A control method for grinding and polishing of flat stone slabs

A control method and slate technology, applied in grinding/polishing equipment, grinding automatic control devices, metal processing equipment, etc., can solve problems such as time and energy consumption, and achieve the effect of minimizing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

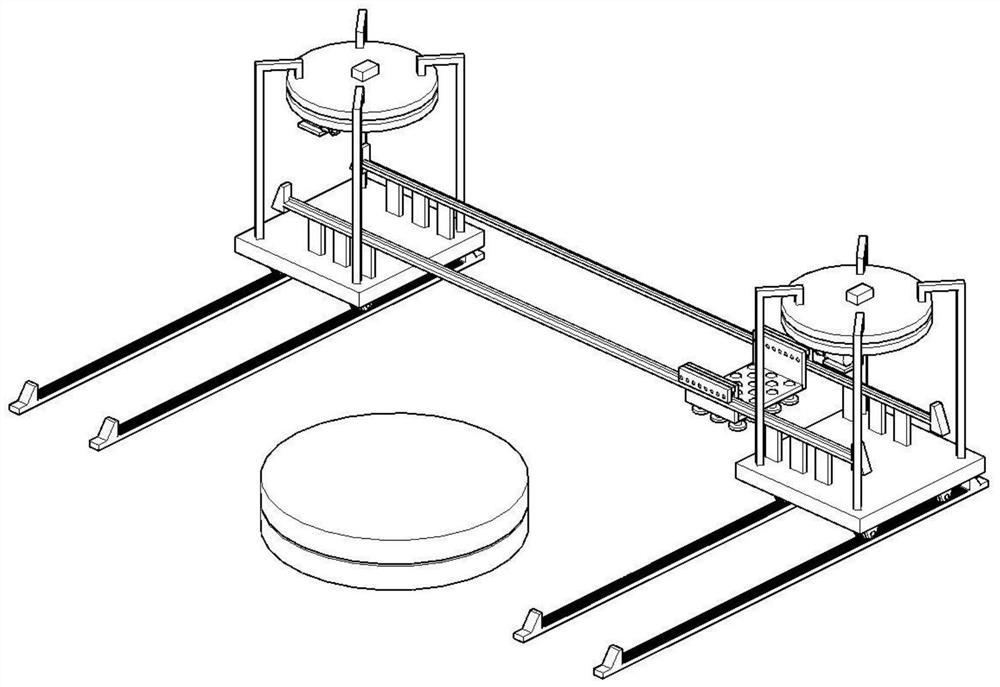

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

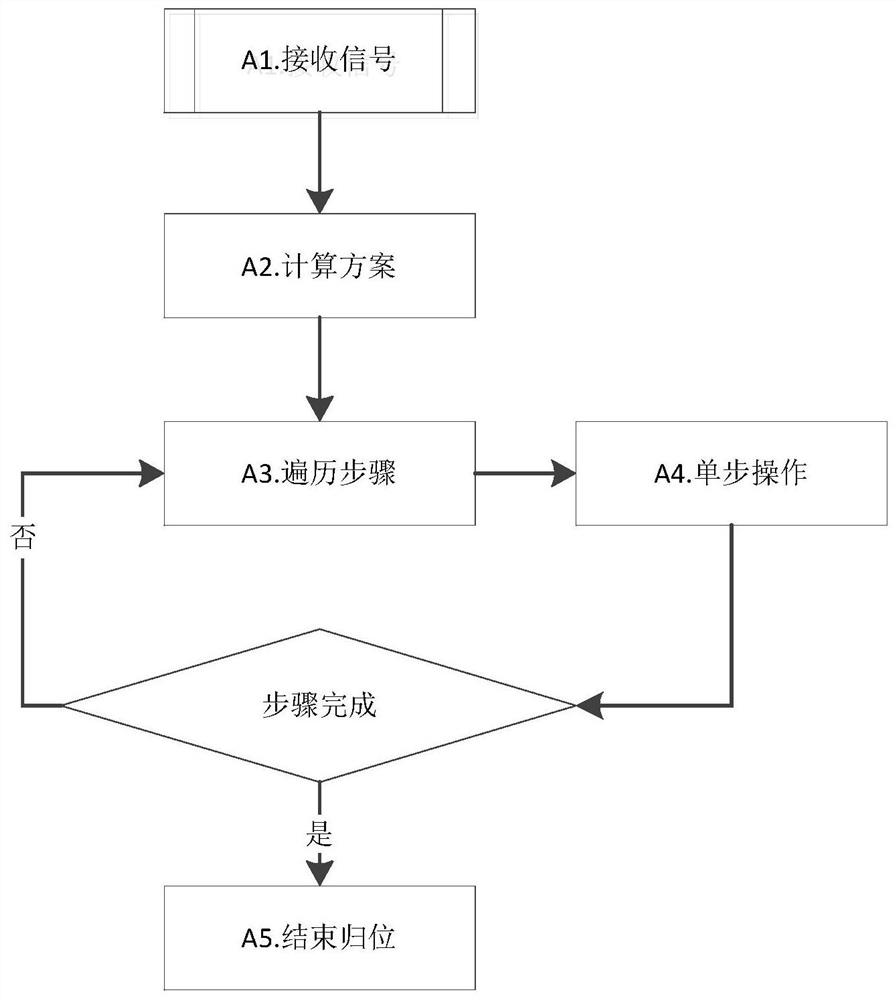

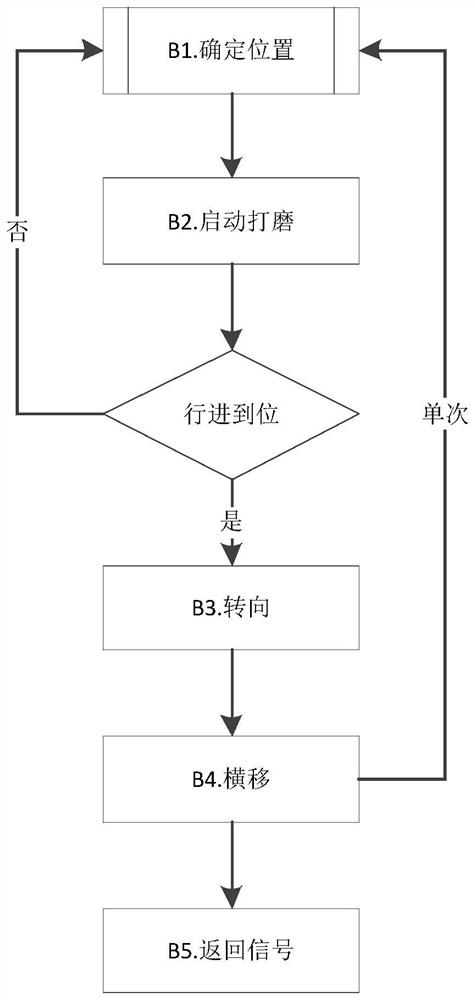

[0029] Such as figure 1 A grinding and polishing control method for a plane slate is shown, comprising the following steps:

[0030] A1. Receive signal: Receive instructions from the outside, the instructions include the size of the stone slab, the position of the stone slab and the start time;

[0031] A2. Calculation scheme: Take out the length value in the size of the stone slab, and calculate the coverage section of the stone slab in the front and rear directions according to the position of the stone slab, and then calculate the number of times of grinding and polishing, the position of the starting point and the position of the end point according to the coverage length of the grinding disc;

[0032] A3. Traverse step: call step A4 according to the number of times of grinding and polishing required, call step A4 once every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com