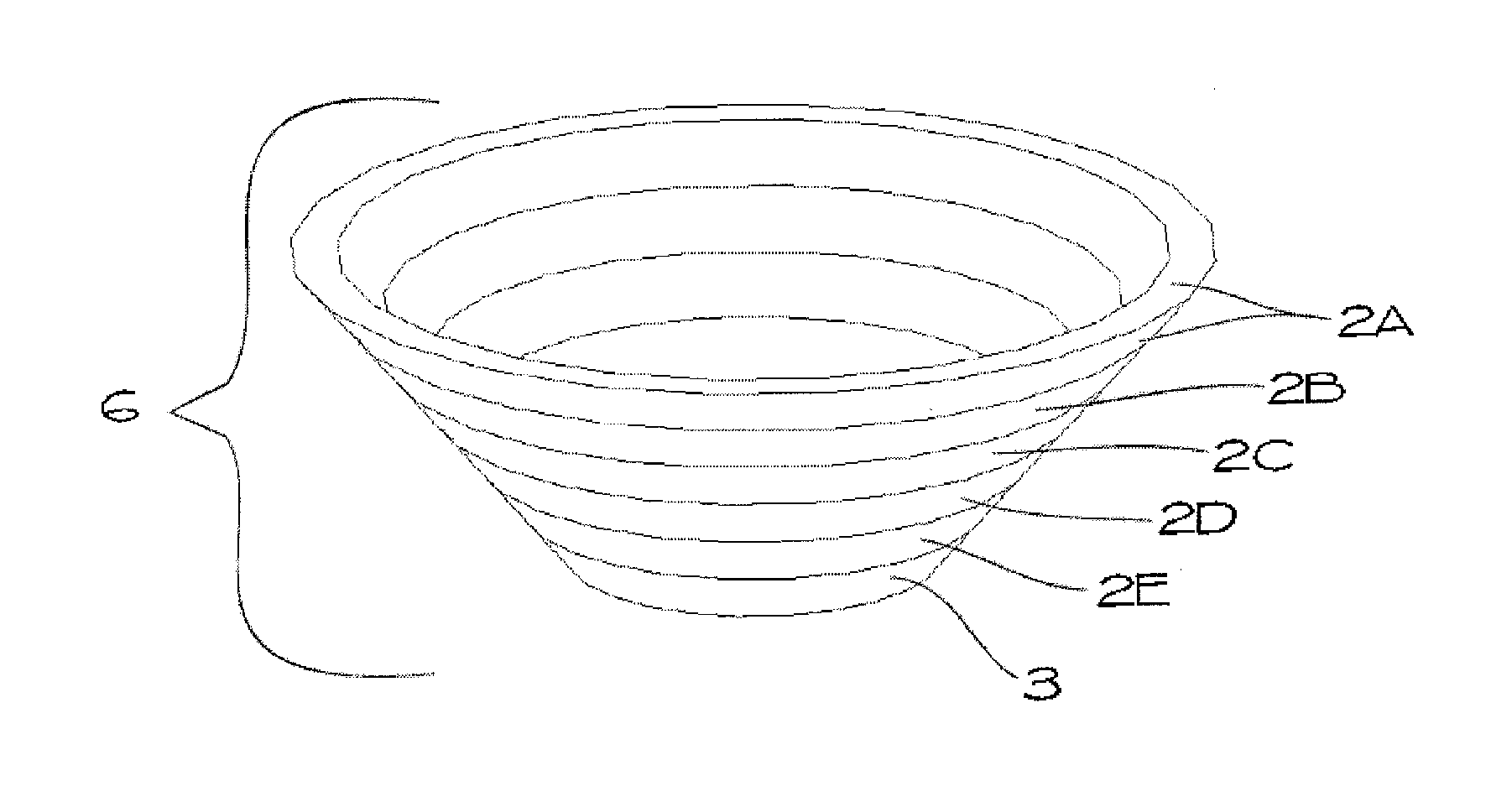

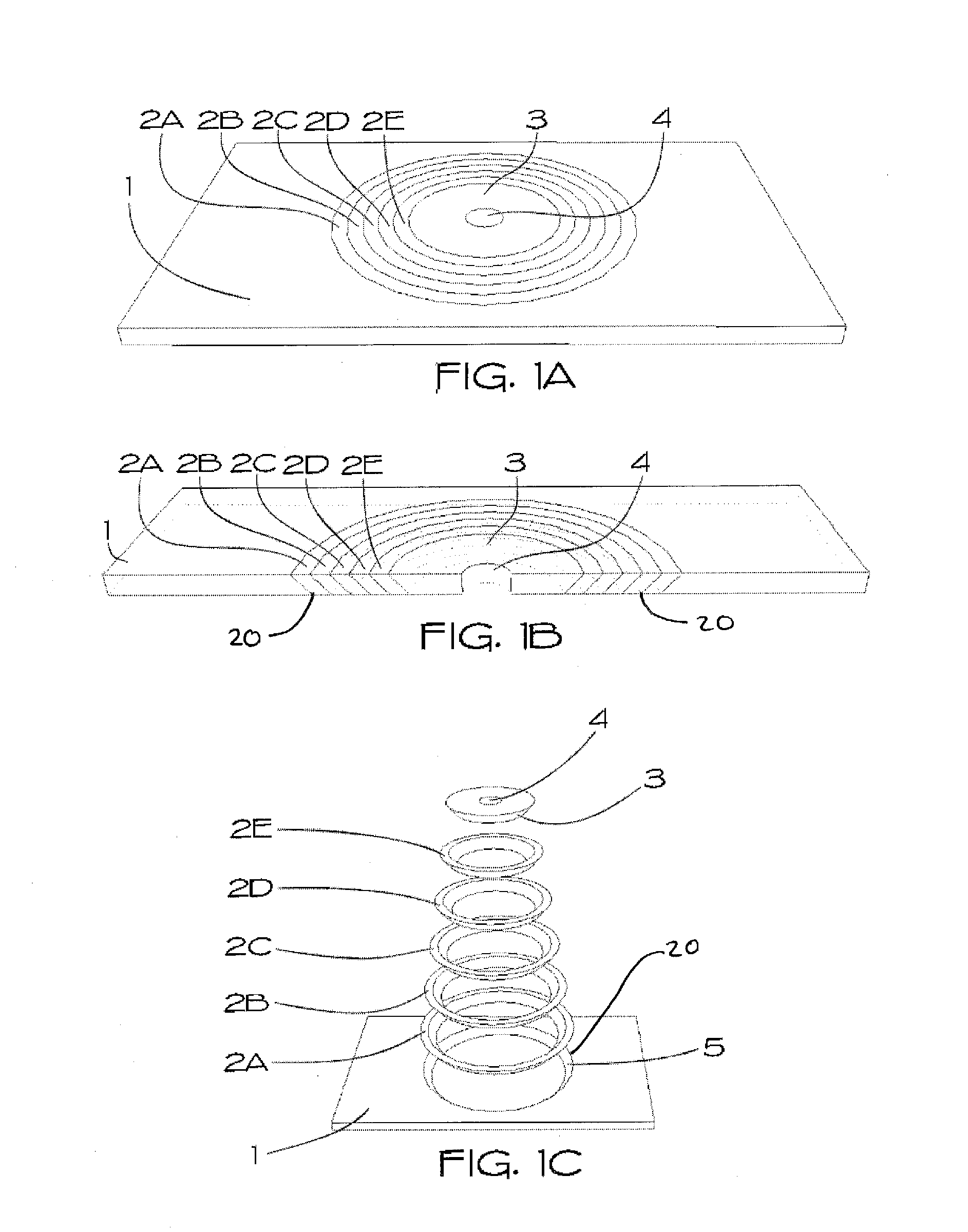

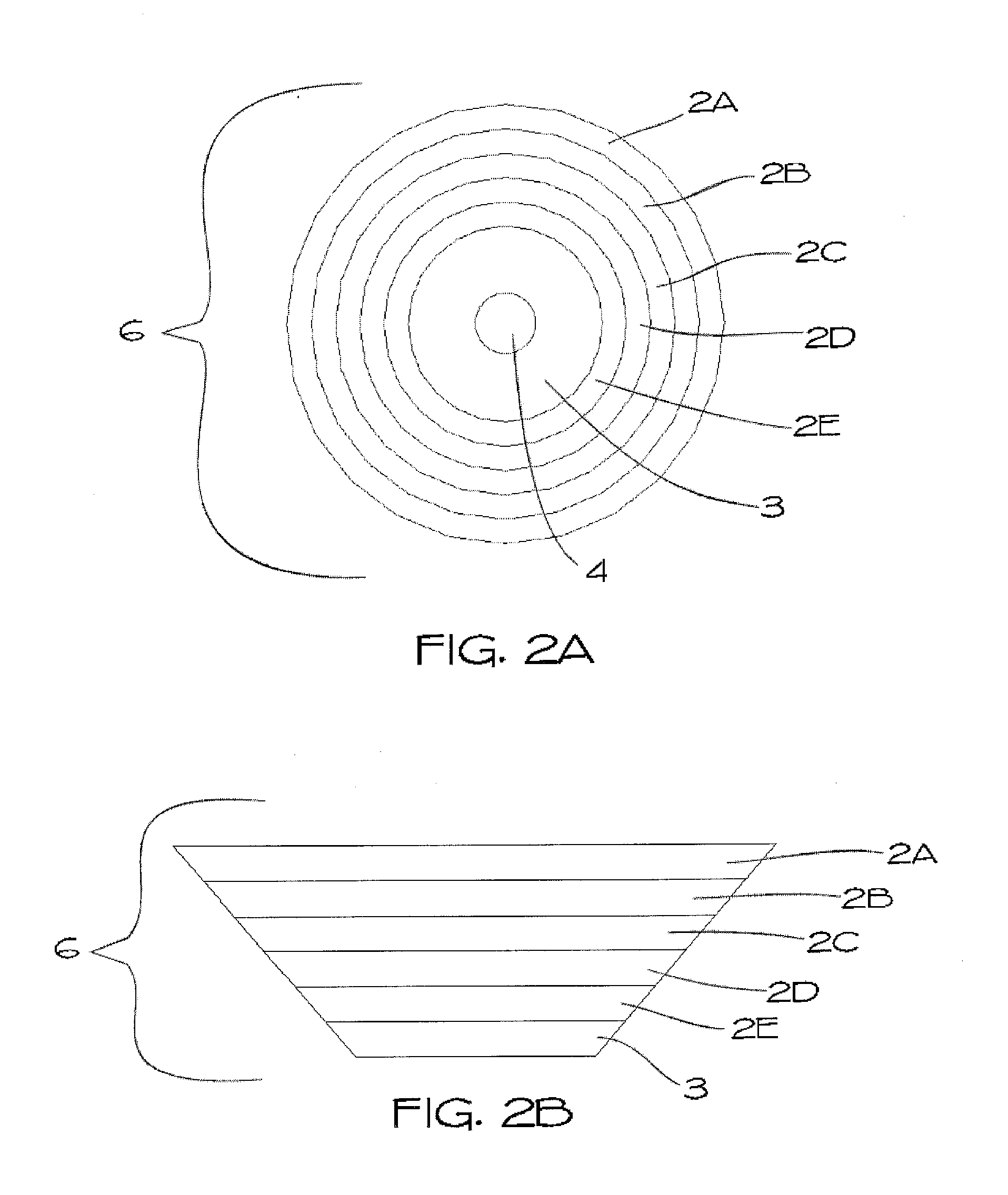

Basin

A basin manufactured from a solid slab of stone having a depth of multiple times the thickness of the original slab, which may match the naturally occurring patterns of said slab when used as a countertop, and a method of producing the same.

Owner:CASEY MICHAEL

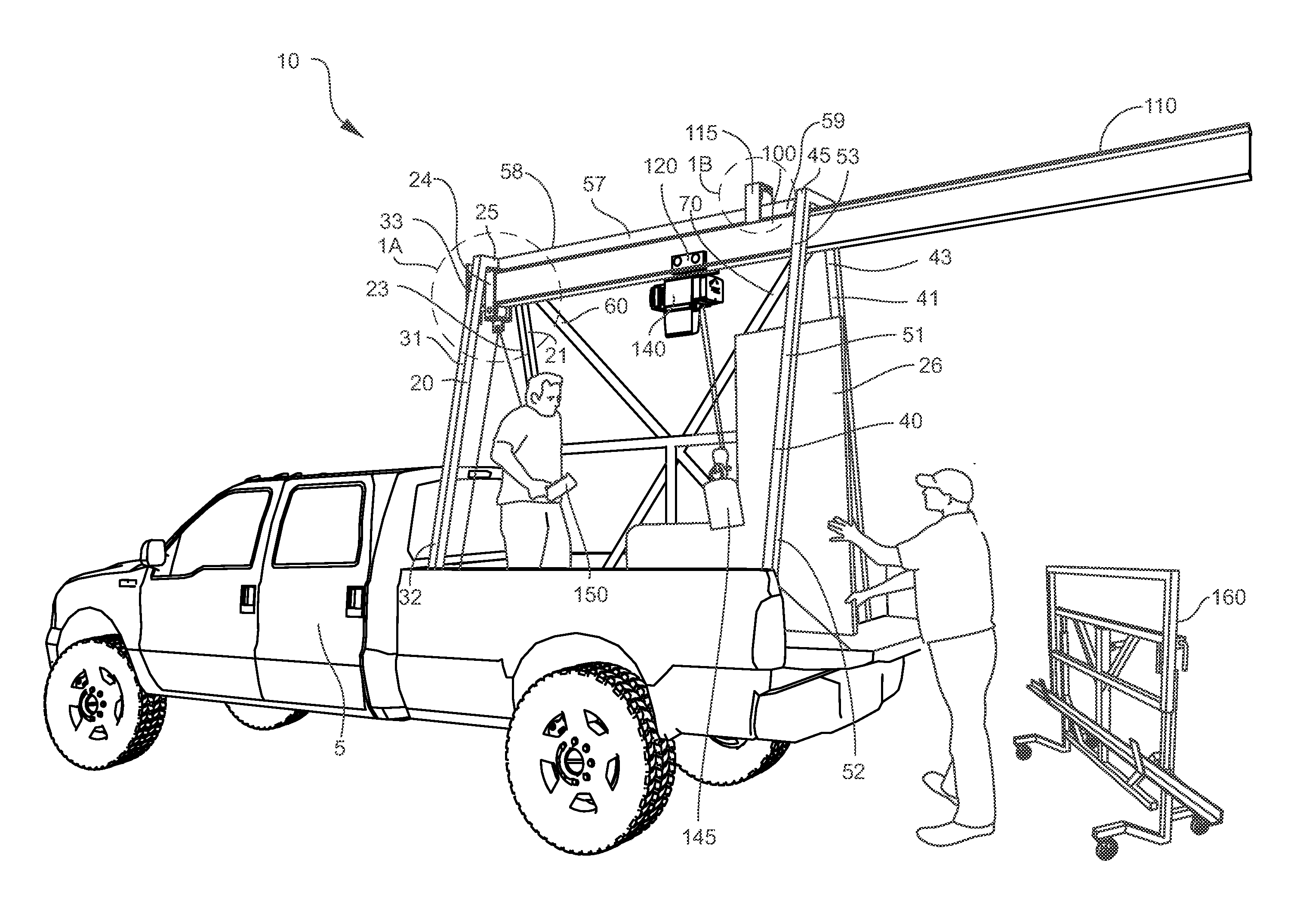

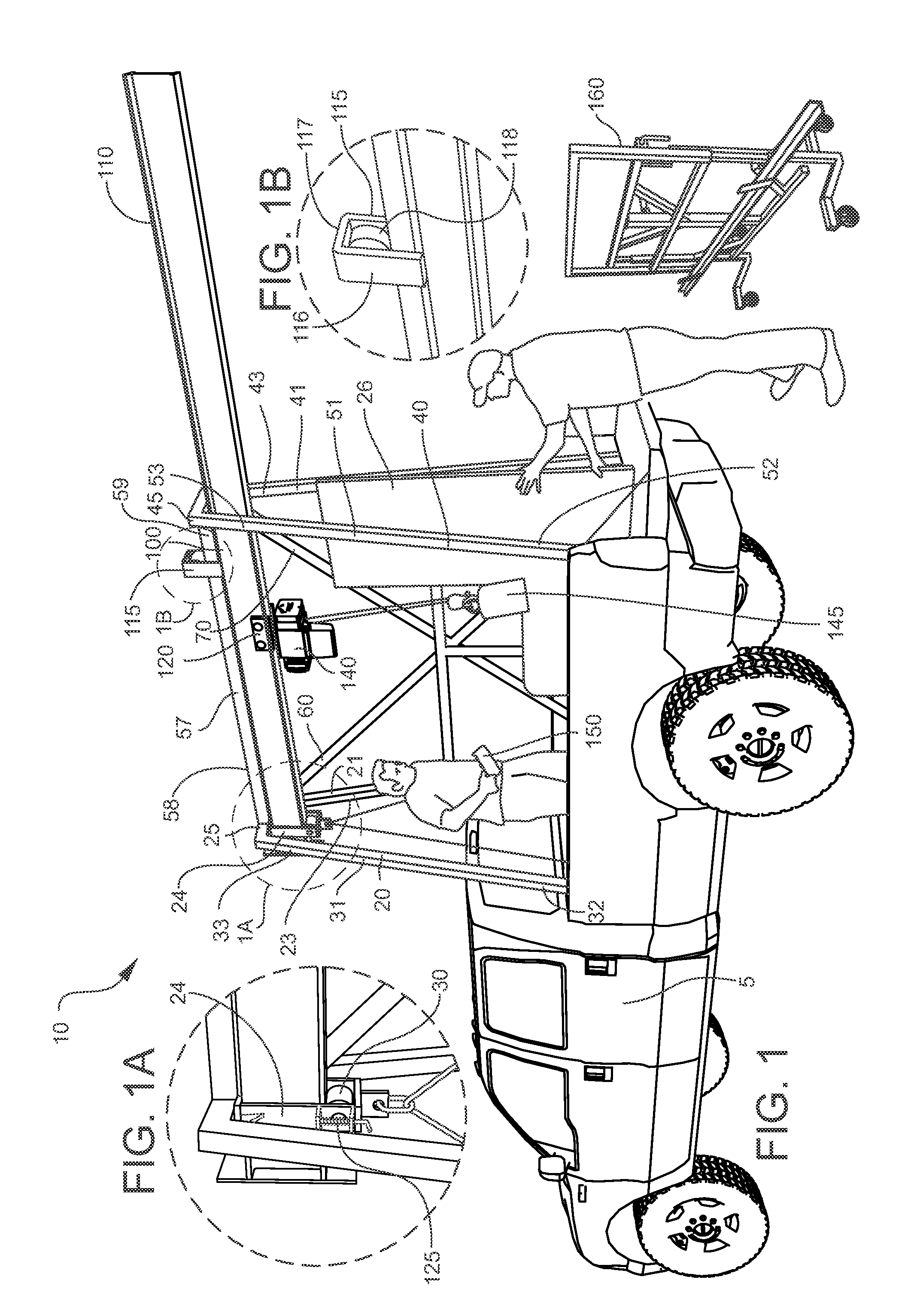

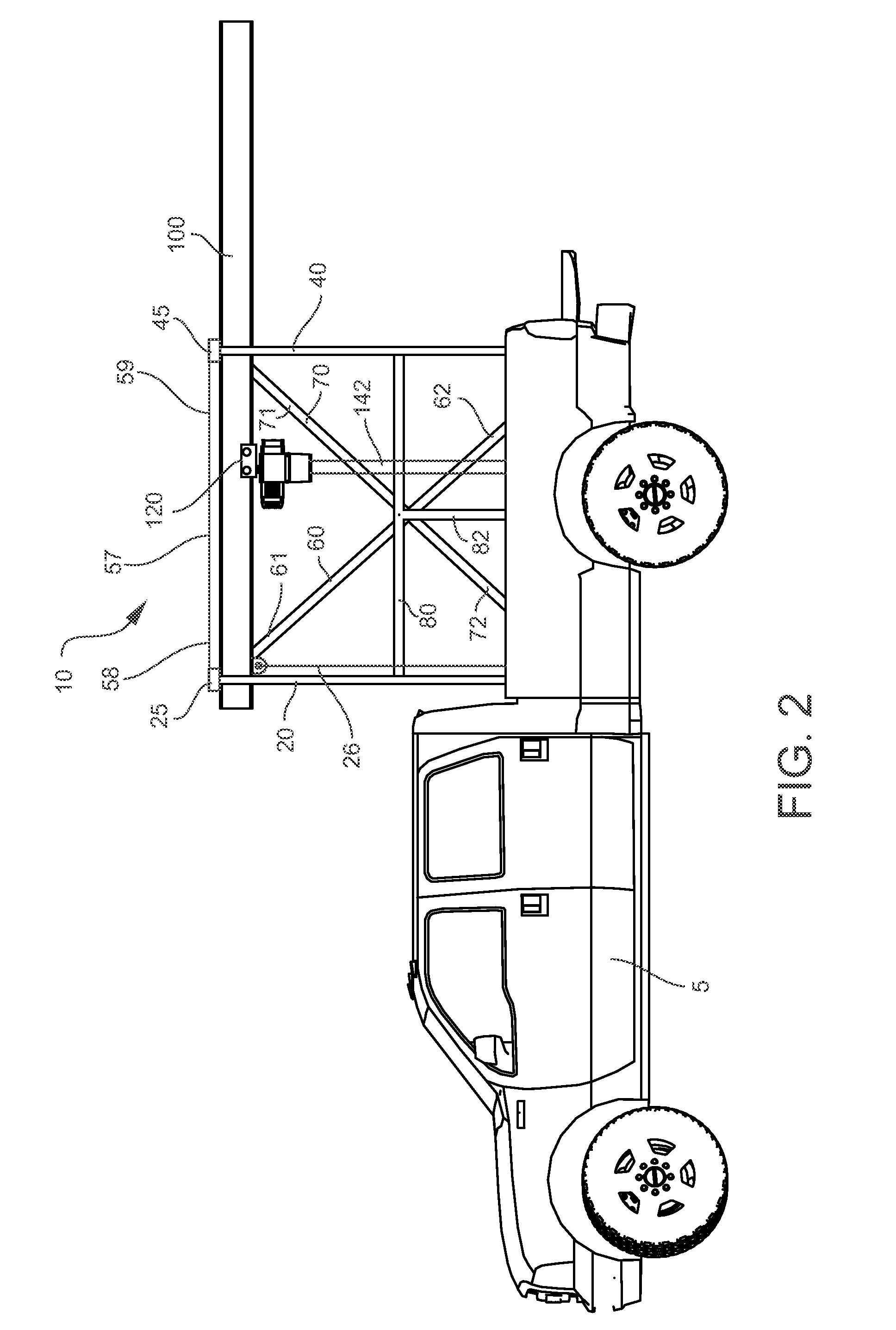

Vehicle Crane

InactiveUS20160039325A1Aid in stabilizationVehicles with cranesRefuse receptaclesEngineeringBack support

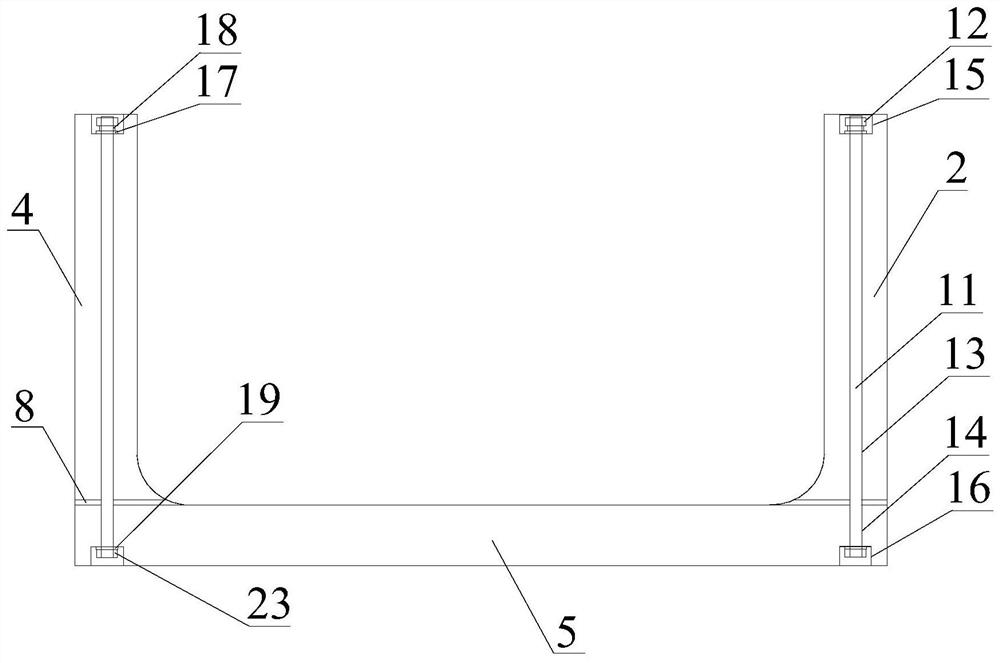

A crane system for loading and unloading stone slabs comprising: a front support structure including: a pair of vertical legs each secured at a bottom end to the bed or wall of a vehicle; a front horizontal cross beam secured to a top end of the vertical legs; a back support structure including: a pair of vertical legs each secured at a bottom end to the bed or wall of a vehicle; a back horizontal cross beam secured to a top end of the vertical legs; a pair of bracing members secured to the vertical legs and to each other to aid in the stabilization of the system; a horizontal lift beam slideably secured to the front and back horizontal cross beams; a trolley assembly slidably secured to the horizontal lift beam; and a hoist mechanism secured to the trolley assembly.

Owner:SEPTIMIO AUGUSTO P

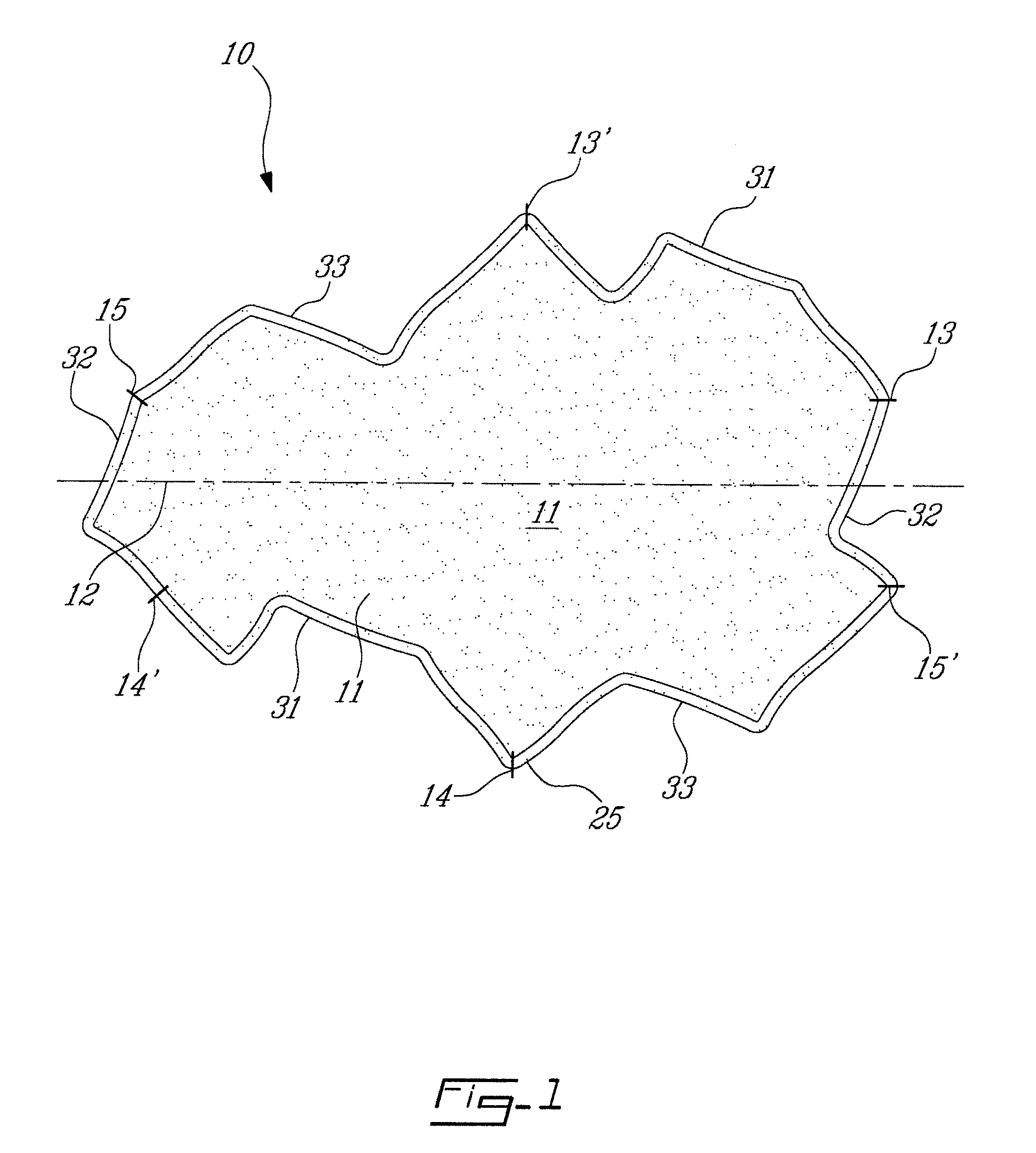

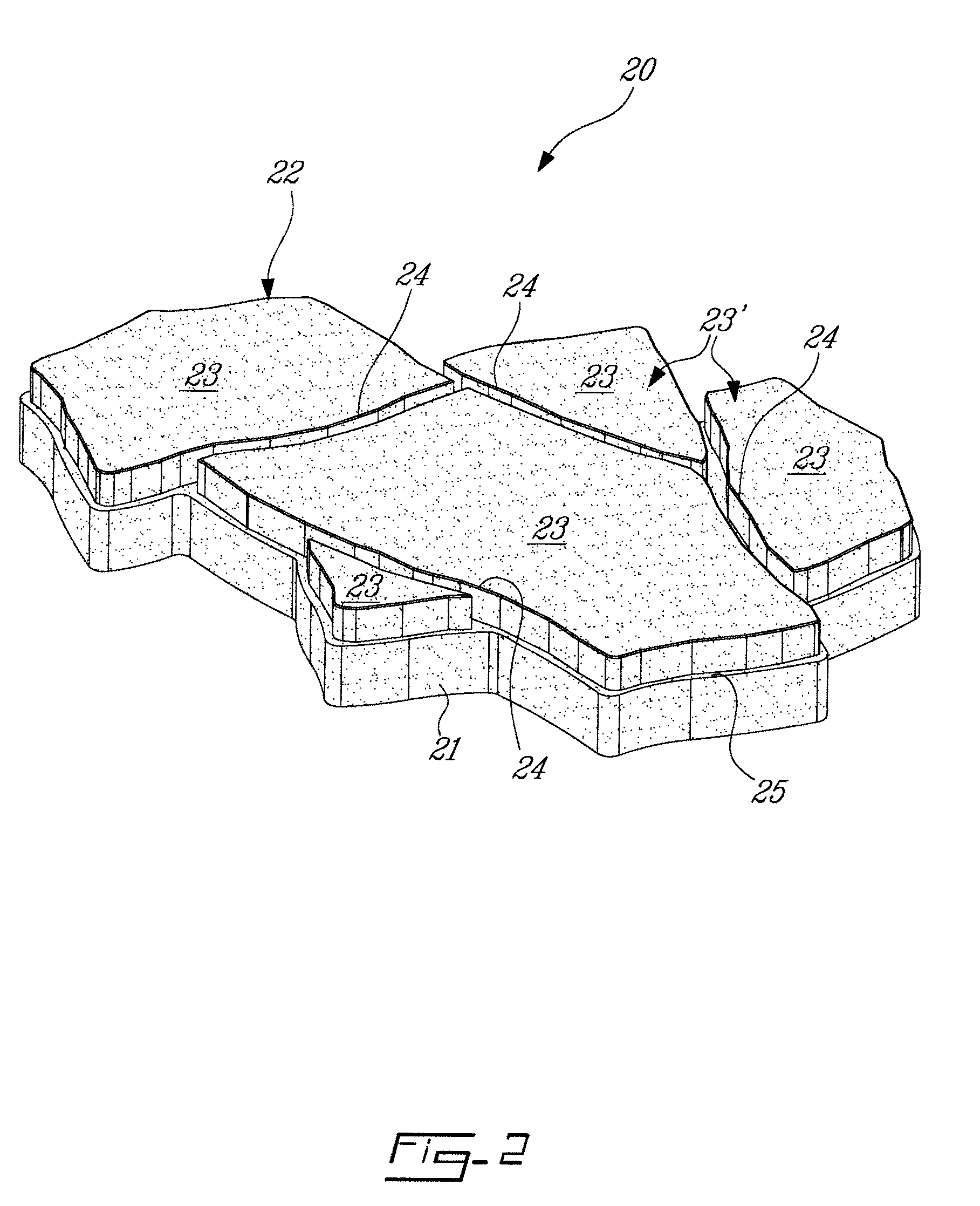

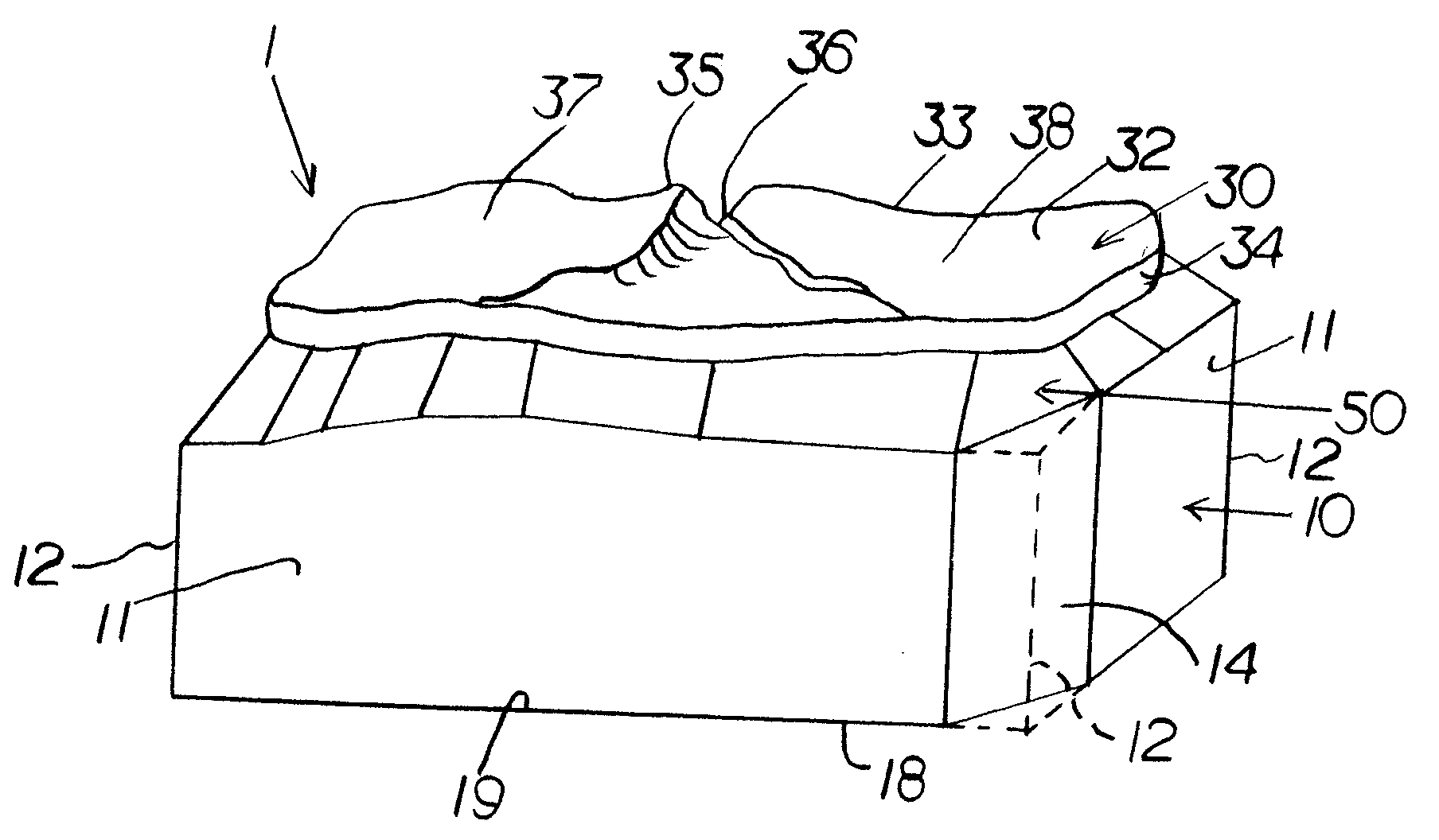

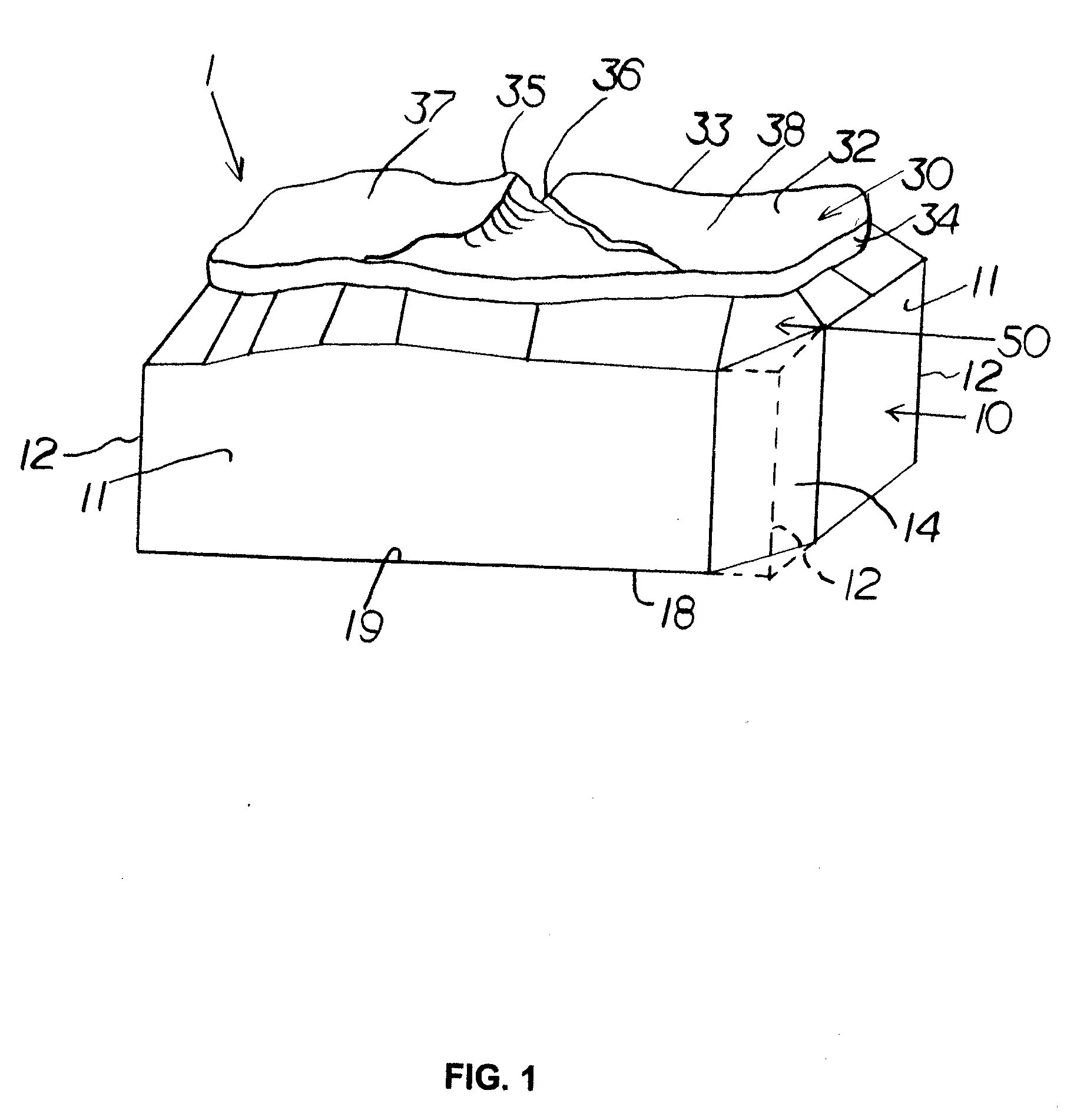

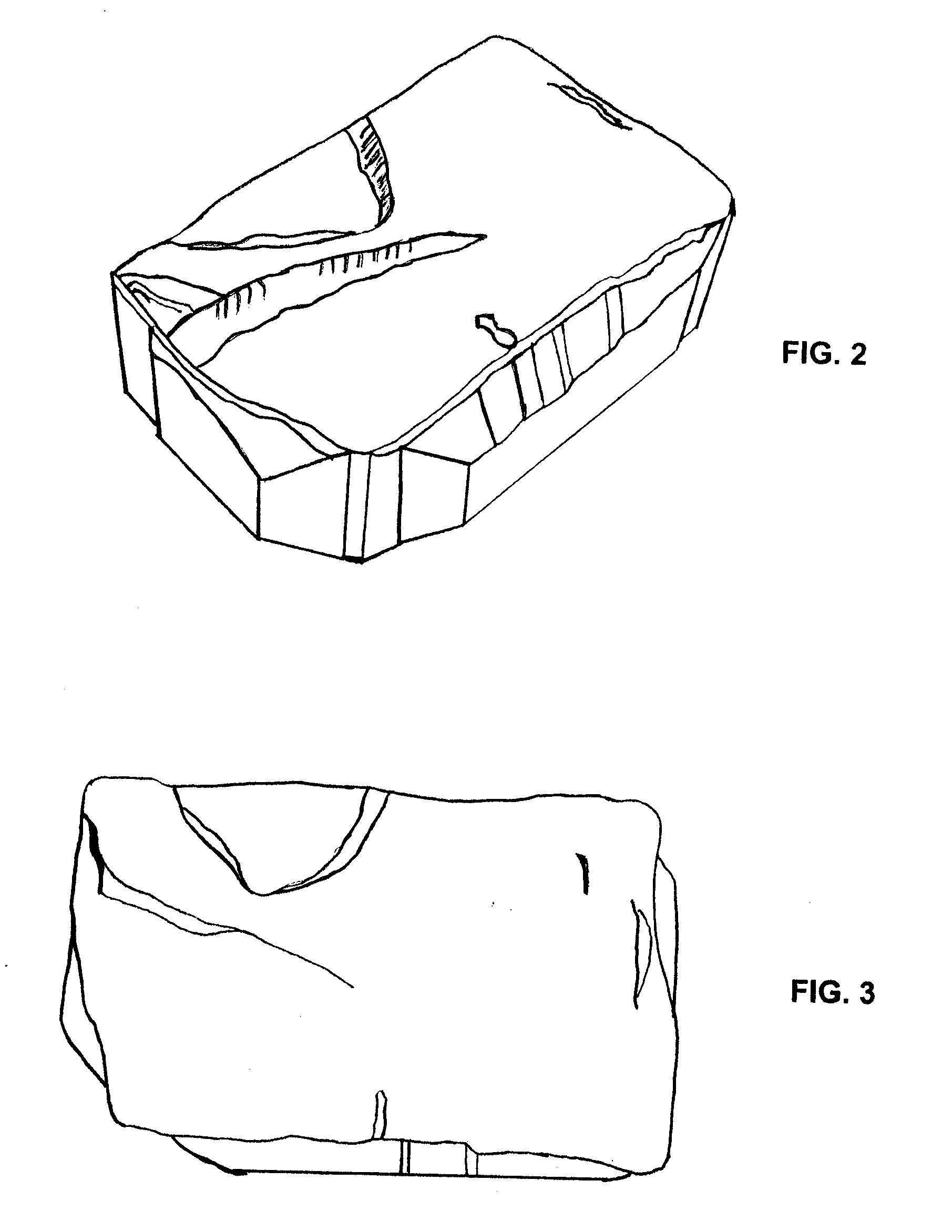

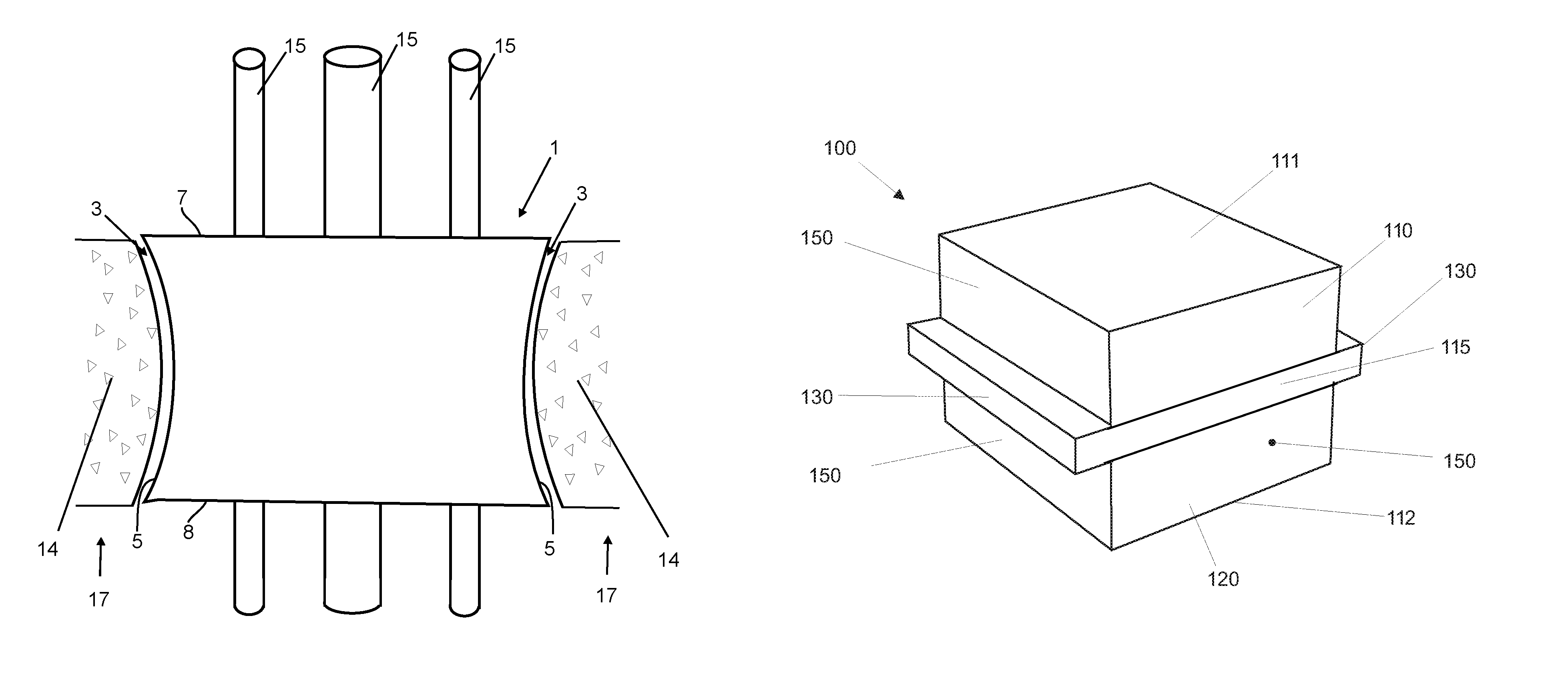

Artificial flagstone

ActiveUS20090155497A1Reliable surface coveringIncrease variabilityHair accessoriesDead plant preservationFlagstoneRepeat pattern

An artificial stone is disclosed for use in creating a covering a supporting surface. The artificial stone includes a base portion for placement on the supporting surface, which base portion is shaped as a right regular prism for patterned, fitting arrangement of the flagstone with like flagstones to produce a continuous surface covering. The base portion has a regular base contour. The stone further includes a top portion with a facing surface, the facing surface having an irregularly shaped top contour different from the base contour and an intermediate portion connecting the top portion with the base portion. The intermediate portion has an inclined wall extending between the top portion and a sidewall of the base portion. Stones of this construction can easily be arranged in a regular, repeated pattern to generate a continuous covering for the supporting surface without the surface of the resulting covering having a regular, patterned appearance. The irregular top contours of the stones, simulate the appearance of natural stone.

Owner:LES MATERIAUX DE CONSTR OLDCASTLE CANADA

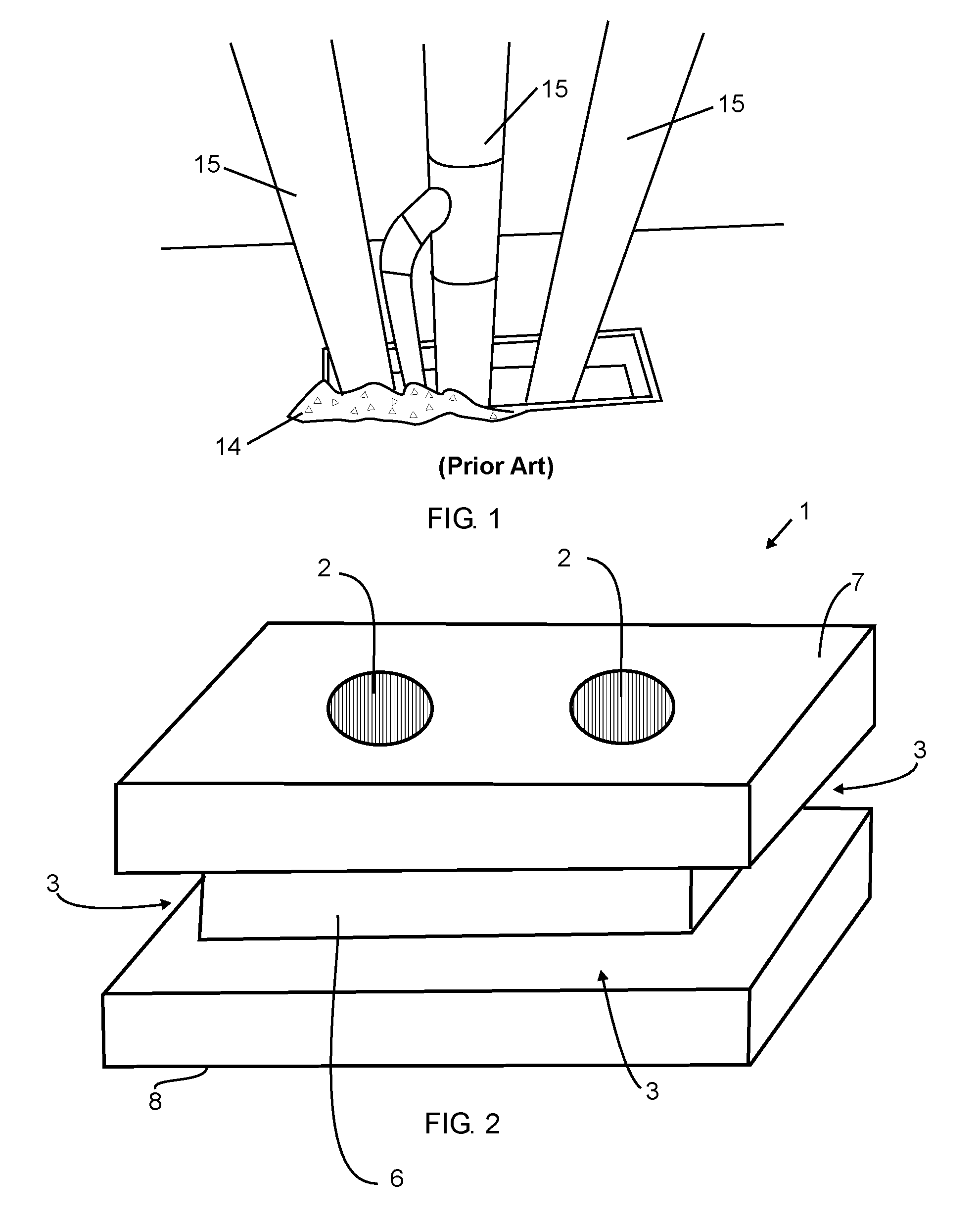

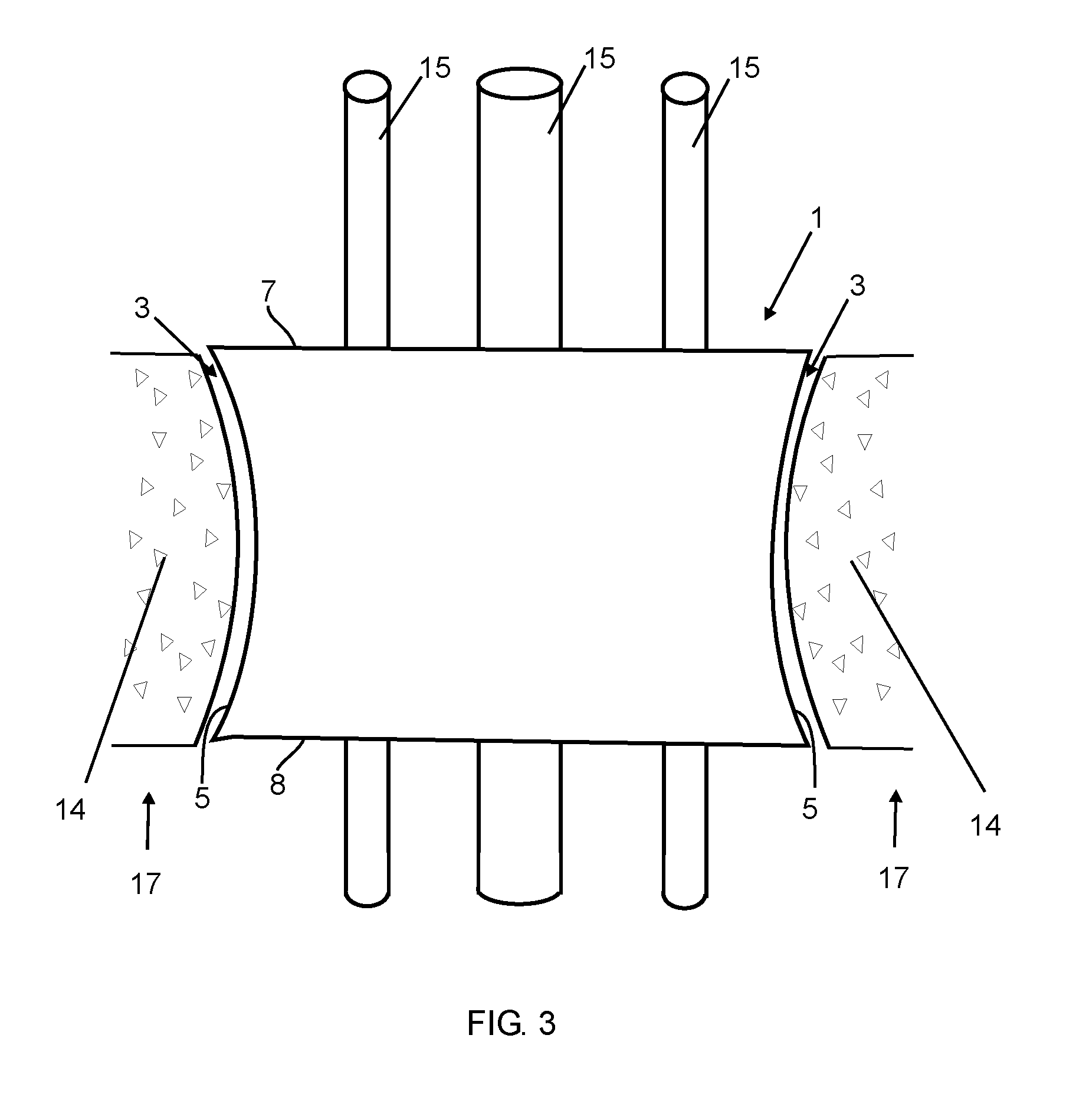

Supporting element for pipes in buildings and application method of a pipe supporting element in a flagstone

Owner:VICENTE DE AZEVEDO EBOLI MARIA ISABEL

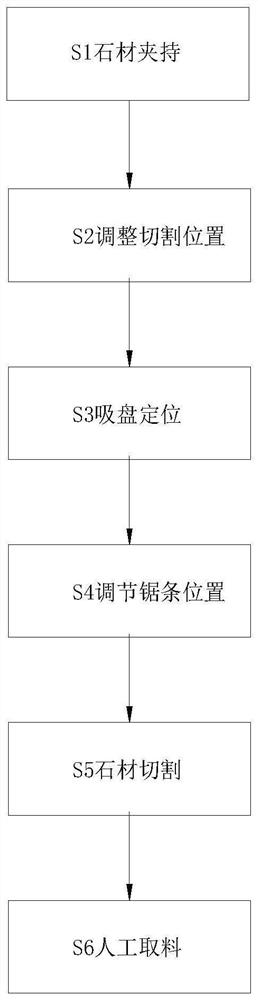

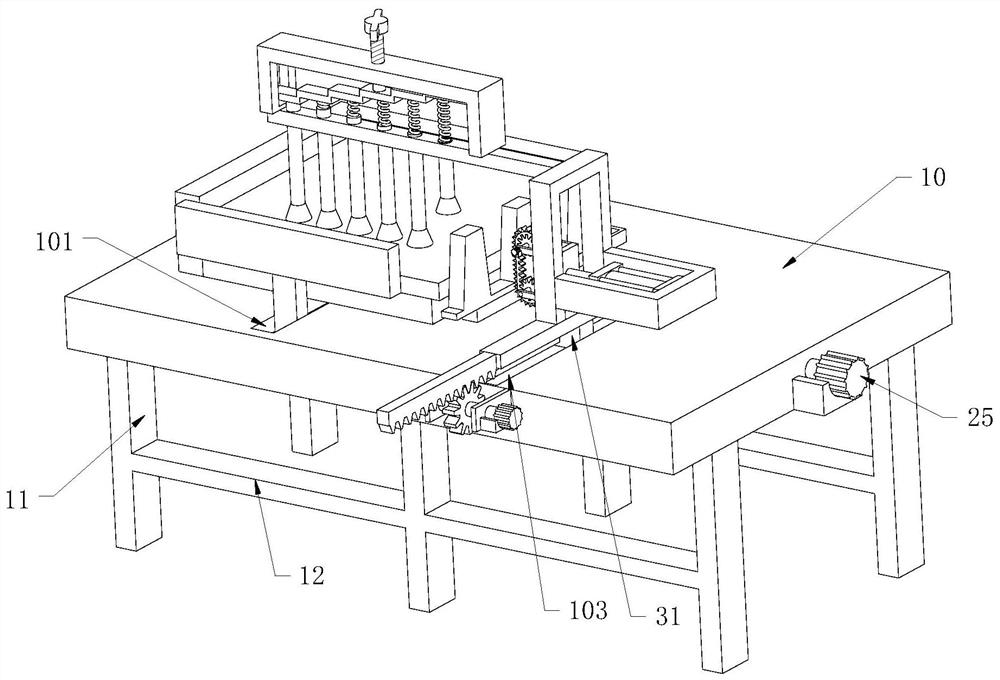

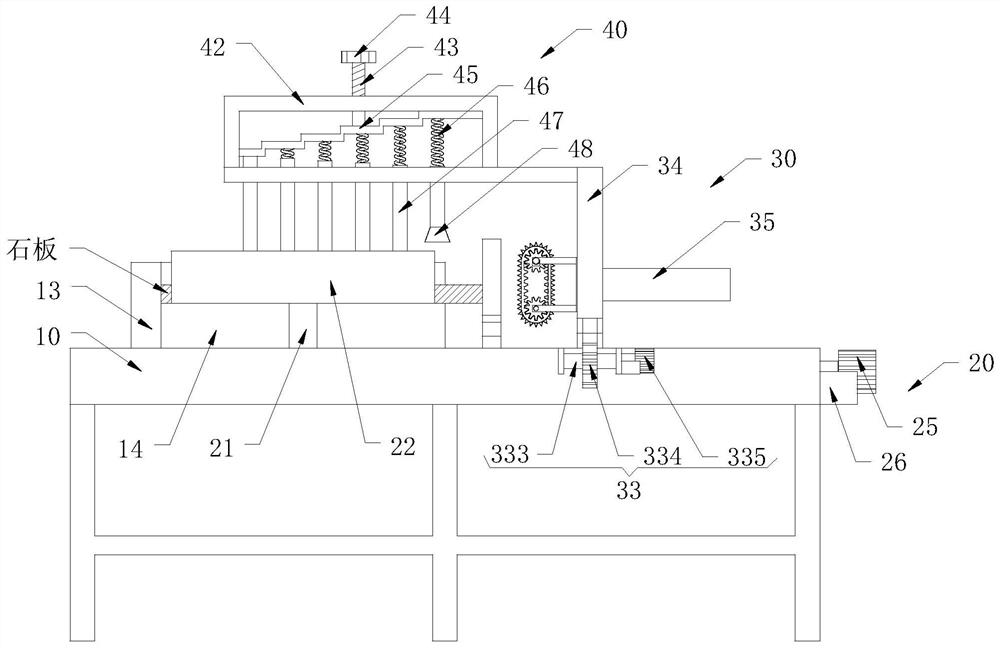

Stone processing and treatment method for indoor decoration material of building

InactiveCN112454679ANot easy to shiftAvoid offsetCovering/liningsWorking accessoriesLinear motionFlagstone

The invention relates to a stone processing and treatment method for an indoor decoration material of a building, and using stone processing and manufacturing equipment. The equipment comprises a workbench and a fixing device arranged at the top of the workbench, wherein a cutting device is arranged at the right side of a bottom plate, and a locating device is arranged at the left side of a firstn-shaped frame. According to the invention, an electric cross-shaped sliding block can move forwards in the width direction of a second cross-shaped groove through cooperation of designed locating baffle, fixing plate and second cross-shaped groove, the electric cross-shaped sliding block drives the locating baffle to move synchronously, and two groups of adjacent trapezoidal plates in the locating baffle are moved to the front end and the rear end of a drawn horizontal straight line; therefore, reciprocating linear motion of the locating baffle can be realized, the corners of a rectangular stone plate to be machined can be conveniently fixed and adjusted at the same time, the cutting machining position is not blocked, time and labor are saved, and the rectangular stone plate to be machined can be cut at any position.

Owner:南京乐飞电科技有限公司

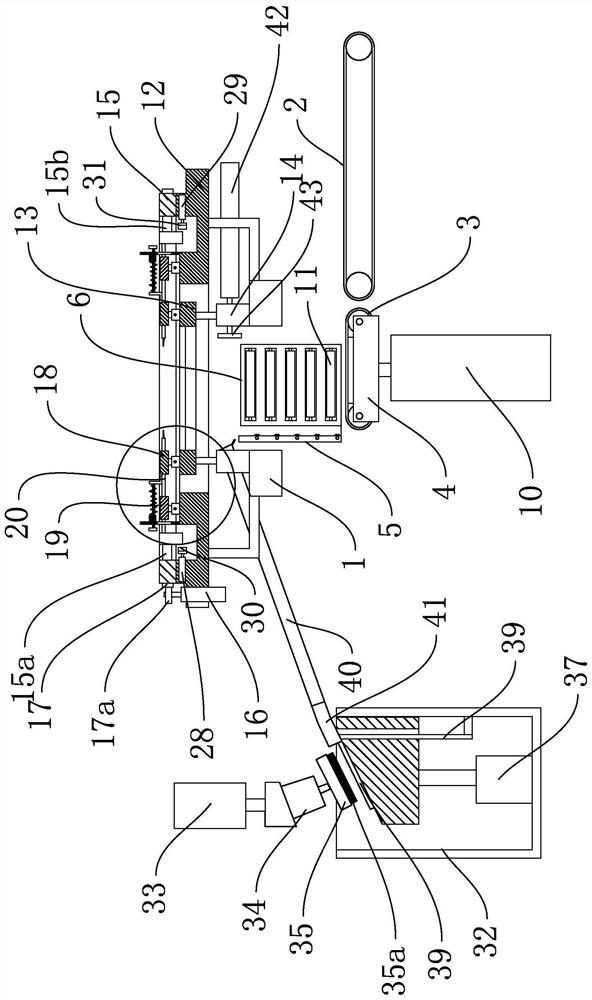

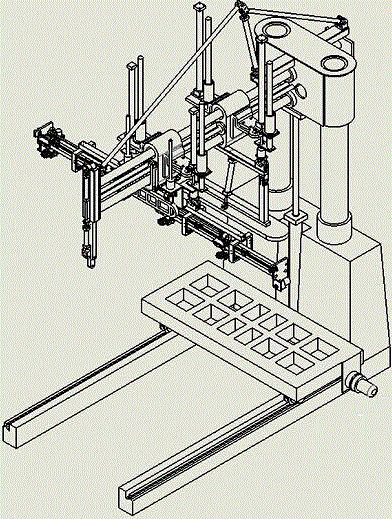

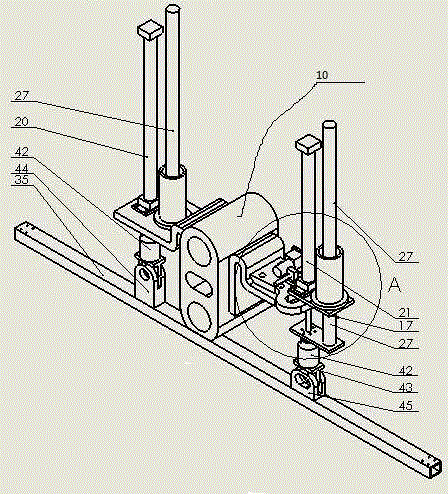

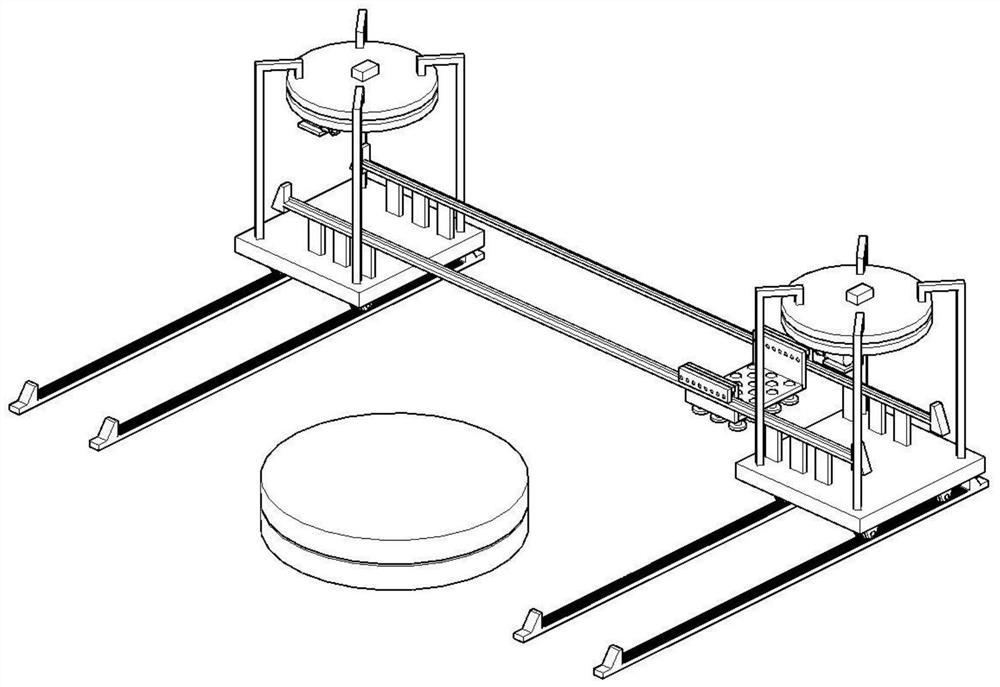

Automatic stone unloader

InactiveCN104441261ASmall footprintFully automaticWorking accessoriesStone-like material working toolsBogieFlagstone

An automatic stone unloader comprises an automatic slabstone relative-parallelism adjuster, an automatic large-grooving-parallelism adjuster, a frame, a cutting device, a clamp, a vacuum sucker and a bogie. The relative position of a crossbeam and stone can be adjusted by ascending and descending of the frame, the cutting device can cut a scar deep in 3-5mm at the joint of slabstone and stone, the slabstone can move forwardly and backwardly by the aid of the clamp with the vacuum sucker, the motion distance is + / -15mm, the scar at the joint of the slabstone and the stone can be separated, a manipulator with the vacuum sucker can suck the slabstone have separated from the stone, and after rising 50mm, the slabstone is leveled and moved to the upper side of the bogie and laid down. The automatic stone unloader has the advantages of small occupation space, full automation and high efficiency and safety, and can move optionally according to production needs.

Owner:曾华东

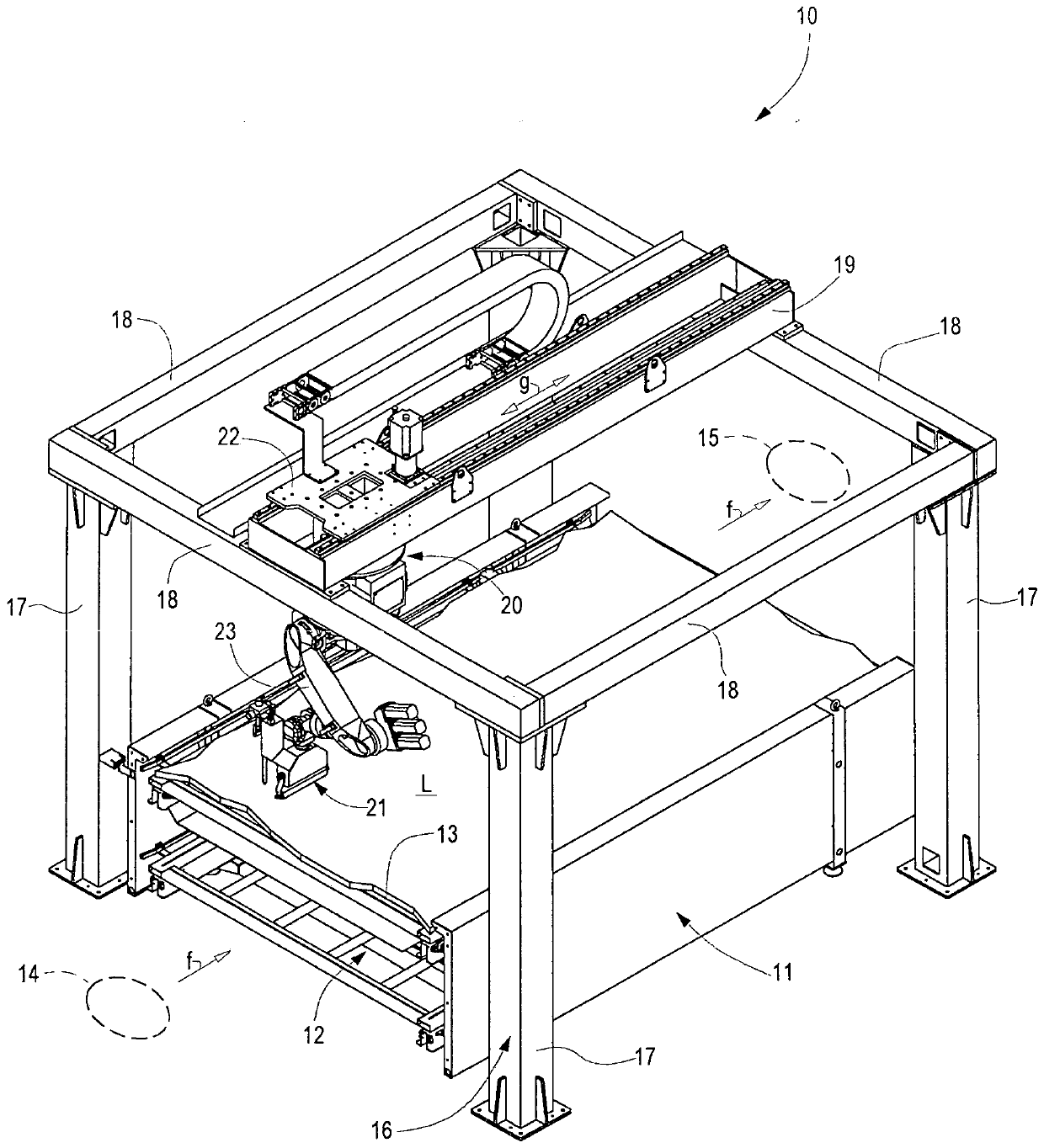

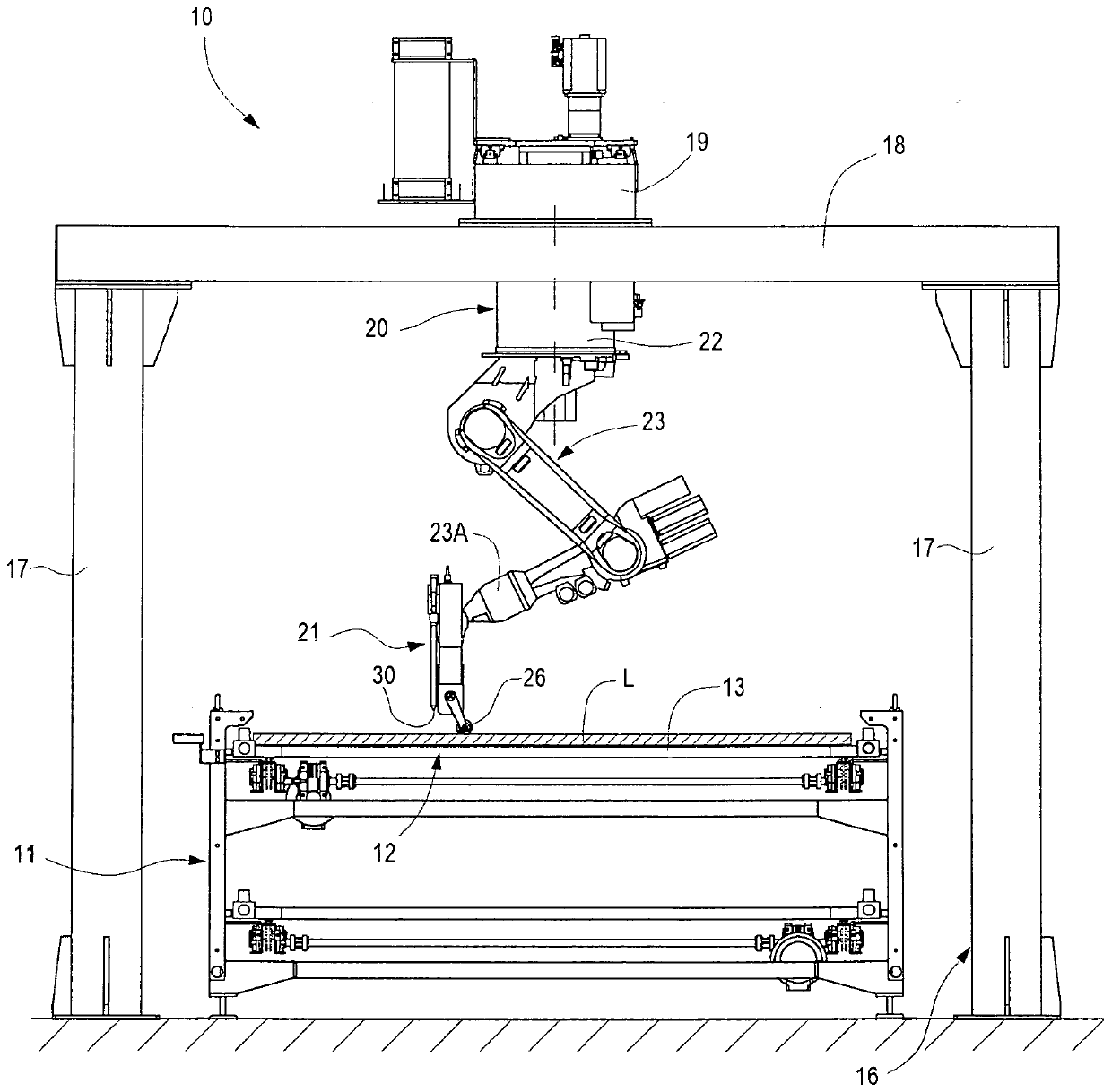

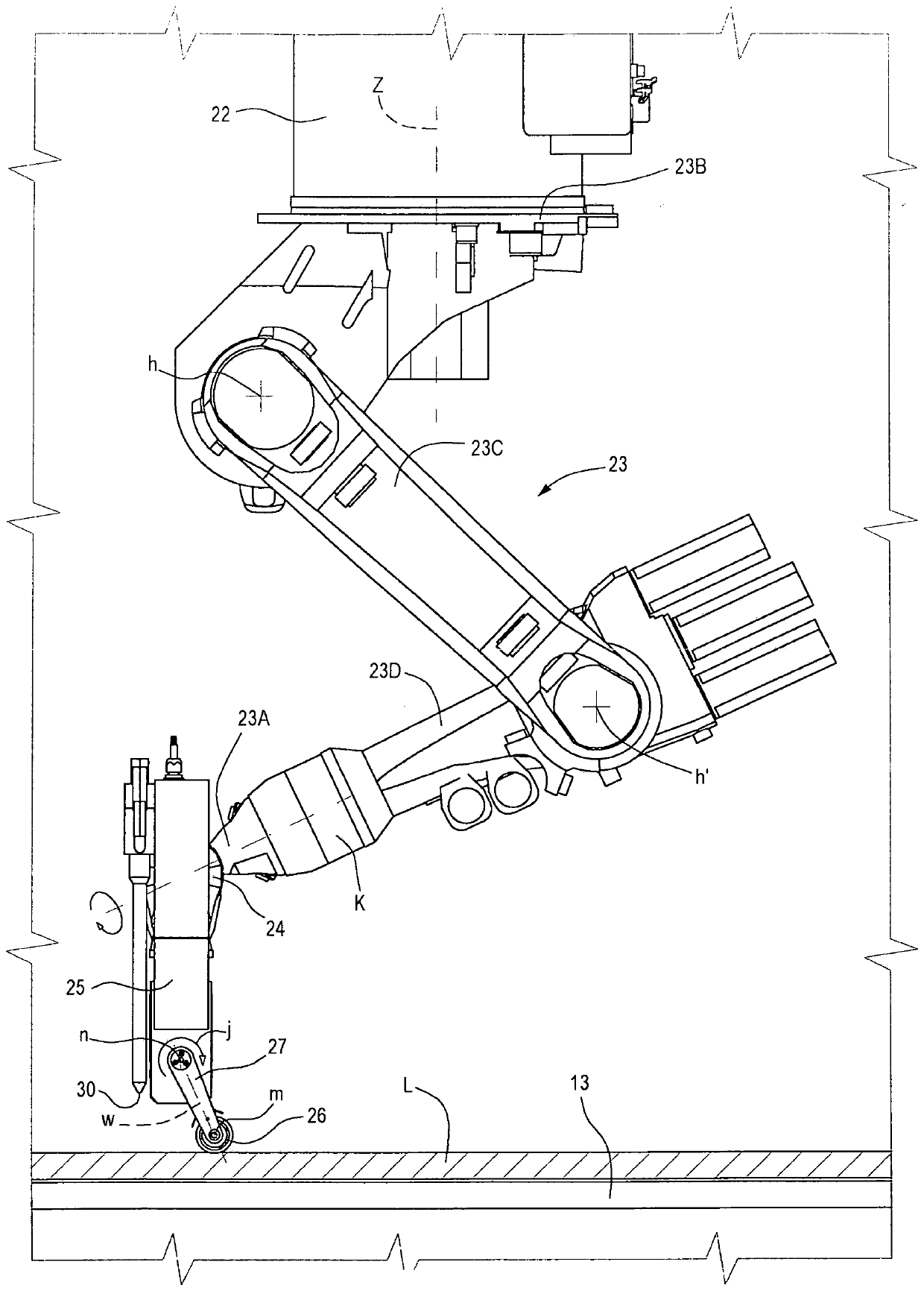

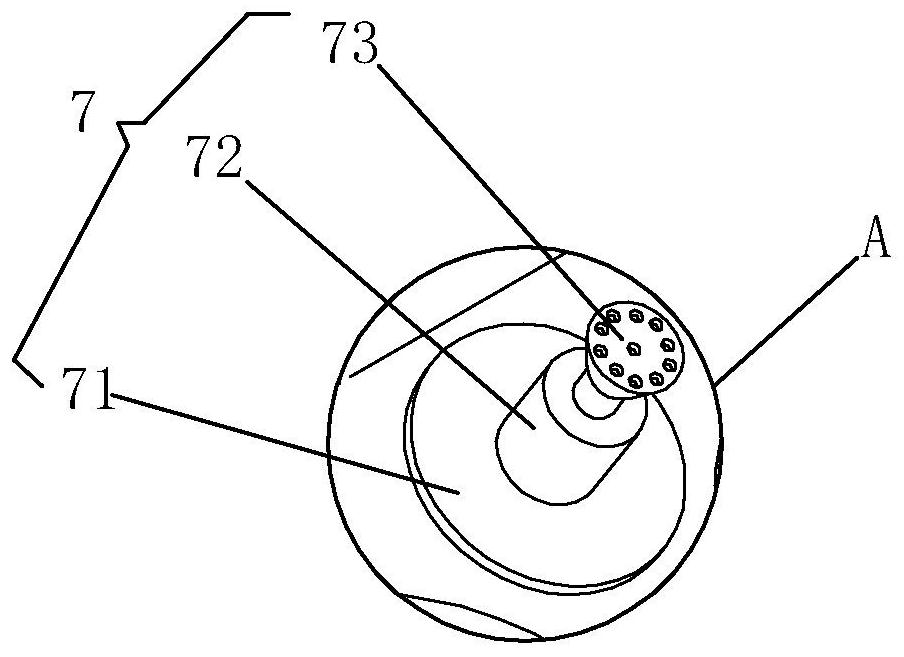

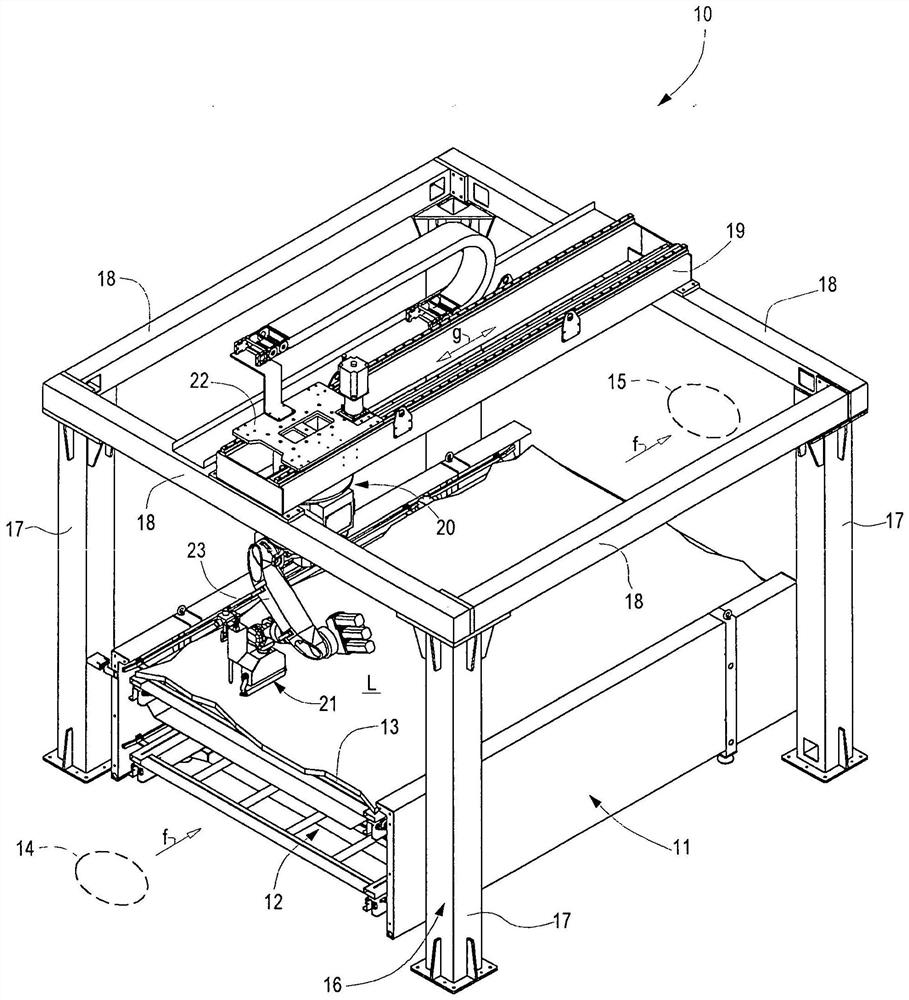

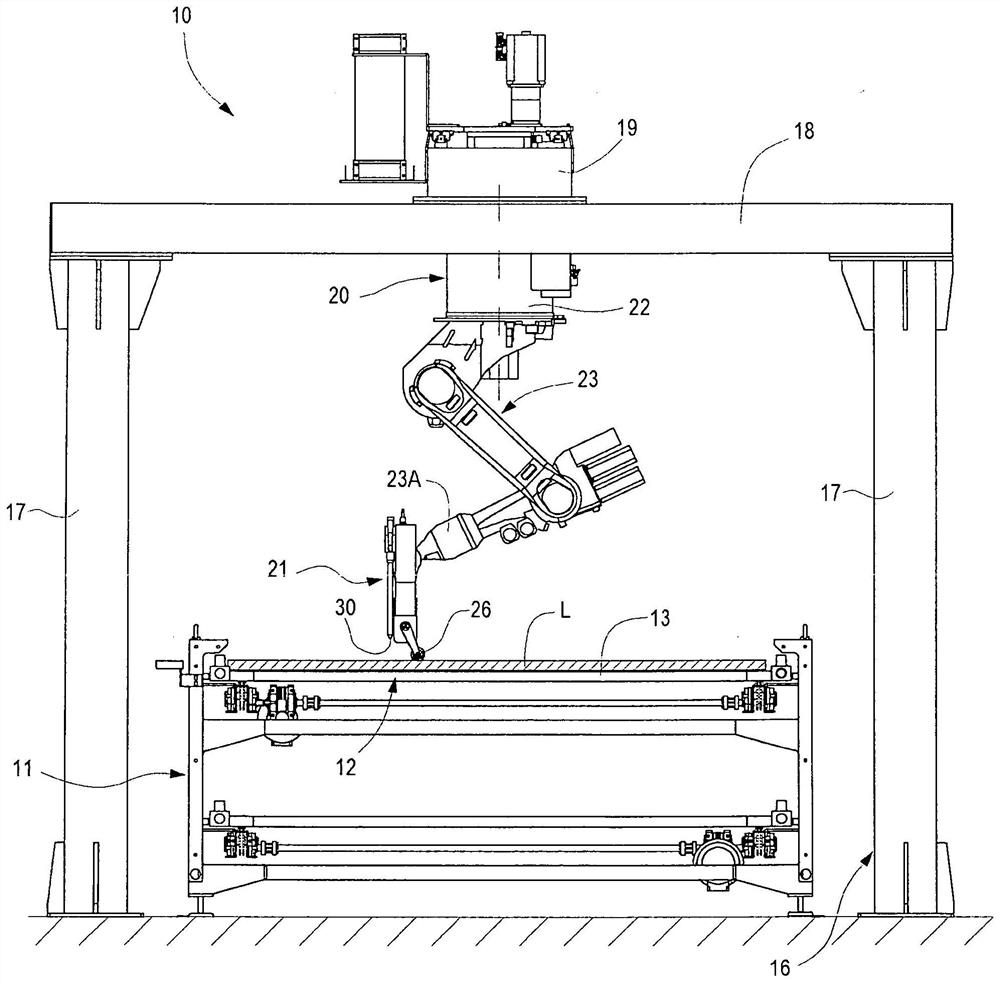

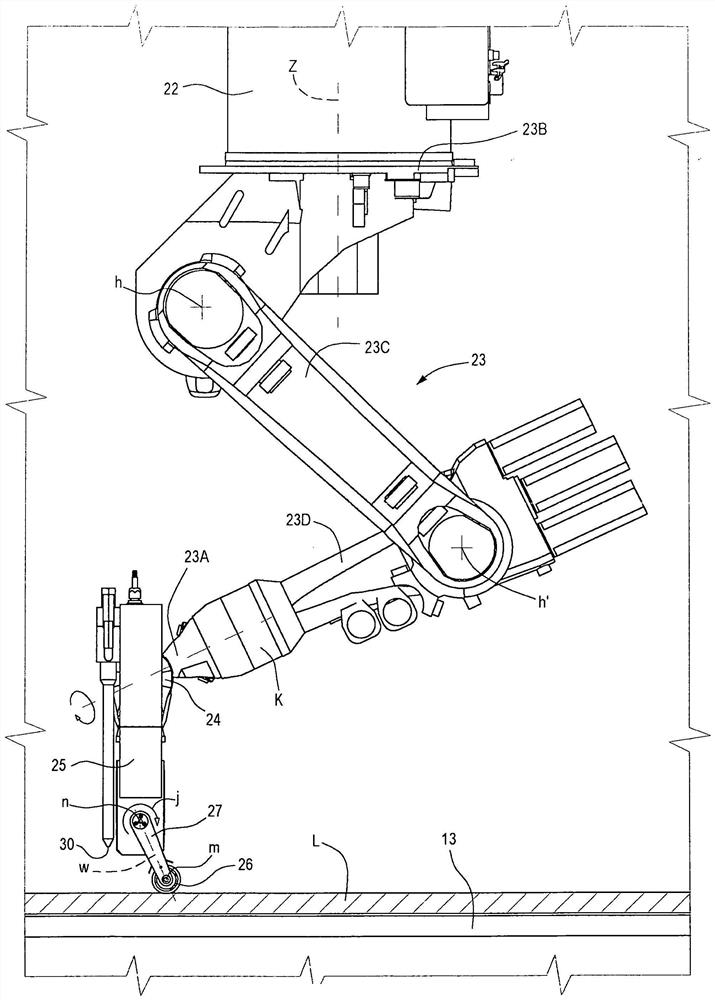

Station for applying fluid substances to stone materials

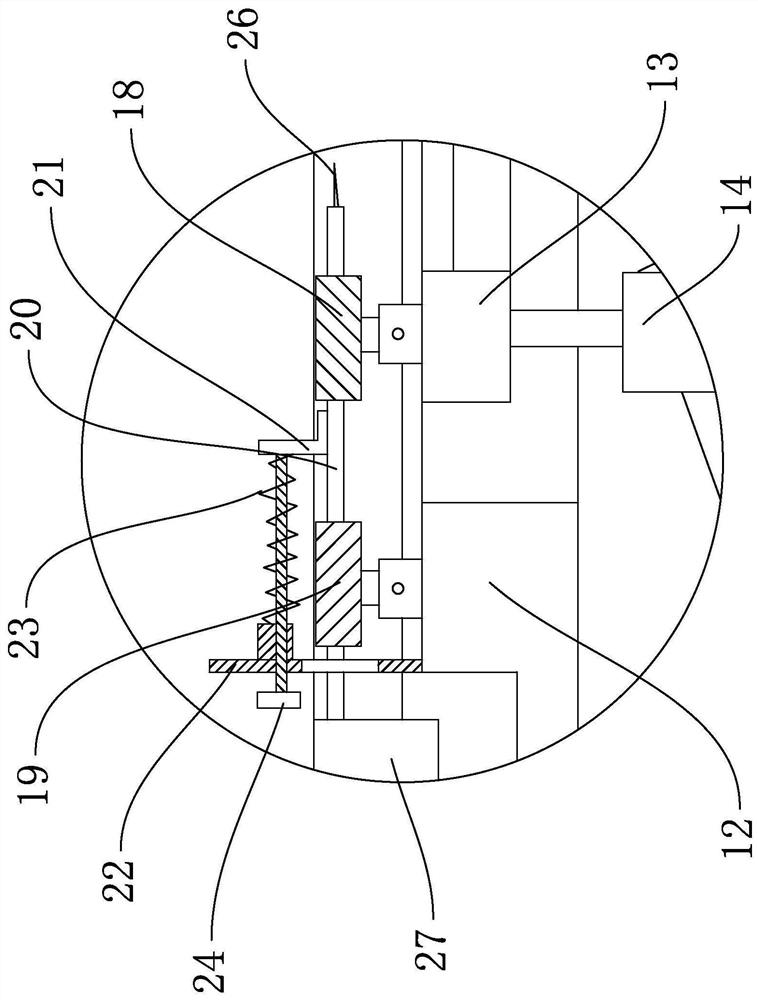

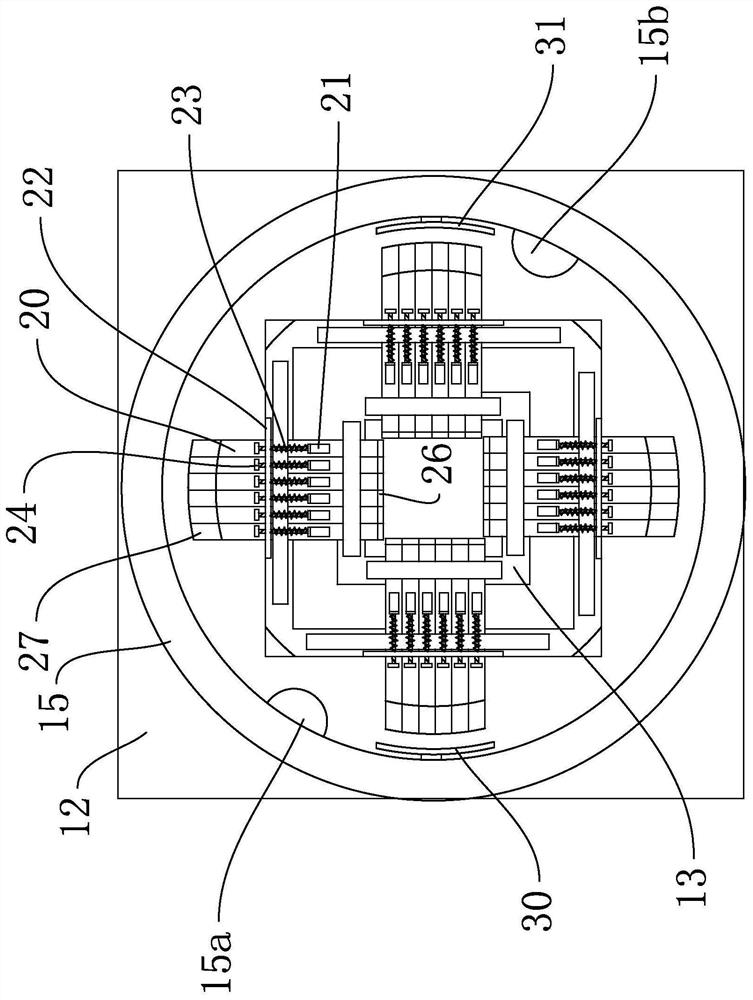

A station (10) for applying fluid substances to stone materials (L), comprising a support surface (13) for supporting a stone slab and an applicator (21) for applying the fluid substance to the slab,said applicator (21) comprises a distribution roller (26) or blade (126) suitable to press the slab and to move on it in order to distribute the fluid substance over the slab, an automated moving device (20) being provided for moving said applicator (21), to allow the automated distribution of the fluid substance.

Owner:普罗默特克有限责任公司

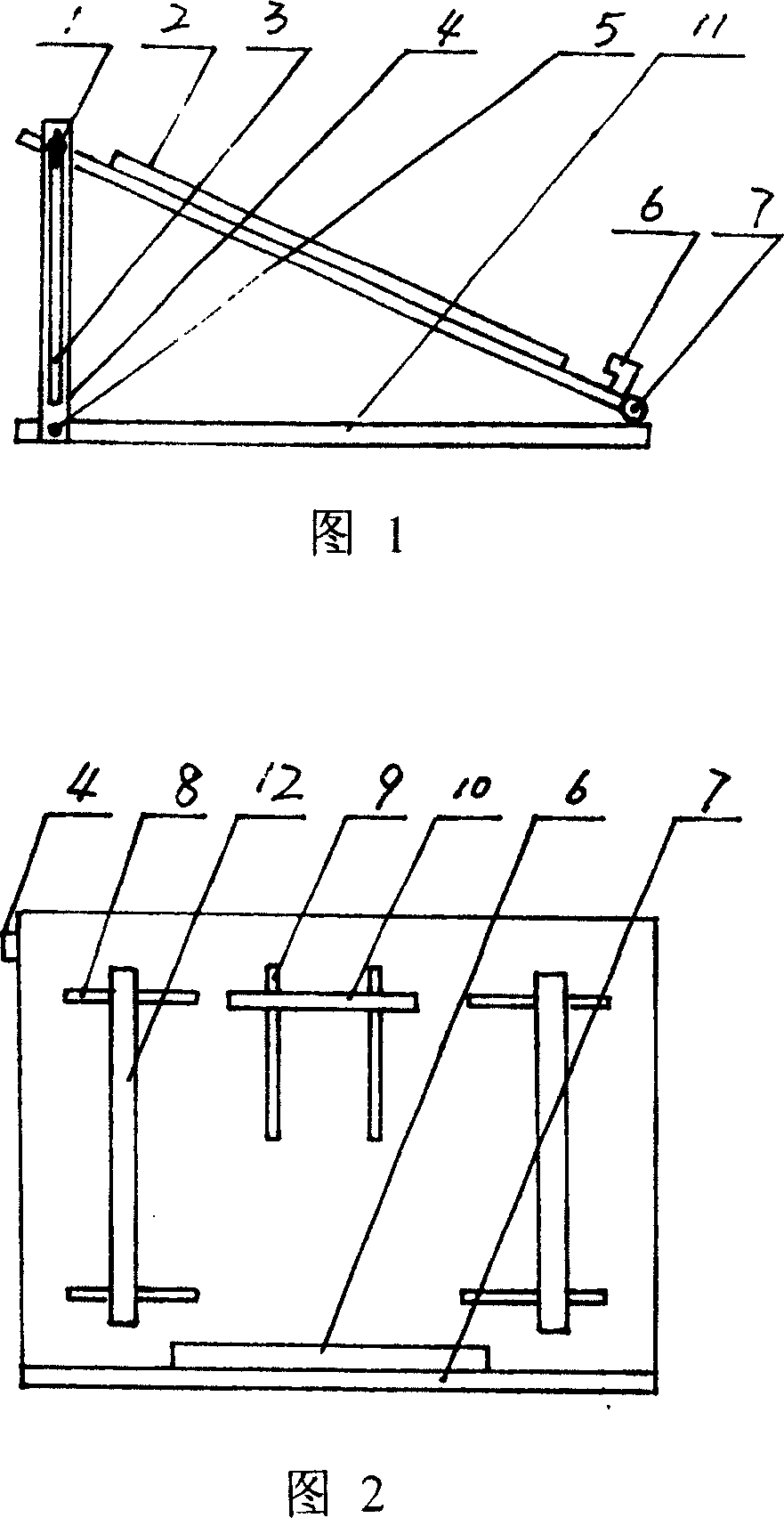

Positioning clamp for machining flagstone surface and method for grinding flagstone surface

InactiveCN100360278CAvoid wear and tear defectsImprove efficiencyEdge grinding machinesPositioning apparatusFlagstoneEngineering

This invention relates to a stone plate processing location jig and a grinding method, which belongs to jig and grinding method field. The location jig is on the table surface of jig borer, and the sheet material is on the clamp and be fasten; the method comprises: adjusting angle regulating stem to make the sheet surface in a needed angle; setting grinding quantity of jig borer; opening jig borer; its bistrique will move automatically downwards to drive the stone plate being grinded until reach to the designed quantity, or the bistrique will move automatically to contact the stone plate, and the table surface shift will force the stone plate being grinded until reach to the designed quantity.

Owner:厉国苗

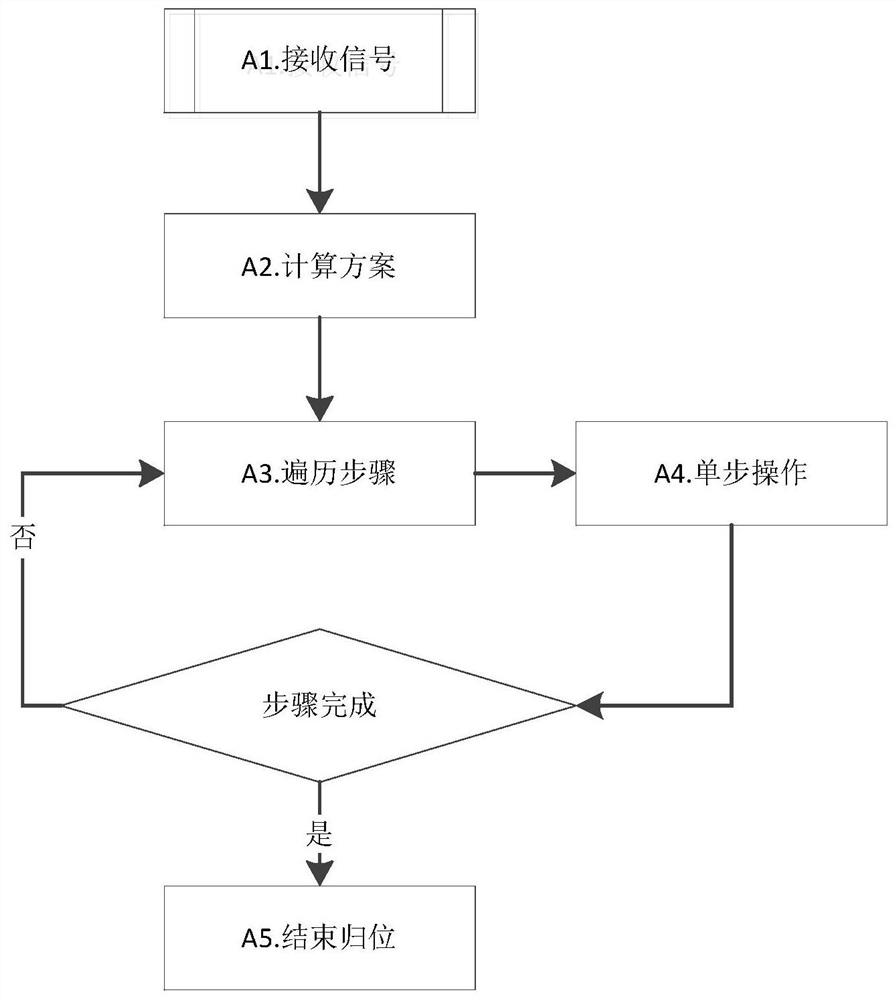

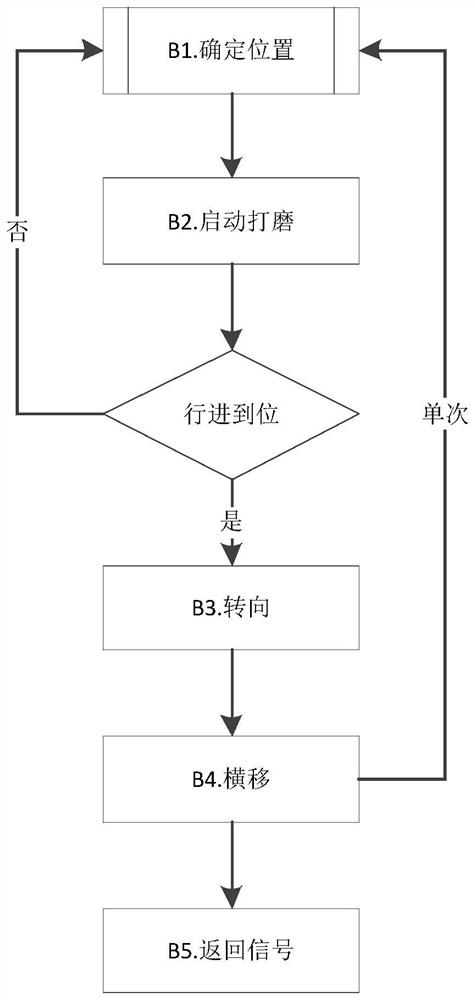

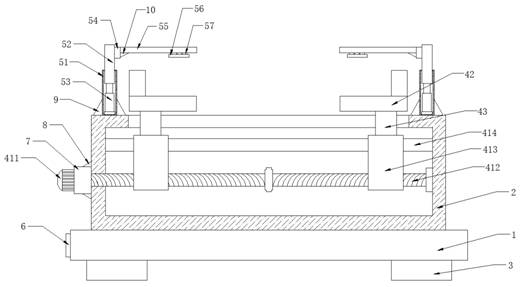

A control method for grinding and polishing of flat stone slabs

InactiveCN108818160BMinimize costAutomatic grinding controlPlane surface grinding machinesFlagstoneStart time

The invention provides a polishing control method for a plane stone plate. The method comprises the following steps: A1, receiving a signal: receiving an instruction from outside, wherein the instruction comprises size of the stone plate, position of the stone plate and starting time; A2, calculating scheme: taking a length value from the size of the stone plate, and according to the position of the stone plate, calculating a stone plate covering section in forward and backward directions, and according to abrasive wheel covering length, calculating polishing frequency, a starting point position and a termination point position; A3, traversing; A4, operating by one-step; and A5, ending and homing. The method is capable of, through a control mode that an abrasive wheel is determined to be longitudinally reciprocated, and each reciprocation process exactly has a transverse upward displacement control mode, ensuring minimum cost of polishing.

Owner:贵州筑信达创科技有限公司

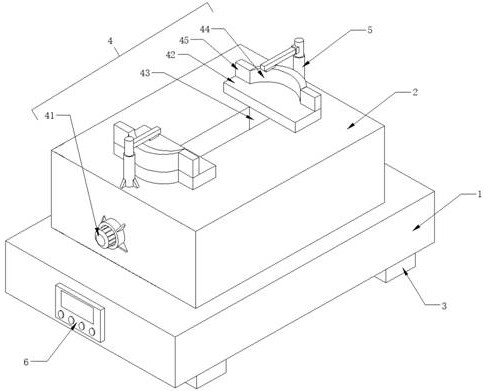

Clamping device facilitating stone machining

PendingCN114643655AConvenient for other processingHigh strengthGrinding drivesWorking accessoriesFlagstoneEngineering

The clamping device facilitating stone machining comprises a bottom plate and a mounting box mounted at the top end of the bottom plate, a plurality of supporting legs are arranged at the bottom end of the bottom plate, a clamping mechanism used for clamping stone plates is arranged in the mounting box, and a notch is formed in the upper end of the mounting box; the clamping end of the clamping mechanism extends upwards to the position above the mounting box through the notch, and the two ends of the upper end of the mounting box are provided with two sets of fastening mechanisms used for fixing the two ends of the stone placed on the clamping mechanism correspondingly. The invention relates to the technical field of stone machining, in particular to a clamping device facilitating stone machining, supporting legs play a role in supporting a bottom plate and a mounting box, the clamping distance of a clamping mechanism is adjusted according to the diameter of a stone slab, and the clamping distance of the clamping mechanism is adjusted through a controller till the stone slab to be machined can be just placed. And the fastening mechanism is controlled by the controller to limit the slabstone in the vertical direction, so that the slabstone can be fixed in all directions.

Owner:麻城市三盛石业有限公司

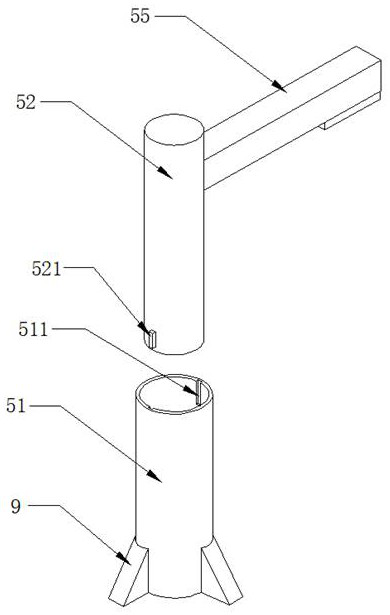

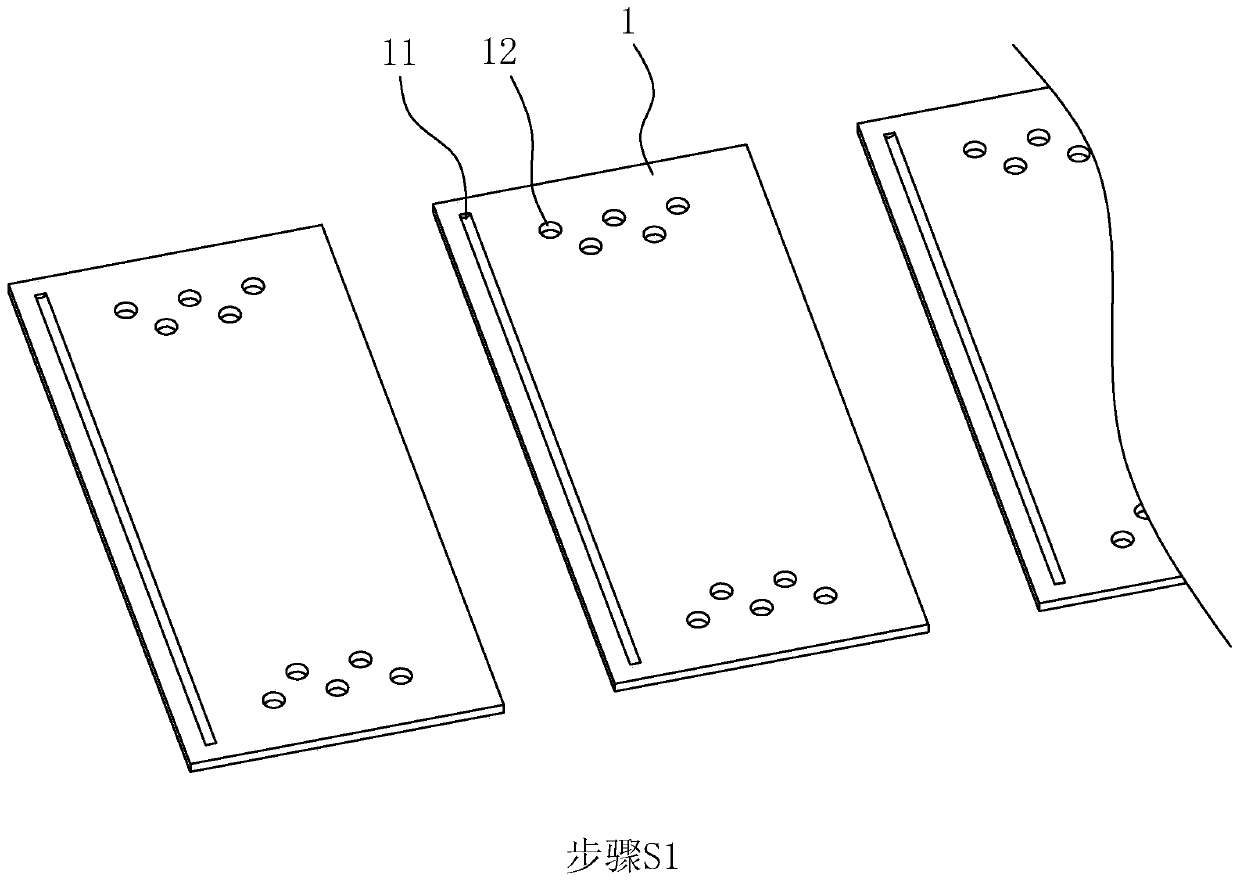

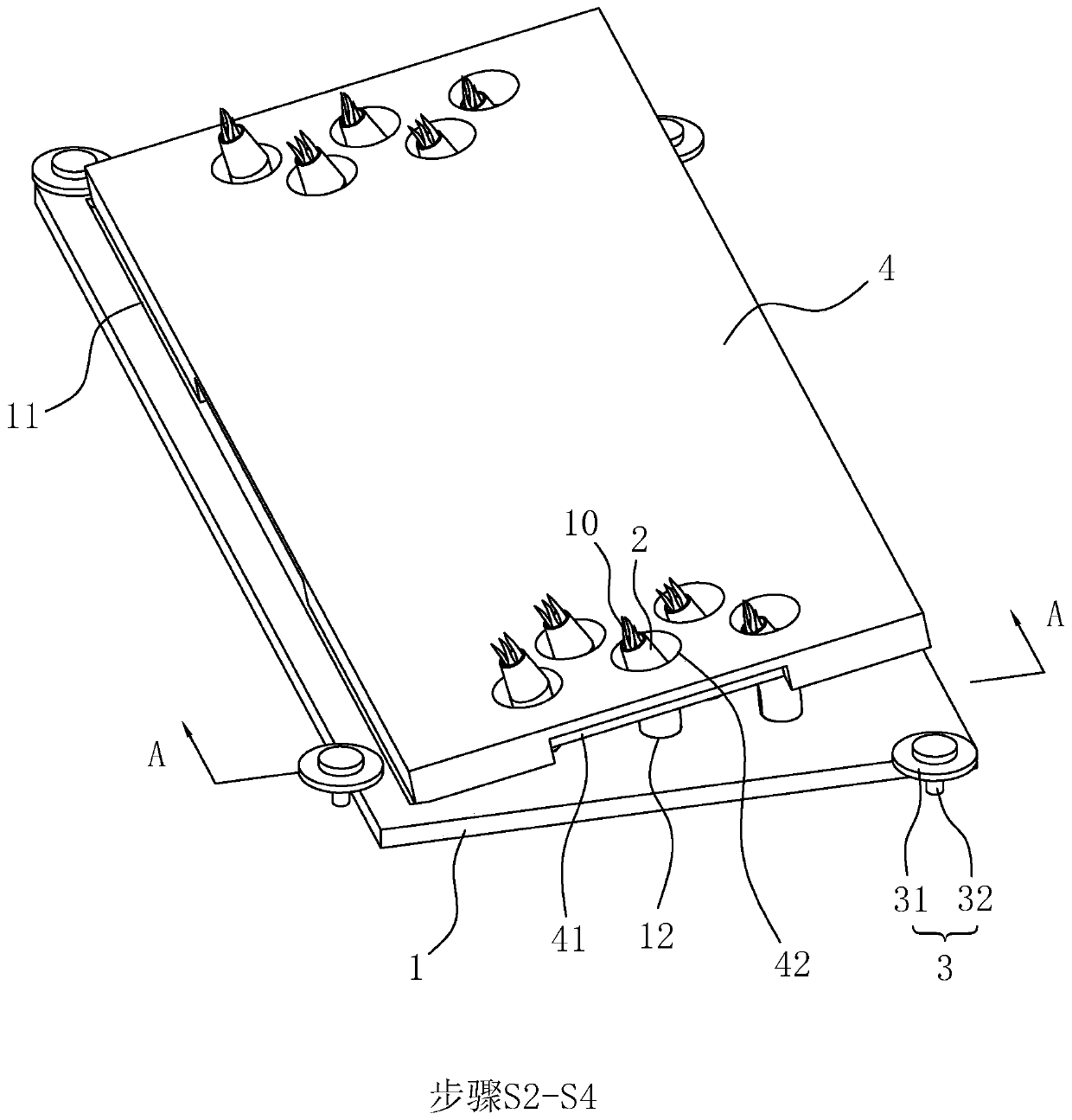

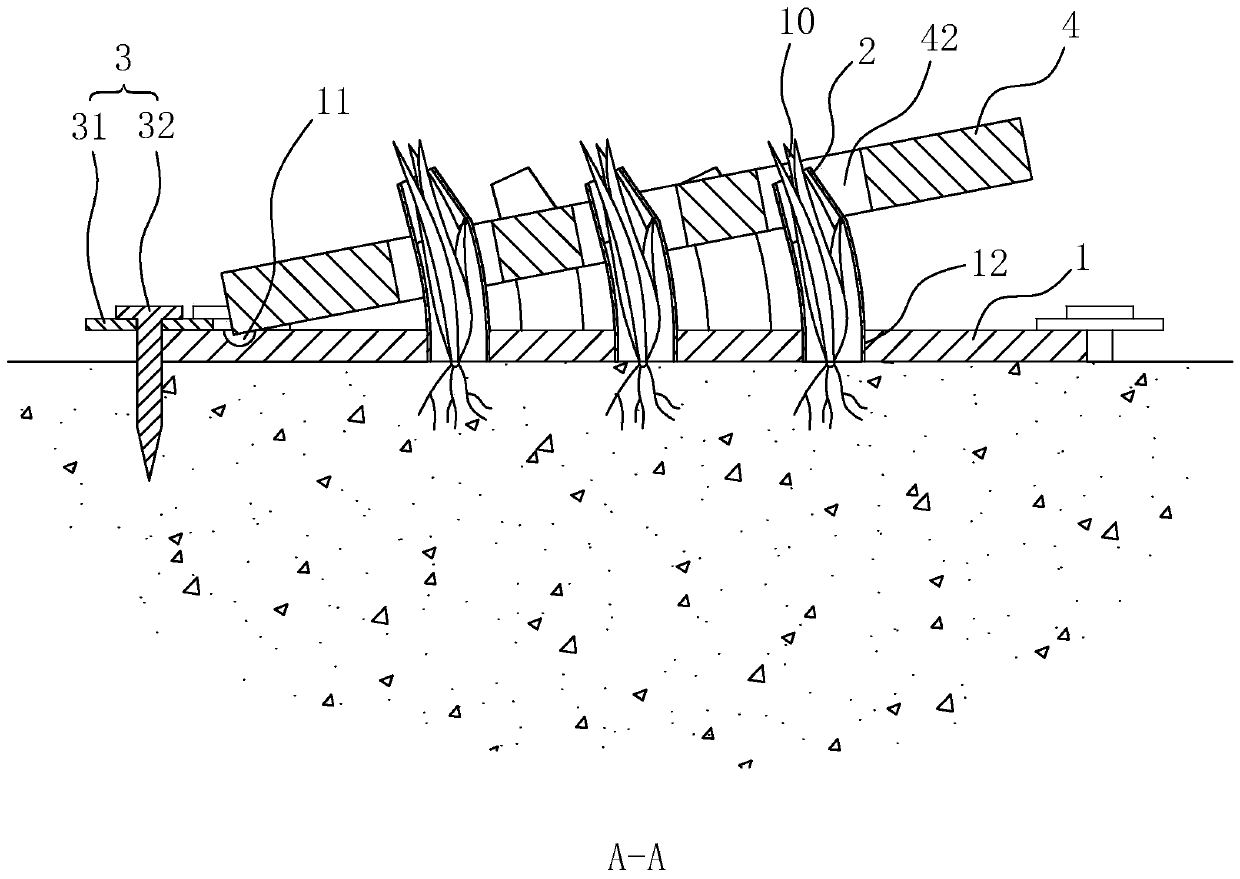

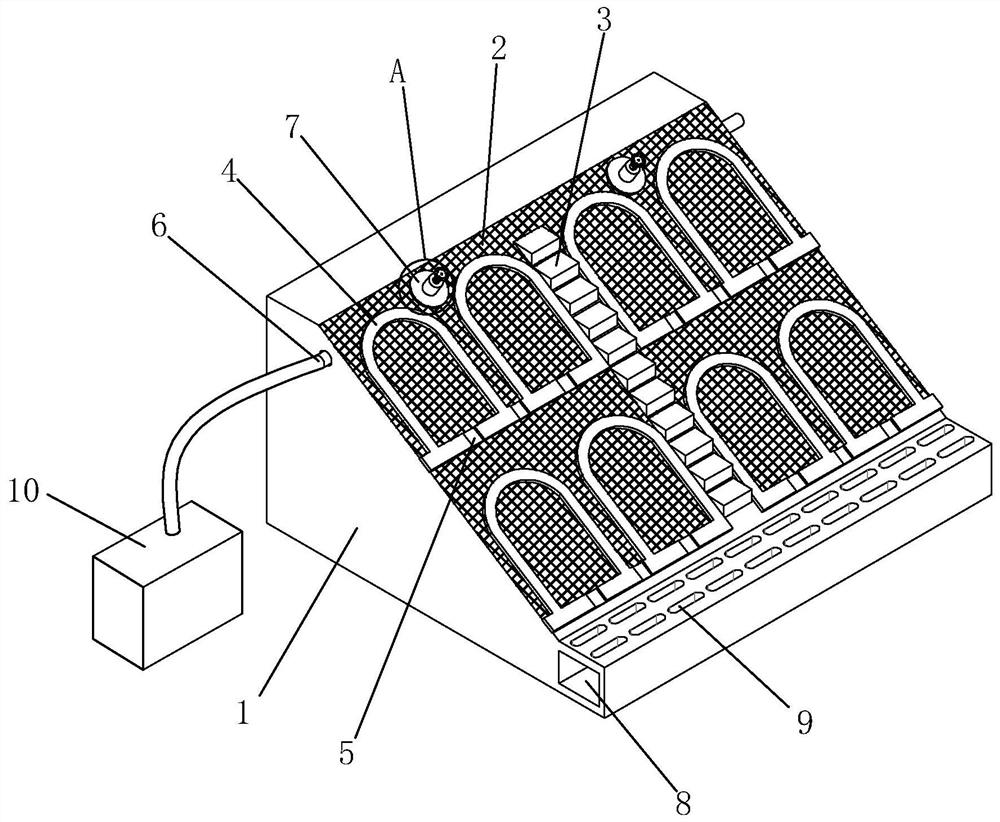

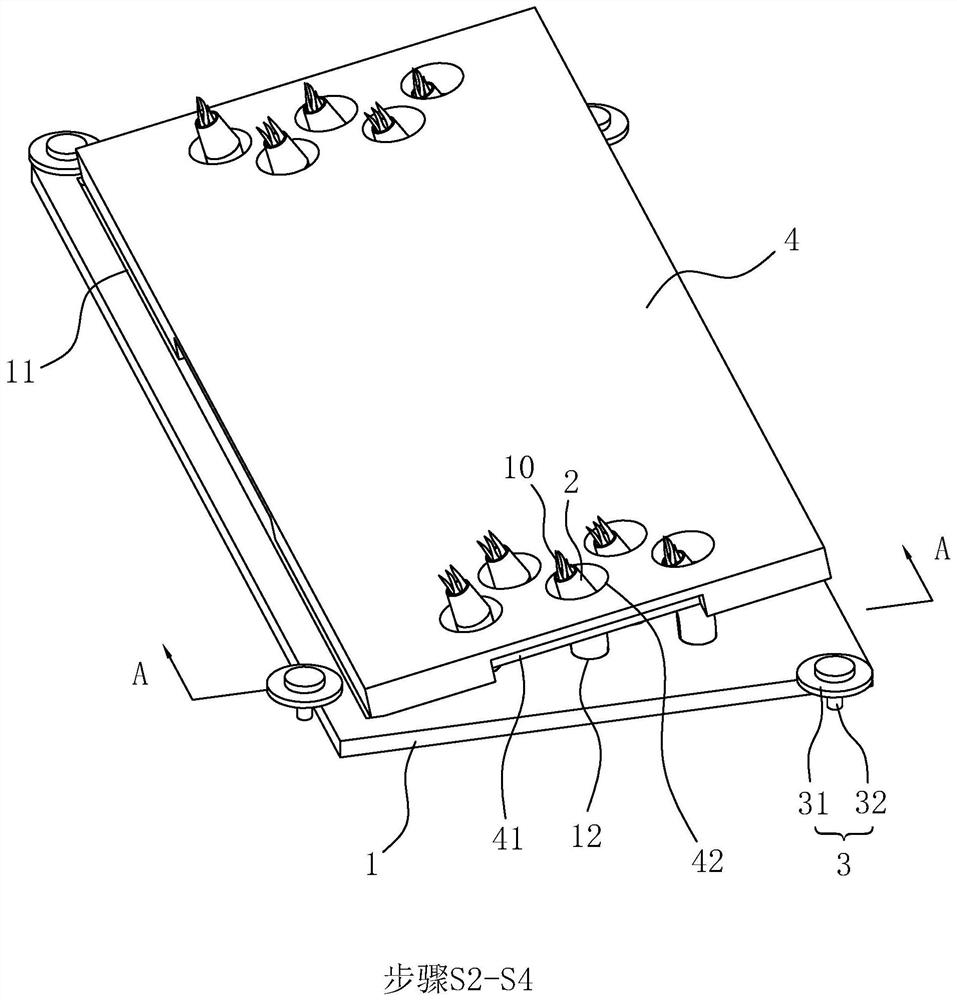

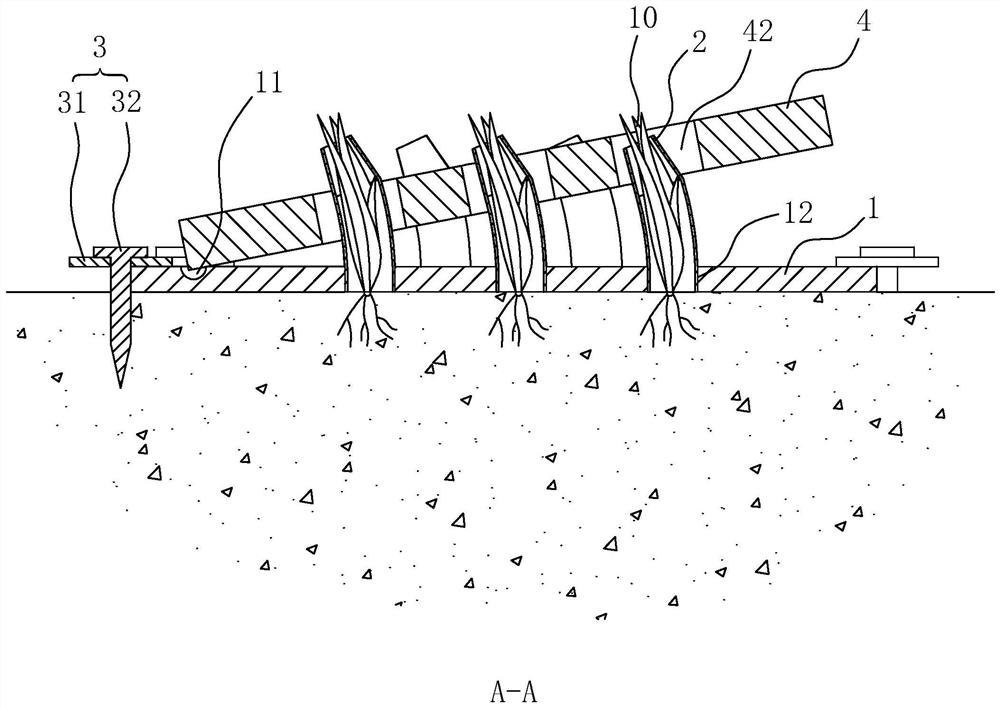

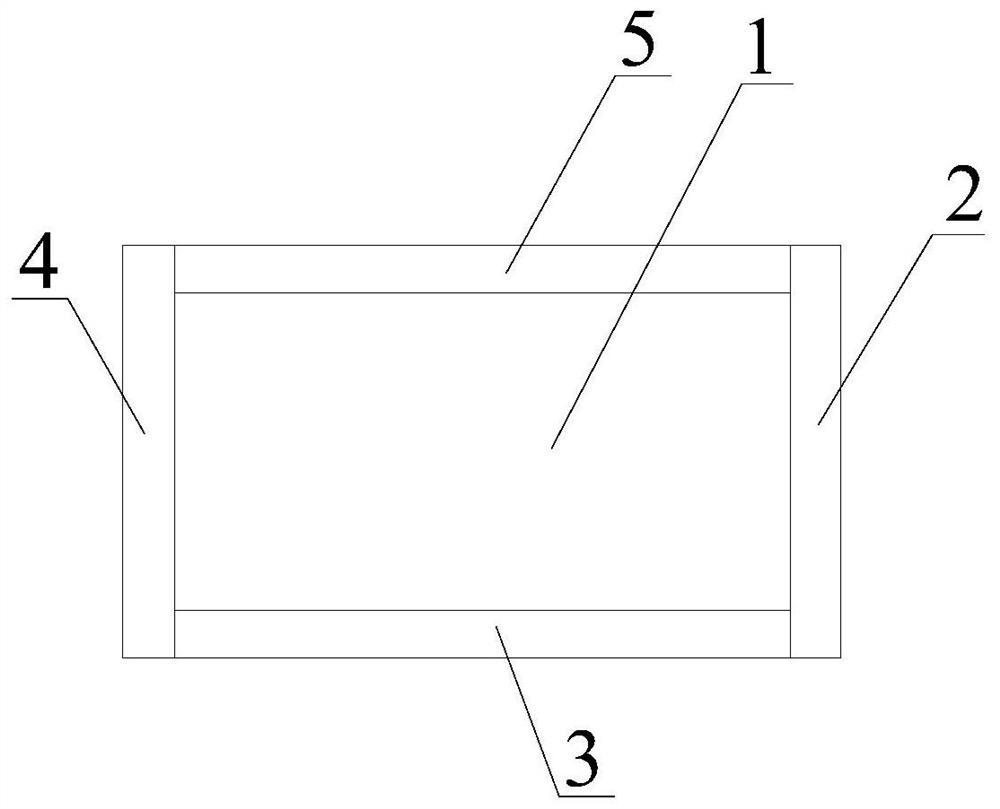

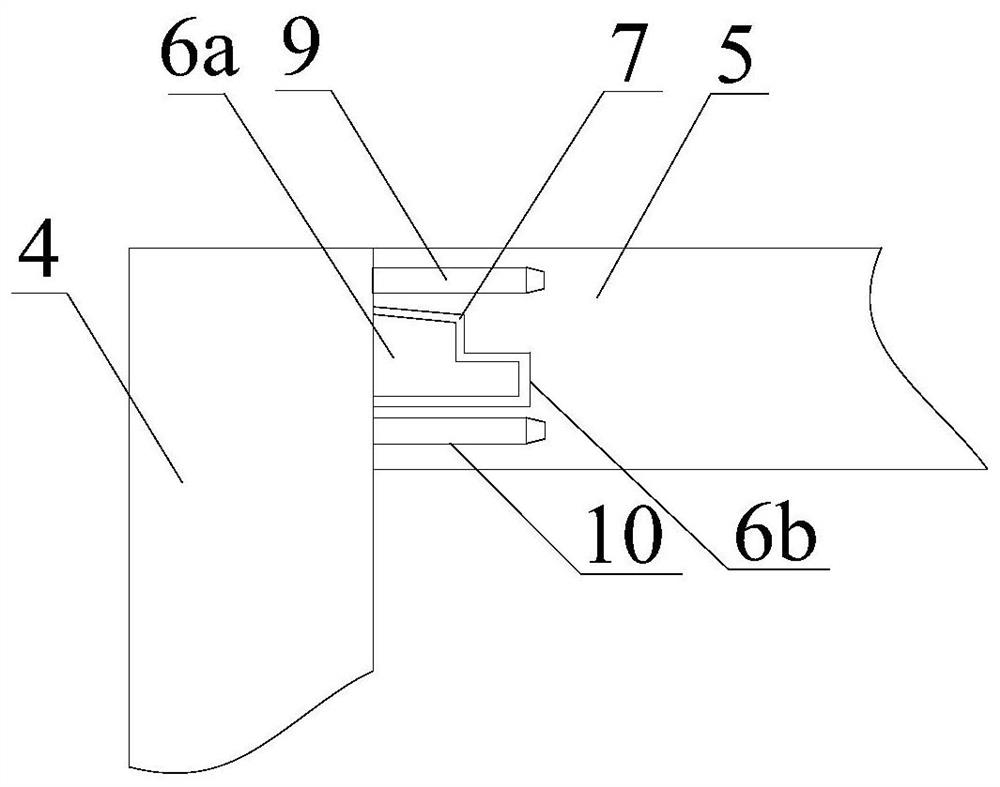

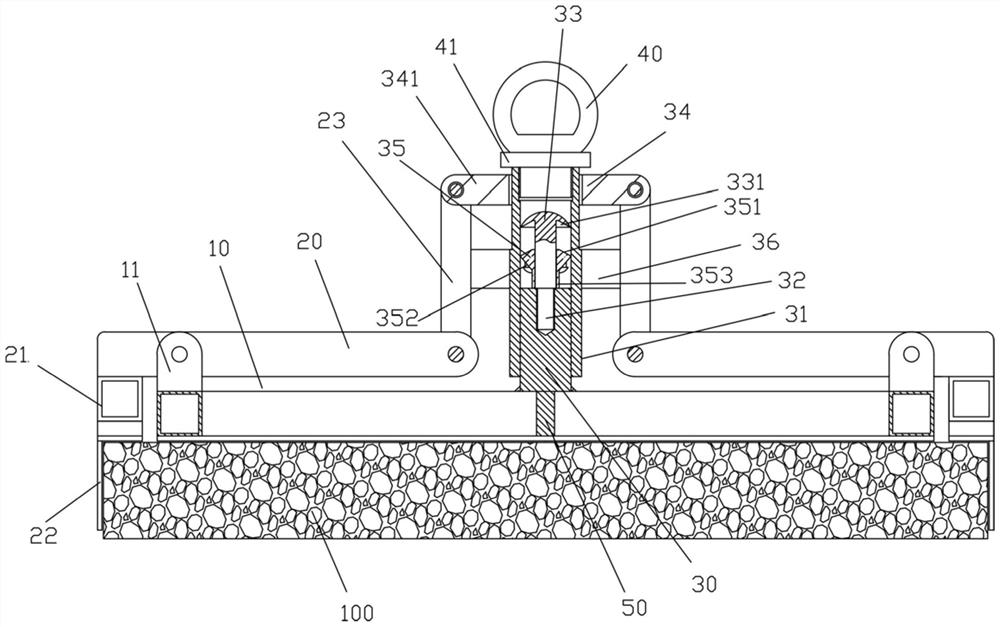

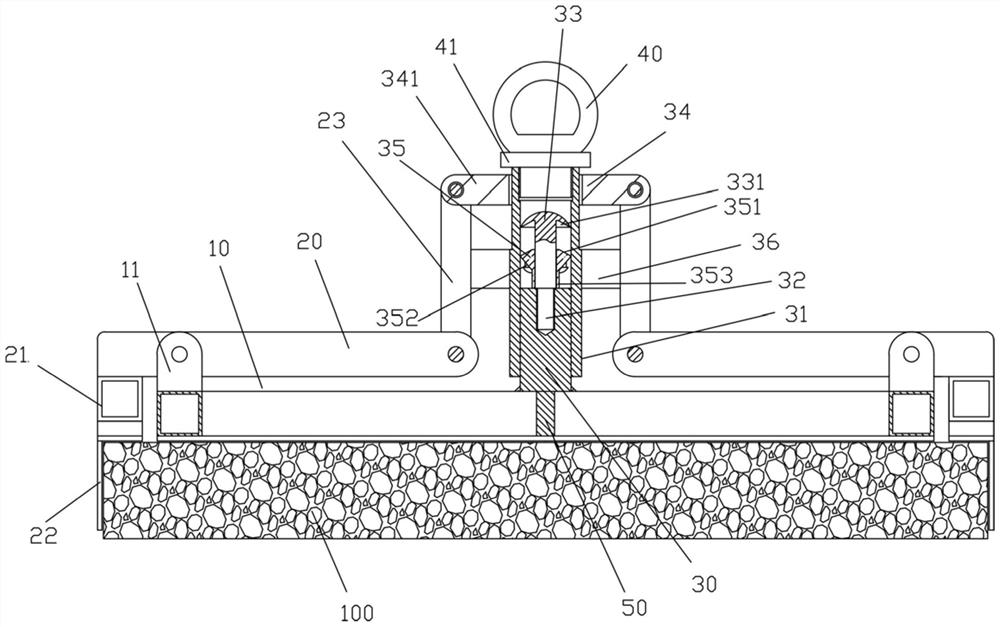

Paving method of stone plate

ActiveCN111021191AMeet needsImprove greening effectSingle unit pavingsSidewalk pavingsFlagstoneAgricultural engineering

The invention discloses a paving method of a stone plate and relates to garden engineering. According to the technical scheme, the paving method of the stone plate is characterized by comprising the following steps: S1, laying a plurality of base plates on the land, wherein the base plates are laid in the travel path direction of a road, and a plurality of planting holes are formed in the plate faces of the base plates in a penetrating mode; S2, planting plants in the planting holes, and maintaining the plants to survive; S3, taking and inserting sleeves into the planting holes, wherein the sleeves are arranged outside the plants in a sleeving mode, and the upper ends of the sleeves protrude out of the top face of the base plate; S4, covering the base plate with a stone plate, wherein through holes corresponding to the planting holes one to one are formed in the stone plate and in the process of stacking the stone plates, the sleeves penetrate through the through holes; and S5, pullingout the sleeves to complete laying. By means of the paving method, the plants grow out of the stone plates, the stone plates and the plants can be integrated, the greening effect is further enhanced,and the requirements of modern people are met; according to the paving method, plants are not prone to being pressed during construction, and the plants easily survive in the base plates and the stone plates.

Owner:CHENGTONG KAISHENG ECOLOGICAL CONSTR CO LTD

A green protection slope for garden design

Owner:浙江原野建设有限公司

Station for applying fluid substances to stone

A station (10) for applying a fluid substance to stone (L), comprising a support surface (13) for supporting the stone slab and an applicator (21) for applying the fluid substance to the slab, Said applicator (21) comprises dispensing rollers (26) or scrapers (126) adapted to press and move over the slabs in order to distribute the fluid substance on the slabs, provided with automatic moving means (20) for moving The applicator (21) thus allows automatic dispensing of the fluid substance.

Owner:普罗默特克有限责任公司

Stone slab building block paving structure suitable for traffic loads at all levels

InactiveCN110820459AImprove structural strengthIncrease pressureSingle unit pavingsRoads maintainenceFlagstoneArchitectural engineering

Owner:盐城市兆泉项目管理有限公司

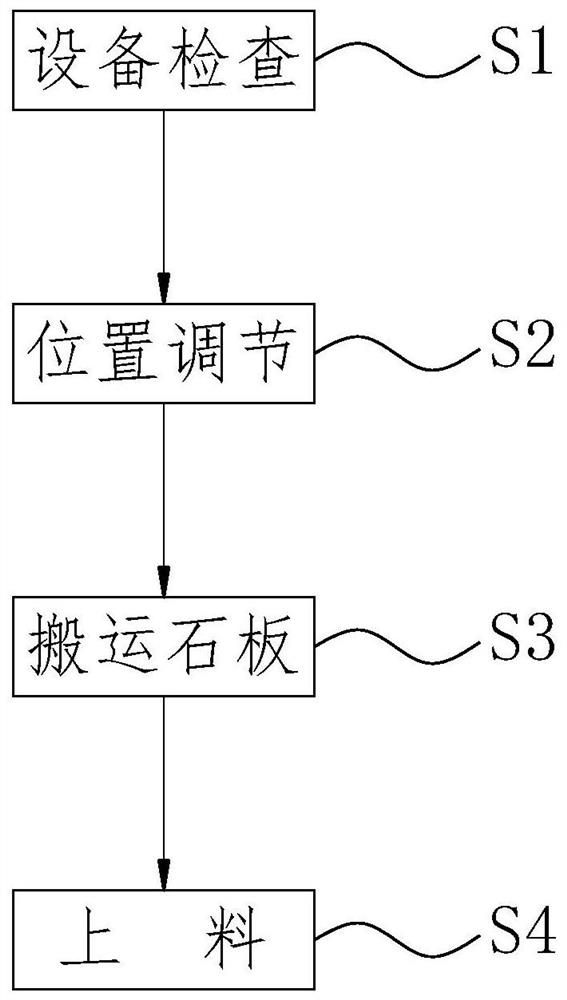

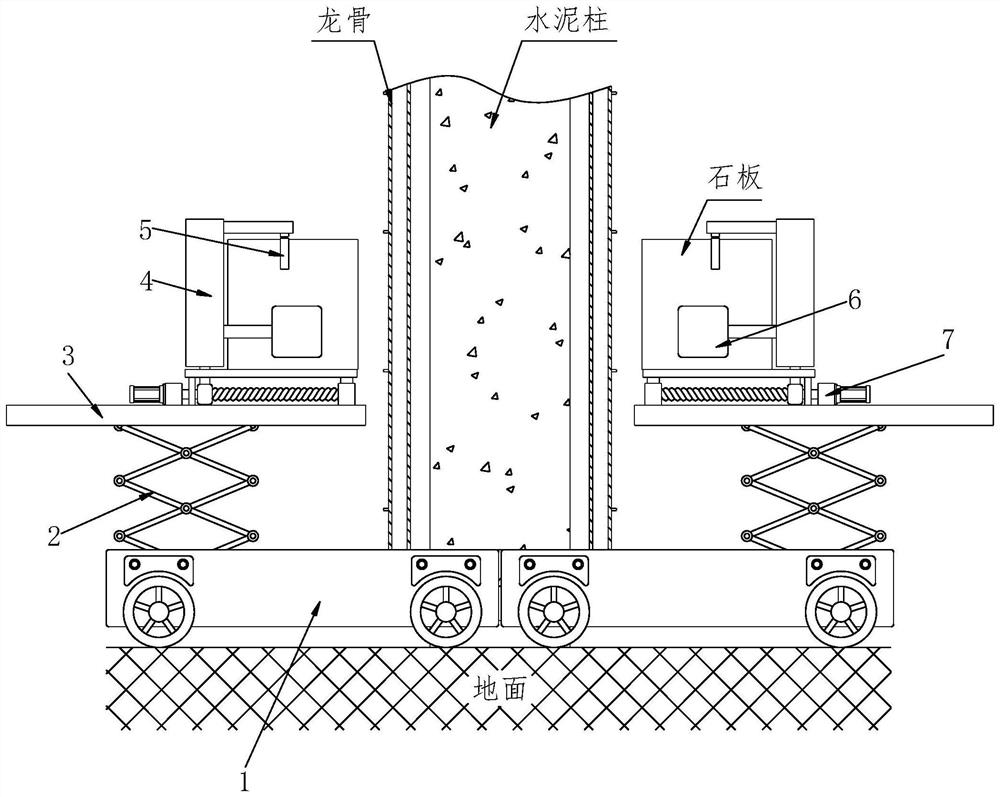

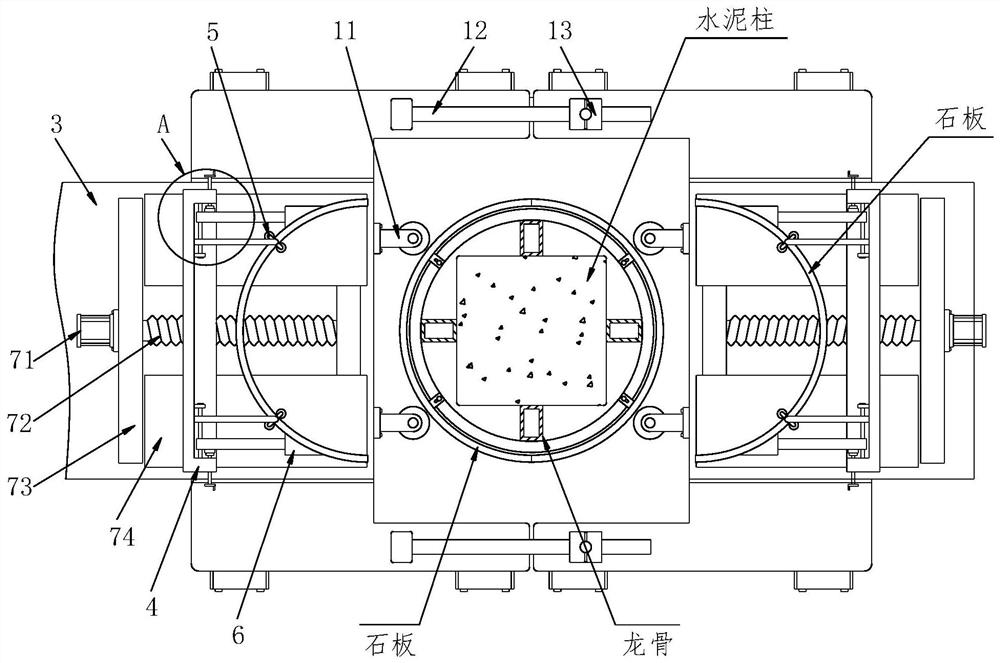

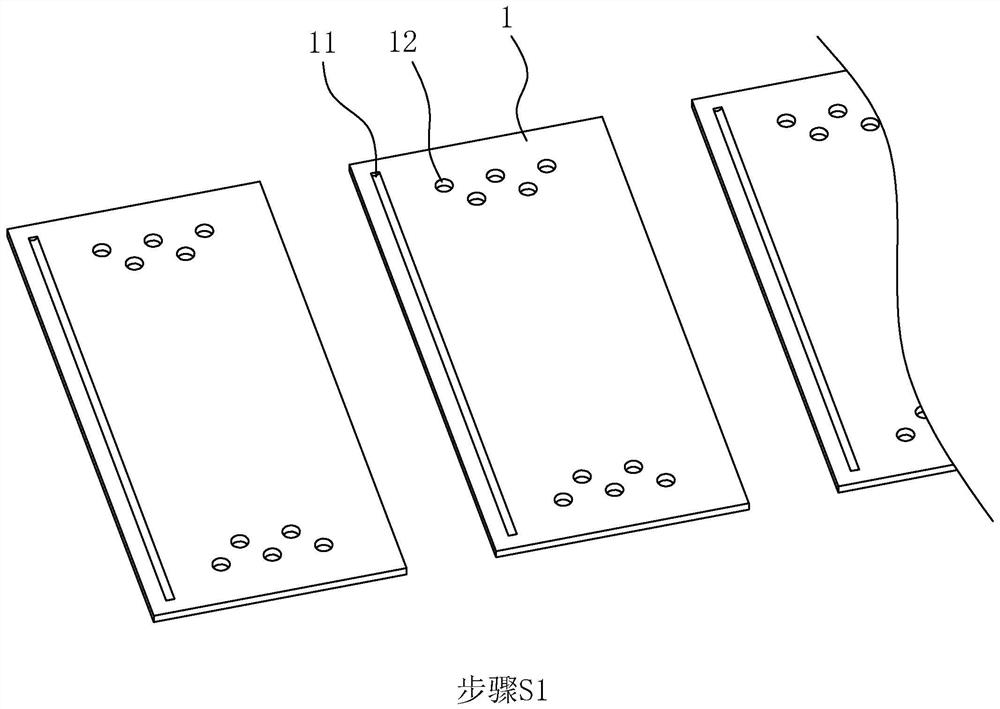

A dry-hanging construction method for building decoration facing stone

ActiveCN111058604BMove quicklyThe method is simple and fastBuilding constructionsFlagstoneStructural engineering

Owner:上海美凯龙装饰工程集团有限公司

Method for paving stone slabs

ActiveCN111021191BMeet needsImprove greening effectSingle unit pavingsSidewalk pavingsFlagstoneAgricultural science

The invention discloses a method for laying stone slabs, which relates to gardening engineering. The key points of the technical solution are as follows: step S1: laying a plurality of backing boards on the ground, and the position of the backing boards is laid in the direction of the road , the plate surface of the backing plate is provided with a plurality of planting holes; step S2: plant plants in the planting holes, and maintain the plants to make them survive; step S3: take the casing and insert it into the planting hole, put the casing outside the plant, The upper end of the tube protrudes from the top surface of the backing plate; step S4: take the stone plate and cover it on the backing plate, and the stone plate is provided with through holes corresponding to the planting holes one by one; in the process of stacking the stone plates, make the casing pass through each through hole ; Step S5: pulling out the casing to complete the laying. Through this laying method, the plants appear as a posture growing from the stone slabs, and the stone slabs and plants can be integrated, which further strengthens the greening effect and meets the needs of modern people; this laying method is not easy to crush the plants during construction, and the plants are placed on the backing plate. , It is easy to survive in the stone slab.

Owner:CHENGTONG KAISHENG ECOLOGICAL CONSTR CO LTD

A combination Motuo stone pot

ActiveCN108836098BGuaranteed tightnessAvoid wastingCooking-vessel materialsCooking vessel constructionsFlagstoneStructural engineering

The invention discloses a combined Motuo stone pot and belongs to the field of Motuo soapstone processing. The combined Motuo stone pot comprises four side plates and a square Motuo stone bottom plate, wherein the four side plates comprise a first Motuo stone plate, a second Motuo stone plate, a third Motuo stone plate and a fourth Motuo stone plate; contact surfaces of the first Motuo stone plate, the second Motuo stone plate, thethird Motuo stone plate and the fourth Motuo stone plate are all connected through clamping devices; the clamping devices comprise limiting bulges and limiting clamping grooves matched with the limiting bulges; a first sealing copper piece is arranged on the contact surface of two adjacent side plates; second sealing copper pieces are arranged on contact surfacesof the four side plates and the square Motuo stone bottom plate. Both the four side plates and the square Motuo stone bottom plate of the combined Motuo stone pot can be made of leftovers generated in a manufacturing process, so that waste of Motuo soapstone can be avoided.

Owner:荆门它山之石电子科技有限公司

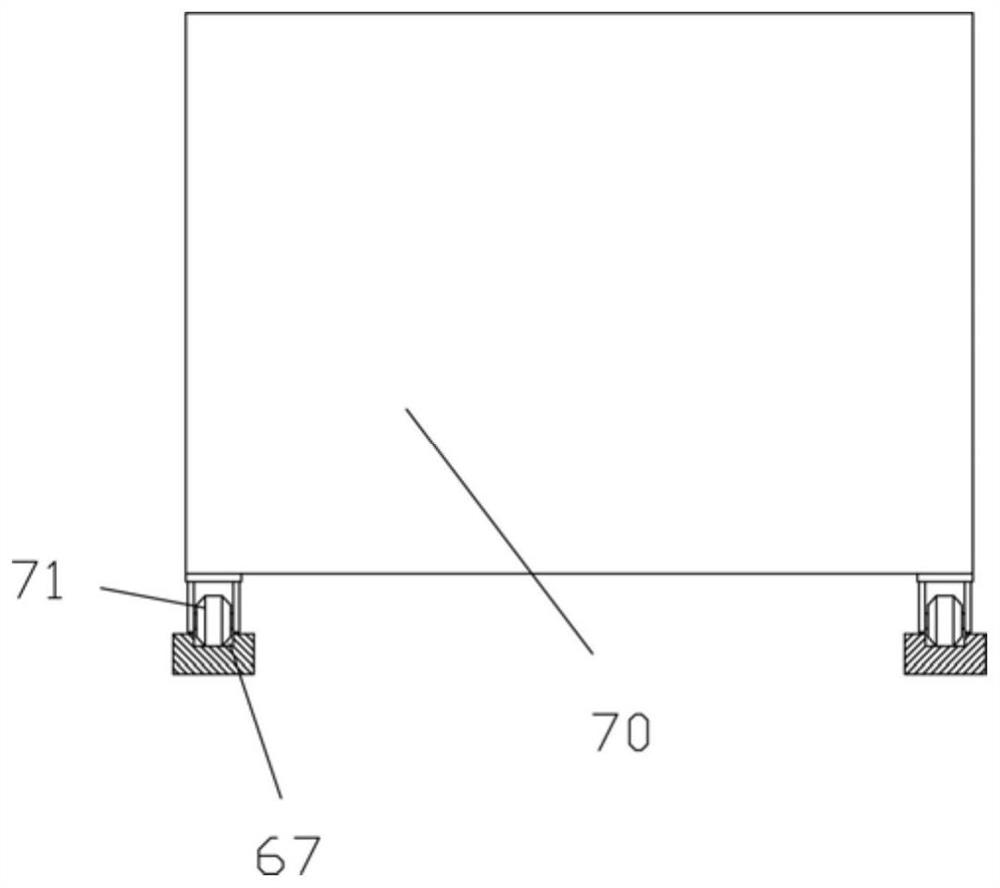

A balanced handling trolley for paving stone slabs

ActiveCN113022663BEasy loading and unloadingNo need to manually lift and placeSupporting partsHand carts with one axisFlagstoneDrive shaft

Owner:绍兴兆园铜业科技有限公司

Stone unloader and unloading method

PendingCN111497041AGuarantee personal safetySupport fully automatic controlWorking accessoriesConveyor partsFlagstoneAutomatic control

The invention provides a stone unloader which comprises a transportation trolley, a steel rail system, a working device and a panel removal device. The working device comprises a slabstone bottom chiseling mechanism, a slabstone breaking mechanism and a first slabstone suction disc. The invention further provides a slabstone automatic unloading method. The stone unloader can achieve mechanical unloading operation and can support full-automatic control, is high in work efficiency and guarantees the personal safety of a worker fundamentally.

Owner:吴周贵

Balanced carrying trolley for stone slab paving

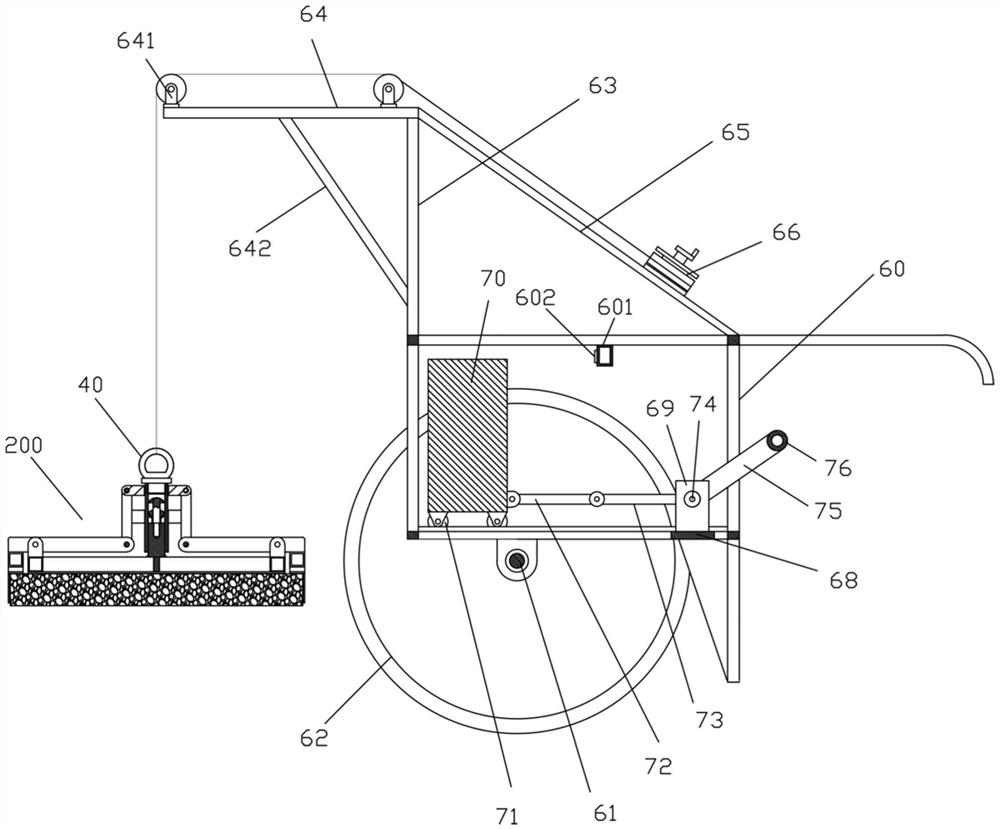

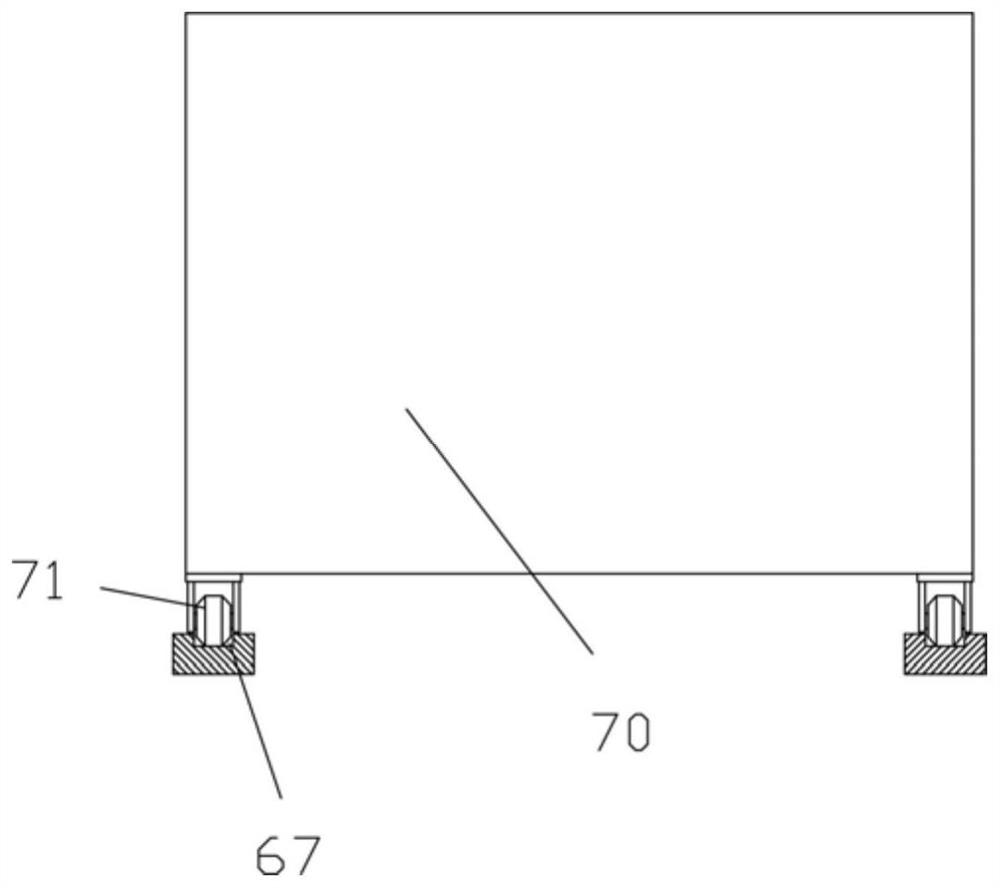

ActiveCN113022663AEasy loading and unloadingNo need to manually lift and placeSupporting partsHand carts with one axisFlagstoneControl theory

The invention discloses a balanced carrying trolley for stone slab paving. The balanced carrying trolley comprises a trolley frame and a grabbing mechanism. A transmission shaft extending front and back is arranged at the bottom of the trolley frame, and wheels are hinged to the ends of the transmission shaft through bearings; a vertical column is fixed to the top face of the middle of a top beam on the front portion of the trolley frame, a horizontal fixing beam extending forwards is fixed to the top end of the vertical column, the front end of an oblique beam is fixed to the rear end of the horizontal fixing beam, the rear end of the oblique beam is fixed to the top beam on the rear portion of the trolley frame; pulley seats are fixed on the left part and the right part of the top surface of the horizontal fixing beam, a hand winch is fixed on the top surface of the rear part of the oblique beam, and a steel wire rope of the hand winch is hung on pulleys of the two pulley seats. The stone slab can be automatically grabbed and lifted, then the trolley frame is pushed to a supporting frame, the trolley frame automatically descends to place the stone slab on the supporting frame, loading and unloading are convenient, manual lifting and placing are not needed, and the manual labor amount is greatly reduced.

Owner:绍兴兆园铜业科技有限公司

Imitated bowlder artificial flagstone

The invention relates to a jade-like artificial stone slab, which is made of the following components according to the proportion by weight: 60-80 parts of aluminum hydroxide; 20-25 parts of composite powder; 71-82 parts of water reducer; 1-3 parts of accelerator 0.2-0.3 parts of potassium peroxide ethyl ketone; 28-32 parts of unsaturated resin; 24-45 parts of gray gravel; 0.1-0.3 parts of pigment paste; 0.1-0.8 parts of alloy powder; Powder 36-50 parts; auxiliary agent 0.35-0.5 parts. The advantages of the present invention are: the stone formula of the present invention, the imitation jade mosaic is made of polymer composite materials, and is made by modern production technology. It is environmentally friendly, non-toxic, and non-radiative. It is a new generation of environmentally friendly building materials. Diverse, colorful, crystal clear, can be produced according to various requirements of customers, flexible and changeable, convenient for decoration and matching, and create a colorful living space.

Owner:南通戈雅石业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com